Patents

Literature

358 results about "Small droplet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

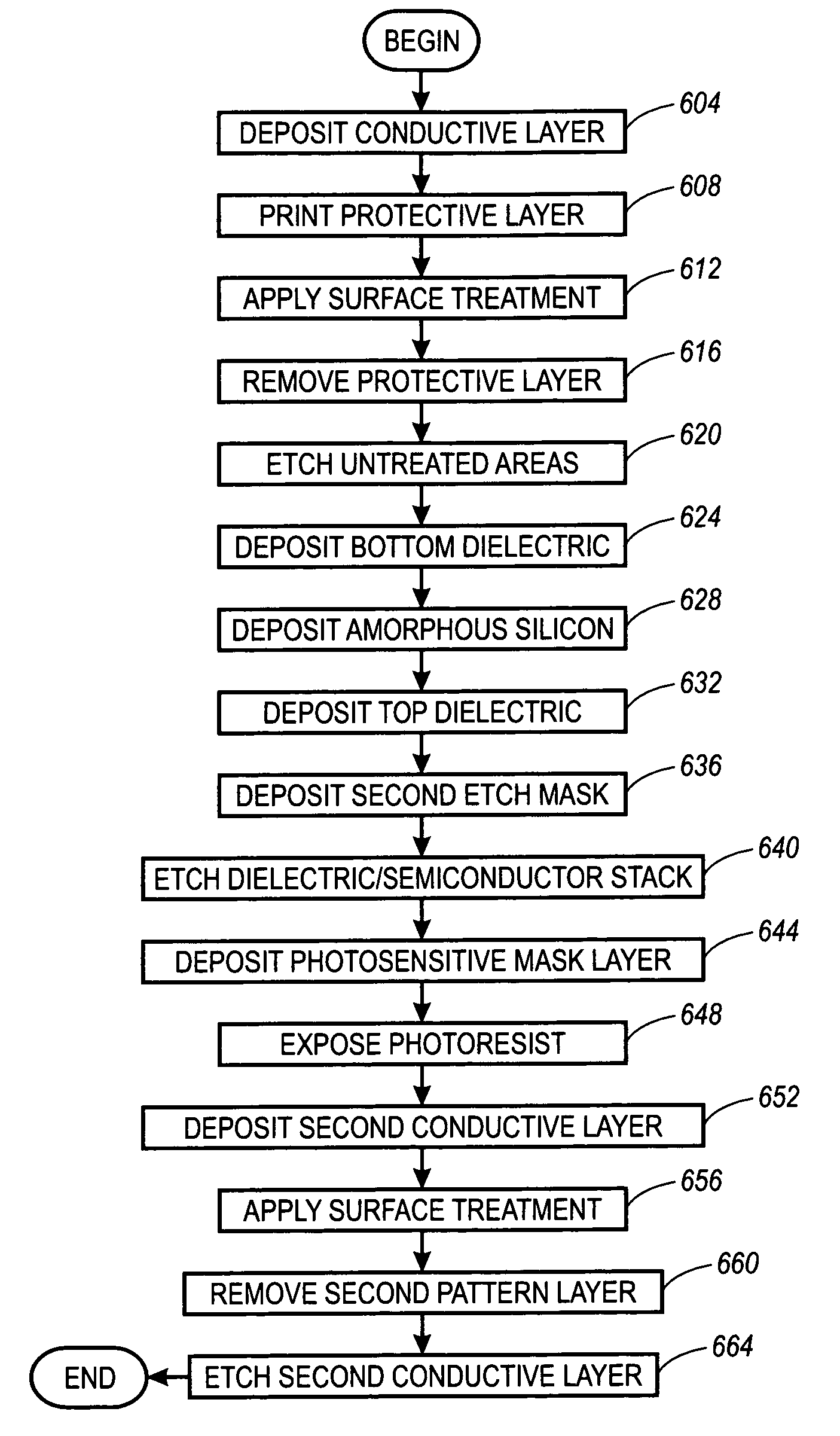

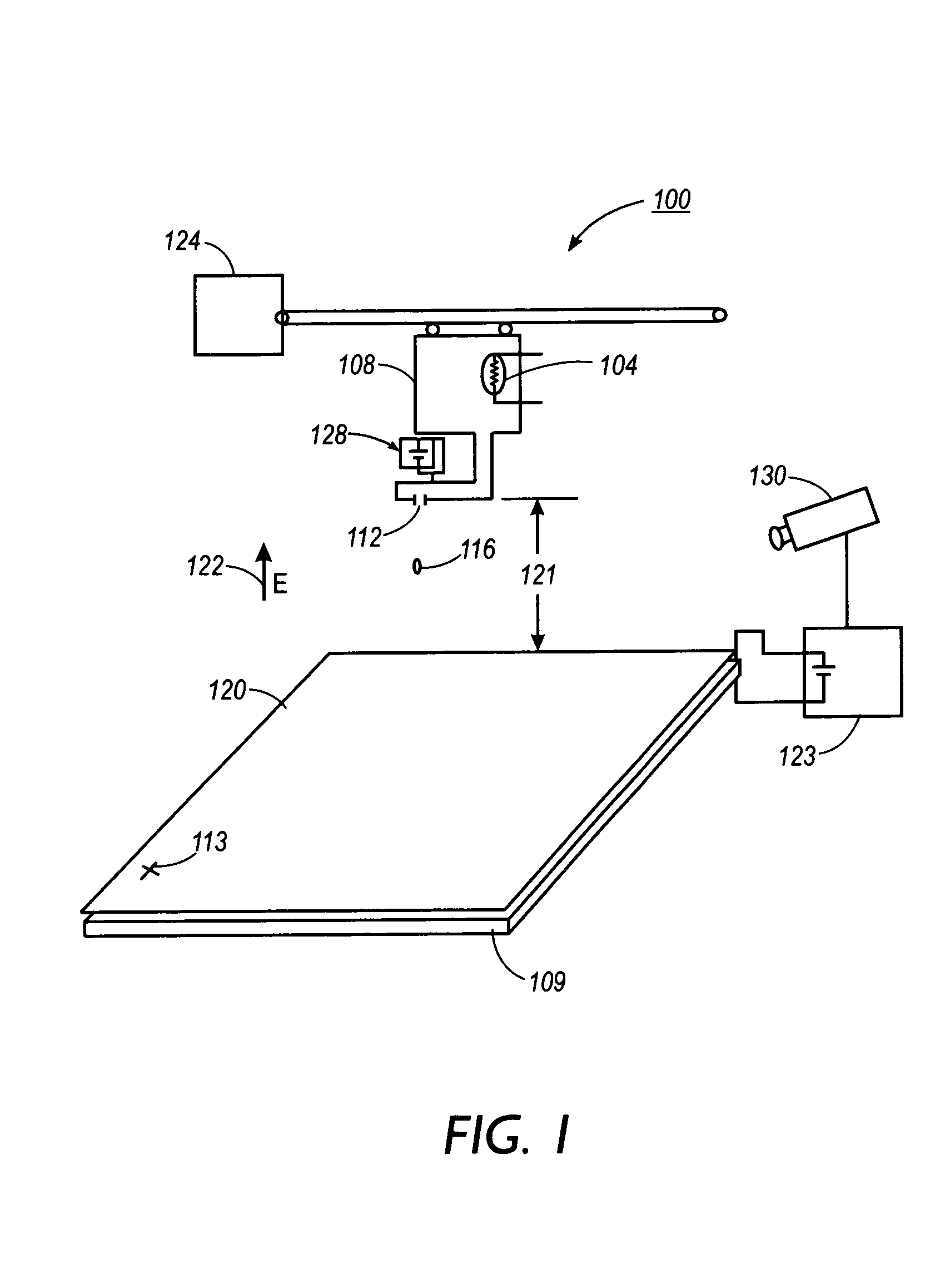

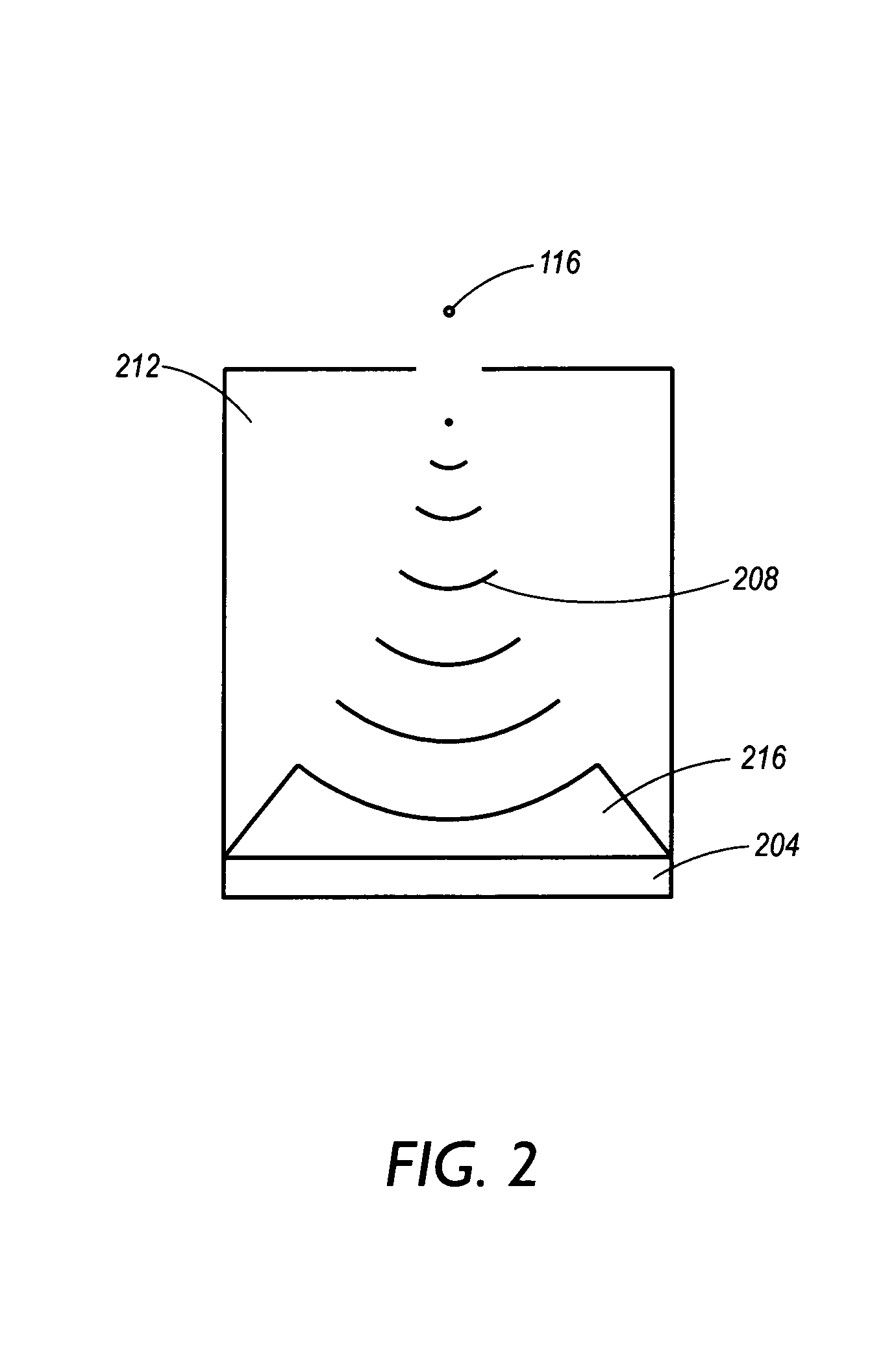

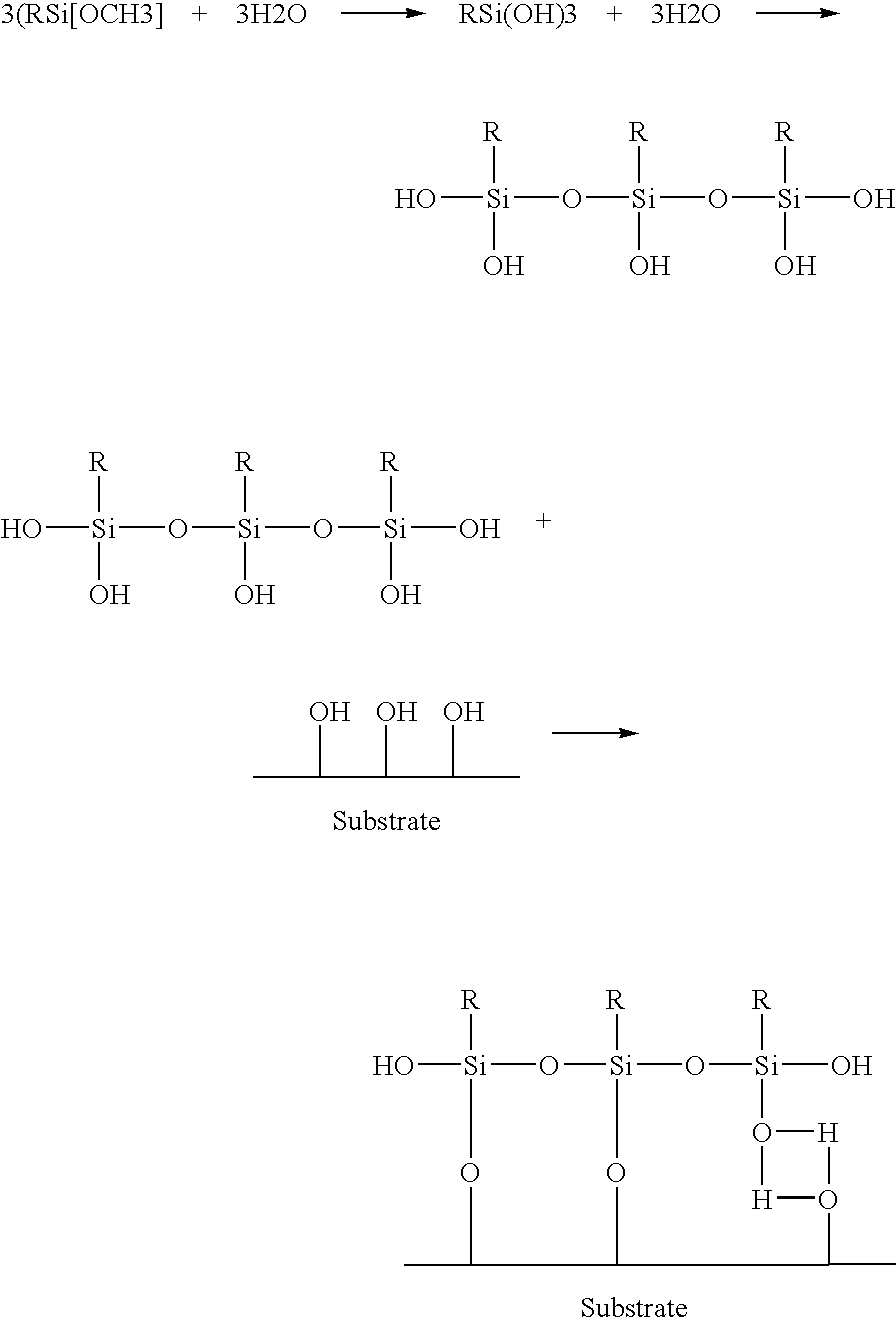

Method for fabricating fine features by jet-printing and surface treatment

A method and system for masking a surface to be etched is described. The method includes the operation of heating a phase-change masking material and using a droplet source to eject droplets of a masking material for deposit on a thin-film or other substrate surface to be etched. The temperature of the thin-film or substrate surface is controlled such that the droplets rapidly freeze after upon contact with the thin-film or substrate surface. The thin-film or substrate is then treated to alter the surface characteristics, typically by depositing a self assembled monolayer on the surface. After deposition, the masking material is removed. A material of interest is then deposited over the substrate such that the material adheres only to regions not originally covered by the mask such that the mask acts as a negative resist. Using such techniques, feature sizes of devices smaller than the smallest droplet printed may be fabricated.

Owner:XEROX CORP

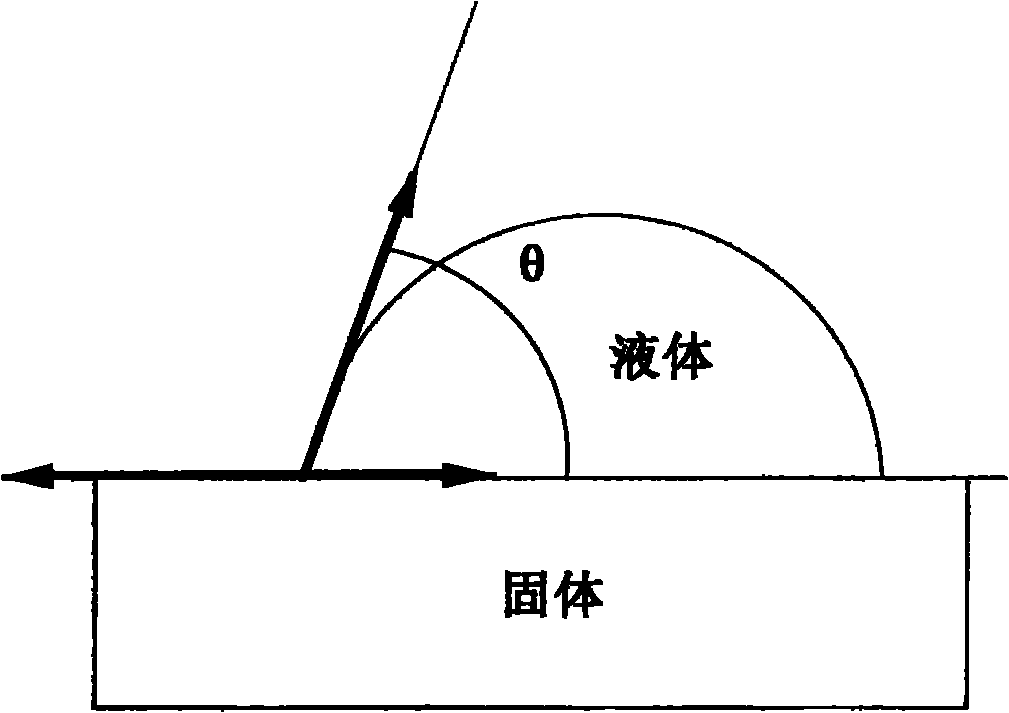

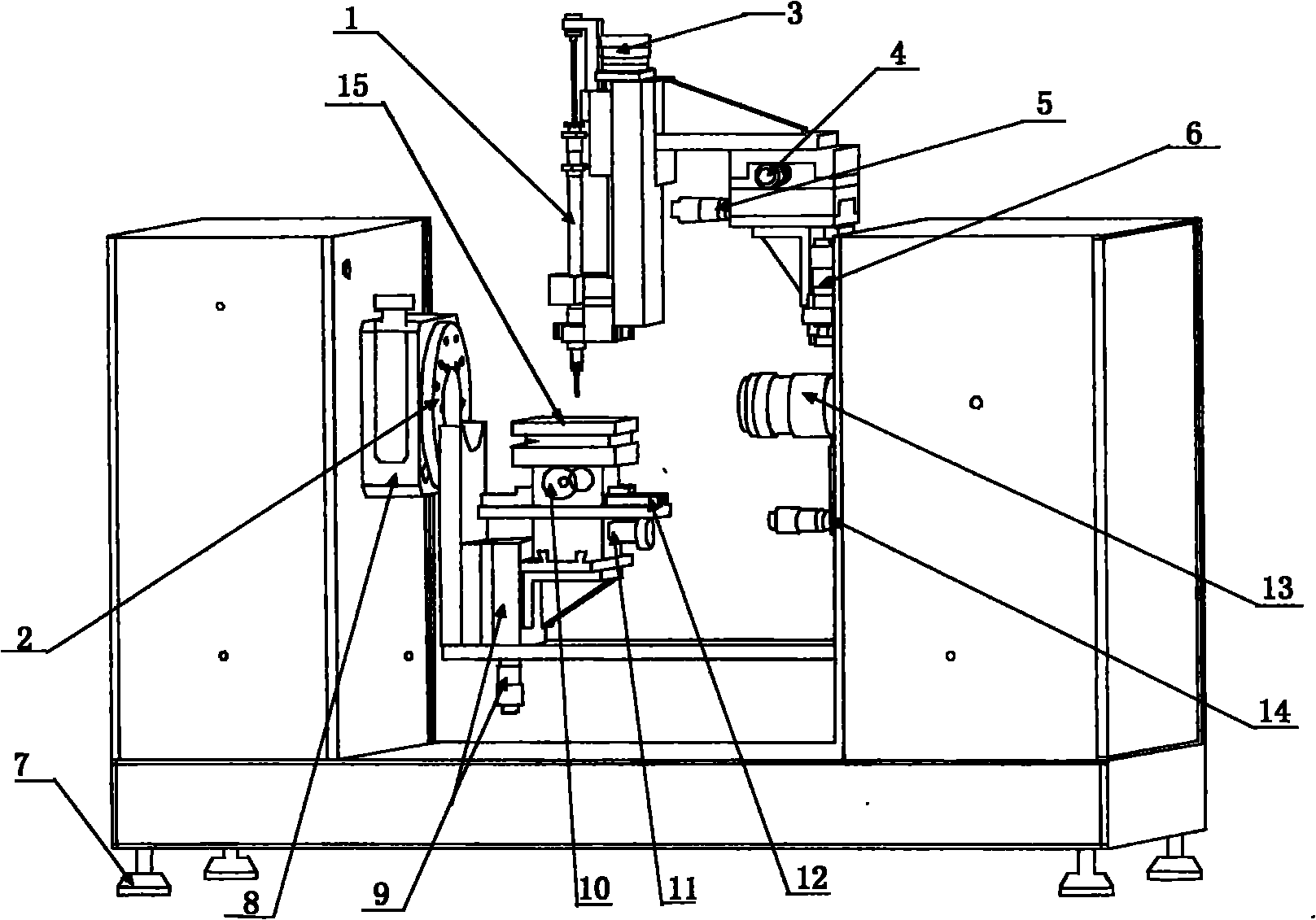

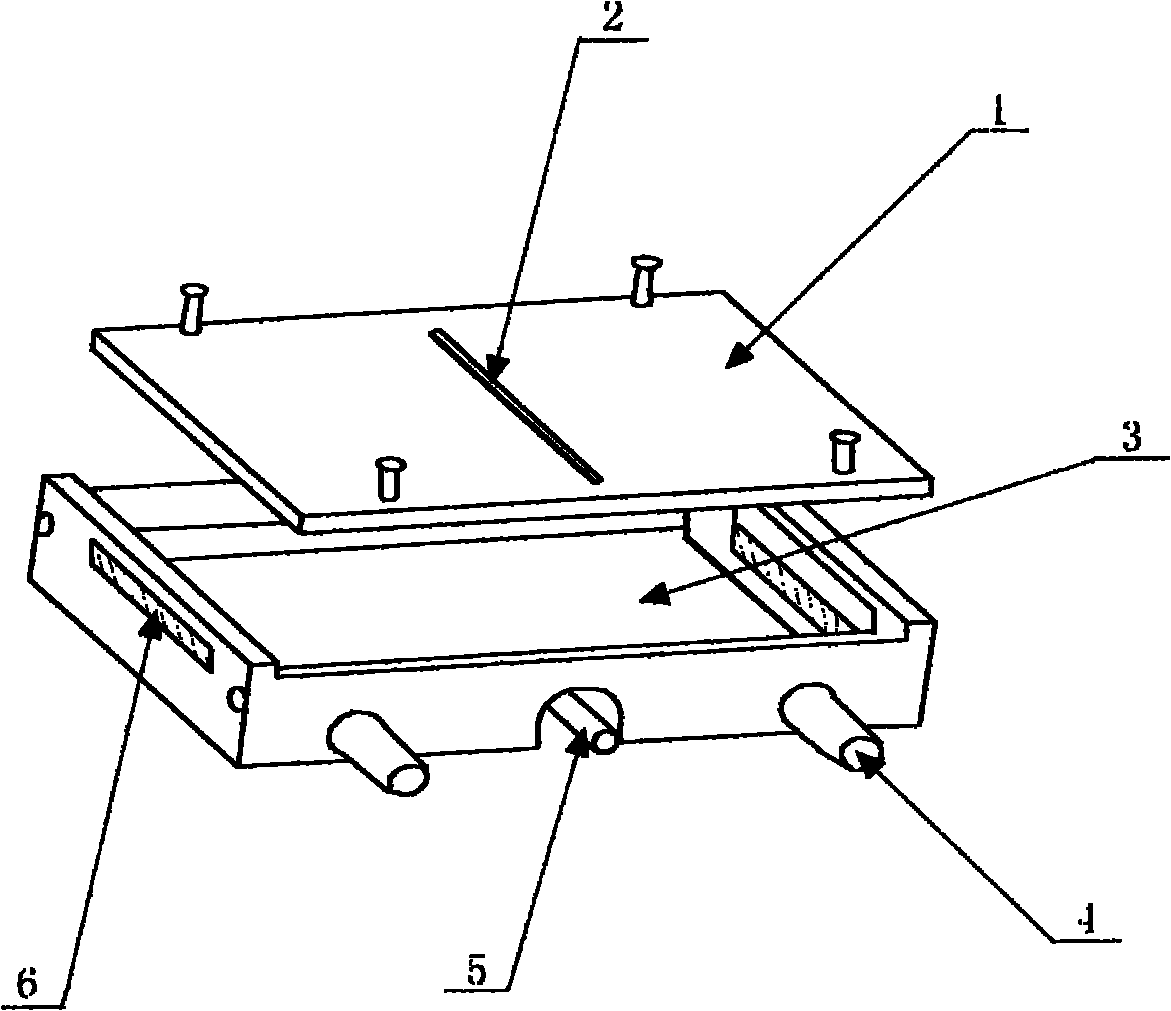

Apparatus and method for testing solid-liquid dynamic and static contact angles by actual liquid droplet method

InactiveCN101865807AHigh precisionEasy to operateSurface tension analysisPeristaltic pumpSmall droplet

The invention discloses an apparatus and a method for testing solid-liquid dynamic and static contact angles by an actual liquid droplet method. The method comprises the following steps of: during the testing, placing a solid phase sample on a sample table; controlling X, Y and Z of the sample table to move to a focusing position of a lens; sucking the liquid phase sample into a micro sample injector, injection pump or peristaltic pump; controlling the X, Y and Z of the sample injector to move to the focusing position; dripping a small droplet of the liquid and adsorbing the droplet to a needle head; moving the needle head to the surface of the solid phase sample until the liquid phase sample is adsorbed to the surface of the solid; making a software system control an optical imaging system (CCD) to capture a real-time picture and analyzing the picture by using the actual liquid droplet method; and displaying calculated solid-liquid contact angle value, solid surface free energy value and adhesion work value and managing the values by a database. The apparatus and the method can completely improve the accuracy of the analysis of the solid-liquid interfacial tension, are simple to operate, can be widely applied and have high popularization value.

