Patents

Literature

136results about How to "Excellent durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

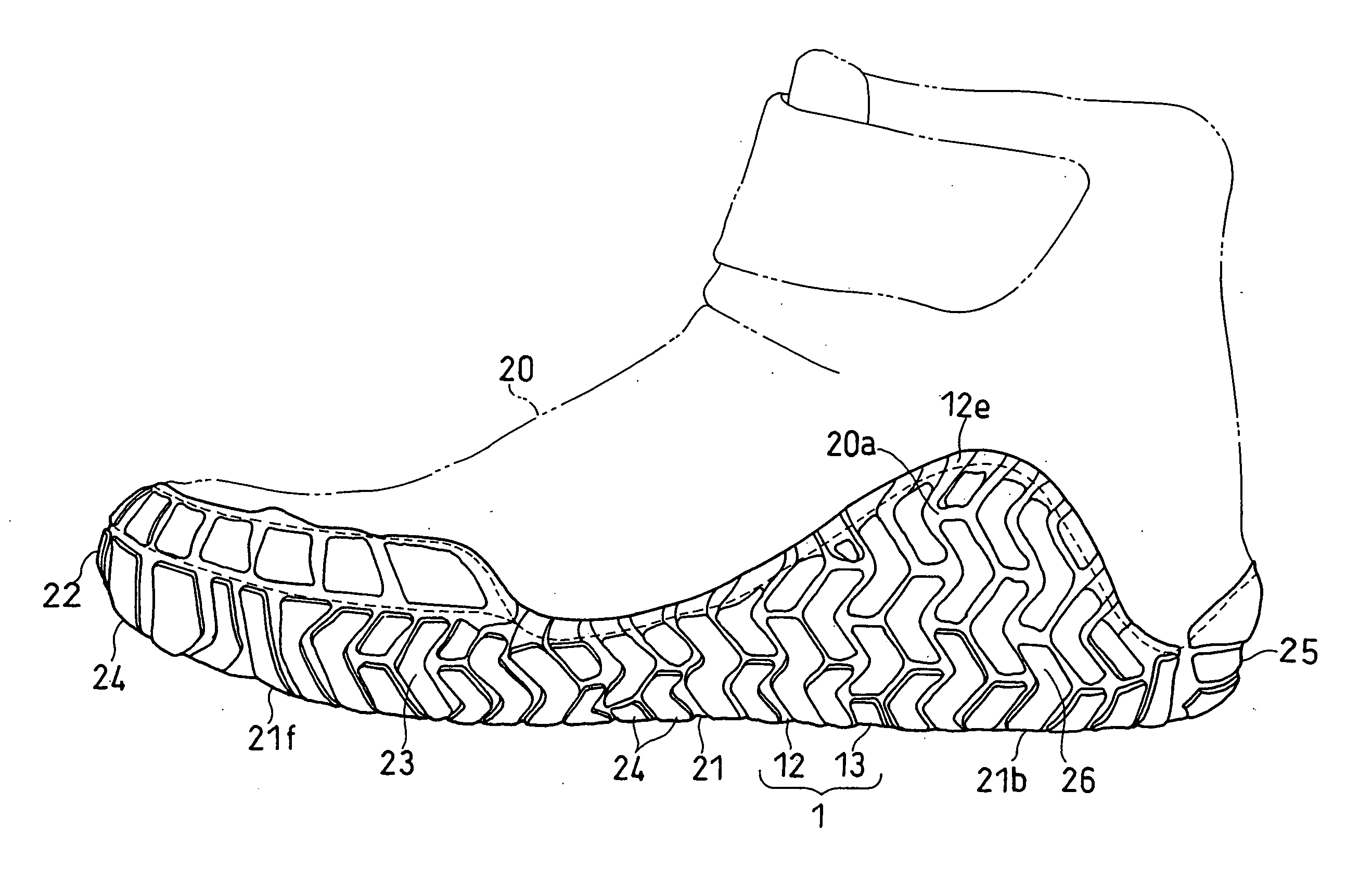

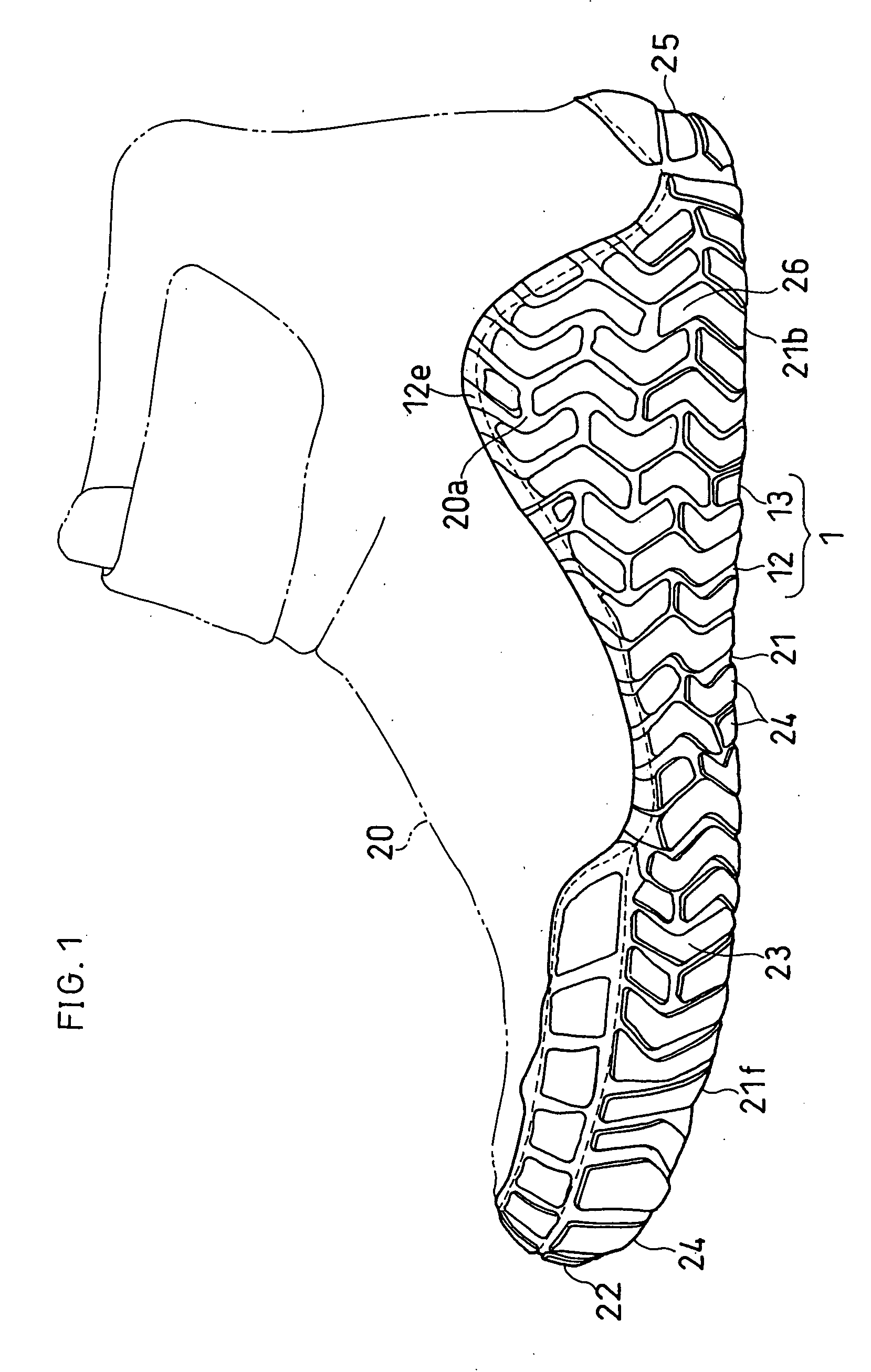

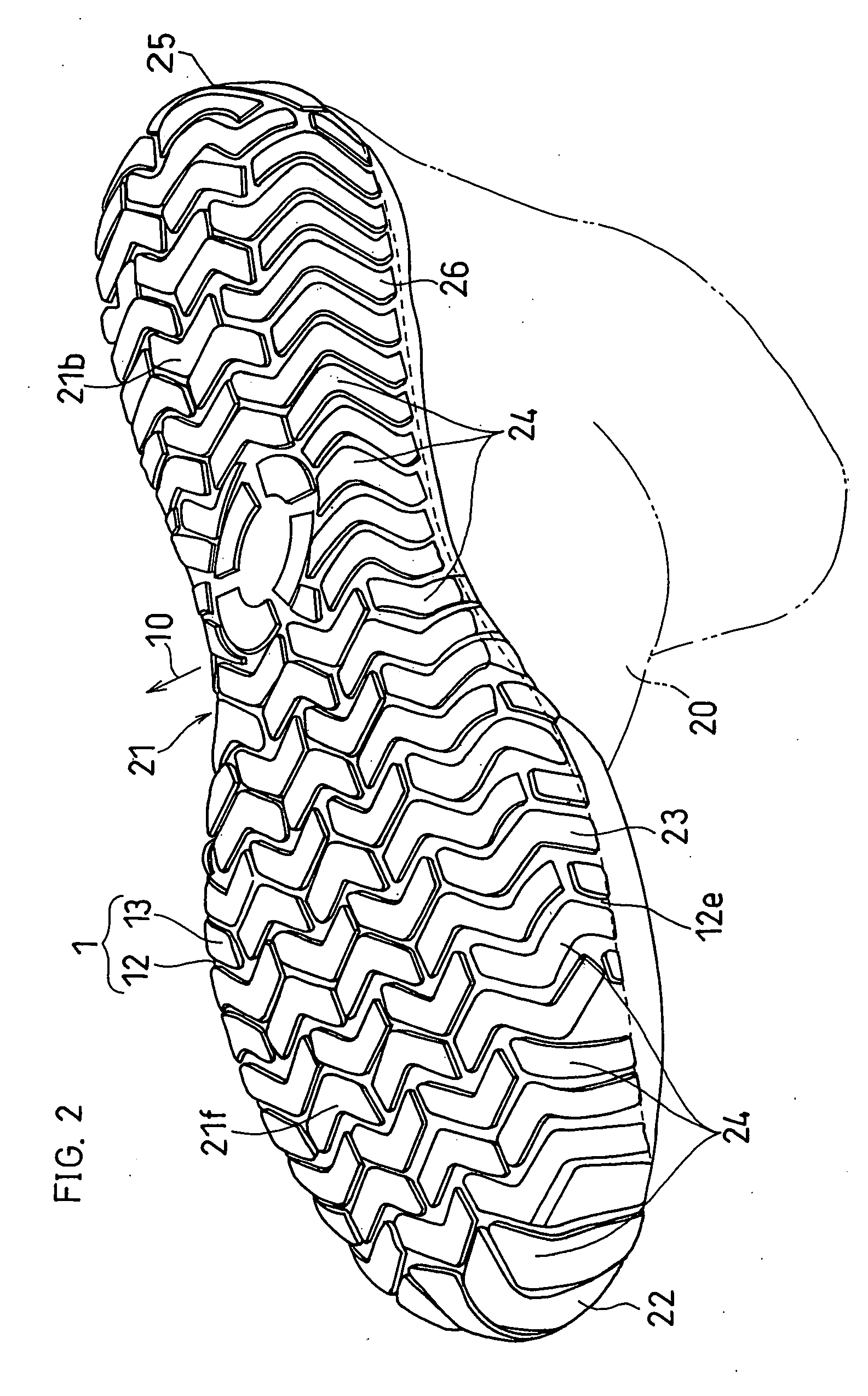

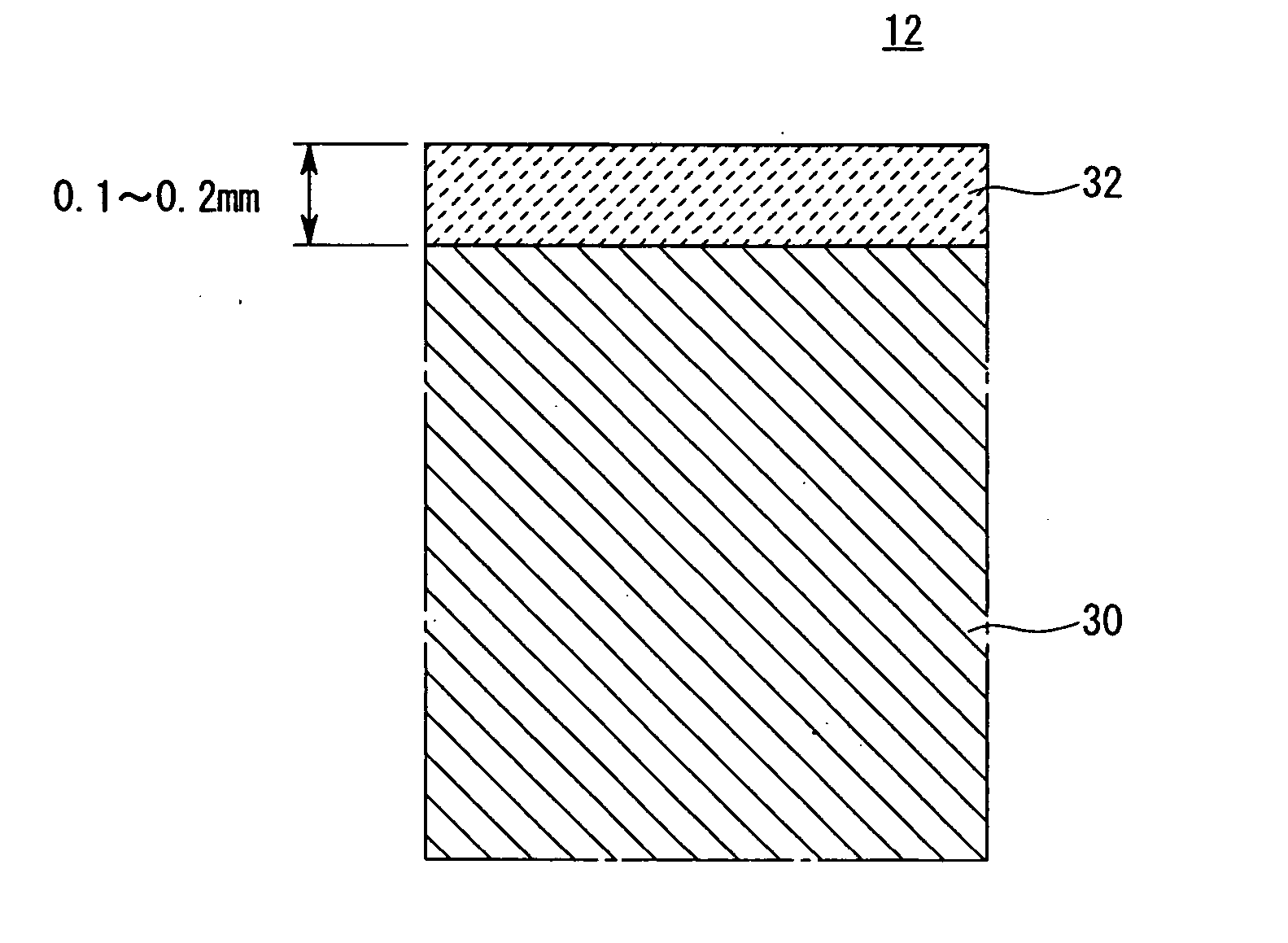

Shoe with slip preventive member

An object of the present invention is to enhance durability of the non-slip member of the shoe where a lot of non-slip protuberances are fixed to the surface of a base fabric. The shoe of the present invention comprises an upper 20 that covers an instep of a foot, a sole 21 having a ground contact surface and a non-slip member 1 provided on an outer surface of the upper 20 and / or the sole 21. The non-slip member 1 comprises a base fabric 12 composed of a knitted fabric of a multilayer structure, the base fabric including an external knitted fabric layer 123 having a first surface 121 exposed to the outside and an internal knitted fabric layer 124 having a second surface 122 on a opposite side of the first surface 121 and a plurality of resin or rubber non-slip protuberances 1 that are fixed to the base fabric 12 and protrude from the first surface 121 of the external knitted fabric layer 123. A yarn constituting the external knitted fabric layer 123 is thicker than a yarn constituting the internal knitted fabric layer 124.

Owner:ASICS CORP

1, 5-naphthyridine compound and organic light-emitting device

InactiveUS20080116789A1High luminanceExcellent durabilityOrganic chemistryDischarge tube luminescnet screensStereochemistryAryl

The present invention provides a novel 1,5-naphthyridine compound represented by the following general formula [I]:wherein R1, R2, R4 and R5 each represent one selected from a hydrogen atom, a substituted or unsubstituted alkyl group, and the like; and R3 and R6 each represent one selected from a substituted or unsubstituted aralkyl group, a substituted or unsubstituted aryl group, and the like.

