Patents

Literature

91results about How to "Fast disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

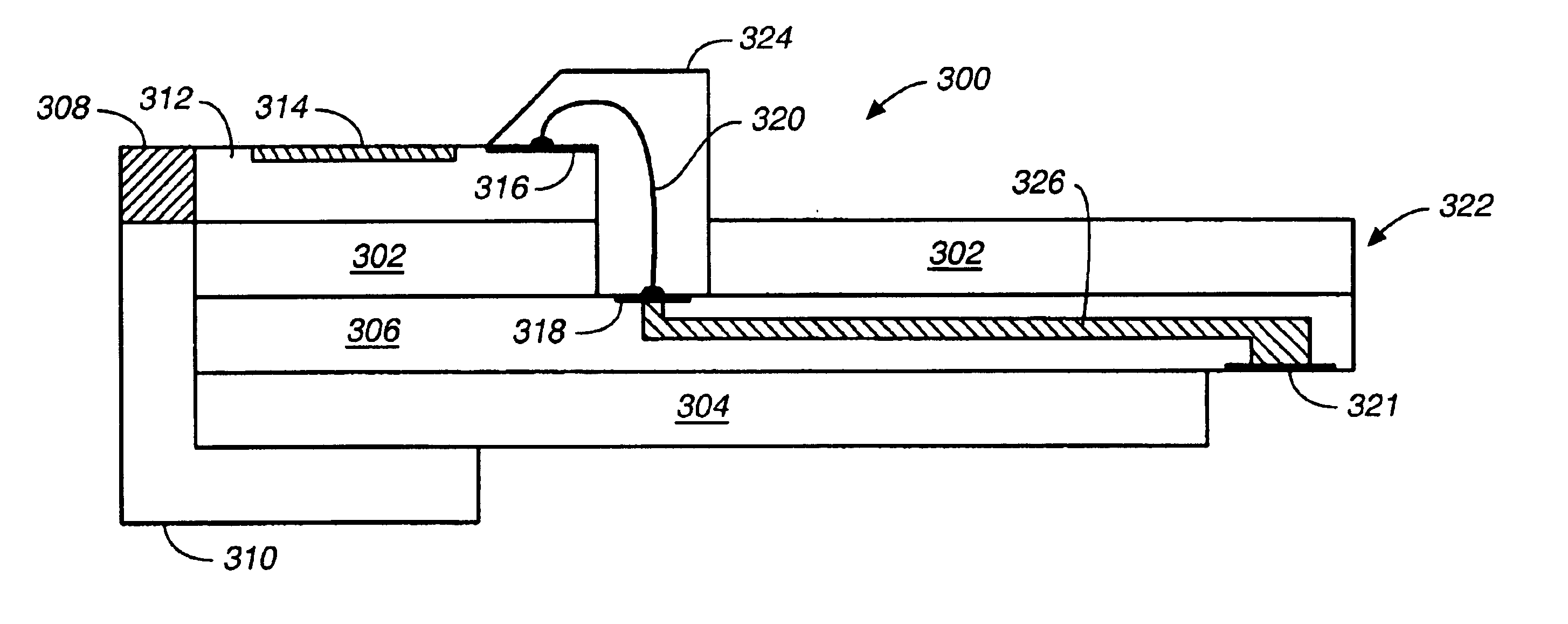

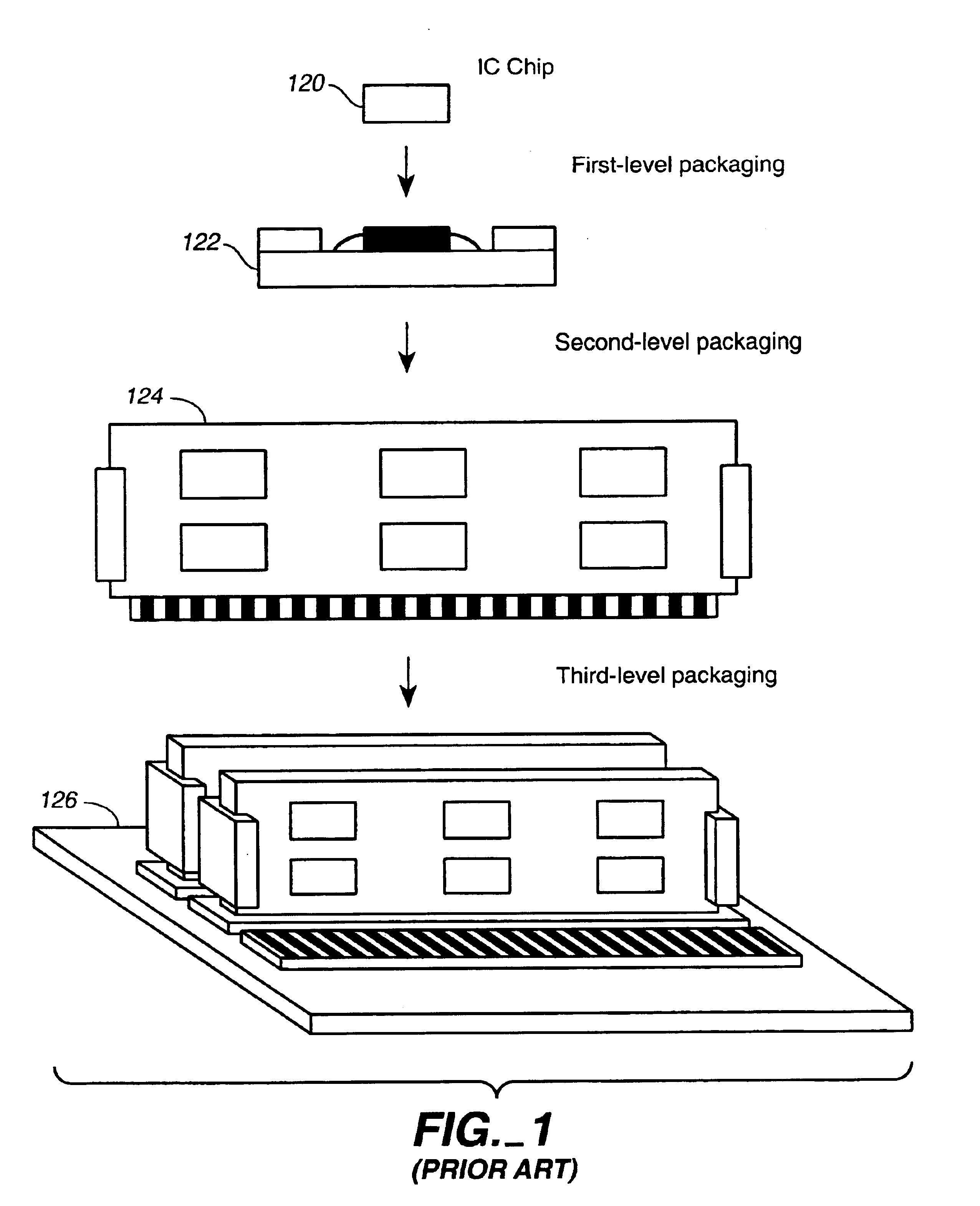

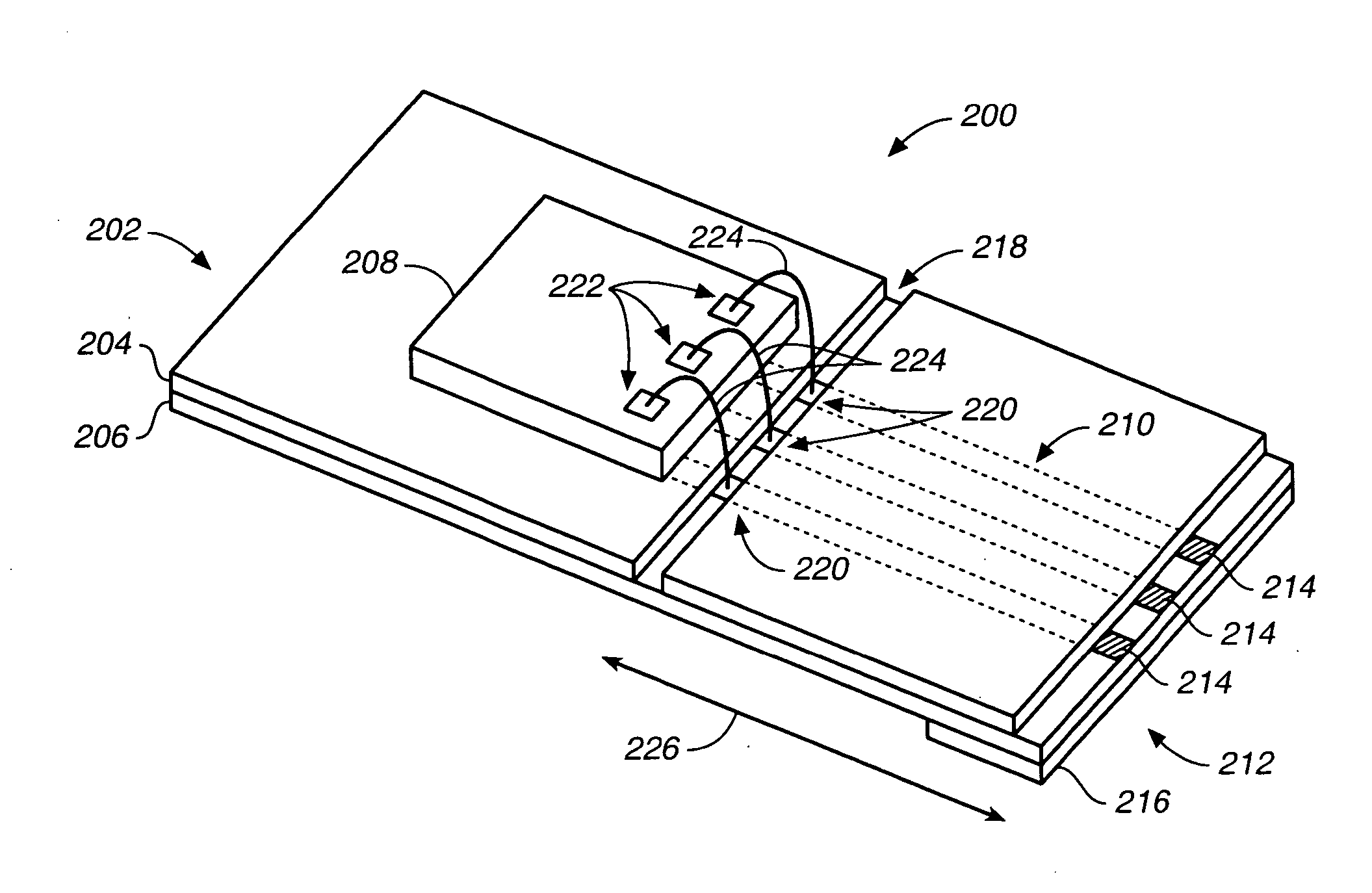

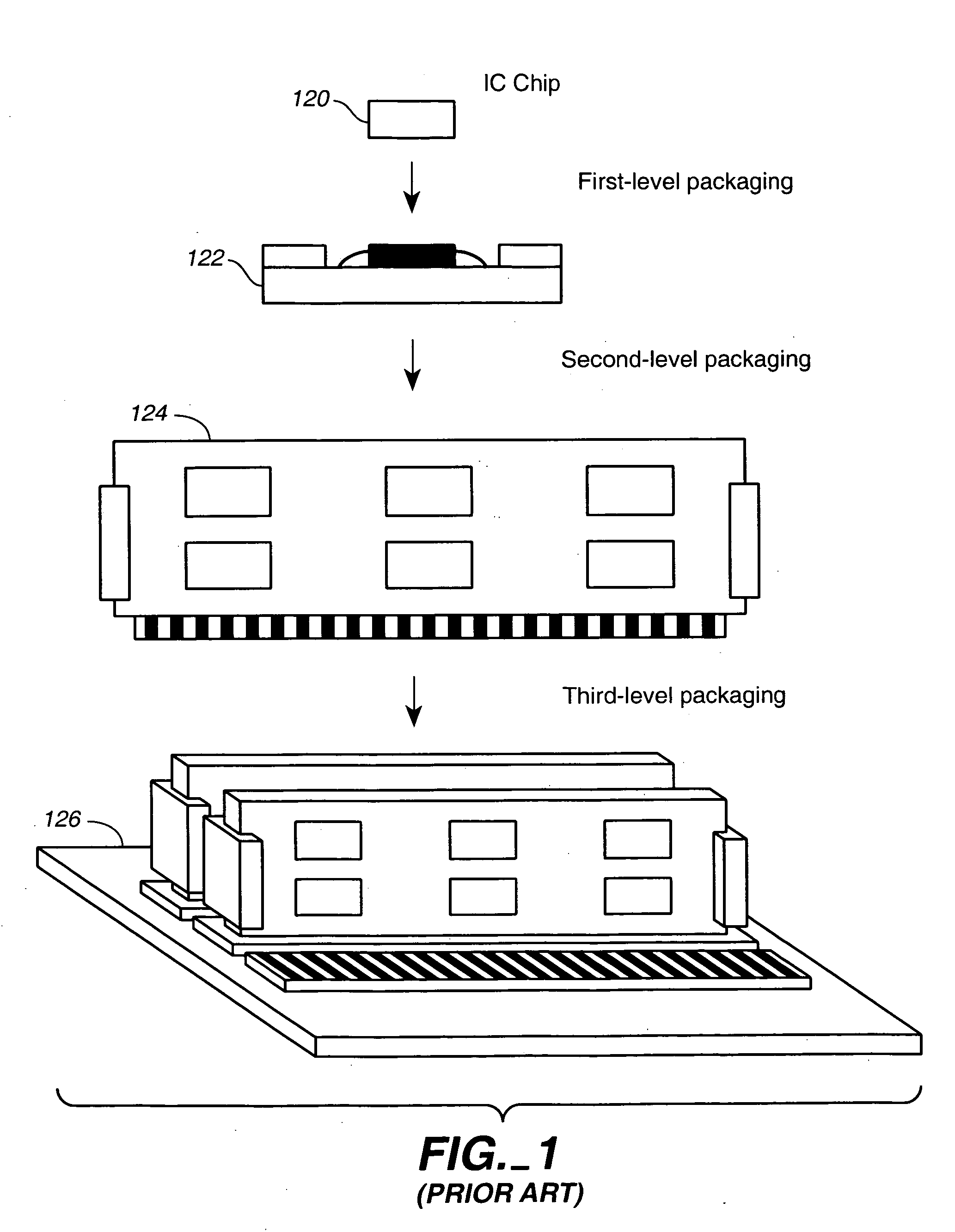

Fingerprint sensor and interconnect

InactiveUS6924496B2Firmly connectedPrecise positioningSemiconductor/solid-state device detailsSolid-state devicesFingerprintIntegrated circuit

Flexible interconnect packaging system. The system includes a flexible substrate material that includes internal traces coupled to fingerprint sensor mounted to the substrate. Bonding pads of the fingerprint sensor are connected to conductive trace pads of the internal traces using techniques such as, wire bonding, ball / bump methods, tape automated bonding (TAB), or any other applicable bonding methodology for integrated circuits. The final package includes a pre-molded package the forms an open cavity, thereby allowing a sensor surface of the fingerprint sensor to be exposed for access by a user.

Owner:SOCIONEXT INC

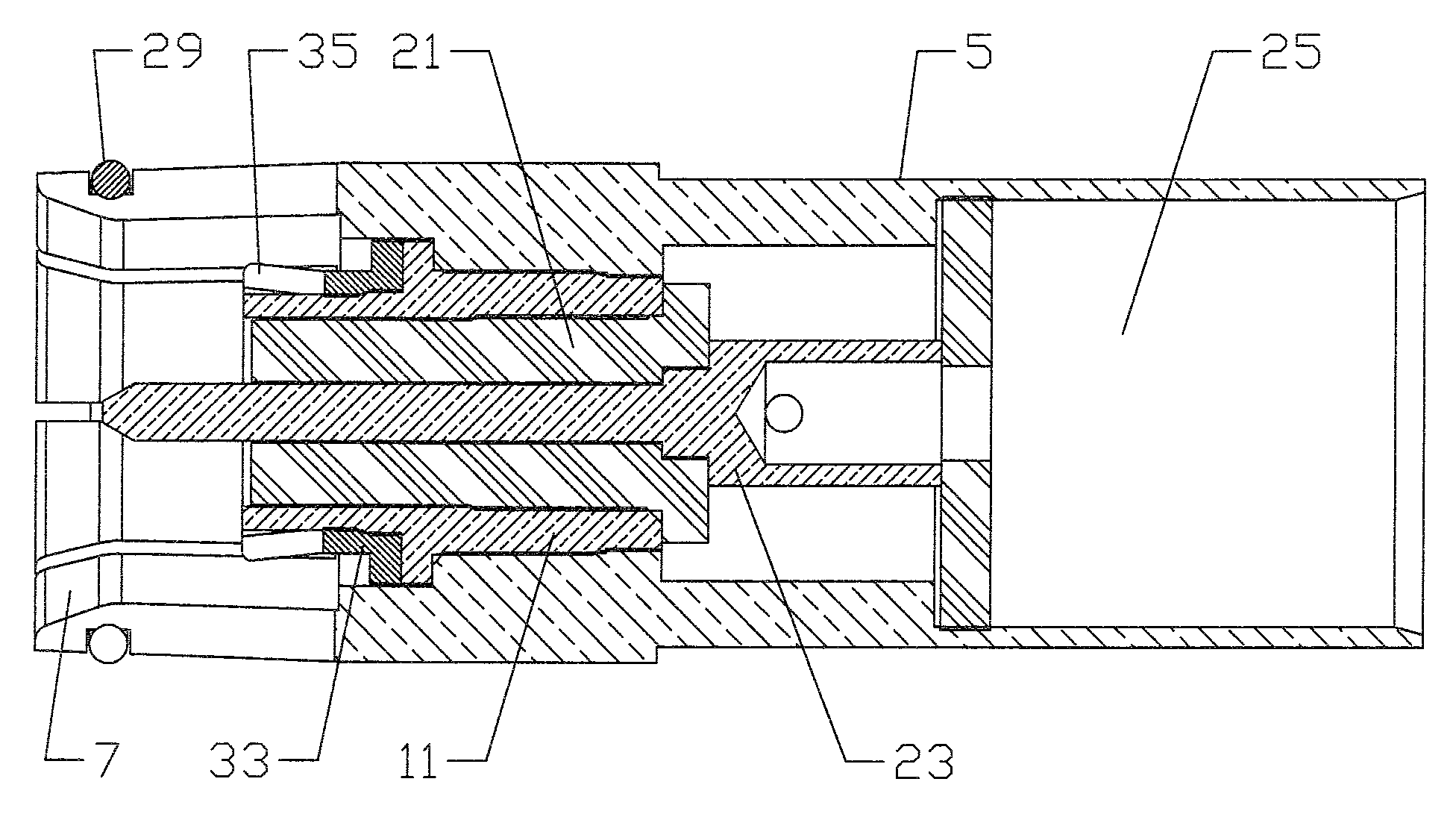

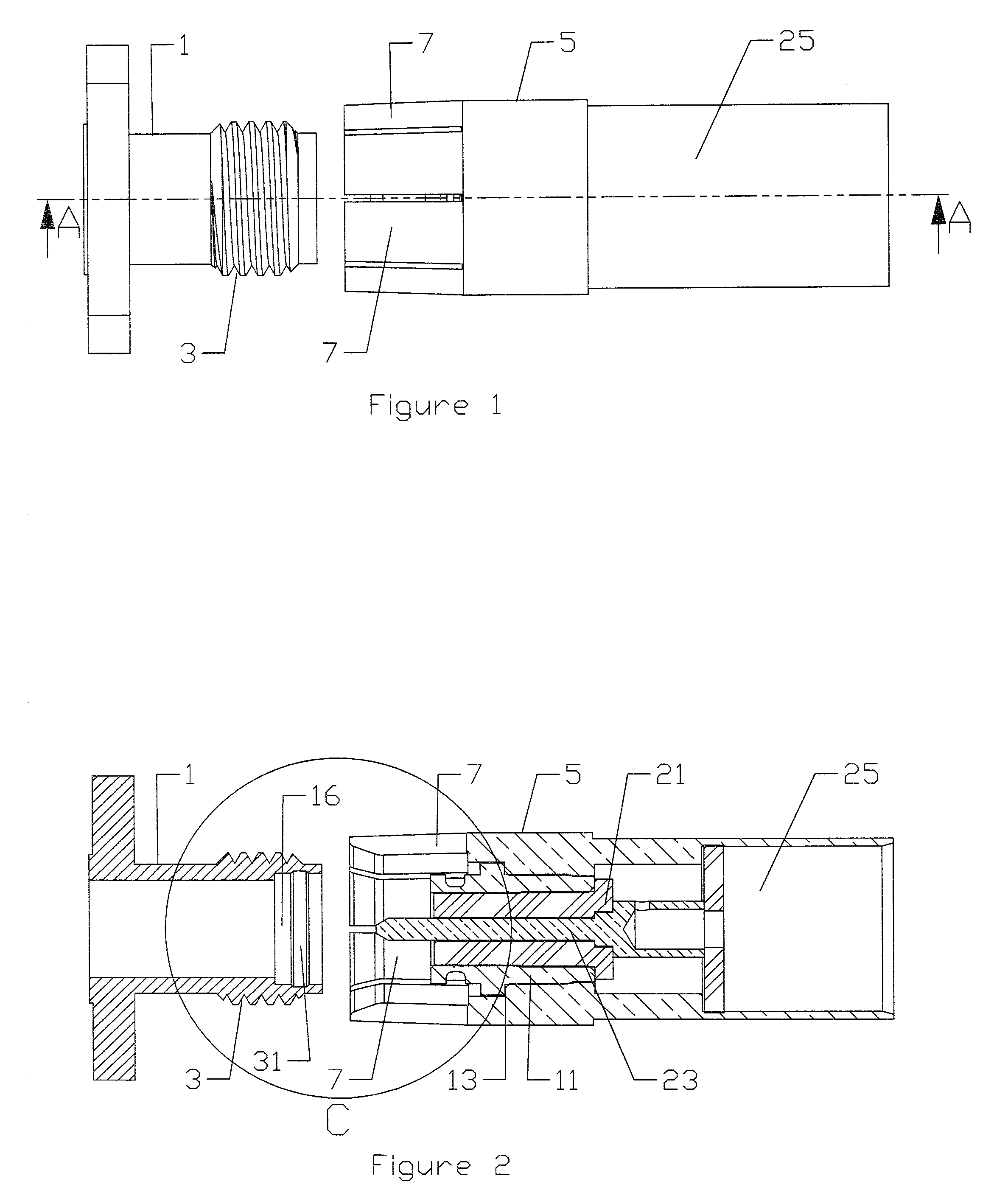

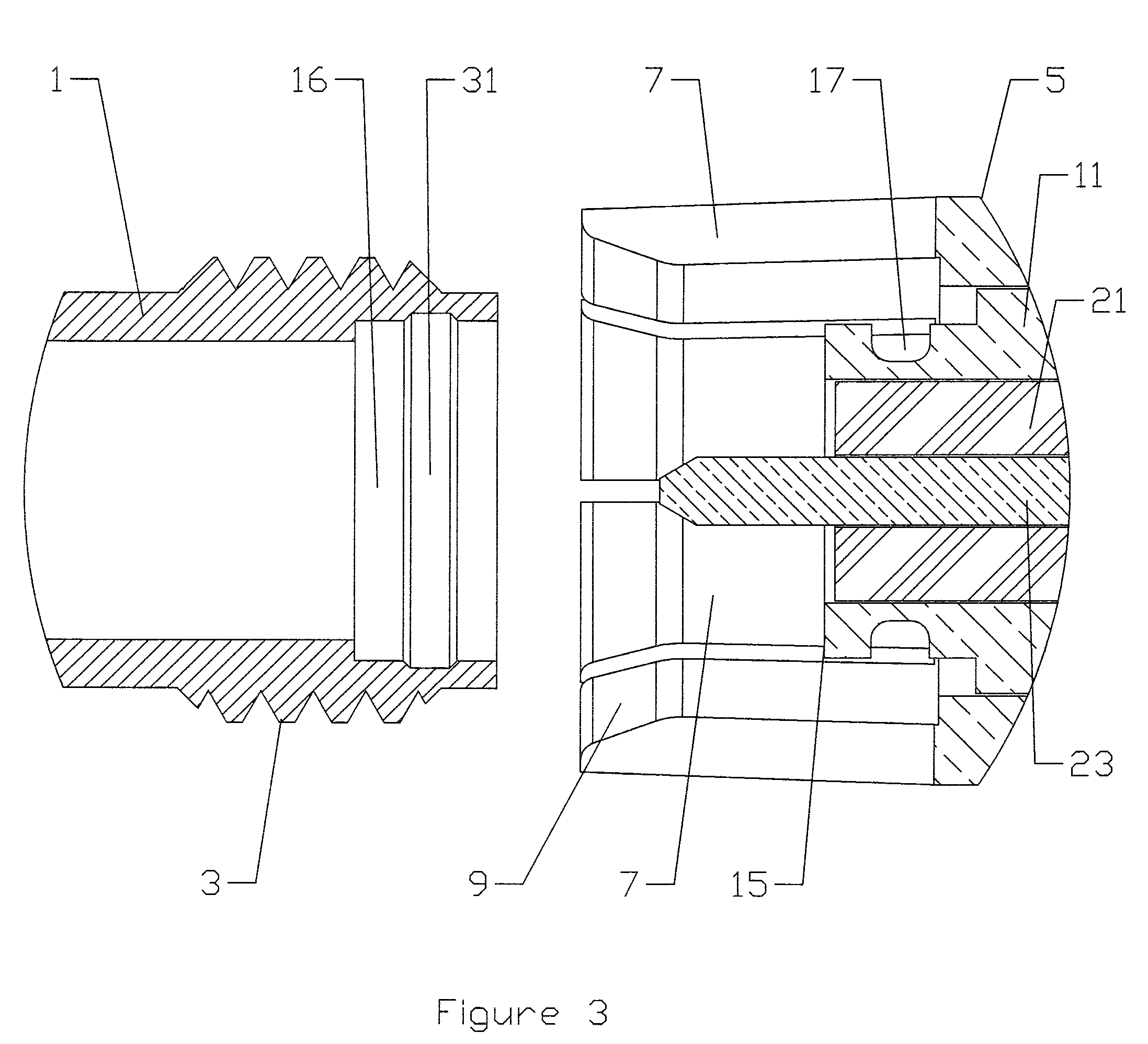

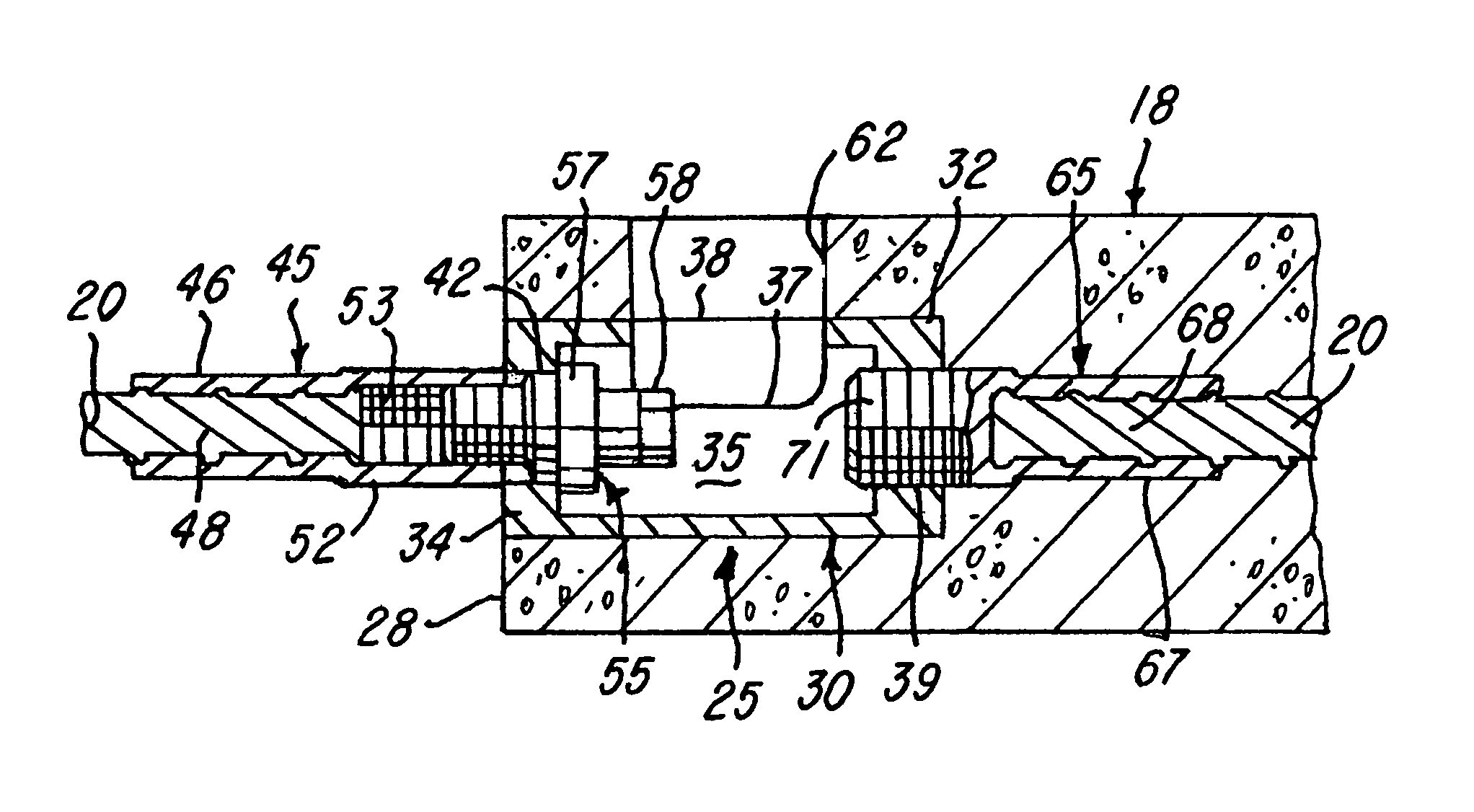

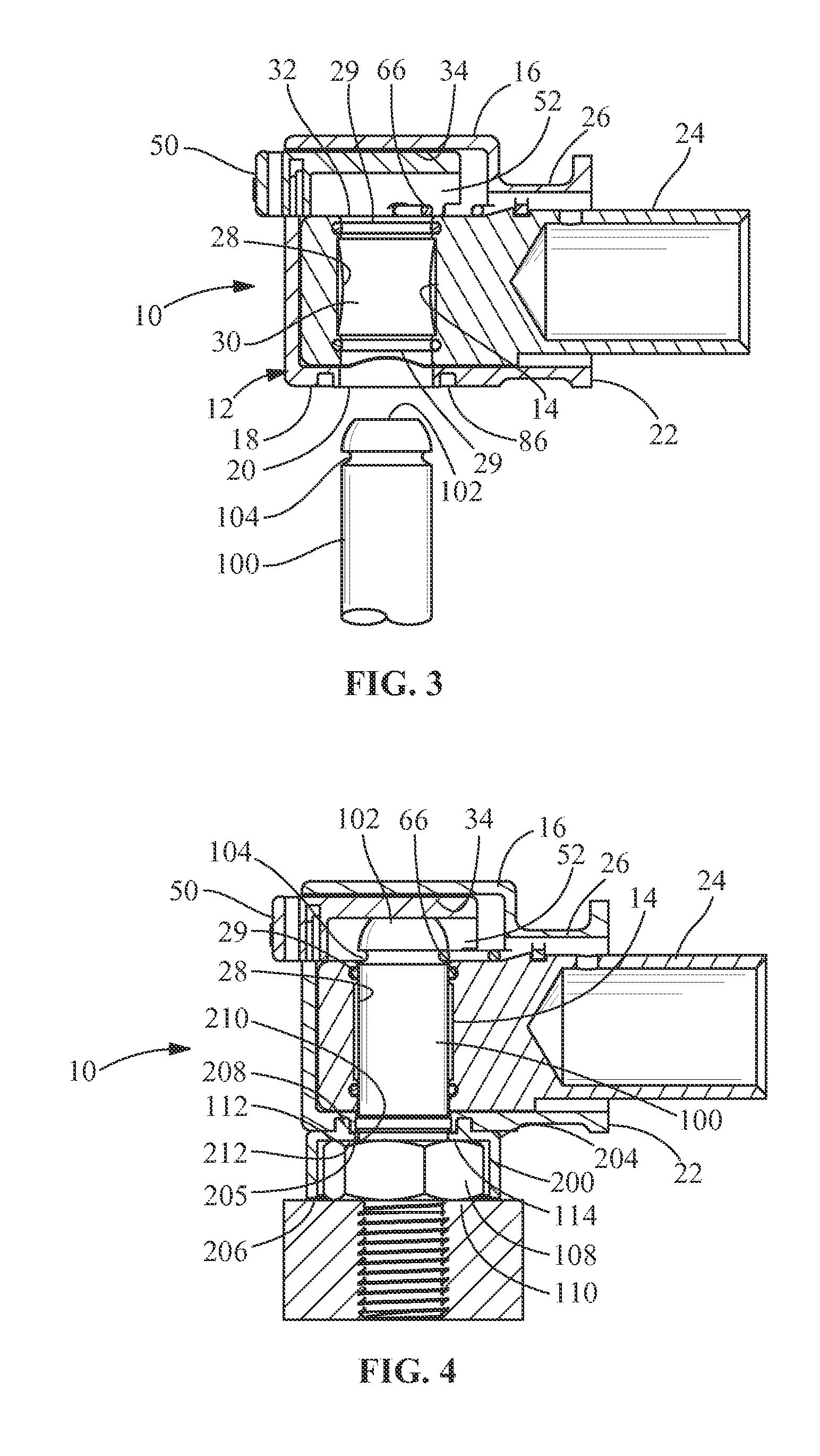

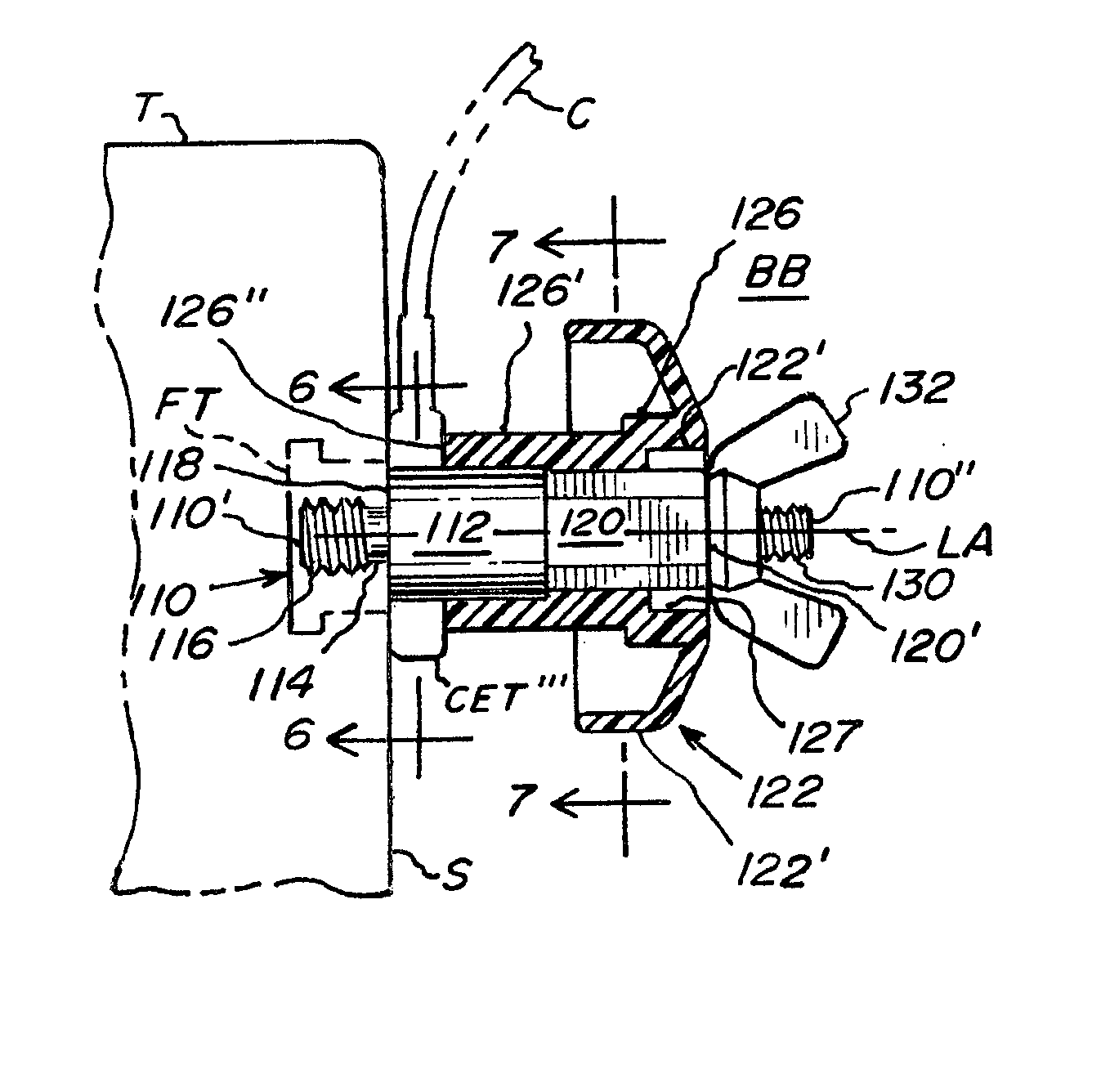

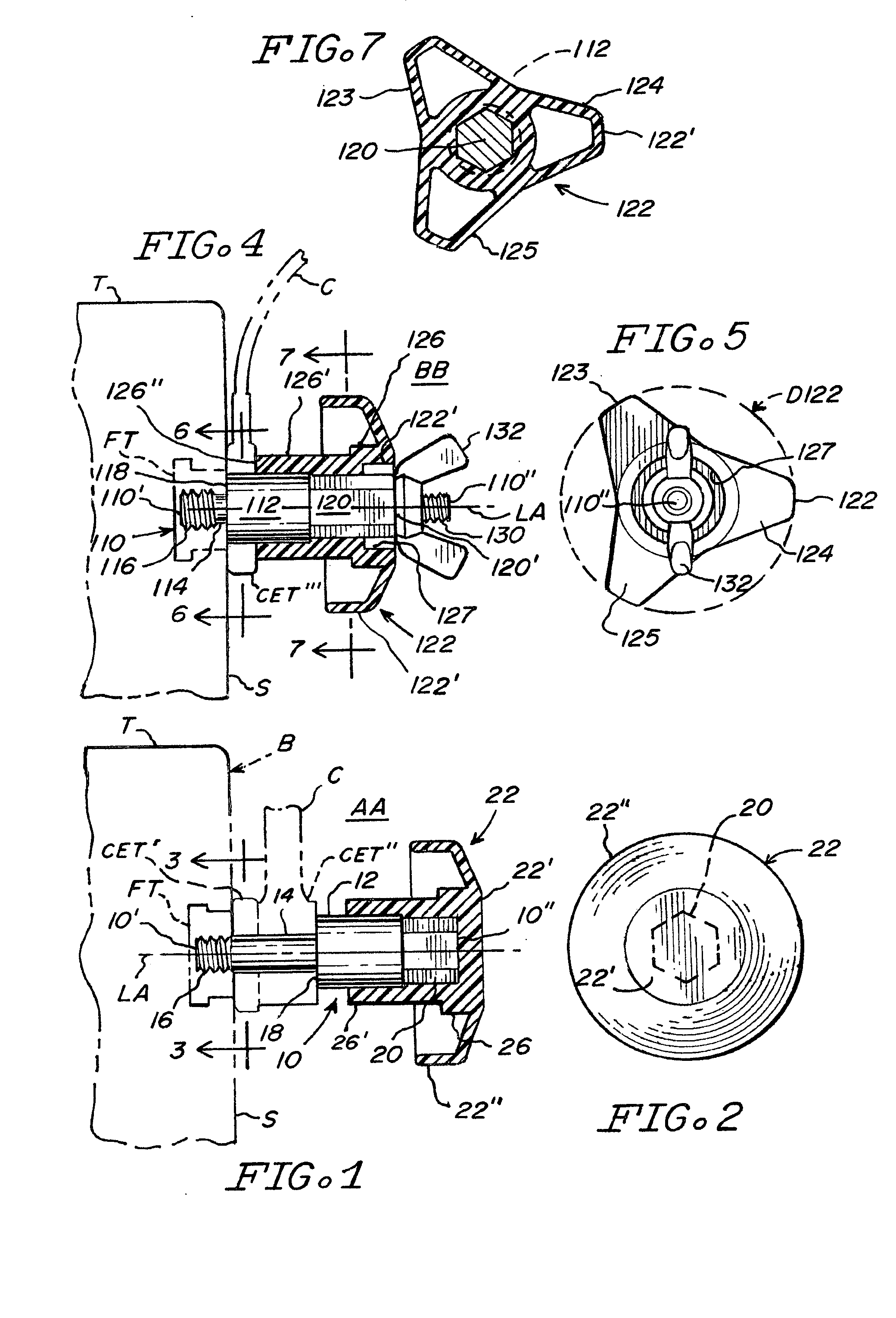

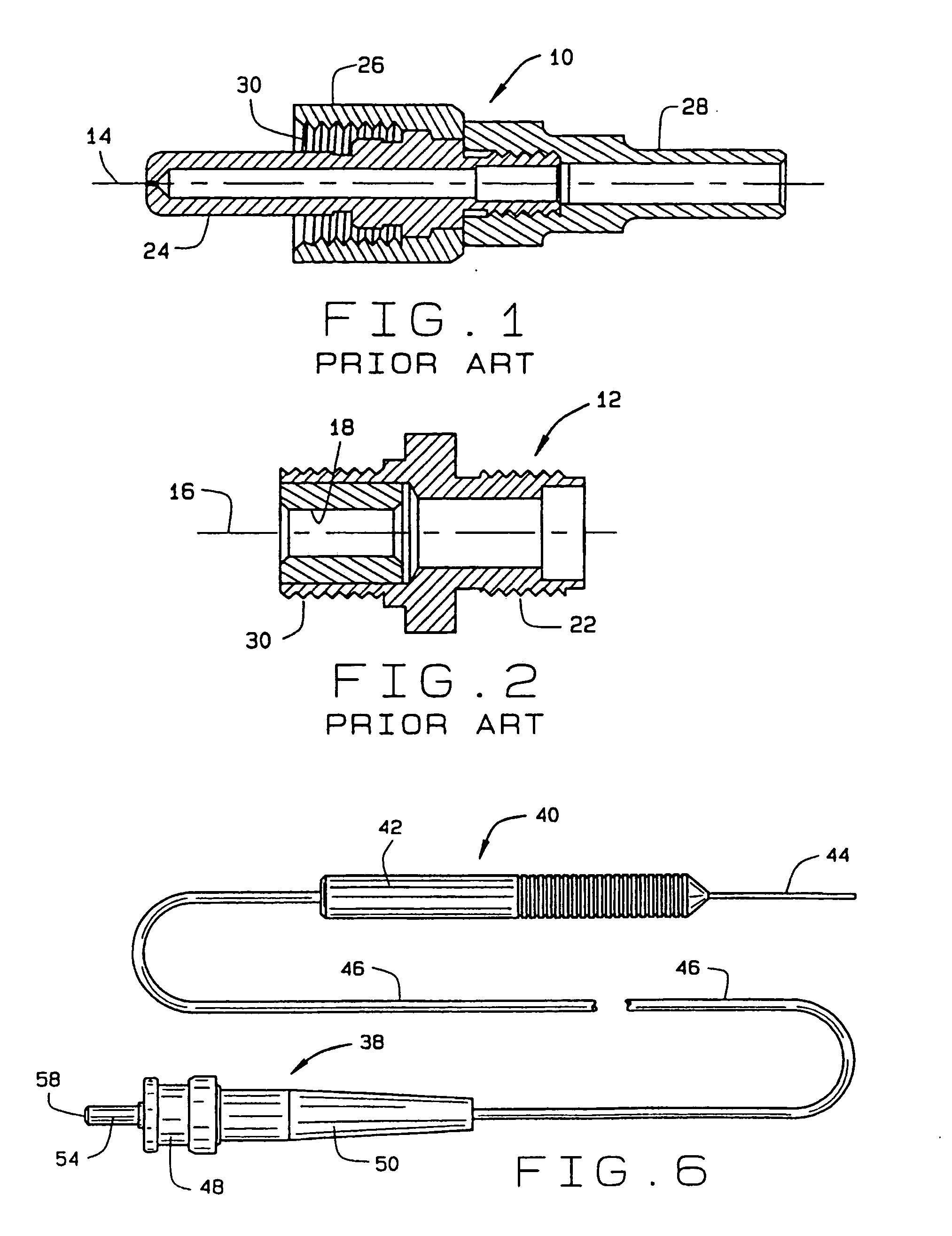

Push-on connector interface

InactiveUS7347727B2Eliminate needReduce frictionEngagement/disengagement of coupling partsElectrically conductive connectionsEngineeringInterconnection

