Patents

Literature

910results about "Oven incrustations prevention/removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibrating debris remover

InactiveUS7084553B2Efficient disseminationOvercomes drawbackSievingPiezoelectric/electrostriction/magnetostriction machinesEngineeringTransverse wave

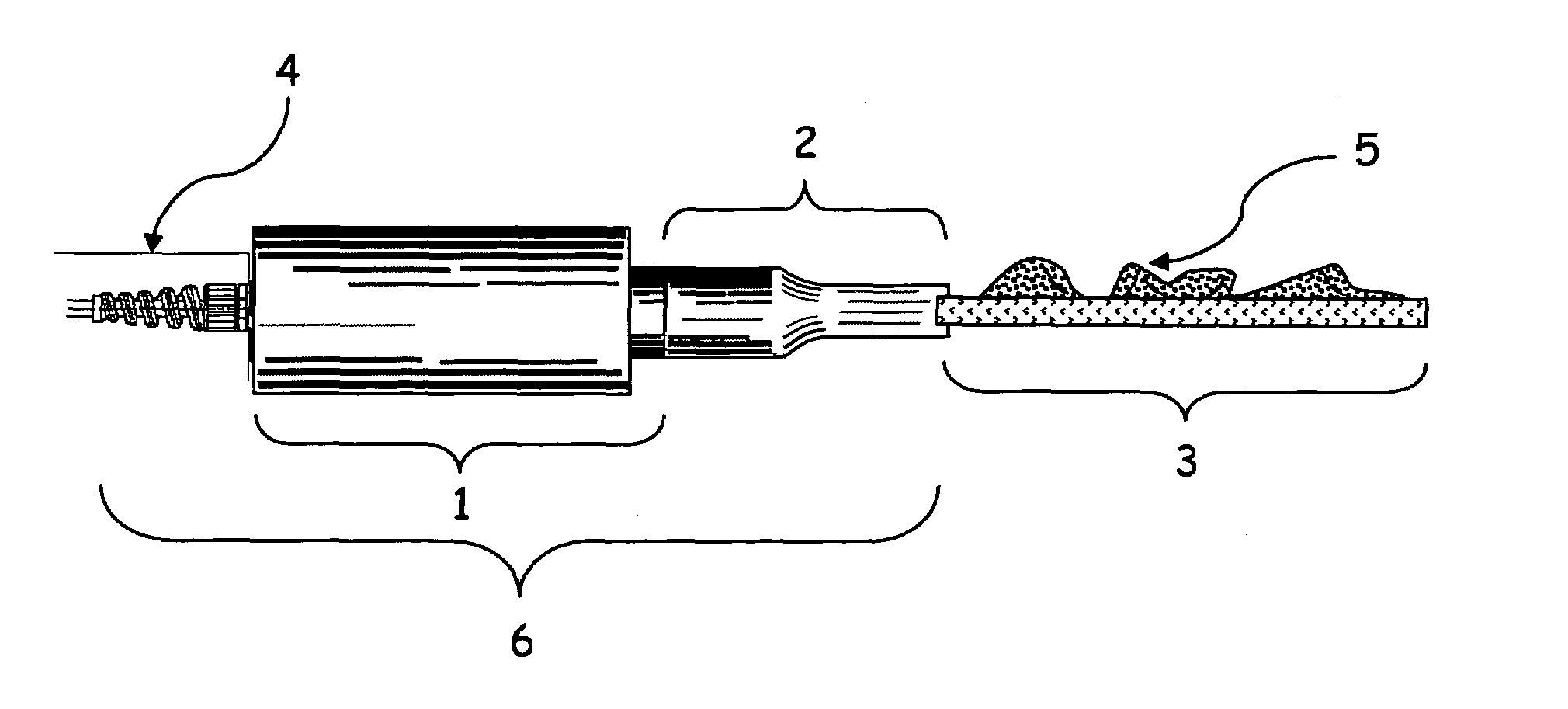

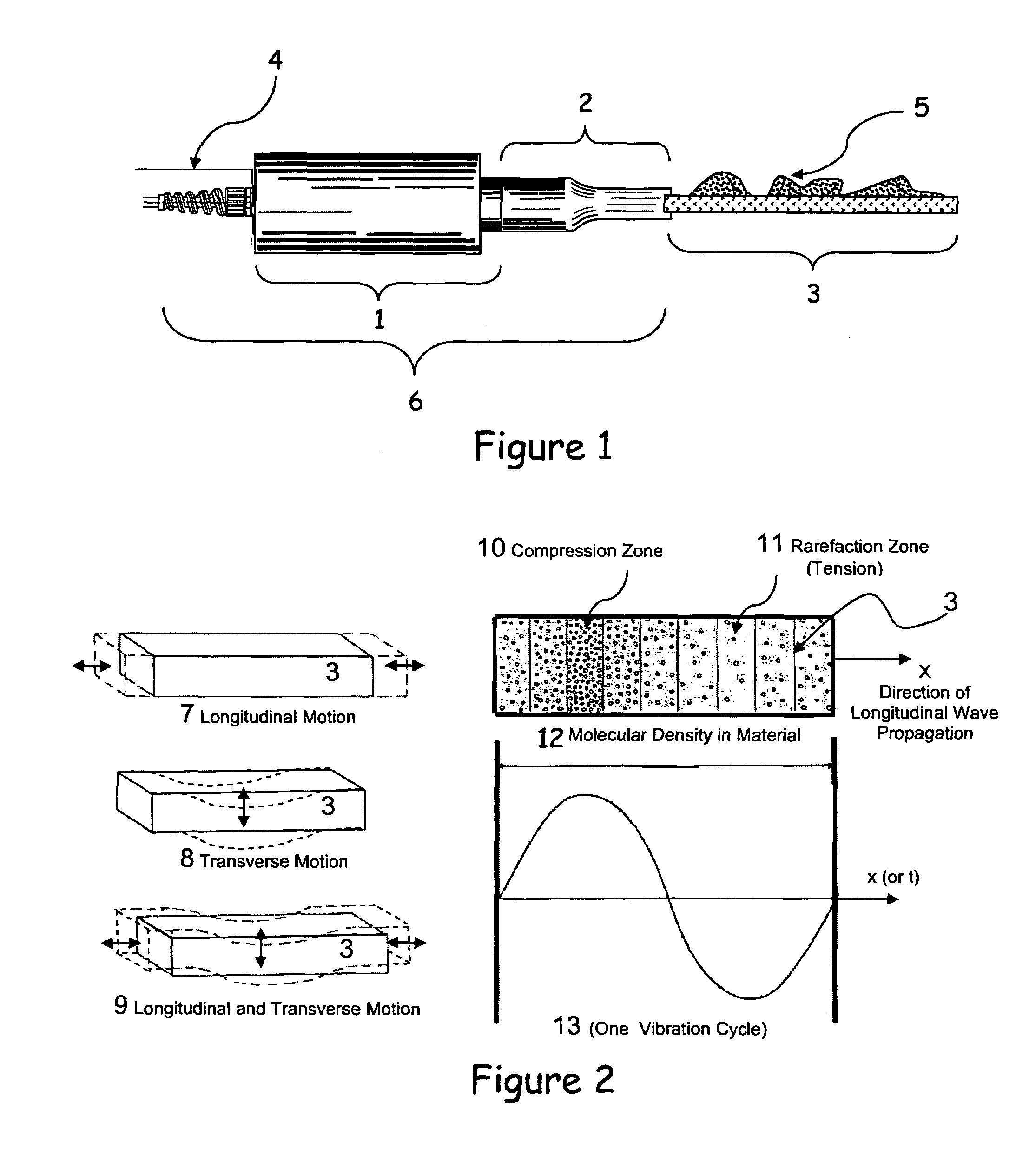

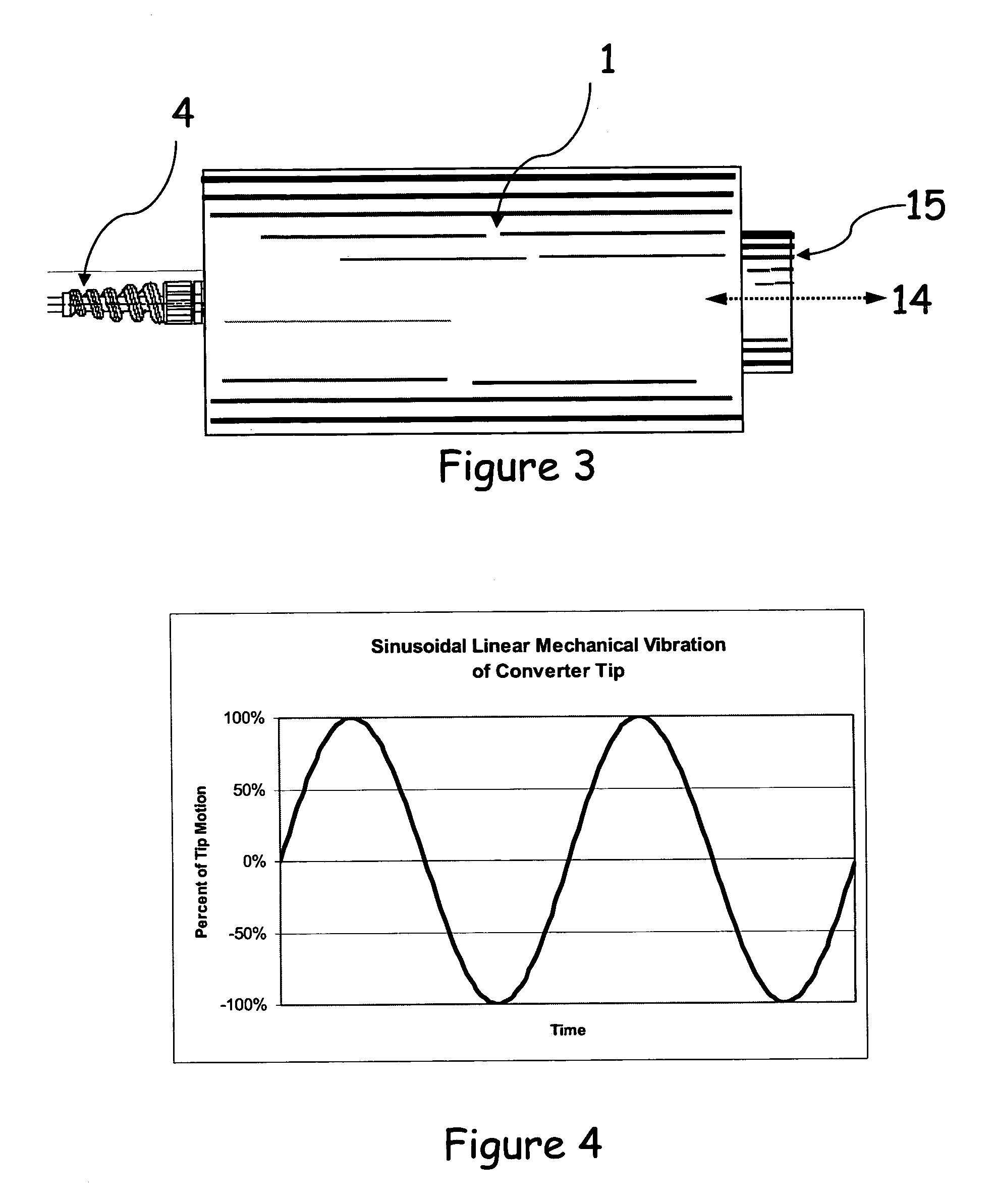

This invention relates to a device which is either permanently attached or removable to the edge of a material such as a vehicular glass window. This device may be comprised of a converter sub-unit (vibrator) and an amplifying coupler. These elements are arranged so as to propagate mechanical motion generated by the converter sub-unit through the amplifying coupler and into the edge of the attached material. The resulting vibration motion in the material, which could take the form of a longitudinal compression / rarefaction wave, transverse wave, or a combination of the two waveforms, is of a sufficient magnitude so as to cause the adhesive bond between the material's surface and other solid debris, such as ice, to be quickly broken. This allows the debris to fall away while not damaging the material. The vibration motion in the material is also of sufficient magnitude to remove a liquid such as water from the material surface.

