Patents

Literature

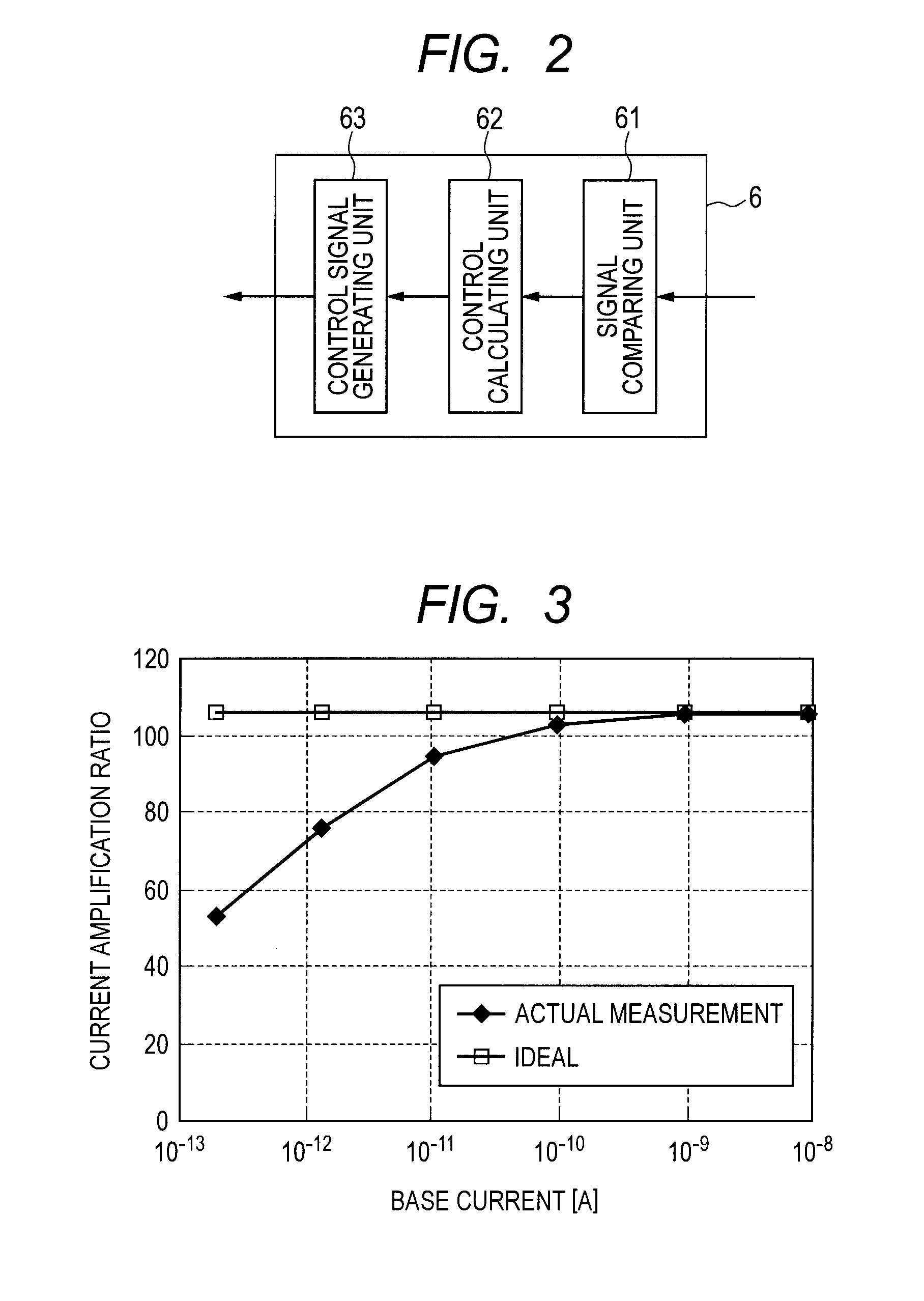

170 results about "Manufacturing variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing Variation Variation is a disparity between an actual measure of a product characteristic and its target value. ... Stable manufacturing processes are those for which process variation is the result of random causes. As a result, stable processes produce products that adhere to specifications to a greater degree than those produced by unstable processes.

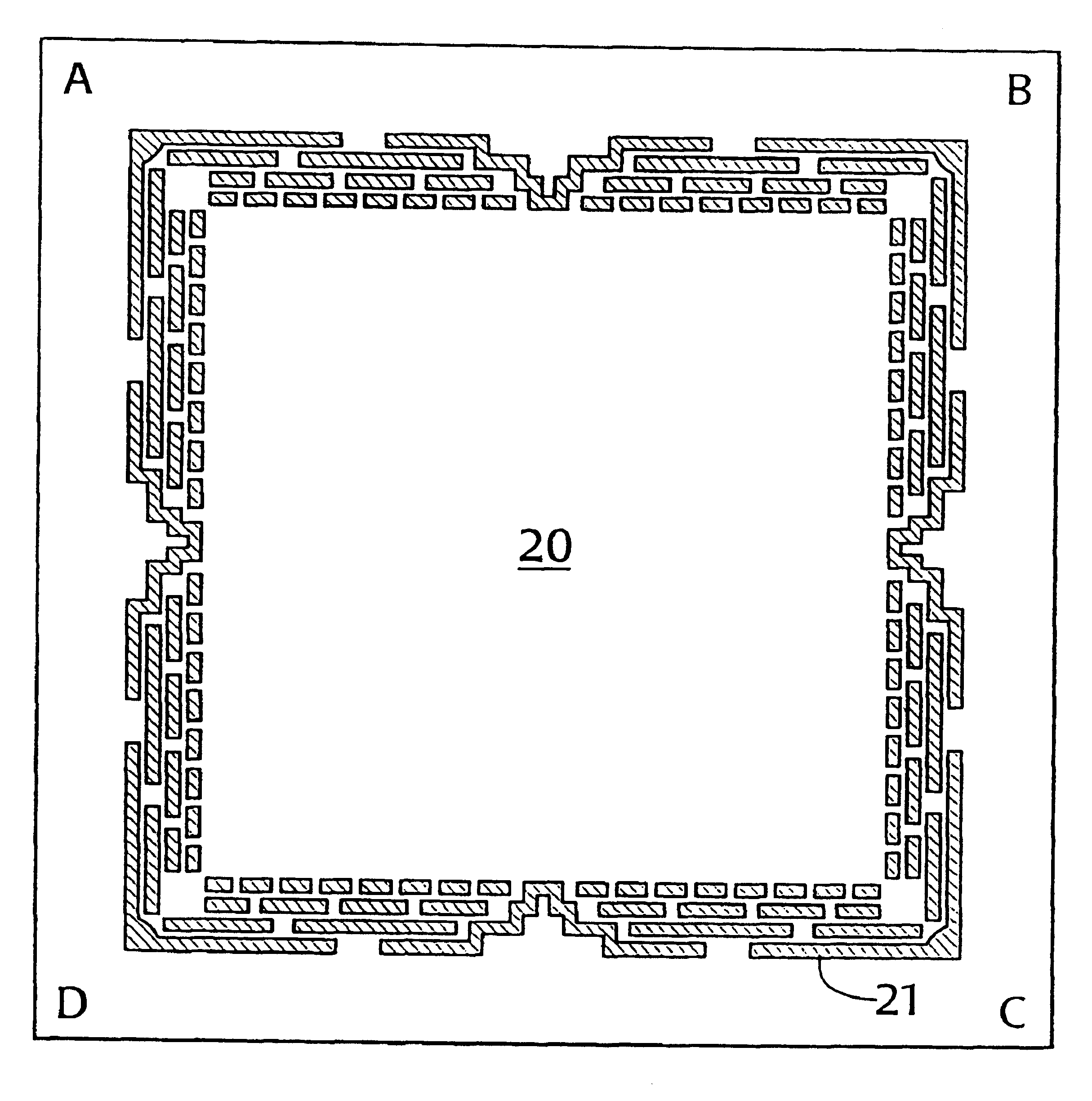

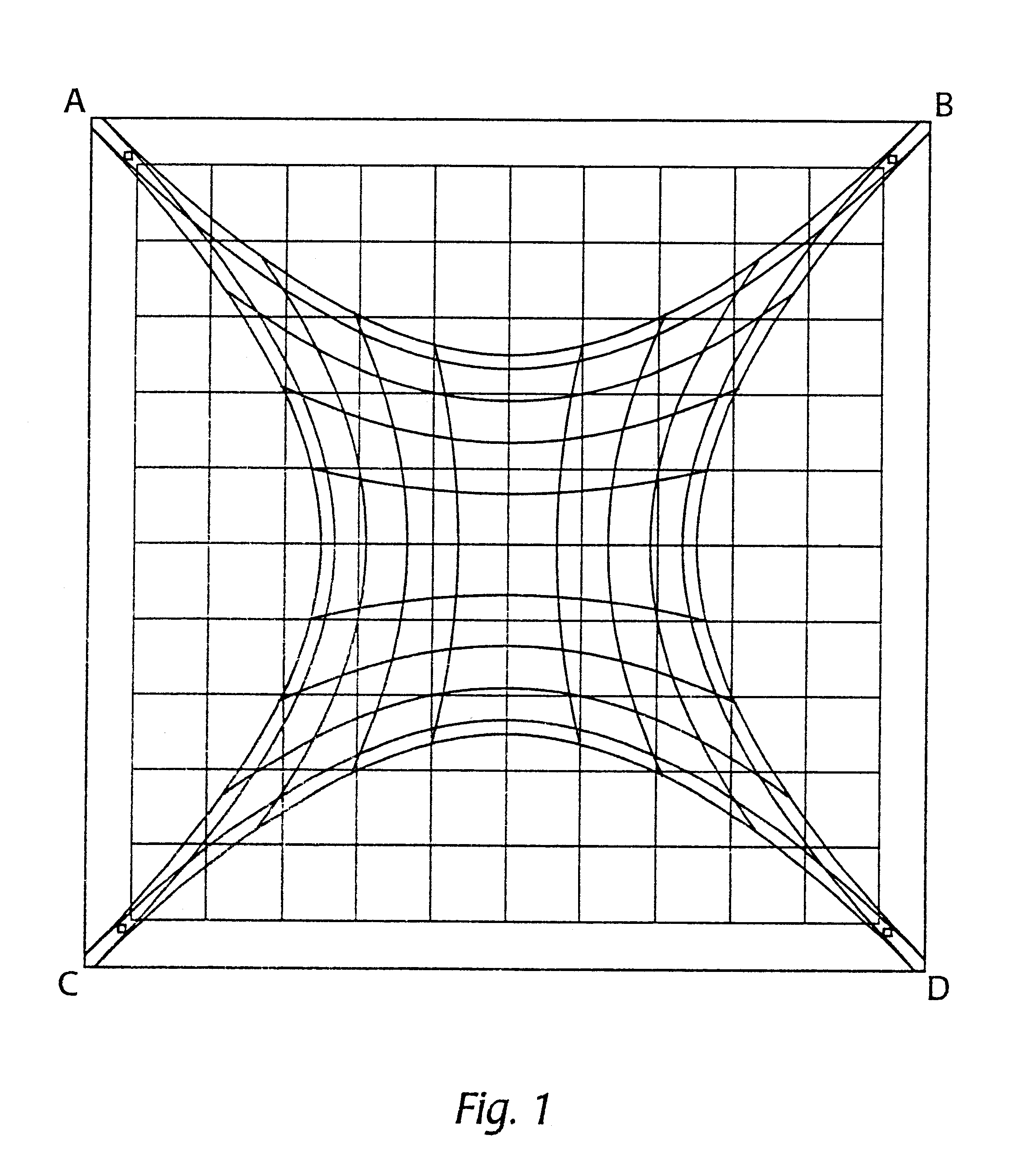

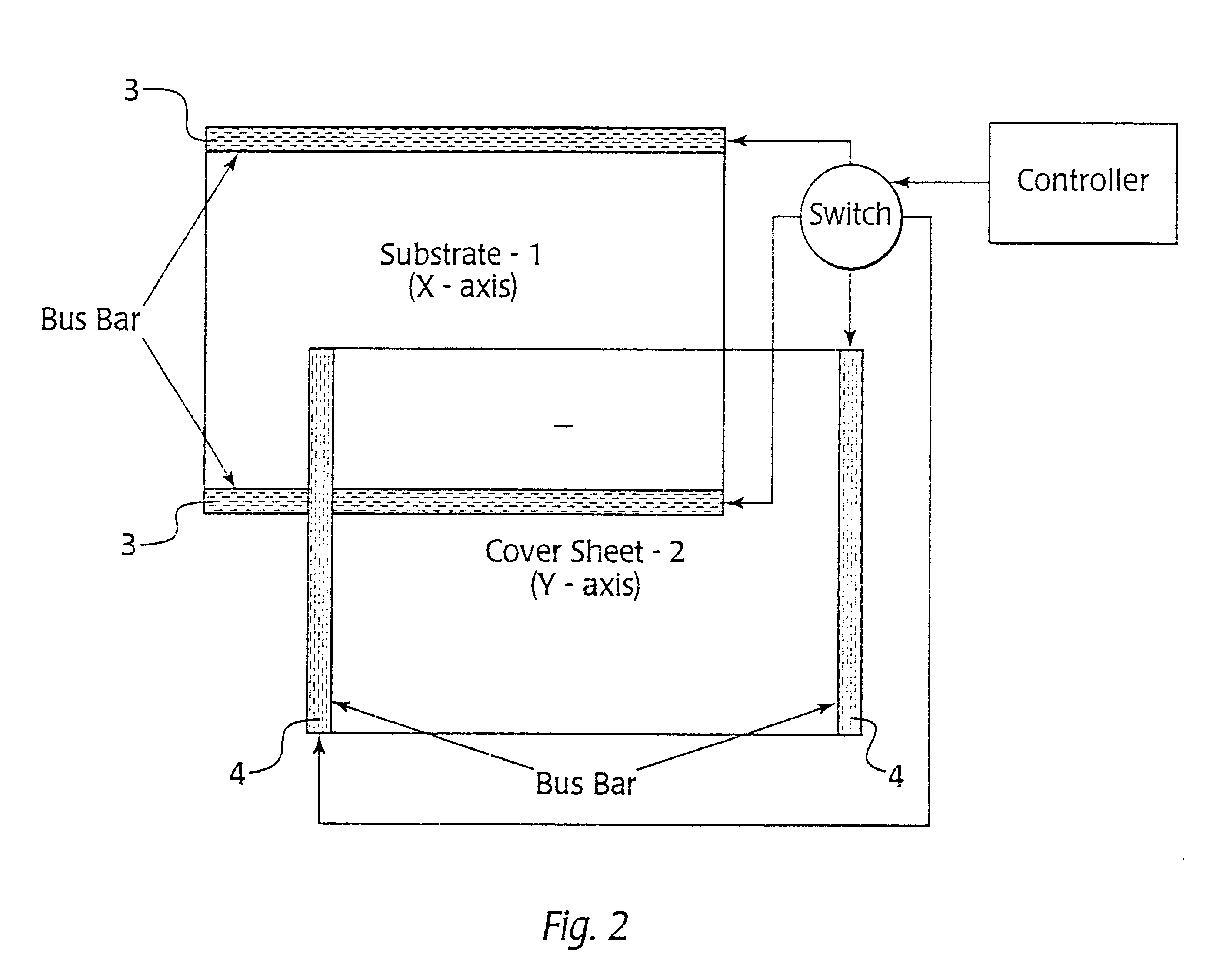

Algorithmic compensation system and method therefor for a touch sensor panel

InactiveUS6506983B1Efficient mappingEfficient polynomial coefficient storageTransmission systemsUsing electrical meansCurve fittingTouchscreen

A general method is described for producing an inexpensive touchscreen system that provides accurate positional information and compensates for manufacturing variations without complicated sensor arrangements. Utilizing a set of sensed signals that are unique to each location on the touchscreen sensor, equations for X and Y are derived via curve fitting methods. The coefficients of the equations are stored with the sensor. During touchscreen operation the coefficients are used to calculate X and Y to the desired accuracy directly and independently.

Owner:ELO TOUCH SOLUTIONS INC

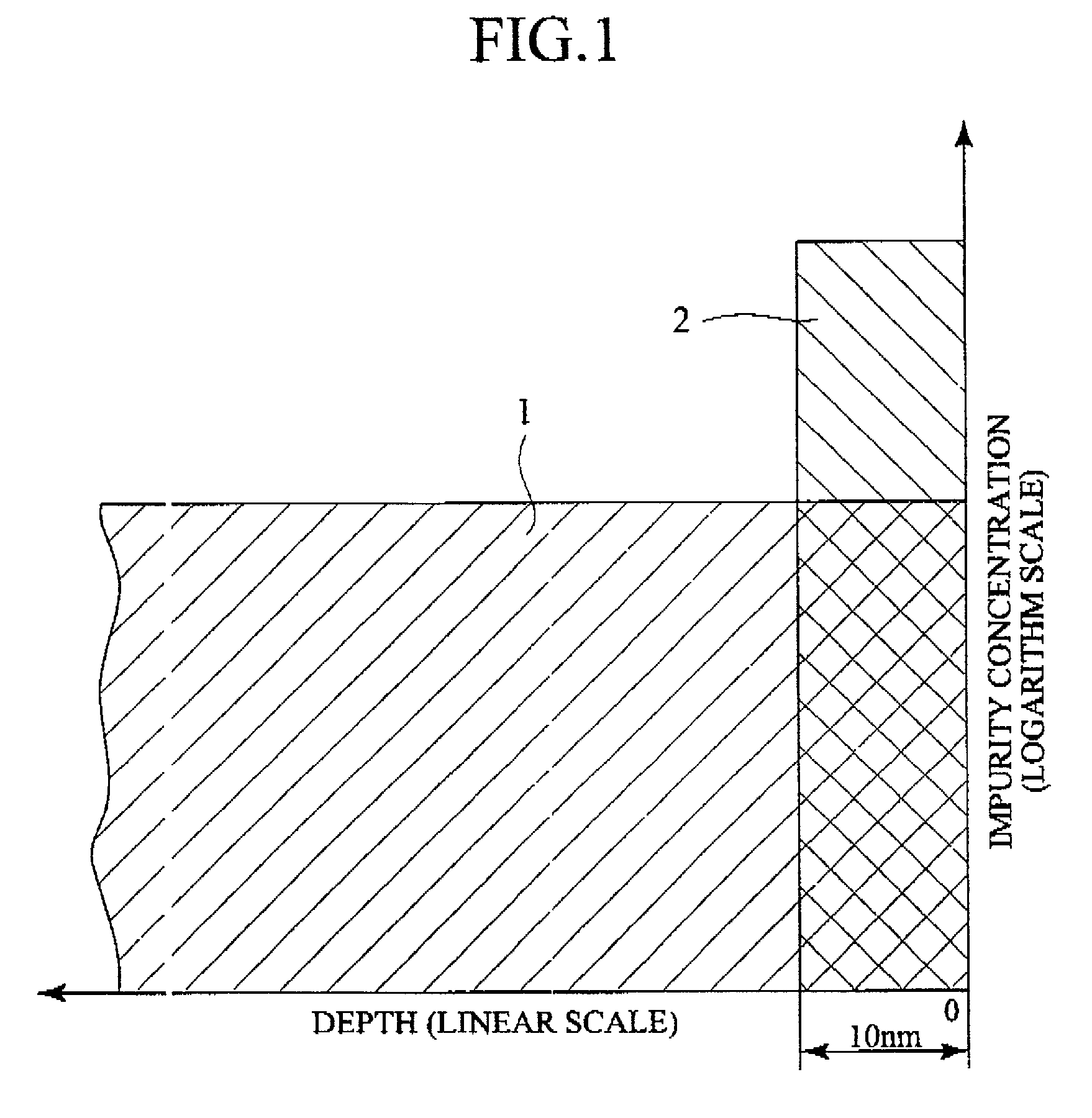

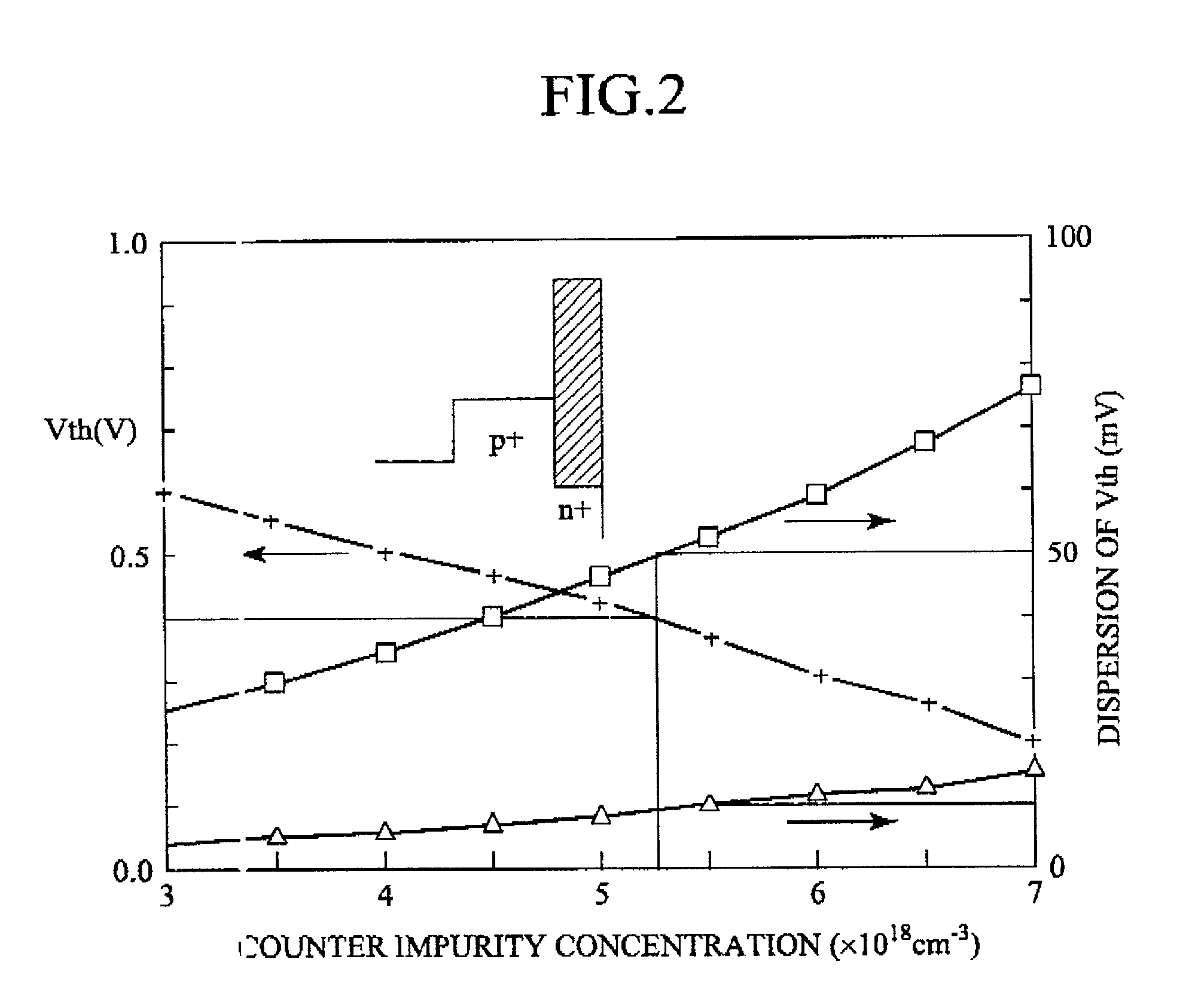

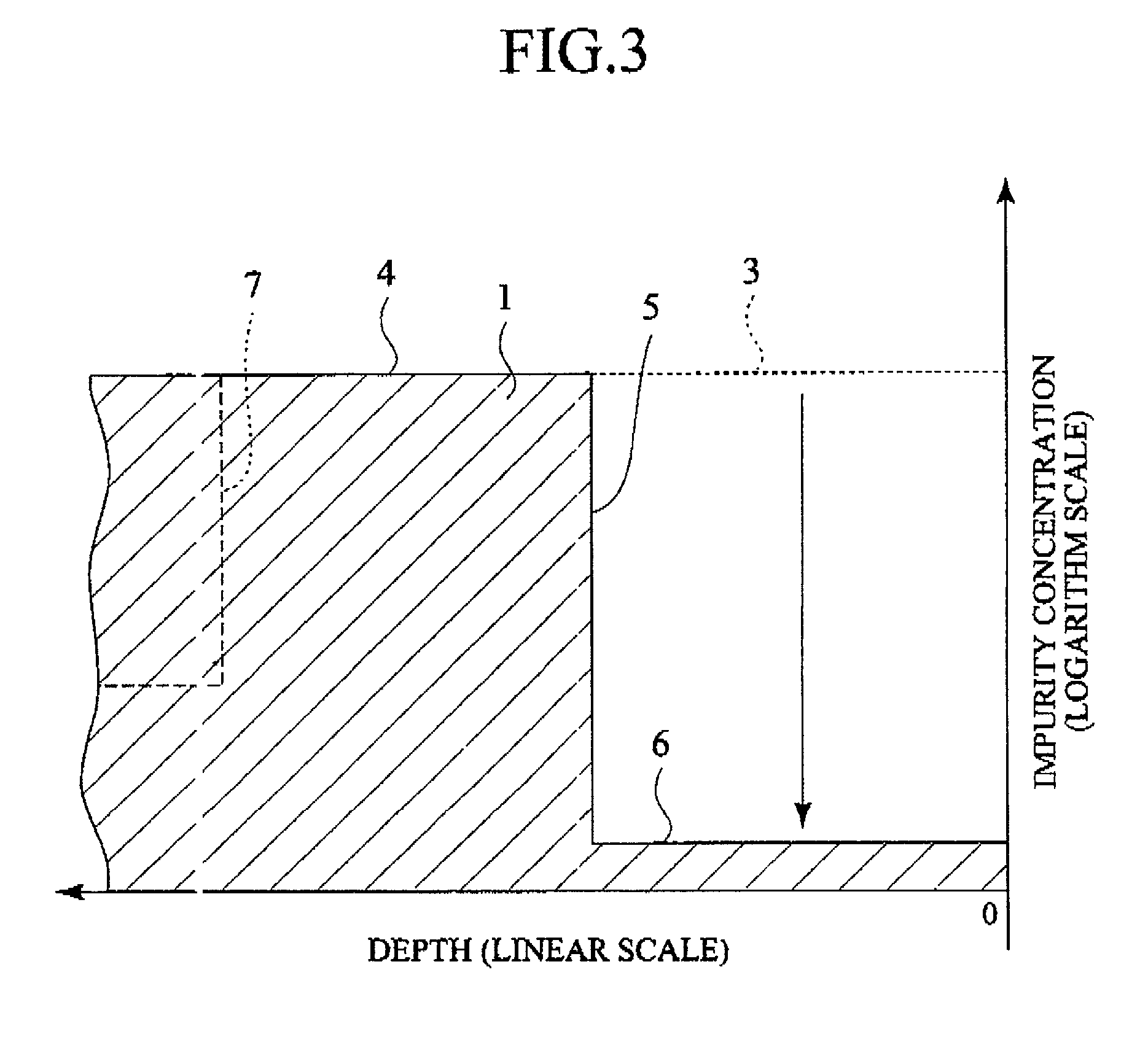

Low threshold voltage semiconductor device

InactiveUS7078776B2Easy to changeSuppression of short channel effectsTransistorSolid-state devicesElectrical conductorSemiconductor package

A semiconductor device has a first semiconductor region formed in a semiconductor substrate and having a first conductivity type due to first-conductivity-type active impurities contained in the first semiconductor region, and a second semiconductor region formed between the first semiconductor region and the surface of the semiconductor substrate and having a second conductivity type due to second-conductivity-type active impurities contained in the second semiconductor region. The second semiconductor region contains first-conductivity-type active impurities, whose concentration is zero or smaller than a quarter of a concentration of the second-conductivity-type active impurities contained in the second semiconductor region. An insulating film and a conductor are formed on the second semiconductor region. Third and fourth semiconductor regions of the second conductivity type are formed at the semiconductor surface in contact with the side faces of the second semiconductor region. This semiconductor device is capable of suppressing net impurity concentration variations as well as threshold voltage variations to be caused by a short channel effect or manufacturing variations.

Owner:KK TOSHIBA

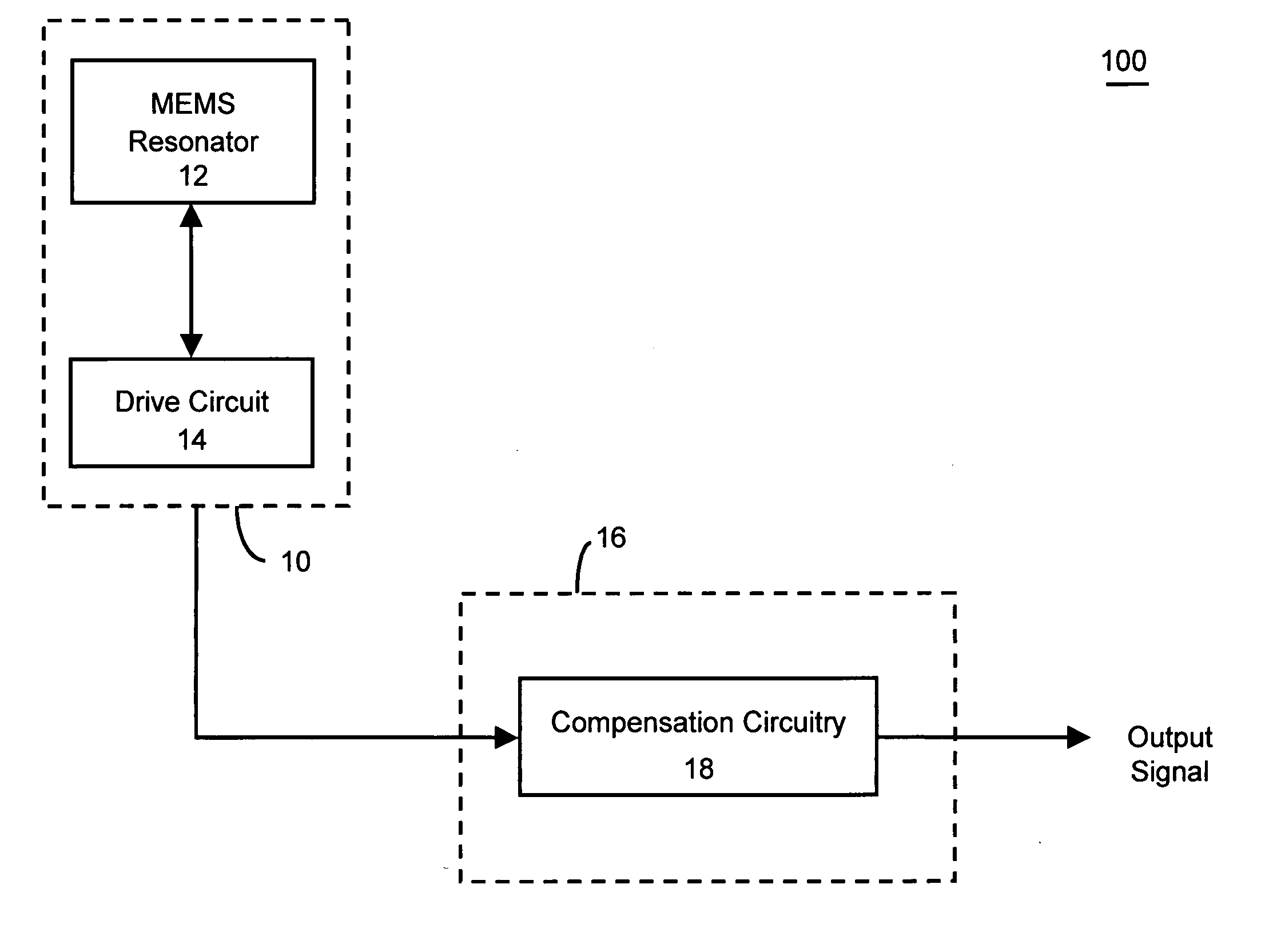

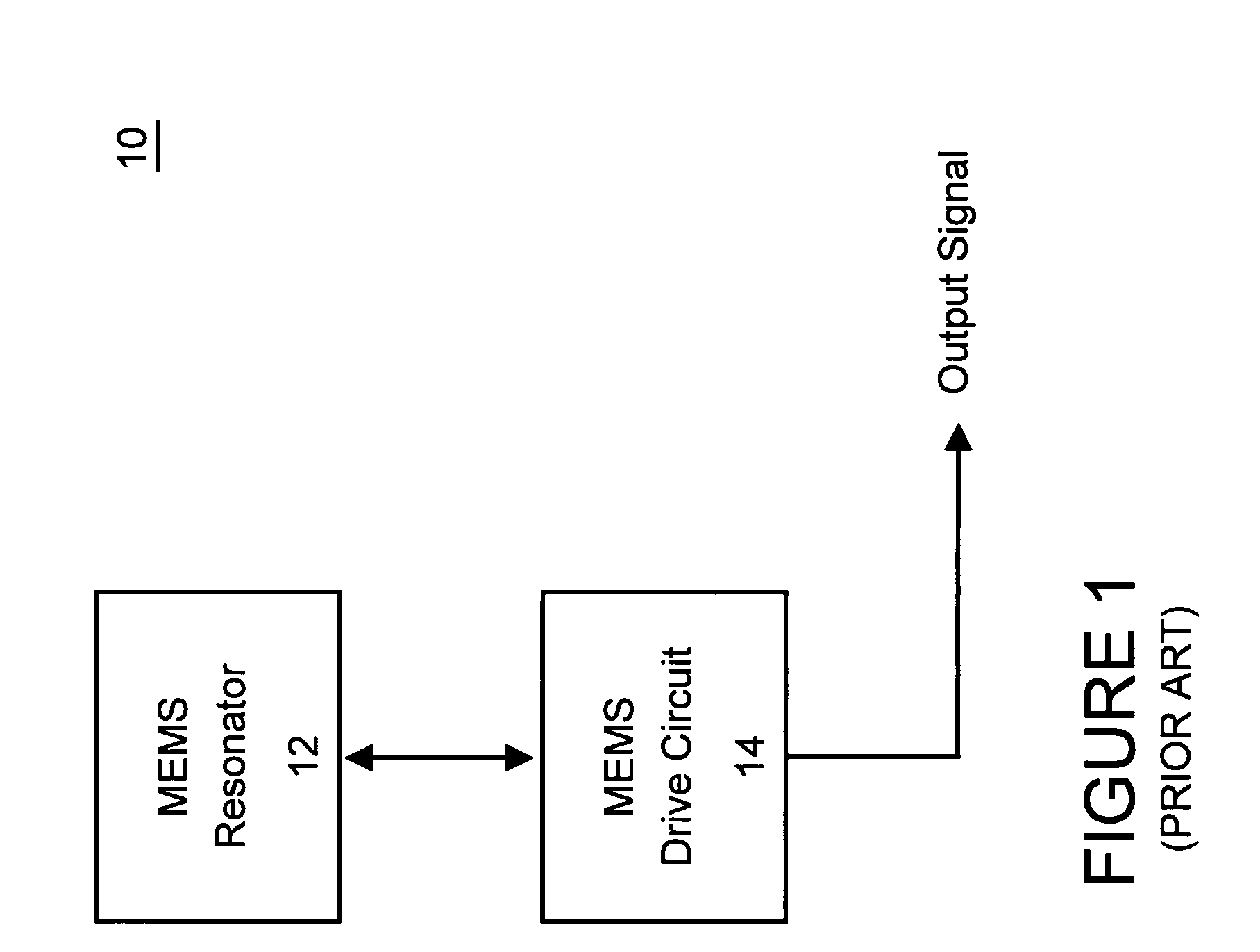

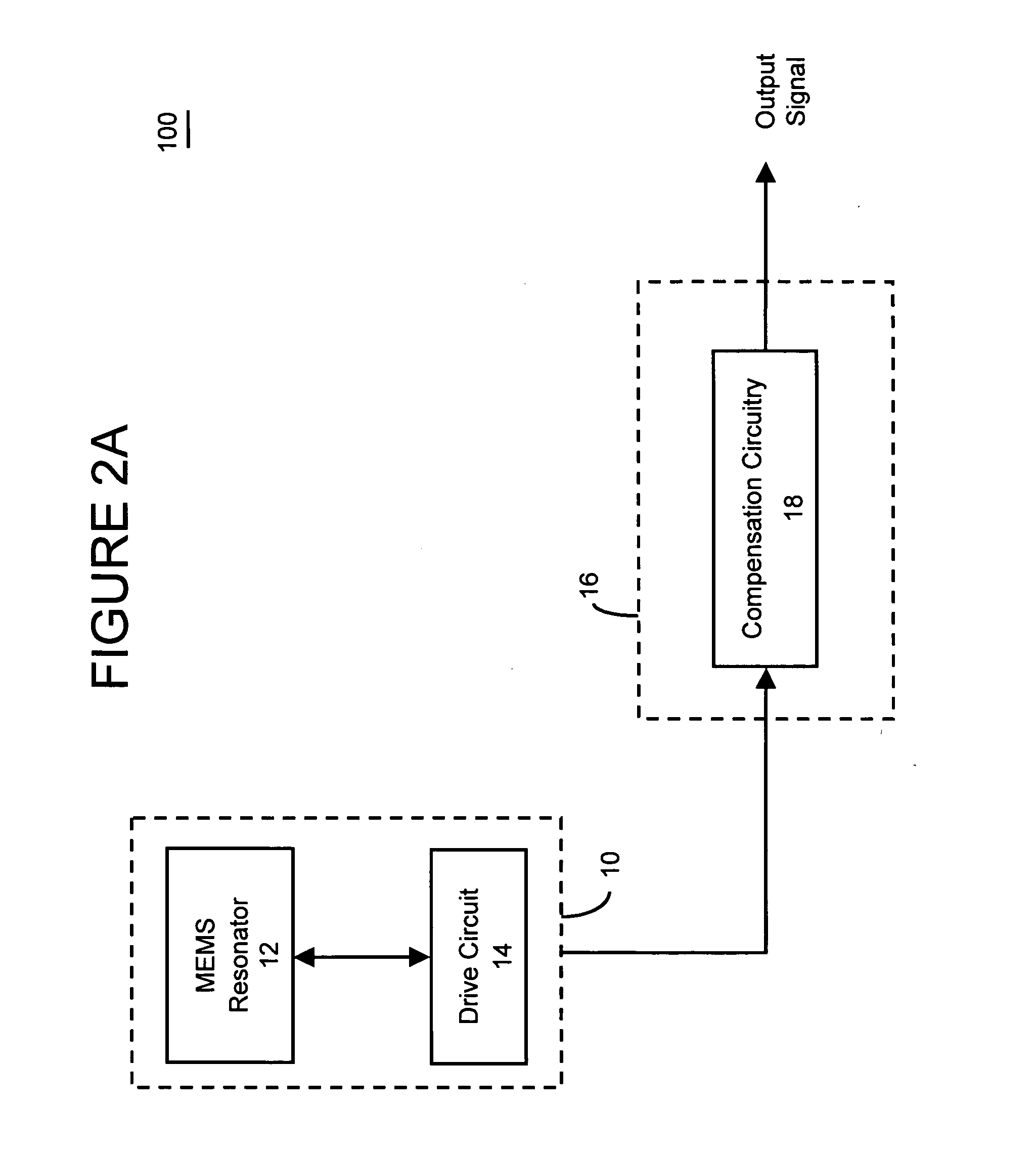

Frequency and/or phase compensated microelectromechanical oscillator

ActiveUS20050151592A1Reduce the gap widthIncreasing available voltage to applyRadiation pyrometryPulse automatic controlFrequency synthesizerFrequency multiplier

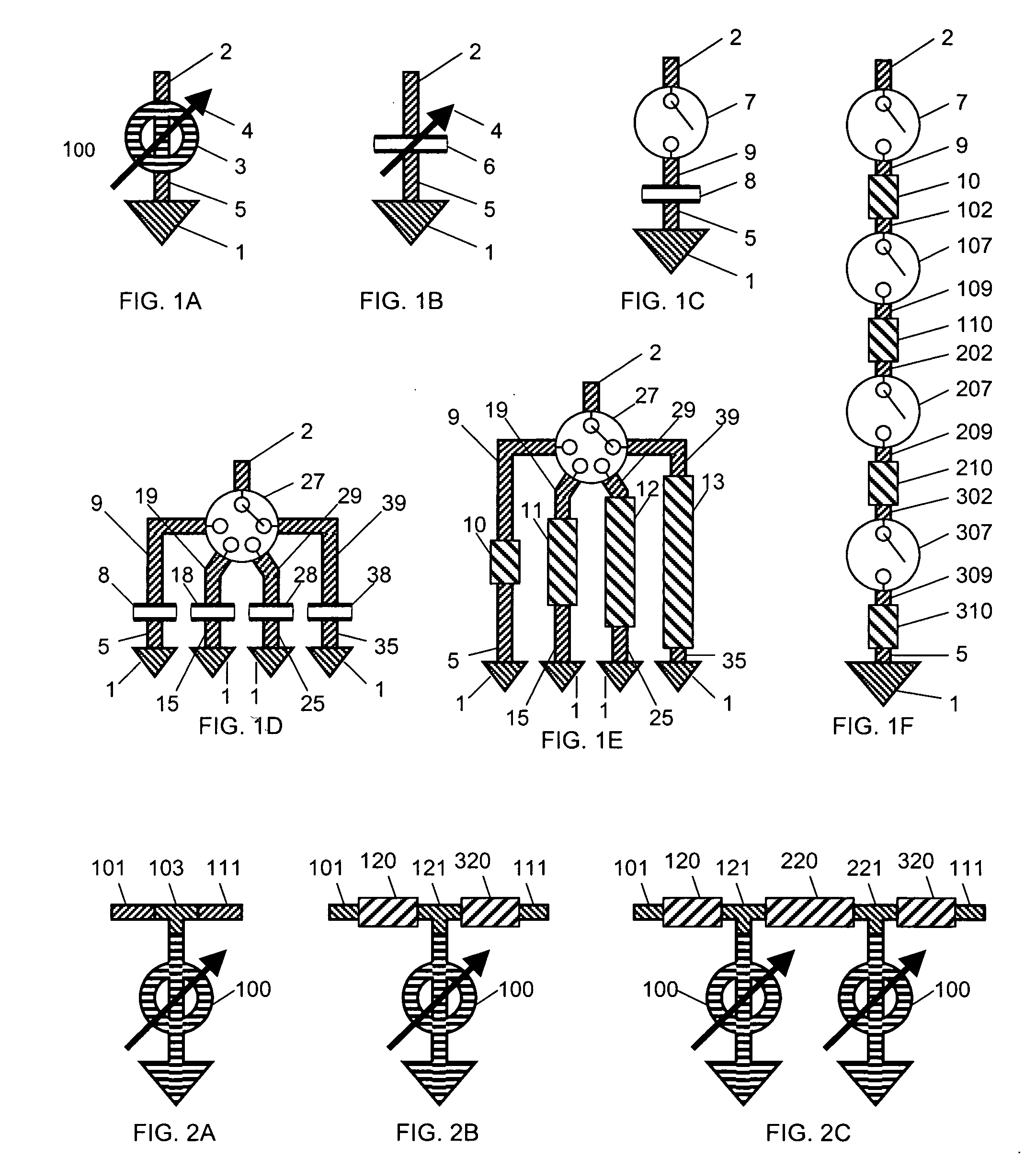

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a compensated microelectromechanical oscillator, having a microelectromechanical resonator that generates an output signal and frequency adjustment circuitry, coupled to the microelectromechanical resonator to receive the output signal of the microelectromechanical resonator and, in response to a set of values, to generate an output signal having second frequency. In one embodiment, the values may be determined using the frequency of the output signal of the microelectromechanical resonator, which depends on the operating temperature of the microelectromechanical resonator and / or manufacturing variations of the microelectromechanical resonator. In one embodiment, the frequency adjustment circuitry may include frequency multiplier circuitry, for example, PLLs, DLLs, digital / frequency synthesizers and / or FLLs, as well as any combinations and permutations thereof. The frequency adjustment circuitry, in addition or in lieu thereof, may include frequency divider circuitry, for example, DLLS, digital / frequency synthesizers (for example, DDS) and / or FLLs, as well as any combinations and permutations thereof.

