Tamping coke oven machine side furnace door and furnace top smoke catching method and device

A technology for tamping coke ovens and soot, which is applied in coke ovens, furnace prevention/removal of fouling, petroleum industry, etc. Remarkable energy-saving effect, no secondary pollution, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

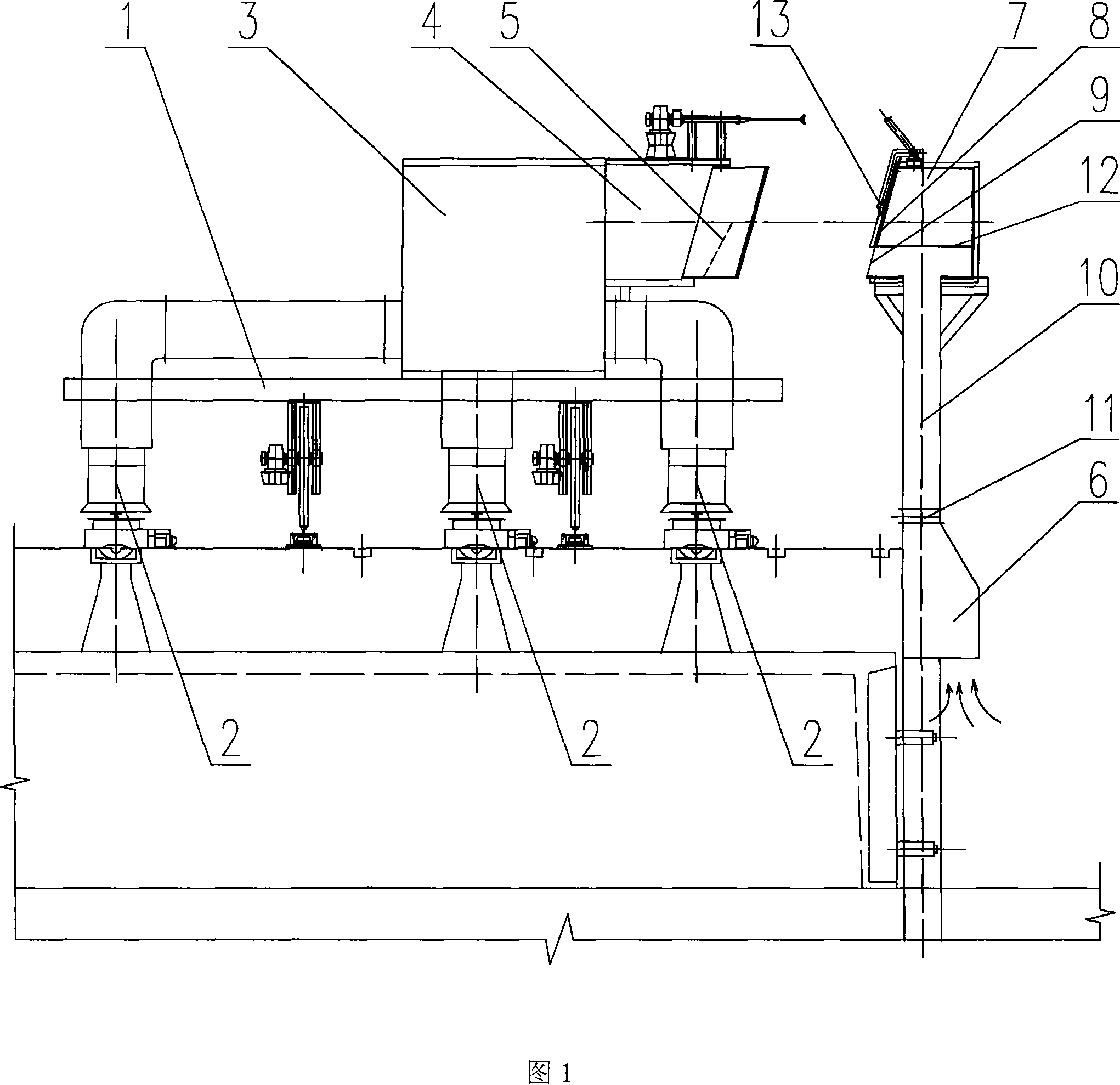

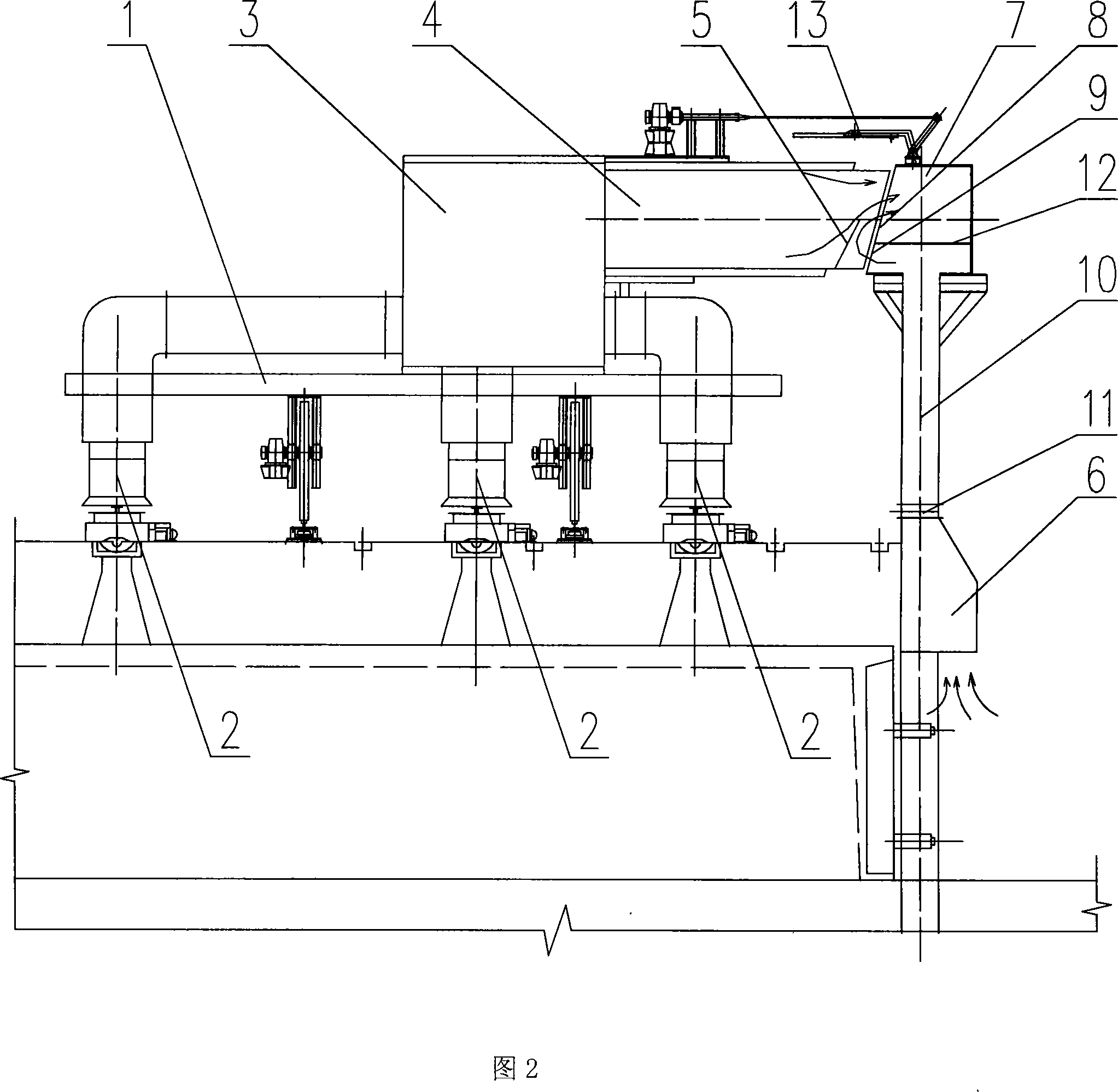

[0012] As shown in Figure 1, a method of tamping coke oven machine side furnace door and furnace top smoke and dust collection, in this method, the two streams of smoke and dust are combined in the double interface flap valve through the machine side furnace door smoke dust control component and the furnace top smoke dust control component , and guide the merged smoke and dust into the ground dust removal station through the double-port flap valve.

[0013] The device involved in the method includes two parts, the machine-side furnace door smoke control assembly and the furnace top smoke control assembly. Set of 4, the suction hood is set above the machine side furnace door, connected to the double interface flap valve 7 through the connecting pipe 10, and the machine side furnace door smoke and dust conduction interface 9 and the combined smoke and dust conduction interface are provided on the double interface flap valve 7 The interface 8, the furnace door smoke and dust cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com