Owner:CANON KK

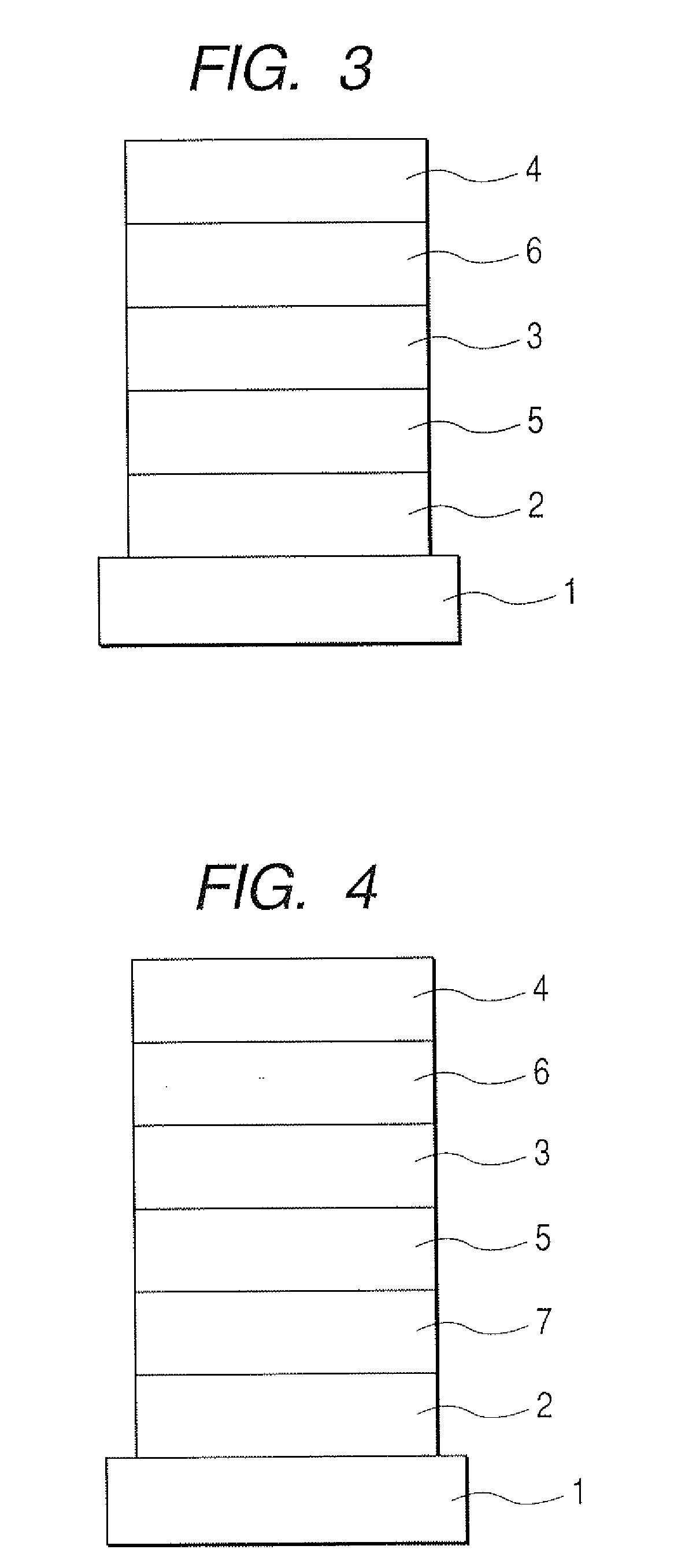

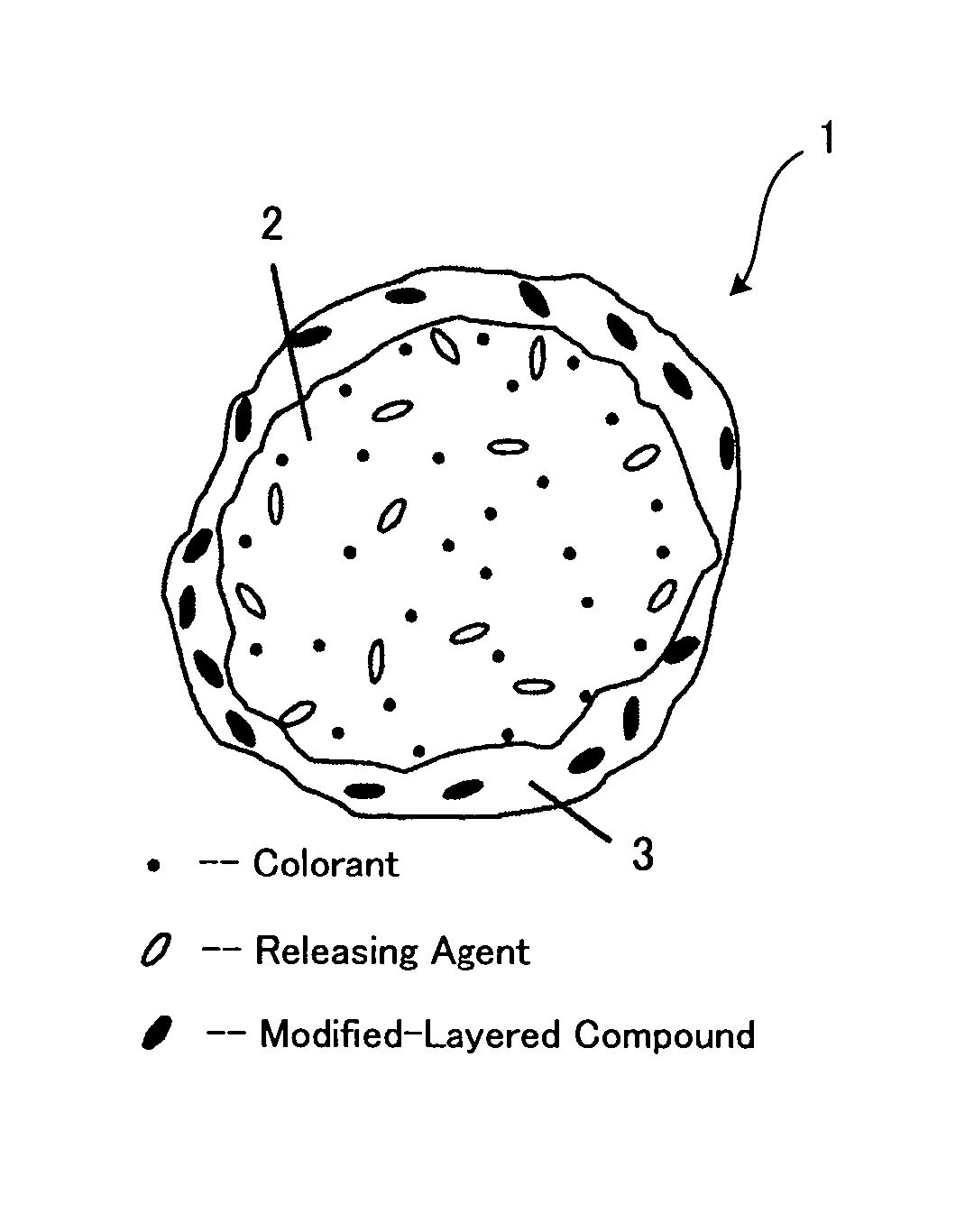

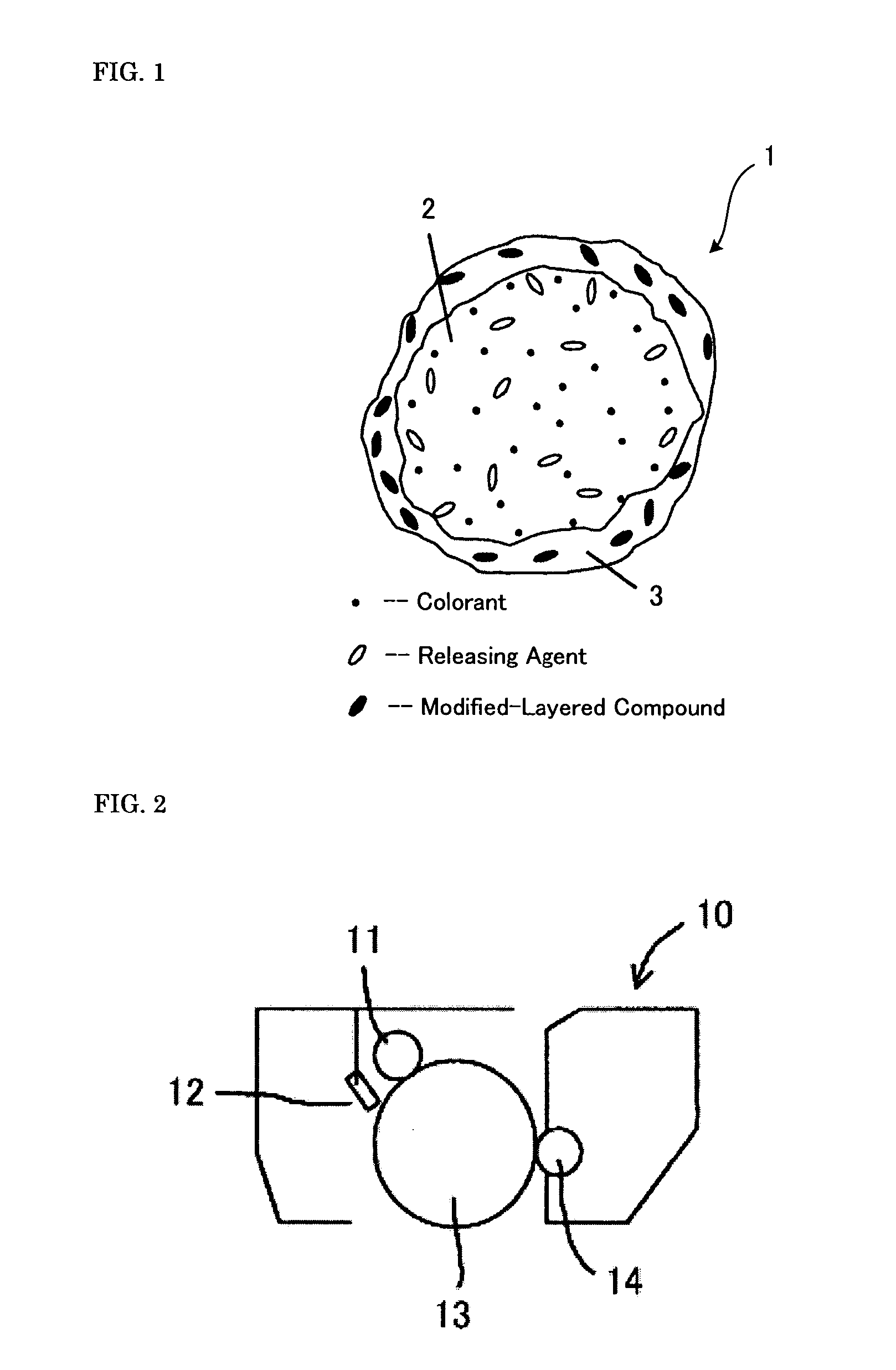

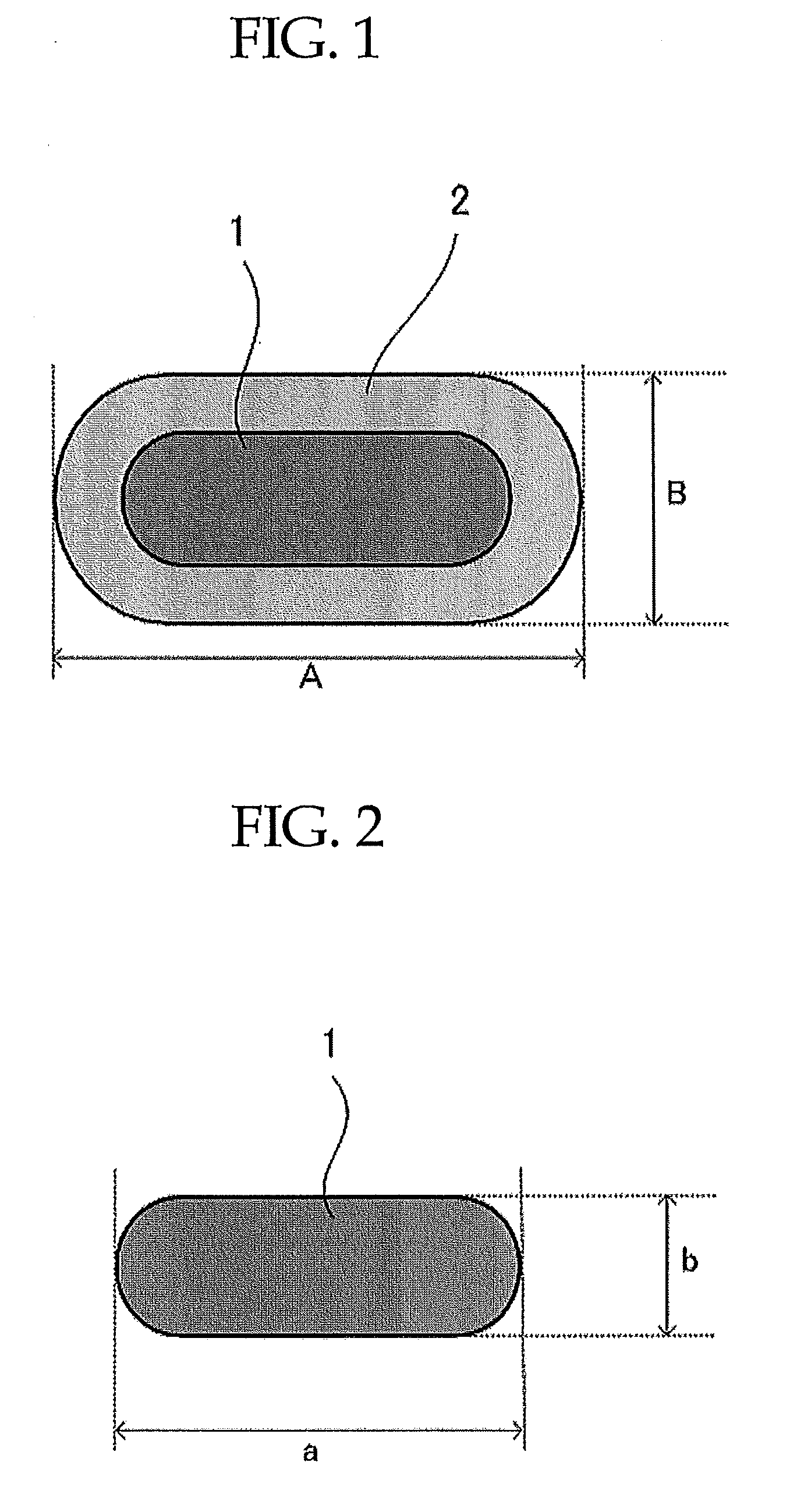

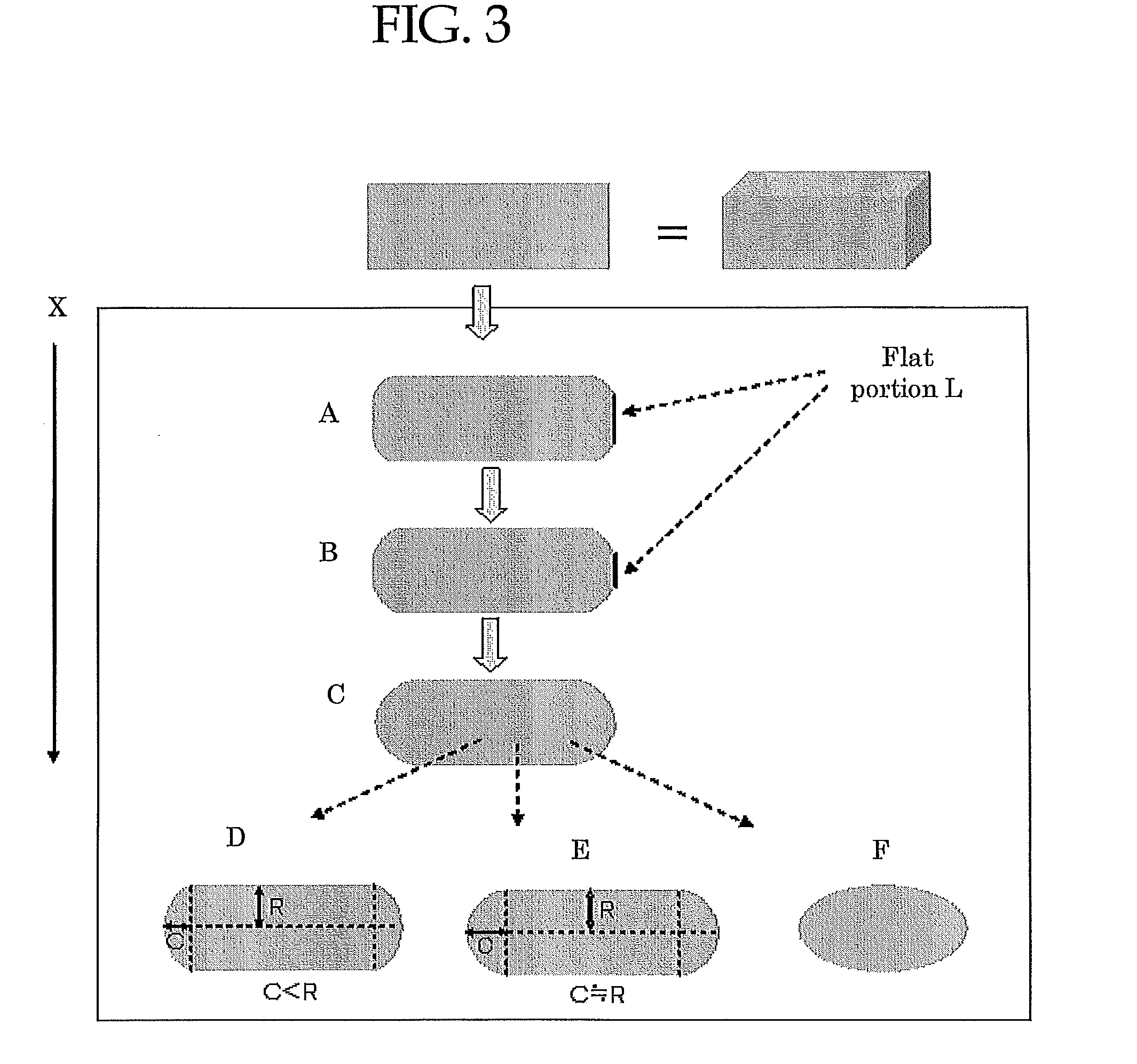

Toner, production method thereof, toner container, developer, image forming apparatus and process cartridge using the same

To provide a toner, having: a core and a shell which covers the core, wherein the core at least contains a colorant and a binder resin (A), the shell at least contains a binder resin (B) and a modified-layered inorganic mineral obtained by modifying at least a part of interlayer ions of a layered inorganic mineral with organic ions, the binder resin (A) at least contains a polyester resin, and the binder resin (B) at least contains a vinyl copolymer resin.

Owner:RICOH KK

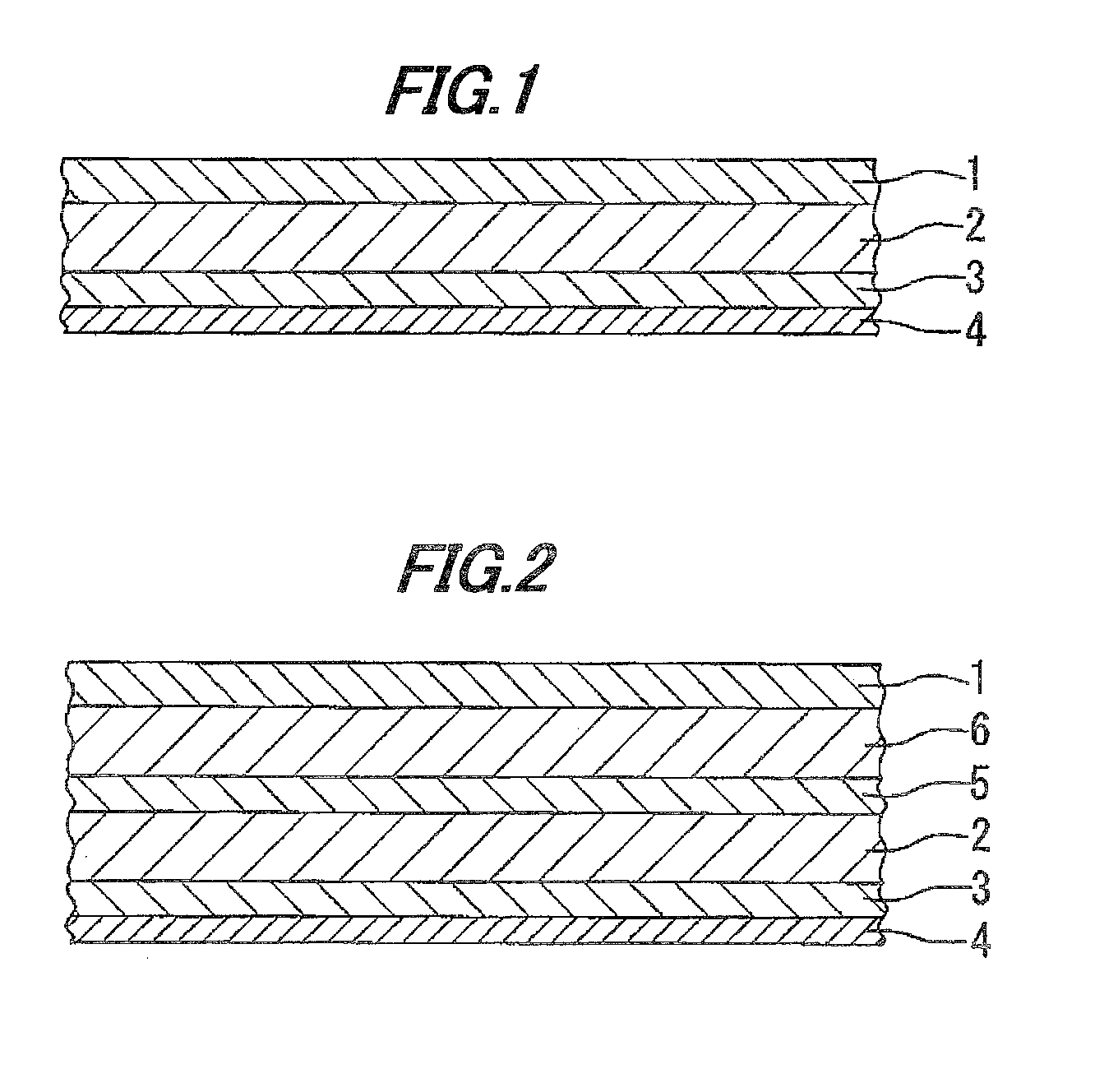

Polarizing film, method for producing polarizing film, polarizing plate, method for producing polarizing plate, and Anti-glare vehicular film

InactiveUS20100157426A1Large surface areaExcellent durabilityAntiglare equipmentOptical articlesPolymer chemistryAnisotropy

The present invention provides a polarizing film which contains at least dichroic anisotropic metal nanoparticles and a thermoplastic resin, wherein the polarizing film has a thickness of 12.5 μm or less.

Owner:FUJIFILM CORP

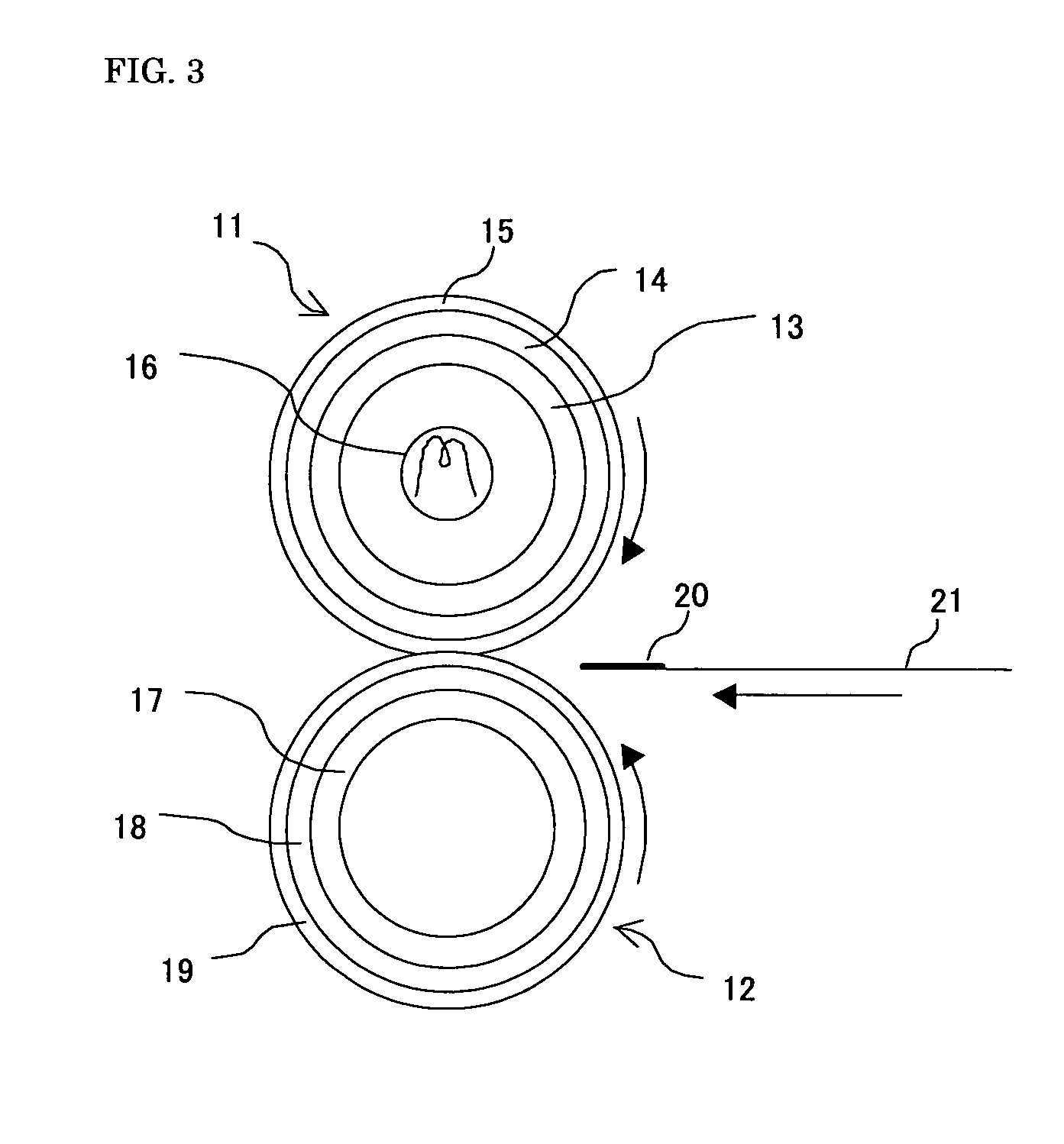

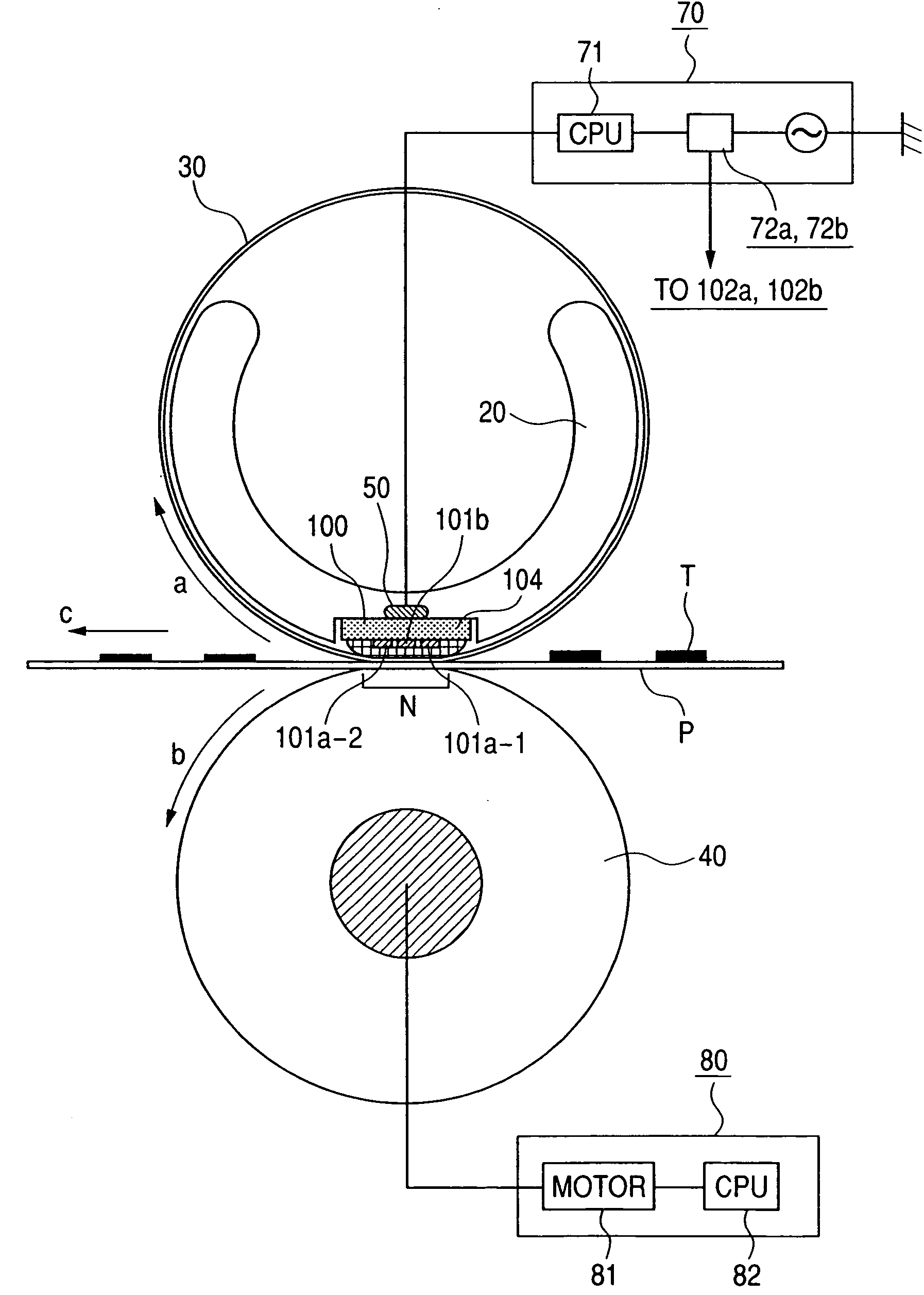

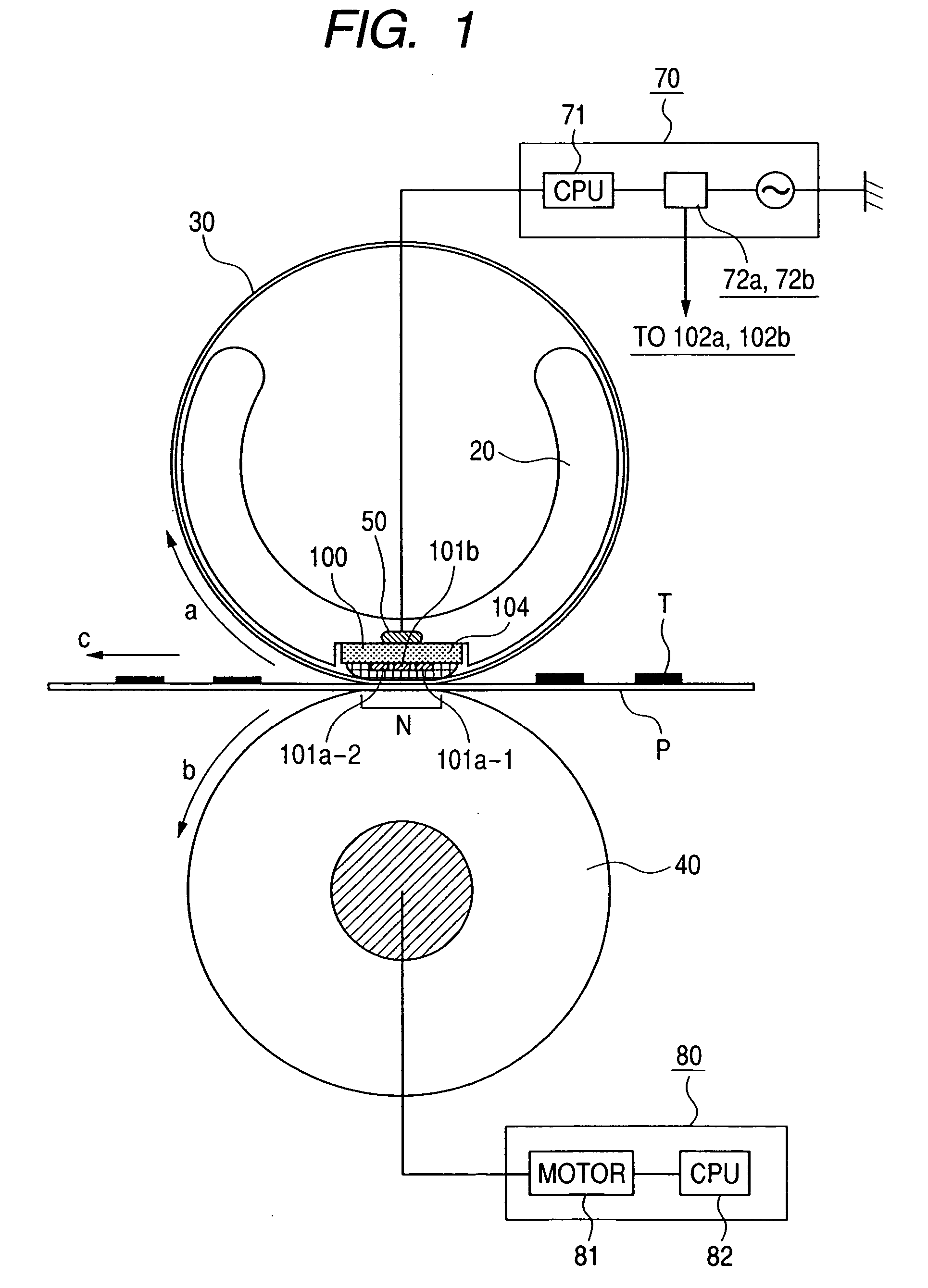

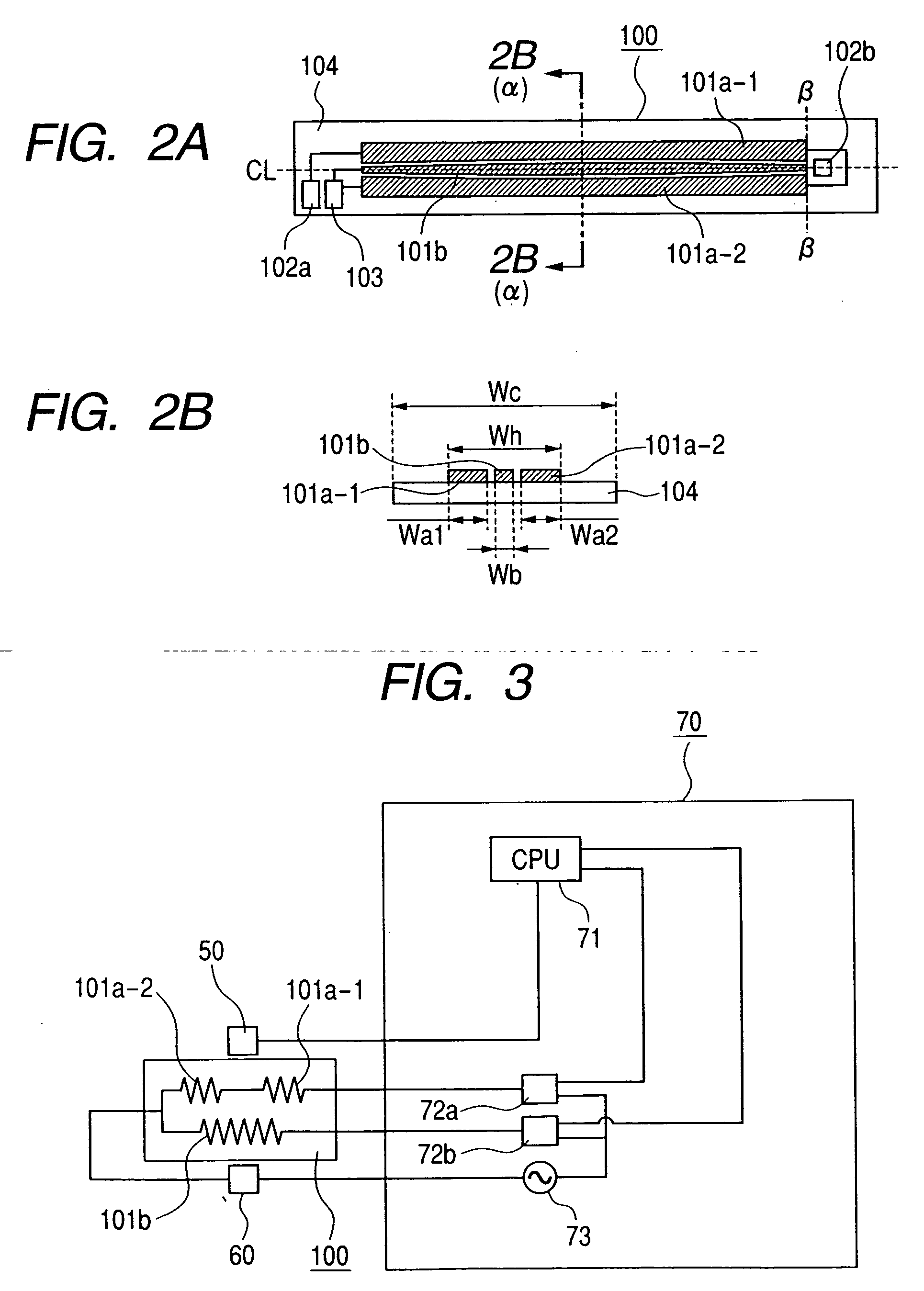

Image heating apparatus and heater therefor

ActiveUS20050280682A1Excellent durabilityIncreased durabilityOhmic-resistance heatingElectrographic process apparatusElectricityEngineering

The n image heating apparatus for heating an image formed on a recording material, includes a heater including a substrate, and plural heat generating resistors formed on the substrate along a longitudinal direction thereof, and plural switching elements connected electrically between a power source and the plural heat generating resistors, wherein the plural heat generating resistors include at least two first heat generating resistors driven by a first switching element and at least a second heat generating resistor driven by a second switching element, and the second heat generating resistor is provided between the at least two first heat generating resistors in a direction of a shorter side of the substrate. In this manner there can be provided an image heating apparatus with a heater of an excellent durability, and a heater adapted for use in such apparatus.

