Patents

Literature

609 results about "Anisotropic conductive adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

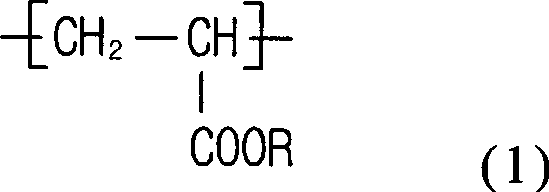

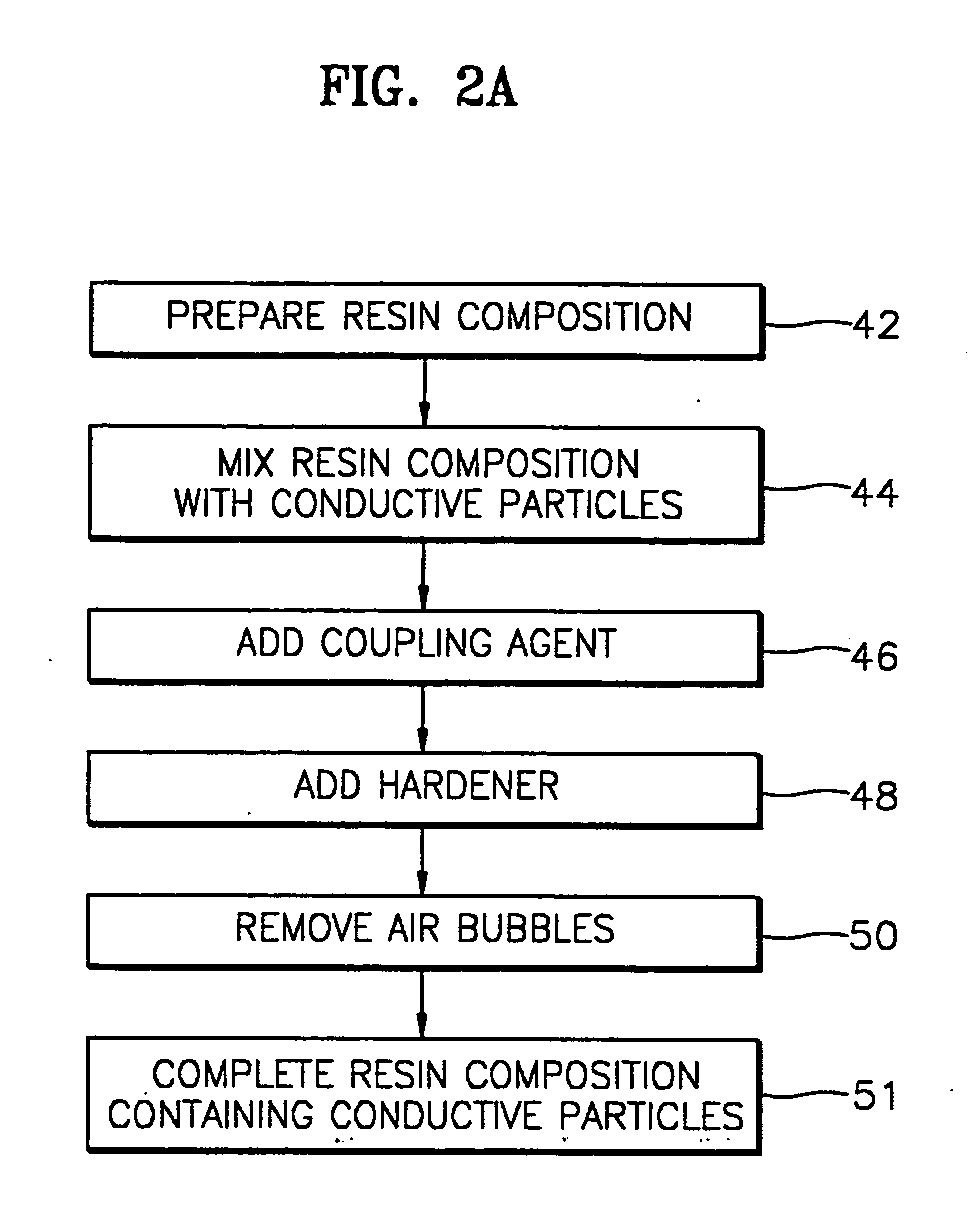

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

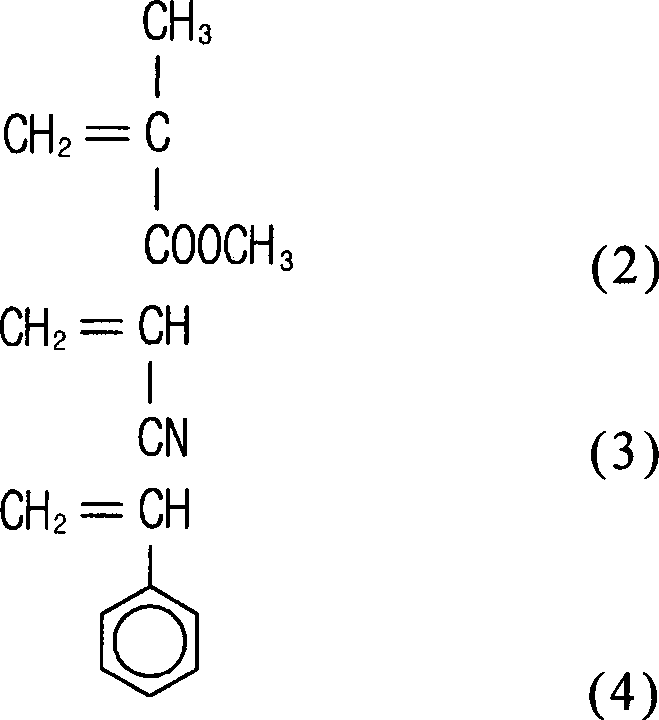

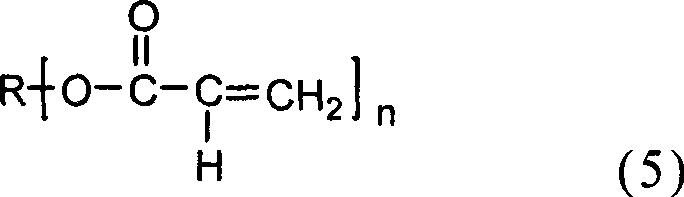

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

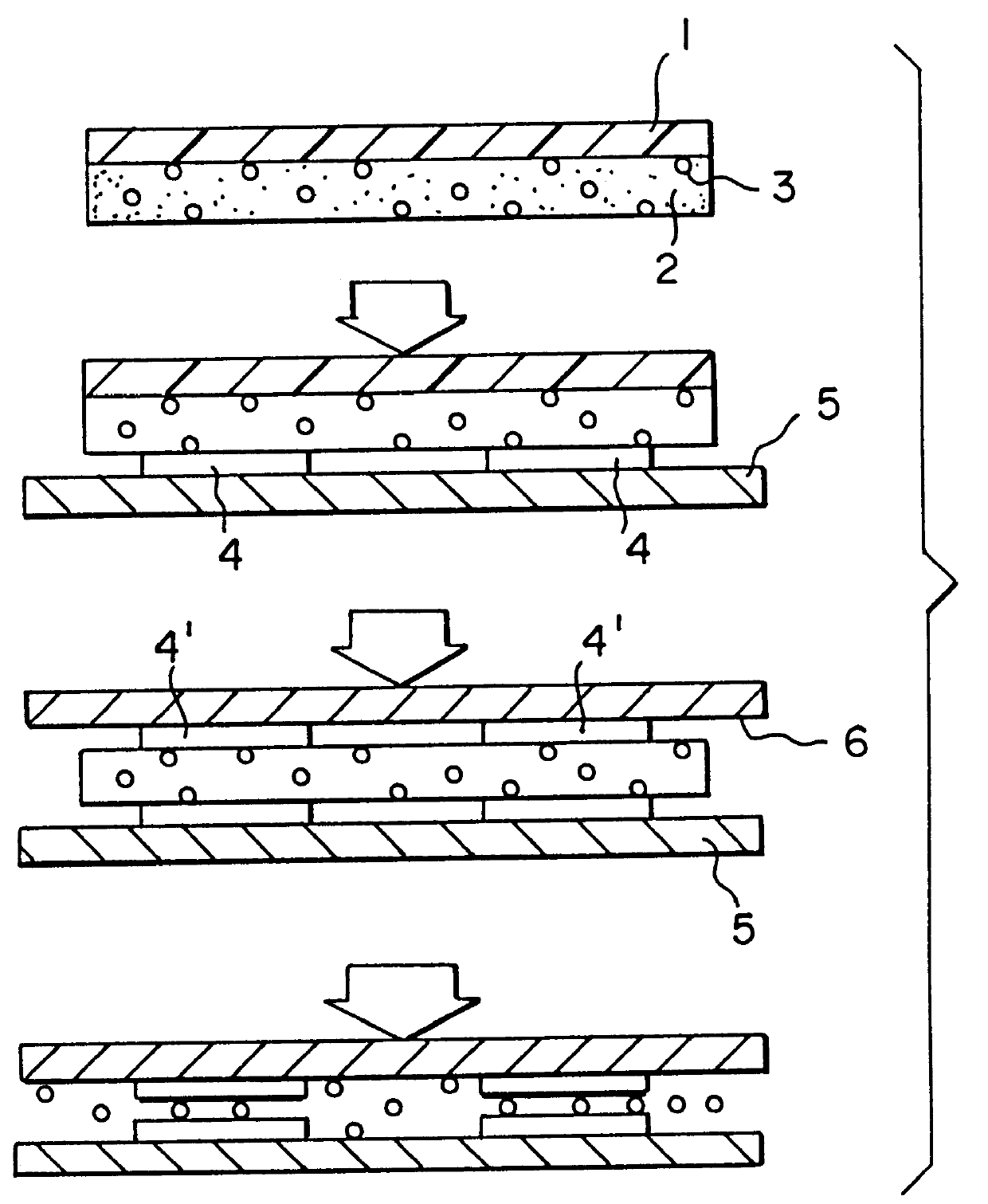

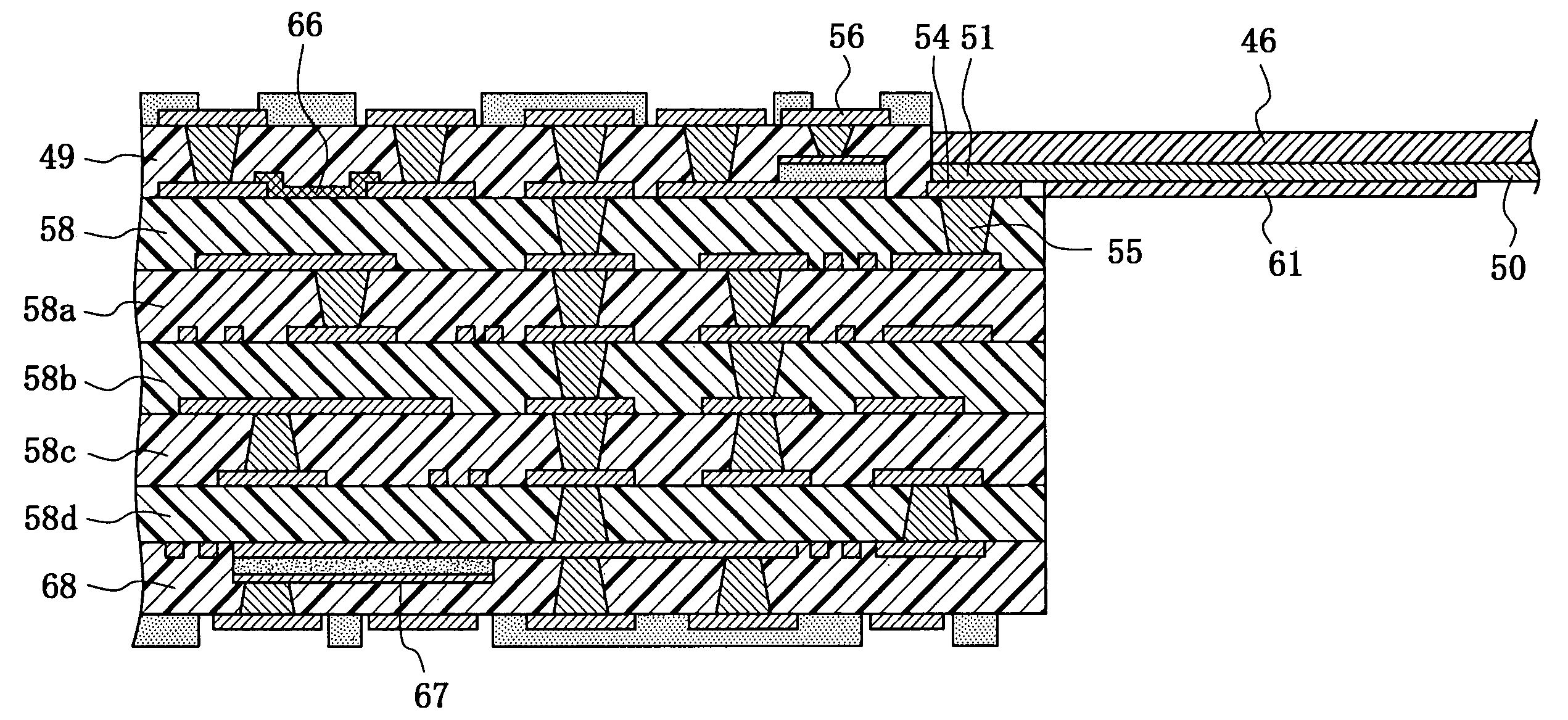

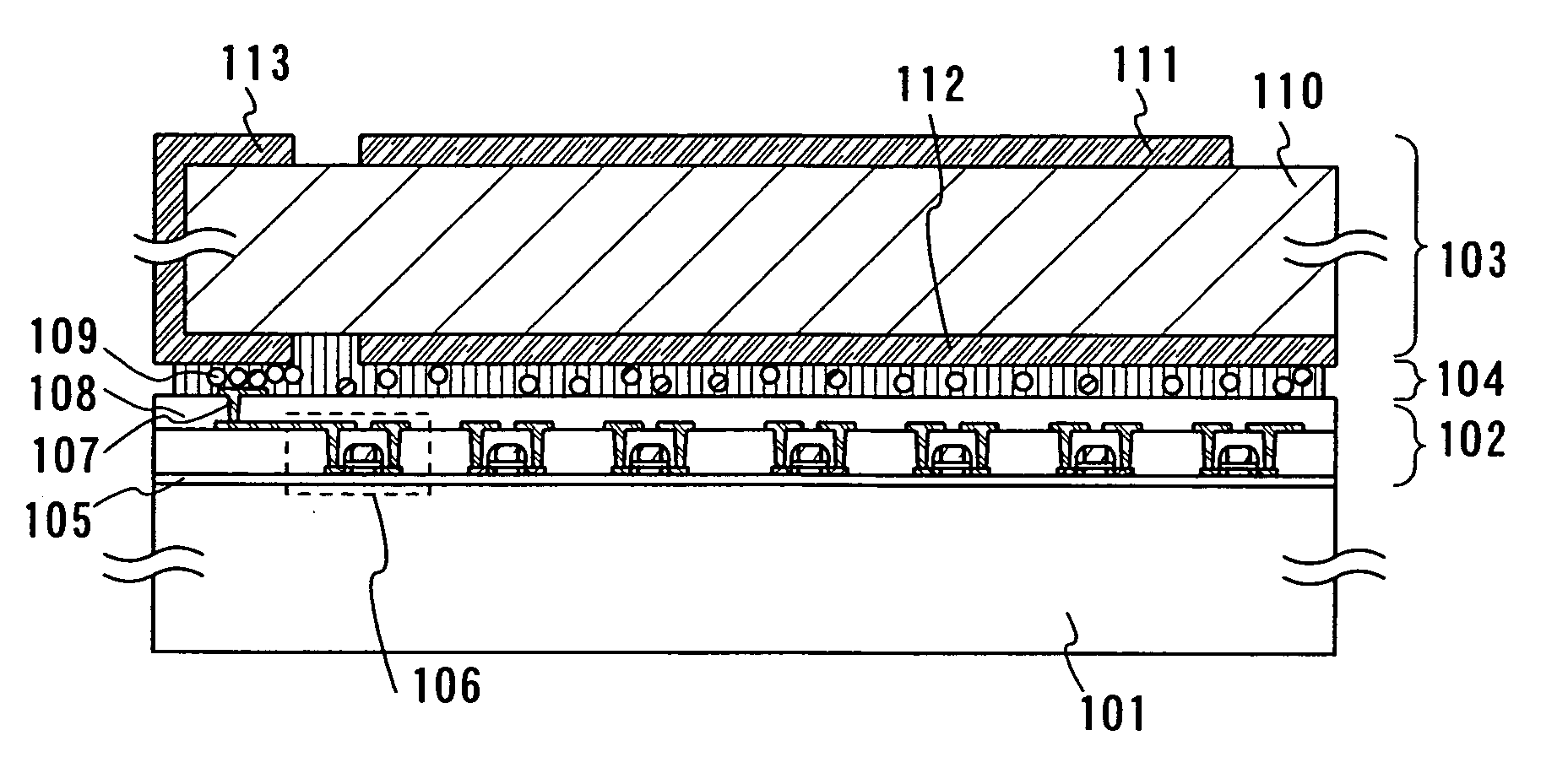

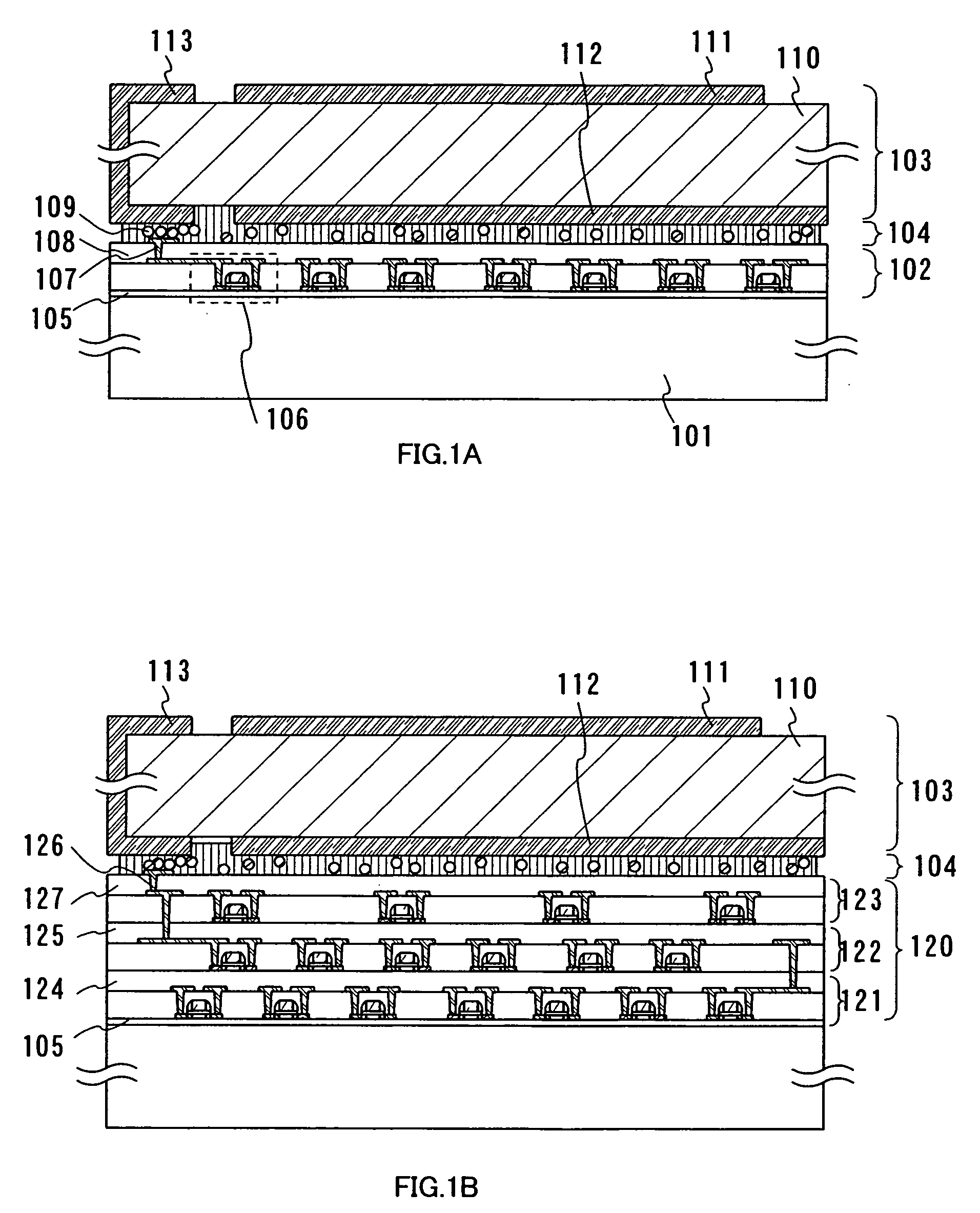

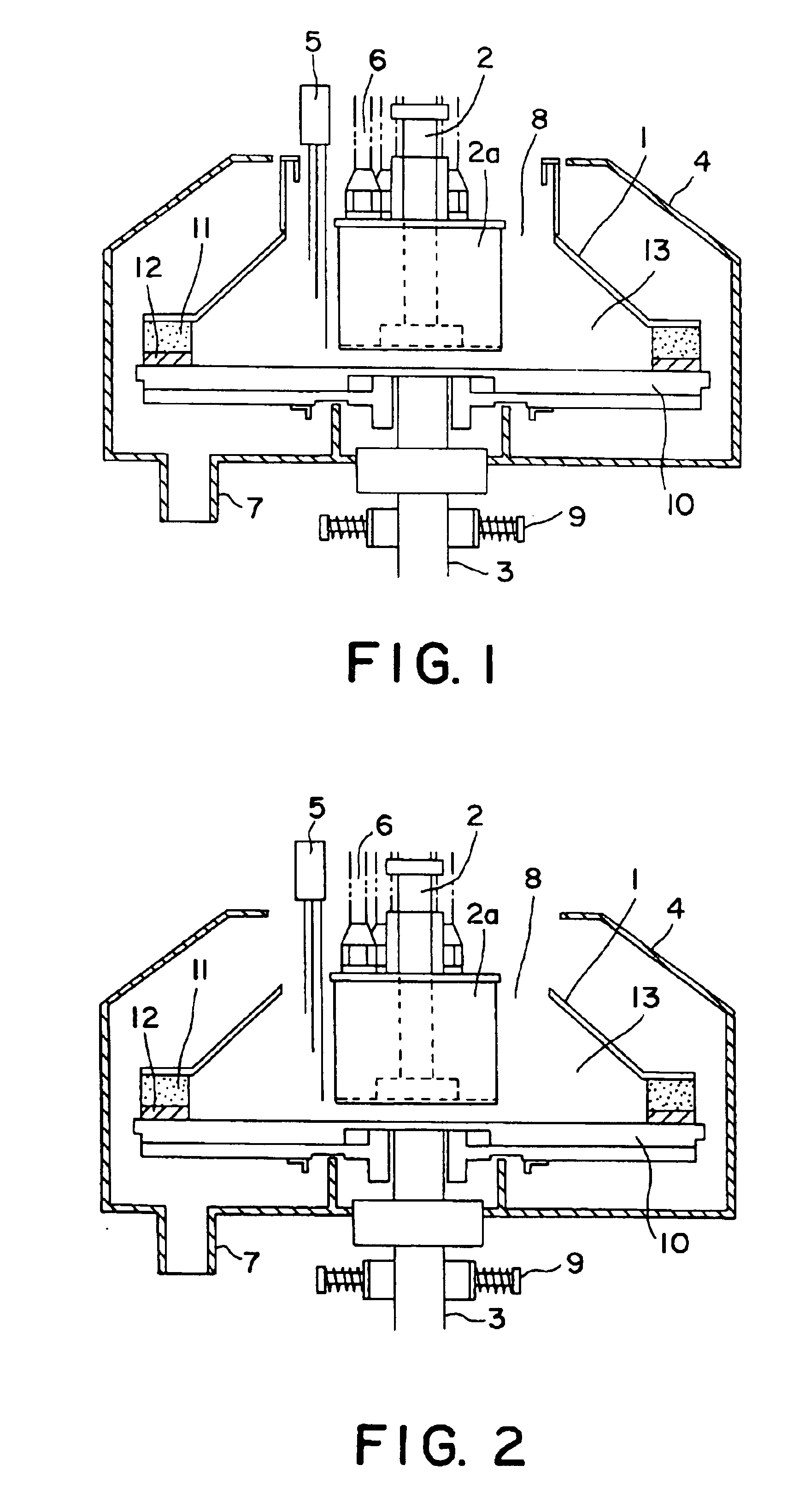

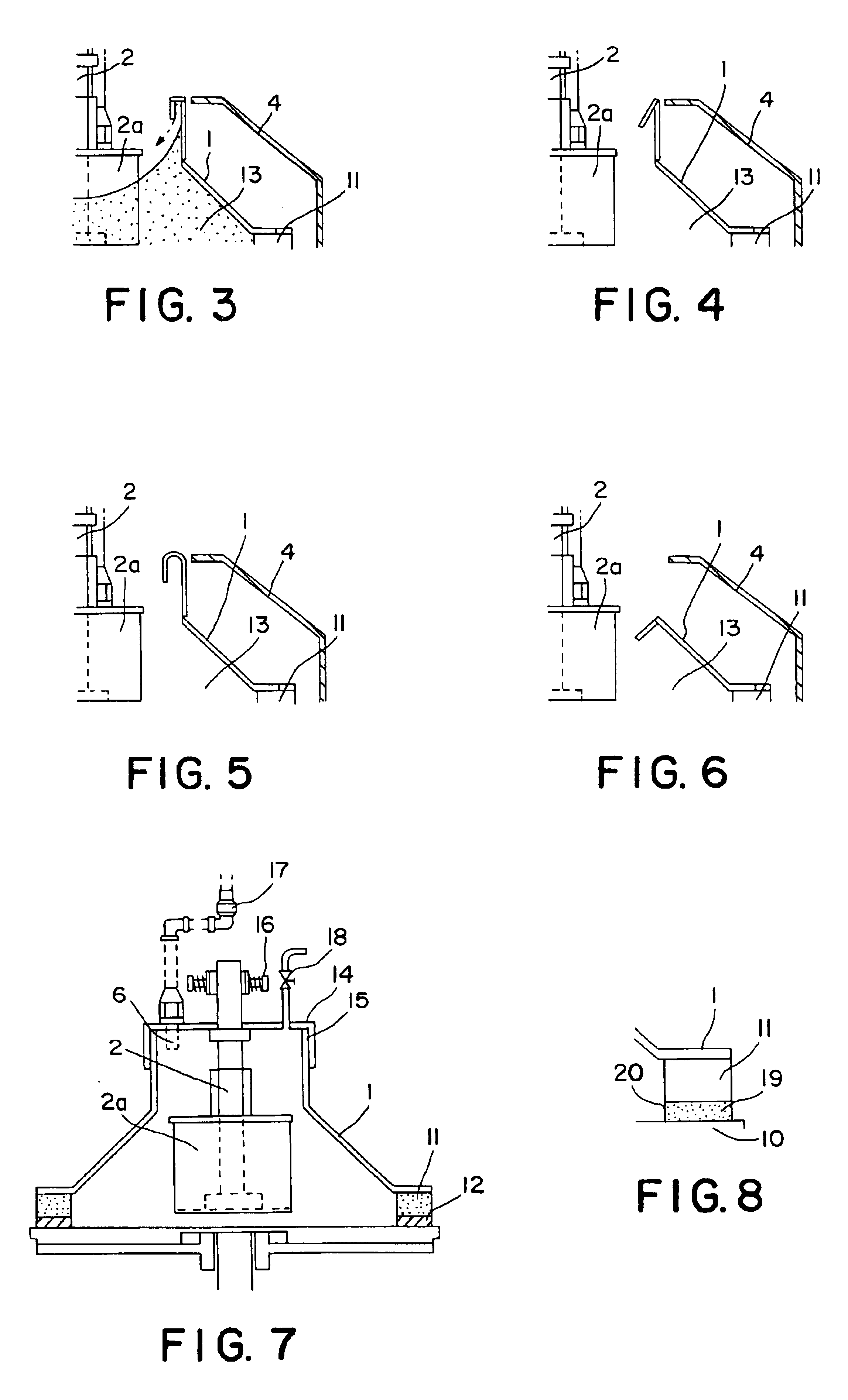

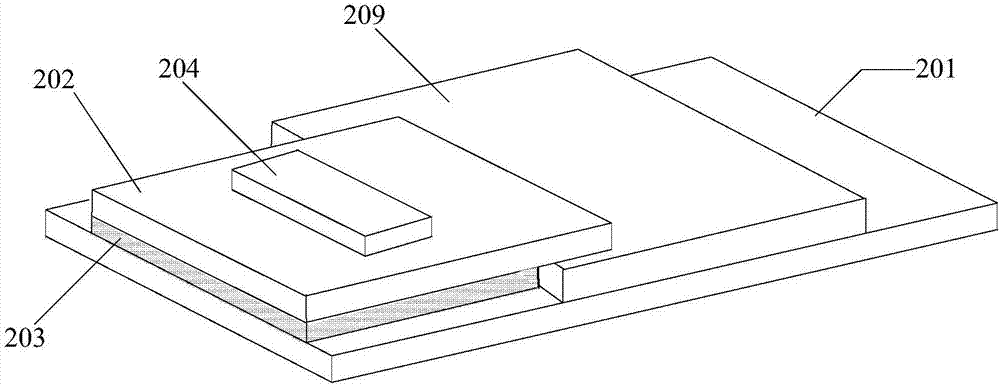

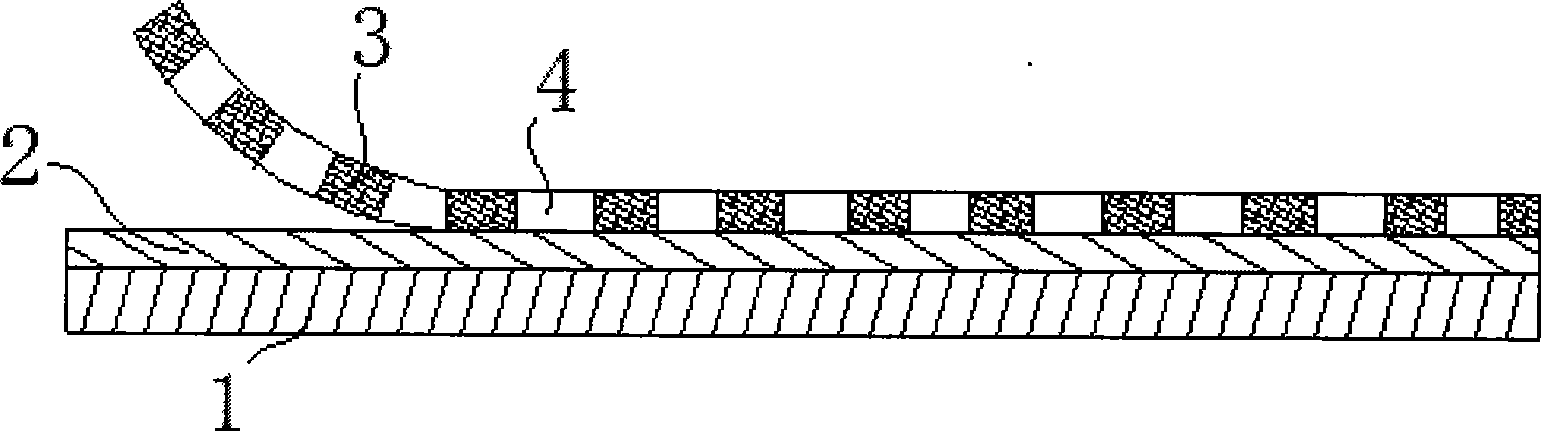

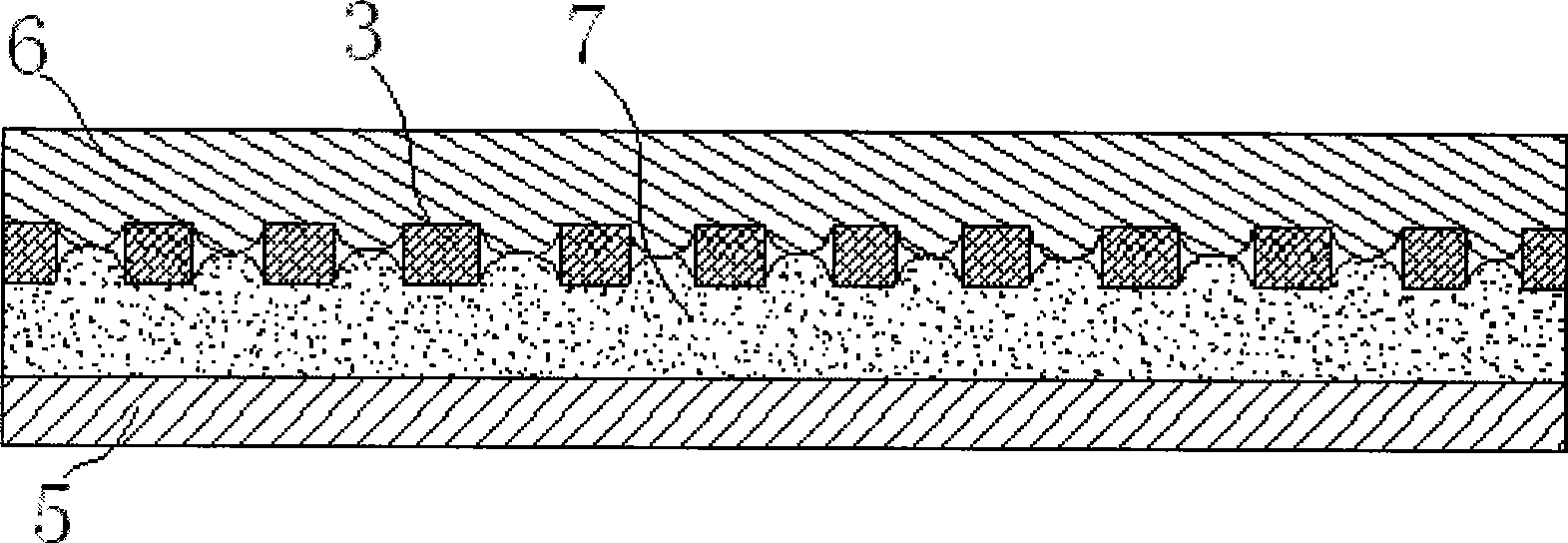

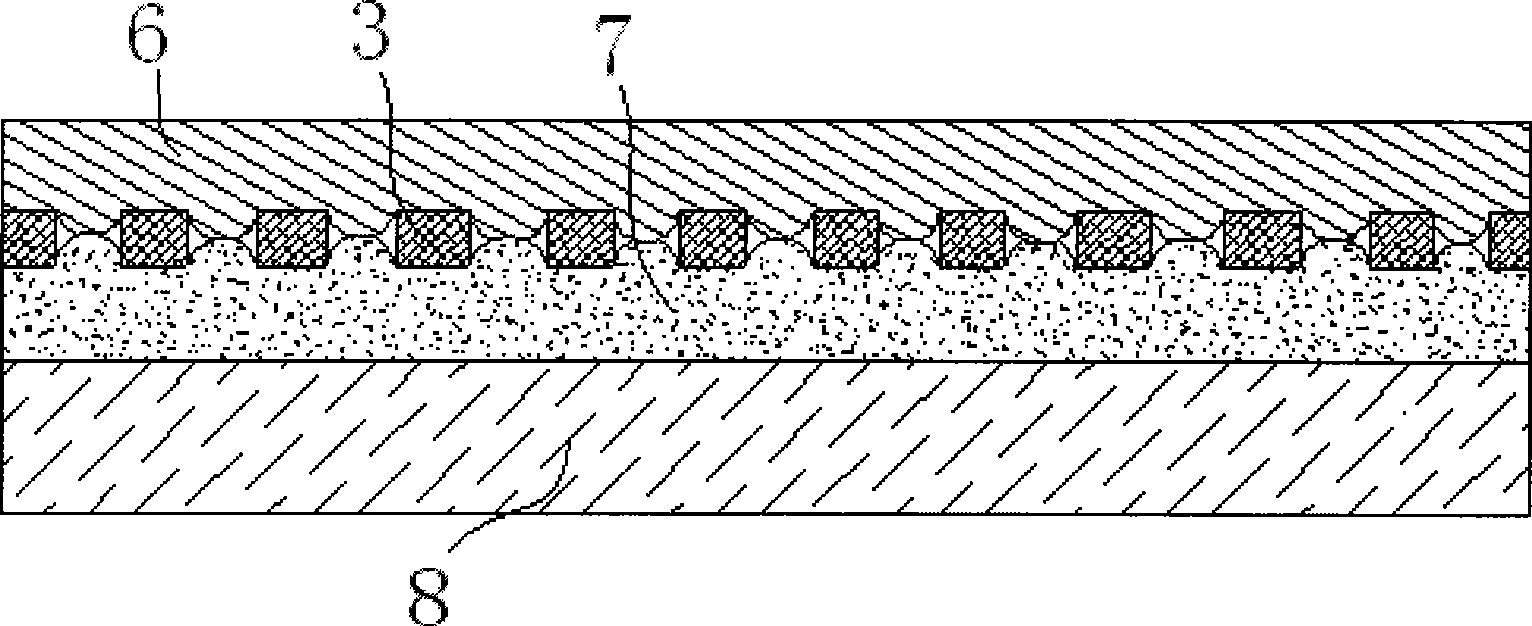

Rigid-flex wiring board and method for producing same

InactiveUS20070012475A1Signal transmission is stableImprove electrical performancePrinted circuit assemblingIncandescent ignitionAnisotropic conductive adhesiveElectrical connection

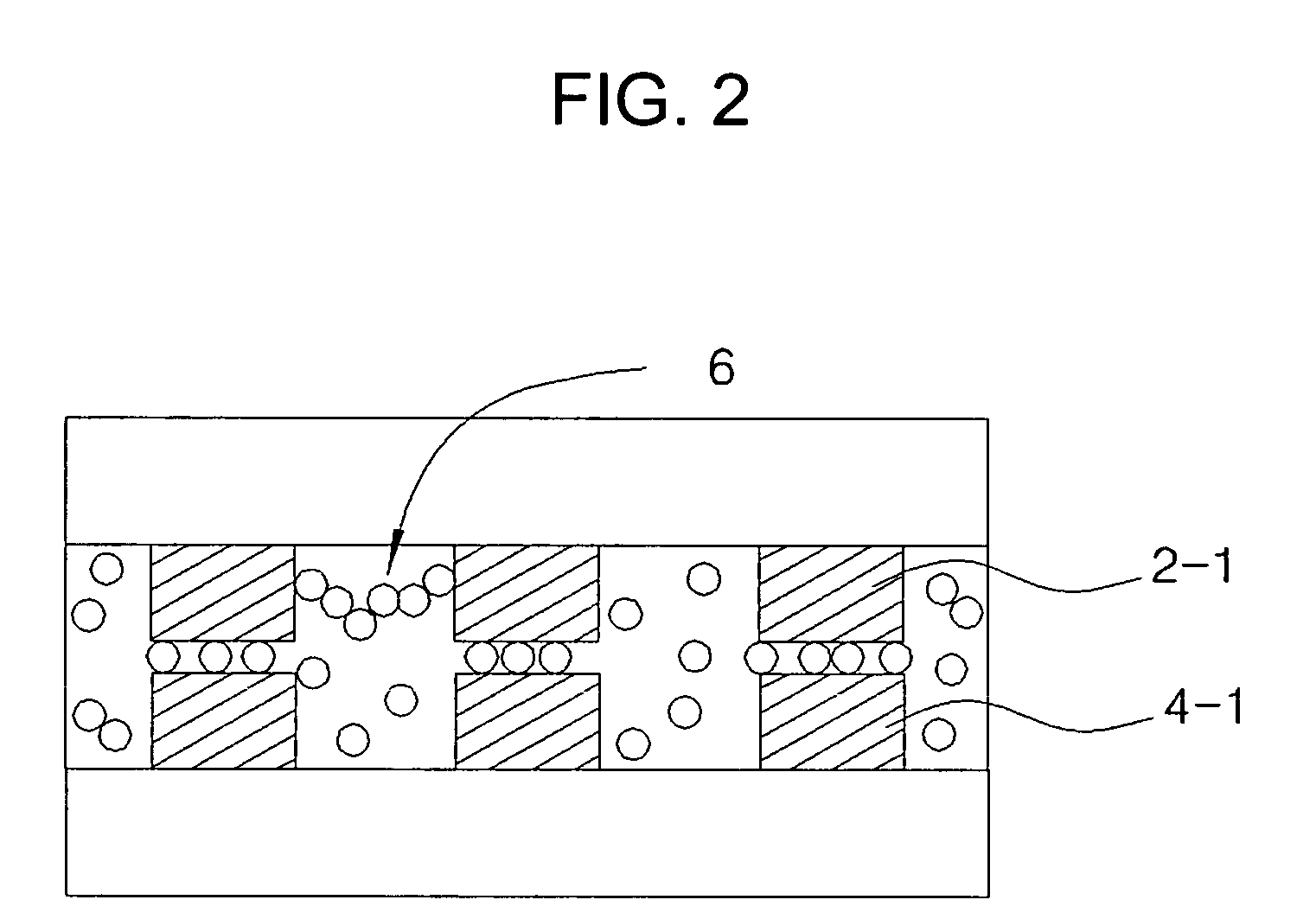

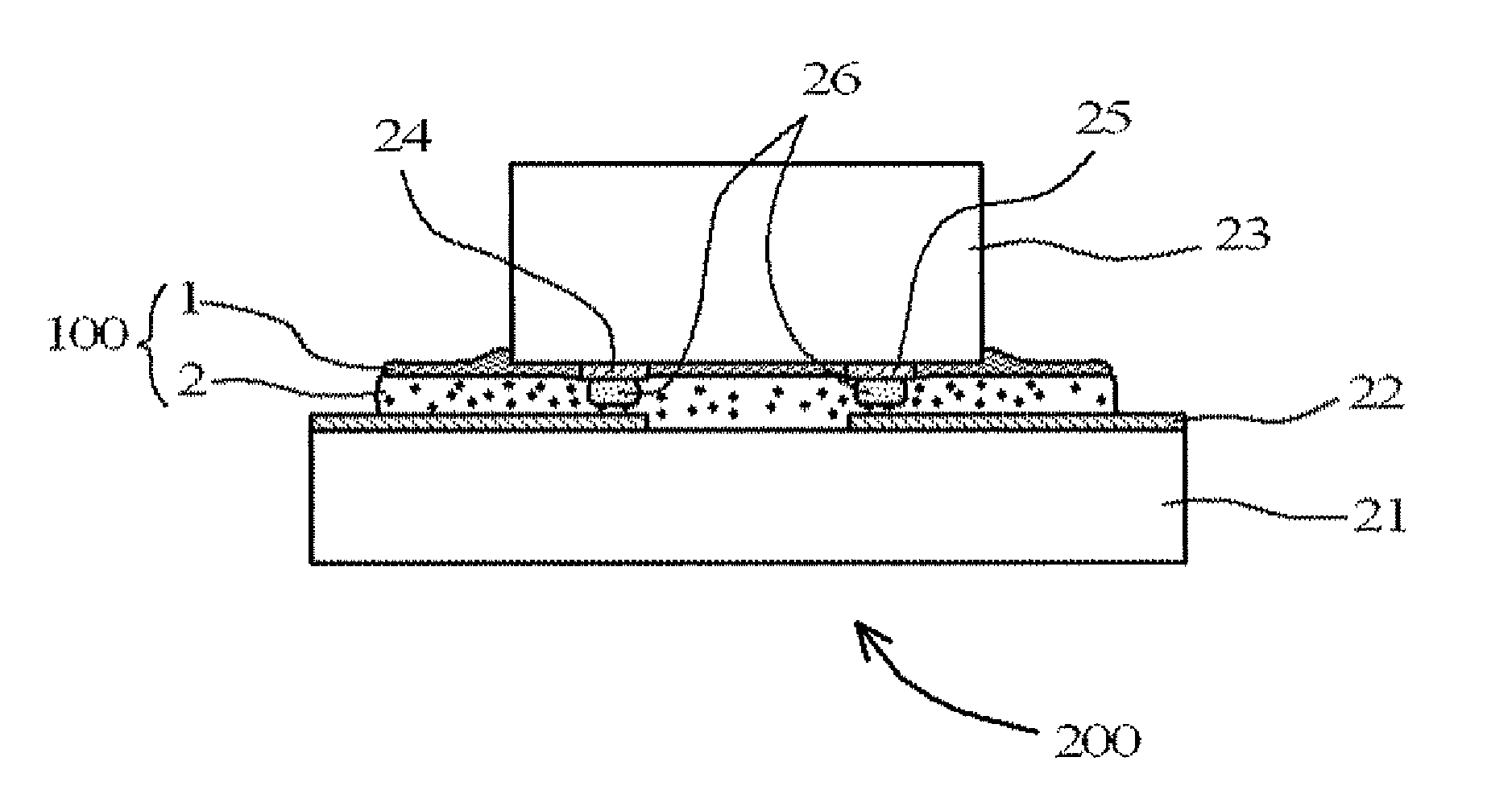

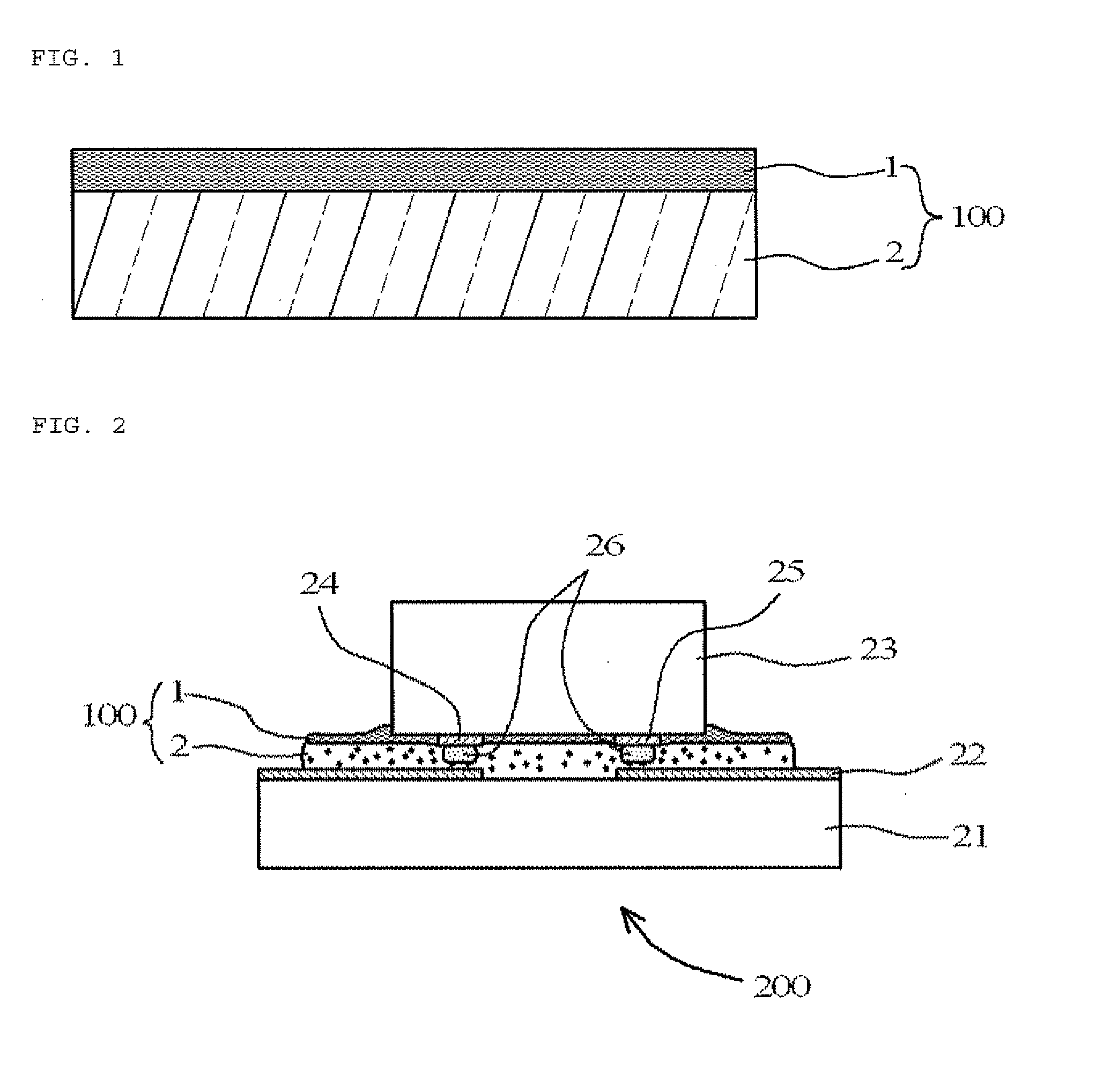

In a flex-rigid wiring board in which a rigid substrate formed from a rigid base material and a flexible substrate formed from a flexible base material are stack-joined and electrically connected to each other, the flexible substrate including a conductive layer having interconnecting electrode pads provided on at least one surface thereof, and the rigid substrate including a conductive layer having interconnecting electrode pads provided on at least one surface