Patents

Literature

1785results about How to "Good touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

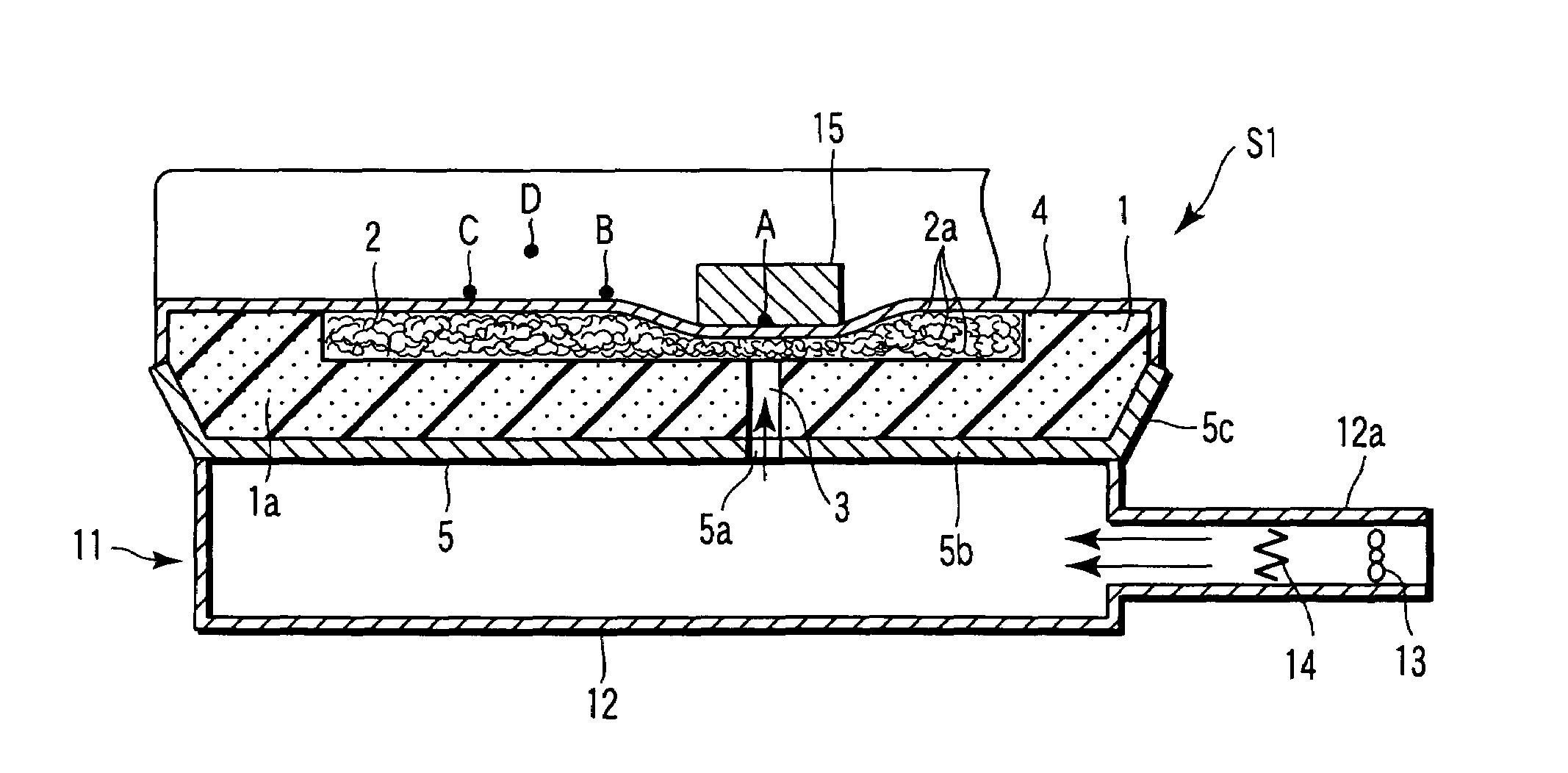

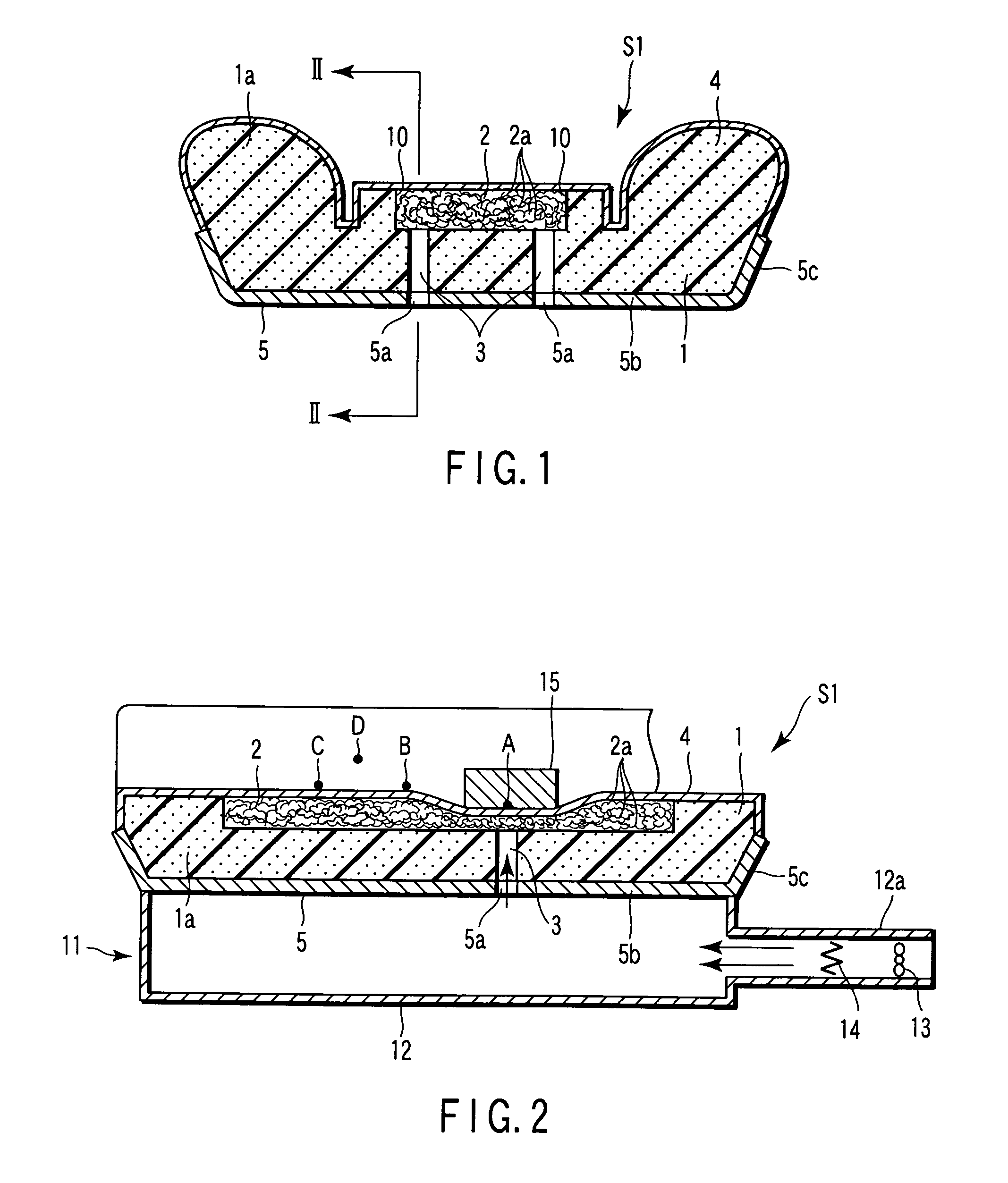

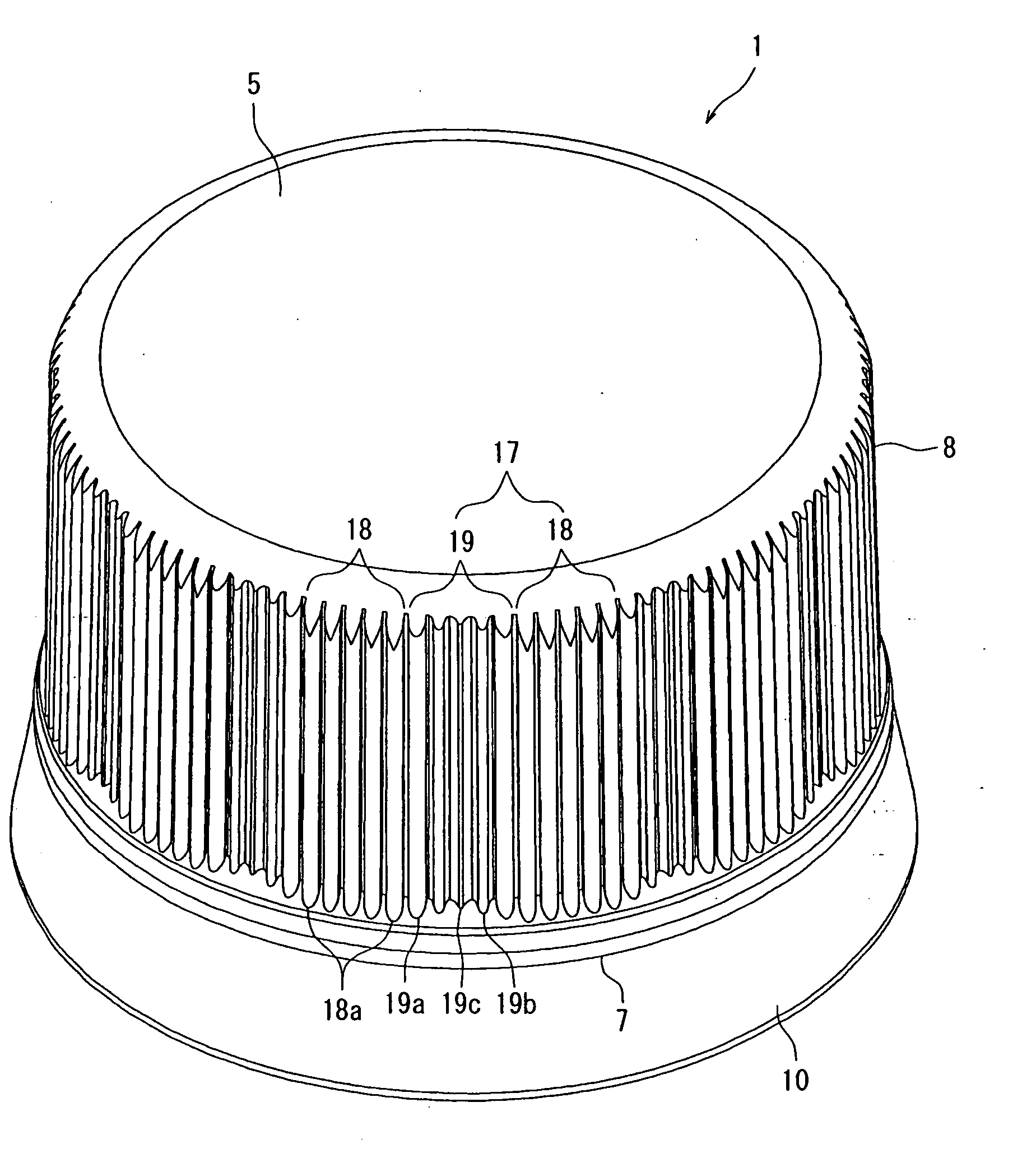

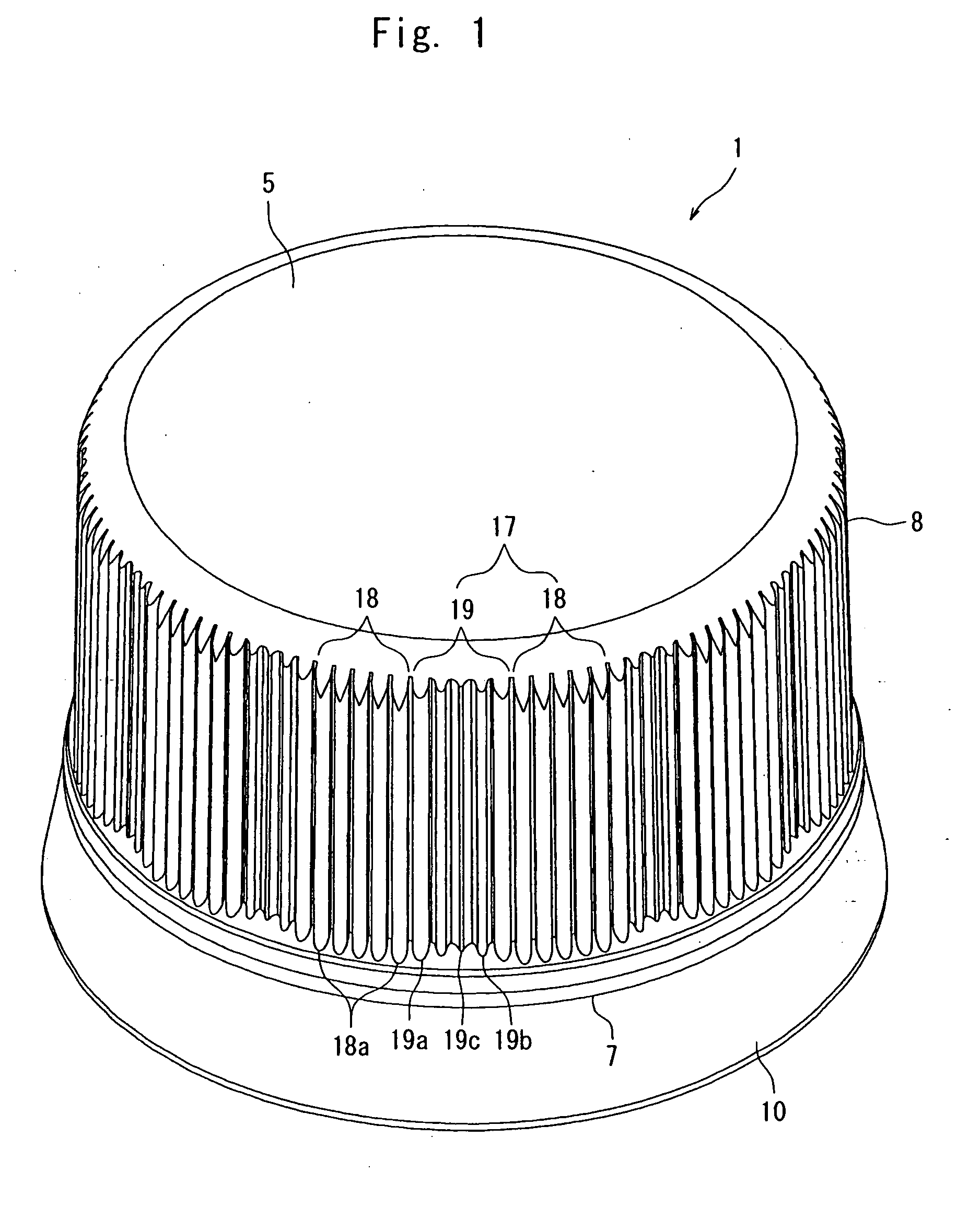

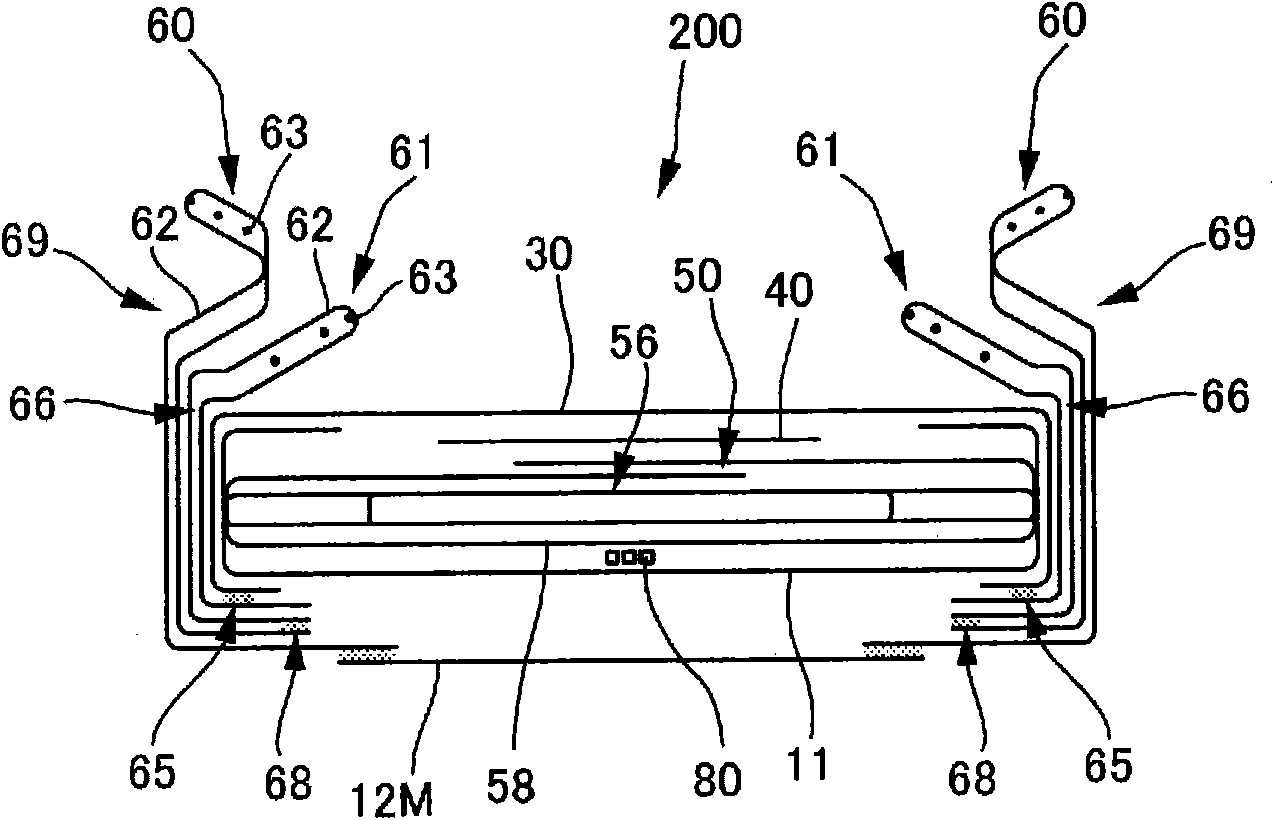

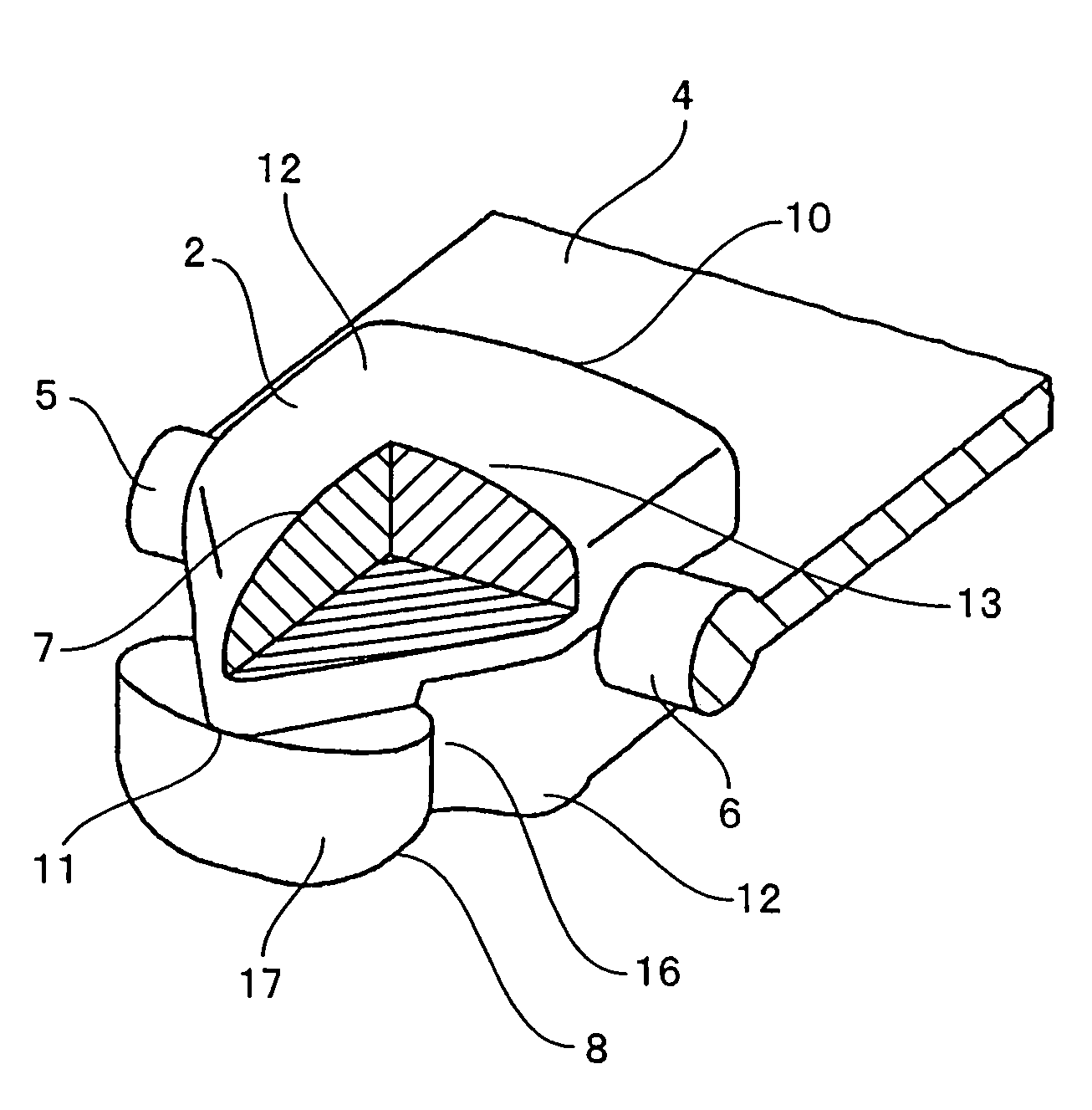

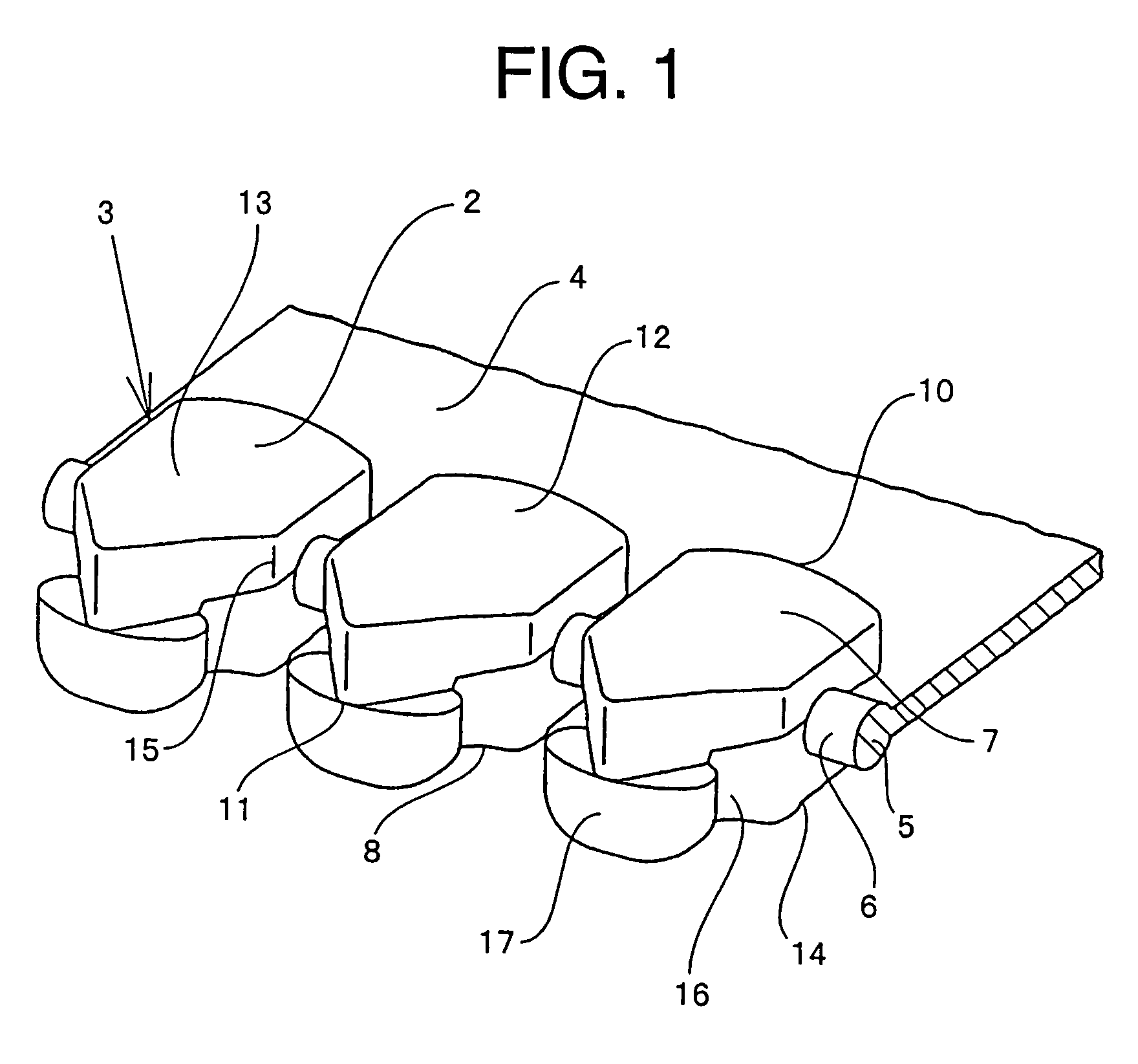

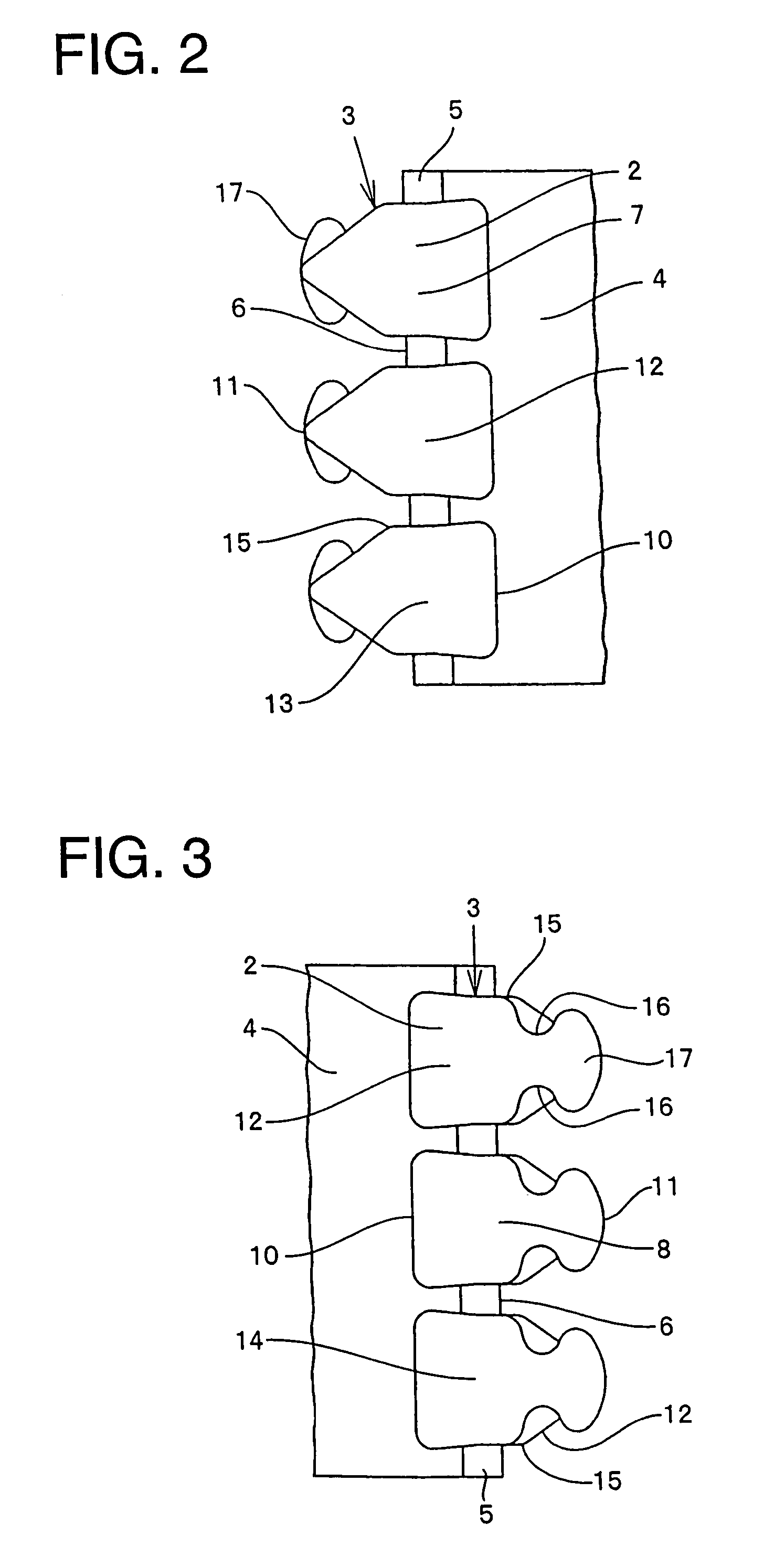

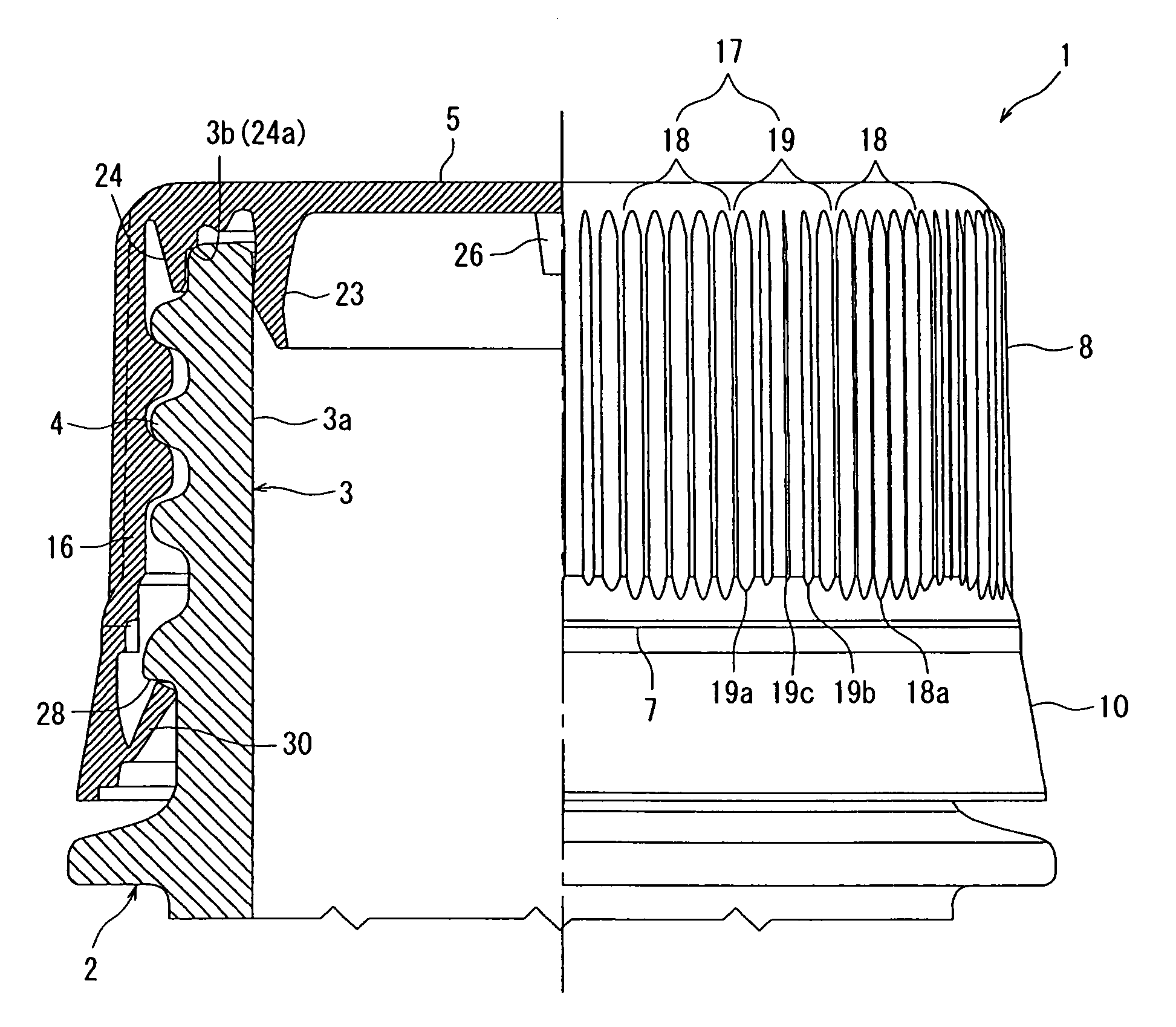

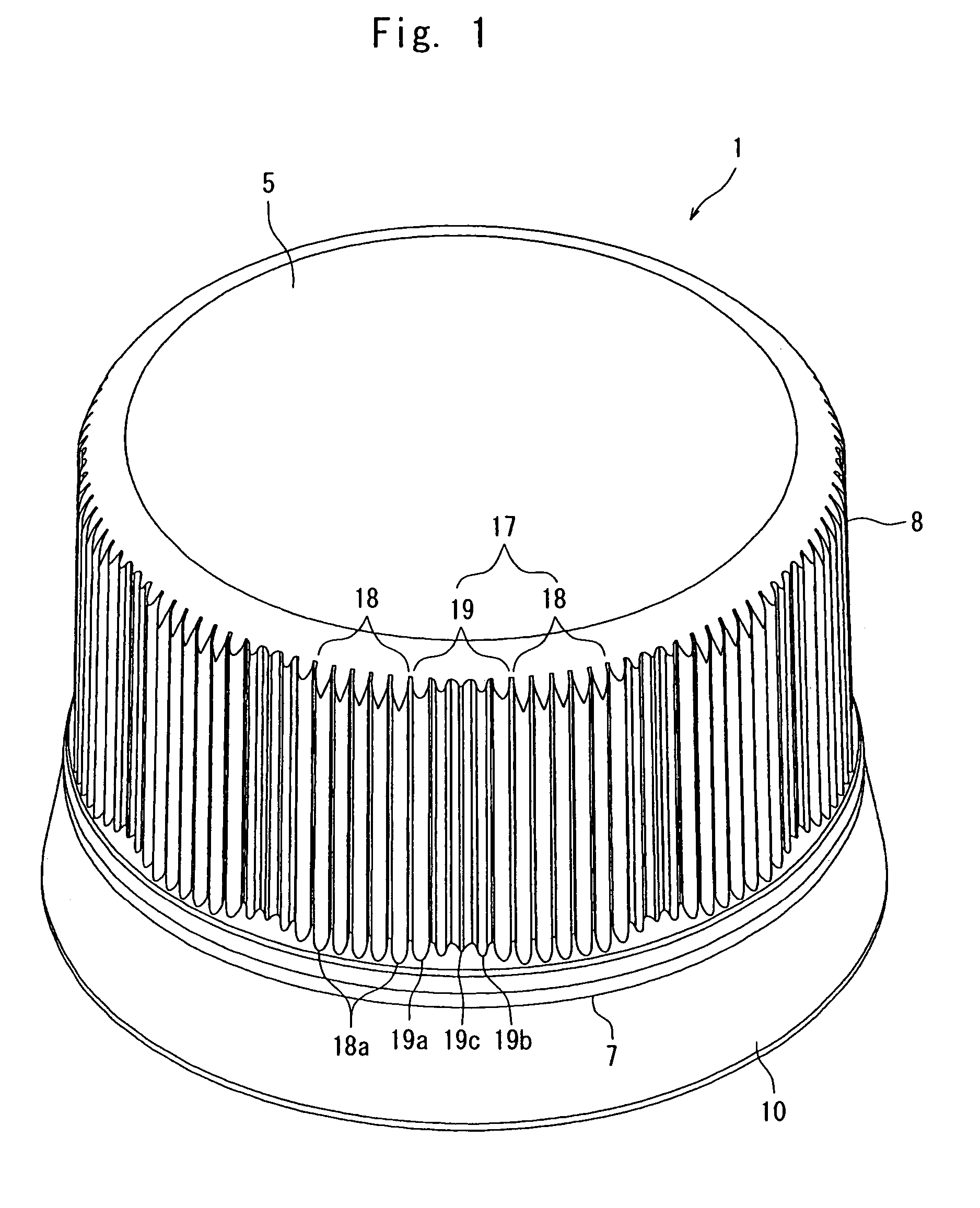

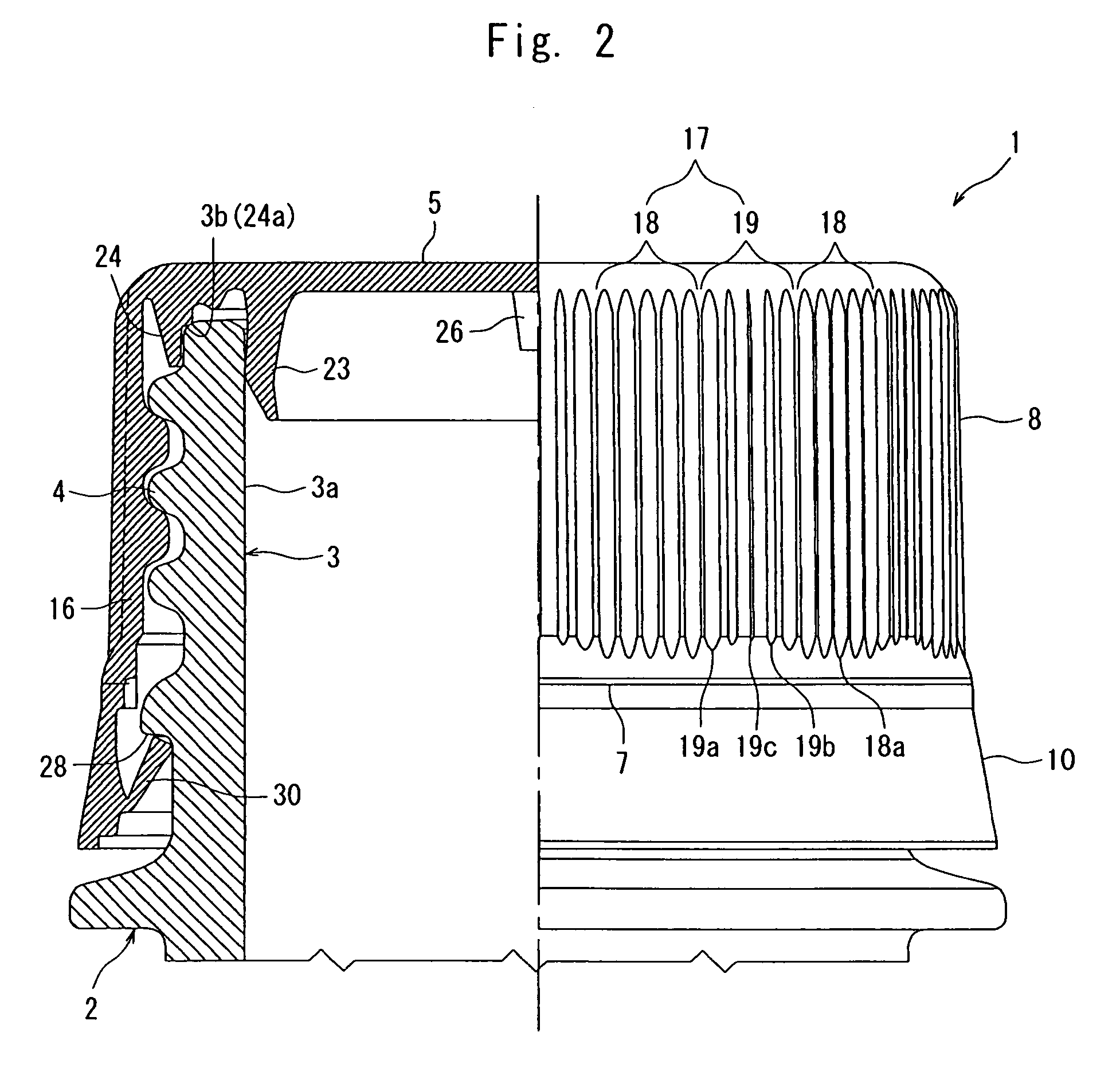

Breathable seat

InactiveUS7070232B2Improve buffering effectPrevent satisfactorySeat coveringsStuffed mattressesEngineeringCushion

A breathable seat comprises a seat body formed of urethane foam, a three-dimensional network cushion body incorporated in that region of the seat body which bears a user's body, a seat cover having breathability, and a pan frame. The cushion body is formed of a large number of continuous linear elements of thermoplastic resin. The linear elements are looped windingly so that their respective contact portions are fused together. The seat body is formed having venting holes that penetrate the urethane foam in its thickness direction. The venting holes communicate with the cushion body and apertures of the pan frame. The seat cover envelops the seat body and the cushion body.