Owner:LUDWICZAK DAMIAN R

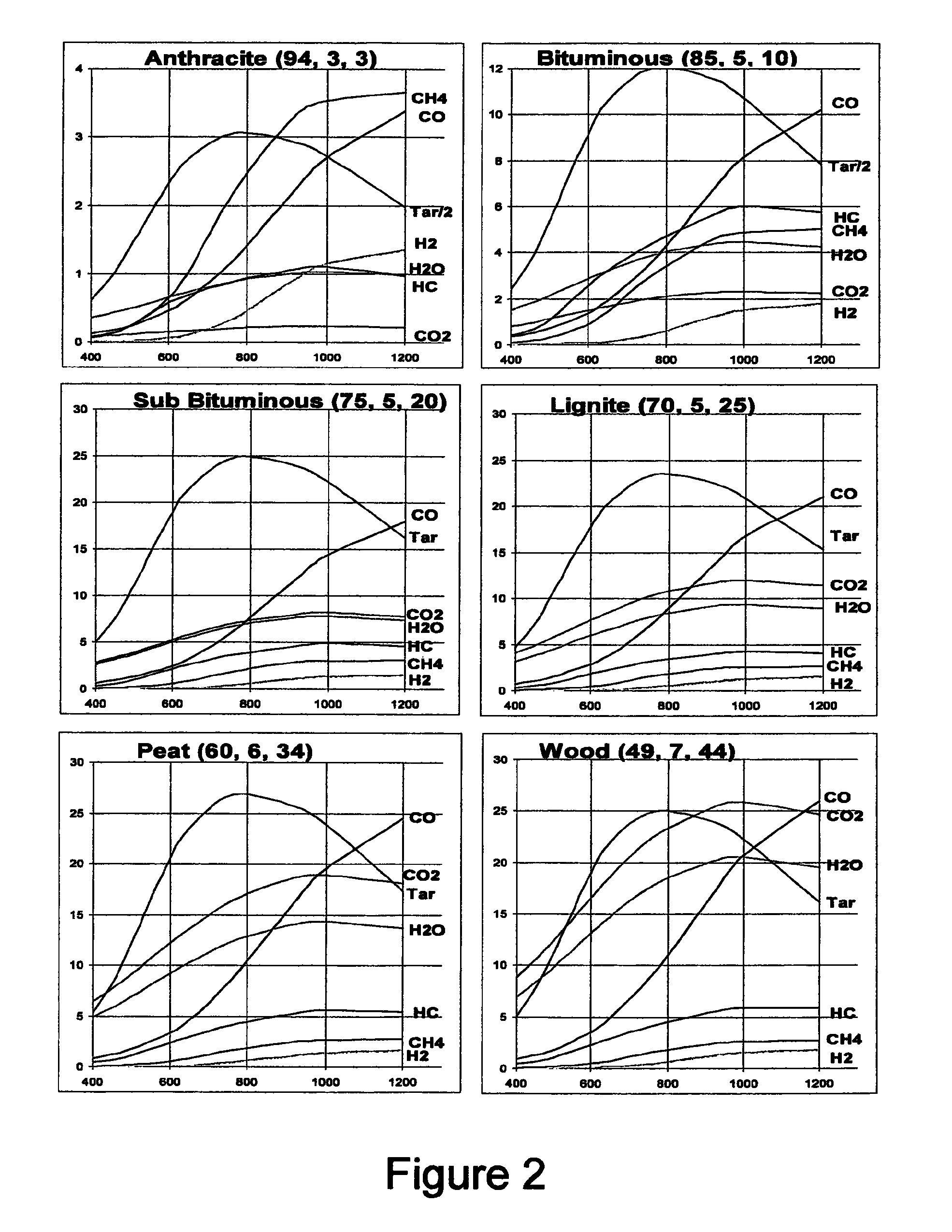