Owner:上海梭伦信息科技有限公司

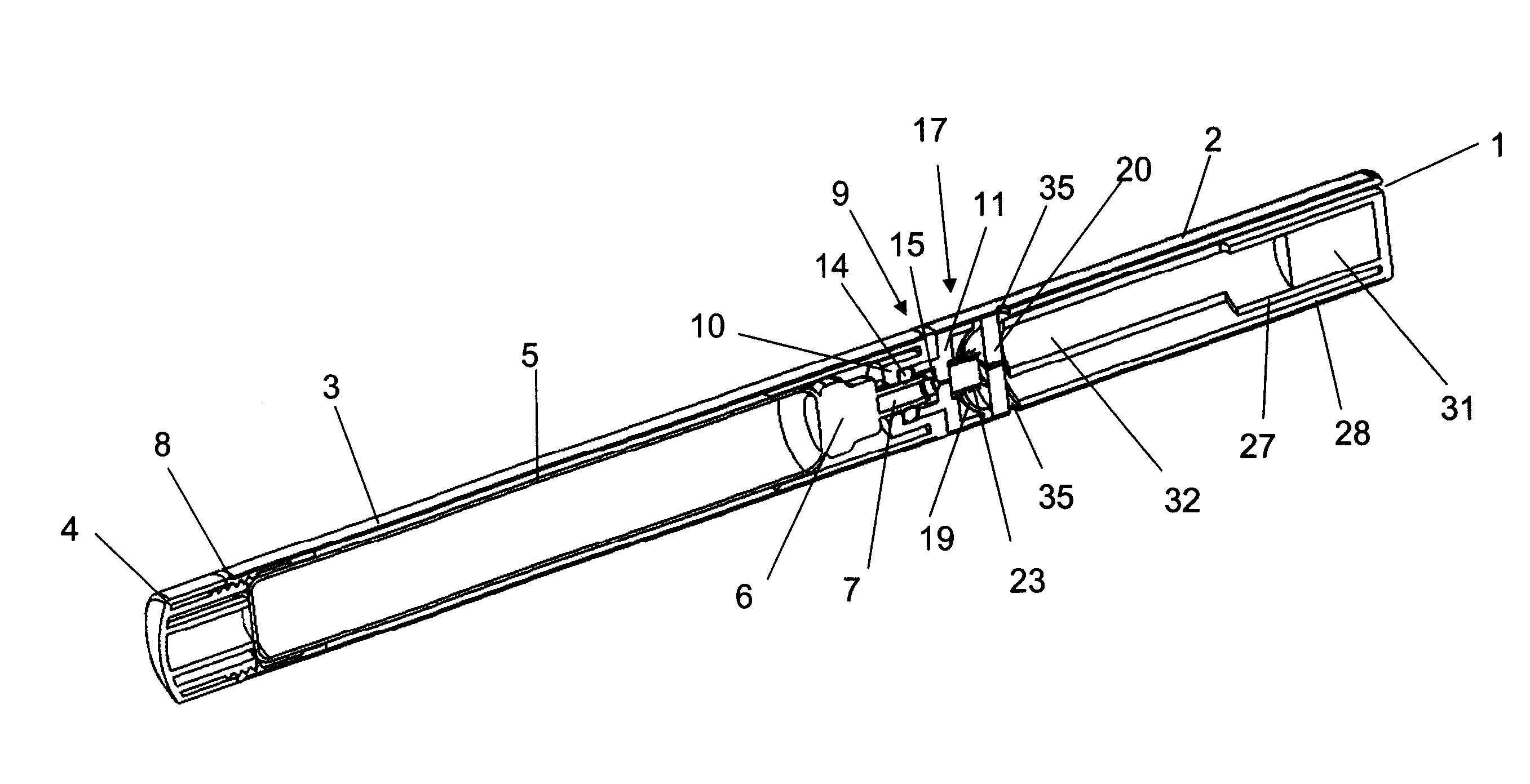

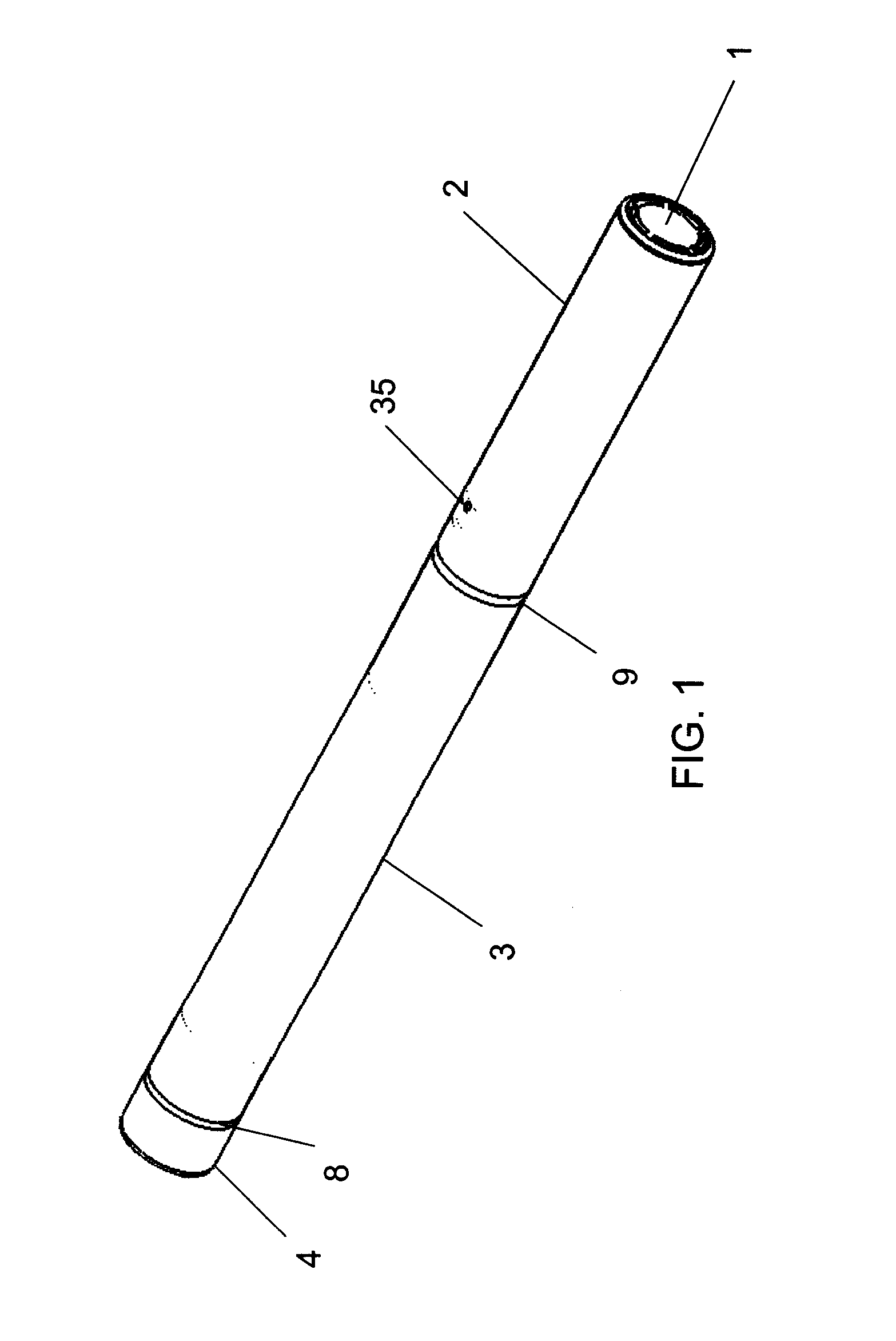

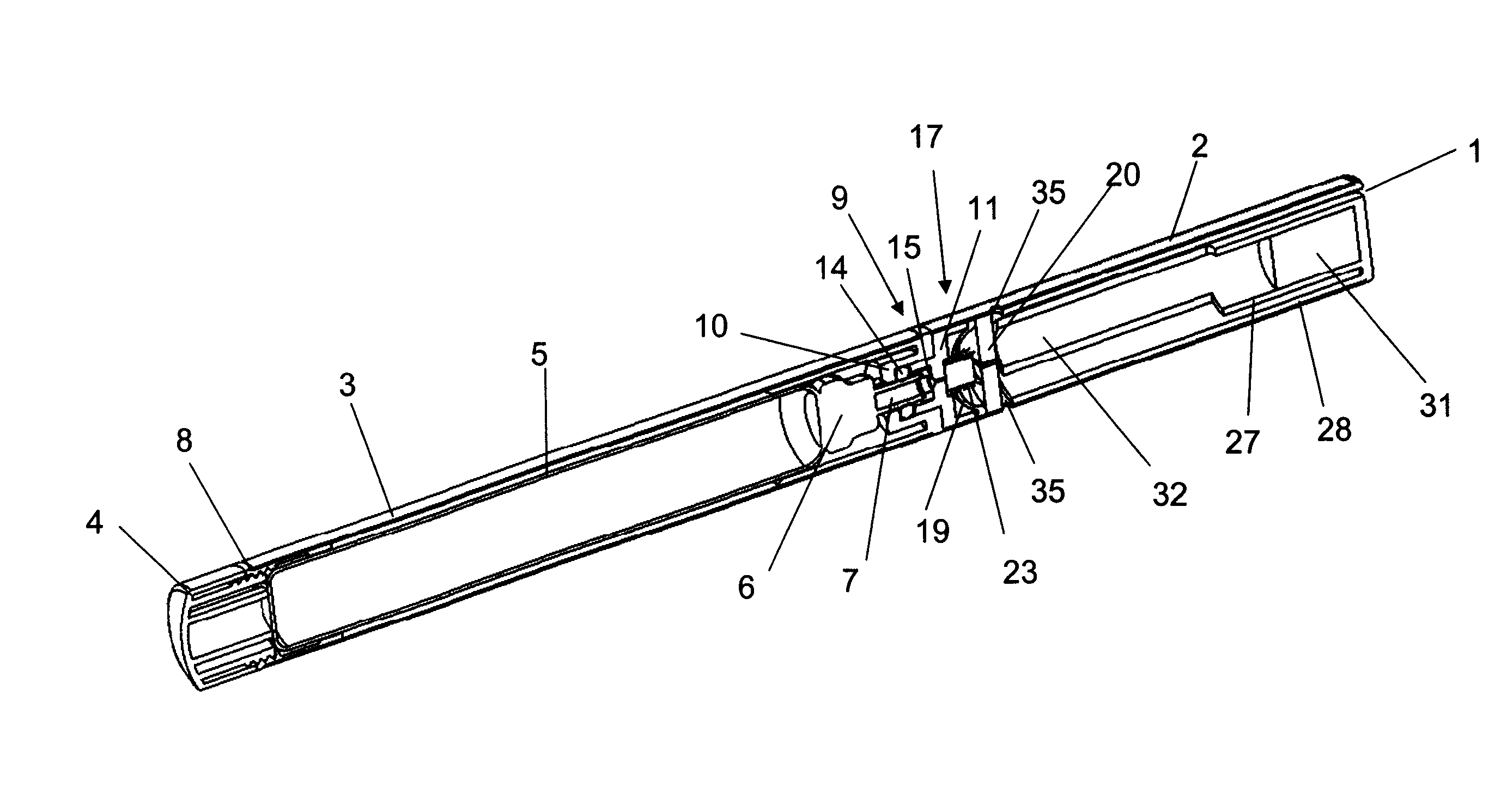

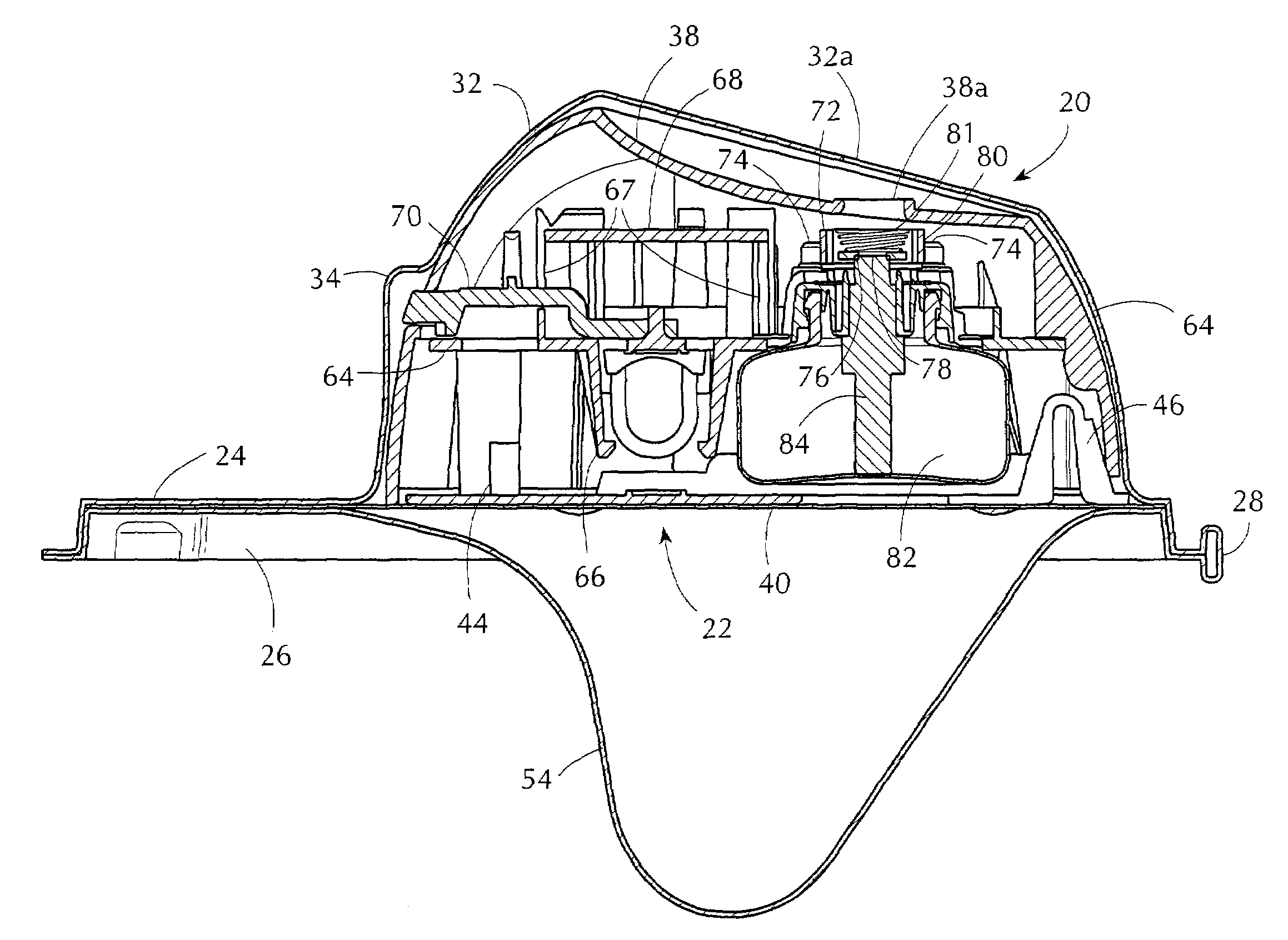

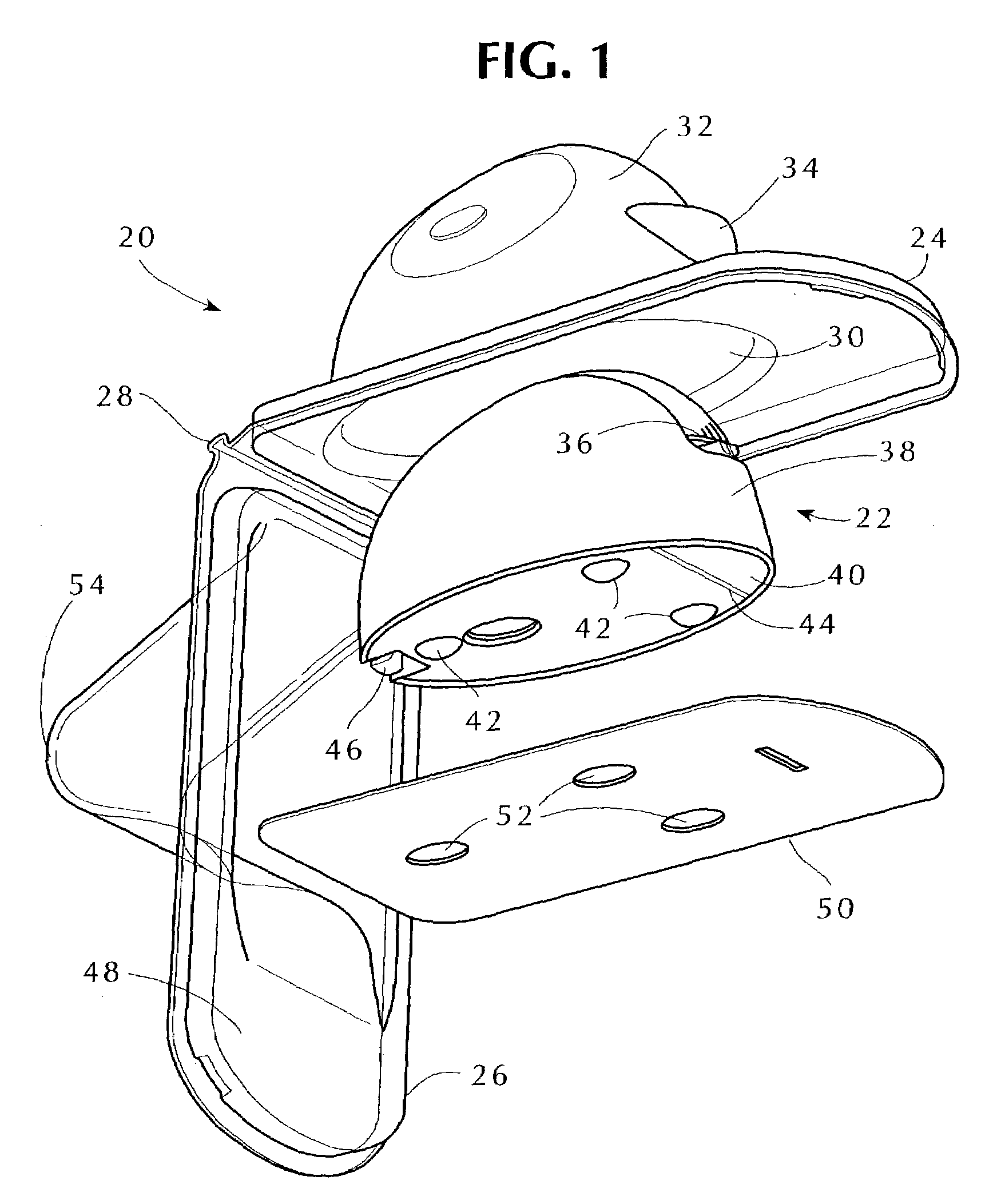

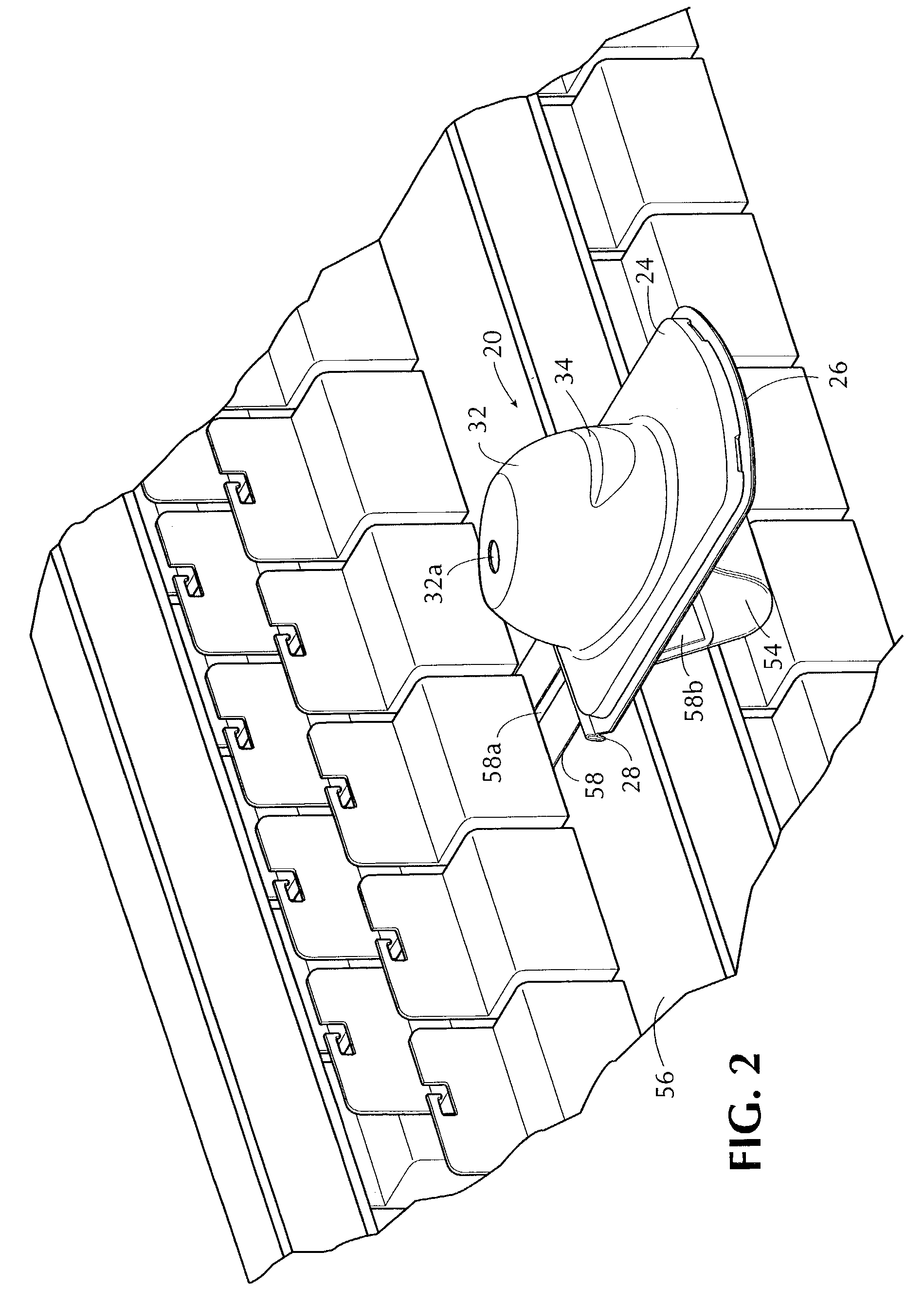

Aerosol Dispensing Device

An aerosol dispensing device comprises a tubular body (2, 3) that provides a plenum (32), a mouthpiece (1) having an outlet (34), a valve (17) for dispensing fluid from a canister (5) as an aerosol with relatively large and small droplet sizes into the plenum for supply to a user through the mouthpiece, and a baffle arrangement (26, 27) that provides first (33) and second (36) passageways each coupled at one end to the plenum and so configured to receive relatively small and large size droplets in the aerosol respectively, the other end of the first passageway (33) extending to the outlet (34) in the mouthpiece to supply the small size droplets to the user, and the other end of the second passageway (36) being closed to inhibit passage of the large size droplets to the mouthpiece outlet, and containing a absorbent pad (31) to prevent leakage of liquid from the canister. The pad (31) may be pre-loaded with a flavourant.

Owner:NICOVENTURES HLDG

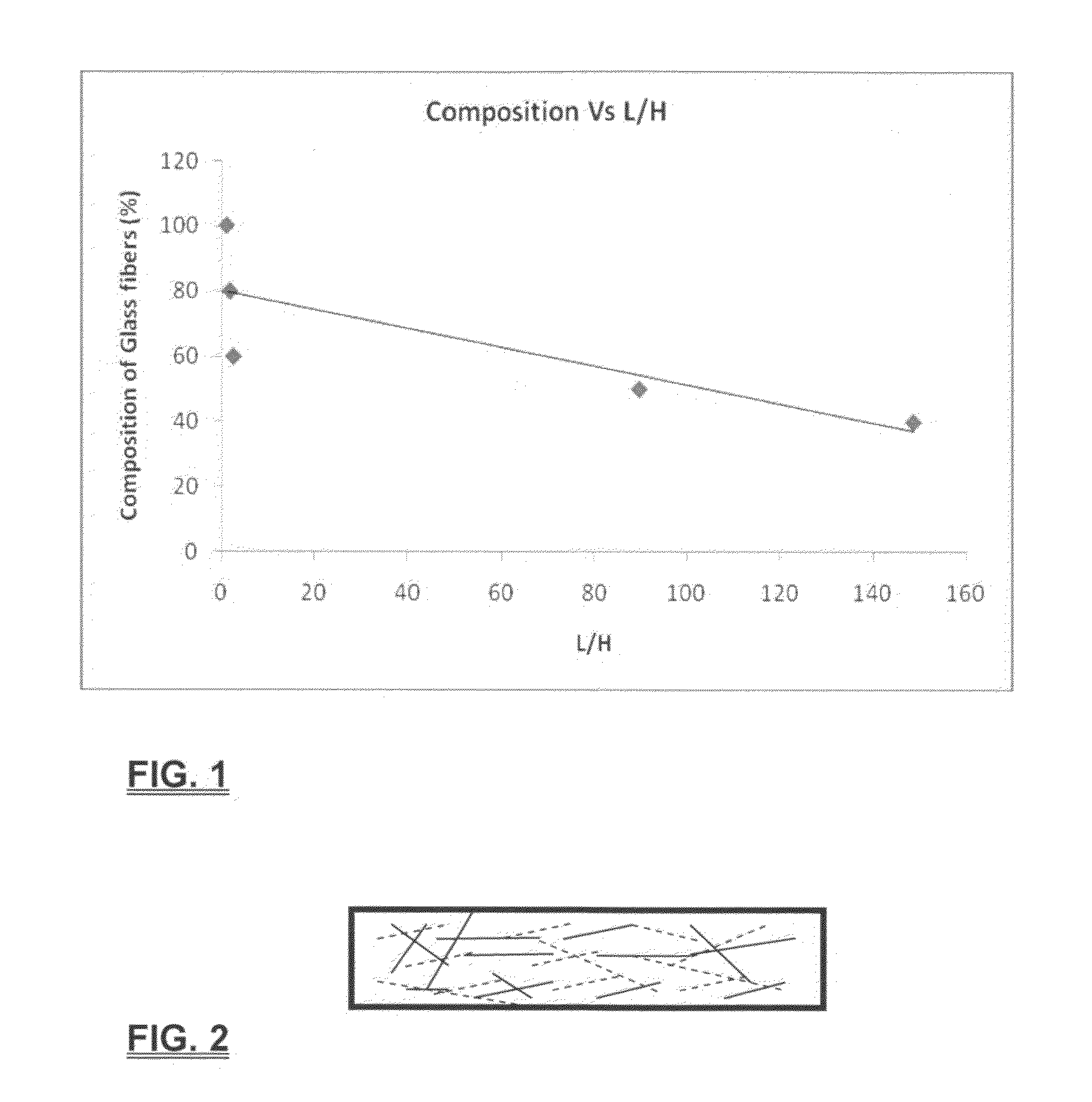

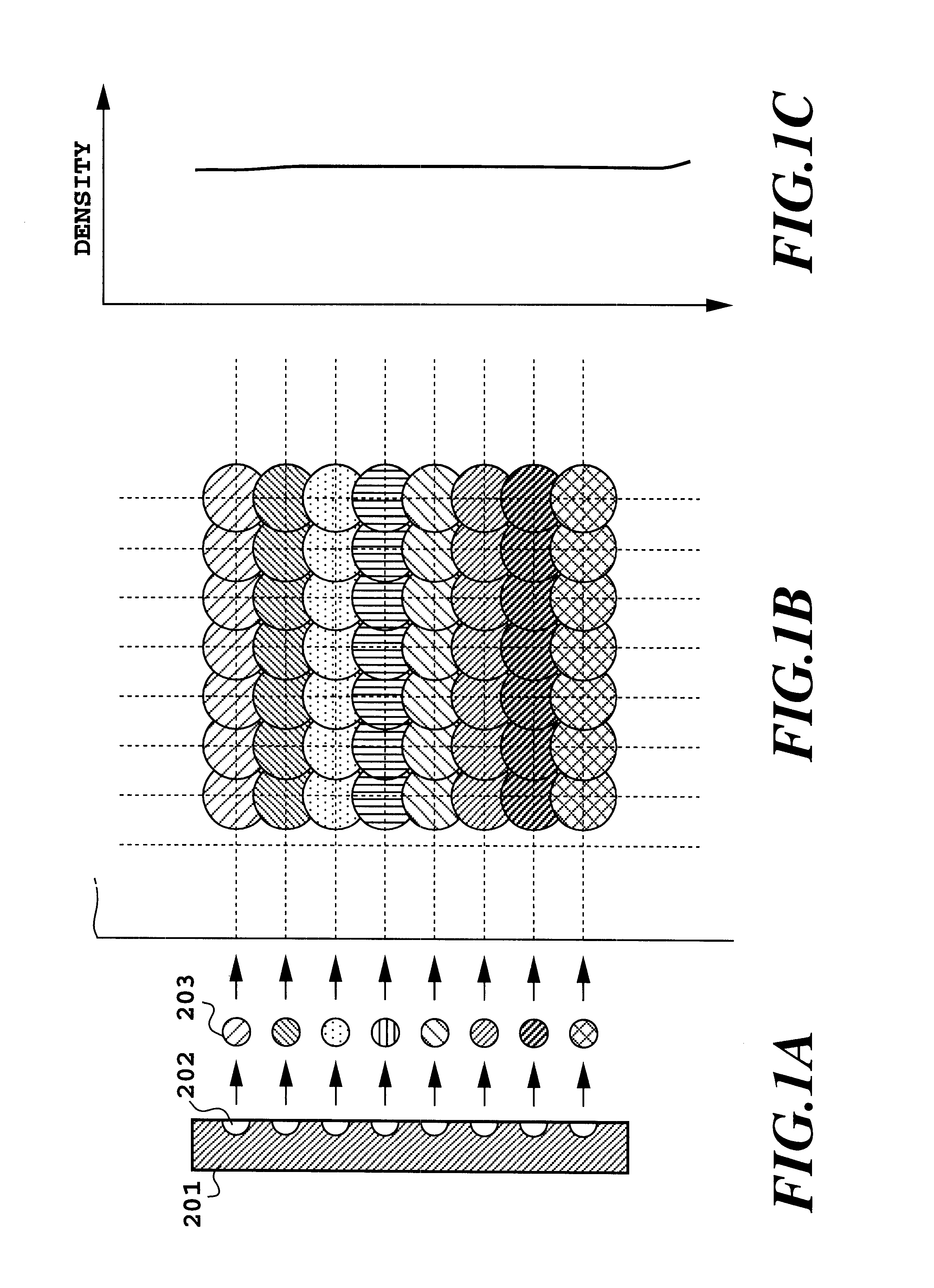

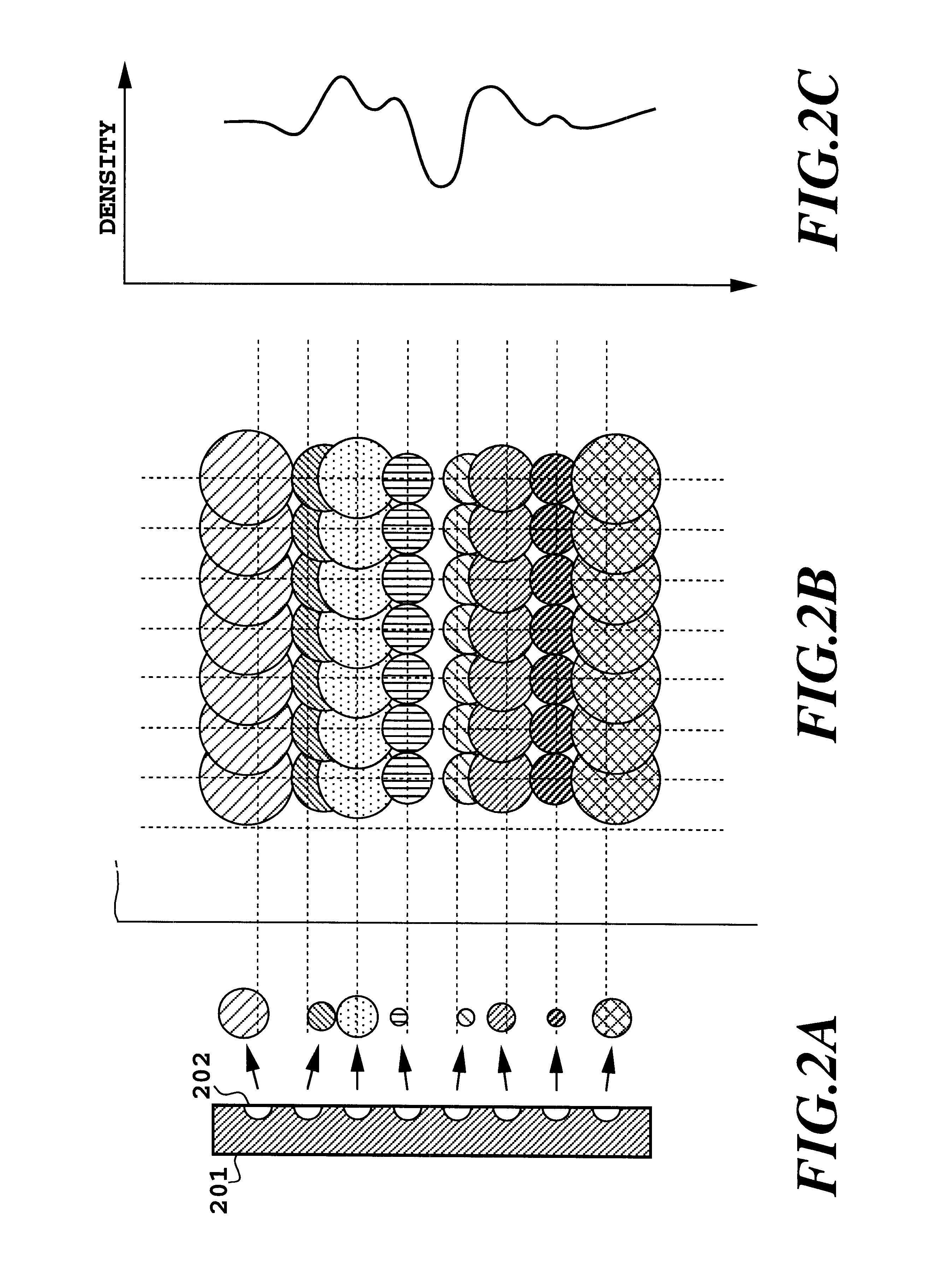

Mixed hydrophilic/hydrophobic fiber media for liquid-liquid coalescence

ActiveUS20100200512A1Liquid suspension thickening by filtrationWater/sewage treatmentWashburn's equationFiber

An immiscible lipophilic or hydrophilic liquid phase separated respectively from a continuous hydrophilic phase or a lipophilic phase liquid. Fibers having hydrophilic and hydrophobic properties are mixed, layered, etc., and formed into a filter. The separation mechanism involves capture of small droplets of the immiscible phase, coalescence of the small droplets into larger droplets as the immiscible liquid flows through the fiber filter, and release of the large immiscible droplets from the filter. With respect to separation of a hydrophilic immiscible fluid such as water in a lipophilic continuous fluid such as oil, the hydrophobic fibers will cause small water droplets to migrate towards the hydrophilic fibers whereby large droplets are formed on hydrophilic surface. The large droplets stay on hydrophilic fiber surface for extended periods of time and continue to coalescence until they are so large that they can no longer be maintained by the hydrophilic fibers and are released and drained off of the filter. In designing such filter, wettability of the filter media is an important parameter. The filter media can be designed by mixing hydrophilic and hydrophobic fibers in various proportions to achieve an optimum wettability range for separation of the immiscible liquid from the continuous phase liquid. The wettability of filter media can be characterized by a modified Washburn Equation.

Owner:THE UNIVERSITY OF AKRON

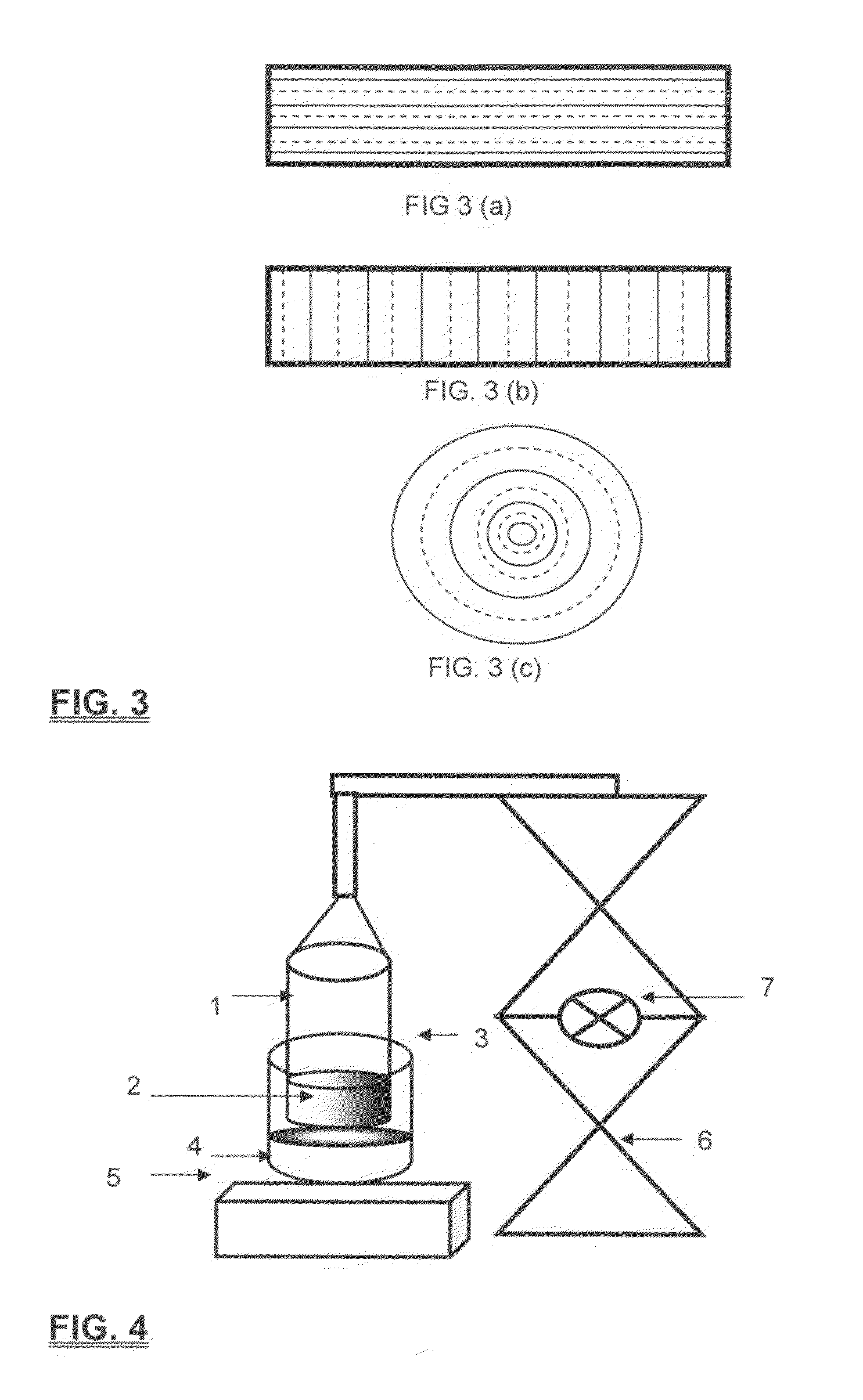

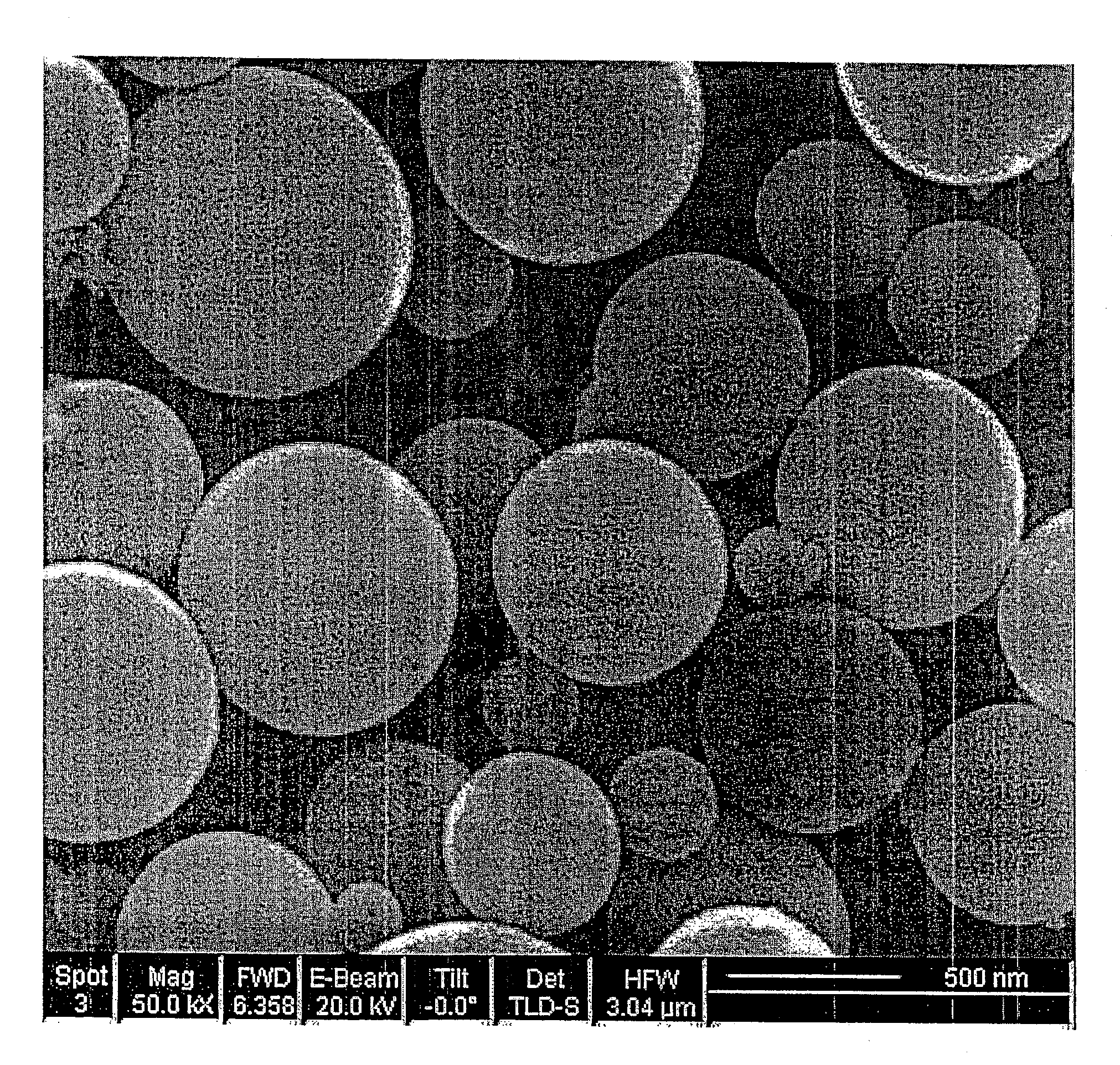

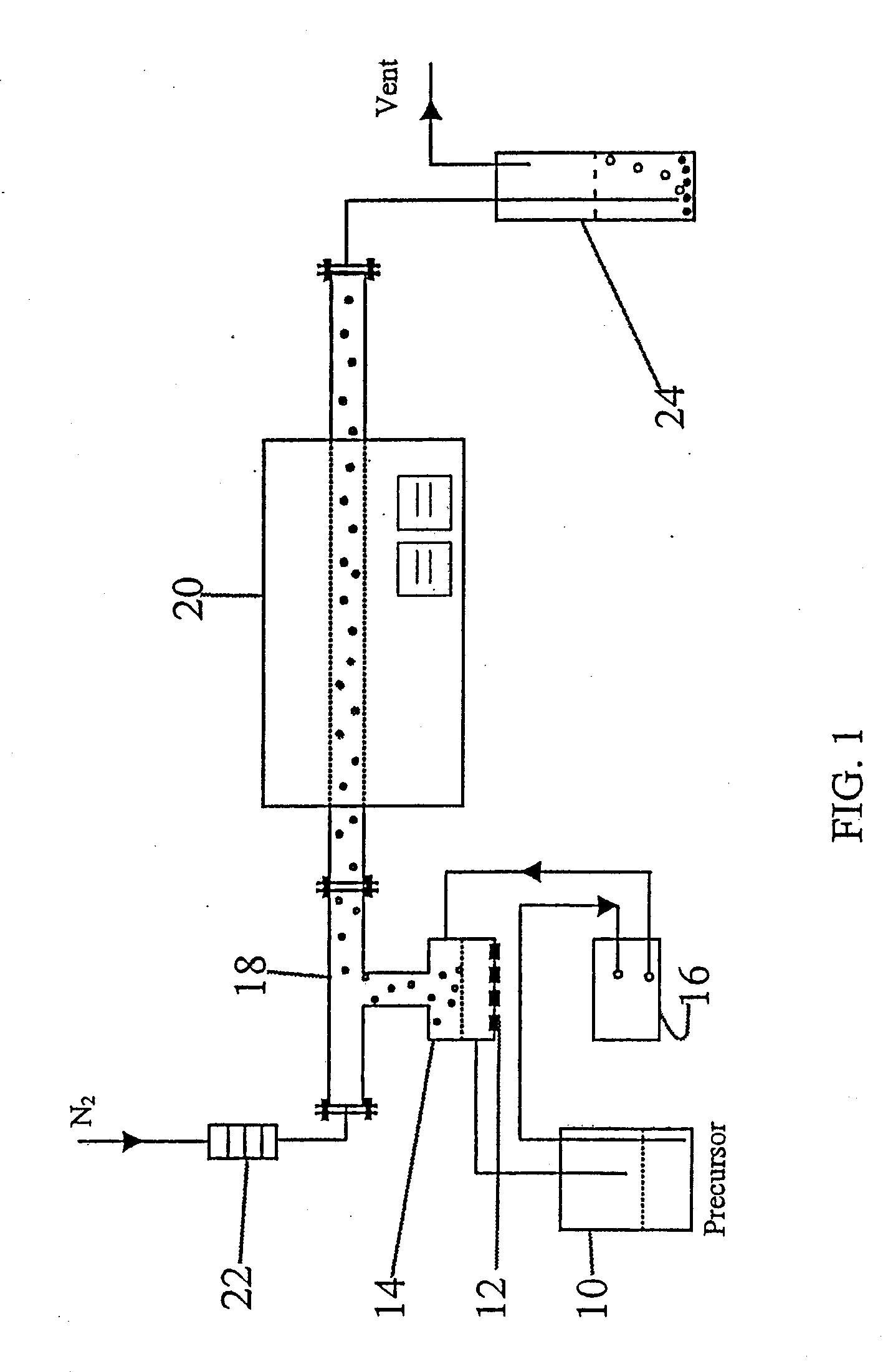

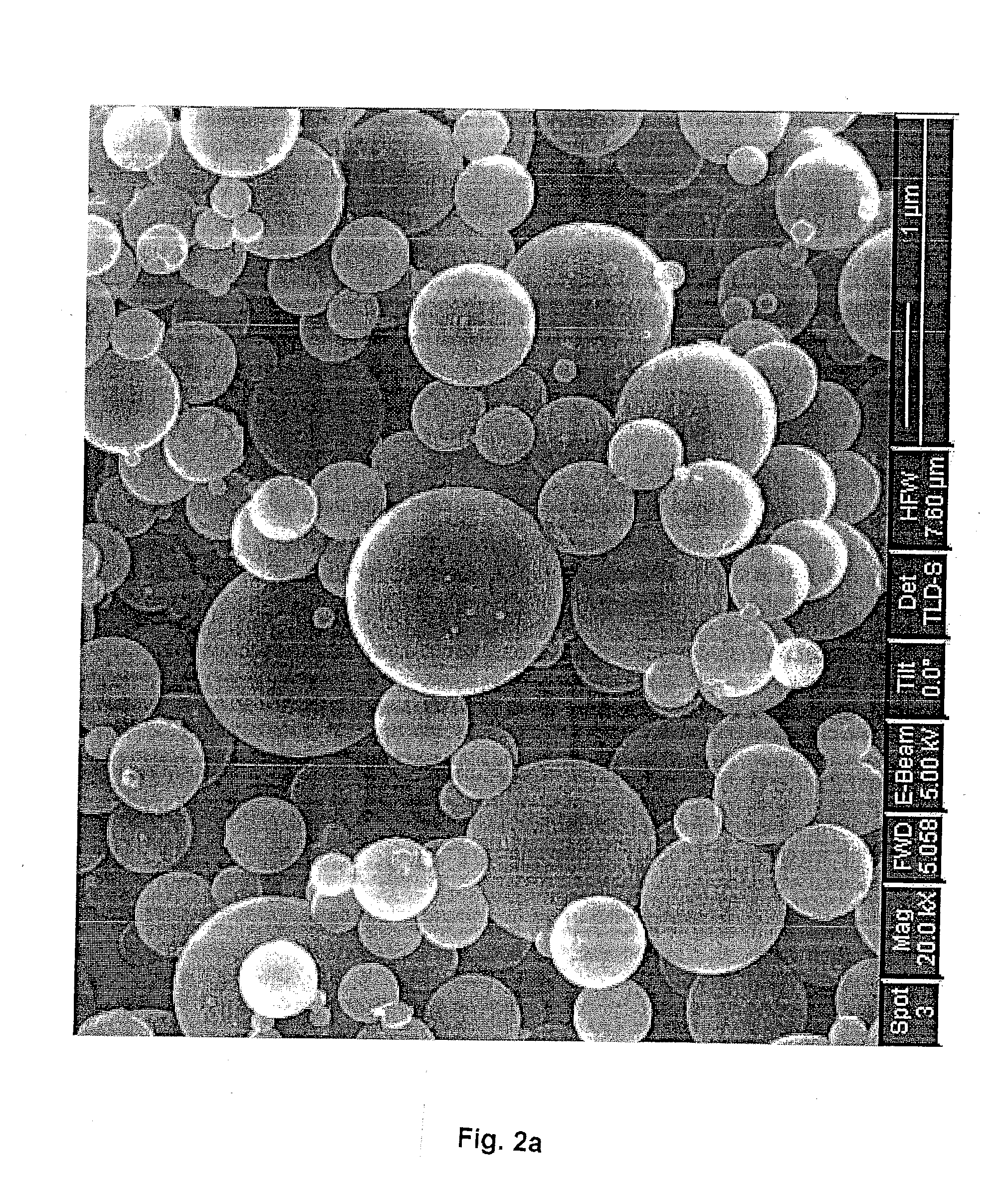

Controllable Synthesis of Porous Carbon Spheres, and Electrochemical Applications Thereof

InactiveUS20110082024A1Good dispersionExcellent ORR activityMaterial nanotechnologyReactant parameters controlColloidal silicaSmall droplet

The invention disclosed relates to porous carbon of spherical morphology having tuned porosity and to a method of making same, comprising: (a) providing a precursor solution, by combining in an aqueous solution a colloidal silica template material and a water-soluble pyrolyzable carbon source, wherein the particle size of the colloidal silica template and the colloidal silica / carbon source weight ratio are controlled, (b) atomizing the precursor solution into small droplets by ultrasonic spray pyrolysis (c) directing the droplets into a high temperature furnace operating at a temperature of 700-1200° C., under an inert gas atmosphere, where the droplets are transformed into solid spherical composite carbon / silica particles, (d) collecting the resulting composite carbon / silica particles exiting from the furnace, and (e) removing the silica from the particles, to provide substantially pure porous carbon of spherical morphology having tuned porosity defined by surface area and pore size. The porous carbon according to the invention is used as catalyst supports in PEM fuel cells, as electrodes in supercapacitors and lithium in batteries, for hydrogen storage and as earners for drug delivering.

