Patents

Literature

66 results about "Belleville washer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

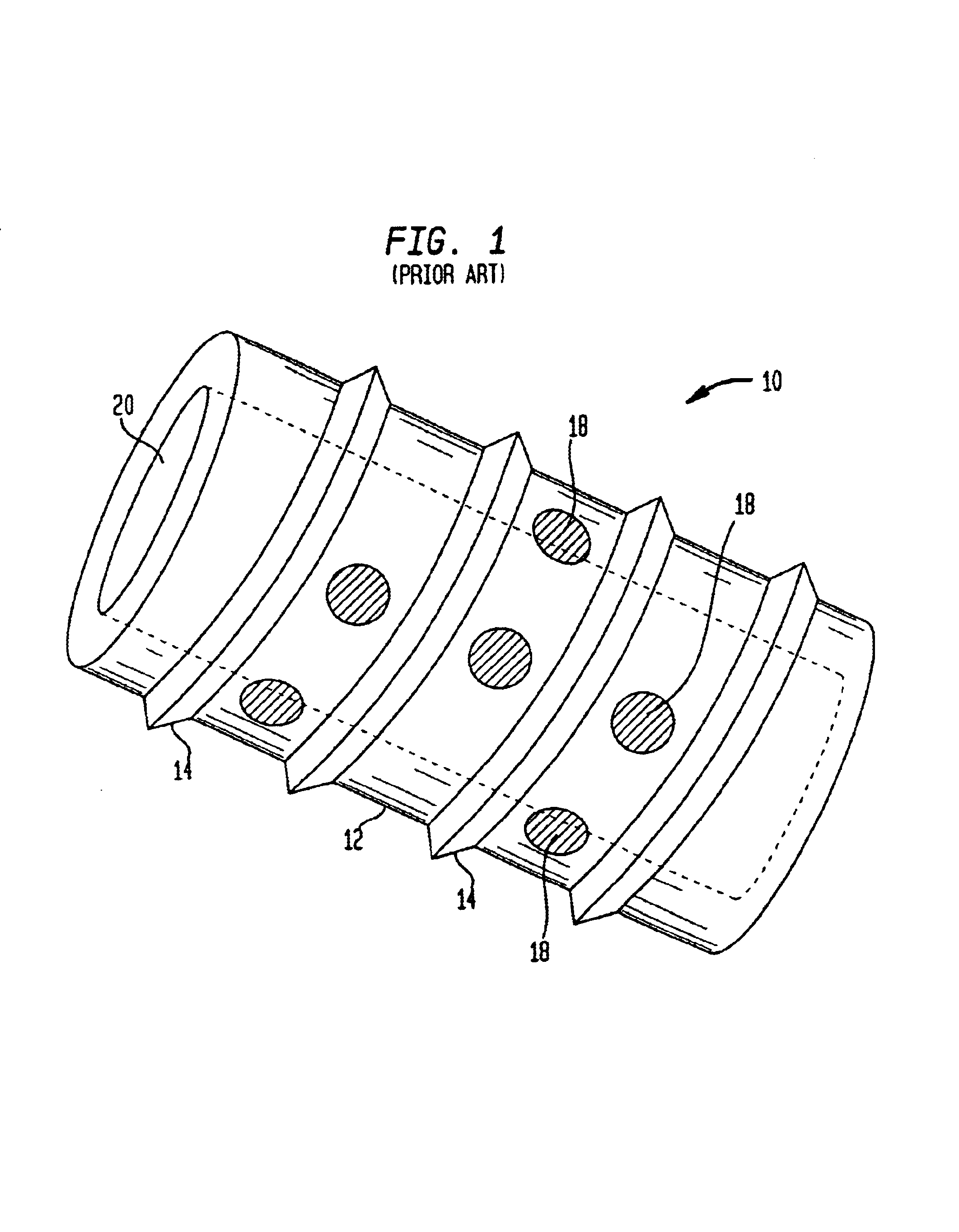

A Belleville washer, also known as a coned-disc spring, conical spring washer, disc spring, Belleville spring or cupped spring washer, is a conical shell which can be loaded along its axis either statically or dynamically. A Belleville washer is a type of spring shaped like a washer. It is the frusto-conical shape that gives the washer its characteristic spring.

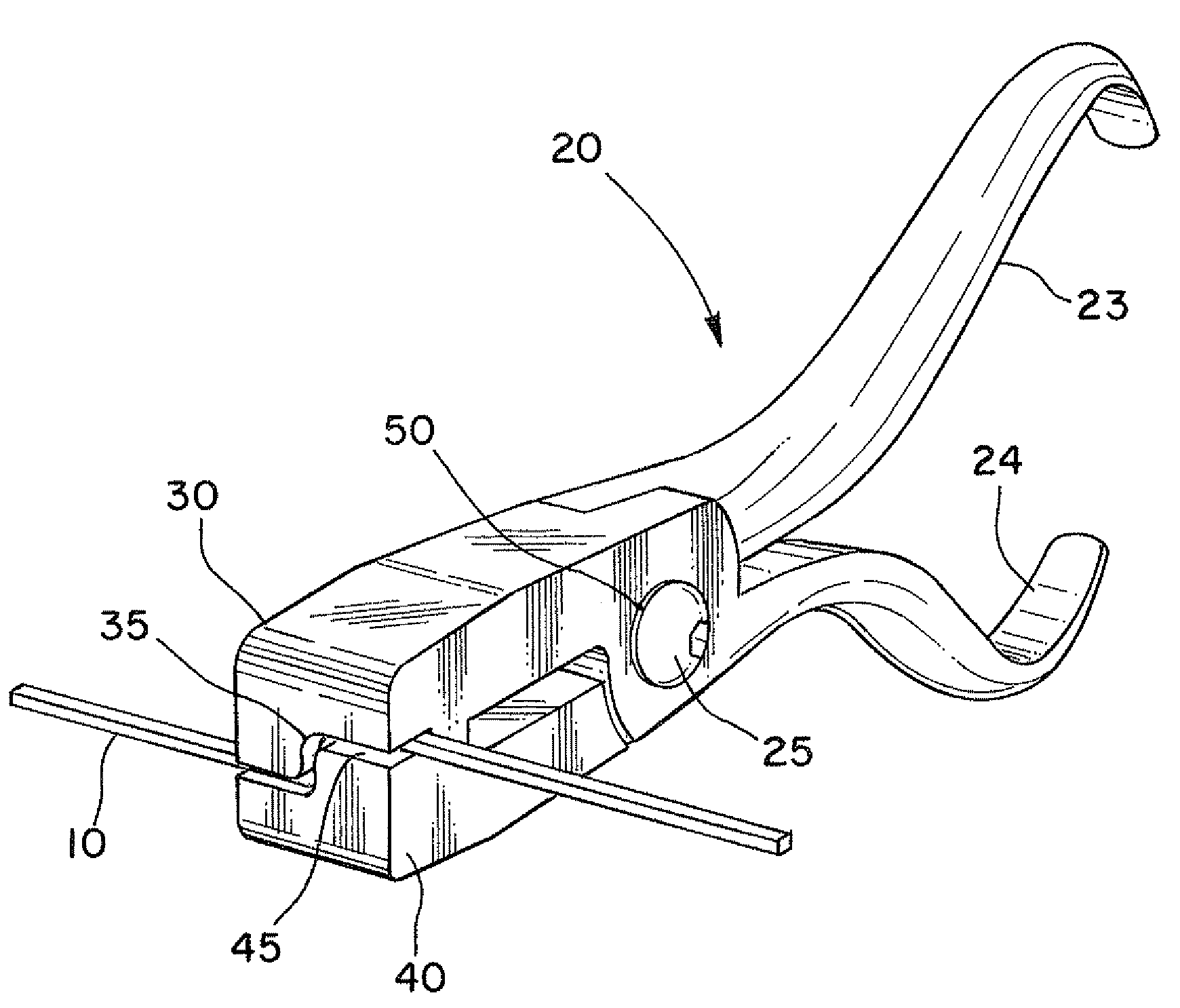

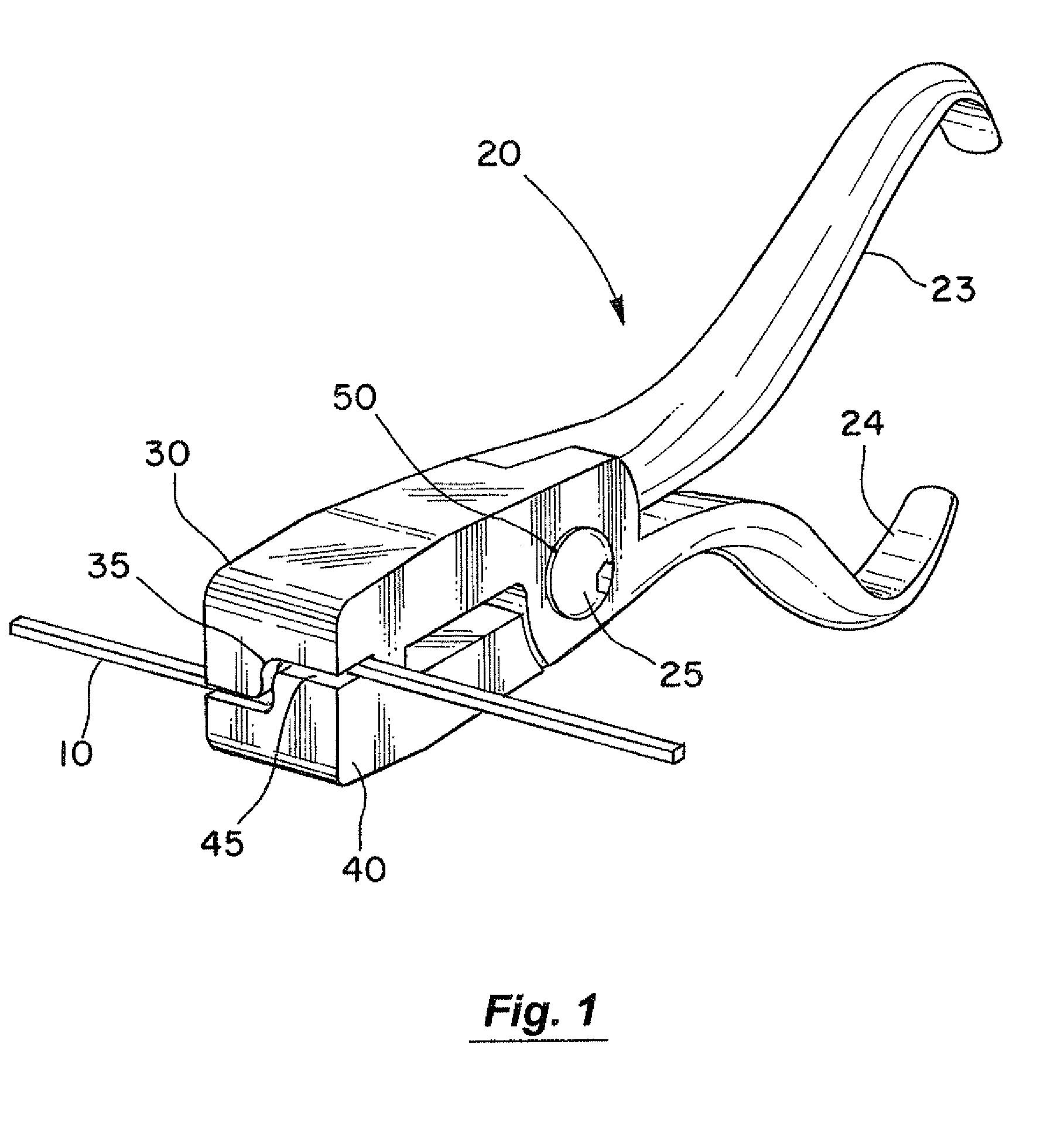

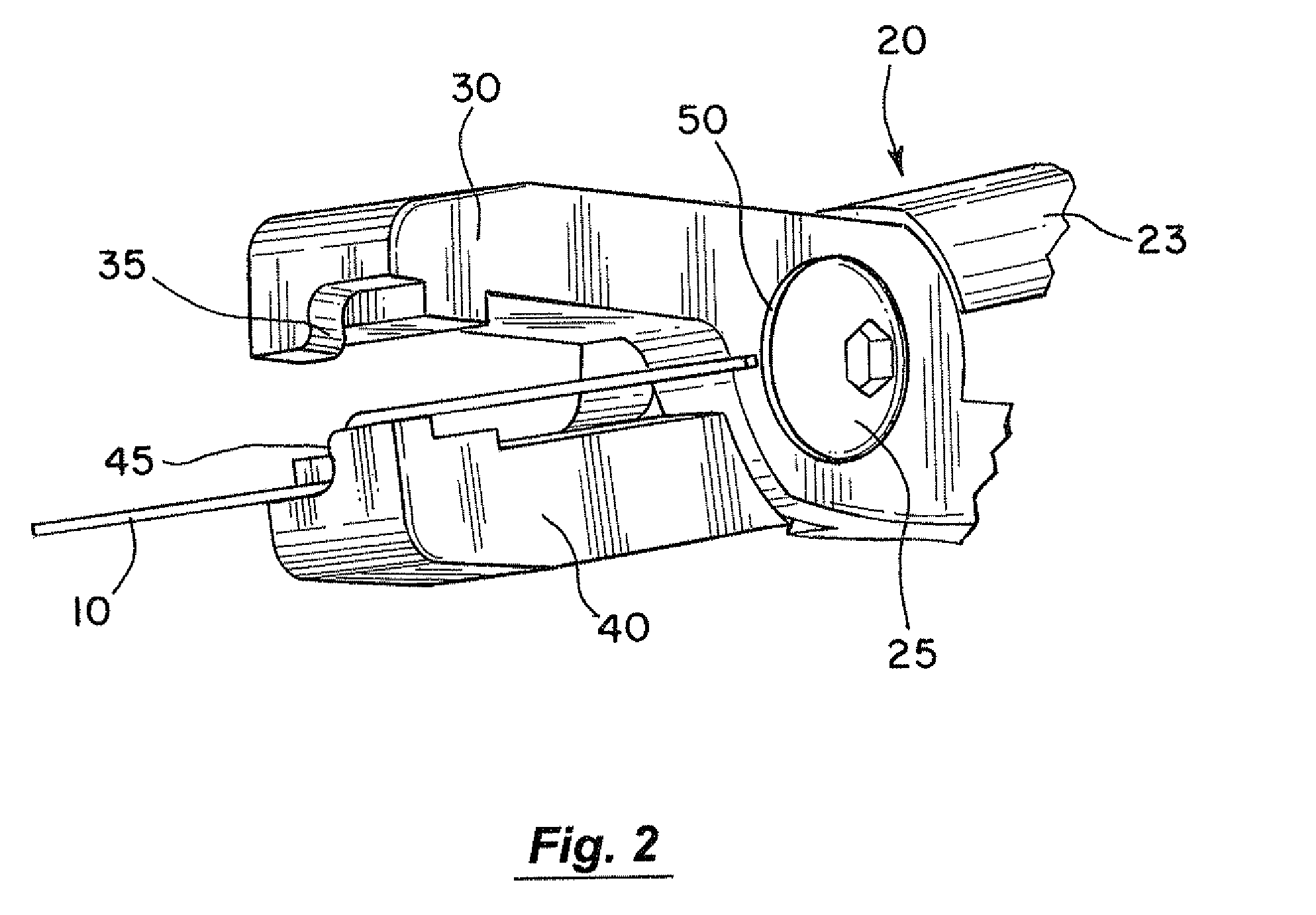

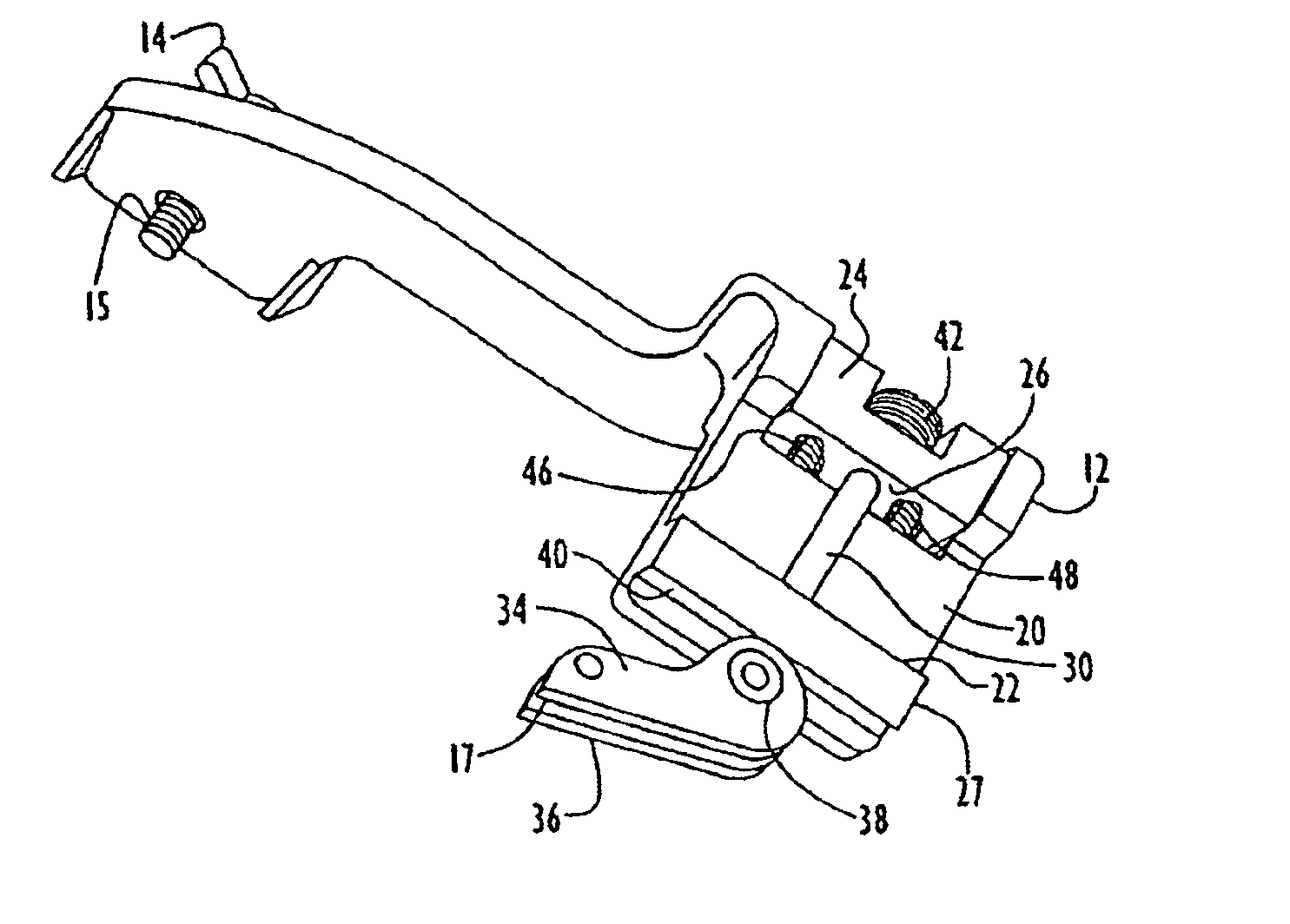

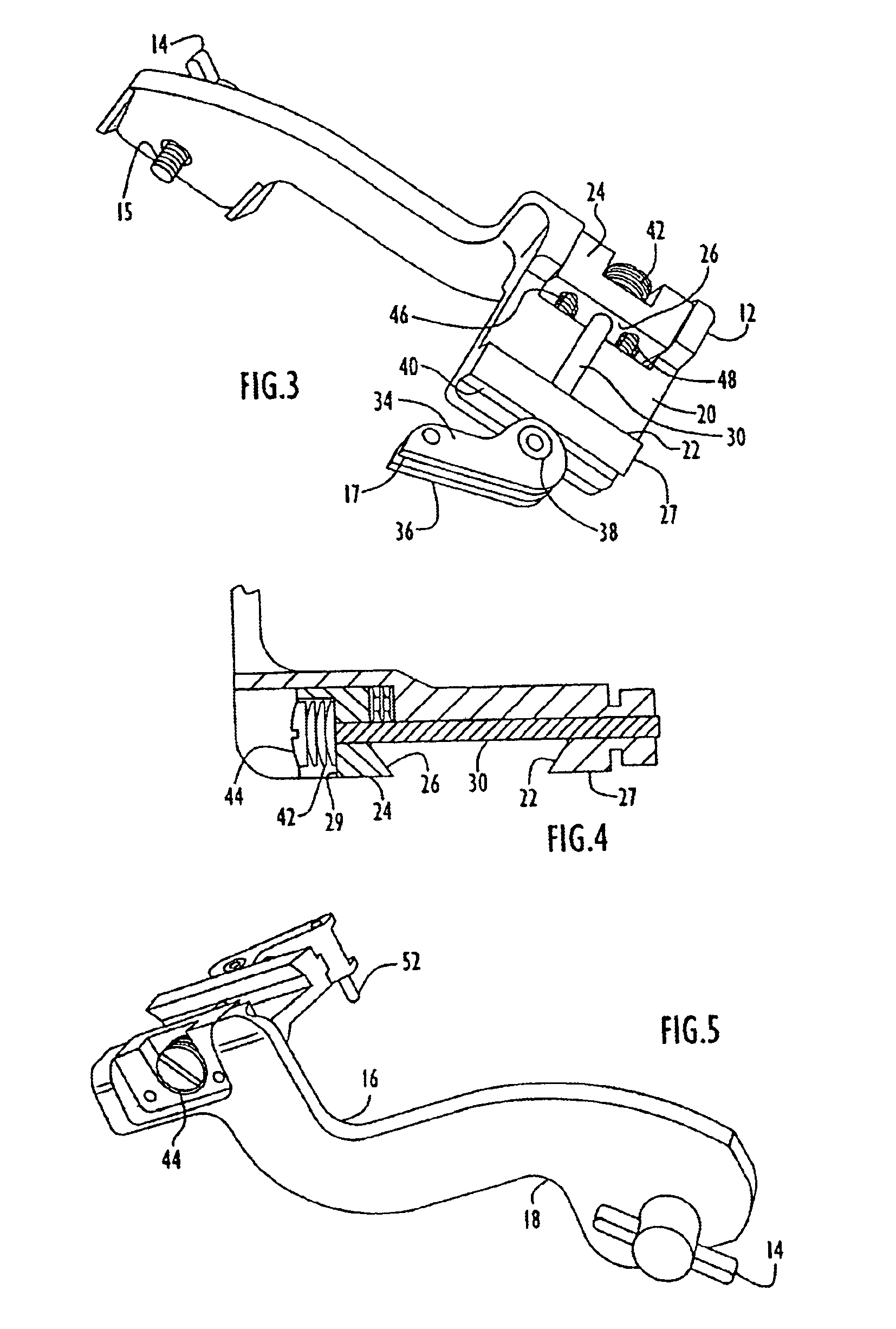

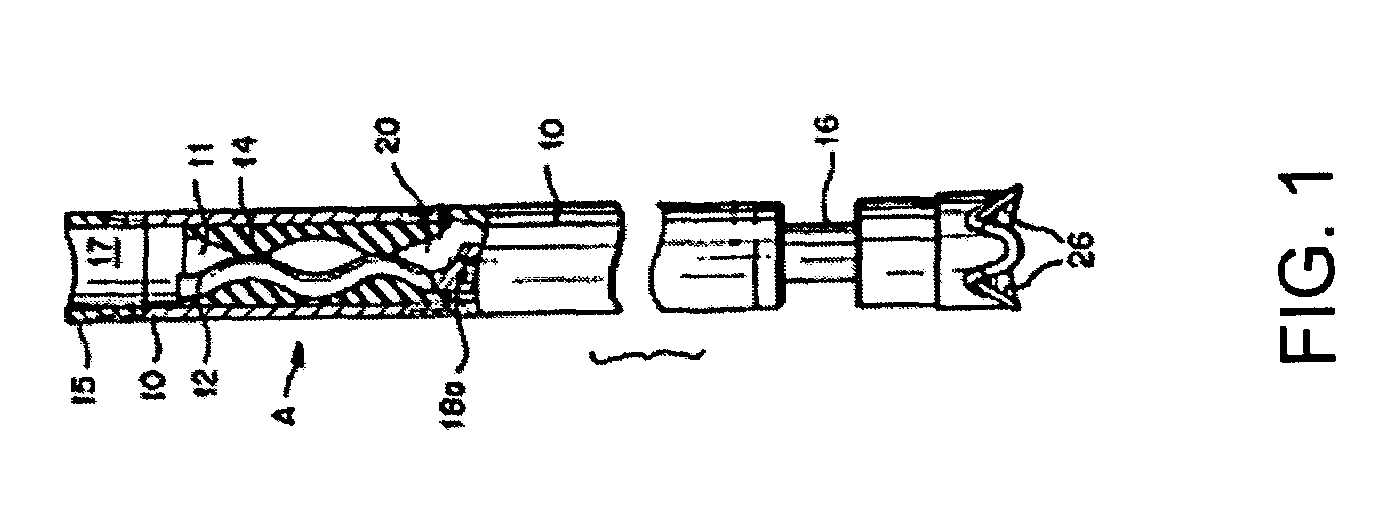

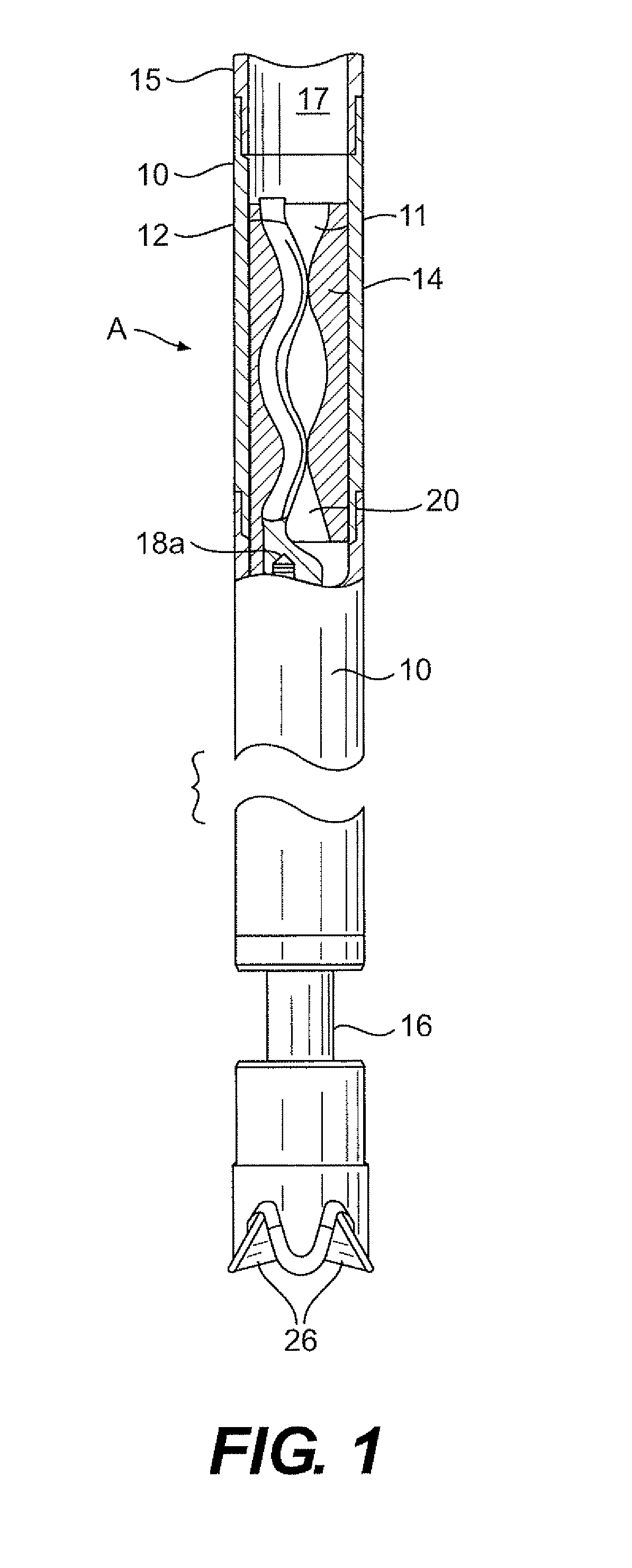

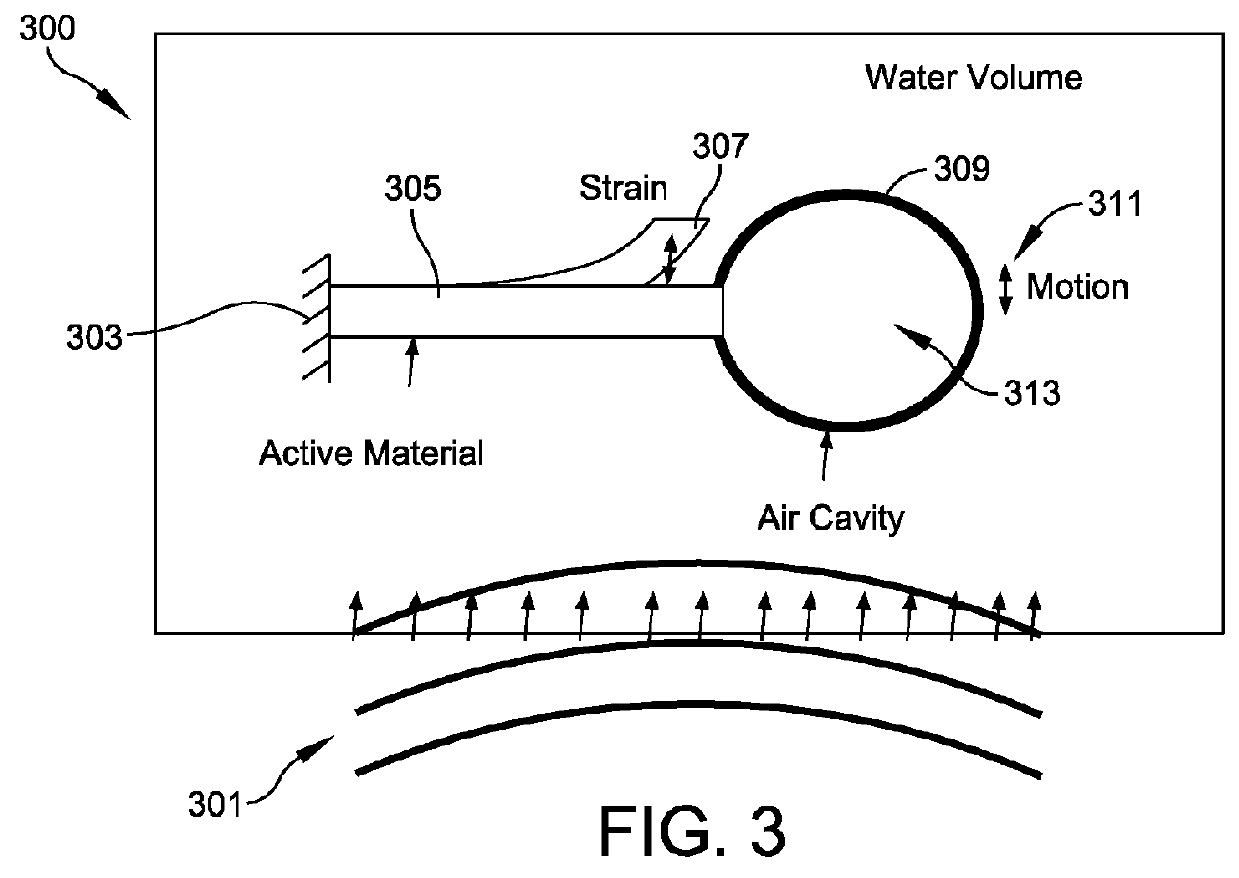

Pliers for forming orthodontic wires

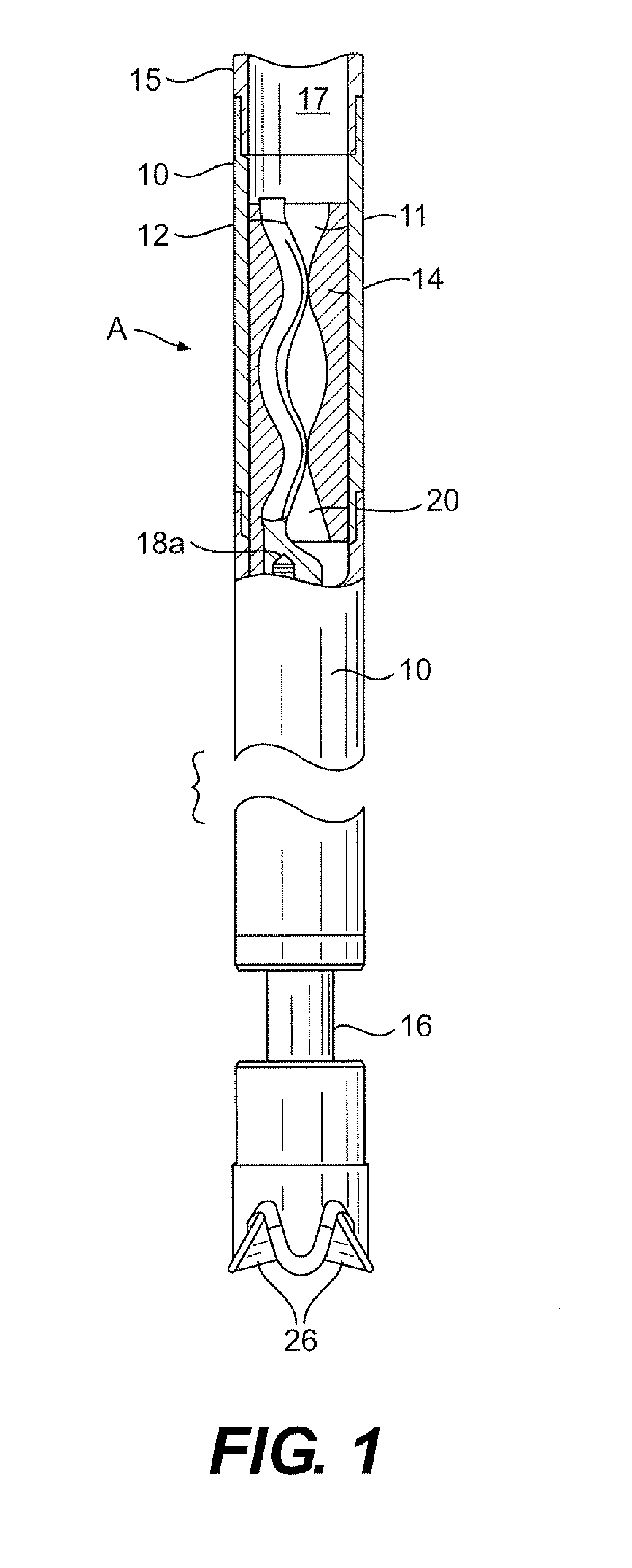

A pliers for forming orthodontic wires has opposing beaks with complementary wire-forming surfaces that include interfering portions. A hinge mechanism enables the beaks to open and close by rotating about an axis, and also allows a range of axial motion between the beaks sufficient to prevent interference between the wire-forming surfaces as the beaks are closed. By preventing such interference, novel over-bending capabilities can be achieved to form useful bending of low spring rate wire. A spring, such as a Belleville washer, exerts a biasing force parallel to the hinge axis to maintain alignment of the beaks, but allows the required range of axial motion between the beaks to prevent interference.