thereof in a position opposite to the interconnecting electrode pads on the rigid substrate, are locally connected electrically to each other with an anisotropic conductive adhesive layer interposed between conductive layers of substrate portions each including at least the interconnecting electrode pads. In this flex-rigid wiring board, transmission of high-frequency signals can be prevented from being delayed, noises can be suppressed, and an excellent electrical connection and connection reliability be assured.

Owner:IBIDEN CO LTD

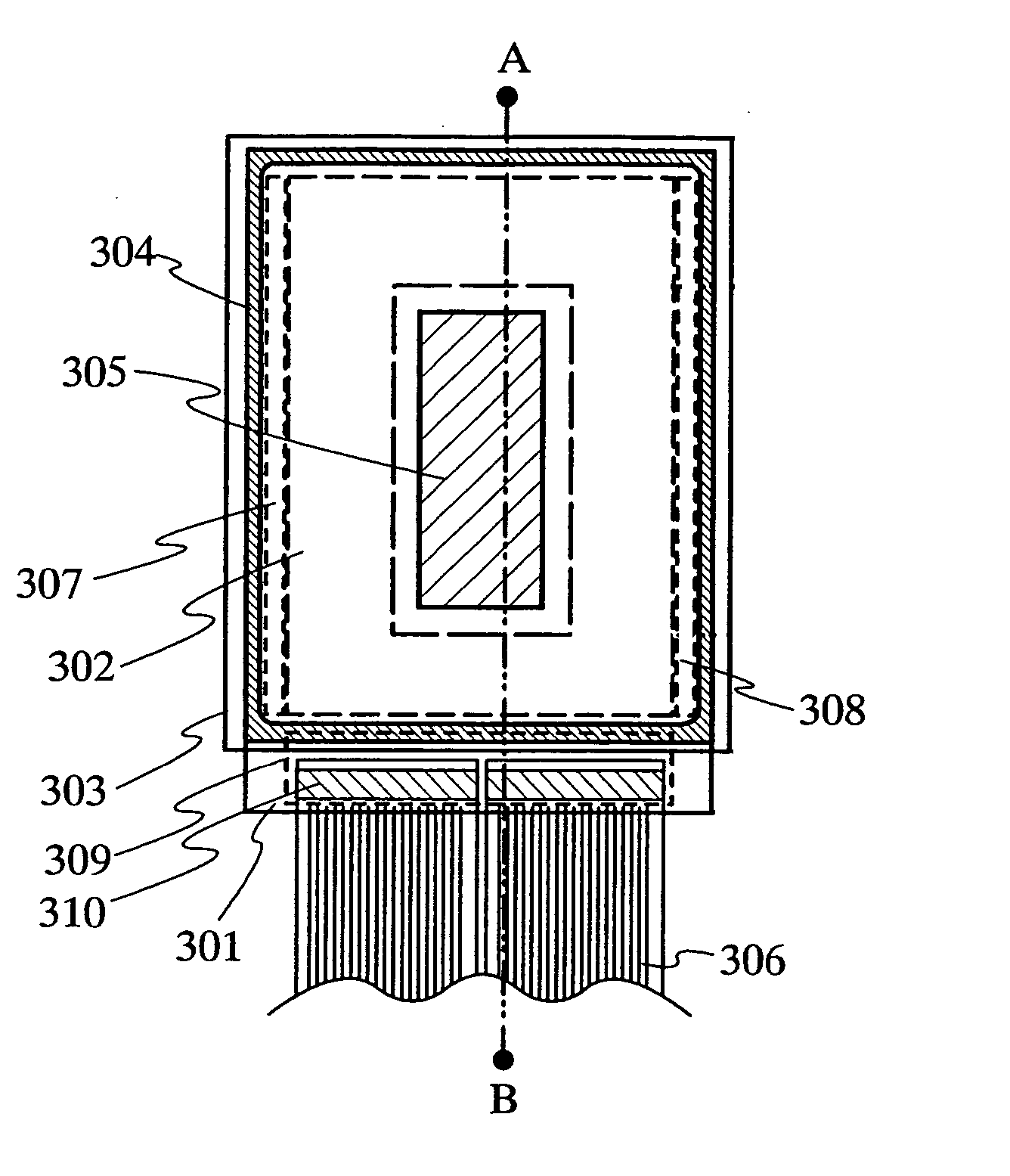

Wireless chip and electronic appliance having the same

InactiveUS20060202269A1High mechanical strengthDifficult can be blockedAntenna supports/mountingsSemiconductor/solid-state device detailsGround contactAnisotropic conductive adhesive

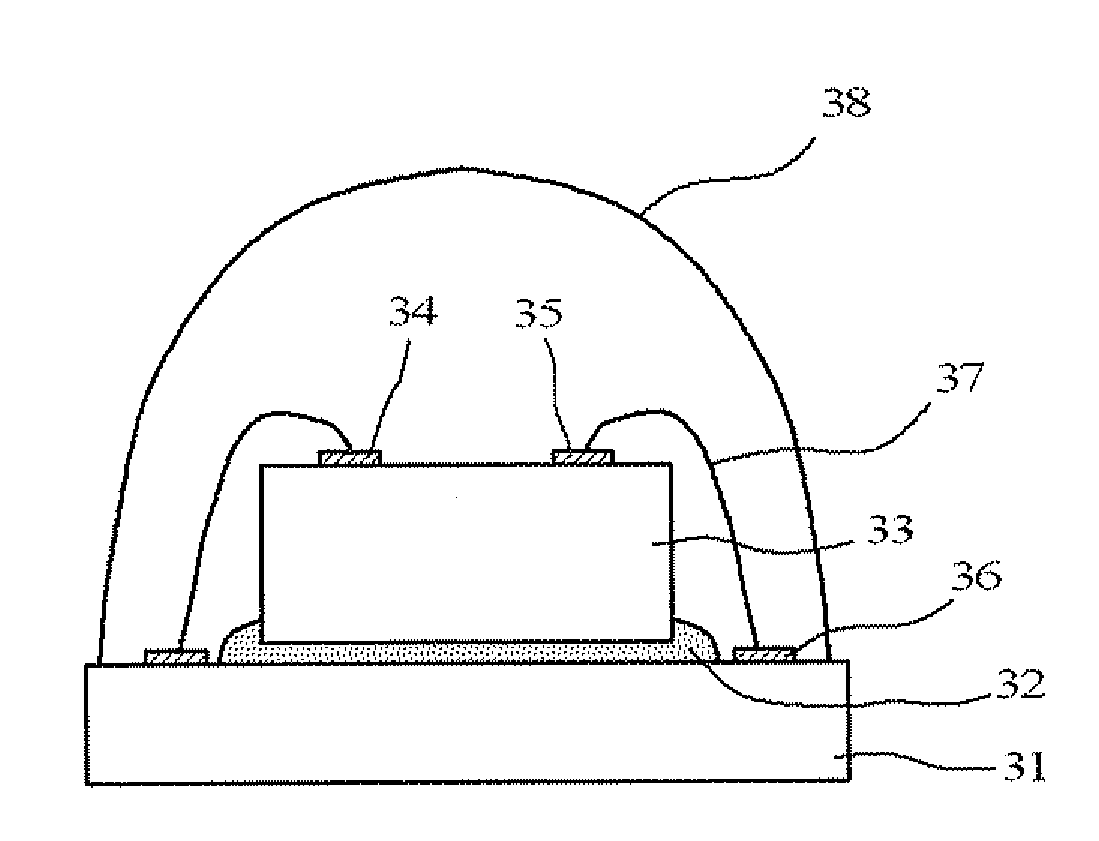

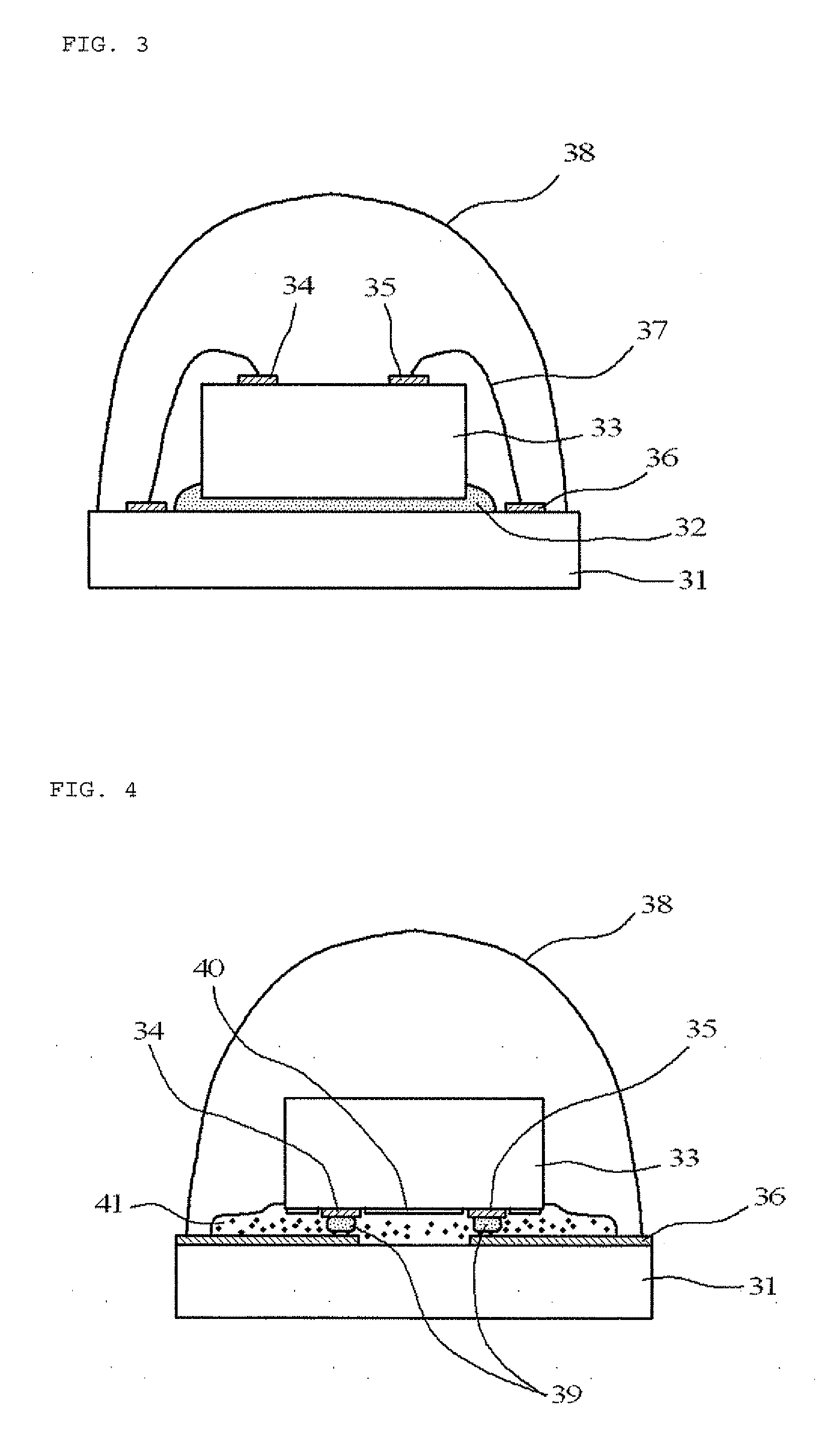

The present invention provides a wireless chip having high mechanical strength. Moreover, the present invention also provides a wireless chip which can prevent an electric wave from being blocked. In a wireless chip of the present invention, a layer having a thin film transistor formed over an insulating substrate is fixed to an antenna by an anisotropic conductive adhesive, and the thin film transistor is connected to the antenna. The antenna has a dielectric layer, a first conductive layer, and a second conductive layer; the first conductive layer and the second conductive layer has the dielectric layer therebetween; the first conductive layer serves as a radiating electrode; and the second electrode serves as a ground contact body.