Owner:ROBERT BOSCH GMBH

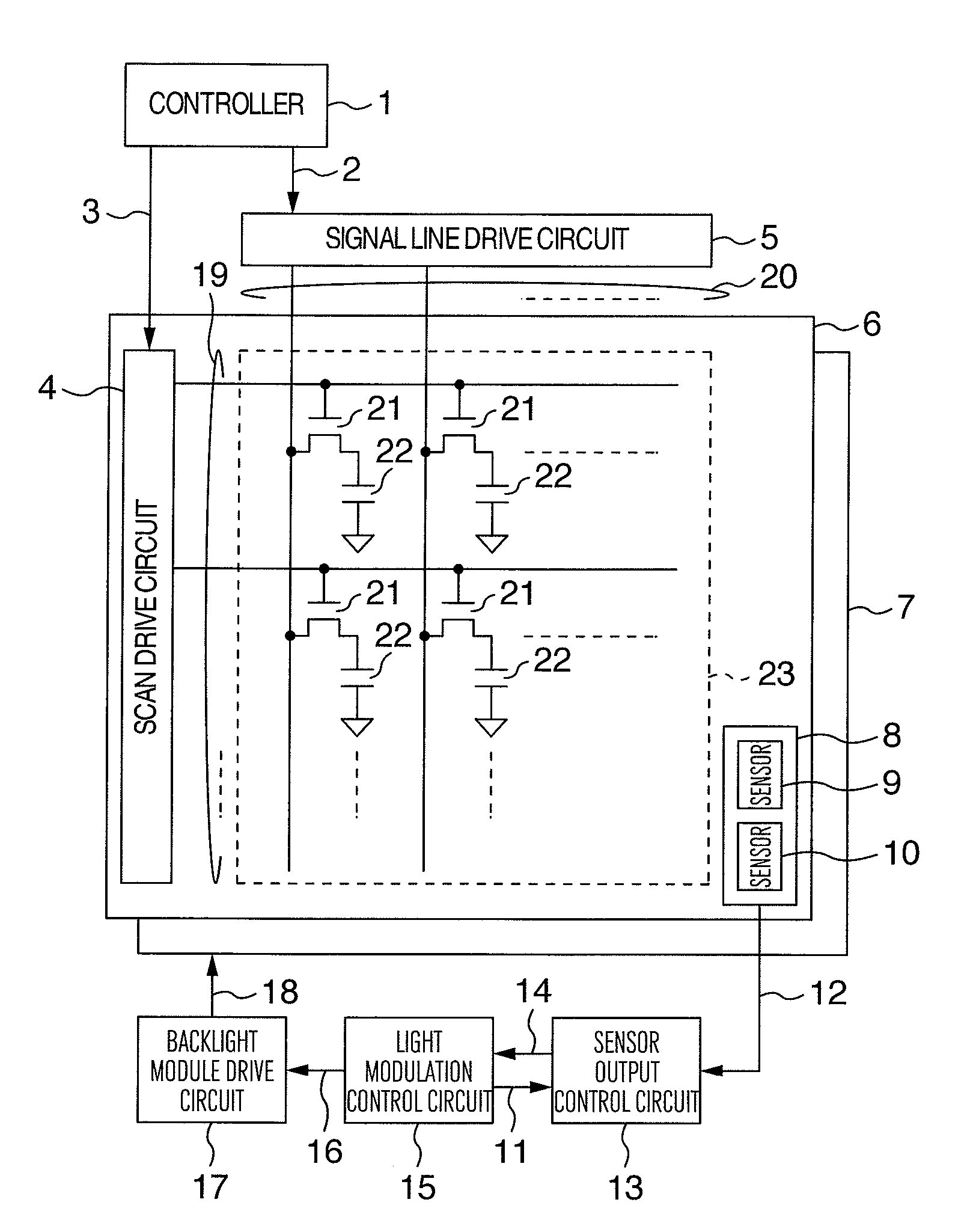

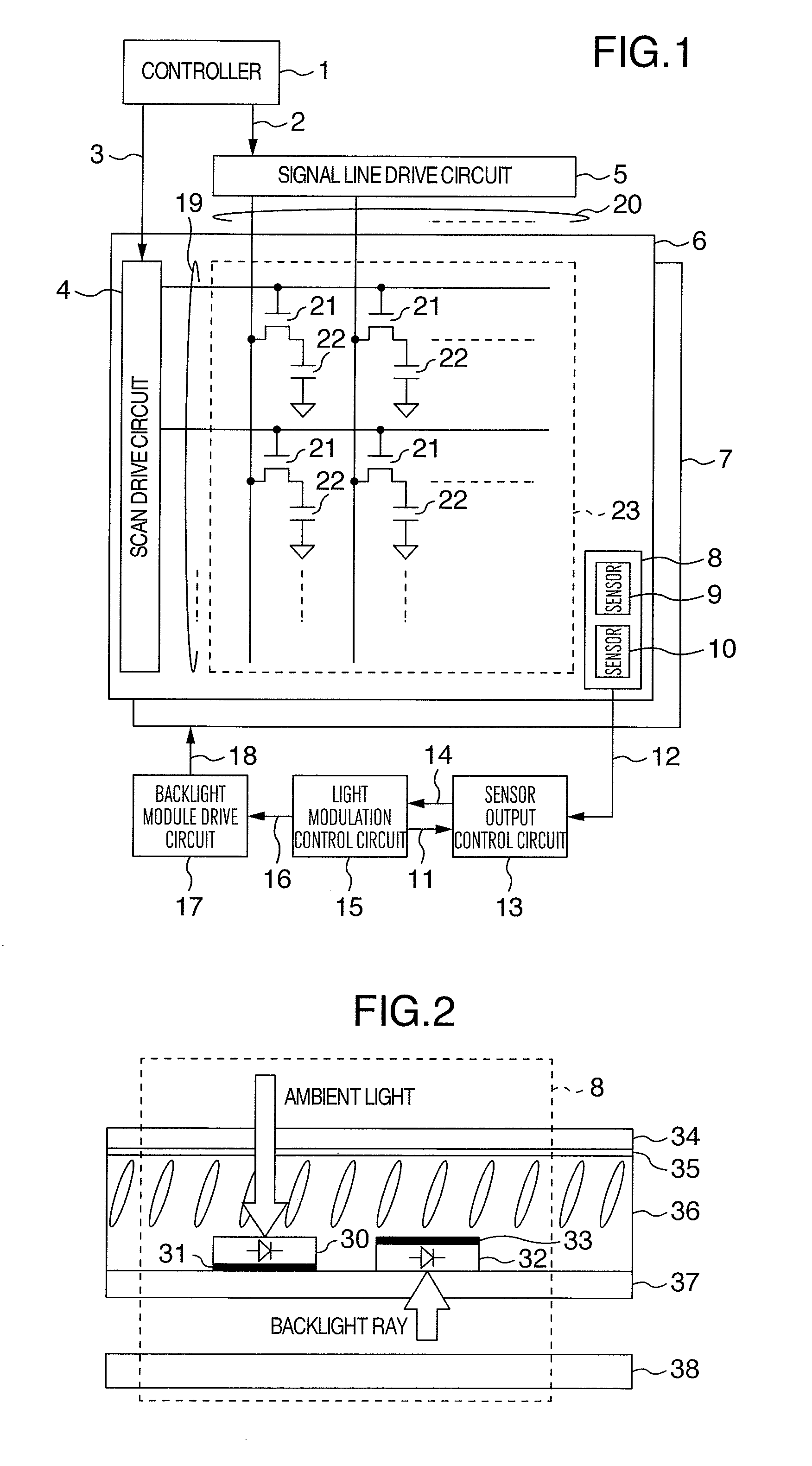

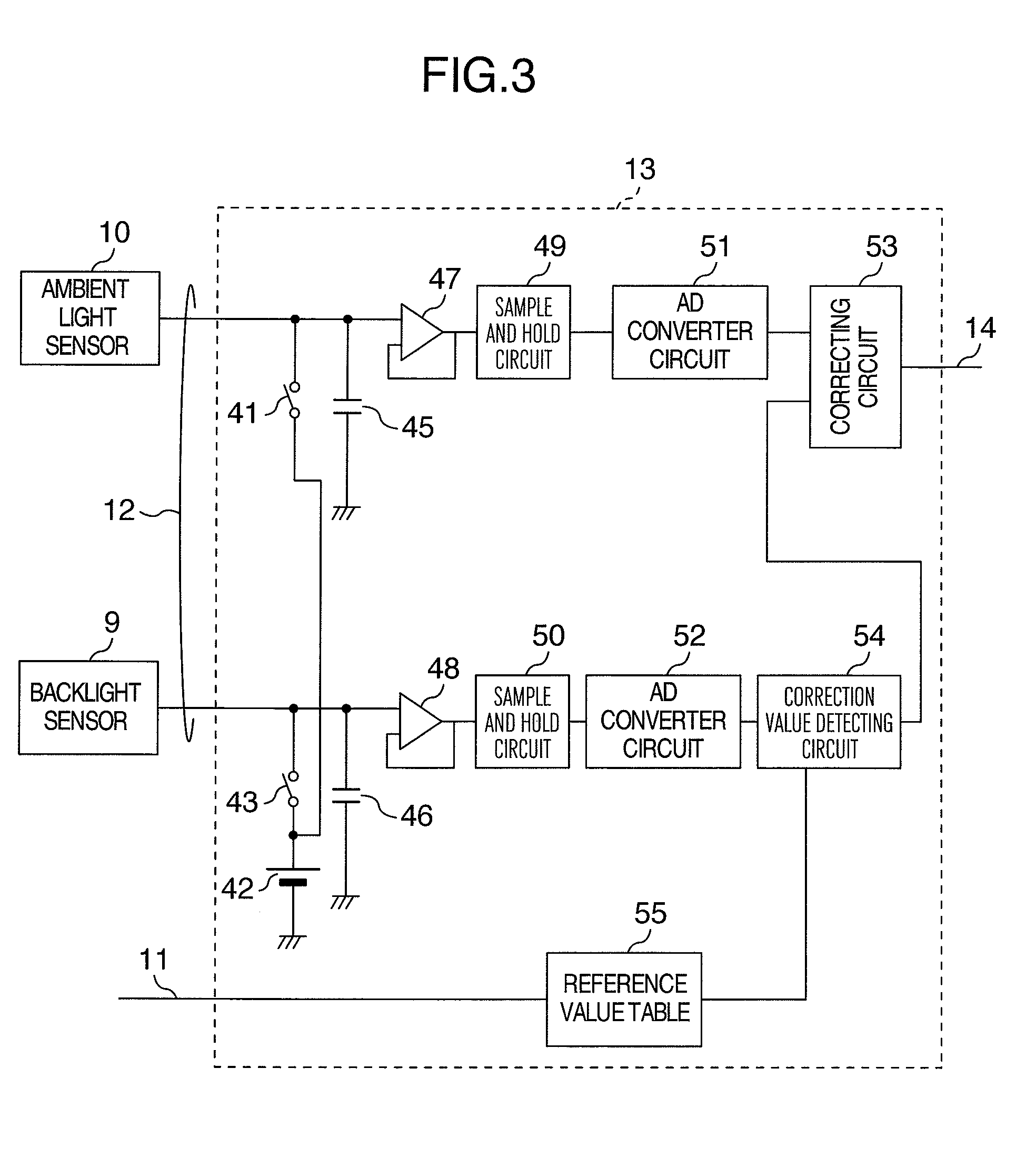

Display Device

InactiveUS20070268241A1Manufacturing variation can be decreasedImprove output accuracyStatic indicating devicesLiquid-crystal displayDisplay device

An ambient light sensor 10 and a backlight sensor 9 are located on the liquid crystal panel 6 adjacently to each other, for correcting a variation of an output characteristic of the ambient light sensor 10. This location keeps the manufacturing variation of each liquid crystal panel 6 even in these two light sensors 9 and 10. A degree of variation of an output of the backlight sensor 9 for sensing a ray of backlight from a backlight module relative to a predetermined reference value is detected. Based on the detected result, the output of the ambient light sensor 10 is corrected. This operation makes it possible to improve sensing accuracy of the ambient light sensor 10 and keep the light modulation even in each liquid crystal panel provided with the ambient light sensor 10.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

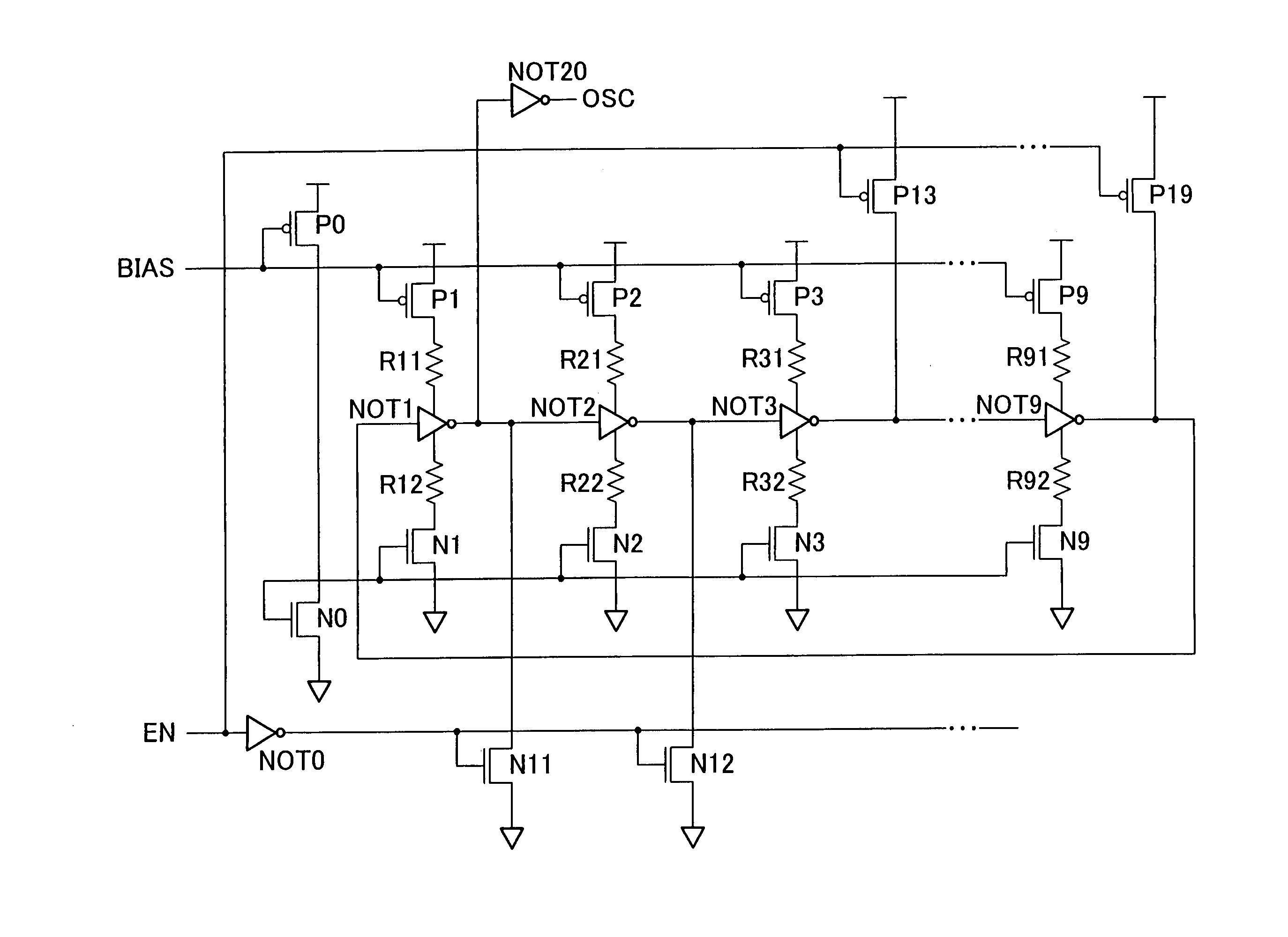

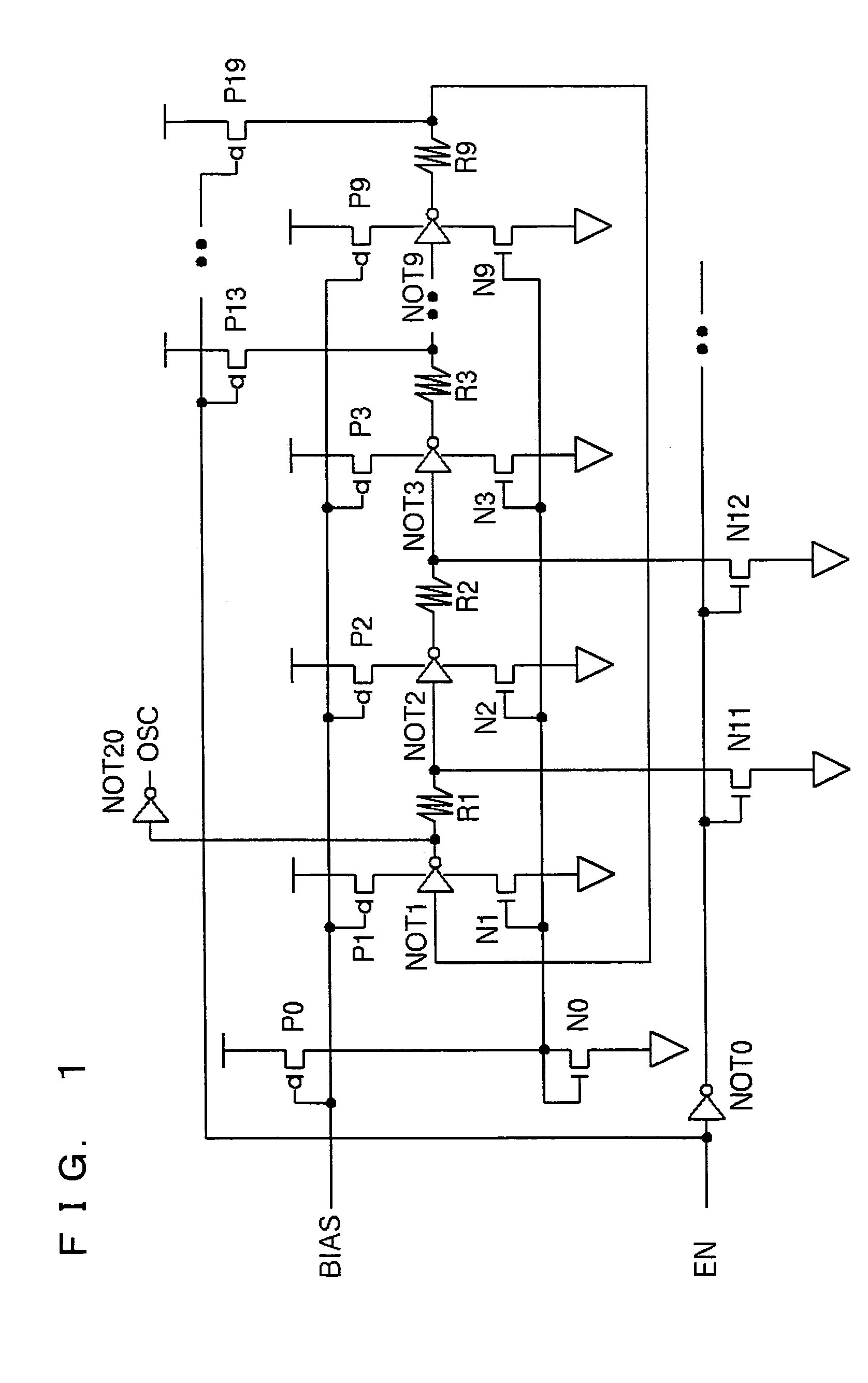

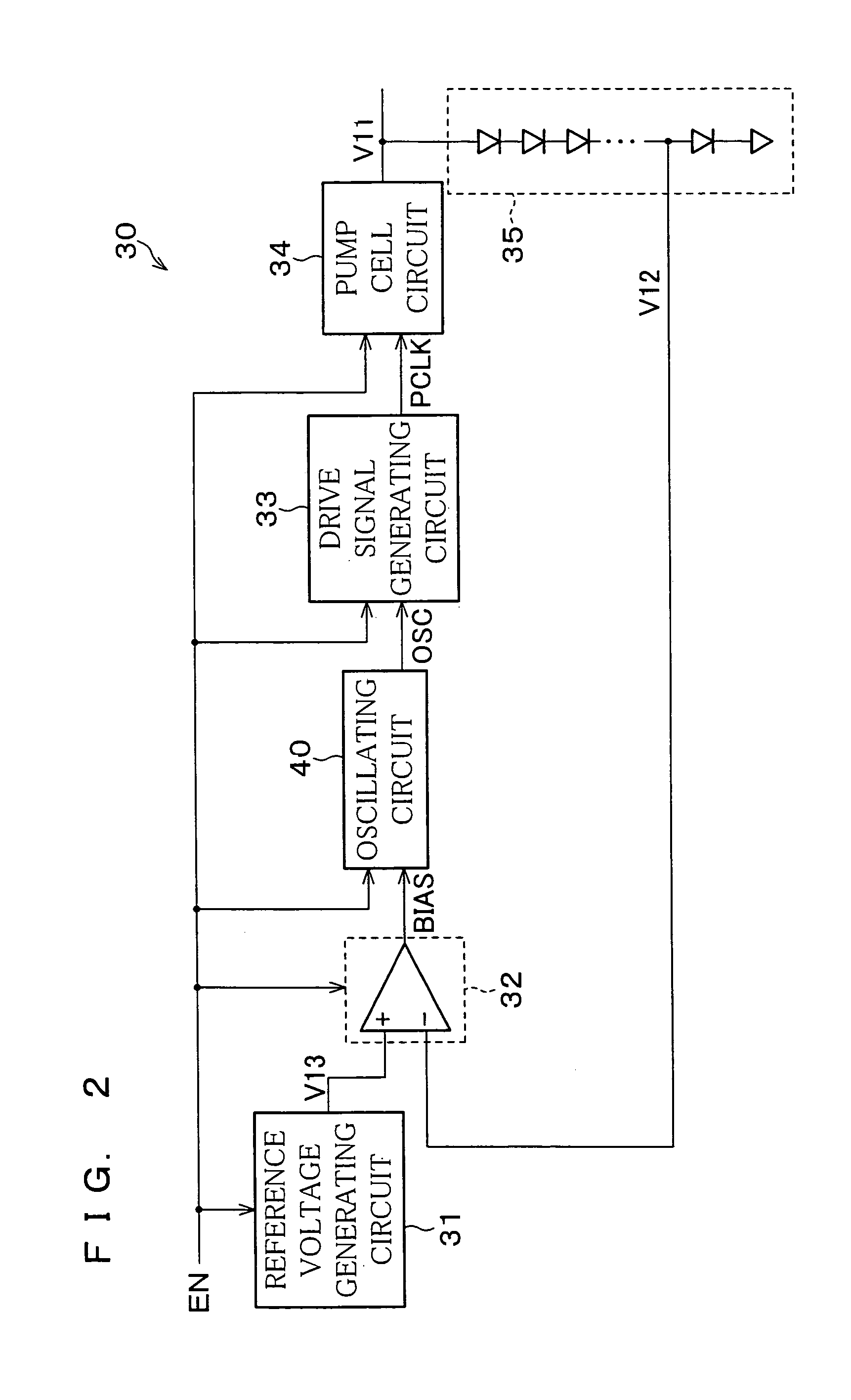

Oscillating circuit, booster circuit, nonvolatile memory device, and semiconductor device

InactiveUS7180794B2Suppress the variation in the oscillating frequencies of an output signalChange in resistancesSolid-state devicesRead-only memoriesPower inverterEngineering

In a ring oscillator constituting an oscillating circuit, resistor circuits are used as delay circuits to be connected to respective inverters. That is, the inverters and the resistors are connected in series so that the resistor is provided between the adjacent inverters. With the arrangement, it is possible to provide an oscillating circuit which is less dependent on any of power supply voltages, temperatures, and manufacturing variations, while maintaining a characteristic in which the oscillating frequency decreases as an output voltage of a booster circuit increases.

Owner:TAMIRAS PER PTE LTD LLC

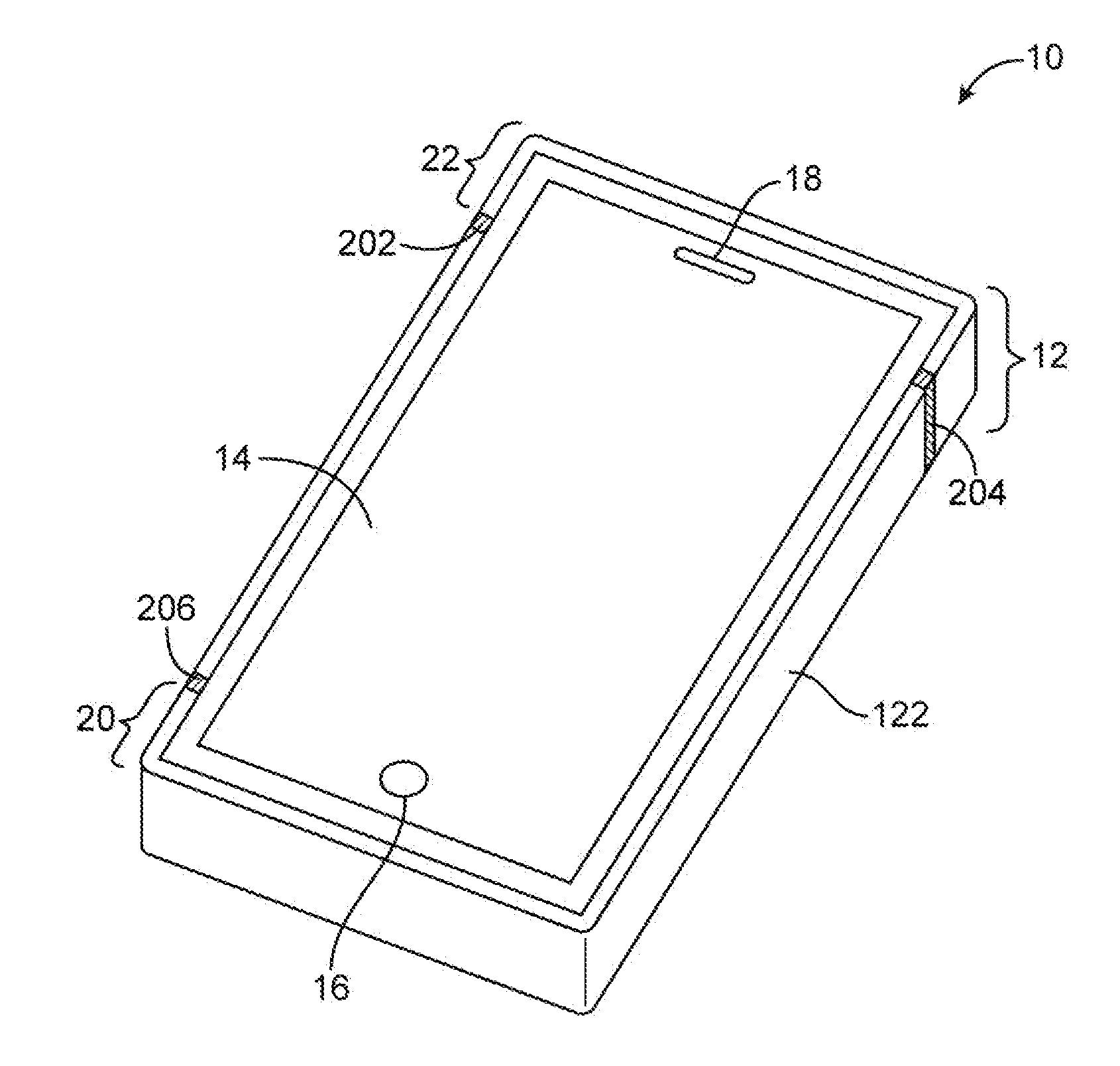

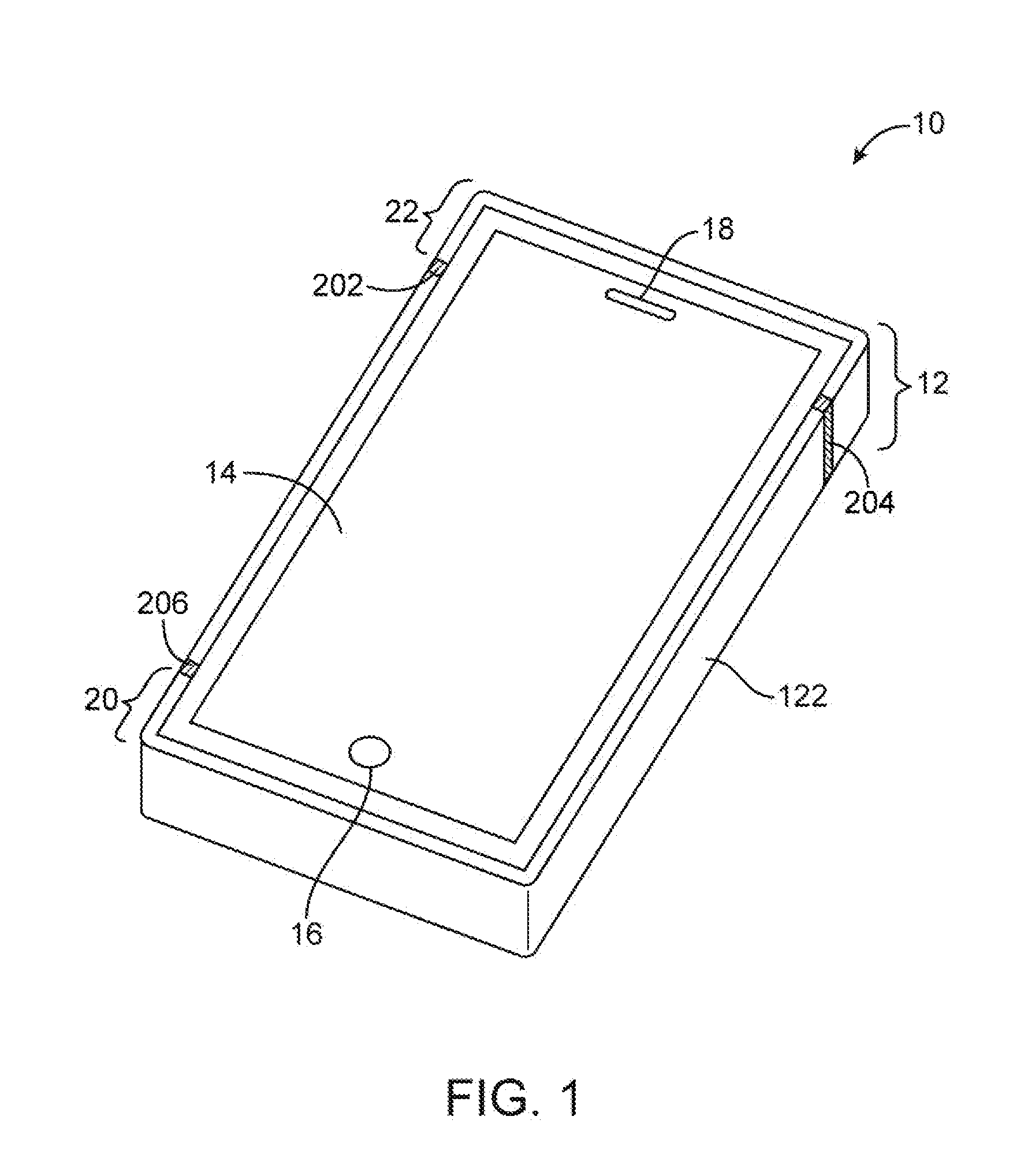

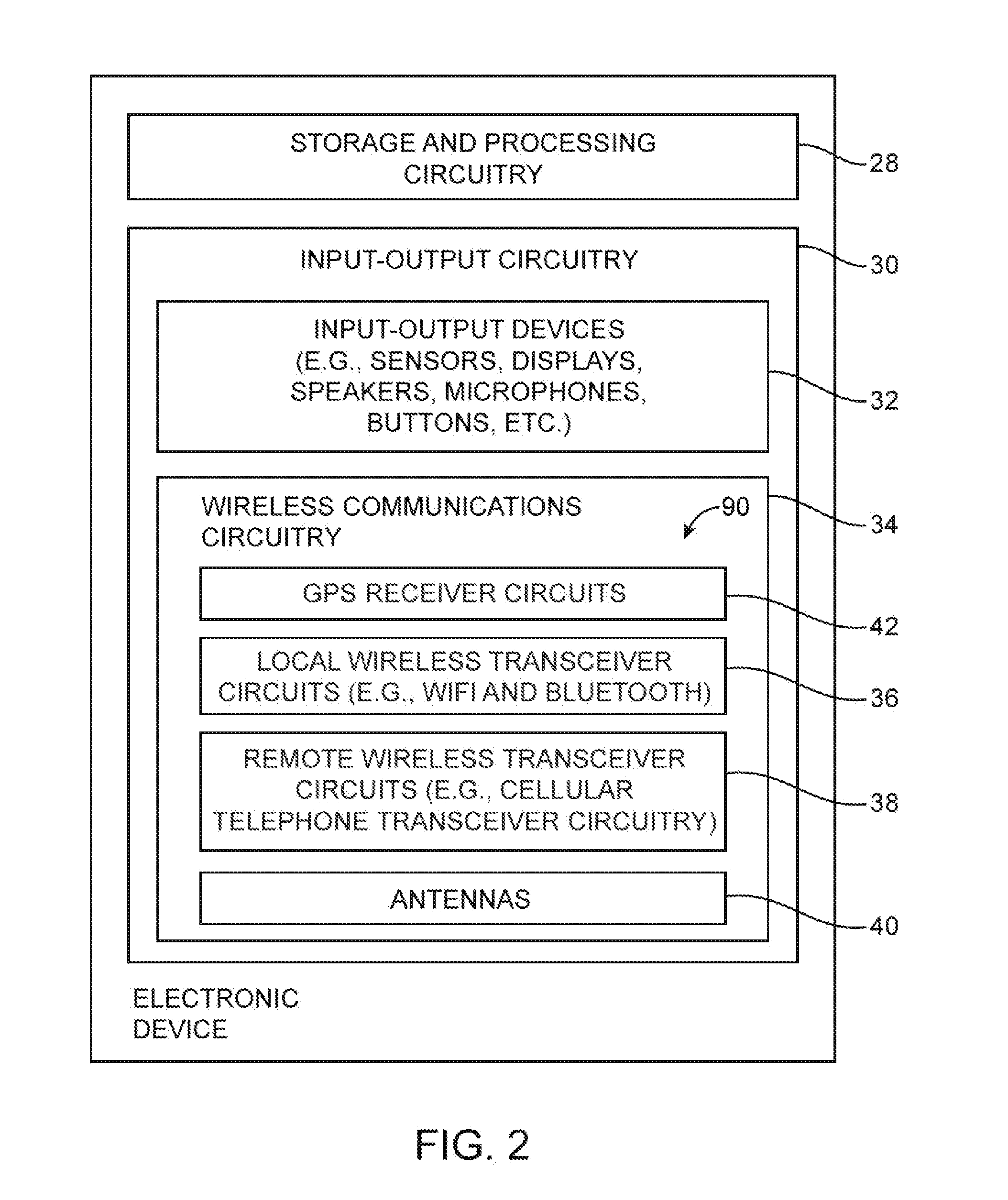

Customizable antenna feed structure

ActiveUS20130050046A1Electronic circuit testingAntennas earthing switches associationContact padManufacturing variation

Custom antenna structures may be used to compensate for manufacturing variations in electronic device antennas. An antenna may have an antenna feed and conductive structures such as portions of a peripheral conductive electronic device housing member. The custom antenna structures compensate for manufacturing variations that could potentially lead to undesired variations in antenna performance. The custom antenna structures may make customized alterations to antenna feed structures or conductive paths within an antenna. An antenna may be formed from a conductive housing member that surrounds an electronic device. The custom antenna structures may be formed from a printed circuit board with a customizable trace. The customizable trace may have a contact pad portion on the printed circuit board. The customizable trace may be customized to connect the pad to a desired one of a plurality of contacts associated with the conductive housing member to form a customized antenna feed terminal.

