Patents

Literature

65results about How to "Improve conduction reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

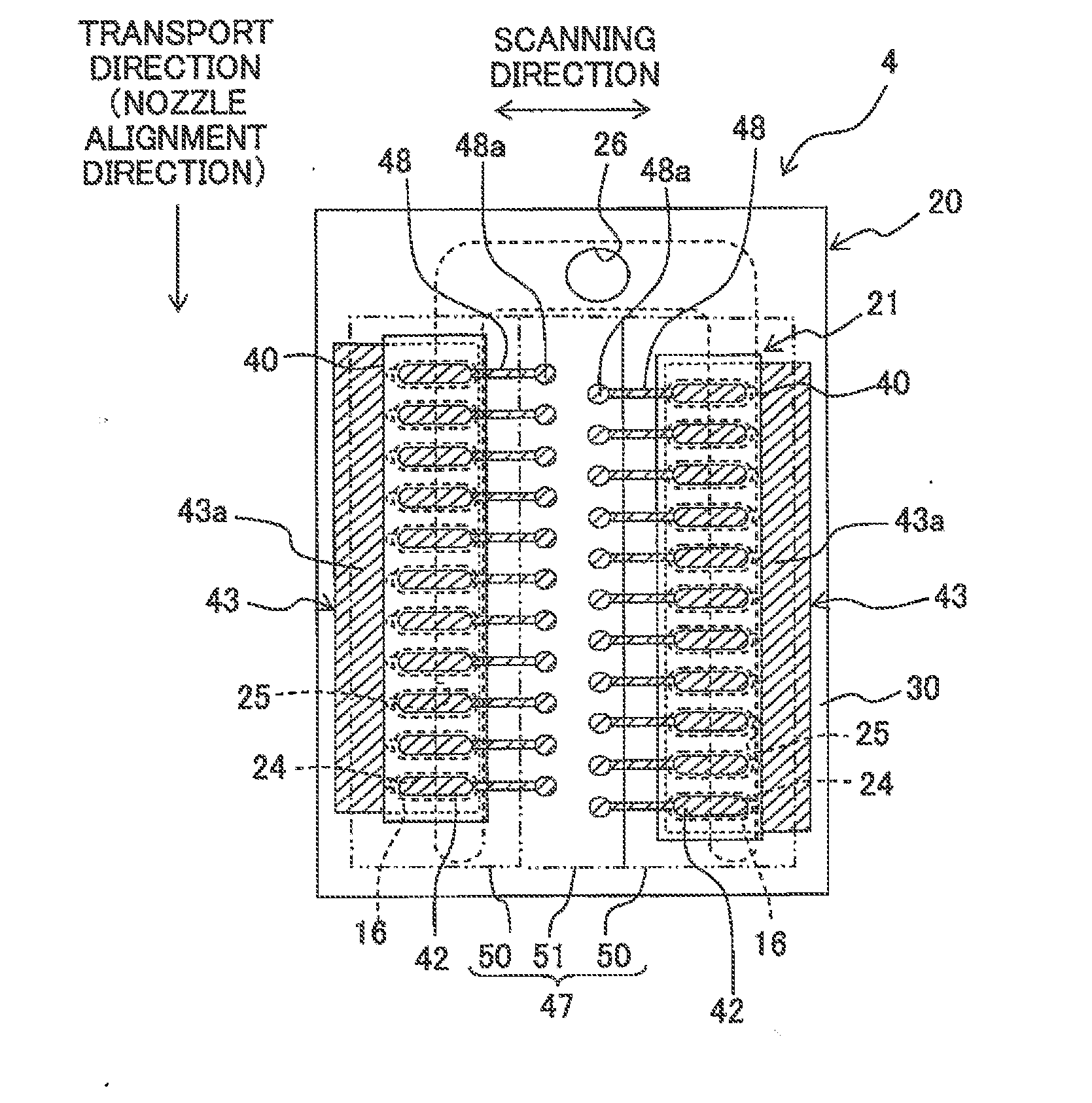

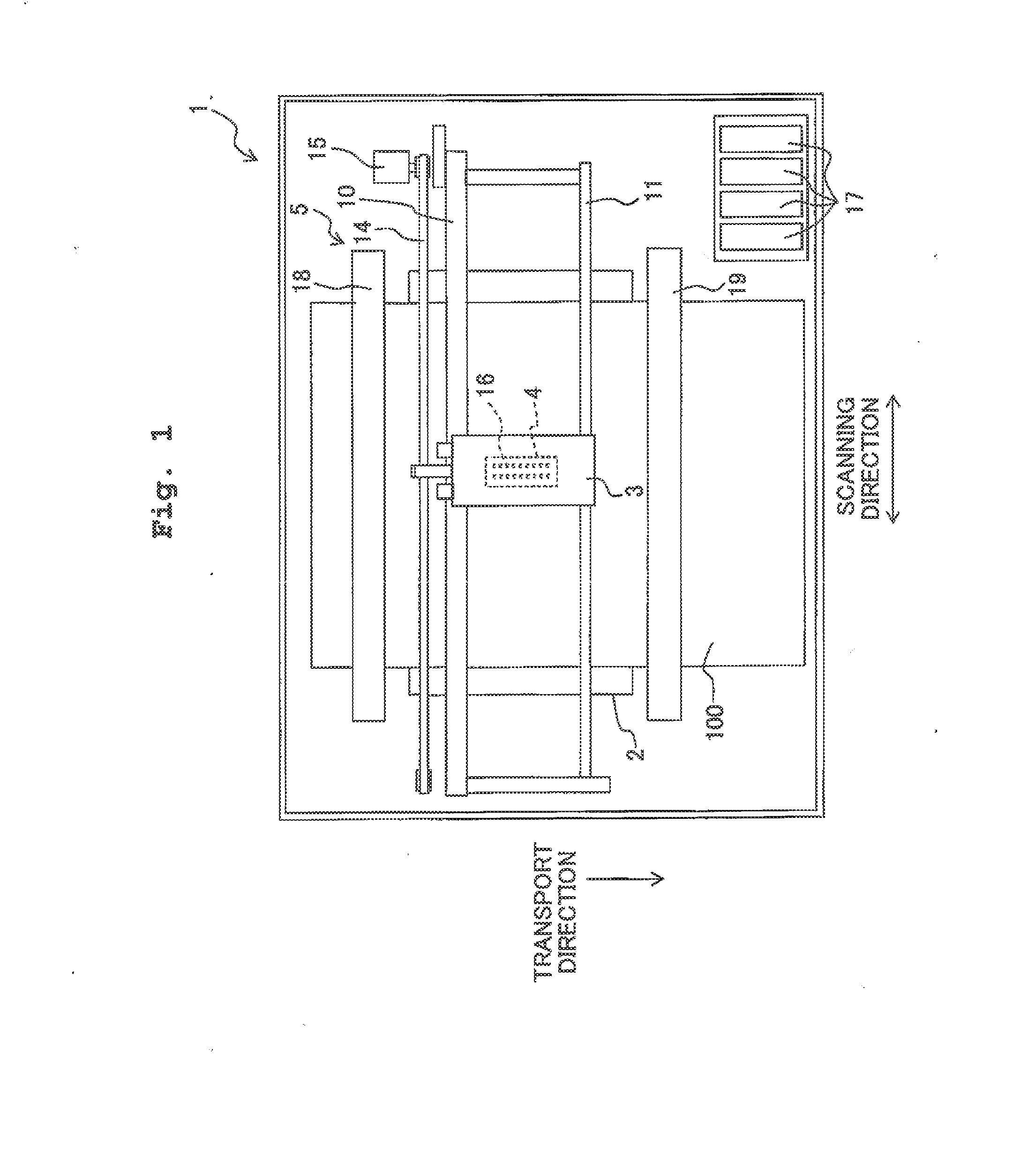

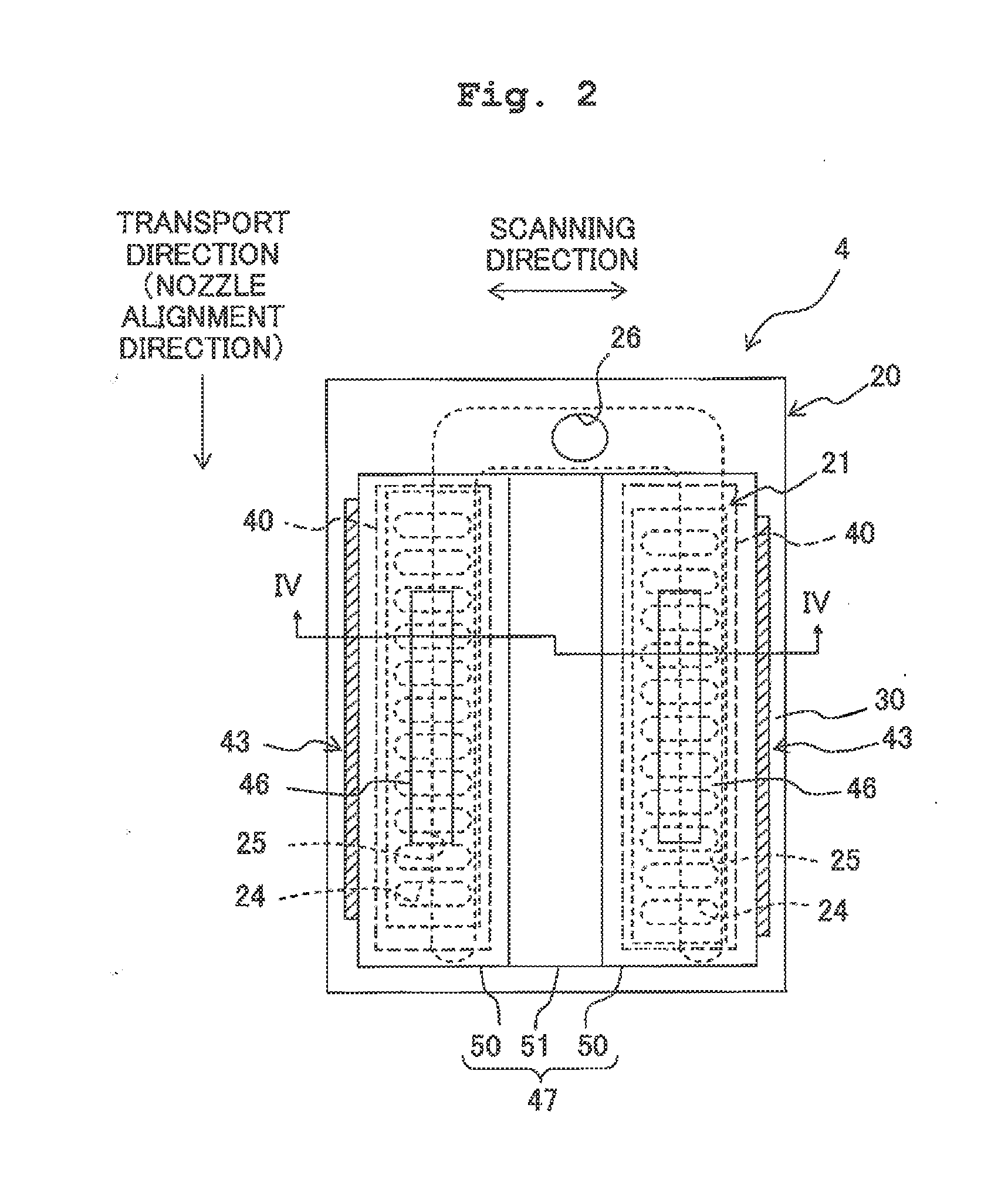

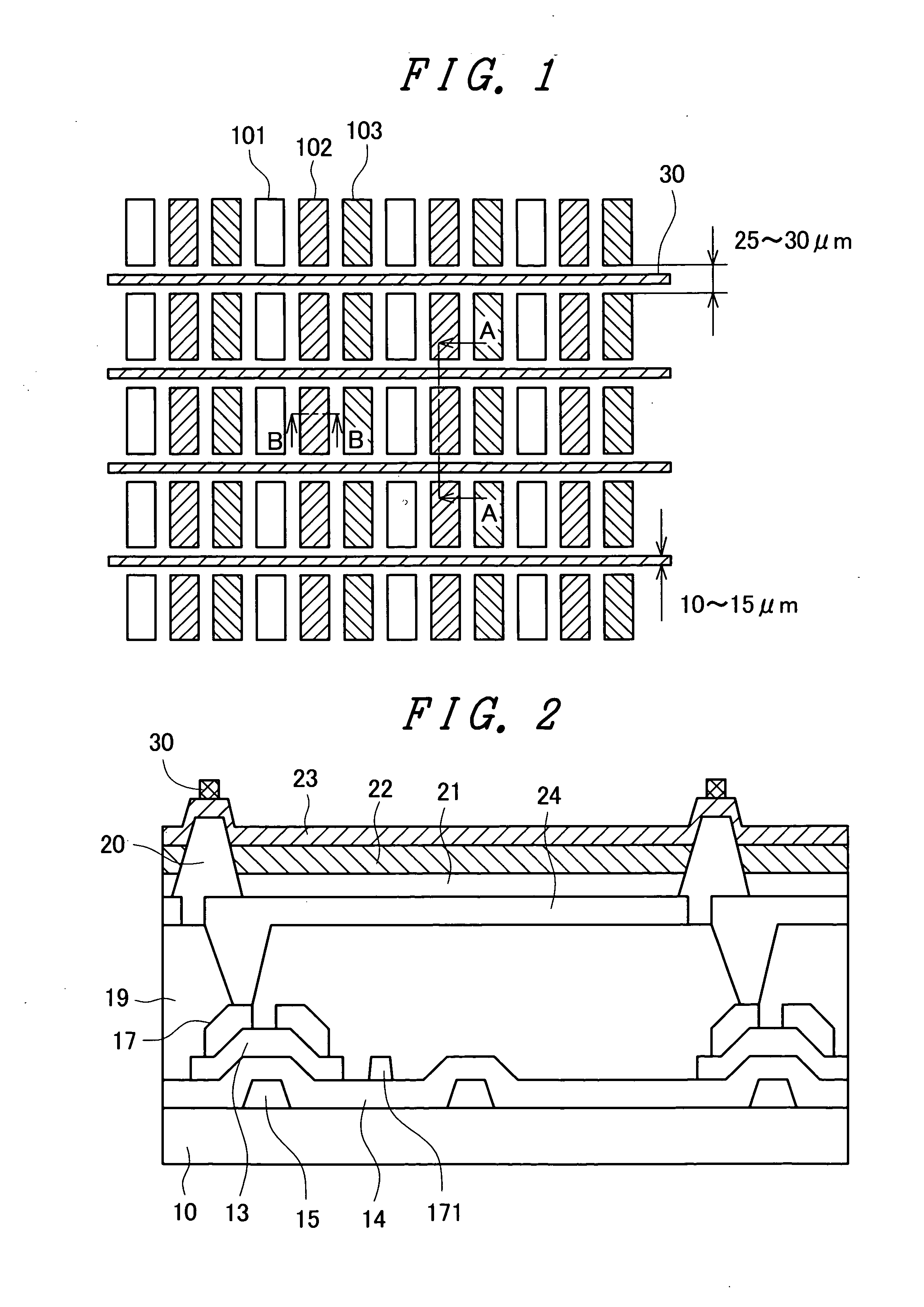

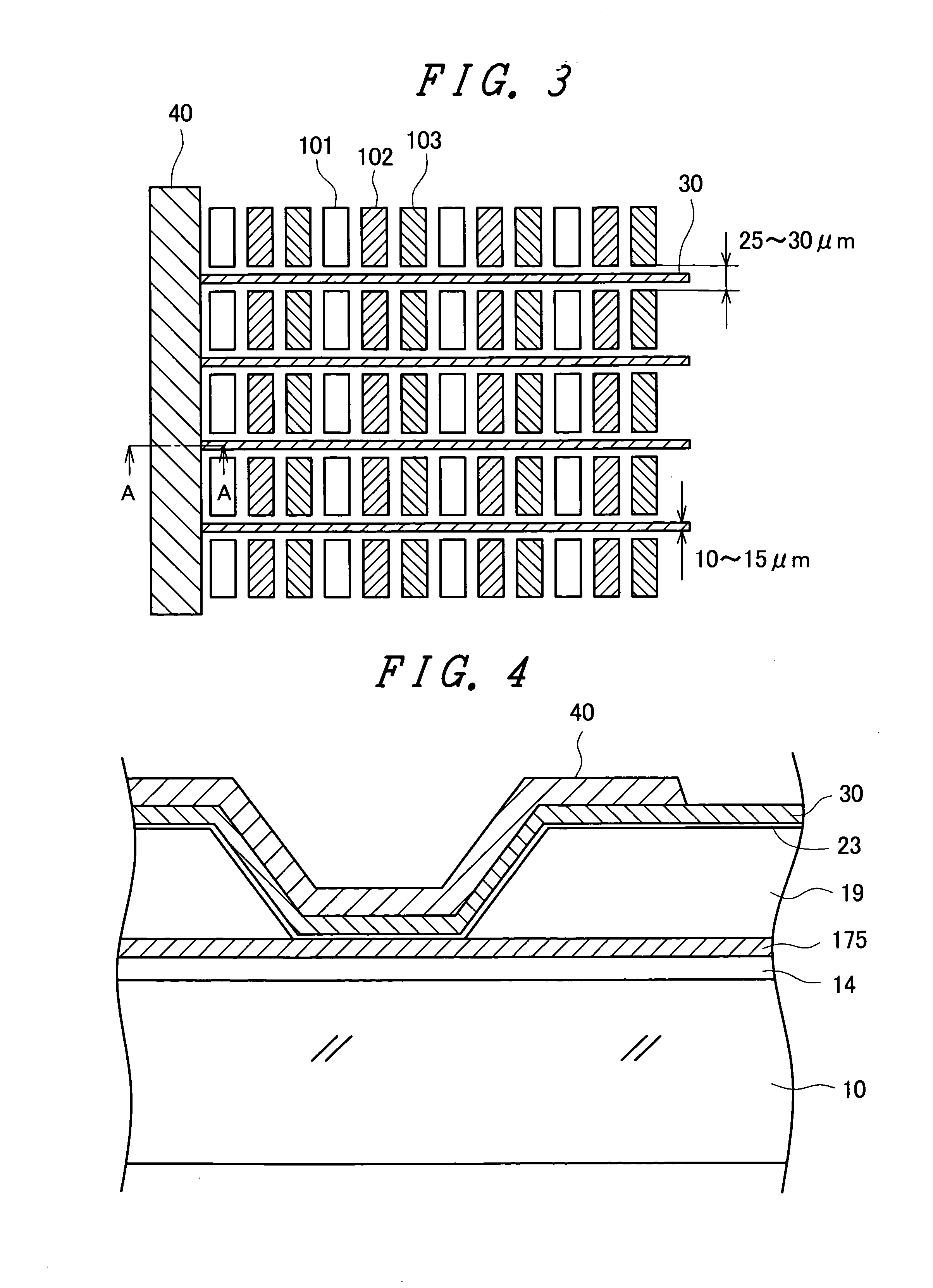

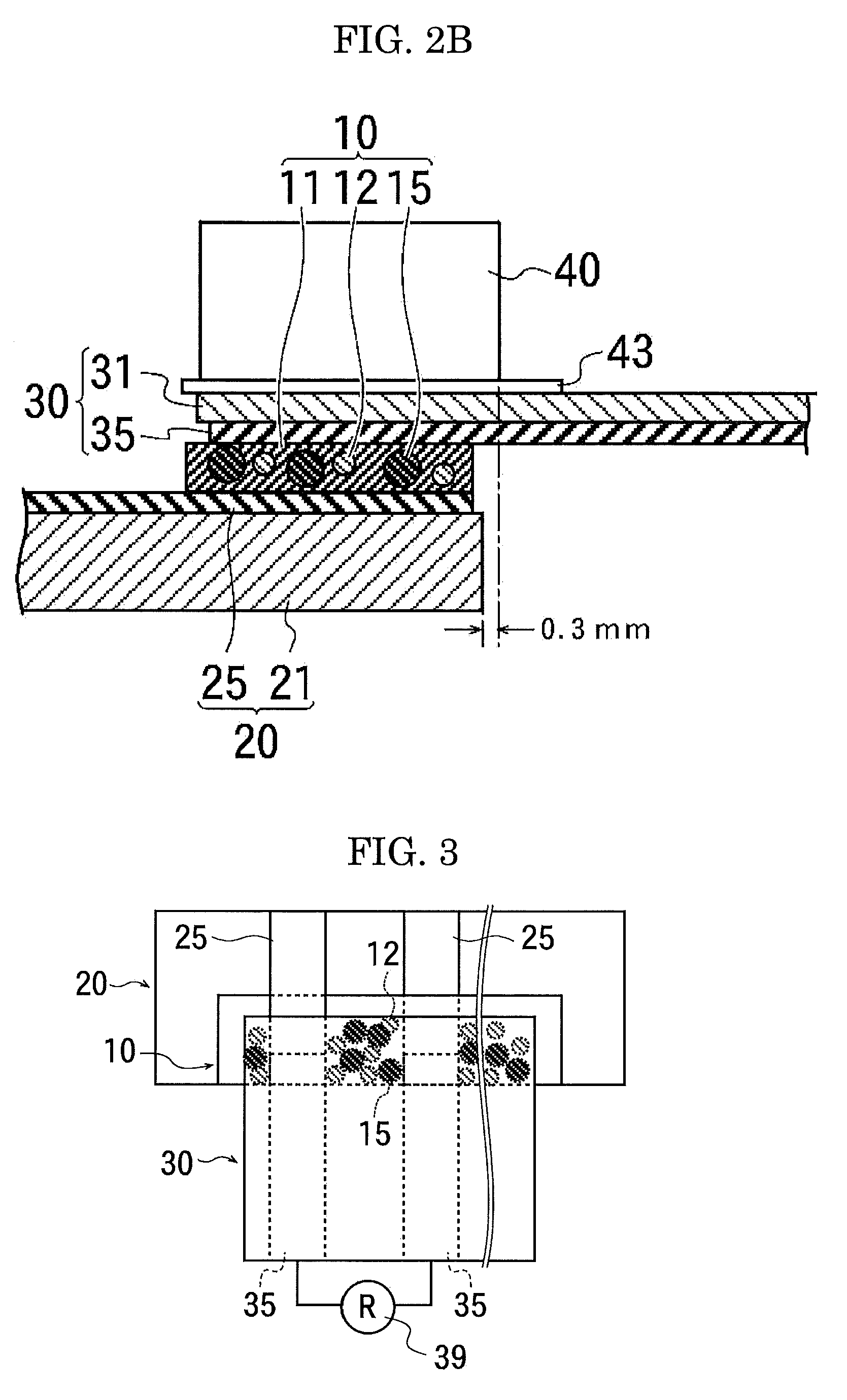

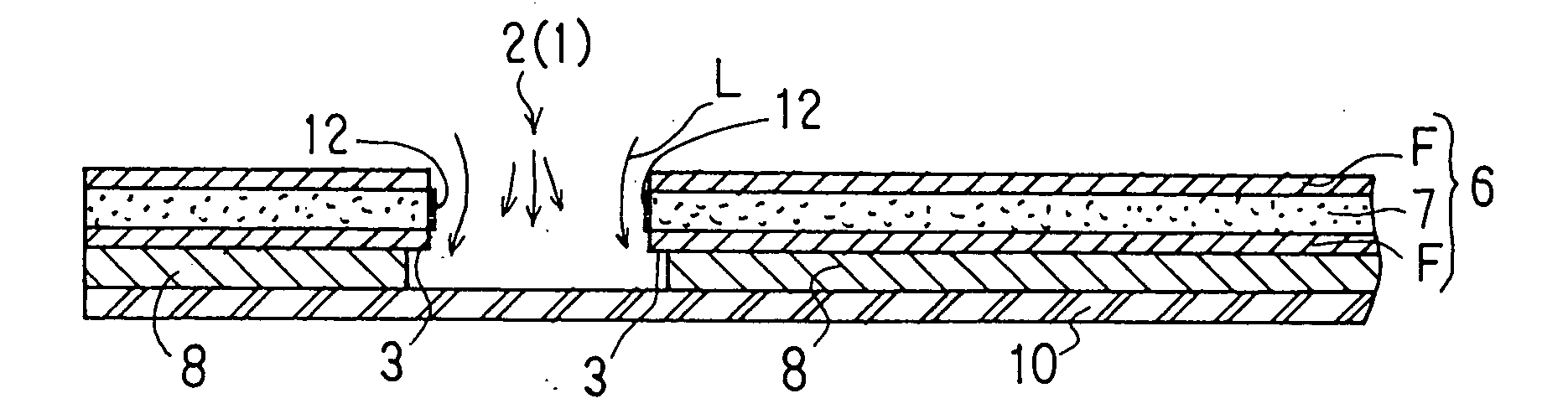

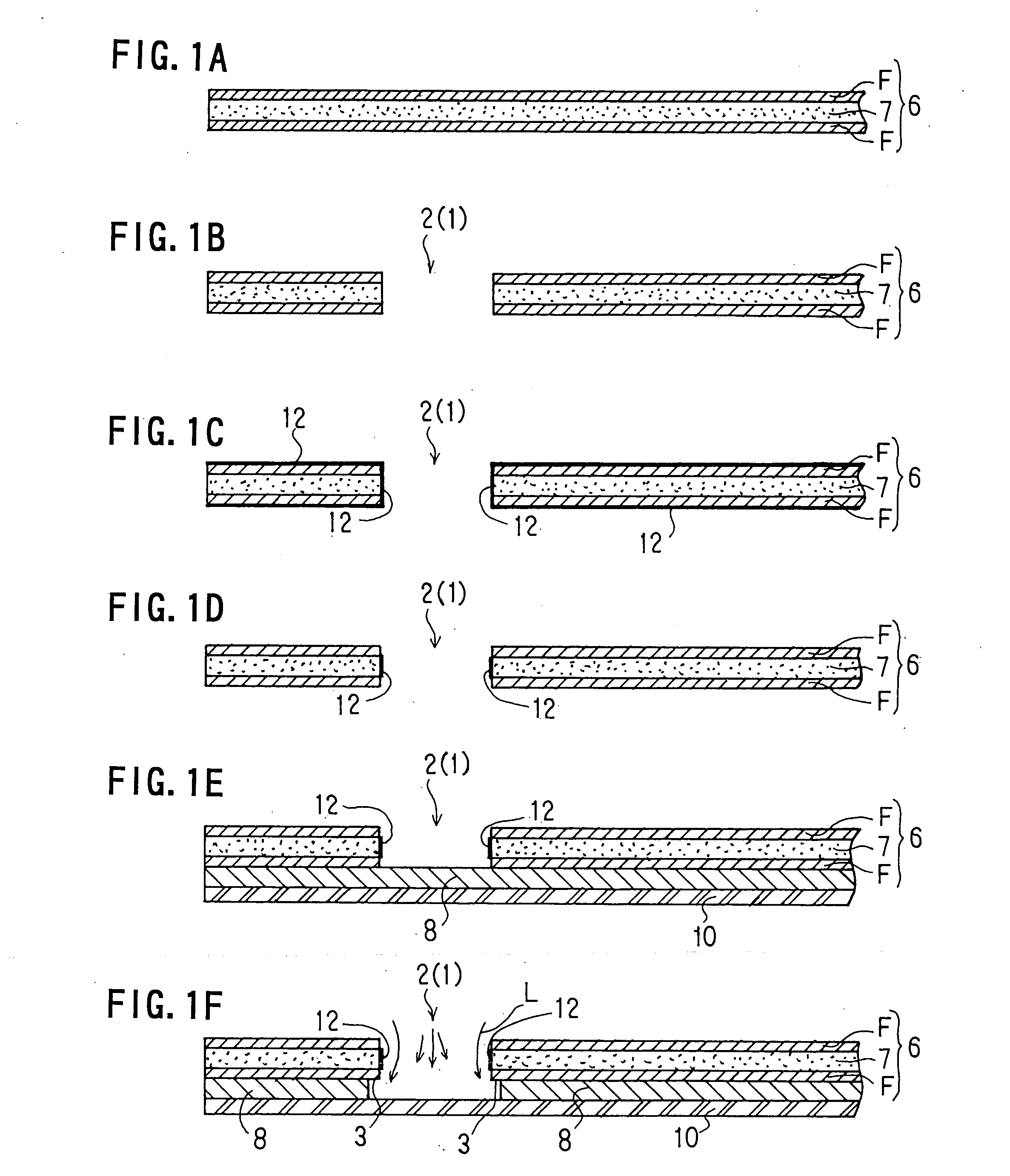

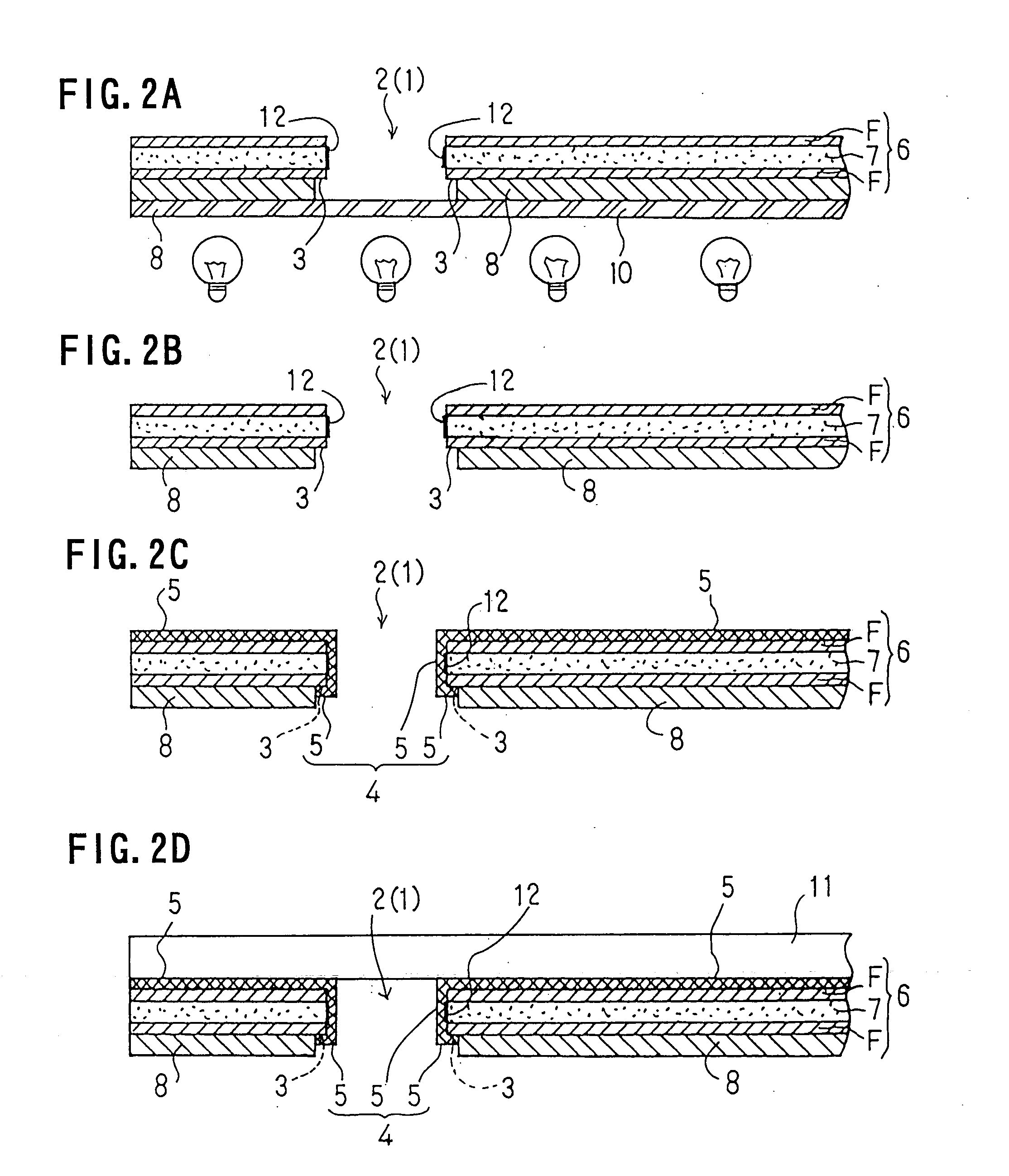

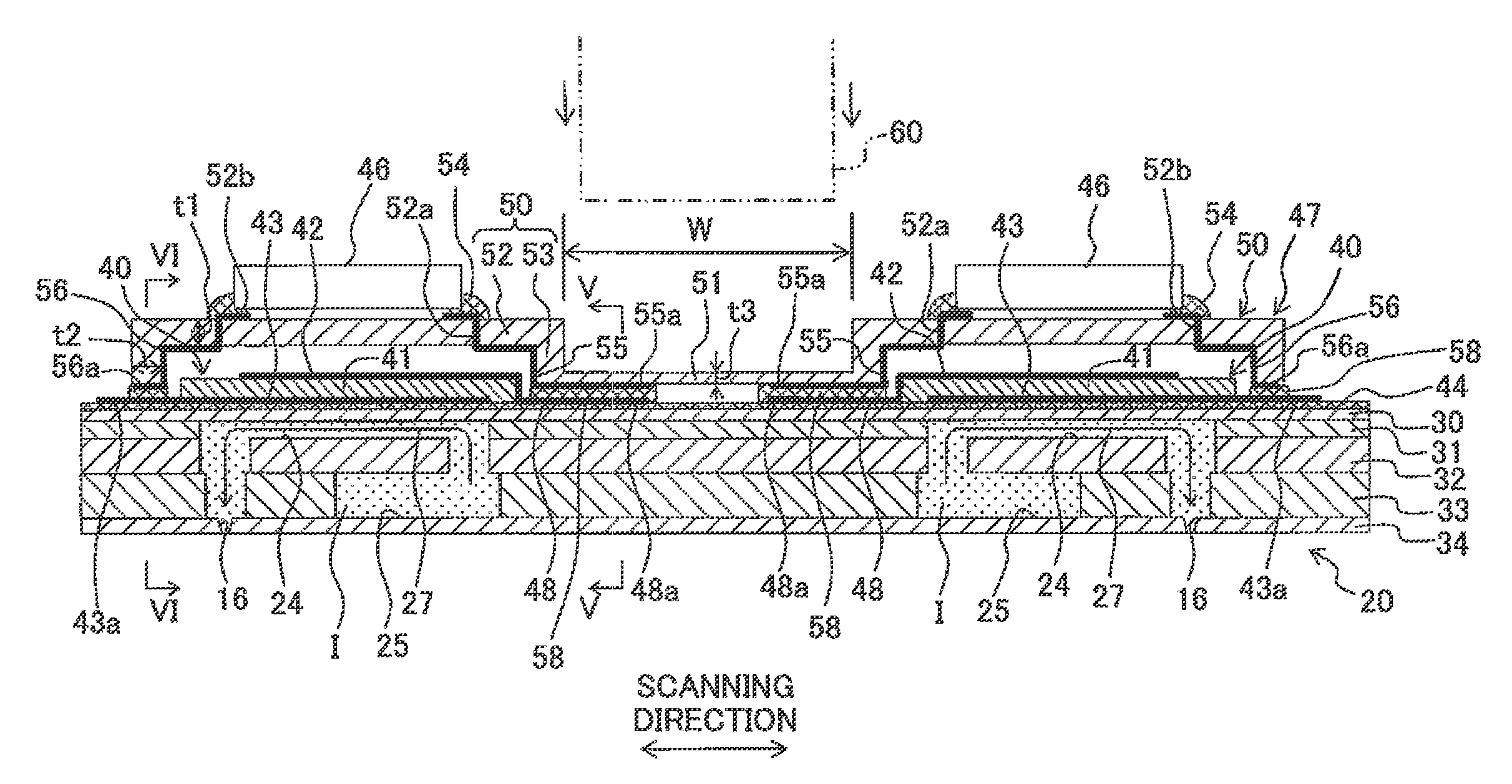

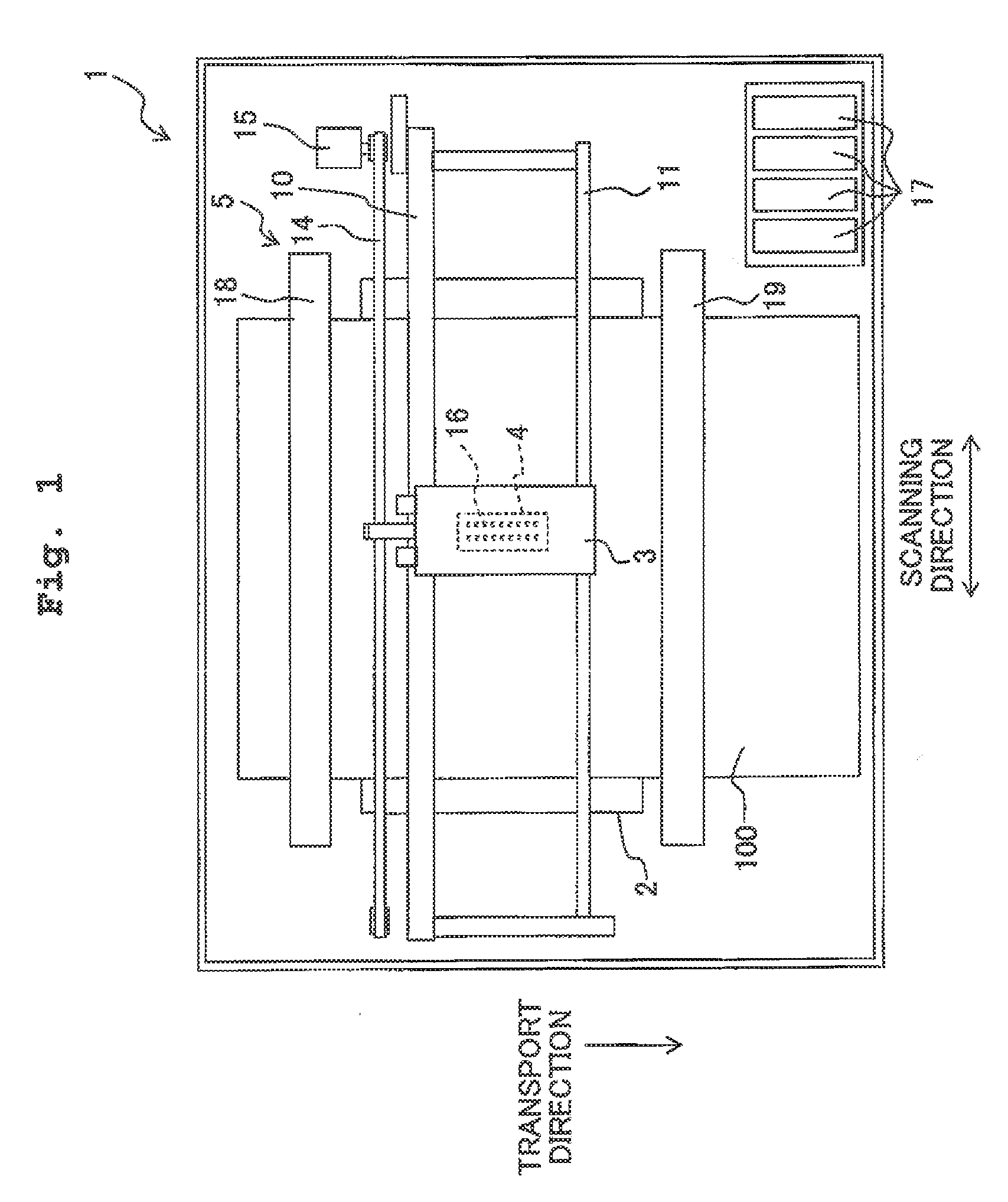

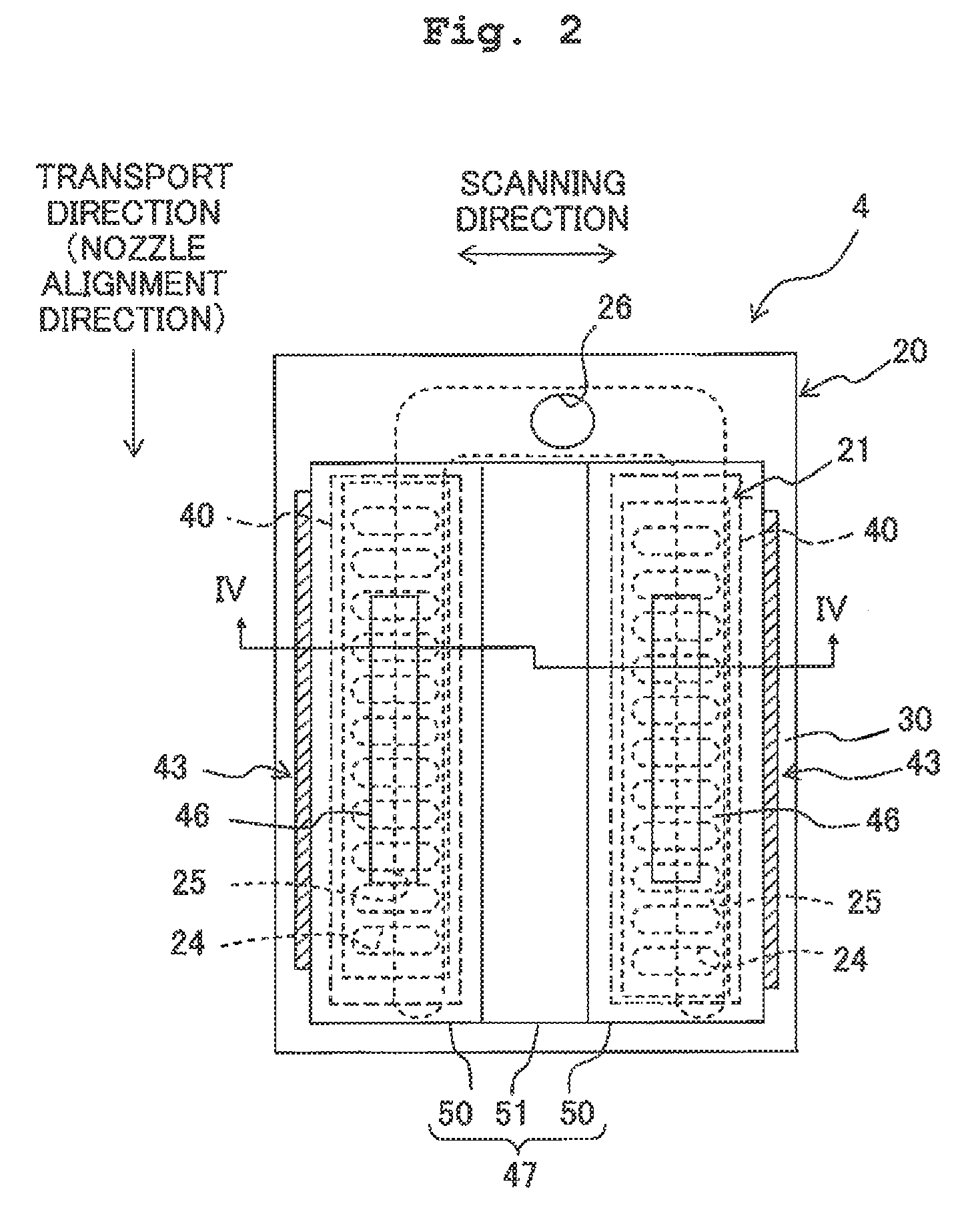

