Methods, apparatus and computer readable storage mediums for model-based diagnosis of gearboxes

A gear box, model technology, applied in complex mathematical operations, instruments, electrical testing/monitoring, etc., can solve problems such as no solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

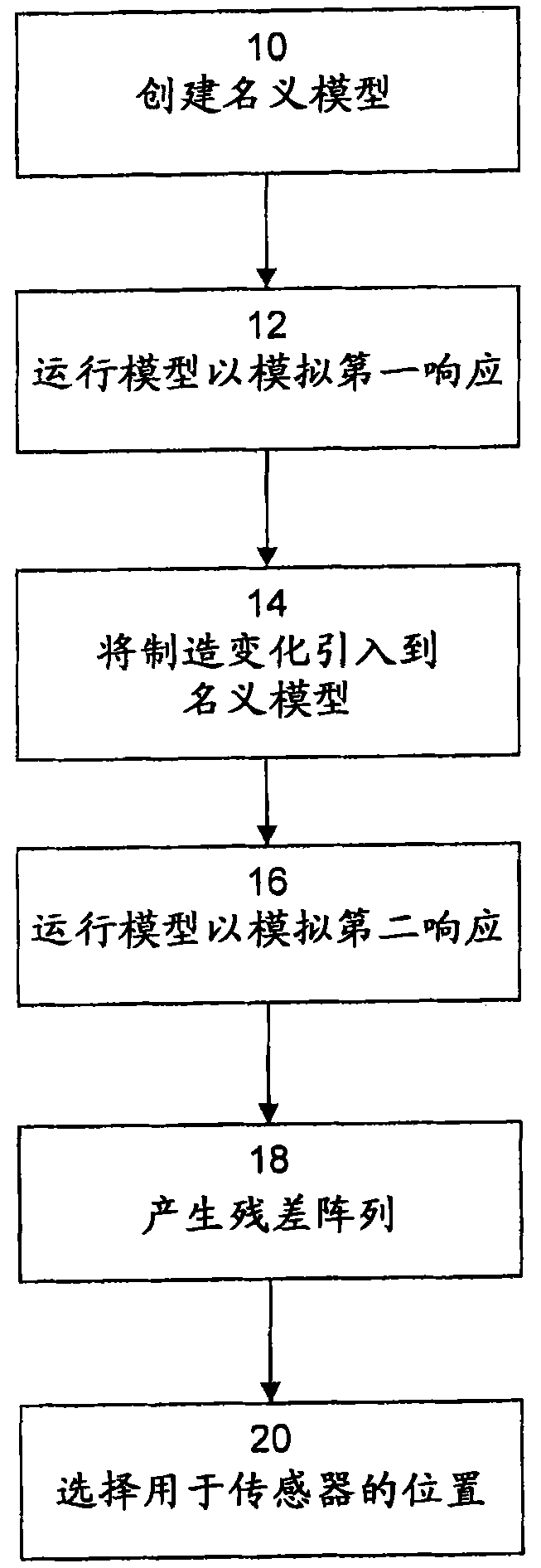

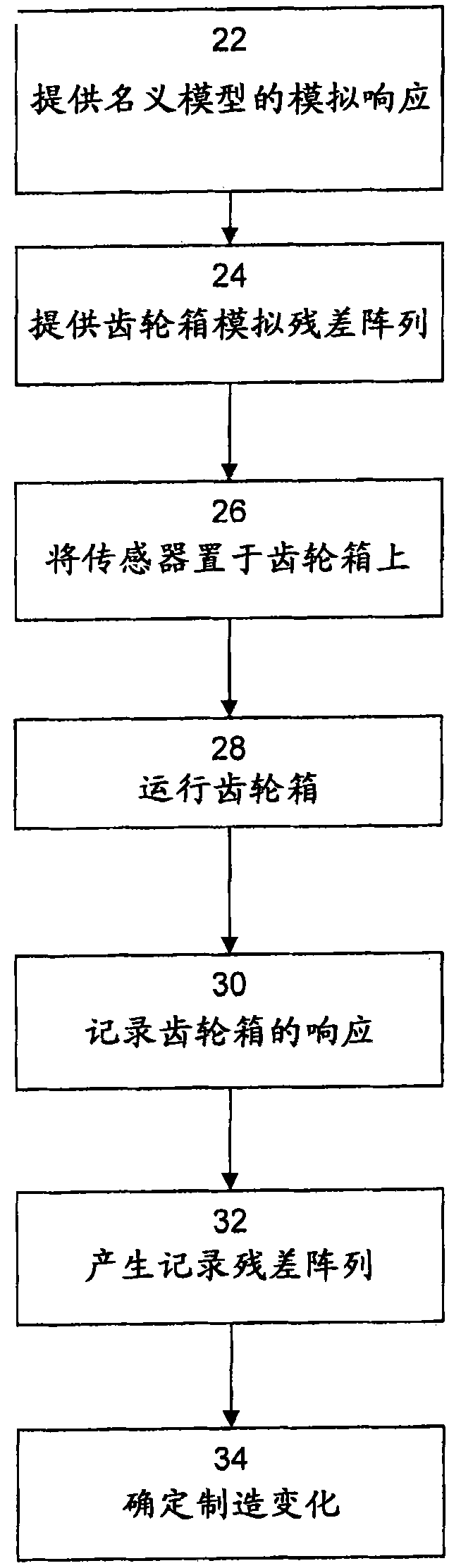

[0045] According to one aspect of the invention, a model-based approach is used to determine sensor locations in or on a gearbox, drive train or generator of a geared machine such as a wind turbine. The sensors can be end-of-line test sensors, or condition monitoring sensors.

