Patents

Literature

231results about How to "Good matte effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

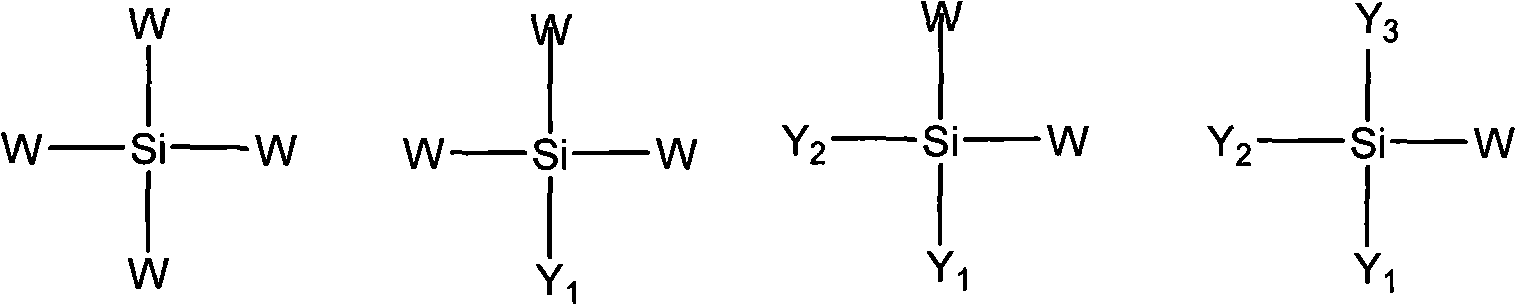

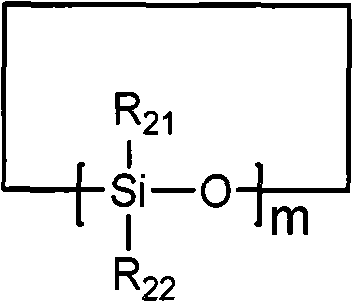

Release agent and application thereof

The invention discloses a release agent. The release agent comprises polysiloxane compound of which the molecule has more than three silicon-hydrogen (Si-H) bonds, semigloss particles, an emulsifying agent and water. The invention also provides the application of the release agent in the preparation of semigloss type rubber products, semigloss type plastic products or semigloss type composite material products. The release agent of the invention has simple construction, high release property and a good semigloss effect, and can form a harder film after being cured, so that the semigloss particles are fixed on the film without being transferred to the molded products, and semi-permanent demoulding is realized; the obtained products after multiple demoulding still have basically constant glossiness and high storage stability without being influenced on the product property. The release agent of the invention is almost suitable for all moulds, particularly has higher caking property with metal moulds and has a wide application range.

Owner:HENKELCHINAINVESTMENT

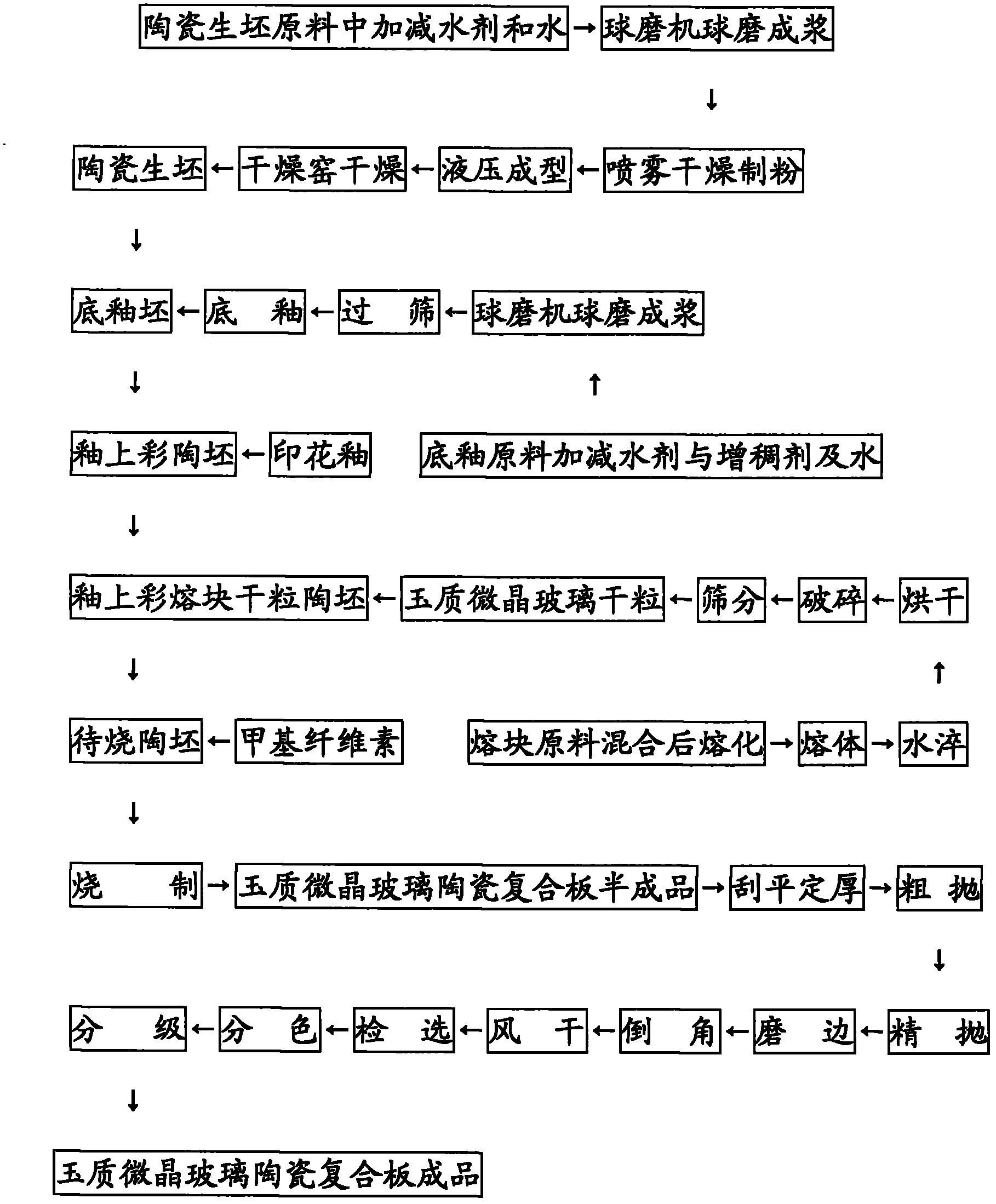

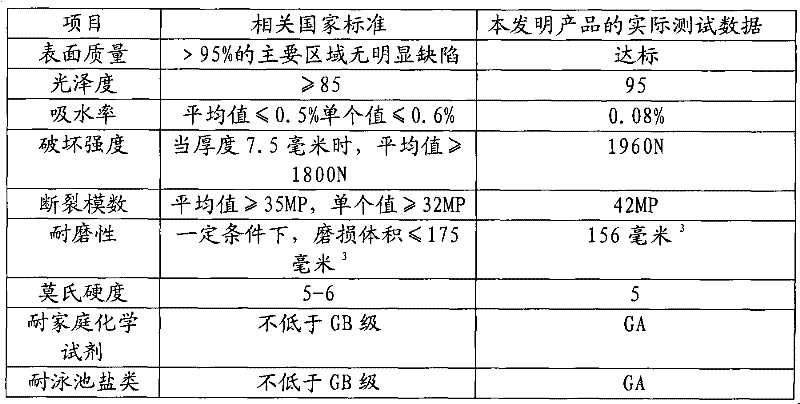

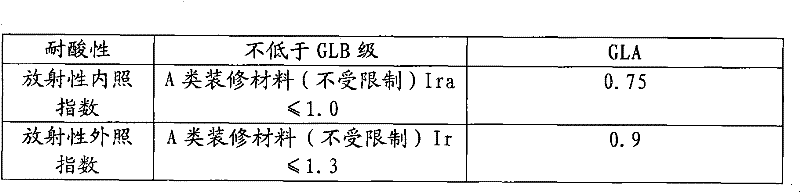

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

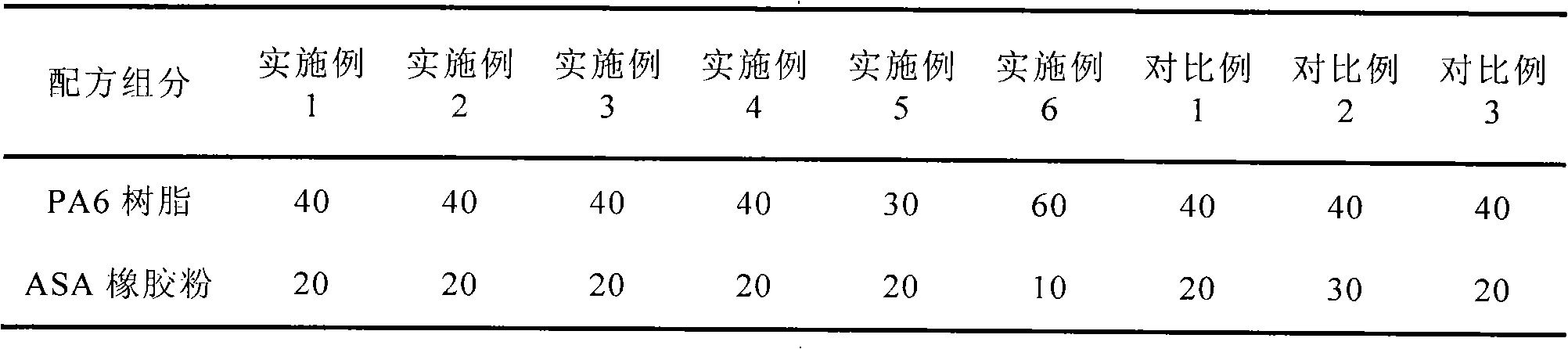

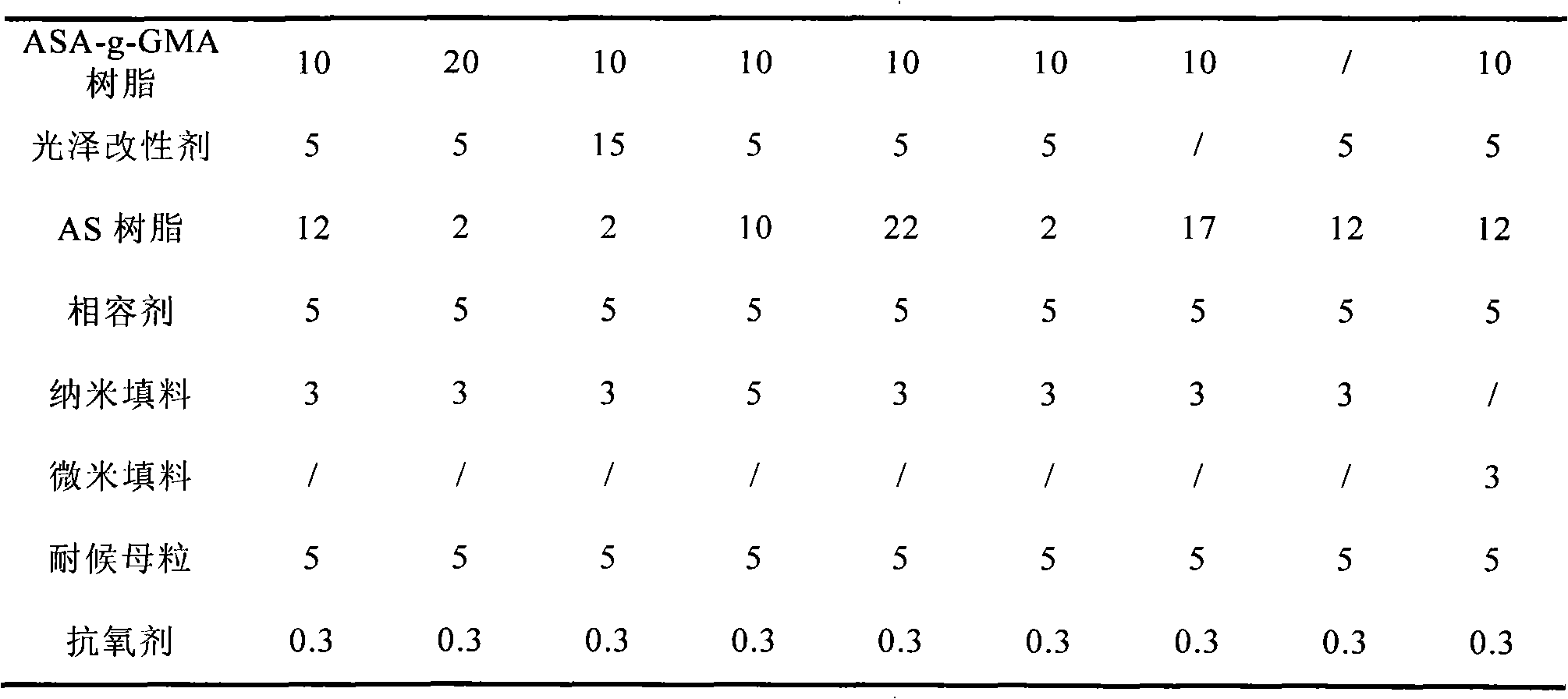

Alloy resin composition and preparation method thereof

The invention relates to an alloy resin composition and a preparation method thereof. The composition comprises the following components in part by weight: 30-60 parts of polyamide resins, 15-50 parts of ASA (Acetylsalicylic Acid) rubber powder, 10-20 parts of ASA-g-GMA (Glycidyl Methacrylate) resins, 5-15 parts of glossy modifiers, 0-30 parts of AS (Arsenic) resins, 1-8 parts of compatilizers, 5-10 parts of weather-resistant master batch, 1-5 parts of nano fillers and 0.05-0.5 part of antioxidant. The preparation method comprises the following steps of: adding the mixture of all raw materials expect for the weather-resistant master batch to a main charging hole of a double-screw extruder, adding the weather-resistant master batch from a side charging hole, and then carrying out extrusion and pelleting to obtain the product. The alloy resin composition obtained in the method has a softer leopard surface matting effect, a more glossy shiny side lighting effect and better low temperature impact resistance and weather resistance, and is especially suitable for automobile interiors and exteriors with high requirements, such as instrument frames, air outlets of air conditioners, storage boxes, doorknobs, cosmetic mirrors, heat-radiating gratings, rearview mirrors, middle post plates, license plates and the like above wasitlines.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