Owner:APPLE INC

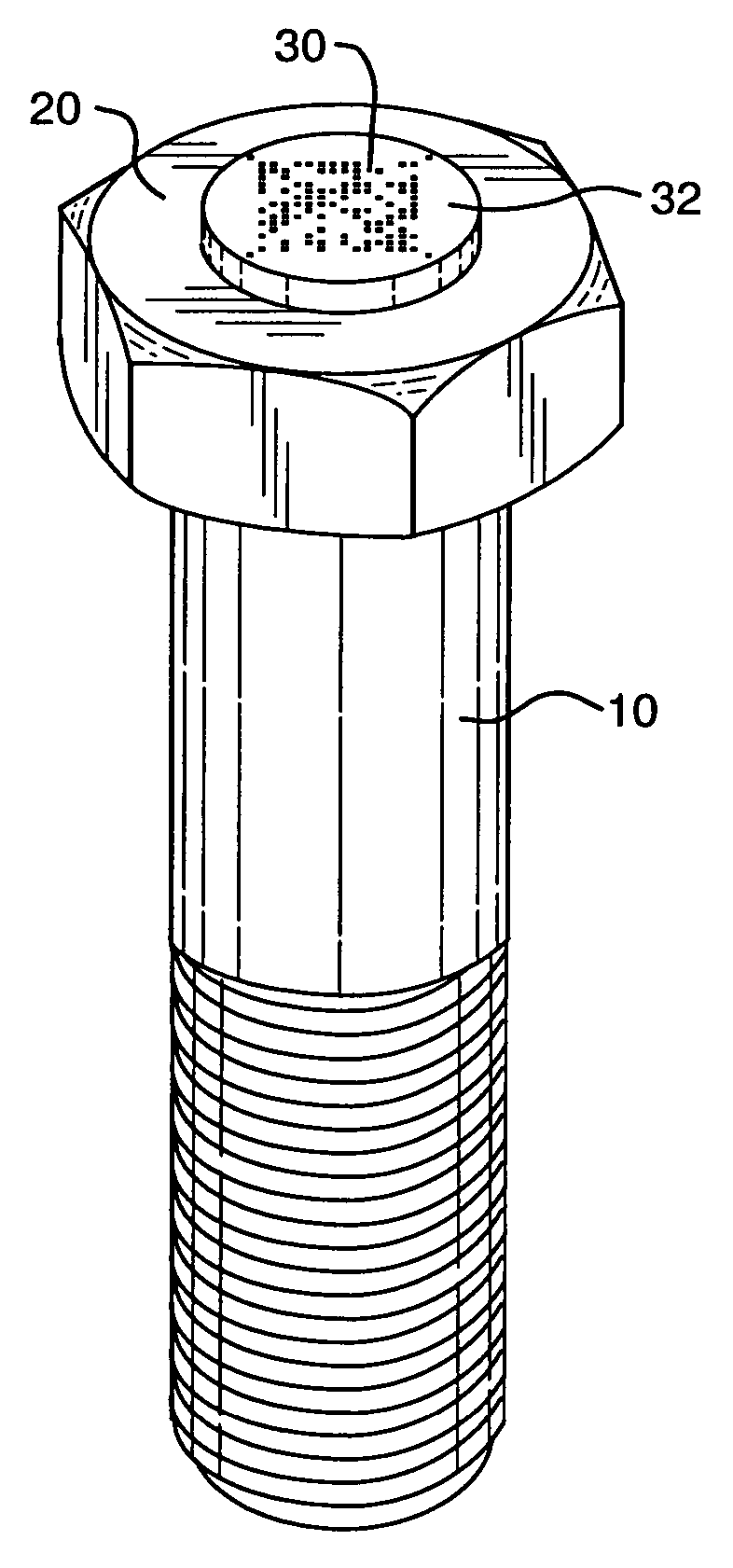

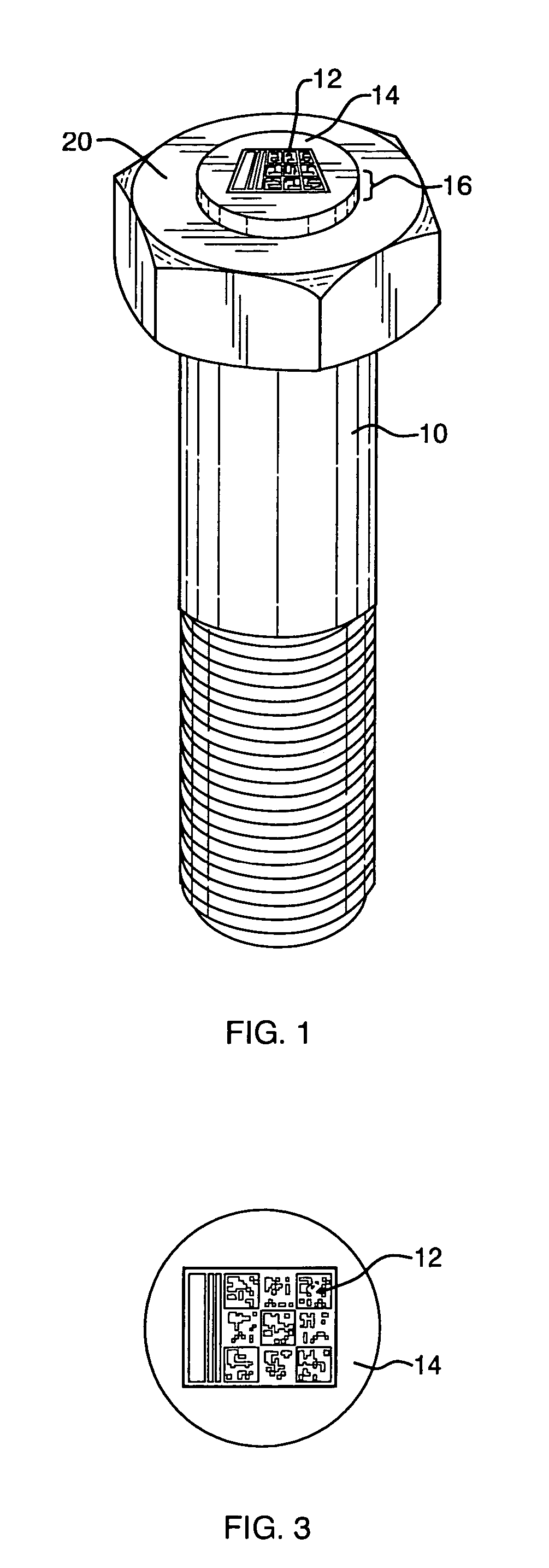

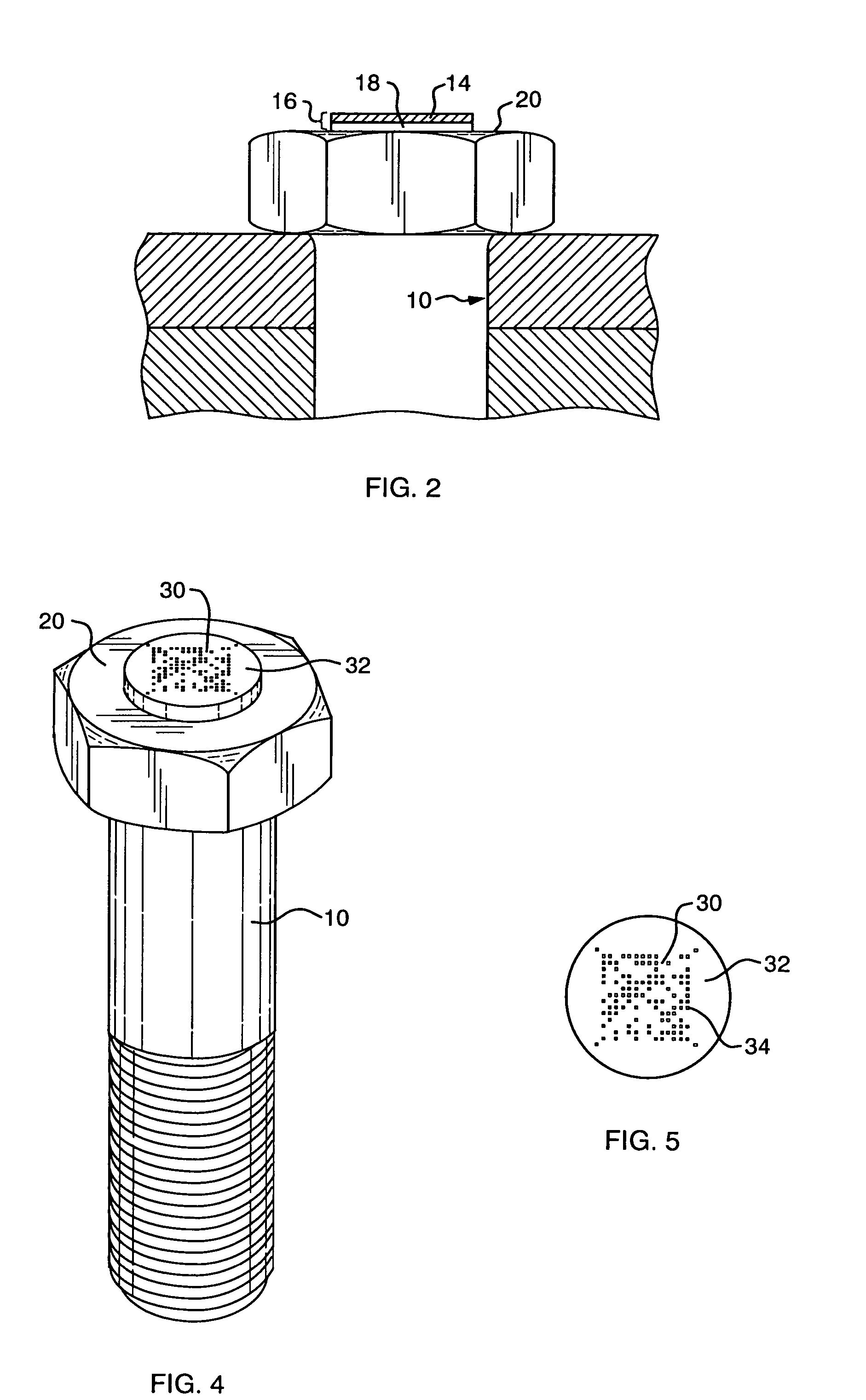

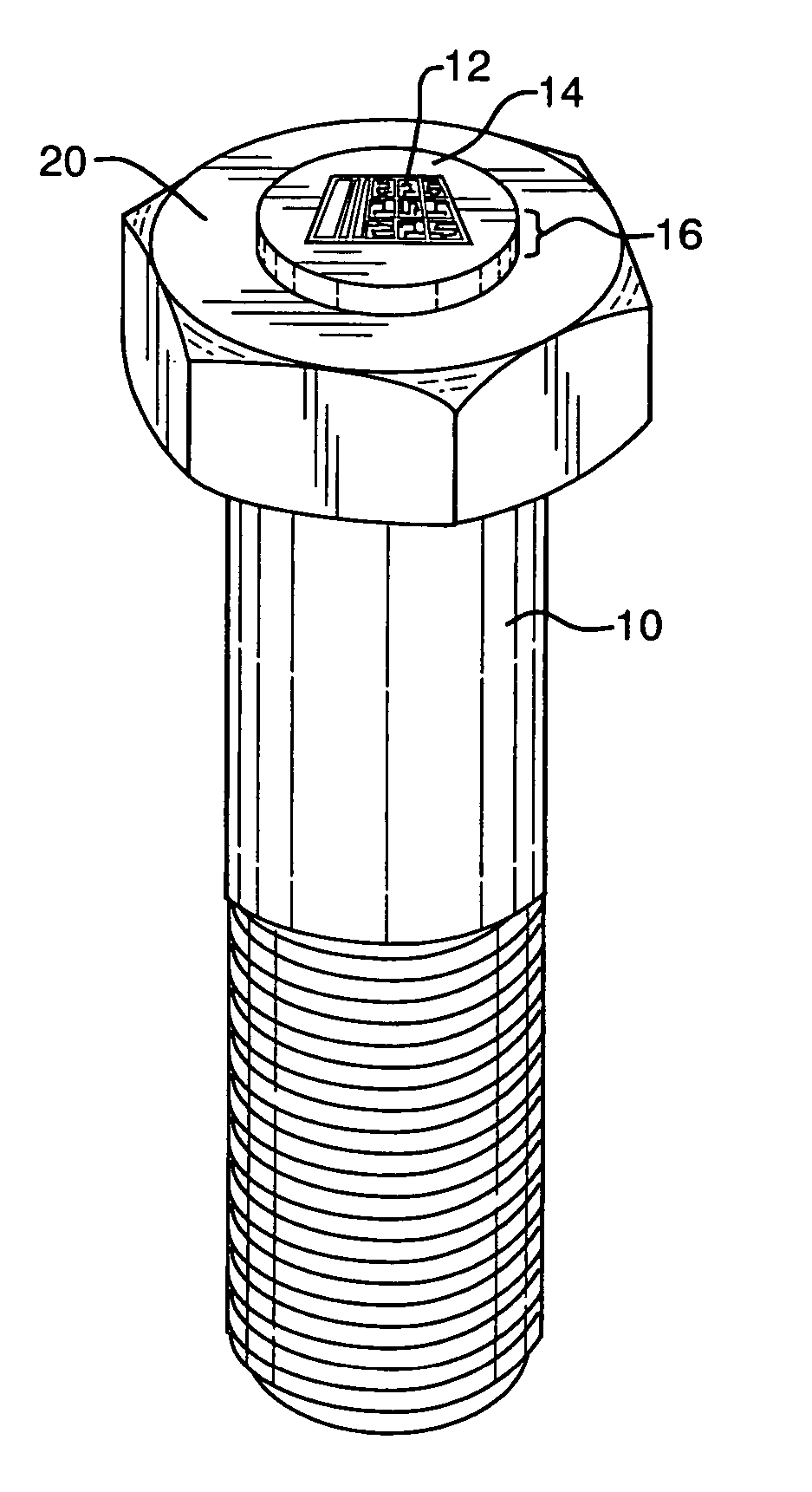

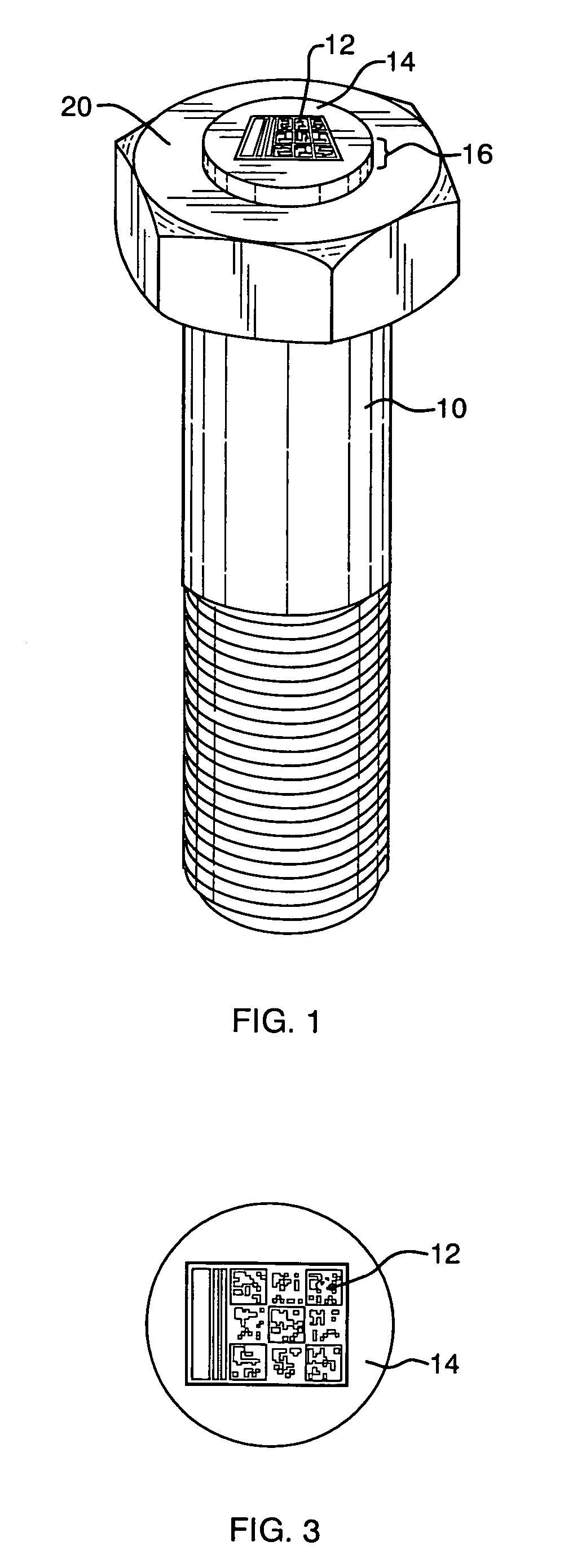

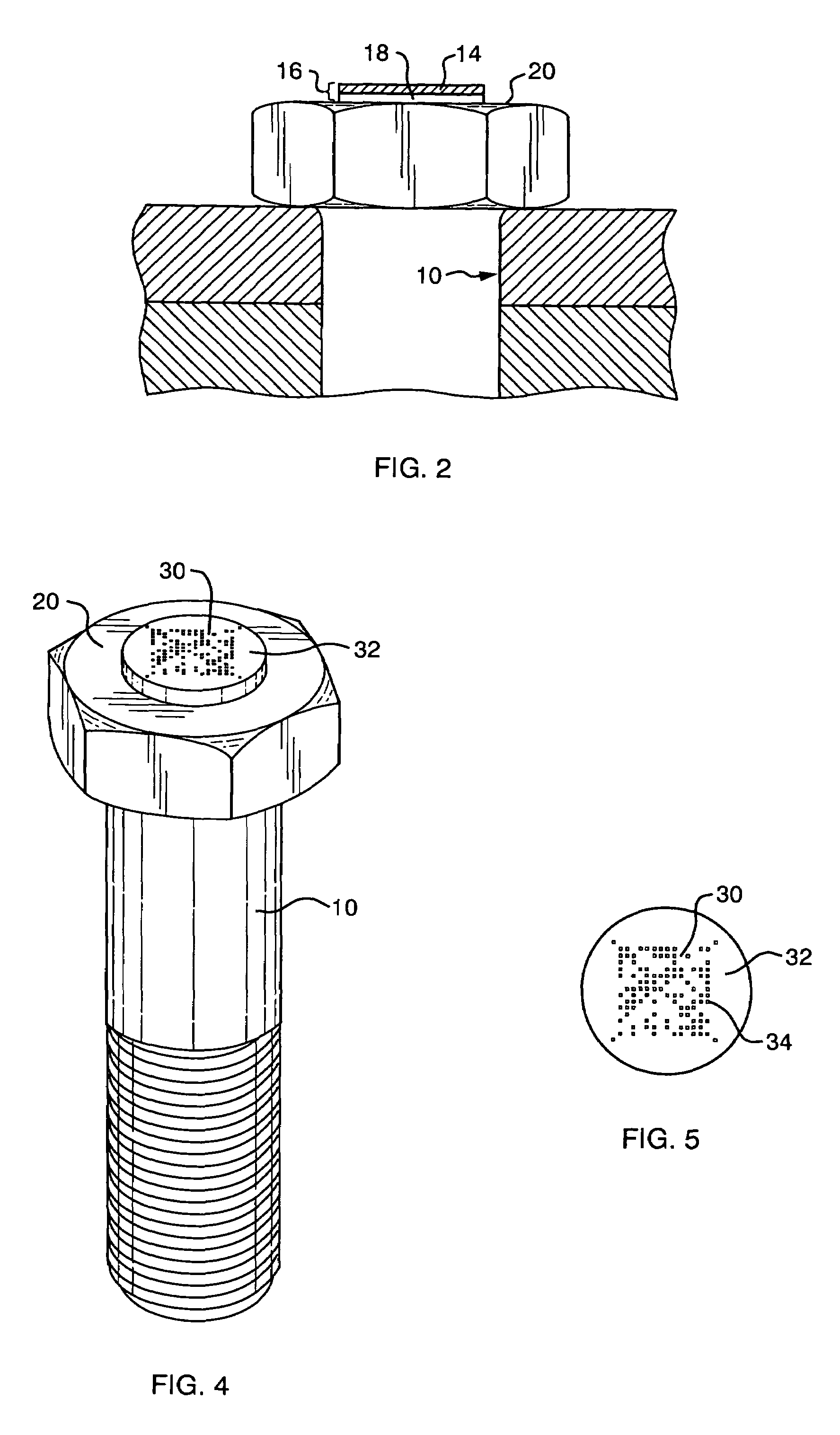

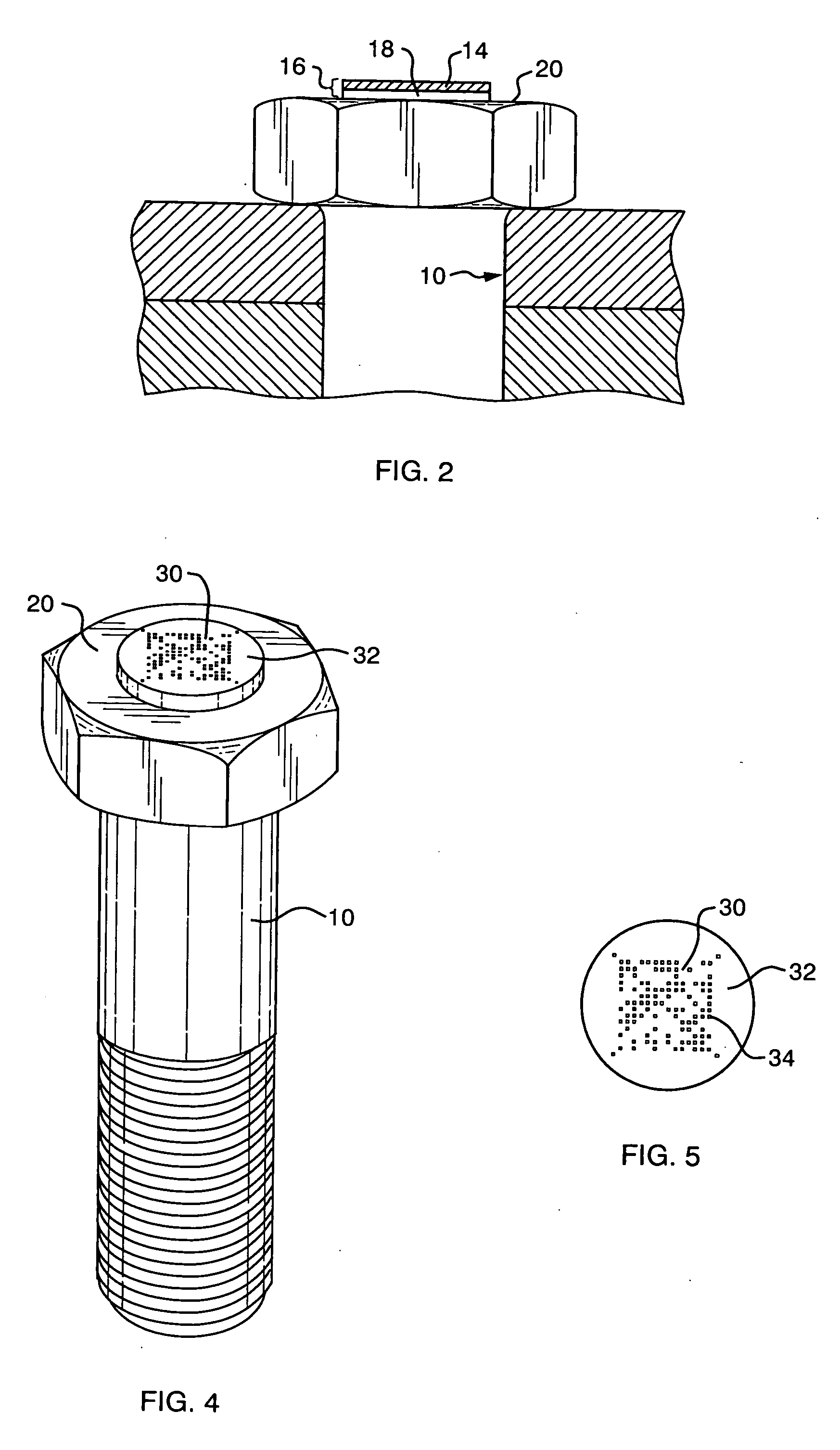

Load indicating member with identifying mark

InactiveUS6990866B2Reliable precise load measurementVehicle seatsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringManufacturing variation

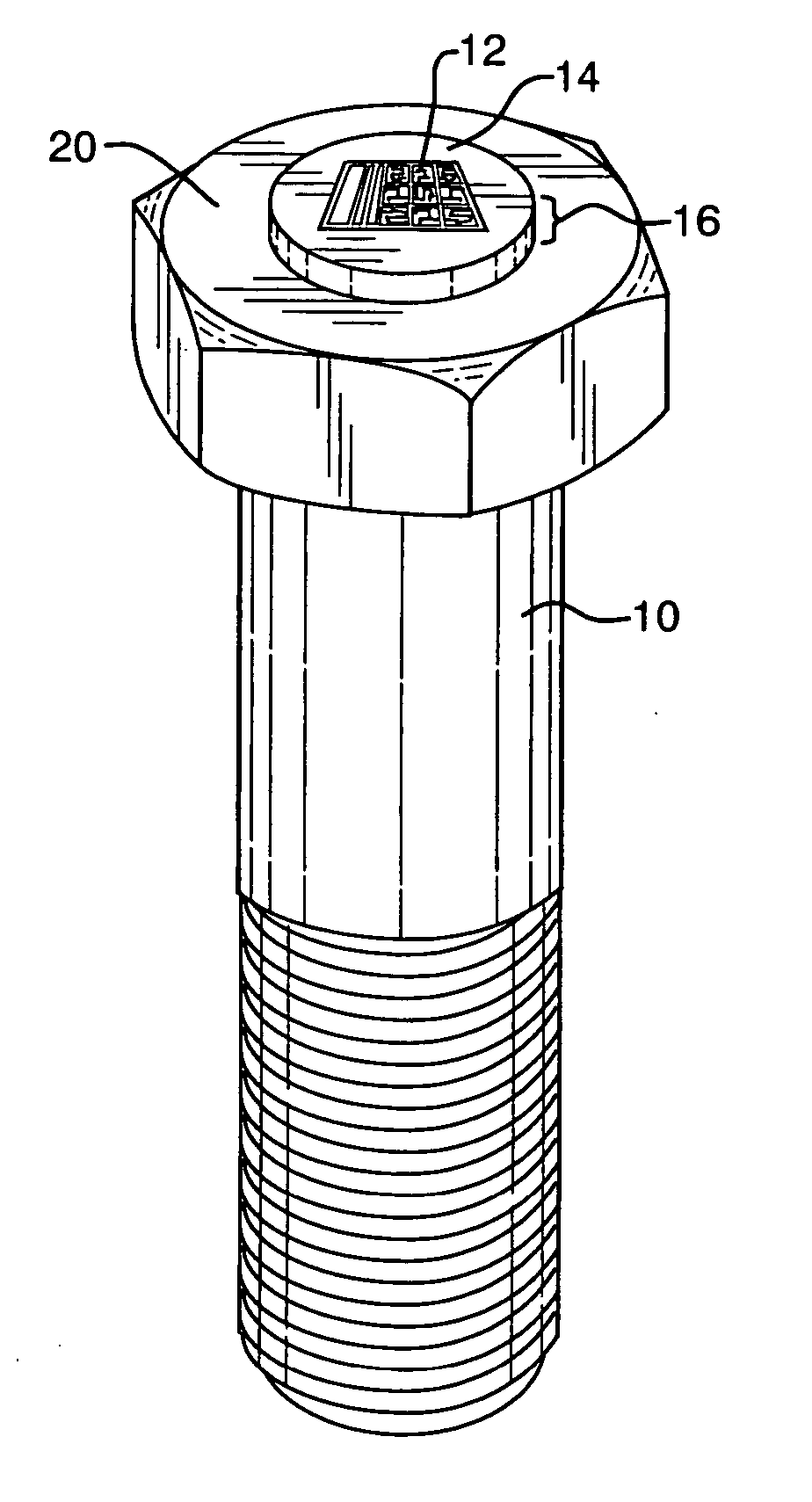

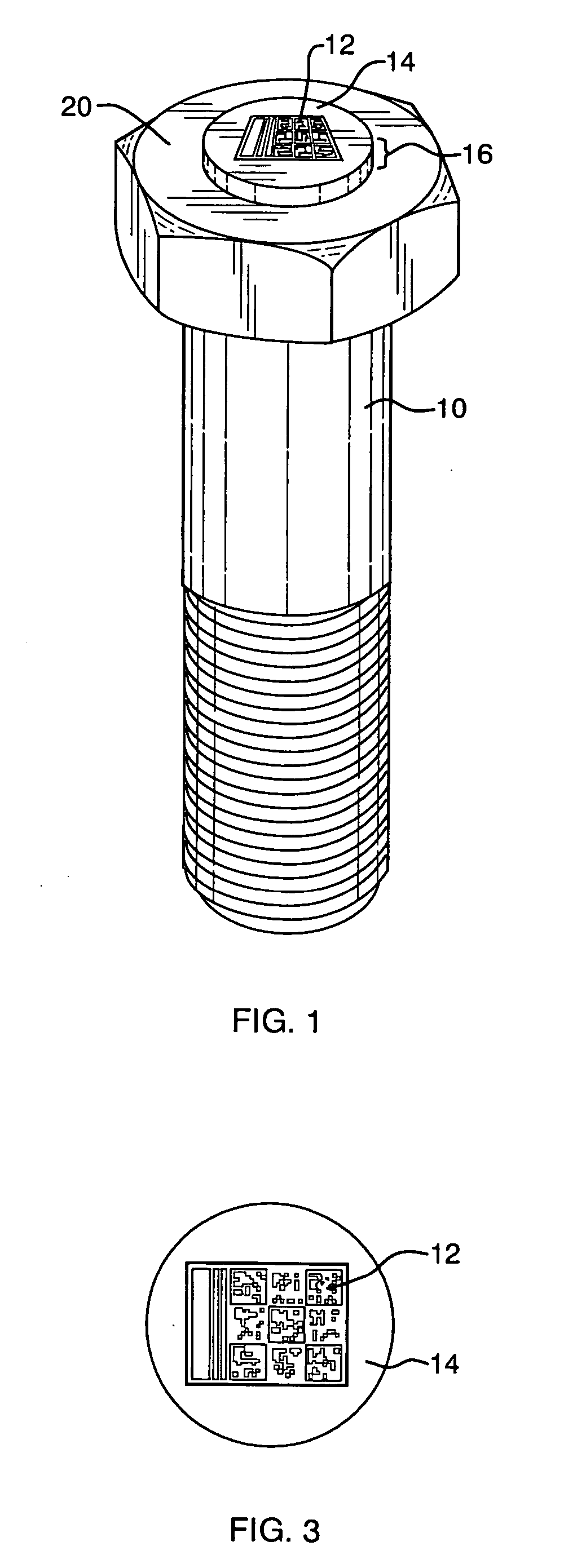

A load indicating member is provided with a permanent identifying mark which can be read and used to determine ultrasonic measurement parameters specific to the load indicating member to provide more precise and more reliable load measurements by compensating for differences resulting from manufacturing variations in individual load indicating members. The parameters specific to the load indicating member can be stored in coding applied to the load indicating member or in a database that can be accessed remotely, for example, using the Internet.

Owner:INNOVATION PLUS

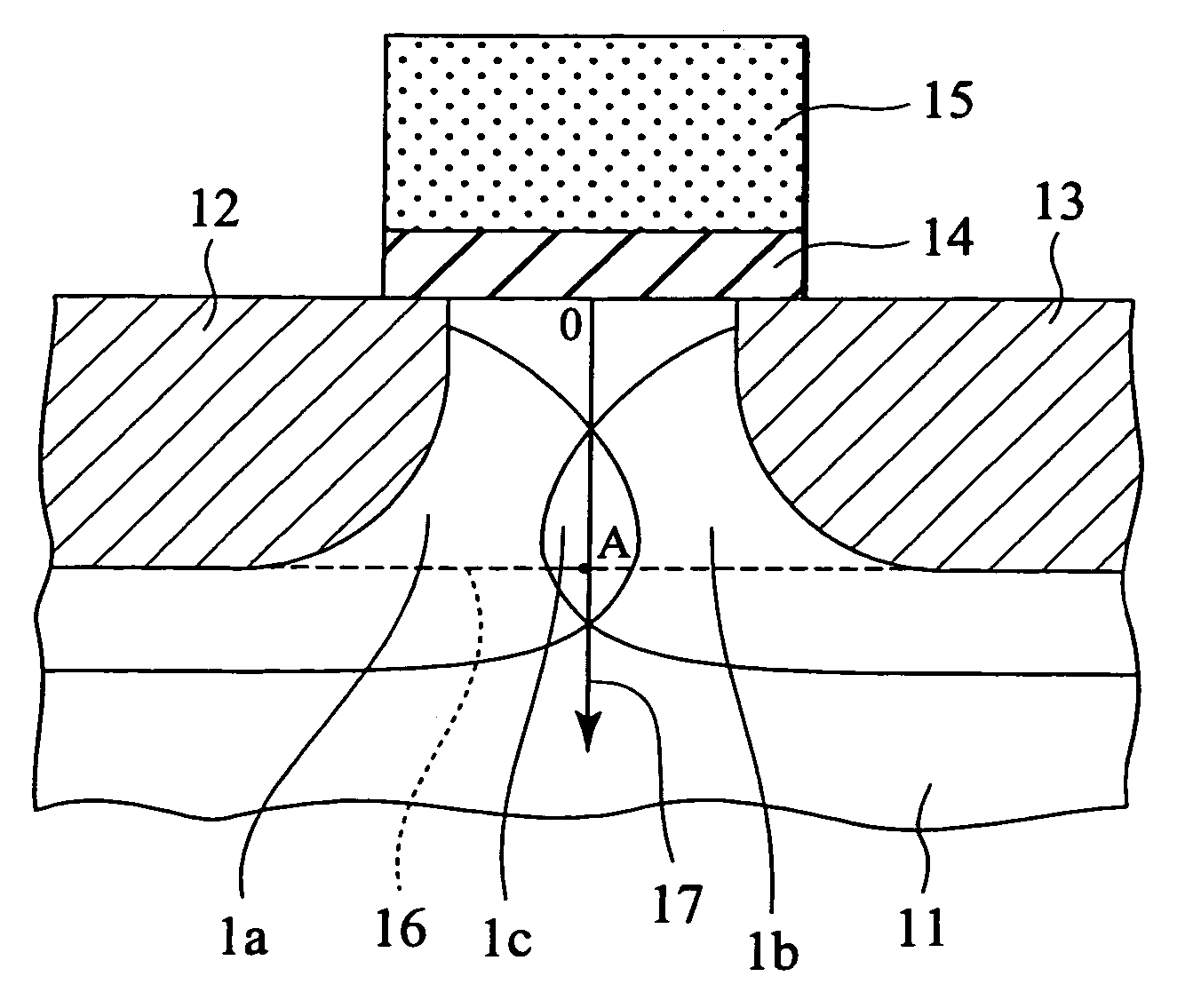

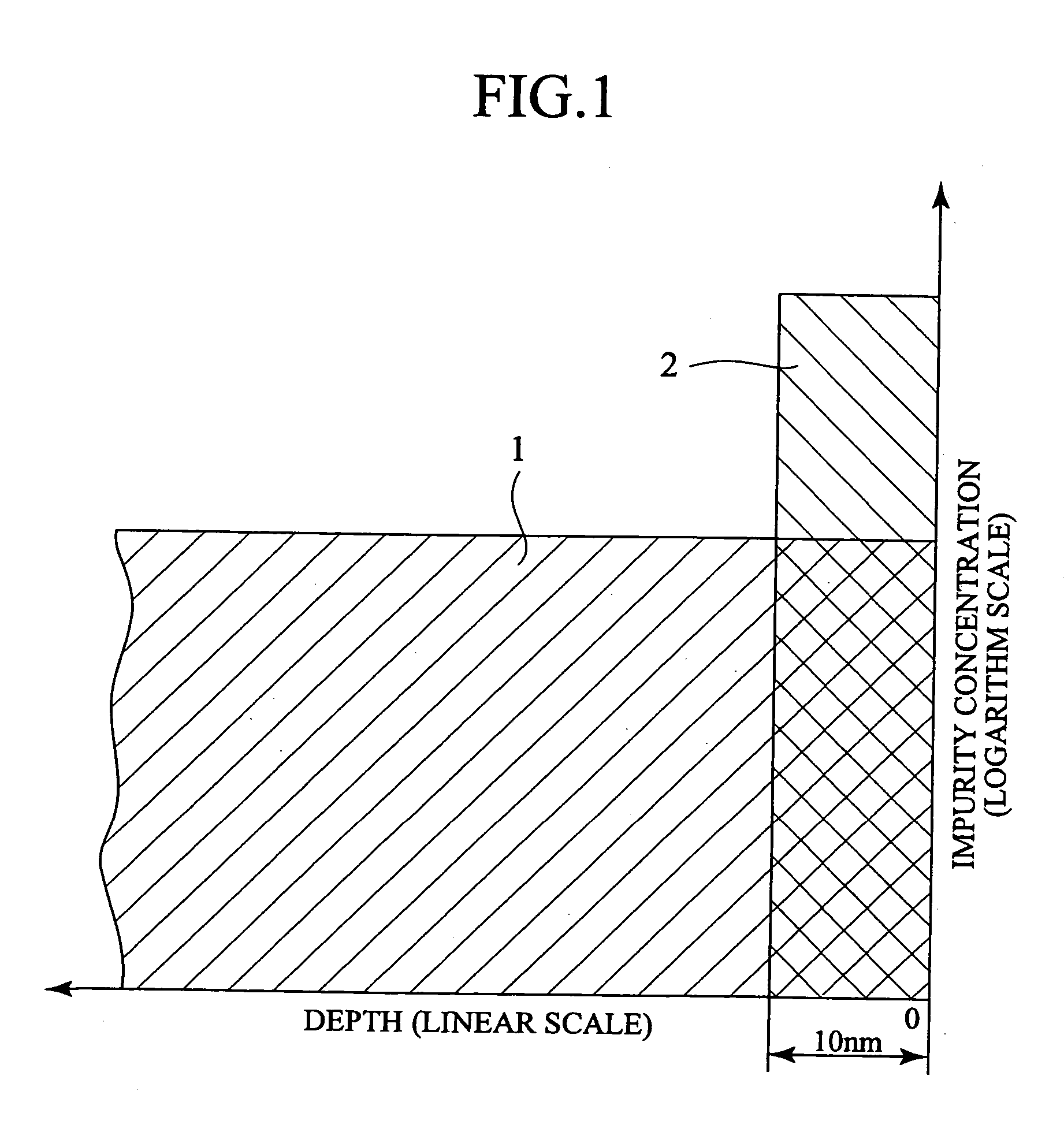

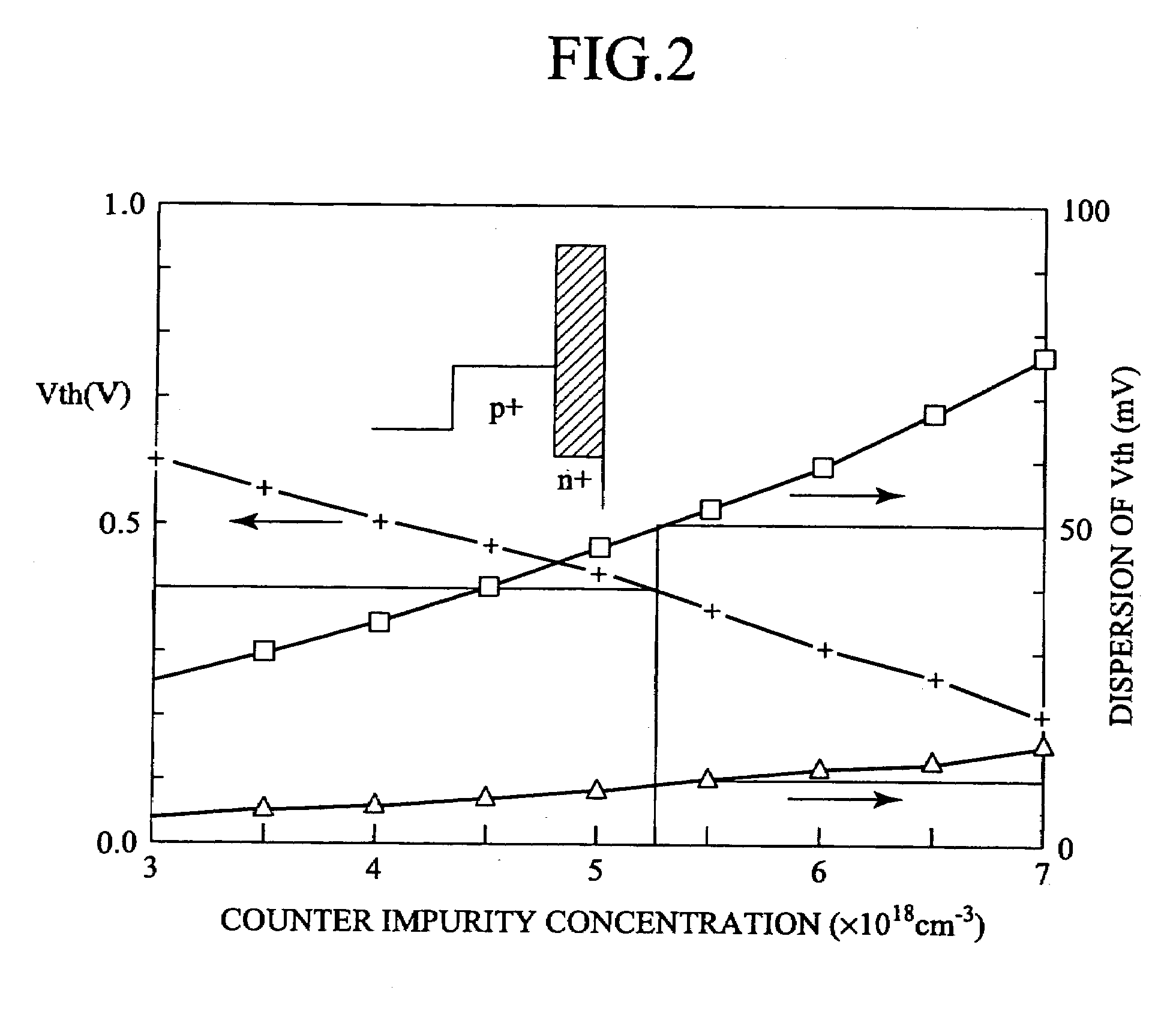

Semiconductor device and method of manufacturing the same

InactiveUS20010009292A1Minimizes heat treatmentSteep impurity concentration profileTransistorSolid-state devicesElectrical conductorManufacturing variation

A semiconductor device has a first semiconductor region formed in a semiconductor substrate and having a first conductivity type due to first-conductivity-type active impurities contained in the first semiconductor region, and a second semiconductor region formed between the first semiconductor region and the surface of the semiconductor substrate and having a second conductivity type due to second-conductivity-type active impurities contained in the second semiconductor region. The second semiconductor region contains first-conductivity-type active impurities whose concentration is zero or smaller than a quarter of a concentration of the second-conductivity-type active impurities contained in the second semiconductor region. An insulating film and a conductor are formed on the second semiconductor region. Third and fourth semiconductor regions of the second conductivity type are formed at the semiconductor surface in contact with the side faces of the second semiconductor region. This semiconductor device is capable of suppressing net impurity concentration variations as well as threshold voltage variations to be caused by a short channel effect or manufacturing variations.