Owner:CANON KK

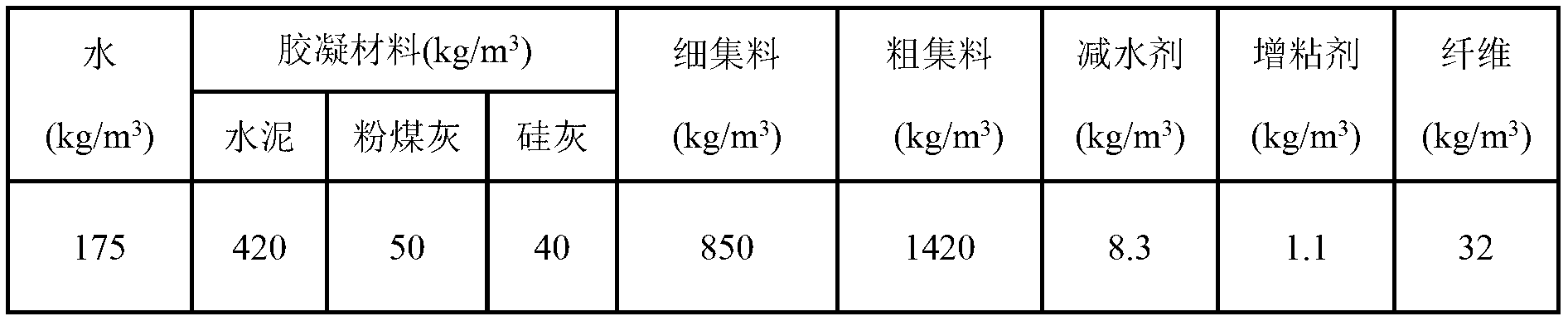

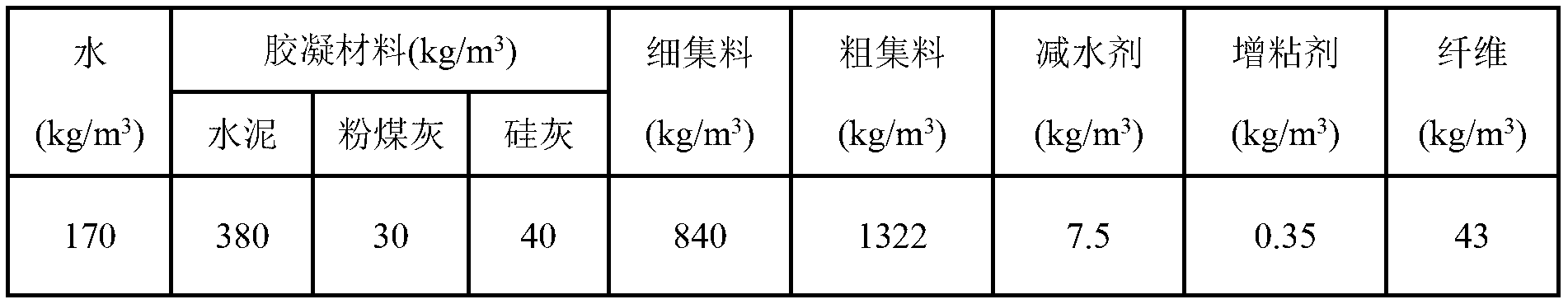

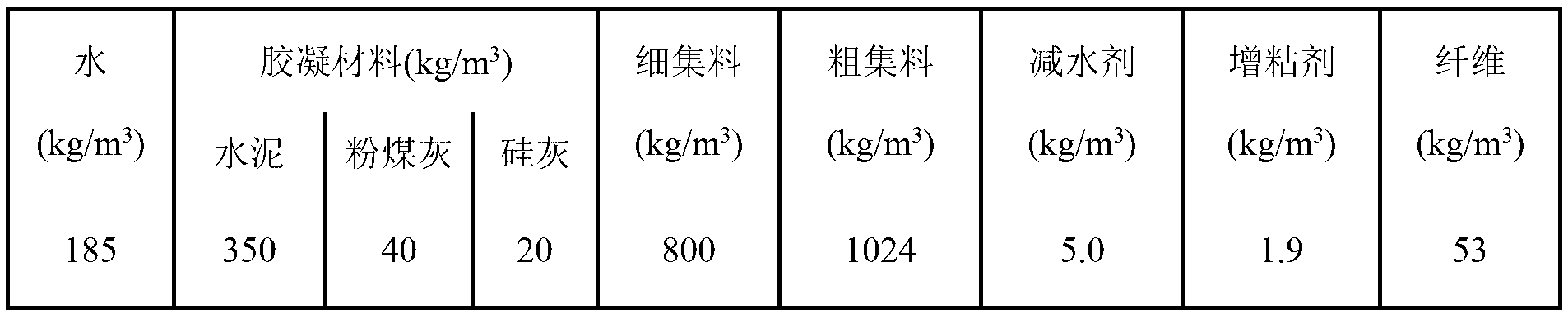

Anti-radiation concrete produced from slag aggregate, and production method thereof

InactiveCN103224369ATotal momentum downReduce the degree of stratificationSolid waste managementSlagTackifier

The invention relates to anti-radiation concrete produced from slag aggregate, and a production method thereof so as to effectively consume and utilize mineral waste, and improve an anti-radiation performance and durability of concrete. The anti-radiation concrete produced from slag aggregate comprises the following raw materials, by weight, 140-190 parts of water, 350-630 parts of a cementing material, 750-850 parts of a fine aggregate, 1000-1500 parts of a coarse aggregate, 0.35-1.9 parts of a tackifier, 2.1-7.5 parts of a water reducing agent, and 30-70 parts of fibers, wherein the cementing material comprises cement and a mineral admixture, the mineral admixture comprises silicon ash and fly ash, the cementing material comprises 300-500 parts by weight of the cement, 20-60 parts by weight of the silicon ash and 30-70 parts by weight of the fly ash, the coarse aggregate is a high titanium heavy slag coarse aggregate, the fine aggregate comprises high titanium heavy slag sand and lead powder according to a mass ratio of 1:0.2-3.0, the tackifier is methyl cellulose ether, and the fibers are one or a plurality of material selected from polypropylene fibers, steel fibers and lead fibers.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

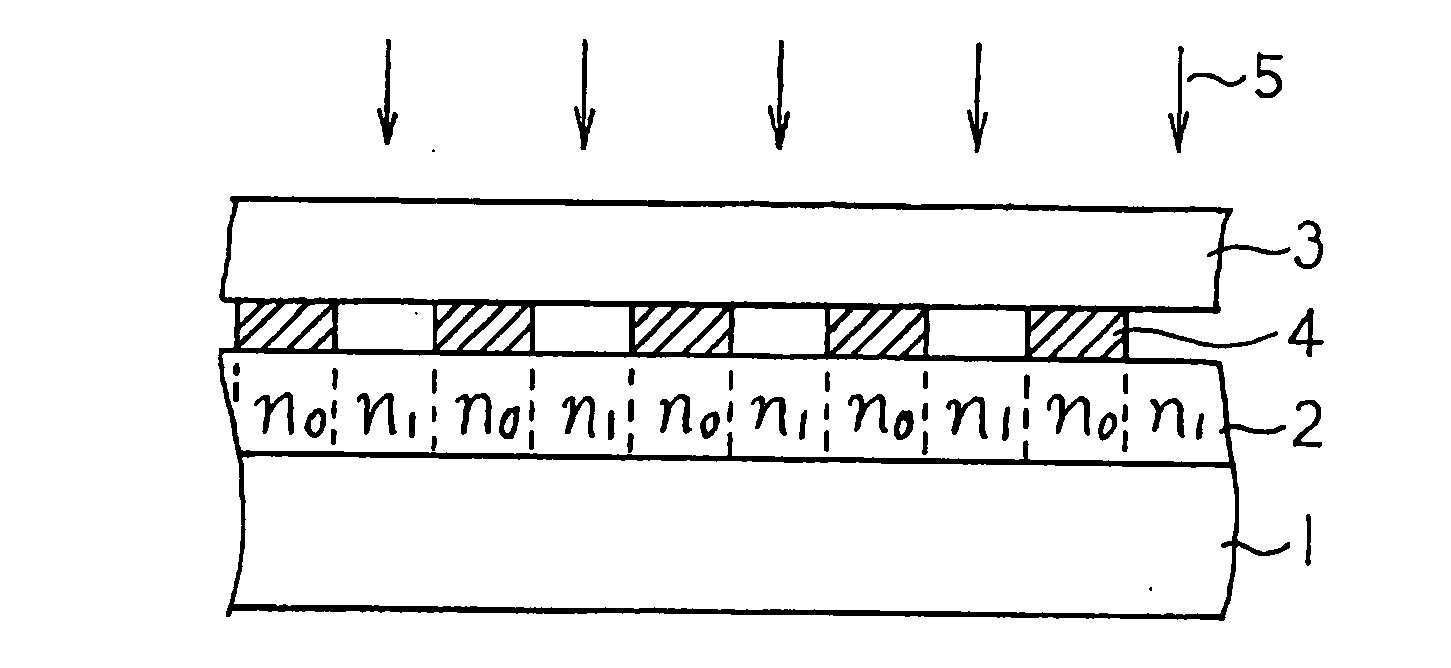

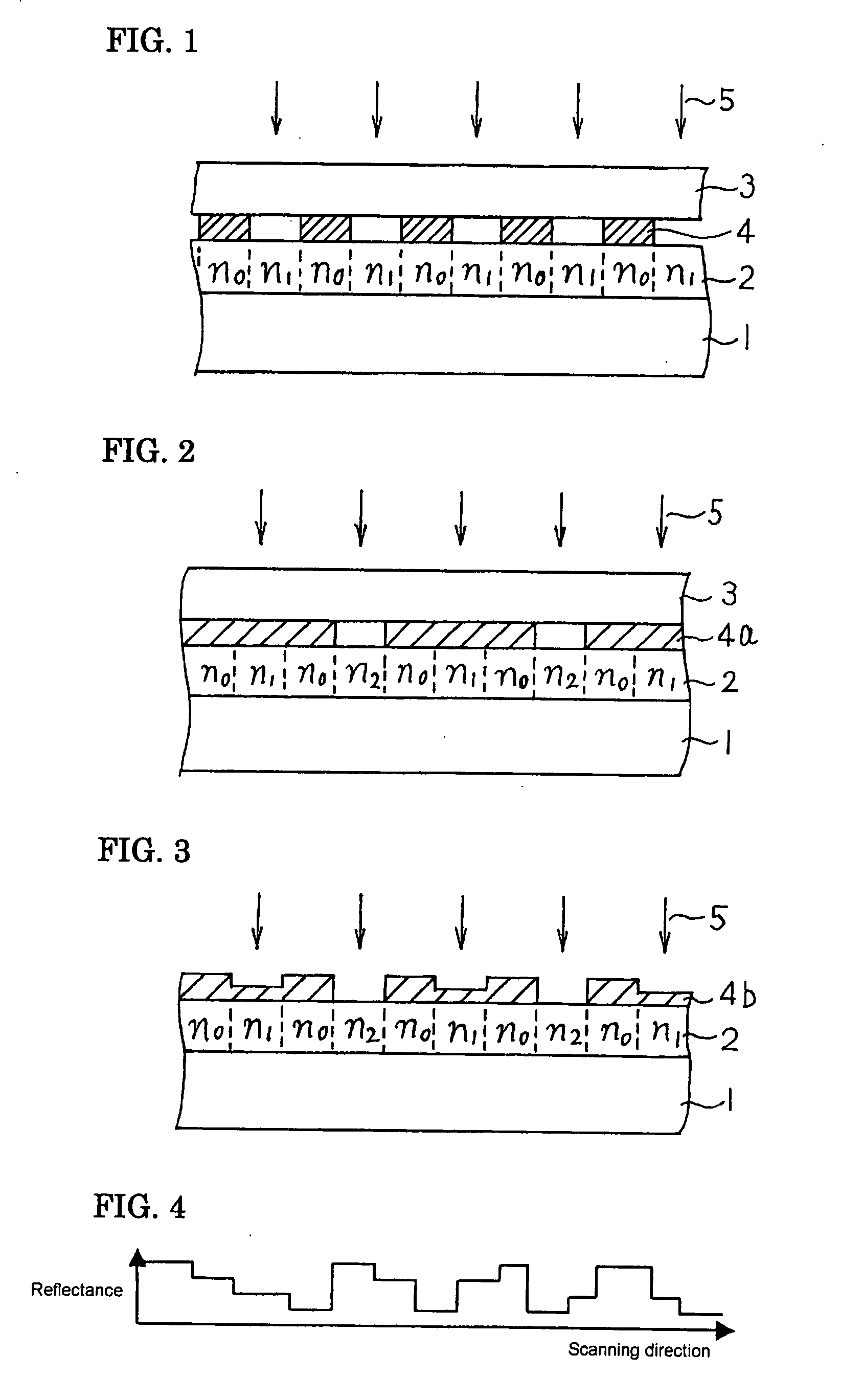

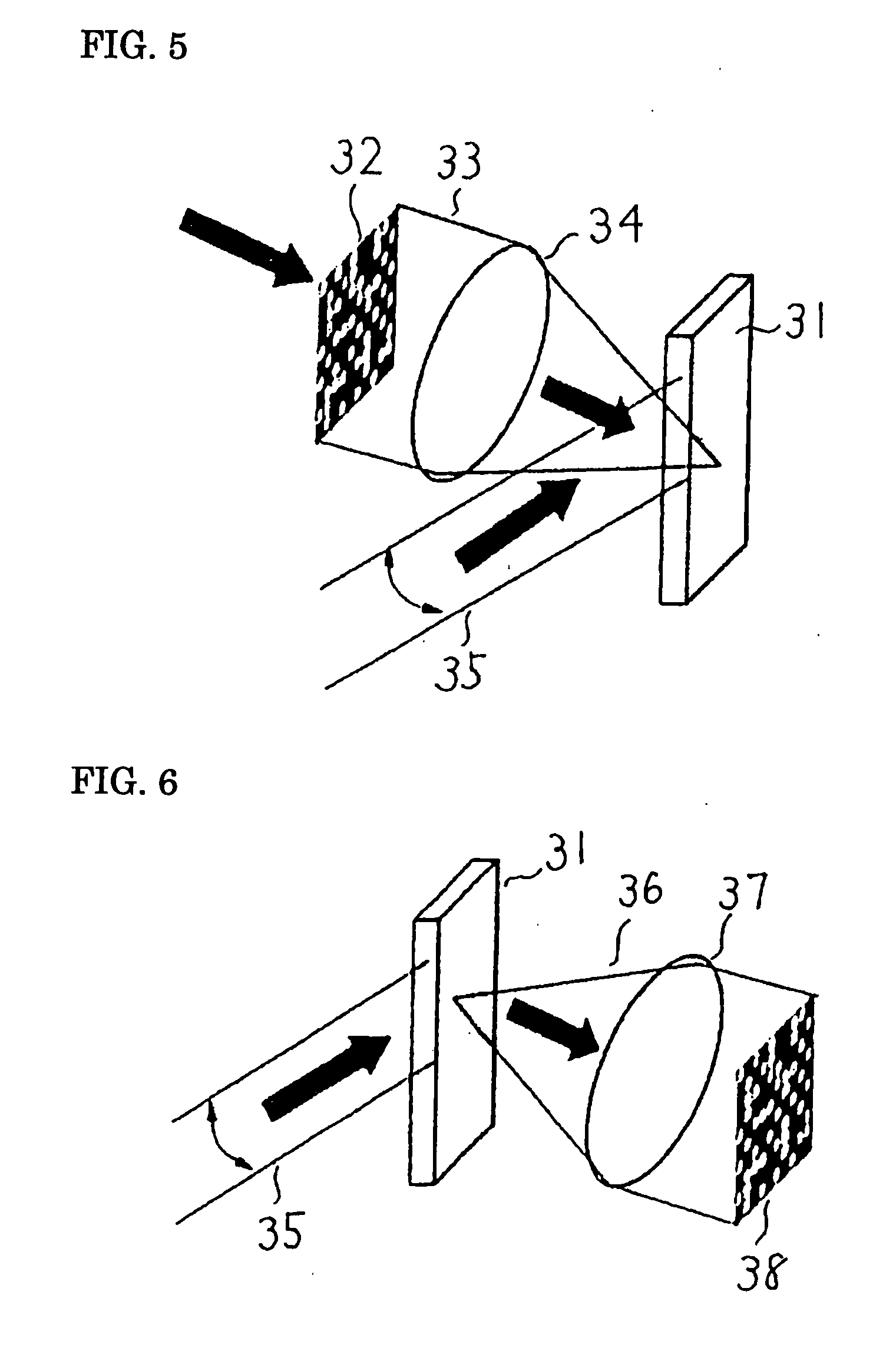

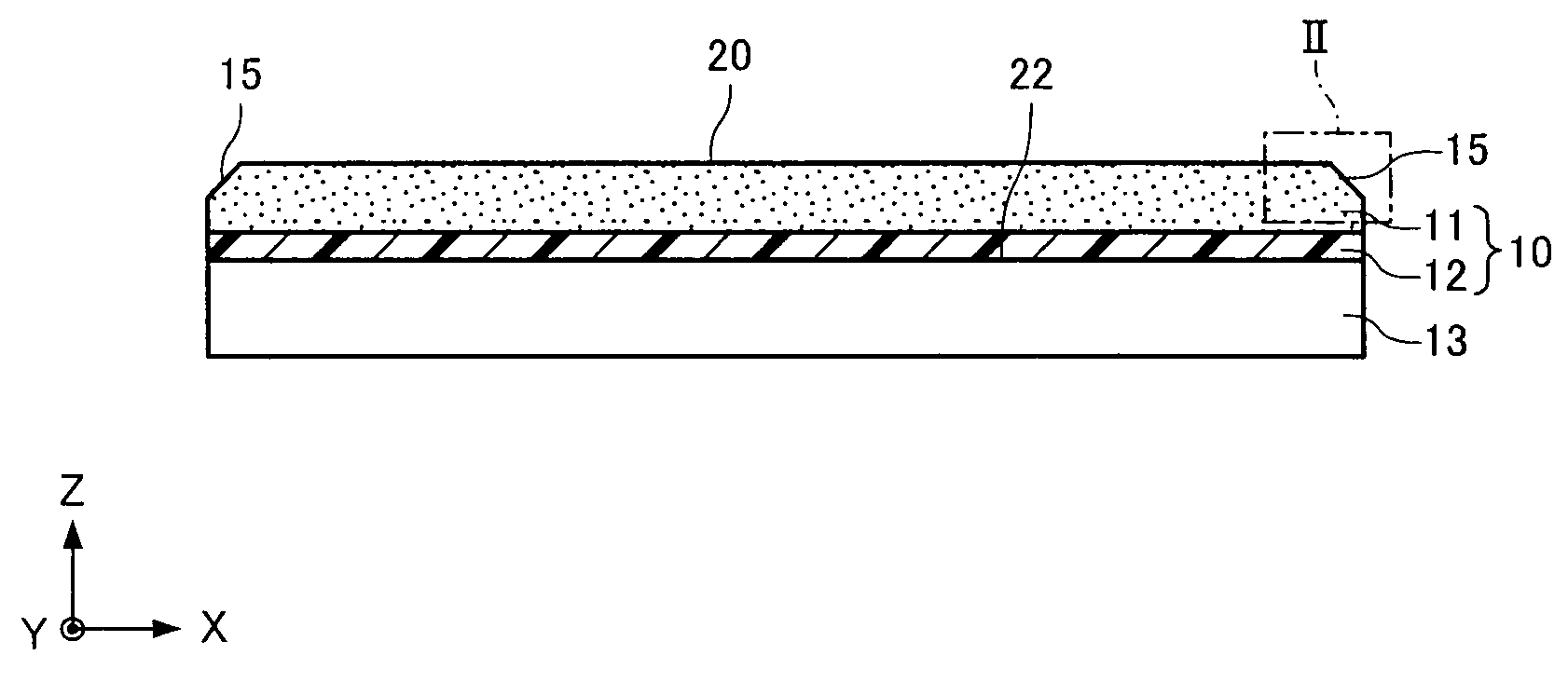

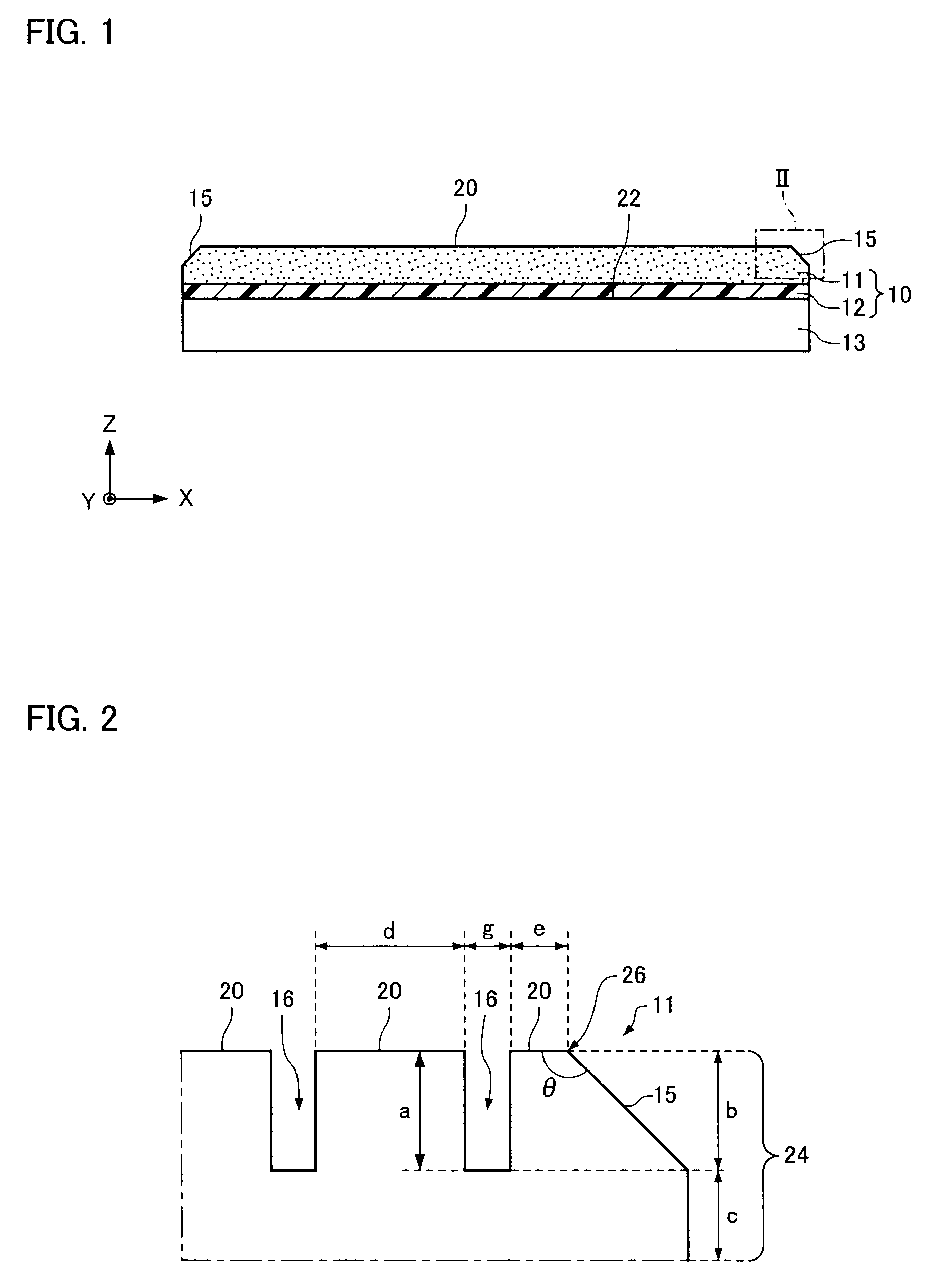

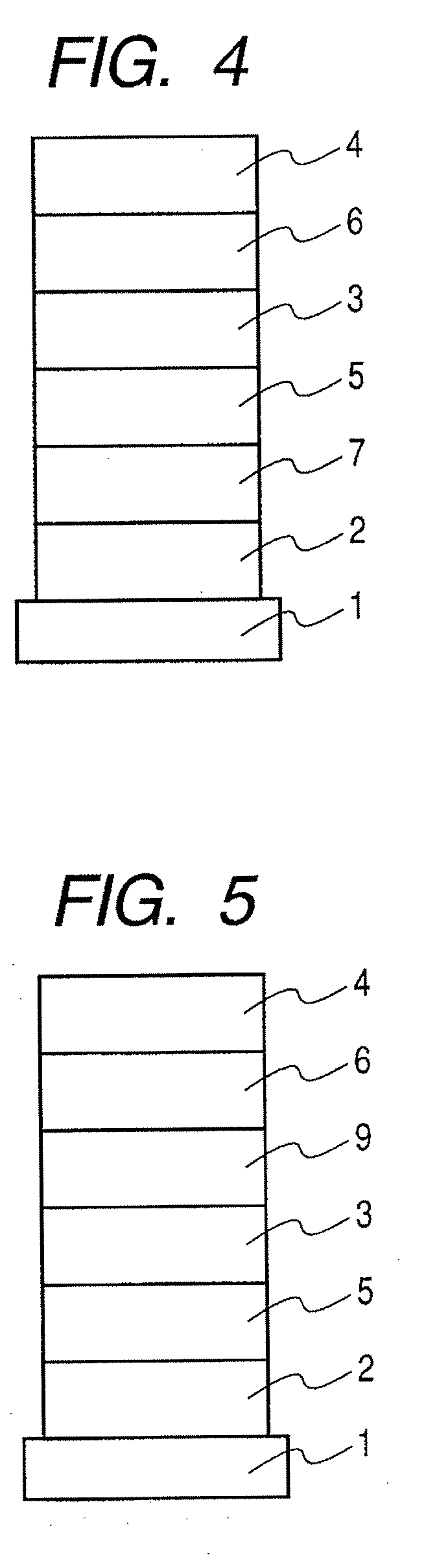

Optical Information Recording Medium, and Recording Method and Manufacturing Method Thereof

InactiveUS20090010135A1Easily record informationExcellent durabilityRecord information storageOptical beam guiding meansRefractive indexHigh density

To provide an optical information-recording medium that can easily record information at high density and has excellent durability at low cost.The optical information-recording medium includes a diamond-like carbon (DLC) layer (2) deposited on a substrate (1), in which information is recorded on the optical information-recording medium by irradiating recording spot regions selected from a plurality of recording spot regions with an energy beam (5) to increase the refractive index of the DLC layer (2) in the irradiated recording spot regions.