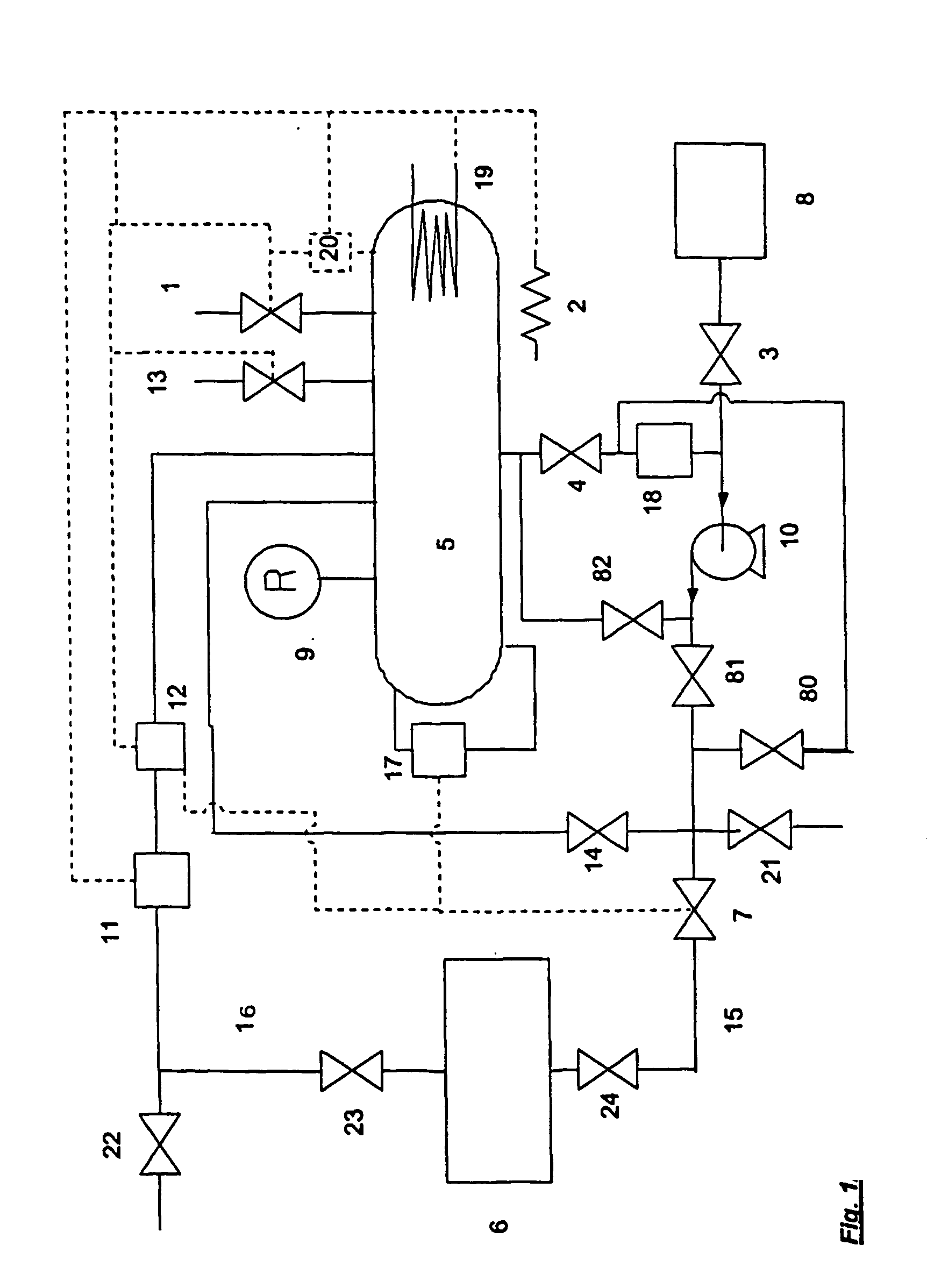

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

