Patents

Literature

149results about How to "Easily produce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

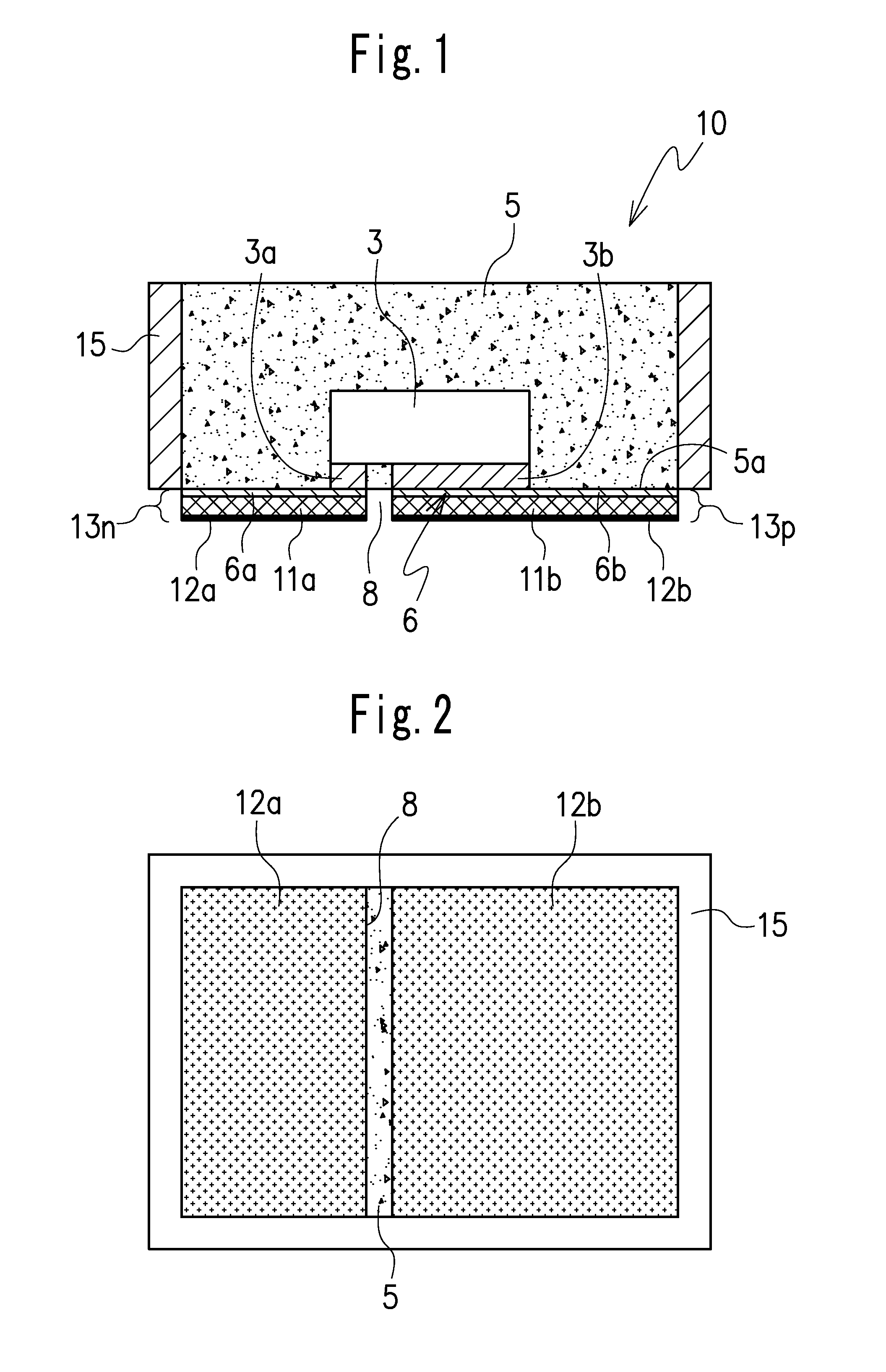

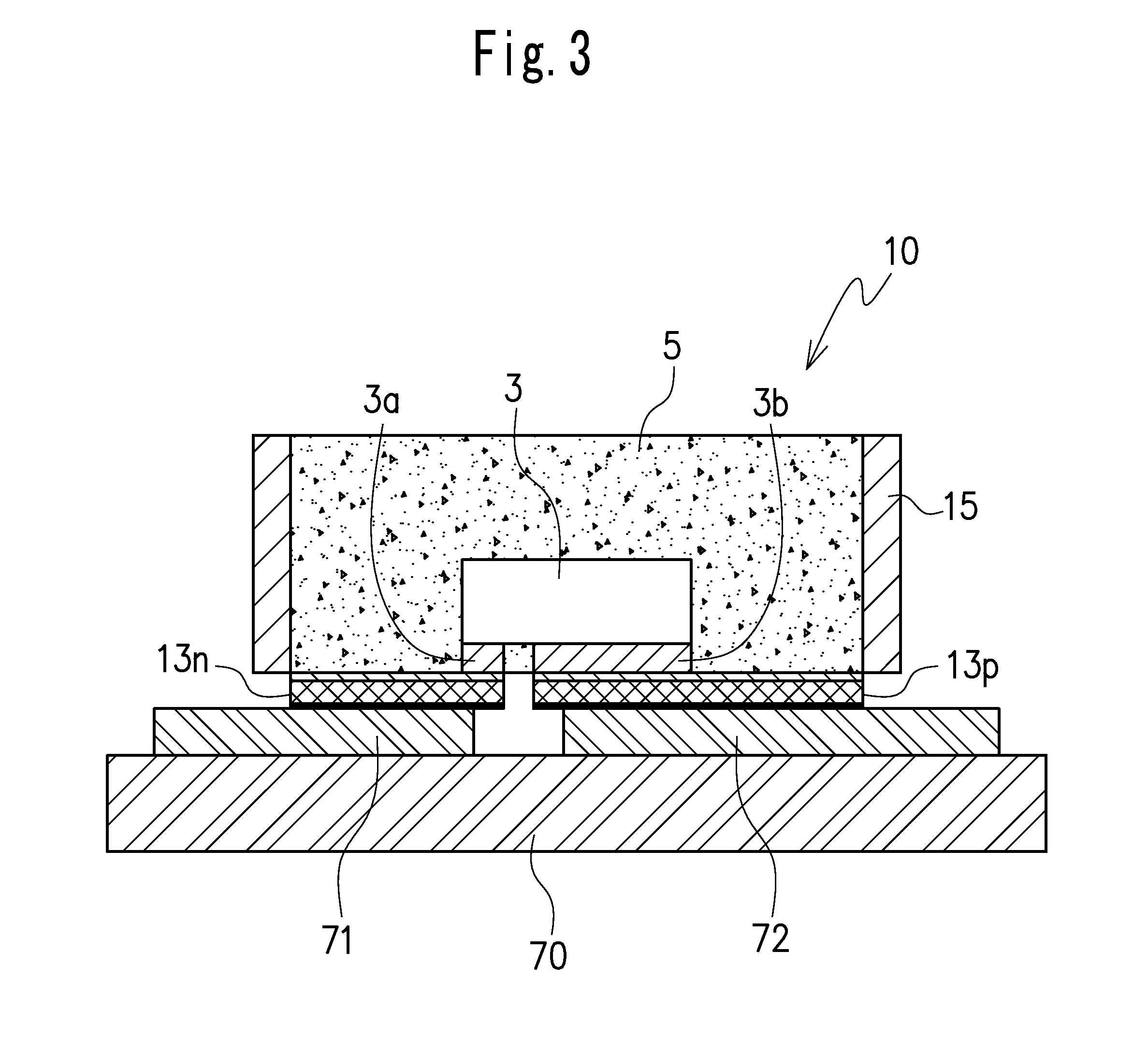

Touch panel

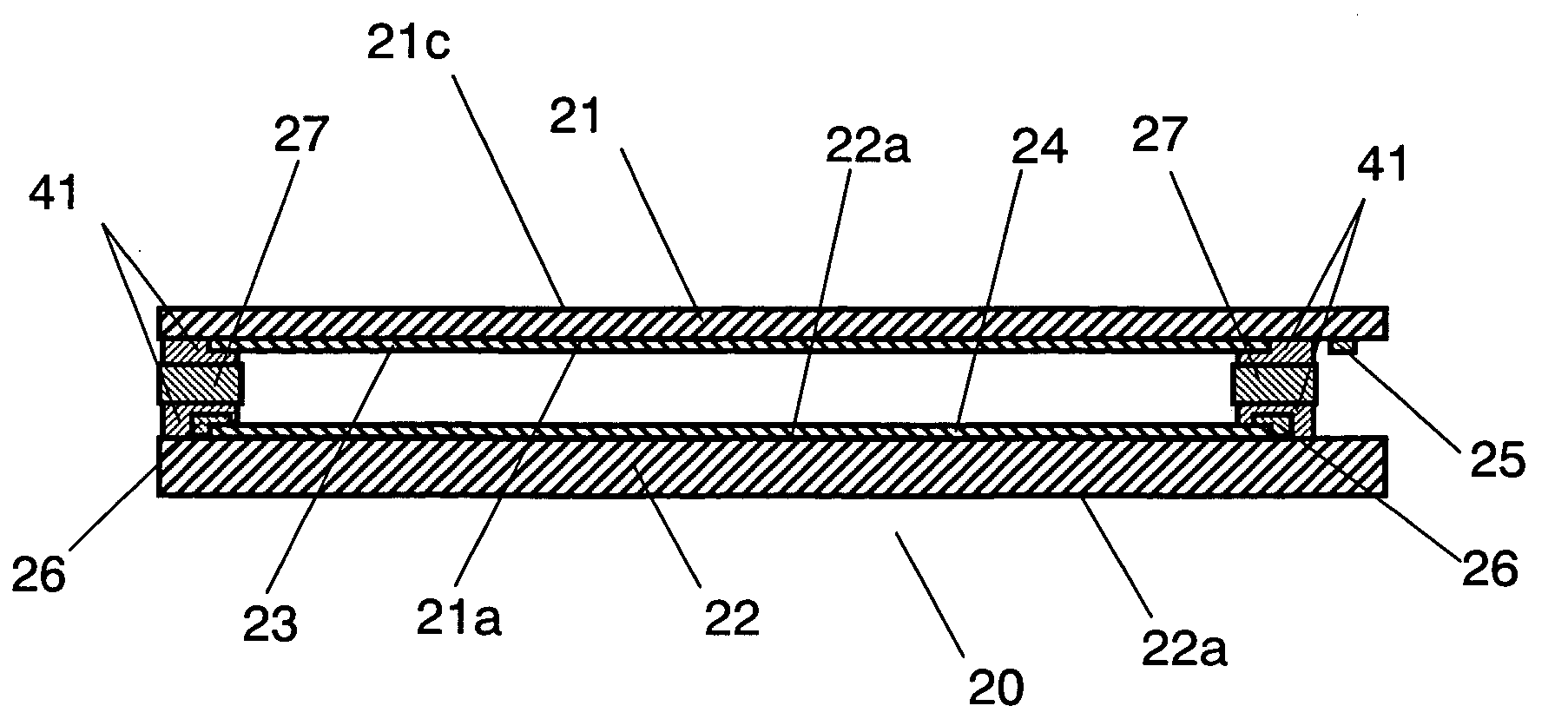

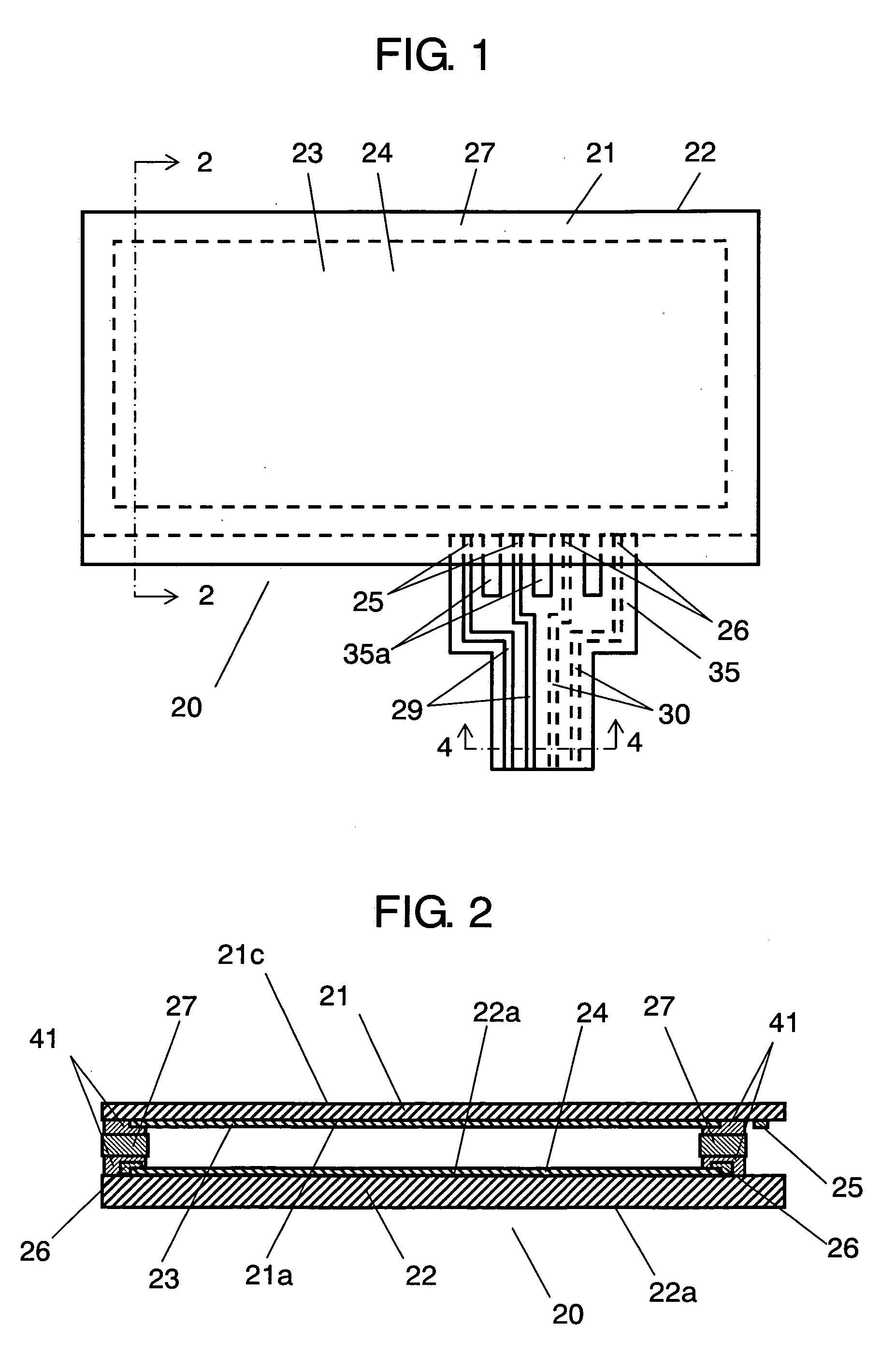

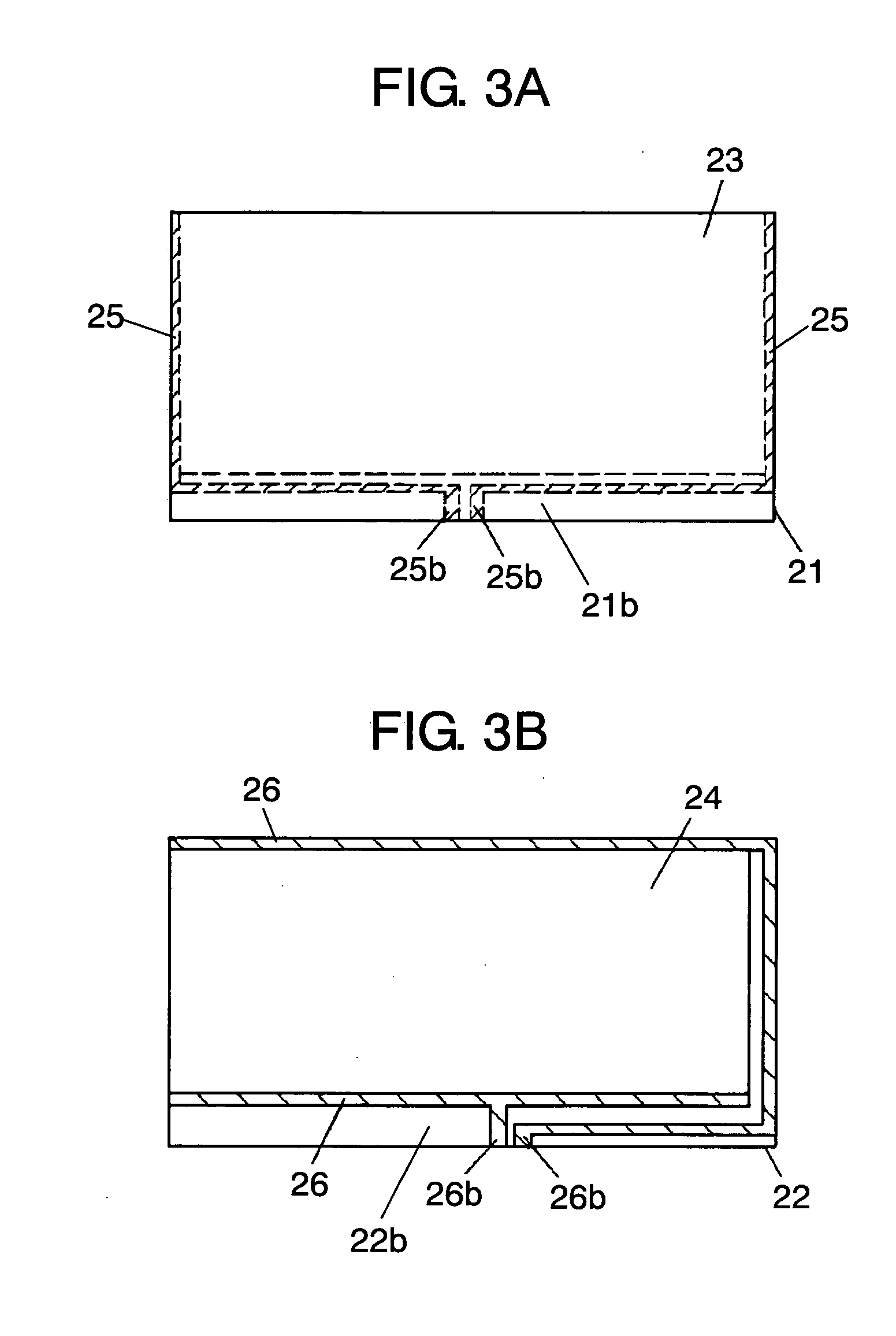

InactiveUS20070182720A1Easily produceReliable operation and electrical connection and separationEngagement/disengagement of coupling partsCoupling contact membersTouch panelExtremity Part

A touch panel includes a first substrate, a second substrate, a wiring substrate provided with a plurality of wiring patterns formed thereon, and an anisotropic conductive adhesive layer. The first substrate has a first conductive layer and first electrodes extending from two opposite sides of the first conductive layer. The second substrate has a second conductive layer confronting the first surface with a space, and second electrodes extending from two opposite sides of the second conductive layer. The anisotropic conductive adhesive layer connects a terminal portion of the wiring patterns to at least one of the first electrodes and the second electrodes. The wiring substrate has a slit or an aperture between the wiring patterns at one end thereof. The touch panel of this structure is easy to produce, and provides reliable operation and electrical connection and separation.

Owner:PANASONIC CORP

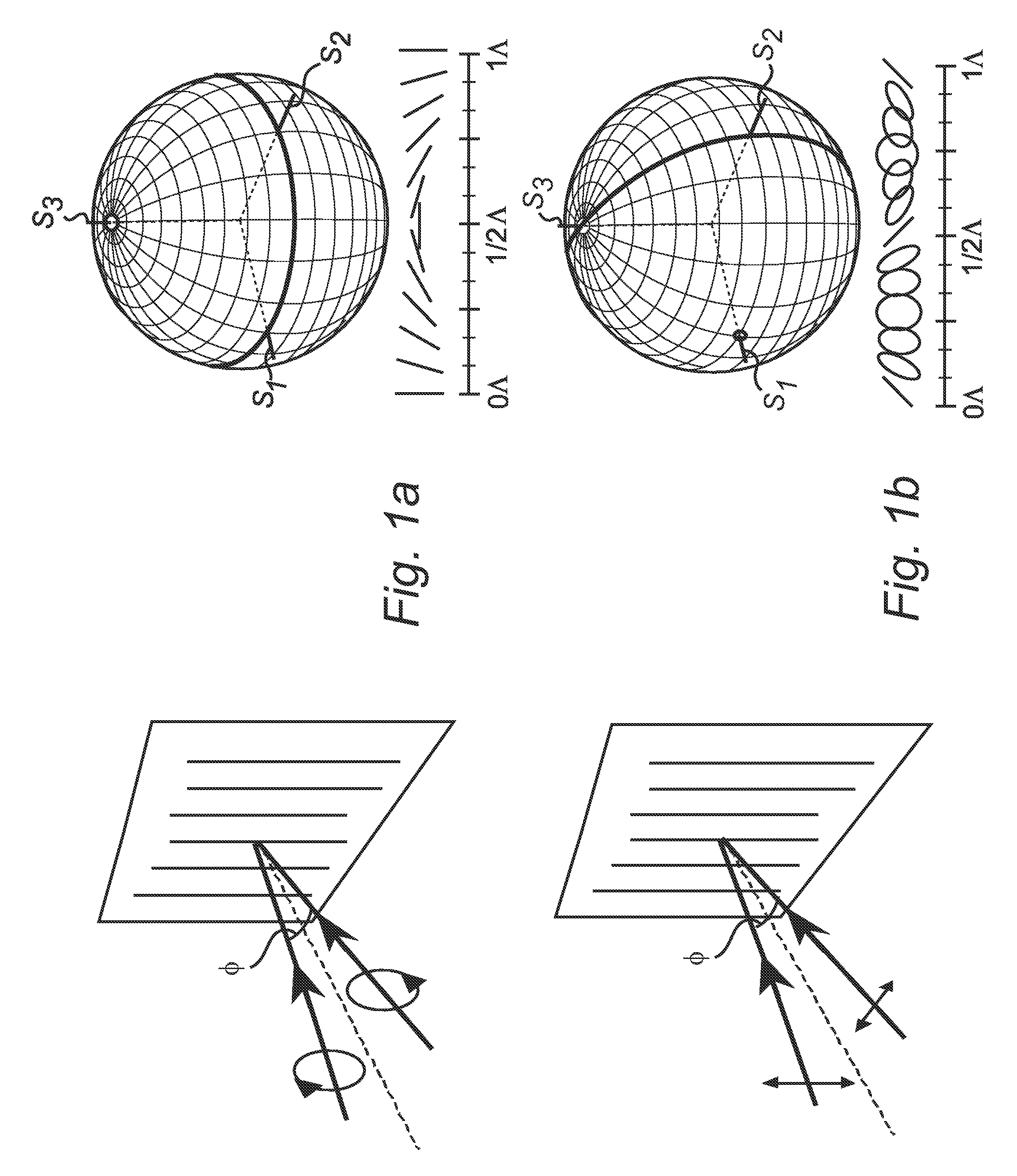

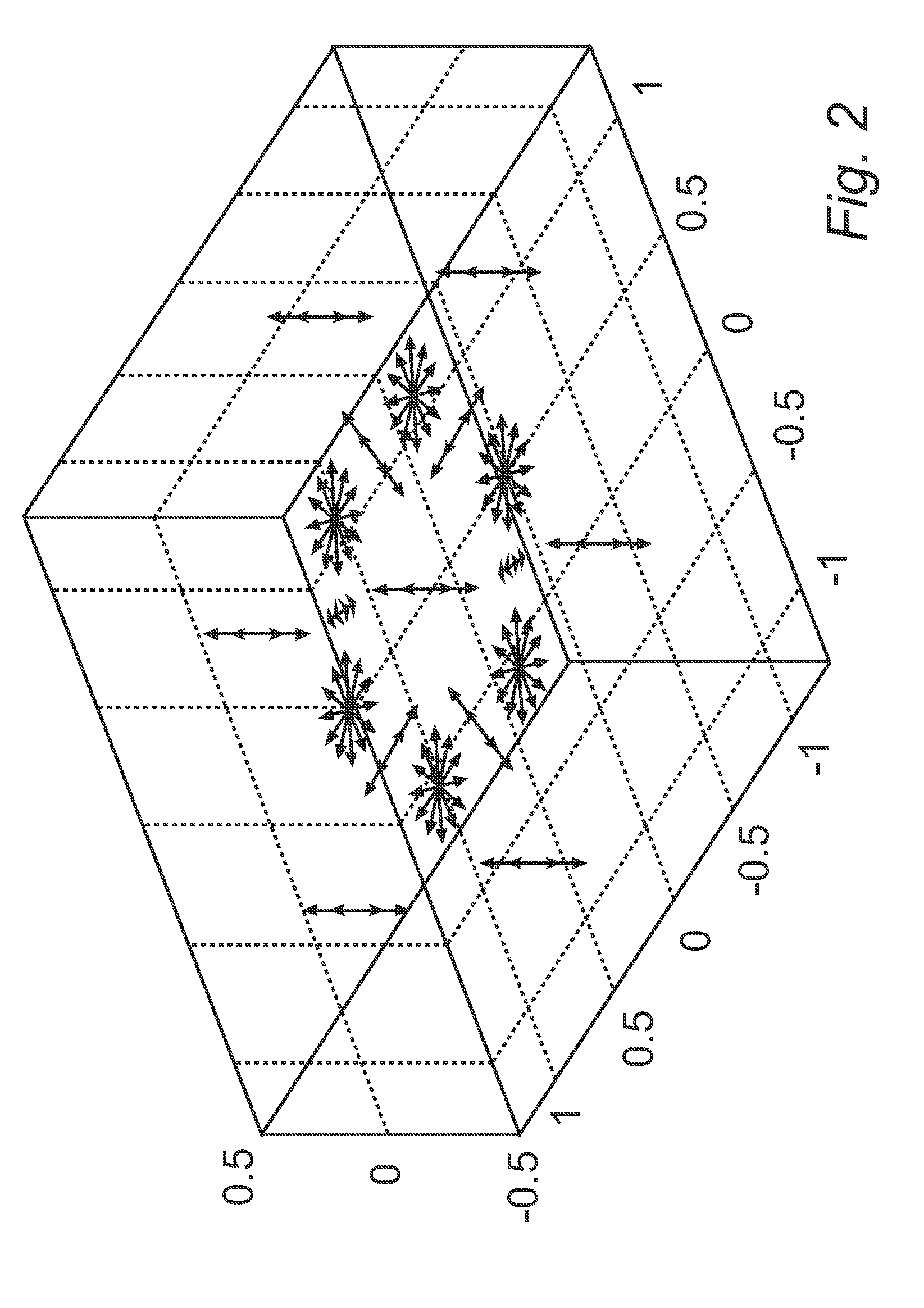

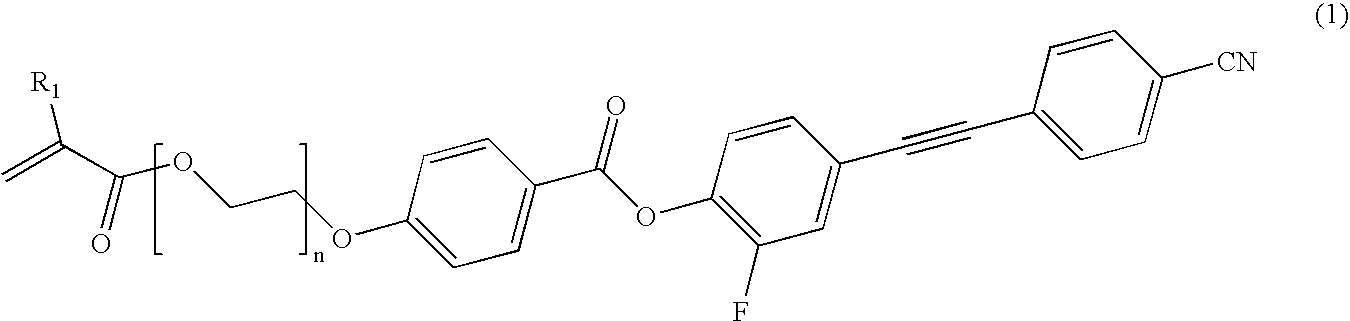

Polarization Gratings in Mesogenic Films

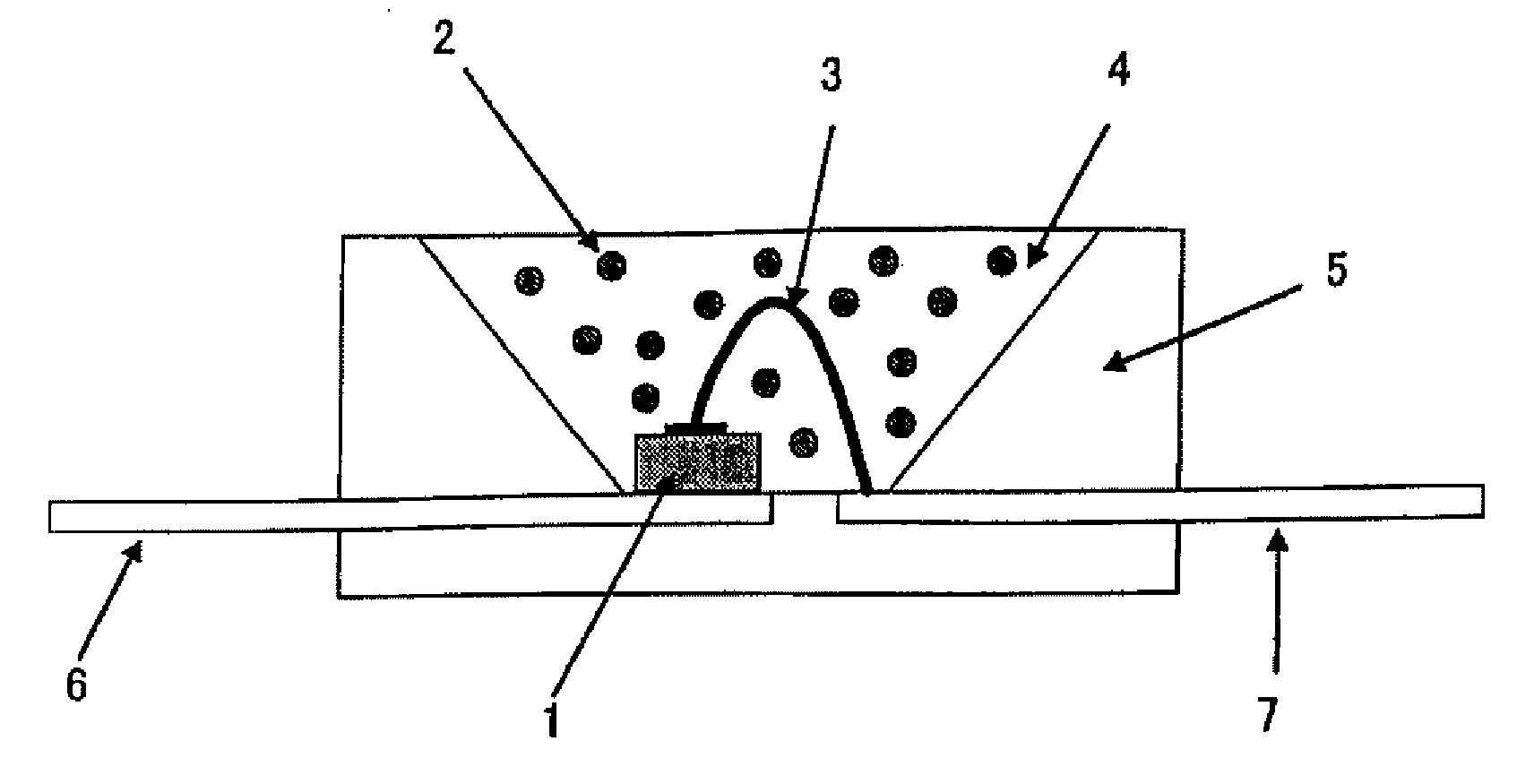

ActiveUS20080278675A1Easily produceHigh diffraction efficiencyPolarising elementsNon-linear opticsPolarization sensitiveLiquid crystal

A polarization grating comprising a polarization sensitive photo-alignment layer (2) and a liquid crystal composition (3) arranged on said photo-alignment layer is provided. An alignment pattern, corresponding to the polarization pattern of a hologram, is recorded in the photo-alignment layer, and the liquid crystal composition is aligned on the photo-alignment layer. As the origin for the alignment of the liquid crystal composition is a polarization hologram recorded in a photo-alignment layer, an essentially defect-free pattern can be obtained with this approach.

Owner:STICHTING DUTCH POLYMER INST

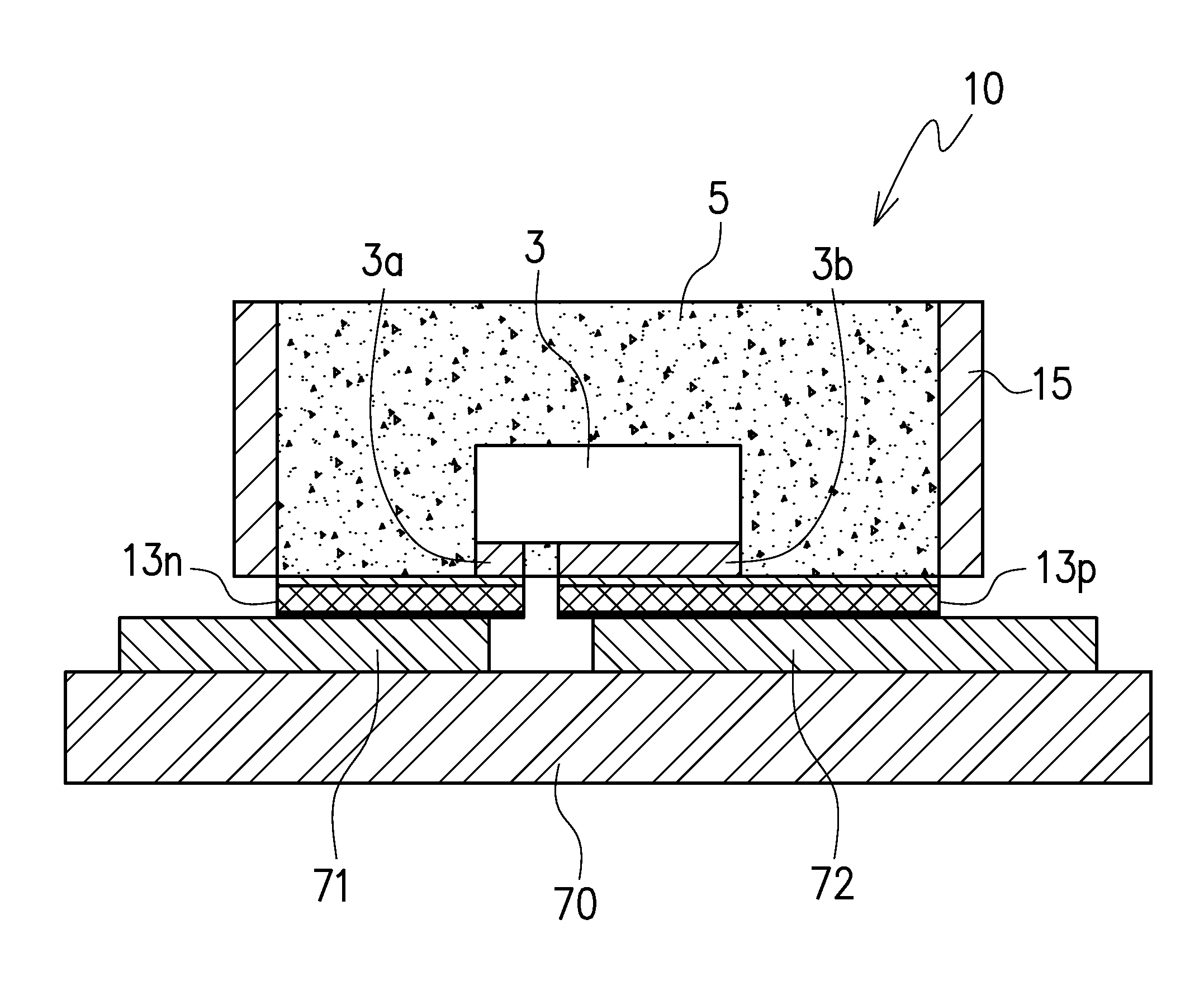

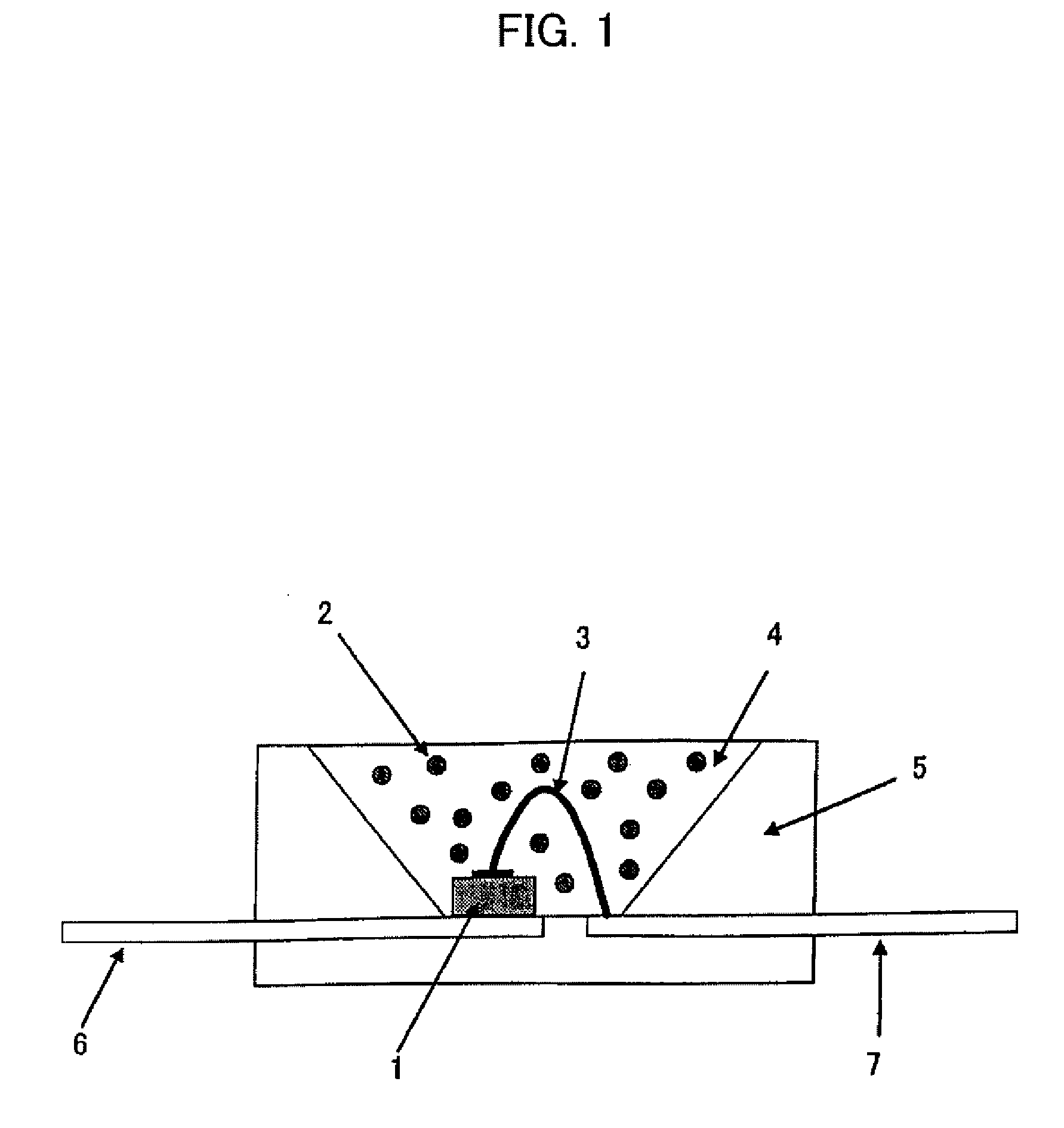

Method of producing light- emitting device and light-emitting device

ActiveUS20120302124A1Easily produceEasy to produceDischarge tube luminescnet screensElectroluminescent light sourcesExternal connectionEngineering

It is an object to produce a thin light-emitting device in an extremely simple method that does not include a substrate on which a light-emitting element is to be mounted.A method of producing a light-emitting device, including: preparing a plurality of light-emitting elements each including element electrodes in a pair; arranging the plurality of light-emitting elements in a sealing member to expose at least one surface of each of the element electrodes in a pair provided to each of the light-emitting elements; forming external connection electrodes in a plurality of pairs on the sealing member, the external connection electrodes in each pair being electrically connected to the element electrodes in a pair provided to each of the light-emitting elements; and obtaining a plurality of light-emitting devices by dividing the sealing member with the plurality of light-emitting elements, the light-emitting devices each including a light-emitting element having element electrodes in a pair, a sealing member sealing the light-emitting element while at least one surface of each of the element electrodes in a pair is exposed, and external connection electrodes in a pair provided on the sealing member and electrically connected to the element electrodes in a pair.