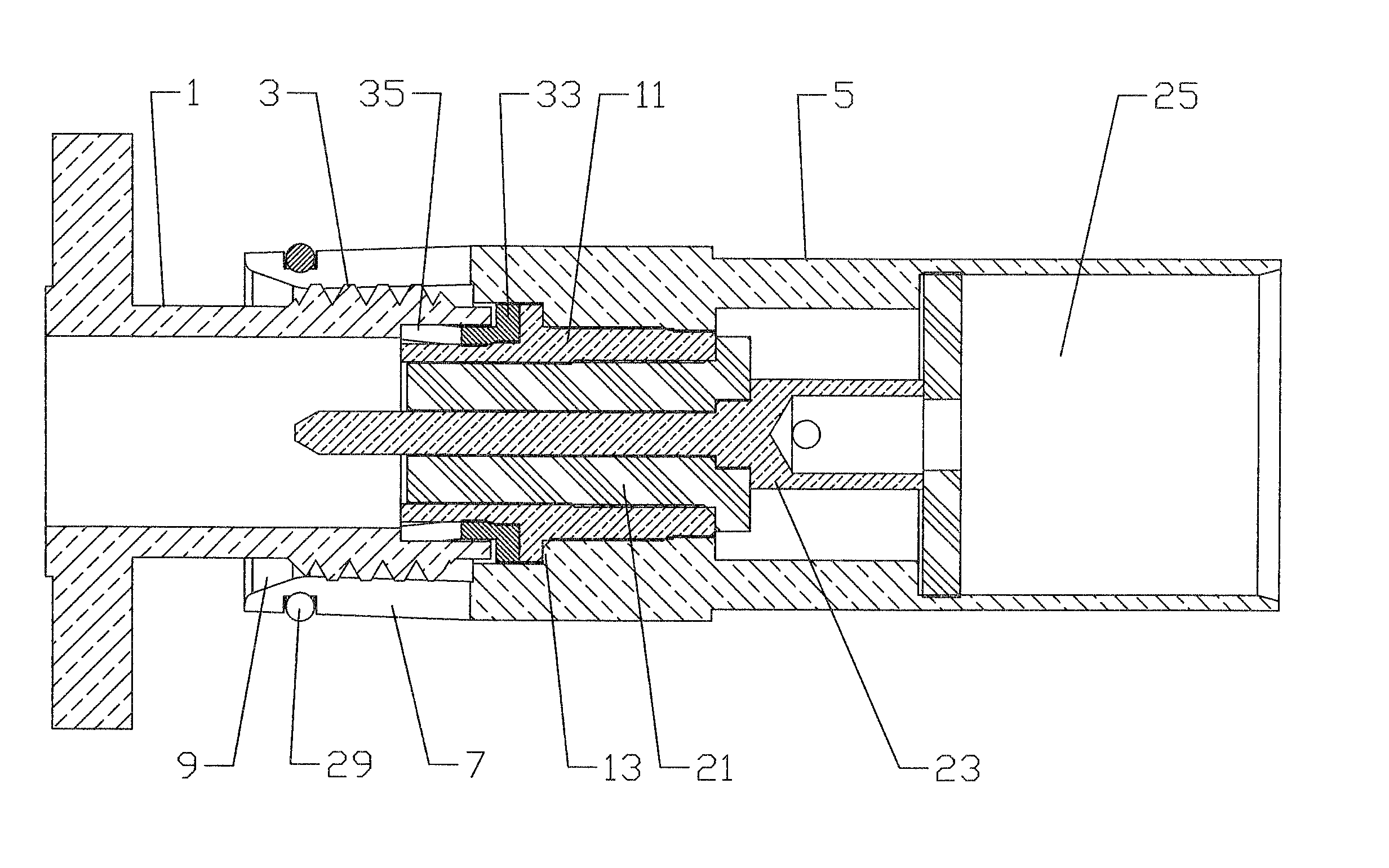

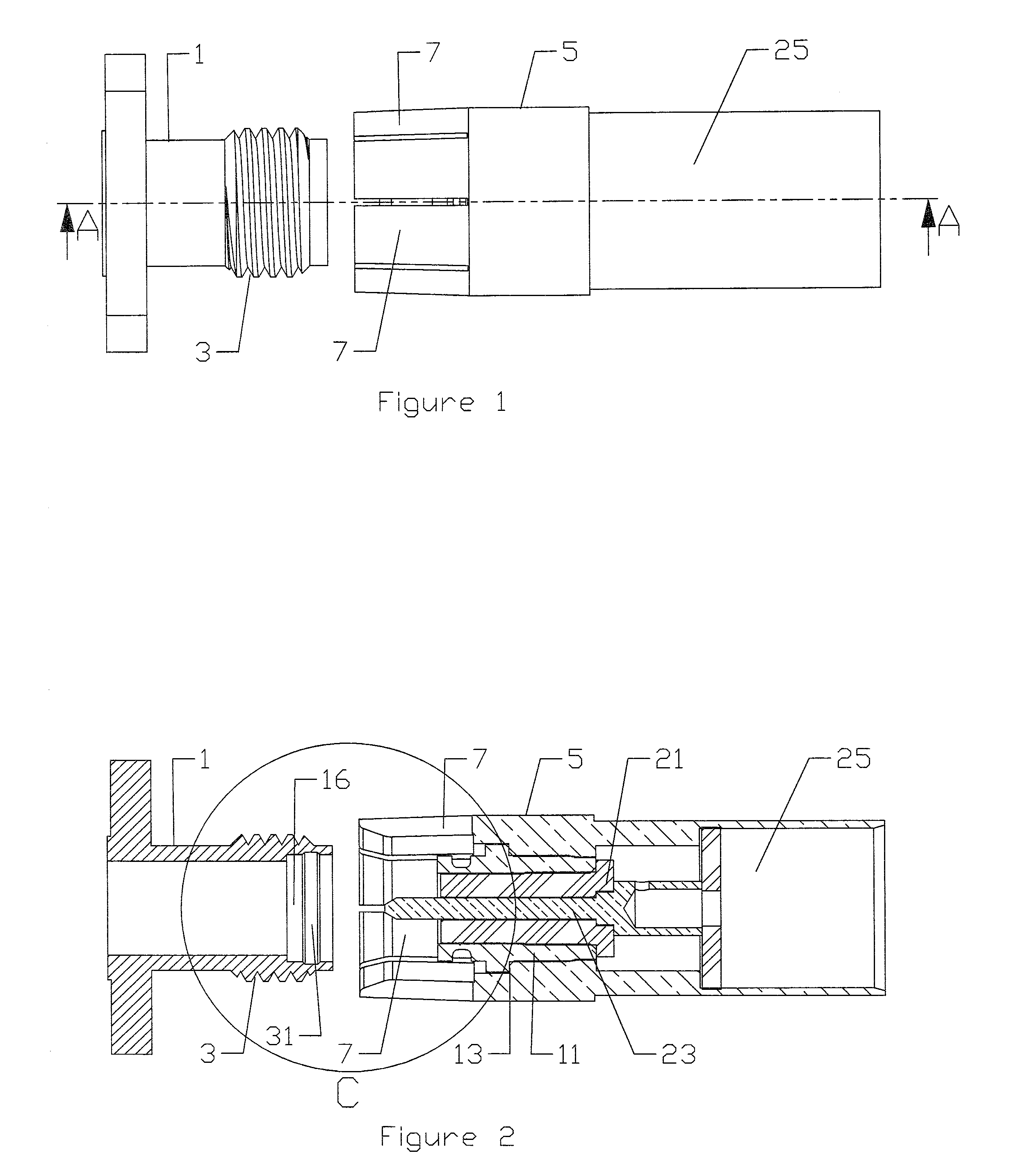

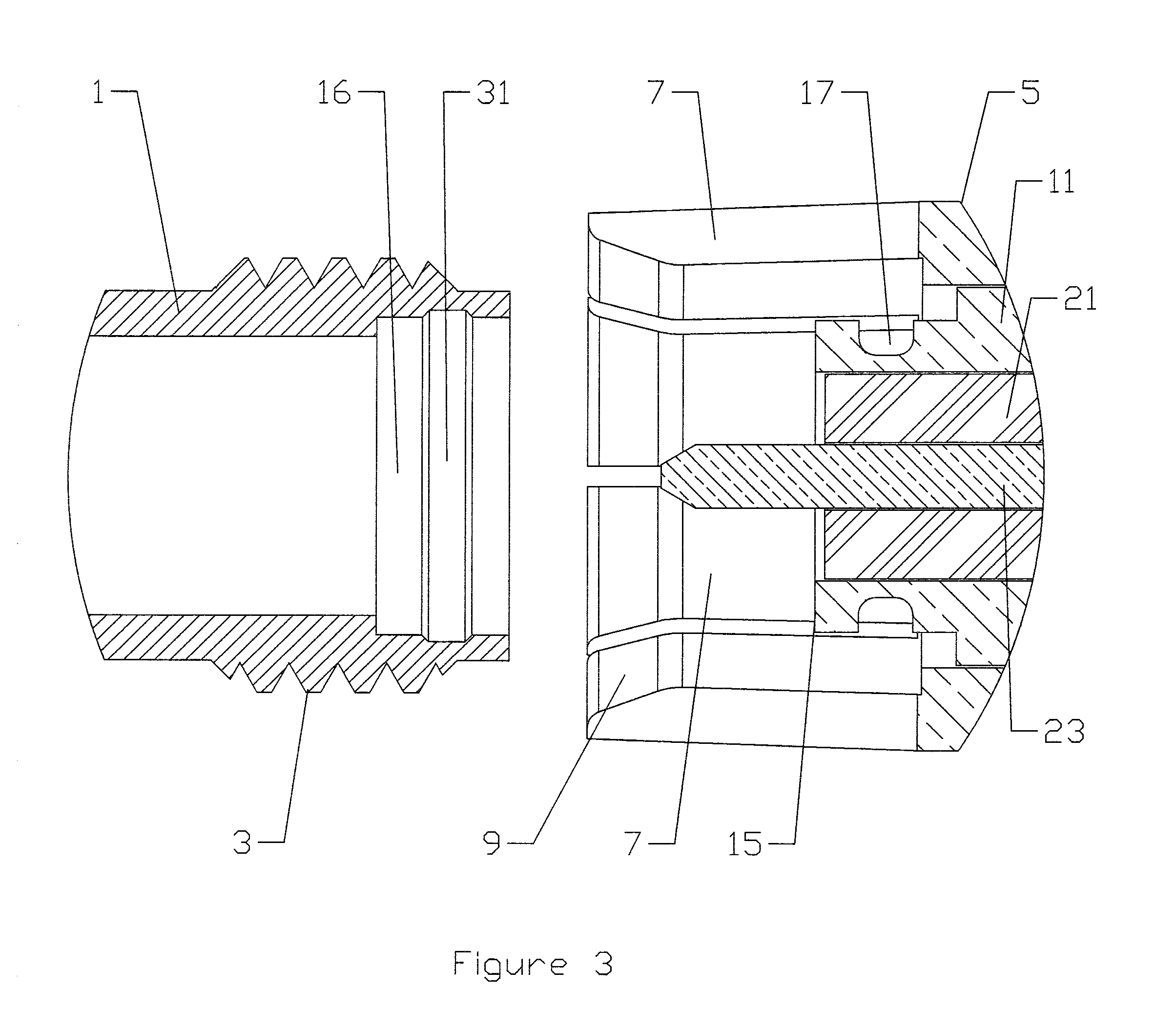

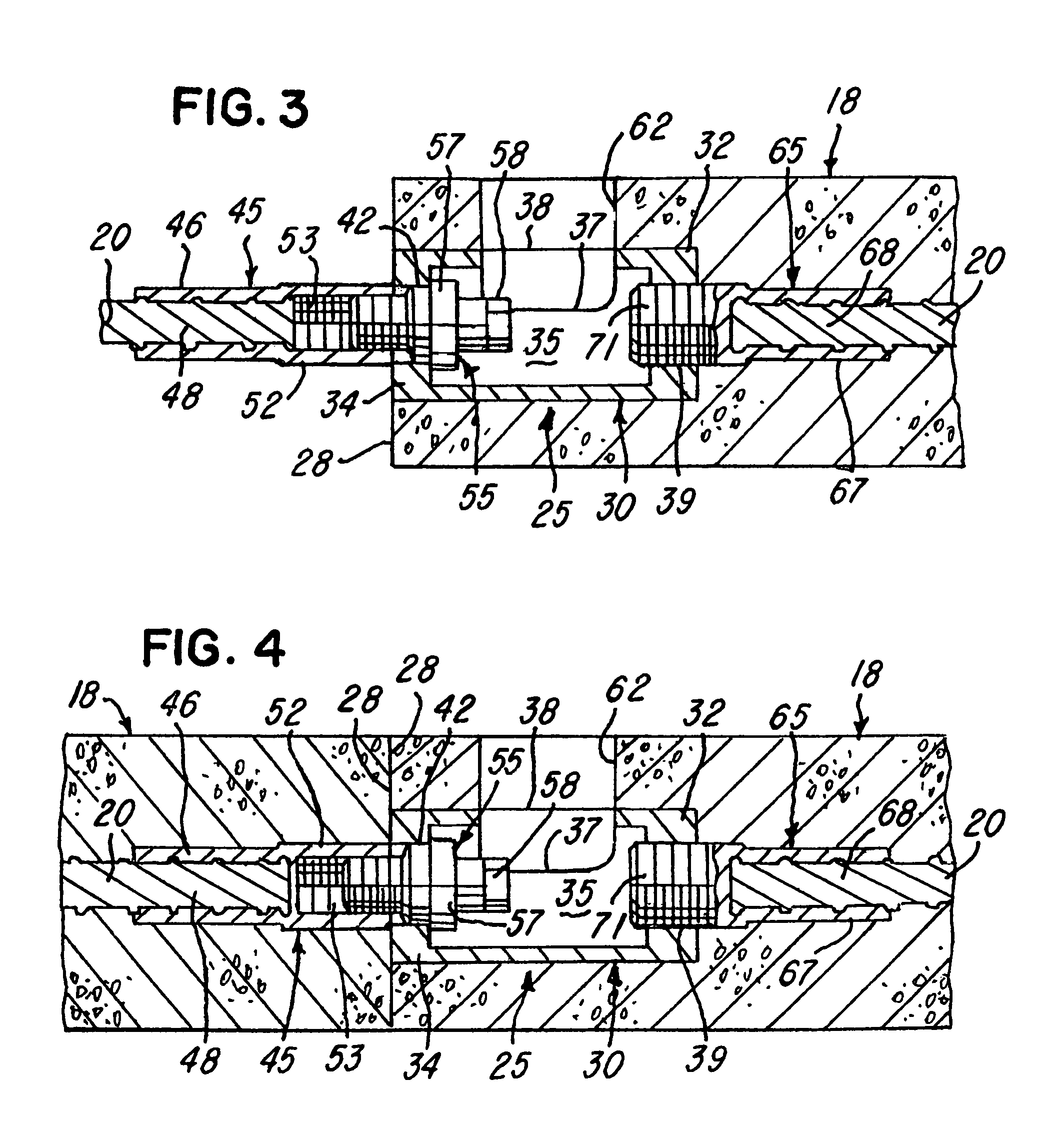

A push-on connector interface and associated spring ring adapted for use with, for example, existing standardized threaded female connectors, for example SMA or Type N connectors. A plurality of spring fingers of the male connector body engage the, typically threaded, outer diameter surface of the female connector body. A sleeve within the male connector body may be adapted to extend within a bore of the female connector body. A spring or spring ring located, for example, positioned within a groove or press-fit upon the sleeve has a plurality of deflectable protrusions which deform between the sleeve and an inner diameter surface of the bore and or are biased against the inner diameter surface. The connections formed by the bias of spring fingers and the deformation and or bias of the spring or spring ring creating a reliable mechanical and electrical interconnection between the male and female connector bodies.

Owner:ANDREW LLC

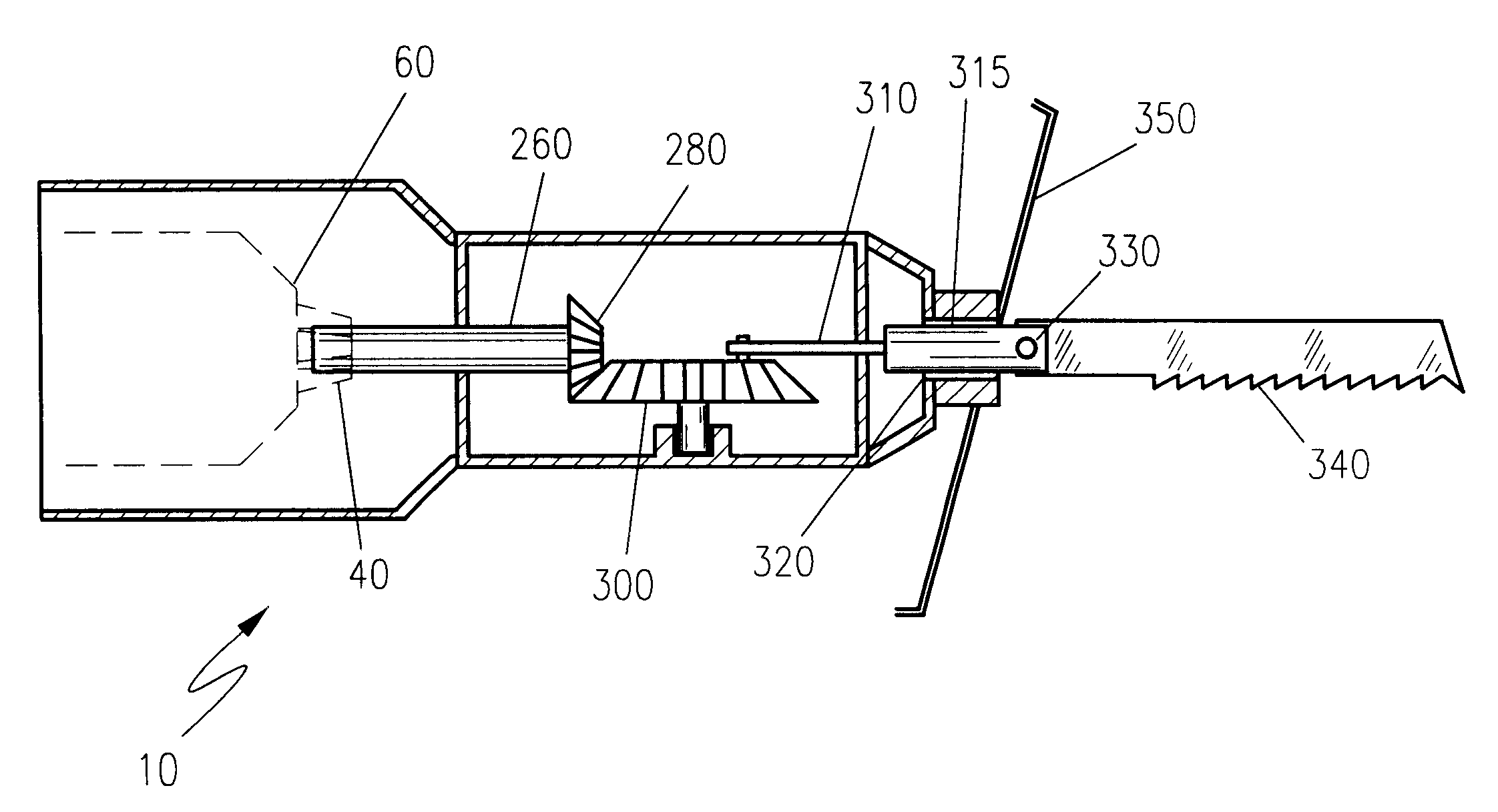

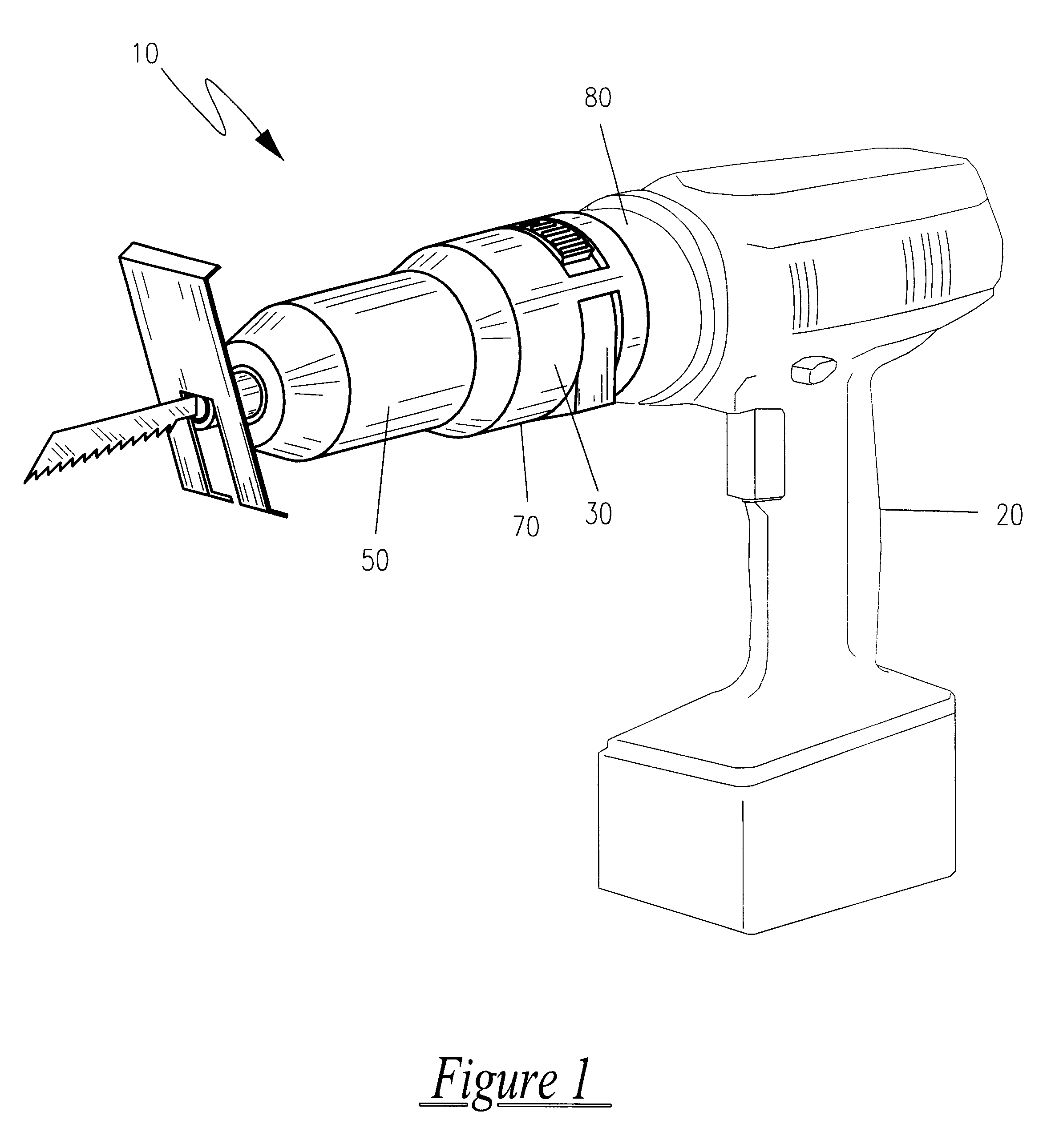

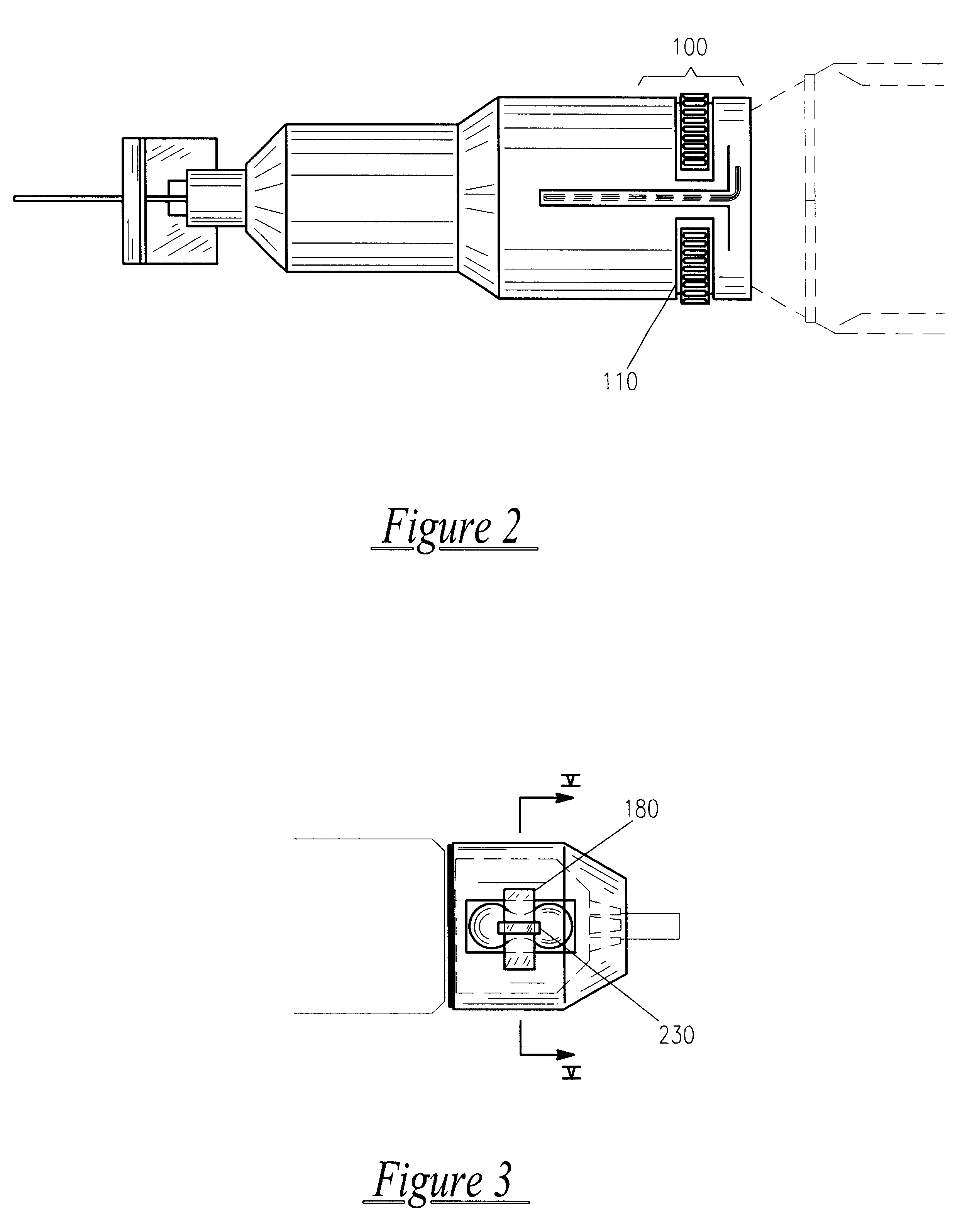

Reciprocating saw attachment for electric drill

InactiveUS6264211B1Save spaceShorten the timeDrilling machinesTransportation and packagingGear wheelCoupling

A universal, quick connect, reciprocating saw attachment for electric drills is disclosed, designed as an adapter that converts a power rotary drill into a reciprocating saw. The present invention converts the rotary action of a drill into the necessary reciprocating action to power a saw blade. The present invention adapts to the housing of various cordless drills and provides for a connection of a steel shank to the drill chuck. A gear box with a reciprocating mechanism inside the housing then provides a coupling to a saw blade to provided the necessary cutting action of a conventional reciprocating saw. Additionally, there are buttons that are designed to expand in and out to tighten the chuck which holds the adapter. The housing is made of a heavy duty impact resistant plastic with the associated gears and reciprocating mechanism made from hardened steel. Coupled with a cordless drill, and a saw blade, the present invention provides for the functions of two, usually separate, power tools in the convenience of one.

Owner:GRANADO RENE

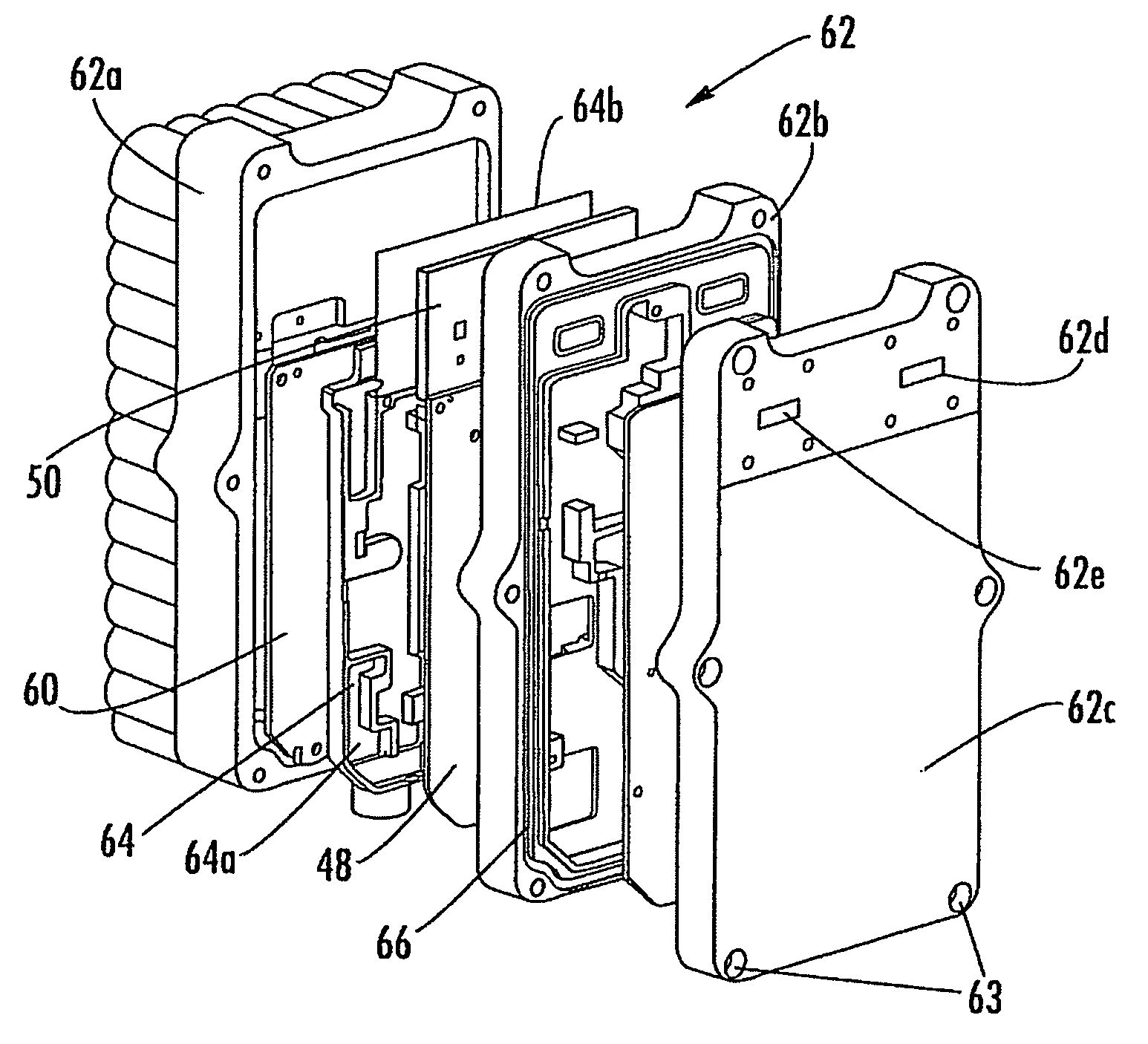

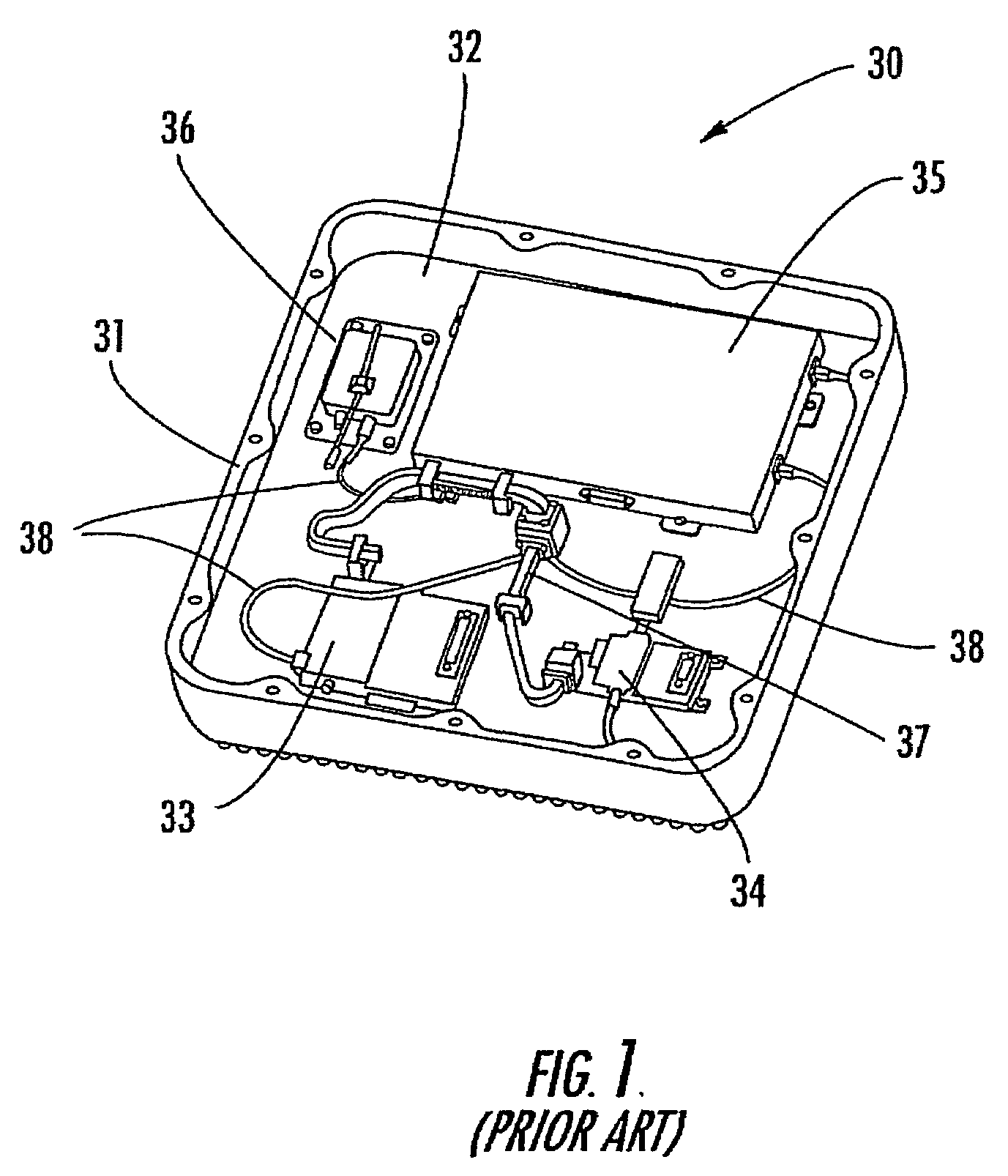

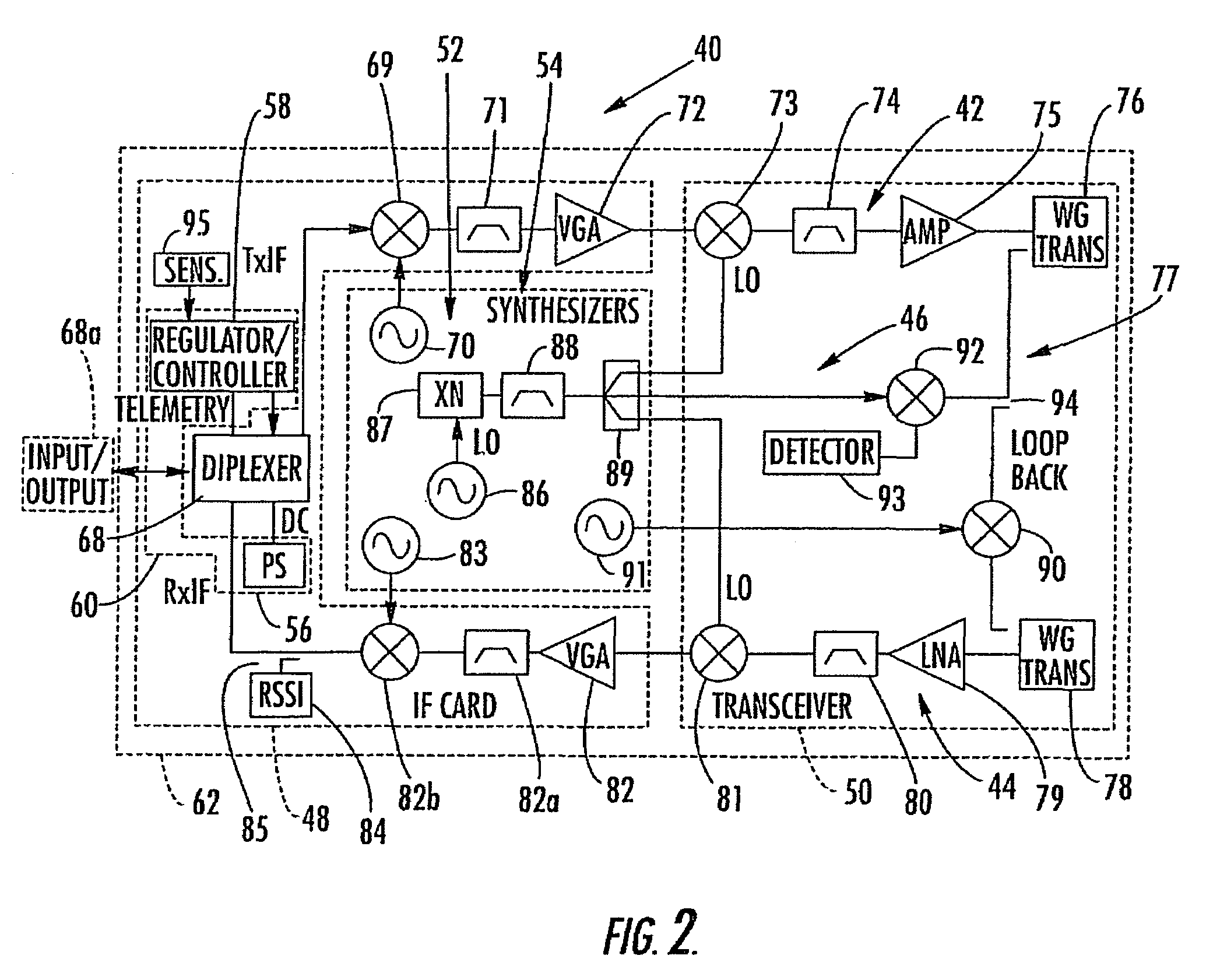

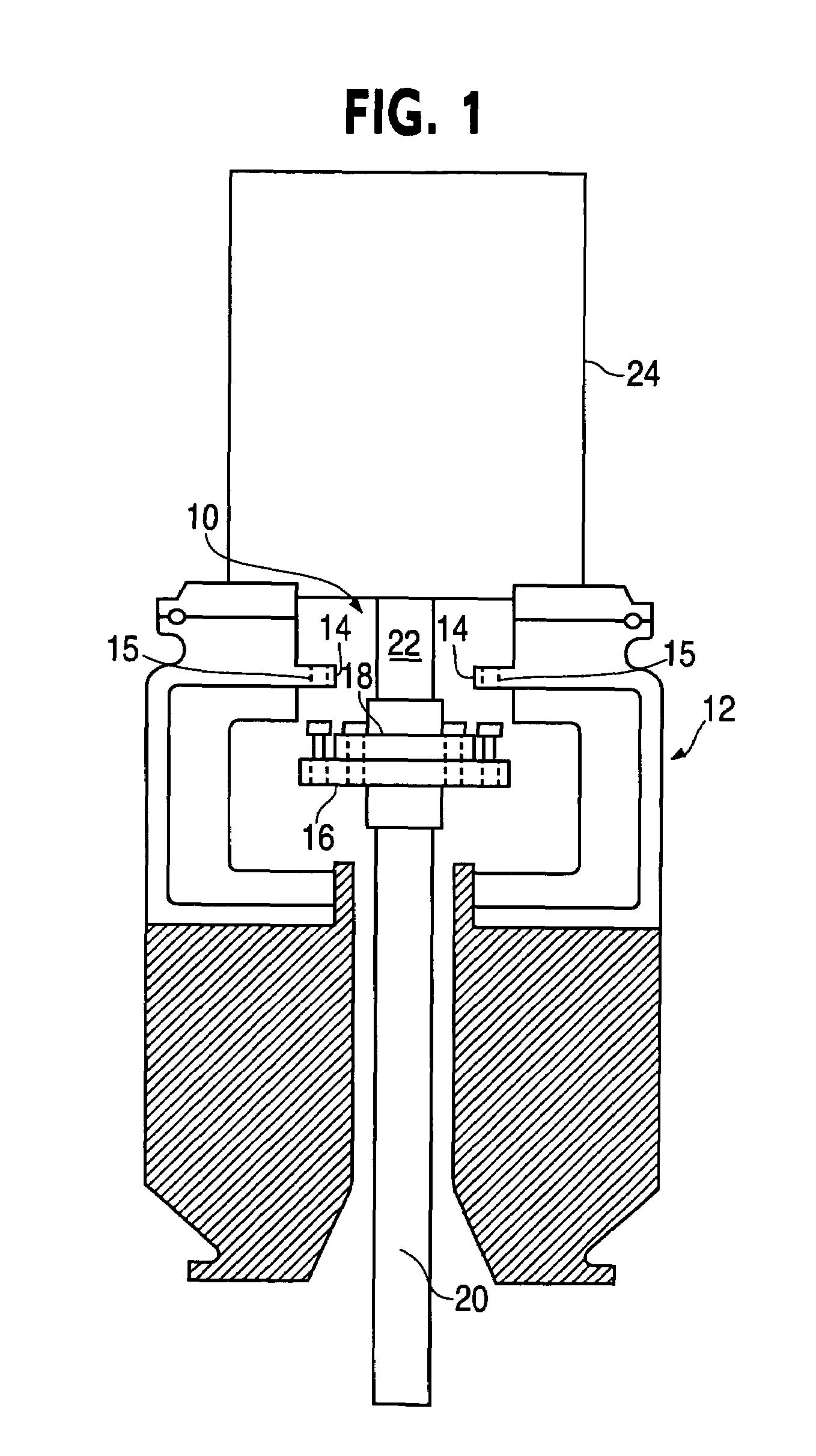

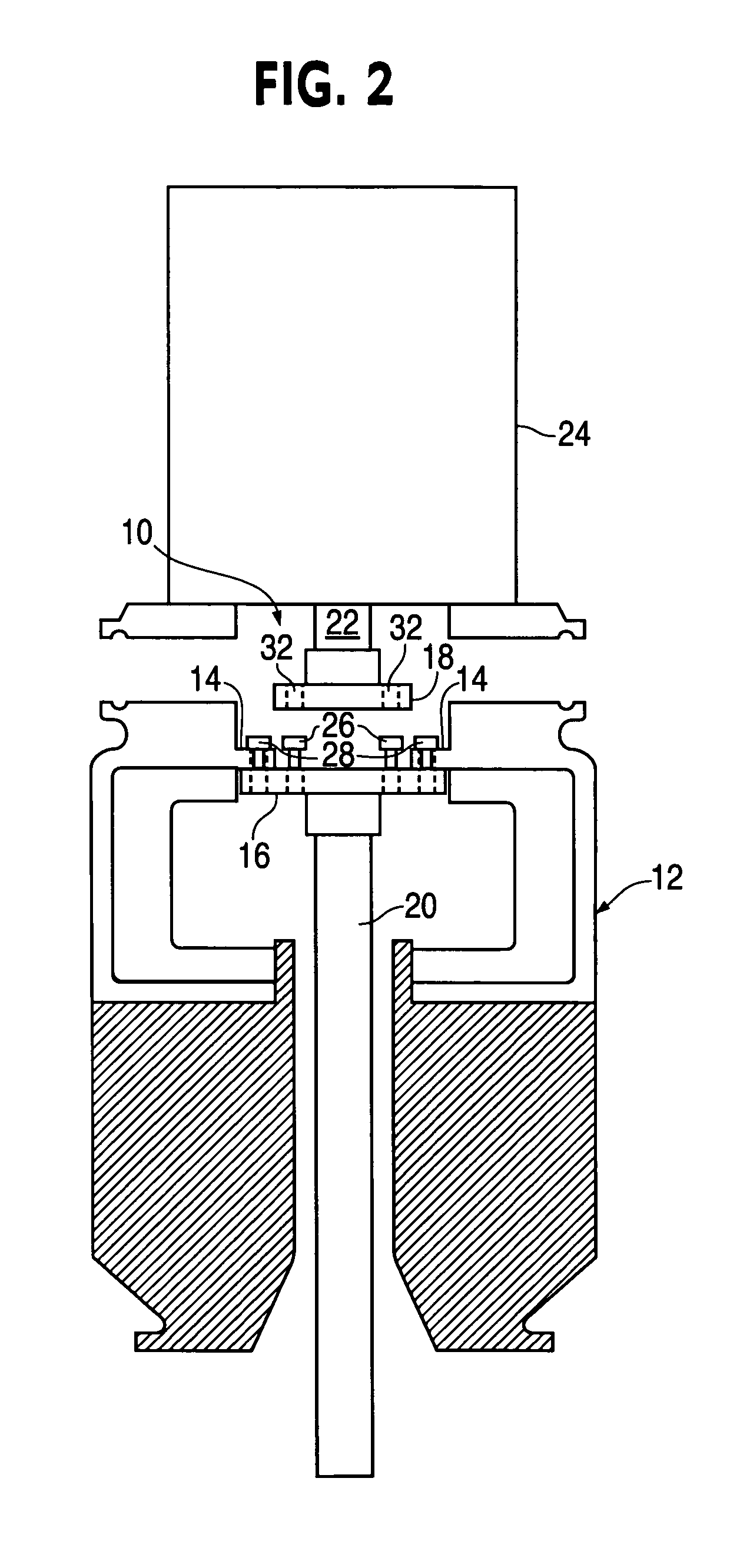

Highly integrated microwave outdoor unit (ODU)

InactiveUS7050765B2Fast disconnectionUse minimizedActive radio relay systemsRadiating element housingsLocal oscillator signalTransceiver

A lightweight millimeter wave outdoor unit includes a lightweight housing with a heat sink and mounting member configured for mounting on the antenna to form a wireless link. A millimeter wave transceiver board is formed of ceramic material and mounted within the housing. It includes a millimeter wave transceiver circuit that has microwave monolithic integrated circuit (MMIC) chips and operable with the transmit and receive boards. An intermediate frequency (IF) board has components forming an intermediate frequency circuit operable with the millimeter wave transceiver circuit. A frequency synthesizer board has a signal generating circuit for generating local oscillator signals to the transceiver circuit. A controller board has surface mounted DC and low frequency discrete devices thereon forming power and control circuits that supply respective power and control signals to other circuits on other boards. A quick connect / disconnect assembly is operative with the housing for allowing the housing to be rapidly connected and disconnected to the antenna circuit contact members interconnect circuits between boards.