Owner:SEMICON ENERGY LAB CO LTD

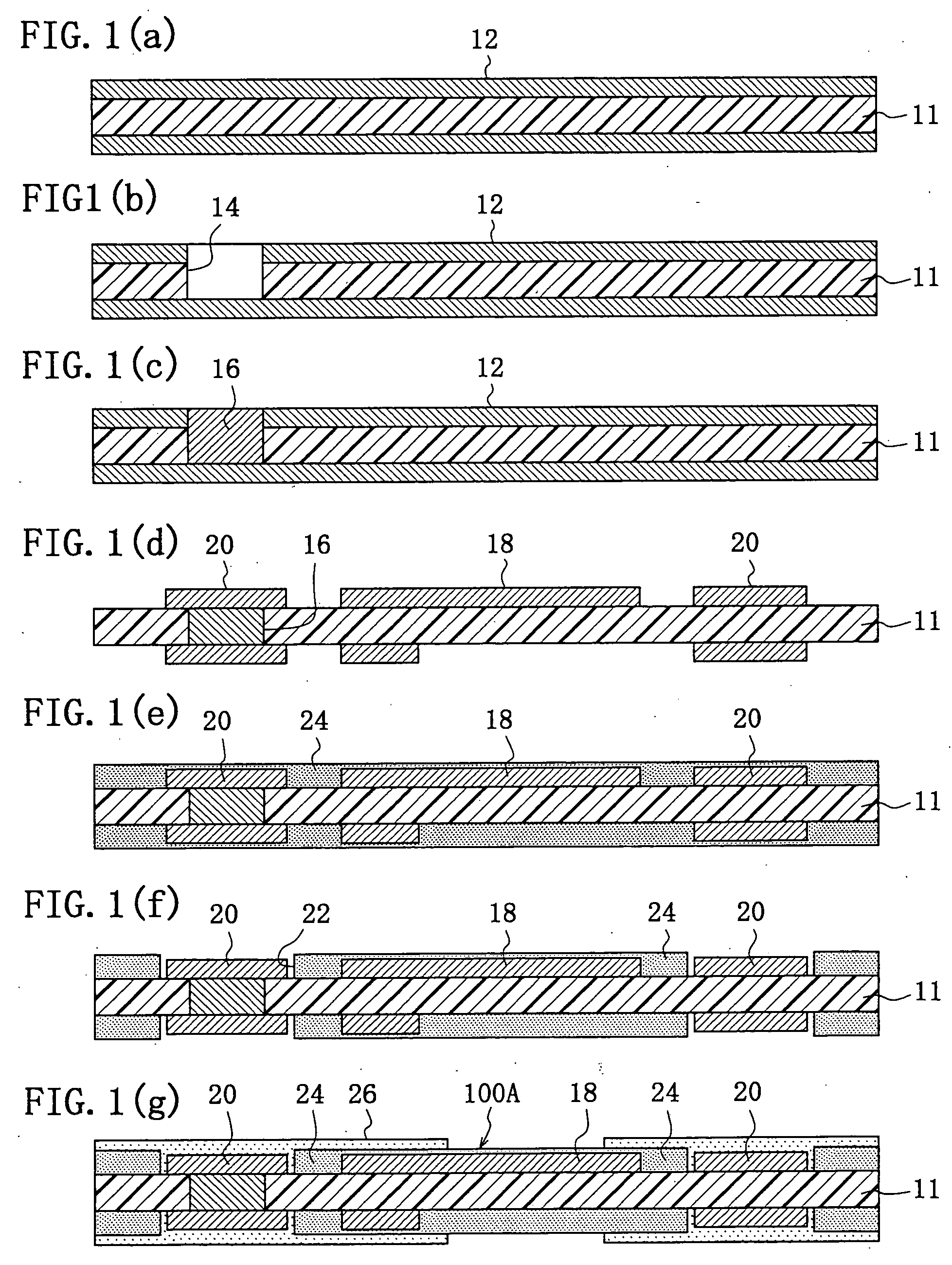

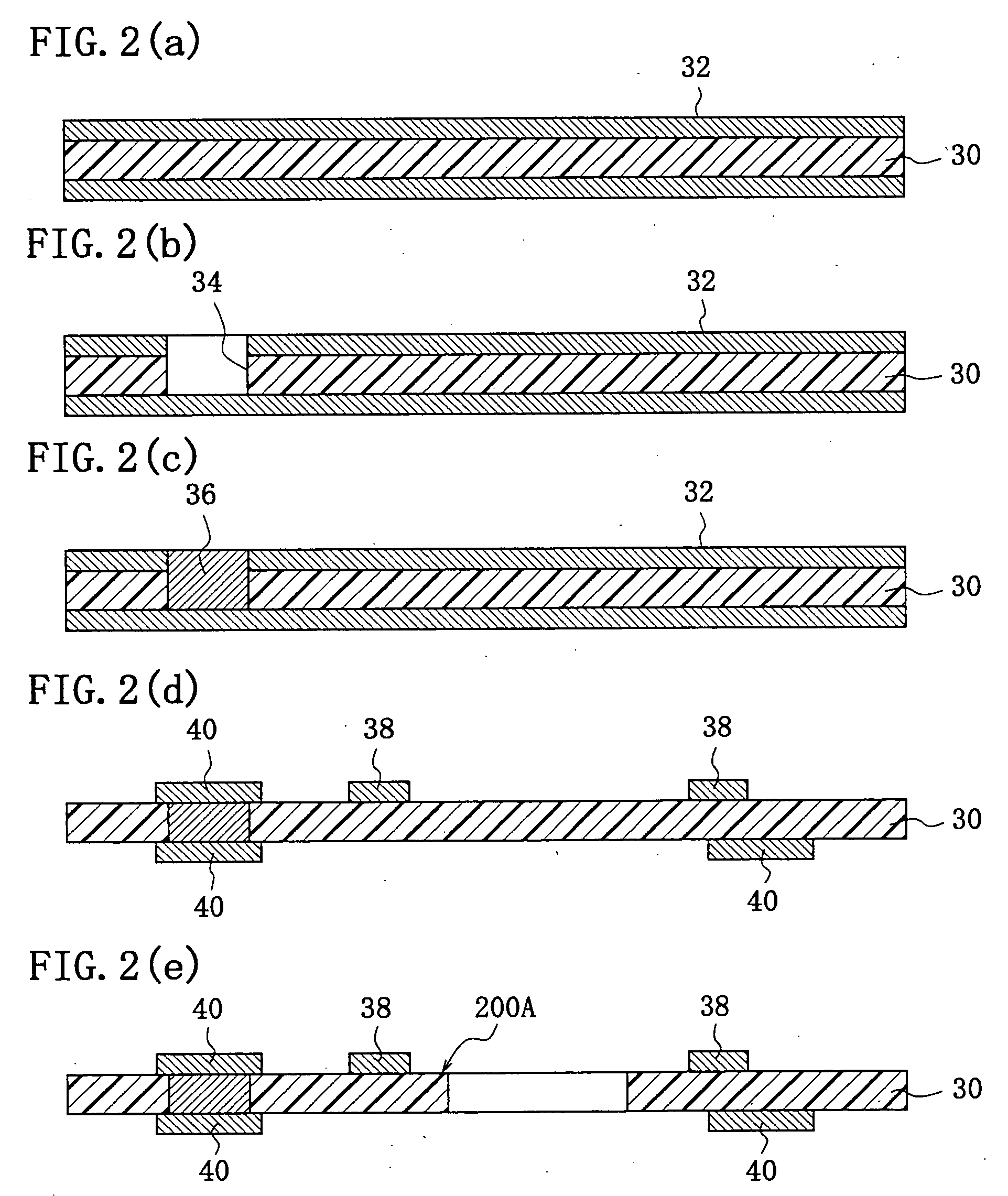

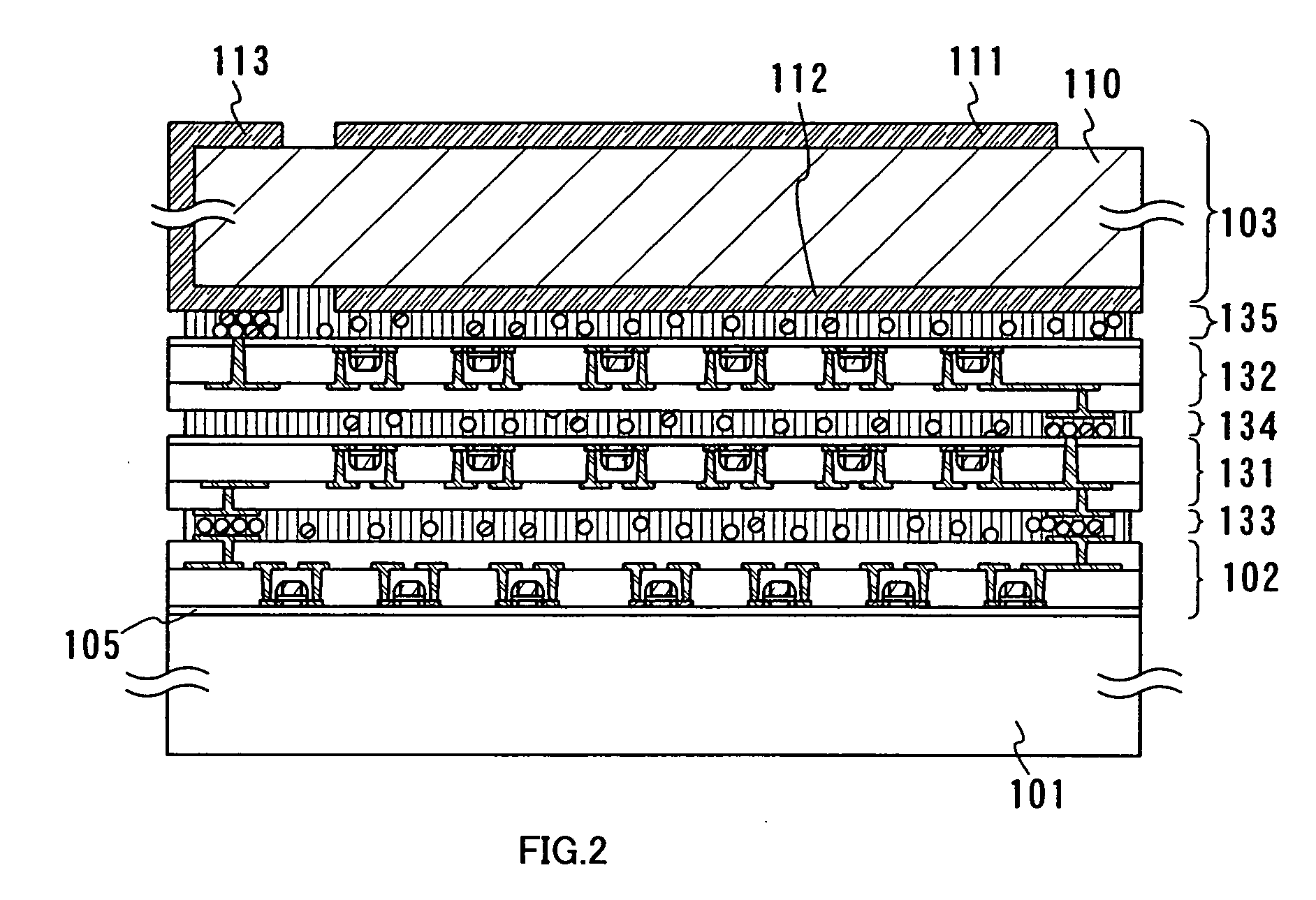

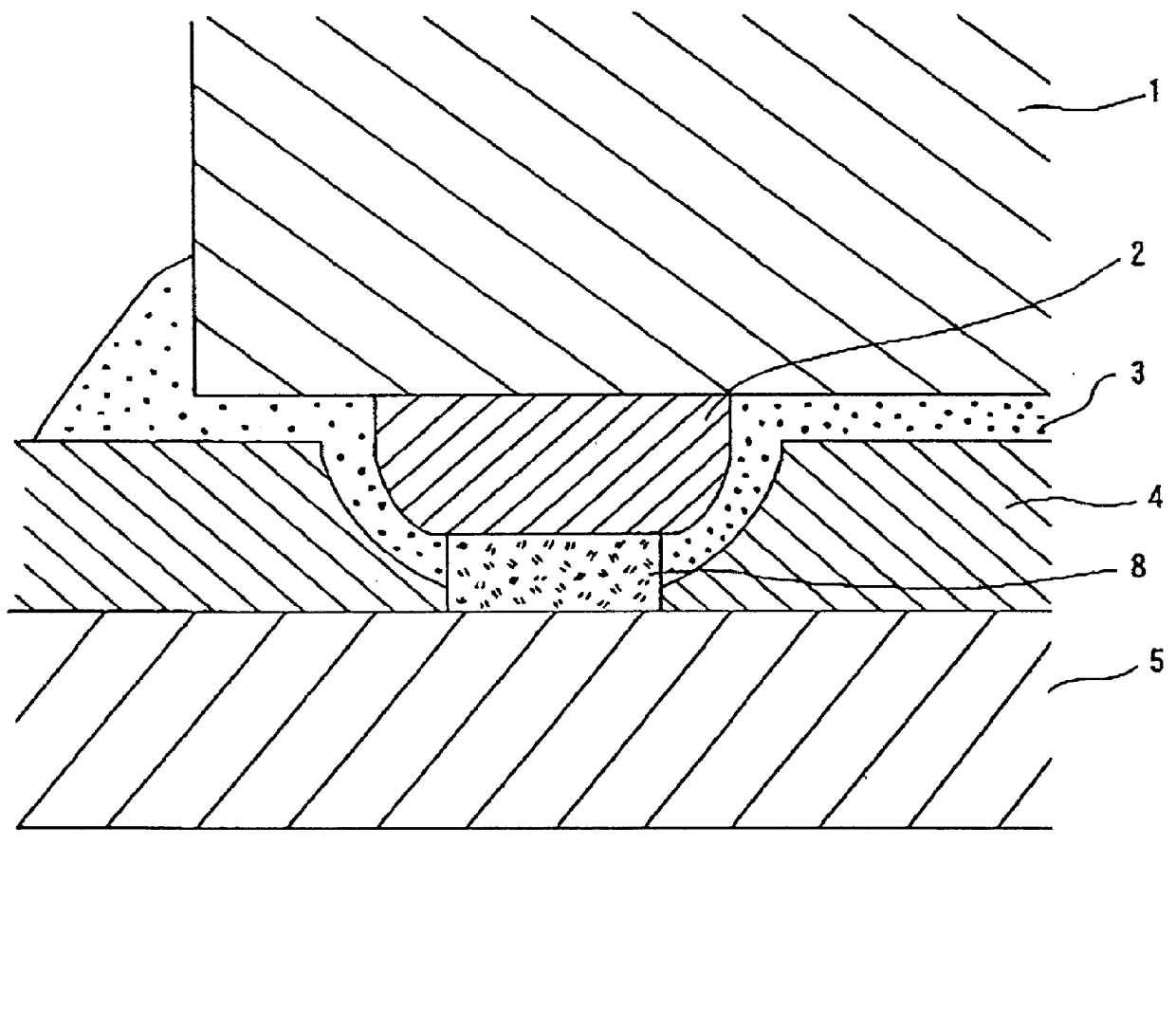

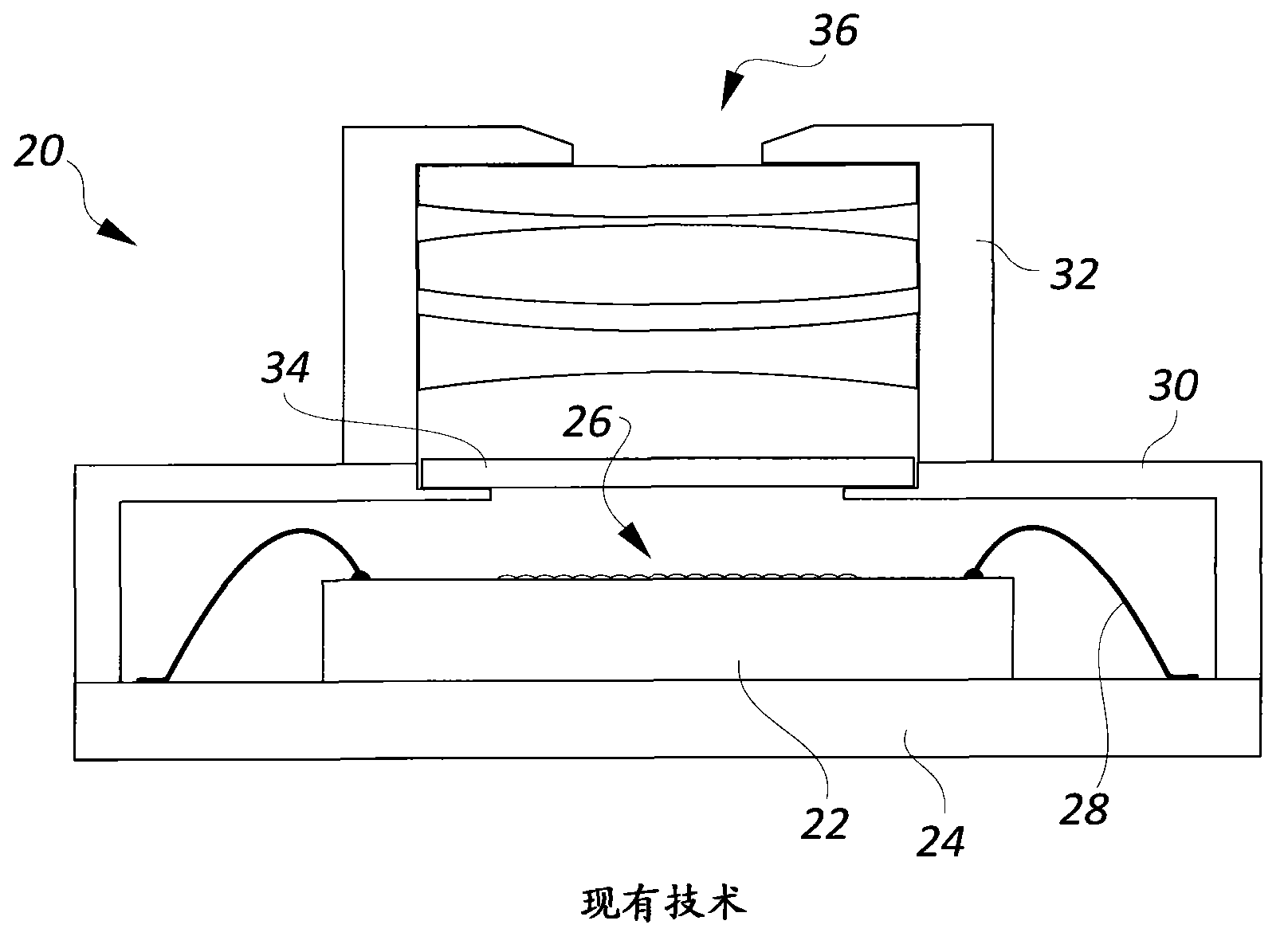

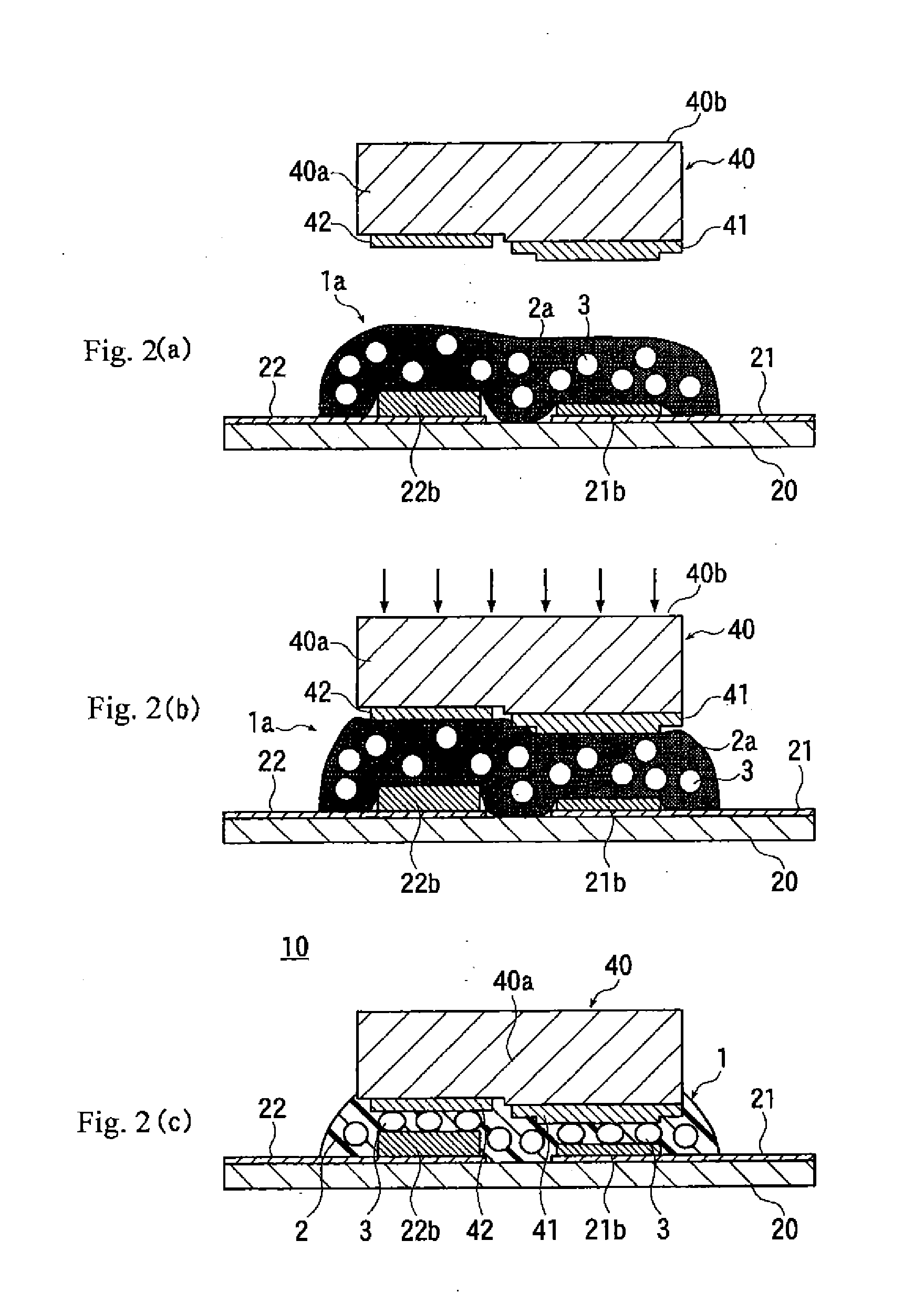

Flip chip mounting method and semiconductor apparatus manufactured by the method

InactiveUS6137183ASemiconductor/solid-state device detailsSolid-state devicesAnisotropic conductive adhesiveEngineering

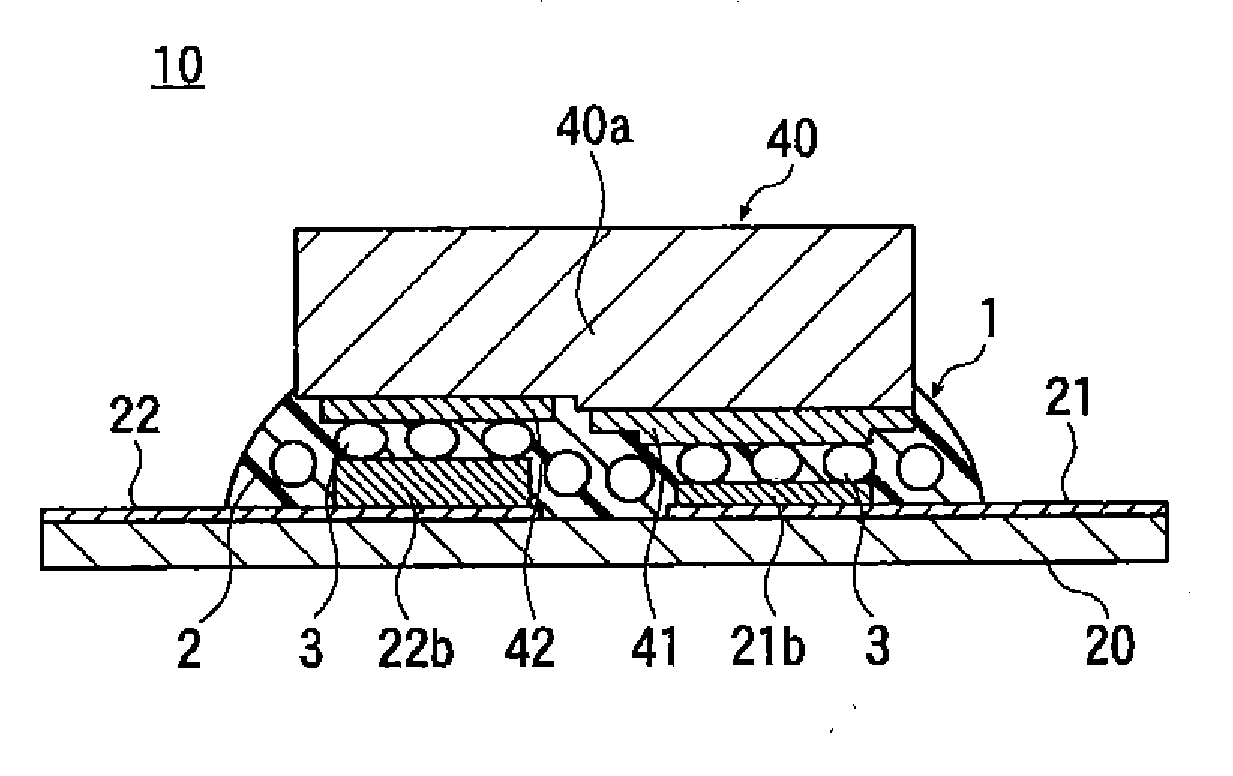

An improved flip chip mounting method is provided for mounting an IC chip on a substrate. The IC chip has one surface and electrodes formed on the one surface, and the IC chip is positioned so that the electrodes oppose the substrate. The IC chip and the substrate are heat bonded to one another with a sheet of anisotropic conductive adhesive and paste-like adhesive being placed between the IC chip and the substrate.

Owner:SEIKO EPSON CORP

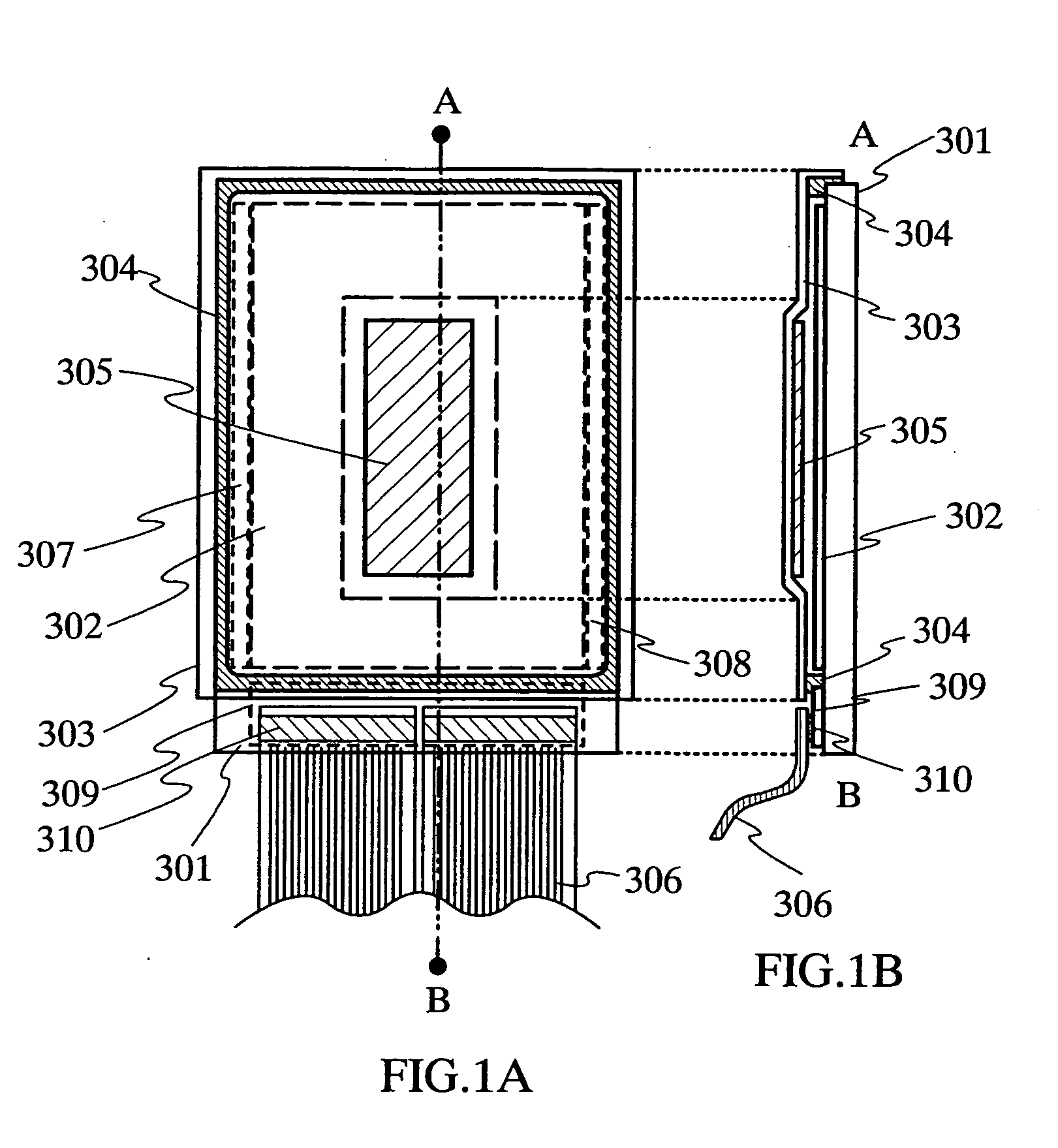

Semiconductor Device and Electronic Device Having the Same

InactiveUS20080169349A1High mechanical strengthDifficult can be blockedSemiconductor/solid-state device detailsSolid-state devicesGround contactAnisotropic conductive adhesive

It is an object of the present invention to provide a wireless chip of which mechanical strength can be increased. Moreover, it is an object of the present invention to provide a wireless chip which can prevent an electric wave from being blocked. The invention is a wireless chip in which a layer having a thin film transistor is fixed to an antenna by an anisotropic conductive adhesive or a conductive layer, and the thin film transistor is connected to the antenna. The antenna has a dielectric layer, a first conductive layer, and a second conductive layer. The dielectric layer is sandwiched between the first conductive layer and the second conductive layer. The first conductive layer serves as a radiating electrode and the second conductive layer serves as a ground contact body.

Owner:SEMICON ENERGY LAB CO LTD

Wafer level optical sensor package and low profile camera module, and method of manufacture

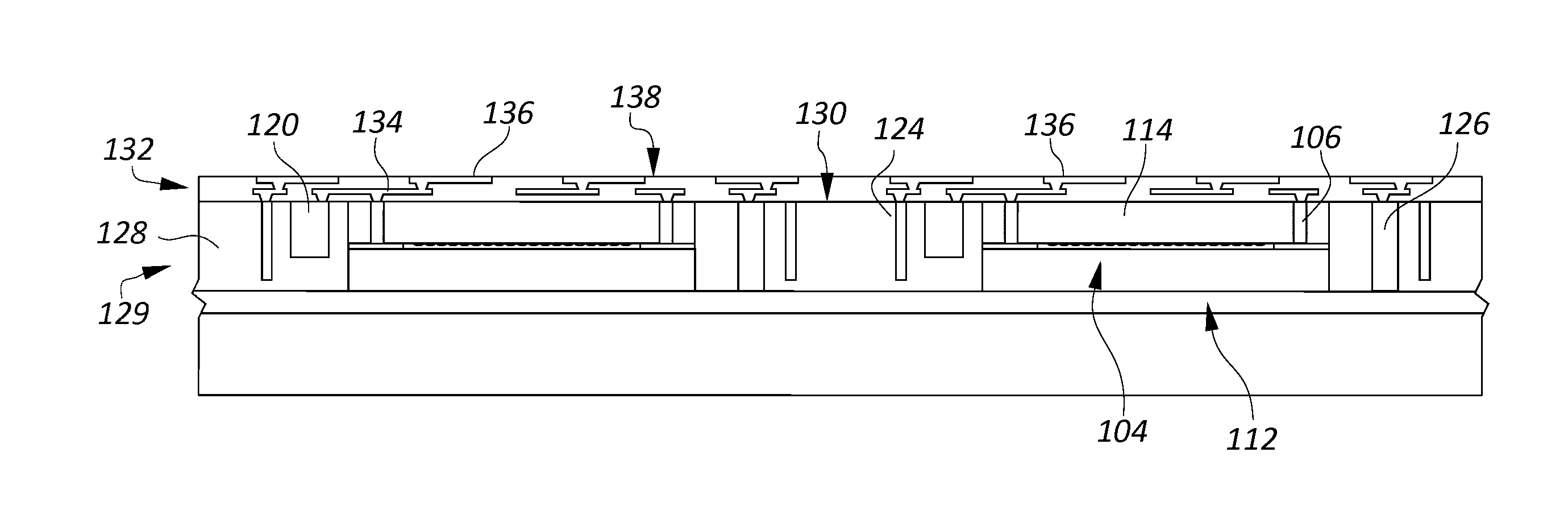

The invention provides a wafer lever optical sensor package and low profile camera module and a method of manufacture. The wafer-level camera sensor package includes a semiconductor substrate with an optical sensor on a front surface. Through-silicon-vias (TSV) extend through the substrate and provide I / O contact with the sensor from the back side of the substrate. A glass cover is positioned over the front surface, and the cover and substrate are embedded in a molding compound layer (MCL), the front surface of the MCL lying coplanar with the front of the cover, and the back surface lying coplanar with the back of the substrate. Surface-mount devices, electromagnetic shielding, and through-wafer-connectors can be embedded in the MCL. A redistribution layer on the back surface of the MCL includes bottom contact pads for mounting the package, and conductive traces interconnecting the contact pads, TSVs, surface-mount devices, shielding, and through-wafer-connectors. Anisotropic conductive adhesive is positioned on the front of the MCL for physically and electrically attaching a lens array.