Owner:NAT RES COUNCIL OF CANADA

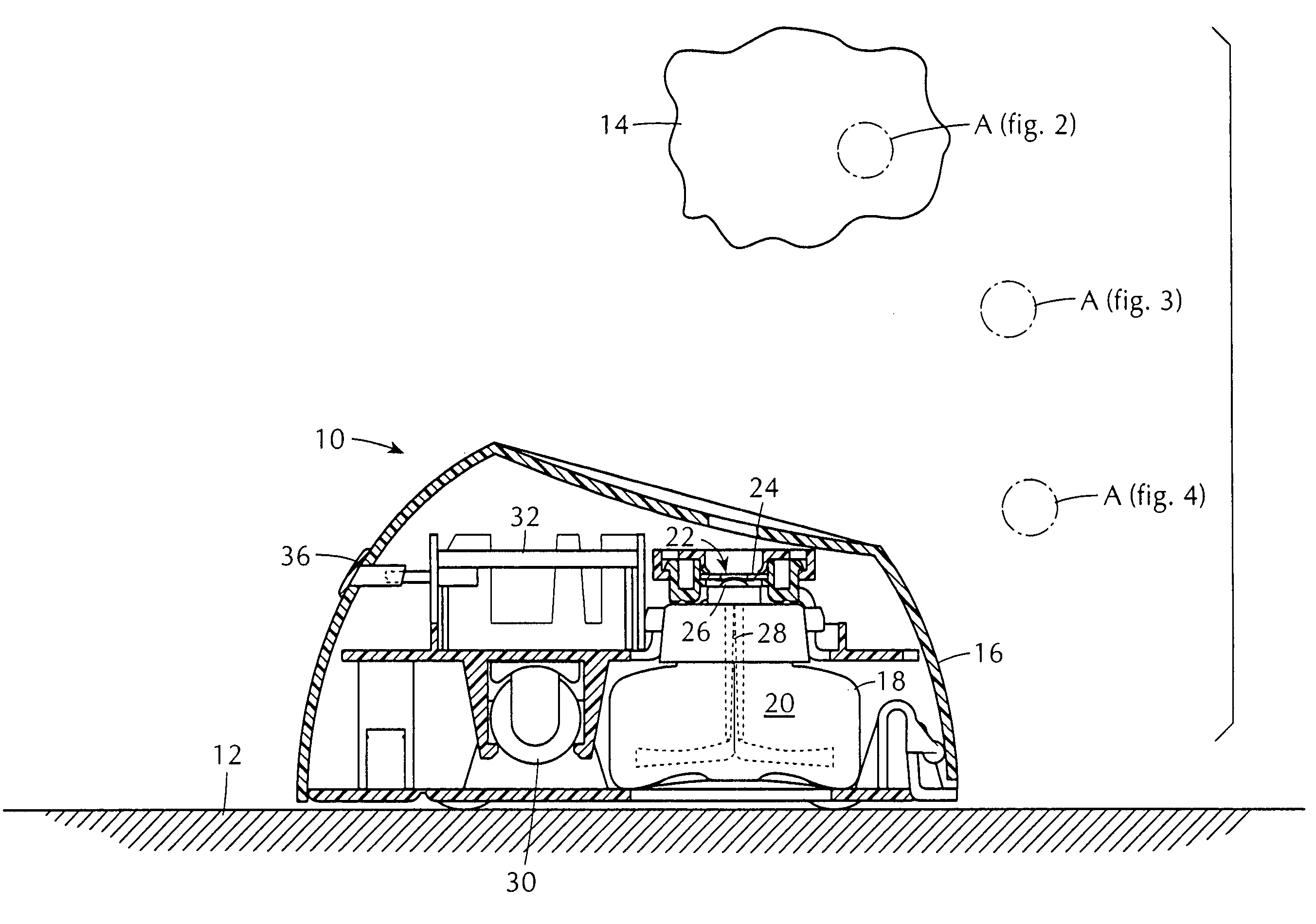

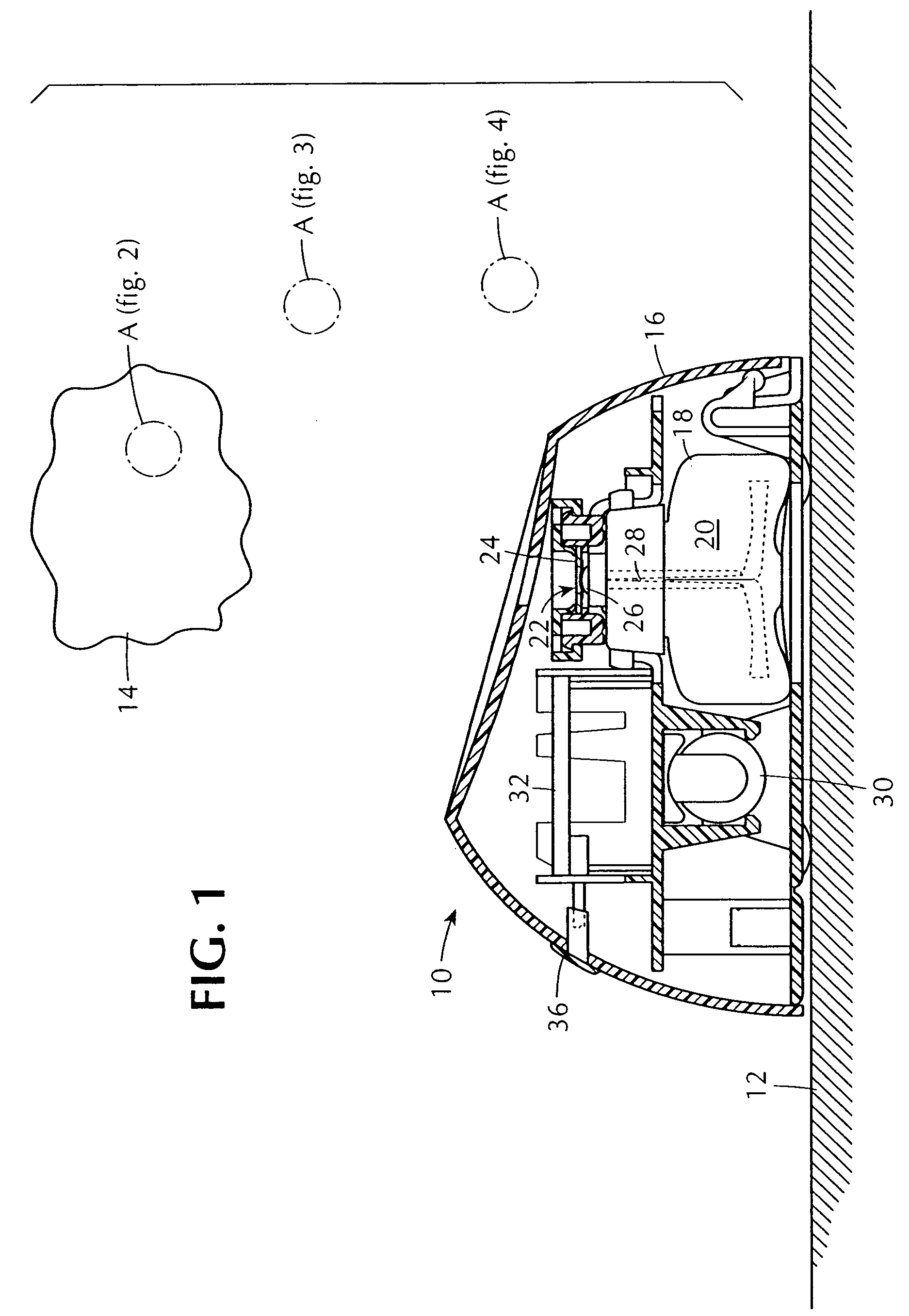

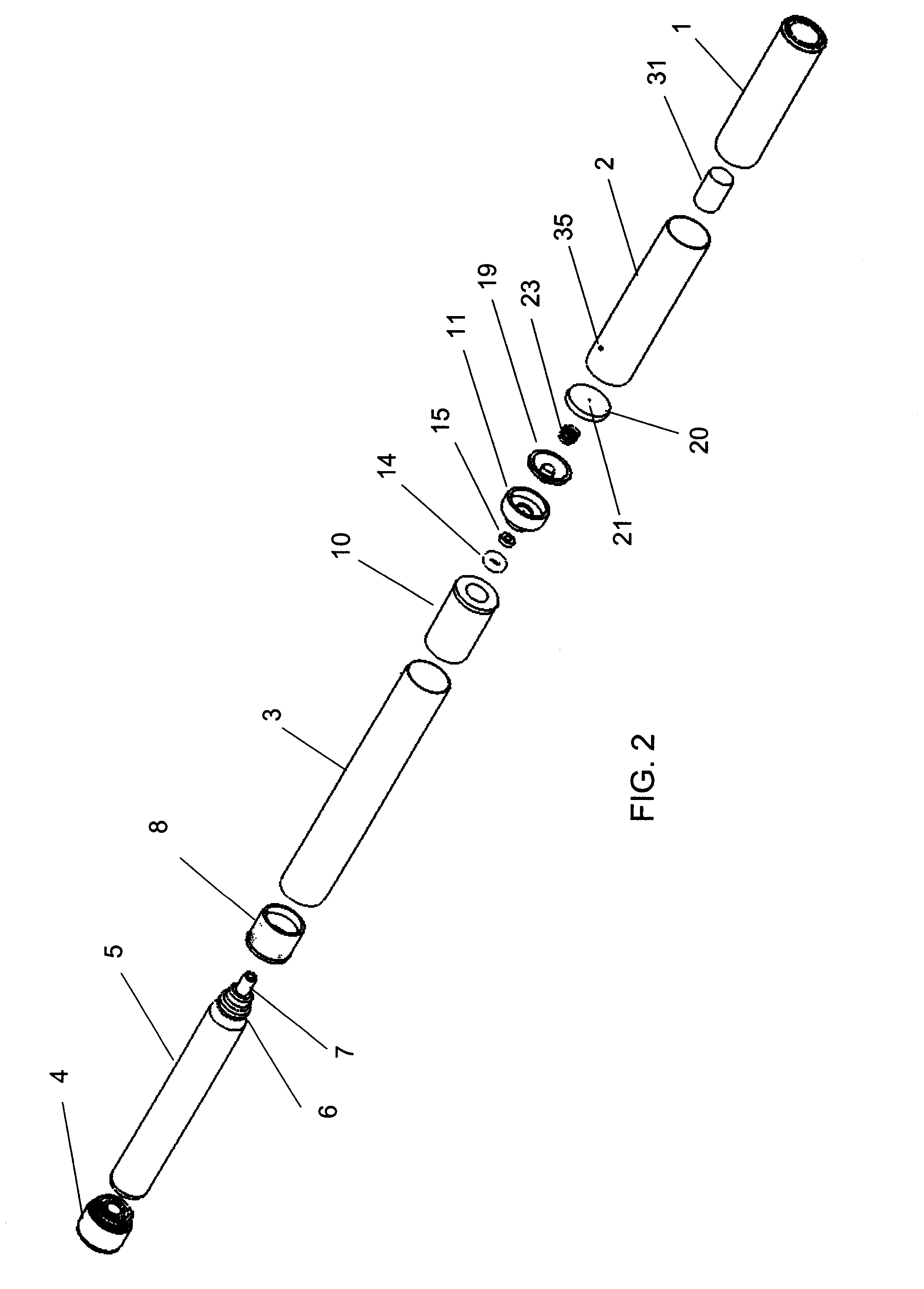

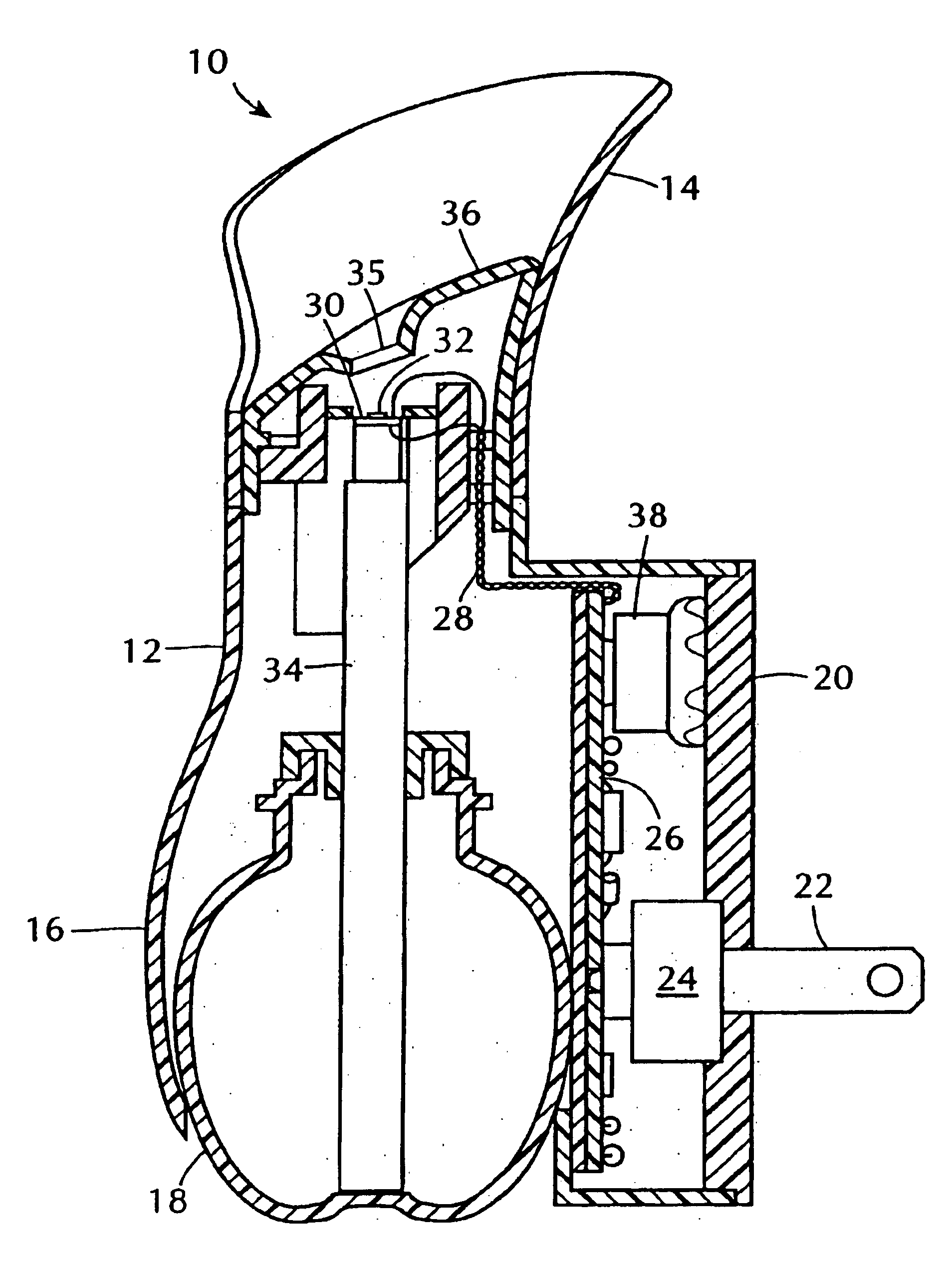

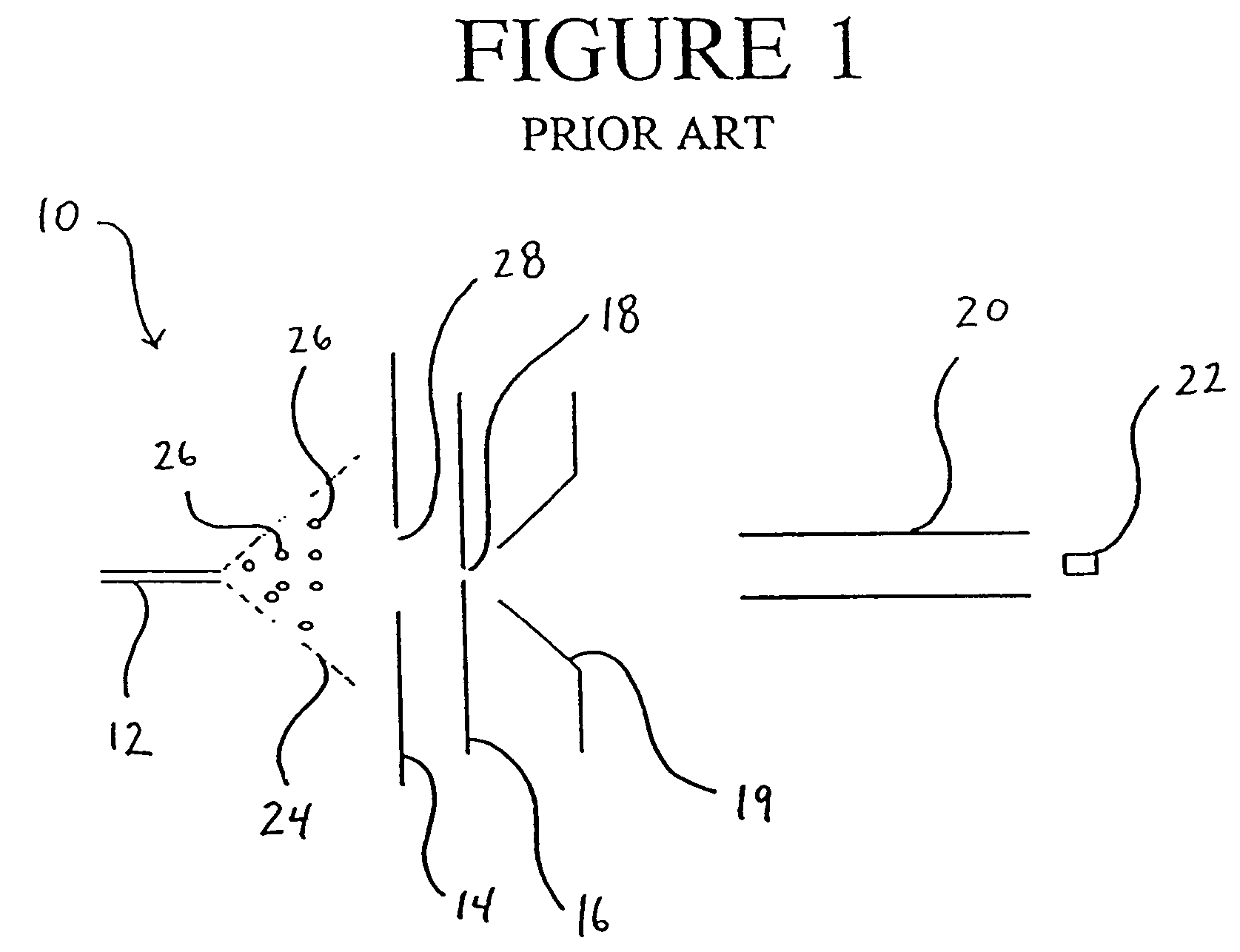

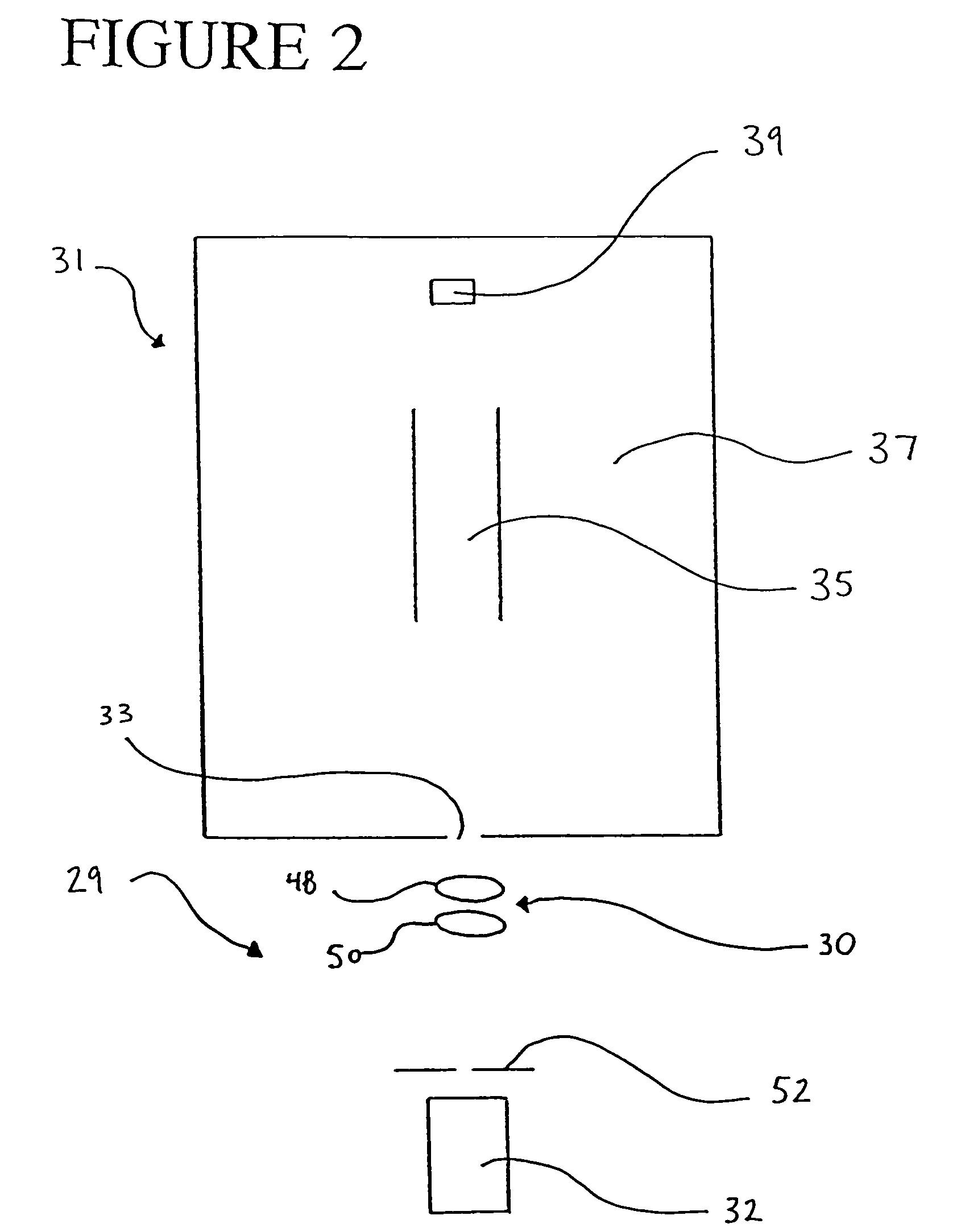

Method and apparatus for evaporating multi-component liquids

An atomizer 10 atomizes a multi-component liquid from a reservoir 20 into a cloud 14 comprising small droplets 38 which are ejected into the atmosphere to a certain height and allowed to fall toward a surface 12. Essentially complete evaporation is assured by maintaining the size of the droplets, the liquid's component vapor pressures and the height through which the droplets fall according to a predetermined relationship. Also, the suitability of a liquid for evaporation in a vibrating plate atomizer is determined by measuring the rate of size decrease and the surface tension of a pendant drop of the liquid after a predetermined amount of the liquid has evaporated from the drop.

Owner:SC JOHNSON & SON INC

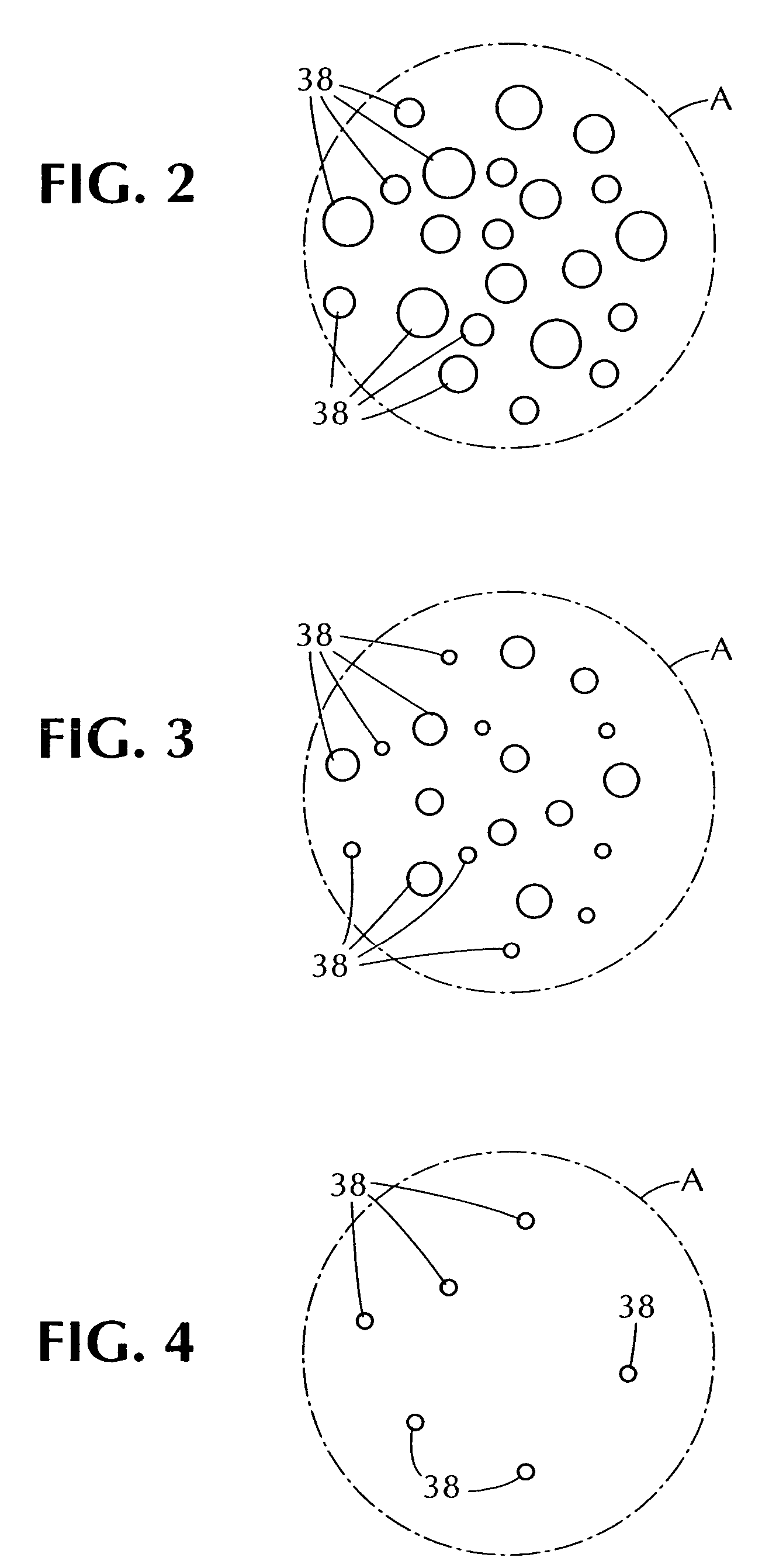

Aerosol dispensing device

An aerosol dispensing device comprises a tubular body that provides a plenum, a mouthpiece having an outlet, a valve for dispensing fluid from a canister as an aerosol with relatively large and small droplet sizes into the plenum for supply to a user through the mouthpiece, and a baffle arrangement that provides first and second passageways each coupled at one end to the plenum and so configured to receive relatively small and large size droplets in the aerosol respectively, the other end of the first passageway extending to the outlet in the mouthpiece to supply the small size droplets to the user, and the other end of the second passageway being closed to inhibit passage of the large size droplets to the mouthpiece outlet, and containing a absorbent pad to prevent leakage of liquid from the canister. The pad may be pre-loaded with a flavourant.

Owner:NICOVENTURES HLDG

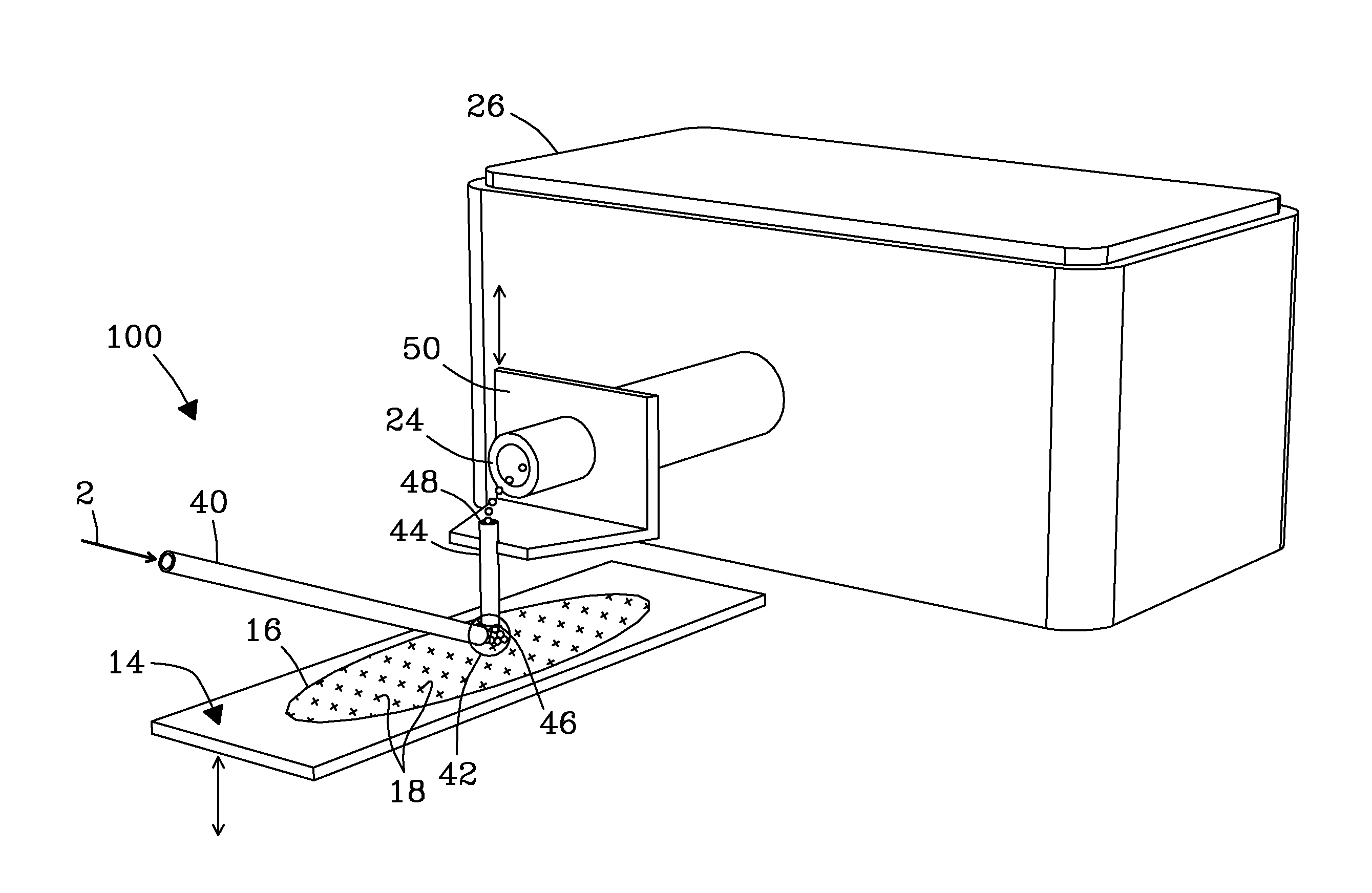

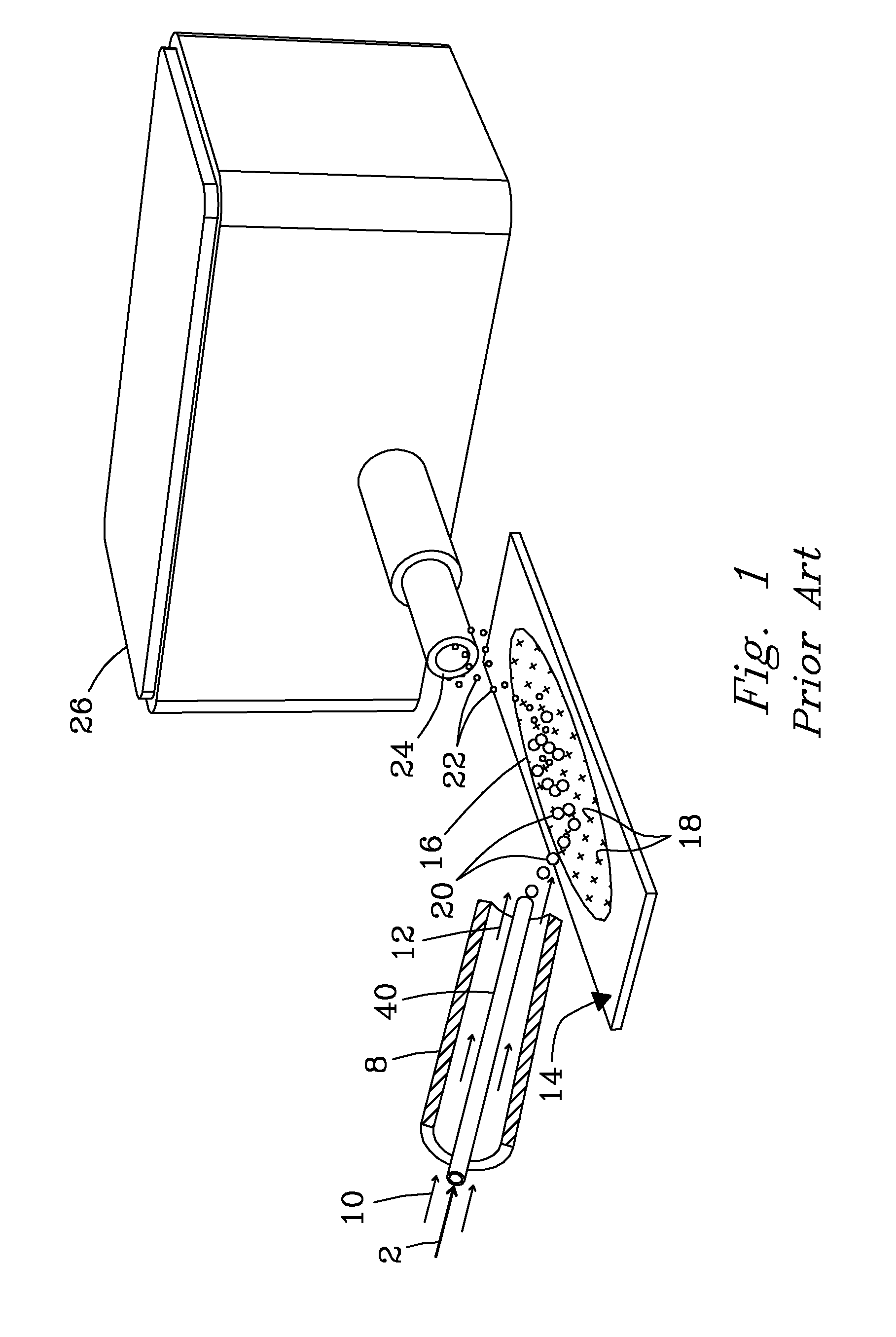

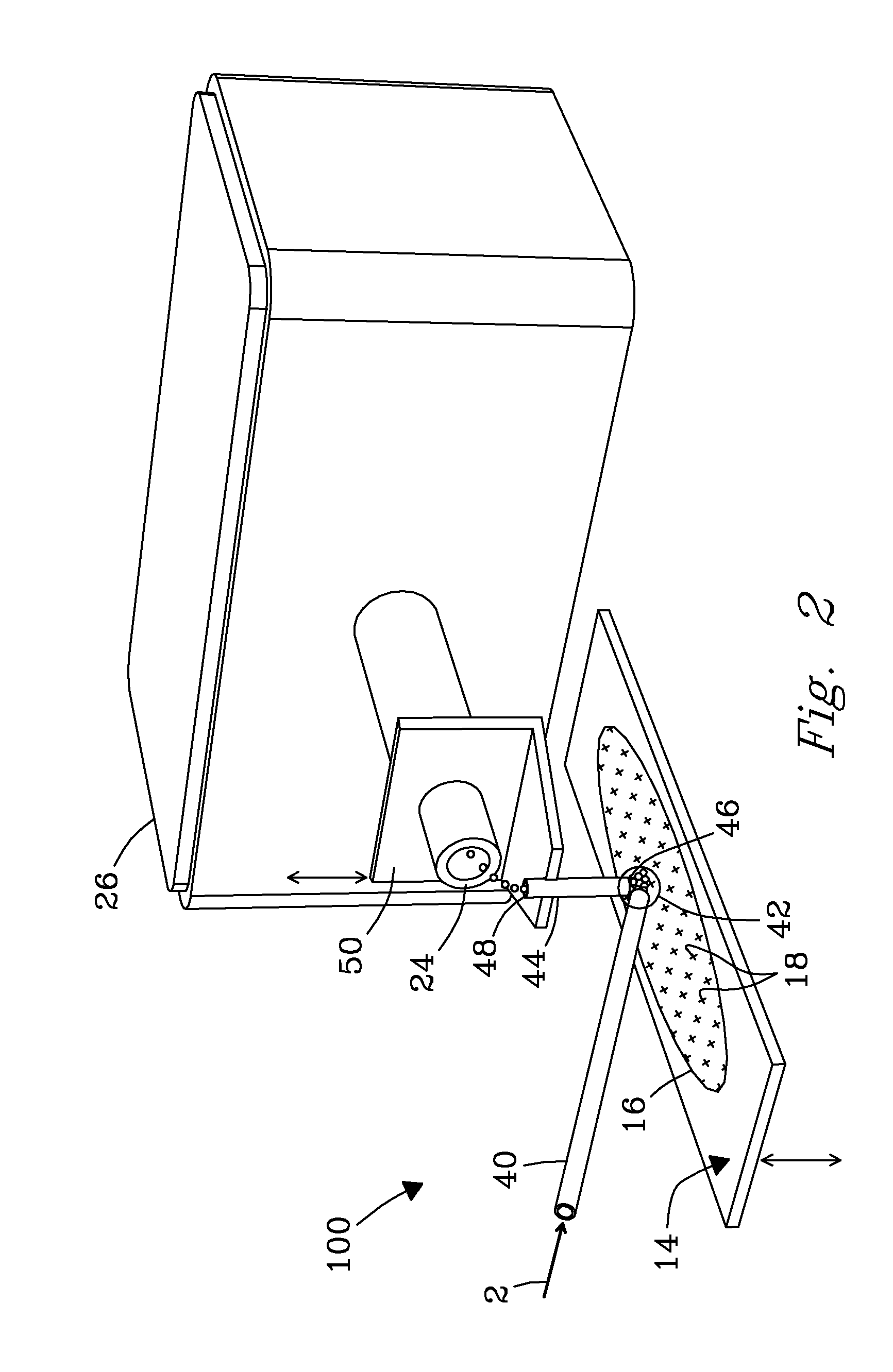

Point of purchase fragrance sampling

InactiveUS6969008B2Reduce lossesInterference nearbyMovable spraying apparatusSpray nozzlesVena contracta diameterSmall droplet

A fragrance sampling system for use in a store comprises a piezoelectrically vibrated orifice plate atomizer mounted to extend from a support structure in the store, such as a shelf and operated to emit puffs of very small droplets of the liquid fragrance and eject them upwardly into the atmosphere such that they become fully evaporated before contacting any supporting surface. The atomizer is controlled by electrical circuits which limit the times during which atomization occurs.