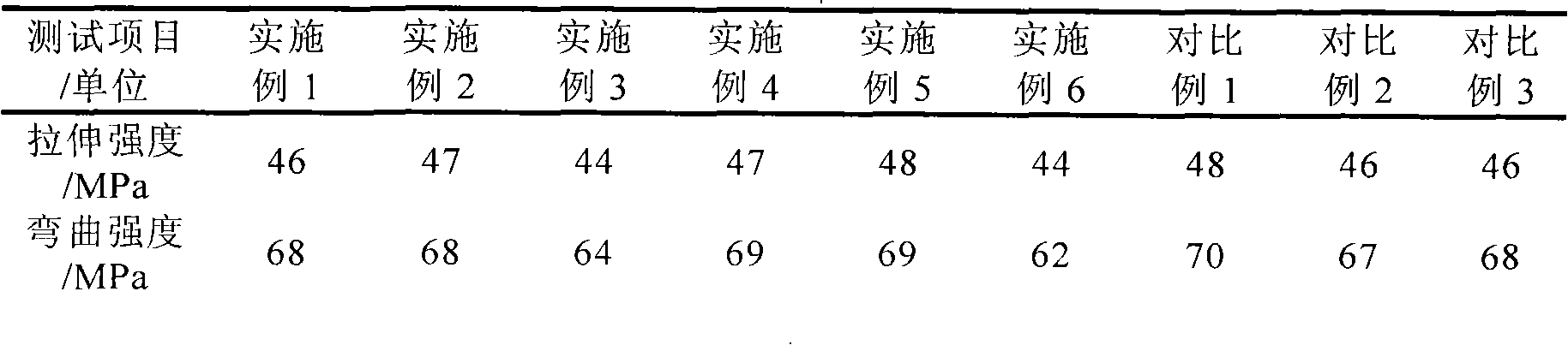

PVC (polyvinyl chloride) decorative film surface treating agent, PVC decorative film treated with same and preparation method thereof

InactiveCN102702953AGood PVC adhesionImprove smoothnessOrnamental structuresSpecial ornamental structuresWater basedEmulsion

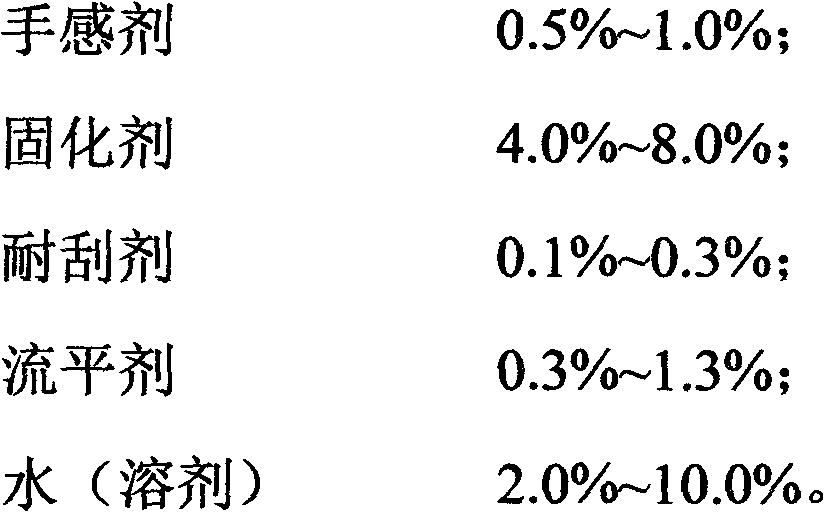

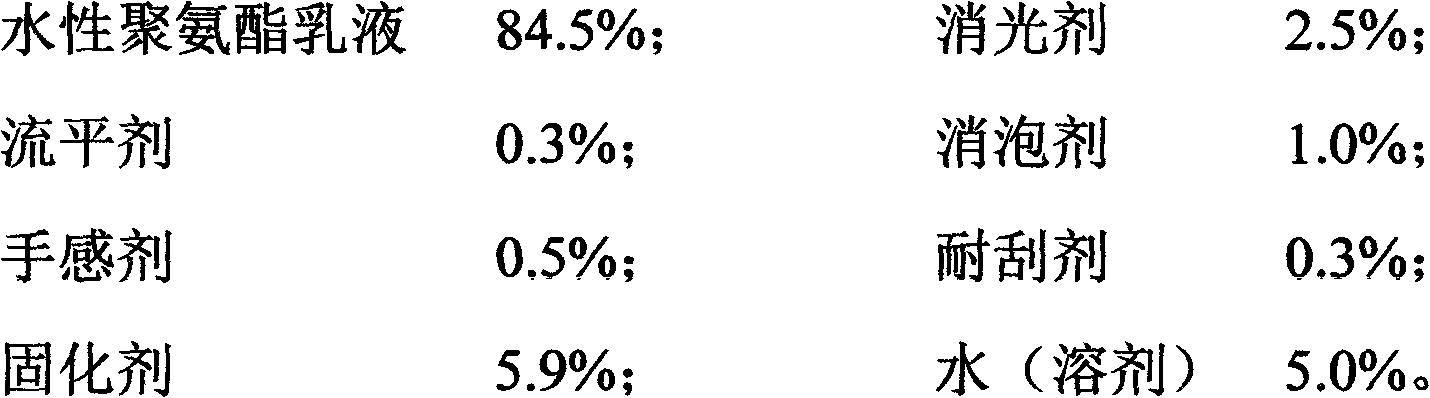

The invention discloses a PVC (polyvinyl chloride) decorative film surface treating agent and a PVC decorative film treated with the same. The surface treating agent comprises the following components in percentage by weight: 80.0-92.0% of water-based polyurethane emulsion, 2.0-4.0% of flatting agent, 0.5-1.5% of defoaming agent, 0.5-1.0% of hand feeling agent, 4.0-8.0% of curing agent, 0.1-0.3% of scraping inhibitor, 0.3-1.3% of leveling agent and 2.0-10.0% of water. The PVC decorative film treated with the surface treating agent has the advantages of excellent matte performance, scraping resistance, favorable compatibility with other decorating materials, and the like, and feels soft.

Owner:FOSHAN TIANJIN PLASTICS

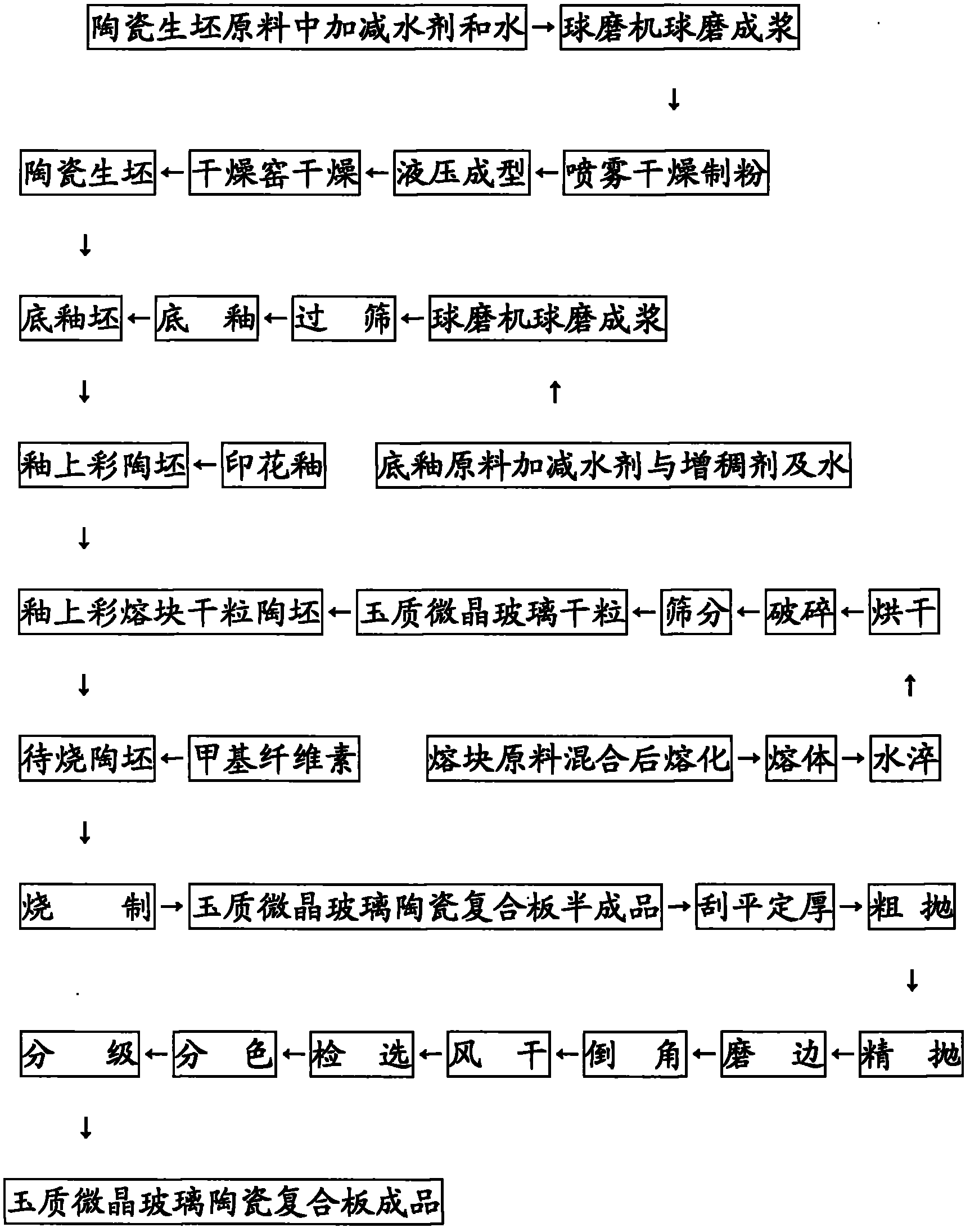

Method for producing base coat being matched with blank and having excellent glazing effect

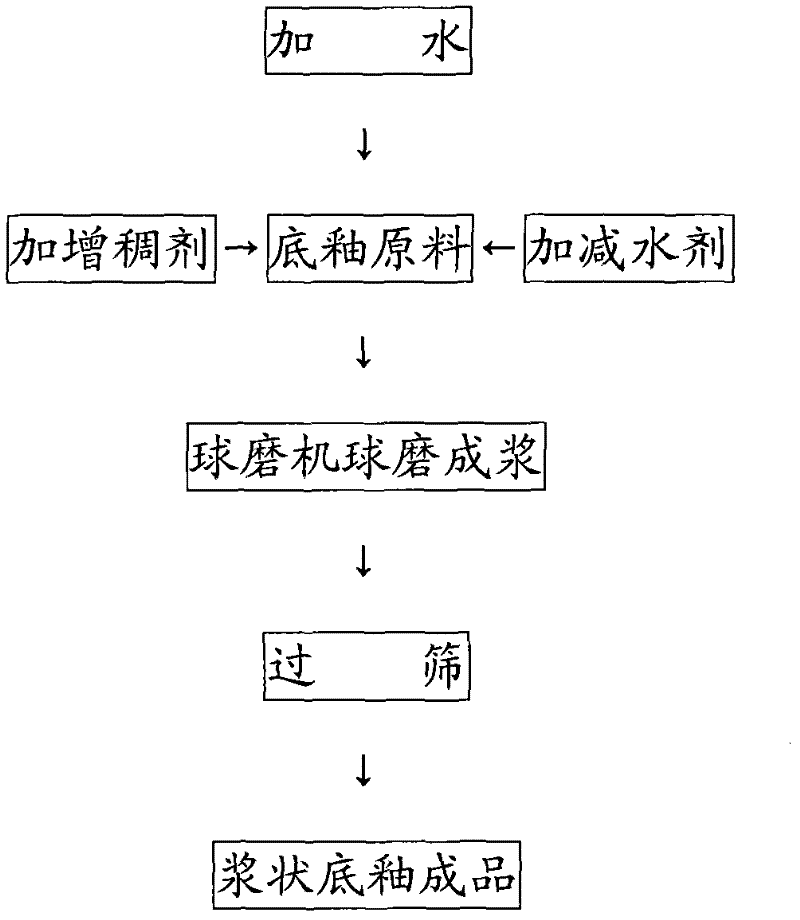

The invention provides a method for producing a base coat being matched with a blank and having an excellent glazing effect and relates to the technical field of building materials. Materials are selected within a preset component scope of the base coat and the technology is standardized. The method comprises the following steps: mixing roasted kaolin, quartz, potash feldspar, soda feldspar, calcite, steatite, dolomite, zinc oxide, zircon powder and nepheline, which are less than 100 meshes and are 2-30kg, thereby obtaining the raw materials of the base coat; adding thickening agents, water reducing agents and a right amount of water into the raw materials of the base coat, wherein the thickening agents and the water reducing agents are both 0.3-0.5% of the raw materials of the base coat; and putting into a ball mill, thereby milling into a slurry base coat end product, wherein the end product comprises the following chemical components: 40-60% of SiO2, 15-25% of Al2O3, 5-15% of CaO, 0-8% of MgO, 2-10% of K2O+Na2O, 0-8% of ZnO, 3-12% of ZrO3, 0-2% of thickening agents and water reducing agents, and the fineness is 0.4-0.5% of ten-thousand hole screening. The method is used for producing the base coat. The base coat is matched with the blank and is excellent in glazing effect.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Method for manufacturing high-strength direct-spreading knife-scraping tarpaulin

ActiveCN101117772AWaterproofOil-resistantLiquid surface applicatorsFibre treatmentPlasticizerHigh intensity

The present invention discloses a manufacturing method of tarpaulin with high strength and direct coating knife scraping, and the method is performed as per the following steps: (1)a composition with a certain weight including PVC paste resin, plasticizer, stabilizer, filling, fire resistant agent and painting is mixed to form coating agent; (2)the mixed coating agent is grinded and filtrated; (3)1-5kg cross-linking agent is added into each 100kg coating agent, and are evenly coated on a base cloth, and drying is executed; (4)after plasticizing and forming, surface treatment agent is used for treating. The tarpaulin manufactured with the method in the present invention has the advantages of waterproof, oil resistance, dirt resistance, fireproof, aging resistance, stripping resistance, etc., which can be used for carriage tarpaulin, carriage side curtain cloth and cloth for a container with the top opened; train tarpaulin and ship tarpaulin; building material, applied for building material for soft roof, such as a supermarket, a stadium and a sightseeing building; for military use, for temporary rest of the field army, headquarters during wartime, etc.

Owner:浙江锦达新材料股份有限公司

Aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and preparation method thereof

ActiveCN106349914AImprove performanceNo adverse phenomena such as whiteningAntifouling/underwater paintsPaints with biocidesWaxSurface finish

The invention relates to an aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and a preparation method thereof. The aqueous matt surface finishing agent is prepared from the following components: aqueous polyurethane resin, water, silicon dioxide matting powder, polysiloxane water dispersoid, aqueous wax emulsion, an aqueous wetting agent, an aqueous de-foaming agent and a thickening agent. The invention further relates to a preparation method of the aqueous matt surface finishing agent for the PVC leather. The aqueous matt surface finishing agent for the PVC leather, disclosed by the invention, has an excellent matt surface effect, a good heavy and skin feeling and a pollution-resisting performance and is aqueous and environment-friendly; meanwhile, the aqueous matt surface finishing agent has the advantages of good adhesive force, scratching resistance, bending resistance and forest resistance, and can meet the higher and higher requirements on skin feeling and pollution resistance of home decorations, electric appliances, furniture, automobile interiors and the like.