Owner:SUMITOMO ELECTRIC IND LTD

Chemical mechanical polishing pad

ActiveUS20090209185A1Reduce scratchExcellent durabilityAbrasion apparatusSemiconductor/solid-state device manufacturingChemical-mechanical planarizationEngineering

Owner:JSR CORPORATIOON

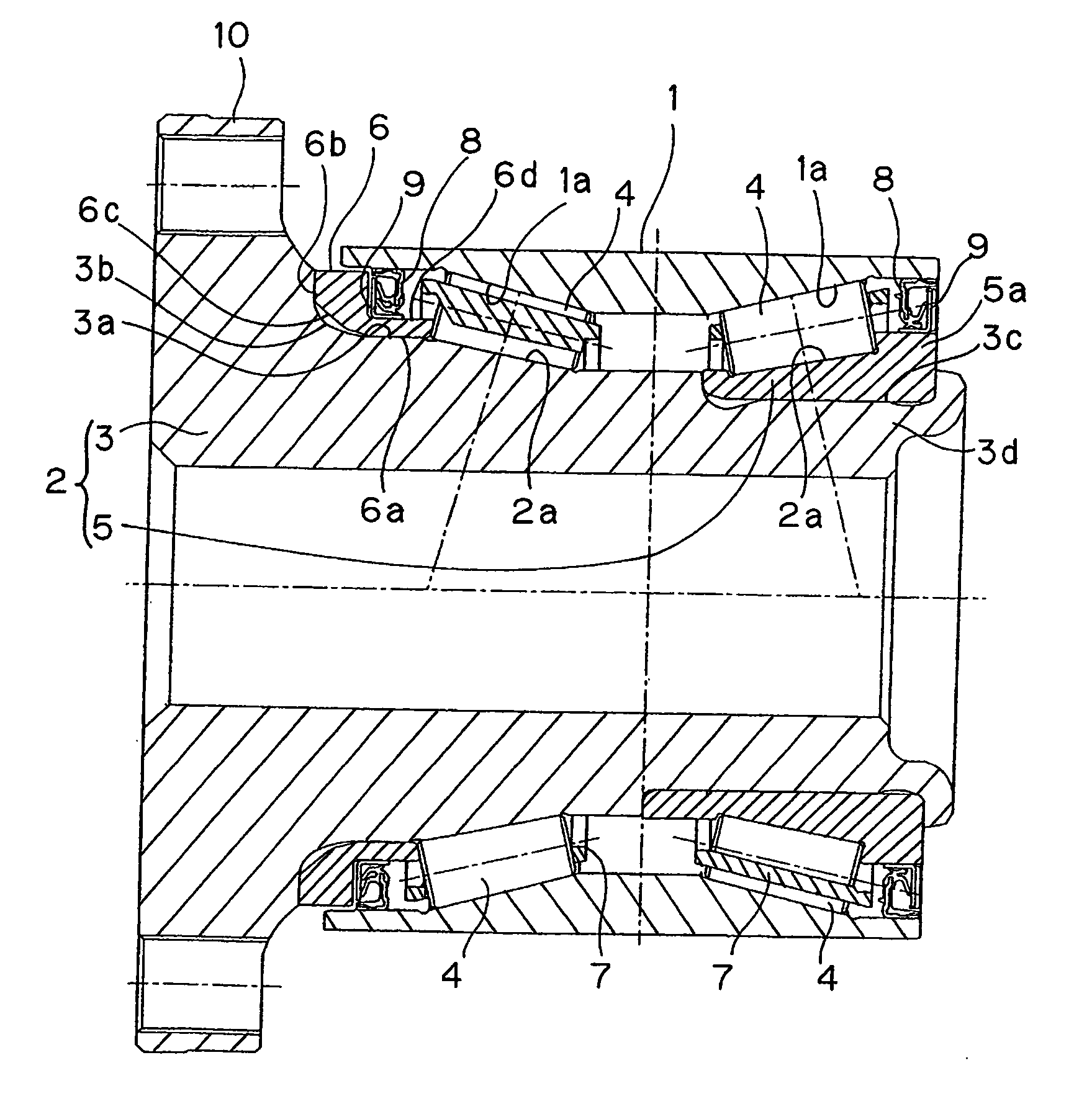

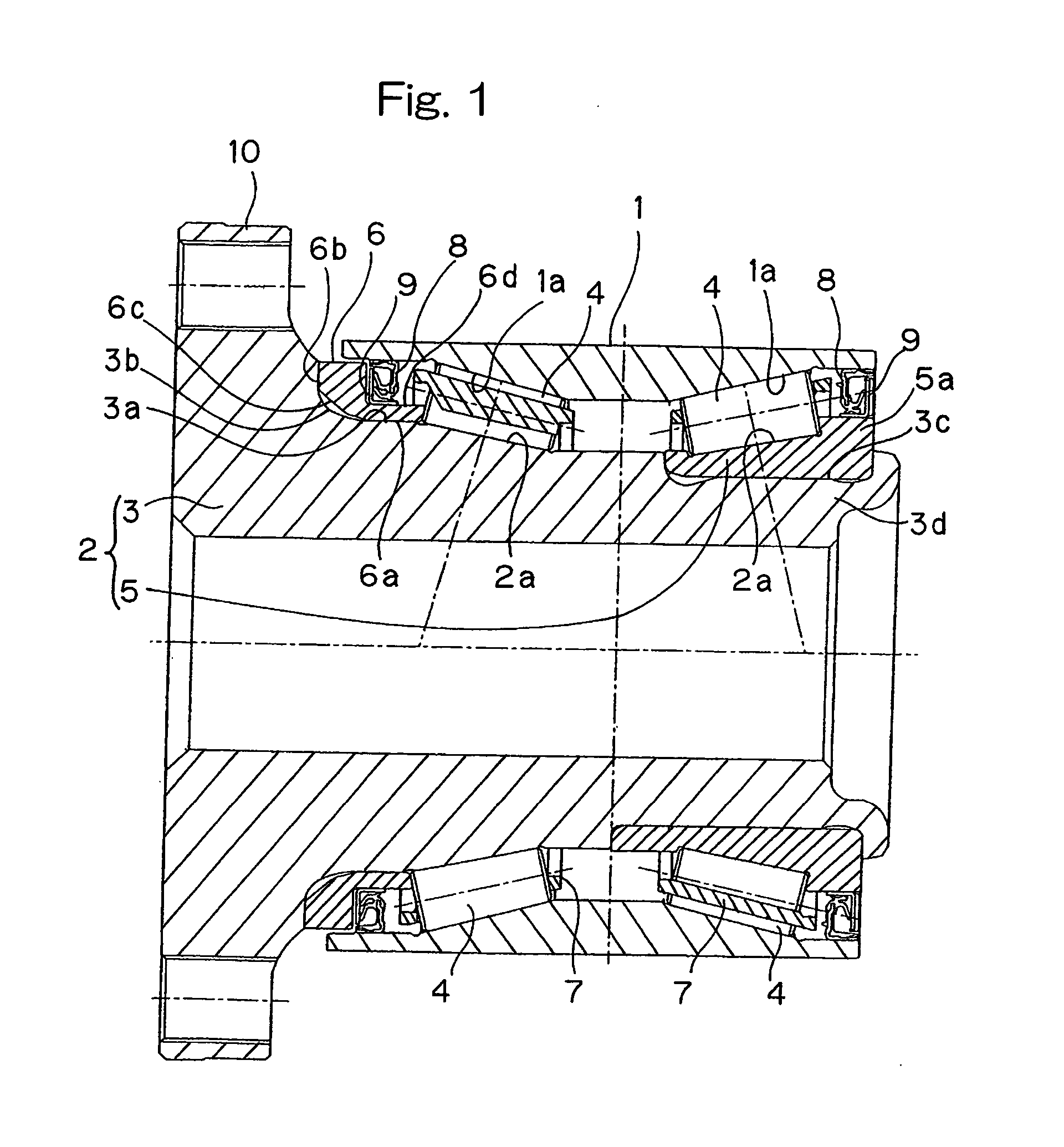

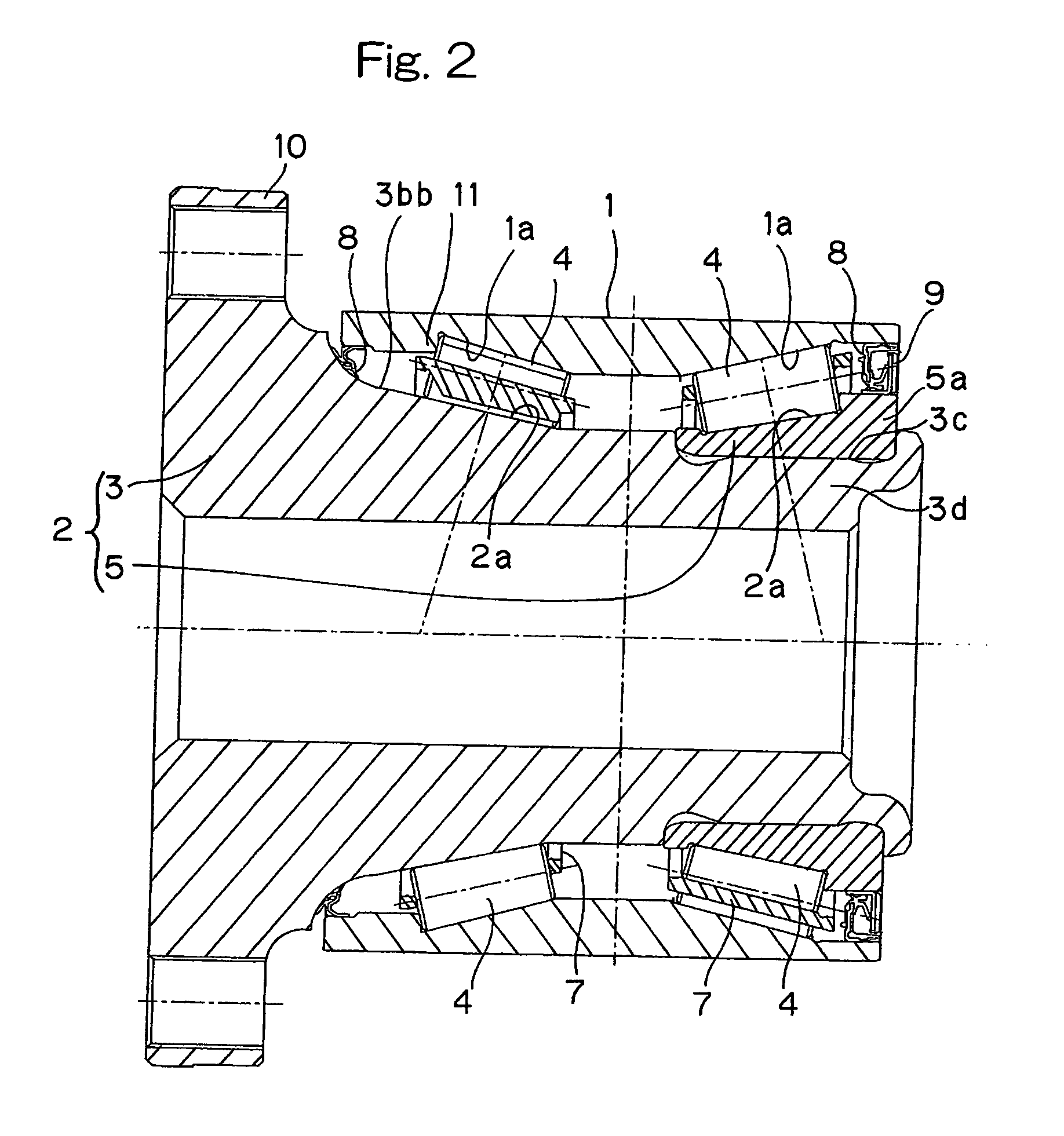

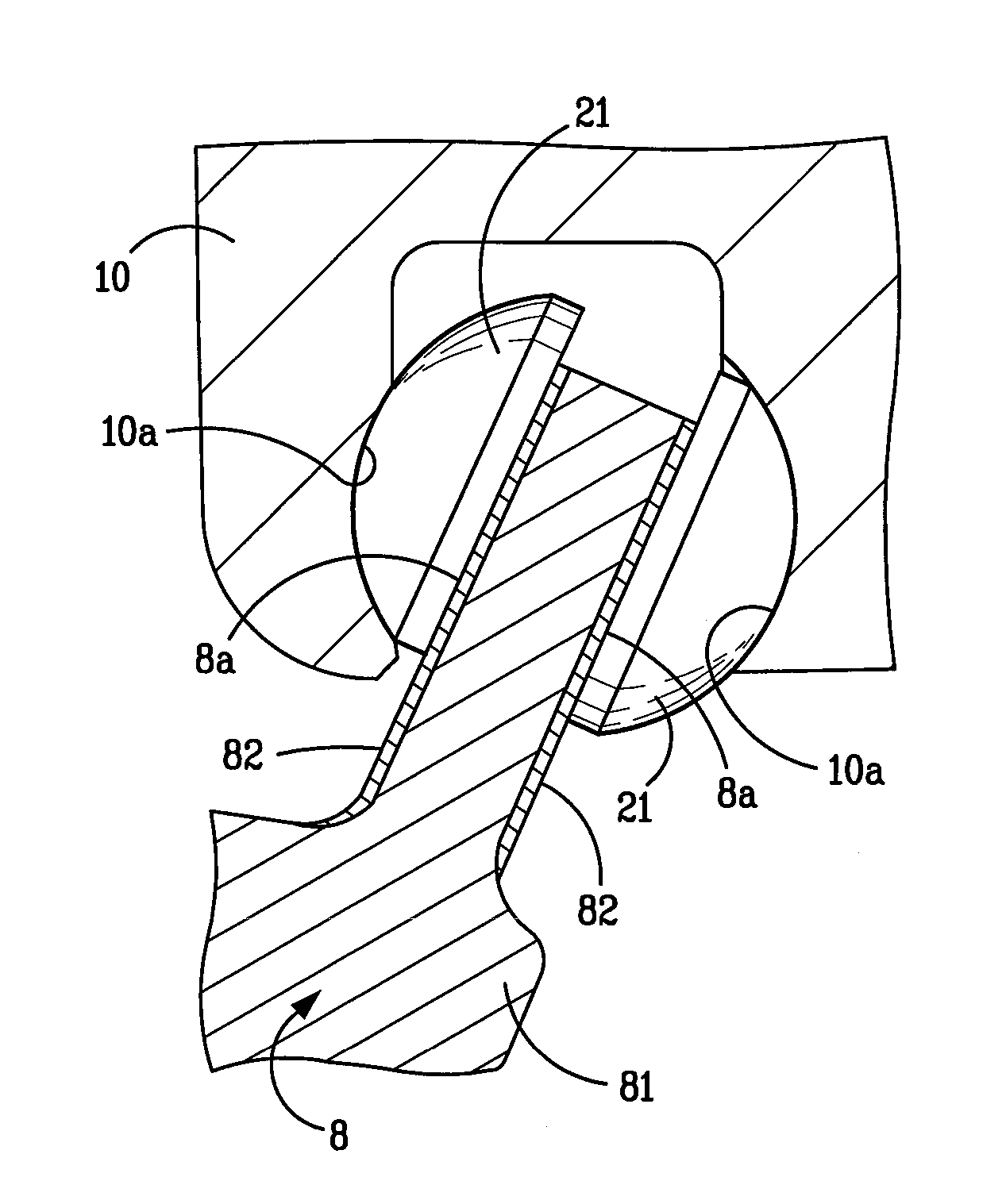

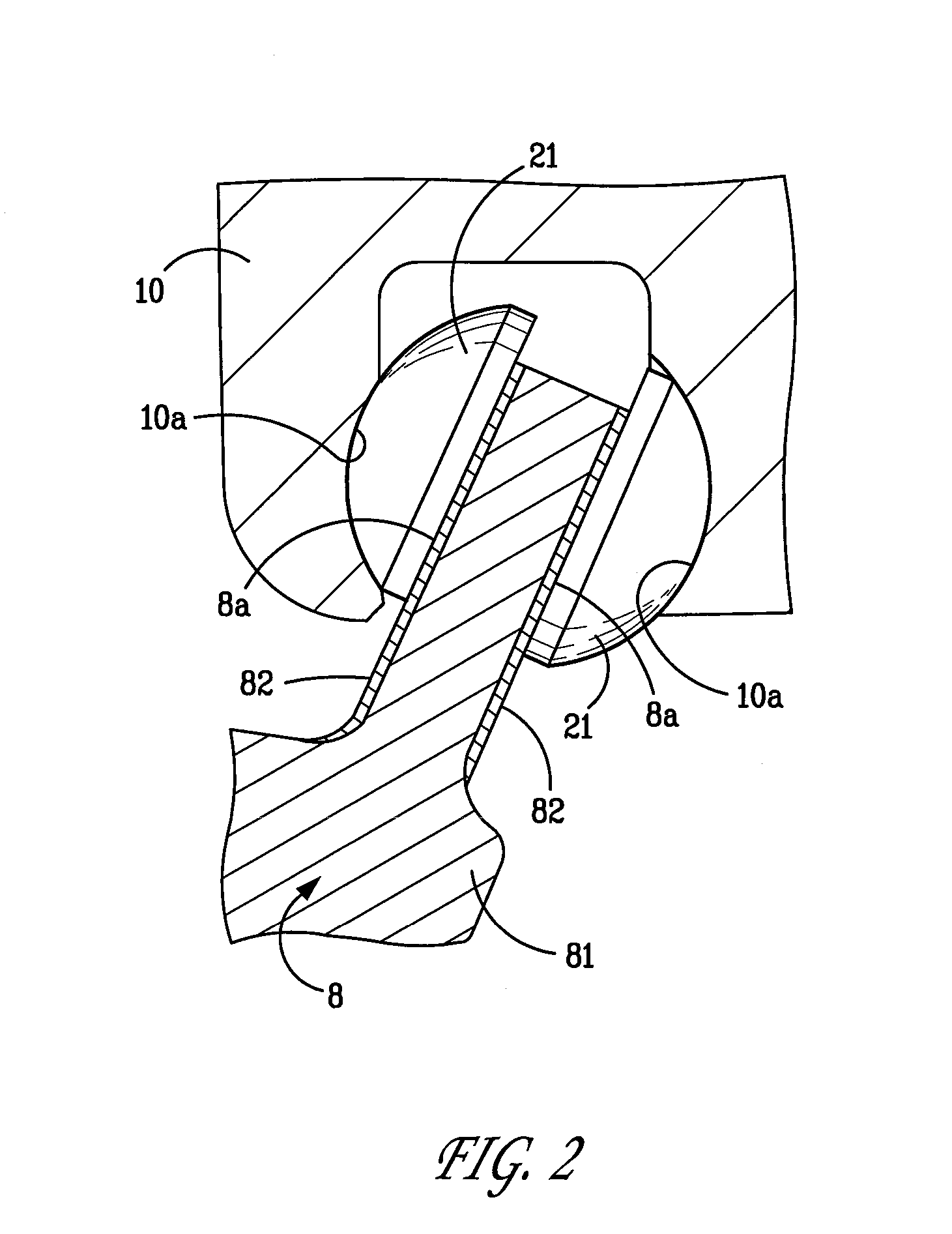

Tapered roller bearing device for wheel

InactiveUS20070031079A1Stress concentration lessenExcellent durabilityRoller bearingsHubsEngineeringSingle row

To provide a tapered roller bearing assembly for supporting a vehicle wheel, in which stress concentration in the vicinity of a collar adjacent a hub flange is lessened to improve the durability, the assembly includes an outer member (1) having a plurality of tapered rolling faces (1a), an inner member (2) having a corresponding number of tapered rolling faces (2a), a corresponding number of rows of tapered rollers (4). The inner member (2) includes a hub axle (3) with a hub flange (10) adjacent an outboard end, and a single row inner race (5) mounted externally on an inboard end of the hub axle (3). The rolling faces (2a) are formed on the hub axle (3) and the single row inner race (5). A collar ring (6) in contact with the large ends of the tapered rollers (4) of the outboard row is provided as a flange ring (6) separate from the hub axle (3) and fitted on the hub axle (3) at a position adjacent the hub flange (10).

Owner:NTN CORP

Polyimide film and process for producing the same

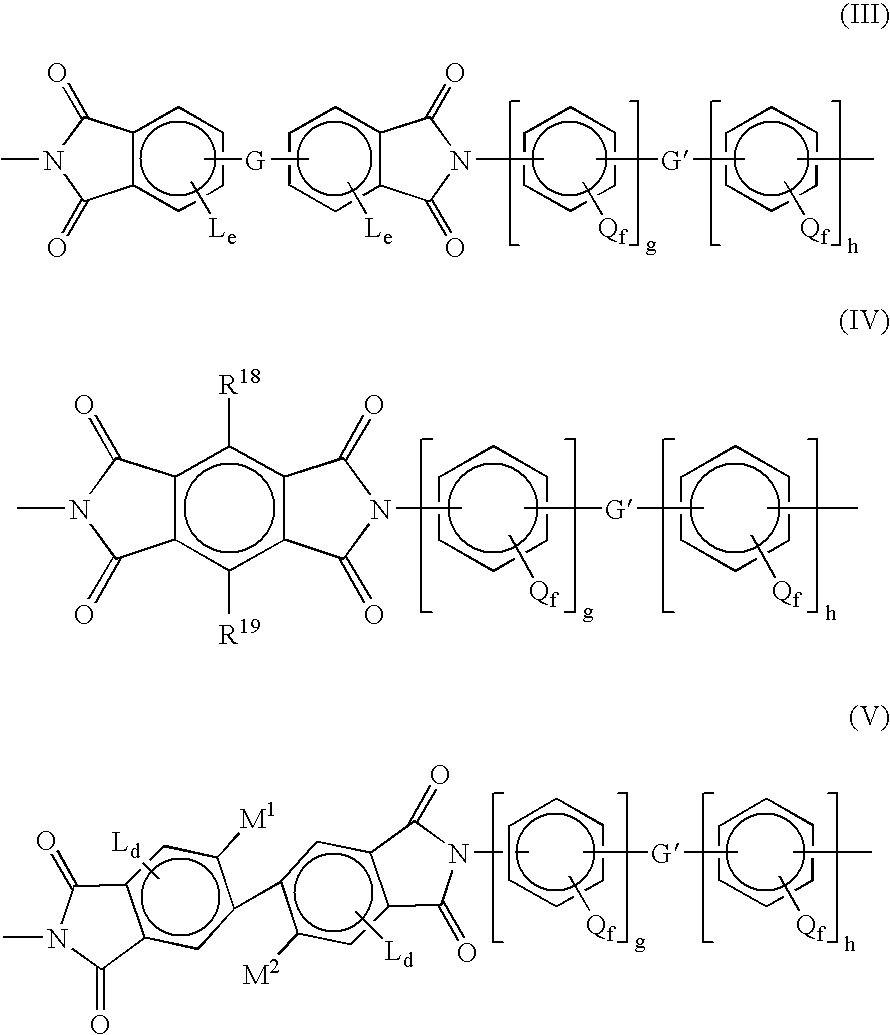

InactiveUS20050221023A1Excellent durabilityIncreased durabilityLiquid crystal compositionsCoatingsChemistryPolyimide

A polyimide film having a biaxial optical anisotropy and excellent durability is provided. A solution of polyimide having an imidization ratio of 98% to 100% is applied onto a plastic base, and then the solution is dried, thus forming a polyimide coating. Subsequently, the polyimide coating is stretched together with the plastic base so as to satisfy nx>ny>nz, wherein nx and ny indicate a refractive index in a direction exhibiting a maximum refractive index within a plane and that in a direction perpendicular thereto and nz indicates a refractive index in a thickness direction.