Owner:SC JOHNSON & SON INC

Low lactose, low moisture shelf-stable, bakeable savory cheese product and process for preparing it

InactiveUS20020155198A1Good cheese flavorSuitable cheeseBaking mixturesConfectionerySmall dropletAdditive ingredient

A savory, smooth-textured, bakeable and shelf-stable product is prepared as a three-phase formulation, including an aqueous liquid phase, a dispersed fat phase and a solids phase, preferably containing cheese in significant proportion. The liquid phase is present in sufficient quantity to suspend and disperse the fat and solids phases. The dispersed fat must have sufficiently small droplet size raise the viscosity for this phase sufficiently to result in a creamy texture for the final product. The savory flavor ingredients are present as undissolved solids of sufficiently small particle size to provide the proper flavor release for the flavor and a texture consistent with the savory flavor. Preferred cheese products will have a lubricous, slippery, smooth mouthfeel and a flavor release that endures until the palate is essentially clean. The product can be applied to unbaked doughs prior to baking and retain their desired properties after baking. The product can also be packaged for use as is with any number of complimentary foods.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

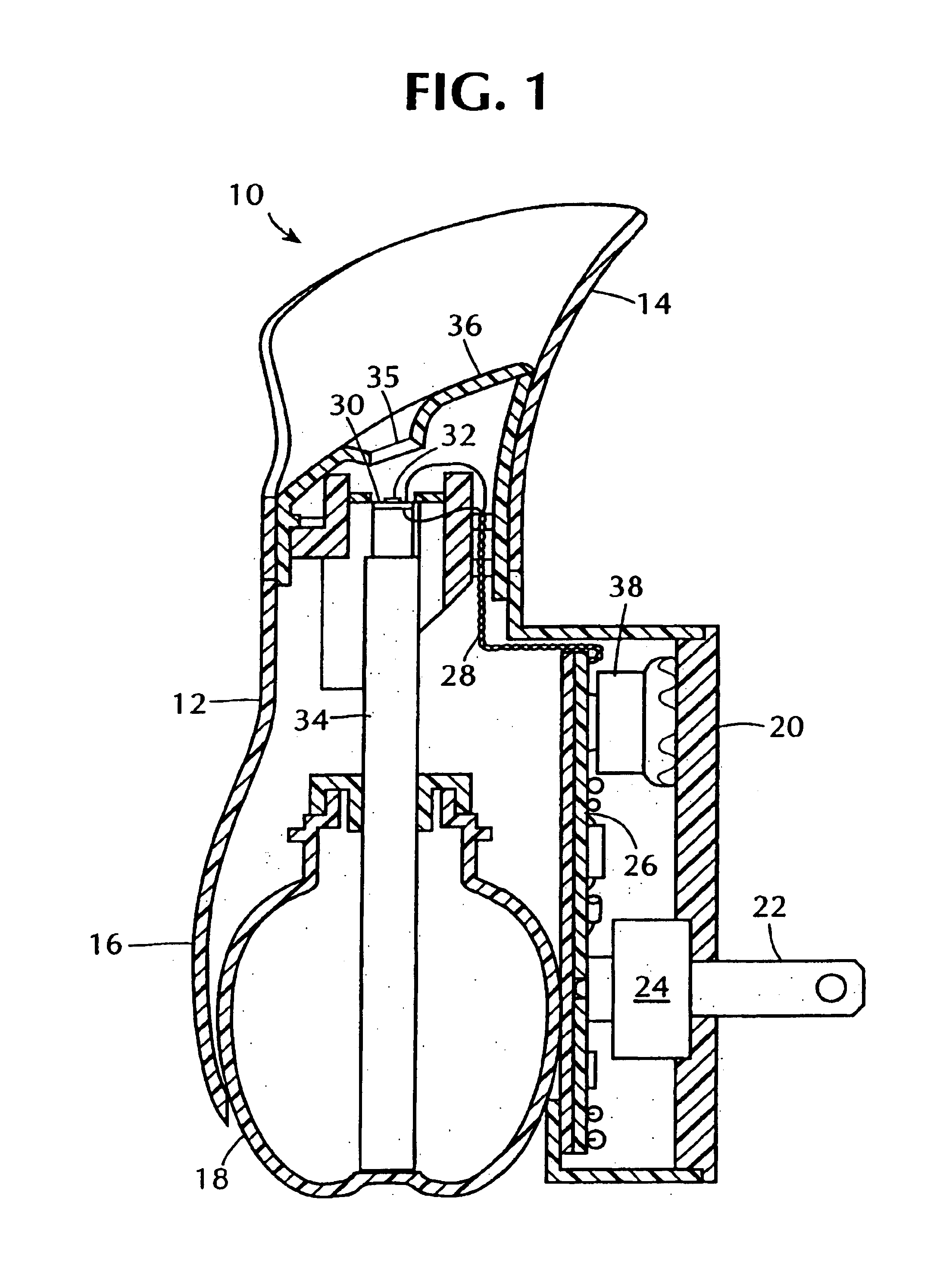

Plug-in type liquid atomizer

InactiveUS6857580B2Faster rateFast disconnectionMovable spraying apparatusSpray nozzlesElectricitySmall droplet

A piezoelectrically actuated liquid atomizer device which applies alternating voltages from an ordinary wall outlet to a piezoelectric actuator intermittently and at a high rate sufficient to cause an atomization plate which is vibrated by the actuator to form small droplets from liquid which is supplied to the plate. The intermittent application of voltages to the piezoelectric actuator is carried out according to a duty cycle in which the off times are adjustable. An override of the duty cycle is provided so that the piezoelectric actuator operates continuously for intervals which are manually or automatically controlled.

Owner:SC JOHNSON & SON INC

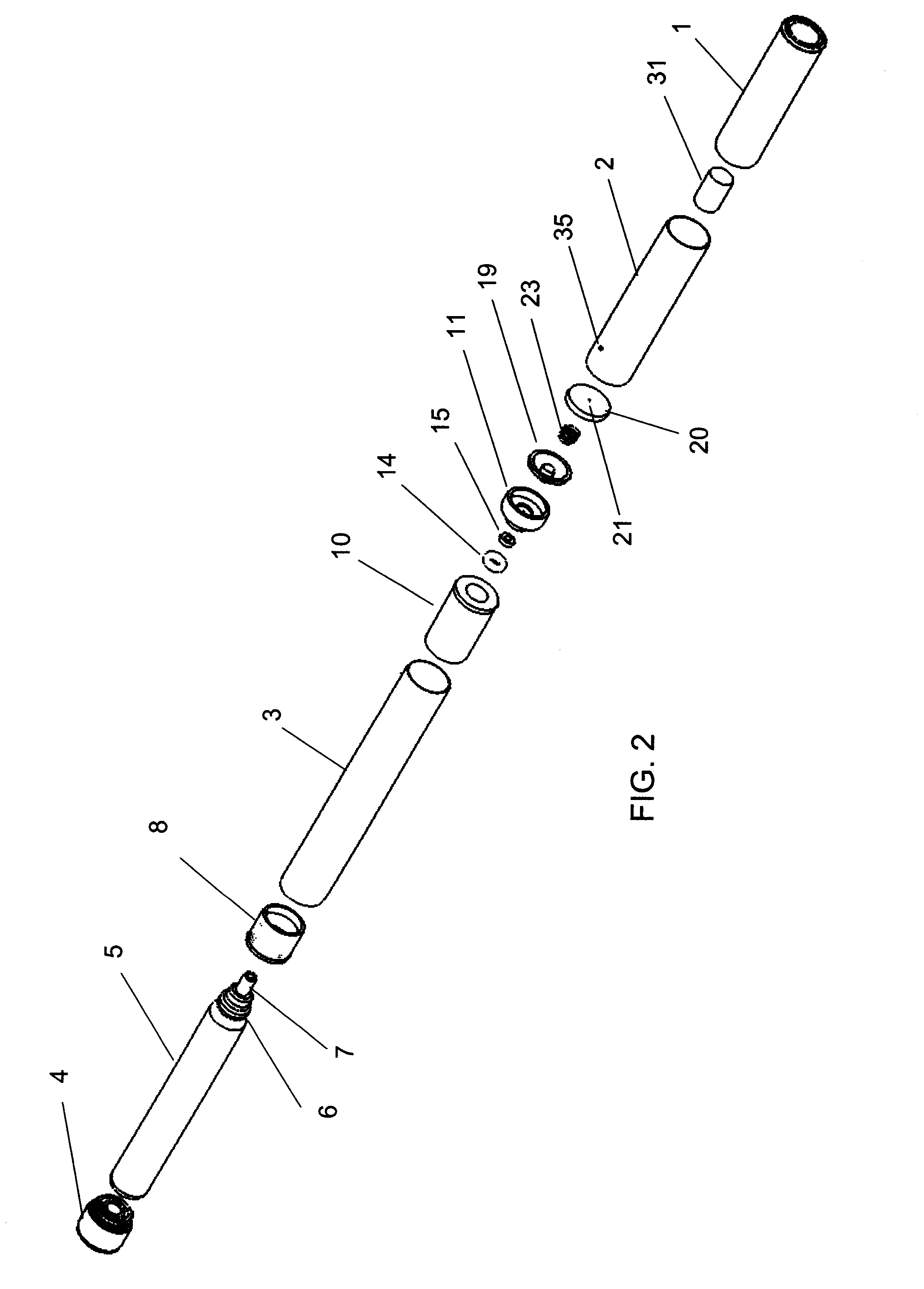

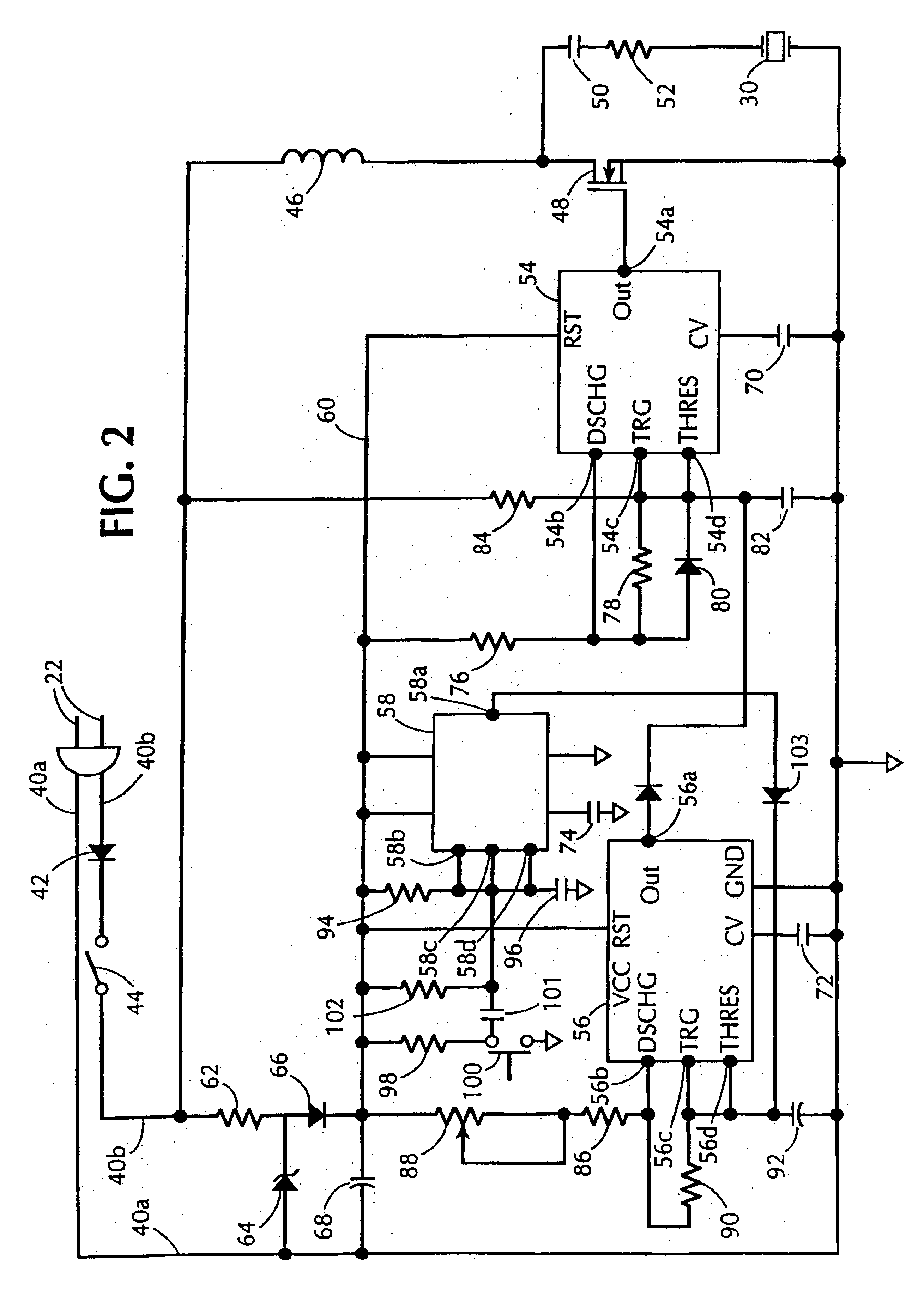

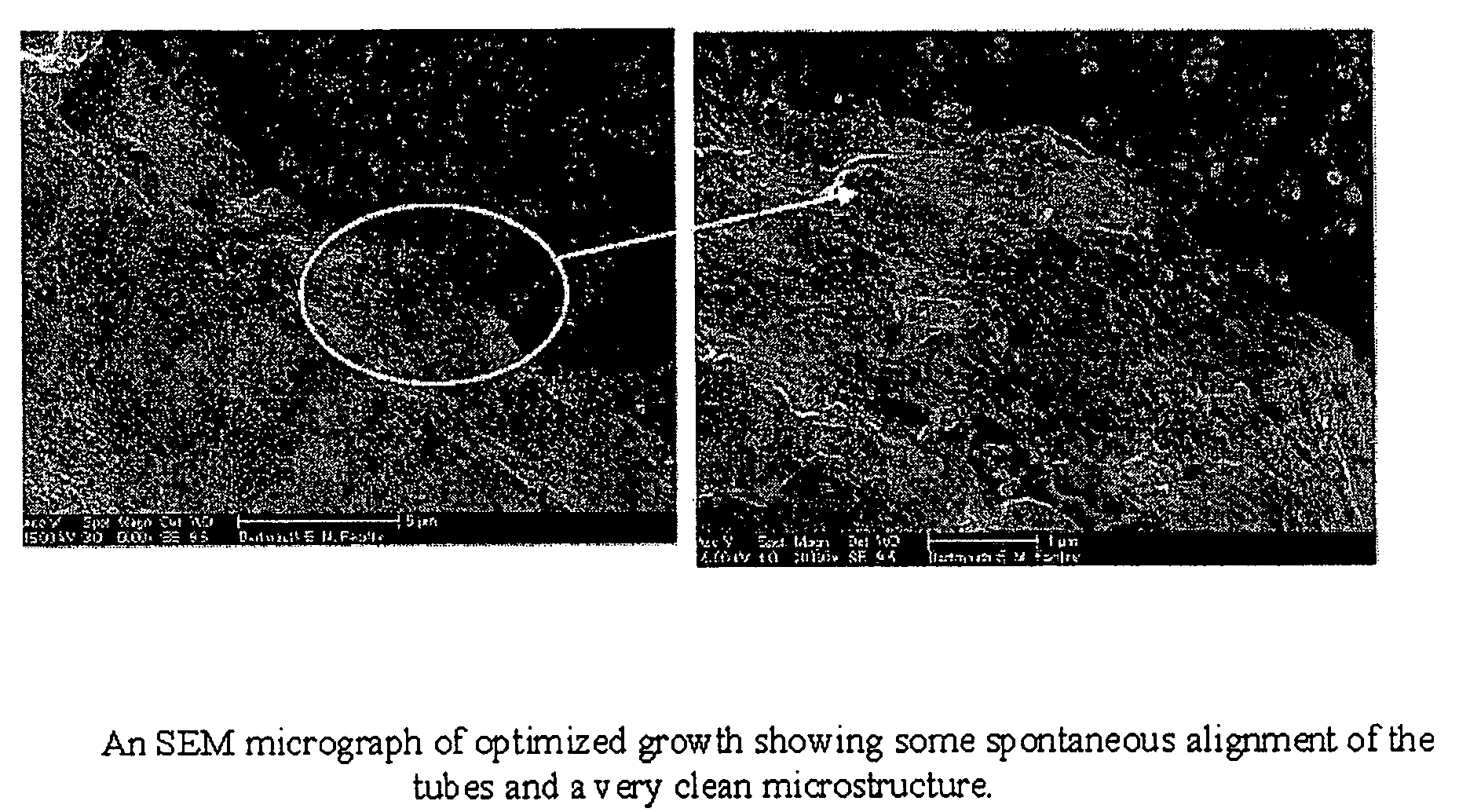

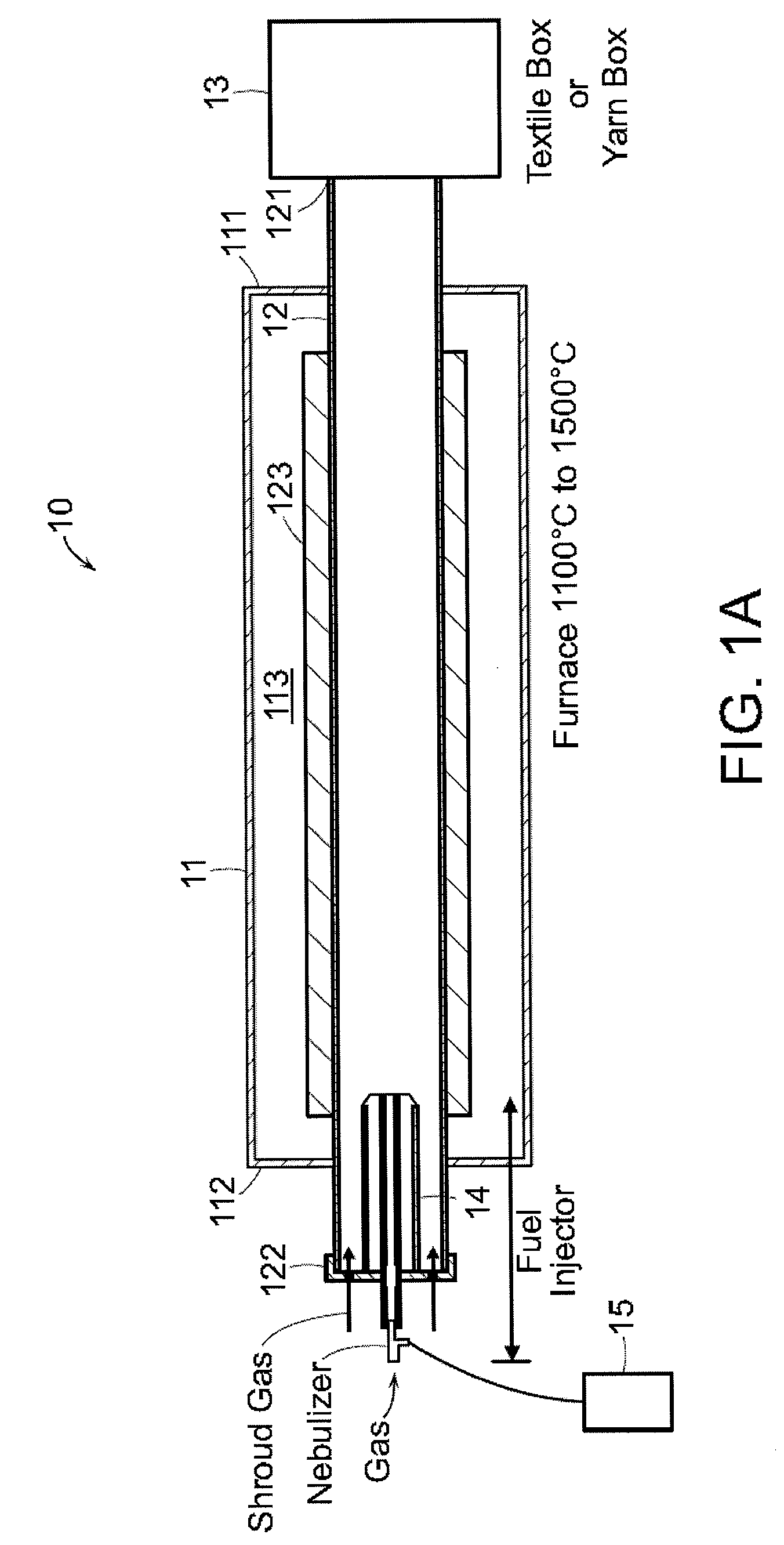

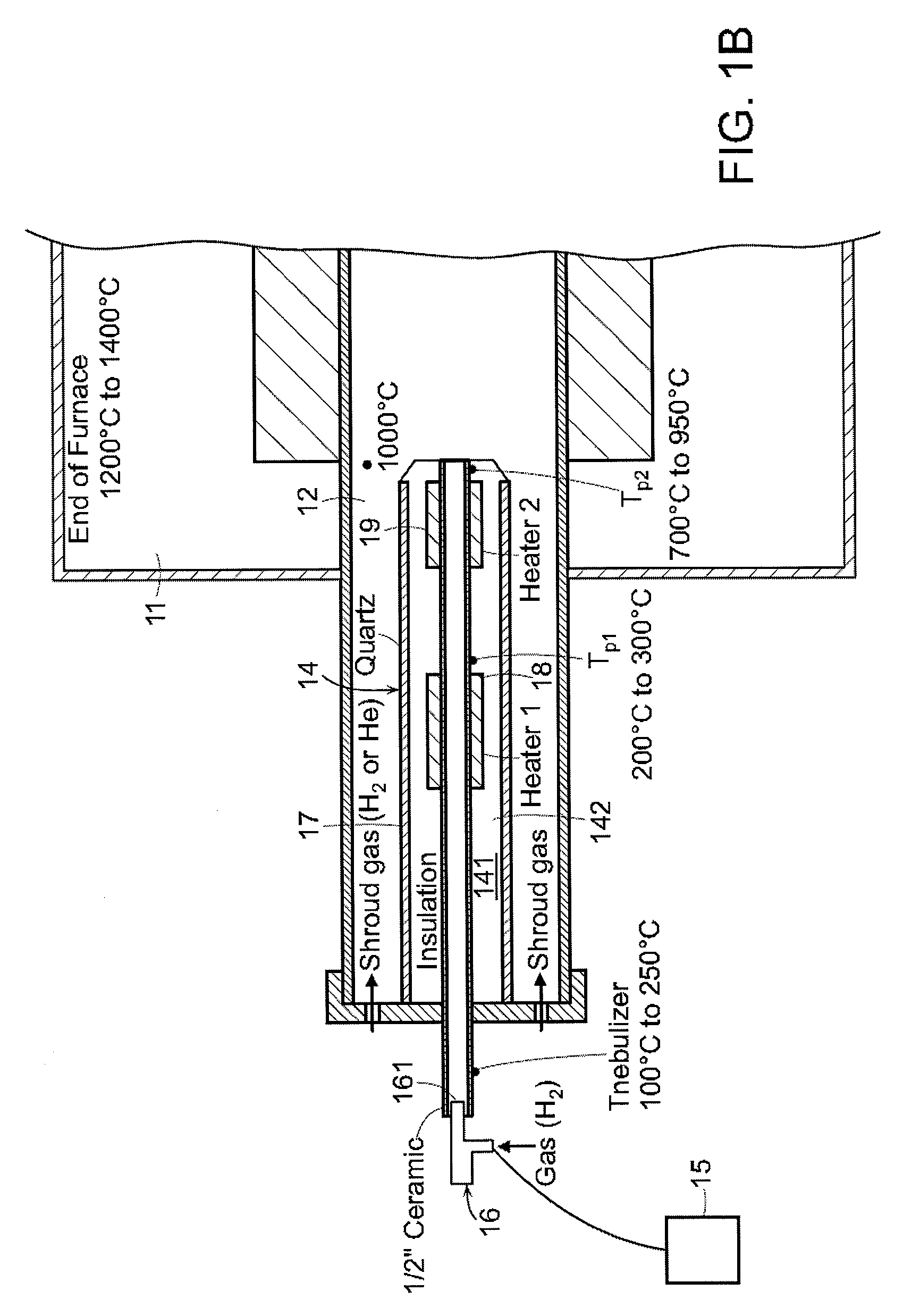

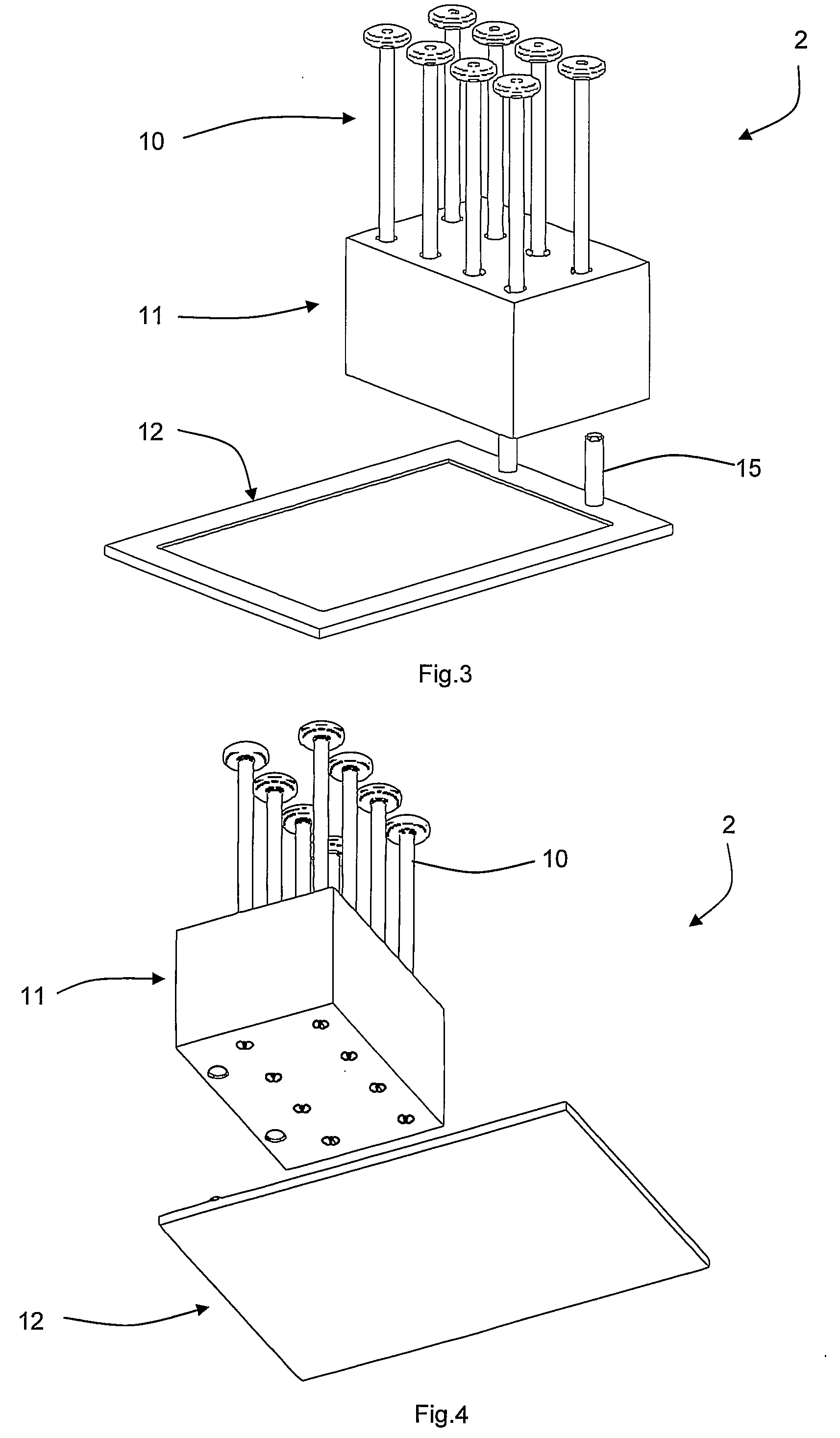

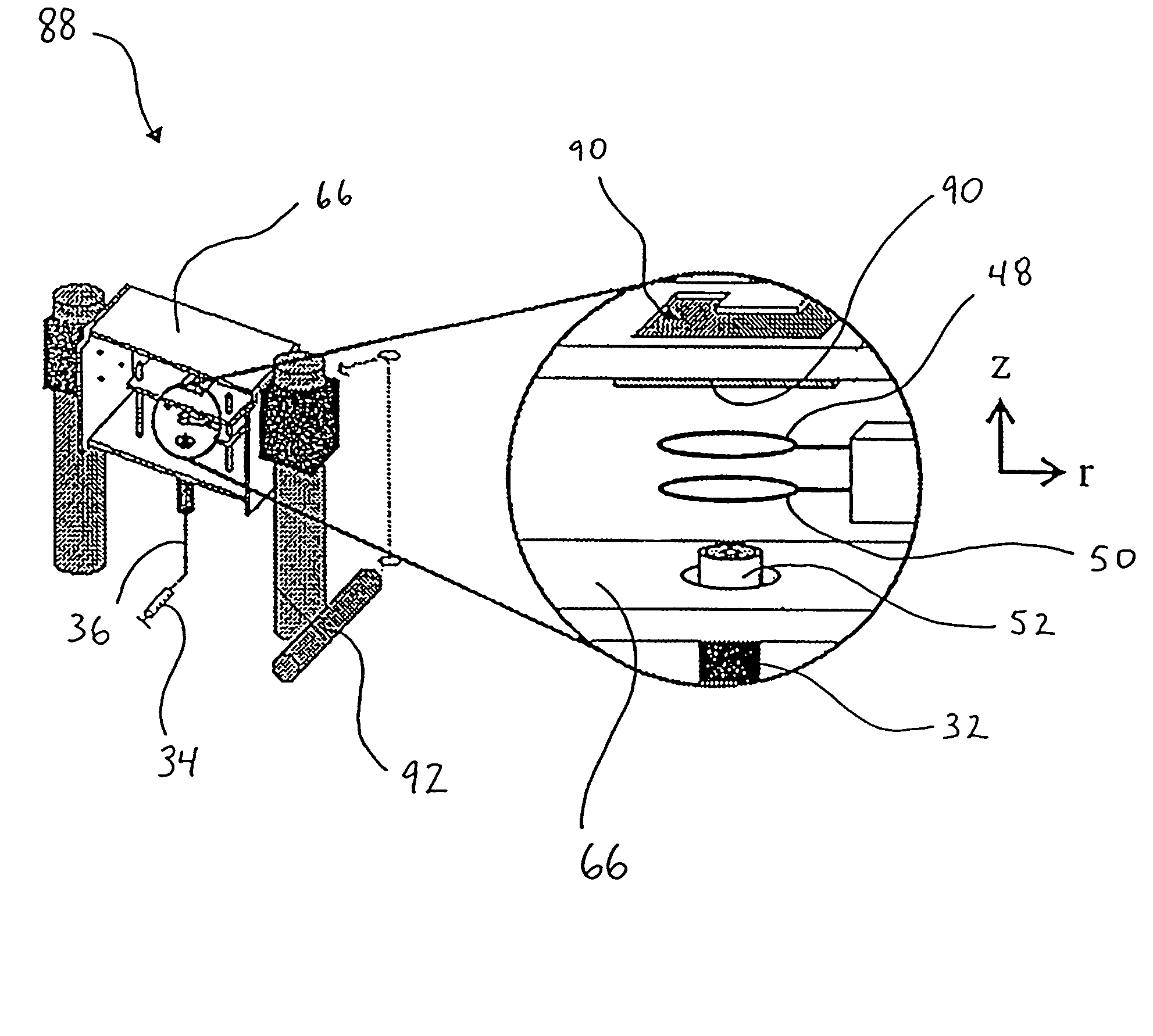

Injector Apparatus and Methods for Production of Nanostructures

ActiveUS20090117025A1Minimizing turbulent flowPromote growthMaterial nanotechnologyGaseous chemical processesSmall dropletNanostructure

An apparatus for use with a reactor for synthesis of nanostructures is provided. The apparatus includes a chamber having one end in fluid communication with the reactor and defining a pathway along which a fluid mixture for the synthesis of nanostructures can be injected into the reactor. The apparatus also has a tube in fluid communication with an opposite of the chamber to impart a venturi effect in order to generate from the fluid mixture small droplets prior to introducing the fluid mixture into the chamber. A heating zone is situated downstream from the tube to provide a temperature range sufficient to permit the formation, from components within the fluid mixture, of catalyst particles upon which nanostructures can be generated. A mechanism is further provided at a distal end of the chamber to minimize turbulent flow as the fluid mixture exits the chamber, and to impart a substantially laminar flow thereto. A method for synthesis of nanostructures is also provided.

