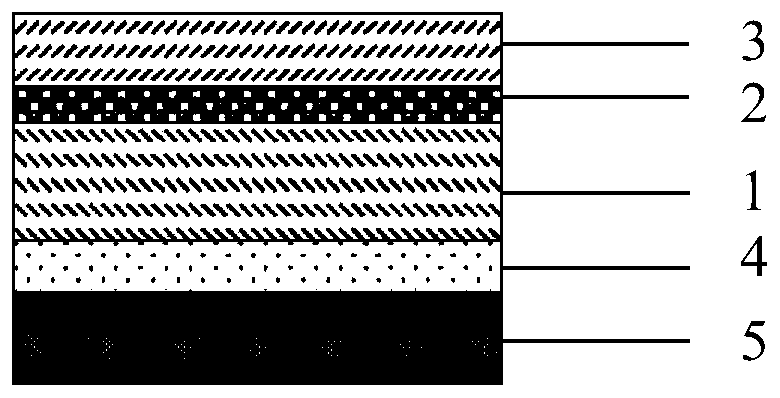

Matt paint face protection film

A technology of protective film and matte paint, applied in the direction of film/flake adhesive, coating, adhesive, etc., can solve the problem of inability to apply car paint protection film and thermal curing self-healing coating, etc. , to achieve the effect of improving antifouling performance, good matte effect and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of semi-finished paint protection film:

[0040] On a translucent polyester release film with a thickness of 30 μm, use known technology to obtain an assembly glue with a thickness of 10 μm, and then laminate it with a polyvinyl chloride film with a thickness of 100 μm, and roll it to obtain a semi-finished paint protection film for use. .

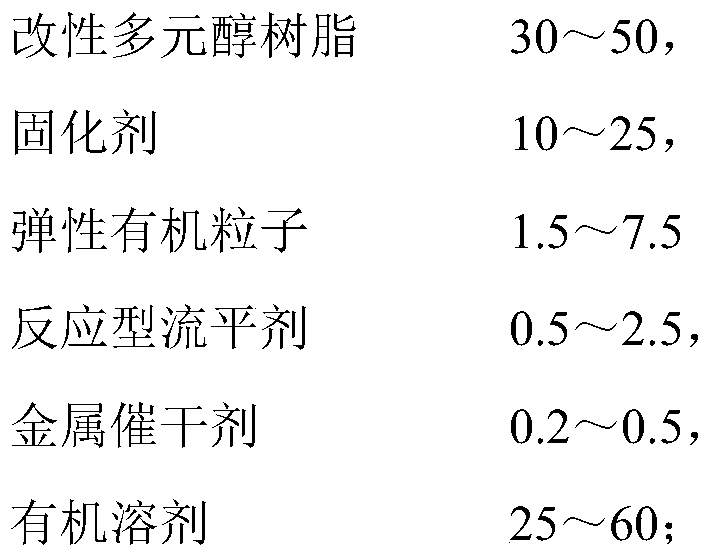

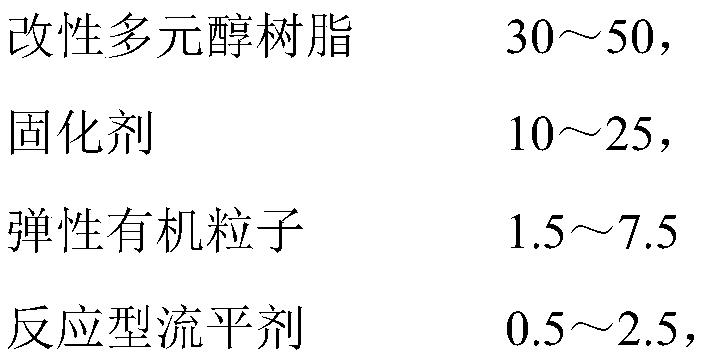

[0041] (2) Preparation of self-healing coating solution:

[0042]

[0043]

[0044] Add 30 kg of modified polyol resin [LCR-100, NATOCO], 1.5 kg of elastic organic particles [polybutyl acrylate, average particle size 1 μm, Sekisui Chemical], 0.5 kg of reactive leveling agent in the container [BYK-370, BYK], 0.2 kg of metal drier [organotin drier DY-12, Deyin Chemical] and 60 kg of toluene, stirred at high speed for 30 minutes. Add 6.7 kg of curing agent 1 [hexamethylene diisocyanate, Asahi Kasei] and 3.3 kg of curing agent 2 [isophorone diisocyanate, Evonik] 30 minutes before coating, stir at high speed for 10 ...

Embodiment 2

[0048] (1) Preparation of semi-finished paint protection film:

[0049] On a translucent polyester release film with a thickness of 38 μm, an assembly glue with a thickness of 20 μm was obtained by known technology, and then laminated with a thermoplastic polyurethane film with a thickness of 150 μm, and rolled to obtain a semi-finished paint protection film for use.

[0050] (2) Preparation of self-healing coating solution:

[0051]

[0052] Add 35 kg of modified polyol resin [HFC-PNS1, HARIMA], 3.0 kg of elastic organic particles [polyurethane, average particle size 5 μm, root resin], 1.0 kg of reactive leveling agent [Silok-359] into the container , Sloco], 0.27 kg of metal drier [organic bismuth drier B1610, Casol additive] and 51 kg of ethyl acetate, stirred at high speed for 30 min. Add 10.2 kg of curing agent 1 [trimethylhexamethylene diisocyanate, BASF] and 3.8 kg of curing agent 2 [dicyclohexylmethane-4,4'-diisocyanate, Wanhua] 30 minutes before coating, and stir ...

Embodiment 3

[0056] (1) Preparation of semi-finished paint protection film:

[0057] On a translucent polyester release film with a thickness of 50 μm, use known technology to obtain an assembly glue with a thickness of 30 μm, and then laminate it with a thermoplastic polyurethane film with a thickness of 200 μm, and roll it to obtain a semi-finished paint protection film for use.

[0058] (2) Preparation of self-healing coating solution:

[0059]

[0060] Add 40 kg of modified polyol resin [TRE-2-S2, ASIA], 4.5 kg of elastic organic particles [nylon, average particle size 8 μm, BASF], 1.5 kg of reactive leveling agent [Teck- 2110, Tiger], 0.35 kg of metal drier [rare earth drier B-18, Kasol additive] and 42 kg of acetone, stirred at high speed for 30 min. Add 13.6 kg of curing agent 1 [xylylene diisocyanate, mol] and 3.9 kg of curing agent 2 [cyclohexane dimethylene diisocyanate, Mitsui Takeda] 30 minutes before coating, stir at high speed for 10 minutes, and wait use.

[0061] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com