Owner:NHK SPRING CO LTD

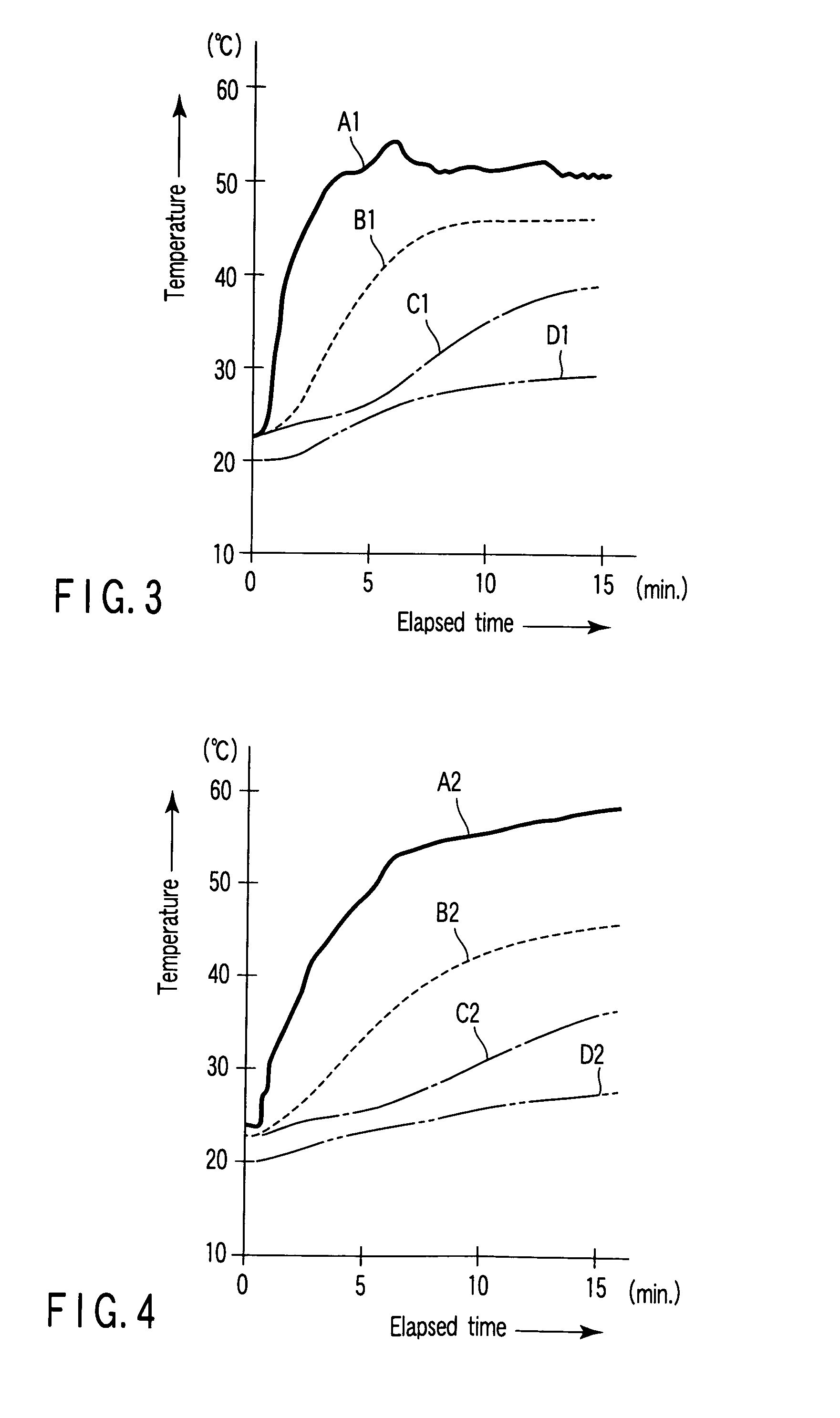

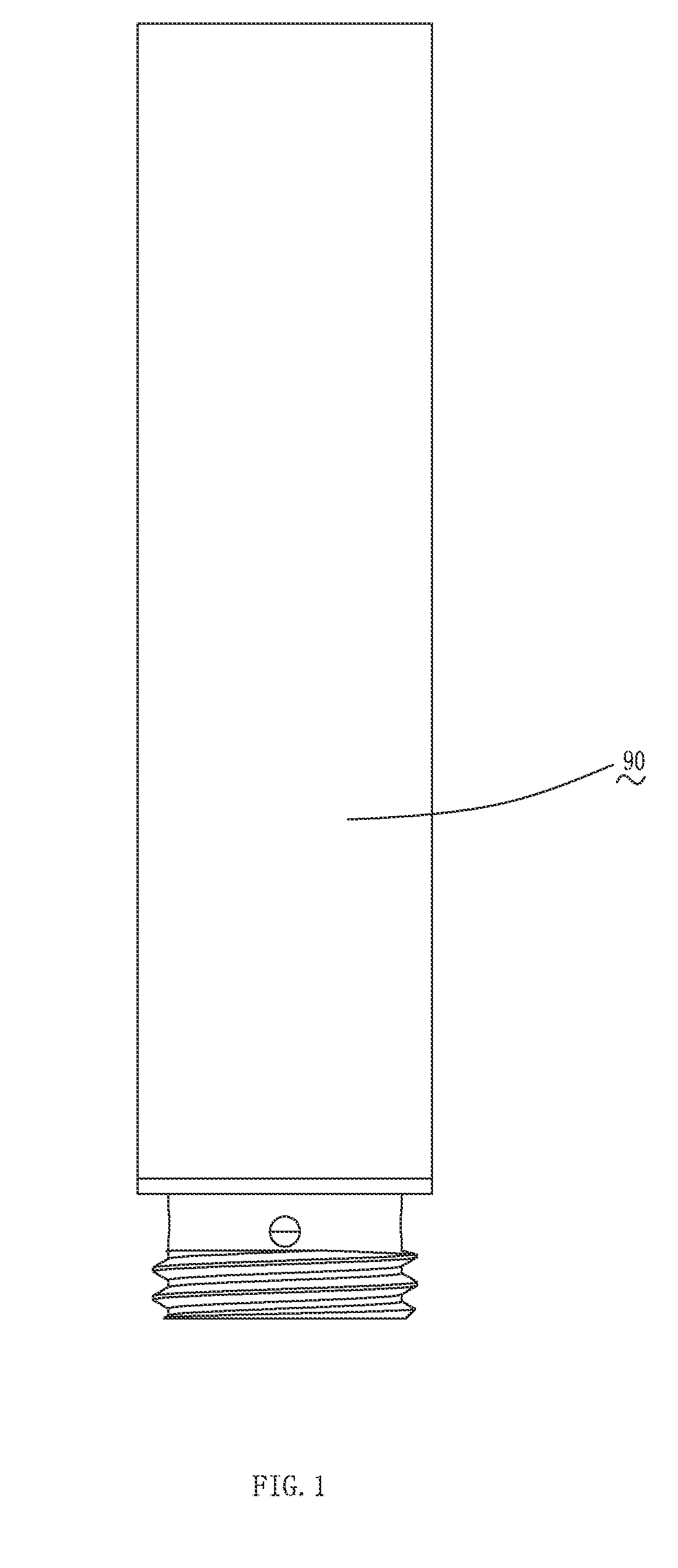

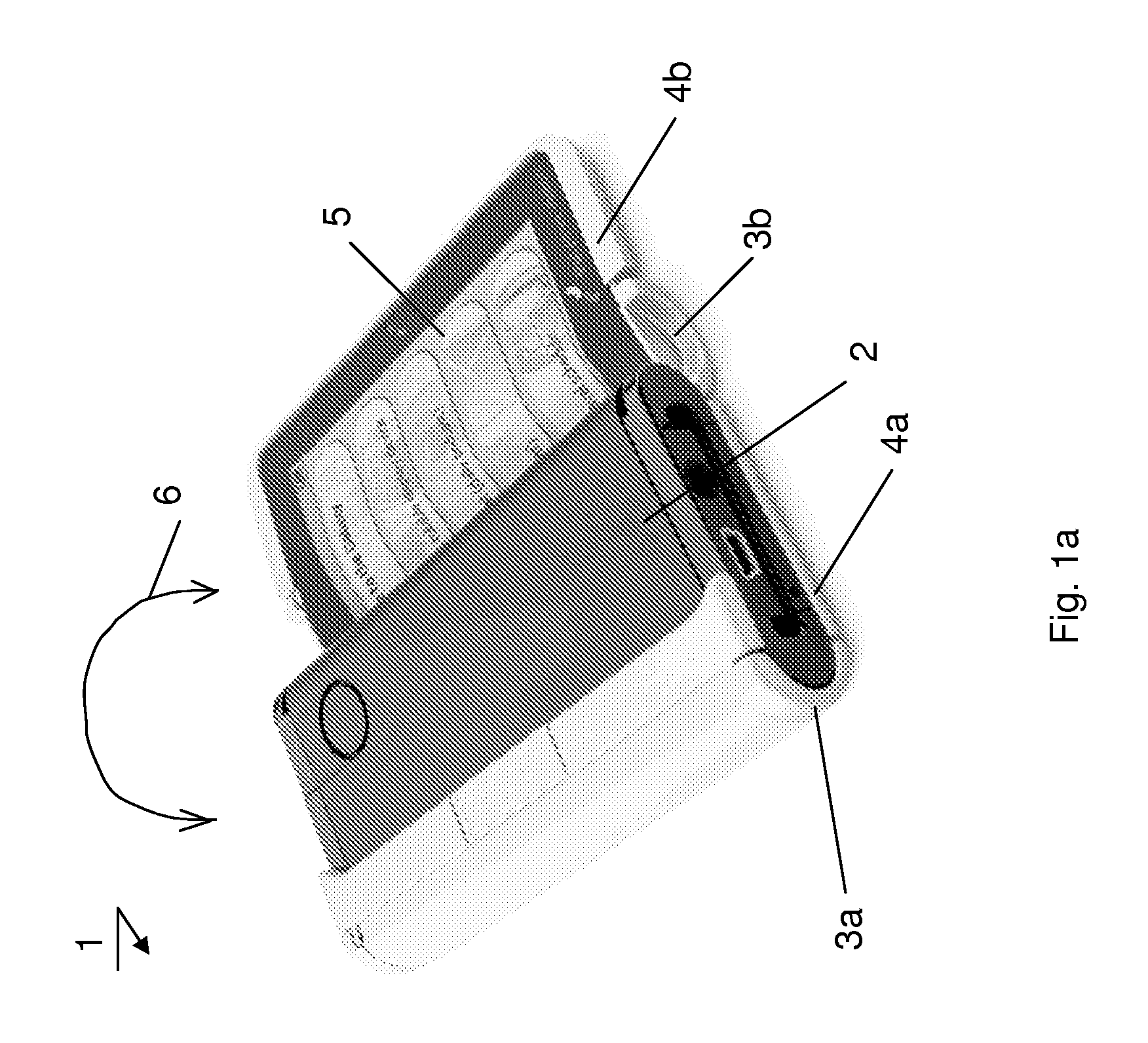

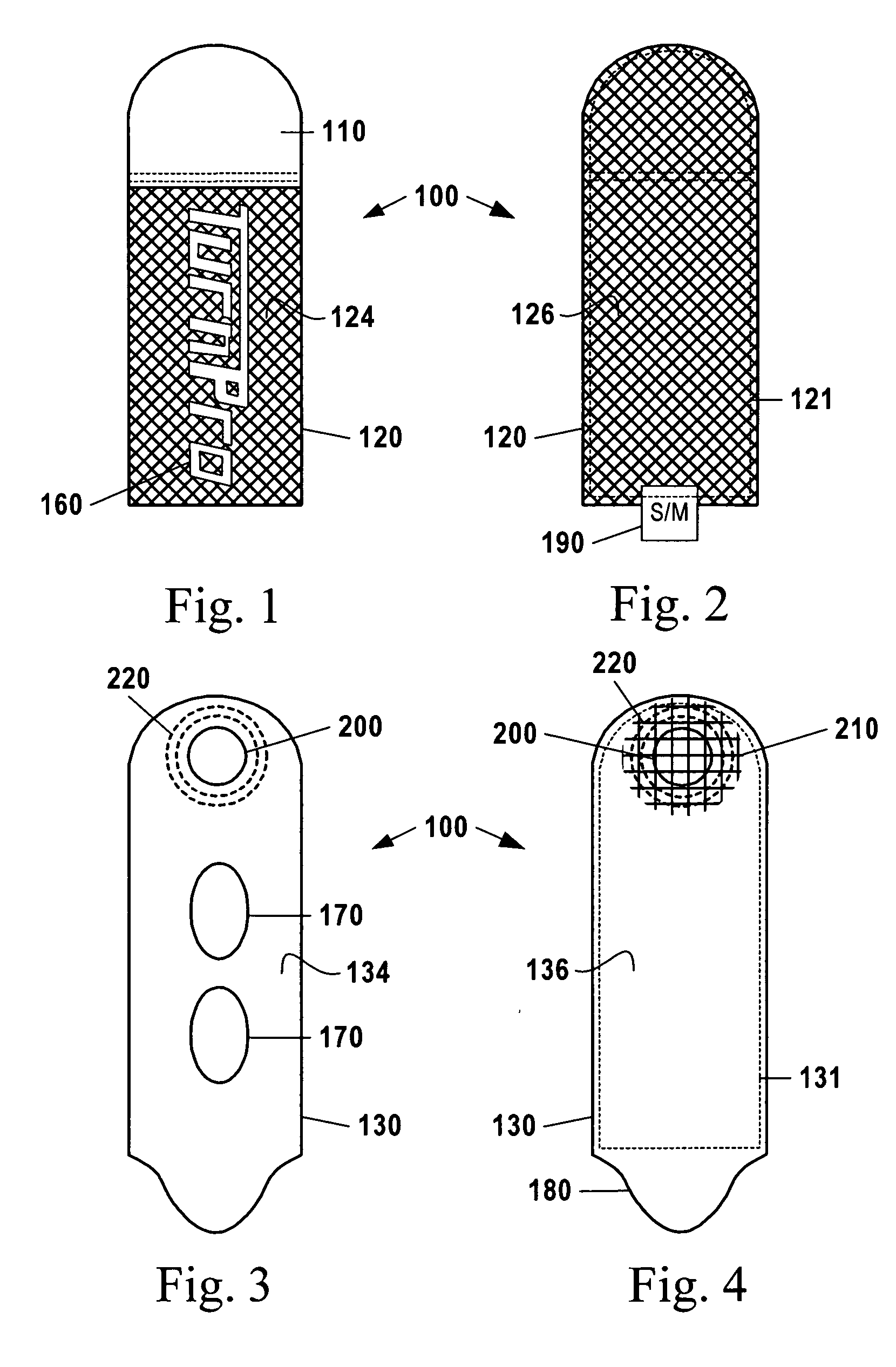

Electronic Cigarette and Soft Absorption Stem Thereof

InactiveUS20140182610A1Compact internal structureUnique smoke pathTobacco pipesTobacco devicesElectronic cigaretteSoft materials

A soft absorption stem for an electronic cigarette is provided, comprising a sleeve, a cigar liquid tank disposed inside the sleeve, an atomization device and a liquid guiding component. The sleeve is made of soft material; a plurality of venting slots is extended axially from one end of the sleeve to the other end thereof and disposed on an inner wall of the sleeve; the sleeve includes a mouthpiece end and a connection end; a suction hole communicating with the venting slots is provided on the mouthpiece end; smoke produced by atomization of the atomization device flows out of the sleeve from the venting slots across the suction hole. The electronic cigarette makes the user more comfortable when holding the sleeve in hand and containing in mouth, having more compact internal construction, having unique smoke path, and having increased cigar liquid storage capacity.