Owner:LINDQUIST JOHN T II +1

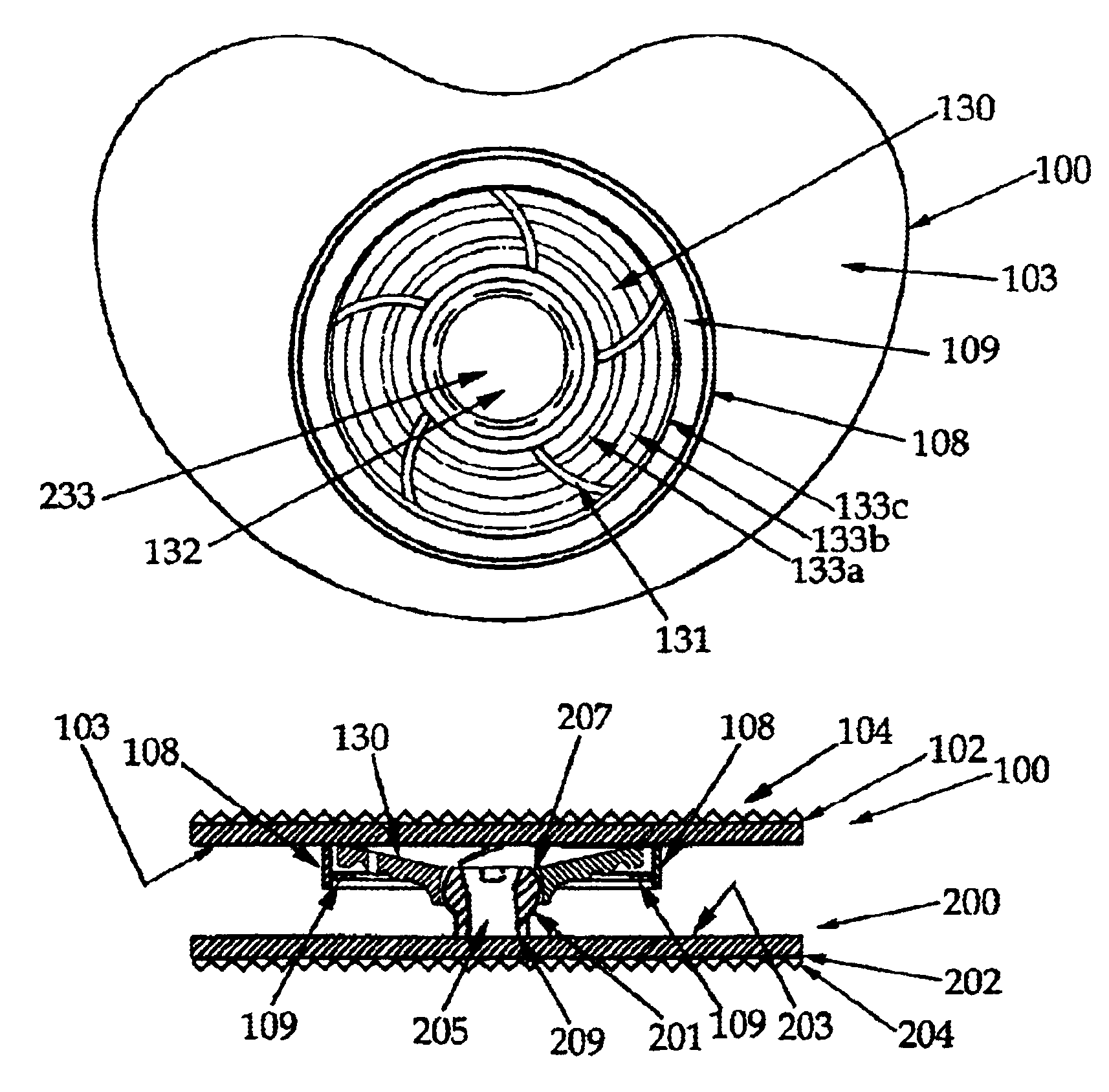

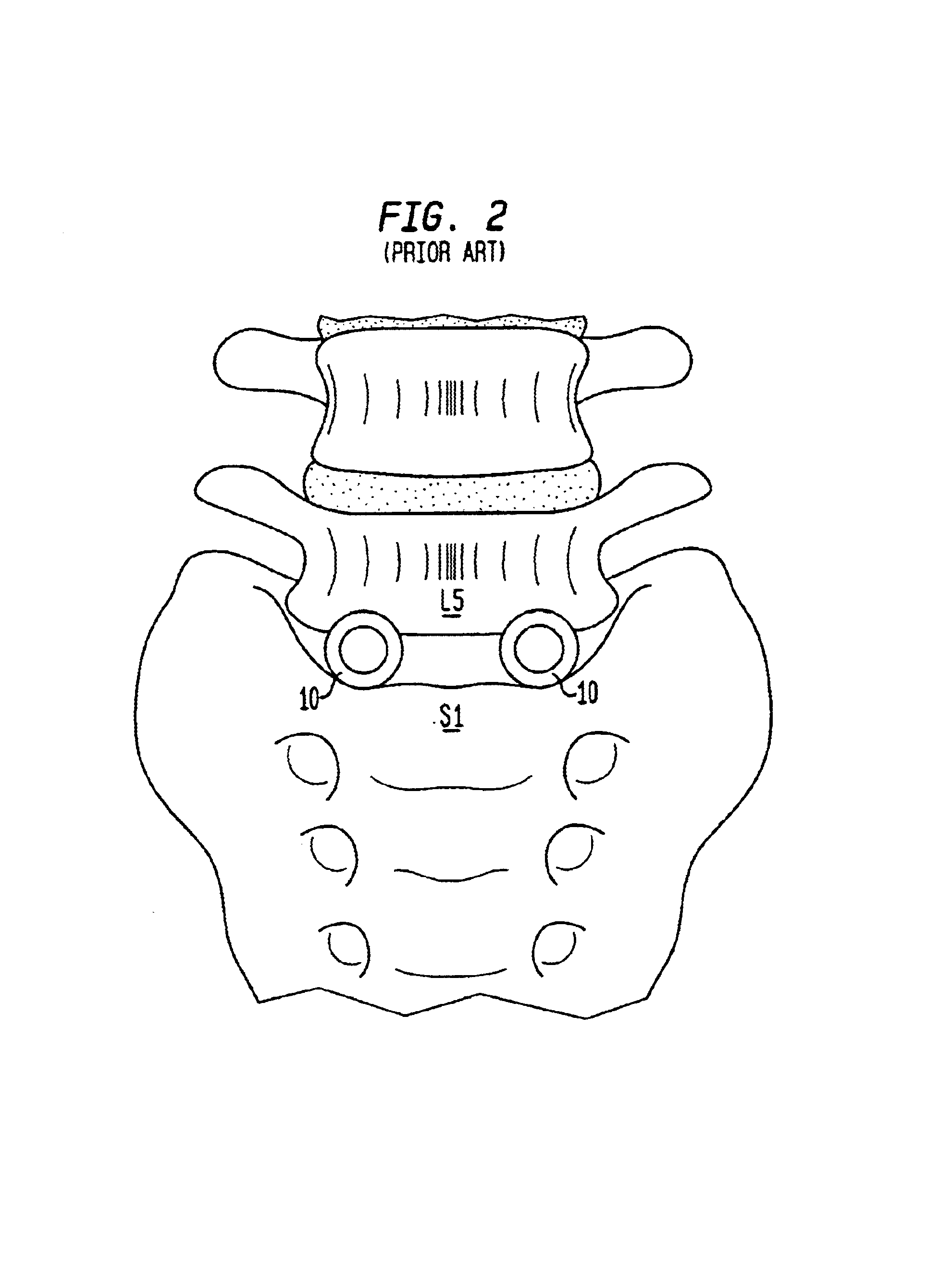

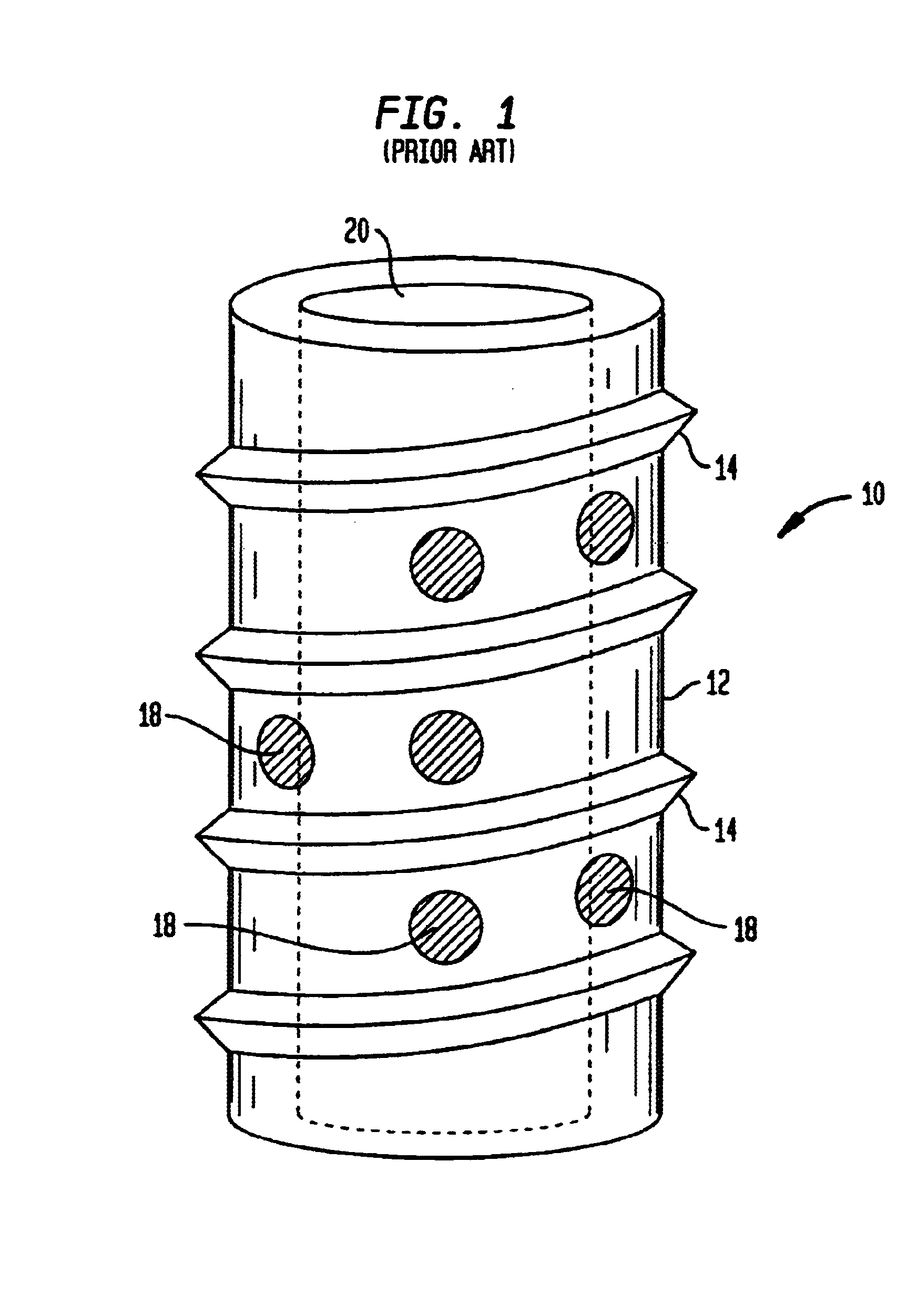

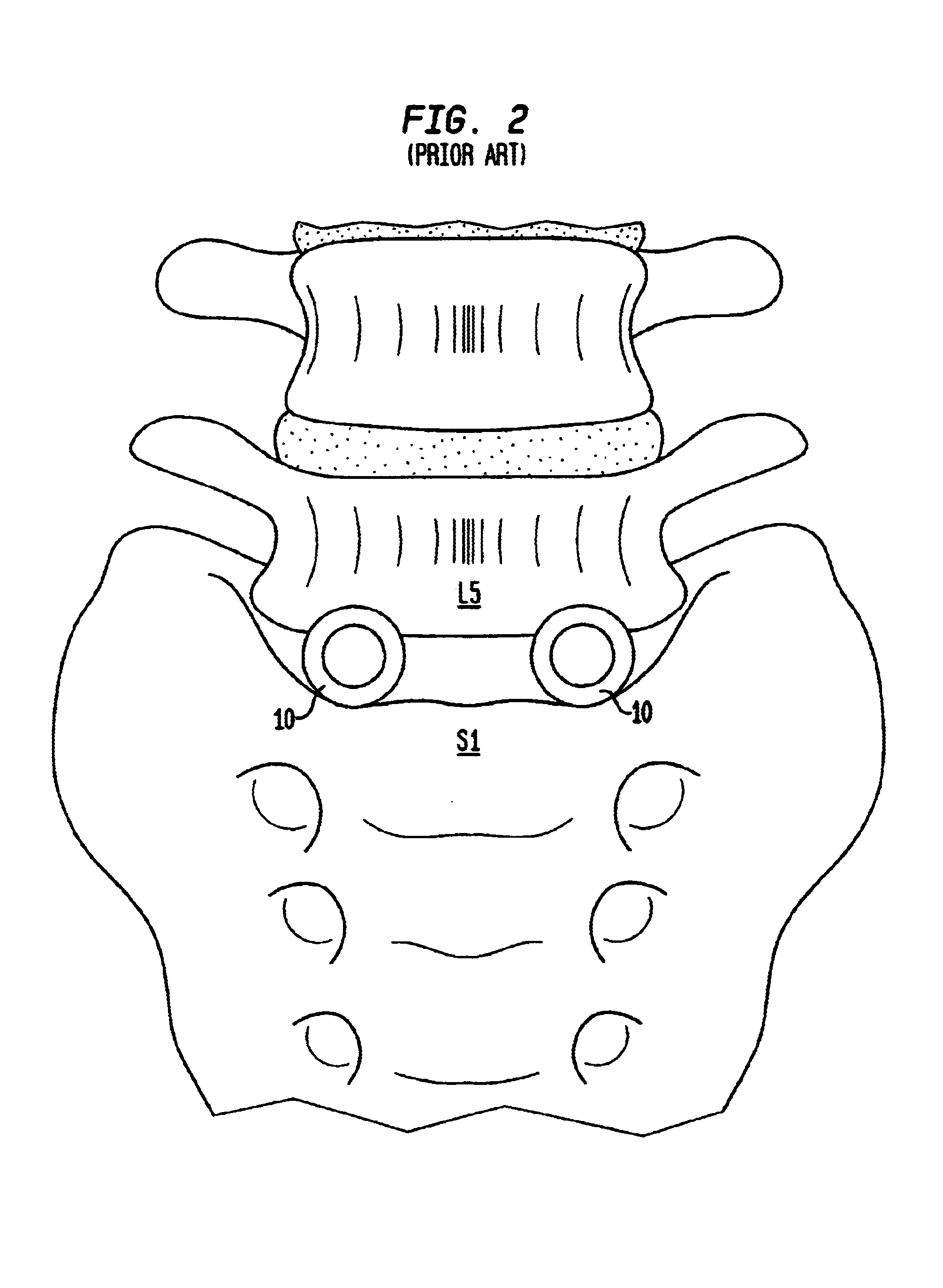

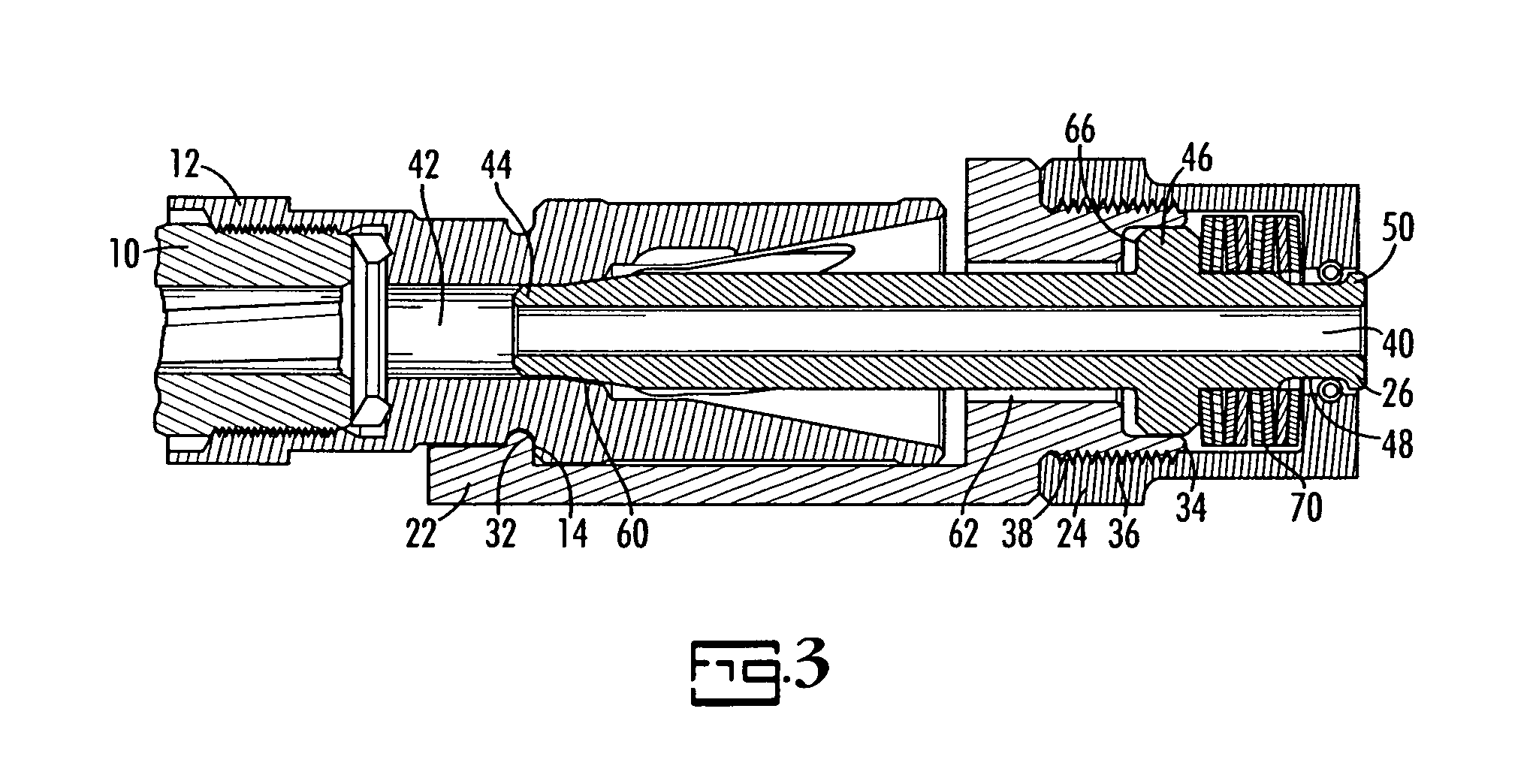

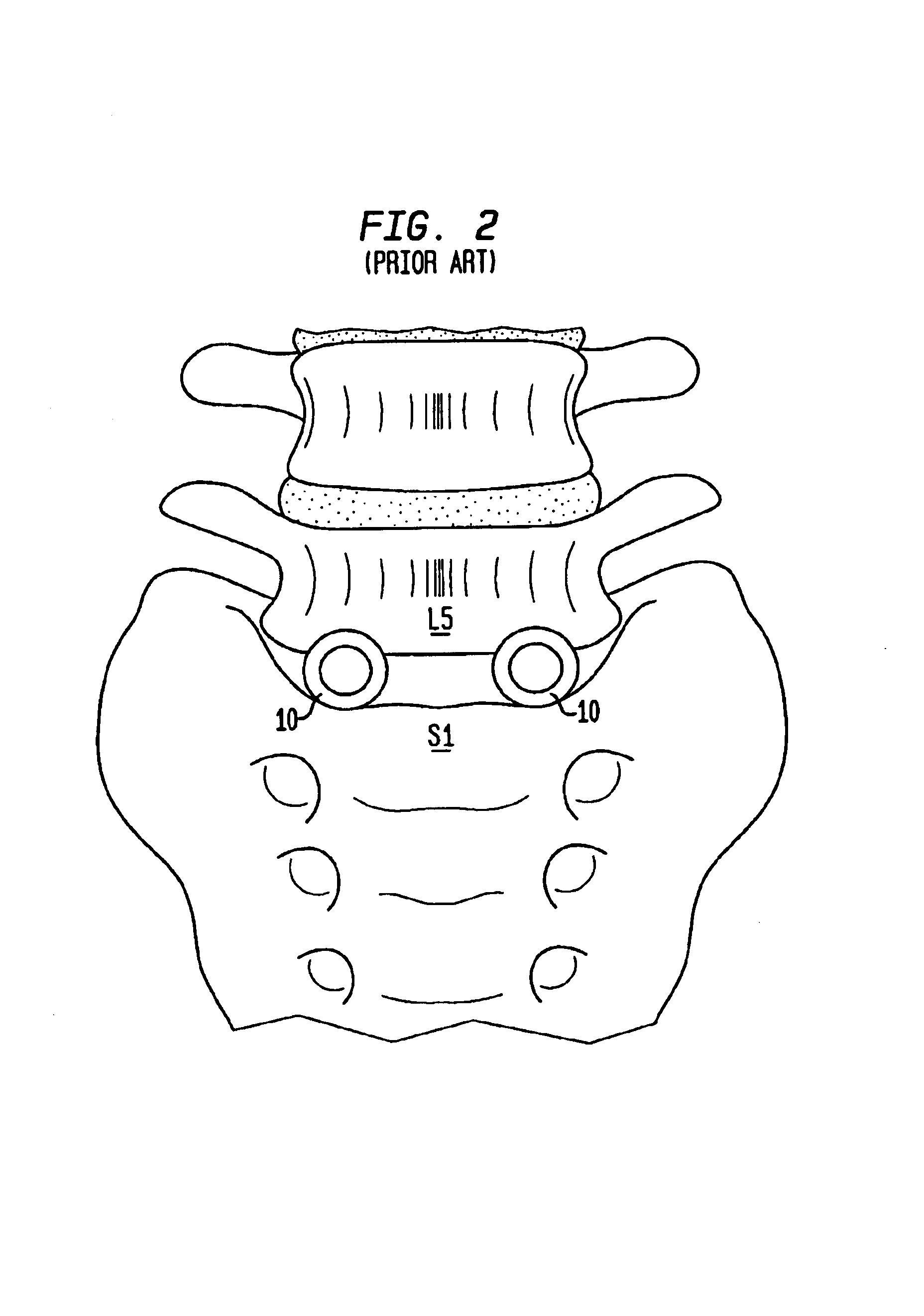

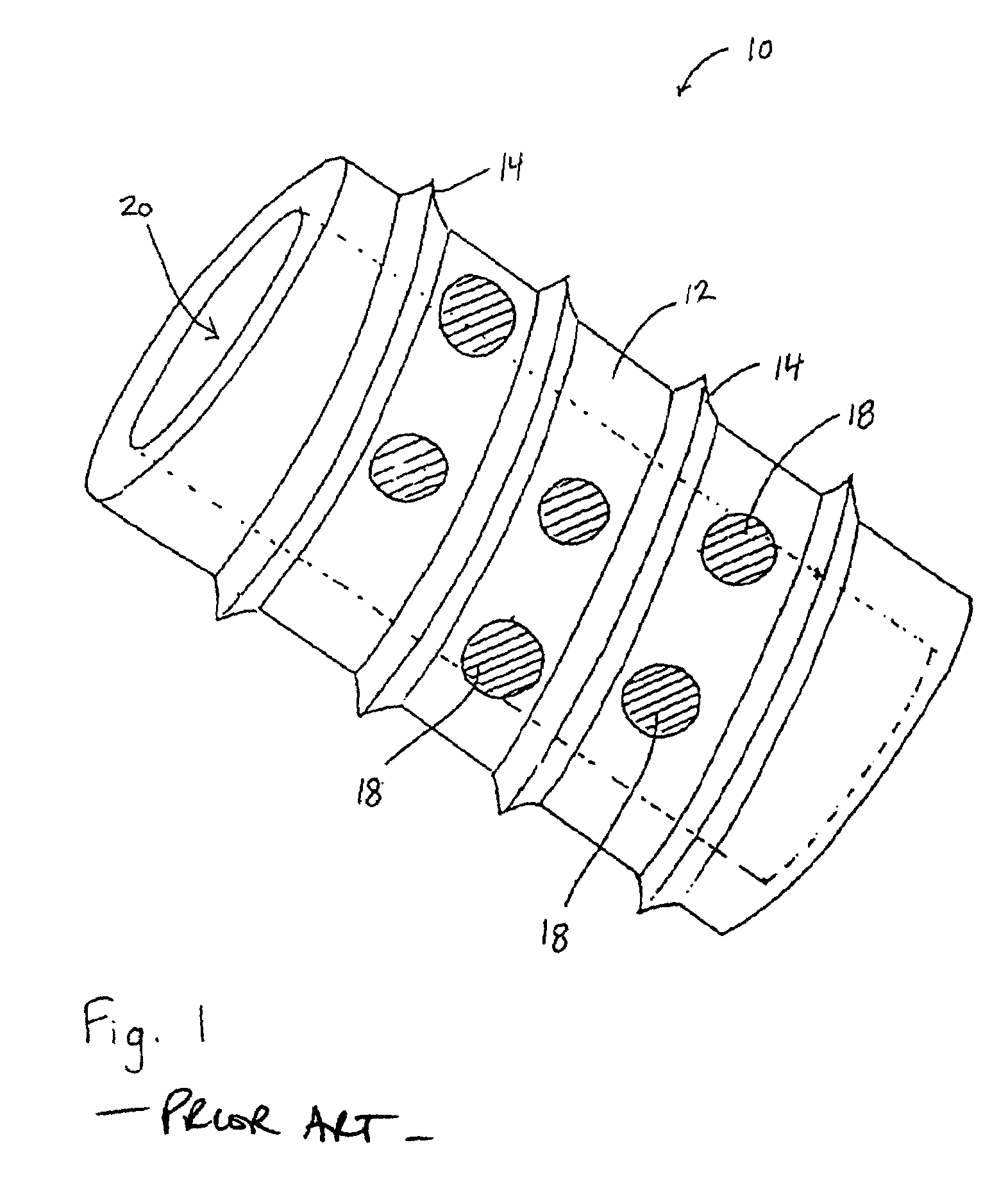

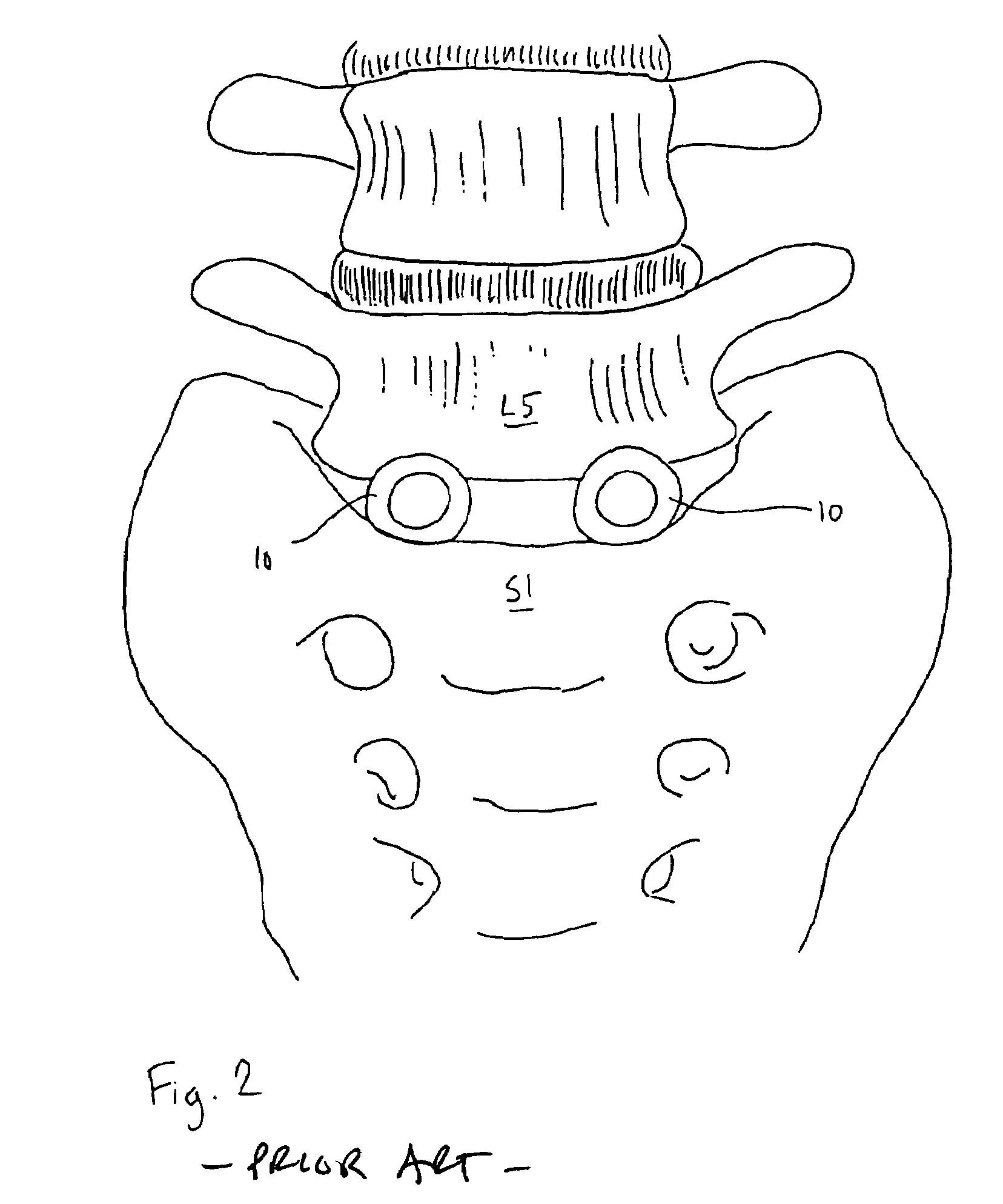

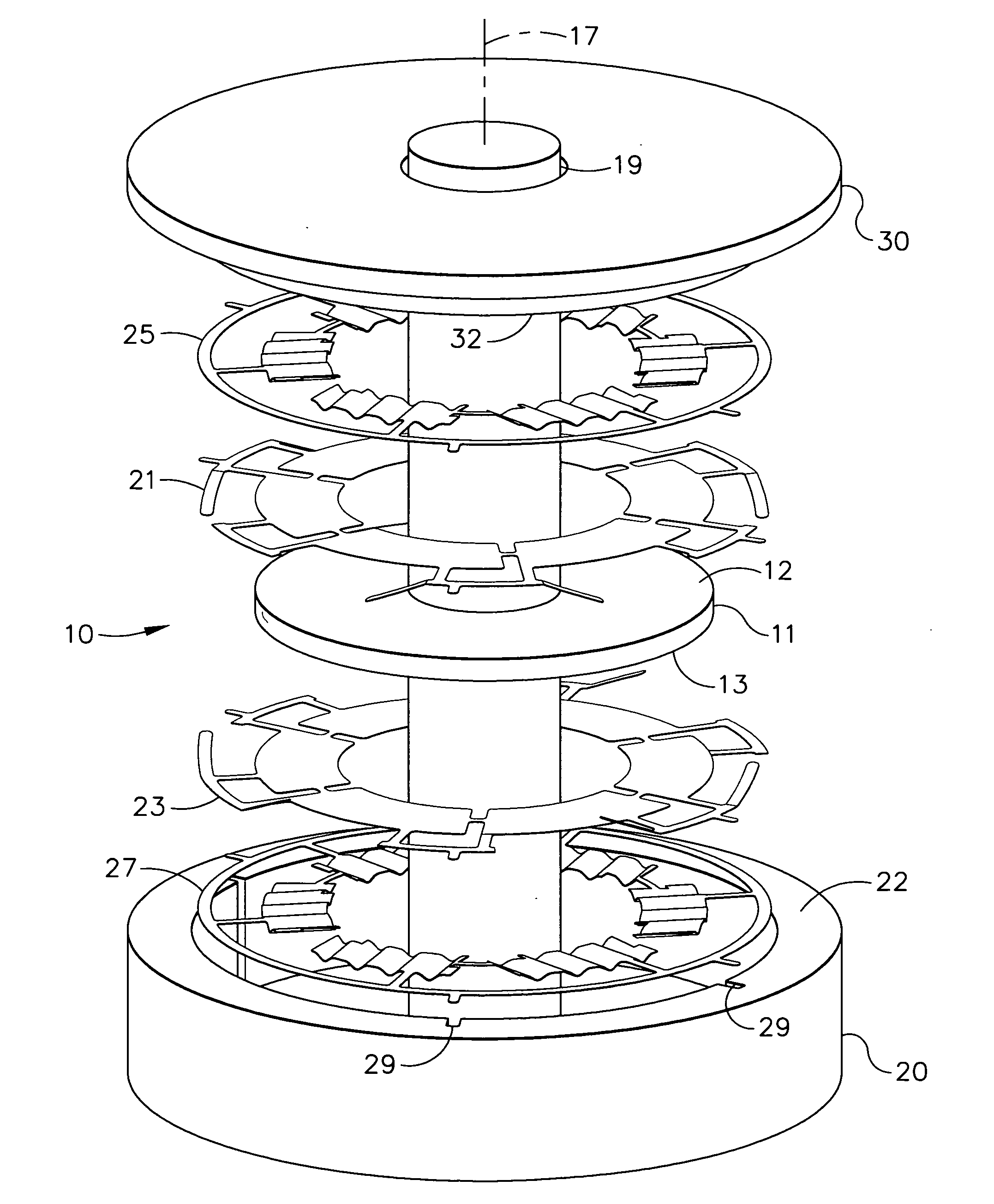

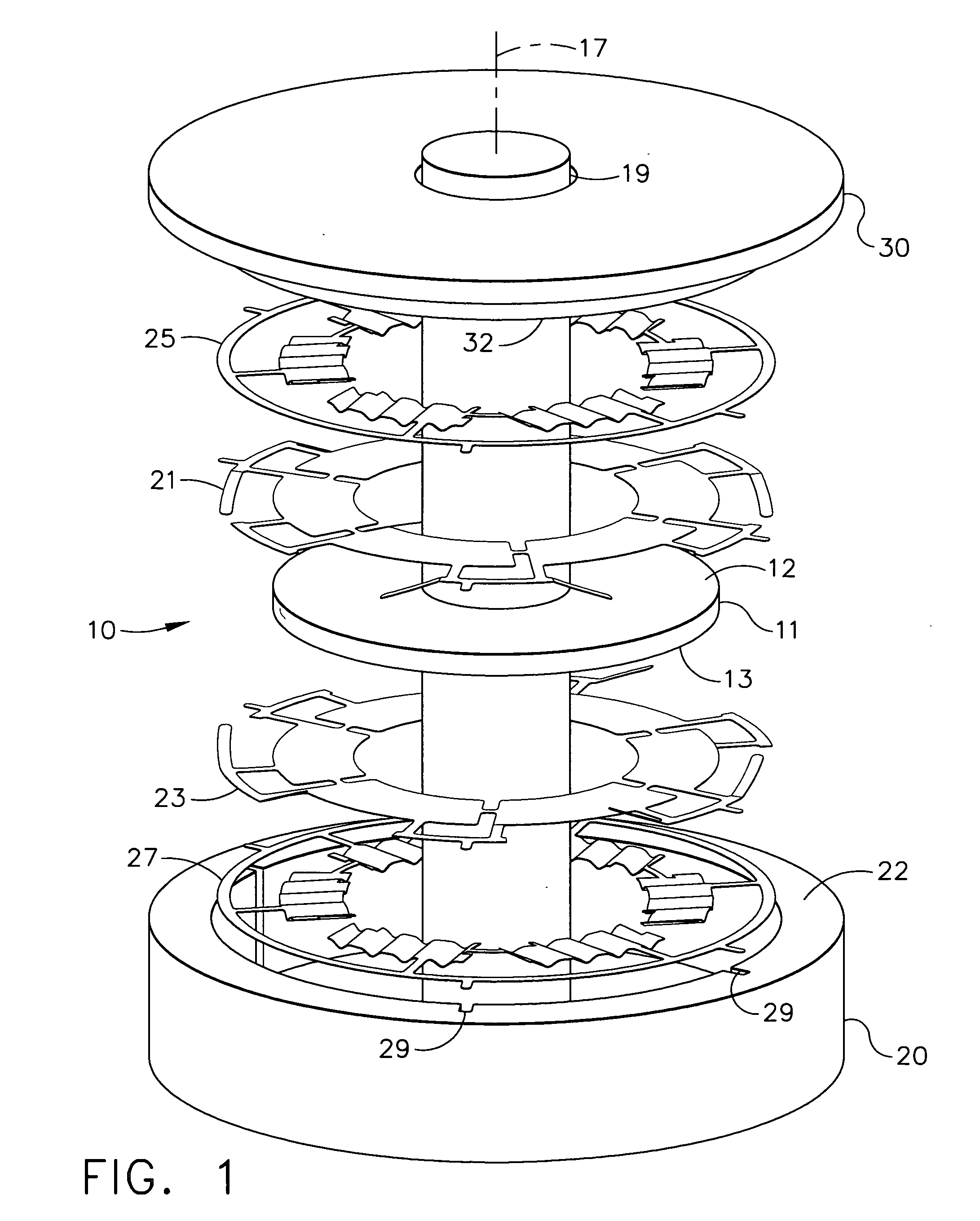

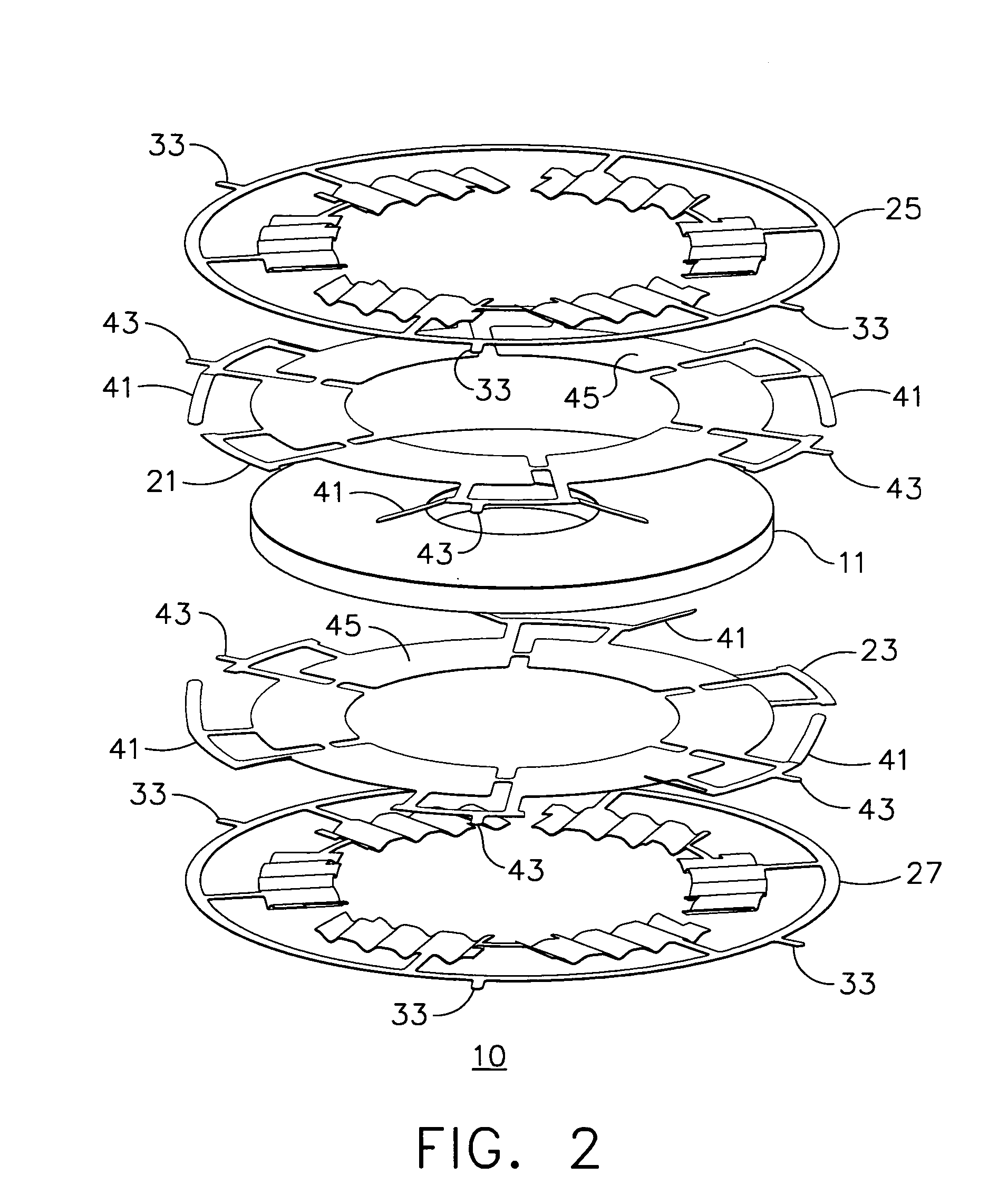

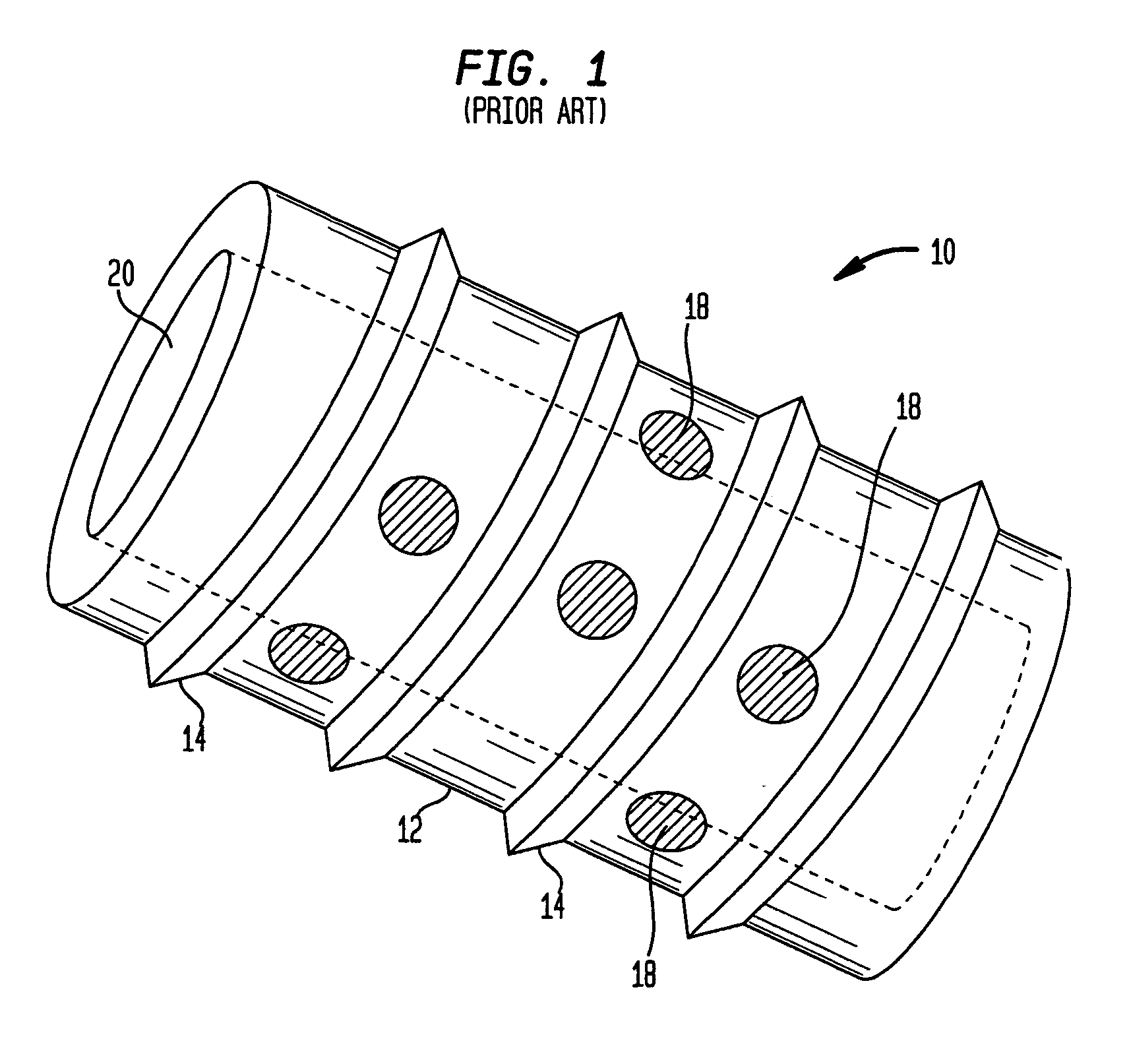

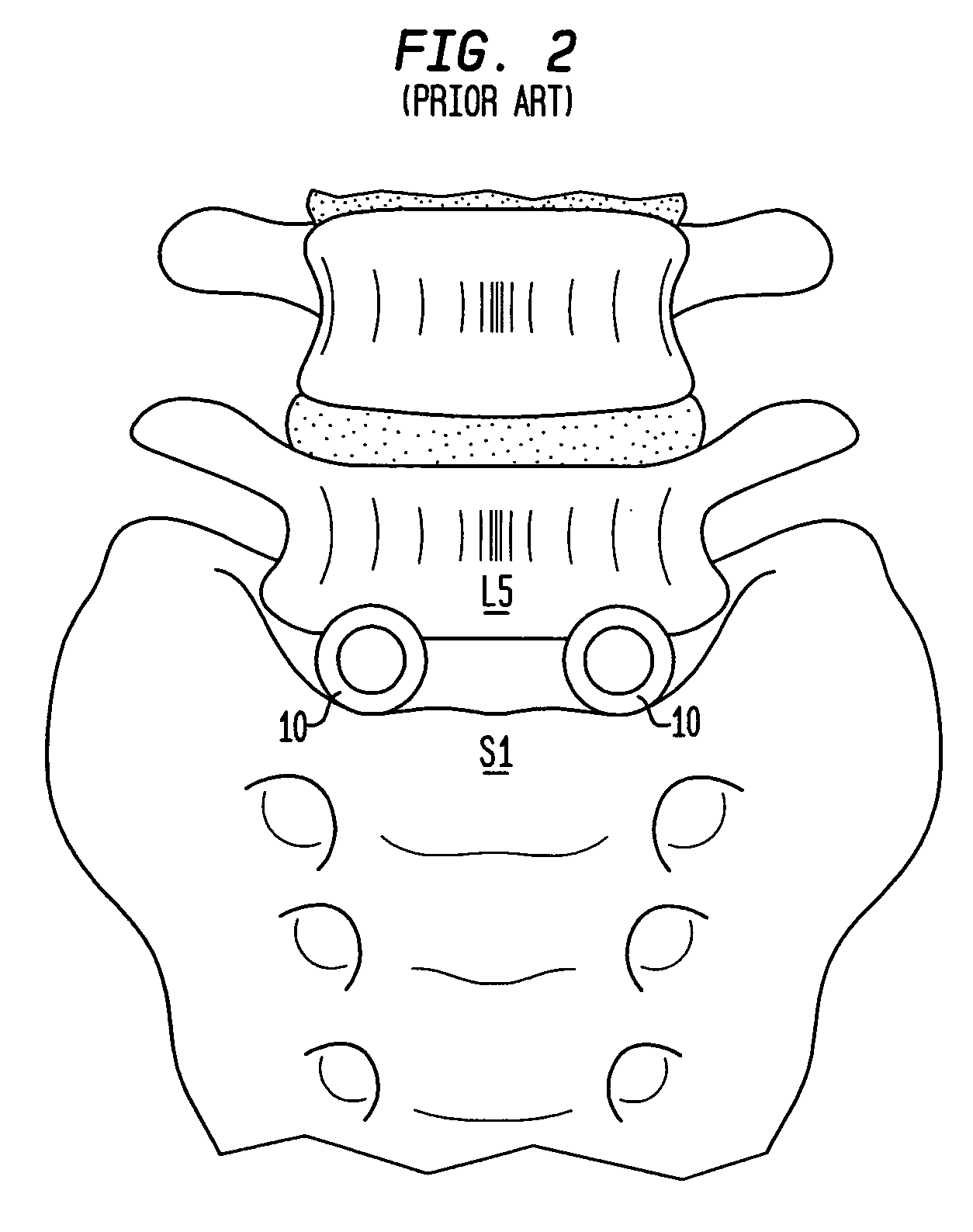

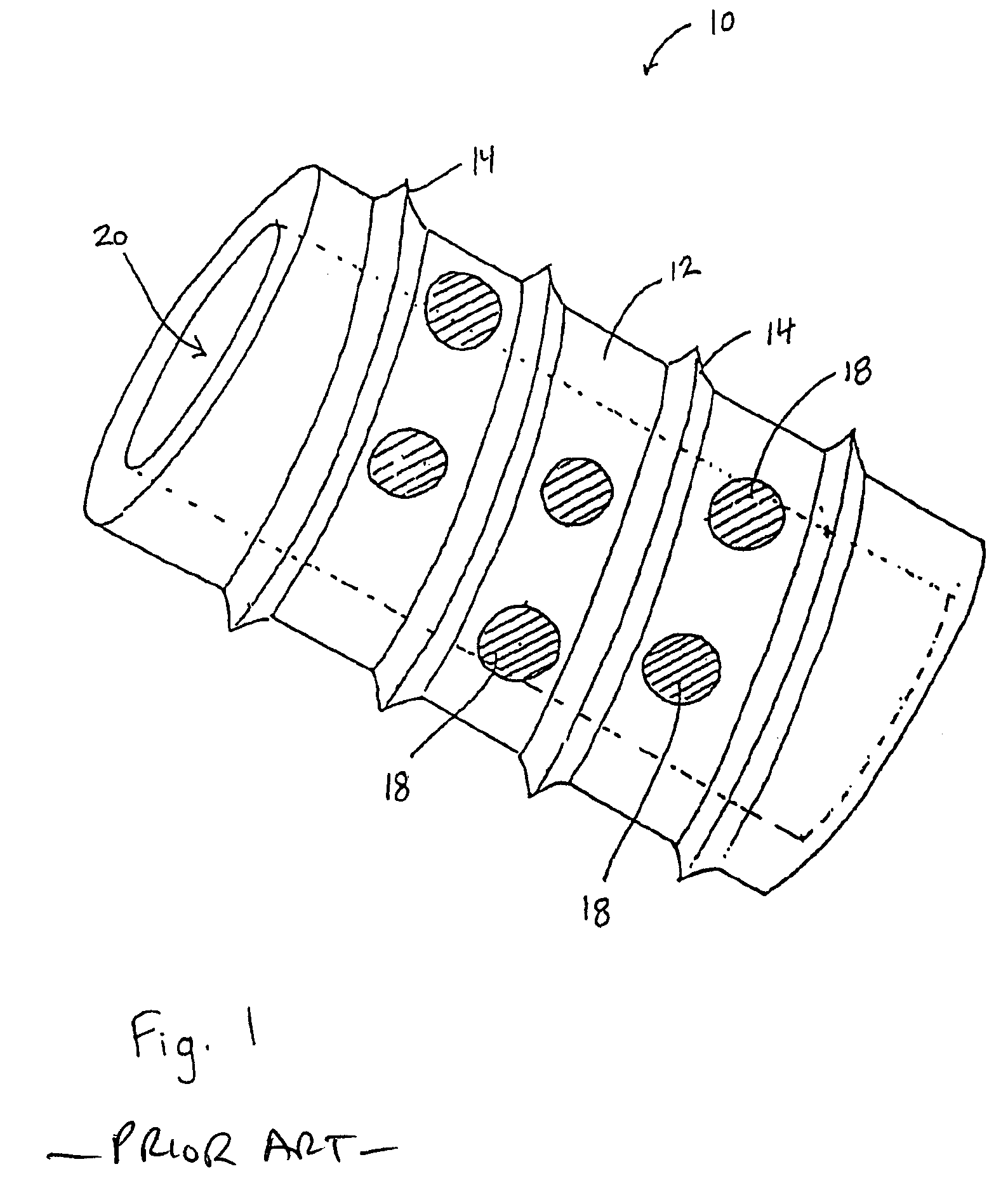

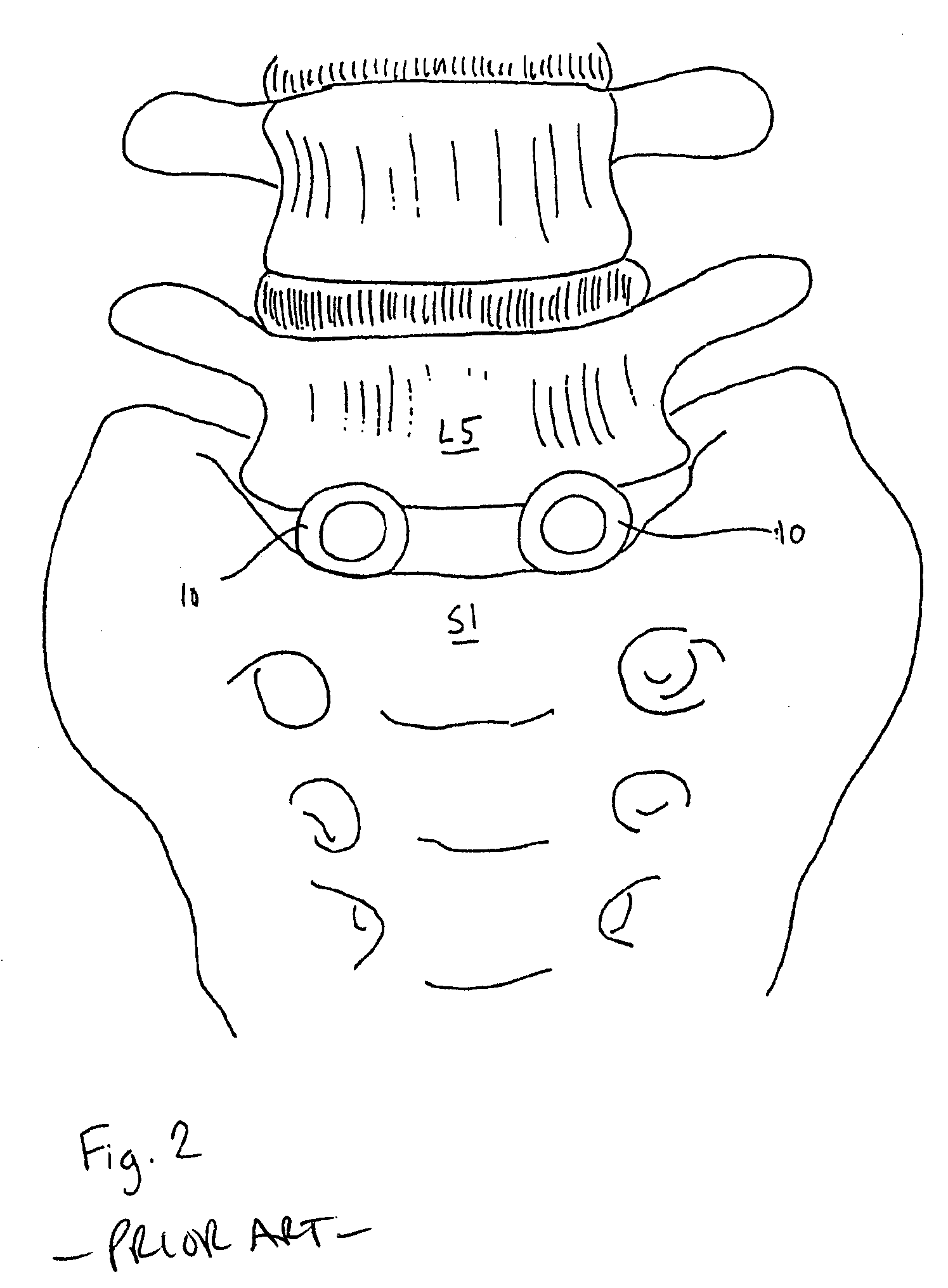

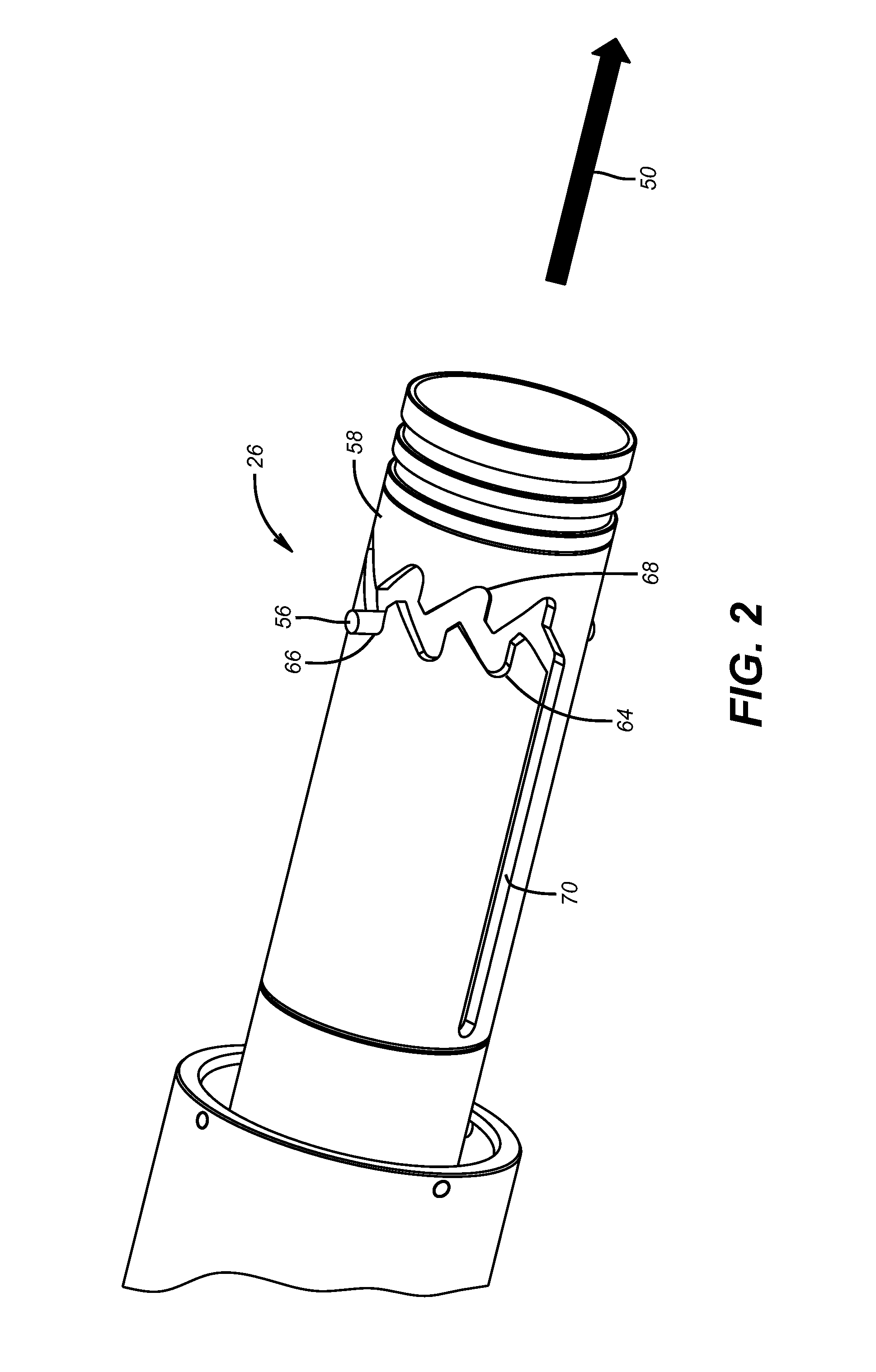

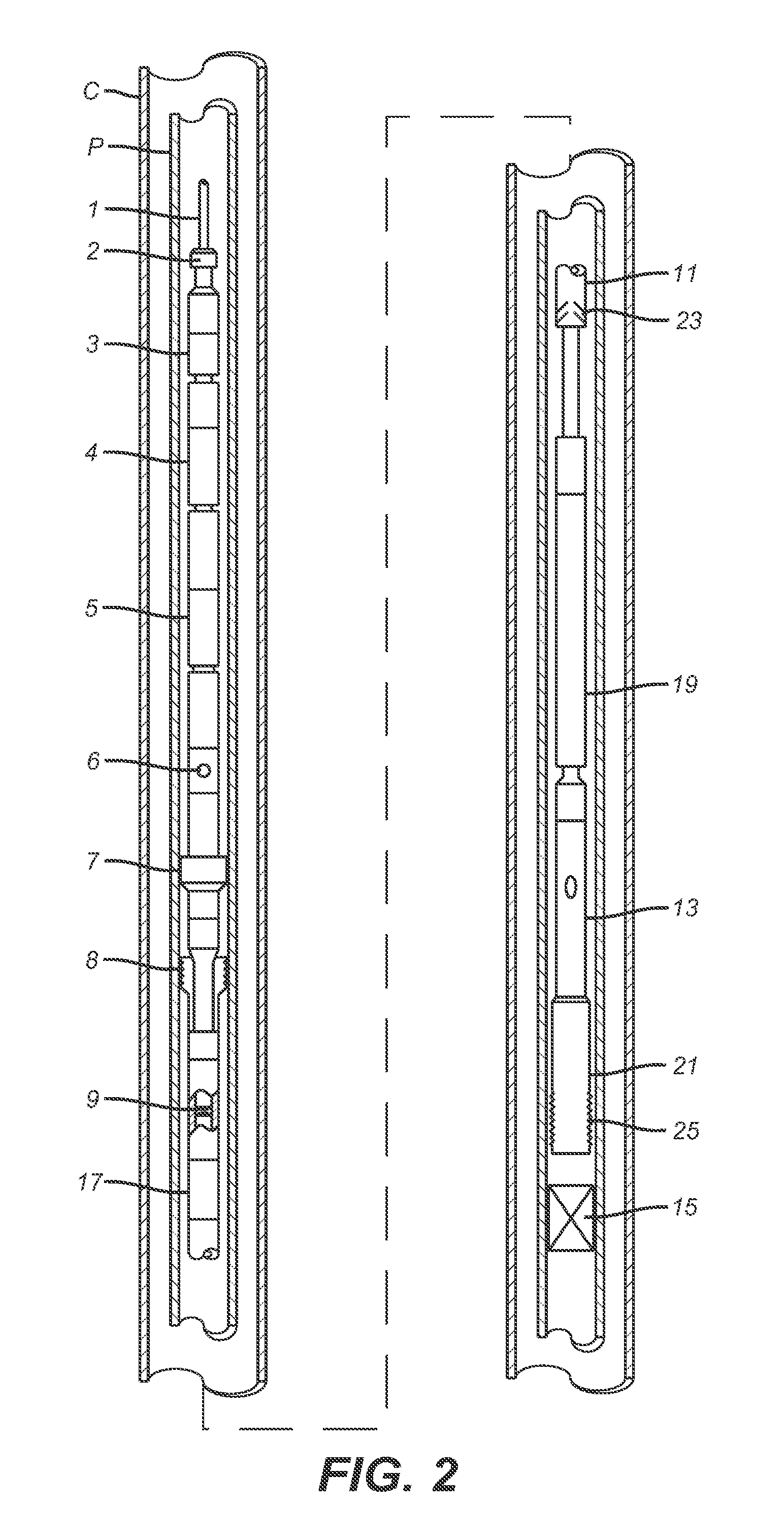