Owner:NANCOMP TECHNOLOGIES INC

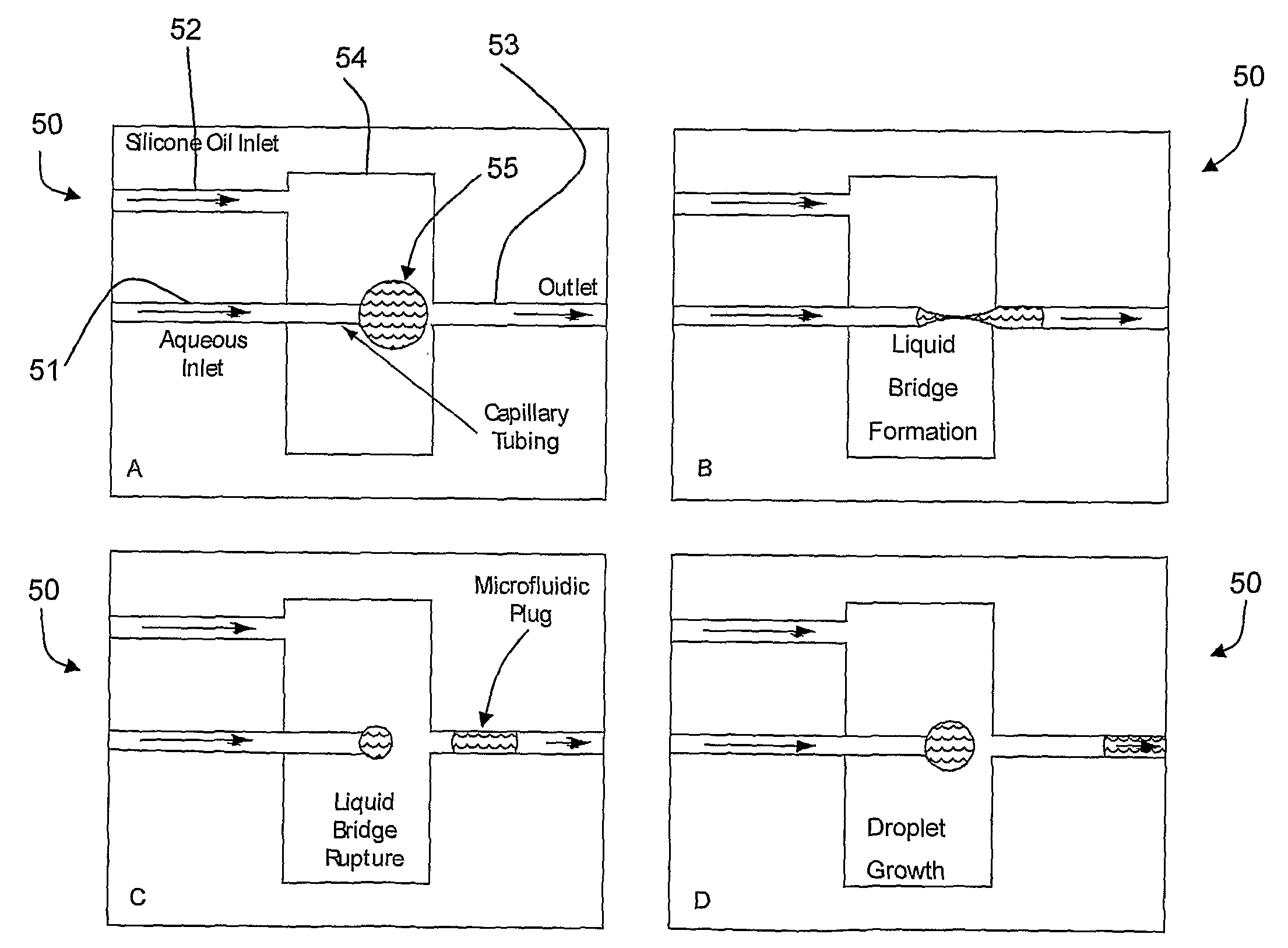

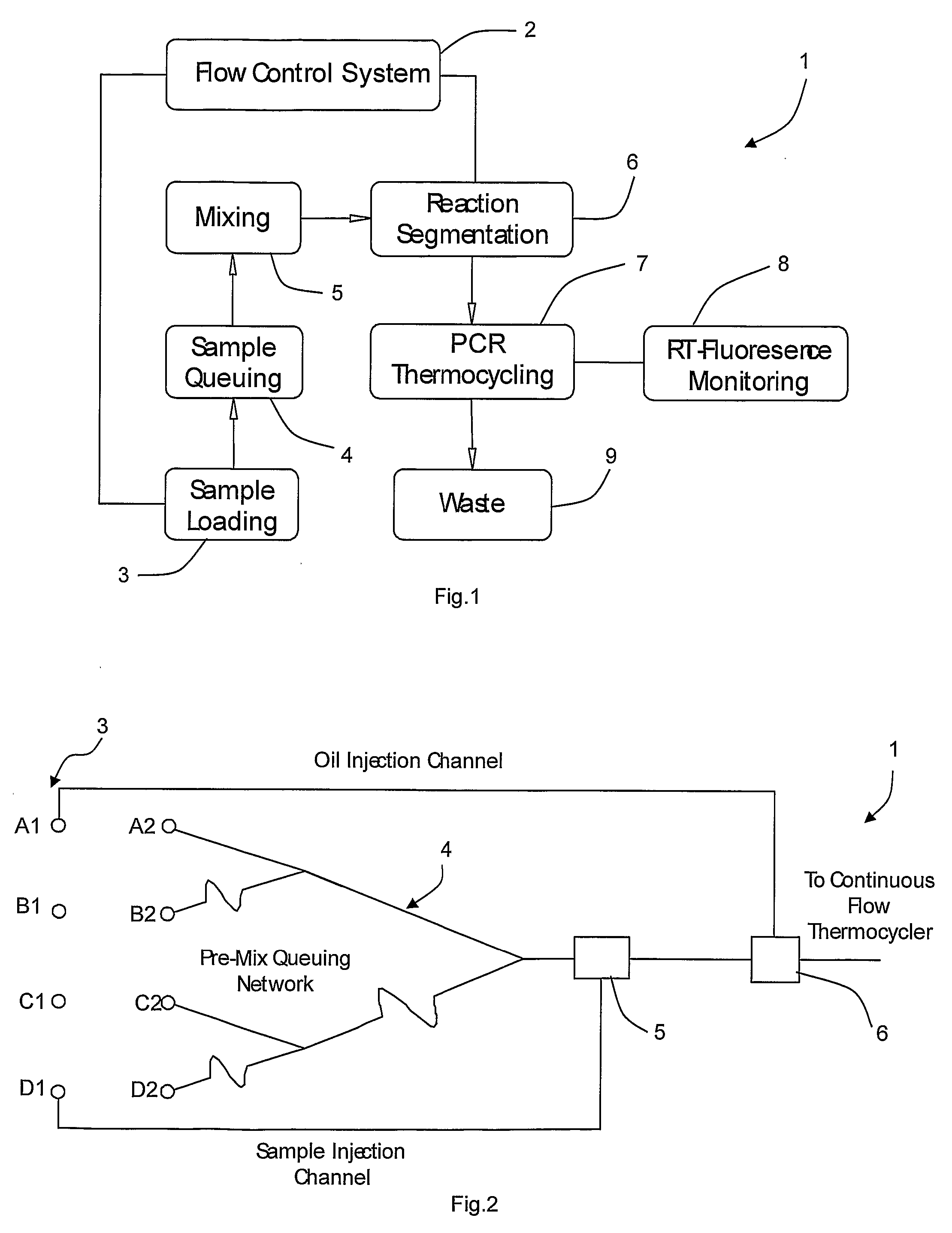

Liquid Bridge and System

ActiveUS20080277494A1Heating or cooling apparatusMaterial analysis by optical meansSmall dropletVolumetric Mass Density

A bridge (30) comprises a first inlet port (31) at the end of a capillary, a narrower second inlet port (32) which is an end of a capillary, an outlet port (33) which is an end of a capillary, and a chamber (34) for silicone oil. The oil is density-matched with the reactor droplets such that a neutrally buoyant environment is created within the chamber (34). The oil within the chamber is continuously replenished by the oil separating the reactor droplets. This causes the droplets to assume a stable capillary-suspended spherical form upon entering the chamber (34). The spherical shape grows until large enough to span the gap between the ports, forming an axisymmetric liquid bridge. The introduction of a second droplet from the second inlet port (32) causes the formation of an unstable funicular bridge that quickly ruptures from the, finer, second inlet port (32), and the droplets combine at the liquid bridge (30). In another embodiment, a droplet (55) segments into smaller droplets which bridge the gap between the inlet and outlet ports.

Owner:STOKES BIO LTD

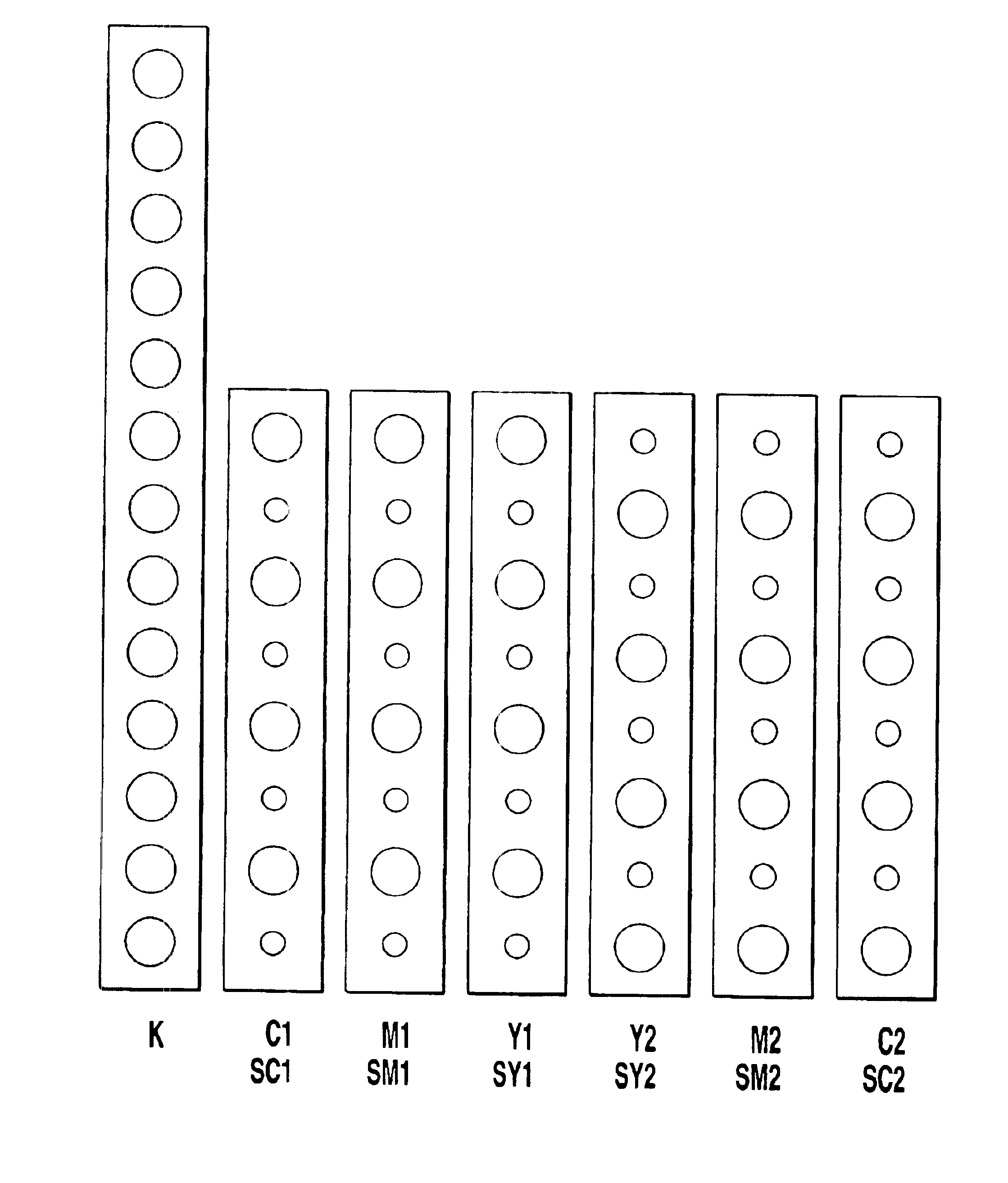

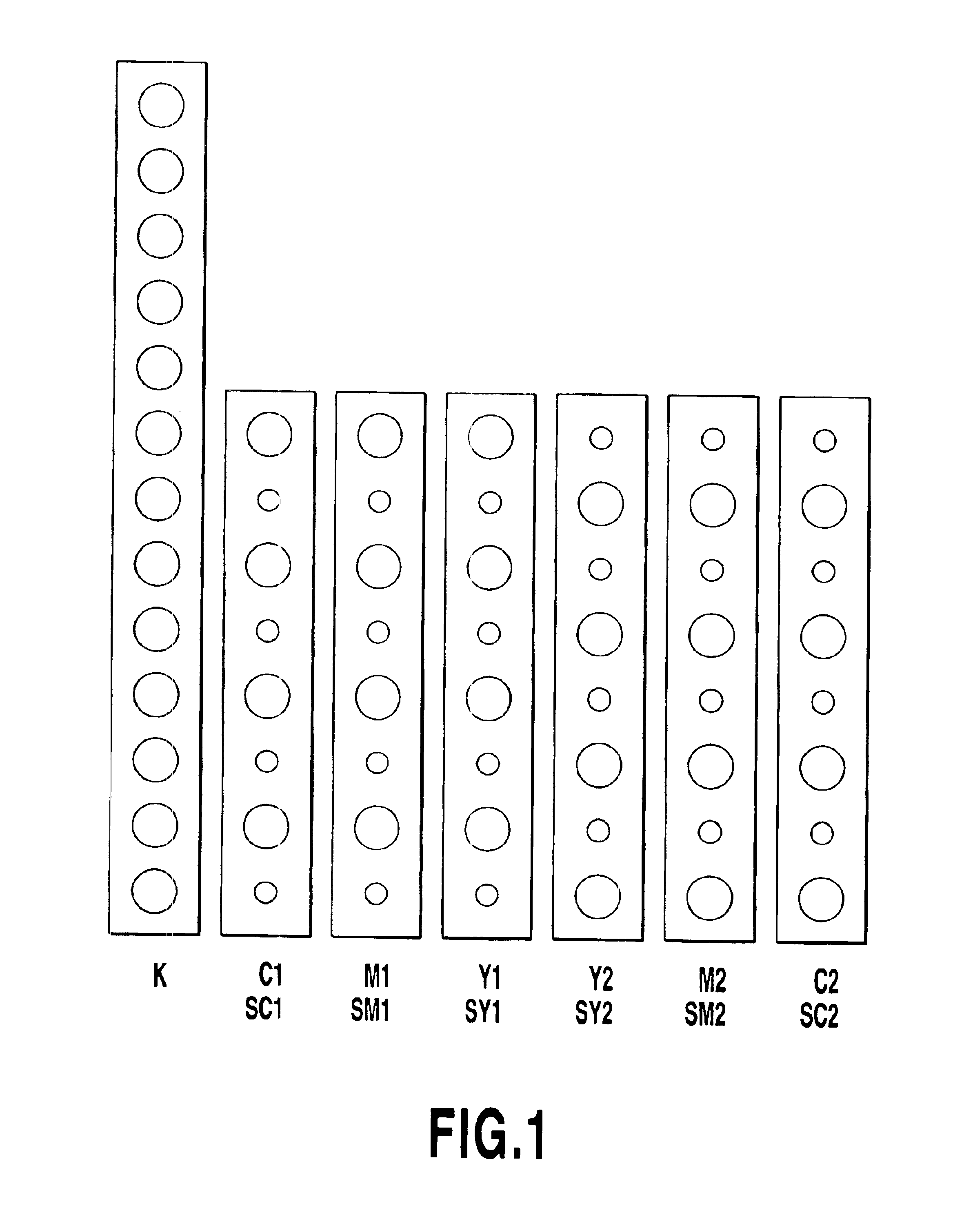

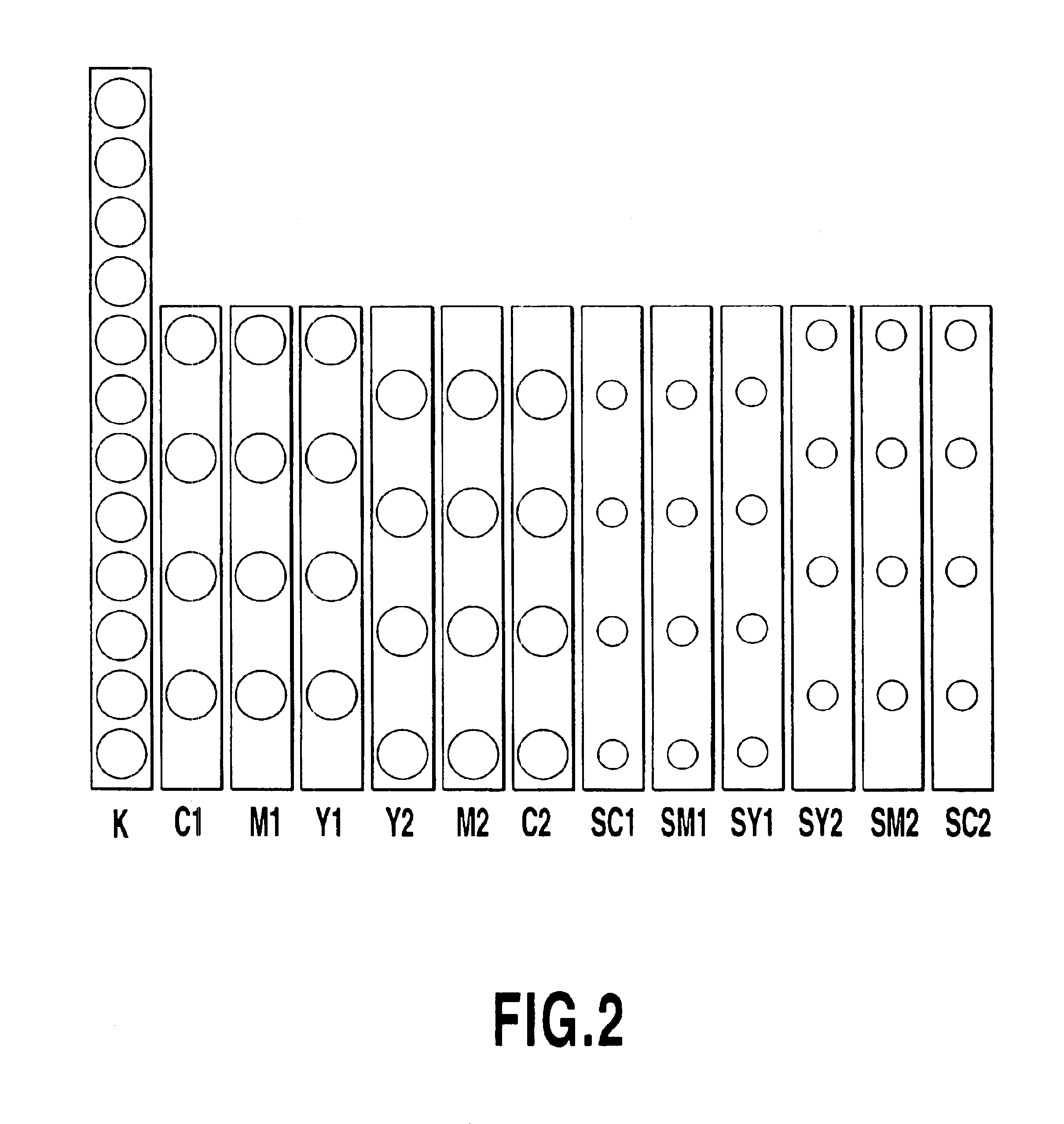

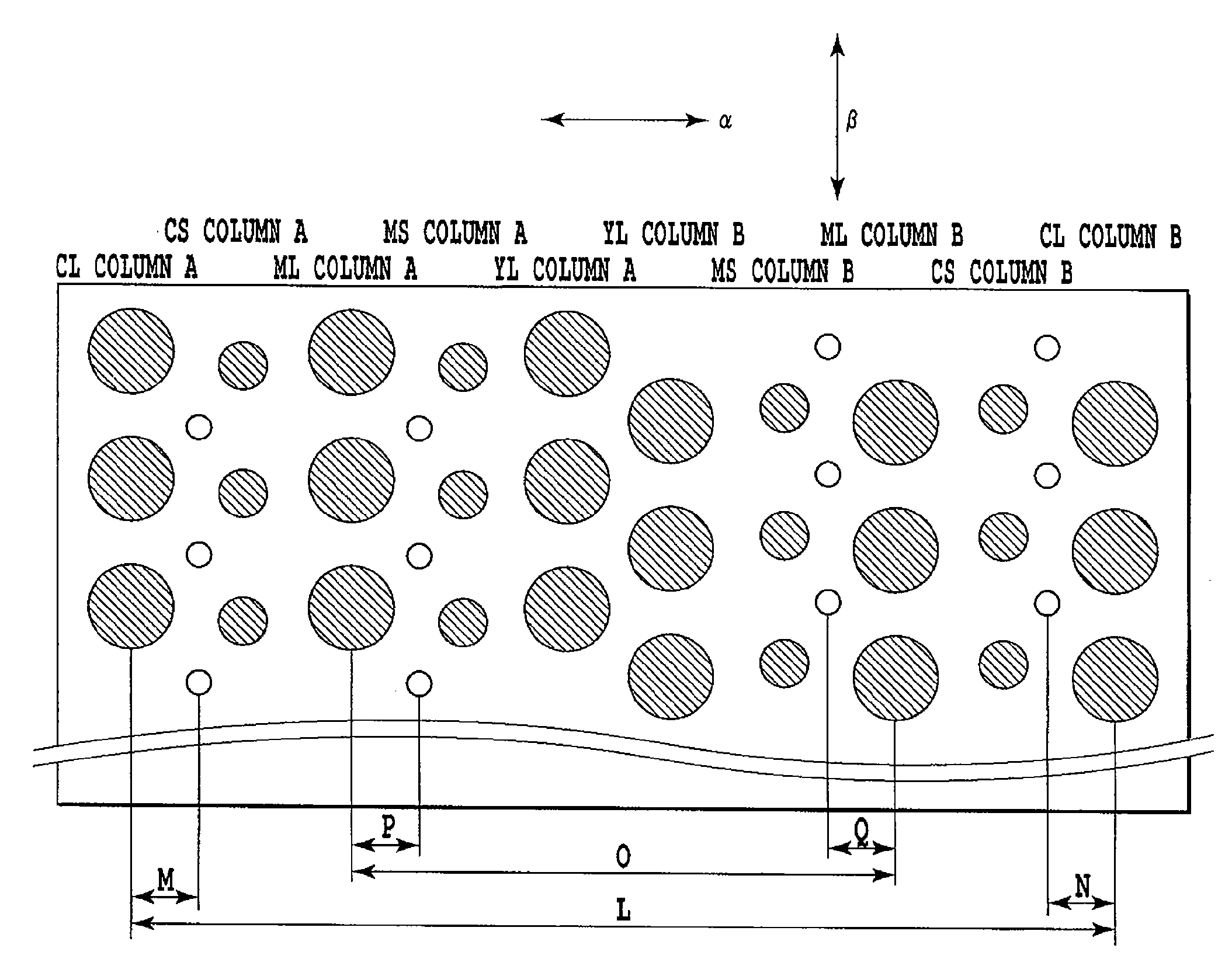

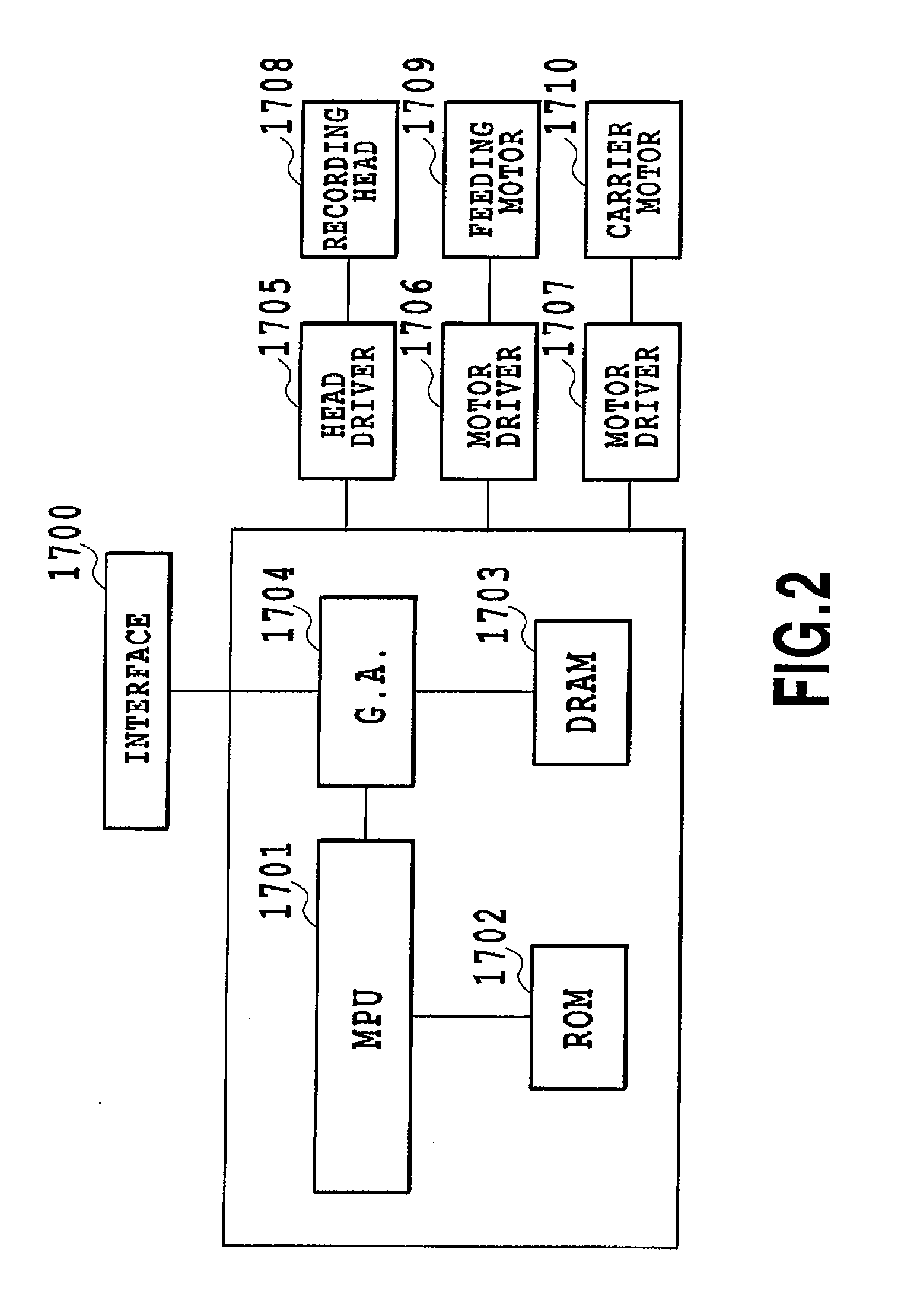

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6464319B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusSmall dropletPrinting registration

In the case where an image is formed with a mixture of large and small droplets by bi-directional printing in an ink jet printing apparatus in which ink is ejected in the form of, e.g., a droplet for printing operation while scanning by a print head, misalignment caused by a difference in ejection speed between the large and small droplets is prevented. For this purpose, there is provided a printing registration method according to the present invention comprises the steps of forming reference dots with the large and small droplets in forward scan printing, forming shifted dots in reverse scan printing on changed registration conditions, acquiring a adjustment value of the condition of dot forming positions on the basis of optical characteristics according to a plurality of shifting amounts of the relative printing positions between forward scanning and reverse scanning, controlling the order of formation of the large and small dots in the forward scanning and the reverse scanning, and correcting the adjustment value according to the offset amount of the small dot forming positions on the basis of the difference in ejection speed or the like.

Owner:CANON KK

Printing data producing method for printing apparatus

InactiveUS6877833B2Reduce image qualityQuality improvementDigitally marking record carriersDigital computer detailsSmall dropletEngineering

A printing apparatus can reduce degradation in print quality of a printed image, notably in a highlight portion or an intermediate gradation portion, in the case where the image is printed by forming dots of a plurality of sizes. Specifically, data causing larger and smaller cyan ink droplets, respectively, to be ejected is independently subjected to a conversion to n-value process. Thus, the data for larger ink droplets is present in a portion of printing data which corresponds to the highlight portion or intermediate gradation portion of the image. During printing, larger dots are formed in this area, thereby making it difficult to perceive possible stripes caused by the offset of the positions at which smaller droplets impact a sheet.

Owner:CANON KK

Focused analyte spray emission apparatus and process for mass spectrometric analysis

ActiveUS20110220784A1High resolutionMaintain temperatureSamples introduction/extractionIsotope separationSmall dropletAnalyte

An apparatus and process are disclosed that deliver an analyte deposited on a substrate to a mass spectrometer that provides for trace analysis of complex organic analytes. Analytes are probed using a small droplet of solvent that is formed at the junction between two capillaries. A supply capillary maintains the droplet of solvent on the substrate; a collection capillary collects analyte desorbed from the surface and emits analyte ions as a focused spray to the inlet of a mass spectrometer for analysis. The invention enables efficient separation of desorption and ionization events, providing enhanced control over transport and ionization of the analyte.

Owner:BATTELLE MEMORIAL INST

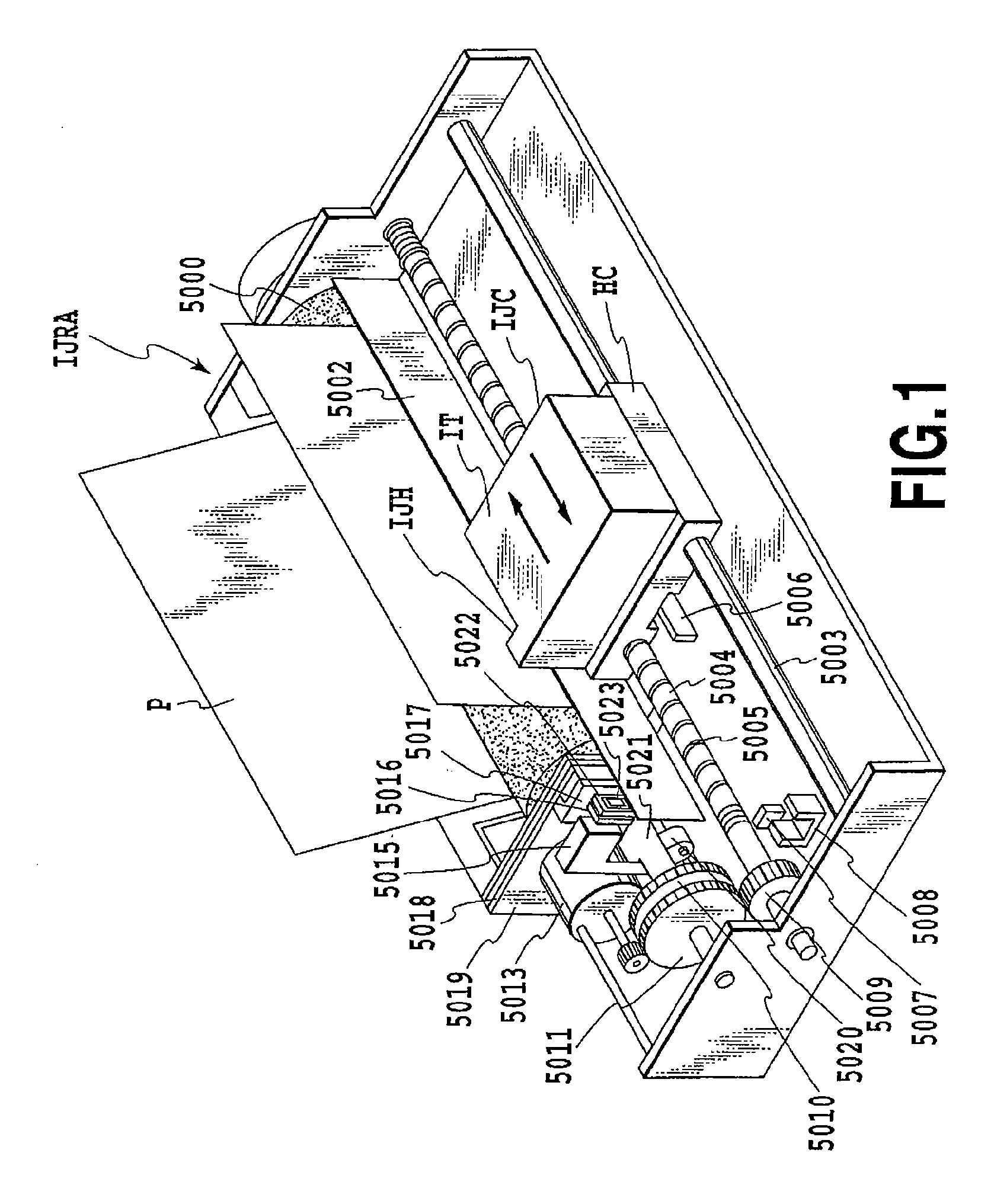

Ink jet recording head and ink jet recording apparatus

InactiveUS20080143786A1High image quality recordingRecording unevennessInking apparatusSmall dropletImaging quality

An ink jet recording head and an ink jet recording apparatus are provided to prevent occurrence of a white line or recording unevenness due to a head tilt, and realize a high image quality recording. For this purpose, in a recording head provided with nozzles ejecting three types of droplets, a large droplet, medium droplet and small droplet, nozzles are configured such that any nozzles are not arranged on the same line at the centers thereof in the main scanning direction.

