Patents

Literature

470results about How to "Inject evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

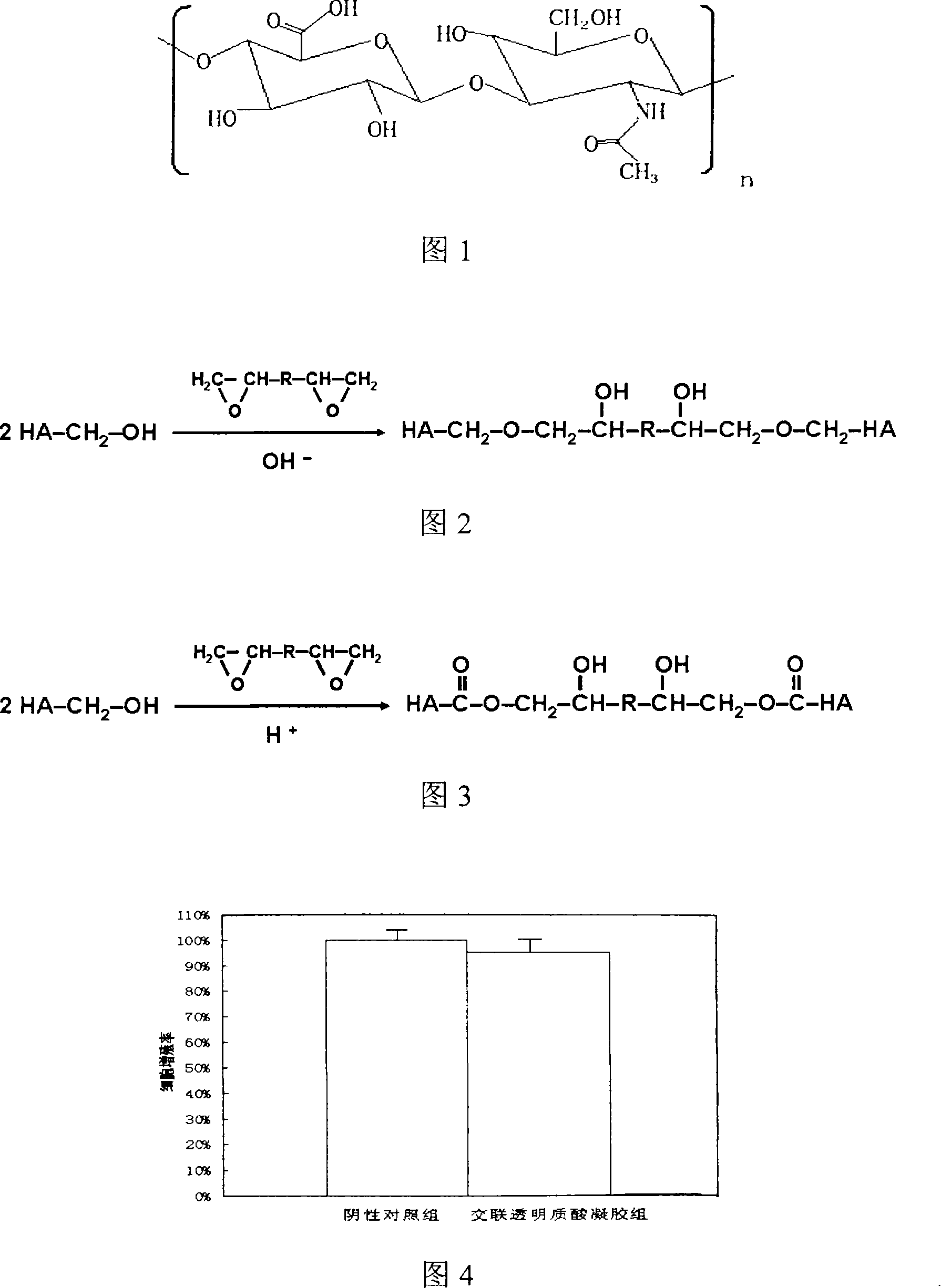

Method for preparing crosslinked hyaluronic acid microgel for tissue filling

The invention relates to a preparation method of cross-linking hyaluronic acid microgel for tissue filler; wherein, the monolithic gel is generated by the cross-linking reaction of the hyaluronic acid and the di-epoxide in the certain mold and processed by acid solution; the purification and dialysis by physiological balanced solution are processed; the microgel is made by extrusion of mechanical equipment. The cross-linking hyaluronic acid microgel has the advantages of (1) specific physical properties that the storage modulus (G') is 500-2000Pa, the loss modulus (G'') is 50-200Pa, the phase angle (Delta) is below 20 and the complex viscosity (Eta*) is 10-3500Pa x s as described by the dynamic viscoelasticity at frequency of 0.05-10Hz, (2) good stability that the performance of gel is independent of high pressure-high temperature treatment and the enzymolysis-resistant performance is excellent, (3) injectable property that the size of fine particle is 50-1000Mum, (4) good biocompatibility of no cytotoxicity, (5) biodegradability of being fully degraded by hyaluronidase, and (6) being suitable for tissue filler and bio-medical treatment.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

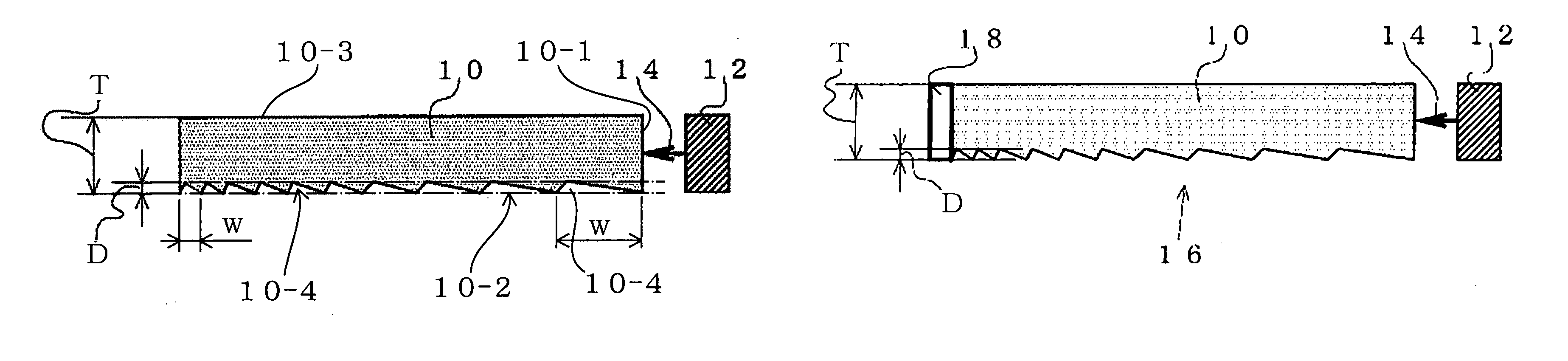

Light guide plate

InactiveUS20070189033A1Made lighterIncrease productionOptical light guidesRefractorsLight guideOptoelectronics

A light guide plate has a light emitting surface and a prism surface opposite to the light emitting surface. The prism surface includes a plurality of grooves extending parallel to each. The grooves have a constant depth, and widths of the grooves are varied, thereby adjusting the apex angles of the grooves. The depth of the grooves can be set to be not more than 20 microns.

Owner:CITIZEN ELECTRONICS CO LTD

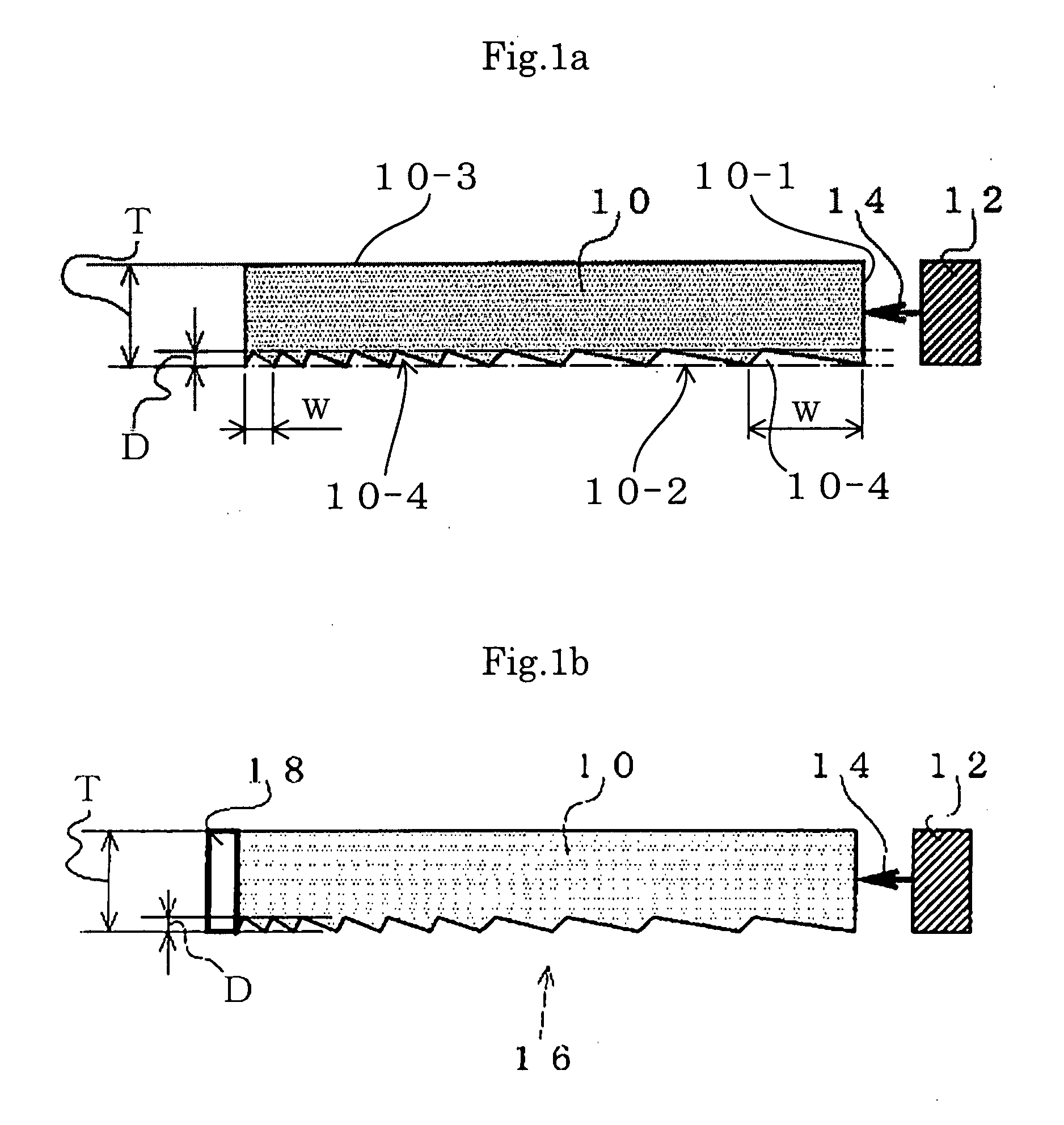

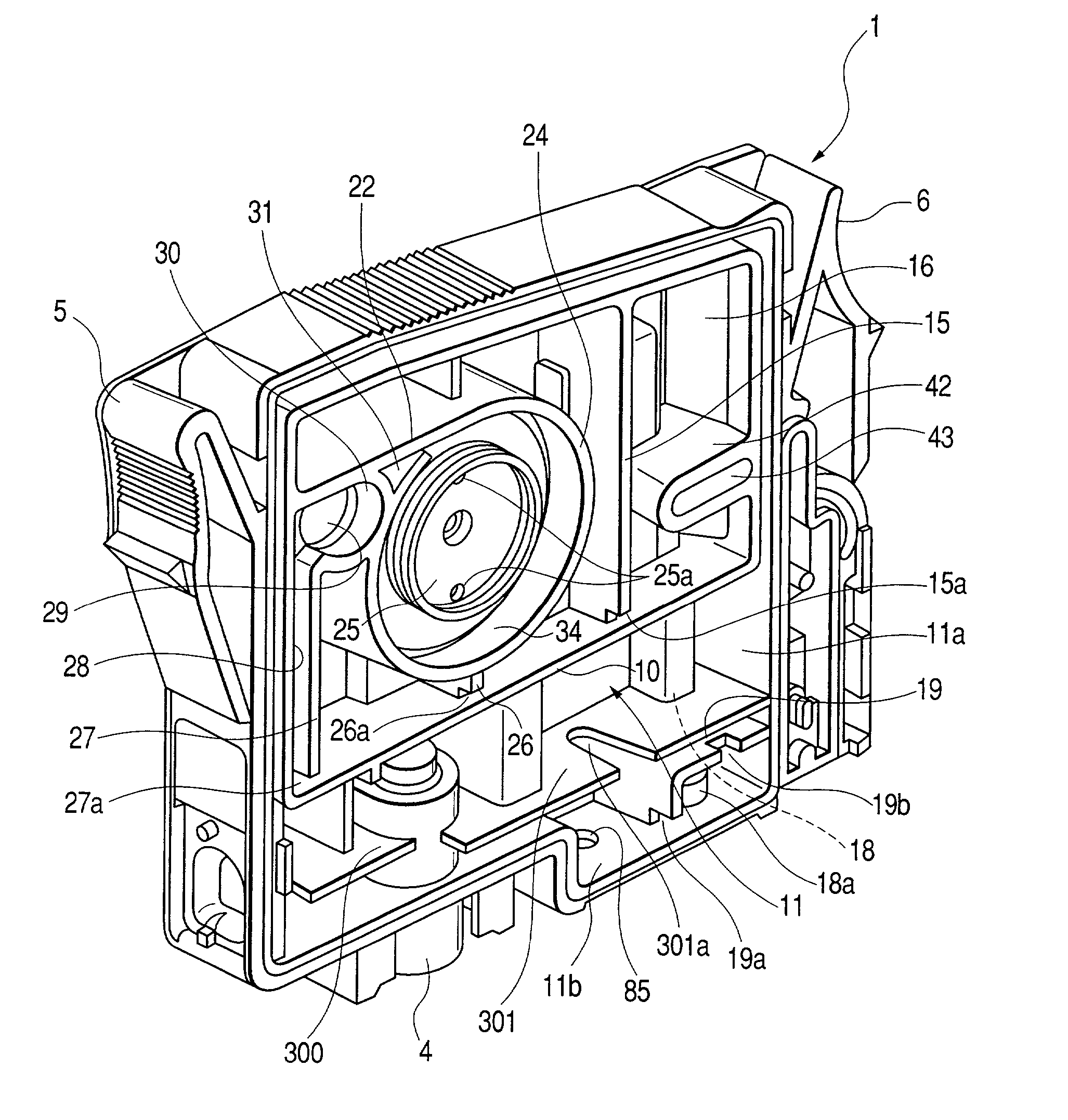

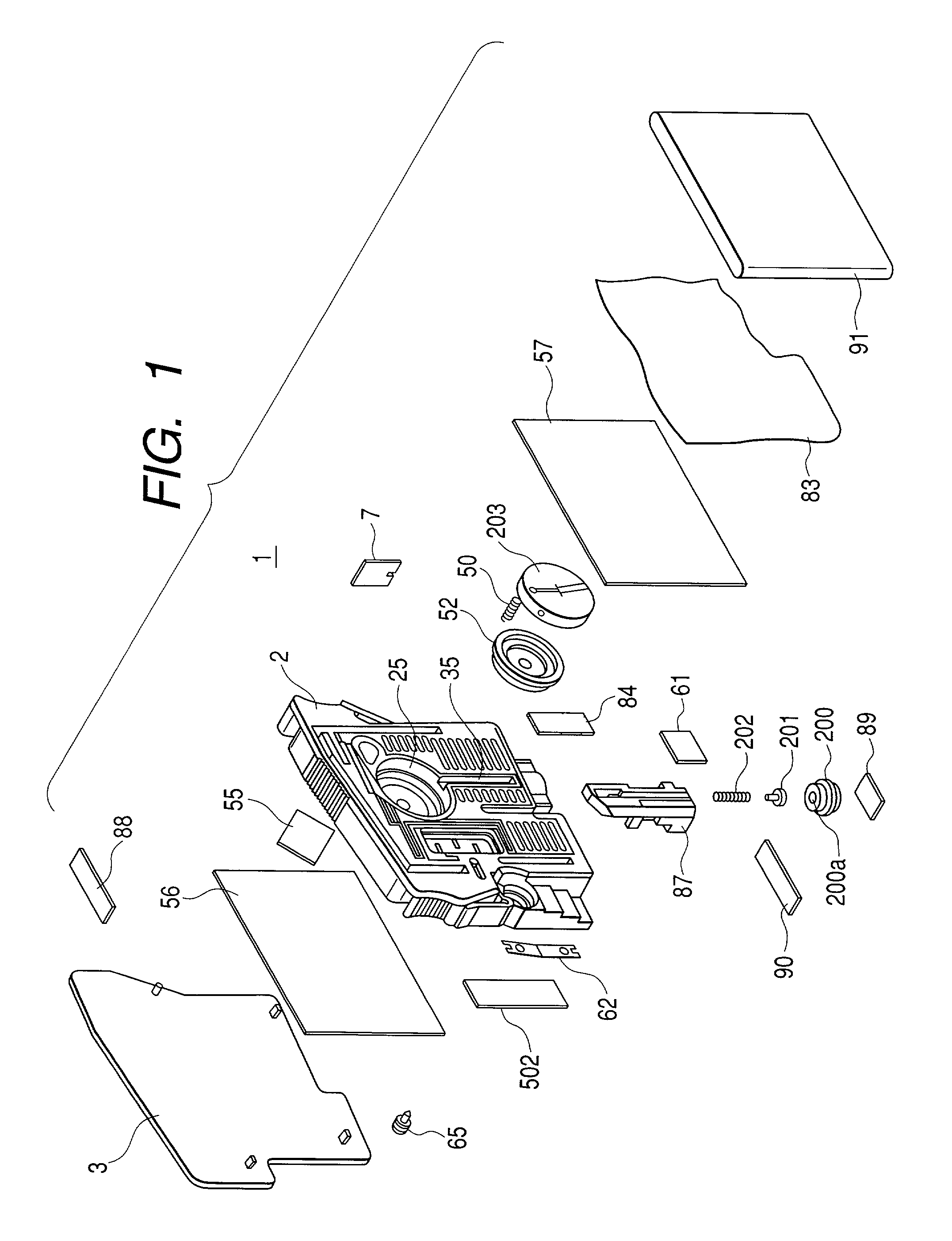

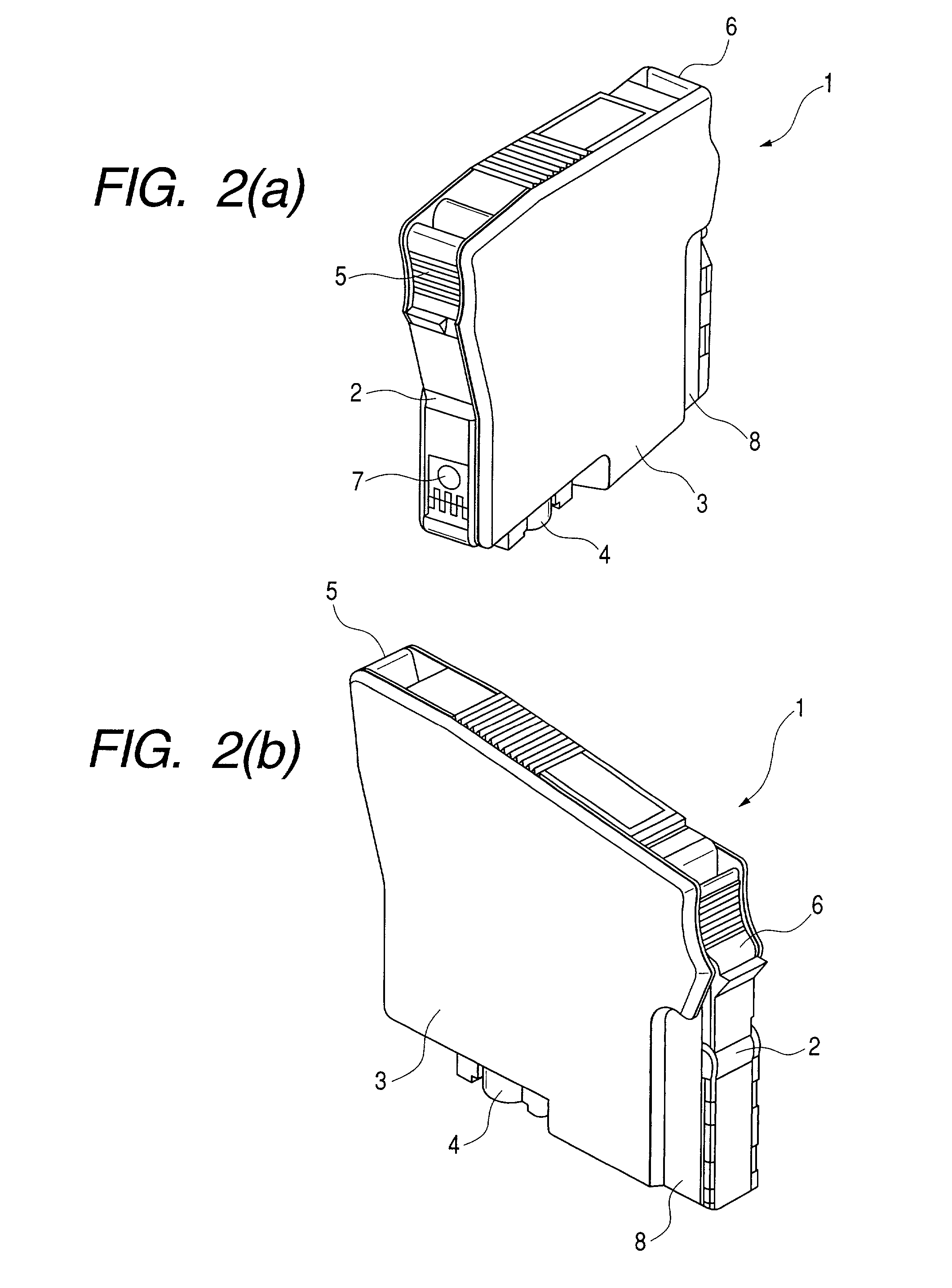

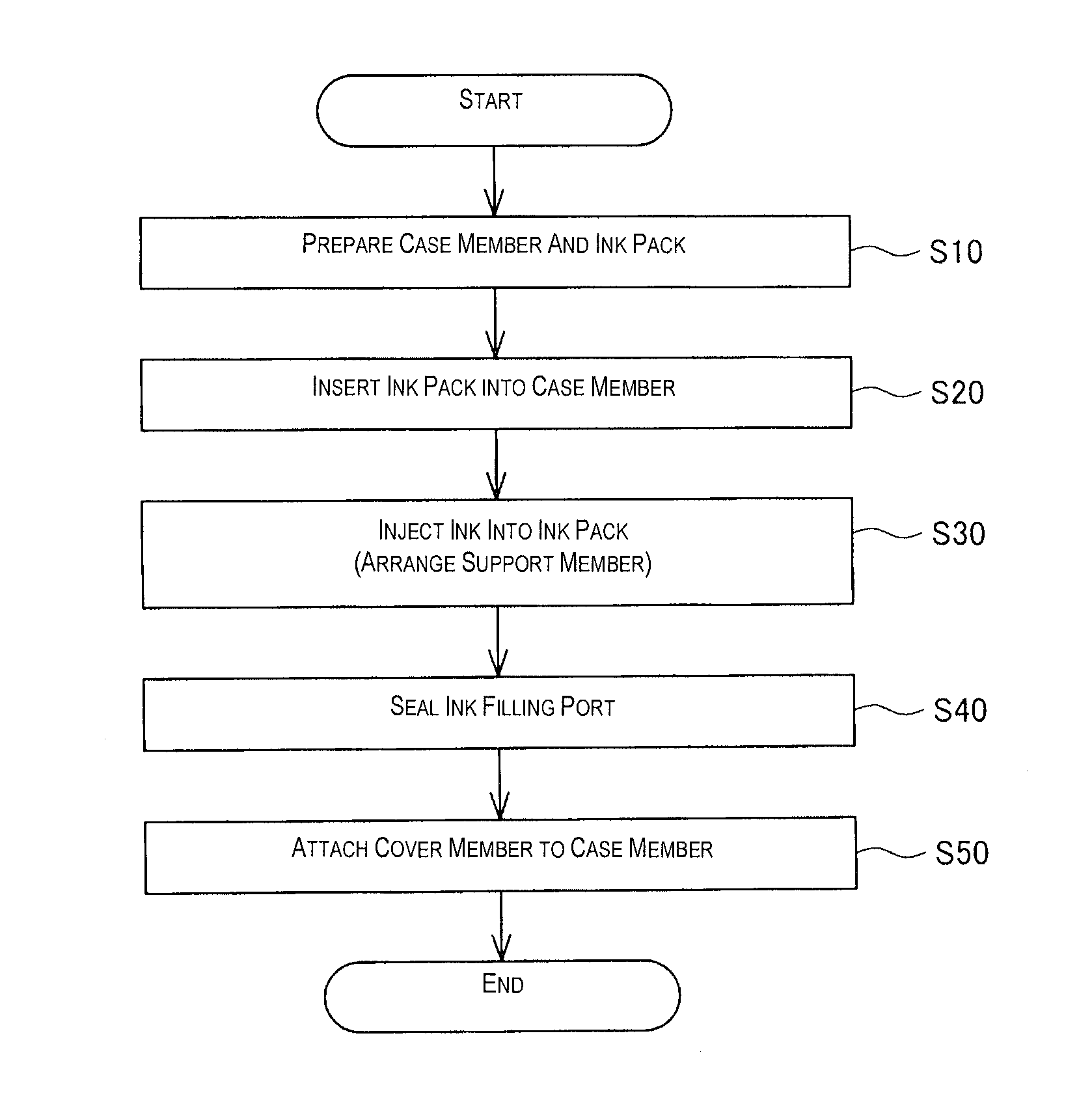

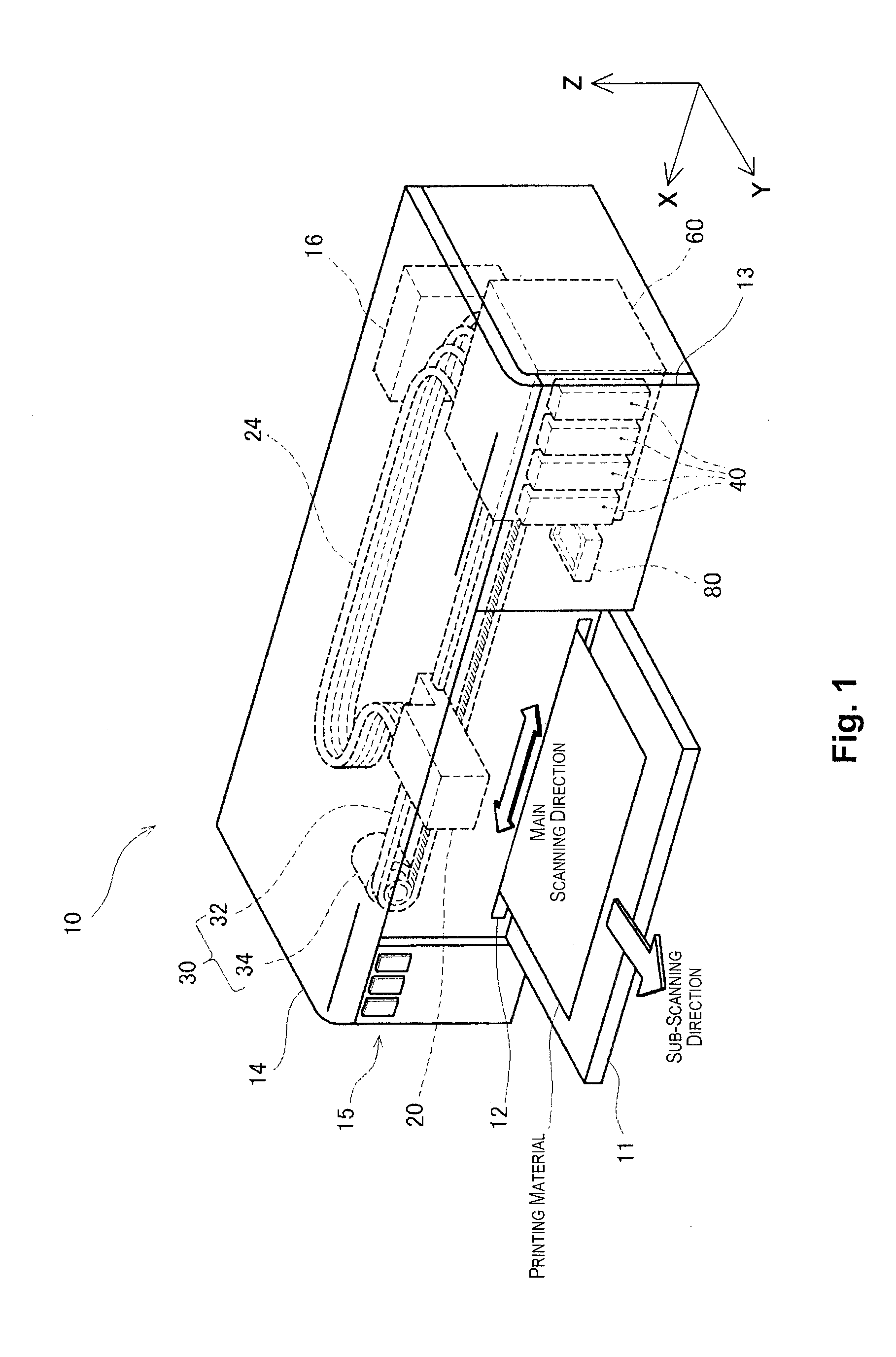

Ink cartridge and method of ink injection thereinto

An ink cartridge 1 is detachably connected to a head of a record apparatus and has a container main body 2 having an ink tank chamber 11 opened to the atmosphere in a state in which the head and the cartridge are connected and a first opening 85 through which ink can be injected into the ink tank chamber (second ink storage chamber 16, etc.,). Such an intermediate wall 301 partitioning the ink tank chamber 11 into two space parts 11a and 11b placed side by side in an ink injection direction is disposed in the ink tank chamber 11 and is formed with a through part 301a through which ink can be injected.

