Water-based matte touch gloss oil and preparation method thereof

A water-based, matte technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as scratches, poor touch, and yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

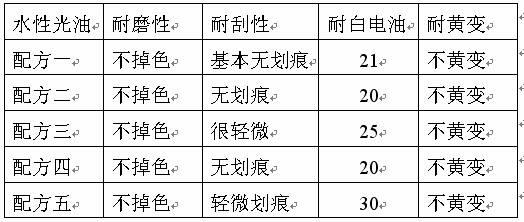

Examples

Embodiment 1

[0026] Water-based varnish formula one

[0027] Waterborne polyurethane dispersion 70%;

[0028] Modified acrylic elastic emulsion 14%;

[0029] Leveling agent 3%;

[0030] Coupling agent 3%;

[0031] Hand feeling wax paste 5%;

[0032] Matting powder 2%;

[0033] Hand feeling anti-scratch agent 1%;

[0034] Defoamer 0.3%

[0035] Water 1.7%

[0036] The sum of the mass percentages of the above raw materials is 100%.

[0037] Preparation

[0038] At room temperature, first add water-based polyurethane dispersion, then add matting powder and a part of defoaming agent, disperse for about 30 minutes, and rotate at 900~1200r / min to ensure that the matting powder is completely dispersed, then reduce the speed to 600~900 r / min min, add the modified acrylic elastic emulsion, disperse evenly, and then add the hand feeling wax slurry, leveling agent, coupling agent, hand feeling anti-scratch agent and the remaining defoamer in sequence. Disperse for about 10 minutes to disper...

Embodiment 2

[0040] Water-based varnish formula two

[0041] Waterborne polyurethane dispersion 68%;

[0042] Modified acrylic elastic emulsion 15%;

[0043] Leveling agent 3%;

[0044] Coupling agent 3%;

[0045] Hand feeling wax paste 5%;

[0046] Matting powder 2%;

[0047] Hand feeling anti-scratch agent 1%;

[0048] Defoamer 0.3%

[0049] Water 2.6%

[0050] The sum of the mass percentages of the above raw materials is 100%.

[0051] The preparation method is the same as that of Embodiment 1, so details are not repeated.

Embodiment 3

[0053] Water-based varnish formula three

[0054] Waterborne polyurethane dispersion 75%;

[0055] Modified acrylic elastic emulsion 10%;

[0056] Leveling agent 3%;

[0057] Coupling agent 3%;

[0058] Hand wax 4%;

[0059] Matting powder 2%;

[0060] Hand feeling anti-scratch agent 1%;

[0061] Defoamer 0.3%

[0062] Water 1.7%

[0063] The sum of the mass percentages of the above raw materials is 100%.

[0064] The preparation method is the same as that of Embodiment 1, so details are not repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com