Owner:STMICROELECTRONICS SRL

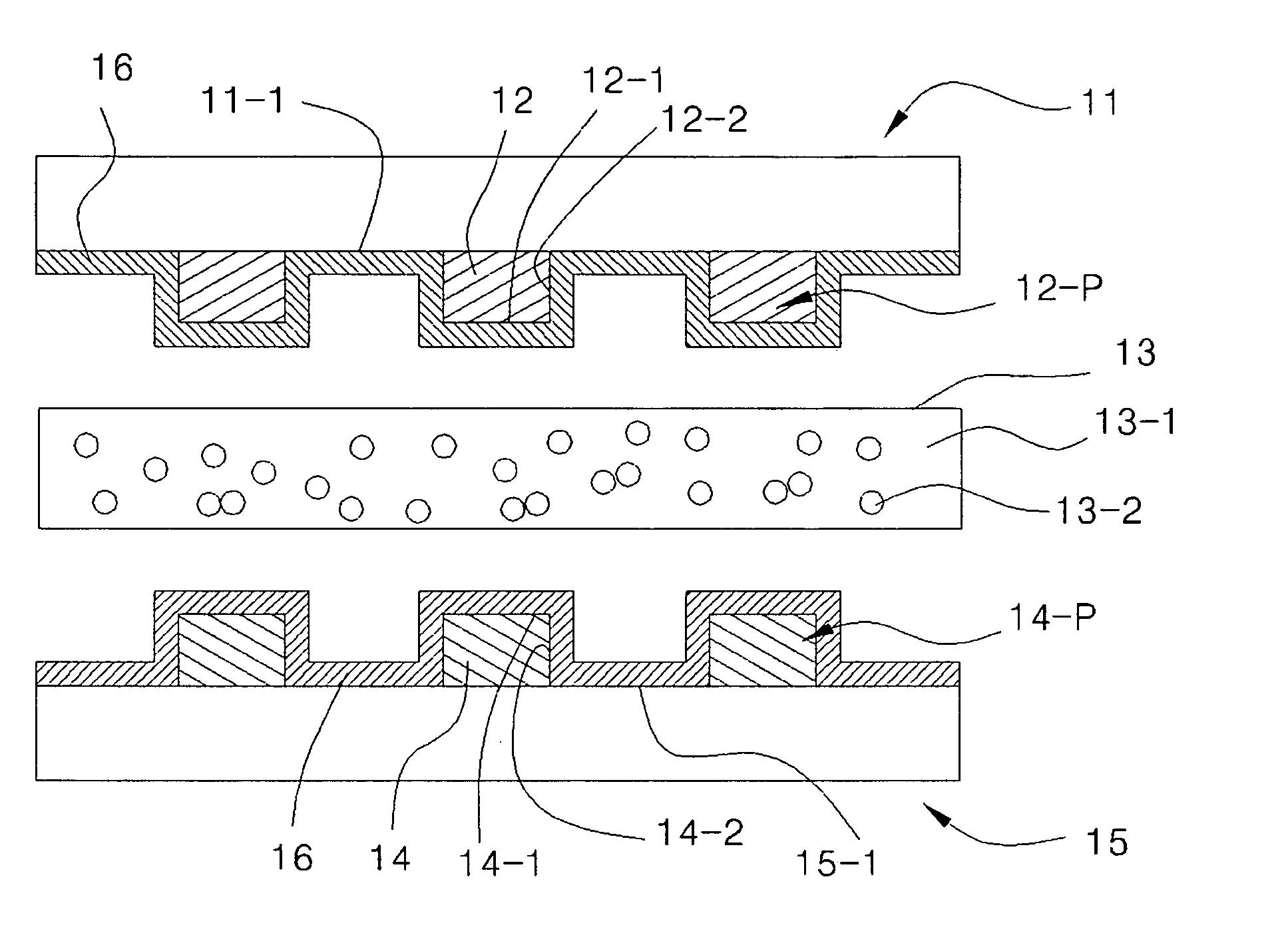

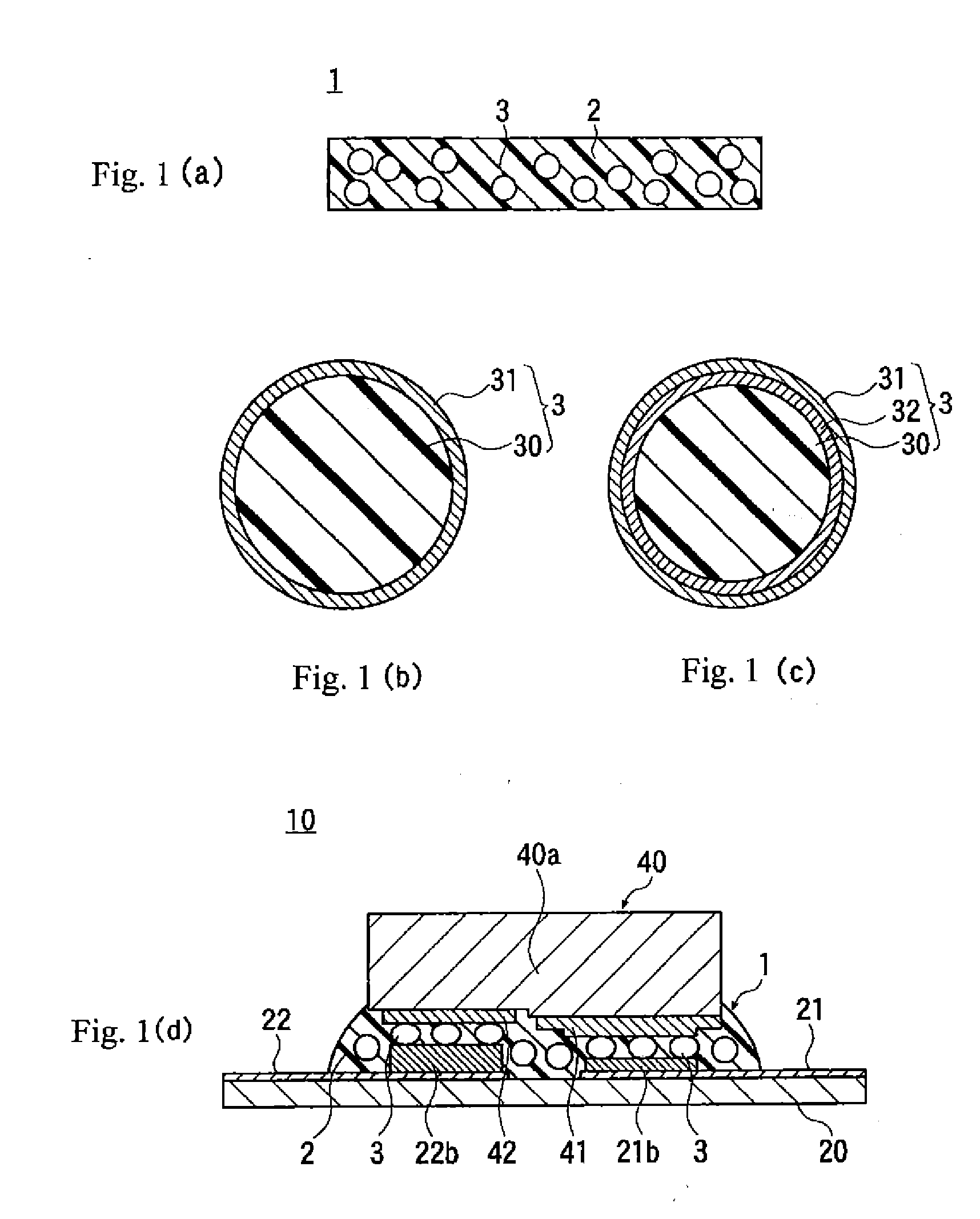

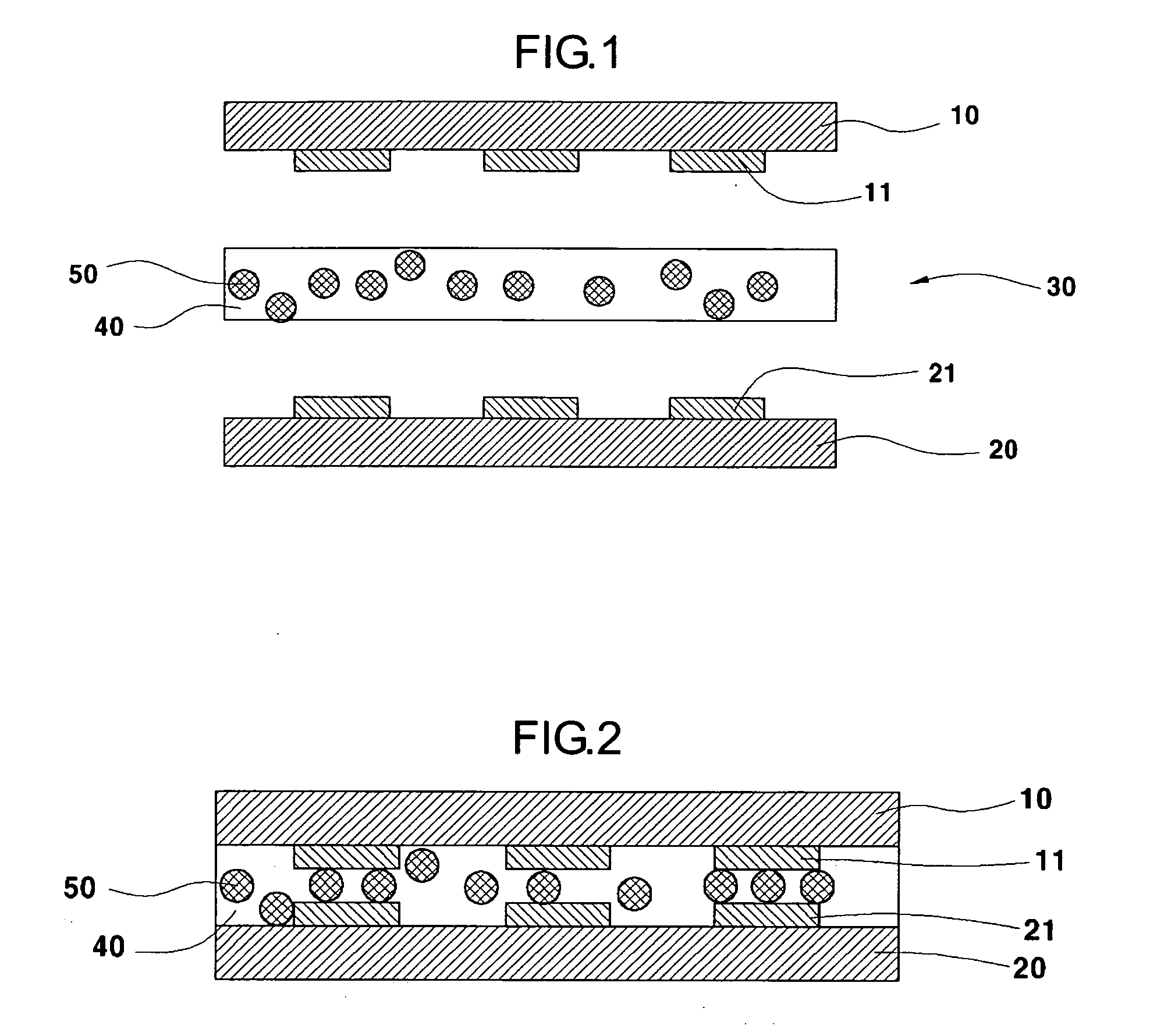

Conductive particles and method and device for manufacturing the same, anisotropic conductive adhesive and conductive connection structure, and electronic circuit components and method of manufacturing the same

InactiveUS6906427B2Efficient executionInhibit aggregationElectrolysis componentsSemiconductor/solid-state device detailsAnisotropic conductive adhesiveElectrical connection

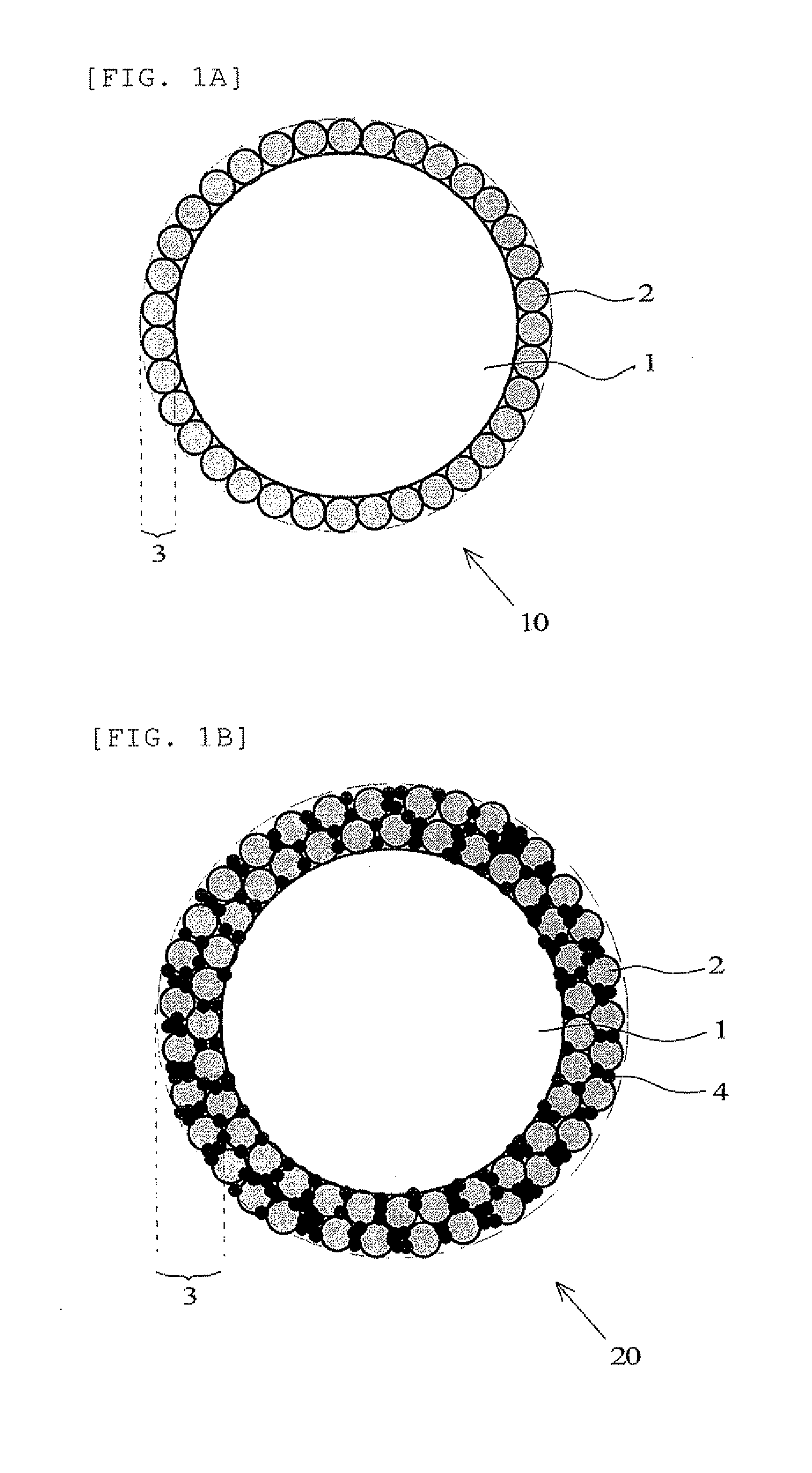

An electrical connection is formed by using a double laminated conductive fine particle provided with a conductive metal layer on the surface of a spherical elastic base particle by electroless plating and electroplating and a layer of a low-melting-point metal on the surface of the conductive metal layer and wherein the conductive metal layer comprises a plurality of metal layers.

Owner:SEKISUI CHEM CO LTD

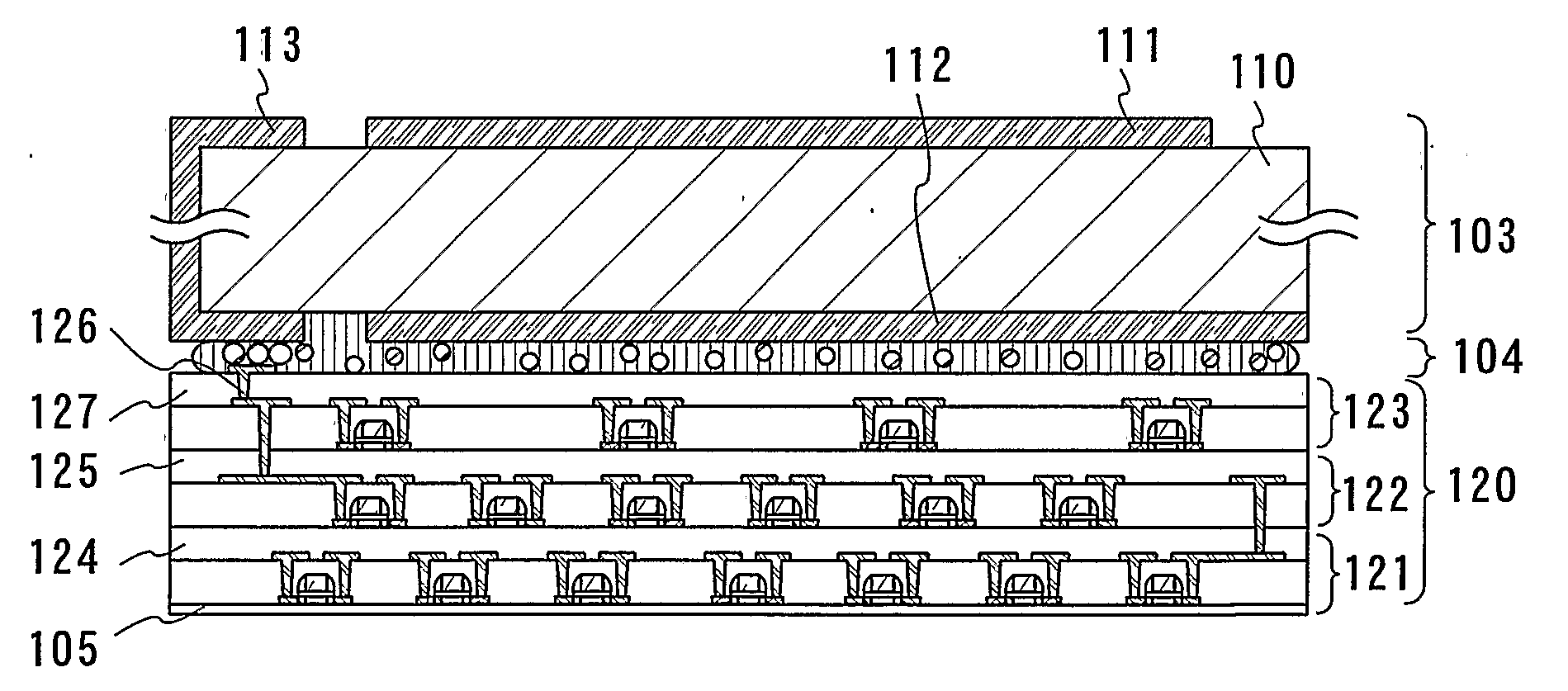

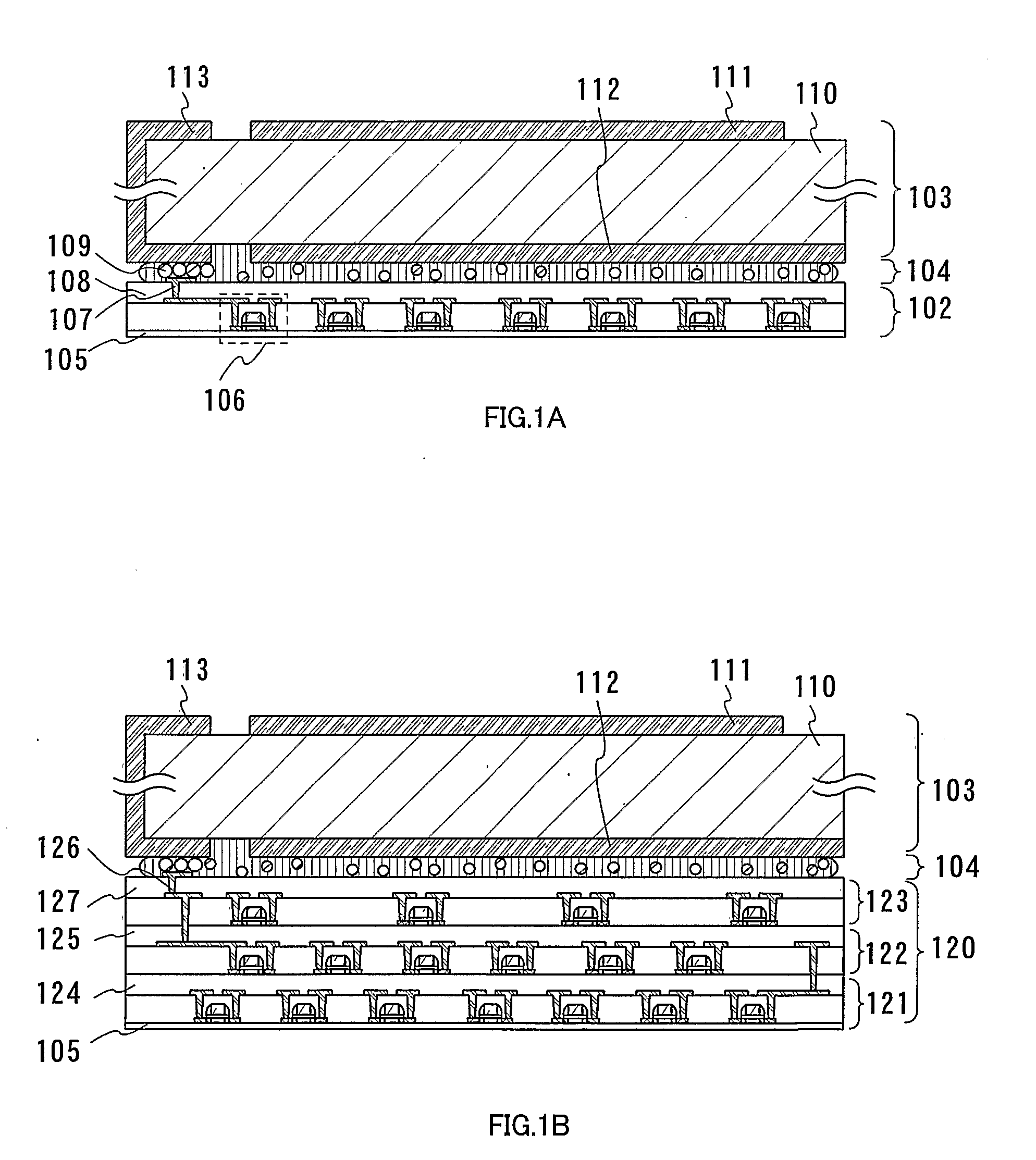

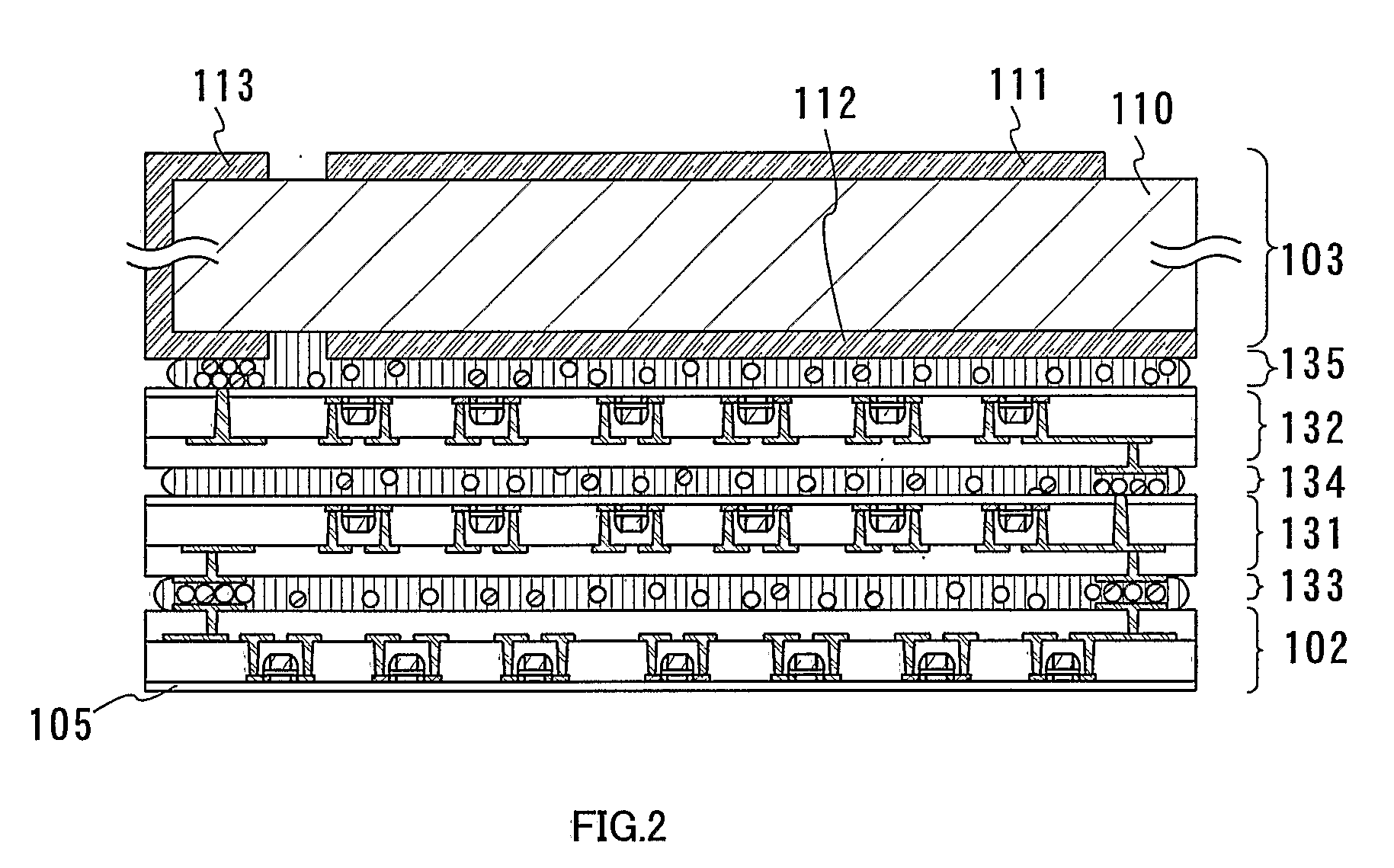

Light emitting device, manufacturing method thereof, and electronic apparatus

ActiveUS20050231107A1Improve reliabilitySimple structureDischarge tube luminescnet screensStatic indicating devicesDriver circuitProduction rate

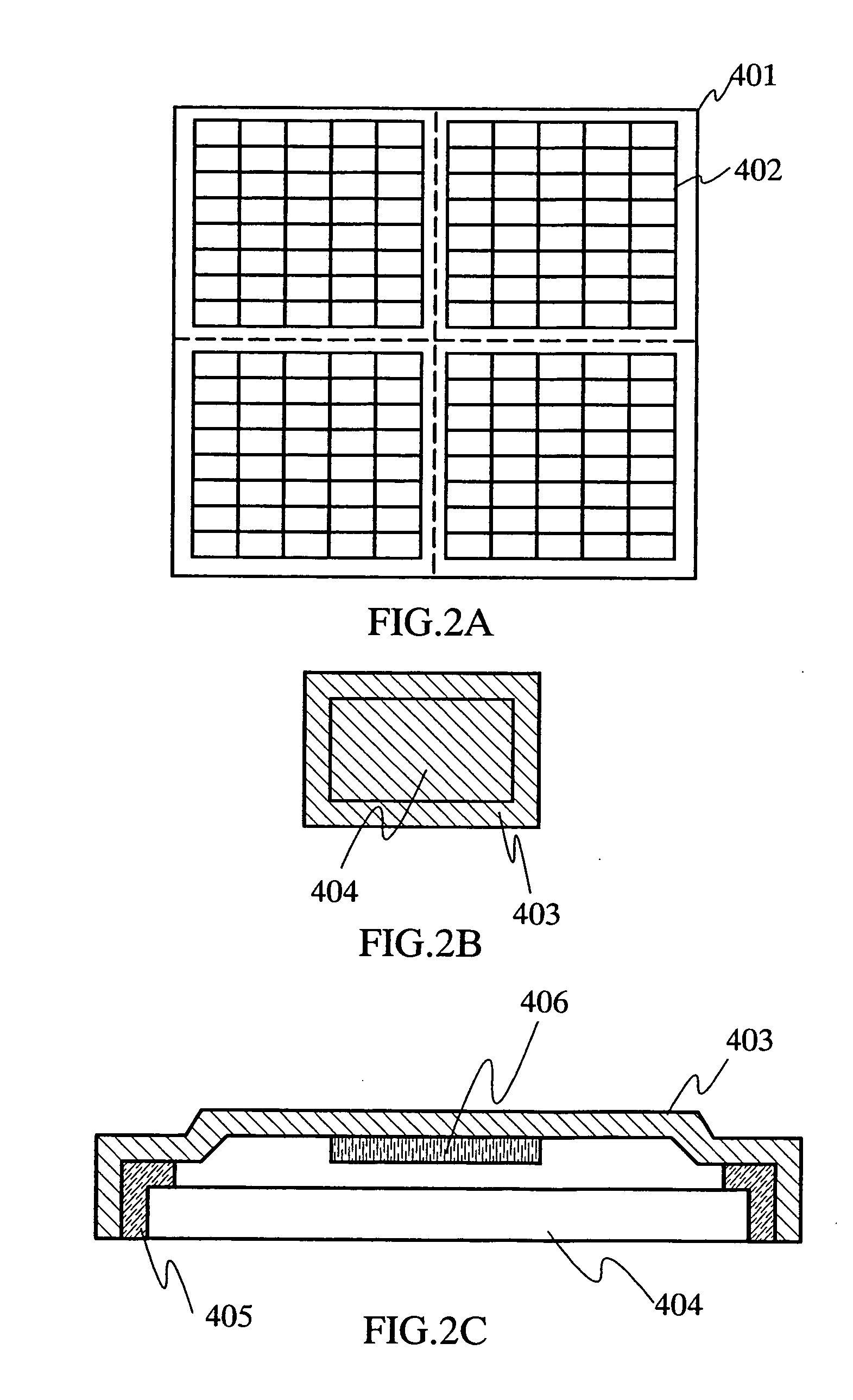

Further reduction in frame portion is achieved in the case where a driver circuit and a pixel portion are formed on a common substrate. Also, a light emitting device is provided with an advantageous structure for obtaining a large number of panels by use of a large substrate, whereby the number of panels taken out from a substrate can be increased, leading to better productivity. According to the invention, a terminal electrode is provided in the position overlapping a peripheral circuit portion, and the terminal electrode is connected to an FPC with an anisotropic conductive adhesive material. In addition, a covering material is firmly fixed by using a sealant that is in contact with the edge and periphery of a substrate.