Owner:KK TOSHIBA

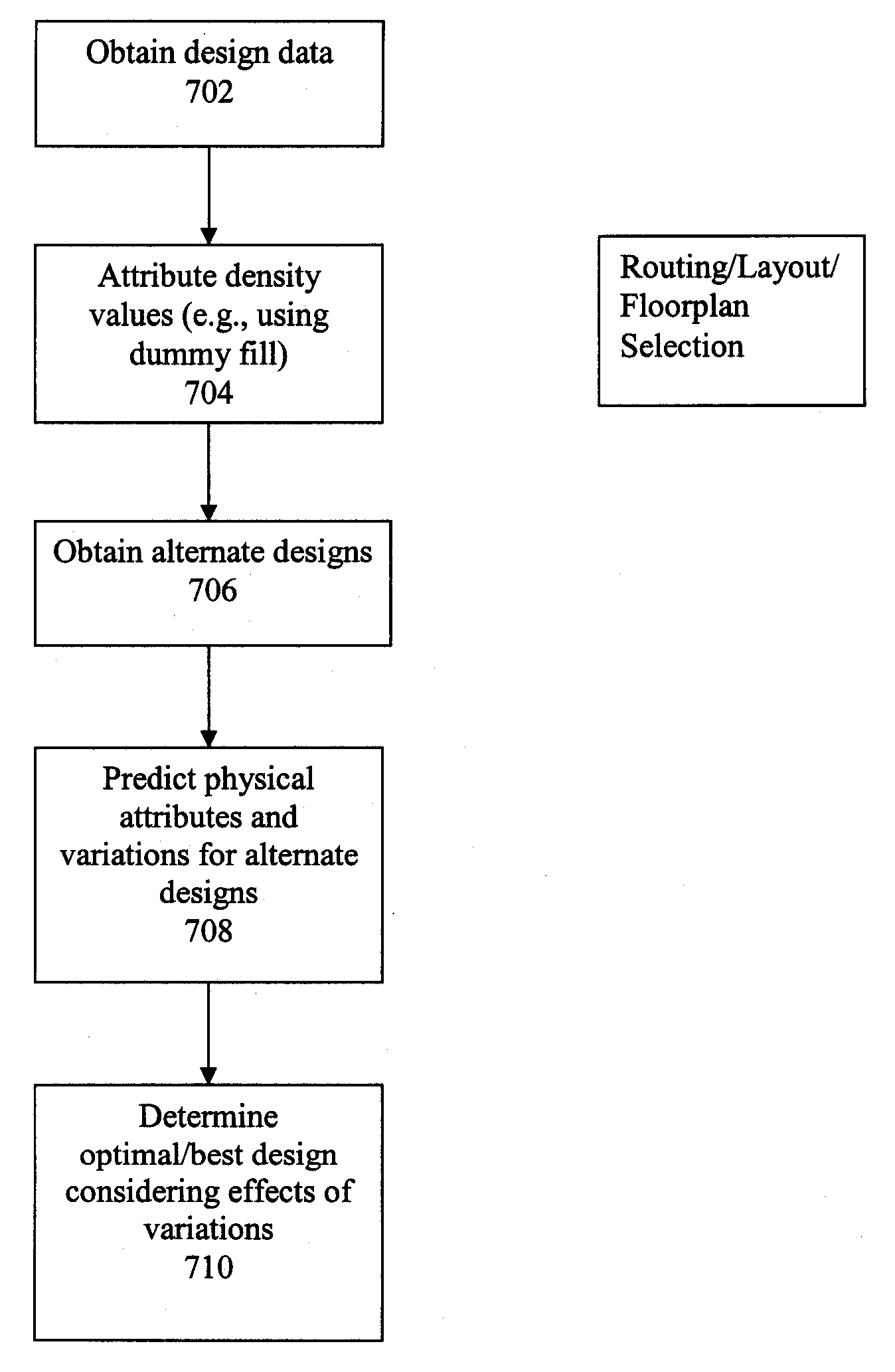

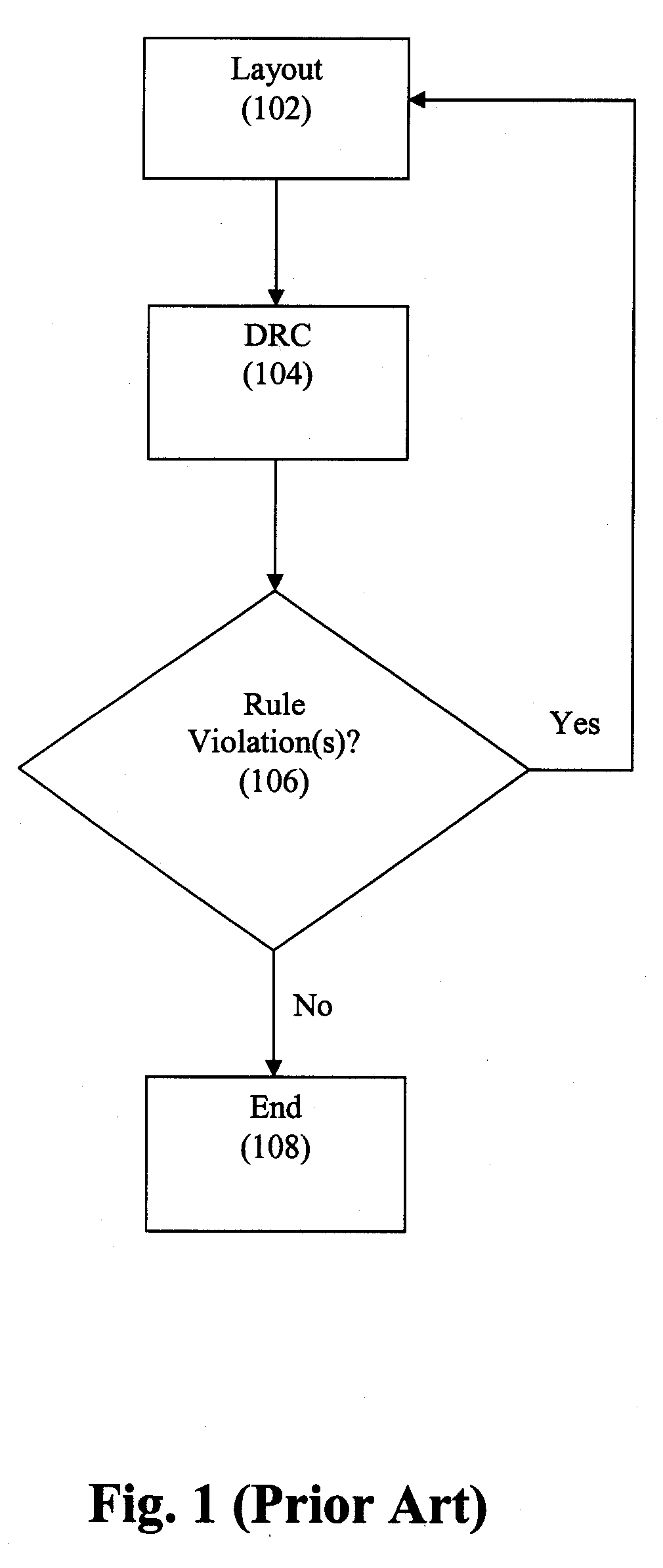

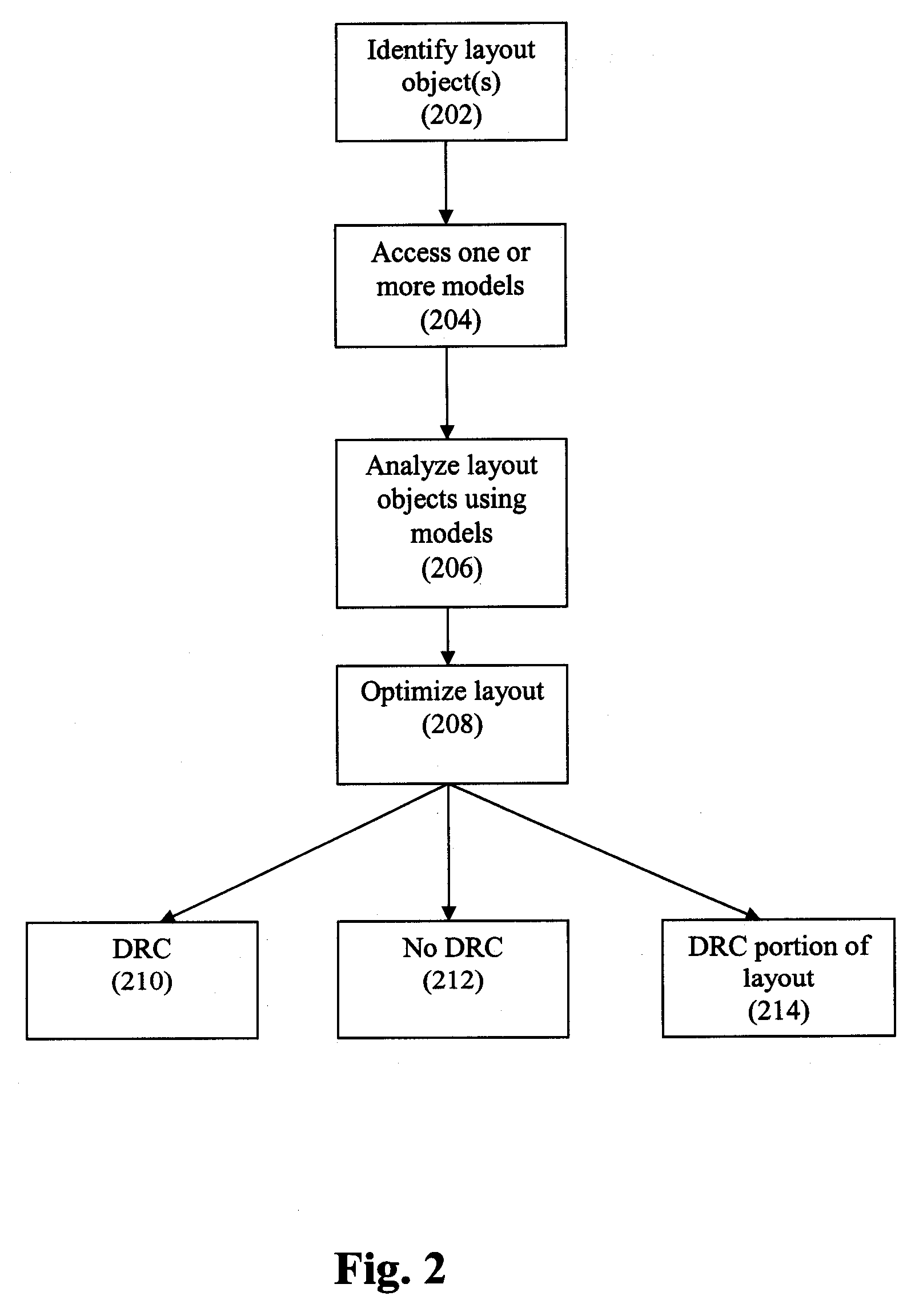

Method and System for Model-Based Routing of an Integrated Circuit

ActiveUS20080163150A1Minimize changesSignificant changeComputer aided designSoftware simulation/interpretation/emulationEngineeringManufacturing variation

Disclosed is a method, system, and computer program product for implementing model-based floorplanning, layout, placement, and routing. Models are used to guide the placement and routing of polygons on the IC layout based upon predictions of manufacturing variations.

Owner:CADENCE DESIGN SYST INC

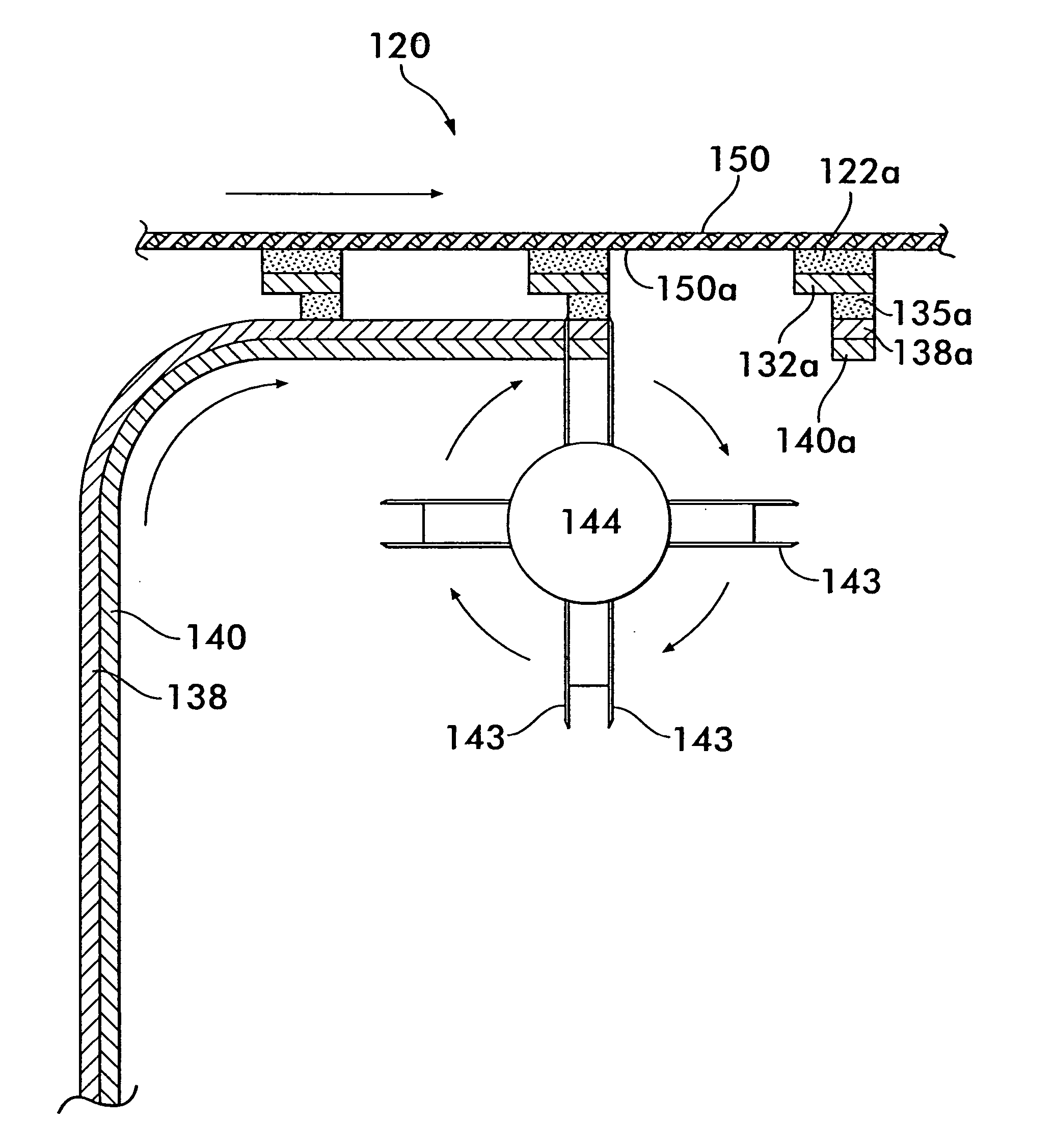

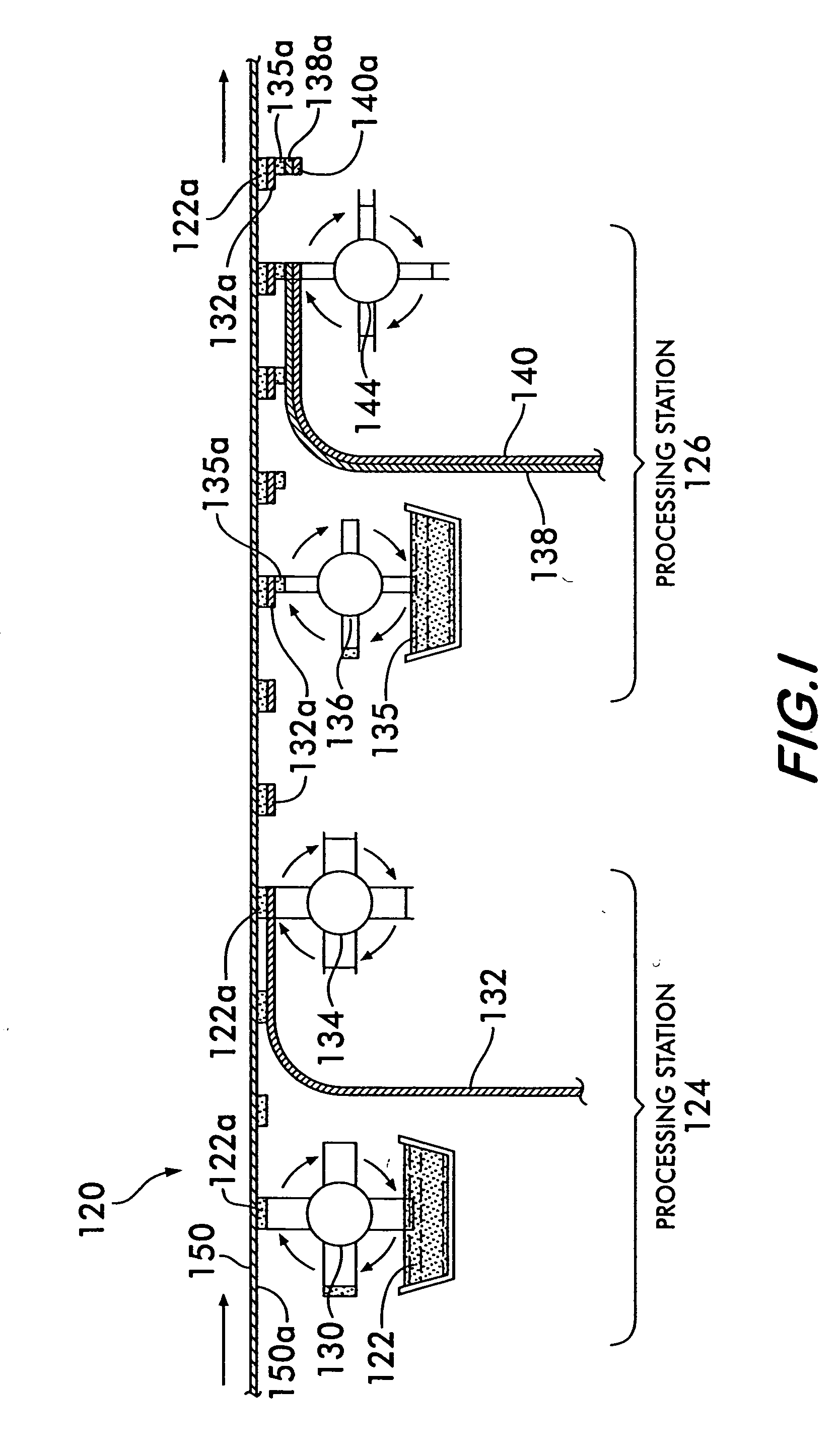

Pre-configured light modules

ActiveUS6967447B2Electrical apparatusElectroluminescent light sourcesLight signalManufacturing variation

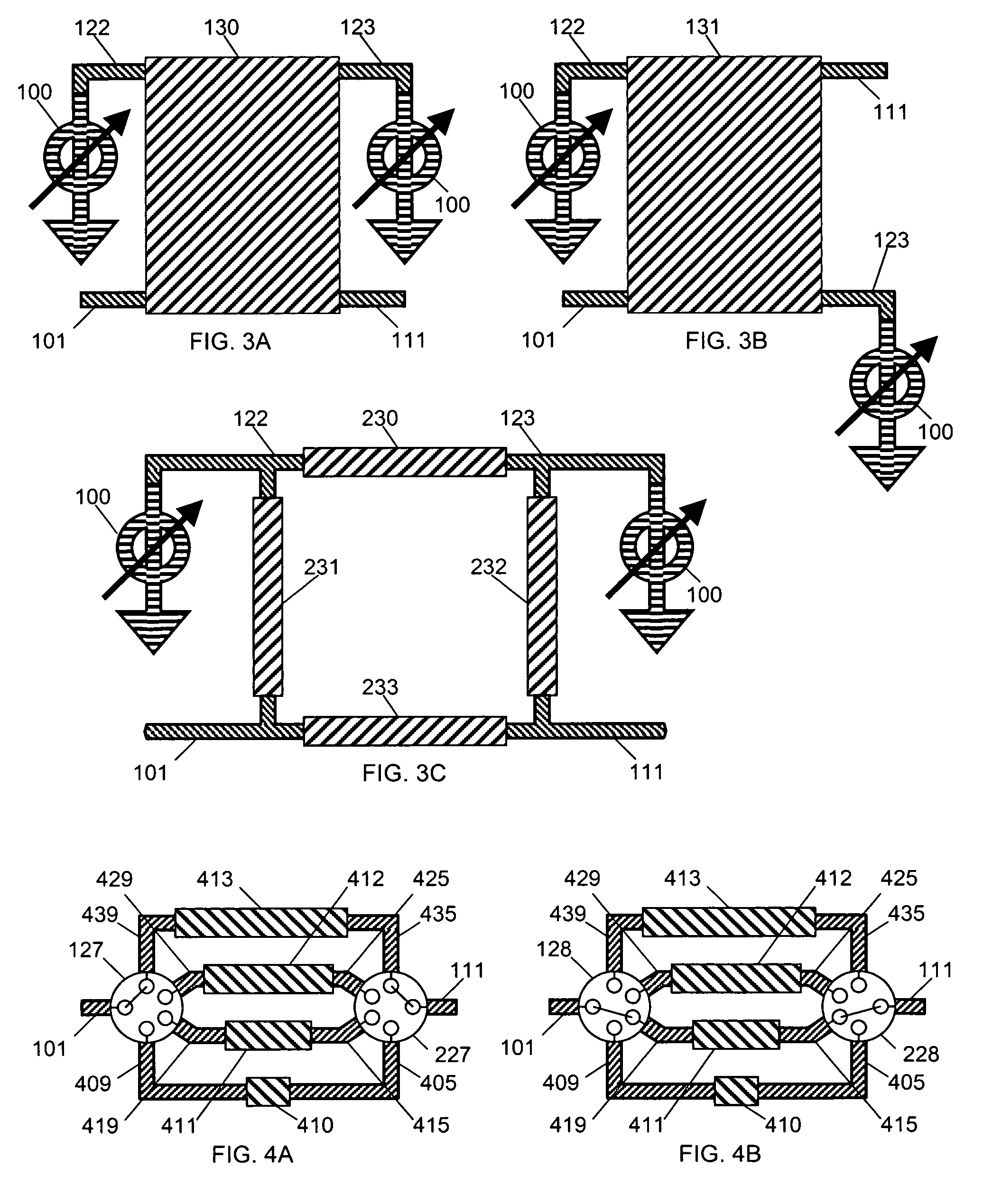

The present invention includes a light source having N light generators, a receiver, and an interface circuit. Each light generator emitting light of a different wavelength, the intensity of light generated by the kth generator is determined by a signal Ik coupled to that light generator. The receiver receives a color coordinate that includes N color components, Ck, for k=1 to N, wherein N is greater than 1. The interface circuit generates the Ik for k=1 to N from the received color components and a plurality of calibration parameters. The calibration parameters depend on manufacturing variations in the light generators. The calibration parameters have values chosen such that a light signal generated by combining the light emitted from each of the light generators is less dependent on the manufacturing variations in the light generators than a light signal generated when Ik is proportional to Ck for k=1 to N.

Owner:AVAGO TECH INT SALES PTE LTD

Method for aligning capacitor plates in a security tag and a capacitor formed thereby

InactiveUS20050183264A1Radiating elements structural formsPrinted capacitor incorporationCapacitanceEngineering

A circuit element the presence of the circuit element includes first and second capacitor plates disposed over the surface of the substrate in an aligned relationship with each other. The aligned relationship has manufacturing variations in the relative positioning of the first and second capacitor plates and a dielectric layer disposed between the first and second capacitor plates. At least one of the first and second capacitor plates is formed substantially smaller relative to the other of the first and second capacitor plates. The at least one of the capacitor plates is disposed at a predetermined offset in at least one planar direction from an edge of the other of the first and second capacitor plates. The predetermined offset is selected according to the manufacturing variations to prevent variations in the value of capacitance of the capacitor due to the manufacturing variations.

Owner:CHECKPOINT SYST INC

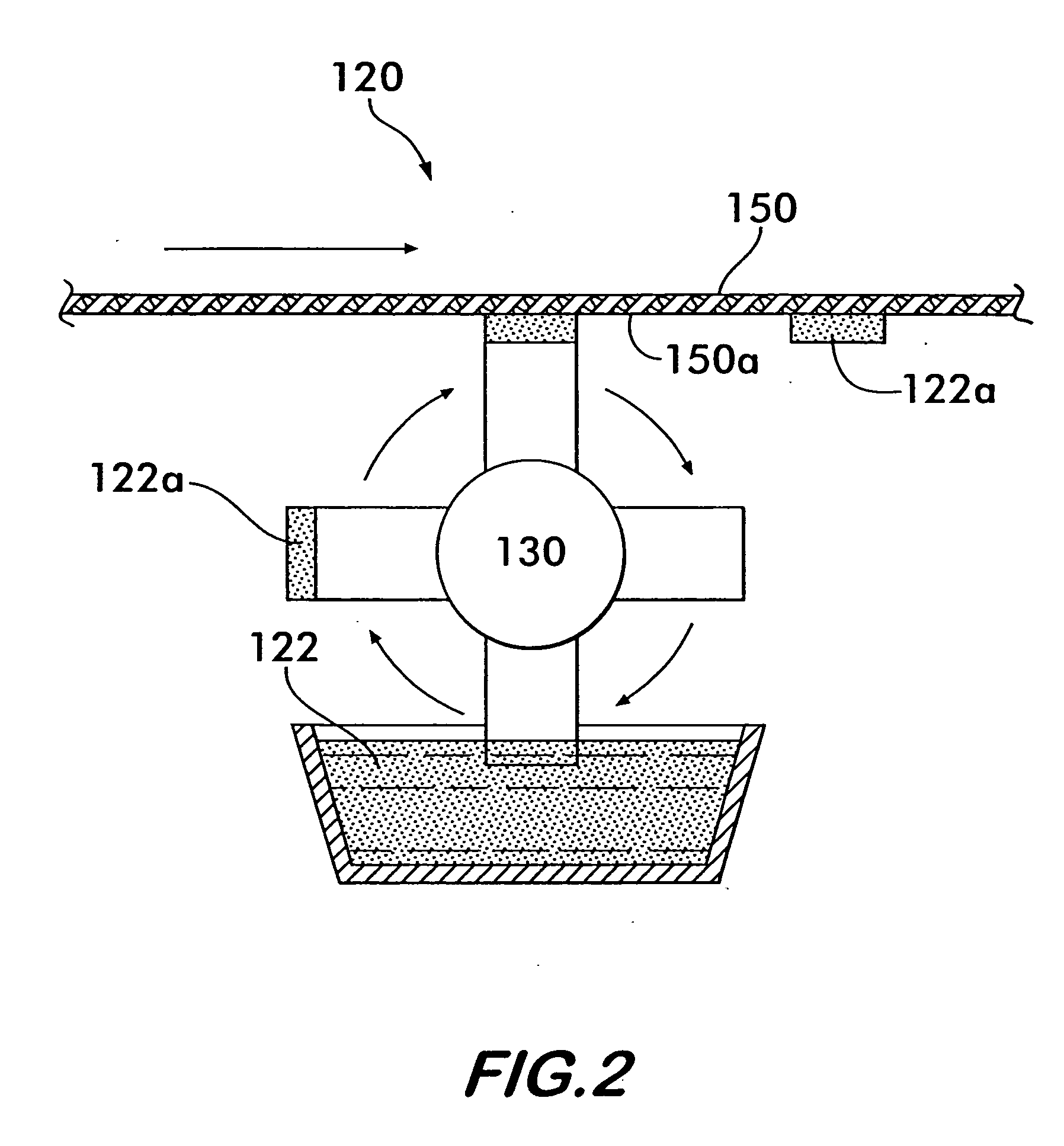

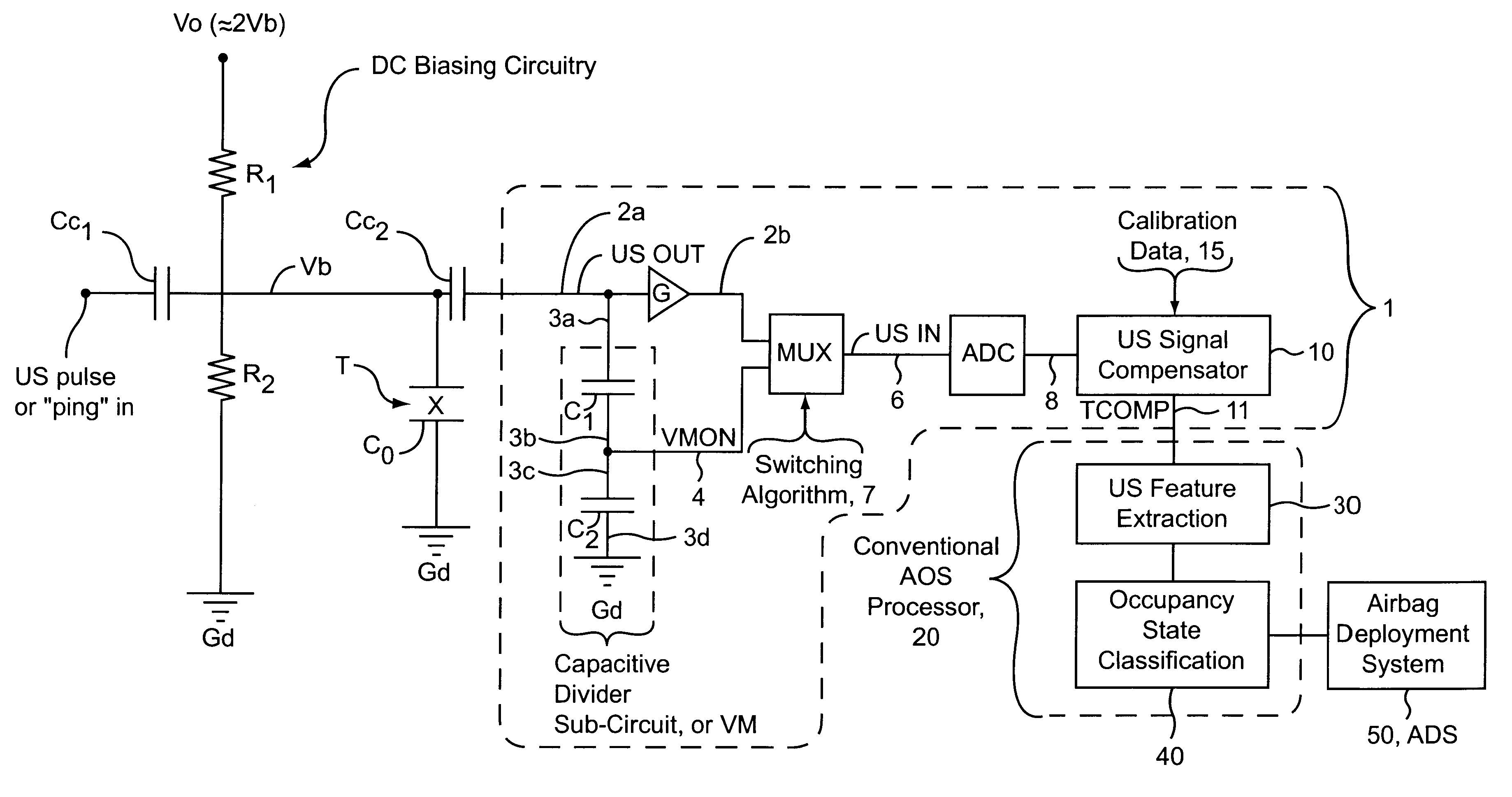

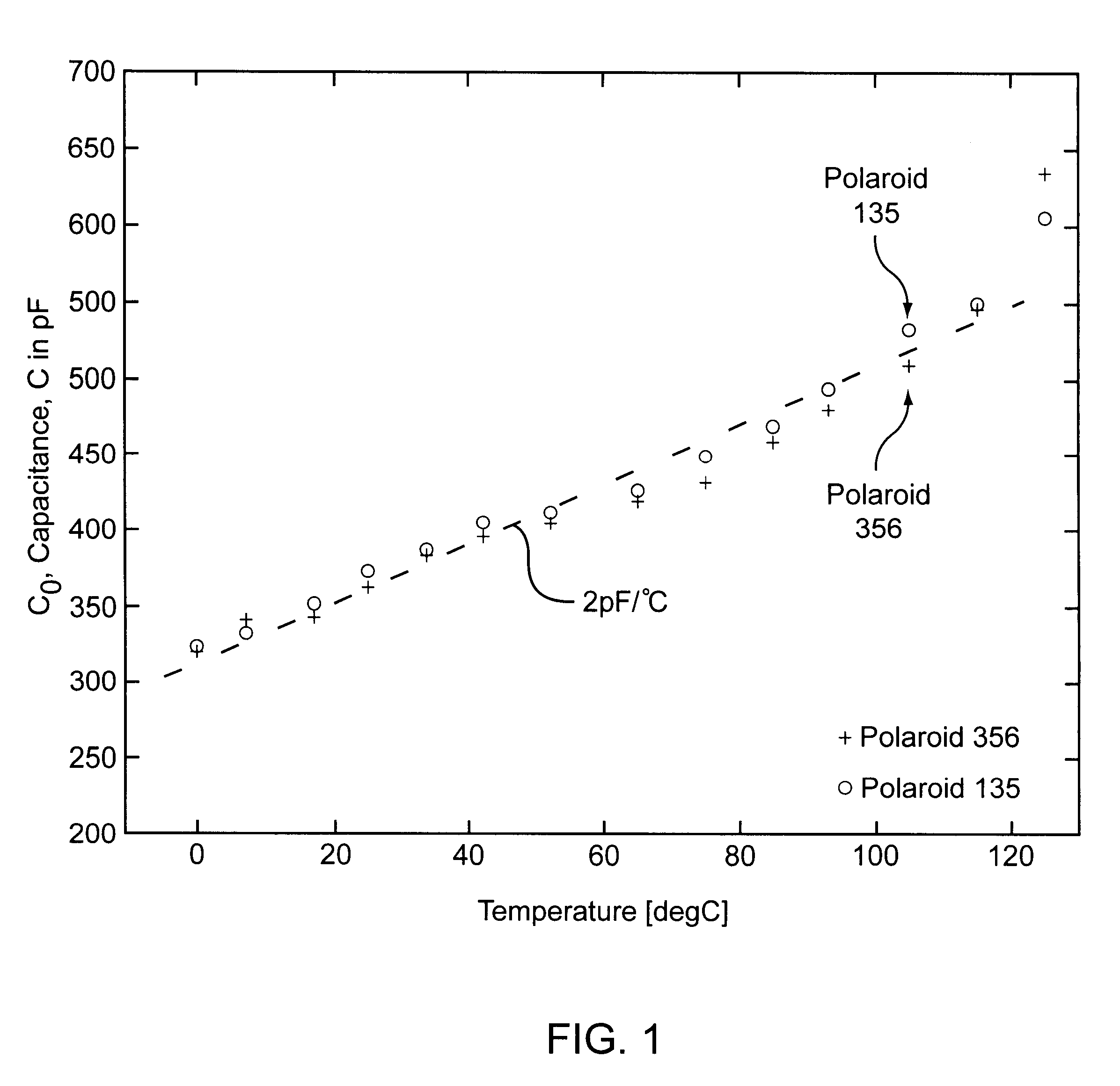

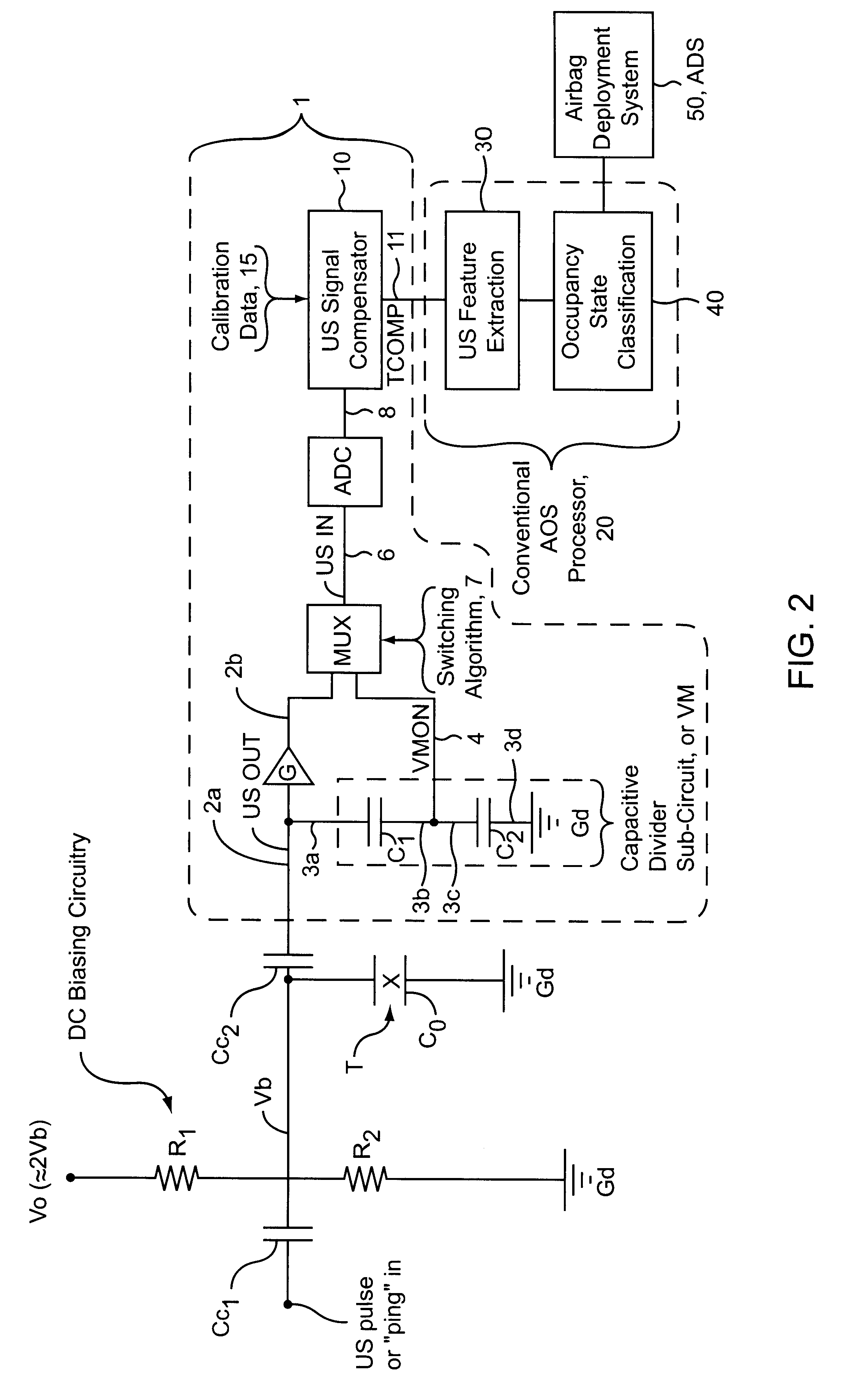

Ultrasound transducer temperature compensation methods, apparatus and programs

InactiveUS6314380B1Improve performanceNoise figure or signal-to-noise ratio measurementDigital data processing detailsCapacitanceEngineering

Method, apparatus and computer programs are described for compensating for the effect of temperature on the sensitivity of electrostatic ultrasound (US) transducers, particularly as used in an automotive occupancy sensing (AOS) systems for sensing the nature or type of occupant and the location of the occupant with respect to the vehicle interior. The invention permits the AOS to classify the occupancy state of the vehicle from a US echo signal substantially free of the effects of temperature on signal amplitude. A capacitive divider or voltage monitor is employed to measure the capacitance of the transducer. The voltage monitor output is used by the scaling algorithm of a compensator to determine the scaling factor to be applied to the US transducer signal to compensate for the effect of temperature on the transducer sensitivity. Calibration procedures and software are disclosed for determining the coefficients of the scaling algorithm to compensate for temperature effects and also to compensate for installation factors, transducer manufacturing variations, and circuit board effects. The system disclosed is useful for other types of signal processing in addition to temperature compensation of AOS ultrasonic signals, and may be used in other ranging devices such as cameras, golf or binocular range finders, and measuring devices and instruments.

Owner:ROBERT BOSCH CORP

Load indicating member with identifying element

InactiveUS7441462B2Eliminate disadvantagesPrecise and reliable loadLoad modified fastenersScrewsEngineeringManufacturing variation

A load indicating member is provided with an identifying element which can be accessed and used to determine ultrasonic measurement parameters specific to the load indicating member to provide more precise and more reliable load measurements by compensating for differences resulting from manufacturing variations in individual load indicating members. The parameters specific to the load indicating member can be stored in coding applied to the load indicating member or in a database that can be accessed remotely, for example, using the Internet.

Owner:INNOVATION PLUS

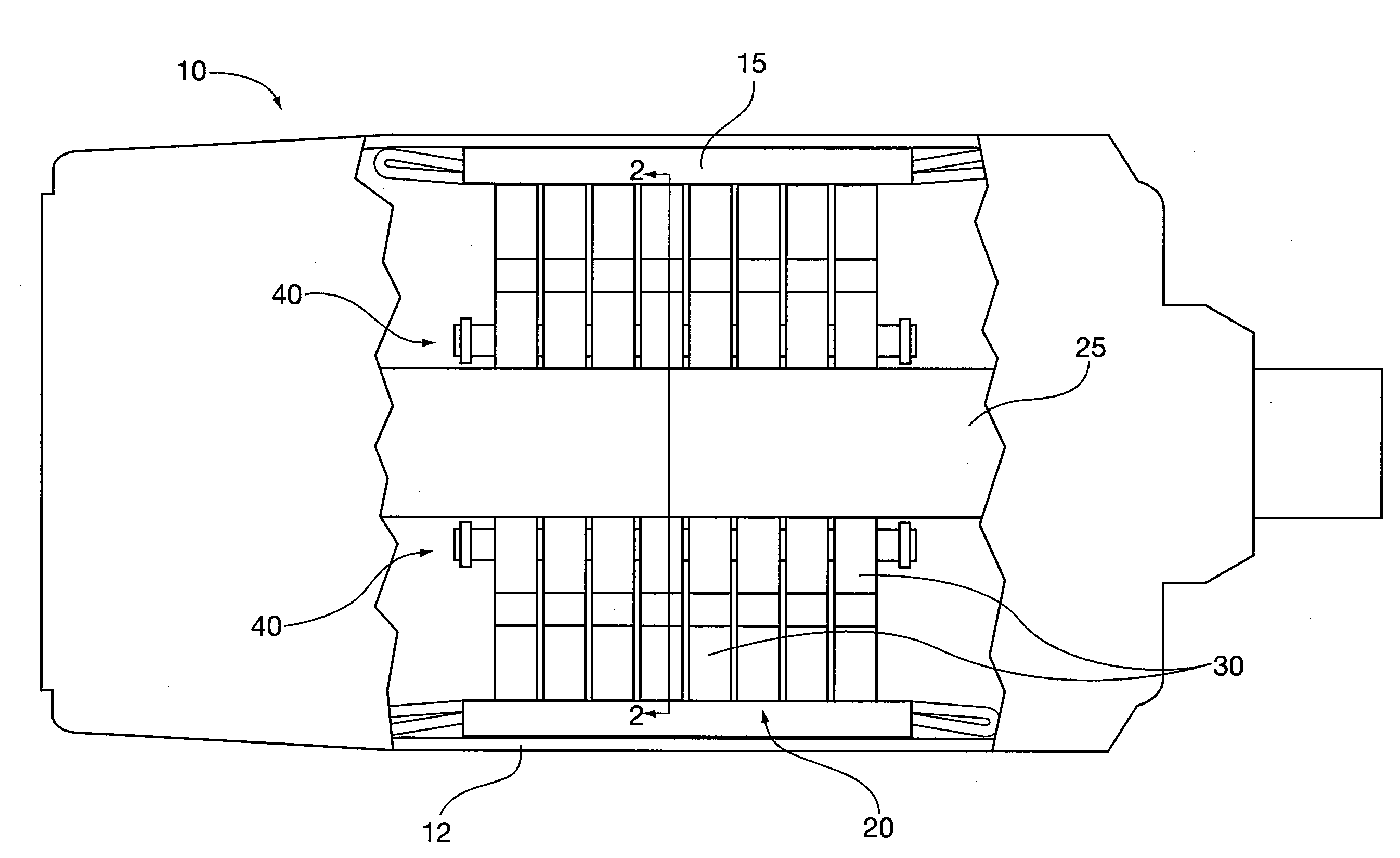

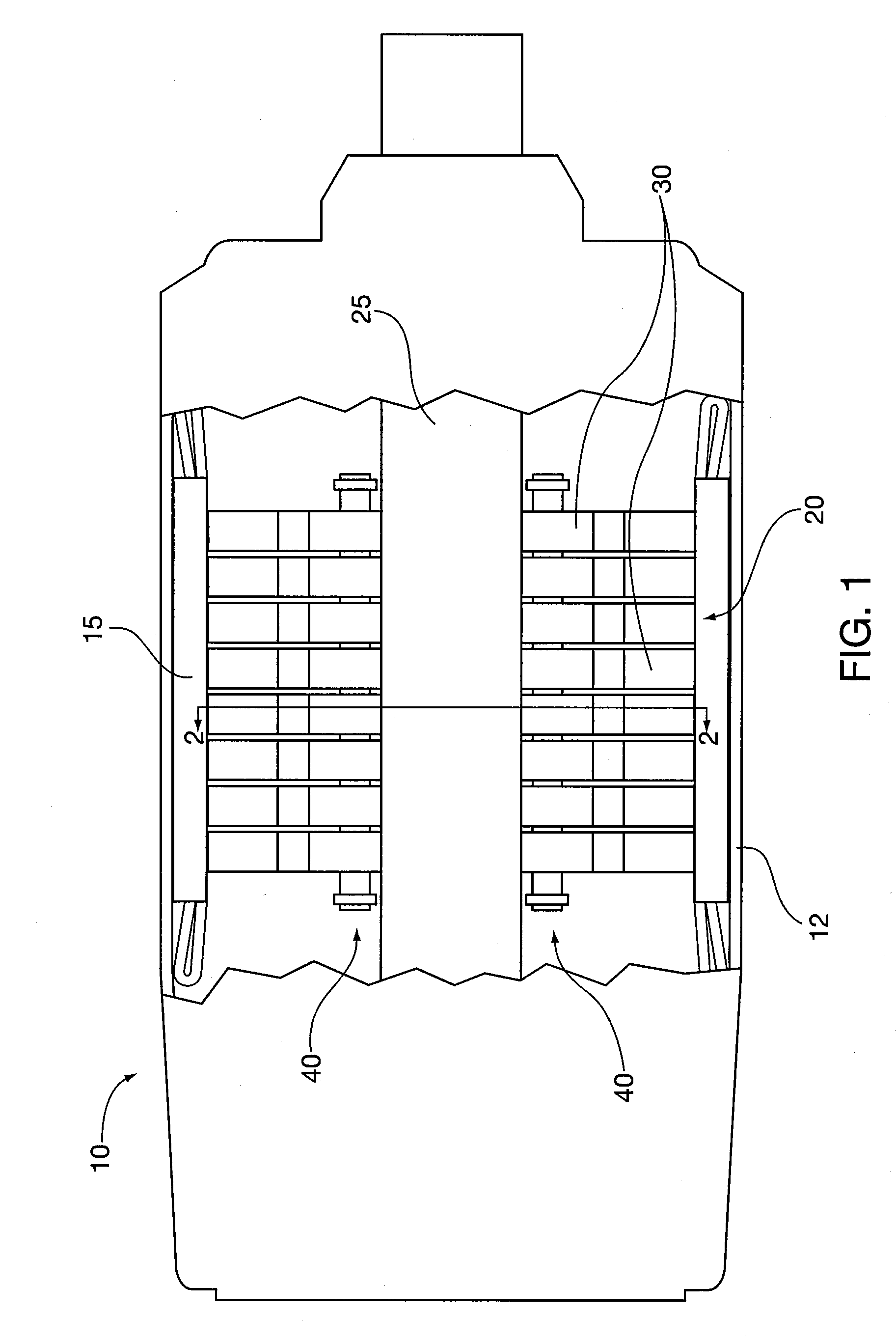

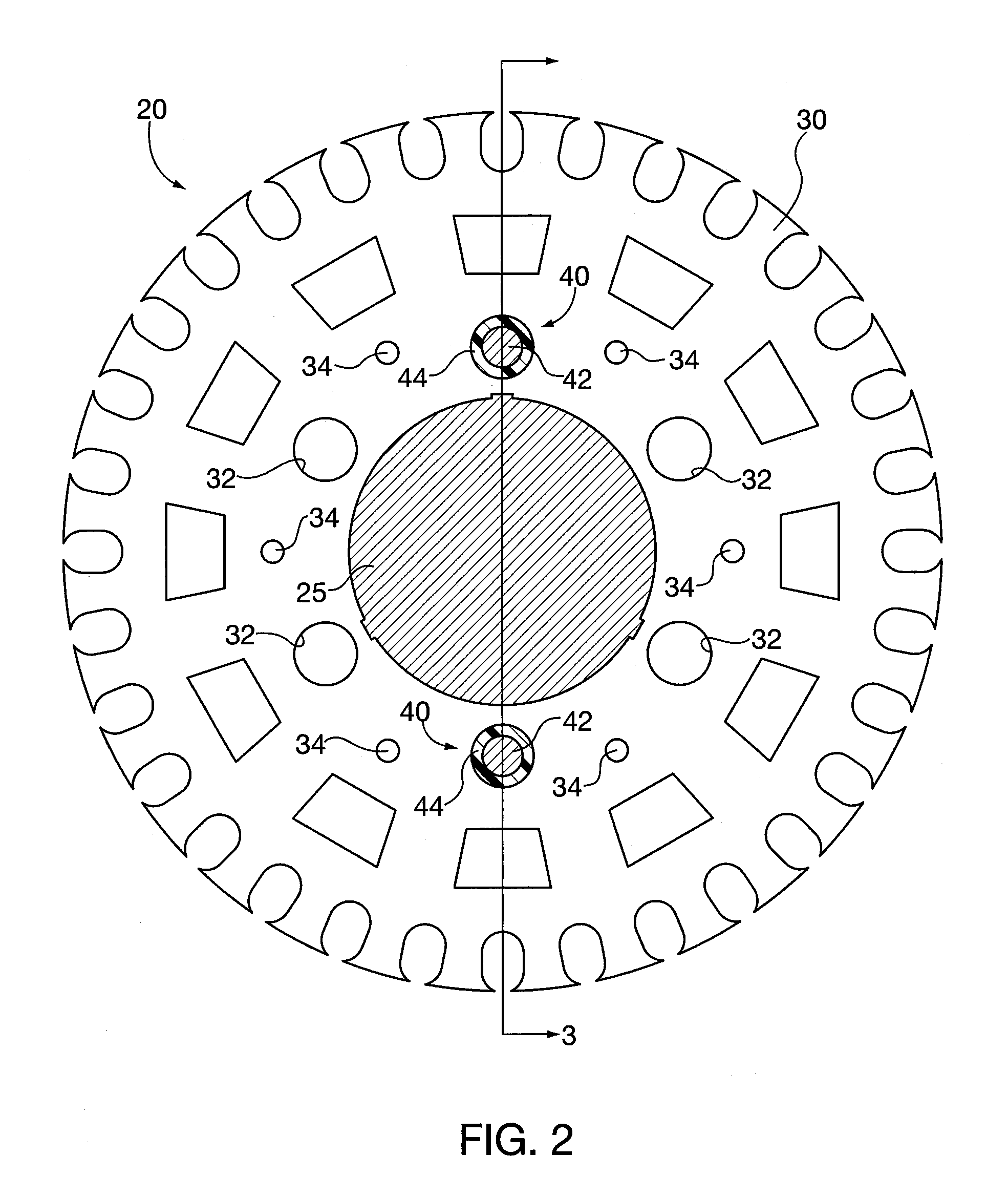

Method of Tuning Bending and Torsion Stiffness of Ducted Rotor Core of An Induction Motor

ActiveUS20110074242A1Change stabilityMotor critical vibration speed can be alteredMagnetic circuit rotating partsStatic/dynamic balance measurementInduction motorMotor vibration

Electrodymamic machine rotating mass, including for example induction motor rotors, stiffness tuning methods include selective orientation and compression of modular tie rod assemblies into through bores formed in the rotor lamination core outboard of the rotor shaft during motor manufacture, repair or refurbishment. Stiffness tuning enables a motor manufacturer to tune a rotor's rotordynamic stability, and hence the assembled motor's critical vibration speed. Electrodynamic machine rotating mass tuning can be adjusted in response to machine physical design, operational application and manufacturing variation attributes that impact the assembled machine's critical vibration frequency. Thus the present invention offers a systematic, holistic approach to motor vibration refinement through use of a simple kit of modular tie rod assemblies oriented and tightened in a selected array. Rotor stiffness tuning can be tested virtually on computer work stations. Additional actual rotor stiffness tuning can be performed during manufacture.