Owner:CANON KK

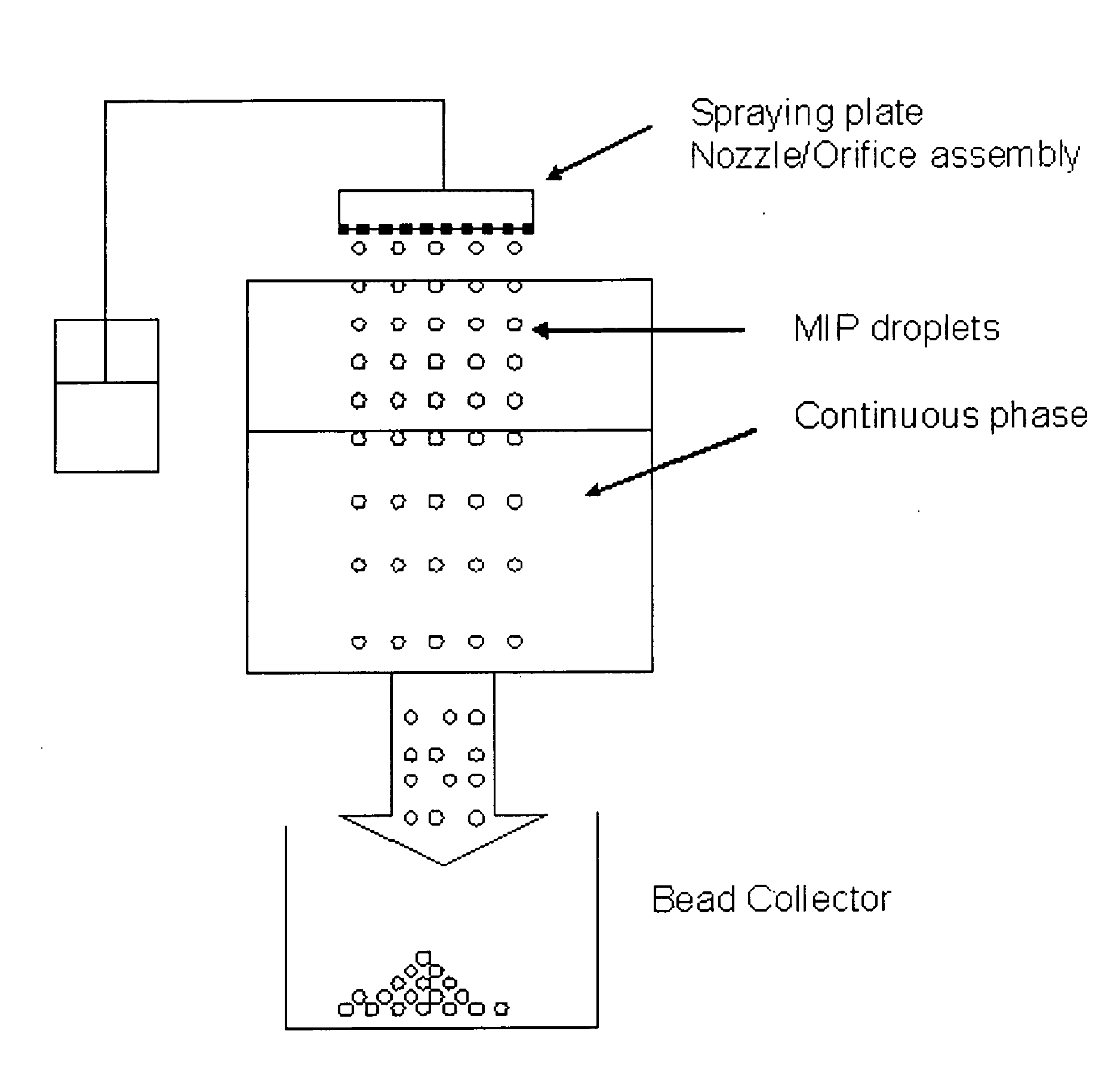

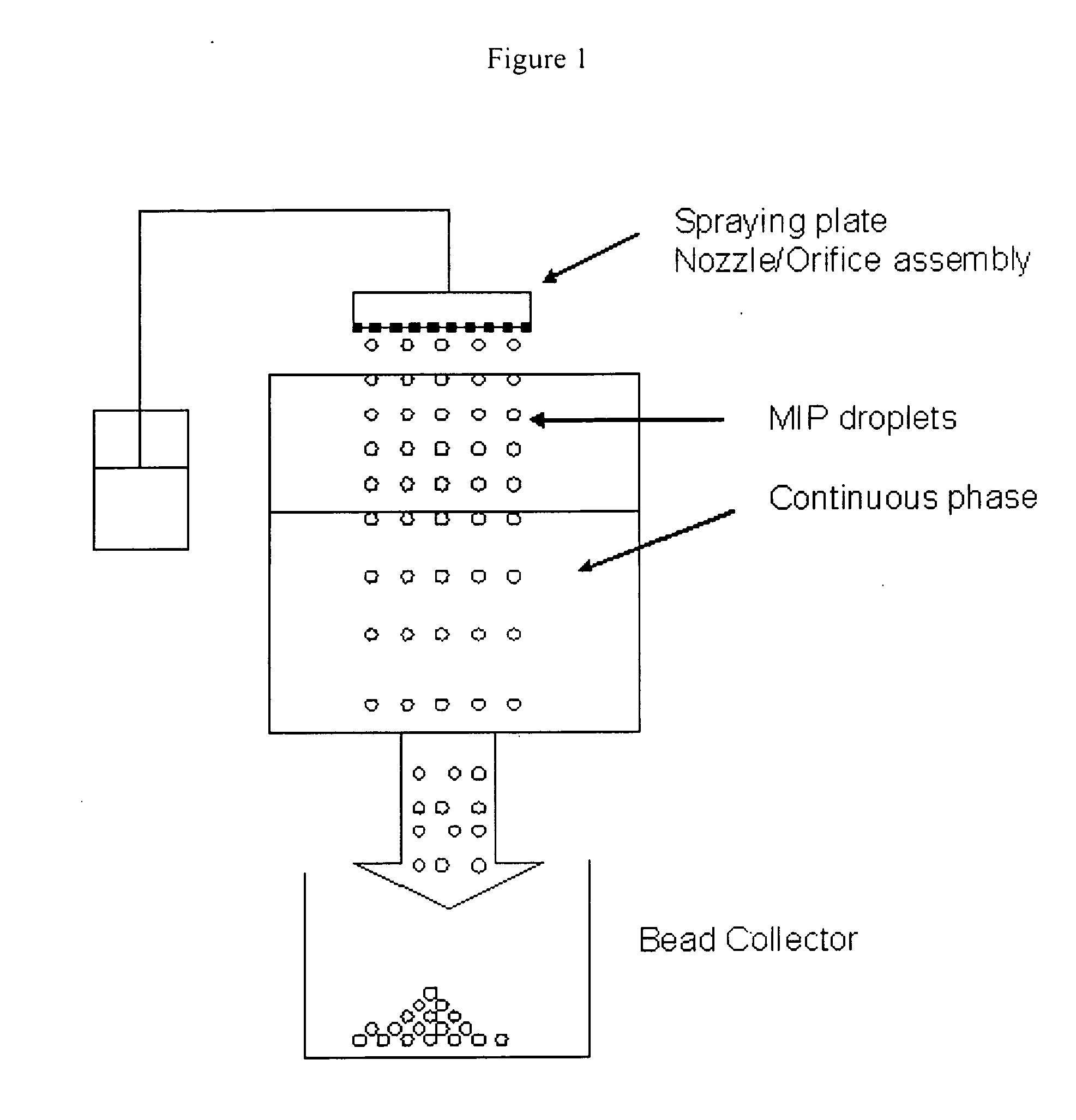

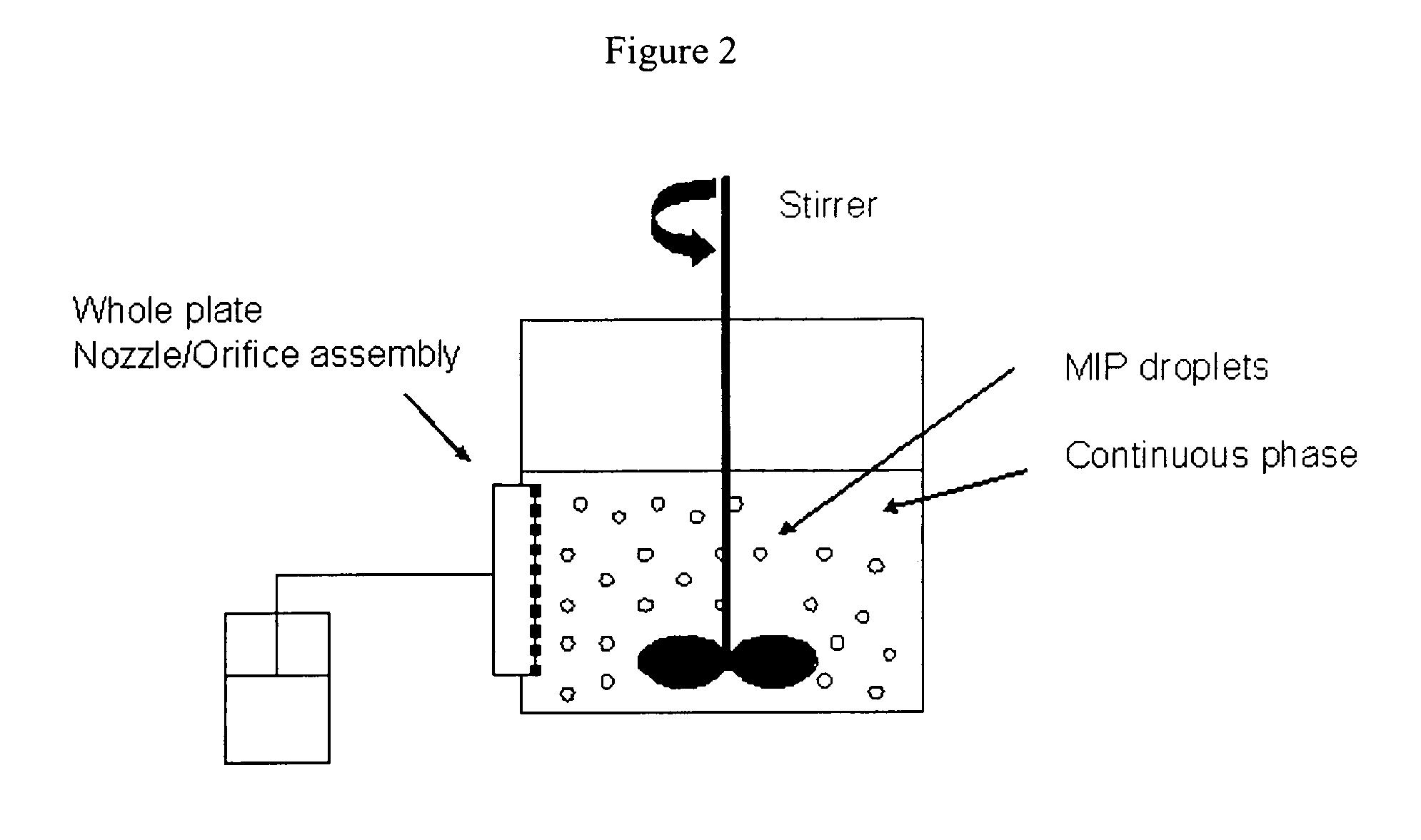

Monodisperse Molecularly Imprinted Polymer Beads

InactiveUS20090281272A1Low yieldPoor process controlOrganic-compounds/hydrides/coordination-complexes catalystsGranulation by liquid drop formationSmall dropletMolecularly imprinted polymer

The invention relates to a molecularly imprinted polymer resin characterized by a monodisperse size distribution prepared by forming monomer droplets via a membrane, polymerizing said droplets in an appropriate continuous phase, and harvesting the resulting polymer particles. The invention also relates to a method for producing a molecularly imprinted polymer resin, wherein a monomer solution is forced through a dispersing device capable of forming small droplets, the droplets are projected into a continuous phase in which a polymerization is initiated leading to solidification of the droplets into beads.

Owner:MIP TECH AB

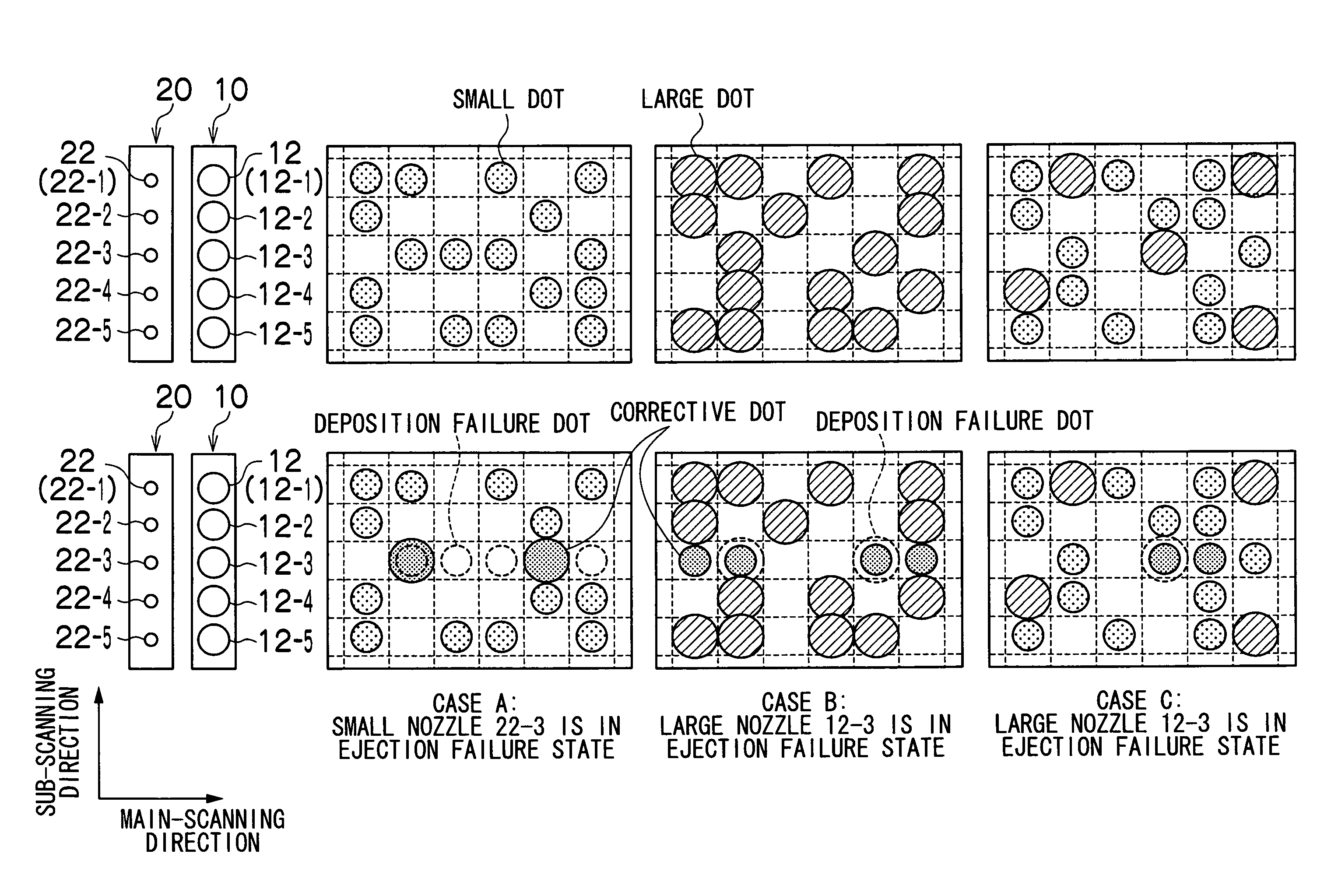

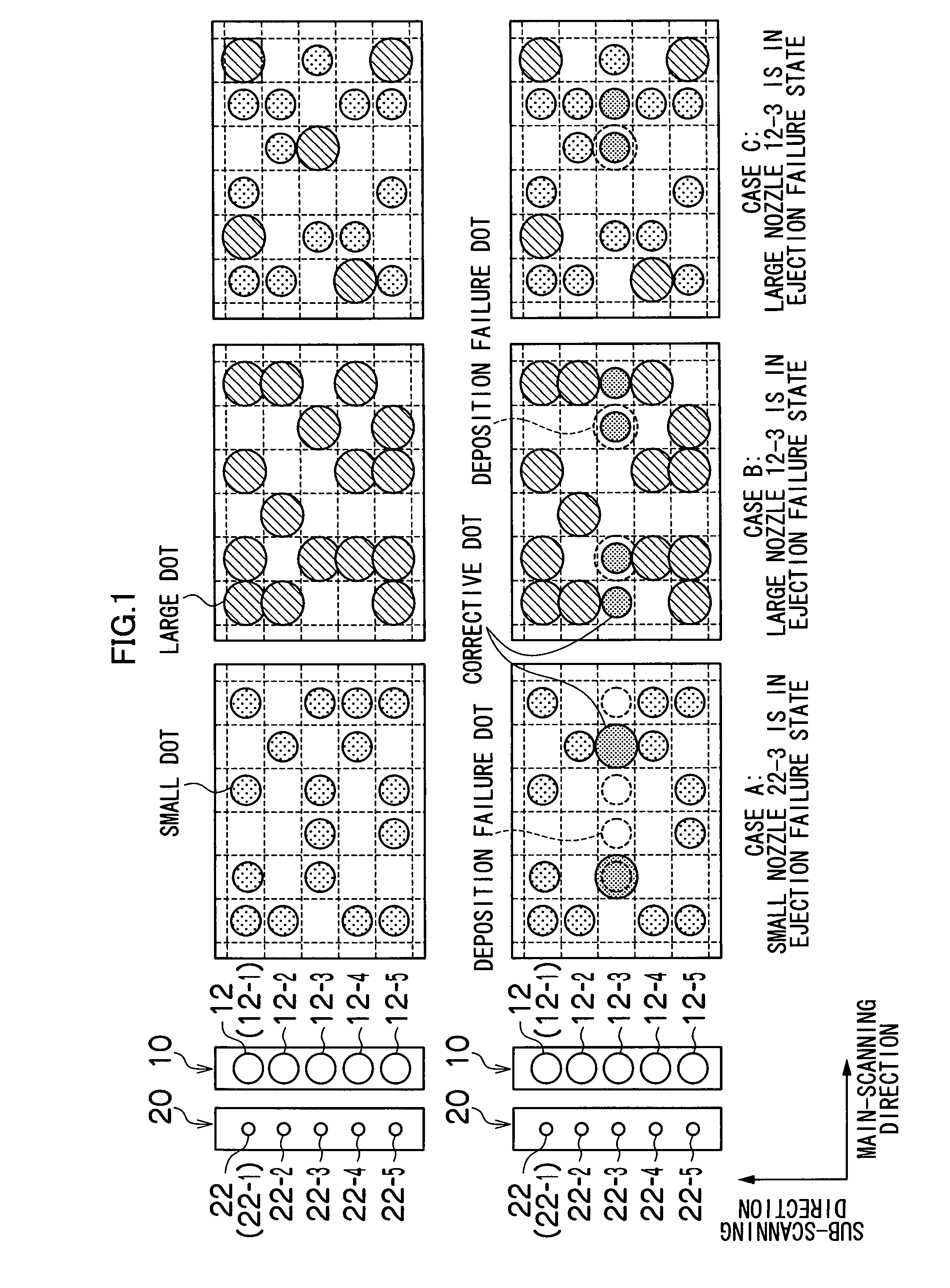

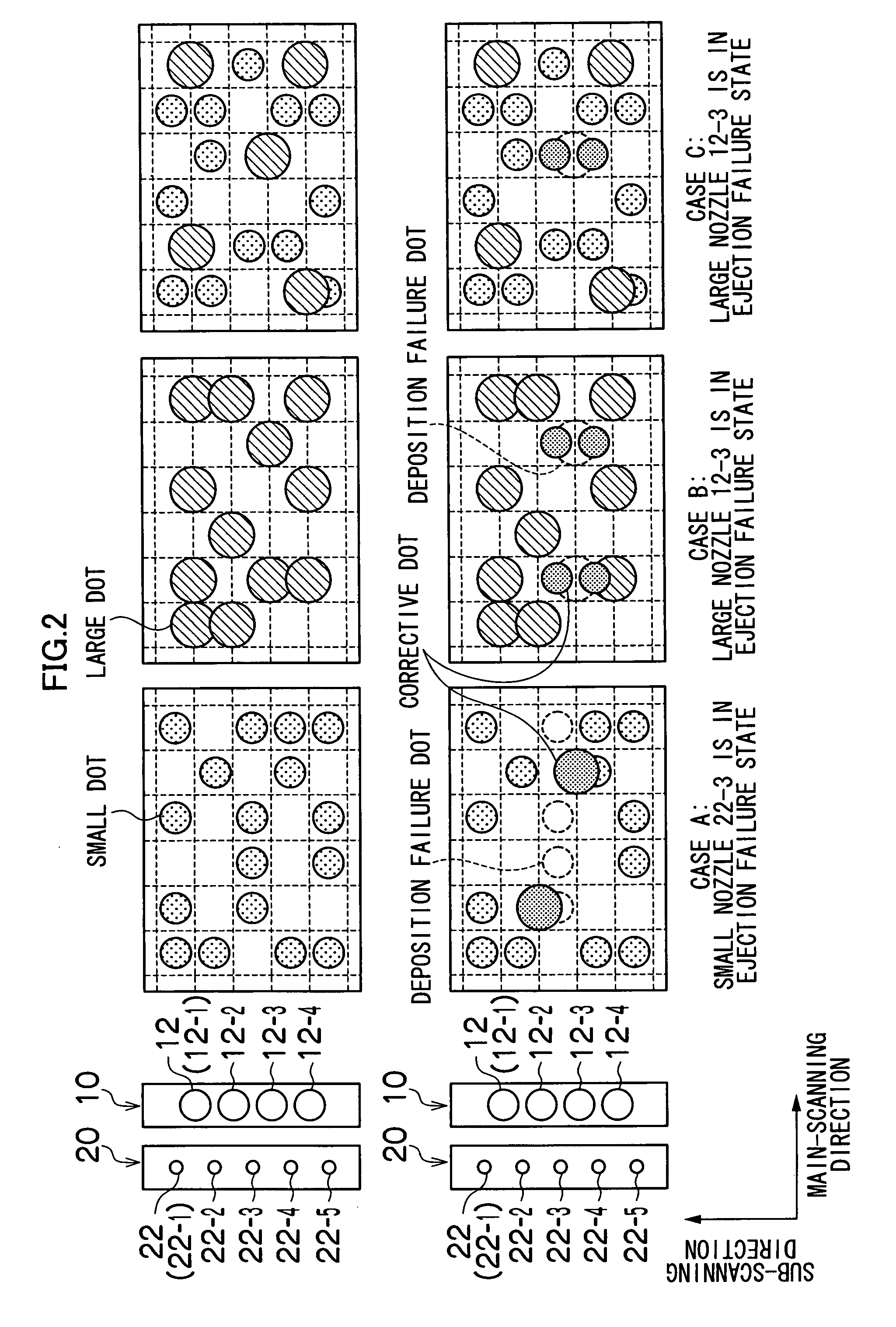

Image forming apparatus and method

InactiveUS20070211101A1Improve visibilityReduce load concentrationOther printing apparatusSmall dropletImage formation

The image forming apparatus includes: a first group of large nozzles which eject large droplets of liquid for a color; a second group of small nozzles which eject small droplets of the liquid for the color, the small droplets having volume smaller than the large droplets; a dot data creation device which creates dot data according to input image data; a dot data correction device which corrects the dot data if there is an abnormal nozzle in one of the first and second groups, in such a manner that a corrective nozzle is selected from the other of the first and second groups, and droplet ejection performed by the corrective nozzle substitutes for droplet ejection that is originally to be performed by the abnormal nozzle; and a driving device which drives the large and small nozzles to eject the large and small droplets according to the corrected dot data.

Owner:FUJIFILM CORP

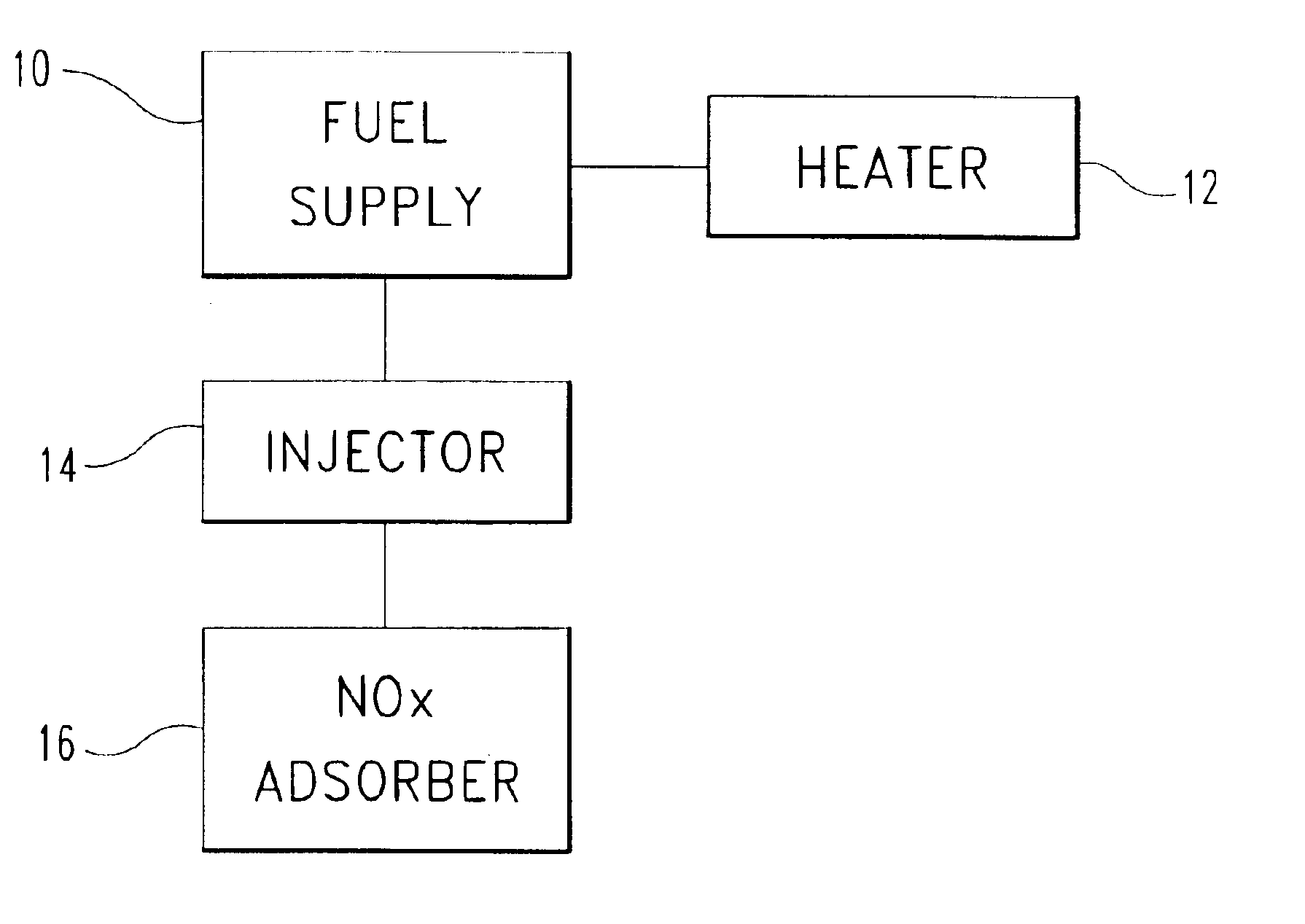

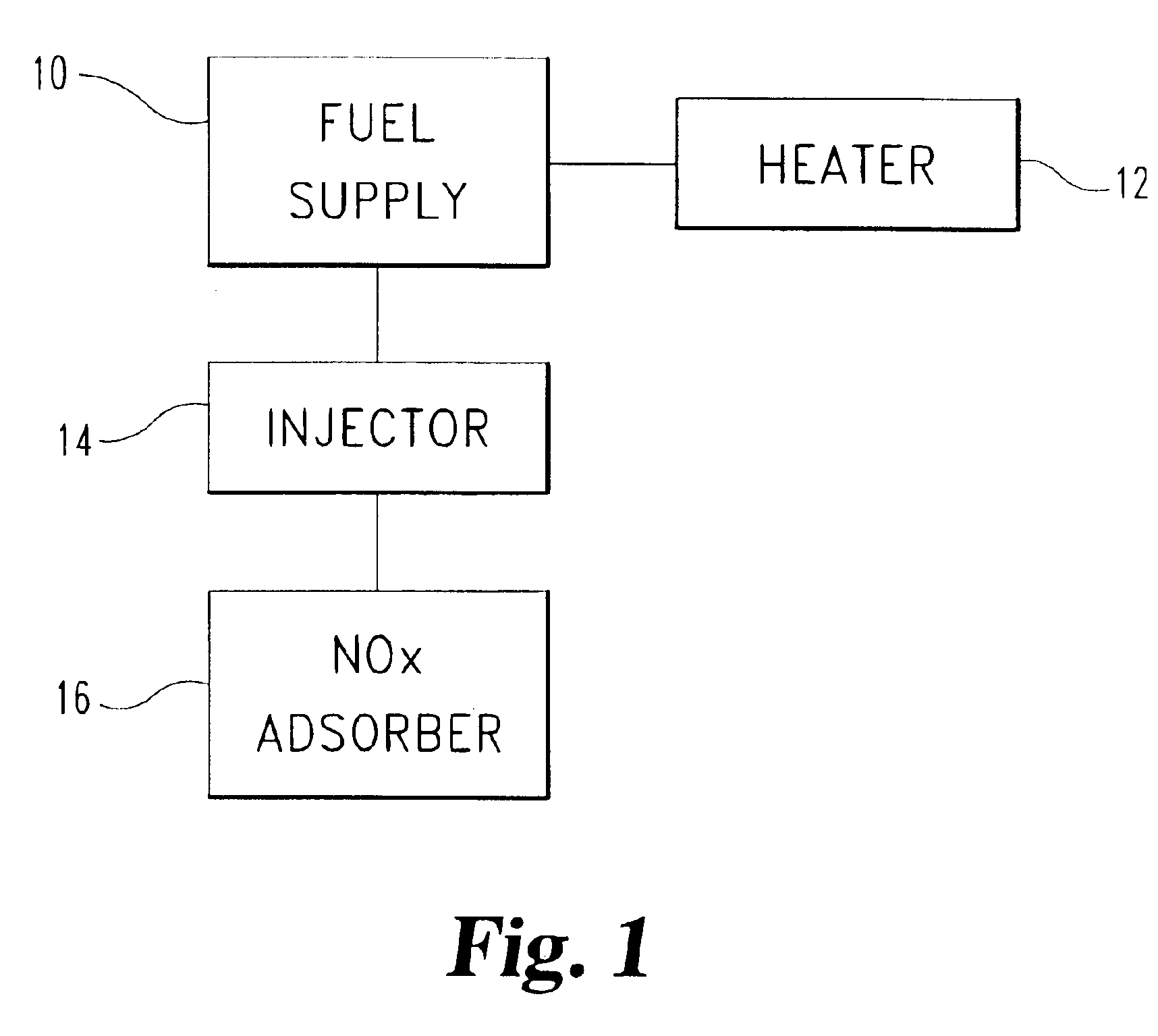

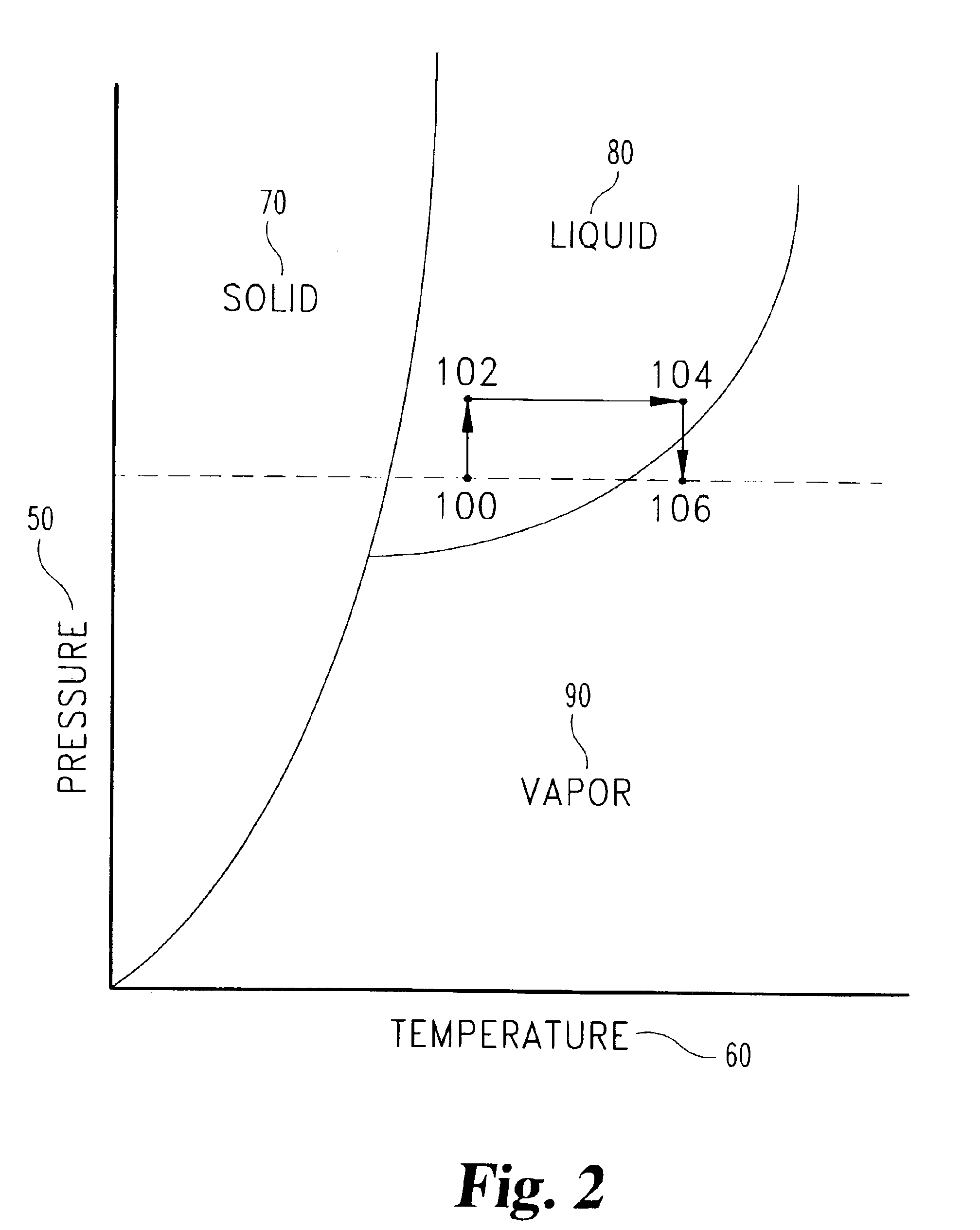

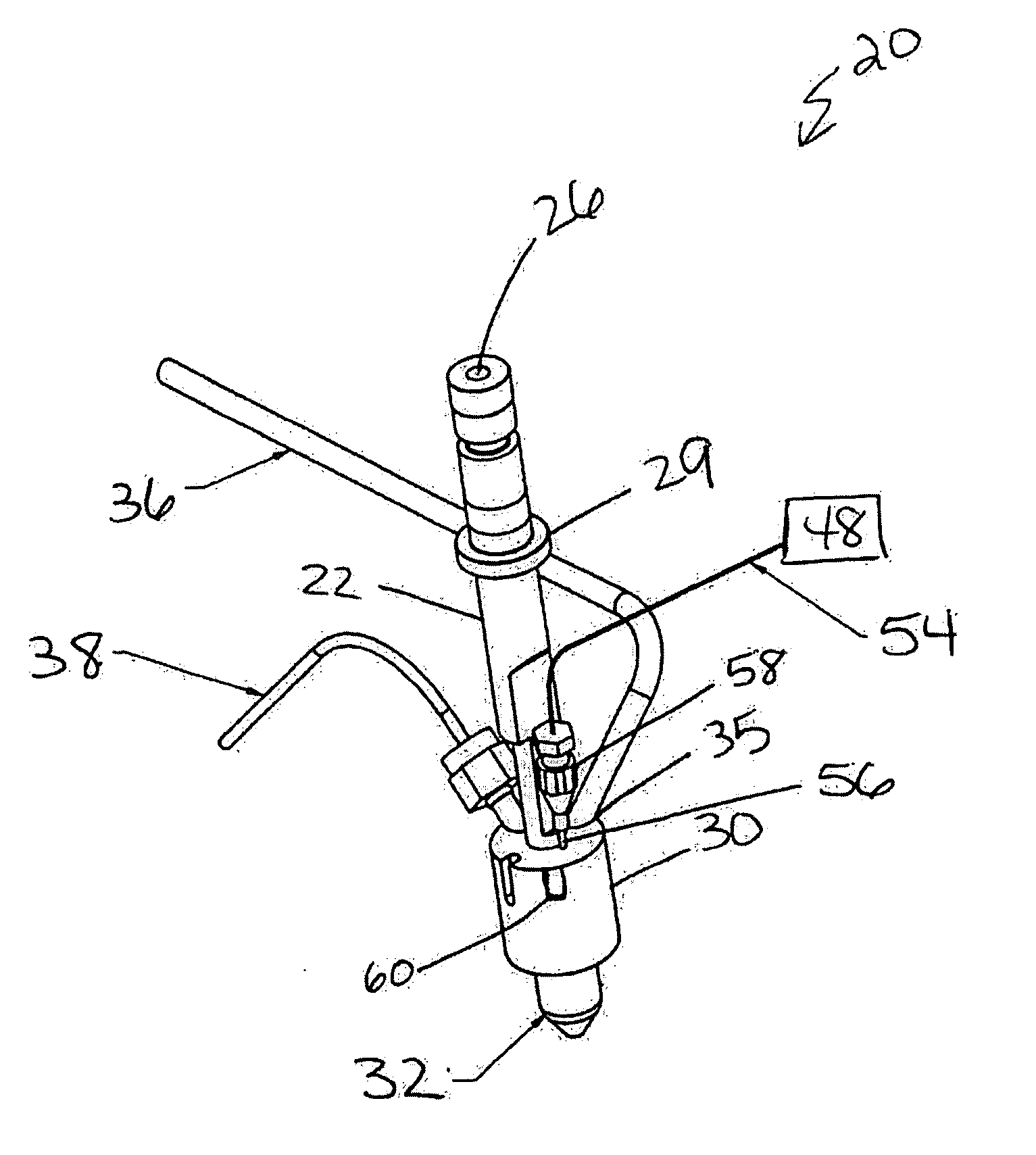

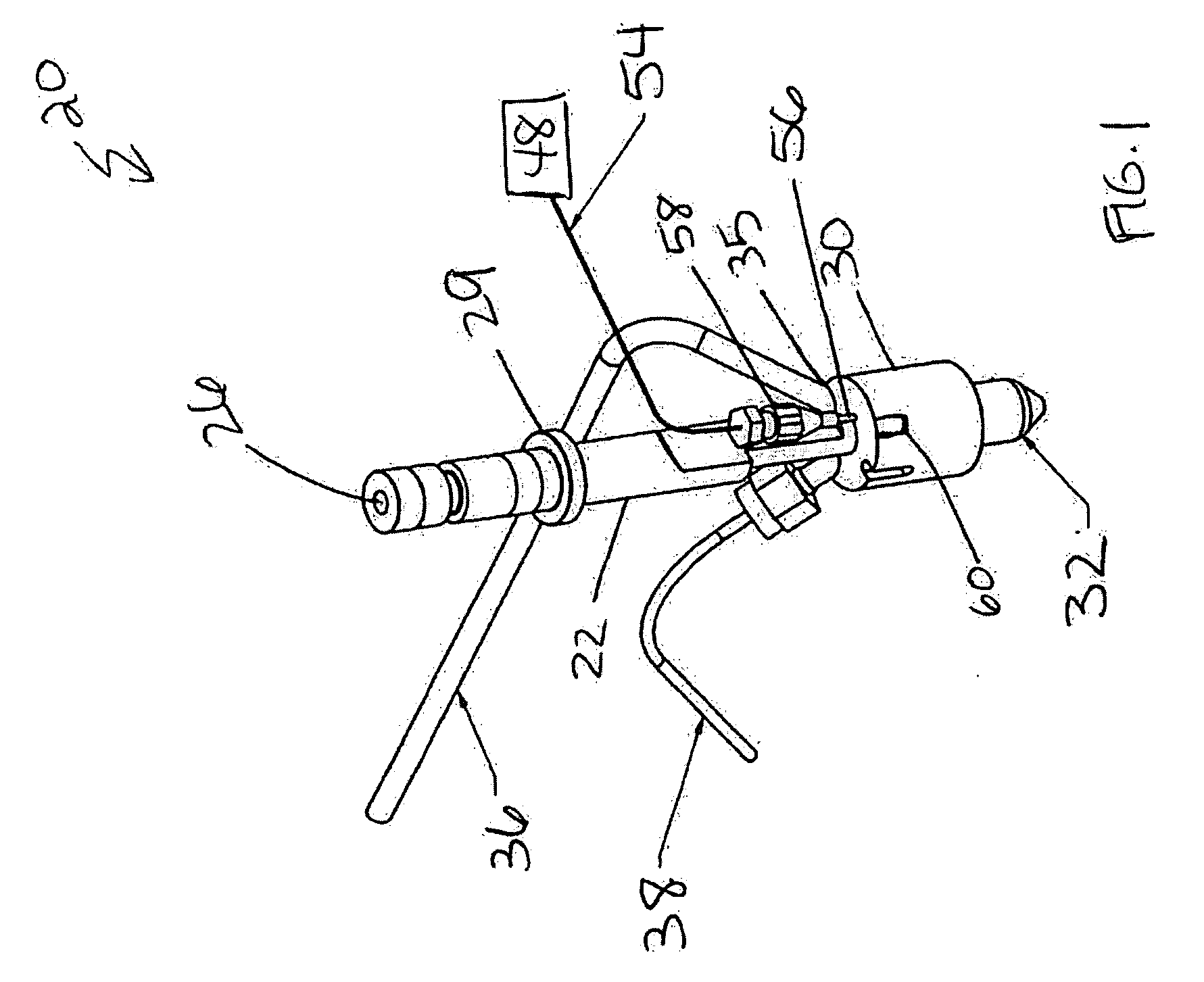

System and method for enhancing internal combustion engine aftertreatment applications by superheated fuel injection

InactiveUS6922987B2Enhancing aftertreatment applicationLower emission levelsInternal combustion piston enginesExhaust apparatusPremature agingSmall droplet

The present invention provides for a system and process for enhancing internal combustion engine aftertreatment applications by superheated fuel injection. The system includes a fuel supply upstream of a fuel injector of an aftertreatment application. The system also includes a heater for heating the fuel in the fuel supply. A temperature controller can be used to maintain the heated fuel in a liquid form. When liquid fuel in the pressurized fuel supply is heated, then upon exiting the injector the pressure of the fuel drops rapidly, resulting in atomization of the liquid. The vaporized fuel thereby produced is comprised of extremely small droplets and is elevated in temperature, which reduces the possibility of condensation on internal surfaces of the aftertreatment system. This fine droplet size and resistance to condensation enhances the NOx conversion efficiency of adsorbers. Problems related to premature aging of catalysts and fuel penalties can also be reduced.