Owner:HUIZHOU KIMREE TECH

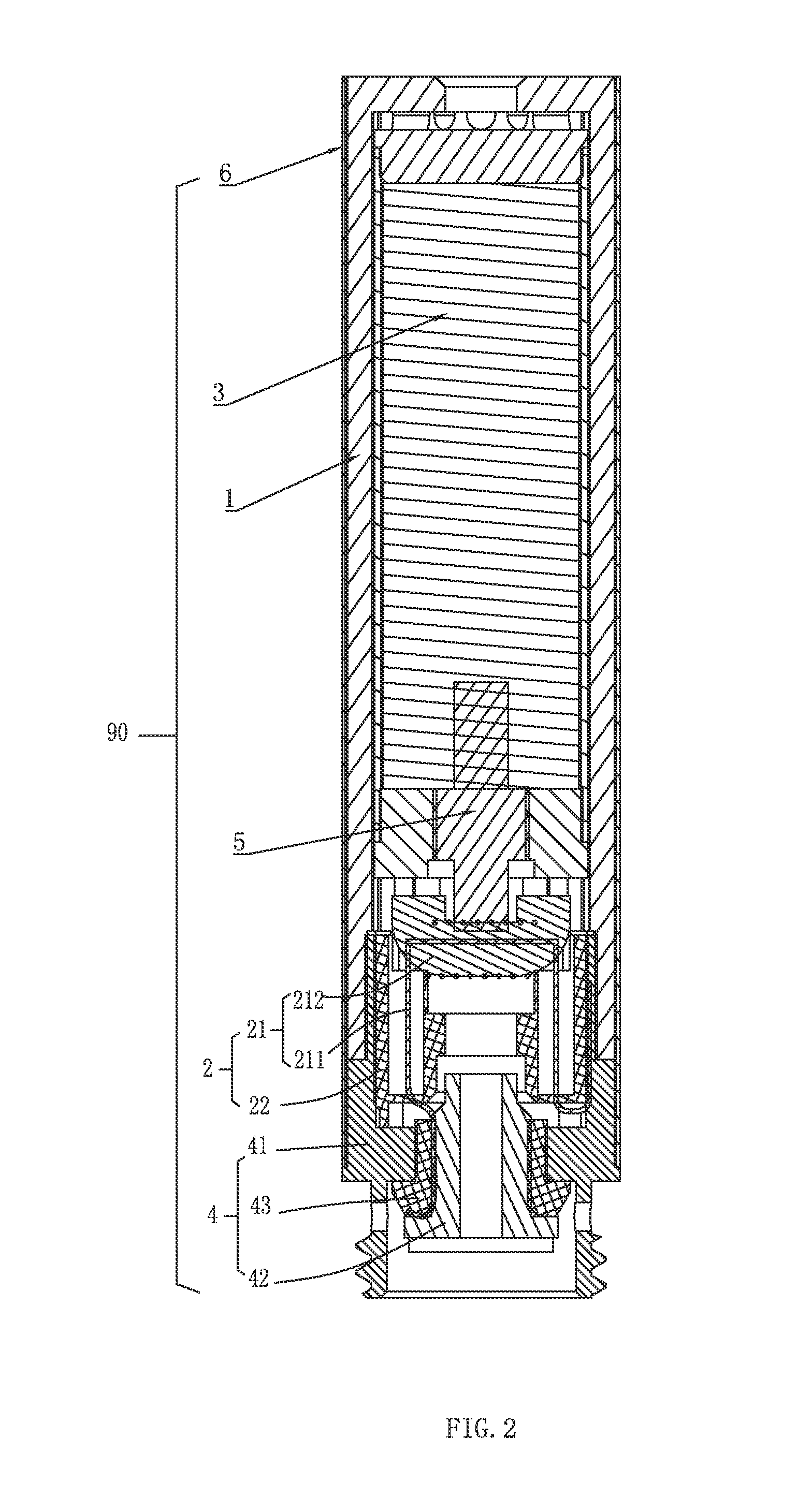

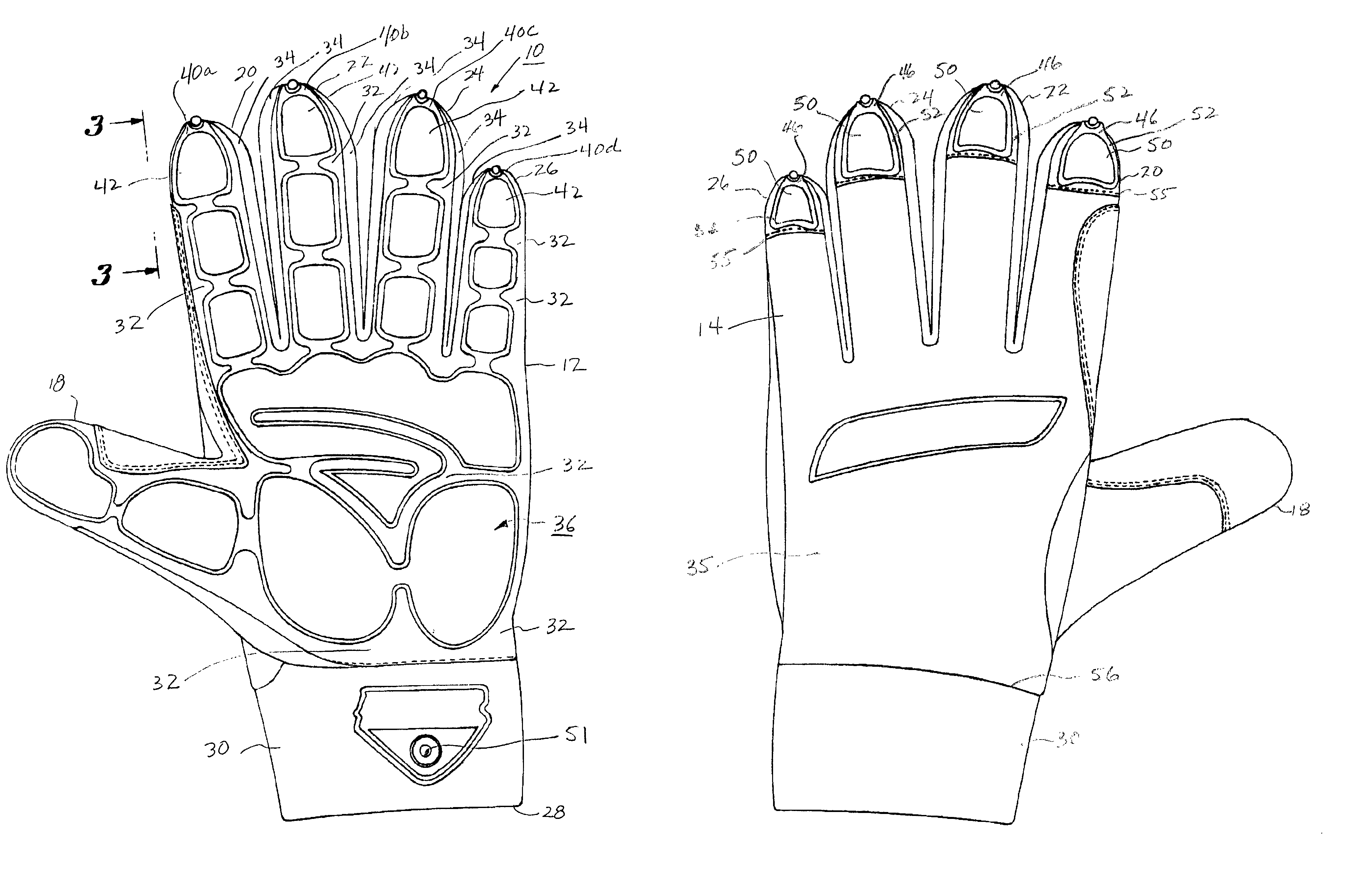

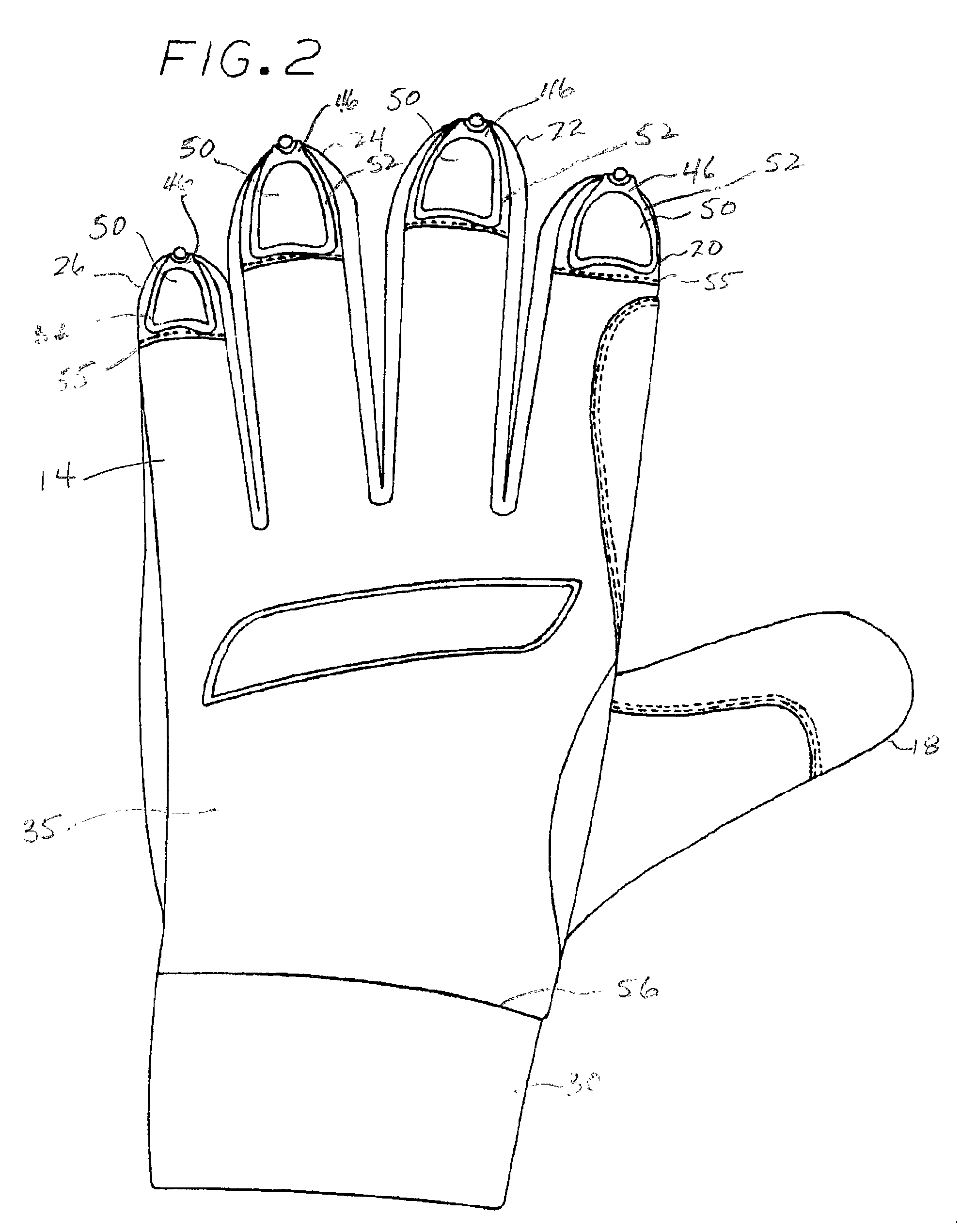

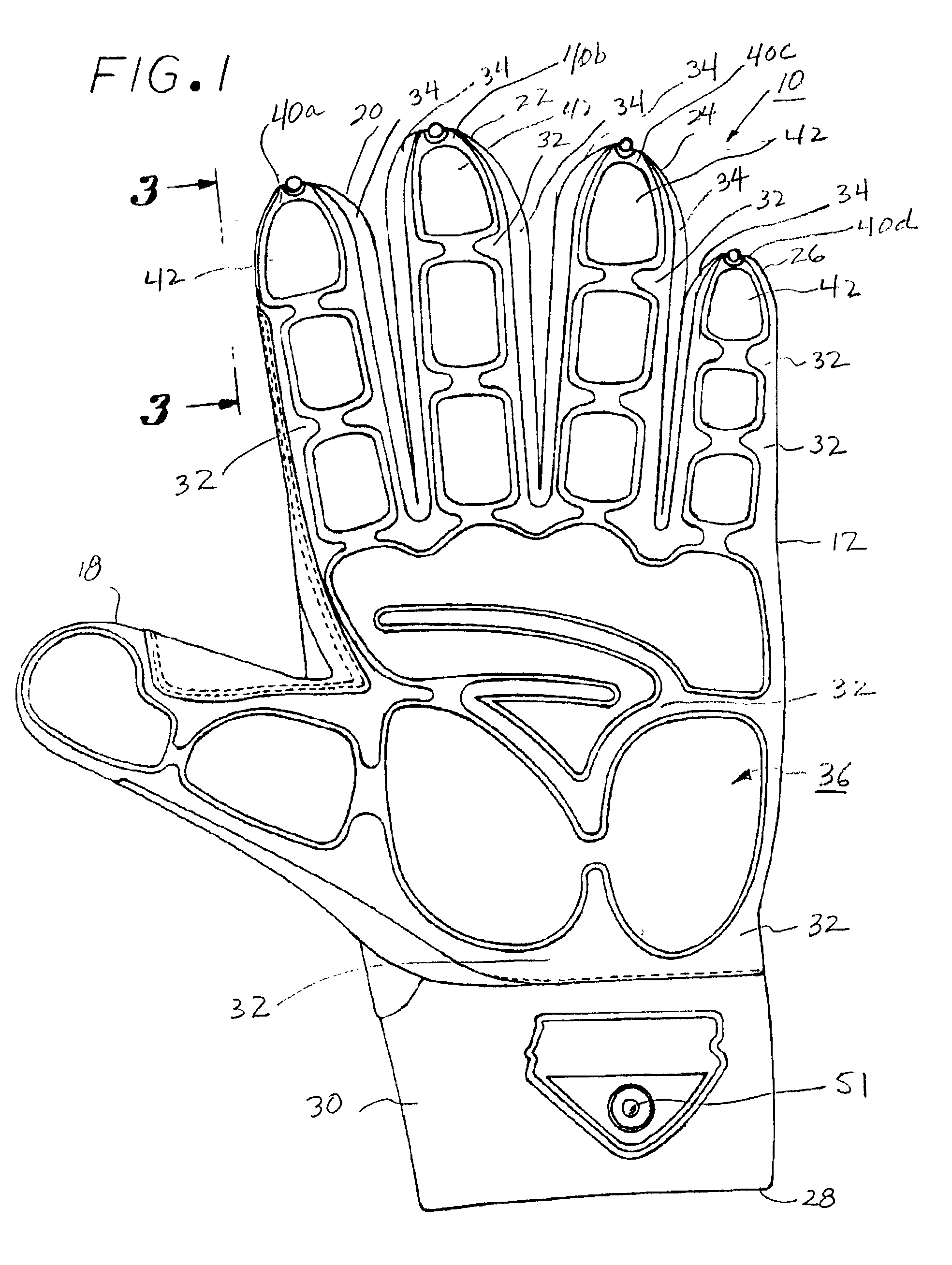

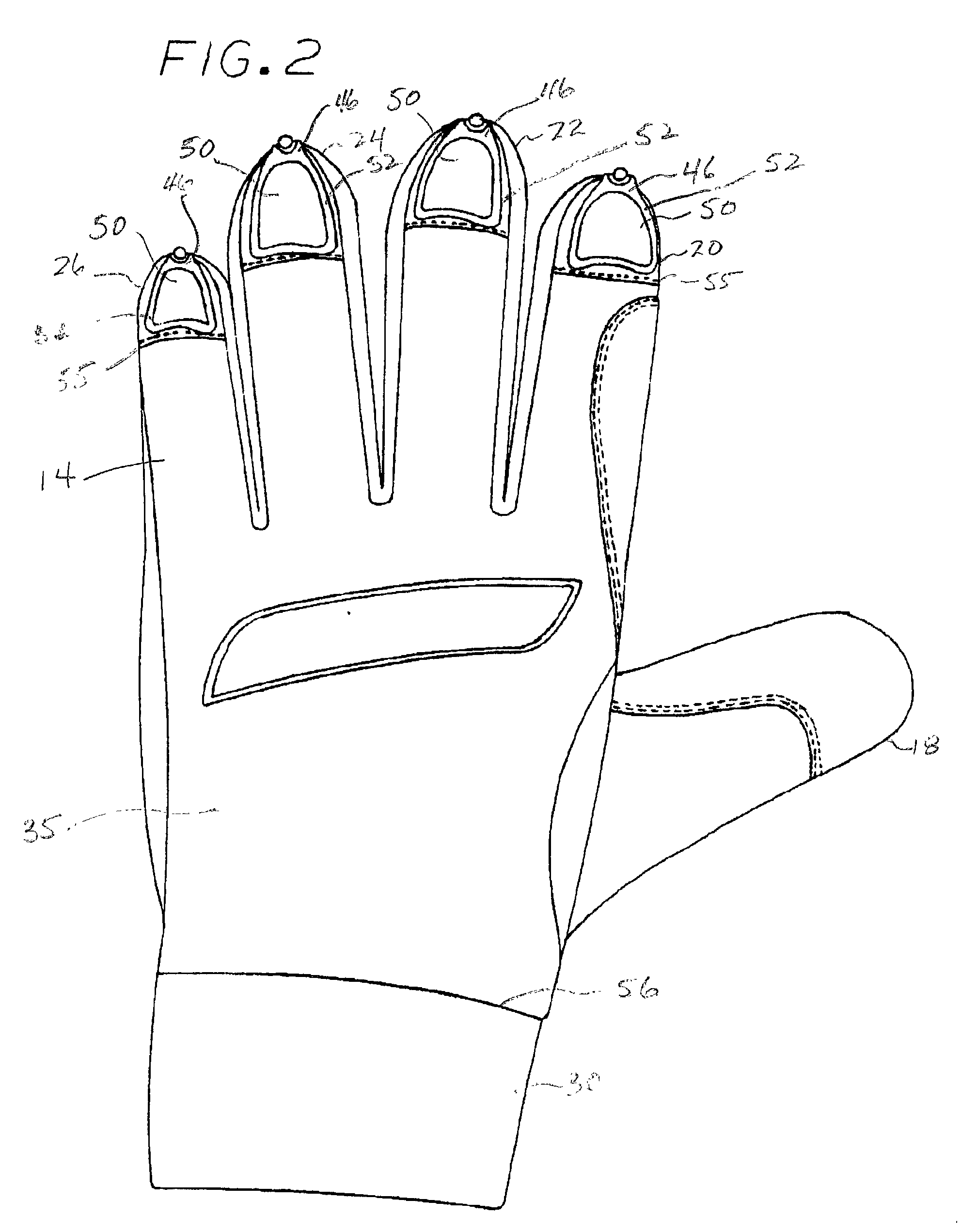

Glove having molded rubber palm pattern with a portion that rolls over fingertips

InactiveUS7100212B2High sensitivityImprove efficiencyGlovesEye treatmentMechanical engineeringHand palms

Owner:BRIGHTON BEST INT INC

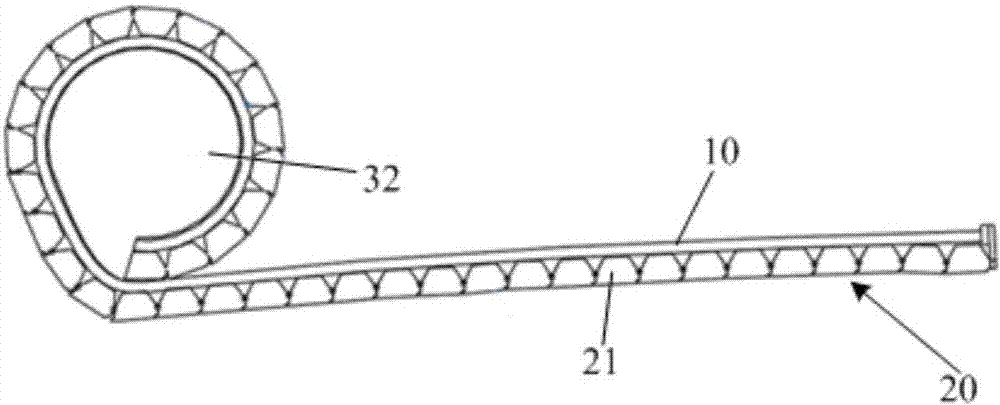

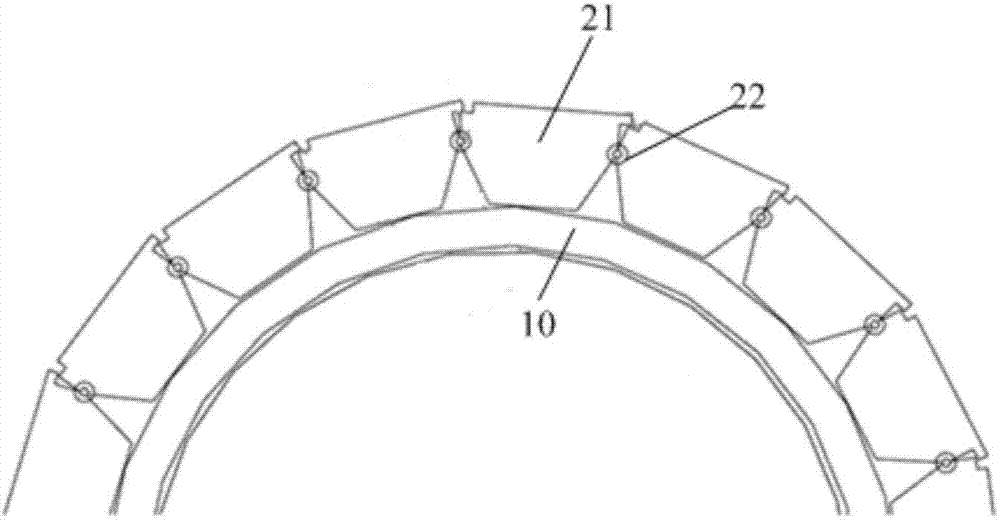

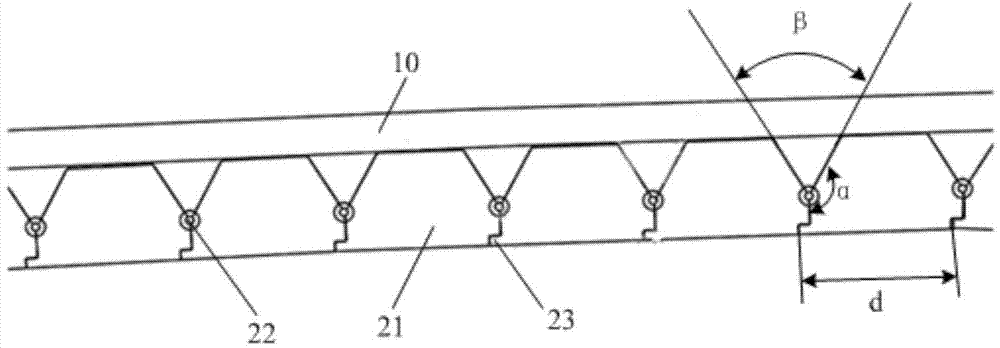

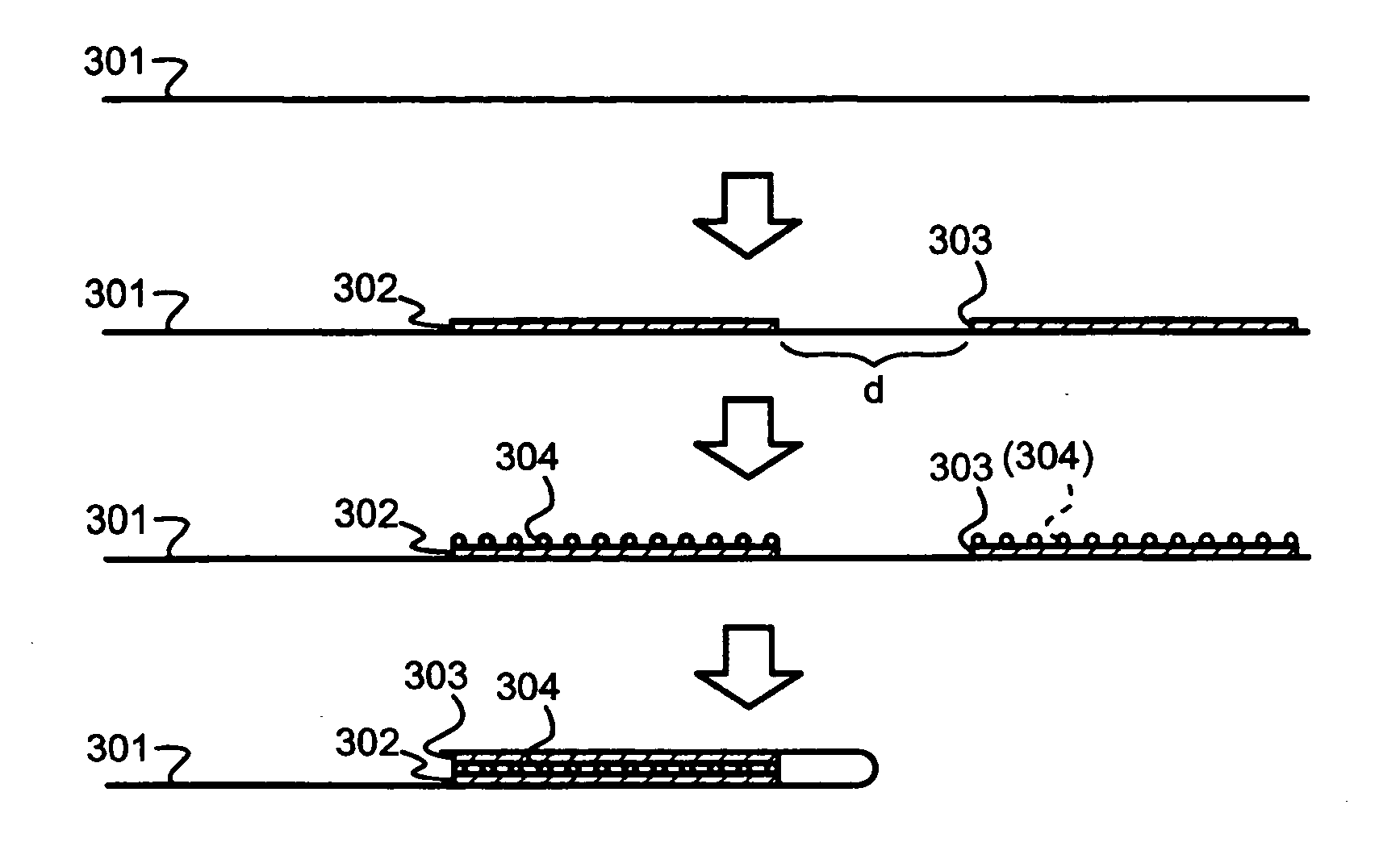

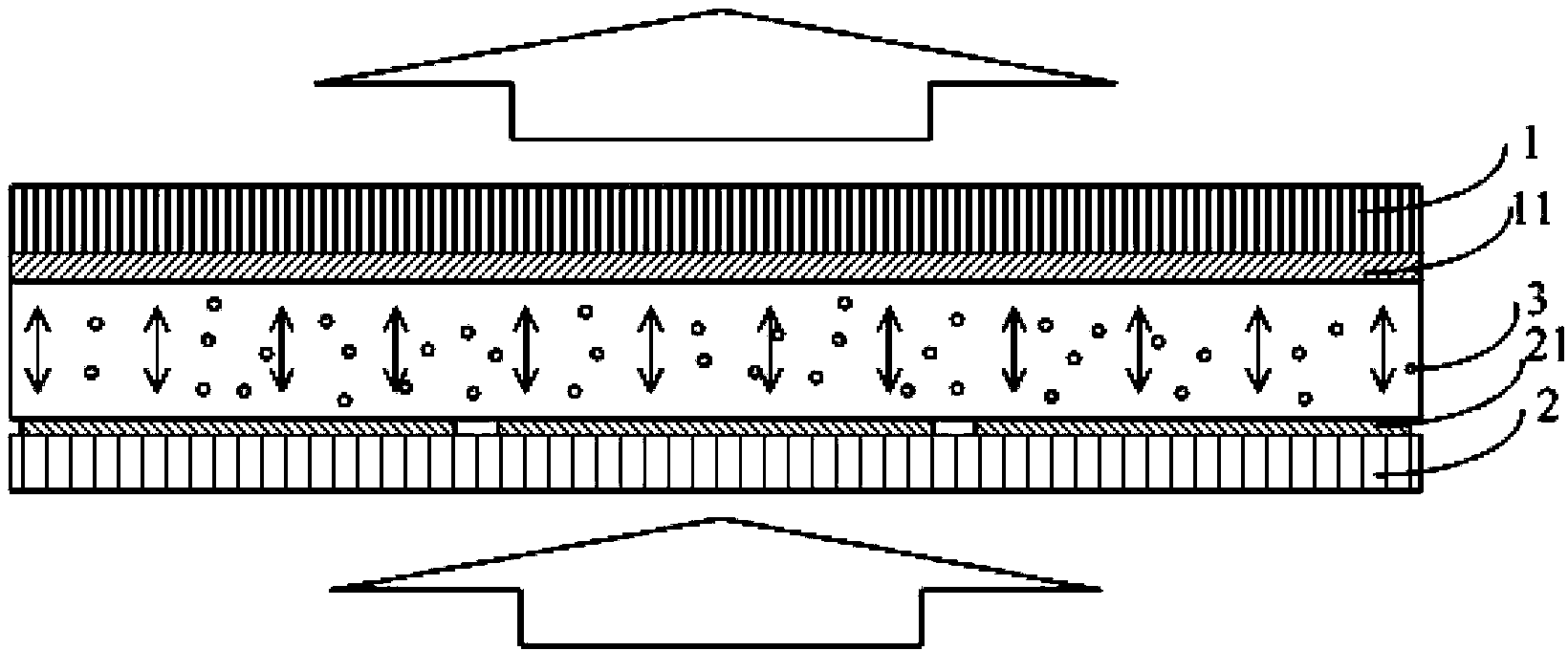

Flexible display device

InactiveCN104714699APlay a supporting roleGood touchDigital data processing detailsInput/output processes for data processingEngineeringFlexible display

The invention provides a flexible display device comprising a flexible display screen and a supporting structure used for supporting the flexible display screen, wherein the flexible display screen is fixedly connected with the supporting structure and is fixed on the supporting surface of the supporting structure, and the supporting surface of the supporting structure can form a plane or a curved surface selectively. According to the flexible display device provided by the invention, such operations as touch control and click can be performed on the flexible display screen, and thus the application range of the flexible display screen is expanded.

Owner:BOE TECH GRP CO LTD

Glove having molded rubber palm pattern with a portion that rolls over fingertips

InactiveUS20040025227A1Eliminates seam lineIncrease awarenessGlovesEye treatmentHand palmsEngineering

Owner:BRIGHTON BEST INT INC

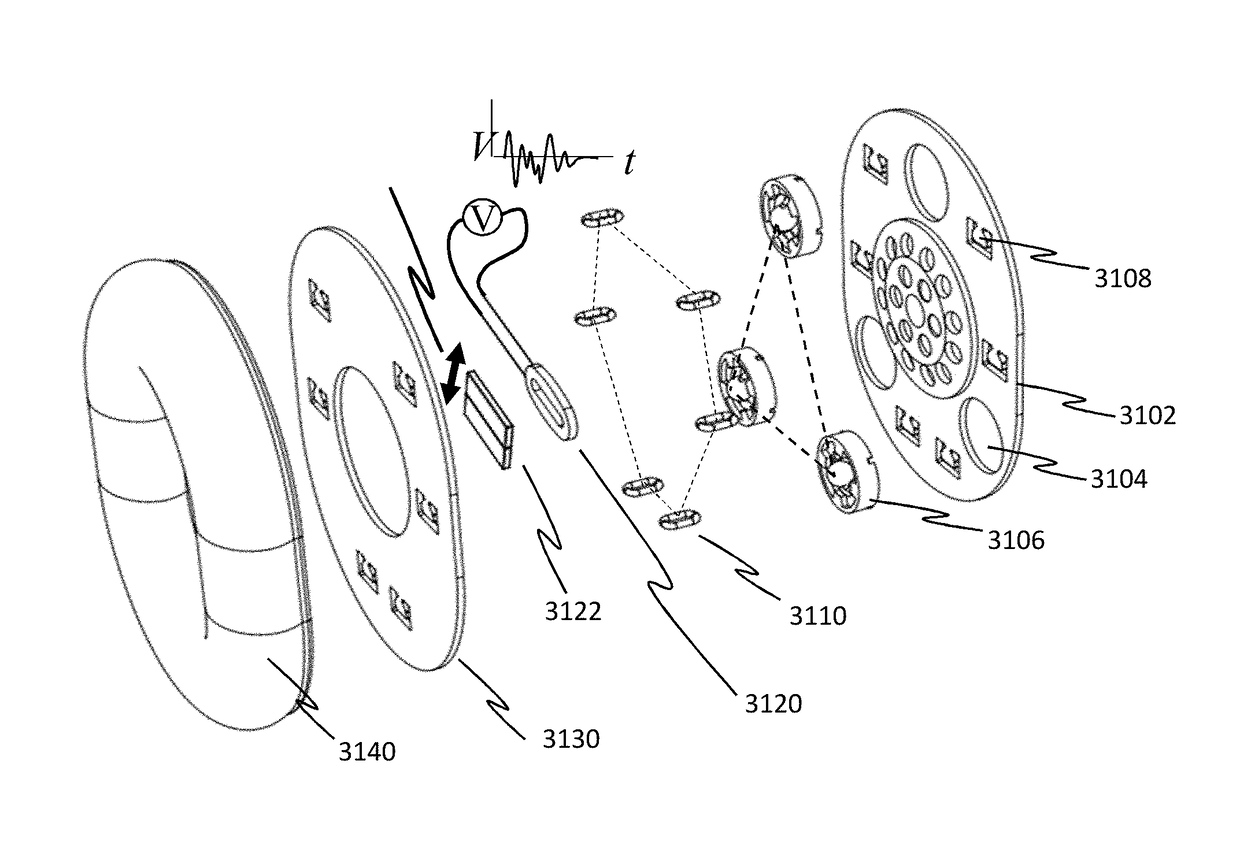

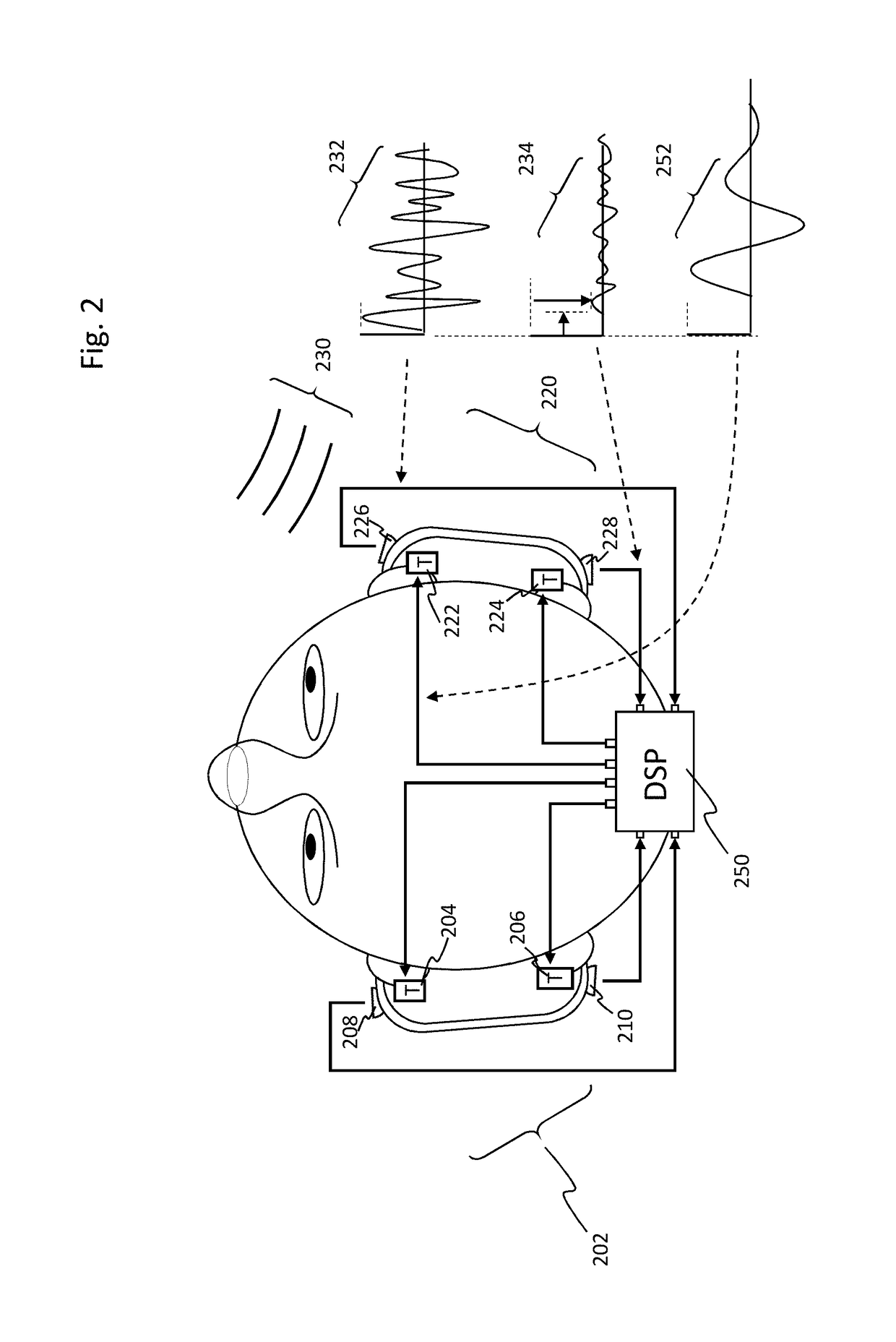

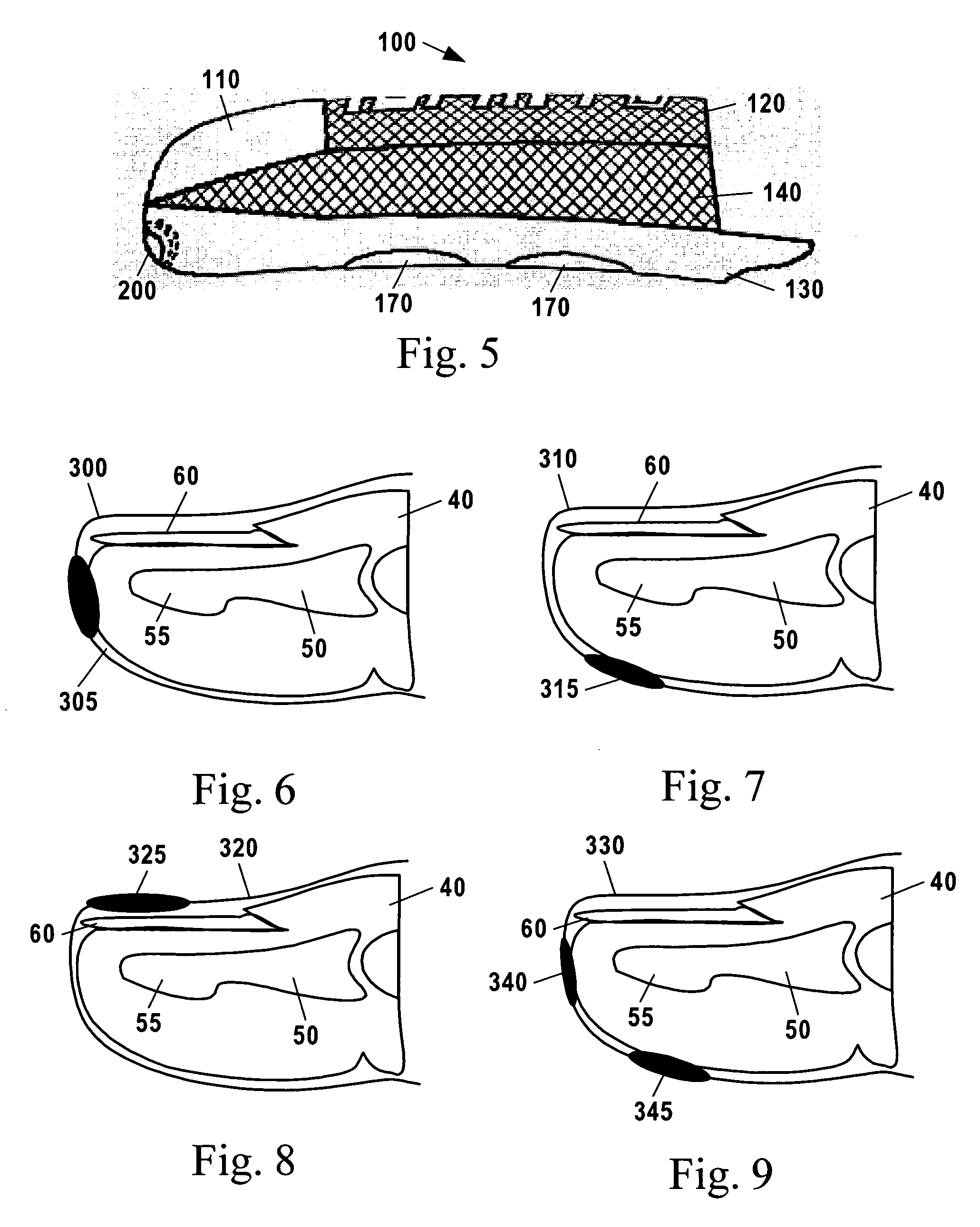

Apparatus and methods for audio-tactile spatialization of sound and perception of bass

ActiveUS20170180863A1Accurately produce wide range of tactile frequencyImprove user experienceHeadphones for stereophonic communicationBone conduction transducer hearing devicesImage resolutionTactile illusions

The apparatus and methods of the present invention provide quiet, compact, robust hardware that can accurately produce a wide range of tactile frequencies at a perceptually constant intensity. For greater expressiveness, some apparatus for moving the skin in multiple axes are also disclosed. Signal processing methods are presented to enhance the user's experience of audio spatialization. The methods transform audio signals into directional tactile cues matched to the time resolution of the skin, and which exploit directional tactile illusions.