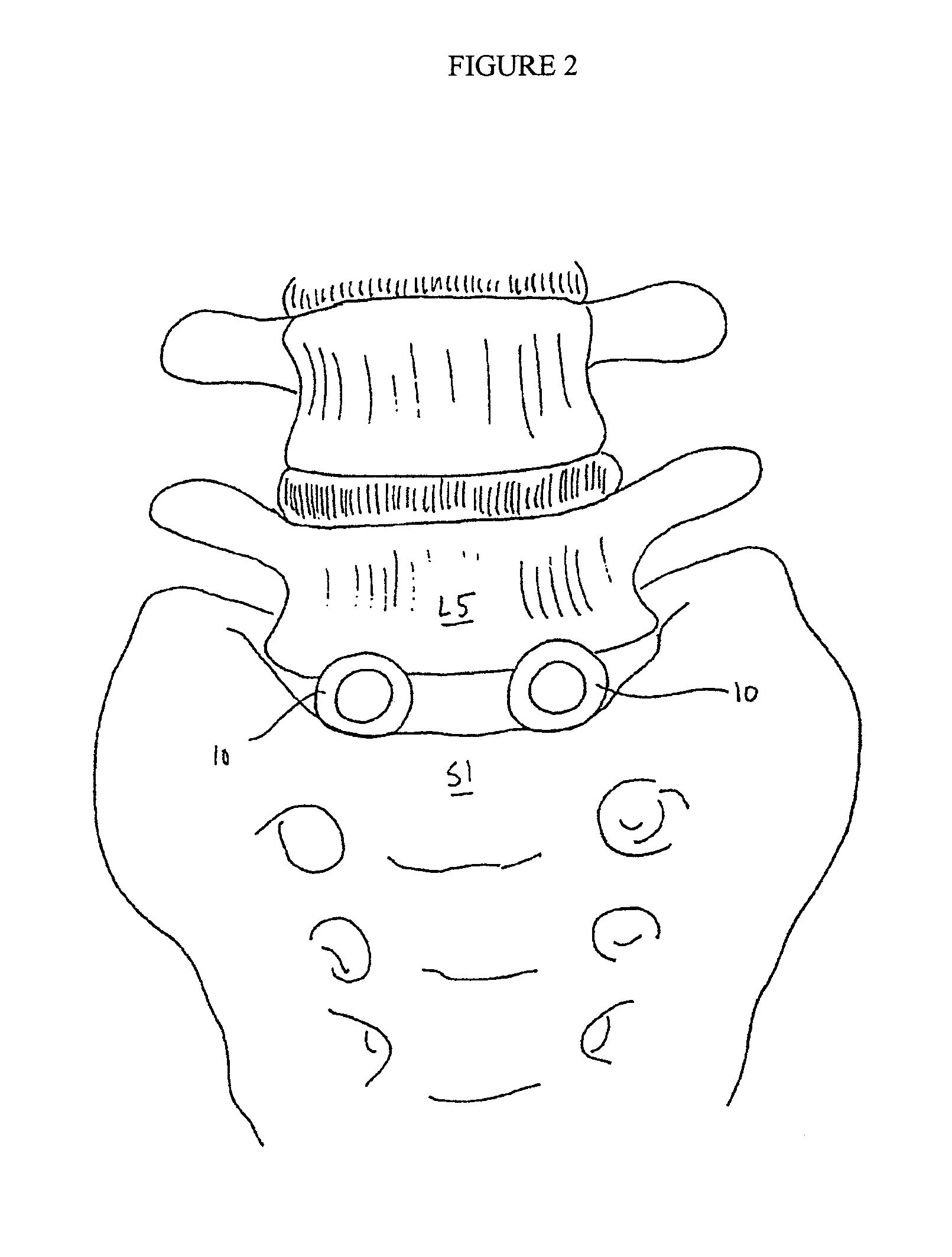

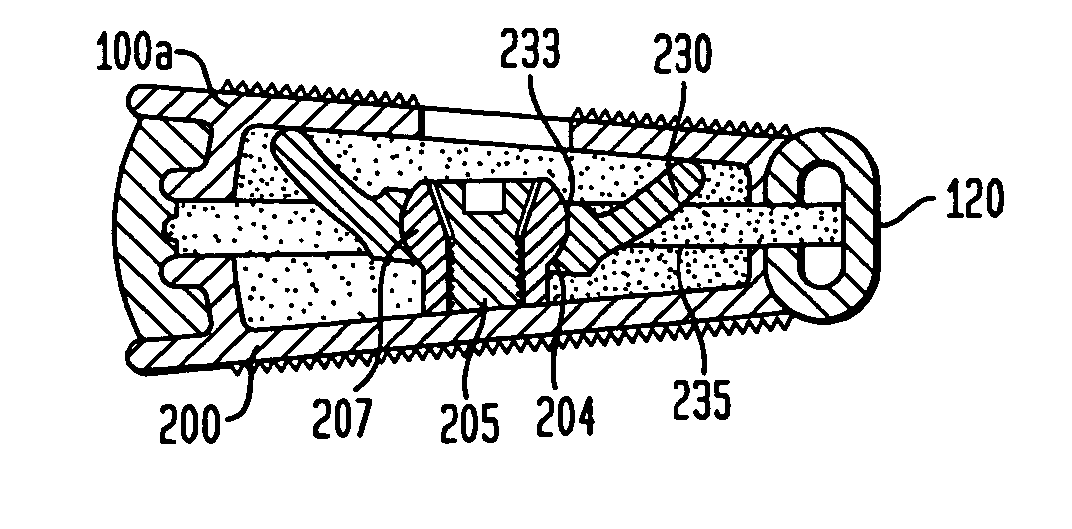

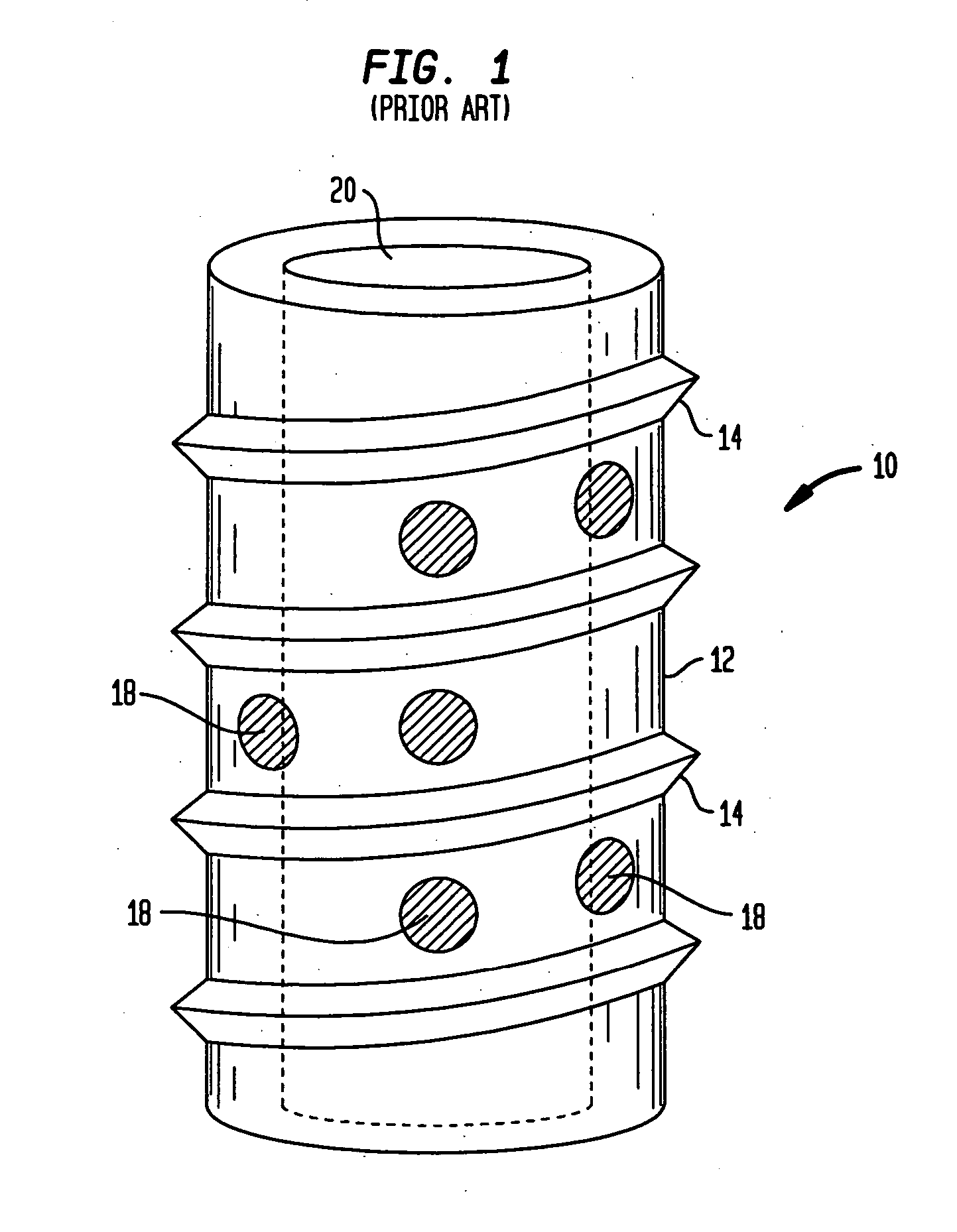

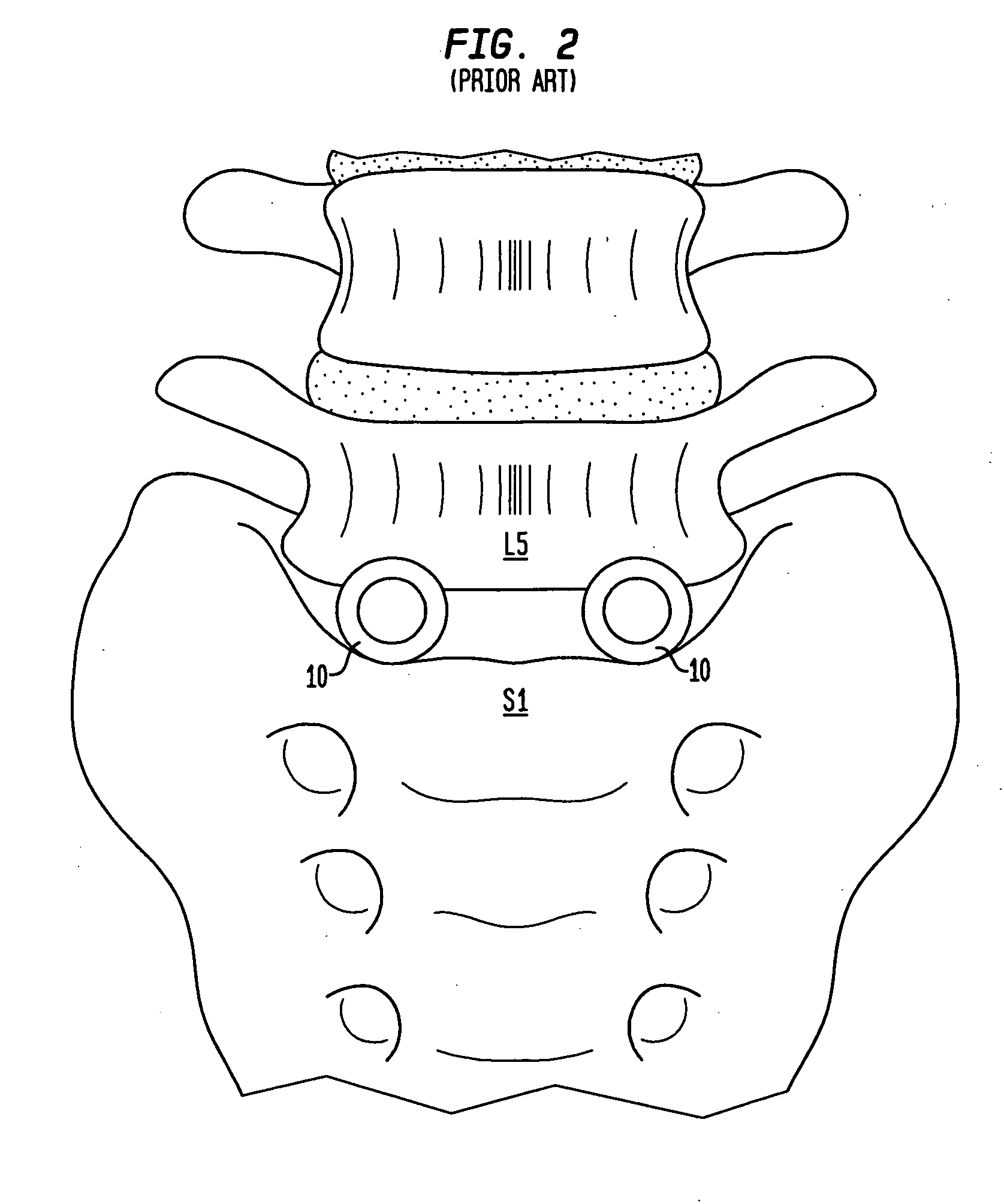

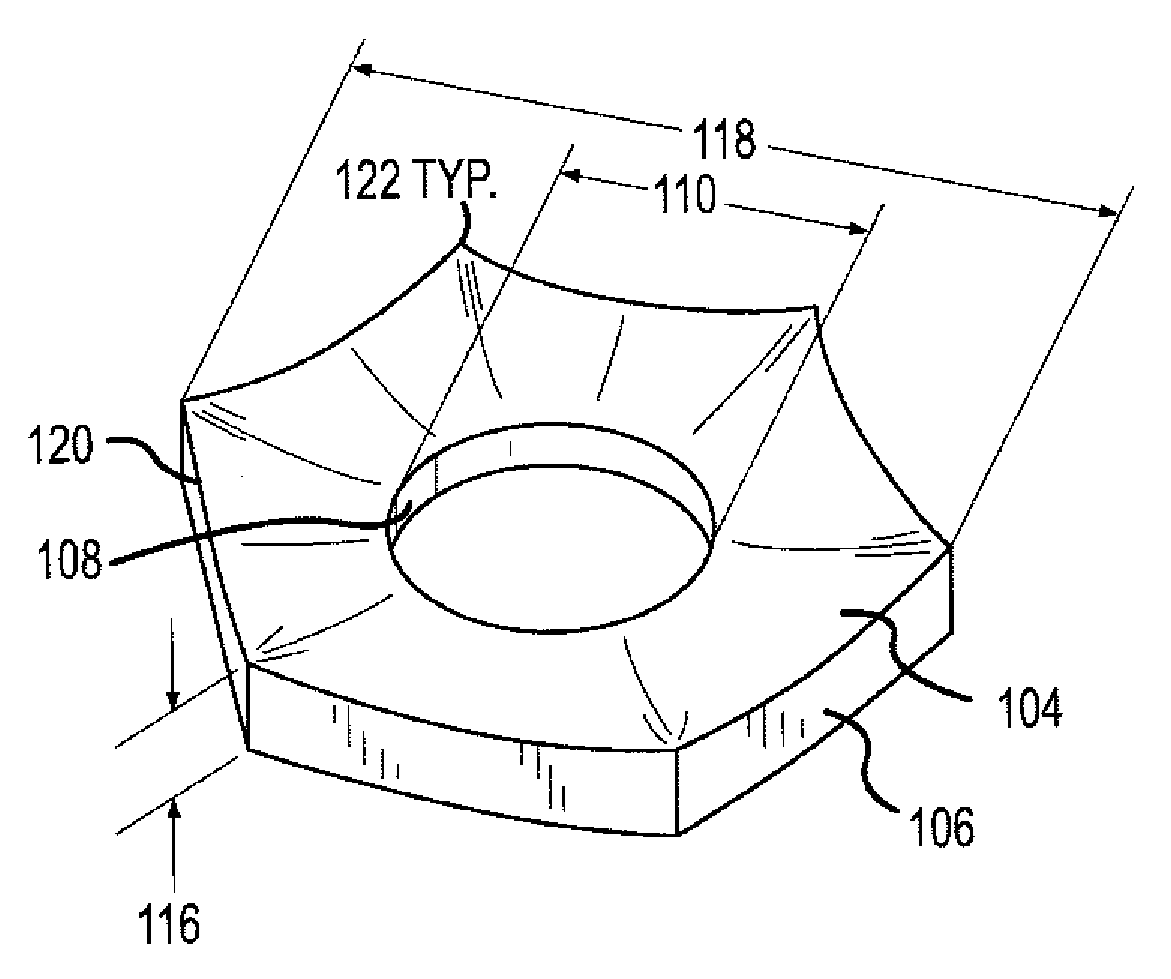

Intervertebral spacer device utilizing a spirally slotted belleville washer having radially spaced concentric grooves

InactiveUS6863688B2Reduce capacityAvoid skewJoint implantsSpinal implantsEngineeringBelleville washer

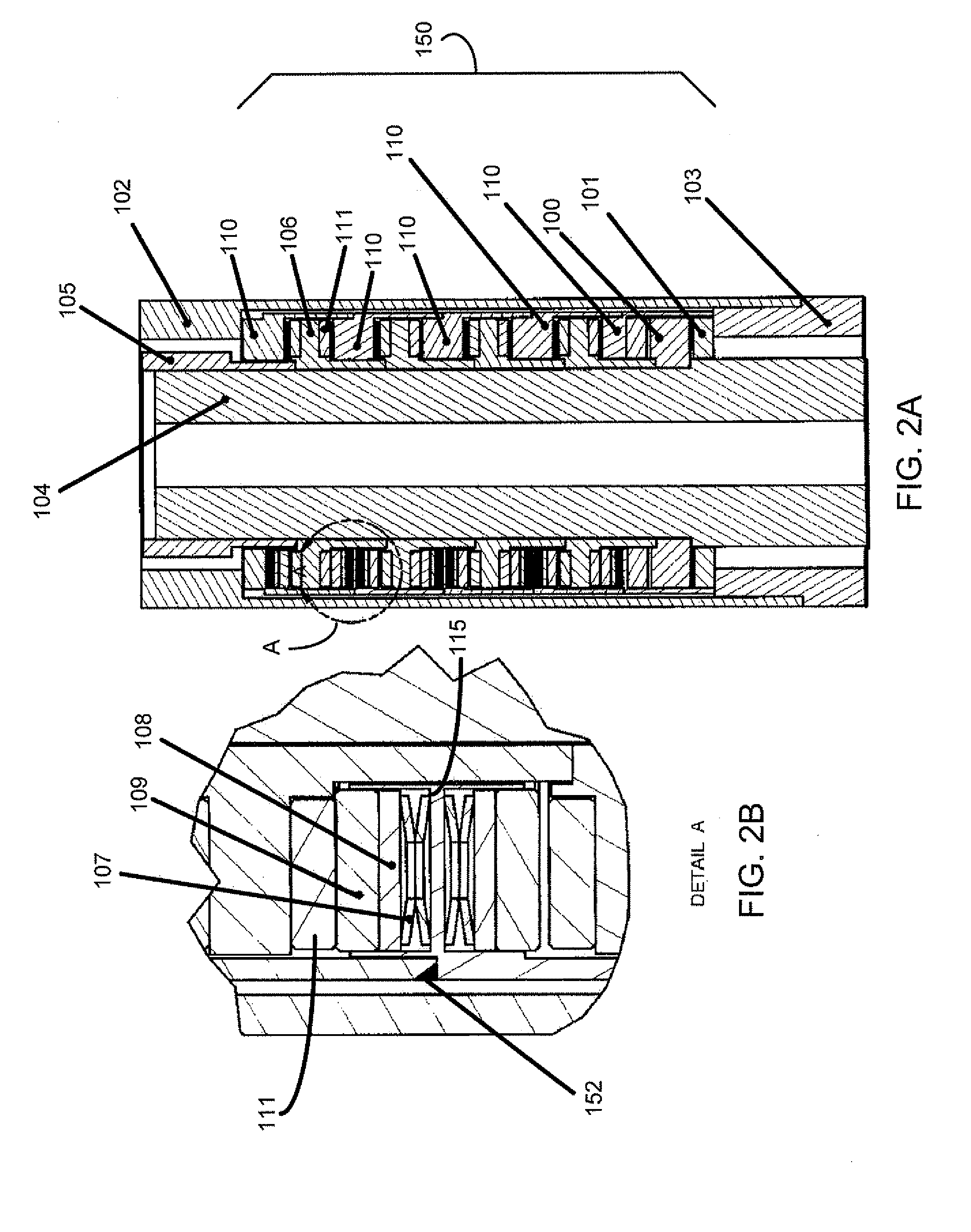

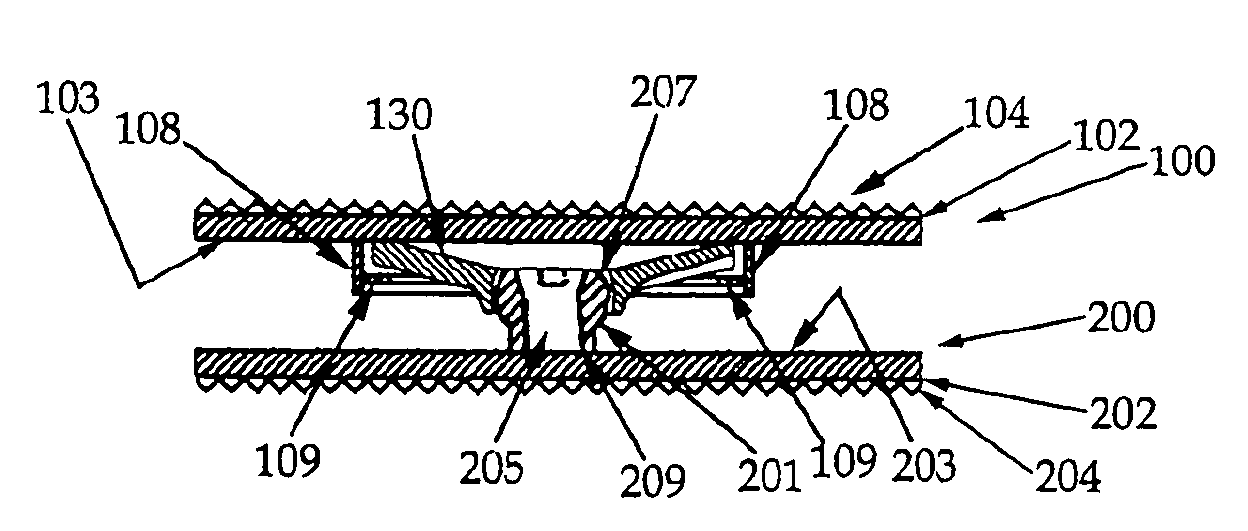

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer having radially spaced concentric grooves. In a preferred embodiment there is a single such belleville washer which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate.