Owner:CITIZEN WATCH CO LTD +1

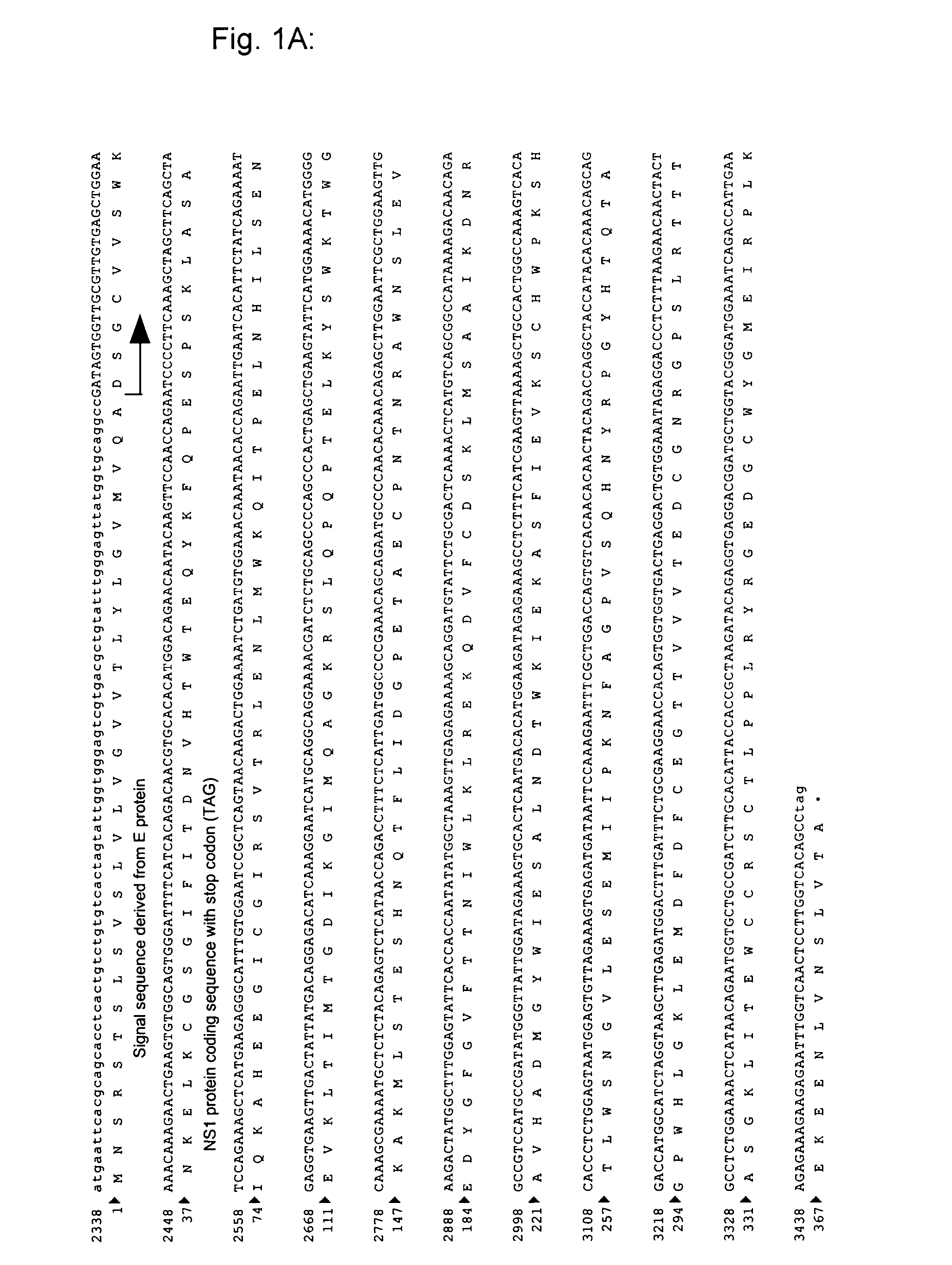

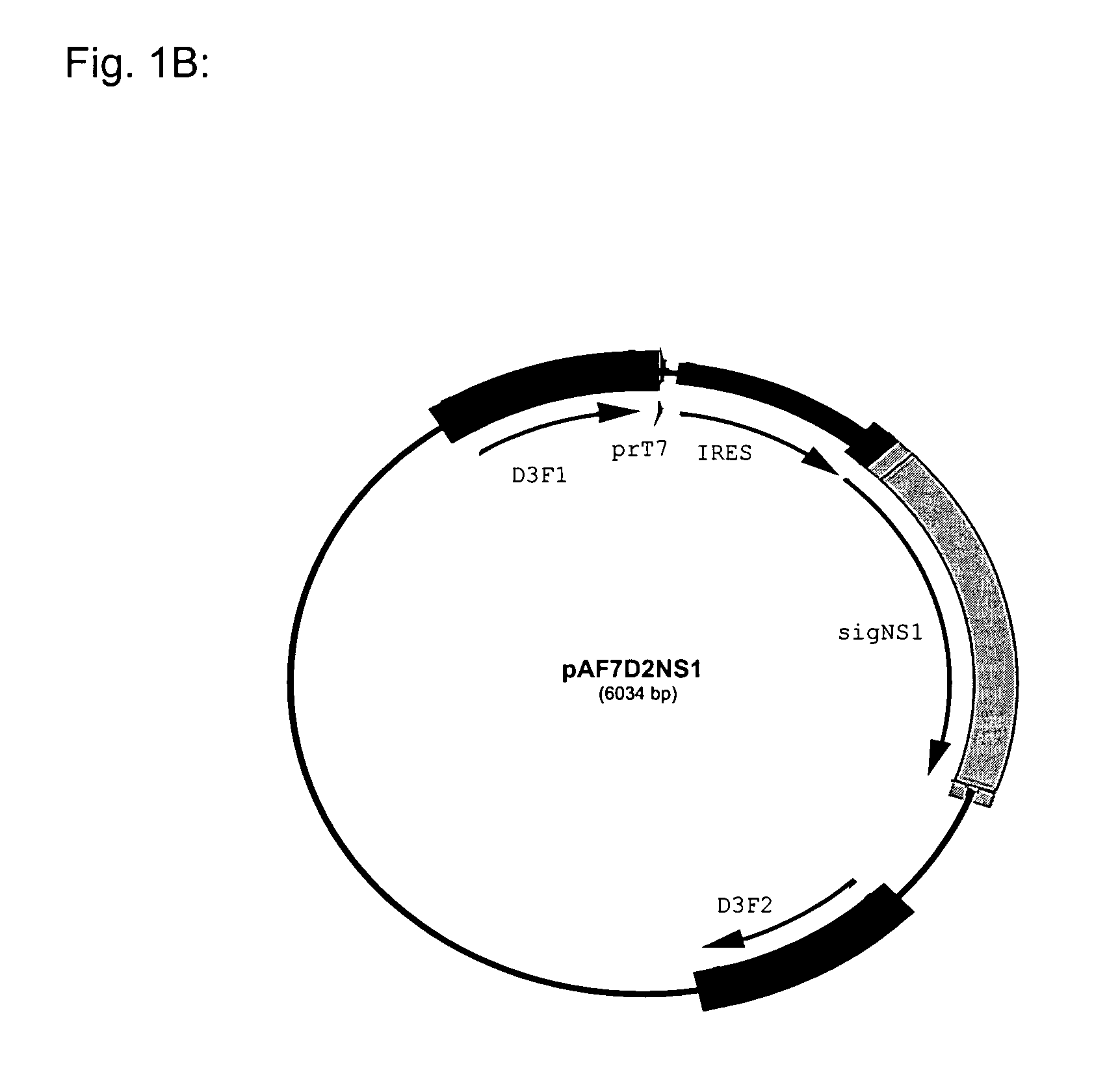

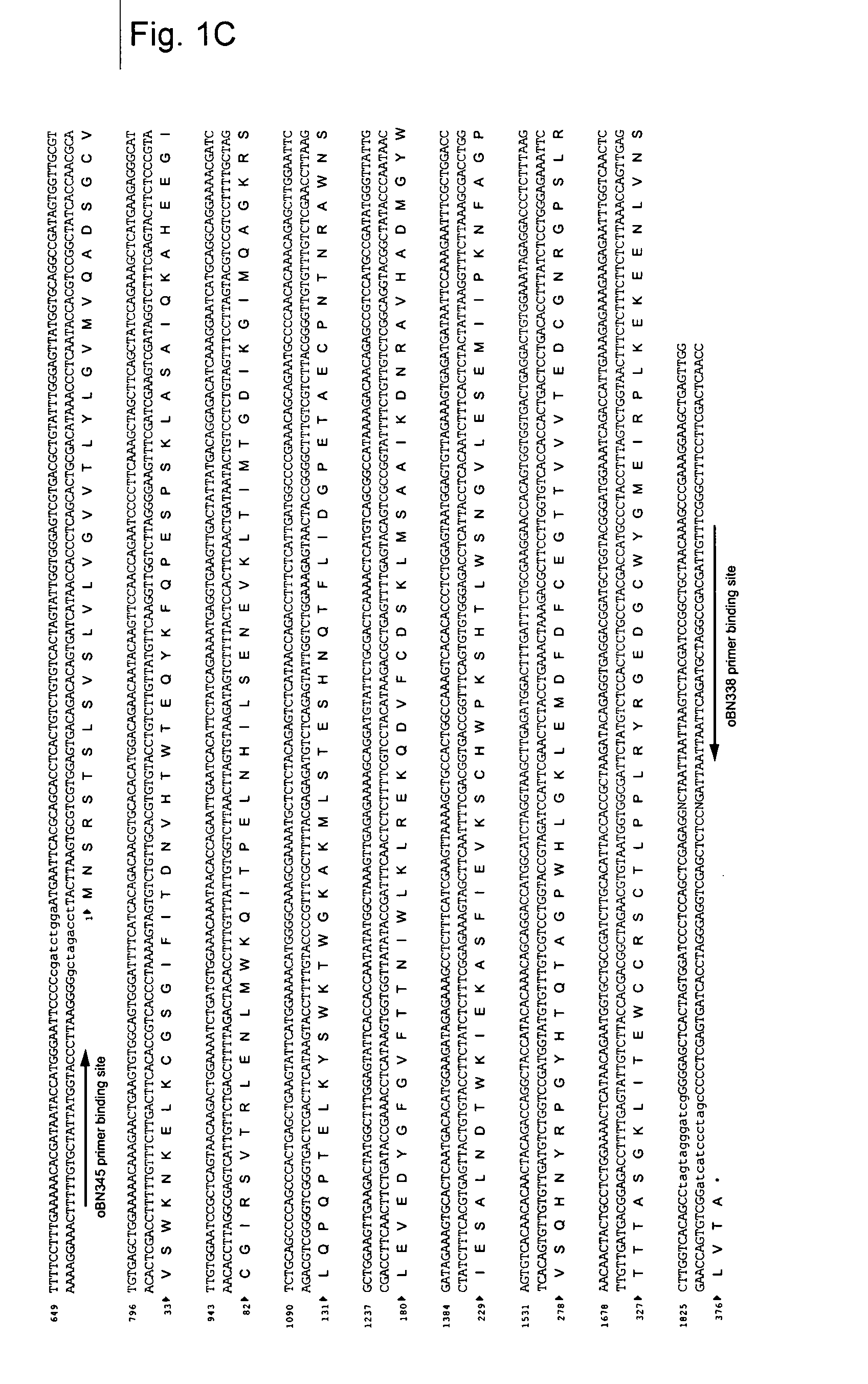

Flavivirus ns1 subunit vaccine

InactiveUS20060159699A1Easily produceEasy to produceOrganic active ingredientsSsRNA viruses positive-senseSerotypeSubunit vaccines

The present invention relates to NS1 proteins or parts thereof of Flaviviruses, in particular of Dengue viruses useful for vaccination against said Flavivirus and against one or more other Flaviviruses. The invention further concerns the NS1 protein or parts thereof of one Dengue virus serotype, in particular serotype 2, useful for vaccination against Dengue viruses from all serotypes. The invention further concerns DNA comprising an expression cassette coding for a Flavivirus NS1 or parts thereof, vectors comprising said DNA and vaccines containing or expressing a Flavivirus NS1.

Owner:VENTURE TECH SDN BHD +1

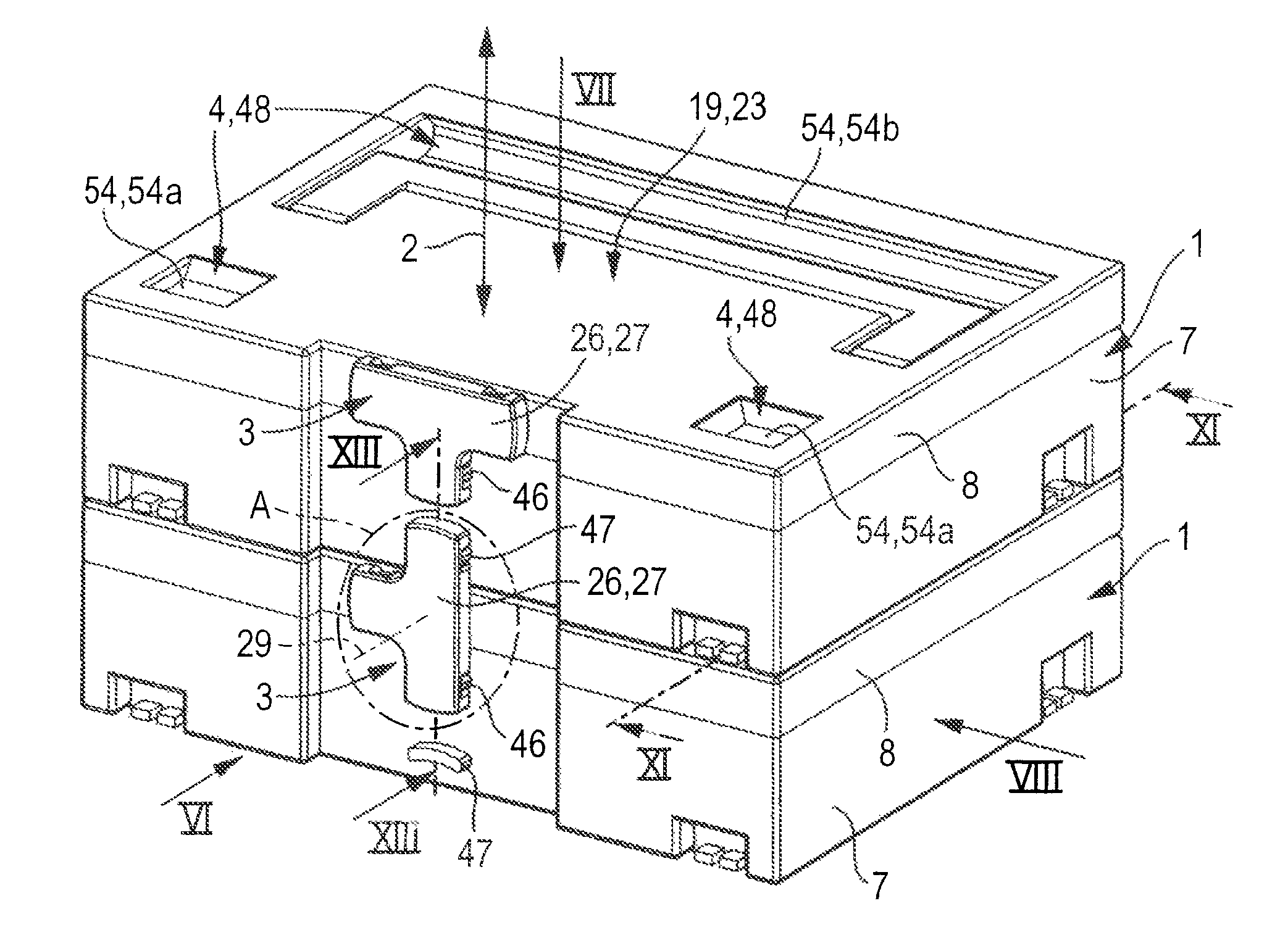

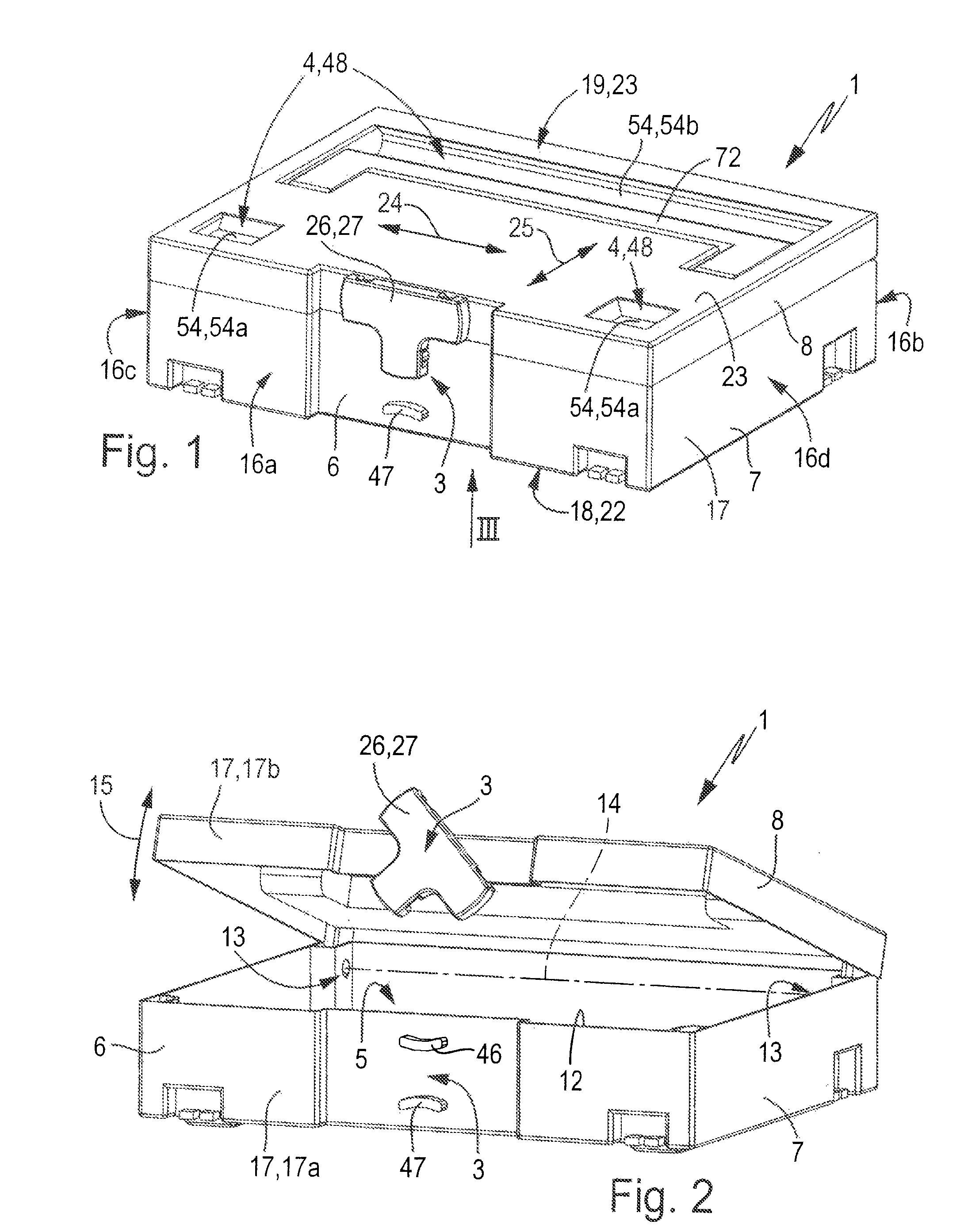

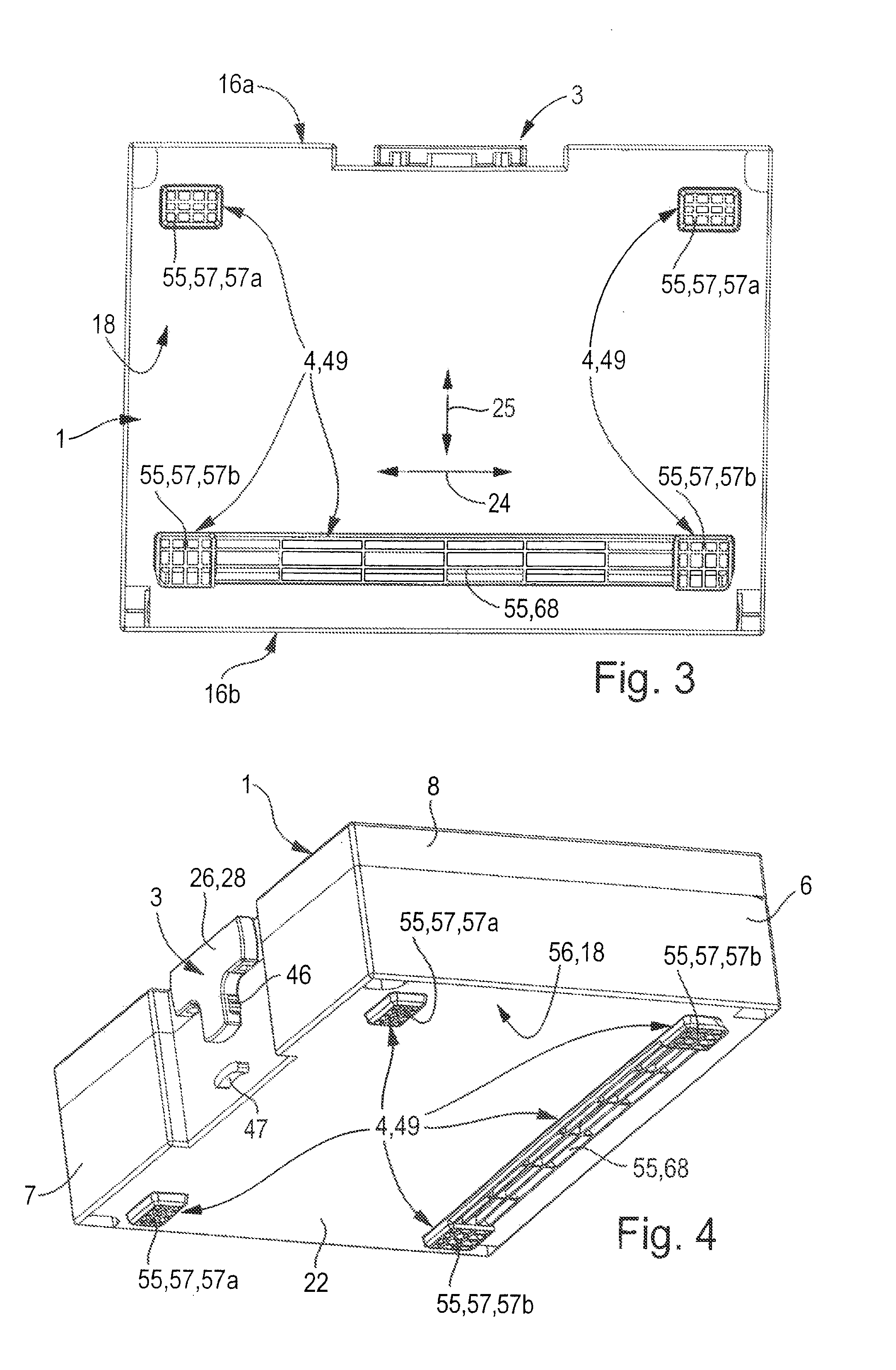

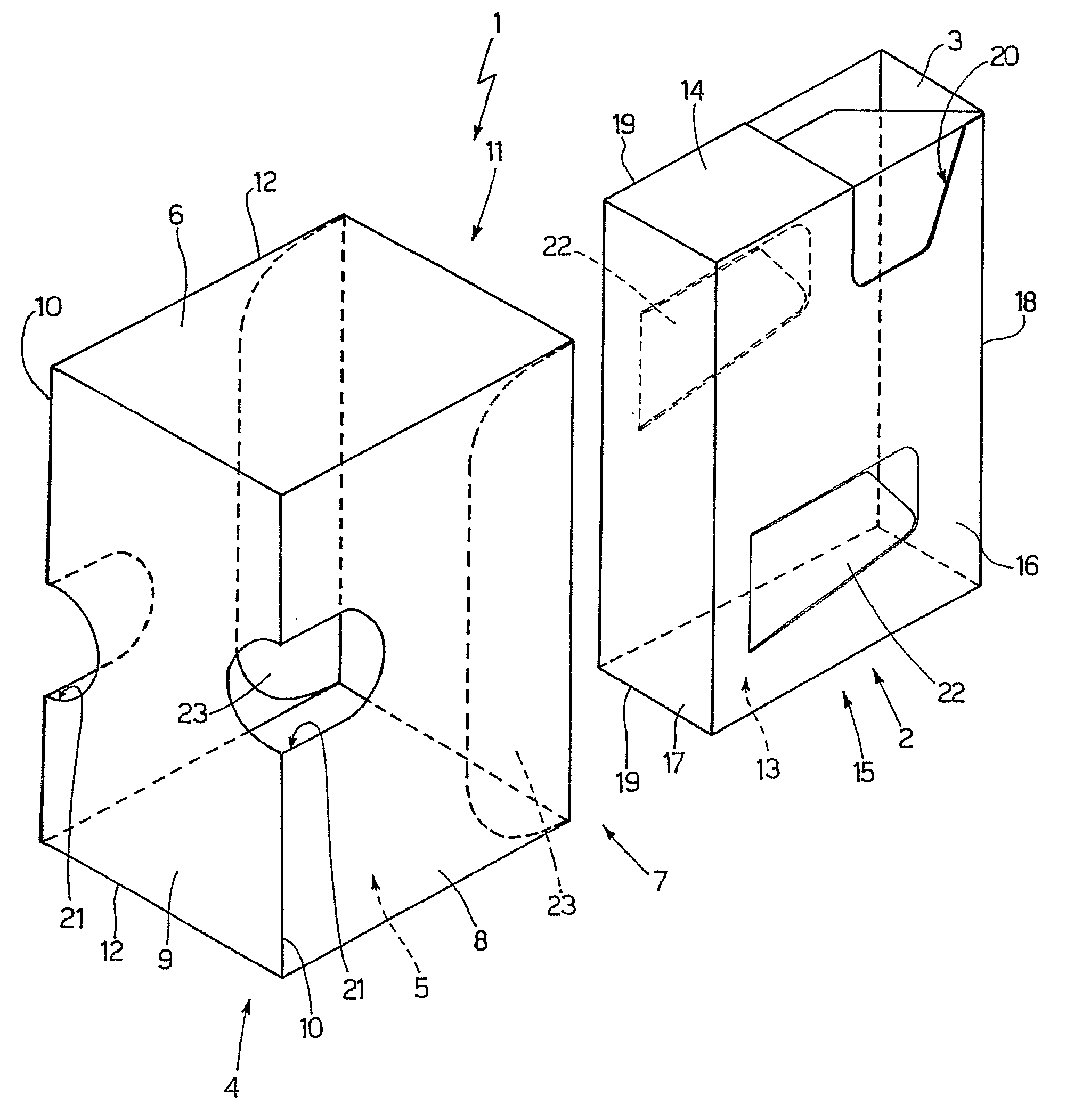

Stackable container assembly with reciprocal locking of the stacked containers

It is a matter of a container assembly with at least one stackable container (1) which has a bottom part (7) and a lid (8) mounted on top thereof Several containers (1) may be so stacked that the lid (8) of the lower container (1) is located between two bottom parts (7). The container (1) is equipped with at least one connecting device (3) which has coupling means (26) mounted movably on the lid (8) of the container (1). The coupling means (26) are movable, for the connection of two containers (1) mounted one above the other, into a connected position relative to the lid (8), in which they are simultaneously in connecting engagement with the bottom parts (7) of both stacked containers (1).

Owner:TTS TOOLTECHNIC SYST

Metal Nanoparticle, Metal Nanoparticle Colloid, Method for Storing Metal Nanoparticle Colloid, and Metal Coating Film

InactiveUS20090029148A1Easily produceHighly conductiveMaterial nanotechnologyConductive materialConductive coatingOrganic acid

The object of the present invention is provide a metal nanoparticle which has a nano-sized average diameter while being highly stable as a particle, and a method for producing such metal nanoparticle. Particularly provides a metal nanoparticle having characteristics such as particle diameter and particle size distribution suitable for forming a conductive coating layer, and a method for producing such metal nanoparticle. The metal nanoparticle of the present invention is characterized in that it is obtained by reacting a reducing agent act on a solution containing an organic acid metal salt and an amine.

Owner:NIPPON SHOKUBAI CO LTD

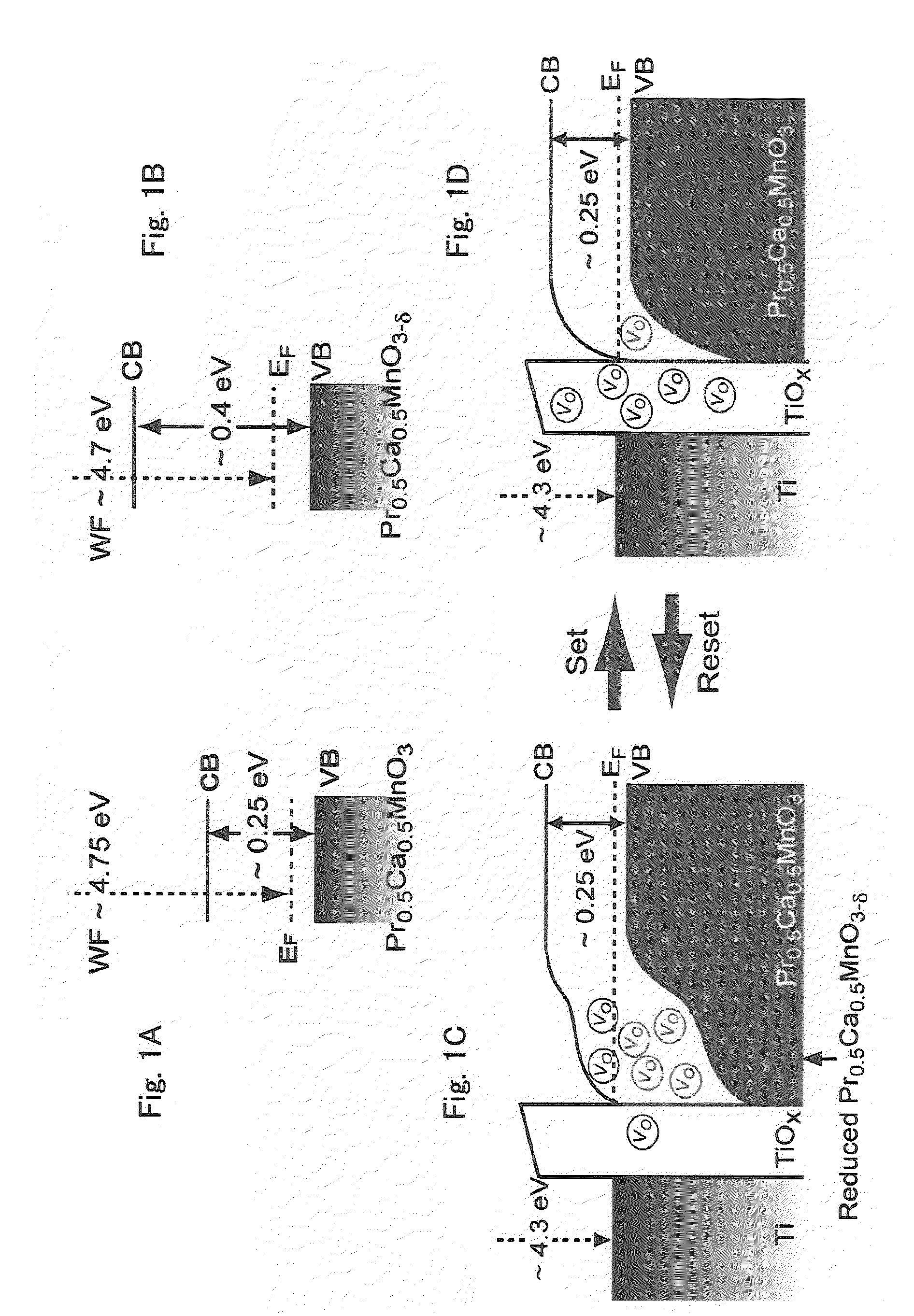

Nonvolatile variable resistive element and nonvolatile semiconductor memory device

InactiveUS20120268980A1Reduce cell areaEasily produceSolid-state devicesDigital storageResistive elementElectric field

A large-capacity and inexpensive nonvolatile semiconductor memory device that prevents a leak current and is operated at high speed is implemented with a nonvolatile variable resistive element. A memory cell array includes the nonvolatile variable resistive elements each including a variable resistor composed of a metal oxide film to cause a resistance change according to an oxygen concentration in the film, an insulation film formed on the variable resistor, first and second electrodes to sandwich the variable resistor, and a third electrode opposite to the variable resistor across the insulation film. A writing operation is performed by applying a voltage to the third electrode to induce an electric field having a threshold value or more, in a direction perpendicular to an interface between the variable resistor and the insulation film, and a resistance state of the variable resistor is read by applying a voltage between the first and second electrodes.

Owner:SHARP KK +1

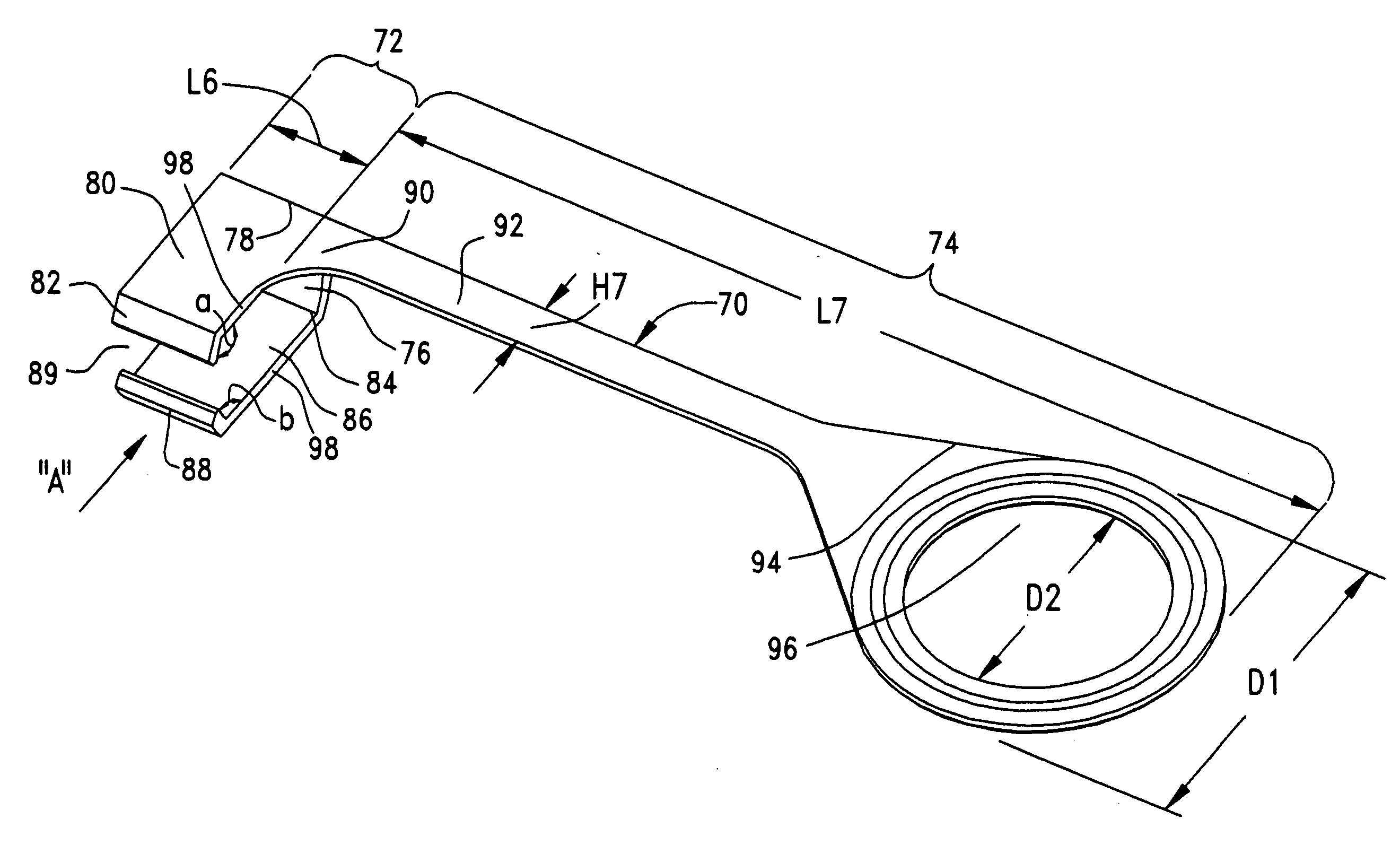

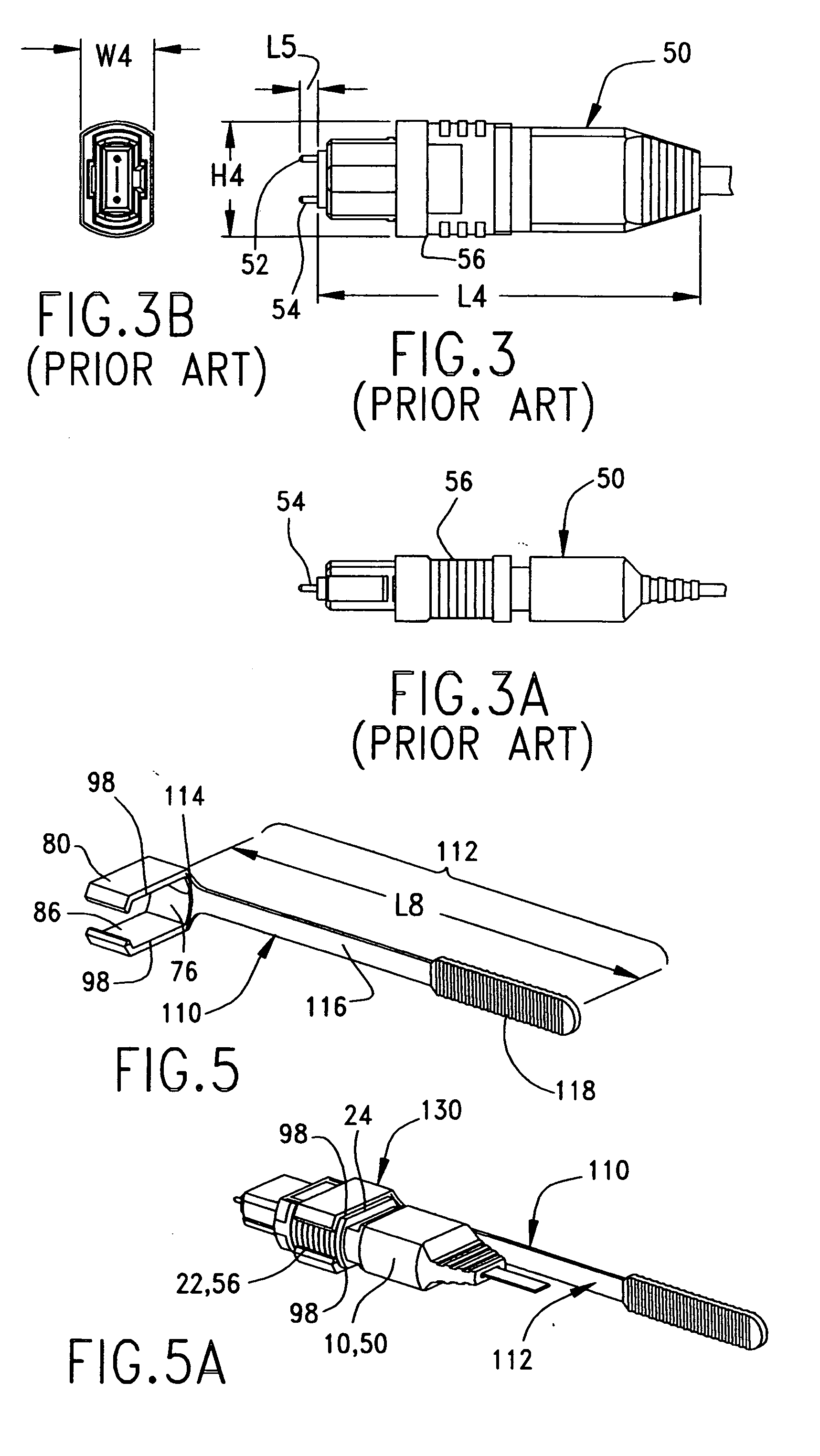

Fiber optic connector removal clips

A removal clip is provided for disconnecting a fiber optic connector from an array of installed fiber optic connectors. The removal clip includes an engagement portion for engaging the connector and a force transmitting structure that allows digital removal force from a user to be applied at a distance from the connector. The engagement portion may be generally U-shaped and includes opposing latch arms configured to accommodate the body of a fiber optic connector. The latch arms permit the engagement portion to snap attach to the connector. The force transmitting structure may include a beam and a handle extending axially or radially from the gripping section. Also included is an assembly of a removal clip attached to a fiber optic connector.