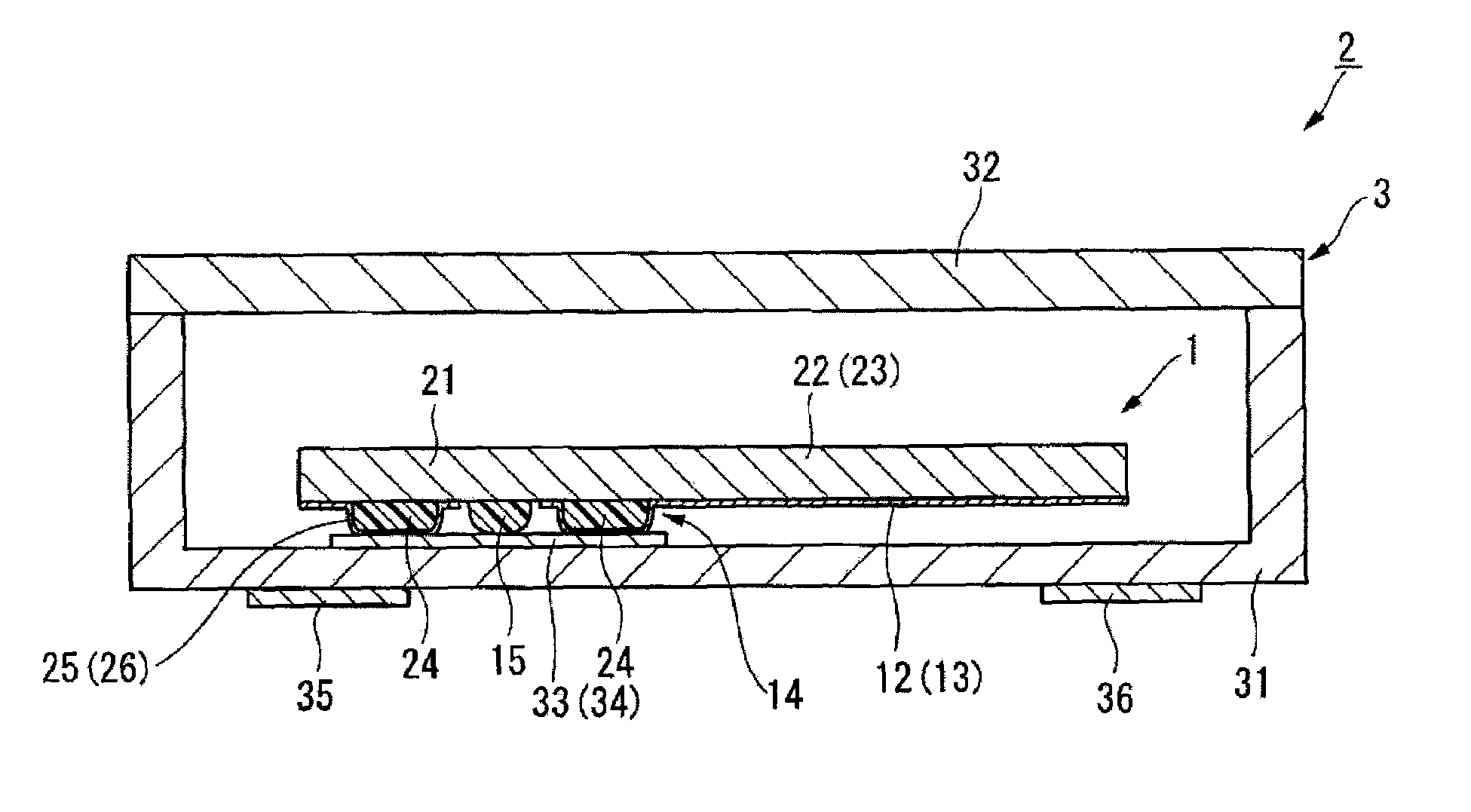

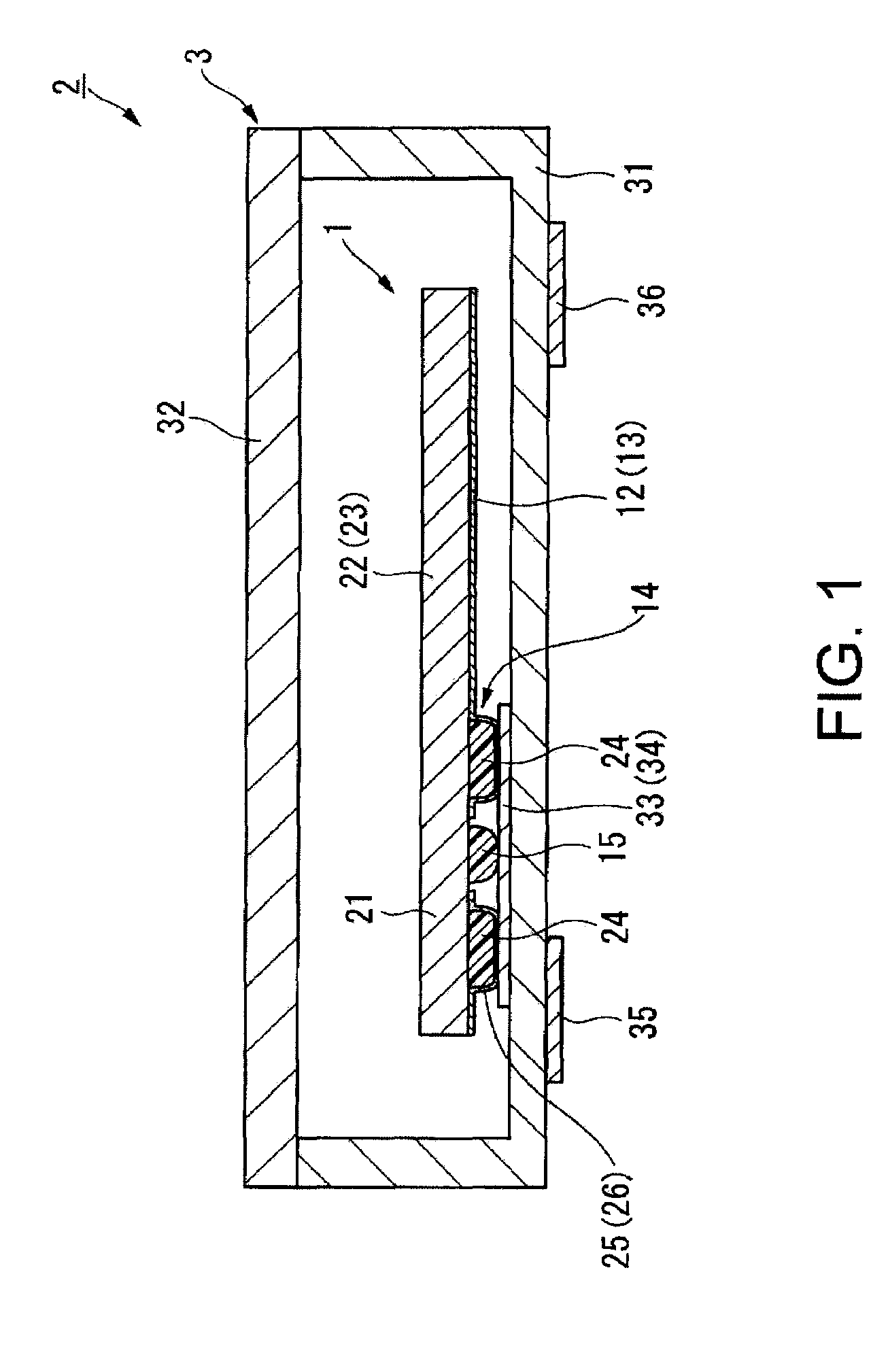

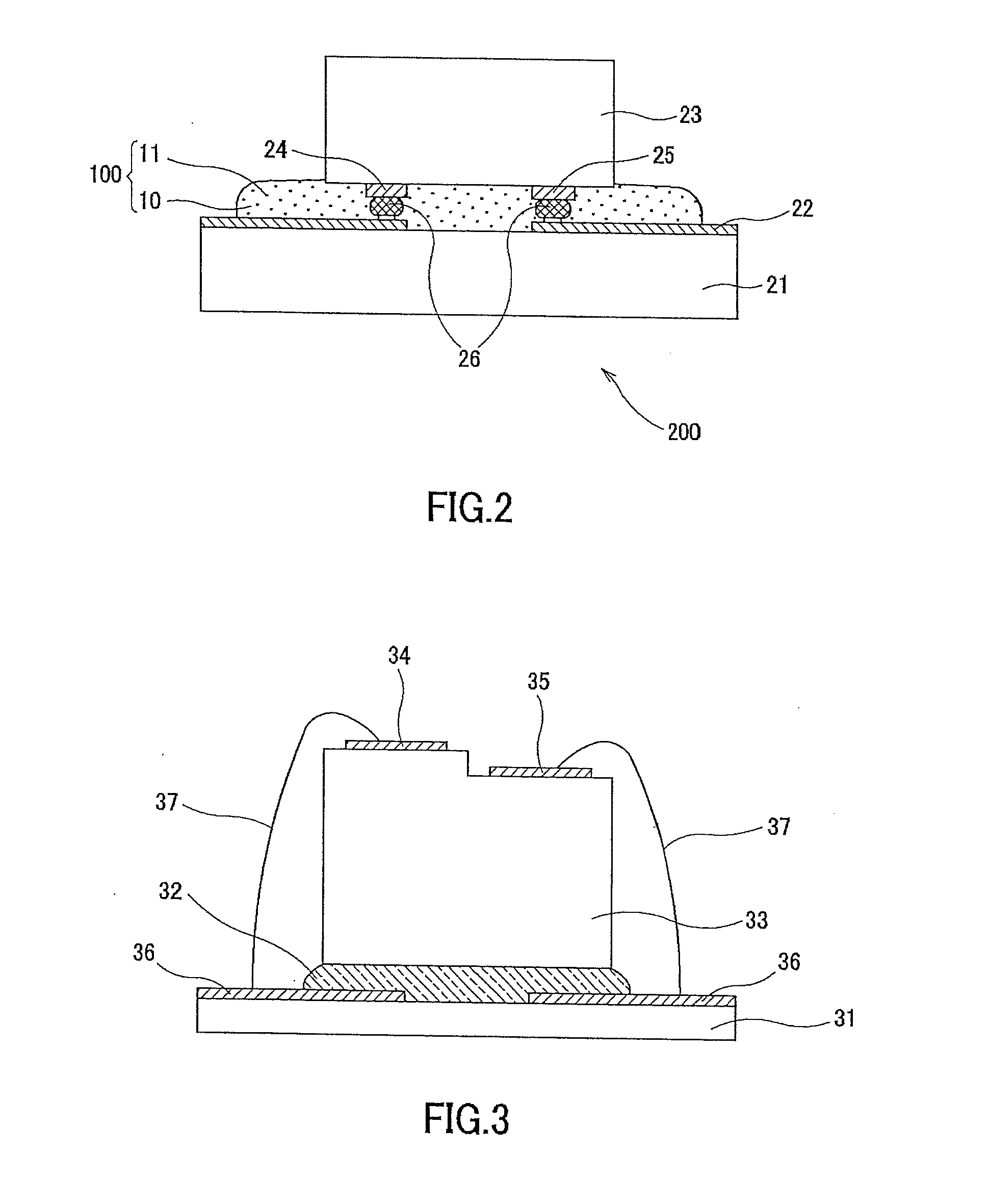

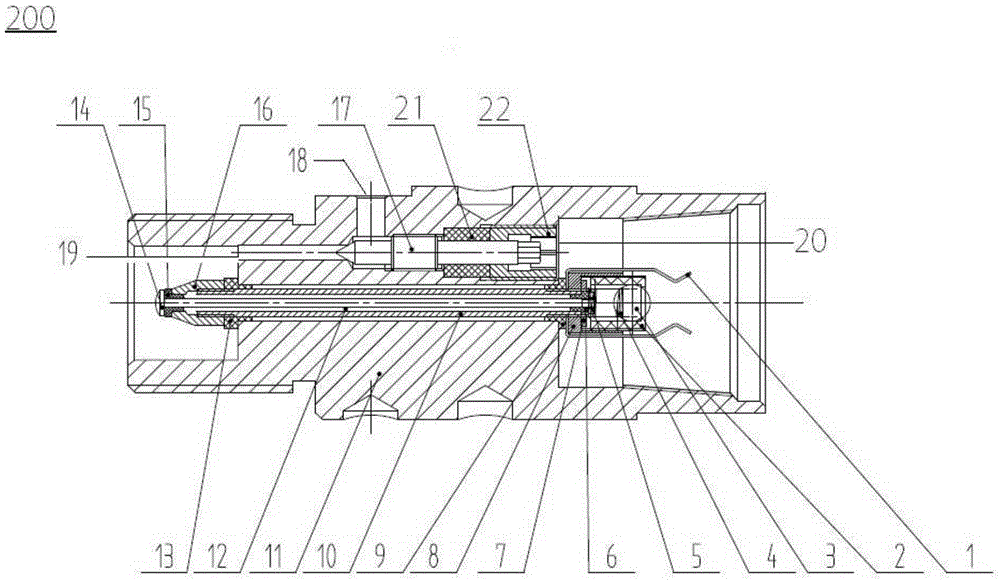

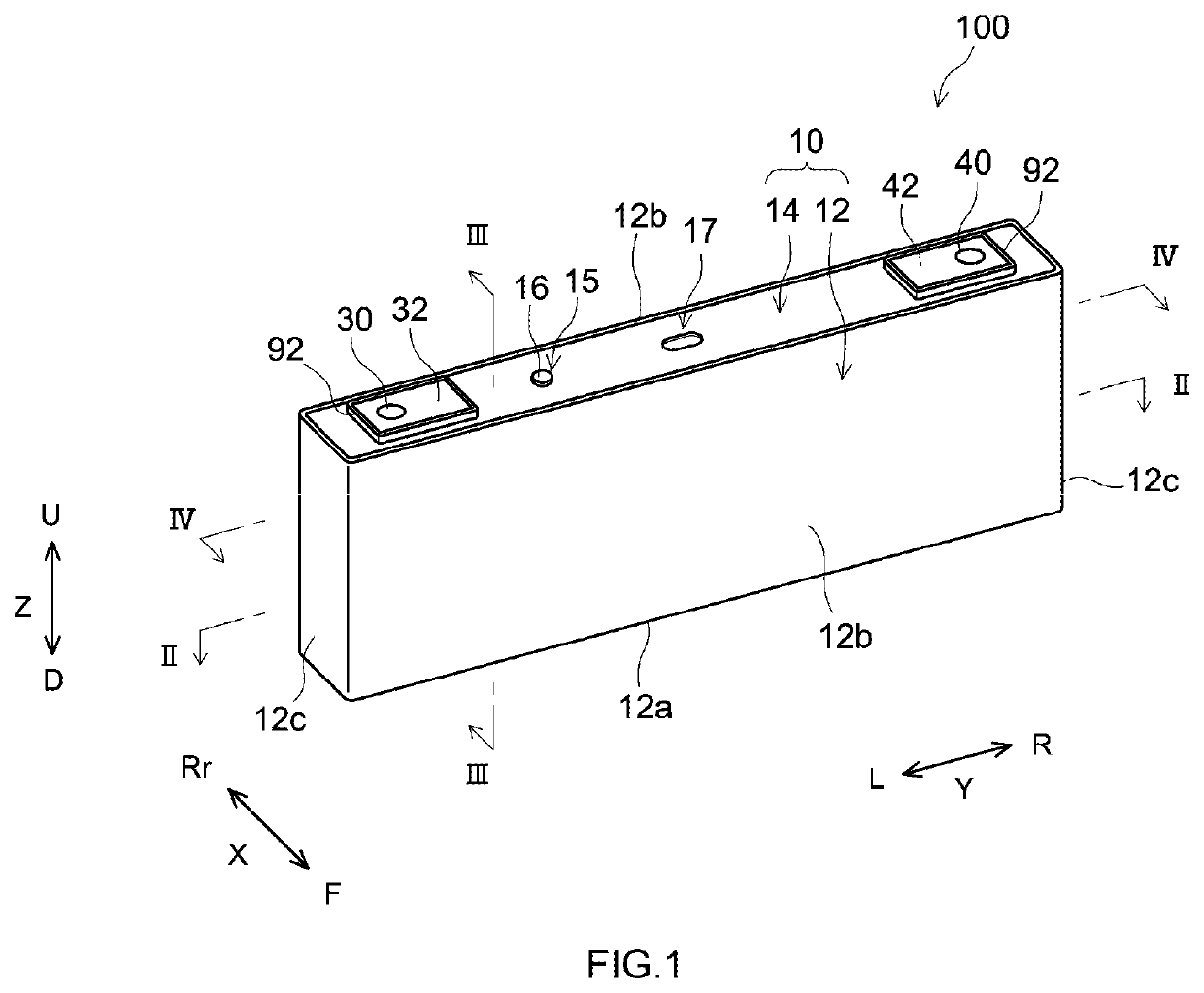

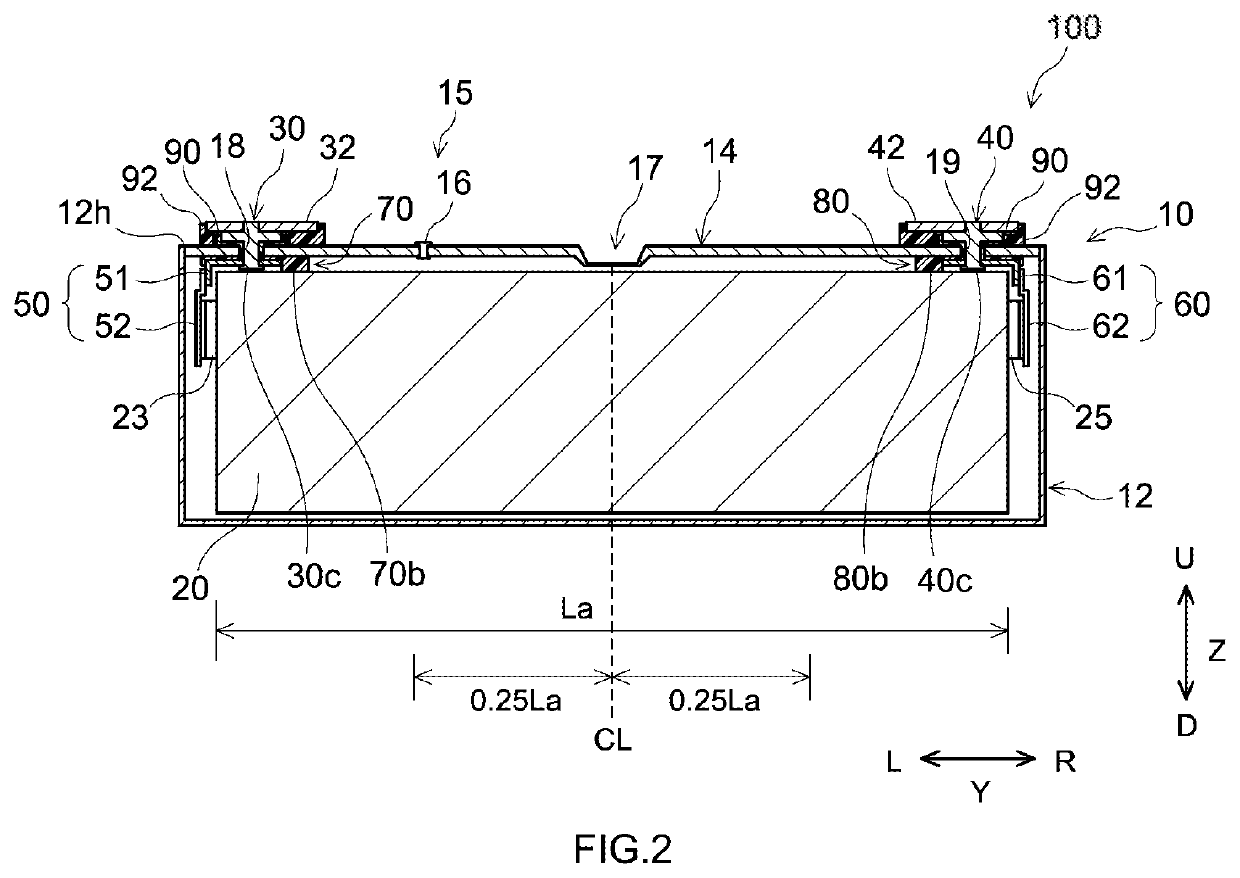

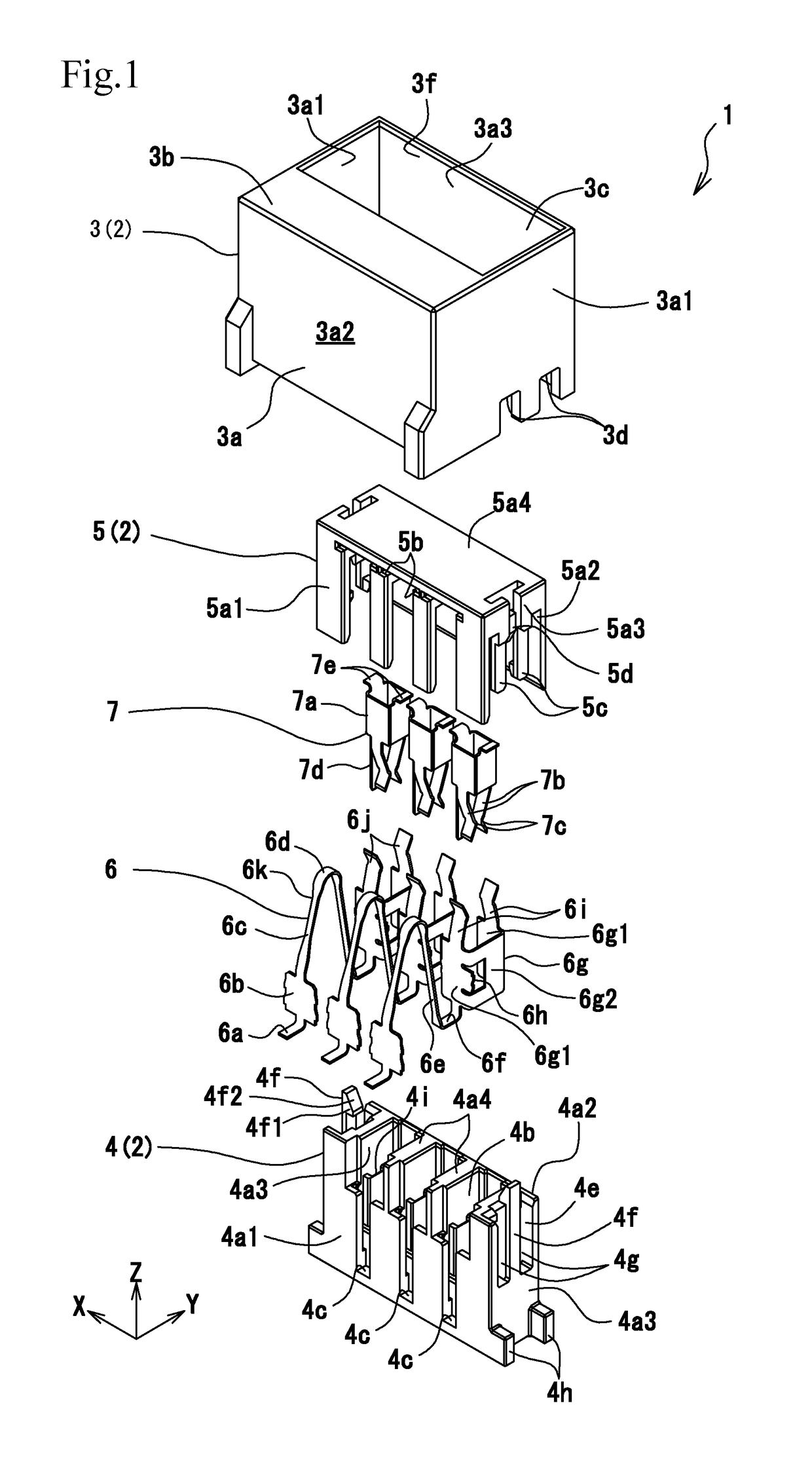

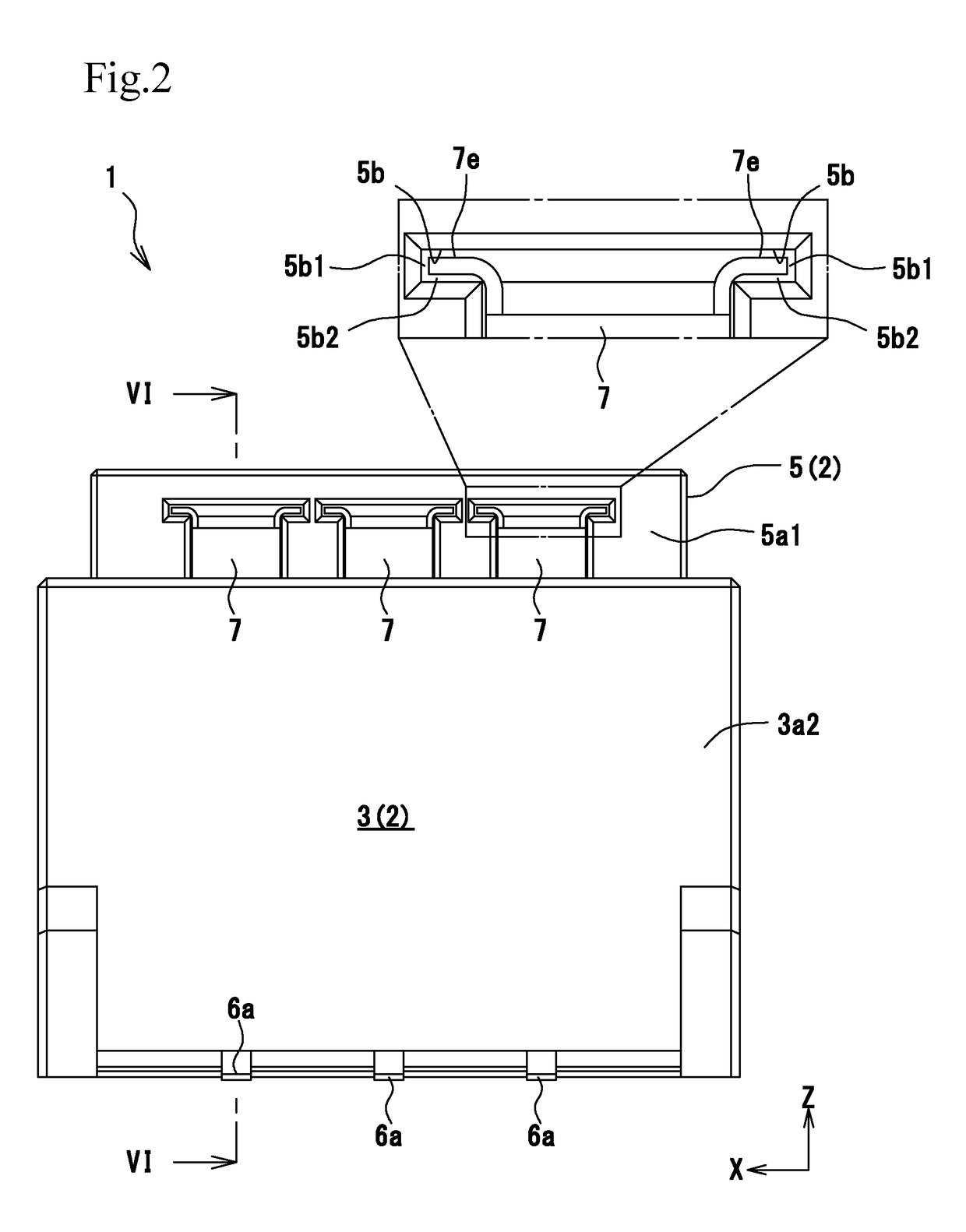

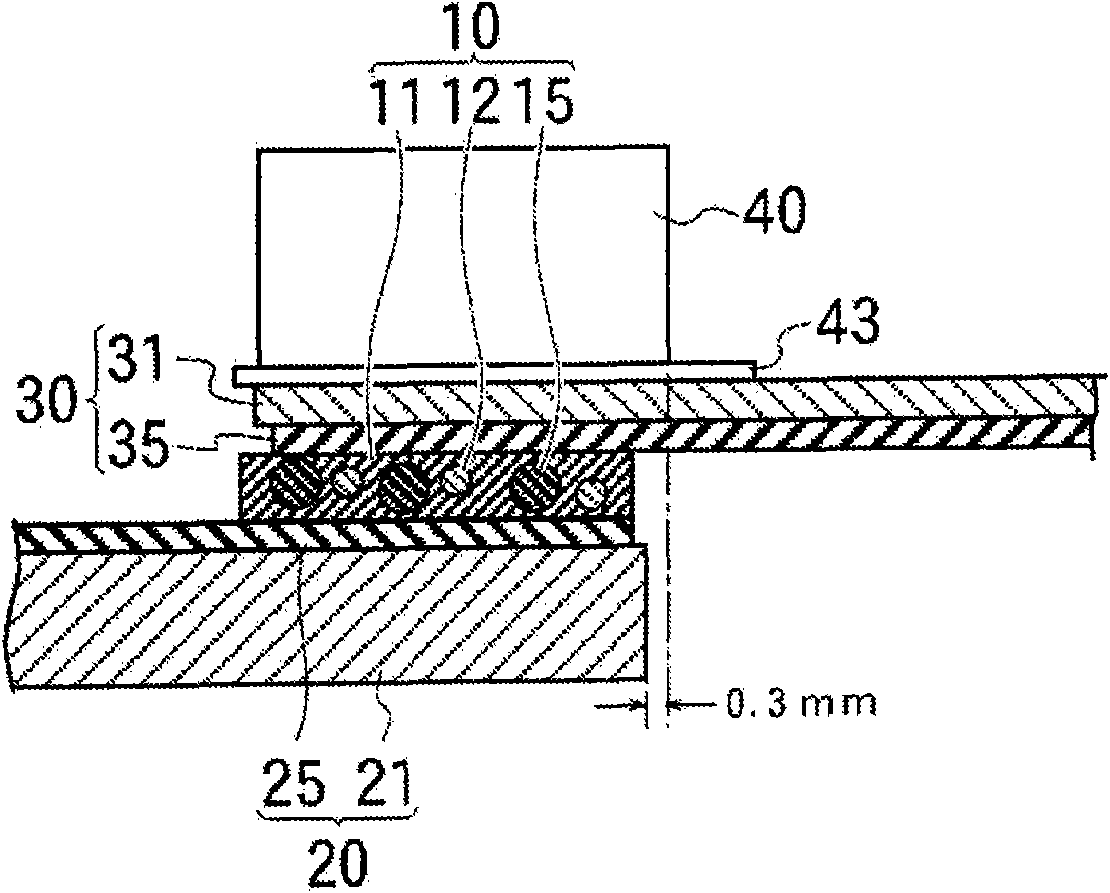

Liquid jetting apparatus and piezoelectric actuator

ActiveUS20140132677A1Easy to implementImprove conduction reliabilityPiezoelectric/electrostrictive/magnetostrictive devicesPrintingPiezoelectric actuatorsEngineering