Owner:SEIKO EPSON CORP

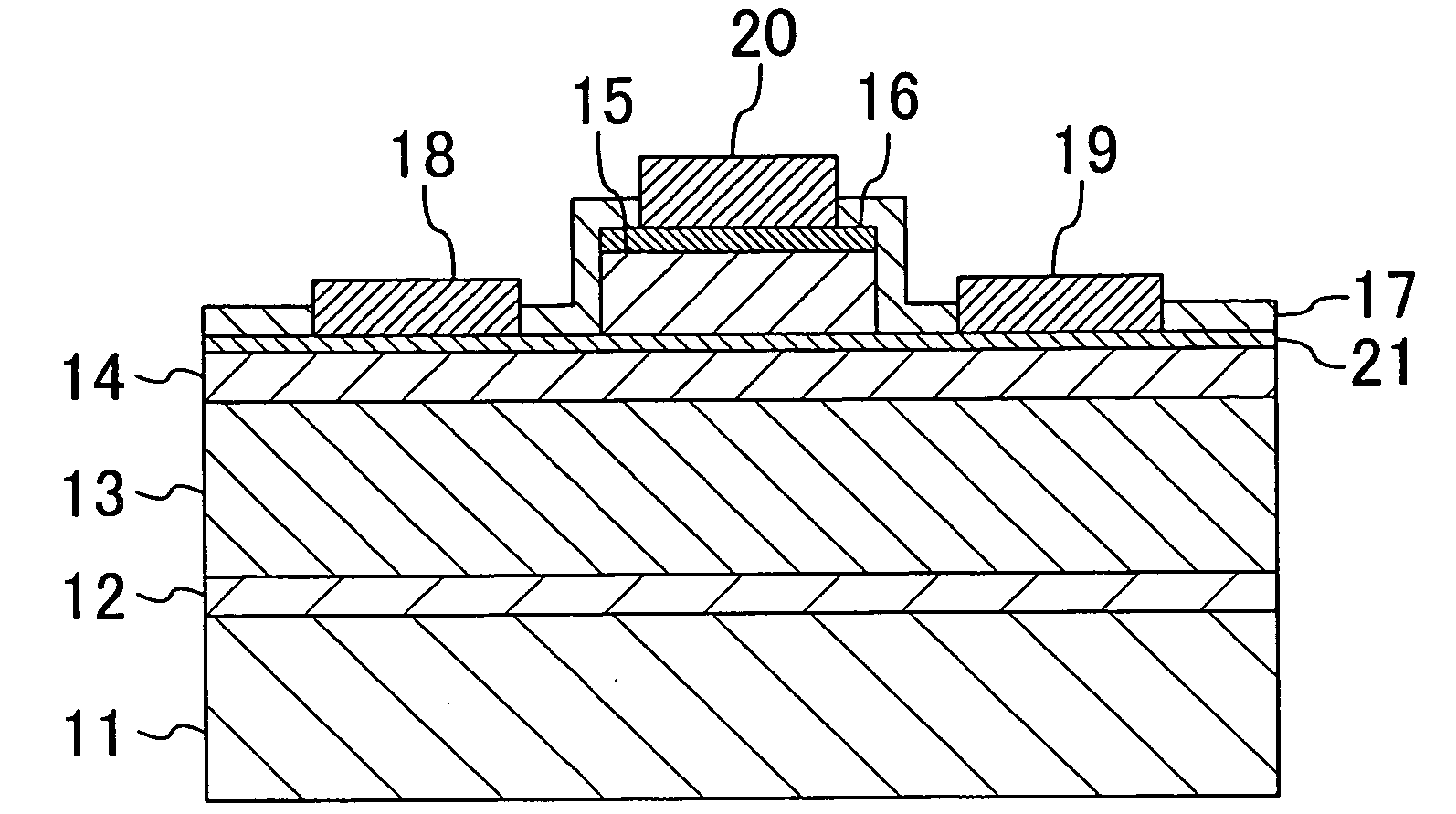

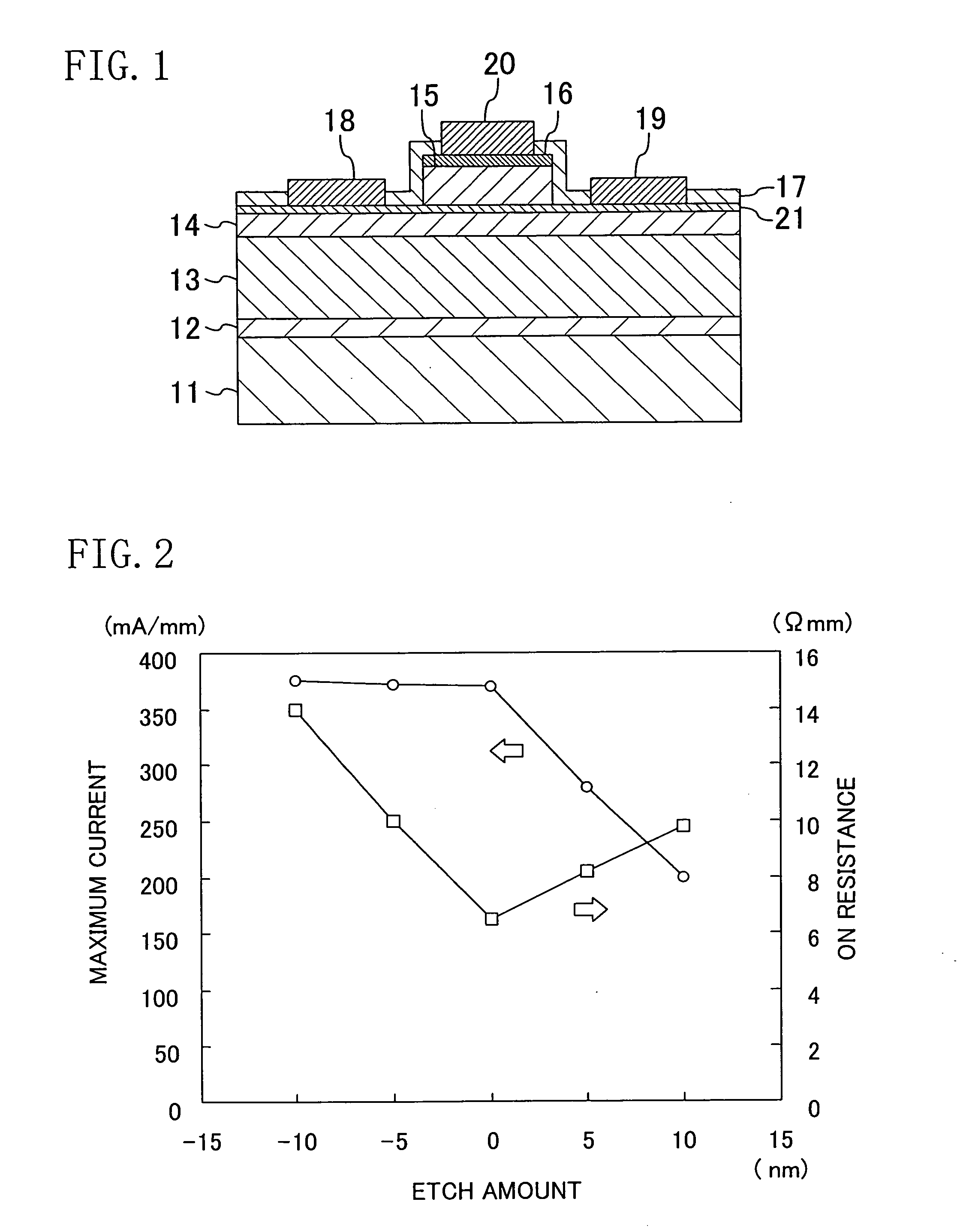

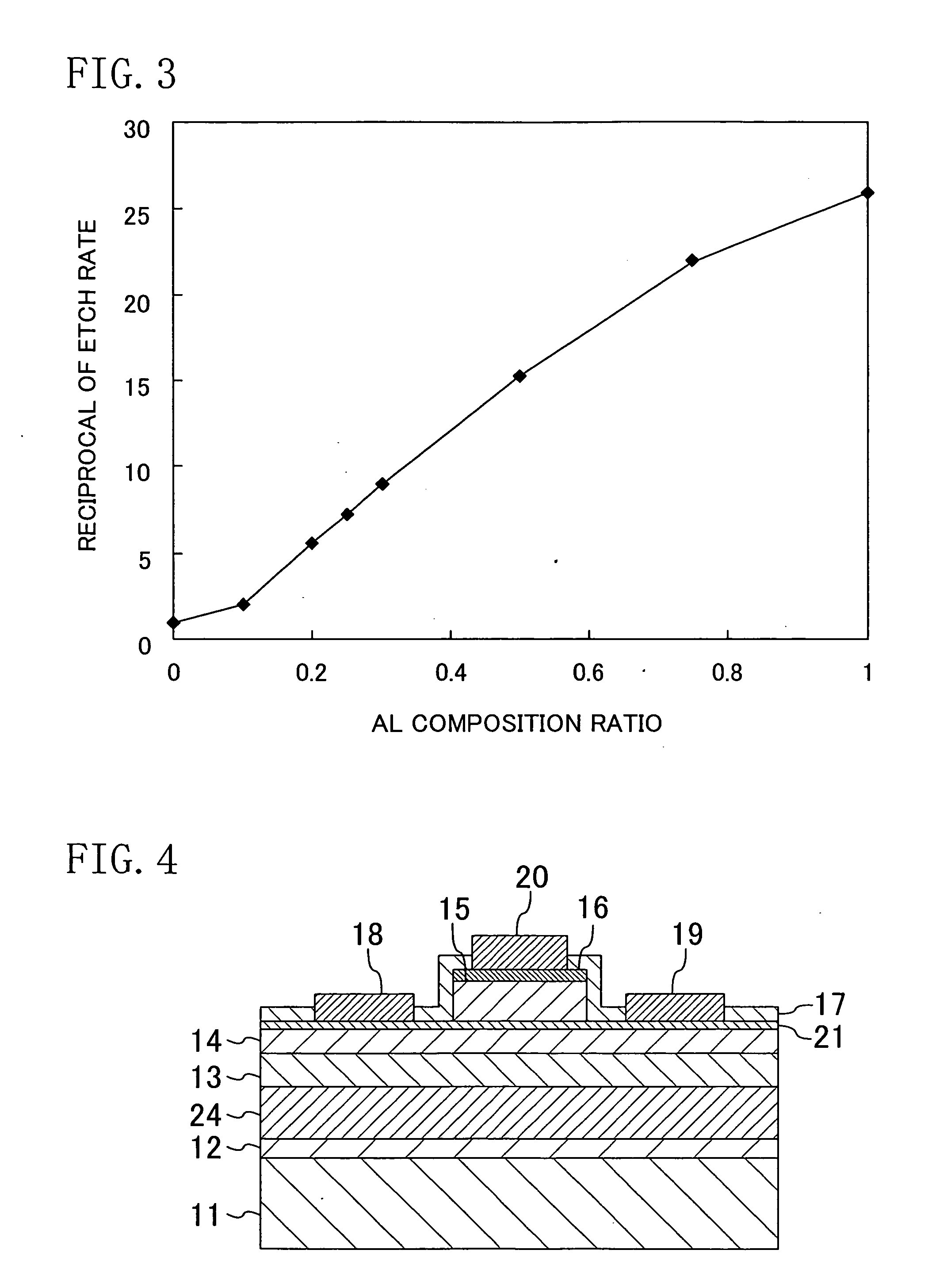

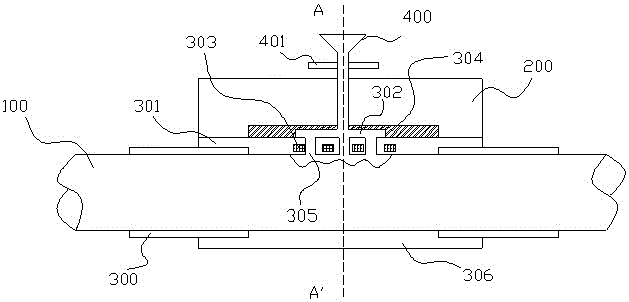

Transistor

ActiveUS20070176215A1Deterioration of characteristicHigh currentSemiconductor/solid-state device manufacturingSemiconductor devicesControl layerElectrical conductor

A transistor includes a first semiconductor layer formed on a substrate, a second semiconductor layer formed on the first semiconductor layer and has a band gap larger than that of the first semiconductor layer, a control layer formed on the second semiconductor layer and contains p-type impurities, a gate electrode formed in contact with at least part of the control layer and a source electrode and a drain electrode formed on both sides of the control layer, respectively. A third semiconductor layer made of material having a lower etch rate than that of the control layer is formed between the control layer and the second semiconductor layer.