Owner:REVEAL IMAGING

Push-on Connector Interface

InactiveUS20050164552A1Eliminate needReduce frictionEngagement/disengagement of coupling partsElectrically conductive connectionsEngineeringInterconnection

A push-on connector interface and associated spring ring adapted for use with, for example, existing standardized threaded female connectors, for example SMA or Type N connectors. A plurality of spring fingers of the male connector body engage the, typically threaded, outer diameter surface of the female connector body. A sleeve within the male connector body may be adapted to extend within a bore of the female connector body. A spring or spring ring located, for example, positioned within a groove or press-fit upon the sleeve has a plurality of deflectable protrusions which deform between the sleeve and an inner diameter surface of the bore and or are biased against the inner diameter surface. The connections formed by the bias of spring fingers and the deformation and or bias of the spring or spring ring creating a reliable mechanical and electrical interconnection between the male and female connector bodies.

Owner:ANDREW LLC

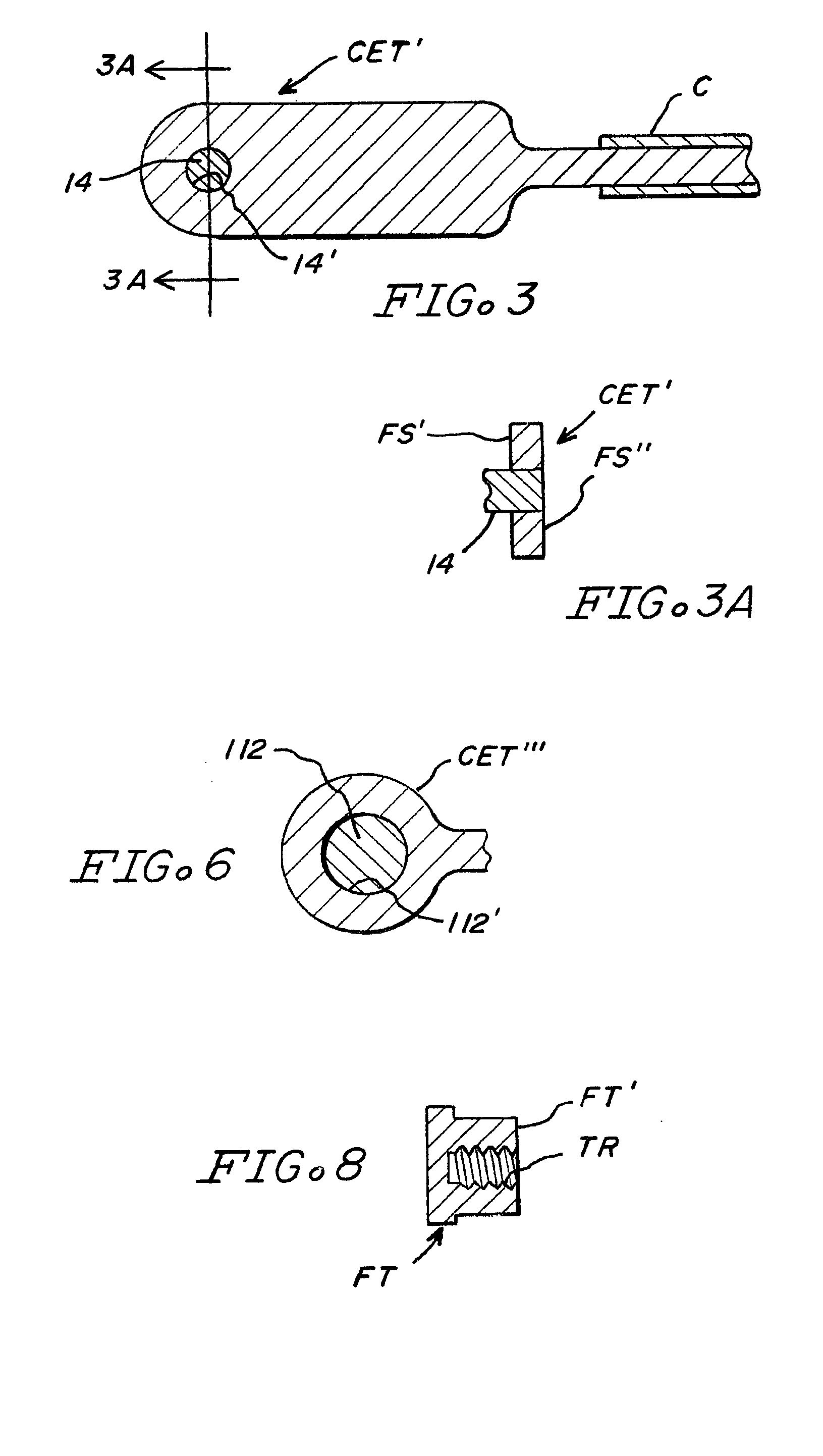

Coupler system for adjacent precast concrete members and method of connecting

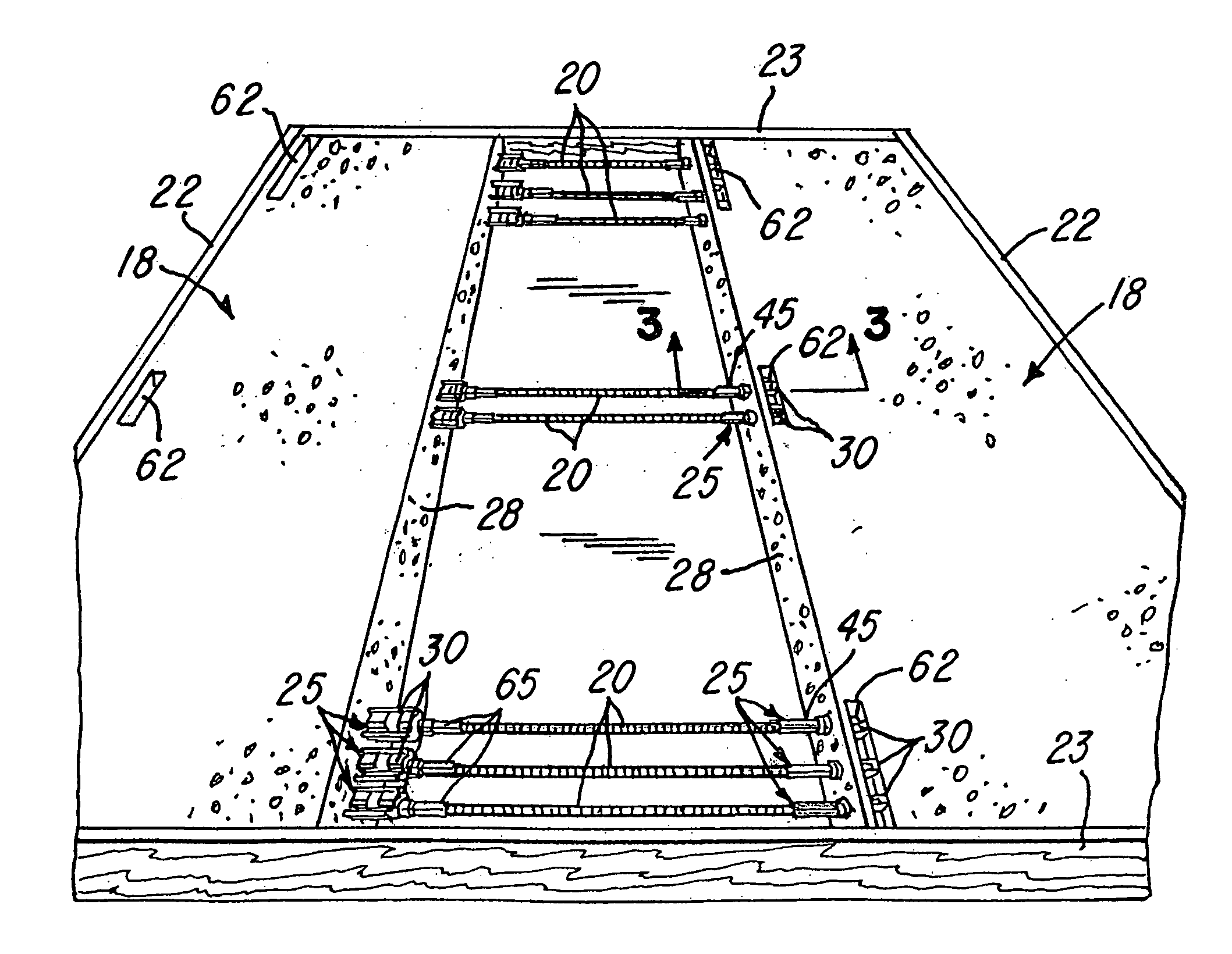

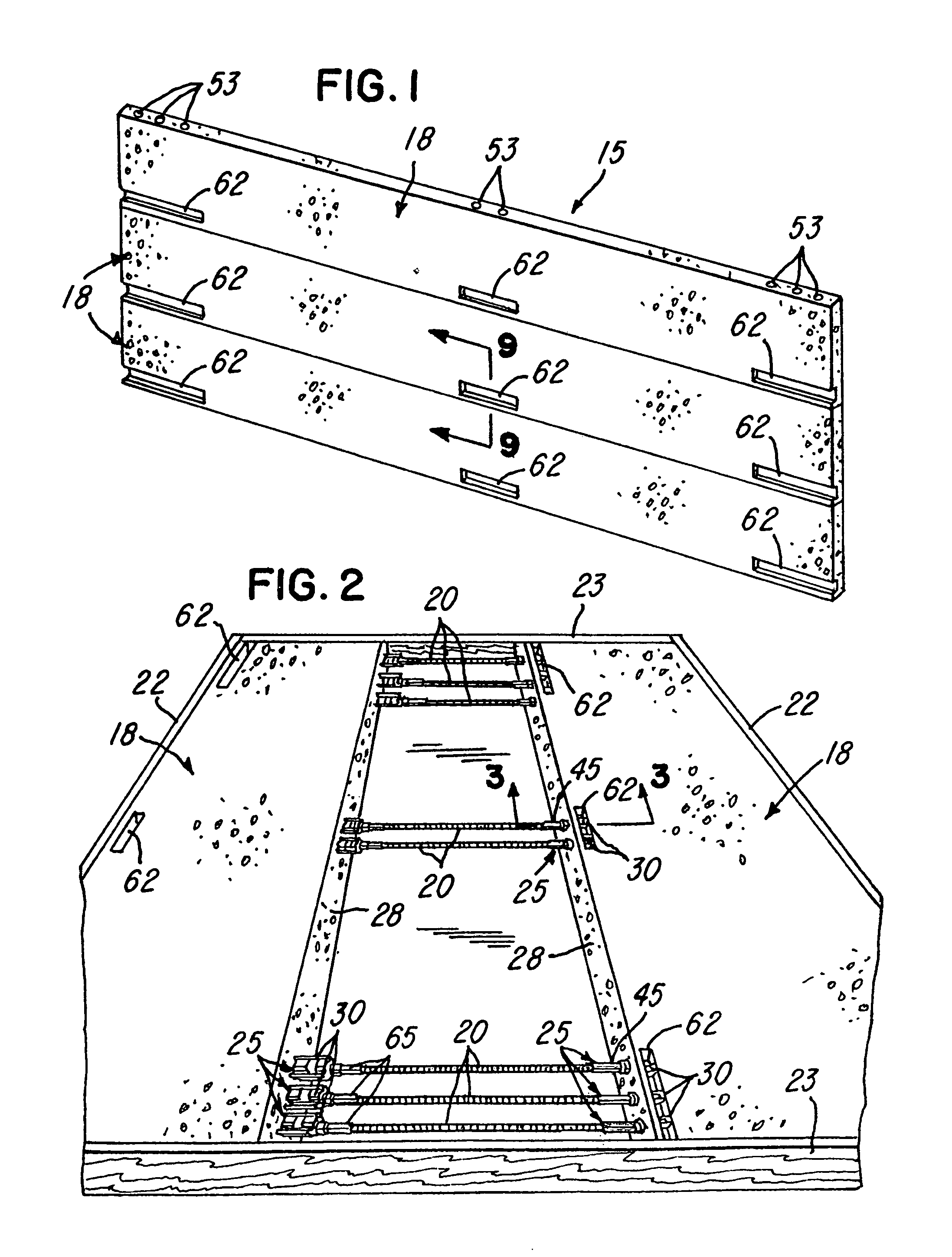

ActiveUS20090139177A1Quick stackQuickly and efficiently stackedBuilding material handlingMetal-working hand toolsReinforced concreteRebar

Adjacent precast reinforced concrete modules or members are secured together by a plurality of coupler systems each including a cast metal coupler body embedded in an edge portion of the first concrete member and connected by a coupling member to a reinforcing bar within the first concrete member. The coupler body has an internal cavity with a side opening and an end opening extending to the cavity, and reinforcing wings border the side opening. The second concrete member has another coupling member rigidly connected to an axially aligned reinforcing bar and includes an end portion with a threaded bore. A bolt is inserted into the cavity through the side opening, aligned with the end opening and then threaded into the bore where the bolt is tightened with a wrench extending into the cavity through the side opening. A reusable locating pin may be used to align the concrete members.

Owner:BARSPLICE PRODS

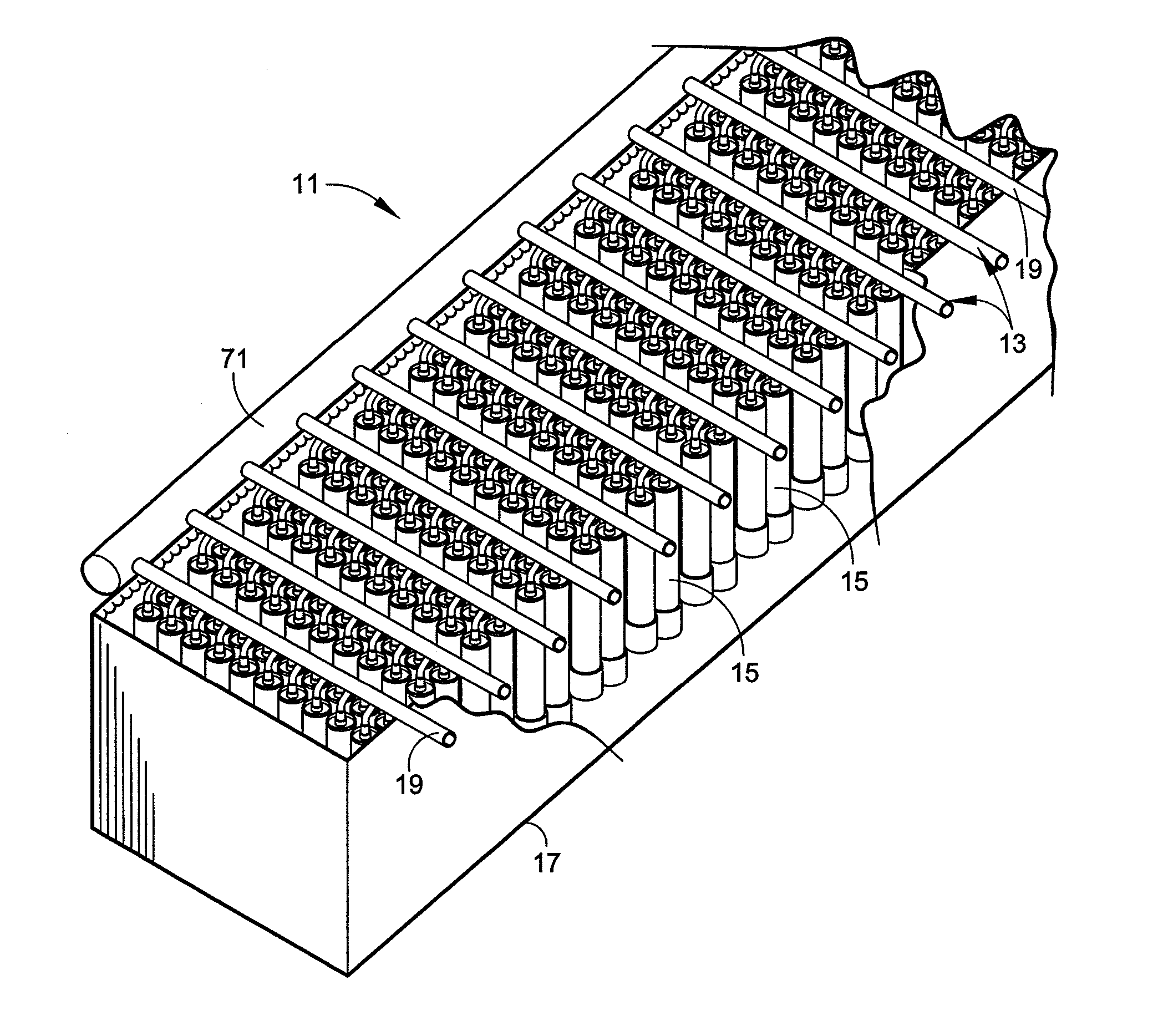

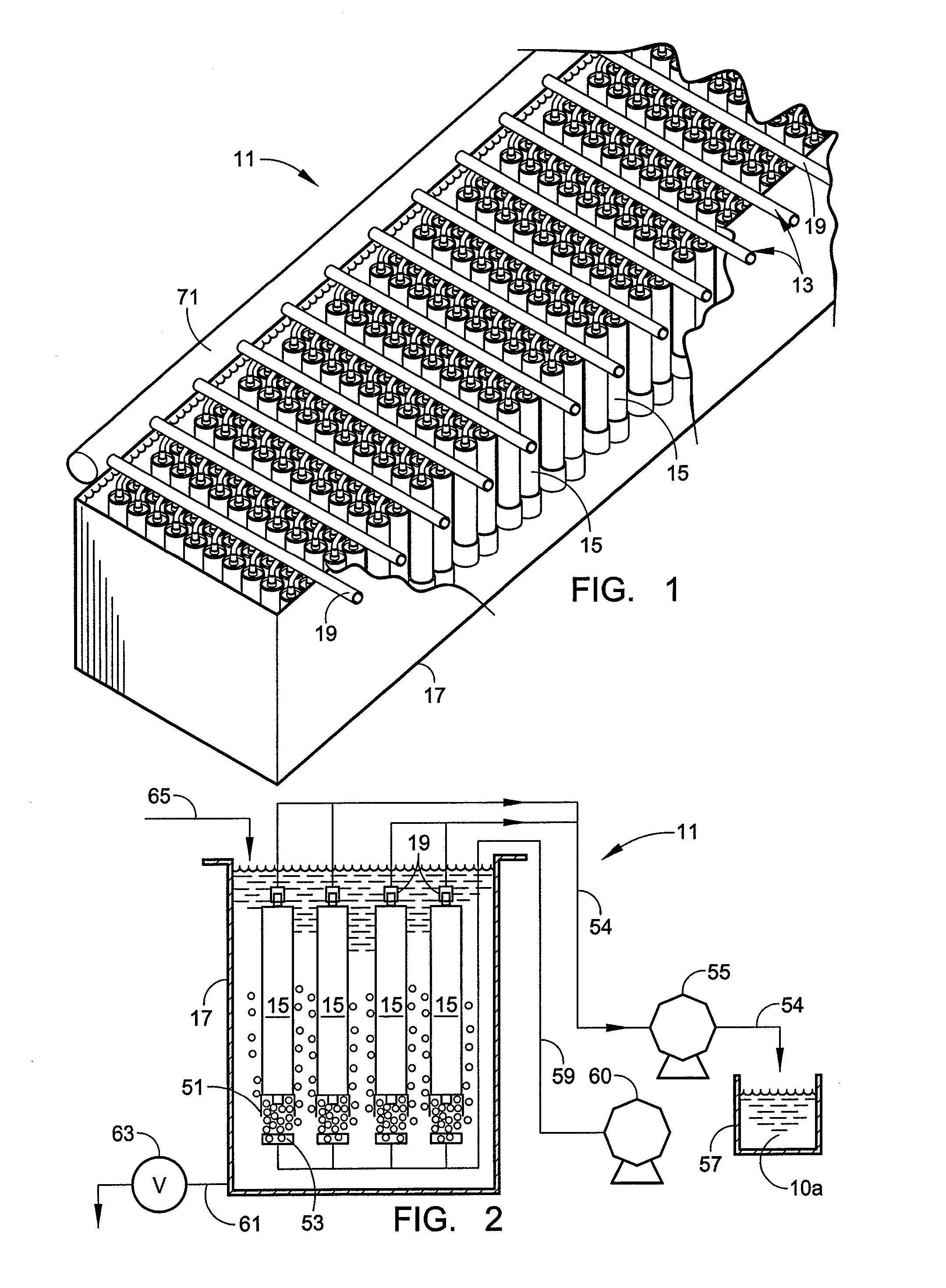

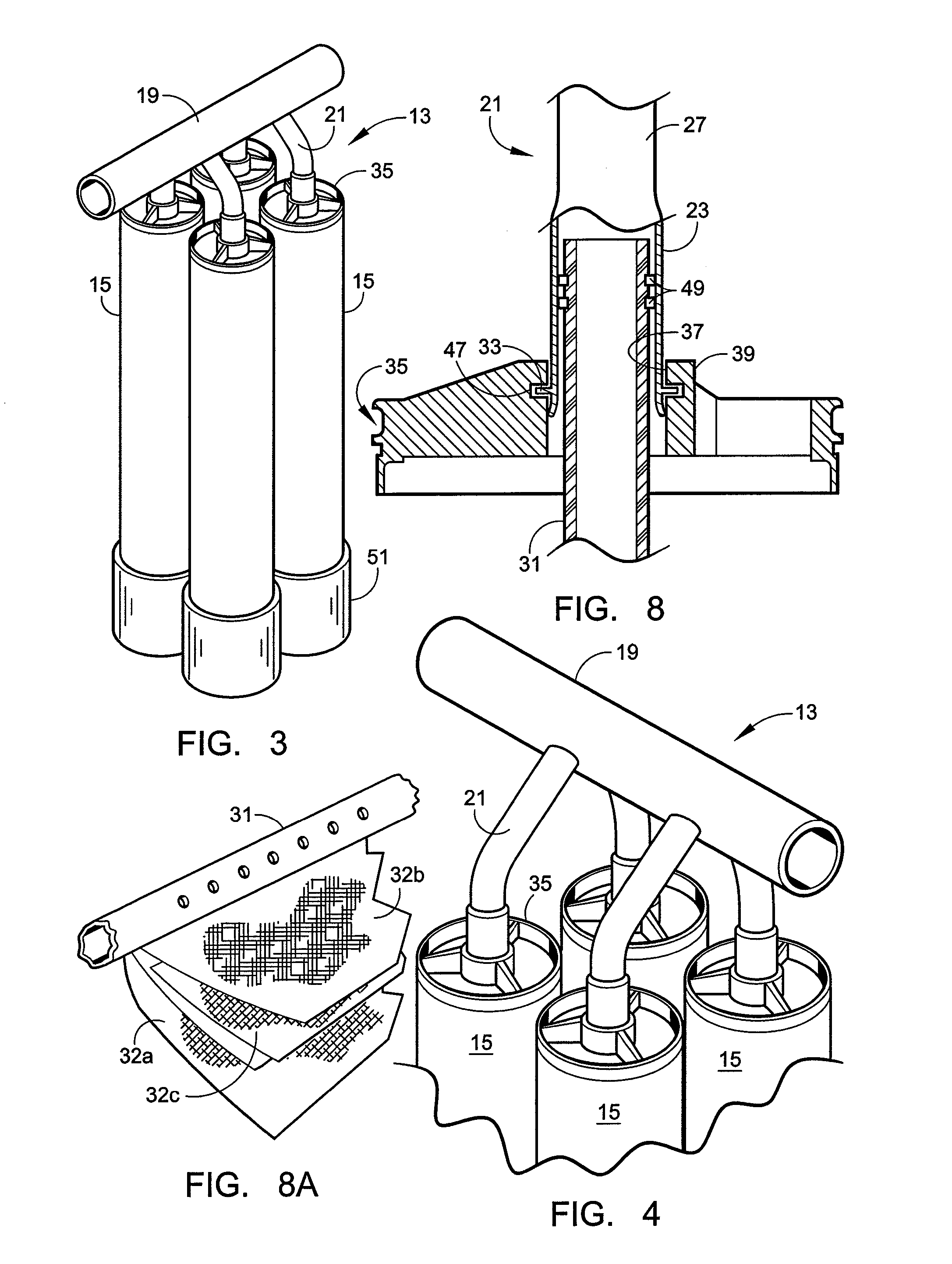

Network for supporting spiral wound membrane cartridges for submerged operation

Methods and apparatus are provided for positioning a plurality of cylindrical spirally wound membrane filtration elements in a body of aqueous feedstock employing manifold conduits that support vertically aligned filtration elements via short lengths of pipe. Efficient and effective connections are made between the ends of such support pipes and the adjacent end of each filtration element by bayonet-type fittings, which allow straightforward, detachable interconnection by axially moving the cylindrical element into place and then rotating the element a quarter turn. Support in this manner provides full access to the open lower ends of the element through which, during operation, streams of rising gas bubbles are caused to pass, fed from underlying bubblers or the like. The manifold conduits may be located either above or below the preferably vertically oriented filtration elements.

Owner:TRISEP CORP

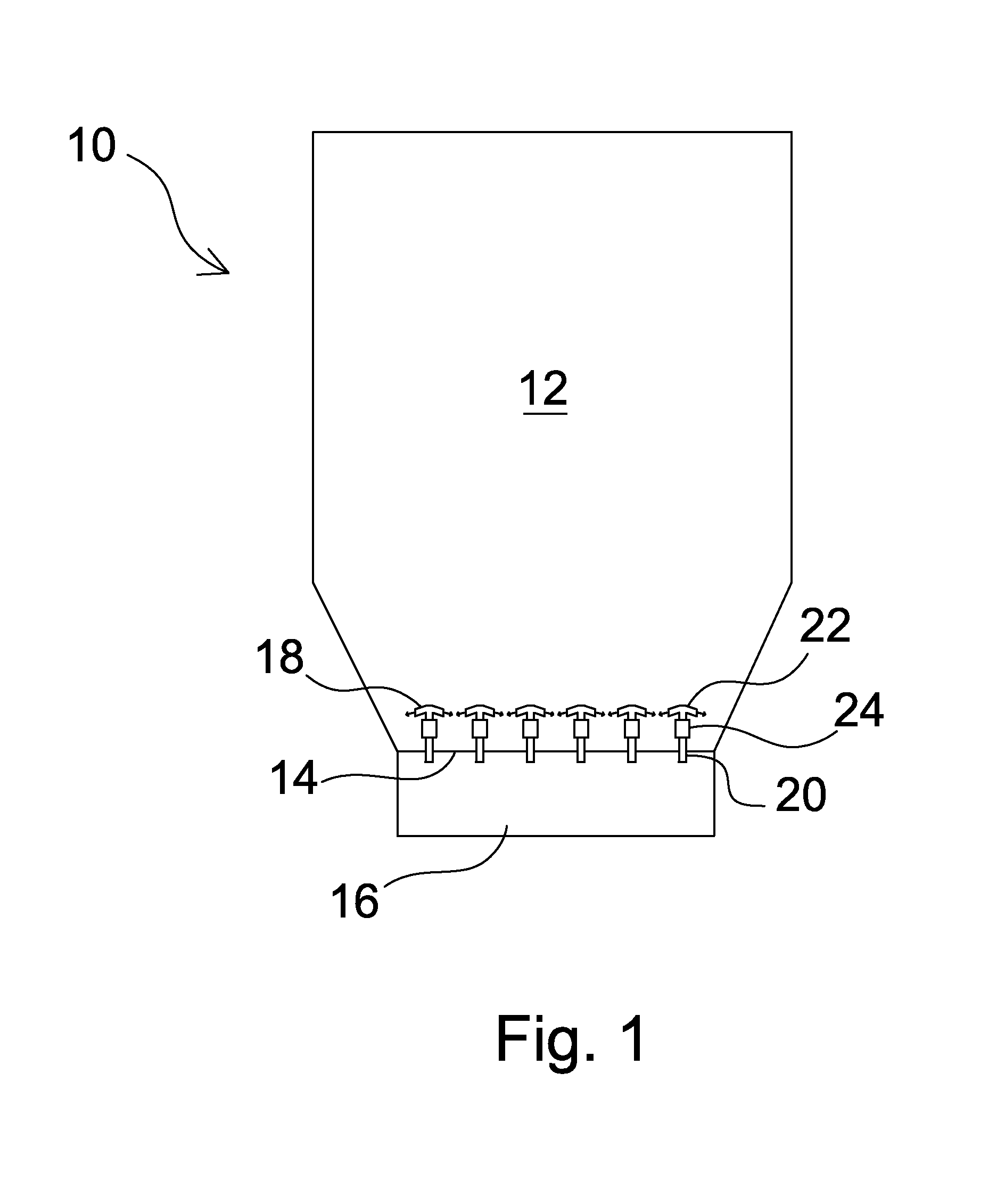

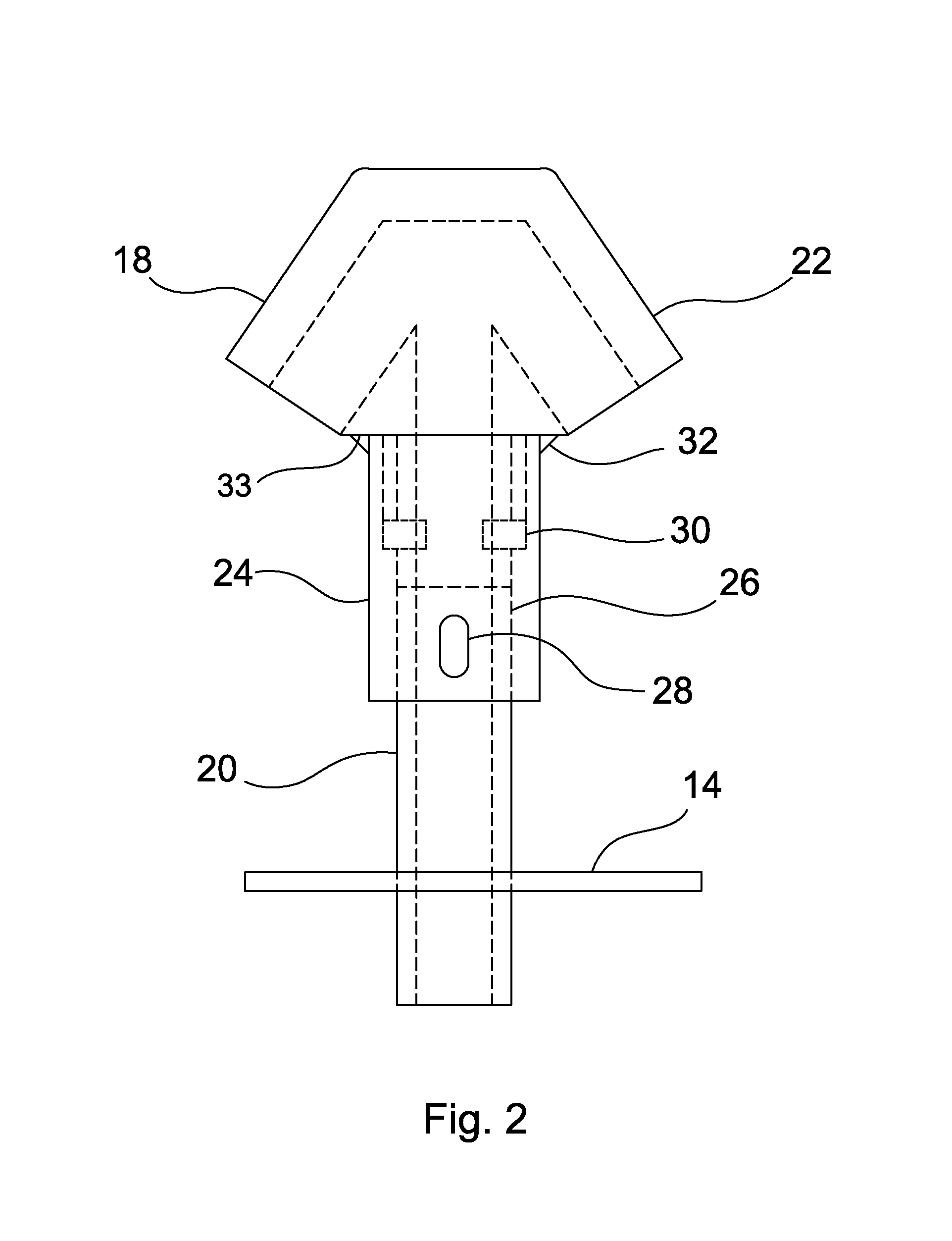

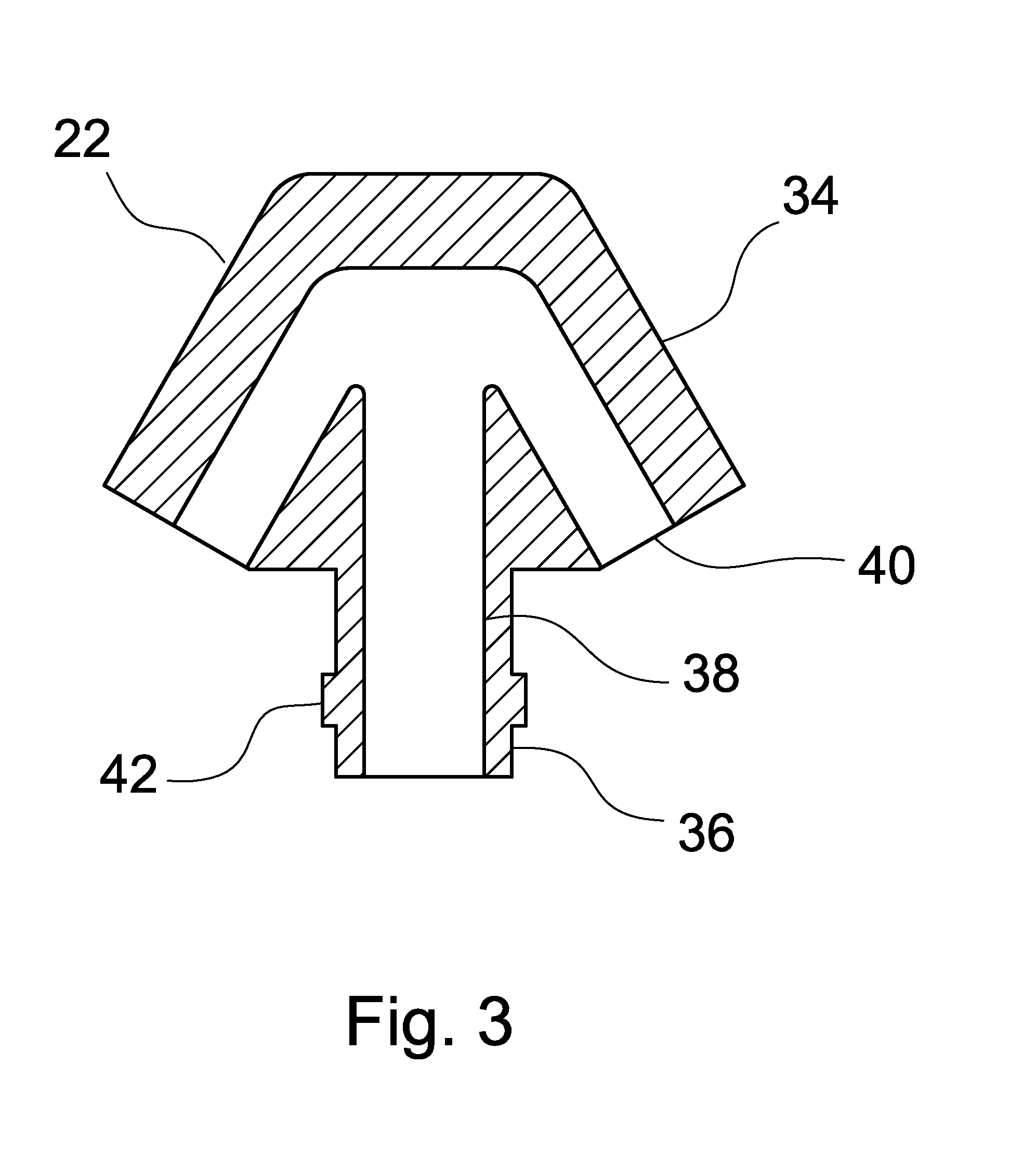

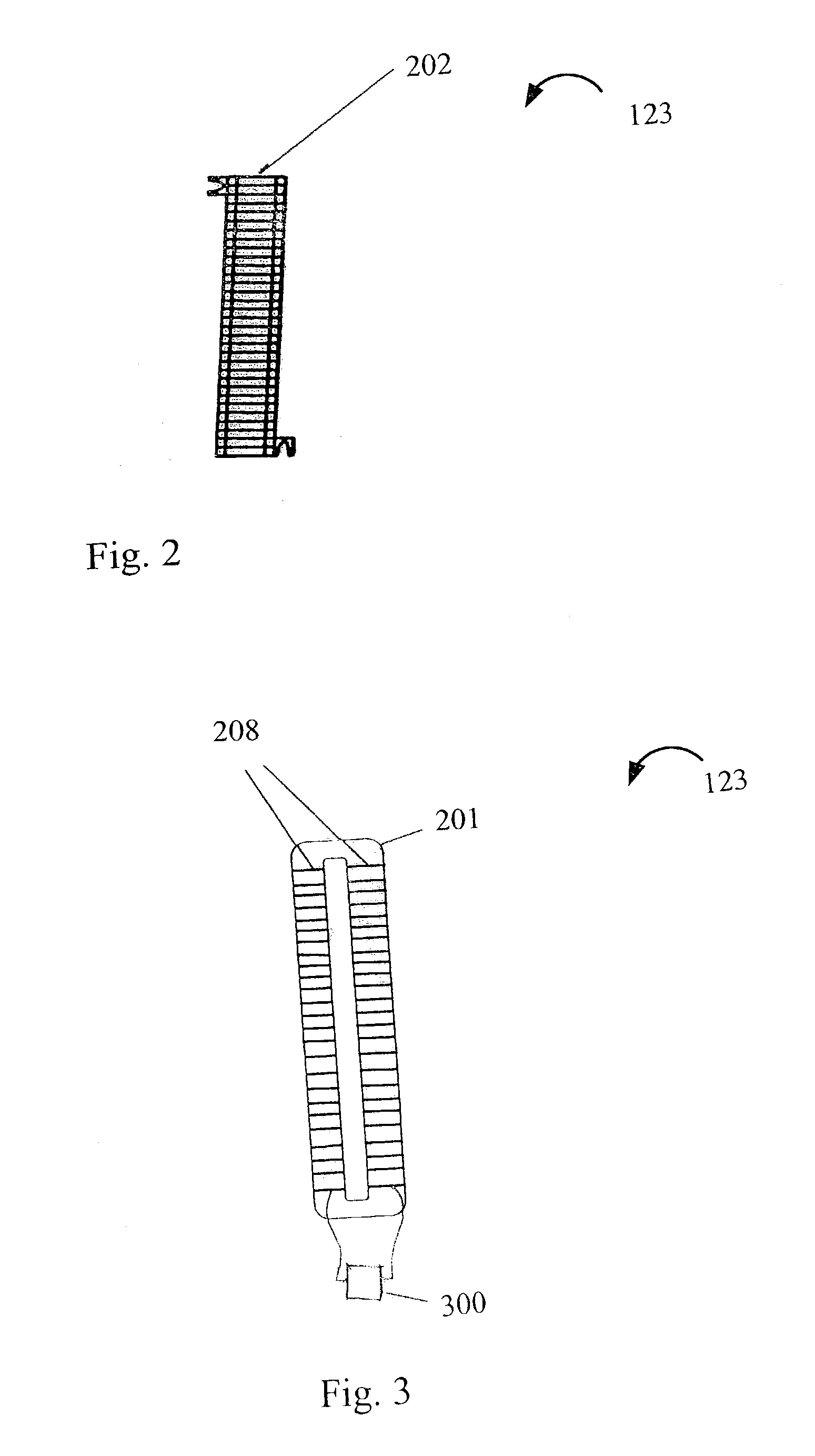

Method of sensor packaging

InactiveUS20050205980A1Firmly connectedPrecise positioningSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

The present invention is directed to a method of making flexible interconnect packaging, in particular, packaging for fingerprint sensor chips. The chip is mounted on a flexible substrate having conductive traces leading to a connector at an end of the substrate. Wires are used to connect contact pads with the conductive traces, and a rigid frame is mounted below the substrate and chip. The conductive traces are preferably internal within the substrate and are exposed by forming a cavity in the substrate adjacent to the chip. Also disclosed are electronic devices which incorporate the foregoing fingerprint sensing apparatus.