Owner:TACTION TECH

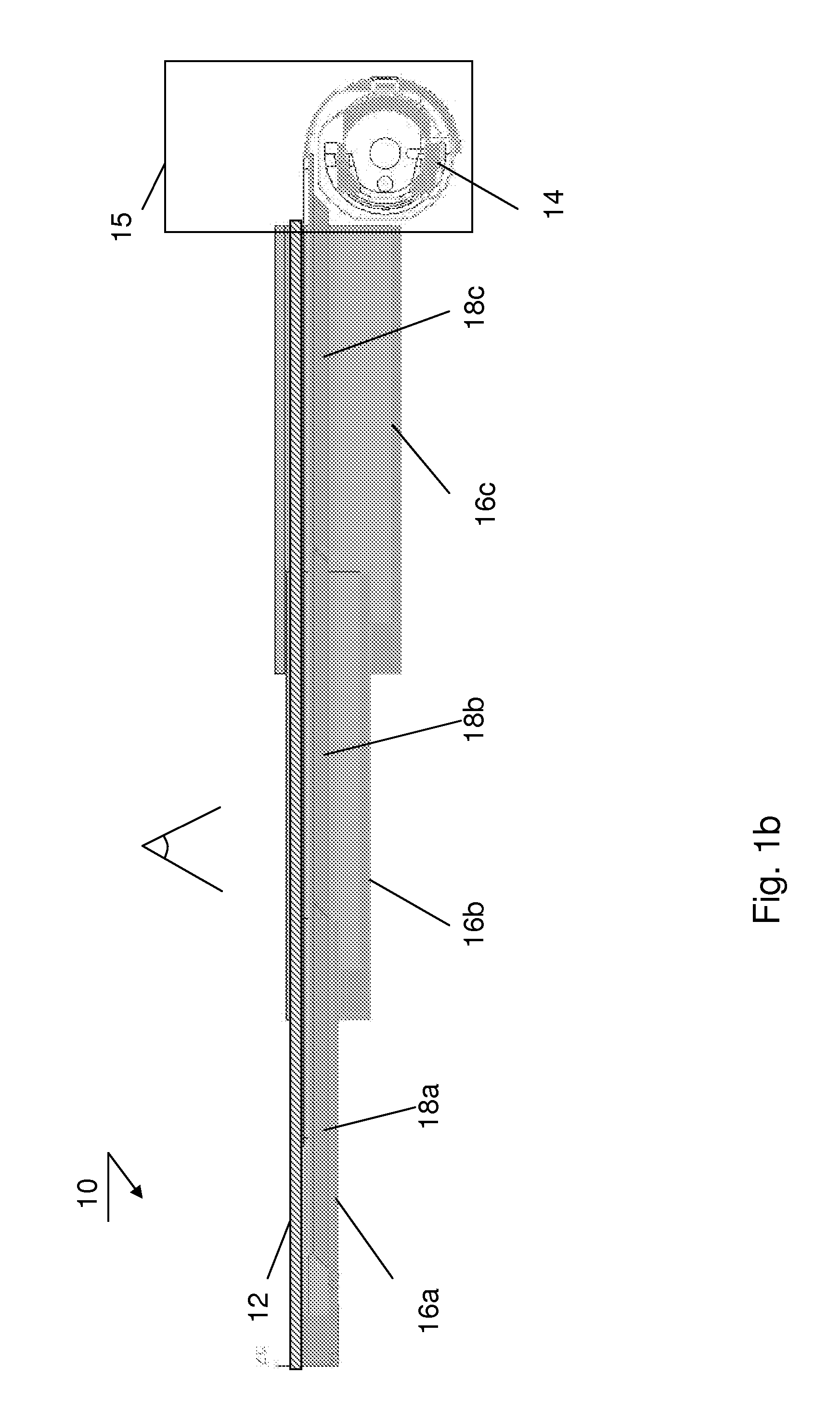

Electronic apparatus with improved functionality

ActiveUS20110018820A1Good touchFunction increaseCathode-ray tube indicatorsDetails for portable computersEngineeringFlexible display

The invention relates to an electronic apparatus comprising a flexible display 12 cooperating with a housing 15 and conceived to be alternated between an at least partially collapsed state and an at least partially extended state, said housing 15 comprising a substantially rigid portion 16a, 16b, 16c conceived to at least partially support an outer region of a surface of the flexible display in the extended state, wherein said rigid portion 16a, 16b, 16c is arranged for at least partially receiving a functional module 18a, 18b, 18c of the electronic apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

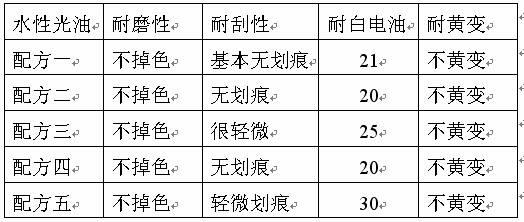

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

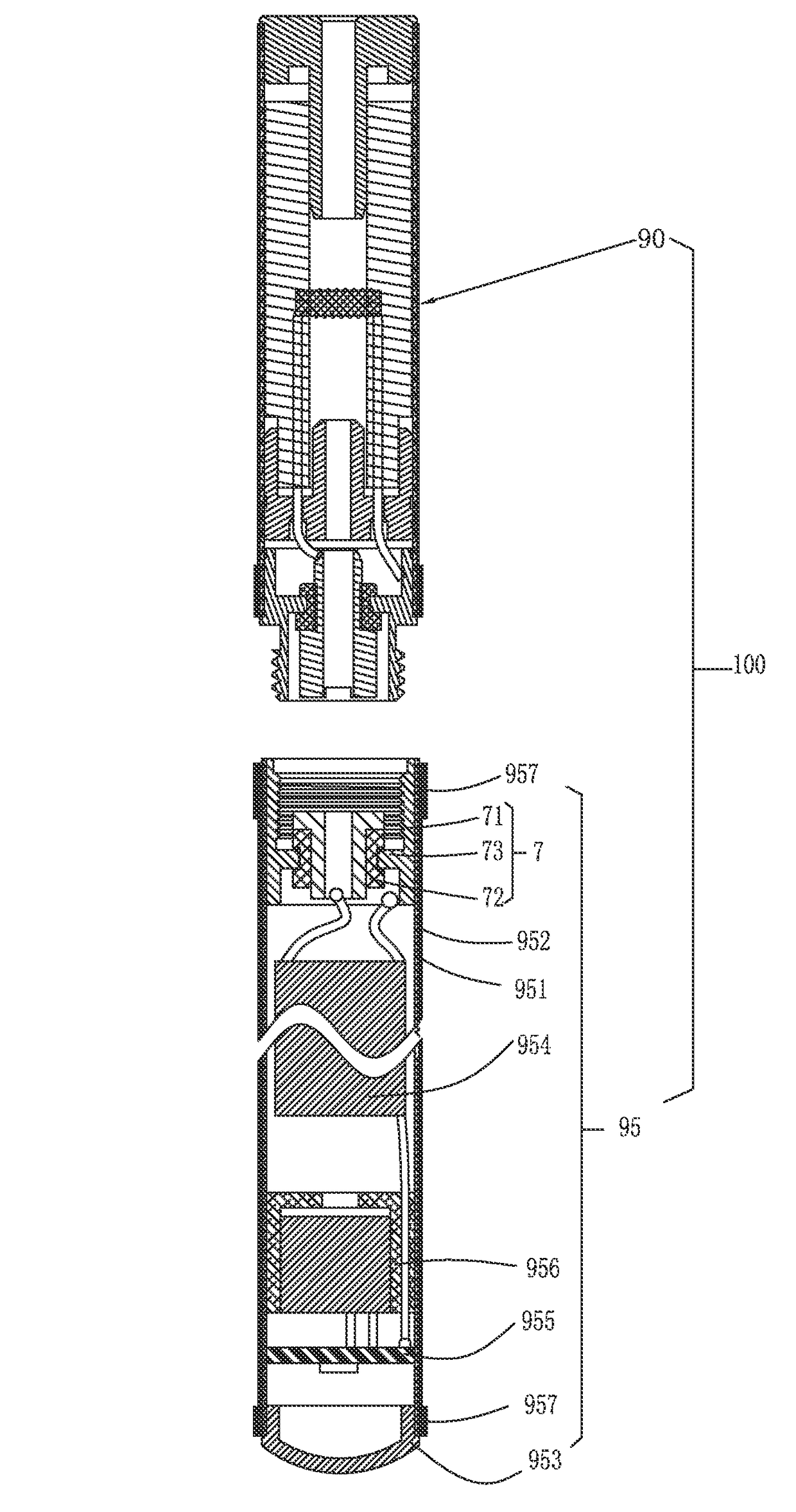

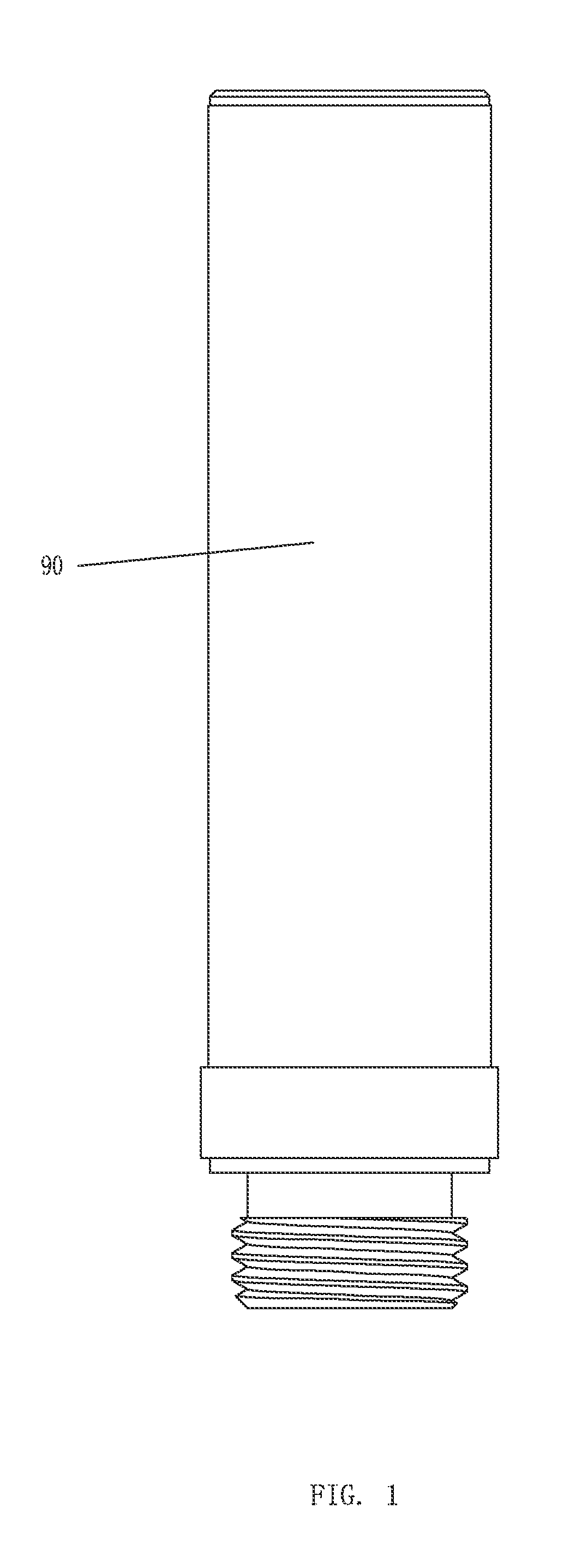

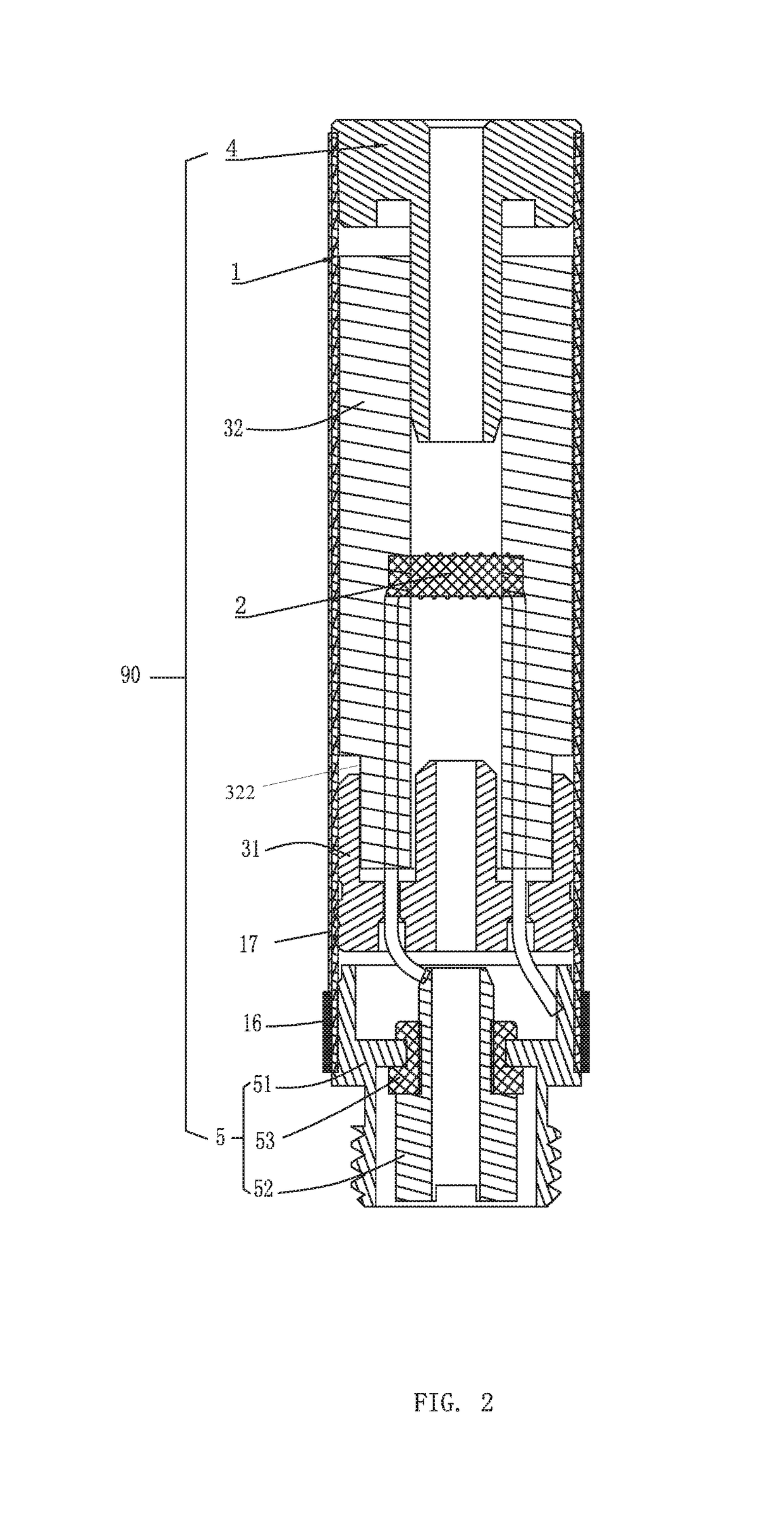

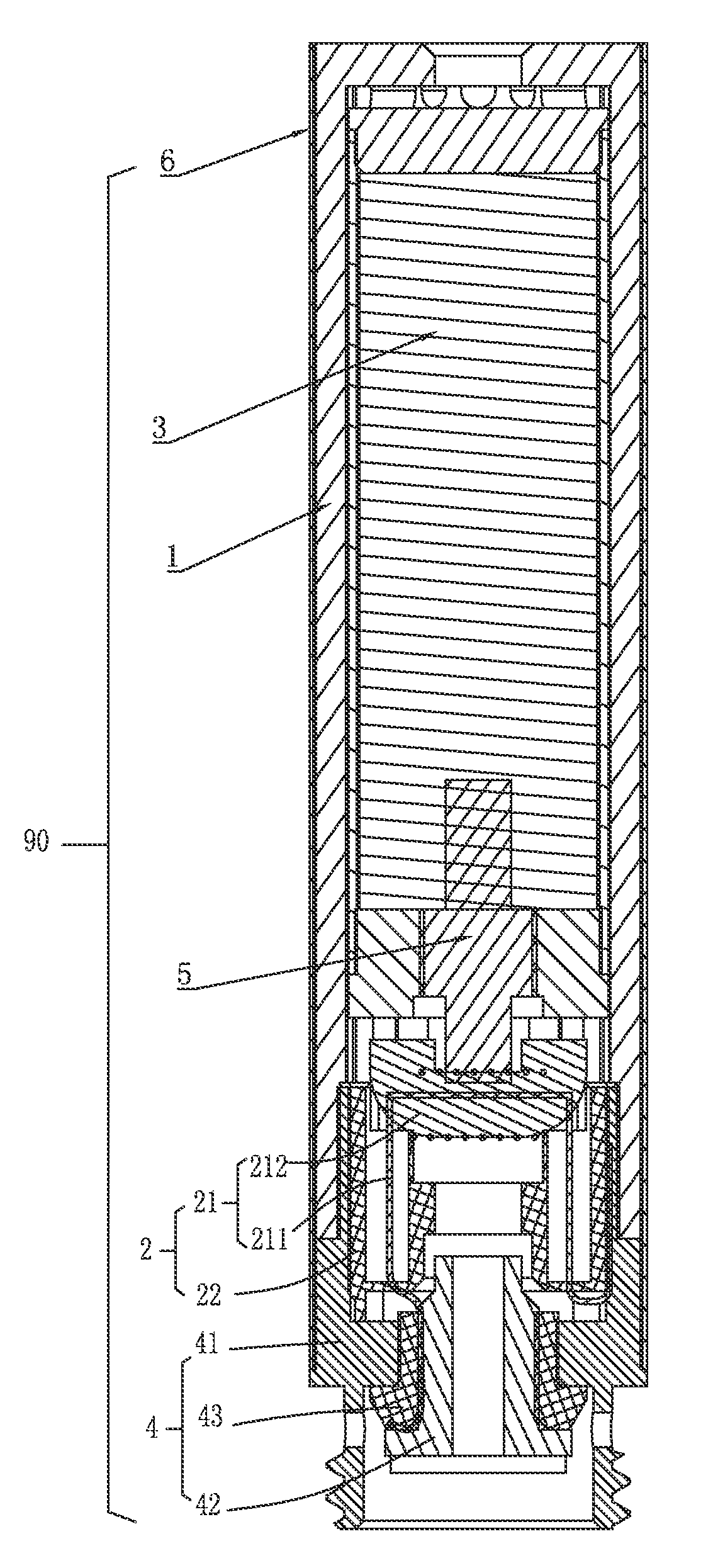

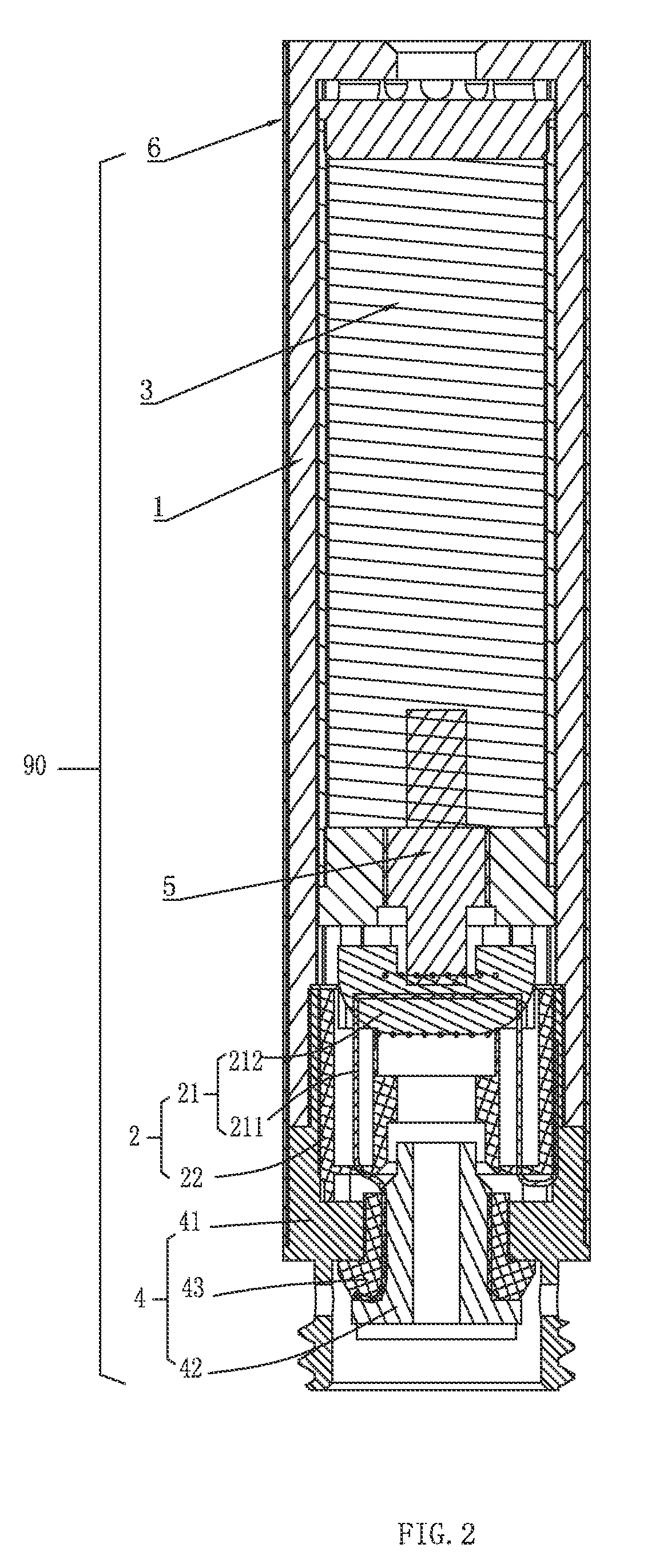

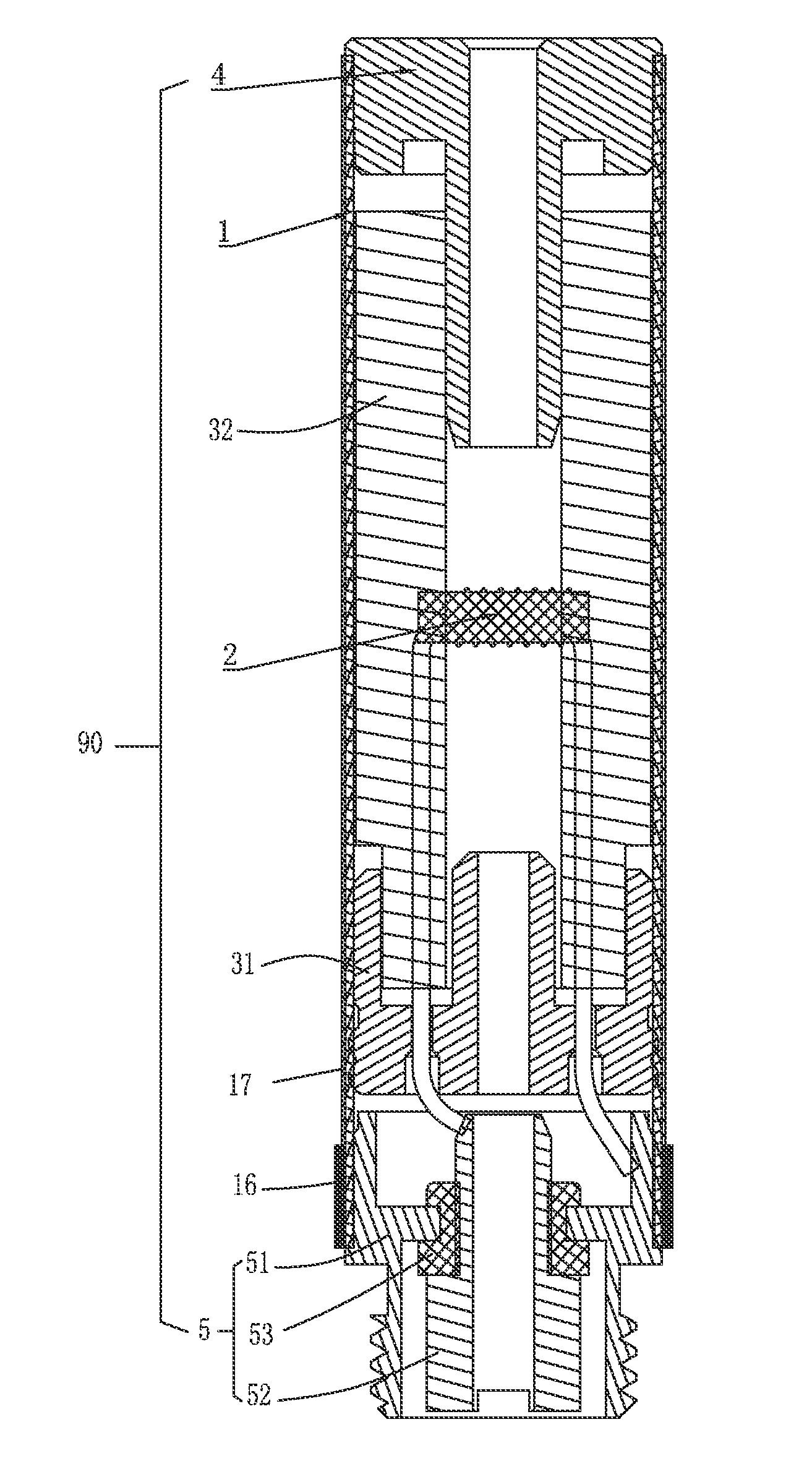

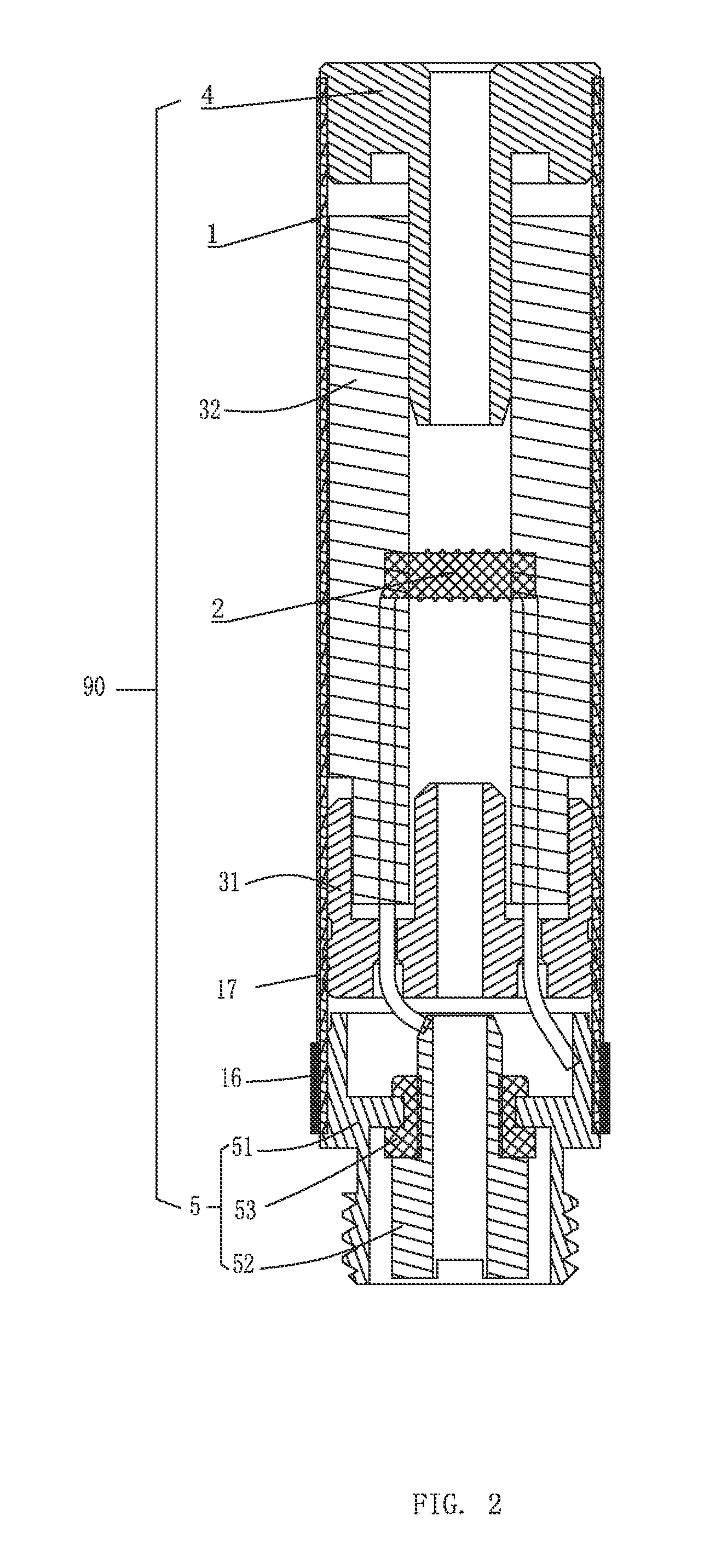

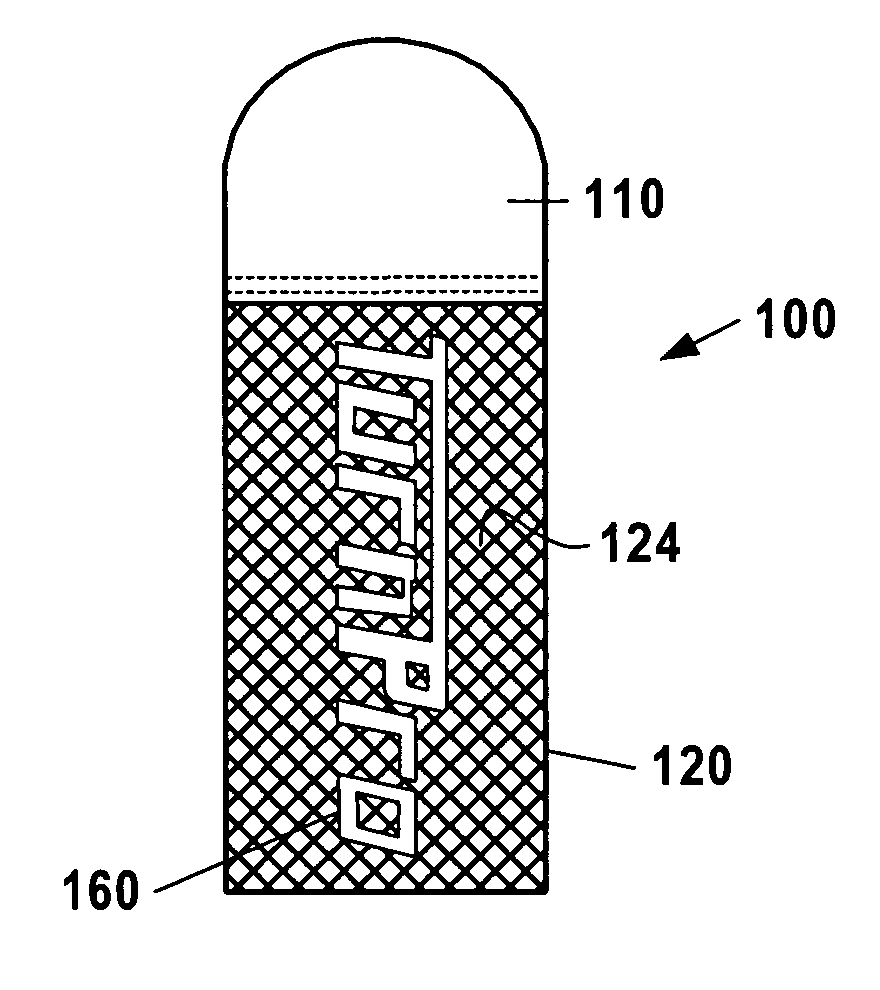

Electronic cigarette and its soft sucking rod

InactiveUS9603387B2Good touch feel and mouth feelSimple and compact internal structureOhmic-resistance electrodesTobacco pipesLiquid smokeSoft materials