Owner:HOWMEDICA OSTEONICS CORP

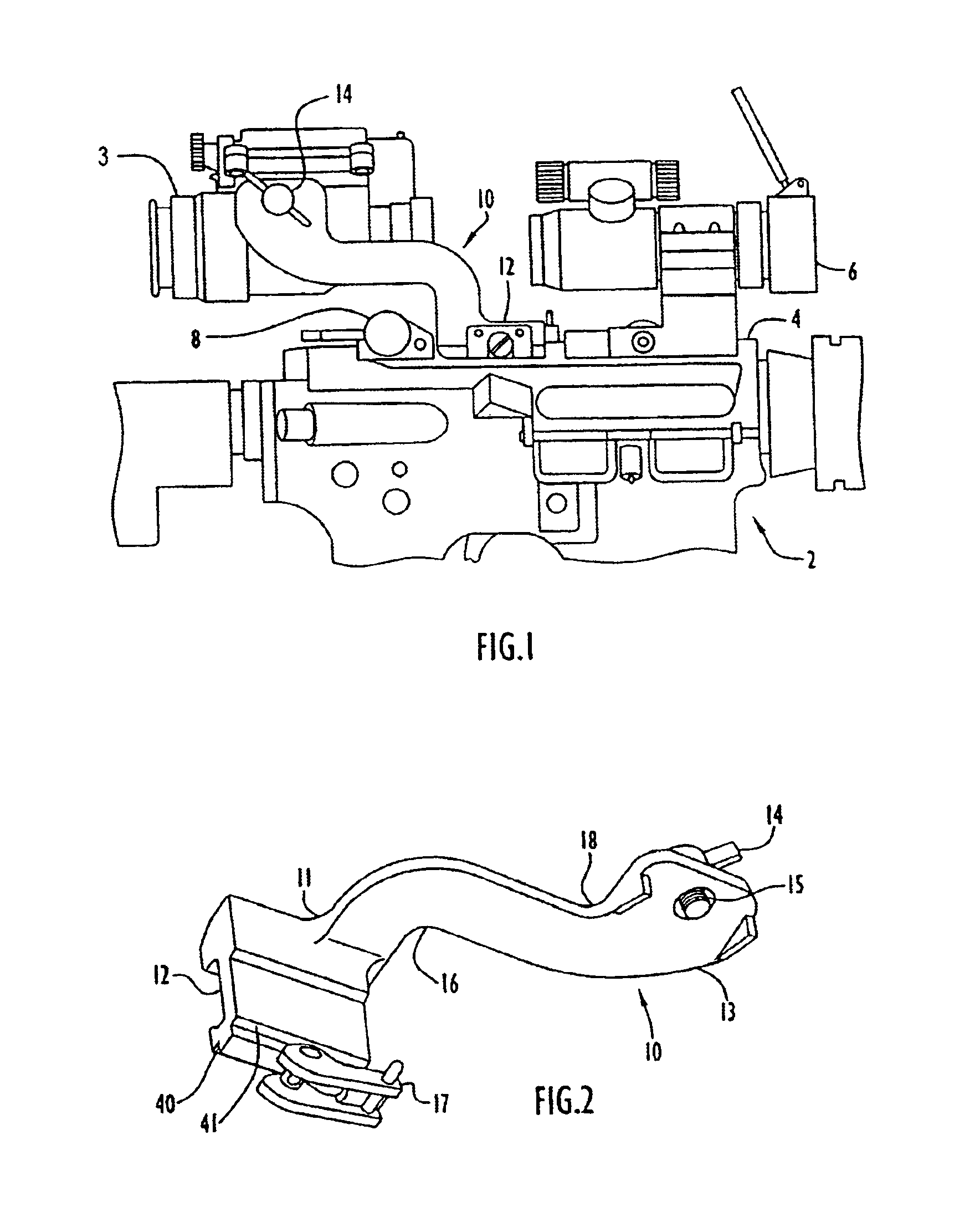

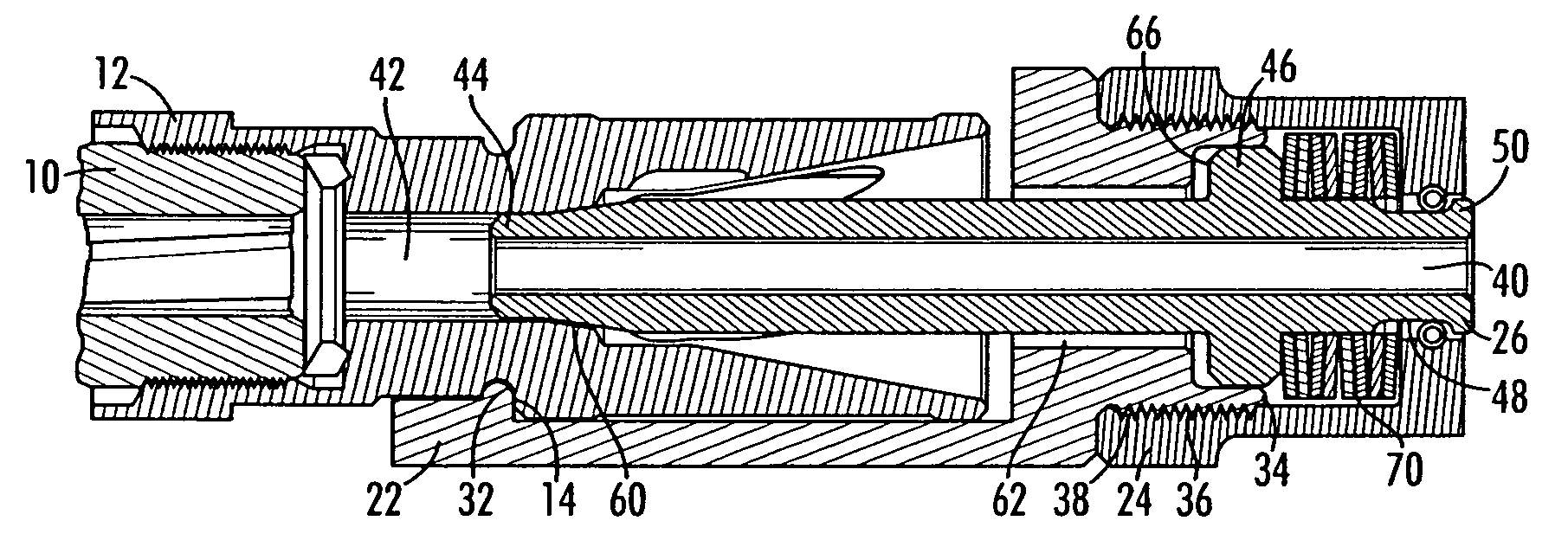

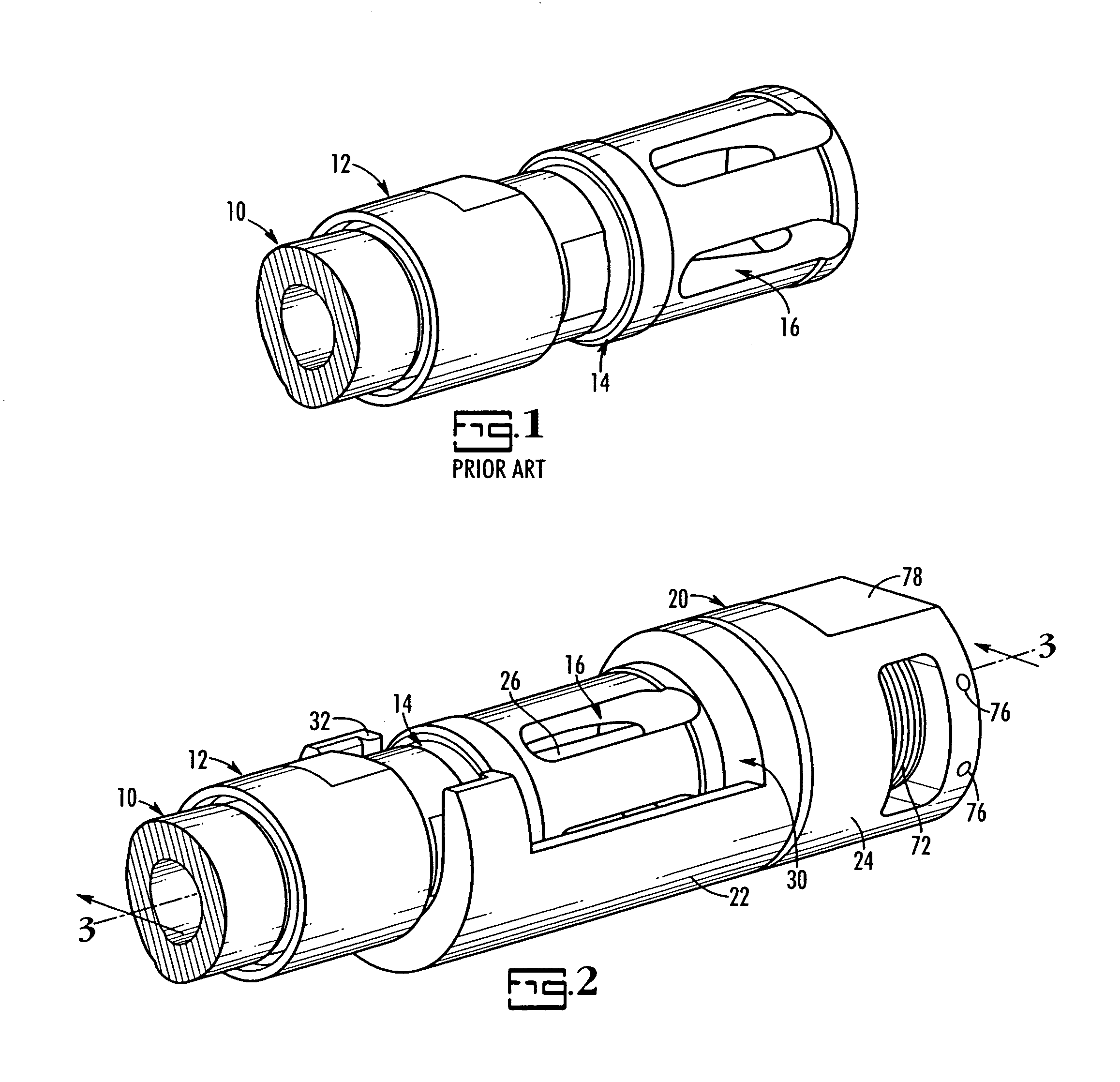

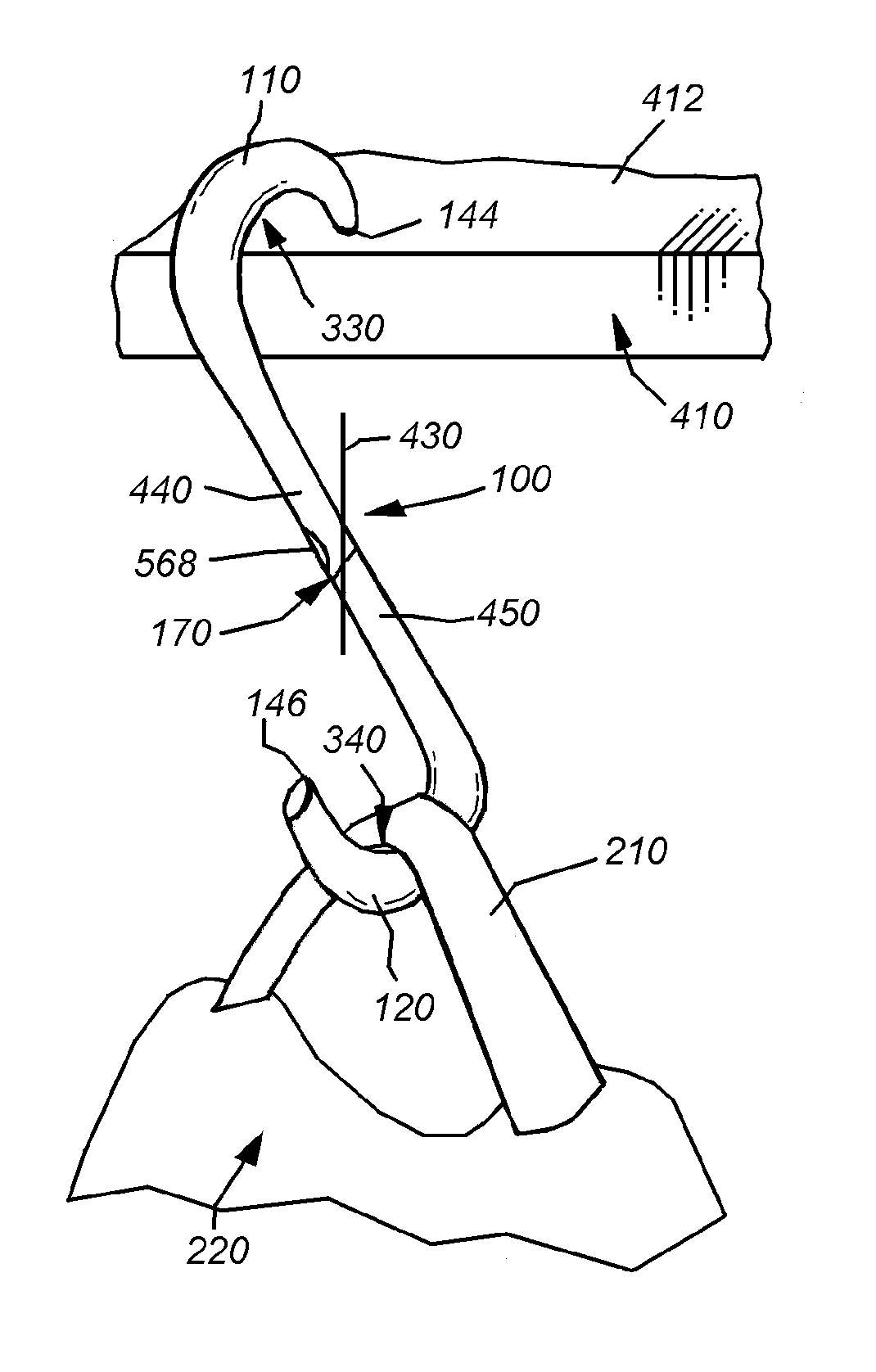

Clamp for weapon mount

InactiveUS6931778B1Clearance can be providedPrecise positioningSighting devicesPistolsBelleville washerCam

A weapon mount for mounting a night vision device to the receiver rail of a weapon. A self-device adjusting cam operated connection device is present at one end region of the mount for attaching to the receiver rail, while the night vision device is connected at the other end region of the mount with a knob operated mounting screw. The knob and mounting screw are a one piece design and the mounting screw is captivated by an E-clip. The cam operated connection device may be adjusted to accommodate different size receiver rails by the provision of compressible means, such as Belleville washers.

Owner:ITT MFG ENTERPRISES LLC

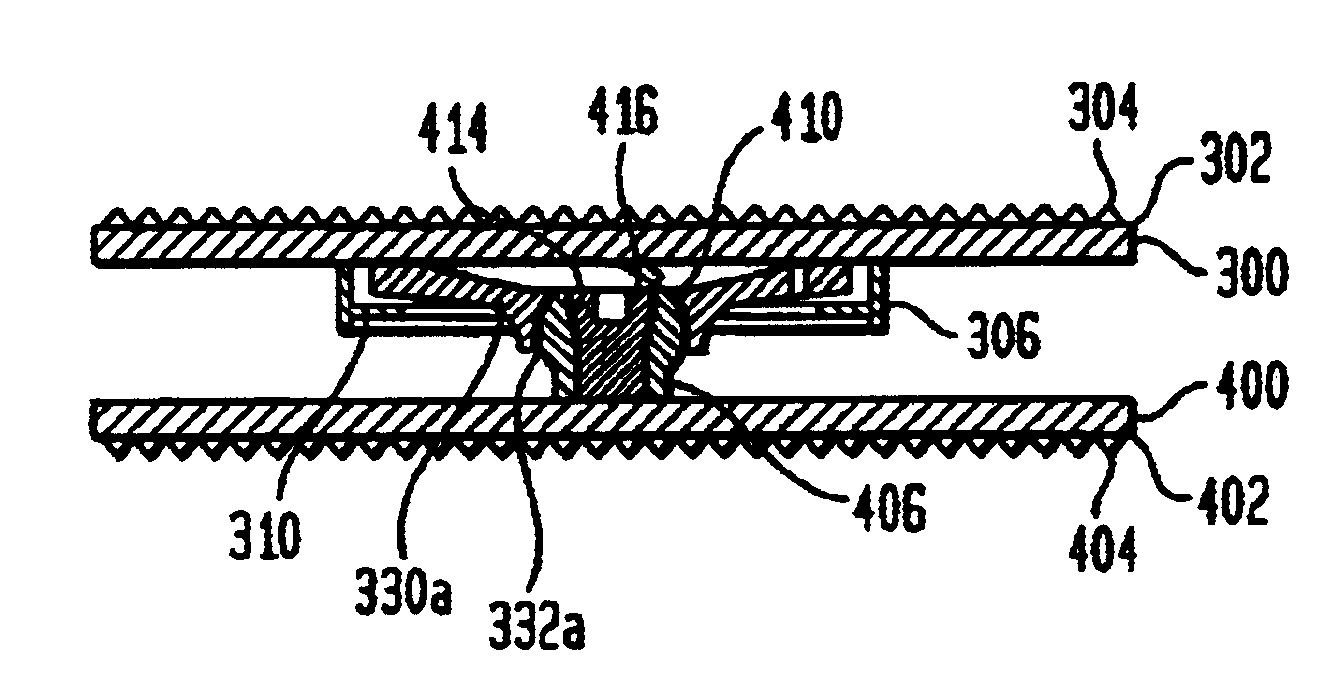

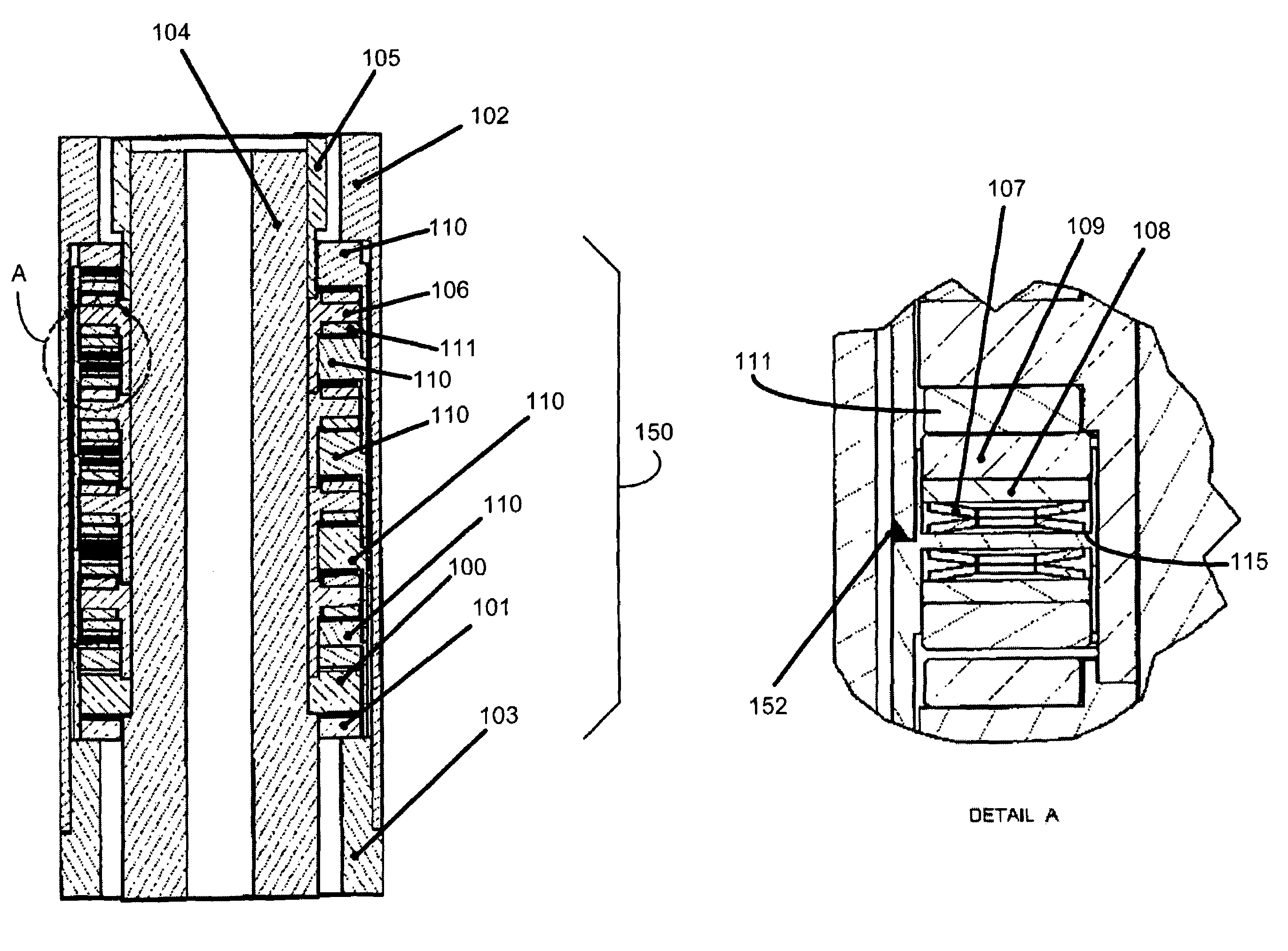

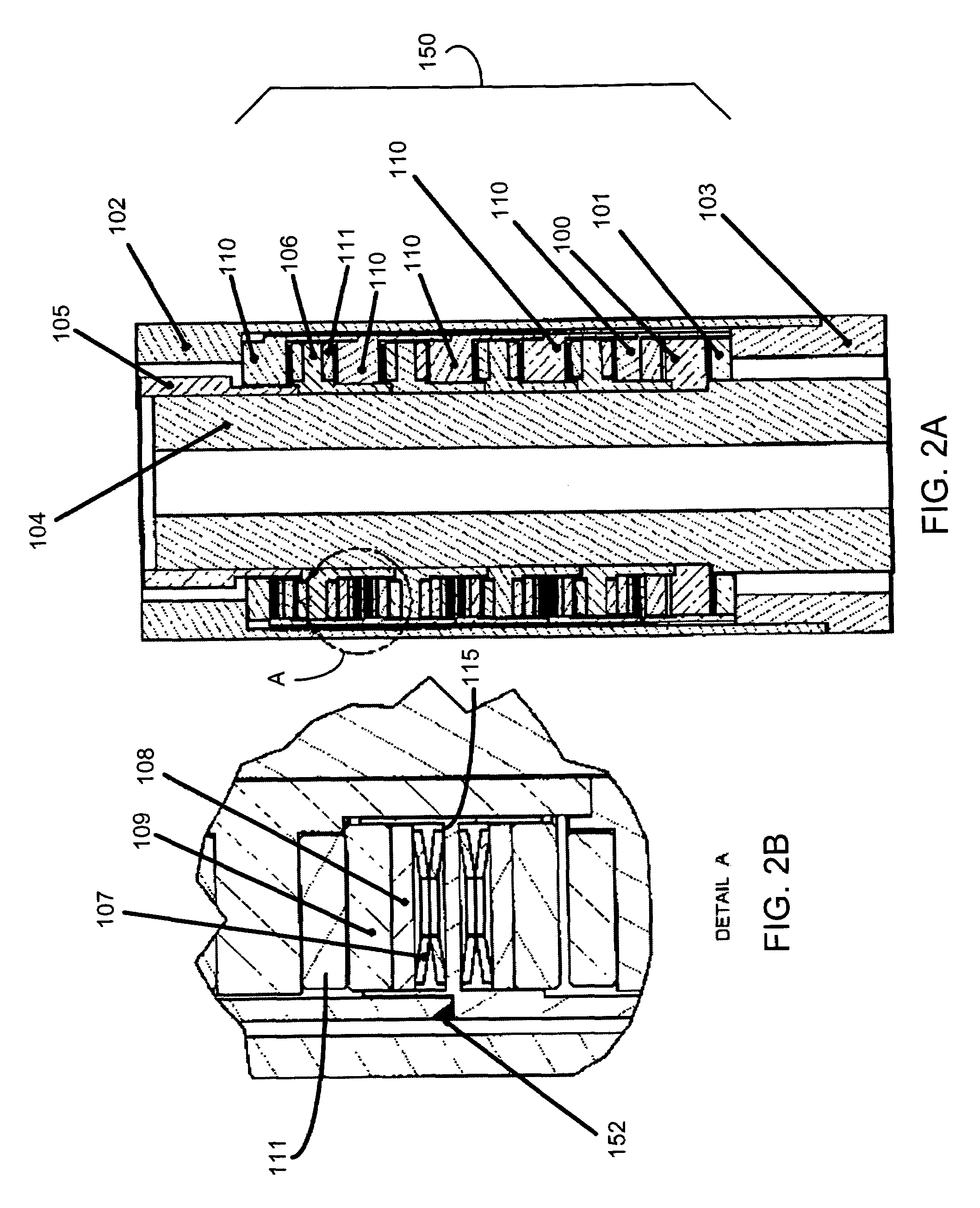

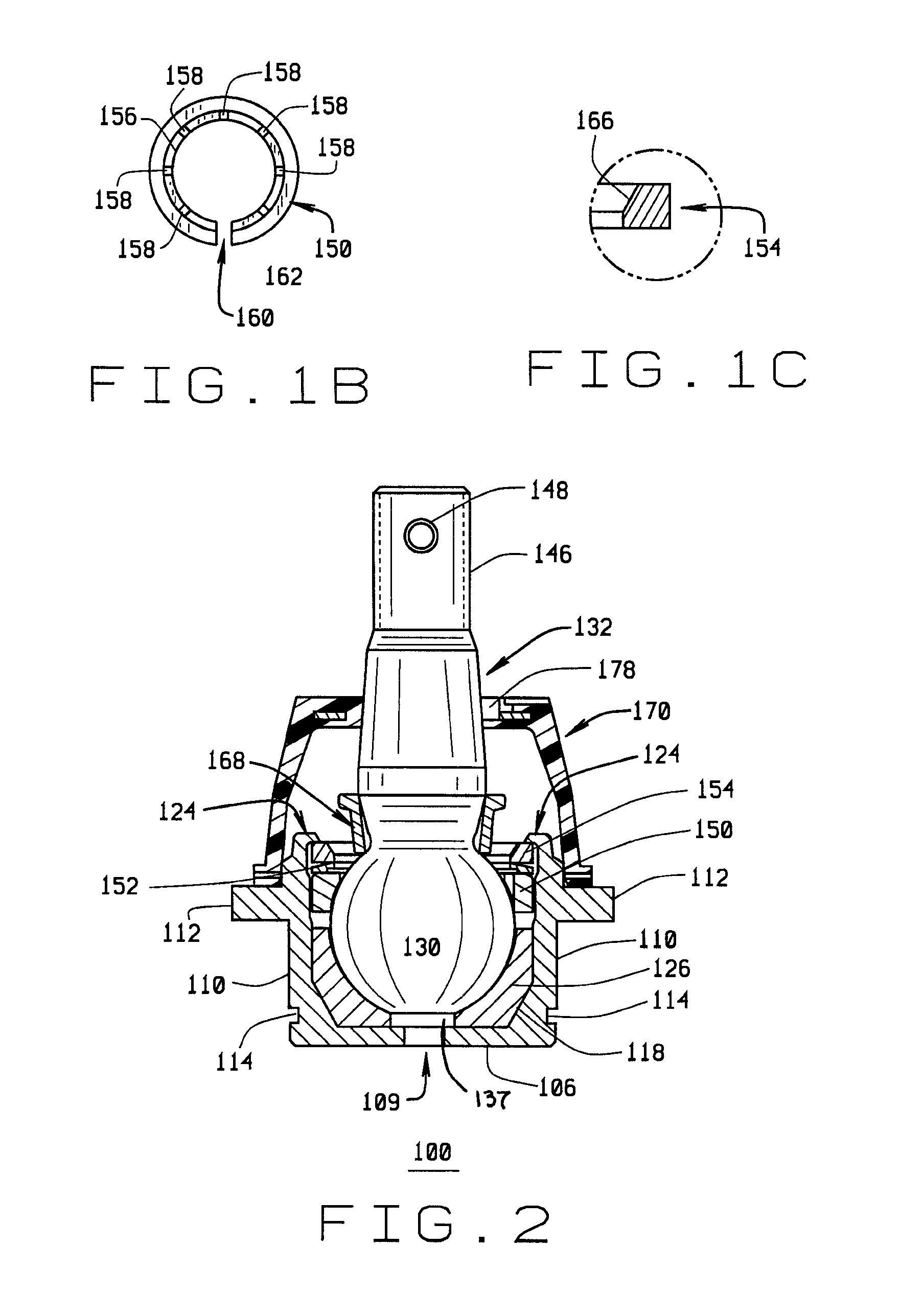

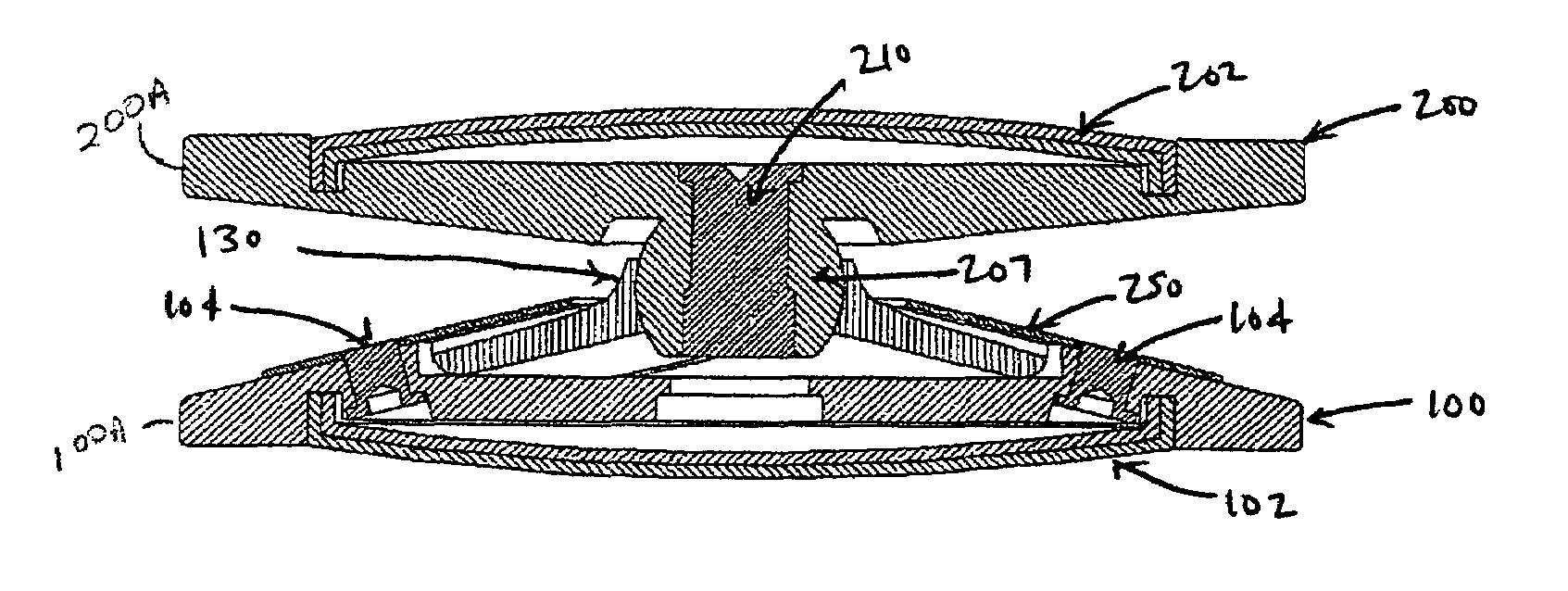

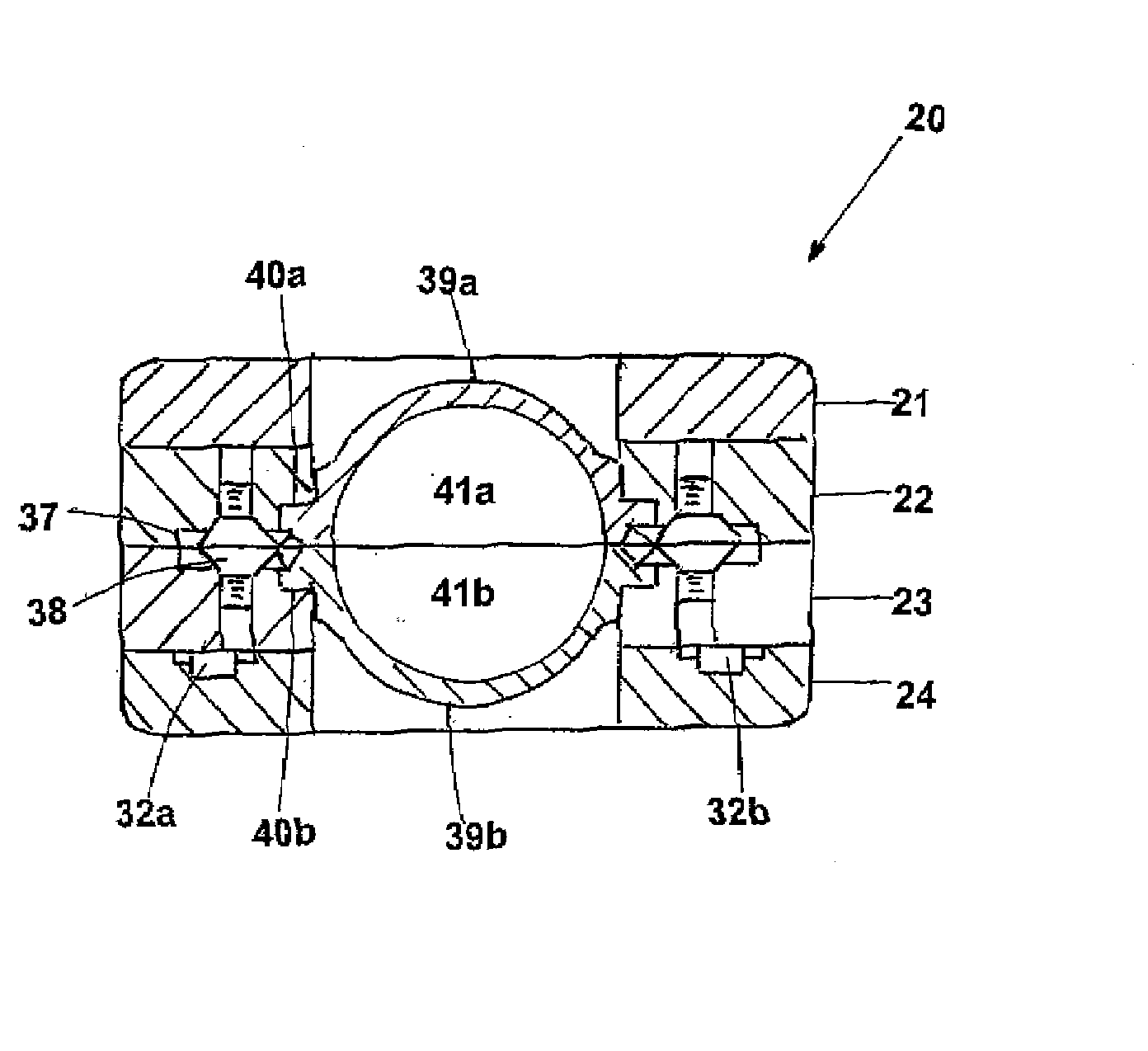

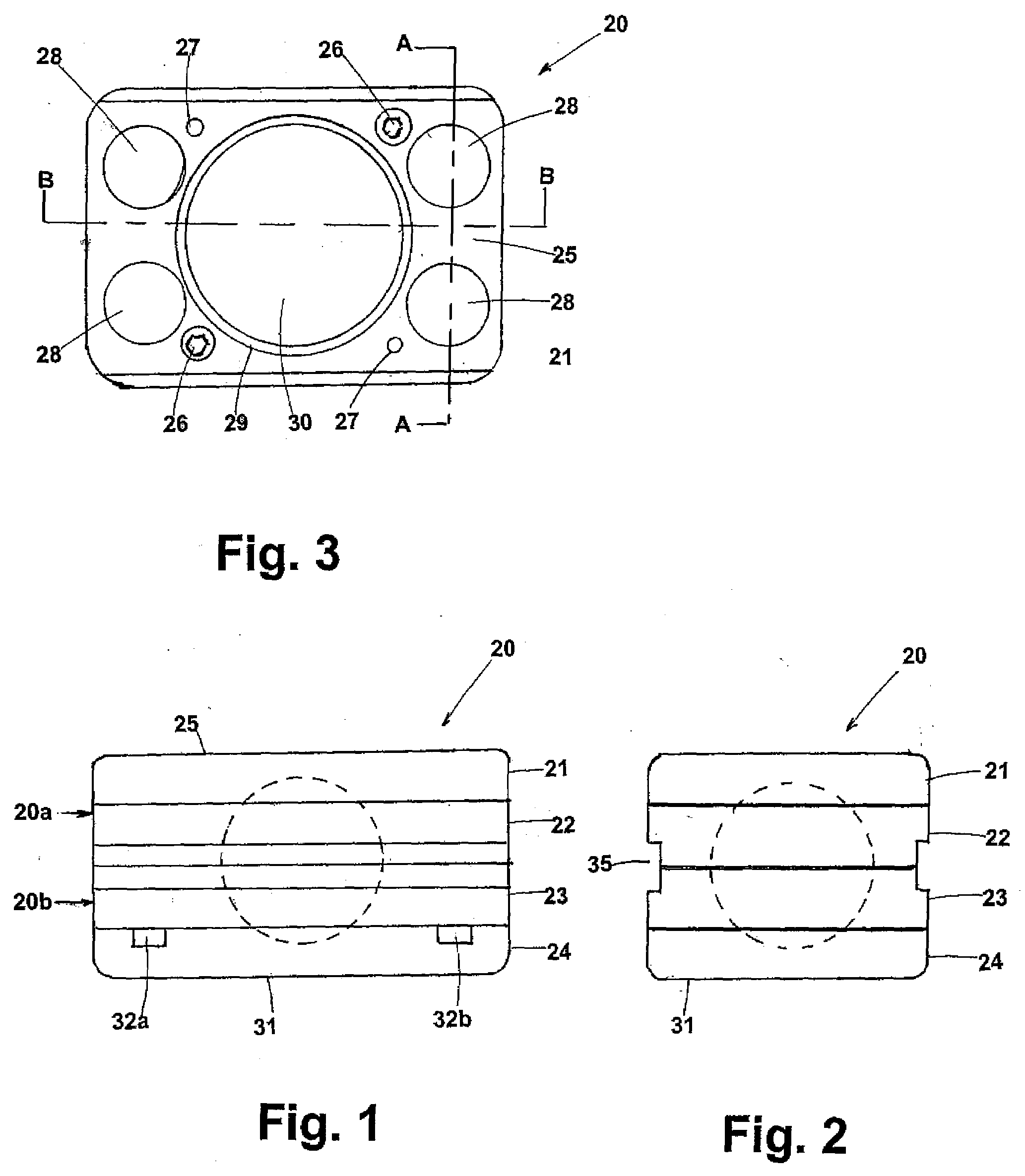

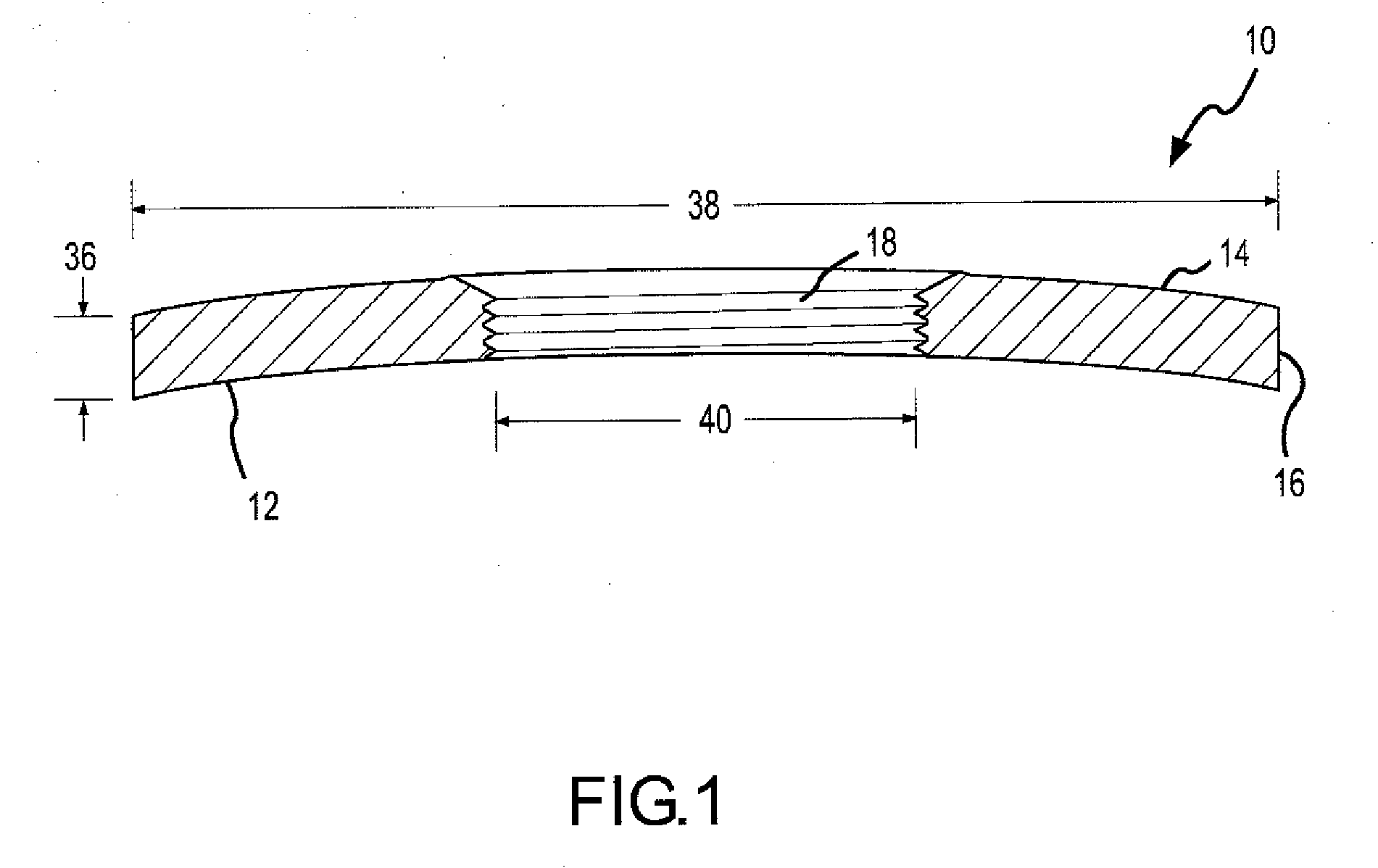

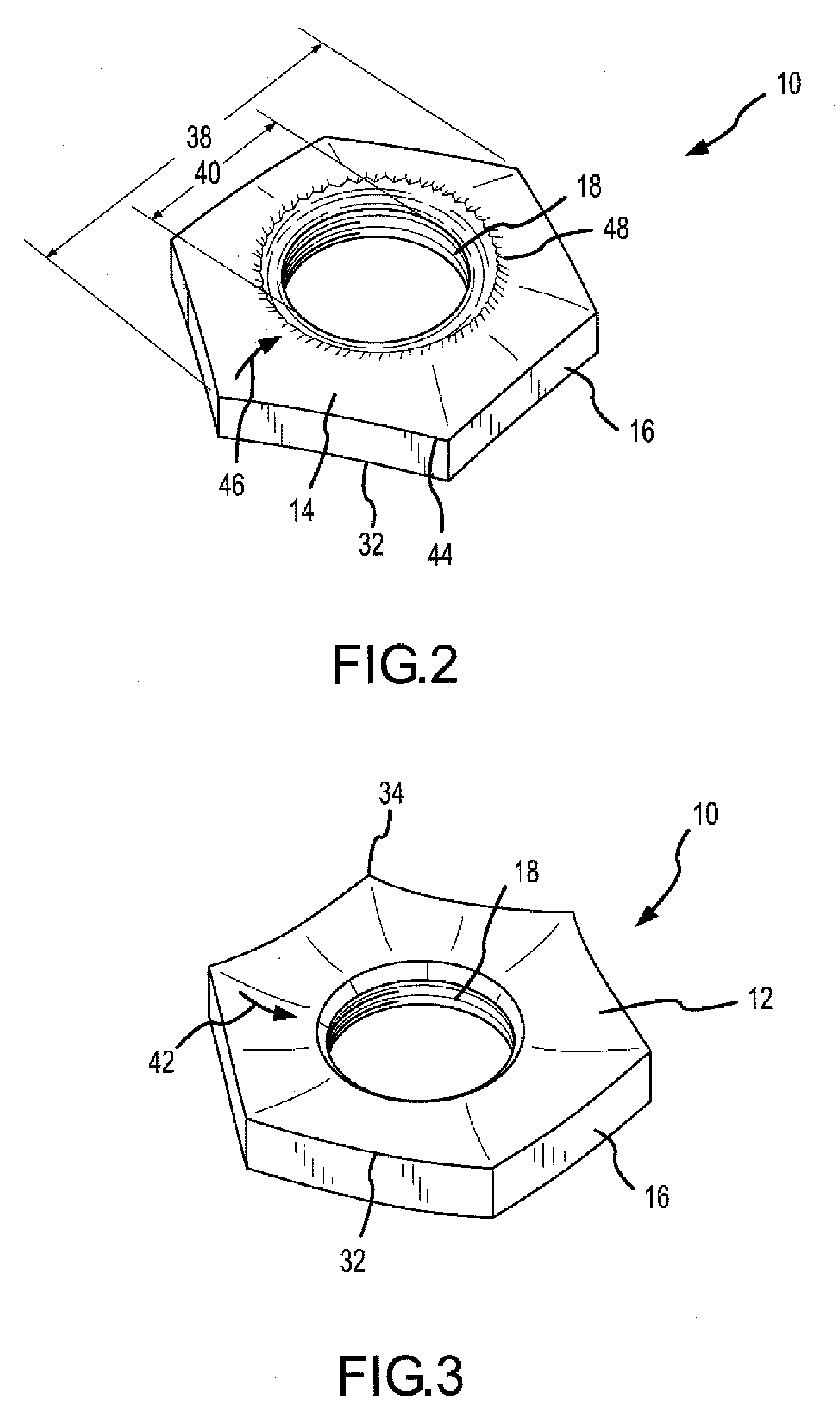

Artificial intervertebral disc having a slotted belleville washer force restoring element

InactiveUS6918934B2Avoid skewImprove securityJoint implantsSpinal implantsIntervertebral discVertebral bone

An artificial disc having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer, and in some embodiments the belleville washer is also radially thinning or thickening. Various illustrated embodiments use two washers or one washer. For double washer embodiments, the wide ends of the washers seat against respective opposing plates, in some embodiments each being maintained thereagainst by a retaining wall and ring or a circular recess and retaining shield. For single washer embodiments, the narrow end of the washer can be modified to have a curvate socket for rotatably mounting onto a semispherical protuberance extending from one of the plates.