Owner:SOCIONEXT INC

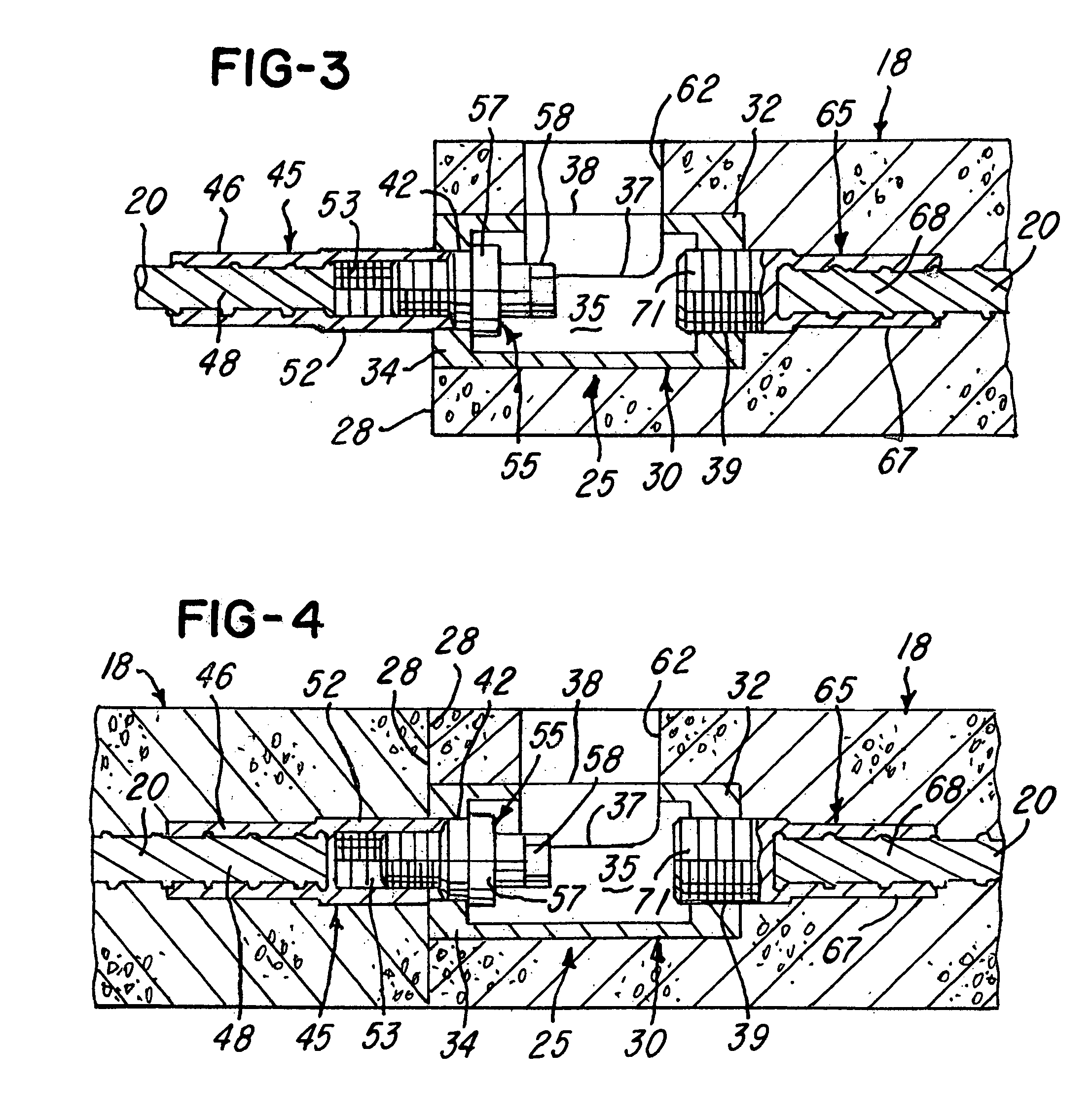

Coupler system for adjacent precast concrete members and method of connecting

ActiveUS7975444B2Quick stackQuickly and efficiently stackedBuilding material handlingMetal-working hand toolsReinforced concreteEngineering

Adjacent precast reinforced concrete modules or members are secured together by a plurality of coupler systems each including a cast metal coupler body embedded in an edge portion of the first concrete member and connected by a coupling member to a reinforcing bar within the first concrete member. The coupler body has an internal cavity with a side opening and an end opening extending to the cavity, and reinforcing wings border the side opening. The second concrete member has another coupling member rigidly connected to an axially aligned reinforcing bar and includes an end portion with a threaded bore. A bolt is inserted into the cavity through the side opening, aligned with the end opening and then threaded into the bore where the bolt is tightened with a wrench extending into the cavity through the side opening. A reusable locating pin may be used to align the concrete members.

Owner:BARSPLICE PRODS

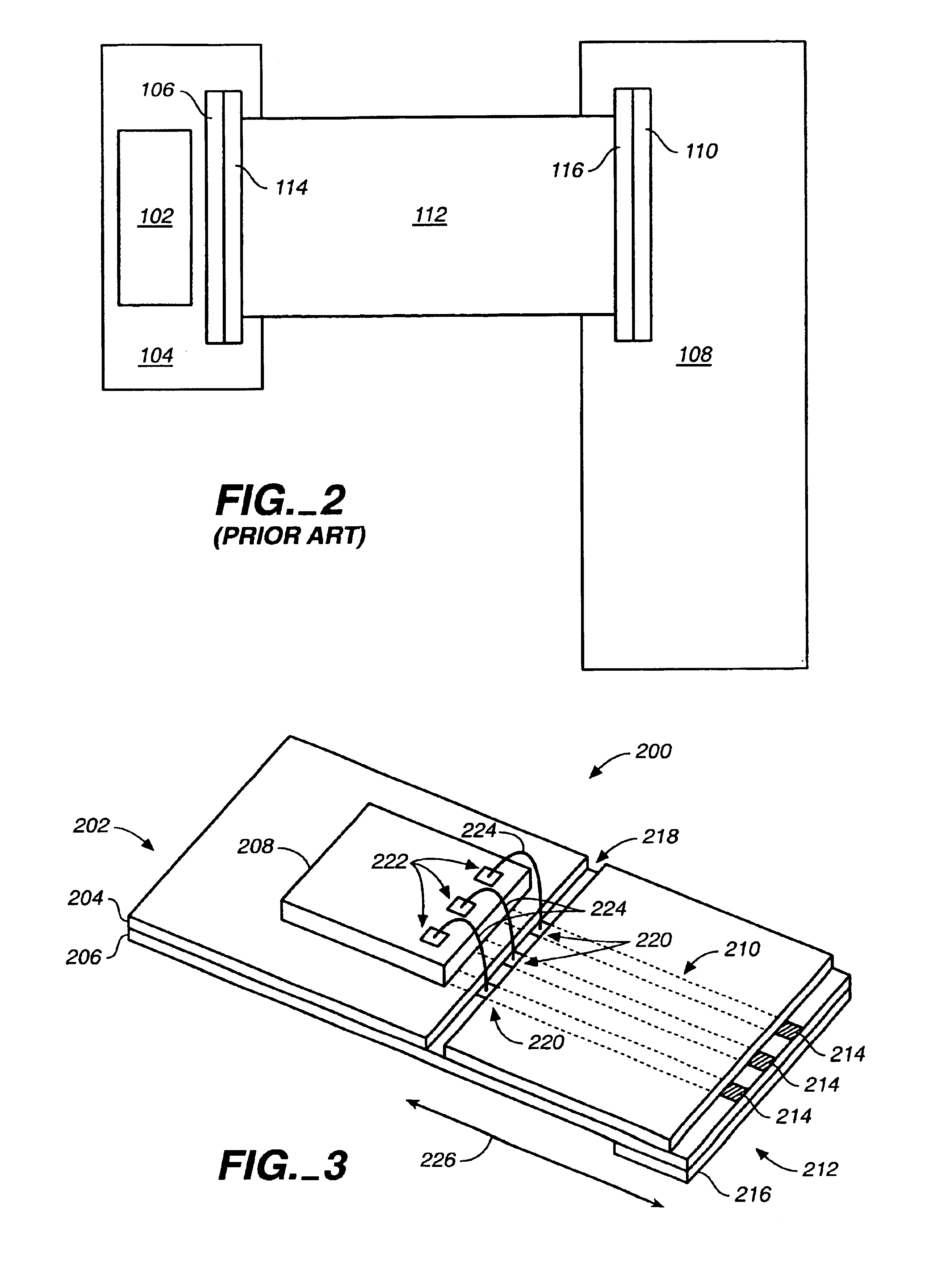

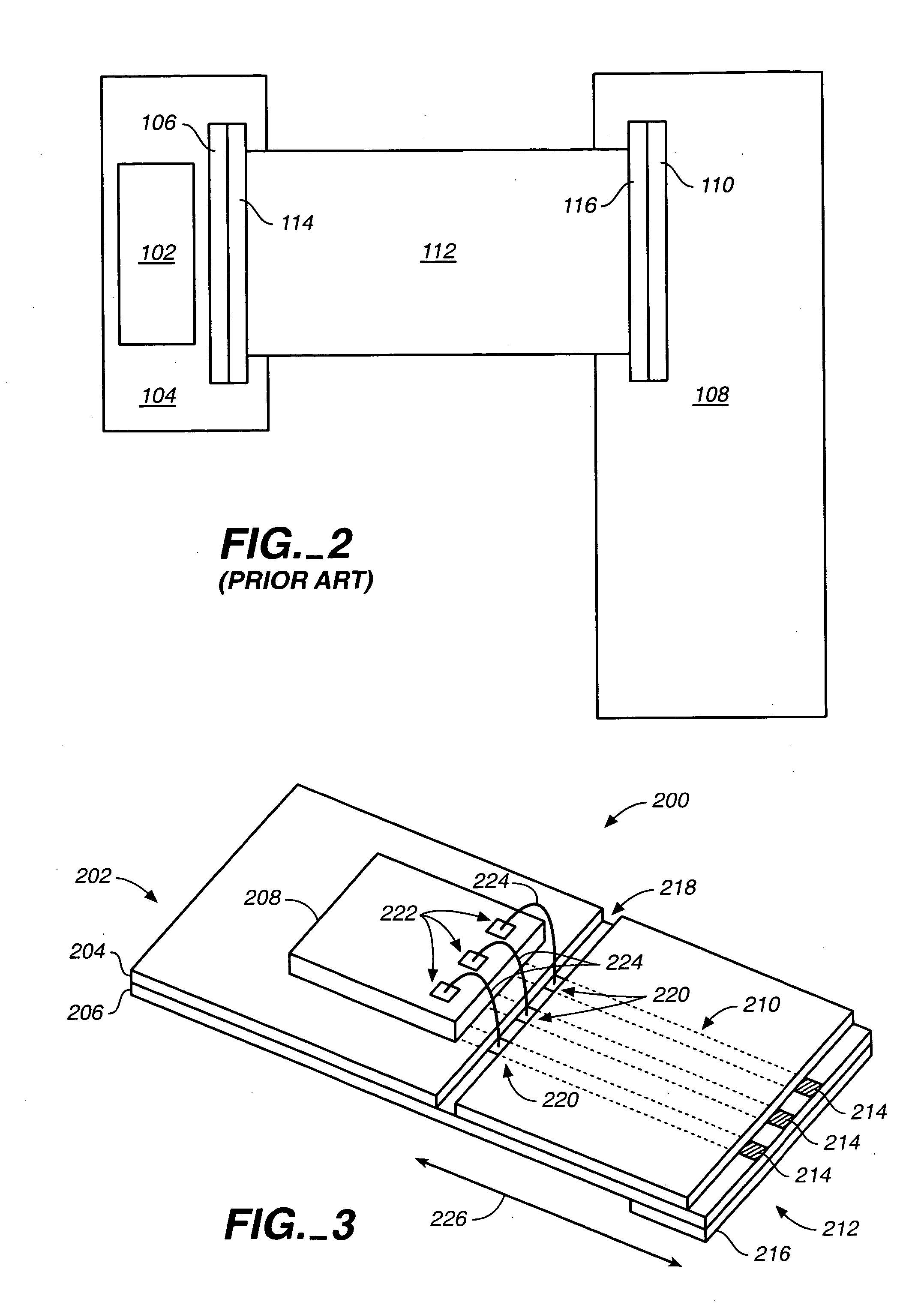

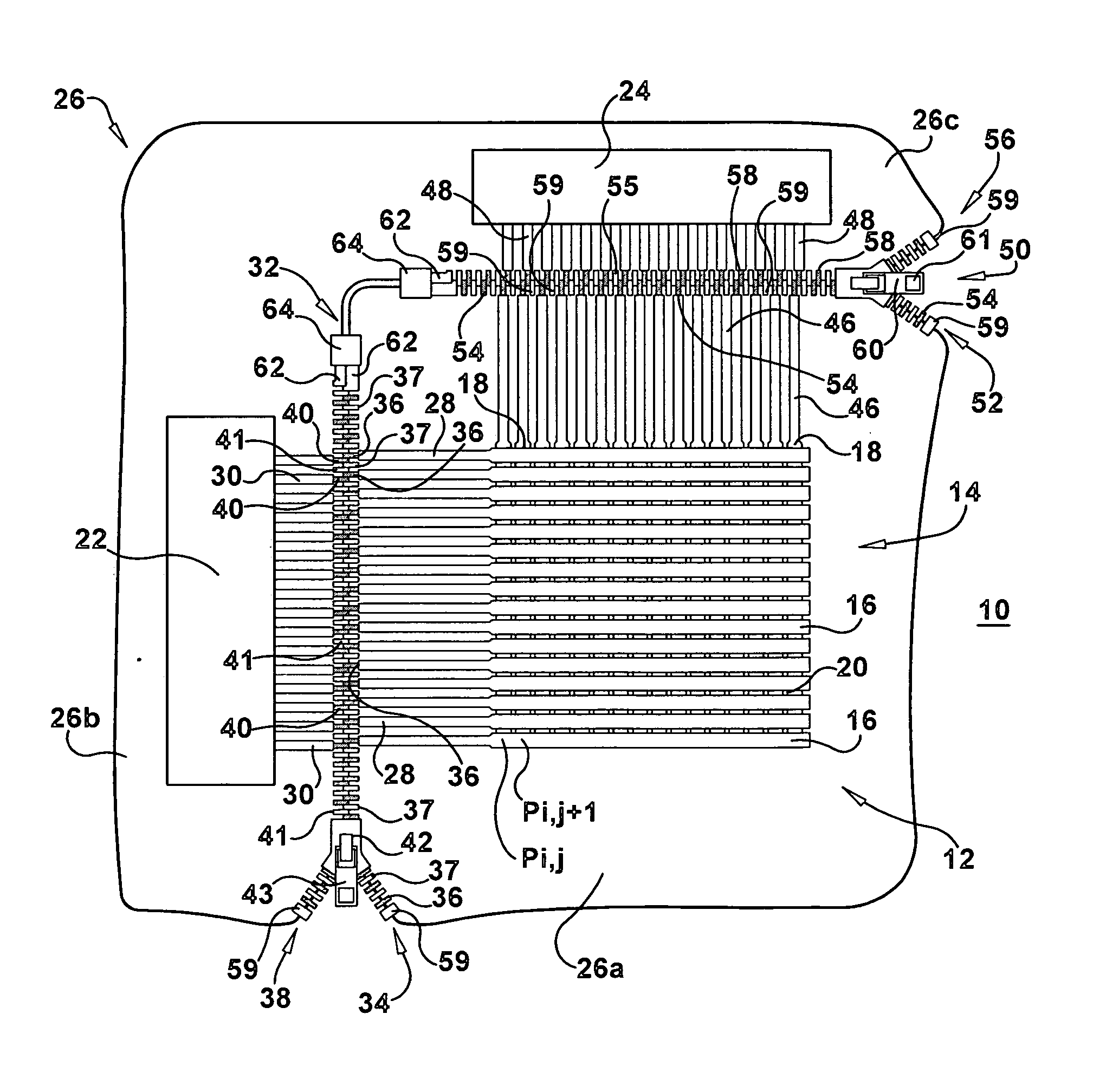

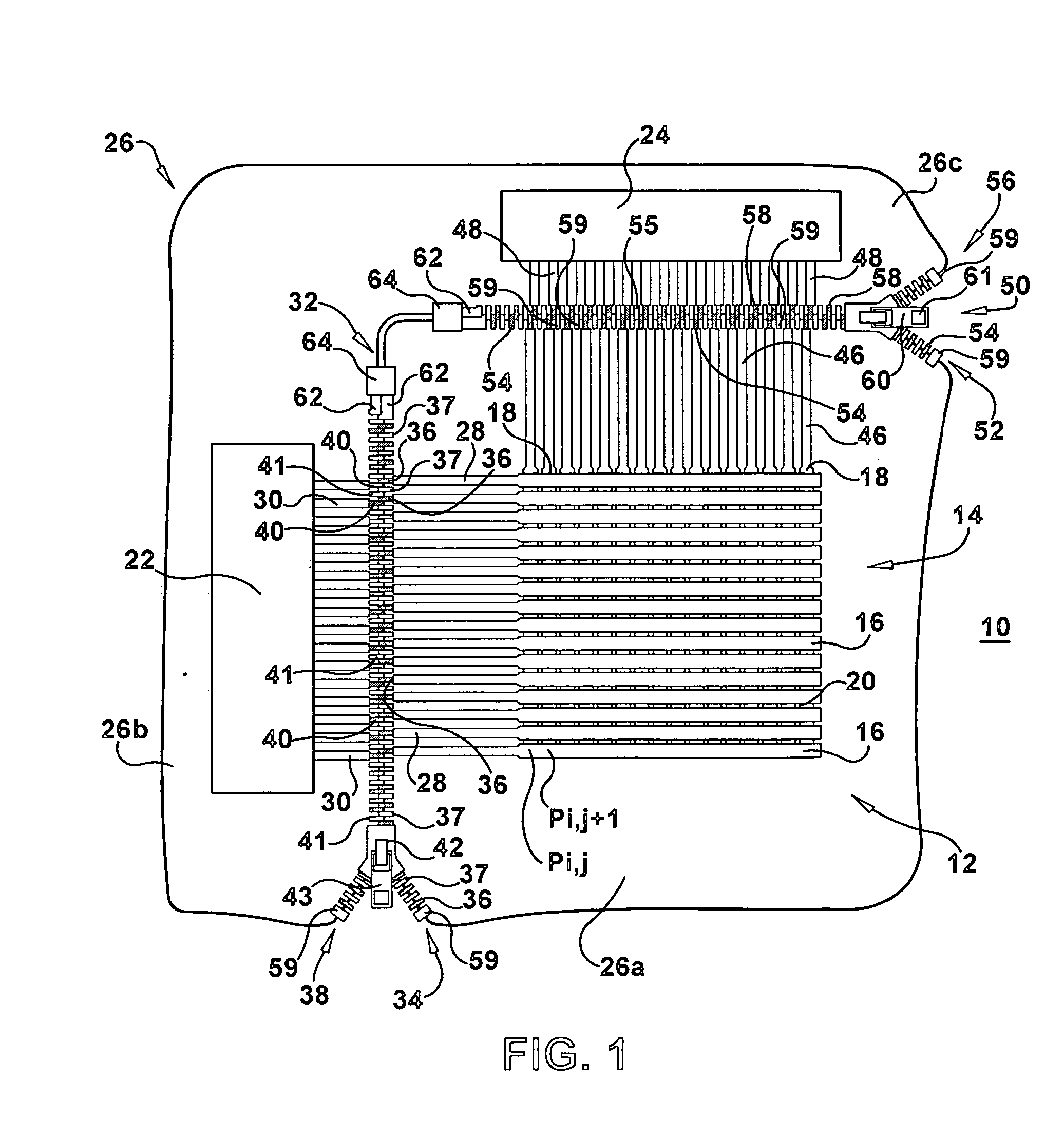

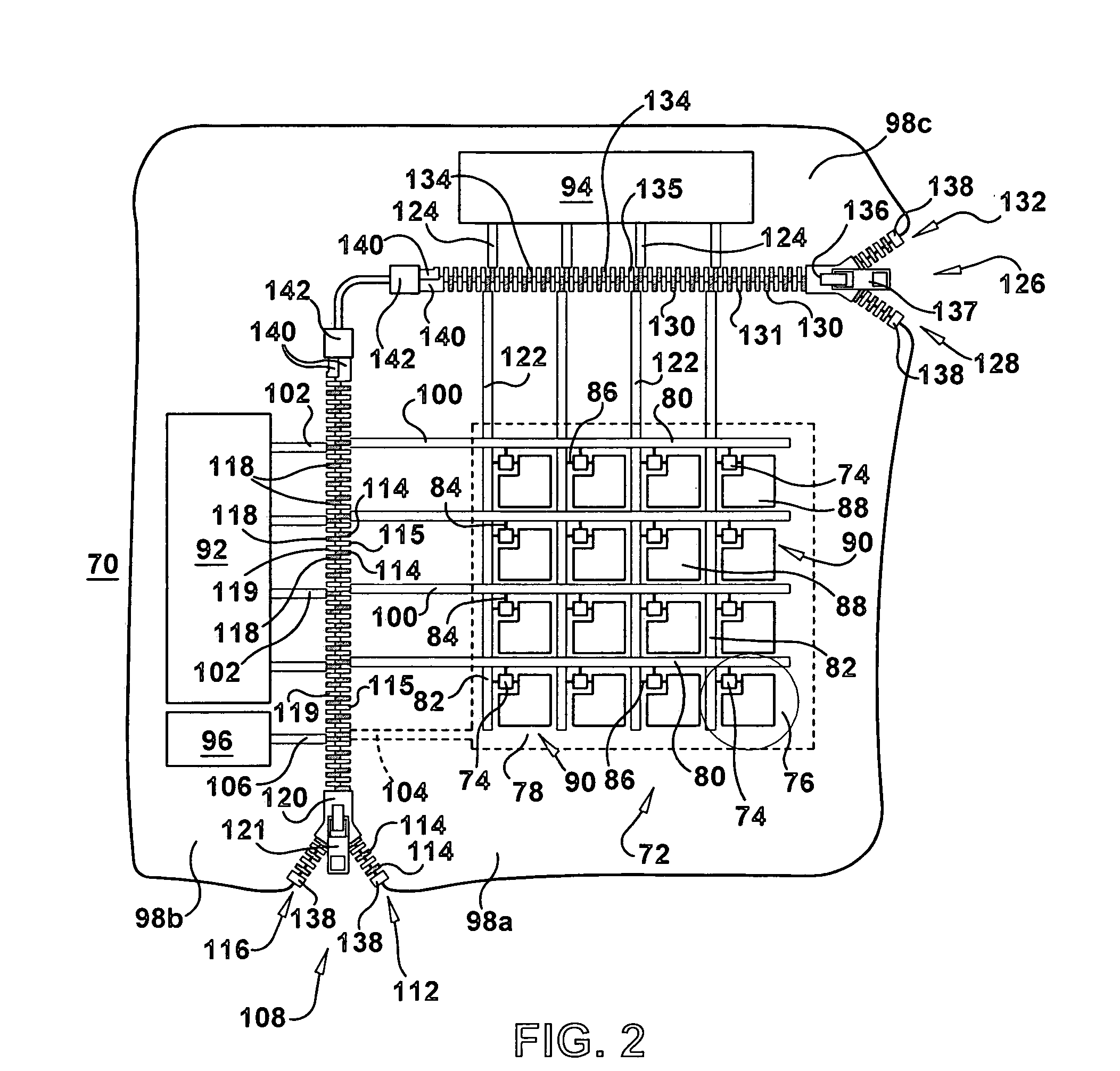

Display device with electrical zipper interconnect

InactiveUS20060103641A1Extreme ease of useFast disconnection timePrinted circuit aspectsCathode-ray tube indicatorsActive matrixDisplay device

A display device includes an electronic display adapted to produce images, an electronic device that electrically communicates with the display and a zipper interconnect adapted to enable electrical connection between the display and the electronic device. The electronic display can be a reflective display such as a liquid crystal display or an emissive display such as one containing light emitting diodes. The electronic device that communicates with the display can be drive electronics adapted to electrically address the display so as to produce the images. In particular, the display is a cholesteric liquid crystal display that can be bistable and in the form of a passive matrix, active matrix or direct drive display. The zipper interconnect can include two rows of conductive teeth that are each electrically connected to one or more of: display electrodes, drive electronics, controller or associated electronics supported on one or more substrate portions. One set of traces can be connected to the display device (or to devices permanently connected thereto) on one substrate portion while the other set of traces can be connected to associated electronics on another substrate portion. When the zipper interconnect is moved so as to engage the teeth of the first and second rows together an electrical connection is made between the display device (or to devices permanently connected thereto) and associated electronics. Electrically insulative teeth can alternate with conductive teeth in the rows of teeth.

Owner:KENT DISPLAY SYST

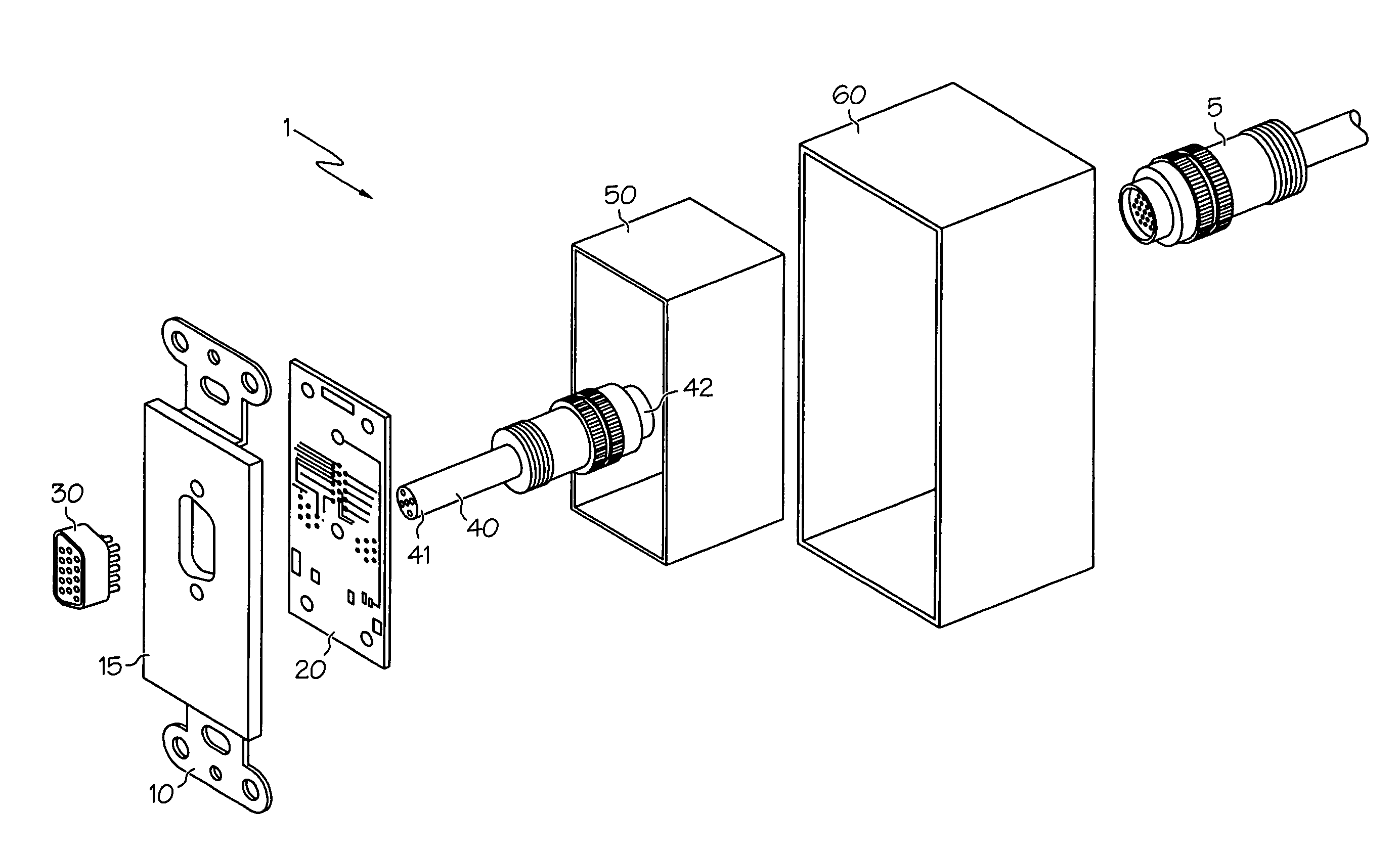

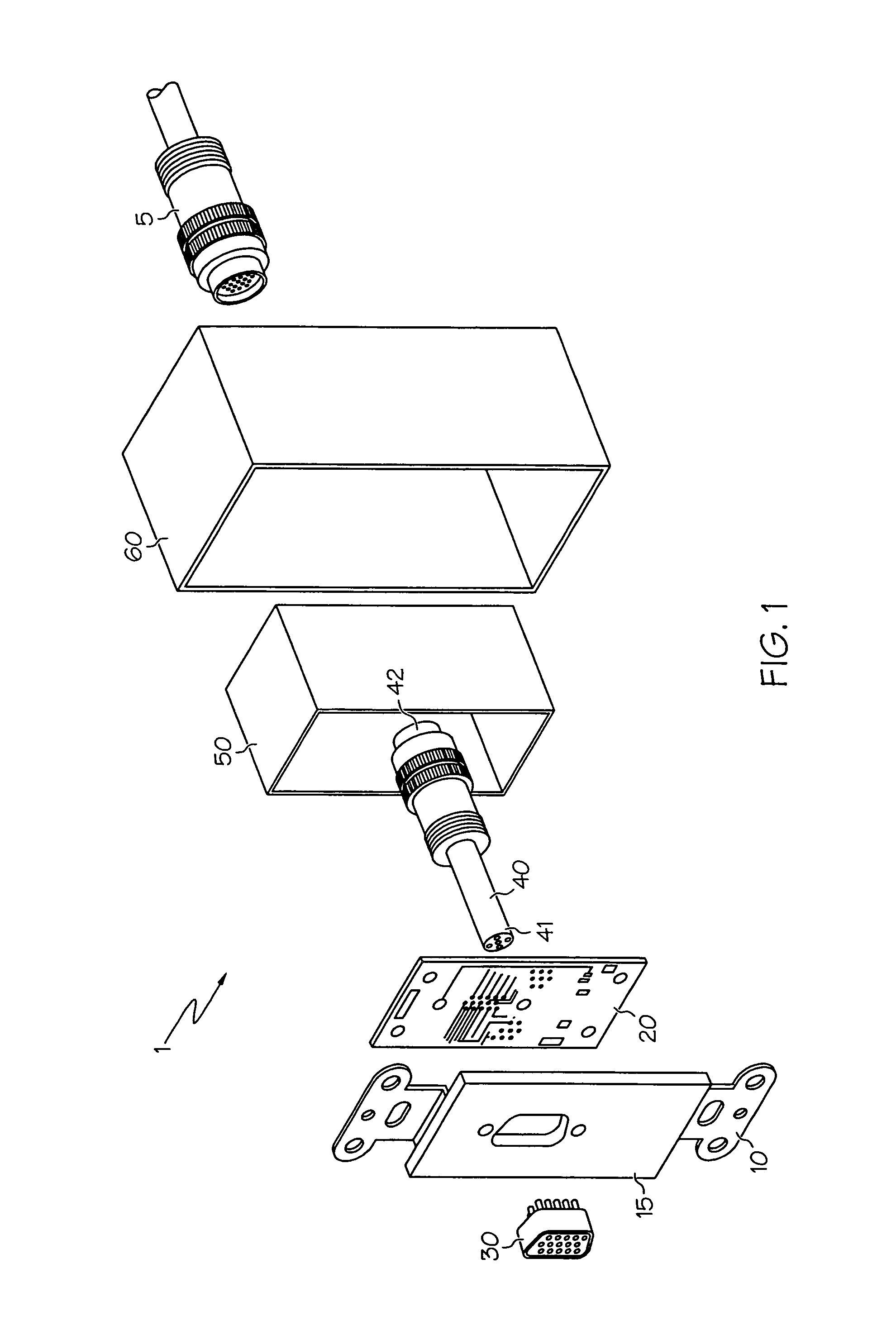

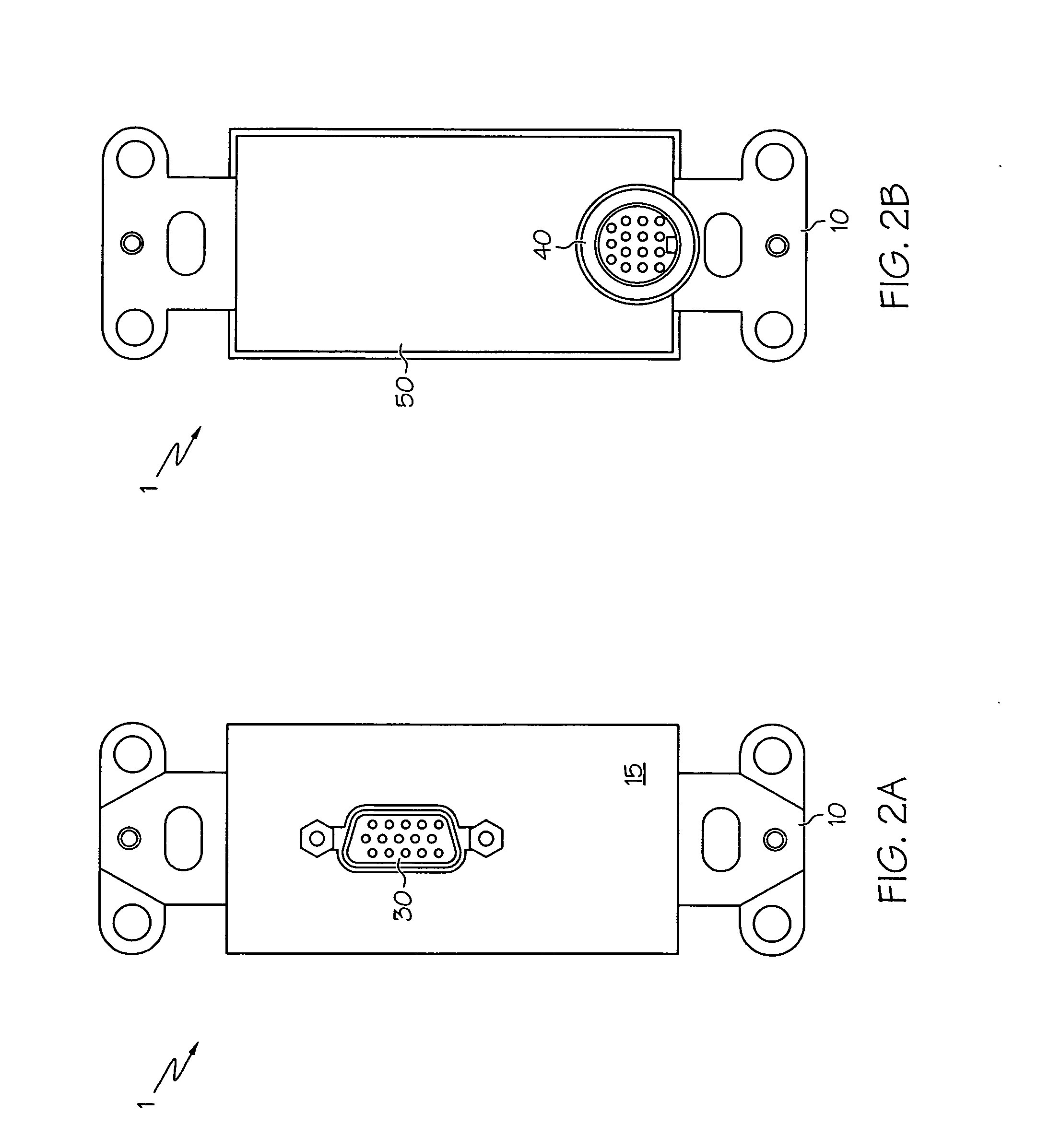

Integrated wall plate assembly and premise wiring system incorporating the same

ActiveUS20070037442A1Promotes wall plate autonomyConvenient to accommodateCouplings bases/casesCoupling device detailsCouplingAudio frequency

A wall plate for premise wiring. The wall plate is preterminated with a quick-connect coupling to enable fast connection and disconnection with a complementary quick-connect coupling on a wire configured to carry an electrical signal, such as digital or analog audio, visual or related signal. The wall plate may include numerous signal interfaces for audio, visual or combination audio / visual application. By including all of the components into a modular package, installation and removal of the wall plate for premise wiring upgrades is enhanced.

Owner:ORTRONICS INC

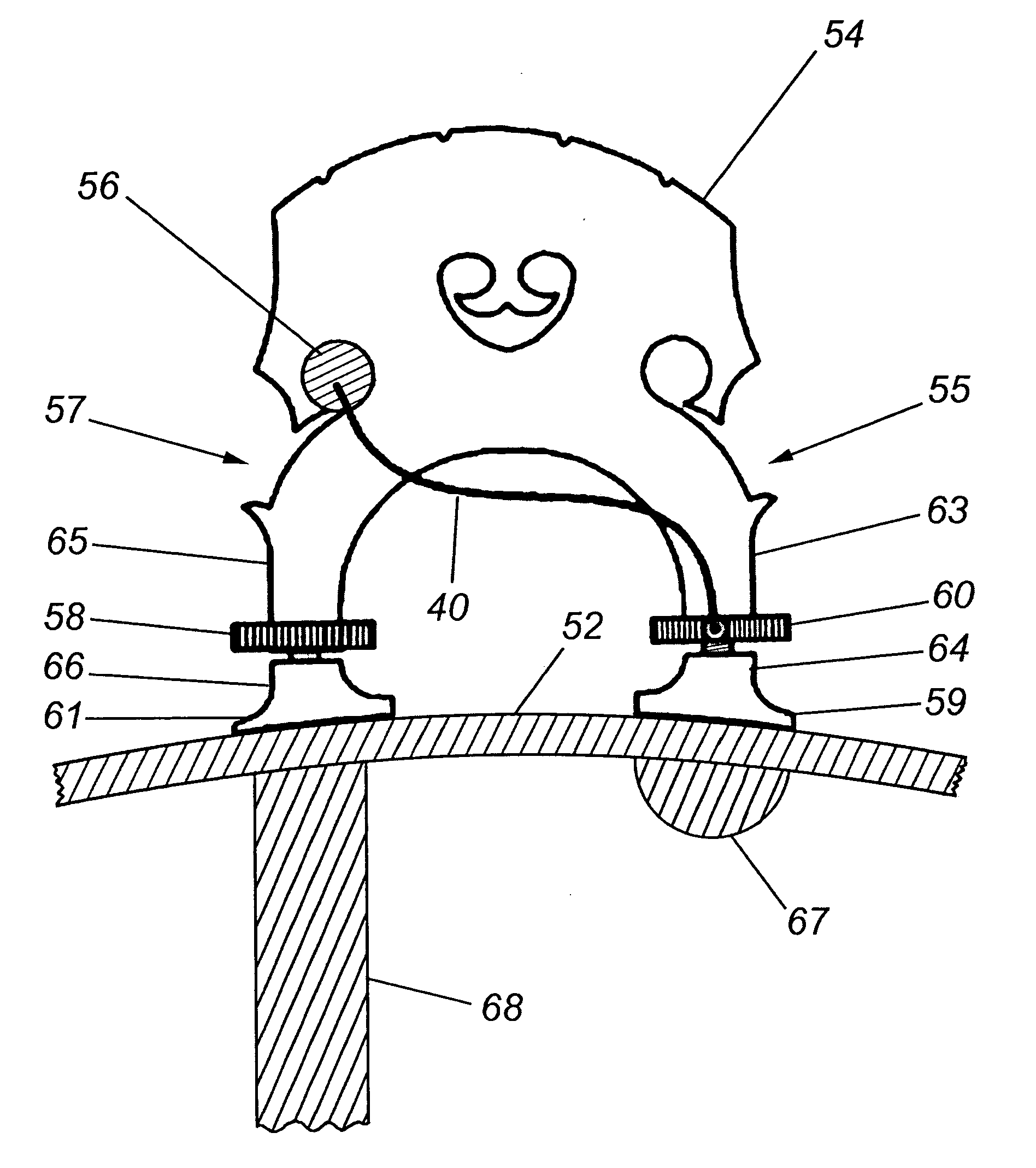

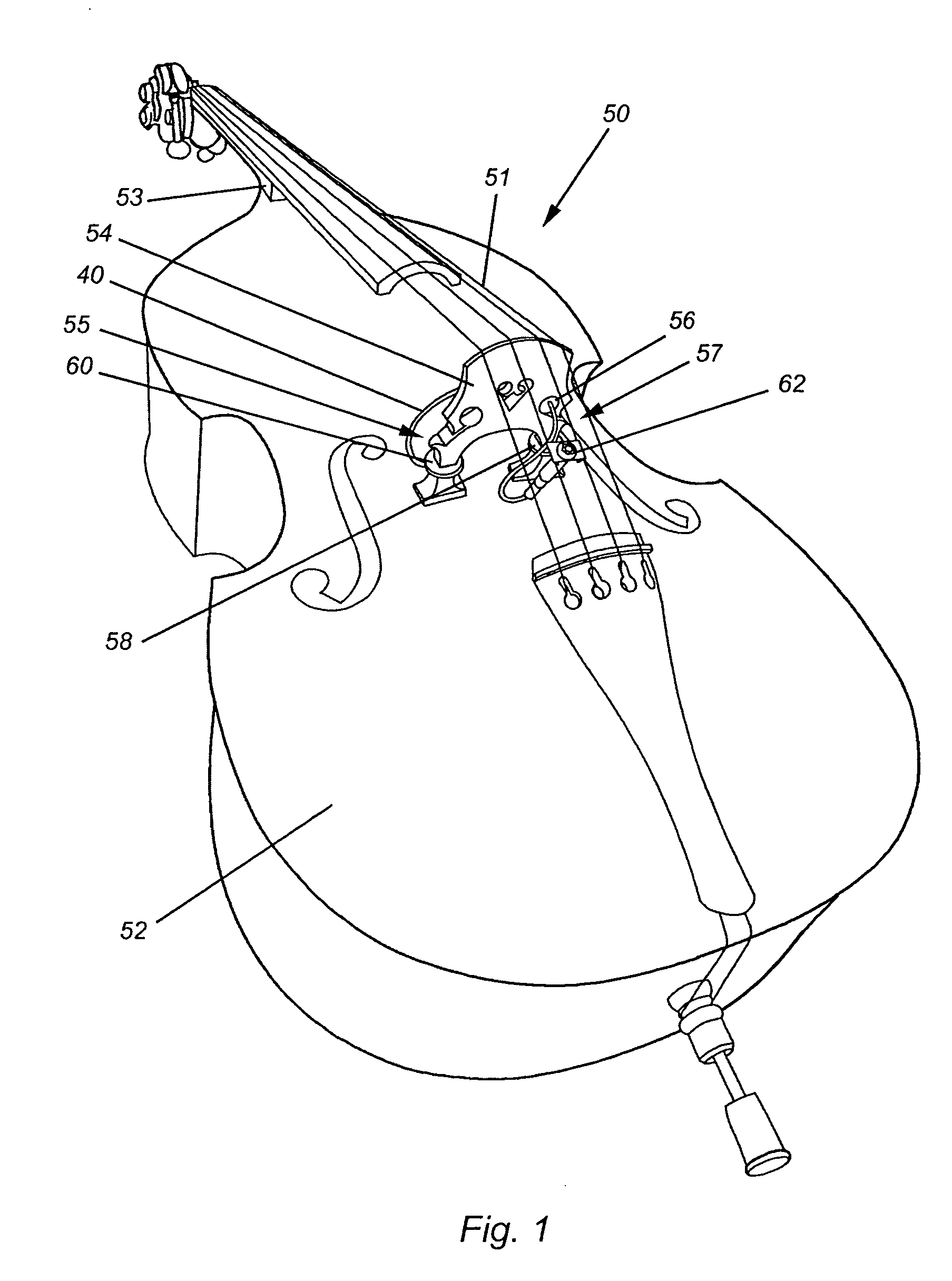

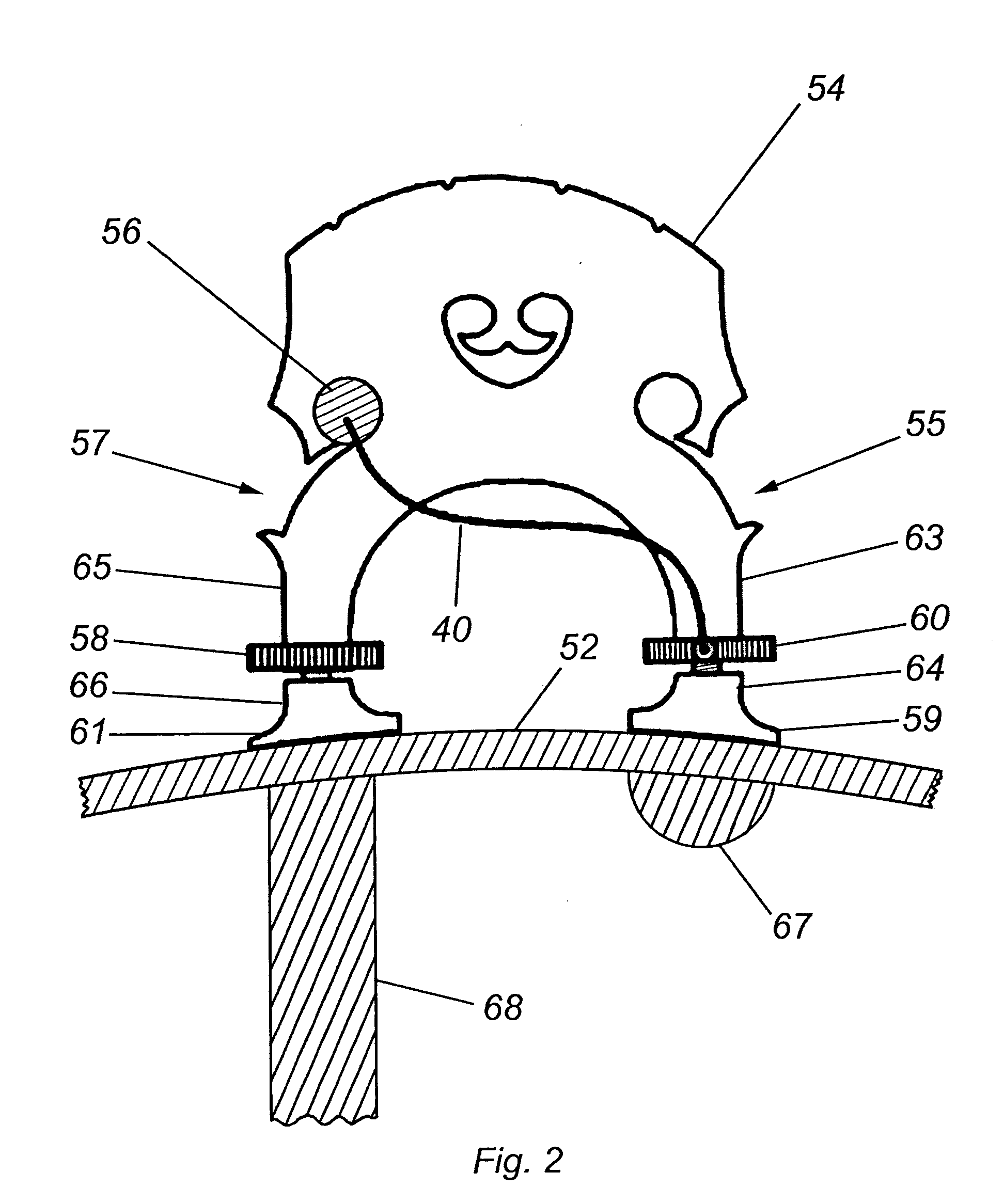

Musical instrument transducer

InactiveUS20050011342A1Limited effectPreventing tangling and damageElectrophonic musical instrumentsEngineeringTransducer

A plurality of force sensing transducer elements are enclosed in a stringed musical instrument bridge height adjuster, designed to be installed as one of a pair of height adjusters in the legs of the bridge. The transducers are disposed to allow rotation of the adjuster to control how the modes of vibration in the bridge affect the transducers, thus allowing the player to adjust the tonal response of the transducers to the instrument and to their own sound preference. An inline jack-plug pair allows the output cable of the transducer to be quickly disconnected and reconnected to avoid straining or tangling the cable while adjusting the tone and the bridge height.