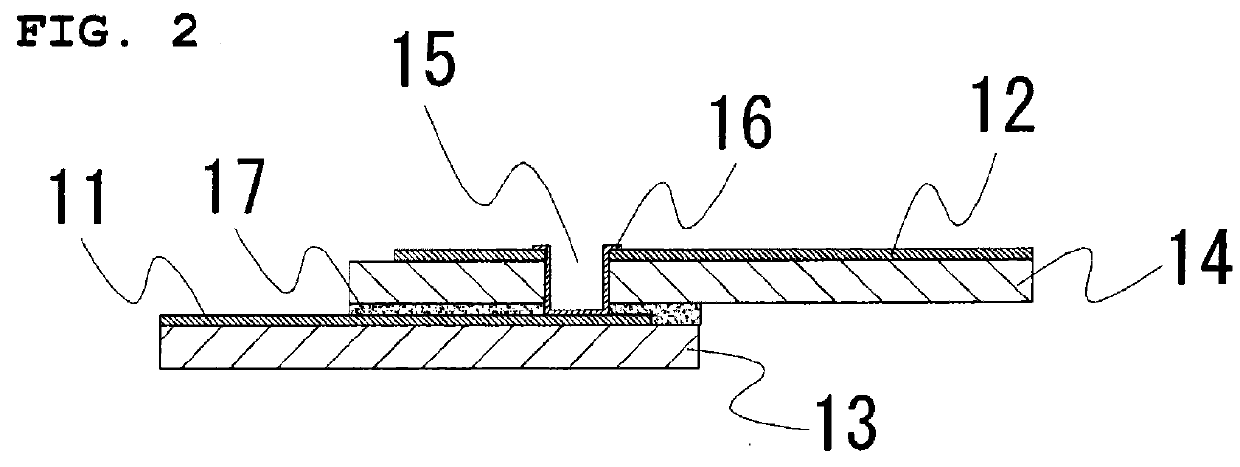

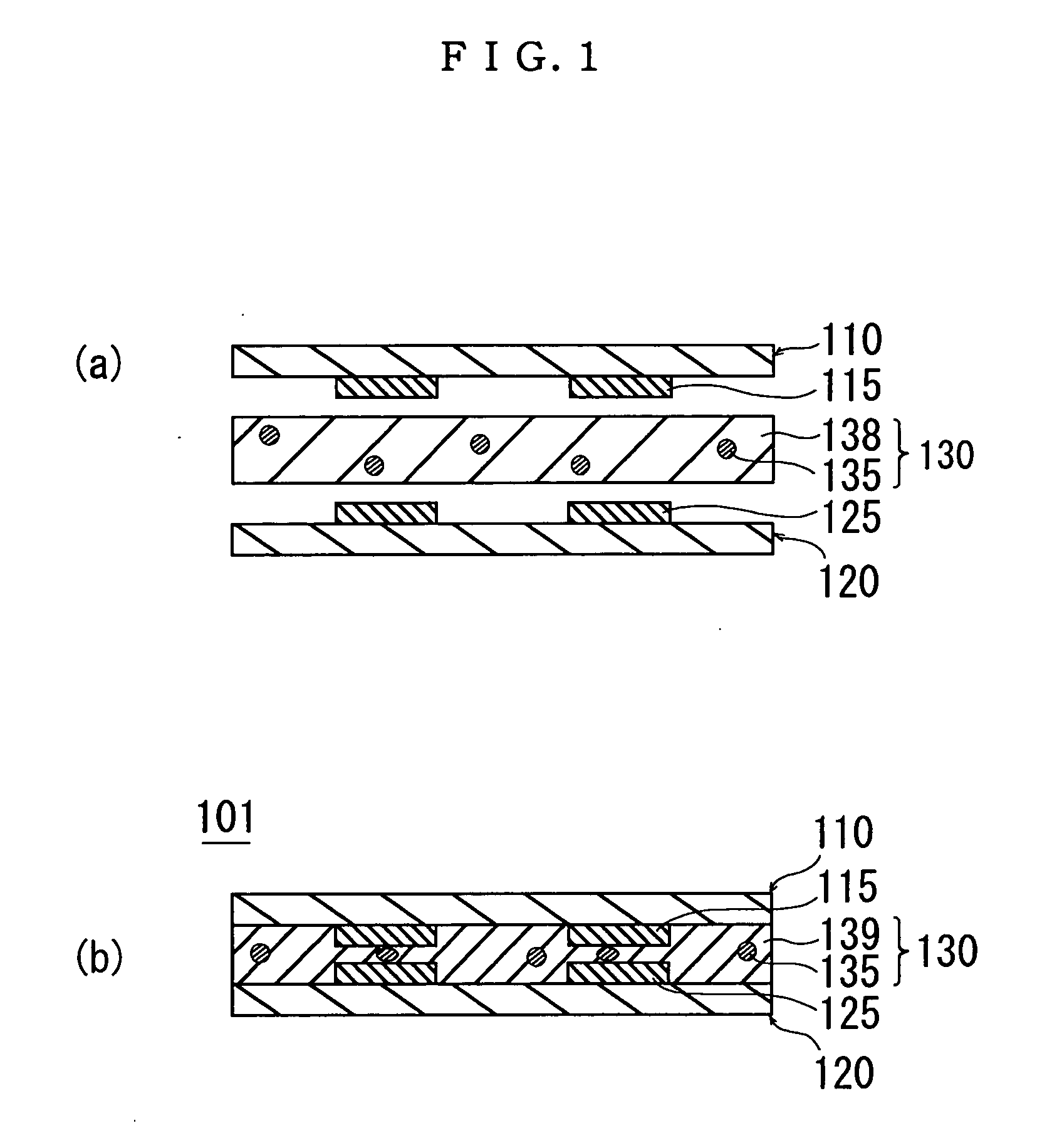

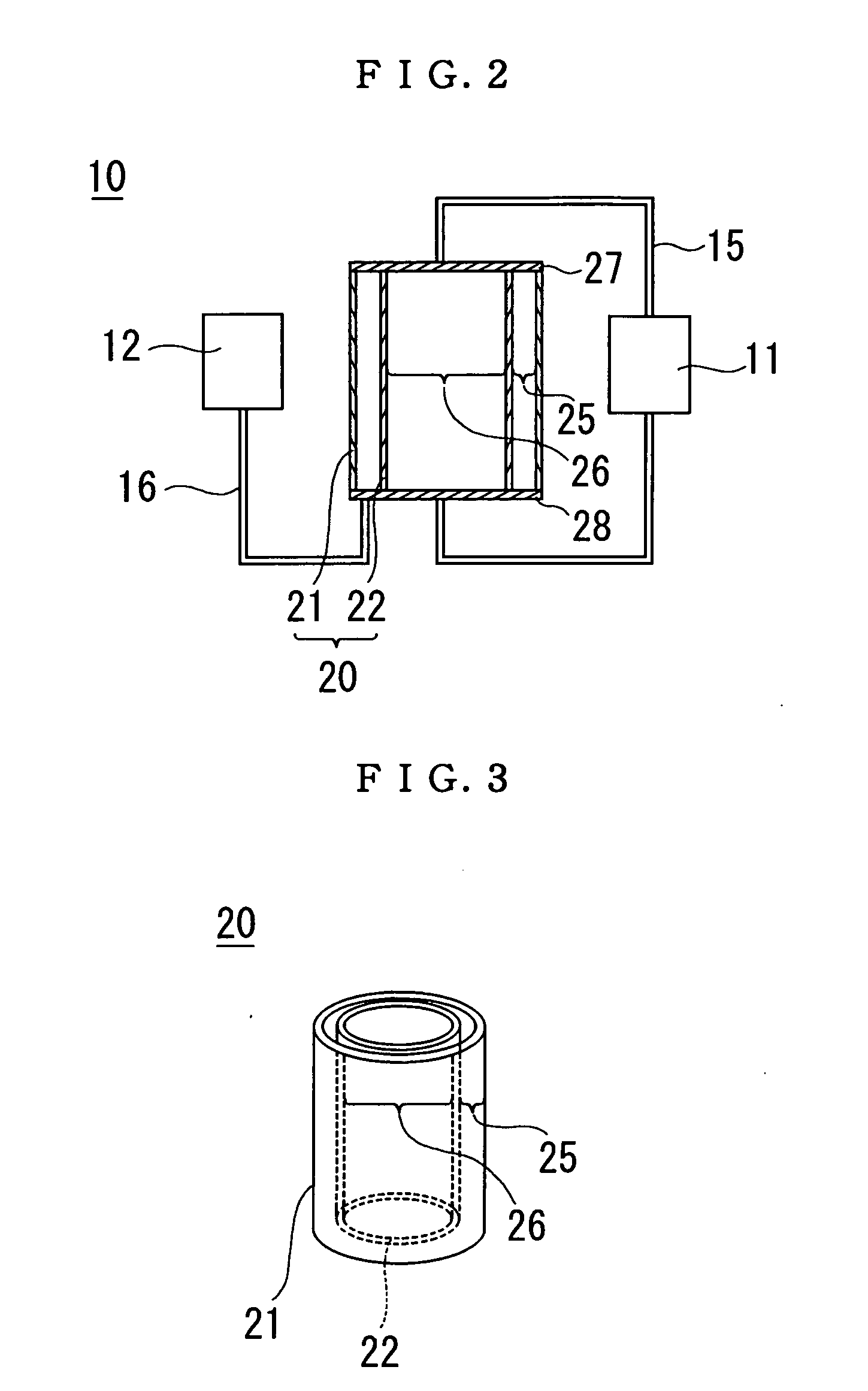

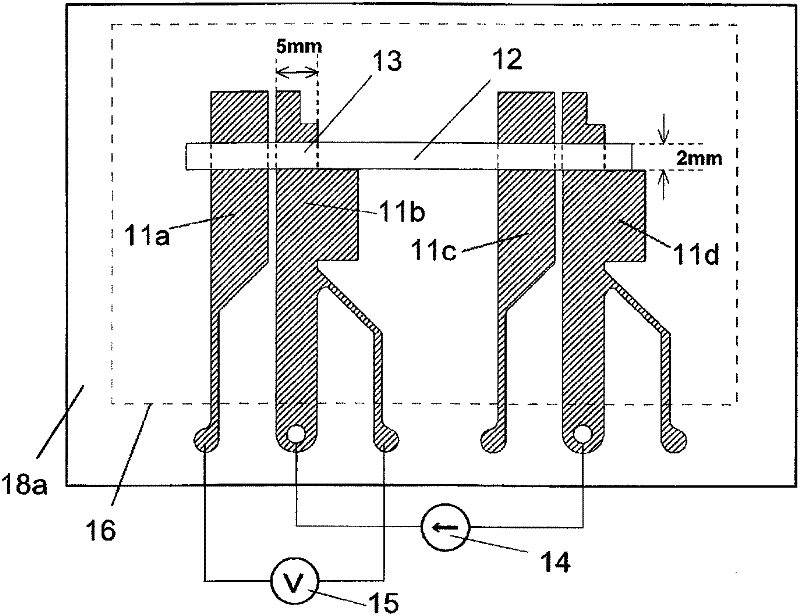

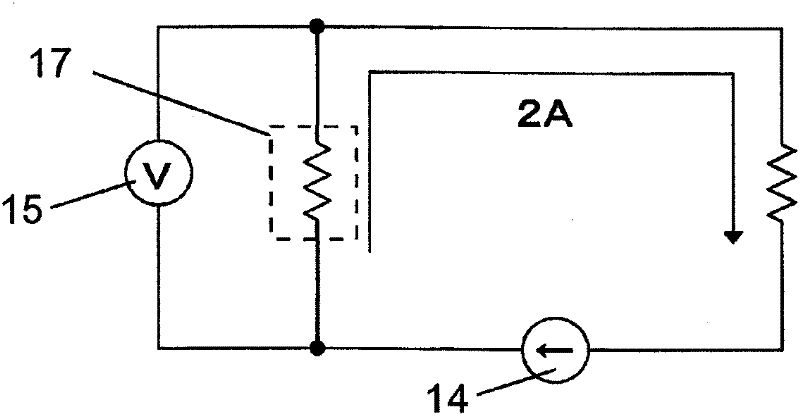

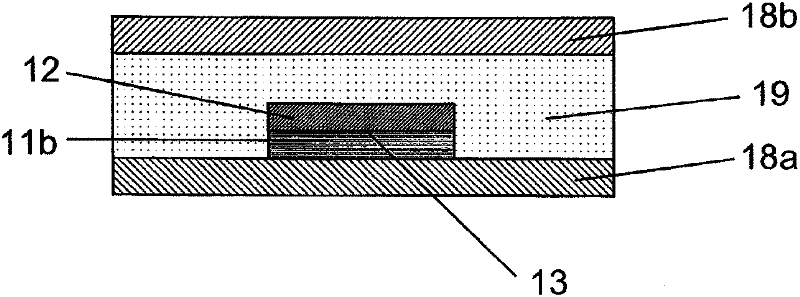

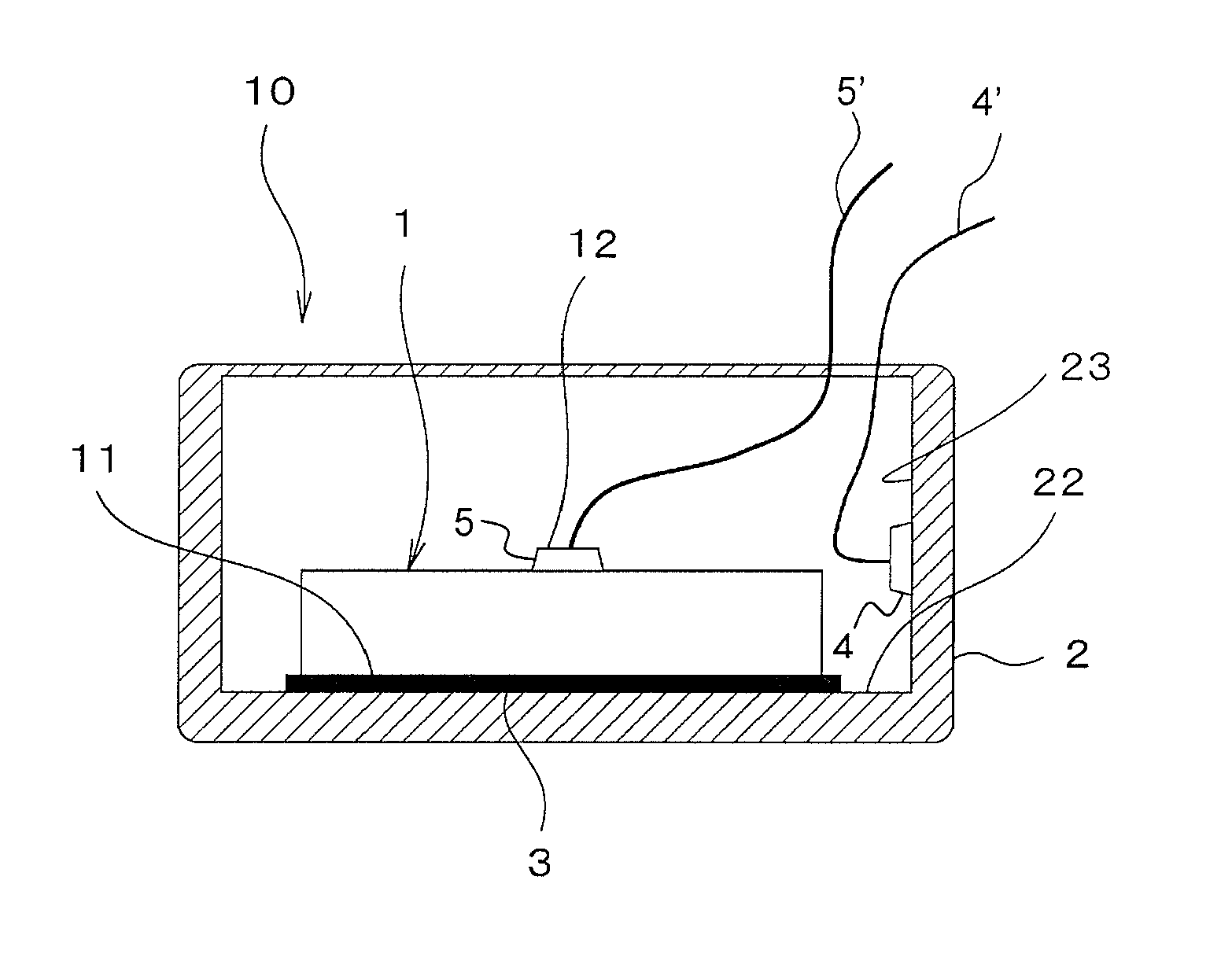

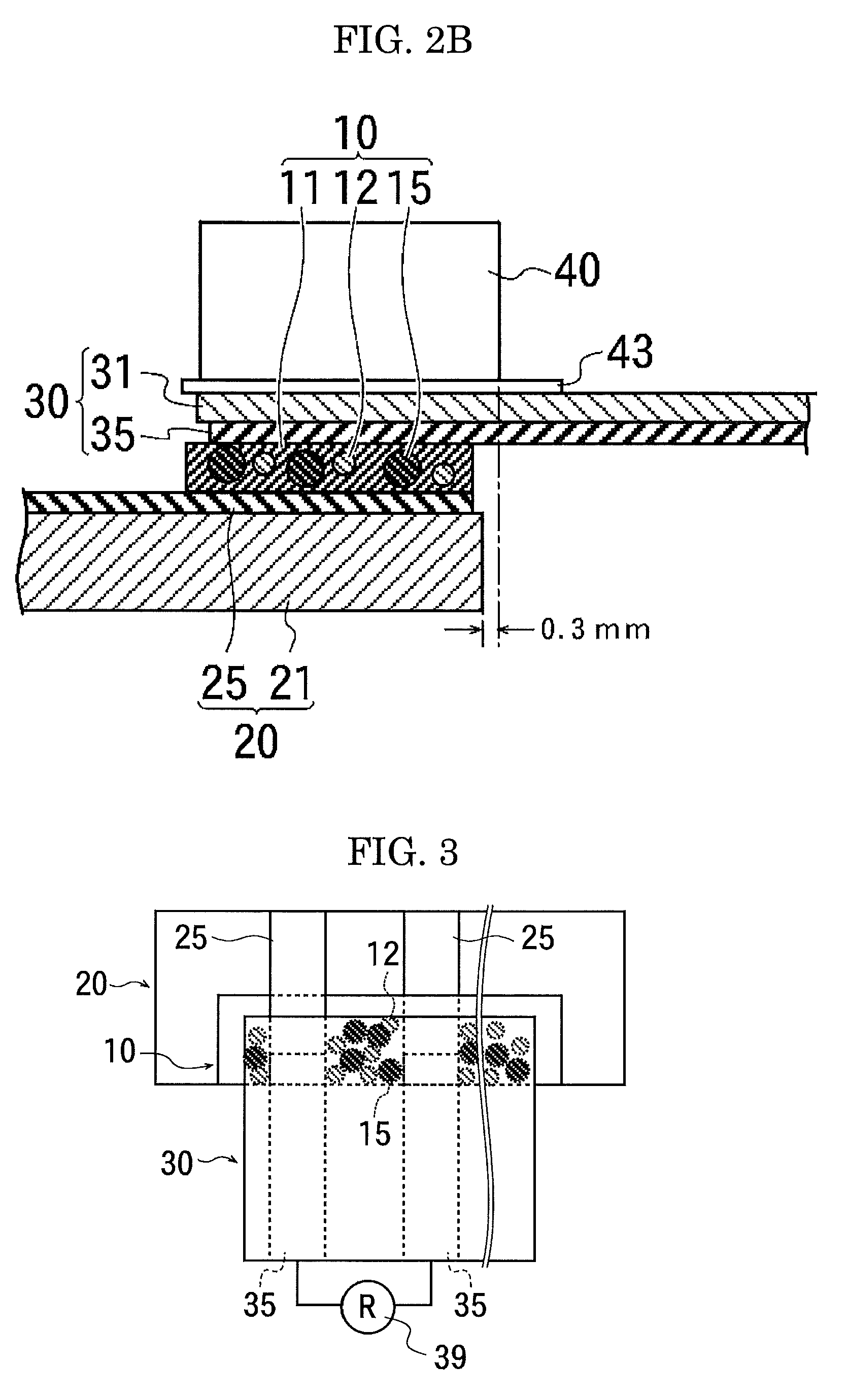

There is provided a liquid jetting apparatus, including: a channel structure in which a liquid channel including a nozzle and a pressure chamber communicating with the nozzle is formed; a piezoelectric element including a piezoelectric body and an electrode; a driving device; and a cover member joined to the surface of the channel structure. A first wiring section connected to the electrode is formed on the surface of the channel structure, and the cover member includes a cover body section and a wiring connection section. A second wiring section is formed in the cover member. The wiring connection section is joined to the surface of the channel structure in a state that the second wiring section is electrically conductive with the first wiring section. A thickness, of the wiring connection section is thinner than a thickness of the cover body section.

Owner:BROTHER KOGYO KK

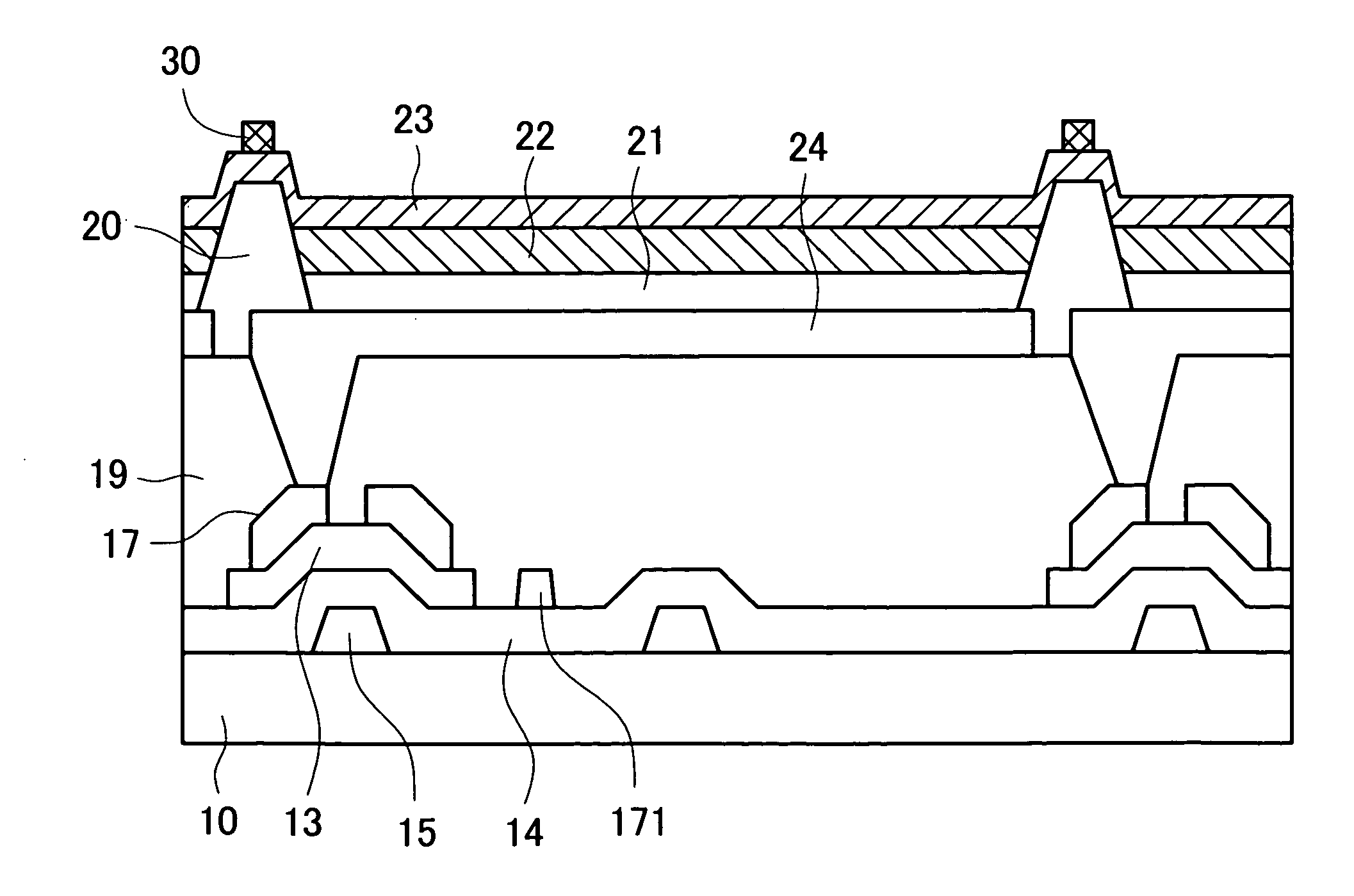

Organic electro-luminescent display device

ActiveUS20090096371A1Avoid failureImprove conduction reliabilityDischarge tube luminescnet screensLamp detailsInsulation layerGas phase

A top-emission-type organic EL display device which exhibits uniform screen brightness is realized by preventing a voltage drop of an upper electrode formed of a transparent conductive film. Pixels each of which is sandwiched between an upper electrode and a lower electrode are arranged in a matrix array to form a display region. An auxiliary electrode extends in the lateral direction between the pixels and the pixels for preventing a voltage drop of the upper electrode. A current supply line which supplies an electric current to the upper electrode and the auxiliary electrodes are made conductive with each other by forming a through hole in an insulation layer. To ensure reliability of connection at the through hole, a contact electrode made of metal which overlaps with the auxiliary electrode is formed on the through hole by vapor deposition.

