Patents

Literature

86results about How to "Satisfactory durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

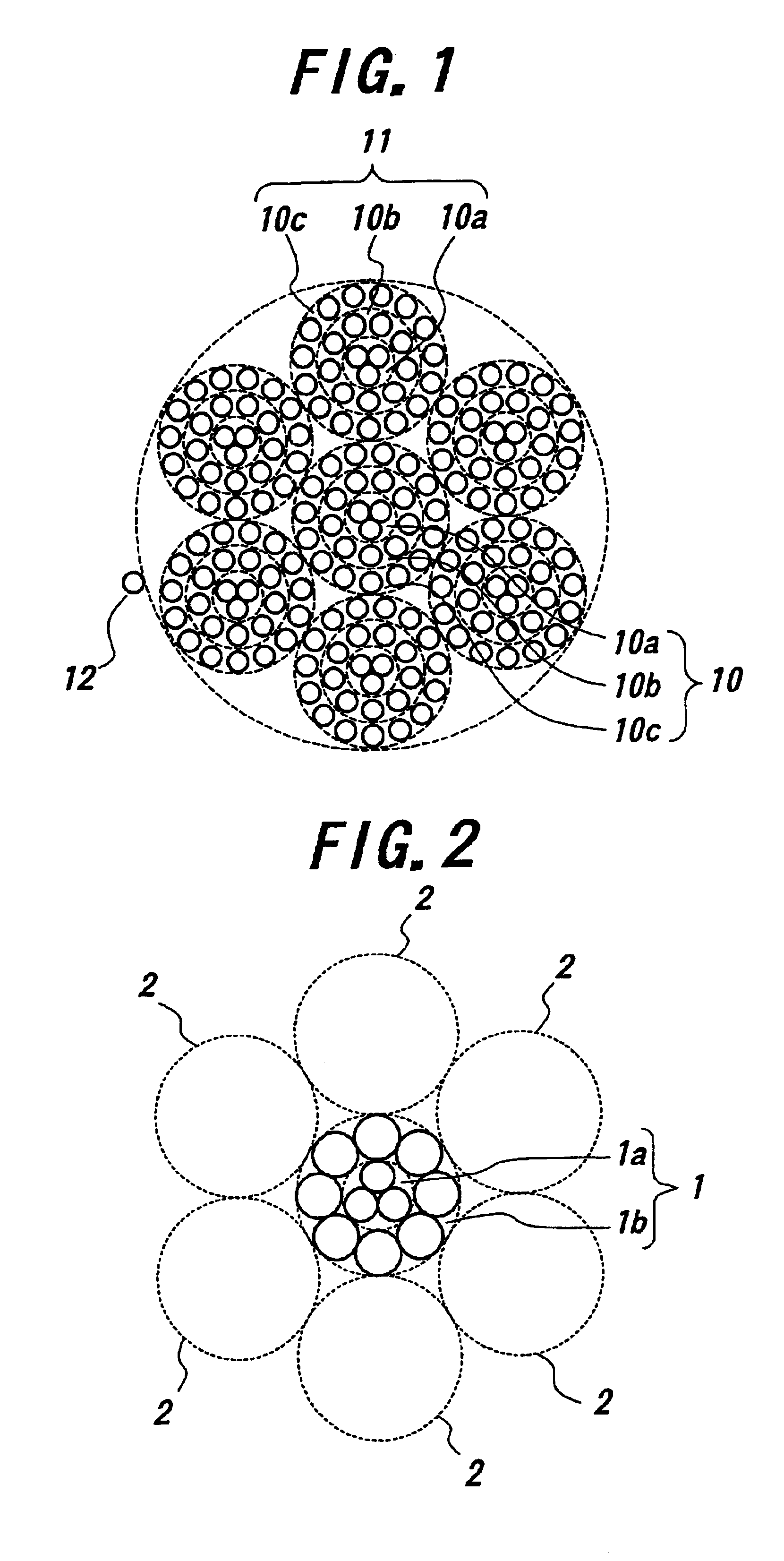

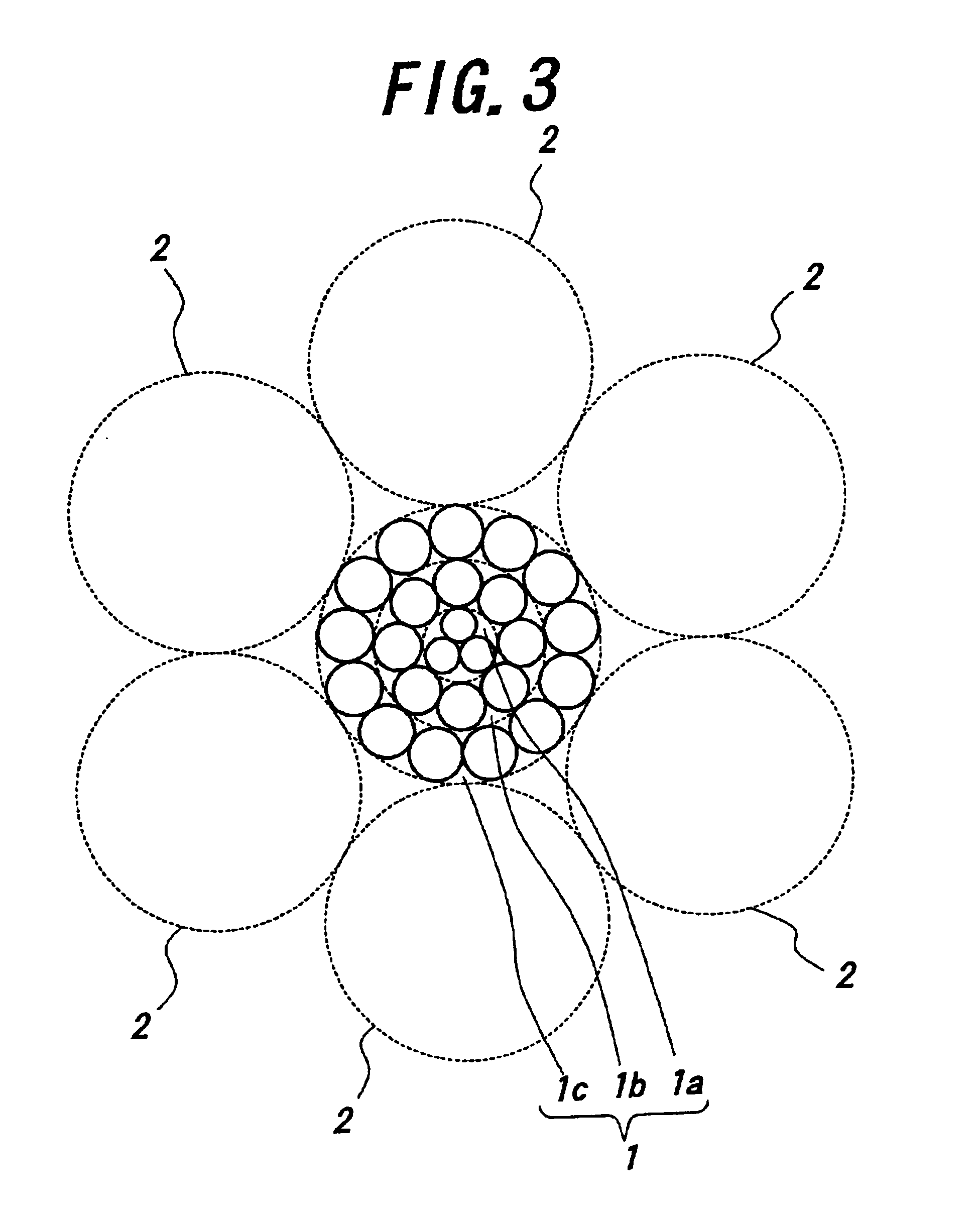

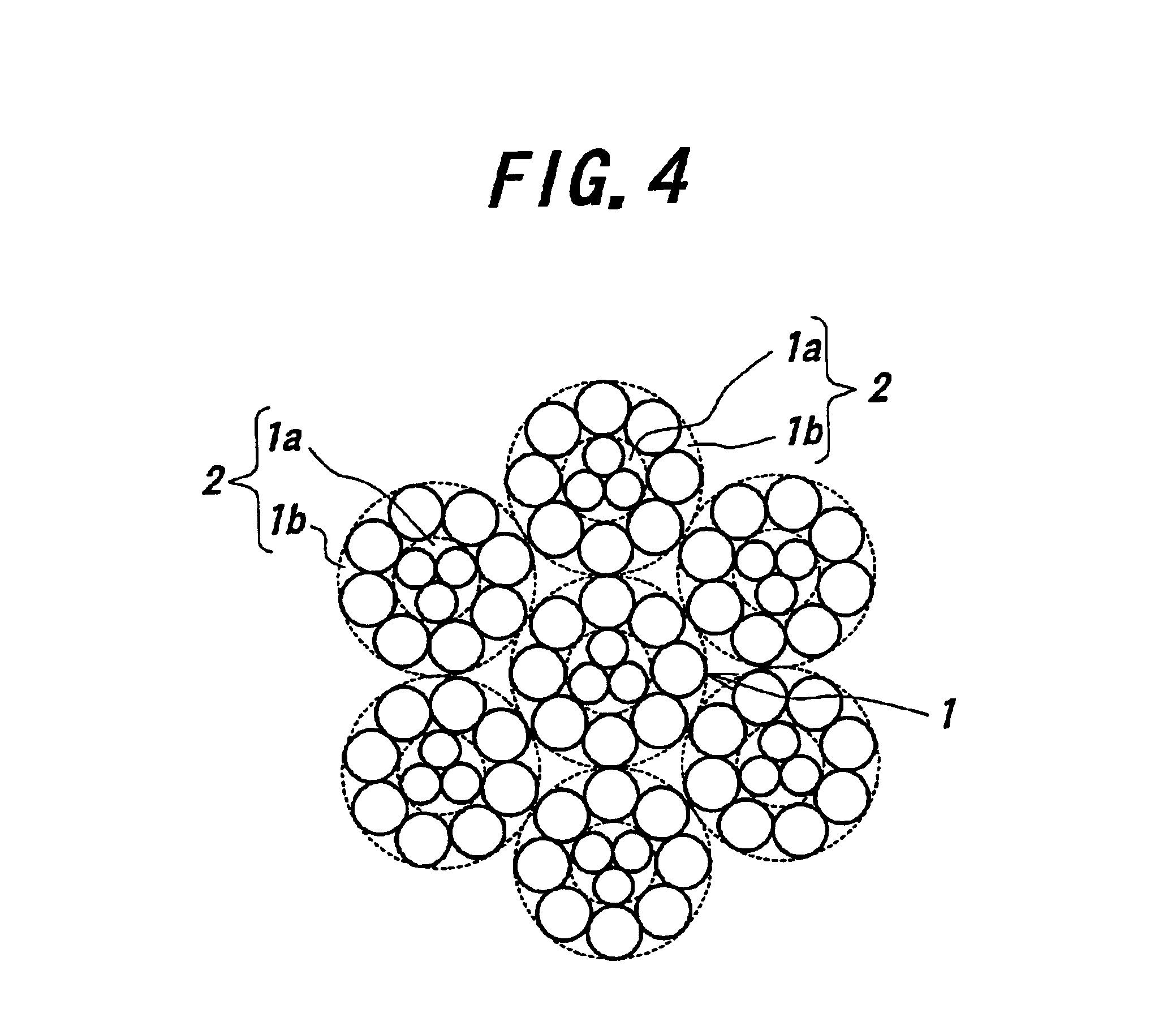

Steel cord for the reinforcement of a rubber article and tire

InactiveUS6863103B1Satisfactory durabilityLower tenacityPneumatic tyre reinforcementsYarnReinforced rubberEngineering

A steel cord having a strand construction formed by twisting a plurality of sheath strands each formed by twisting plural filaments around a core strand formed by twisting plural filaments is provided. At least one of the core strand and the sheath strands has a construction of twisting one or more sheath layers each made of plural filaments around a core made of one or plural filaments, and a diameter of a filament constituting an outermost sheath layer is made larger than that of a filament constituting at least one layer located inside thereof, whereby precedent breakage in a part of the filaments is avoided to improve the durability of the steel cord.

Owner:BRIDGESTONE CORP

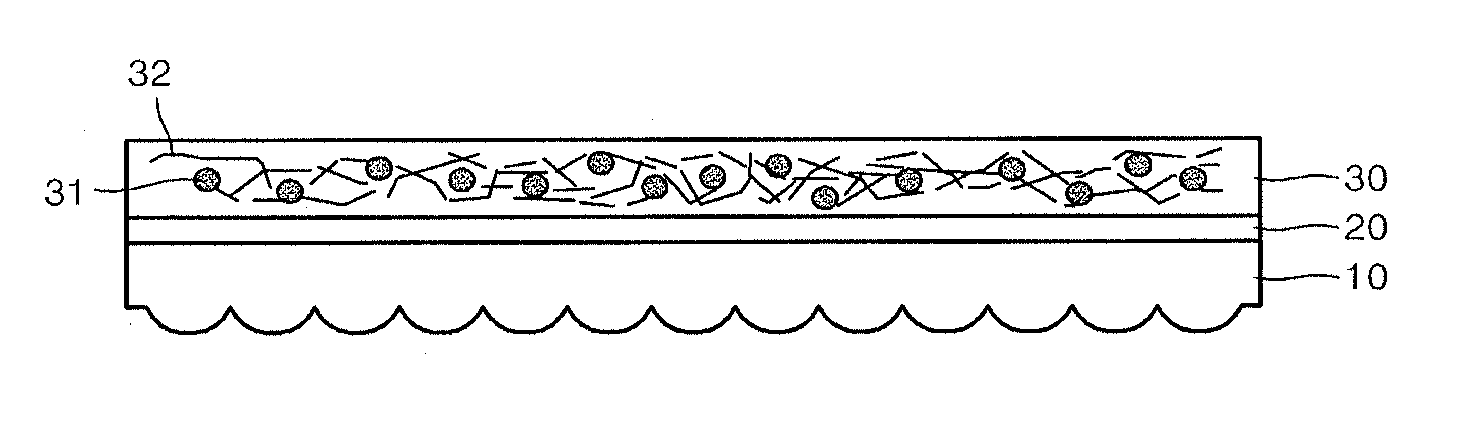

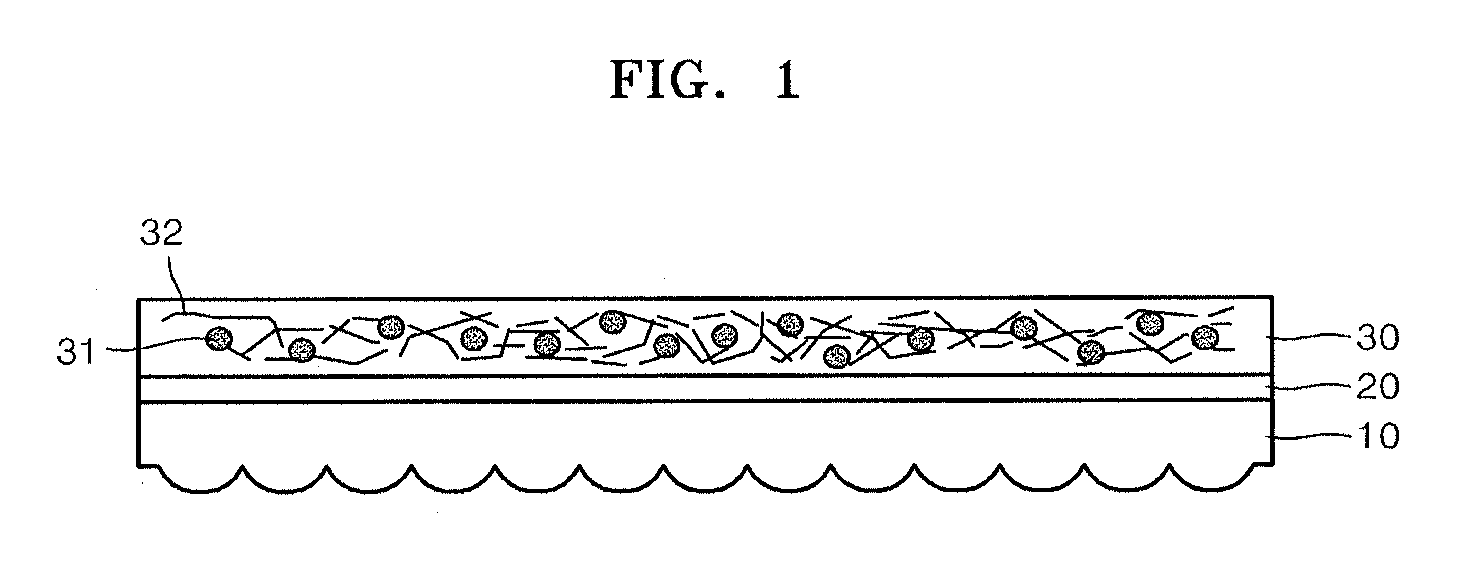

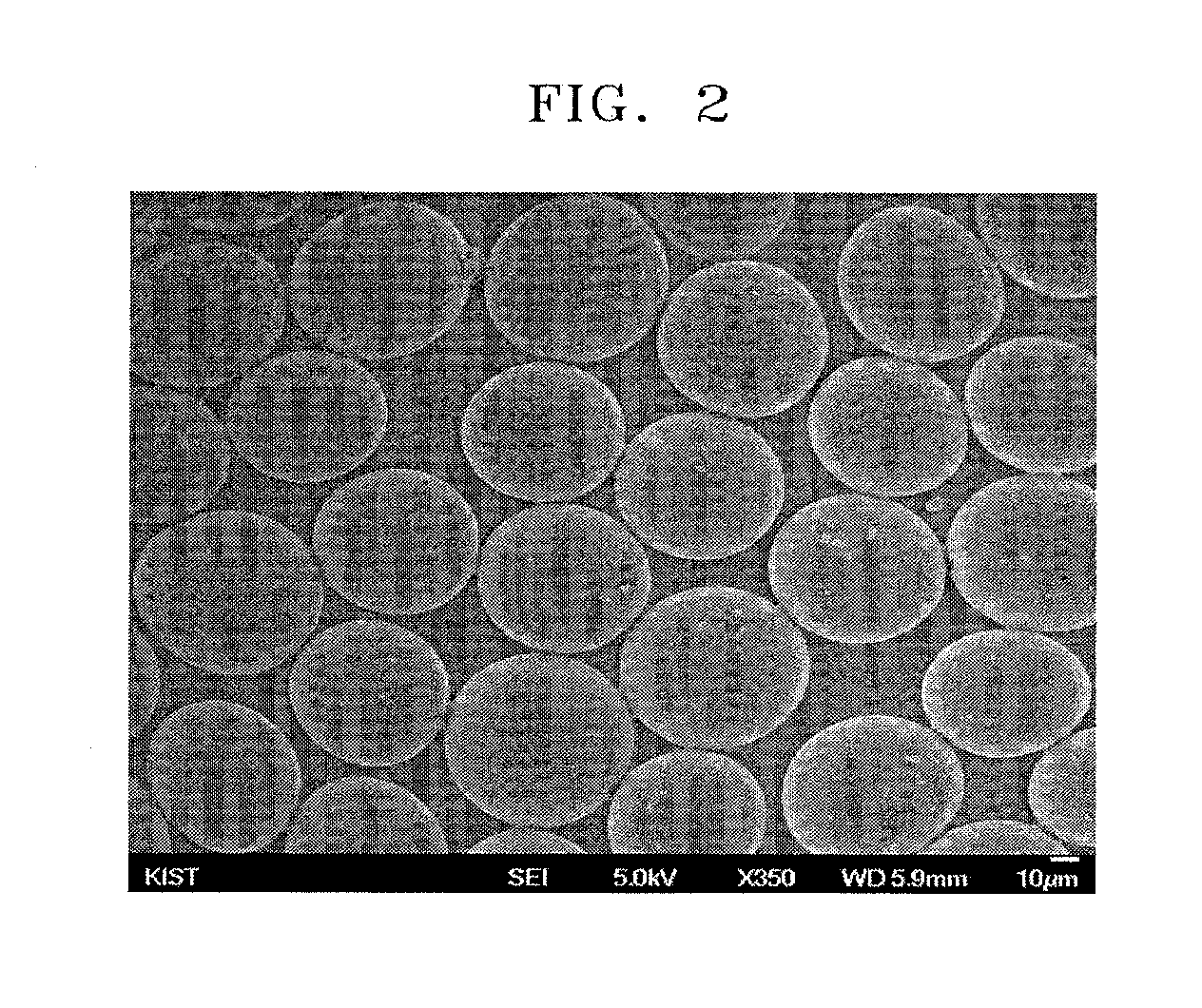

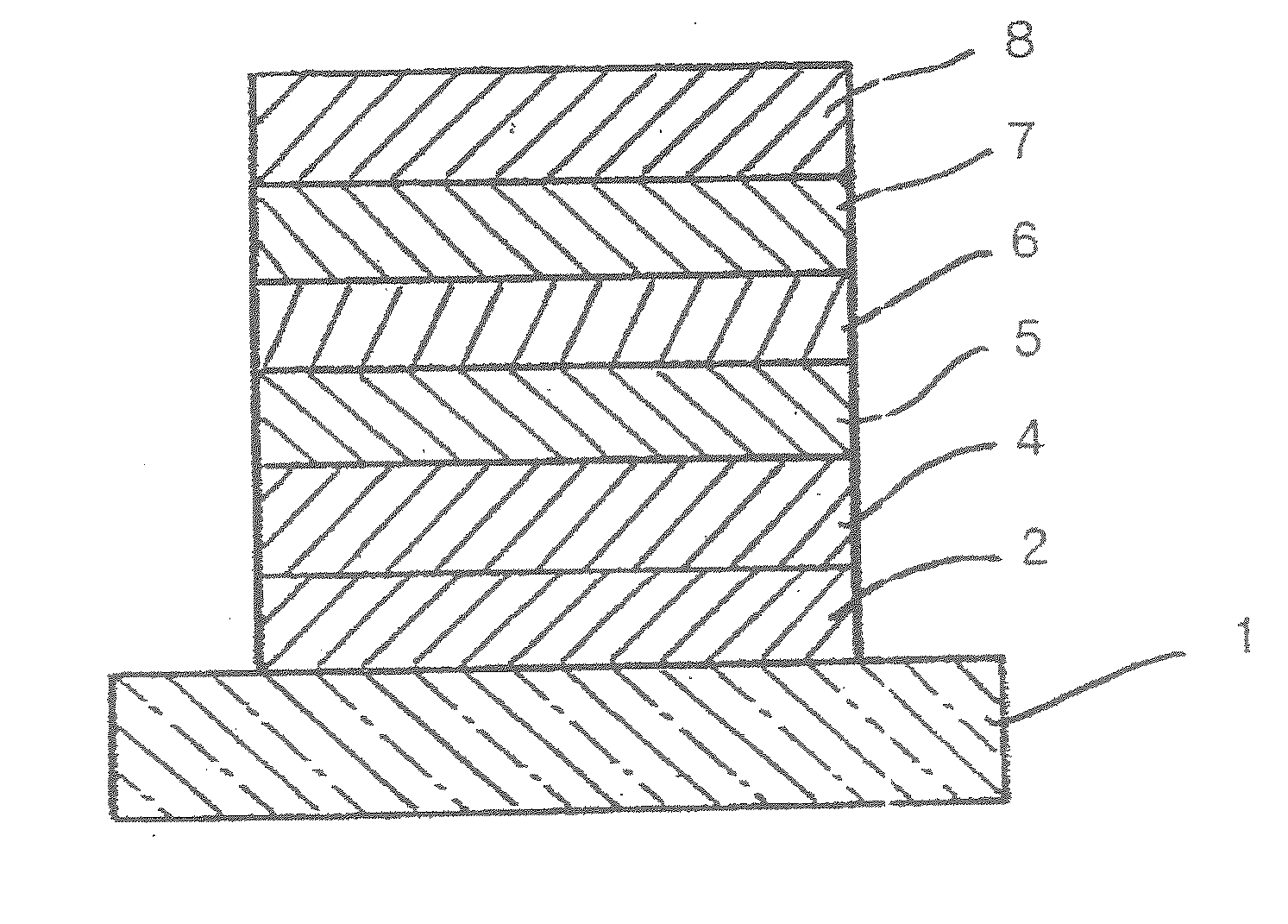

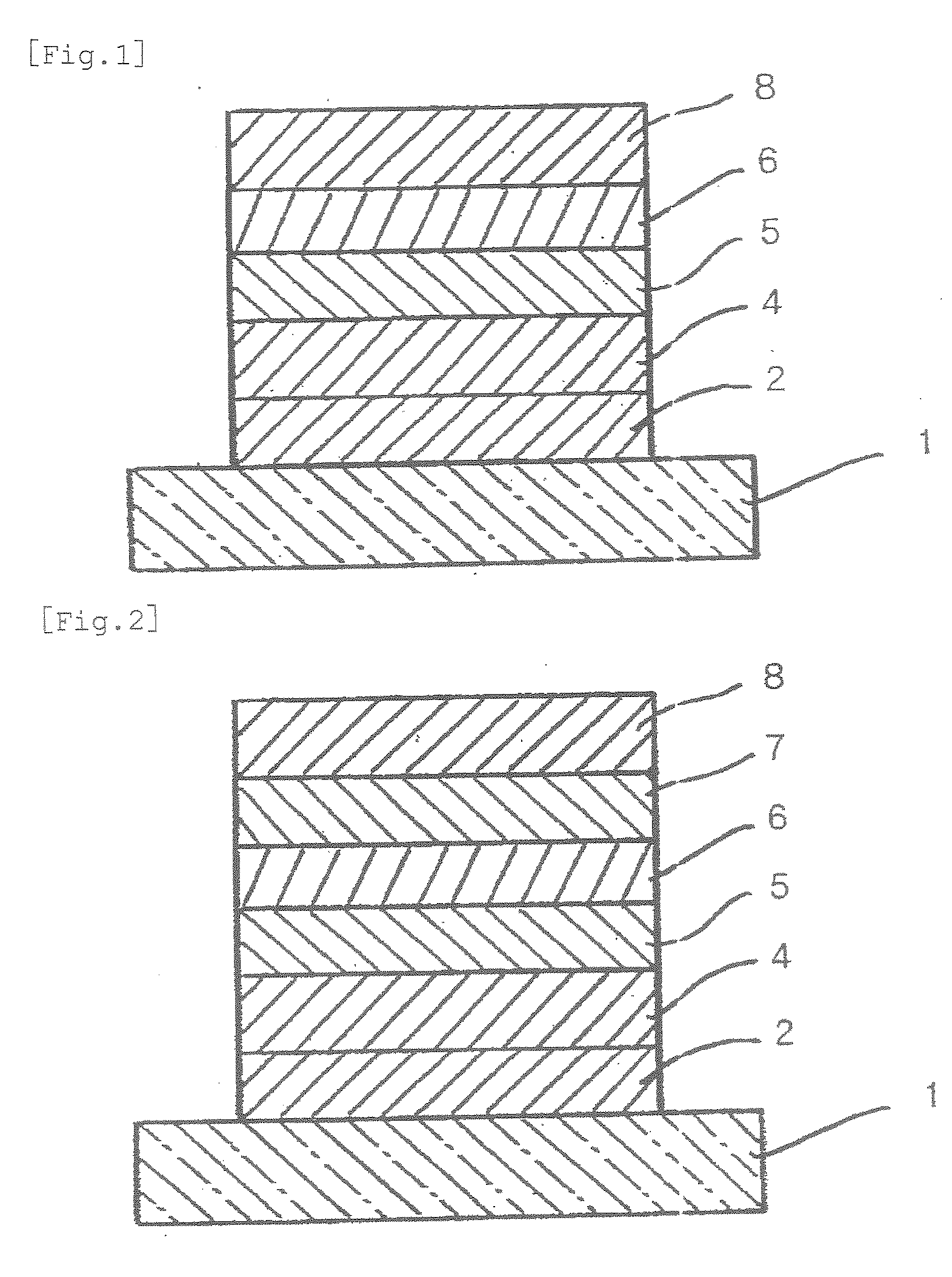

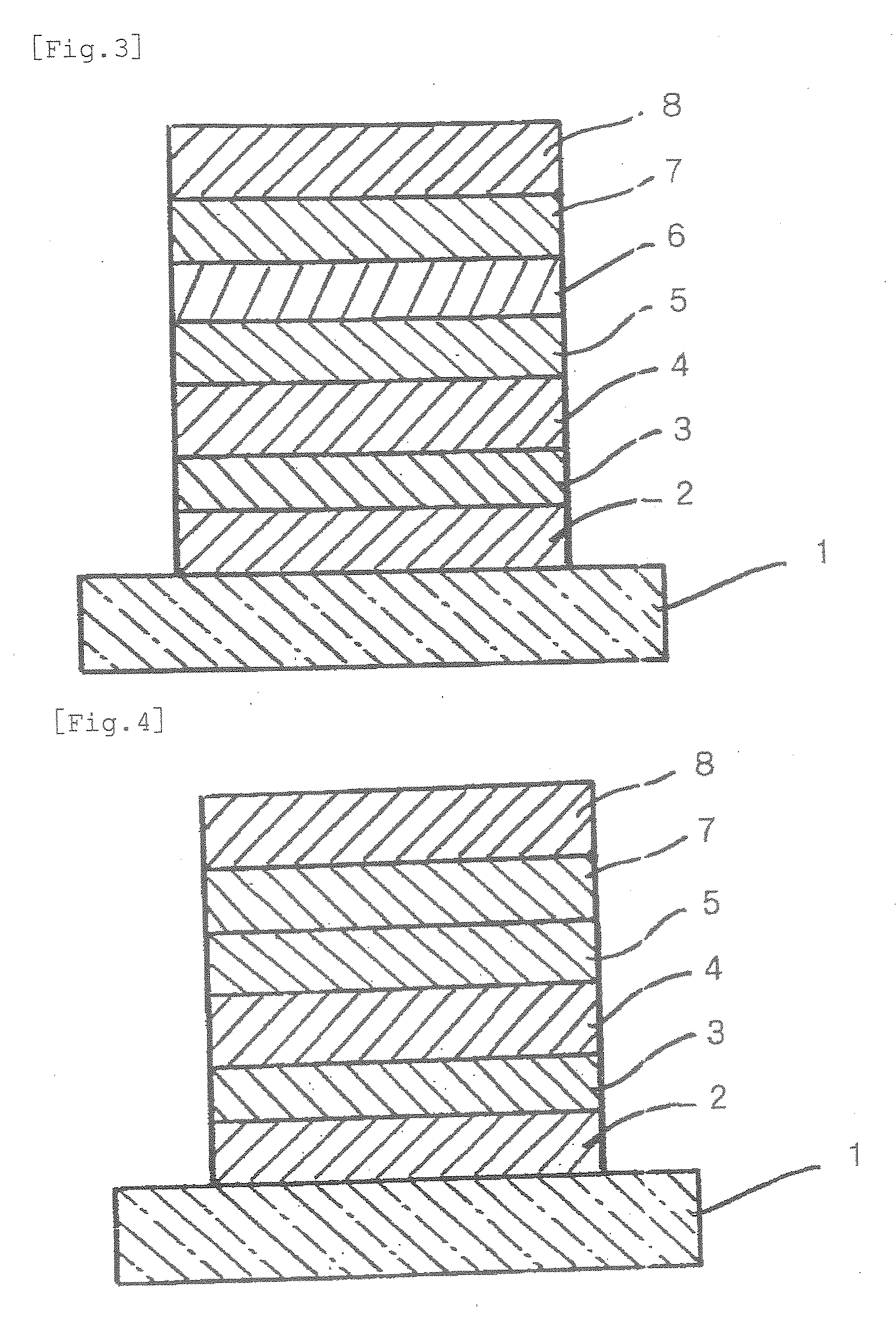

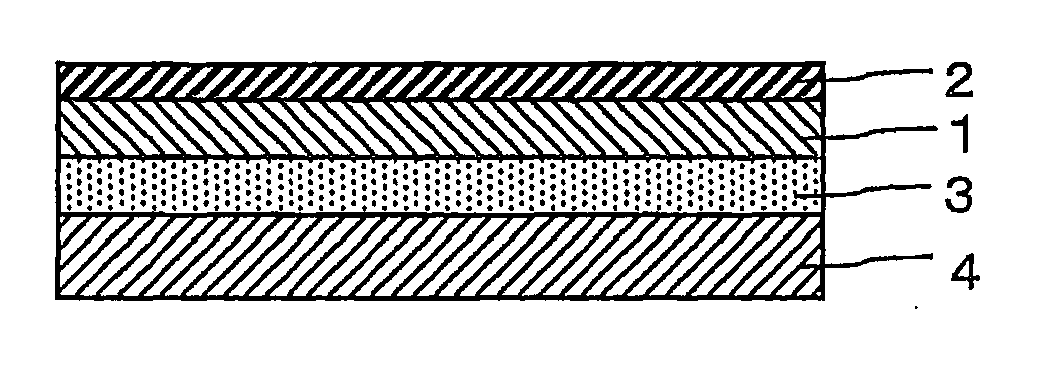

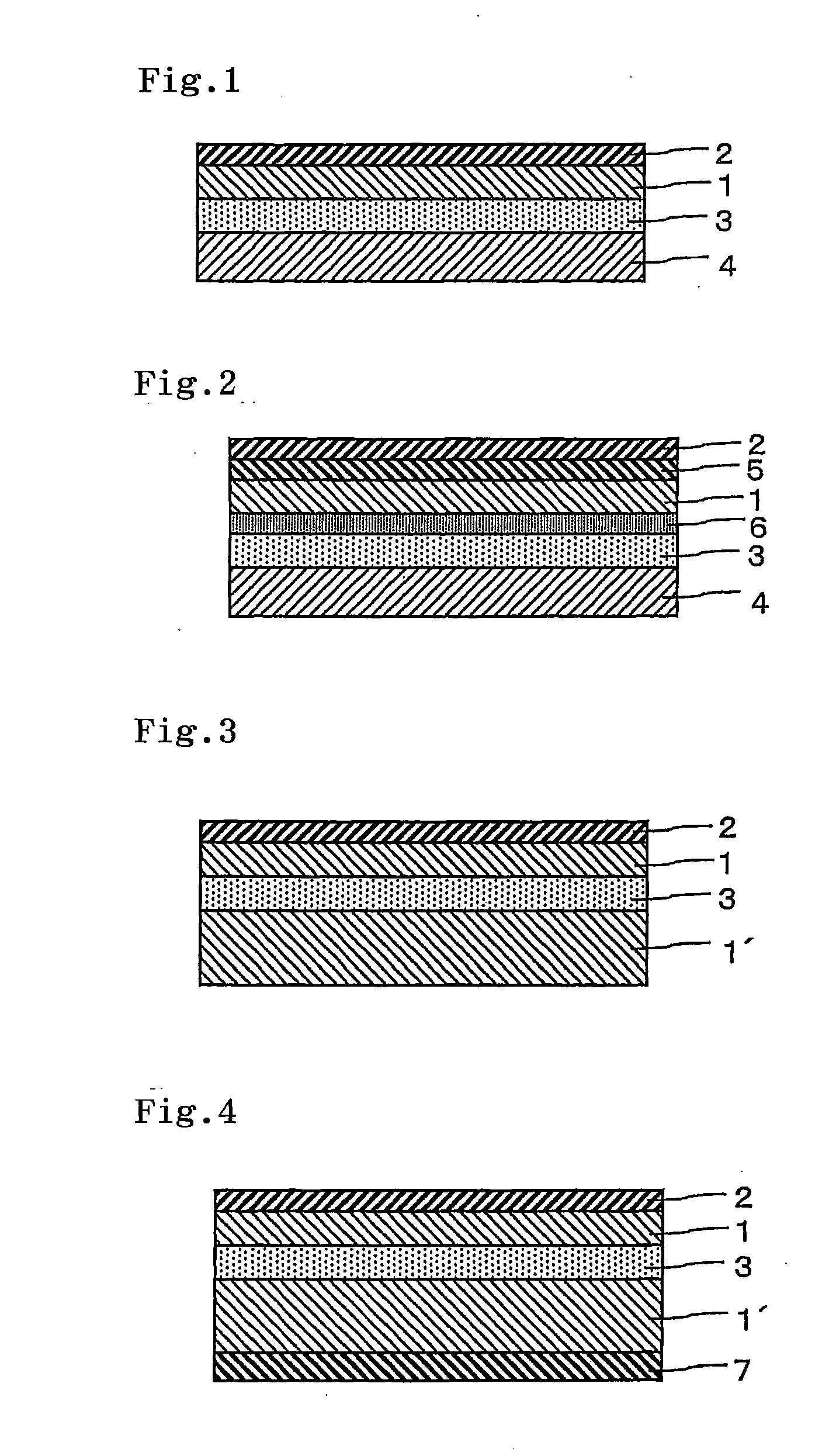

Color conversion luminescent sheet and fabrication method for the same

InactiveUS20120156436A1Satisfactory durabilitySatisfactory resistanceSynthetic resin layered productsSolid-state devicesNanofiberOptoelectronics

A color conversion luminescent sheet and a method of preparing the same, the color conversion luminescent sheet including: an optical sheet having a plurality of protrusions and depressions on its lower surface; a conductive layer disposed on the upper surface of the optical sheet; a color conversion luminescent layer deposited on the upper surface of the conductive layer and comprising a mixture of nanofibers and nanobeads having a binder resin and a color conversion luminescent material; and a protective layer on the upper surface of the color conversion luminescent layer, the protective layer having a stacked structure including an organic polymer protective layer and an inorganic thin protective layer.