Owner:CUMMINS FILTRATION INC

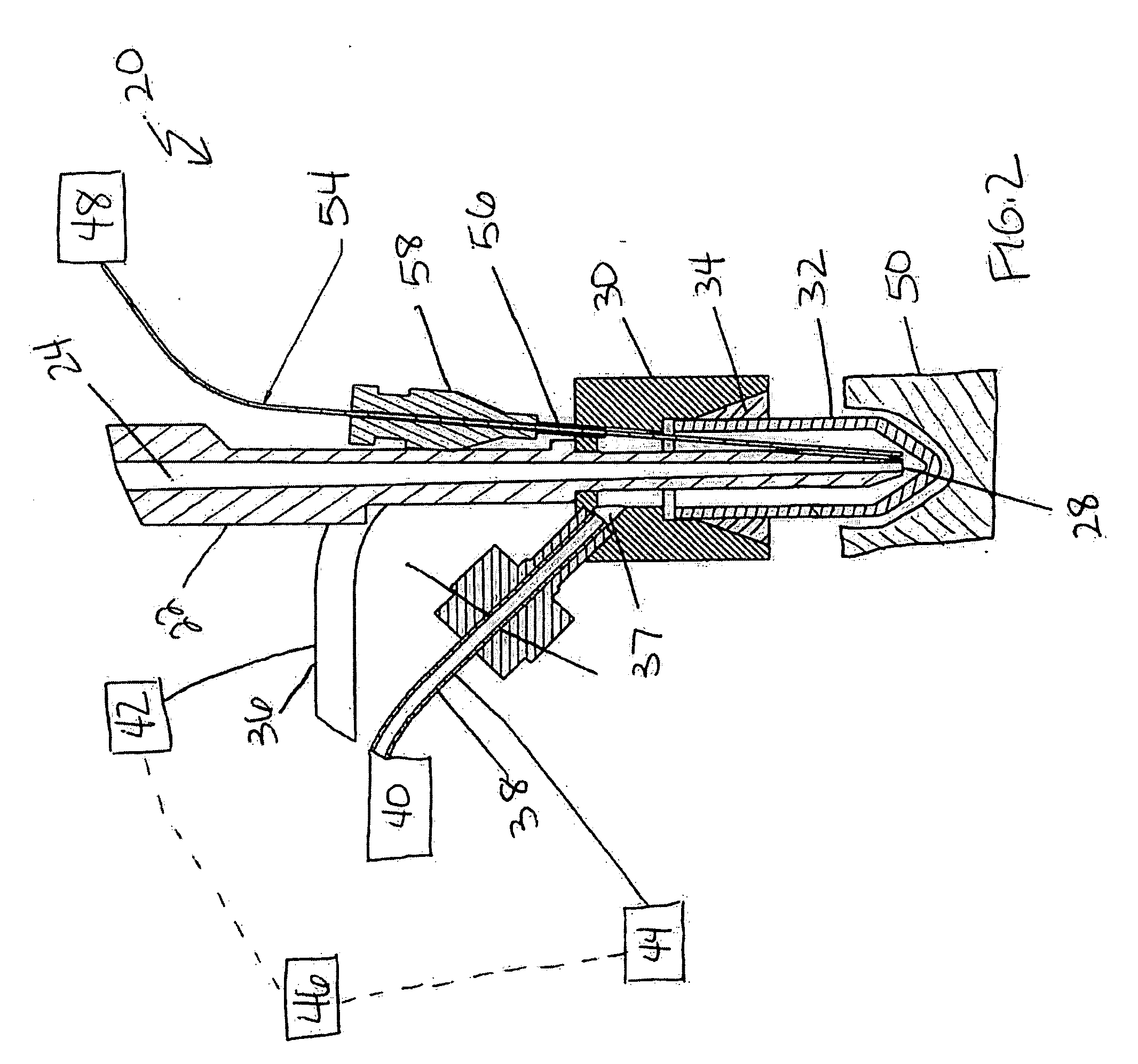

Dual outlet pyrolyzer for biological agent detection system

ActiveUS20060006327A1Avoid chargingWider diameterChemical analysis using combustionTime-of-flight spectrometersSmall dropletEngineering

A chemical biological detection system detects the presence of biological agents in the air. The system includes a pyrolyzer having an inlet through which air is drawn into the pyrolyzer and a pyrotube that collects a sample of particles extracted from the air. The pyrolyzer further includes an exhaust line that exhausts the air drawn into the pyrolyzer and a sample line that directs the gases eluted from the sample collected in the pyrotube to a mass spectrometer for sample identification. After the sample is collected in the pyrotube, the sample is analyzed. A small droplet of a methylating reagent is added to the sample. If the sample includes any biological agents, the methylating reagent derivatizes organic materials to make them more volatile. The sample is then pyrolyzed, and the eluted gas sample is drawn through the sample line and into the mass spectrometer for identification of any biological agents.

Owner:HAMILTON SUNDSTRAND CORP

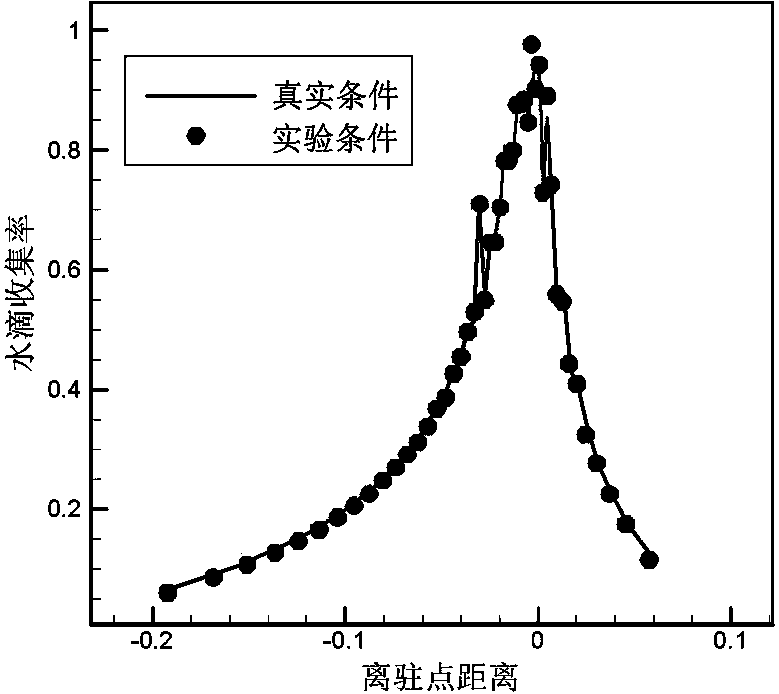

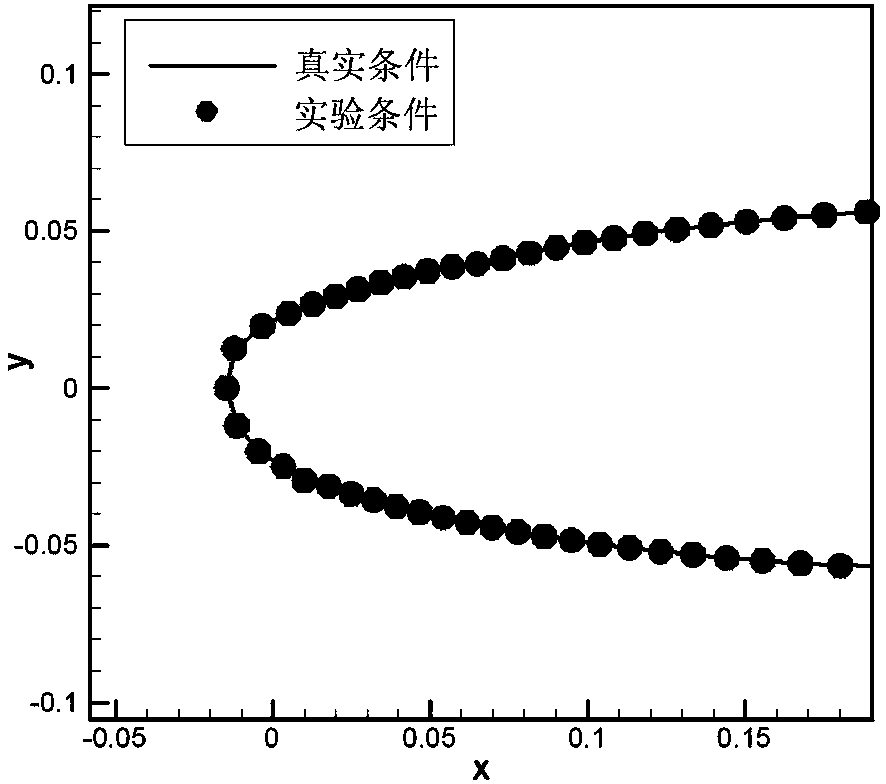

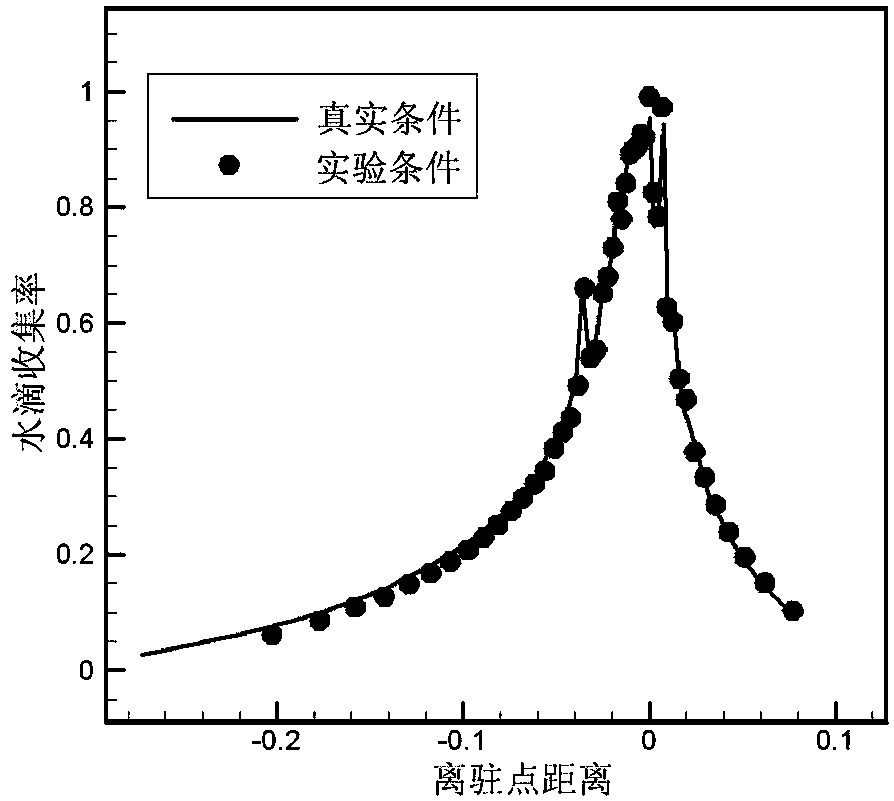

Computing method of model parameters in icing wind tunnel experiment under supercooled large droplet condition

InactiveCN104268399AMeet the similarity requirementsSpecial data processing applicationsJet aeroplaneScale model

The invention discloses a computing method of model parameters in an icing wind tunnel experiment under a supercooled large droplet condition and aims at solving the problems that an existing parameter selecting method for a supercooled small droplet icing experiment does not function well if being applied to a supercooled large droplet icing experiment and that the real icing condition cannot be reflected by icing on a scale model of the airplane. The computing method of the model parameters in the icing wind tunnel experiment under the supercooled large droplet condition is capable of orderly giving the experimental parameters of a wind tunnel test section such as air velocity, average droplet grain diameter, air pressure, liquid water content, icing time and low supercooled water temperature corresponding to real icing flying conditions by use of a theoretical derivation and numerical computation method after determining the scale relation of the model and the real airplane. An aircraft icing wind tunnel experiment is performed according to the converted test parameters, and the experimental result and the real result are capable of meeting the similarity requirement on the major characteristics of the icing process. As a result, the computing method of the model parameters in the icing wind tunnel experiment under the supercooled large droplet condition is capable of obtaining the model parameters for the icing wind tunnel experiment; the corresponding parameters are capable of reflecting the real icing condition in the icing wind tunnel experiment.

Owner:AERODYNAMICS NAT KEY LAB

Low-pressure steam turbine

A low-pressure turbine is provided with guide vanes and rotating vanes, the vane blades of which have a coating that is hydrophobic or water-repellant and has a smooth surface. The coating preferably contains amorphous carbon. The hydrophobic property of the coating has the result that small droplets contained in the steam phase, upon impacting a coated vane blade, roll off across the vane blade in the form of small droplets and further follow the steam flow. This prevents moisture losses and increases the efficiency of the turbine. It also prevents the small droplets on the vane blades from coalescing into larger drops or into a fluid film. This prevents erosion due to the impact of large drops on vanes and other components of the turbine.

Owner:GENERAL ELECTRIC TECH GMBH

Anti-icing material and surface treatments

InactiveUS20090294724A1High densityHigh strengthOther chemical processesDe-icing equipmentsSmall dropletPolyvinyl alcohol

An anti-icing composition including a chemically-bound nano-layer based on a multivalent atom such as silicon or titanium, and whiskers of hydroxyls, polyols, polyethers, polyamines, poly-acids or mixtures of such hydrophilic functionalities. This base layer may be used as such or have an additional coating overlying it, e.g., comprising a polymeric polyol such as polyvinylalcohol or polyglycol. The second layer may also be chemically bonded to the surface or to the first layer. Surface treatment with such composition prevents small droplets of water from freezing on the surface and reduces dramatically their friction with the surface. The result is the prevention of icing of the surface, reduction in the adhesion of ice to the surface and reduction in the accumulation of ice layers. The anti-icing composition also makes removal of ice from the surface much easier once accumulated, and is useful in reducing de-icing requirements of aircraft and in retarding in-flight ice formation. Other applications include coating window panels and vehicles exposed to icing conditions and preventing bulk particles from adhering to each other in icy conditions.

Owner:APPEALING PRODS

Method and apparatus for producing a discrete droplet for subsequent analysis or manipulation

InactiveUS7785897B2Radiation/particle handlingSamples introduction/extractionSmall dropletDesolvation

Owner:SIMON FRASER UNIVERSITY

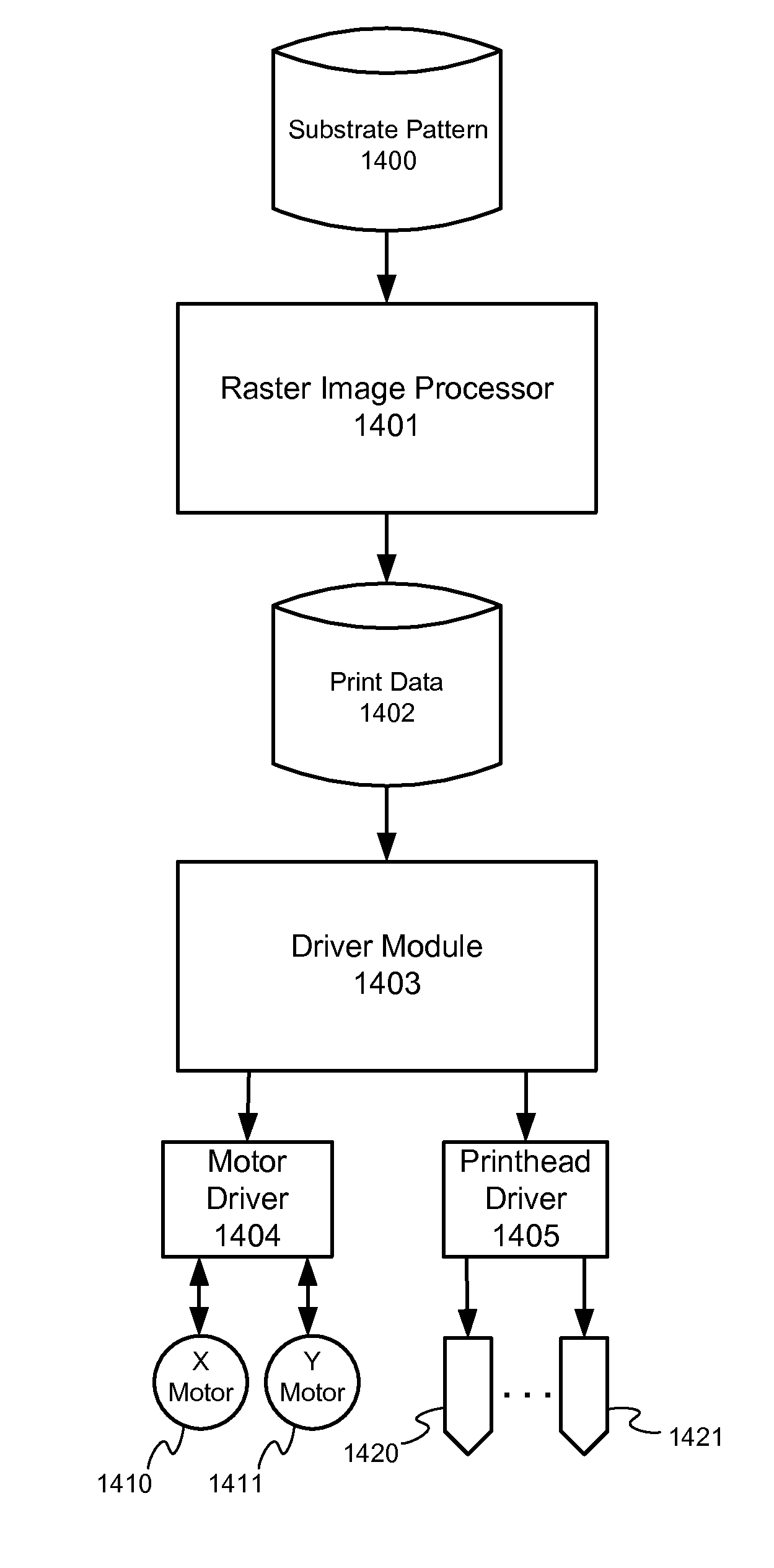

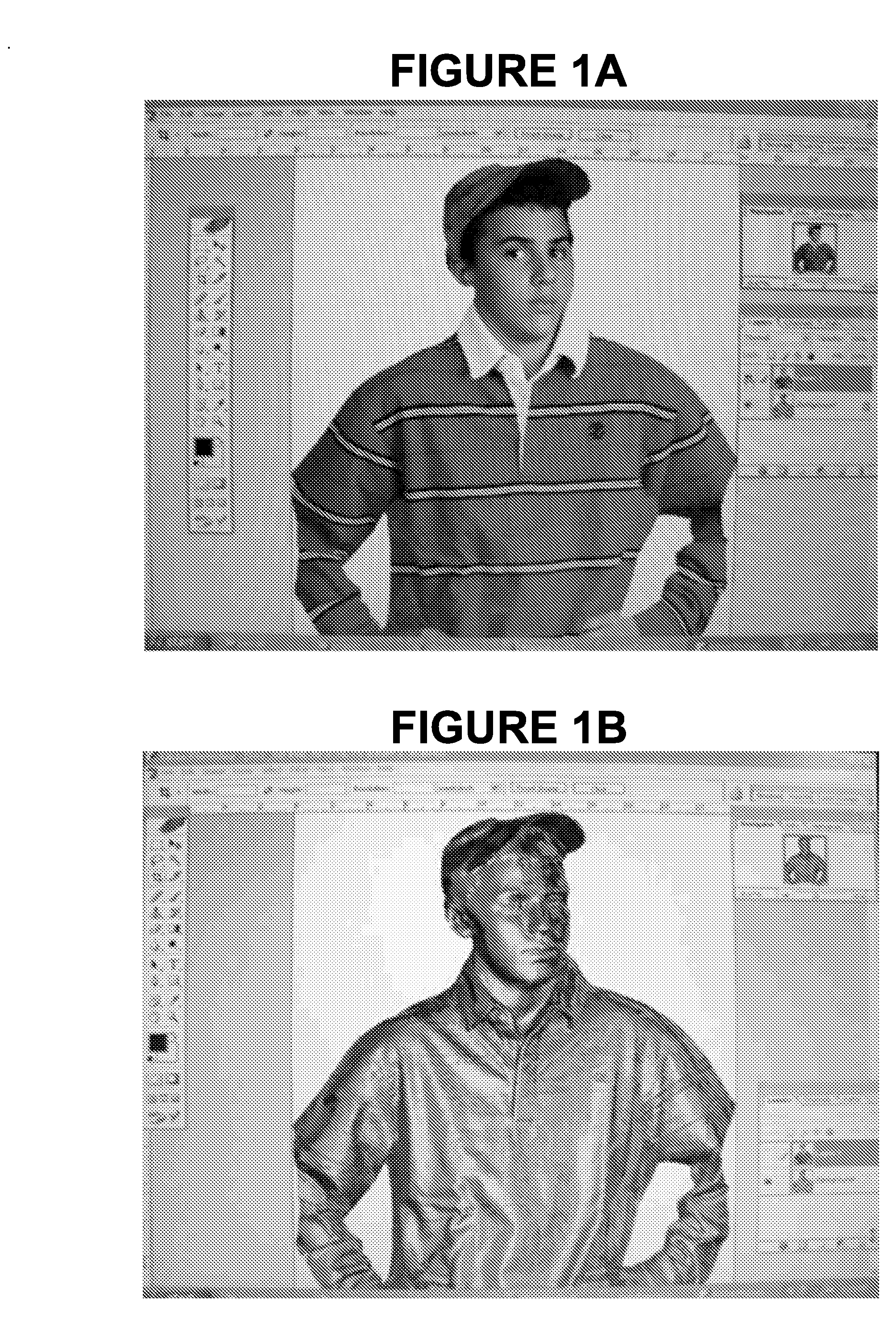

Method and Apparatus For Three-Dimensional Digital Printing

Techniques are presented for digital ink jet printing upon a substrate with a significant third dimension. Droplets in the range of 120 pL to 200 pL have been found suitable for substrates with variability, in the third dimension, of up to approximately 4 cm. A larger droplet can be generated by utilizing a plurality of drive pulses, each of which generates a smaller droplet, and having the plurality of smaller droplets combine in mid-air. The data to be printed can be derived from a 3D model and such 3D model can also be used to guide shaping of the substrate. The 3D model can be produced from 2D image data. If the 2D image data is a two-dimensional portrait photograph, a result, of using the present invention, can be a realistic portrait in the form of a bas-relief sculpture.

Owner:3DPHOTOWORKS

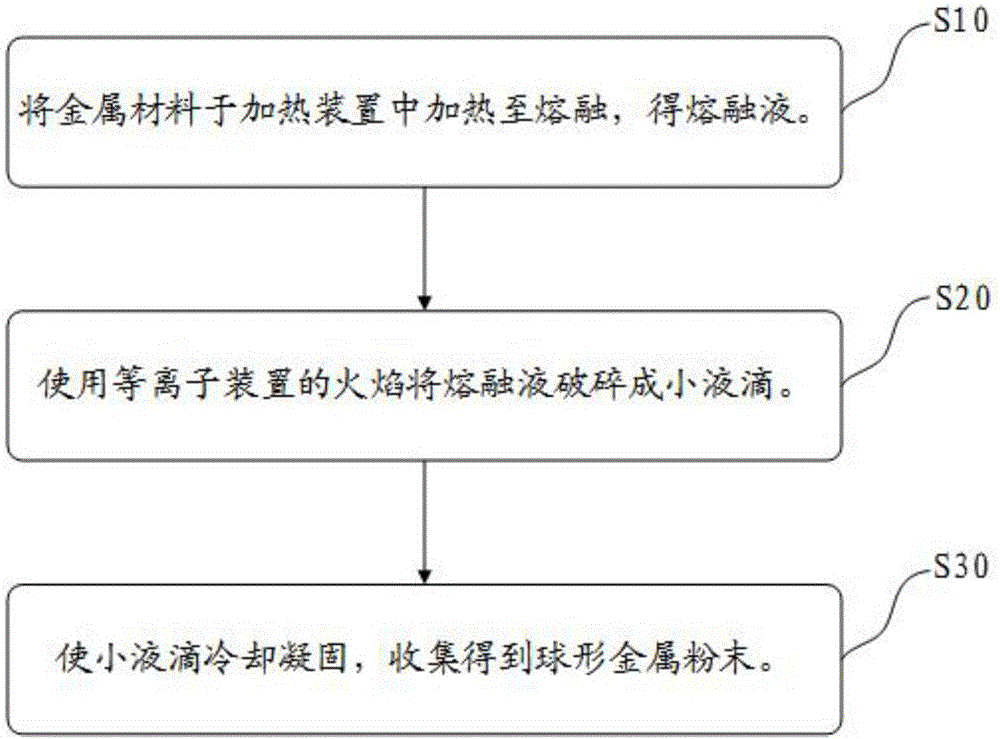

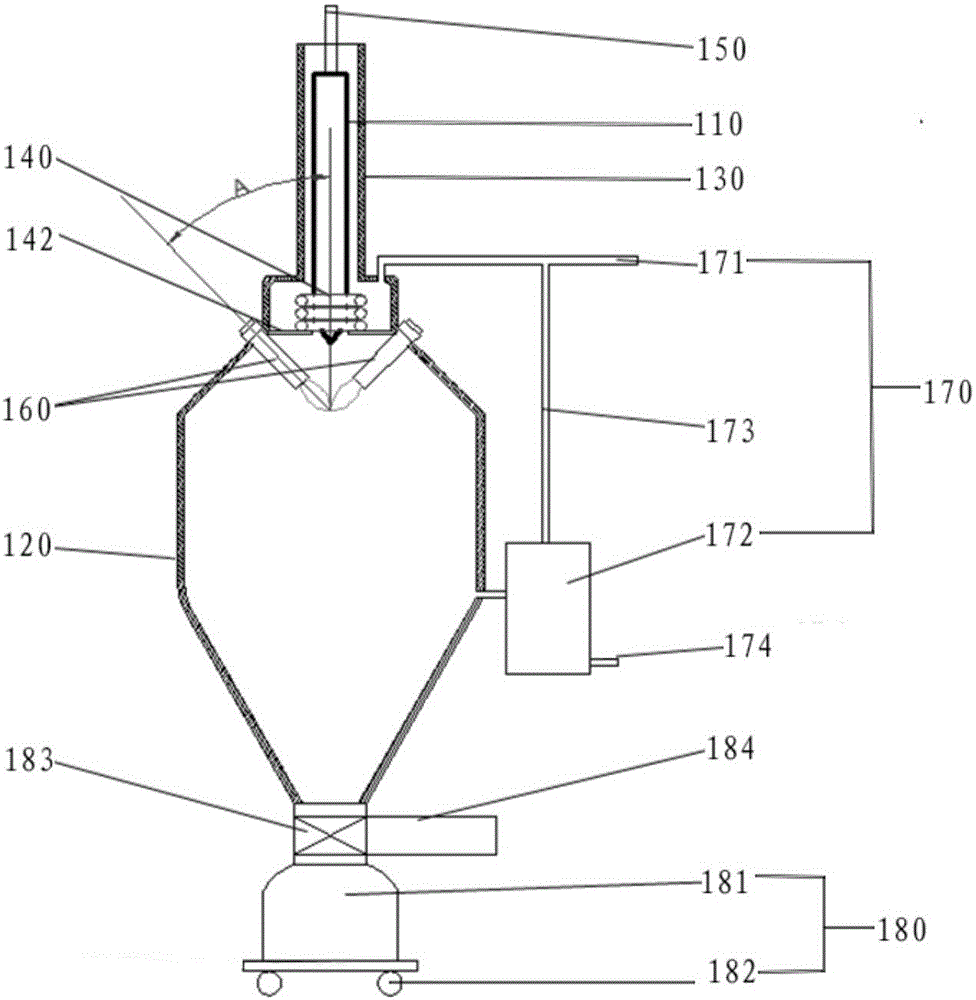

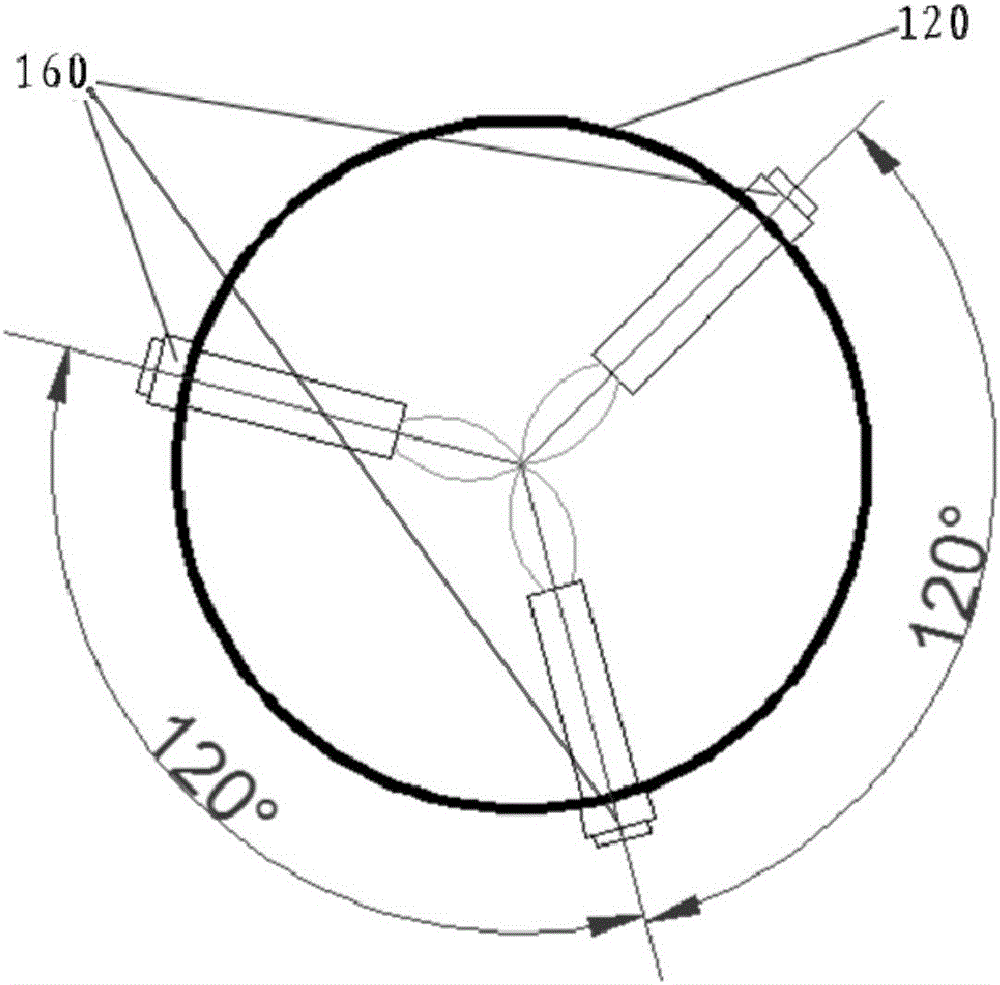

Spherical metal powder and preparation method thereof

ActiveCN105855560AReduce surface tensionReduce consumptionTransportation and packagingMetal-working apparatusSmall dropletPrill

The invention relates to a preparation method of spherical metal powder. The preparation method comprises the steps of heating a metal bar to melt in a heating device, so as to obtain melted liquid, and breaking the melted liquid into small droplets by using plasma as droplet breakage power, so that the small droplets are cooled and solidified and are collected so as to obtain the spherical metal powder. According to the spherical metal powder prepared by adopting the preparation method, almost no satellite particle exists, the oxygen content is less than 1200 ppm, and the occupancy of the powder below 53 mum reaches 90% according to weight percent; the spherical metal powder has the advantages of high degree of sphericity, narrow particle size distribution, low impurity content, good flowability, low oxygen content, no satellite particle, simple process, reliable technique, easiness in control over product particle size, high production efficiency and low inert gas consumption and is suitable for mass production, and the particle size distribution satisfies the 3D printing requirements.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