Owner:FISHMAN TRANSDUCERS

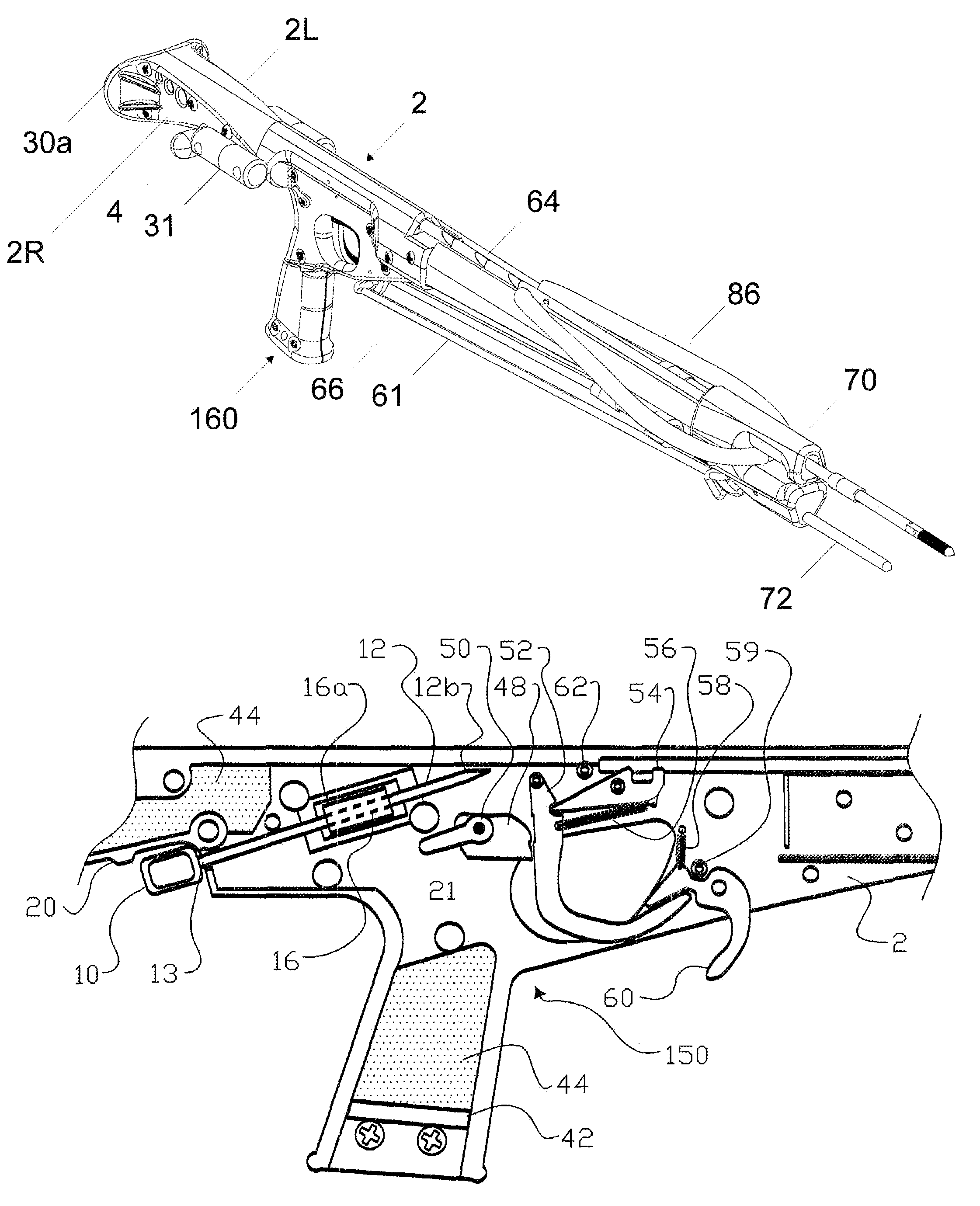

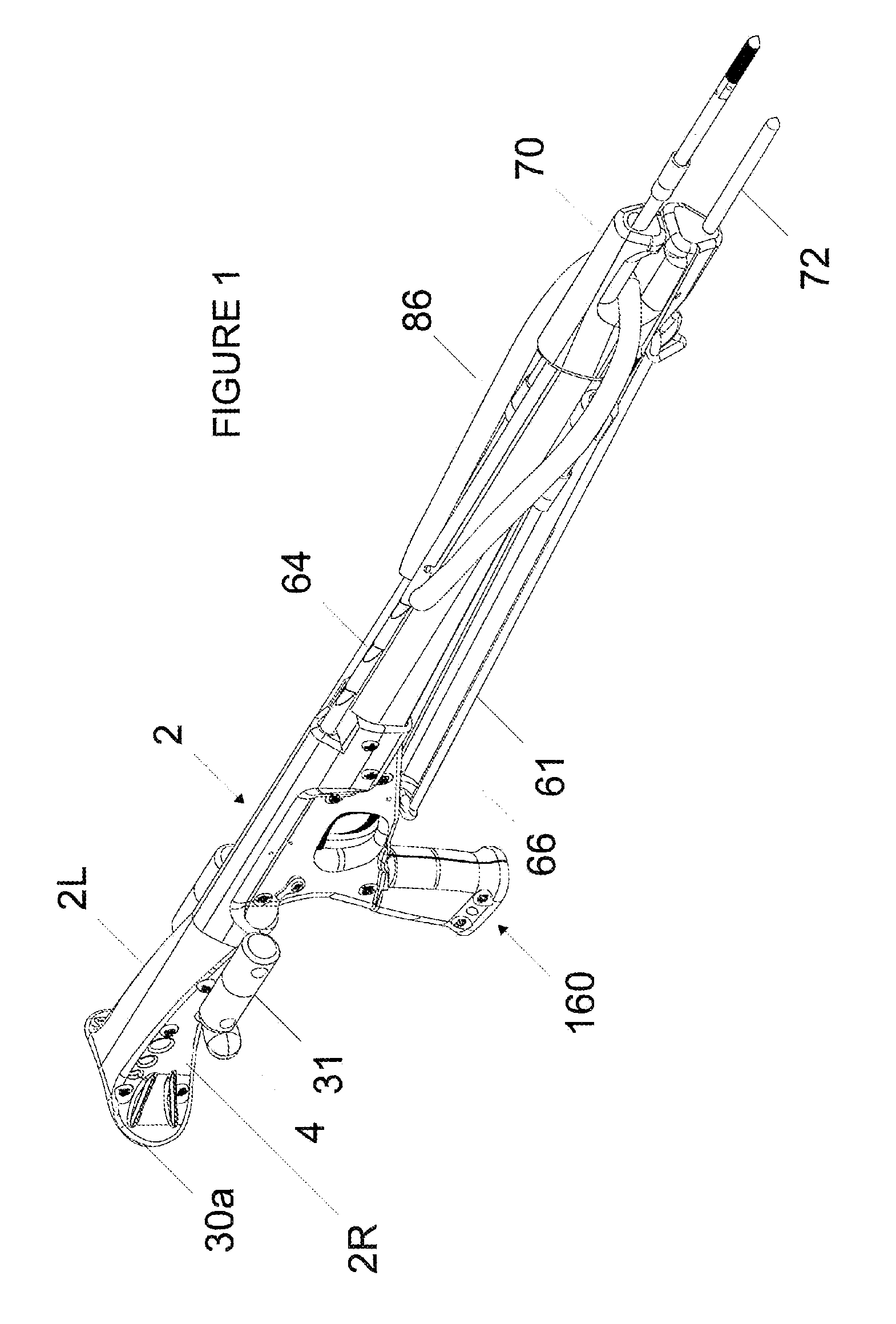

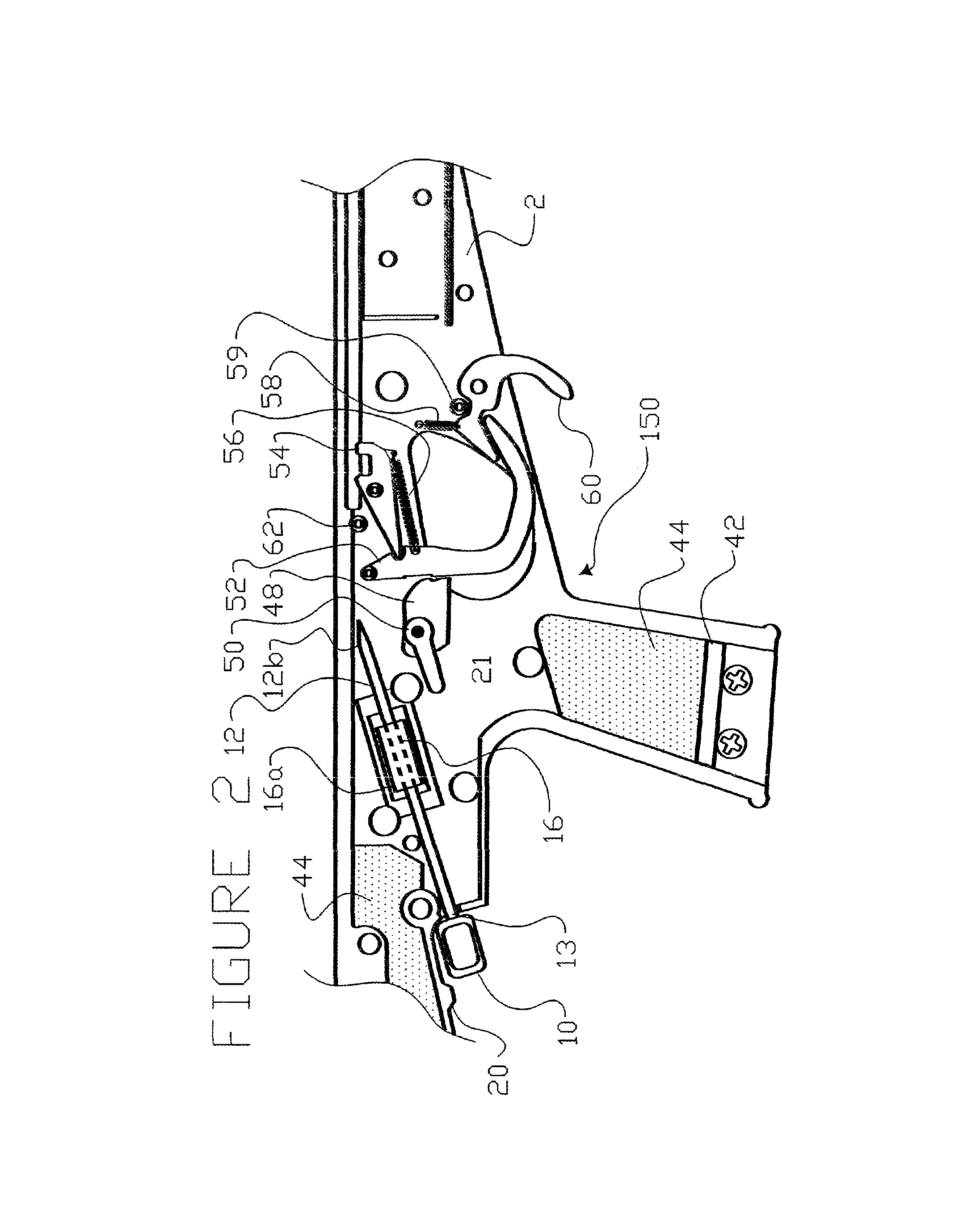

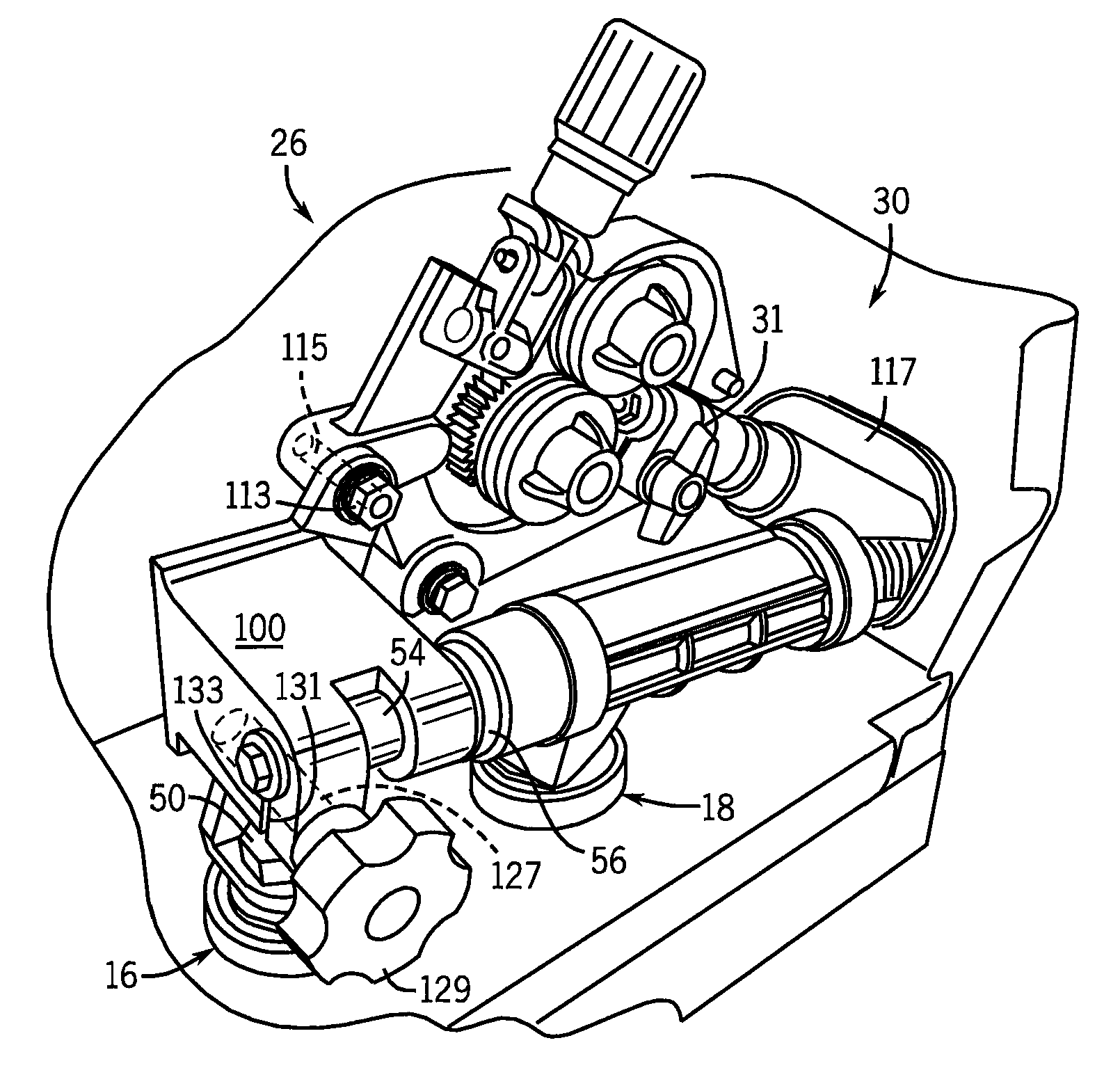

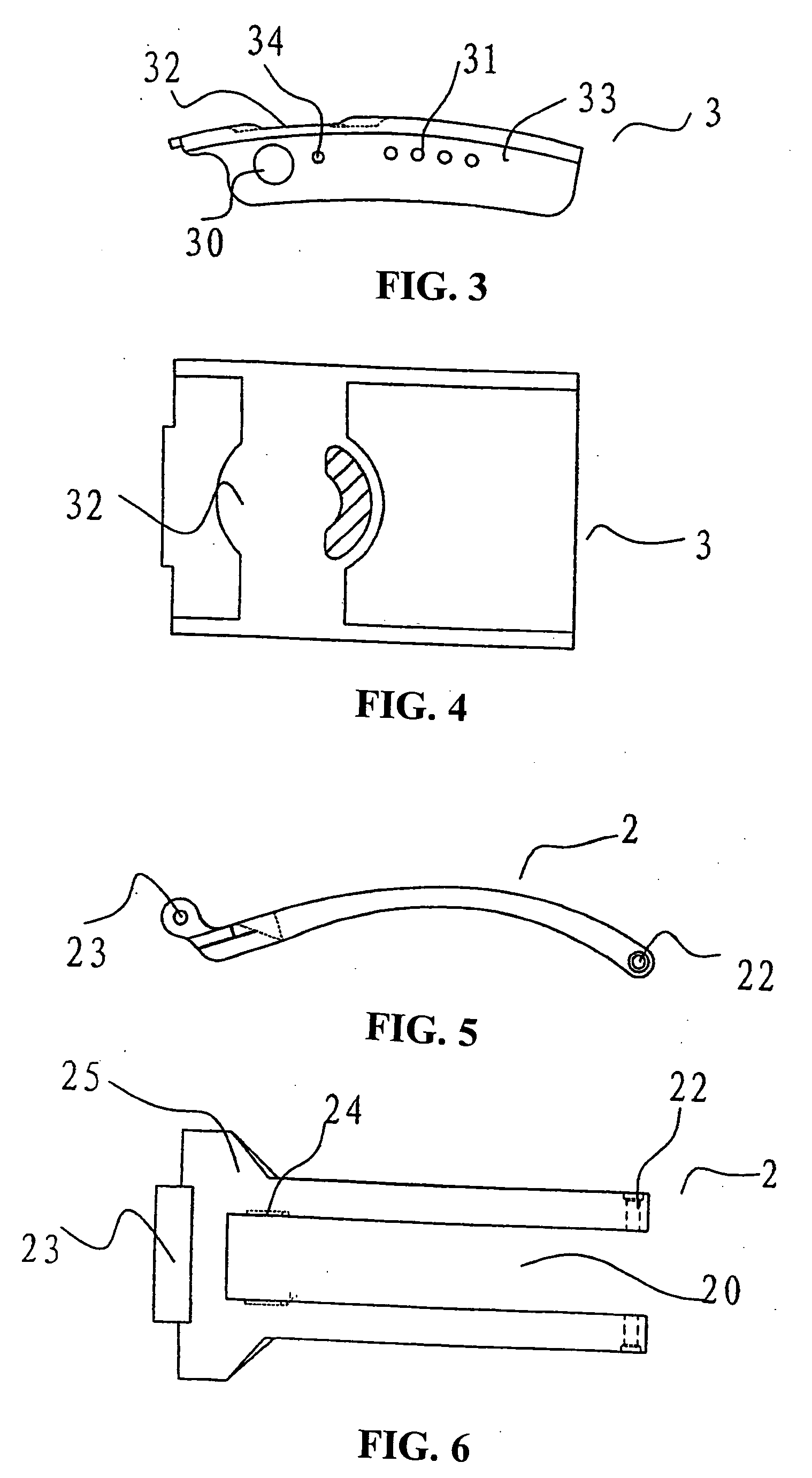

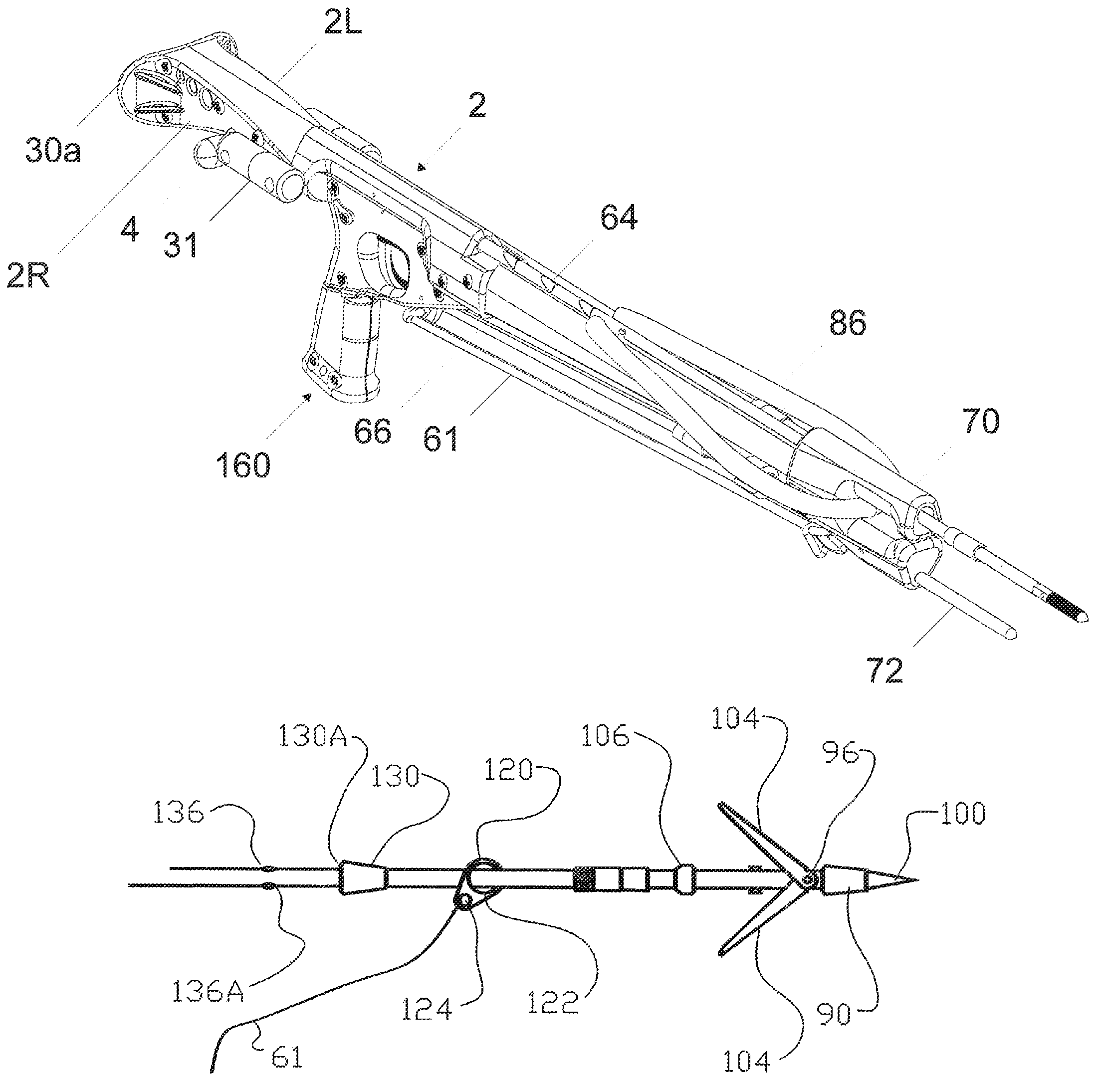

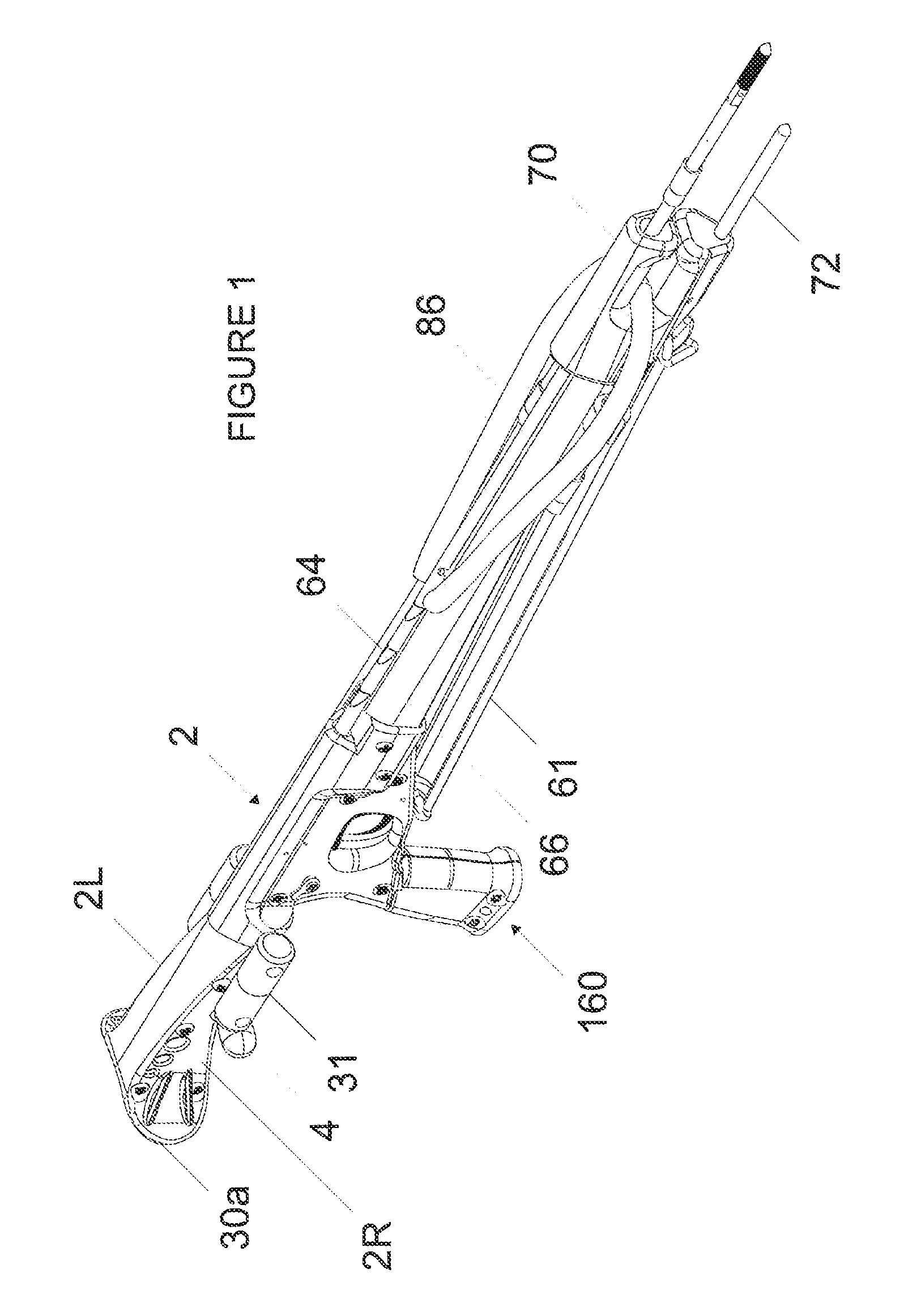

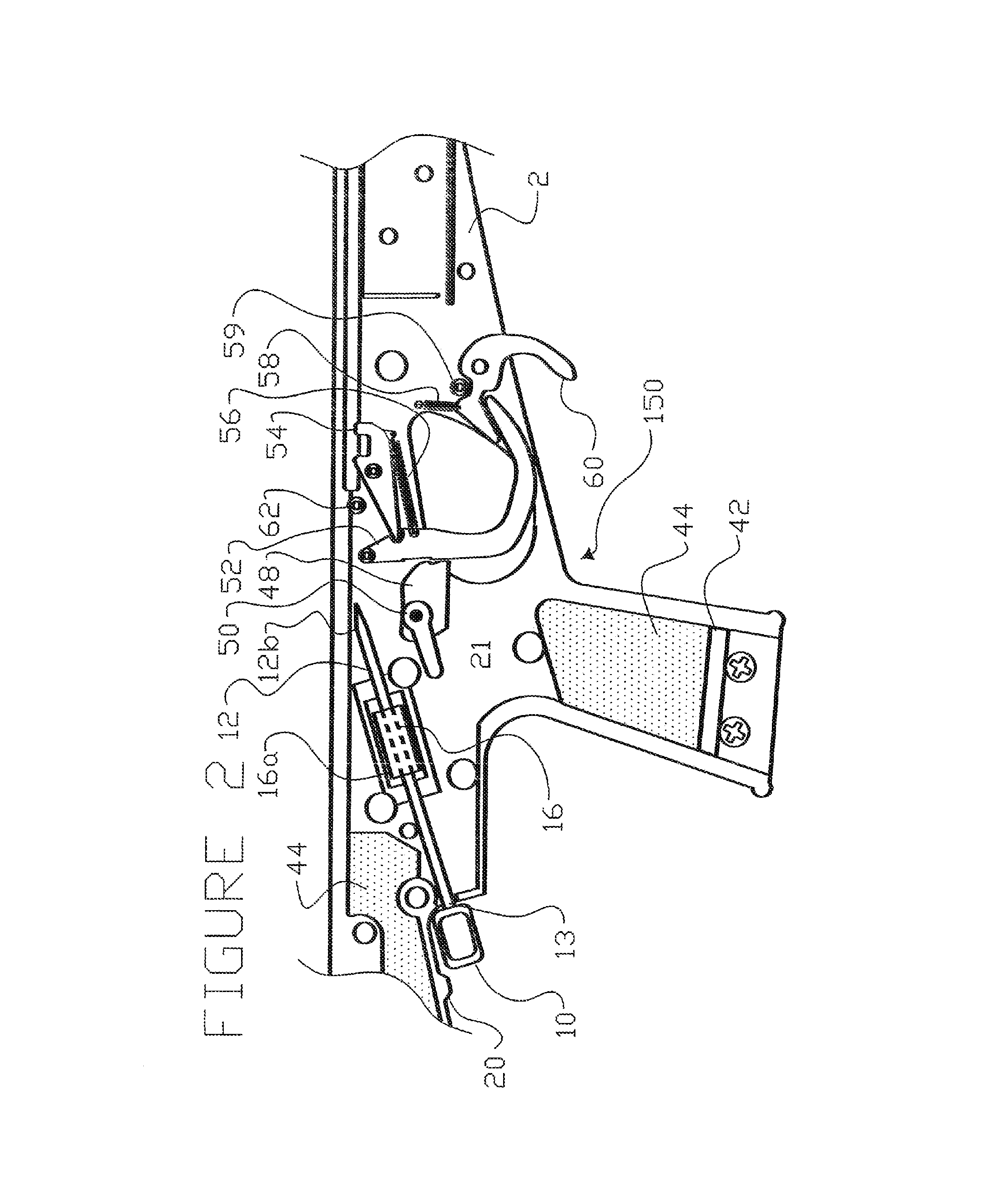

Fishing speargun

InactiveUS8387602B1Improve permeabilityAvoid impact damageSpring gunsFiring/trigger mechanismsEngineering

A band-powered speargun has a release mechanism incorporating a line-drop feature for releasing a coiled line attached to a spear. An approach to attaching the line to the spear involves a linking ring having a size selected so that the ring passes over a protective cone near the spear tip and is captured by an element protruding outward from the spear shaft. The protective cone also shields hinged barbs from impact damage. The gun may also incorporate a muzzle kill spike and a separate hand-held kill spike that is normally stored in a specially designed cavity in the speargun grip.