Owner:WANHUA CHEM GRP CO LTD +1

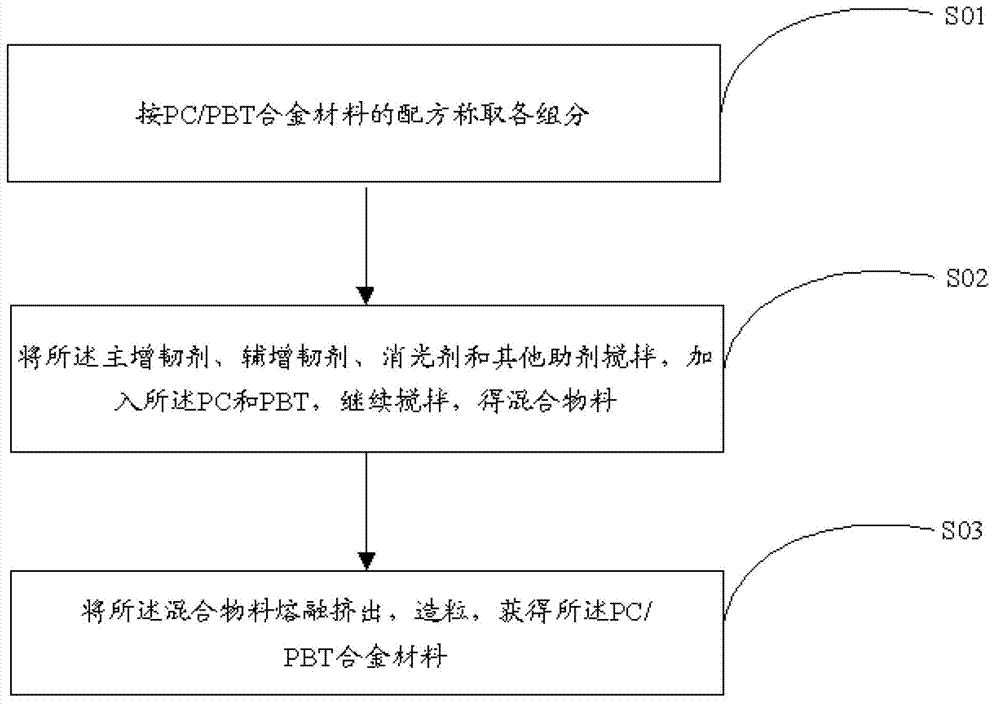

Low-luster PC/PBT (polycarbonate/polybutylene terephthalate) alloy material and preparation method thereof

InactiveCN102850746AMaterials are readily availableGood fluidityPolyethylene terephthalateAlloy composite

The invention provides a low-luster PC / PBT (polycarbonate / polybutylene terephthalate) alloy material which comprises the following components in percentage by weight: 60-72% of PC, 12-18% of PBT, 2-8% of main toughener, 1-4% of auxiliary toughener, 2-7% of flatting agent and 6-15% of other assistants. The main toughener is an ethylene-butyl methacrylate-glycidyl acrylate multipolymer, and the auxiliary toughener is a methyl methacrylate-butadiene-styrene impact modifier in a core-shell structure. The invention also provides a preparation method of the low-luster PC / PBT alloy composite material. The low-luster PC / PBT alloy material has the advantages of excellent comprehensive properties, favorable low-temperature-resistant effect and favorable matte effect, and can be used on automobile internal decorations, satellite receiving antenna and satellite signal receiver shells, and other devices in need of matting.

Owner:SHENZHEN KEJU NEW MATERIAL

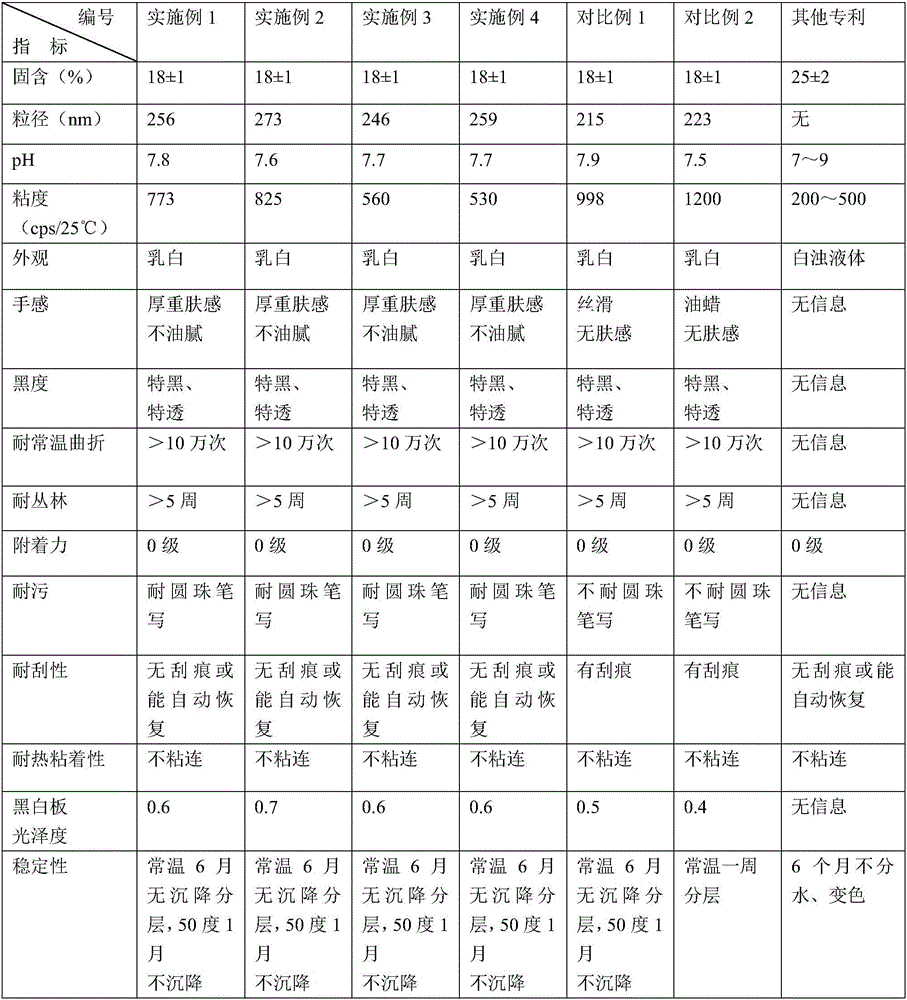

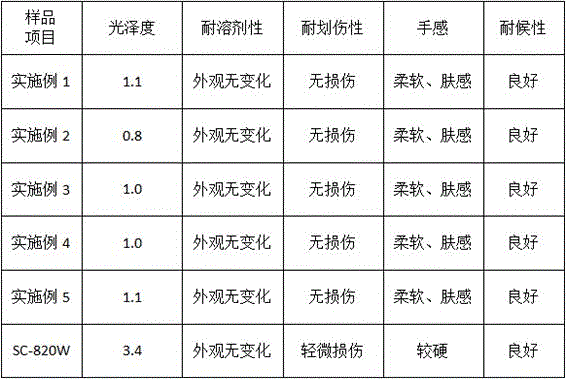

Waterborne polyurethane surface treating agent for synthetic leather and preparation method thereof

InactiveCN106634524AGood dispersionGood matte effectPolyurea/polyurethane coatingsTextiles and paperEmulsionWear resistant

The invention relates to a waterborne polyurethane surface treating agent for synthetic leather and a preparation method thereof. The waterborne polyurethane surface treating agent for the synthetic leather is formed by compounding, by weight, 40-50 parts of deionized water, 2-4 parts of silicon dioxide matting powder, 45-55 parts of waterborne polyurethane emulsion, 1.5-2.0 parts of highly-smooth organosilicon flatting agent, 2-4 parts of weak anion organosilicone wear-resistant agent, 3-5 parts of nonionic organosilicone feeling agent, 0.2-0.3 part of non-ionic waterborne defoamer and 1-2 parts of associative waterborne polyurethane thickening agent. The waterborne polyurethane surface treating agent has functional advantages of having skin touch and being matt and resistant to scratching and solvents.

Owner:LIAONING FIXED STAR FINE CHEM

Magic glazed tile and production method thereof

The invention discloses a magic glazed tile and a production method thereof. The method comprises orderly applying bottom glaze and surface glaze to a ceramic blank subjected to biscuiting through a glaze pouring device, carrying out ink-jet printing on the surface glaze through an ink-jet printer to obtain patterns, carrying out fixed-point printing on the patterns with matt convex glaze and bright convex glaze in turn through first and second silk-screen printing devices continuously arranged, when the ink-jet printing ink does not contain red ink, carrying out fixed-point printing on the patterns with bright red glaze through a third silk-screen printing device and applying candy glaze to the surface of a tile. The method can produce the glazed tiles with matt and bright gloss patterns on the surface. The magic glazed tile has good three-dimensional feeling and soft light and high contrast ratio patterns similar to embossment on the tile surface. The matt convex glaze and bright convex glaze have a high coincidence degree and clear edges, through use of bright red glaze for embellishment, the patterns are lifelike and through use of the candy glaze, the four types of decorative effects makes the tile surface clear and vivid and the whole tile surface shows a magical decorative effect.