The present invention relates to a soft sucking rod for electronic cigarette, the soft sucking rod includes a sucking rod sleeve and a liquid smoke cup configured within the sucking rod sleeve and an atomizer; the sucking rod sleeve is made of soft materials, the liquid smoke cup is configured with a liquid storage component therein for accommodating liquid smoke, the liquid storage component defines a through hole coaxially extended therethrough as a smog channel, the atomizer is configured in the smog channel of the liquid smoke cup, the atomizer atomizes the liquid smoke which is near the atomizer and stored in the liquid storage component. The soft sucking rod has good touch feel and mouth feel when hold in hand, and has simple and compact internal structure and low manufacturing cost.

Owner:HUIZHOU KIMREE TECH

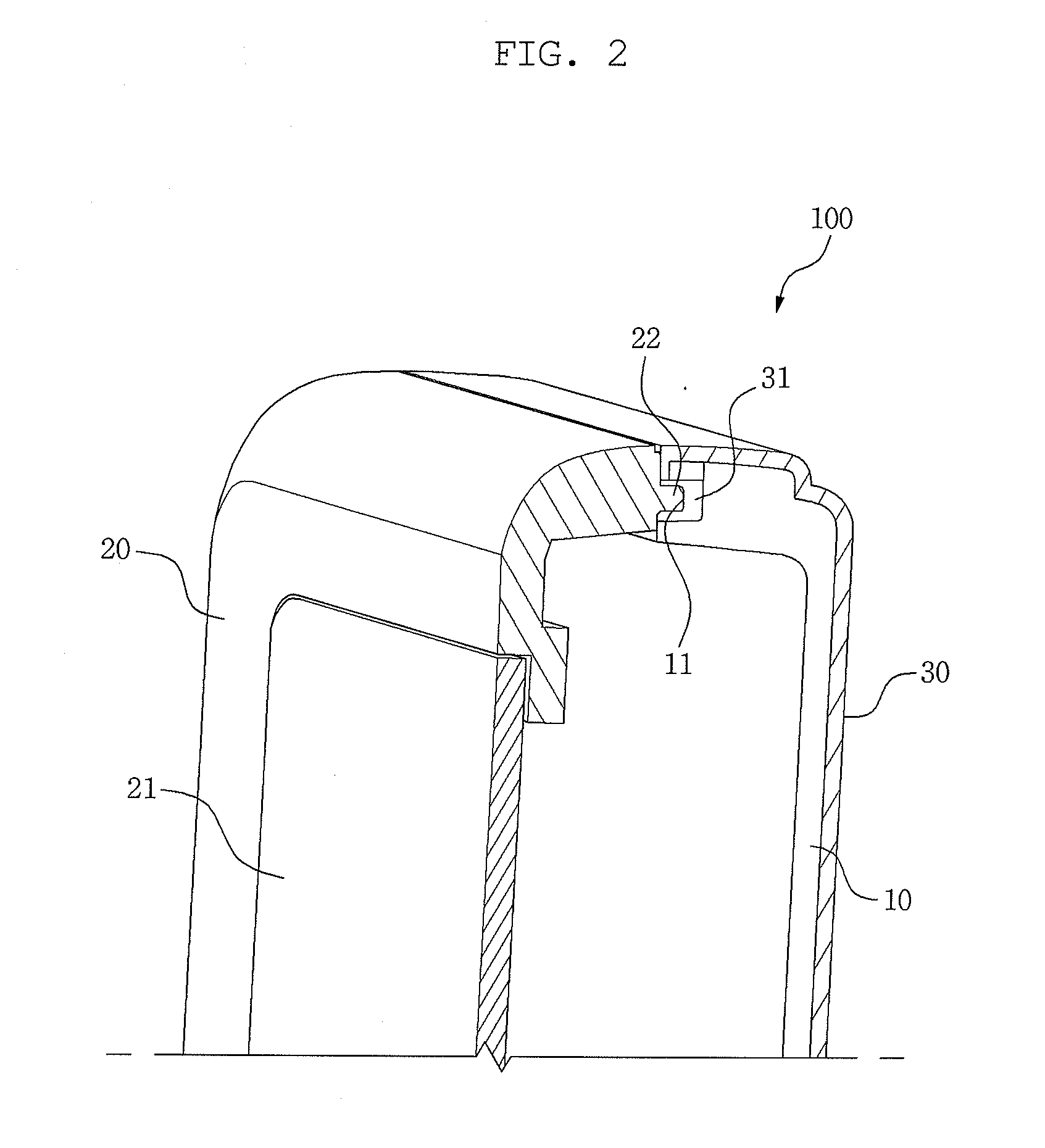

Container cap

ActiveUS20080087625A1Improved container performanceImprove performanceCapsClosure using stoppersEngineeringMechanical engineering

Owner:JAPAN CROWN CORK CO LTD

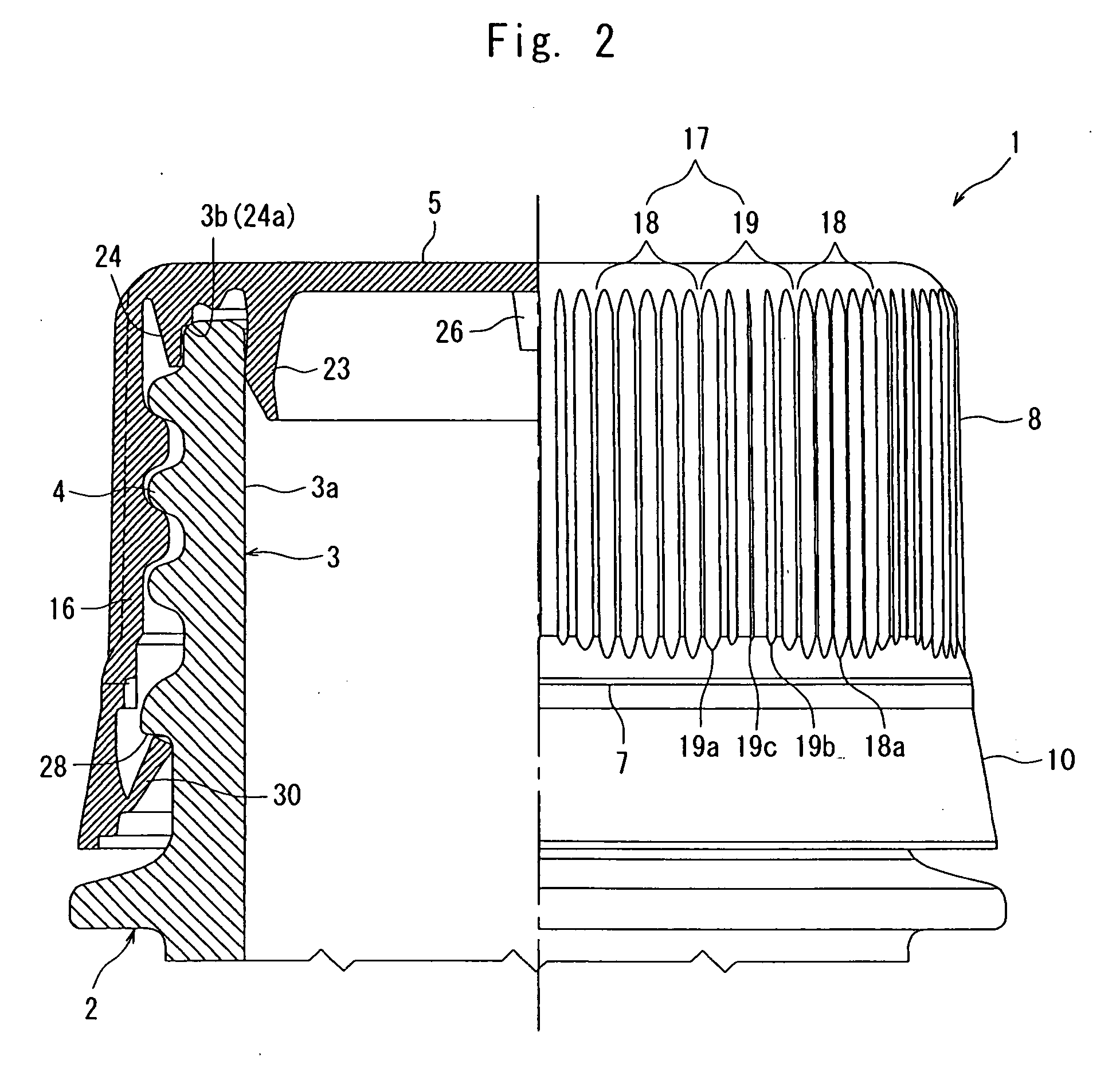

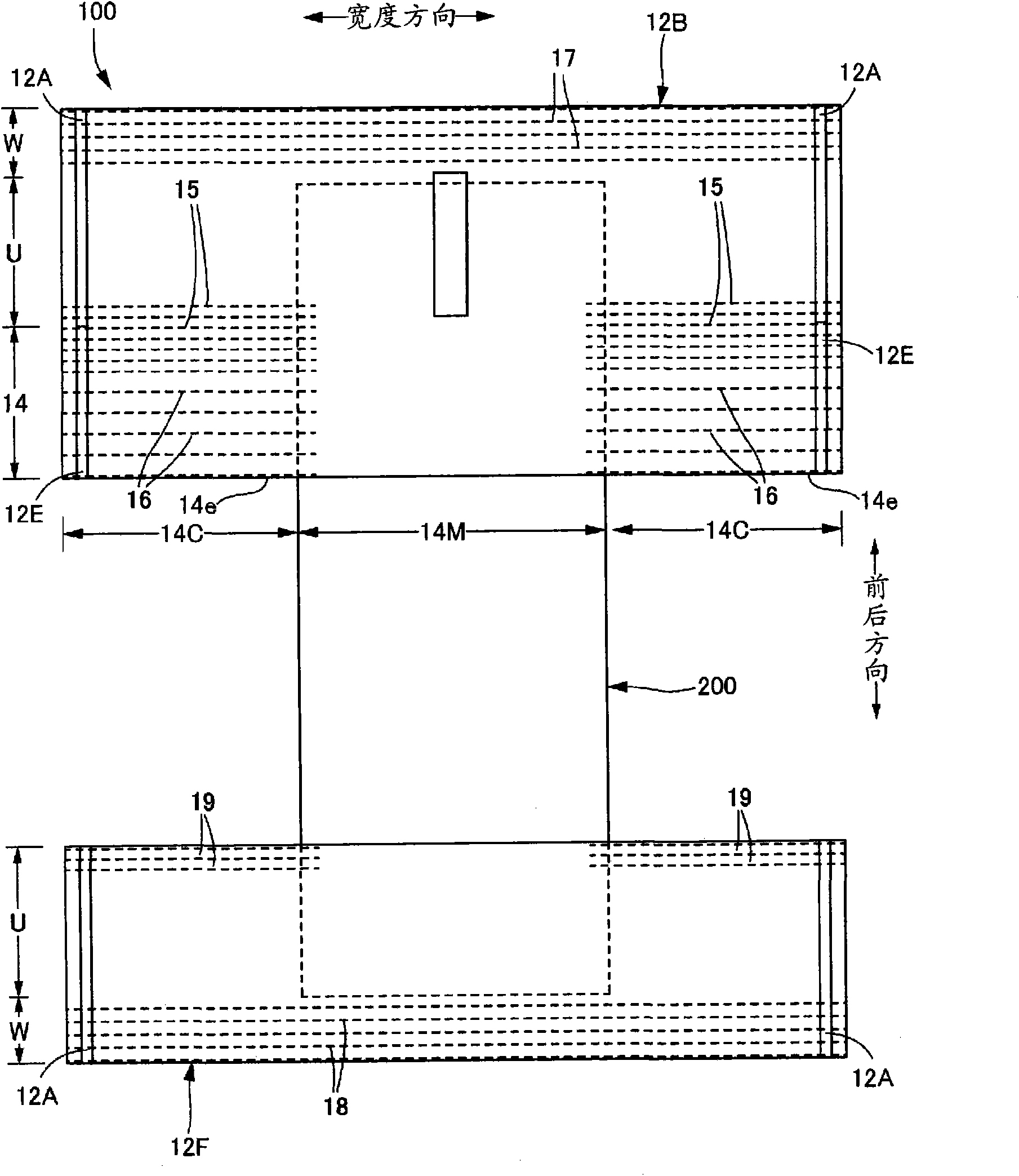

Pants type disposable diaper

ActiveCN101909568AExcellent breathability and flexibilityEnsure fitBandagesDisposable diaperEngineering

A pants type disposable diaper in which side seal sections simultaneously achieve both sufficient seal strength and ease of separation. In the pants type disposable diaper, a belly-side exterior sheet (12F) and a rear-side exterior sheet (12B) are separated from each other without being connected to each other on the crotch side. The exterior sheets (12F, 12B) have a waist-side folded back portion (21) and a crotch-side folded back portion (22). The crotch-side edge of the waist-side folded back portion (21) and the waist-side edge of the crotch-side folded back portion (22) agree with each other. The number of plies in that portion of a sheet-like air permeable material (12) which is at a waist-side end and the number of plies in that portion of the sheet-like air permeable material (12)which is at a crotch-side end are the same. Further, the number of plies in that portion of the sheet-like air permeable material (12) which is at an intermediate section between the waist-side end and the crotch-side end is the same as or less than the number of plies in those portions of the sheet-like air permeable material (12) which are at the waist-side end and the crotch-side end.

Owner:DAIO PAPER CORP

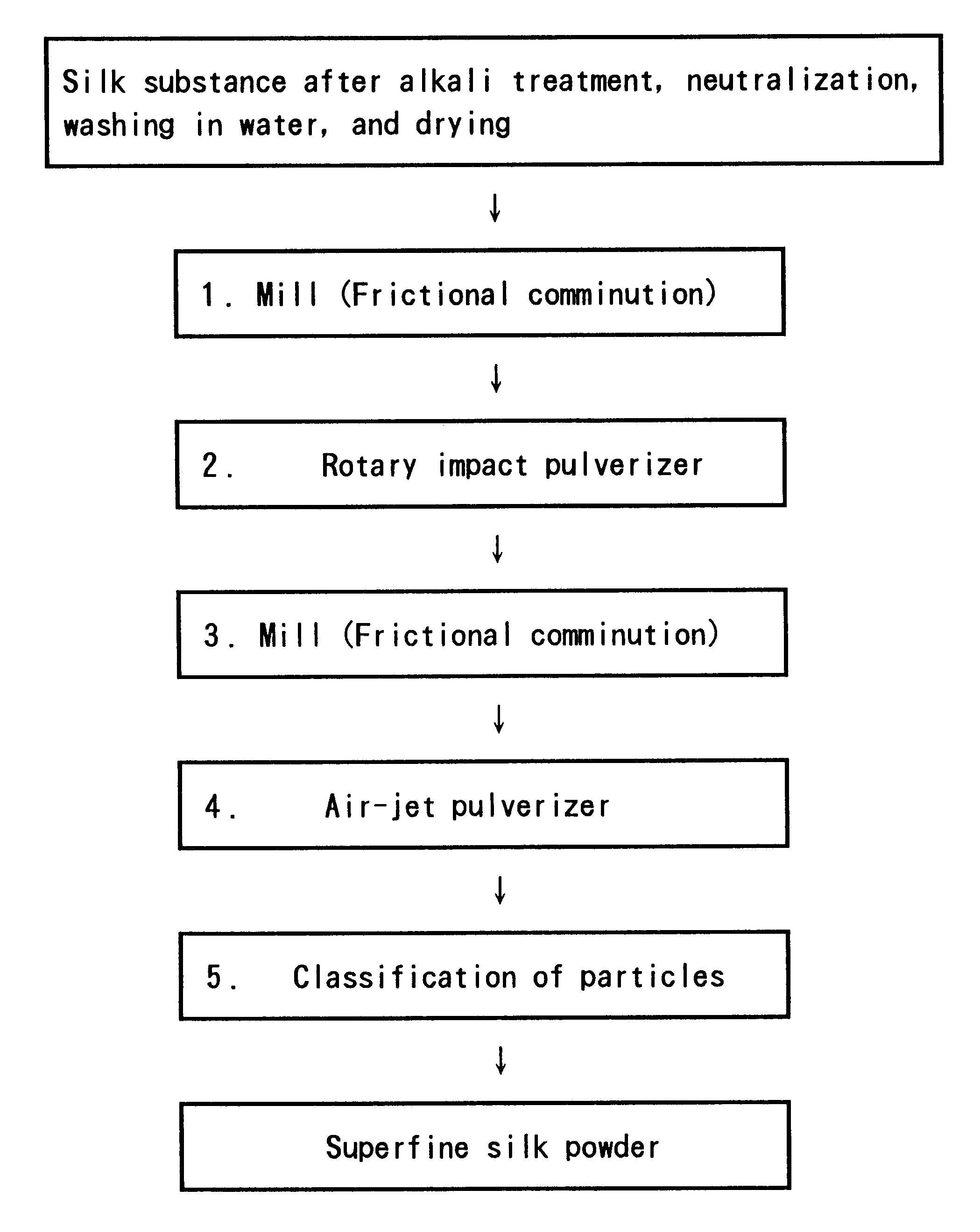

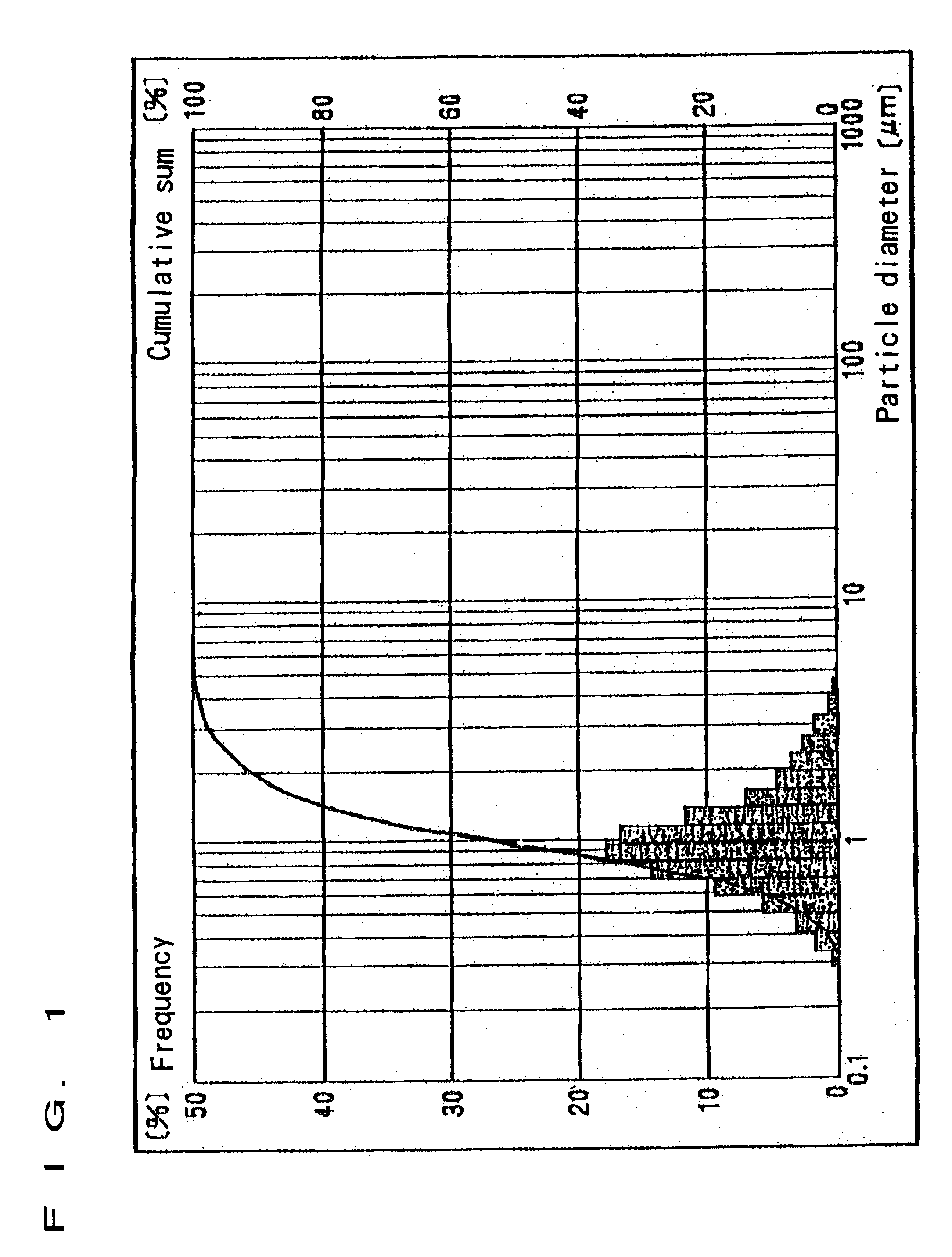

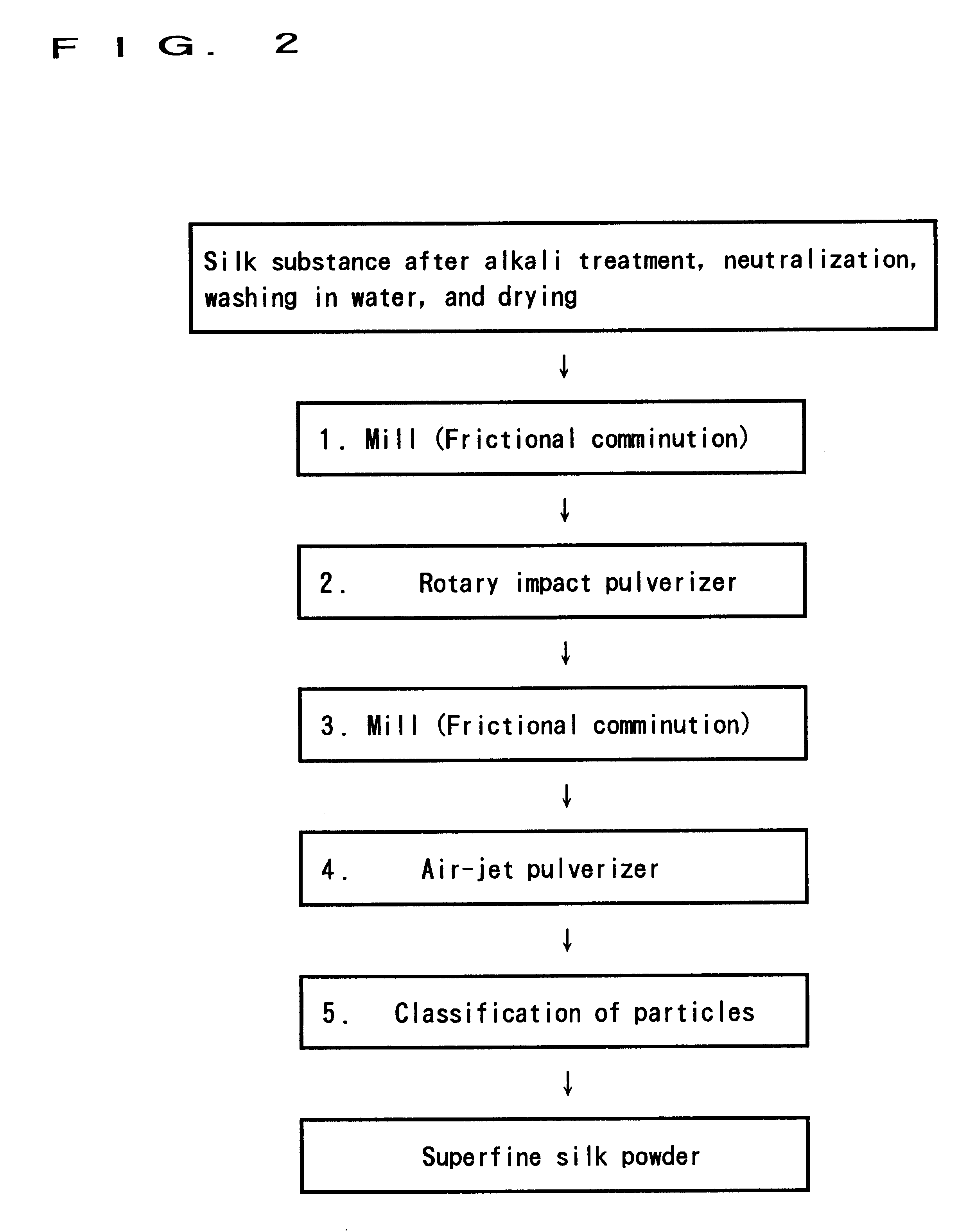

Method for manufacturing crystalline superfine silk powder

The main theme of the invention is to provide a method for manufacturing industrially, by mechanically comminuting silk yarn, crystalline silk fibroin powder below 3 mum in an average particle diameter, which can be used for various applications. A silk substance such as cocoon filament, silk yarn, or raw silk is brought into an alkali aqueous solution under a pressure of 1 through 5 atmospheric pressure at temperatures from 100° C. through 150° C. to reduce the tensile strength of the silk substance to around 0.02 g / d or less. Thereafter, the resultant silk substance is subjected to dealkalization and drying. Subsequently, the resultant dried silk substance is comminuted into powder below 3 mum in an average particle diameter. Thus, the crystalline silk fibroin powder below 3 mum in an average particle diameter is manufactured.

Owner:JAPAN AS REPRESENTED BY DIRECTOR GENERAL OF NAT INST OF SERICULTURAL & ENTOMOLIGICAL SCI MINIST OF AGRI FORESTRY & FISHERIES +1

Environmental protection type Nano Coating

An envirnomental protection type nano-paint with high resistance to ultraviolet ray, bacteria, mildew, brush, acid, and alkali, photocatalyzing function and amphophobic performance is prepared from filming material, nano material chosen from TiO2, SiO2 and zinc oxide, additive and water.