Owner:INNOMOTICS LLC

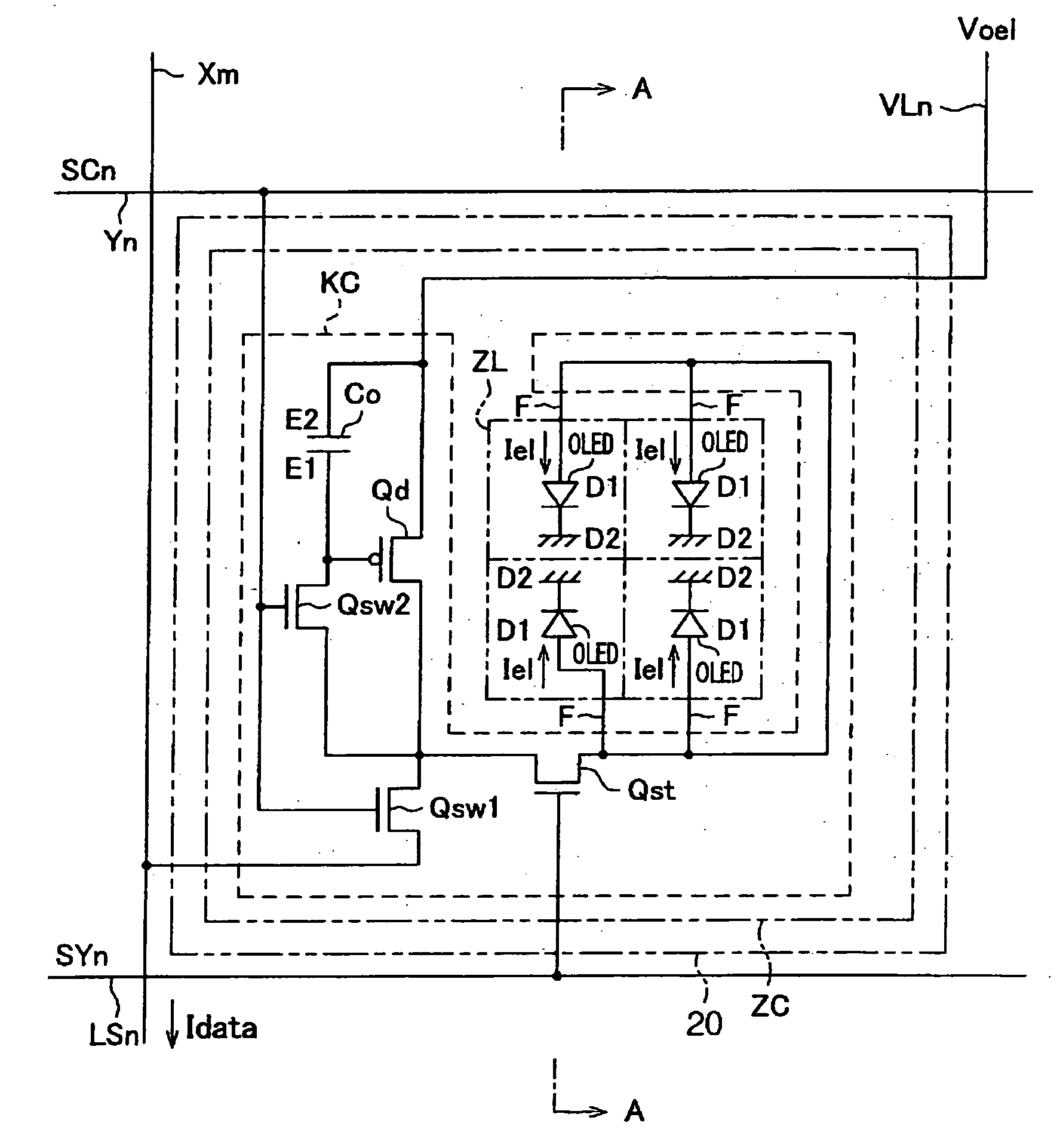

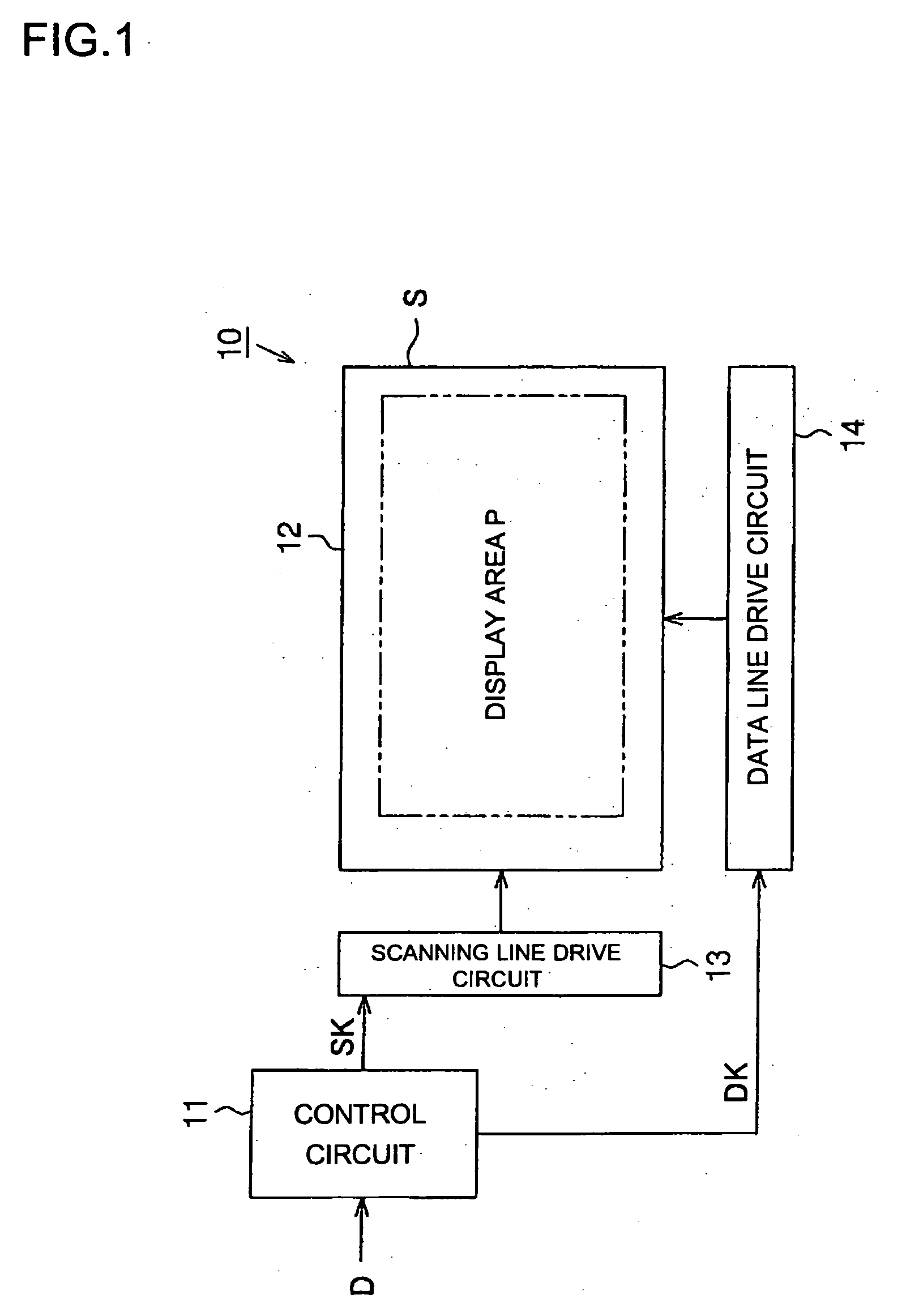

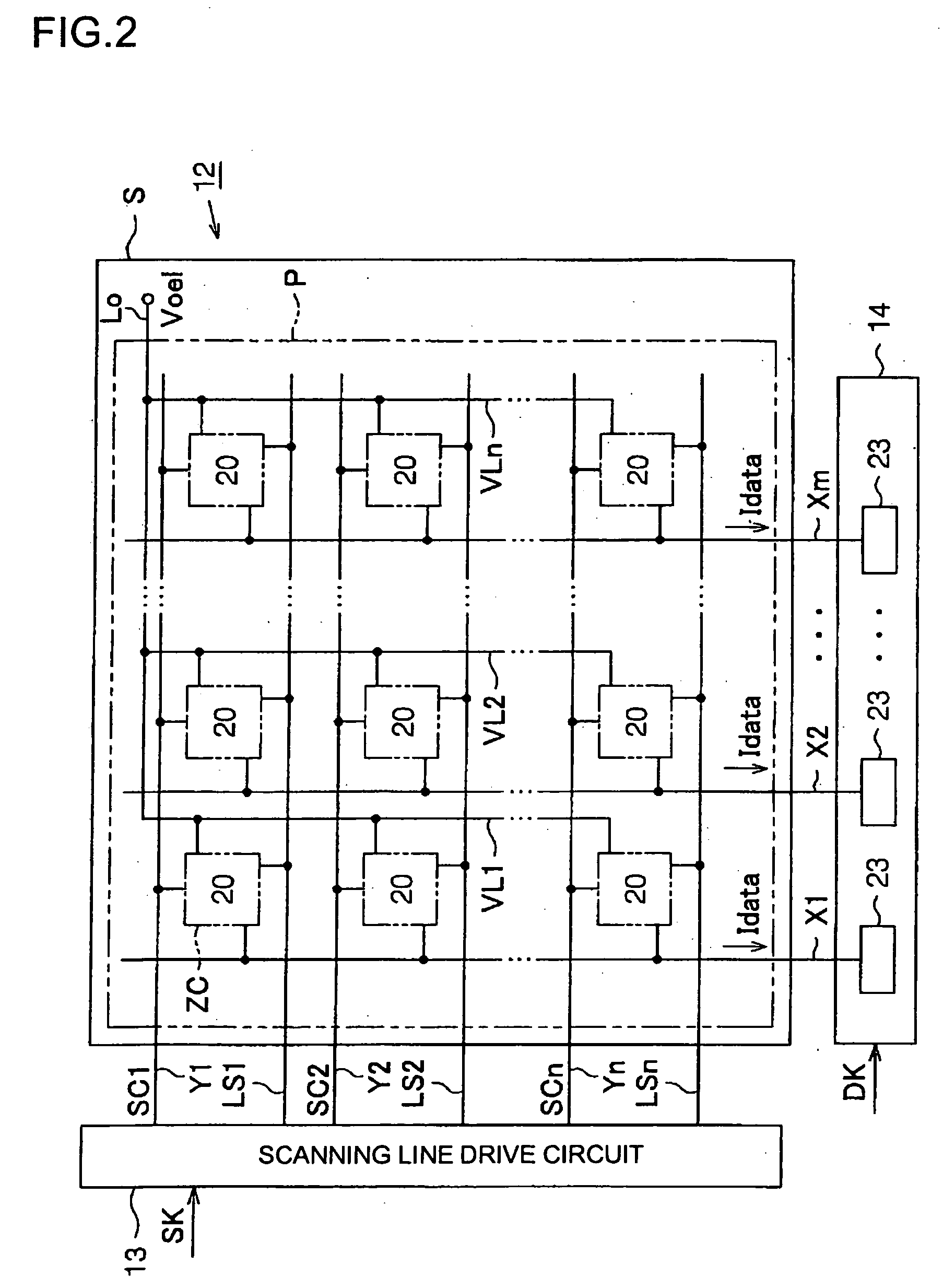

Electronic device, element substrate, electro-optical device, method of producing the electro-optical device, and electronic apparatus

ActiveUS20040233140A1Drive precisionQuality improvementStatic indicating devicesElectroluminescent light sourcesEngineeringManufacturing variation

To provide an electronic circuit, an element substrate, an electronic device, an electro-optical device, and an electronic apparatus, which make it possible to perform a precise controlling operation even if manufacturing variations occur, a circuit formation area is an annular formation area of a pixel of a display panel, and does not include a substantially central portion of the pixel. A light emission area is provided in the substantially central portion. One drive circuit is formed in the circuit formation area, and four organic elements OLED are formed in the light emission area. The drive circuit and the organic elements OLED are connected parallel to each other with wirings.

Owner:SEIKO EPSON CORP

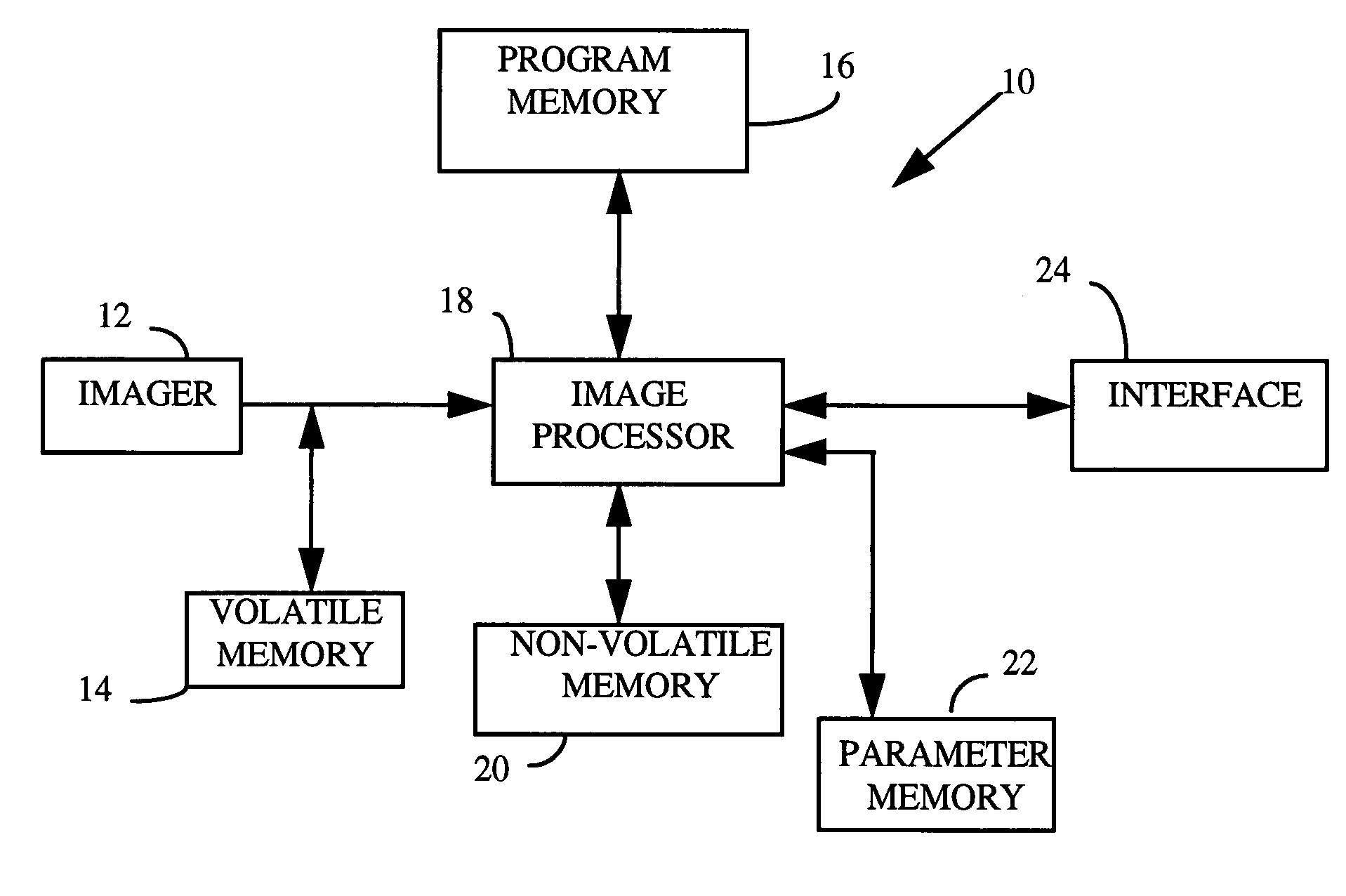

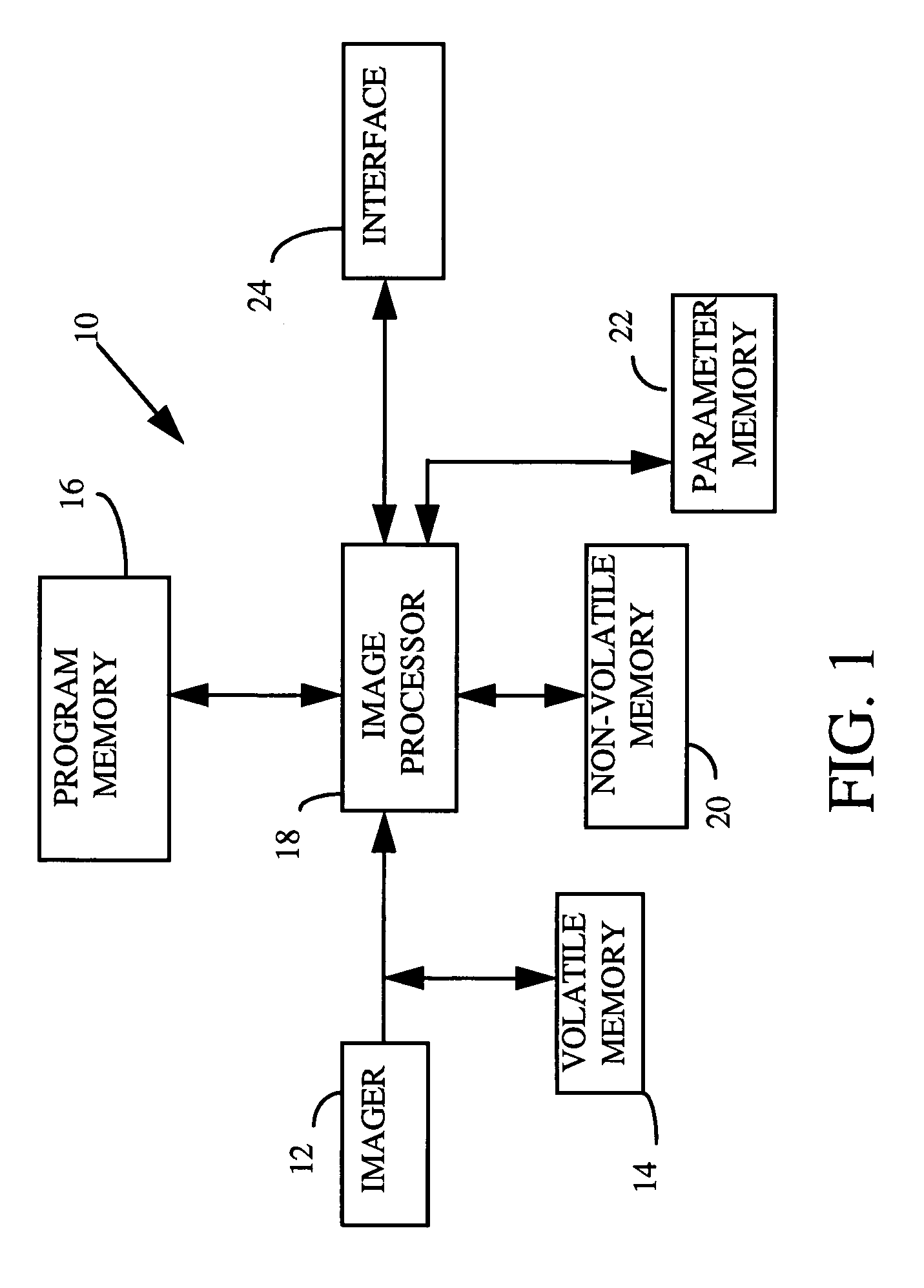

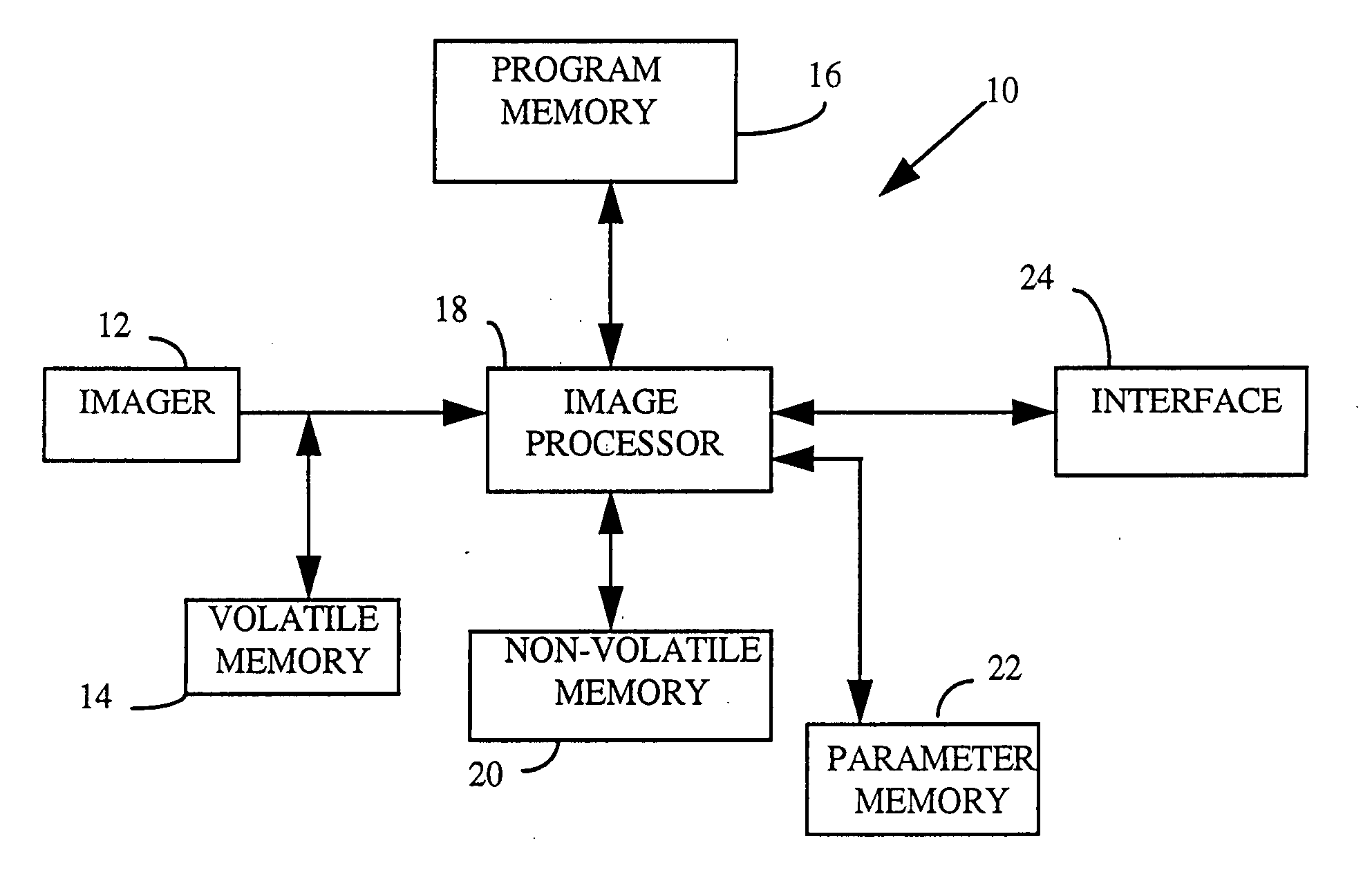

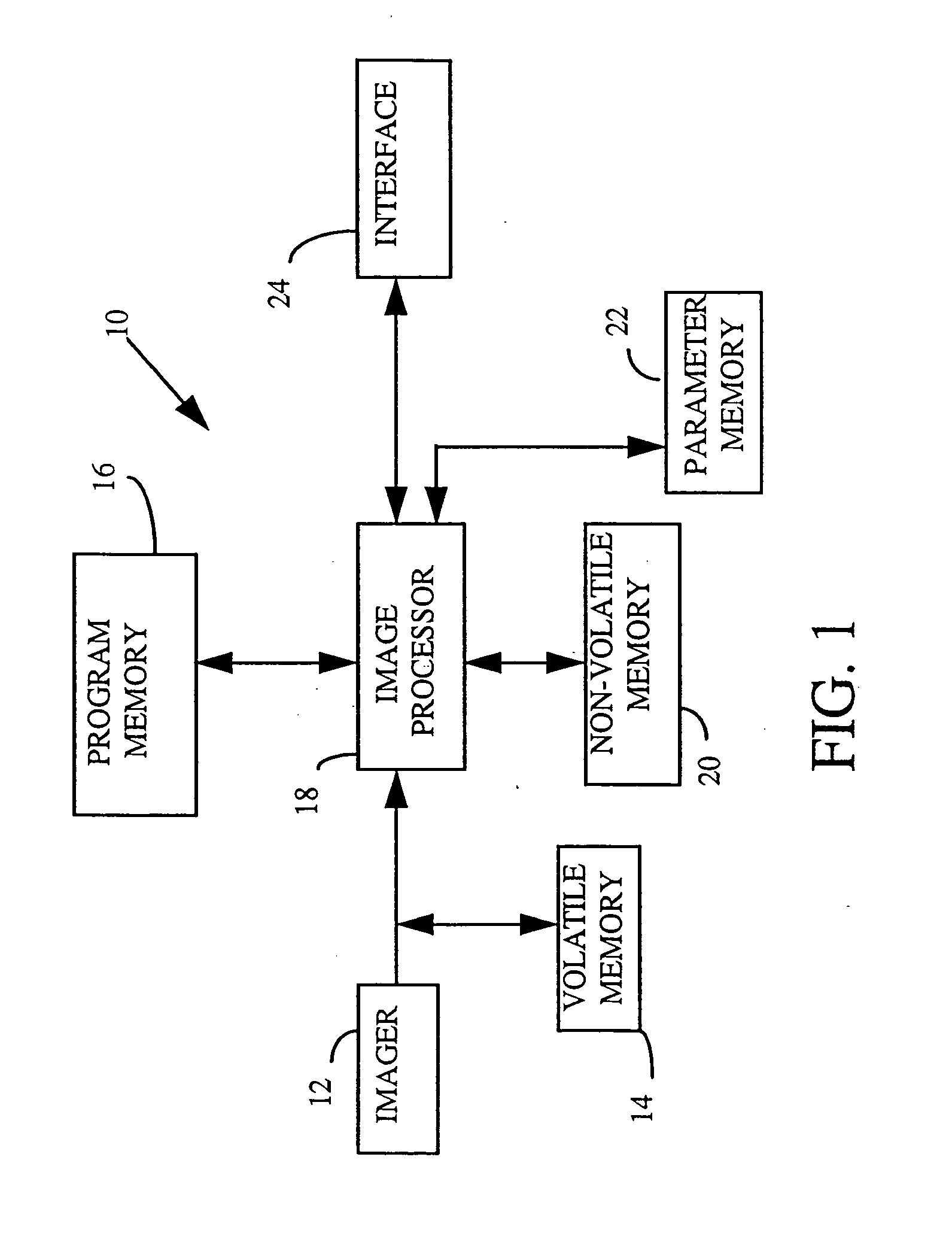

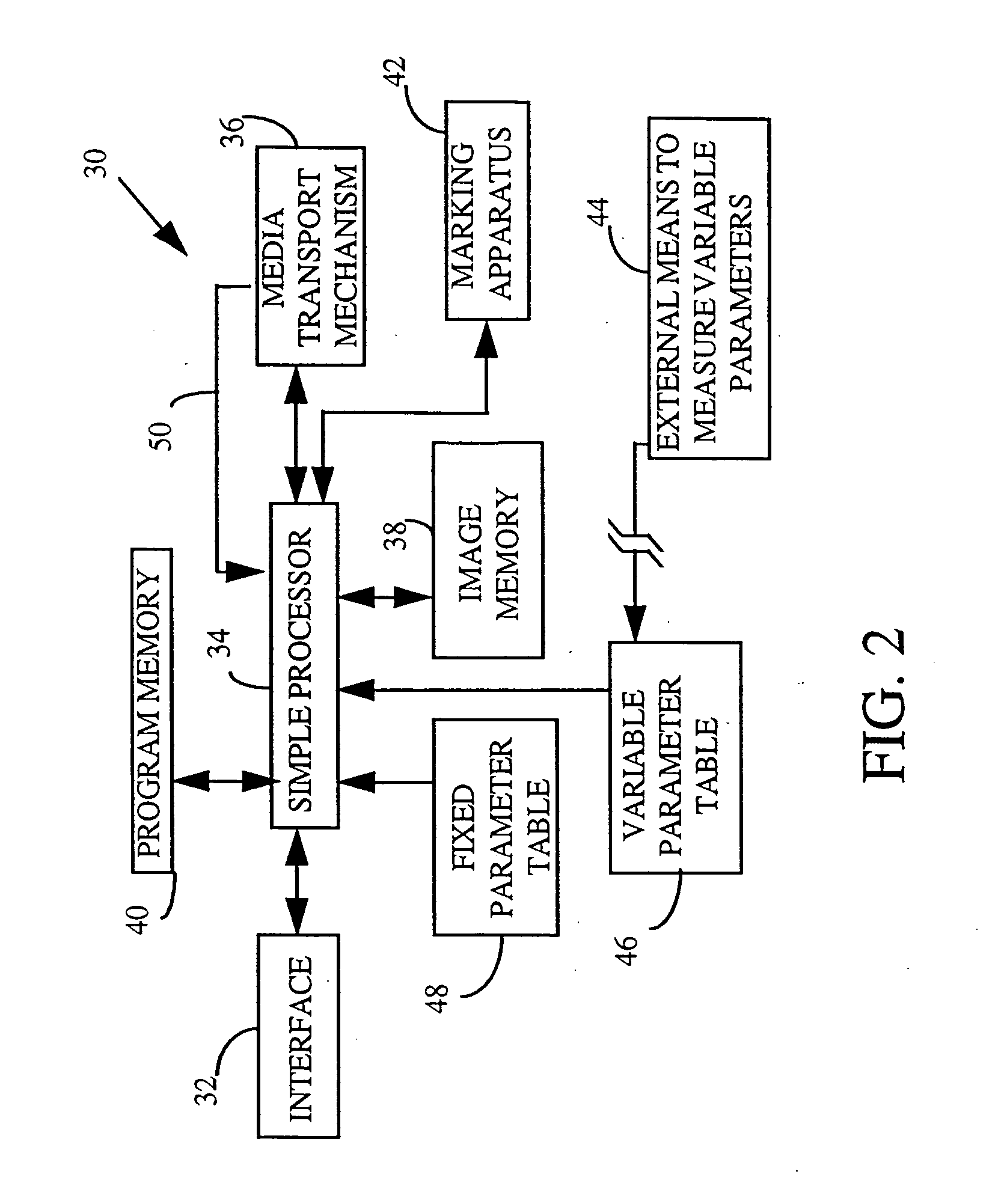

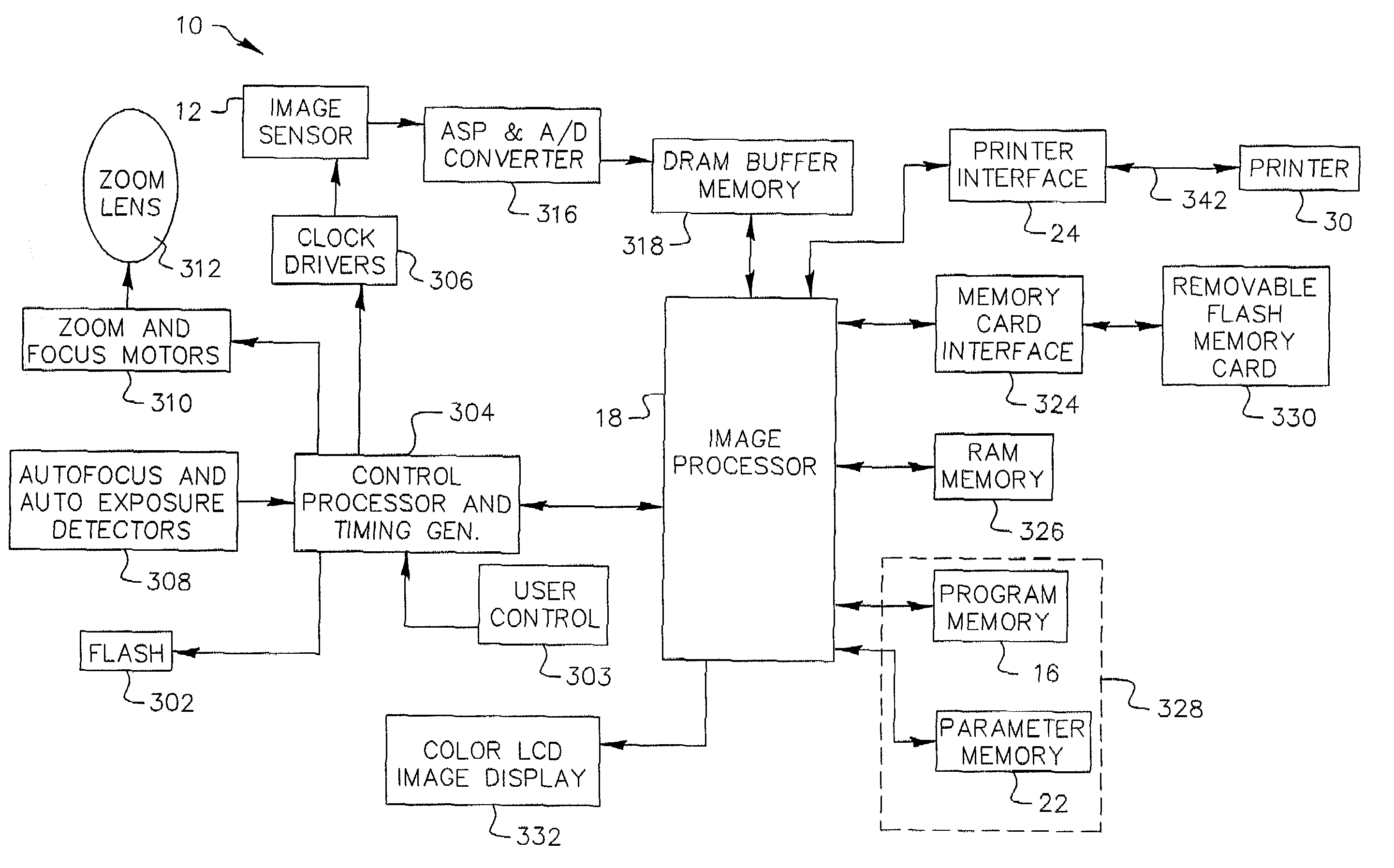

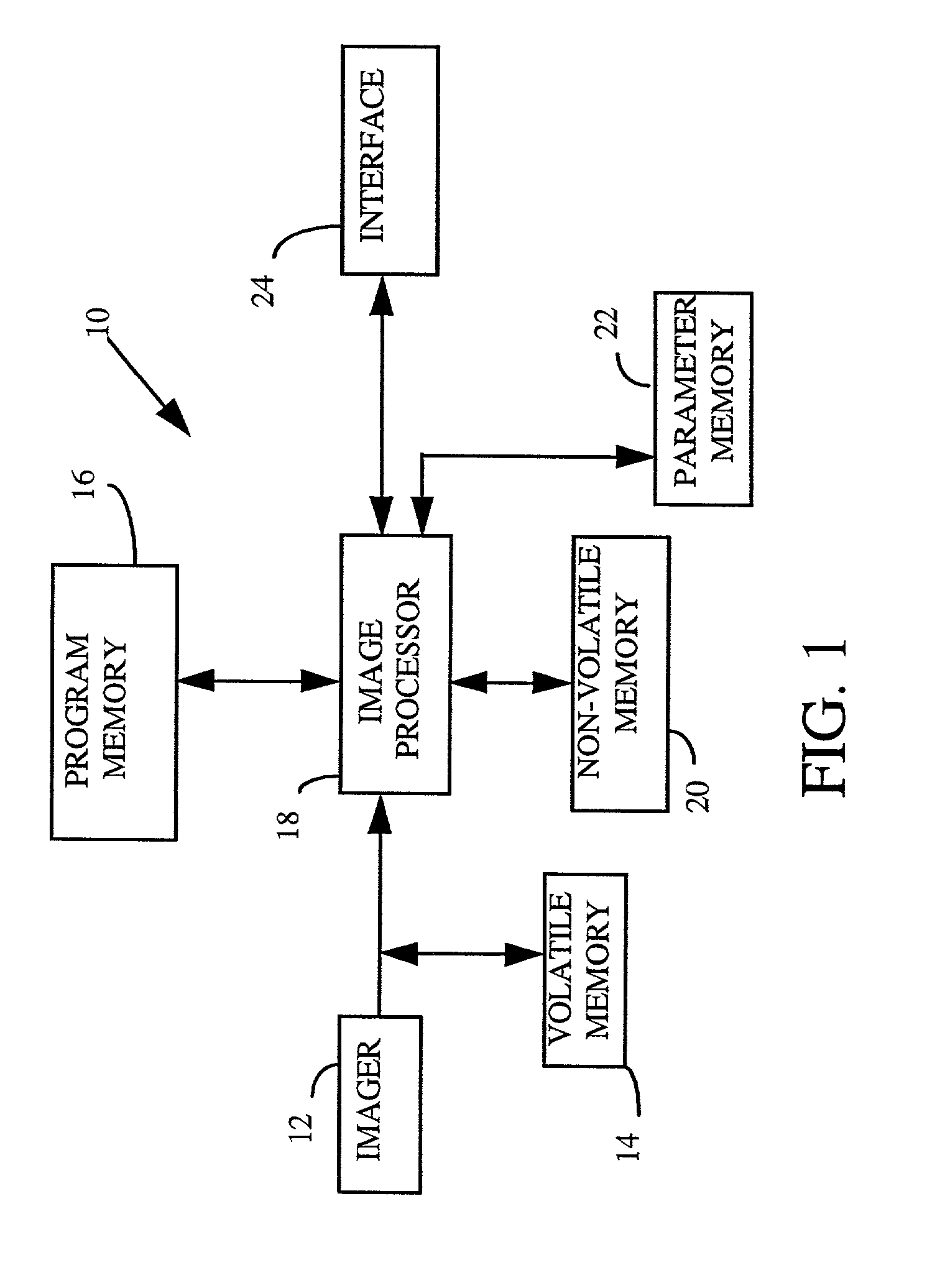

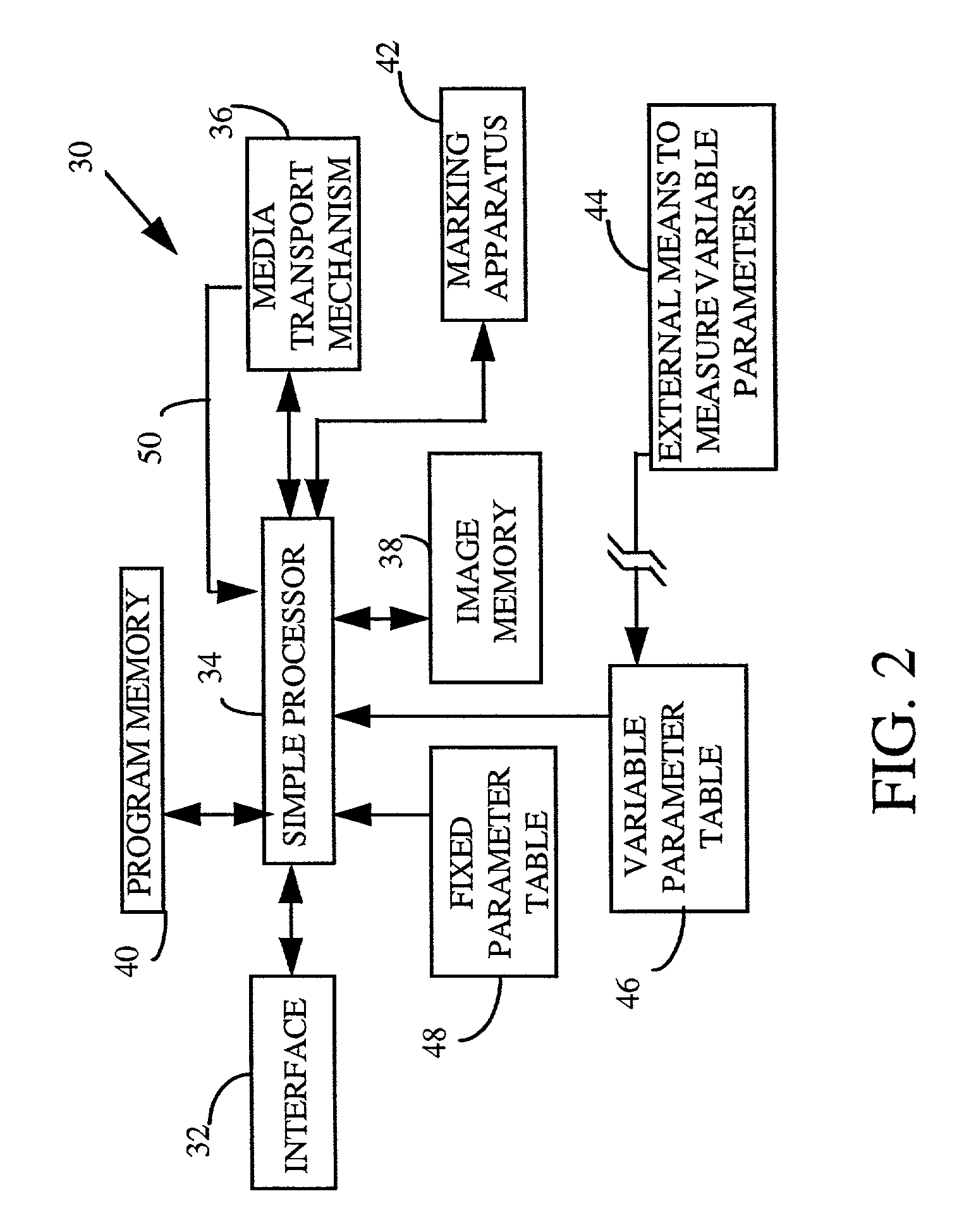

Printer parameter compensation by a host camera

InactiveUS6940541B1Low costReduce system costTelevision system detailsColor television signals processingImaging processingMedia type

A system wherein already-existing computing and memory resources in an electronic camera are used to process an image for printing. Rather than duplicating, in printers, computing and memory resources that are already in digital cameras, significant computing and memory resources need exist only in the camera. A digital camera can support many different printers, each with its own set of parameters such as for example print size, pixel size, colorimetry, sensitometry, and artifacts compensation. Printer parameters are uploaded from the printer to the camera to provide a basis for image processing specific to the associated printer; whereby compensation may be done for variations in the printer characteristics which may occur as a result of printer manufacturing variations, and further so that compensation may be done for different media types which may be installed in the printer.