Owner:KOREA INST OF SCI & TECH

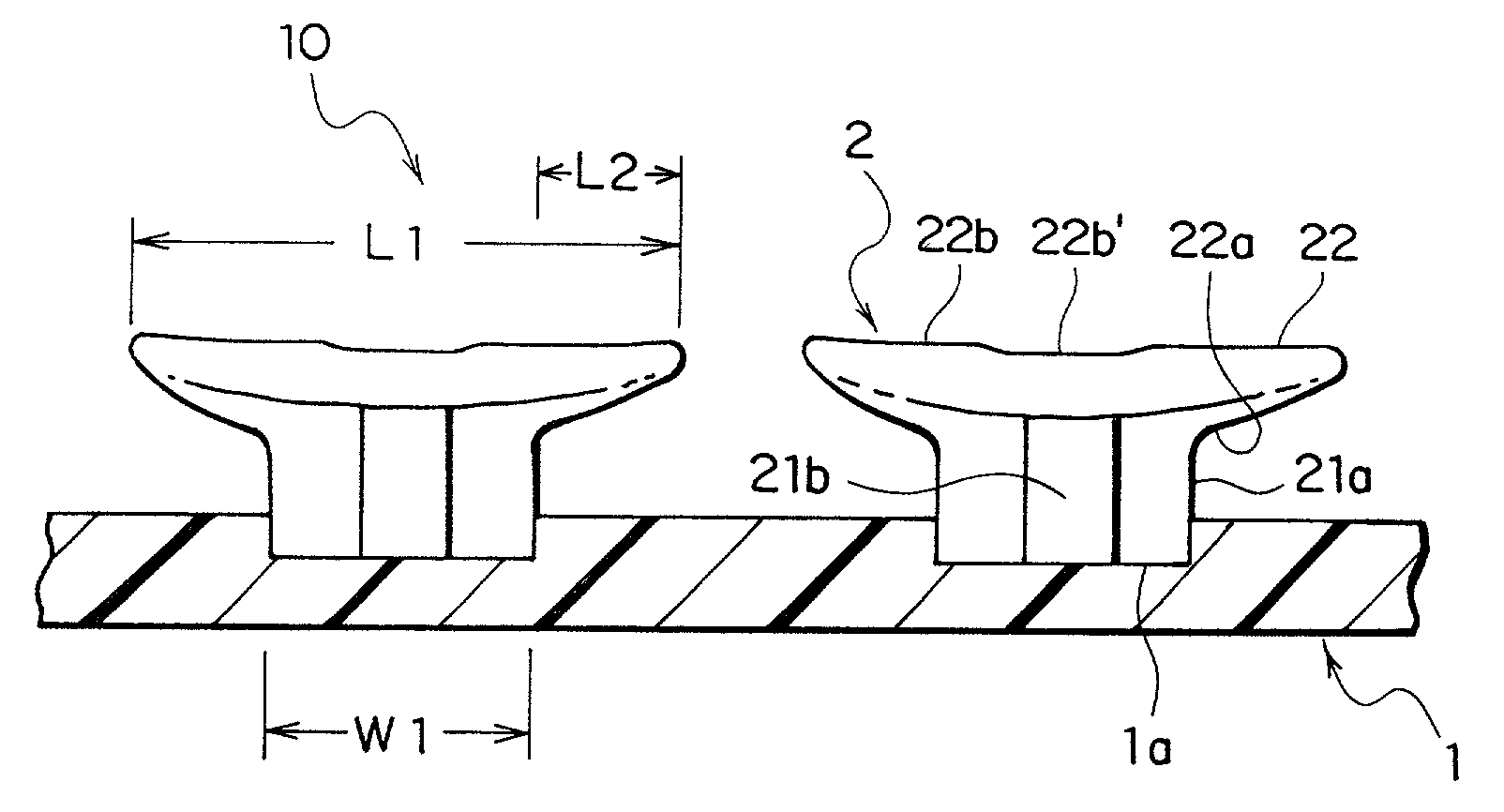

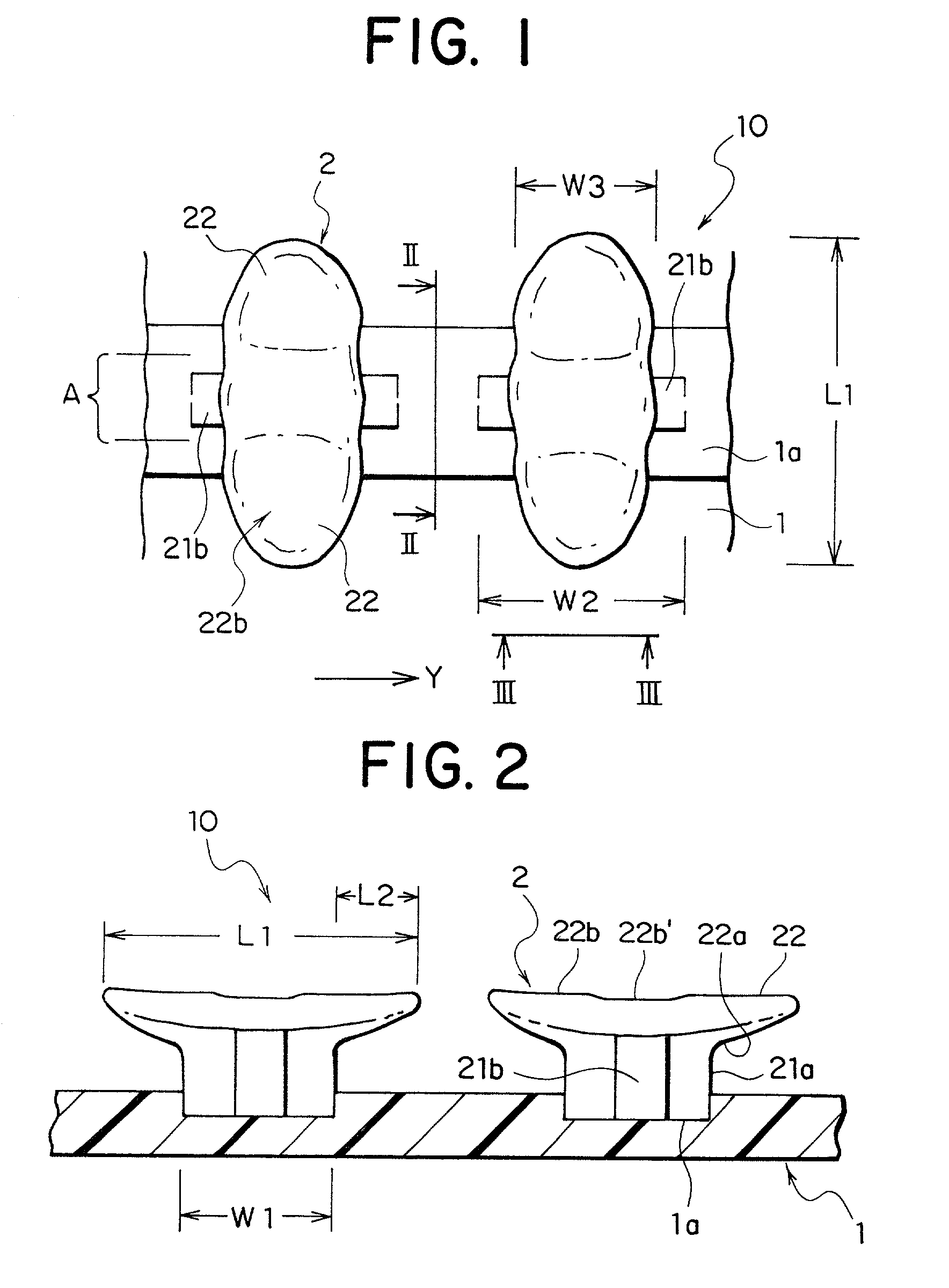

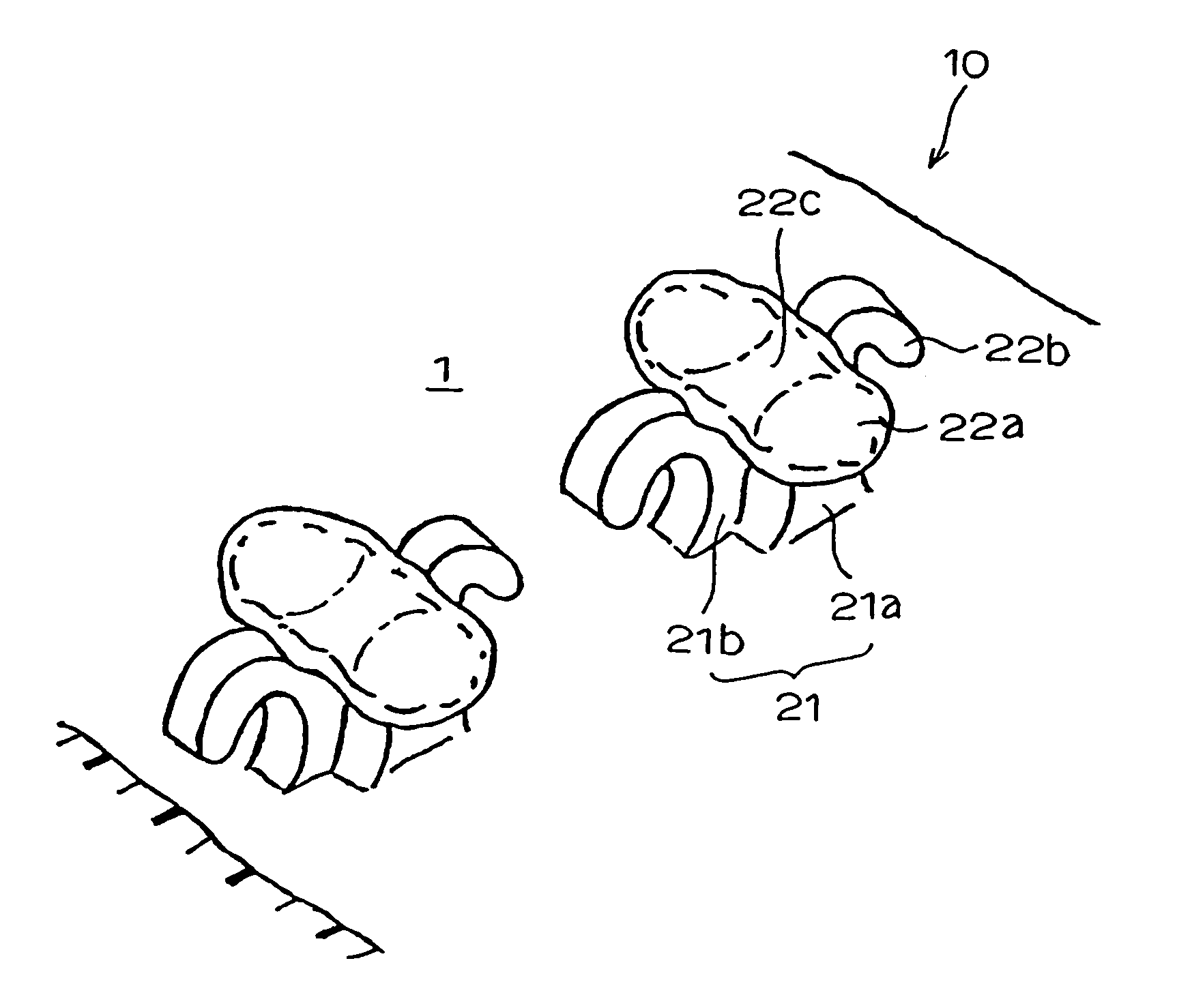

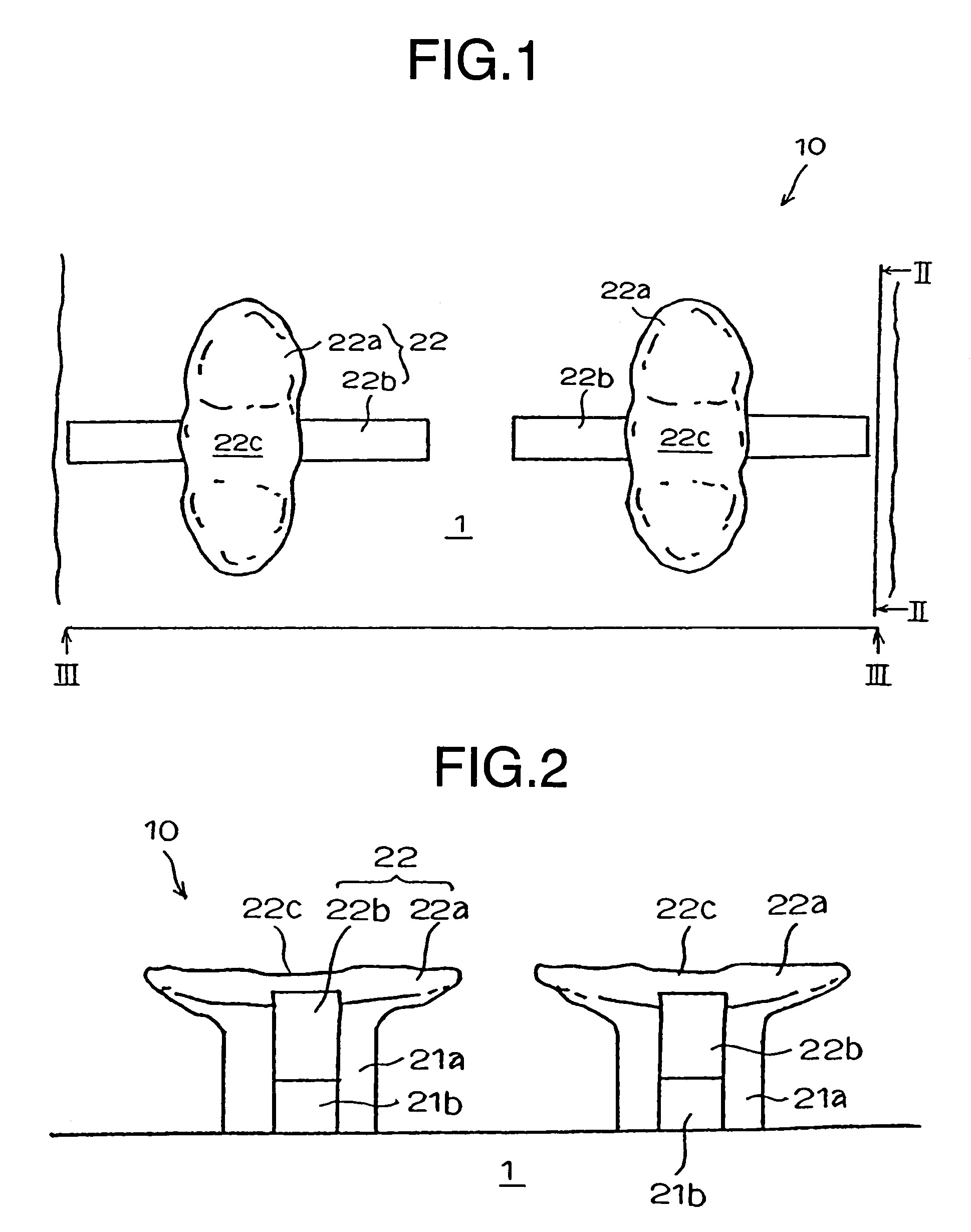

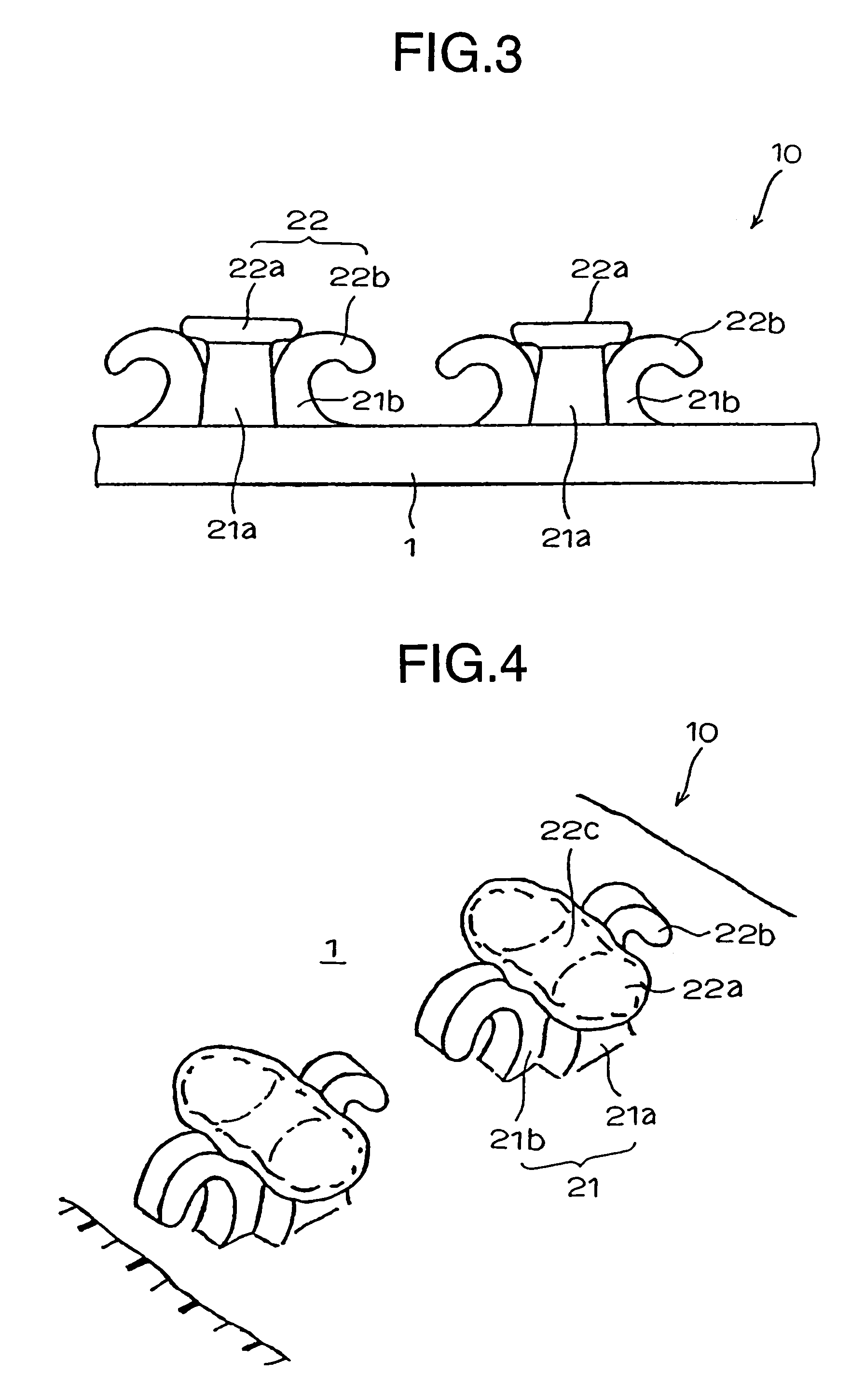

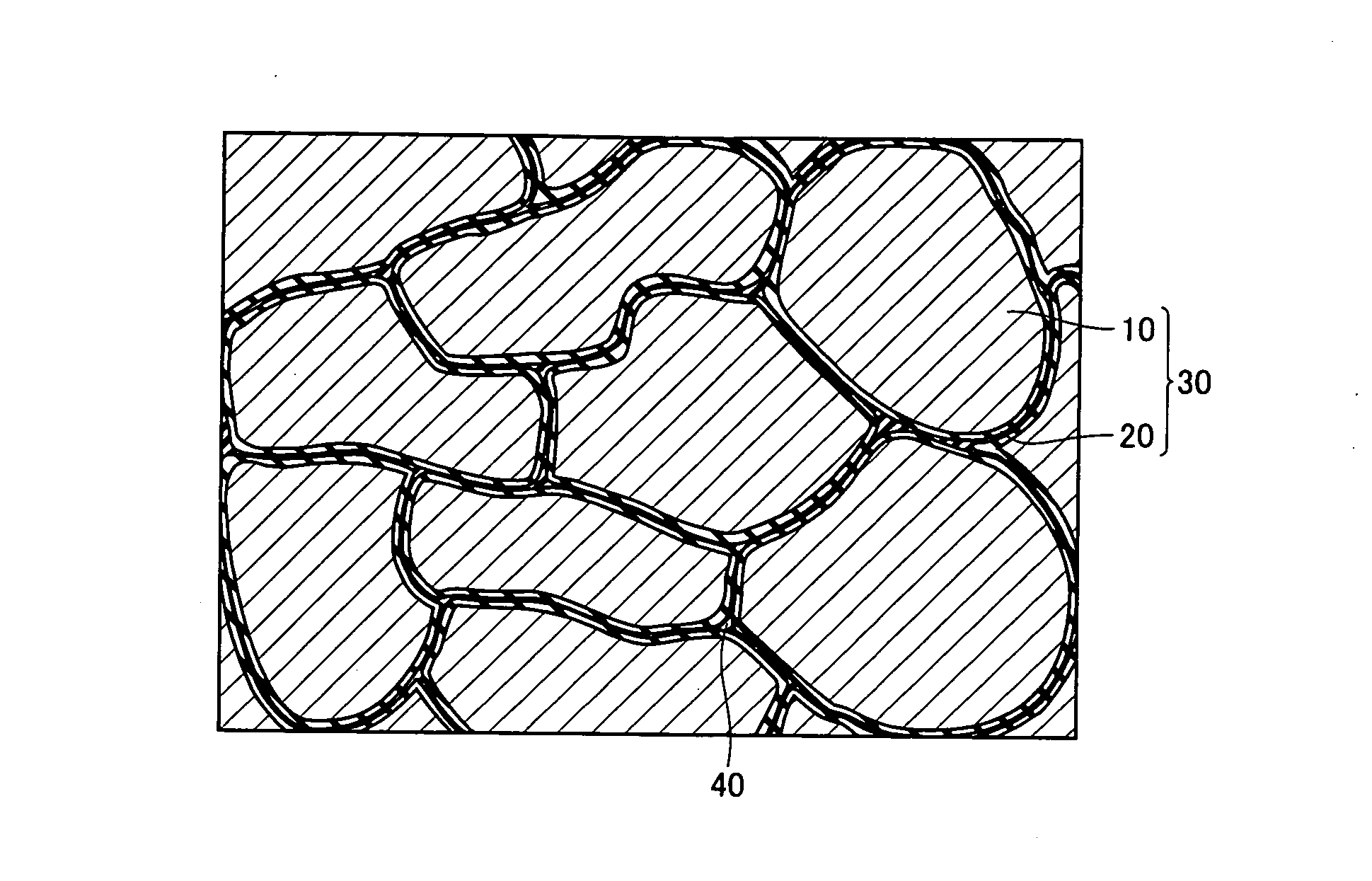

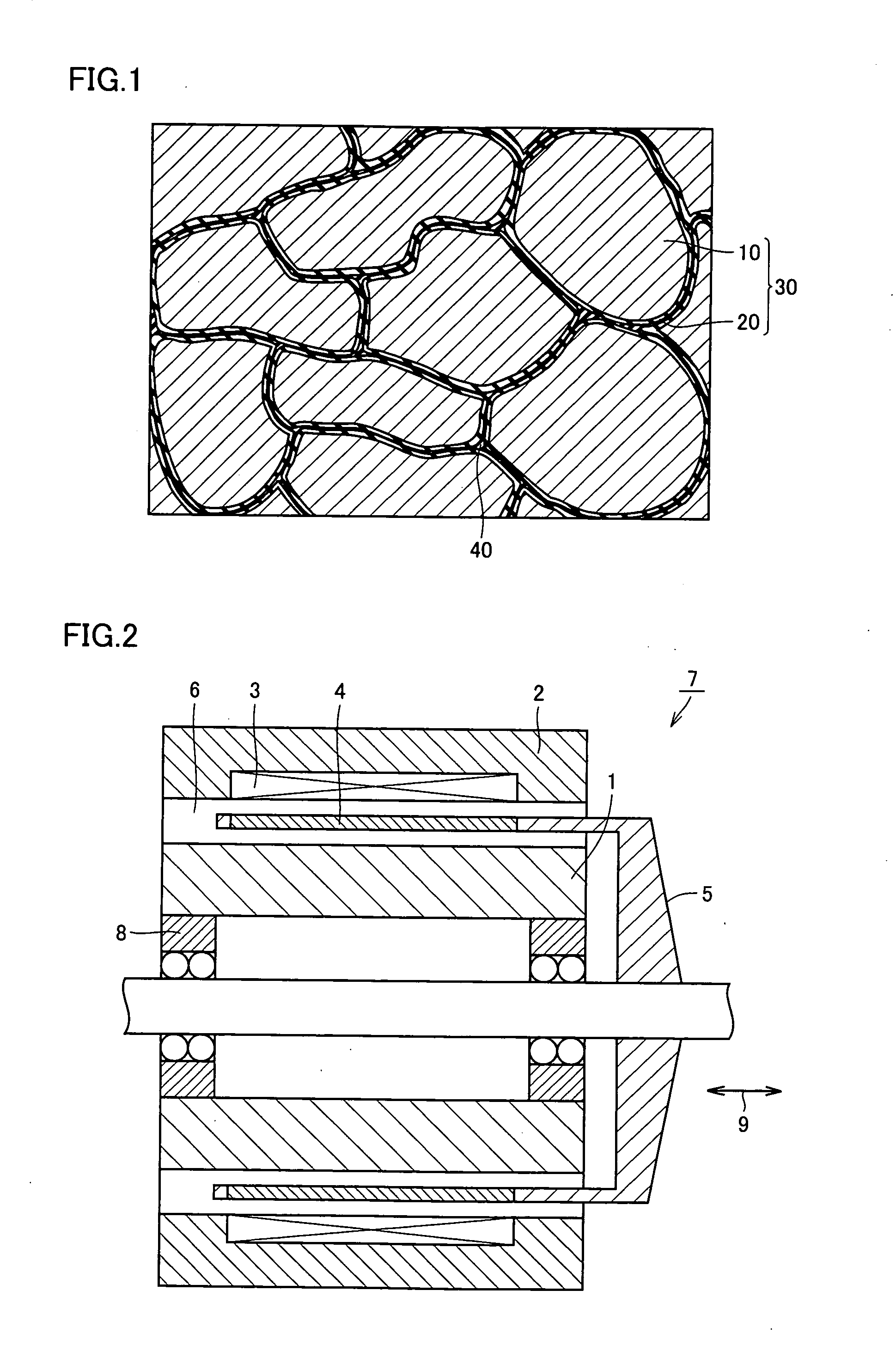

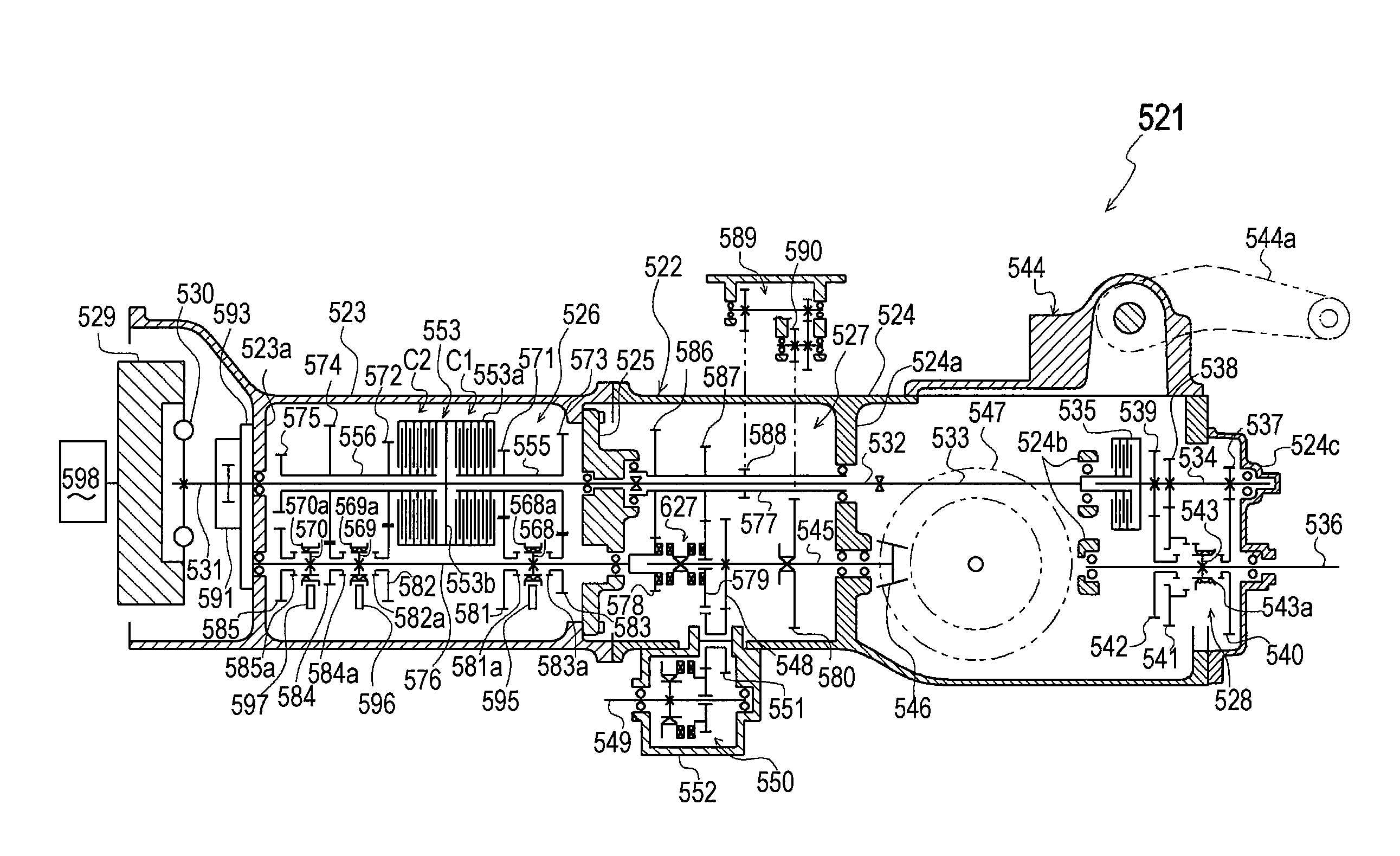

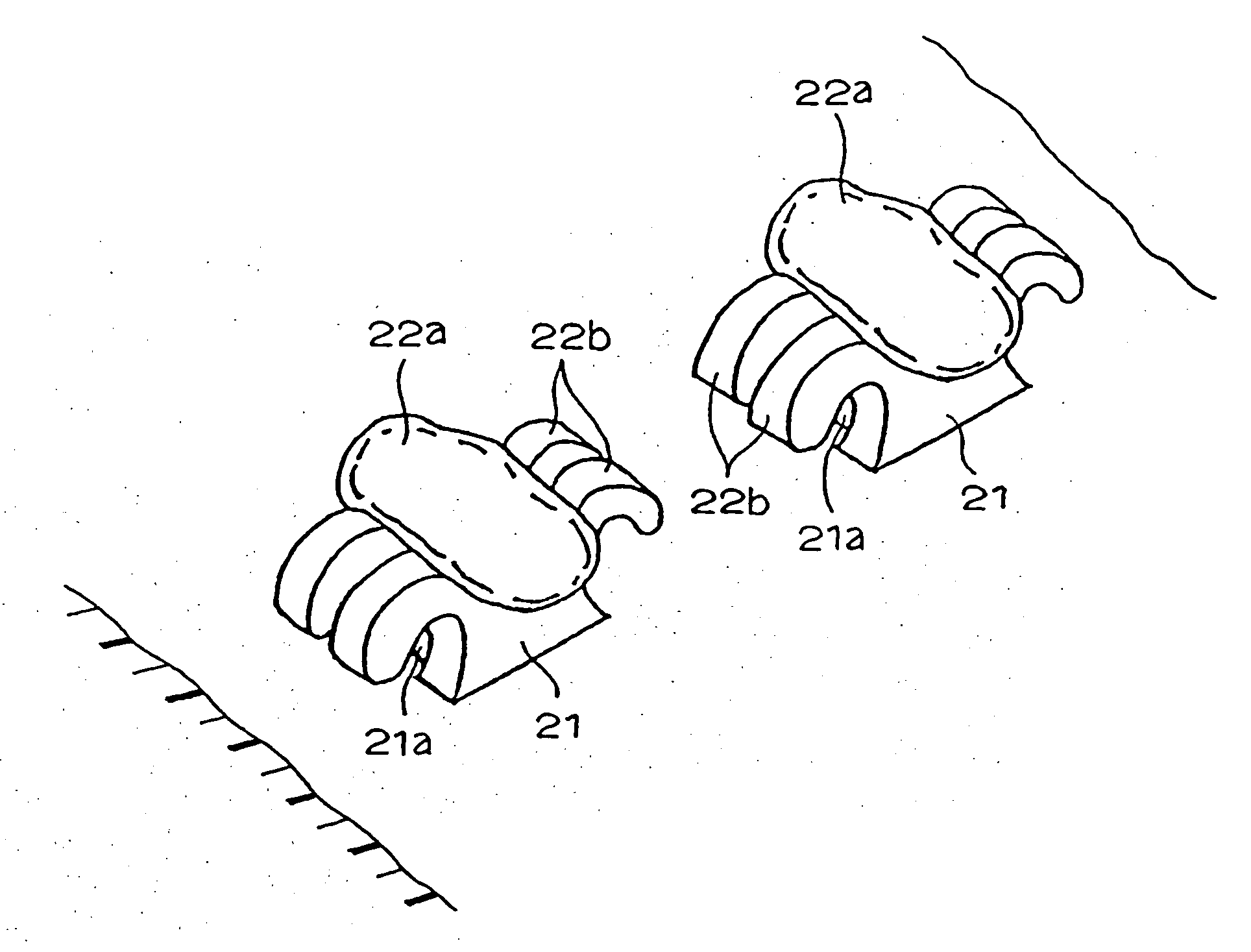

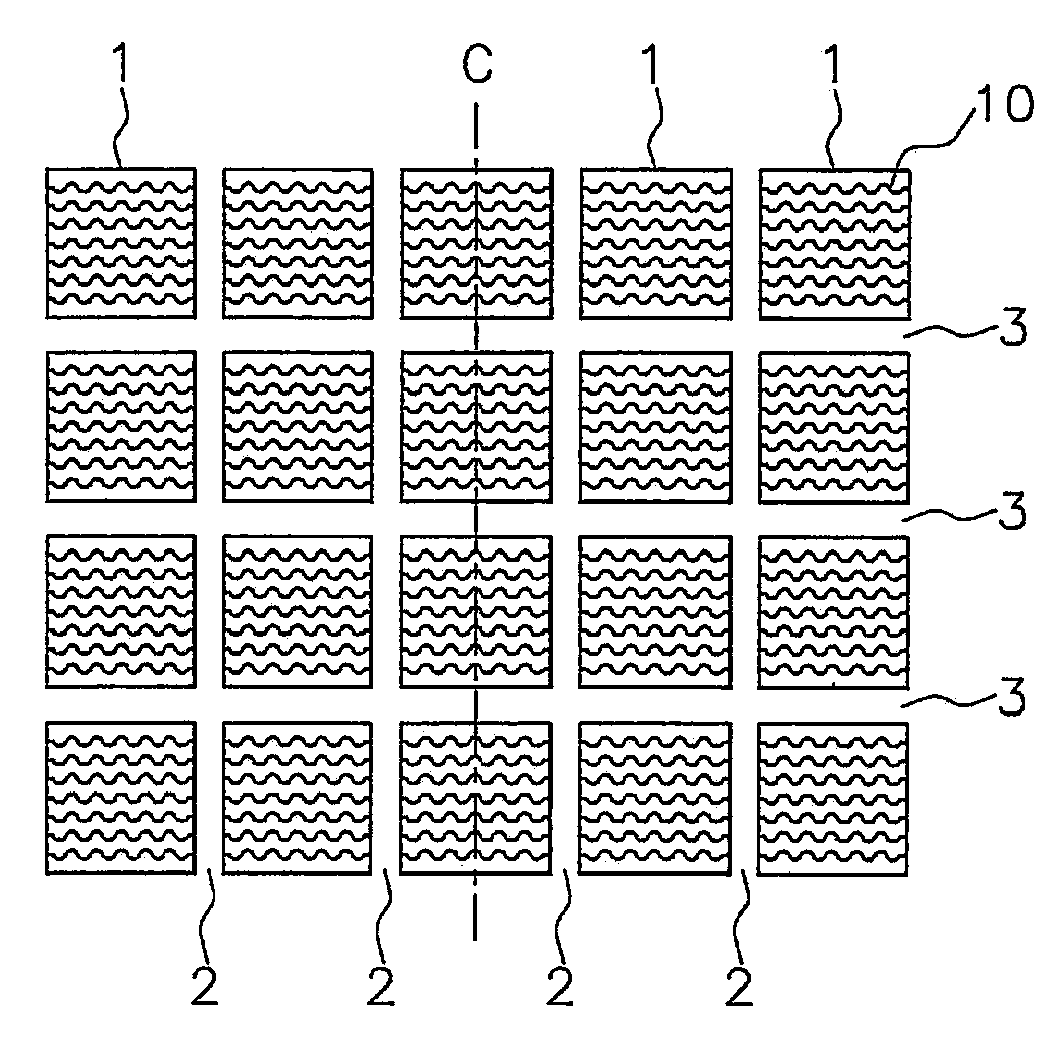

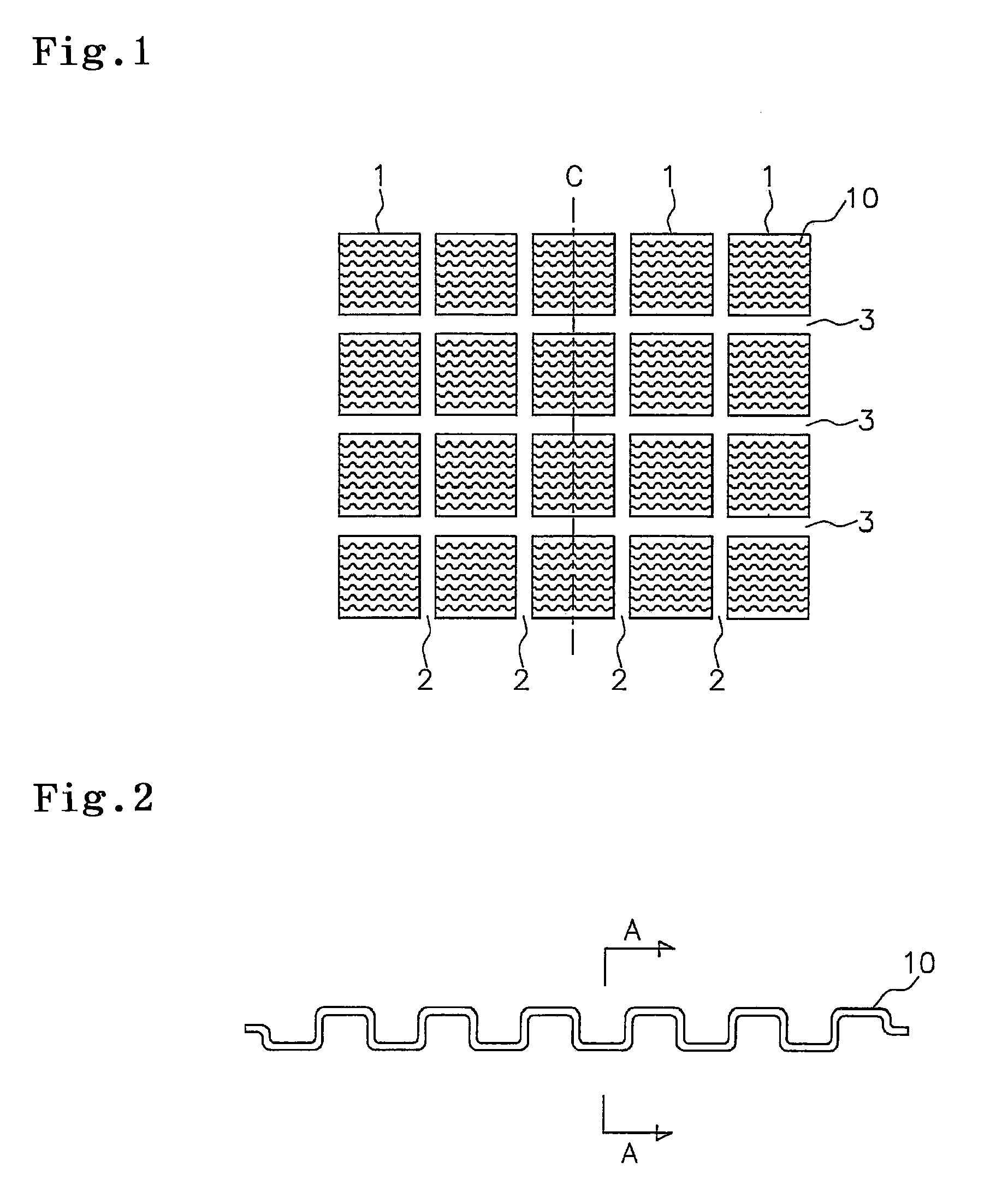

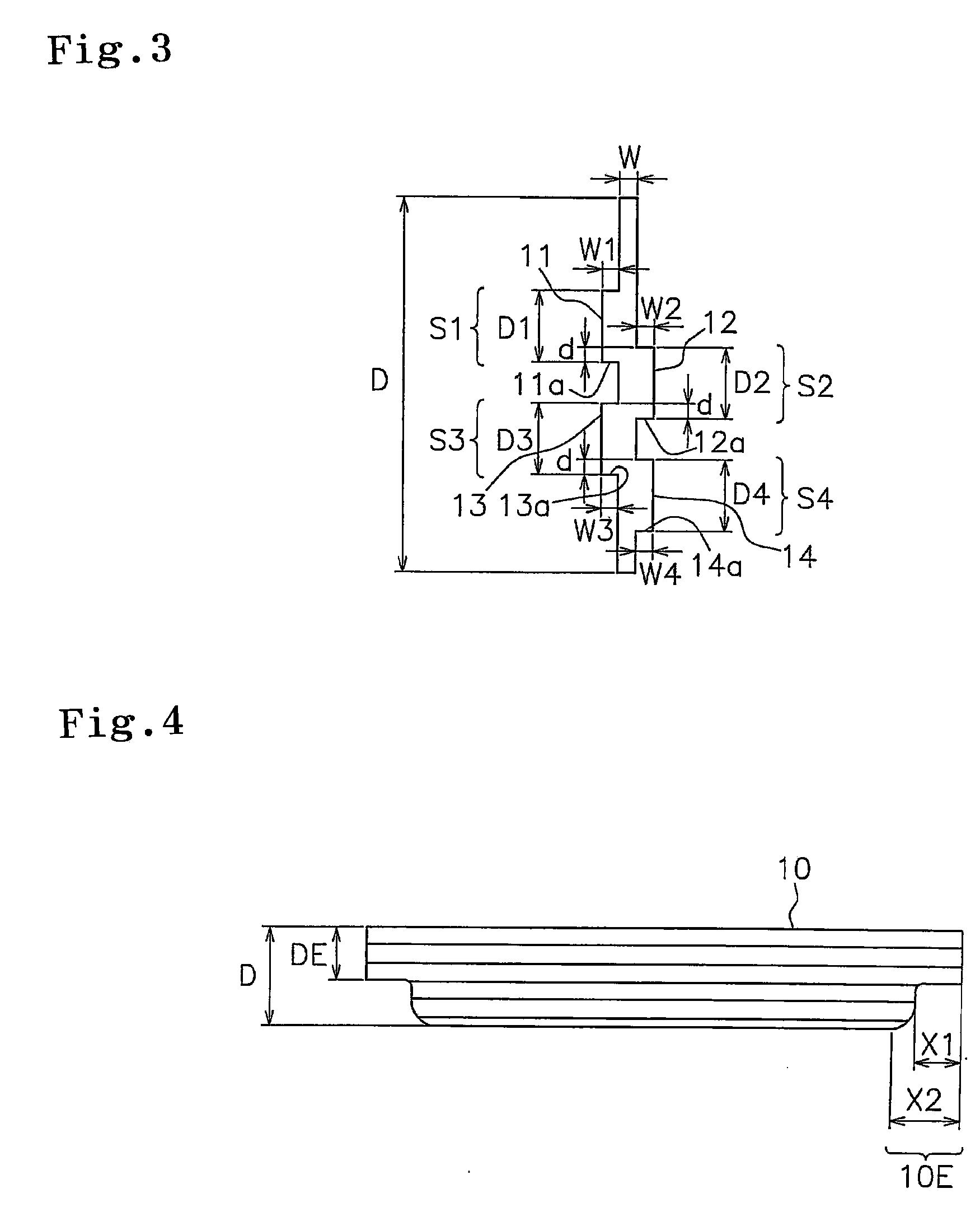

Integral molded surface fastener, and continuous manufacturing method and continuous manufacturing apparatus therefor

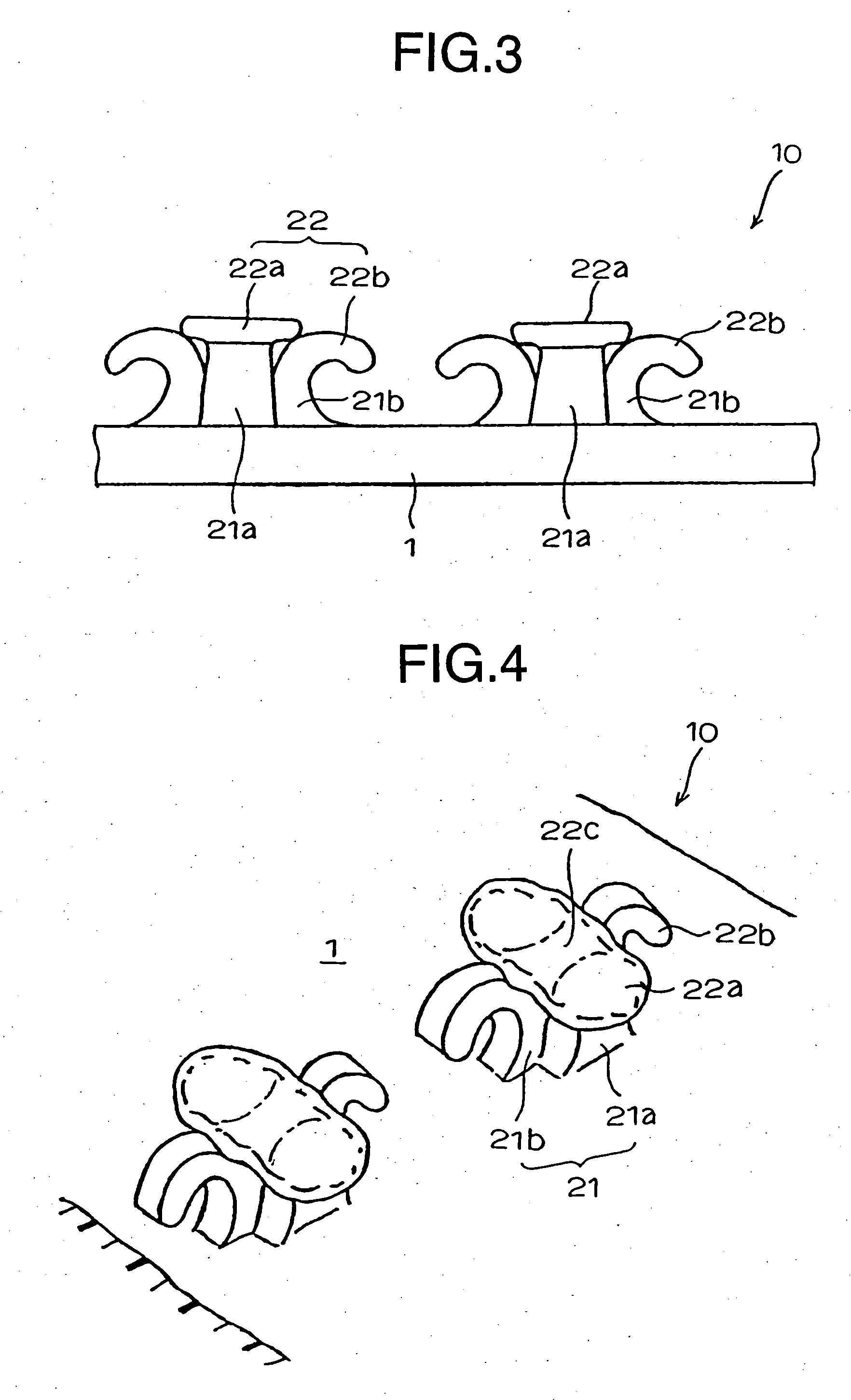

InactiveUS20020124359A1Increase participation rateSatisfactory durabilitySnap fastenersLayered productsFiberEngineering

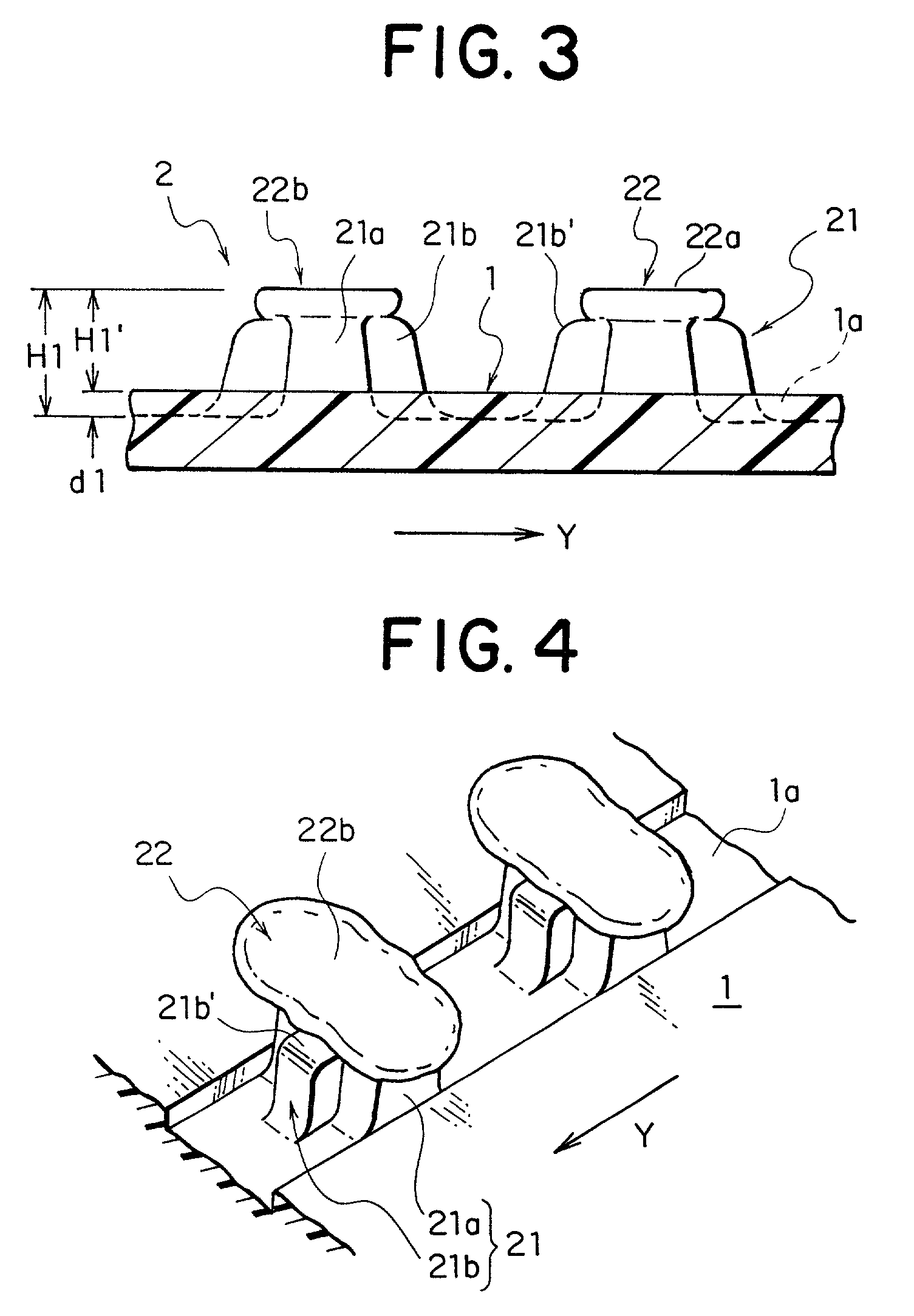

An integral molded surface fastener having minute and peculiar engaging elements, which engage with minute, thickly wooded fiber piles securely while each engaging element secures appropriate engagement strength, shearing strength and separation strength is provided. Further, texture of a surface of the surface fastener is improved and a height of the engaging elements protruded from a surface of a substrate is lower than a conventional type, thereby preventing the engaging elements from being fallen down by a pressing strength. At the same time, a high engaging ratio with a mating pile piece is secured and a durability required for this kind of fastener is satisfied. Preferably, a desired