Owner:NITTO DENKO CORP

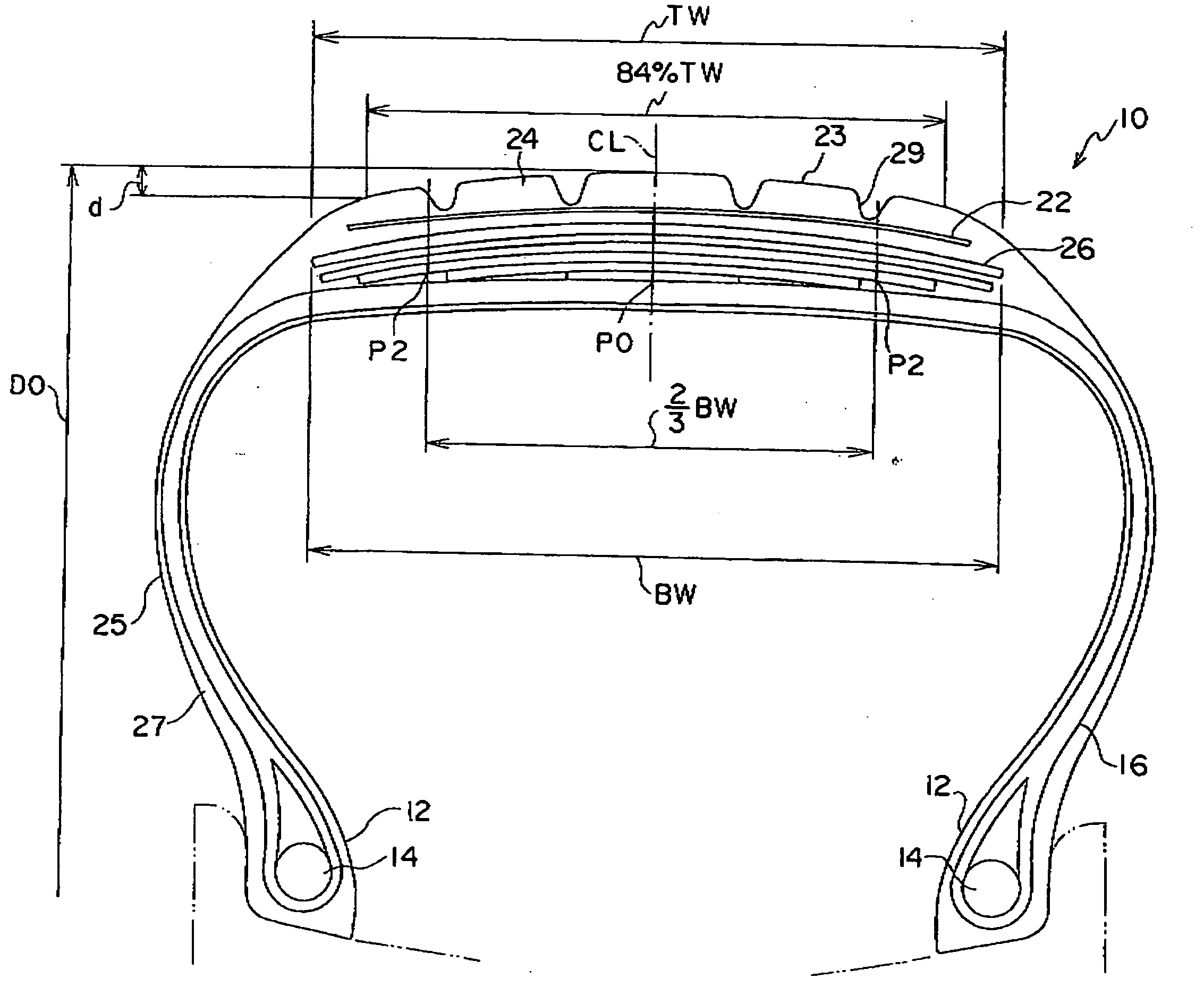

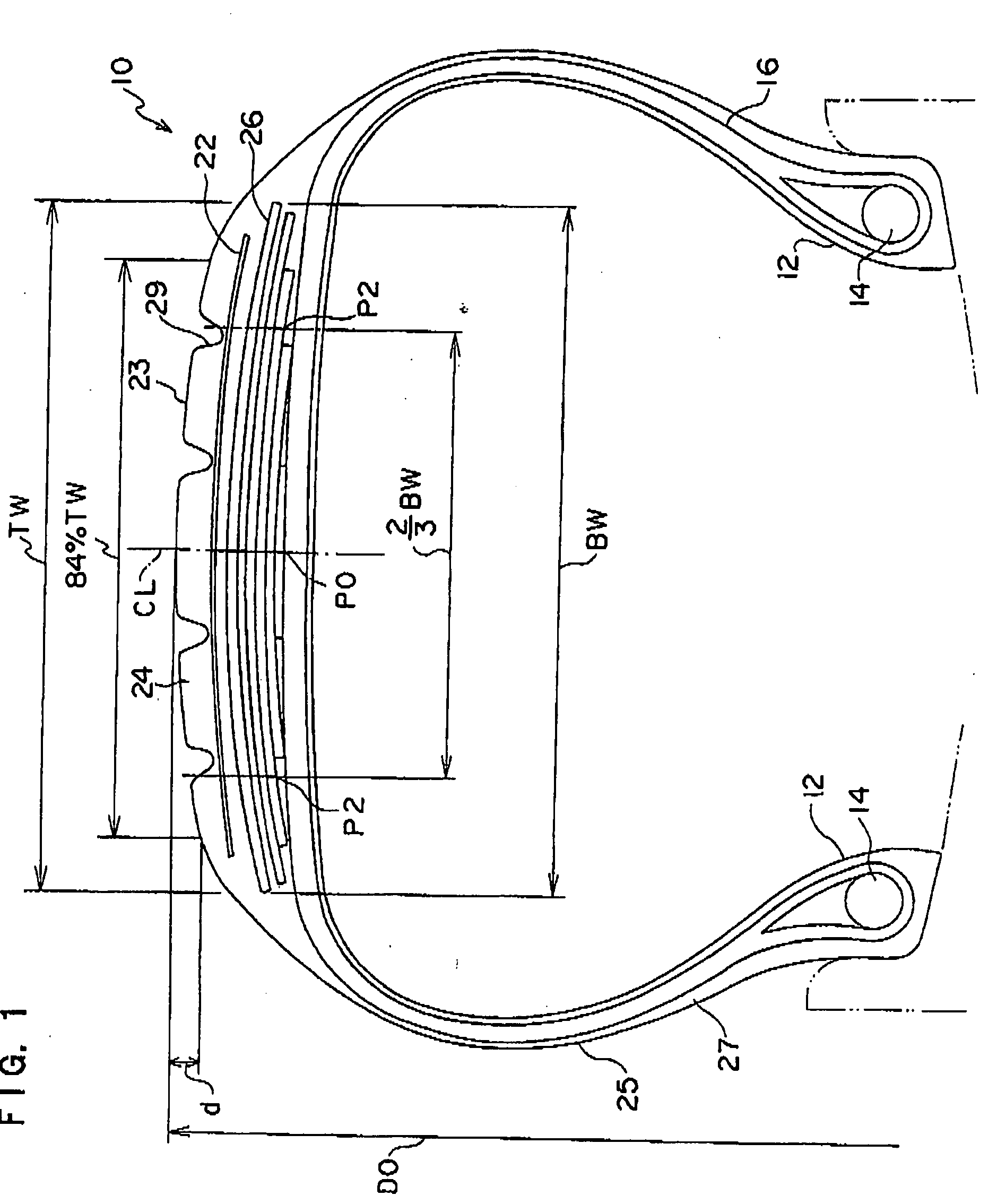

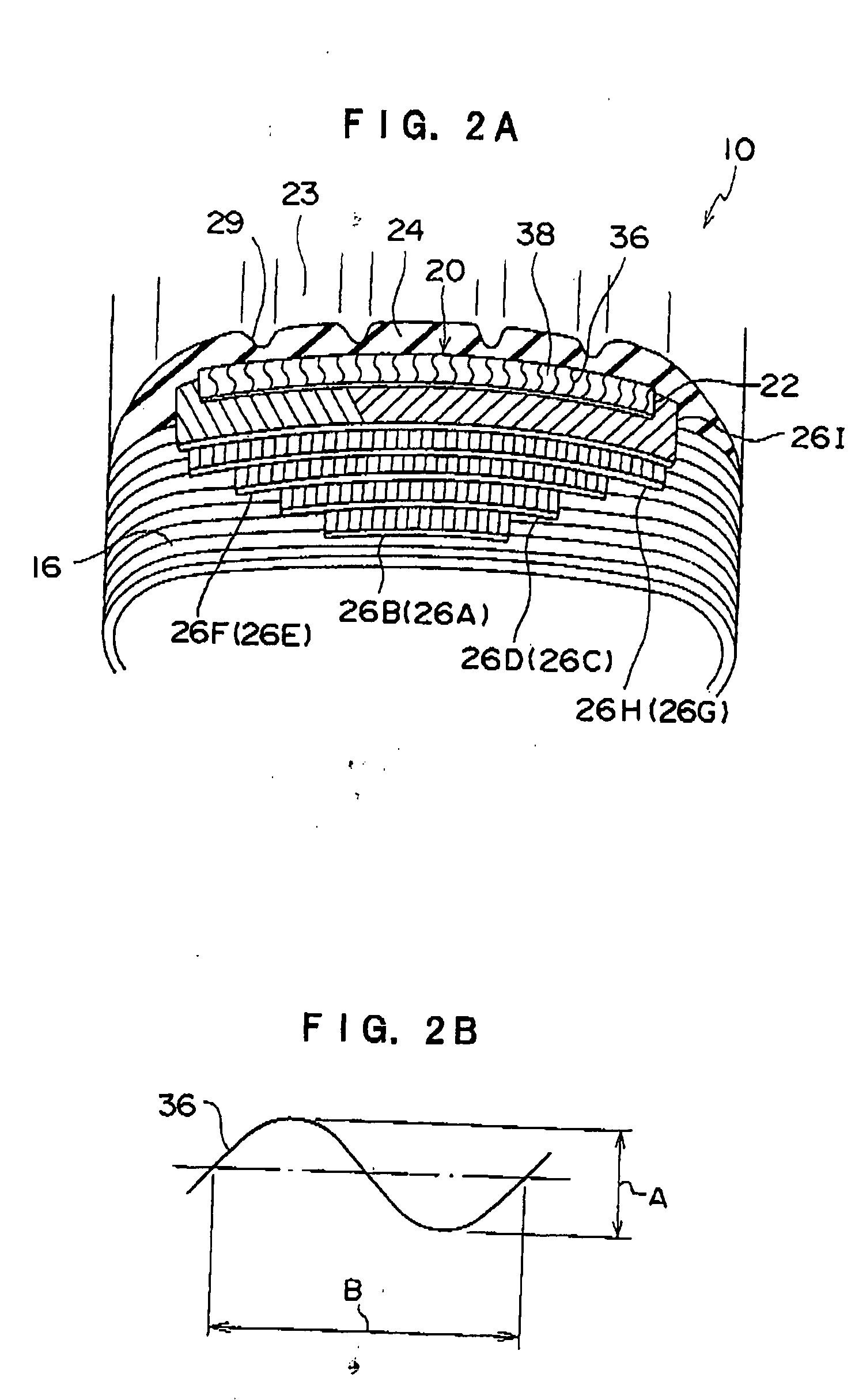

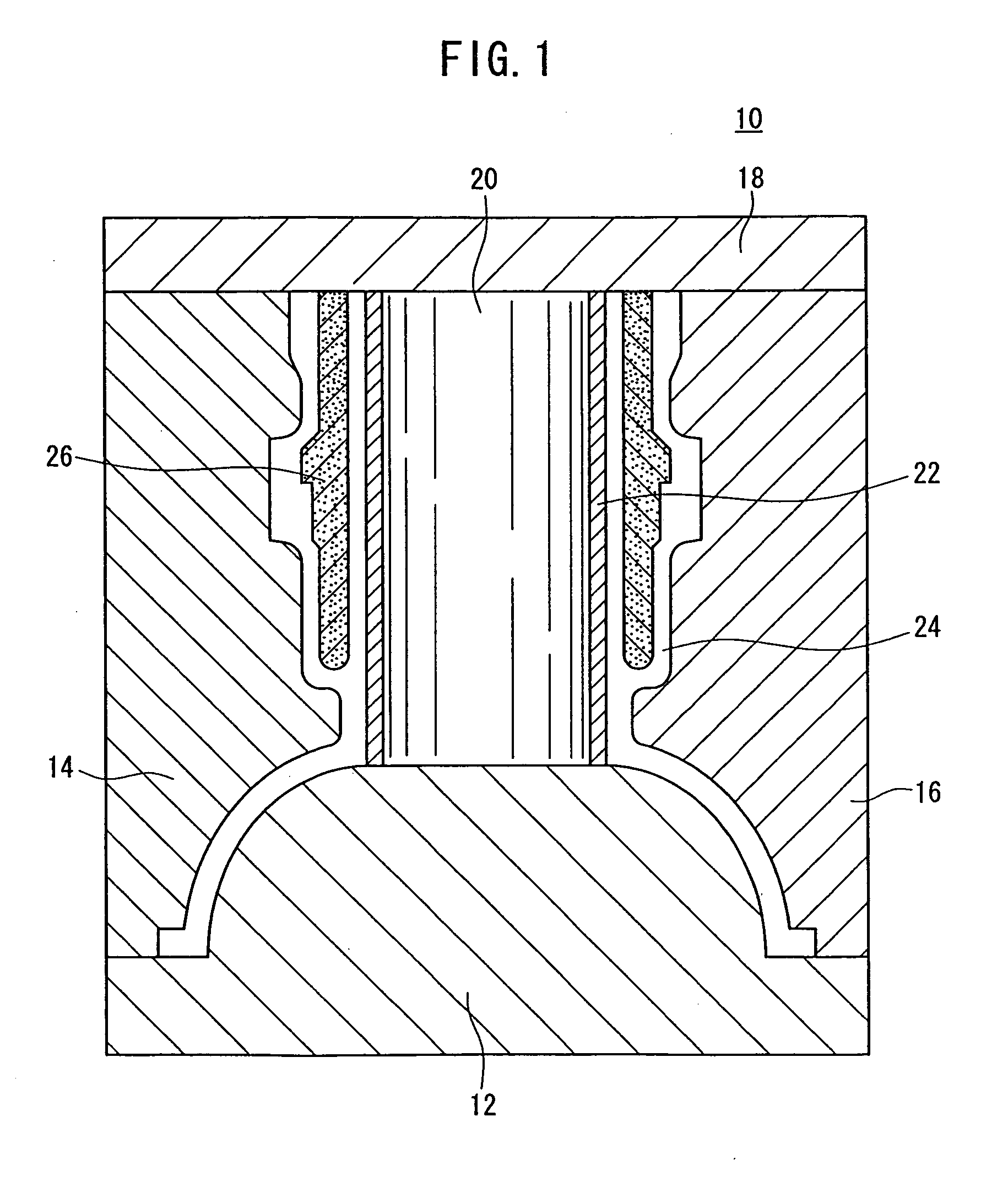

Pneumatic Radial Tire

InactiveUS20080277037A1Excellent durabilityIncreased durabilityPneumatic tyre reinforcementsTyre tread bands/patternsAirplaneInternal pressure

A pneumatic tire for airplanes that assures a good high-speed durability and wear characteristics without its excellent durability against foreign object being impaired is provided. The number of plies of the main belt layer 26 is substantially continuously decreased from the crown center part P0 to the shoulder part, and if the circumferential rigidity in the crown center part P0 of the main belt layer 26 and the circumferential rigidity of the main belt layer 26 at the position P2 which provides ⅔ of the width of the main belt layer 26 are M0 and M2, respectively, the ratio M2 / M0 between both is set at a value greater than 0.2 and smaller than 0.8, whereby, while the quantity of materials used for the main belt layer 26 being minimized, the amount of the tread rubber circumferential elongation in the tread central region at the time of air filling to a prescribed internal pressure and at the time of high speed revolution can be efficiently suppressed for suppressing the radial growth of the tire. Because the amount of circumferential elongation of the tread rubber layer 24 is suppressed, and thus the degree of tension of the tread rubber layer 24 is lowered, the resistance to penetration of a foreign object is increased, and even if a foreign object should stick into the tire, the growth of the crack can be suppressed.

Owner:BRIDGESTONE CORP

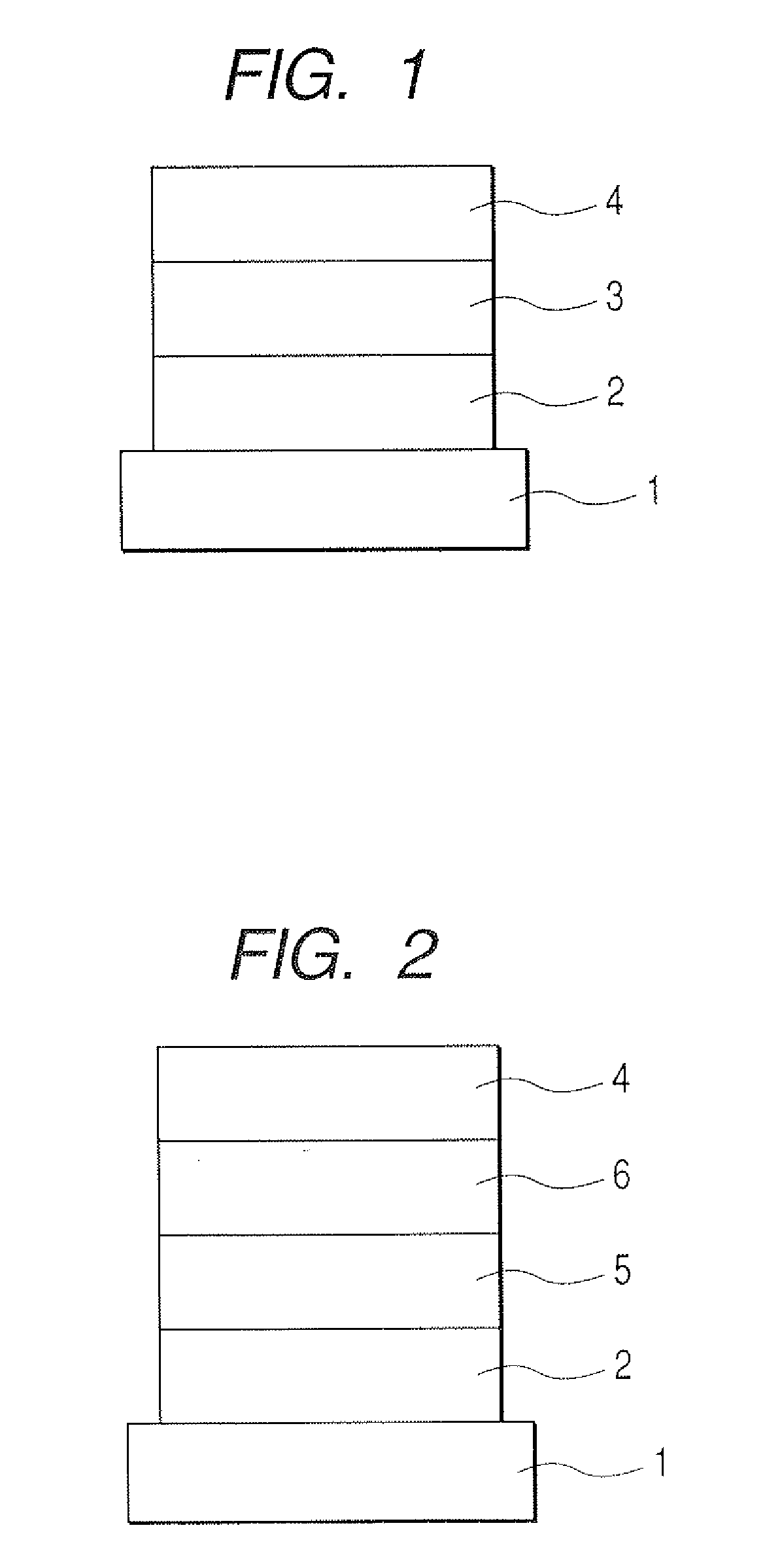

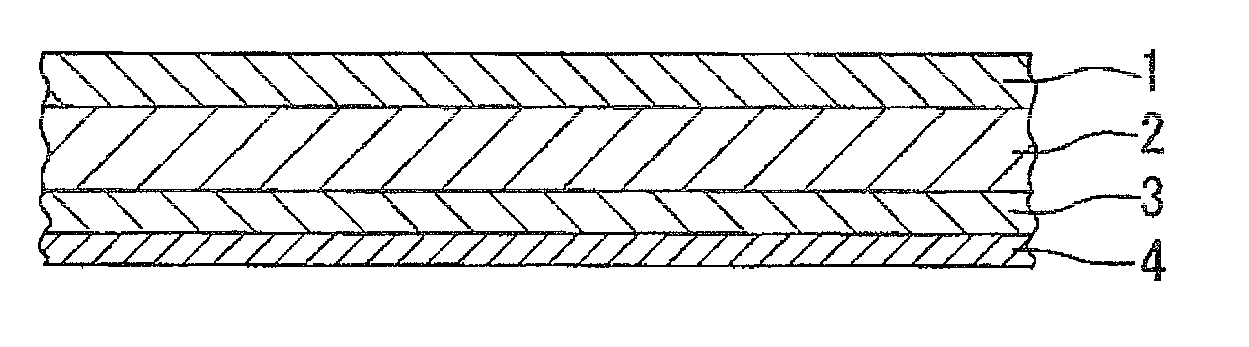

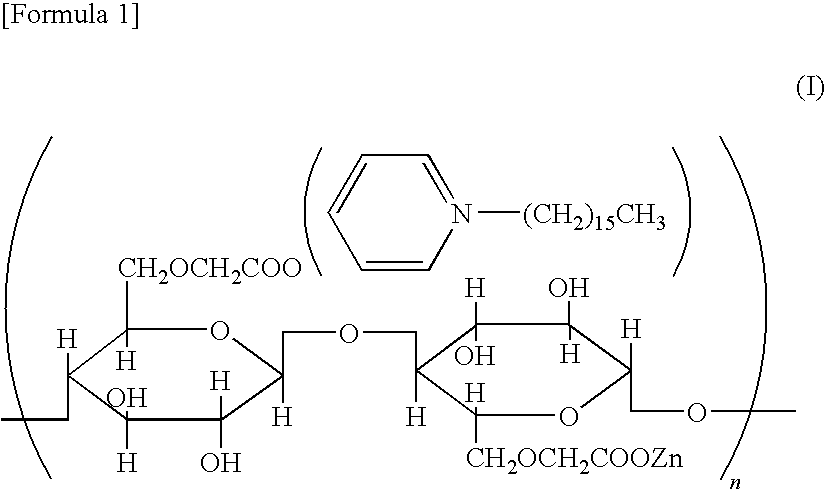

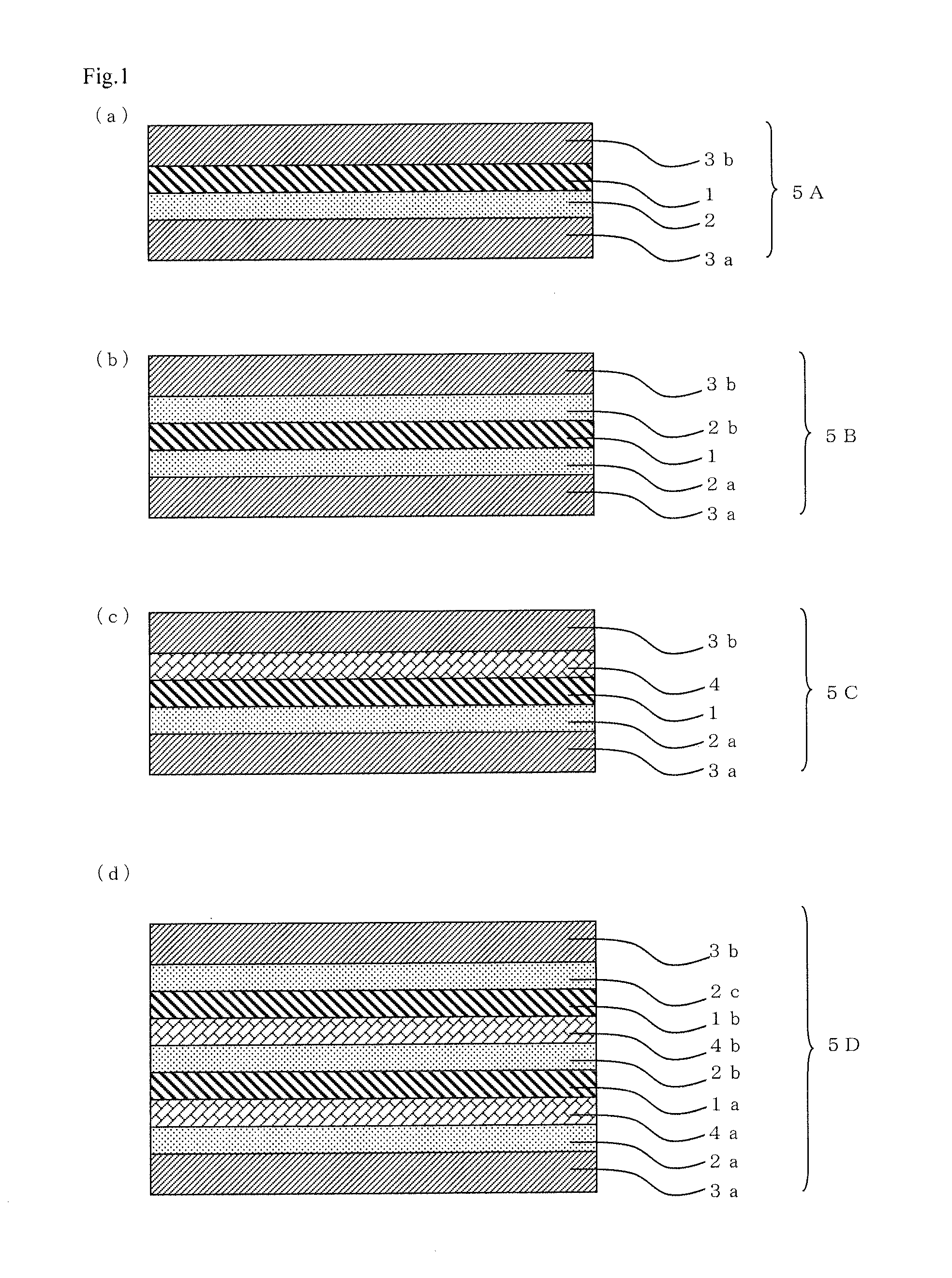

Gas barrier laminate, method for producing same, member for electronic devices, and electronic device

ActiveUS20150099094A1Excellent gas barrier capabilityExcellent durabilityFibre treatmentSynthetic resin layered productsStatic friction coefficientStatic friction

The present invention provides: a gas barrier laminate comprising a base, a primer layer, and a gas barrier layer, the primer layer and the gas barrier layer being sequentially stacked on at least one side of the base, the primer layer having a modulus of elasticity at 90° C. of 1.6 GPa or more, and a coefficient of static friction between a surface of one side of the gas barrier laminate and a surface of the other side of the gas barrier laminate being 0.35 to 0.8; a method for producing the gas barrier laminate; an electronic device member comprising the gas barrier laminate; and an electronic device.

Owner:LINTEC CORP

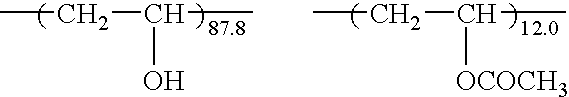

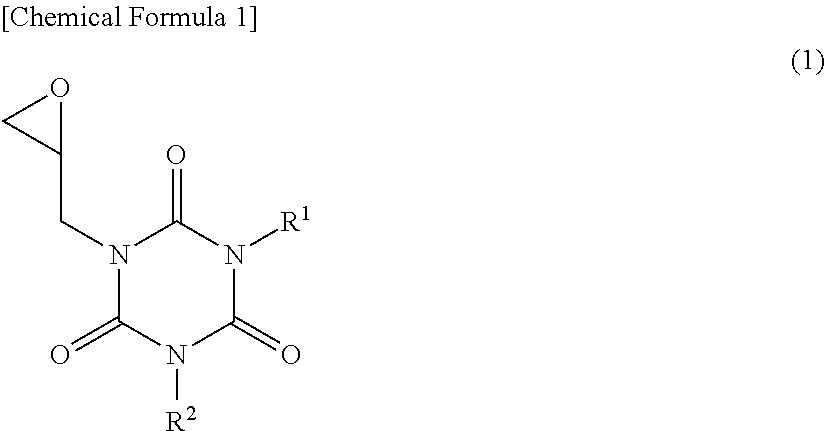

Pressure-sensitive adhesive composition, pressure-sensitive adhesive and optical film

InactiveUS20110236605A1Enhance durabilityExcellent durabilityLiquid crystal compositionsPolyureas/polyurethane adhesivesPressure sensitiveChemistry

A pressure-sensitive adhesive composition which is excellent in durability under high temperature and humidity conditions and can thus inhibit bright defect even when applied to a large-sized optical film; a pressure-sensitive adhesive; and an optical film. A pressure-sensitive adhesive composition comprising an acrylic copolymer (A) bearing a reactive functional group, an acrylic copolymer (B) and an isocyanate compound (C), wherein the quantity of the isocyanate compound (C) is 5 to 30 parts by weight per 100 parts by weight of a mixture of the acrylic copolymer (A) and the acrylic copolymer (B) and the elongation at break and 200% modulus as determined at 25 degrees C. by the tensile test are 300 to 1000% and 0.2 to 3 N / mm2 respectively.

Owner:NIPPON CARBIDE KOGYO KK

Ceramic heater and gas sensor element

ActiveUS20130048627A1Excellent durabilityPrevent shortHeater elementsMaterial analysis by electric/magnetic meansCeramic heaterEngineering

A ceramic heater in which a heater pattern is formed on a ceramic substrate is disclosed. The heater pattern has a heating element and lead portions. The heating element has heating connection ends and the lead portions have lead connection ends. The heating element and the lead portions are connected at joints which are formed by overlaying the heating connection ends and the lead connection ends. The heater pattern, as viewed in a direction perpendicular to a plane in which the heater pattern is formed, has inwardly recessed concavities formed on both width wise sides of each of the joints. The concavities include portions in each of which a profile of the respective heating connection end crosses a profile of the respective lead connection end.

Owner:DENSO CORP

Industrial waste residue activating grinding aid

InactiveCN1451624APromotes hydration activityAchieve clinker effectOther chemical processesSolid waste disposalBiochemical engineeringElectric consumption

An activating grinding aid for industrial waste residues is prepared from catalyst (1-8 wt.%), activating agent (30-80 wt.%), setting regulator (0-20 wt.%), grinding aid (3-12 wt.%) and carrier (3-30wt.%). Its advantages are effective use of industrial waste residues, low electric consumption of grinder, and improve cement performance.