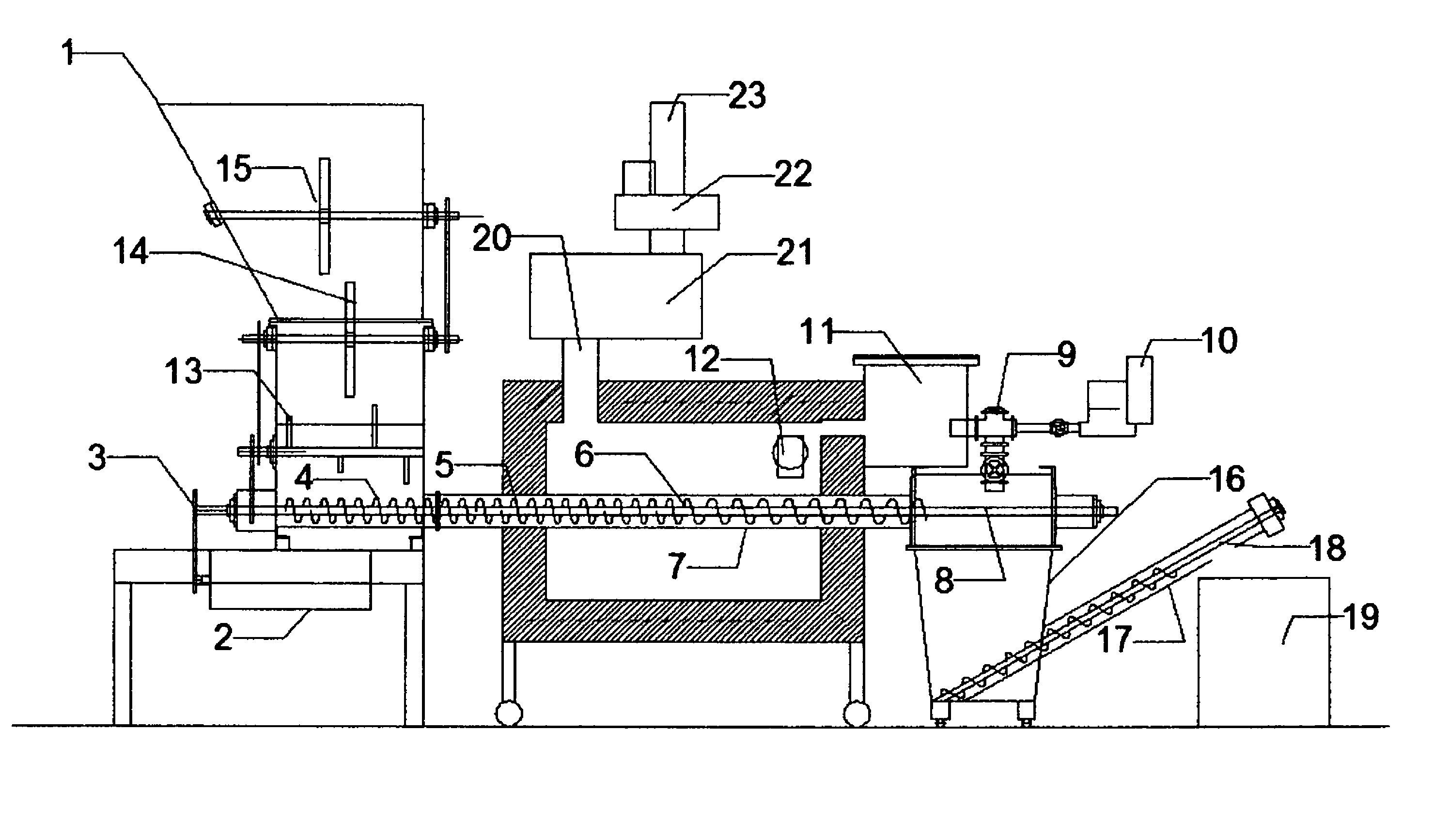

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