plasticity and tearing strength of the flat substrate are secured. More specifically, a molded surface fastener having minute engaging elements of thermoplastic resin formed together with a substrate by continuous molding is provided, the engaging elements being hook-type engaging elements each comprised of a single column portion having a substantially cross-shaped section provided by intersection of a first column portion and a second column portion and rectangular thin plate-like engaging heads extended in the shape of wings in opposite directions along the width direction of the first column portion intersecting the second column portion around a top end of the column portion, and having substantially the same width dimension as the width dimension of a top end of the second column portion.

Owner:YKK CORP

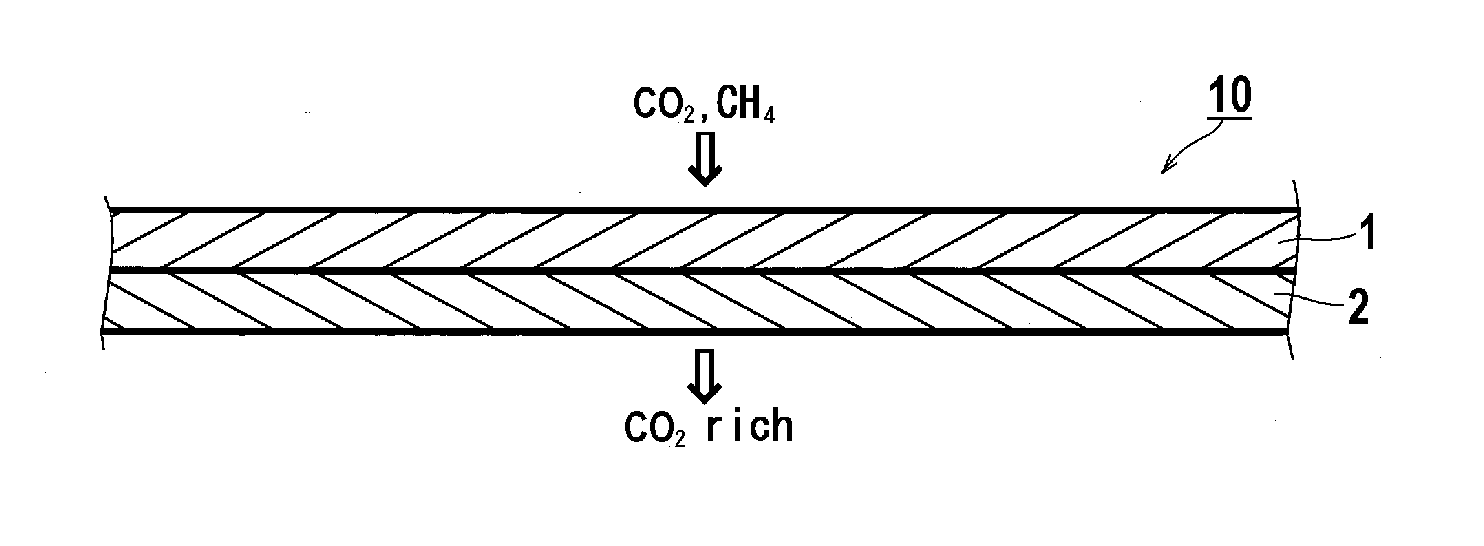

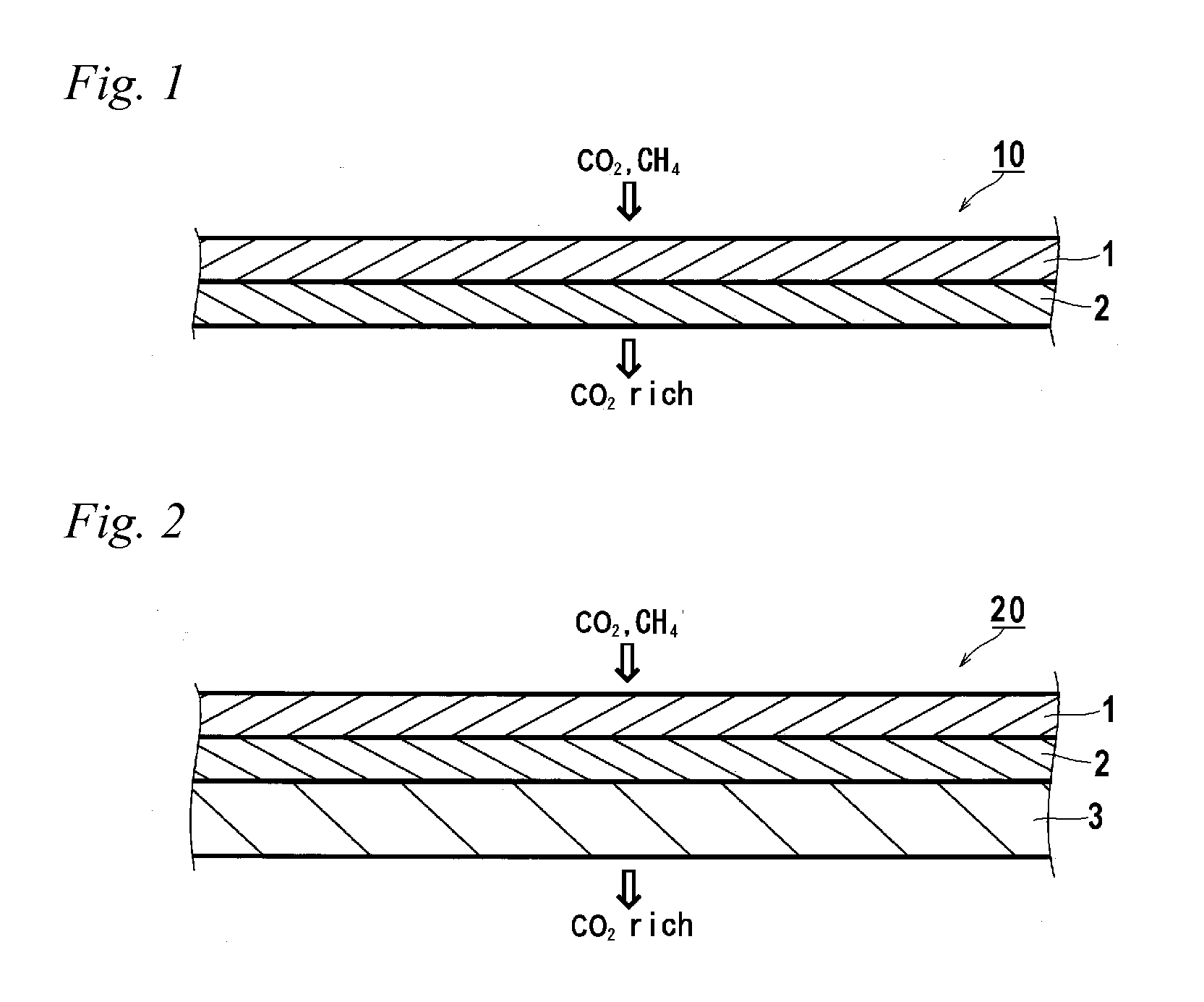

Gas separation membrane, gas separation module, gas separation apparatus, and gas separation method

InactiveUS20150258505A1Satisfactory mechanical strengthImprove permeabilitySemi-permeable membranesMembranesBenzoxazoleSolubility

A gas separation membrane having a gas separating layer containing a polybenzoxazole resin, in which the polybenzoxazole exhibits a solubility of 1% by mass or more to any one solvent selected from tetrahydrofuran, chloroform, methyl ethyl ketone, and N-methylpyrrolidone, at a temperature of 30° C., a gas separation module utilizing the gas separation membrane, a gas separation apparatus, and a gas separation method.