Owner:BRUINGTON ROBERT KEVIN

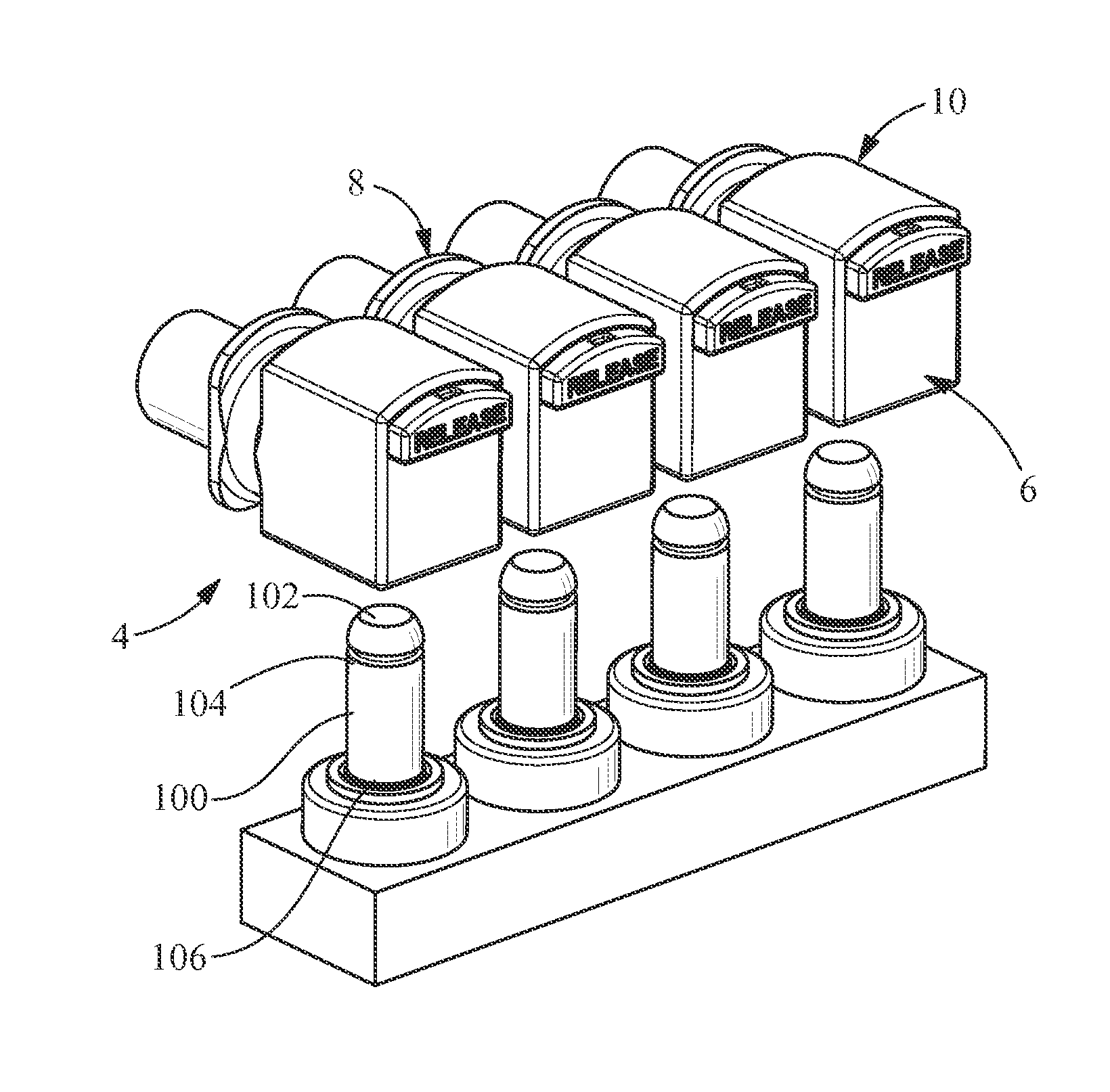

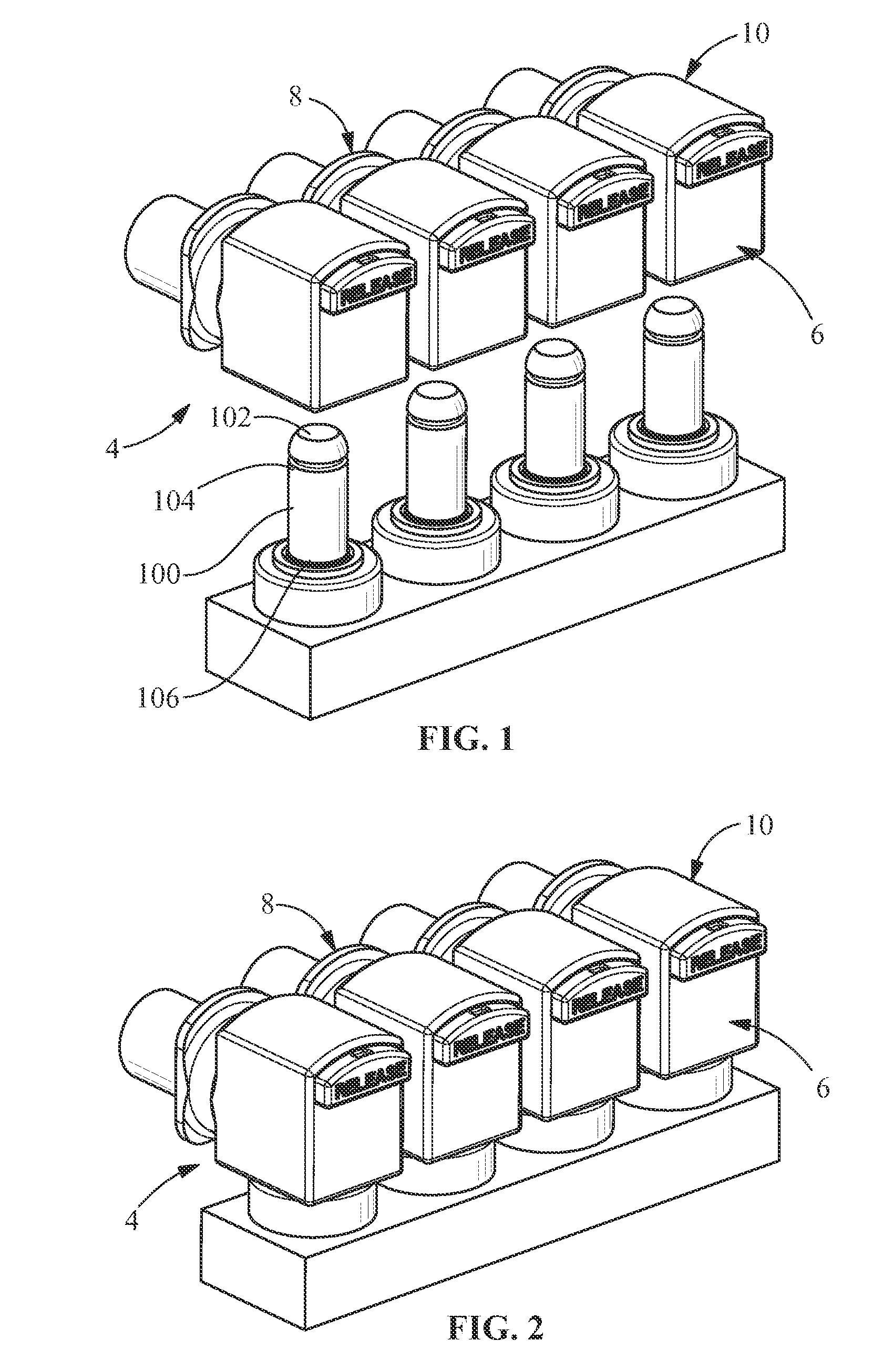

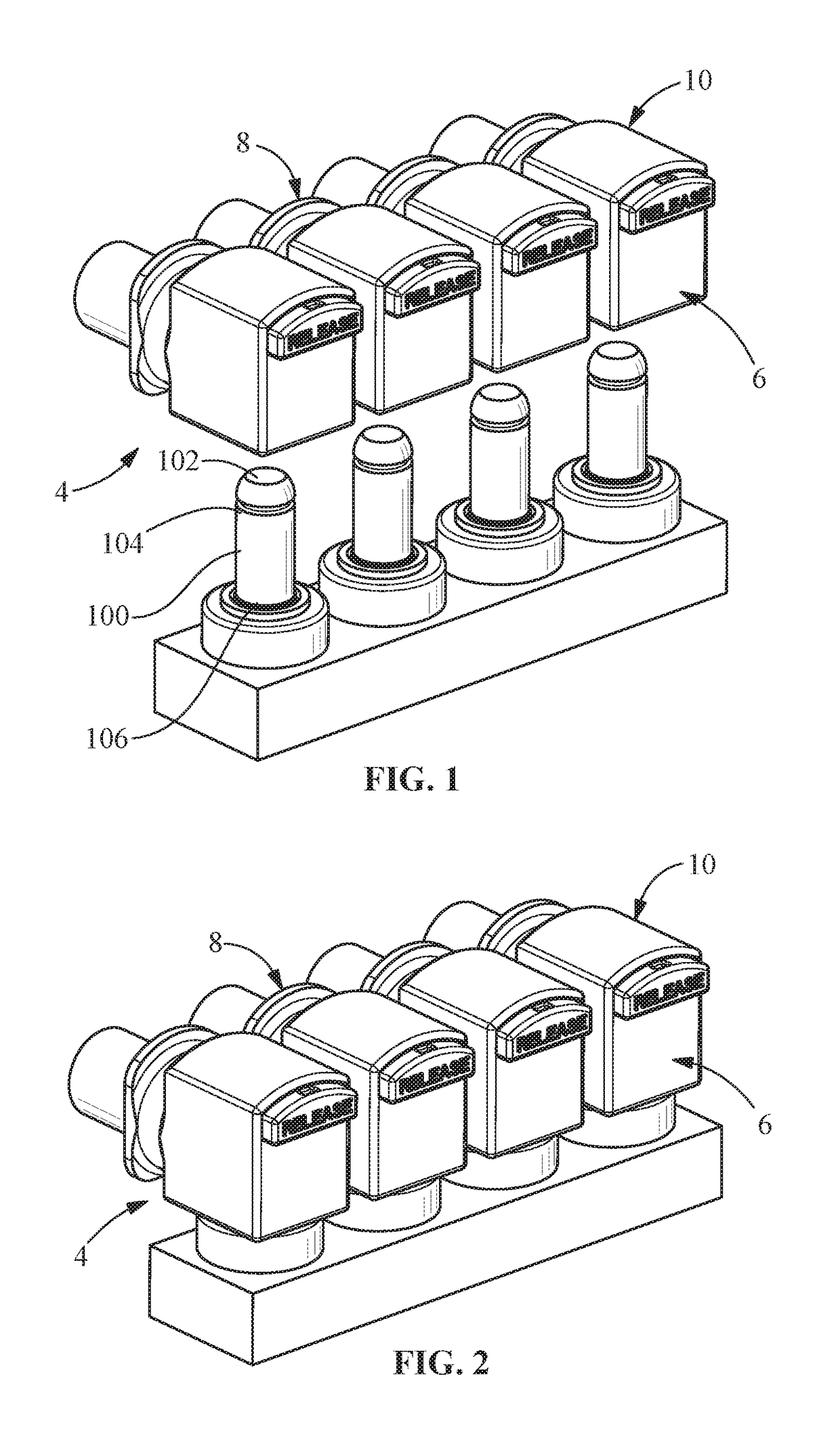

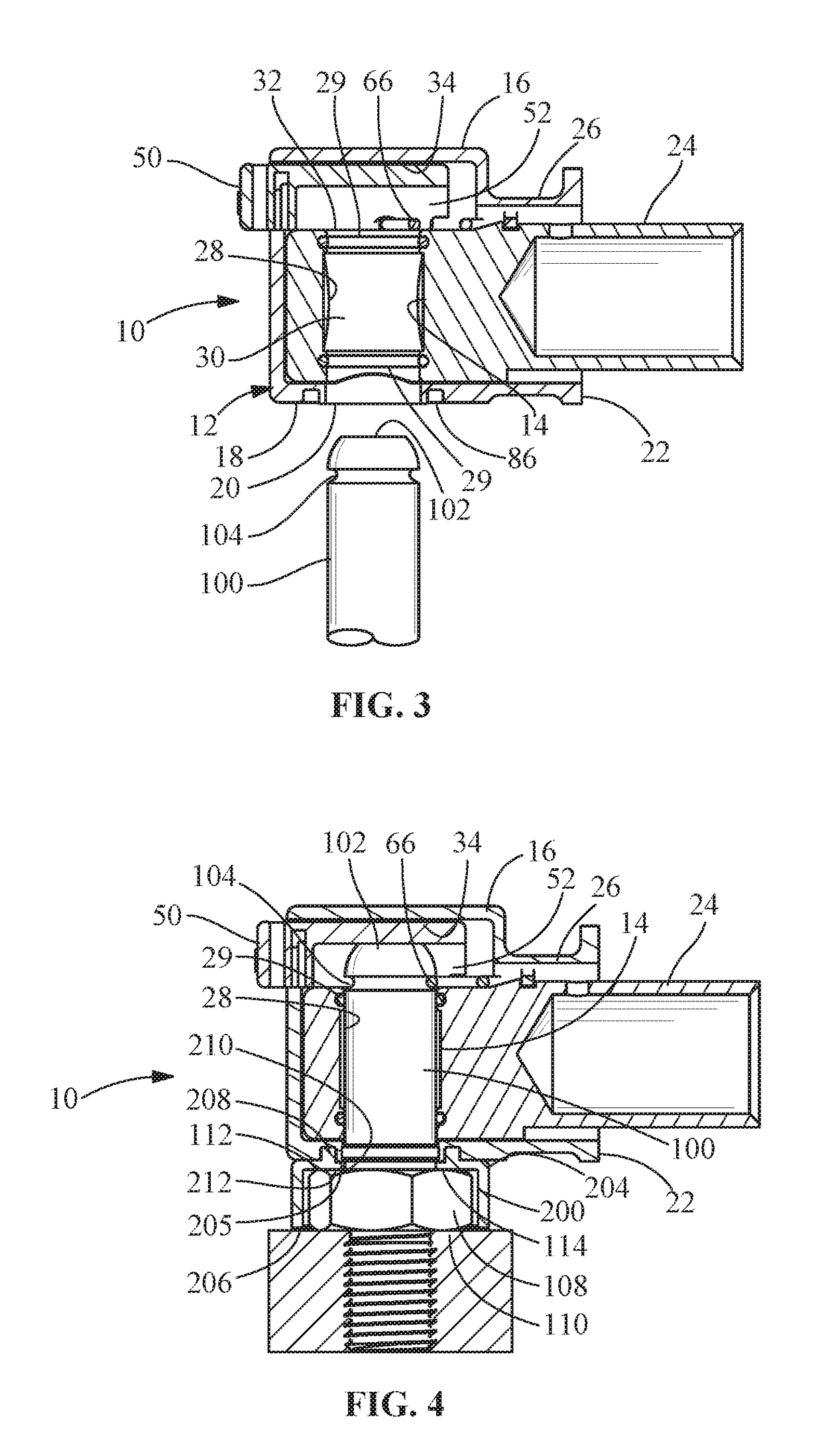

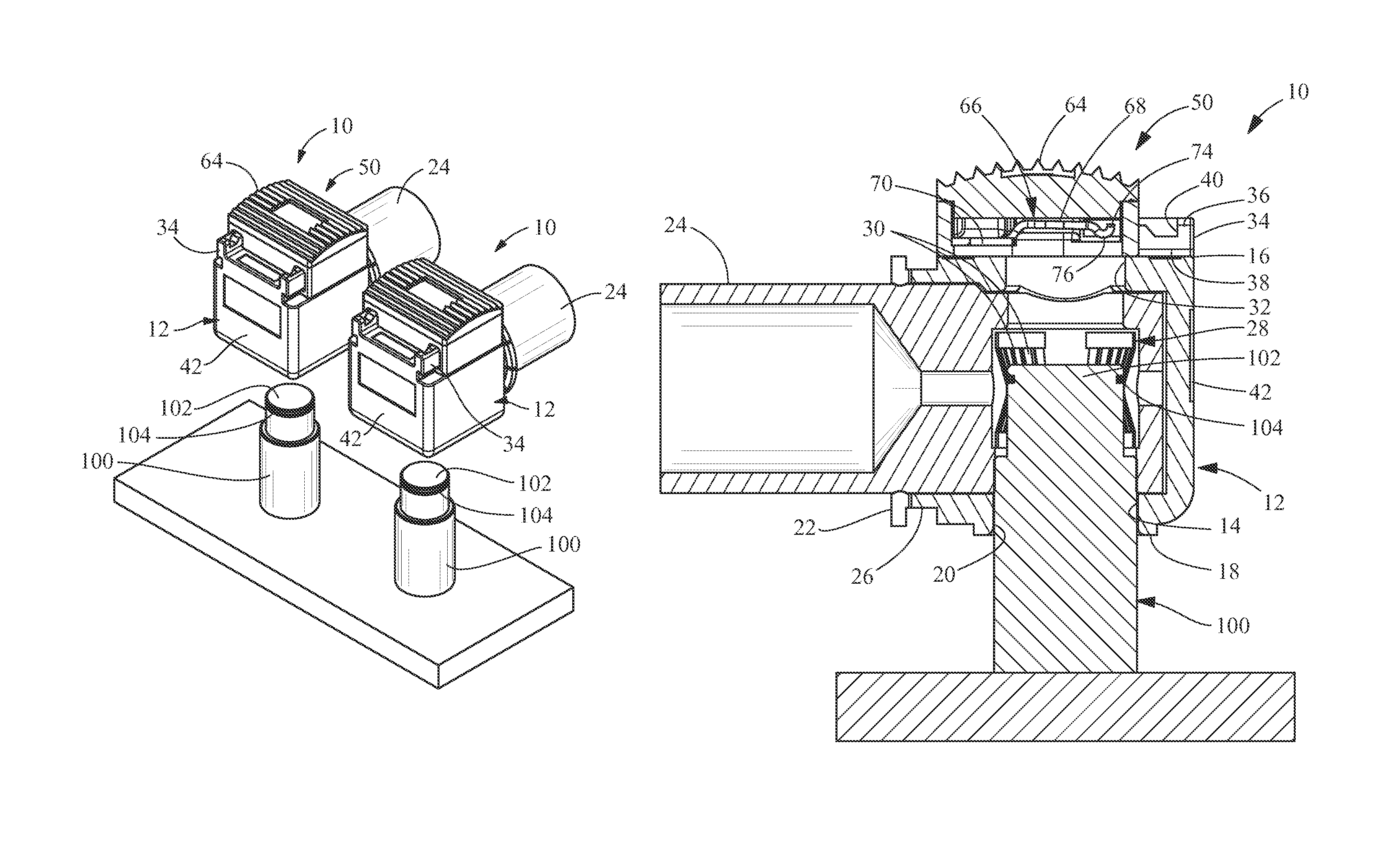

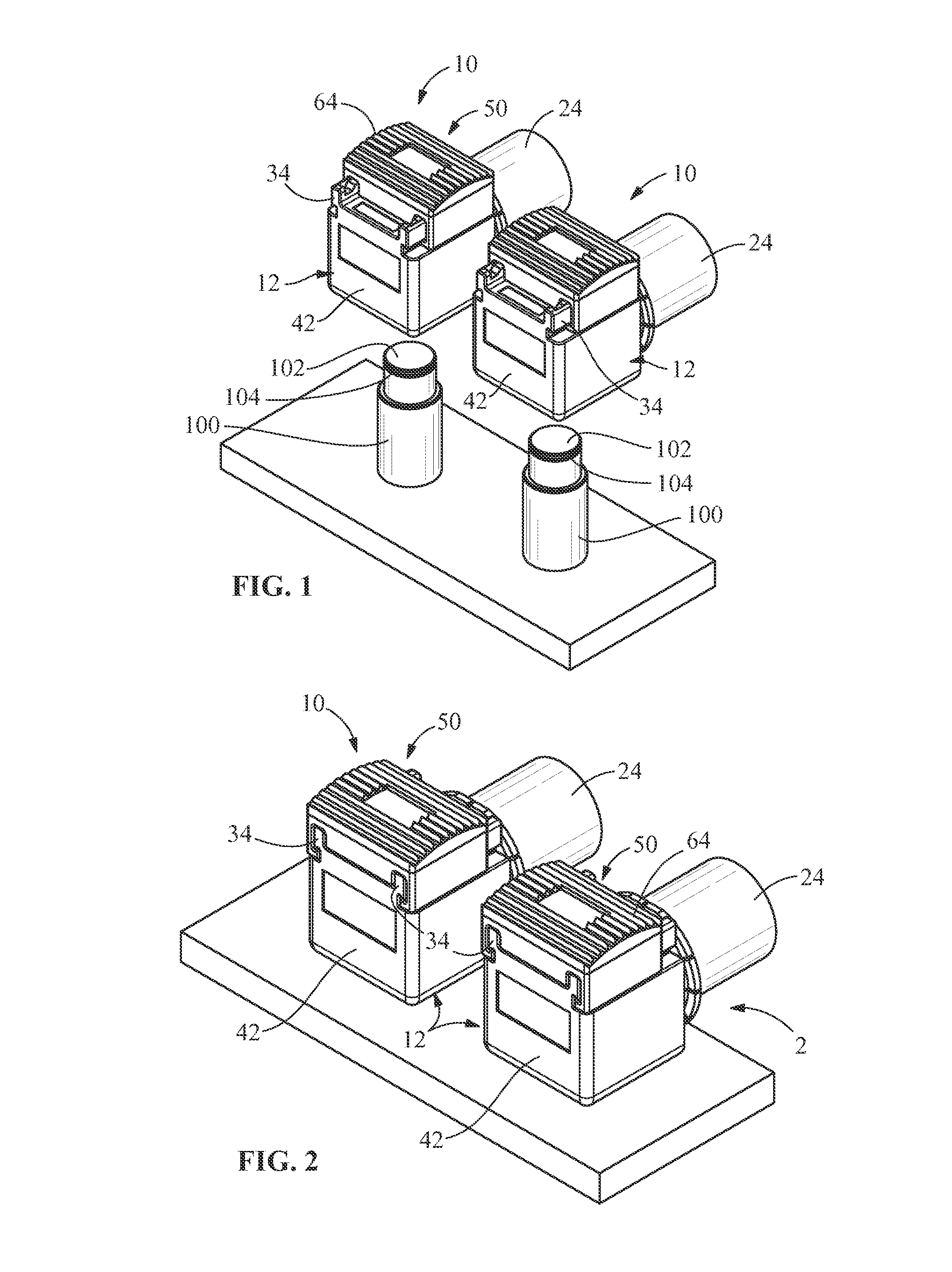

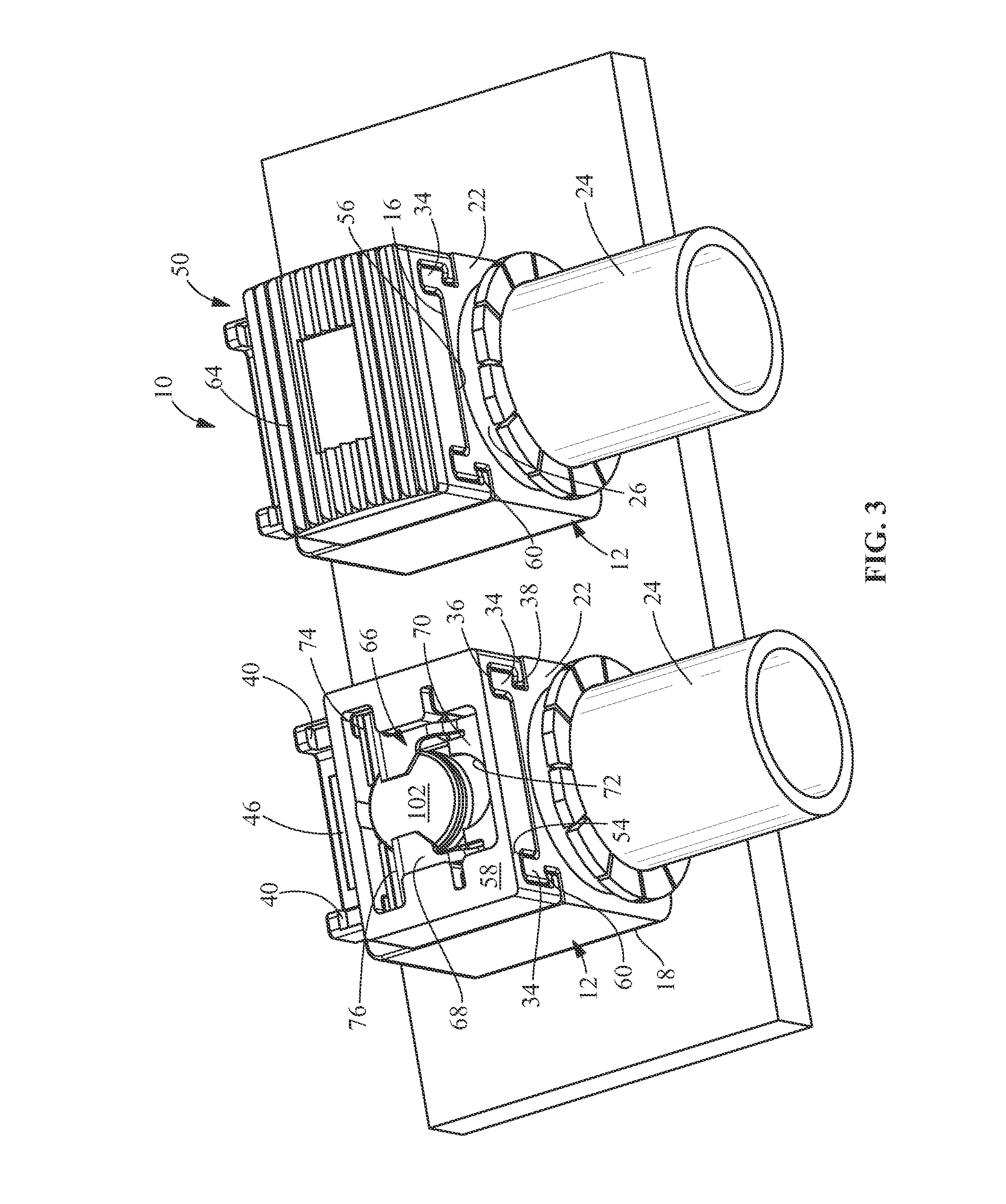

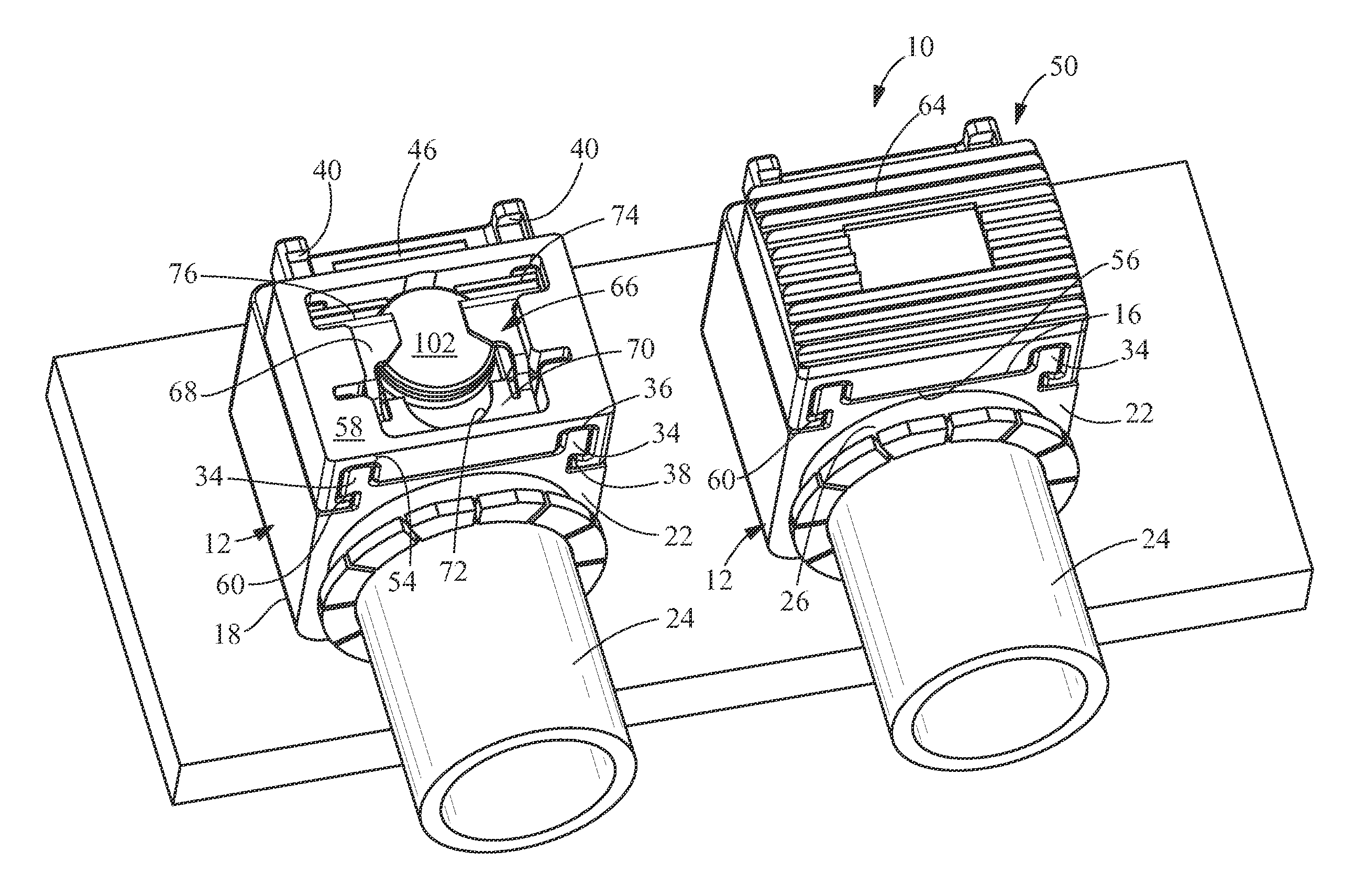

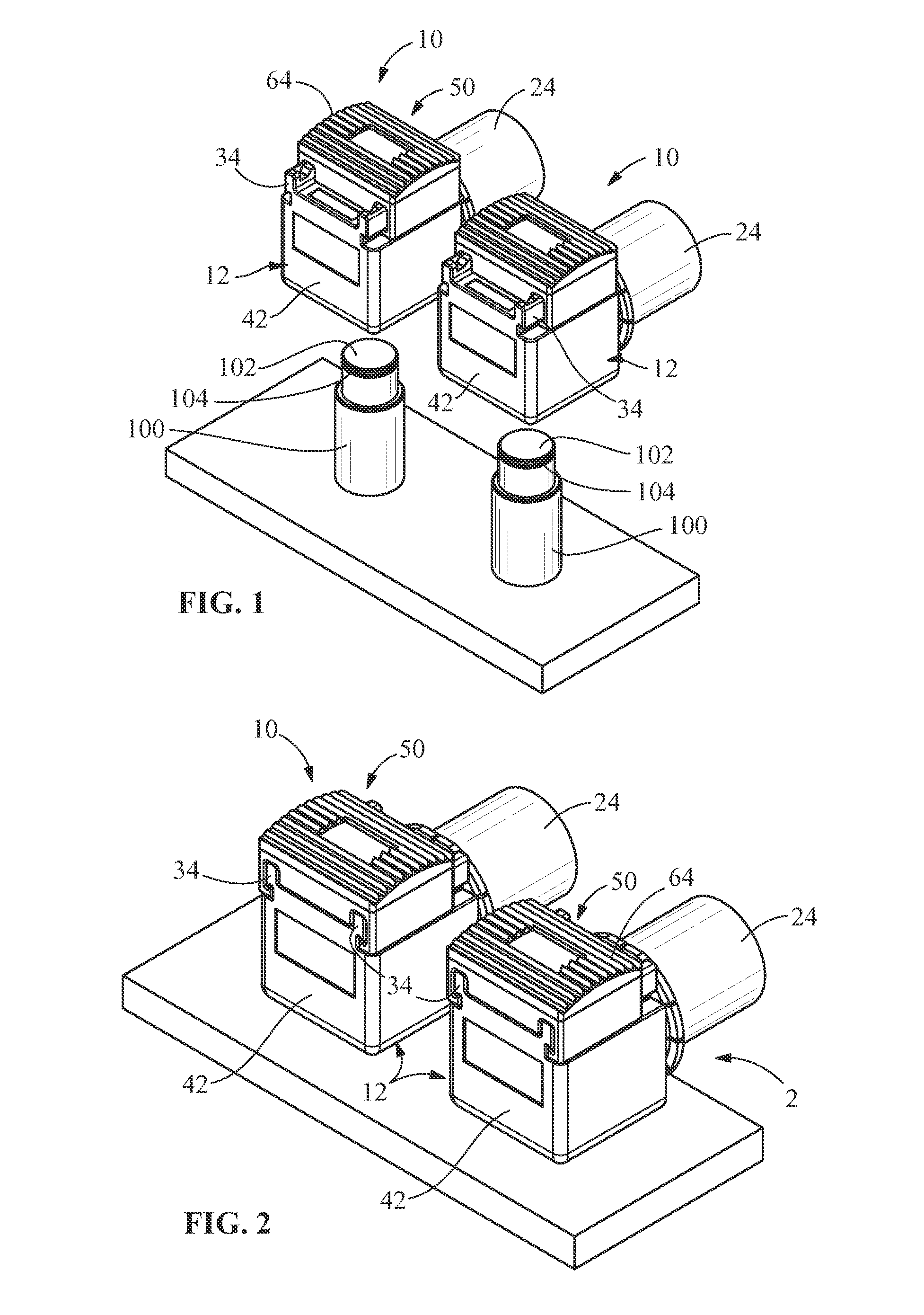

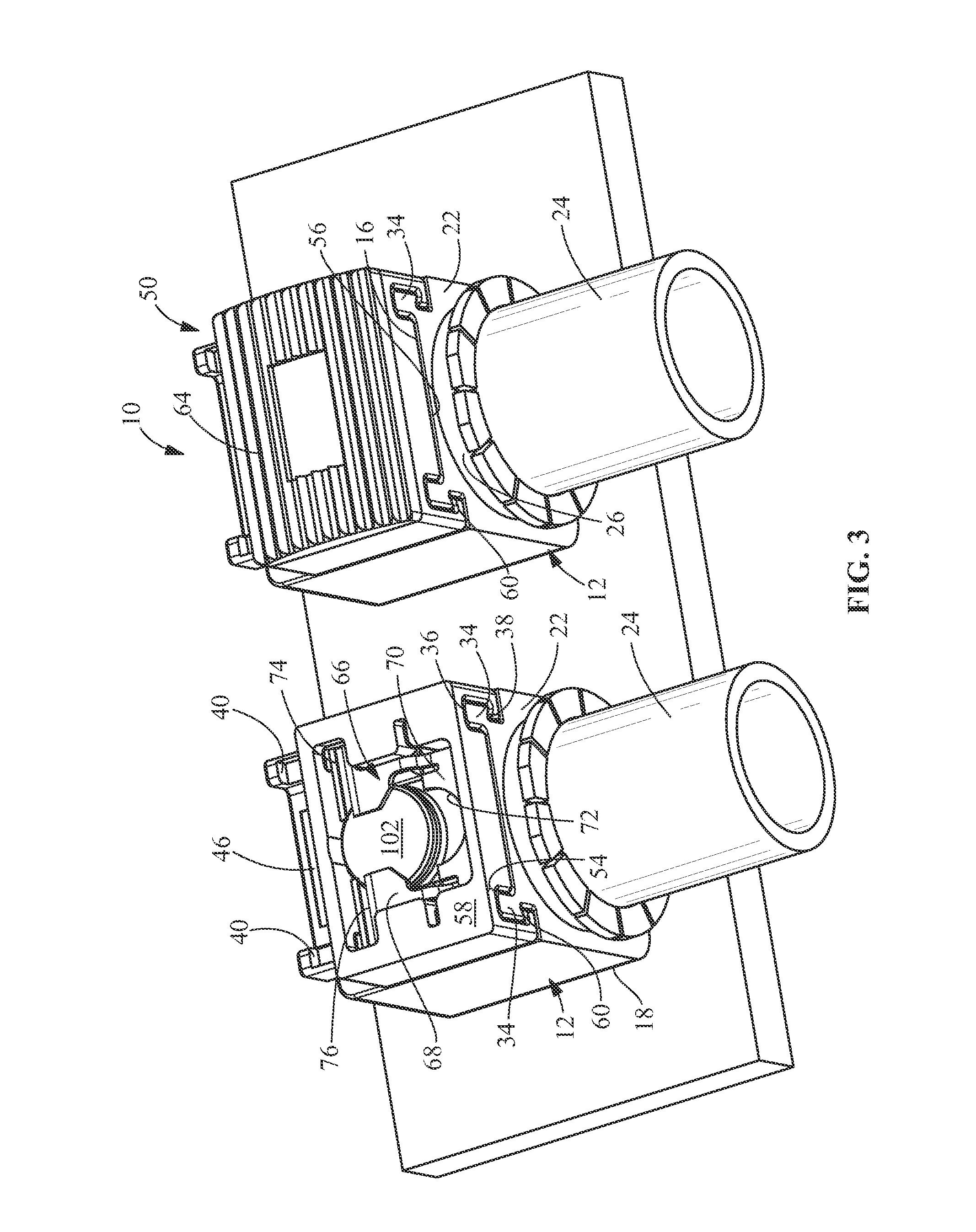

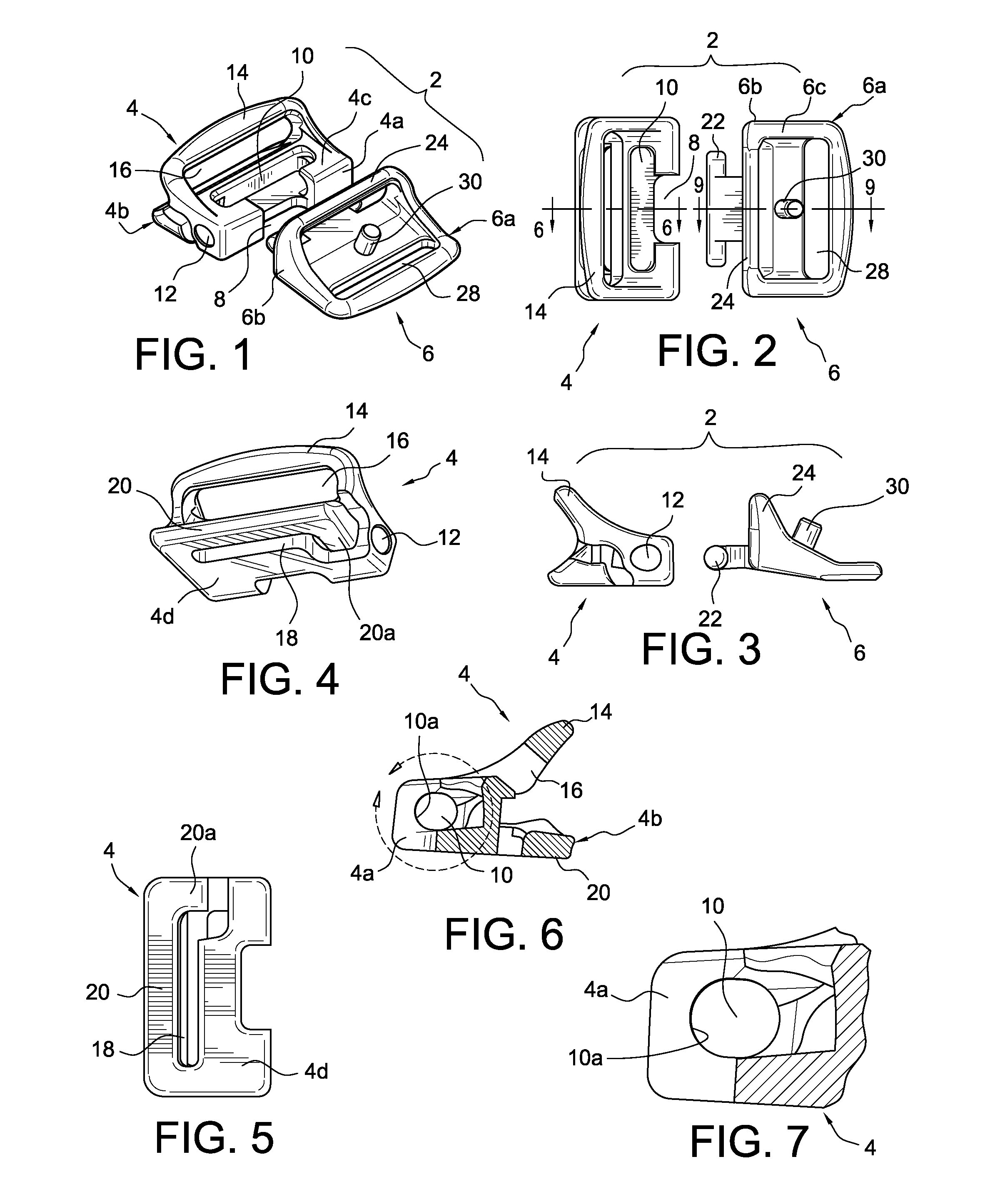

Quick connect power connector

ActiveUS9077114B2Quick and simple and reliable connectionFast disconnectionIncorrect coupling preventionElectric connection basesElectrical connectorElectrical and Electronics engineering

An electrical connector for connecting to a terminal post. The electrical connector includes a housing body, a contact and a locking release member. The housing body includes a post receiving passage for receiving the terminal post therein. The contact is provided in the post receiving passage and is positioned about the circumference of the post receiving passage. The contact will make an electrical engagement with a terminal post inserted into the post receiving passage regardless of the orientation of the terminal post with respect to the contact. The locking release member is moveably mounted to the housing body and is moveable between a first position and a second position. The locking release member cooperates with a locking spring member. The locking spring member has a locking section which cooperates with a recess of the terminal post when the locking release member is in the first position.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

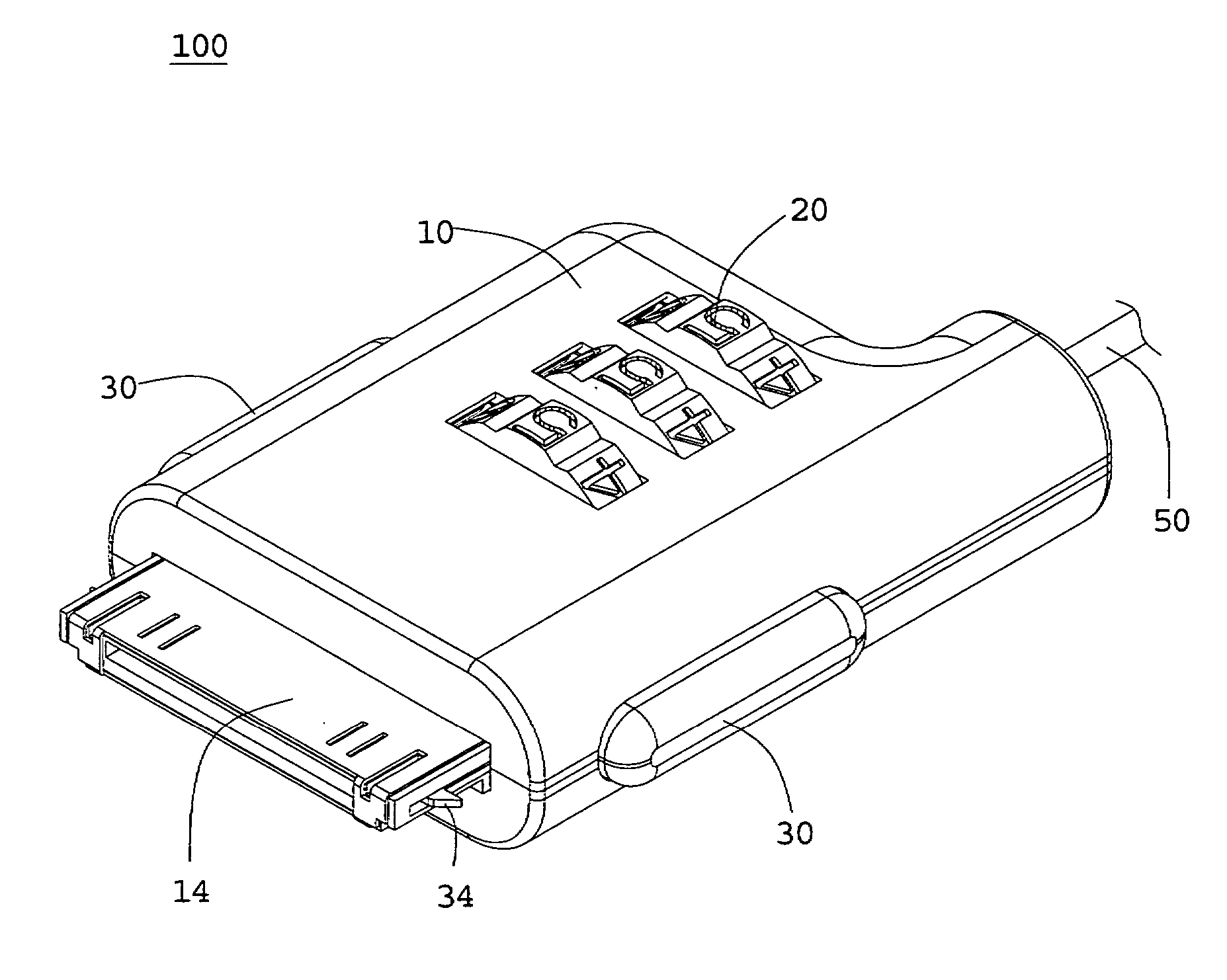

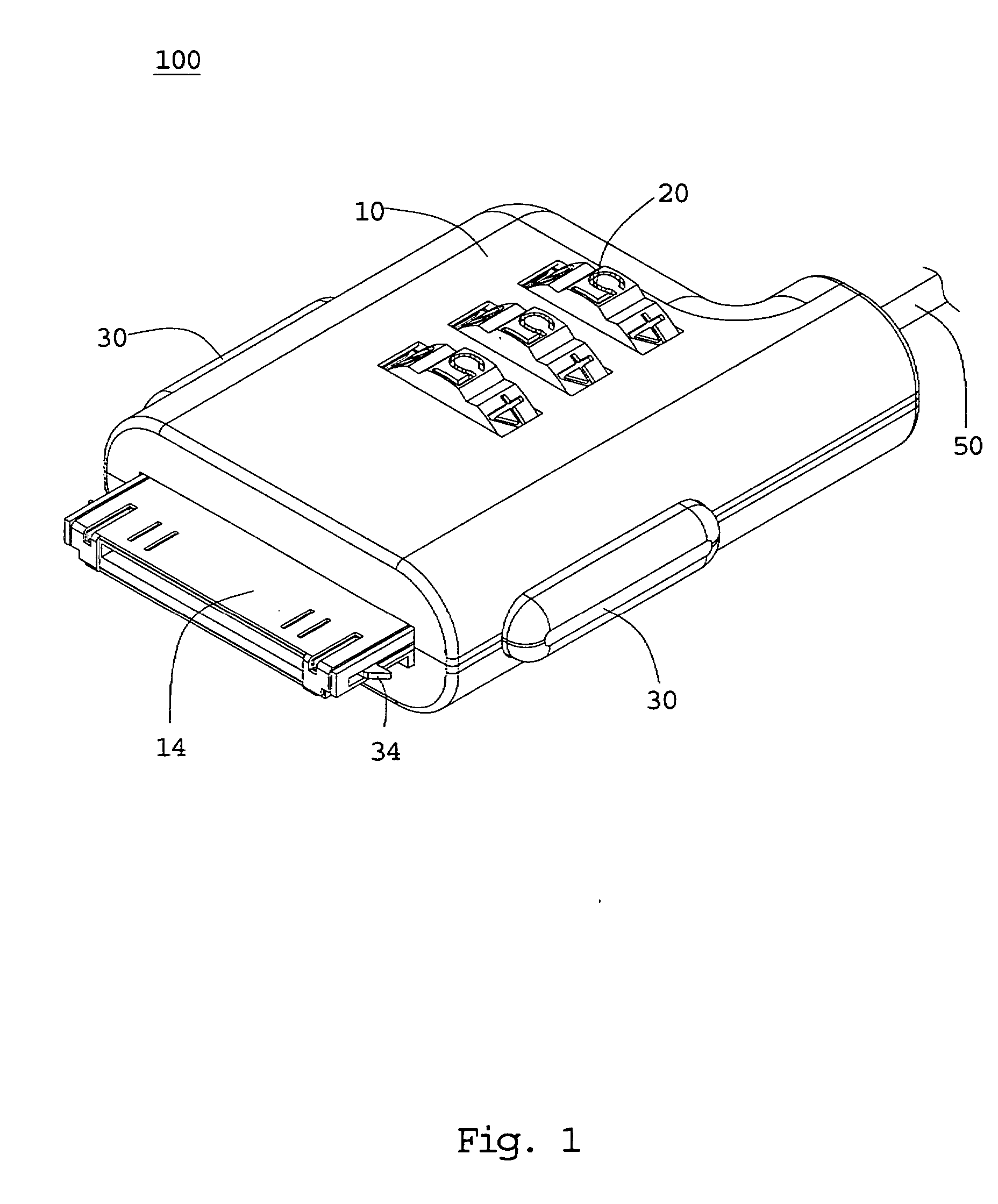

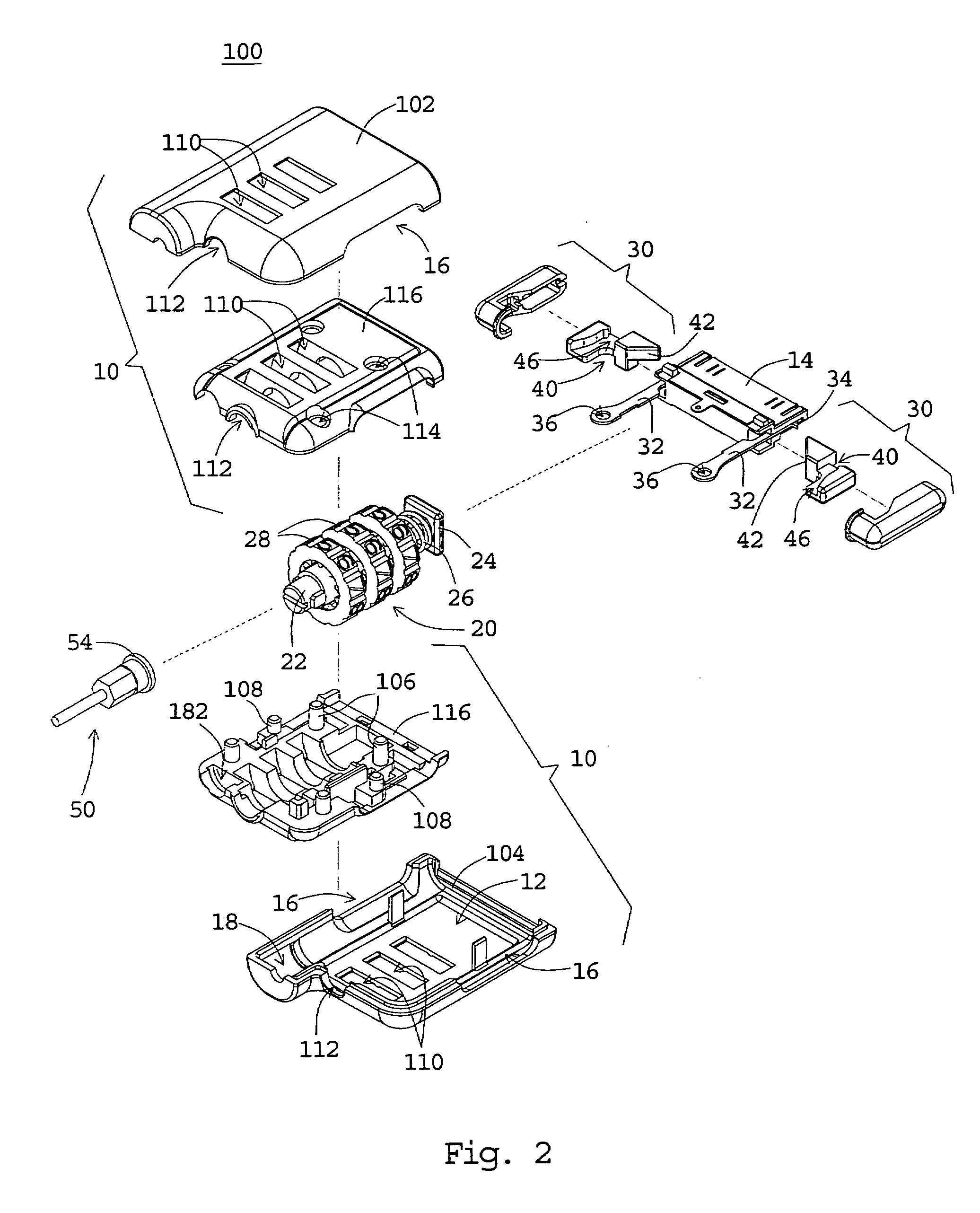

Burglarproof lock for electronics devices

InactiveUS20070175248A1Prevent theftHandy in operating and quick in connecting and disconnectingClothing locksLocks for portable objectsEngineeringMechanical engineering

Owner:SINOX CO LTD

Quick connect power connector system

ActiveUS10122117B2Quick and simple and reliable connectionFast disconnectionOne pole connectionsIncorrect coupling preventionElectrical connectorBinding post

