Exhaust air system, semi-conductor manufacturing installation for manufacturing thin film by the same and method thereof

A technology for manufacturing devices and semiconductors, which is applied in the field of chemical vapor deposition equipment, and can solve the problems of cleaning efficiency and reduced productivity of semiconductor manufacturing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the drawings, like elements are numbered with like numbers.

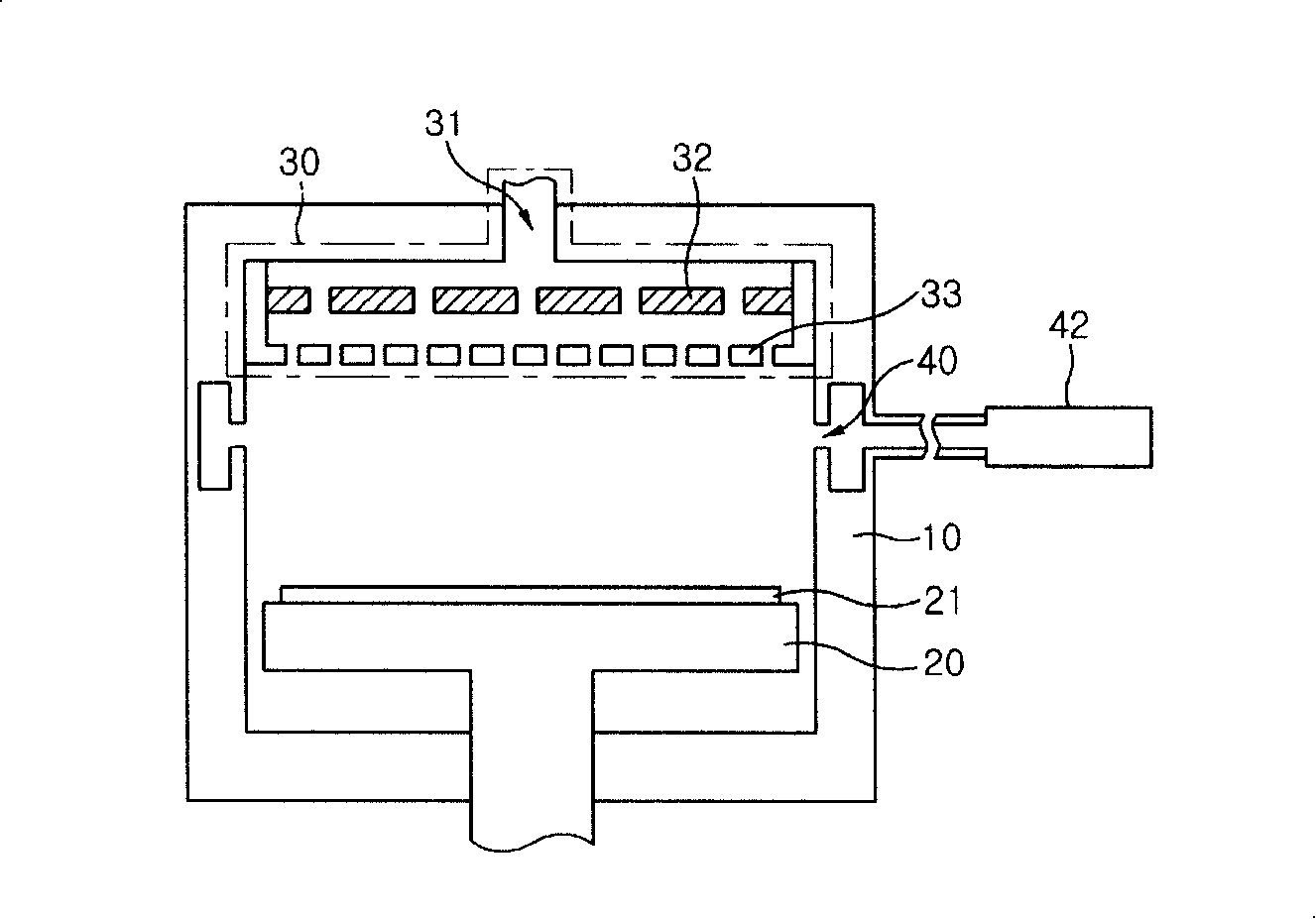

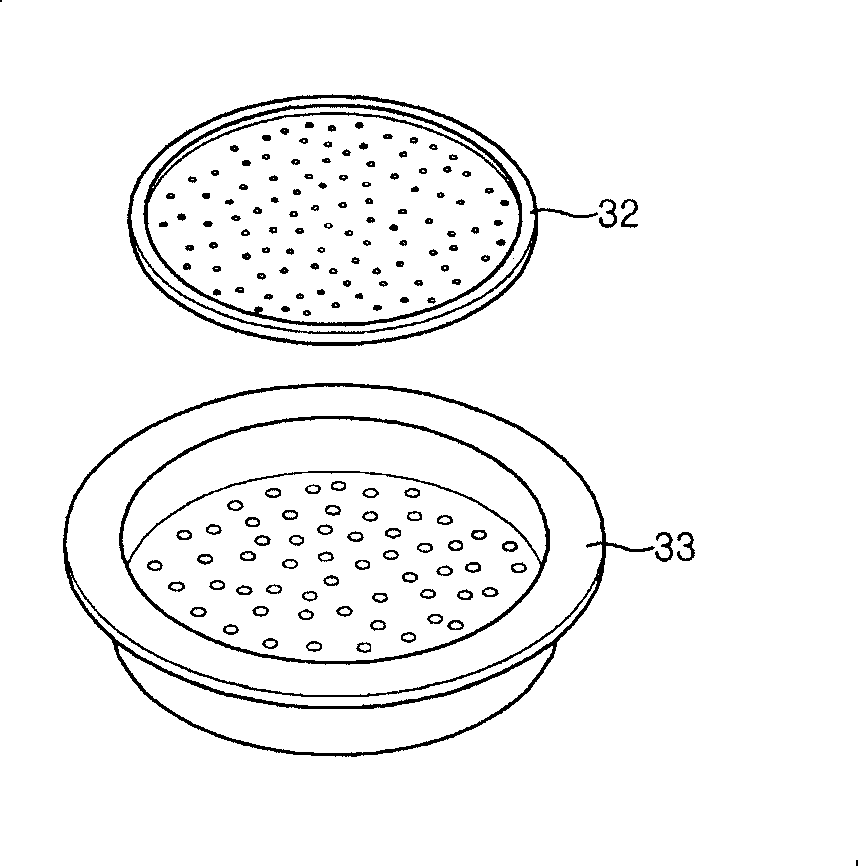

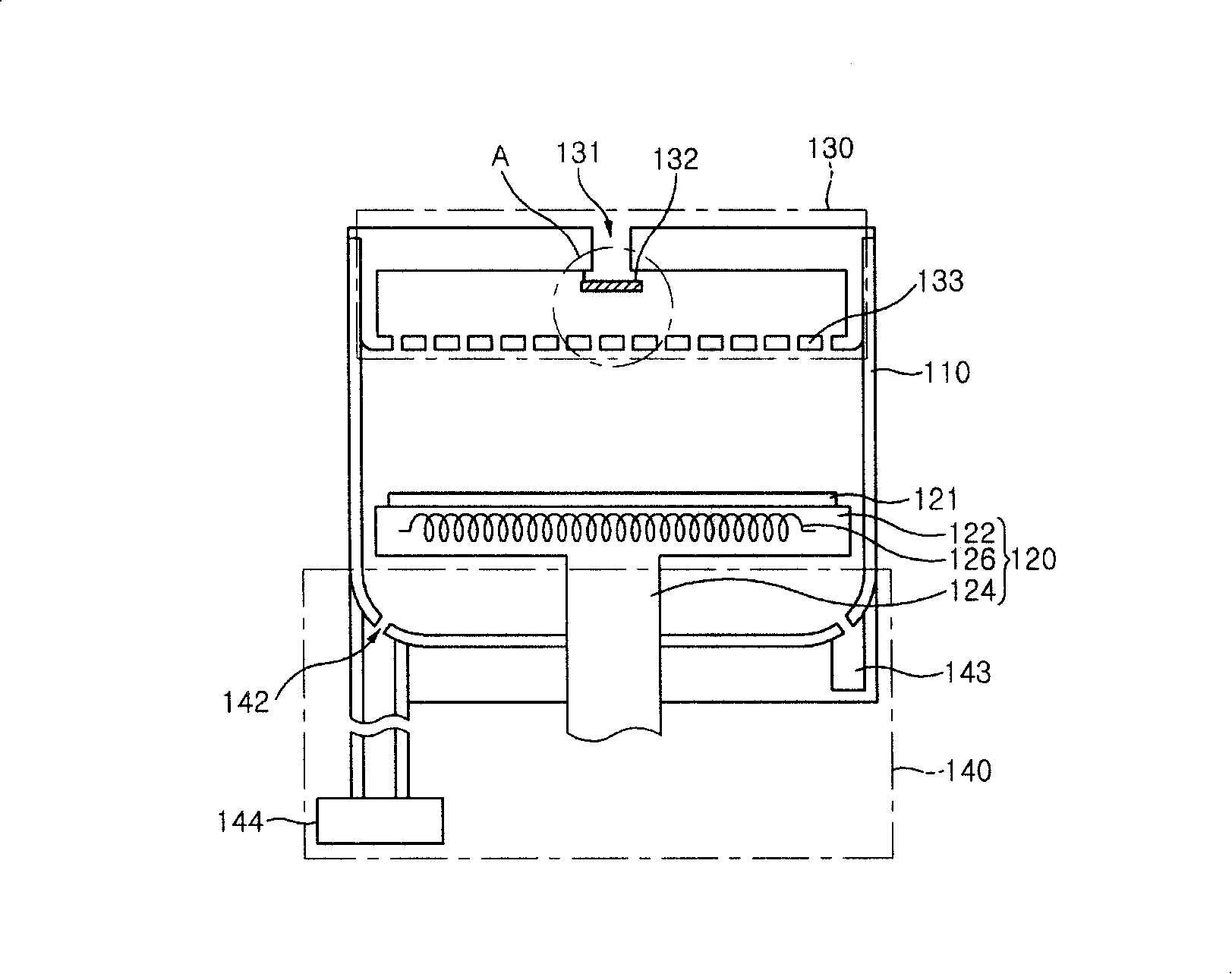

[0053] image 3 According to an embodiment of the present invention, a conceptual cross-sectional view of a semiconductor manufacturing device is drawn, Figure 4 is displayed image 3 A magnified view of part A of the Figures 5A to 5E 6A to 6C are conceptual cross-sectional views illustrating baffles according to an embodiment of the present invention, Figure 7 is a conceptual schematic diagram illustrating a pump interface according to an embodiment of the present invention.

[0054] Please refer to Figure 3 to Figure 7 , the semiconductor manufacturing device of the present invention includes a chamber 110, a shower head unit 130, a heating block 120 and a pump interface 140, wherein the chamber 110 has a predefined reaction space and a predefined bottom curved surface, and the shower head unit 130 includes a gas supply hole baffle 132 combined with 131 to inject gas into chamber 110, heating bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com