Owner:FUJIFILM CORP

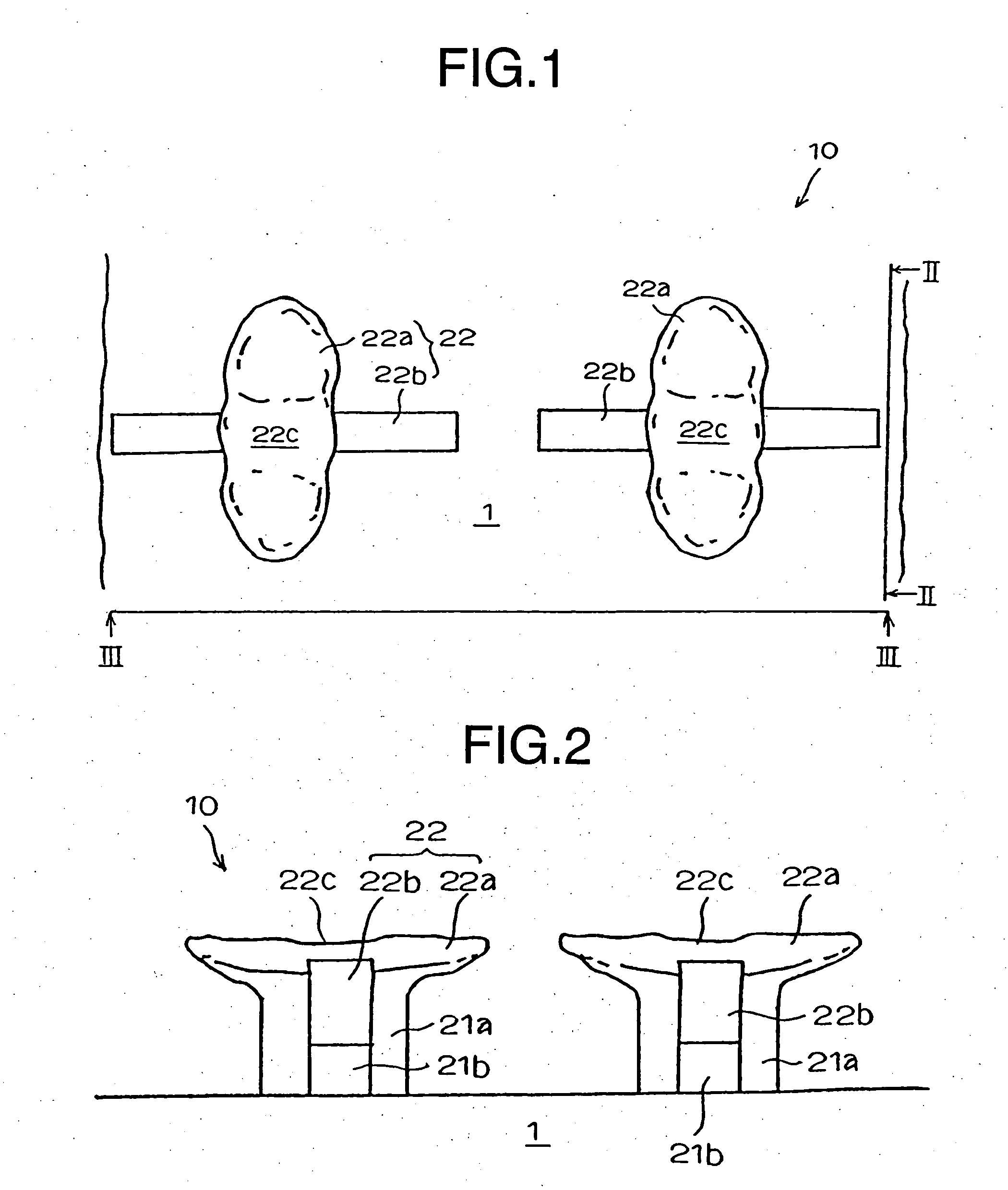

Integrally molded surface fastener, and continuous production method and continuous production device therefor

ActiveUS7350276B2Increase participation rateSatisfactory durabilitySnap fastenersClothes buttonsEngineeringShear force

In a molded surface fastener (10) having engaging elements (2) of minute dimension of thermoplastic resin molded together with a base member (1) by continuous molding, each engaging element (2) comprises first and second engaging portions (22a, 22b) each having a different configuration extending in parallel to a surface of the base member from a top end of a pillar portion (21) rising from the base member (1) such that they intersect at right angle. The second engaging head (22b) has an ordinary hook shape structure while the first engaging head (22a) has a wing-like thin plate structure as seen in a plan view.The engaging elements having such a structure in which each engaging element has appropriate engagement force, shearing force and separation force so as to keep an excellent tactile feeling of a surface of the surface fastener, prevents itself from falling down against a pressing force, secures a high engagement ratio with mating pile pieces and satisfies a durability.

Owner:YKK CORP

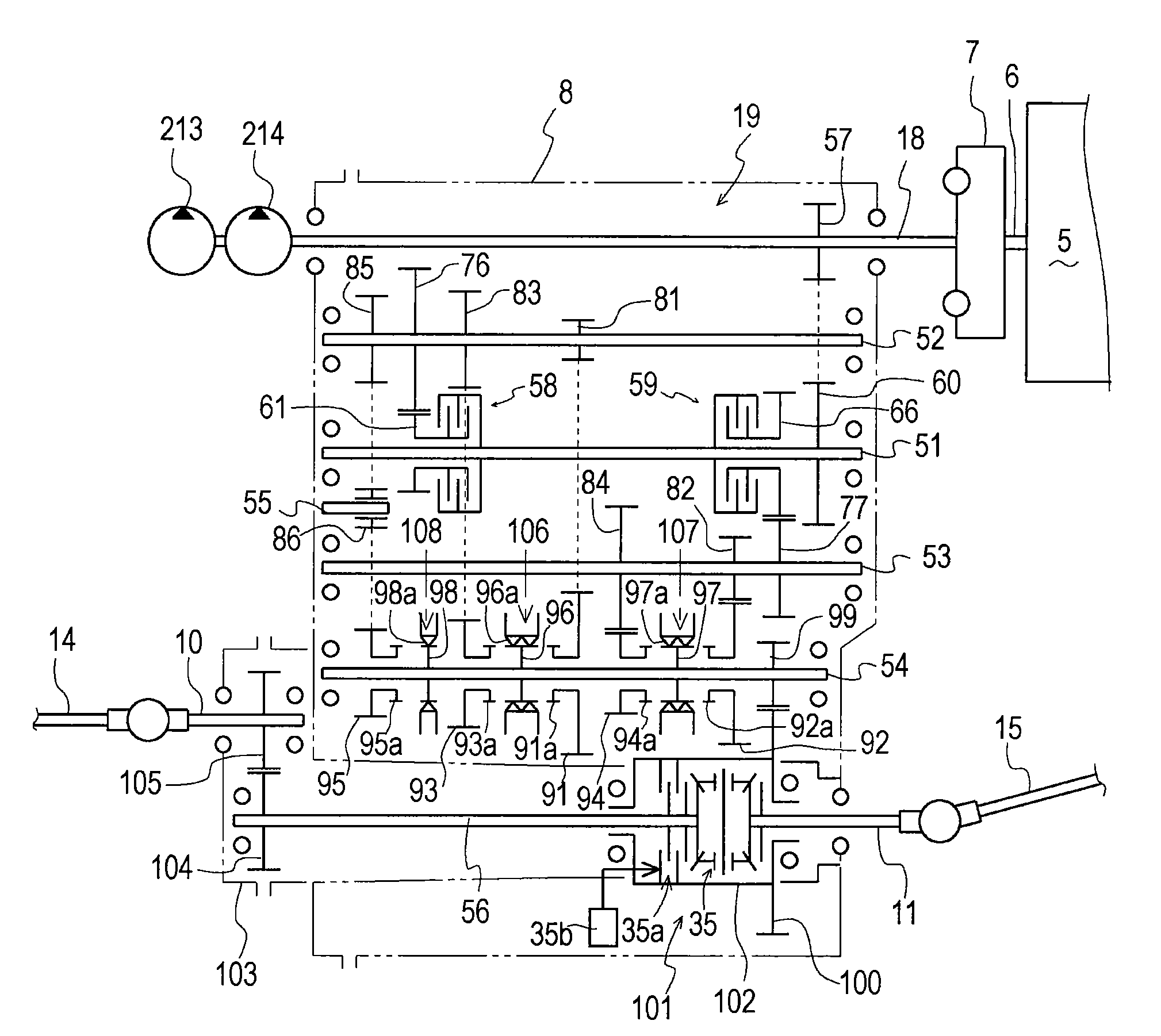

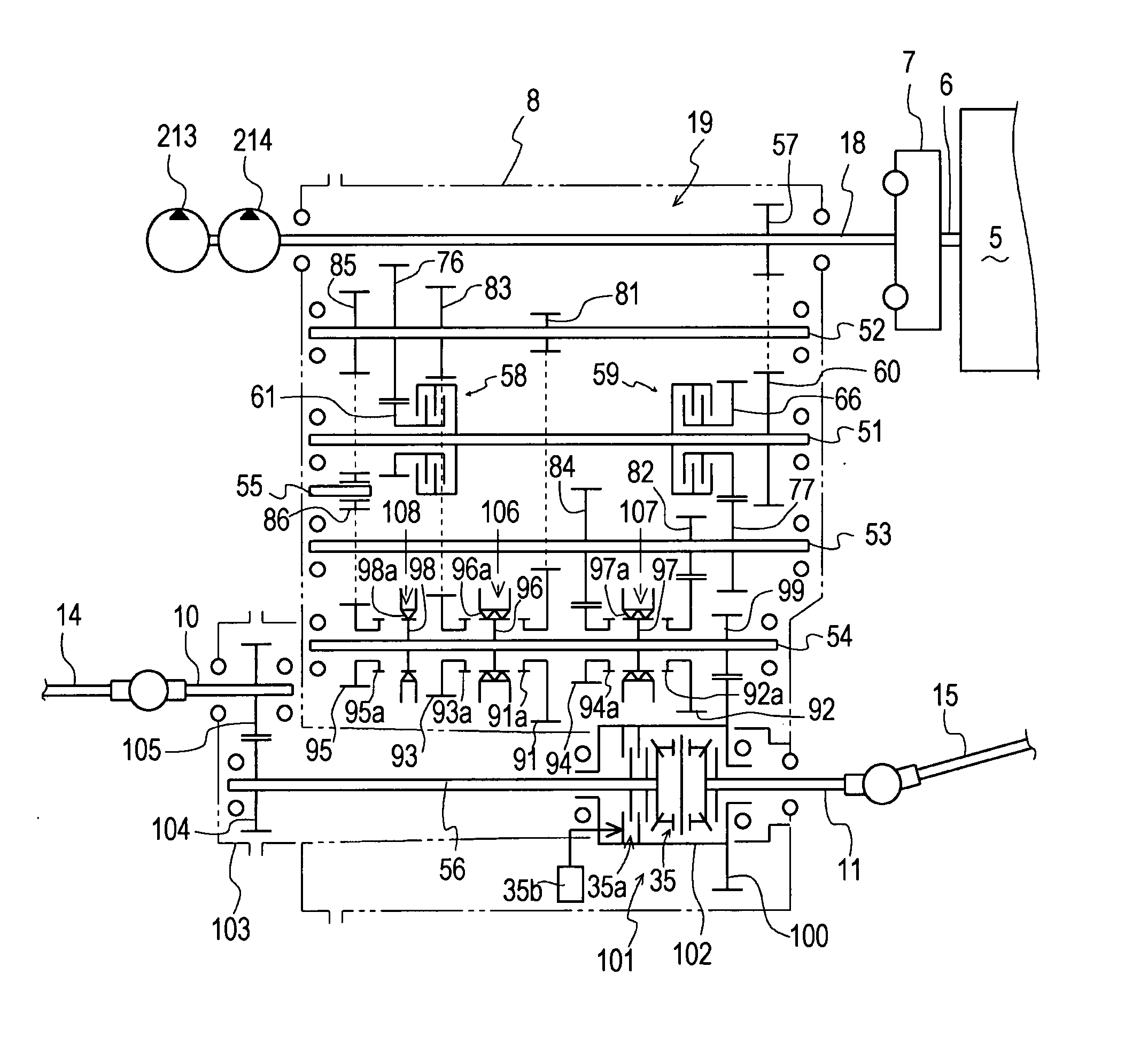

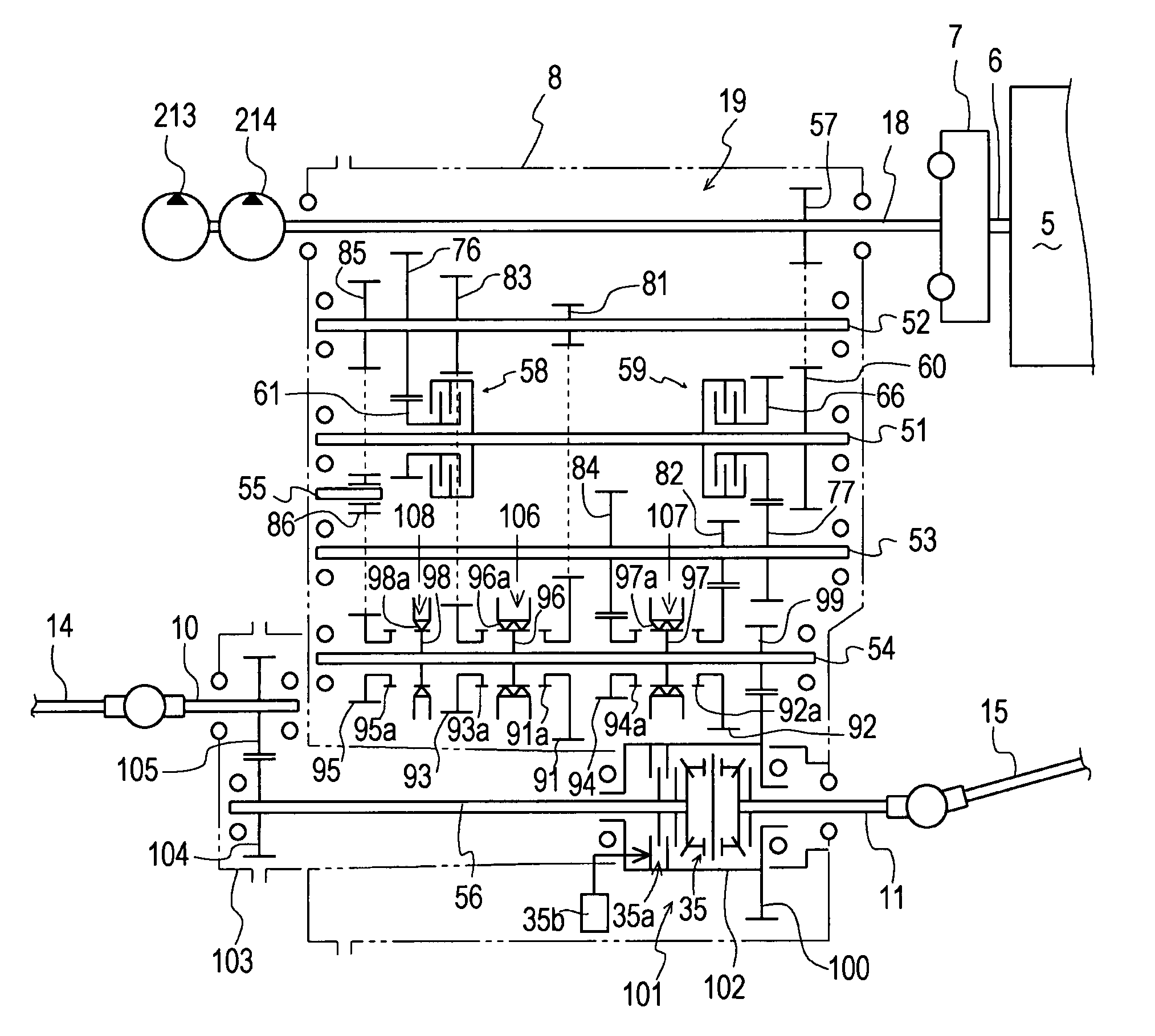

Vehicle Transmission System

ActiveUS20090120710A1Increased rate is largeIncrease ratingsDigital data processing detailsToothed gearingsTransmitted powerTransmission system

A vehicle has an engine, an accelerator for controlling the rotary speed of the engine, an axle and a multi-speed transmission for transmitting power from the engine to the axle. The multi-speed transmission includes an odd-numbered speed drive train for an odd-numbered speed level, a first clutch for the odd-numbered speed drive train, an even-numbered speed drive train for an even-numbered speed level, and a second clutch for the even-numbered speed drive train. In correspondence to operation of the accelerator and an actual speed of the axle, either the odd-numbered speed drive train or the even-numbered speed drive train is selected so as to transmit power from the engine to the axle. A shift-up or shift-down timing between the odd-numbered speed level and the even-numbered speed level relative to variation of the actual speed of the axle is changed according to detection of a tilt angle of the vehicle or a weight of the vehicle.

Owner:KANZAKI KOKYUKOKI MFG

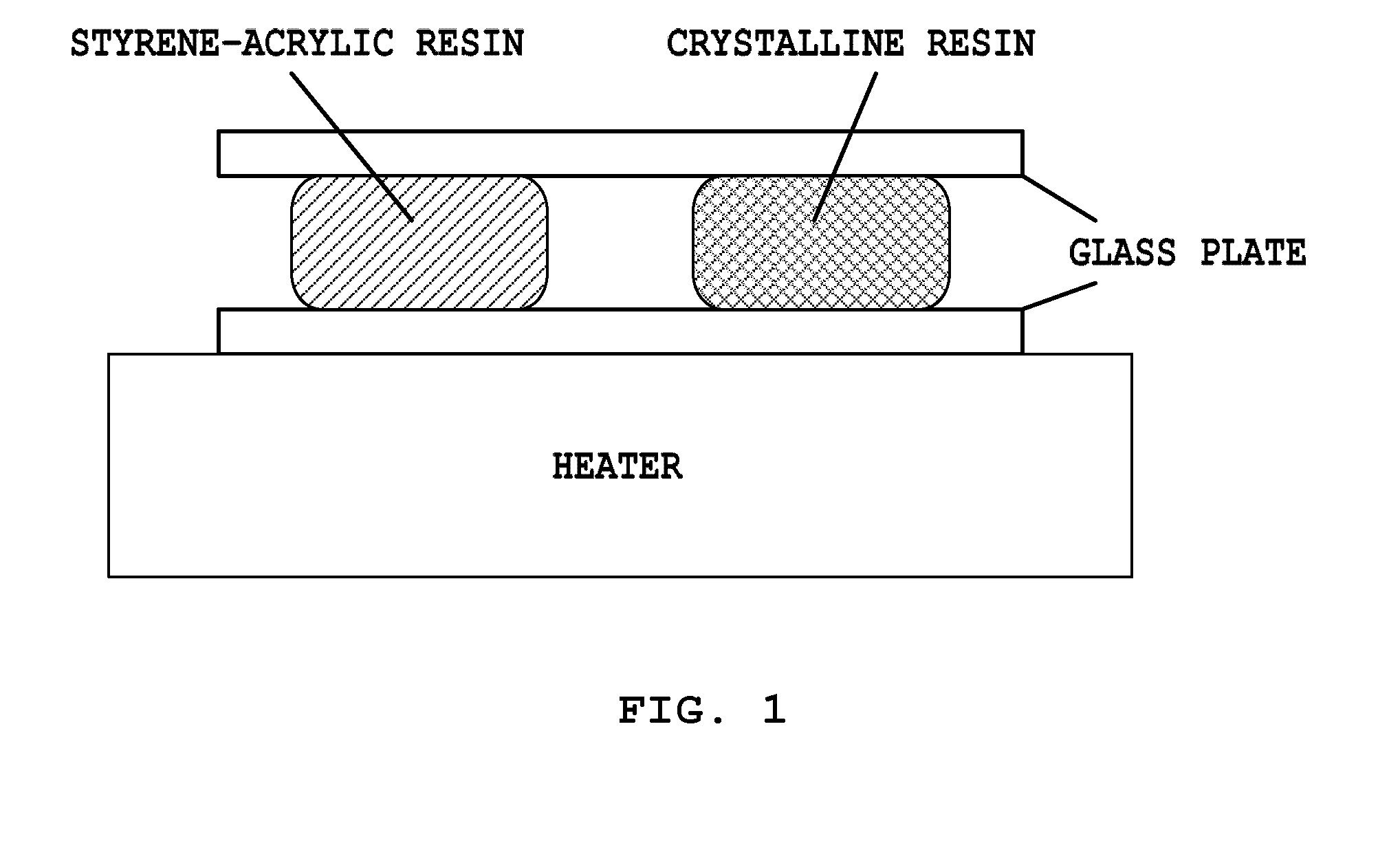

Toner

ActiveUS9835964B2Good dispersibilitySatisfactory heat-resistant storabilityDevelopersPolymer scienceAcrylic resin

Owner:CANON KK

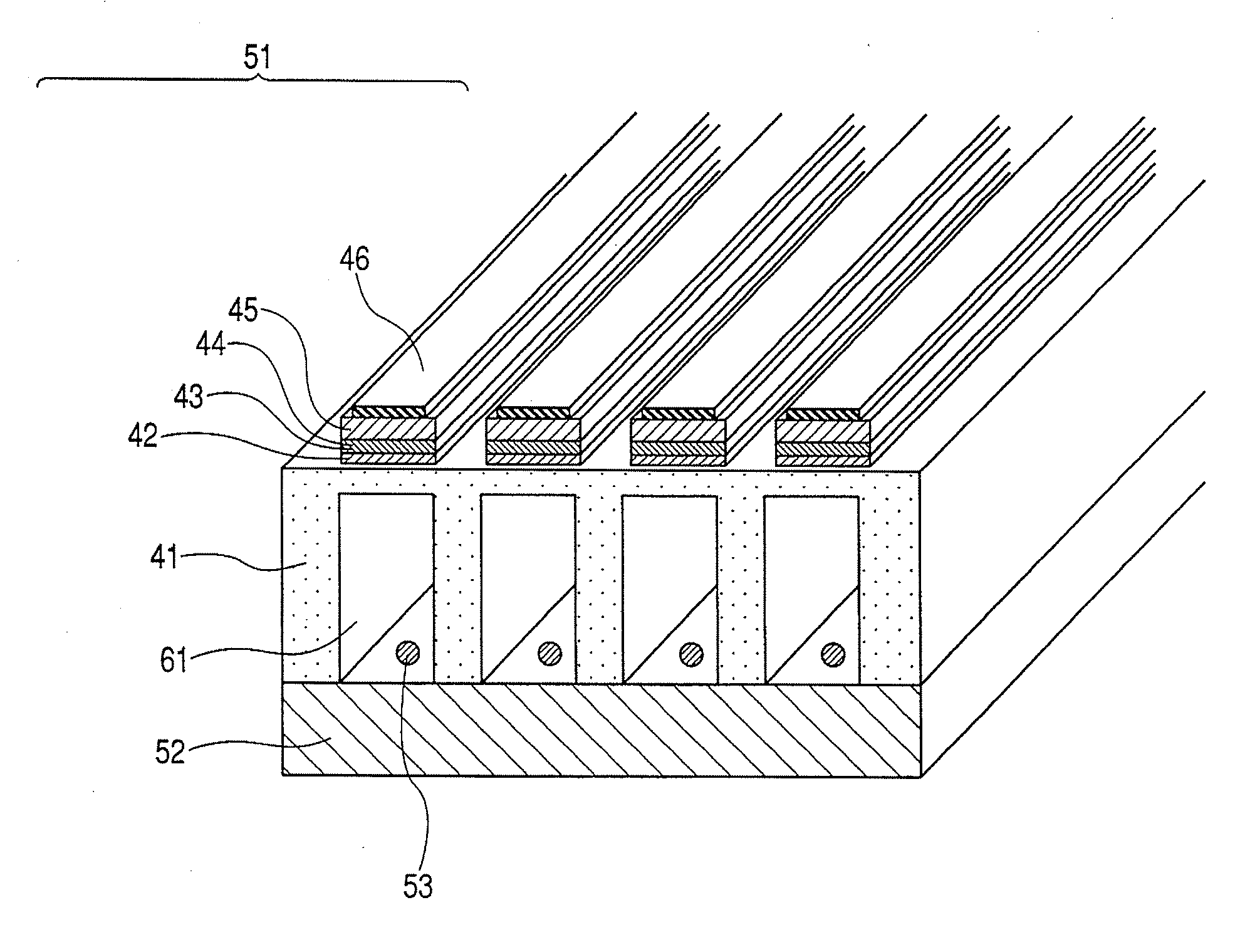

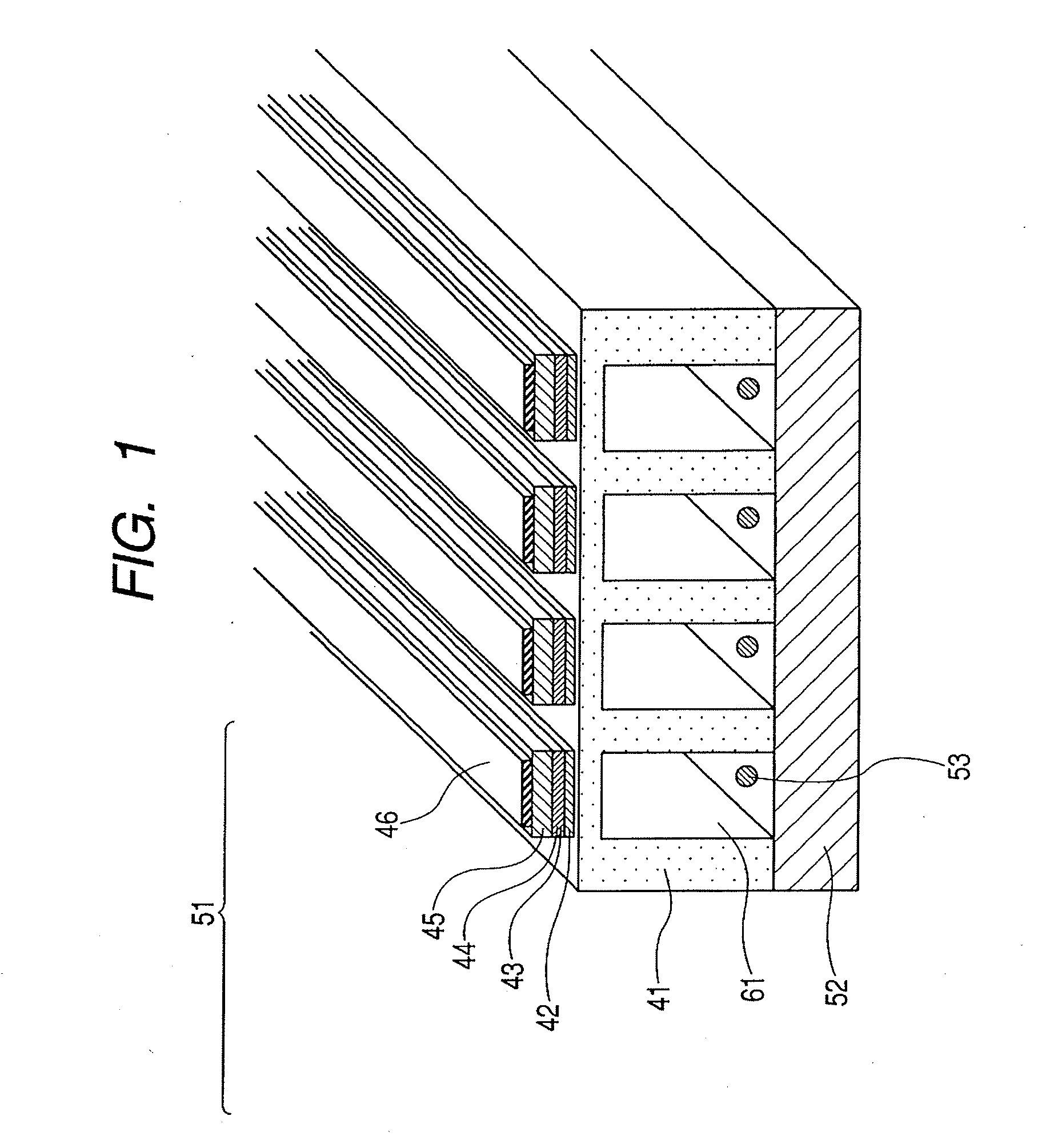

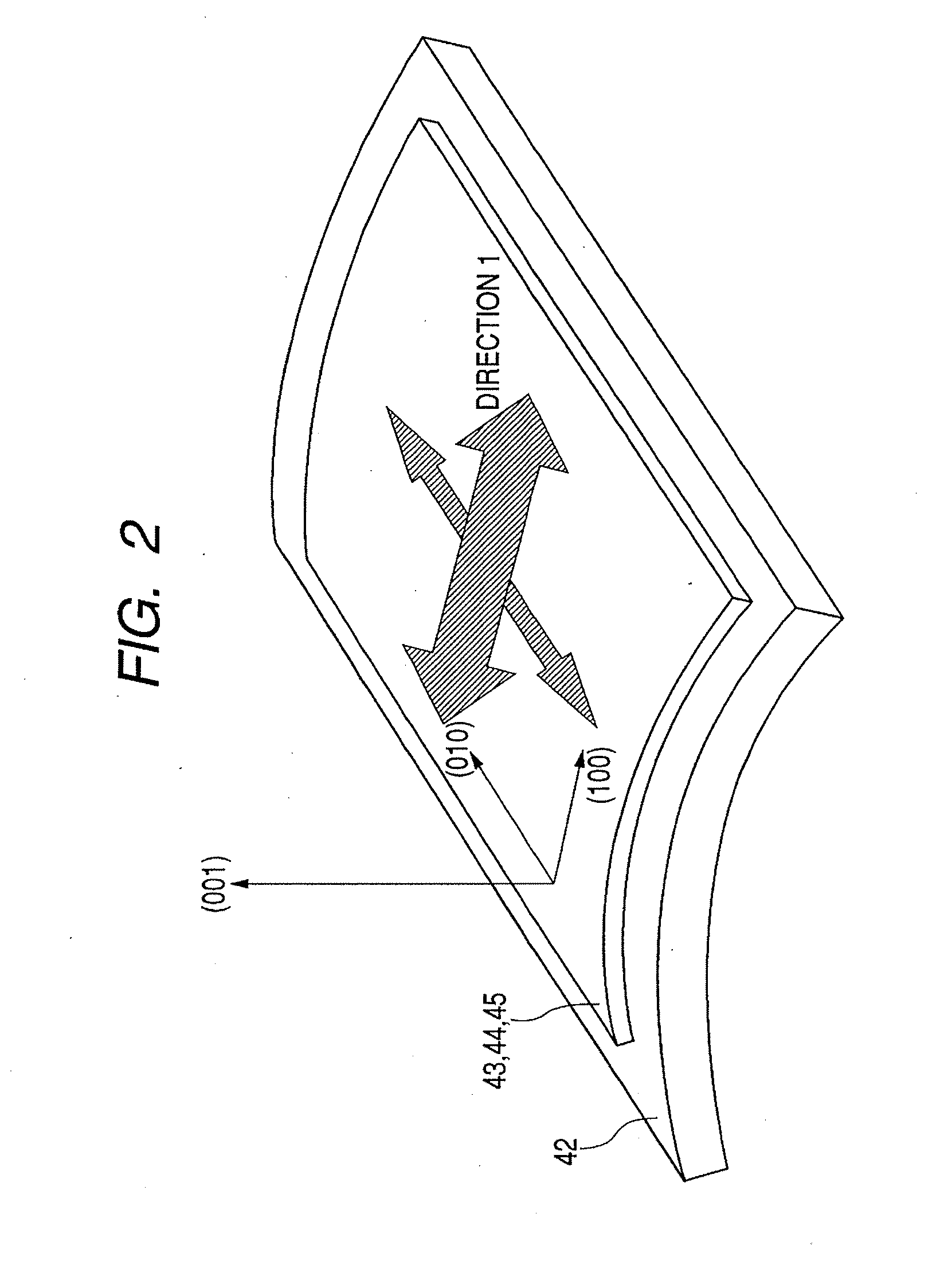

Piezoelectric element, ink jet head and producing method for piezoelectric element

InactiveUS20080012910A1Excellent piezoelectric propertiesSatisfactory durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringPlane parallel

A piezoelectric element comprises a piezoelectric film disposed on a substrate and a pair of electrodes disposed in contact with the piezoelectric film and utilizing a bending mode. The piezoelectric film includes domains constituted of a tetragonal crystal and including an a-domain which is formed by a crystal having a (100) plane parallel to the film surface of the piezoelectric film, the a-domains include an A-domain having a normal axis of (001) plane substantially parallel to a principal bending direction of the piezoelectric film and a B-domain having a normal axis of (001) plane substantially perpendicular to the principal bending direction of the piezoelectric film, and the A-domains have a volume proportion larger than 50 vol % with respect to the sum of the volume of the A-domains and the volume of the B-domains.

Owner:CANON KK

Three-piece solid golf ball

InactiveUS20050181891A1Adequate spin performanceGood flying performanceGolf ballsSolid ballsThermoplastic polyurethaneHardness

A three-piece solid golf ball having a solid core, an intermediate layer enclosing the solid core, and a cover layer enclosing the intermediate layer and having a large number of dimples formed in its surface, characterized in that the core deforms as much as 3.4 to 4.1 mm under a load which changes from 10 kg to 130 kg, the intermediate layer has a surface hardness of 64 to 69 in terms of Shore D hardness, the cover layer is formed mainly from thermoplastic polyurethane such that it has a lower hardness than the intermediate layer, with the difference in hardness between the cover layer and the intermediate layer being 10 to 16 in terms of Shore D hardness, the intermediate layer and the cover layer have a total thickness of 2.2 to 3.0 mm, the cover layer has a thickness of 0.8 to 1.3 mm, and the dimples have at least four different diameters and / or depths, with the average depth being 0.14 to 0.17 mm, and amount to 250 to 390 in all. The three-piece solid golf ball exhibits adequate spin performance by iron shot and approach shot. It also exhibits good flying performance and durability.