Owner:PANASONIC CORP

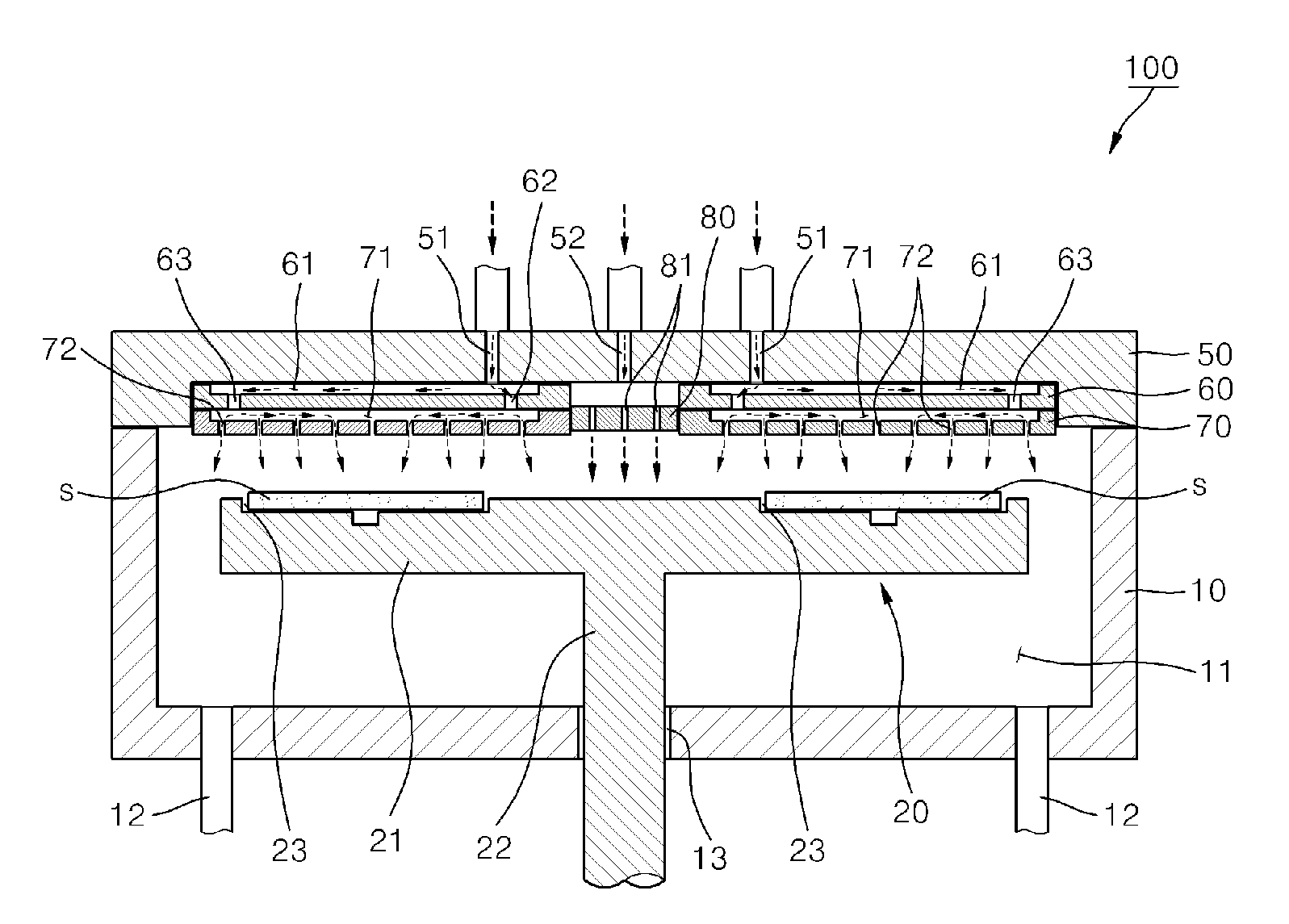

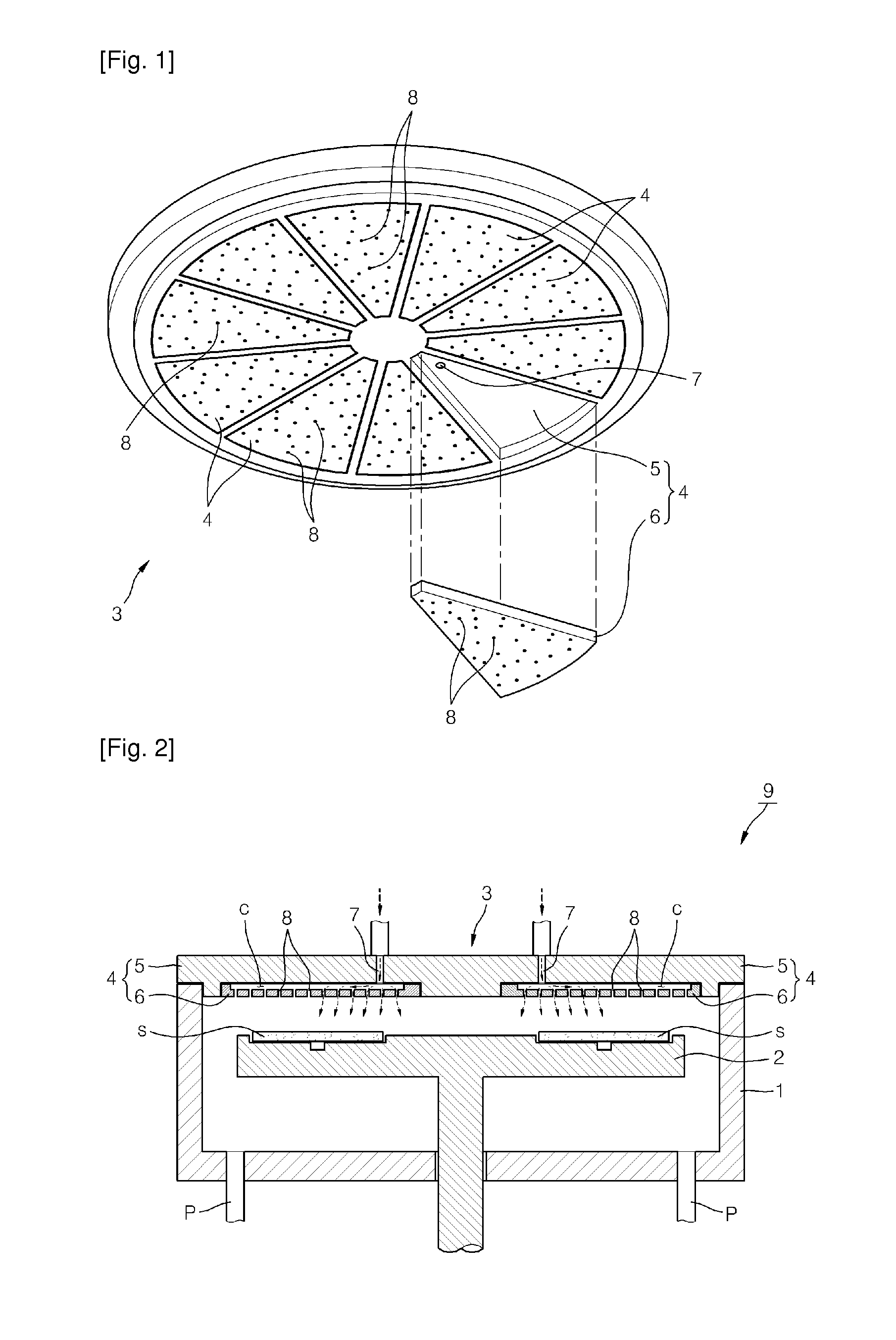

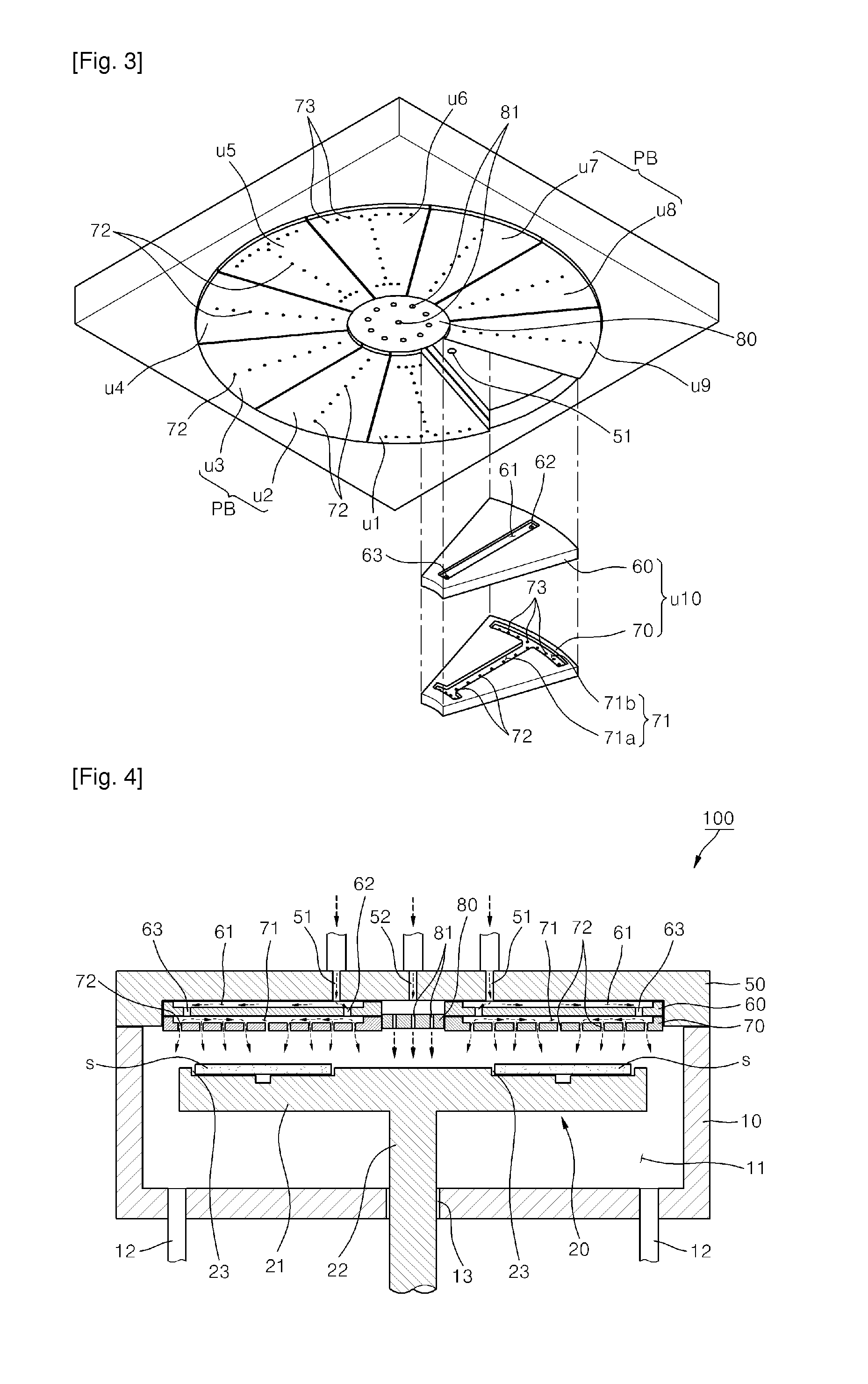

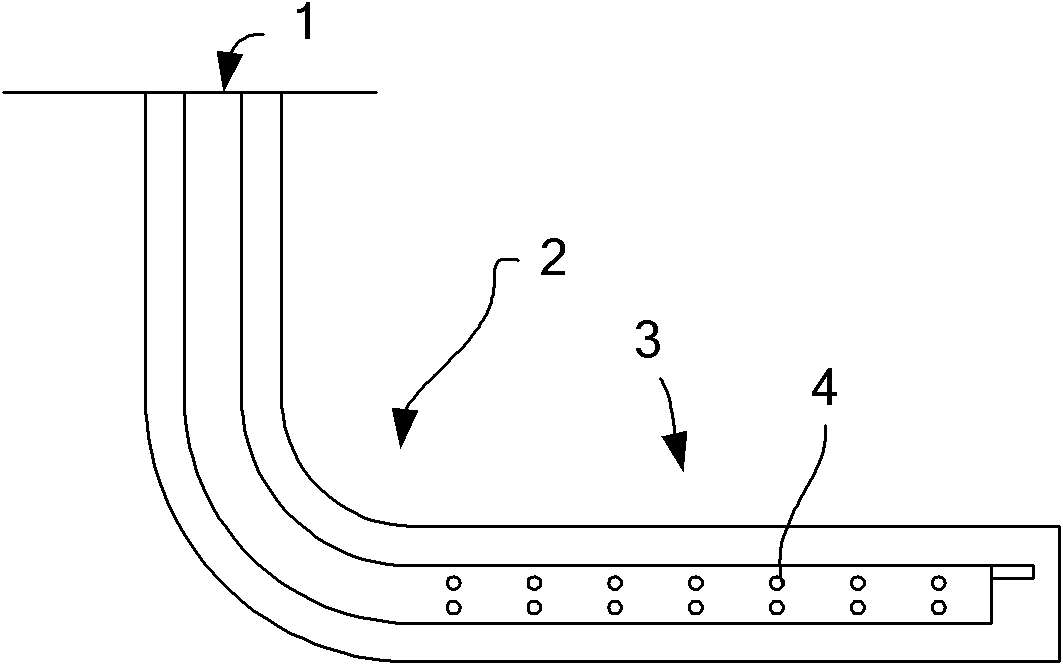

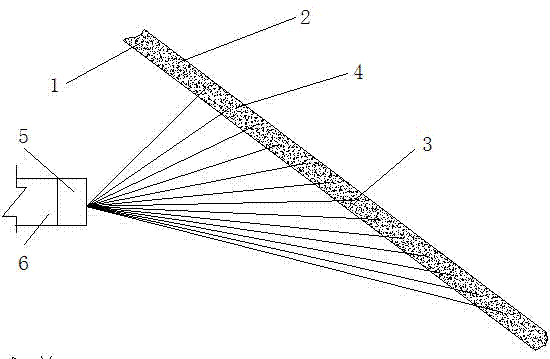

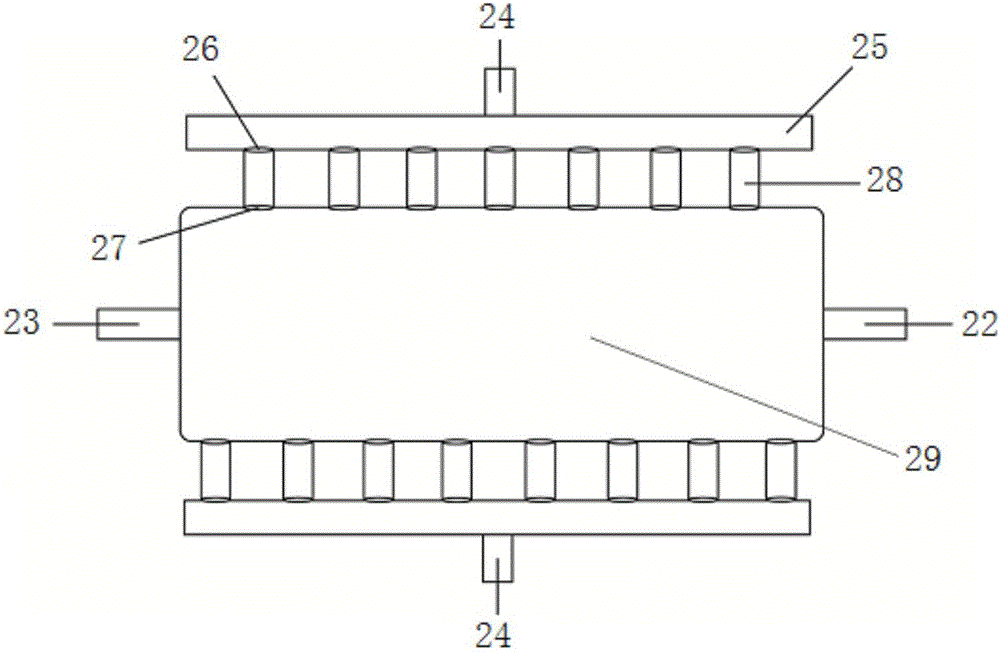

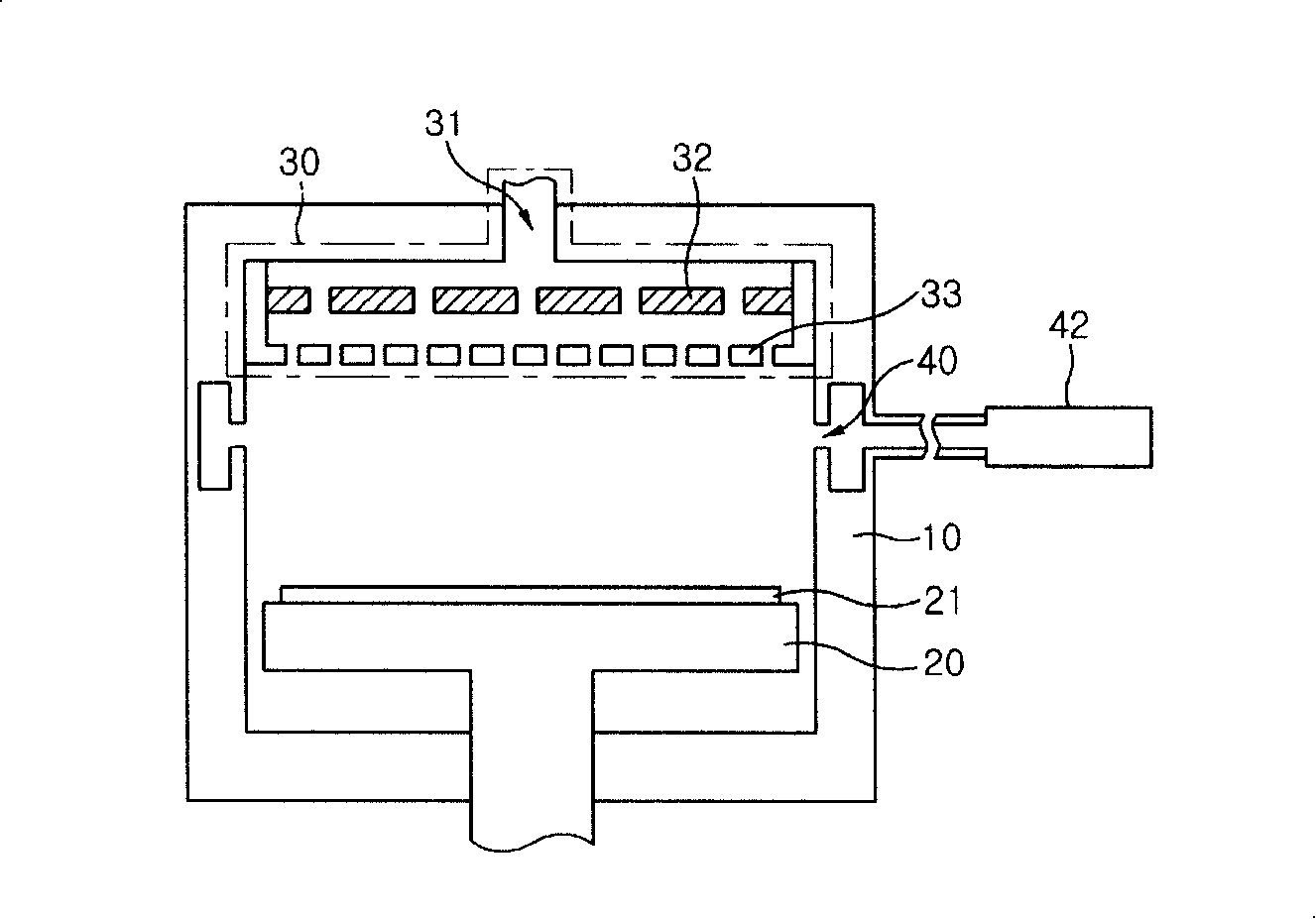

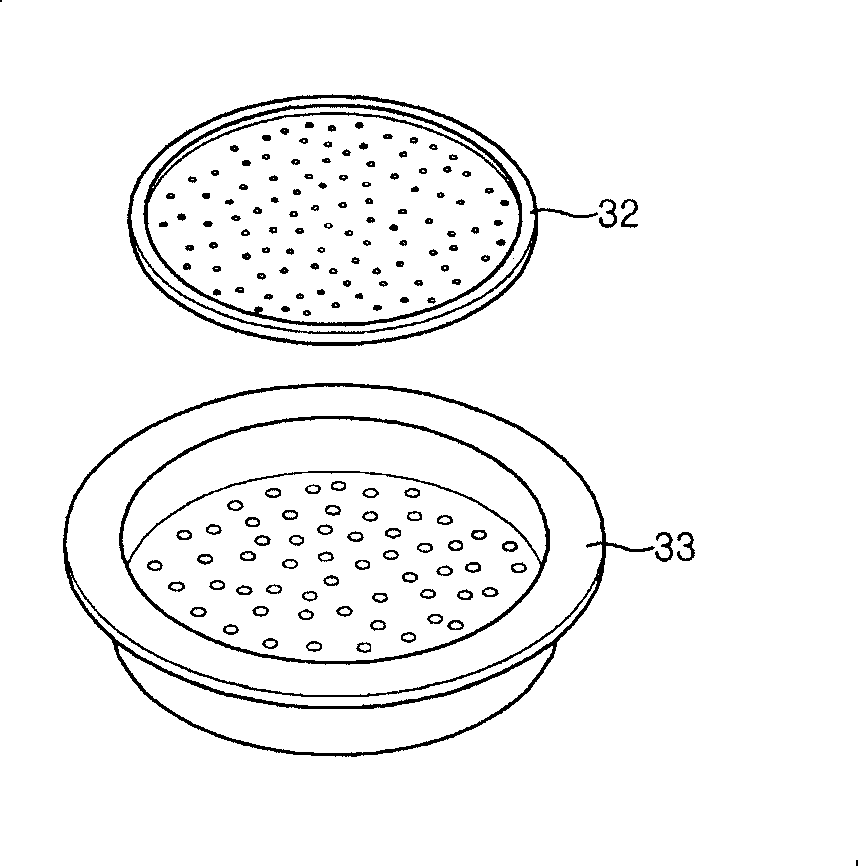

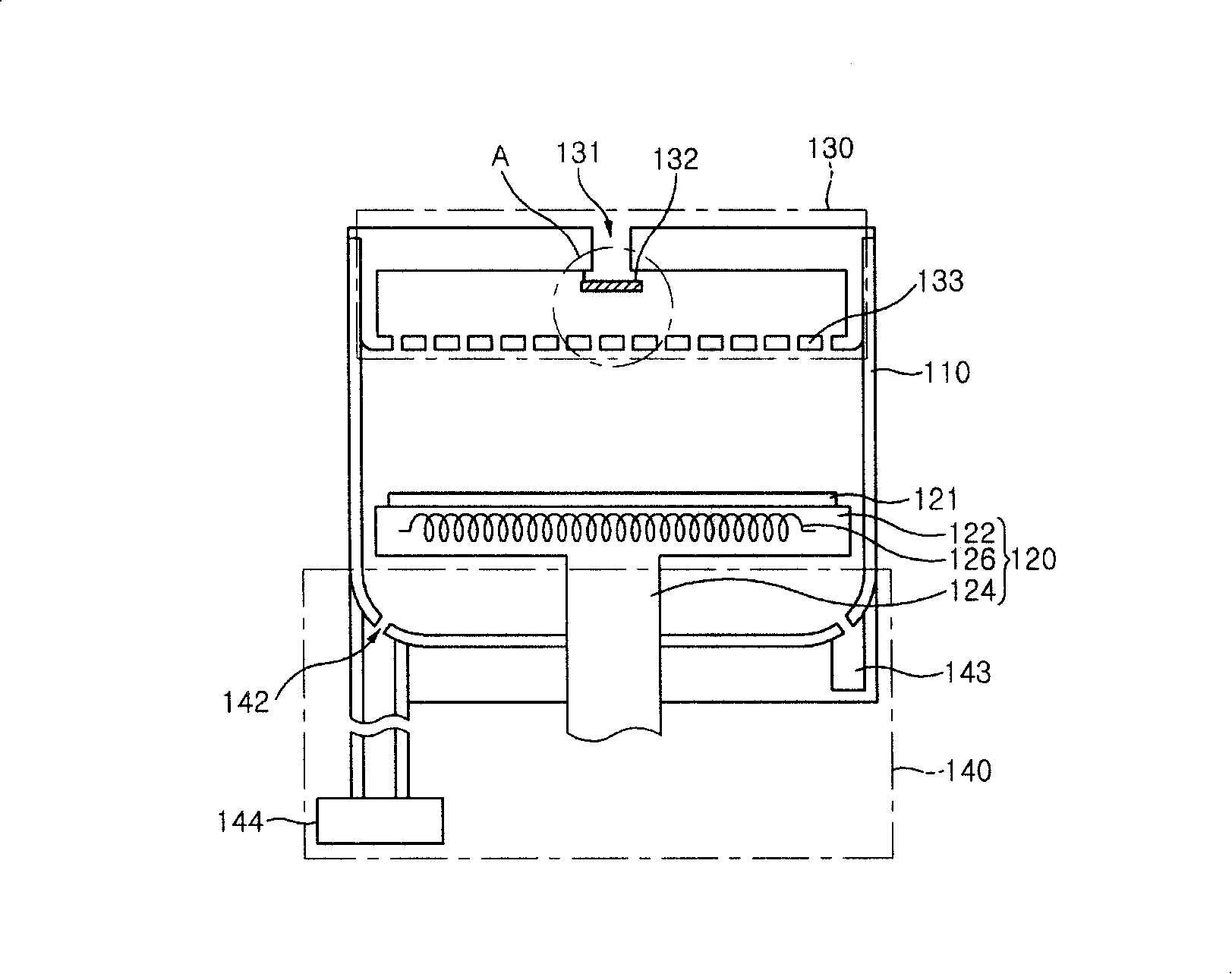

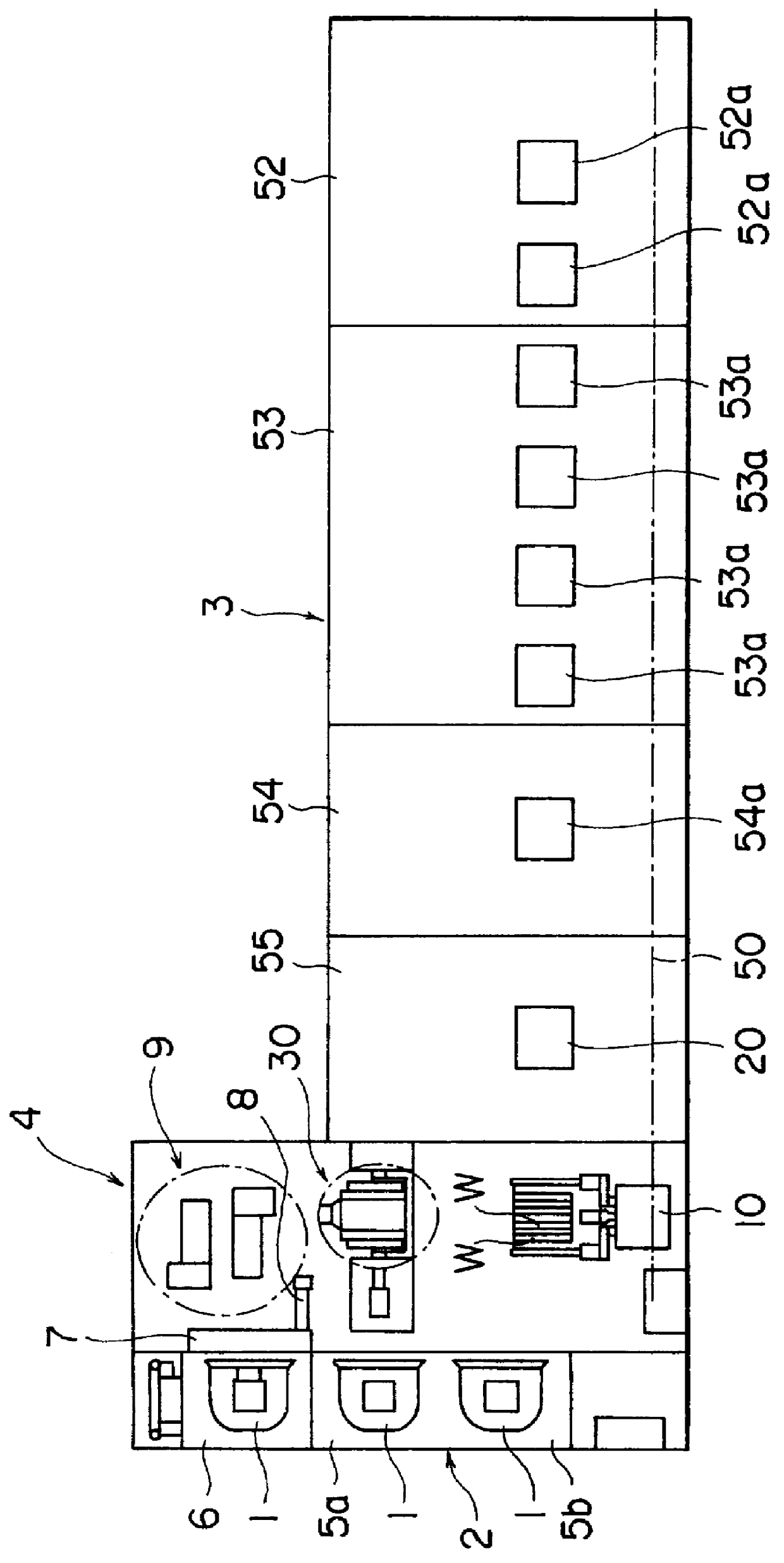

Gas injection apparatus and substrate processing apparatus using same

ActiveUS20120152171A1Inject evenlyUniform supplySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringInjection device

Provided are a gas injection device and substrate processing apparatus using the same. The gas injection device includes a plurality of gas injection units disposed above a substrate support part rotatably disposed within a chamber to support a plurality of substrates, the plurality of gas injection units being disposed along a circumference direction with respect to a center point of the substrate support part to inject a process gas onto the substrates. Wherein each of the plurality of gas injection units includes a top plate in which an inlet configured to introduce the process gas is provided and an injection plate disposed under the top plate to define a gas diffusion space between the injection plate and the top plate along a radius direction of the substrate support part, the injection plate having a plurality of gas injection holes under the gas diffusion space to inject the process gas introduced through the inlet and diffused in the gas diffusion space onto the substrate. In at least one gas injection unit of the plurality of gas injection units, the process gas is introduced into the gas diffusion space at a plurality of points.

Owner:WONIK IPS CO LTD

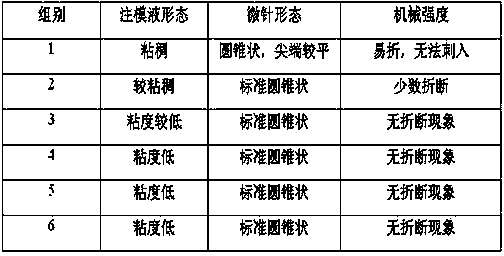

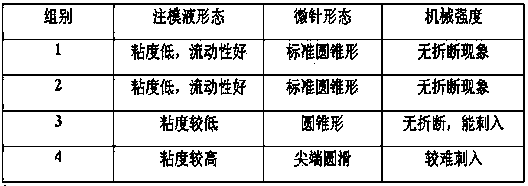

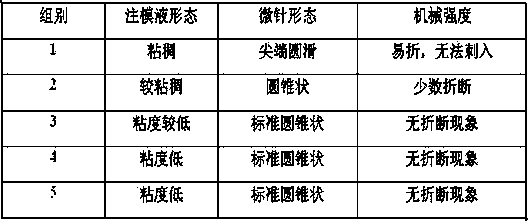

Soluble hyaluronic acid micro-needle patch

ActiveCN103893018ALow viscosityImprove liquidityCosmetic preparationsToilet preparationsHyaluronic acidPolymer chemistry

The invention relates to the technical field of skin-care products, and particularly relates to a soluble hyaluronic acid micro-needle patch. The patch comprises a micro-needle array and a base, and is prepared from the following raw materials in percentage by weight: 75-98.7 percent of hyaluronic acid or salt thereof, 0.8-24.5 percent of hyperbranched polymer and 0.5-24.2 percent of functional active component, wherein the hyperbranched polymer contains active amino or hydroxy at the terminal, and can be dissolved in water and biodegradable; the viscosity of the hyaluronic acid aqueous solution can be remarkably reduced due to addition of the hydroxy or amino terminated hyperbranched polymer, the fluidity is increased, and the hyaluronic acid aqueous solution can be cast into a film and injected into micropores of a die conveniently; a remarkable effect can be achieved when a little amount of the hyperbranched polymer is added, and the selected hyperbranched polymer is biodegradable, so that the prepared hyaluronic acid micro-needle has high safety and good biocompatibility; furthermore, pressure injection molding is adopted during mold injection, and the hyaluronic acid aqueous solution can be smoothly injected into micropores of a die.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

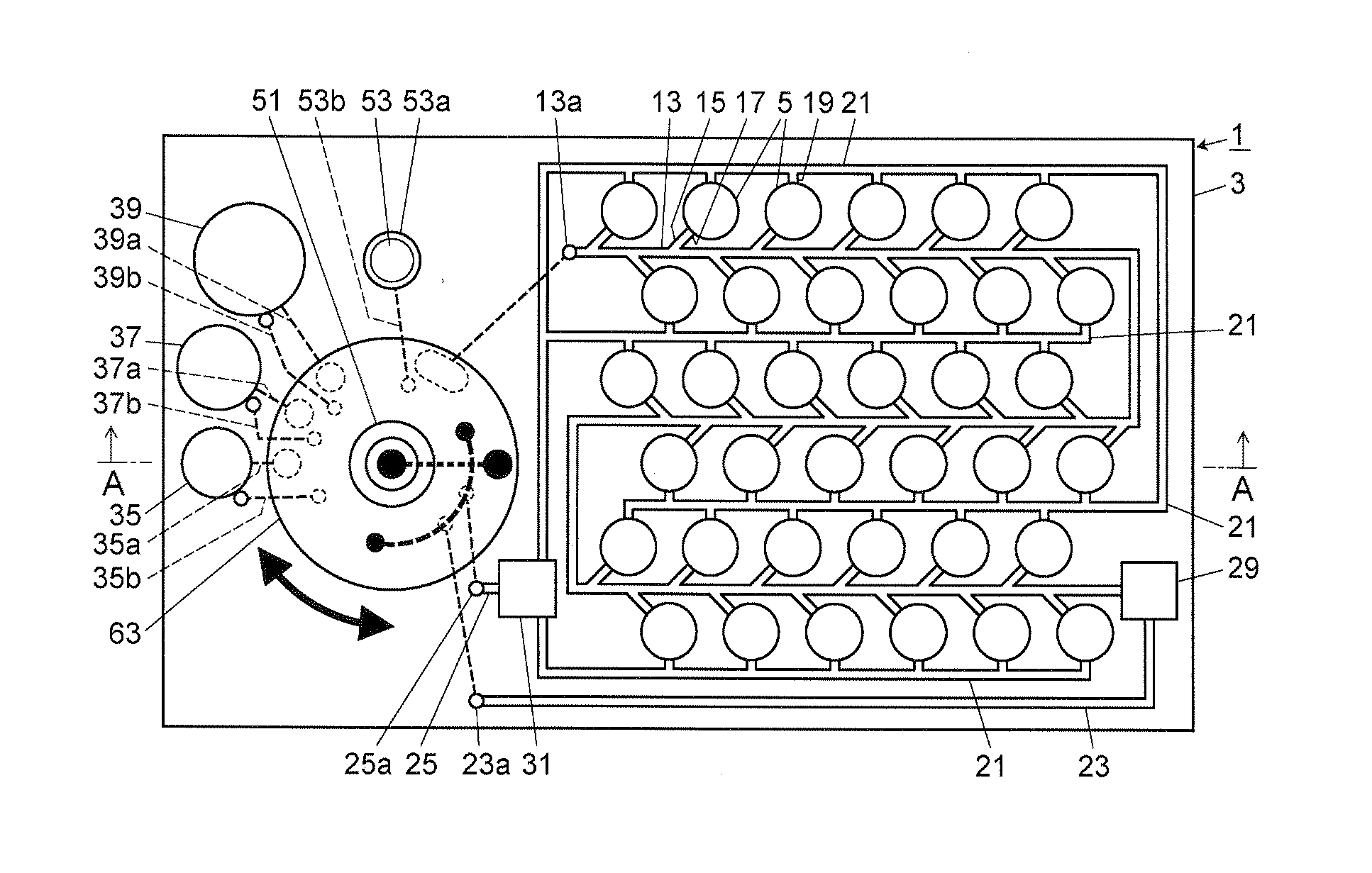

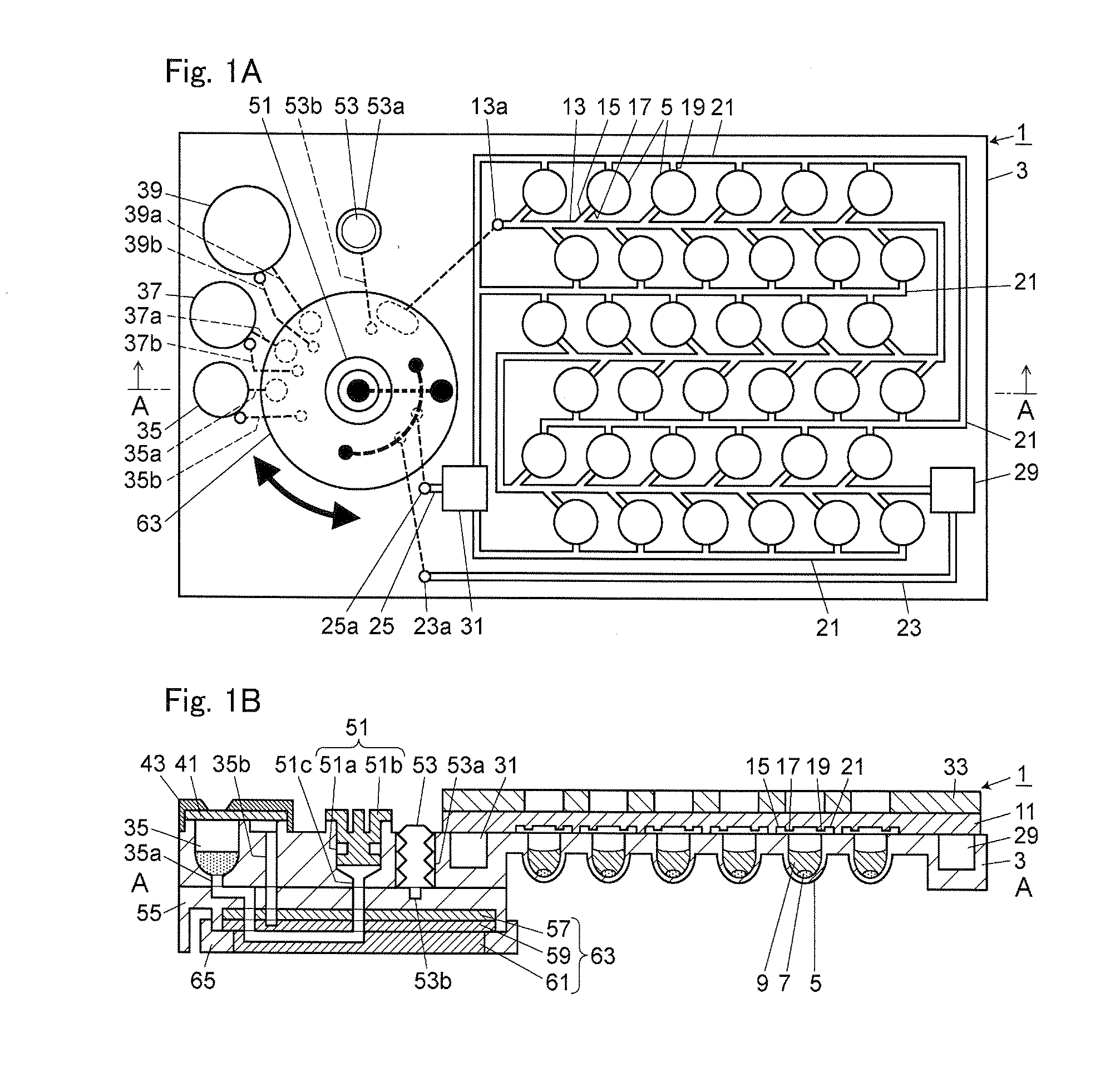

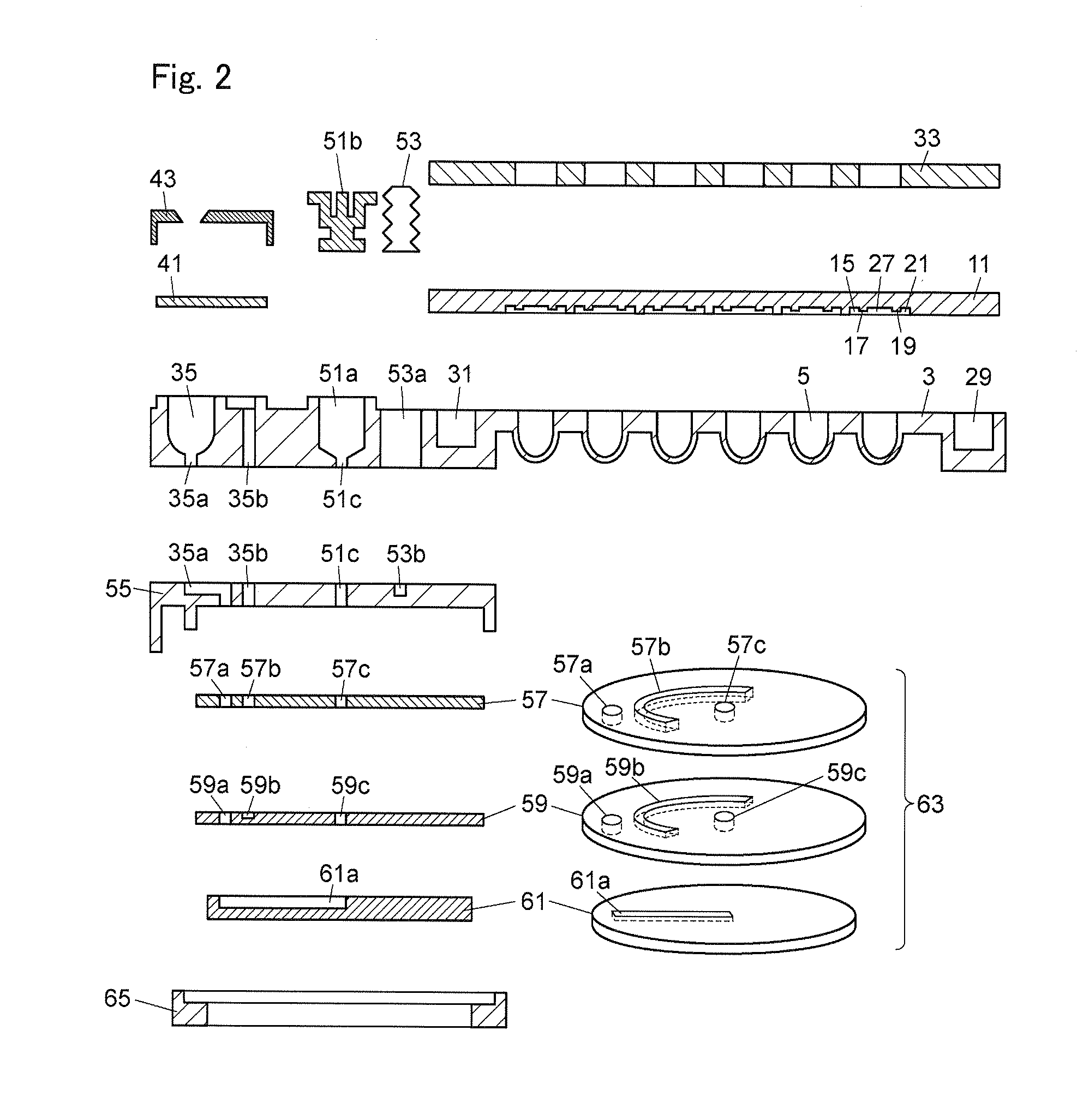

Reactor plate and reaction processing method

ActiveUS20110003286A1Avoid enteringInject evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsForeign matterMain channel

Disclosed herein is a reactor plate which prevents the entry of foreign matter from the outside and the pollution of a surrounding environment. A reactor plate (1) includes a reaction well (5), a reaction well channel connected to the reaction well (5), and reaction well air vent channels (19) and (21) connected to the reaction well (5). The reaction well channel has a main channel (13), a metering channel (15) branched off the main channel (13), and an injection channel (17) of which one end is connected to the metering channel (15) and the other end is connected to the reaction well (5). The main channel (13) and the reaction well air vent channel (21) can be hermetically sealed. The injection channel (17) is formed narrower than the metering channel (15) not so as to allow the passage of a liquid at a liquid introduction pressure applied to introduce the liquid into the main channel (13) and the metering channel (15) and at a purge pressure applied to purge the liquid from the main channel (13) but so as to allow the passage of the liquid at a pressure higher than the liquid introduction pressure and the purge pressure.