Owner:广东协进陶瓷有限公司

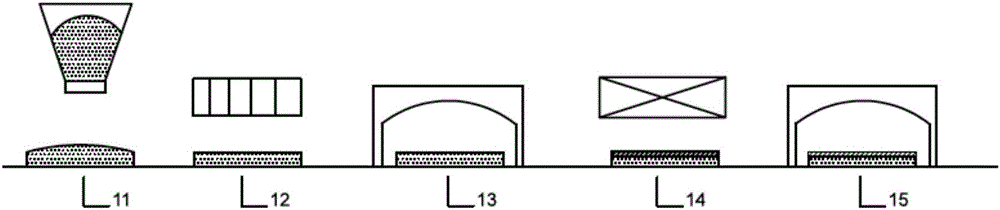

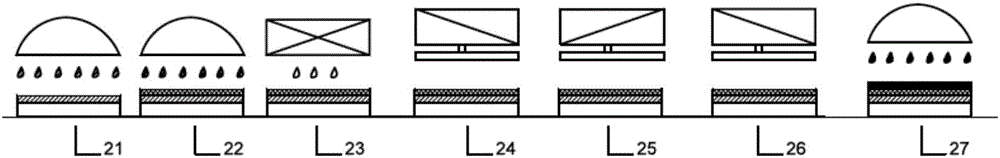

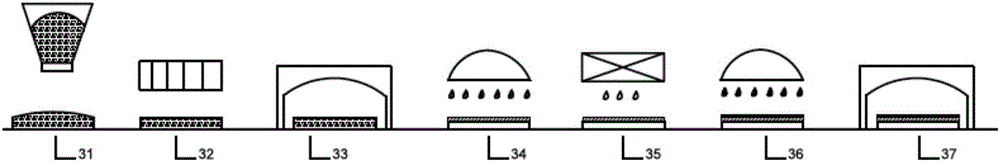

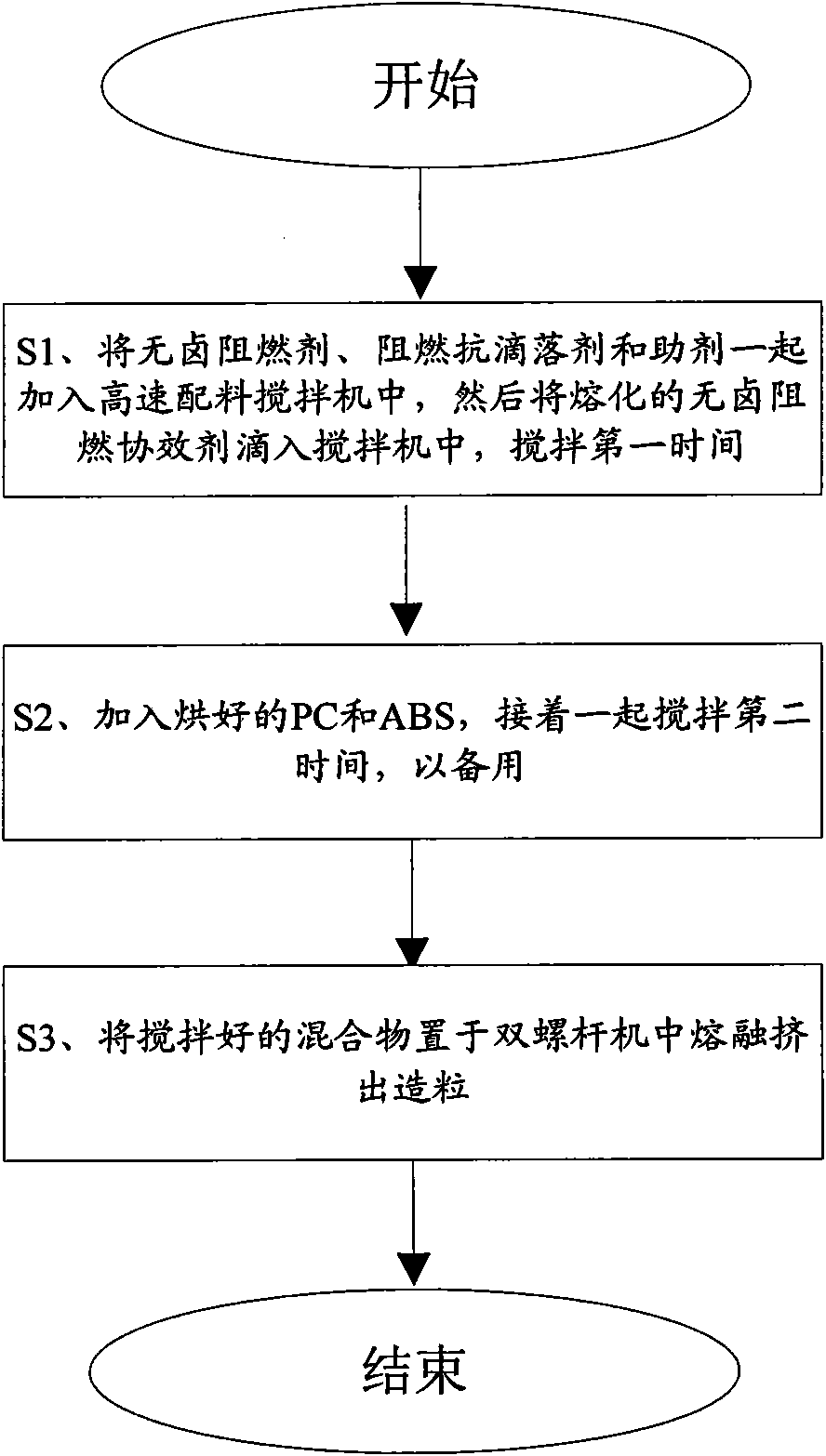

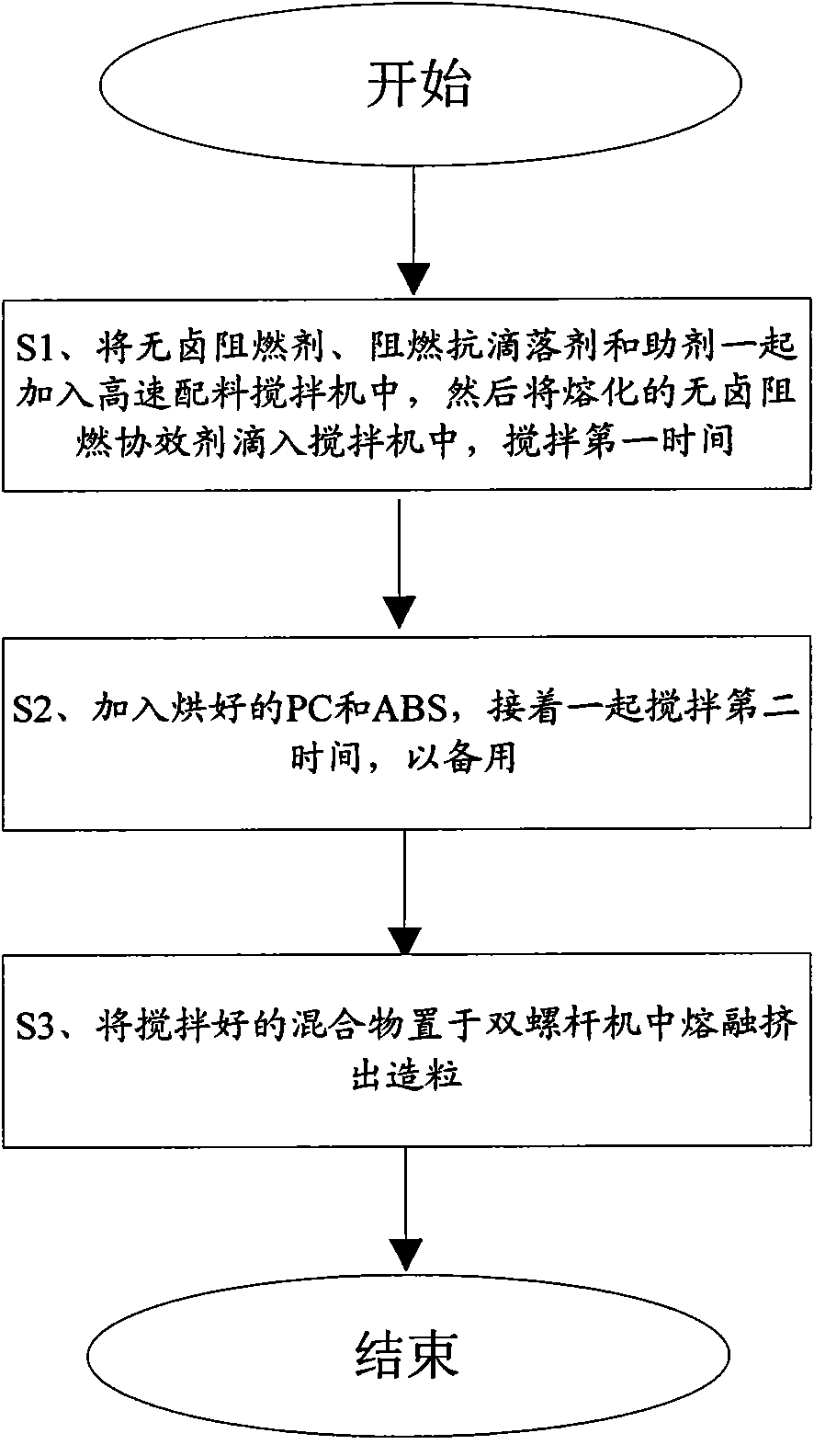

PC/ABS alloy and preparation method thereof

The invention relates to a PC / ABS alloy and a preparation method thereof.The method comprises the following steps: S1. adding non-halogen flame-retardant agent, inflaming retarding and anti-drippage agent into a high-speed burdening agitator, then dropwise adding melted non-halogen flame-retardant synergist into the agitator and agitating for a first time; S2. adding dried PC and ABS and agitating for a second time for standby use; S3. placing the agitated mixture in a double-screw machine for melt extrusion for pelleting.The prepared PC / ABS alloy comprises the following raw materials according to parts by weight: 60-68 parts of PC, 12-18 parts of ABS, 7-12 parts of non-halogen flame-retardant agent, 1-3 parts of non-halogen flame-retardant synergist, 0.1-1 part of inflaming retarding and anti-drippage agent and 6-20 parts of auxiliary.The PC / ABS alloy features good inflaming retarding effect and good comprehensive property and is halogen-free and environment-friendly; in addition, the alloy features fine suboptical effect and can be applied to components such as automobile upholsteries in need of suboptical effect and the like.

Owner:徐东

Single-face matt polyester film and preparation method thereof

InactiveCN101259771AGood matte effectHigh light transmittanceSynthetic resin layered productsPolyesterSurface layer

The invention discloses a single-side matt polyester film with a layered structure comprising at least a first film layer and a second film layer which are co-extruded, compounded with each other and arranged next to each other; the first film layer is arranged on the surface layer of the polyester film and is a matt layer, which contains 50 to 80 wt percent of the polyester, 20 to 50 wt percent of nylon polymer and 0 to 0.5 wt percent of crystal nucleating promoter; the second film layer is a highly transparent layer, the main component of which is the polyester. The invention also discloses a method for manufacturing the single-side matt polyester film. As the method does not require the aforehand special preparation of the matt master batch, the whole process is simple. The manufactured polyester film not only has favorable matt effect, but also has excellent transmittance and is in particular applicable to the use for printing, aluminum plating and compounding in the field of packaging.

Owner:WEIFANG FUWEI PLASTIC

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

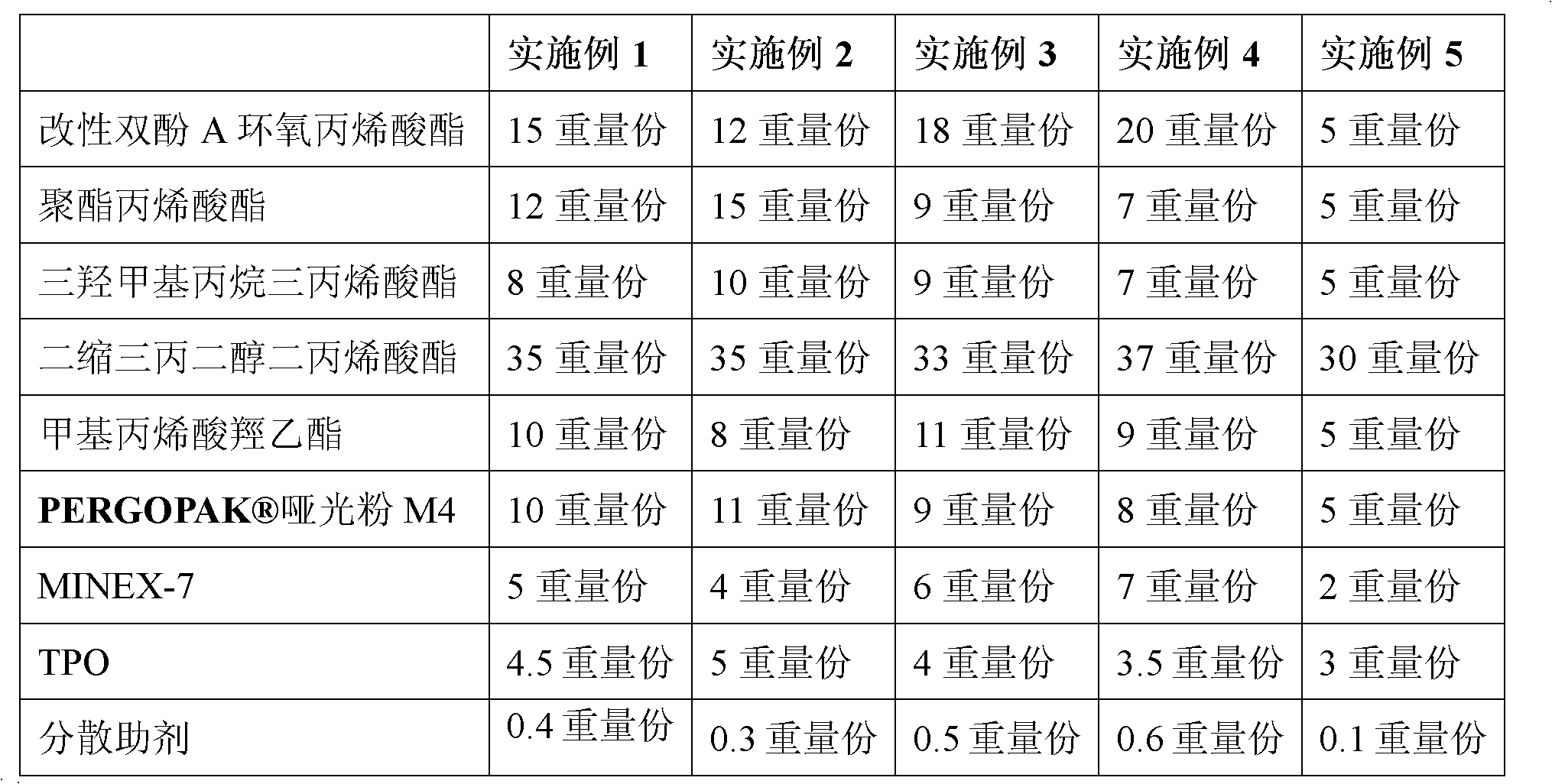

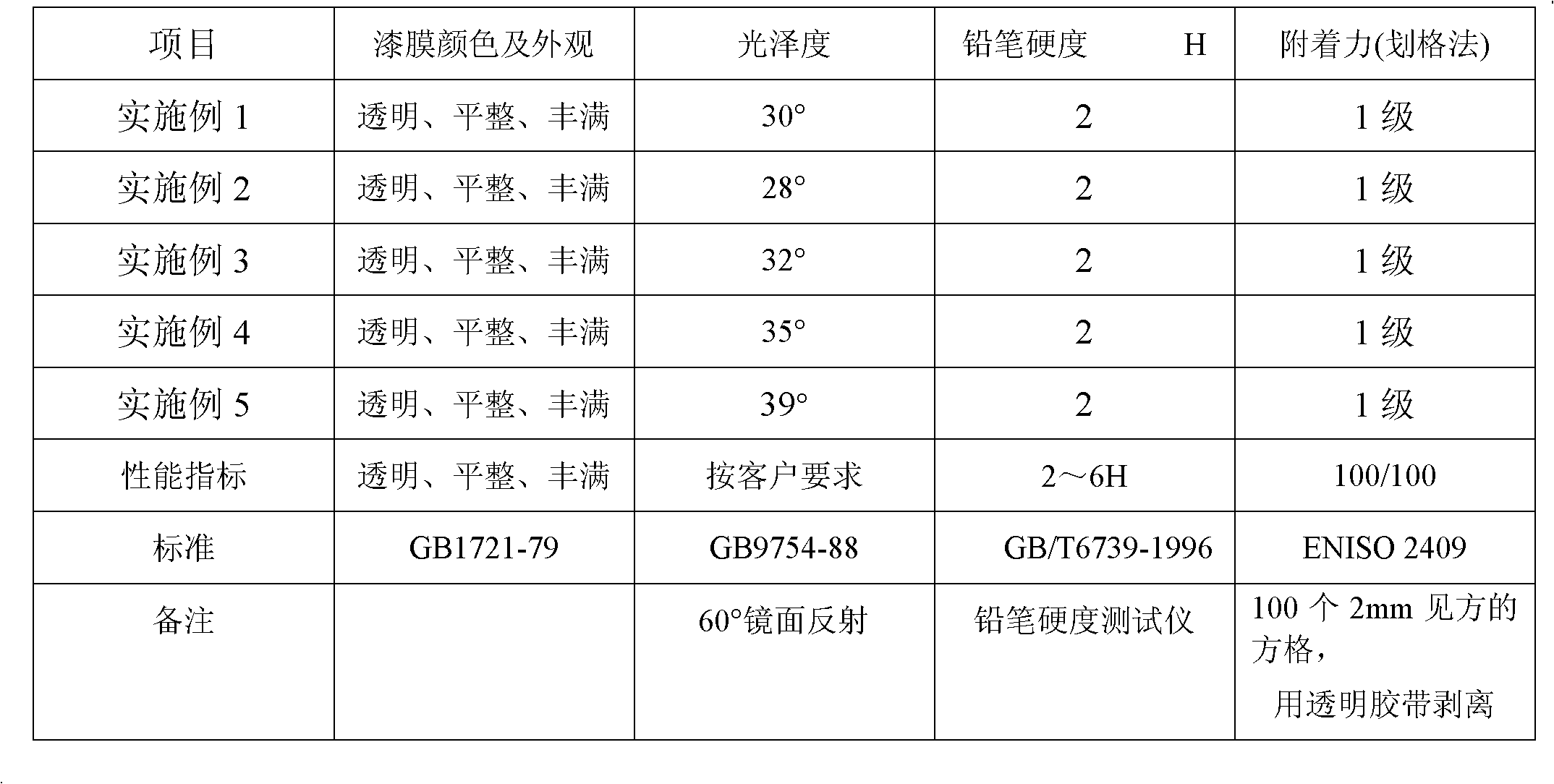

Ultraviolet ray-curable low-gloss flow-coating paint and preparation method thereof

ActiveCN102533063AGood matte effectImprove liquidityEpoxy resin coatingsPolyester coatingsPolyesterUltraviolet

The invention discloses an ultraviolet ray-curable low-gloss flow-coating paint and a preparation method thereof. The ultraviolet ray-curable low-gloss flow-coating paint comprises the following components in part by weight: 5-20 parts of modified bisphenol A epoxy acrylate, 5-15 parts of polyester acrylate, 5-15 parts of three-functional active monomer, 30-40 parts of two-functional active monomer, 5-15 parts of monofunctional active monomer, 5-15 parts of organic matting powder, 2-10 parts of MINEX-7, 3-10 parts of ultraviolet ray initiator and 0.1-1 part of additive. The preparation method comprises the following steps of: adding components except the organic matting powder and the MINEX-7 into a high-speed dispersion kettle according to the parts by weight; after uniformly stirring, adding the organic matting powder and the MINEX-7, and continuously dispersing uniformly; vacuumizing, and deforming; and painting a surface in a flow-coating way; and after detection, technical indexes of the painted surface are good and the gloss is below 30 degrees.