Owner:BRIDGESTONE SPORTS

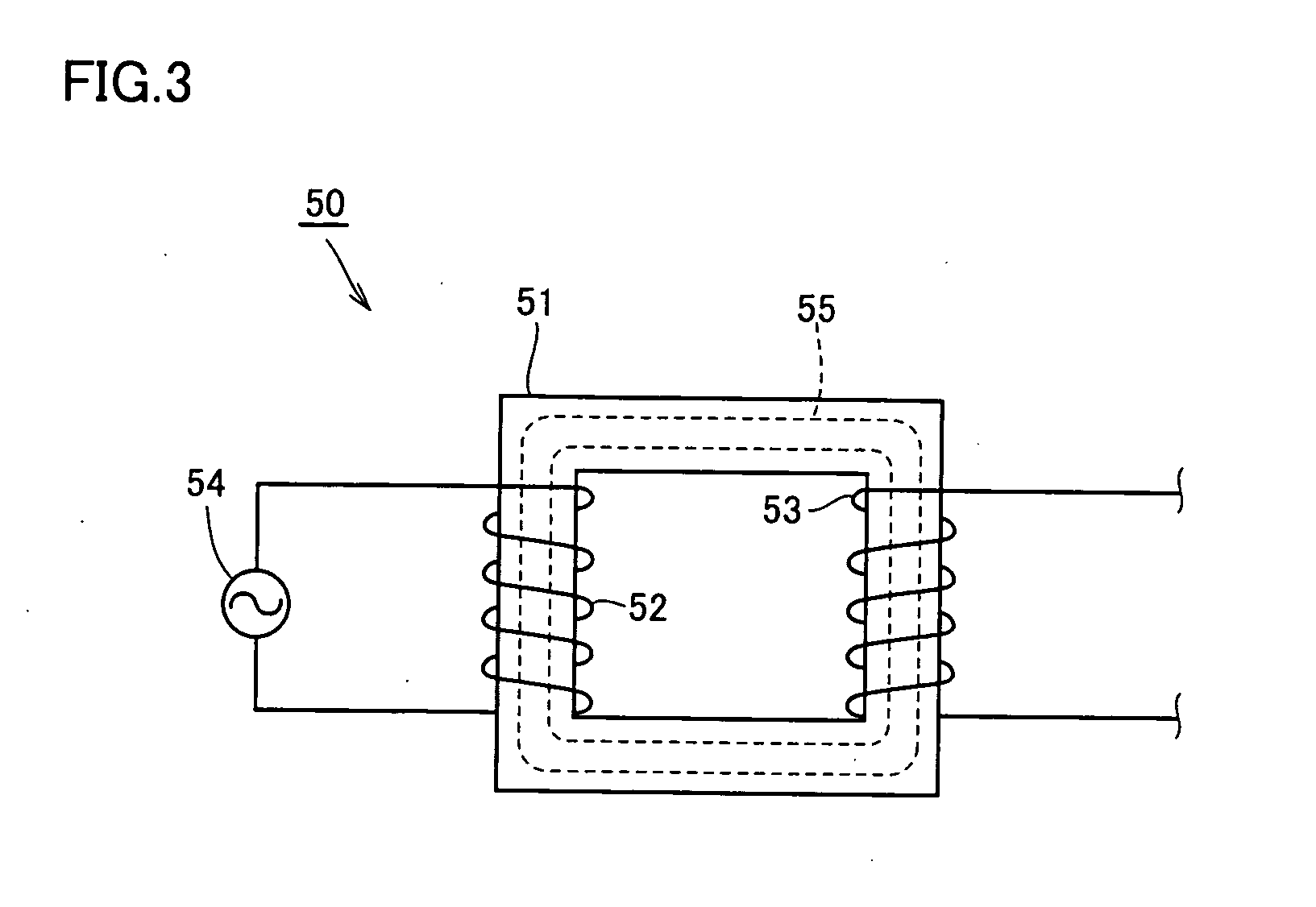

Soft magnetic material, motor core, transformer core, and method for manufacturing soft magnetic material

InactiveUS20110104476A1High resistivityIncreased durabilitySynthetic resin layered productsMetal-working apparatusTransformerOrganic matter

A soft magnetic material includes a composite magnetic particle and an organic substance. The composite magnetic particle has a metallic magnetic particle and a coating layer coating the metallic magnetic particle and containing an oxide therein. The organic substance is formed by adding at least one of a thermoplastic resin and a higher fatty acid having an effect of increasing resistivity of the material, to a non-thermoplastic resin having an effect of improving durability such as material fatigue limit. The organic substance is contained in the soft magnetic material by not less than 0.001% by mass and not more than 0.2% by mass. The present invention provides a soft magnetic material having high magnetic property and mechanical strength and also having fatigue property and resistivity satisfying durability enough for use as a motor core or the like, and a method for manufacturing the same. Further, the invention provides a motor core and a transformer core made of the soft magnetic material. A core loss can significantly be reduced in a motor core made of the soft magnetic material.

Owner:SHARP KK +1

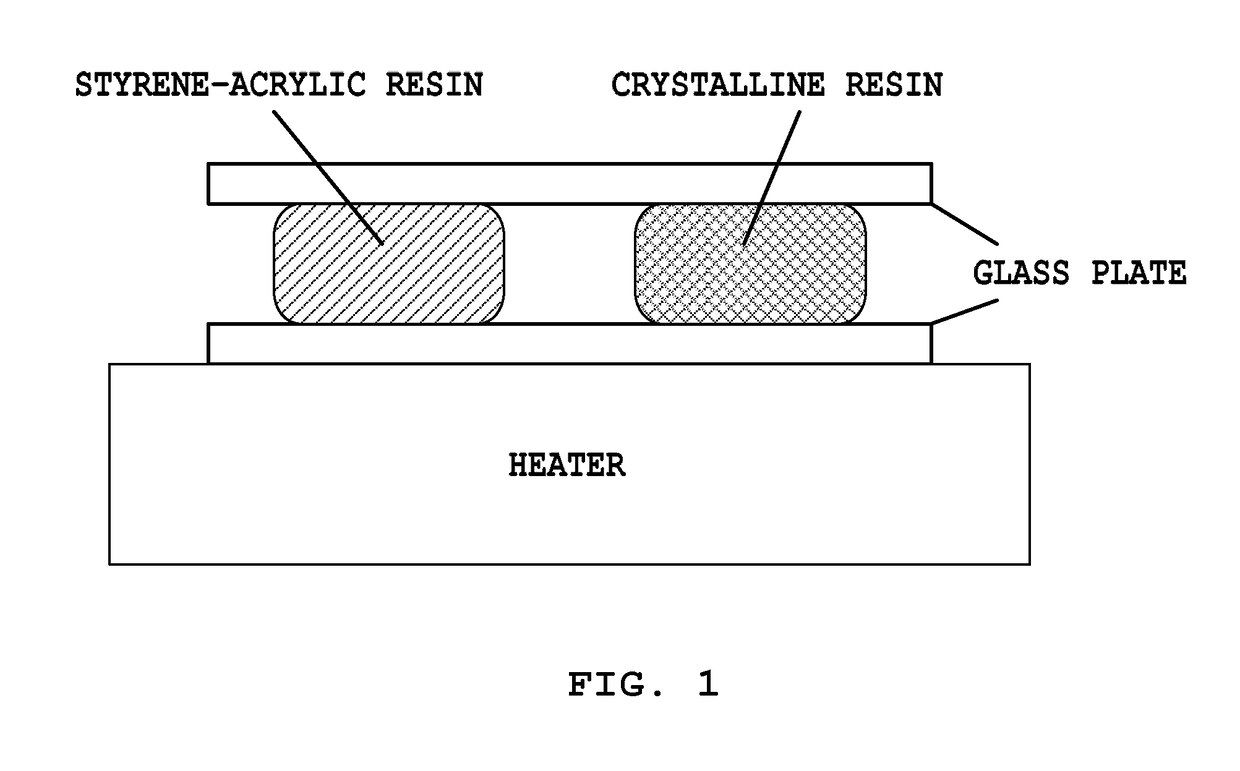

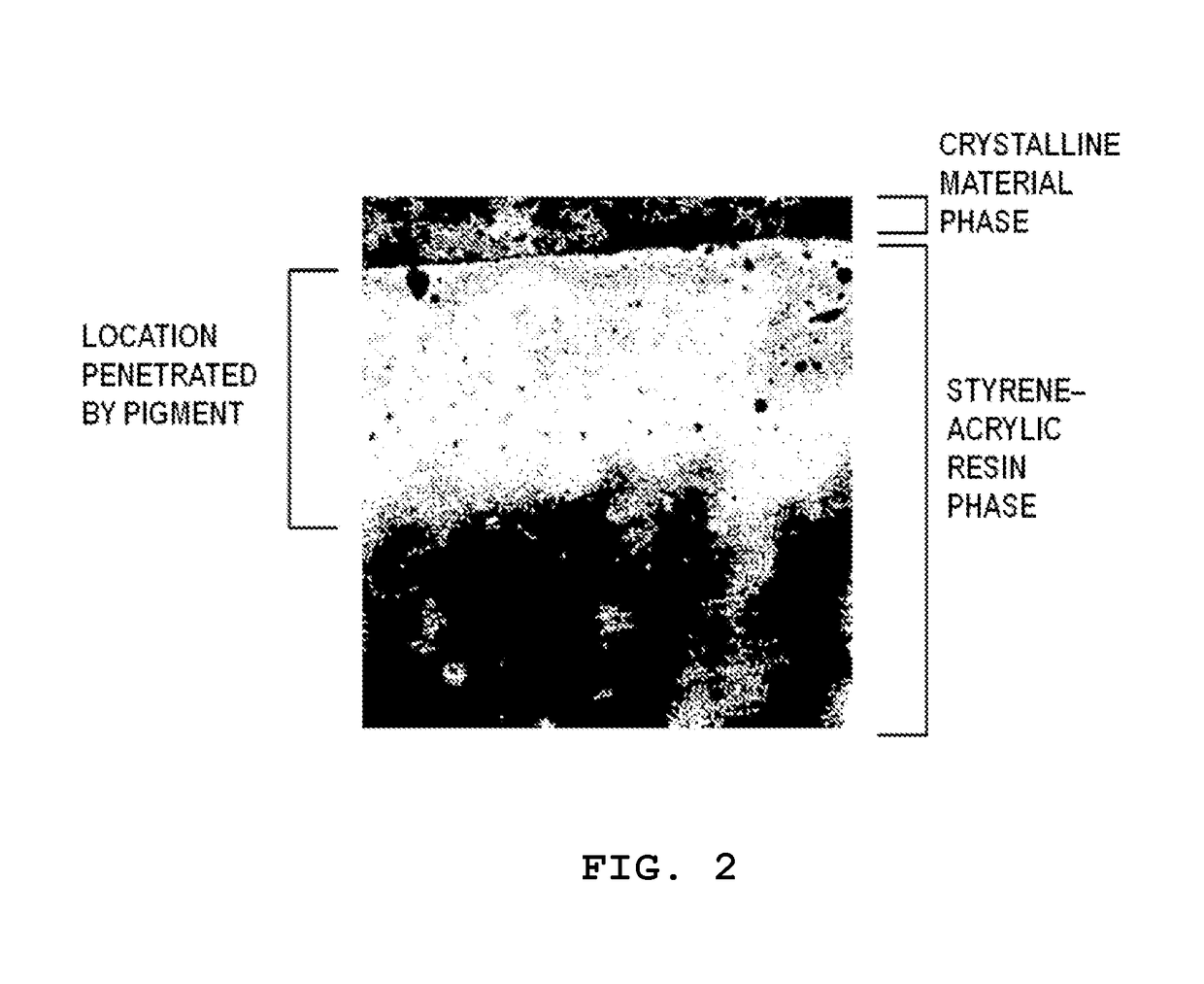

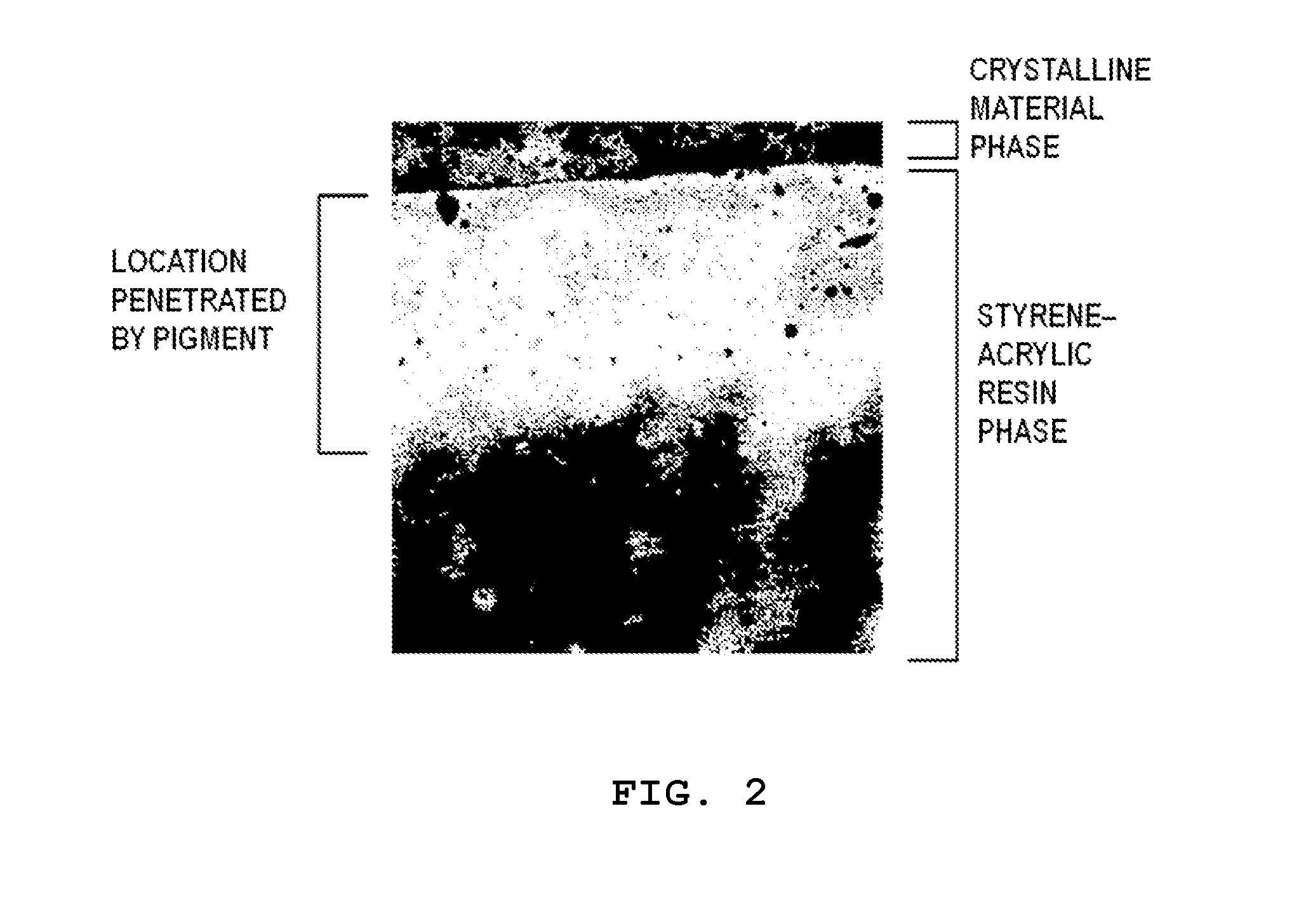

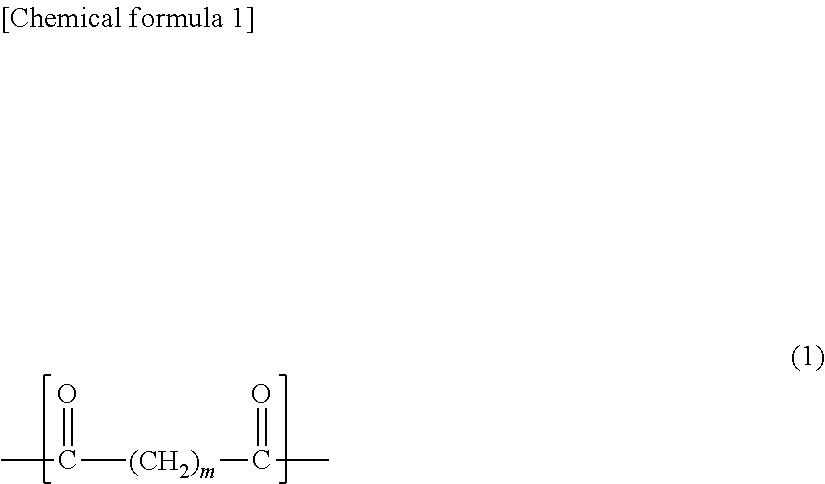

Toner

ActiveUS20150153669A1Excellent dispersibility of colorantSatisfactory heat-resistant storabilityDevelopersPolymer chemistryStyrene

The present invention provides a toner that exhibits an excellent colorant dispersibility and hence maintains the formation of a high-quality image, that is capable of low-temperature fixing, and that has a satisfactory heat-resistant storability and a satisfactory durability, in which the toner comprising a toner particle that contains a colorant and a binder resin containing a styrene-acrylic resin and a crystalline resin, wherein a compatibility parameter (V) between the styrene-acrylic resin and the crystalline resin satisfies 0.40≦V≦1.10.