Owner:SHIMADZU CORP

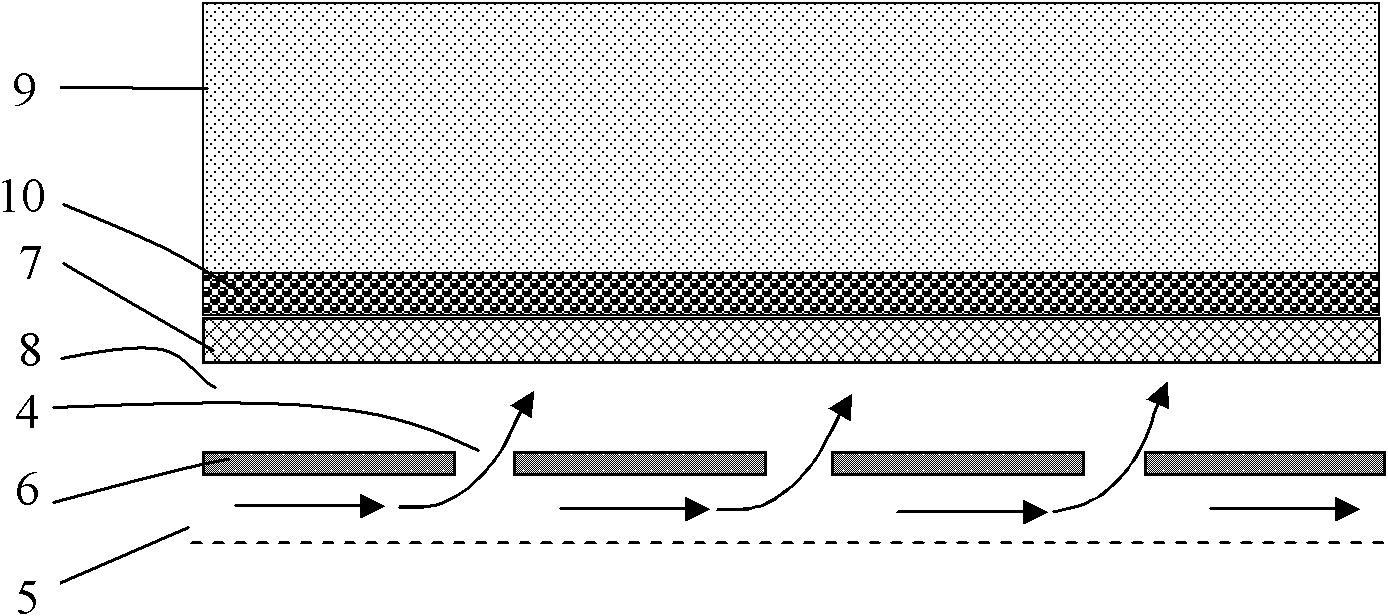

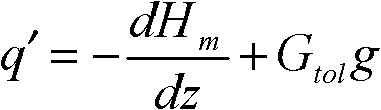

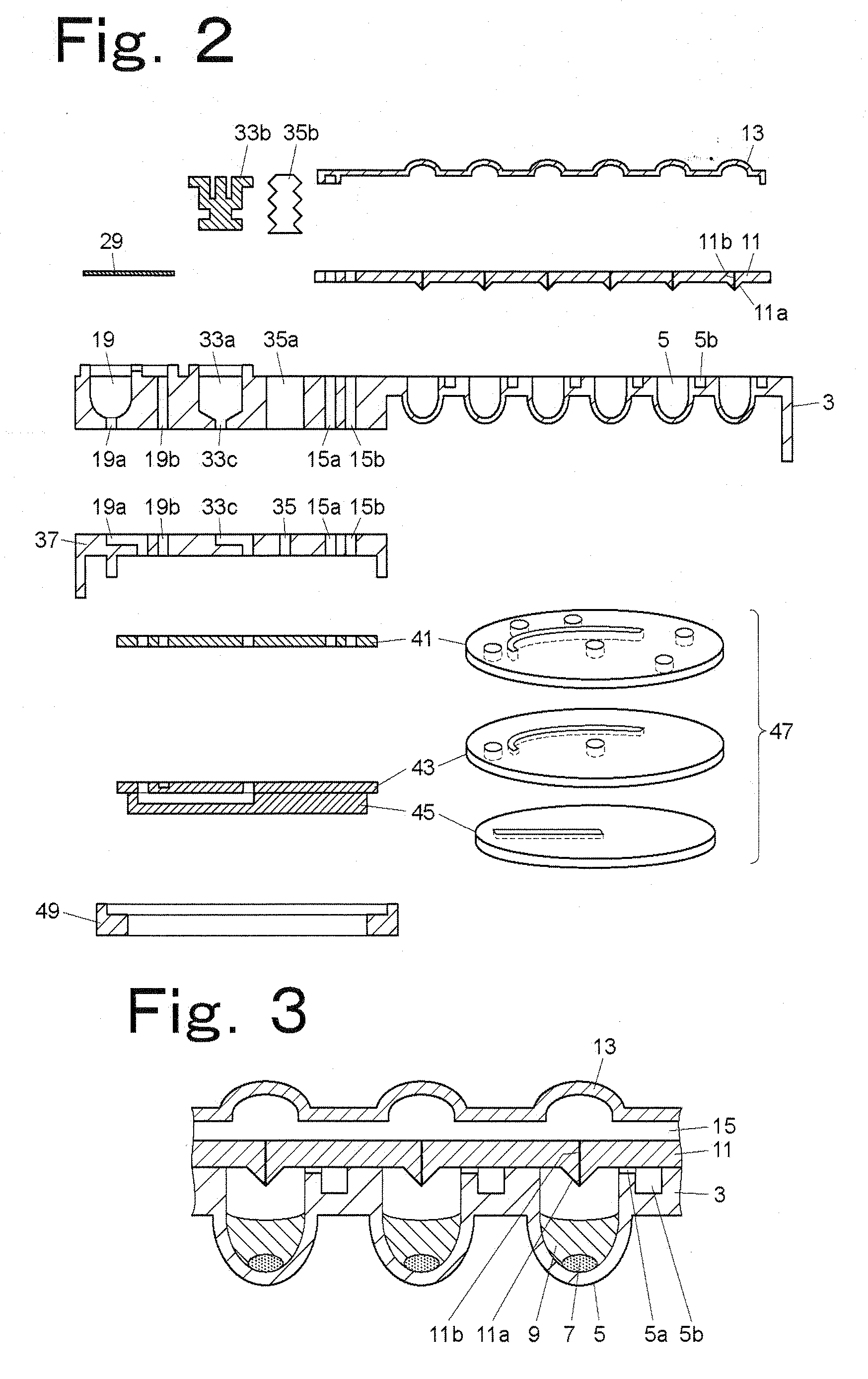

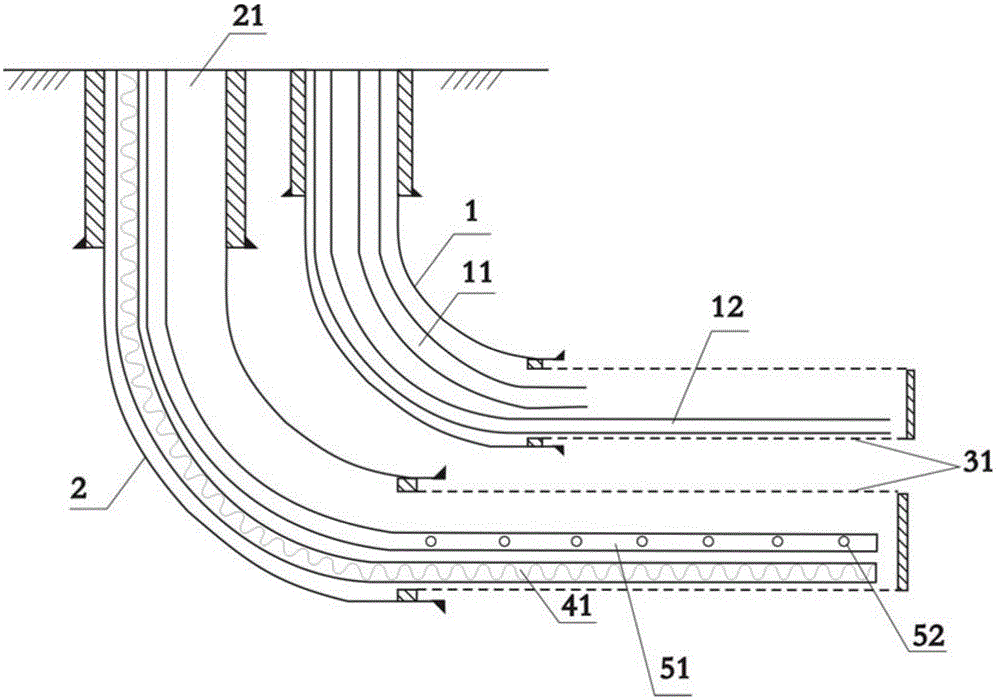

Method for uniformly injecting multi-component thermal fluid in horizontal well

The invention provides a method for uniformly injecting a multi-component thermal fluid in a horizontal well. The method comprises the following steps: (1) segmenting horizontal segments in the horizontal well; (2) initially setting the size of each discharge orifice on a tubular column in each segment of the horizontal well and the number of discharge orifices at a tail end; (3) detecting the temperature, pressure and dryness of the multi-component thermal fluid; (4) obtaining the on-way temperature, pressure, dryness and heat loss of each shaft segment of the horizontal well by iterative calculation; (5) obtaining the actual number of the discharge orifices on the tubular column in each segment of the horizontal well and the size of each discharge orifice by iterative calculation; and (6) drilling the tubular column based on the calculation result, putting the tubular column subject to drilling down into the well, and injecting the multi-component thermal fluid in the tubular column. The invention has the advantages of wide oil pool application range, relatively simple technology and low cost, and ensures that the oil pool at the horizontal well segment can be subject to uniform steam injection without changing the traditional well orifices and steam injection pipes. Besides, by using the invention, the producing degree of the oil reservoir is improved and the optimal exploitation effect can be ensured by injecting the multi-component thermal fluid in the horizontal well of the exploited oil pool.

Owner:CHINA NAT OFFSHORE OIL CORP +2

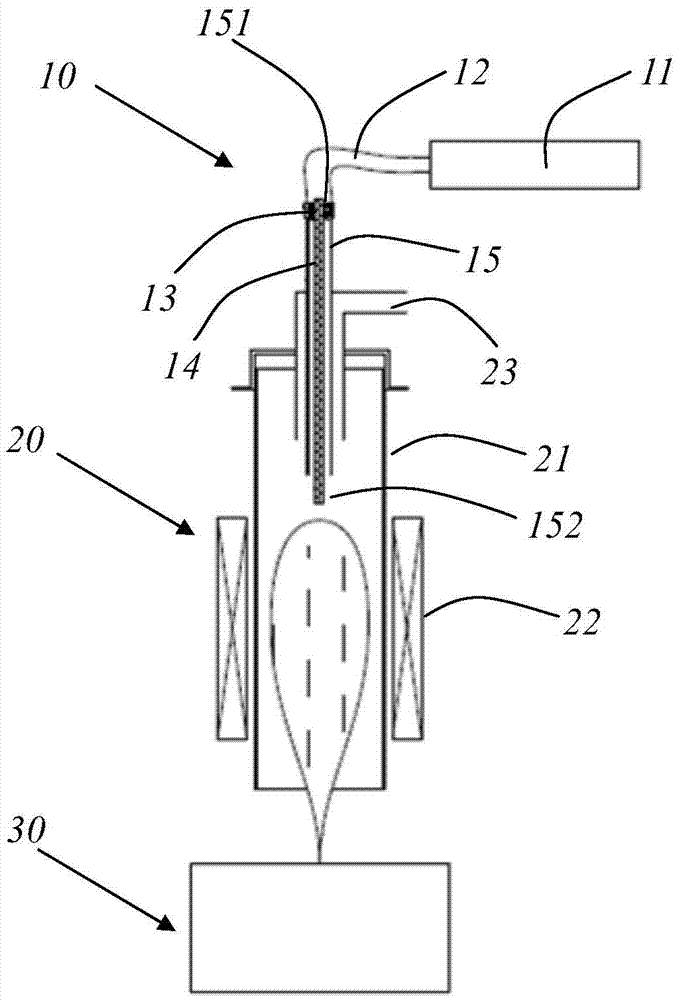

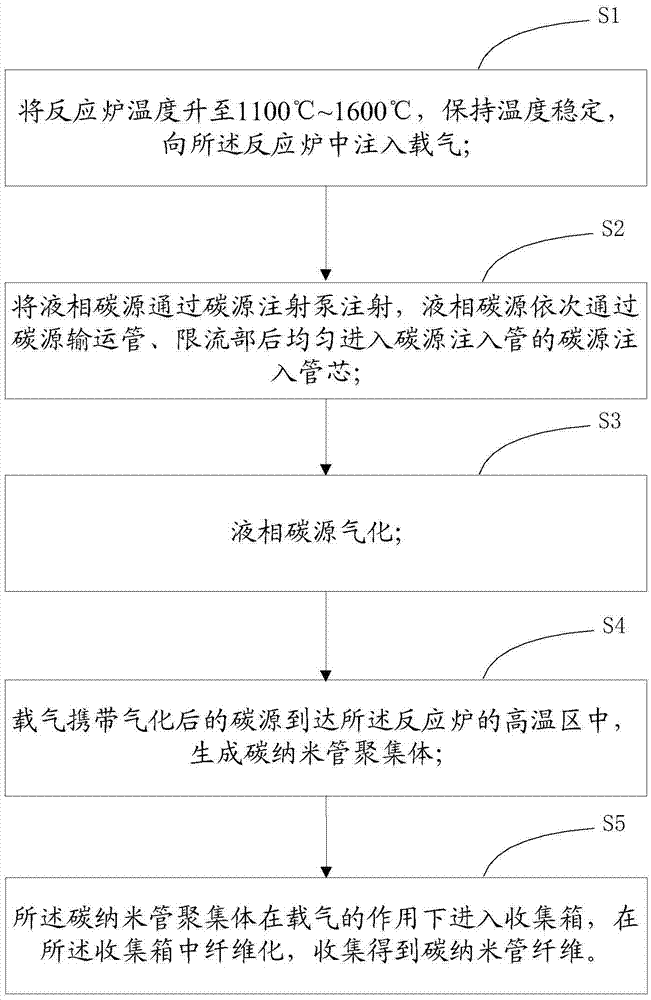

Vertical continuous preparing device for carbon nano tube fibers and preparing method

The invention provides a vertical continuous preparing device for carbon nano tube fibers. The vertical continuous preparing device comprises a carbon source injector, a tube furnace and a collecting box communicated with the tube furnace. The carbon source injector comprises a carbon source injection pump, a carbon source injection tube, a carbon source conveying tube and a flow limiting part, wherein one end of the carbon source injection tube is located in the tube furnace, the carbon source injection pump and the carbon source injection tube are communicated through the carbon source conveying tube, and the flow limiting part is arranged between the carbon source conveying tube and the carbon source injection tube. The carbon source injection pump injects a liquid-phase carbon source into the tube furnace through the carbon source conveying tube and the carbon source injection tube, a carbon source injection tube core is further arranged in the carbon source injection tube, one end of the carbon source injection tube core is arranged in the flow limiting part, and the other end of the carbon source injection tube core protrudes and stretches out of the carbon source injection tube. Compared with the prior art, the carbon source injector which is simple in structure and low in cost is adopted so that the liquid-phase carbon source can be uniformly injected and gasified, and finally the purpose of stably and continuously preparing the carbon nano tube fibers is achieved.

Owner:SUZHOU CREATIVE CARBON NANOTECH

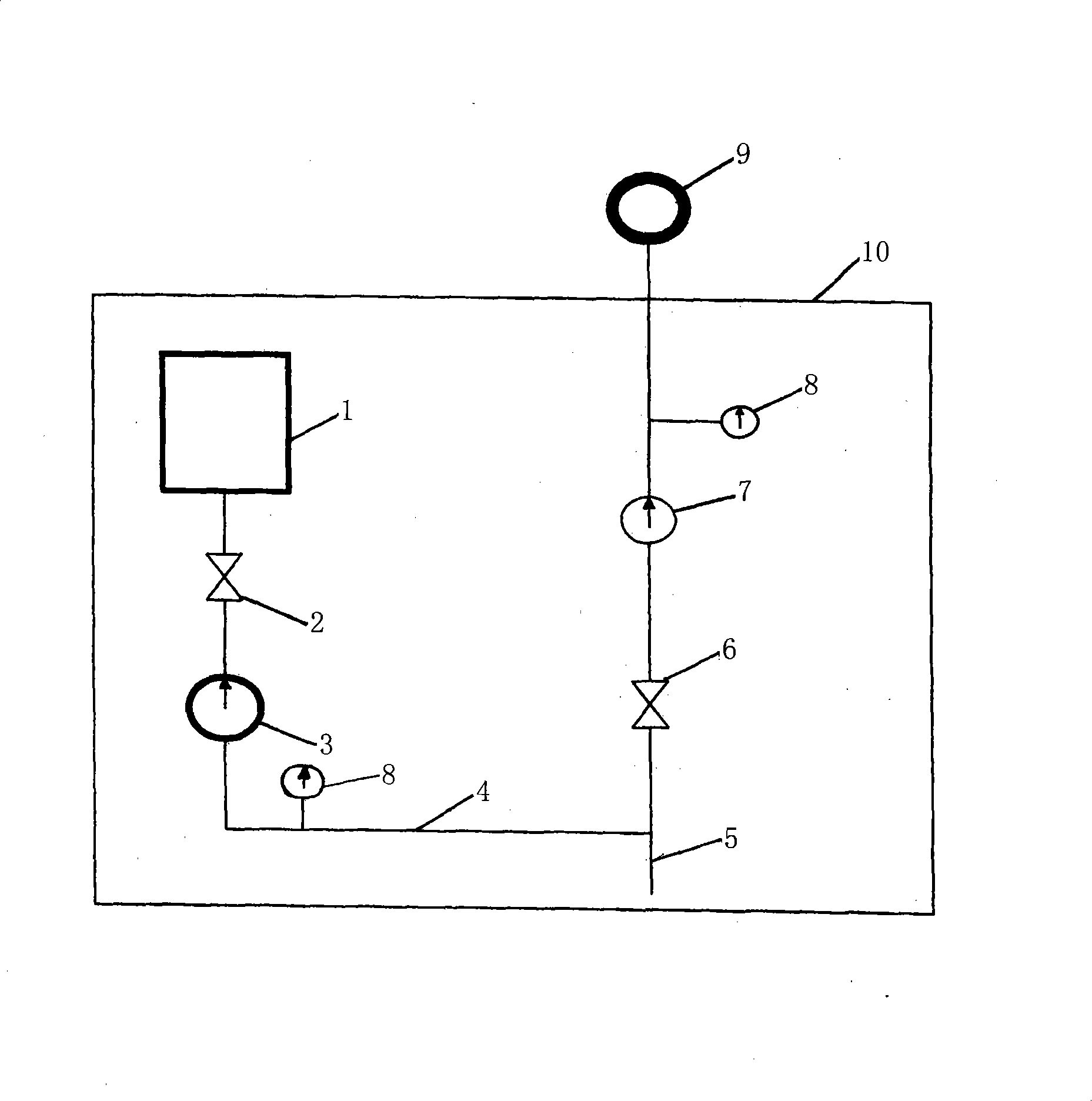

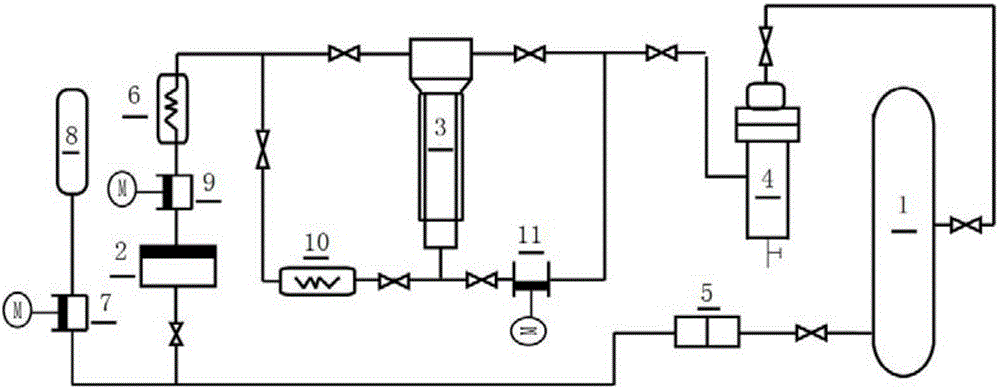

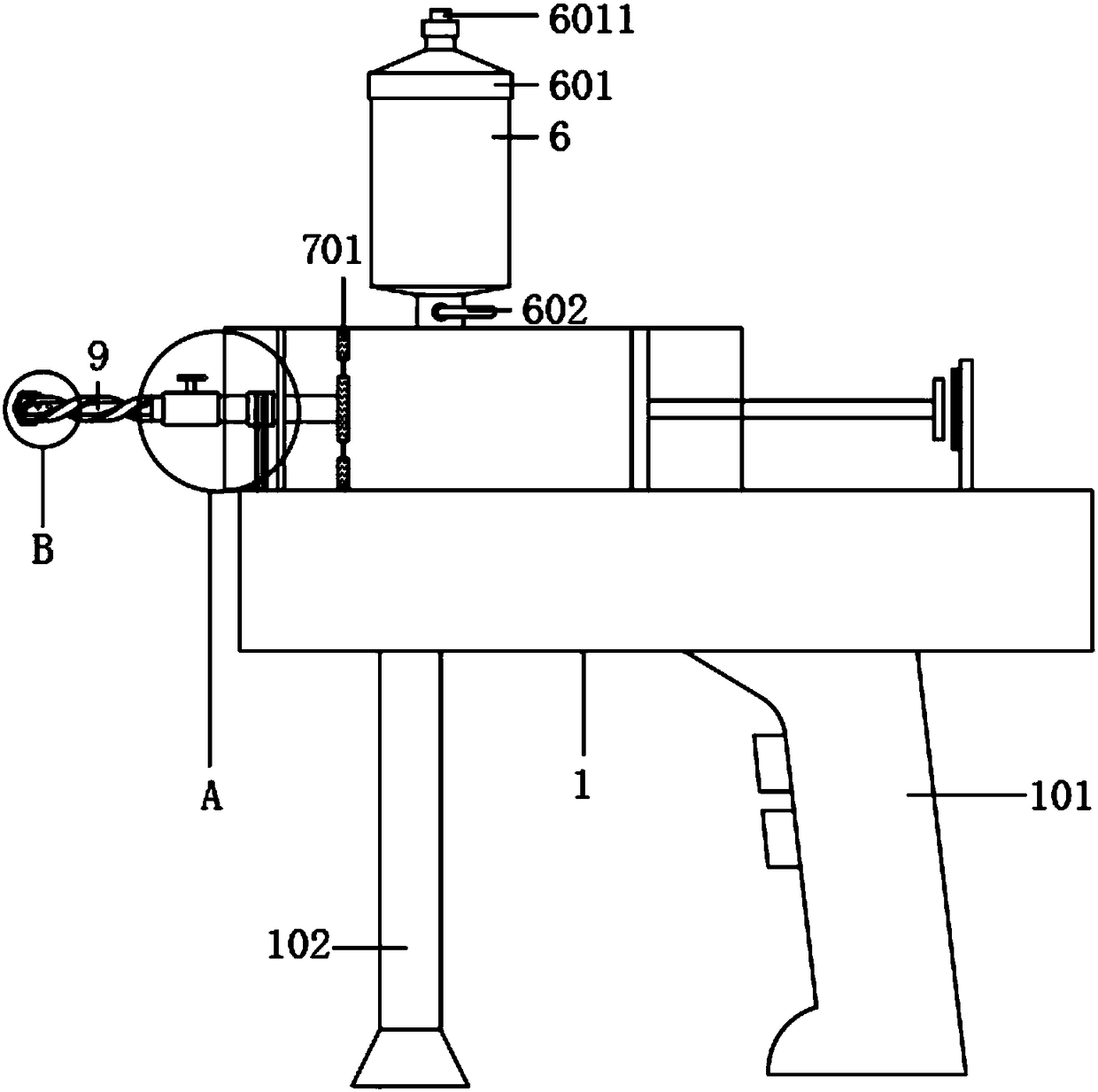

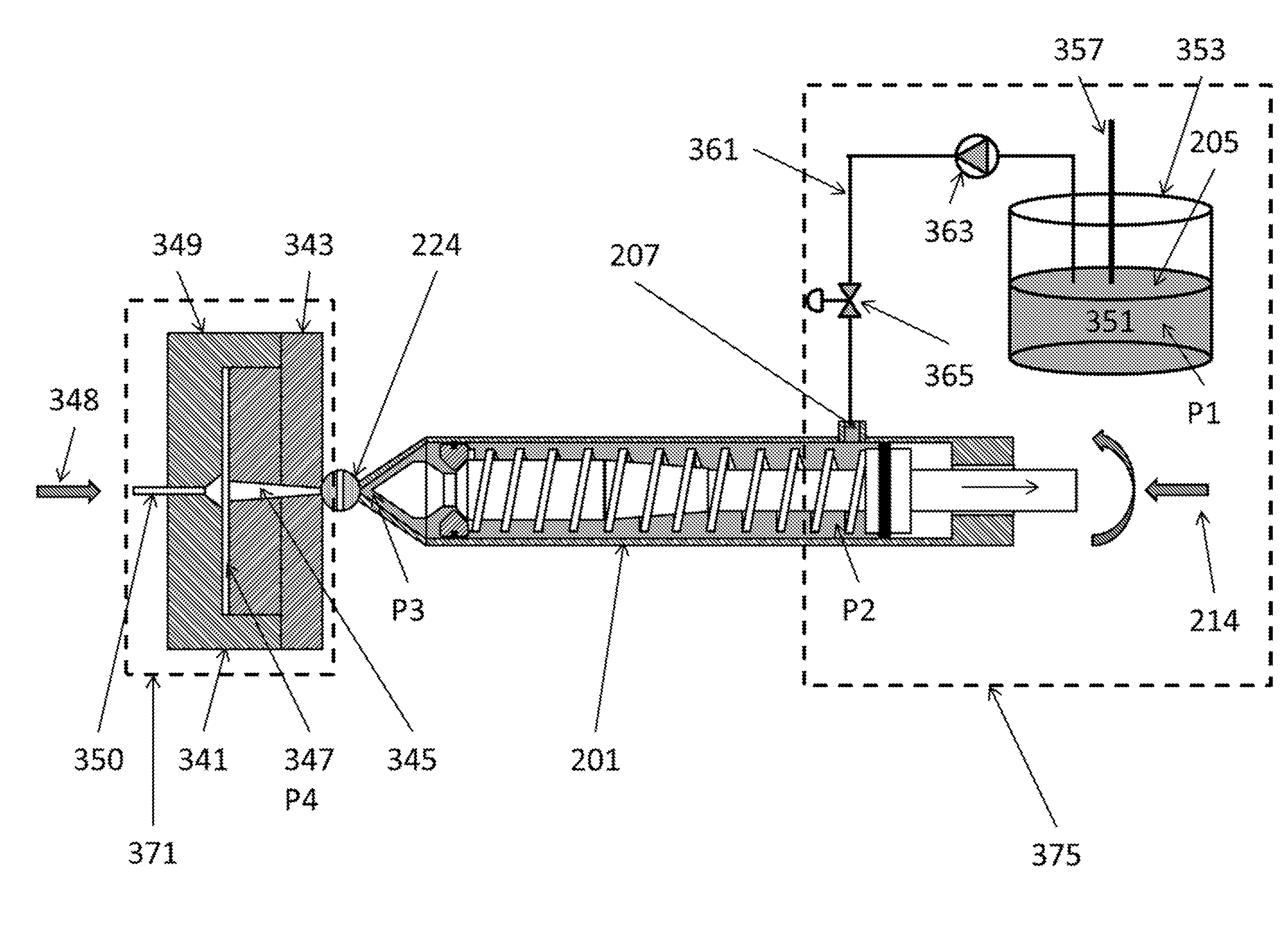

On-line injection profile-control and flooding-control method and device

InactiveCN101245699ARealize Regulatory ControlStable and reliable concentrationFluid removalLine tubingLiquid storage tank

The invention relates to a method and a device for injecting profile control online. The method includes that a plugging agent is injected in a water injection well. The plugging agent injected in the water injection well is injected online and the steps are that: (A) the plugging agent is stored into a liquid storage tank; (B) the plugging agent is simultaneously injected along with the injected water by a special injection device; (C) the plugging agent is mixed into an online water injection pipeline through a metering plunger pump; (D) the plugging agent is mixed with the injected water in the water injection pipeline, injected into the well together and reach an oil layer; (E) the total injecting flow and injecting pressure on the well opening are measured by a flowmeter and a pressure gauge. The device includes the liquid storage tank, a control valve, the metering plunger pump, an injection agent tube, the water injection pipeline, a throttle valve, the flowmeter, the pressure gauge and the water injection well. One end of the injection agent tube is connected on the water injection pipeline and the other end is connected with the metering plunger pump, the control valve and the liquid storage tank in sequence. The water injection pipeline is connected with the water injection well through the throttle valve and the flowmeter. The method and the device have the function of controllable water injection and simultaneous injection and are broadly applied into the water injection technique of petroleum exploitation.

Owner:DONGYING SHIDA COMPREHENSIVE TECH

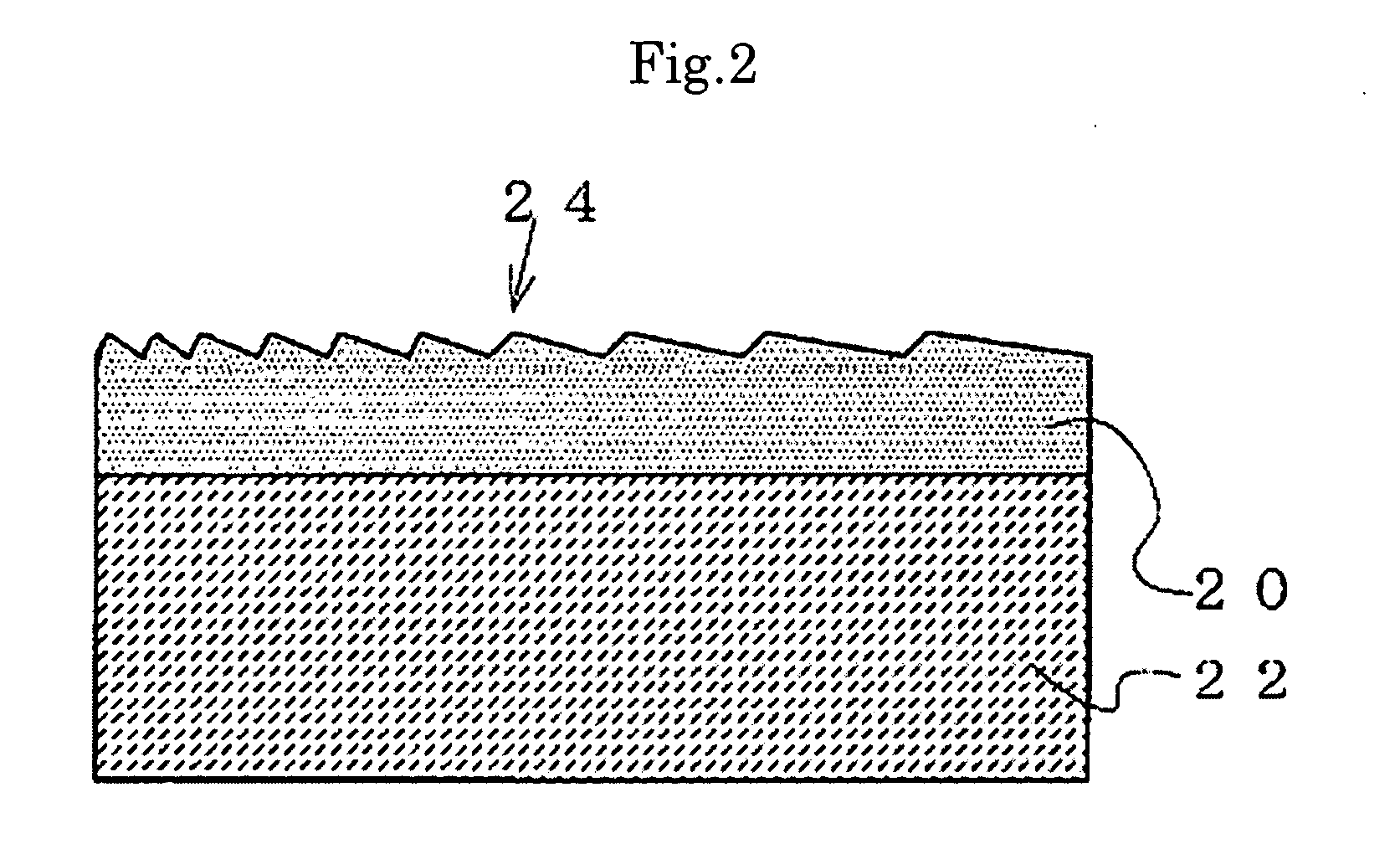

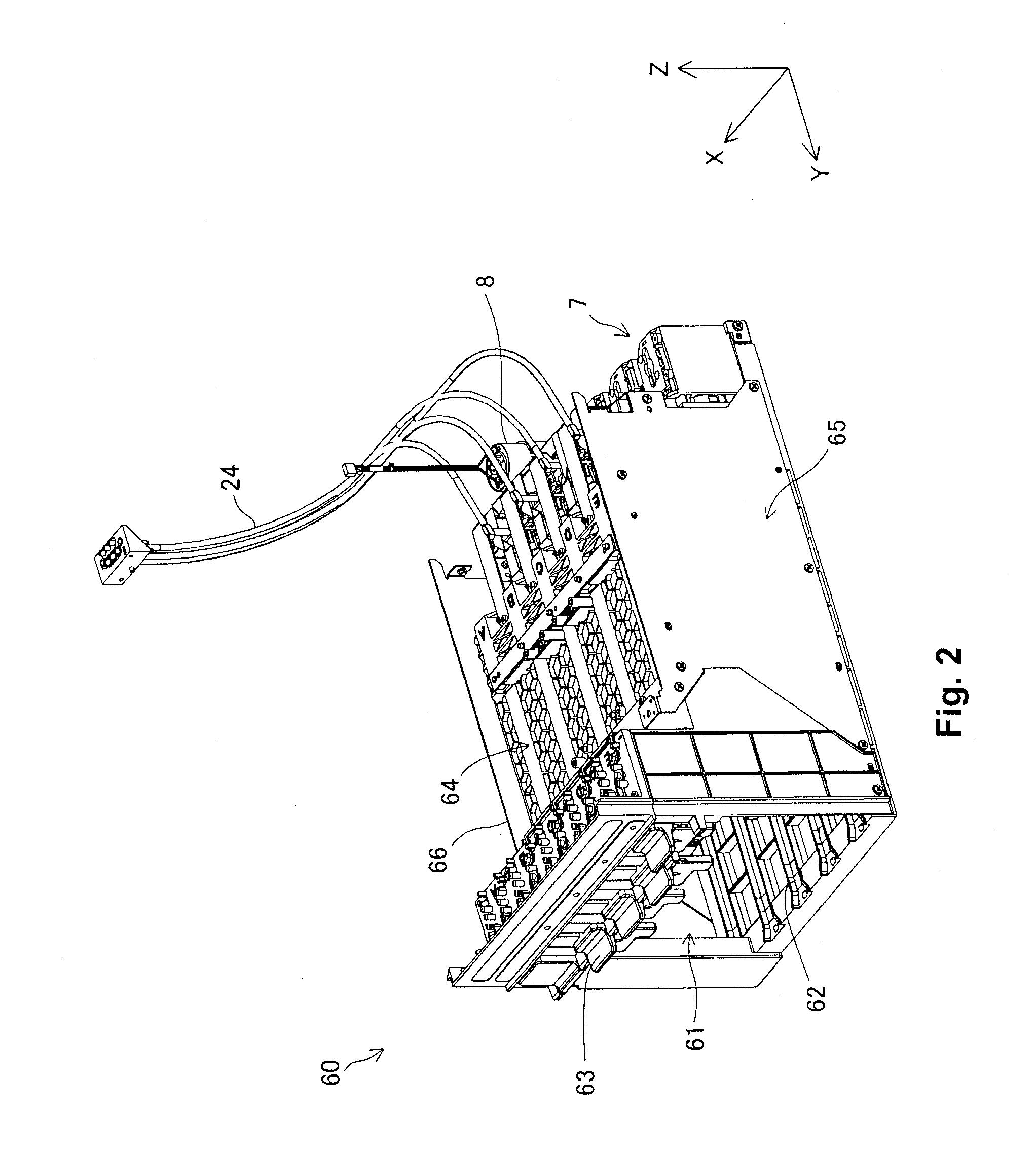

Liquid container and liquid consumption apparatus

ActiveUS20130186513A1Easy to assembleEfficient fillingSolid materialLiquid materialEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

