High-frosted all-matte flexible halogen-free flame-retardant thermoplastic elastomer dedicated material for wires and cables and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

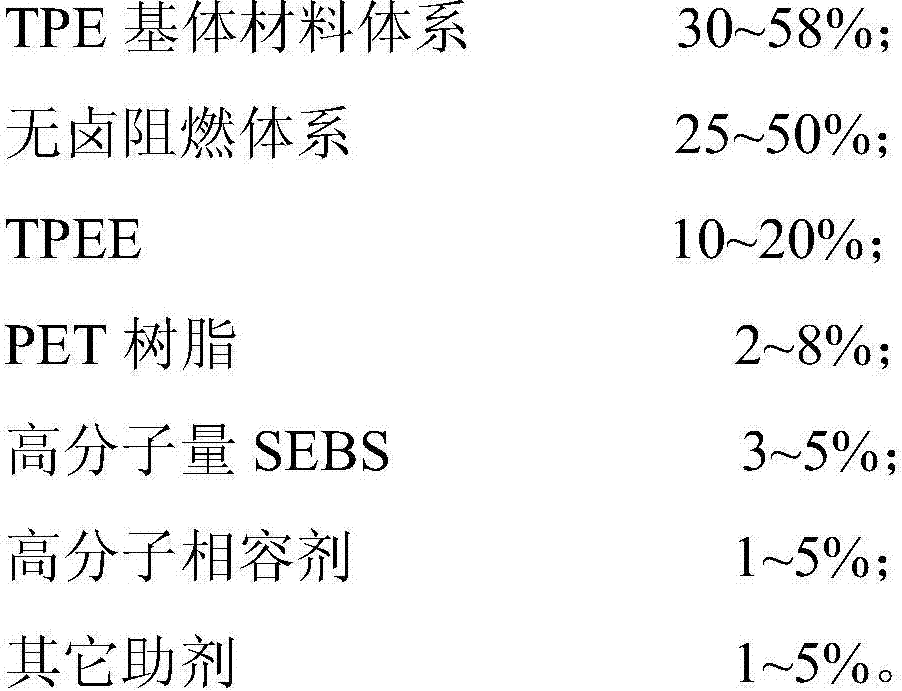

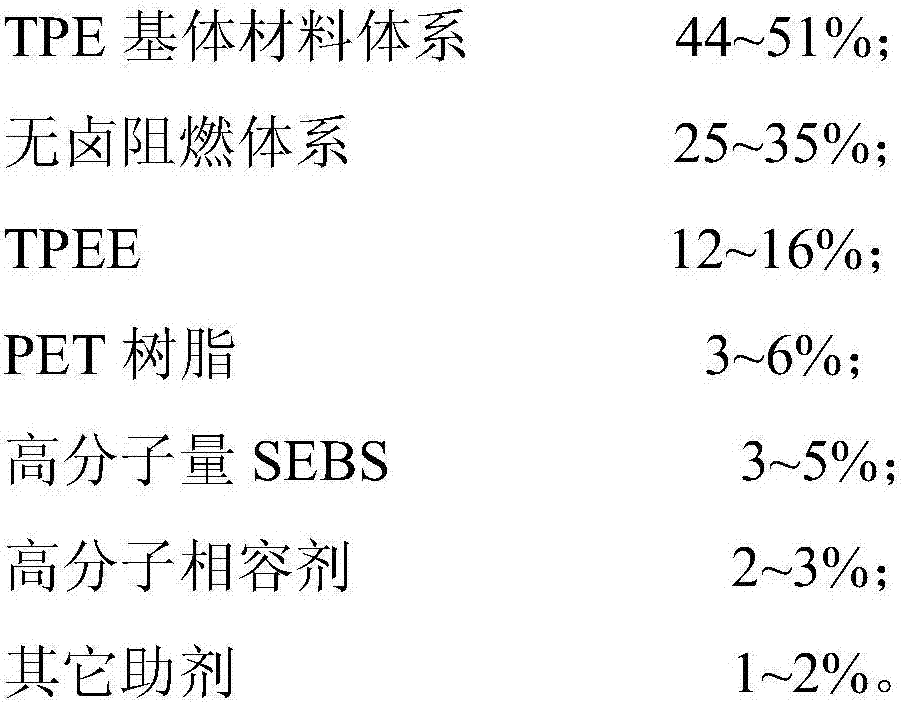

Method used

Image

Examples

Embodiment 1

[0049] (1) Mixing of high frosted full matte halogen-free flame retardant TPE system