Owner:SEMICON ENERGY LAB CO LTD

Wafer level optical sensor package and low profile camera module, and method of manufacture

ActiveUS20130320471A1Less spaceEliminates possible sourceSolid-state devicesSemiconductor/solid-state device manufacturingRedistribution layerContact pad

A wafer-level camera sensor package includes a semiconductor substrate with an optical sensor on a front surface. Through-silicon-vias (TSV) extend through the substrate and provide I / O contact with the sensor from the back side of the substrate. A glass cover is positioned over the front surface, and the cover and substrate are embedded in a molding compound layer (MCL), the front surface of the MCL lying coplanar with the front of the cover, and the back surface lying coplanar with the back of the substrate. Surface-mount devices, electromagnetic shielding, and through-wafer-connectors can be embedded in the MCL. A redistribution layer on the back surface of the MCL includes bottom contact pads for mounting the package, and conductive traces interconnecting the contact pads, TSVs, surface-mount devices, shielding, and through-wafer-connectors. Anisotropic conductive adhesive is positioned on the front of the MCL for physically and electrically attaching a lens array.

Owner:STMICROELECTRONICS PTE LTD

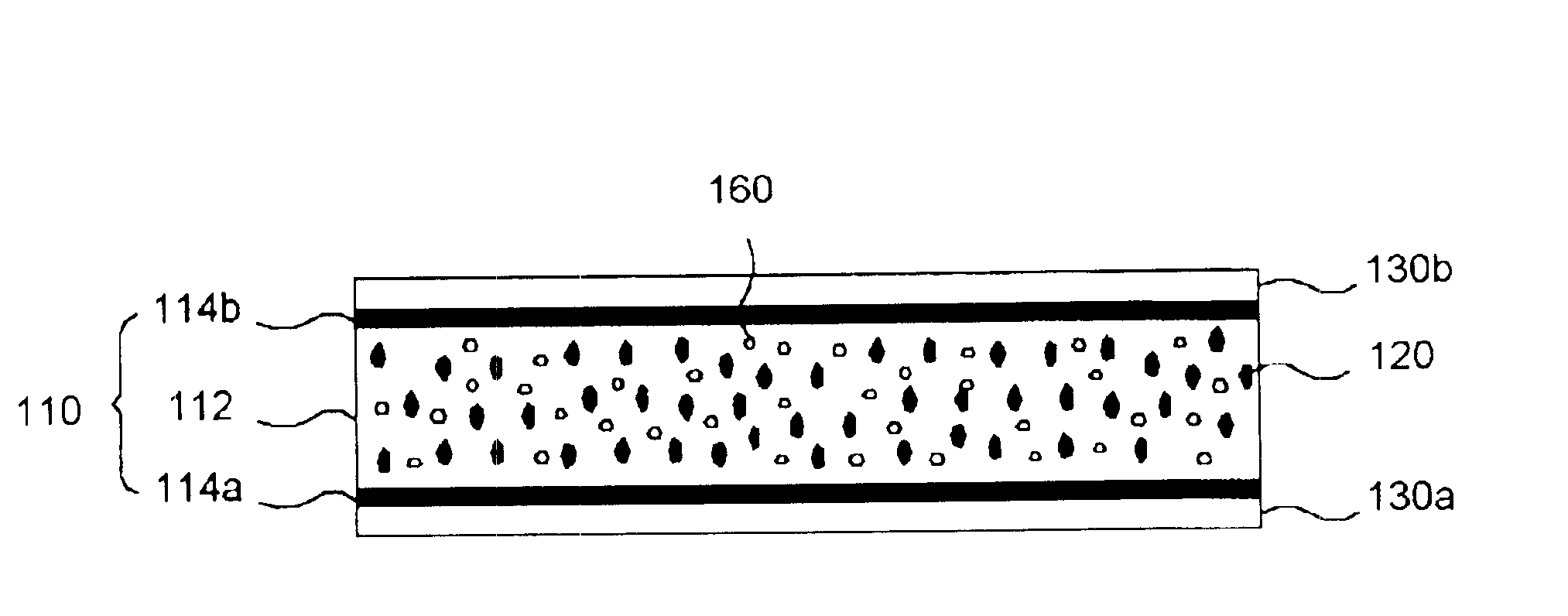

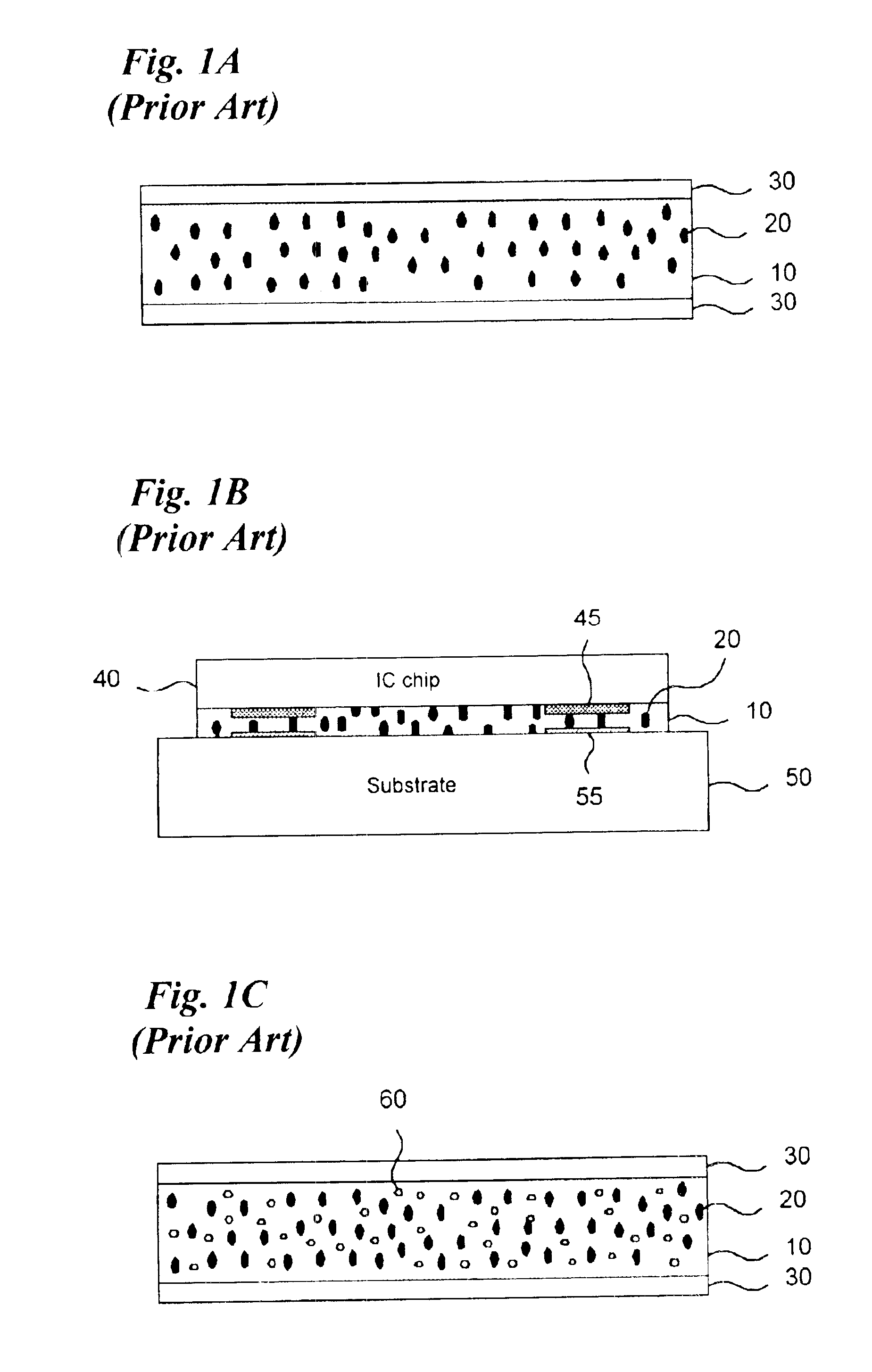

High adhesion triple layered anisotropic conductive adhesive film

InactiveUS6878435B2High bonding strengthImprove adhesionNon-insulated conductorsSolid-state devicesEpoxyAnisotropic conductive film

Disclosed is a triple layered ACA film adapted for enhancing the adhesion strength of a typical single layer Anisotropic Conductive Film or for enhancing the adhesion strength of the ACA film in flip chip bonding. The triple layered ACA film of the invention comprises: a main ACA film based upon epoxy resin and containing conductive particles having a particle size of 3 to 10 μm and optionally non-conductive particles having a particle size of 0.1 to 1 μm; and adhesion reinforcing layers based upon epoxy resin and formed at both sides of the main ACA film.

Owner:KOREA ADVANCED INST OF SCI & TECH

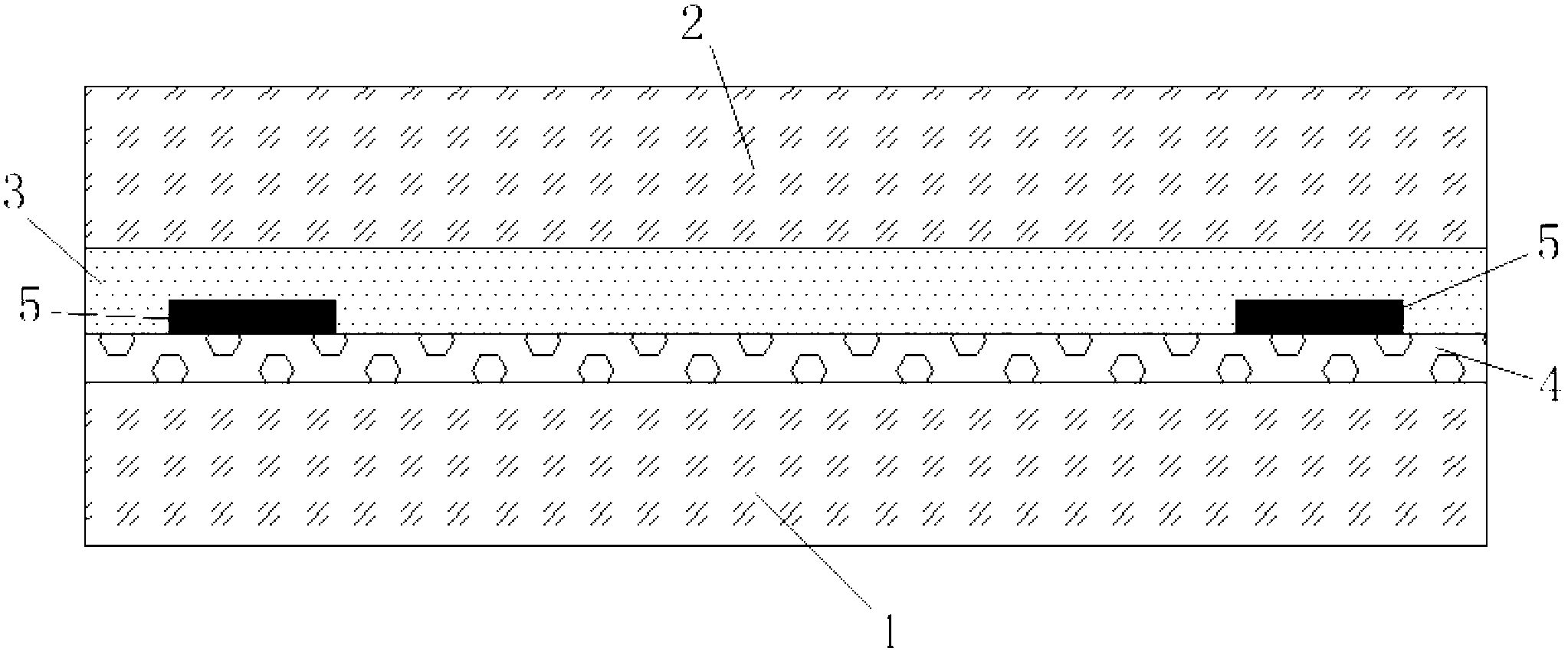

Electrically-heatable low-emissivity coated laminated glass

ActiveCN102795793ALow costSave hot pressing processAnisotropic conductive filmAnisotropic conductive adhesive

The invention relates to the field of laminated glass, particularly a laminated glass with high heat reflectivity and electric heating function applicable to the field of vehicles or construction, more particularly an automobile windshield glass installed on a vehicle. The electrically-heatable low-emissivity coated laminated glass comprises two glass substrates, a middle polymer sandwiched between the two glass substrates, low-emissivity film and a bus, wherein the low-emissivity film is arranged on at least one glass substrate surface in contact with the middle polymer; the bus is distributed on the low-emissivity film; and the bus is a pressure-sensitive adhesive or anisotropic conductive adhesive. According to the electrically-heatable low-emissivity coated laminated glass provided by the invention, the ACF (anisotropic conductive film) or PSA (pressure-sensitive adhesive) is used as the bus in combination with the low-emissivity film to heat the laminated glass, thereby removing frost and melting ice; and thus, compared with the adoption of other buses, the invention simplifies the production technique, is convenient to operate, lowers the material cost and enhances the production efficiency and process yield.

Owner:FUYAO GLASS IND GROUP CO LTD

Display panel, display apparatus and display panel manufacturing method

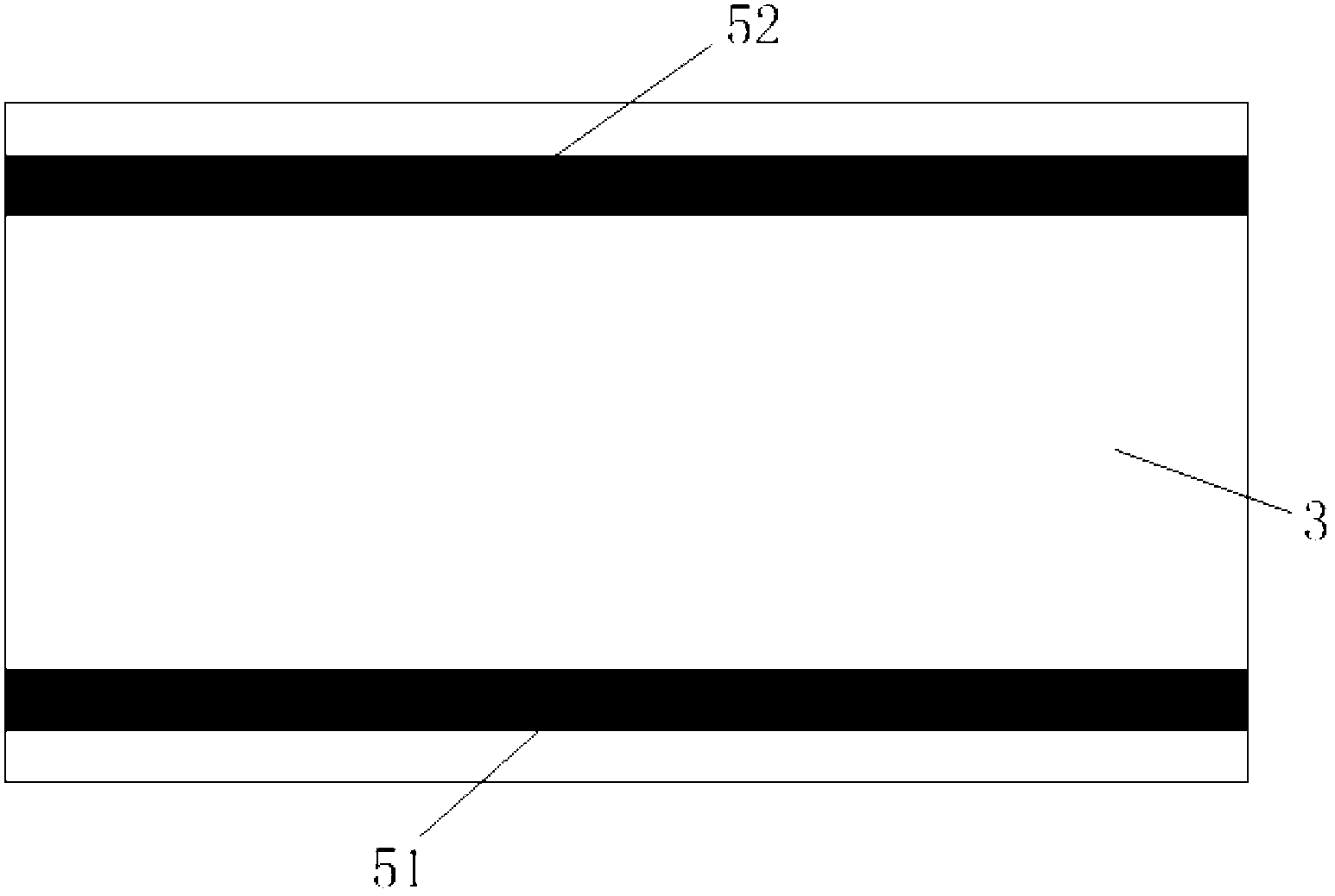

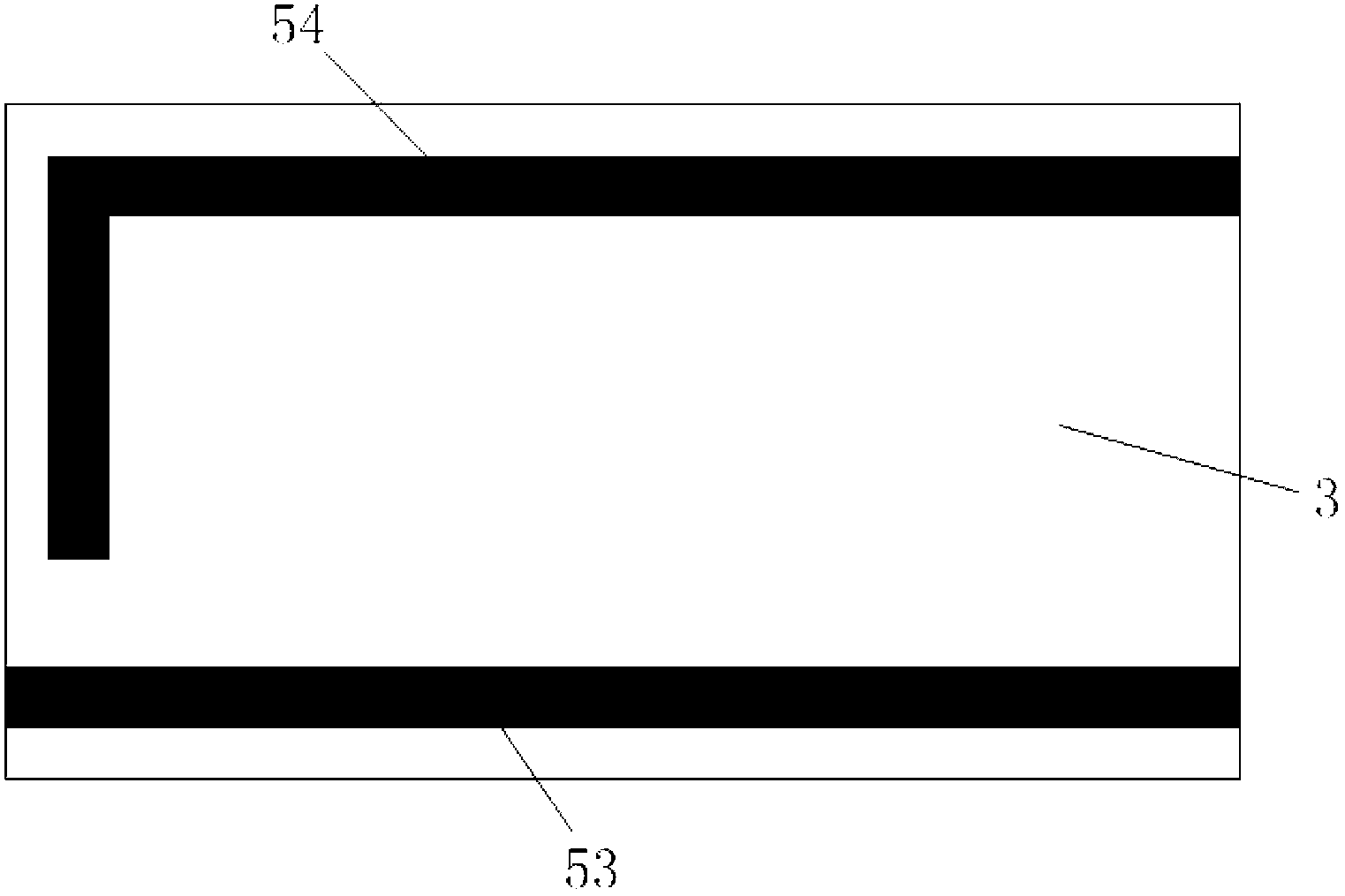

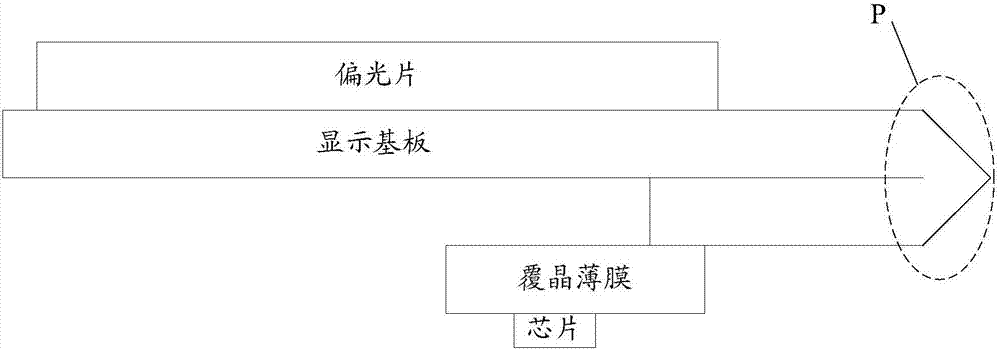

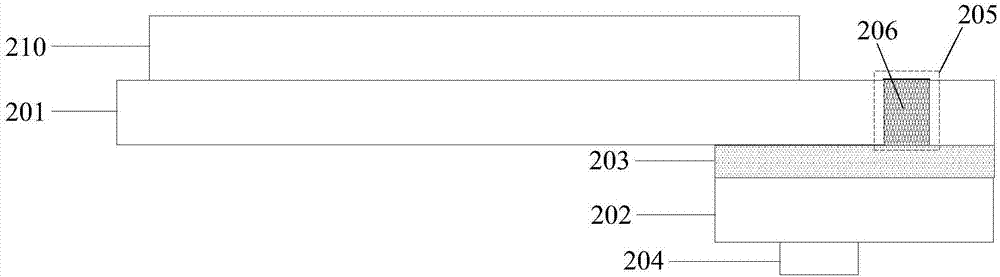

InactiveCN106973520ANarrow bezelEliminate bending processPrinted circuit assemblingSemiconductor/solid-state device detailsAnisotropic conductive adhesiveConductive materials

The invention discloses a display panel, a display apparatus and a display panel manufacturing method. The display panel comprises a display substrate, a flip chip thin film, an anisotropic conductive adhesive arranged between the display substrate and the flip chip thin film and an integrated circuit chip, wherein the flip chip thin film is arranged on a side, facing away from a display surface, of the display substrate; the integrated circuit chip is fixed on a side, facing away from the display substrate, of the flip chip thin film; the flip chip thin film is fixed on the side, facing away from the display surface, of the display substrate via the anisotropic conductive adhesive; a circumference of the display surface of the display substrate is provided with at least a plurality of connection holes that run through the display substrate and electric conduction material which all the connection holes are filled with, and signal wires positioned on the circumference of the display surface of the display substrate are connected with connection terminals arranged on the flip chip thin film via the electric conduction material. Thus, connection terminal bending technologies are not needed, a circumference of the display panel can be prevented from connection terminal bending areas, and narrowness of a frame of the display panel can be improved.