Owner:HOWMEDICA OSTEONICS CORP

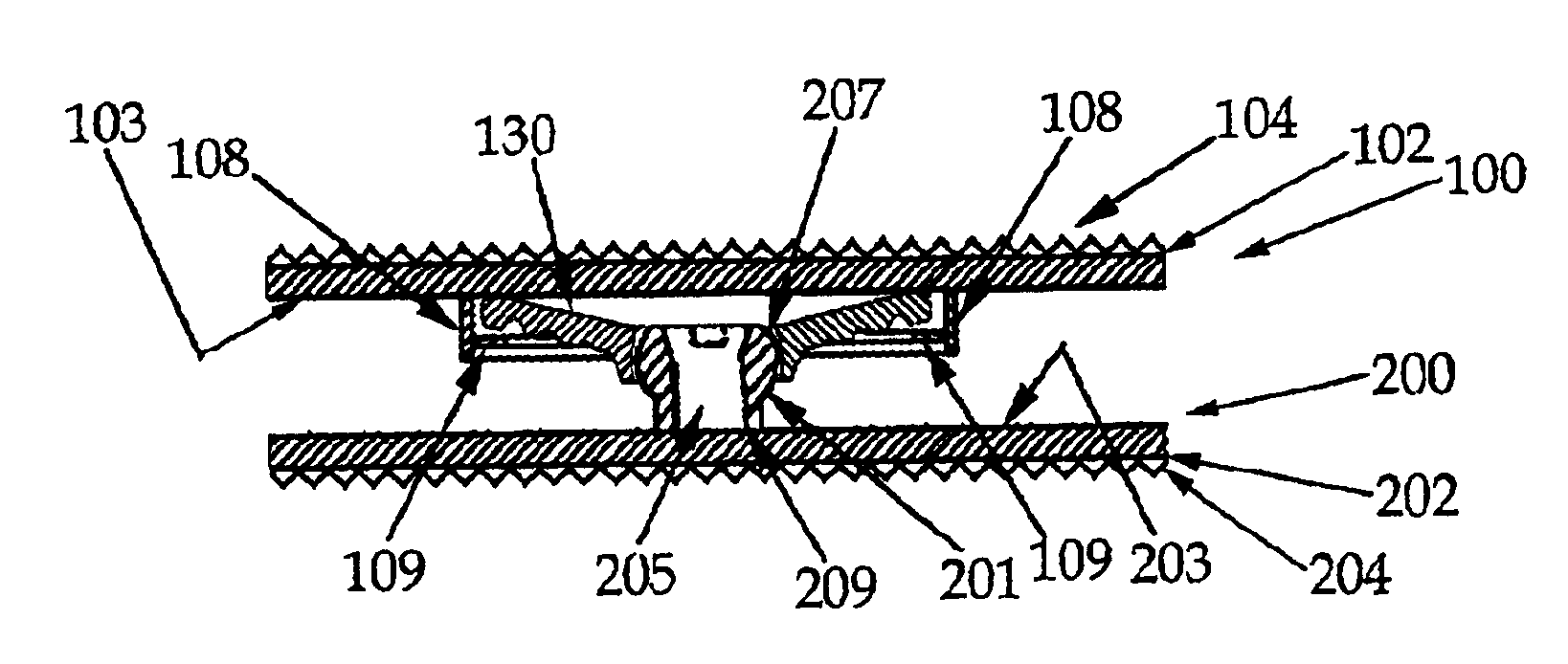

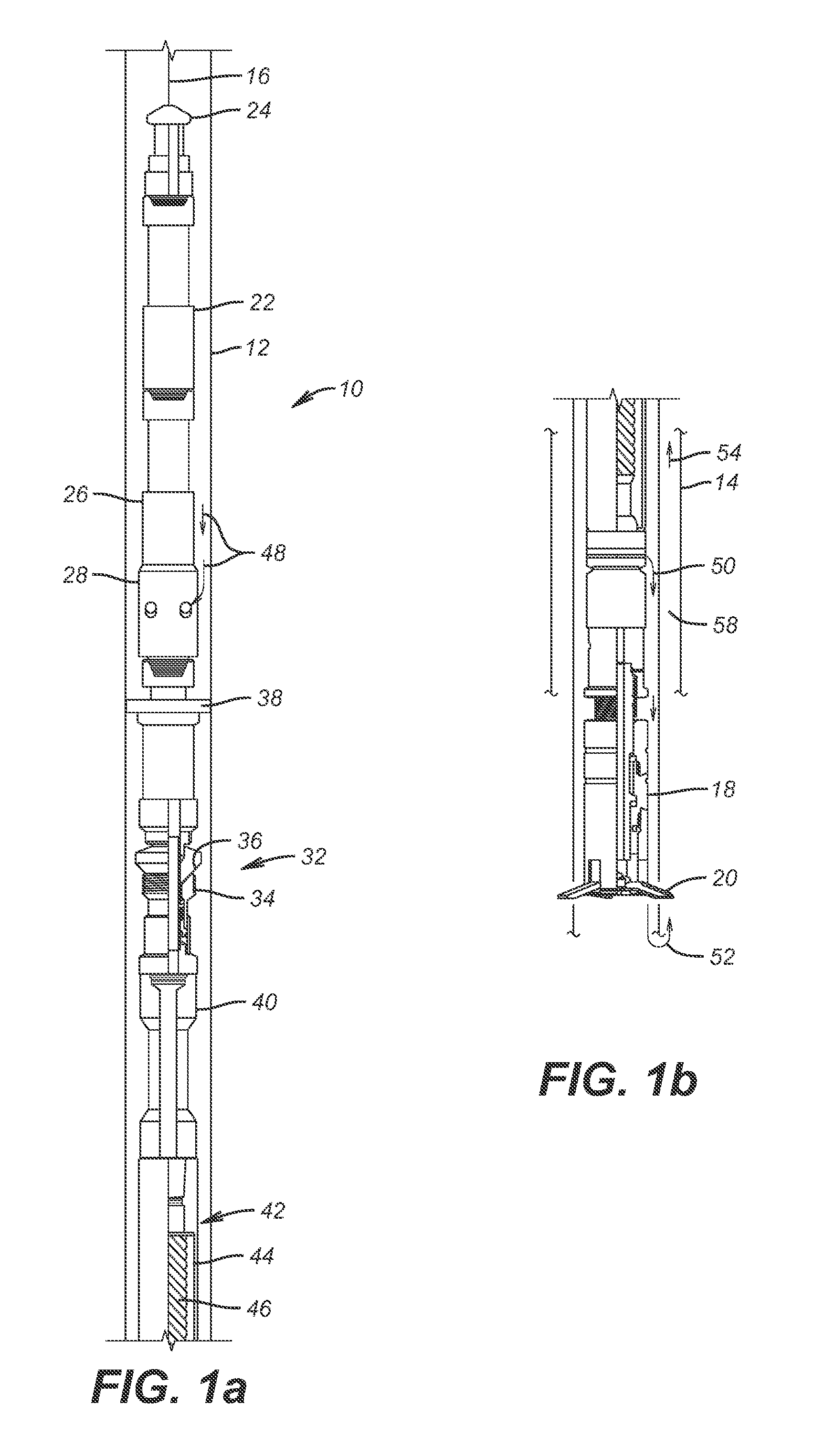

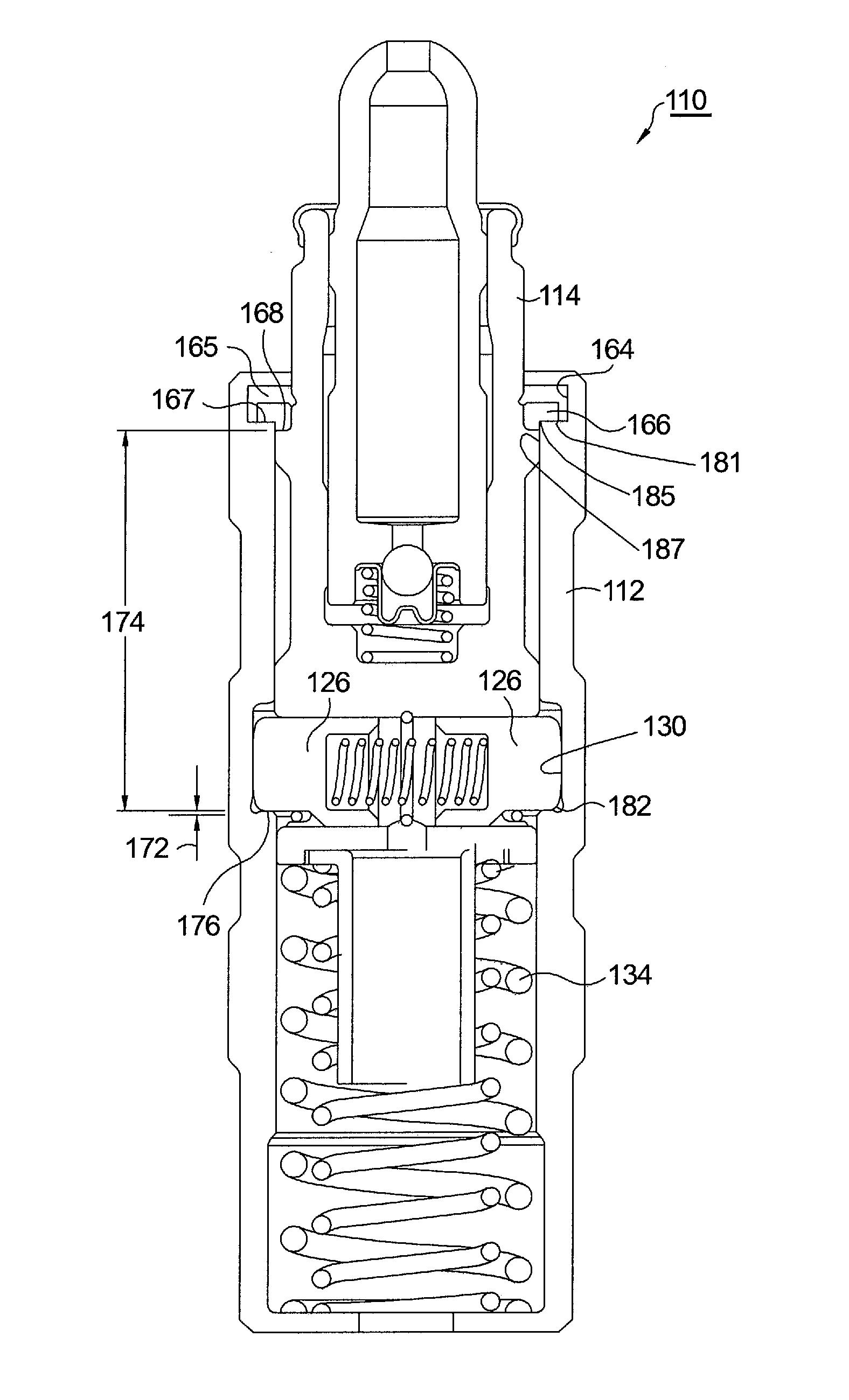

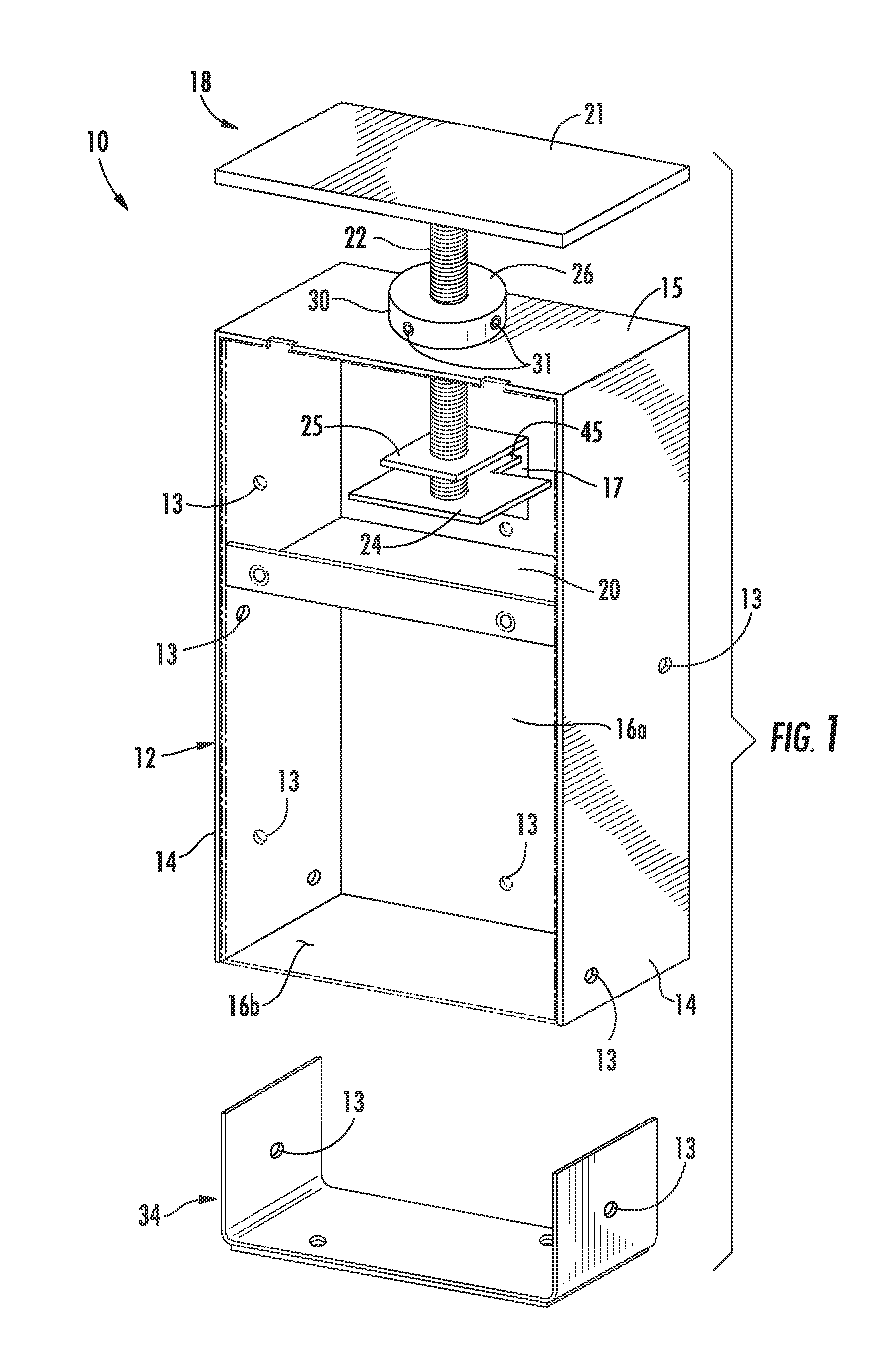

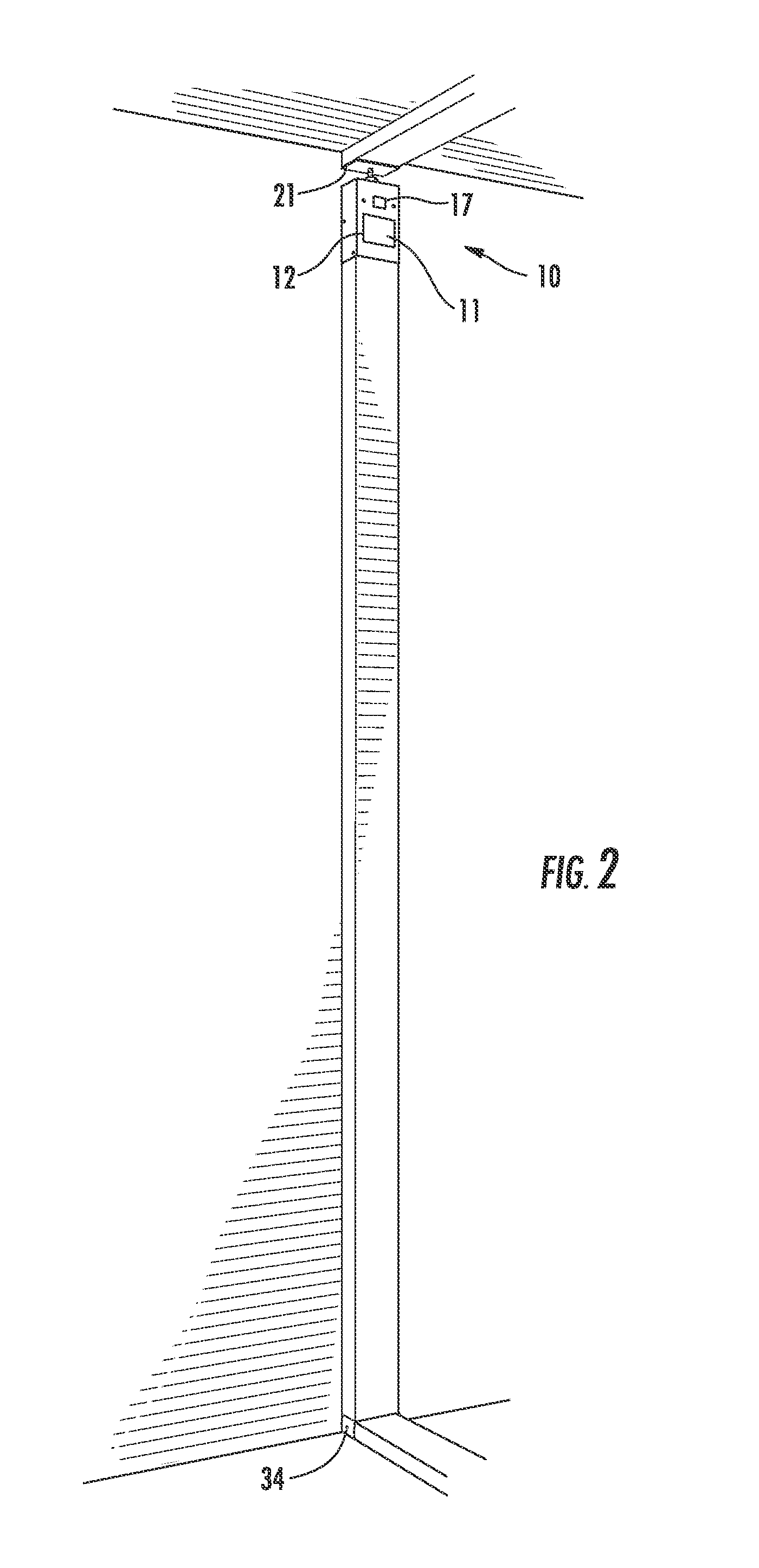

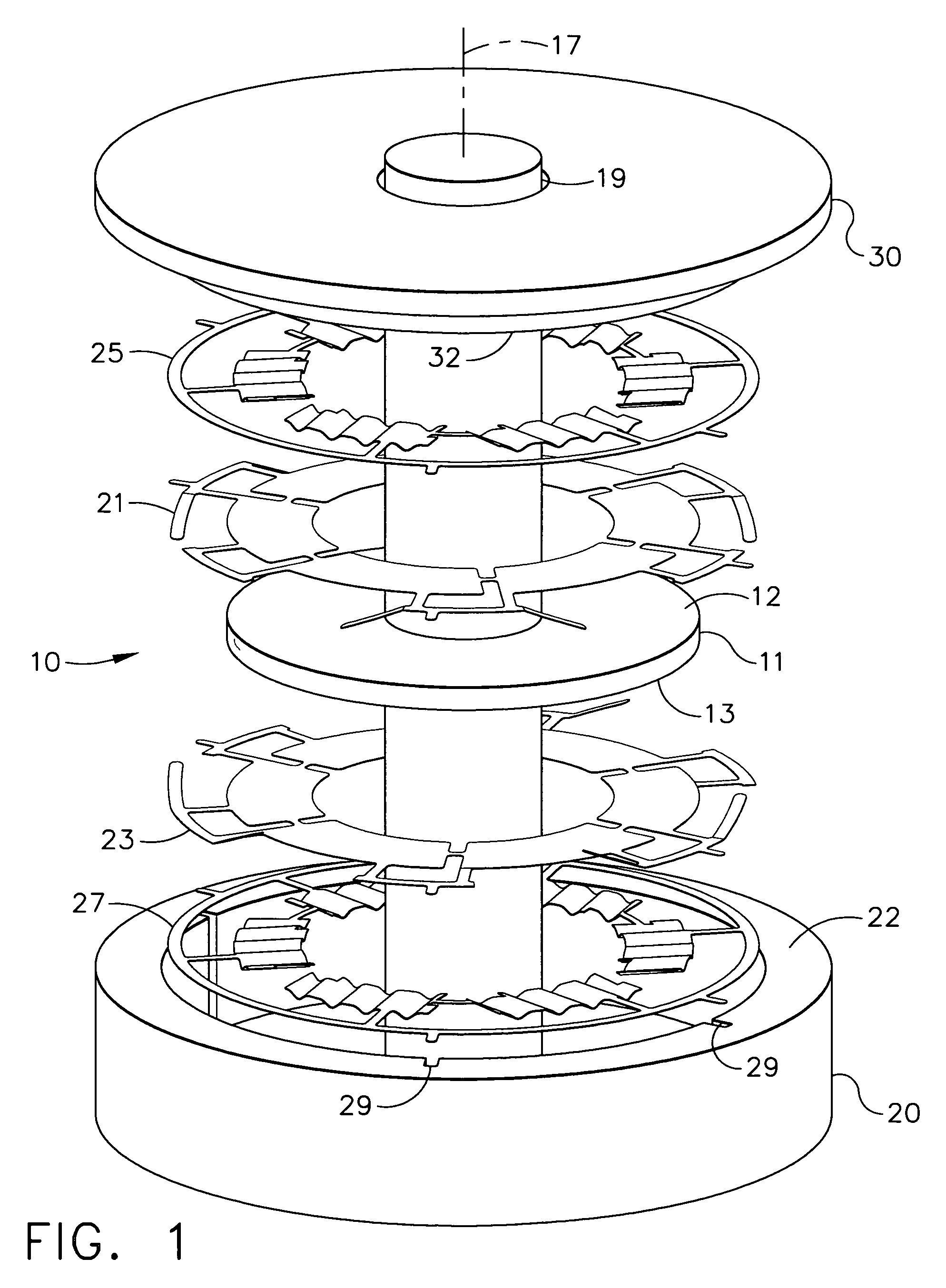

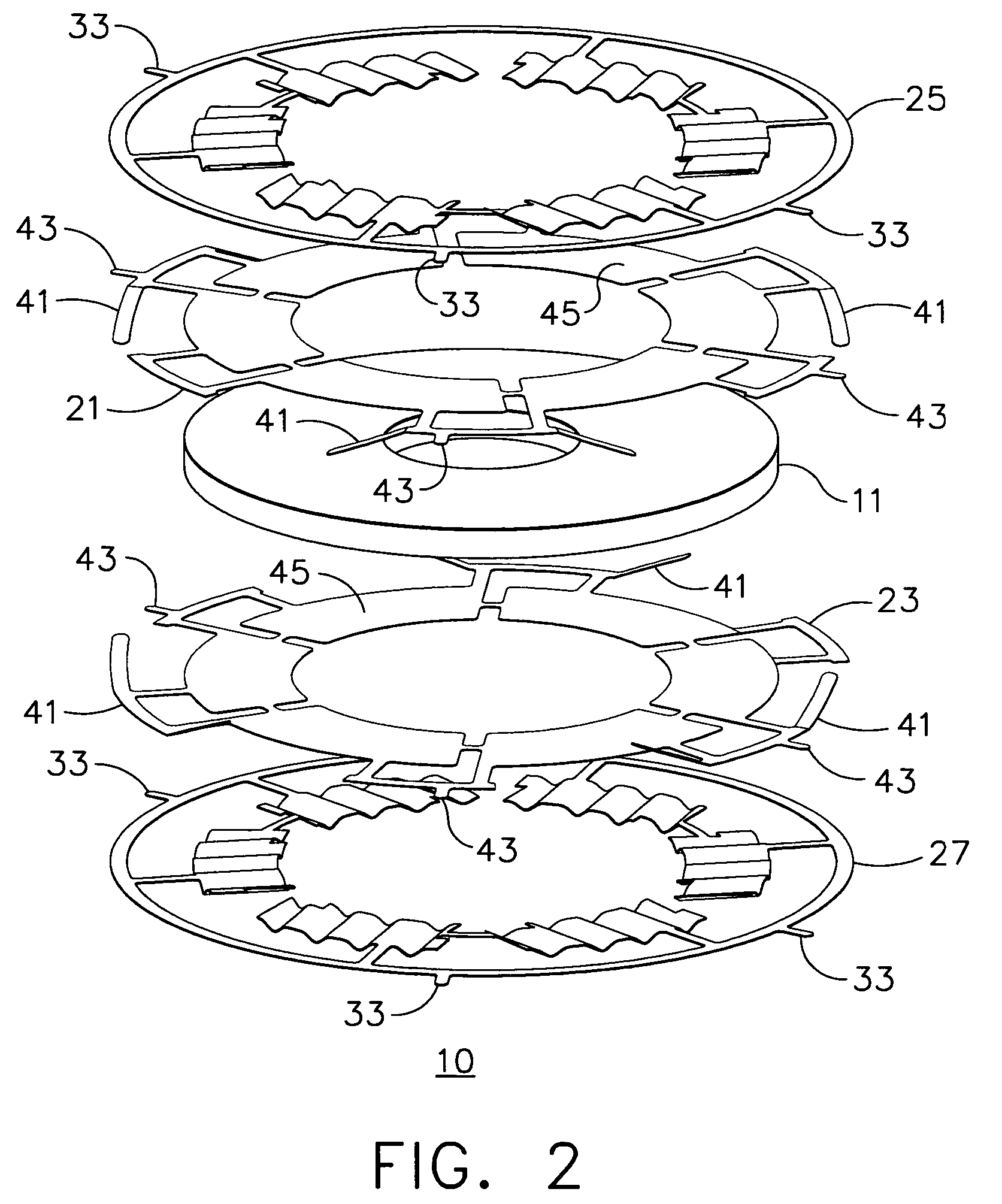

Thrust bearing assembly

ActiveUS20090268995A1Avoiding costly finish-grinding/lappingAccurate locationBearing assemblyShaftsWear resistantThrust bearing

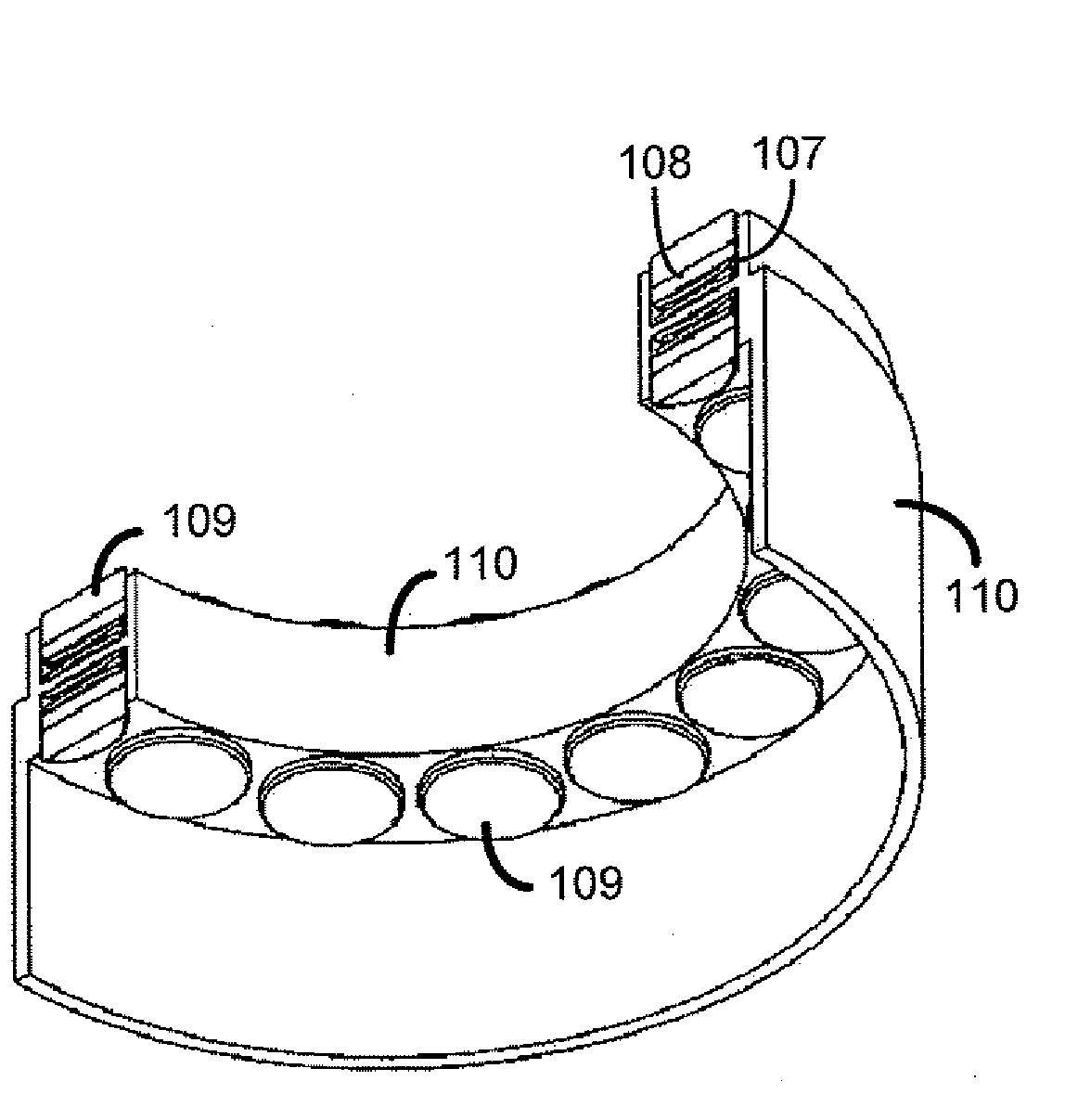

A thrust bearing assembly comprising a bearing runner and a bearing carrier, the carrier defining a plurality of thrust pad sites annularly around the carrier, with a thrust pad disposed at a site and with the carrier limiting movement of the thrust pad in a direction generally radial to the longitudinal axis of the runner while allowing the thrust pad to move in a direction generally parallel to the longitudinal axis. Though the range of movement is limited, the pads can tilt under load to form a hydrodynamic wedge as is known in the art. An embodiment comprises a bearing runner having a wear resistant face and a bearing carrier defining thrust pad sites disposed annularly around the carrier. In one implementation, at each site, a deflection element (e.g., Belleville washer) is disposed in a cavity and a pad is disposed over the deflection element. The pad can be at least partially disposed within the cavity. The wear resistant face contacts the pad. Another embodiment rigidly connects pads disposed oil opposite sides of a stationary bearing carrier. Another embodiment attaches pads to a bearing carrier using pad holder assemblies.

Owner:CERADYNE

Adaptor for firing blank ammunition

An adaptor for use with a flash suppressor on a gun barrel in order to allow the gun to repeatedly fire blank rounds of ammunition. The adaptor has a stem that chokes the flow of gases from an exploding round in order to create a back pressure. A body is used to couple the stem to the flash suppressor and permit a cap to be threaded to the body. The cap urges the stem into the throat of the flash suppressor when tightened to the body while the body grips the flash suppressor to hold the stem and cap in place. Belleville washers in the cap pre-loaded and urge the stem into the throat and hold it there securely during repeating firing of the gun.

Owner:FN HERSTAL +1

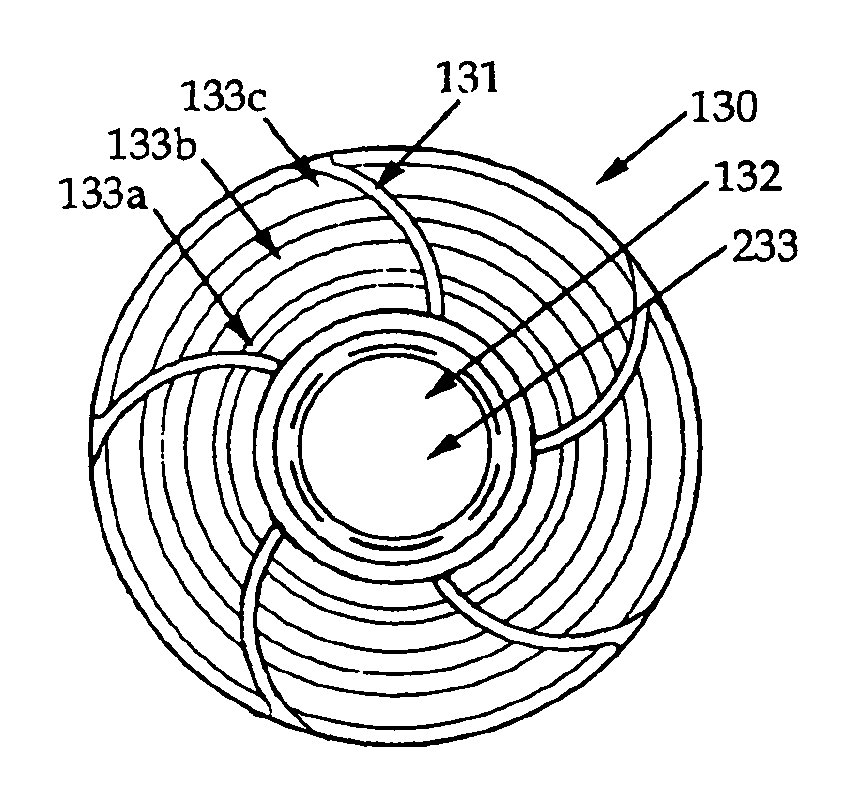

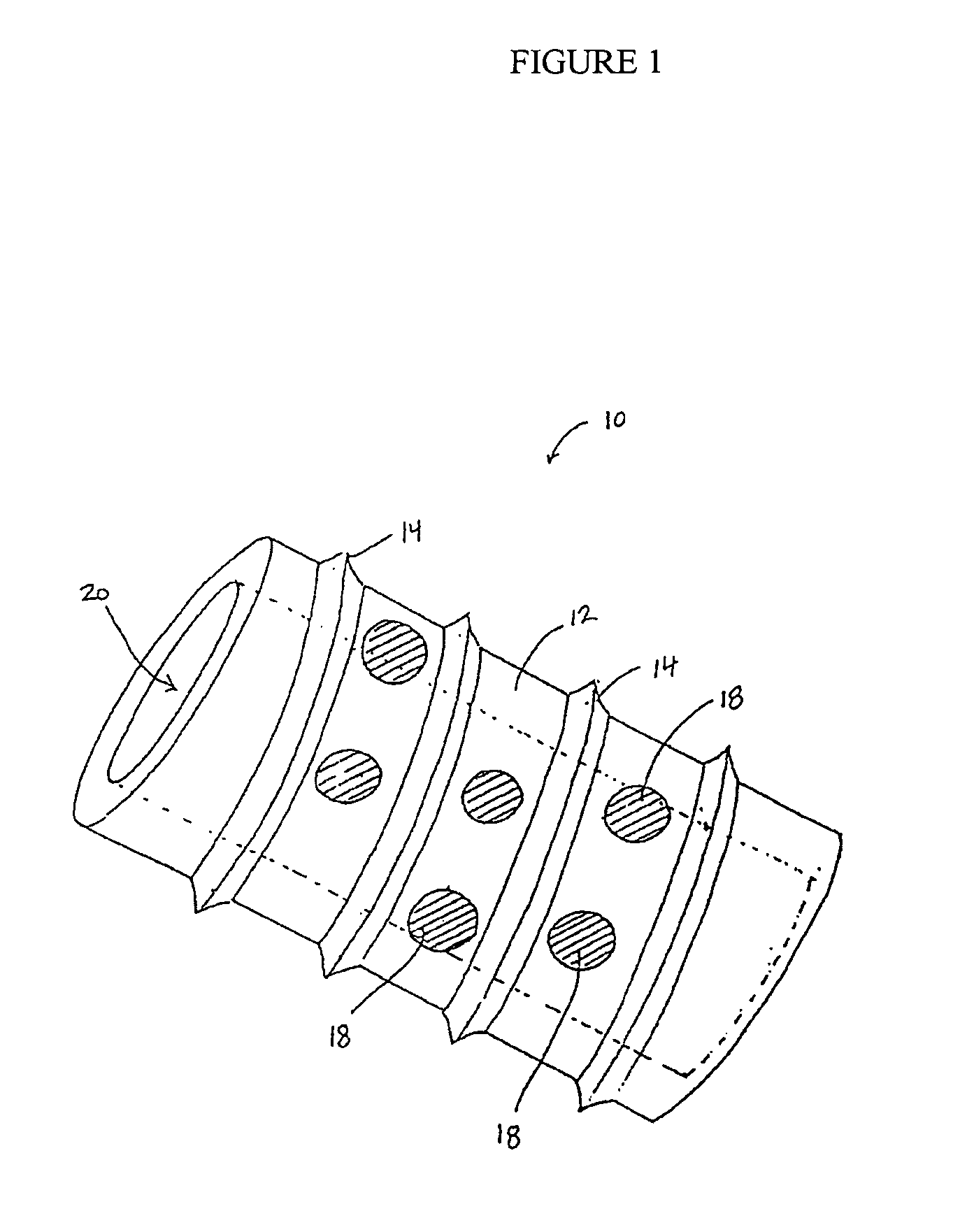

Intervertebral spacer device utilizing a belleville washer having radially spaced concentric grooves

InactiveUS6887274B2Reduce capacityAmple spring-like performanceJoint implantsSpinal implantsEngineeringBelleville washer

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one belleville washer having radially spaced concentric grooves. In a preferred embodiment there is a single such belleville washer which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate.