Owner:MOLEX INC

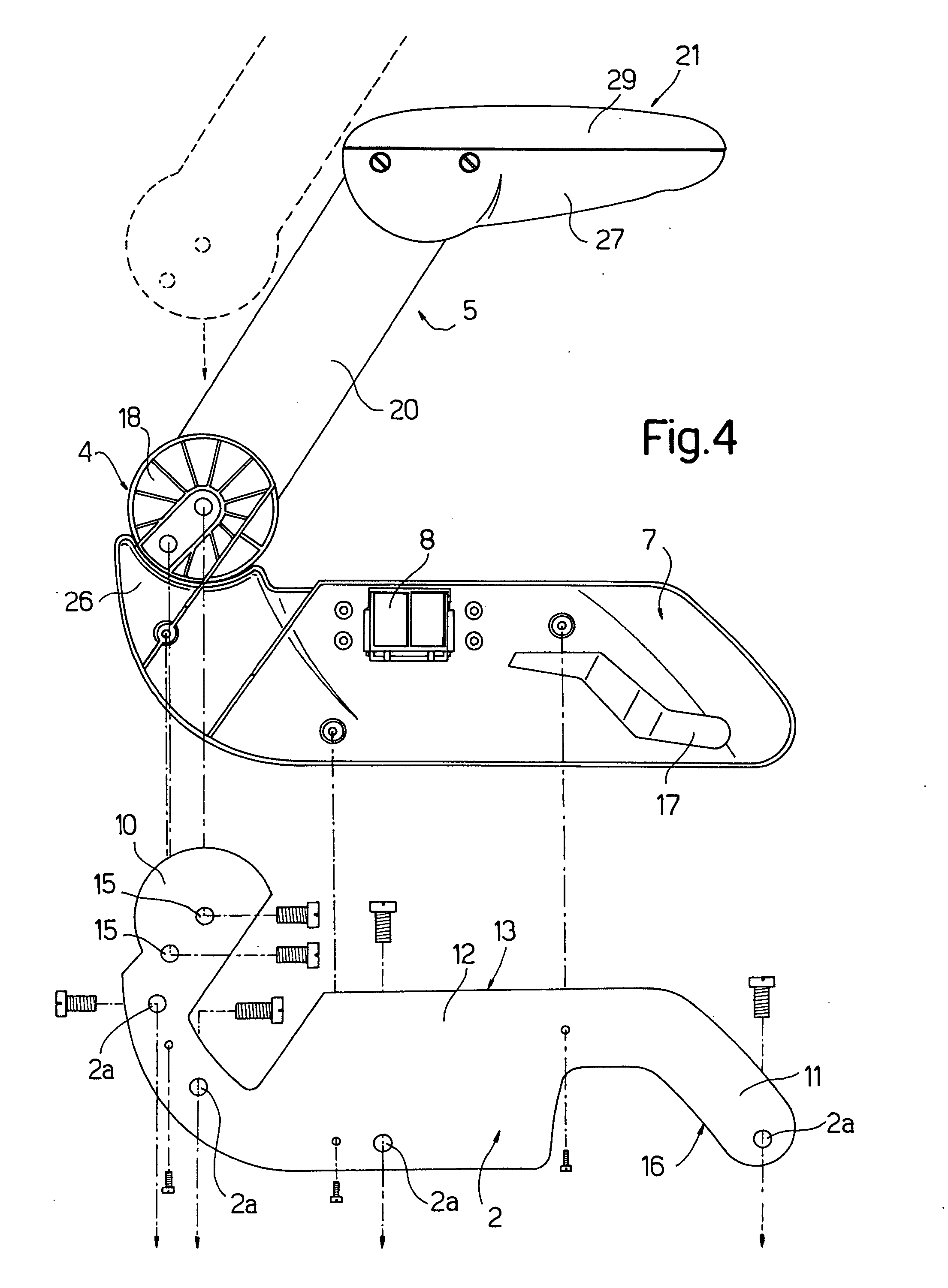

Tensioning or deflection pulley for a belt drive

A tensioning or deflection pulley for a belt drive includes a carrier and a track roller comprised of an inner ring, an outer ring, and a connecting assembly, including a wheel disk extending between the inner and outer rings, and a rib assembly disposed in both sides of the disk in circumferential spaced-apart relationship, for interconnecting the inner and outer rings. The track roller is supported on the carrier by a sealed rolling-contact bearing via a fastening screw. A first sealing element is connected to the track roller on a carrier-distal side, and a second cap-shaped sealing element is disposed between the carrier and the track roller and detachably secured to the inner ring of the track roller to thereby seal the track roller on both sides.

Owner:INA SCHAEFFLER KG

Silicon single crystal wafer for IGBT and method for manufacturing silicon single crystal wafer for IGBT

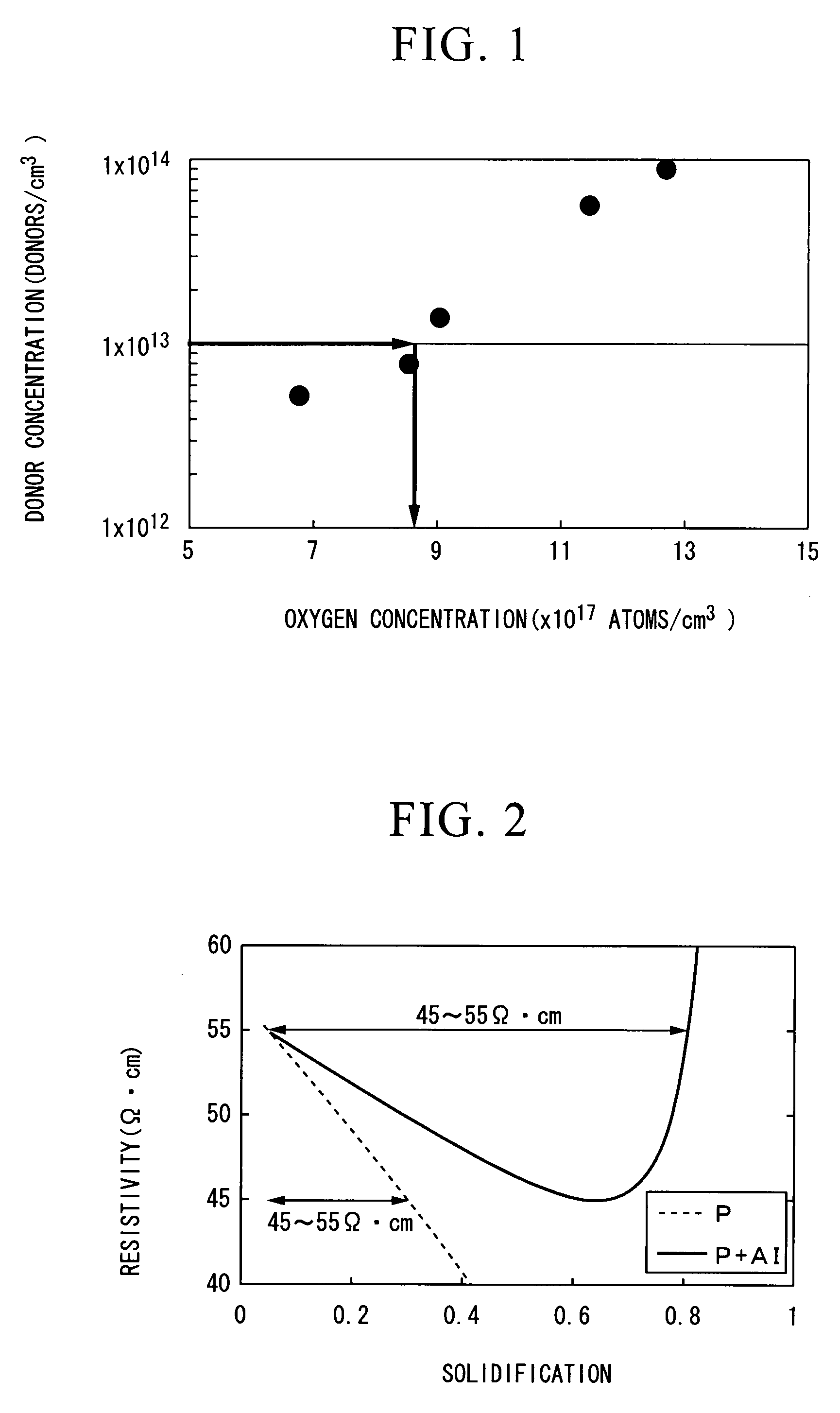

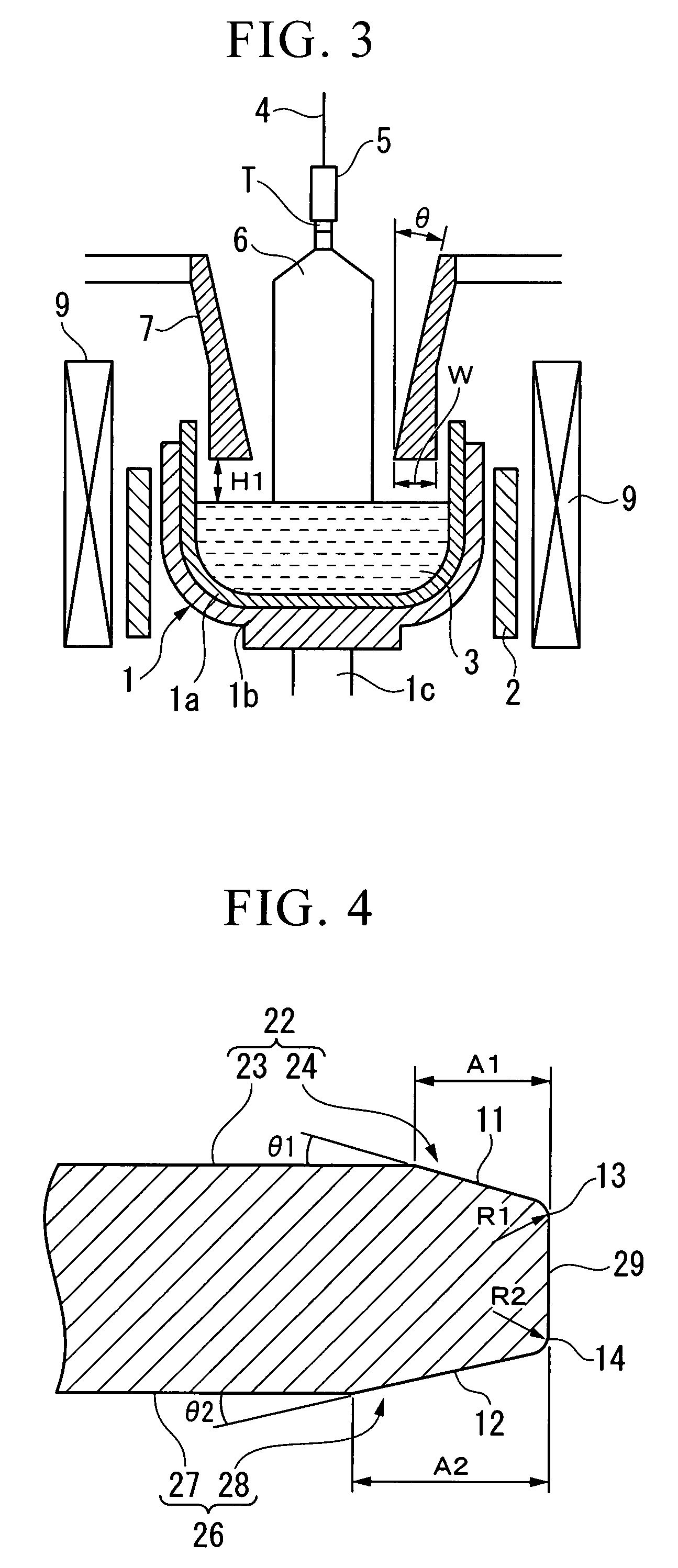

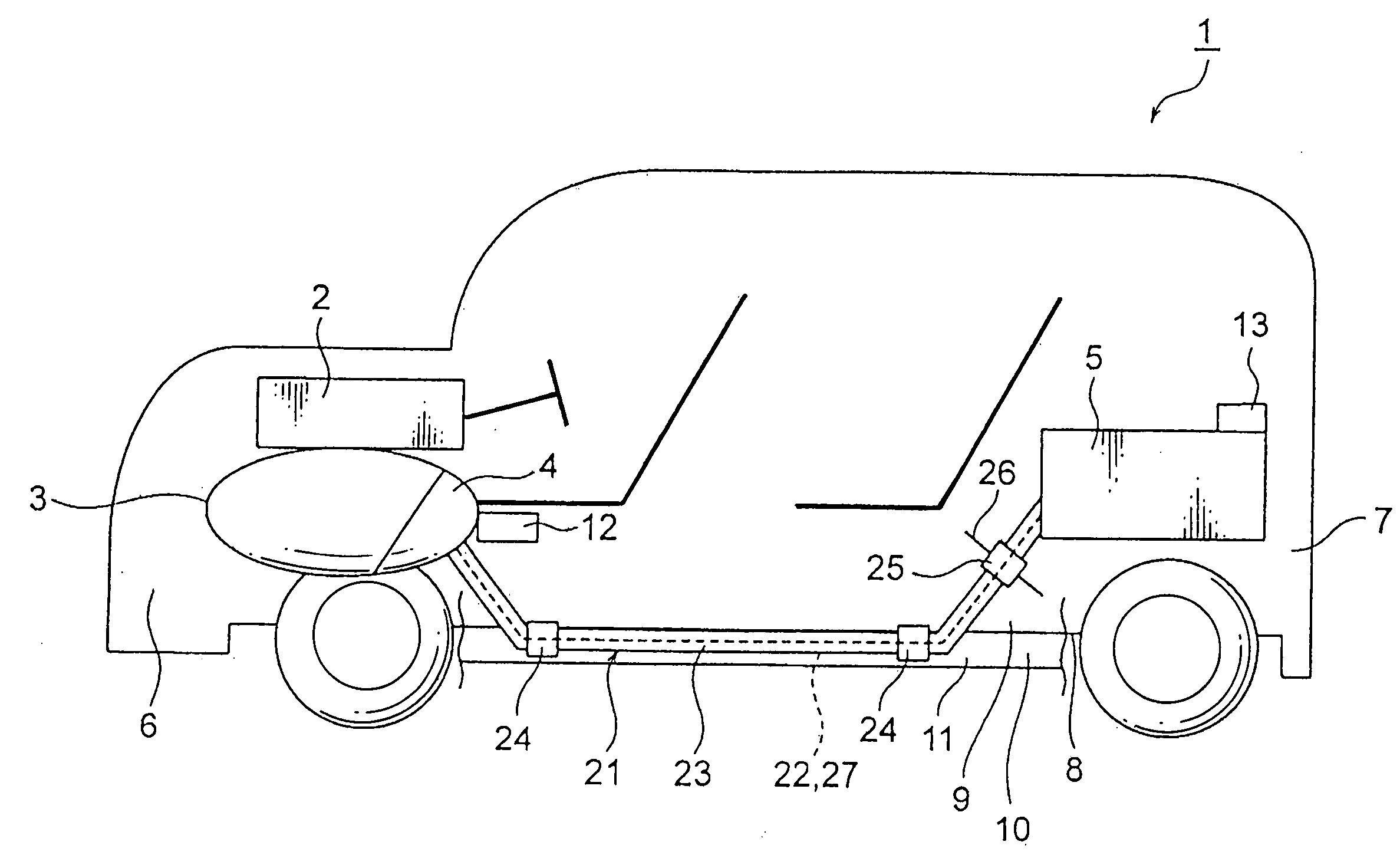

ActiveUS20070193501A1Reduce variationEasily producePolycrystalline material growthSemiconductor/solid-state device manufacturingDislocationDopant

In this silicon single crystal wafer for IGBT, COP defects and dislocation clusters are eliminated from the entire region in the radial direction of the crystal, the interstitial oxygen concentration is 8.5×1017 atoms / cm3 or less, and variation in resistivity within the wafer surface is 5% or less. This method for manufacturing a silicon single crystal wafer for IGBT includes introducing a hydrogen atom-containing substance into an atmospheric gas at a hydrogen gas equivalent partial pressure of 40 to 400 Pa, and growing a single crystal having an interstitial oxygen concentration of 8.5×1017 atoms / cm3 or less at a silicon single crystal pulling speed enabling pulling of a silicon single crystal free of grown-in defects. The pulled silicon single crystal is irradiated with neutrons so as to dope with phosphorous; or an n-type dopant is added to the silicon melt; or phosphorous is added to the silicon melt so that the phosphorous concentration in the silicon single crystal is 2.9×1013 to 2.9×1015 atoms / cm3 and a p-type dopant having a segregation coefficient smaller than that of the phosphorous is added to the silicon melt so that the concentration in the silicon single crystals is 1×1013 to 1×1015 atoms / cm3 corresponding to the segregation coefficient thereof.

Owner:SUMCO CORP

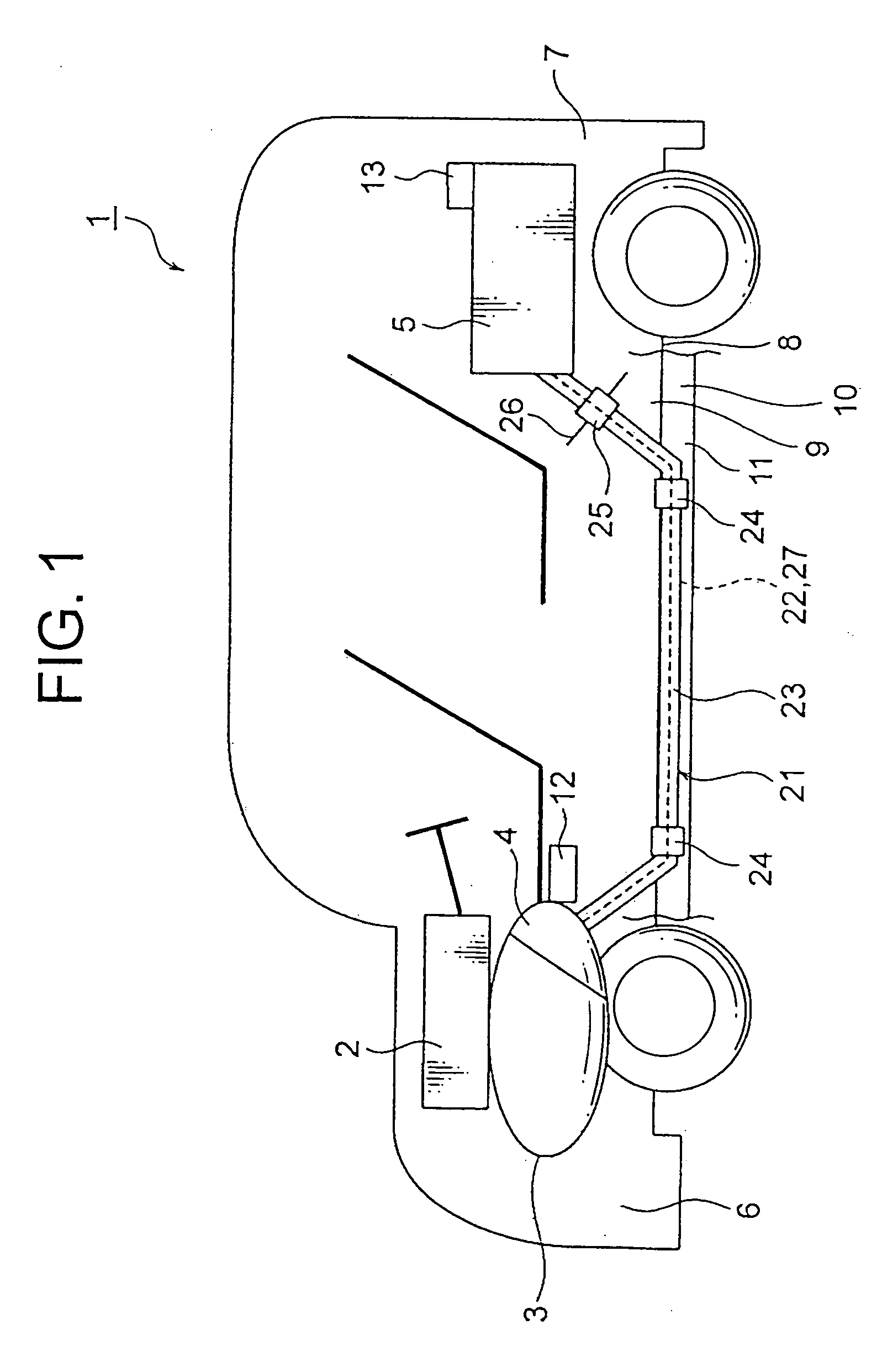

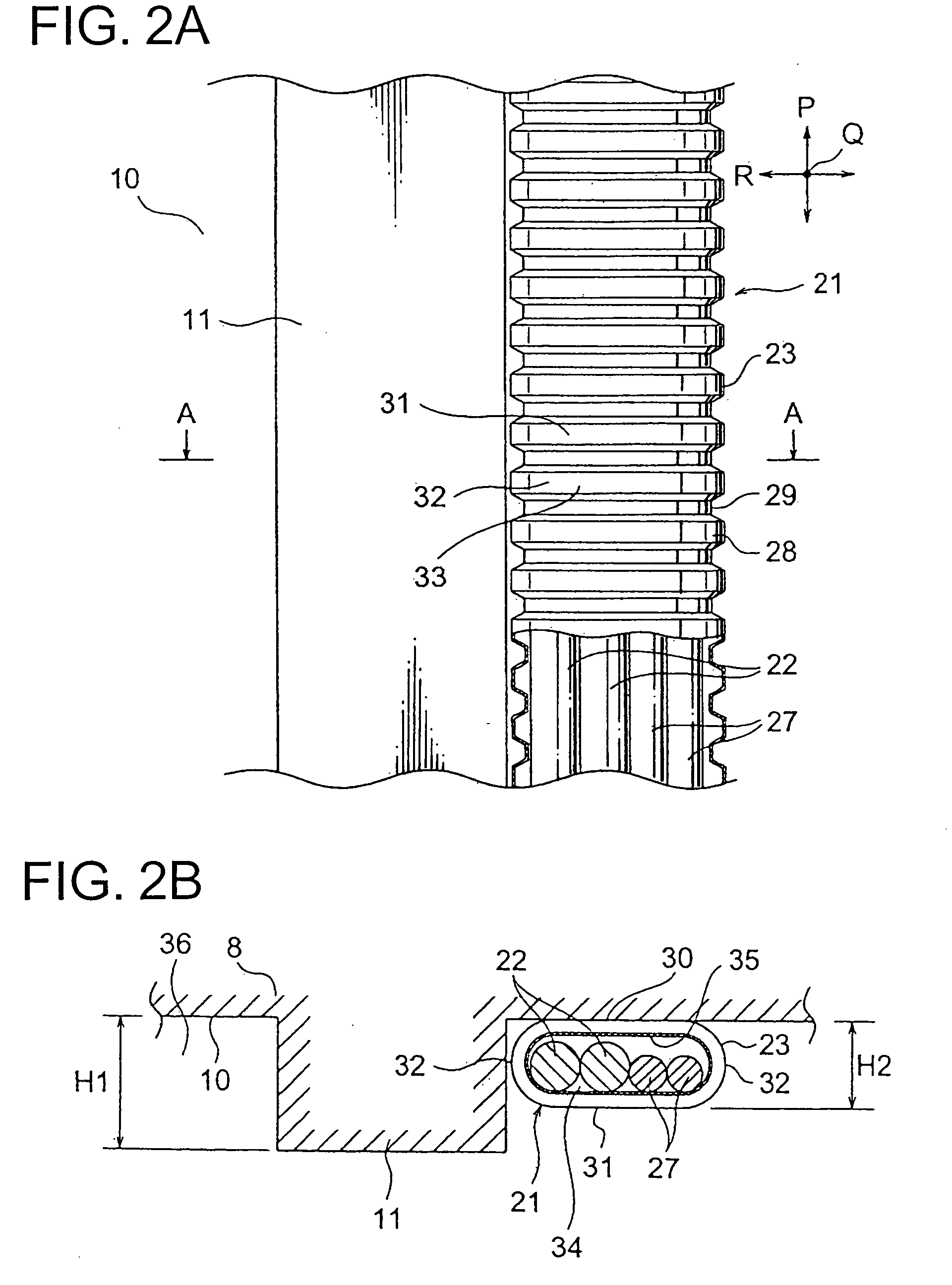

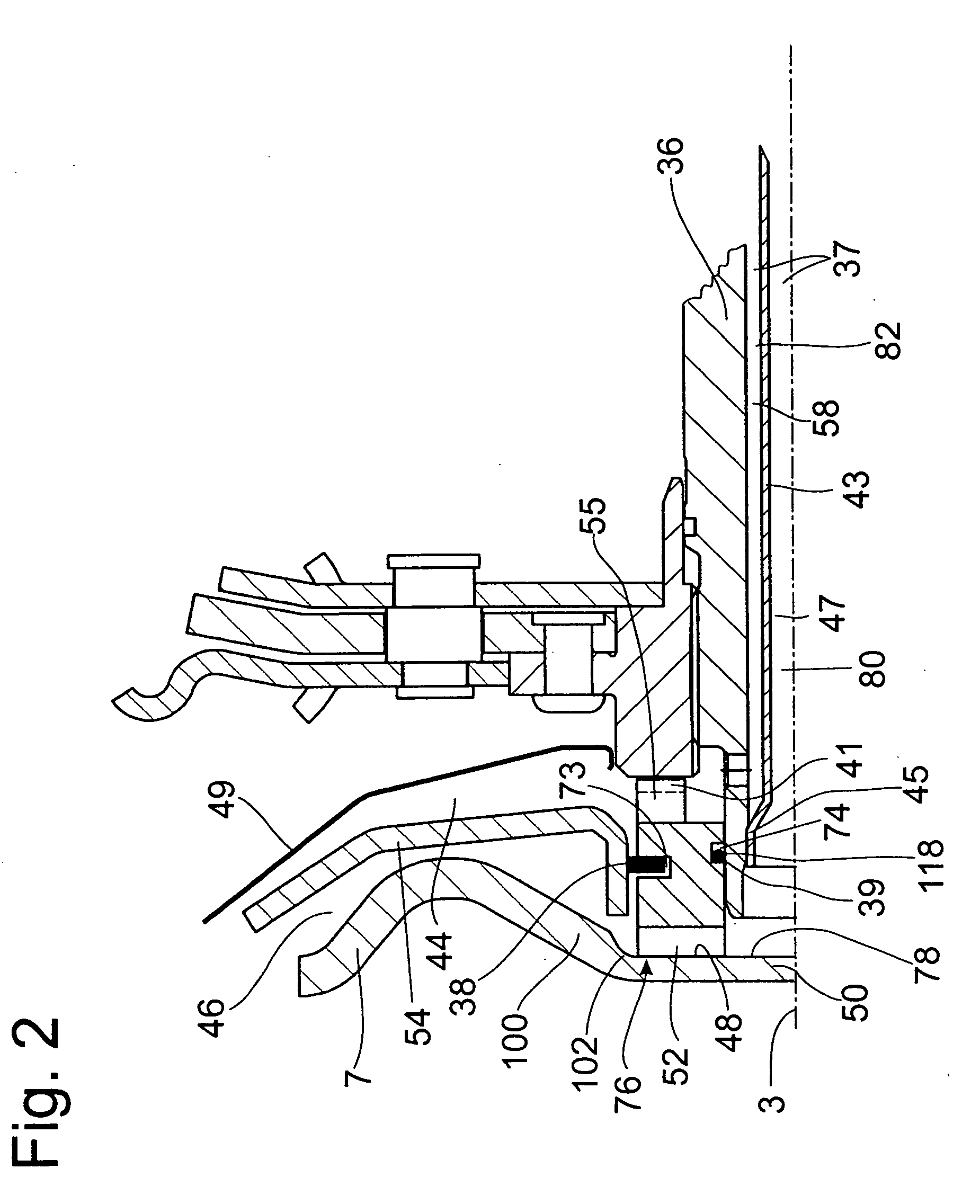

Method for producing wiring harness

ActiveUS20100043225A1Easily produceMinimal sizeLine/current collector detailsElectric connection structural associationsHigh pressureElectrical and Electronics engineering

In a first production process, firstly, a flat corrugate tube 23 having a necessary length for wiring is prepared. Next, a grommet 25 and a protector 24 are assembled with the flat corrugate tube 23 at predetermined positions. In a second production process, high-voltage power lines 22 and low-voltage electric wires 27 are inserted into the flat corrugate tube 23 from the one opening 40 toward the other opening 41. In a third production process, ends of the high-voltage power lines 22 and the low-voltage electric wires 27 exposed from the one opening 40 and the other opening 41 of the flat corrugate tube 23 are treated. When the third production process is finished, the production of the wiring harness 21 is finished.

Owner:YAZAKI CORP

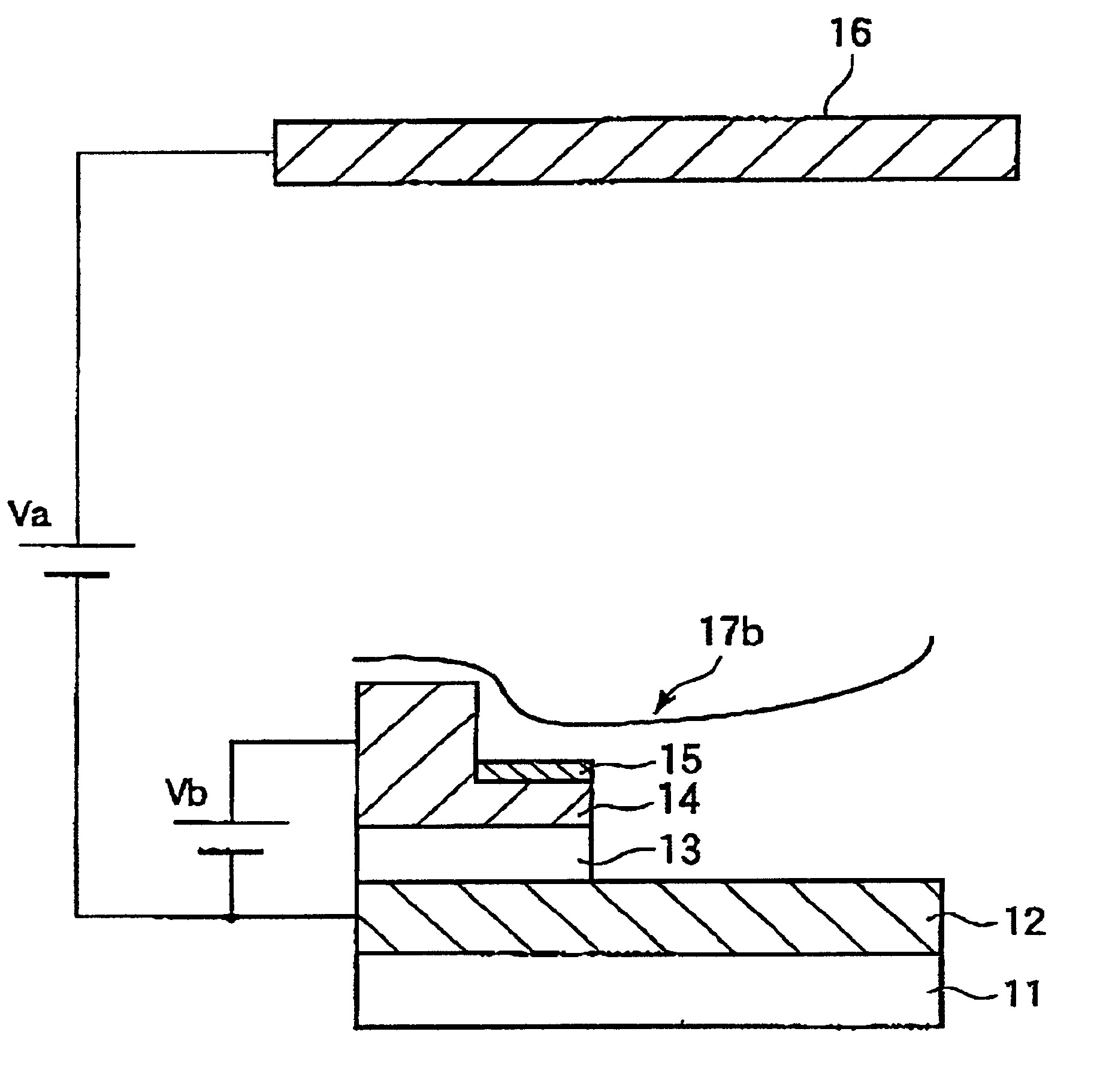

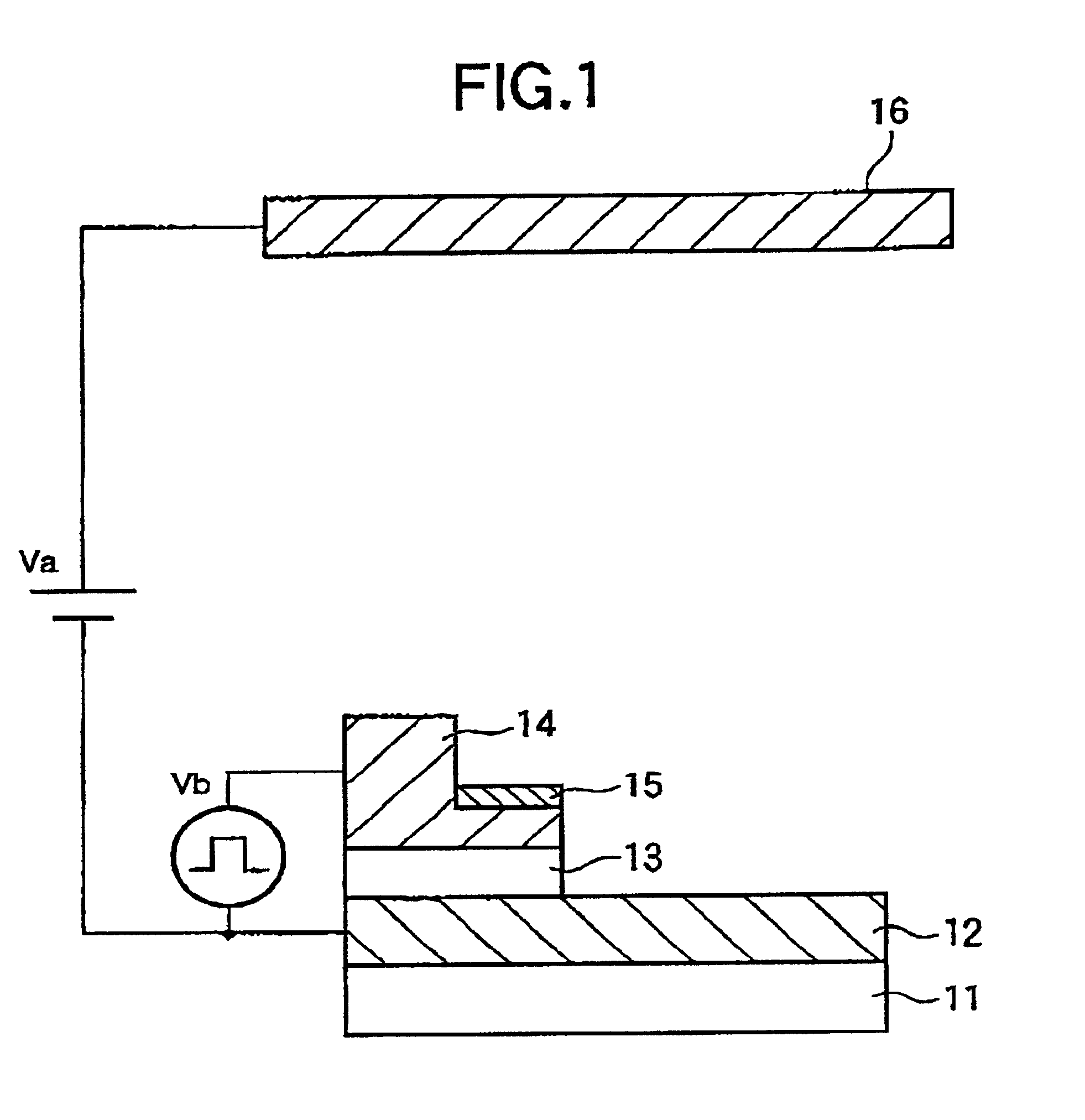

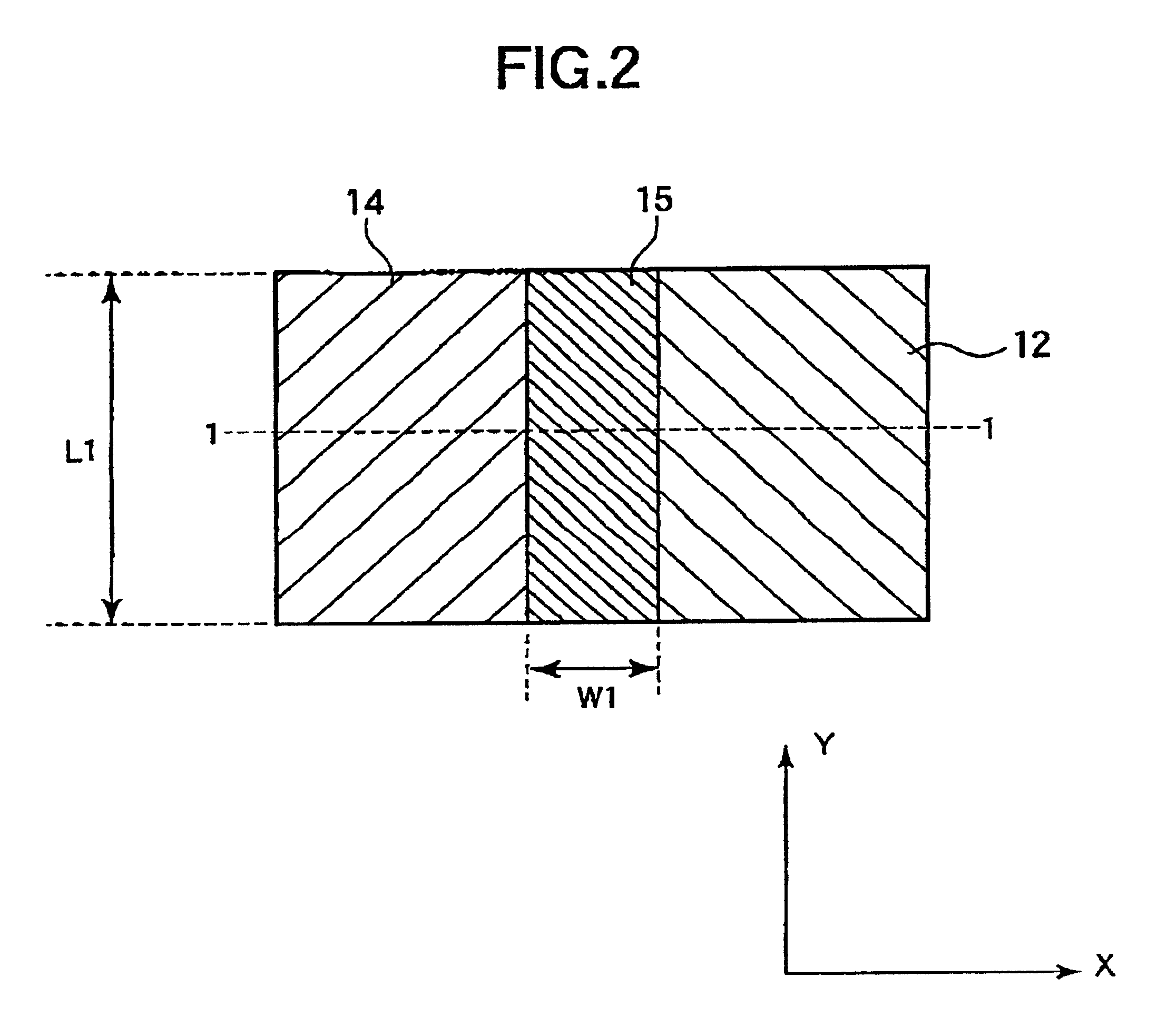

Electron-emitting device, electron source, image forming apparatus, and electron-emitting apparatus

InactiveUS6853126B2Easily produceSmall beam diameterMaterial nanotechnologyControl electrodesOptoelectronicsImaging equipment

Disclosed is an electron-emitting device, an electron source, and an image-forming apparatus that have uniform electron-emitting characteristics, emit electron beams whose diameters are small, have simple constructions, and are easy to be manufactured. The electron-emitting device comprising: a first electrode arranged on a surface of a substrate; an insulating layer arranged on the first electrode; a second electrode arranged on the insulating layer; and an electron-emitting film arranged on the second electrode, where the second electrode has two side surfaces that oppose each other in a direction parallel to the surface of the substrate, and the electron-emitting film is arranged so as to be shifted toward one of the two side surfaces.