Owner:SAMSUNG DISPLAY CO LTD +1

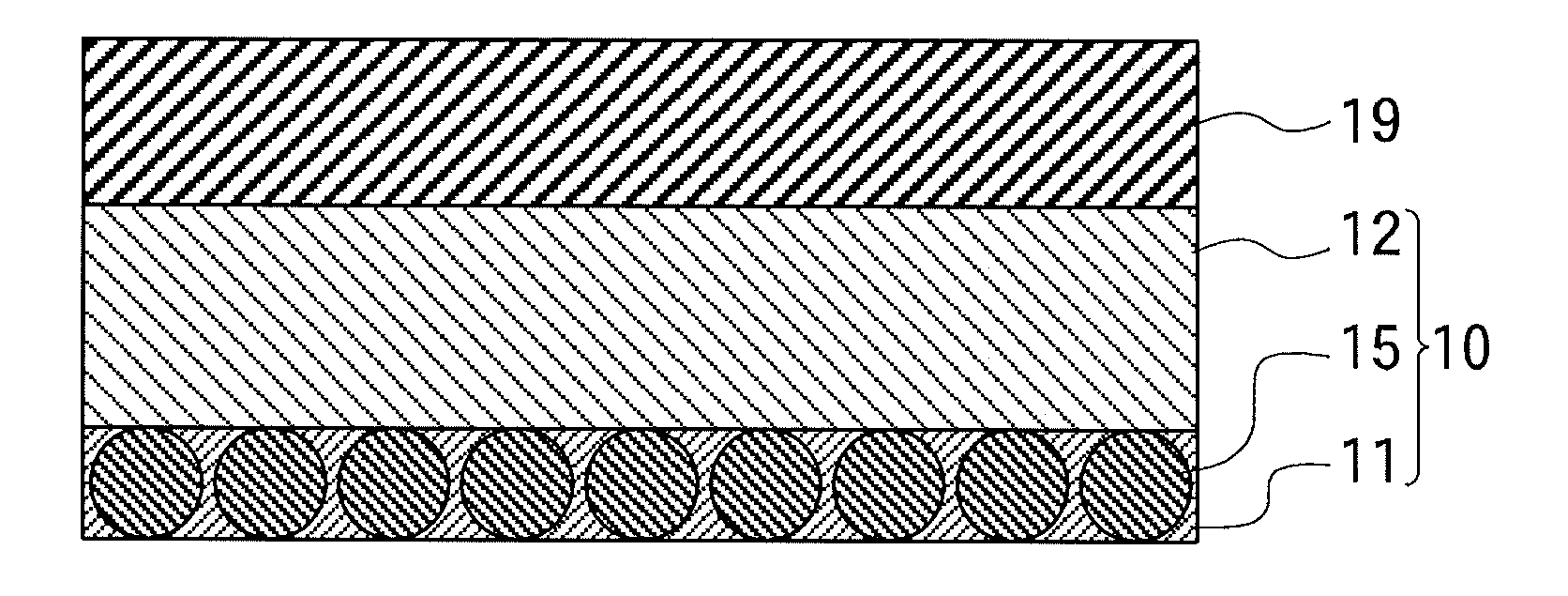

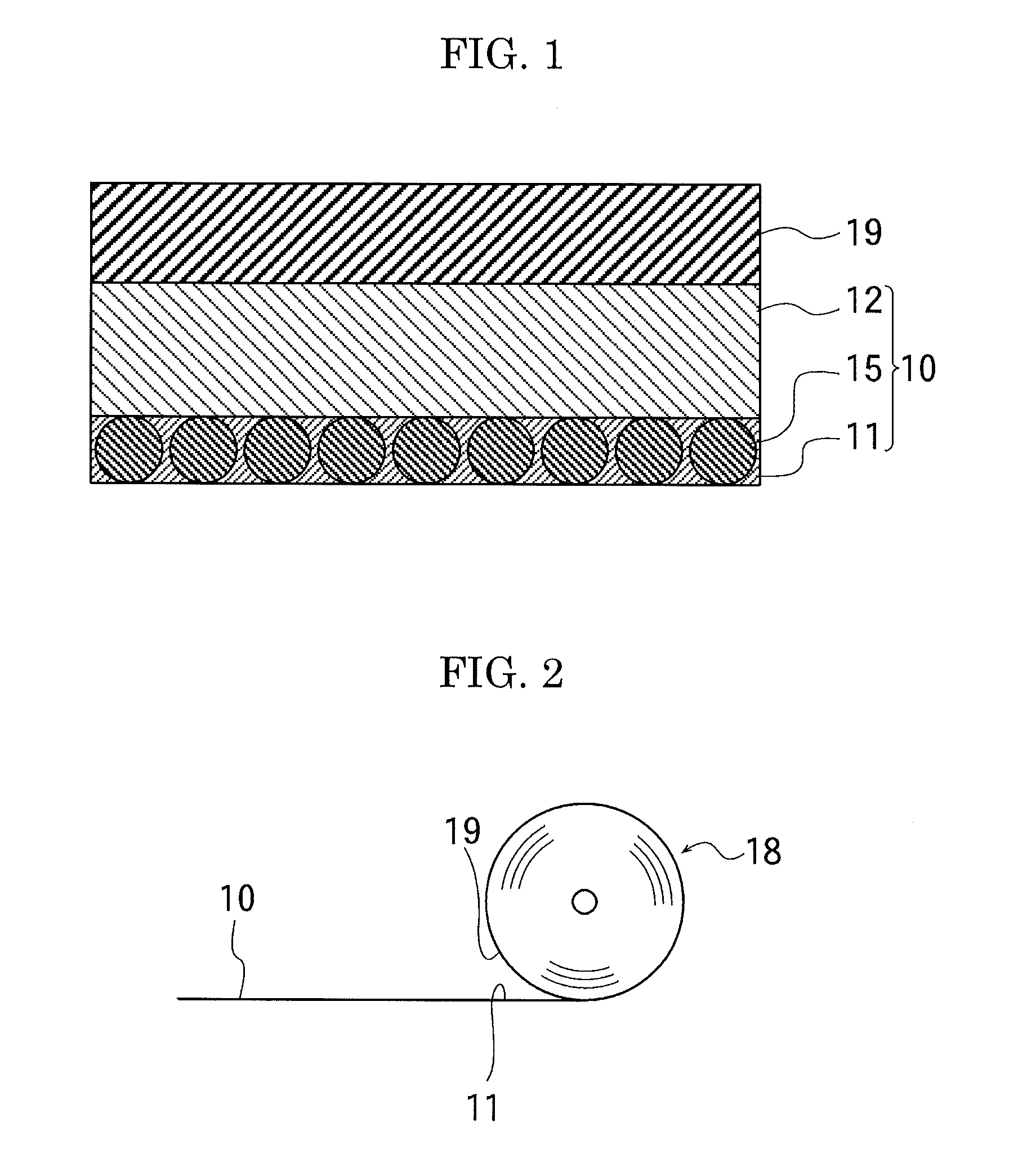

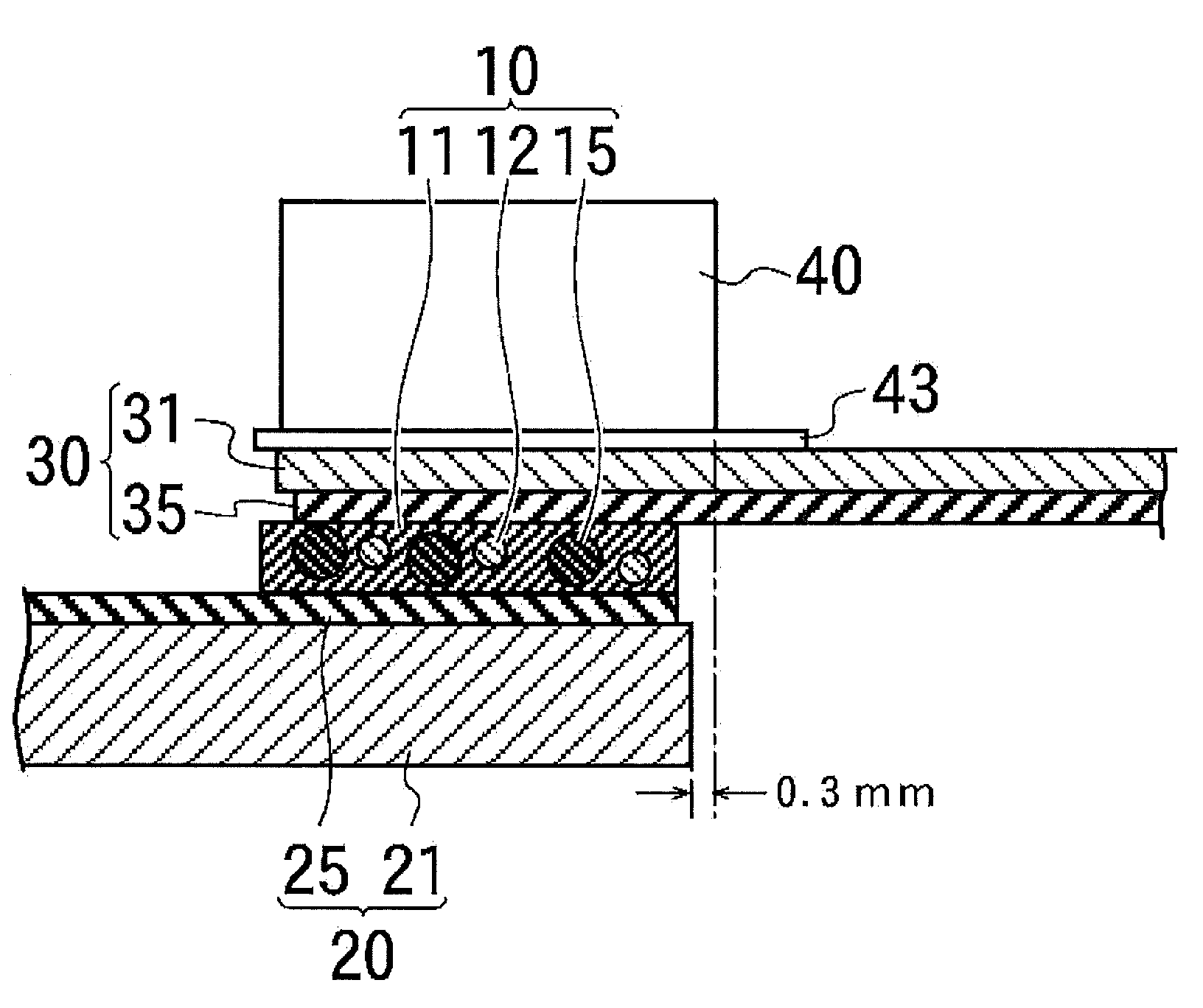

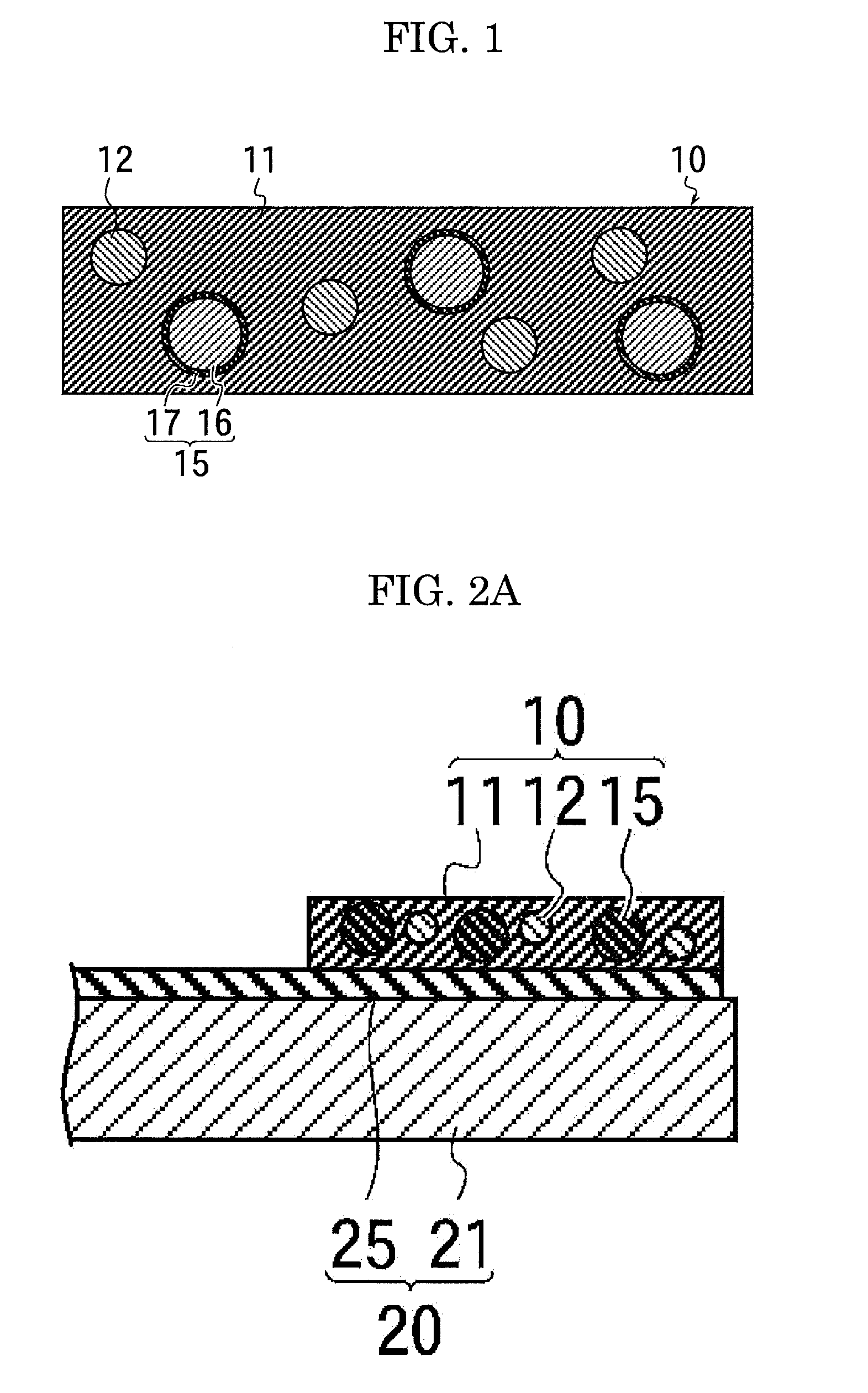

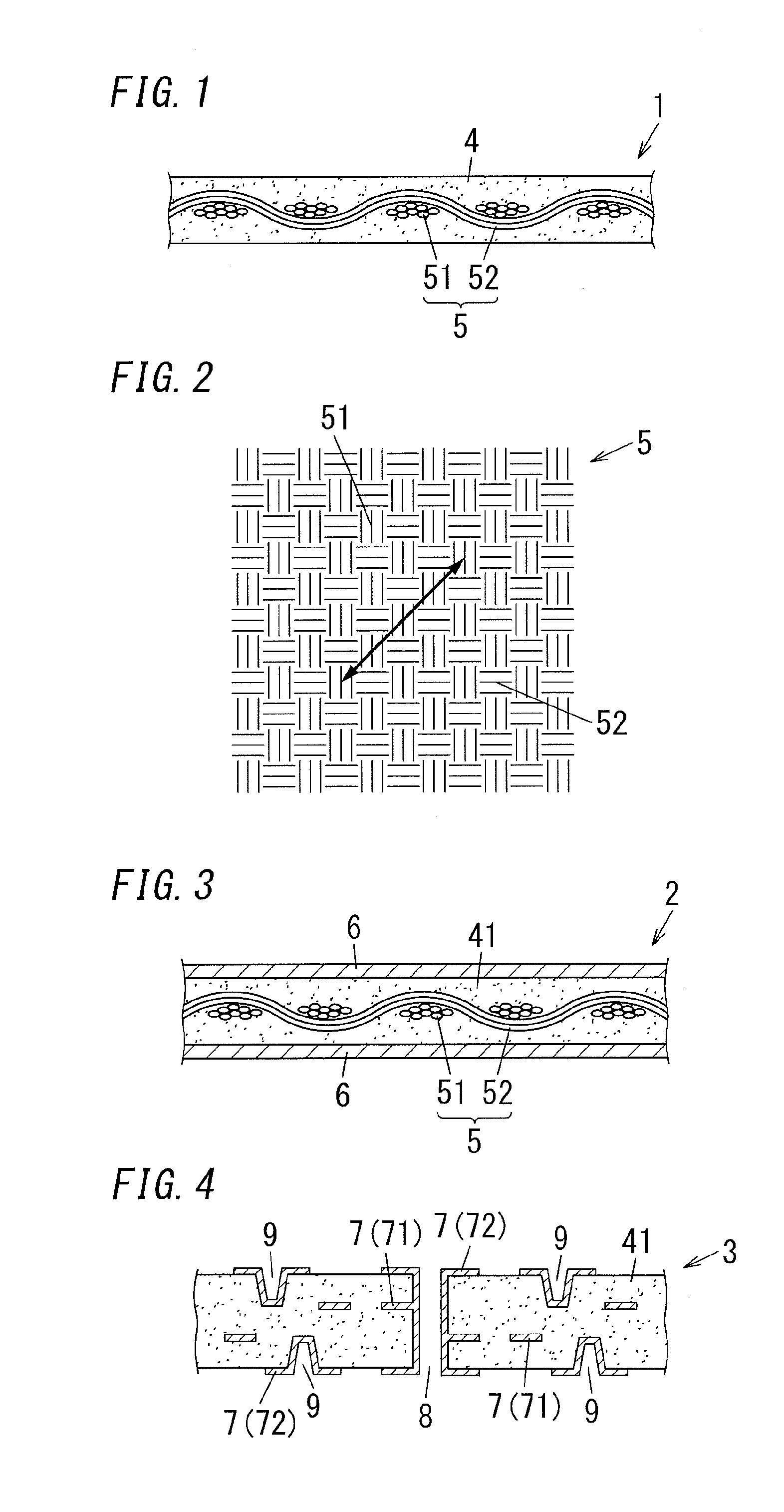

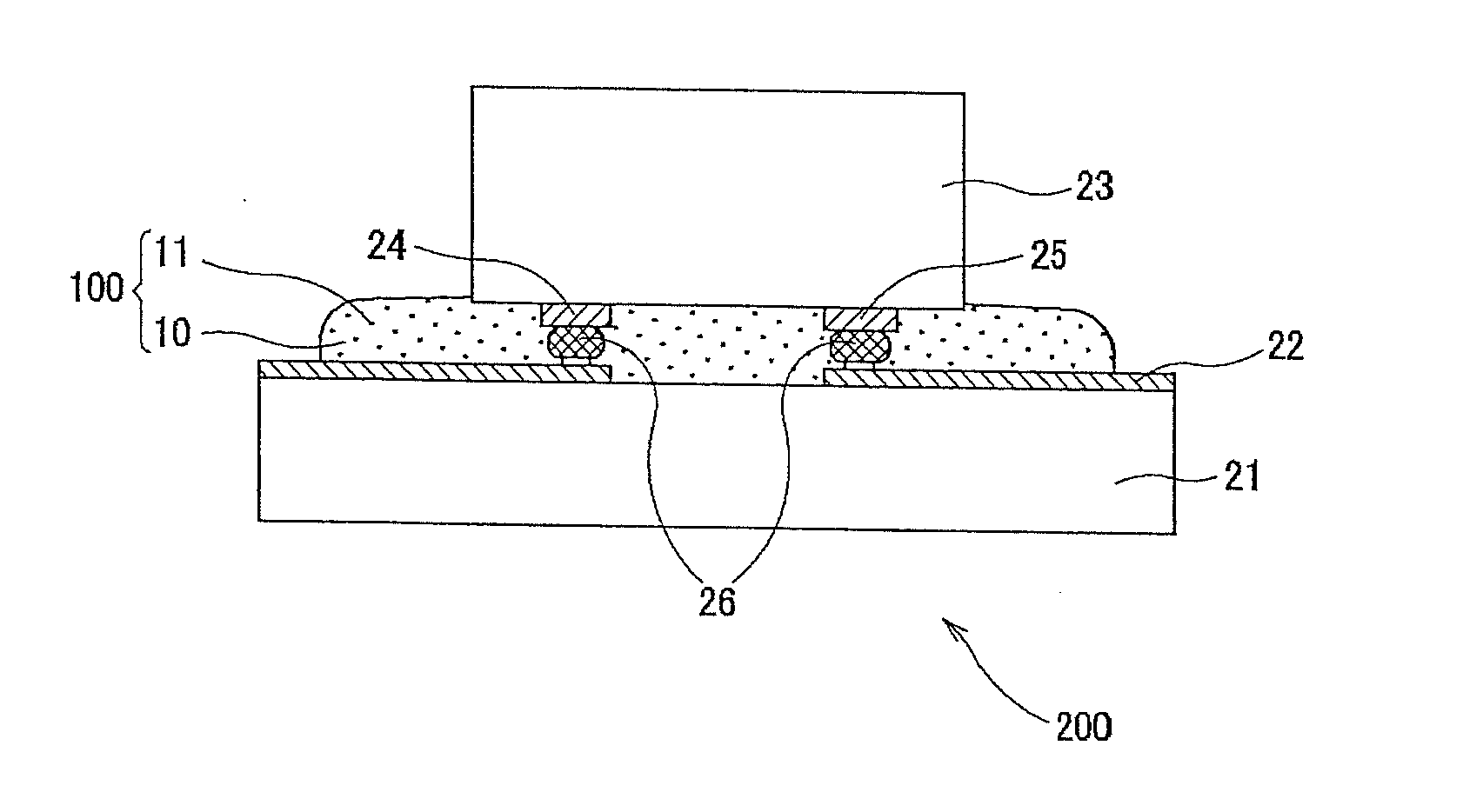

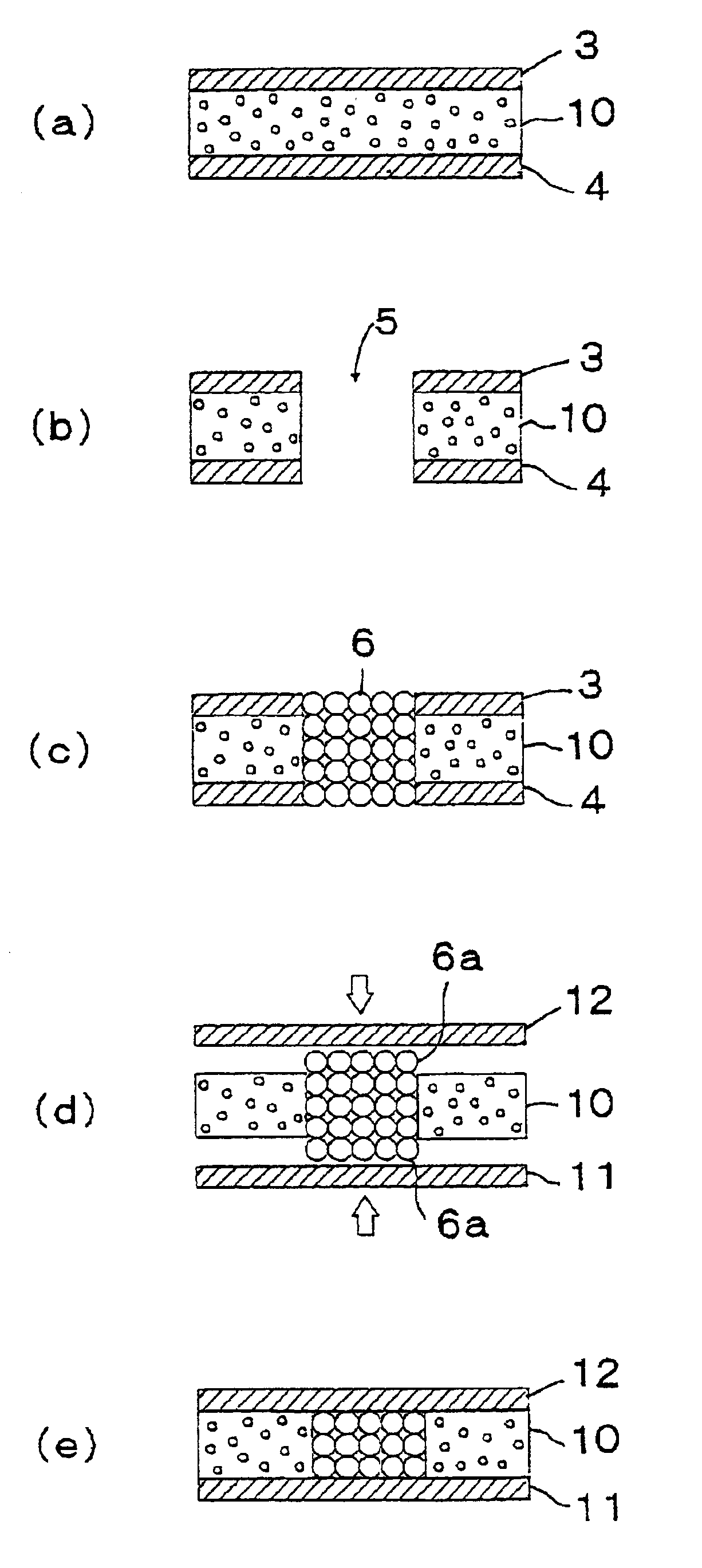

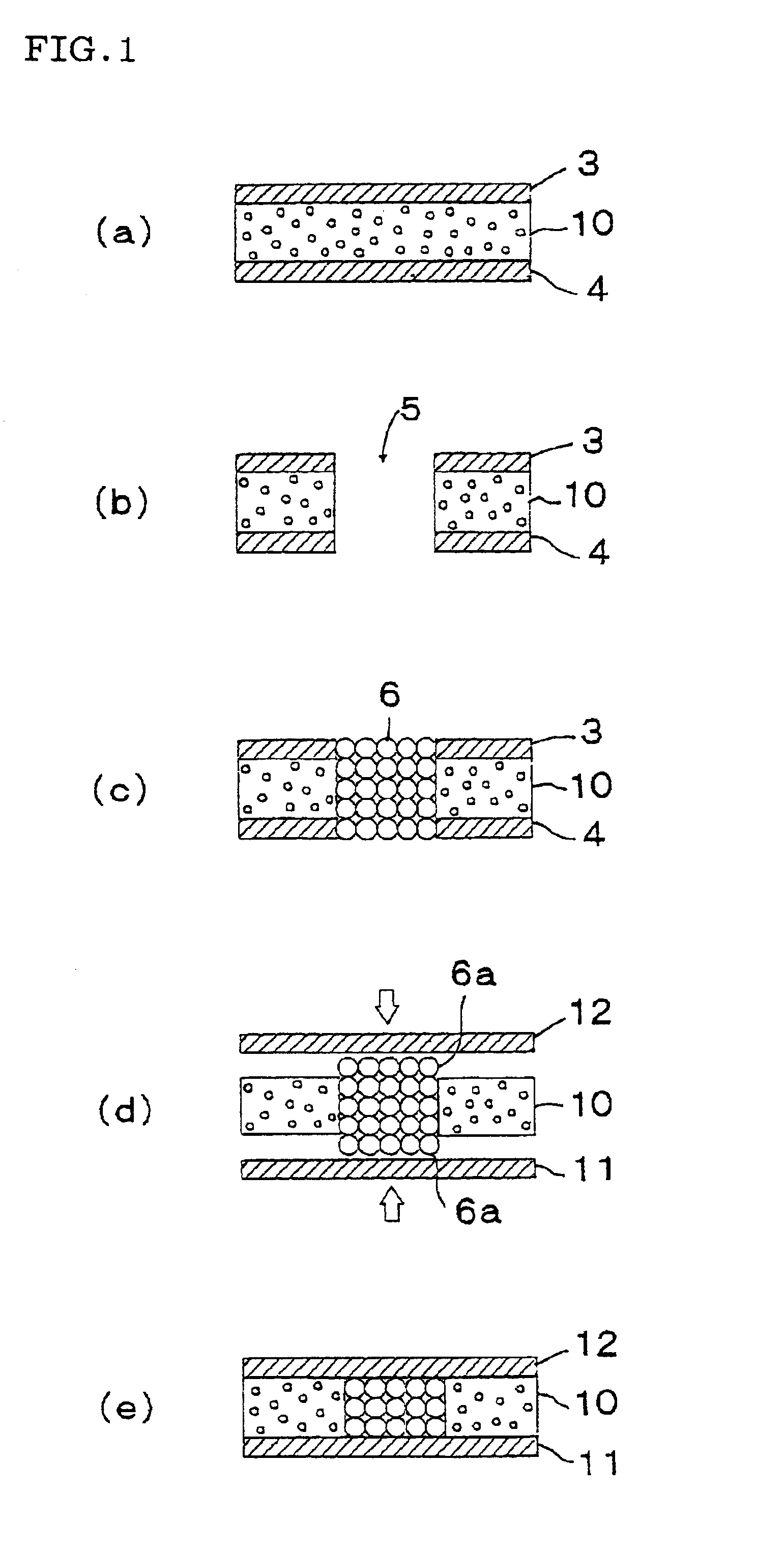

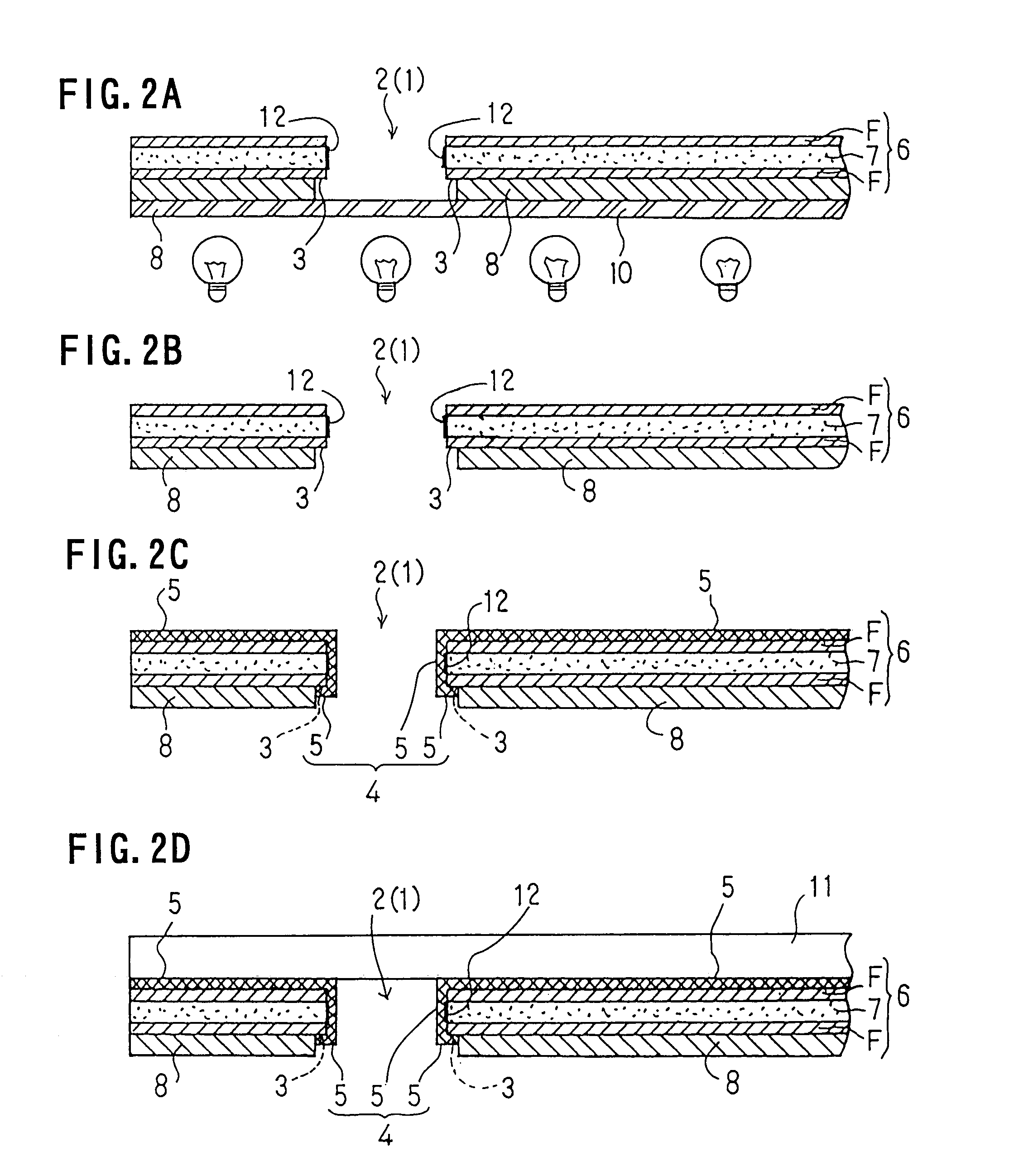

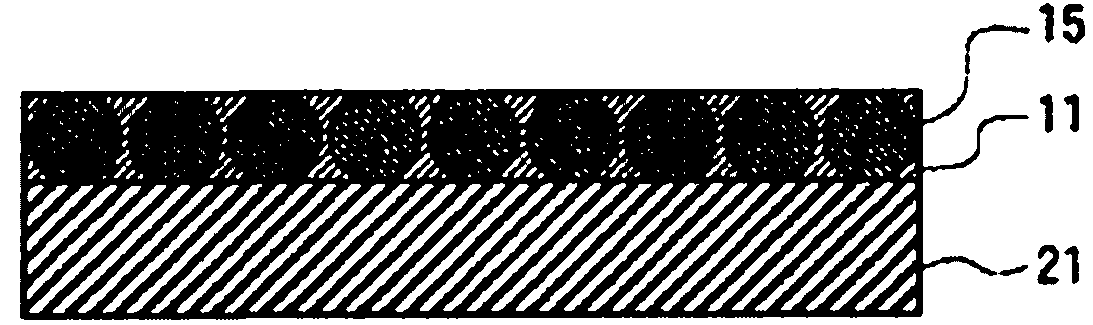

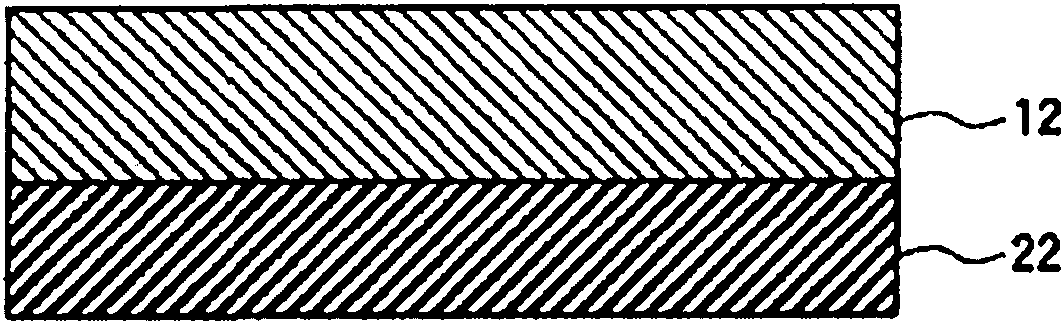

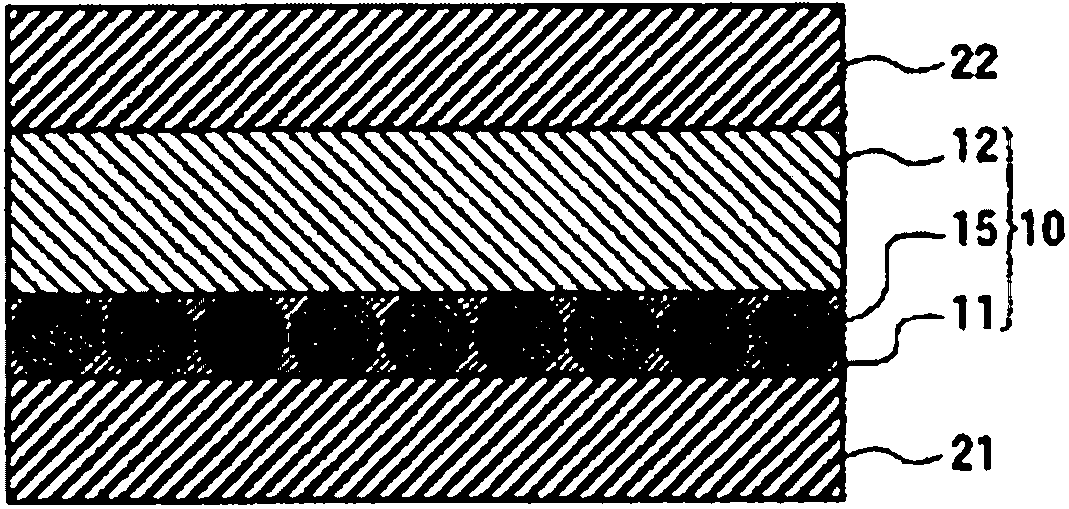

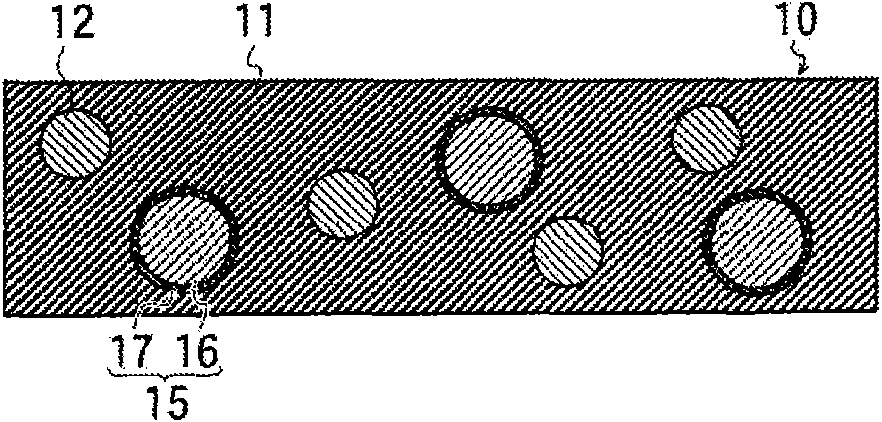

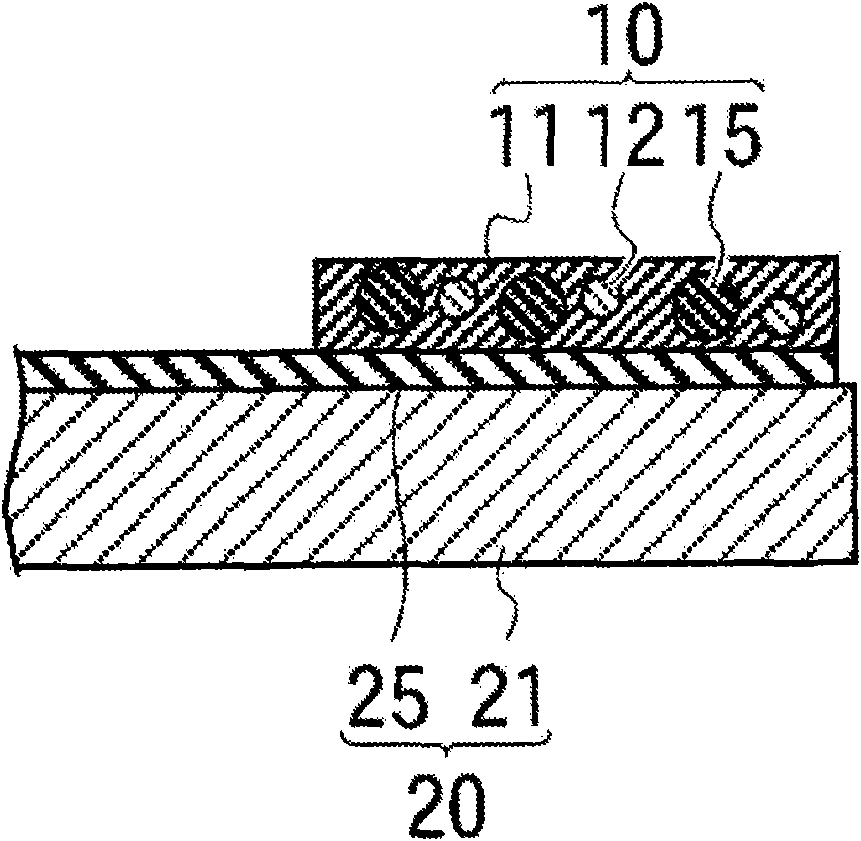

Adhesive film, connecting method, and joined structure

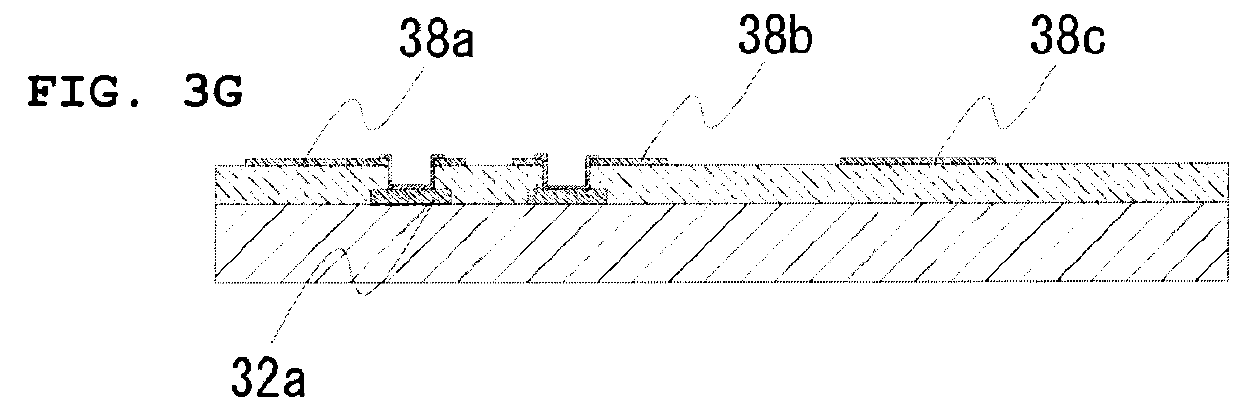

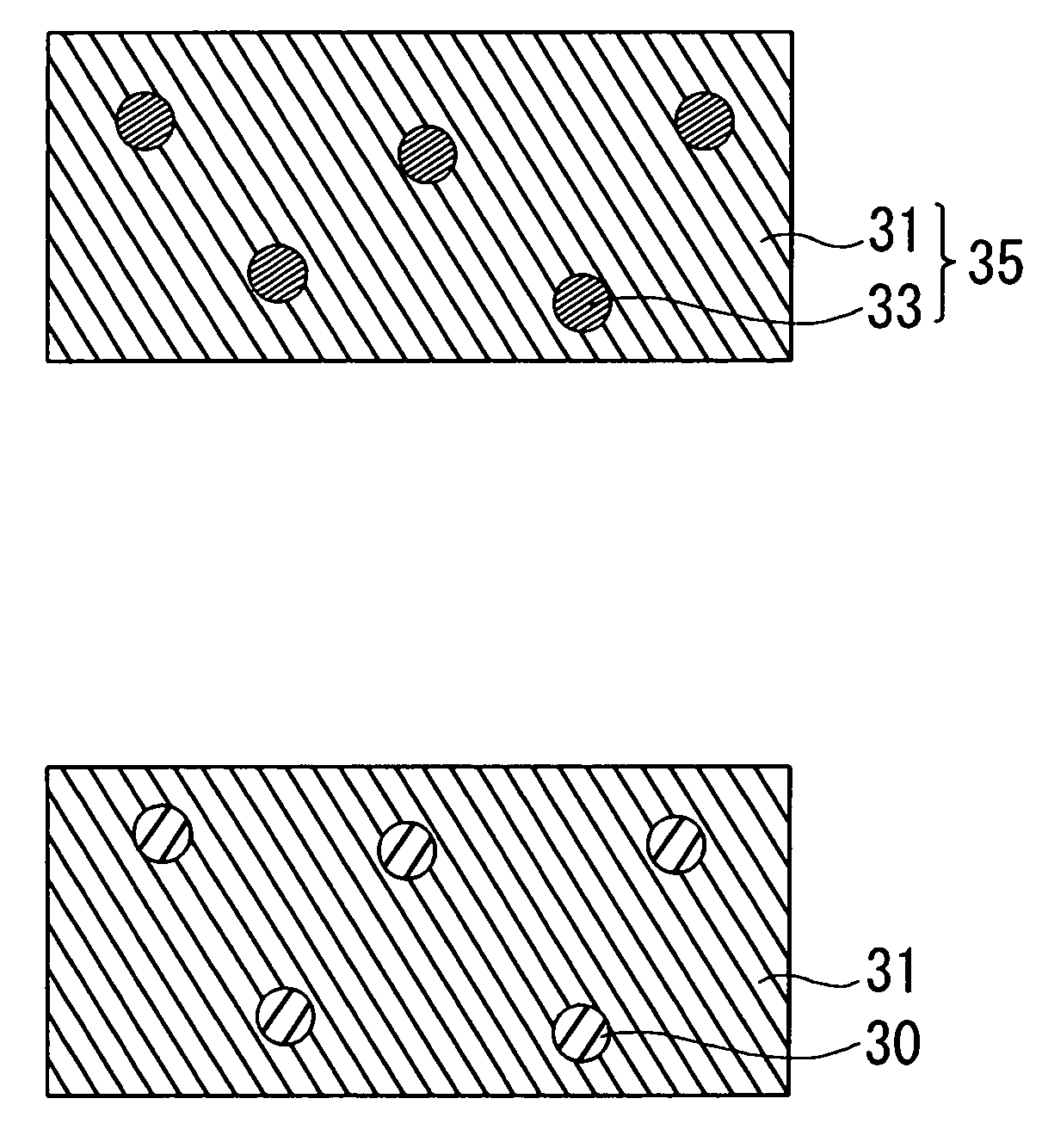

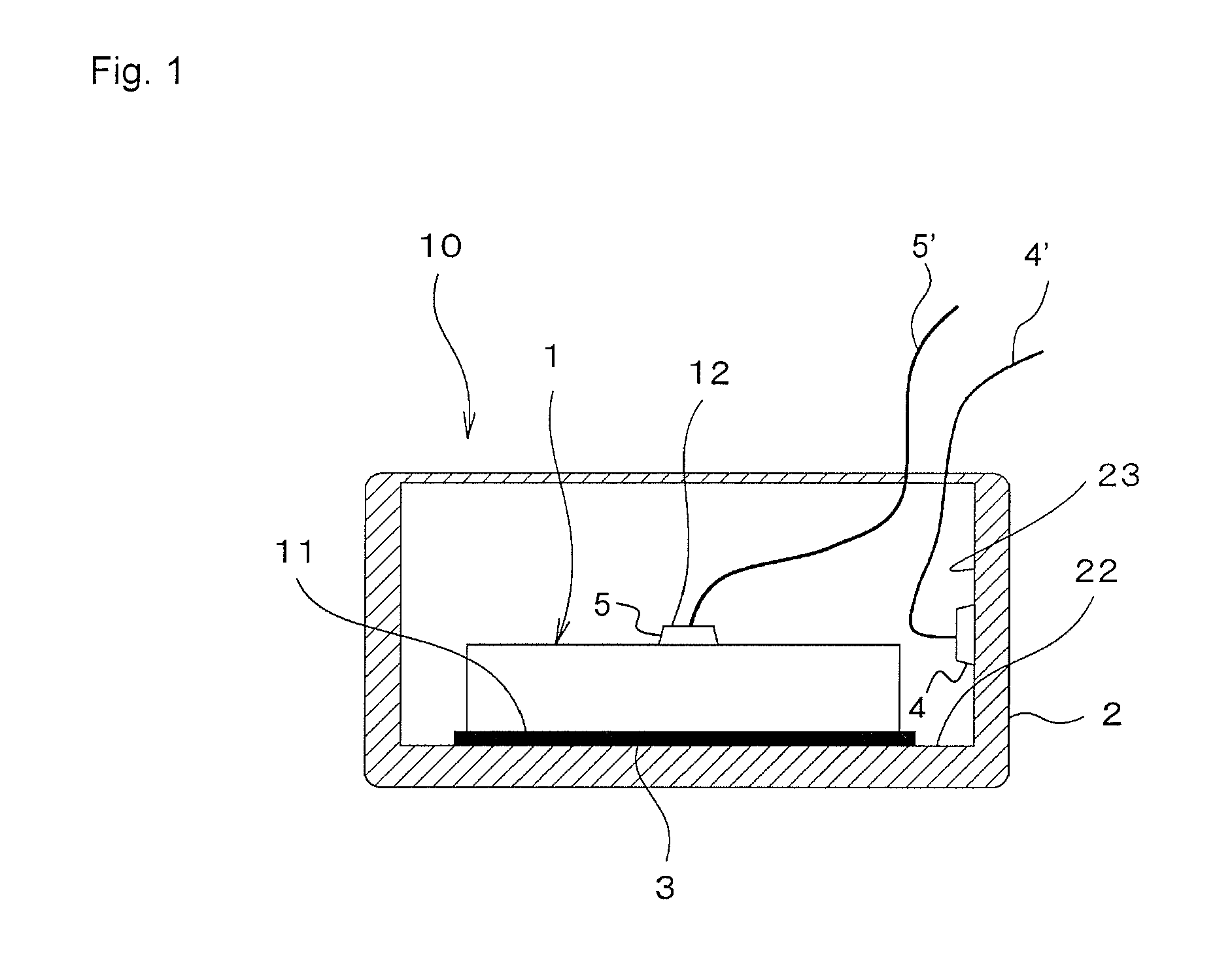

ActiveUS20100096175A1Improve conduction reliabilityHigh viscosityNon-insulated conductorsSolid-state devicesViscosityChemistry