Owner:BOE TECH GRP CO LTD +1

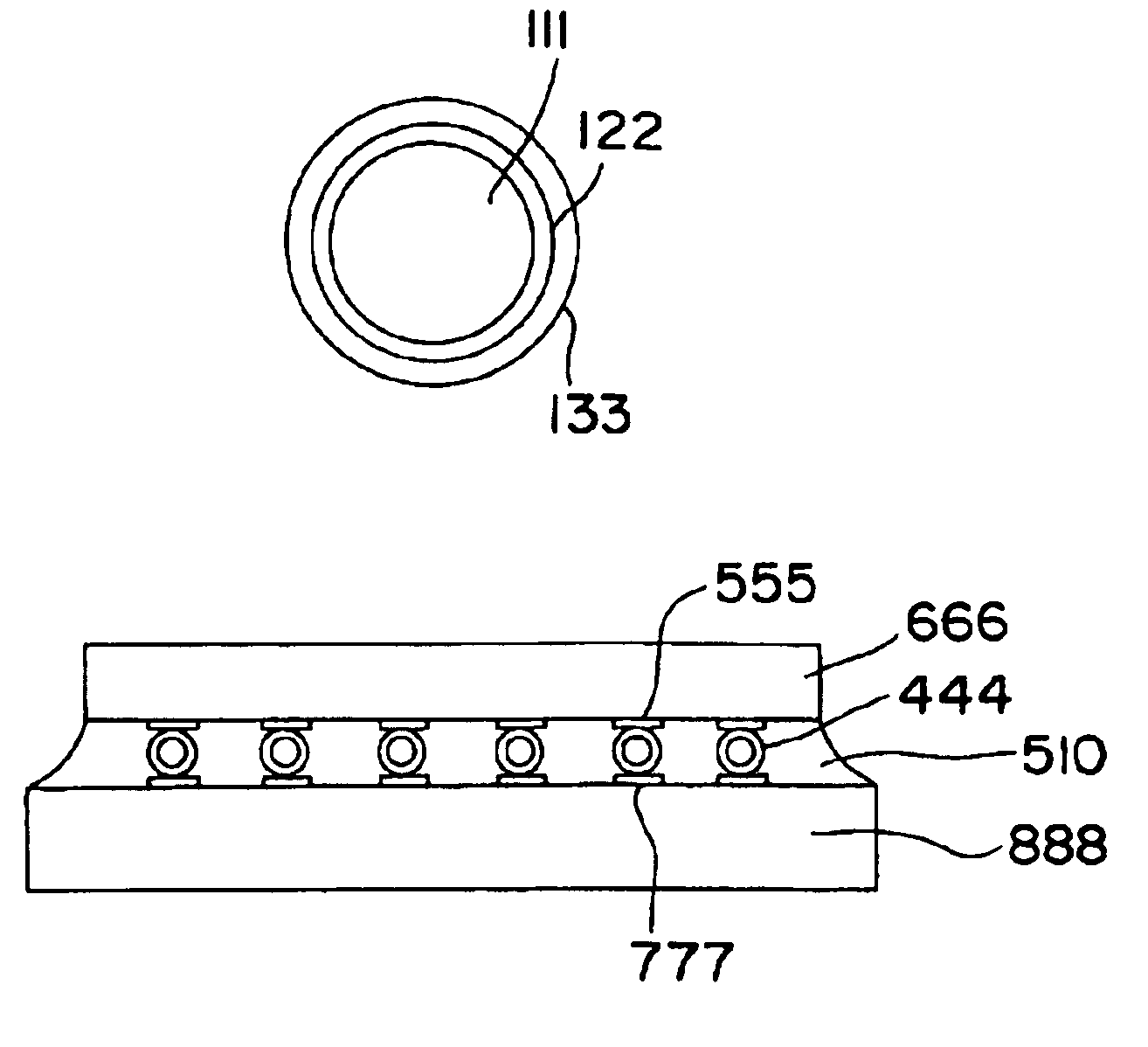

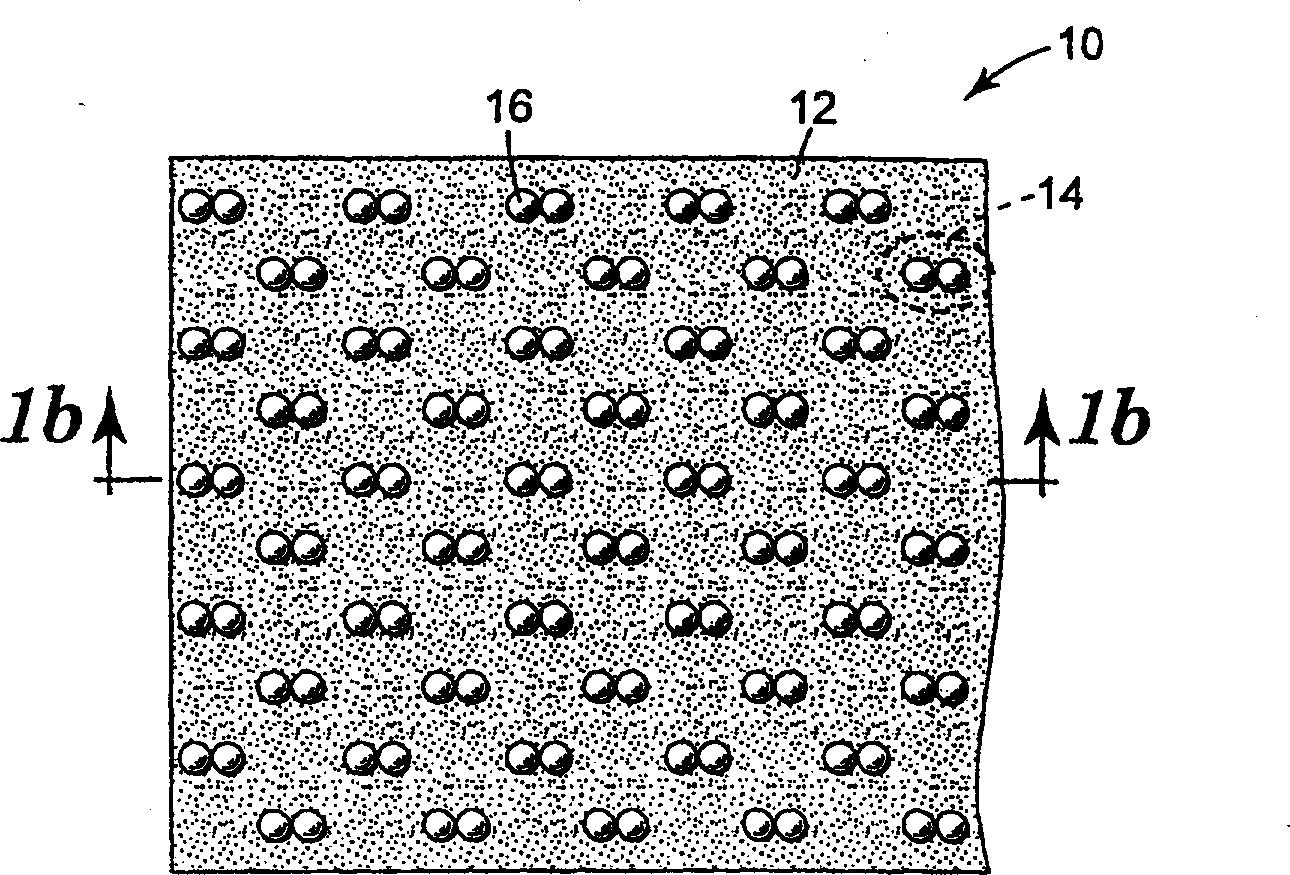

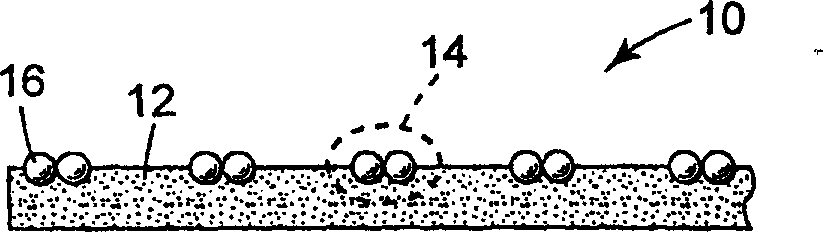

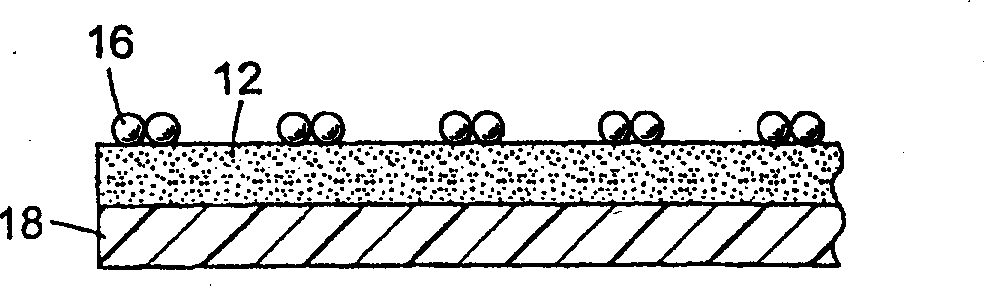

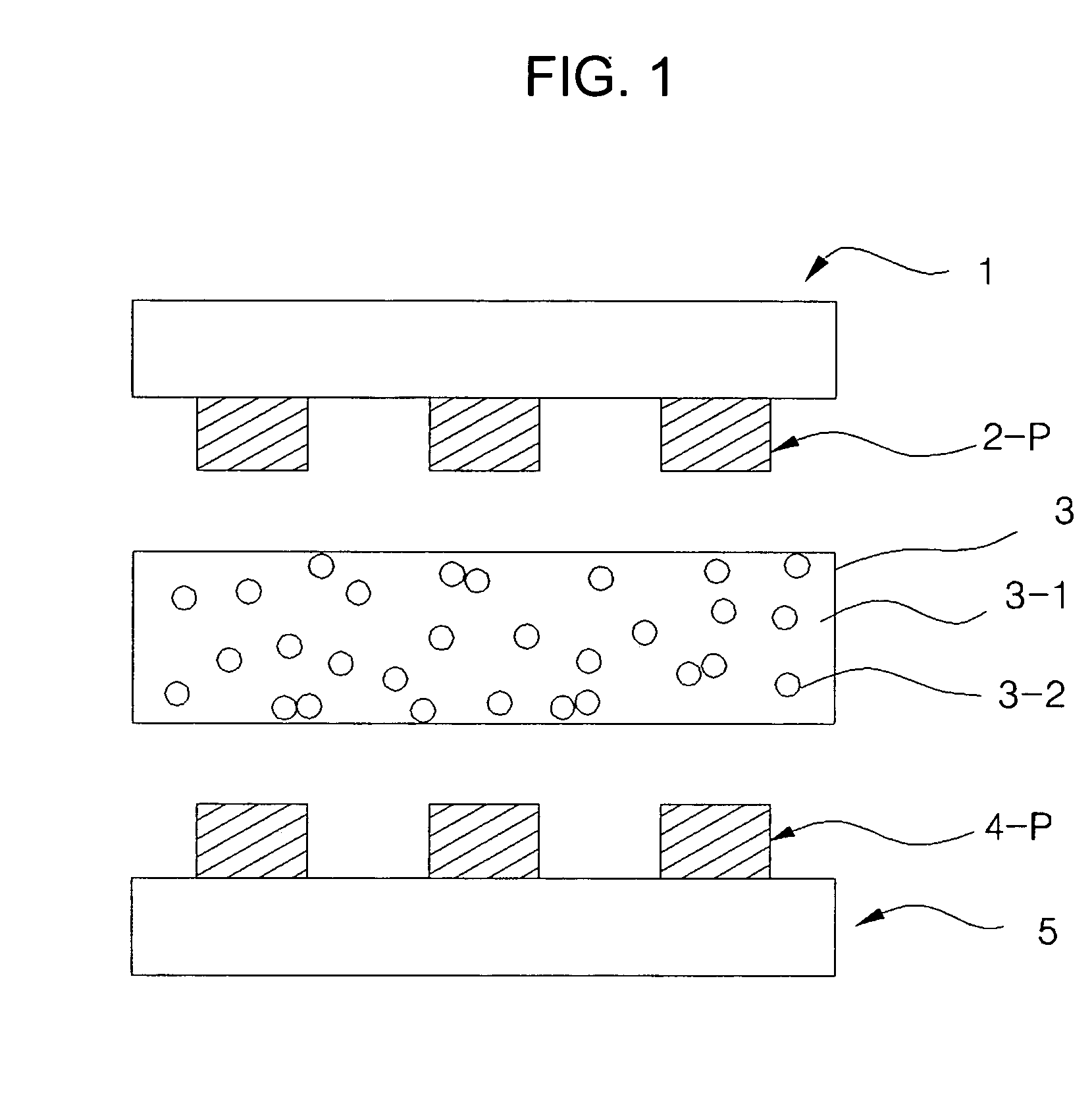

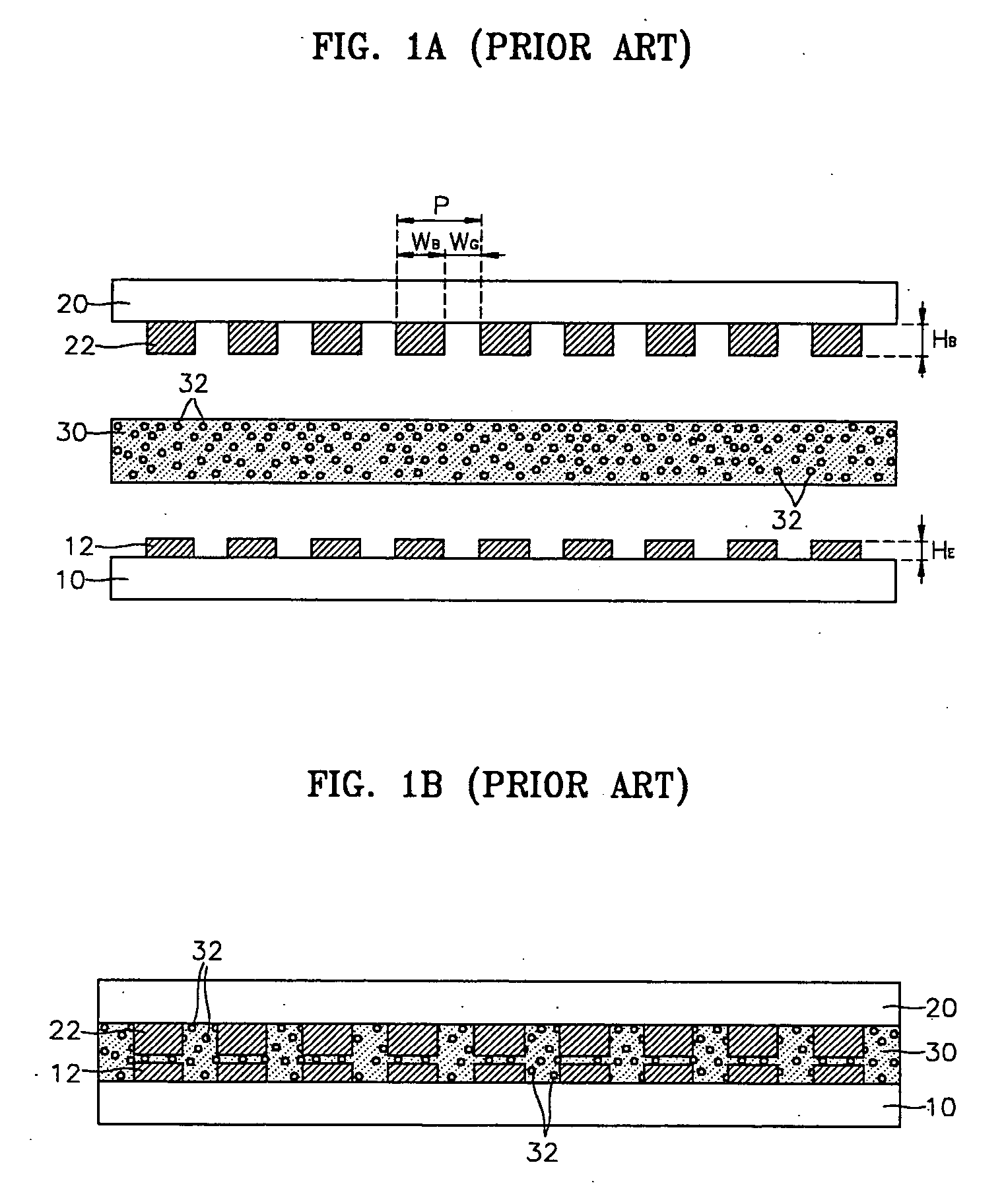

Fine pitch anisotropic conductive adhesive

InactiveCN1307625AHigh densityPrinted circuit assemblingFilm/foil adhesivesAnisotropic conductive adhesiveFine pitch

Disclosed is an anisotropic conductive adhesive (10) having an adhesive layer (12) and conductive particles (16) individually adhered to the adhesive layer, the conductive particles being arranged in an ordered array. The size of the conductive particles is at least somewhat smaller than the thickness of the adhesive layer. Also disclosed is an anisotropic conductive adhesive having an adhesive layer, conductive particles individually adhered to the adhesive layer, and a release liner (28) having an ordered array of dimples. The conductive particles reside in a single layer in the dimples. The anisotropic conductive adhesive is made by placing the conductive particles in an ordered array of dimples on a low adhesion surface. An adhesive layer is then laminated on top such that the conductive particles individually adhere to the adhesive layer. The anisotropic conductive adhesive may be used to electrically connect fine pitch electrodes on opposing circuit layers.

Owner:3M CO

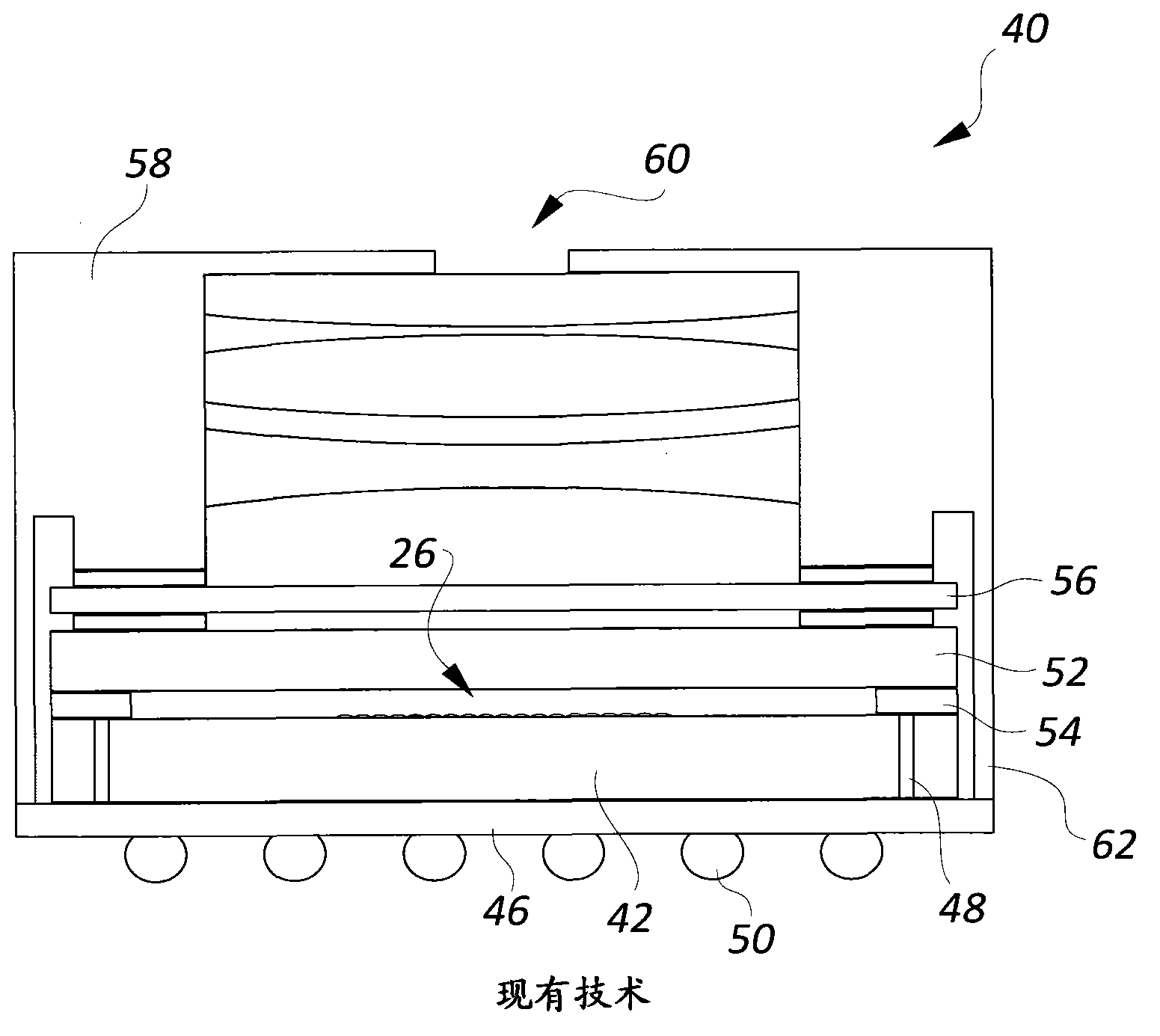

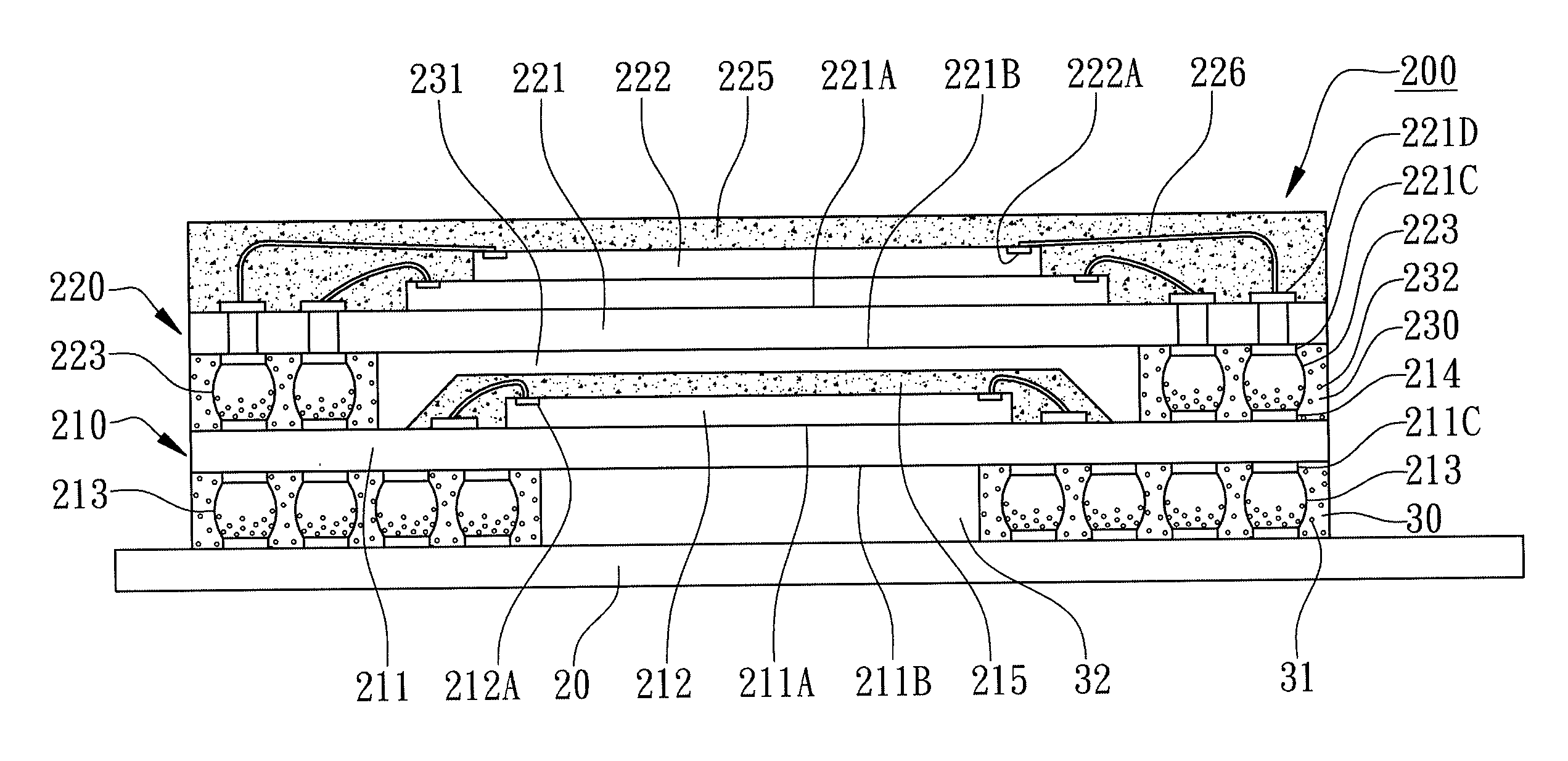

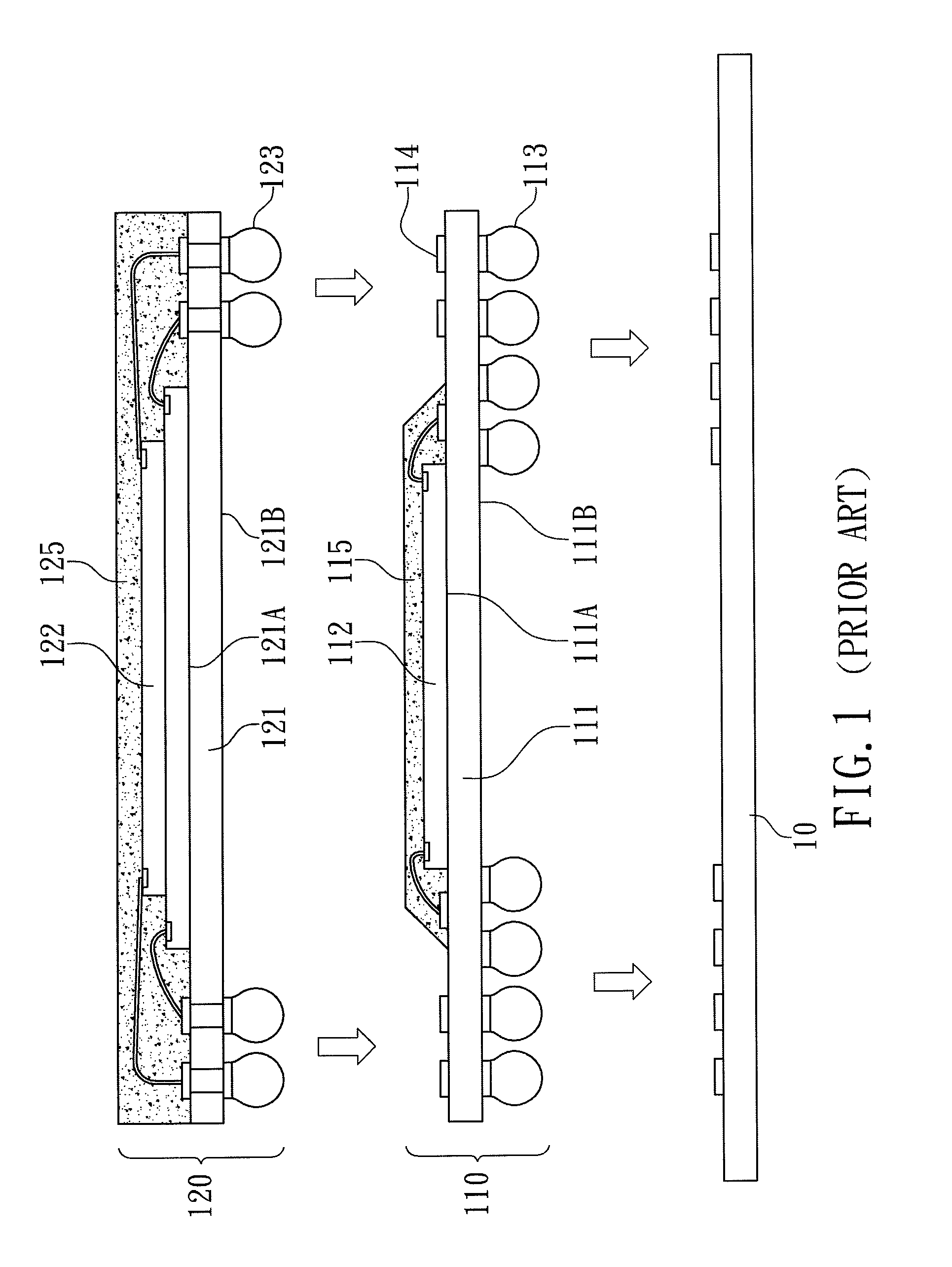

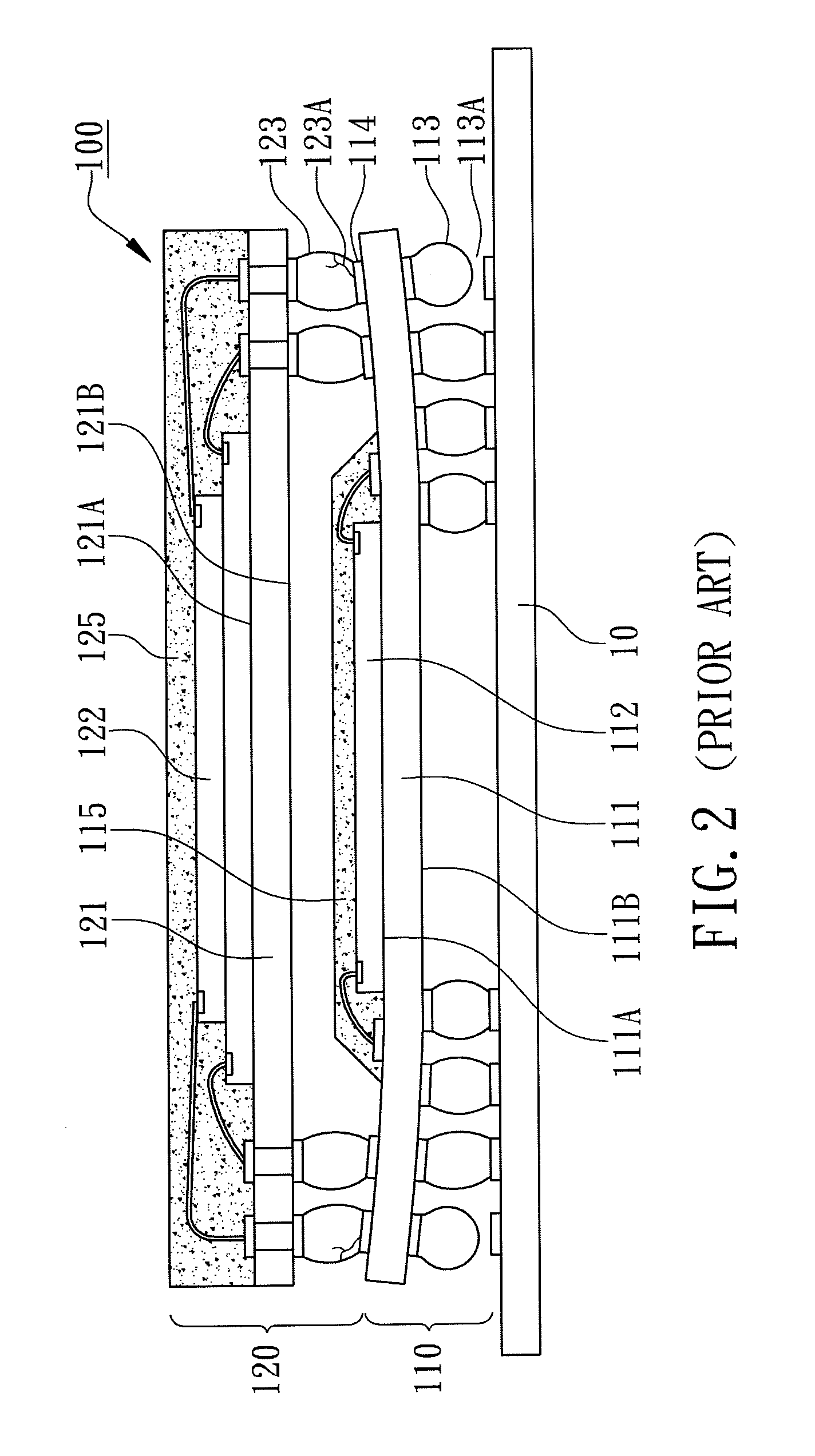

Package-on-package semiconductor device

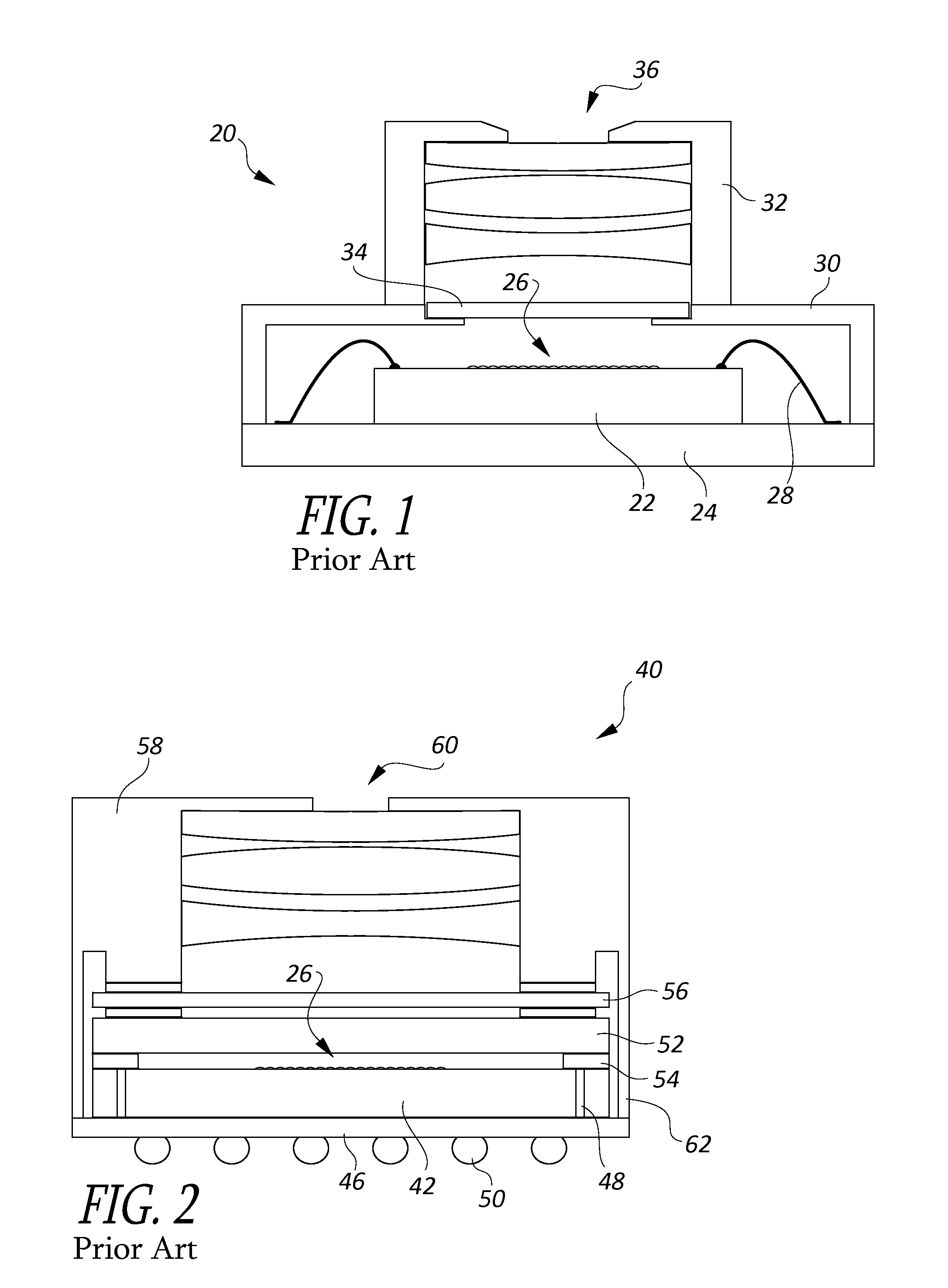

InactiveUS20120267782A1Reinforced jointsReduce warpageSemiconductor/solid-state device detailsSolid-state devicesAnisotropic conductive adhesiveElectrical connection

Disclosed is a package-on-package semiconductor device comprising a bottom package, a top package thereon and a ACA (Anisotropic Conductive Adhesive) layer. A plurality of ball pads are disposed on the peripheries of an upper surface of the substrate of the bottom package. A plurality of solder balls are disposed at the peripheries of the lower surface of the substrate of the top package. The ACA layer having a central opening is interposed between the bottom package and the top package where the ACA layer contains a plurality of conductive particles. Therein, the size of the central opening and the thickness of the ACA layer are selected such that the anisotropic conductive adhesive layer adheres the peripheries of the upper surface of the bottom package to the peripheries of the lower surface of the top package and the solder balls are encapsulated inside the anisotropic conductive adhesive layer. The solder balls encapsulate some of the conductive particles to mechanically joint and electrically connect to the ball pads. Thereby, the bonding strength of the solder balls can be improved and the warpage of the substrate of the bottom package is effectively reduced to avoid failure of electrical connections between both packages caused by the breaking of soldering joints.