Owner:CANON KK

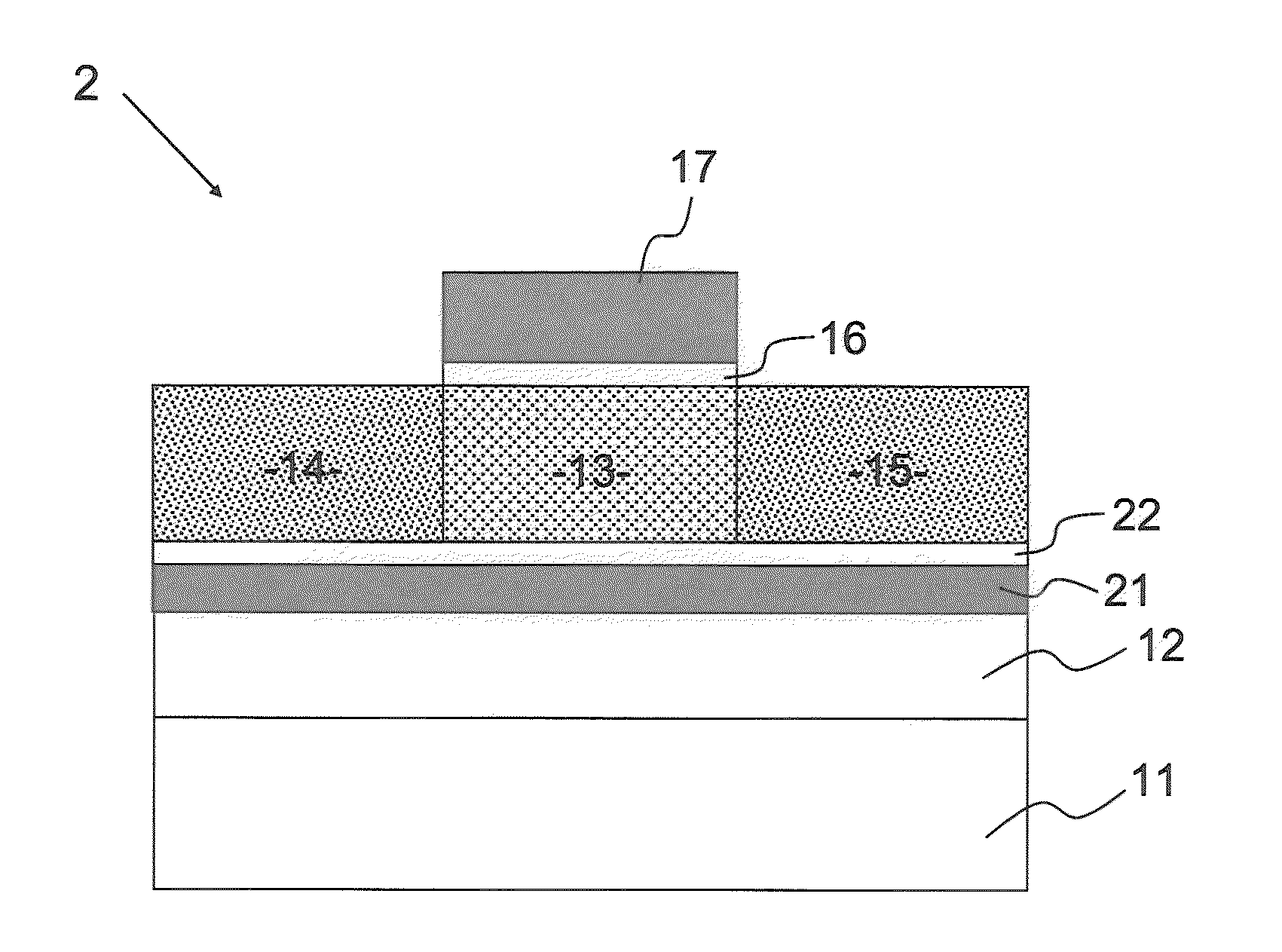

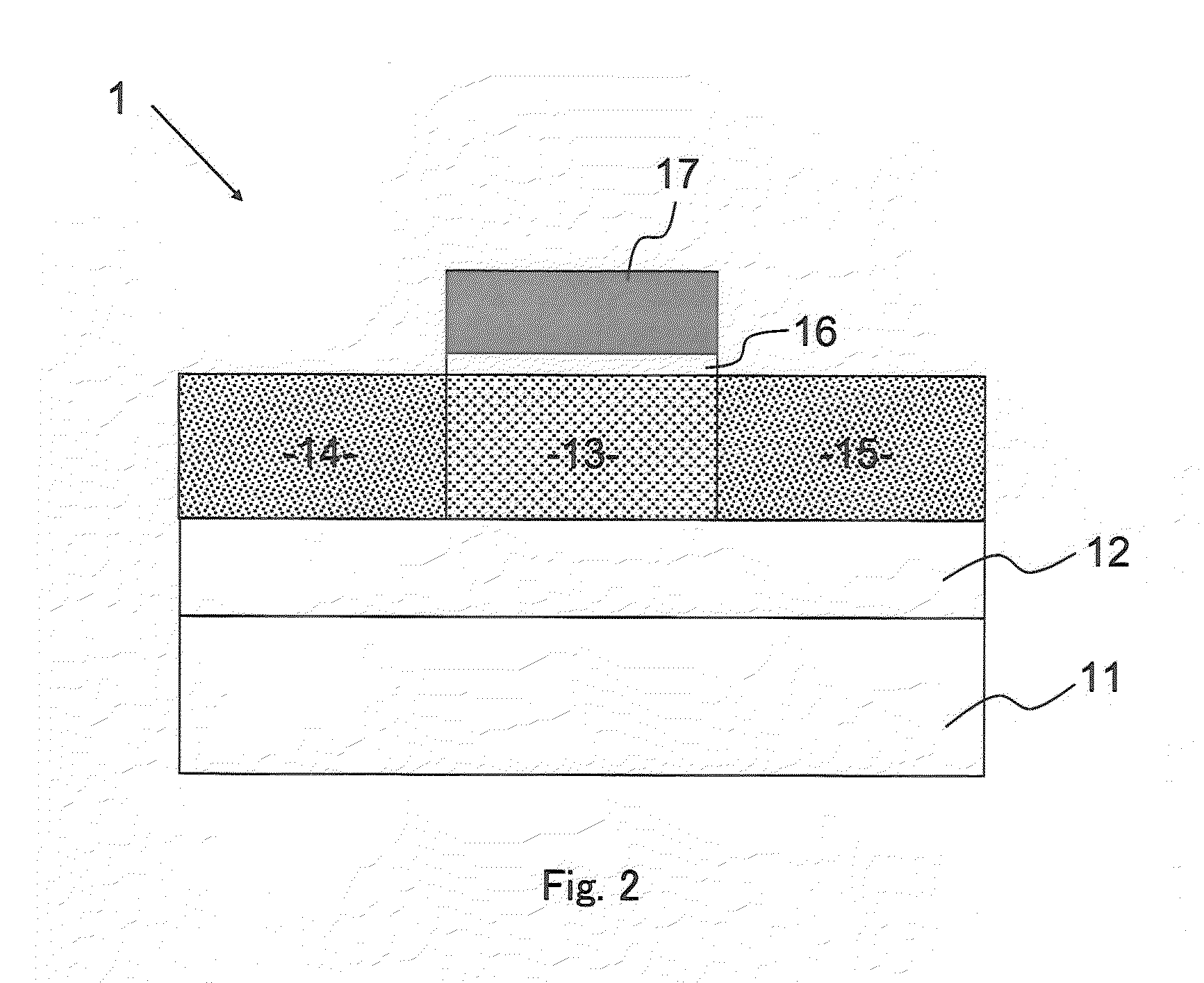

Organic Electroluminescence Display Device

ActiveUS20070200123A1Without decrease luminous efficiencyEasily produceIncadescent screens/filtersDischarge tube luminescnet screensOrganic electroluminescenceMedia layer

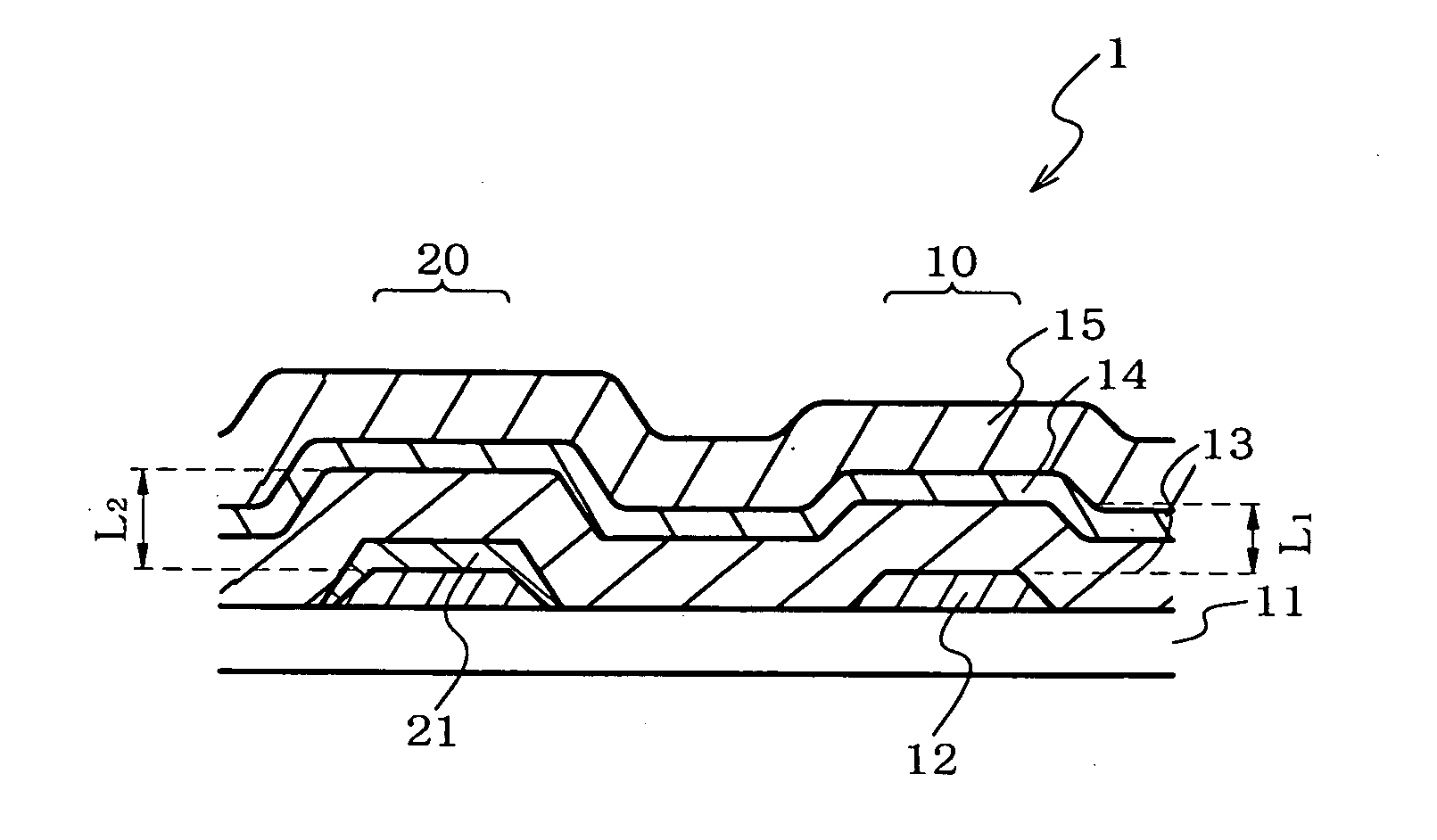

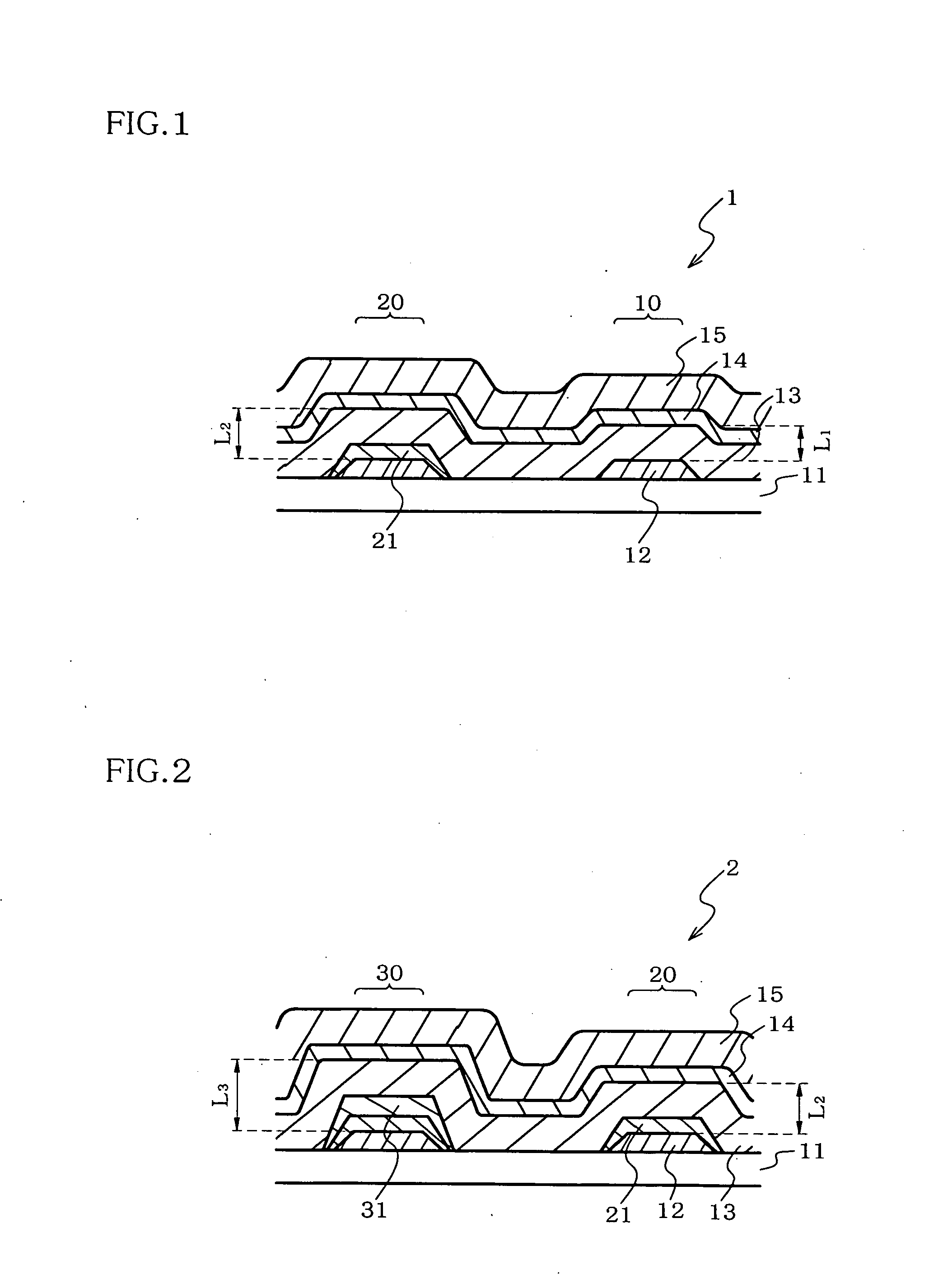

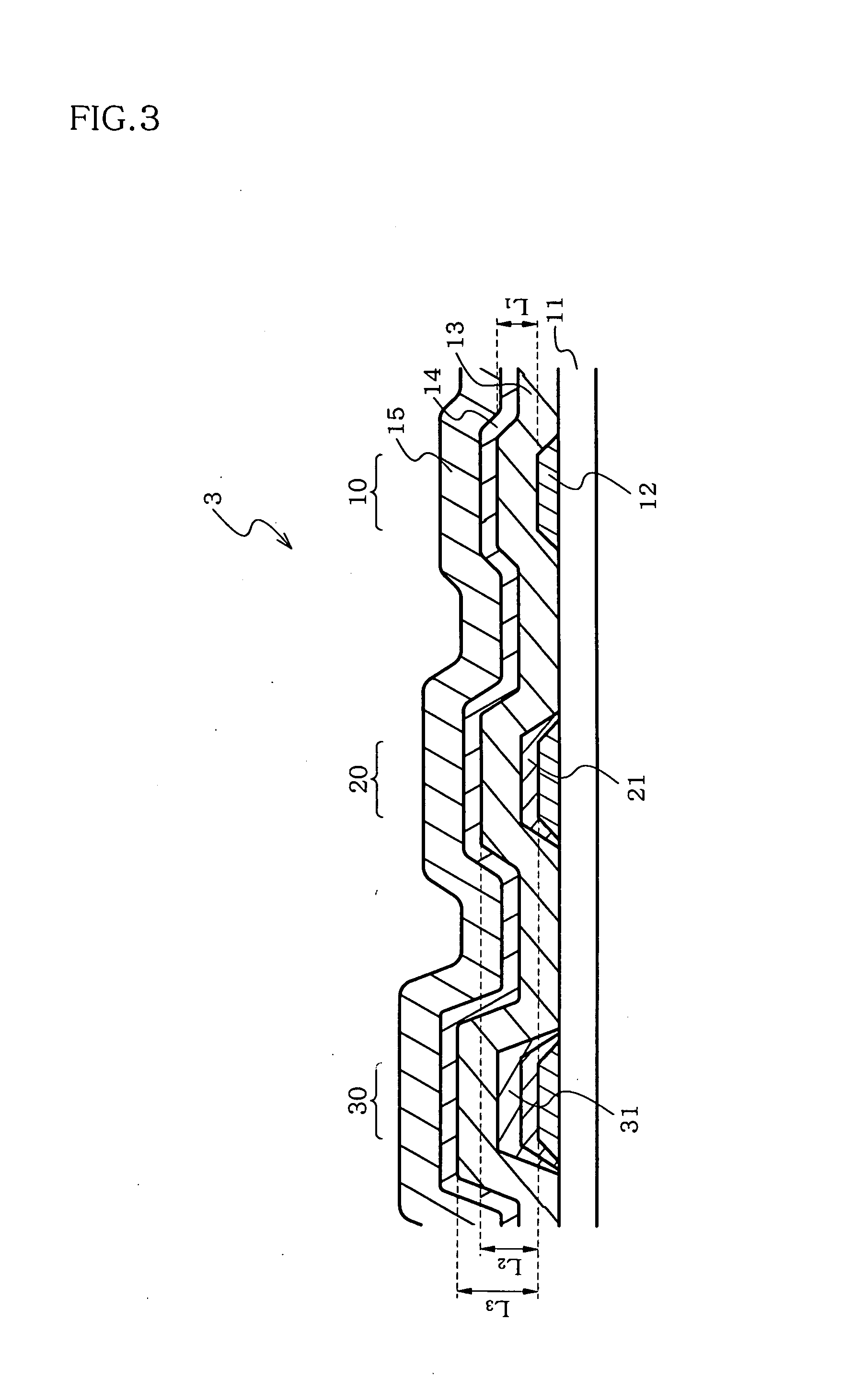

An organic electroluminescent display (1) including: a substrate (11); and a first organic electroluminescent device part (10) and a second organic electroluminescent device part (20) placed side by side on a surface of the substrate; the first organic electroluminescent device part (10) including at least a light reflective conductive layer (12), an organic luminescent medium layer (13), and a transparent electrode layer (15) in this order and including a light reflective layer (14) inside or outside of the organic luminescent medium layer (13) or the transparent electrode layer (15); the second organic electroluminescent device part (20) including at least a light reflective conductive layer (12), a first inorganic compound layer (21), an organic luminescent medium layer (13), and a transparent electrode layer (15) in this order and including a light reflective layer (14) inside or outside of the organic luminescent medium layer (13) or the transparent electrode layer (15); and an emission spectrum of light from the first organic electroluminescent device part (10) differing from an emission spectrum of light from the second organic electroluminescent device part (20).

Owner:IDEMITSU KOSAN CO LTD

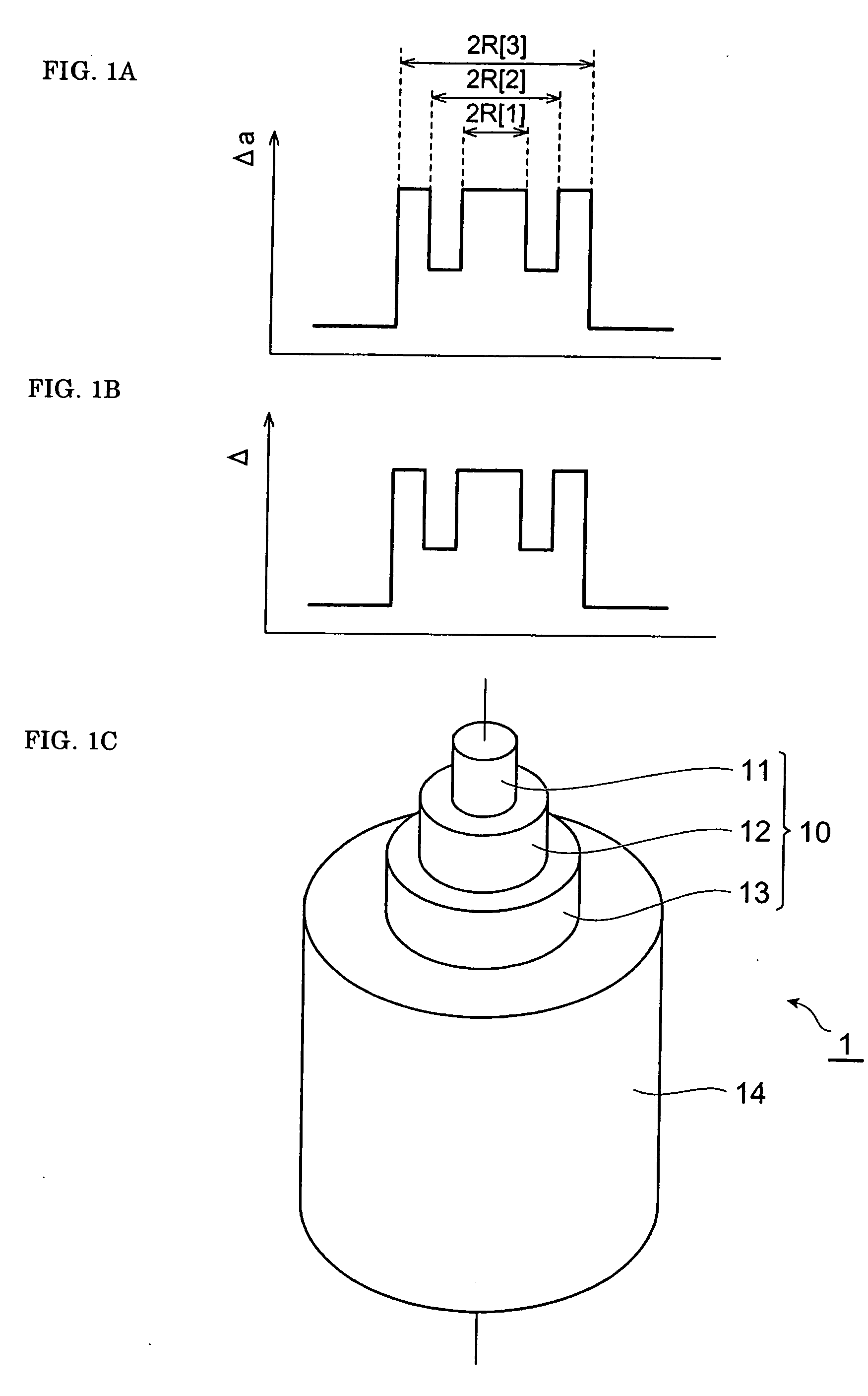

Constructing preforms from capillaries and canes

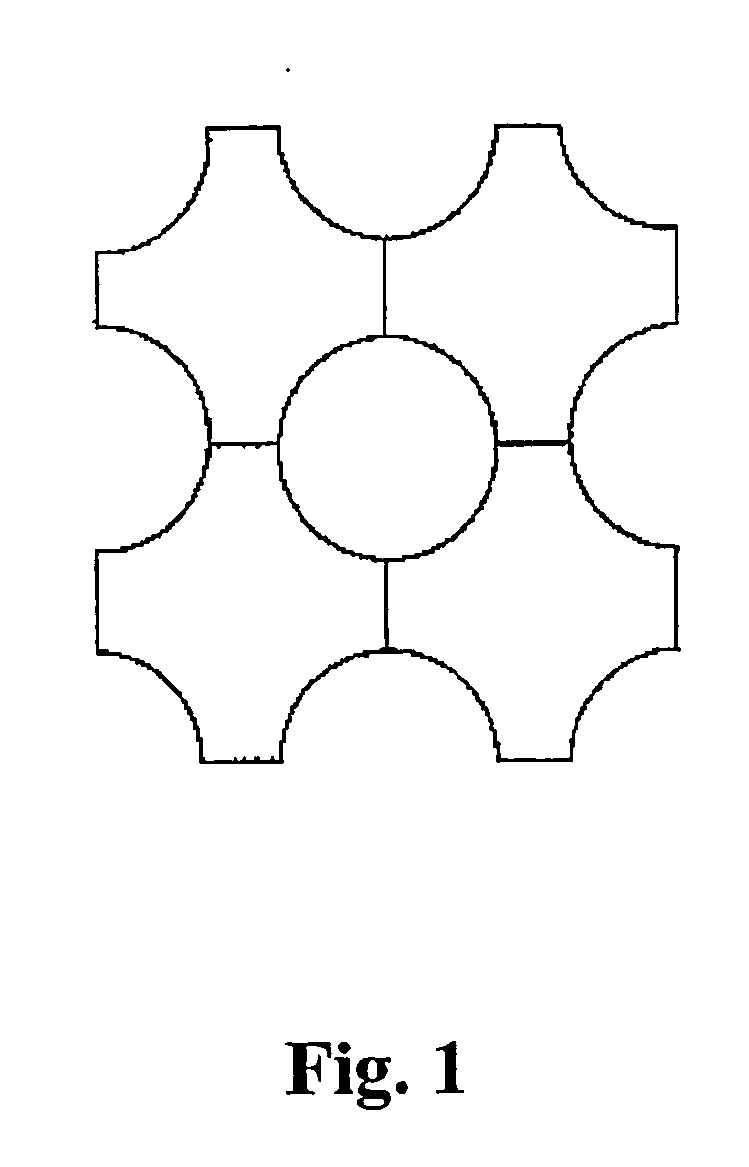

InactiveUS20050147366A1Easily produceConsiderable complexityGlass making apparatusOptical articlesHoley fiberEngineering

The invention relates to a method of producing a preform for a holey optical fibre, and more particularly, to a method of producing polymer holey optical fibre using novel capillary and cane designs that allow a construction of complex holey structures. The capillaries may have a complex internal structure including multiple holes, holes of non-circular shape, off-centre holes, holes of different sizes, or any combination of these. The canes may have a complex external shape to define interstitial holes when the canes arc combined in a stack (see FIG. 1). The capillaries and canes may be made of different materials and combined within the same structure.

Owner:THE UNIV OF SYDNEY

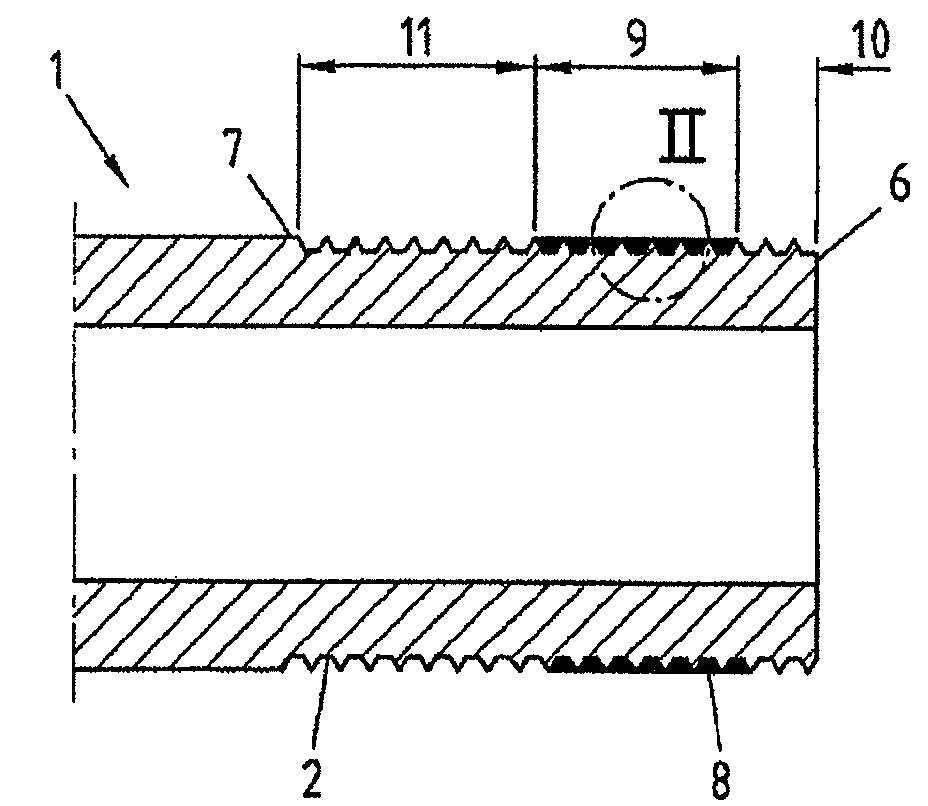

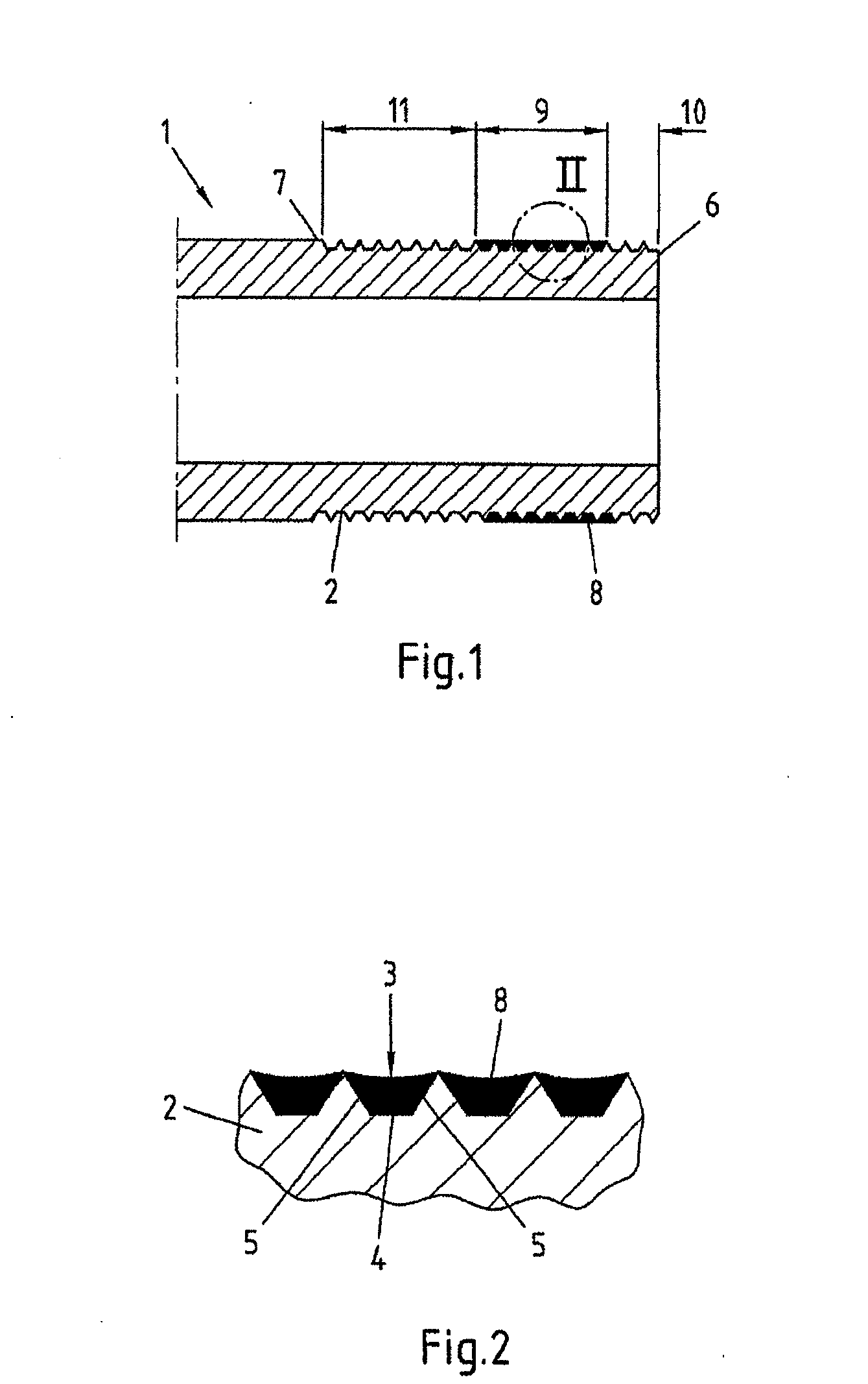

Connection element for producing a fluid-tight screw connection, and method for the production thereof

ActiveUS20090123226A1Easily produceLarge piece countFluid pressure sealed jointsJoints with sealing surfacesEpoxideEngineering

Owner:VIEGA TECH GMBH & CO KG

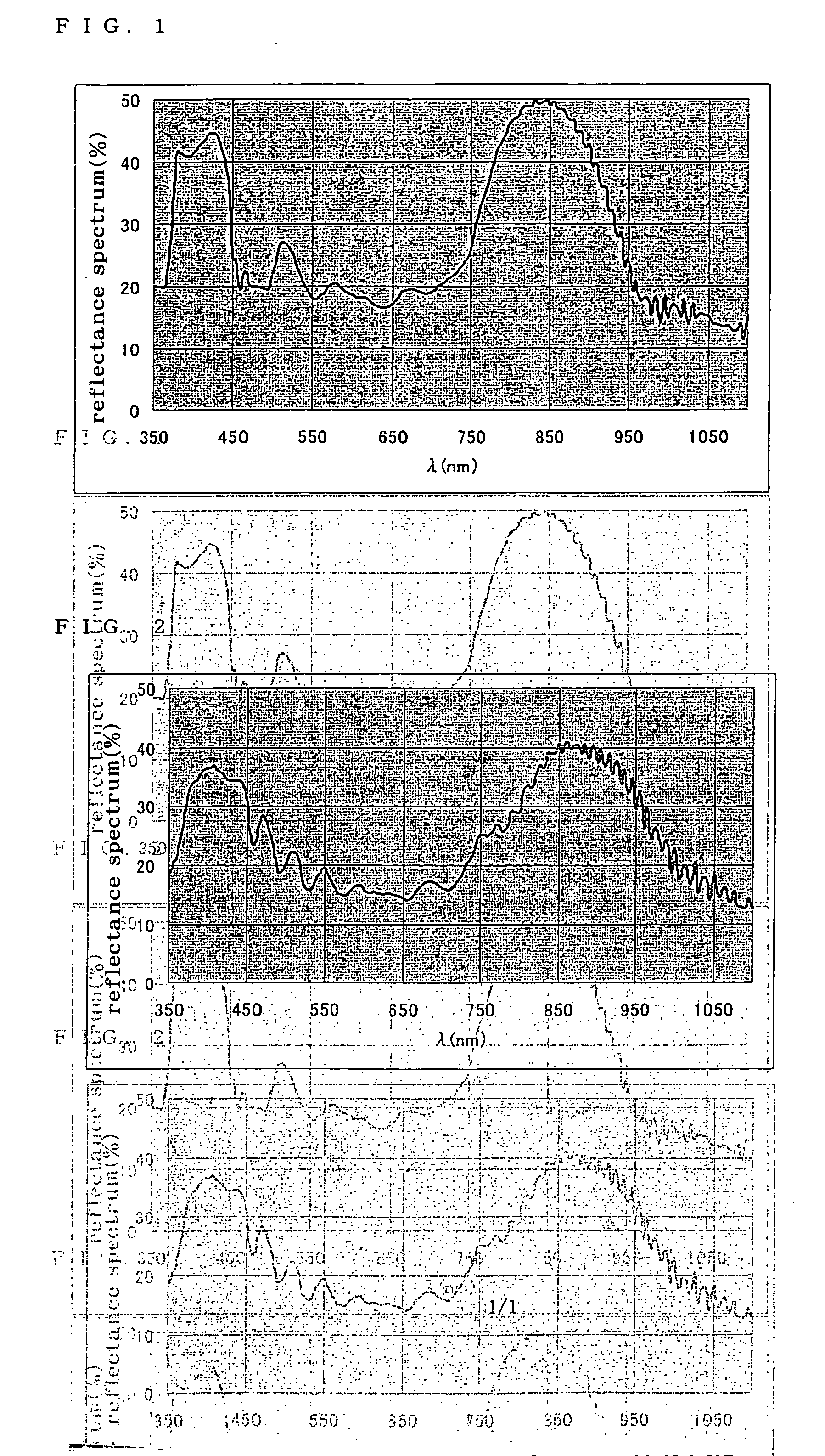

Cholesteric liquid crystalline film, method for production thereof and circularly polarized light reflecting film, two wavelength region reflection type reflecting film

InactiveUS20060209238A1Easily producePolarising elementsNon-linear opticsChemistryLiquid crystalline

A cholesteric liquid crystal film of the invention consist of a single layer, which is a cholesteric liquid crystal film, formed by applying a liquid crystal mixture containing a polymerizable mesogen compound (A) and a polymerizable chiral agent (B) to an alignment substrate, and applying ultraviolet irradiation to the mixture, wherein a cholesteric liquid crystal film has at least two independent selective reflection wavelength bands. The cholesteric liquid crystal film can be prepared by a simple and easy procedure.