Owner:JIANGSU LITIAN TECH

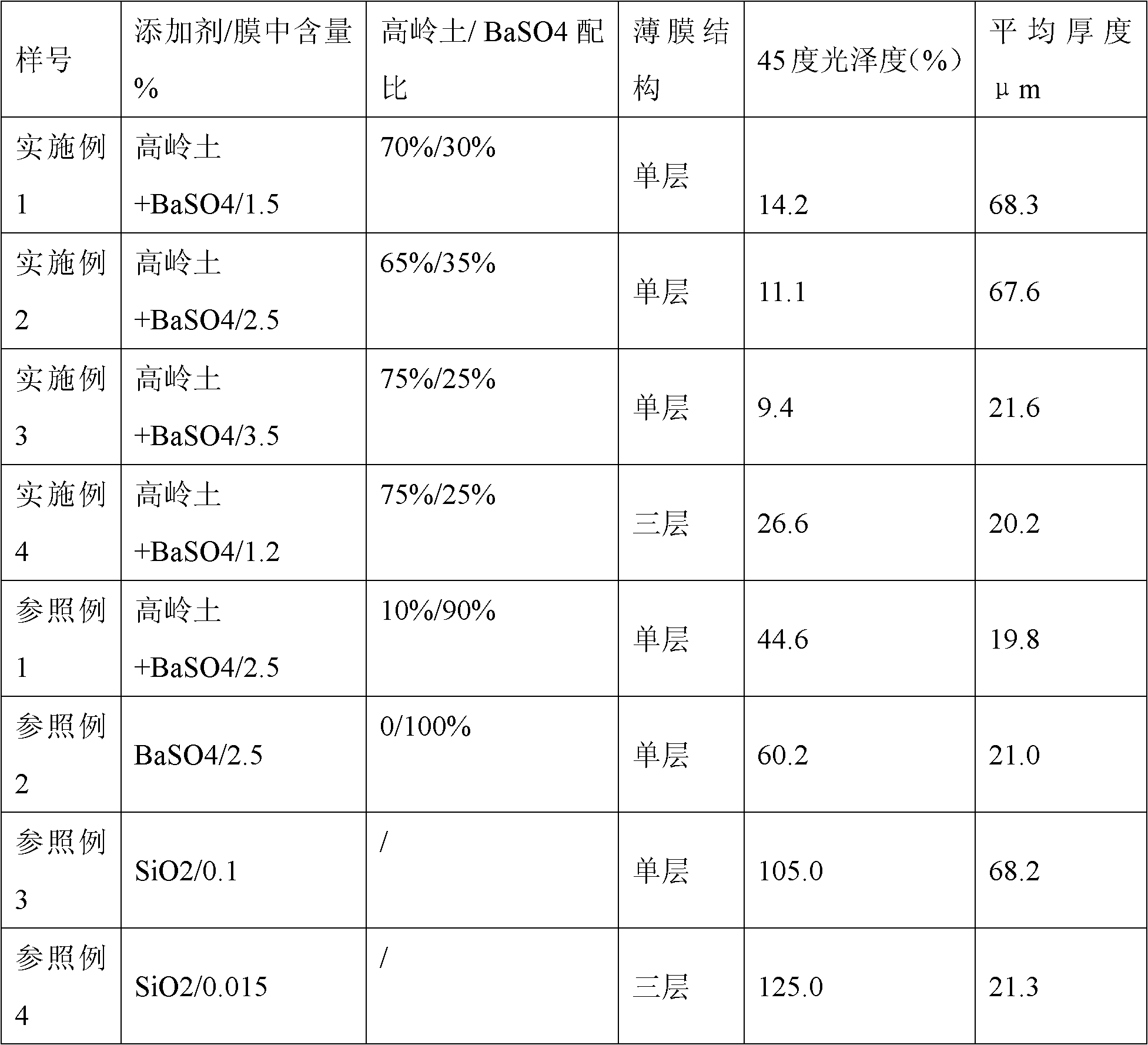

Matt polyester film preparation method

ActiveCN103102474AMatte effect is goodHigh glossSynthetic resin layered productsFlat articlesPolyesterChemistry

The invention discloses a matt polyester film preparation method, which comprises that: a dibasic acid, a dihydric alcohol and an additive dispersion liquid are subjected to an esterification reaction under an effect of a catalyst; a stabilizer is added to carry out a condensation polymerization reaction to obtain a matt film polyester; the matt film polyester is subjected to drying, melt extrusion at a temperature of 270-290 DEG C, vertical and horizontal double direction stretching, heat shaping, relaxing, cooling, traction and rolling to prepare the matt polyester film having a single layer or multi-layer structure, wherein the vertical and horizontal double direction stretching is performed at a temperature of 80-120 DEG C and under a stretching ratio of 3.0-4.0:1, the additive in the additive dispersion liquid comprises 60-80% by mass of kaolin and 40-20% by mass of barium sulfate, and an average particle size of the additive is 0.3-0.5 mum. Compared to the conventional polyester film, the matt polyester film prepared by the method has a good matt effect, wherein 45 DEG gloss is less than 30%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Black matte polyimide film and preparation method thereof

The invention discloses a polyacrylonitrile-blended black matte polyimide film and a preparation method thereof. Polyacrylonitrile and polyamide acid are prepared by virtue of an in situ polymerization method to form a blended solution with a molecular interpenetrating network. The preparation method comprises the following steps: mixing polyacrylonitrile powder particles with a high-polarity nonprotic organic solvent, heating, stirring to adequately dissolve, cooling, adding aromatic binary primary amine, after the dissolving is complete, adding aromatic binary anhydride, heating and stirring to obtain a uniform blended solution in which polyacrylonitrile and polyamide acid are in micro-phase separation, wherein different separation phase domains can be obtained by selecting polyacrylonitrile with different weight-average molecular weights; and carrying out salivation, drying, heating and amination on the blended solution, so as to obtain the black matte polyimide film. The black matte polyimide film has relatively high power frequency electric strength, excellent mechanical properties, extremely low light transmittance and a good black matte effect.

Owner:无锡高拓新材料股份有限公司

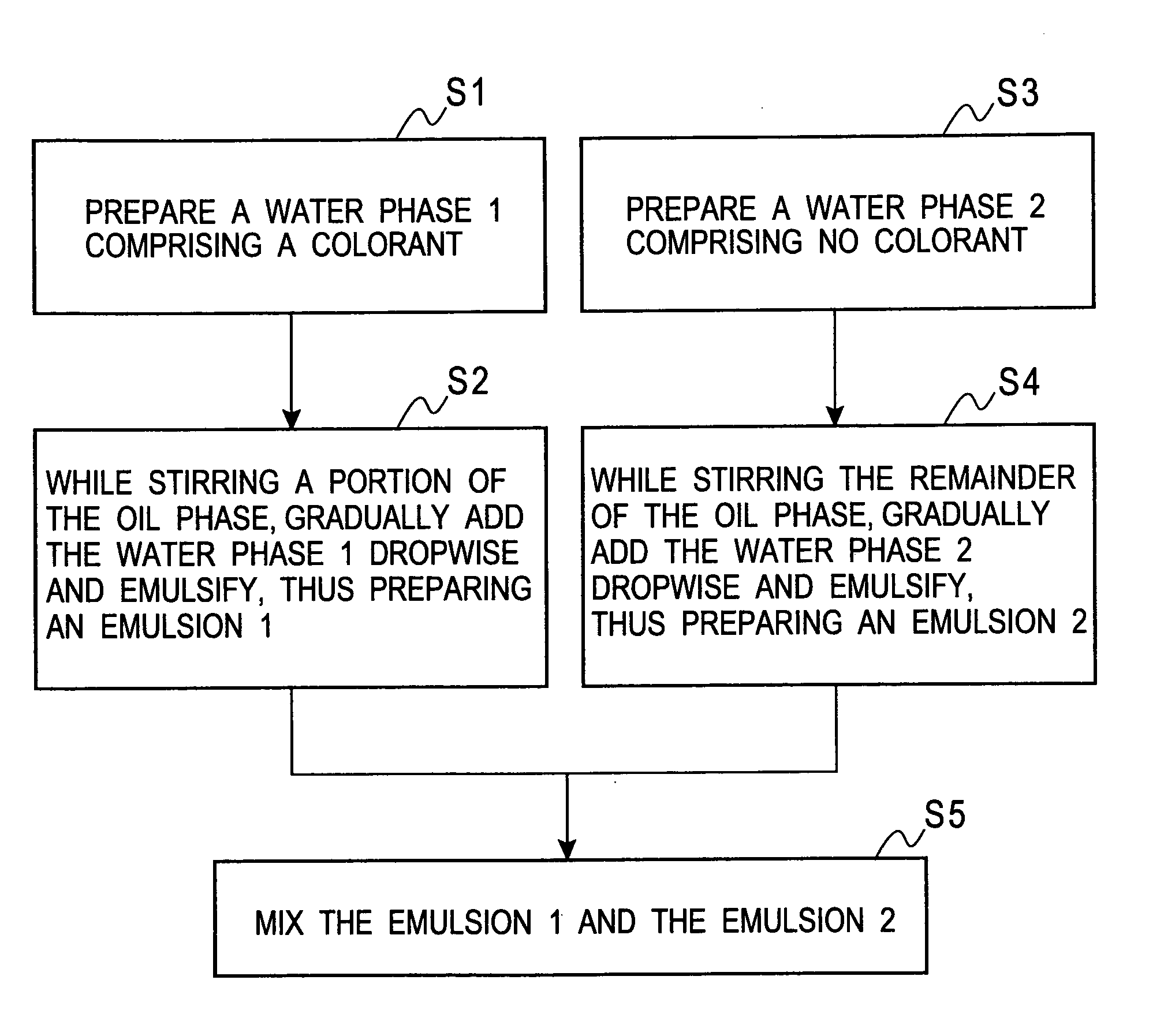

Emulsion ink and method for producing same

ActiveUS20100086693A1High printing densityHigh densityDuplicating/marking methodsInksImaging qualityWater in oil emulsion

An emulsion ink capable of generating a printed image quality having favorable print density and a favorable matte finish. A water-in-oil emulsion ink having an oil phase and a water phase, wherein the ink has a first water phase comprising a colorant and a second water phase comprising no colorant, and the amount (mass) of the first water phase is less than the amount (mass) of the second water phase.

Owner:RISO KAGAKU CORP

Cosmetic use of a composition including an ascorbic acid compound and polyamide particles

InactiveUS20060057092A1Slowing down production of sebumGood matte effectCosmetic preparationsToilet preparationsPolymer scienceOil emulsion

The present invention relates to the cosmetic use, for the care of greasy skin, of a composition including, in a physiologically acceptable medium, (a) at least one water-soluble ascorbic acid compound and (b) porous polyamide particles having a mean diameter, by volume, of less than or equal to 10 μm, provided that the composition is not a water-in-oil emulsion.