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

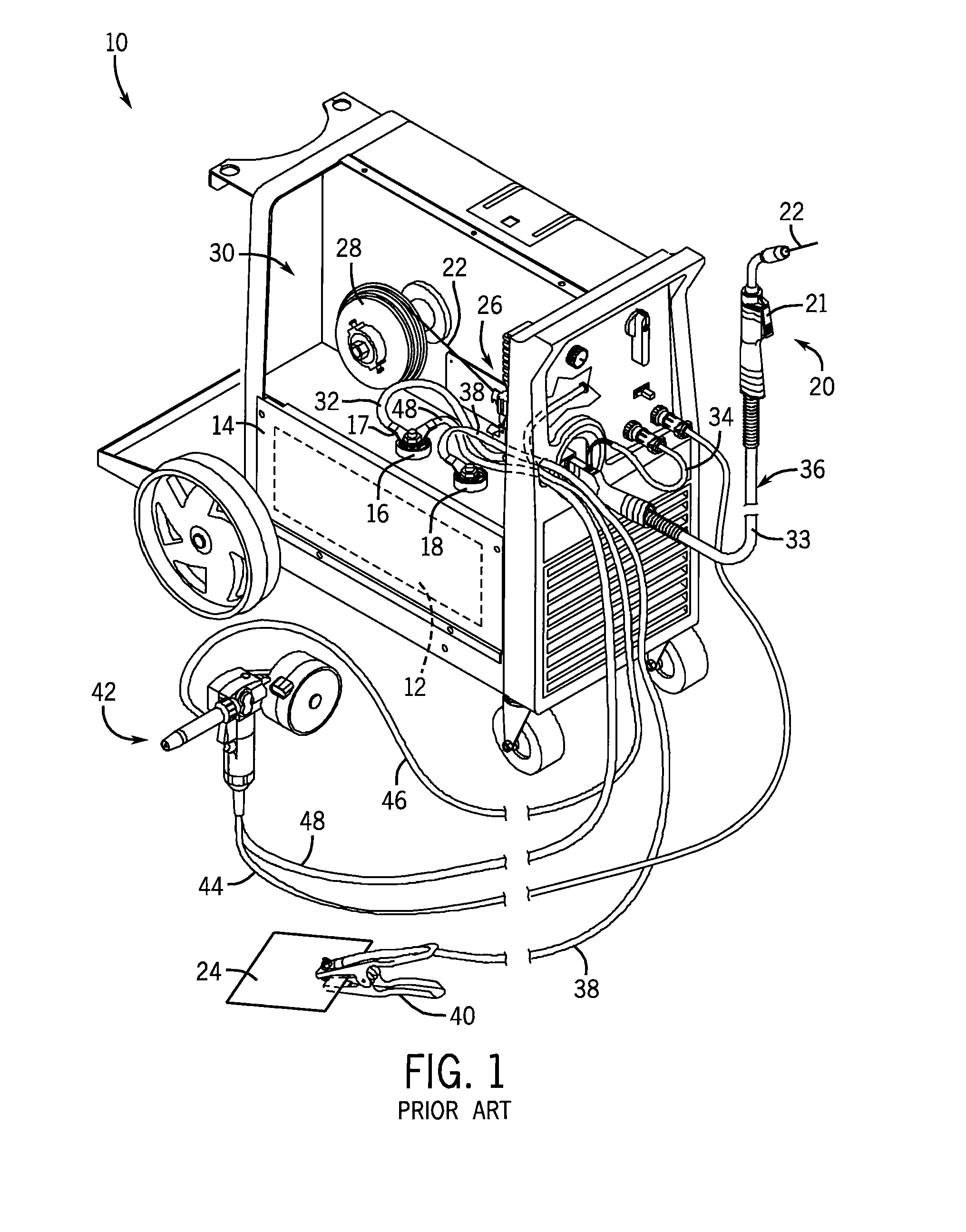

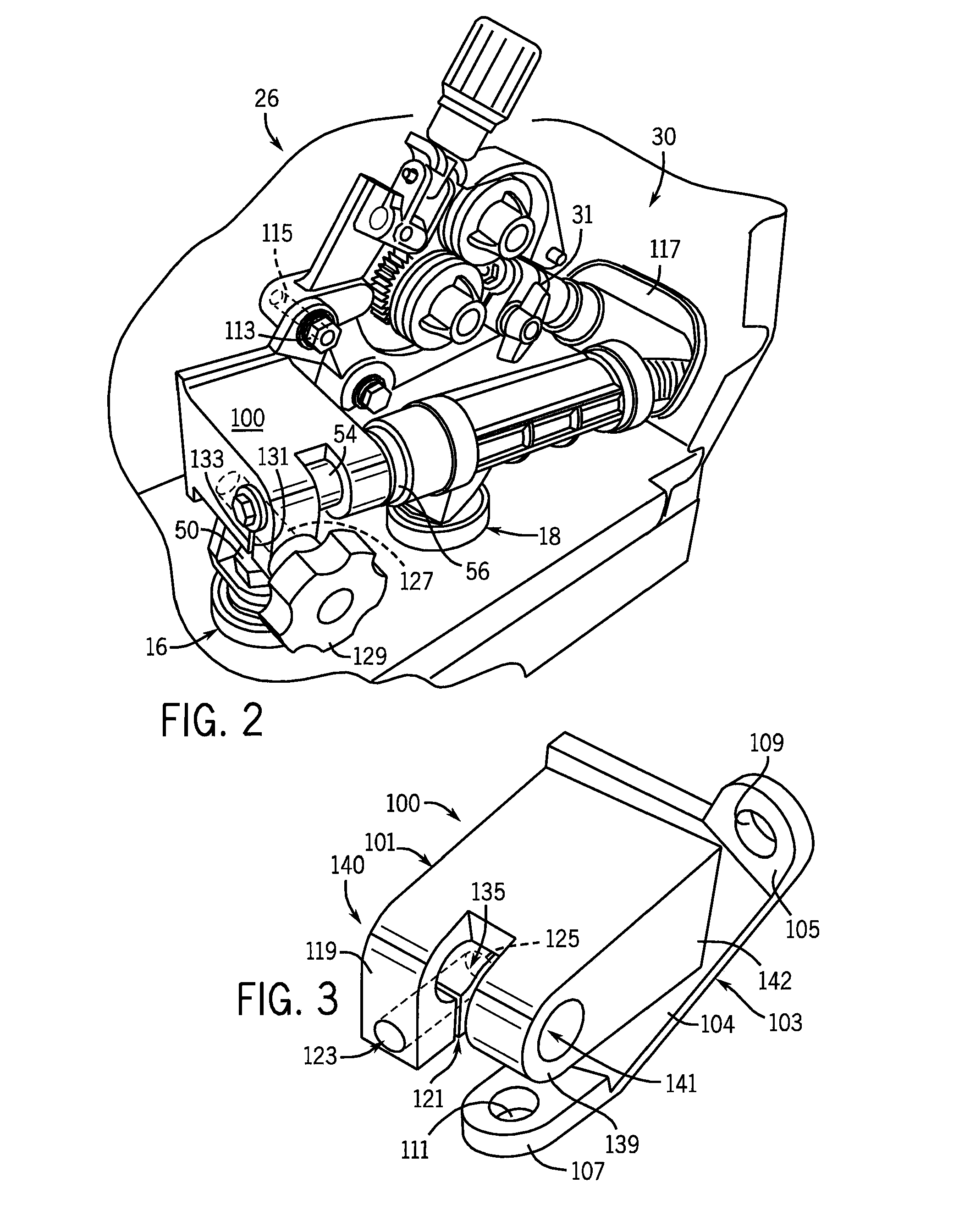

Dual power pin connector assembly for a mig welding machine

ActiveUS20090212034A1Fast disconnectionRapid connection and disconnectionElectrode supporting devicesWelding accessoriesElectricityPower cable

A dual power pin connector assembly for connecting both a MIG welding gun and a spoolgun to a welding machine. The dual power pin connector is comprised of a busbar portion that electrically and mechanically couples the positive output terminal of the welding machine power supply to a wire drive for the MIG welding gun. The connector is further comprised of an integral quick release assembly / clamping portion that electrically and mechanically connects the positive power supply terminal to a power supply cable for the spoolgun. The clamping portion receives and retains a power pin coupled to one end of the spoolgun power cable in a receptacle that is manually tightened and loosened.

Owner:ILLINOIS TOOL WORKS INC

Clasp assembly for a watch chain

InactiveUS20050262668A1Fast disconnectionImprove the safety of useBraceletsWrist-watch strapsEngineeringScrew thread

A clasp assembly, which can be disconnected or connected with a watch chain quickly, includes a clasp cap, an inner bend plate, outer band plate, a screw, a rivet and an elastic shaft. The inner bend plate comprises an arc plate body and two cylindrical bodies, the two cylindrical bodies disposed on one end of the plate body, a thread hole provided on the surface of a distal end of each cylindrical body, a through hole provided on the other end of the plate body and a convex clasp provided on each side of the plate body. A groove is provided in the middle of the outer bend plate and a through hole is formed on one end of the out bend plate, which comprises two sections spaced by the groove, and linked with the through hole of the inner bend plate by engaging with the rivet pivotally. A through hole is formed on the other end of the outer bend plate which remains integral, and concave clasps are disposed symmetrically on the inner sides of the outer bend plate. The clasp cap is pivotally connected with the thread hole of the inner bend plate by the screw, through holes disposed in two side plates of the clasp cap. A hook clasp and a locking clasp for being connected with the watch chain are mounted on the elastic shaft engaging with the through holes, the locking clasp fitting into the hook clasp. A security cover is pivotally mounted on the rivet connecting the outer bend plate with the watch chain.

Owner:JOLLY HOPE ENTERPRISE

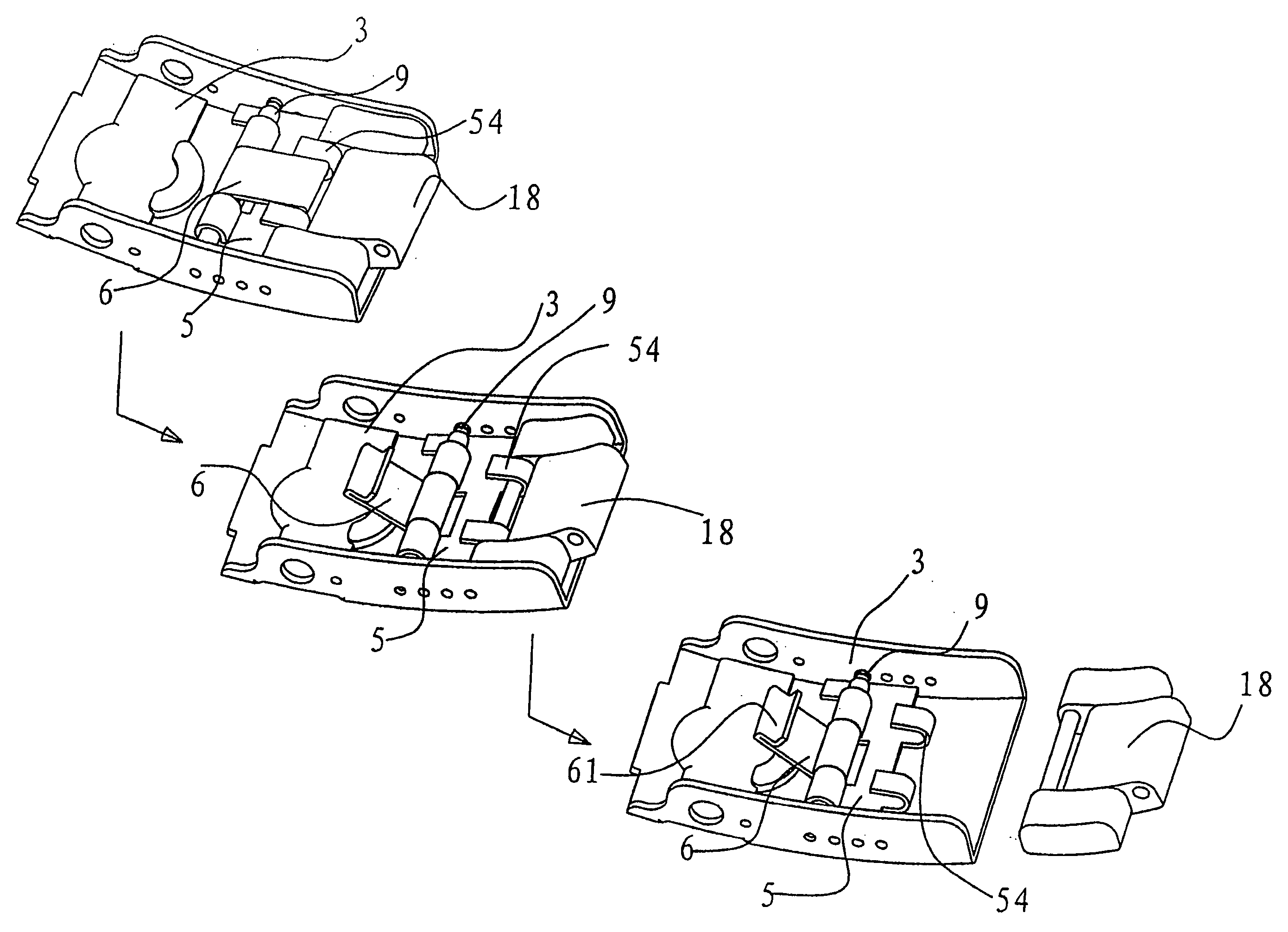

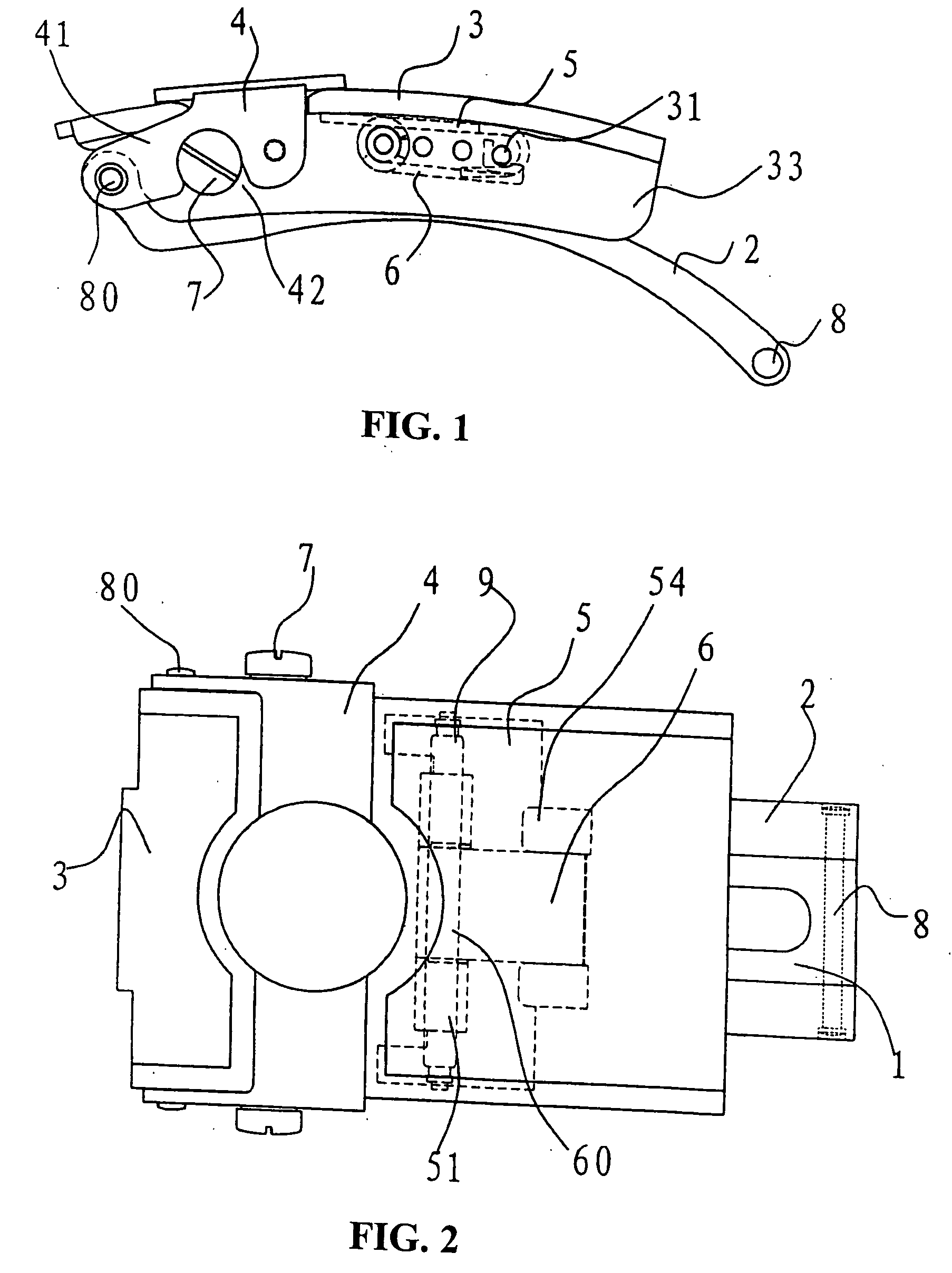

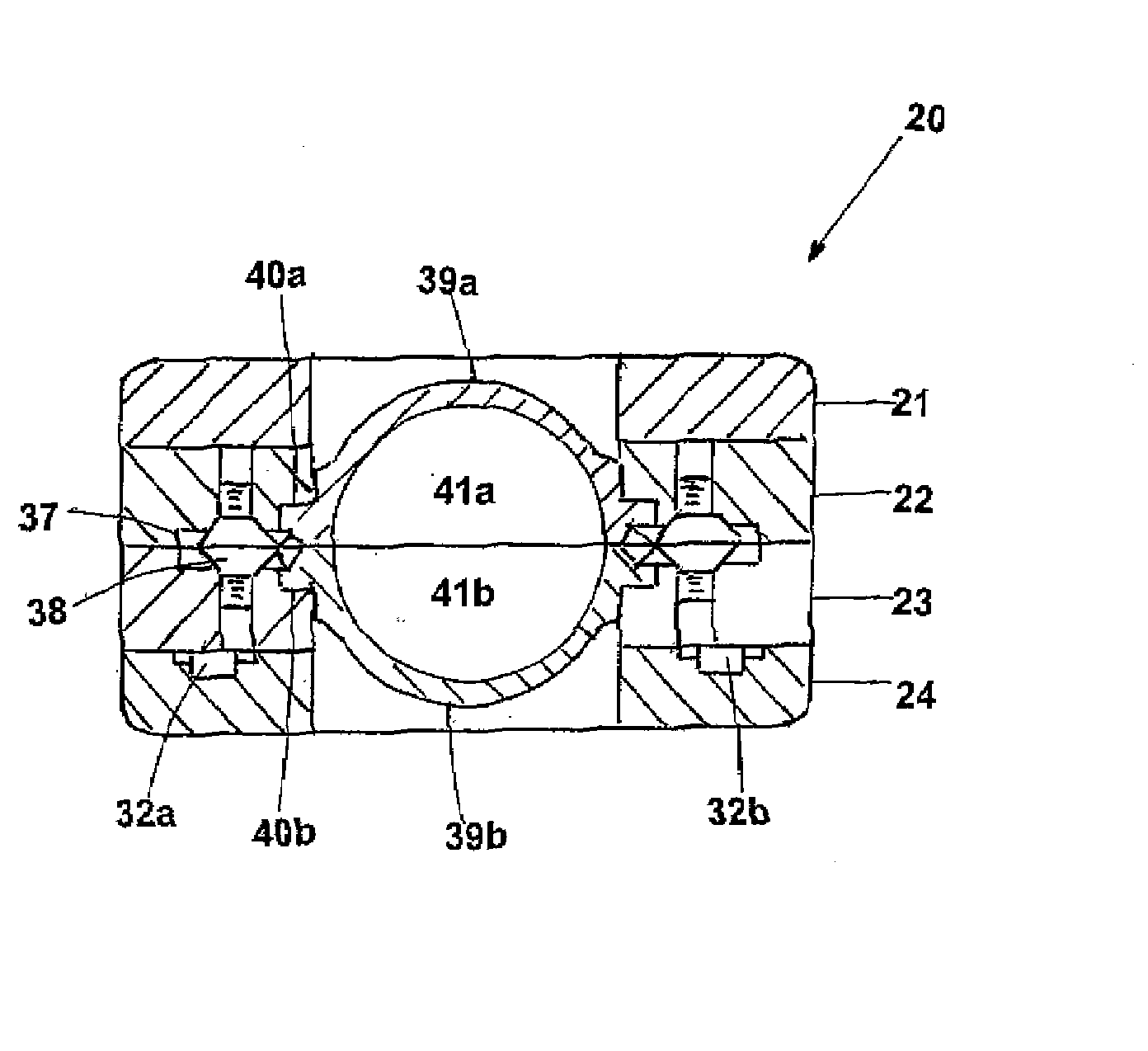

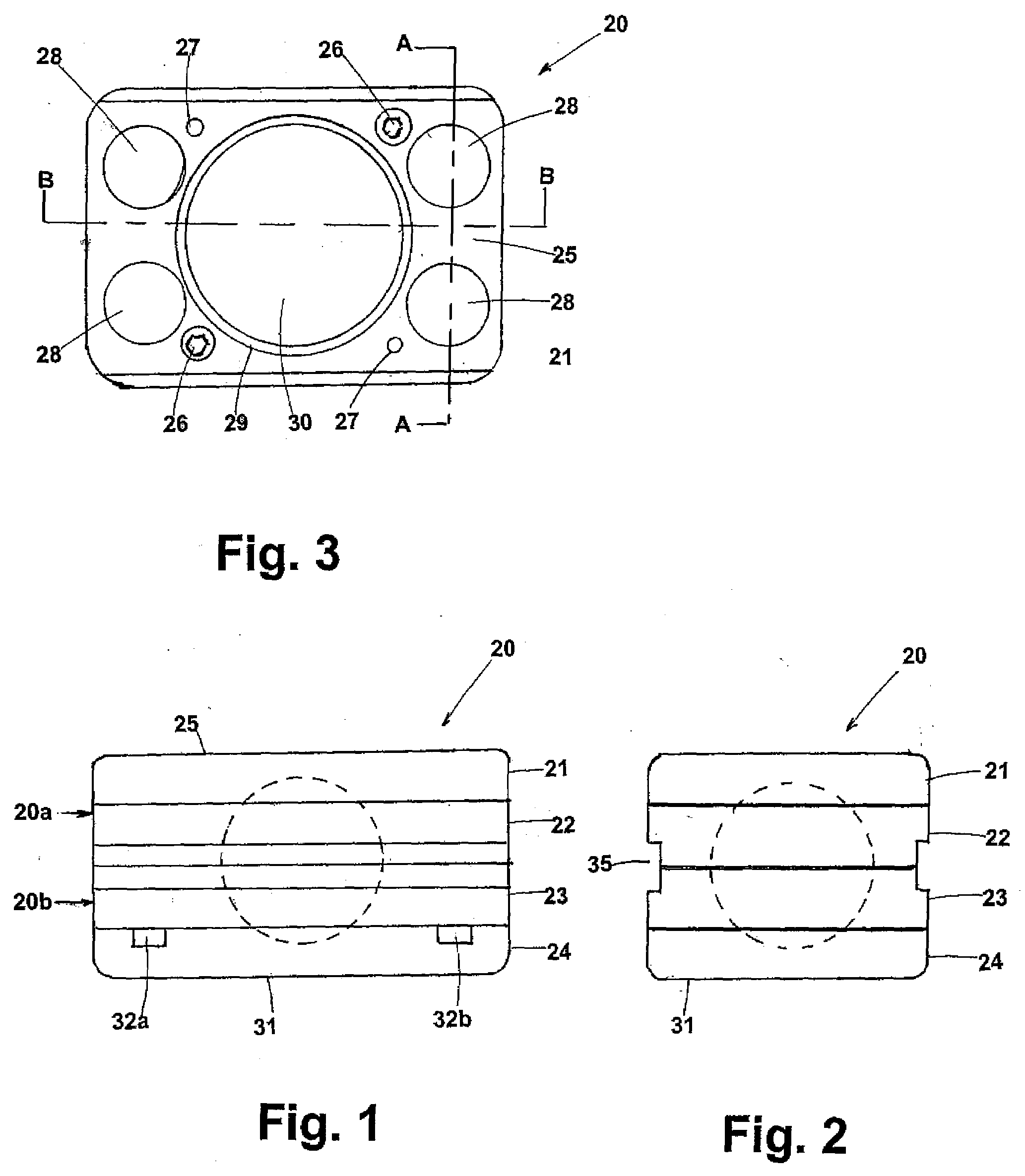

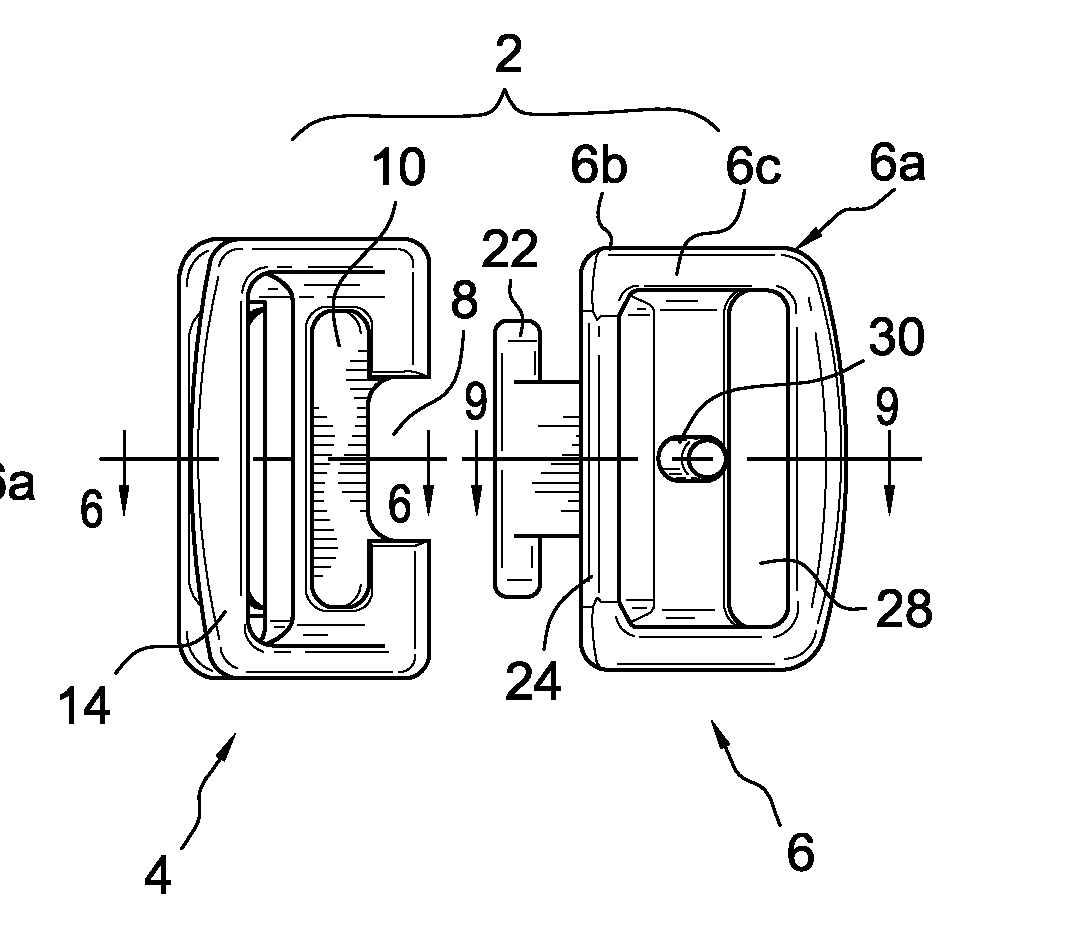

Quick connect power connector

ActiveUS9059542B2Quick and simple and reliable connectionFast disconnectionIncorrect coupling preventionElectric connection structural associationsEngineeringElectrical connector

An electrical connector for connecting to a terminal post. A contact is provided in electrical engagement with the terminal post regardless of the orientation of the contact with respect to the terminal post. A locking slide is moveably mounted to the housing body. A first reference member is provided on a first end of the body of the connector, the first reference member is provided proximate a first sidewall of the body of the connector. A second reference member is provided on the first end of the body of the connector, the second reference member is provided proximate a second sidewall of the body of the connector. When the locking slide is in the prelocked position, the first reference member is visible and when the locking slide is in the locked position, the second reference member is visible.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

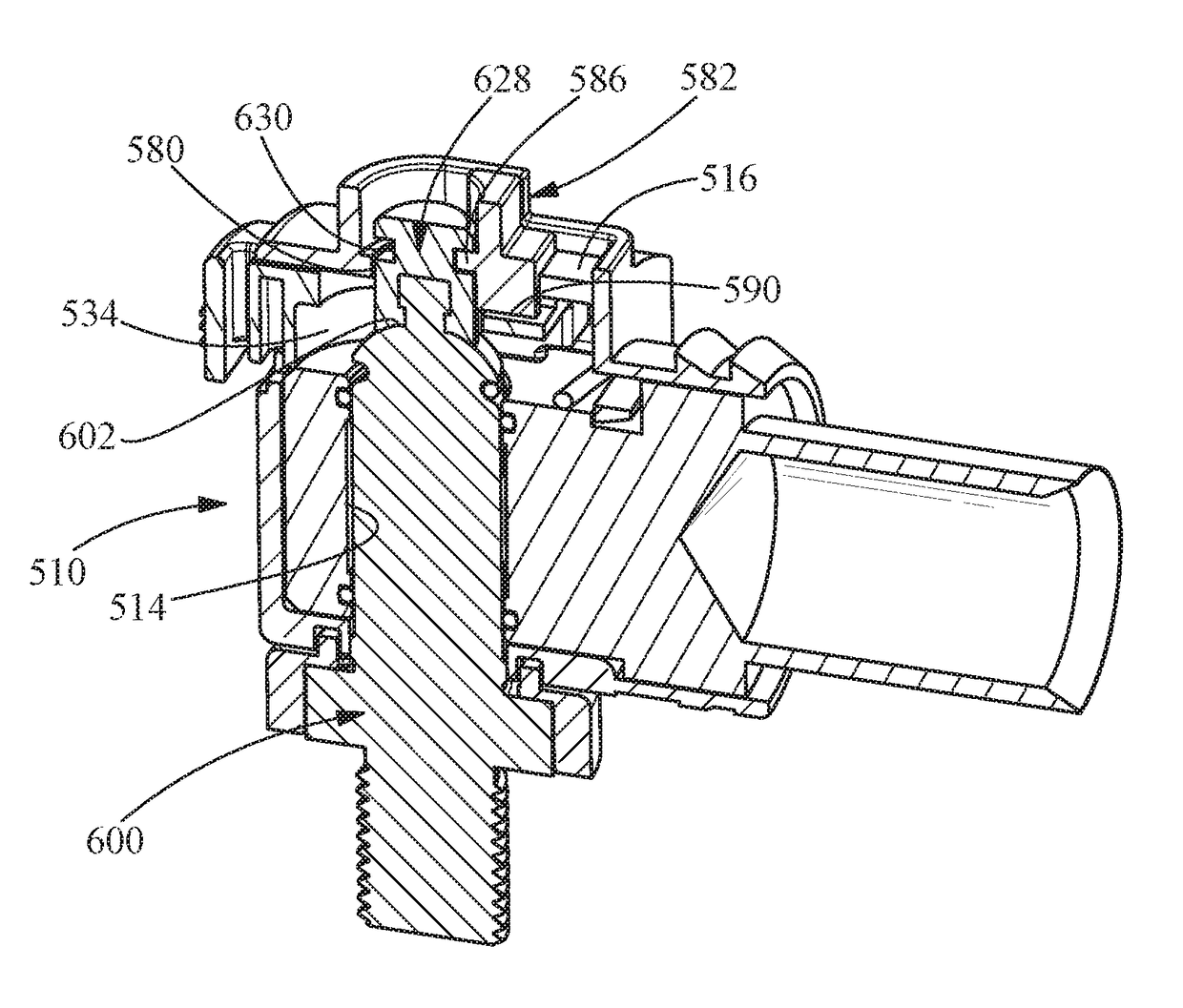

High pressure quick connect coupling and seal

InactiveUS6994380B2Easy and quick connectionMinimal physical effortFluid pressure sealed jointsJoints with sealing surfacesCouplingEngineering

A quick connect and disconnect pipe coupling and seal assembly including a first generally cylindrical coupling head having a bore therein for connection to a first conduit and a raised annular ring, a second generally cylindrical coupling head having a bore therein for connection to a second conduit, external male threads, and an annular recess for receiving an O-ring, and a generally cylindrical coupling ring for holding the first coupling head therein, the coupling ring having a threaded bore for receipt of the external male threads of the second coupling head to connect the first coupling head to the second coupling head and to force the O-ring received in the annular recess of the second coupling head into contact with the annular ring on the first coupling head to form a high pressure seal between the first coupling head and the second coupling head.

Owner:HILOSEAL TECH LLC

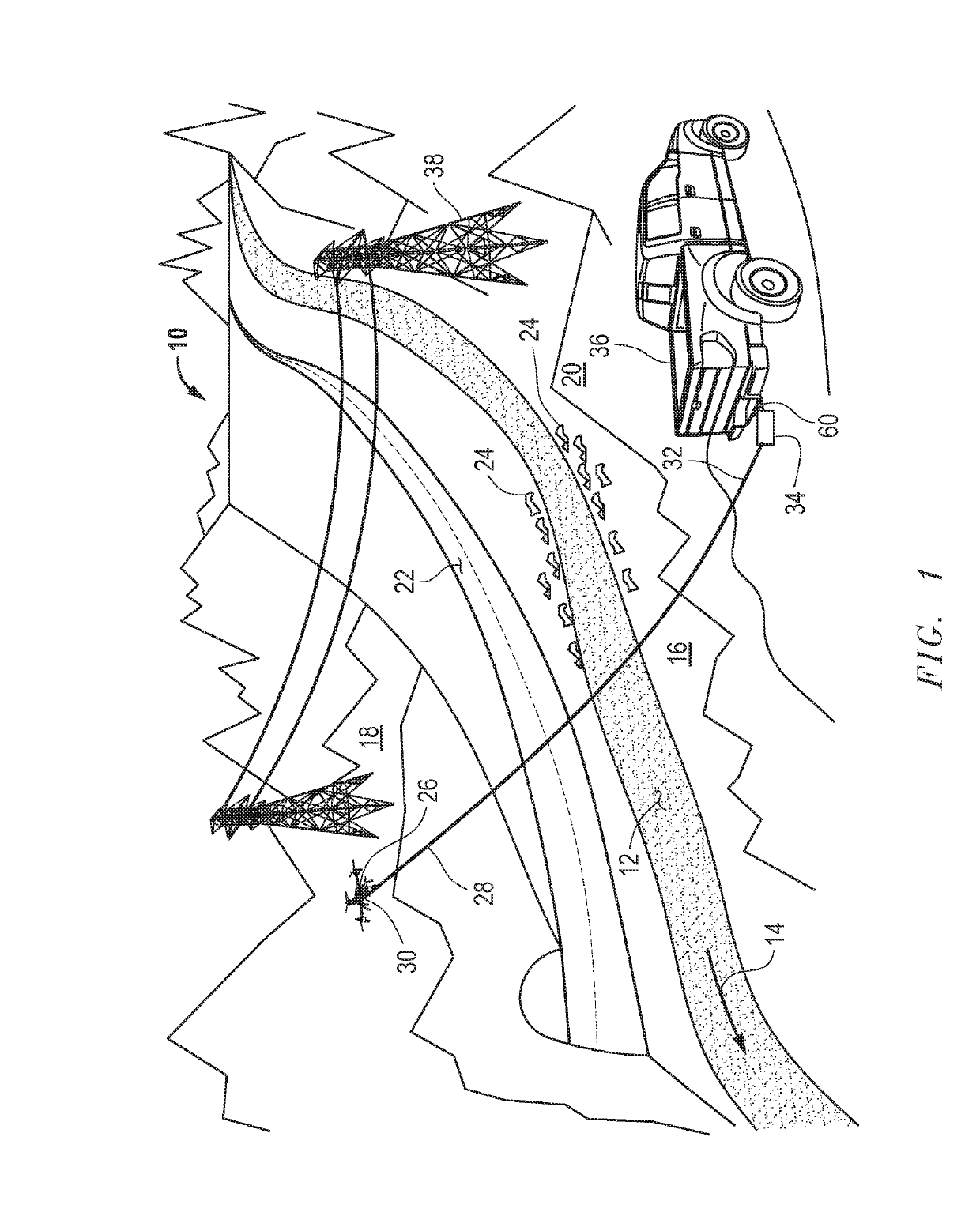

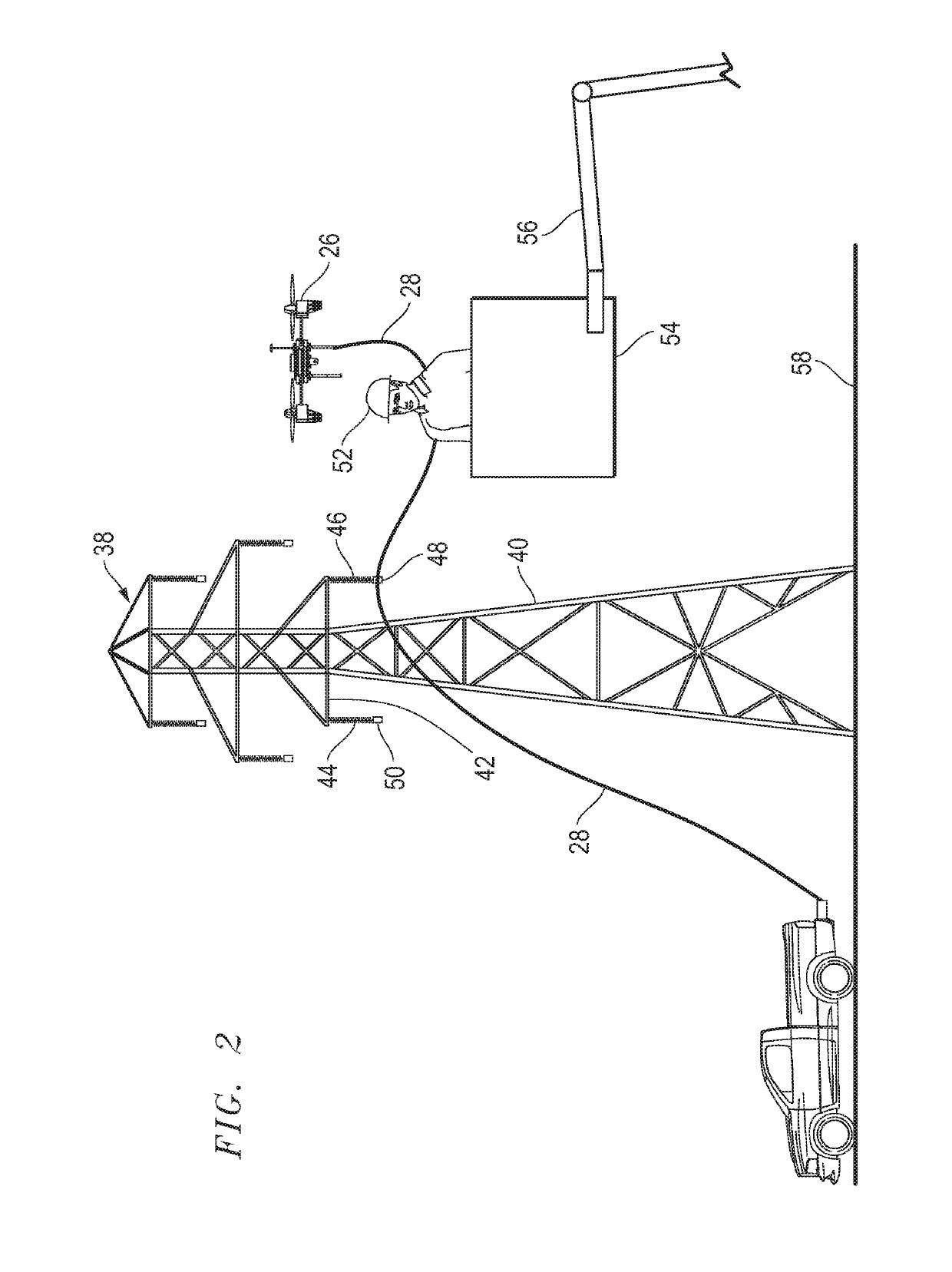

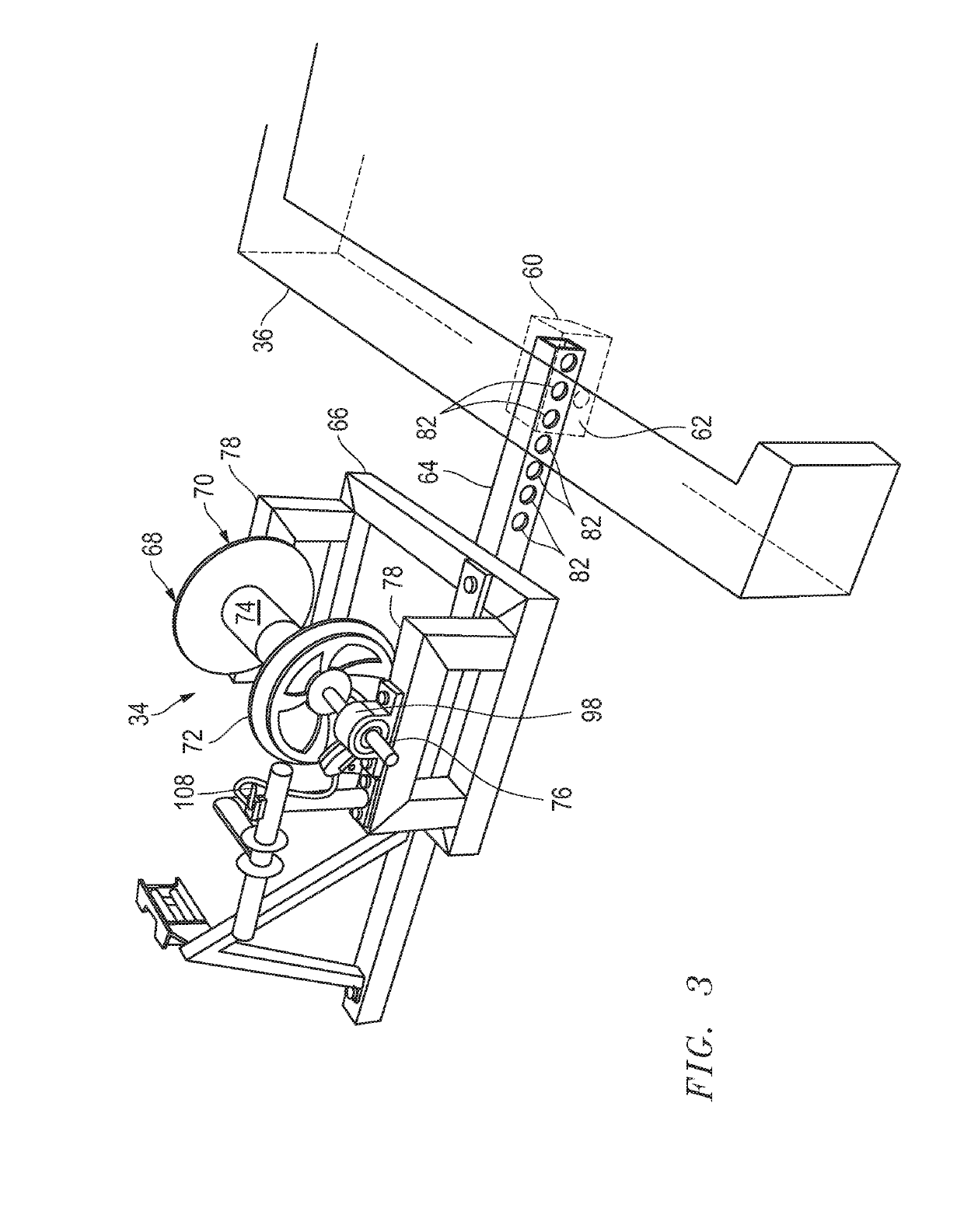

Apparatus and method for placing and tensioning an aerial rope through a traveler of a power line

ActiveUS20190218076A1Fast disconnectionReduce tensionUnmanned aerial vehiclesRemote controlled aircraftEngineeringCalipers

An apparatus for controlling tension in a pulling rope that is attached to a flying, unmanned aerial device or drone may utilize a cylinder around which the rope is wound, a shaft that longitudinally passes through the cylinder, a disc brake rotor that is mounted to the shaft, a brake caliper that is mounted circumferentially at a periphery of the disc brake rotor, and a brake lever that tensions a cable that is attached to, and movable to control movement of, the brake caliper, which may be hydraulic, against surfaces the disc brake rotor. The brake lever may be hand actuated and mounted to a handlebar. A frame may be part of the apparatus and support apparatus components and may have a protruding hitch portion that inserts into a vehicle's receiver hitch. An adjustable pulling rope guide support through which the rope is threaded, mounts to the frame.