Owner:NITTO DENKO CORP

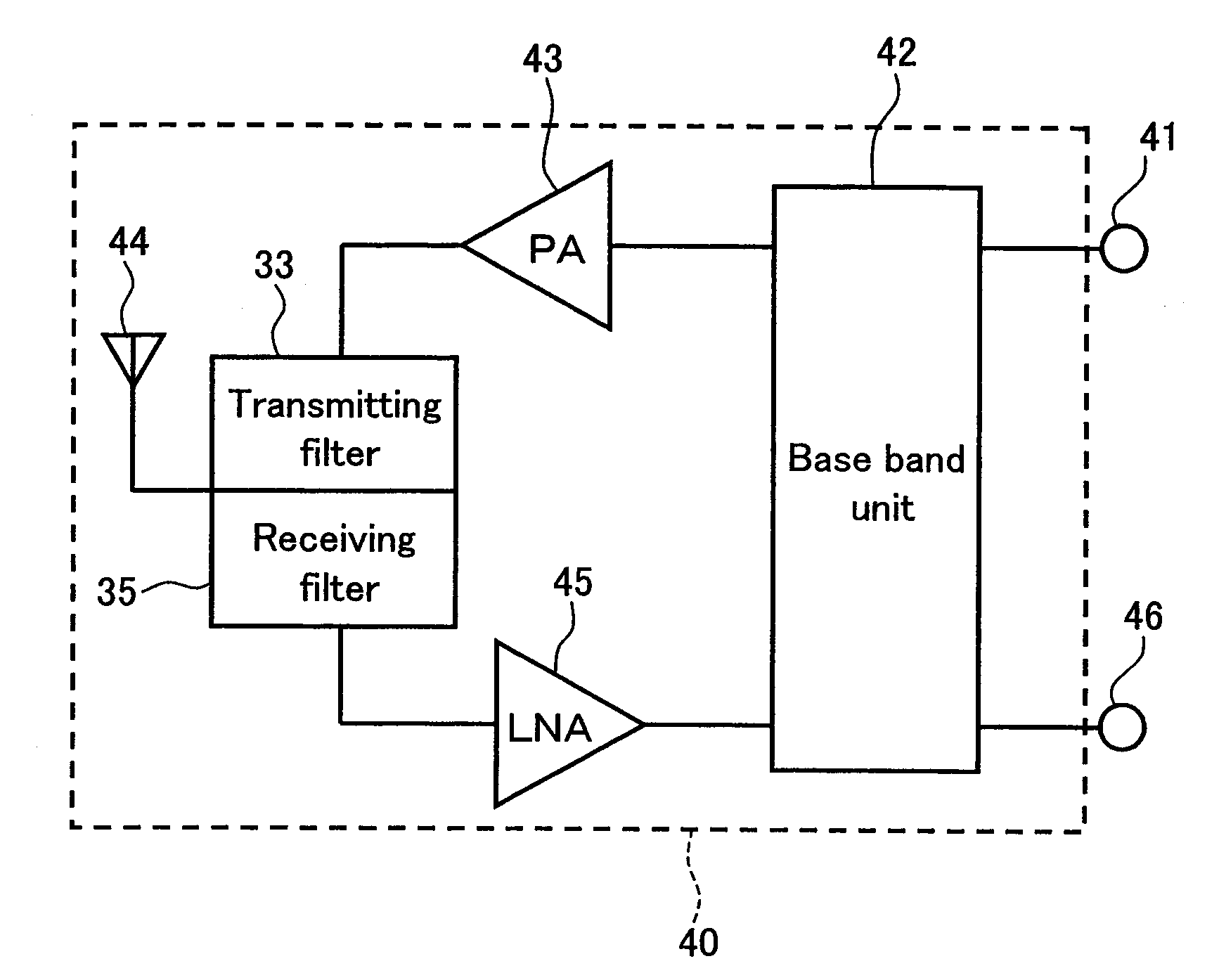

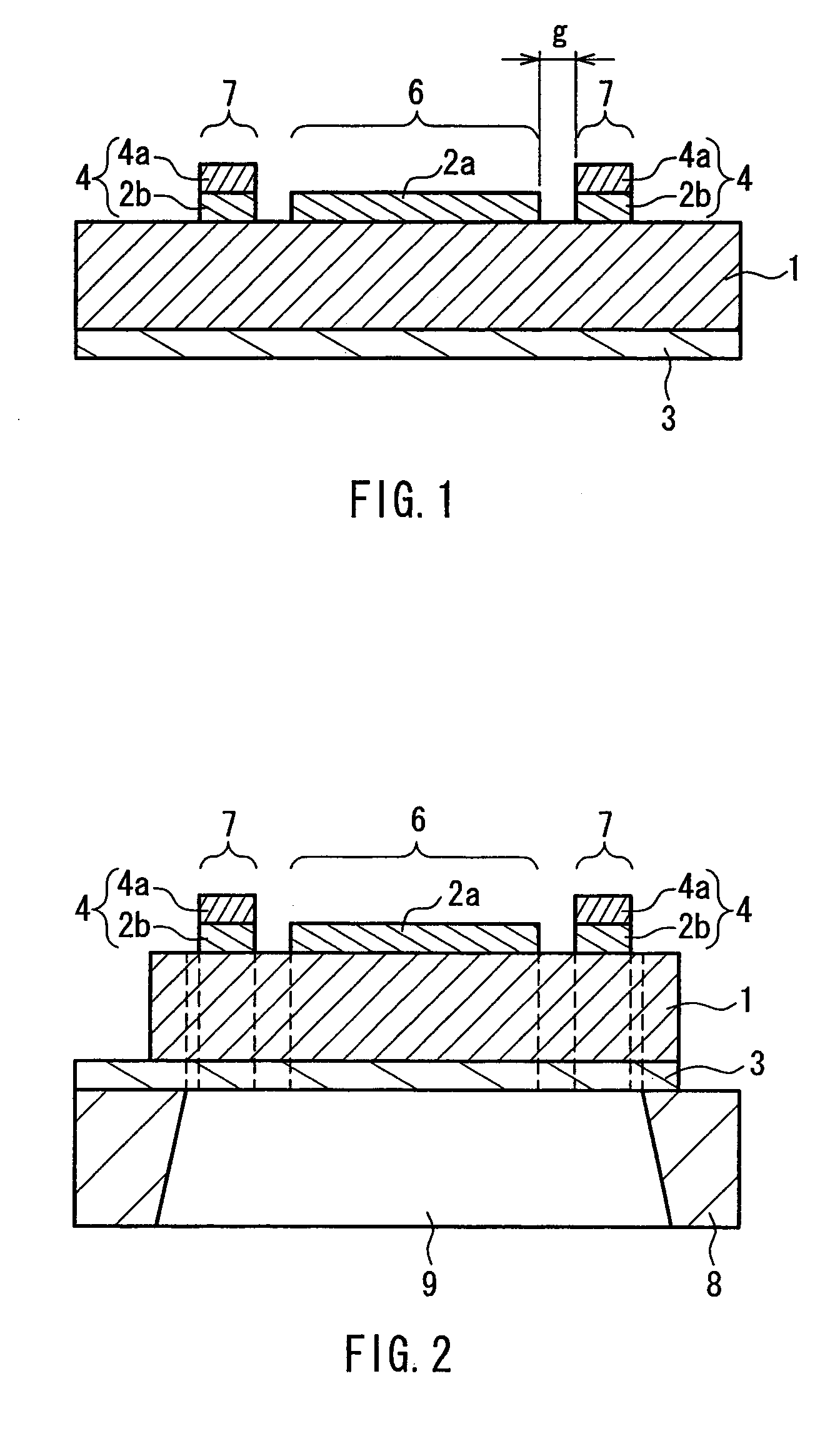

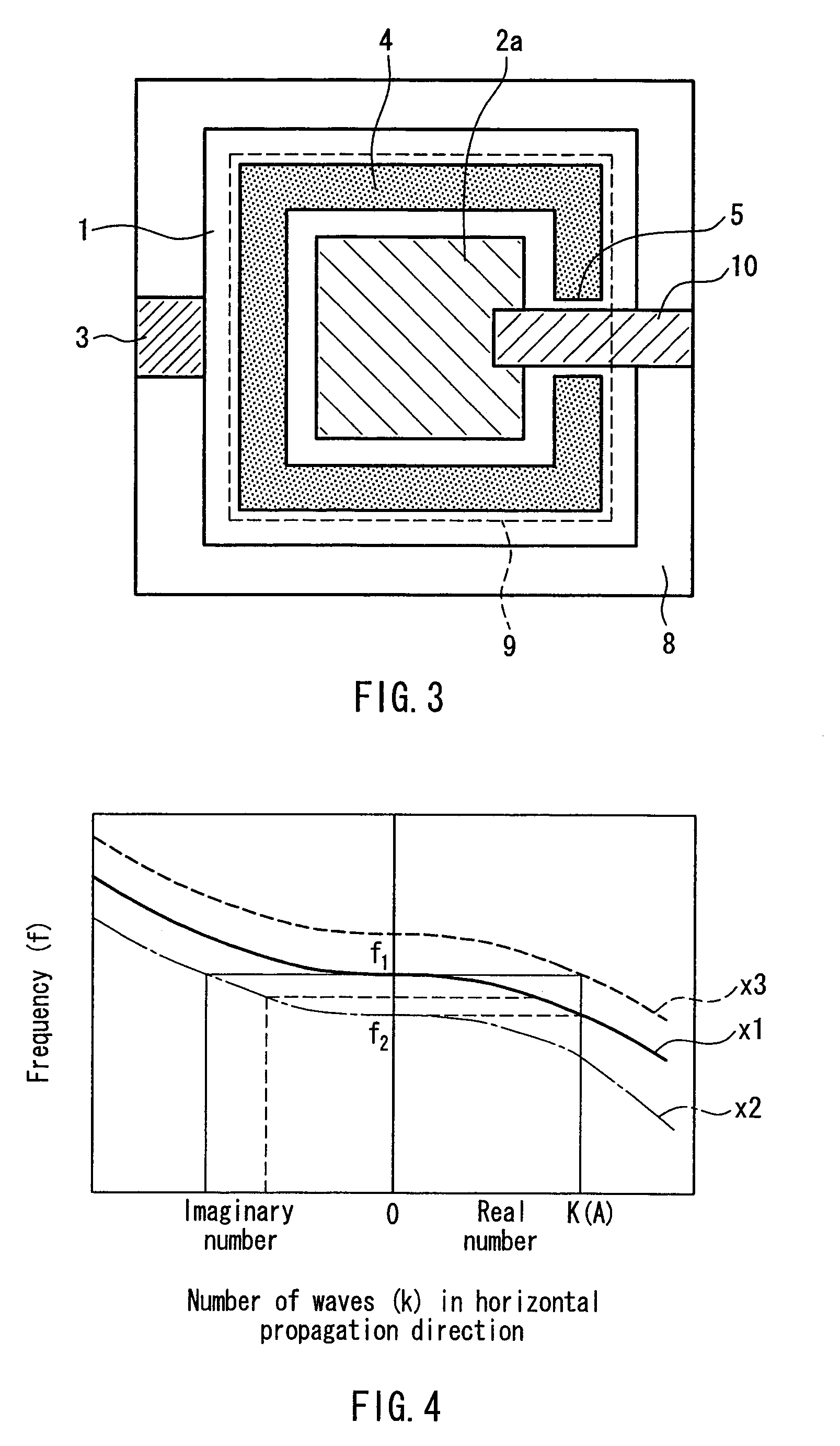

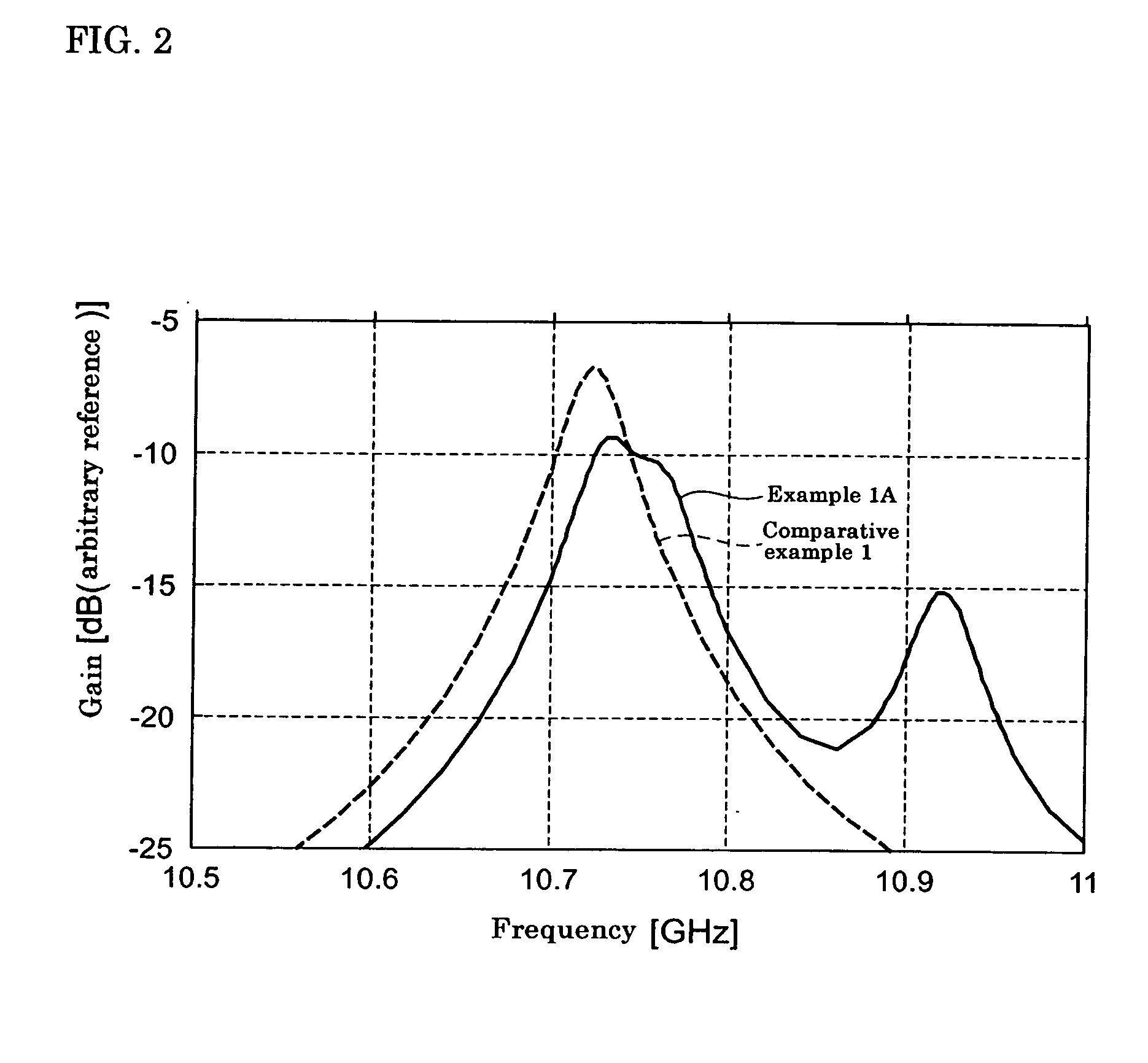

Film bulkacoustic wave resonator and method for manufacturing the same

InactiveUS20080051039A1High accuracyEasily produceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesPhysicsAuxiliary electrode

A film bulk acoustic wave resonator including a piezoelectric body 1, and a first electrode 2 and a second electrode 3 that are provided respectively on the main surfaces of the piezoelectric body, the piezoelectric body being applied an electric field through the first and the second electrodes so as to generate a resonant vibration. A first mass load material portion 4 having an annular shape is provided outside the planar region of the first electrode on the main surface of the piezoelectric body, a mass load effect thereof being larger than that of the first electrode. The outer periphery of the first electrode and the inner periphery of the first mass load material portion are spaced apart from each other, whereby the first electrode and the first mass load material portion are electrically insulated from each other. The first mass load material portion has a laminated structure including a first auxiliary electrode layer 2a and a load material layer 4a formed on the auxiliary electrode layer. The first auxiliary electrode is formed with the same material to have the same thickness as the first electrode. Energy loss can be reduced, while the first mass load material portion can be formed easily with high precision.

Owner:PANASONIC CORP

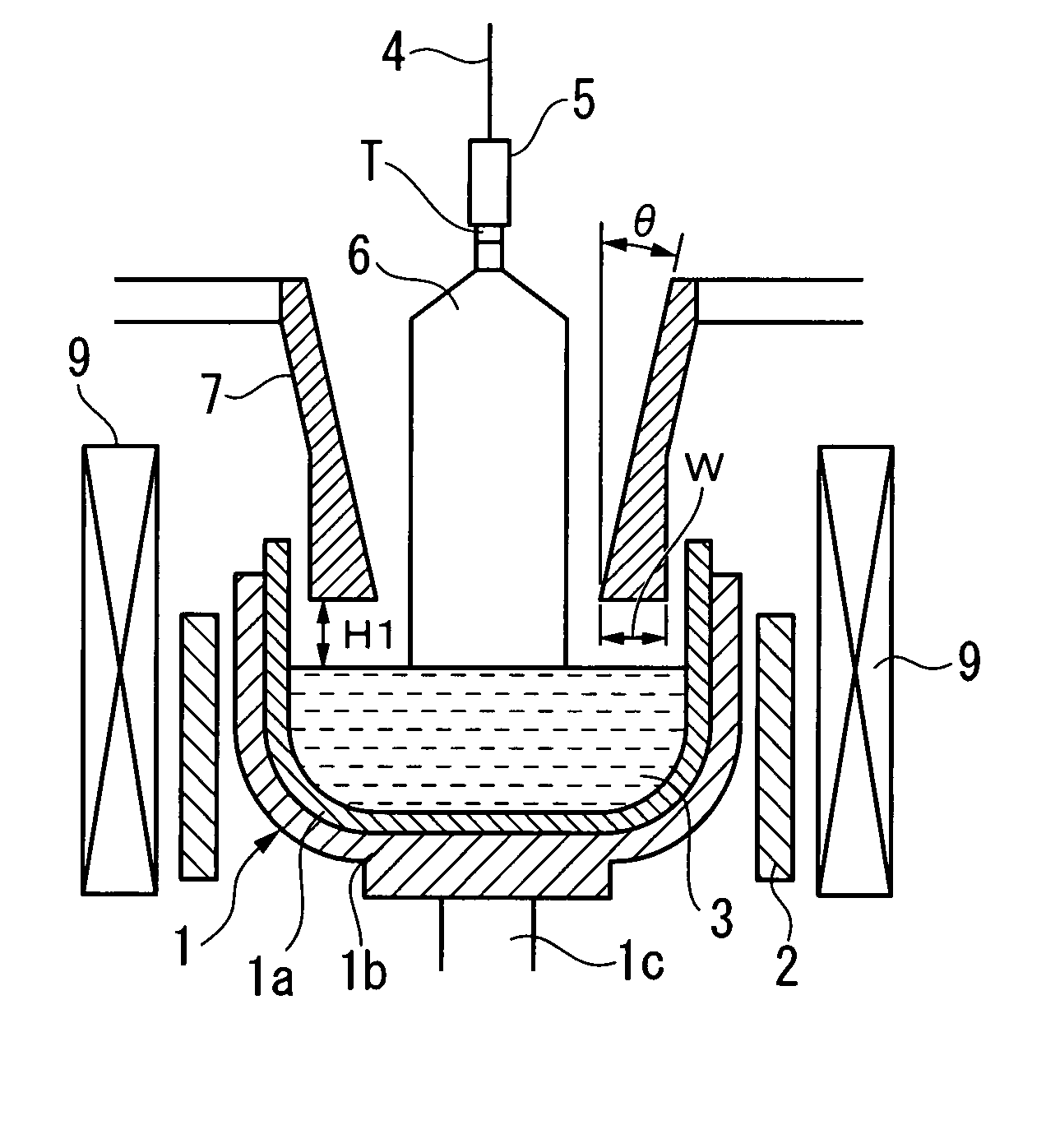

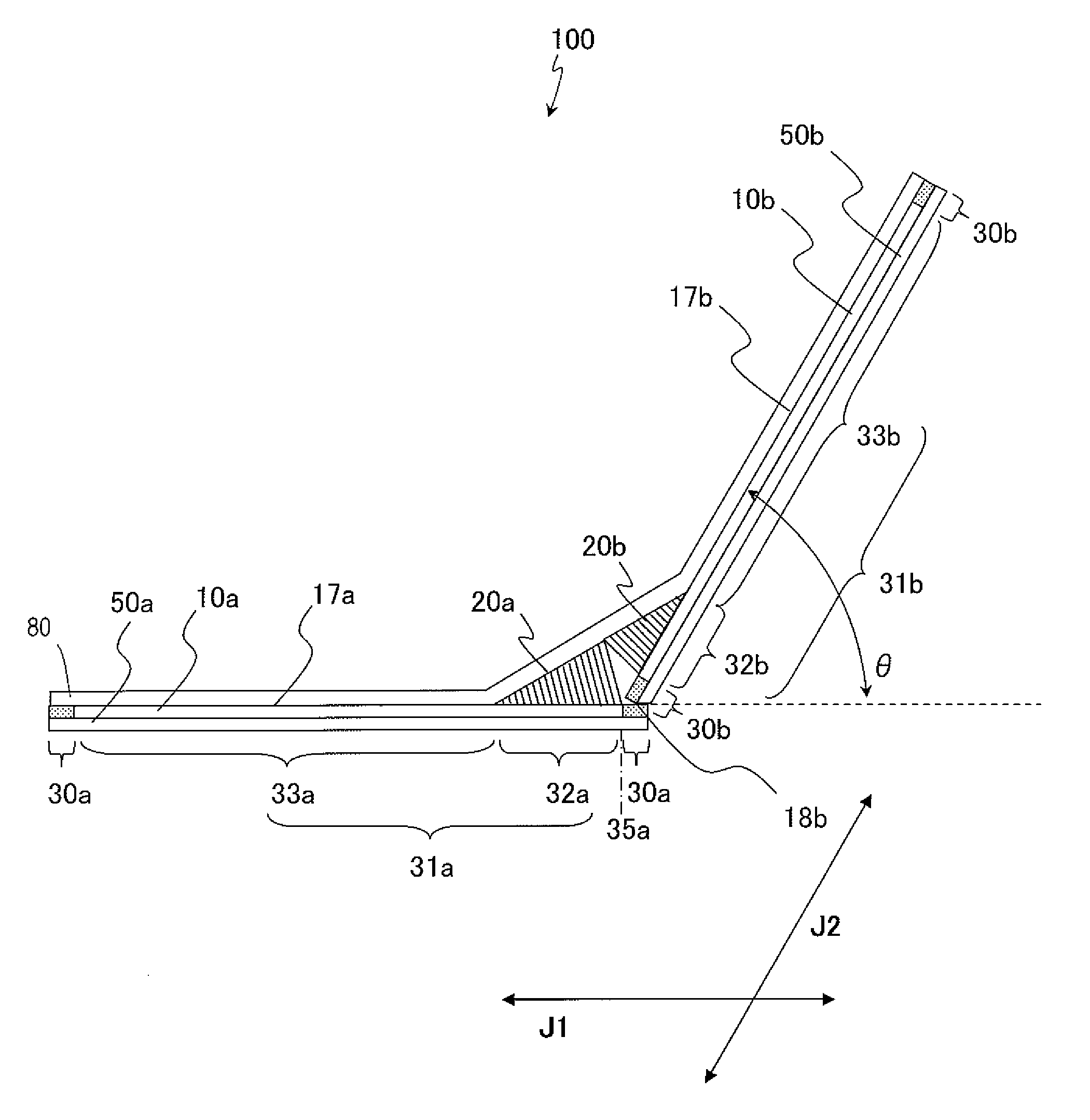

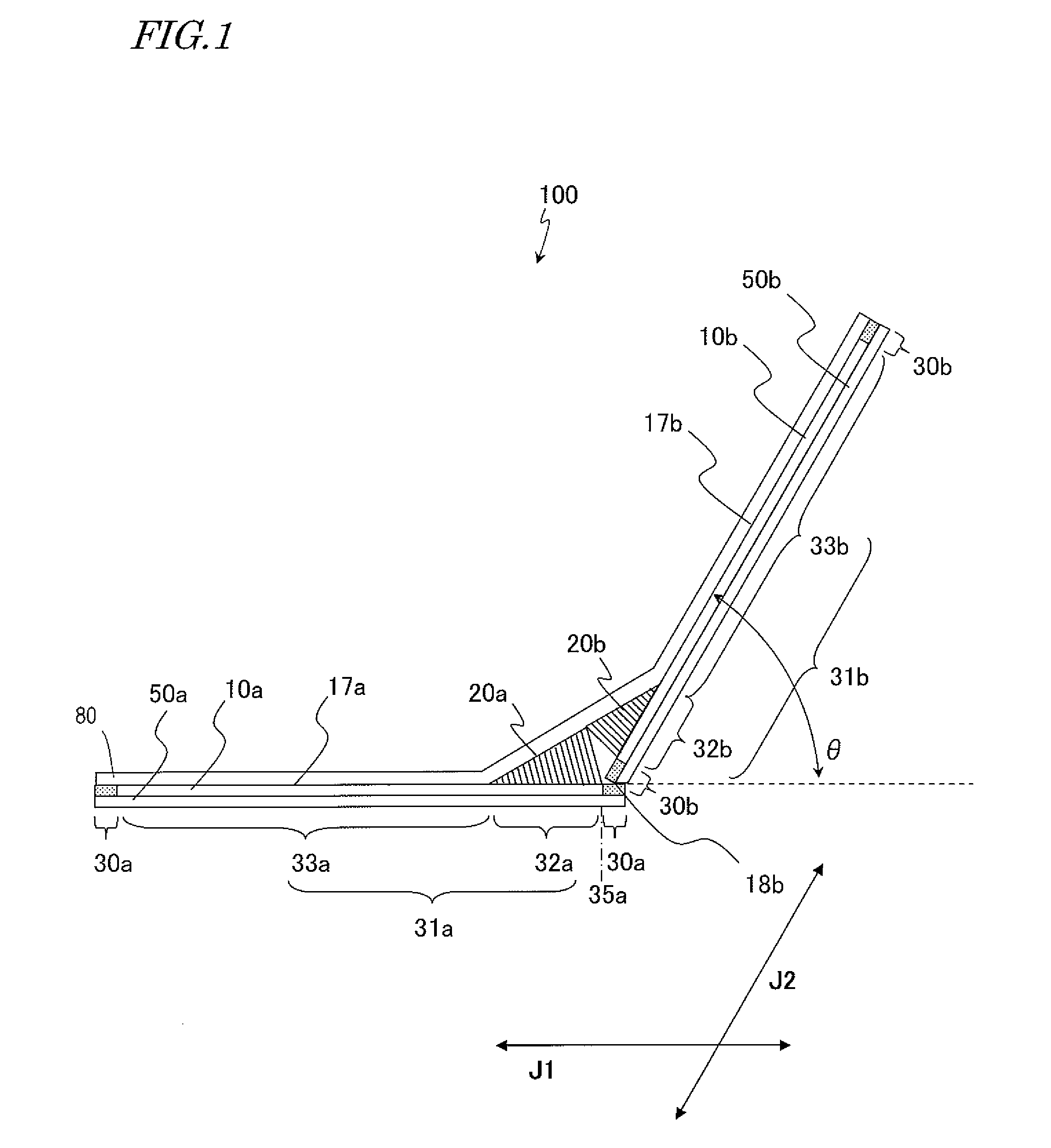

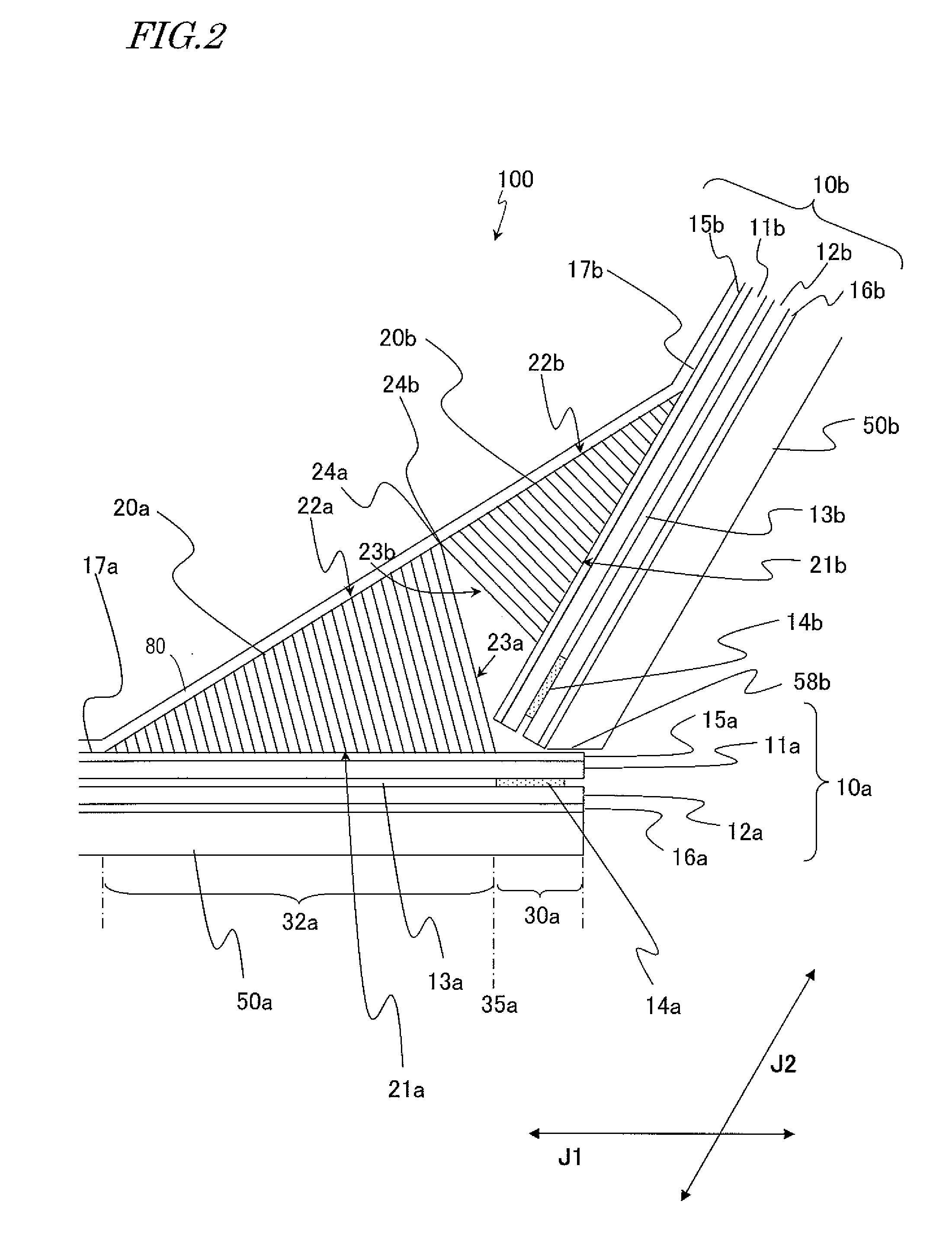

Display apparatus and method for manufacturing display apparatus

A display device (100) includes a plurality of display panels having a display region (31a, 31b) and a frame region (30a, 30b). The plurality of display panels include first and second display panels adjoining each other (10a, 10b); the frame region (30a) of the first display panel is overlapped by a side face (18b) of the second display panel so that an angle θ defined by viewer-side surfaces (17a, 17b) is more than 0° but less than 180°; first and second light guide elements (20a, 20b) are disposed on the viewer's side of peripheral display regions (32a, 32b); the light guide elements have an incident face, an outgoing face, and a plurality of light guiding portions; the distance between the incident face and the outgoing face increases away from the peripheral display region and toward the frame region; the volume of the first light guide element is larger than the volume of the second light guide element; and the outgoing faces of the first and second light guide elements are covered by a functional film. According to the present invention, there is provided a direct-viewing type display device which is easier to produce or incurs lower cost than conventionally, and in which the frame regions of the display panels, or a joint in the case of tiling, are obscured.