Owner:LOREAL SA

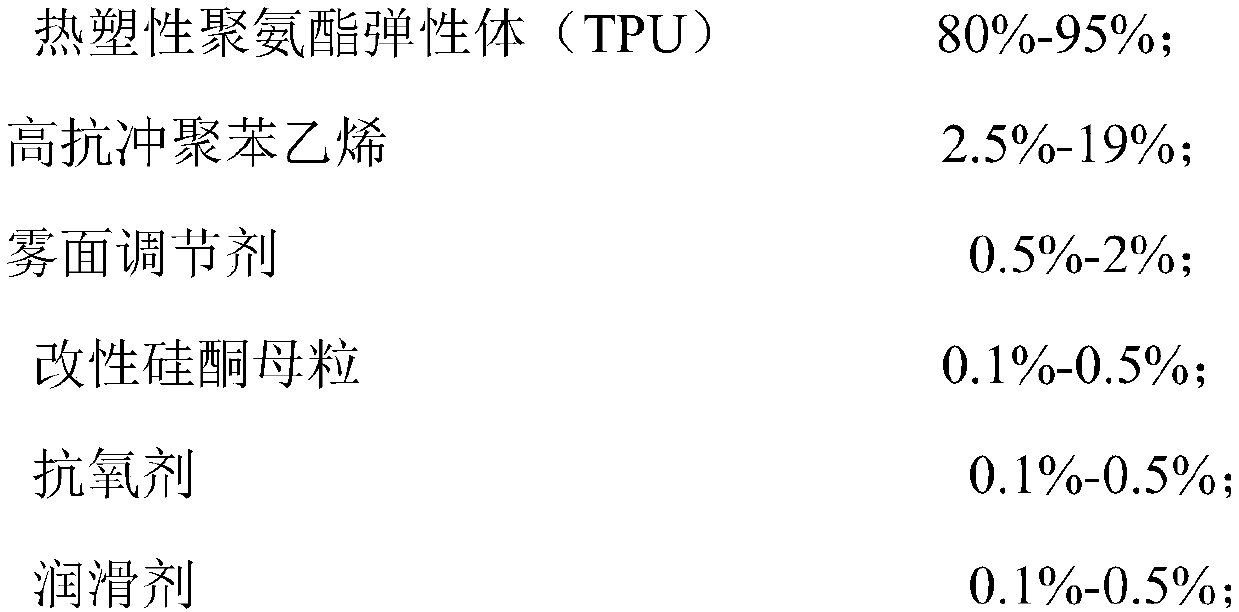

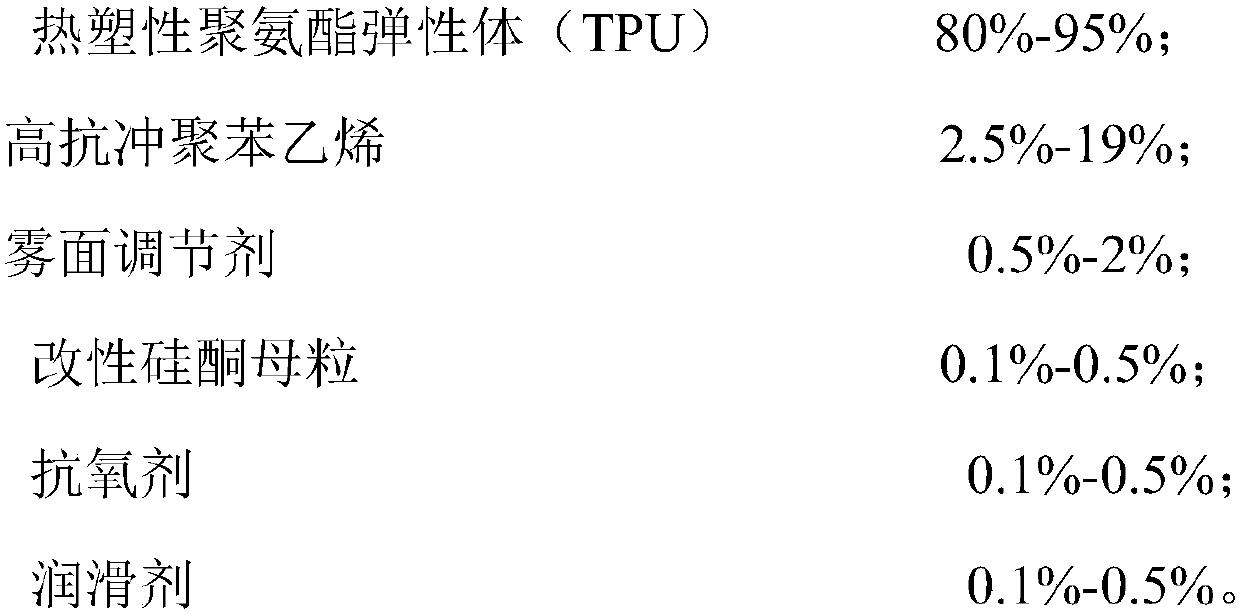

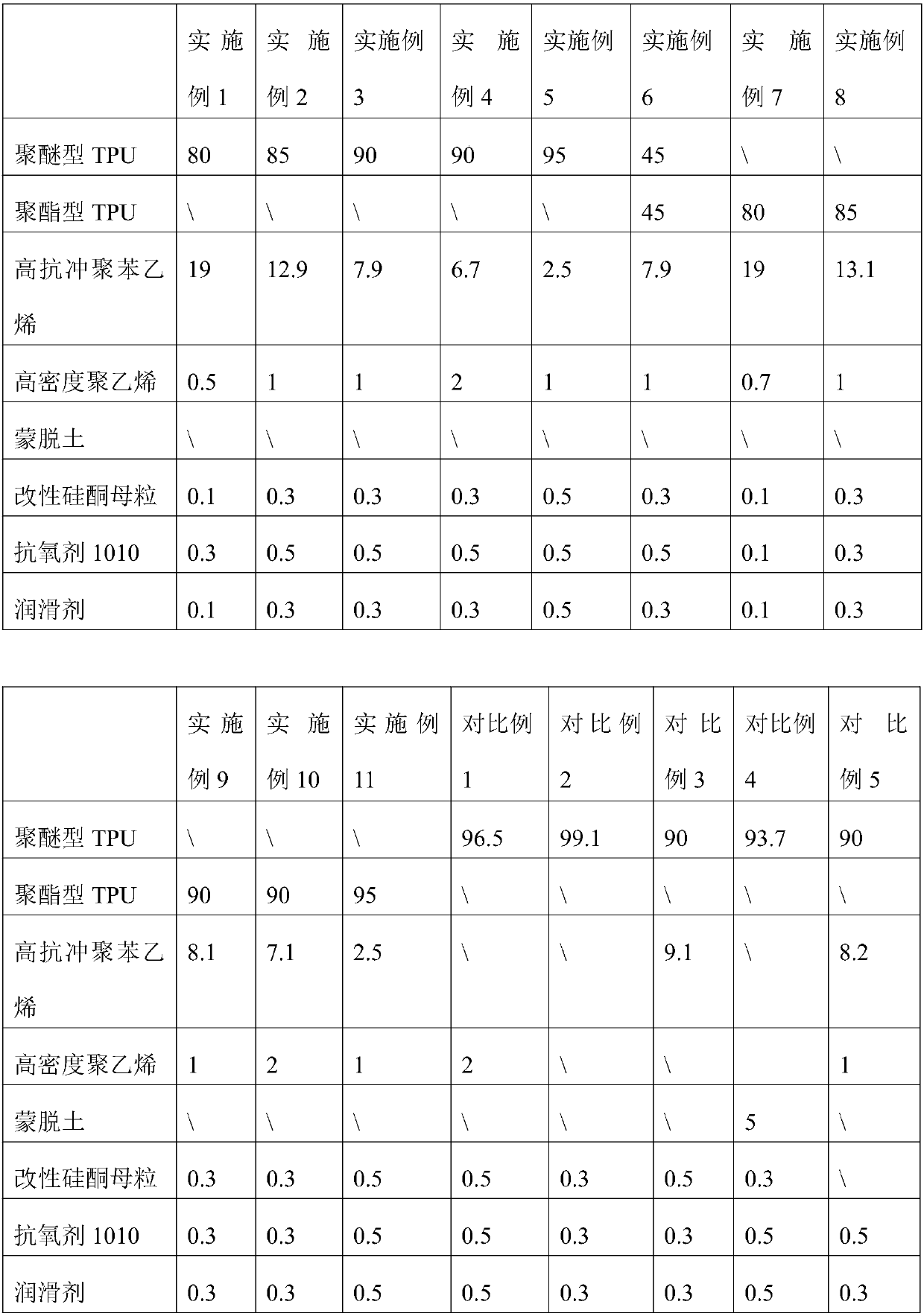

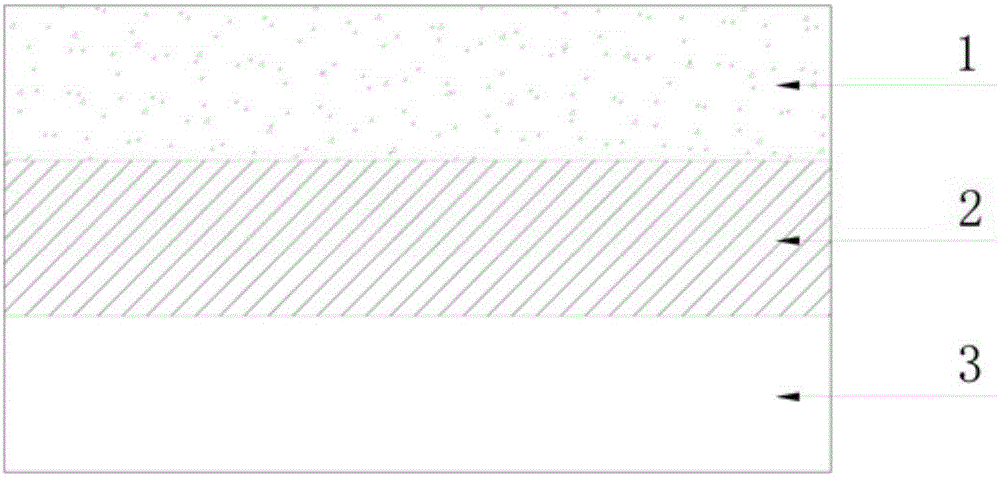

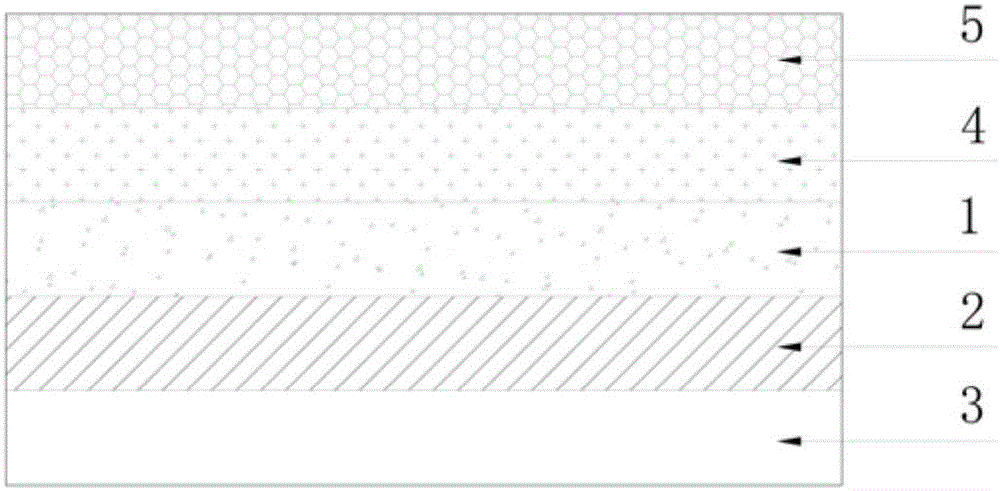

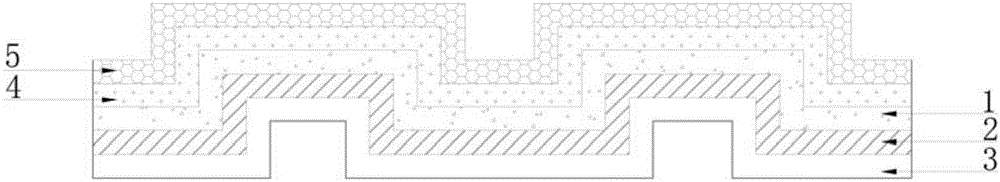

High-physical-property matte thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN108102347AImprove the disadvantages of reduced physical properties and poor matte effectGood matte effectAntioxidantThermoplastic polyurethane

The invention discloses a high-physical-property matte thermoplastic polyurethane elastomer and a preparation method thereof. The high-physical-property matte thermoplastic polyurethane elastomer is prepared from the following ingredients in percentage by mass: 80 to 95 percent of thermoplastic polyurethane elastomer, 2.5 to 19 percent of high impact polystyrene, 0.5 to 2 percent of matte surfaceregulating agents, 0.1 to 0.5 percent of modified silicone master batch, 0.1 to 0.5 percent of antioxidant and 0.1 to 0.5 percent of lubricating agent. Compared with the prior art, the high-physical-property matte thermoplastic polyurethane elastomer has the advantages that the matte surface effect is good; the cost is lower; the defects of material physical property reduction due to the use of inorganic matte surface agent and poor matte surface effect are avoided; the defect of higher cost due to the use of other organic macromolecular material matte surface agents is avoided; in addition, the processing process can be regulated according to practical requirements to obtain the ideal matte effect.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

Coated mist release paper

InactiveCN102704333AGood film formingGood combination fastnessNon-fibrous pulp additionCoatings with pigmentsBenzoyl peroxidePolyvinyl alcohol

The invention discloses coated mist release paper which is obtained by coating a matte lamination release agent on raw paper. According to a material formula, the matte lamination release agent consists of 15-70% of polyvinyl alcohol aqueous solution, 20-65% of emulsion type organosilicon release agent, 6-12% of stabilizer, 0.3-2% of emulsifier, 1.2-4.5% of catalyst, 0.5-3.5% of crosslinking agent and 2-10% of matting filler. The stabilizer is at least one of agar, gelatin and water-soluble starch; the emulsifier is at least one of sodium polyphosphate, Twain 80 and tributyl phosphate; the catalyst is platinum catalyst or benzoyl peroxide; and the crosslinking agent is methyl hydrogen polysiloxane oil. The coated mist release paper is simple in production technology flow, low in cost and convenient in operation.

Owner:斯迪克新型材料(江苏)有限公司

IMR (in-mold decoration by roller) matte ink and preparation and application methods thereof

The invention belongs to the technical field of inks and particularly relates to IMR (in-mold decoration by roller) matte ink and preparation and application methods thereof; the IMR matte ink is characterized by being made from, by weight, 20-30% of resin, 0-1% of a filling material, 3-20% of a dulling material, 0.2-1% of an aid, and 48-76.8% of a solvent. The IMR matte ink may replace matte coating spraying process, IMR printed surface can be matted, the cost is low, the yield is high, VOCs (volatile organic compounds) emission is low, and the IMR matte ink preparation and application methods are simple and feasible and high in efficiency and use small space.

Owner:CHINA PAINT MFG CO SHENZHEN

High-toughness matte modified polylactic acid material for 3D printing and preparation method of high-toughness matte modified polylactic acid material

ActiveCN109575539AImprove poor toughnessImprove anti-agingAdditive manufacturing apparatusElastomerAntioxidant

The invention relates to a high-toughness matte modified polylactic acid material for 3D printing and a preparation method of the high-toughness matte modified polylactic acid material. The modified polylactic acid material is prepared from, by weight, 100 parts of polylactic acid, 10-15 parts of a main toughening agent, 5-8 parts of an auxiliary toughening agent, 20-40 parts of filler, 3-6 partsof silicon dioxide matting powder, 0.1-0.5 part of a titanate coupling agent, 0.1-0.6 part of an antioxidant, 0.1-0.6 part of a light stabilizer and 0.2-0.5 part of a lubricant, wherein the main toughening agent is a soft-core hard-shell type core-shell copolymer with methyl methacrylate as a shell, the auxiliary toughening agent refers to an elastomer toughening agent containing anhydride or epoxy group, and the filler refers to barium sulfate powder or calcium carbonate powder. The high-toughness matte modified polylactic acid material for 3D printing is excellent in toughness, remarkable inaging resistance and great in matte surface effect.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Novel water-based low-gloss ultraviolet-curable paint and preparation and application methods thereof

InactiveCN109666396AAvoid Jelly-like PhenomenaDelicate feelPolyurea/polyurethane coatingsPolyether coatingsWaxWater based