Owner:张海波

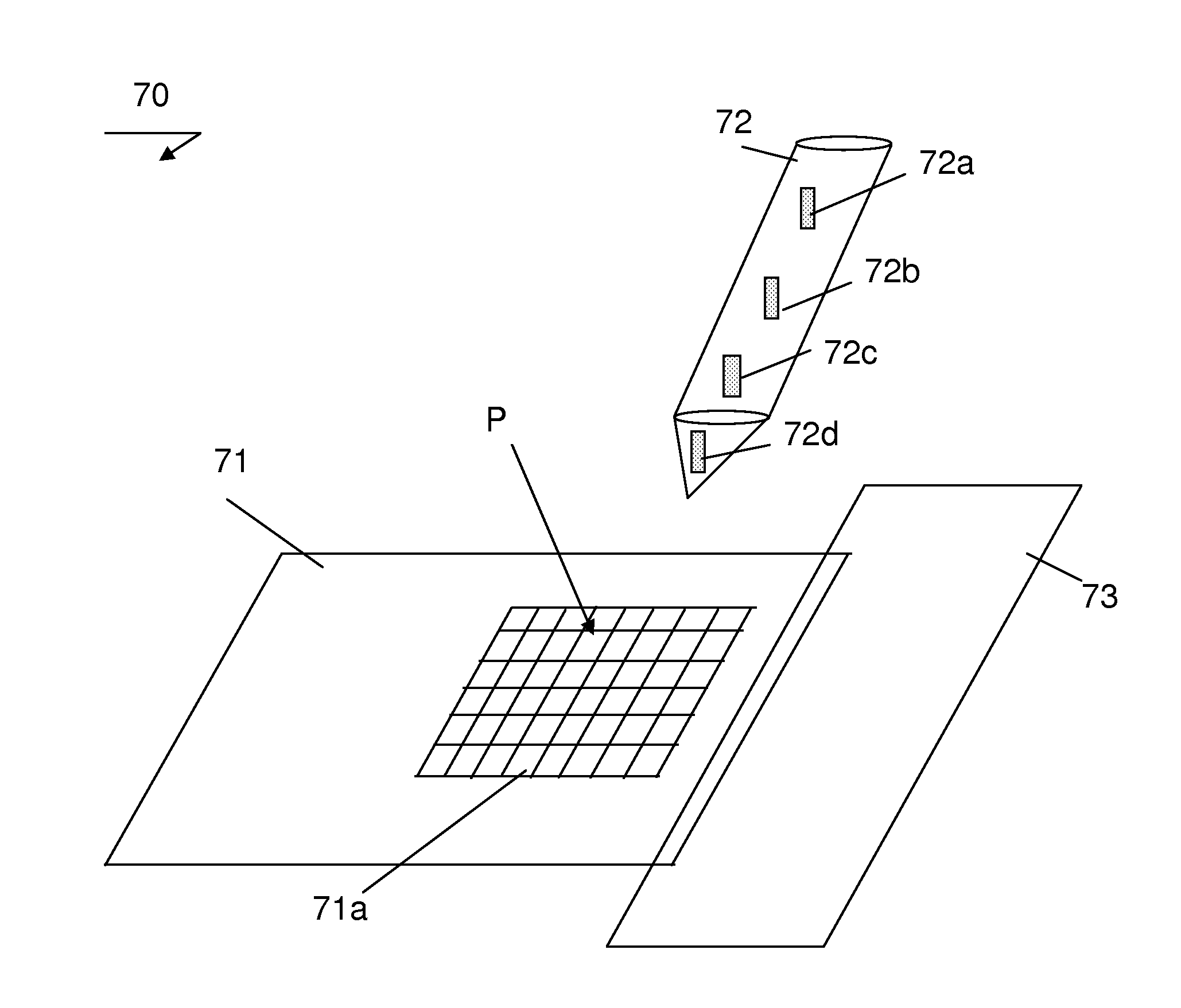

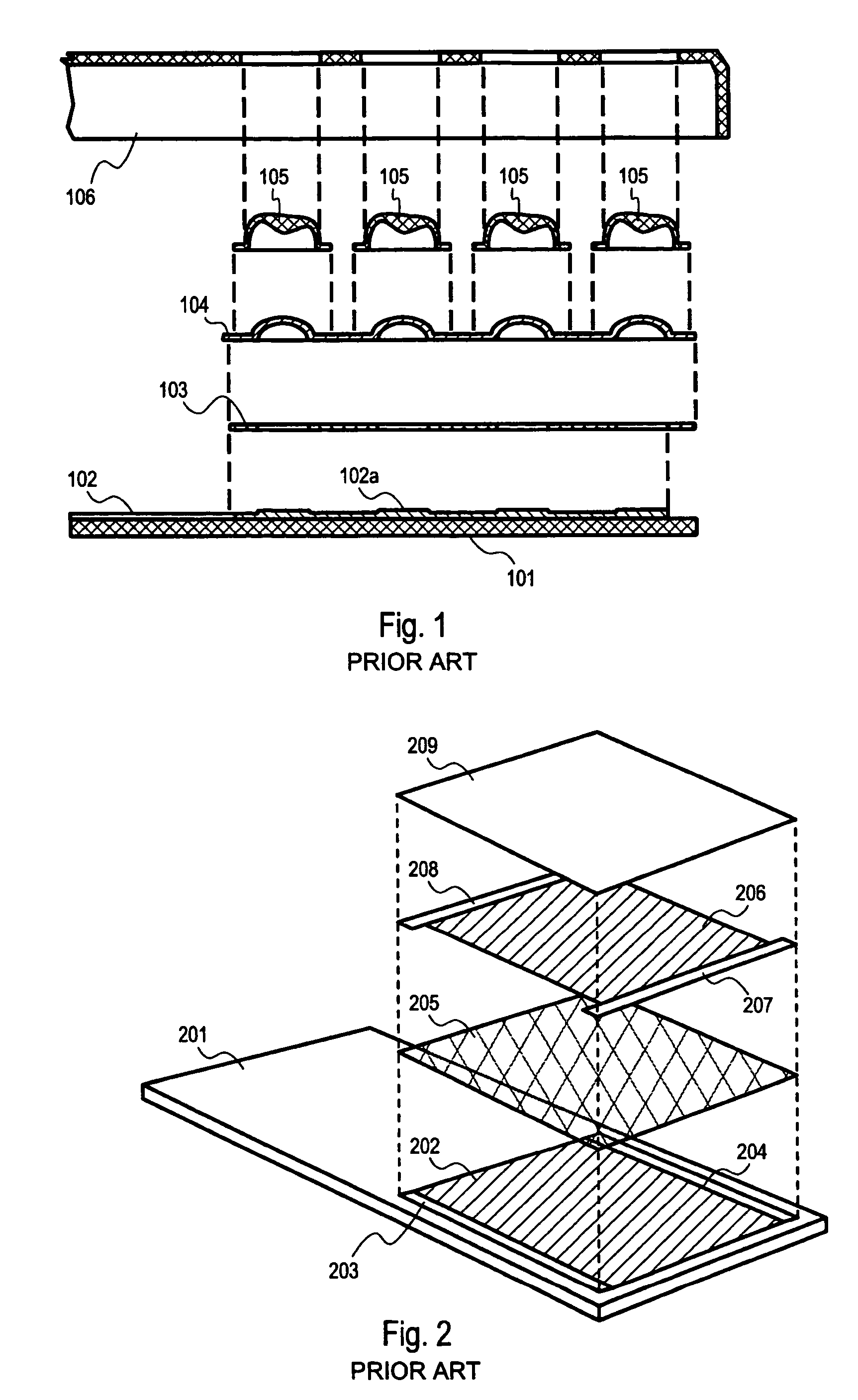

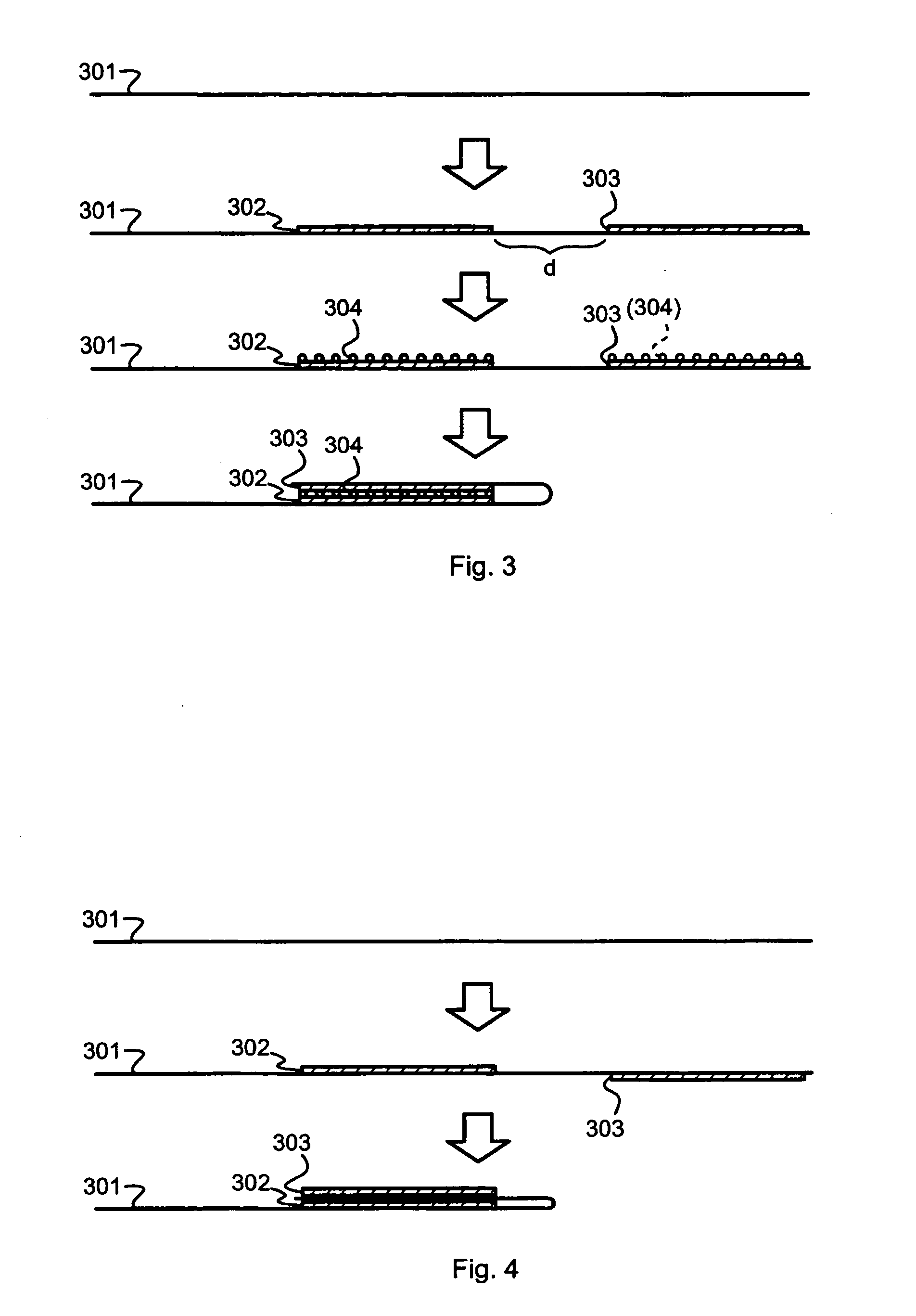

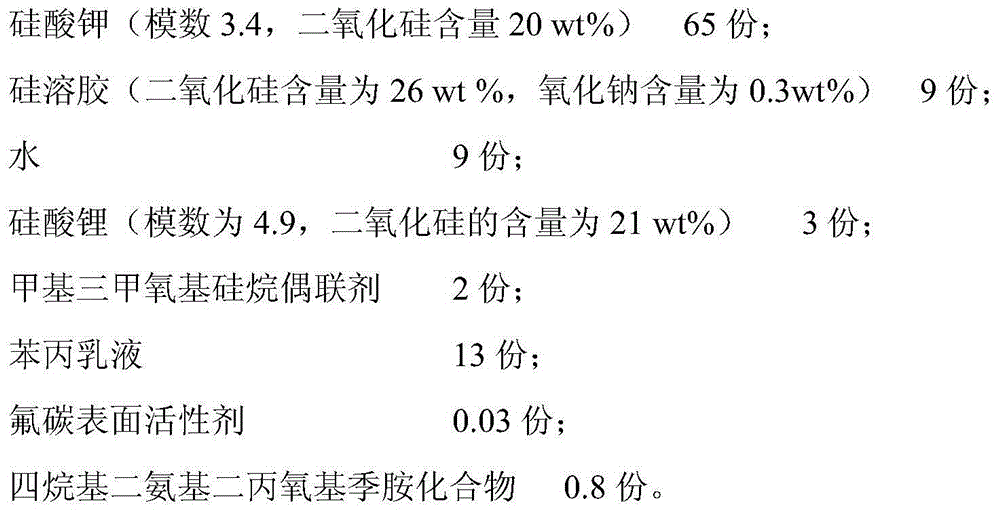

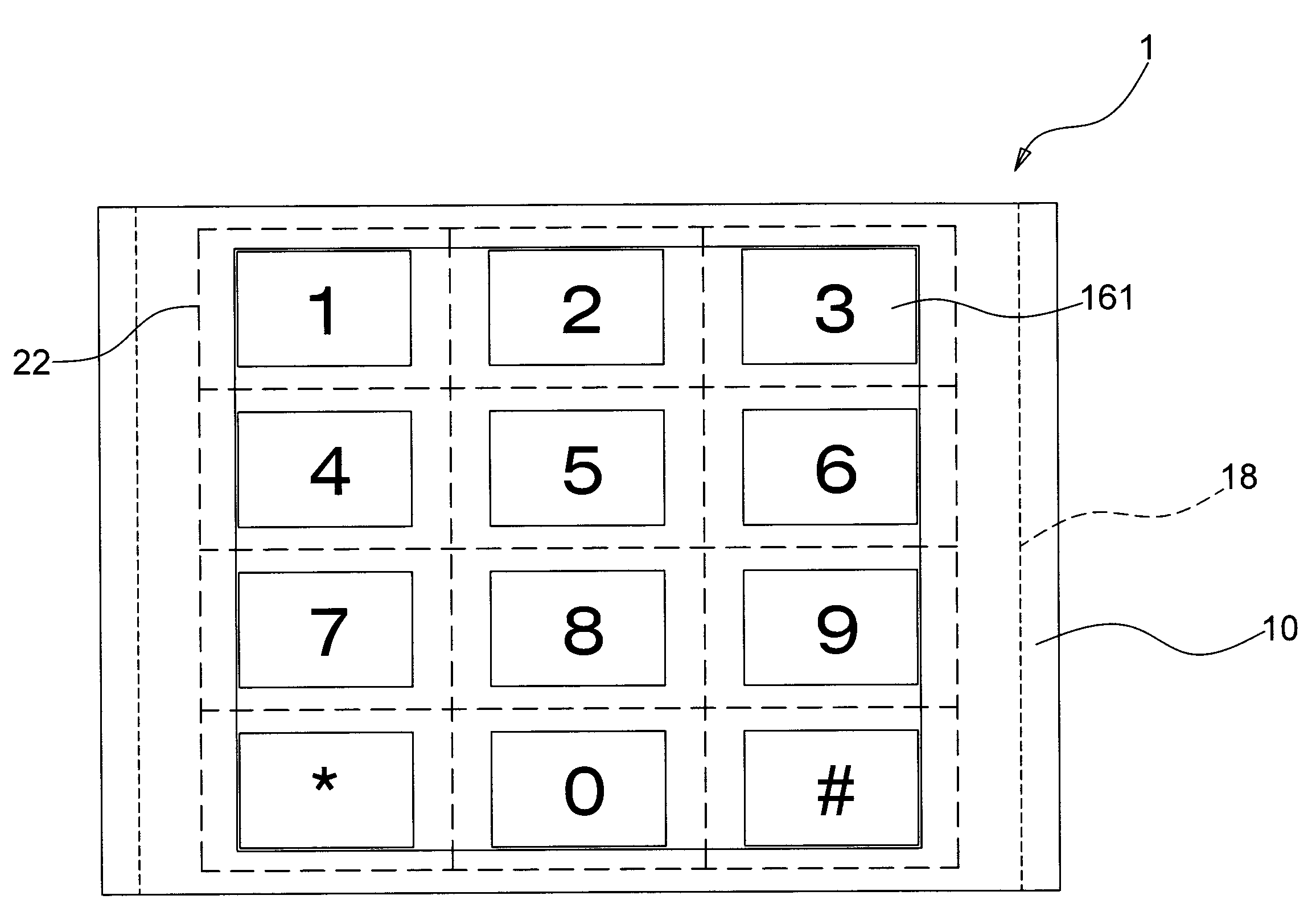

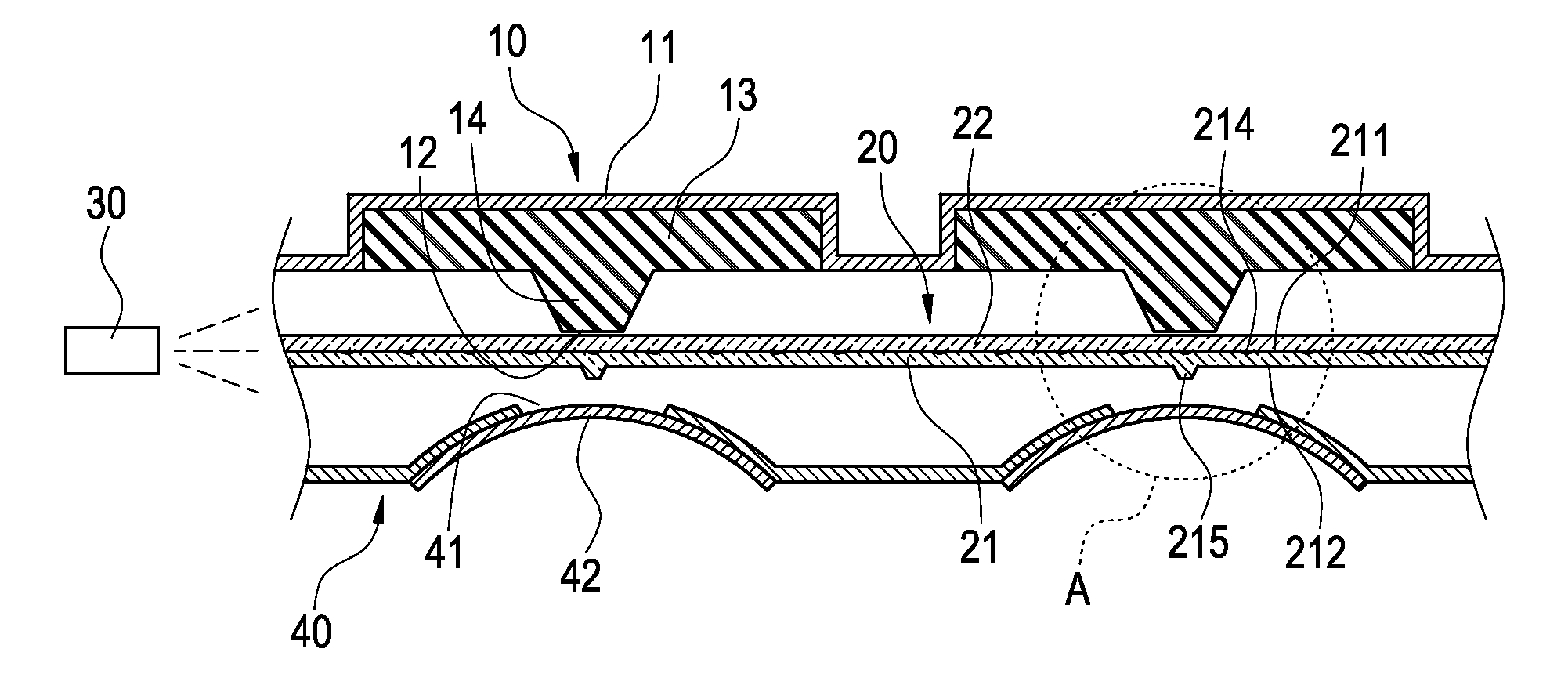

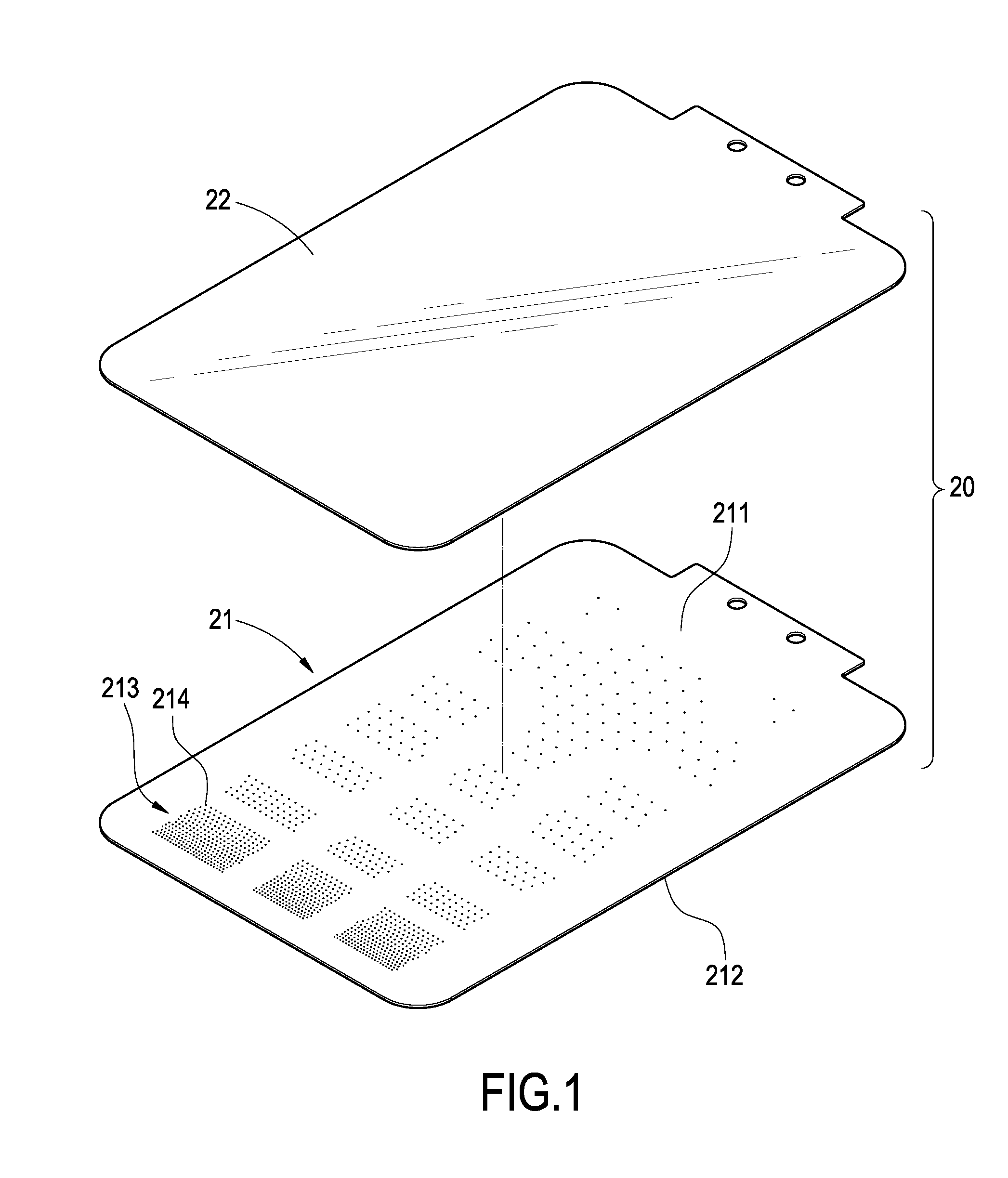

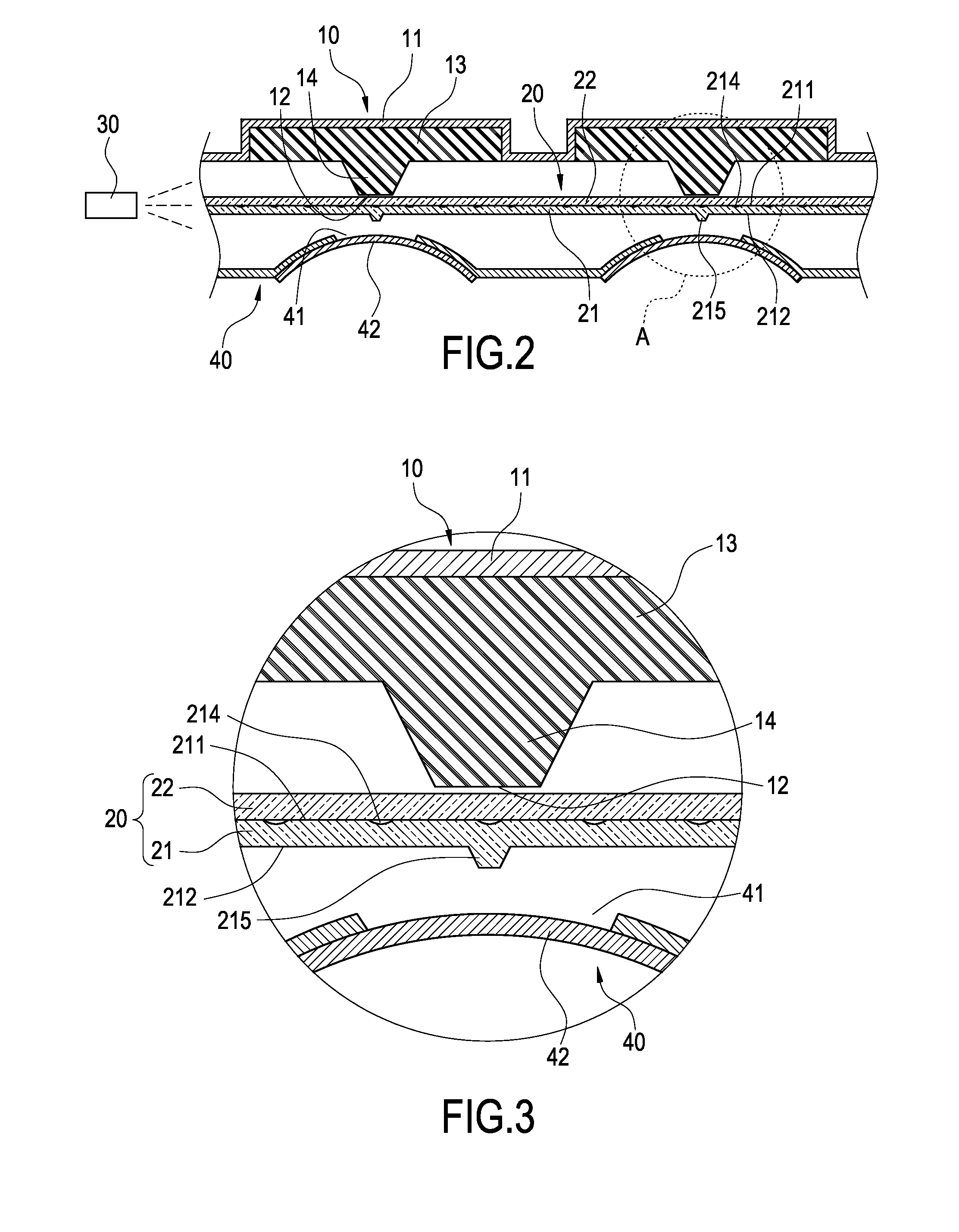

Printable electromechanical input means and an electronic device including such input means

ActiveUS20050146510A1Reduce the numberAdapt to a wide rangePrinted circuit aspectsCathode-ray tube indicatorsElectricity

Electromechanical input means for a portable electronic device comprise first and second layers of conductive or resistive material. The second layer overlaps the first layer at least partly so that the overlapping parts of the first and second layers together are responsive to touching or pressing to produce an electric input signal to the portable electronic device. There is a dielectric support layer for the first and second layers. At least a part of the dielectric support layer for the first layer continues past the first layer and is bent back to act as the dielectric support layer for the second layer.

Owner:RPX CORP

Electronic cigarette and soft absorption stem thereof

InactiveUS9198466B2Compact internal structureUnique smoke pathTobacco devicesElectronic cigaretteLiquid tank

A soft absorption stem for an electronic cigarette is provided, comprising a sleeve, a cigar liquid tank disposed inside the sleeve, an atomization device and a liquid guiding component. The sleeve is made of soft material; a plurality of venting slots is extended axially from one end of the sleeve to the other end thereof and disposed on an inner wall of the sleeve; the sleeve includes a mouthpiece end and a connection end; a suction hole communicating with the venting slots is provided on the mouthpiece end; smoke produced by atomization of the atomization device flows out of the sleeve from the venting slots across the suction hole. The electronic cigarette makes the user more comfortable when holding the sleeve in hand and containing in mouth, having more compact internal construction, having unique smoke path, and having increased cigar liquid storage capacity.

Owner:HUIZHOU KIMREE TECH

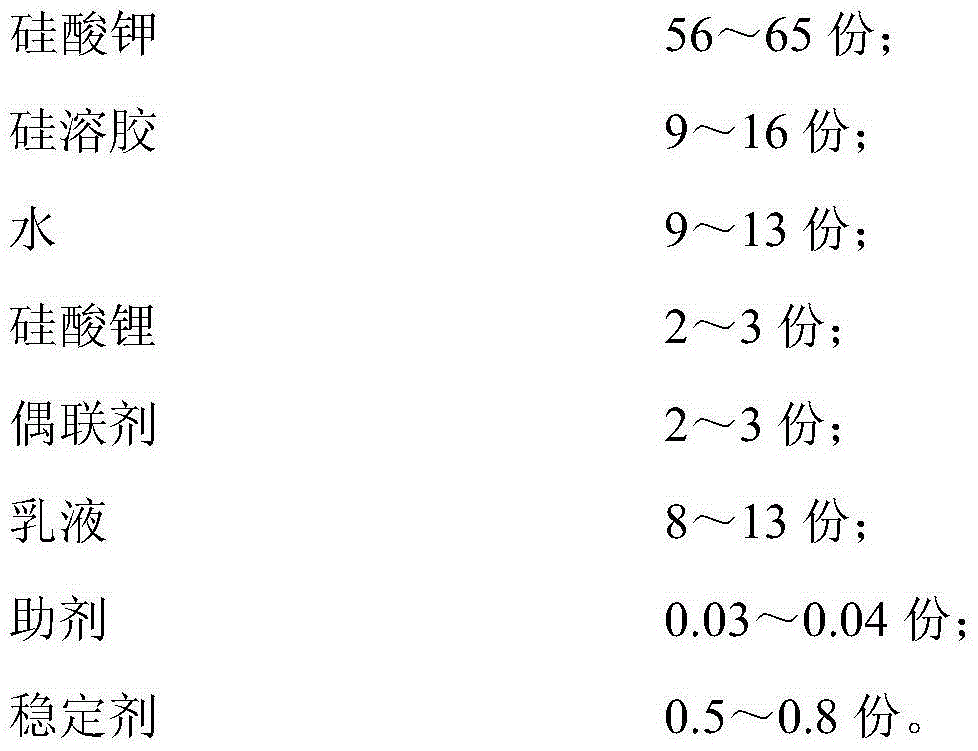

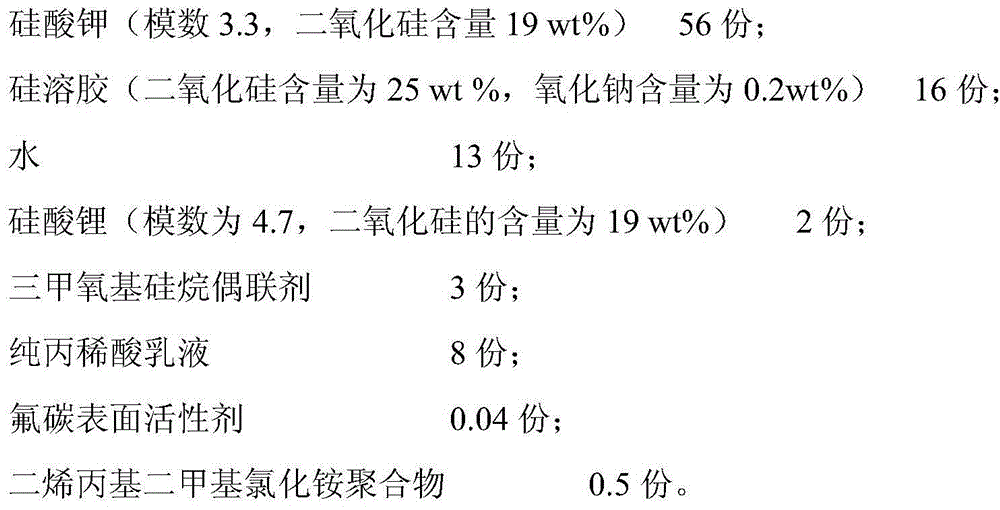

Water-based inorganic resin and preparation method thereof

InactiveCN103602107AGood resistance to salt sprayHigh hardnessAlkali metal silicate coatingsAnti-corrosive paintsWater basedLithium

The invention discloses water-based inorganic resin and a preparation method thereof. The preparation method comprises the following steps: carrying out hydrolysis reaction on a formula amount of potassium silicate, silica sol and lithium silicate under the effect of a coupling agent, and after reaction is stable, adding elastic emulsion so as to adjust the flexibility, thus obtaining the water-based inorganic resin with excellent properties. The water-based inorganic resin prepared by the method is environment-friendly, odorless, non-toxic, non-ignitable and unexplosive, and has very excellent salt fog resistance, permanent corrosion resistance, high hardness, strong adhesive force and heat and humidity resistance, and therefore, the water-based inorganic resin has wide development space in numerous heavy corrosion protection fields and atmosphere and ocean steel structure heavy corrosion protection fields.