Owner:尹小林

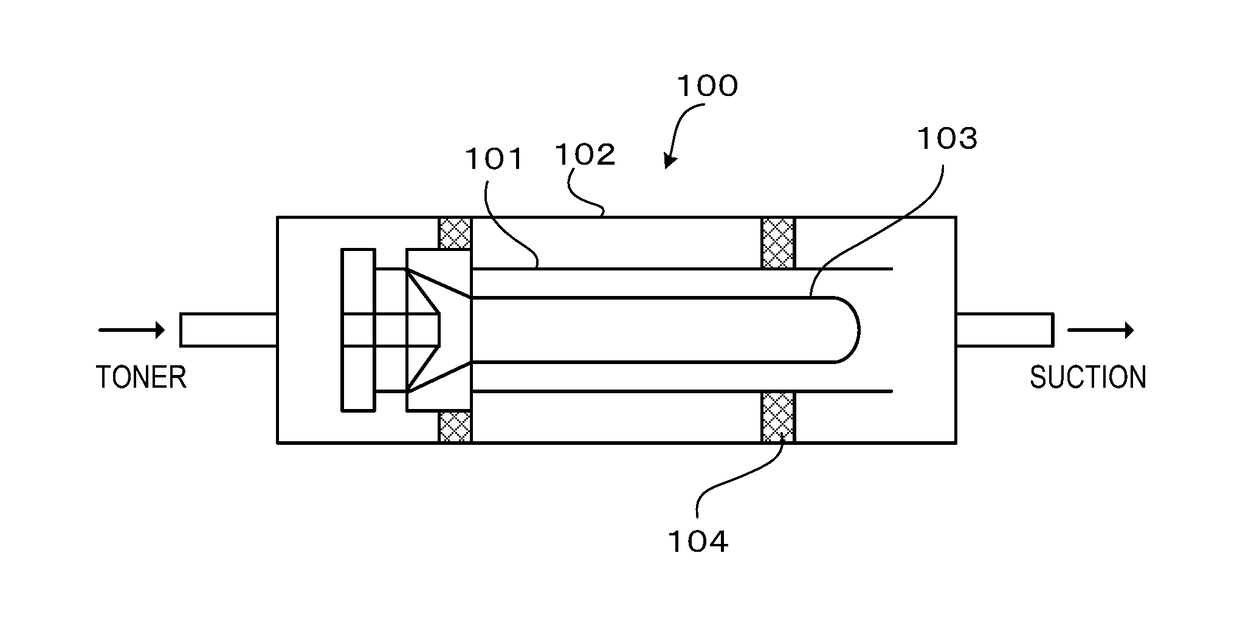

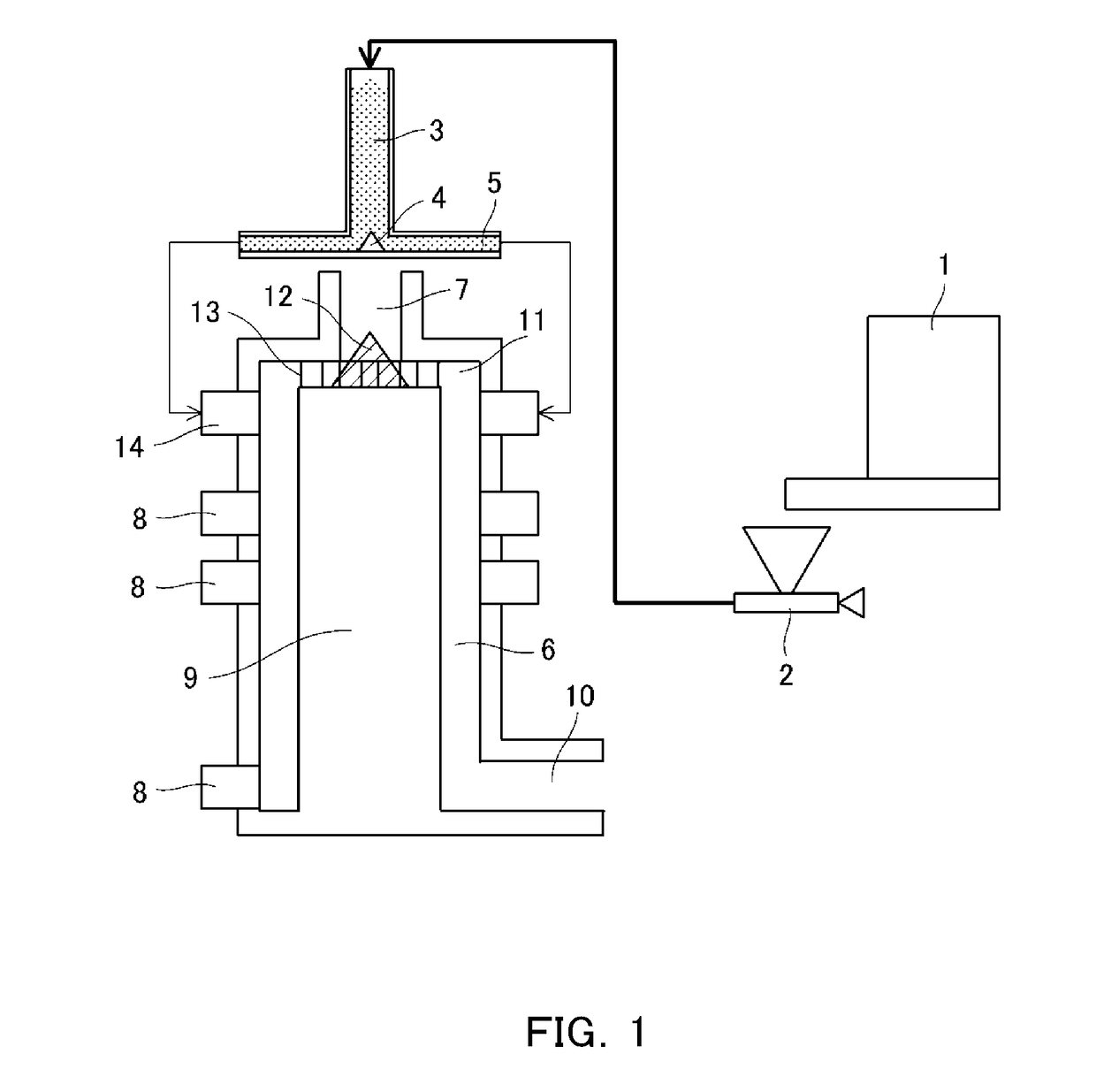

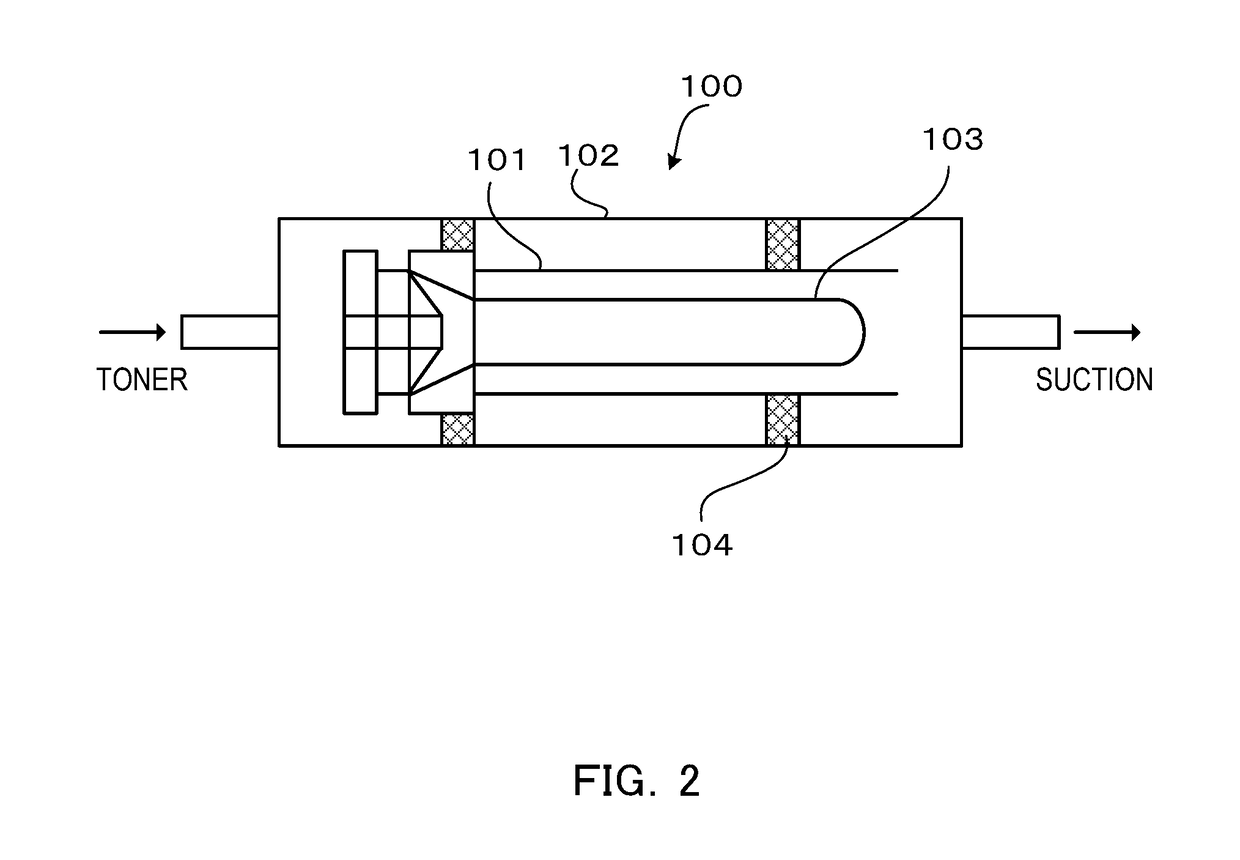

Toner

By controlling the migration to the toner particle surface of the crystalline polyester present in the toner particle, a toner is provided that exhibits an excellent durability in long-term use, a stable charging performance after holding in a high-temperature, high-humidity environment, and an excellent low-temperature fixability, in which the toner having a toner particle that contains an amorphous resin, a crystalline polyester, and a wax, wherein the toner particle includes, at the surface thereof, a coat layer containing a cyclic polyolefin resin.

Owner:CANON KK

Mold for casting and method of surface treatment thereof

InactiveUS20060201650A1High hardnessExcellent durabilityFoundry mouldsSolid state diffusion coatingHardnessShot peening

A method of the surface treatment of a mold for casting, which comprises subjecting a cavity surface of a fixed mold made by the use of a SCM420 material to first shot peening, a sulfurizing-nitriding treatment and second shot peening. The resulting cavity surface of the fixed mold exhibits a high hardness of 700 or higher in terms of Vickers hardness due to the presence of a sulfurized and nitrided layer, and further has a compression residual stress of more than 1200 Mpa and a largest height, which is a surface roughness value defined by JIS standard, of 8 μm or less.

Owner:HONDA MOTOR CO LTD

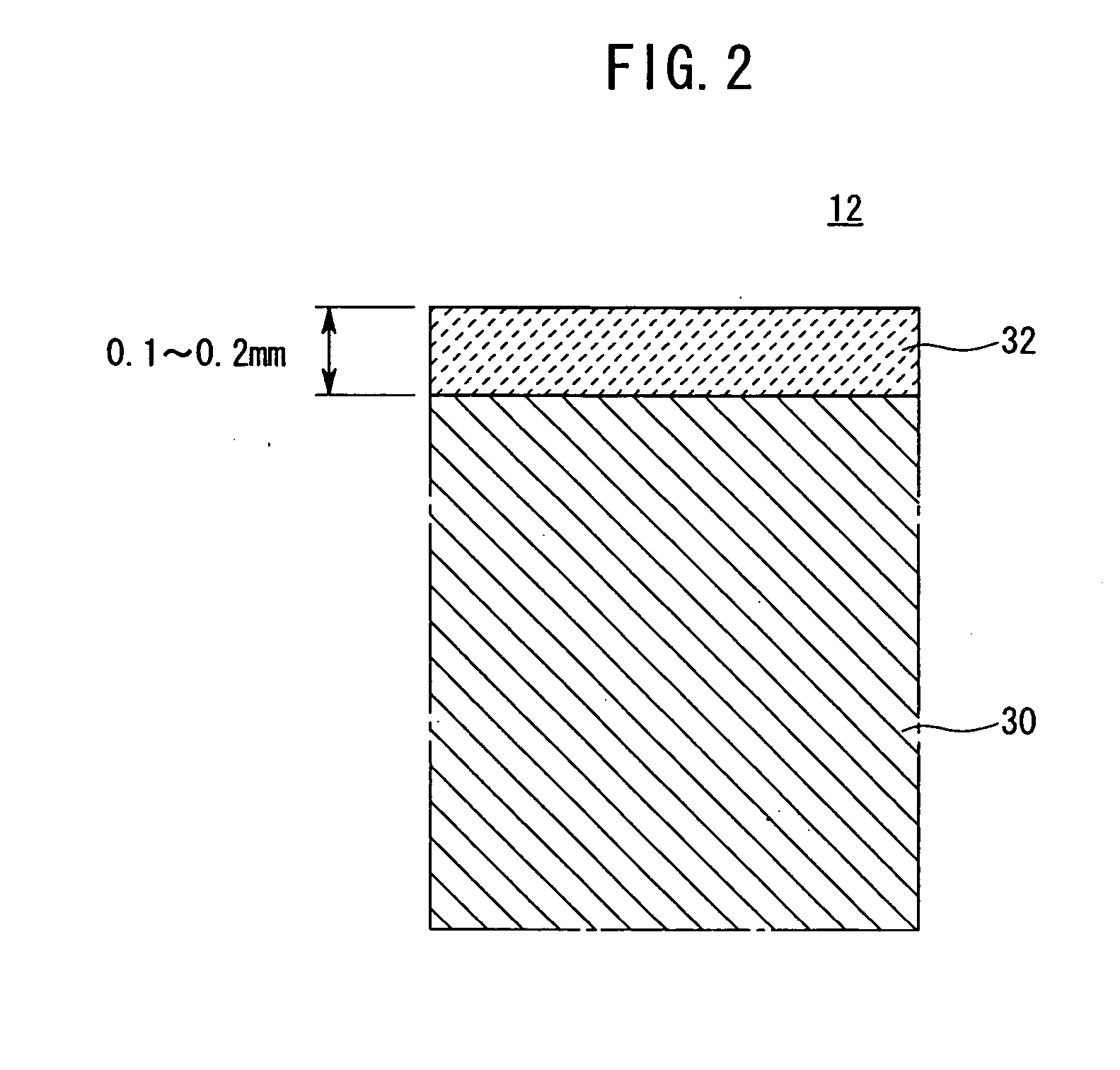

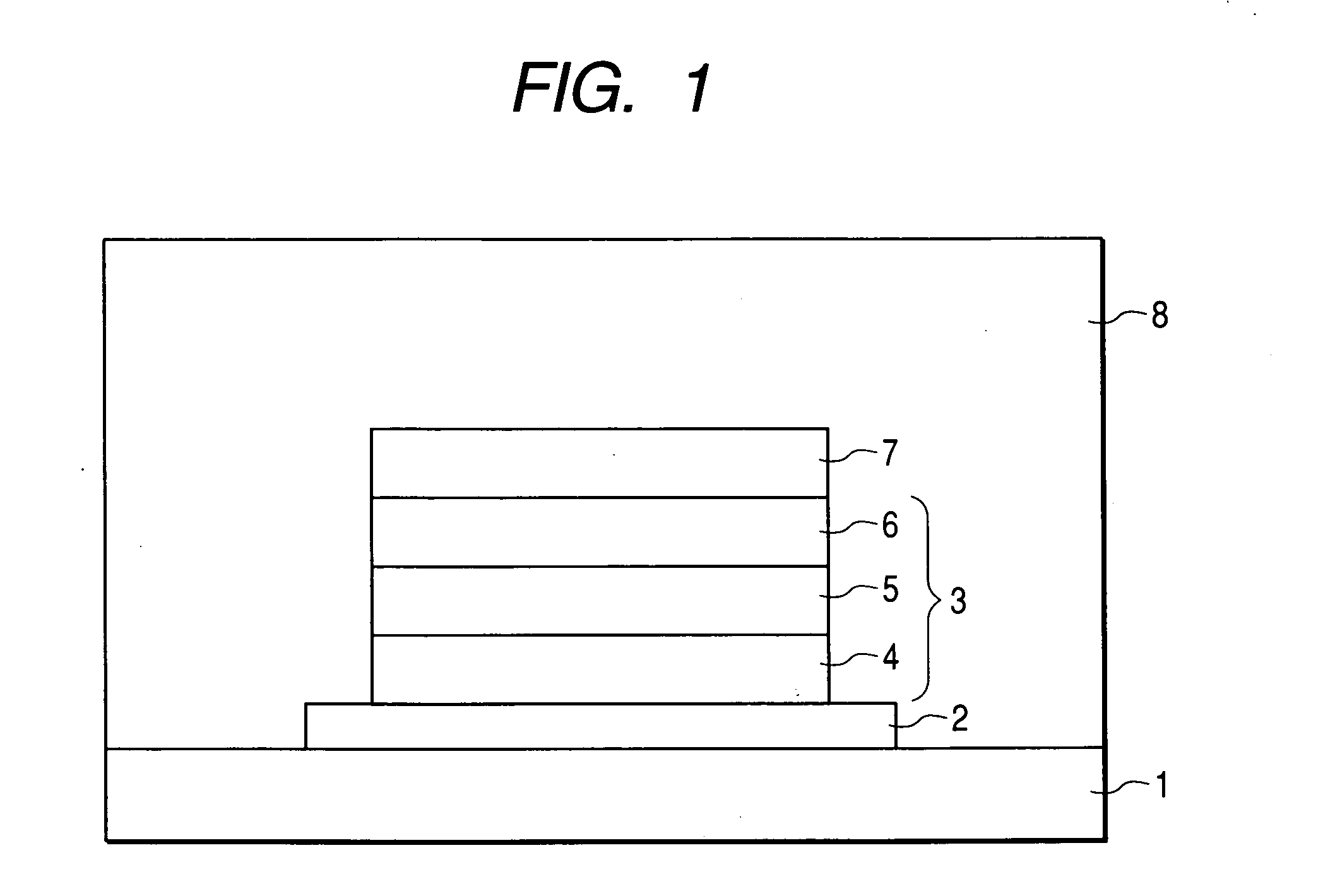

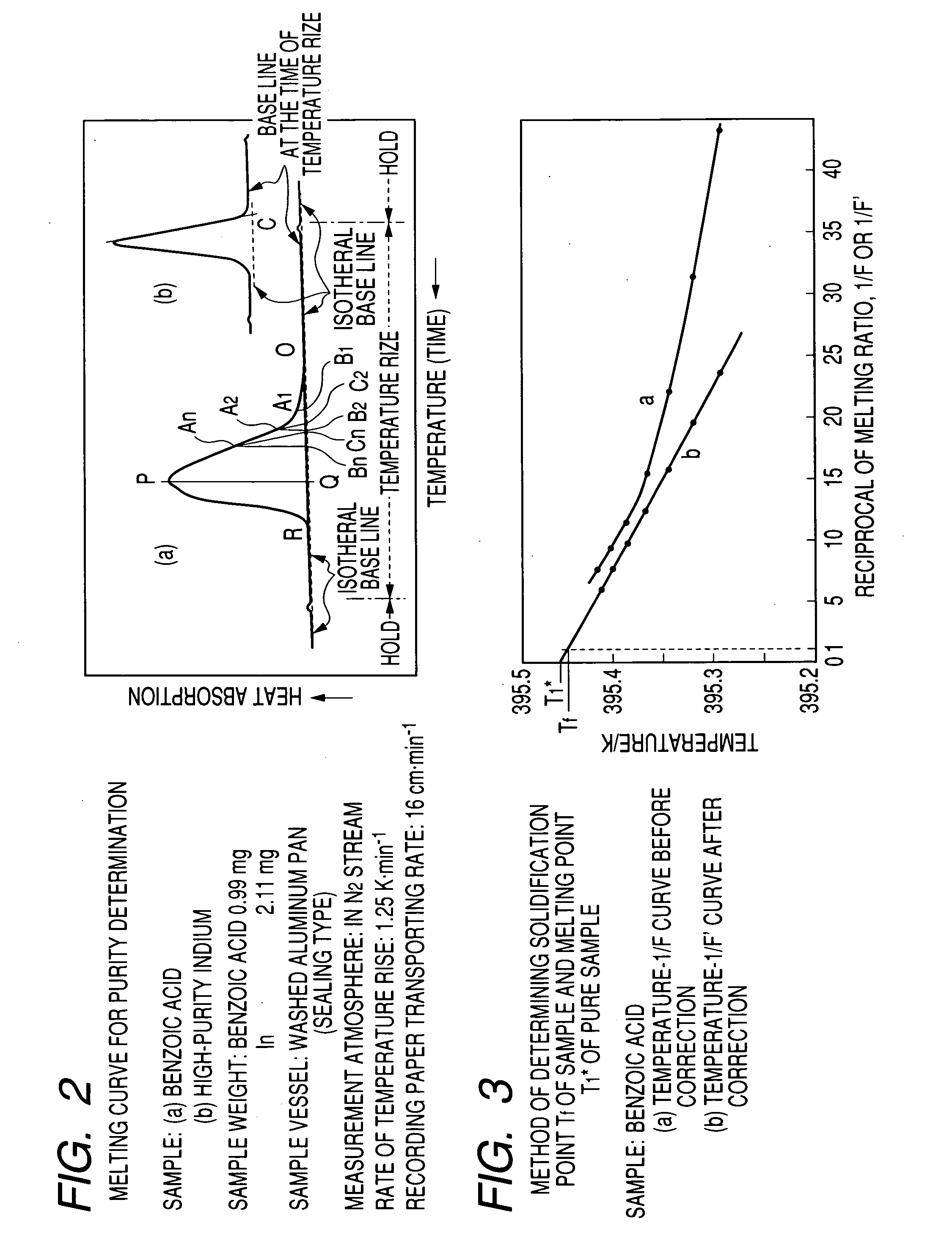

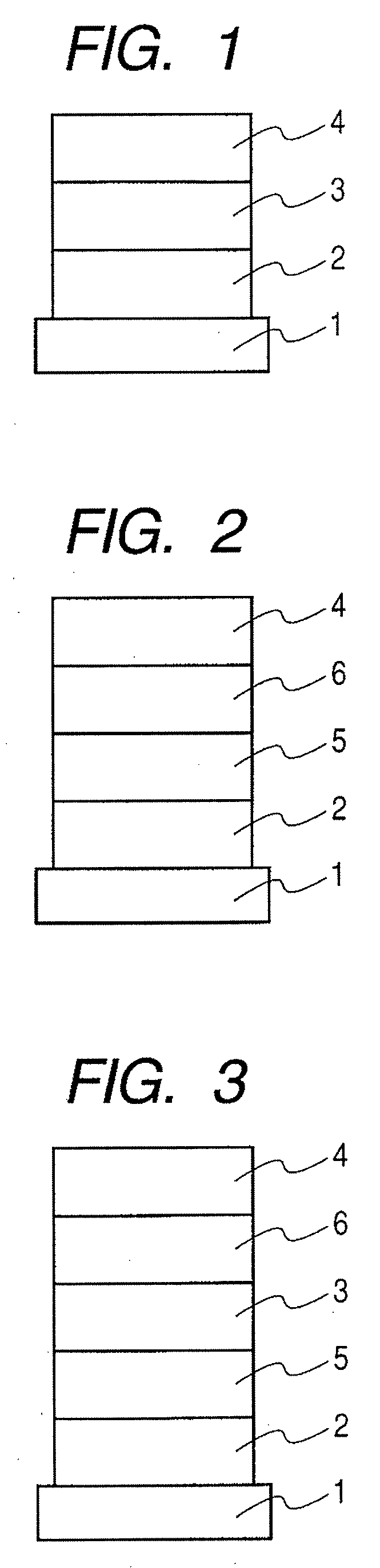

Organic light-emitting device

InactiveUS20050127827A1No attenuation of emission luminanceExcellent durabilityDischarge tube luminescnet screensElectroluminescent light sourcesUltrasound attenuationOrganic compound

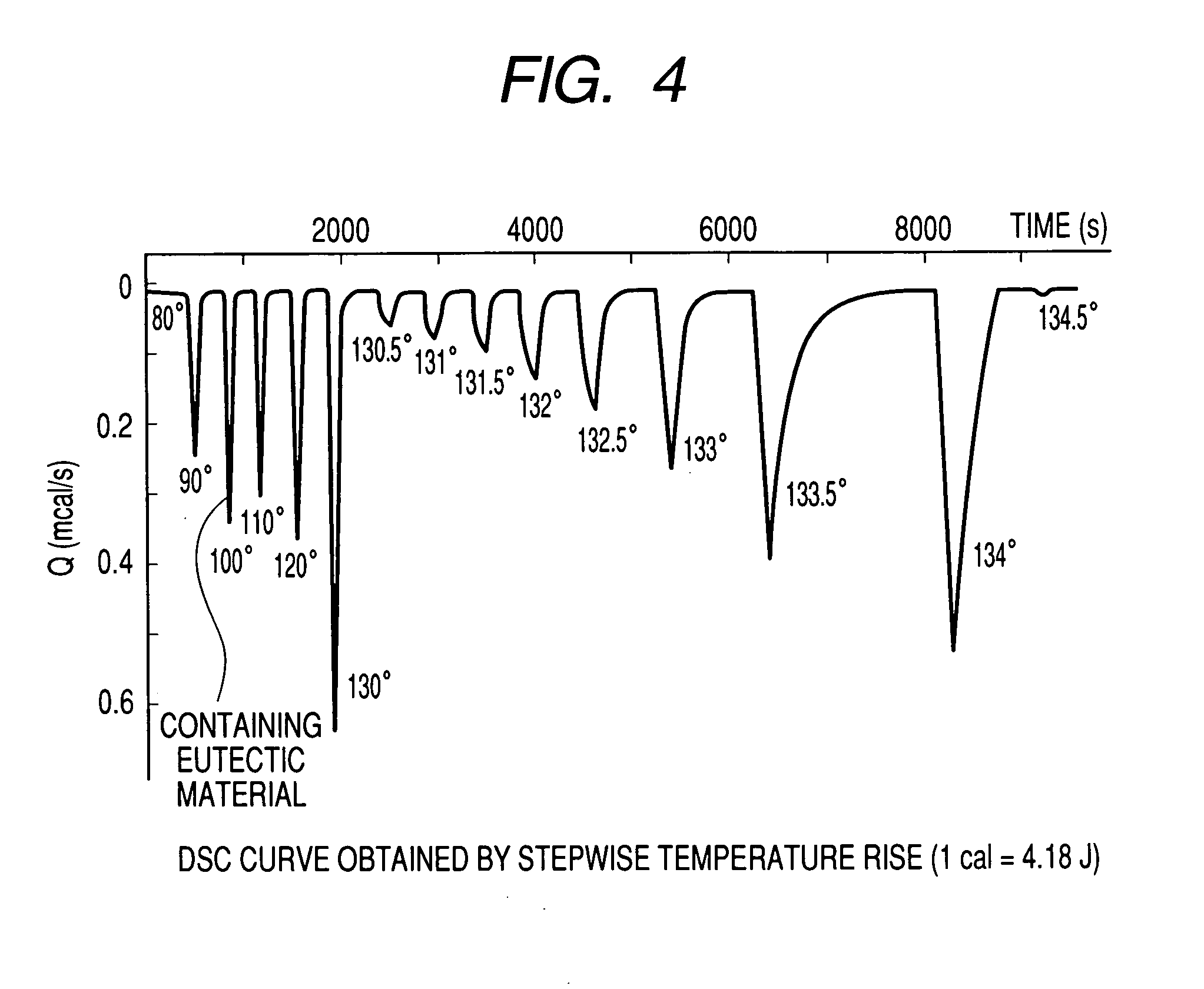

The present invention provides a practical organic light-emitting device which shows no attenuation of emission luminance even when driven for a long period of time and which is excellent in durability. The organic light-emitting device of the present invention is an organic light-emitting device including an organic compound layer having at least an organic luminescent layer, the organic compound layer being sandwiched between a pair of electrodes composed of an anode and a cathode, in which at least one of the organic compounds used for forming the organic compound layer has a purity of 99 mol % or more in analysis according to a differential scanning calorimetry method.

Owner:CANON KK

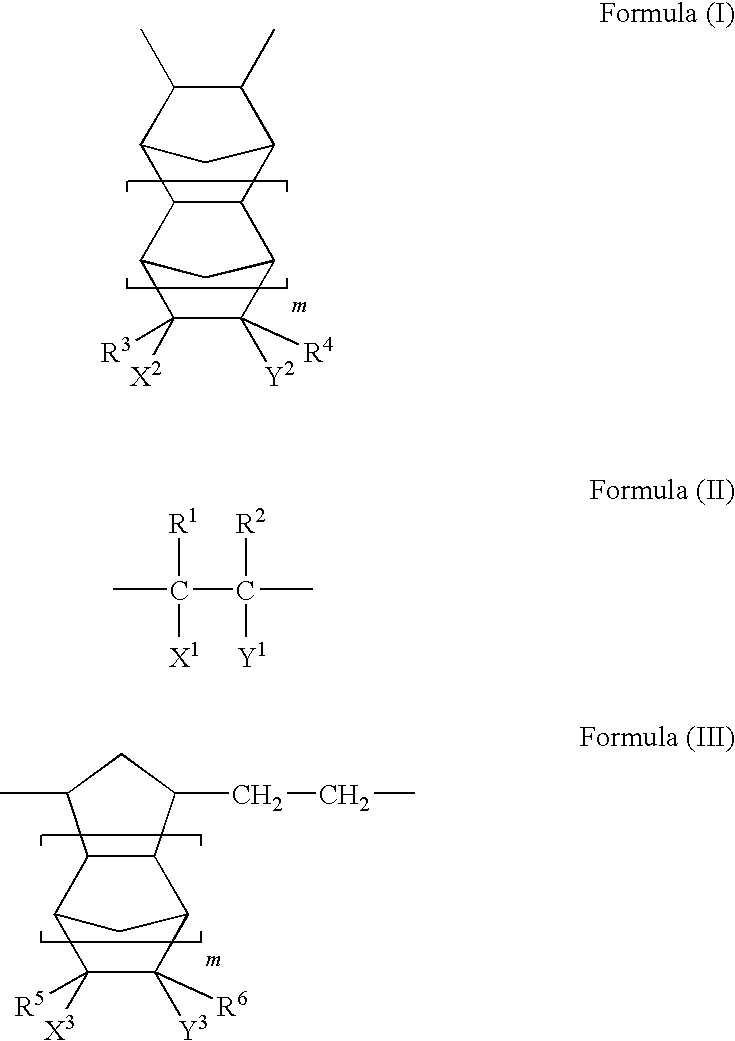

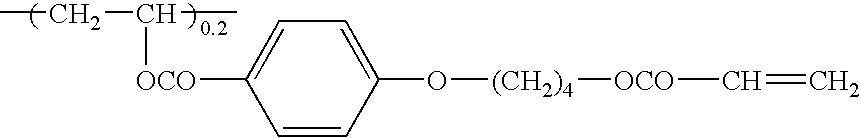

Sheet and interior material

ActiveUS20070197116A1Elegant appearanceExcellent durabilityFibre typesWoven fabricsPolycarbonateWoven fabric

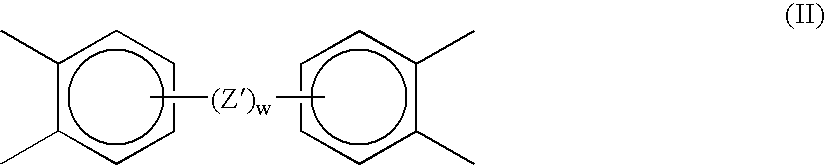

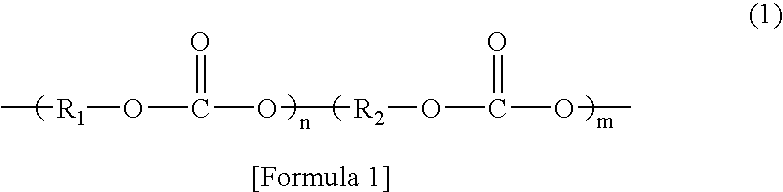

A sheet comprising a non-woven fabric in which ultra-fine fibers of a single fiber thickness of 0.5 dtex or less are entangled and an elastomeric binder mainly composed of a polyurethane, wherein said polyurethane is a polycarbonate-based polyurethane having a polycarbonate skeleton represented by the following general formulas (1) and (2), and having a gelation point of 2.5 ml or more and less than 6 ml. (In the formula, R1 and R2 are aliphatic hydrocarbon groups with 7 to 11 carbons, and they may be same or different. Furthermore, n and m are positive integers, and when R1 and R2 are different, it is a block copolymer or a random copolymer) (In the formula, R3 and R4 are aliphatic hydrocarbon groups with 3 to 6 carbons, and they may be same or different. Furthermore, x and y are positive integers, and when R3 and R4 are different, it is a block copolymer or a random copolymer)

Owner:TORAY IND INC

Polarizing Plate and Liquid Crystal Display Device

InactiveUS20090244445A1Excellent durabilitySmall fluctuationLamination ancillary operationsSynthetic resin layered productsPolarizerLiquid-crystal display

A polarizing plate comprising a polarizer, and a cycloolefin polymer film having a surface bonded to at least one surface of the polarizer, the surface of the cycloolefin polymer film having a mean surface roughness Ra falling within the range from 10 nm to 200 nm, and a shrinkage ratio of the polarizer, after being allowed to stand in an atmosphere at 105° C. for 10 hours, being equal to or smaller than 20% in the direction of transmission axis thereof, is disclosed.