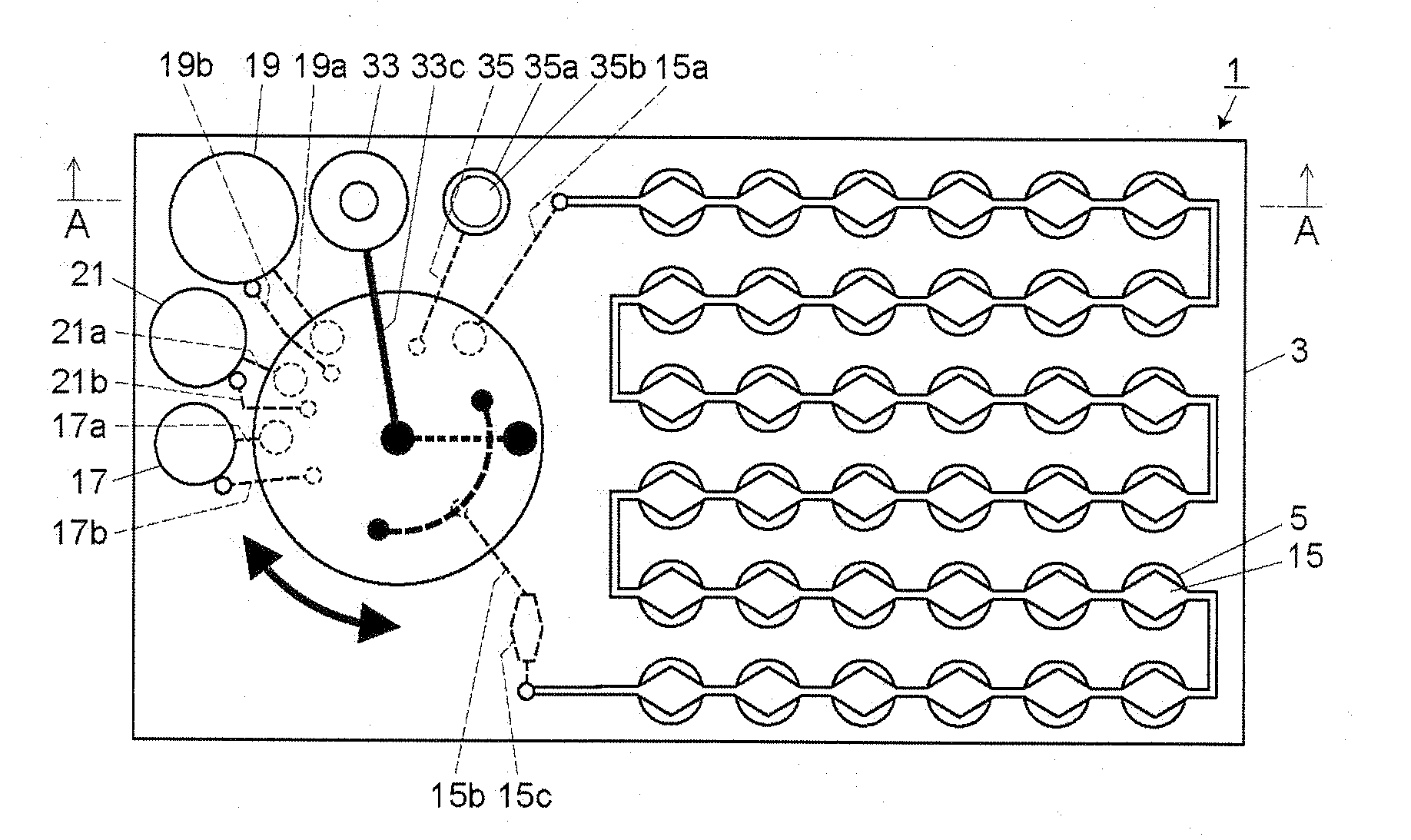

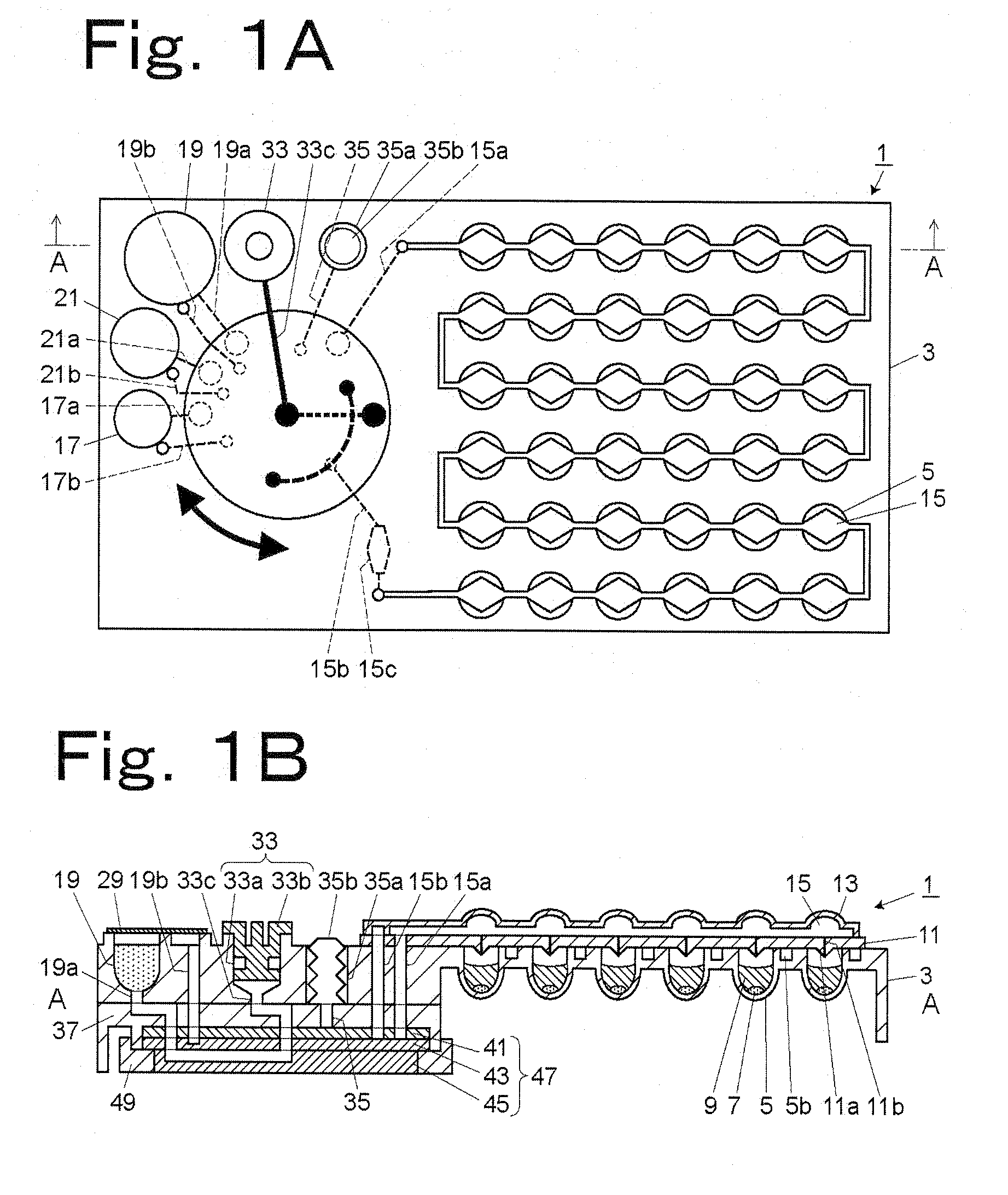

Reaction container plate and reaction treatment apparatus

InactiveUS20100028986A1Avoid enteringInject evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsForeign matterEngineering

Disclosed herein is a reaction container plate which prevents the entry of foreign matter from the outside and the pollution of an outside environment. A reaction container plate (1) includes a sealed reaction container (5), a reaction container channel (15) connected to the reaction container (5), a sealed container (17) provided separately from the reaction container (5), a sealed container channel (17a) connected to the sealed container (17), a syringe (33) for sending a liquid, a switching valve (47) for connecting the syringe (33) to the introduction channel (15) or the sealed container channel (17a), and a sealed container air vent channel (17b) of which one end is connected to the sealed container (17). When the syringe (33) is connected to the sealed container (17) via the switching valve (47) to inject a liquid contained in the syringe (33) into the sealed container (17) and to suck a liquid contained in the sealed container (17) into the syringe (33), a gas contained in the sealed container (17) is moved between the sealed container (17) and the sealed container air vent channel (17b).

Owner:SHIMADZU CORP

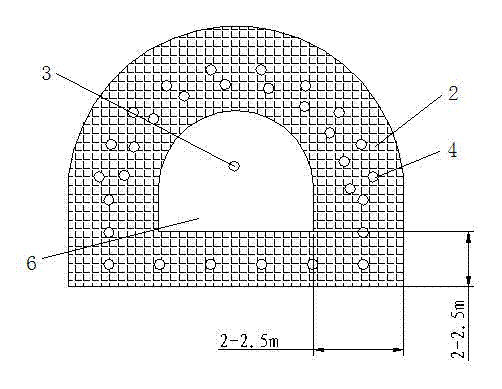

Hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method

The invention discloses a hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method which includes that when roadway drivage reaches a 10m coal layer vertical distance, fracturing holes of a coal layer are drilled, the coal layer is subjected to hydraulic fracturing, and the water injection amount reaches the preset value after above 3MPa pressure drop appears in fracturing; a plurality of grouting holes are drilled when the roadway drivage reaches a 5m coal layer vertical distance; coal layer methane gases are extracted through the fracturing holes and the grouting holes; the coal layer is subjected to quantitative grouting through the grouting holes with grouting pressure to be above 15MPa; and roadway drivage is continued after grouting solidification, and rock cross-cut coal uncovering is completed. Single hole grouting amount includes grouting hole grouting amount M1 and coal layer permeation grouting amount M2 and is calculated according to M=M1+M2=rho*eta / K *(pi*D<2> / 4 *L +pir<2>*l*P)*10<-6>, wherein rho is a grouting density, eta is a storage coefficient, K is a grouting foaming expansion rate, D is a drilling diameter, L is grouting hole length, r is a penetration radius of slurry in the coal layer, l is length of the grouting holes in the coal layer and p is a coal layer porosity. The hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method has the advantages of being capable of fast and safely performing rock cross-cut coal uncovering, avoiding re-handling, and improving social benefit.

Owner:重庆市能源投资集团科技有限责任公司 +1

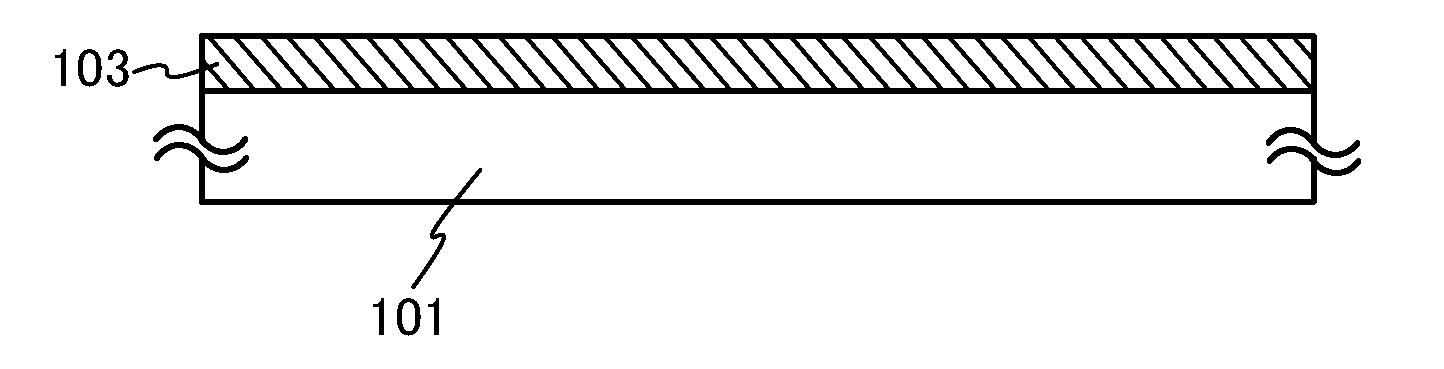

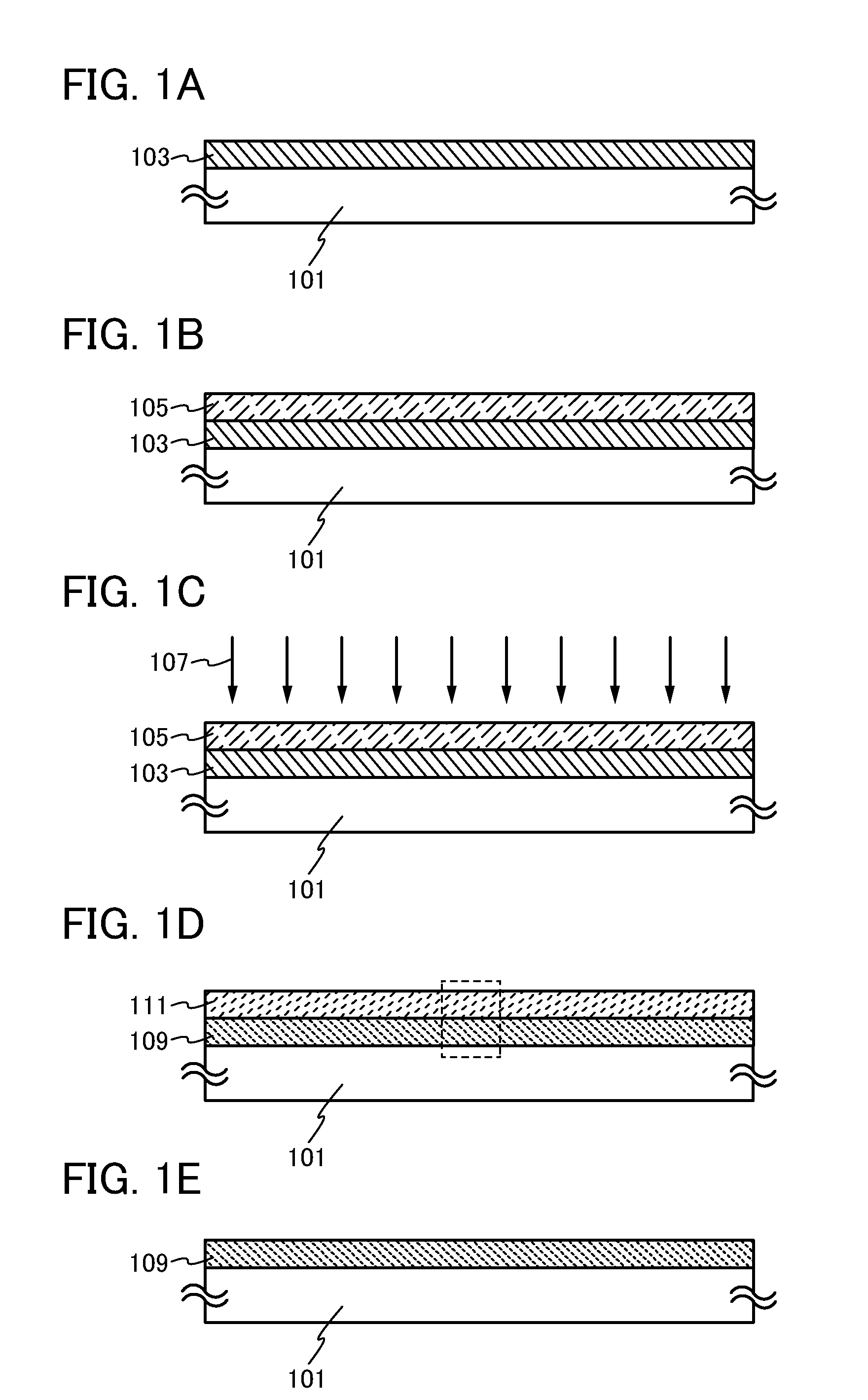

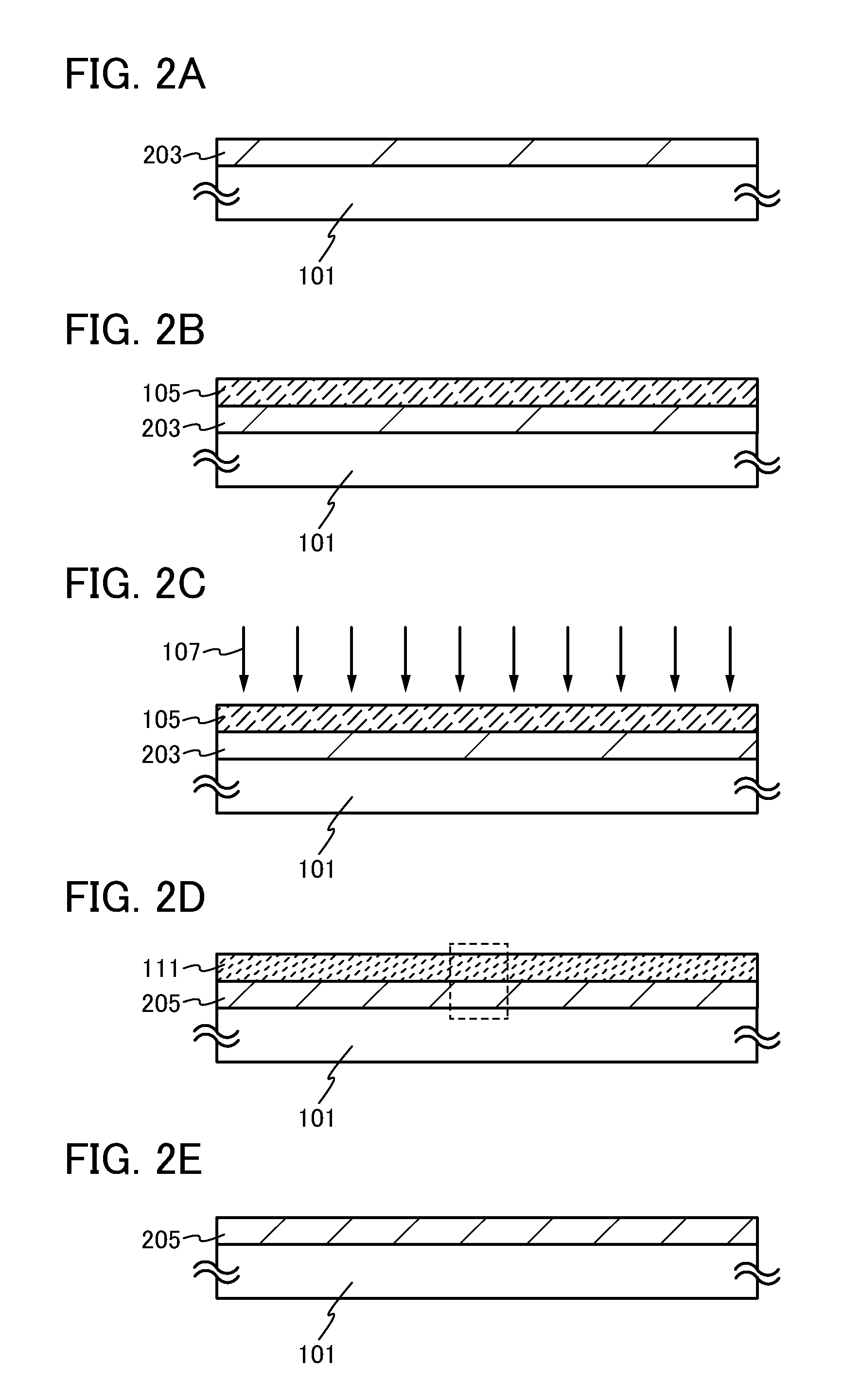

Method for forming oxide semiconductor film and method for manufacturing semiconductor device

InactiveUS20130137232A1Easy to disassembleShorten the timeSemiconductor/solid-state device manufacturingSemiconductor devicesOxygenDepth direction

An oxide semiconductor film is formed over a substrate. A sacrifice film is formed to such a thickness that the local maximum of the concentration distribution of an injected substance injected into the oxide semiconductor film in the depth direction of the oxide semiconductor film is located in a region from an interface between the substrate and the oxide semiconductor film to a surface of the oxide semiconductor film. Oxygen ions are injected as the injected substance into the oxide semiconductor film through the sacrifice film at such an acceleration voltage that the local maximum of the concentration distribution of the injected substance in the depth direction of the oxide semiconductor film is located in the region, and then the sacrifice film is removed. Further, a semiconductor device is manufactured using the oxide semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

Well structure and method for underground modified mining of heavy oil and super heavy oil reservoir

ActiveCN104563981AFully exposed to the effect of modificationAchieve high temperature in-situ modificationFluid removalDrilling compositionElectrical resistance and conductanceMicrowave

The invention provides a well structure and a method for underground modified mining of a heavy oil and super heavy oil reservoir. The well structure comprises oil tubes, a catalyst injection tube and a heating device; injection holes unevenly distributed are formed in the horizontal section of the catalyst injection tube; the heating device comprises a high-energy fused salt heating tube, an electric heating tube, an electric resistance wire heating device, an electromagnetic heating device, a radio-frequency heating device or a microwave heating device; the oil tubes comprise parallel dual oil tubes, concentric dual oil tubes or single continuous punched oil tubes; the invention also provides the method for performing the modified mining on the heavy oil reservoir by utilizing the well structure. According to the well structure and the method for the underground modified mining of the heavy oil and super heavy oil reservoir, provided by the invention, oil can be rapidly dissolved and the viscosity of crude oil is greatly reduced, so the fluidity of mined fluid is further increased, and long-time continuous modification of the oil reservoir can be realized.

Owner:PETROCHINA CO LTD

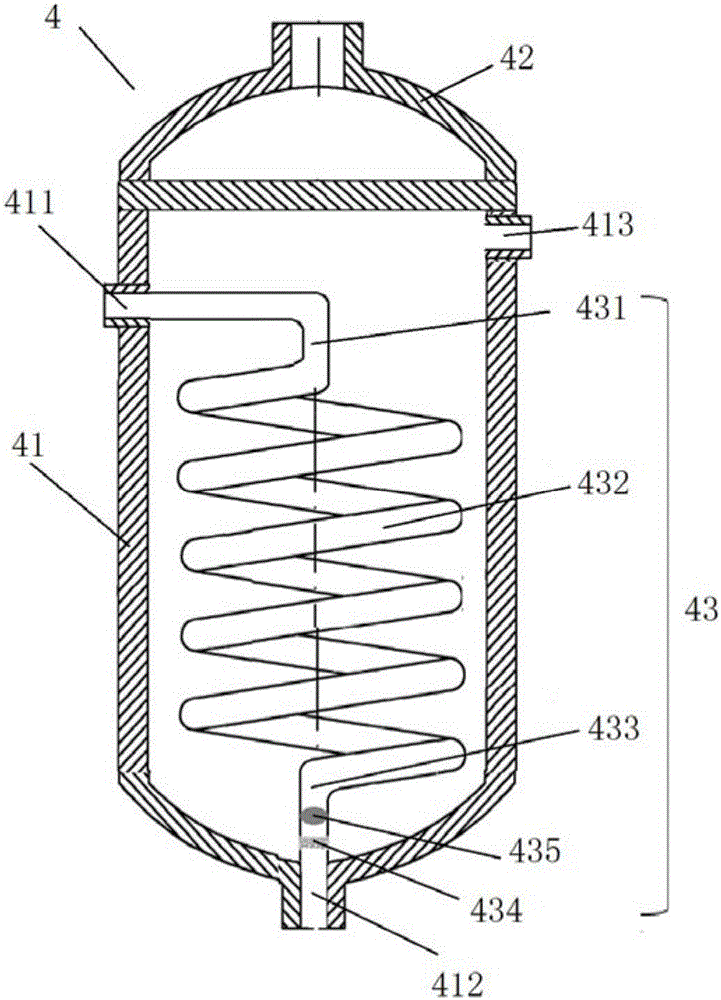

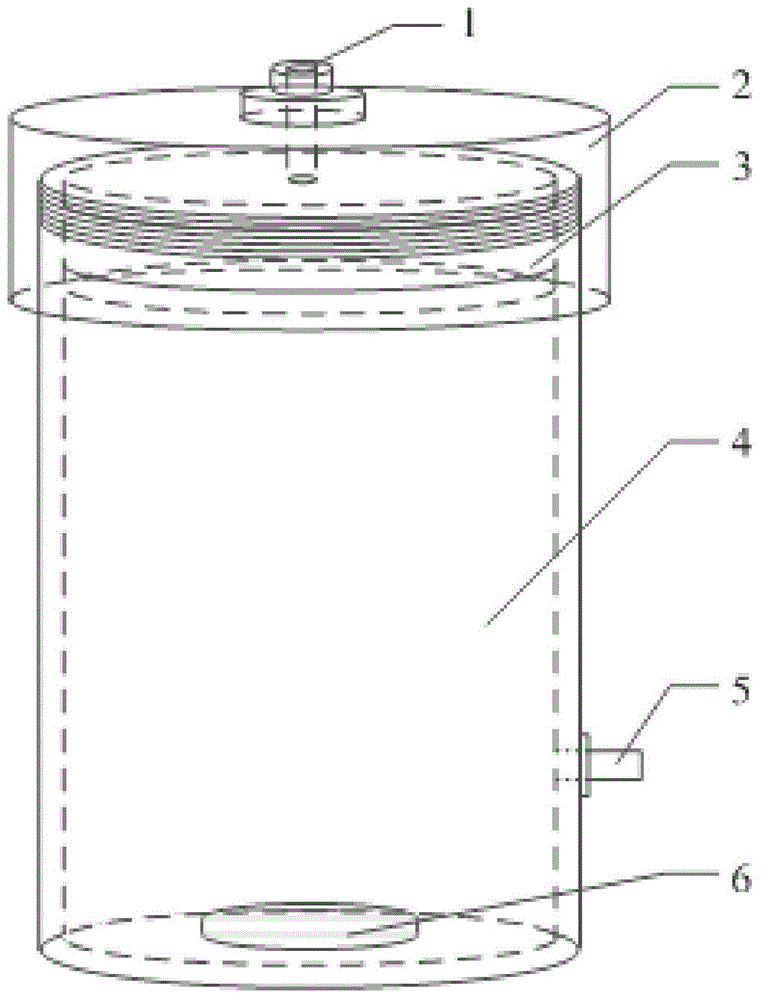

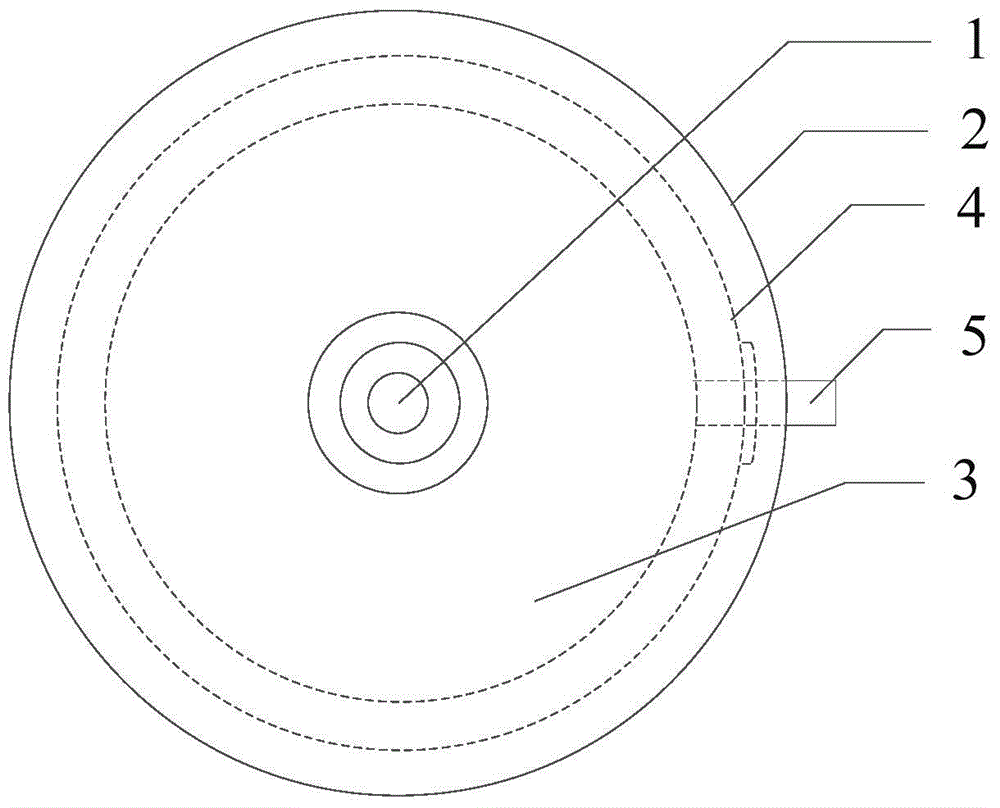

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Hand-hold wiping and sampling device

ActiveCN101571458AEasy to operateReduced Pollution ChancesWithdrawing sample devicesHand heldEngineering

Owner:NUCTECH CO LTD

Exhaust air system, semi-conductor manufacturing installation for manufacturing thin film by the same and method thereof

InactiveCN101179005AImprove uniformityEvenly distributedElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlReaction temperature

A semiconductor manufacture device and a film manufacture method with the device are provided. The semiconductor manufacture device comprises a chamber with preliminary defined reaction space and a nozzle element, which is used for injecting preliminary defined gas transmitted through a gas supply hole into the chamber. The nozzle element comprises a baffle board, a heating block and a pump interface. The baffle board and the gas supply hole are hanged together. The heating block is under the nozzle element so that a wafer can be placed over the heating block. The pump interface comprises a plurality of discharge ports. As high temperature control can be realized easily, a high temperature hard cover can be formed to improve the quality of the film. Besides, the reaction gas can be evenly distributed on the nozzle and travel through the nozzle and be quickly injected into the substrate of the heater by using the baffle board, which is hanged together with the gas supply hole. Further more, the time taken by the reaction gas to travel through the nozzle and reach the substrate is minimized, which in turn minimizes the time to stabilize the reaction temperature. In addition, maintenance time and cost of the device are reduced.