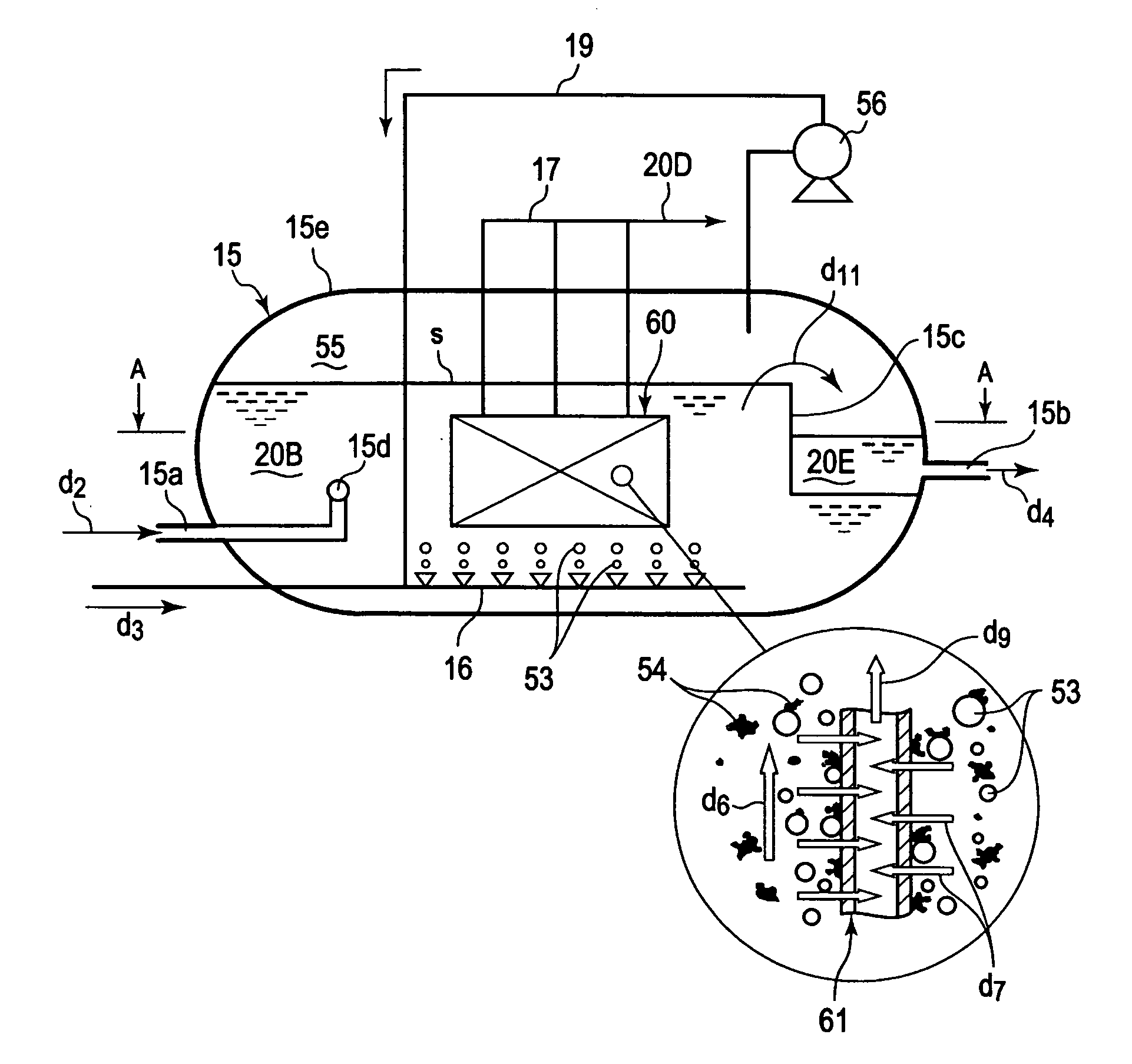