[0050] Add SEBS and white oil into the mixer, and complete the oil-filling of SEBS under low-speed stirring; mix the oil-extended SEBS and other components evenly under high-speed stirring;

[0051] (2) Extrusion granulation

[0052] Completing the mixing, plasticizing and extruding granulation of the composition in a co-rotating twin-screw extruder;

[0053] (3) Material performance test

[0054] The dried material is injected into the injection molding machine to produce standard samples specified in various test standards, and the relevant material properties are tested. Qualified cables are prepared on the wire and cable pulling equipment, samples are taken and relevant wire and cable tests are carried out.

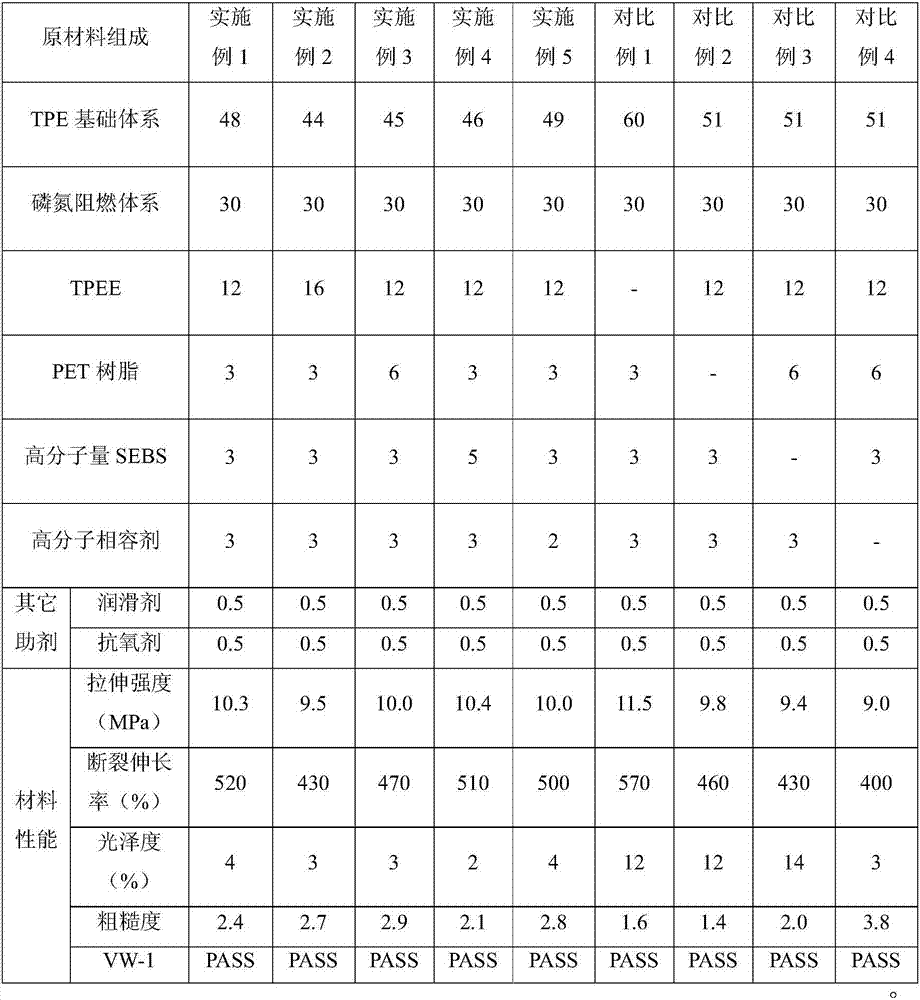

[0055] Among the main concerns are the tensile properties, gloss, roughness of the material and the flame retardancy of the cable. The materials and proportions in the examples ...

Embodiment 2

[0057] The implementation process is the same as in Example 1, the only difference being the adjustment of the ratio of TPE base material and TPEE. Other materials and proportioning are shown in Table 2, and the obtained material results are shown in Table 2.

Embodiment 3

[0059] The implementation process is the same as in Example 1, the difference is only in adjusting the ratio of TPE base material and PET resin. Other materials and proportioning are shown in Table 2, and the obtained material results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com