Owner:CANON KK

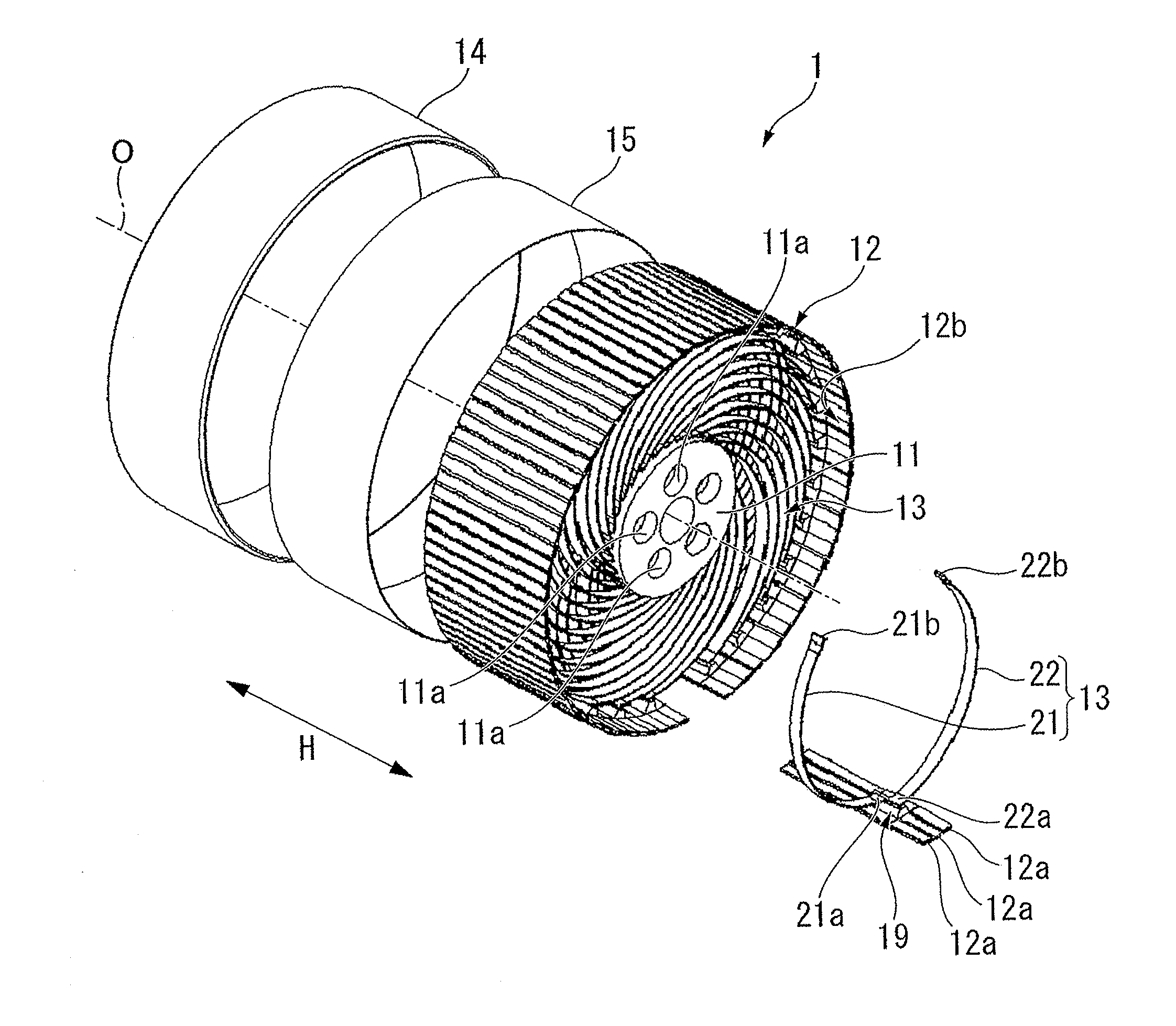

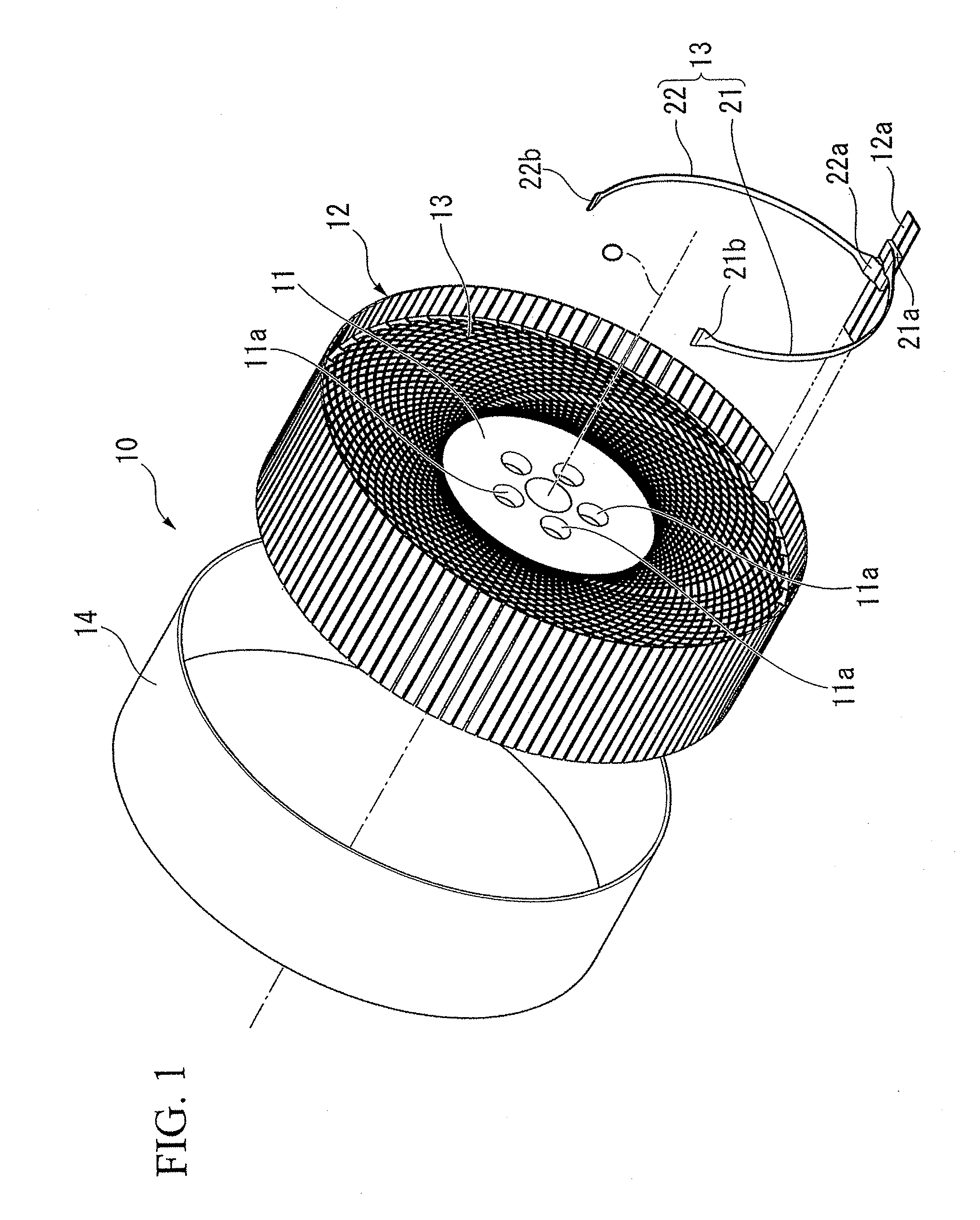

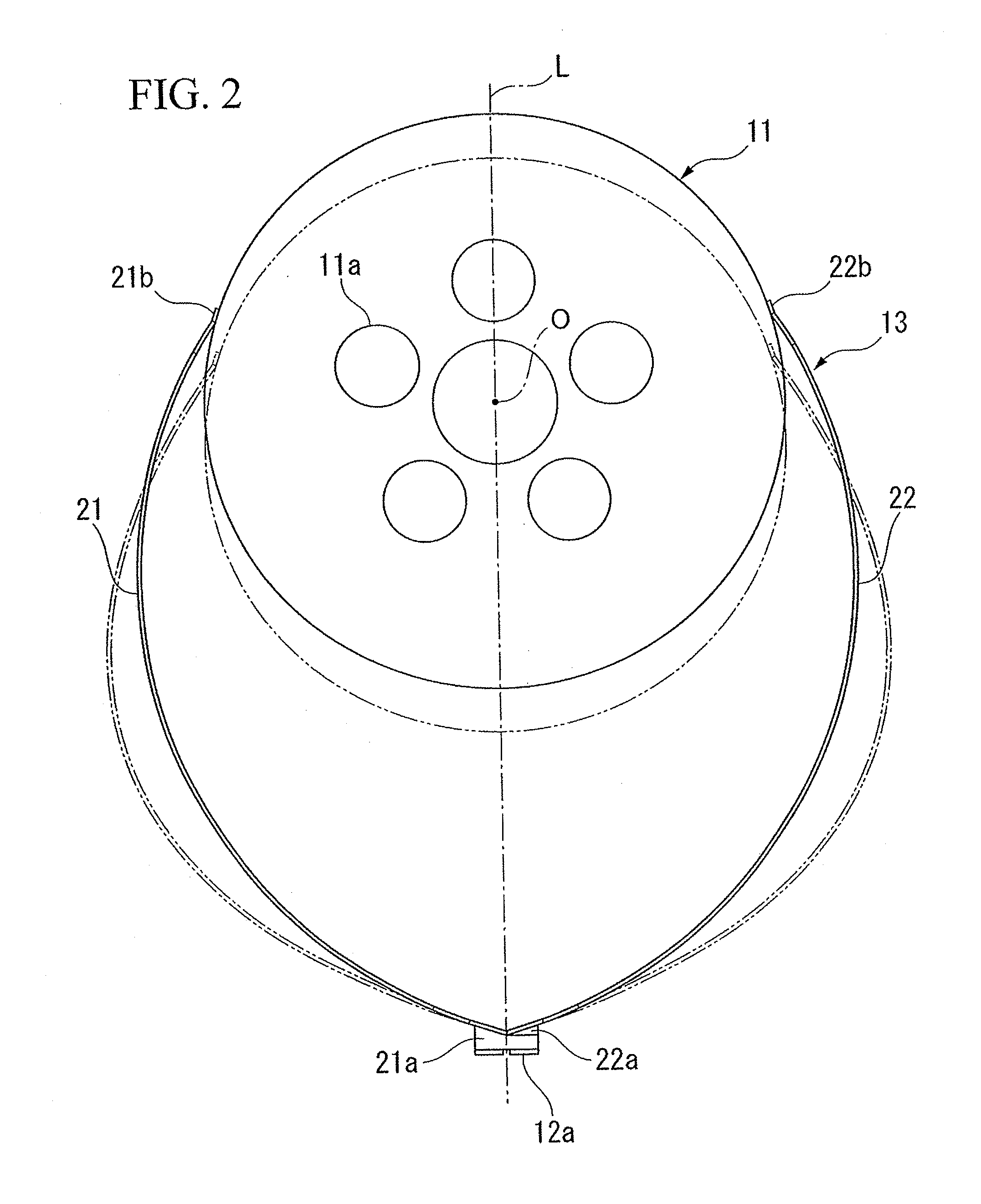

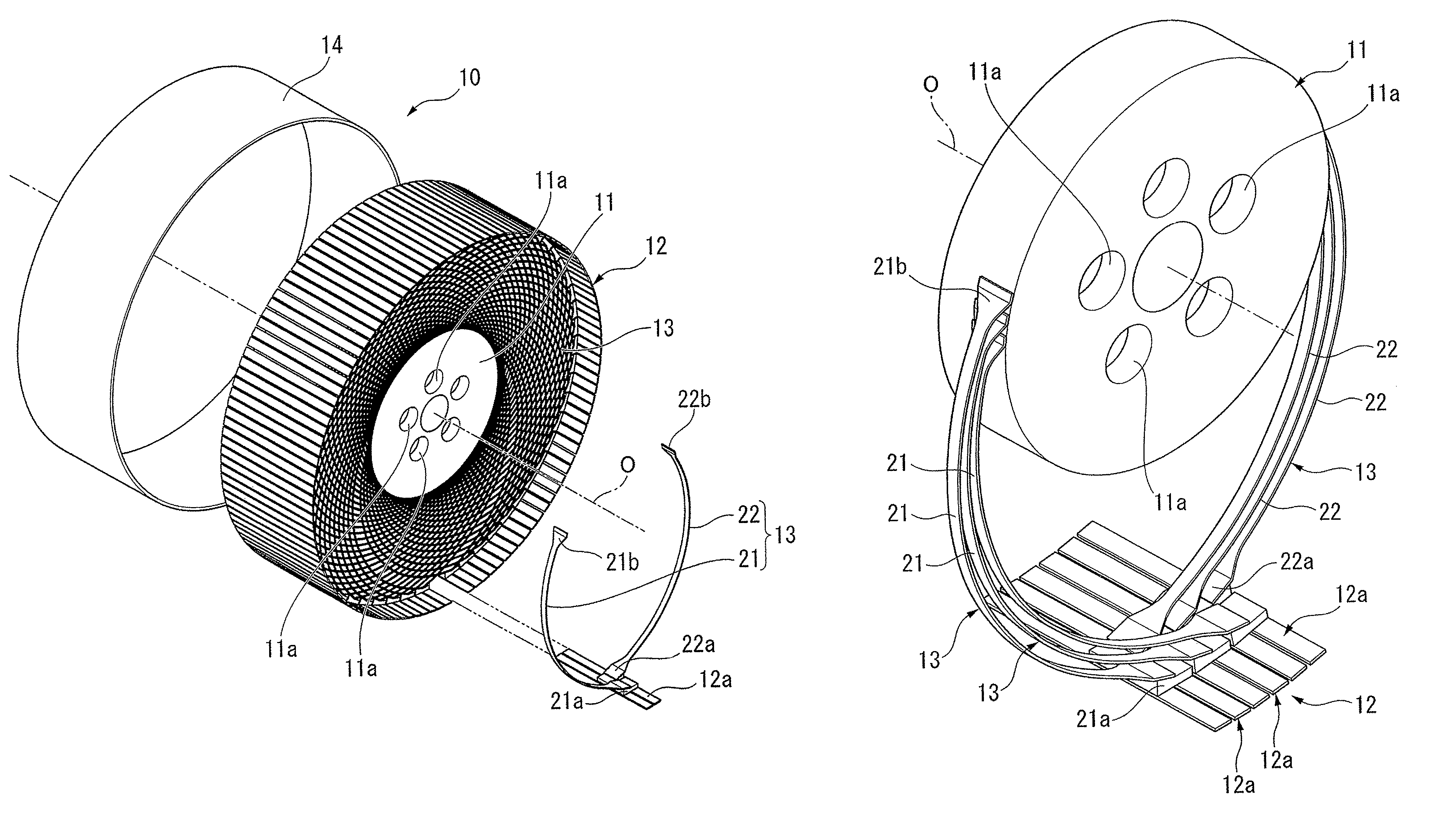

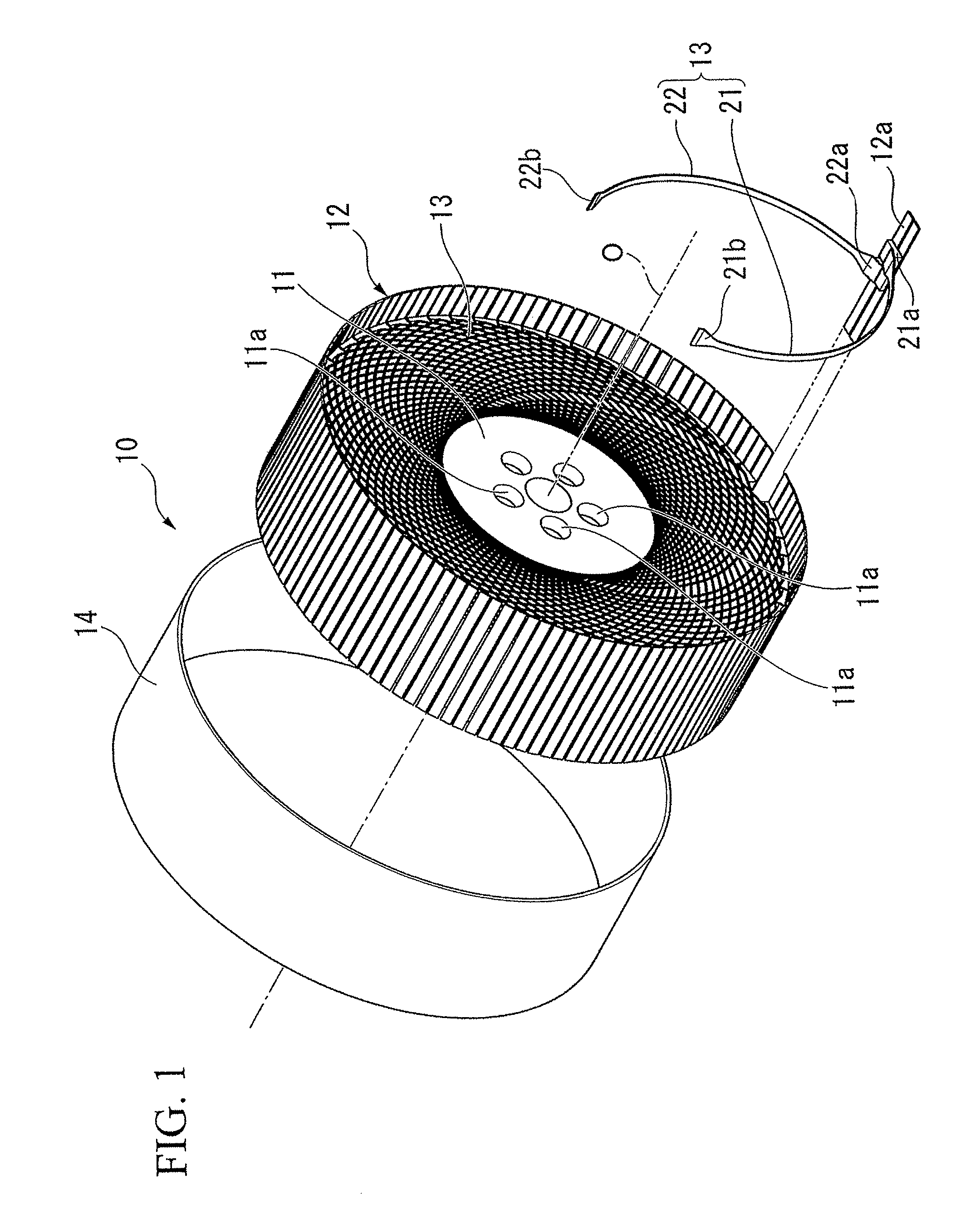

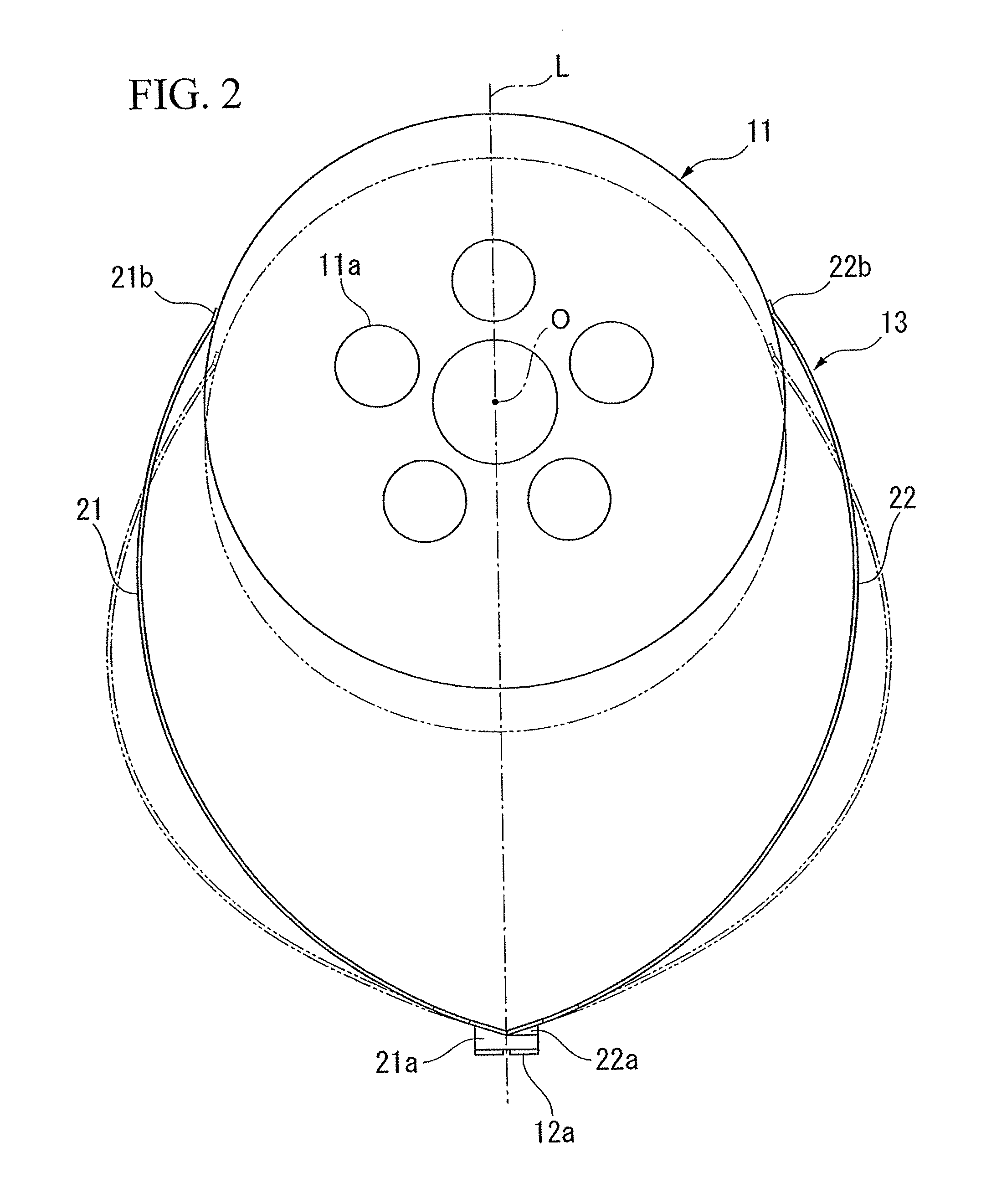

Non-pneumatic tire

ActiveUS20100218869A1Increase in hardnessSuppression of resistance riseNon-inflatable tyresHigh resiliency wheelsRolling resistanceHardness

A plurality of connection members 13 connecting an installation disk 11 to a ring-shaped body 12 are formed, in a side view of the non-pneumatic tire, to be axisymmetrical about an imaginary line connecting the respective first ends 21a and 22a of first connection plates 21 and second connection plates 22 to an axial line O and extending in a tire-radial direction. The connection members 13 are arranged in a tire-circumferential direction such that the first connection plates 21 are arranged at a first tire-widthwise position in the tire-circumferential direction and that the second connection plates 22 are arranged at a second tire-widthwise position in the tire-circumferential direction. According to the invention, it is possible to suppress an increase in the weight, hardness, and rolling resistance to secure satisfactory ride qualities and handling qualities, and it is possible to prevent a blowout from occurring.

Owner:BRIDGESTONE CORP

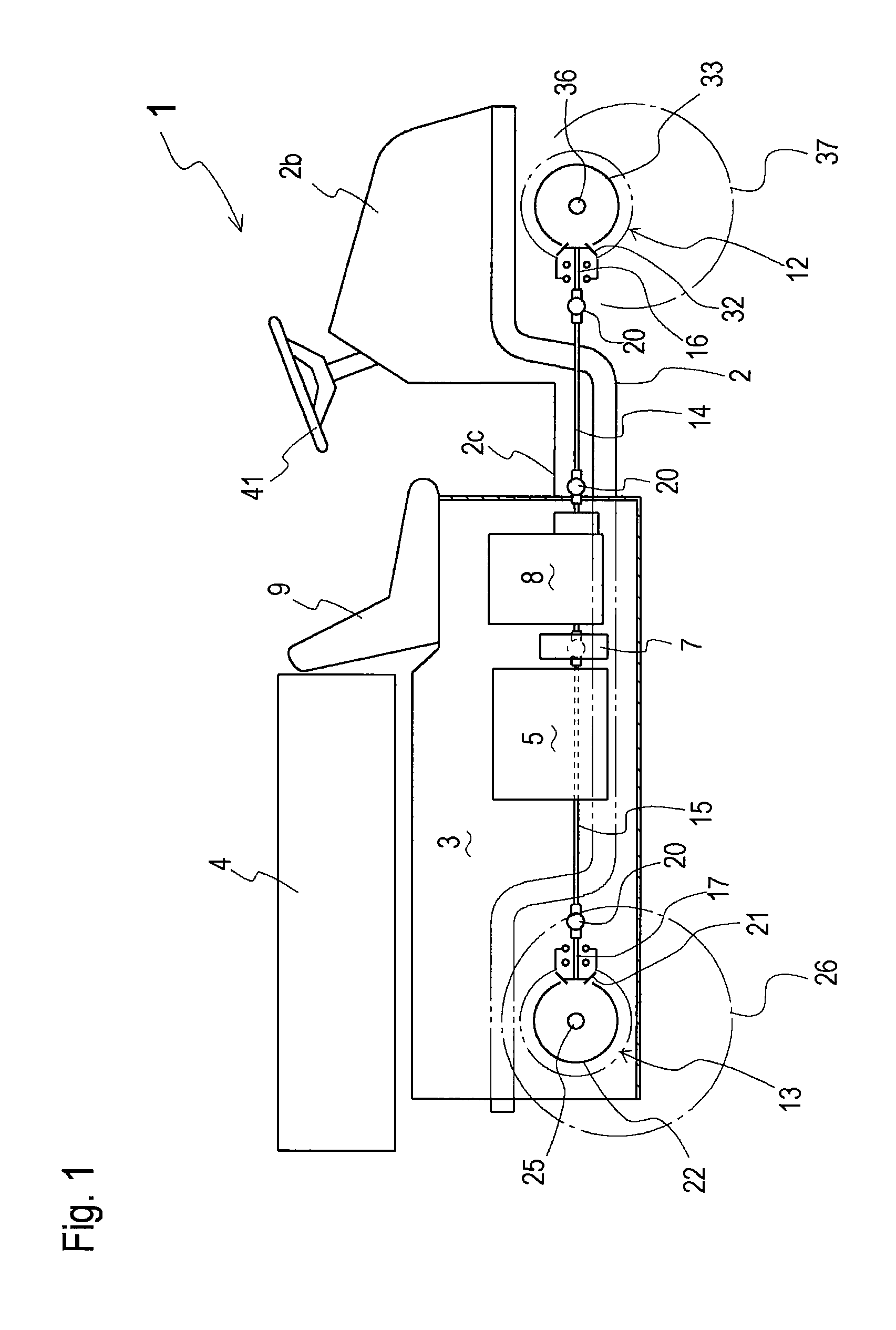

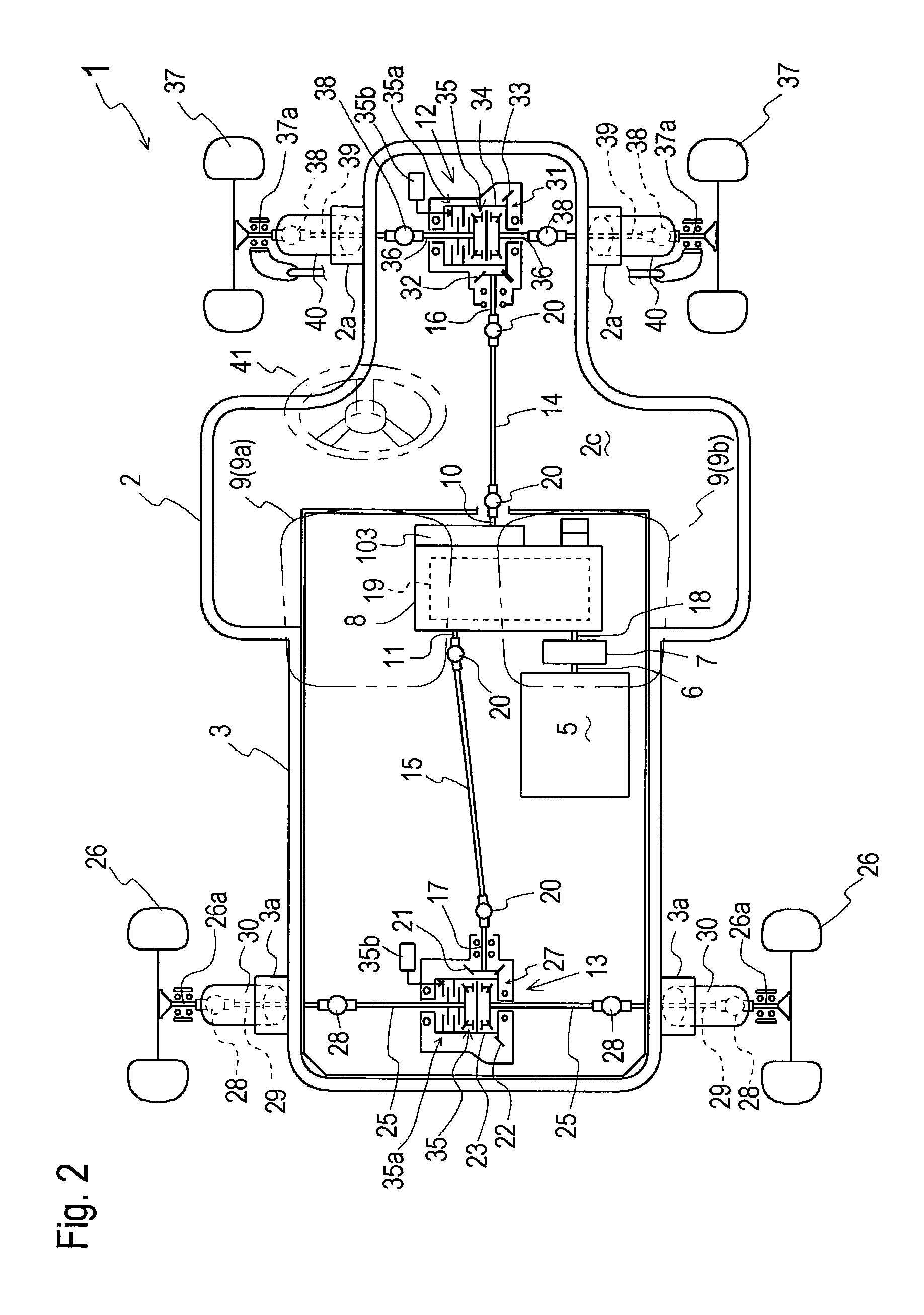

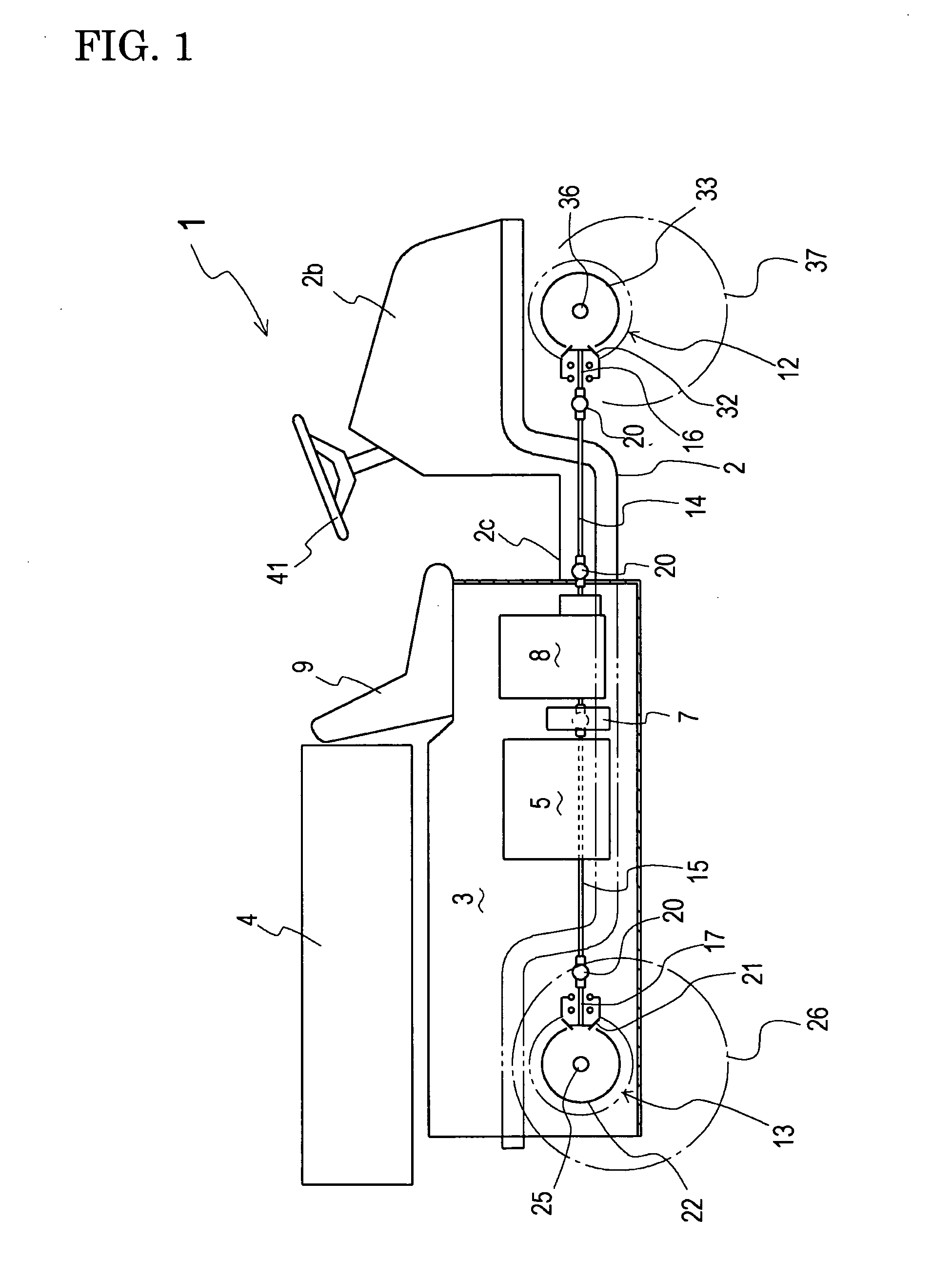

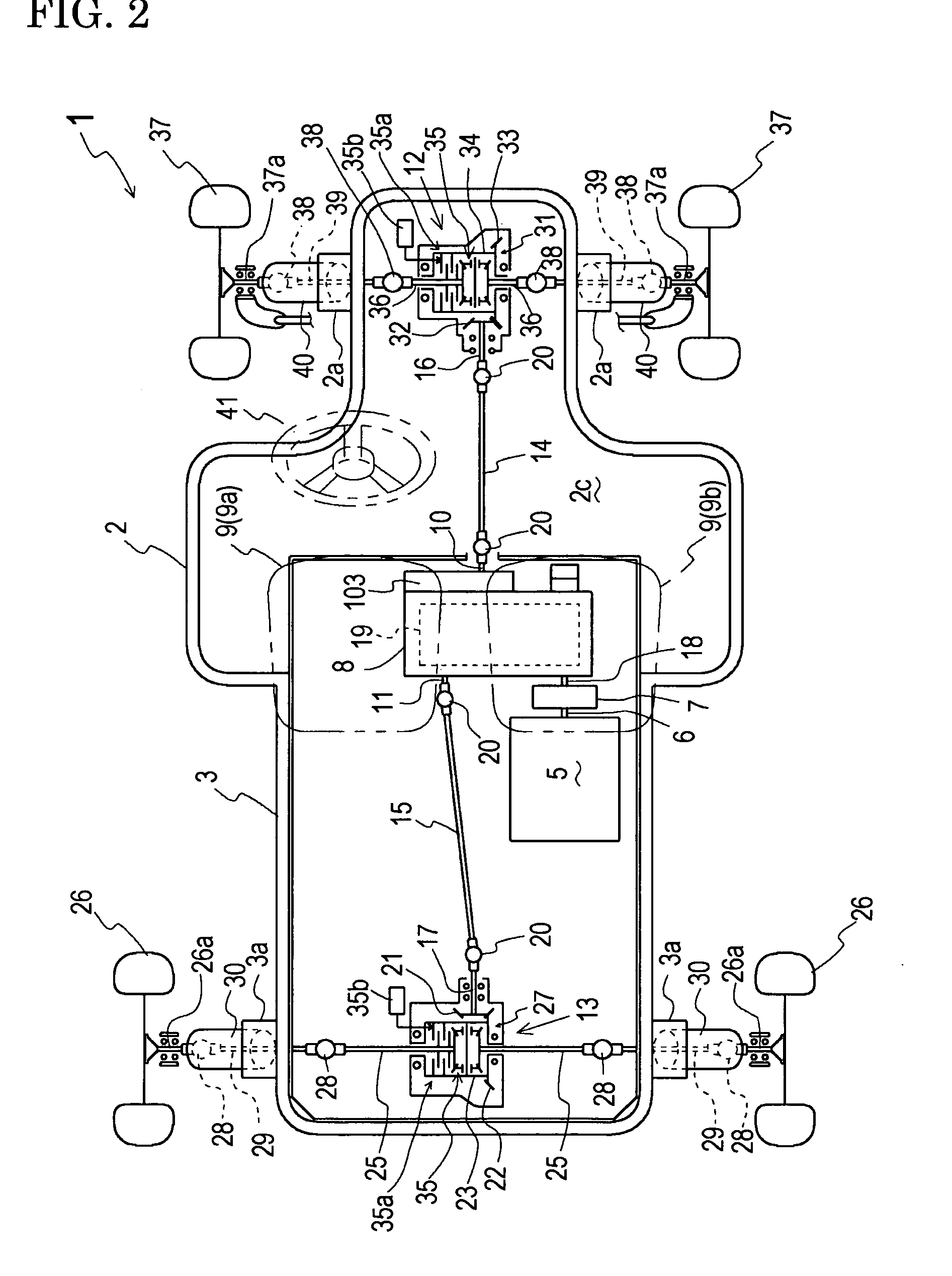

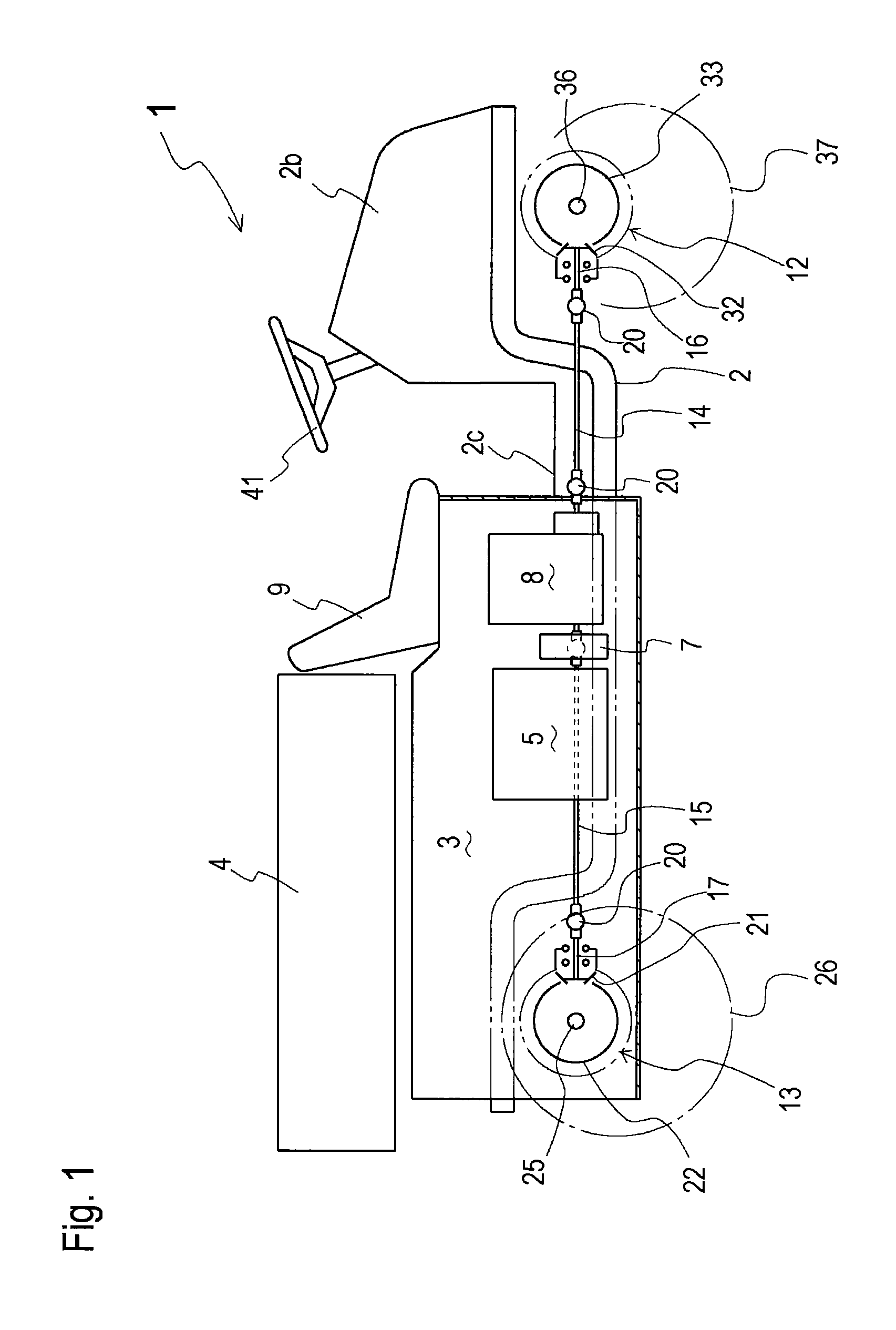

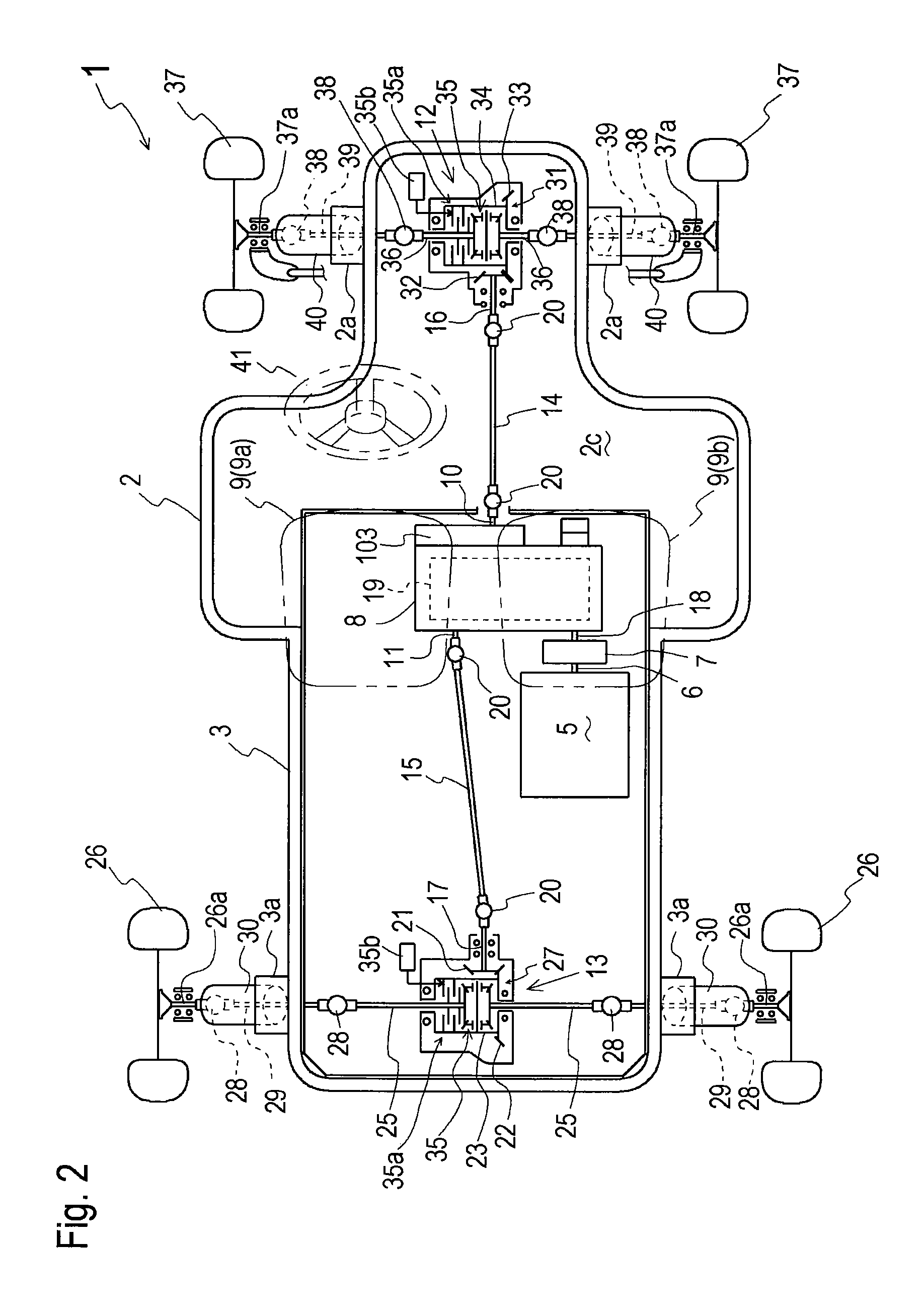

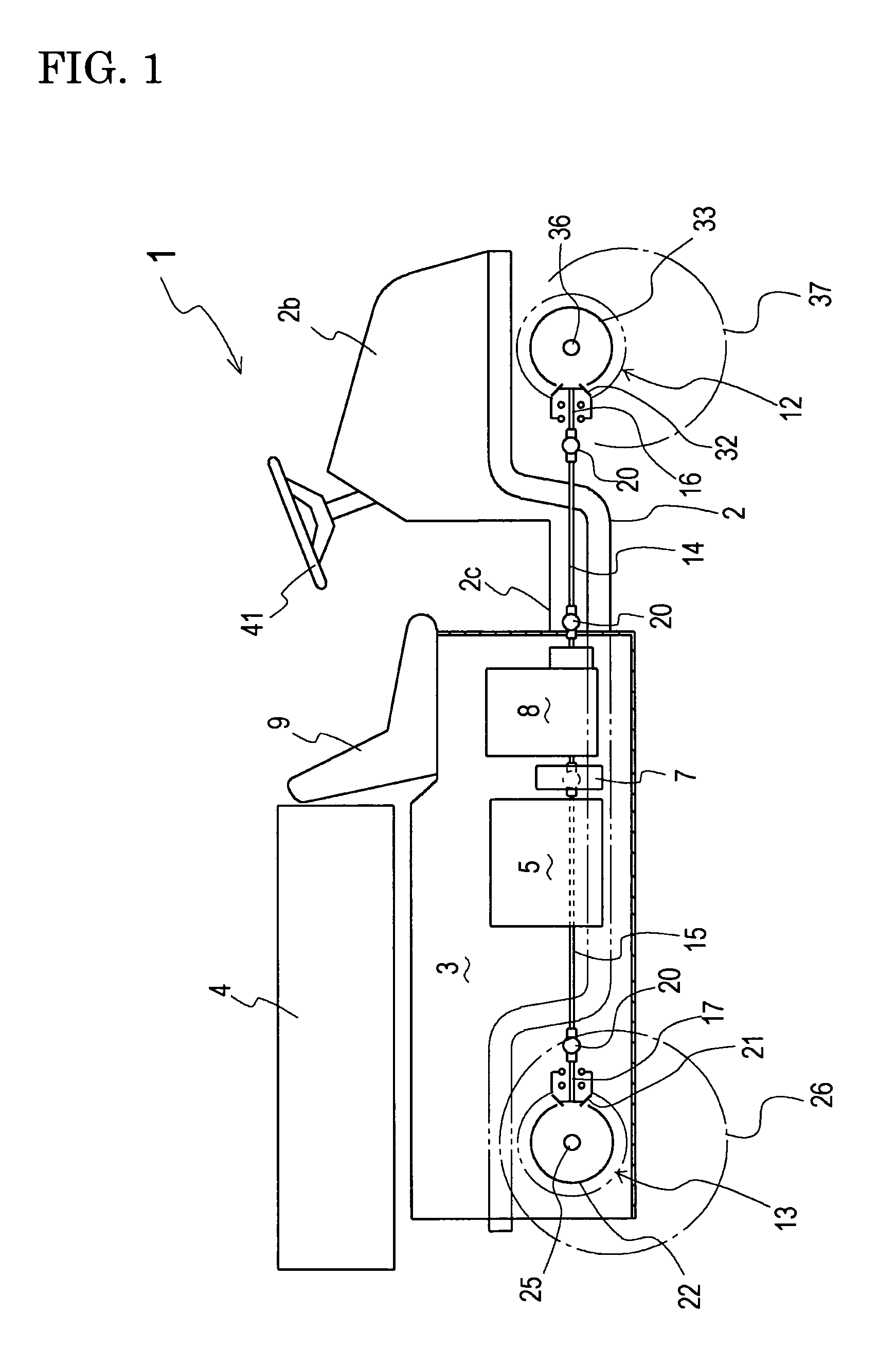

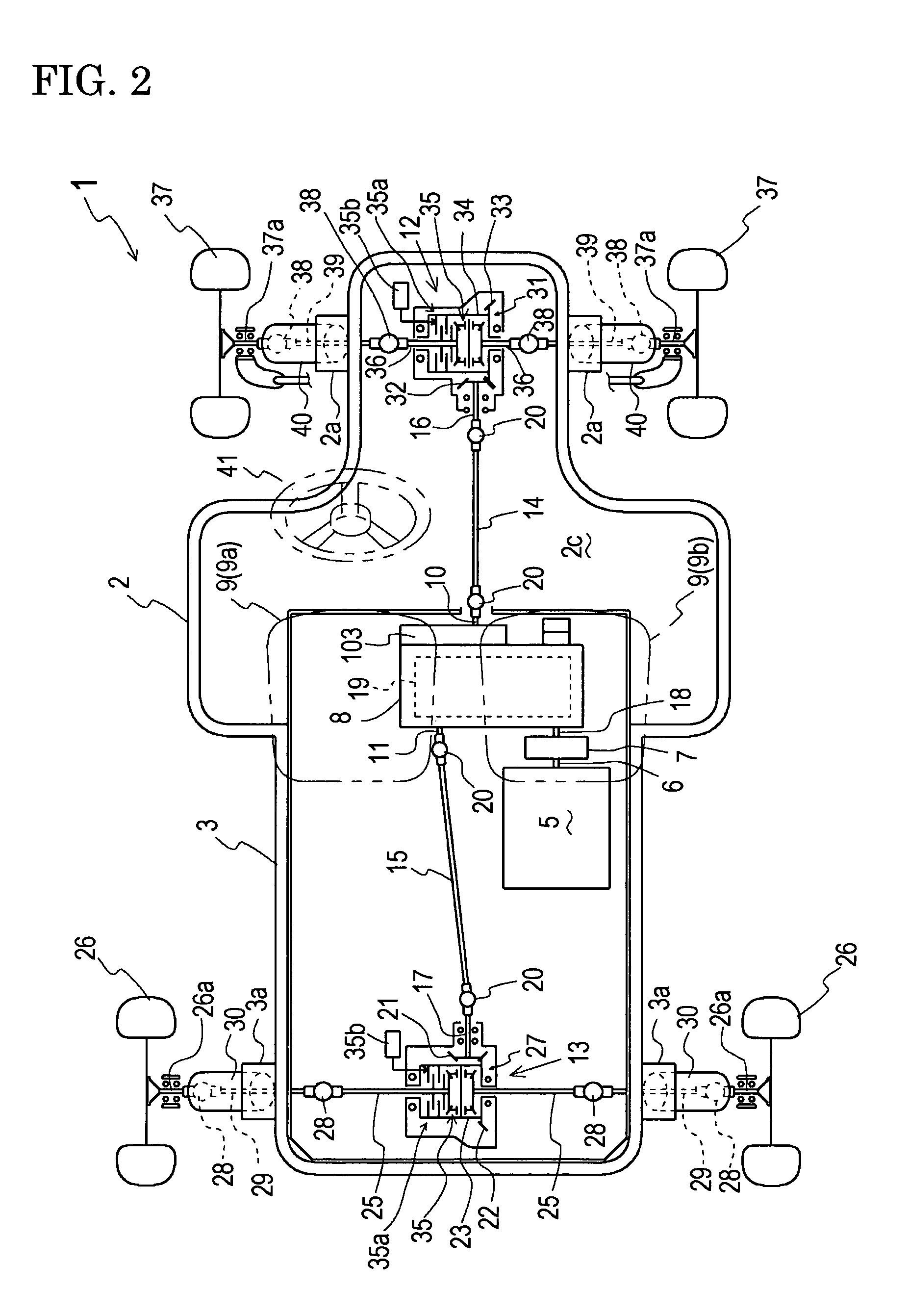

Vehicle

ActiveUS20070017309A1Increased rate is largeIncrease ratingsGear lubrication/coolingToothed gearingsTransmitted powerClutch

A vehicle has an engine, an accelerator for controlling the rotary speed of the engine, an axle and a multi-speed transmission for transmitting power from the engine to the axle. The multi-speed transmission includes an odd-numbered speed drive train for an odd-numbered speed level, a first clutch for the odd-numbered speed drive train, an even-numbered speed drive train for an even-numbered speed level, and a second clutch for the even-numbered speed drive train. In correspondence to operation of the accelerator and an actual speed of the axle, either the odd-numbered speed drive train or the even-numbered speed drive train is selected so as to transmit power from the engine to the axle. A shift-up or shift-down timing between the odd-numbered speed level and the even-numbered speed level relative to variation of the actual speed of the axle is changed according to detection of a tilt angle of the vehicle or a weight of the vehicle.