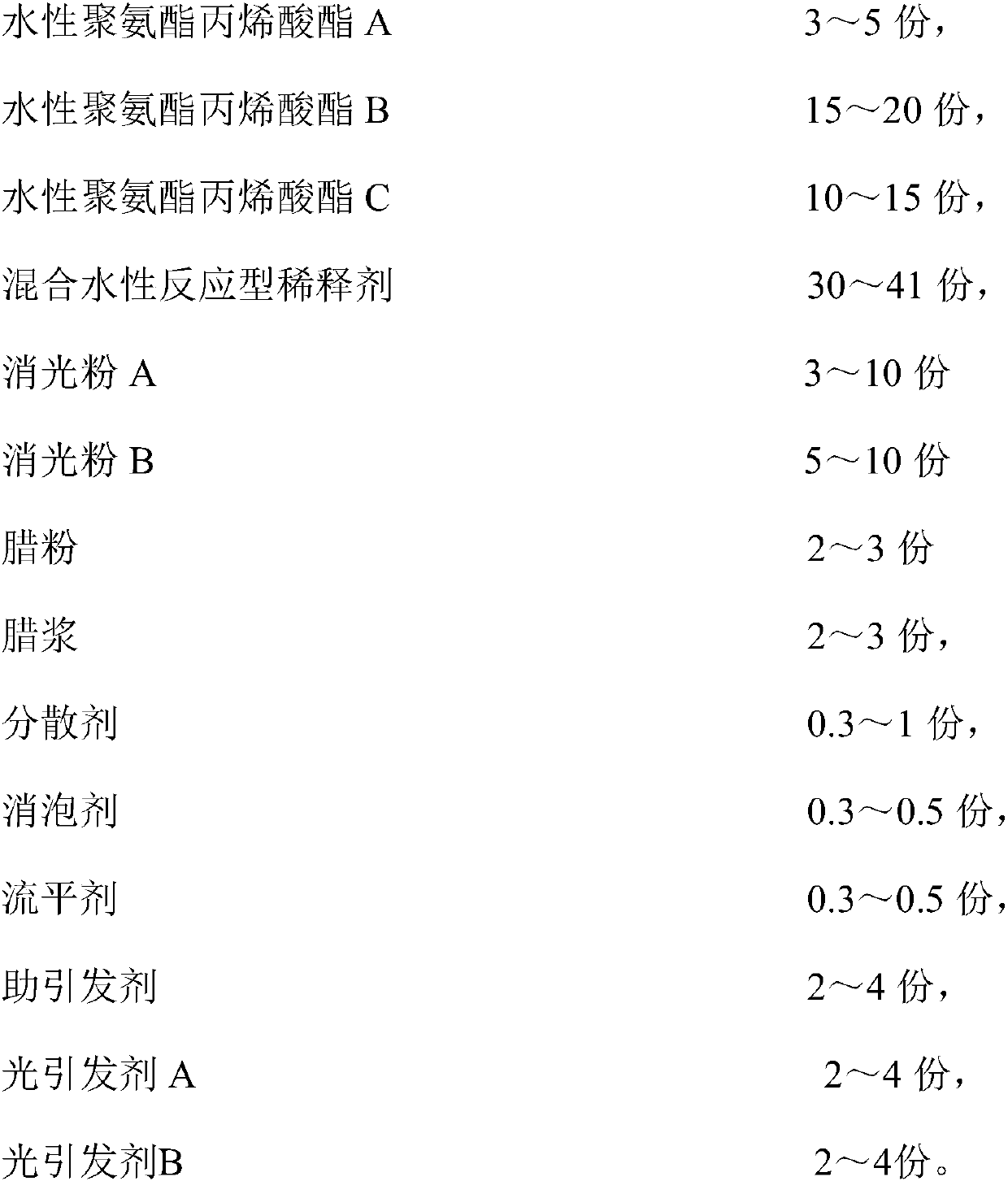

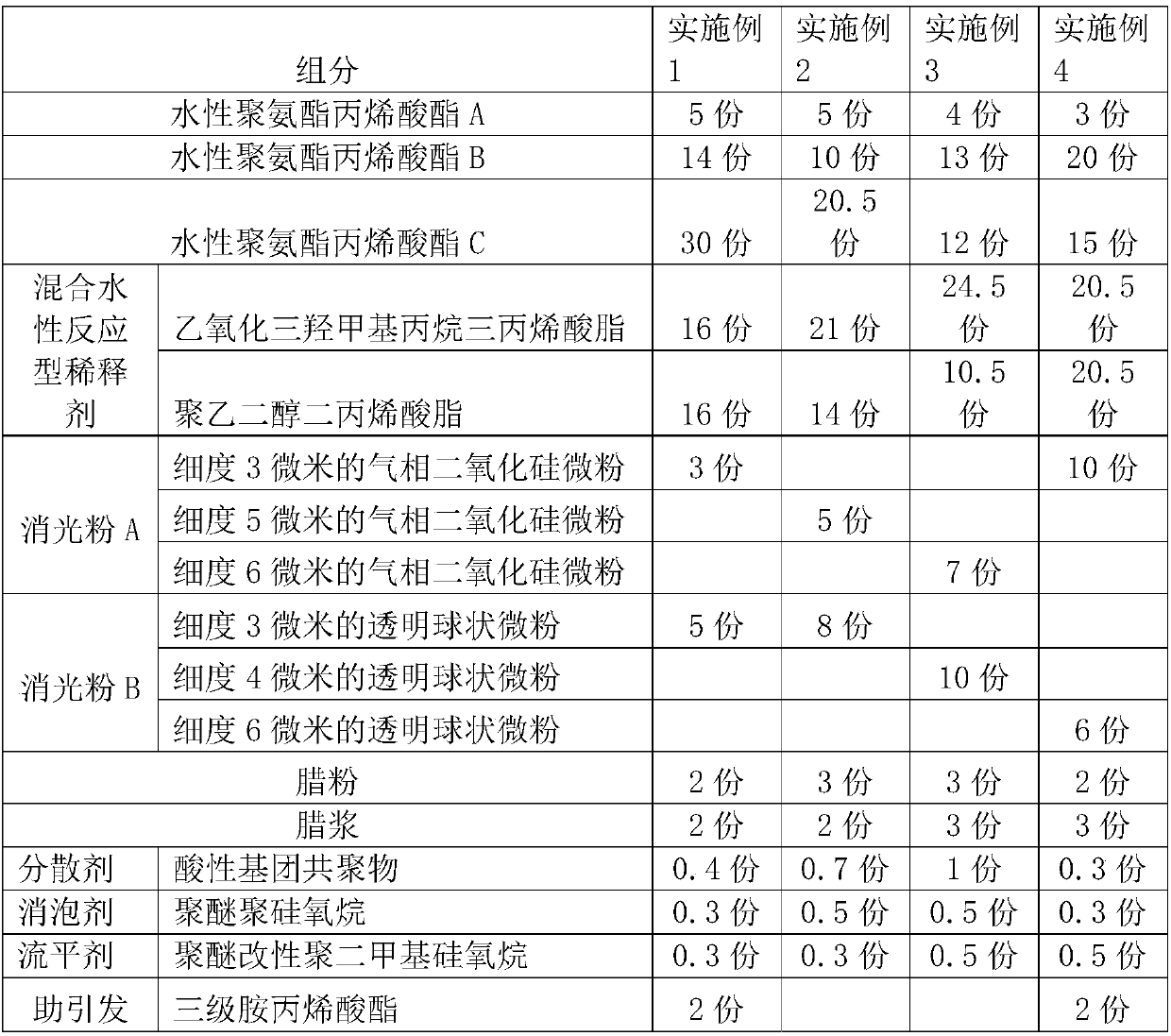

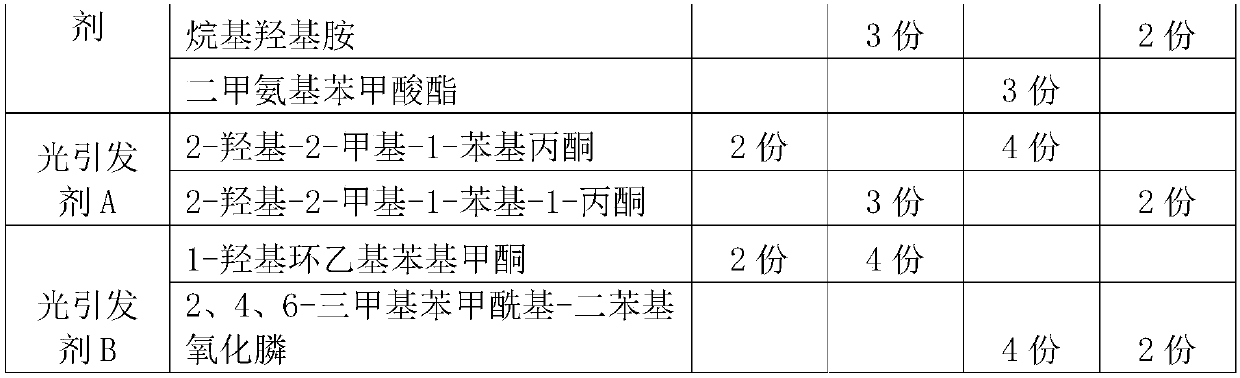

The invention discloses a novel water-based low-gloss ultraviolet-curable paint and preparation and application methods thereof. According to the technical scheme, the novel water-based low-gloss ultraviolet-curable paint is composed of, by weight part, 3-5 parts of waterborne polyurethane acrylate A, 15-20 parts of waterborne polyurethane acrylate B, 10-15 parts of waterborne polyurethane acrylate C, 30-41 parts of mixed waterborne reactive diluent, 3-10 parts of matting powder A, 5-10 parts of matting powder B, 2-3 parts of wax powder, 2-3 parts of wax slurry, 0.3-1 part of dispersing agent,0.3-0.5 part of defoaming agent, 0.3-0.5 part of flatting agent, 2-4 parts of auxiliary initiator, 2-4 parts of photoinitiator A and 2-4 parts of photoinitiator B. According to the novel water-basedlow-gloss ultraviolet-curable paint and the preparation and application methods thereof, the novel water-based low-gloss ultraviolet-curable paint can achieve level-5 matting effects after being dried, and meanwhile, is uniform in surface gloss, fine in hand feeling, high in transparency and resistance to coin scratching and applicable to ultralow-matting products.

Owner:张聪聪

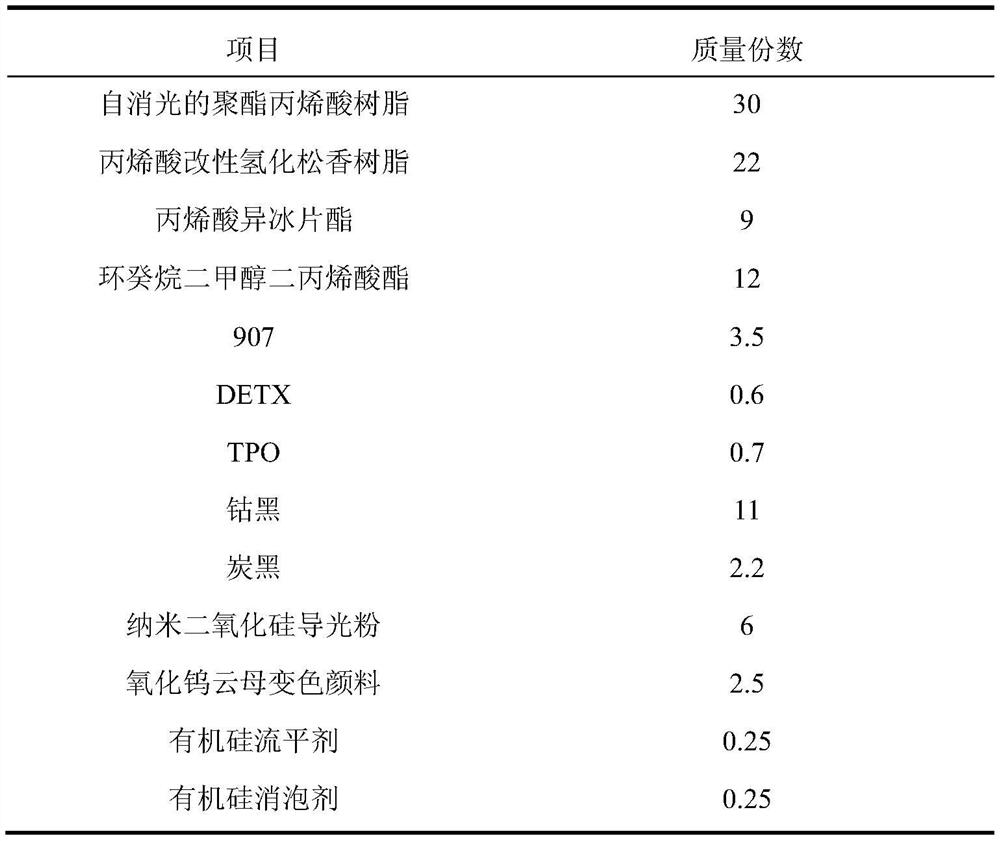

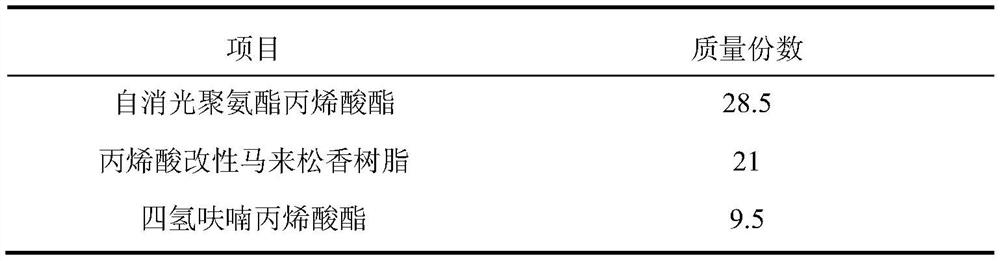

LED UV-cured black ink, preparation method and application thereof

The invention discloses LED UV-cured black ink, which comprises, by weight, 20 to 40 parts of self-extinction light-cured resin, 15 to 35 parts of acrylic acid modified rosin resin, 5 to 15 parts of UV monofunctional monomer, 5 to 20 parts of UV multifunctional monomer, 1 to 10 parts of photoinitiator, 0.5 to 8 parts of photochromic pigment, 5 to 20 parts of inorganic black pigment, 3 to 15 partsof light guide powder, 0.5 to 5 parts of carbon black, 0.05 to 0.5 part of leveling agent and 0.05 to 0.5 part of defoamer. According to the LED UV-cured black ink, an LED UV curing technology is creatively adopted, photochromism and light guide technologies are combined, a wet film is formed after a base material is coated with the black ink with high covering power, the same curing efficiency ofthe wet film from the surface to the bottom is achieved through LED UV light curing, and a coating formed after curing meets the performance requirement of thermocuring ink.

Owner:HUNAN SOKAN NEW MATERIAL

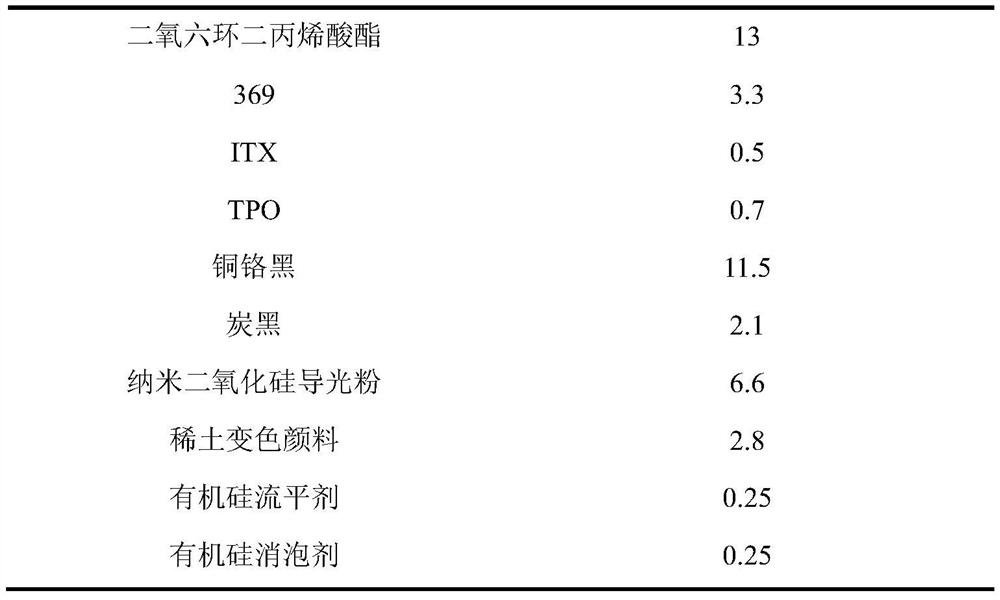

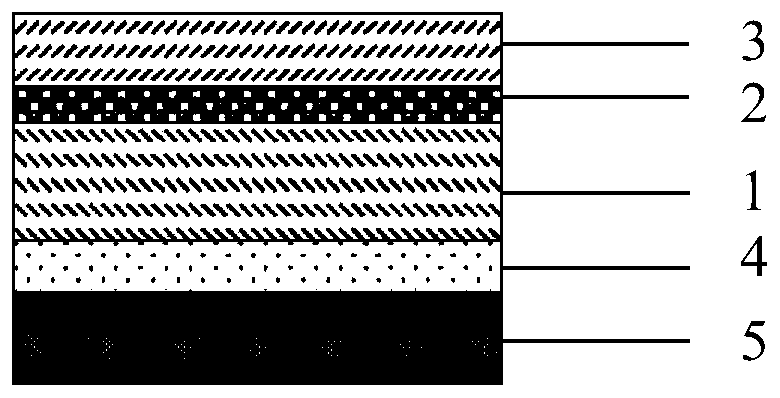

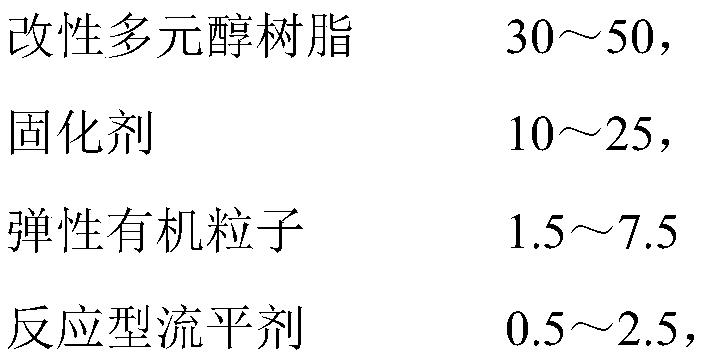

Matt paint face protection film

ActiveCN109735249AAddresses self-healing performance degradationGood matte effectFilm/foil adhesivesPolyurea/polyurethane coatingsTectorial membraneEngineering

The invention discloses a matt paint face protection film which comprises a transparent supporting body. A matt self-repair layer and a transparent protection film are sequentially arranged on one optical surface of the transparent supporting body, assembly glue and a semi-transparent release film are sequentially arranged on another optical surface of the transparent supporting body, the matt self-repair layer is formed by coating self-repair coating liquid and then heating for curing, the self-repair coating liquid contains elastic organic particles, modified polyol resin, curing agent and other components, particle size of the elastic organic particles is 1-5um, and the curing agent is formed by mixing a curing agent 1 and a curing agent 2 according to a proportion of 2:1-5:1. The mattpaint face protection film is high in matt effect and self-repair effect, has yellowing resistance and antifouling performance and can be applied in the field of paint face protection of automobile surfaces.