Owner:SHARP KK

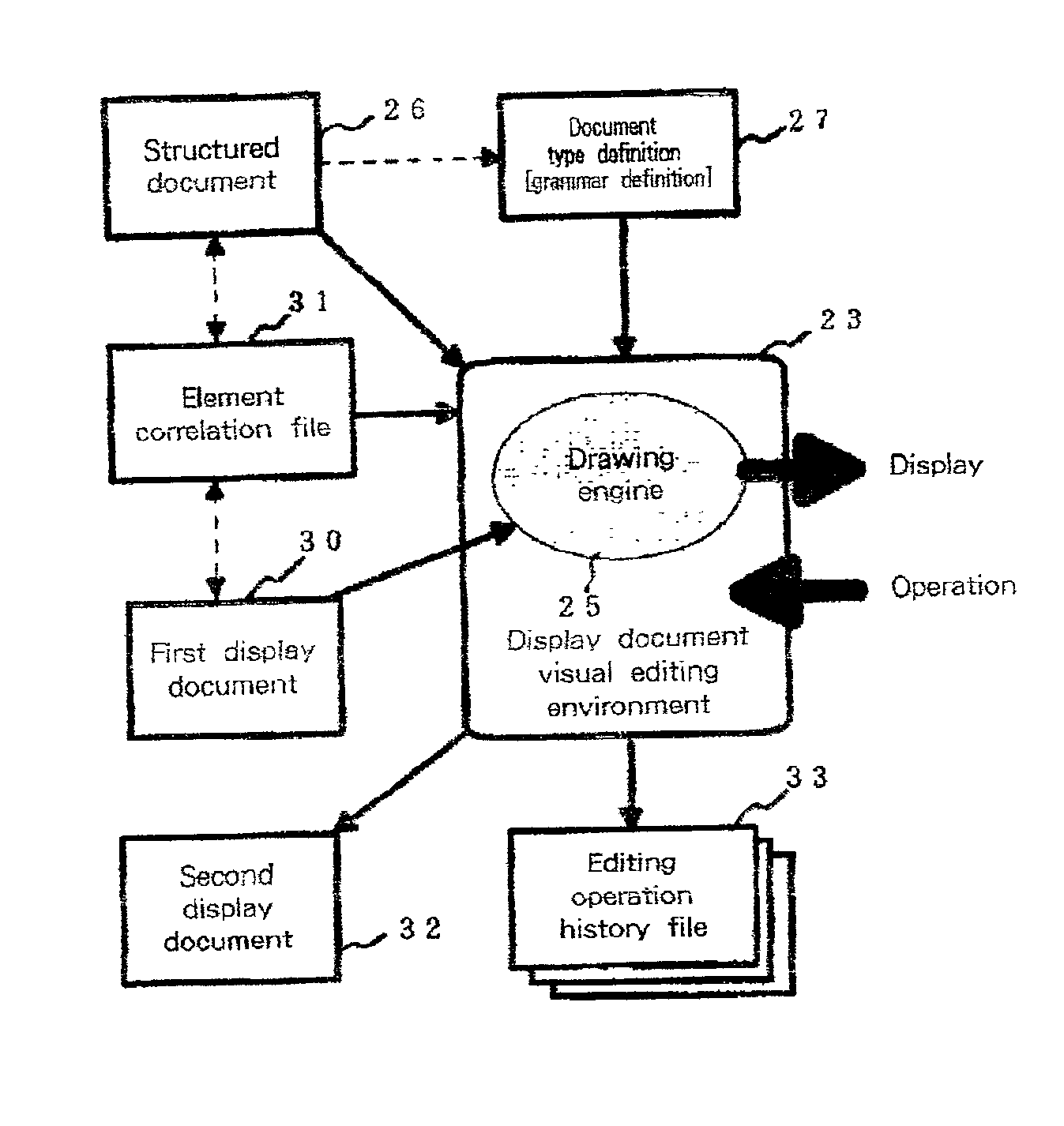

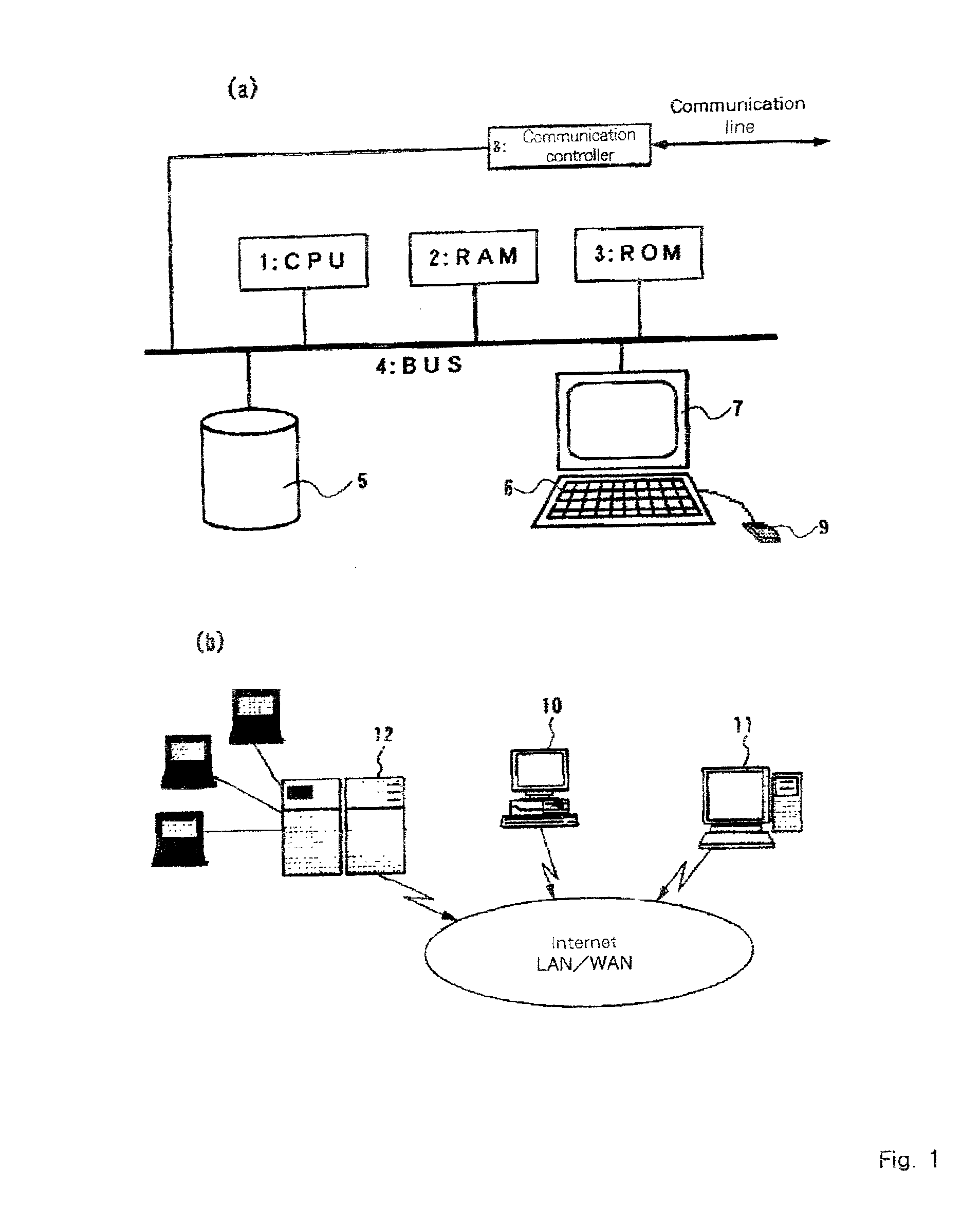

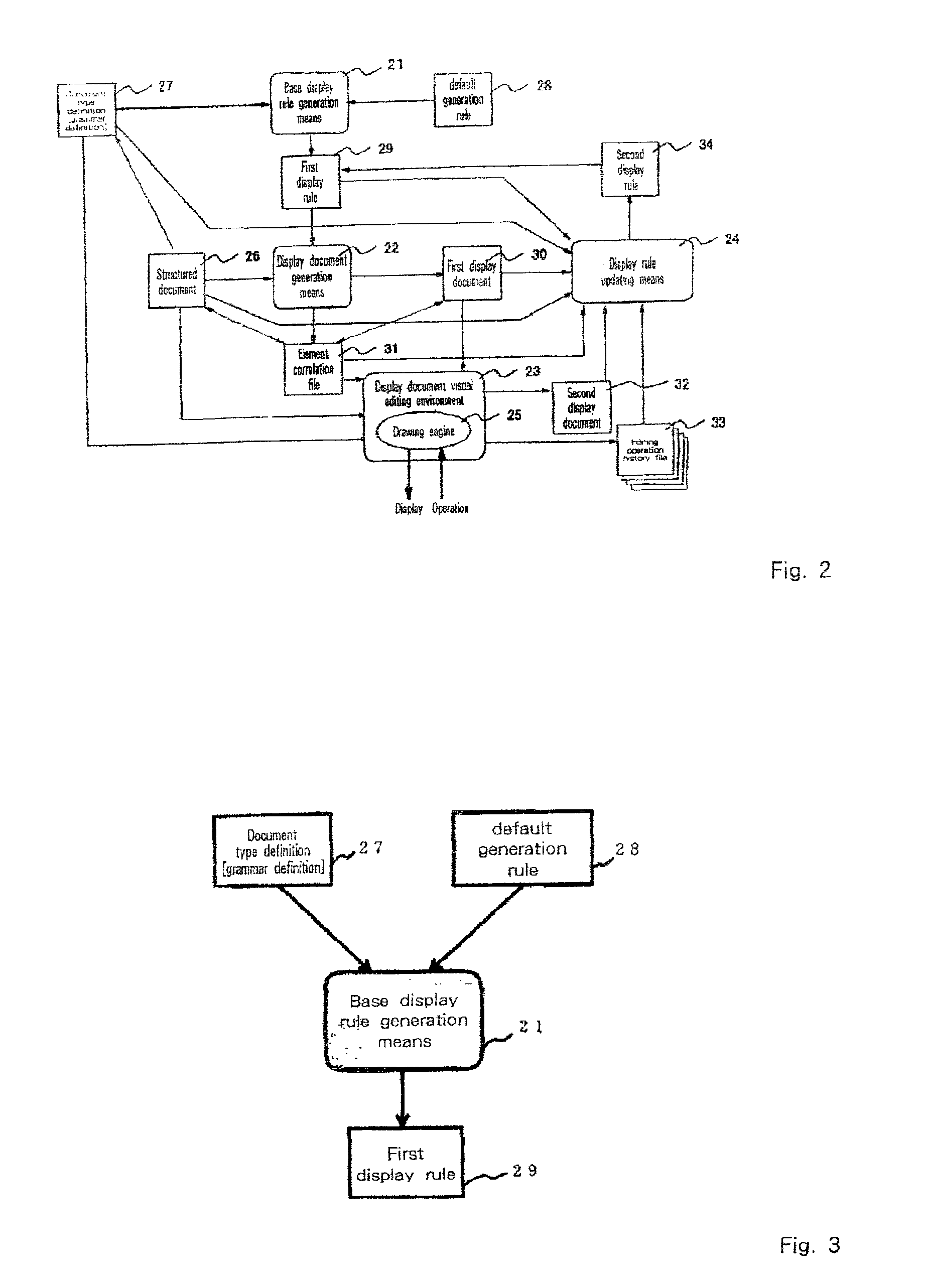

Method, system for, and program product for generating a display rule for a structured document, and for changing a structured document and its document type definition

InactiveUS6950984B2Easily produceDescribe useDigital computer detailsNatural language data processingDocument type definitionStructured document

A technique is provided for automatically and visually generating a display rule for a structured document based on an exemplary operation. Base display rule generation means 21 generates a first display rule 29, which is a base, by using a document type definition 27 for a structured document 26 and a default generation rule 28 that is determined in advance. Display document generation means 22 employs the first display rule 29 and the structured document 26 to generate a first display document 30 and an element correlation file 31. Tie first display document 30 is edited in a display document visual editing environment 23, and a second display document 32 and an editing operation history file 33 are generated. Display rule updating means 24 refers to the second display document 32, the editing operation history file 33, the element correlation file 31 and the structured document 26 to generate a second display rule 34 that reflects the editing contents.

Owner:IBM CORP +1

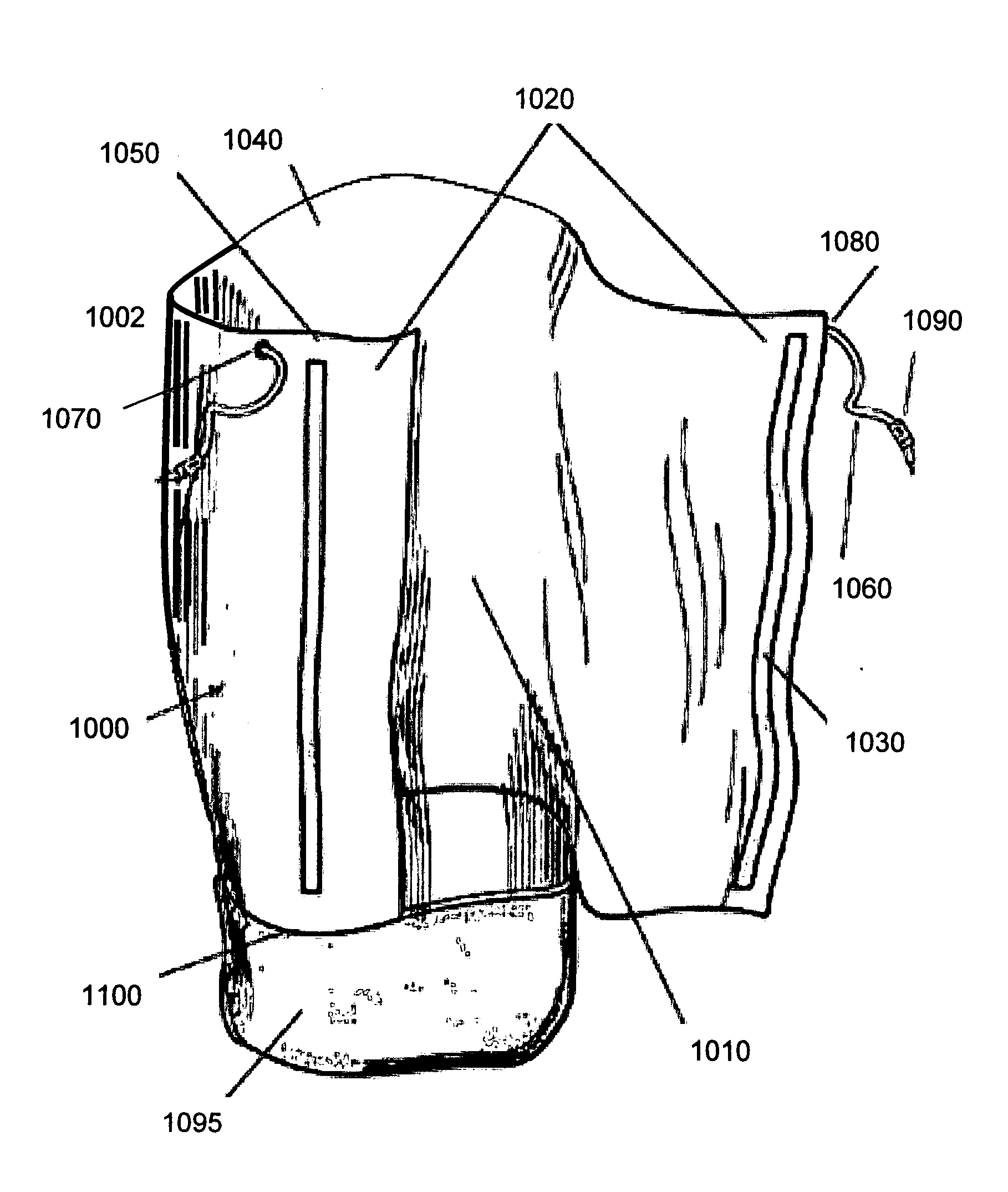

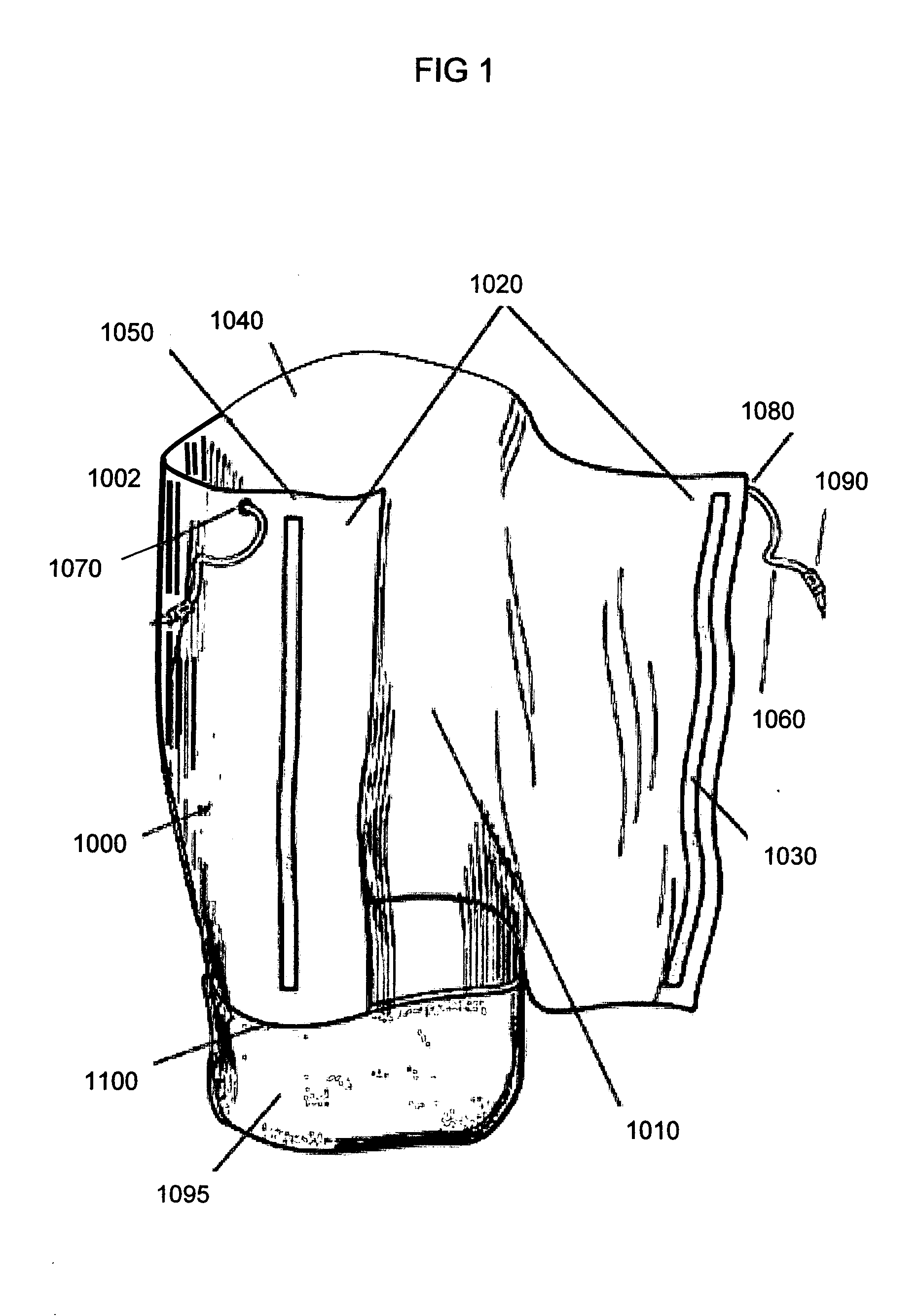

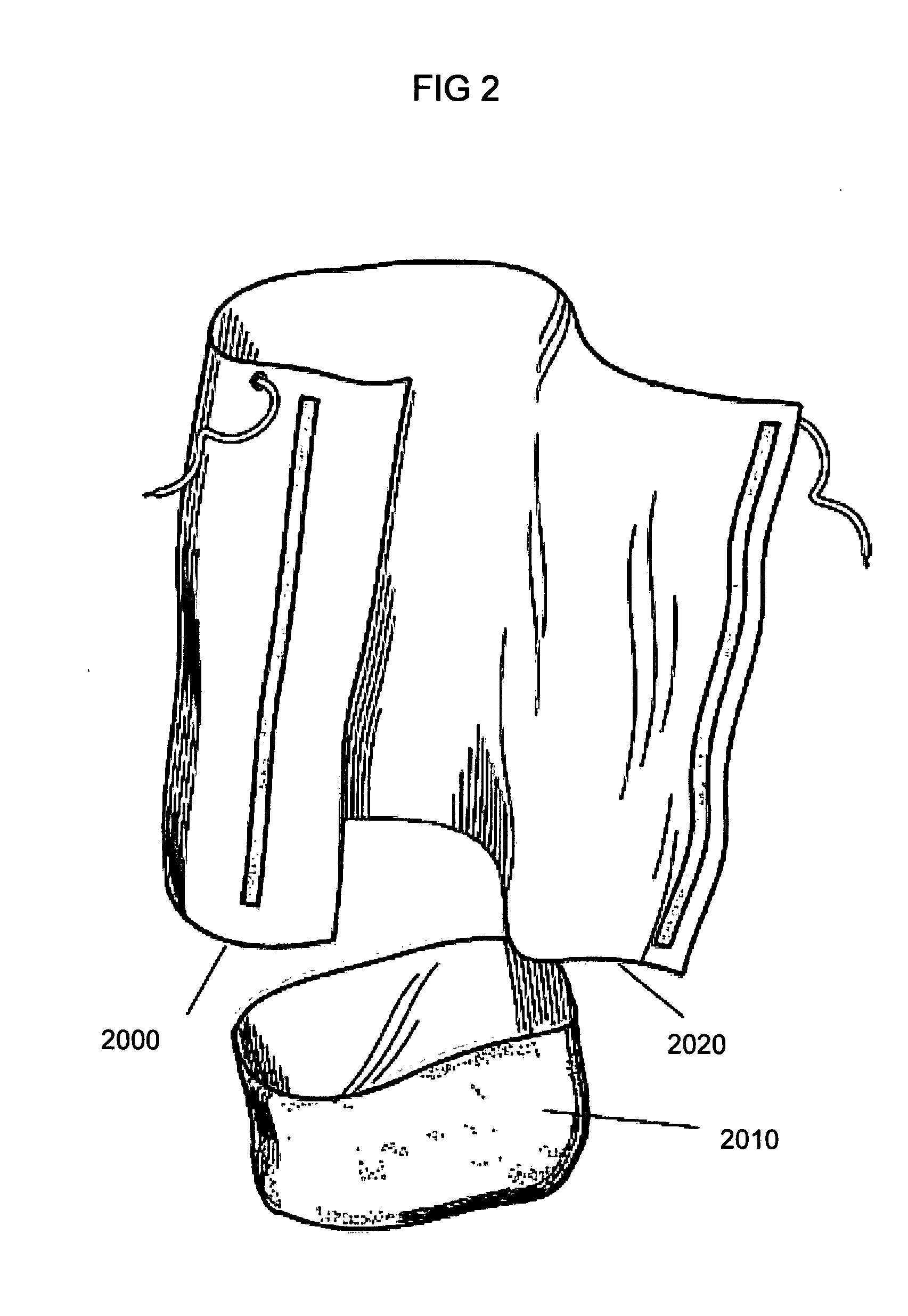

Apparel for protecting lower body from wetness

InactiveUS20090025118A1Increase lengthEasily produceTravelling rugBaby linensEngineeringEnlarged foot

A protective wrap for protecting the wearer from wetness that is designed to be easy to get into and out of, having an upper portion that protects the user's torso and a lower, enlarged foot enclosure that is removably attached. A vertical front flap opening is secured with a Velcro™ closure. The foot enclosure is attached with a horizontal, outdoor-type zipper. The wrap is designed for warmth and protection from elements, such as rain and cold, for a user who is sitting, standing, or moving about, and particularly those users who are in a wheelchair. The foot enclosure, which may have a non-skid bottom, may be made with carrying handles, and serve as a bag to conveniently carry the wrap and other items as desired.

Owner:POTHIER JUDITH

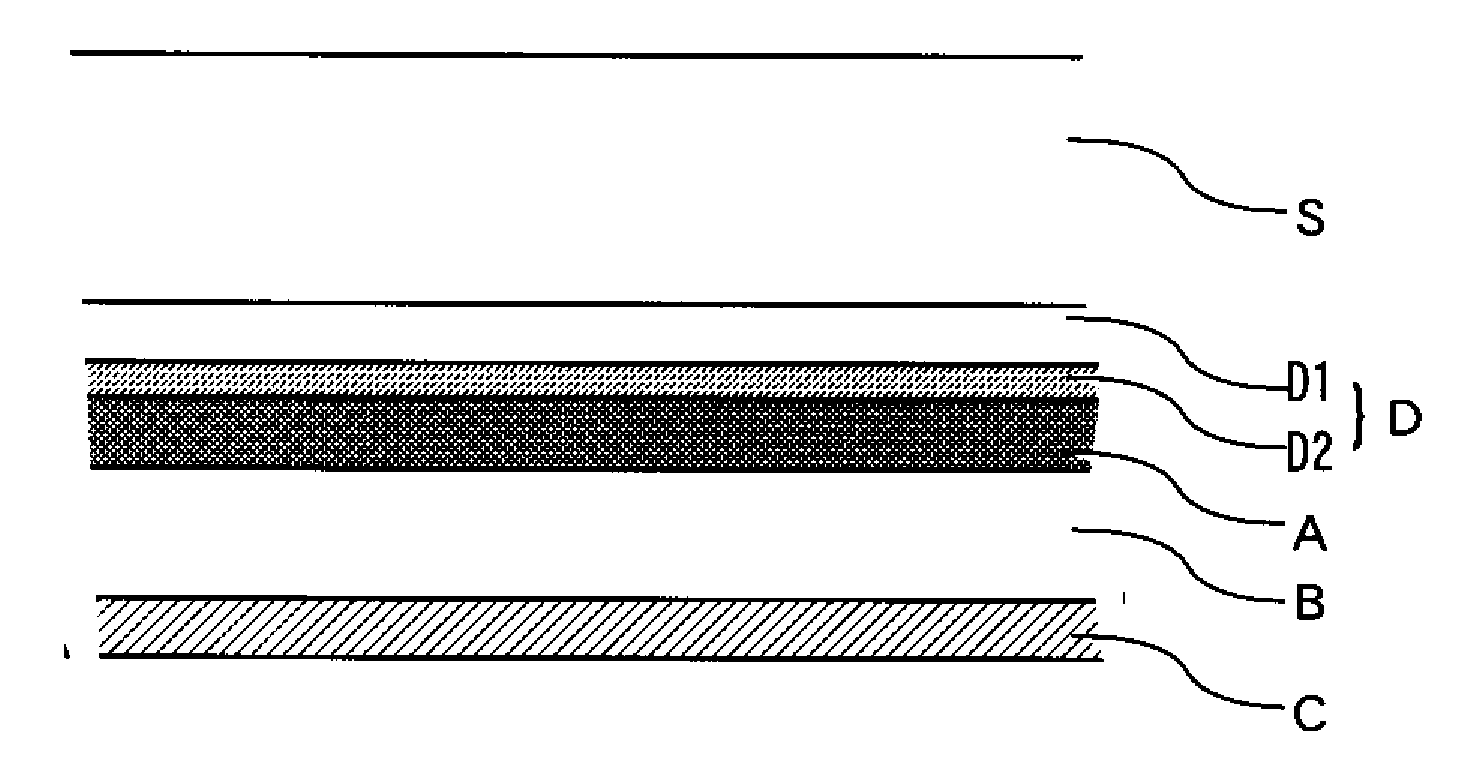

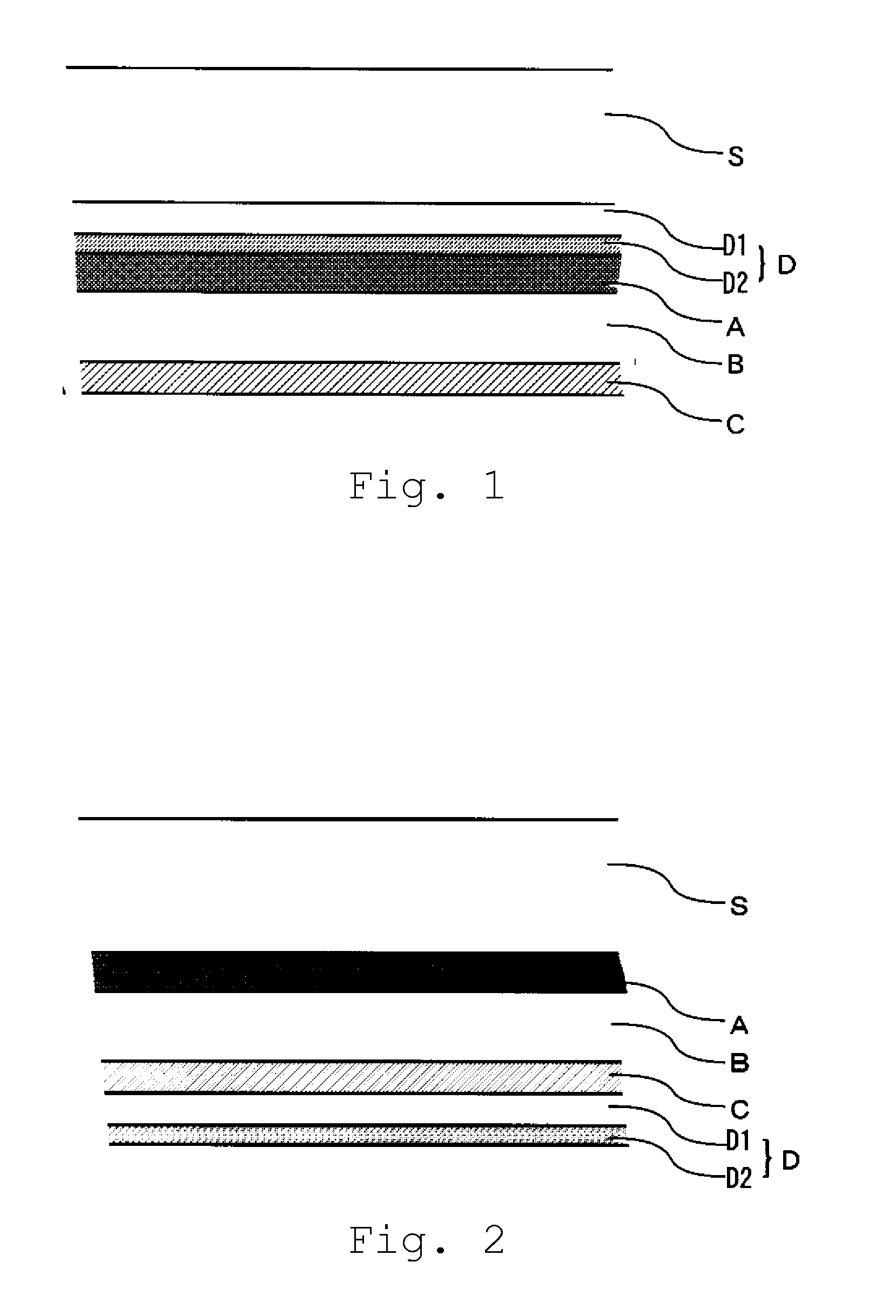

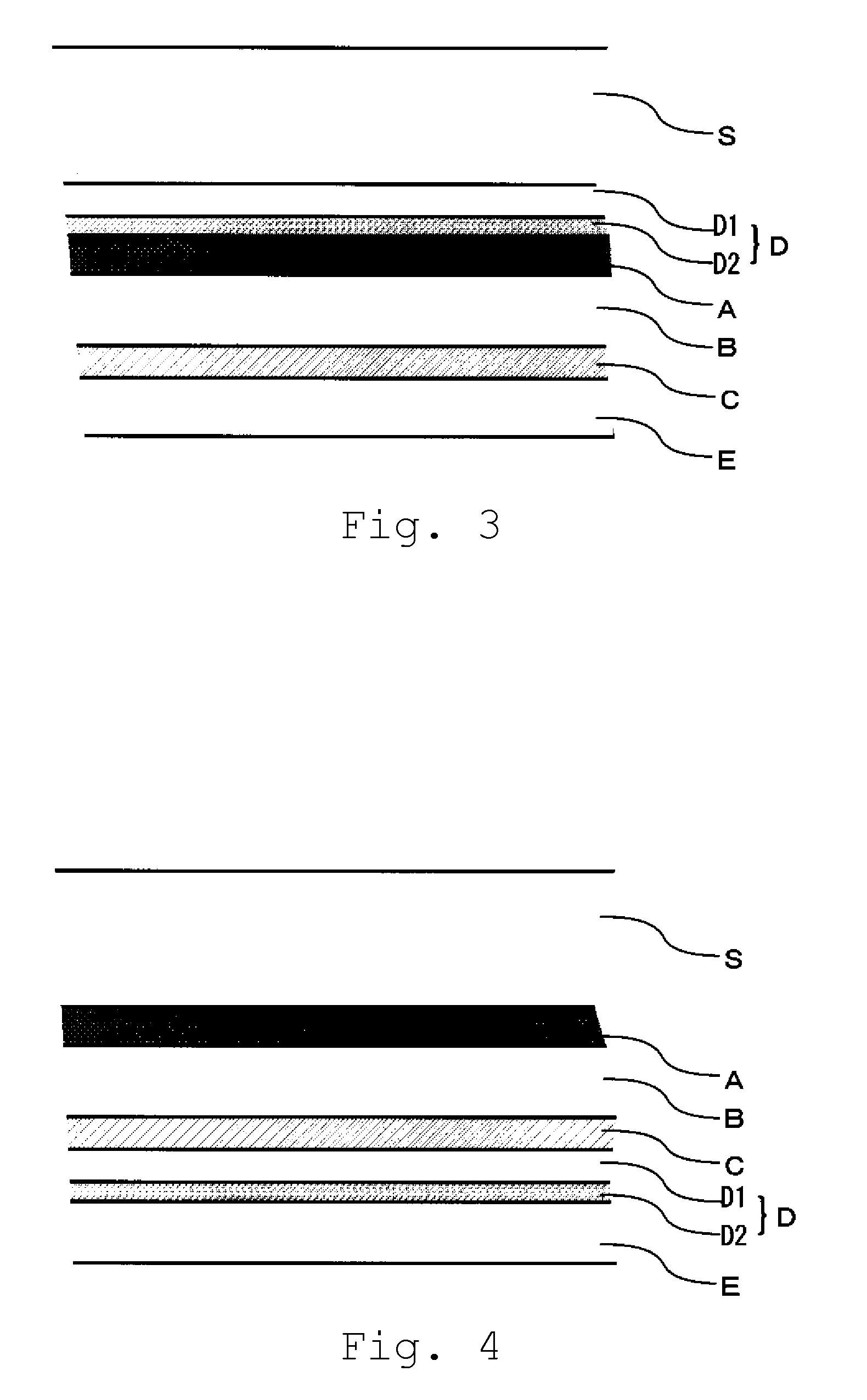

Infrared reflective laminate

InactiveUS20110043901A1Easily produceImprove power generation efficiencyMirrorsDiffusing elementsChemistryReflectivity

This invention provides an infrared reflective layered product, particularly a back sheet for solar cells, which, even when it has a black colored or chromatically colored appearance, can reflect infrared radiation with certain wavelengths to prevent heat accumulation and, at the same time, has excellent heat resistance. The infrared reflective layered product comprises the following layer (B) as a base layer, the following layer (A) layered on one side of the layer (B), and the following layer (C) layered on the other side of the layer (B).Layer (A): a colored resin layer which has an absorptance of a light with a wavelength of 800-1400 nm of not more than 10%.Layer (B): a thermoplastic resin layer which shows a dimensional change (s) satisfying 1%≧s≧−1% when left at 150° C. for 30 minutes.Layer C: a colored resin layer having a reflectance of a light with a wavelength of 400-1400 nm of not less than 50%.Preferably, the layer (A) is formed of a resin containing an infrared transmittable coloring agent, and the layer (C) is formed of a resin containing a white pigment. A water vapor barrier layer (D) may be additionally provided.

Owner:TECHNO POLYMER CO LTD

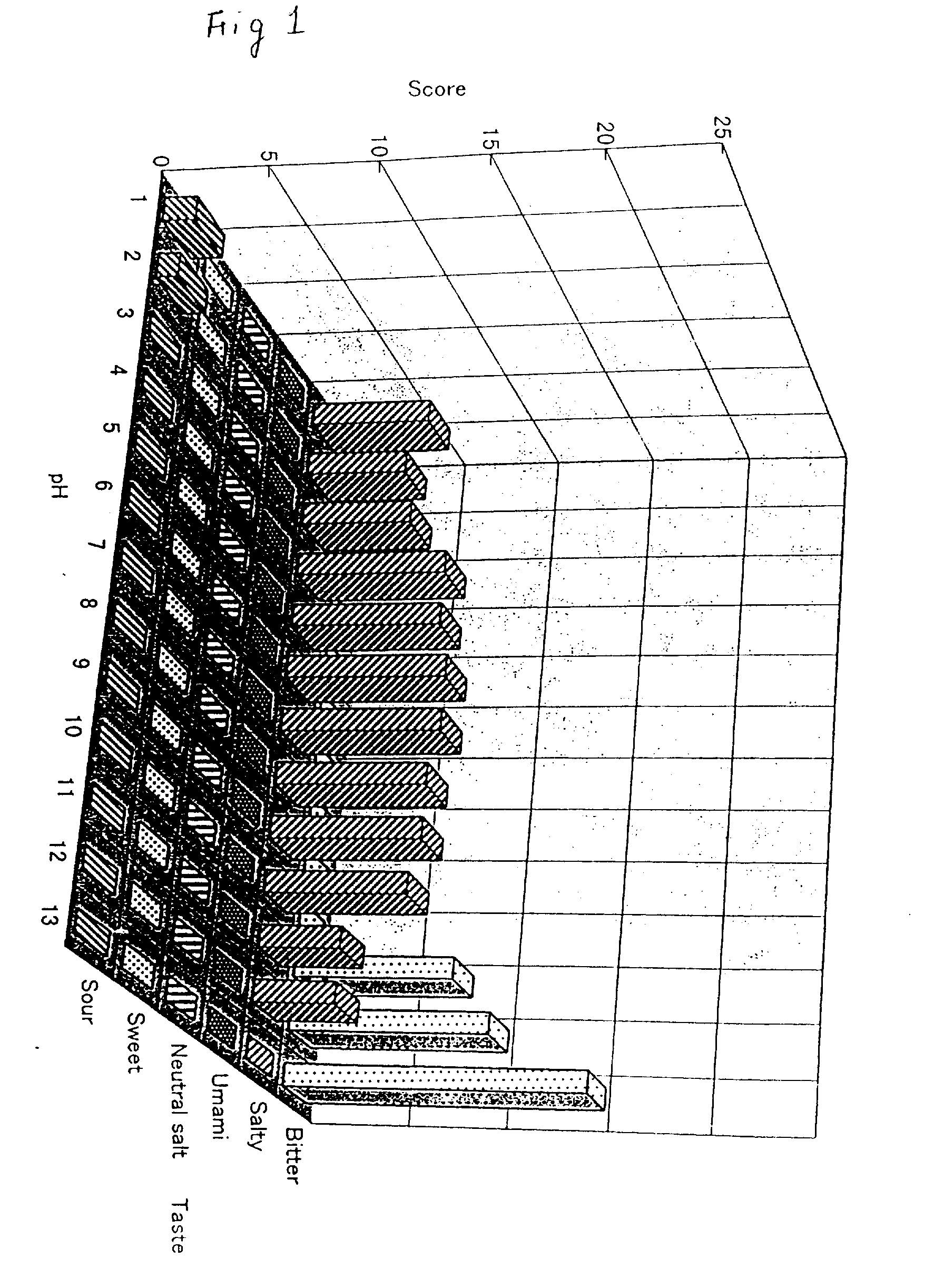

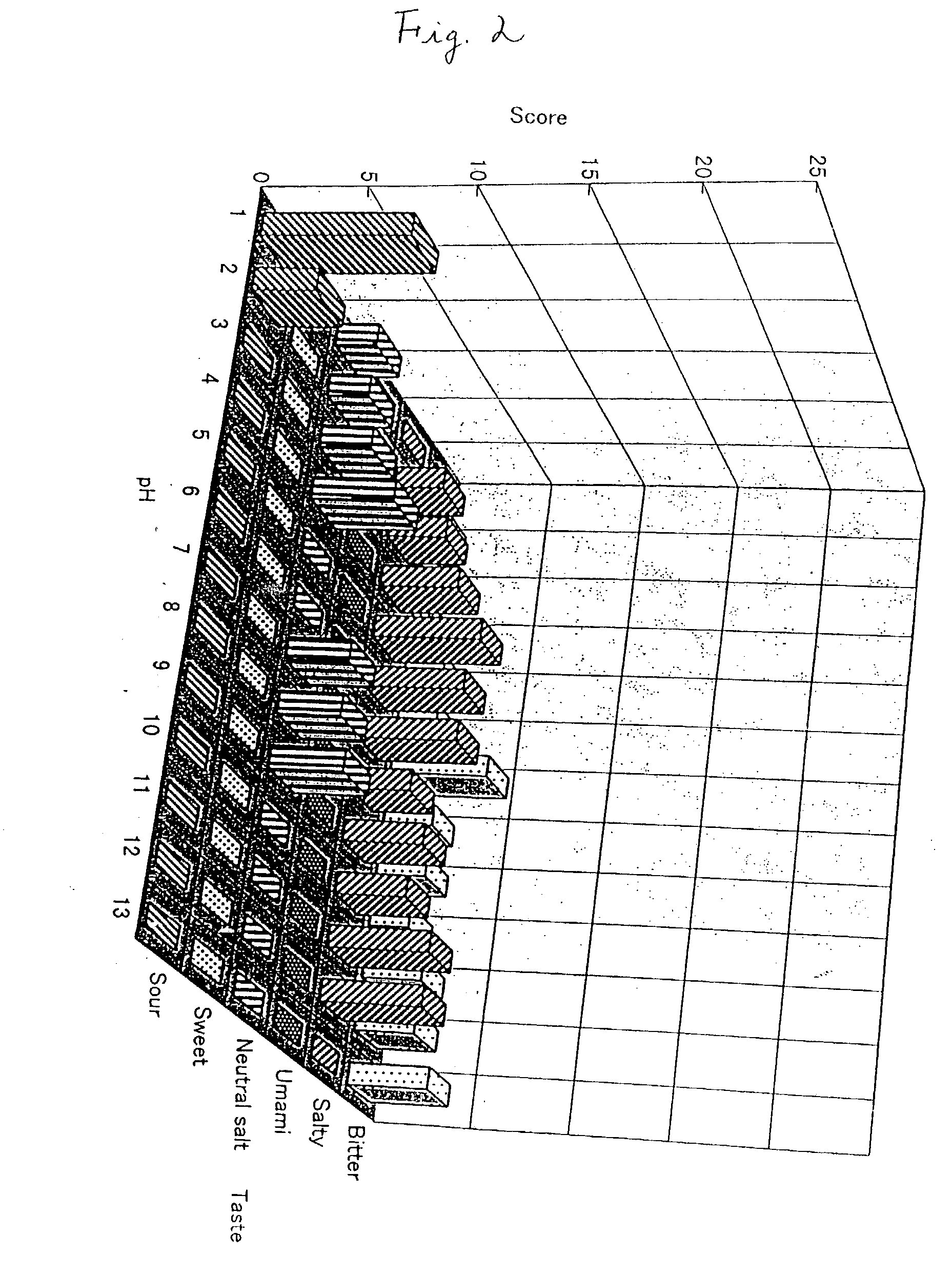

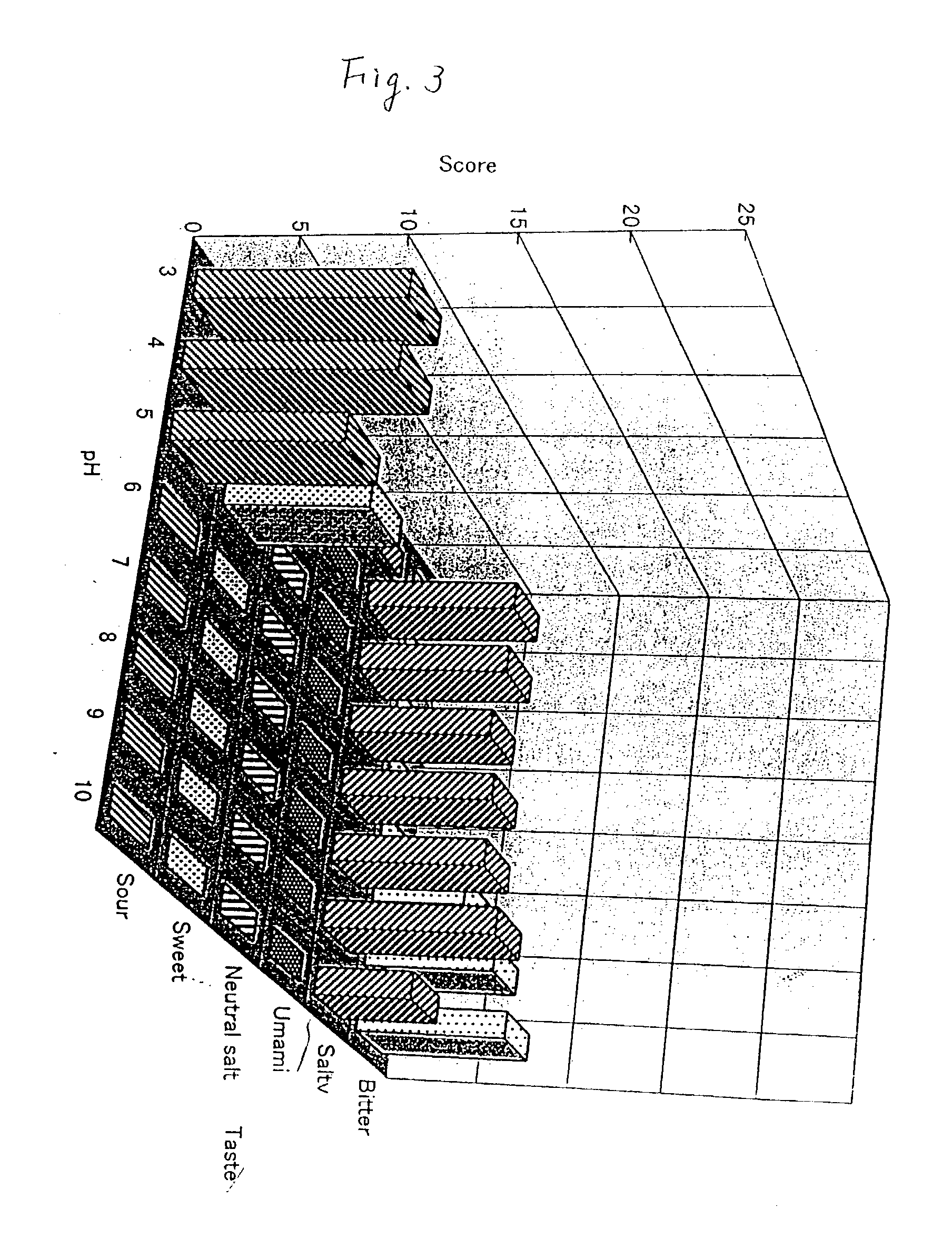

Taste-improving agent and method of using the same

InactiveUS20030099760A1Easily produceRaise the ratioPharmaceutical non-active ingredientsFood preparationDrugBasic amino acids

Taste-improving agents which are basic neutral salts of citric acid and a basic amino acid reacting with citric acid to yield an essentially tasteless salt and preferably selected from the group consisting of arginine, lysine and ornithine. These basic neutral salts are tasteless in themselves but have the capability of when associated in small amounts with any of a broad variety of foods of modifying the taste characteristics of food in enhancing saltiness, reducing bitterness and ofttimes reducing sourness, increasing sweetness or the sensation of sweetness, increasing Umami and improving neutral salt taste. They are free of sodium and hence especially suitable for sodium-restricted diets by elevating the perception of saltiness in a sodium-free manner and without increasing bitterness. They can also be combined with pharmaceuticals or drugs intended for oral administration to counteract an unpleasant taste.