Owner:HOWMEDICA OSTEONICS CORP

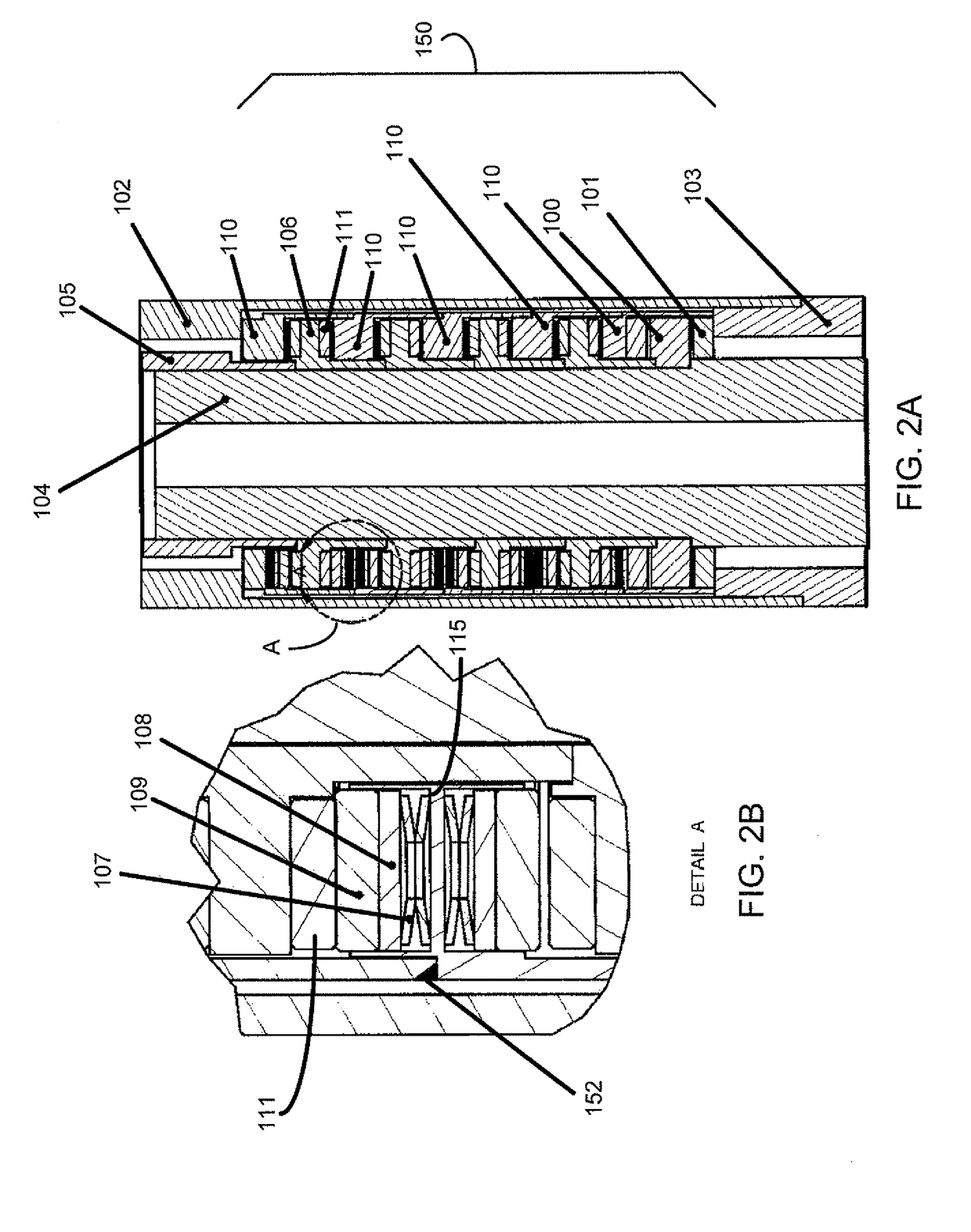

Thrust bearing assembly

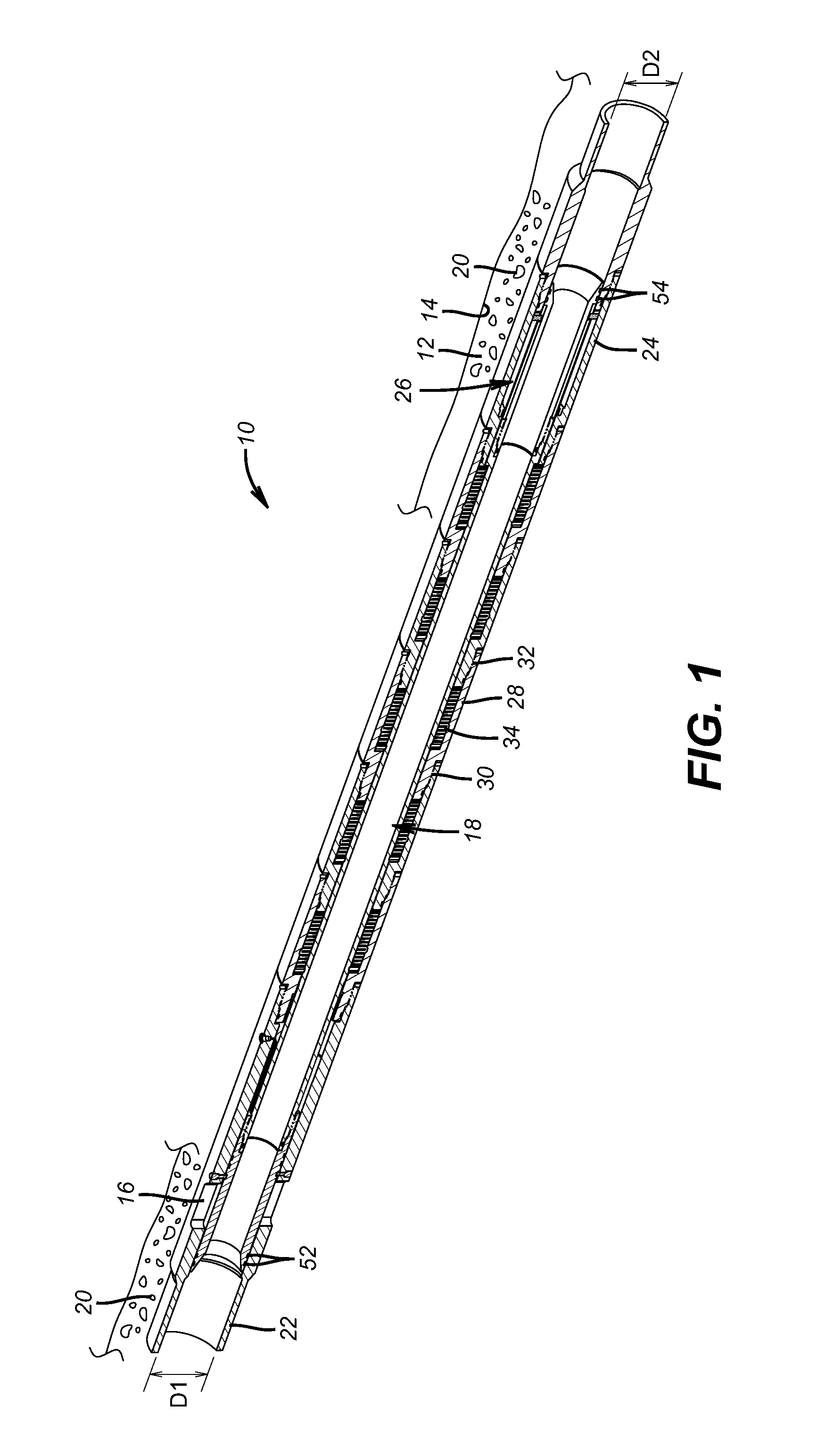

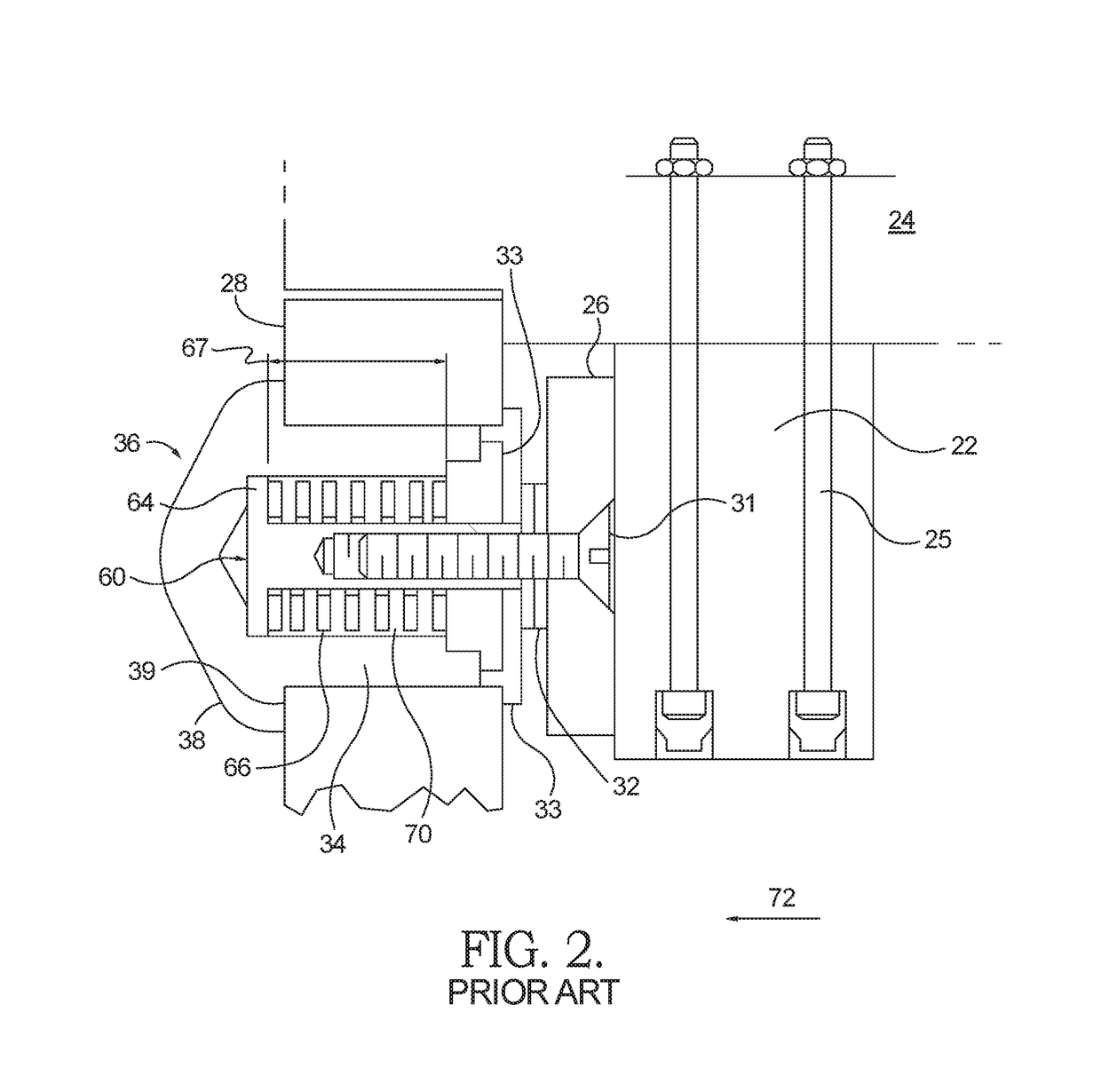

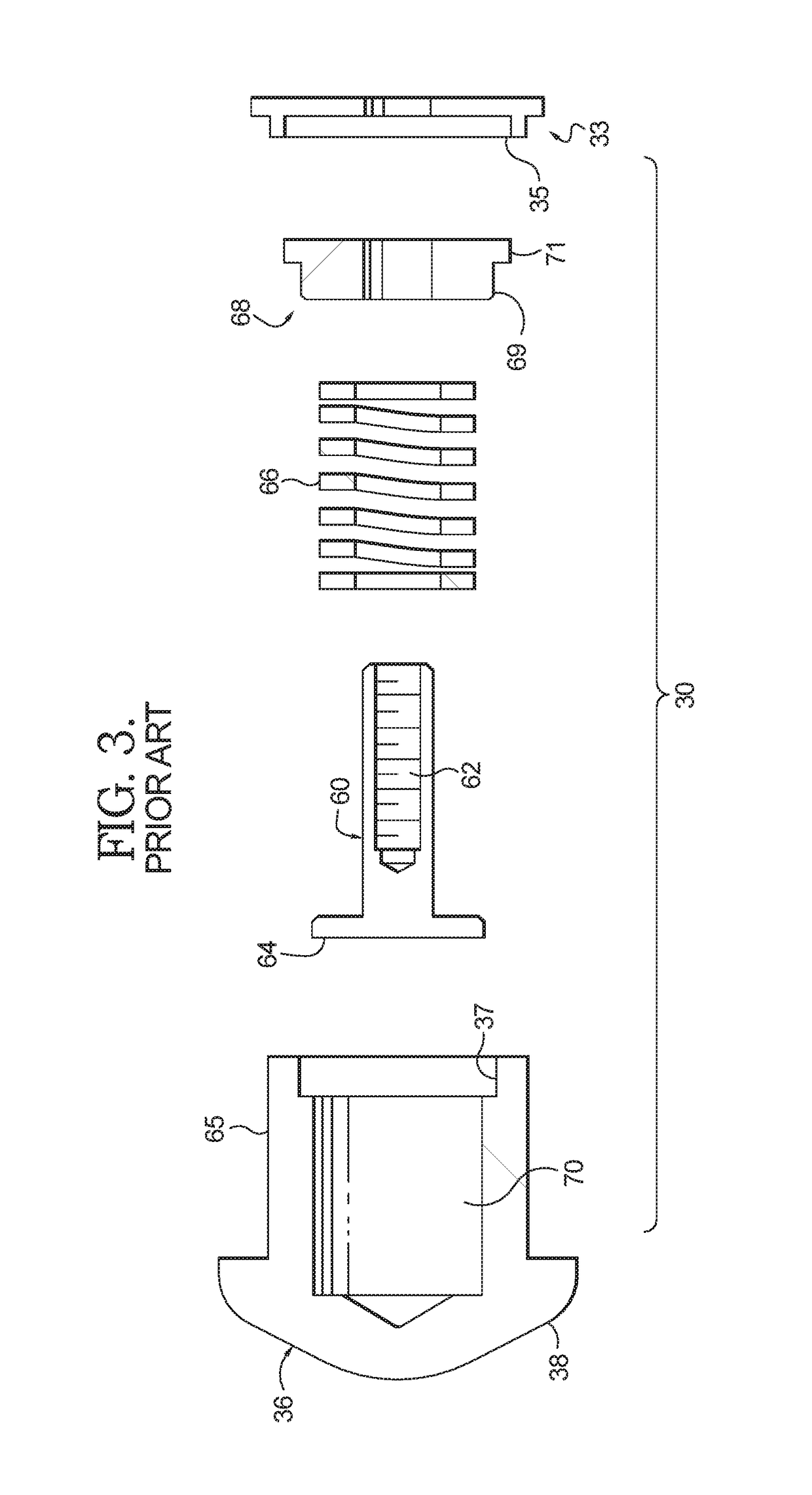

ActiveUS7306059B2Avoiding costly finish-grinding/lappingBearing assemblyBorehole drivesWear resistantThrust bearing

A thrust bearing assembly in which each thrust pad is individually mounted on a deflection element. An embodiment of the invention comprises a rotating bearing runner having a wear resistant face and a stationary bearing carrier defining a plurality of cavities disposed annularly around the carrier. A deflection element, such as a Belleville washer, is disposed in a cavity of the plurality of cavities and a pad is disposed over the deflection element. The pad is at least partially disposed within the cavity. The wear resistant face of the rotating bearing runner contacts the pad.

Owner:CERADYNE

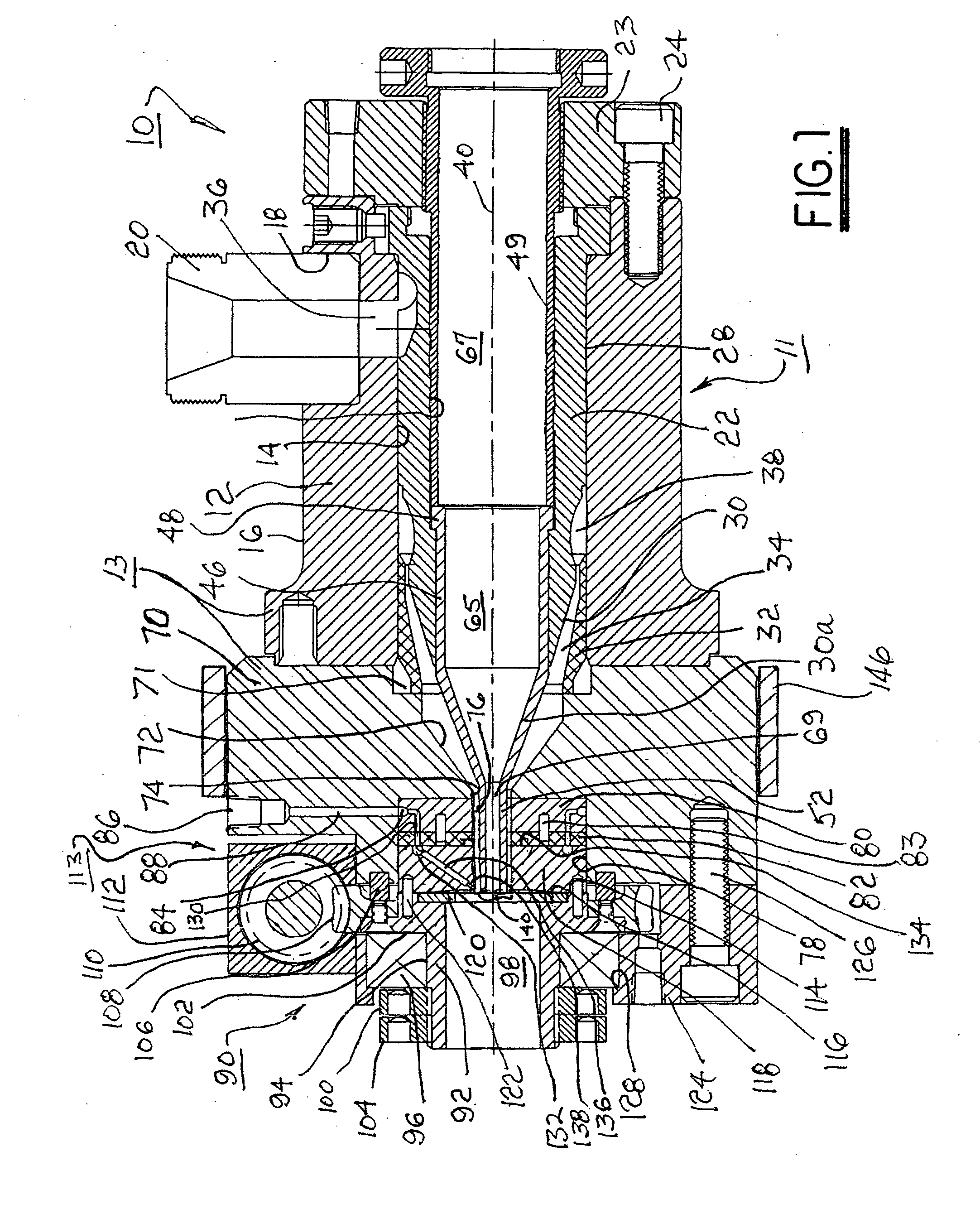

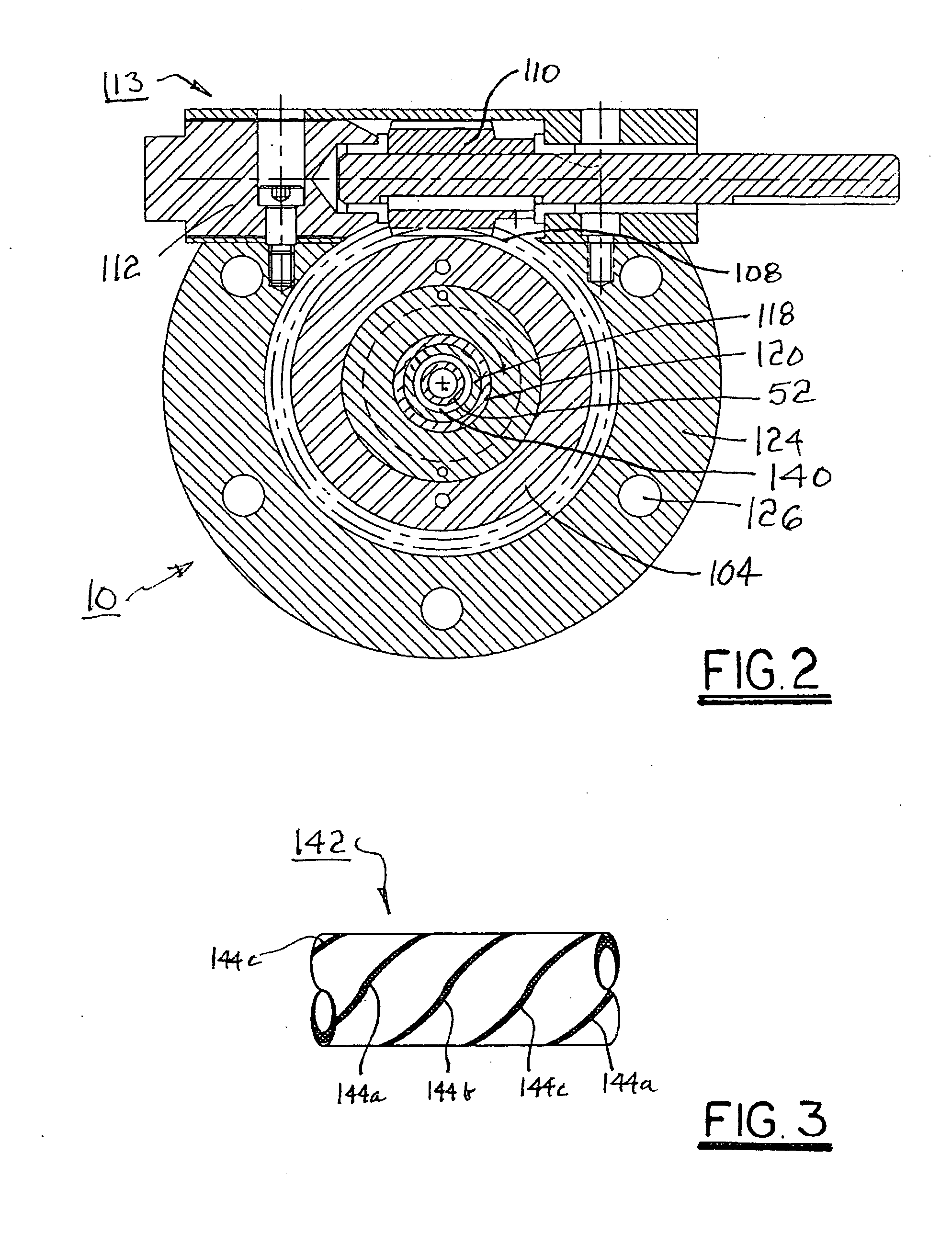

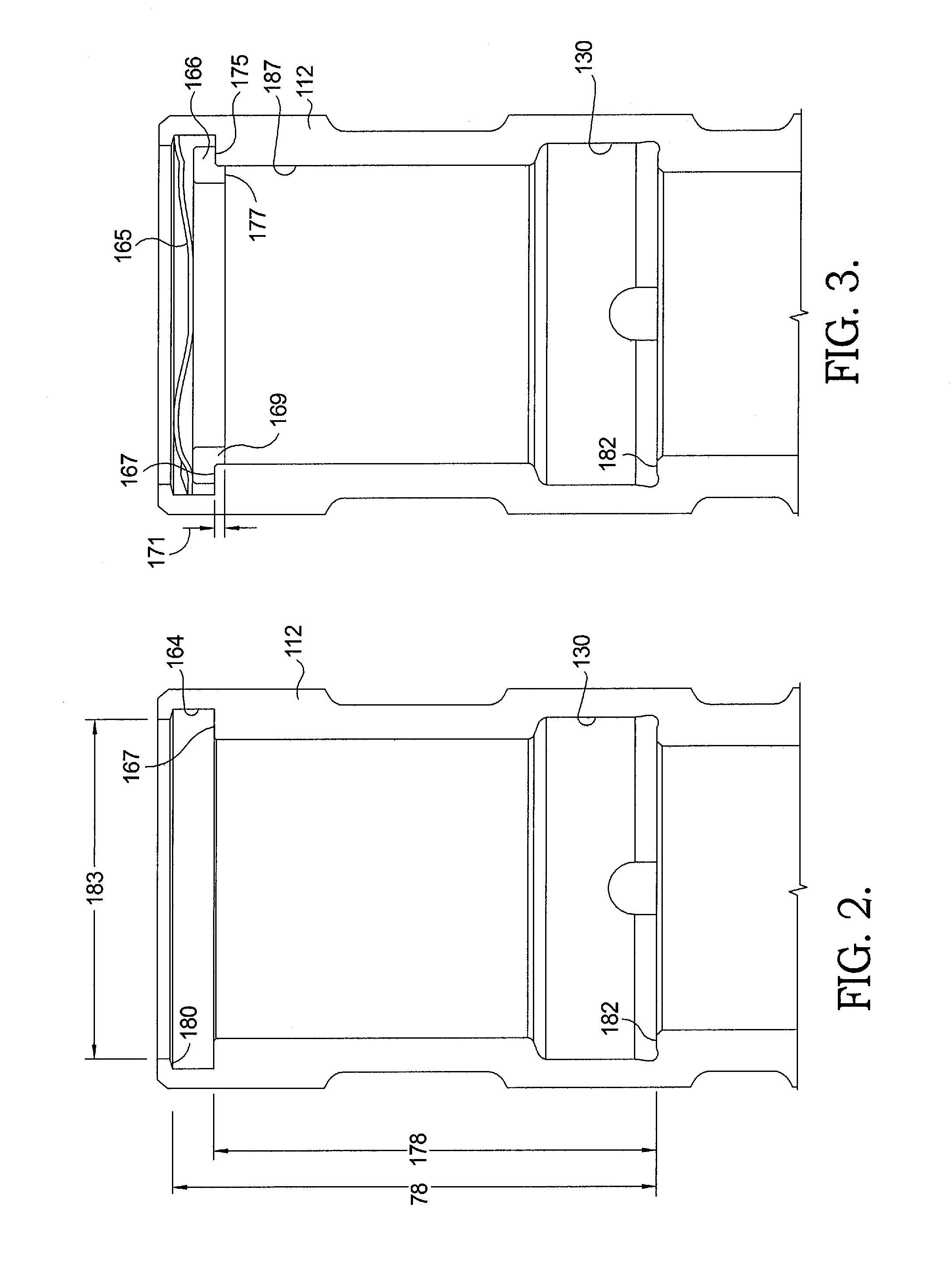

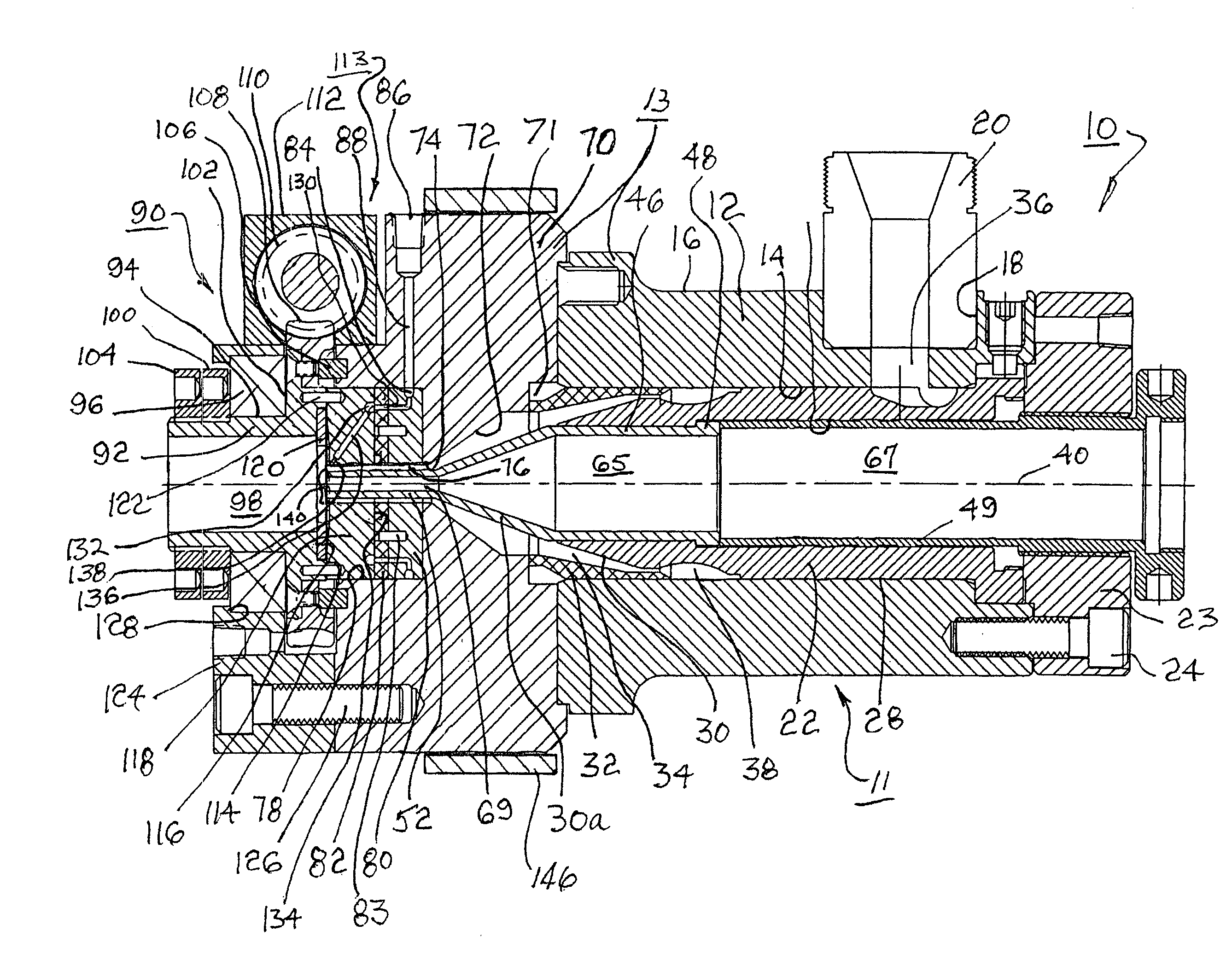

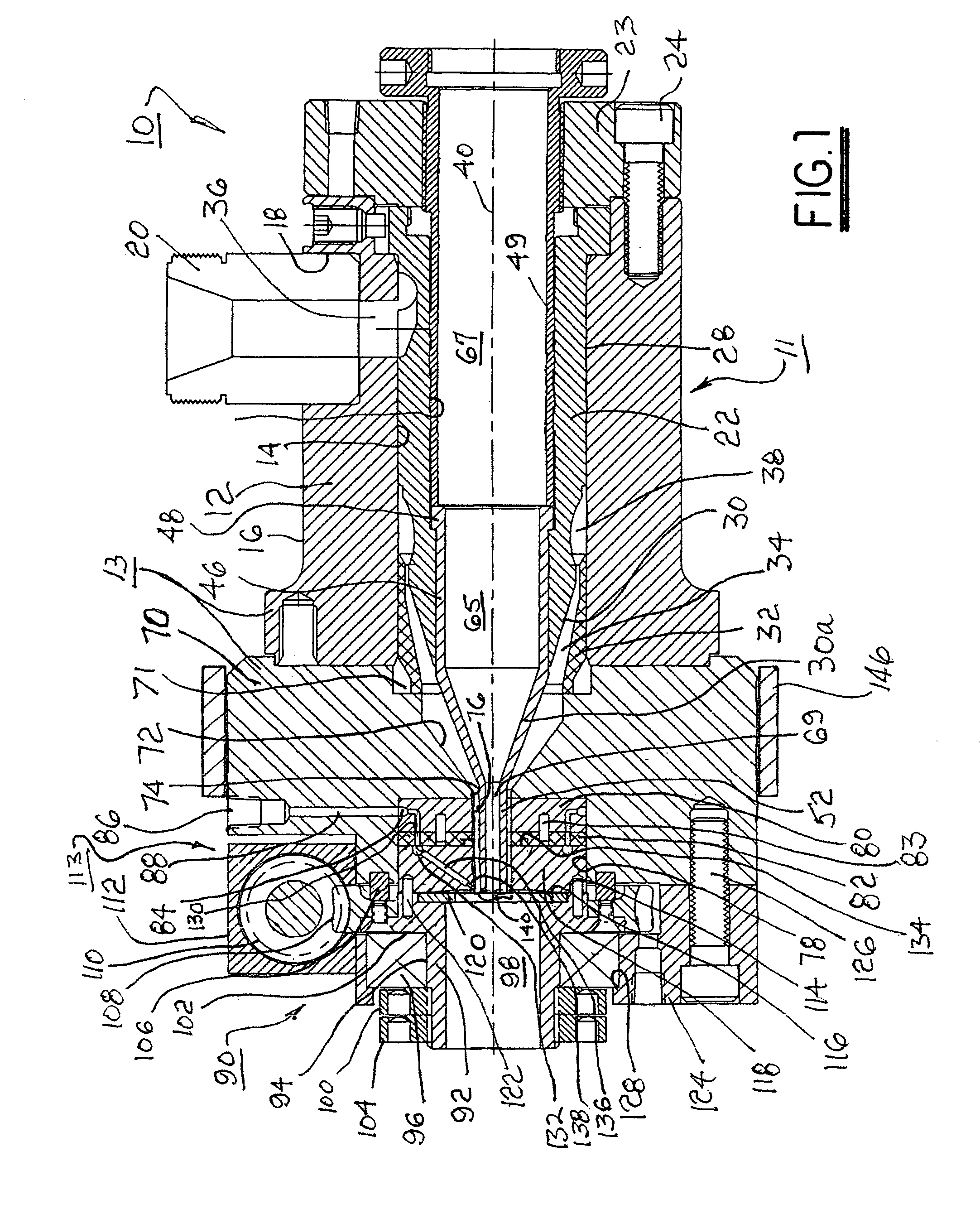

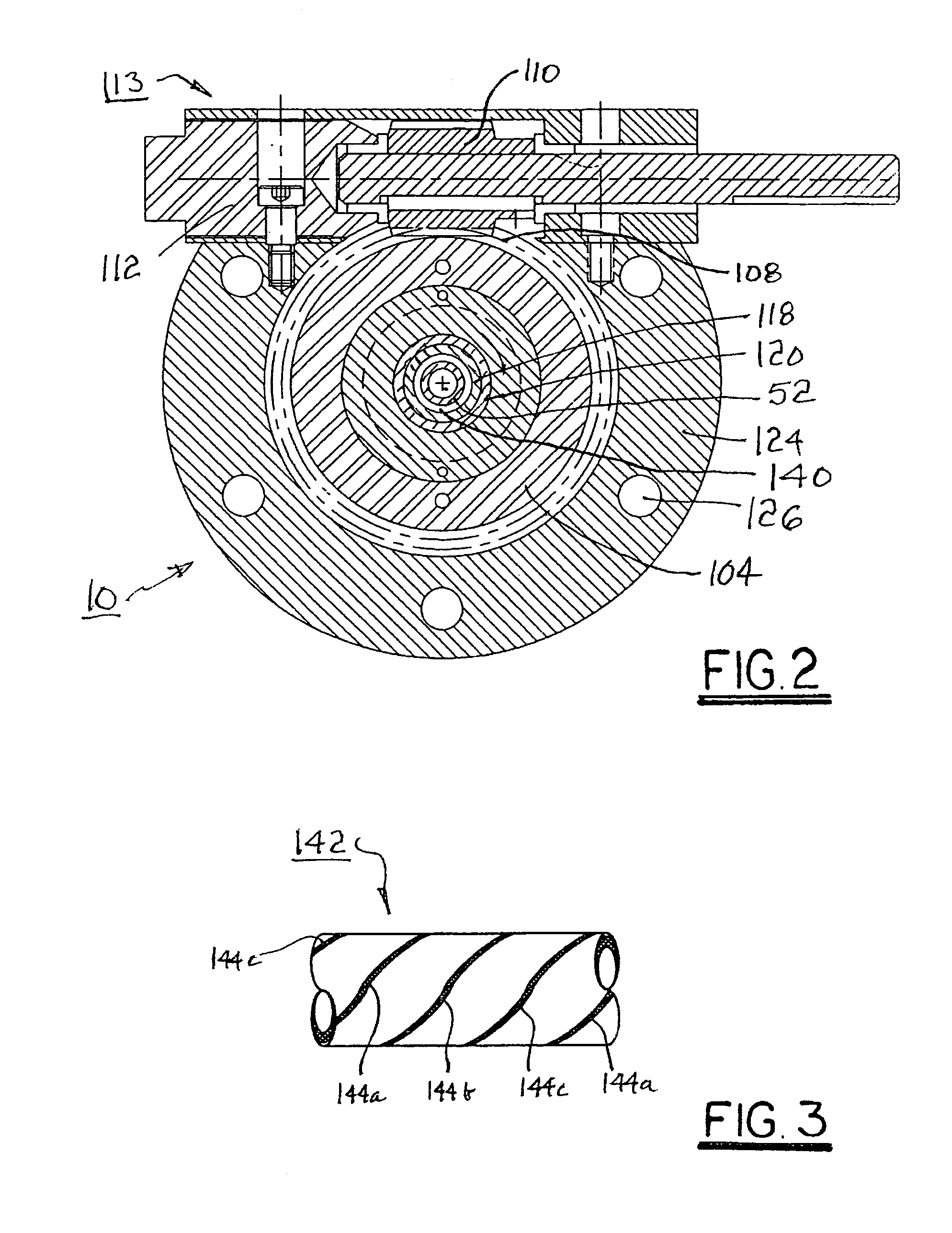

Rotatable head for forming spiral extrusions

InactiveUS20050260408A1Increase sealing forceAvoid pollutionConfectioneryFilament/thread formingEngineeringCounterbore

A polymer extrusion crosshead assembly for forming a spirally-striped extrusion. The assembly includes conventional components for admitting, turning, and accelerating primary molten polymer toward a novel rotating die sub-assembly. A body element includes an axial counterbore for receiving a manifold supply block in communication with a source of secondary striping polymer. A wear plate is attached to the manifold block. The die sub-assembly includes a striping die having an annular passage for conveying the primary polymer to form an extruded tube or a core material coating. The die is loaded against the wear plate by a Belleville washer. The die includes one or more striping nozzles in communication with the manifold block for injecting secondary striping polymer into the annular stream of primary polymer flowing through the die, creating a longitudinal stripe of striping polymer. Rotating the die while extruding both polymers yields a helically striped (spiral) extrusion.