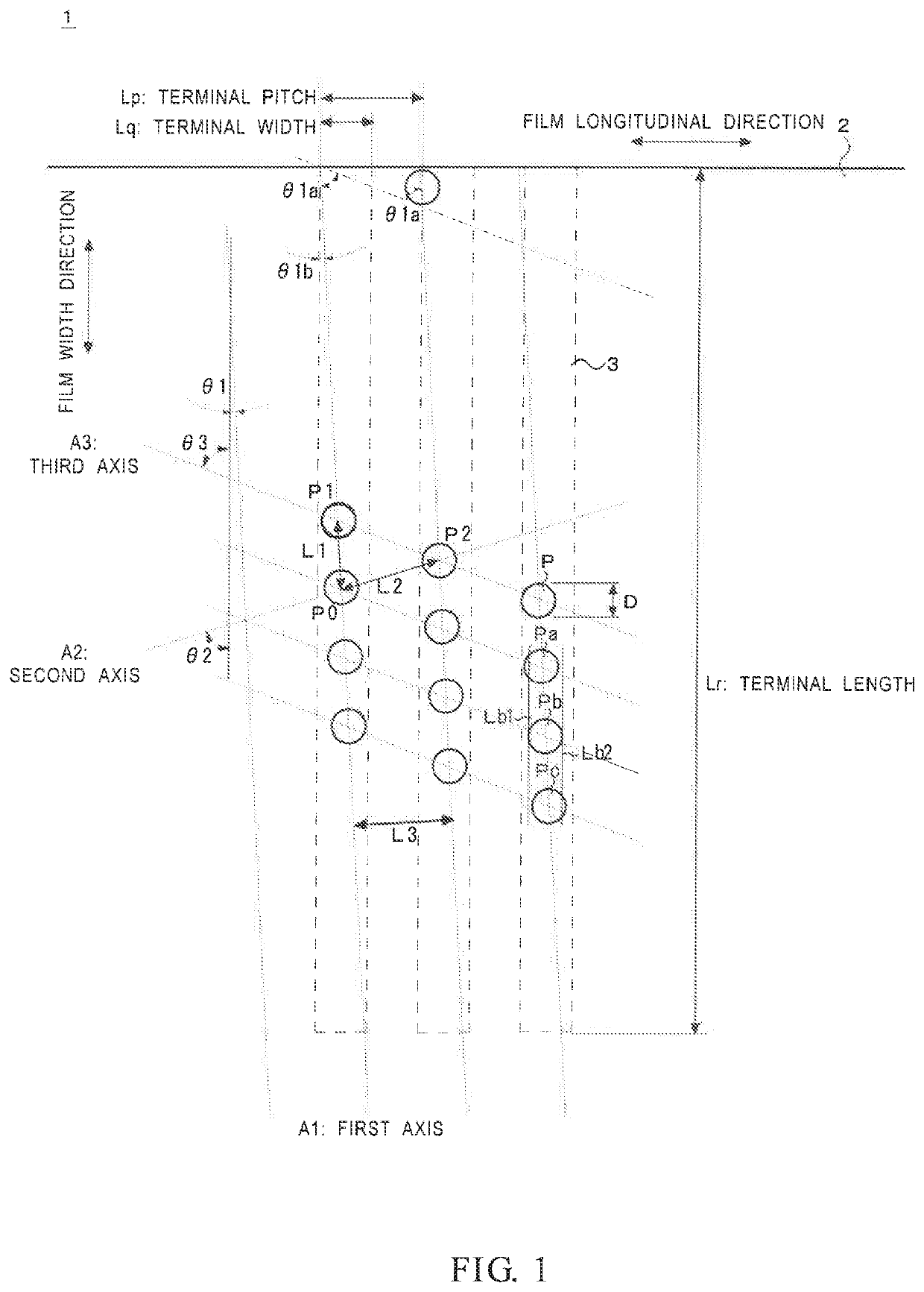

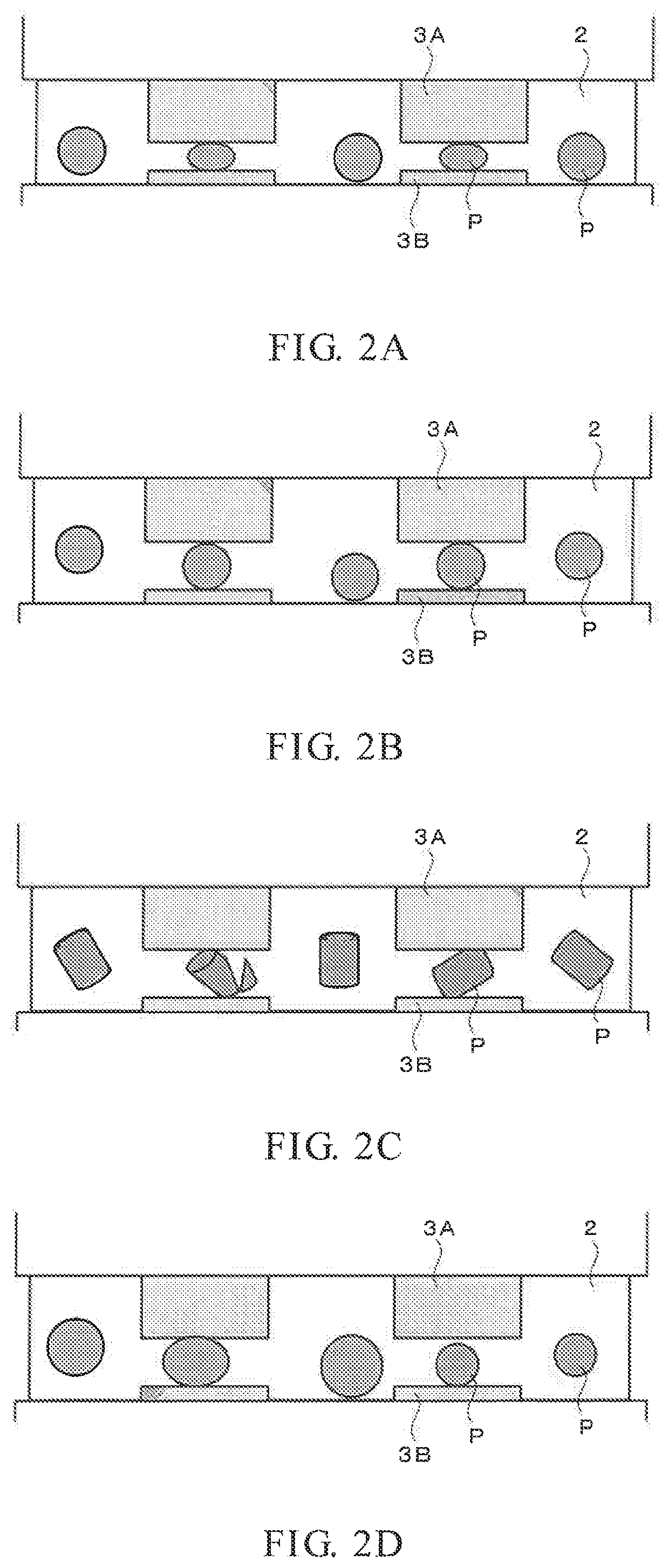

An adhesive film, containing a first adhesive layer in which conductive particles are dispersed, and a second adhesive layer adhered to the first adhesive layer, wherein the lowest viscosity of the first adhesive layer attained at or below the curing temperature is higher than that of the second adhesive layer attained at or below the curing temperature, where the curing temperature is a temperature at which the adhesive layer starts to cure, wherein the first and second adhesive layers are respectively disposed to a substrate side and an electronic part side, and the adhesive film is configured to join the electronic part and the substrate by heating and pressurizing the substrate and the electronic part with the adhesive layer being therebetween, and wherein the first adhesive layer has a thickness which is less than two times of an average particle diameter of the conductive particles.

Owner:DEXERIALS CORP

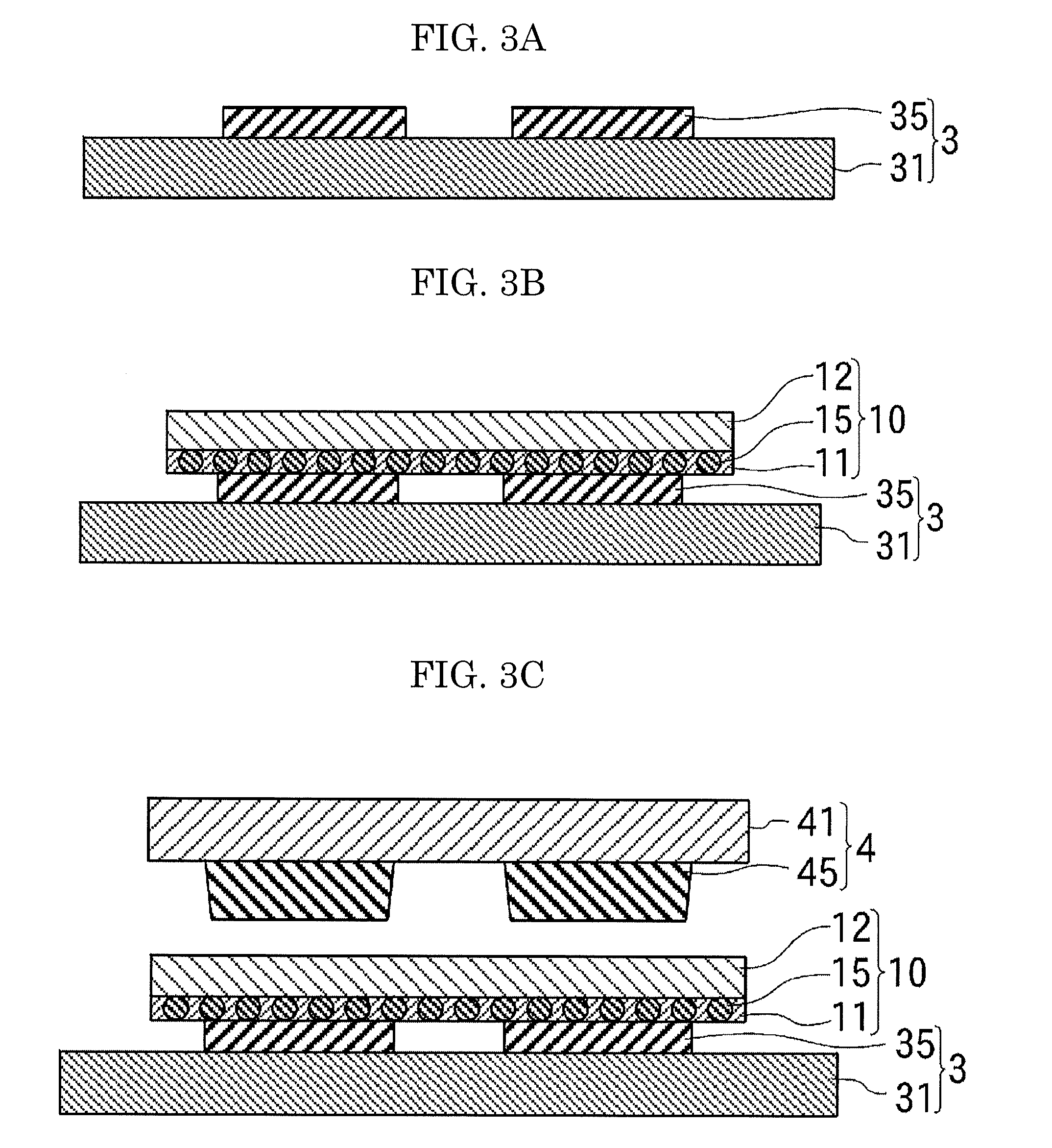

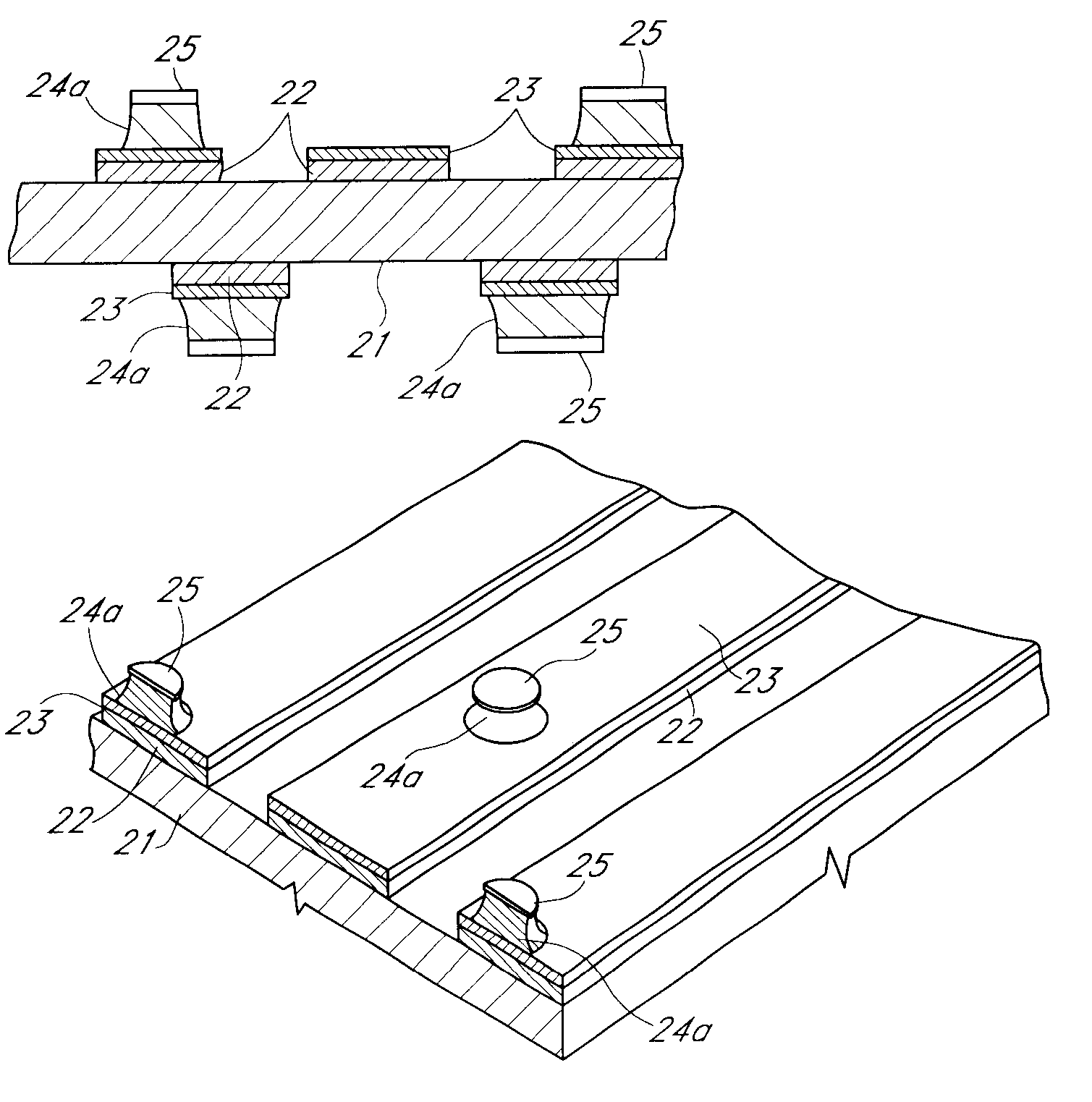

Method of manufacturing multilayer wiring board

InactiveUS6555209B1Reduce the overall diameterImprove conductivityElectrical connection printed elementsFilm packagingMechanical engineeringMask layer

A method of manufacturing a multilayer wiring board comprising a step of forming an upper wiring layer (27), a part thereof being electrically connected to a pillar-shaped metallic body (24a), after he pillar-shaped metal body (24a) is formed on a lower wiring layer (22) is characterized in that the step of forming the metallic body includes a sub-step of forming a plating layer (24) constituting the metallic body, a sub-step of forming a mask layer (25) on the surface where the metal body is formed, of the plating layer, and a sub-step of etching the plating layer. The manufacture can be carried out with simple equipment combination of conventional steps and the wiring layer can be made fine. Moreover, a multilayer wiring board having a high reliability can be manufactured,

Owner:DENKA CO LTD

Method for connecting electronic part and joined structure

ActiveUS20100080995A1Accurate countImprove conduction reliabilitySolid-state devicesPrinted circuit manufactureAnisotropic conductive adhesiveOptoelectronics

A method for connecting an electronic part, which contains: mixing a dispersing solvent, an adhesive resin which is dissolved in the dispersing solvent, conductive particles, and insulating particles which have smaller particle diameters than those of the conductive particles so as to prepare an anisotropic conductive adhesive; placing a terminal of a substrate and a terminal of an electronic part so as to face each other via the anisotropic conductive adhesive, and applying heat and pressure to the substrate and the electronic part so as to sandwich the conductive particles between the terminal of the substrate and the terminal of the electronic part to thereby deform the conductive particles, in which the pressure is smaller than pressure at which the conductive particles are destroyed, and smaller than pressure at which the particle diameters of the conductive particles become equal to the particle diameters of the insulating particles.

Owner:DEXERIALS CORP

Metal film forming method and conductive ink used in said method

InactiveUS20160057866A1Improve conduction reliabilitySimple moldingSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceReducing agent

An object of the invention is to provide a simple method capable of easily forming a metal film on a surface of a perforated substrate that is adjacent to the hole in the substrate. The metal film forming method includes a step of heating a perforated substrate having a hole while a surface of the substrate adjacent to the hole is in contact with a conductive ink containing a metal salt and a reducing agent.

Owner:JSR CORPORATIOON

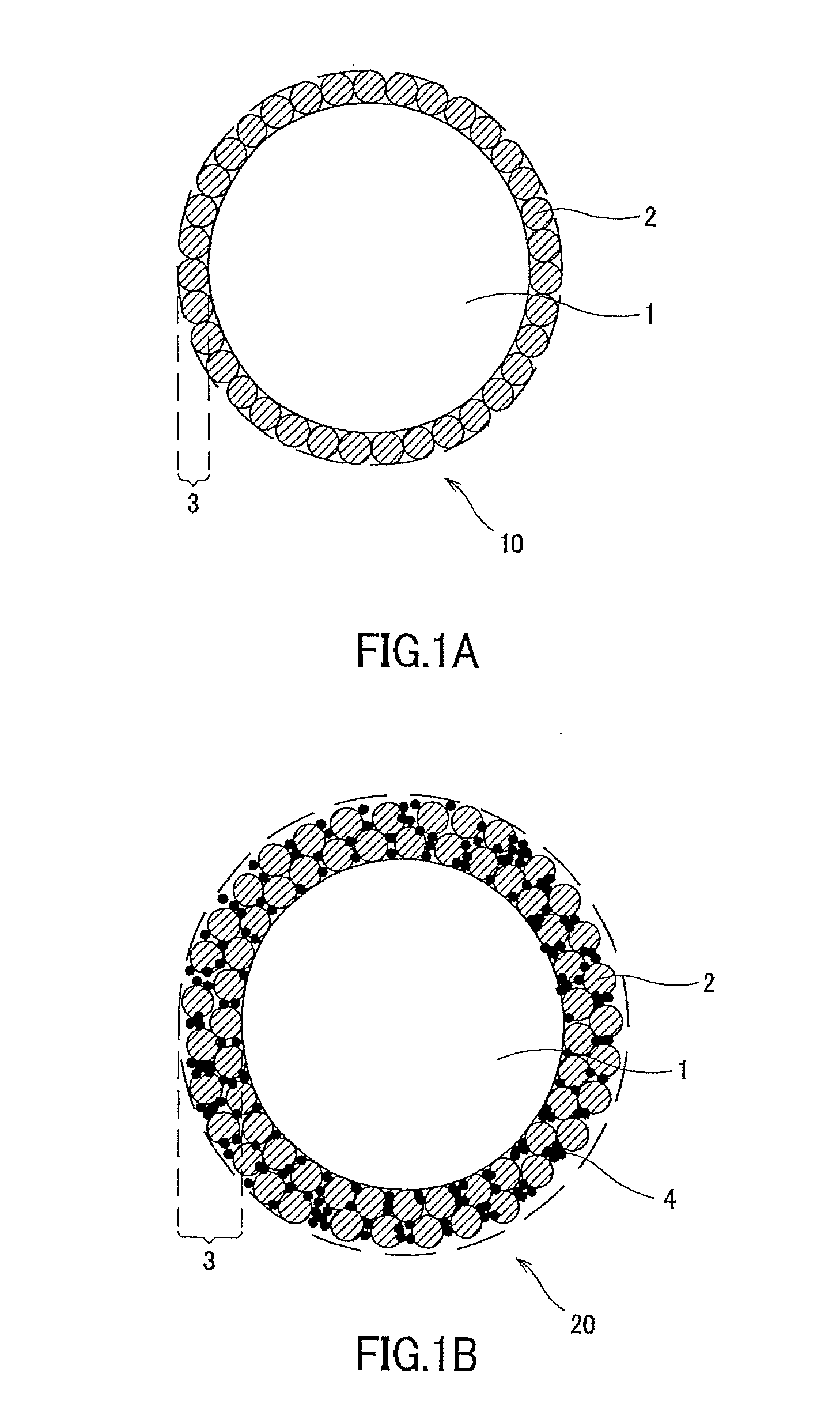

Resin particle, conductive particle and anisotropic conductive adhesive containing the same

InactiveUS20050228144A1Improve conduction reliabilitySufficient compression deformation ratioGlass/slag layered productsWood layered productsAcrylic resinConductive coating

Resin particles comprised of an acrylic resin. Not only is the maximum compression deformation ratio thereof as great as 60% or more but also the load required for 60% compression deformation is as small as 60 mN or less. Wiring boards are therefore coupled in using an anisotropic conductive adhesive obtained by first manufacturing conductive particles having a conductive coating formed on a resin particle surface of the resin particles by adhering a conductive material to the surface of the above resin particles as a core. On dispersing the conductive particles in an adhesive material, the conductive particles sandwiched between metallic wires of the wiring boards are greatly deformed by a small load, so that the electrical devices having a high conduction reliability can be obtained.

Owner:SONY CORP

Electroconductive pressure-sensitive adhesive tape

InactiveCN102295897AImprove adhesionImprove workabilityFilm/foil adhesivesUsing wave/particle radiation meansMetal foilEngineering

The present invention has an object to provide an electroconductive pressure-sensitive adhesive tape that achieves excellent tackiness and high electrical conductivity even when it is used in a finer shape (in particular, a narrow shape) and that has a small change in resistance value over time and achieves stable electrical conductivity even when it is used for a long time or in a harsh environment. The electroconductive pressure-sensitive adhesive tape of the present invention is an adhesive tape including a metal foil and a pressure-sensitive adhesive layer having an electroconductive filler on at least one side of the metal foil. The electroconductive pressure-sensitive adhesive tape has a surface exposure ratio of the electroconductive filler on a surface of the pressure-sensitive adhesive layer of 2 to 5%.

Owner:NITTO DENKO CORP

Printed wiring board manufacturing method

InactiveUS20060257793A1Improve conduction reliabilityDefective conductionPrinted circuit aspectsSemiconductor/solid-state device manufacturingResistTectorial membrane

This printed wiring board manufacturing method comprises the steps of providing a large number of through holes (for a through-hole) in a substrate made of an insulating material of which both sides are coated with a copper foil; making the inside of the through holes electrically conductive, coating the substrate with a photosensitive dry film, and developing and hardening the photosensitive dry film as a plating resist; and copper-plating the inside of the through holes and the opening periphery thereof. The manufacturing method further comprises the steps of coating the copper-plated area with a metal protective film, eliminating the photosensitive dry film; forming a circuit pattern; and conducting an overlaying treatment as a post-processing step.

Owner:MARUWA

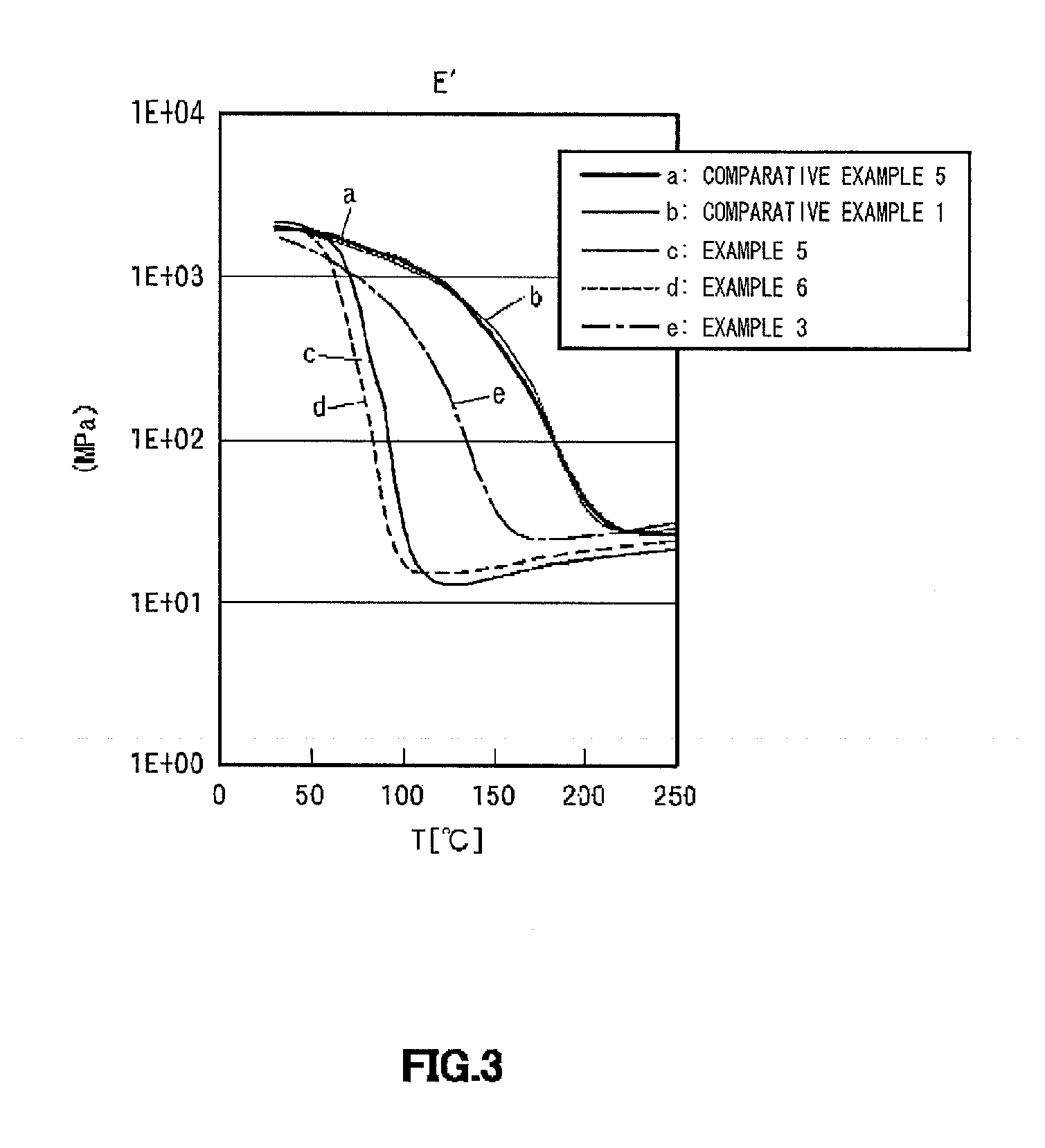

Curable resin composition, adhesive epoxy resin paste, die-bonding agent, non-conductive paste, adhesive epoxy resin film, non-conductive epoxy resin film, anisotropic conductive paste, and anisotropic conductive film

InactiveUS20130056686A1Improve conduction reliabilityImprove crack resistanceFilm/foil adhesivesConductive materialEpoxyConductive paste

To provide a curable resin composition that can improve resistant properties such as thermal impact resistance even in a high-temperature and high-humidity environment and has a high adhesive property, high conduction reliability and superior crack resistant property. The curable resin composition contains an epoxy resin and an epoxy resin-use curing agent, and is characterized in that a difference between a maximum value of tan δ in a viscoelastic spectrum and a value of the tan δ at −40° C. thereof is 0.1 or more.