Owner:FUJIFILM CORP

Soldering paste flux and soldering paste

InactiveUS20140083567A1Storage stability be excellentExcellent durabilityWelding/cutting media/materialsSoldering mediaPrepolymerSolder paste

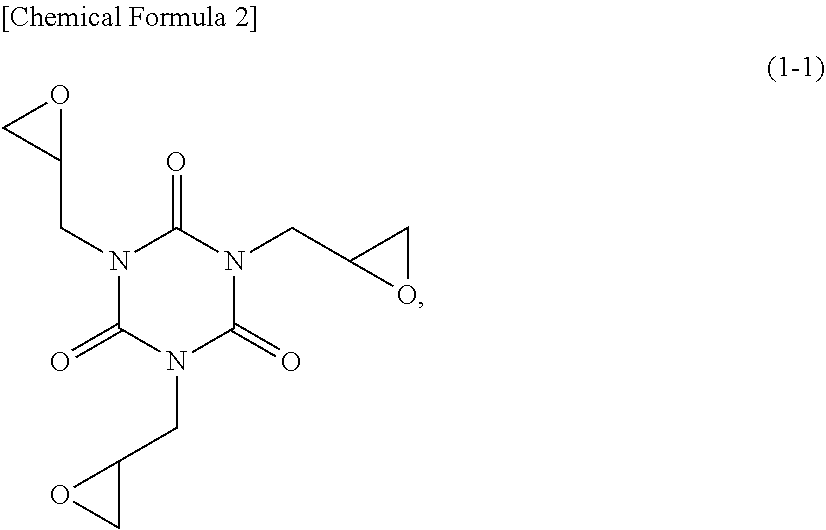

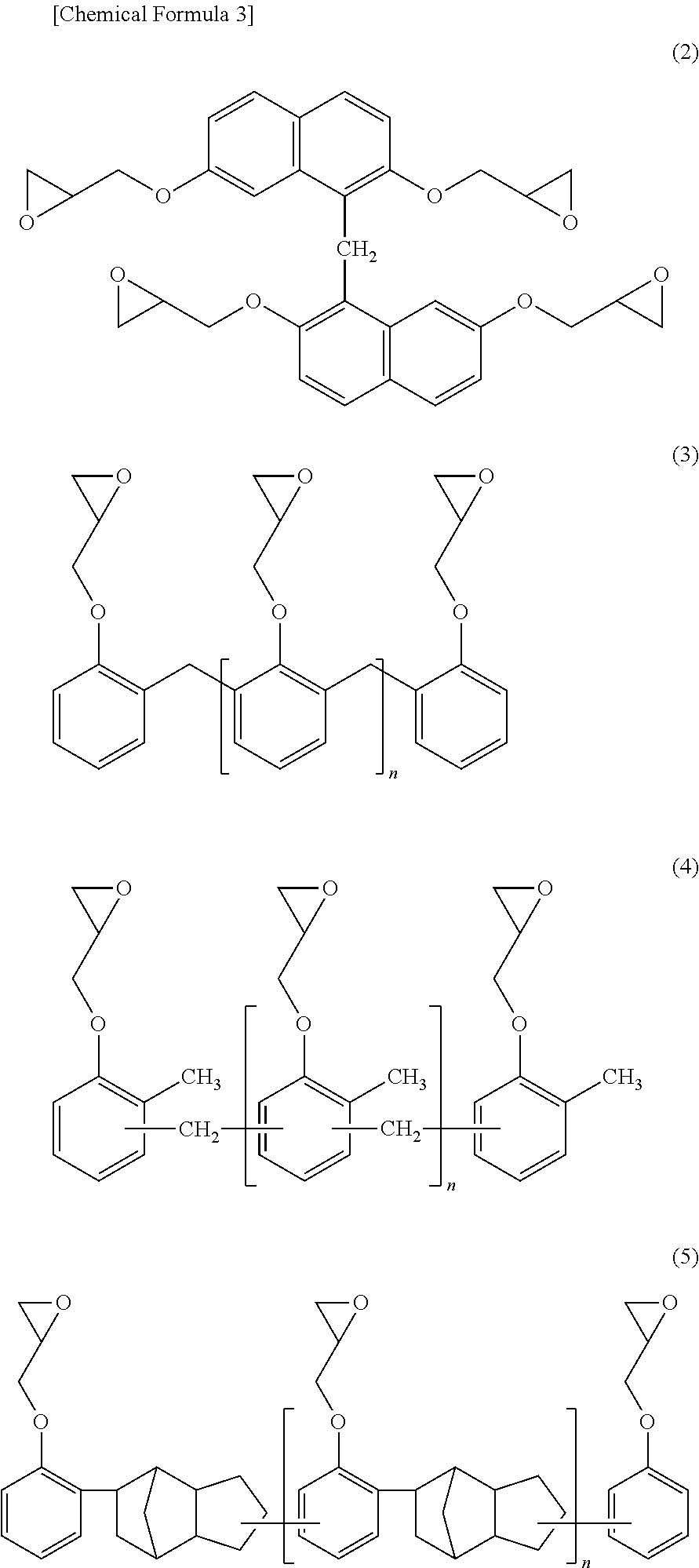

The present invention relates to a soldering paste flux, and the soldering paste flux includes (A) a thermosetting prepolymer, (B) a polyfunctional epoxy monomer or oligomer having three or more functional groups in a molecule, (C) a carboxylic acid having a melting point of 80 to 170° C., and (D) a cyanate ester having two or more cyanato groups in a molecule.

Owner:HARIMA CHEM

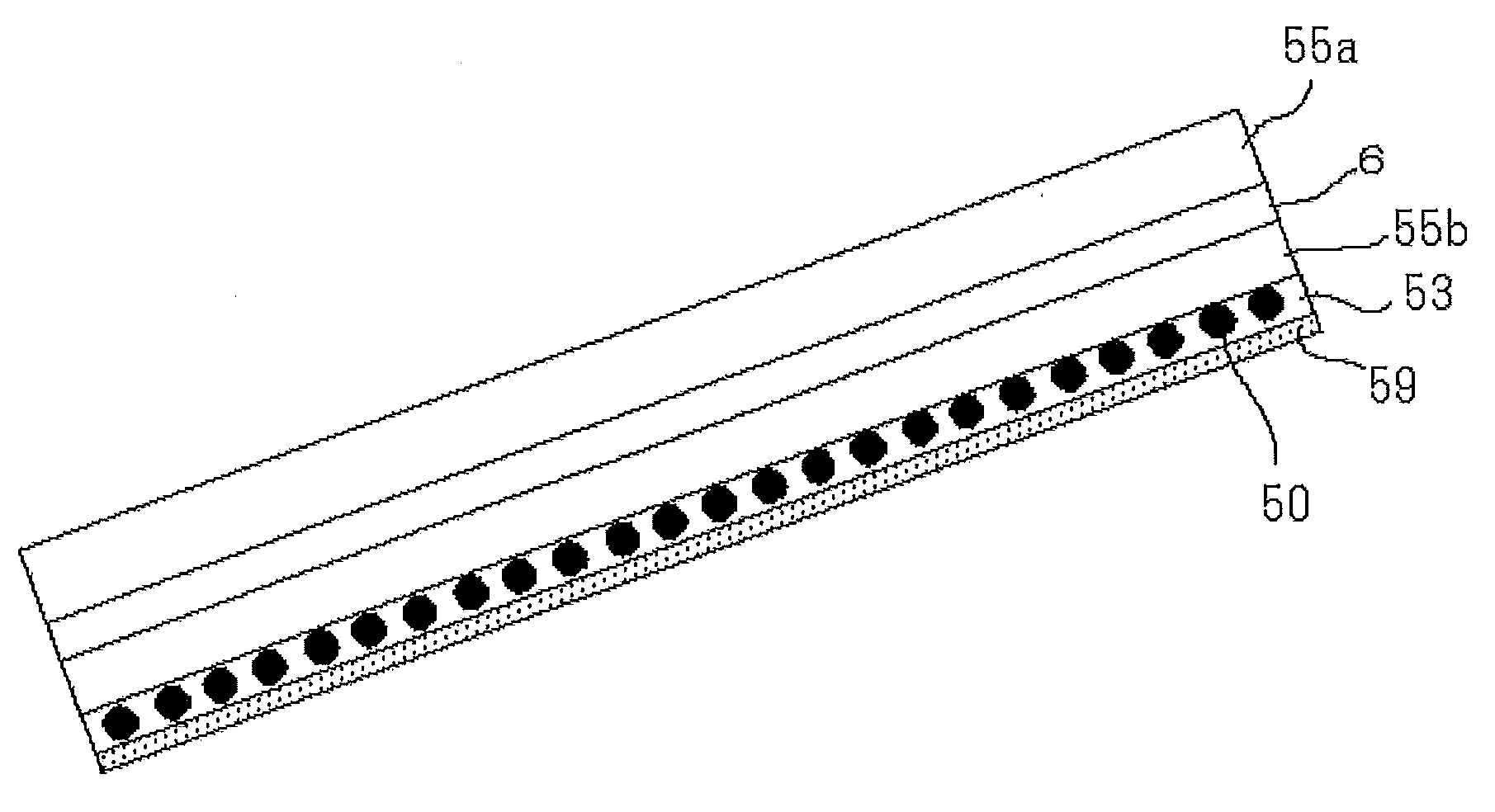

Power storage device separator

InactiveUS20110206972A1Excellent durabilityLong useNon-fibrous pulp additionNatural cellulose pulp/paperPower storageIon permeability

Provided is a power storage device separator that is realized in the form of a heat-resistant, solvent-resistant, and dimensionally stable thin film. Also provided is a power storage device separator that can be realized in the form of a thin film which has excellent ion permeability and low resistance, which makes short-circuiting between electrodes and self-discharging difficult to occur, and in addition, which has excellent durability even after long periods of use under high temperature environments in the presence of organic solvents and ionic solutions.

Owner:TOMOEGAWA CO LTD

Composition for Polyurethane Foam, Polyurethane Foam Obtained From the Composition, and Use Thereof

InactiveUS20090127915A1Appropriate hardness and ball reboundExcellent durabilityVehicle seatsOrganic compound preparationIsocyanateChemistry

The polyurethane foam composition of the present invention comprises at least water, a catalyst, a surfactant, a polyisocyanate, and a polyol and / or a polymer-dispersed polyol in which polymer fine particles obtained by polymerizing a compound having an unsaturated bond are dispersed in a polyol, wherein the polyol comprises at least (A) a plant-derived polyol produced by using a raw material obtained from plants and (B) a low-monol polyol having an overall degree of unsaturation of 0.050 meq / g or less. The polyurethane foam relating to the present invention is obtained by foaming this polyurethane foam composition. The polyurethane foam contributes to reducing environmental burdens and attains hardness and ball rebound suitable for a cushioning material and excellent durability in a balanced manner.