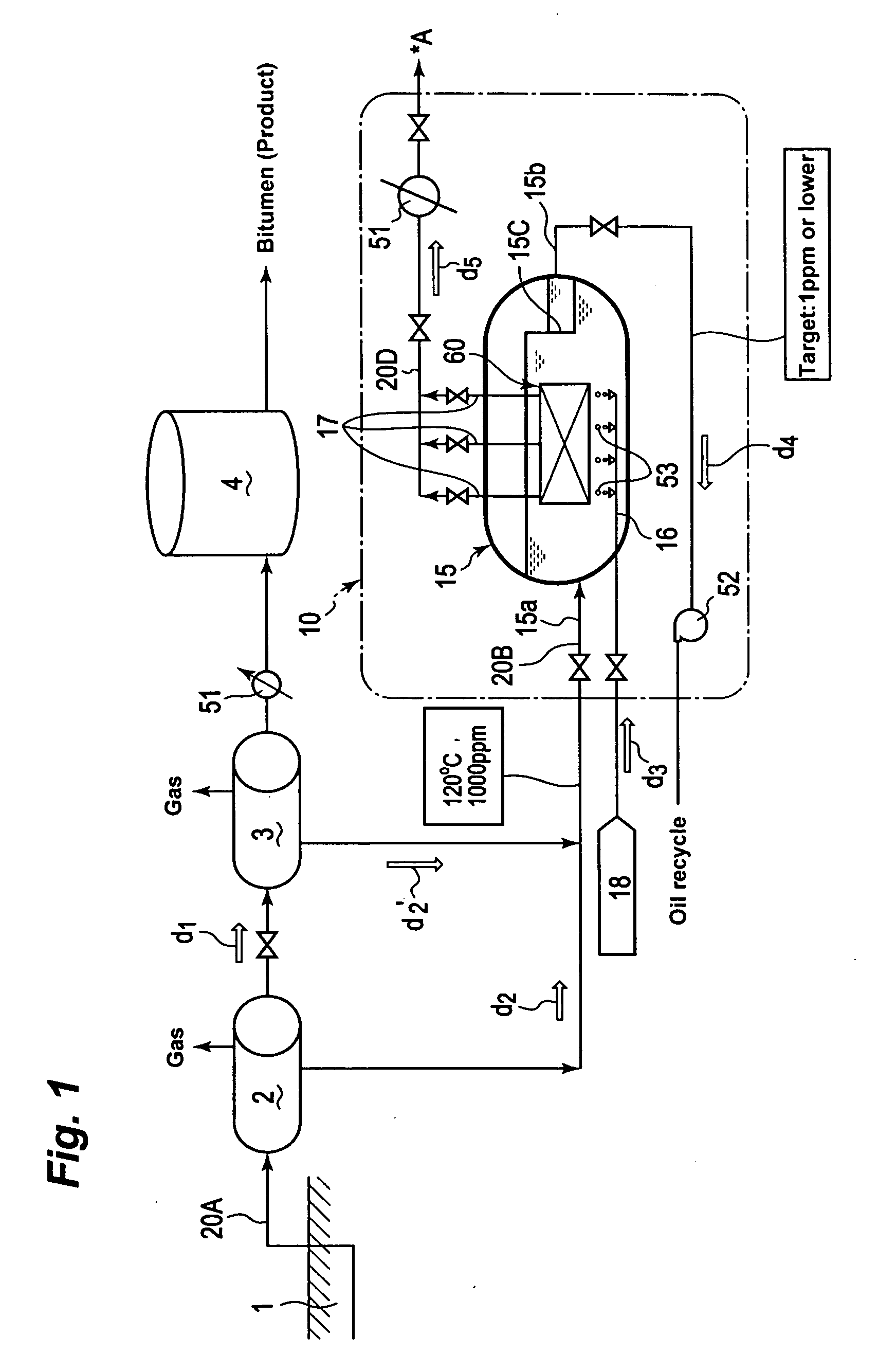

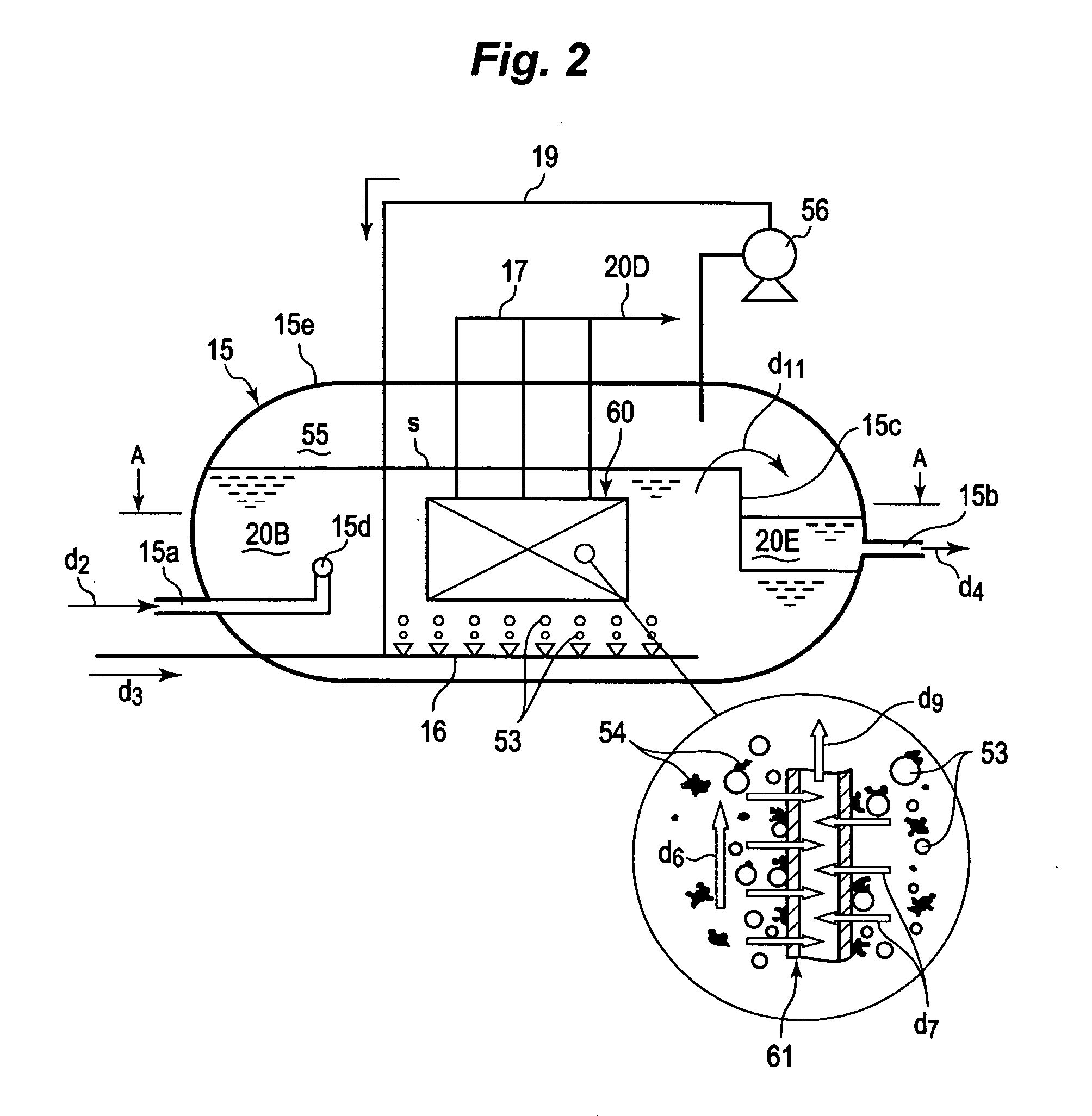