Owner:KANZAKI KOKYUKOKI MFG

Activation energy beam curable coating composition

InactiveUS6017974AExcellent antistatic property and abrasion resistanceExcellent in antistatic property and transparency and abrasion resistanceMixing methodsCoatingsCoated surfacePolymer science

An activation energy beam curable coating composition containing (A) a polymer having an organopolysiloxane unit and a quaternary ammonium salt unit and (B) a polyfunctional acrylate having 3 or more acryloyl groups in the molecule is disclosed. A film excellent in abrasion resistance, antistatic properties and transparency can be formed by applying the activation energy beam curable coating composition of the present invention to the surface of a material, and irradiating the coated surface with an activation energy beam.

Owner:MITSUBISHI CHEM CORP

Vehicle transmission system

ActiveUS8050827B2Satisfactory durabilityEfficient actionDigital data processing detailsToothed gearingsTransmitted powerTransmission system

A vehicle has an engine, an accelerator for controlling the rotary speed of the engine, an axle and a multi-speed transmission for transmitting power from the engine to the axle. The multi-speed transmission includes an odd-numbered speed drive train for an odd-numbered speed level, a first clutch for the odd-numbered speed drive train, an even-numbered speed drive train for an even-numbered speed level, and a second clutch for the even-numbered speed drive train. In correspondence to operation of the accelerator and an actual speed of the axle, either the odd-numbered speed drive train or the even-numbered speed drive train is selected so as to transmit power from the engine to the axle. A shift-up or shift-down timing between the odd-numbered speed level and the even-numbered speed level relative to variation of the actual speed of the axle is changed according to detection of a tilt angle of the vehicle or a weight of the vehicle.

Owner:KANZAKI KOKYUKOKI MFG

Vehicle

ActiveUS7601095B2Satisfactory durabilityEfficient actionToothed gearingsGear lubrication/coolingTransmitted powerClutch

A vehicle has an engine, an accelerator for controlling the rotary speed of the engine, an axle and a multi-speed transmission for transmitting power from the engine to the axle. The multi-speed transmission includes an odd-numbered speed drive train for an odd-numbered speed level, a first clutch for the odd-numbered speed drive train, an even-numbered speed drive train for an even-numbered speed level, and a second clutch for the even-numbered speed drive train. In correspondence to operation of the accelerator and an actual speed of the axle, either the odd-numbered speed drive train or the even-numbered speed drive train is selected so as to transmit power from the engine to the axle. A shift-up or shift-down timing between the odd-numbered speed level and the even-numbered speed level relative to variation of the actual speed of the axle is changed according to detection of a tilt angle of the vehicle or a weight of the vehicle.

Owner:KANZAKI KOKYUKOKI MFG

Integrally molded surface fastener, and continuous production method and continuous production device therefor

ActiveUS20060096072A1Improve bending strengthSecuring resistanceSnap fastenersClothes buttonsFastenerEngineering

In a molded surface fastener (10) having engaging elements (2) of minute dimension of thermoplastic resin molded together with a base member (1) by continuous molding, each engaging element (2) comprises first and second engaging portions (22a, 22b) each having a different configuration extending in parallel to a surface of the base member from a top end of a pillar portion (21) rising from the base member (1) such that they intersect at right angle. The second engaging head (22b) has an ordinary hook shape structure while the first engaging head (22a) has a wing-like thin plate structure as seen in a plan view. The engaging elements having such a structure in which each engaging element has appropriate engagement force, shearing force and separation force so as to keep an excellent tactile feeling of a surface of the surface fastener, prevents itself from falling down against a pressing force, secures a high engagement ratio with mating pile pieces and satisfies a durability.

Owner:YKK CORP

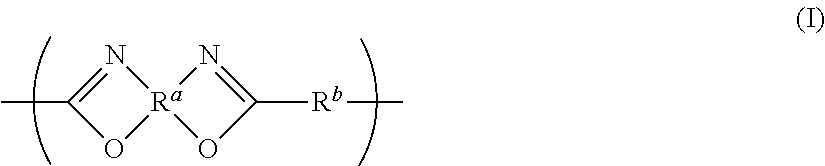

Organic compound, charge transport material and organic electroluminescent device

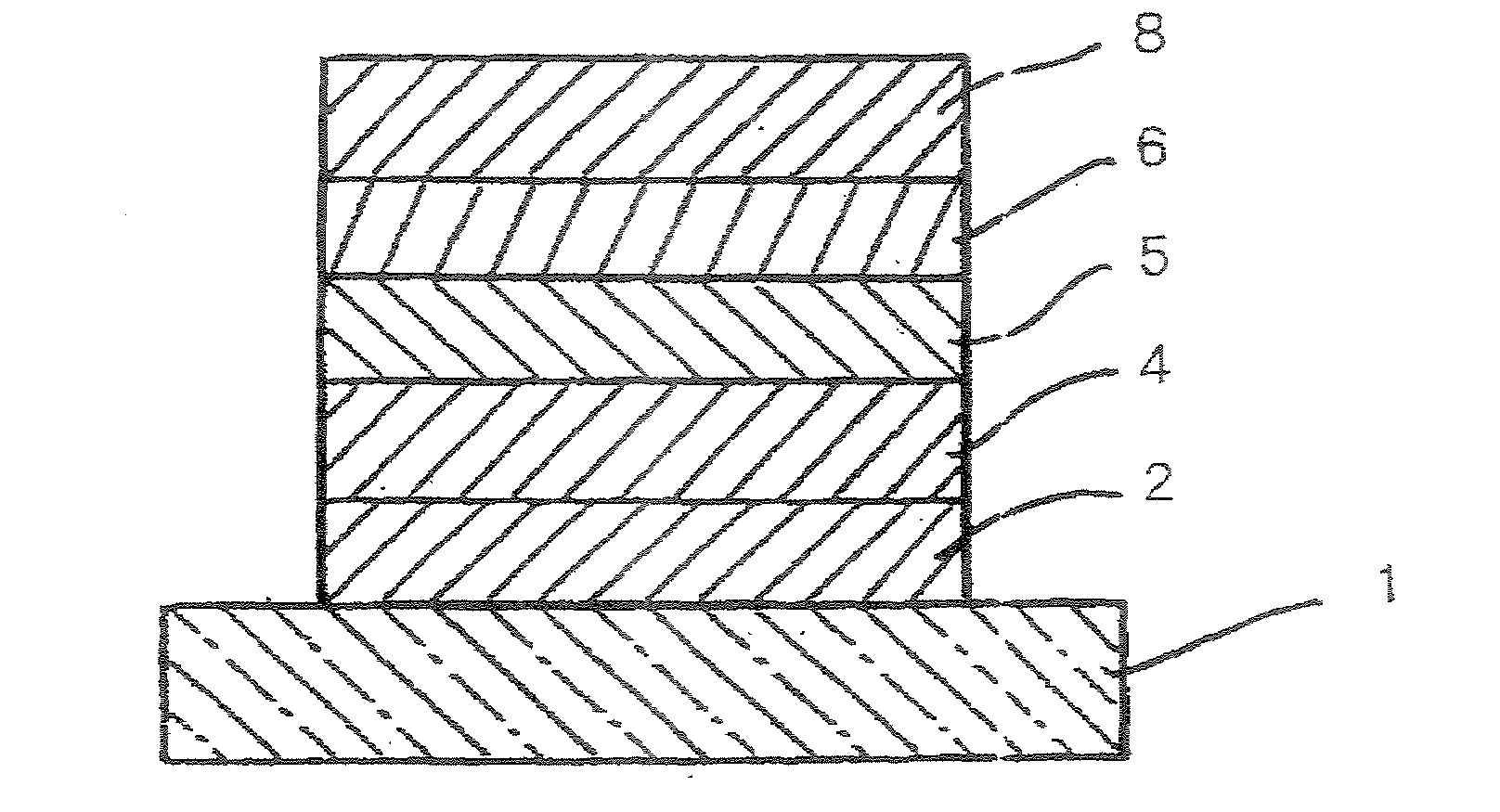

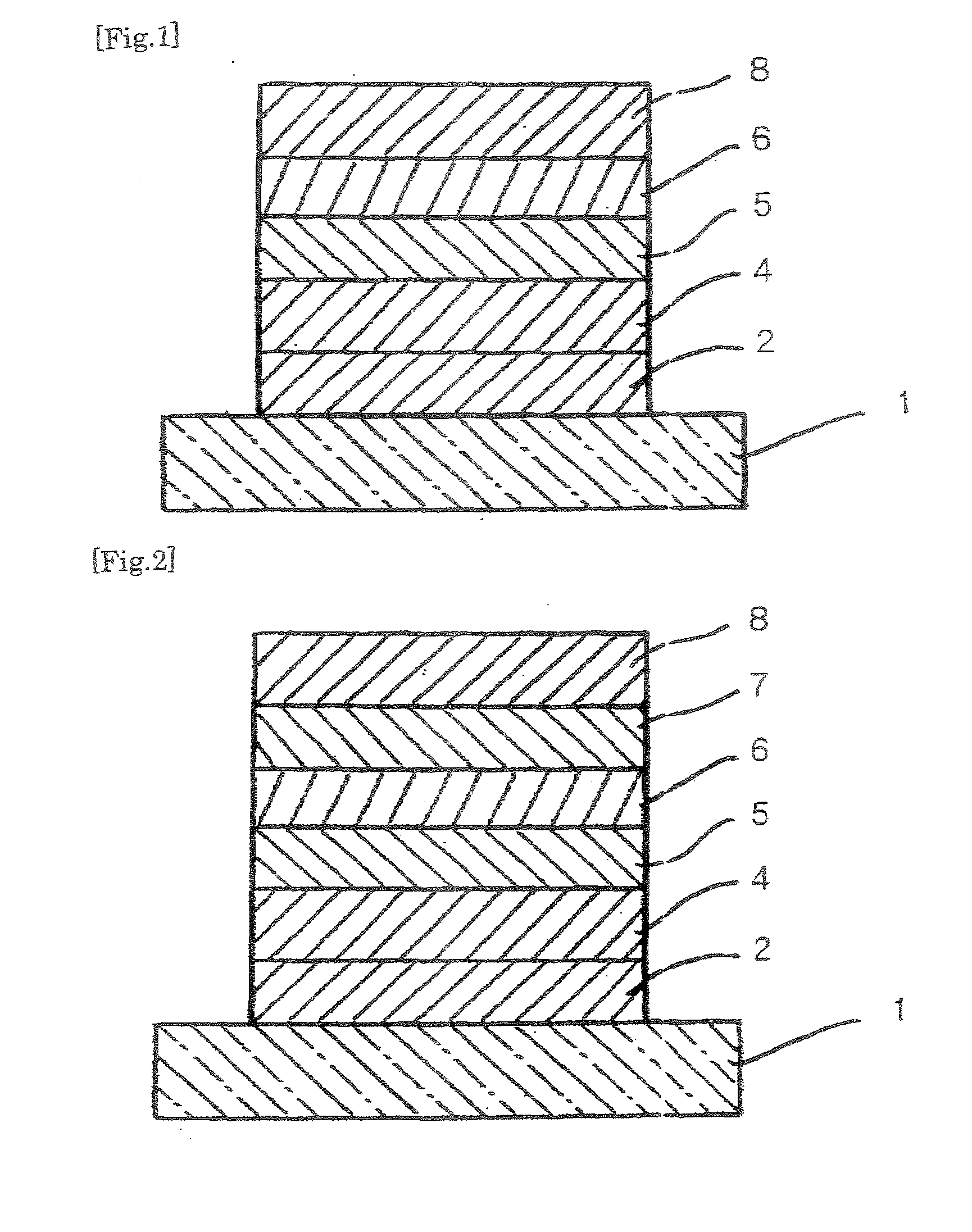

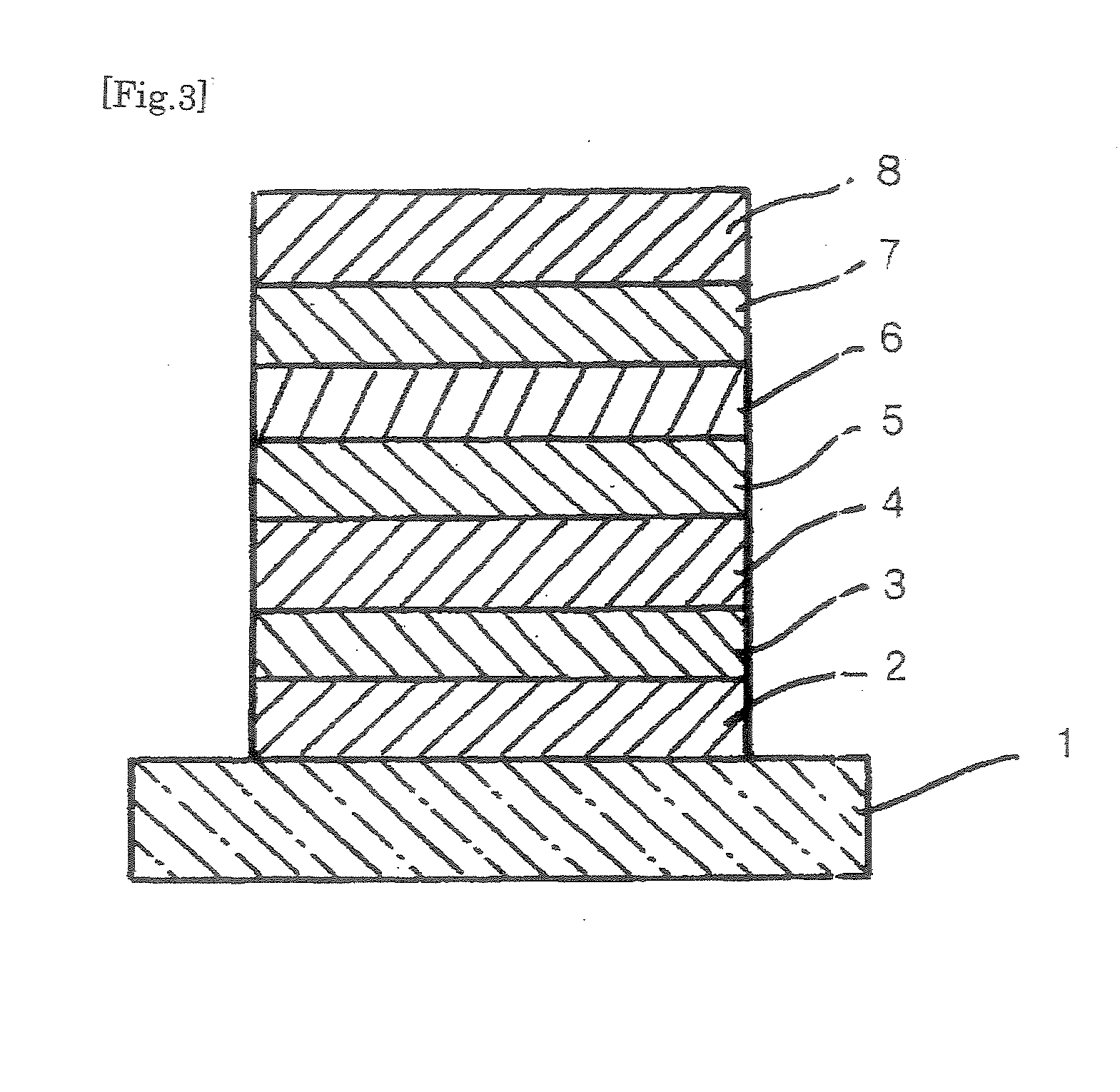

ActiveUS20090021146A1Good electron transport propertiesSatisfactory durabilityOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceOrganic compound

An organic compound is represented by following Formula (I):wherein Cz1 and Cz2 may be the same as or different from each other and each represent a carbazolyl group; Q1 and Q2 may be the same as or different from each other and each represent a direct bond or an arbitrary linkage group; and Cz1, Cz2, Q1, Q2, Ring B1 and Ring B2 may each be substituted. The organic compound and charge transporting material show both excellent hole transporting ability and excellent electron transporting ability and have satisfactory durability against electric oxidation / reduction and a high triplet excitation level. An organic electroluminescent device using the organic compound emits light with a high efficiency and is highly stably driven.

Owner:PIONEER CORP +1

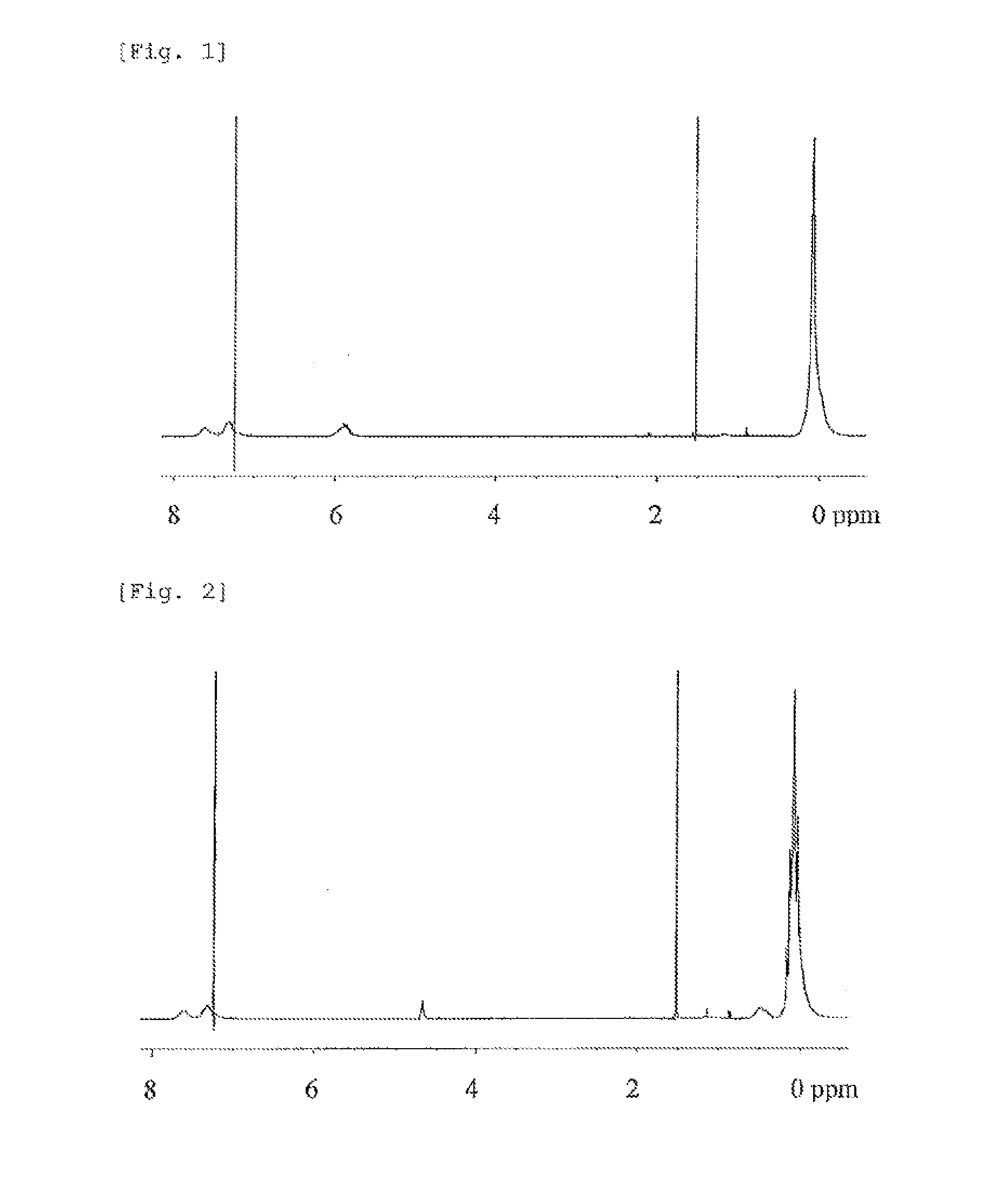

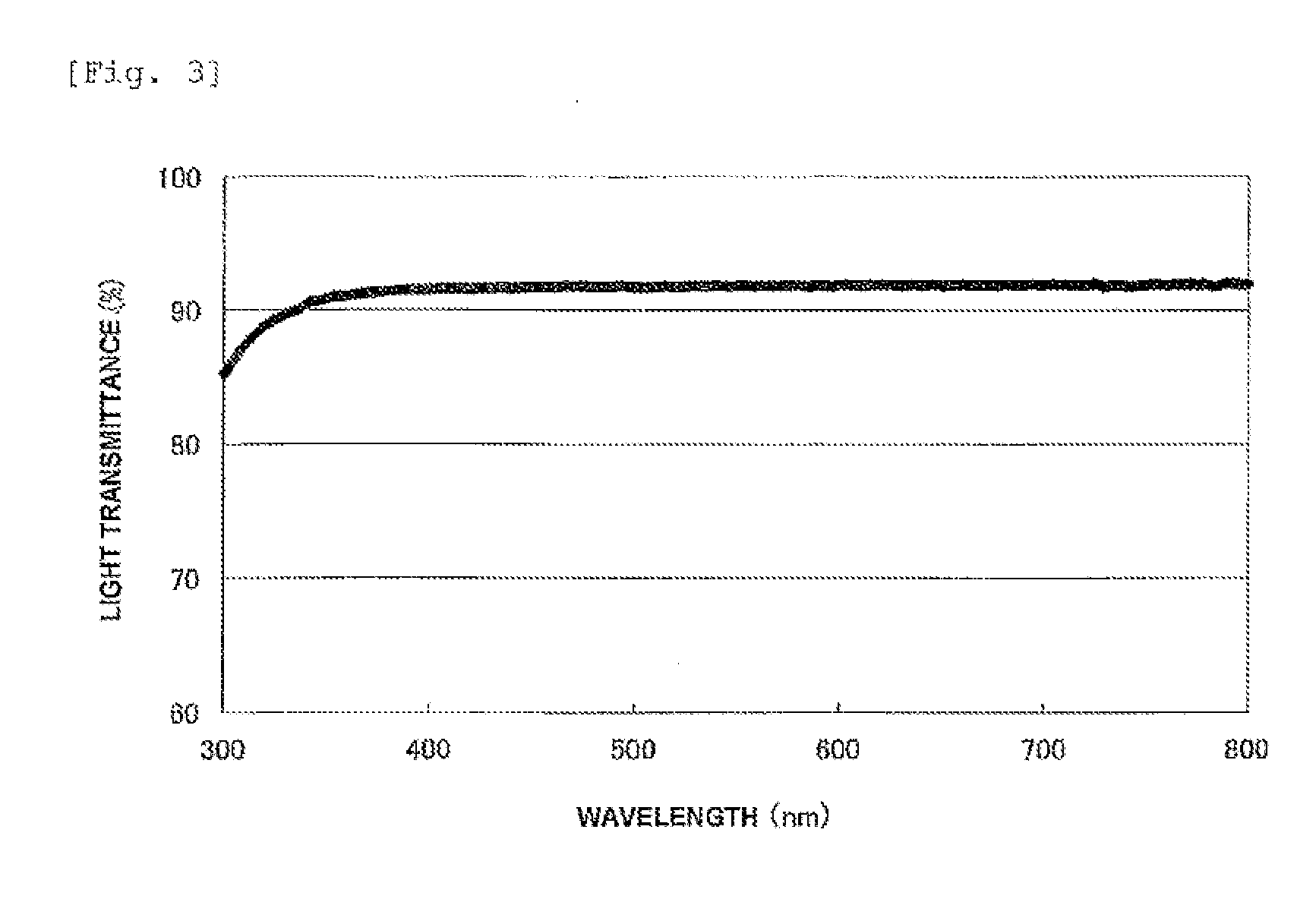

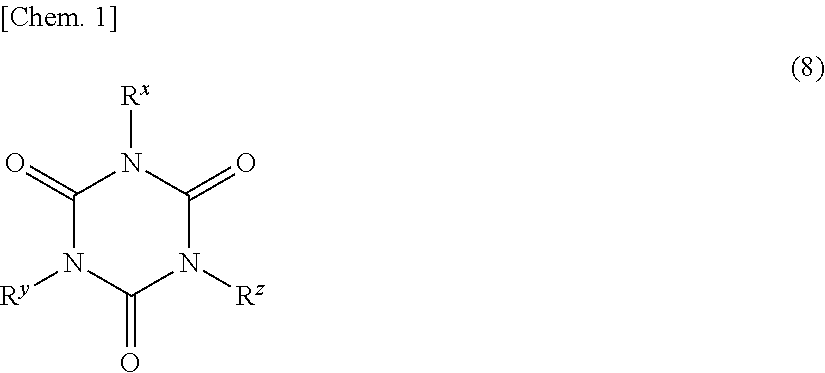

Curable resin composition and cured product thereof

ActiveUS20140332987A1Excellent heat resistance and transparency and flexibilityExcellent reflow resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceTriallyl isocyanurate

Provided is a curable resin composition capable of forming a cured product which has excellent heat resistance, transparency, and flexibility and particularly excels in reflow resistance and barrier properties to a corrosive gas. The curable resin composition includes a ladder-type polyorganosilsesquioxane and an isocyanurate compound such as a triglycidyl isocyanurate compound, a monoallyl diglycidyl isocyanurate compound, a diallyl monoglycidyl isocyanurate compound, or a triallyl isocyanurate compound.