Owner:DEXERIALS CORP

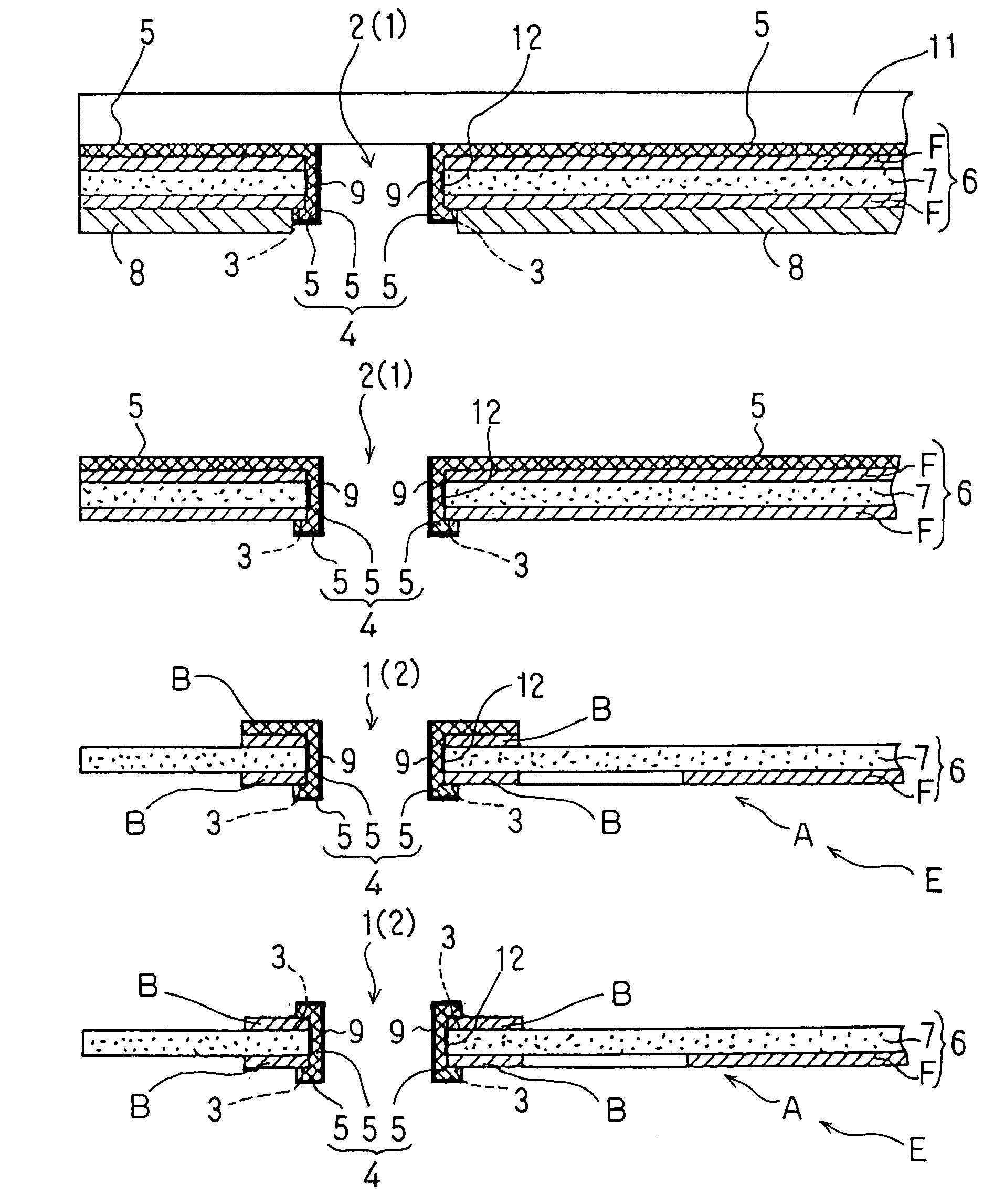

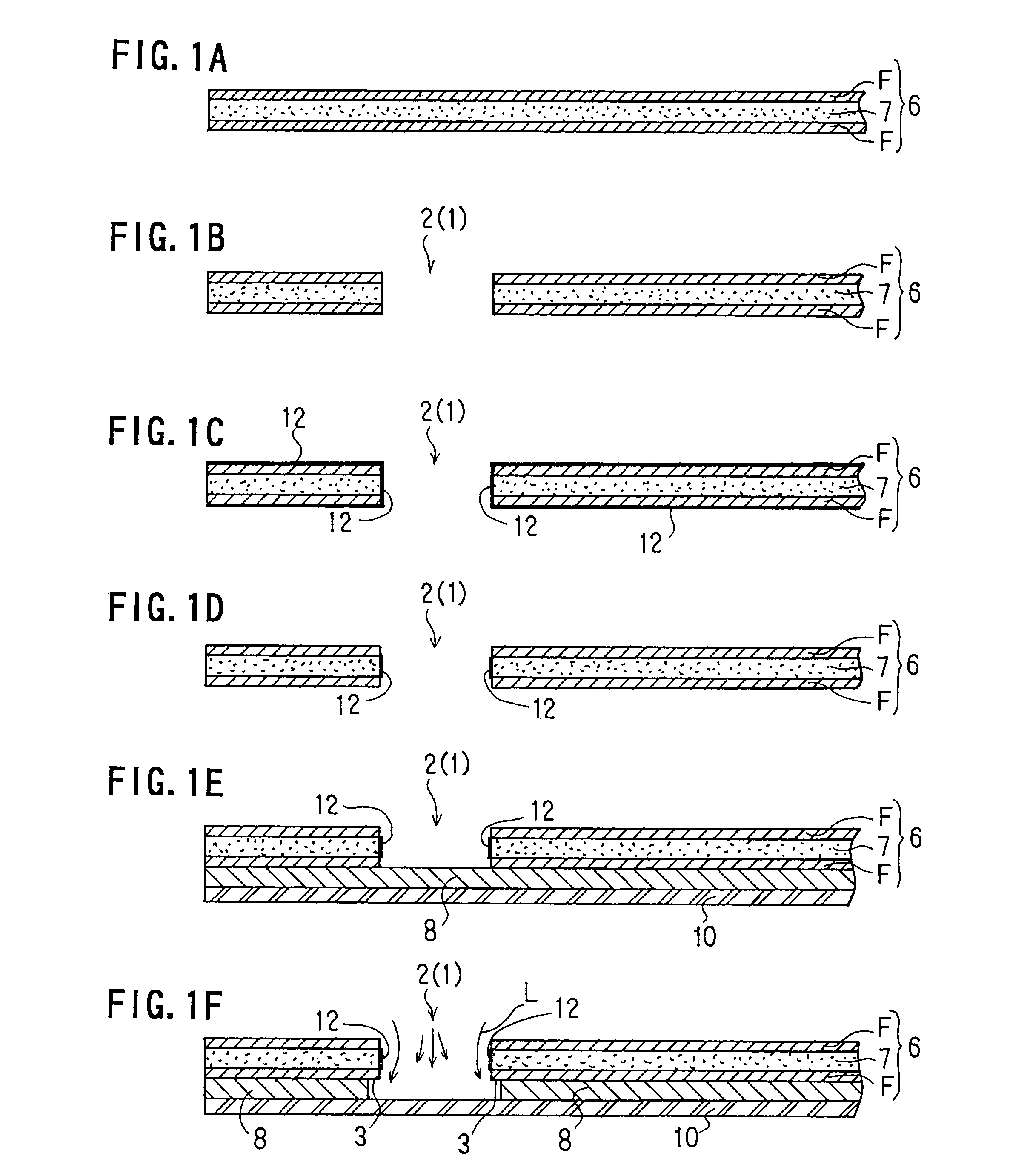

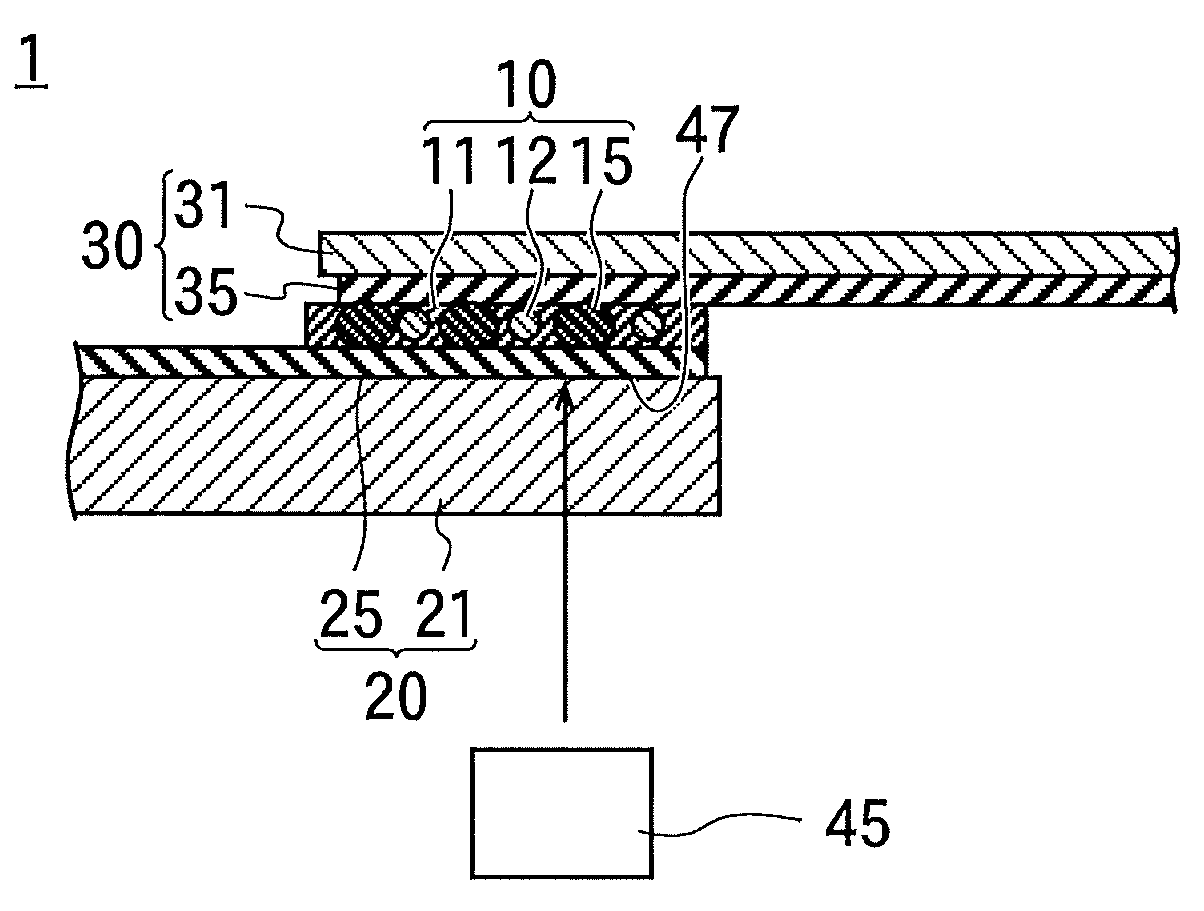

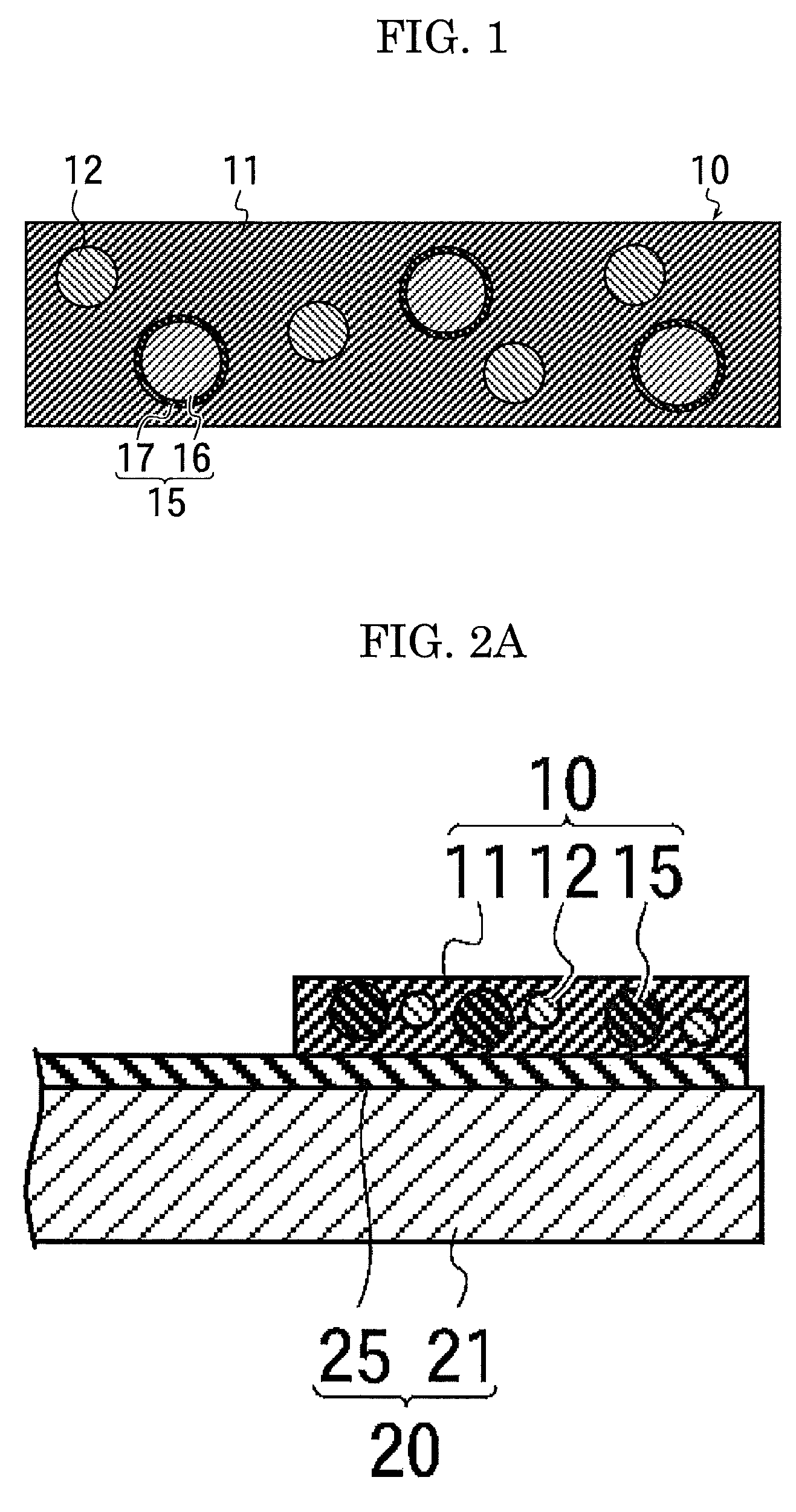

Liquid jetting apparatus and piezoelectric actuator

ActiveUS9238364B2Performed easily and reliablyEasy to implementMagnetostrictive device manufacture/assemblyPrintingPiezoelectric actuatorsEngineering

There is provided a liquid jetting apparatus, including: a channel structure in which a liquid channel including a nozzle and a pressure chamber communicating with the nozzle is formed; a piezoelectric element including a piezoelectric body and an electrode; a driving device; and a cover member joined to the surface of the channel structure. A first wiring section connected to the electrode is formed on the surface of the channel structure, and the cover member includes a cover body section and a wiring connection section. A second wiring section is formed in the cover member. The wiring connection section is joined to the surface of the channel structure in a state that the second wiring section is electrically conductive with the first wiring section. A thickness, of the wiring connection section is thinner than a thickness of the cover body section.

Owner:BROTHER KOGYO KK

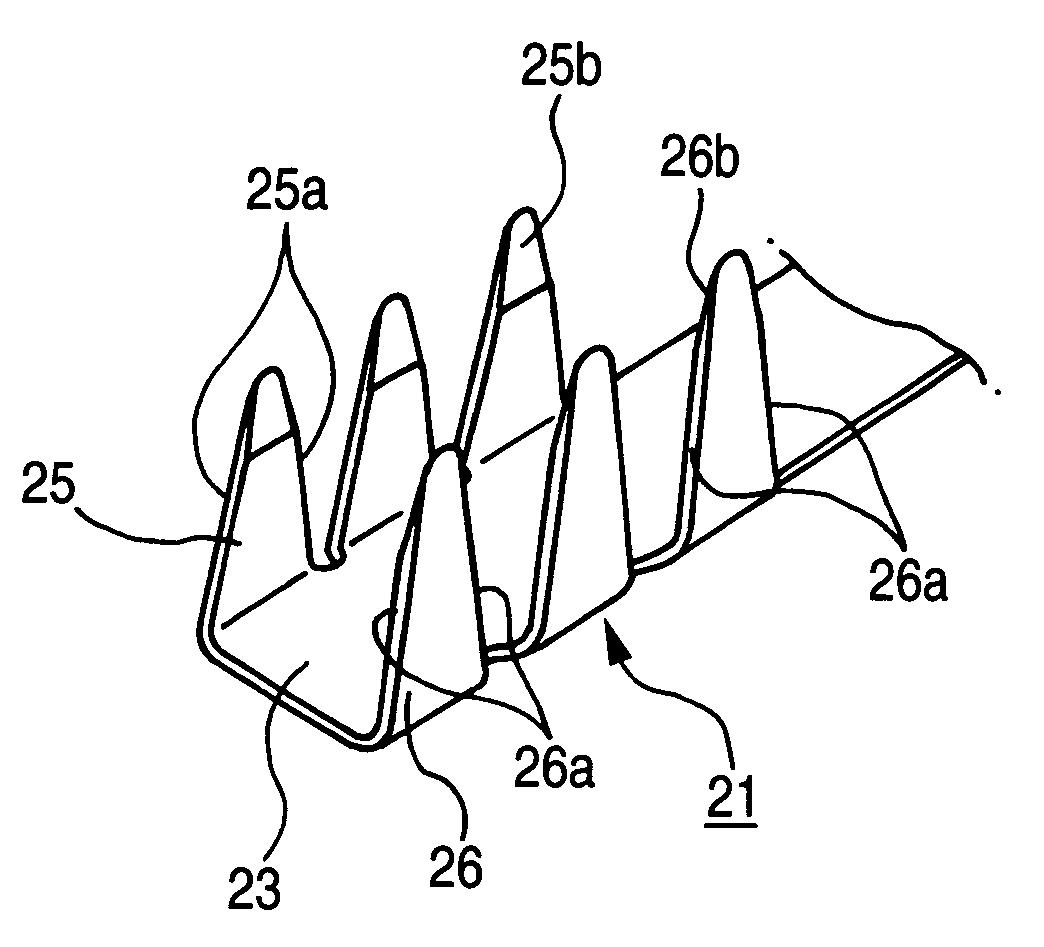

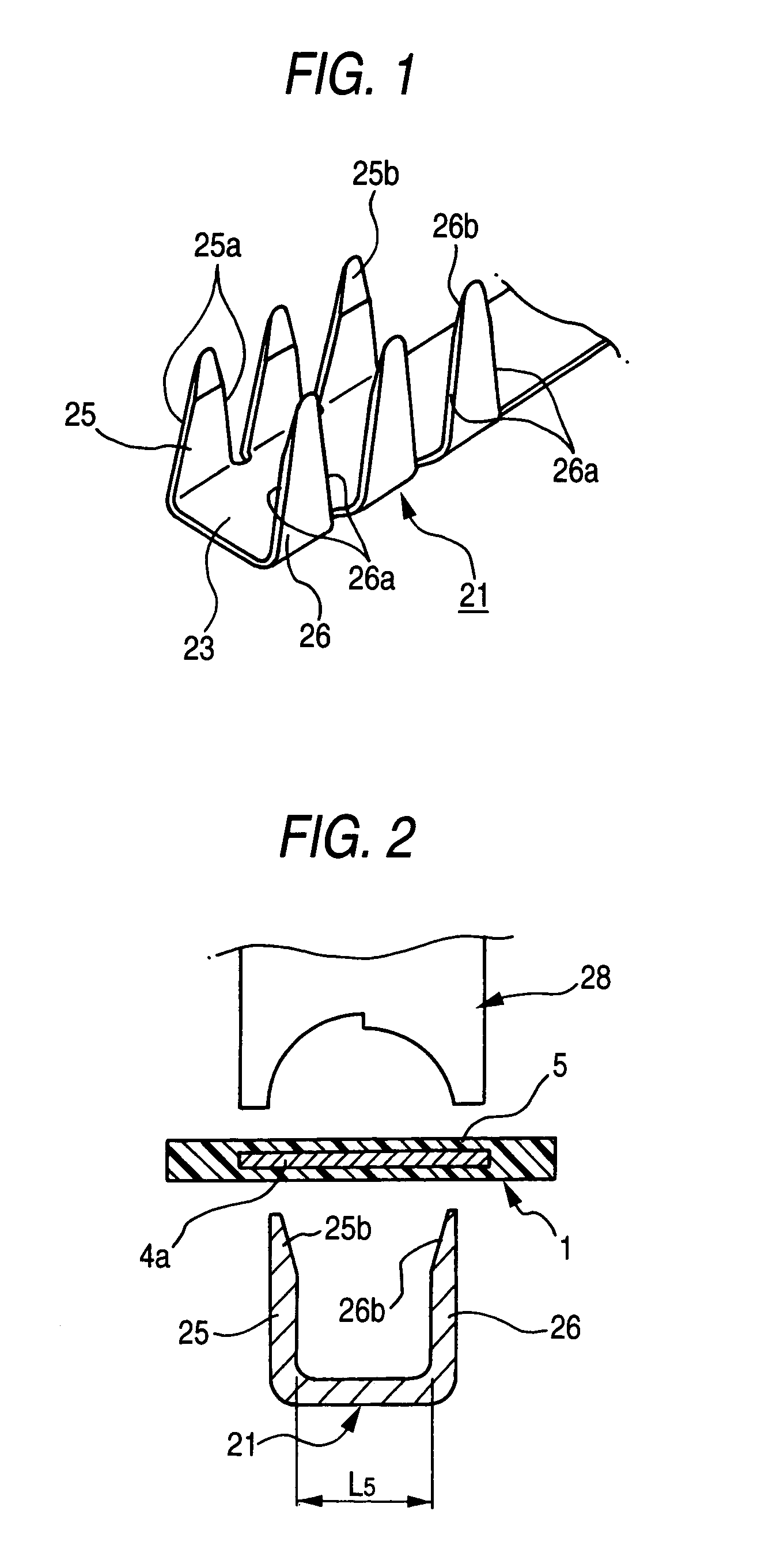

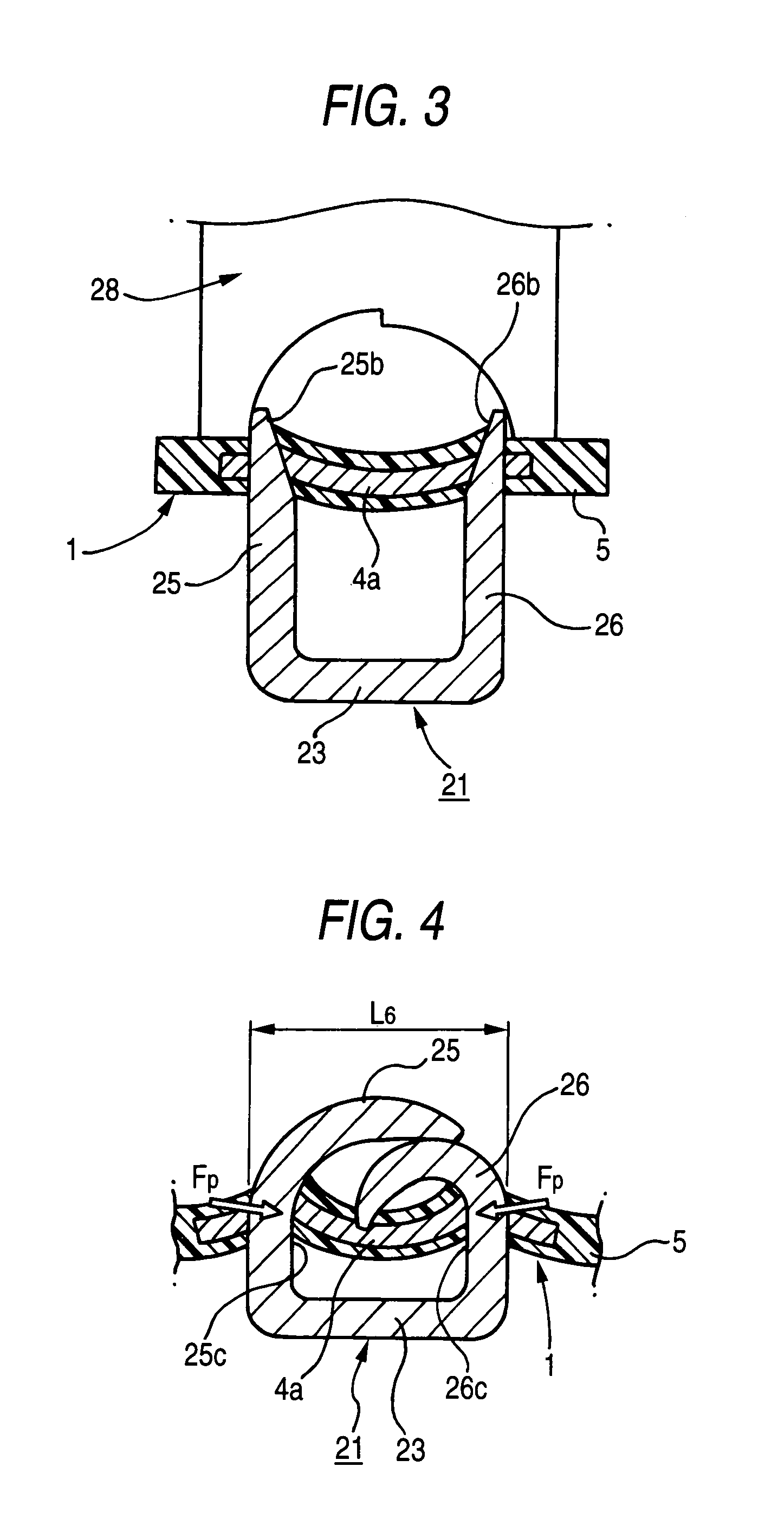

Electric connecting terminal

InactiveUS7040914B2Improve conduction reliabilityPrinted circuit assemblingConnections effected by permanent deformationElectrical conductorEngineering

An electric connecting terminal (21) is connected to a flat circuit body (1) by causing tips of one pair of piercing portions (25, 26) erected on both side edges of a plane portion (23) to penetrate through a coating (5) and a conductor (4a) in the flat circuit body (1) and then folding the tips in such a direction as to approach each other. Taper surfaces (25b, 26b) for gradually reducing a plate thickness toward the tip are provided on internal surface sides of the piercing portions (25, 26).

Owner:YAZAKI CORP

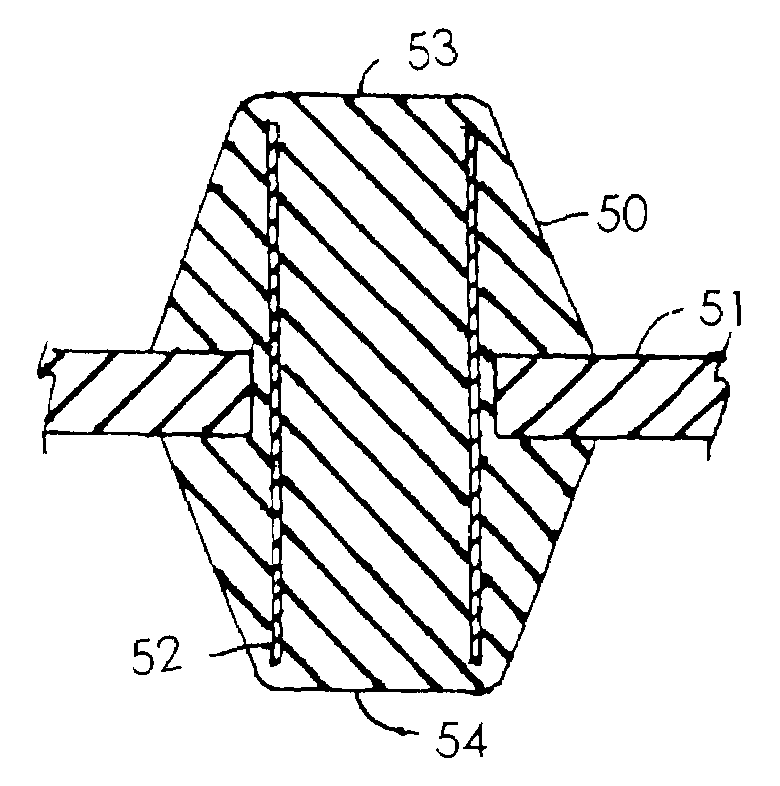

Mounting structure of electronic component and method of manufacturing electronic component

InactiveUS20100079962A1Prevent degradationImprove conduction reliabilityImpedence networksComponent plug-in assemblagesEngineeringElectronic component

A mounting structure includes: an electronic component including: a functional element having a predetermined function; a first resin protrusion section having a surface covered by a covering film including a conductive section electrically connected to the functional element; and a second resin protrusion section that is disposed inside an area surrounded by the first resin protrusion section, and has adhesiveness at least on a surface of the second resin protrusion section, and a base member having a connection electrode and adapted to mount the electronic component. In the structure, the second resin protrusion section mounts the electronic component on the base member in a condition in which the conductive section of the covering film has conductive contact with the connection electrode due to elastic deformation of the first resin protrusion section.

Owner:SEIKO EPSON CORP

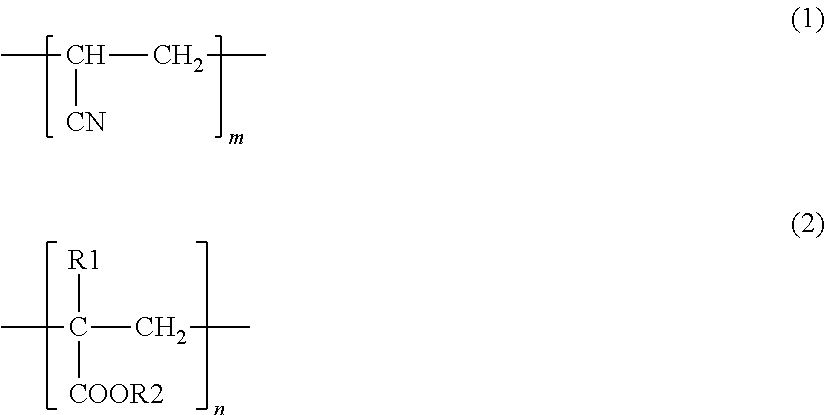

Prepreg, metal-clad laminate, and printed wiring board

InactiveUS20150282302A1Reduce warpageDecrease desmear etching amountSynthetic resin layered productsPrinted circuit aspectsEpoxyPolymer chemistry

A prepreg containing: a resin composition; and a woven fabric base material. The resin composition contains: (A) at least one of an epoxy resin having a naphthalene skeleton and a phenolic curing agent having a naphthalene skeleton; (B) a high molecular weight compound having at least structures represented by formulae (1) and (2 ) or at least a structure represented by the formula (2), no unsaturated bond between carbon atoms, and a weight-average molecular weight of 250,000 to 850,000; and (C) an inorganic filler. (C) The inorganic filler is subjected to surface treatment with a silane coupling agent represented by a formula (3).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

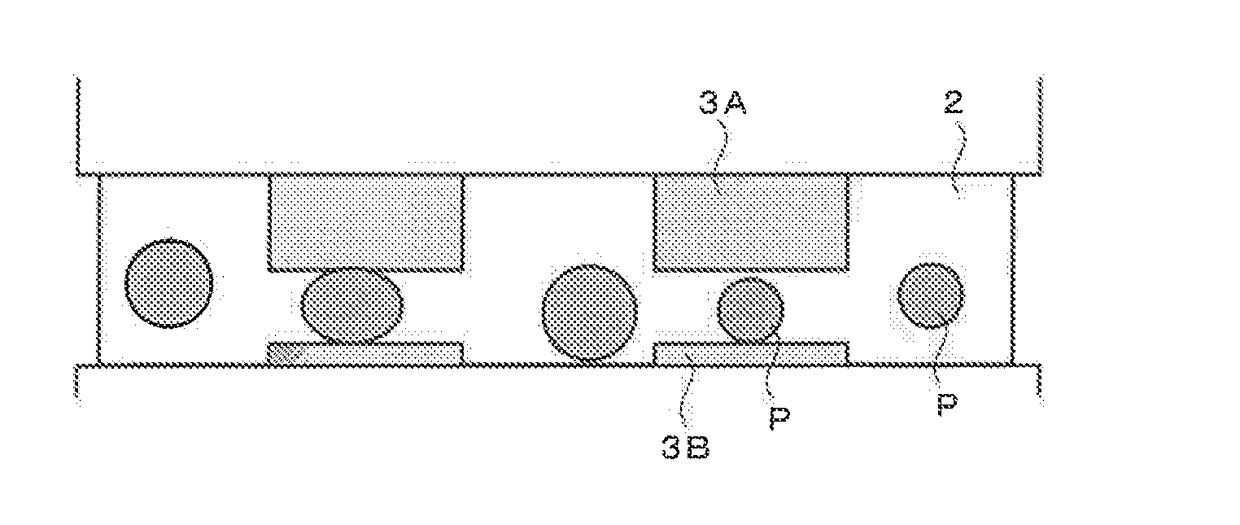

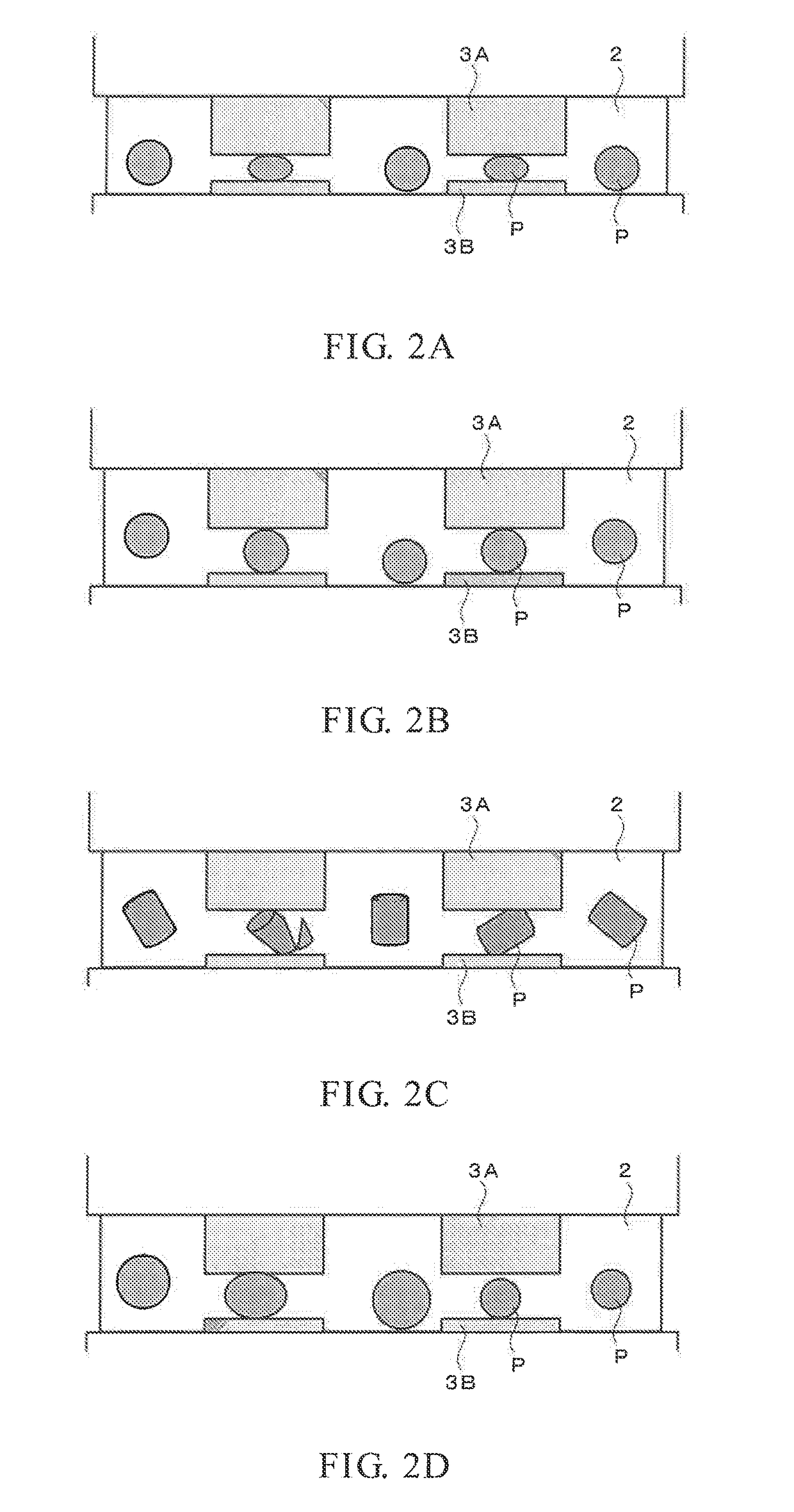

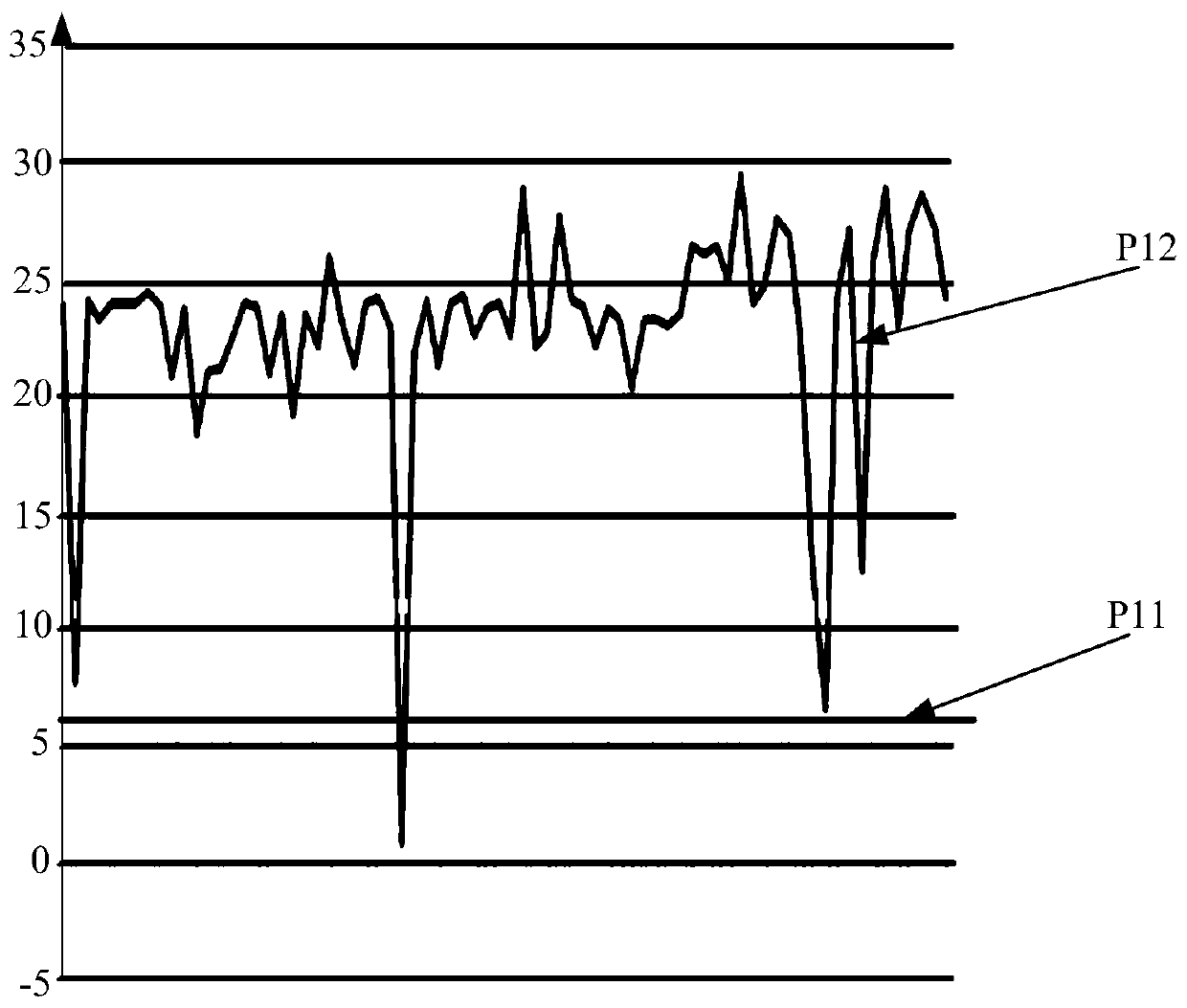

Anisotropic Electrically Conductive Film and Connection Structure

ActiveUS20180301432A1Sufficient capturingReduce areaNon-insulated conductorsSemiconductor/solid-state device detailsAnisotropic conductive filmSpherical form

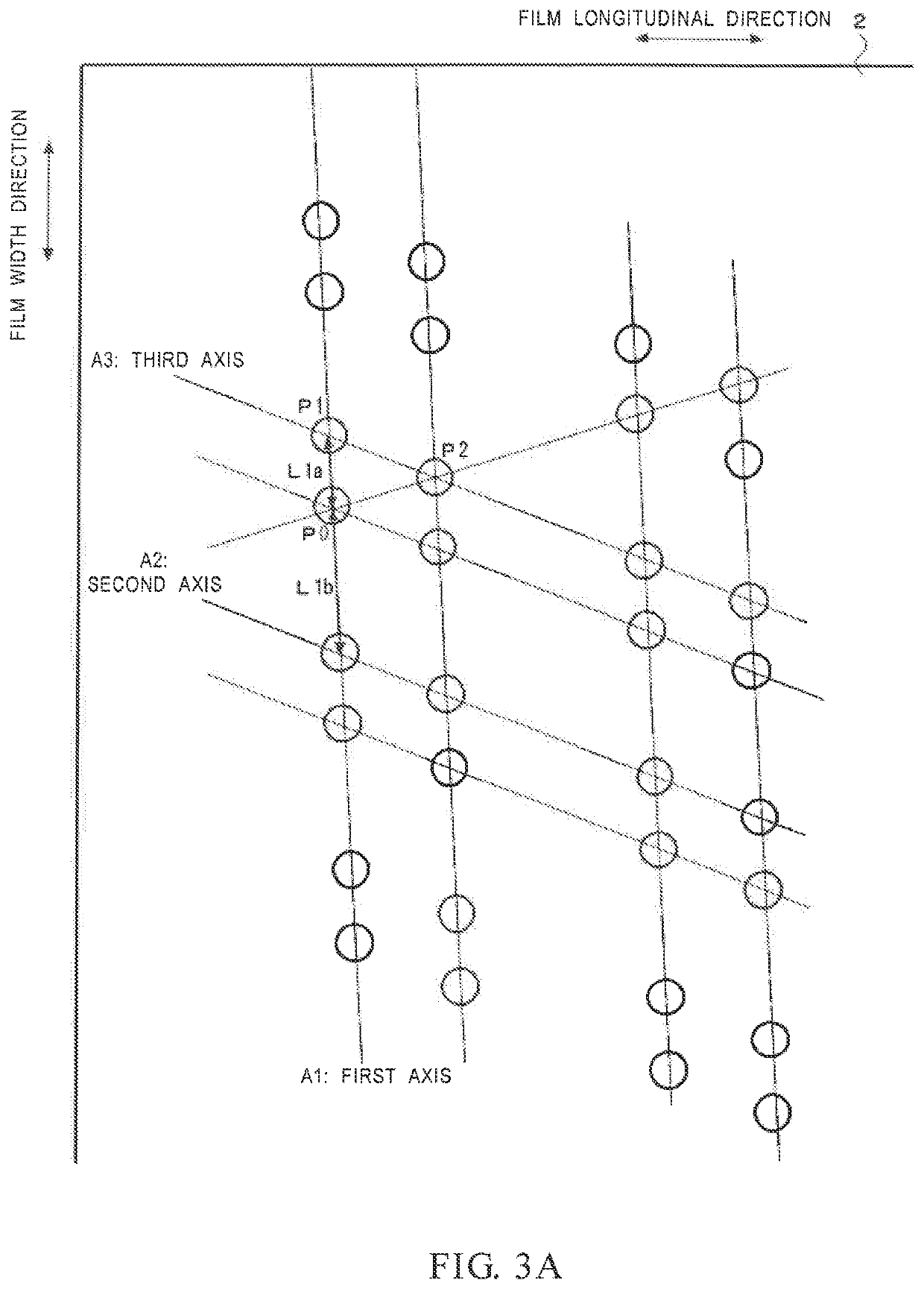

An anisotropic electrically conductive film includes electrically conductive particles disposed in an electrically insulating adhesive layer. The particles are arranged at a predetermined pitch along first axes, arranged side by side, and are substantially spherical. The particle pitch at the first axes and the axis pitch of the first axes are both greater than or equal to 1.5D, D being an average particle diameter of the particles. Directions of all sides of a triangle formed by a particle (P0), which is one of the electrically conductive particles at one of the first axes, an electrically conductive particle (P1), which is at the one of the first axes and adjacent to the particle (P0), and an electrically conductive particle (P2), which is at another one of the first axes that is adjacent to the one of the first axes, are oblique to a film width direction of the conductive film.