Owner:HEFEI LUCKY SCI & TECH IND

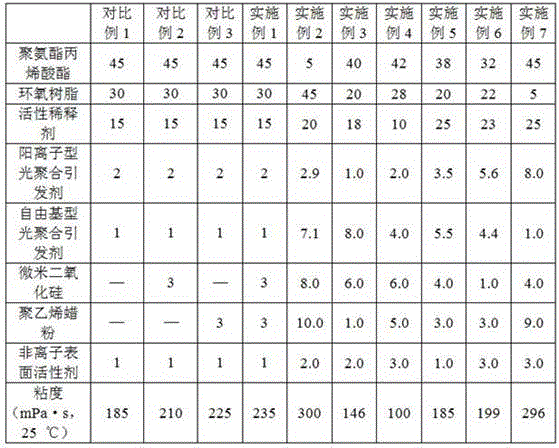

Matte photosensitive resin for photocuring quick molding and preparation method thereof

InactiveCN106647167AGood matte effectImprove surface qualityAdditive manufacturing apparatusPhotosensitive materials for photomechanical apparatusUrethane acrylateReactive diluent

The invention discloses matte photosensitive resin for photocuring quick molding and a preparation method thereof. The resin is prepared from the following raw materials in parts by weight: 5-45 parts of urethane acrylate, 5-45 parts of epoxy resin, 10-25 parts of reactive diluent, 1-8 parts of cationic photoinitiator, 1-8 parts of free radical photoinitiator, 1-10 parts of micron silicon dioxide, 1-10 parts of polyethylene wax powder and 1-3 parts of nonionic surfactant. The photosensitive resin has an excellent matte effect due to the addition of micron silicon dioxide and polyethylene wax powder after photocuring quick molding, and clear printing textures on the surface of a molded part manufactured by photocuring quick molding cannot be observed due to the introduction of the matte effect, so that the surface quality of the molded part can be remarkably improved. Therefore, the manufactured three-dimensional solid has better mechanical performance, the shrinkage and warpage situation of the molded part can be reduced, the printing accuracy can be improved, and the practicality is stronger.

Owner:HENAN INST OF ENG

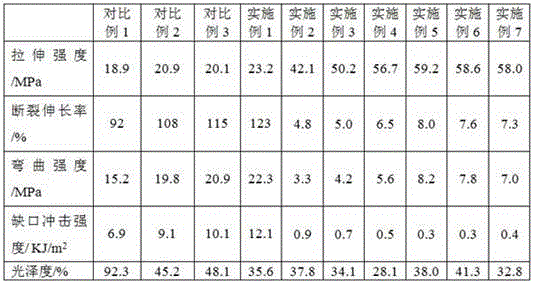

Facial scrub and preparation method thereof

InactiveCN106727022AKeep MoisturizedReduce solubilityCosmetic preparationsToilet preparationsAluminum magnesium silicateEthylhexyl palmitate

The invention discloses a facial scrub and a preparation method thereof. The facial scrub comprises a moisturizing agent, xanthan gum, disodium EDTA, ethylhexyl palmitate, an emulsifying agent, a thickening agent, aluminum starch octenylsuccinate, cocamidopropyl betaine, aluminum magnesium silicate, walnut shell powder, triethanolamine, tocopheryl acetate, titanium dioxide, a skin conditioning agent, a functional additive and water, wherein the moisturizing agent is selected from one or more of glycerol and butanediol; the emulsifying agent is selected from one or more of glyceryl stearate, PEG-100 stearate, polysorbate-60 and sorbitan stearate; and the thickening agent is selected from one or more of cetostearyl alcohol and stearic acid. The facial scrub has the advantage of improving the scrubbing effect in the presence of water.

Owner:HANGZHOU FACECARE COSMETICS

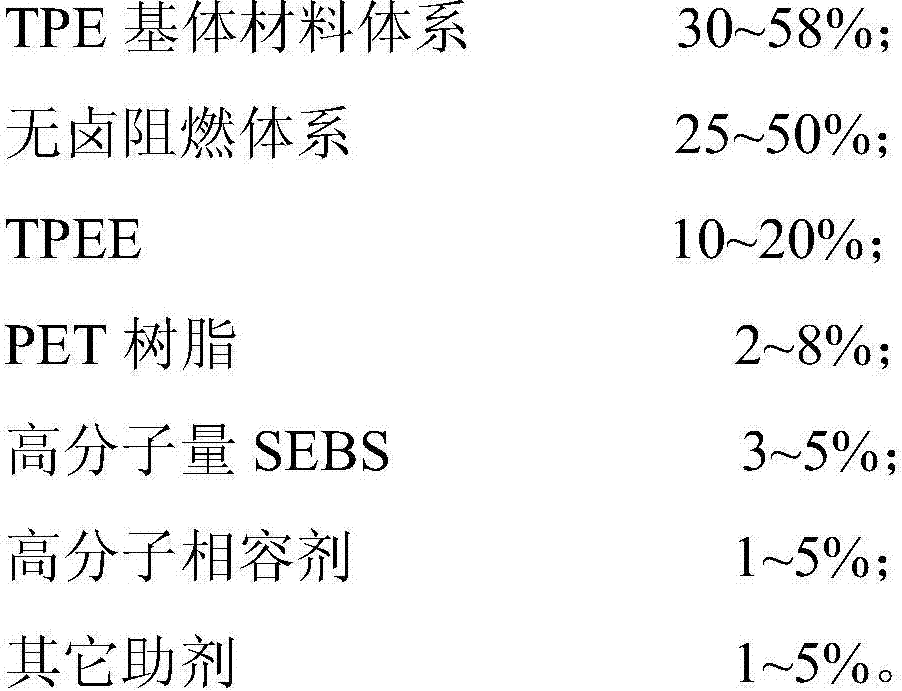

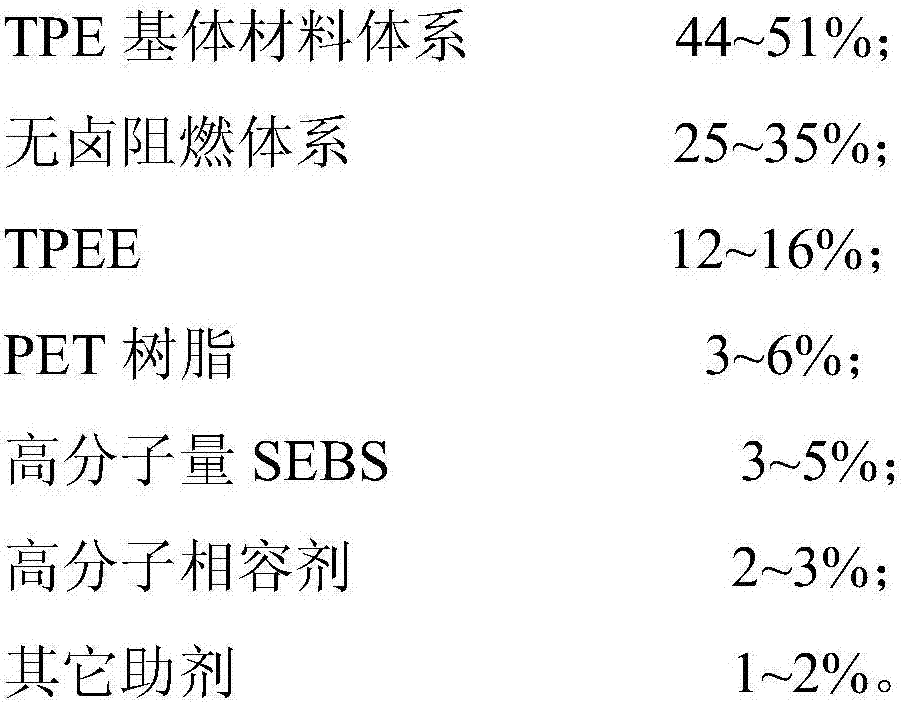

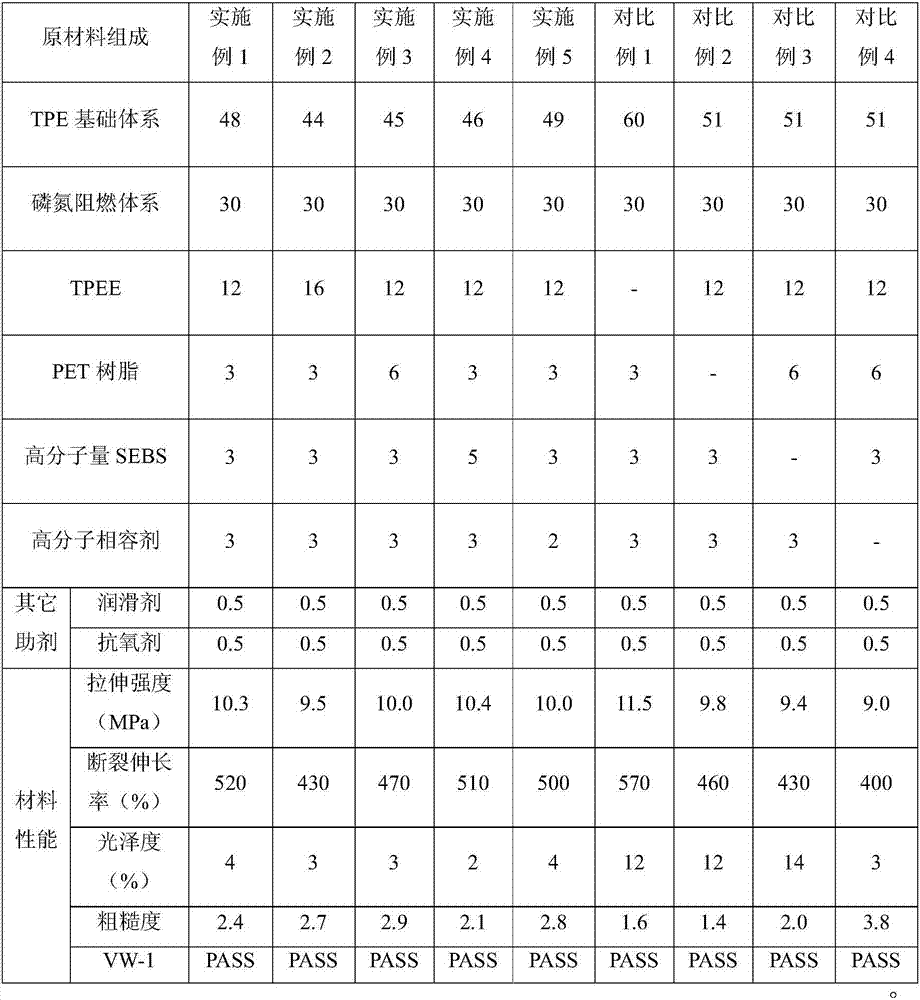

High-frosted all-matte flexible halogen-free flame-retardant thermoplastic elastomer dedicated material for wires and cables and preparation method thereof

ActiveCN107189319AImprove flame retardant performanceHigh strengthPlastic/resin/waxes insulatorsElastomerThermoplastic

The invention discloses a high-frosted all-matte flexible halogen-free flame-retardant thermoplastic elastomer dedicated material for wires and cables, comprising a TPE (thermoplastic elastomer) base material system, a halogen-free flame-retardant system and other aids, and also comprising an appearance adjusting system; the appearance adjusting system comprises TPEE (thermoplastic polyether ester elastomer), PET (polyethylene terephthalate) resin, high-molecular-weight SEBS (styrene-ethylene / butylene-styrene block copolymer) and a high-molecular-weight compatibilizer; the molecular weight of the high-molecular-weight SEBS is 350000 to 450000. In order to solve the problem that both delustering and frosting in the prior art cause performance deterioration in material, the invention provides the high-frosted all-matte flexible halogen-free flame-retardant thermoplastic elastomer dedicated material for wires and cables; the appearance adjusting system is composed of the TPEE, PET resin, high-molecular-weight SEBS and high-molecular-weight compatibilizer, the appearance adjusting system is combined with a base system, and wires and cables prepared have high-delustered appearance and fine frost effect, with properties of the material maintained.

Owner:ZHEJIANG UNIV

Novel flame-retardant cable material and preparation method thereof

InactiveCN107236185AImprove performanceGood physical propertiesPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention discloses a novel flame-retardant cable material. The cable material is prepared from raw materials in parts by weight as follows: 15-35 parts of polyvinyl chloride, 3-8 parts of an ethylene-octylene copolymer, 13-18 parts of ethylene-vinyl acetate, 18-33 parts of high impact polypropylene, 7-18 parts of nitrile rubber, 1-2 parts of stearic acid, 12-23 parts of filler, 1.5-3.3 parts of a heat stabilizer, 0.7-1.2 parts of an antioxidant, 1-2 parts of an antibacterial agent, 4-8 parts of a plasticizer, 3-5 parts of a compatilizer and 1-3 parts of a flame retardant. The novel flame-retardant cable material has excellent performance, good physical performance, wide temperature adaptation range, high-temperature resistance, good flame-retardant performance, antibacterial and anti-corrosion capacity and long service life.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Preparation method of magnesium alloy matt thin strip for mobile phone shell

InactiveCN102337439AUniform surface roughnessReduce lossMetal rolling arrangementsSurface roughnessMechanical property

The invention discloses a preparation method of a magnesium alloy matt thin strip for a mobile phone shell. The preparation method is characterized in that a laser roughening roller is used for rolling in the final pass of a cold rolling process, thus the surface roughness of a board is uniform and a good matt effect is achieved. Compared with a magnesium alloy board subjected to chemical matt treatment, the loss of the magnesium alloy raw material is reduced by 15-30%, and the no silking and pine grains are generated on the surface of the board. In the preparation method, alloying elements of the magnesium alloy are adjusted, thus the alloy has excellent surface quality and is suitable for preparing the matt surface. The prepared thin strip finished product has excellent mechanical properties, wherein the tensile strength is 280-320MPa, the elongation percentage is 8-10%, the earing rate is reduced to 1-3%, and the average strain ratio is 1.2-1.6; the adhesive force of painting on the surface of the magnesium alloy thin strip is improved; and the coating performance of the thin strip is improved.

Owner:JIANGSU HAODA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com