Owner:OKAI HIDEO

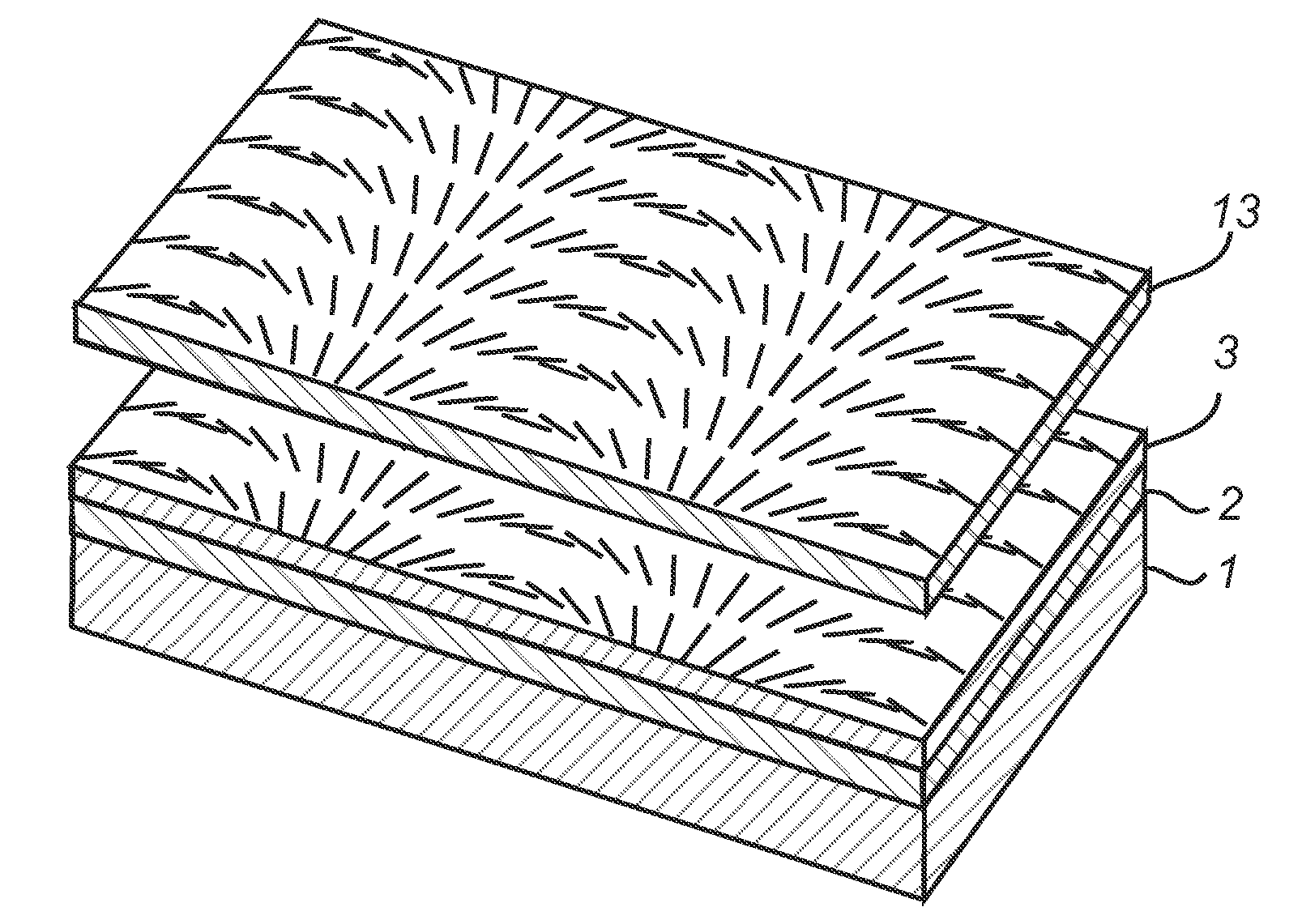

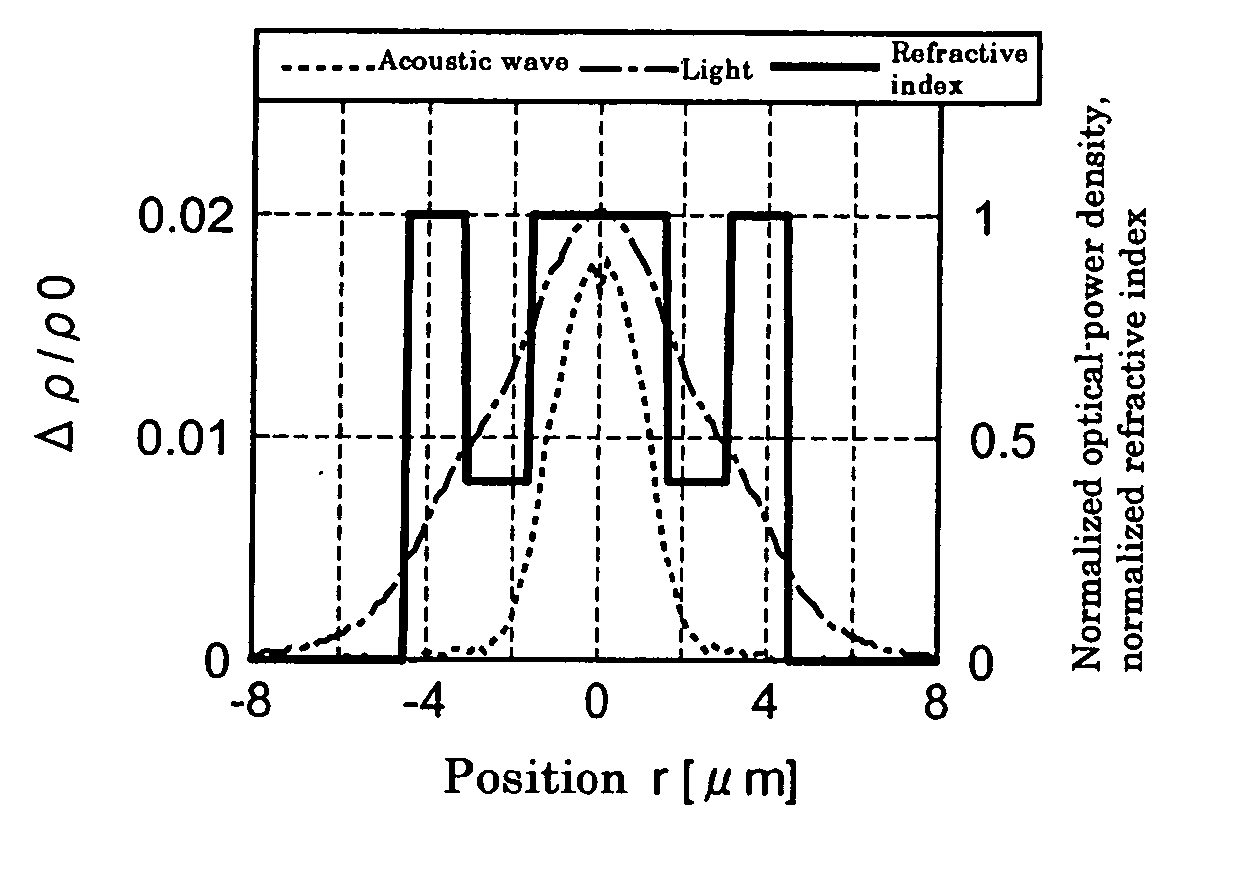

Optical fiber

InactiveUS20060171648A1Suppress sbEasily produceOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAcoustic waveOptical fiber

An optical fiber not only can suppress SBS but also can be produced easily. The optical fiber 1 comprises an optical core region 10 including the center axis and an optical cladding region 14 surrounding the optical core region 10. The optical core region 10 is composed of a first region 11, a second region 12, and a third region 13 in this order from the inside. The third region 13, which is a part of the optical core region 10, is a ring-shaped acoustic core region. The propagation mode of an acoustic wave can be localized in the third region 13.

Owner:SUMITOMO ELECTRIC IND LTD

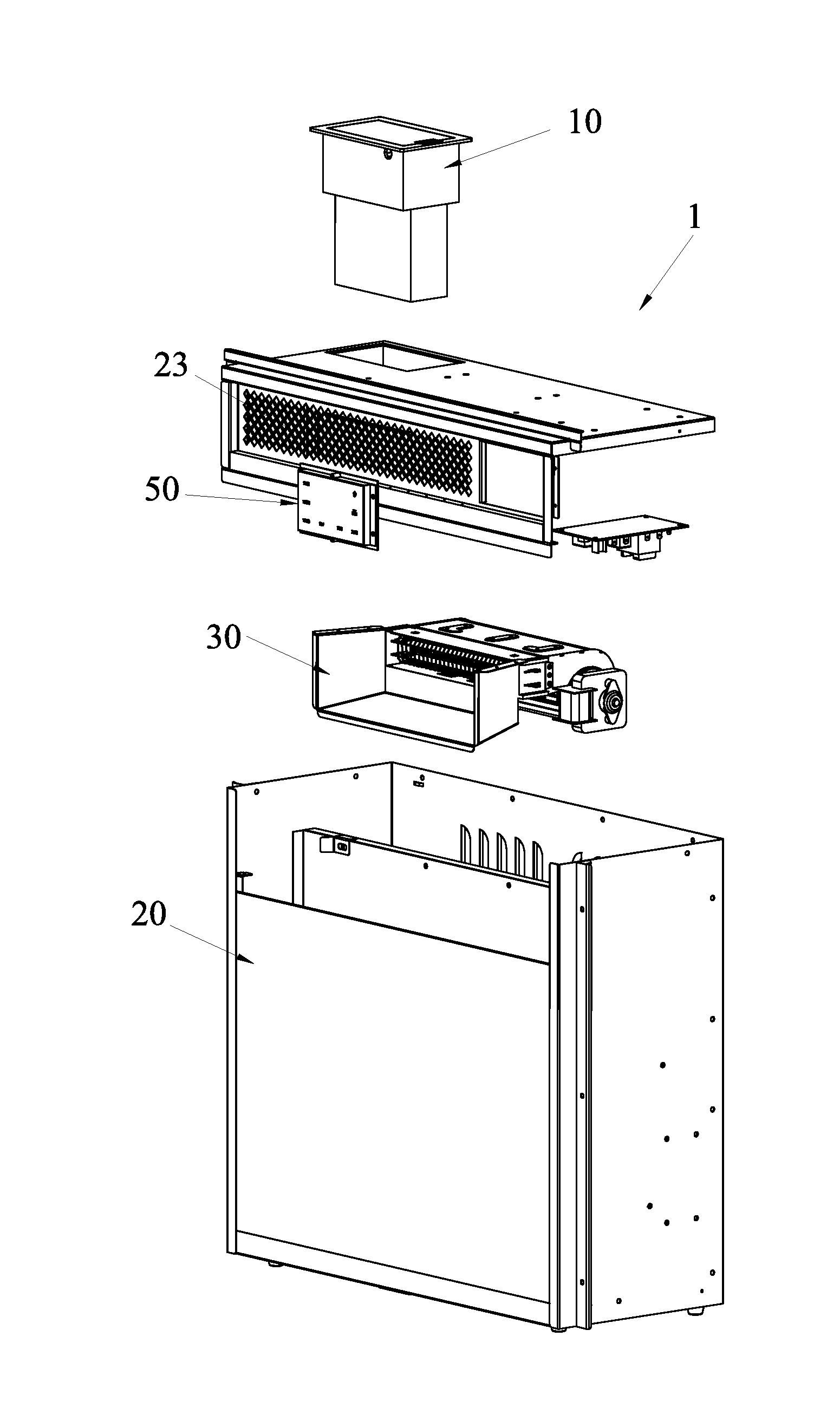

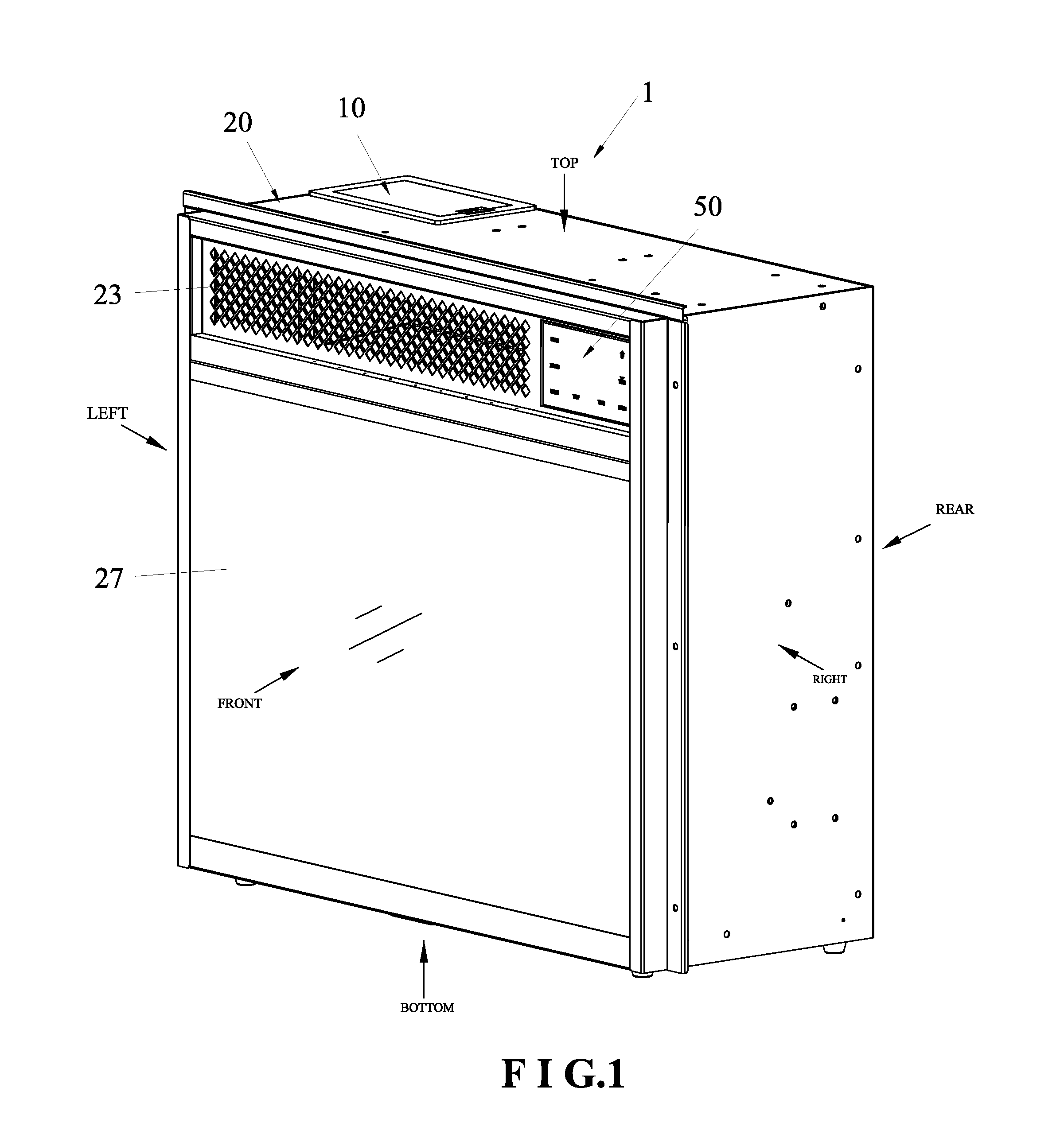

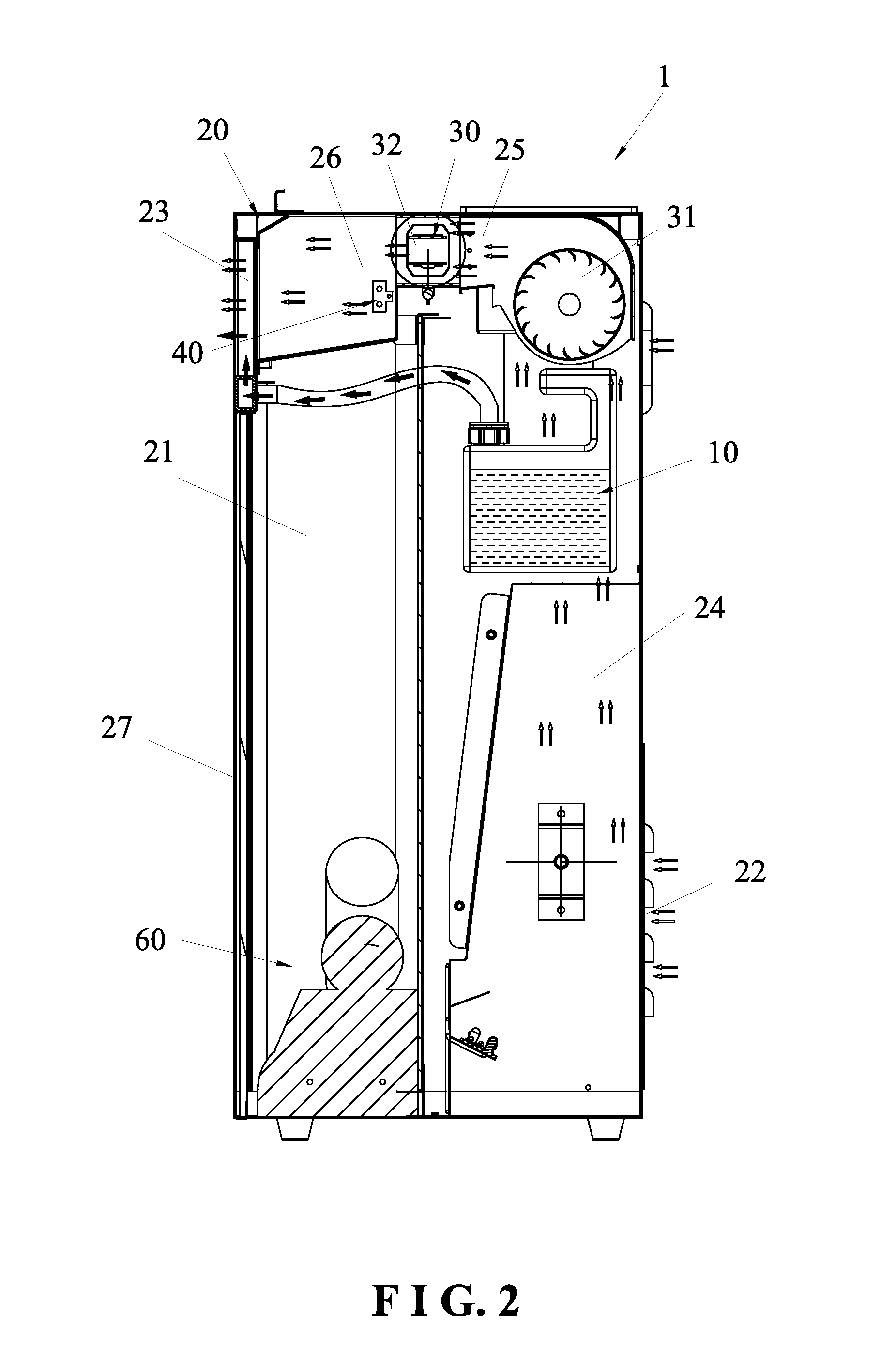

Electric fireplace having humidifying device

ActiveUS20160169537A1Simple structureEasily produceDomestic stoves or rangesLighting and heating apparatusElectricityEngineering

The present invention discloses an electric fireplace having a humidifying device. The electric fireplace includes a casing. A flame imitation device, a heating device, an air purifying device, the humidifying device, and a touch control panel are provided in the casing. The electric fireplace is combined with the flame imitation device, the air purifying device, and the heating device to provide multiple functions. The user can watch the realistic flame and inhale fresh but not dry warm wind. The humidifying device includes a water container, a cotton rod, a fixing knob, an atomization plate, a hollow pipe, and a fog output box. The humidifying device delivers the water to the atomization plate through the cotton rod to generate atomized particles. The present invention has a simple structure and can be produced easily.

Owner:LU MIN HSUN

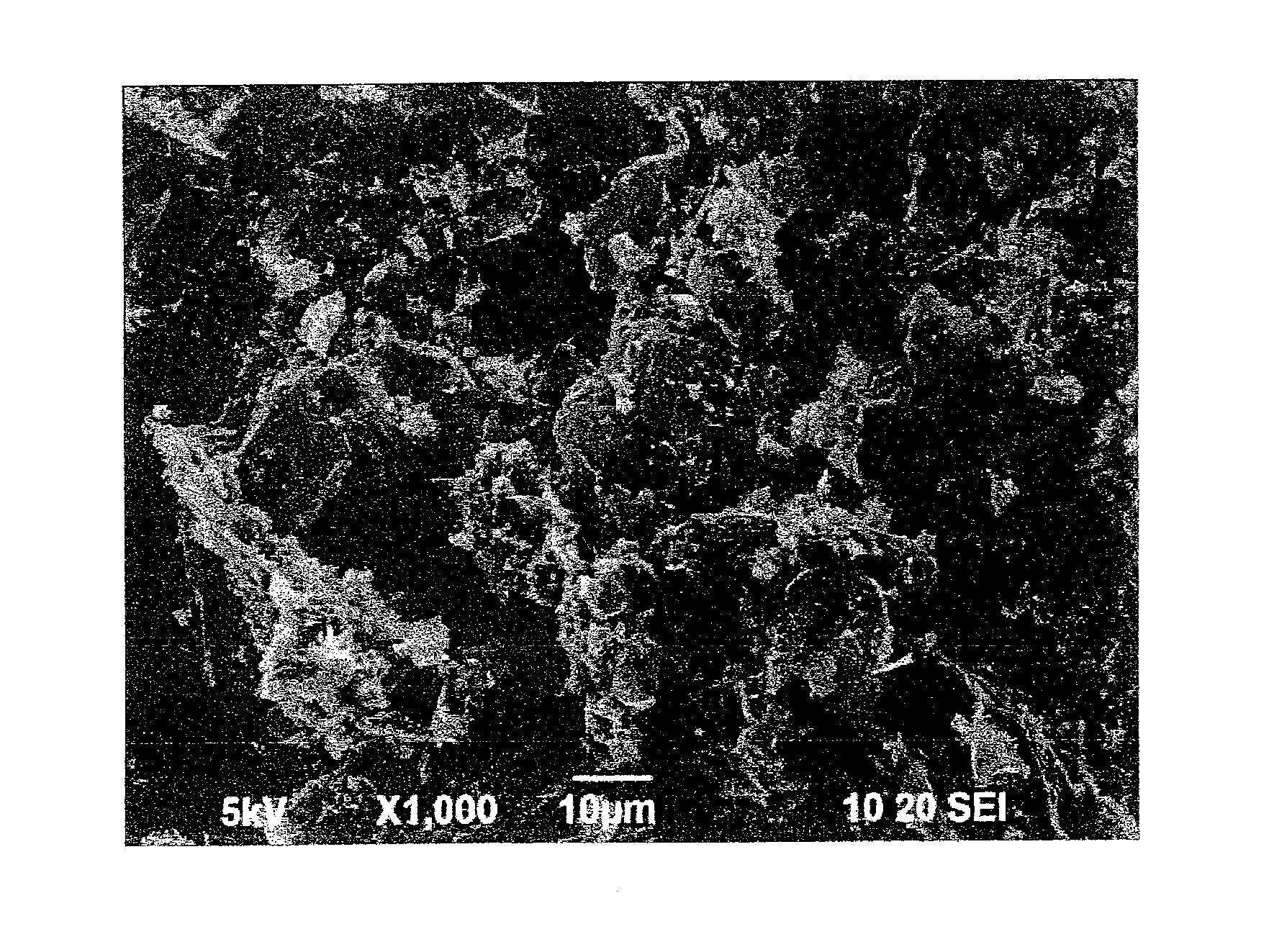

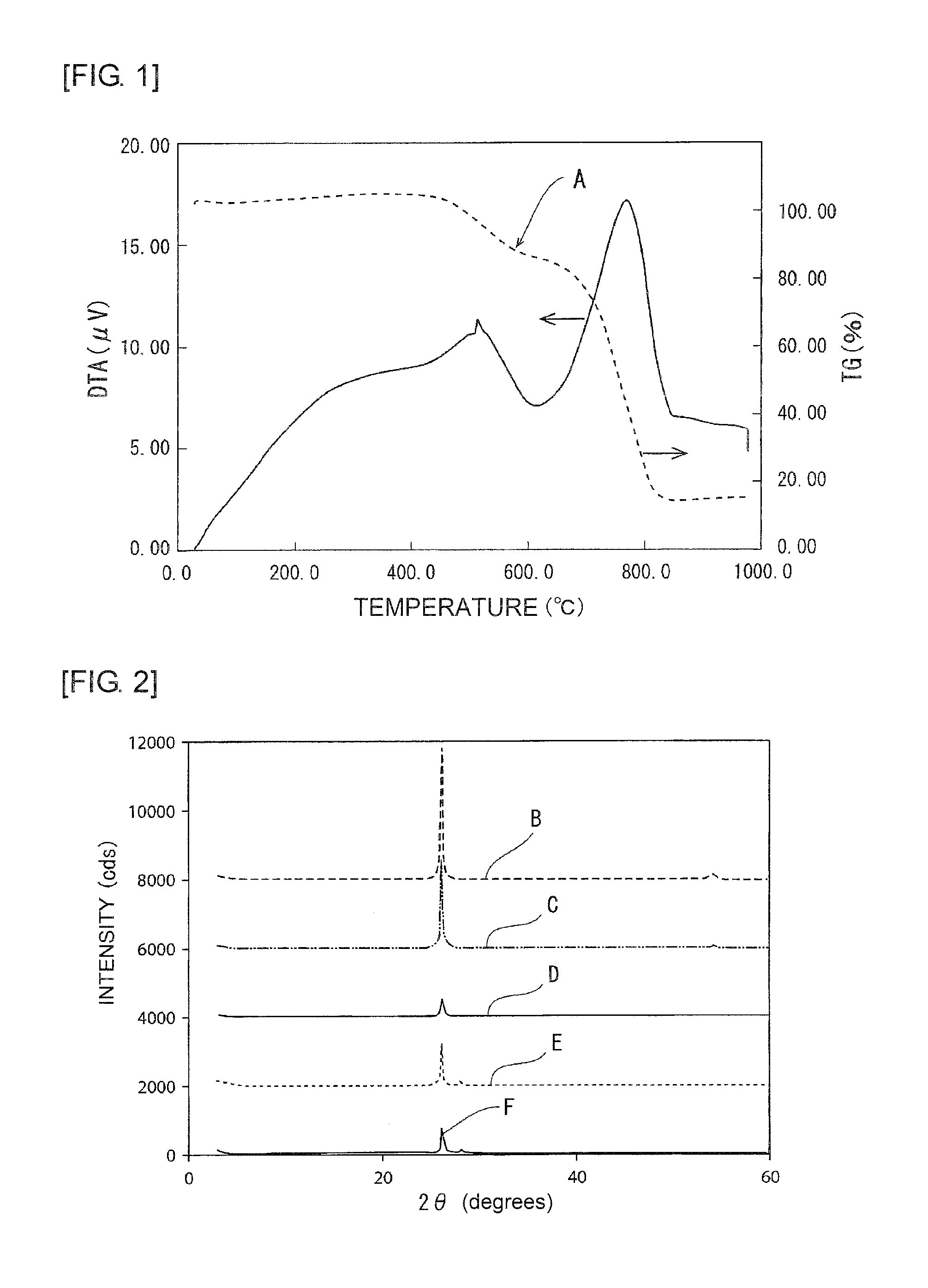

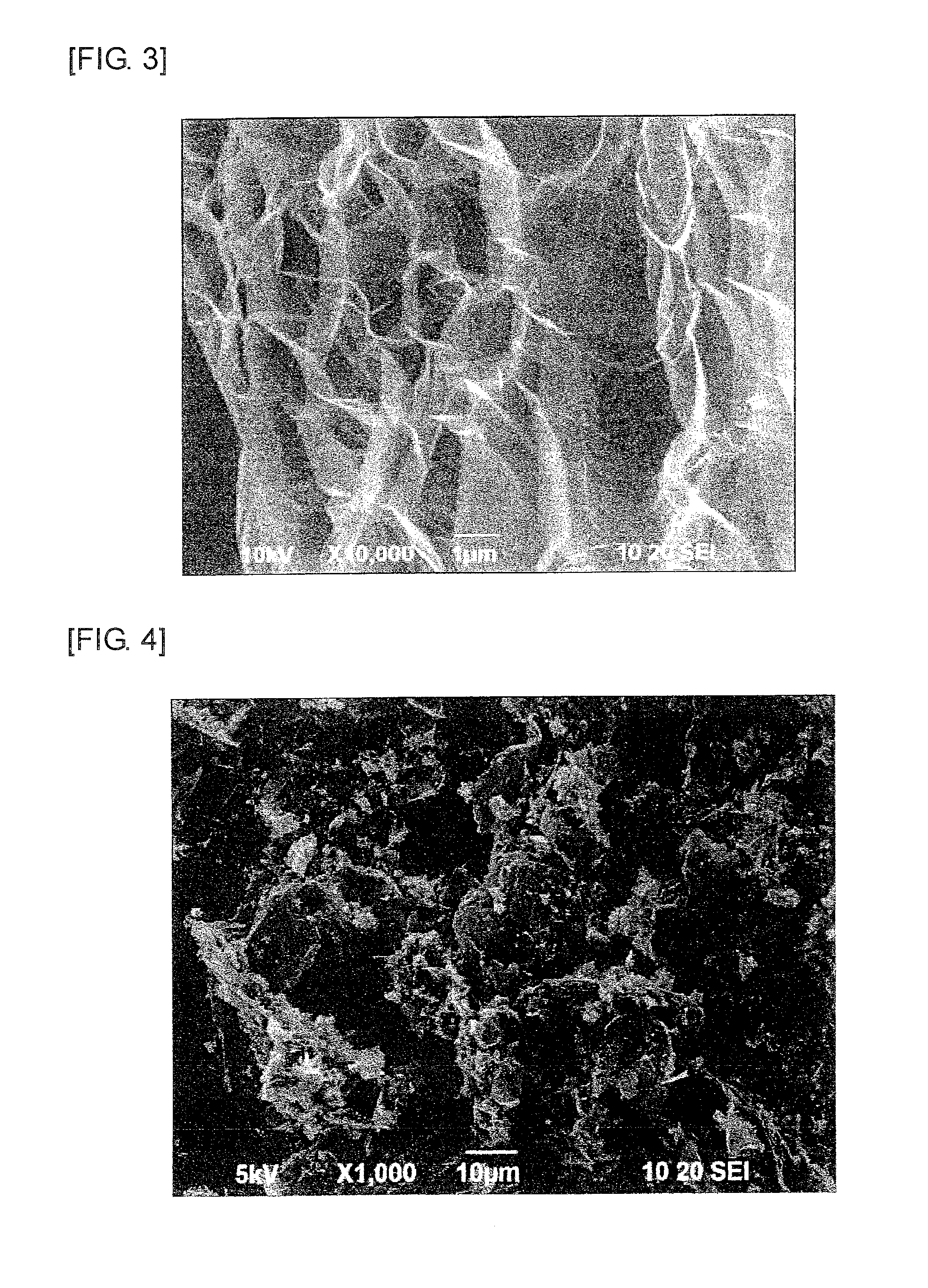

Fine particle-exfoliated graphite composite, negative electrode material for lithium ion secondary battery, and methods for producing the same, and lithium ion secondary battery

ActiveUS20150270534A1Easily produceEasy to produceNon-metal conductorsFinal product manufactureSolventCharge and discharge

There is provided a method for producing a negative electrode material for lithium ion secondary batteries that is easily produced and is less likely to cause deterioration in charge and discharge cycle characteristics. A method for producing a negative electrode material for lithium ion secondary batteries, comprises steps of heating a raw material composition comprising resin-retained partially exfoliated graphite having a structure in which graphene is partially exfoliated and Si particles to dope the partially exfoliated graphite with the Si particles, the partially exfoliated graphite being obtained by pyrolyzing a resin in a composition in which the resin is fixed to graphite or primary exfoliated graphite, thereby exfoliating the graphite or primary exfoliated graphite while allowing part of the above resin to remain; providing a composition comprising the above partially exfoliated graphite doped with the Si particles, a binder resin, and a solvent; and shaping the above composition.