Owner:MITSUI CHEMICALS POLYURETHANES INC

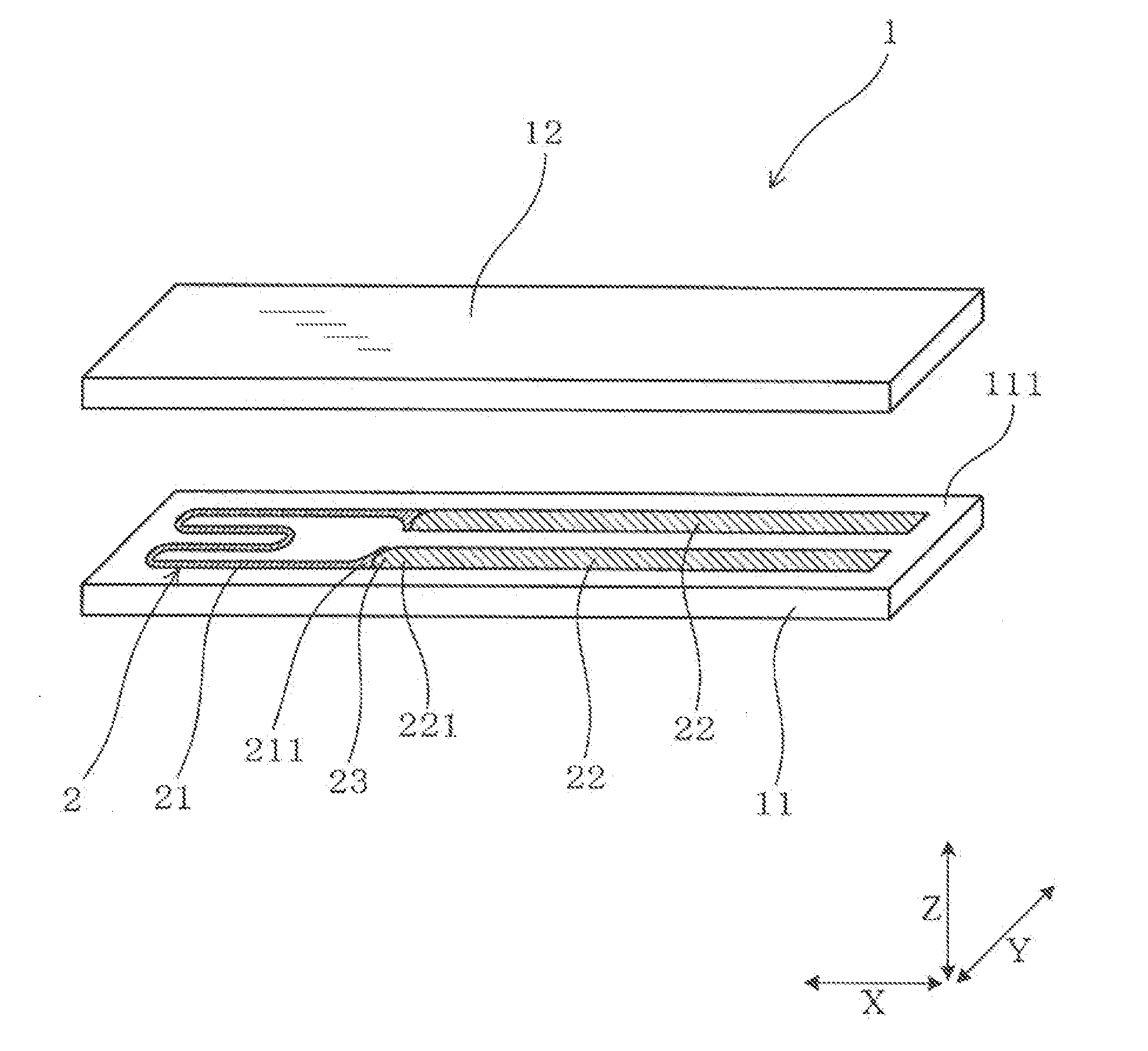

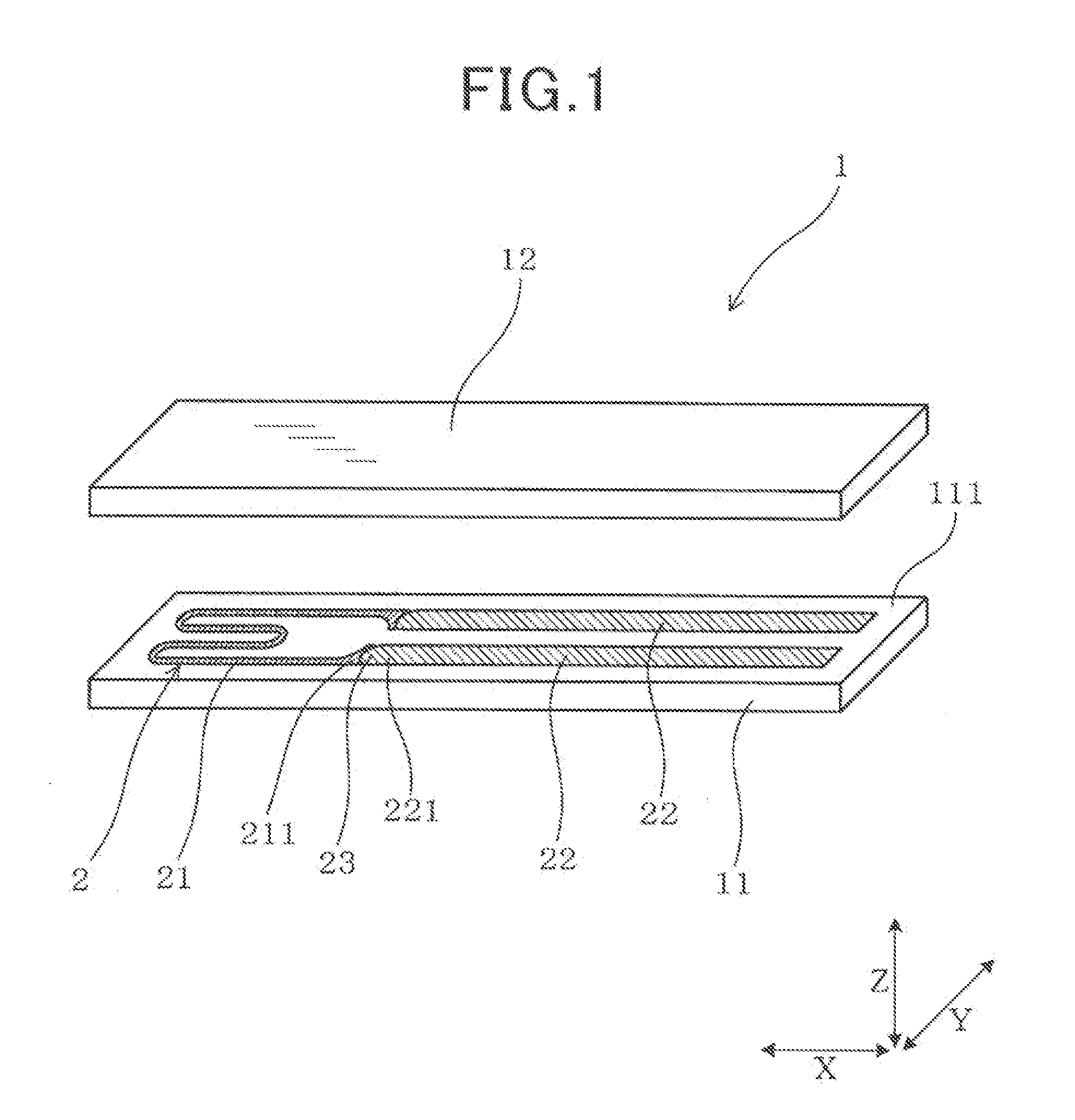

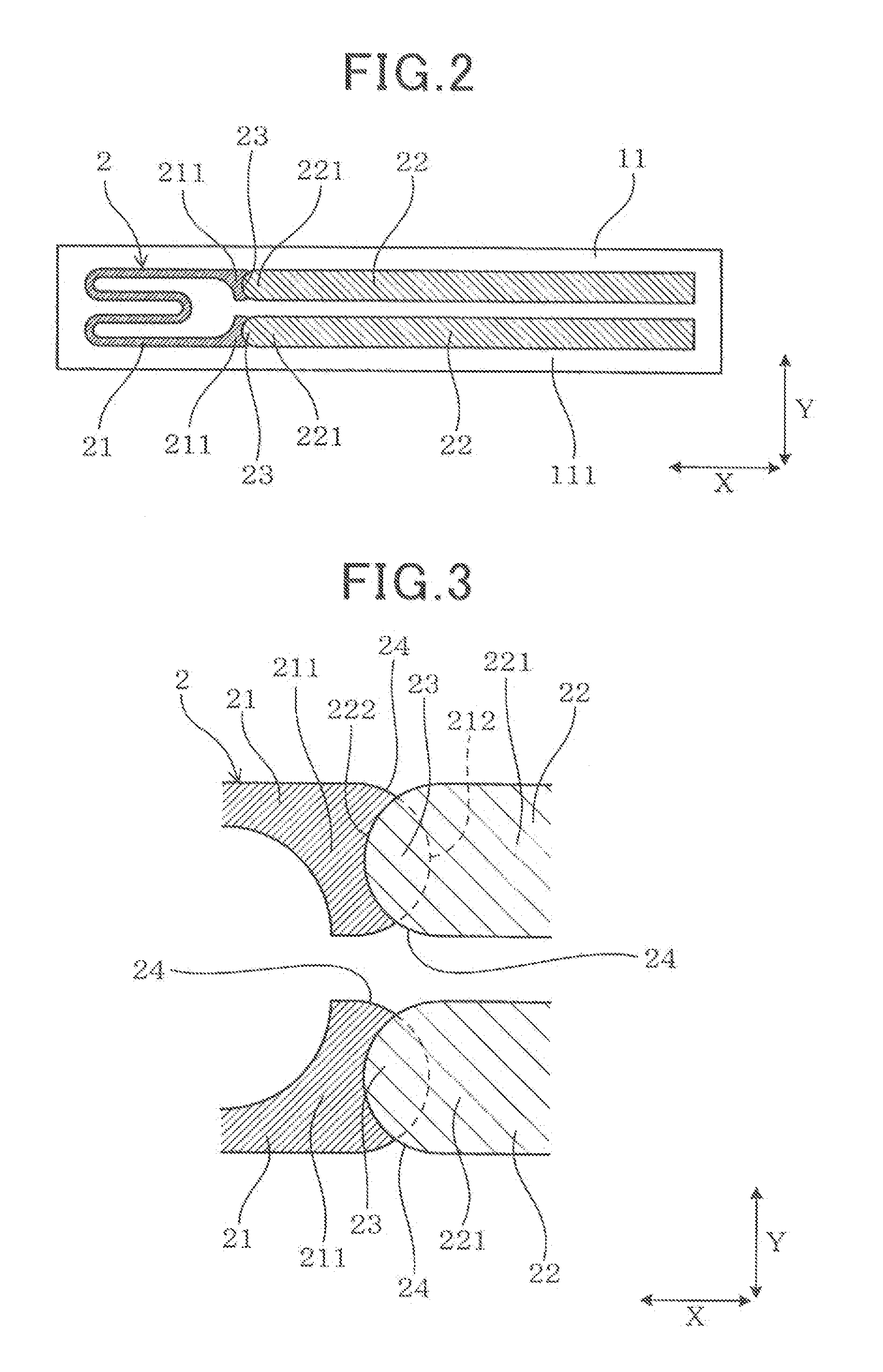

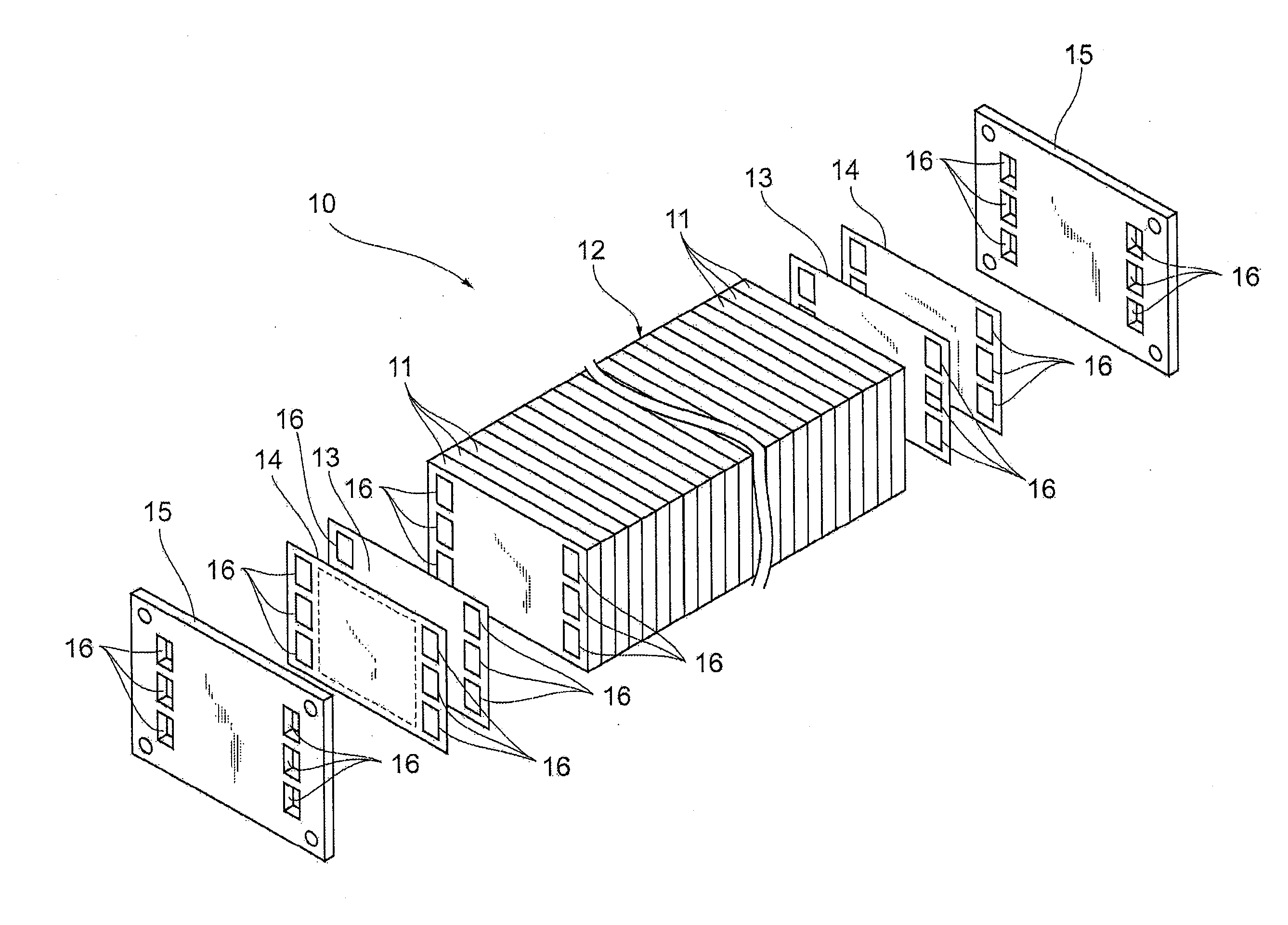

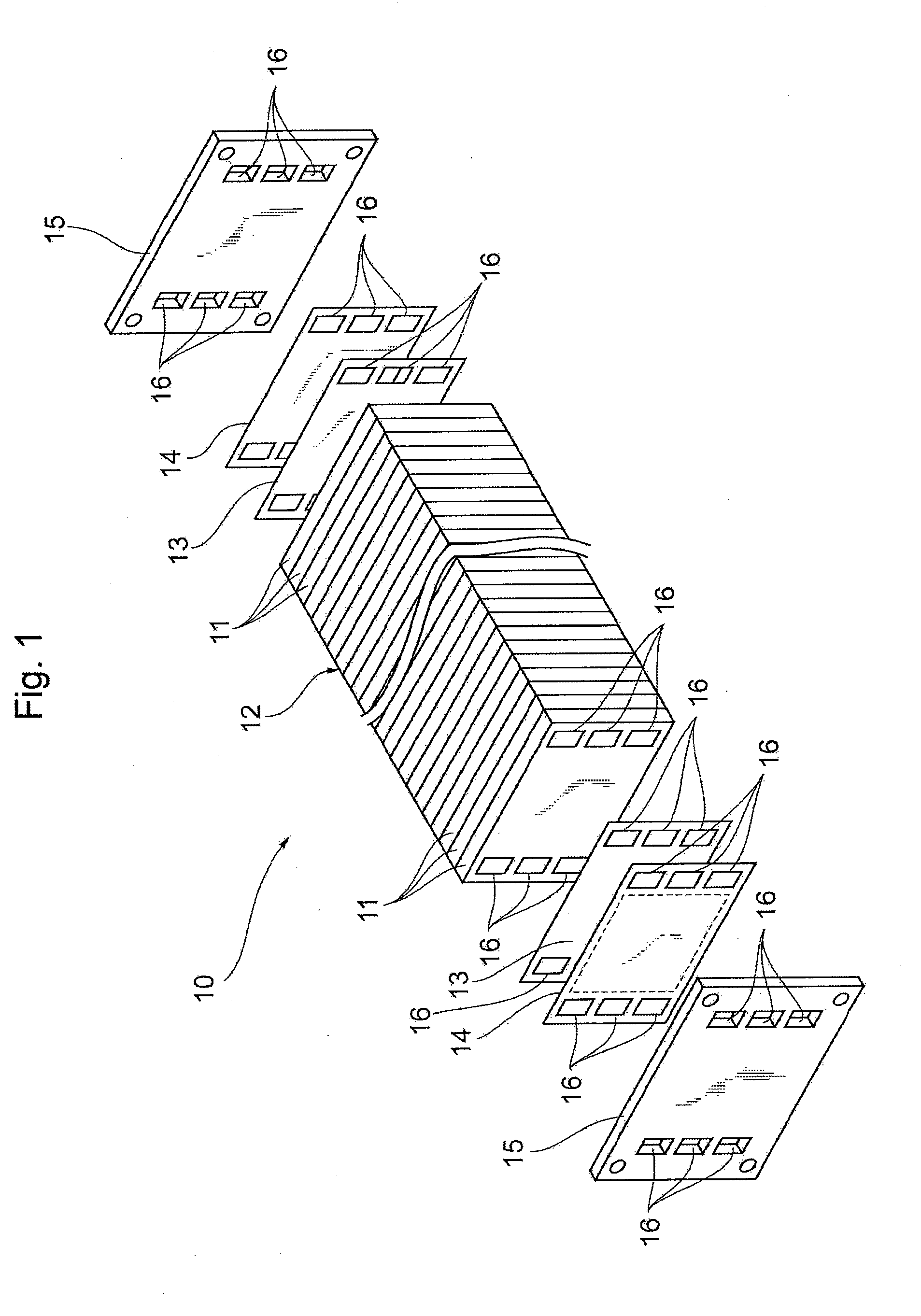

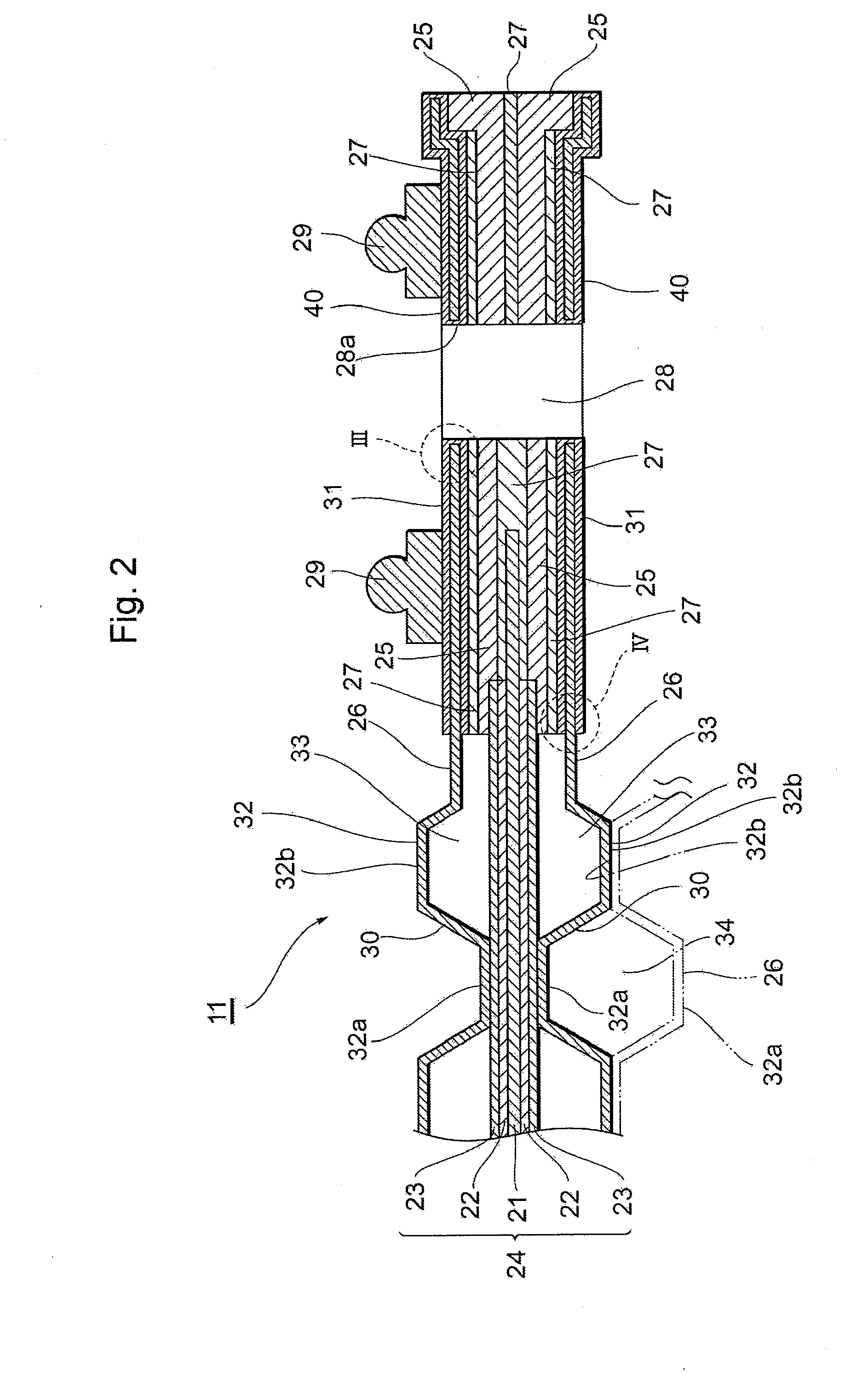

Plate member for fuel cell, manufacturing method of the plate member, and fuel cell

ActiveUS20100227246A1Excellent durabilityPrevent deteriorationFinal product manufactureFuel cell auxillariesEngineeringMechanical engineering

There is disclosed a plate member for a fuel cell which is laminated together with a membrane-electrode assembly to constitute a fuel cell having cells and is provided with a channel forming portion which forms a fluid channel to supply and discharge a fluid to / from the membrane-electrode assembly and / or the cells. The plate member for the fuel cell includes a first covering portion which covers the channel forming portion, and a second covering portion which covers an edge of the first covering portion together with a portion around the edge of the first covering portion.

Owner:TOYOTA JIDOSHA KK

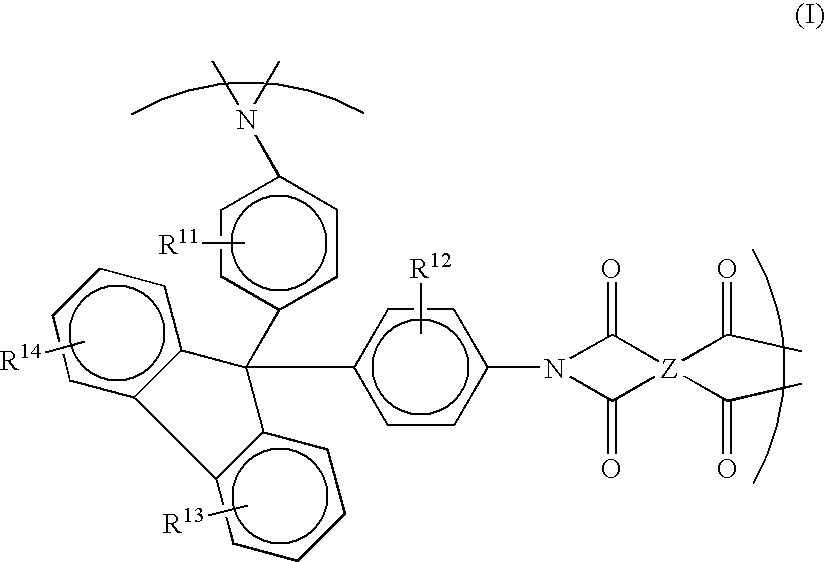

Fluorene compound and organic light-emitting device using the compound

InactiveUS20070257603A1High luminanceExcellent durabilityDischarge tube luminescnet screensOrganic compound preparationFluorenePhotochemistry

Owner:CANON KK

Active material for electrode and non-aqueous secondary battery using the same

ActiveUS7316862B2Large capacityExcellent durabilityElectrode carriers/collectorsOrganic electrolyte cellsLarge capacityLithium

A lithium-containing complex oxide represented by General Formula: Li1+x+αNi(1−x−y+δ) / 2Mn(1−x−y−δ) / 2MyO2 (where 0≦x≦0.15, −0.05≦x+α≦0.2, 0≦y≦0.4; −0.1≦δ≦0.1 (when 0≦y≦0.2) or −0.24≦δ≦0.24 (when 0.2<y≦0.4); and M is at least one element selected from the group consisting of Mg, Ti, Cr, Fe, Co, Cu, Zn, Al, Ge, Zr and Sn) is provided. The lithium-containing complex oxide contains secondary particles formed of flocculated primary particles. The primary particles have a mean particle diameter of 0.3 to 3 μm, and the secondary particles have a mean particle diameter of 5 to 20 μm. By using this lithium-containing complex oxide as a positive active material, a non-aqueous secondary battery having a high capacity, excellent cycle durability and excellent storage characteristics at a high temperature is achieved.

Owner:MAXELL HLDG LTD

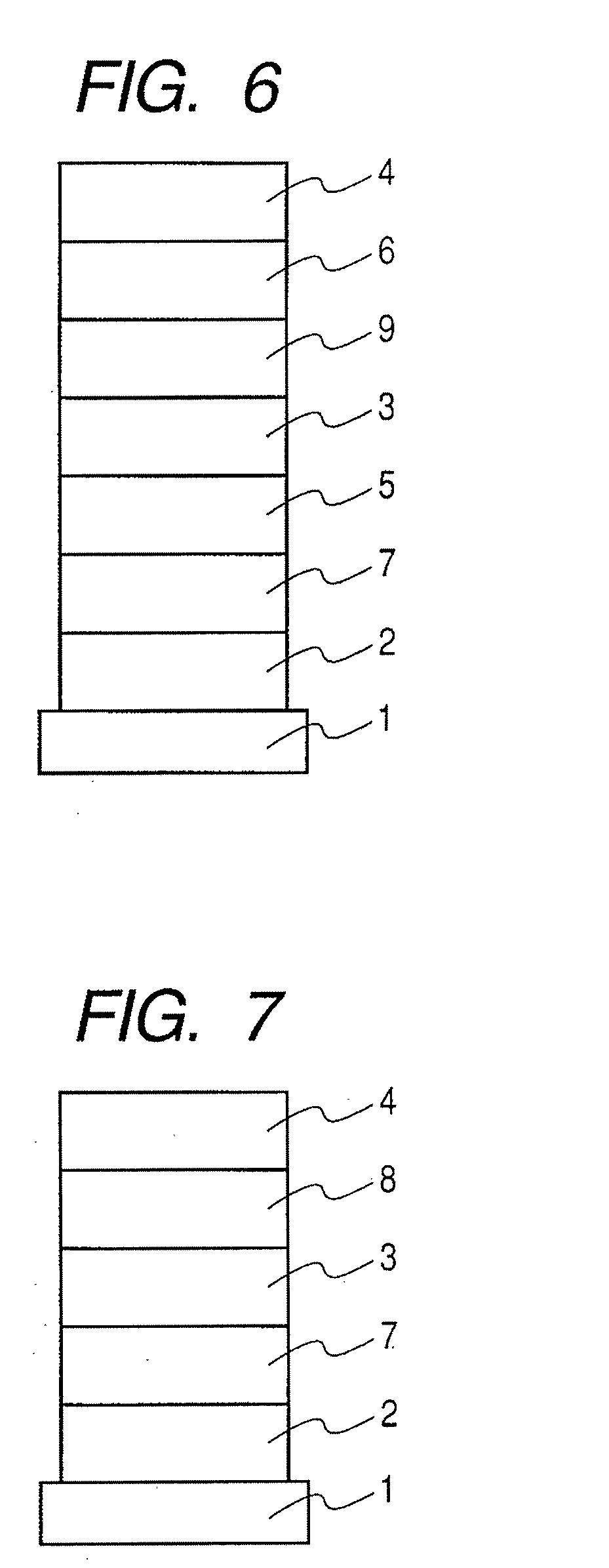

Antimicrobial fiber and its production method, and antimicrobial fiber product comprising the antimicrobial fiber, its production method and regeneration method

InactiveUS20100113537A1Excellent effectExcellent durabilityBiocideBiochemical fibre treatmentChemistryAmmonium

An antimicrobial fiber bearing an anionic functional group, and a method of producing it wherein at least a part of the anionic functional group forms a quaternary ammonium salt and at least another part thereof forms an antimicrobial metal salt. The quaternary ammonium salt is preferably a cetylpyridinium salt, and the antimicrobial metal salt is preferably a zinc salt. The fiber is preferably a carboxyalkylated cellulose fiber. An antimicrobial fiber product comprising the antimicrobial fiber.

Owner:ALCARE

Gas barrier adhesive sheet, method for producing same, electronic member, and optical member

ActiveUS20140178622A1Excellent gas barrier capabilityExcellent durabilityNon-macromolecular adhesive additivesSynthetic resin layered productsPressure sensitiveChemistry

The present invention is a gas barrier pressure-sensitive adhesive sheet comprising at least one gas barrier layer and at least one pressure-sensitive adhesive layer, the at least one pressure-sensitive adhesive layer having a storage modulus at 23° C. of 1.5×104 to 1.0×107 Pa, and the gas barrier pressure-sensitive adhesive sheet not including a base layer. The present invention provides: a gas barrier pressure-sensitive adhesive sheet that makes it possible to easily provide the adherend with a gas barrier capability without significantly increasing the thickness of the gas barrier pressure-sensitive adhesive sheet, does not show delamination (separation) at the interface between the pressure-sensitive adhesive layer and another layer even when subjected to high-temperature / high-humidity conditions, and exhibits excellent bendability, a method for producing the same, an electronic member that includes the gas barrier pressure-sensitive adhesive sheet, and an optical member that includes the gas barrier pressure-sensitive adhesive sheet.

Owner:LINTEC CORP

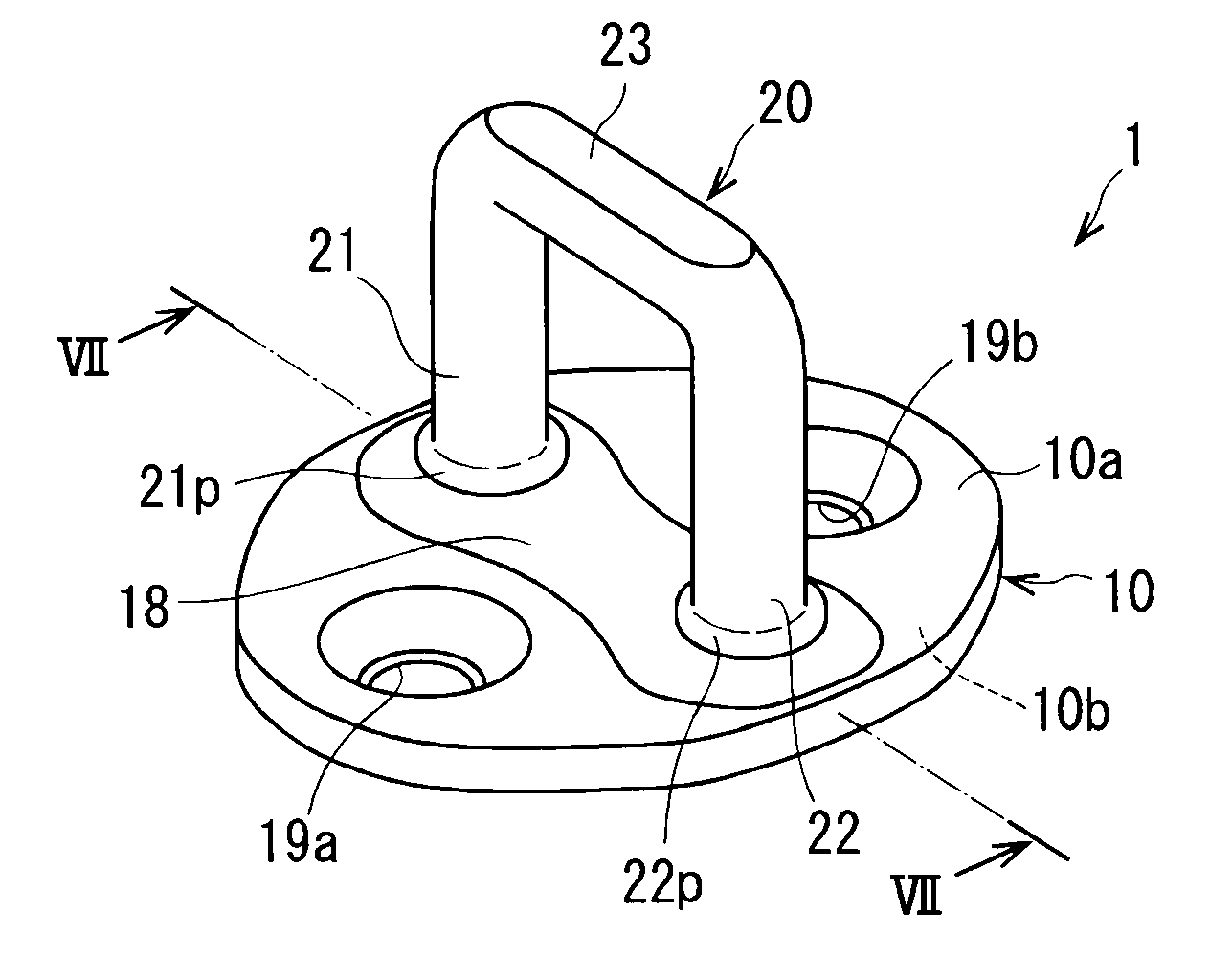

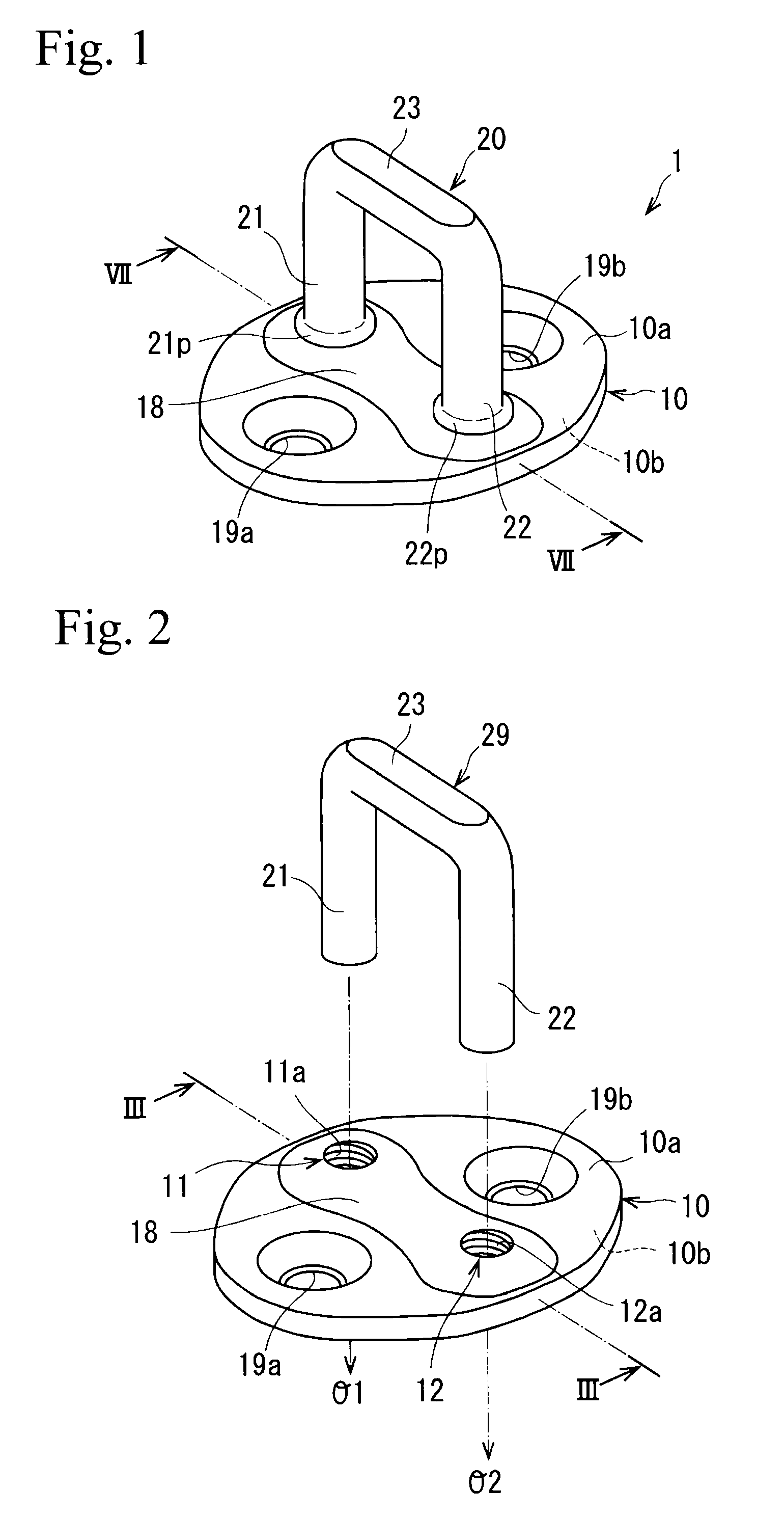

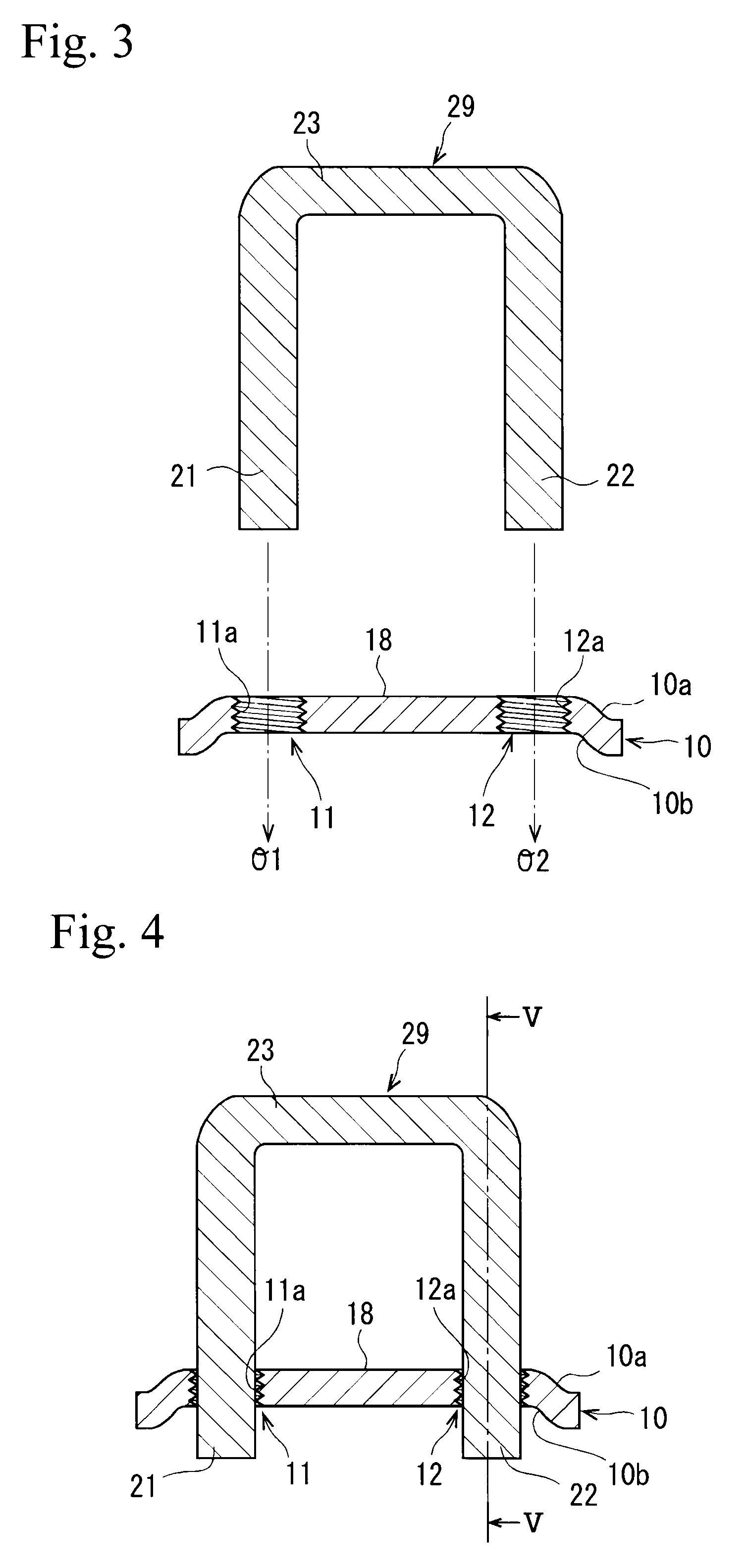

Striker used for vehicular opening/closing member and its manufacturing method

InactiveUS20090079208A1Excellent durabilityIncreased durabilityNoise-prevention/anti-rattling lockingMetal rolling stand detailsEngineering

A striker further excellent in durability is provided. A striker for a vehicular opening / closing member of the invention includes a base plate made of a steel penetrated with a post hole, and a post projected from the base plate by being caulked in a state of inserting an end portion of a rod member made of steel to the post hole. An inner face of the post hole is formed with at least one groove recessed in an outer direction of a diameter relative to an axis center of the post hole. The end portion clamps a surface side edge and a back face side edge of the post hole and is made to plastically flow at inside of the groove.

Owner:ANSEI CORP

Sliding member

InactiveUS20080190284A1Excellent durabilityIncreased durabilityPositive displacement pump componentsBearing componentsSecondary layerMetallurgy

To provide a sliding member that exhibits excellent durability and is free of lead. A swash plate for a compressor as the sliding member of the invention contains a base material having on the surface thereof a sliding layer constituting at least a sliding surface, on which shoes slide. The sliding layer contains a first layer that contains an amorphous hard carbon (diamond-like carbon) film containing Si (DLC-Si film) and is formed on the base material, and a second layer that is formed on the first layer and contains polyamideimide (PAI) containing a solid lubricant such as MoS2.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com