Owner:TES CO LTD

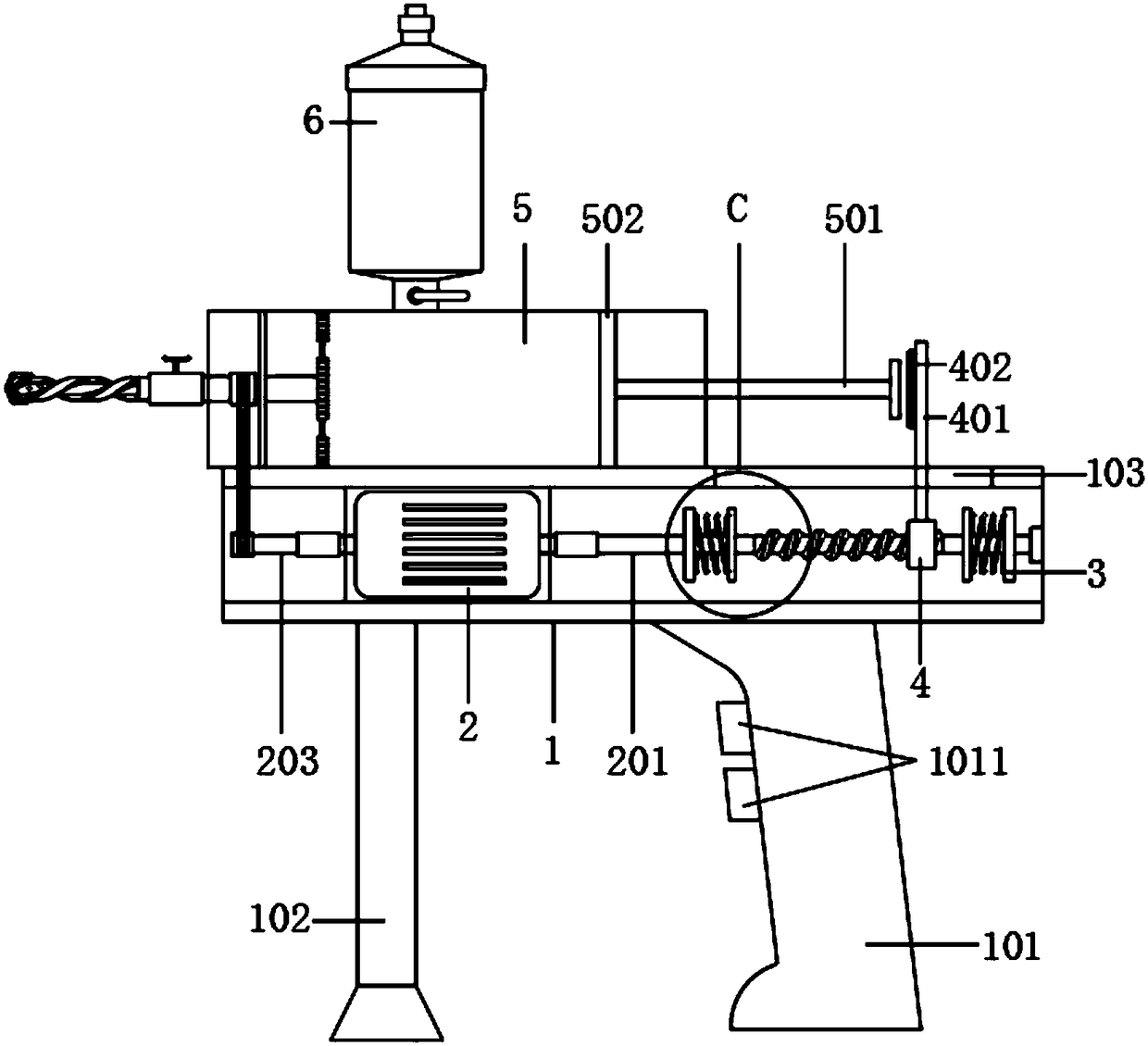

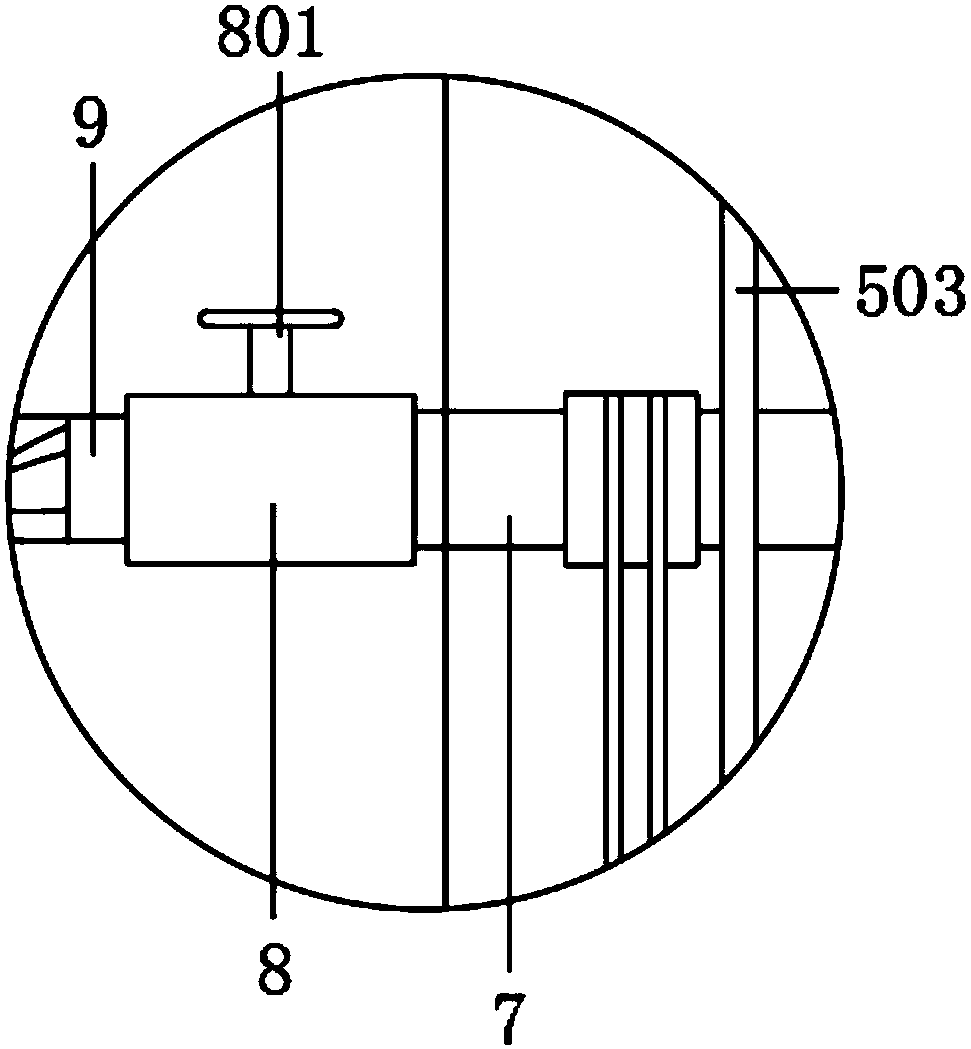

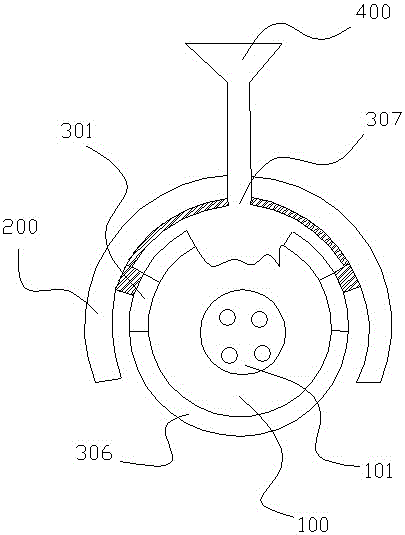

Trunk injector for injecting disease-treating chemical into trunk

InactiveCN108243774AShorten the timeEasy to useTransportation and packagingRotary stirring mixersDrive shaftEngineering

The invention provides a trunk injector for injecting a disease-treating chemical into a trunk. The trunk injector comprises a screw rod, spring seats, a slider, a chemical adding tank, a driven shafttube and a threaded connecting sleeve and is characterized in that a first rotary shaft and a second rotary shaft are respectively connected to two ends of a double-shaft motor, the screw rod is connected to the first rotary shaft, the spring seats are respectively arranged on the first rotary shaft parts located at two ends of the screw rod, a push rod at the top of the slider penetrates a slidegroove in an injector body to be arranged on the rear side of a piston rod, the inner side of a transparent chemical tube is provided with a rubber plate and the piston rod, a sealing partition is further embedded into the inner side of the front end of the transparent chemical tube, five arc-shaped brushes are connected to one end, penetrating the sealing partition, of the driven shaft tube, a drill bit is connected to one end, penetrating the transparent chemical tube, of the driven shaft tube through the threaded connecting sleeve, a hand wheel sealing column penetrates the middle of the threaded connecting sleeve, and the chemical adding tank is connected to the top of the transparent chemical tube through a pipeline. The trunk is capable injecting the chemical into the trunk during drilling.

Owner:闻斌壹

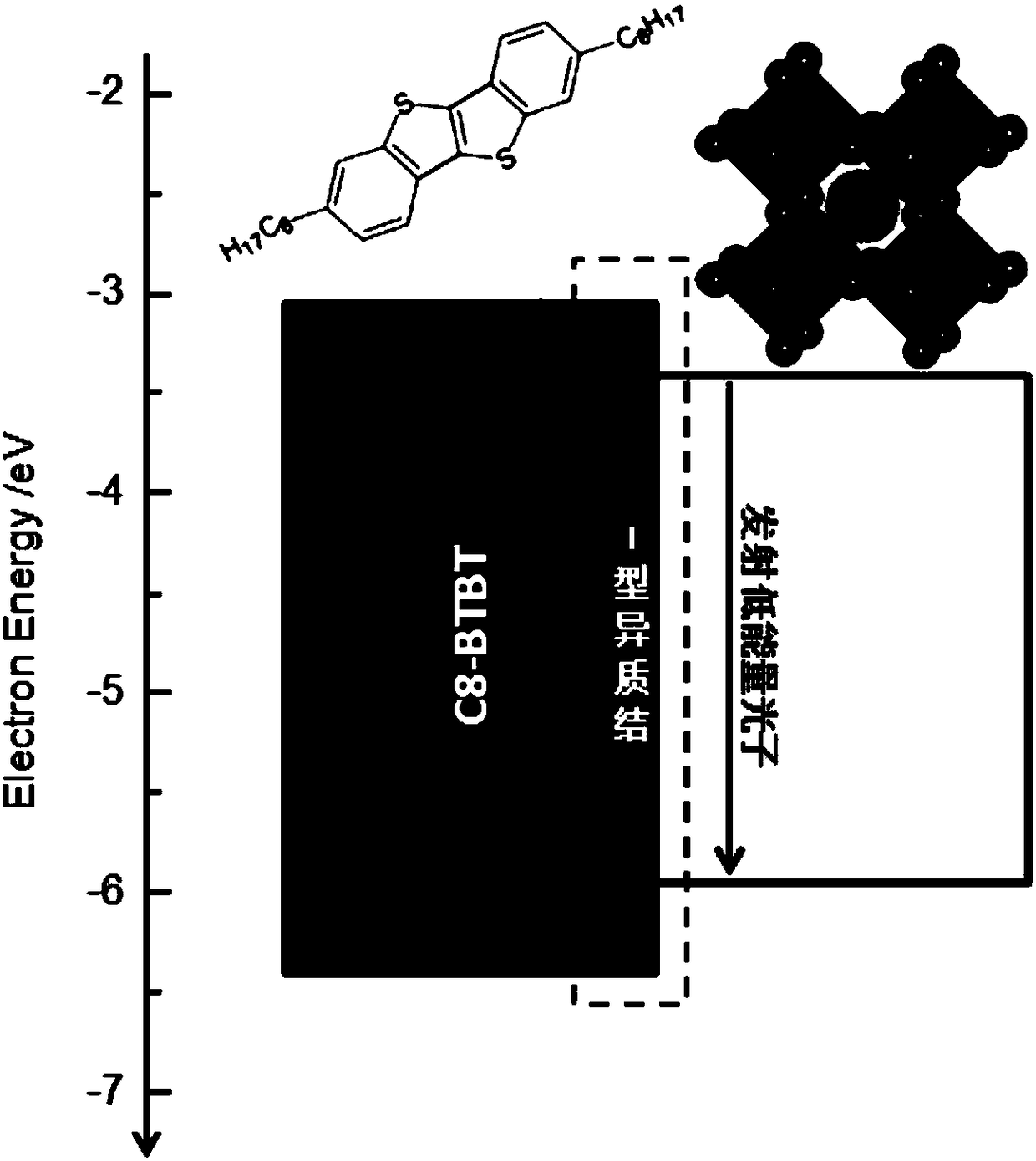

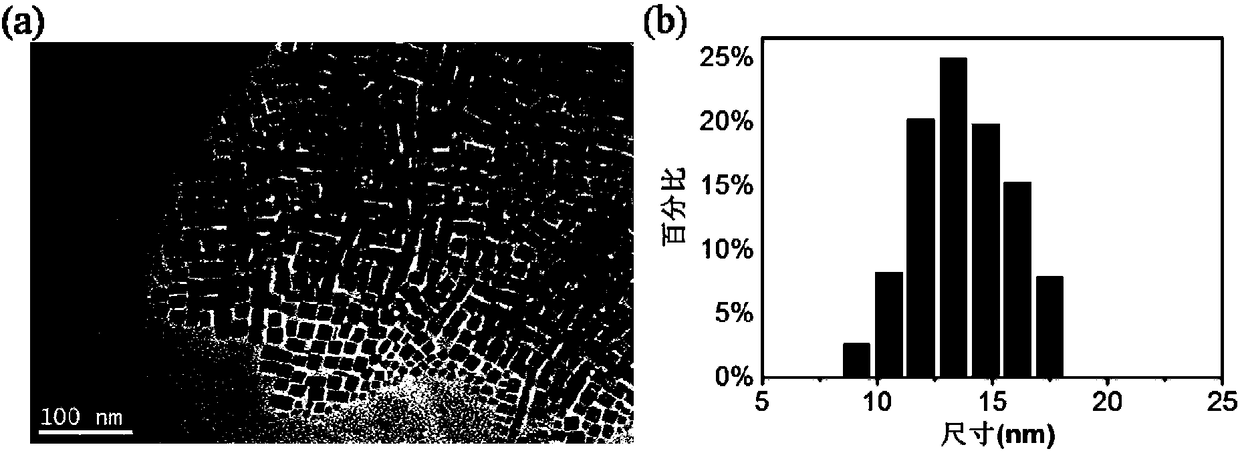

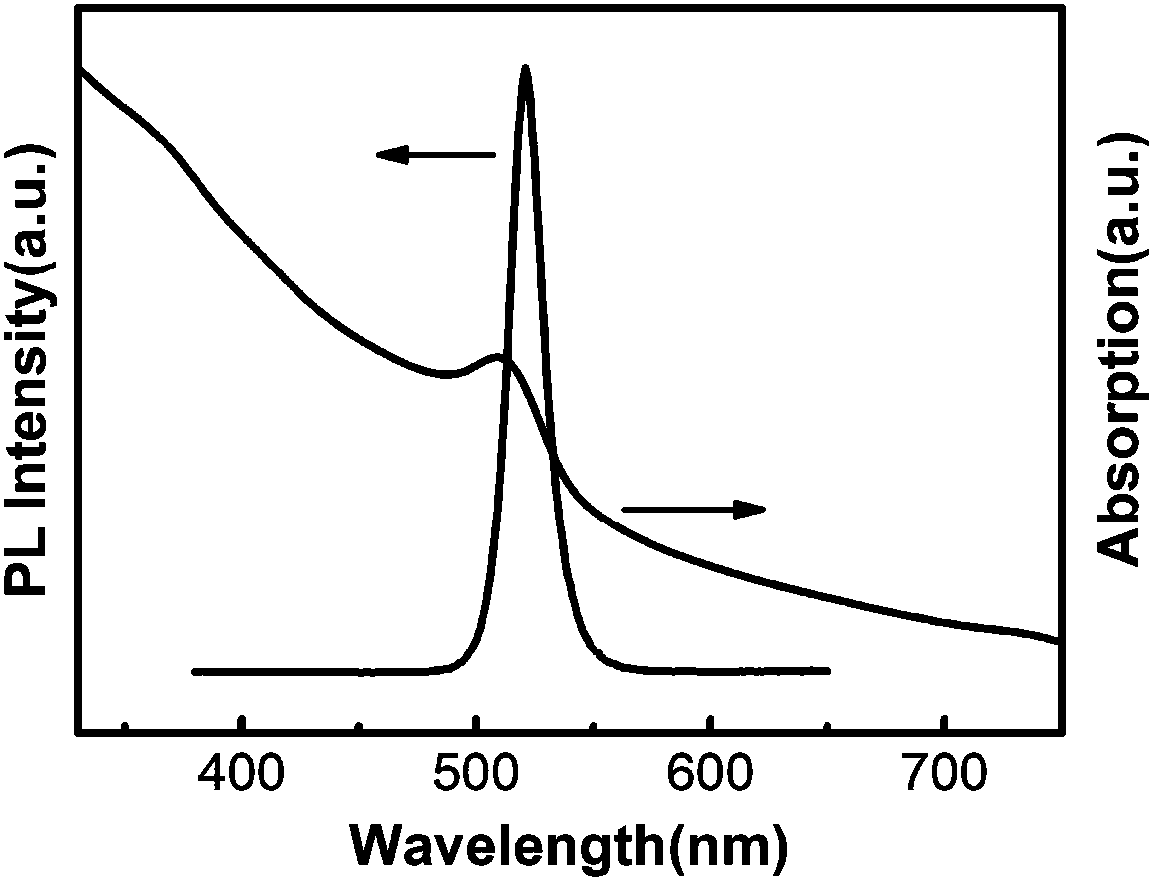

Optical thin film based on inorganic perovskite quantum dot and conjugated organic small molecule eutectic structure

ActiveCN108192593AHigh fluorescence intensityEnhanced photoluminescence intensitySolid-state devicesSemiconductor/solid-state device manufacturingMaterial DesignHigh energy

The invention discloses an optical thin film based on an inorganic perovskite quantum dot and a conjugated organic small molecule eutectic structure. The optical thin film is characterized in that theoptical thin film based on the inorganic perovskite quantum dot and conjugated organic small molecule eutectic structure is obtained by commonly dispersing the inorganic perovskite quantum dot and aconjugated organic small molecule into an organic solvent to form a composite dispersion solution, and carrying out a dipping and drawing, inkjet printing or spin-coating technology on the composite dispersion solution to form the film. According to the optical thin film disclosed by the invention, components can be quantitatively controlled based on components of the composite dispersion solutionto form the eutectic structure, and multiple beneficial effects are provided for functionalized application of the thin film; the fluorescence quantum efficiency and the chemical stability of a quantum dot material can be improved; the thin film can be used for detecting high-energy rays based on absorption properties and a photophysical process of the material designed by the system; a conjugated organic small molecule material with high mobility can reduce energy loss caused by charge injection and transmission under a current driving condition.

Owner:SHANGHAI BEEN SEMICON TECH CO LTD

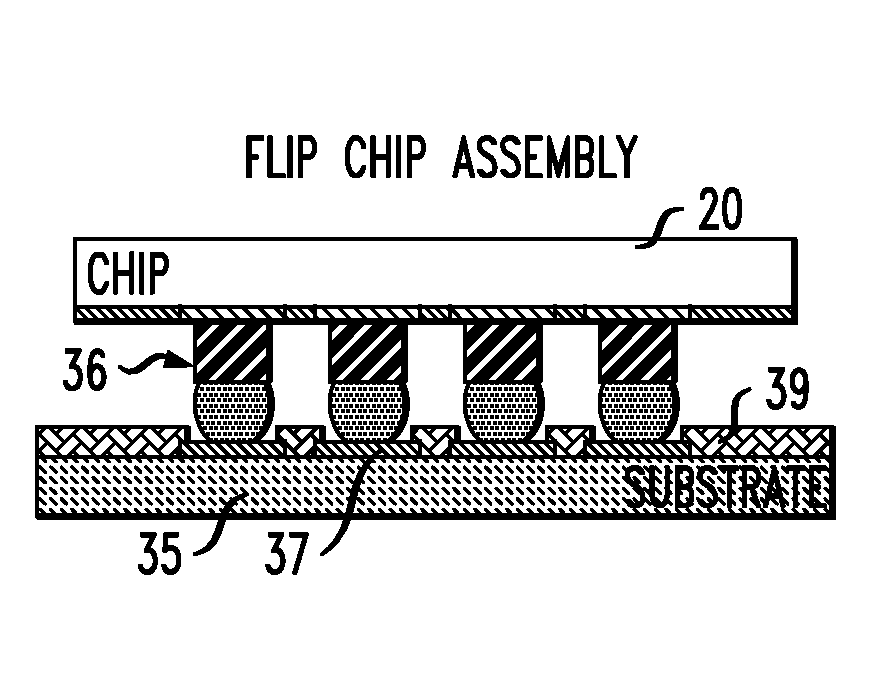

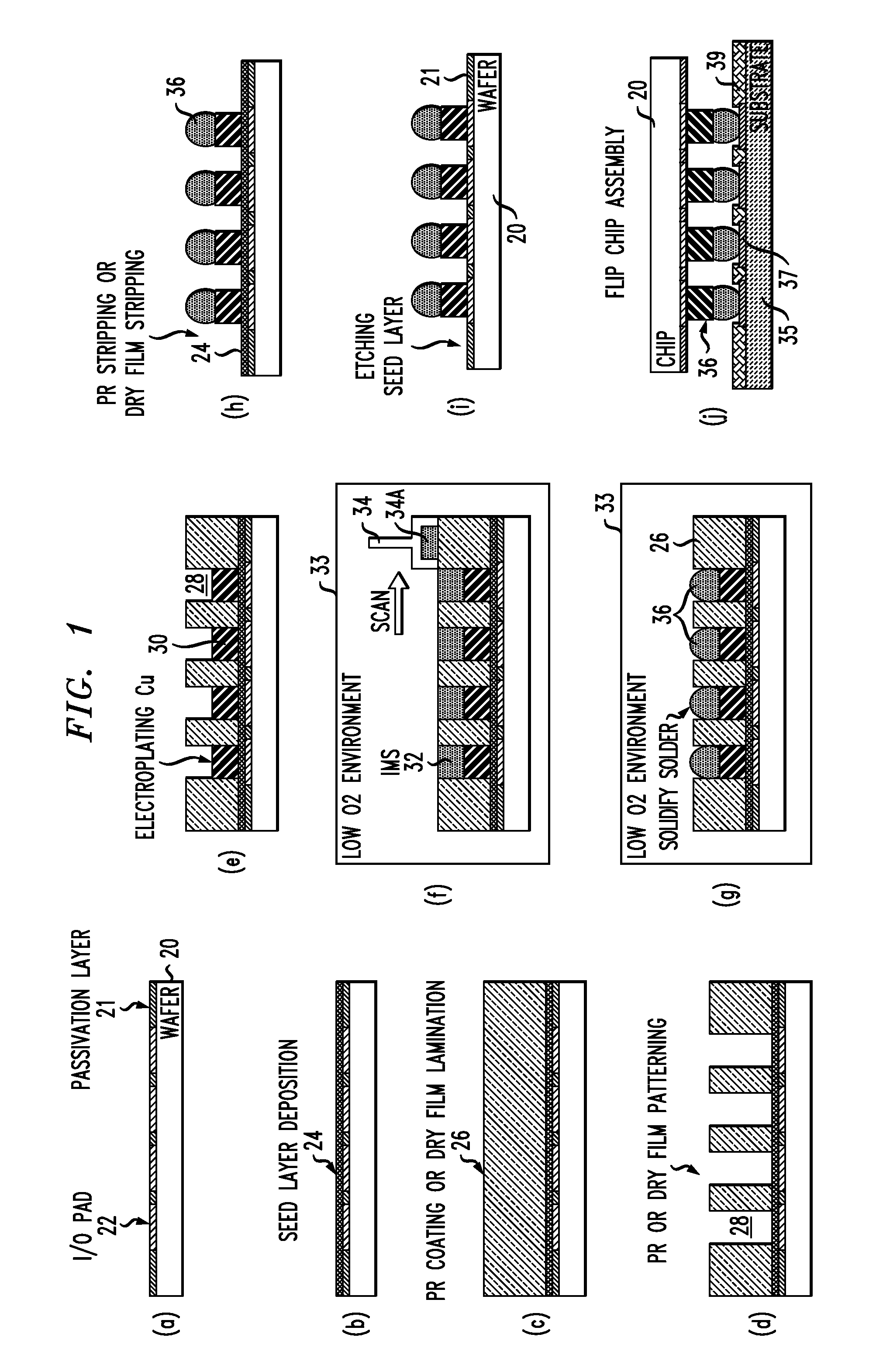

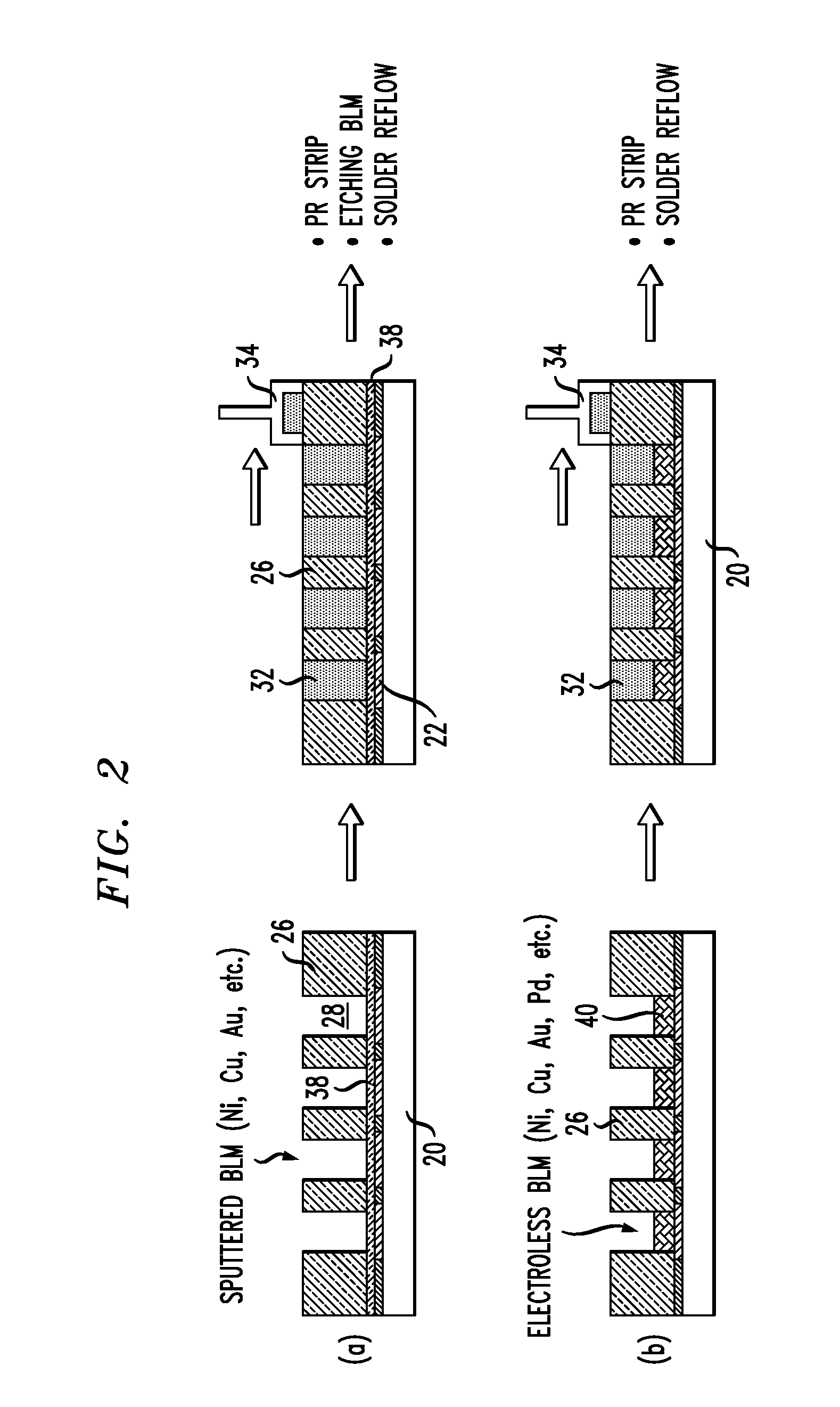

Injection molded solder process for forming solder bumps on substrates

InactiveUS20120305631A1Minimizing and eliminate spillageMinimizing and eliminating spillageExhaust apparatusSolid-state devicesPhotoresistMetallurgy

Solder bumps of uniform height are provided on a substrate through the use of injection molded solder. Copper pillars or ball limiting metallurgy are formed over I / O pads within the channels of a patterned layer of photoresist. Solder is injected over the pillars or BLM, filling the channels. The solder, which does not contain flux, is allowed to solidify. It forms a plurality of solder structures (bumps) of equal heights. Solder injection and solidification are preferably carried out in a nitrogen environment or a forming gas environment. Molten solder can be injected in channels formed in round wafers without spillage using a carrier assembly that accommodates such wafers and a fill head.