Owner:WUXI HUHUANG PAINT

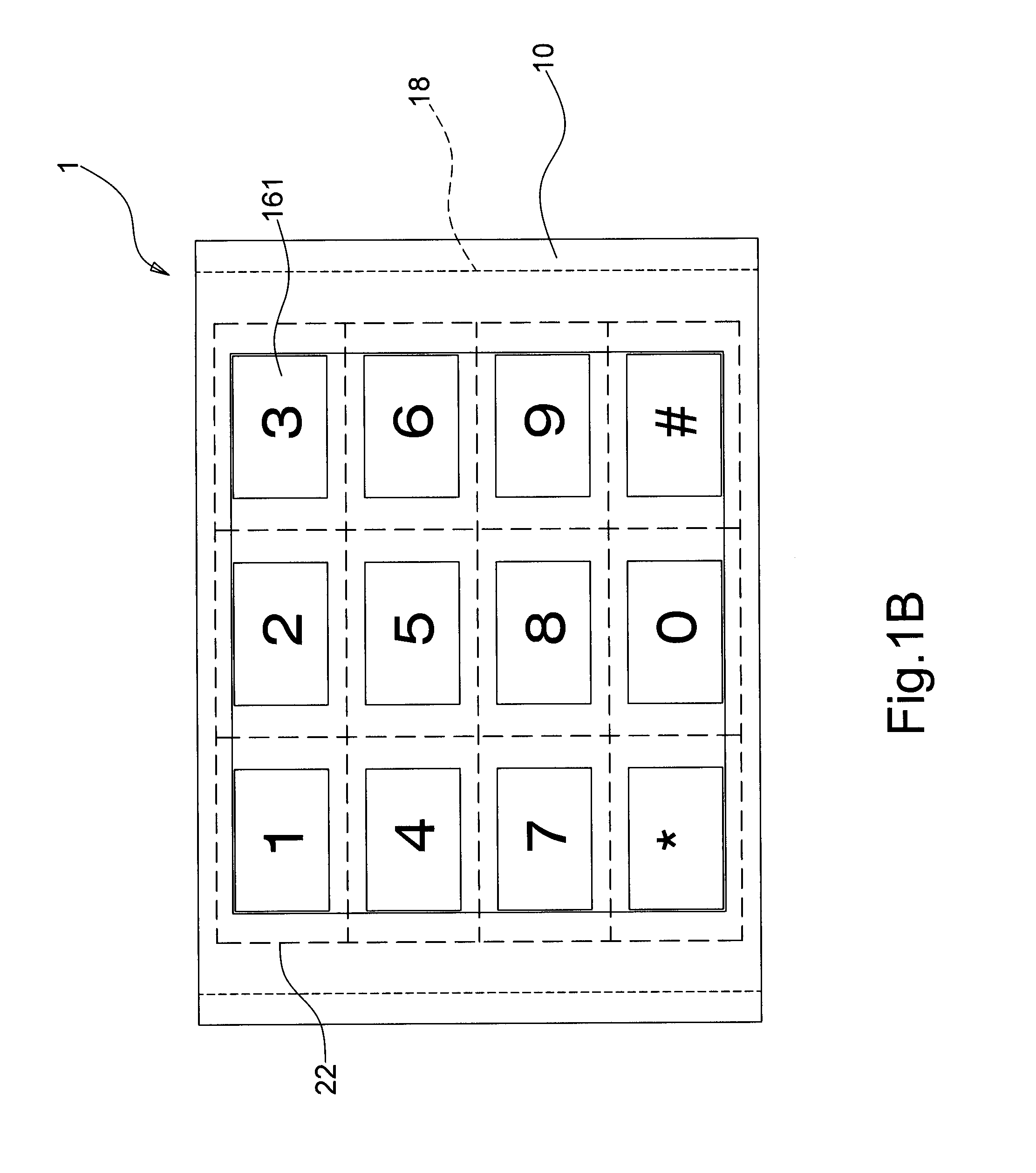

Keypad

InactiveUS20090051571A1Inhibit wearFeel goodEmergency actuatorsEmergency casingsEngineeringDirty environment

A keyboard is disclosed. The keyboard consists of a circuit board, a plurality of metal dome and a button set. The plurality of metal domes is arranged on the circuit board and is electrically coupled to the circuit board. The button set is composed of a plurality of buttons that respectively are corresponding to the metal domes. A piece of leather or cloth is disposed on the button set so as to make users have good sense of touch and prevent figures from being worn or falling off. Thus the aesthetic appeal is improved. Moreover, a supporting frame is disposed on the bottom set so as to prevent the buttons with leather or cloth from moving along with other buttons being pressed. Furthermore, a lighting device is added into the device for projecting light onto surface of the button set. Thus users can operate the buttons under dingy environment.

Owner:URC ELECTRONIC TECHNOLOGY (KUNSHAN) CO LTD

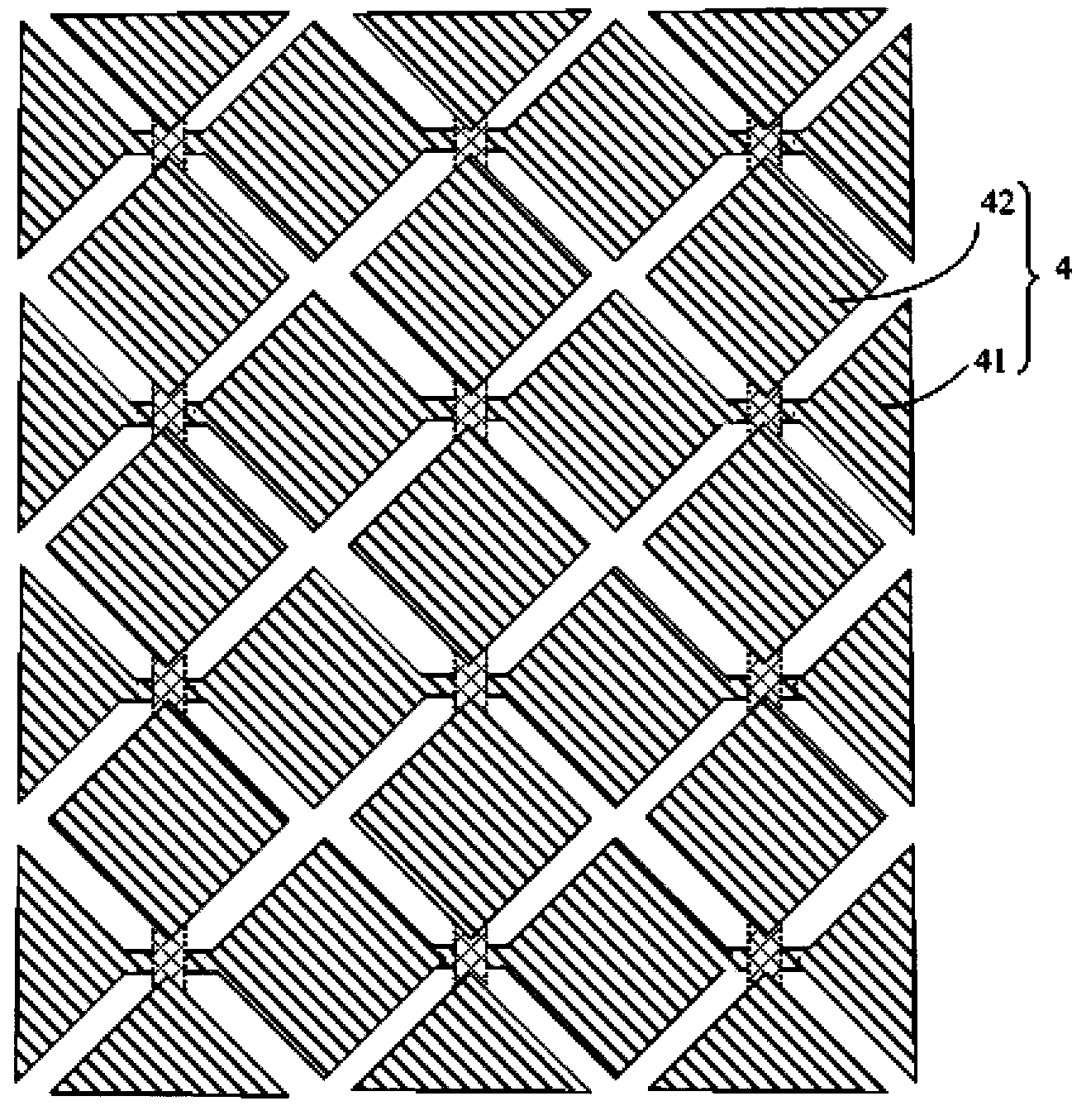

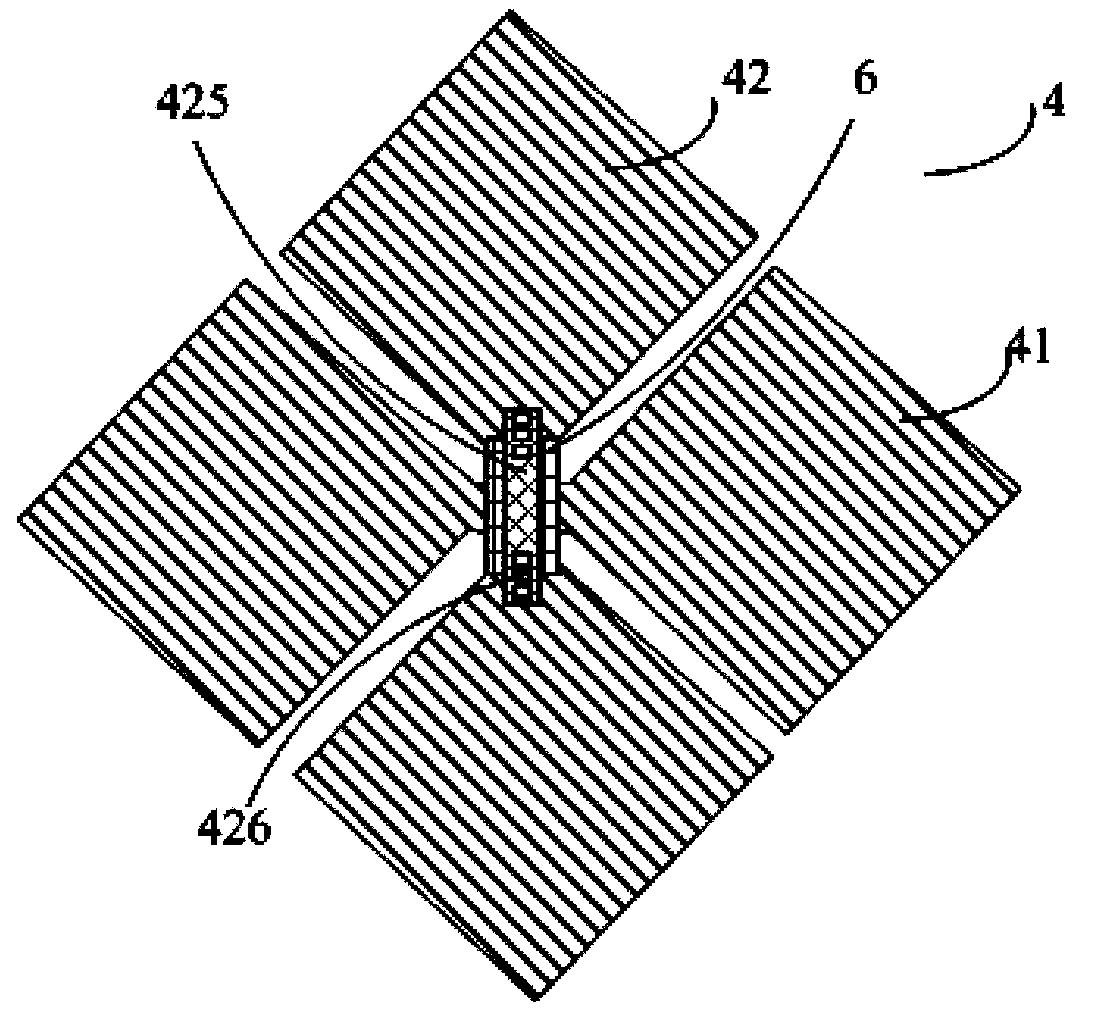

Capacitive touch screen and manufacturing method

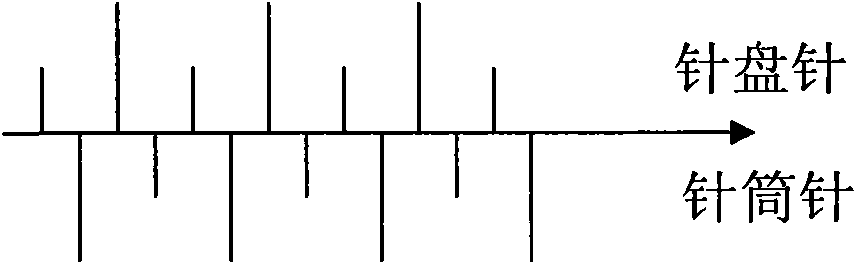

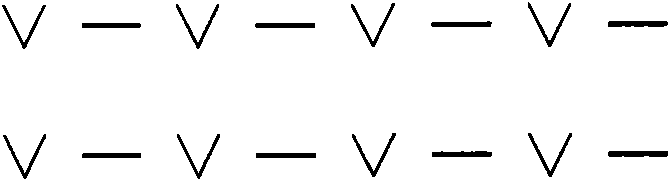

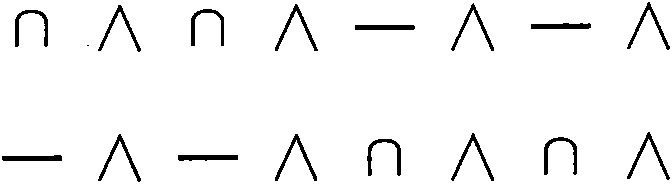

ActiveCN103365518AReduce loadImprove anti-interference abilityNon-linear opticsInput/output processes for data processingTouchscreenCapacitor

The invention belongs to the technical field of display and relates to a capacitive touch screen and a manufacturing method. The capacitive touch screen comprises a base plate and sensor electrodes, wherein the sensor electrodes are arranged on the base plate; each sensor electrode comprises multiple lines of first electrode sets arranged in parallel and multiple lines of second electrode sets arranged in parallel; each first electrode set comprises multiple first electrodes electrically connected in sequence; each second electrode set comprises multiple second electrodes electrically connected in sequence; each first electrode and / or each second electrode comprise / comprises peripheral electrodes and a central electrode, the peripheral electrodes are distributed on the periphery, and the central electrode is electrically isolated from the peripheral electrodes; the adjacent peripheral electrodes on the same line / column are mutually electrically connected. The capacitive touch screen and the manufacturing method have the following benefits: the coupling between the sensor electrodes of the capacitive touch screen and common electrodes is smaller, so that RC (resistor capacitor) load is reduced, the sensor electrodes are faster in charging, and the touch induction sensitivity of the capacitive touch screen is ensured.

Owner:BOE TECH GRP CO LTD +1

Electronic Cigarette and Its Soft Sucking Rod

InactiveUS20150296884A1Good touch feel and mouth feelSimple and compact internal structureOhmic-resistance electrodesTobacco pipesLiquid smokeEngineering

The present invention relates to a soft sucking rod for electronic cigarette, the soft sucking rod includes a sucking rod sleeve and a liquid smoke cup configured within the sucking rod sleeve and an atomizer; the sucking rod sleeve is made of soft materials, the liquid smoke cup is configured with a liquid storage component therein for accommodating liquid smoke, the liquid storage component defines a through hole coaxially extended therethrough as a smog channel, the atomizer is configured in the smog channel of the liquid smoke cup, the atomizer atomizes the liquid smoke which is near the atomizer and stored in the liquid storage component. The soft sucking rod has good touch feel and mouth feel when hold in hand, and has simple and compact internal structure and low manufacturing cost.

Owner:HUIZHOU KIMREE TECH

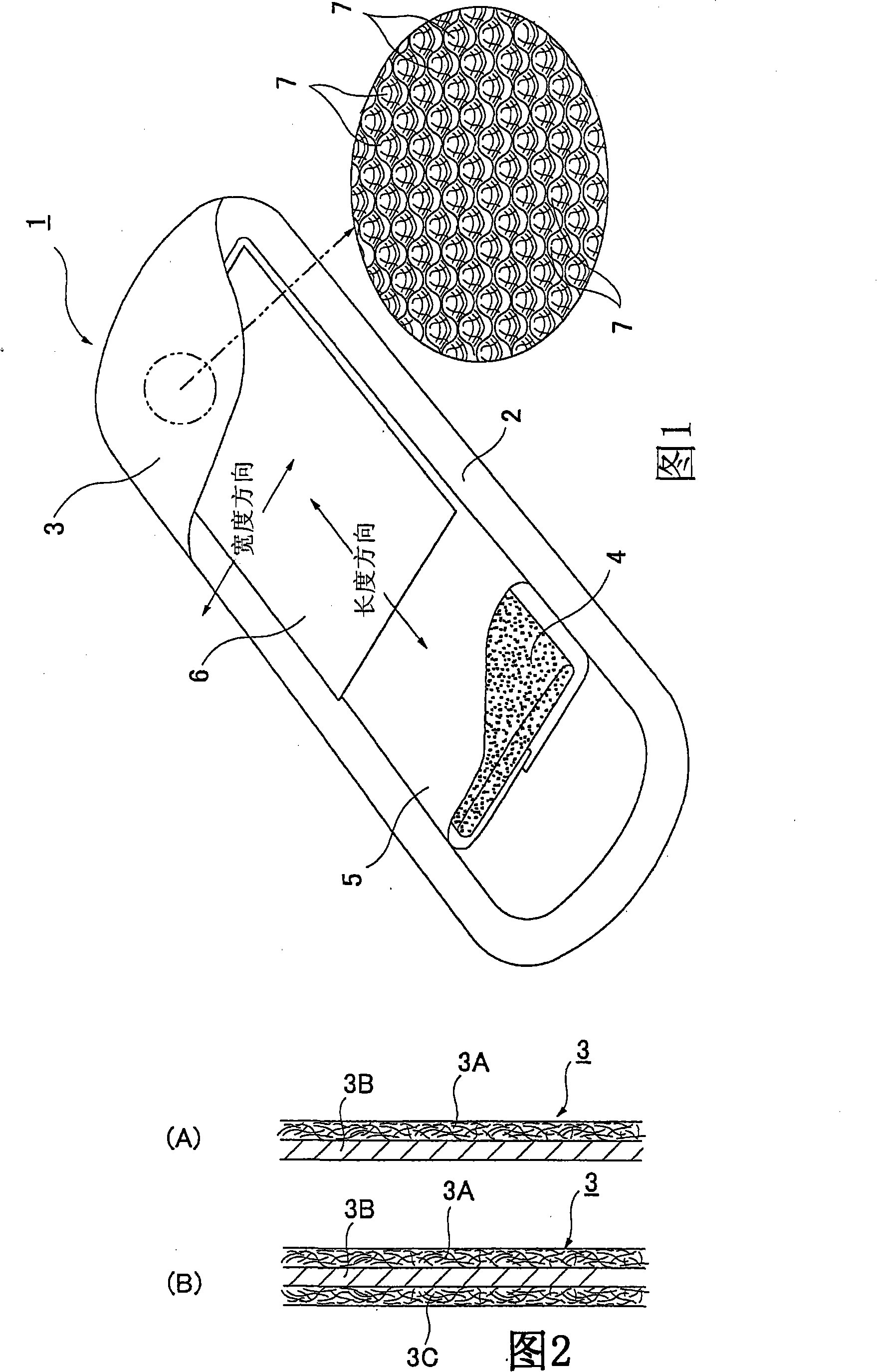

Absorbency substance

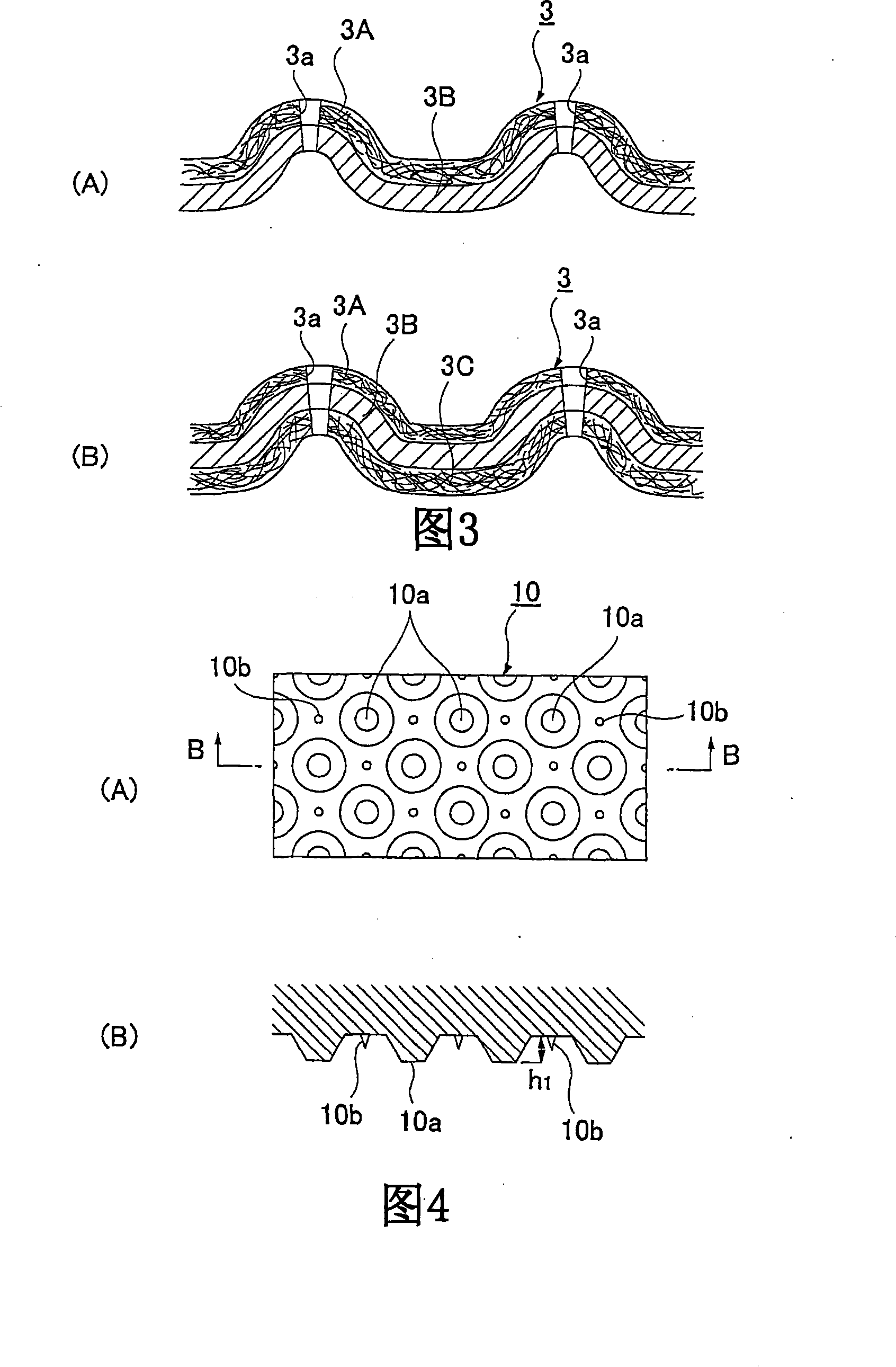

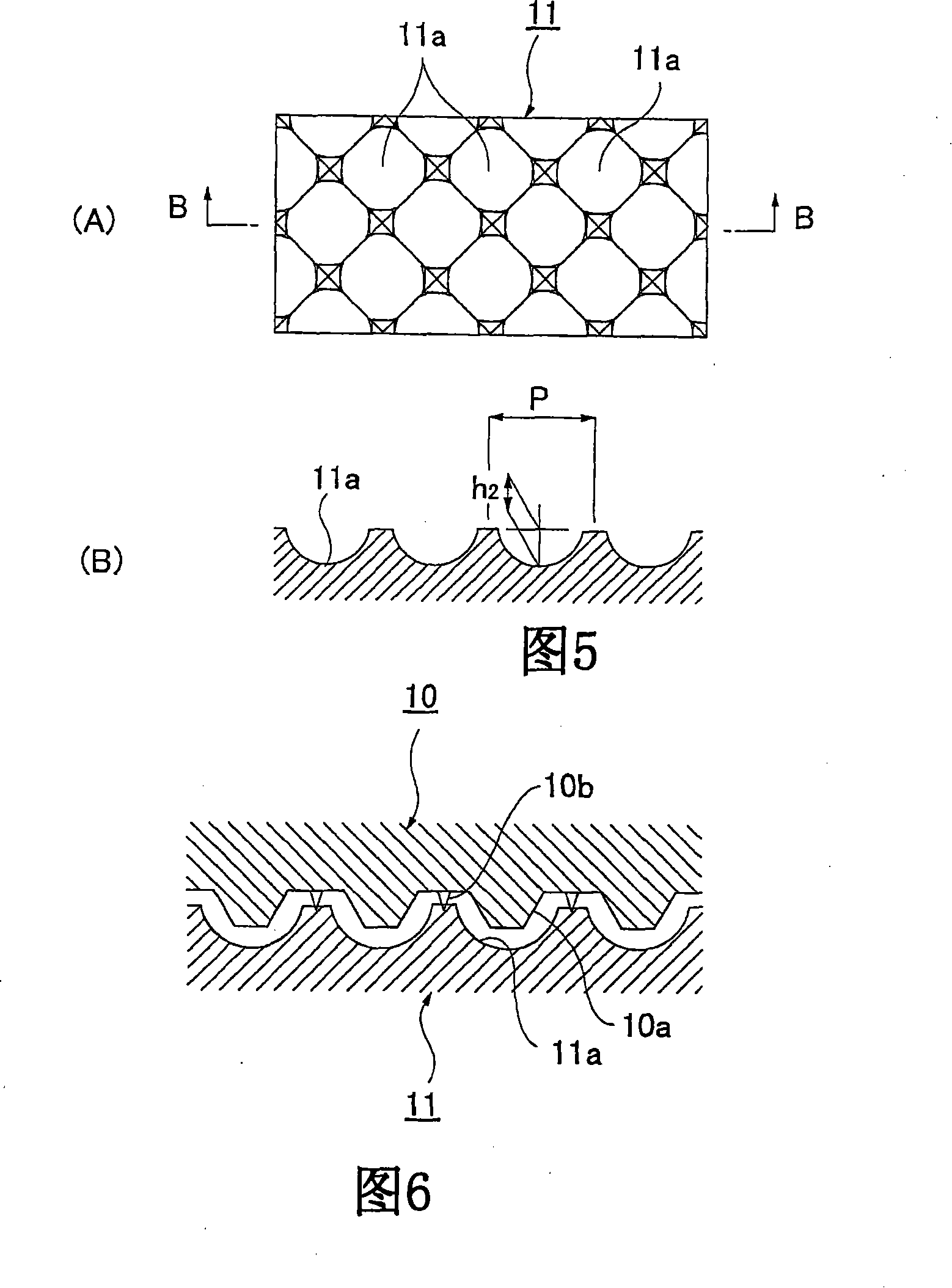

ActiveCN101152114AHolds shape firmlyGuaranteed cushioning effectAbsorbent padsBaby linensSkin contactPlastic film

The present invention provides an absorbability article which has cubic effect, high buffering property, and can keep concave-convex form not only under drying condition but also under the condition of absorbing sap by improving the form retentivity of concave-convex embossed pattern. The absorbability article (1) is provided with an absorbing body (4) between permeating front side and back side thin sheets (3) and (2), wherein, the front side thin sheet (3) is a multi-layer sheet which at least comprises a nonwoven cloth layer (3A) forming the skin contacting surface and a plastic film layer(3B) laminated on the non skin contacting surface of the nonwoven cloth layer, the plastic film layer (3B) is composed of material with a melting point lower than the nonwoven cloth. Under the heating condition with a melting point higher than the melting point of the plastic film layer (3B) and lower than the melting point of the nonwoven cloth layer (3A), the concave-convex embossing process composed of a plurality of projecting parts (7, 7......) projecting outside is executed to the front side thin sheet (3), and the hole making process is executed to the top of the convex embossed pattern or the bottom of the concave embossed pattern of the concave-convex embossed pattern.

Owner:DAIO PAPER CORP

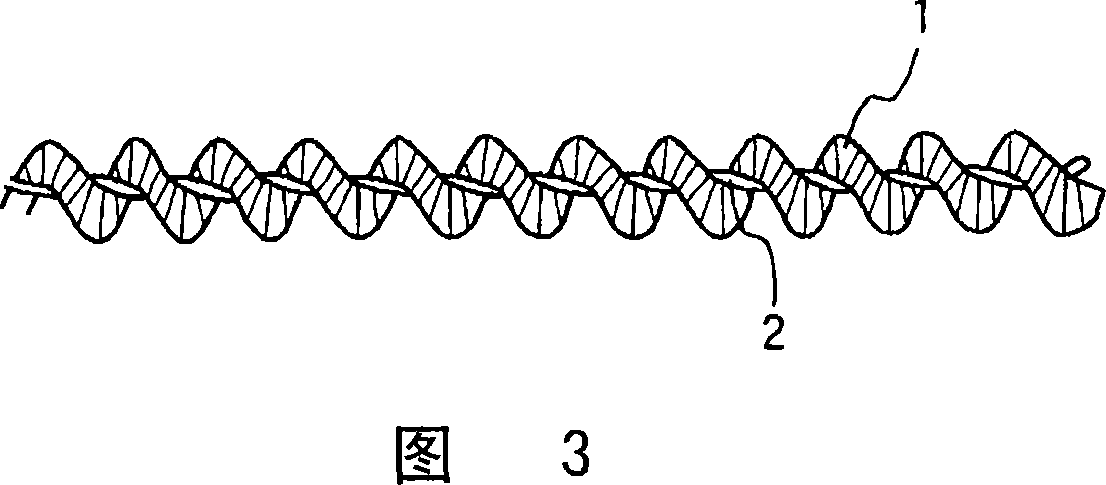

Slide fastener chain

InactiveUS7353570B2Good touchBeautiful appearanceSnap fastenersSlide fastenersSynthetic resinBiomedical engineering

A fastener chain, in which fastener elements each formed into a single unit of synthetic resin are attached at a constant interval along opposing side edges of a pair of fastener tapes, a front surface portion and a rear surface portion are provided on the front and rear sides of the fastener element, the surface of the front surface portion is formed into a curved face entirely swelling out circularly and upward while the rear surface portion is formed into a flat plane which is entirely even, and the front surface and the rear surface of the fastener element may have different shapes or the same shape so as to secure a fastener chain having an excellent tactile feel and beautiful appearance.