Owner:DEXERIALS CORP

Light-reflective anisotropic conductive adhesive agent, and light emitting device

ActiveUS20130049054A1High conduction reliabilityImprove conduction reliabilityNon-macromolecular adhesive additivesConductive materialAnisotropic conductive adhesiveResin composite

A light-reflective anisotropic conductive adhesive and light-emitting device capable of maintaining luminous efficiency of a light-emitting element and preventing the occurrence of a crack to obtain conduction reliability are provided. The light-reflective anisotropic conductive adhesive contains a thermosetting resin composite, conductive particles, and a light-reflective acicular insulating particles. These light-reflective acicular insulating particles are inorganic particles of at least one type selected from the group including titanium oxide, zinc oxide, and titanate.

Owner:DEXERIALS CORP

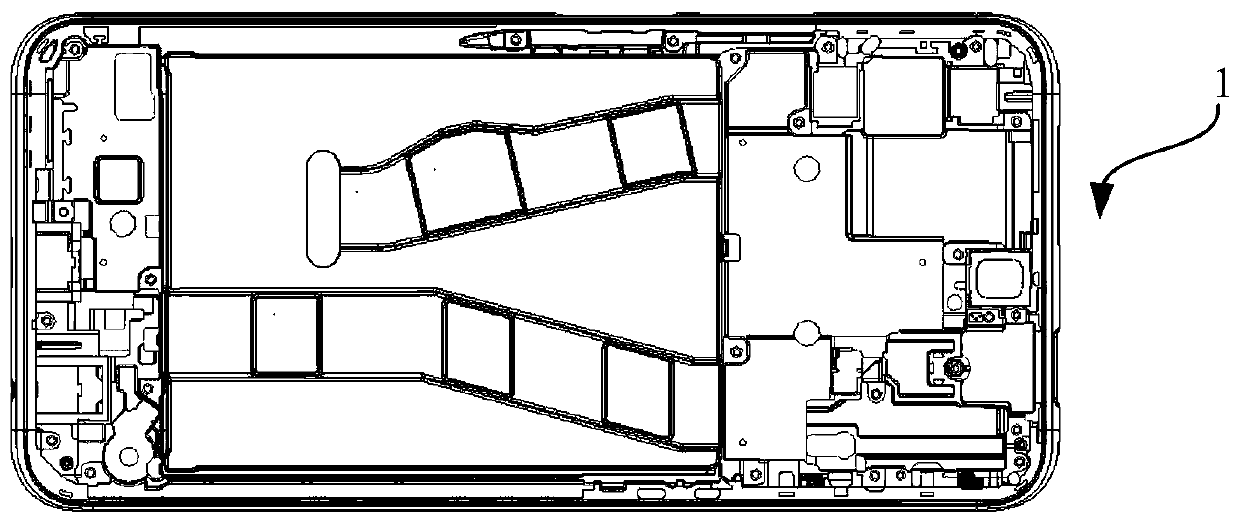

Middle frame assembly, preparation method of middle frame assembly and electronic equipment

ActiveCN111129709AThe phenomenon of increasing sizeImprove conduction reliabilityAntenna supports/mountingsAntennas earthing switches associationConductive coatingStructural engineering

The embodiment of the invention provides a middle frame assembly, a preparation method of the middle frame assembly and electronic equipment, and relates to the technical field of communication equipment. The middle frame assembly is used for being arranged on the electronic equipment. The middle frame assembly comprises: a middle frame body; an antenna laid on the middle frame body; an oxide film, wherein the exterior of the antenna is coated with the oxide film, and the position, located at the feed part of the metal sheet, of the oxide film is a hollow area; and a conductive coating at least covering the hollow area. The middle frame assembly, the preparation method of the middle frame assembly and the electronic equipment provided by the embodiment of the invention are used for improving the contact reliability of the metal elastic piece and the metal sheet so as to improve the receiving and transmitting stability of antenna signals.

Owner:HUAWEI TECH CO LTD

Wiring board and method of manufacturing the same

InactiveUS6761790B2Improve machinabilityImprove reliabilityPorous dielectricsElectrical connection printed elementsConductive pasteMetal foil

Owner:NITTO DENKO CORP

Printed wiring board manufacturing method

InactiveUS7434311B2Improve conduction reliabilityAvoid large displacementPrinted circuit aspectsElectrical connection printed elementsResistCopper plating

This printed wiring board manufacturing method comprises the steps of providing a large number of through holes (for a through-hole) in a substrate made of an insulating material of which both sides are coated with a copper foil; making the inside of the through holes electrically conductive, coating the substrate with a photosensitive dry film, and developing and hardening the photosensitive dry film as a plating resist; and copper-plating the inside of the through holes and the opening periphery thereof. The manufacturing method further comprises the steps of coating the copper-plated area with a metal protective film, eliminating the photosensitive dry film; forming a circuit pattern; and conducting an overlaying treatment as a post-processing step.

Owner:MARUWA

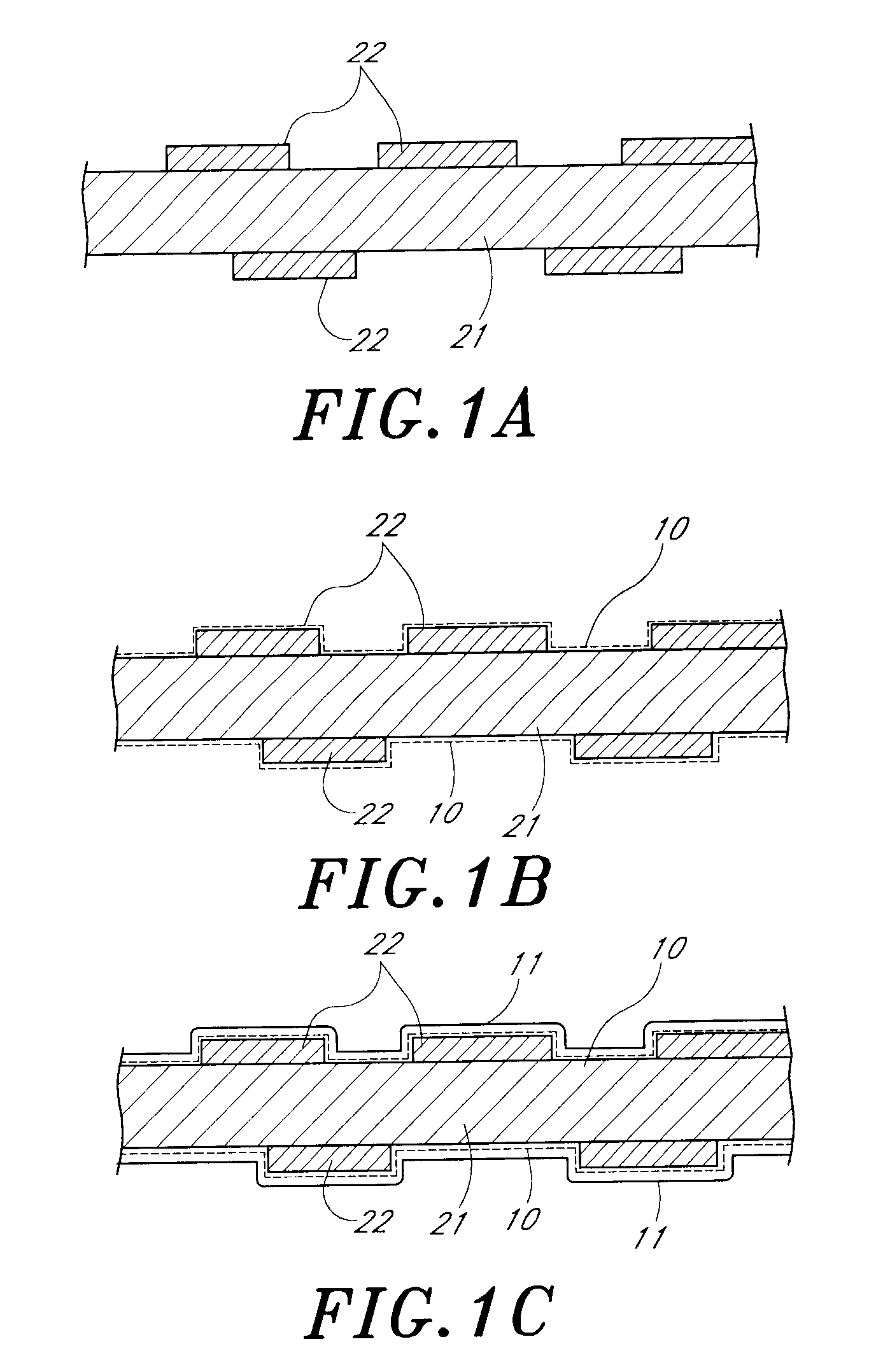

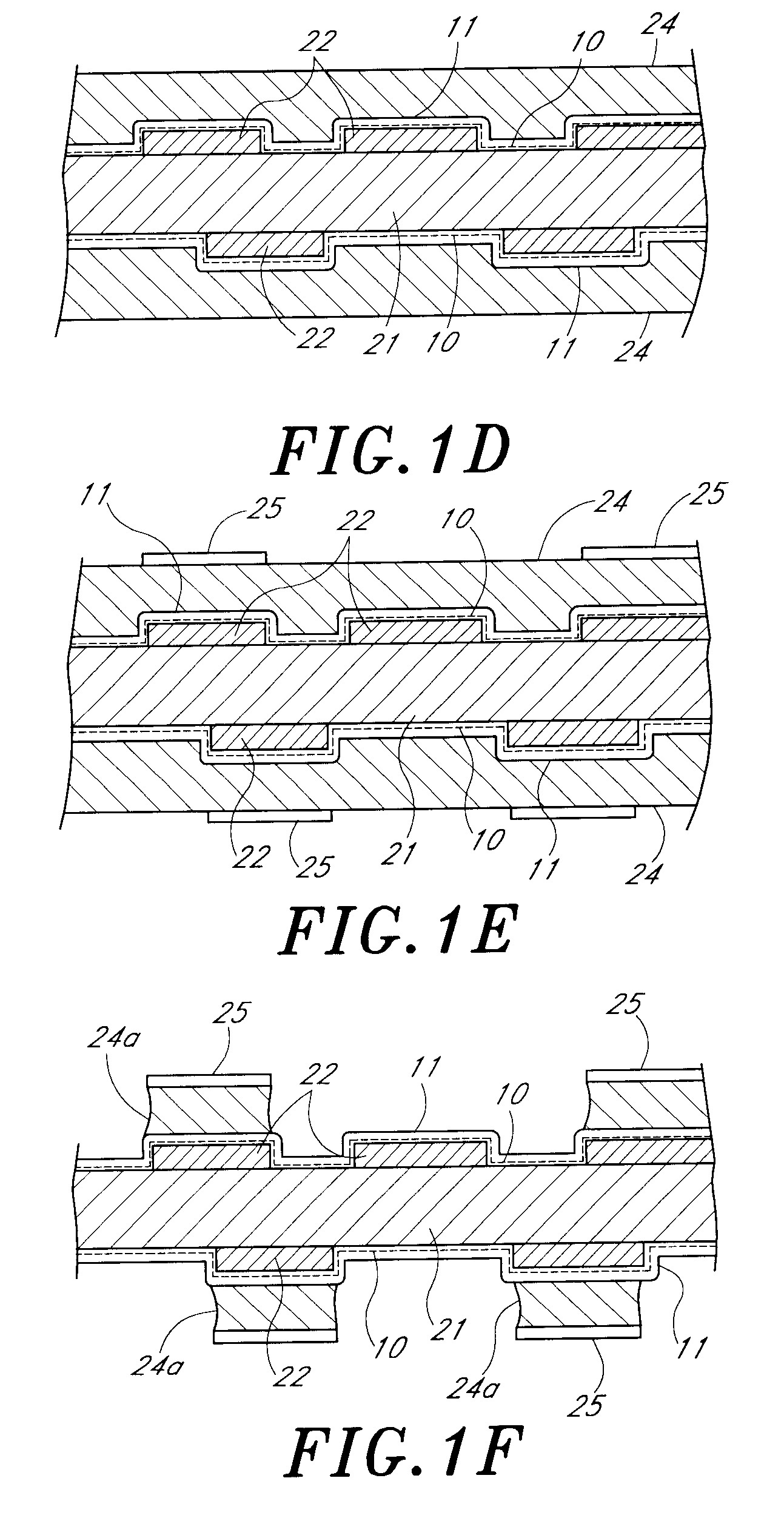

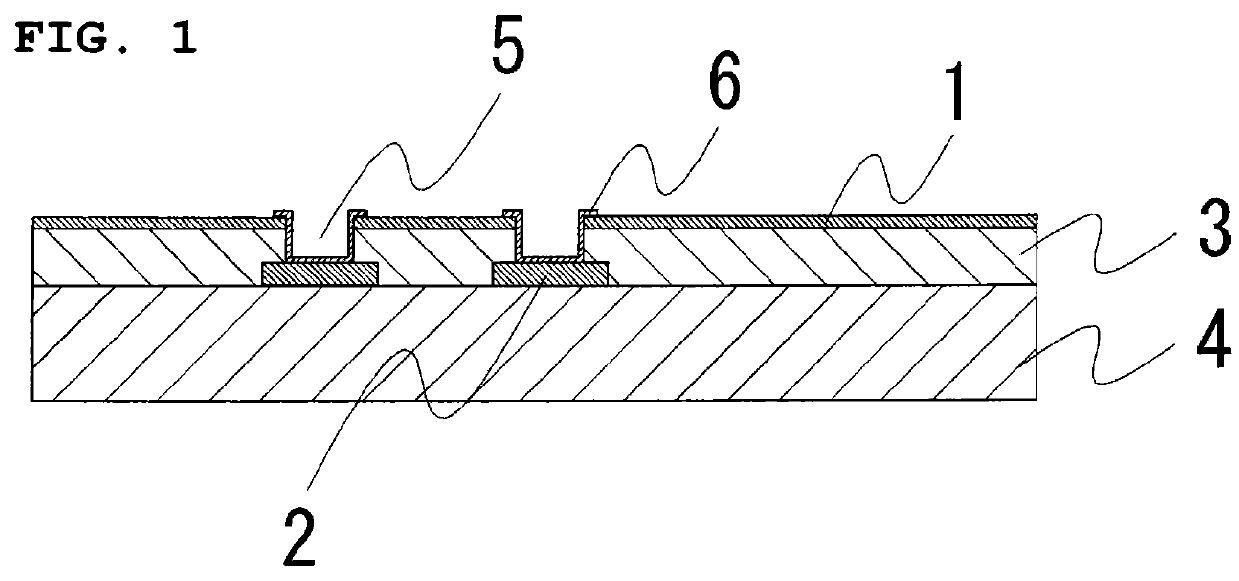

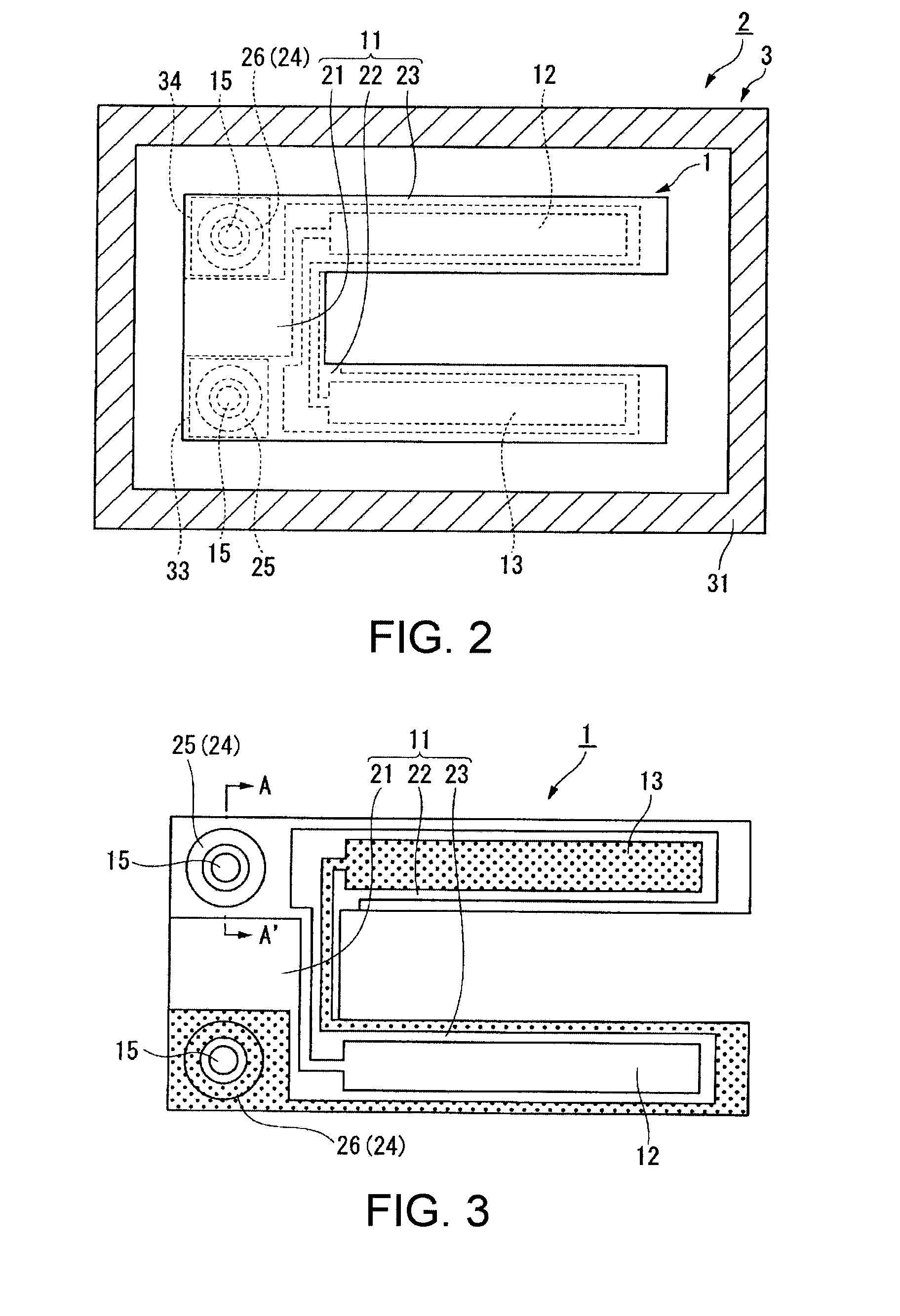

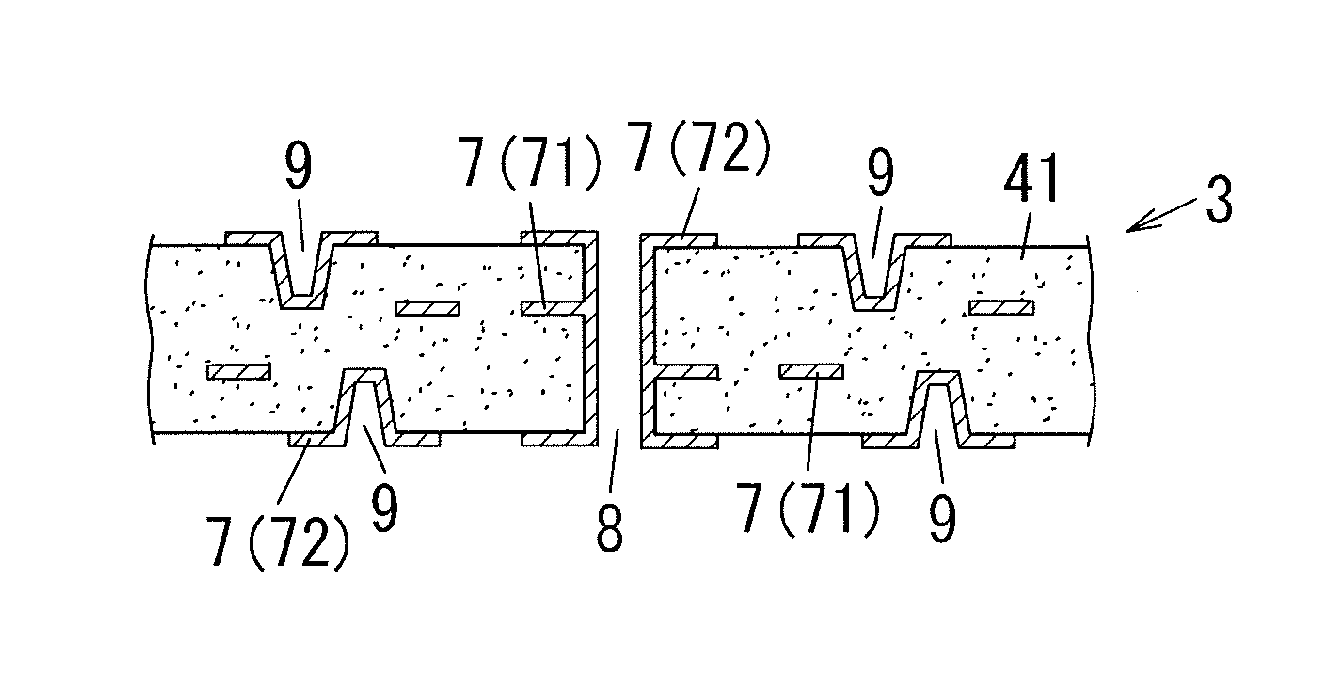

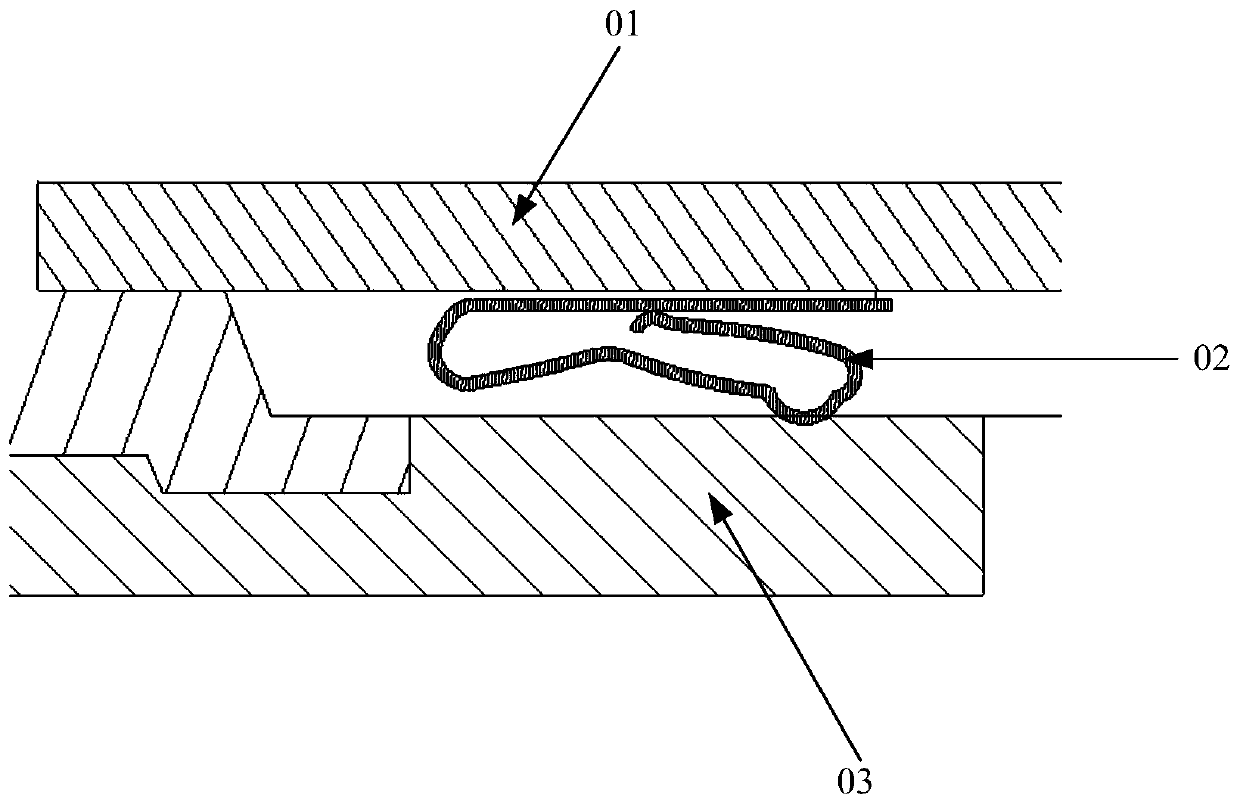

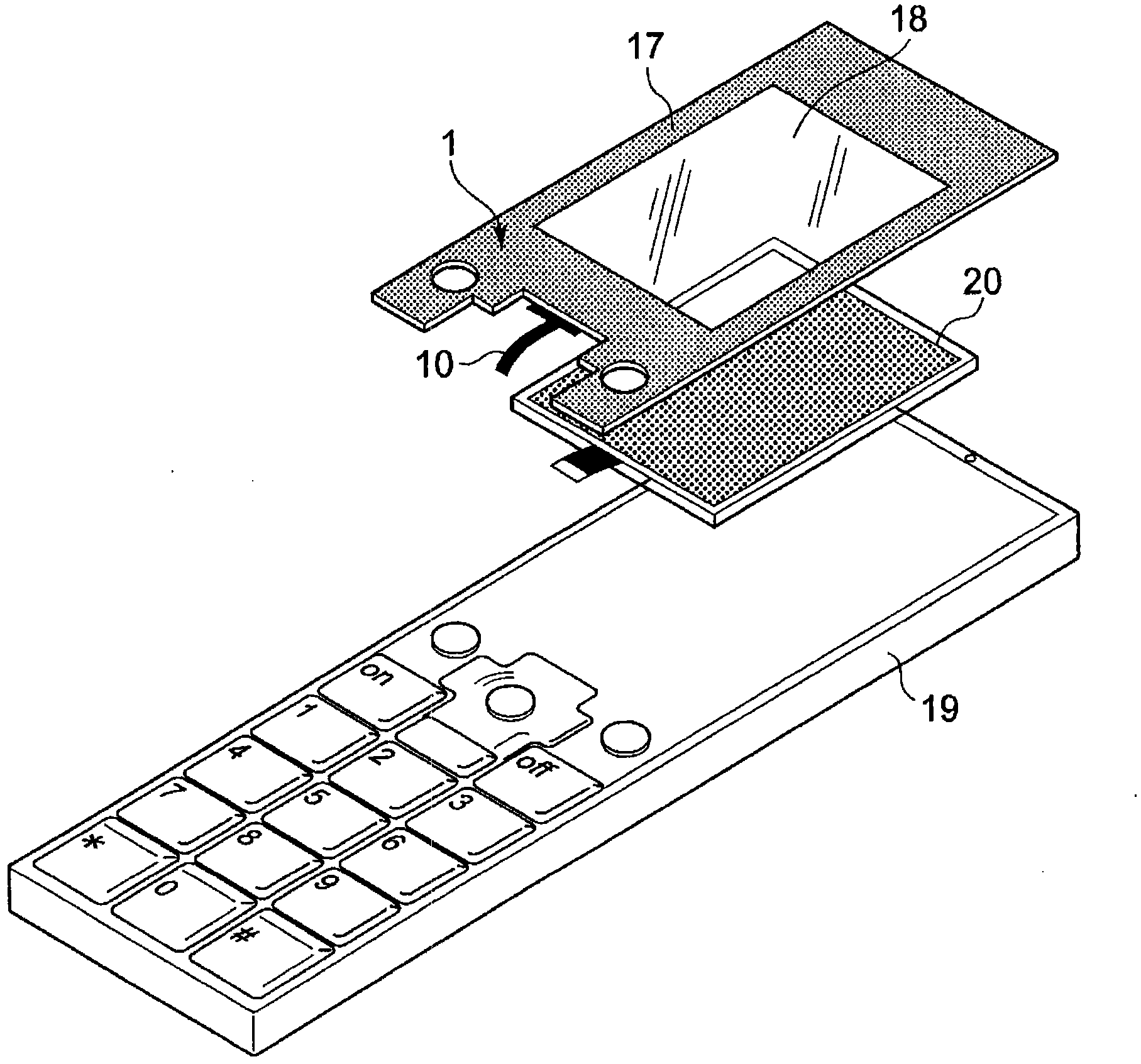

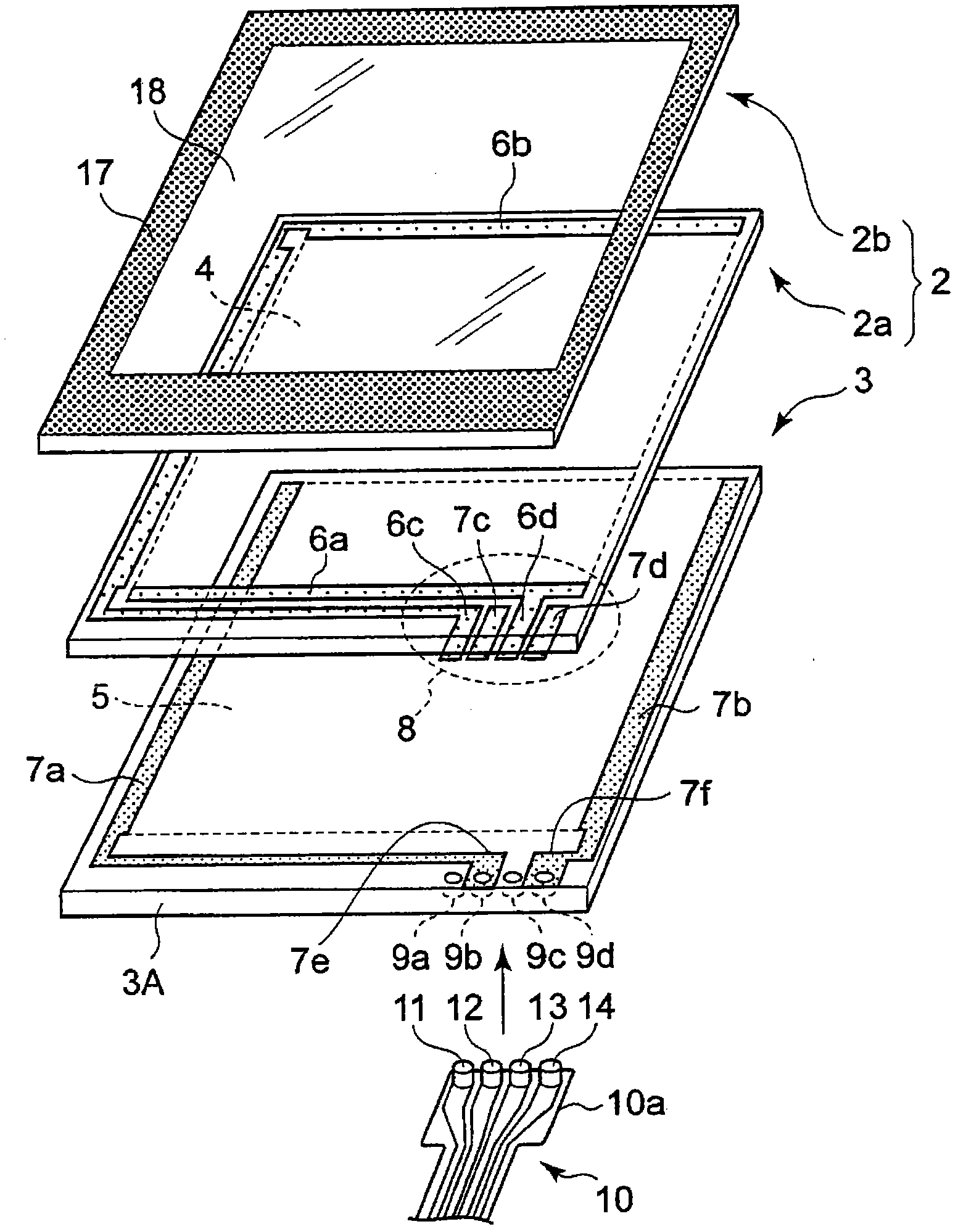

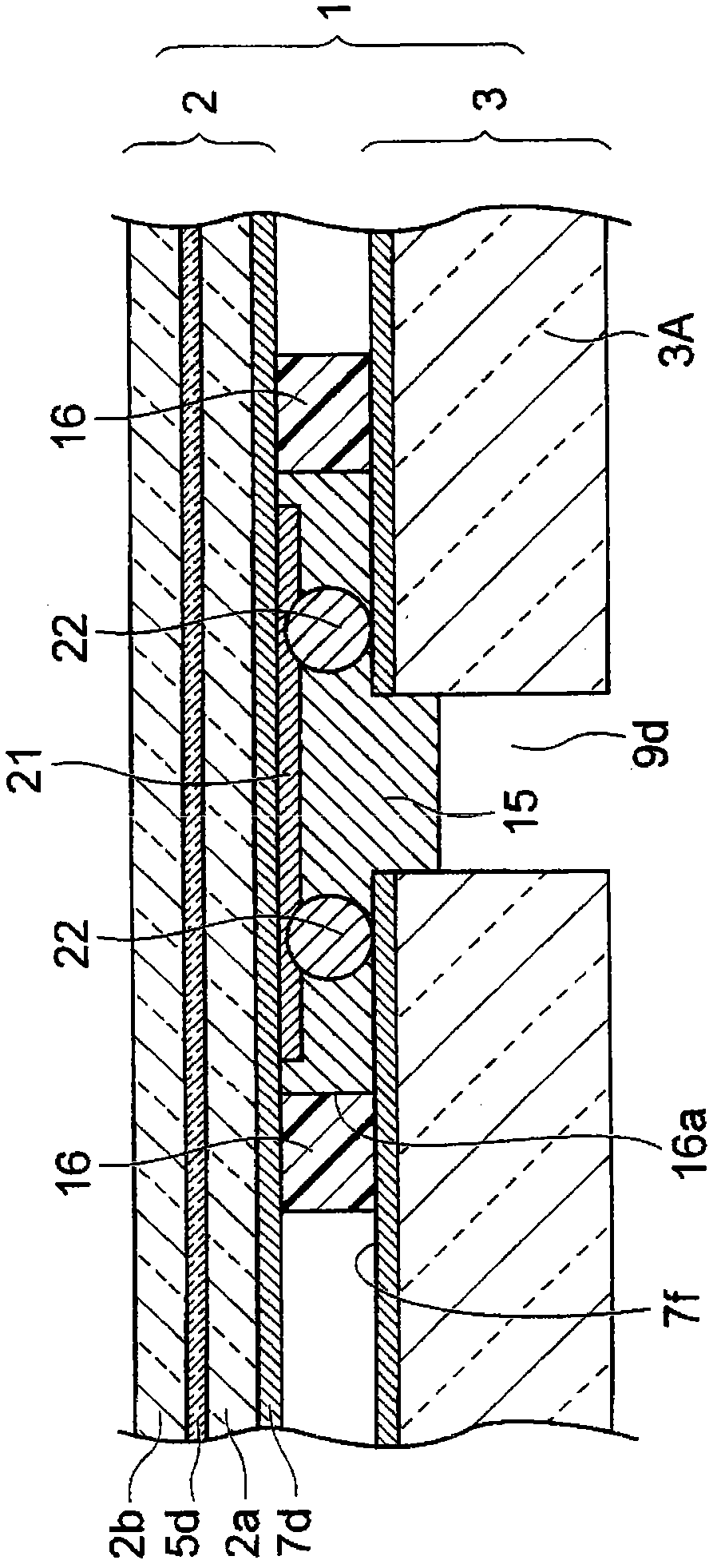

Protection panel provided with touch input function for electronic device display window

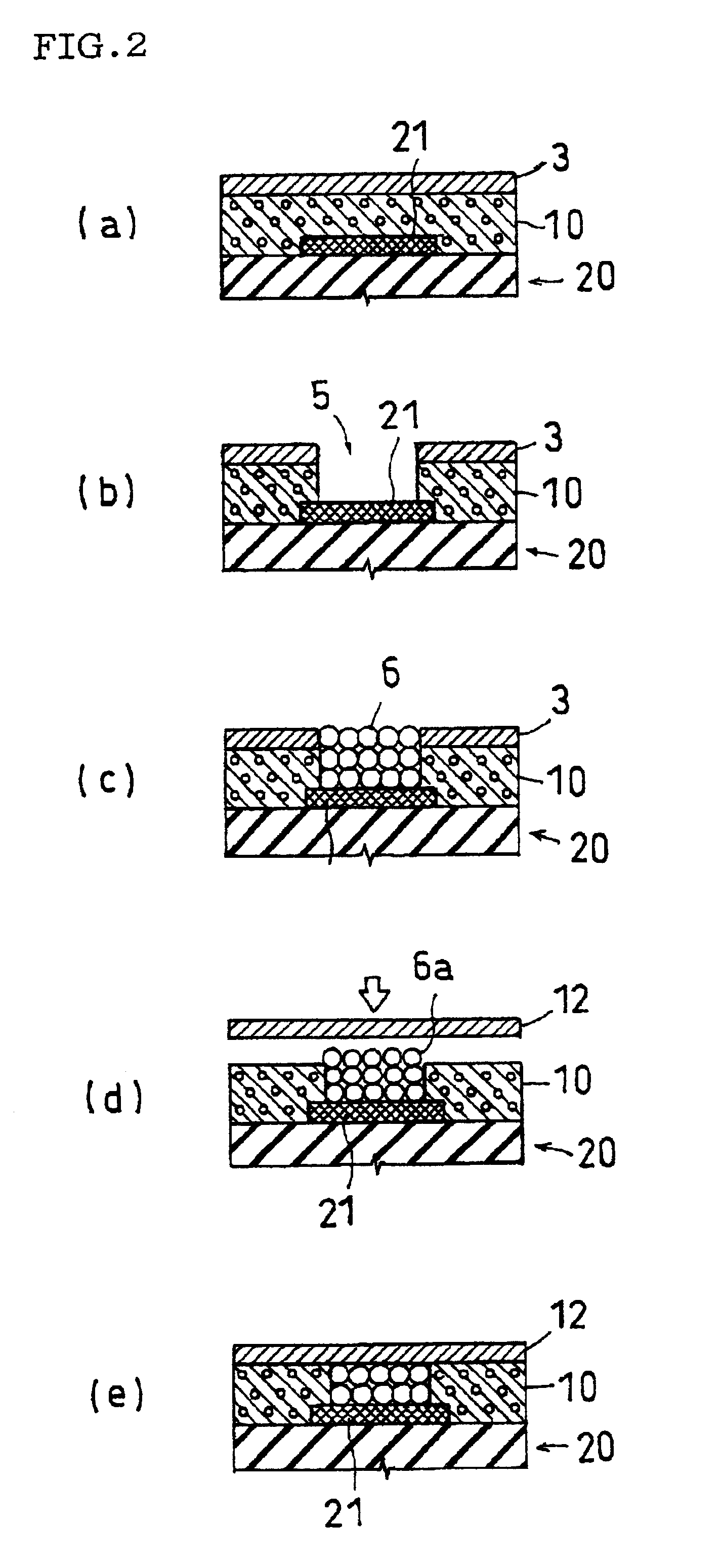

InactiveCN102171631AInject evenlyImprove conduction reliabilityDigital data processing detailsPrinted circuit aspectsAdhesiveEngineering

Provided is a protection panel (1) provided with a touch input function for an electronic device display window having an FPC (10) for extracting electric signals through through holes (9a, 9b, 9c, 9d) arranged on a lower electrode panel (3). An adhesive layer (16) which bonds the lower electrode panel and an upper electrode sheet (2a) has a connecting hole (16a) communicating with the through holes, a plurality of dot spacers (30) are fixedly arranged at intervals between a peripheral section of the through hole on an upper surface of the lower electrode panel and an upper electrode sheet (2) in the connecting hole. The connecting hole wherein gap intervals are maintained by the dot spacers is filled with a conductive adhesive (15) from the through holes.