[0046] End-of-line test sensors include sensors that are placed in or on the gearbox and used immediately after the gearbox or driveline is manufactured. End-of-line test sensors can be used to determine the residuals as well as specific gearbox models, details are described in the following paragraphs.

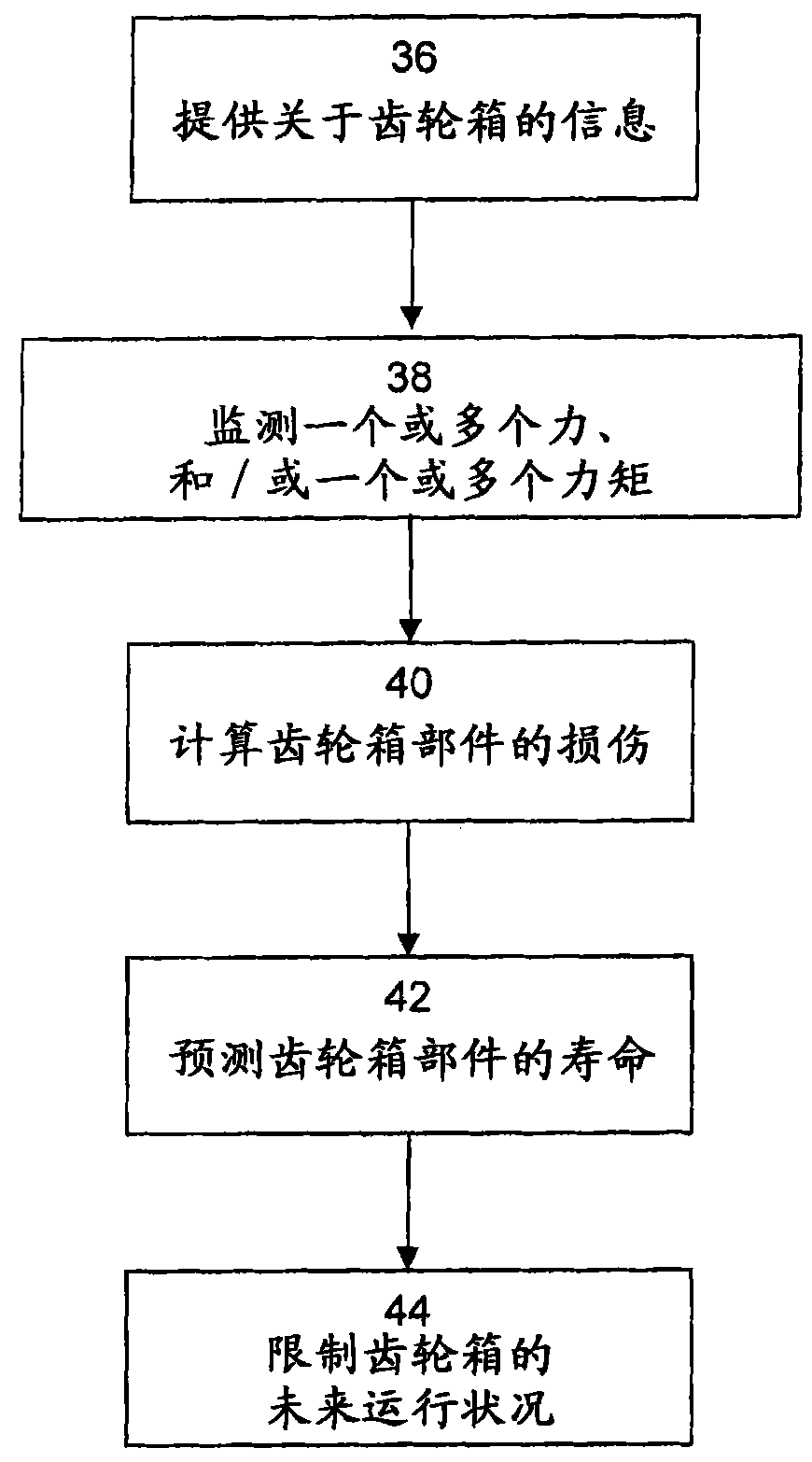

[0047] Condition monitoring sensors include those placed in or on a gearbox or driveline to monitor the forces and moments acting on the gearbox or driveline over the operating life. Condition monitoring sensors can be used to predict damage to components in gearboxes or drivetrains and thus their lifespan.

[0048] The sensors are positioned such that they are able to obtain an optimal amount of inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com