Owner:CANGEN HLDG

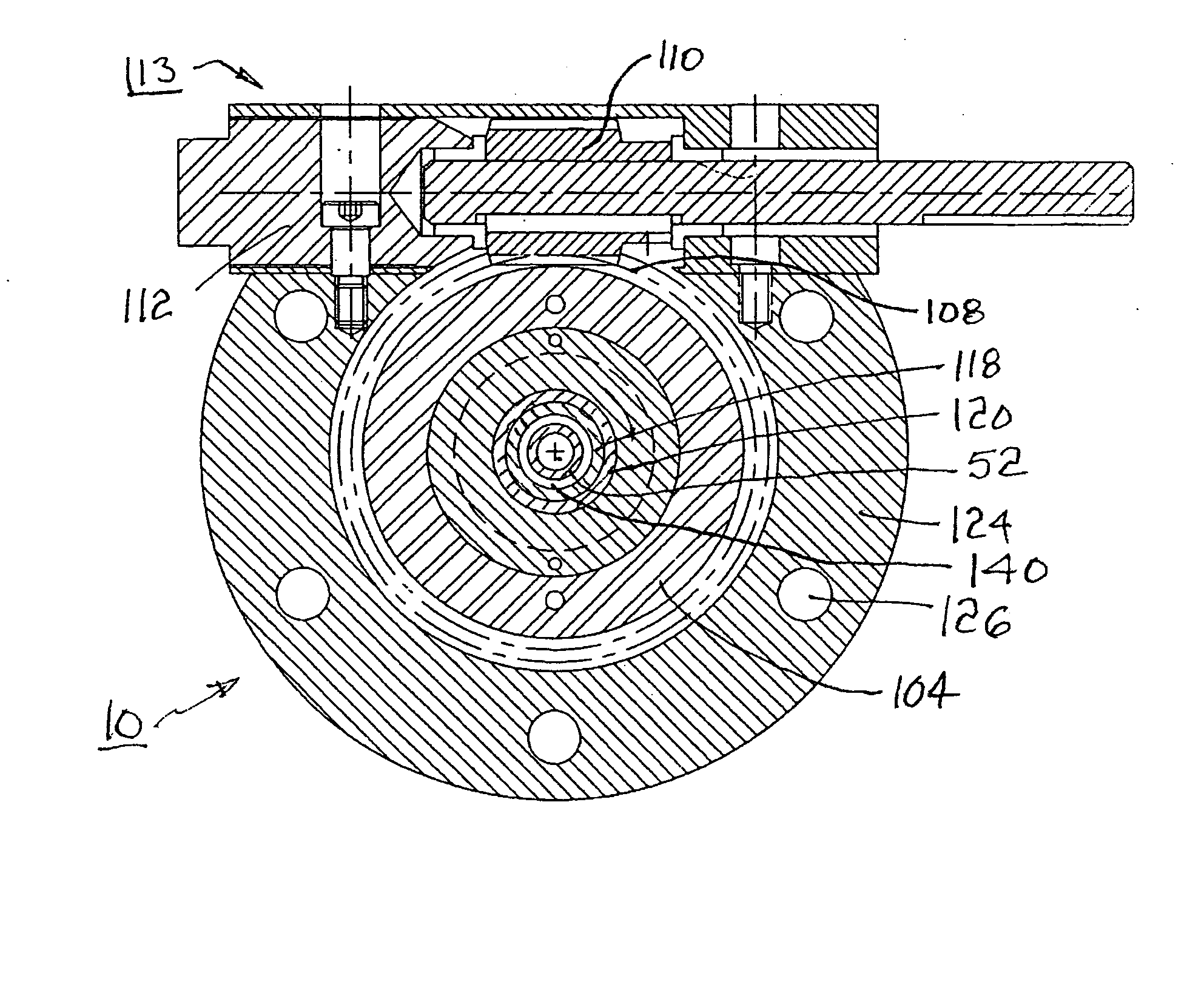

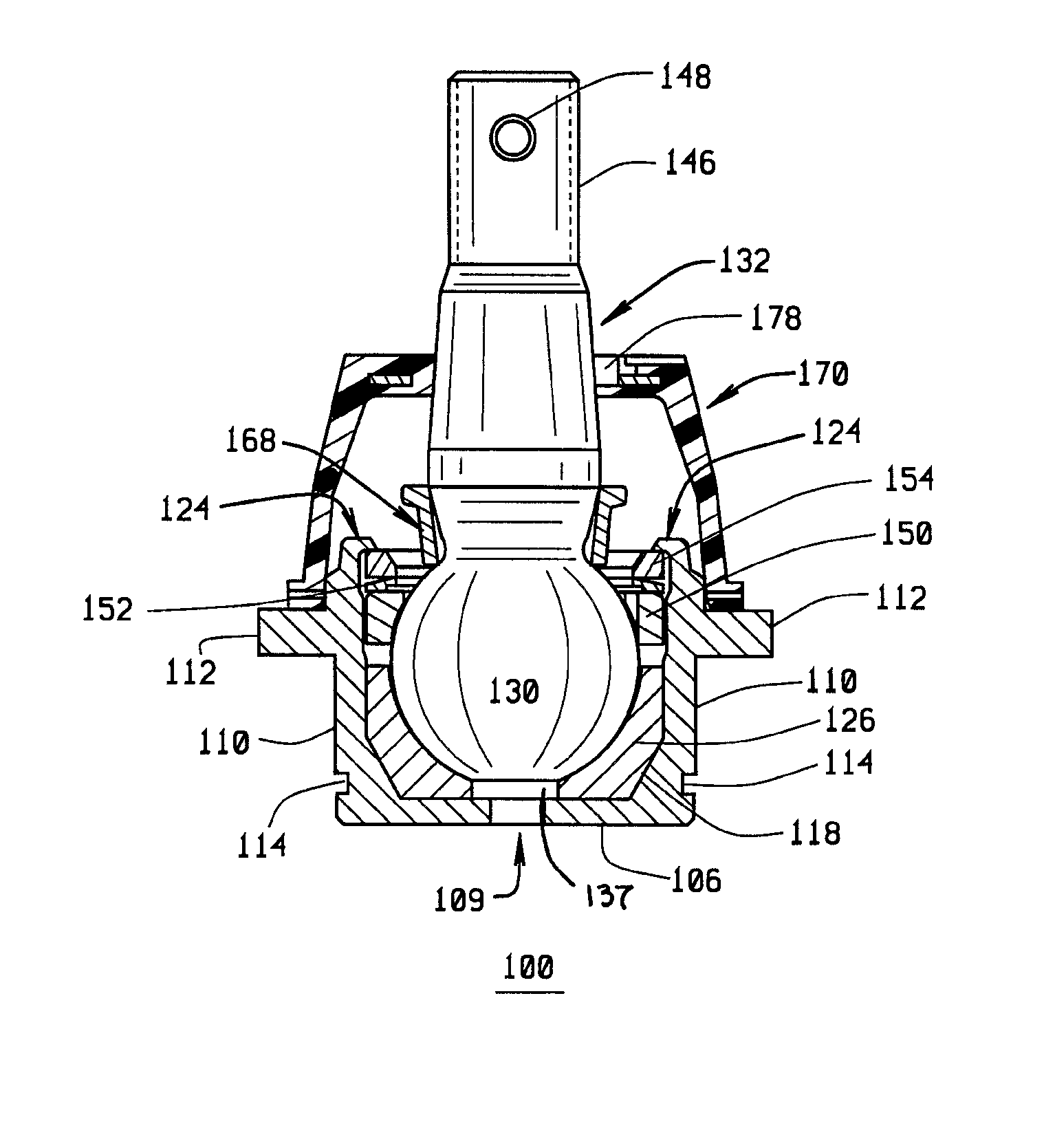

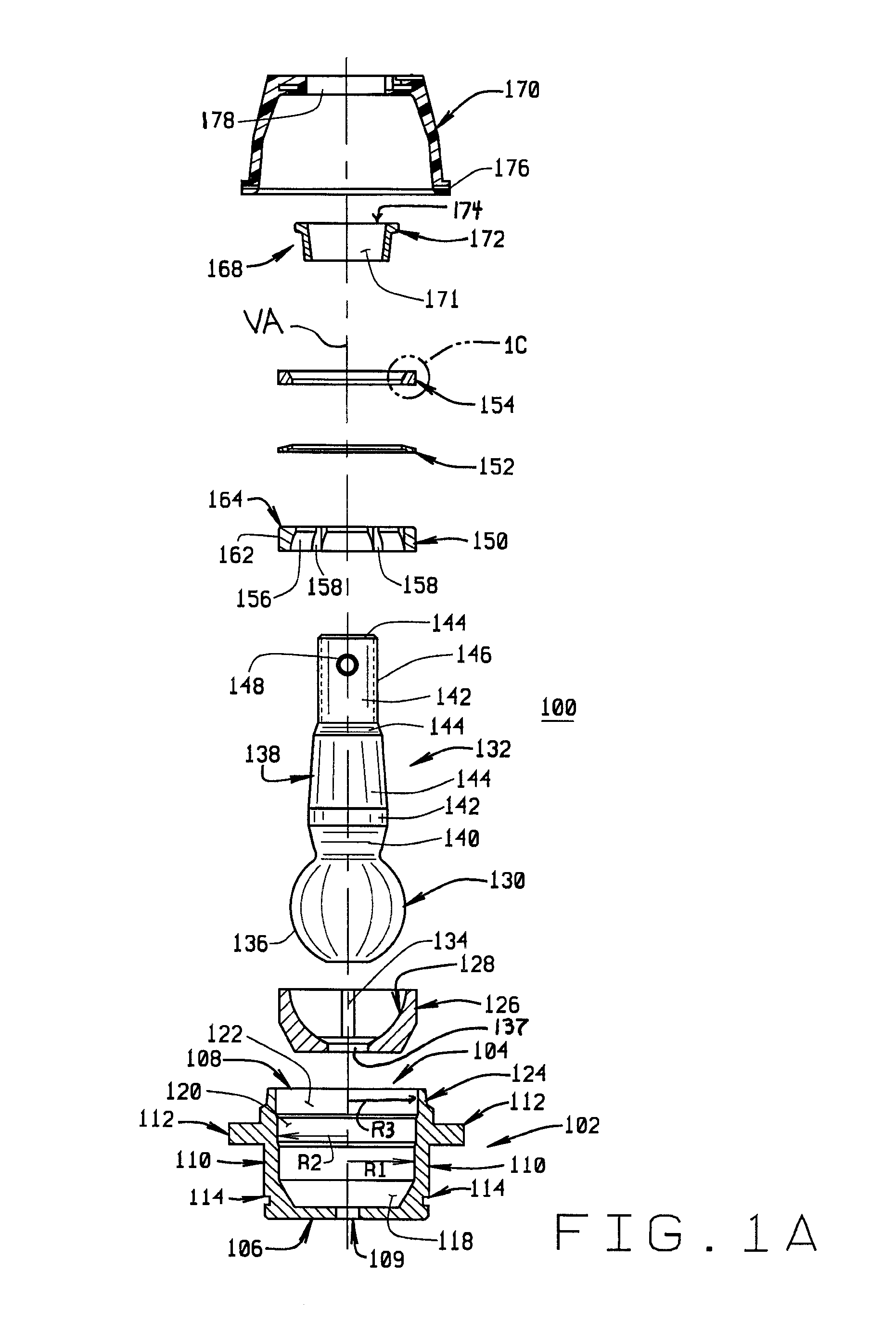

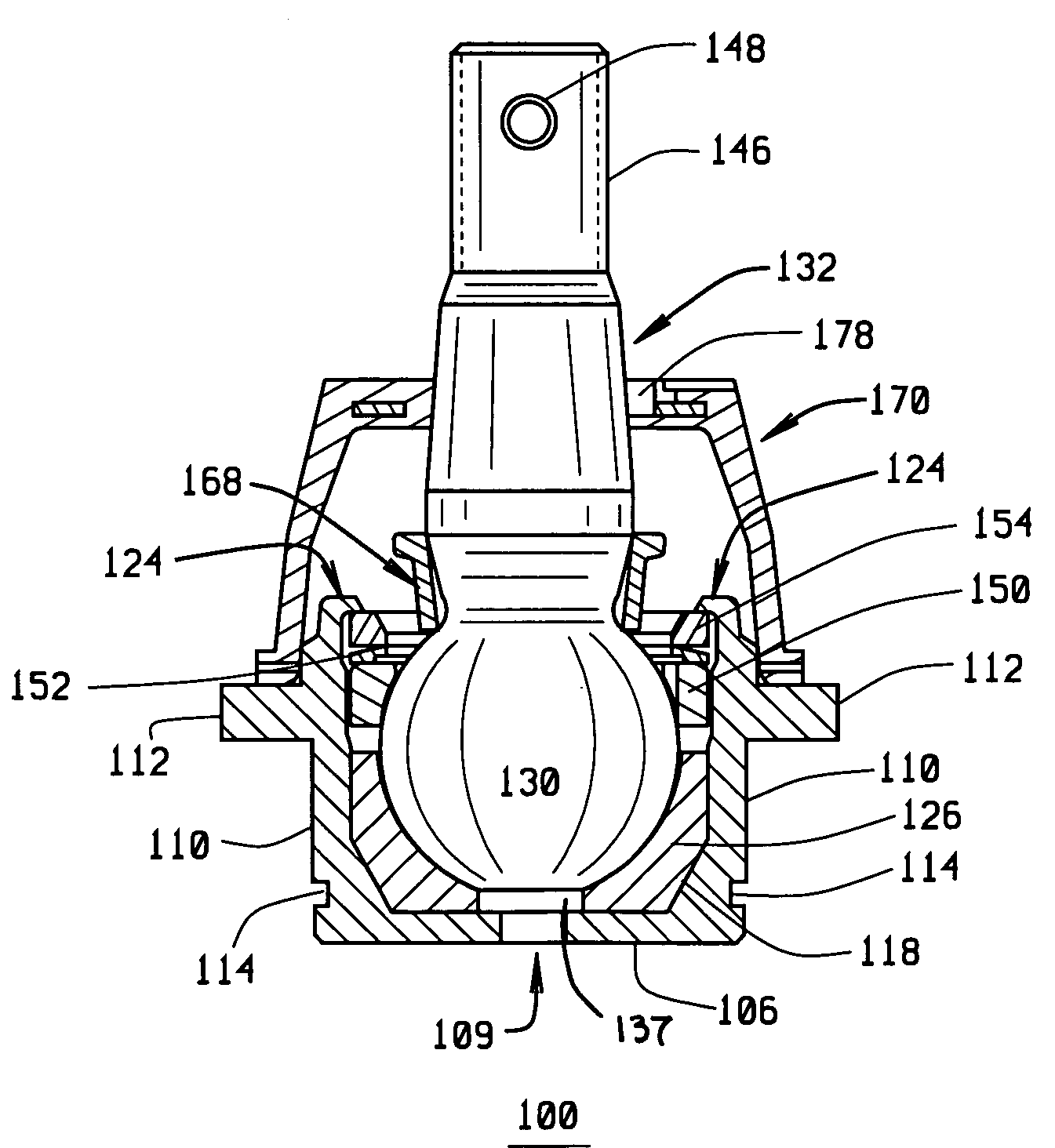

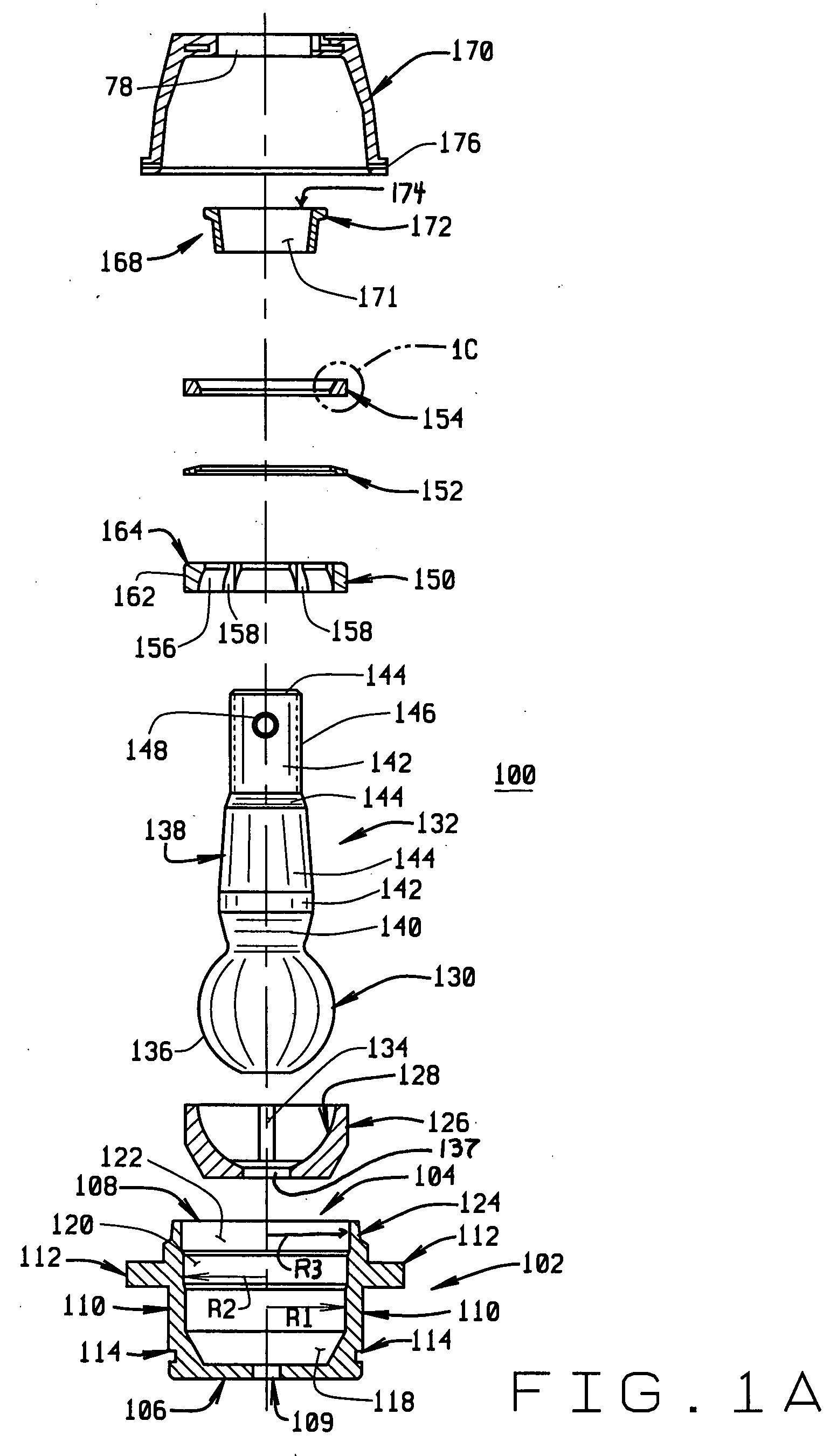

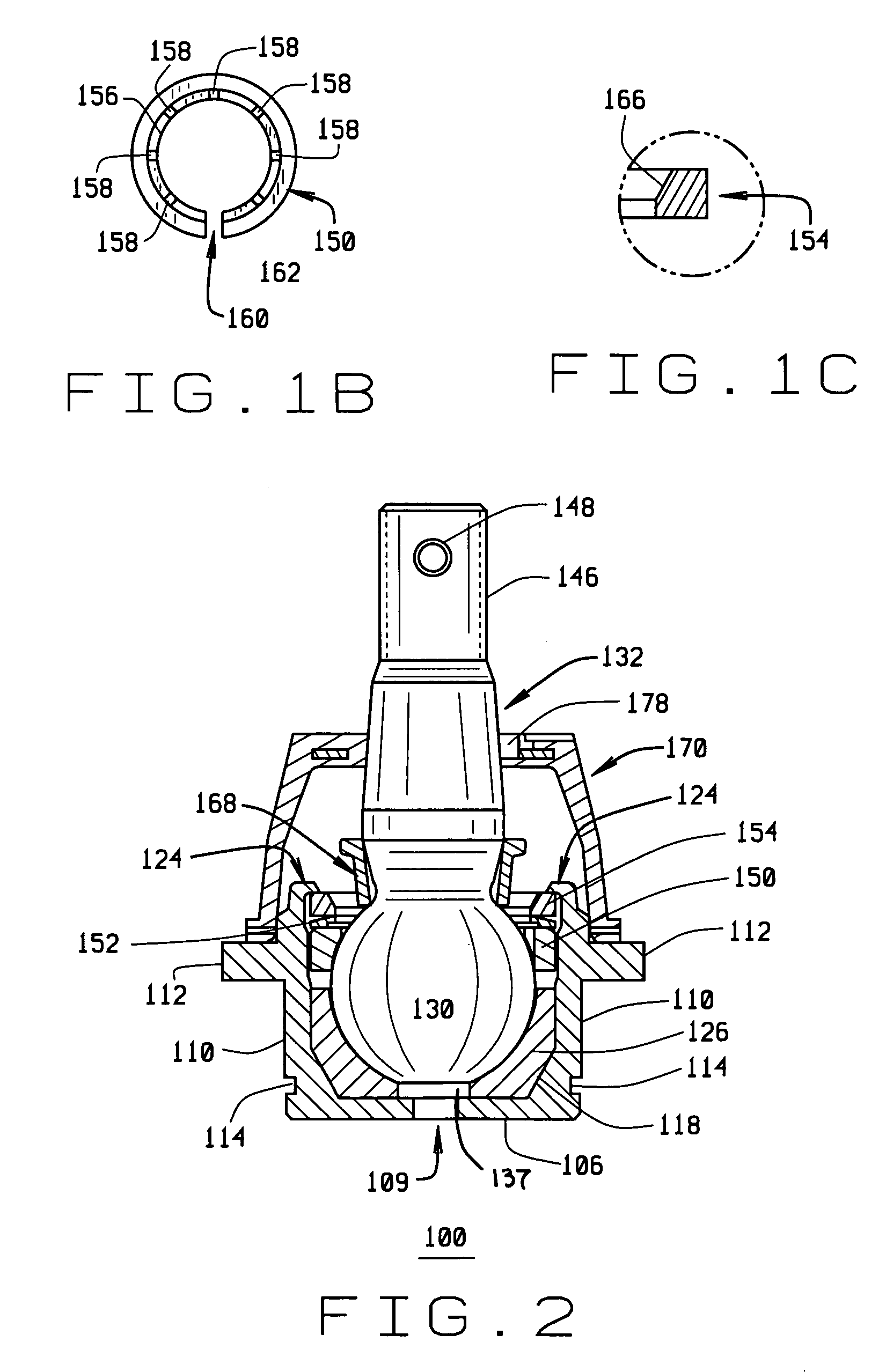

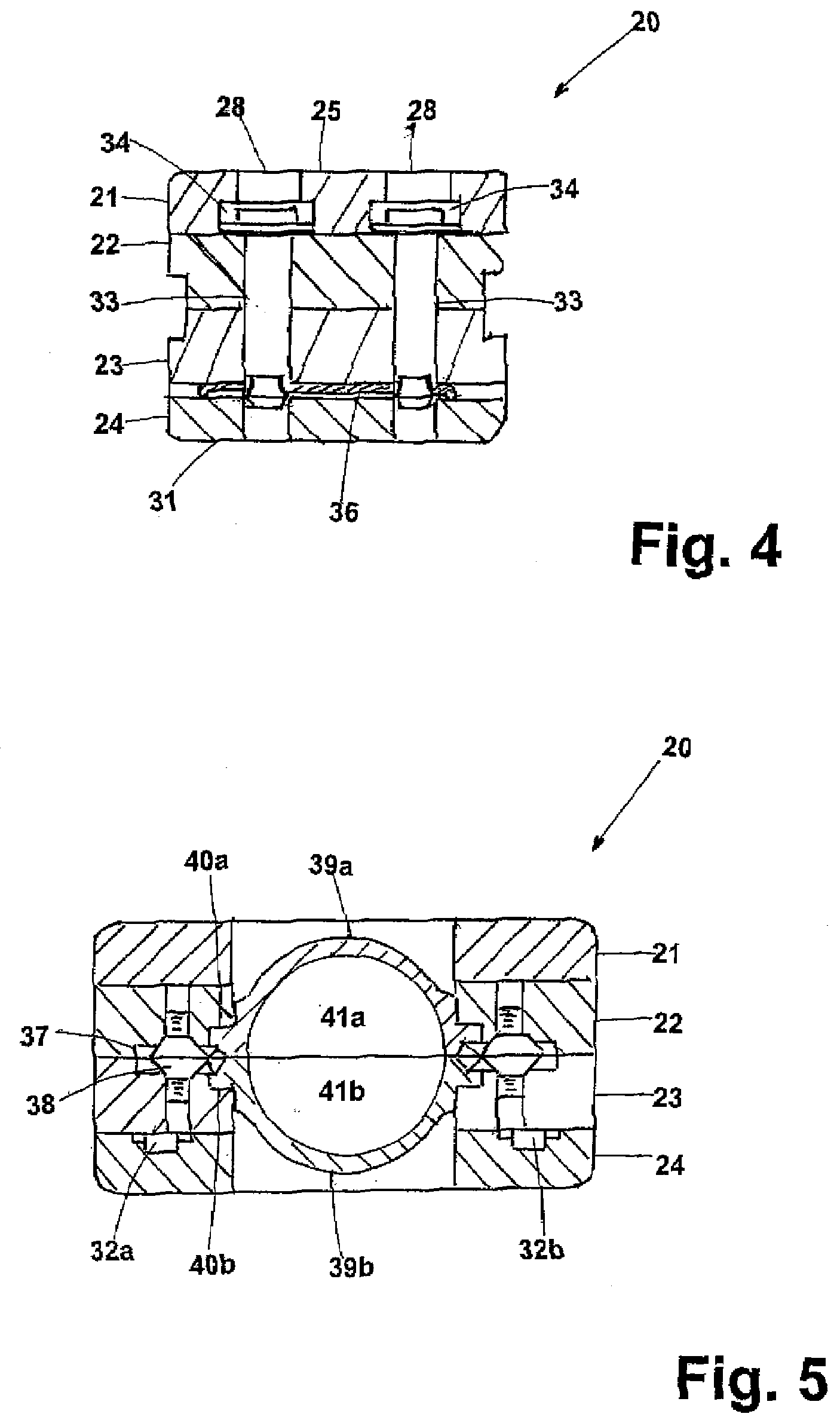

Metal split bearing compression load ball joint

An improved compression load ball joint assembly consisting of a metal housing having an open end and an internal cylindrical chamber which at least partially encloses a portion of a movable stud member, a lower metal bearing, an upper metal split bearing, and a Belleville washer. The upper metal split bearing is disposed opposite the lower metal bearing to engage the movable stud member and the housing simultaneously. The upper metal split bearing is configured to slide within the housing to provide for a constant wear surface against the movable stud member. The lower metal bearing, upper metal split bearing, Belleville washer, and movable stud member are contained within the housing by a cover plate concentrically disposed about the movable stud member and secured within the open end of the housing.

Owner:FEDERAL MOGUL WORLD WIDE LLC

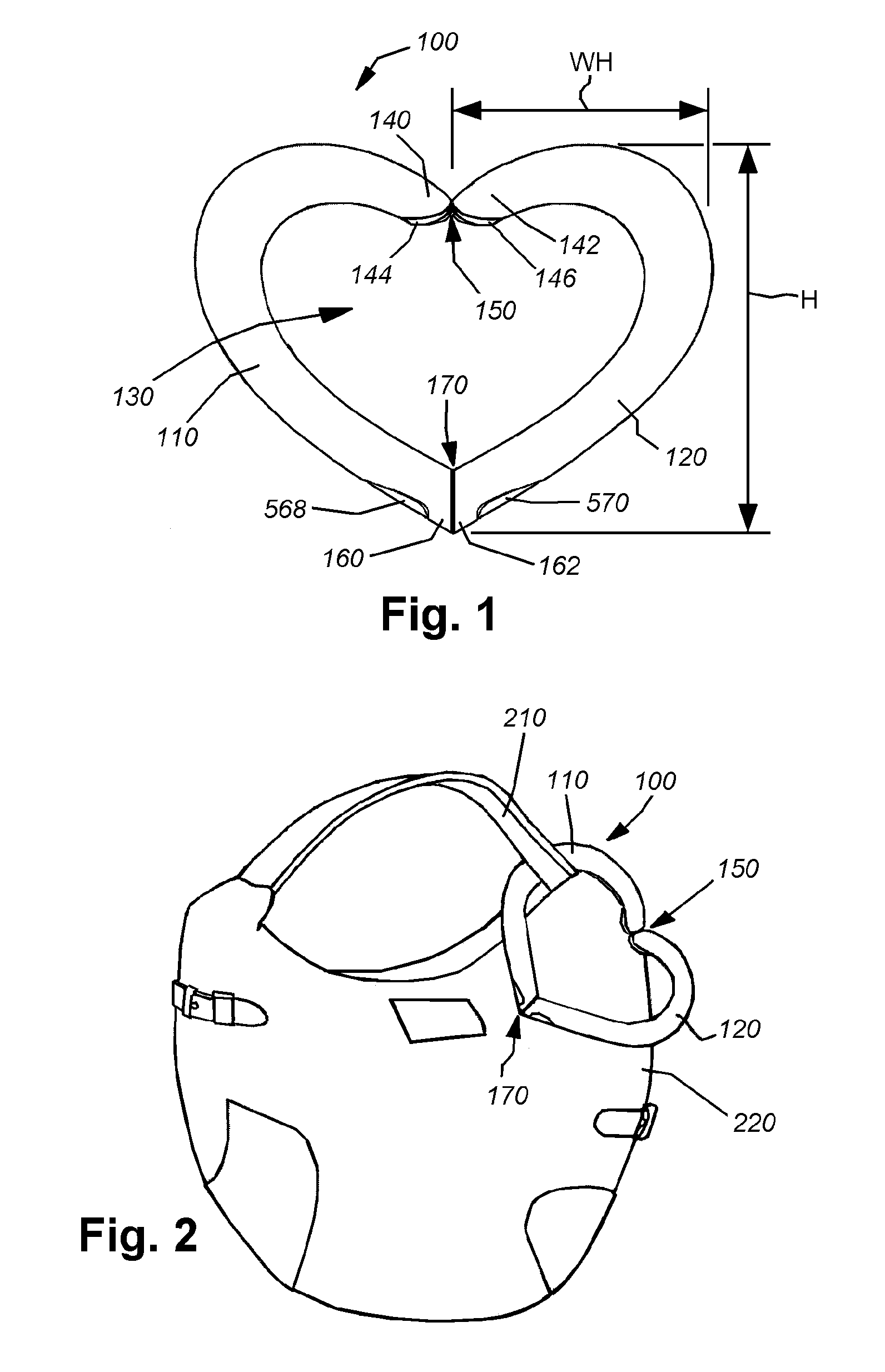

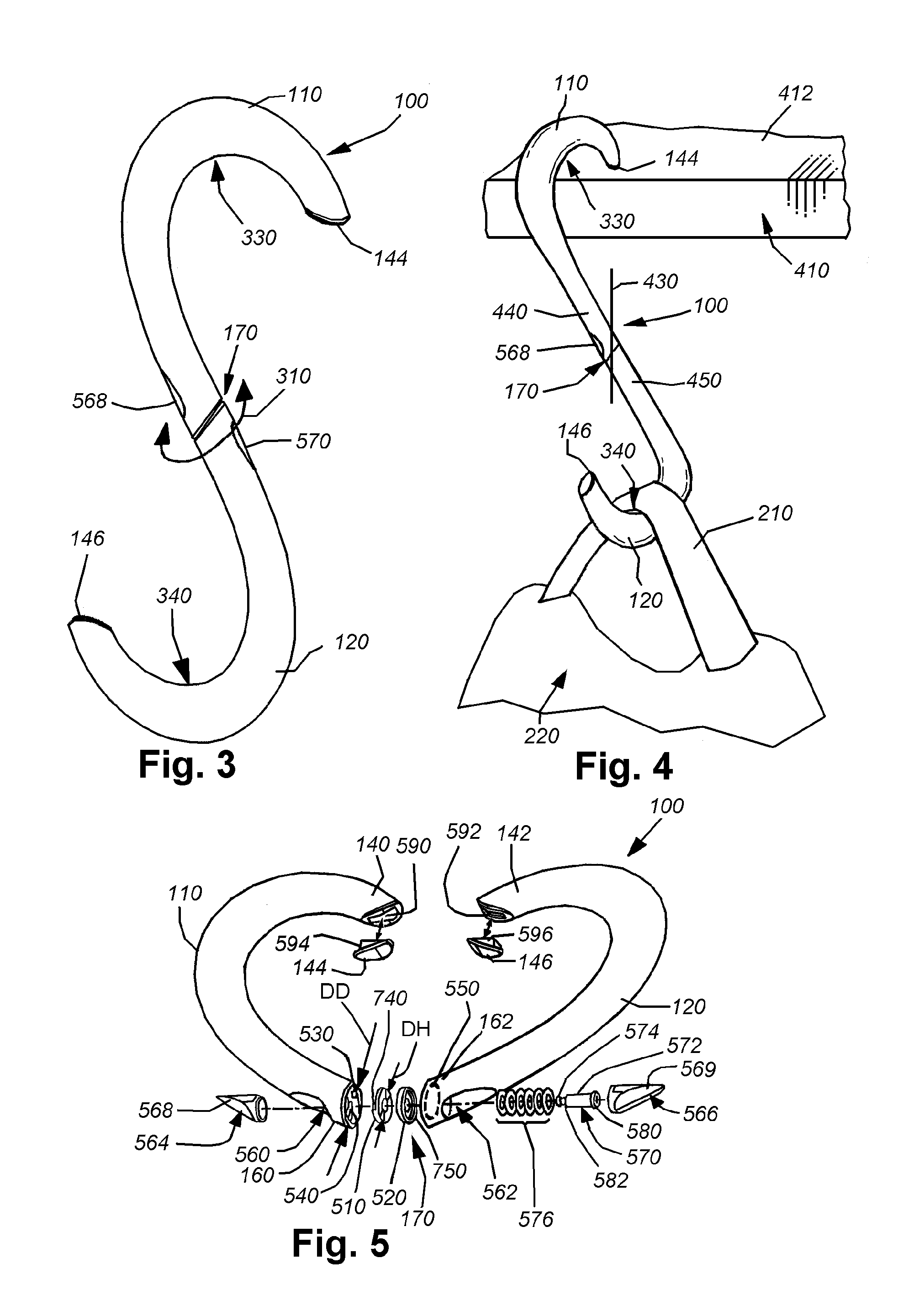

Rotary joint assembly and combination clip-hook and jewelry piece employing the same

ActiveUS20100078541A1Overcome disadvantagesGap is minimalSnap fastenersTravelling carriersDetentBelleville washer

This invention provides a combination clip and hook (clip) for use generally in suspending articles having shoulder or hand straps, or carrying other accessories, such as keys, which is rotatably movable about a rotary joint between a first position in which two opposing, rotatably joined portions of the overall clip structure are oriented together to form a continuous, enclosed shape that can be secured around another strap or loop on an item or piece of clothing, and a second position in which the two portions of the structure are rotated out of the enclosed shape, and into, for example, a substantially S-shaped hook in which one portion of the structure supports the strap of the item and the other portion can be applied to a clothing hook, chair back, table surface, door top, or other supporting member. The joint between the two portions can define a spring-loaded rotating pivot assembly with at least two indexing positions that are opposed by 180 degrees thereby defining the enclosed orientation and hook orientation, respectively. The rotary joint can be constructed with a pair of confronting male and female wedge and detent inserts that are normally biased toward each other by an embedded spring assembly. The spring assembly can comprise a series of Belleville washers arranged in a stack about a pivot shaft.

Owner:CLIPSY

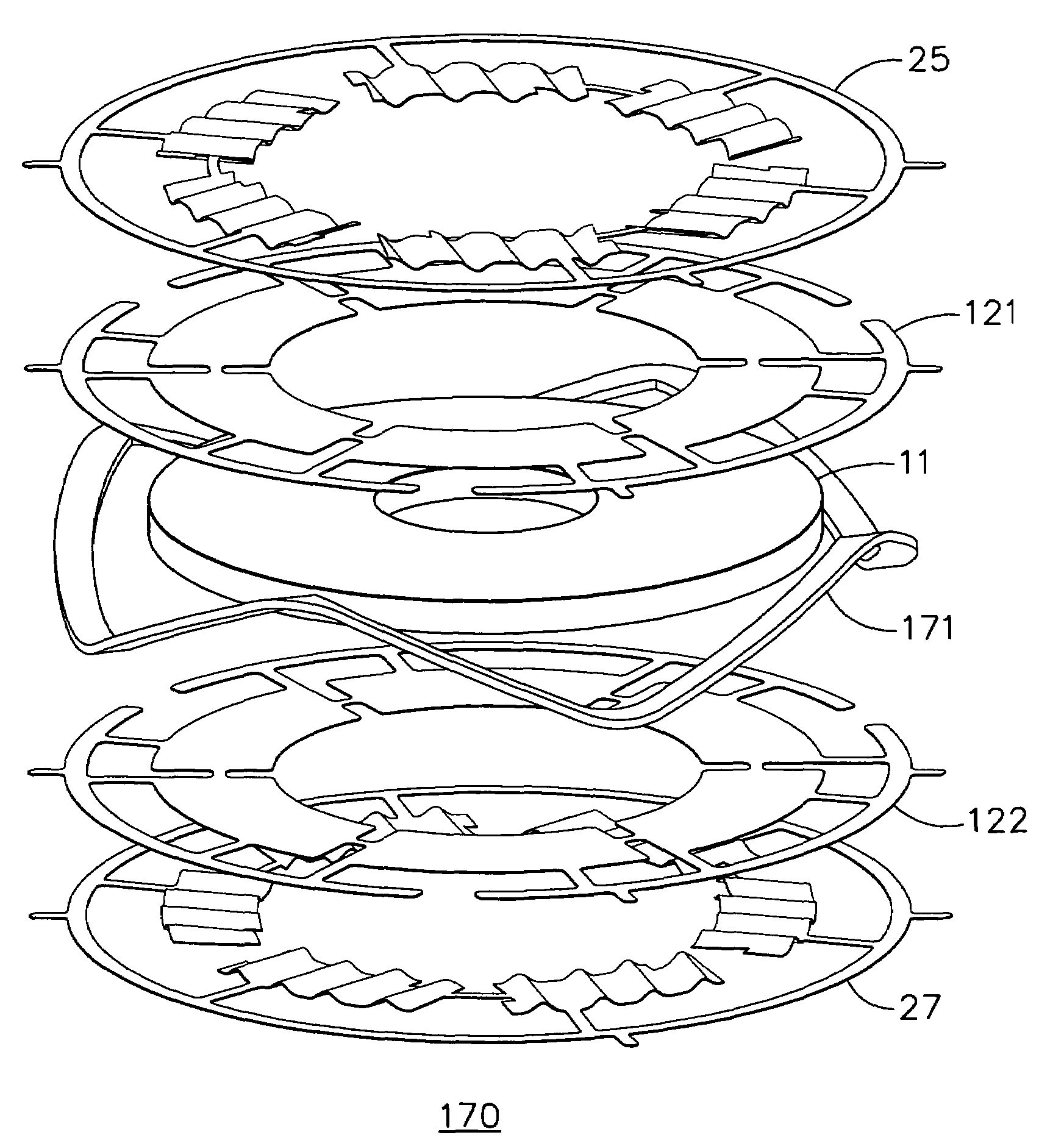

Intervertebral spacer device utilizing a spirally slotted belleville washer having radially spaced concentric grooves

InactiveUS7713302B2Reduce capacityAvoid skewJoint implantsSpinal implantsEngineeringBelleville washer

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer having radially spaced concentric grooves. In a preferred embodiment there is a single such belleville washer which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate.

Owner:HOWMEDICA OSTEONICS CORP

Thrust bearing

ActiveUS20050271311A1Reduced torque requirementsReduced startup torqueShaftsEngine componentsThrust bearingCoil spring

A hydrodynamic bearing set, for use with a thrust disk disposed between planar surfaces of a housing, includes first and second topfoils disposed adjacent first and second thrust disk axial bearing surfaces and removably secured to the housing. An underspring is secured between each planar housing surface and the corresponding topfoil. Dual-leaf spring pairs attached to at least one topfoil periphery function to urge the topfoils away from the thrust disk axial bearing surfaces by applying a force against a planar housing surface, another topfoil, or a spacer washer secured between adjacent topfoil dual-leaf pairs or frictionally retained within the housing. Alternatively, a wavy washer, a conical spring, a Belleville washer, or a coil spring can be substituted for the dual-leaf spring pairs.

Owner:HONEYWELL INT INC

Intervertebral spacer device utilizing a spirally slotted belleville washer having radially extending grooves

InactiveUS7270680B2Improve cycle lifeReduce capacityJoint implantsSpinal implantsEngineeringBelleville washer

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer having radially extending grooves. In a preferred embodiment there is a single such belleville which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified Belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate. The belleville washer has at least one radially extending groove and at least one spiral slot.

Owner:HOWMEDICA OSTEONICS CORP

Metal split bearing compression load ball joint

ActiveUS20050220531A1Easy to assembleSuspensionsCouplings for rigid shaftsEngineeringBelleville washer

An improved compression load ball joint assembly consisting of a metal housing having an open end and an internal cylindrical chamber which at least partially encloses a portion of a movable stud member, a lower metal bearing, an upper metal split bearing, and a Belleville washer. The upper metal split bearing is disposed opposite the lower metal bearing to engage the movable stud member and the housing simultaneously. The upper metal split bearing is configured to slide within the housing to provide for a constant wear surface against the movable stud member. The lower metal bearing, upper metal split bearing, Belleville washer, and movable stud member are contained within the housing by a cover plate concentrically disposed about the movable stud member and secured within the open end of the housing.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Intervertebral spacer device utilizing a belleville washer having radially extending grooves

InactiveUS7208014B2Improve cycle lifeReduce capacityJoint implantsSpinal implantsVertebral boneBelleville washer

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, coupled to one another by a convex element mounted to one of the plates and maintained against the other plate by a retaining wall and a retaining ring.

Owner:HOWMEDICA OSTEONICS CORP

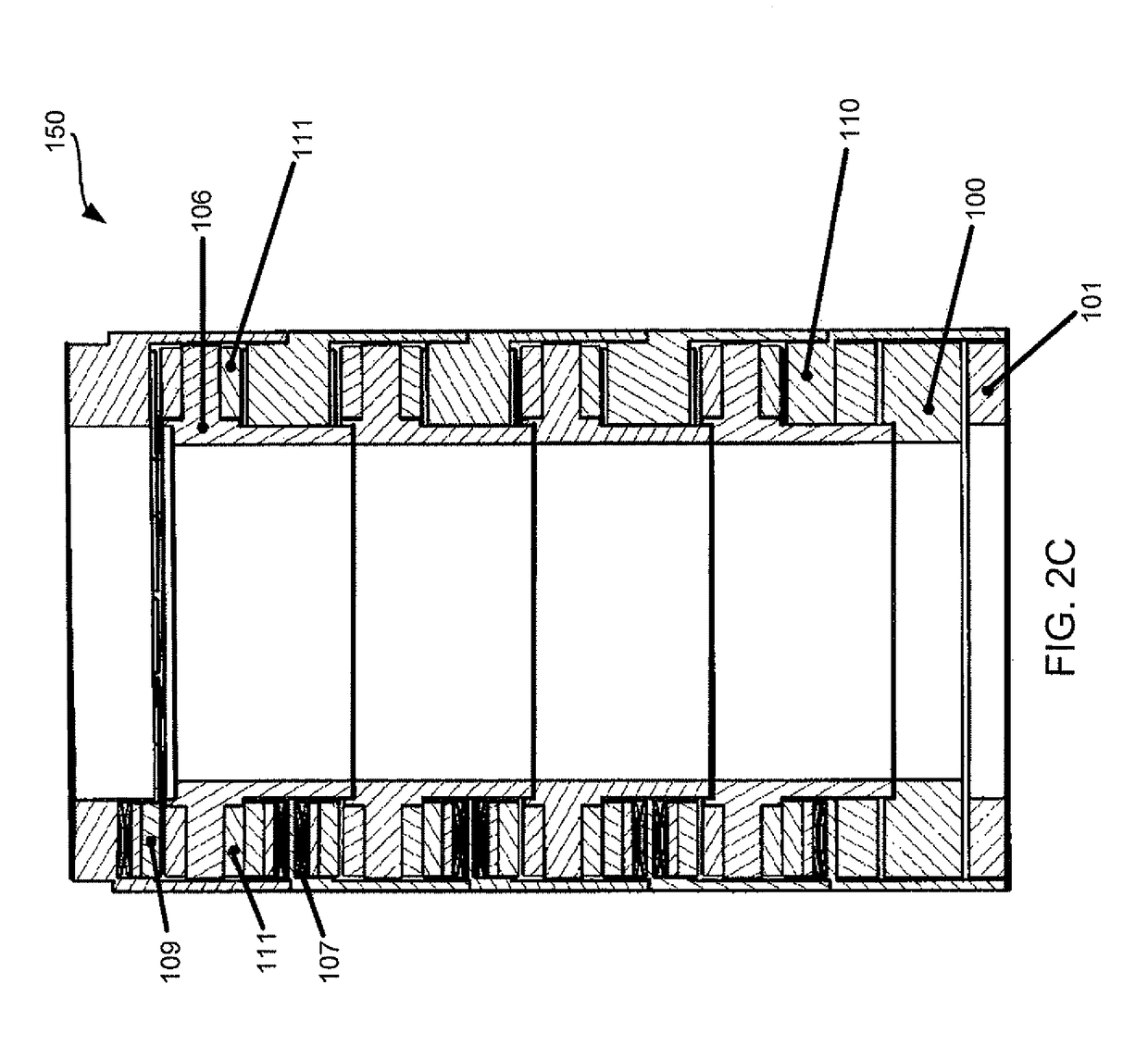

Thrust bearing assembly

ActiveUS8118117B2Avoiding costly finish-grinding/lappingAccurate locationBearing assemblyShaftsWear resistantThrust bearing

A thrust bearing assembly comprising a bearing runner and a bearing carrier, the carrier defining thrust pad sites annularly around the carrier, with a thrust pad disposed at a site and with the carrier limiting movement of the thrust pad in a direction generally radial to the longitudinal axis of the runner while allowing the thrust pad to move in a direction generally parallel to the longitudinal axis. The pads can tilt under load to form a hydrodynamic wedge. A runner may have a wear resistant face. In one implementation, at each site, a deflection element (e.g., Belleville washer) is at least partially disposed within a cavity and a pad is disposed over the deflection element. The wear resistant face contacts the pad. Another embodiment rigidly connects pads disposed on opposite sides of a stationary bearing carrier. Another embodiment attaches pads to a bearing carrier using pad holder assemblies.

Owner:CERADYNE

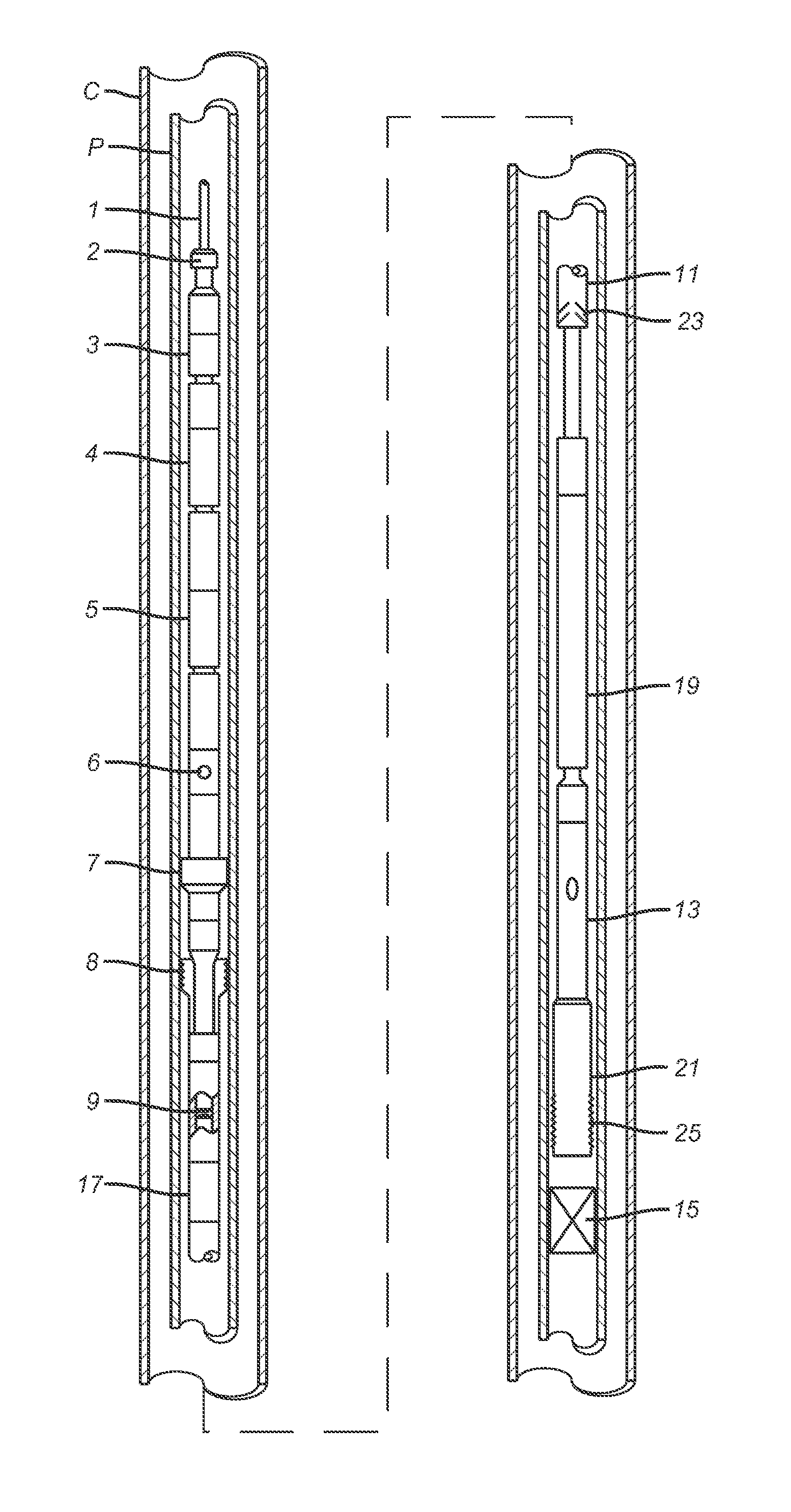

Pressure Actuated Ported Sub for Subterranean Cement Completions

A shifting sleeve has differential piston areas so that applied pressure displaces the sleeve against spring bias, which preferably is a series of Belleville washer stacks associated with modular mandrel components, to obtain the desired opposing force to the movement initiated with pressure applied to differential piston areas. An indexing feature is located between the sleeve and the mandrel passage wall and on a predetermined number of cycles disables the Belleville washer stacks from biasing the sleeve in an opposed direction as when pressure is applied. At this time the pressure in the mandrel acting on the differential piston area simply shifts the sleeve to open a lateral port so that fracturing through the cement that was earlier placed with the port closed can take place.

Owner:BAKER HUGHES INC

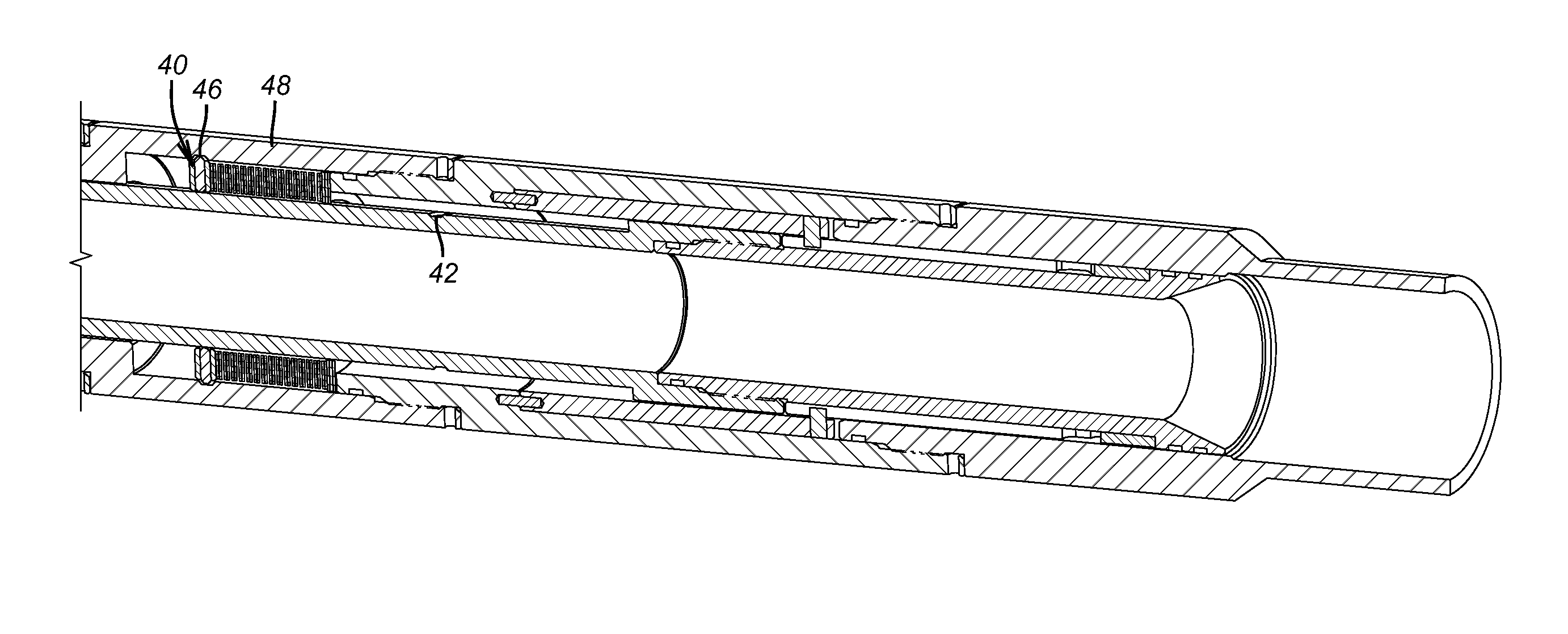

Slickline or Wireline Run Hydraulic Motor Driven Mill

A tool is run in with a bottom hole assembly that includes a seal and support within the tubing where a fish is to be milled. A ported sub allows pressurized fluid pumped from the surface to enter the bottom hole assembly above the sealed support location and to be directed to set an anchor and to a fluid driven motor such as a progressive cavity motor that is in turn connected milling tool at the rotor of the progressive cavity motor. The fluid exiting the stator goes through a debris removal device and can return to the surface through an annulus around the production tubing. A telescoping joint allows the mill to axially progress with a force applied to the fish generated by a tractor or a stack of Belleville washers.