Owner:NISSHA PRINTING COMPANY

Carbon dioxide filling valve and fracturing device

ActiveCN105486183ANot easy to damageImprove conduction reliabilityBlastingElectricityElectrical conductor

The invention discloses a carbon dioxide filling valve and a fracturing device. The filling valve is provided with a valve body and a communication part located in the valve body. The communication part comprises a first electrode and a second electrode. The valve body is provided with a liquid carbon dioxide input port, an output port and a stop valve. Both the first electrode and the second electrode are insulated from the valve body and coupled. The stop valve is used for opening and closing a passage between the input port and the output port. The filling valve is characterized in that the communication part further comprises a third electrode and a fourth electrode which are insulated from the valve body and coupled, the first electrode and the third electrode are insulated from each other, the second electrode and the fourth electrode are insulated from each other, and the communication part is made of a conductor material with the tensile strength over 200 MPa. The filling valve and the fracturing device with the filling valve have the quite reliable electricity conducting performance and the quite high anti-pressure capacity.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Adhesive film, connecting method and connected body

ActiveCN101821347AImprove conduction reliabilityIncrease the number of conductive particlesNon-insulated conductorsNon-macromolecular adhesive additivesVitrificationElectronic component

Provided are an adhesive film which can connect an electronic component to a substrate without causing short-circuiting, a connecting method and a connected body. The adhesive film is provided with a first adhesive layer wherein conductive particles are dispersed, and a second adhesive layer adhered on the first adhesive layer. The first and the second adhesive layers are adhesive films containing a sub resin composition. The first adhesive layer contains a first main resin composition having a glass transition temperature higher than that of the sub resin composition. The second adhesive layer contains a second main resin composition, which has a glass transition temperature higher than that of the sub resin composition but lower than that of the first main resin composition. The reaction peak temperature of the first and the second adhesive layers is lower than the glass transition temperature of the first main resin composition but higher than that of the second main resin composition.

Owner:DEXERIALS CORP

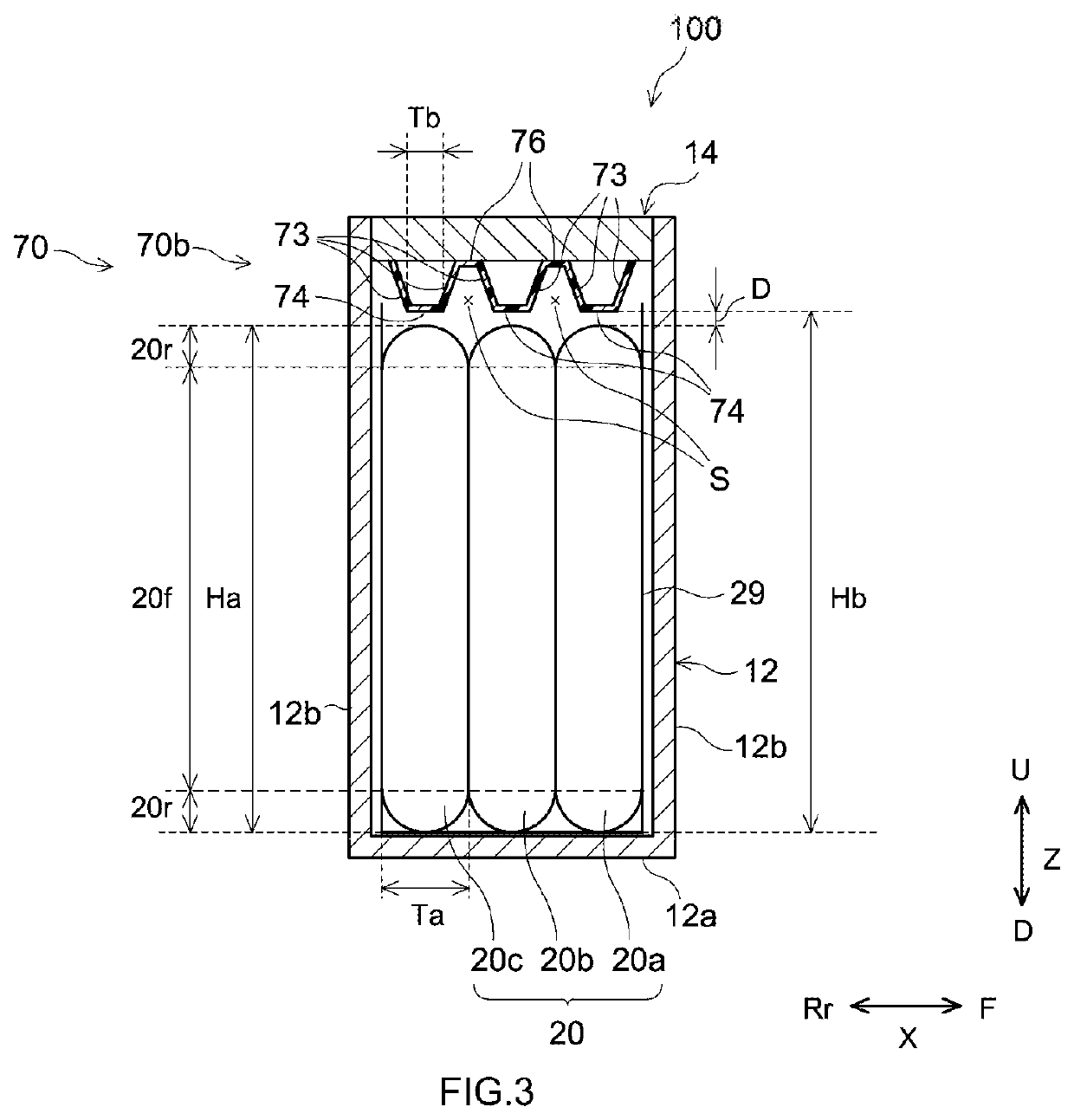

Battery and manufacturing method thereof

PendingUS20220140452A1Reduce load appliedReduce loadFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryElectrical connection

A battery disclosed herein includes an exterior body, a sealing plate sealing an opening of the exterior body, electrode bodies each including a first electrode, an electrode tab group electrically connected to the first electrodes, a terminal attached to the sealing plate and electrically connected to the electrode tab group, a collecting unit electrically connecting the electrode tab rid the terminal, and an insulating member insulating the sealing plate and the collecting unit from each other. The insulating member includes a base portion disposed between the sealing plate and the collecting unit, and protrusion portions protruding, from the sealing plate toward the sides of the electrode bodies.

Owner:PRIME PLANET ENERGY & SOLUTIONS INC

Conductive resin composition, method for manufacturing electronic component using same, bonding method, bonding structure, and electronic component

ActiveUS20110293922A1High hardnessReduce connection resistanceNon-metal conductorsConductive materialPolymer scienceElectronic component

A conductive resin composition which includes (a) a curable resin and (b) hard spherical carbon formed by coating the surface of a spherical base carbon particle with fine carbon particles and / or pitch-derived fine carbon pieces is used to electrically bond two conductive elements. The conductive resin composition is supplied to a space between areas of at least two works respectively having the areas to be electrically connected to each other, and the conductive resin composition is cured while applying a pressure between the areas.

Owner:MURATA MFG CO LTD

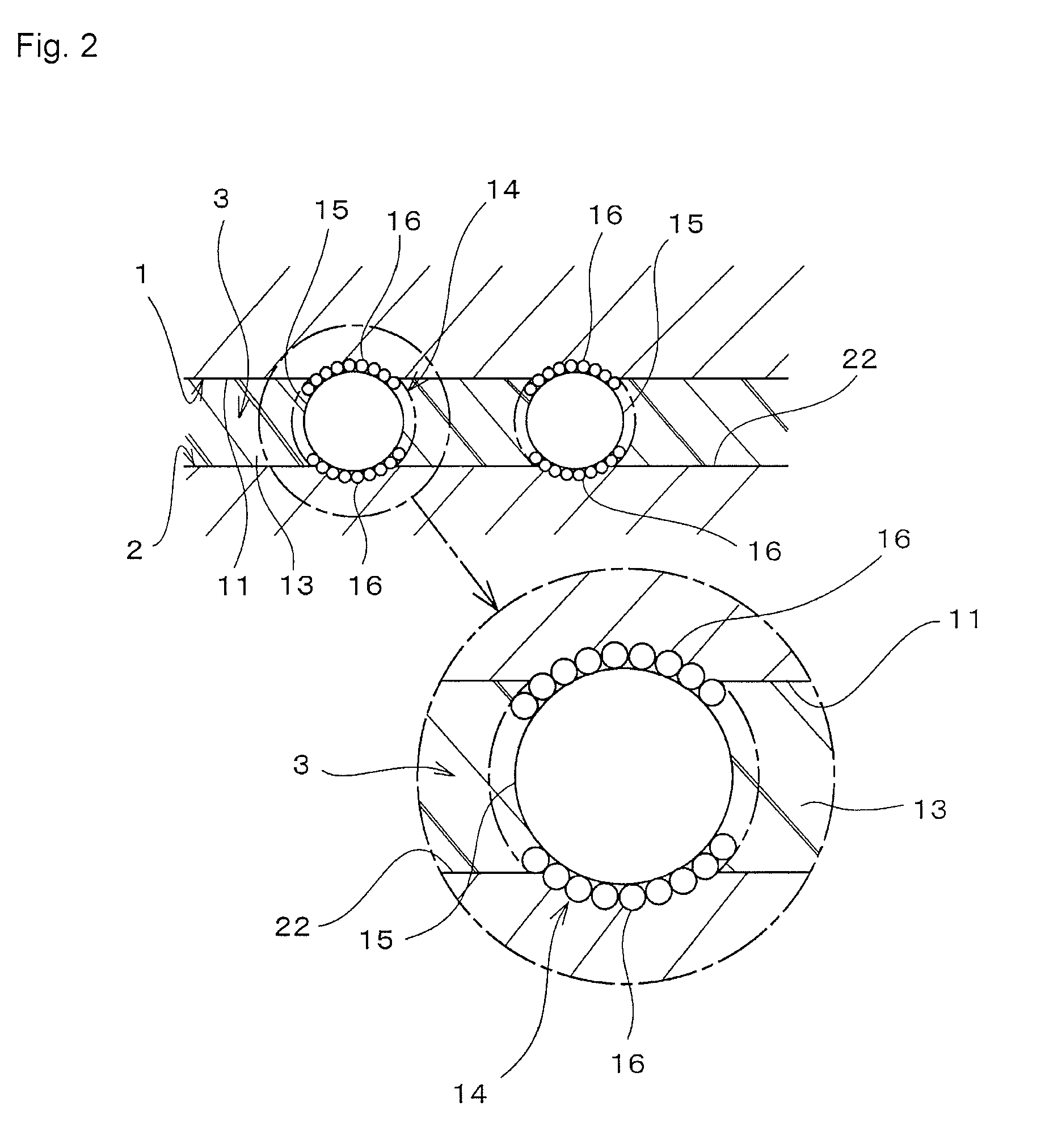

Movable connector

A movable connector with which an insertion force of a connection object that places a load on a solder portion can be reduced, that has a floating function, and that can be reduced in size is provided. As a result of a pushing operation in which an operation housing is pushed into a fixed housing, a relay terminal is conductively connected to a substrate connection terminal, which is in conductive contact with a substrate, and a pin terminal, which is disposed in a movable housing and serves as the connection object, in the movable housing. Accordingly, the overall size of the movable connector can be reduced. In addition, the insertion force applied to the pin terminal is not applied to the solder portion by which the movable connector is fixed to the substrate, so that conduction failure does not occur.

Owner:IRISO ELECTRONICS CO LTD

Electronic component connecting method and joined body

ActiveCN101681858ACorrectly measure the number of catchesImprove conduction reliabilityNon-insulated conductorsNon-macromolecular adhesive additivesAnisotropic conductive adhesiveElectrical connection

A method for electrically connecting an electronic component with high reliability of electrical connection after the electrical connection, enabling correct counting of captured conductive particlesand a joined body are provided. The electronic component connecting method includes a mixing step of mixing a dispersing solvent, an adhesive resin dissolvable into the dispersing solvent, conductiveparticles, and insulating particles whose size is smaller than that of the conductive particles thereby to prepare an anisotropic conductive adhesive and a heating / pressing step of opposing a substrate terminal of a substrate and a component terminal of an electronic component with the anisotropic conductive adhesive interposed therebetween, applying heat and pressing-force to the substrate and the electronic component, holding the conductive particles between the substrate terminal and the component terminal, and thereby deforming the conductive particles. The pressing-force at the heating / pressing step is weaker than both the breakage pressing-force by which the conductive particles are broken and the deformation pressing-force by which the particle size of the conductive particles becomes equal to that of the insulating particles.

Owner:DEXERIALS CORP

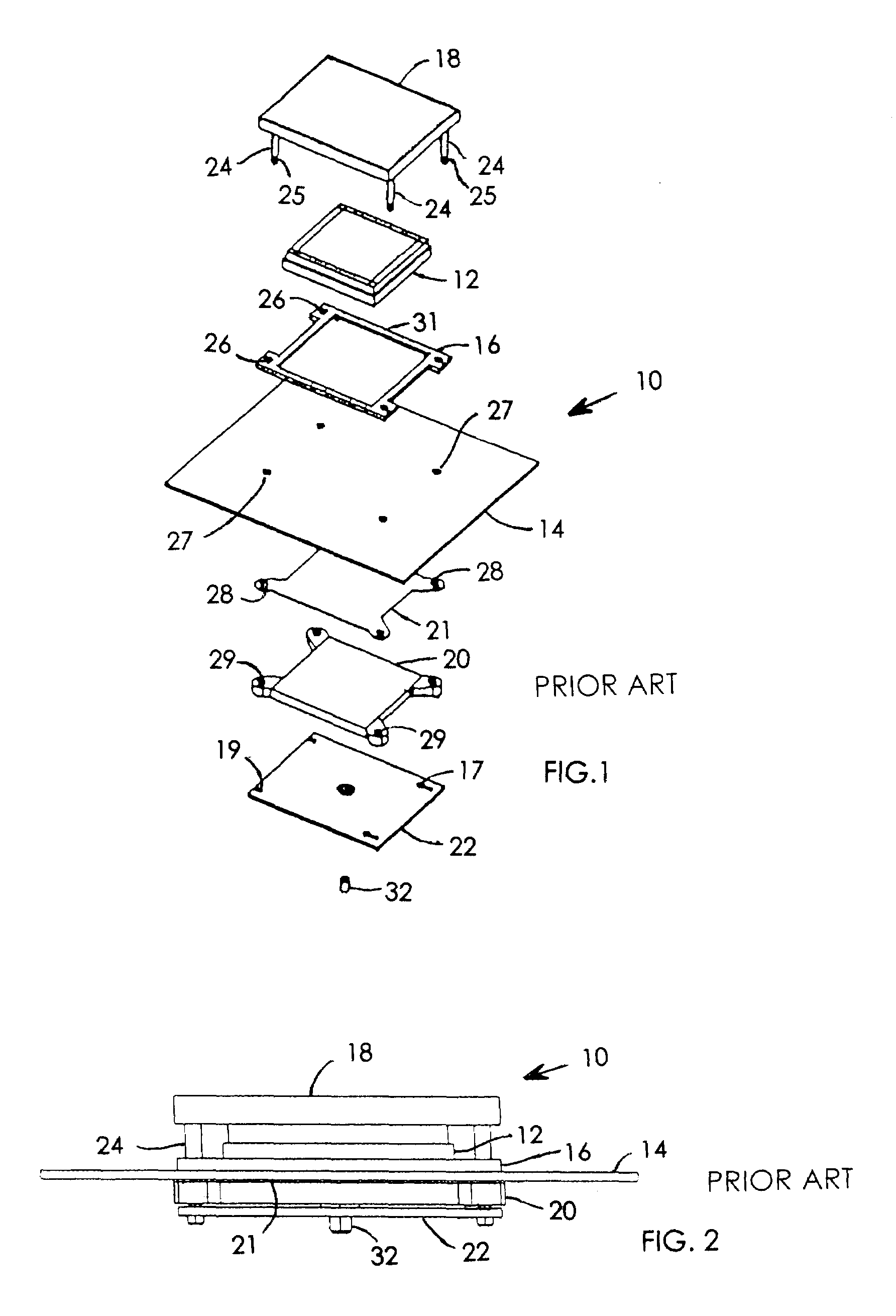

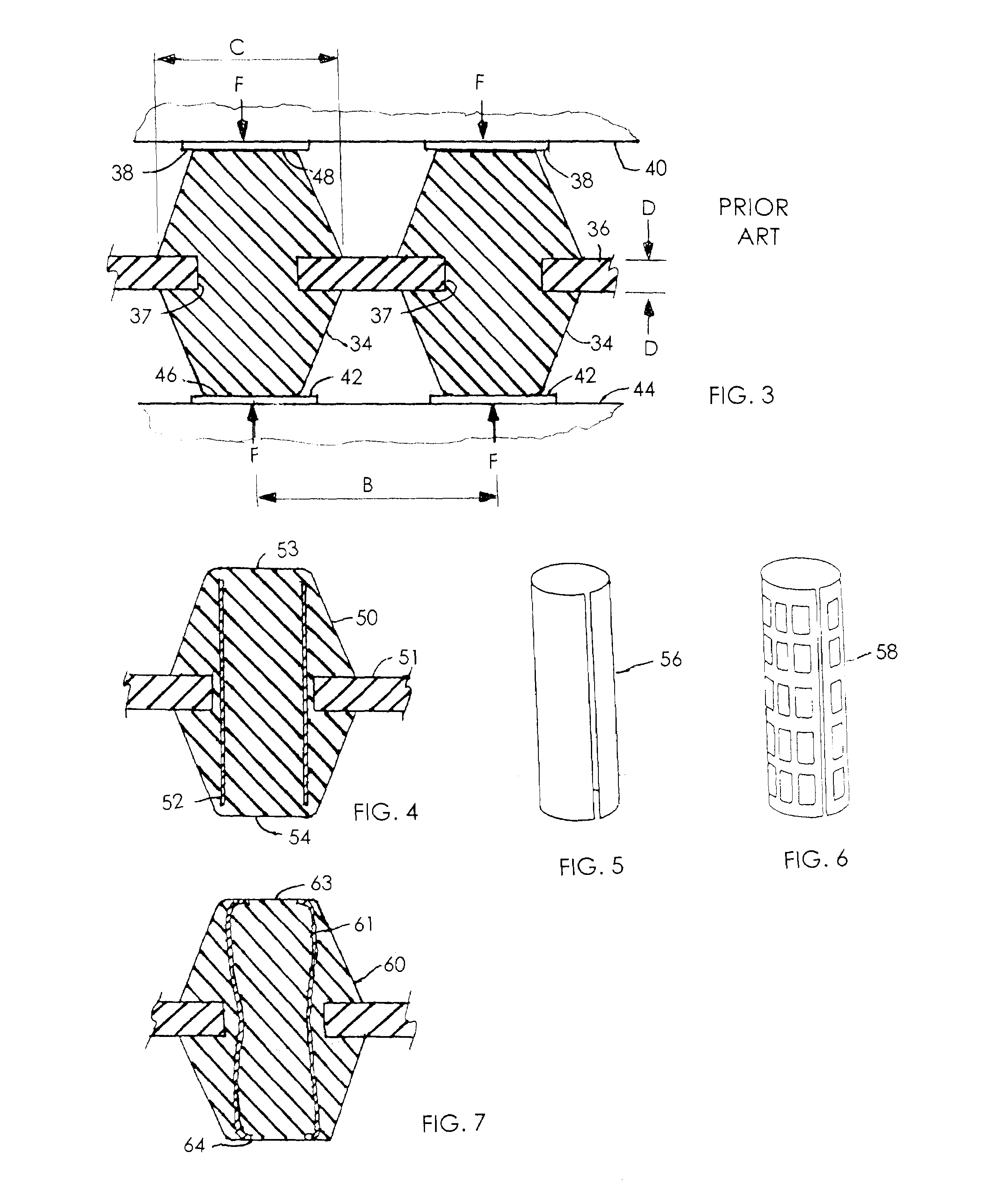

Conductive particle filled polymer electrical contact

InactiveUS7466154B2Reduce riskReduce decreaseElectrical measurement instrument detailsCoupling device detailsEngineeringPolymer

A conductive filled polymer contact which is molded at an aperture through a carrier sheet includes an elongated conductive frame introduced prior to the molding process as an insert which is held captive in the molded contact and which extends from at or near the upper contact surface, through the aperture and terminates at the opposite end at or near the lower contact surface to provide a continuous conductive path through the length of the contact, whereby the sequence of particle to particle interfaces within the molded polymer contact is reduced in number to increase reliability.

Owner:INT BUSINESS MASCH CORP

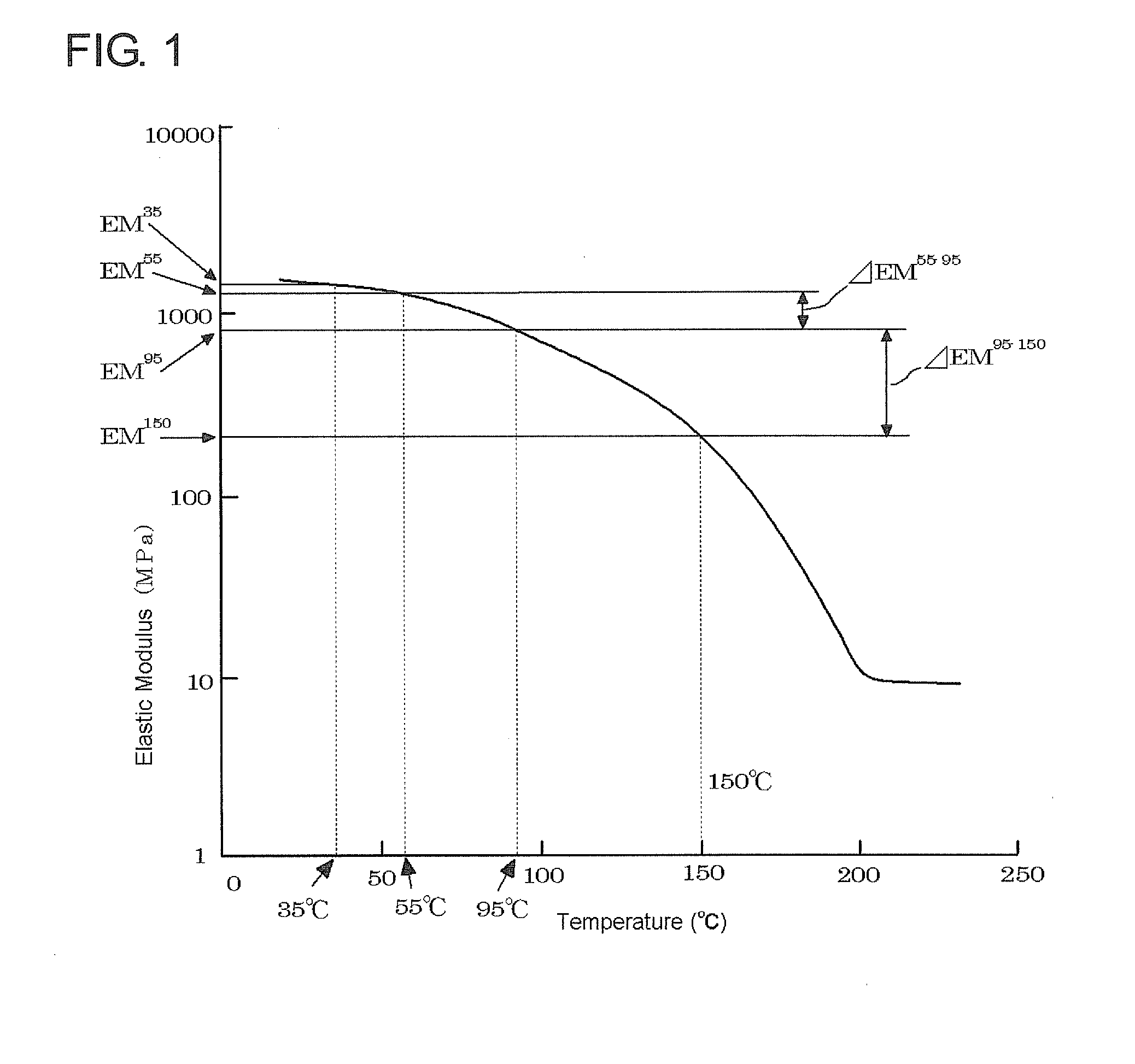

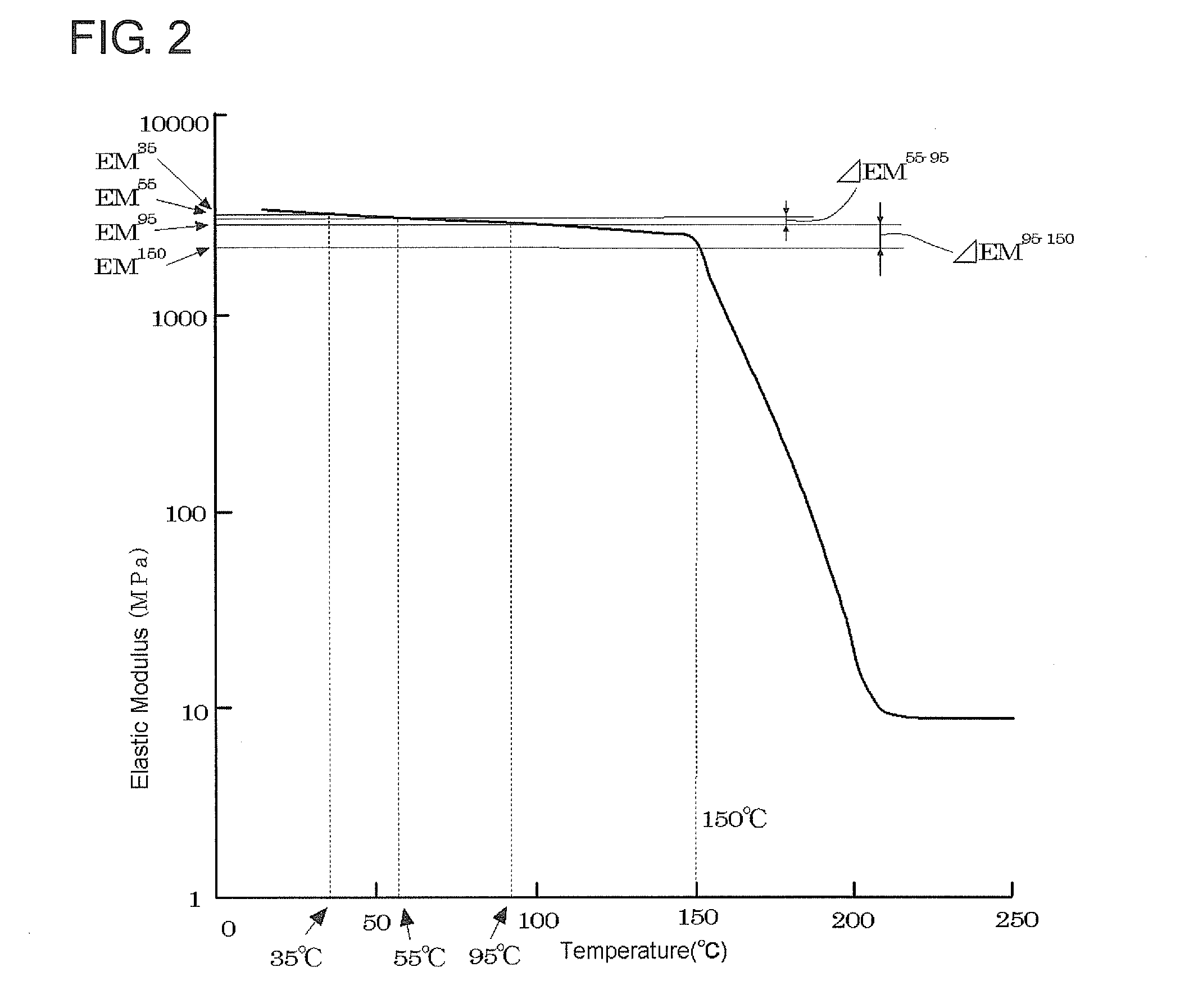

Anisotropic conductive adhesive

InactiveUS20120262931A1Improve conduction reliabilityOptimizationNon-macromolecular adhesive additivesLighting support devicesEpoxyAnisotropic conductive adhesive

An anisotropic conductive adhesive including conductive particles dispersed in an epoxy-based adhesive containing an epoxy compound and a curing agent gives a cured product having the elastic modulus satisfying the expressions (1) to (5), in which EM35, EM55, EM95, and EM150 are values of the elastic modulus of the cured product at 35° C., 55° C., 95° C., and 150° C., respectively, ΔEM55-95 is the rate of change in the elastic modulus between 55° C. and 95° C., and ΔEM95-150 is the rate of change in the elastic modulus between 95° C. and 150° C.,700 MPa≦EM35≦3000 MPa (1)EM150<EM95<EM55<EM35 (2)ΔEM55-95<ΔEM95-150 (3)20%≦ΔEM55-95 (4)40%≦ΔEM95-150 (5).

Owner:DEXERIALS CORP

Method for connecting electronic part and joined structure

ActiveUS8273207B2Accurate measurementImprove conduction reliabilitySolid-state devicesPrinted circuit manufactureAnisotropic conductive adhesiveOptoelectronics

A method for connecting an electronic part, which contains: mixing a dispersing solvent, an adhesive resin which is dissolved in the dispersing solvent, conductive particles, and insulating particles which have smaller particle diameters than those of the conductive particles so as to prepare an anisotropic conductive adhesive; placing a terminal of a substrate and a terminal of an electronic part so as to face each other via the anisotropic conductive adhesive, and applying heat and pressure to the substrate and the electronic part so as to sandwich the conductive particles between the terminal of the substrate and the terminal of the electronic part to thereby deform the conductive particles, in which the pressure is smaller than pressure at which the conductive particles are destroyed, and smaller than pressure at which the particle diameters of the conductive particles become equal to the particle diameters of the insulating particles.

Owner:DEXERIALS CORP

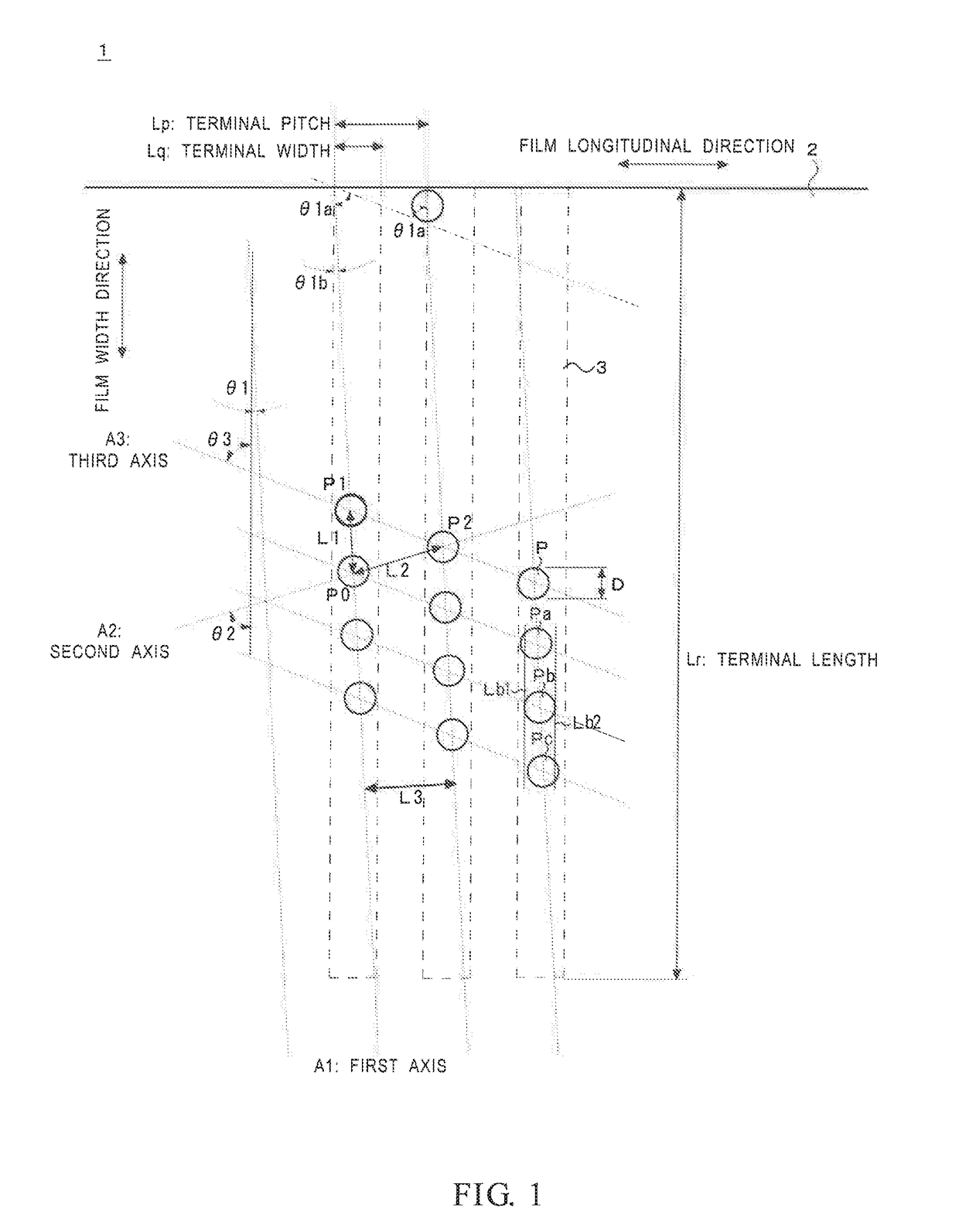

Anisotropic electrically conductive film and connection structure

ActiveUS10546831B2Sufficient capturingReduce areaNon-insulated conductorsSemiconductor/solid-state device detailsAnisotropic conductive filmCondensed matter physics

An anisotropic electrically conductive film includes electrically conductive particles disposed in an electrically insulating adhesive layer. The particles are arranged at a predetermined pitch along first axes, arranged side by side, and are substantially spherical. The particle pitch at the first axes and the axis pitch of the first axes are both greater than or equal to 1.5D, D being an average particle diameter of the particles. Directions of all sides of a triangle formed by a particle (P0), which is one of the electrically conductive particles at one of the first axes, an electrically conductive particle (P1), which is at the one of the first axes and adjacent to the particle (P0), and an electrically conductive particle (P2), which is at another one of the first axes that is adjacent to the one of the first axes, are oblique to a film width direction of the conductive film.

Owner:DEXERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com