Owner:WALTON ADVANCED ENG INC

Liquid crystal display panel binding method and structure

ActiveCN107402466ARealize Narrow Bezel DisplayAvoid badStatic indicating devicesNon-linear opticsLiquid-crystal displayAnisotropic conductive adhesive

The invention provides a liquid crystal display panel binding method and structure. The liquid crystal display panel binding method is that fusion metal material or conductive glue material is applied to the side surface and the upper surface of a TFT substrate to form a conductive pattern connected with a lead wire; and then conductive pattern and a flip-chip thin film can be bond when anisotropic conductive adhesive film is arranged on the side surface of the TFT substrate. The process is simple; a binding area is arranged on the side surface of the TFT substrate, so compared with a binding method of arranging the binding area on the upper surface of the TFT substrate, liquid crystal display panel narrow frame display and narrow frame tiled display can be achieved; and unfavorable effects due to the bend of the flip-chip thin film can be effectively avoided. The liquid crystal display panel binding structure can be achieved by the use of the above binding method; the binding area is arranged on the side surface of the TFT substrate, so liquid crystal display panel narrow frame display and narrow frame tiled display can be facilitated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method of microelectrode connection and connected structure of use threof

InactiveUS20050211464A1Improve reliabilityPrinted circuit assemblingSemiconductor/solid-state device detailsLiquid-crystal displayAnisotropic conductive adhesive

Disclosed is a method for connecting microcircuits formed in a circuit board, such as a Tape Carrier Package (TCP), a Flexible Printed Circuit (FPC), a Liquid Crystal Display (LCD) or a printed circuit board using an anisotropic conductive adhesive including conductive particles, and the connection structure manufactured by the above method. The method comprises the steps of applying an insulating film layer to a circuit board having circuit patterns, and then boding them with an anisotropic conduction adhesive. The circuits that should not be connected by conductive particles included in the anisotropic conductive adhesive are prevented from a short-circuit

Owner:LS MTRON LTD

Light-reflective anisotropic conductive adhesive and light-emitting device

ActiveUS20120193666A1Improve efficiencyLight reflectionNon-macromolecular adhesive additivesConductive materialInorganic particleAnisotropic conductive adhesive

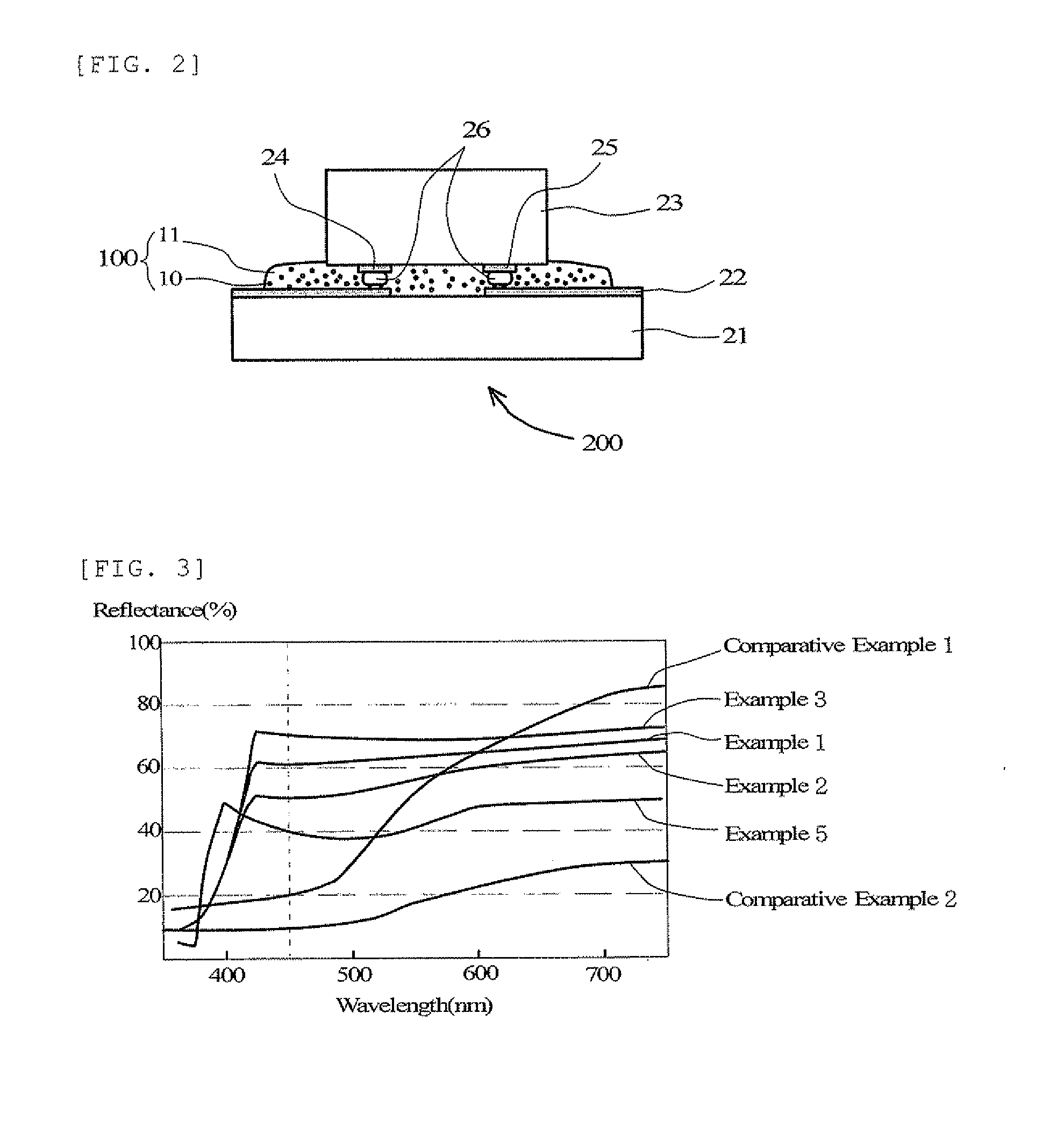

A light-reflective anisotropic conductive adhesive used for anisotropic conductive connection of a light-emitting element to a wiring board includes a thermosetting resin composition, conductive particles, and light-reflective insulating particles. The light-reflective insulating particles are at least one of inorganic particles selected from the group consisting of titanium oxide, boron nitride, zinc oxide, and aluminum oxide, or resin-coated metal particles formed by coating the surface of scale-like or spherical metal particles with an insulating resin.

Owner:DEXERIALS CORP

Anisotropic conductive adhesive

InactiveUS20070213429A1Stable and reliableShort thermocompression bond timeNanostructure manufactureElectrically conductive adhesive connectionsThermal energyNano size

An anisotropic conductive adhesive that provides strong adhesion to metals and organic substrates to generate stable and reliable electric interconnects. The adhesive provides the benefits of short thermocompression bond time at low temperatures. The adhesive contains cationic curable resin, latent cationic catalyst that thermally cures the resin at high speeds and low temperatures, conductive filler, optionally a film forming thermoplastic solid resin and optionally nano size filler. The optional nano filler provides the benefit of reducing the coefficient of thermal energy mismatch, improving the adhesion strength and reducing the total heat of reaction for the system.

Owner:HENKEL KGAA

Anisotropic conductive film and light emitting device

InactiveUS20110266578A1Emission efficiency of the light emitting device does not deteriorateNon-macromolecular adhesive additivesPrinted circuit aspectsAnisotropic conductive filmAnisotropic conductive adhesive

An anisotropic conductive film is provided that does not have a light-reflecting layer on a light emitting diode element which causes costs to increase when a light emitting device that uses an LED element is flip-chip mounted, and that does not cause emission efficiency to deteriorate. Further, a light emitting device that uses such an anisotropic conductive film is provided. This anisotropic conductive film has a structure in which a light-reflecting insulating adhesive layer and an anisotropic conductive adhesive layer are laminated, wherein the light-reflecting insulating adhesive layer has a structure in which light-reflecting particles are dispersed in an insulating adhesive. The light emitting device has a structure in which a light emitting diode element is flip-chip-mounted on a substrate, with this anisotropic conductive film provided between a connection terminal on the substrate and a bump for connection of the light emitting diode element.

Owner:DEXERIALS CORP

Anisotropic conductive adhesive and method for manufacturing same, light-emitting device and method for manufacturing same

InactiveUS20150034989A1Inhibition of adsorptionEfficiently take out lightConductive materialVacuum evaporation coatingAnisotropic conductive adhesiveMetal alloy

an anisotropic conductive adhesive which uses conductive particles where a silver-based metal is used as a conductive layer, having high light reflectance and excellent migration resistance is provided. The anisotropic conductive adhesive includes light reflective conductive particles in an insulating adhesive resin. The light reflective conductive particle includes a light reflective metal layer made of a metal alloy including silver, gold and hafnium formed on the surface of a resin particle as a core by sputtering method. The light reflective metal layer is preferably formed having a composition ratio of a silver of at least 50% by weight to at most 80% by weight: a gold of at least 10% by weight to at most 45%: a hafnium of at least 10% by weight to at most 40% by weight, and a total ratio does not exceed 100% by weight.

Owner:DEXERIALS CORP

Isotropic conductive adhesive and adhesive film using the same

InactiveUS20050288427A1Minimizes its contractionImprove connection reliabilityImpression capsConductive materialAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

Anisotropic conductive adhesive composition and anisotropic conductive film comprising the same

The present invention relates to an anisotropic conductive adhesive composition with high reliability and an anisotropic conductive film. The anisotropic conductive adhesive composition includes an acrylic rubber binder having a weight average molecular weight of about 100,000 to about 1,000,000, a first component including at least one of a mono(meth)acrylate compound and a di(meth)acrylate compound, a second component including at least one of a tri(meth)acrylate compound and a compound having more than three (meth)acrylate groups, an organic peroxisde, and conductive particles. The second component is present in an amount of about 1 to about 10% by weight, based on the total weight of the acrylic rubber, the first component, the second component, the organic peroxide, and the conductive particles.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Anisotropic conductive adhesive

InactiveCN101033379AStable and reliable electrical interconnectionLower coefficient of thermal expansion mismatchNanostructure manufactureNon-macromolecular adhesive additivesThermal energyAnisotropic conductive adhesive

An anisotropic conductive adhesive that provides strong adhesion to metals and organic substrates to generate stable and reliable electric interconnects. The adhesive provides the benefits of short thermocompression bond time at low temperatures. The adhesive contains cationic curable resin, latent cationic catalyst that thermally cures the resin at high speeds and low temperatures, conductive filler, optionally a film forming thermoplastic solid resin and optionally nano size filler. The optional nano filler provides the benefit of reducing the coefficient of thermal energy mismatch, improving the adhesion strength and reducing the total heat of reaction for the system.

Owner:HENKEL KGAA

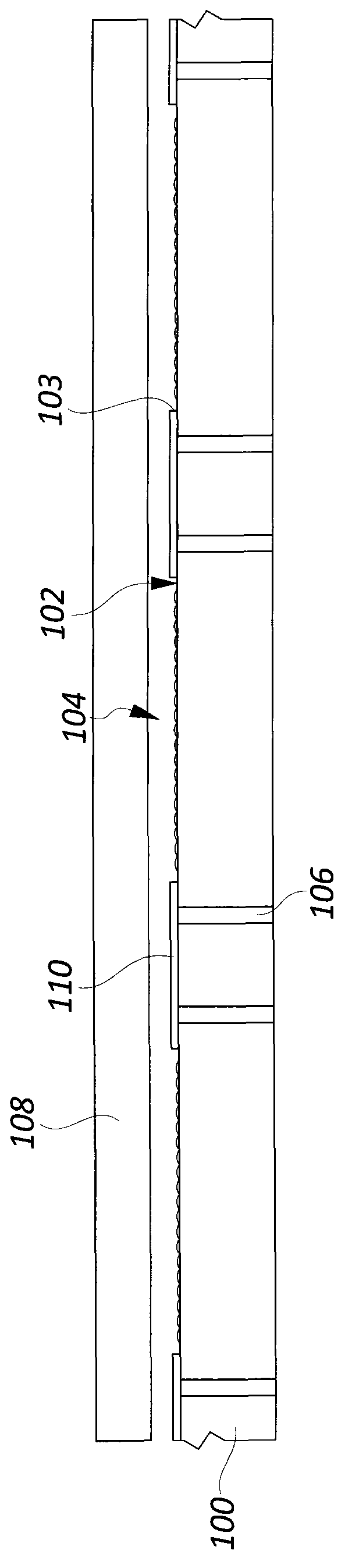

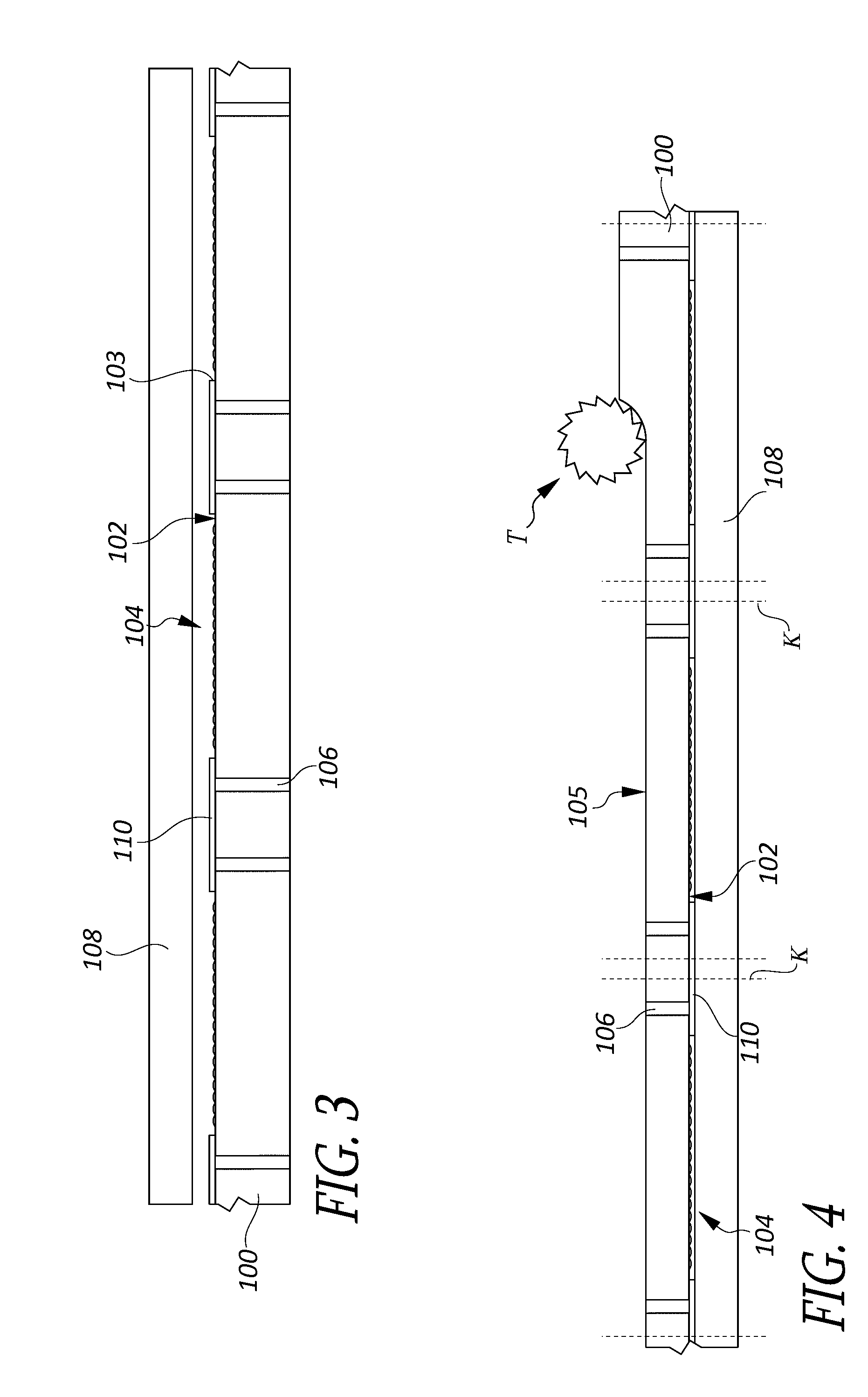

Ultra-thin shielding film and circuit board capable of changing circuit impedance, and method for preparing same

ActiveCN101448362AReduce thicknessStrong enoughPrinted circuit detailsMagnetic/electric field screeningAnisotropic conductive adhesiveMetal foil

The invention provides an ultra-thin shielding film and a circuit board capable of changing circuit impedance, and a method for preparing same. The shielding film capable of changing the circuit impedance consists of an insulated coverage film layer, a metal foil layer, an anisotropic conductive adhesive layer and a protective release film layer; the metal foil layer is provided with meshes according to the impedance requirement design of the product and is arranged between the insulated coverage film layer and the anisotropic conductive adhesive layer; the surface of the anisotropic conductive adhesive layer is covered by the protective release film. The invention has the advantages that the ultra-thin layer of metal foil with a certain mesh dimension which is completely connected together is provided; the metal foil layer and the insulated layer have extremely high peeling strength, can durably bear heat impact and can be used for the multi-time pressing process of a soft / hard combination board; meanwhile, the thickness of a dielectric layer can be reduced and the aim of controlling the impedance can be achieved. Furthermore, the cost is low, the bending performance is excellent and the processing is easy.

Owner:GUANGZHOU FANGBANG ELECTRONICS

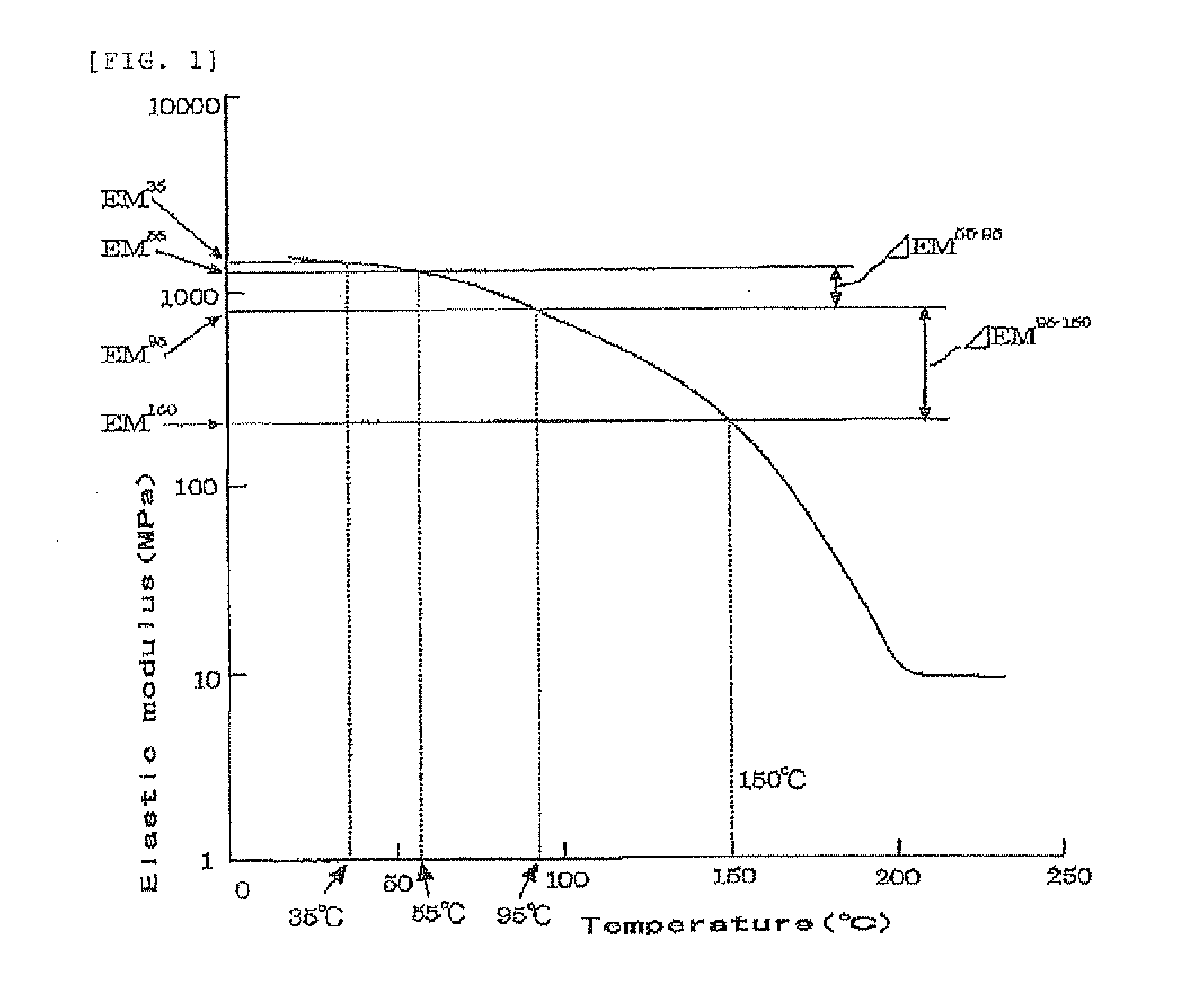

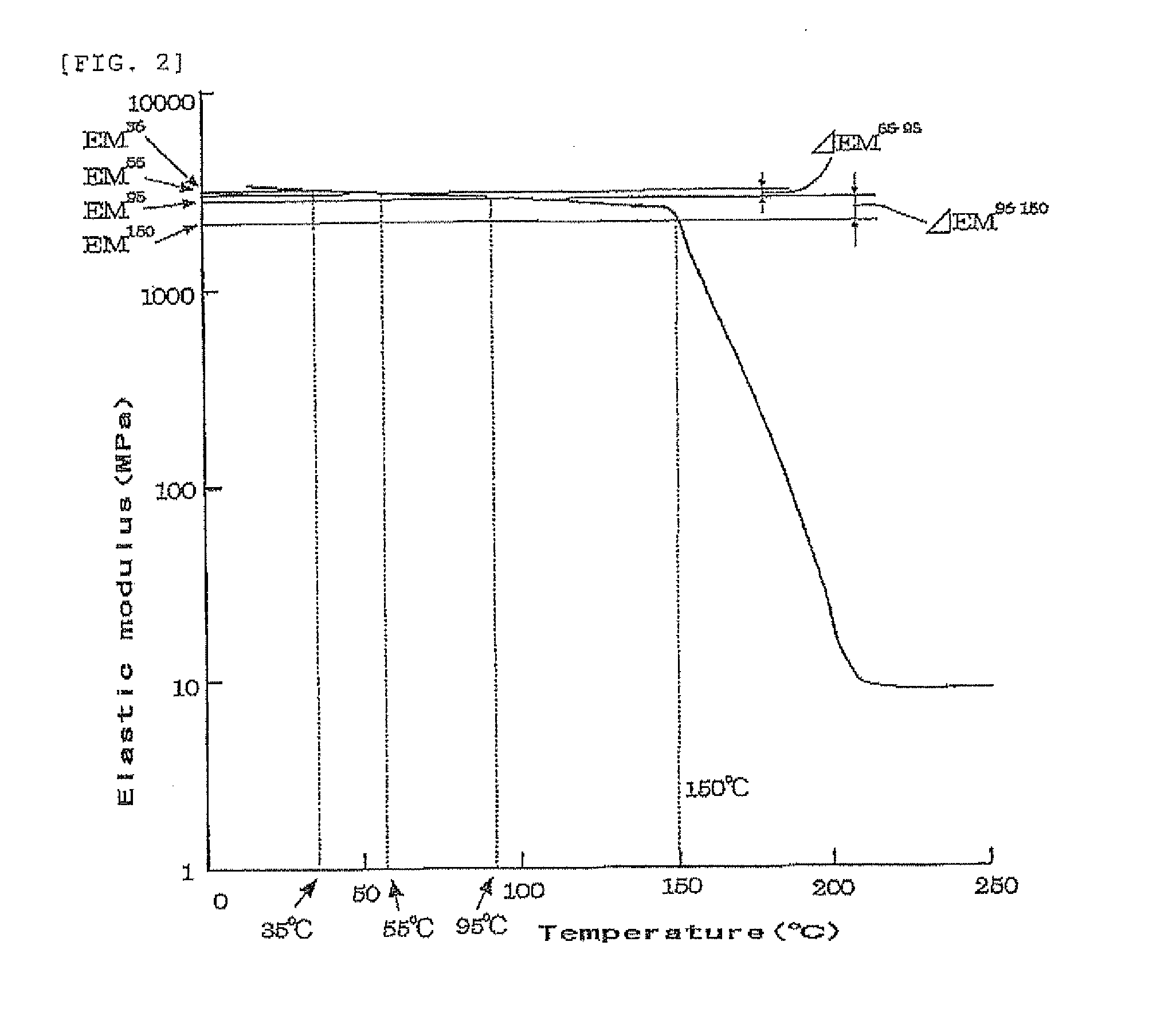

Anisotropic conductive adhesive

InactiveUS20110108878A1OptimizationImprove conduction reliabilityNon-macromolecular adhesive additivesConductive materialAnisotropic conductive adhesiveEpoxy adhesive

An anisotropic conductive adhesive includes an epoxy adhesive containing an epoxy compound and a curing agent and conducive particles dispersed in the epoxy adhesive. When elastic moduluses at 35° C., 55° C., 95° C., and 150° C. of a cured product of the anisotropic conductive adhesive are denoted by EM35, EM55, EM95, and EM150, respectively, and change rates in the elastic modulus between 55° C. and 95° C. and between 95° C. and 150° C. are denoted by ΔEM55-95 and ΔEM95-150, respectively, the following expressions (1) to (5) are satisfied.700Mpa≦EM35≦3000MPa (1)EM150<EM95<EM55<EM35 (2)ΔEM55-95<ΔEM95-150 (3)20% ≦ΔEM55-95 (4)40% ≦ΔEM95-150 (5)