Owner:IBM CORP

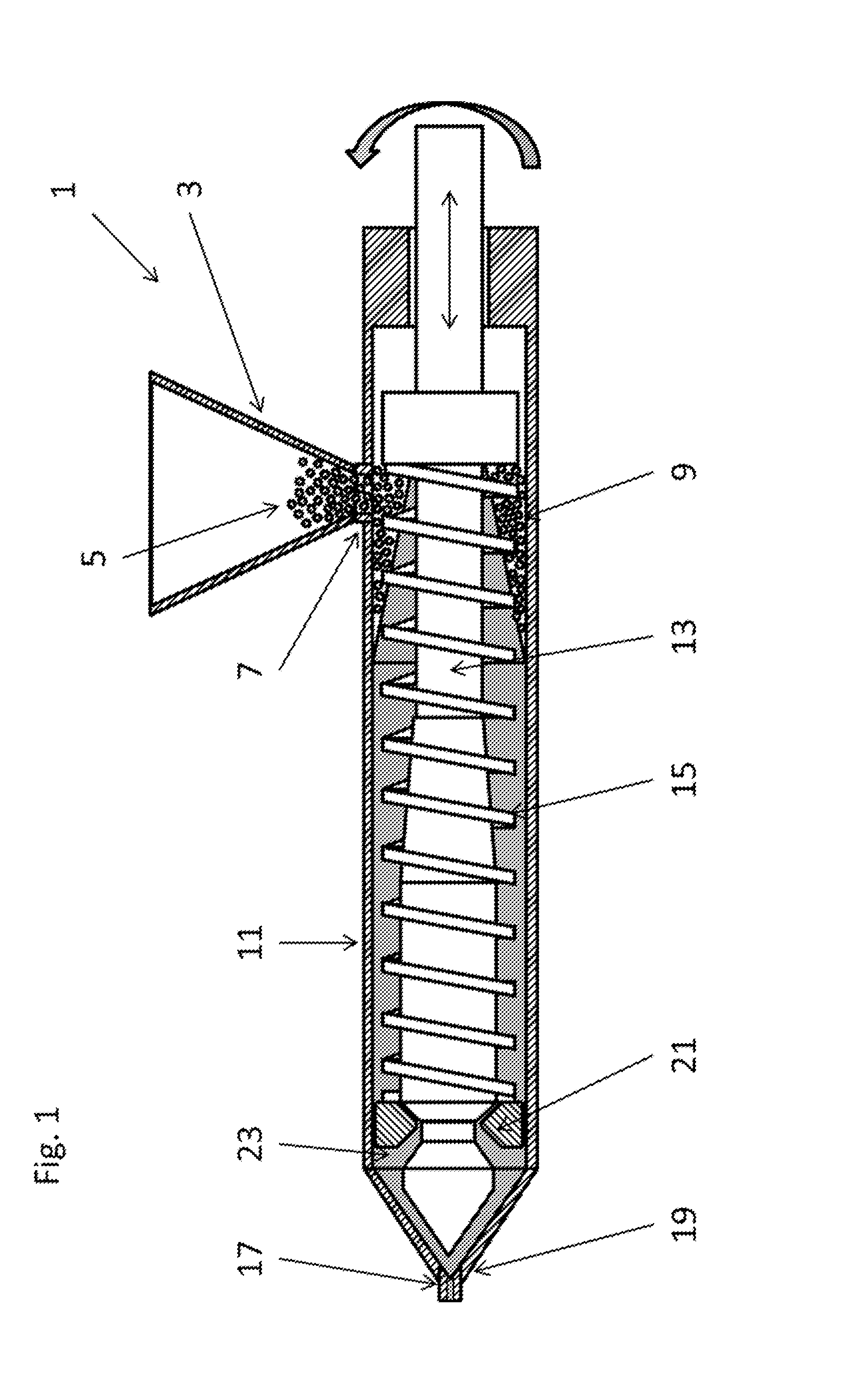

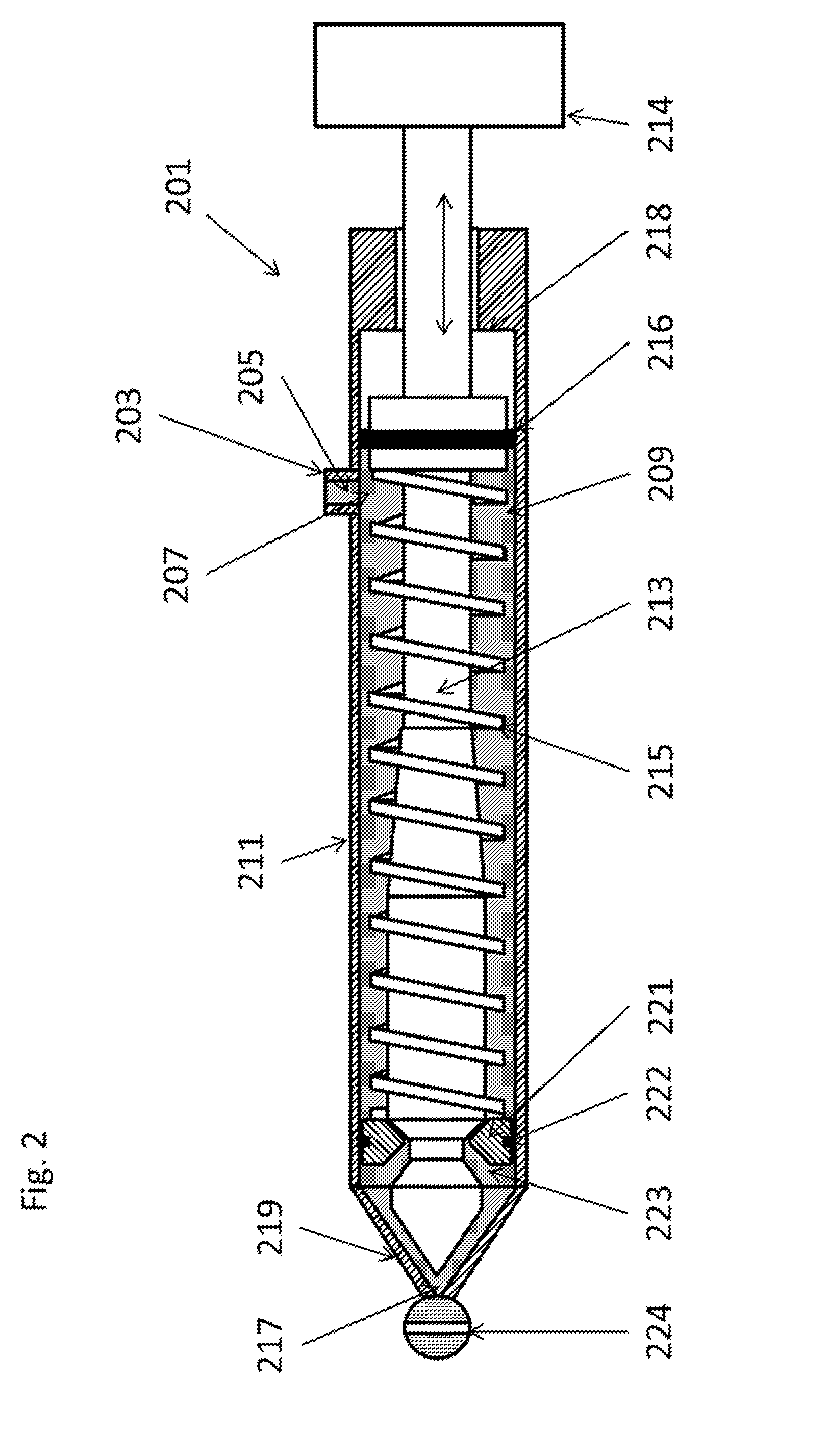

Apparatus and method for the production of expanded foam embryos

The present invention relates to an injection moulded product, an expanded foam product, a method of injection moulding a plastisol an expandable plastic embryo during which the foaming of the plastic embryo is suppressed throughout the moulding operation. The invention further relates to a mould and an injection moulding device.

Owner:DIAB INT AB

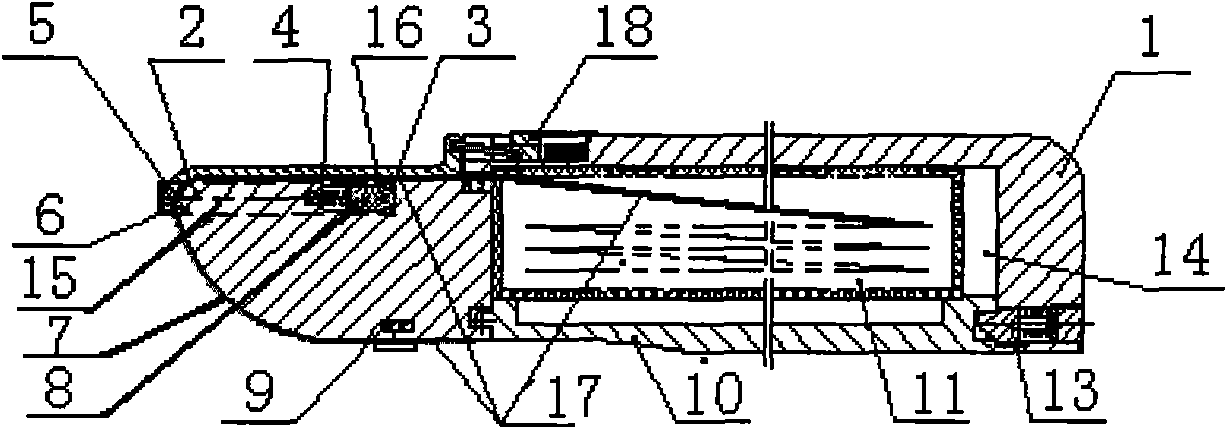

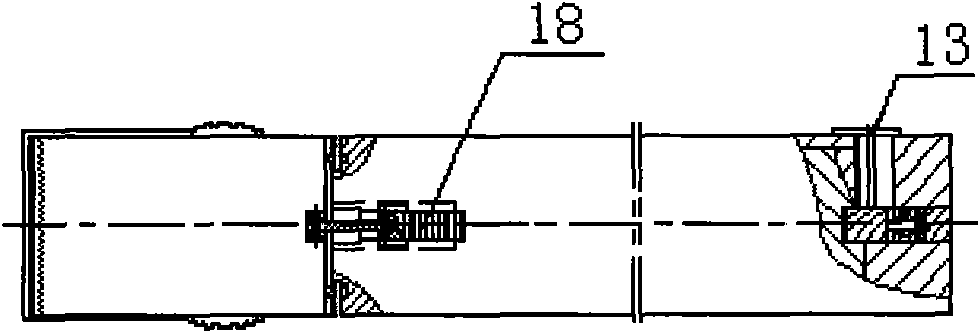

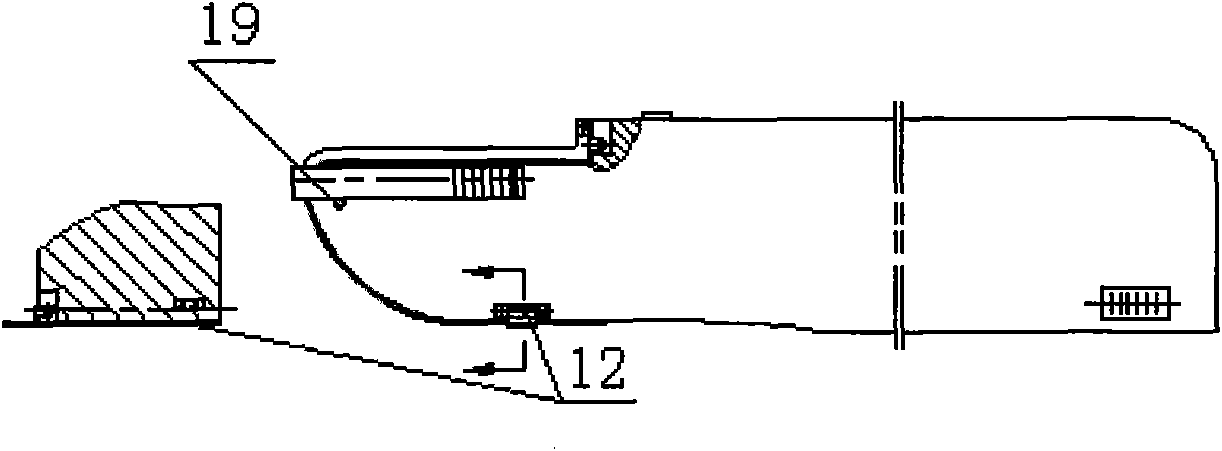

Device for repairing damaged cable

ActiveCN105140832AInject evenlyReduce the problem of patch unevennessApparatus for repairing insulation/armouring cablesInjection portEngineering

The invention discloses a device for repairing a damaged cable. The cable repair device consists of a molding die, a molding die fixing member and a UV glue pouring funnel; and the molding die comprises a die sealing member, a first transparent molding die, a UV glue horizontal flow region, a ultraviolet curing lamp, a molding die shell, a plurality of UV glue outflow ports, a second transparent molding die and a molding die UV glue injection port. By adoption of the abovementioned scheme, the glue adopted by the device for repairing the damaged cable is UV glue, the molding die is internally provided with the ultraviolet curing lamp, and thus UV glue can be cured in very short time through irradiation of the ultraviolet curing lamp, thereby saving much time for electric power workers; and the device is also provided with the UV glue horizontal flow region, the main purpose is to spread glue injected through the funnel in the horizontal flow region, and then the glue is injected to places where the cable is damaged through the plurality of UV glue outflow ports, and thus the glue can be injected to different places evenly.

Owner:国网江苏省电力有限公司金湖县供电分公司 +1

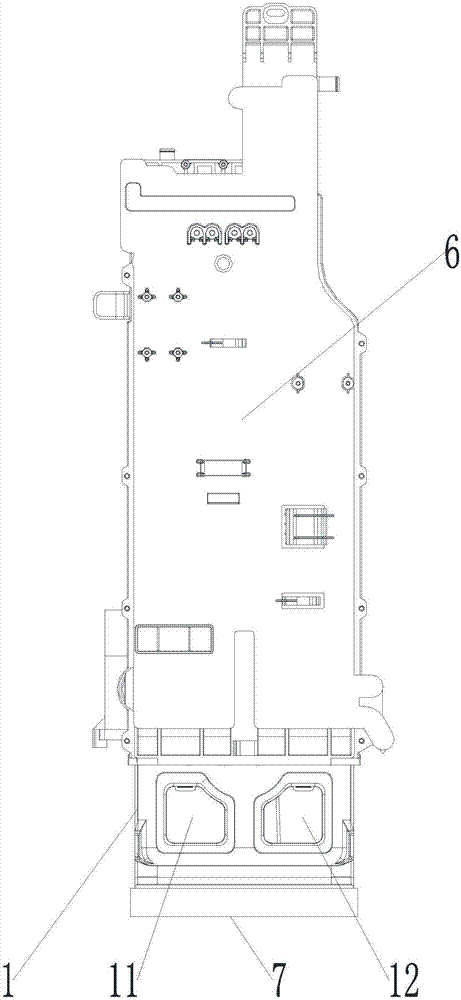

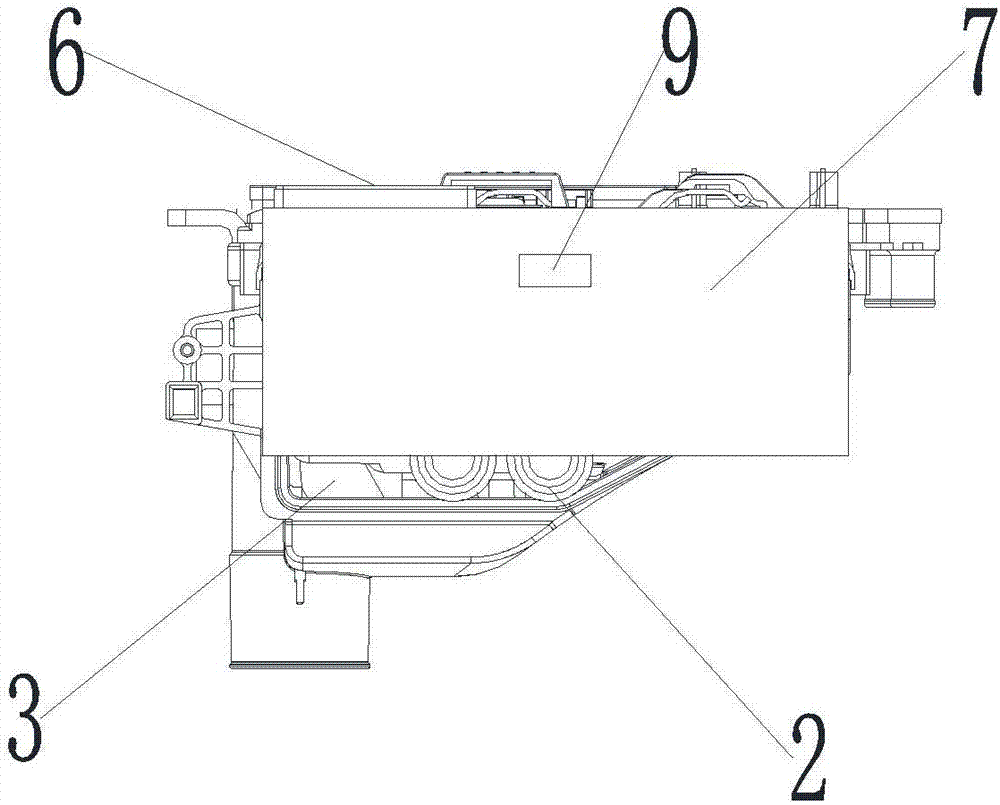

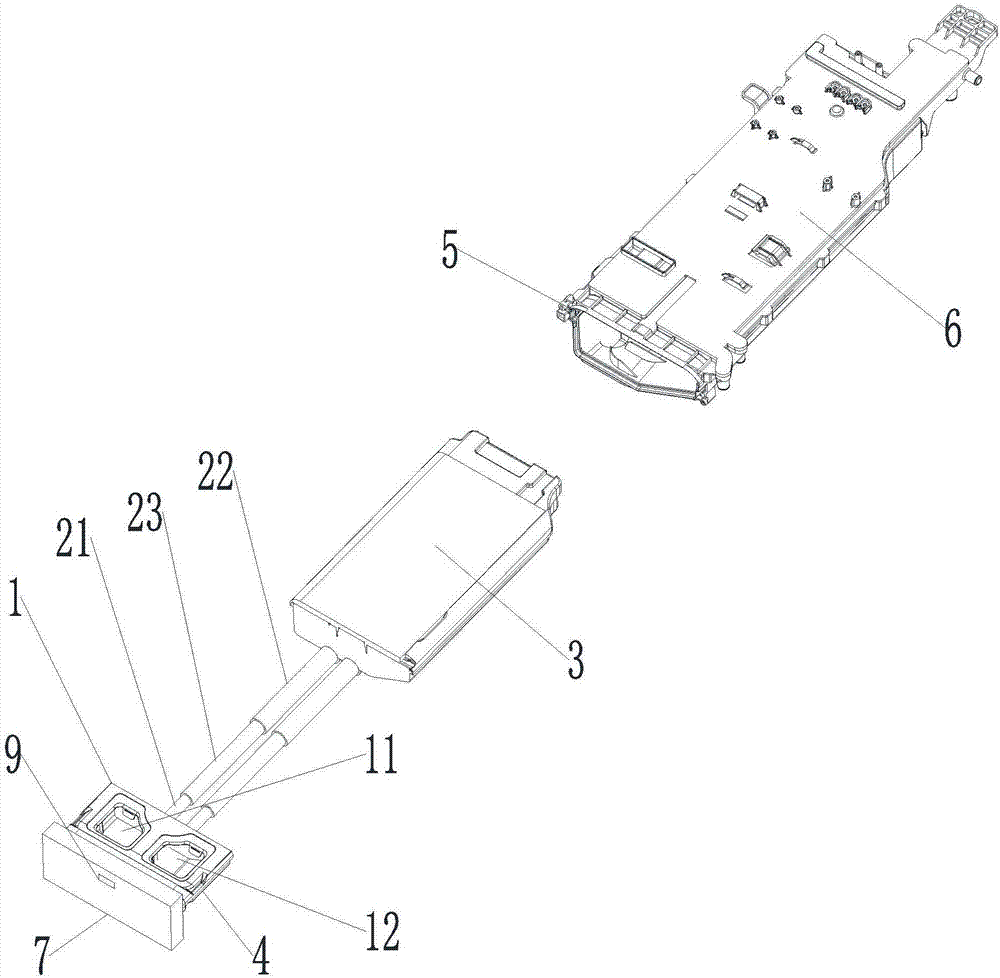

Clothes treatment agent putting assembly used for clothes treatment equipment and clothes treatment equipment

PendingCN107974807AEasy to moveThe delivery operation went wellOther washing machinesTextiles and paperBiomedical engineeringDisposal Technique

The invention belongs to the technical field of clothes treatment, and aims to solve the problem that a clothes treatment agent of existing clothes treatment equipment is inconvenient to put, and accordingly the user experience is poor. Therefore, the invention provides a clothes treatment agent putting assembly used for the clothes treatment equipment and the clothes treatment equipment. The clothes treatment equipment comprises a body; the clothes treatment agent putting assembly comprises a storage container and a putting device, the storage container is fixedly arranged in the body and isused for storing a clothes treatment agent; the putting device can move relative to the storage container and is used for putting the clothes treatment agent; the clothes treatment agent putting assembly further comprises a sleeve device, one end of the sleeve device is communicated with the putting device, and the other end of the sleeve device is communicated with the storage container so that the clothes treatment agent in the putting device can also flow into the storage container while the putting device can move relative to the storage container. When the putting device moves, the sleeveassembly cannot be blocked and wound, so that user operation is facilitated, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

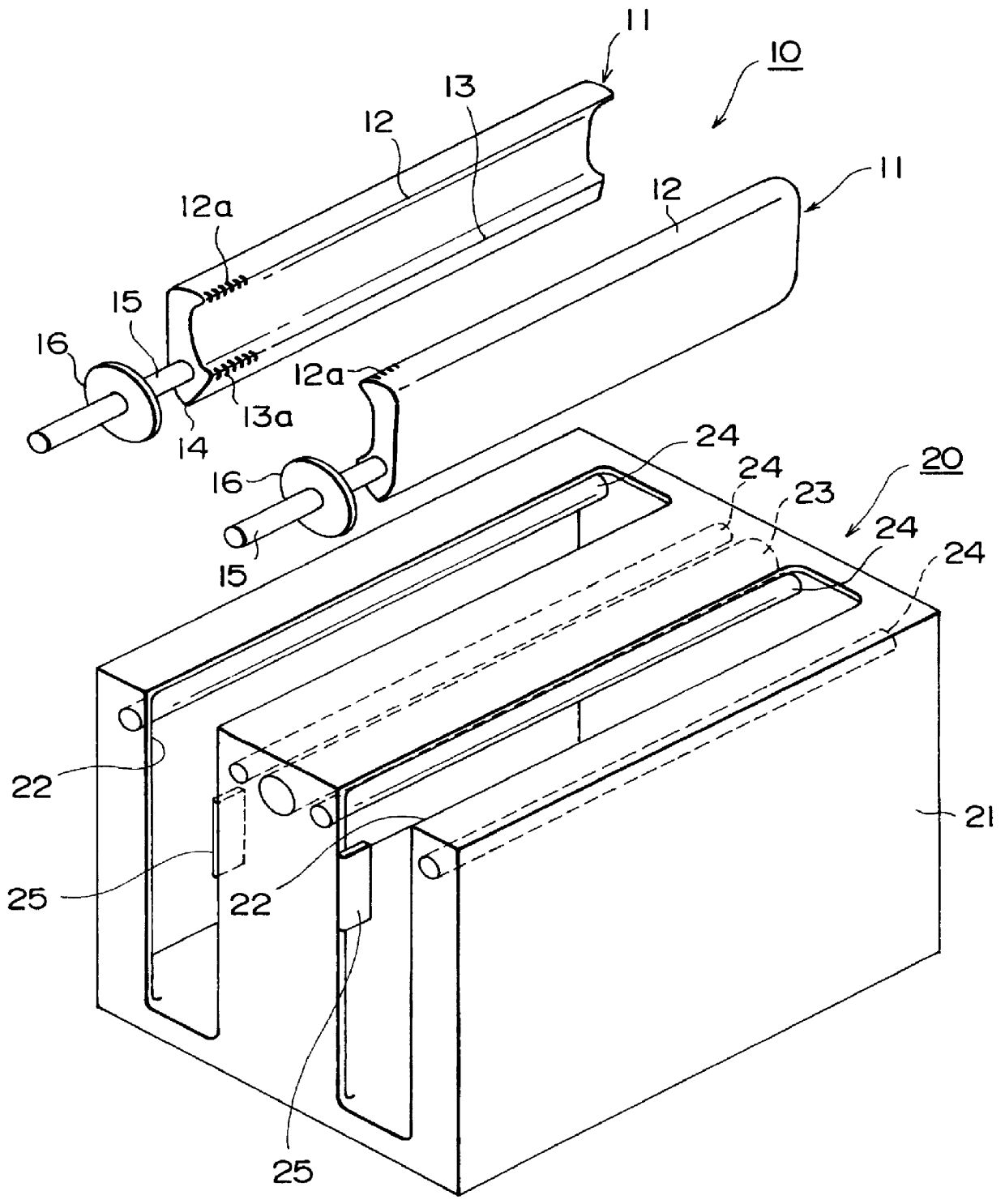

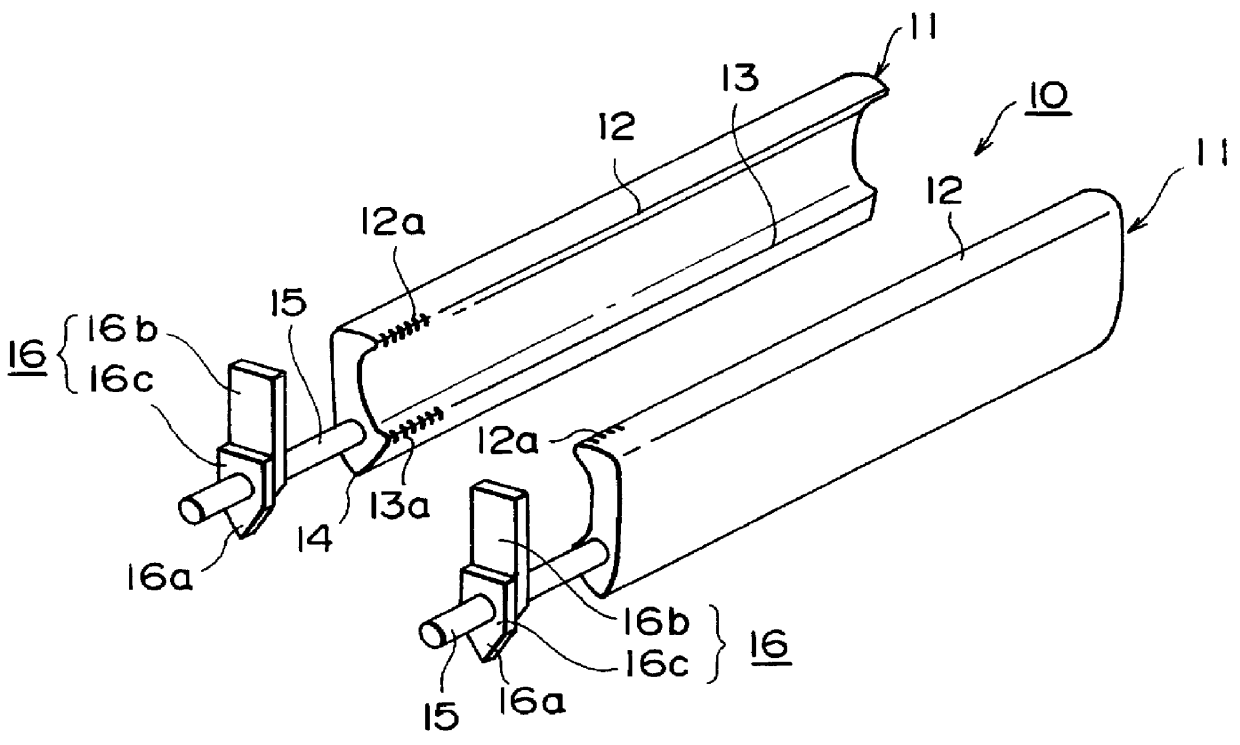

Substrate holder, and system and method for cleaning and drying same

InactiveUS6158596AShorten drying timeImprove throughputLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringDrying time

In a wafer transport chuck 10 for holding wafers W by means of a pair of holding members 11, each of the holding members 11 has an upper holding portion 12 and a lower holding portion 13 which project from the upper and lower portions of a surface facing another holding member 11, respectively. Each of the upper holding portion 12 and the lower holding portion 13 has a circular arc surface facing the held portions of the wafers W. The upper holding portion 12 has a plurality of upper holding grooves 12a, and the lower holding portion 13 has a plurality of lower holding grooves 13a. Thus, it is possible to make the substrate holder smaller without reducing the strength thereof, and it is possible to improve the cleaning and drying efficiency, so that it is possible to reduce cleaning and drying time and to improve throughput.