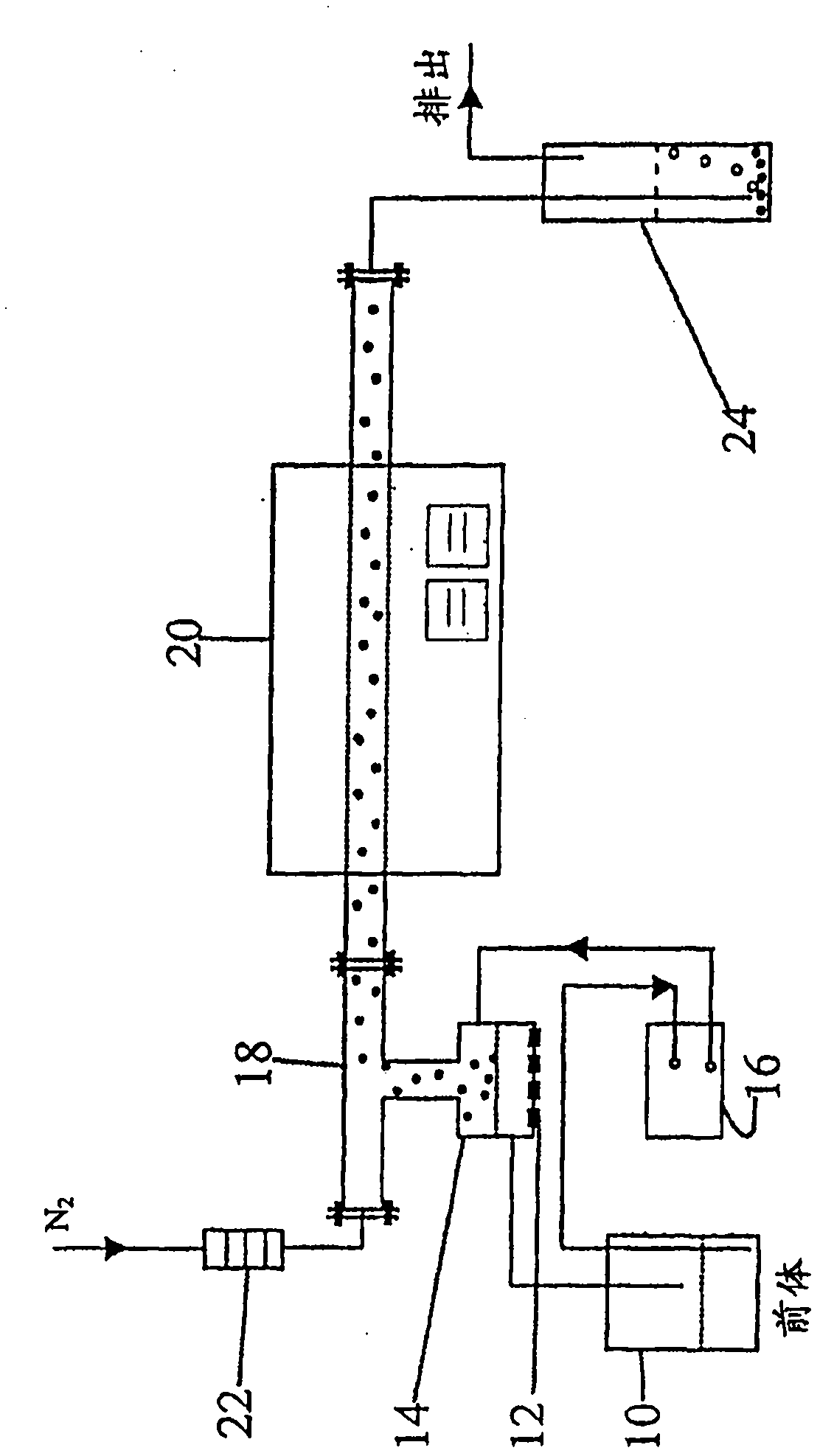

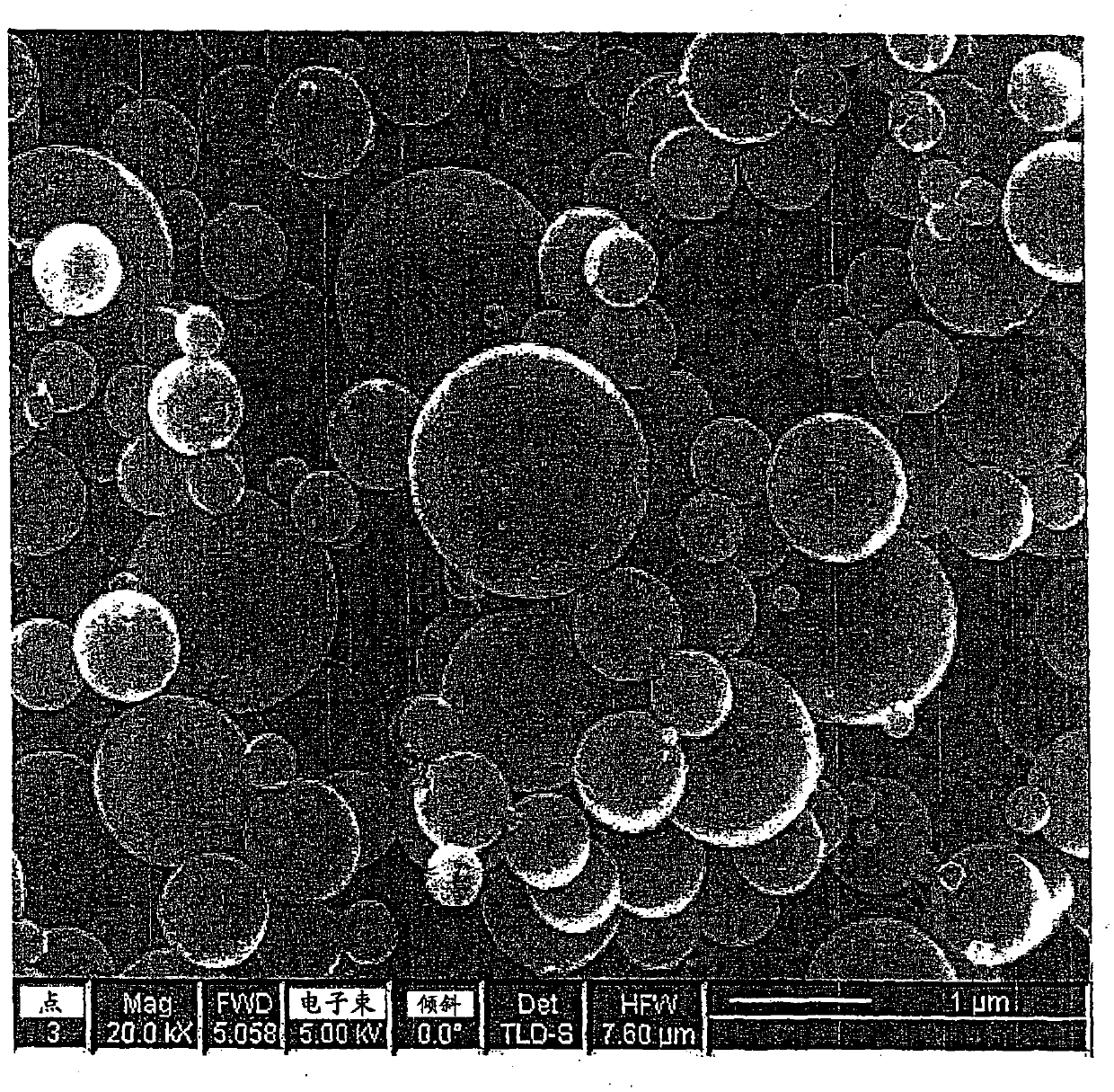

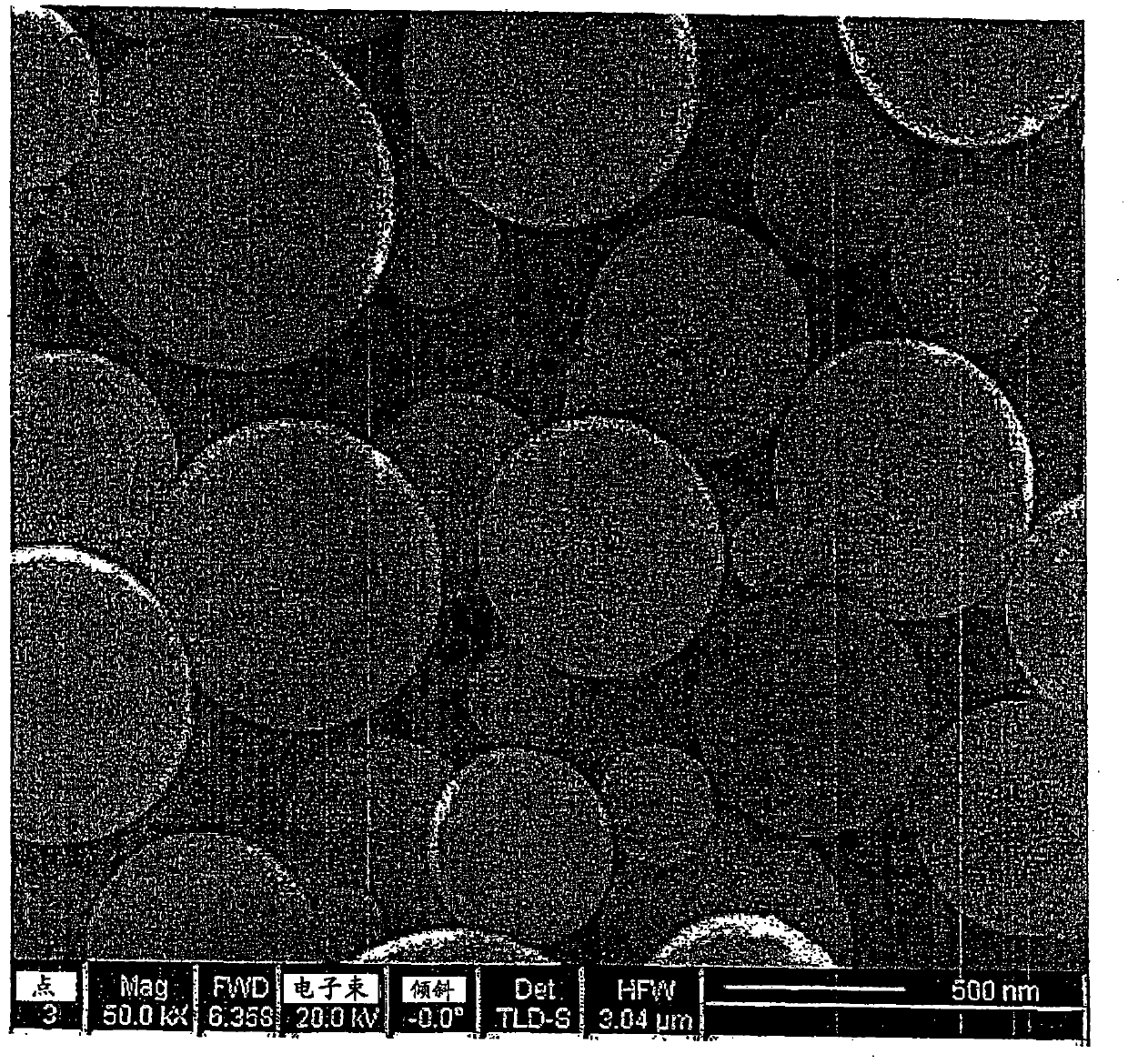

Controllable synthesis of porous carbon spheres, and electrochemical applications thereof

The invention disclosed relates to porous carbon of spherical morphology having tuned porosity and to a method of making same, comprising: (a) providing a precursor solution, by combining in an aqueous solution a colloidal silica template material and a water-soluble pyrolyzable carbon source, wherein the particle size of the colloidal silica template and the colloidal silica / carbon source weight ratio are controlled, (b) atomizing the precursor solution into small droplets by ultrasonic spray pyrolysis, (c) directing the droplets into a high temperature furnace operating at a temperature of 700-1200 0C, under an inert gas atmosphere, where the droplets are transformed into solid spherical composite carbon / silica particles, (d) collecting the resulting composite carbon / silica particles exiting from the furnace, and (e) removing the silica from the particles, to provide substantially pure porous carbon of spherical morphology having tuned porosity defined by surface area and pore size. The porous carbon according to the invention is used as catalyst supports in PEM fuel cells, as electrodes in supercapacitors and lithium in batteries, for hydrogen storage and as earners for drug delivering.

Owner:NAT RES COUNCIL OF CANADA

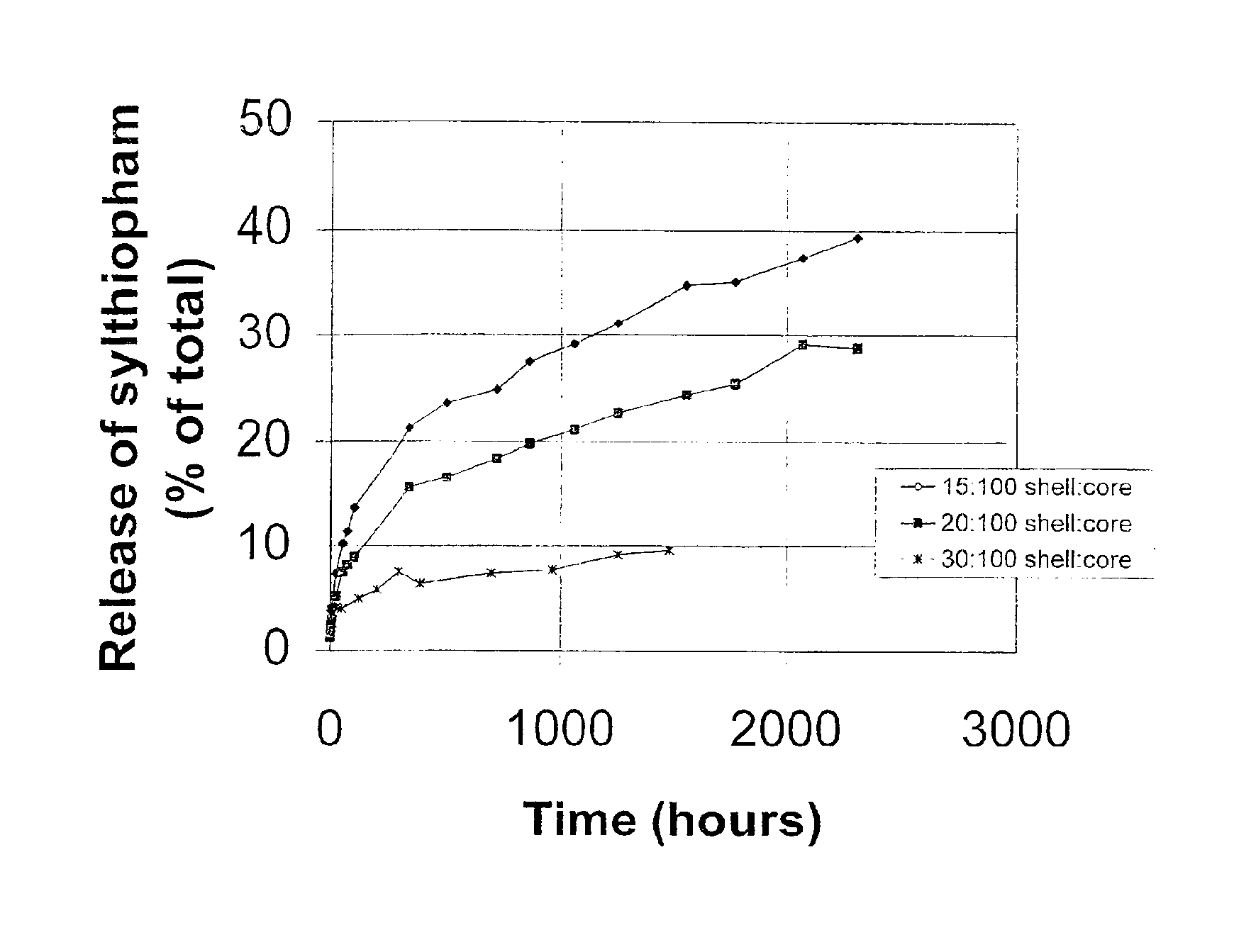

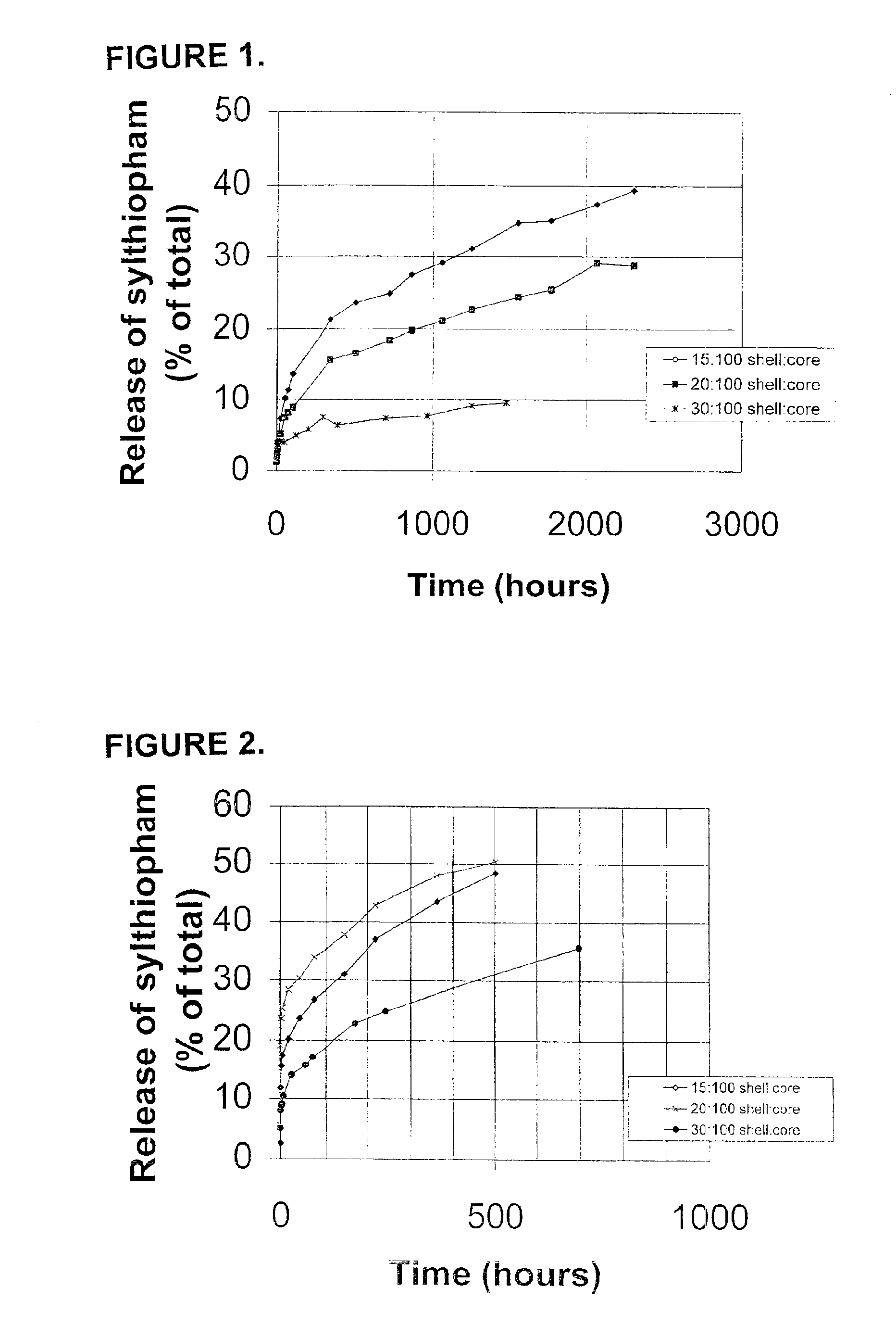

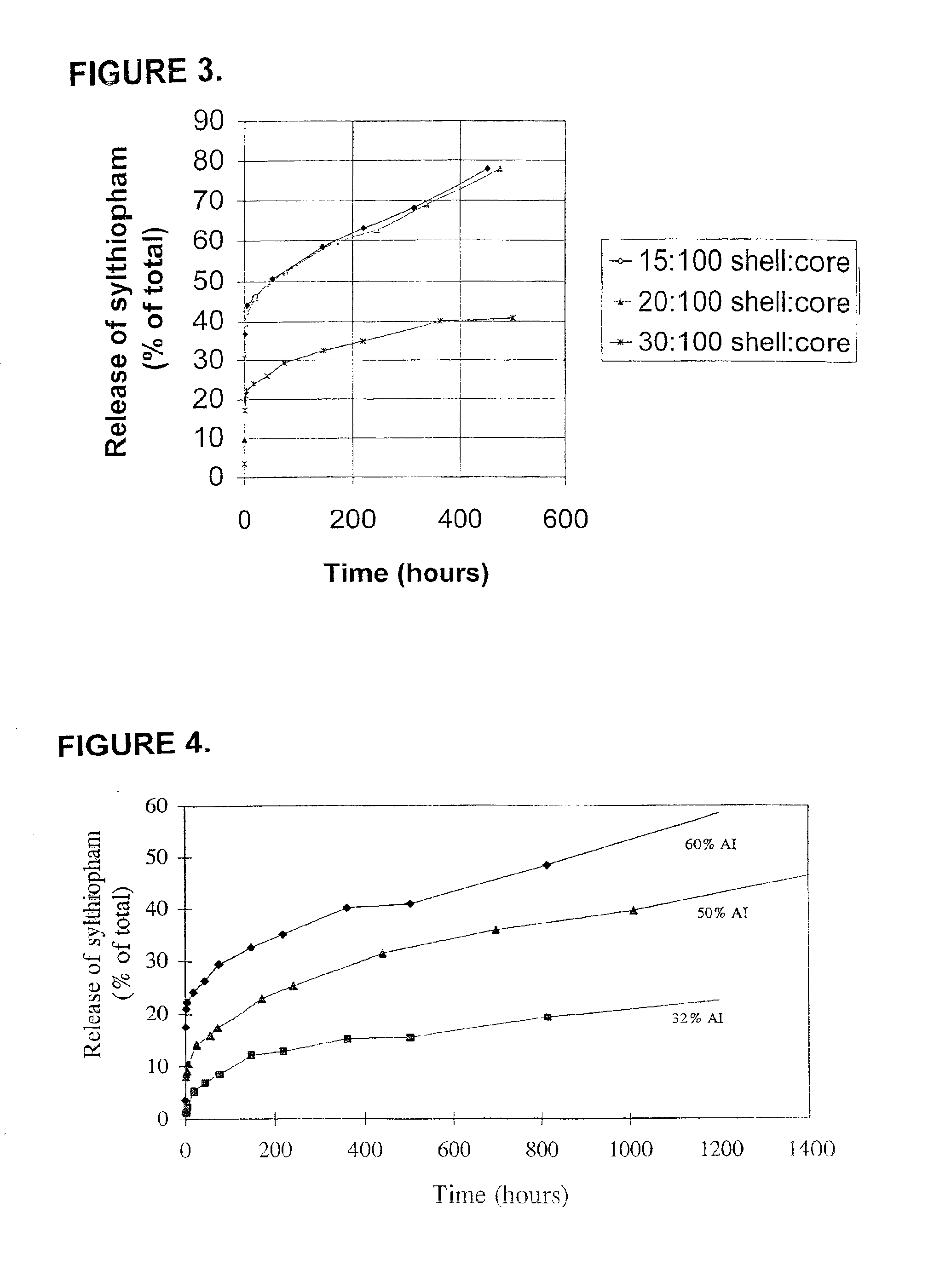

Method of microencapsulating an agricultural active having a high melting point and uses for such materials

A method of producing a controlled release form of an agricultural active material includes the provision of an organic liquid composition in which the active is present, but where the liquid composition is free from aromatic solvents and is maintained below the normal melting point of the active. The liquid composition is formed into small droplets and the droplets are enclosed by a non-water soluble shell to provide microcapsules, the shell of which is designed to release the agricultural active at a pre-selected controlled rate when the microcapsule is exposed to natural environmental conditions. Controlled release forms of agricultural actives are also provided.

Owner:MONSANTO TECH LLC

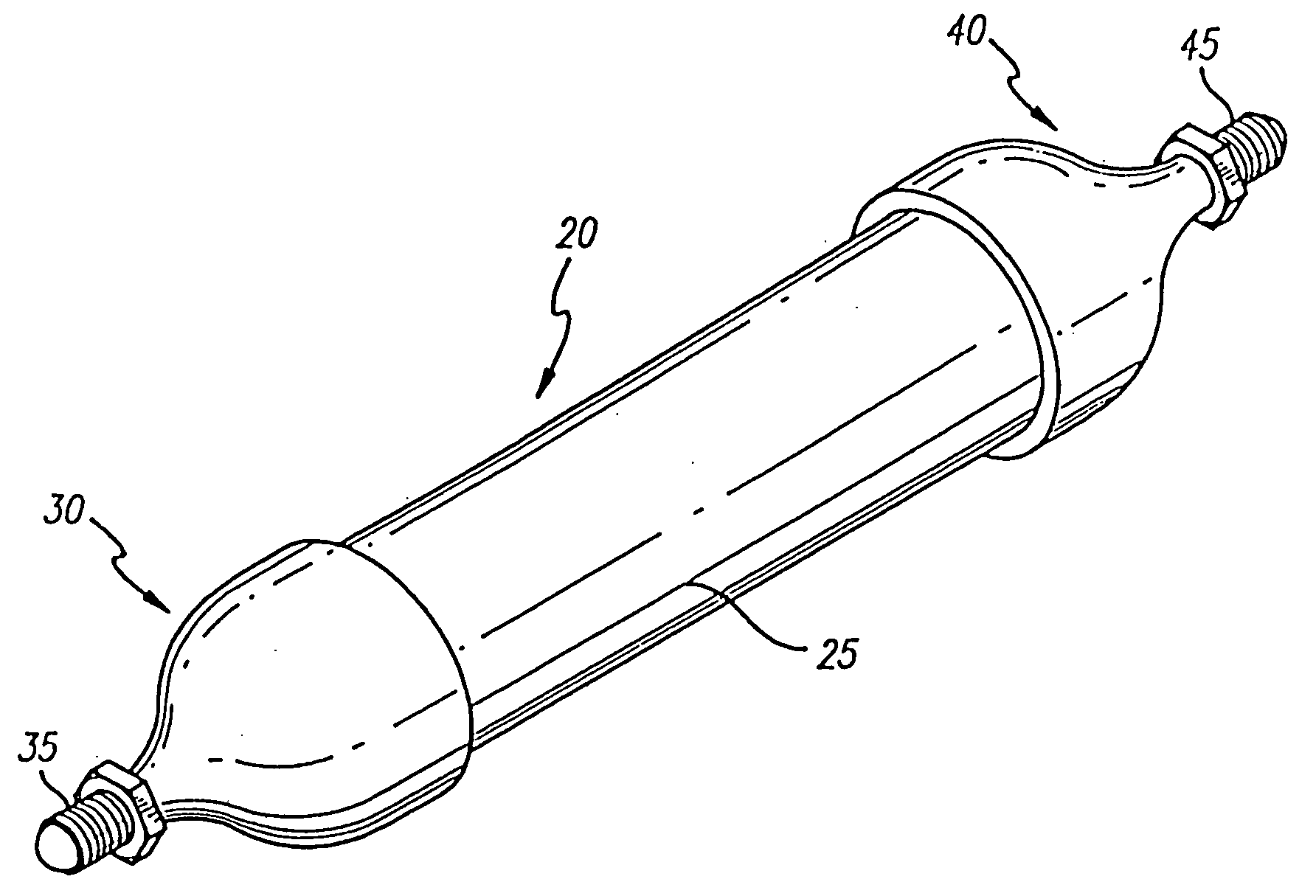

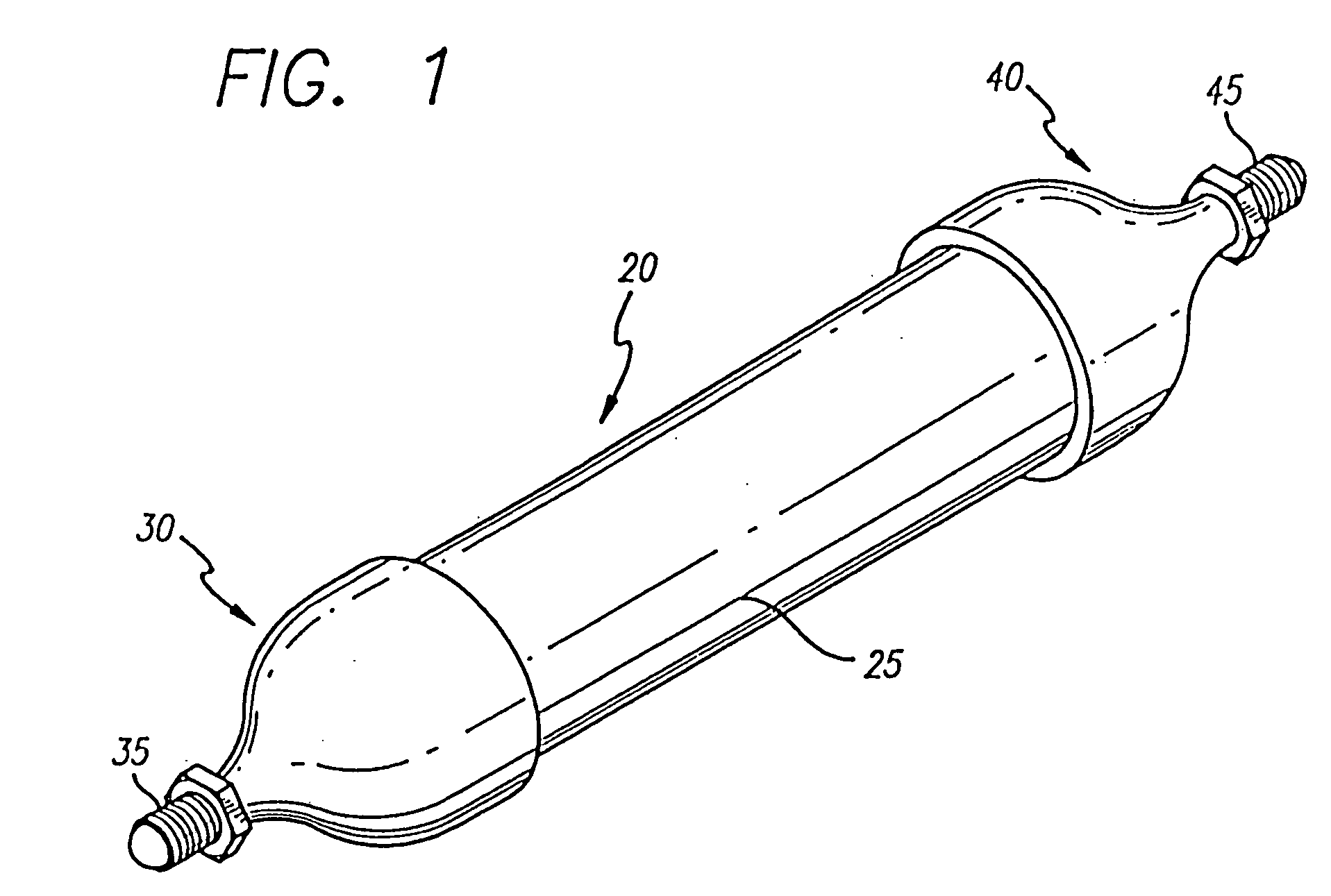

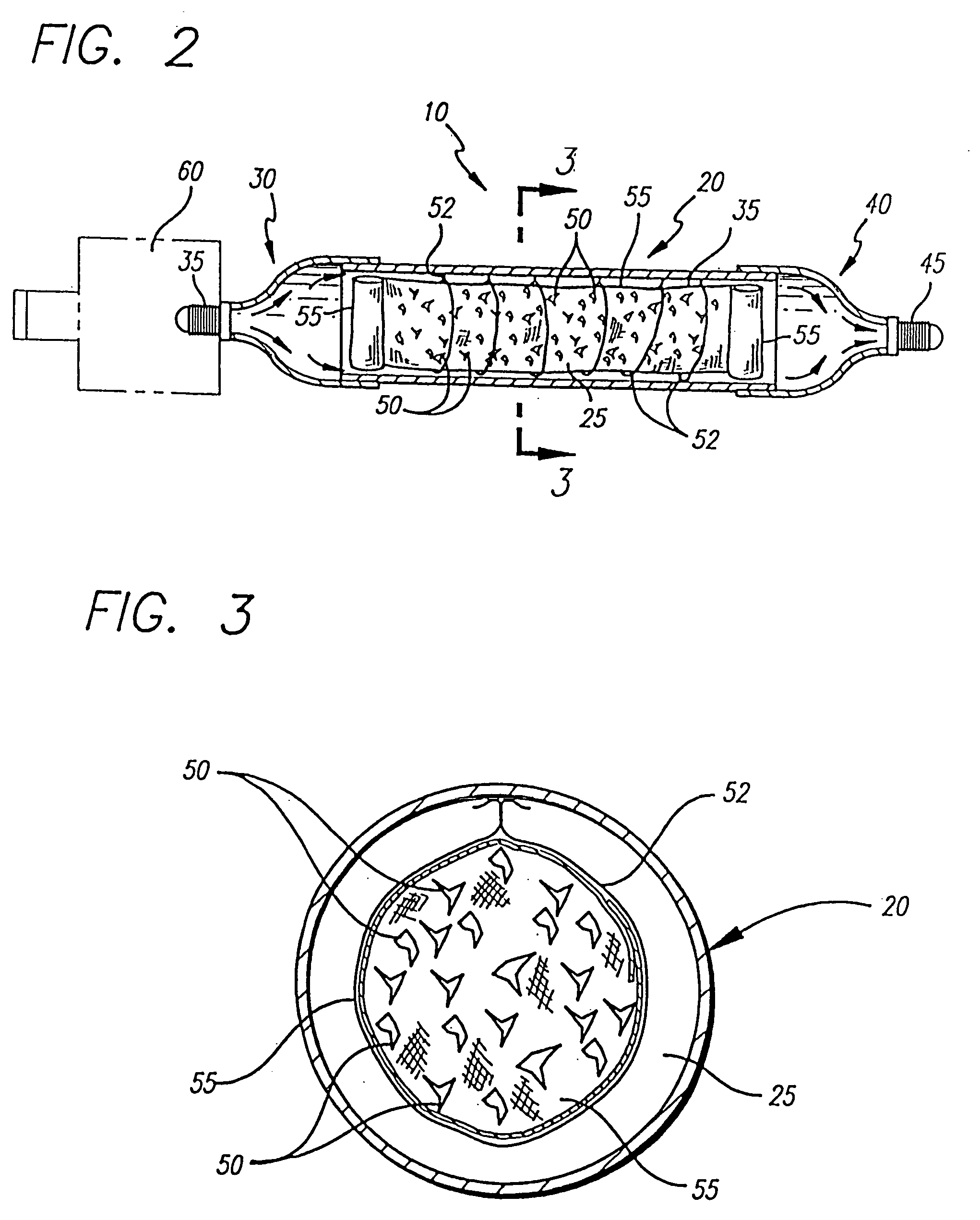

Fuel conditioning assembly

InactiveUS20050145225A1Reduce maintenanceCleaner runningCombustion-air/fuel-air treatmentIdling devicesSmall dropletNuclear engineering

A fuel conditioning assembly having an elongated housing with an inlet, an outlet, and a flow through passage there between. The inlet is coupled with a fuel supply so as to receive fuel flow there through into the flow through passage, wherein a turbulent flow of the fuel is initiated and the fuel is influenced by a combination of elements, in compound or elemental form, some of which are maintained in a select location within the flow through passage by a binding element. These elements may include copper, aluminum, stainless steel, titanium, magnesium, barium, calcium, iron, zirconium, cerium, platinum, and / or palladium which chemically condition the fuel flowing through the flow through passage by rearranging the molecular bonds of the fuel with a catalytic effect. The fuel, regardless of its type is dispersed into very small droplets having high surface areas thereby lowering the vapor density of the fuel and substantially increasing a fuel burn efficiency. Further, the reaction of a variety of these elements, at least with one another, serves to create an electrostatic charge that is conveyed through the flow through passage by an elongate segment and causes fuel molecules to repel one another resulting in the aforementioned catalytic effect a conditioning of the fuel as it passes through the outlet into to any of a variety of fuel combustion assemblies.

Owner:ROYCE WALKER

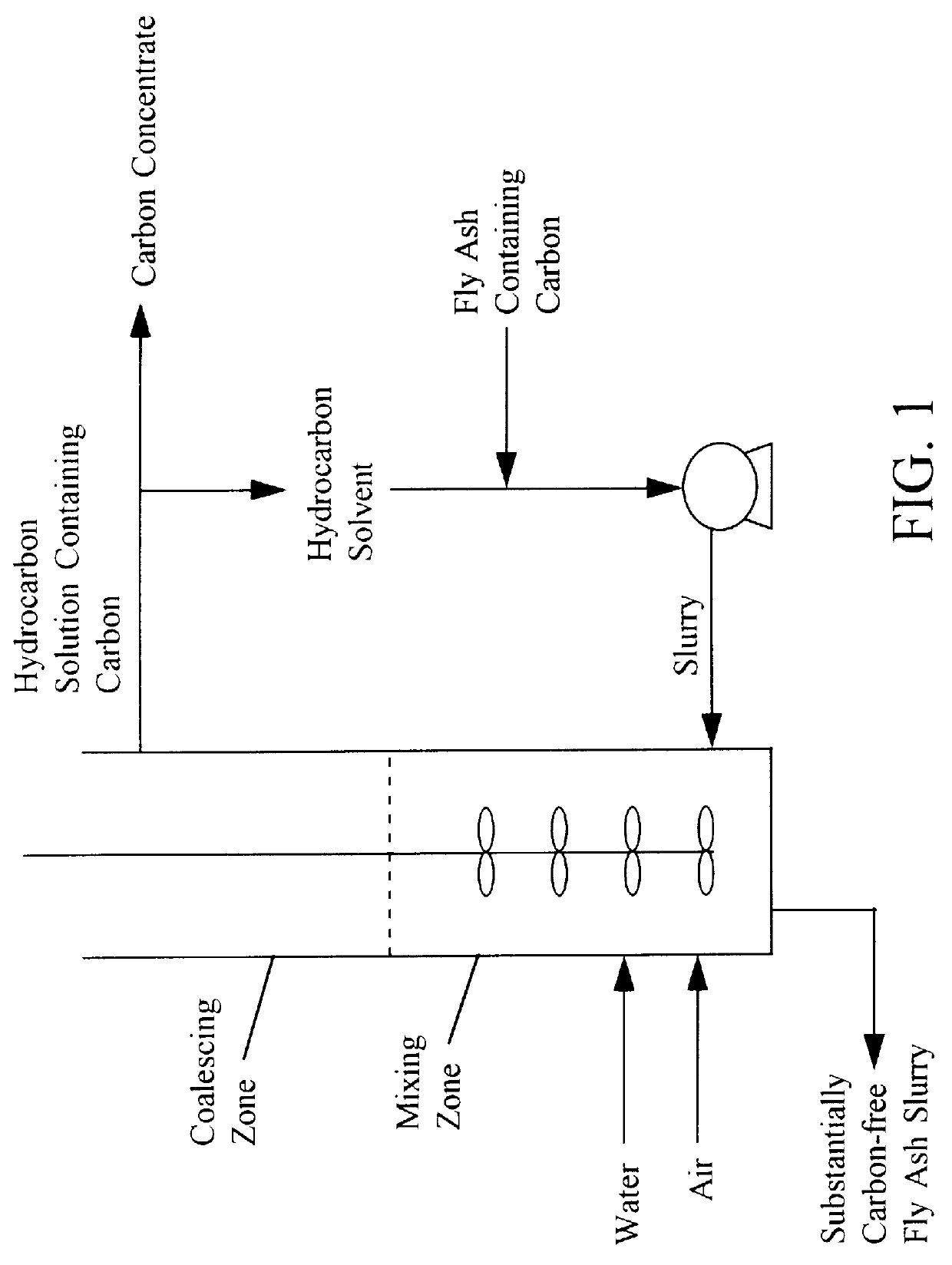

Continuous air agglomeration method for high carbon fly ash beneficiation

The carbon and mineral components of fly ash are effectively separated by a continuous air agglomeration method, resulting in a substantially carbon-free mineral stream and a highly concentrated carbon product. The method involves mixing the fly ash comprised of carbon and inorganic mineral matter with a liquid hydrocarbon to form a slurry, contacting the slurry with an aqueous solution, dispersing the hydrocarbon slurry into small droplets within the aqueous solution by mechanical mixing and / or aeration, concentrating the inorganic mineral matter in the aqueous solution, agglomerating the carbon and hydrocarbon in the form of droplets, collecting the droplets, separating the hydrocarbon from the concentrated carbon product, and recycling the hydrocarbon.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com