Owner:APPLE INC

Printer parameter compensation by a host camera

InactiveUS20050190265A1Low costReduce system costTelevision system detailsDigitally marking record carriersImaging processingMedia type

A system wherein already-existing computing and memory resources in an electronic camera are used to process an image for printing. Rather than duplicating, in printers, computing and memory resources that are already in digital cameras, significant computing and memory resources need exist only in the camera. A digital camera can support many different printers, each with its own set of parameters such as for example print size, pixel size, colorimetry, sensitometry, and artifacts compensation. Printer parameters are uploaded from the printer to the camera to provide a basis for image processing specific to the associated printer; whereby compensation may be done for variations in the printer characteristics which may occur as a result of printer manufacturing variations, and further so that compensation may be done for different media types which may be installed in the printer.

Owner:APPLE INC

Electronically controlled hybrid digital and analog phase shifter

InactiveUS20050270122A1Wide tuning rangeCorrection errorMultiple-port networksDigital technique networkPhase shiftedImage resolution

The inventions presented herein provide a electronically controlled phase shifters that incorporate analog and digital phase shift architectures in a novel manner that realizes the best advantages of each architecture. This combination of complementary phase shift architectures provides the high-performance and low loss characteristics of switched digital phase shift architectures with the high resolution and precision of continuous analog phase shift architectures. The circuit embodiments are electronically controlled, which simplifies implementation of what is a complex circuit. The analog phase shift elements comprise electronically-tuned varactors, which provide fine resolution and enables the incorporation of active compensation for manufacturing variation before use or for environmental conditions during use.

Owner:XCOM WIRELESS

Load indicating member with identifying element

InactiveUS20060123917A1Eliminate disadvantagesPrecise and reliable loadLoad modified fastenersScrewsEngineeringManufacturing variation

A load indicating member is provided with an identifying element which can be accessed and used to determine ultrasonic measurement parameters specific to the load indicating member to provide more precise and more reliable load measurements by compensating for differences resulting from manufacturing variations in individual load indicating members. The parameters specific to the load indicating member can be stored in coding applied to the load indicating member or in a database that can be accessed remotely, for example, using the Internet.

Owner:INNOVATION PLUS

Digital camera providing image processing for an attachable printer

InactiveUS7212229B2Low costReduce system costTelevision system detailsDigitally marking record carriersManufacturing variationSensitometry

A system wherein already-existing computing and memory resources in an electronic camera are used to process an image for printing. Rather than duplicating, in printers, computing and memory resources that are already in digital cameras, significant computing and memory resources need exist only in the camera. A digital camera can support many different printers, each with its own set of parameters such as for example print size, pixel size, colorimetry, sensitometry, and artifacts compensation. Printer parameters are uploaded from the printer to the camera to provide a basis for image processing specific to the associated printer; whereby compensation may be done for variations in the printer characteristics which may occur as a result of printer manufacturing variations, and further so that compensation may be done for different media types which may be installed in the printer.

Owner:APPLE INC

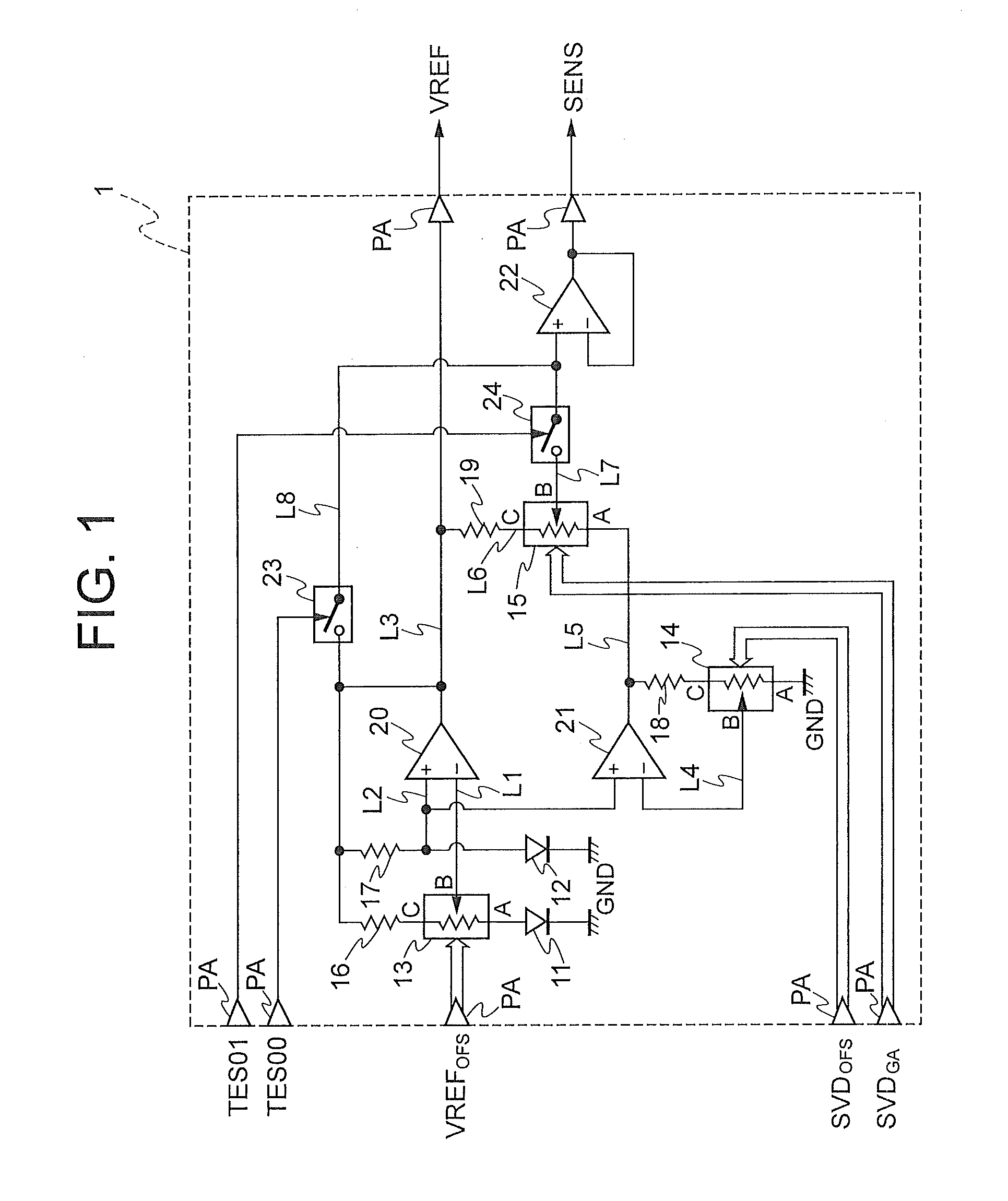

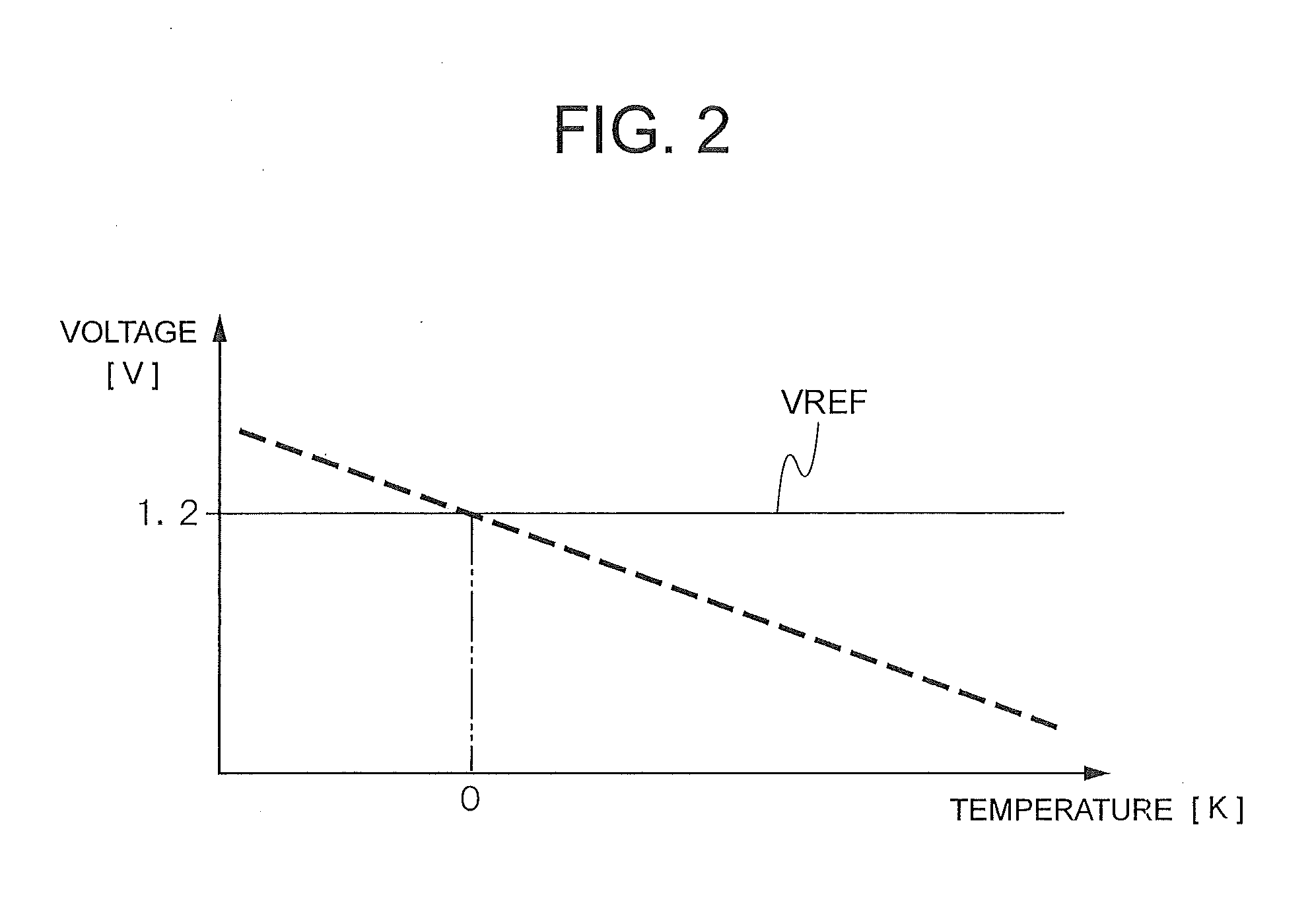

Temperature detector circuit and oscillation frequency compensation device using the same

InactiveUS20070030049A1Manufacturing variation can be decreasedStable output characteristicsThermometers using electric/magnetic elementsGenerator stabilizationFrequency compensationDetector circuits

A temperature detector circuit using a MOS transistor capable of reducing manufacture variation of a mobility and realizing stable output characteristics which are not affected by temperature dependency may be offered. In one example, the temperature detector circuit includes a pair of depression type transistors to output a voltage which is proportional to temperature from a connecting point of a source of a first transistor and a drain of a second transistor. The transistors are the same conducted type of current and are formed in different channel size, which are connected between power supplies in series, and have a configuration in which first transistor's gate and source are connected each other and a first transistor's drain is connected with a second power supply and second transistor's gate and drain are connected each other and a second transistor's source is connected with a first power supply.

Owner:RICOH KK

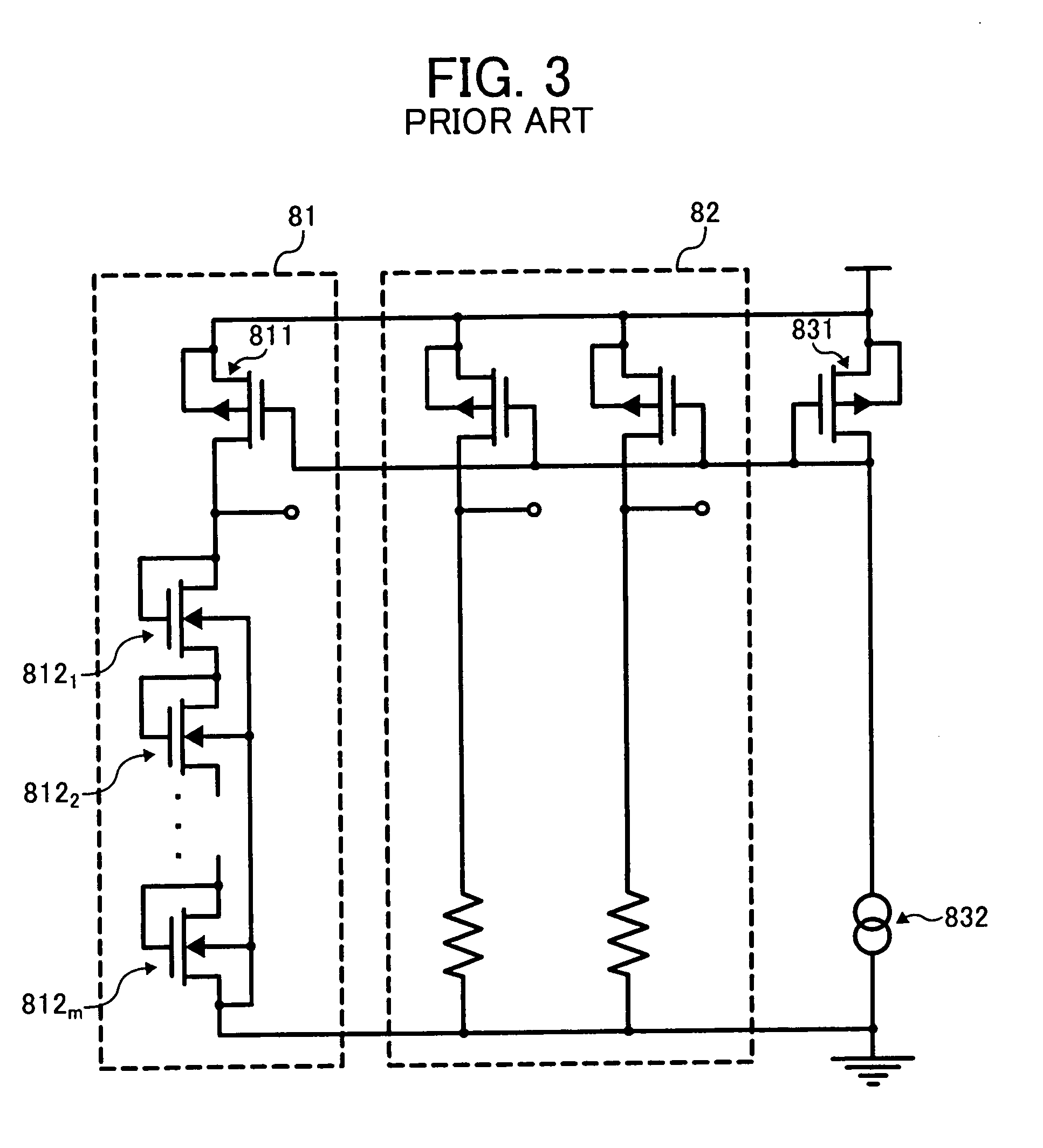

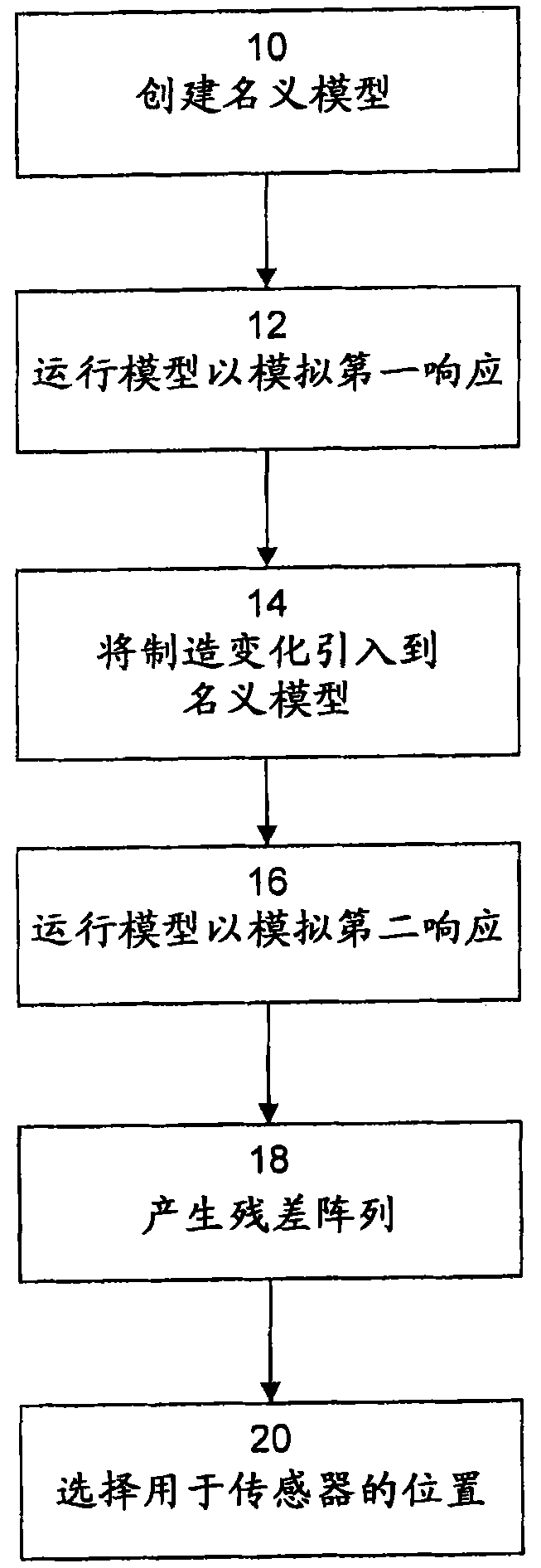

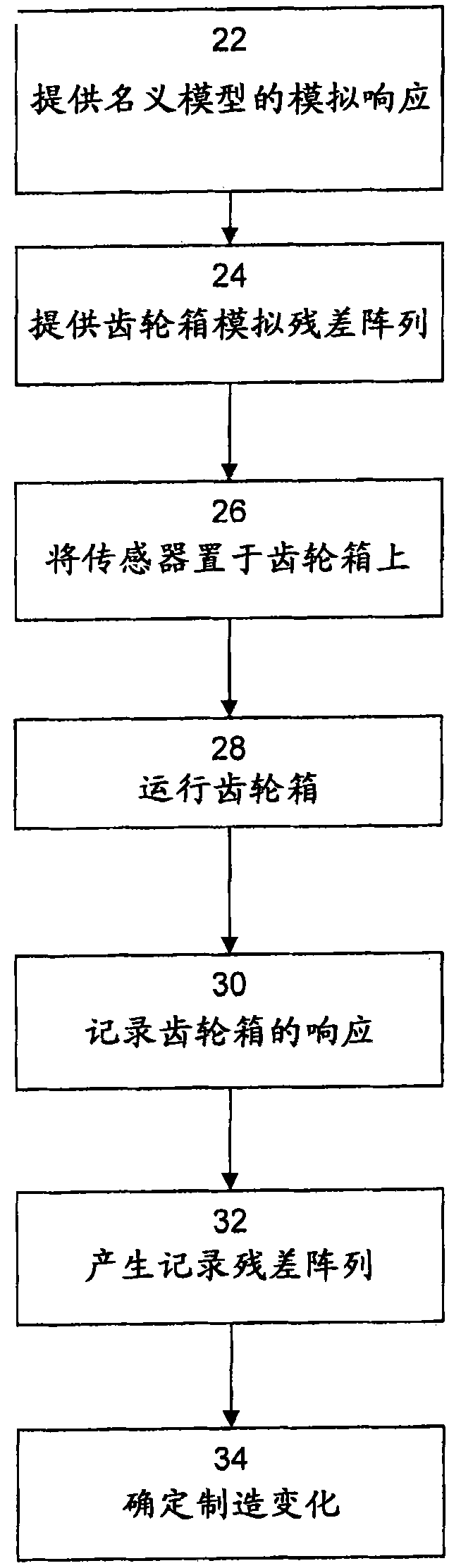

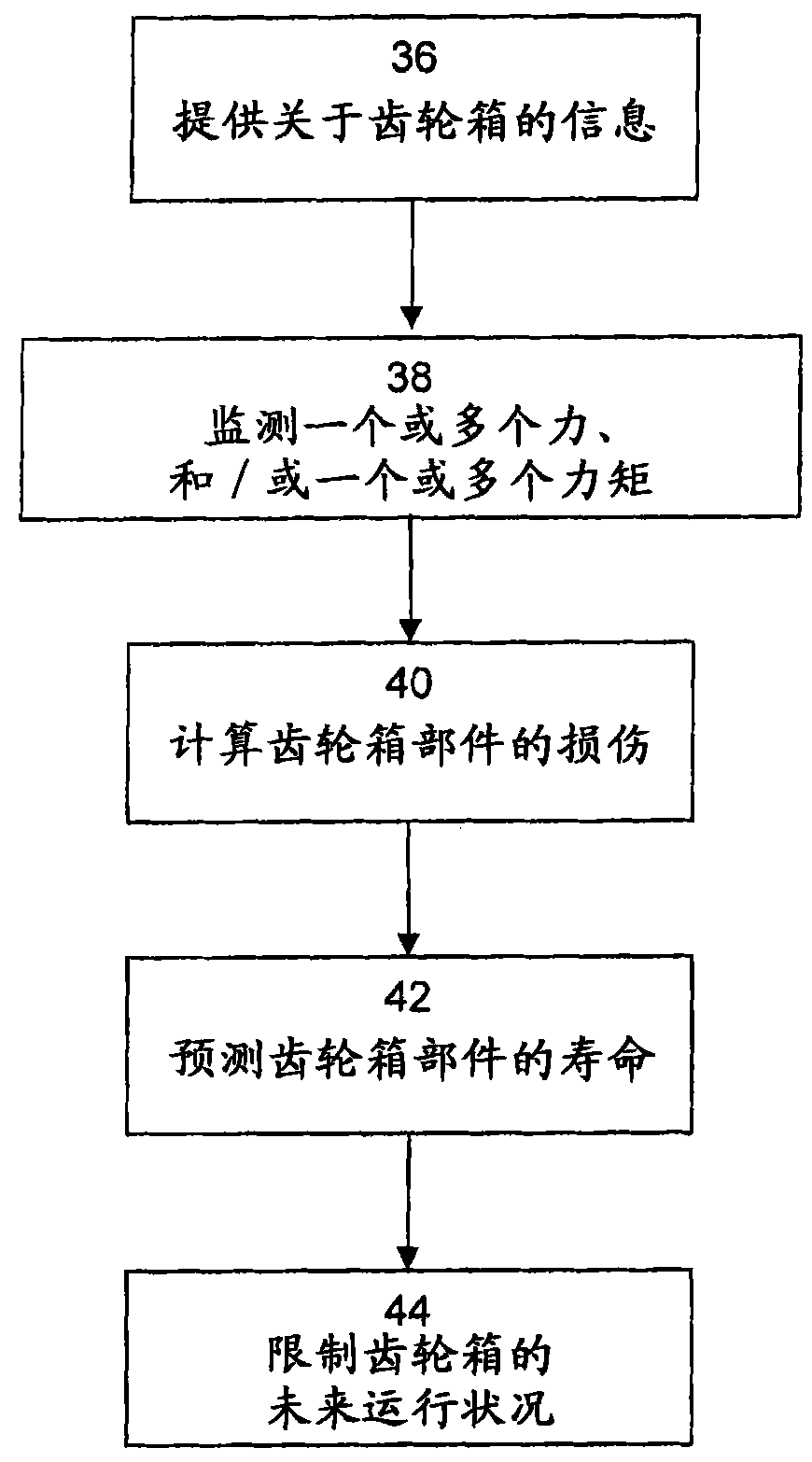

Methods, apparatus and computer readable storage mediums for model-based diagnosis of gearboxes

ActiveCN102016736ALife expectancyElectric testing/monitoringNumerical controlProduction lineManufacturing variation

The invention relates to the diagnosis of faults and damage in a gearbox in order to predict the operational life of a gearbox. An end of line test is performed to infer information on each gearbox on the production line. A highly detailed model of the gearbox is created to determine the optimal sensor positions for the end-of-line test so that the test can discriminate between different types of manufacturing variation. This information is then used to construct a unique, highly detailed model for each gearbox. During operation, forces and moments acting on the gearbox are measured at regular intervals and the model is used to continuously update a prediction of the total damage on each gearbox component. The probability of failure in a given time period is then calculated. An existing condition monitoring system approach such as vibration analysis may be used in parallel with the model-based diagnosis. The overall probability of failure for a required lifetime is calculated and, if necessary, operation is limited to provide a required probability of failure in a given time period.

Owner:INSIGHT ANALYTICS SOLUTIONS HLDG LTD

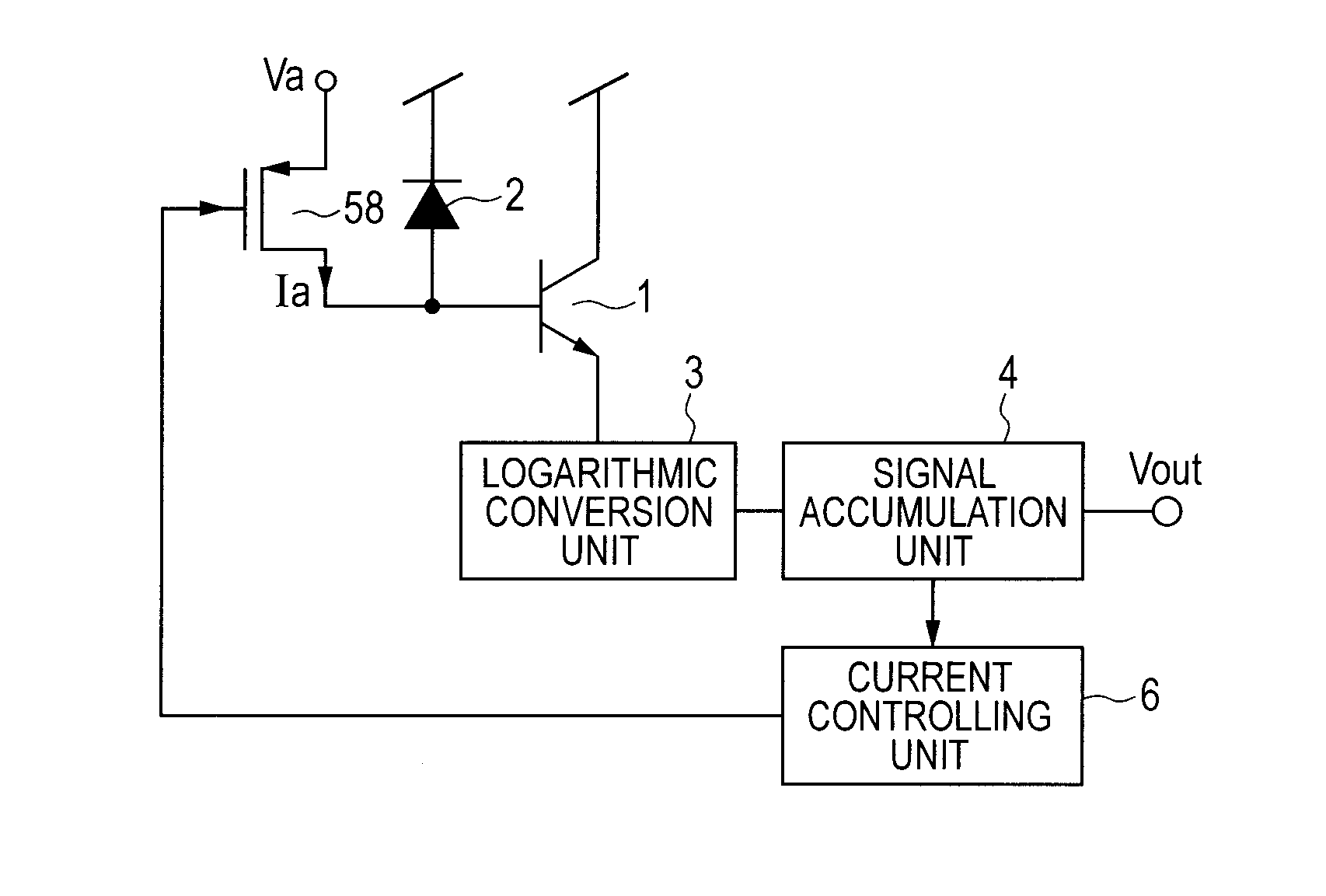

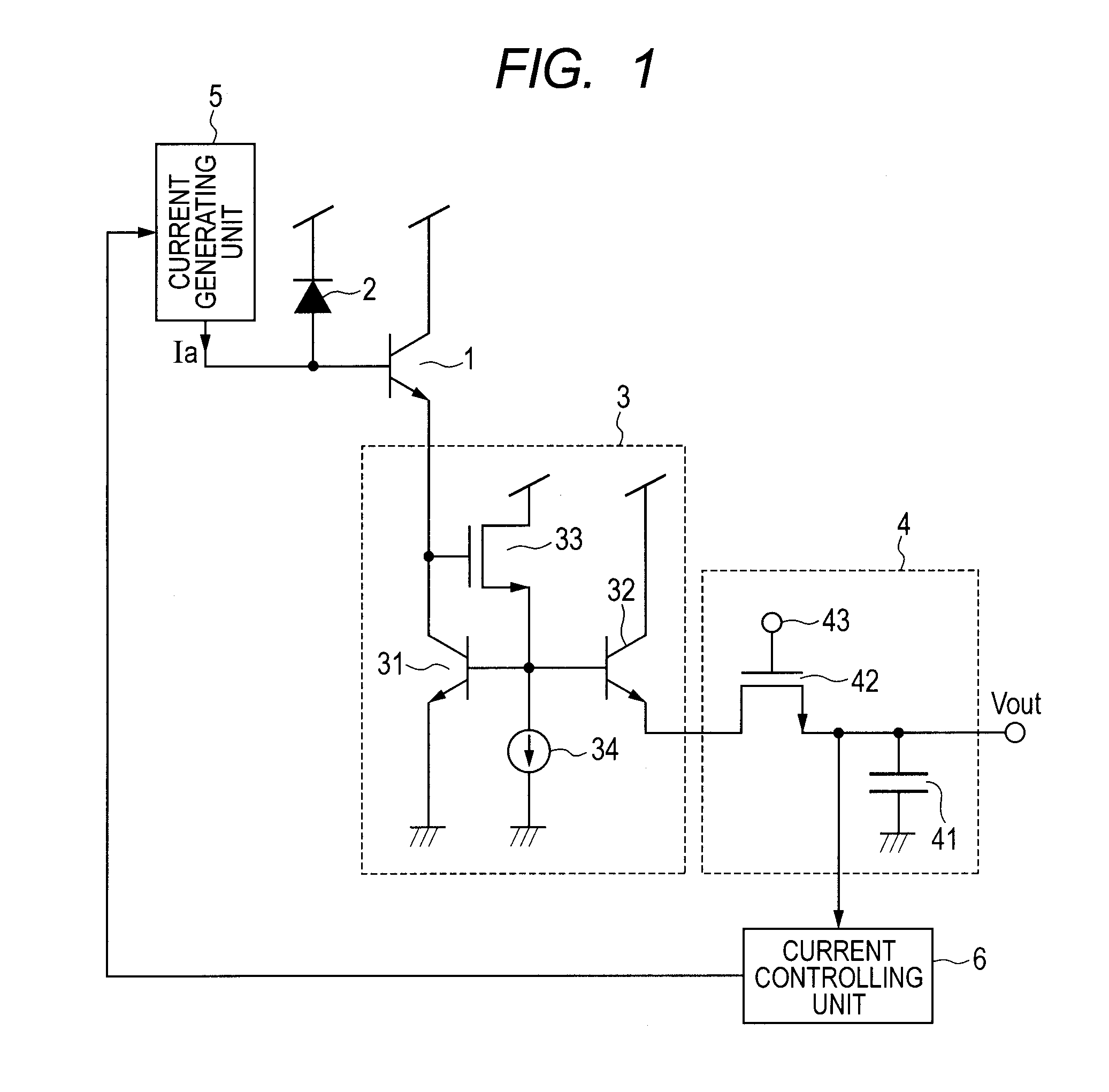

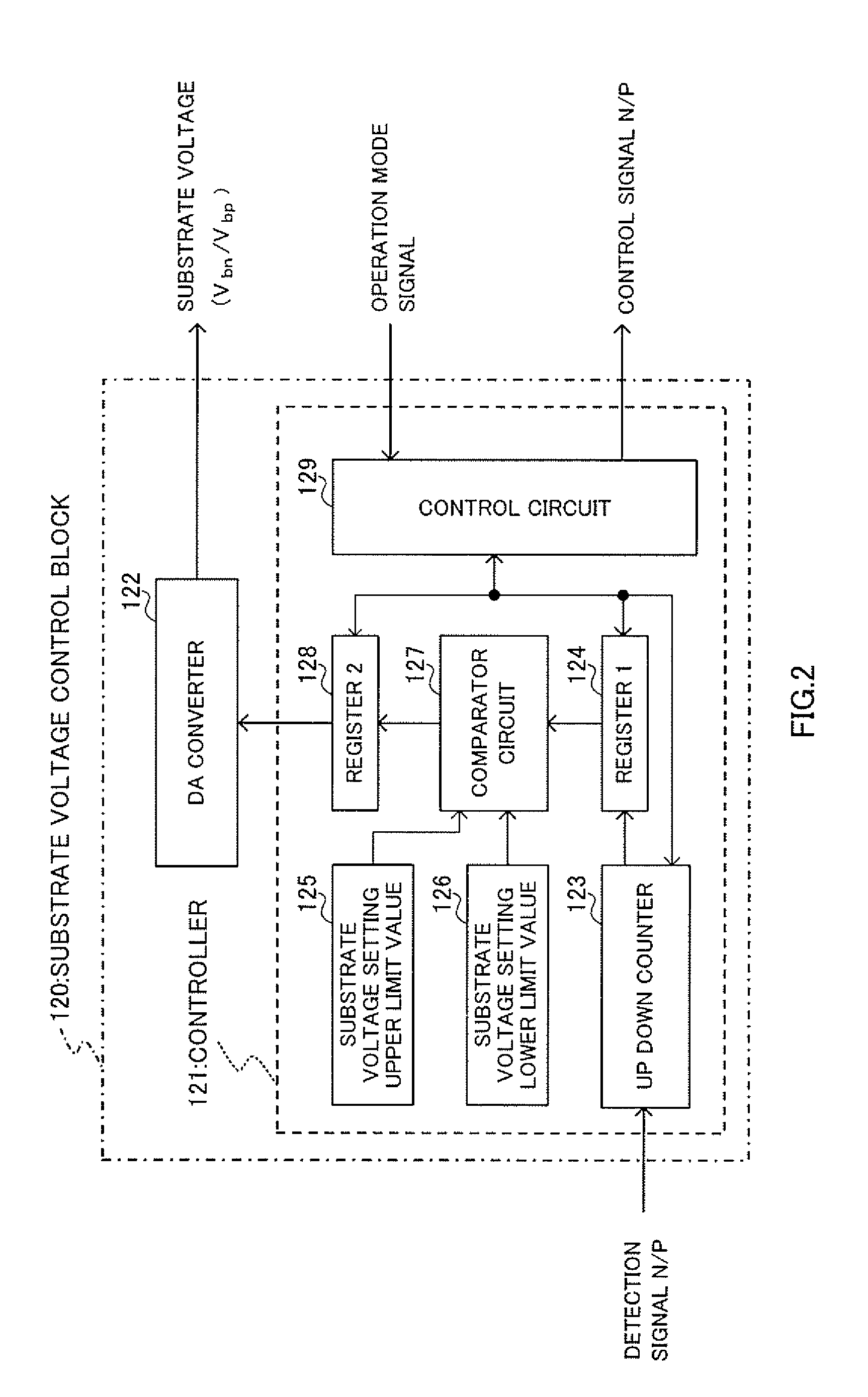

Photoelectric conversion apparatus

InactiveUS20120175503A1Solid-state devicesMaterial analysis by optical meansPhotoelectric conversionEngineering

There is provided a photoelectric conversion apparatus capable of obtaining good photoelectric conversion characteristics regardless of a decrease in current amplification ratio of the phototransistor and manufacturing variations in phototransistor. The photoelectric conversion apparatus includes a photoelectric conversion element that generates a current by photoelectric conversion; a transistor that inputs a current generated by the photoelectric conversion element to a base thereof, amplifies the input current, and outputs the amplified current from an emitter; a logarithmic conversion unit that logarithmically converts the current output from the transistor; a current generating unit that outputs the current to the base of the transistor; and a current controlling unit that controls the output current of the current generating unit in a light shielding state of the photoelectric conversion element based on the signal logarithmically converted by the logarithmic conversion unit.