Owner:BAKER HUGHES INC

Apparatus and Method for Setting Mechanical Lash in a Valve-Deactivating Hydraulic Lash Adjuster

InactiveUS20110061615A1Travel can be limitedValve arrangementsMachines/enginesEngineeringManufacturing variation

A DHLA including a hydraulic lash adjustment mechanism disposed within a plunger slidably disposed within a pin housing that is slidably disposed within an axial bore in an adjuster body. A lash ring disposed in a groove near the outer end of the DHLA body includes a portion extending into the bore to limit travel of the pin housing and thereby set the internal mechanical lash in the DHLA. The lash ring has a thickness selected to provided a predetermined amount of mechanical lash in the assembled lifter, which thickness varies from assembly to assembly to compensate for manufacturing variation in the components. A biasing means such as a wave ring, a Belleville washer or a beveled retaining ring is also installed in the annular groove to urge the lash ring against the lower surface of the groove under all DHLA operating conditions.

Owner:DELPHI TECH IP LTD

Spinal baseplates with ball joint coupling and a retaining member

An artificial intervertebral disc having a pair of opposing plate members for seating against opposing vertebral bone surfaces, separated by a spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer having radially extending grooves. One plate member has a centrally located ball-shaped protrusion that is rotatably coupled in a central socket in the narrow end of the belleville washer, and the wide end of the belleville washer is held against the other plate member by a shield with rivets. Therefore, the disc assembly will not come apart under tension loads applied to the plate members, and the location of the ball joint coupling provides the disc assembly with a centroid of motion that is centrally located between the vertebral bone surfaces, both causing the disc assembly to behave similarly in these respects to a healthy natural intervertebral disc.

Owner:HOWMEDICA OSTEONICS CORP

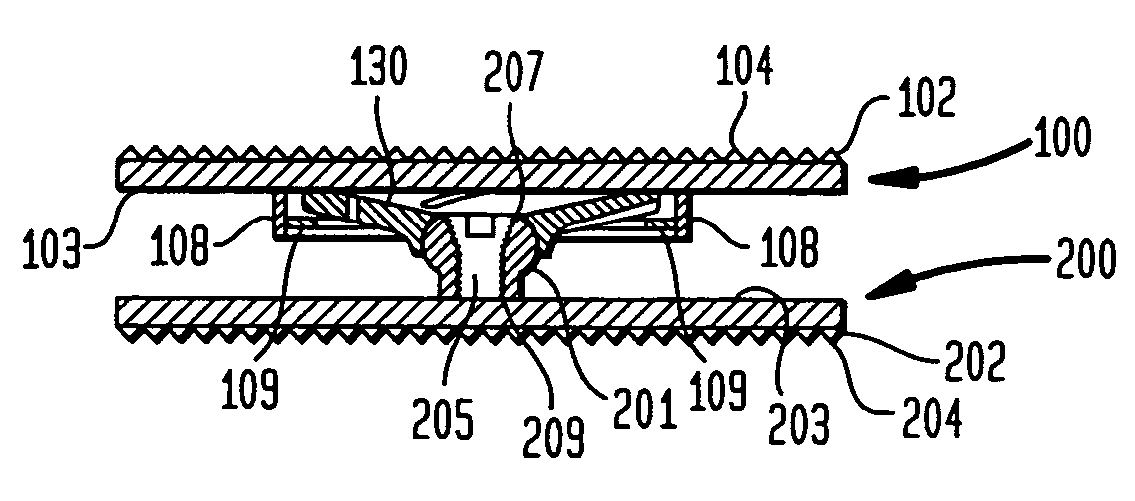

Artificial intervertebral disc having a slotted belleville washer force restoring element

InactiveUS20050234554A1Improve securityStrong forceJoint implantsSpinal implantsIntervertebral discEngineering

An intervertebral spacer device includes first and second plates disposed in a spaced apart relationship, each plate having an inner surface and an outer surface, the inner surfaces of the opposing plates facing one another. The device also includes at least one restoring force providing element disposed between the inner surfaces of the plates, wherein a compressive load applied to the outer surfaces of the first and second plates is counteracted by the at least one restoring force providing element. The at least one restoring force providing element includes at least one slotted belleville washer having a convex shape when unloaded and a flatter shape when loaded, whereby one or more slots of the belleville washer widen when compressively loaded, and whereby the at least one slotted belleville washer is unloaded when no load is applied to the outer surfaces of the first and second plates, and is loaded when the compressive load is applied to the outer surfaces of the first and second plates. The second plate has an annular groove formed in the inner surface of the second plate, the device including a retaining wall and a retaining ring, whereby a wide end of the at least one belleville washer is captured by the retaining wall and the retaining ring for maintaining the wide end adjacent the inner surface of the second plate.

Owner:HOWMEDICA OSTEONICS CORP

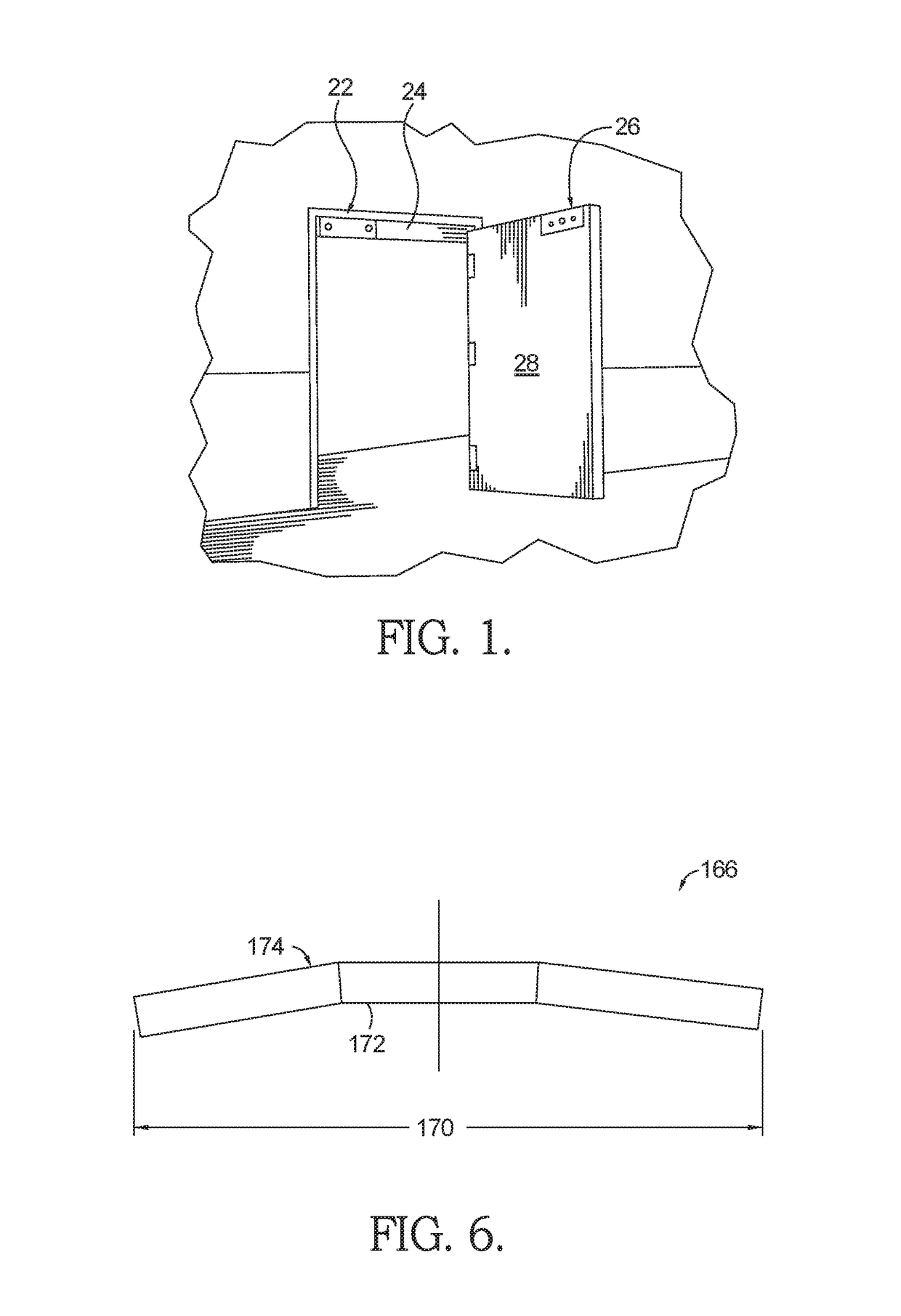

Mold for forming golf ball covers

The present invention is an improved single cavity molding device and method for compression molding polyurethane, polyurea or polyurethane / polyurea hybrid covers over golf ball sub-assemblies. The device utilizes top and bottom mold-halves and is particularly novel in that it does not require the use of bolts to secure the mold-halves. The molding device utilizes a pair mold halves, each having a backing plate and mold frame for housing a hemispherical cavity mold. The invention utilizes a plurality of clamping pins, each pin having its top portion reciprocally disposed in a recess of the backing plate of the top mold. Double spring Belleville washers are coupled to the top portion of each clamping pin and upon the application of a vertical force, the washers are compressed to place the device in a controlled state of tension and also cause the clamping pins, to move downward into a locking position with slidable retainers to therein maintain a compressive force of at least 384 pounds on the golf ball sub-assembly for the molding process. Upon completion of the molding process, a vertical force is applied to the top of the clamping pins wherein they are moved out of a coupled relationship with the engagement loops, and with a coordinating horizontal biasing, the retainers are moved away from the pins, whereby the mold-halves may be then opened and a covered golf ball removed.

Owner:ACUSHNET CO

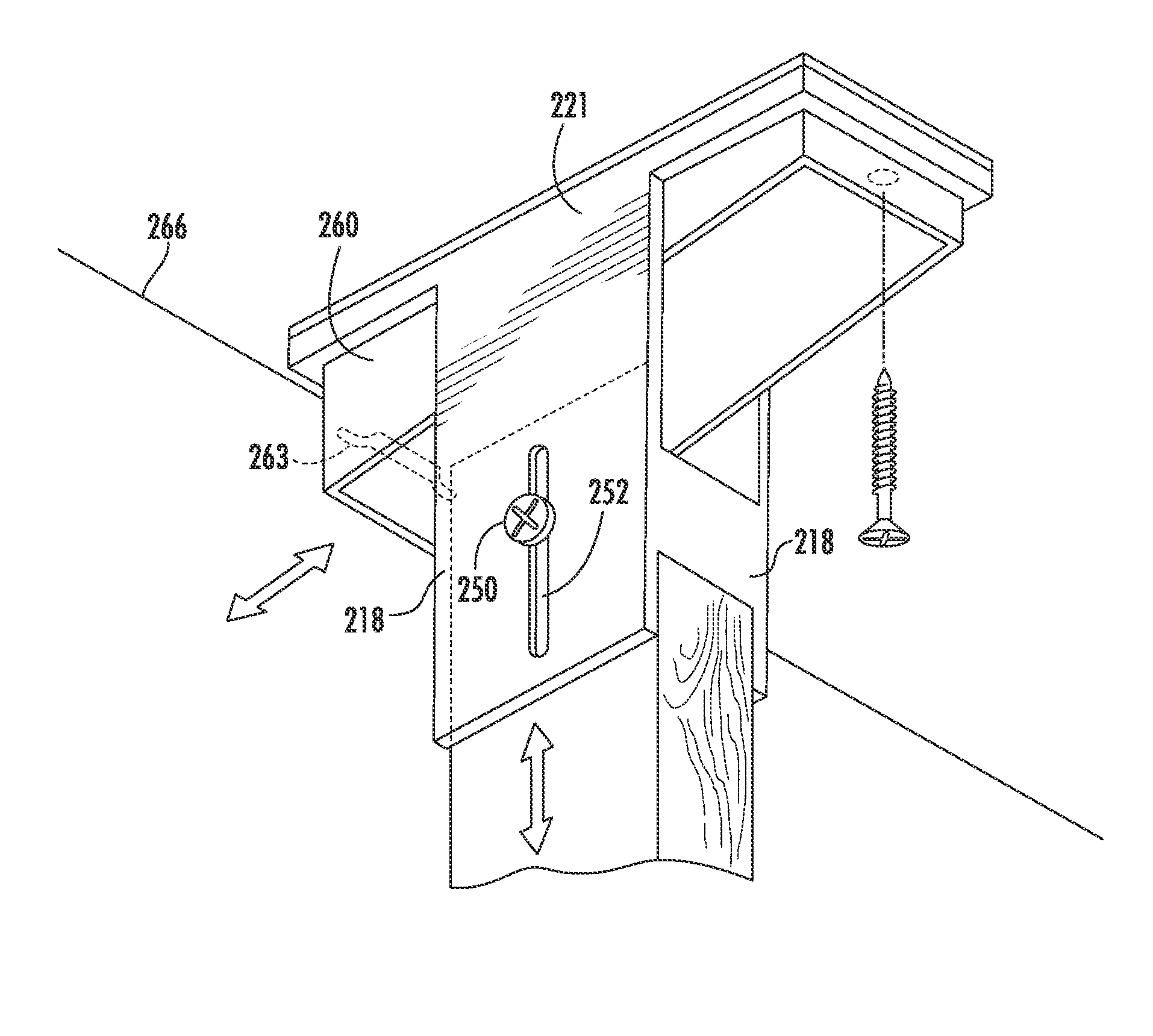

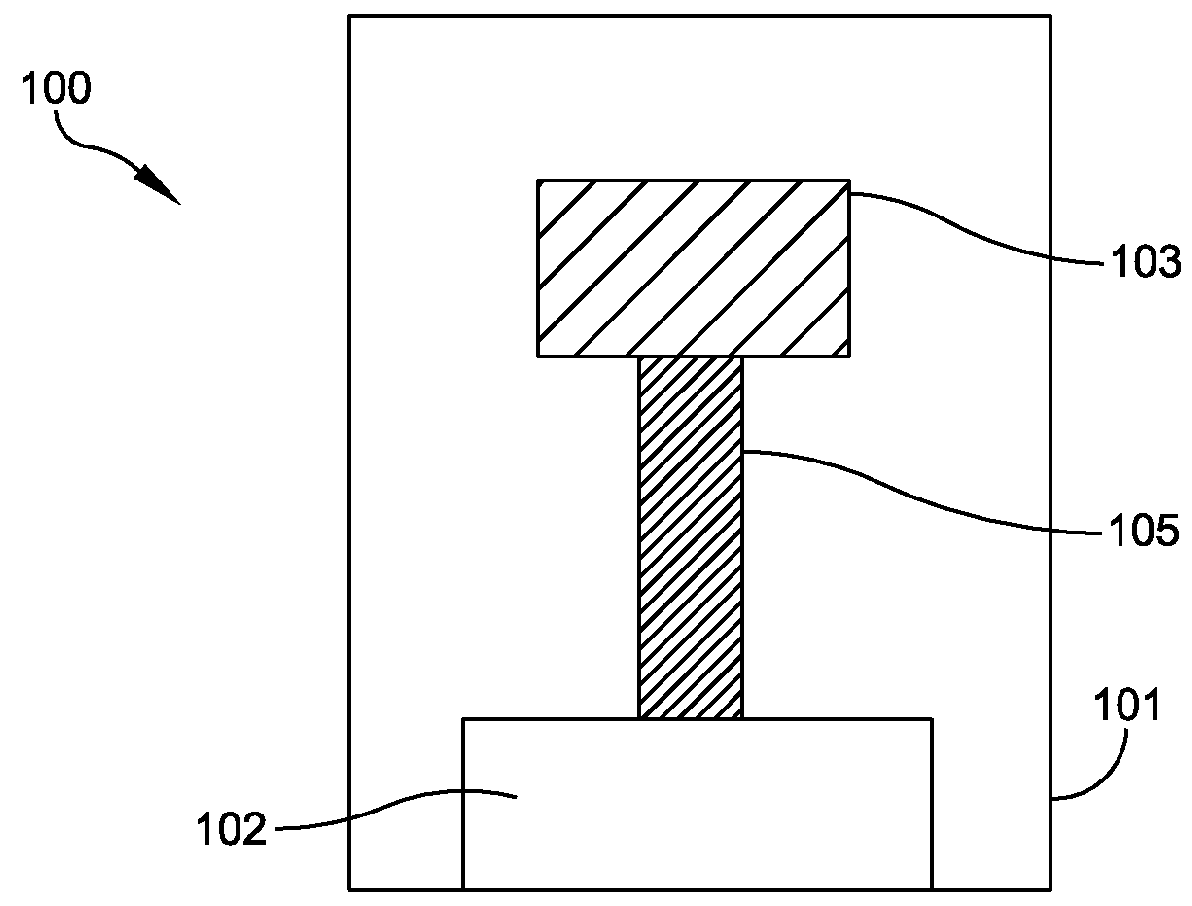

Expandable Stud Bracket

InactiveUS20150152637A1Simple structureAdditional operating advantageWallsBuilding reinforcementsLocking mechanismEngineering

An expandable stud bracket for attachment to a board for construction of a temporary structure of support is disclosed. An embodiment of the bracket includes a receiving portion for securing the bracket to a stud, an adjustable portion opposite the receiving portion and having an extendable rod, an engagement plate attached to an end of the rod and an anchor attached to an end of the rod opposite the engagement plate and for limiting extension of the rod from the bracket, and a locking mechanism attached to the rod for preventing retraction. Optionally, a tensioning mechanism, such as a Belleville washer may be used in a key location to “self-adjust” for shrinkage or tension loss. An embodiment of the disclosed bracket may be attached between two boards to permit better access to the locking mechanism. A reusable fastener is also disclosed.

Owner:KORDECKI JOHN R

Thrust bearing

ActiveUS7497627B2Reduced torque requirementsReduced startup torqueShaftsEngine componentsCoil springThrust bearing

A hydrodynamic bearing set, for use with a thrust disk disposed between planar surfaces of a housing, includes first and second topfoils disposed adjacent first and second thrust disk axial bearing surfaces and removably secured to the housing. An underspring is secured between each planar housing surface and the corresponding topfoil. Dual-leaf spring pairs attached to at least one topfoil periphery function to urge the topfoils away from the thrust disk axial bearing surfaces by applying a force against a planar housing surface, another topfoil, or a spacer washer secured between adjacent topfoil dual-leaf pairs or frictionally retained within the housing. Alternatively, a wavy washer, a conical spring, a Belleville washer, or a coil spring can be substituted for the dual-leaf spring pairs.

Owner:HONEYWELL INT INC

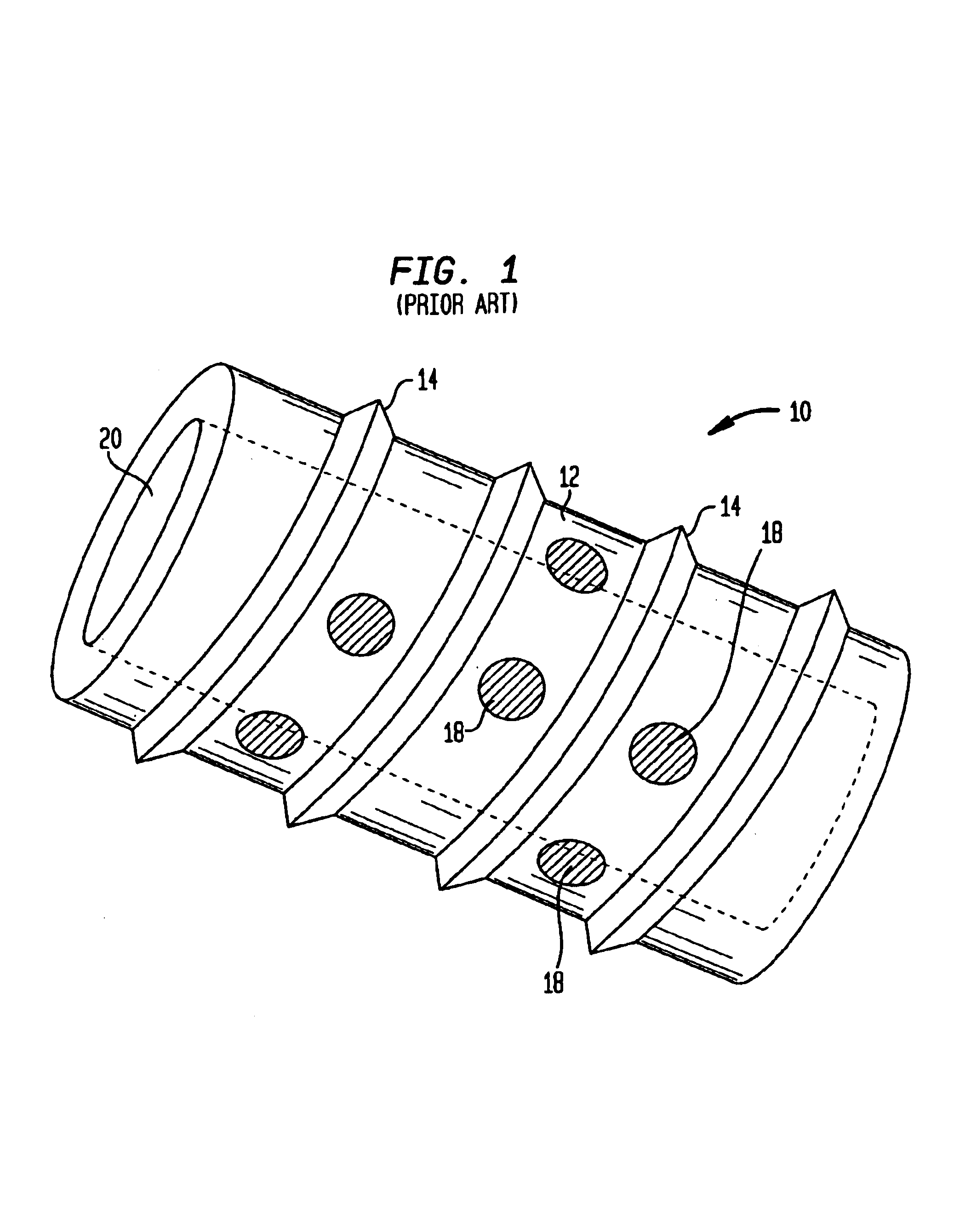

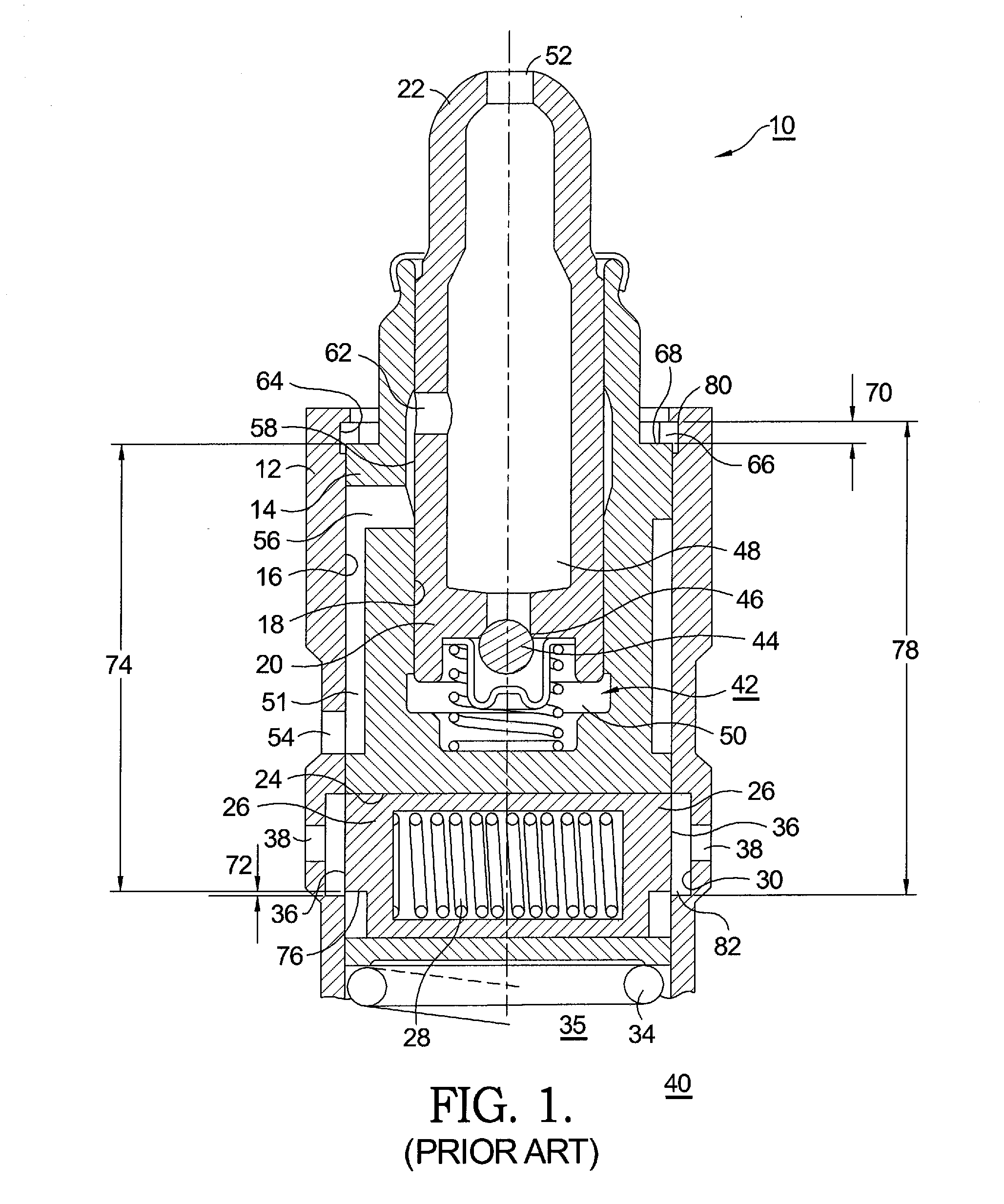

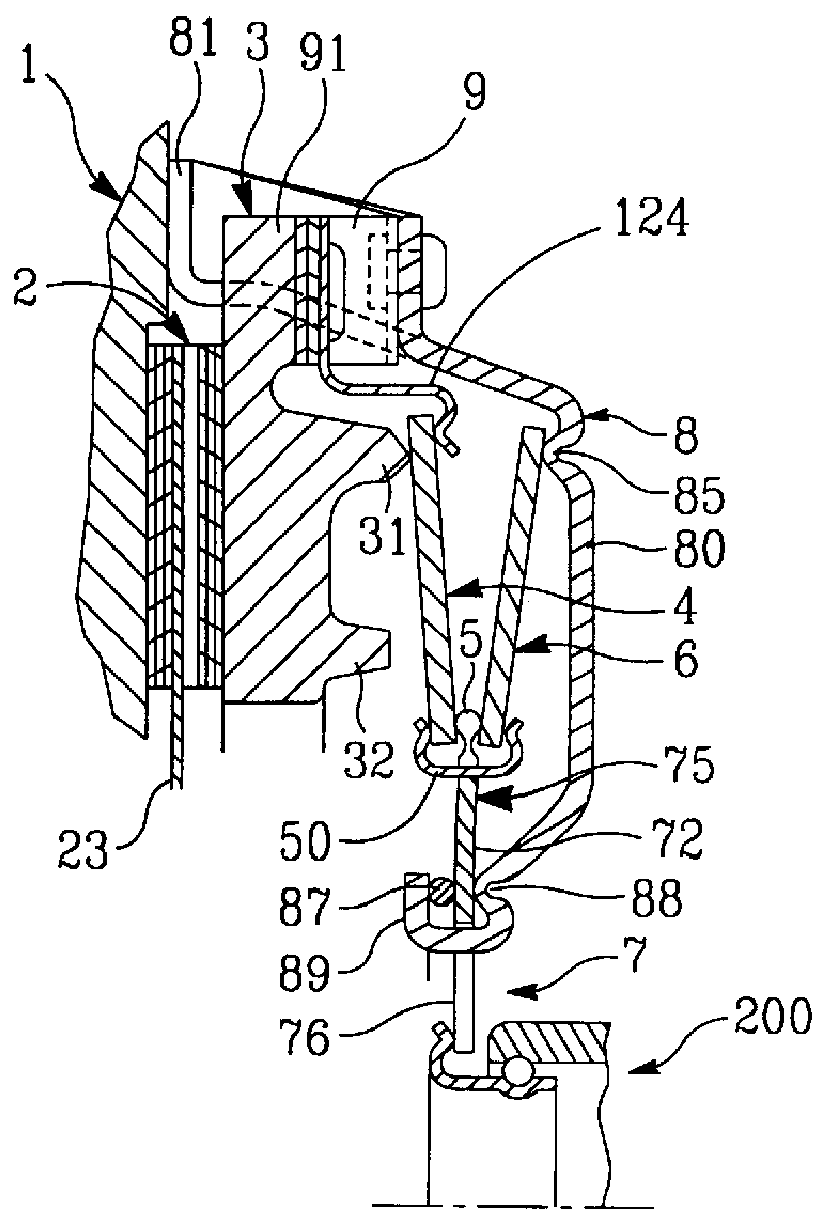

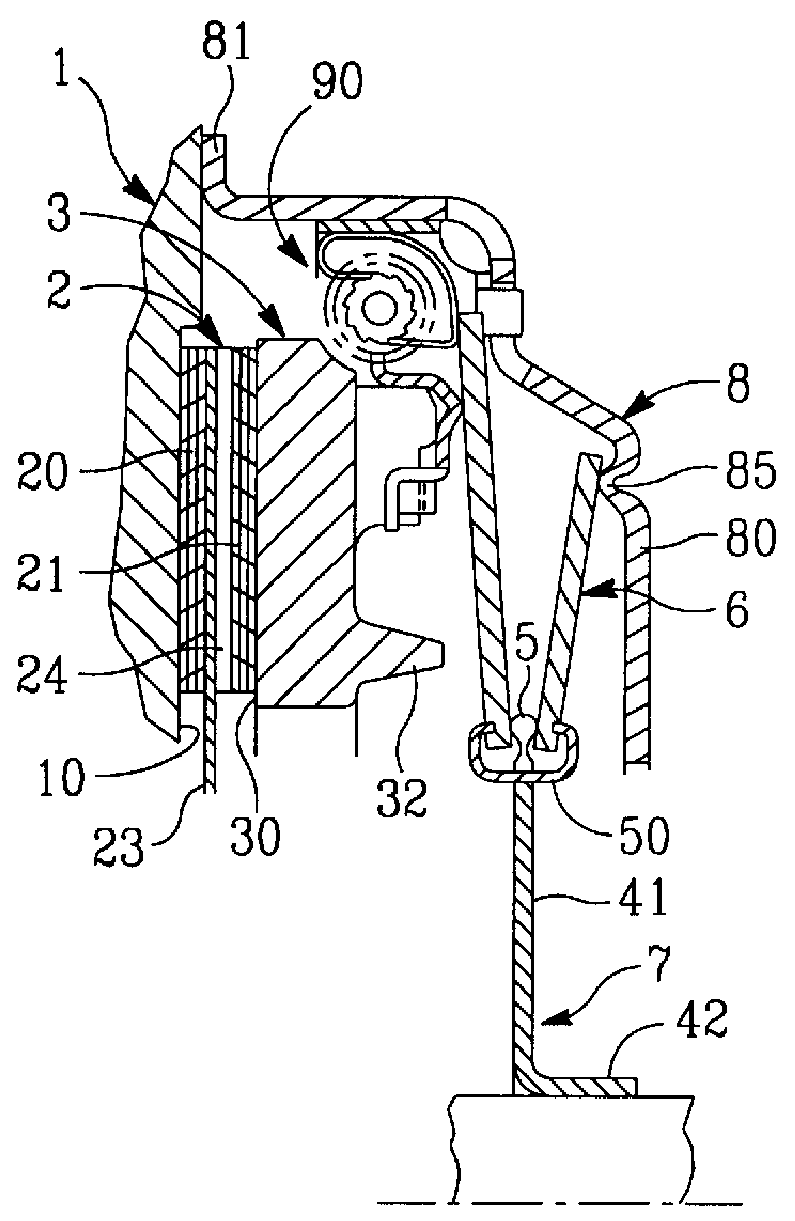

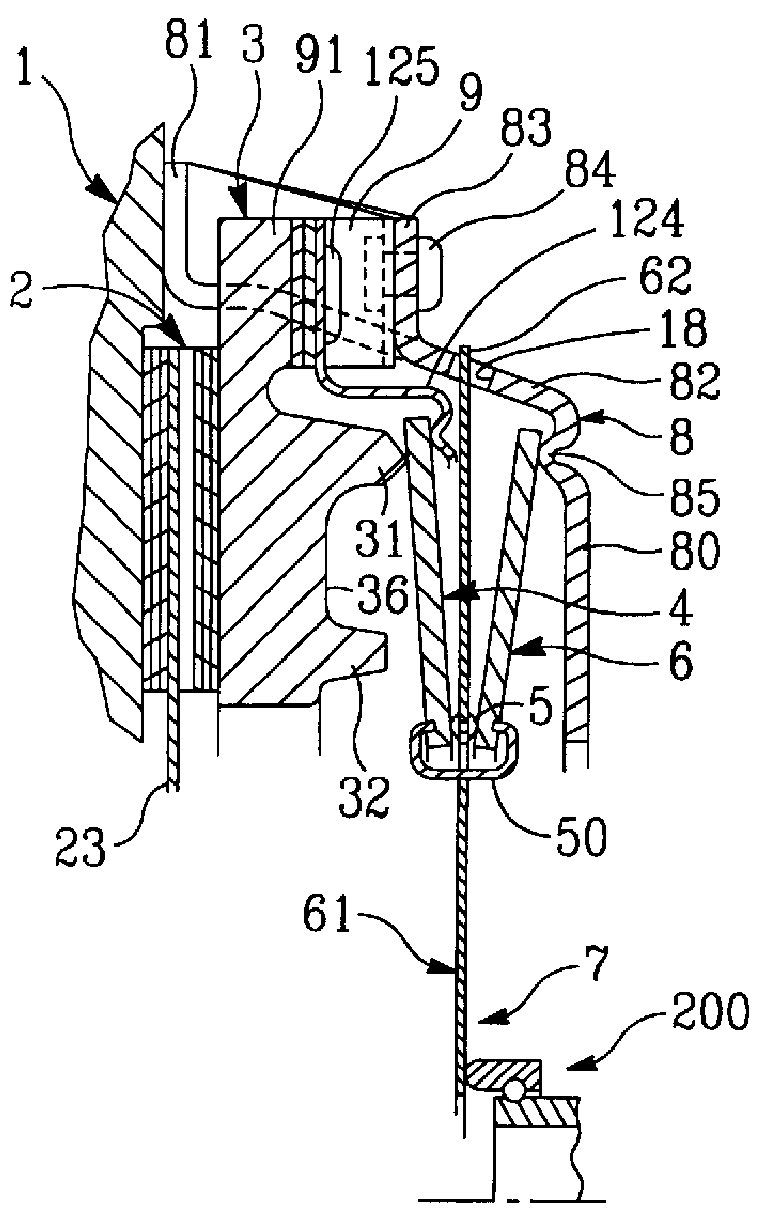

Clutch mechanism for friction clutch with low declutching force

PCT No. PCT / FR98 / 00698 Sec. 371 Date Dec. 4, 1998 Sec. 102(e) Date Dec. 4, 1998 PCT Filed Apr. 7, 1998 PCT Pub. No. WO98 / 45611 PCT Pub. Date Oct. 15, 1998A clutch mechanism, in particular for motor vehicles, comprising a cover (8) with a base (80), a clutch thrust plate (3) with front friction surface (30) co-operating with a clutch friction (2), and, set between the clutch thrust plate (3) rear surface (36) and the cover (8) base (80), resilient clutch means with axial action (4, 6) axially stressing the clutch thrust plate (3) in a direction opposite to the cover (8) base (80) and a declutching device (7) to counter at will the action of said resilient clutch means (4, 6): the resilient clutch means (4, 6) comprise two Belleville washers (4, 6) series-mounted between the clutch thrust plate (3) and the cover (8), and one (4) of the Belleville washers (4, 6) is in contact at its outer periphery with the clutch thrust plate (3), while the other (6) rests at its outer periphery on the cover (8), said washers (4, 6) sloping inversely, means for transmitting the force (5) carried by the declutching device (7) being incorporated between the inner peripheral zones of the Belleville washers.

Owner:VALEO MANAGEMENT SERVICES

Rotatable head for forming spiral extrusions

InactiveUS7247012B2Increase sealing forceAvoid pollutionConfectioneryFilament/thread formingEngineeringBelleville washer

A polymer extrusion crosshead assembly for forming a spirally-striped extrusion. The assembly includes conventional components for admitting, turning, and accelerating primary molten polymer toward a novel rotating die sub-assembly. A body element includes an axial counterbore for receiving a manifold supply block in communication with a source of secondary striping polymer. A wear plate is attached to the manifold block. The die sub-assembly includes a striping die having an annular passage for conveying the primary polymer to form an extruded tube or a core material coating. The die is loaded against the wear plate by a Belleville washer. The die includes one or more striping nozzles in communication with the manifold block for injecting secondary striping polymer into the annular stream of primary polymer flowing through the die, creating a longitudinal stripe of striping polymer. Rotating the die while extruding both polymers yields a helically striped (spiral) extrusion.

Owner:CANGEN HLDG

Reactive Fasteners

Several embodiments of reactive biasing fasteners are described. The fasteners are utilized in place of jam nuts and Belleville washers providing for the storage of a pre-load and effectively providing a locking function to prevent unintended loosening of an associated bolt. The embodiments resiliently deform under load to store pre-load or live load energy. Further, the fasteners provide a means for interfacing with a self-reacting tightening power tool thereby eliminating or minimizing the need for reaction arms. Additionally, several embodiments through the incorporation of a threaded bore effectively act to create a substantially torsionless live load on the portion of a bolt located in the bolt hole of a workpiece when in use. The resilient deformation of the biasing fasteners permits the live load to be stored therein and accordingly lessens the risk of loosening of the bolted joint due to exteriorly applied forces such as but not limited to vibration and thermal expansion and contraction.

Owner:REACTIVE SPRING FASTENERS

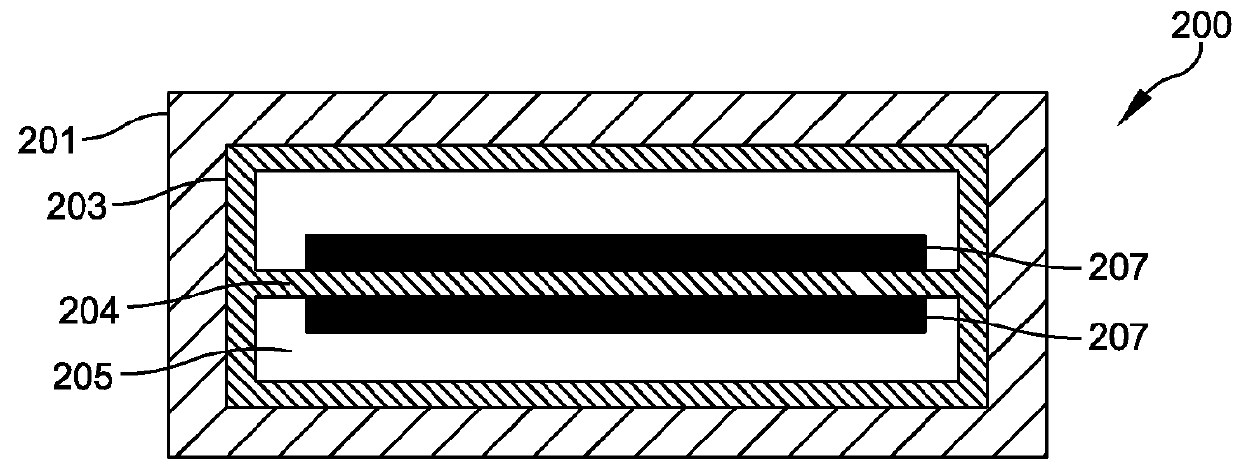

Low density underwater accelerometer

ActiveUS9360495B1Acceleration measurement using interia forcesElectrical transducersAccelerometerUnderwater

A low density accelerometer includes a buoyant outer layer and a rigid hollow housing within the outer layer. The housing includes an upper member and a lower member and is configured to form a groove at the junction of the upper and lower member. A disk shaped sensing element configured in a ring defining an aperture is configured to engage the groove along an outer edge of the annular ring. A solid proof mass is configured to fit in the center of the annular ring and configured with a threaded bore on an upper surface of the proof mass. The mass is secured to the sensing element by a retainer such as a Belleville washer in contact with the upper surface of the sensing element circumferentially about the aperture and a threaded fastener passing through the retainer and the aperture in the sensing element, and threadingly engaging the threaded bore in the proof mass.

Owner:LOCKHEED MARTIN CORP

Resiliently mounted strike plate of an electromagnetic door lock

A strike plate mounting bolt assembly for resiliently mounting a strike plate to a door. The strike plate mounting bolt assembly includes a bolt and a post wherein the bolt is securably engageable with the post. The bolt is inserted through a bore in the door and the post is inserted through a bore in the strike plate. A resilient member such as at least one Belleville washer is disposed between a head of the post and a cavity in the strike plate wherein the at least one Belleville washer is compressed between the post head and cavity upon securing the bolt and post together to provide a resilient mount between the door and strike plate. The at least one Belleville washer may be a number of Belleville washers selectable stacked to form a pack of Belleville washers. By varying the number and orientation of the Belleville washers, the force / deflection characteristics of the pack may be tuned to accommodate the needs of a variety of electromagnetic lock design features.

Owner:HANCHETT ENTRY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com