Owner:TOKYO ELECTRON LTD

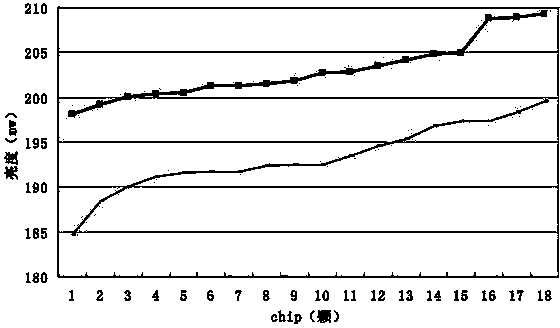

Method for growing quantum well stress release layer of epitaxial structure and epitaxial structure

ActiveCN103413877AImprove compound efficiencyIncrease brightnessSemiconductor devicesTotal thicknessPhysics

The invention provides a method for growing a quantum well stress release layer of an epitaxial structure and the epitaxial structure. The epitaxial structure comprises the quantum well stress release layer with the total thickness of 160nm. The quantum well stress release layer is an HT MQW layer doped with In and Al and comprises a GaN layer with the thickness of 40nm and an AlyInxGa(1-x-y)N layer with the thickness of 2nm, wherein x ranges from 0.05 to 0.08, and y ranges from 0.02 to 0.05. According to the growing method, by modifying the energy band diagram of the HT MQW, electrons entering a luminous zone can be blocked, and the probability that the electrons enter a p layer and are recombined with holes in a nonradiative mode is reduced; moreover, the electrons blocked in the HT MQW are injected into the luminous zone more evenly through two-dimensional diffusion, the efficiency of the recombination between the electrons and the holes is promoted, and the luminance is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

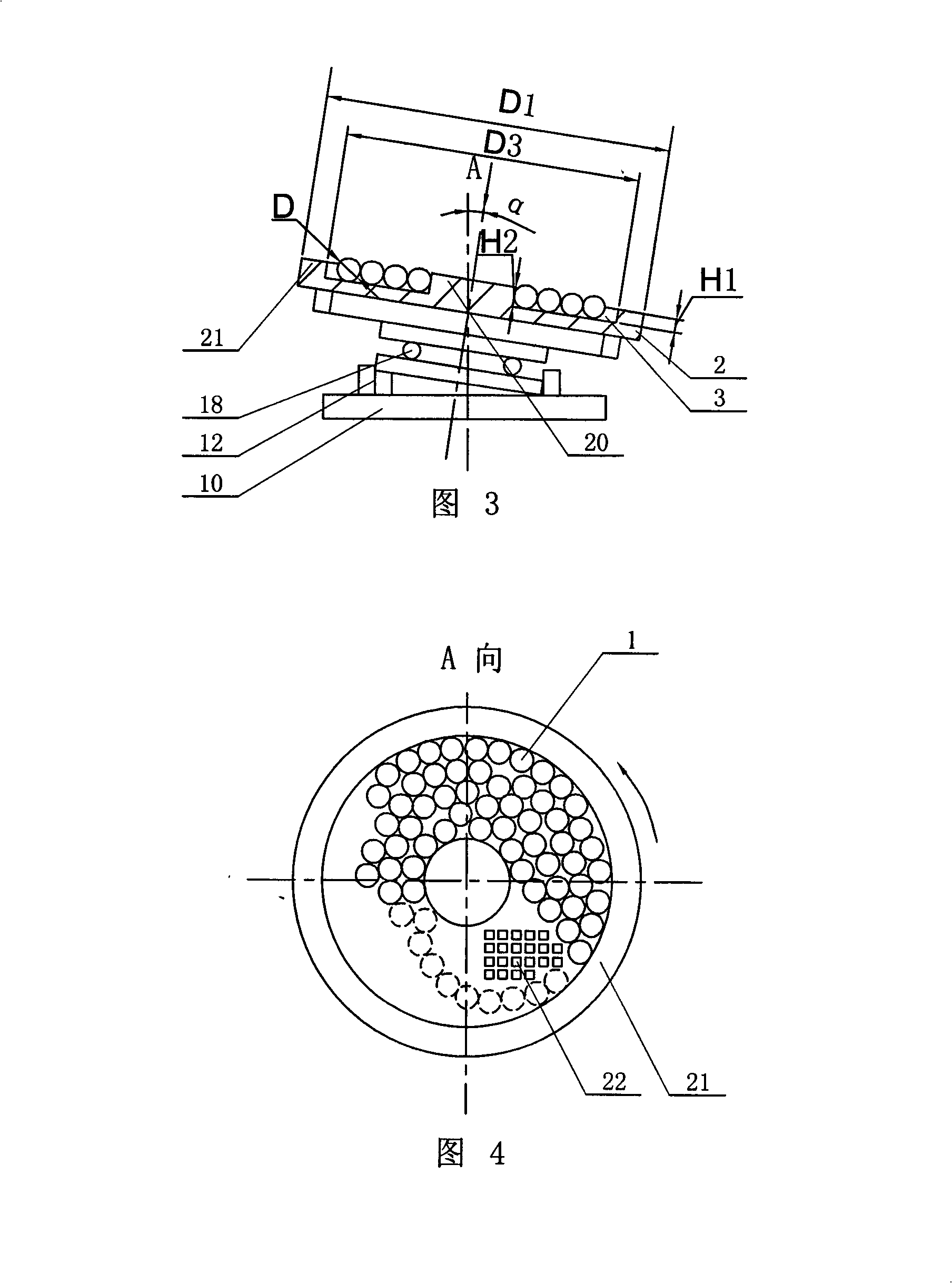

Spherical parts batch plasma based ion injection method and apparatus thereof

InactiveCN101353777AExtended service lifeThe treatment effect is consistentVacuum evaporation coatingSputtering coatingCircular discTime delays

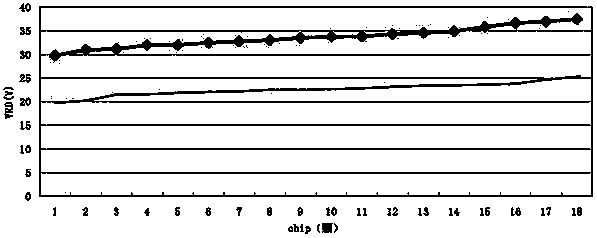

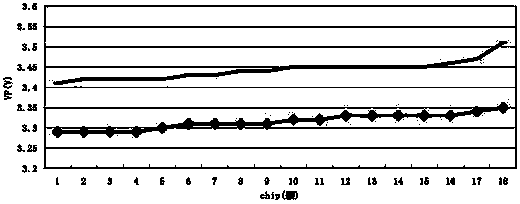

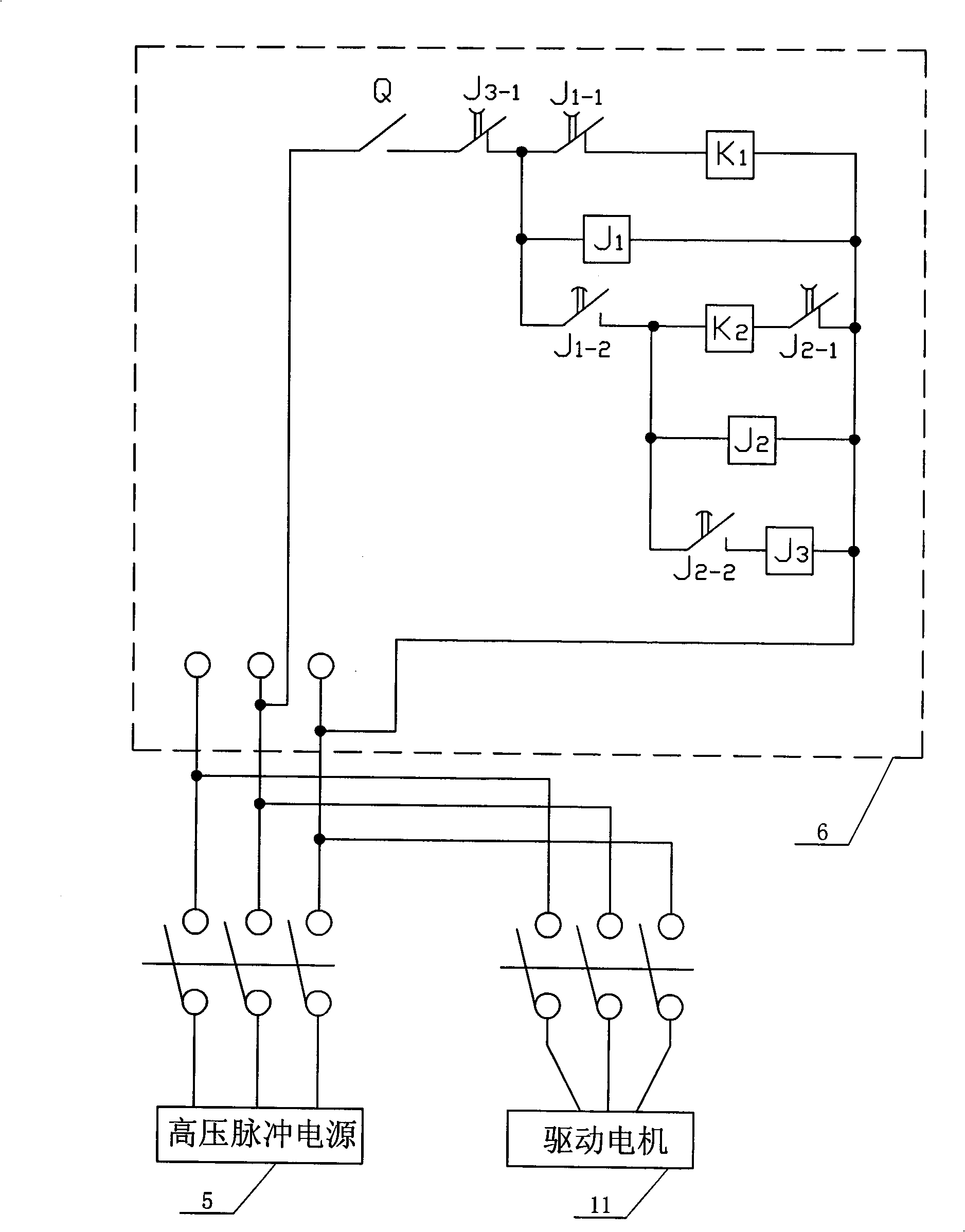

The invention discloses a spherical-component batch plasma-based ion implantation method and a device thereof, relating to a spherical-component plasma-based ion implantation method and a device thereof and aiming at the problem that the plasma-based ion implantation of spherical components which is carried out to spherical components by adopting a device and a method of rotary-workpiece plasma-based ion implantation is uneven and can not realize the uniform treatment effect of the spherical components of the same batch. The method of the invention comprises the following steps: the spherical components are put in a circular groove of an oblique round plate, the rotation of which is controlled by a driving motor and a gear; the rotation of the driving motor is stopped first, a high-voltage pulse power source is turned on, and after time delay by the high-voltage pulse power source, plasma-based ion implantation is carried out to the spherical components; and the starting and stopping of the driving motor and the high-voltage pulse power source are kept synchronously switched. The device of the invention comprises: a synchronous switching controller provides the driving motor and the high-voltage pulse power source with power by No. 1 and No.2 power sources; an output shaft of the driving motor is fixedly provided with a driving gear which is meshed with a driven gear. The device and the method can uniformly implant the surface irons of the spherical components.

Owner:HARBIN INST OF TECH

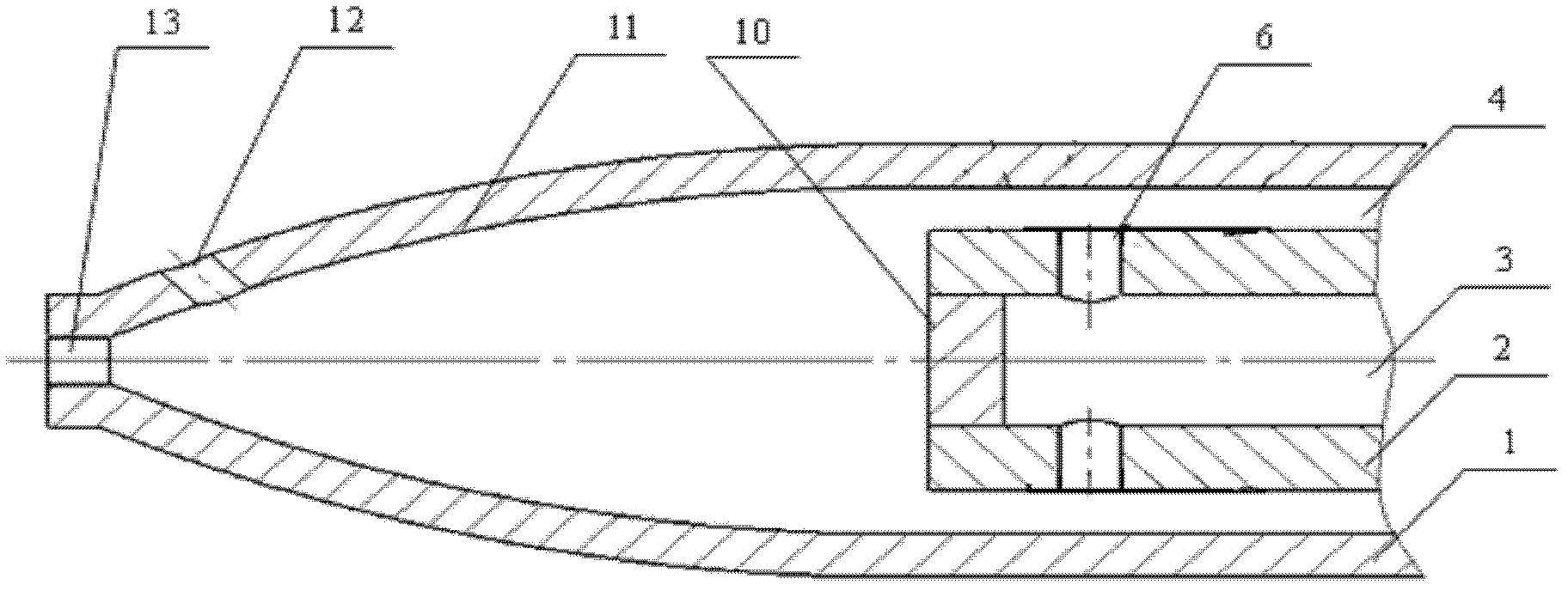

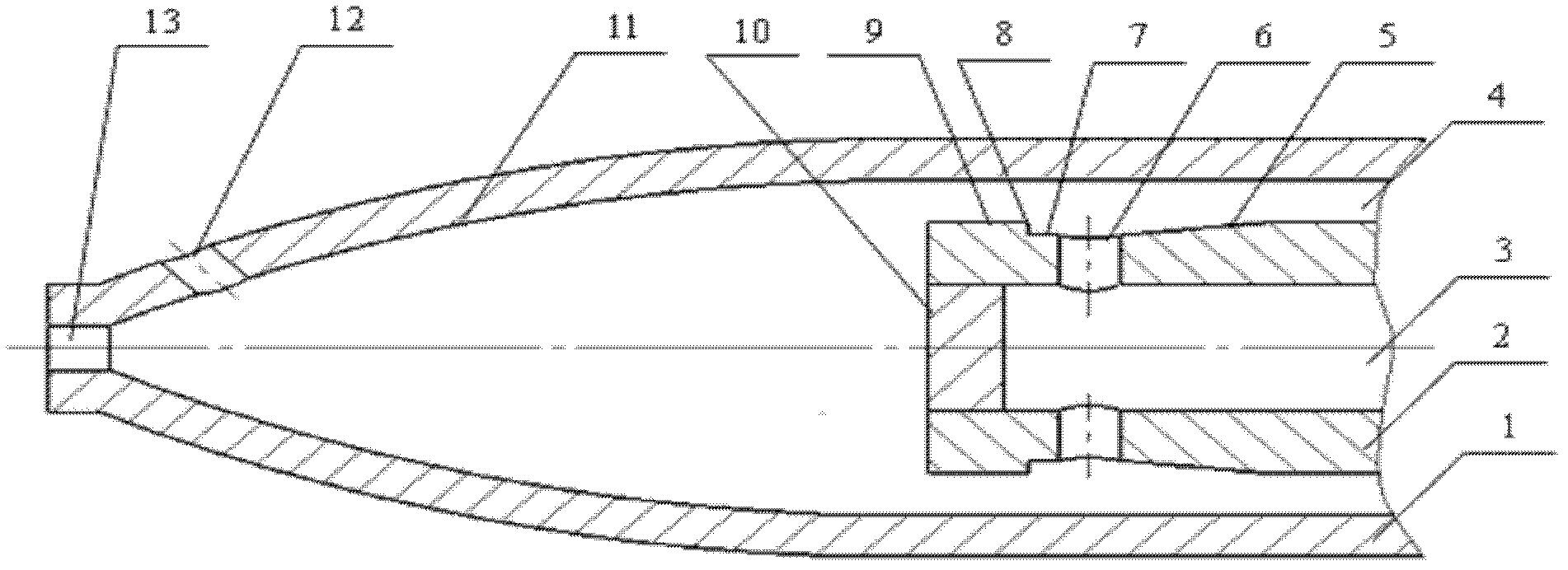

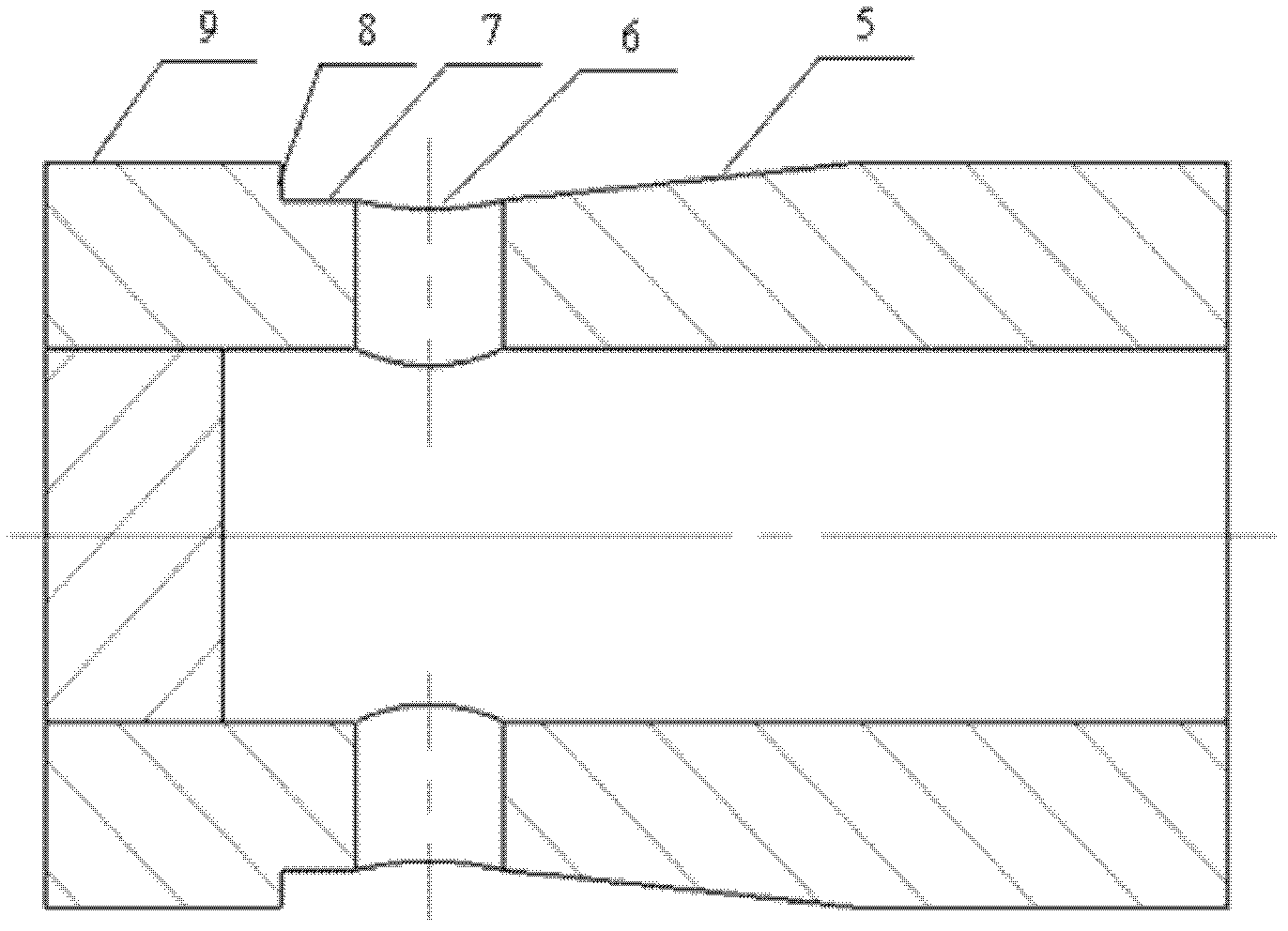

A spray cooling nozzle for grinding

InactiveCN102274807AIncrease contact timeIncrease contact areaLiquid spraying apparatusGrinding/polishing safety devicesSmall dropletEngineering

The invention discloses a spray cooling nozzle for grinding processing. The end face of the grinding liquid pipe (2) is closed, and the end face adjacent to the grinding liquid pipe (2) is evenly provided with a plurality of radial liquid outlet holes along the circumferential direction. (6). The externally injected grinding fluid and the high-pressure gas in the gas pipe are mixed on the outside of the grinding fluid pipe, the liquid droplets ejected from the radial outlet holes are on the windward side, and the flow rate of the grinding fluid in a single radial outlet hole is far The flow rate of the grinding liquid pipe is smaller than that of the grinding liquid pipe, which makes the grinding liquid droplets break up into micron-sized and evenly distributed mist droplets. Spray into the grinding area along the nozzle and maintain a high spray jet velocity to lubricate and cool the grinding area. The invention has the advantages of long gas and liquid contact time, good atomization effect, small diameter and uniform distribution of droplets, high jet velocity, simple manufacturing process and the like, and is suitable for a spray cooling system for grinding processing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

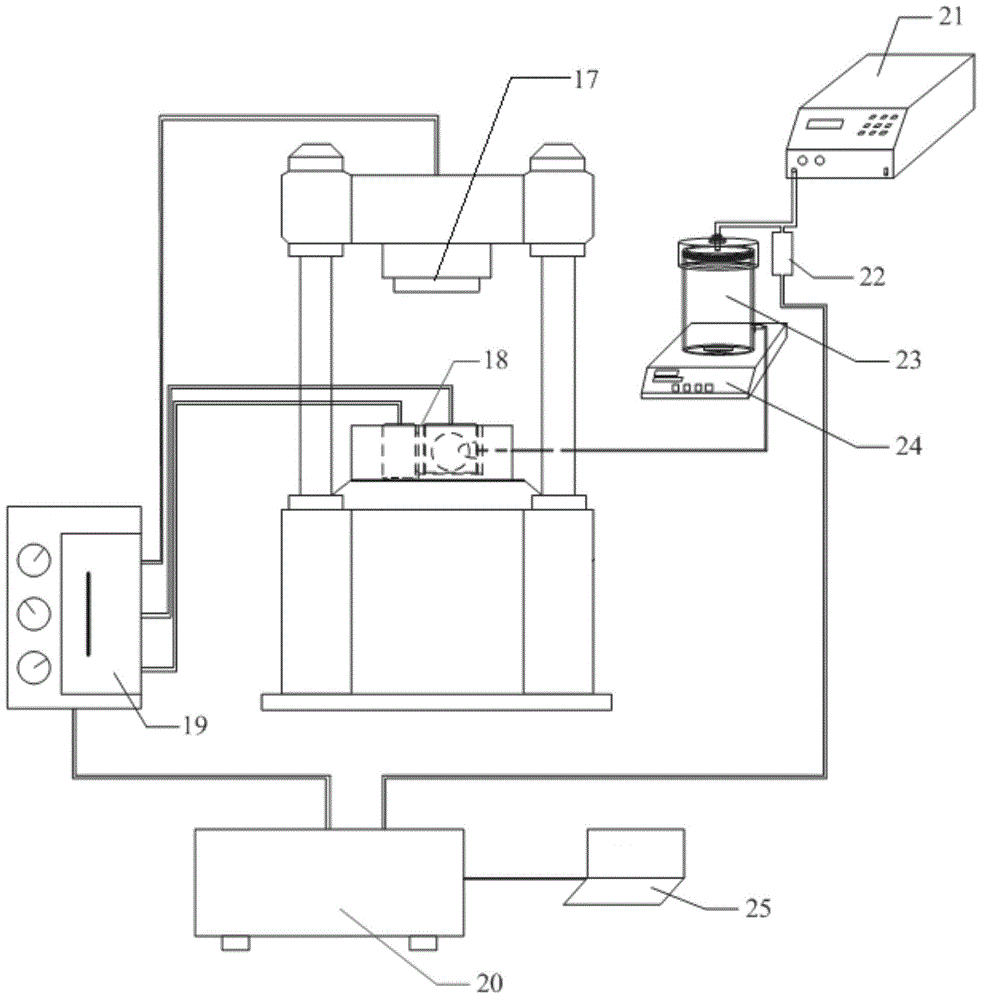

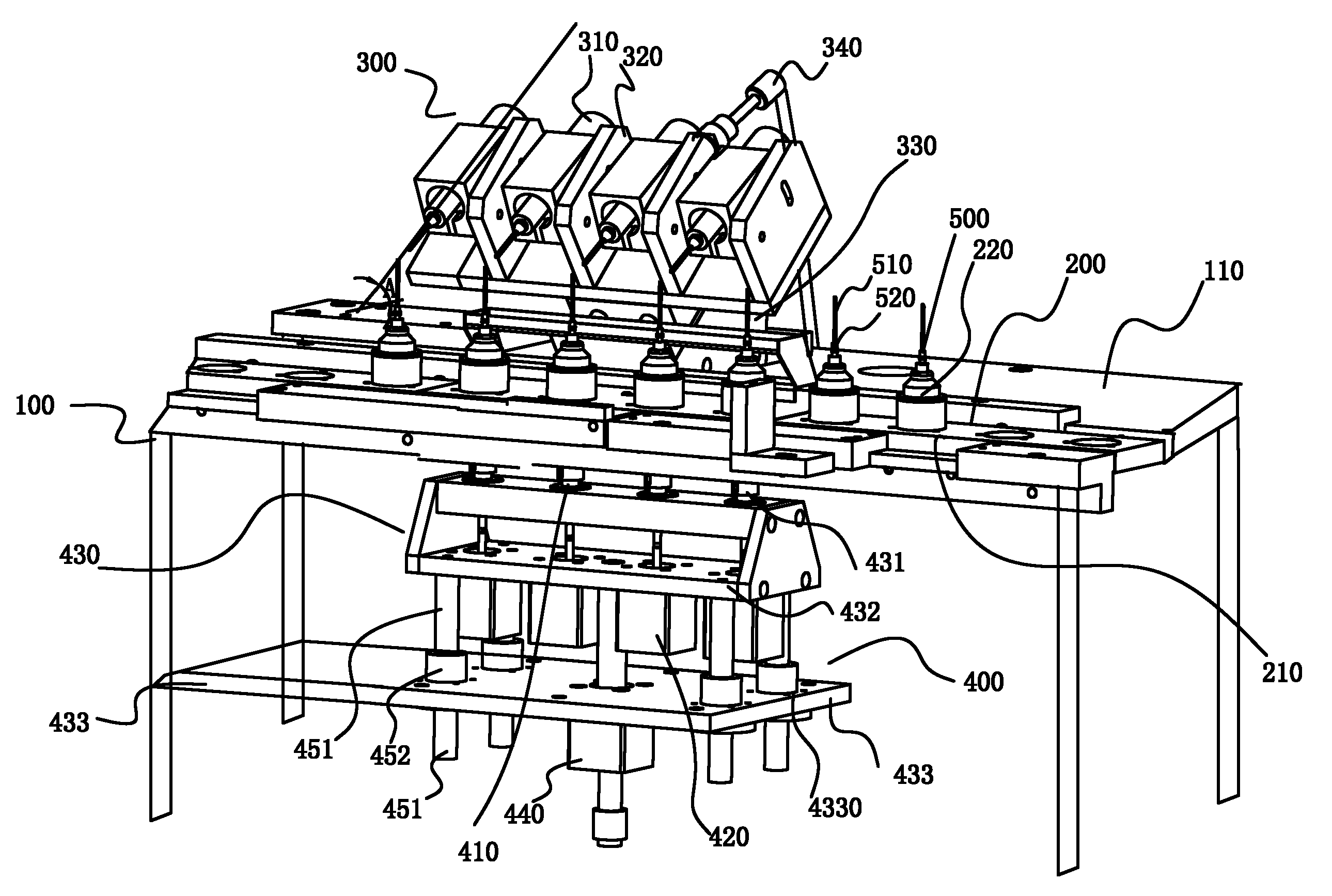

Diverting agent effect evaluation true triaxial test machine

InactiveCN104833583AInject evenlyMaterial strength using tensile/compressive forcesTriaxial shear testControl system

The invention relates to a diverting agent effect evaluation true triaxial test machine which comprises a pressure loading system, a diverting agent injection system d a data collection control system. The pressure loading system comprises a pressure chamber, an oil pressure stabilizing source and a vertical loading device, a pressure chamber outer wall is arranged outside the pressure chamber, a rock sample and a flat jack are arranged inside the pressure chamber, the rock sample is provided with an artificial crack, the flat jack is arranged on a side face adjacent to the rock sample, the vertical loading device directly faces a top face of the rock sample, the vertical loading device and the flat jack are connected with the oil pressure stabilizing source, the diverting agent injection system comprises a constant-flux pump, a liquid injection container and a liquid incoming pipe, the constant-flux pump is connected with the liquid injection container which is connected with the artificial crack through the liquid incoming pipe, the data collection control system comprises a servo controller, a computer and a sensor, the sensor is arranged between the constant-flux pump and the liquid injection container and connected with the servo controller, and the oil pressure stabilizing source and the computer are connected with the servo controller respectively. By the diverting agent effect evaluation true triaxial test machine, optimization of diverting agent construction parameters in the process of fracturing can be realized effectively.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC +1

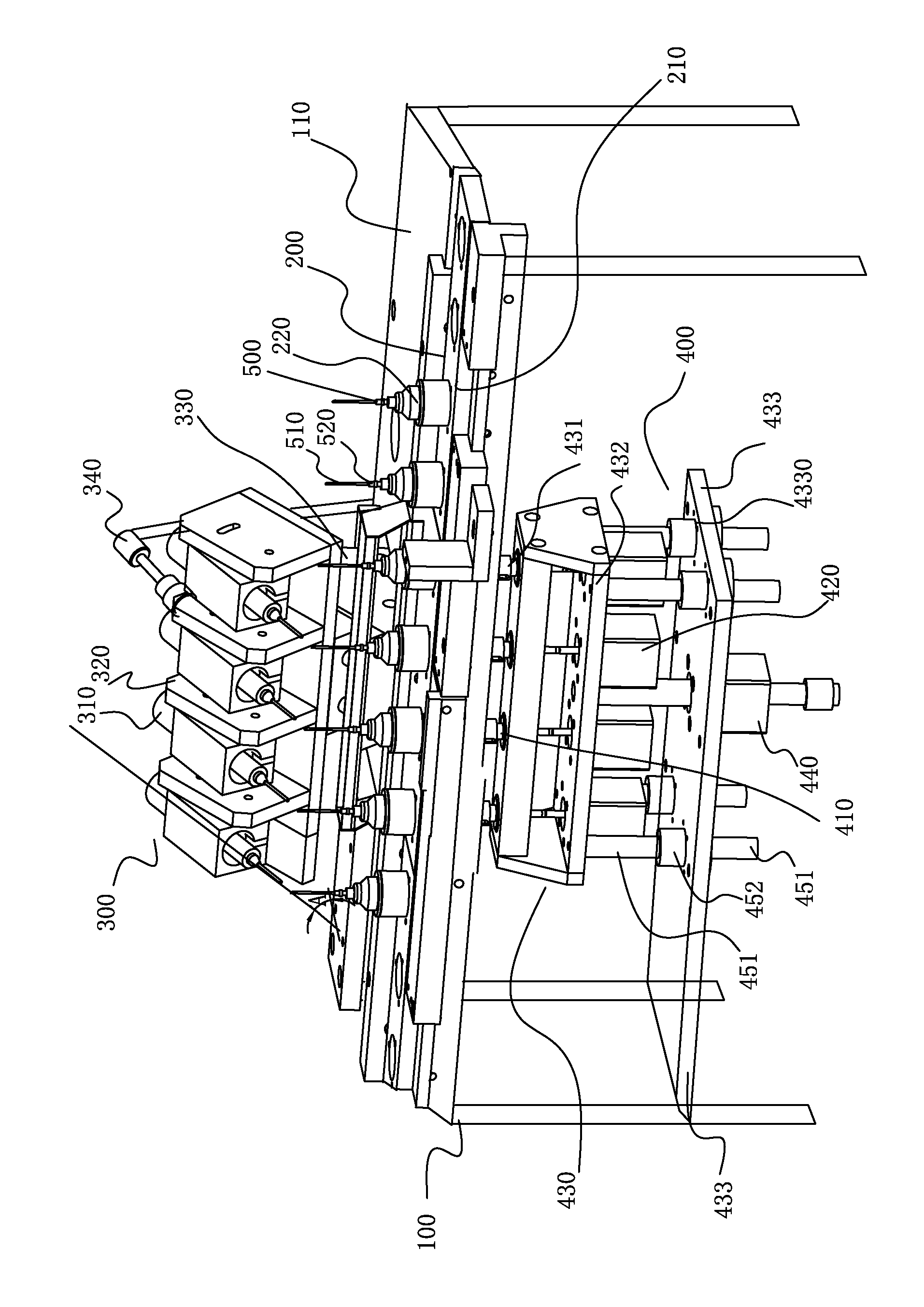

Dispensing device

The invention relates to a dispensing device provided with a rack body, an automatic feeding device, a gluing device, a rotating device and a controlling device, wherein the rack body is provided with a base plate; the automatic feeding device is arranged on the upper part of the base plate; the gluing device is fixed on the base plate; the rotating device is arranged on the lower part of the base plate; the automatic feeding device is provided with a material plate, a material support and a power mechanism; the gluing device is provided with a gluing tube, a gluing rack, a rack support and agluing cylinder; the rack support and the gluing cylinder are fixed to the base plate; the gluing rack is moveably arranged on the rack support; the gluing tube is arranged on the gluing rack; the gluing rack is moveably connected with the gluing cylinder; the rotating device is provided with a driving part and a motor; the driving part is arranged below the material support; the motor is provided with a motor shaft; and the driving part is connected with the motor. Through the dispensing device, a gluing needle is bound to a needle file for gluing so as to have high production efficiently and high product percent of pass.

Owner:贝恩医疗设备(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com