Owner:CANON KK

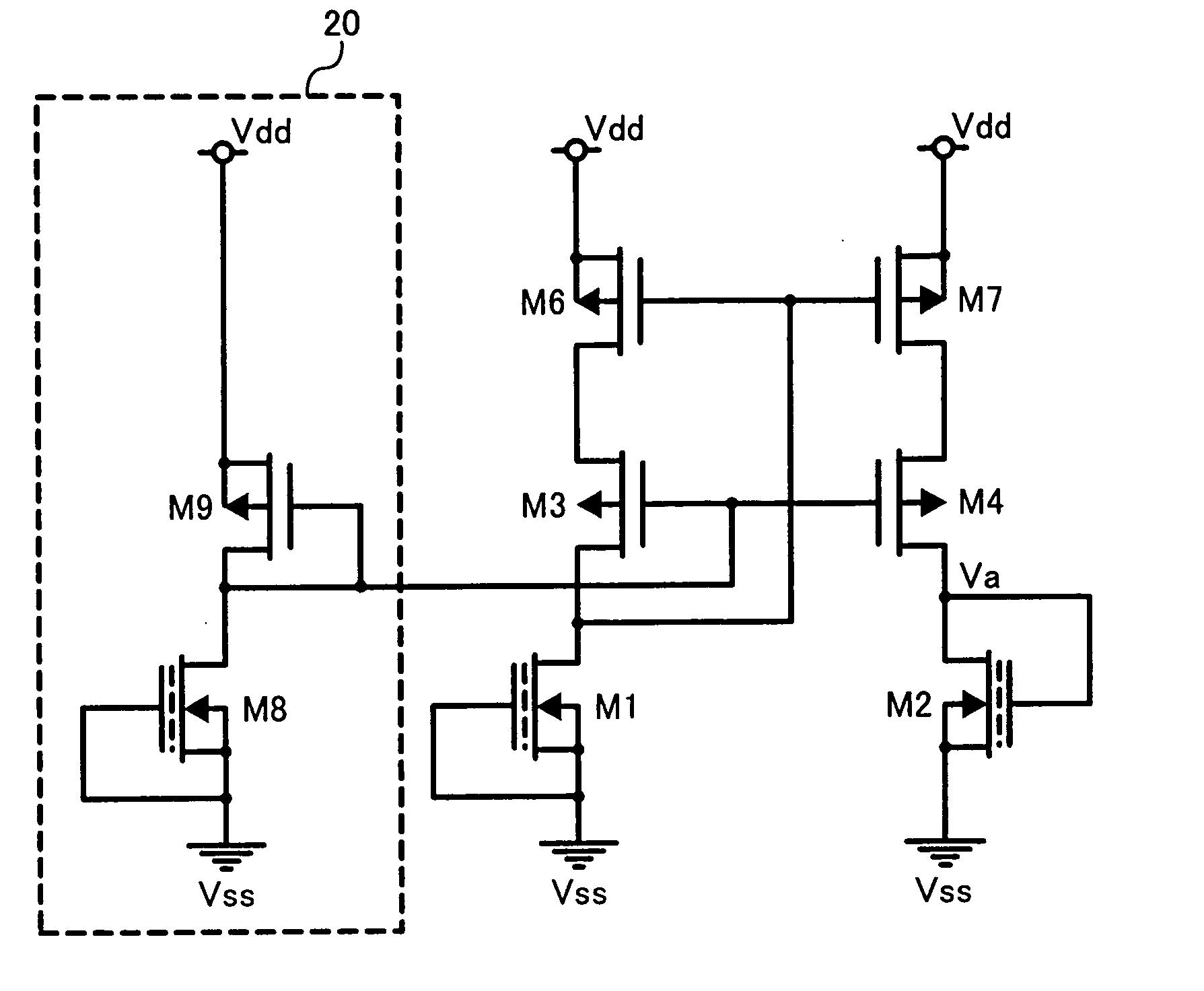

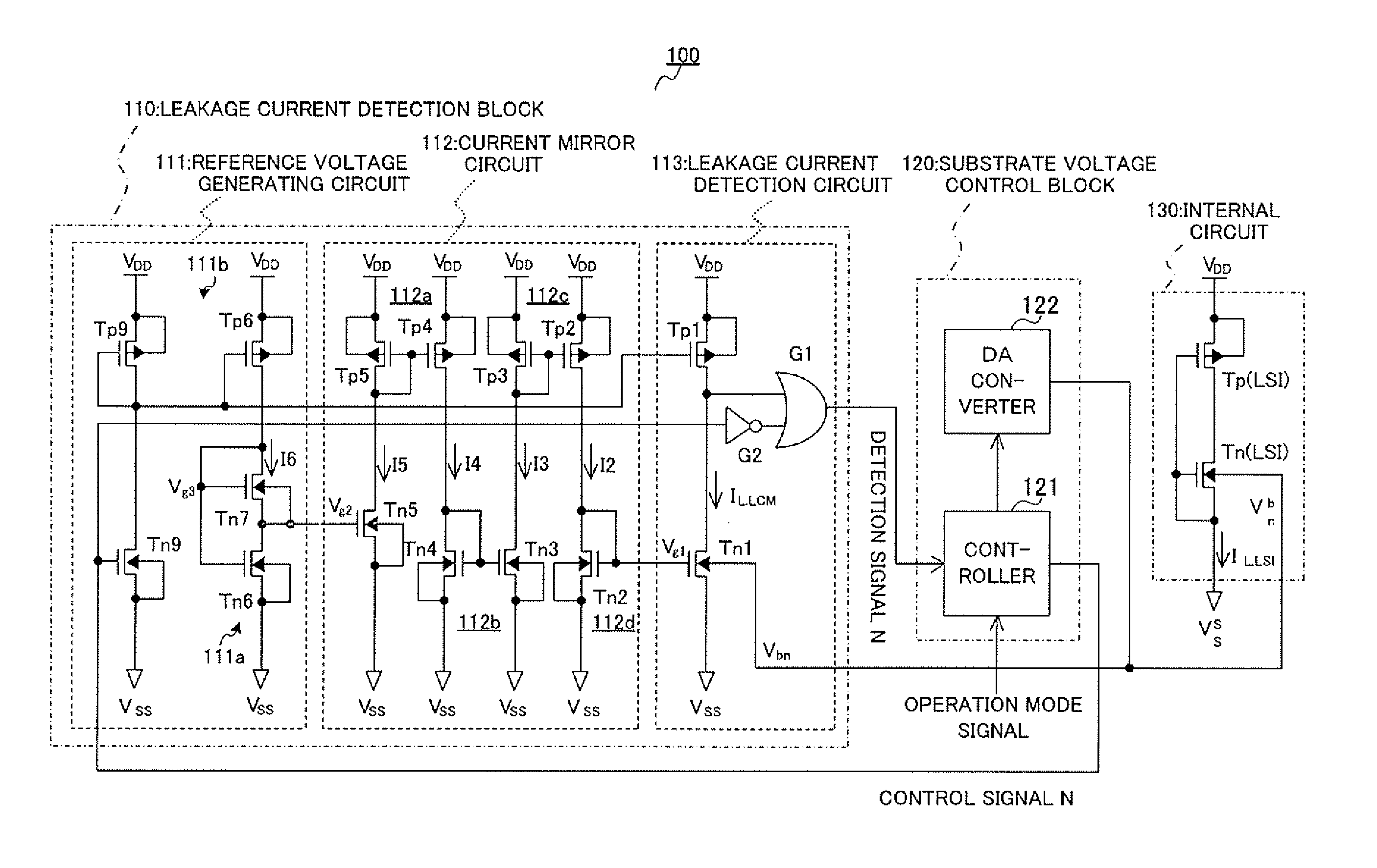

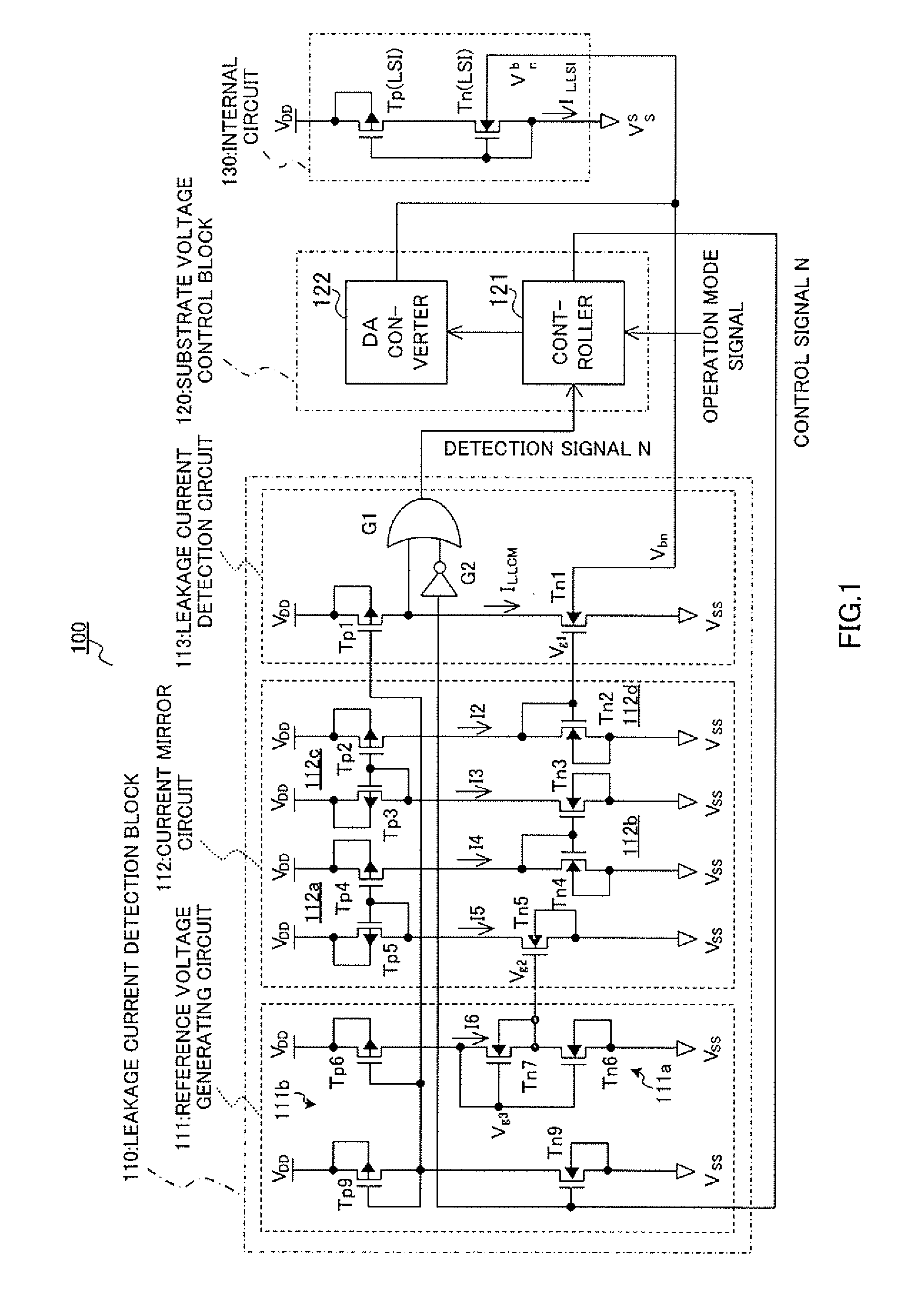

Semiconductor integrated circuit apparatus and electronic apparatus

InactiveUS20070085596A1Detection of leakage is straightforwardRapid responseLogic circuits coupling/interface using field-effect transistorsElectric pulse generator detailsManufacturing variationDrain current

Semiconductor integrated circuit apparatus and electronic apparatus having a leakage current detection circuit where arbitrarily set leakage current detection ratio does not depend on power supply voltage, temperature, or manufacturing variations, and where leakage current detection is straightforward. Semiconductor integrated circuit apparatus extracts a stable potential from the center of two NchMIS transistors, amplifies drain current of an NchMOS transistor taking this potential as a gate potential to a current value of an arbitrary ratio using current mirror circuit, makes this current value flow through NchMOS transistor with the gate and drain connected, and applies drain potential of this NchMOS transistor to the gate of leakage current detection NchMOS transistor.

Owner:PANASONIC CORP

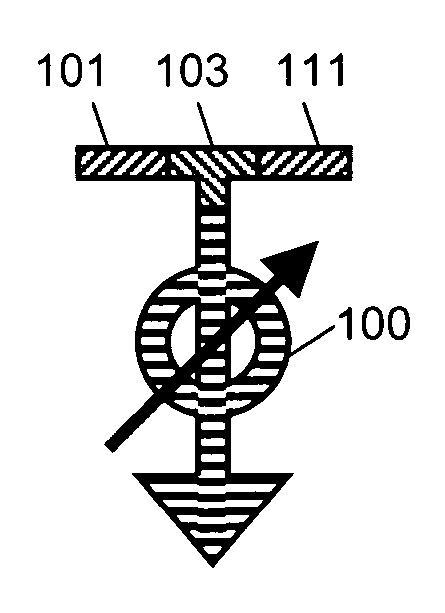

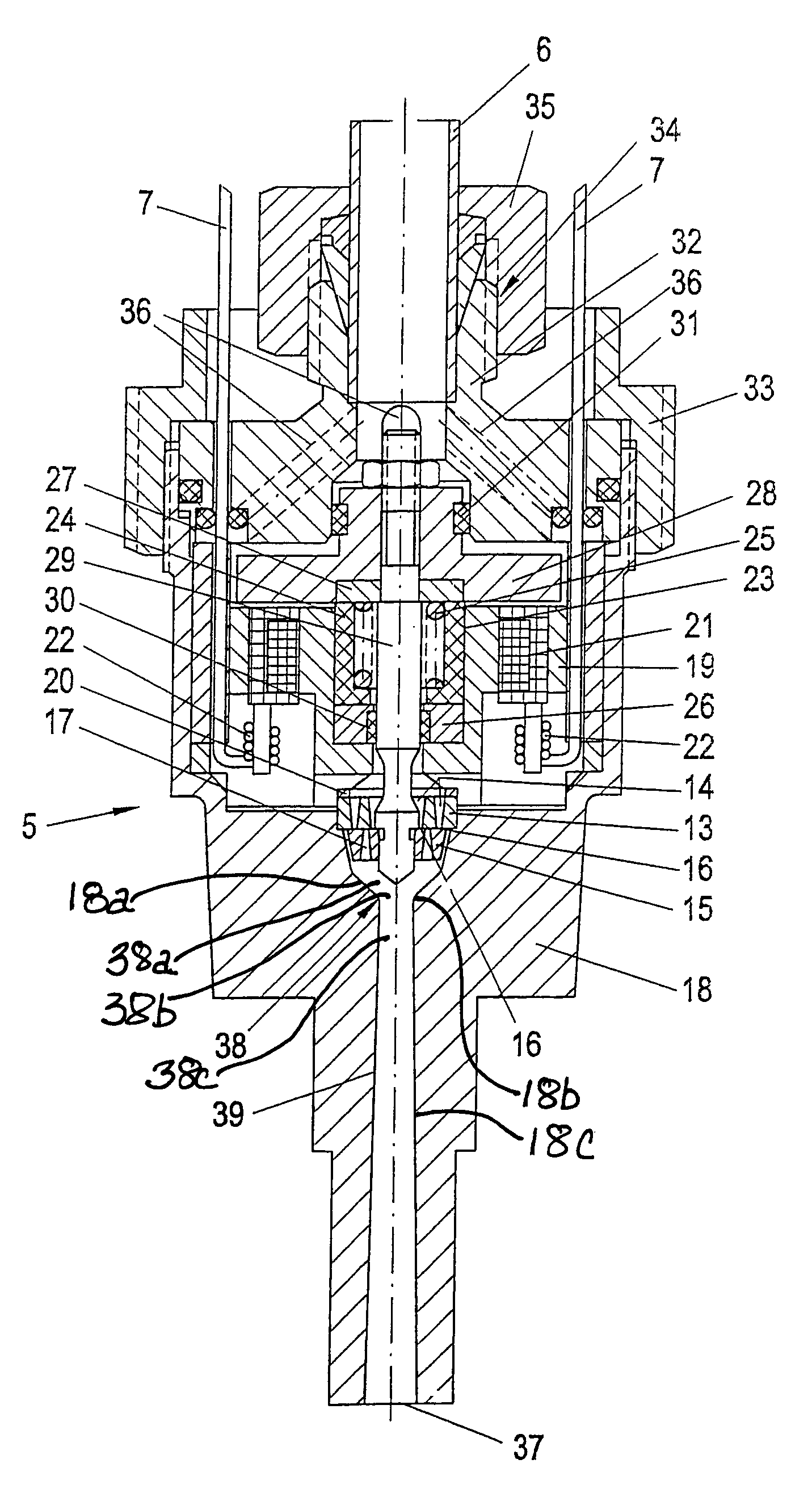

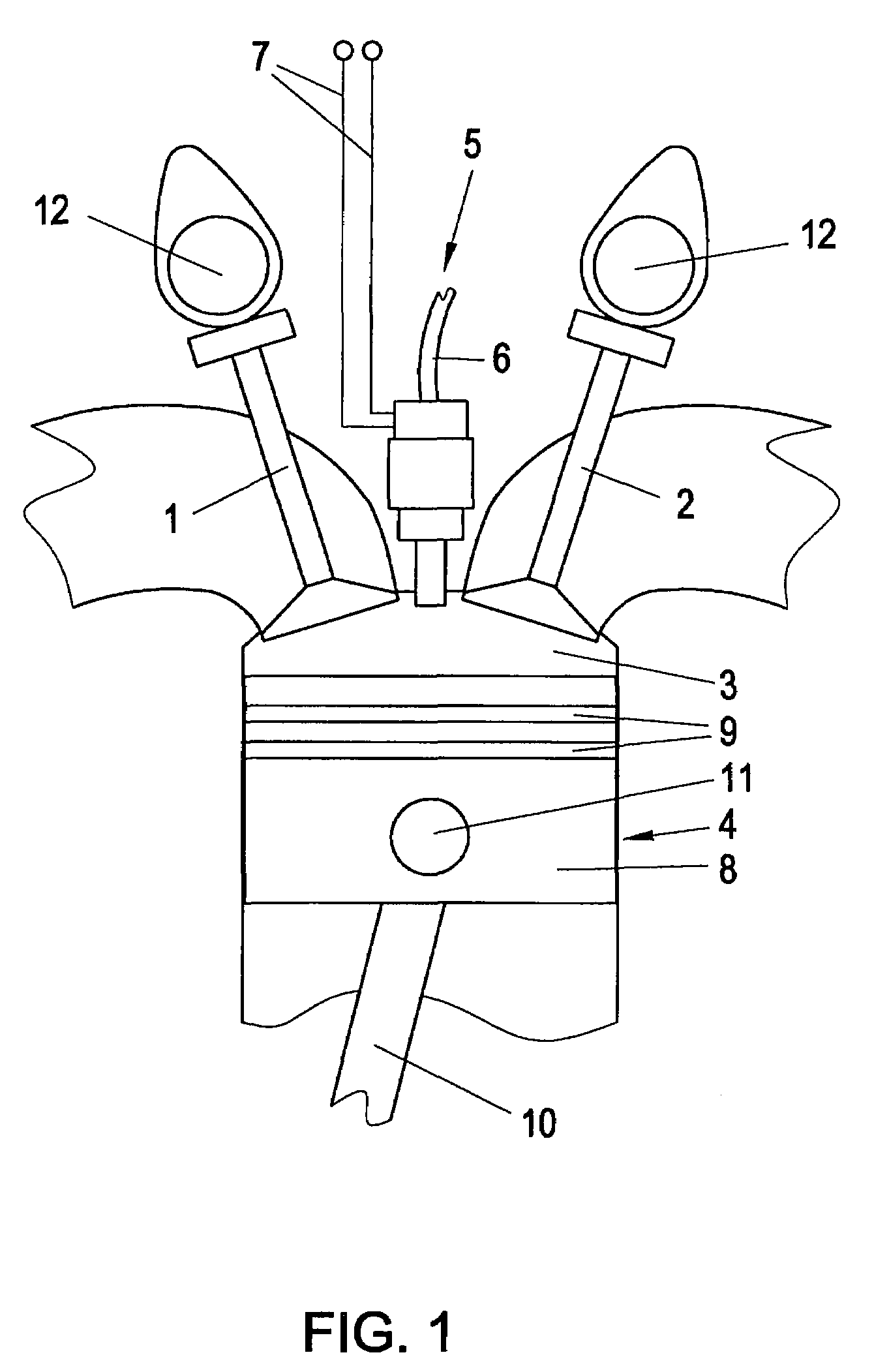

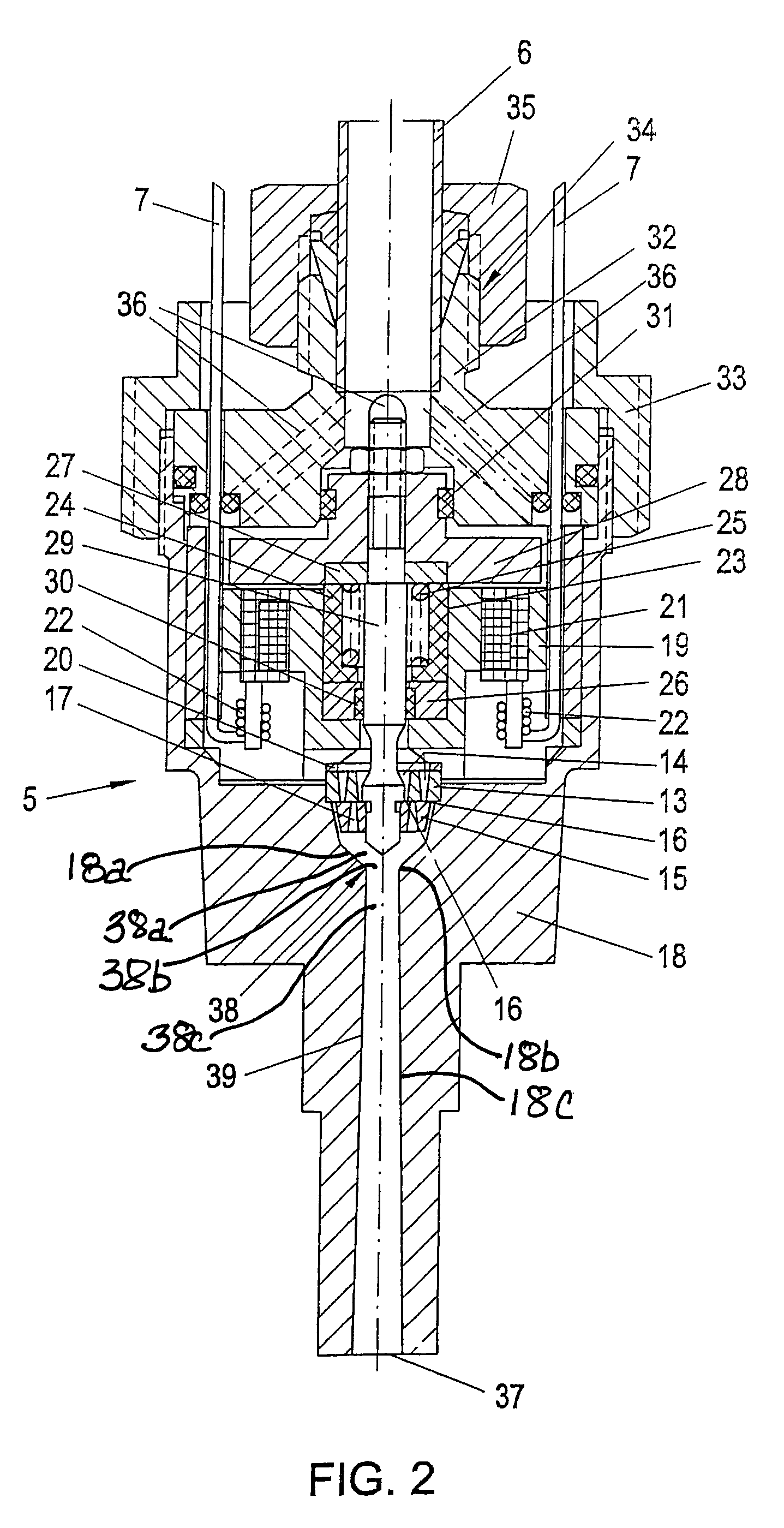

Electromagnetically actuated gas valve

ActiveUS7124998B2Improve sealingEasily and advantageously adjustedOperating means/releasing devices for valvesLift valveCombustion chamberEngineering

An electromagnetically actuated gas valve (5) for gas engines (4) includes a valve seat (13) that has at least one flow-through opening (14) and a corresponding sealing plate (15), with the sealing plate being movably arranged and guided essentially perpendicularly relative to the valve seat (13), with barrier surfaces (16) and discharge openings (17). The sealing plate (15) is loaded against the valve seat (13) by means of a return spring (25) and can be lifted for the purpose of opening it via a solenoid (21). In order to allow for the secure sealing and easy switchability even in the presence of the effect of the combustion chamber pressure, the sealing plate (15) is arranged on the discharge side of the valve seat (13) and connected by means of a stamp (29), which extends through the valve seat (13), with the anchor plate (28) of the solenoid (21). A Venturi tube meter (38) is arranged on the discharge side after the sealing plate (15) for the purpose of calibrating the flow-through correction value and for suppressing any dispersions due to manufacturing variations with regard to the effective flow cross-section, and the cross-section of the Venturi tube meter (38) is smaller than the sum of the effective flow-through cross-sections between valve seat (13) and opened sealing plate (15).

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

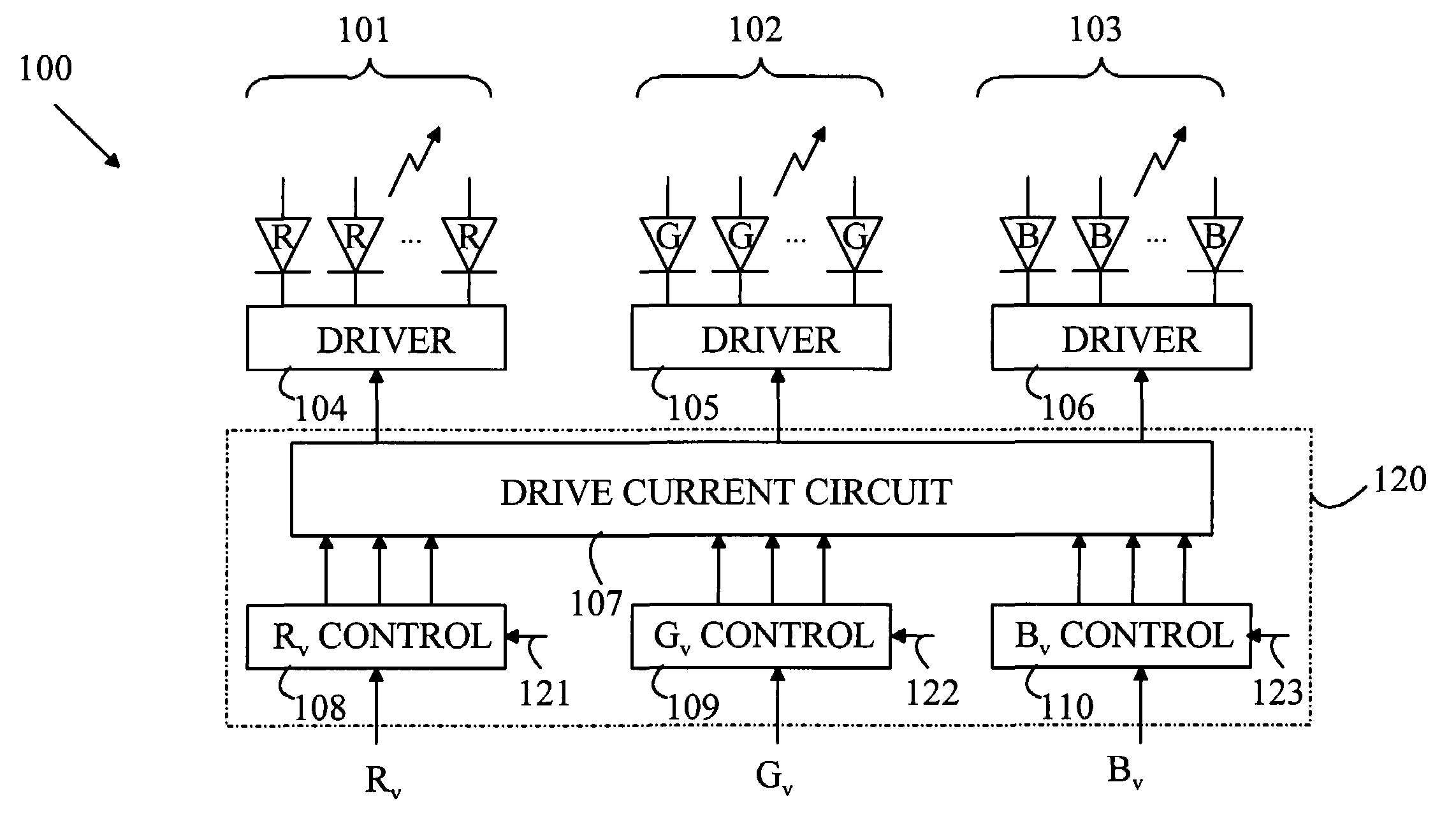

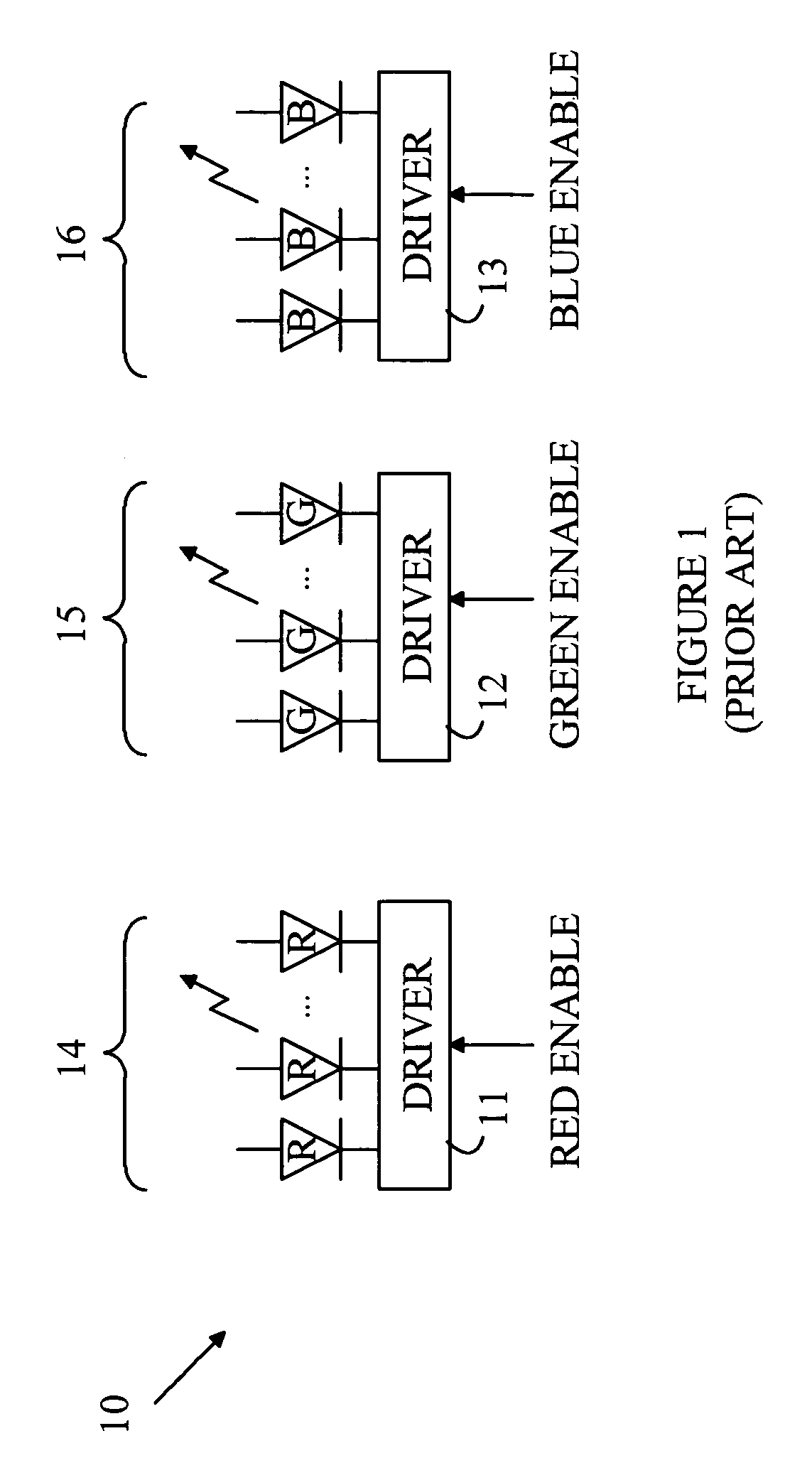

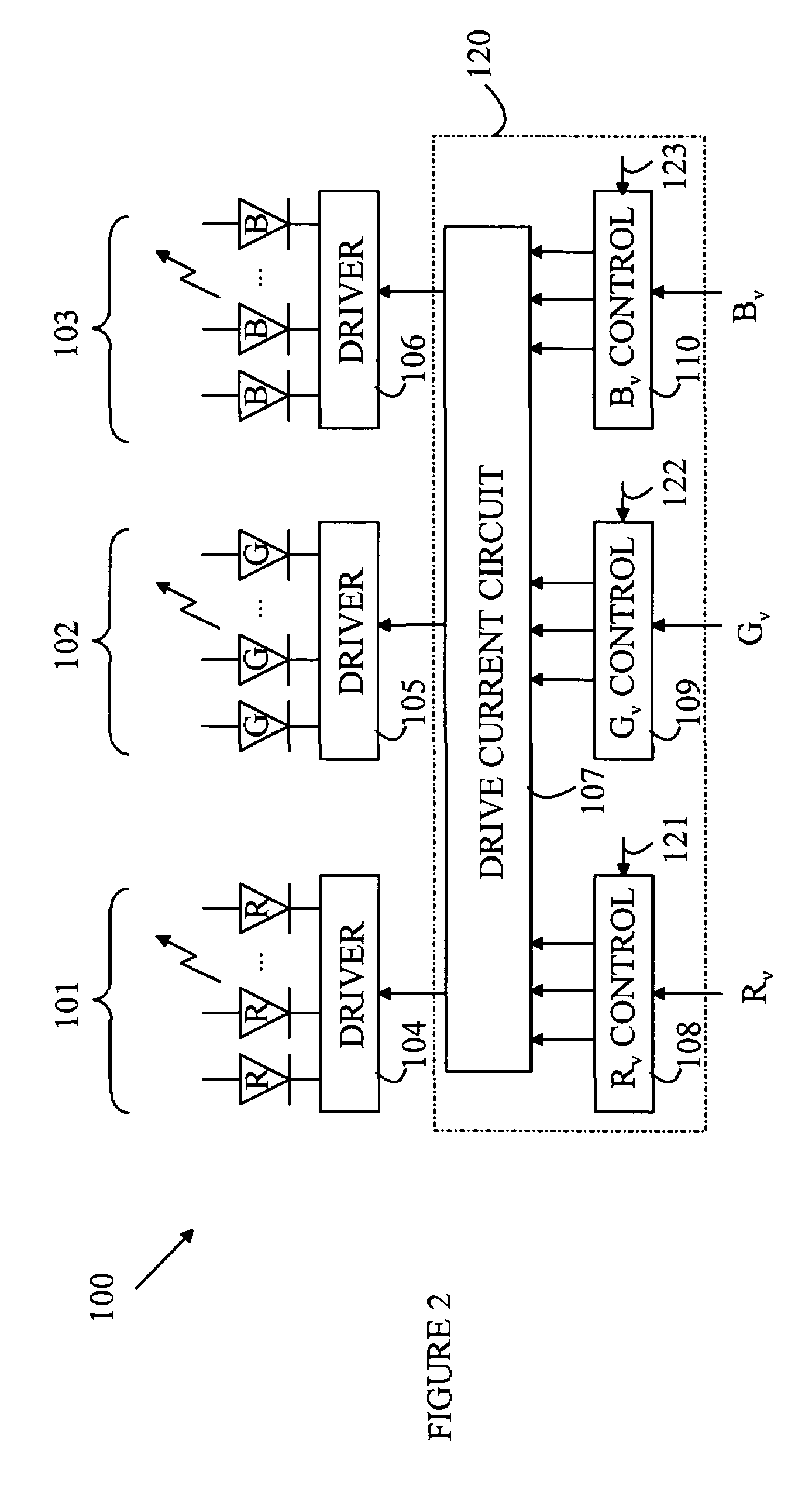

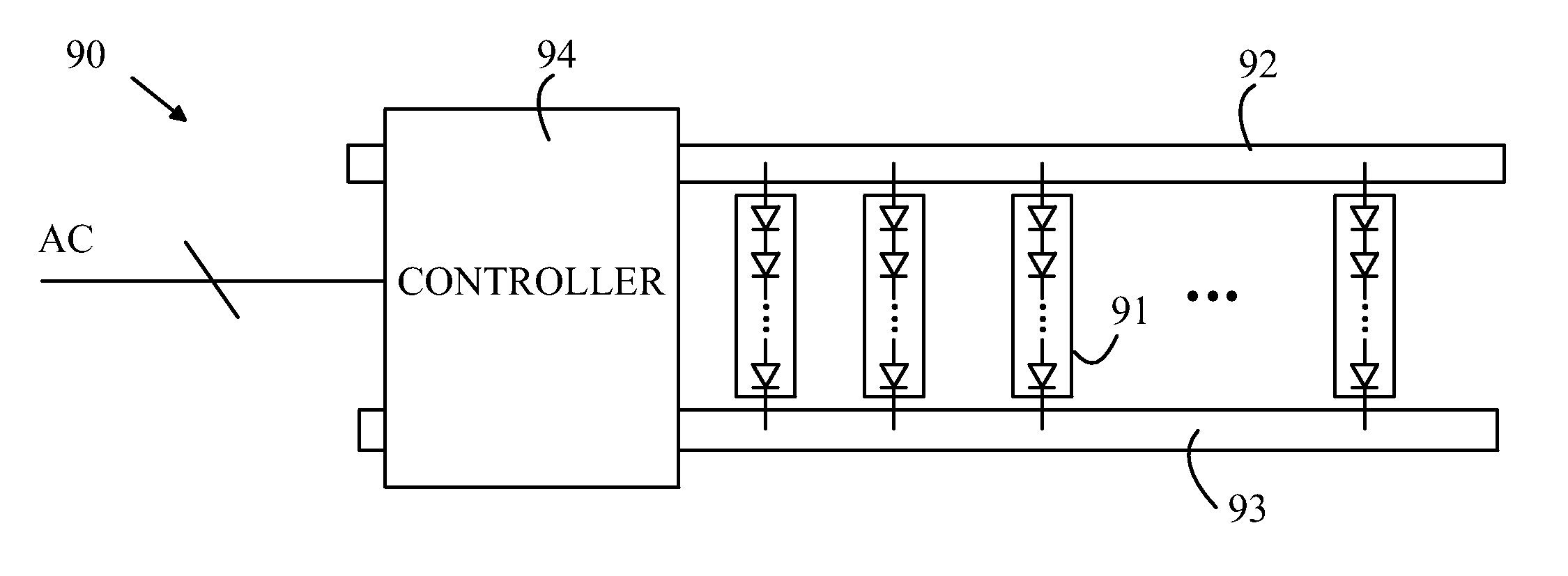

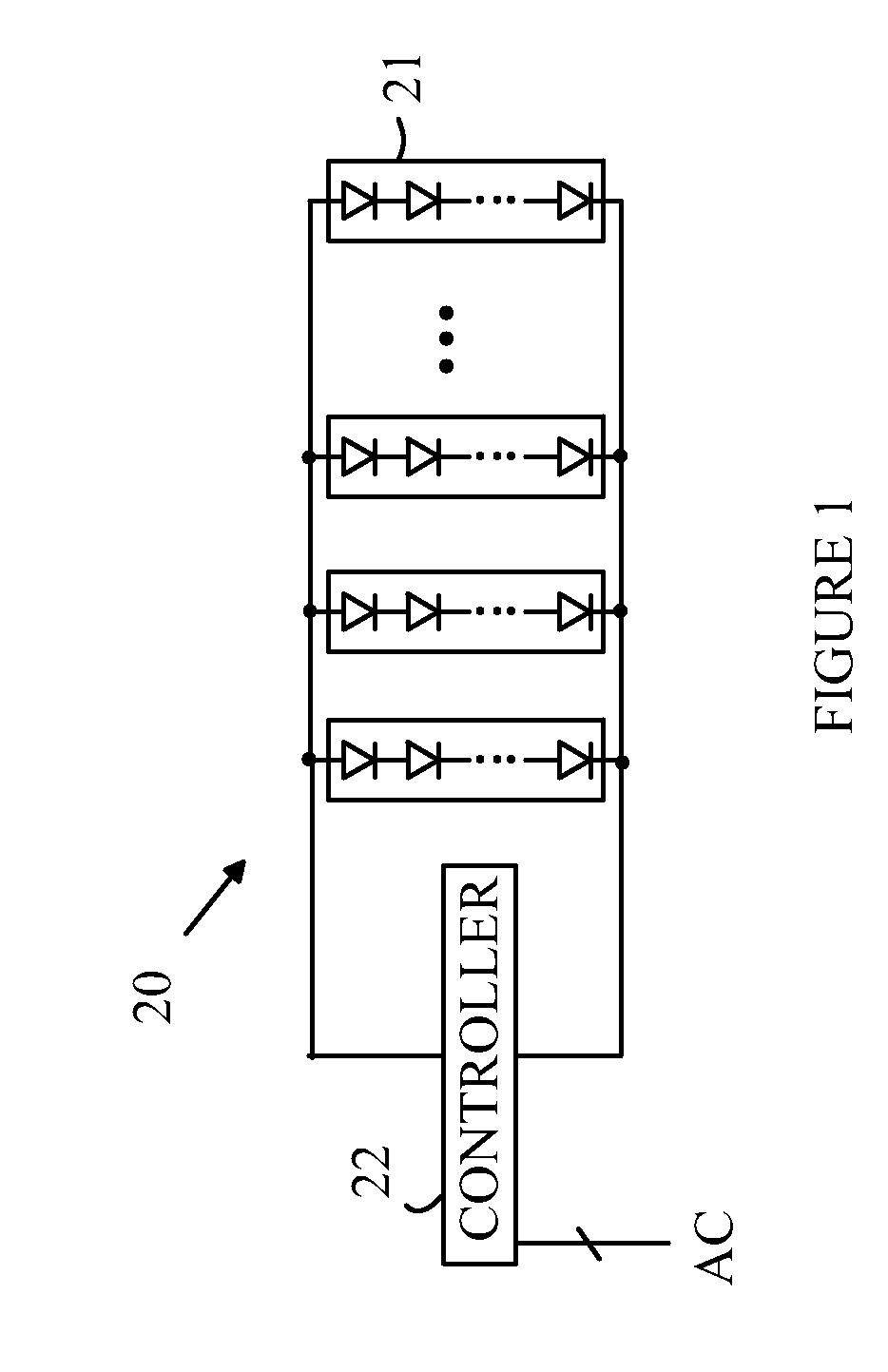

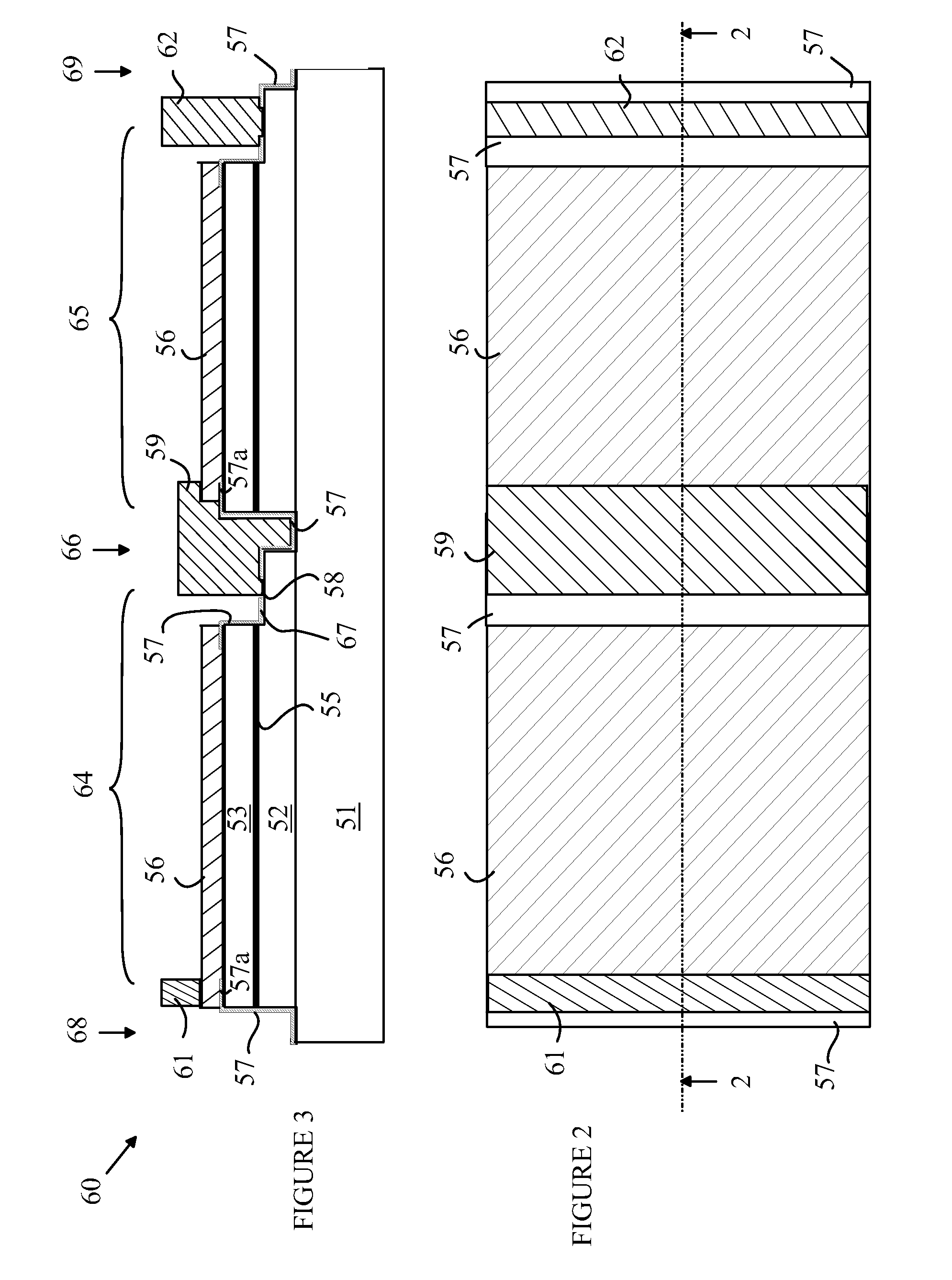

Light sources utilizing segmented LEDs to compensate for manufacturing variations in the light output of individual segmented LEDs

InactiveUS7982409B2Easy to understandElectroluminescent light sourcesSolid-state devicesSignal onEngineering

A light source and method for making the same are disclosed. The light source includes a plurality of Segmented LEDs connected in parallel to a power bus and a controller. The power bus accepts a variable number of Segmented LEDs. The controller receives AC power and provides a power signal on the power bus. Each Segmented LED is characterized by a driving voltage that is greater than 3 times the driving voltage of a conventional LED fabricated in the same material system as the Segmented LED. The number of Segmented LEDs in the light source is chosen to compensate for variations in the light output of individual Segmented LEDs introduced by the manufacturing process. In another aspect of the invention, the number of Segmented LEDs connected to the power bus can be altered after the light source is assembled.