Owner:SEKISUI CHEM CO LTD

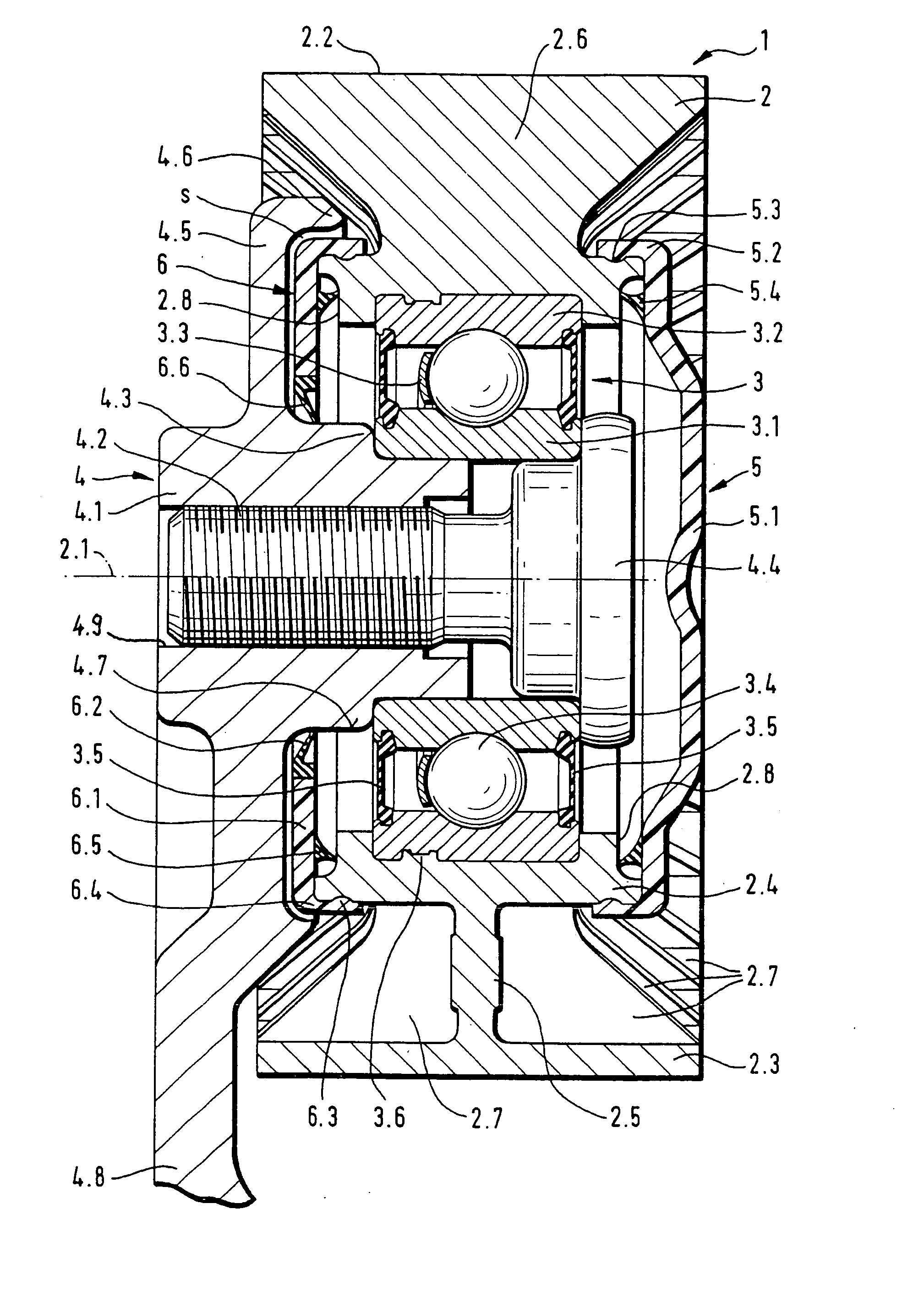

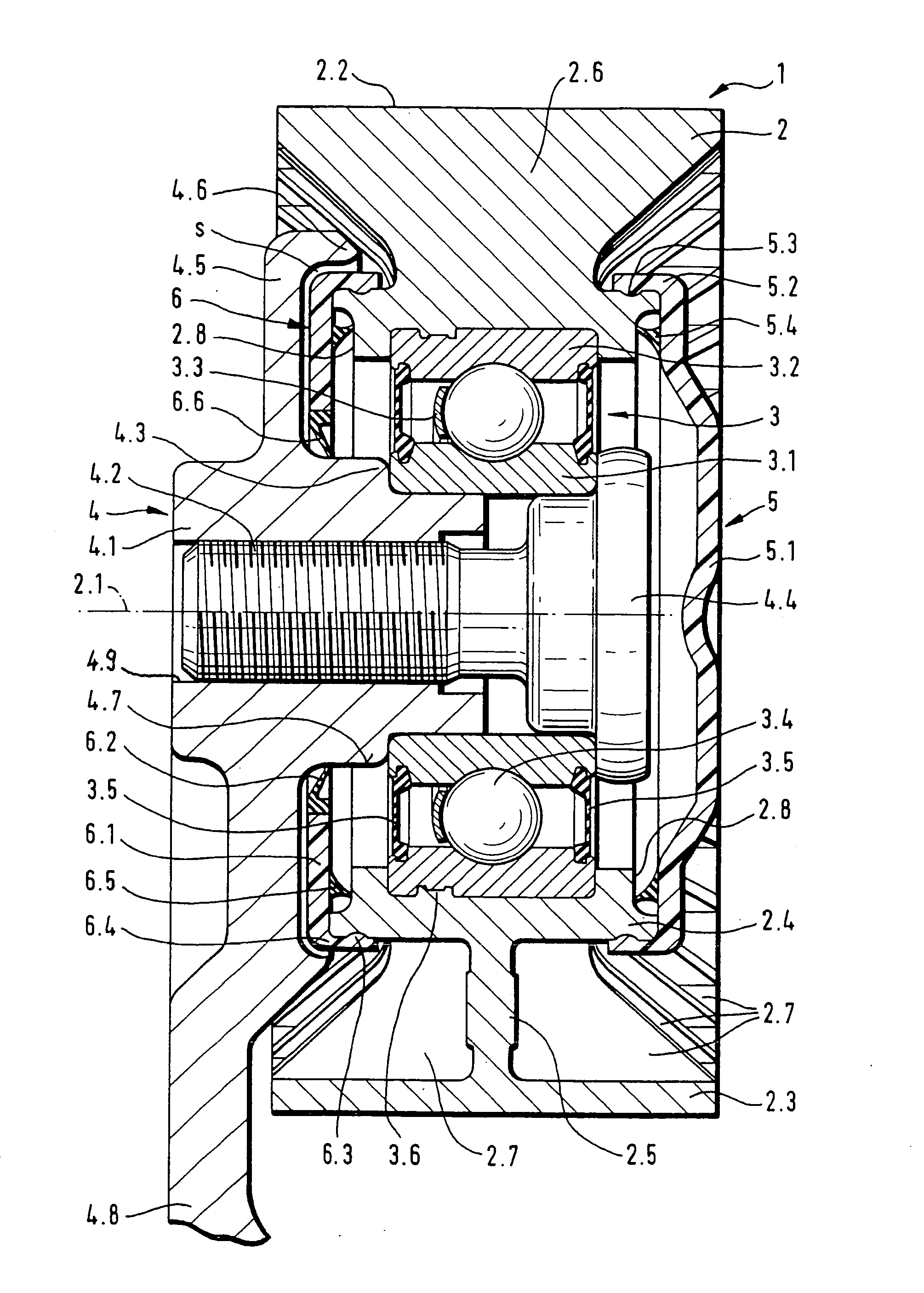

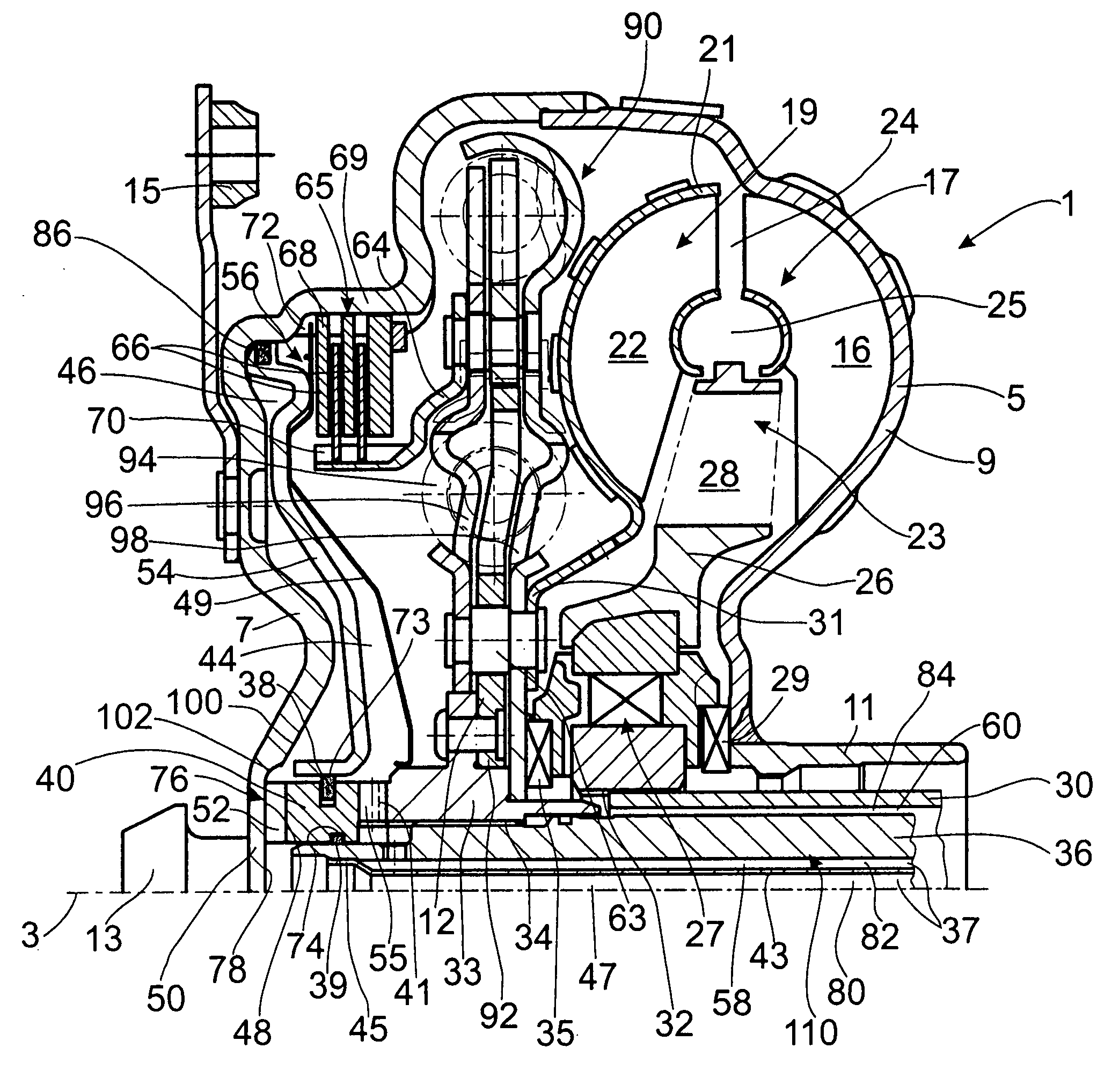

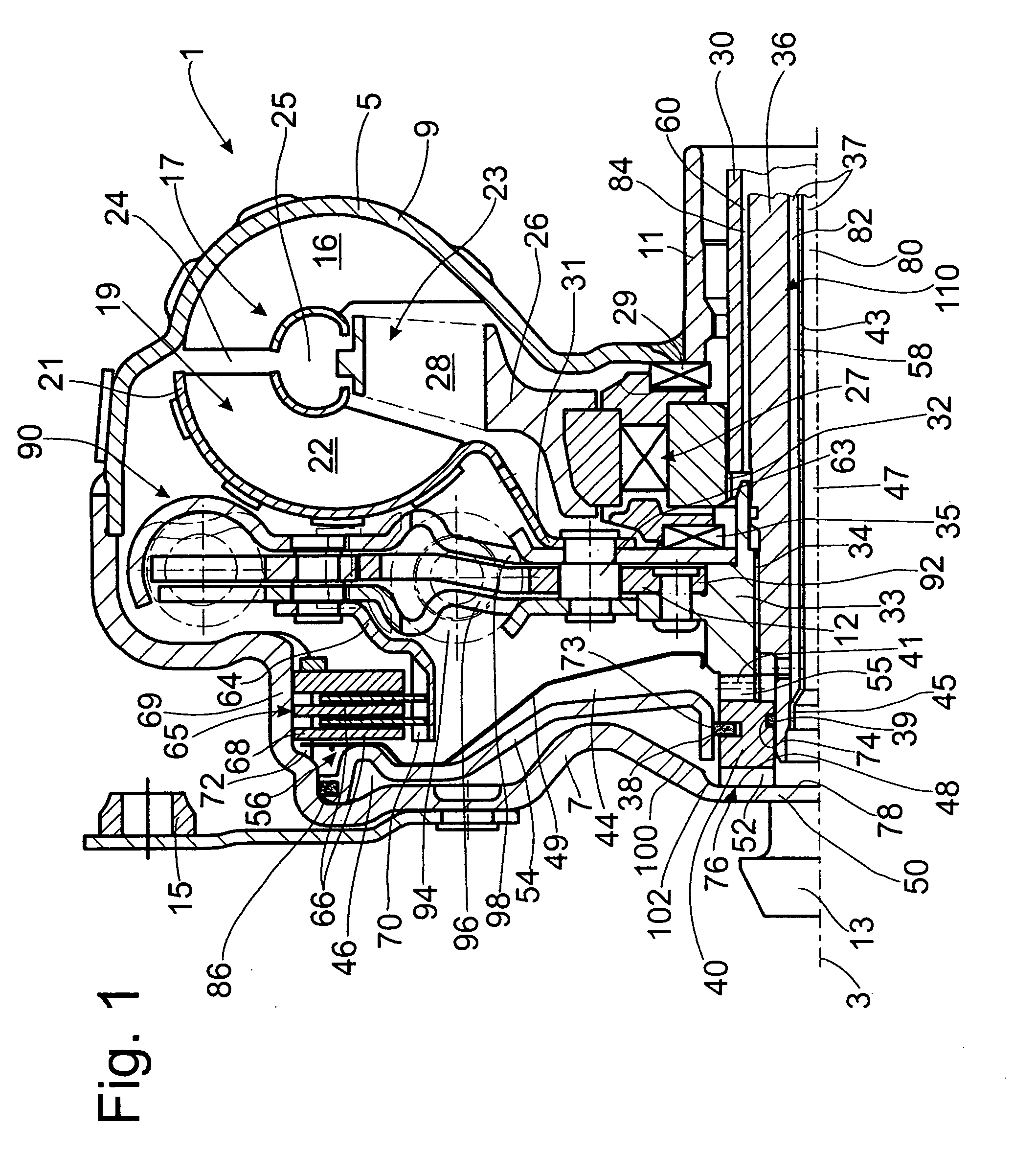

Hydrodynamic clutch device

A hydrodynamic clutch includes a hydrodynamic circuit formed by at least a pump wheel and a turbine wheel in a clutch housing with a drive-side housing wall extending to the axis of rotation, and a bridging clutch with a piston capable of shifting axially relative to the drive-side housing wall. The turbine wheel is connected to a hub, which is connected for rotation in common to a takeoff, and is axially supported between the hydrodynamic circuit and a flow guide element, which is supported between the hub and the drive-side housing wall, and has first and second flow passages which are axially offset from each other. The flow guide element has a drive-side end with an axial bearing area which can be moved into axial contact with an axial bearing, which is either an axial contact surface on the drive-side housing wall or is assigned to the drive-side housing wall.

Owner:ZF FRIEDRICHSHAFEN AG

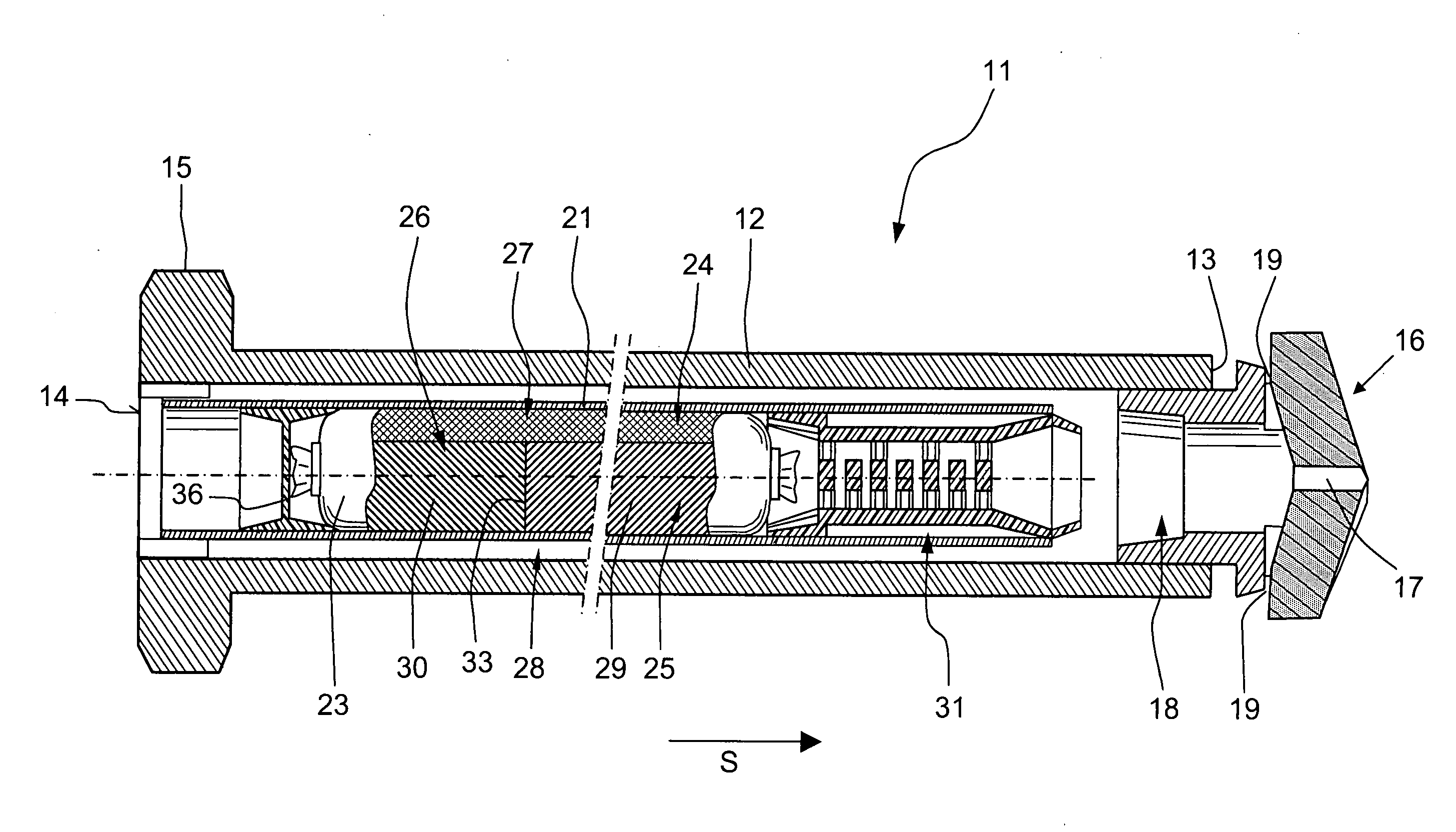

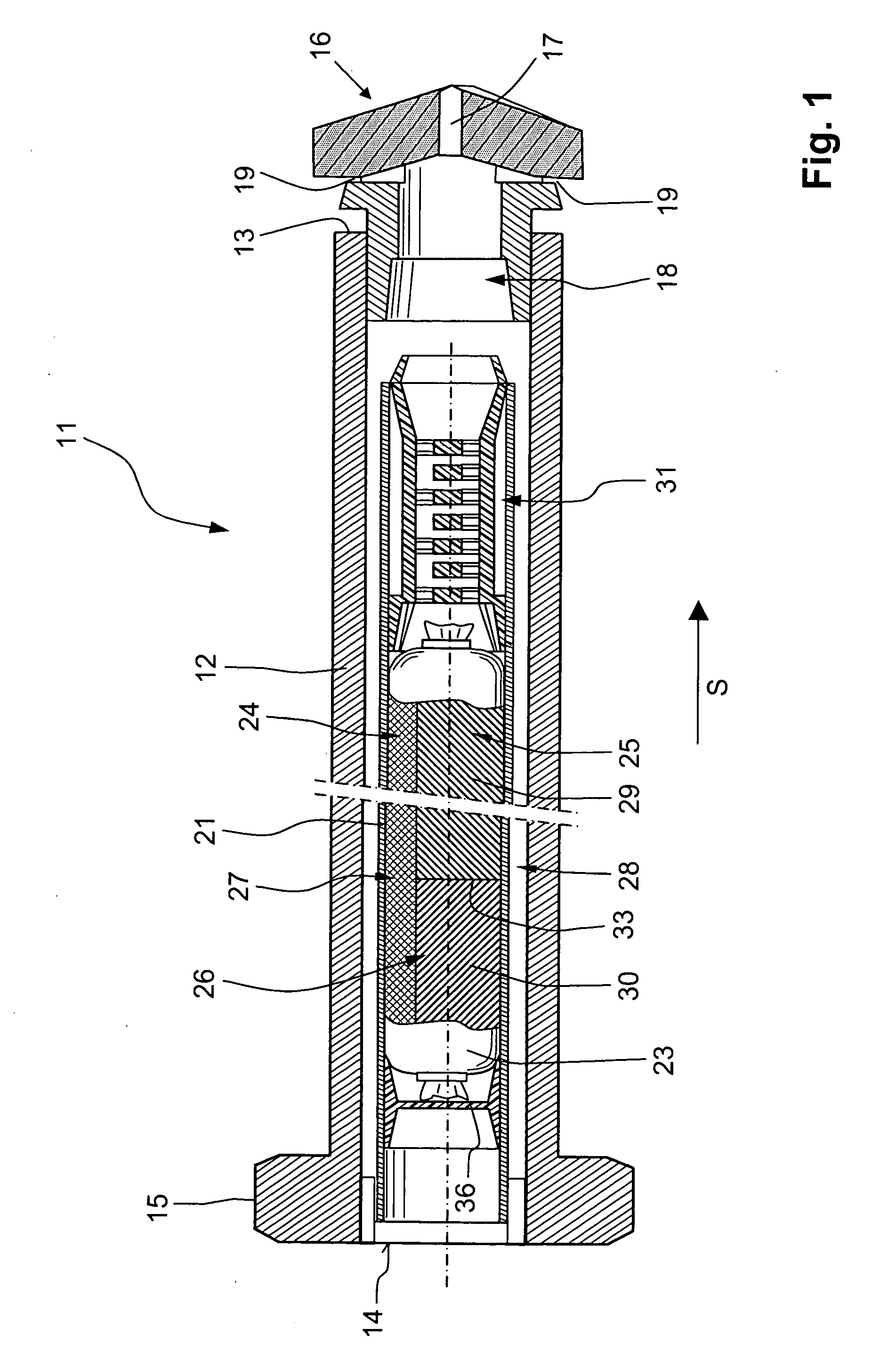

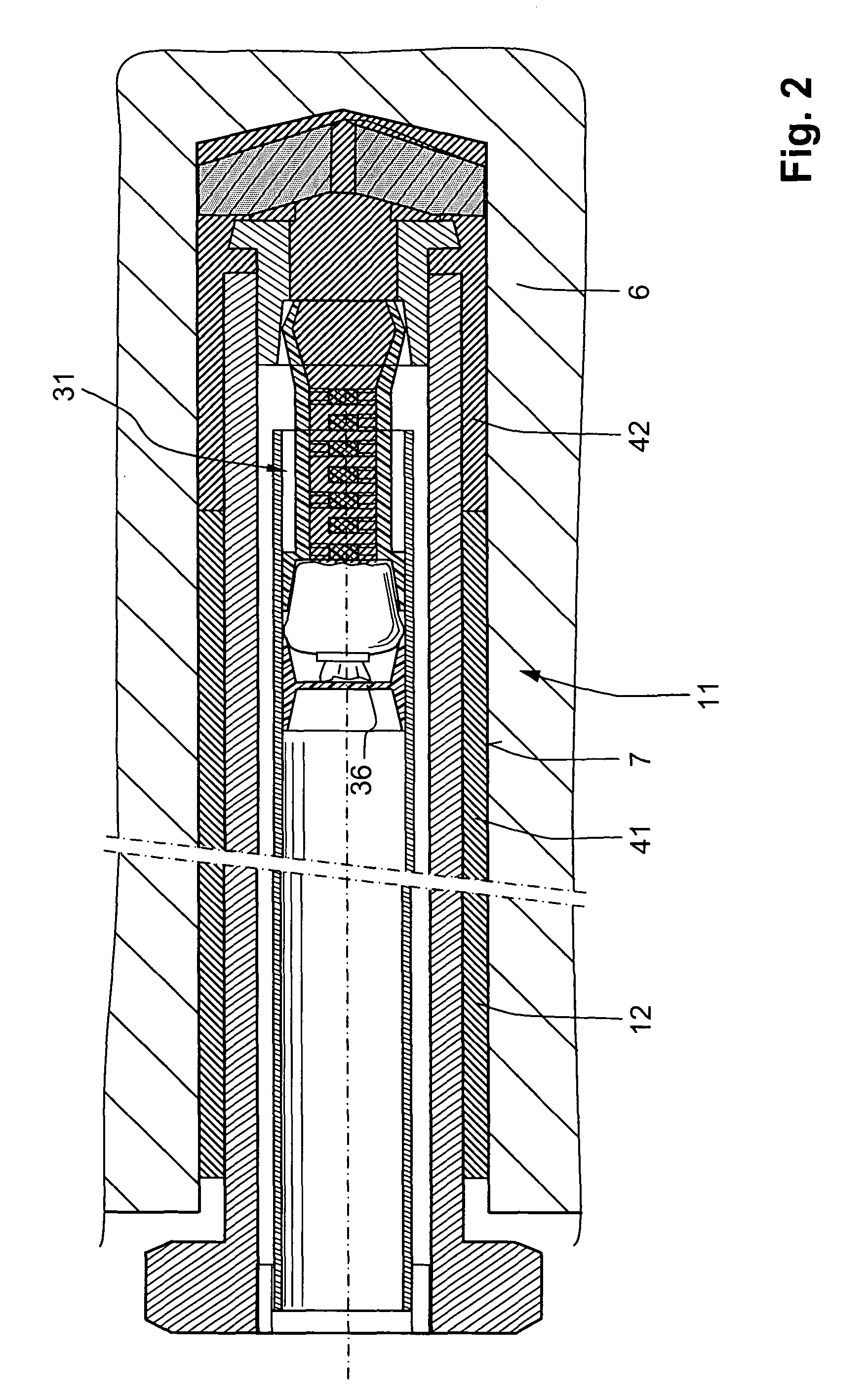

Self-drilling fastening element

InactiveUS20100284762A1Easily arrangeEasily produceSecuring devicesAdhesivesEngineeringMechanical engineering

A self-drilling, chemically anchorable fastening element includes a hollow cylindrical receiving body (12) in which an ejectable, hardenable multi-component mass (26) is located and which includes a hardener (27) and a two-formulation reactive resin (28) hardenable in a mixed, with each other, condition, with the formulations (29, 30) being arranged one after another in the receiving body and with the second formulation (30), which hardens rapidly in a mixed condition with the hardener (27), being located, in a setting direction (S) of the fastening element (11), behind a first formulation (29) of the reactive resin (28) which hardens slower in a mixed condition with the hardener.

Owner:HILTI AG

Fluorescent material, process for producing the same and illuminator employing the same

ActiveUS20100219741A1Stably emitEasily produceDischarge tube luminescnet screensLamp detailsSilicon nitrideNitrogen gas

A fluorescent material comprising: a β-Sialon expressed by the general formula Si6-ZAlZOZN8-Z as a host material; and Eu dissolved in solid solution as a luminescence center, is a powder which, when measured by the laser diffraction scattering method, gives particle diameter distribution in which cumulative 10% diameter (D10) falls within the 7 μm to 20 μm range and 90% diameter (D90) within the 50 μm to 90 μm range, and can be used as a fluorescent material low in luminescence intensity degradation ideal for illuminators. This fluorescent material can be produced by subjecting a raw powder, which is obtained by mixing a silicon nitride powder, aluminum nitride powder, and aluminum-containing or Eu-containing compound as required, to heating at 1850° C. to 2050° C. for 9 hours or longer in a nitrogen or nonoxidizing atmosphere.

Owner:DENKA CO LTD

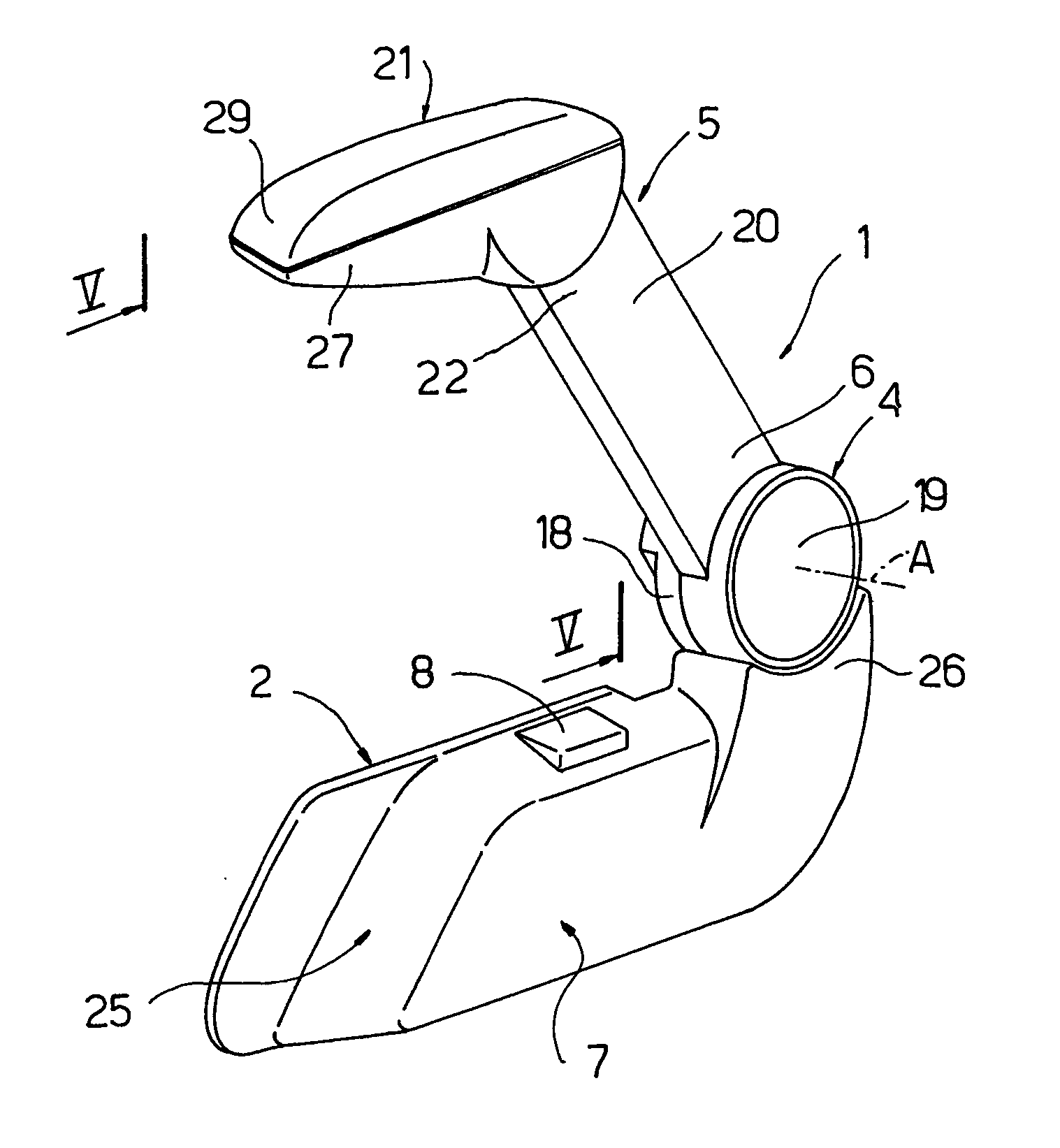

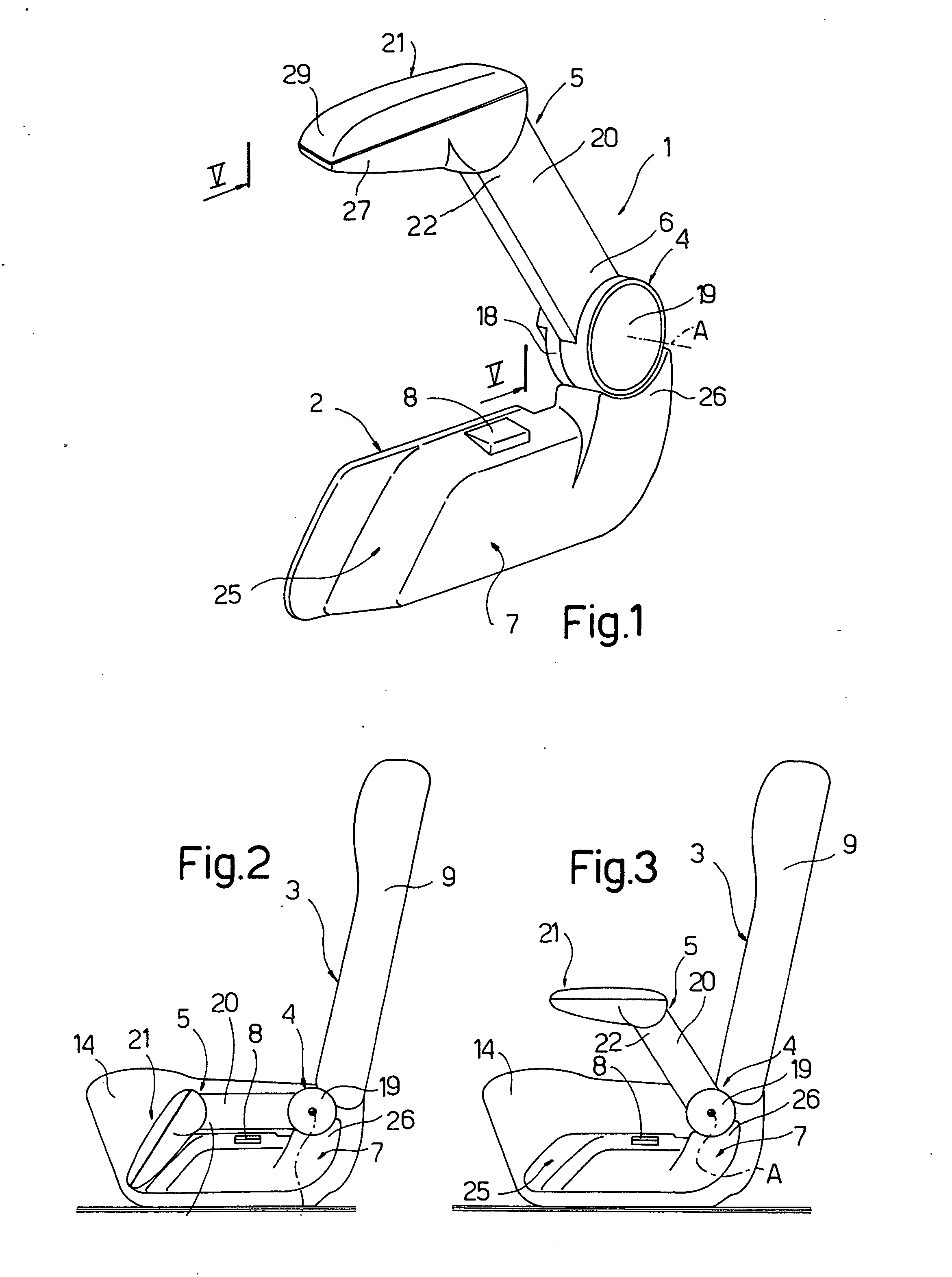

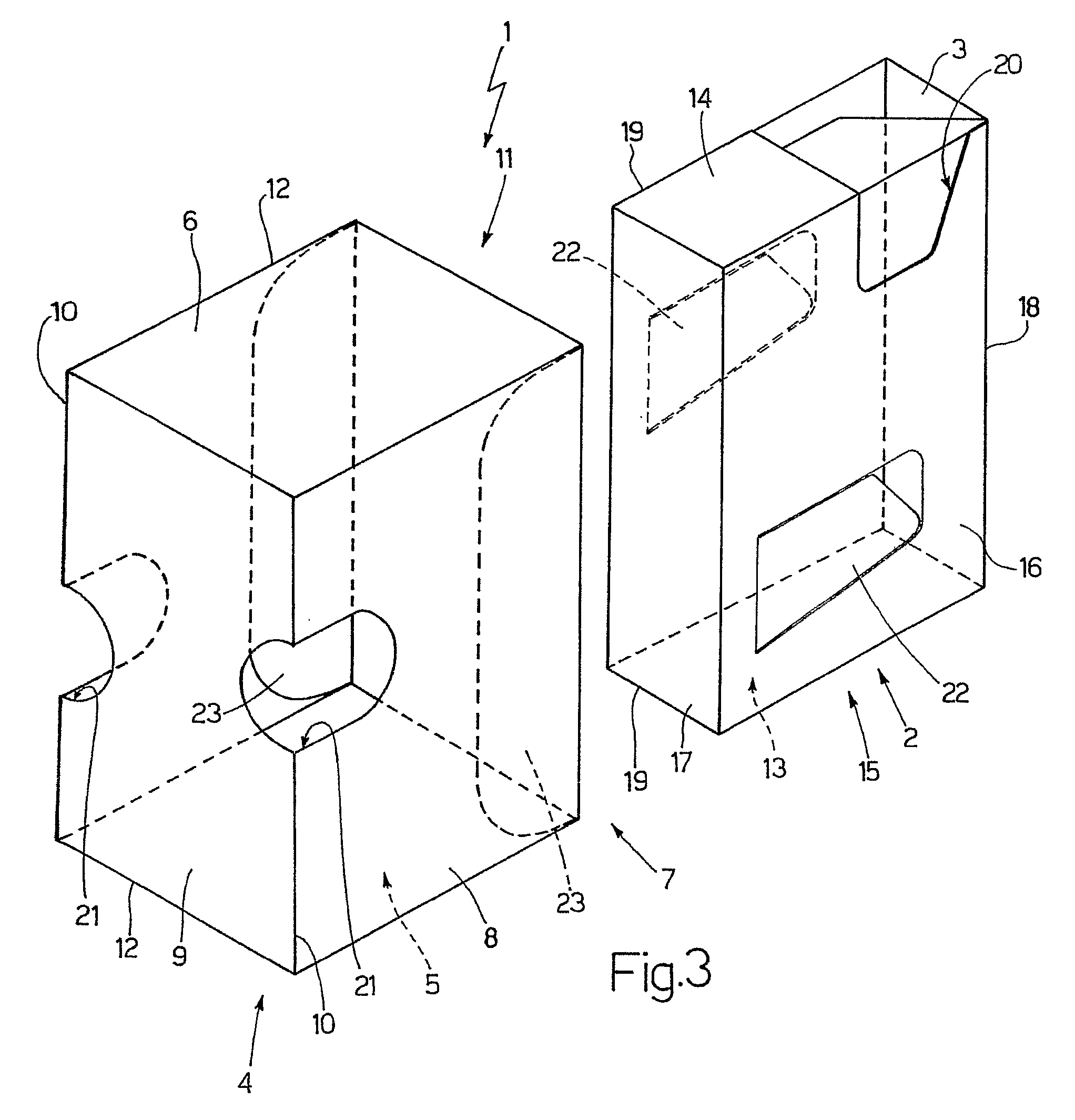

Vehicle seat armrest assembly

An armrest assembly having a fastening plate connected to a vehicle seat; a hinge device connected to the fastening plate; and an armrest connected removably to the hinge device and movable between a work position, in which the armrest is tilted and projects with respect to the fastening plate, and a collapsed position, in which the armrest is adjacent to the fastening plate.

Owner:RUSPA OFFICINE

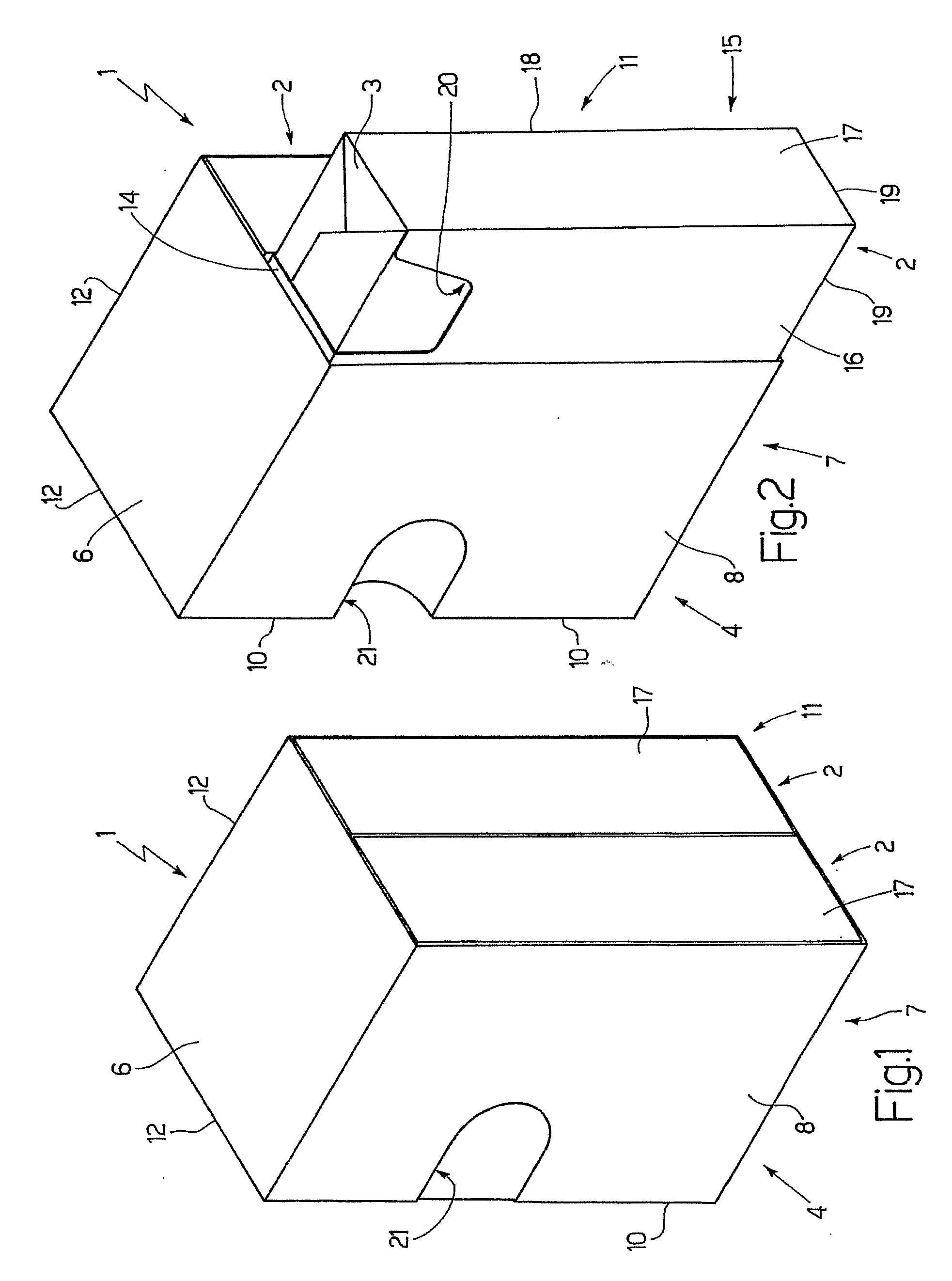

Rigid Package Of Tobacco Articles

InactiveUS20070278115A1Cheap and easy to produceEasily produceContainers for flexible articlesPackaging cigaretteMechanical engineeringStructural engineering

A rigid package of tobacco articles, having two first containers, each housing a group of tobacco articles and housed inside a second container so as to slide with respect to the second container between a closed position, in which the first container is fully inserted inside the second container, and an open position, in which part of the first container projects from the second container.

Owner:GD SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com