Controlled auto-pumping type coke oven side entrance smoke gas collecting apparatus

A technology of flue gas collection and automatic valves, which is applied to coke ovens, charging devices, and furnaces to prevent/remove fouling, etc., to achieve the effects of flexible adjustment, precise control, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

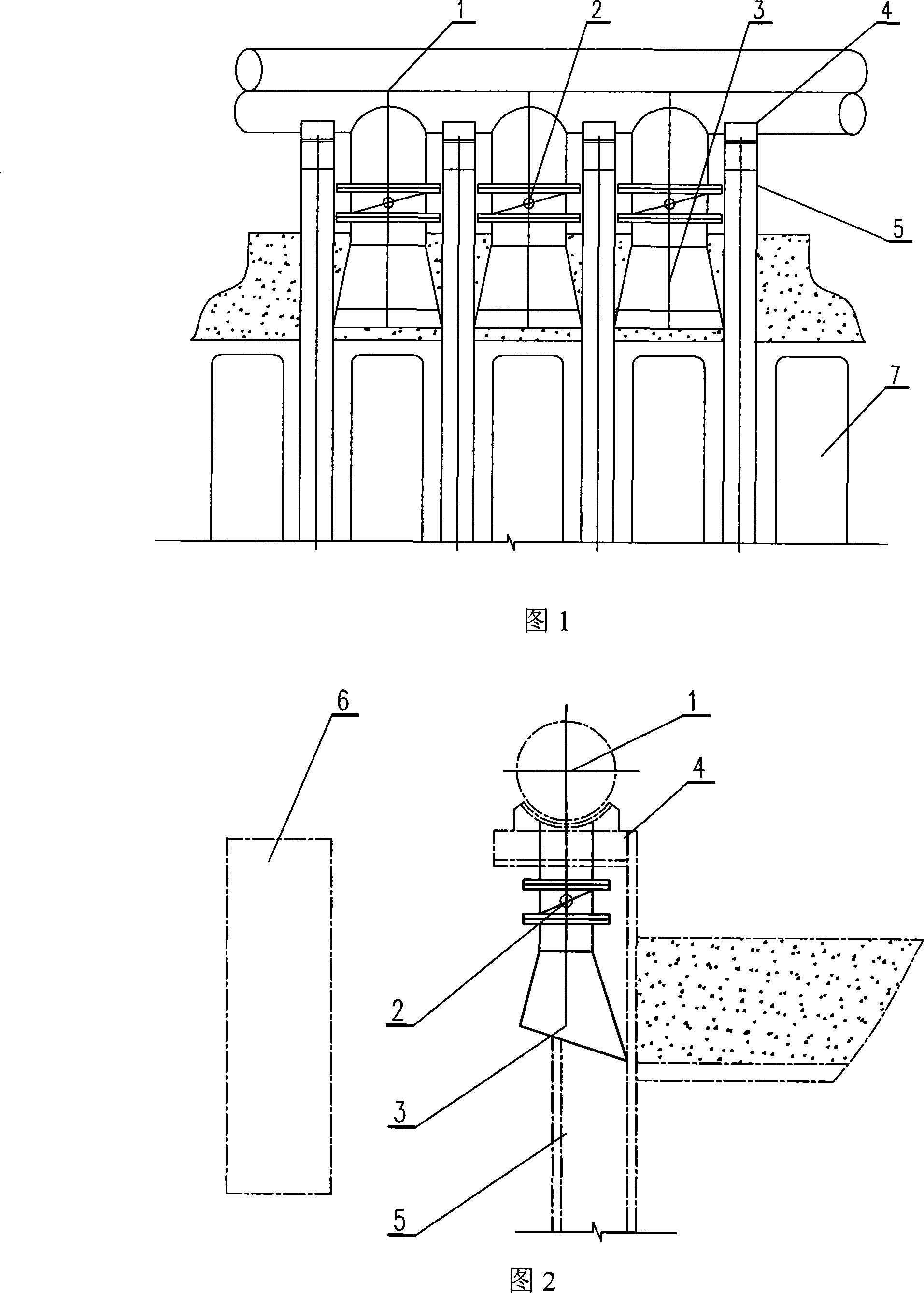

[0013] A controllable automatic suction type coke oven machine side oven door flue gas collection device of the present invention is realized in this way, and the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] See Figure 1 and Figure 2, a controllable automatic suction type coke oven machine side furnace door flue gas collection device, the device consists of a flue gas transmission pipe 1, a controllable automatic valve 2, a lower dust collection hood 3, and a pipe support 4 , the automatic valve control system 6 is composed of a pipe support 4 on the upper part of the coke oven column 5, the flue gas transmission pipe 1 is located on the upper part of the pipe support 4, and the controllable automatic valve 2 is connected to the bottom of the flue gas transmission pipe 1, which can be controlled and automatically The valve 2 is located in the middle of two adjacent furnace pillars 5, and the bottom of the controllab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com