Owner:YKK CORP

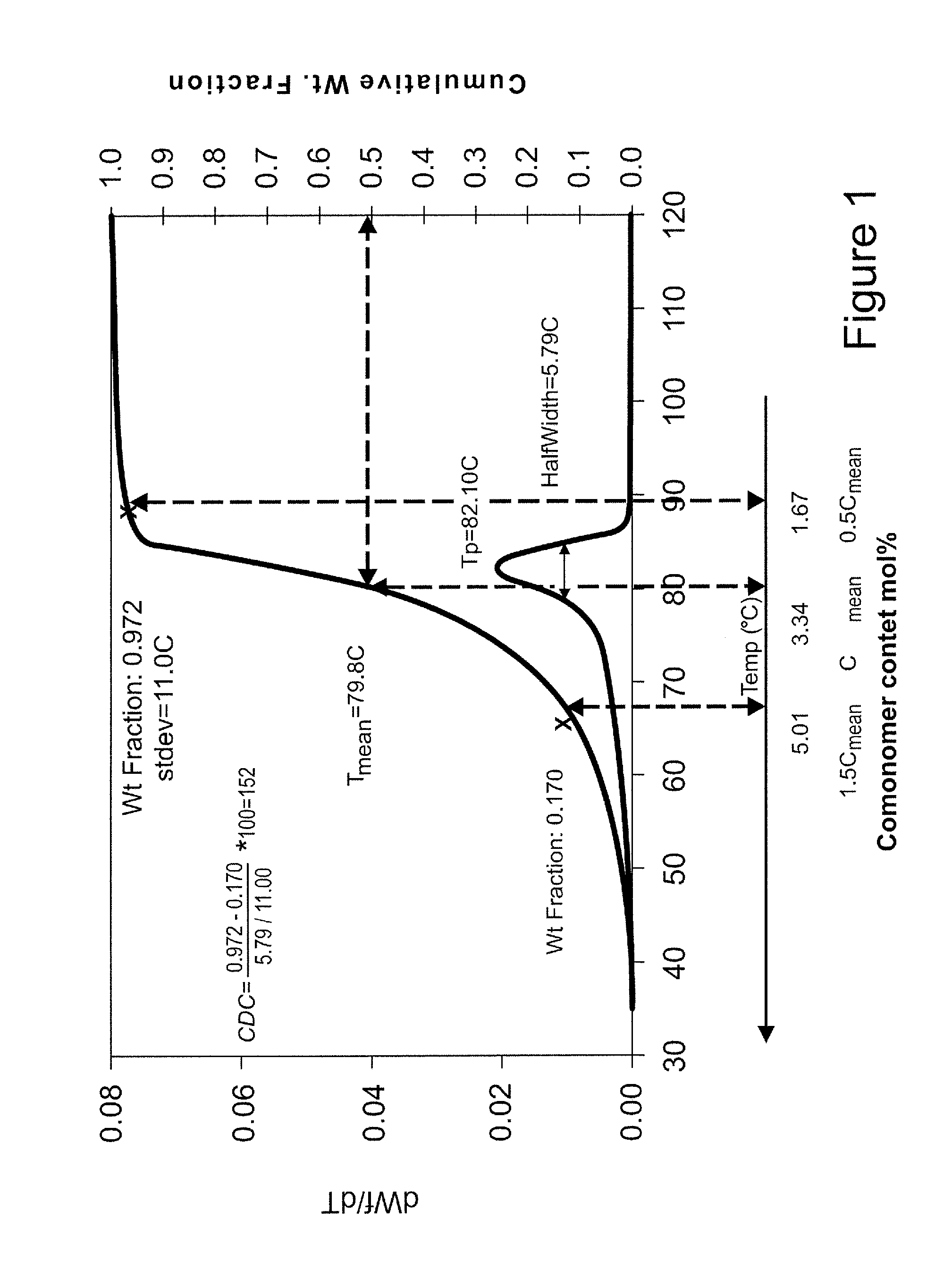

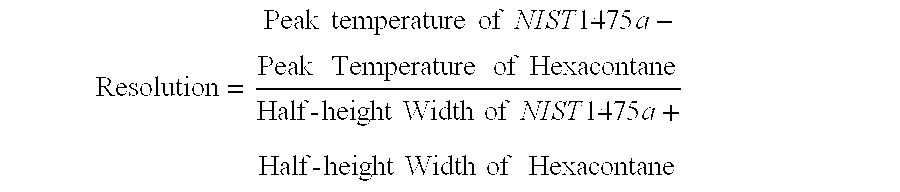

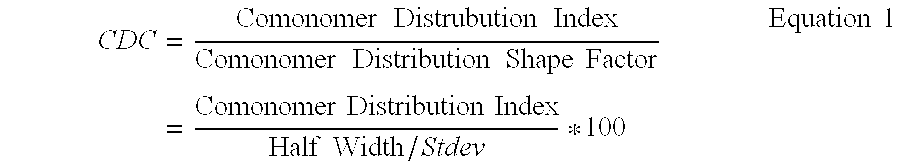

Bicomponent fiber

ActiveUS20110165470A1Good flexibilityGood touchFilament/thread formingAnimal housingPolymer scienceNonwoven fabric

The present invention relates to a new bicomponent fiber, a nonwoven fabric comprising said new bicomponent fiber and sanitary articles made therefrom. The bicomponent fiber contains a polyethylene-based resin forming at least part of the surface of the fiber longitudinally continuously and is characterized by a Co-monomer Distribution Constant greater than about 45, a recrystallization temperature between 85° C. and 110° C., a tan delta value at 0.1 rad / sec from about 15 to 50, and a complex viscosity at 0.1 rad / second of 1400 Pa.sec or less. The nonwoven fabric comprising the new bicomponent fiber according to the instant invention are not only excellent in softness, but also high in strength, and can be produced in commercial volumes at lower costs due to higher thoughputs and requiring less energy.

Owner:TREVIRA GMBH & CO KG

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

Container cap

ActiveUS7607547B2Improve performanceGood touchCapsClosure using stoppersEngineeringMechanical engineering

Owner:JAPAN CROWN CORK CO LTD

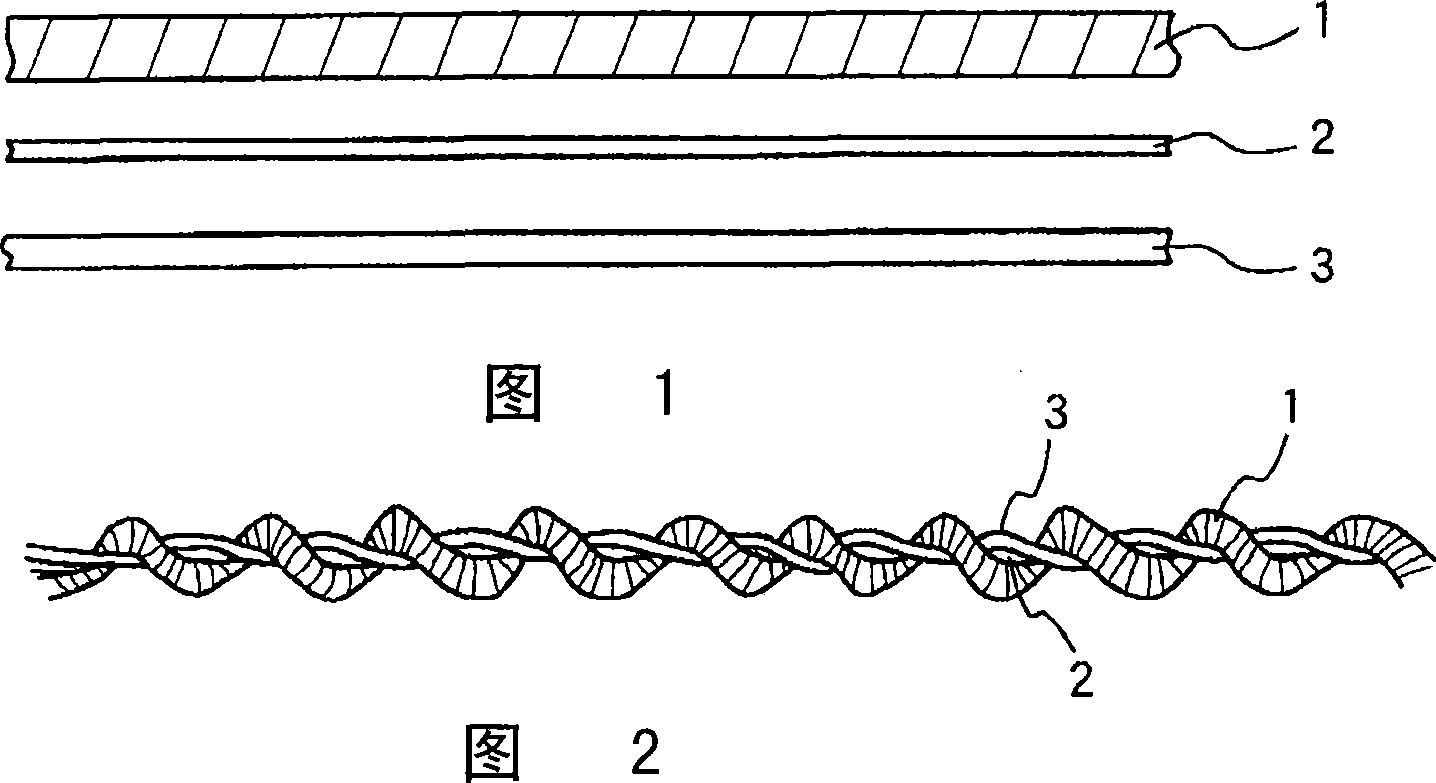

Composite twist yarn

The present invention relates to the production of woven or knitted fabrics or fabrics, which have high yarn strength, can be woven or knitted with high-speed looms or knitting machines, will not cause problems such as thread breakage, and have high stretchability sex. The present invention also prepares a composite twisted yarn, which at least twists a spun yarn and a water-soluble yarn, the twist direction of the composite twisted yarn is opposite to that of the spun yarn, and satisfies the following necessary conditions (1 ) or (2): (1) The twist number of the composite twisted yarn is 1.3-3 times that of the spun yarn, and the ratio (weight ratio) of the spun yarn to the water-soluble yarn is spun yarn / Water-soluble yarn = 20 / 80-98 / 2; (2) further twist the elastic yarn (2) stretched to 2-5 times, and the twist number of the composite twisted yarn relative to the twist number of the spun yarn is 0.3-3 times, while the ratio (weight ratio) of spun yarn (1) to the above-mentioned elastic yarn (2) is spun yarn (1) / elastic yarn (2)=50 / 50-99.9 / 0.1, spun yarn (1) and the total amount of elastic yarn (2) and the ratio (weight ratio) of water-soluble yarn (3) is: total amount of spun yarn (1) and elastic yarn (2) / water-soluble yarn (3)= 30 / 70-99 / 1.

Owner:KURARAY TRADING CO LTD +1

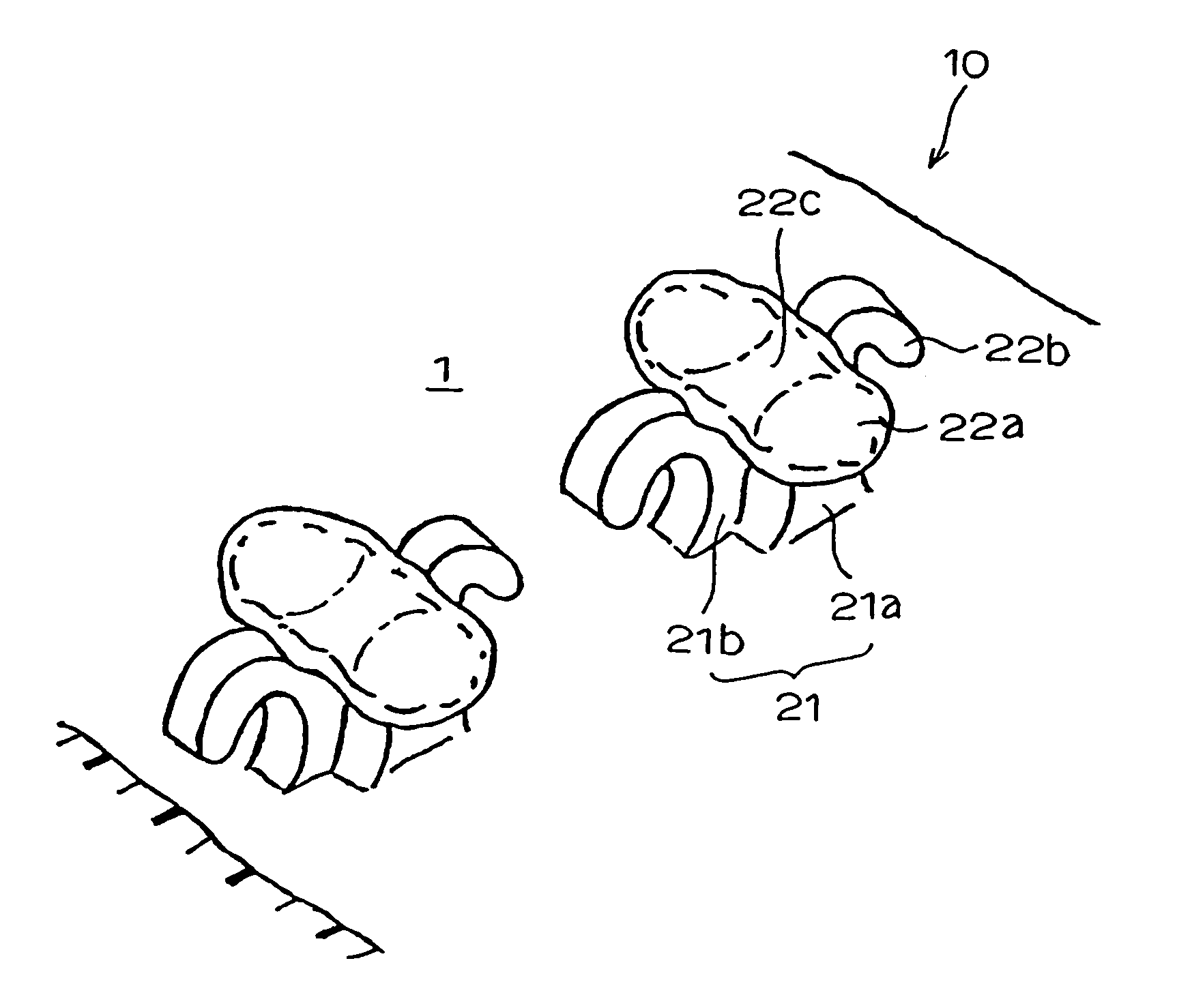

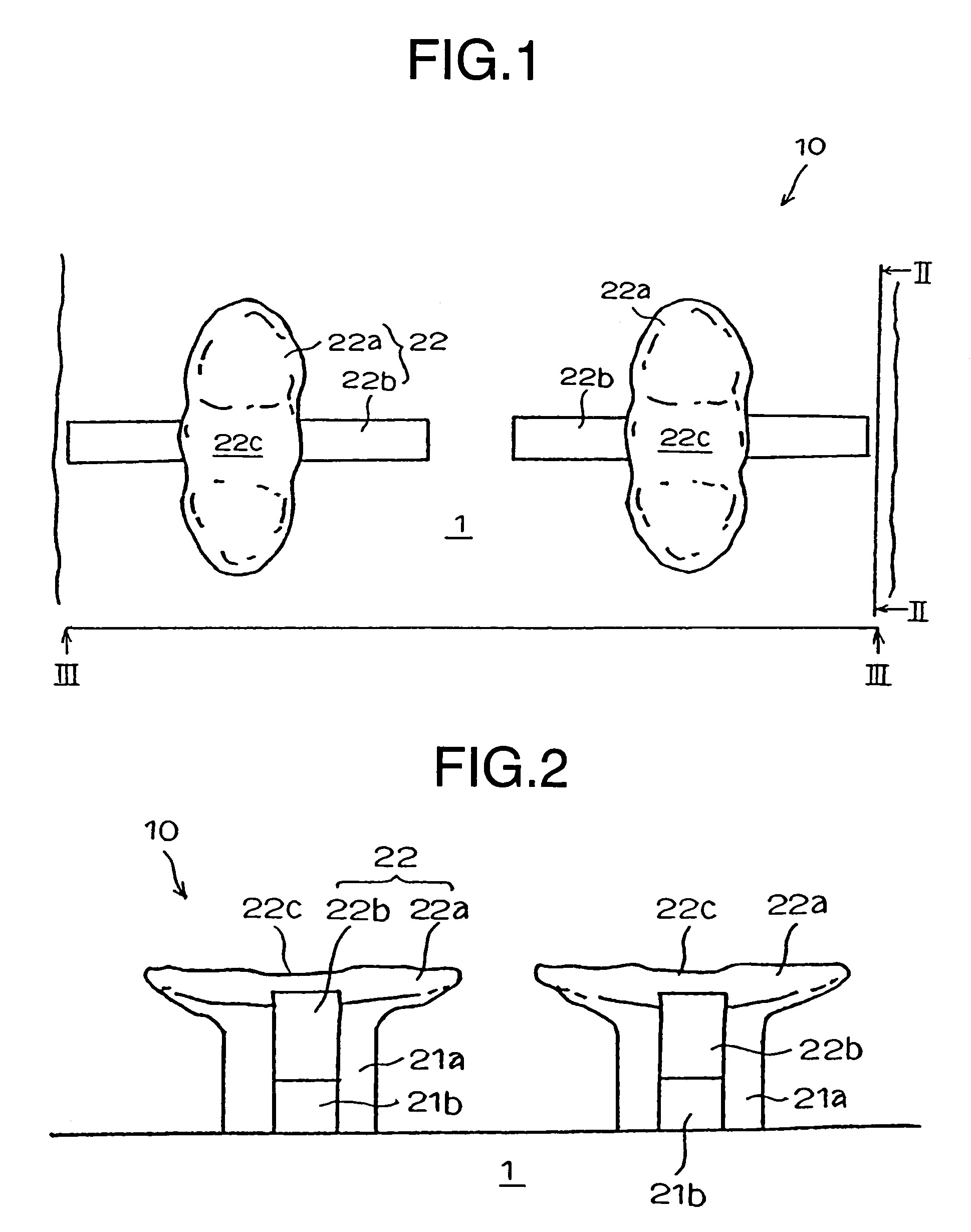

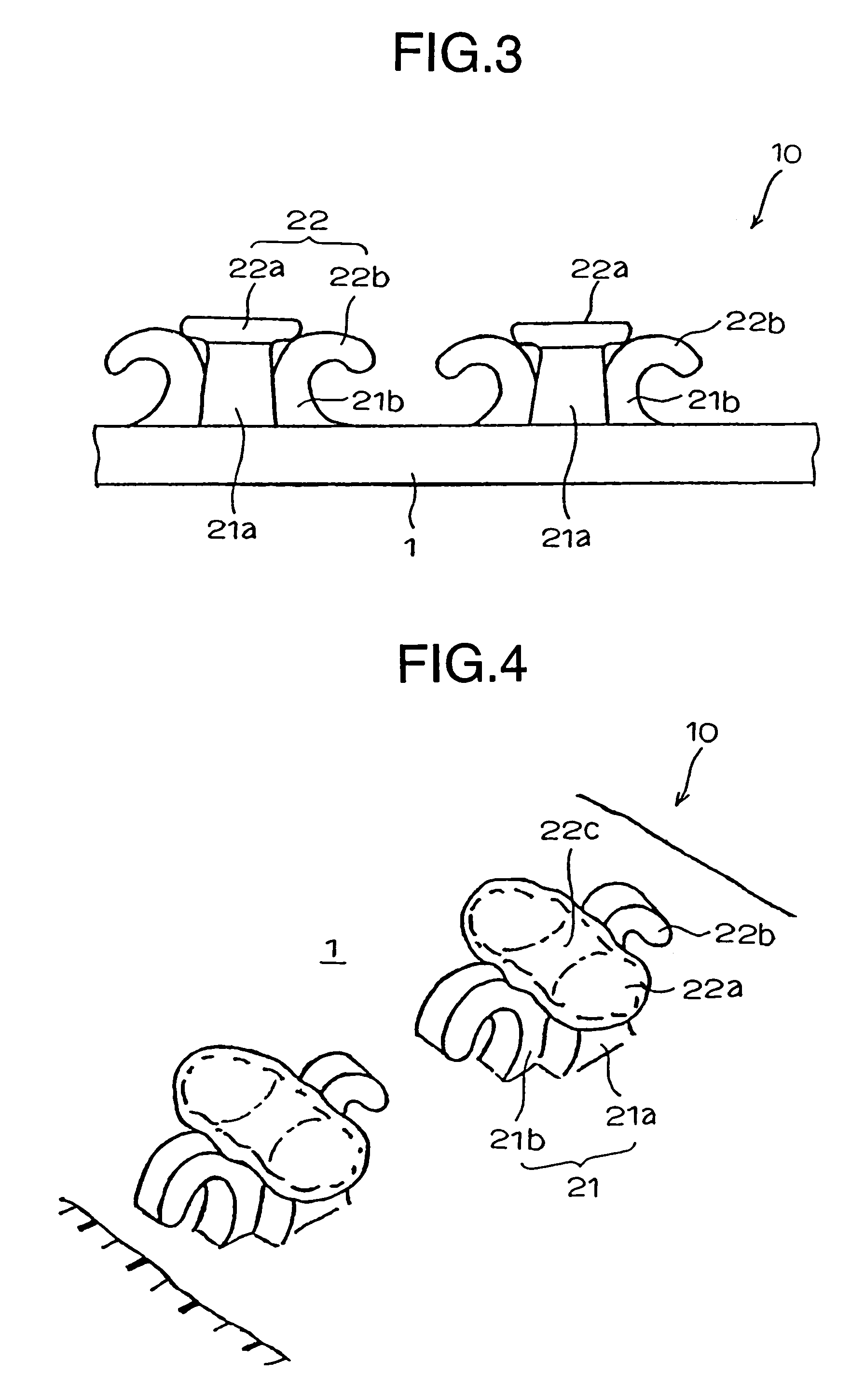

Integrally molded surface fastener, and continuous production method and continuous production device therefor

ActiveUS7350276B2Increase participation rateSatisfactory durabilitySnap fastenersClothes buttonsEngineeringShear force

In a molded surface fastener (10) having engaging elements (2) of minute dimension of thermoplastic resin molded together with a base member (1) by continuous molding, each engaging element (2) comprises first and second engaging portions (22a, 22b) each having a different configuration extending in parallel to a surface of the base member from a top end of a pillar portion (21) rising from the base member (1) such that they intersect at right angle. The second engaging head (22b) has an ordinary hook shape structure while the first engaging head (22a) has a wing-like thin plate structure as seen in a plan view.The engaging elements having such a structure in which each engaging element has appropriate engagement force, shearing force and separation force so as to keep an excellent tactile feeling of a surface of the surface fastener, prevents itself from falling down against a pressing force, secures a high engagement ratio with mating pile pieces and satisfies a durability.

Owner:YKK CORP

Light guiding plate and a keystroke module for use therewith

InactiveUS7423229B2Quick wearExtended service lifeEmergency actuatorsLegendsControl layerLight guide

A keystroke module for use with a light guiding plate includes a contacting and controlling layer, a light guiding plate and a light source. The contacting and controlling layer has a pressing side and a contacting and light guiding side. The light guiding plate is arranged under the contacting and light guiding side of the contacting and controlling layer and further includes a light auxiliary layer and a light inducting layer, which is a soft piece body having a reflecting side, on which plural light guiding parts are arranged, while the auxiliary light layer is a hard transparent piece body that is laminated correspondingly above the reflecting side of the light inducting layer. In addition, the light source is arranged at one side of the light guiding plate for irradiating light from the light auxiliary layer, then the light being reflected out by the reflecting side and the light guiding parts of the light inducting layer; thereby, it is possible to prevent the components contacted with the light inducting layer of the light guiding plate from easy wearing and permanent deforming, and the using lifetime of the light guiding plate or the keystroke module may be prolonged significantly.

Owner:ICHIA TECH

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Magnetic finger glove

ActiveUS20060185057A1Prevents and minimizesGood touchGlovesProtective garmentCircular discNeodymium magnet

A magnetic finger glove helps persons hold, install, and retrieve small metallic objects, such as nuts or screws, in hard-to-reach places. The finger glove is sized and shaped to sheathe and conform to an adult human index finger. A small round disc neodymium magnet is affixed to a fabric assembly in the region corresponding to the fingertip. The magnet weighs less than 0.002 pounds and is small enough to be confined within an area on the fabric assembly of less than 0.5 square inches. Yet, the magnet has a holding force of at least 1 pound.

Owner:TURNPRO

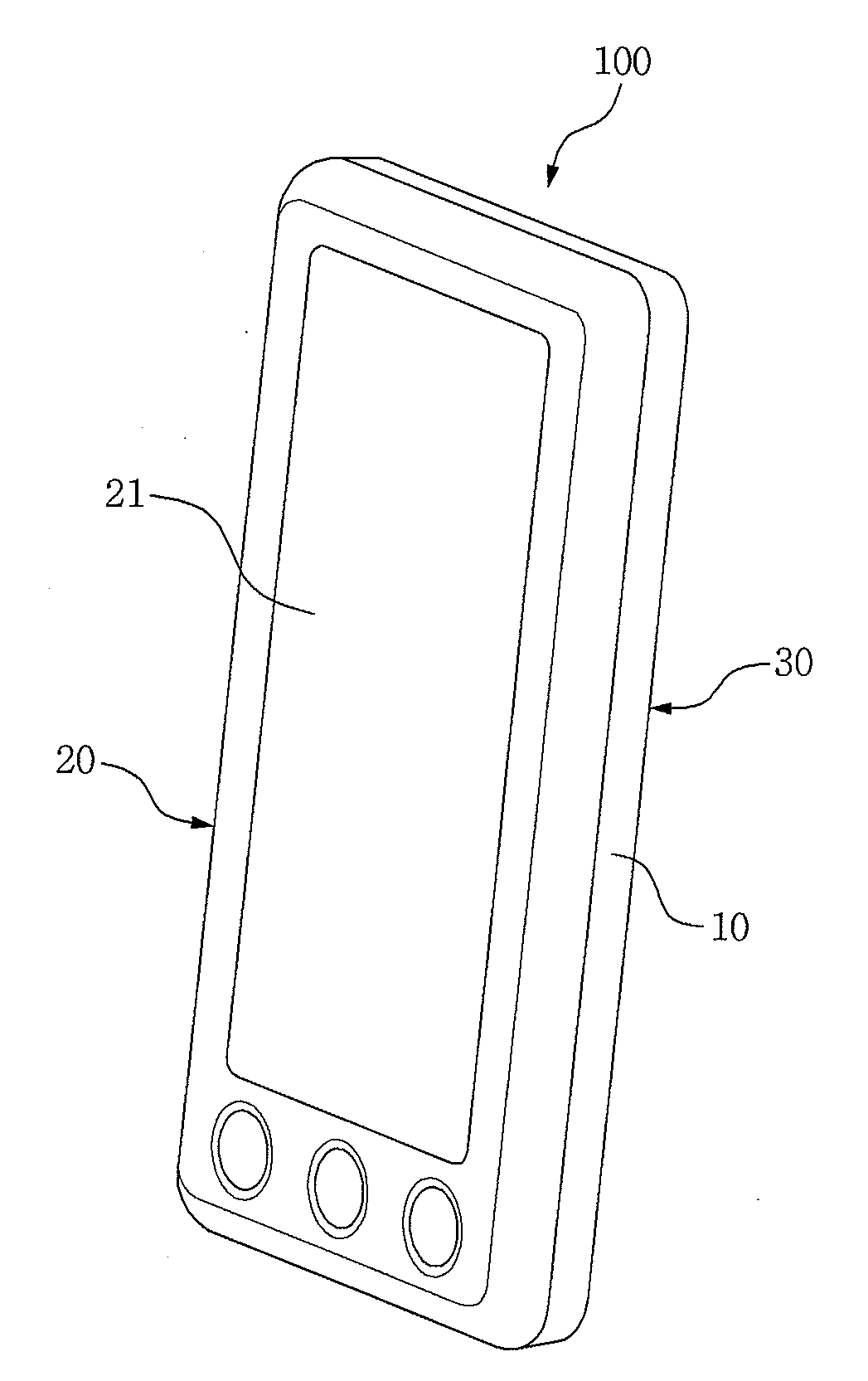

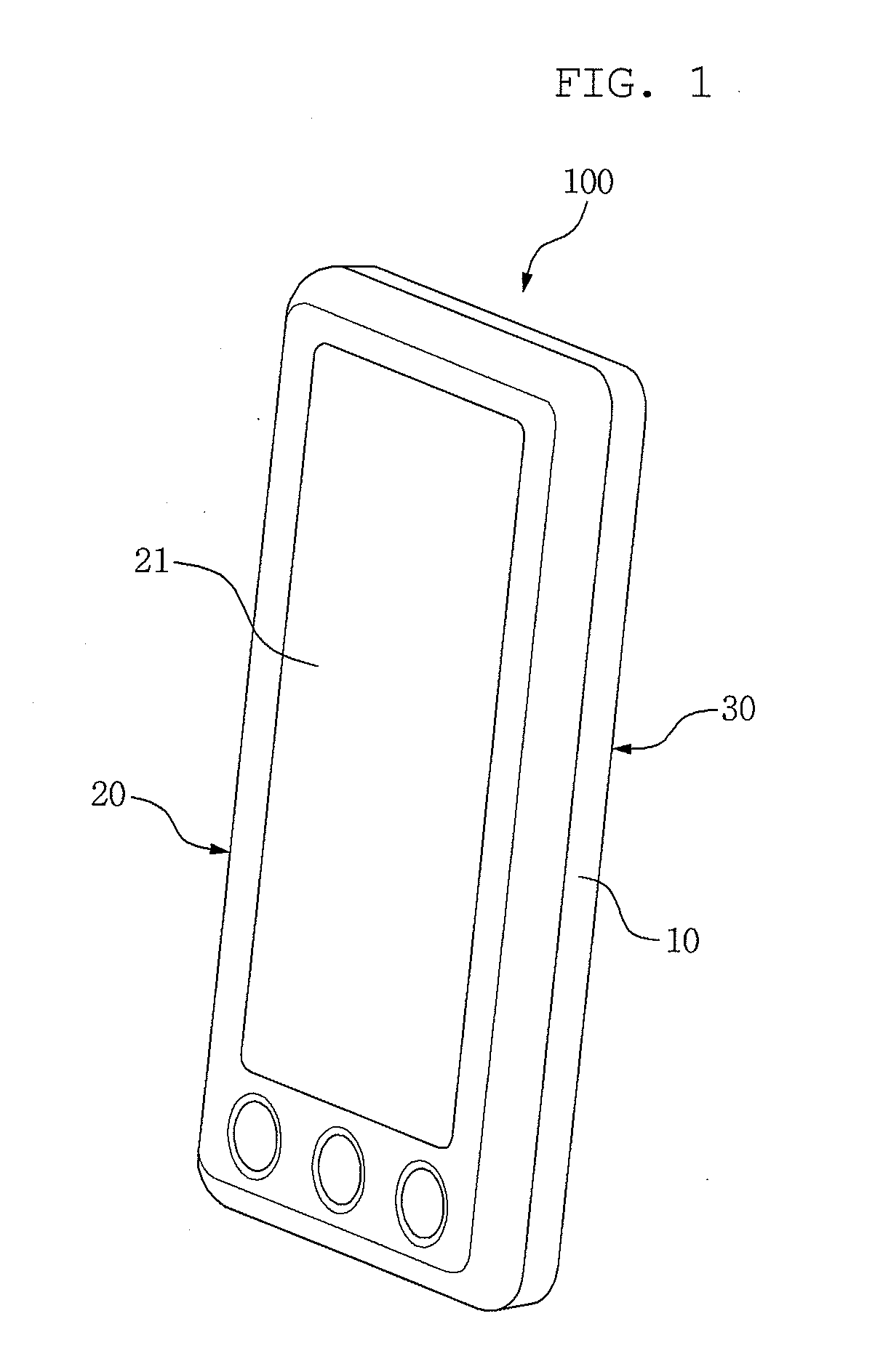

Portable electronic products integrated with silicone

InactiveUS20110136553A1Soft gripGood touchDigital data processing detailsTransmissionSilica gelDouble injection

Disclosed is a portable electronic products integrated with a silicone in which a molding silicone is integrated with an outer side surface of a body housing of the portable electronic products through a double injection or an insert injection molding methods, so that it can feel the soft grip when an user is touched on the outer surface of the portable electronic products. Also, a water proof injection silicone packing part is integrally formed at a combining portion between a cover housing and a body housing, so that it can closely adhere to them, whereby it can be perfectly cut off the moisture from outside.

Owner:WOOJEON & HANDAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com