Owner:BX LED LLC

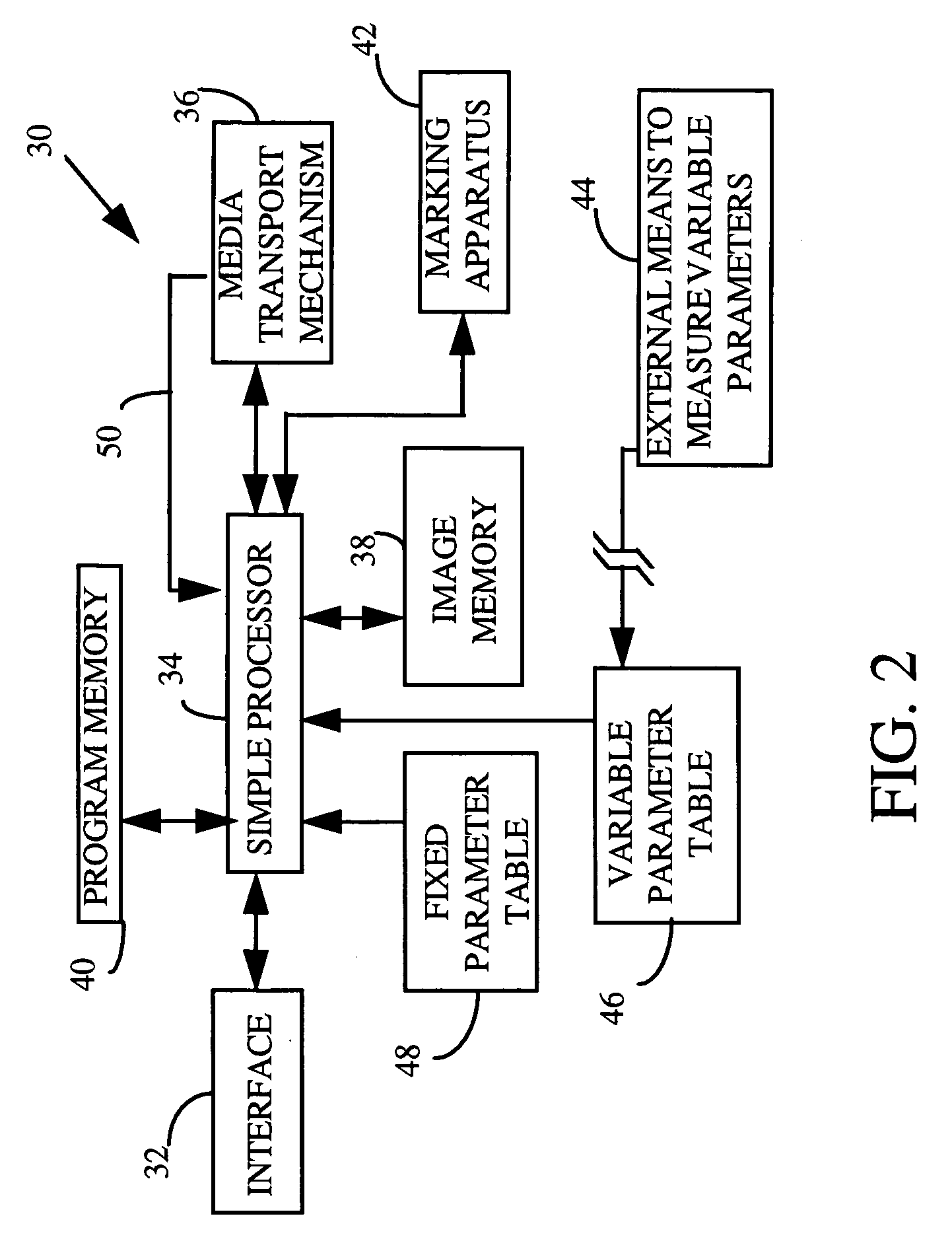

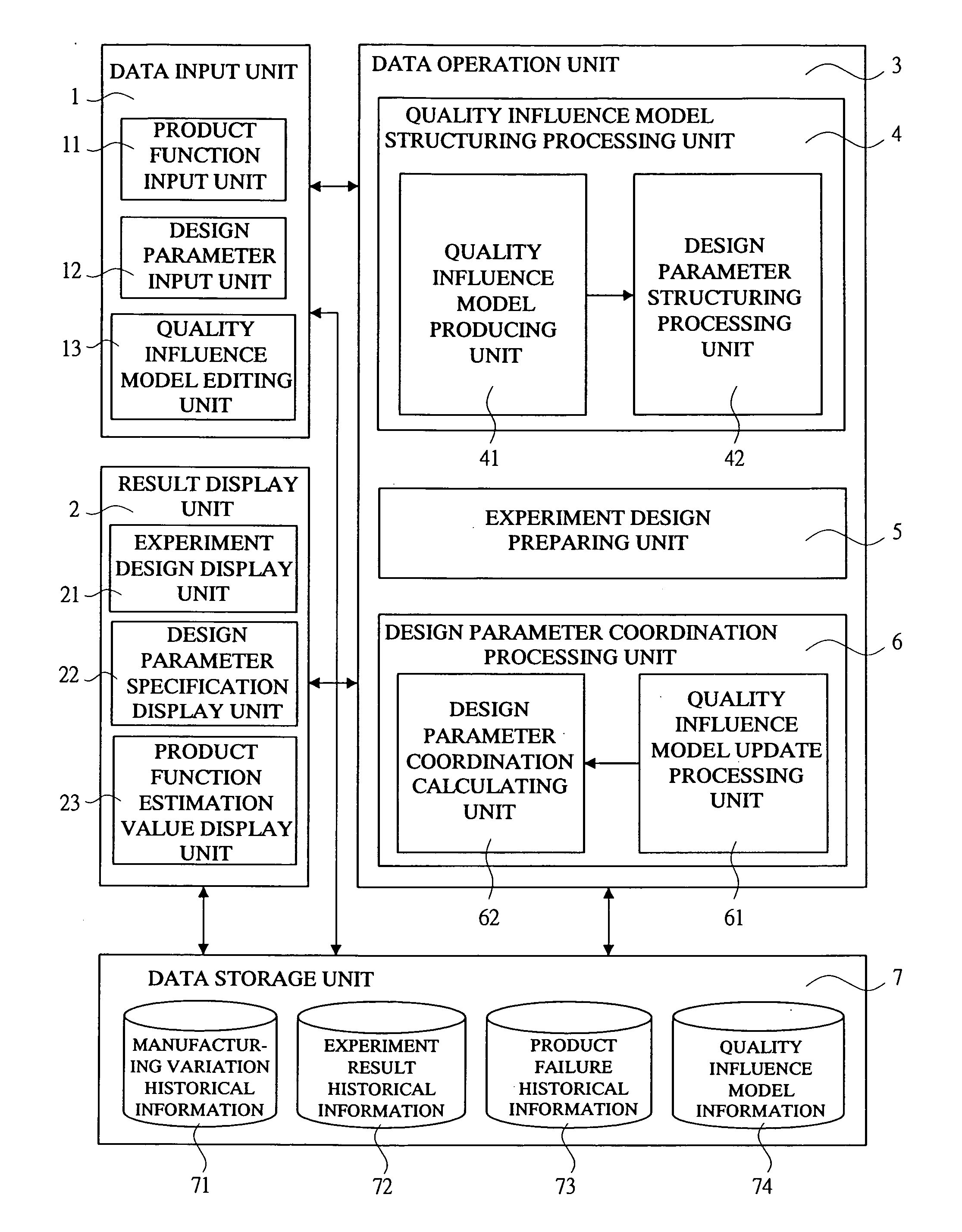

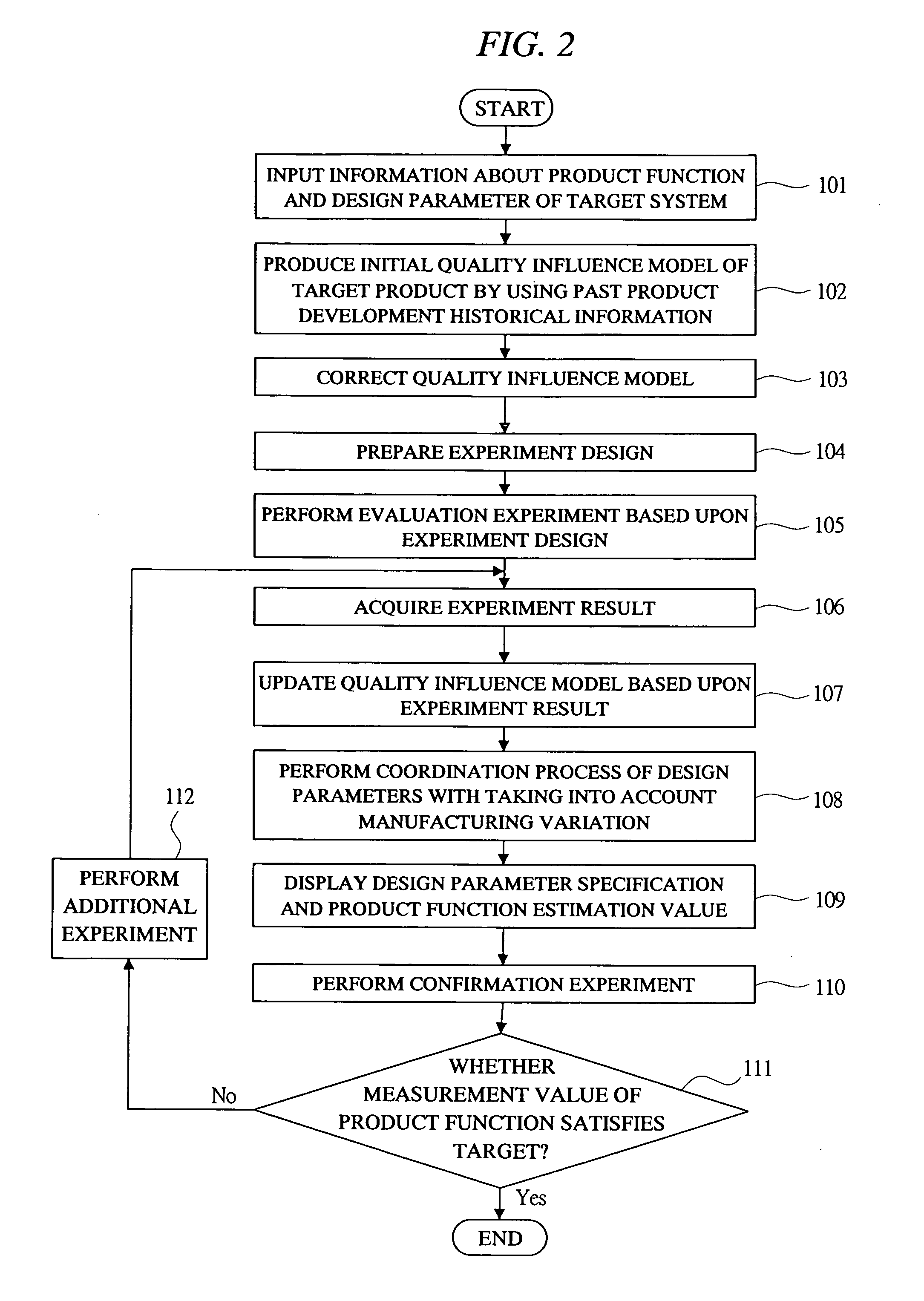

Method for determining parameter of product design and its supporting system

InactiveUS20070078553A1Efficiently determinedReduce developmentProbabilistic CADSpecial data processing applicationsManufacturing variationManufacturing engineering

In a method for determining a design parameter in a product design parameter determination supporting system, interaction between product function and design parameter is structured, a design parameter group with reduced interaction is extracted, an experiment design is prepared based upon the design parameter group, modeling of a quality influence degree between product function and design parameter is performed from an experiment result, and coordination process of a design parameter and estimation of a product function are performed with taking into account a manufacturing variation. By this means, it is possible to realize a system which can determine many design parameters extremely efficiently even in the product development where there are many design parameters and product functions to be handled and interactions are present between the design parameters and product functions.

Owner:HITACHI LTD

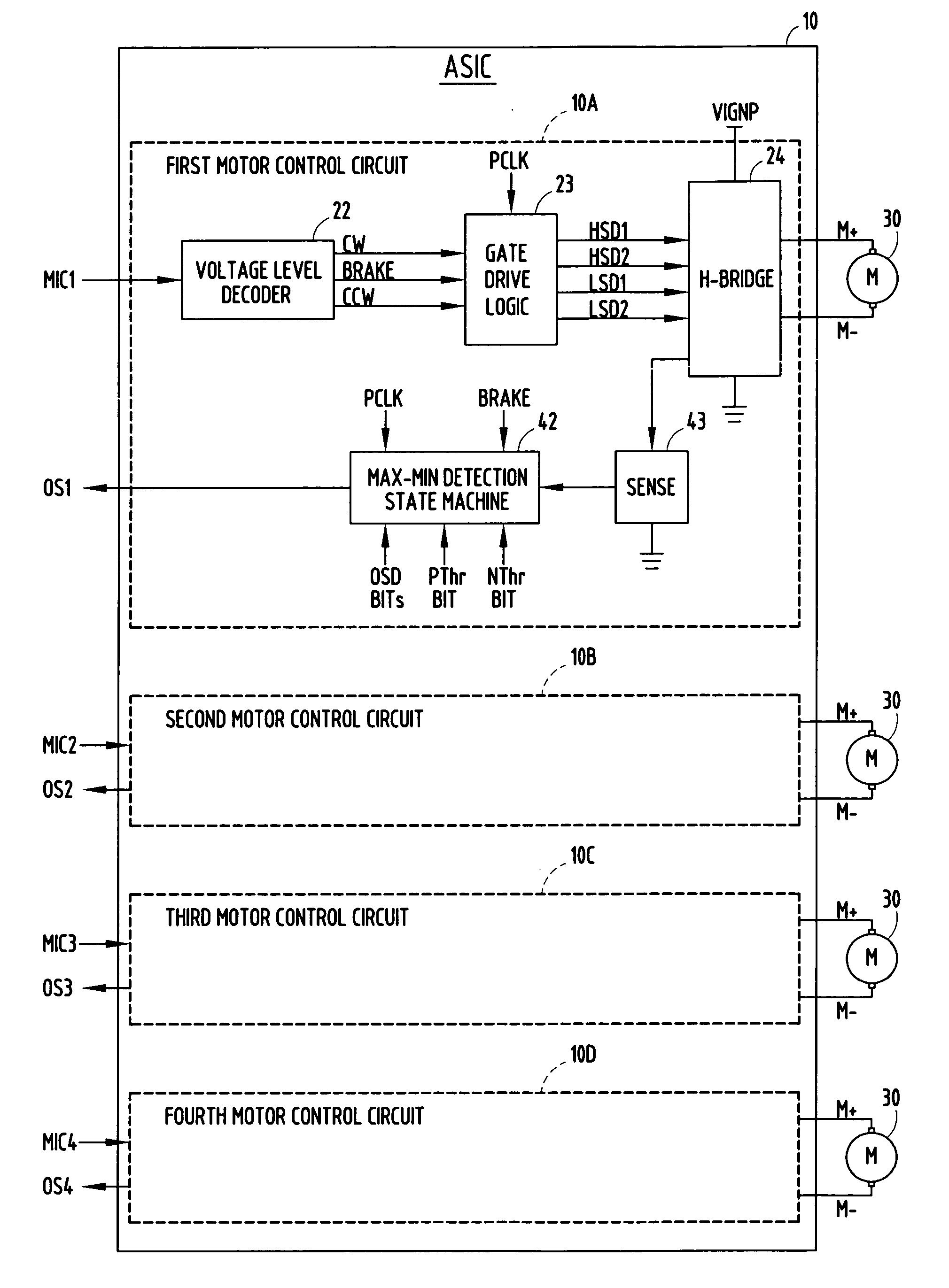

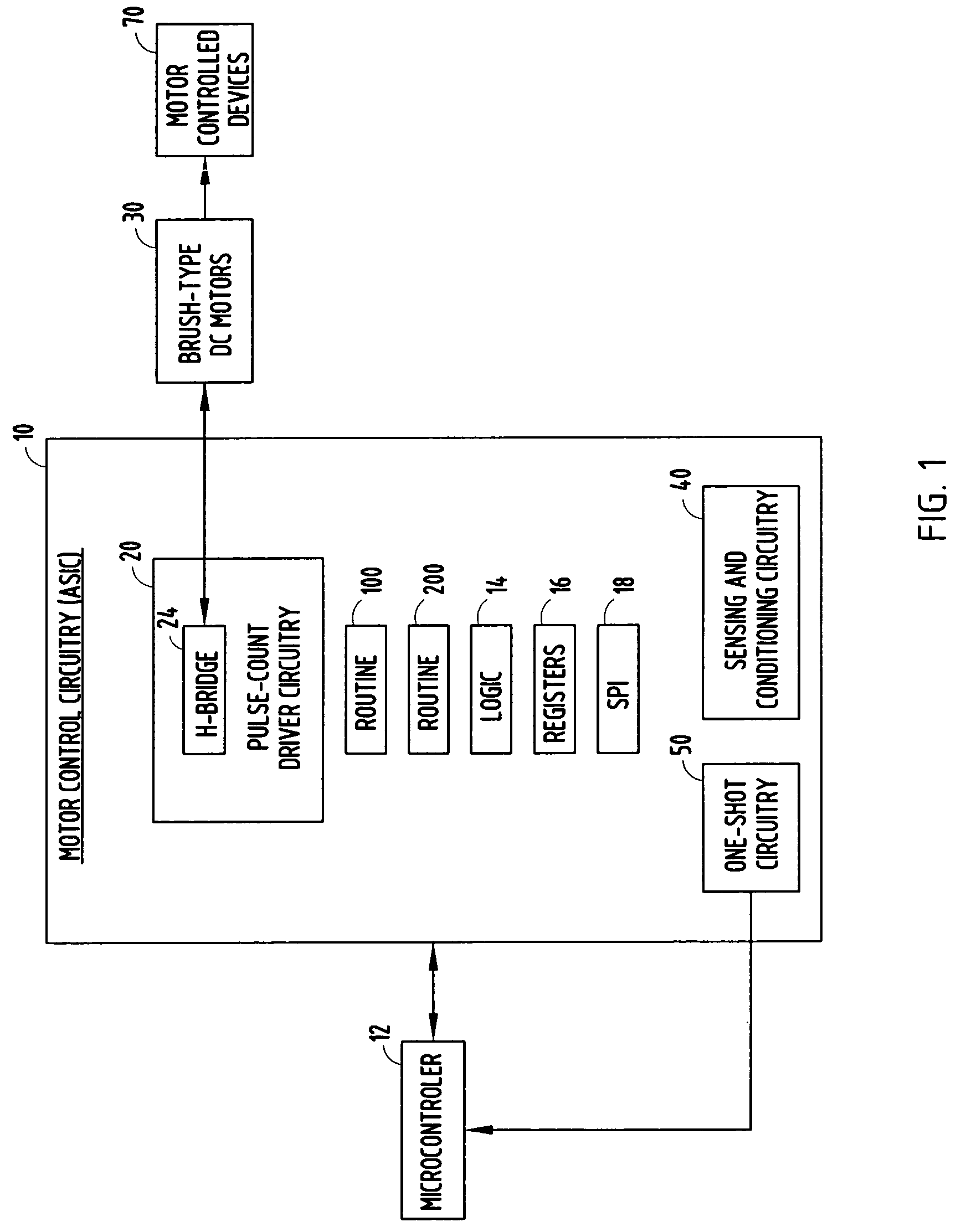

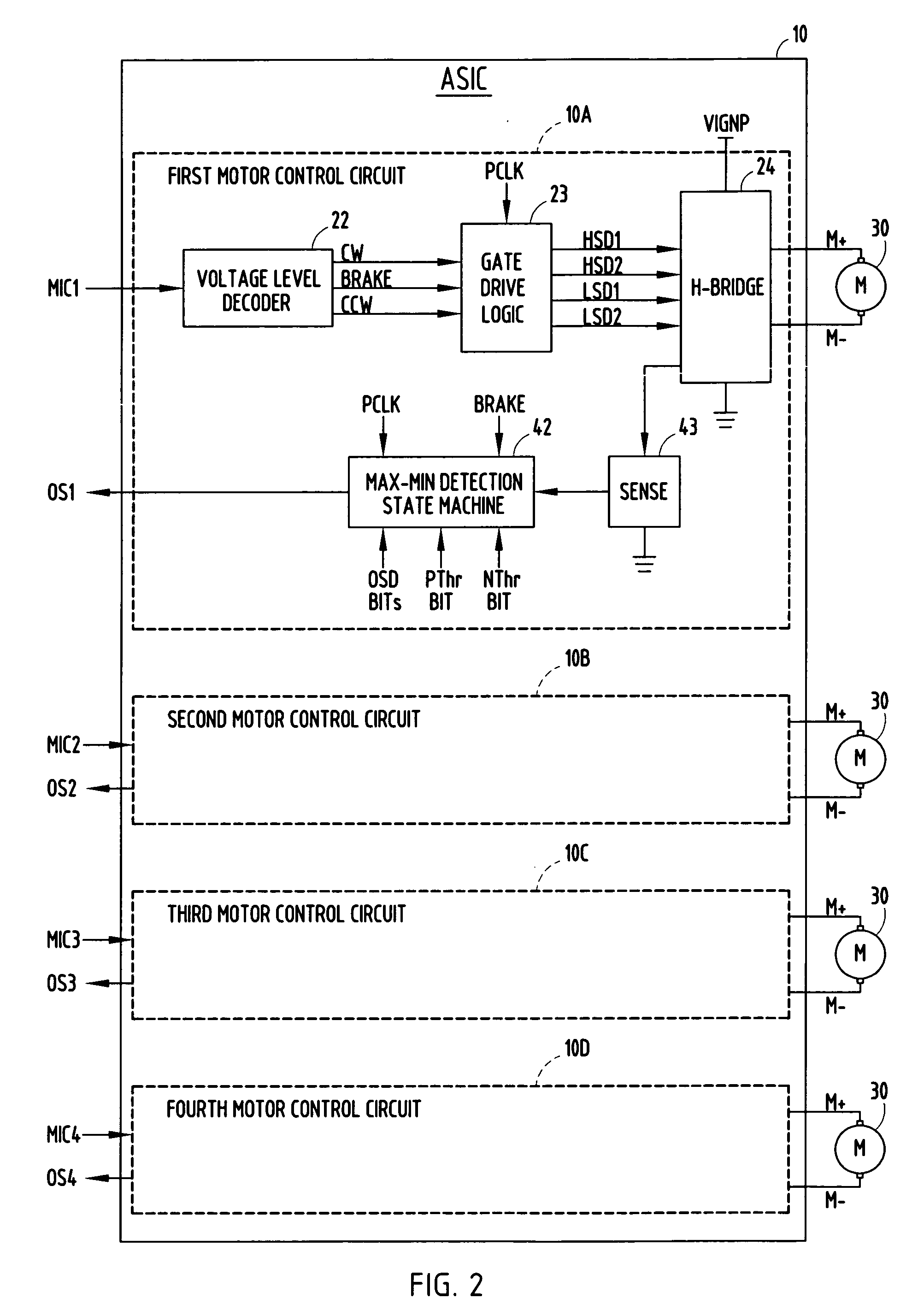

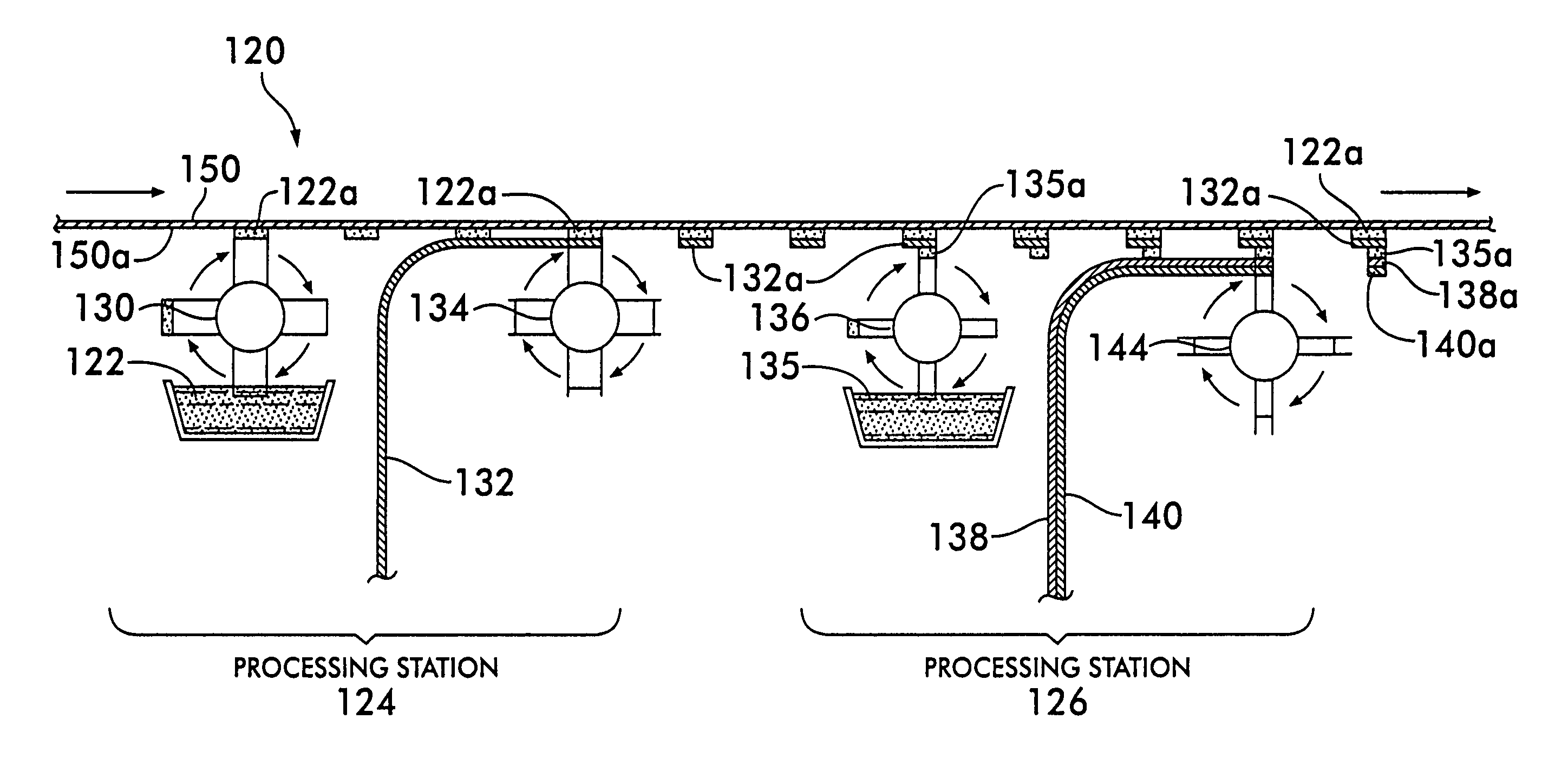

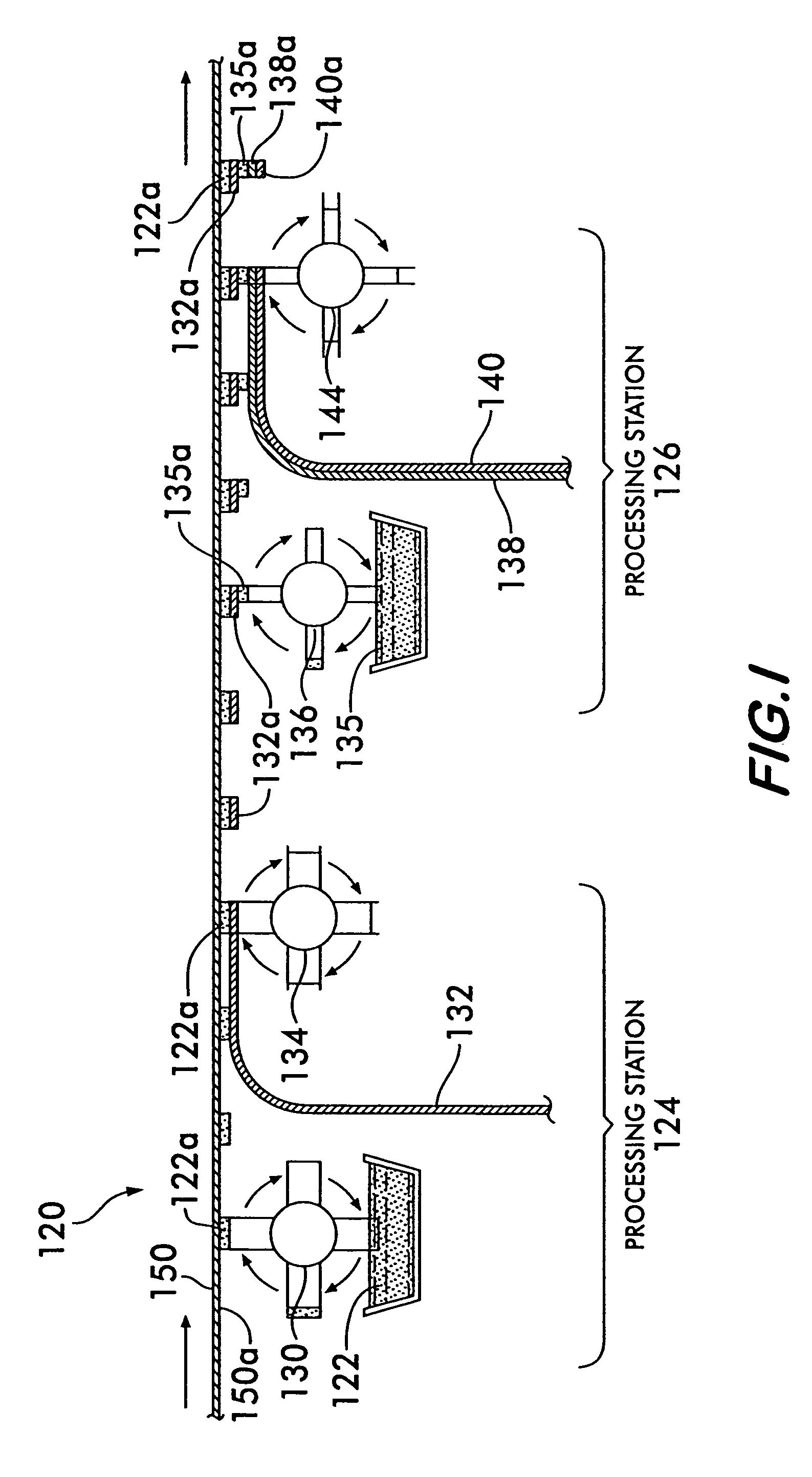

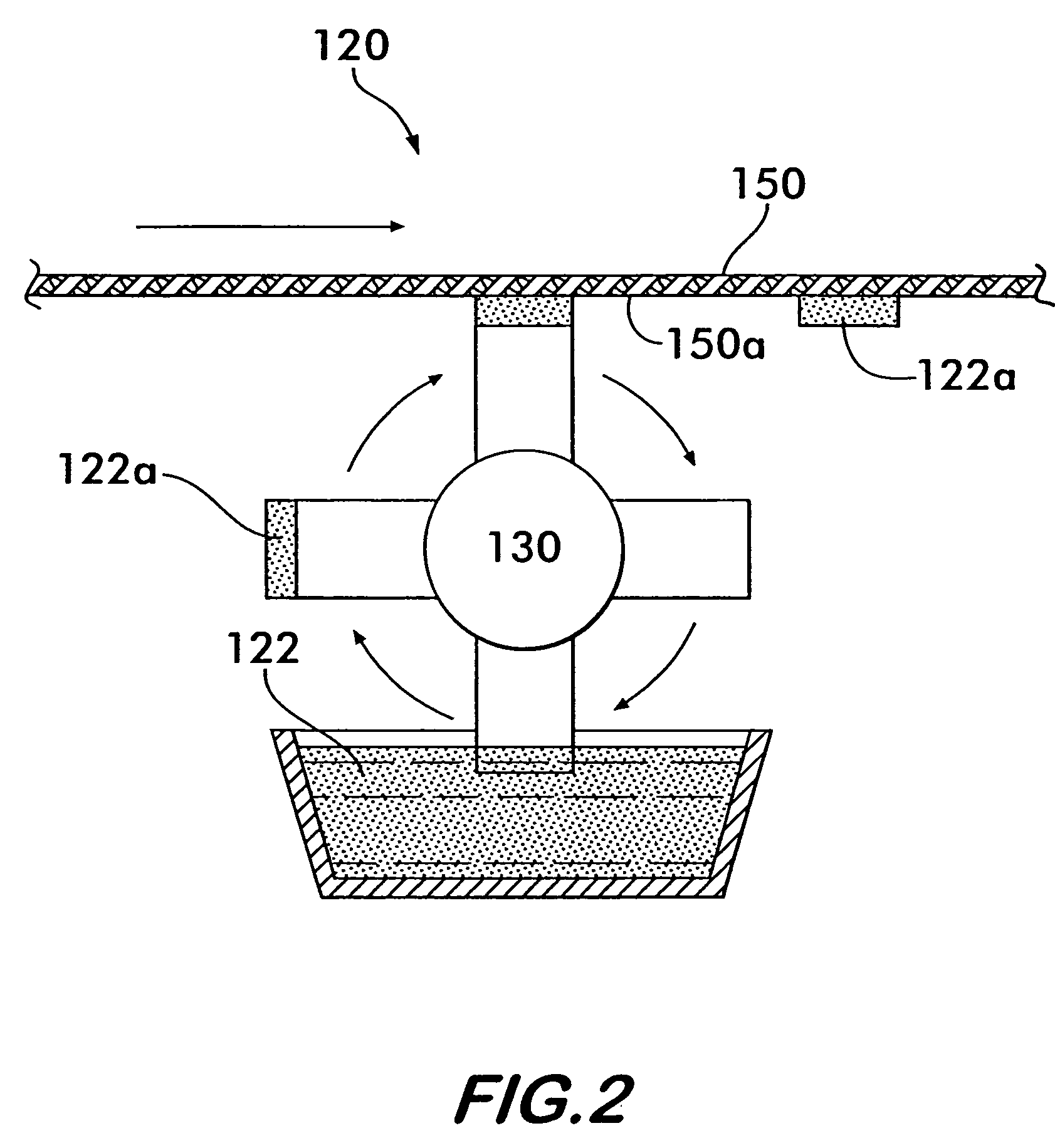

Position detection and external driver multiplexing system for DC motors

ActiveUS20070075656A1Reduced characteristicsReduce noiseAC motor controlField or armature current controlError processingManufacturing variation

A system and method is provided for improved monitoring and controlling of mechanically commutated DC motors. The system and method include DC motors, pulse-count driver circuitry for driving the motors, motor position sensing circuitry, and motor control circuitry. The system and method provide for improved motor current waveform sensing that is able to effectively reject false brake pulses, avoid erroneous processing due to fluctuating battery voltage levels, and reduce the sensitivity to variations in motor current signals due to dynamic motor load, manufacturing variation, system aging, temperature, brush bounce, EMI, and other factors. The system and method also include an improved ability to multiplex additional external motor drivers to the motor control circuitry, select between sequential and simultaneous drive modes using an SPI bit, and monitor the system controller for an error condition and simultaneously driver motors in response to the error condition.

Owner:APTIV TECH LTD

Method for aligning capacitor plates in a security tag and a capacitor formed thereby

InactiveUS7119685B2Fixed capacitor electrodesRadiating elements structural formsCapacitanceEngineering

A circuit element the presence of the circuit element includes first and second capacitor plates disposed over the surface of the substrate in an aligned relationship with each other. The aligned relationship has manufacturing variations in the relative positioning of the first and second capacitor plates and a dielectric layer disposed between the first and second capacitor plates. At least one of the first and second capacitor plates is formed substantially smaller relative to the other of the first and second capacitor plates. The at least one of the capacitor plates is disposed at a predetermined offset in at least one planar direction from an edge of the other of the first and second capacitor plates. The predetermined offset is selected according to the manufacturing variations to prevent variations in the value of capacitance of the capacitor due to the manufacturing variations.

Owner:CHECKPOINT SYST INC

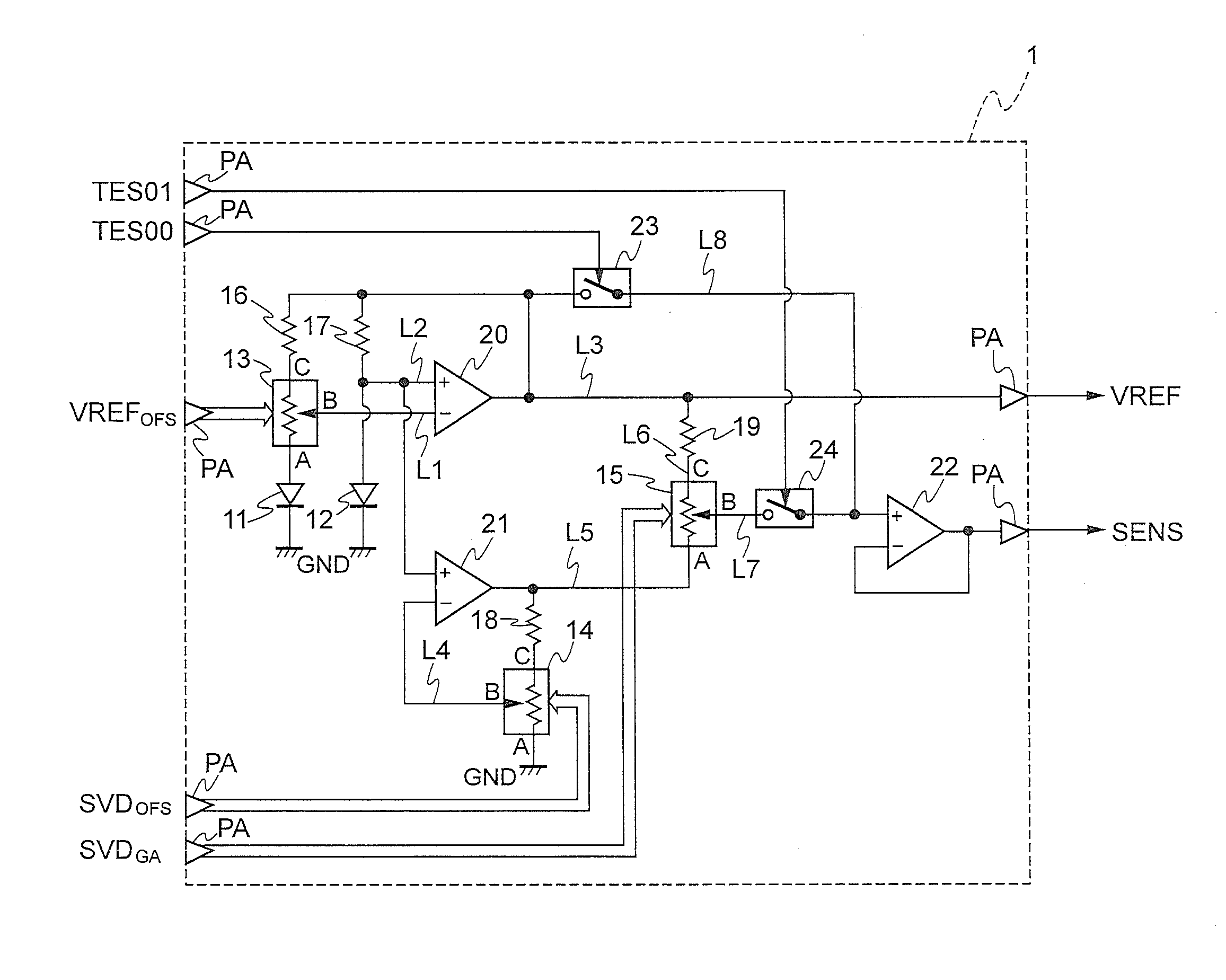

Temperature detection circuit and method of adjusting the same

ActiveUS20130121377A1Reduction in accuracyIncrease temperatureThermometers using electric/magnetic elementsUsing electrical meansEngineeringVoltage reference

A temperature detection circuit that can detect temperature with high accuracy regardless of manufacturing variations, and a method of adjusting the same. The circuit includes: first and second diodes having respective independent p-n junctions; a first current path including a first variable voltage dividing resistor series connected to the first diode; a second current path including a second variable voltage dividing resistor series connected to the second diode; a reference voltage generation part that feeds back a differential voltage to each of the first and second current paths and outputs as a reference voltage the differential voltage indicating a difference between a first divided voltage of the first variable voltage dividing resistor and a potential on the second current path; and a temperature detection signal generation part generating a temperature detection signal based on a second divided voltage of the second variable voltage dividing resistor.

Owner:LAPIS SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com