Owner:DAICEL CHEM IND LTD

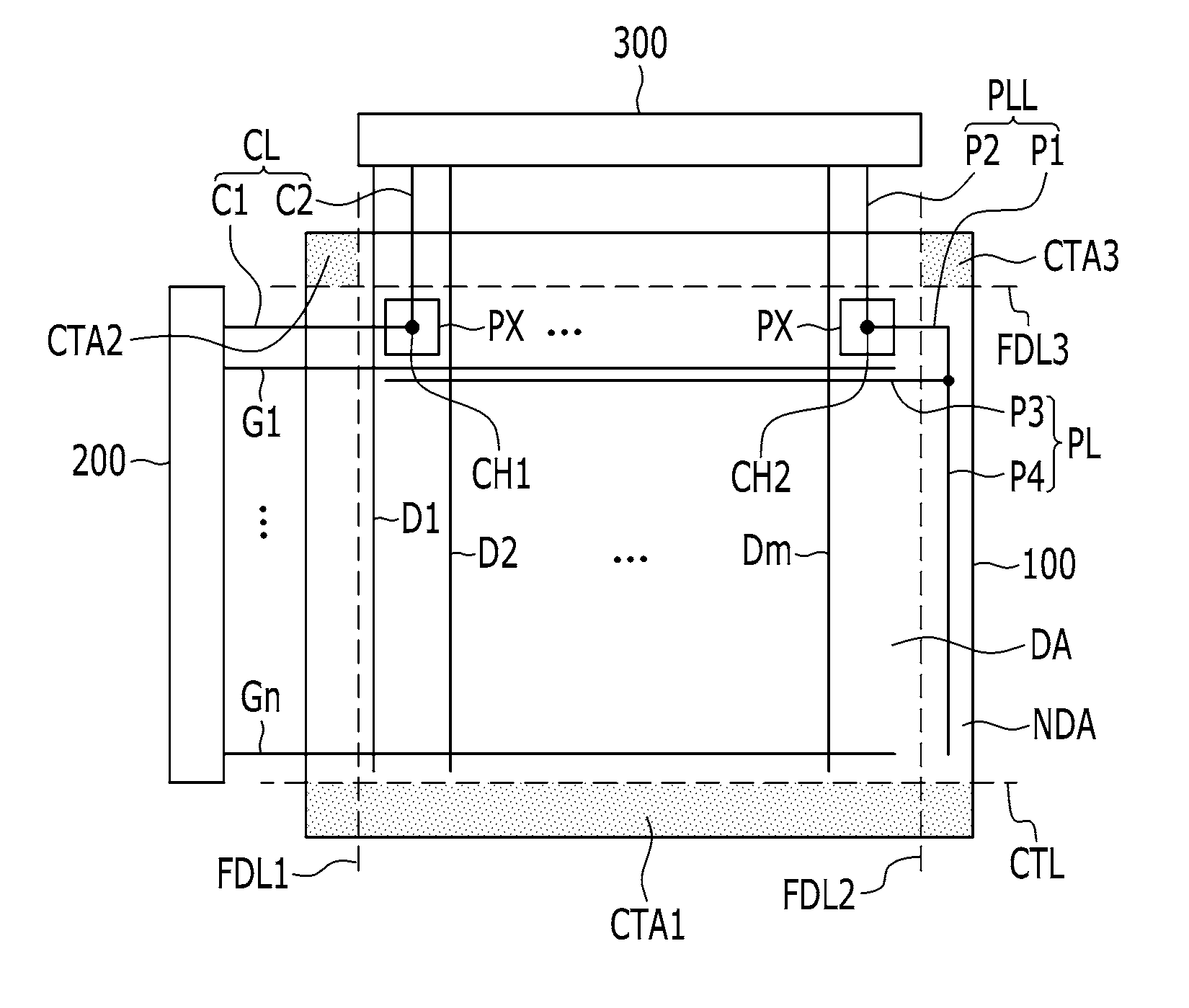

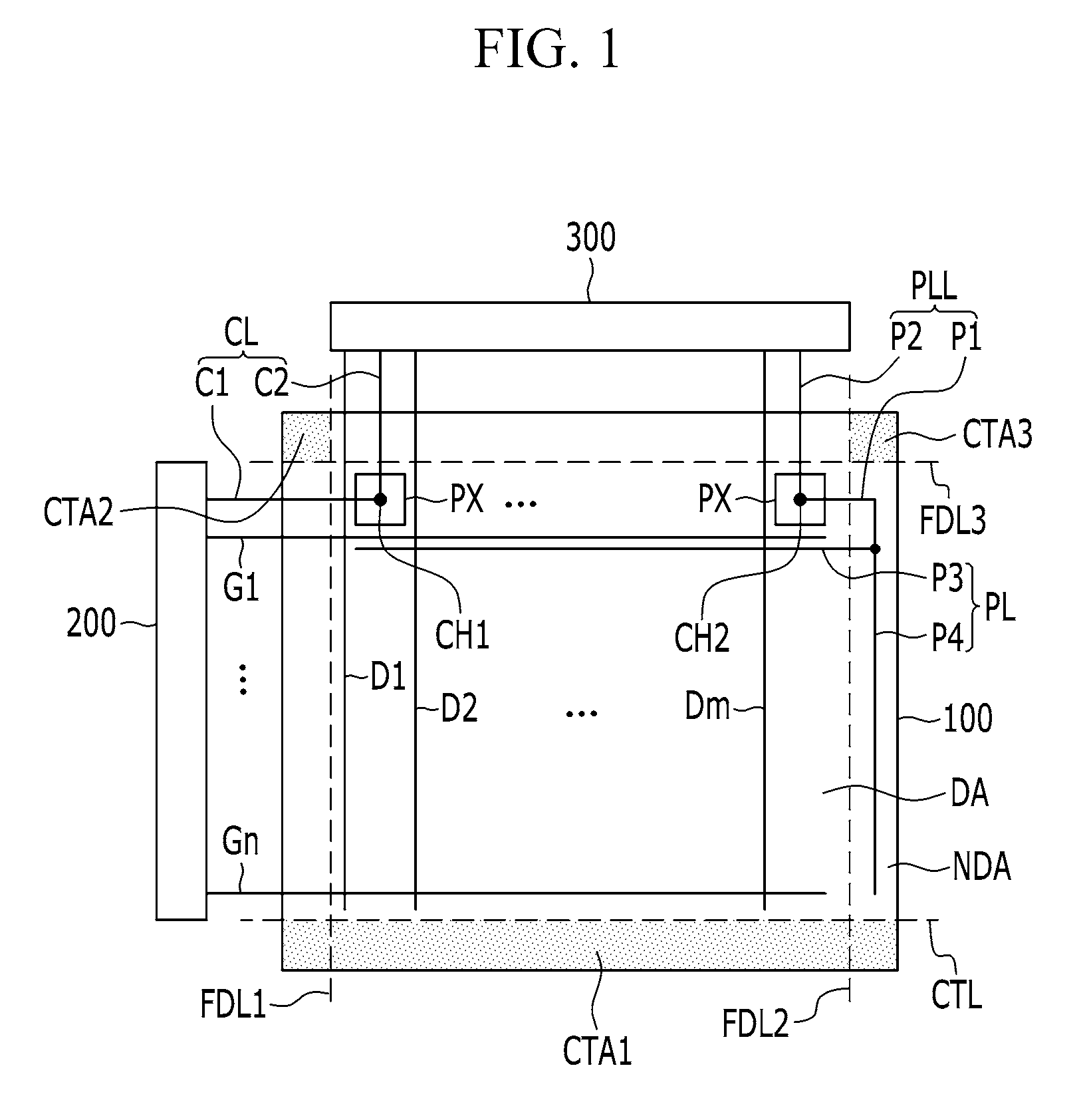

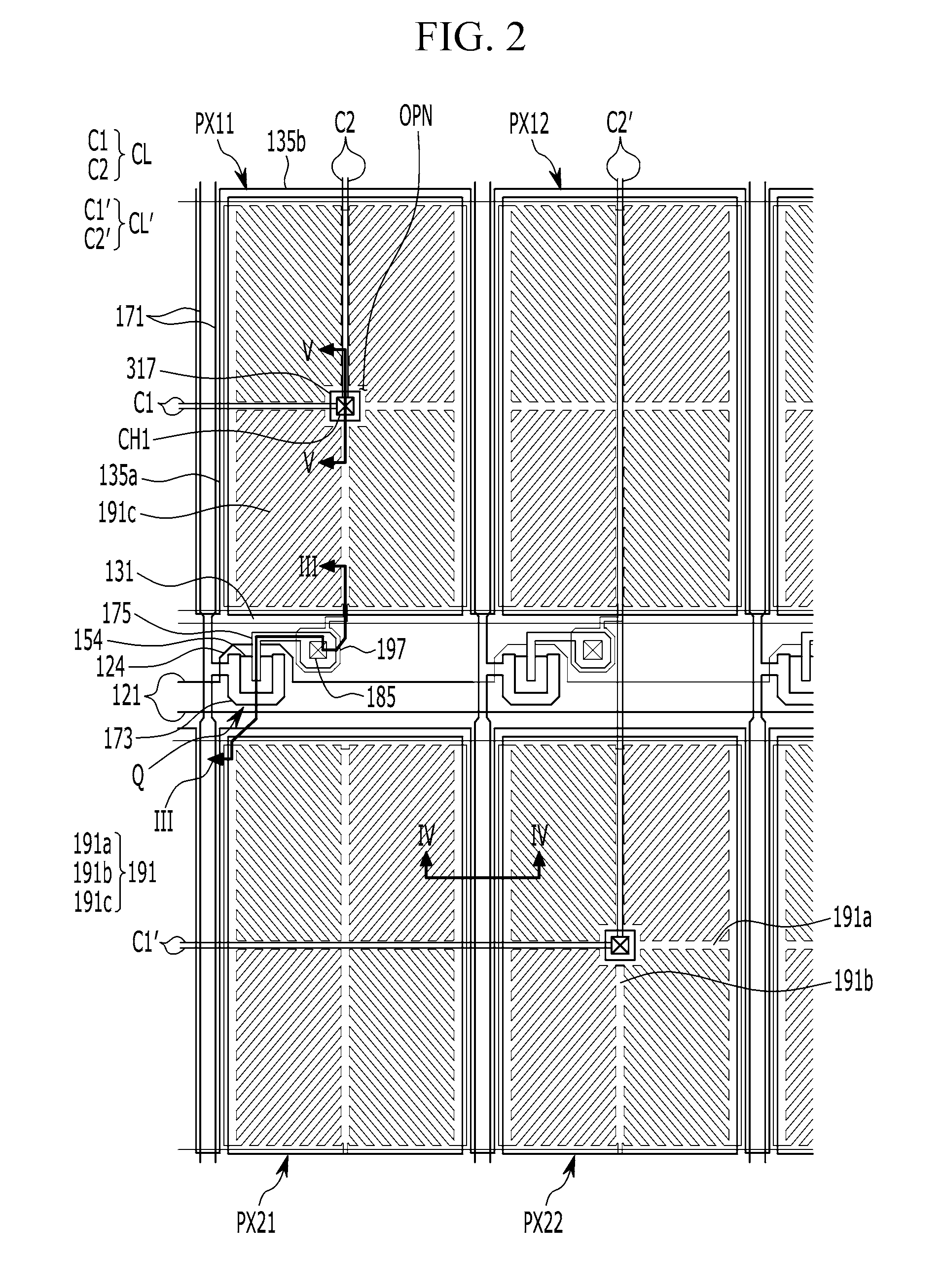

Display device

InactiveUS20170032751A1Satisfactory reliabilitySatisfactory durabilityStatic indicating devicesNon-linear opticsControl signalDisplay device

A display device may include the following elements: a plurality of gate lines extending in a first direction; a plurality of data lines extending in a second direction; a gate driver configured for applying gate signals to the gate lines; a data driver configured for applying data voltages to the data lines; a plurality of pixels electrically connected to the plurality of gate lines and the plurality of data lines; and a control wire set that traverses overlaps an area of a first pixel of the plurality of pixels, electrically interconnects the gate driver and the data driver, and is configured to transmit a control signal from the data driver to the gate driver.

Owner:SAMSUNG DISPLAY CO LTD

Pressure-sensitive adhesive layer for optical applications, pressure-sensitive adhesive layer-attached optical film, and image display device

ActiveUS20140377550A1Reduce surface resistanceNumber of process increaseFilm/foil adhesivesConductive materialPressure sensitiveChemistry

A pressure-sensitive adhesive layer for optical applications of the present invention is made from a pressure-sensitive adhesive for optical applications including a base polymer (A), and the pressure-sensitive adhesive layer for optical applications includes iodine and / or iodide ions (B). The pressure-sensitive adhesive layer for optical applications has an antistatic function and can satisfy a durability.

Owner:NITTO DENKO CORP

Three-piece solid golf ball

InactiveUS7140979B2Adequate spin performanceSatisfactory durabilityGolf ballsSolid ballsThermoplastic polyurethaneHardness

A three-piece solid golf ball having a solid core, an intermediate layer enclosing the solid core, and a cover layer enclosing the intermediate layer and having a large number of dimples formed in its surface, characterized in that the core deforms as much as 3.4 to 4.1 mm under a load which changes from 10 kg to 130 kg, the intermediate layer has a surface hardness of 64 to 69 in terms of Shore D hardness, the cover layer is formed mainly from thermoplastic polyurethane such that it has a lower hardness than the intermediate layer, with the difference in hardness between the cover layer and the intermediate layer being 10 to 16 in terms of Shore D hardness, the intermediate layer and the cover layer have a total thickness of 2.2 to 3.0 mm, the cover layer has a thickness of 0.8 to 1.3 mm, and the dimples have at least four different diameters and / or depths, with the average depth being 0.14 to 0.17 mm, and amount to 250 to 390 in all. The three-piece solid golf ball exhibits adequate spin performance by iron shot and approach shot. It also exhibits good flying performance and durability.

Owner:BRIDGESTONE SPORTS

Laminating adhesive, laminate using the same, and secondary battery

InactiveUS20170088753A1Improve adhesionSatisfactory durabilityNon-macromolecular adhesive additivesCell electrodesPolyolefinAdditive ingredient

It is an object to provide a novel laminating adhesive to thereby allow provision of a laminating adhesive composition for a laminate that provides good adhesion between a metal layer and a plastic layer, has satisfactory moisture barrier properties, heat resistance, insulation properties, durability, etc., also exhibits electrolyte resistance even after low-temperature curing, and does not undergo delamination over time. A laminate that uses the laminating adhesive composition and a secondary battery are also provided. The object is achieved by a laminating adhesive containing a non-chlorine-based polyolefin resin (A), an epoxy compound (B), and an organic solvent (C) including a cyclic alkane compound as an essential ingredient and further including an ester-based solvent or an alcohol-based solvent. In the organic solvent (C), the ratio, in parts by mass, of the cyclic alkane compound to the solvent other than the cyclic alkane compound is within the range of 1 / 1 to 20 / 1.

Owner:DAINIPPON INK & CHEM INC

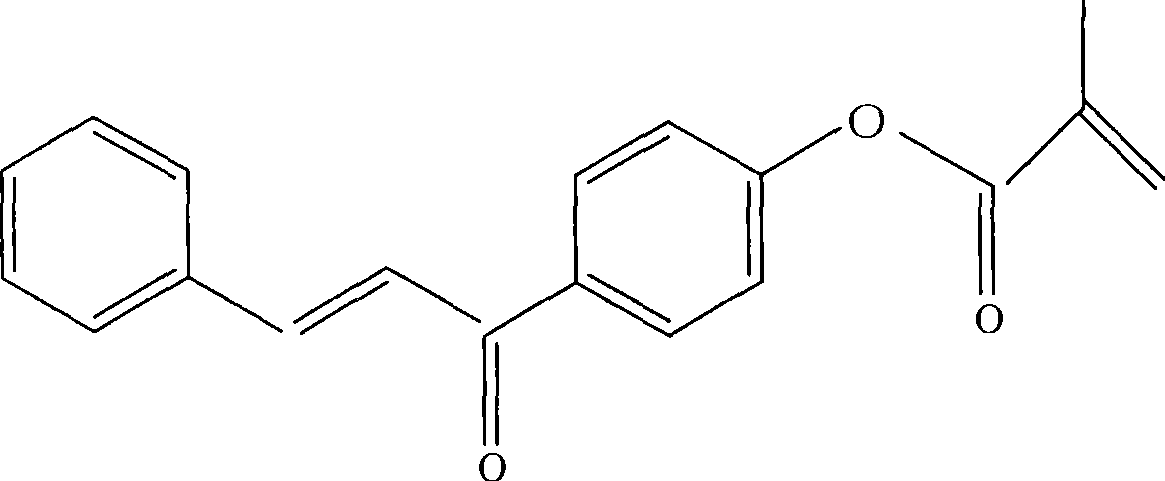

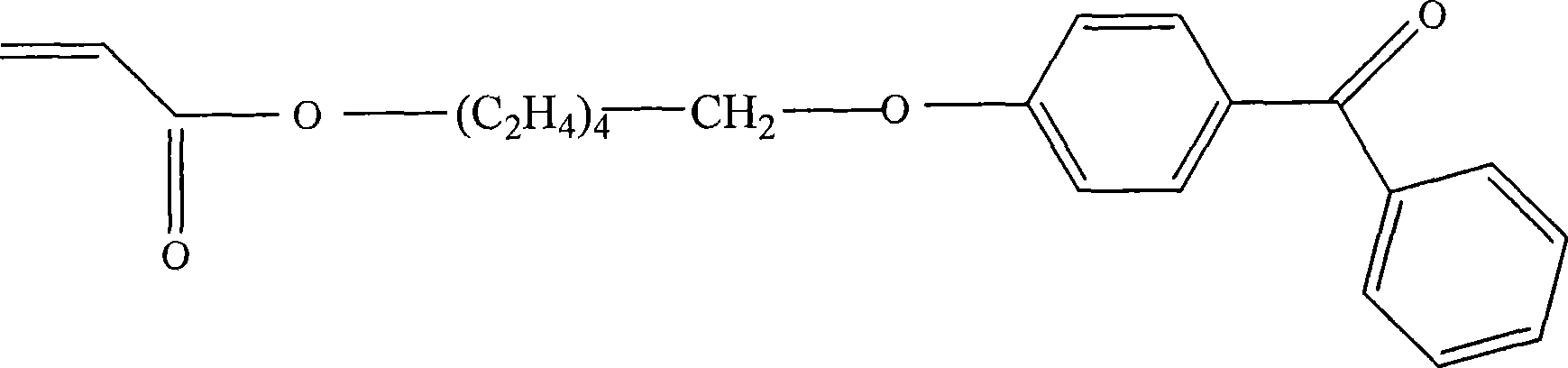

Pressure-sensitive adhesive for optical film, pressure-sensitive adhesive optical film, production method thereof, and image display

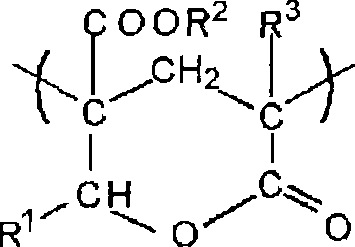

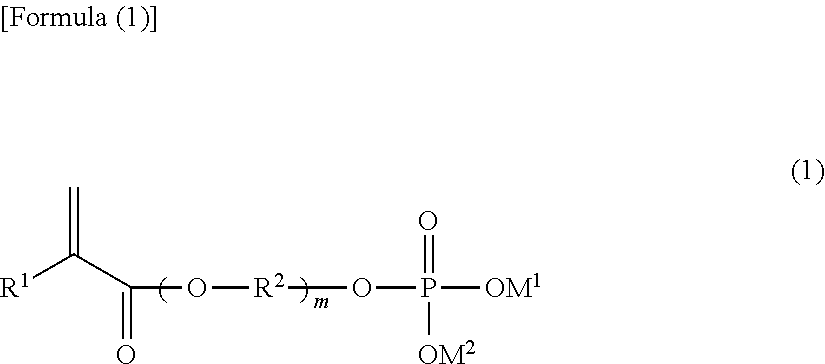

InactiveCN101423737AInhibit sheddingPrevent floatingPolarising elementsEster polymer adhesivesMeth-Optical thin film

A pressure-sensitive adhesive for an optical film of the present invention comprises a (meth)acrylic polymer comprising 50 to 99.99% by weight of alkyl (meth)acrylate monomer unit and 0.01 to 30% by weight of a photocrosslinkable monomer unit having an unsaturated double bond-containing polymerizable functional group and a photocrosslinkable moiety different from the functional group. A pressure-sensitive adhesive layer is formed from the pressure-sensitive adhesive on at least one side of an optical film, wherein the photocrosslinkable moiety of the (meth)acrylic polymer in the pressure-sensitive adhesive is crosslinked by active energy ray irradiation. The pressure-sensitive adhesive can form the pressure-sensitive adhesive layer with a high level of durability and preferable workability.

Owner:NITTO DENKO CORP

Organic compound, charge-transporting material, and organic electroluminescent element

ActiveUS20090191426A2Good electron transport propertiesSatisfactory durabilityOrganic chemistryElectroluminescent light sourcesOrtho positionTriplet state

Owner:PIONEER CORP +1

Pneumatic tire

InactiveUS20090165911A1Easy to bendImprove performanceTyre tread bands/patternsNon-skid devicesGround contactEngineering

An object of the present invention is to provide a pneumatic tire capable of reducing the narrowing of the openings of sipes and increasing ground-contact performance by ensuring the edge effect and the water removal effect thereby increasing on-ice braking performance while providing a satisfactory durability to a sipe-forming blade mounted on the tire manufacturing die. To achieve the above object, each of the sipes formed in a land portion of a tread surface which a pneumatic tire comprises has: a first sipe portion in which a first wide portion having a bottom portion thereof is formed, a second sipe portion in which a second wide portion having a bottom portion thereof and extending in a depth direction from a depth position closer to the tread surface side than the bottom portion of the first wide portion is formed at the side opposite to the first wide portion as viewed in a sipe width direction, the second sipe portion being positioned on the side of the bottom portion of the first sipe portion, and a third sipe portion in which a third wide portion having a bottom portion thereof and extending in a depth direction from a depth position closer to the tread surface side than the bottom portion of the second wide portion is formed at the same side as the first wide portion as viewed in a sipe width direction, the third sipe portion being positioned on the side of the bottom portion of the second sipe portion.

Owner:TOYO TIRE & RUBBER CO LTD

Non-pneumatic tire

ActiveUS8783310B2Increase in hardnessSuppression of resistance riseNon-inflatable tyresHigh resiliency wheelsRolling resistanceRide quality

Owner:BRIDGESTONE CORP

Pressure-sensitive adhesive layer for transparent conductive film, transparent conductive film with pressure-sensitive adhesive layer, transparent conductive laminate, and touch panel

InactiveUS20130093438A1Increased durabilityPrevent peelingNon-macromolecular adhesive additivesCapacitance measurementsMeth-Water dispersible

A pressure-sensitive adhesive layer of the invention for transparent conductive film has a thickness of 10 μm to 100 μm, and is made from a water-dispersible acryl-based pressure-sensitive adhesive that is an aqueous dispersion containing a water-dispersible (meth)acryl-based polymer and a water-soluble basic component, wherein the water-dispersible (meth)acryl-based polymer comprises 100 parts by weight of an alkyl(meth)acrylate with an alkyl group of 4 to 14 carbon atoms, as a monomer unit, and 1 to 8 parts by weight of a carboxyl group-containing monomer as a copolymerized monomer unit, and the pressure-sensitive adhesive layer contains 200 ng to 500,000 ng of the water-soluble basic component per 1 cm2 as determined by measurement of the pressure-sensitive adhesive layer. The pressure-sensitive adhesive layer can have satisfactory durability in a high-temperature or high-temperature, high-humidity environment and can suppress corrosion in a high-temperature, high-humidity environment.

Owner:NITTO DENKO CORP

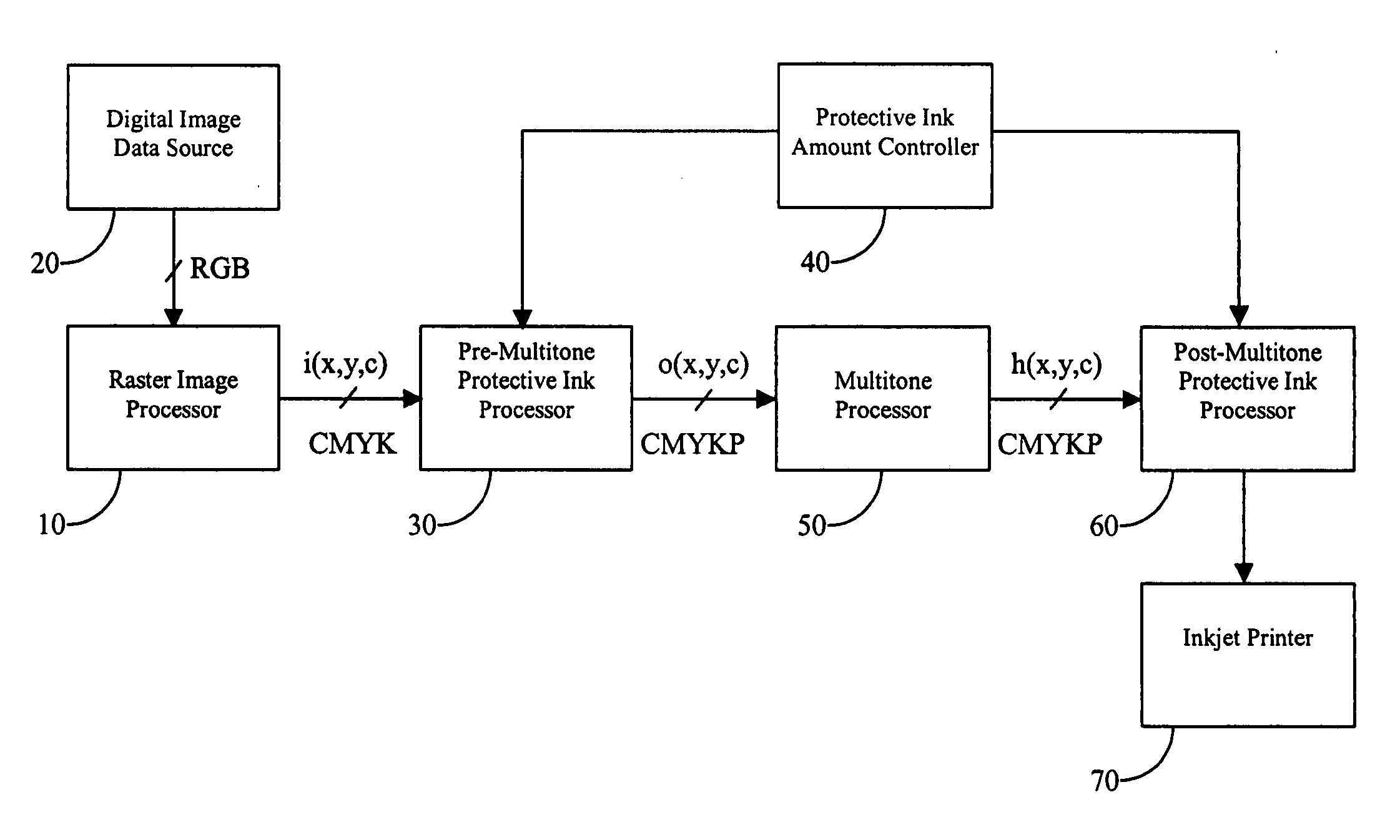

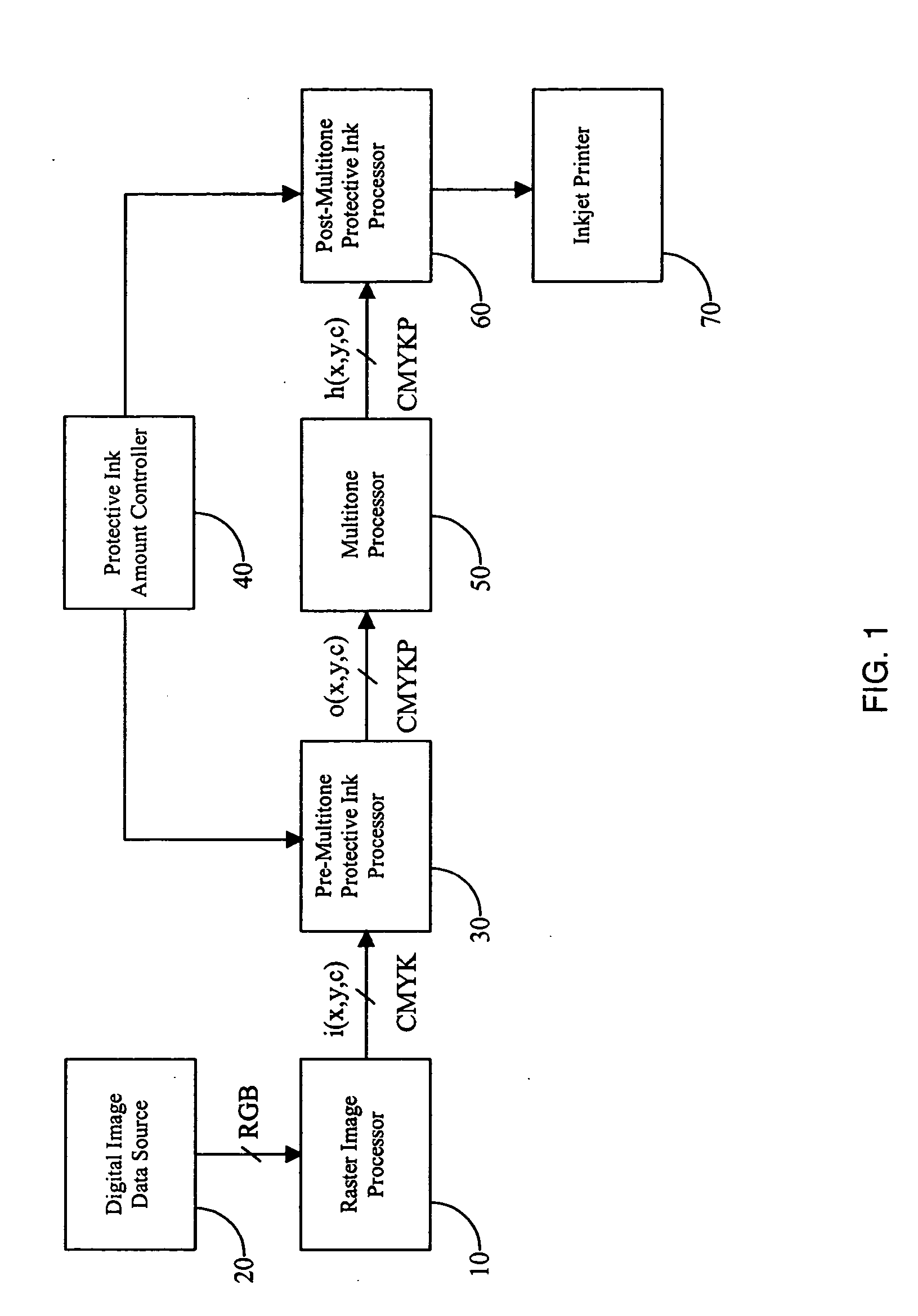

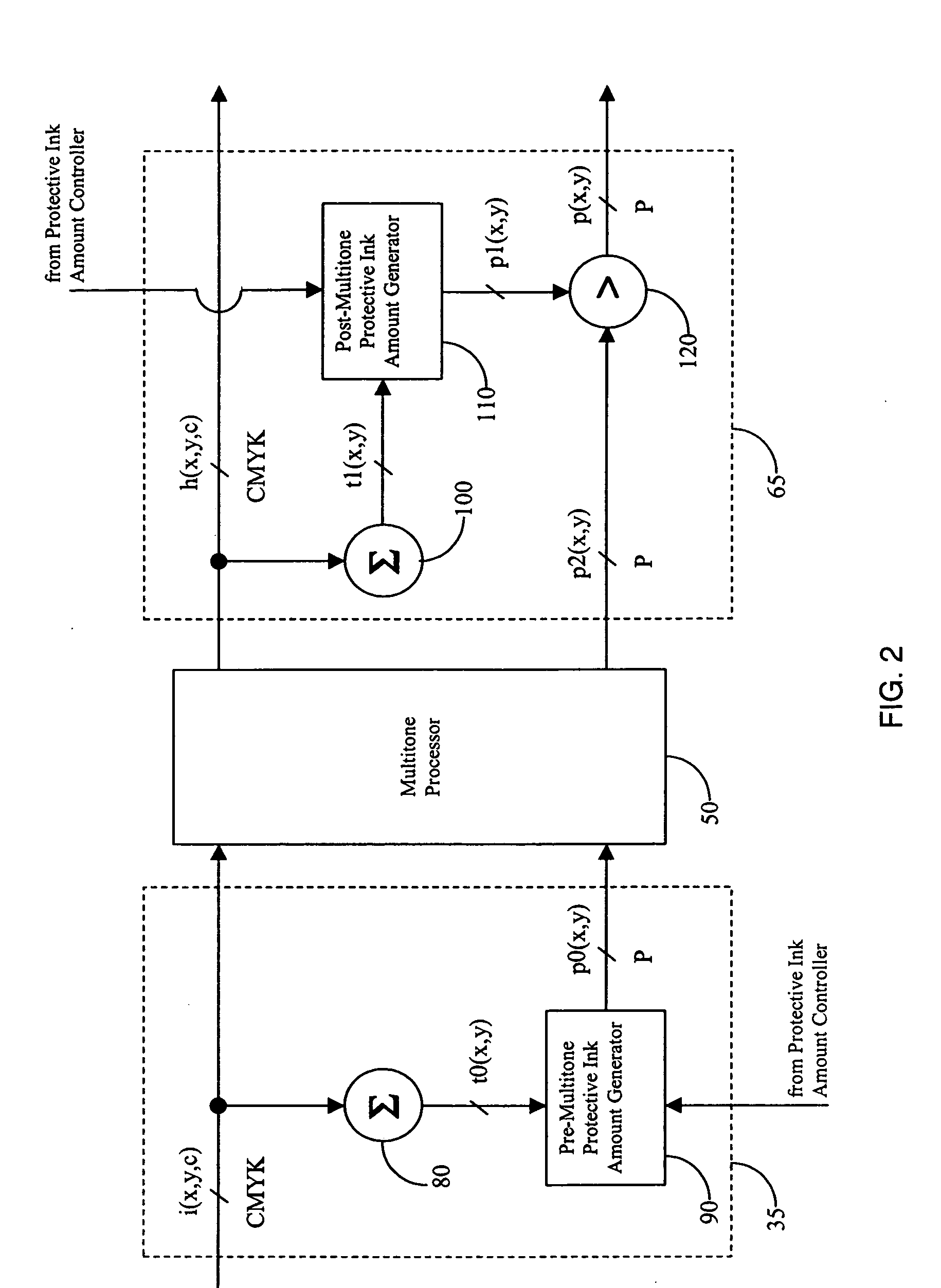

Using inkjet printer to apply protective ink

InactiveUS20050185008A1Increased durabilityQuantity minimizationMeasurement apparatus componentsOther printing apparatusInk printerEngineering

A method of determining and applying a protective ink amount to be printed in addition to a plurality of colored ink amounts to make colored pixels in an image including determining a first protective ink amount responsive to the colored ink amounts, determining multitoned colored ink amounts using a multitone processor responsive to the colored ink amounts, and determining a second protective ink amount responsive to the multitoned colored ink amounts. The method also includes determining the protective ink amount responsive to the first protective ink amount and the second protective ink amount to provide adequate durability for the image, and applying using an inkjet printer the colored ink amounts and the protective ink amount to make the colored image pixels.

Owner:EASTMAN KODAK CO

Acrylic Pressure-Sensitive Adhesive Compositions

ActiveUS20100129569A1Reduce light leakageAdhesion durability is not diminishedLiquid crystal compositionsLiquid surface applicatorsHigh humidityPolymer science

The present invention relates to an acrylic pressure-sensitive adhesive composition, and more precisely, an acrylic pressure-sensitive adhesive composition which is prepared by copoly-merization of a vinyl and / or acrylic monomer having a cross-linkable functional group and comprises 100 weight part of a high molecular weight (meth)acrylic copolymer which is prepared by copolymerization of a vinyl and / or acrylic monomer harboring a cross-linkable functional group and whose weight average molecular weight is 40˜100 times as high as the entanglement molecular weight, 5˜50 weight part of a low molecular weight (meth)acrylic copolymer which does not contain a cross-linkable functional group and whose weight average molecular weight is 2˜15 times as high as entanglement molecular weight, and 0.01˜10 weight part of a multifunctional cross-linking agent. The acrylic pressure-sensitive adhesive composition of the present invention has reliable adhesion durability under high temperature and high humidity and at the same time reduces the light leakage due to the stress relaxation and enhances the cutting-efficiency of a polarizing plate.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com