Owner:DEXERIALS CORP

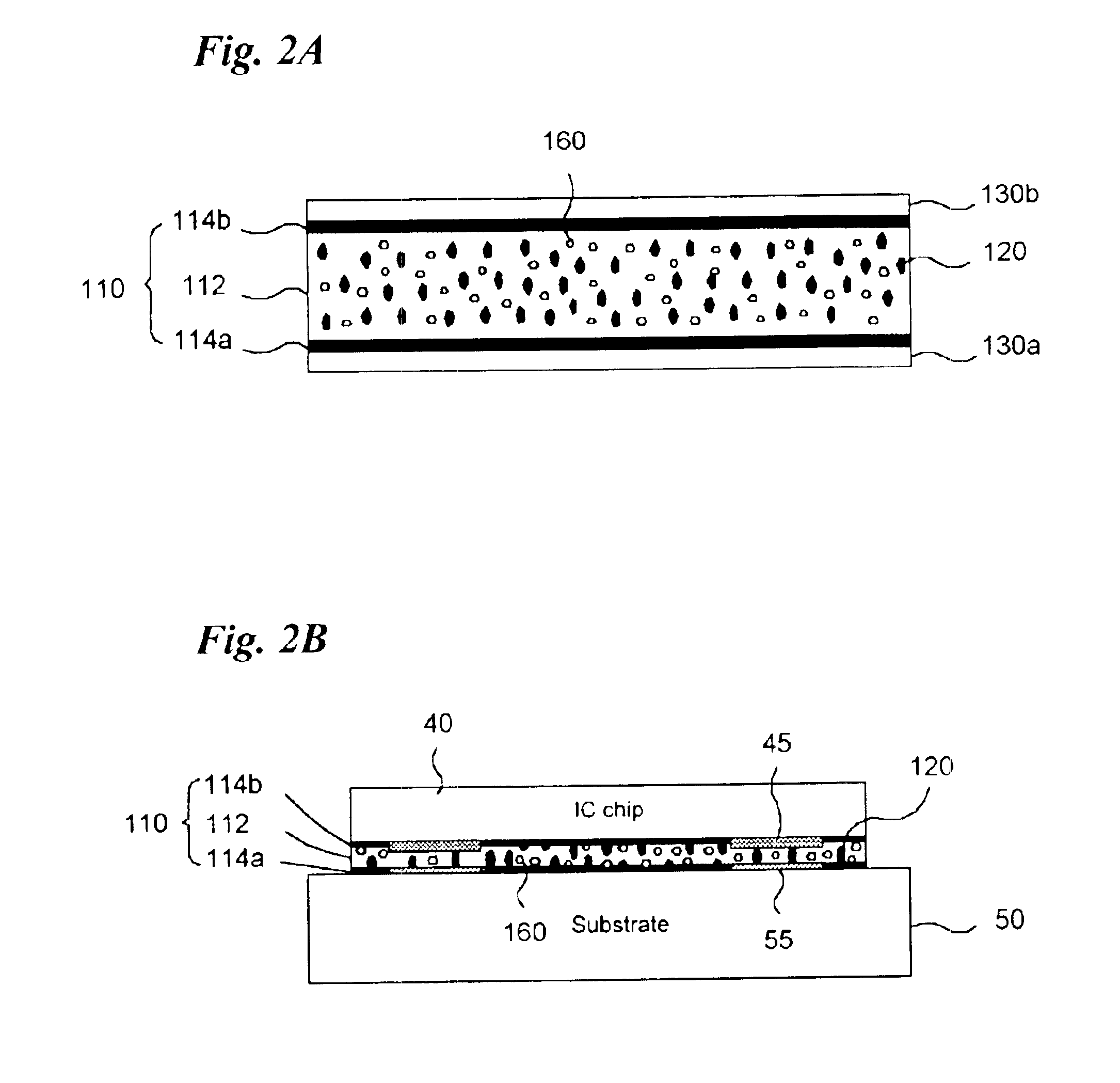

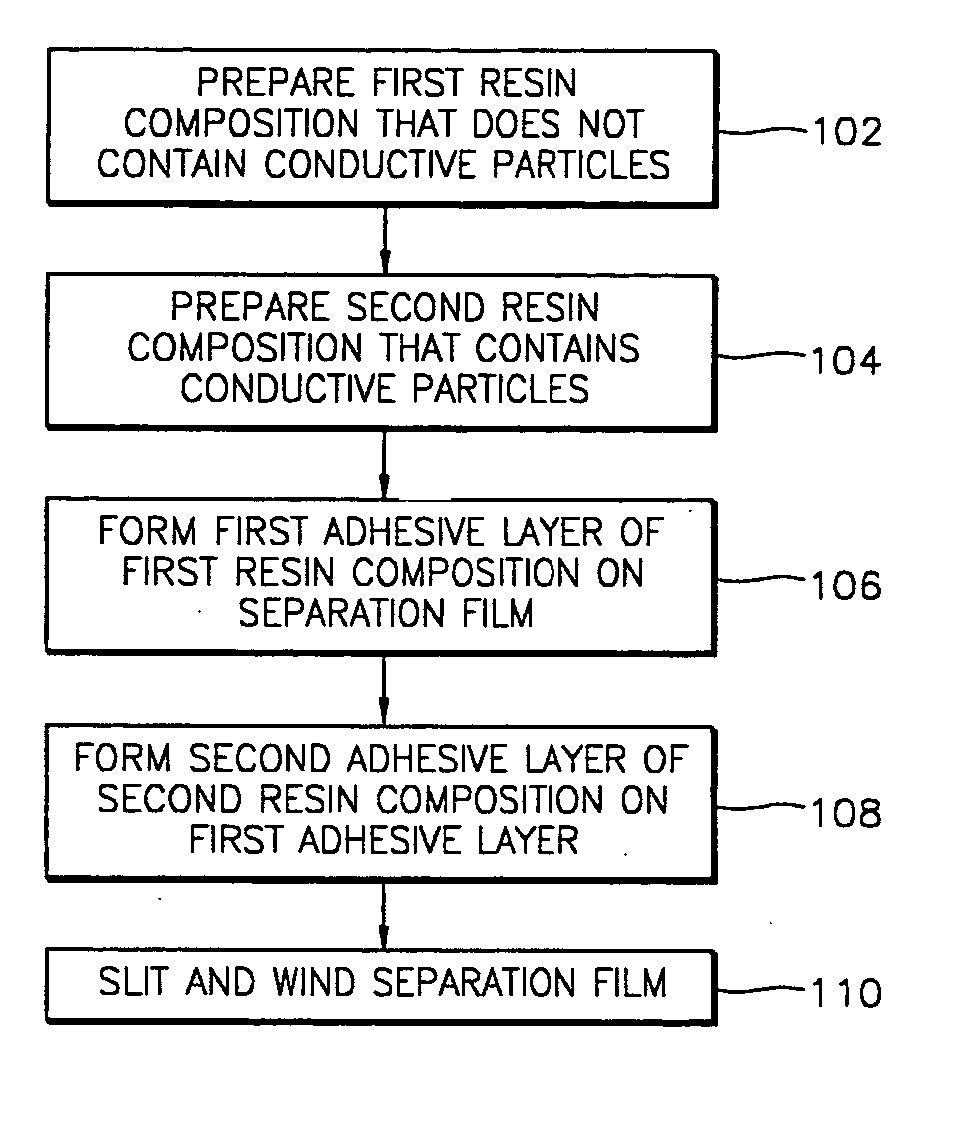

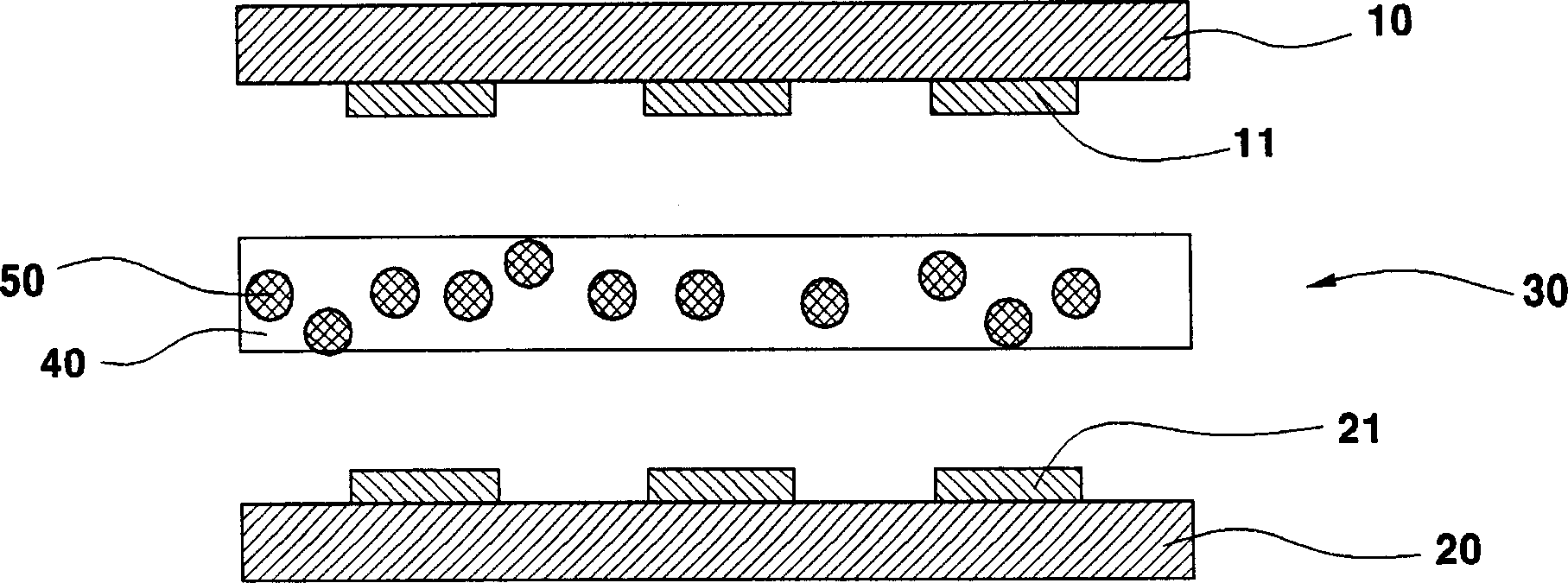

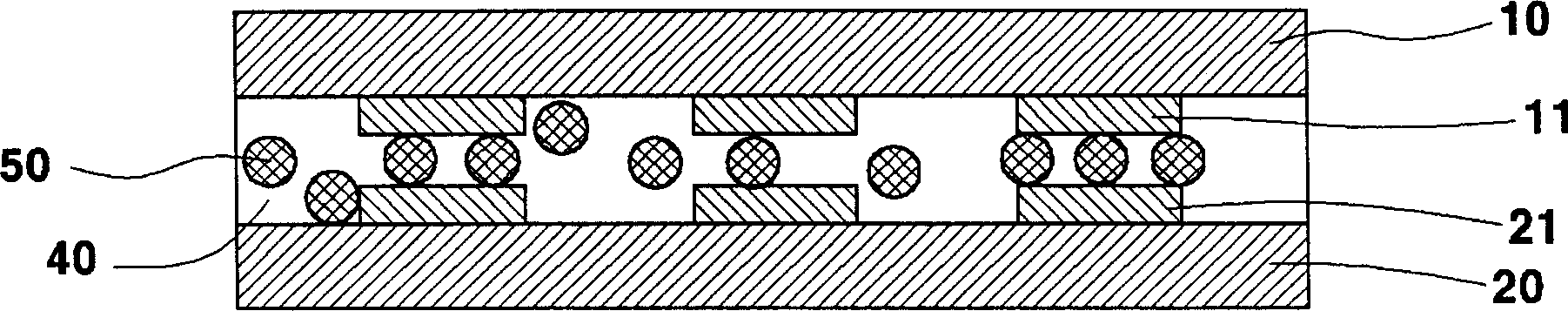

Multilayered anisotropic conductive adhesive for fine pitch

InactiveUS20060033213A1Improve conductivityAdhesive strengthLiquid crystal compositionsSemiconductor/solid-state device detailsAnisotropic conductive adhesiveEngineering

Provided is an anisotropic conductive adhesive for a fine pitch having a conductive adhesive layer and a nonconductive adhesive layer formed on one surface or both surfaces of the conductive adhesive layer. The anisotropic conductive adhesive for a fine pitch can be used to adhere an integrated circuit, on which a plurality of bumps each having a second height are formed, to a substrate, on which a plurality of electrodes each having a first height are formed keeping predetermined distances from each other, so that the integrated circuit is electrically connected to the electrodes. The anisotropic conductive adhesive includes a nonconductive first adhesive layer and a second adhesive layer. The nonconductive first adhesive layer includes a thermosetting resin and a hardener for hardening the thermosetting resin and has a first thickness of ½- 3 / 2 of the second height. The second adhesive layer includes a thermosetting resin, a hardener for hardening the thermosetting resin, and a plurality of conductive particles each having an average particle diameter of ½ or less of the width of gaps between the plurality of electrodes and a first density dispersion, has a second thickness larger than two times the average particle diameter of the conductive particles, and is formed on one surface of the nonconductive first adhesive layer.

Owner:TELEPHUS

Isotropic conductive adhesive and adhesive film using the same

InactiveCN1712483ASmall shrinkageAvoid short circuitPrinted circuit assemblingVinyl aromatic copolymer adhesivesAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention provides an anisotropic conductive adhesive comprising an insulating adhesive component and a large number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains alternating Linked rubber resin. When connecting circuits, by minimizing the thermal shrinkage of the anisotropic conductive adhesive in the polymerization reaction or curing reaction, it is possible to prevent peeling of the adhesive or a decrease in the bonding strength of the circuit. It prevents short-circuit between adjacent electrodes and is excellent in long-term reliability.

Owner:H&S HIGHTECH

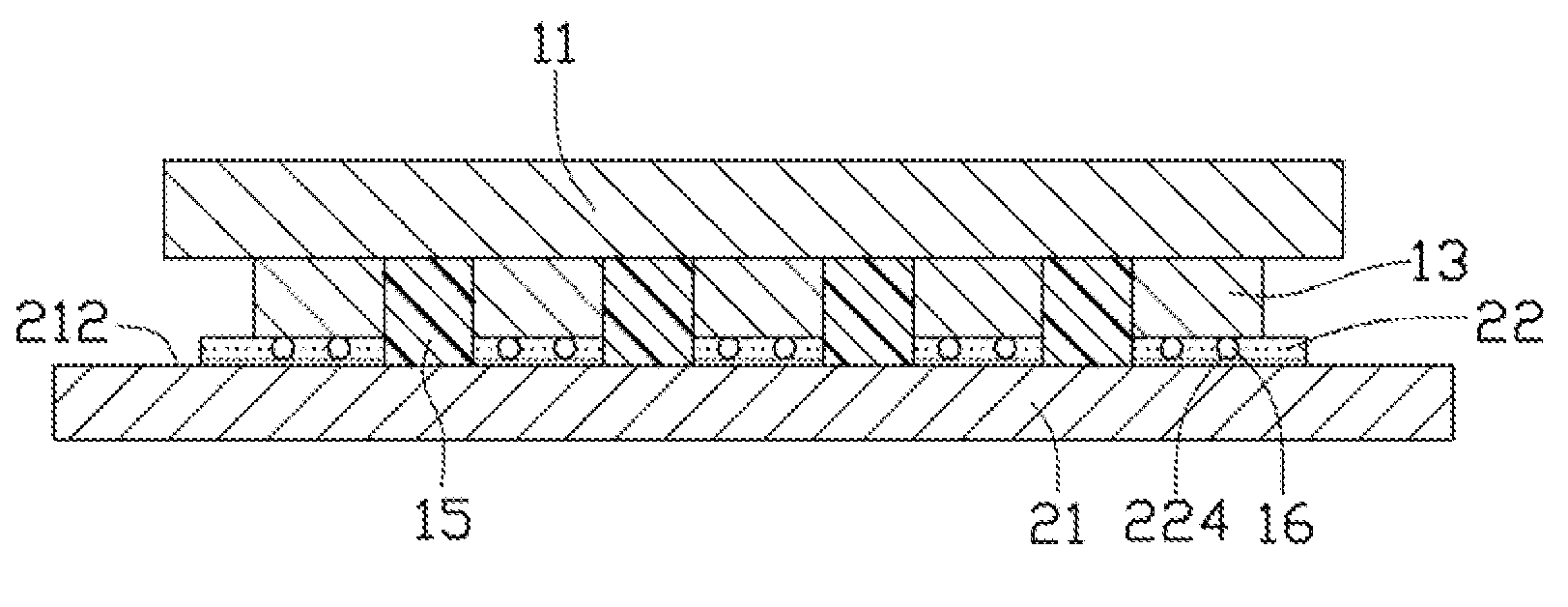

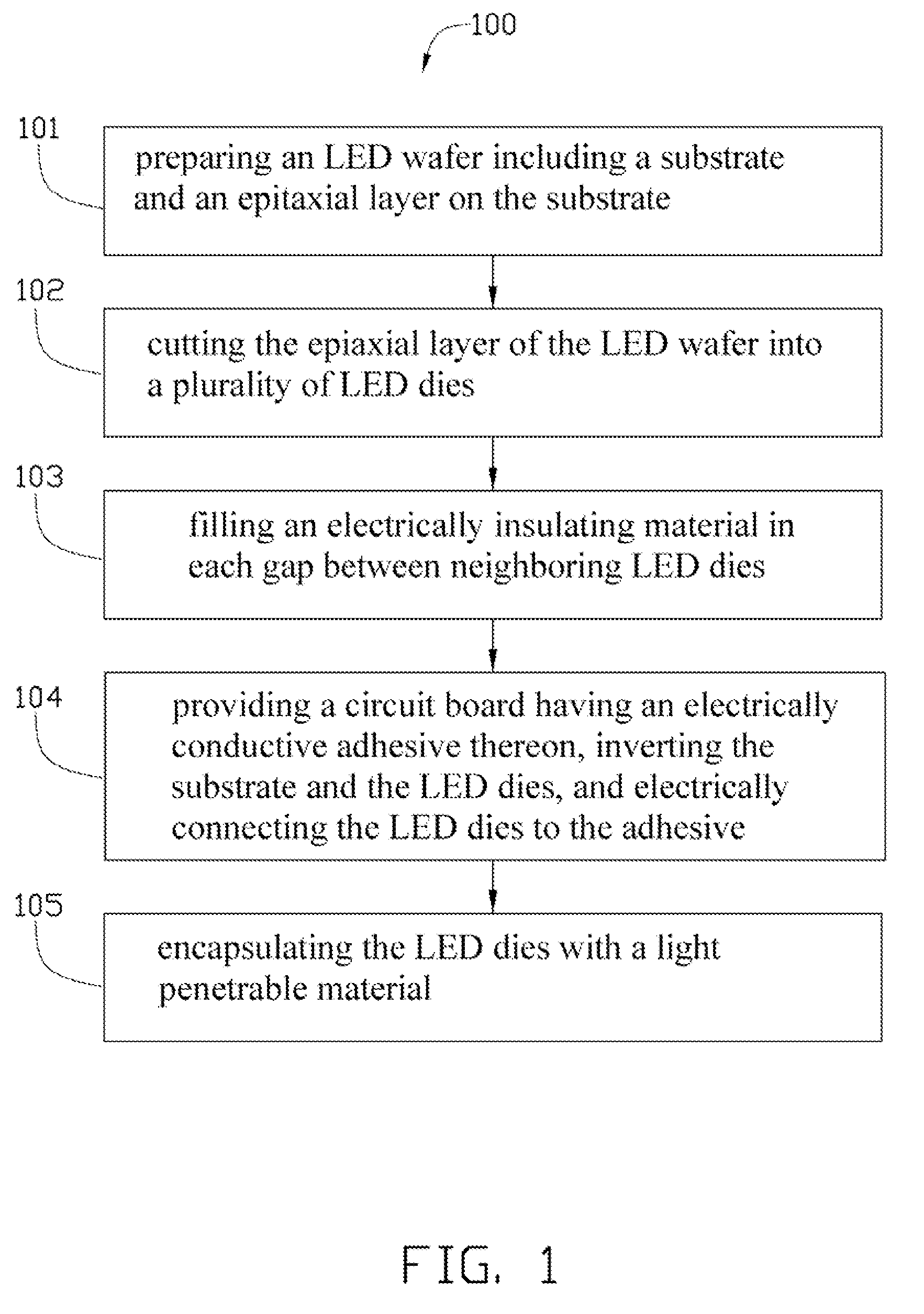

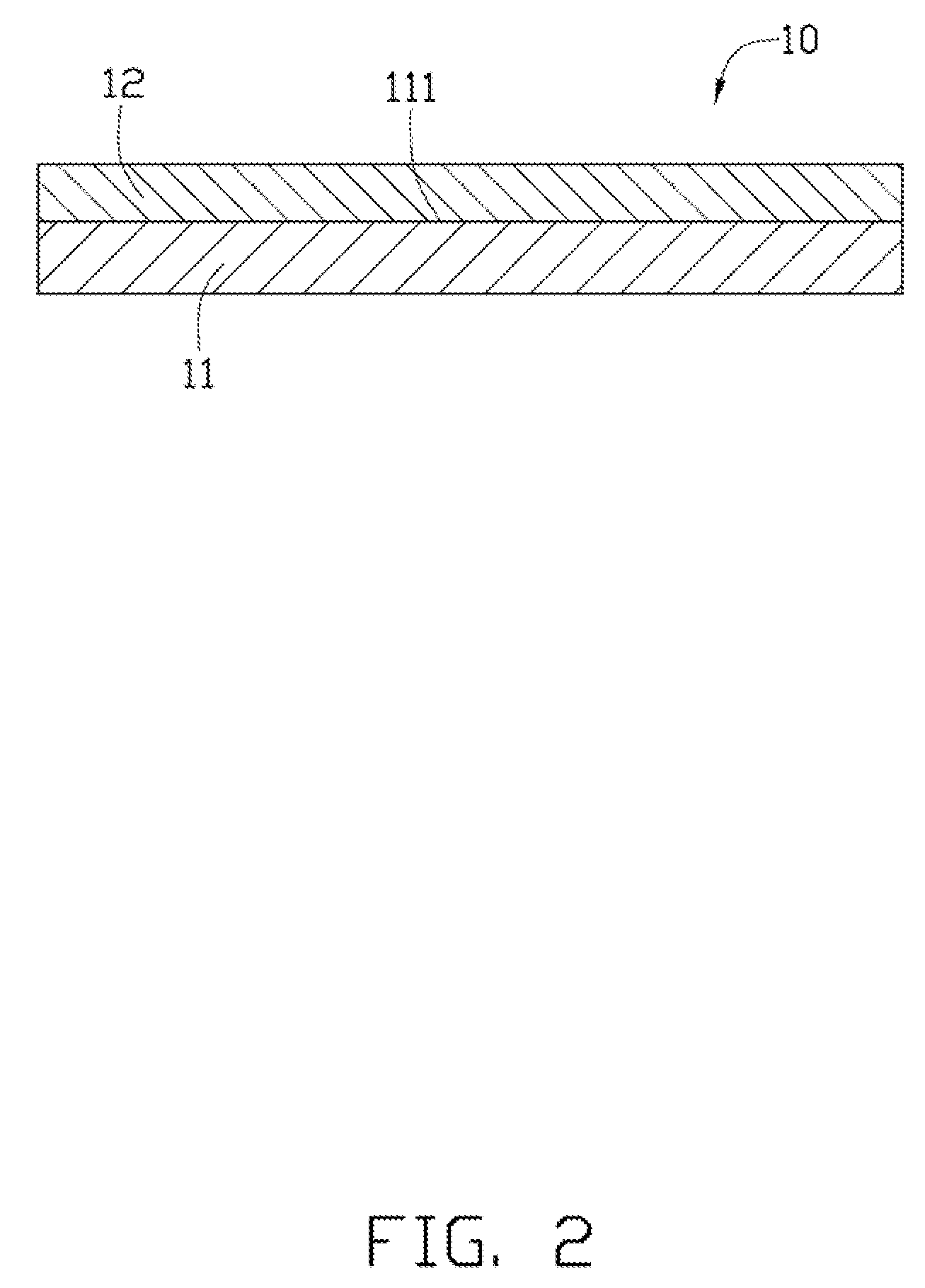

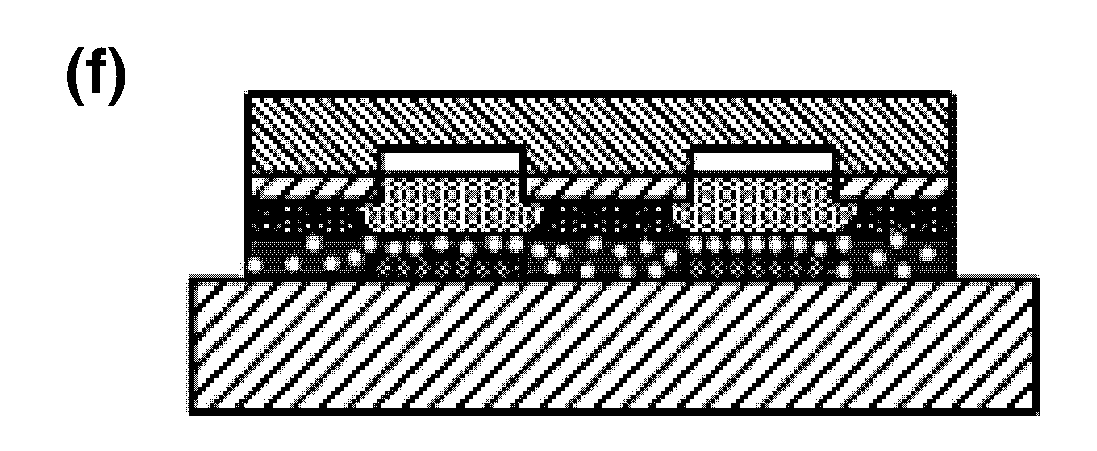

Method of manufacturing light-emitting diode

InactiveUS7811843B1Solid-state devicesSemiconductor/solid-state device manufacturingAnisotropic conductive adhesiveEngineering

A method of manufacturing an LED includes the following steps: preparing an LED wafer including a substrate and an epitaxial layer formed on the substrate; cutting the epitaxial layer of the LED wafer into a plurality of LED dies with a gap defined between every two neighboring dies; filling an electrically insulating material in each gap between neighboring LED dies such that the neighboring LED dies are separated from each other by the insulating material; providing a circuit board having a layer of anisotropic conductive adhesive coated thereon; pressing the LED dies against the adhesive to bring the top surfaces of the LED dies into contact with the adhesive such that the LED dies each are electrically connected to the circuit board via the adhesive; and encapsulating the LED dies with a light penetrable material.

Owner:HON HAI PRECISION IND CO LTD

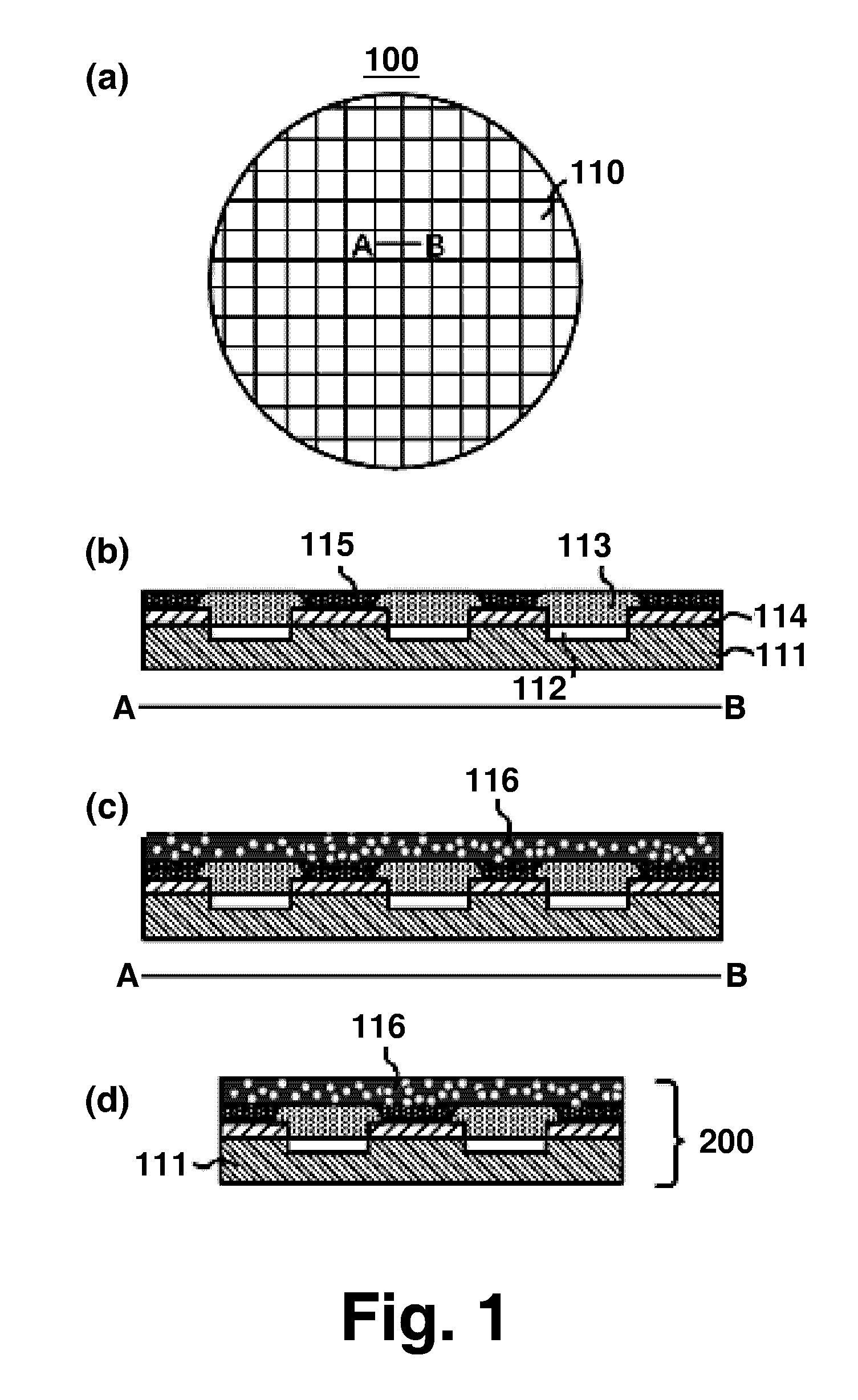

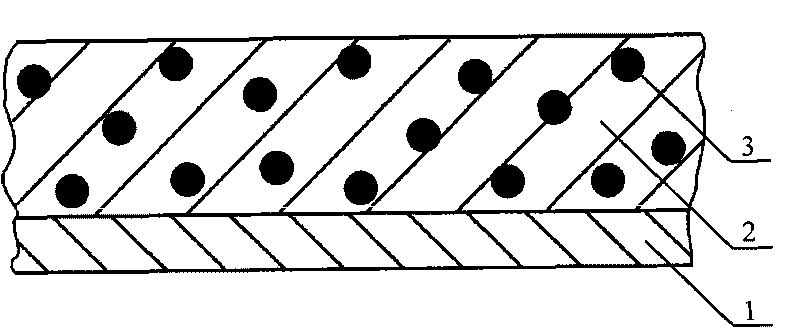

Wafer-level aca flip chip package using double-layered aca/nca

InactiveUS20090029504A1Reduce shadowing effectHigh selectivitySolid-state devicesSemiconductor/solid-state device manufacturingAnisotropic conductive adhesiveEngineering

A method of manufacturing a wafer-level flip chip package is capable of being used to produce a flip chip package by directly coating a flip chip package using anisotropic conductive adhesives (ACA) and non conductive adhesives (NCA) in a solution state as a double layer on a wafer. The method can be used to manufacture a non-conductive mixed solution and a conductive mixed solution and directly coat them on a substrate, such that it is possible to: increase productivity; simplify a manufacturing process; suppress a shadow effect; easily perform thickness control that is difficult with the anisotropic conductive adhesive paste or the non-conductive adhesive paste; and obtain the non-conductive layer and the anisotropic conductive layer in an initial state of a B-stage with a level not losing latent of hardening through a simple drying process to volatilize an organic solvent. Above all, the non-conductive layer and the anisotropic conductive layer is sequentially stacked on the substrate formed with the non-solder bump, making it possible to make the selectivity of electrical conduction and the stability of a connection process excellent, shorten process time and costs, and dramatically reduce consumption of the conductive particles which account for a large portion of total production costs.

Owner:KOREA ADVANCED INST OF SCI & TECH

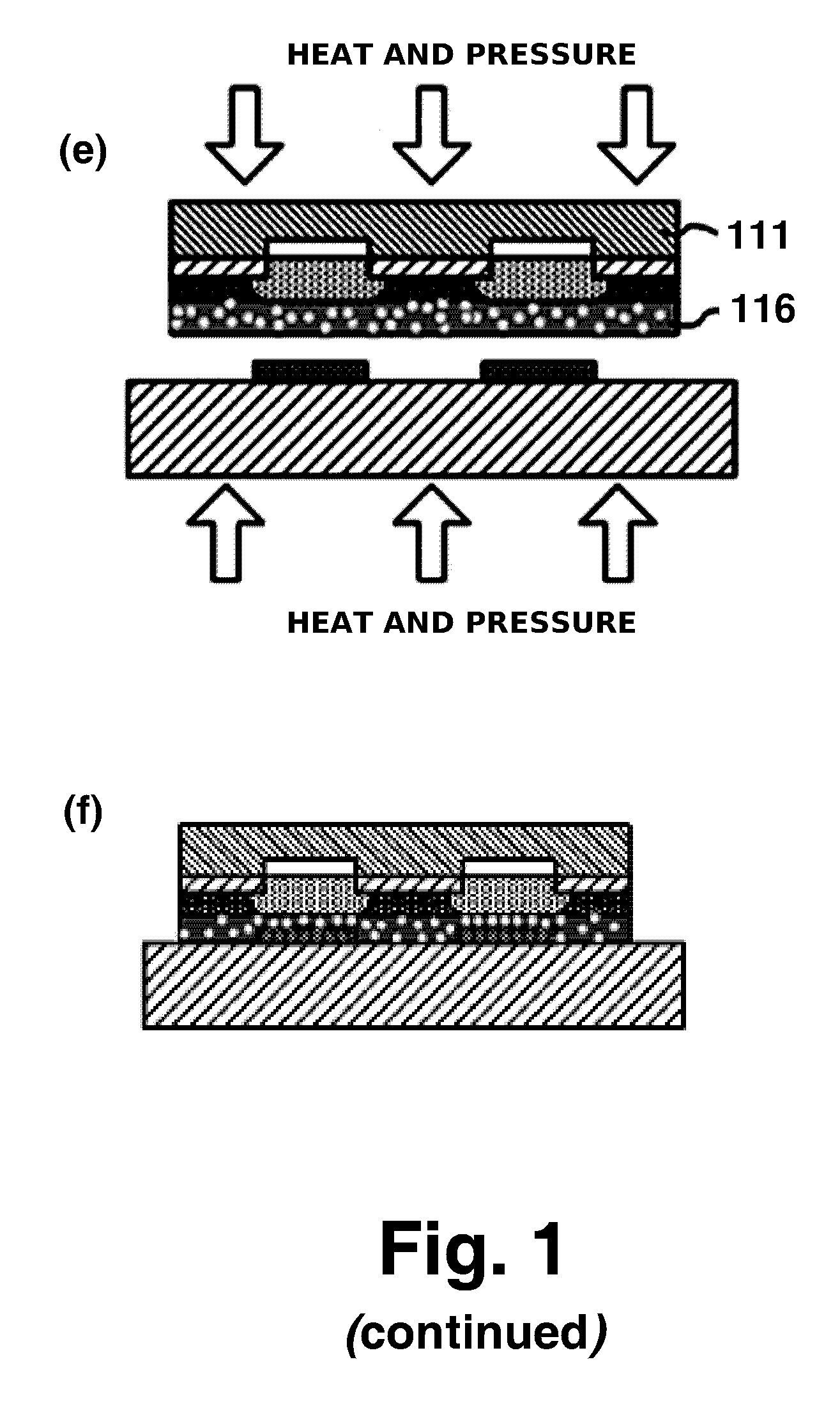

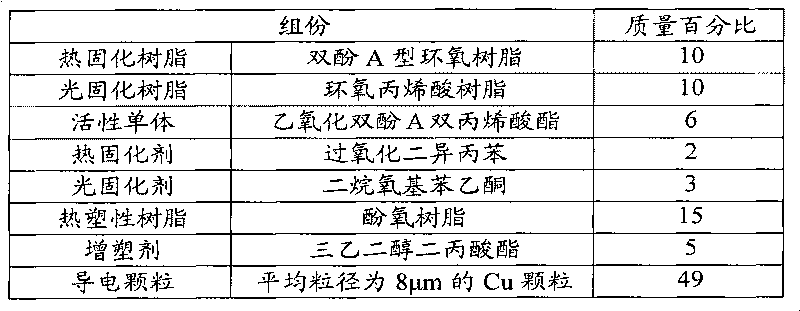

Aeolotropic conductive adhesive and conductive film and electric connection method thereof

InactiveCN101724361AWill not affect the electrical connection effectReliable electrical connectionFilm/foil adhesivesSemiconductor/solid-state device detailsAnisotropic conductive filmElectricity

The invention relates to an aeolotropic conductive adhesive and a conductive film comprising the same. The conductive adhesive is prepared from the following components: a) 20-40w% of cross-linkable cured resin, wherein at least part of the cross-linkable cured resin is light-cured resin and at least part of the cross-linkable cured resin is heat reactive resin; b) 5-20w% of activated monomer; c) heat curing agent and light curing agent with a sum of 1-8w%; d) 10-40w% of thermoplastic resin; e) selectable 3-15% of plasticizer; and f) 20-70w% of conductive particles. The aeolotropic conductive adhesive and the aeolotropic conductive film can be conveniently and effectively used for the electric connection between base plates with a non-transparent circuit or a conductive element. The base plates are not damaged due to the problems of high temperature and high voltage in the process of the electric connection and the effect of the electric connection cannot be influenced due to the non-transparency of the conductive element.

Owner:SICHUAN COC DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com