Owner:QUANTA ASSOC

Mold for forming golf ball covers

The present invention is an improved single cavity molding device and method for compression molding polyurethane, polyurea or polyurethane / polyurea hybrid covers over golf ball sub-assemblies. The device utilizes top and bottom mold-halves and is particularly novel in that it does not require the use of bolts to secure the mold-halves. The molding device utilizes a pair mold halves, each having a backing plate and mold frame for housing a hemispherical cavity mold. The invention utilizes a plurality of clamping pins, each pin having its top portion reciprocally disposed in a recess of the backing plate of the top mold. Double spring Belleville washers are coupled to the top portion of each clamping pin and upon the application of a vertical force, the washers are compressed to place the device in a controlled state of tension and also cause the clamping pins, to move downward into a locking position with slidable retainers to therein maintain a compressive force of at least 384 pounds on the golf ball sub-assembly for the molding process. Upon completion of the molding process, a vertical force is applied to the top of the clamping pins wherein they are moved out of a coupled relationship with the engagement loops, and with a coordinating horizontal biasing, the retainers are moved away from the pins, whereby the mold-halves may be then opened and a covered golf ball removed.

Owner:ACUSHNET CO

Quick connect power connector

ActiveUS20150031228A1Simple connectionQuick and simple and reliable connectionIncorrect coupling preventionElectric connection structural associationsEngineeringElectrical and Electronics engineering

An electrical connector for connecting to a terminal post. A contact is provided in electrical engagement with the terminal post regardless of the orientation of the contact with respect to the terminal post. A locking slide is moveably mounted to the housing body. A first reference member is provided on a first end of the body of the connector, the first reference member is provided proximate a first sidewall of the body of the connector. A second reference member is provided on the first end of the body of the connector, the second reference member is provided proximate a second sidewall of the body of the connector. When the locking slide is in the prelocked position, the first reference member is visible and when the locking slide is in the locked position, the second reference member is visible.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Fishing speargun

Owner:BRUINGTON ROBERT KEVIN

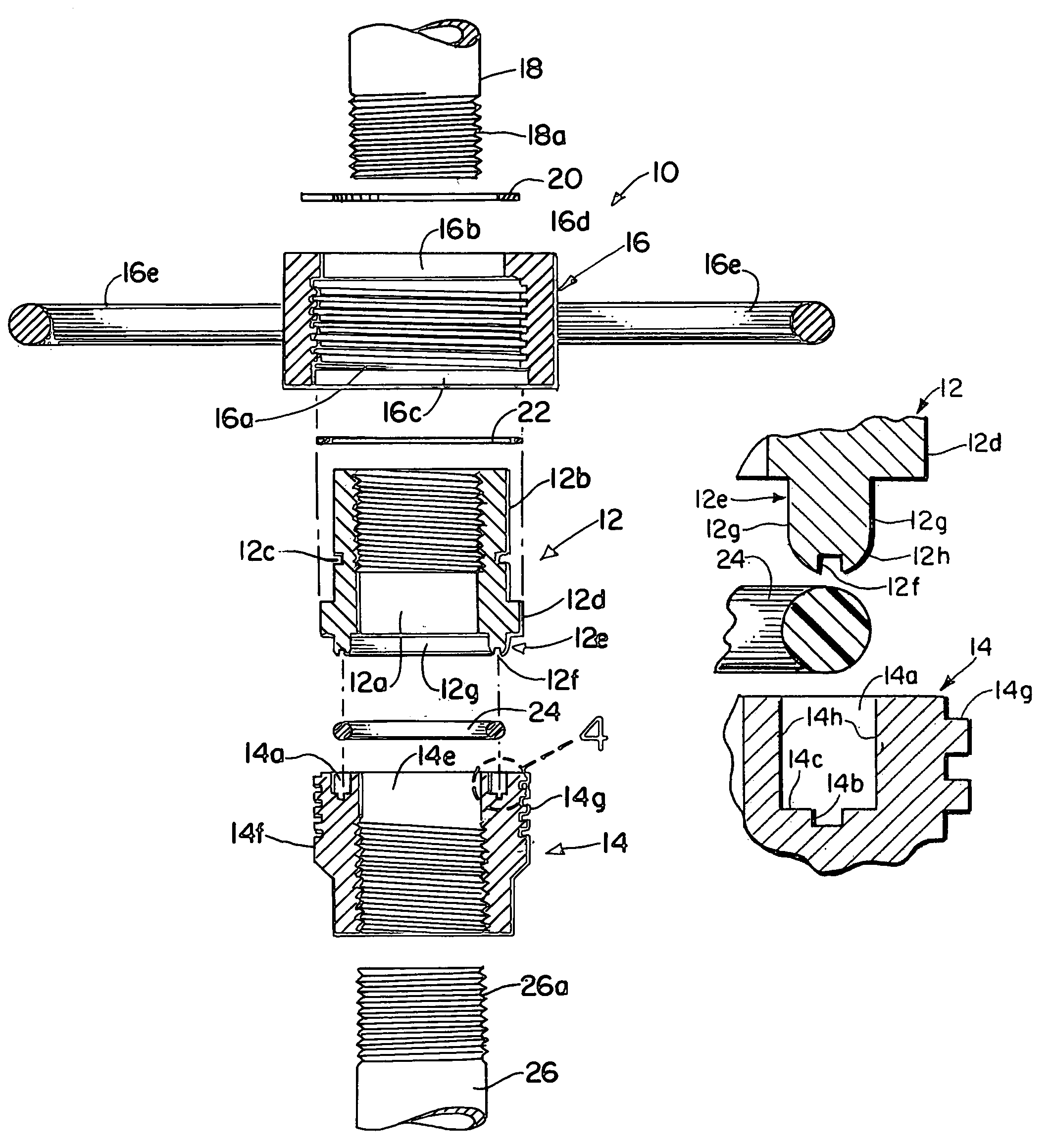

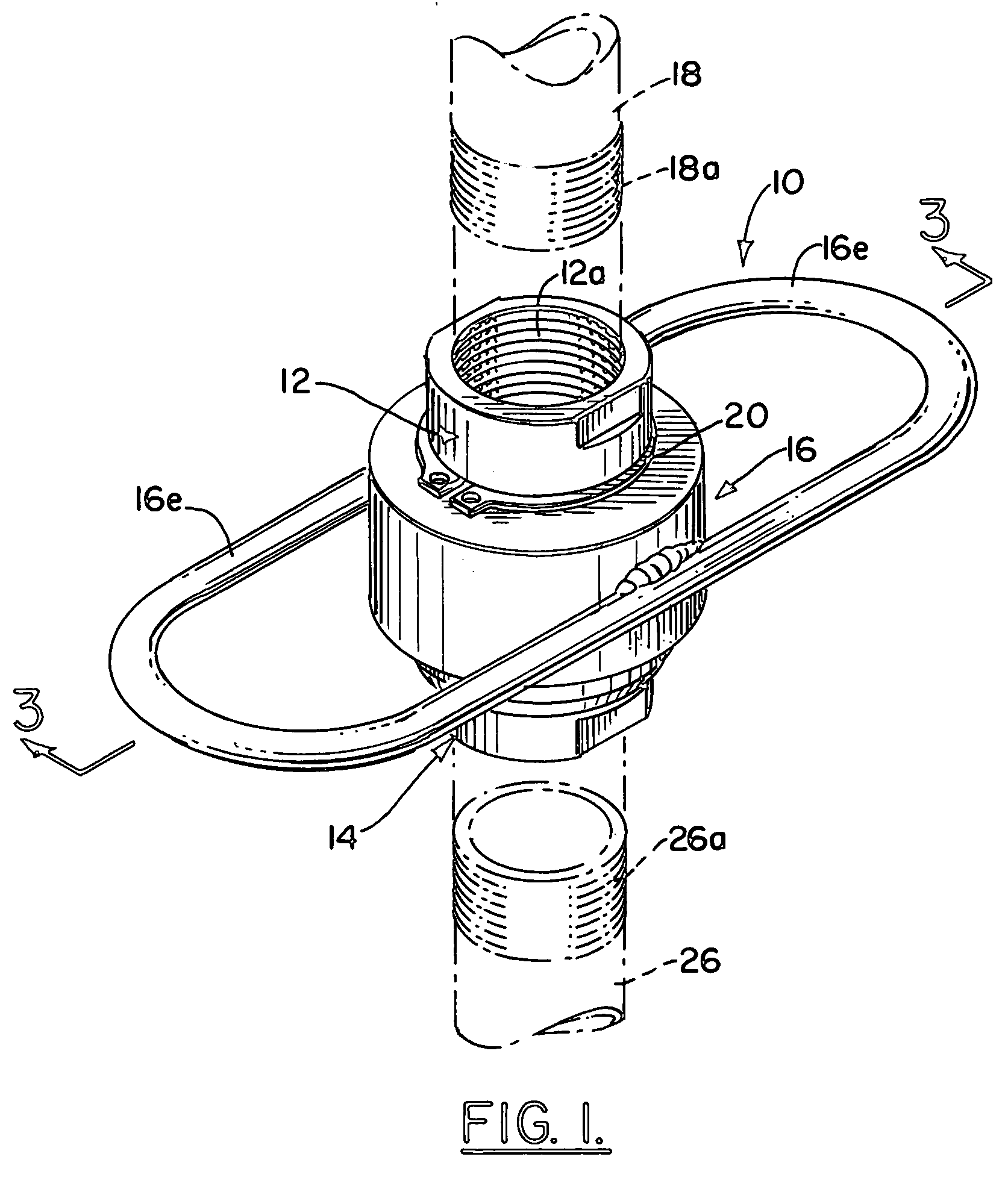

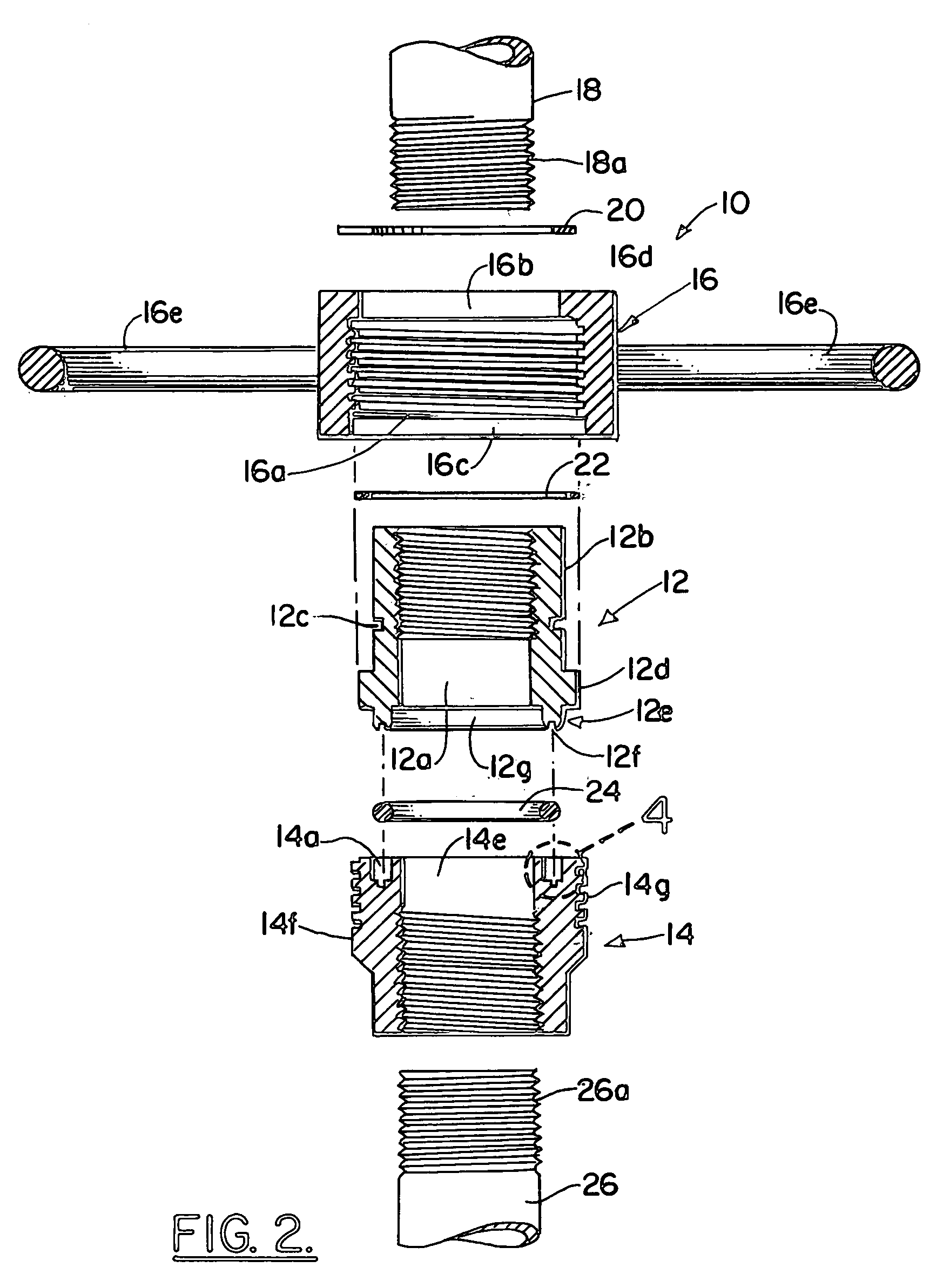

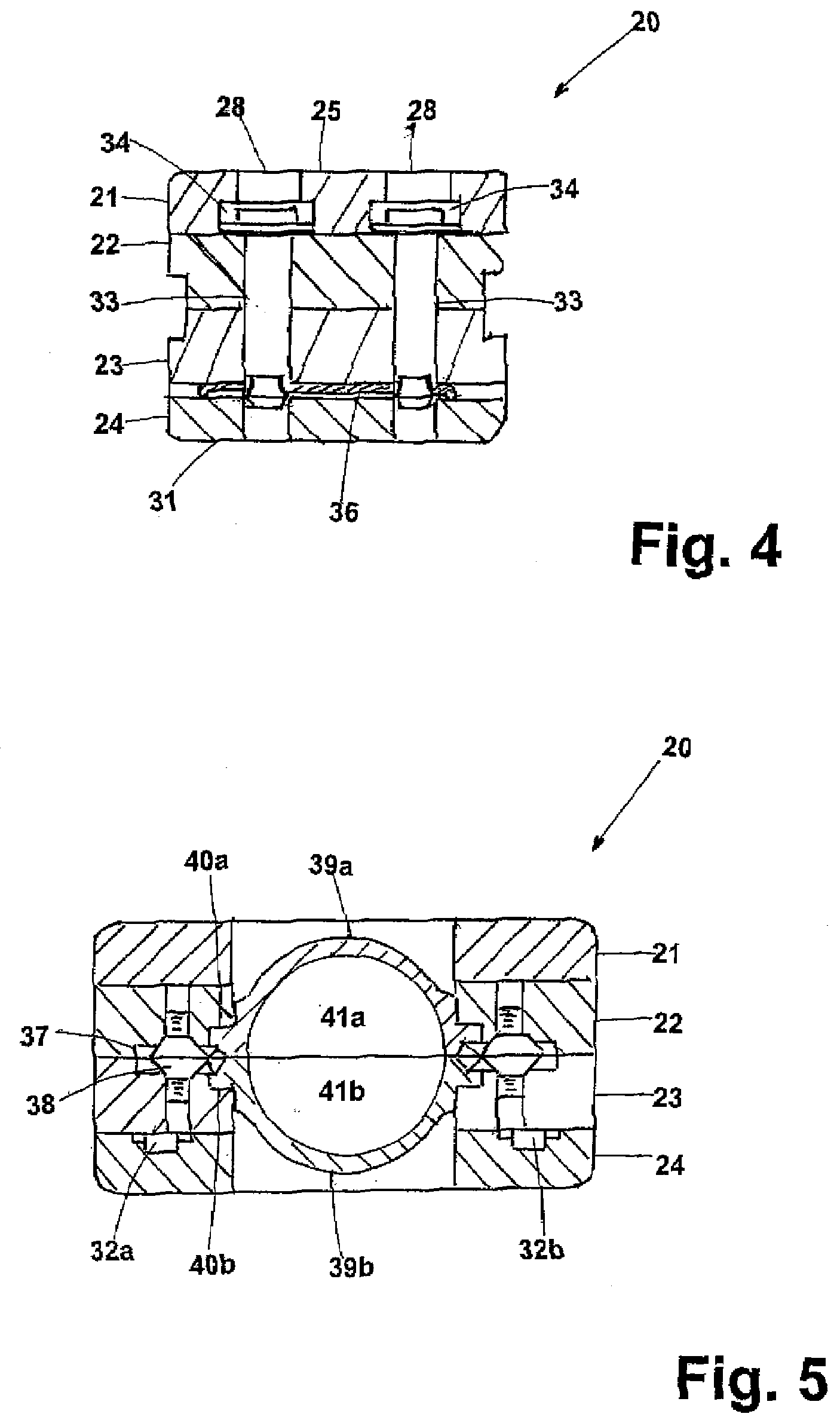

Grid nozzle assembly, a fluidized bed reactor with a grid nozzle assembly and methods of using a grid nozzle assembly

ActiveUS20160016136A1Rapid connection and disconnectionFast disconnectionCooking-vessel materialsFluidized bed combustionBackplaneMesh grid

A grid nozzle assembly for a fluidized bed reactor, a fluidized bed reactor with a grid nozzle assembly, a method of mounting a grid nozzle assembly as a replacement in a fluidized bed reactor, and a method of replacing a grid nozzle assembly in a fluidized bed reactor. The reactor includes a horizontally extending bottom plate, a gas plenum chamber below the bottom plate, and vertical gas pipes having a top end and extending from the gas plenum chamber upwards across the bottom plate. The nozzle assembly includes a nozzle head with a gas channel for injecting fluidizing gas from one of the vertical gas pipes to the reaction chamber and a tube sleeve adapted to be firmly fixed by welding around the top end of the vertical gas pipe. The nozzle head and the tube sleeve form a twist-lock enabling quick connecting and disconnecting.

Owner:AMEC FOSTER WHEELER ENERGIA

Tool-less terminal connector for side mount-type battery

InactiveUS20050101197A1Fast disconnectionElectric connection basesClamped/spring connectionsEngineeringBattery terminal

A tool-less, side mount-type battery terminal connector comprises an elongated conductive body having thread means on the inner end sized to engage a threaded female recessed battery terminal, a central cylindrical portion of larger diameter than the inner end, and knob means on the outer end. A shoulder at the junction of the inner end and the central cylindrical portion functions to clamp an end terminal of an electrical cable to the battery terminal. The knob means is sized to facilitate manual, tool-less rotation of the body.

Owner:WIRTHCO ENG

Adapter for coupling an external post connector or a BNC connector to an SMA bushing

InactiveUS20050265667A1Fast disconnectionFirmly connectedCoupling device connectionsElectric discharge tubesEngineeringLight source

An assembly used to adapt an external post connector, such as a BNC type connector of a microsurgical optic fiber instrument to a threaded SMA type bushing of a light source includes an adapter that can be threaded on the bushing of the light source and is also connectable to the BNC connector.

Owner:SYNERGETICS

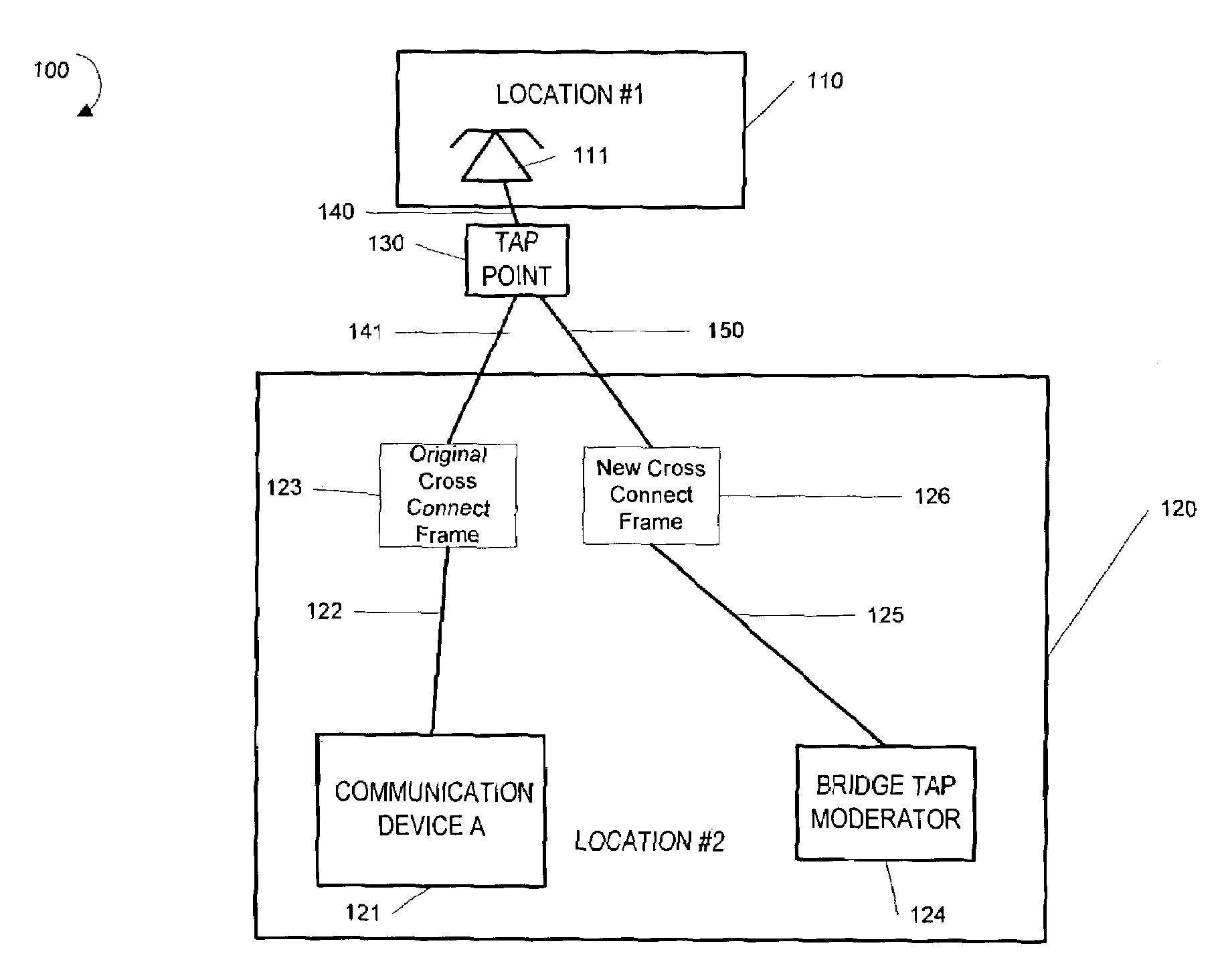

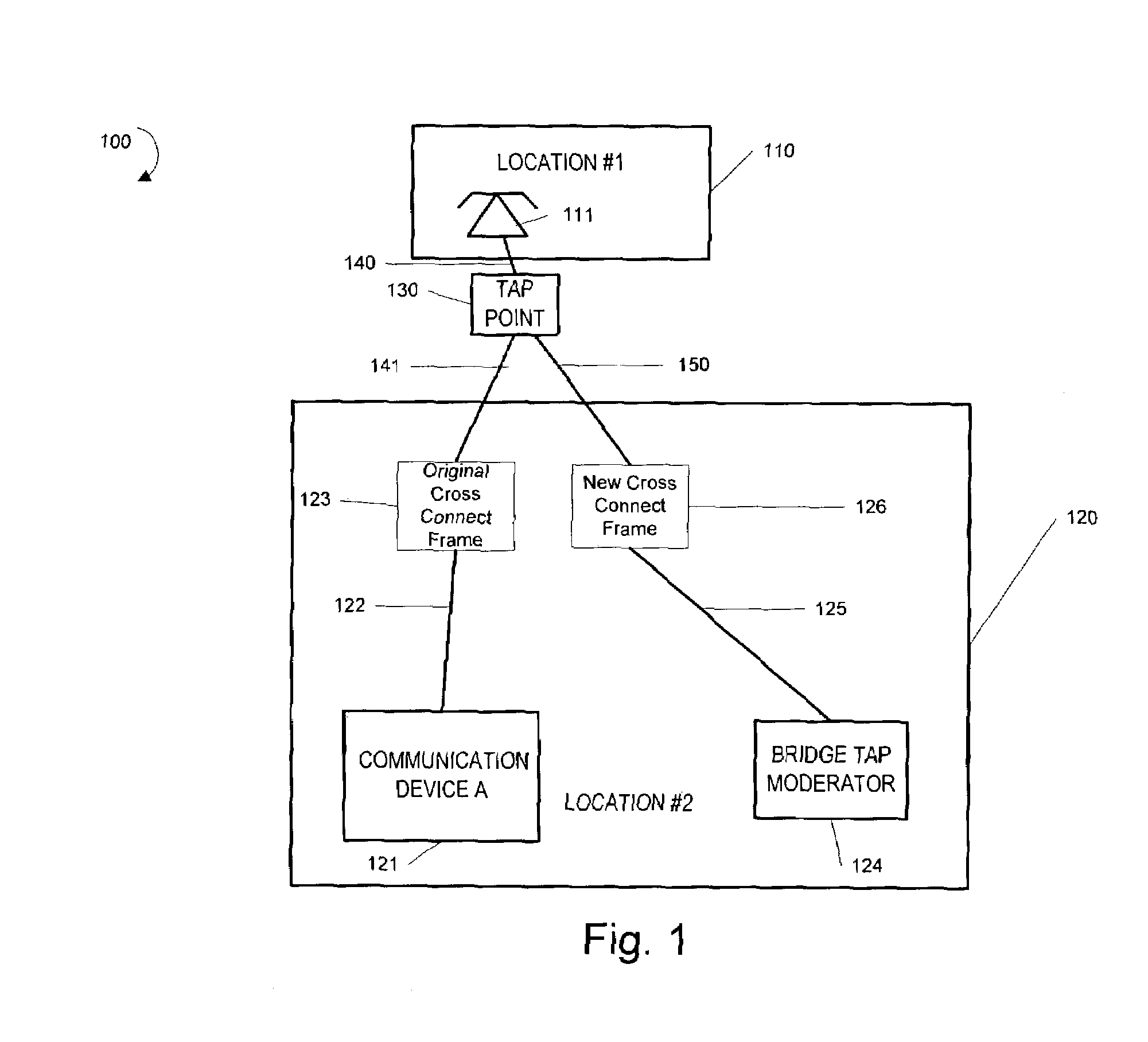

Methods and apparatus for a bridge tap moderator

InactiveUS7076056B1Shorten the durationEliminate the effects ofInterconnection arrangementsSubstation equipmentQuality of serviceLoop length

Methods and apparatus for protecting quality of service during a process involving bridge tap in a communications system are described. Bridge tap may occur during system construction, central office re-concentration, replacement projects, upgrade projects, expansion projects, and installation of back-up cables, etc. Cables, with one end connected to a point in the system, and the other end left unterminated, result in bridge tap. In the bridge tap moderator of the present invention, a plurality of termination networks are attached to a modular connector such that a separate termination load is placed across each connector terminal pair for each corresponding wire pair of the cable. Communication lines can be easily attached to the moderator thereby easily, quickly, and efficiently eliminating bridge tap on a large number of wire pairs. The bridge tap modulator apparatus and method of use also minimize the amount of time bridge tap exists during cable and / or communication device installation. The use of bridge tap moderator results in improved overall system performance reflected in an improvement in attainable sync rate and increase in allowable loop length.

Owner:VERIZON PATENT & LICENSING INC

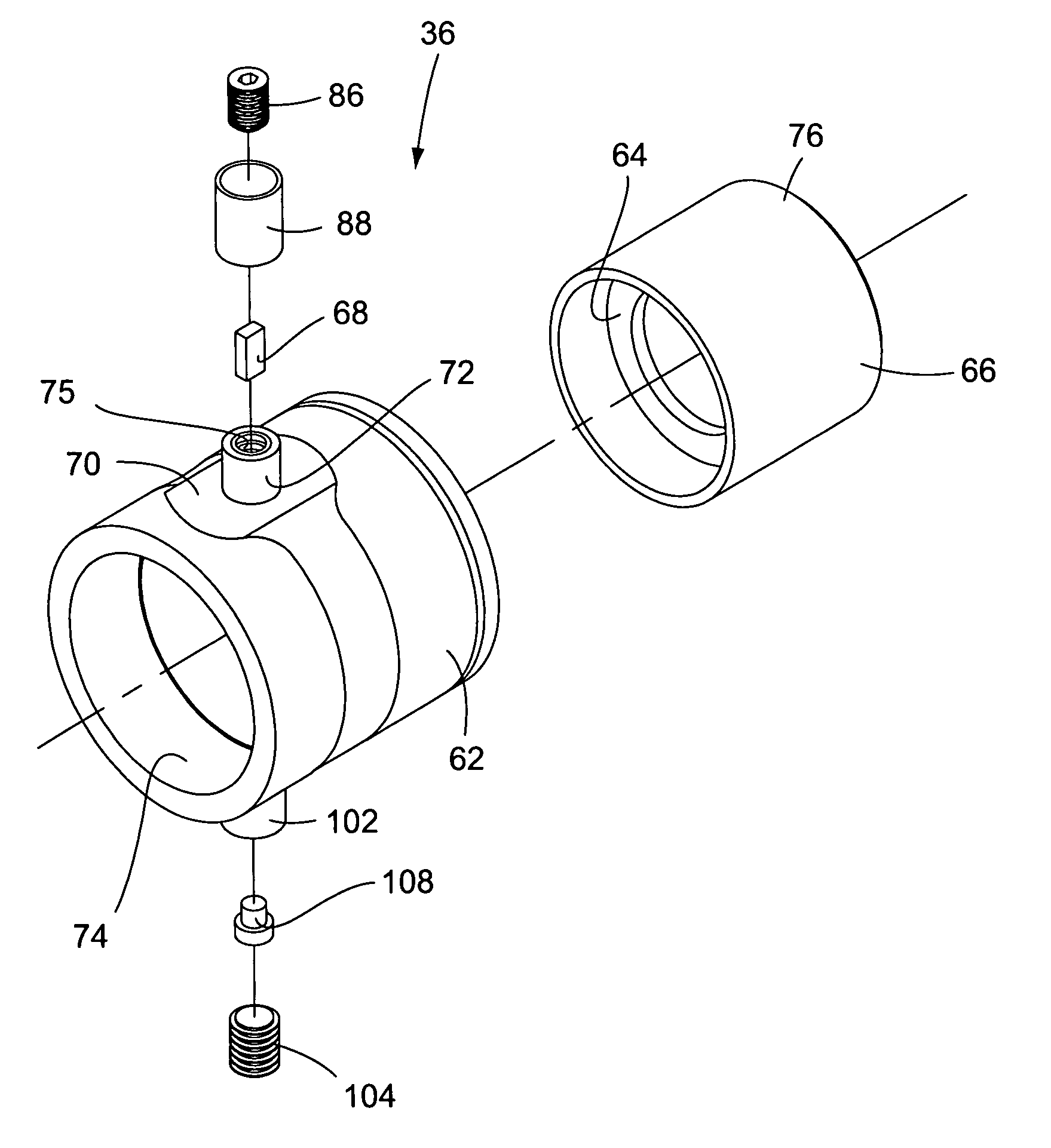

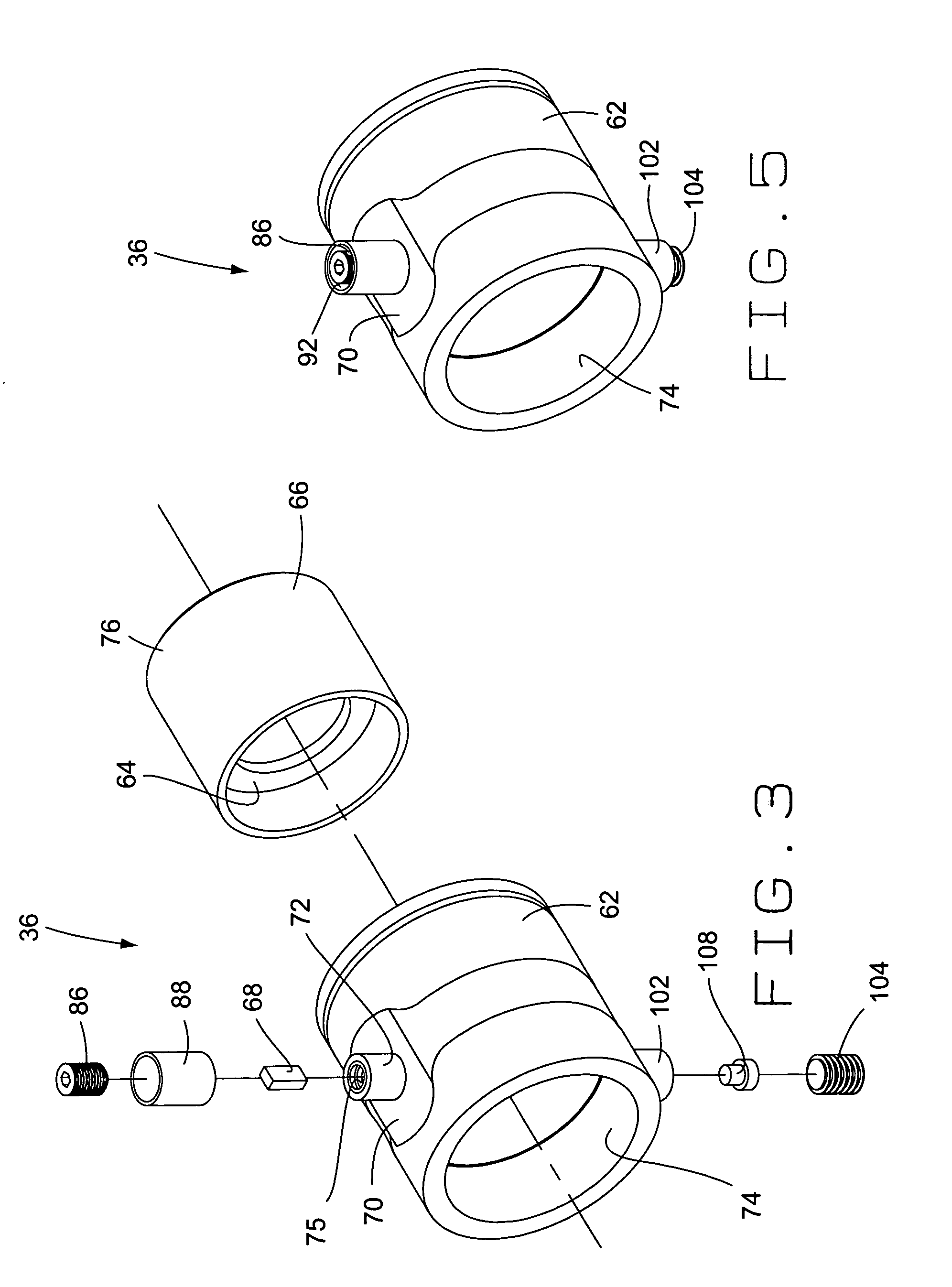

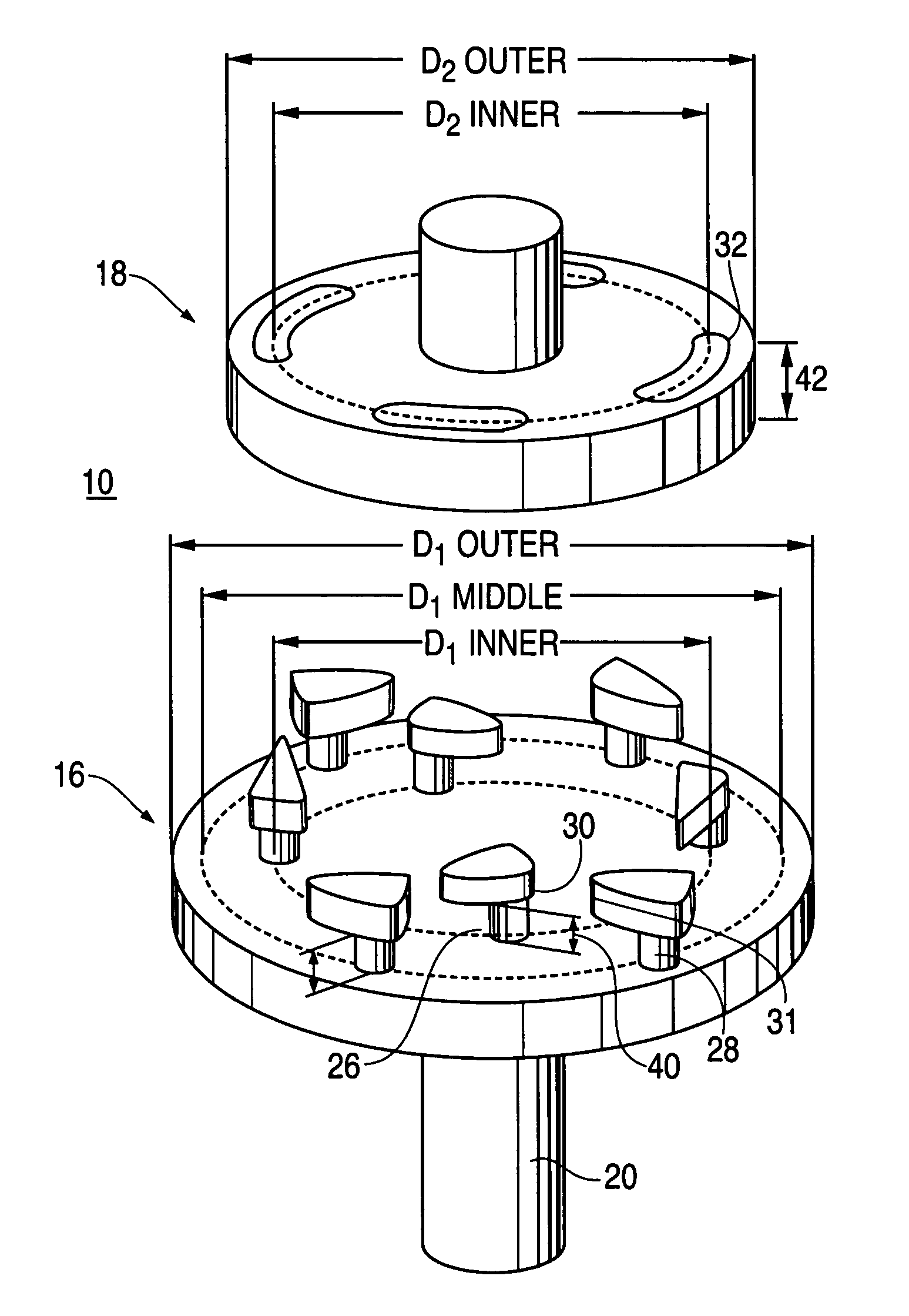

Coupling assembly and method for connecting and disconnecting a shaft assembly

ActiveUS7329065B2Fast disconnectionRapid connection and disconnectionFlanged jointsRotary stirring mixersImpellerCoupling

A coupling assembly that can be used to quickly connect and disconnect an impeller shaft to and from a drive output shaft. A portion of the coupling assembly can be used to secure the impeller shaft inside a mixing vessel so that the impeller shaft can remain secure inside the mixing vessel when the drive is disconnected. The coupling assembly has a first and a second coupling half, a first group of locking pens that extend from the first coupling half and can pass through openings formed in the second coupling half, and second group of locking pins that extend from the first coupling half and can pass through openings formed in the top region of the mixing vessel.

Owner:SPX FLOW INC

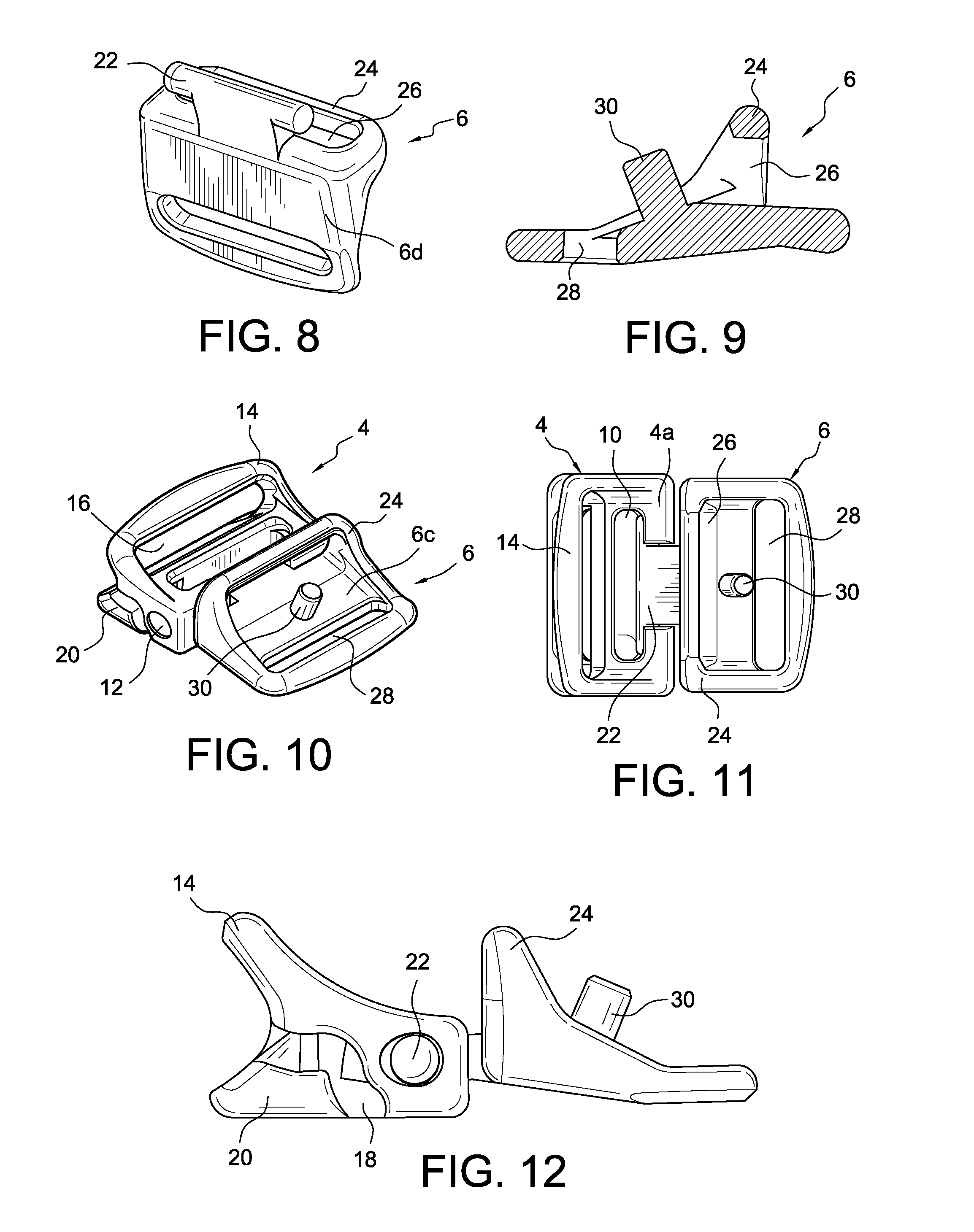

Quick release buckle

InactiveUS20130092139A1Fast disconnectionSnap fastenersFiring/trigger mechanismsEngineeringMechanical engineering

A quick release buckle includes male and female members which are fastened together via a hinge connection. The male member includes a laterally extending pin which fits within a recess in the top front portion of the female member. The recess includes and undercut portion for receiving and retaining the male member pin. Both members include laterally extending top bars on the upper surfaces thereof. Pinching the top bars together releases the male member pin from the female member recess to unfasten the buckle.

Owner:SUMMERS GREGORY E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com