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

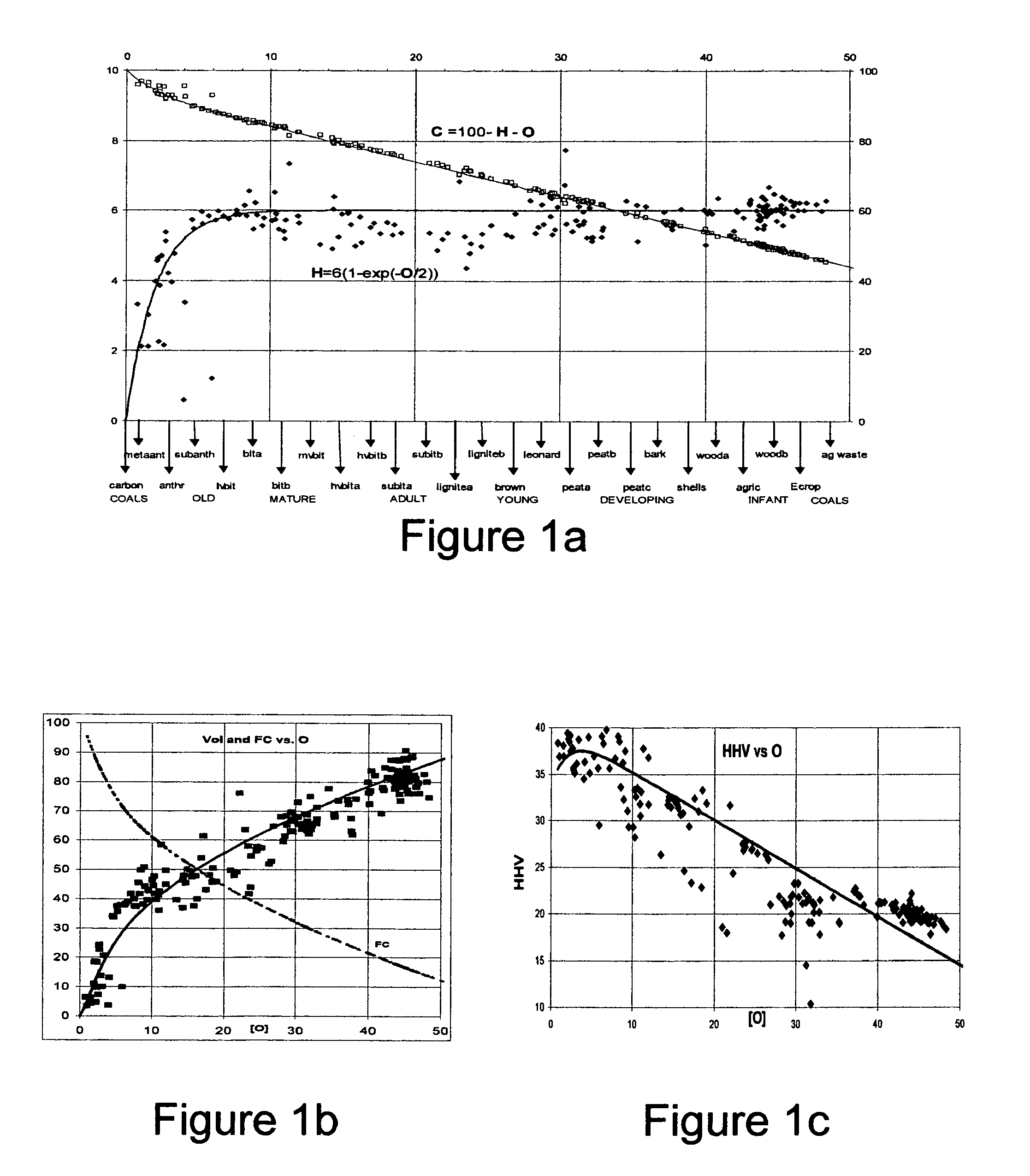

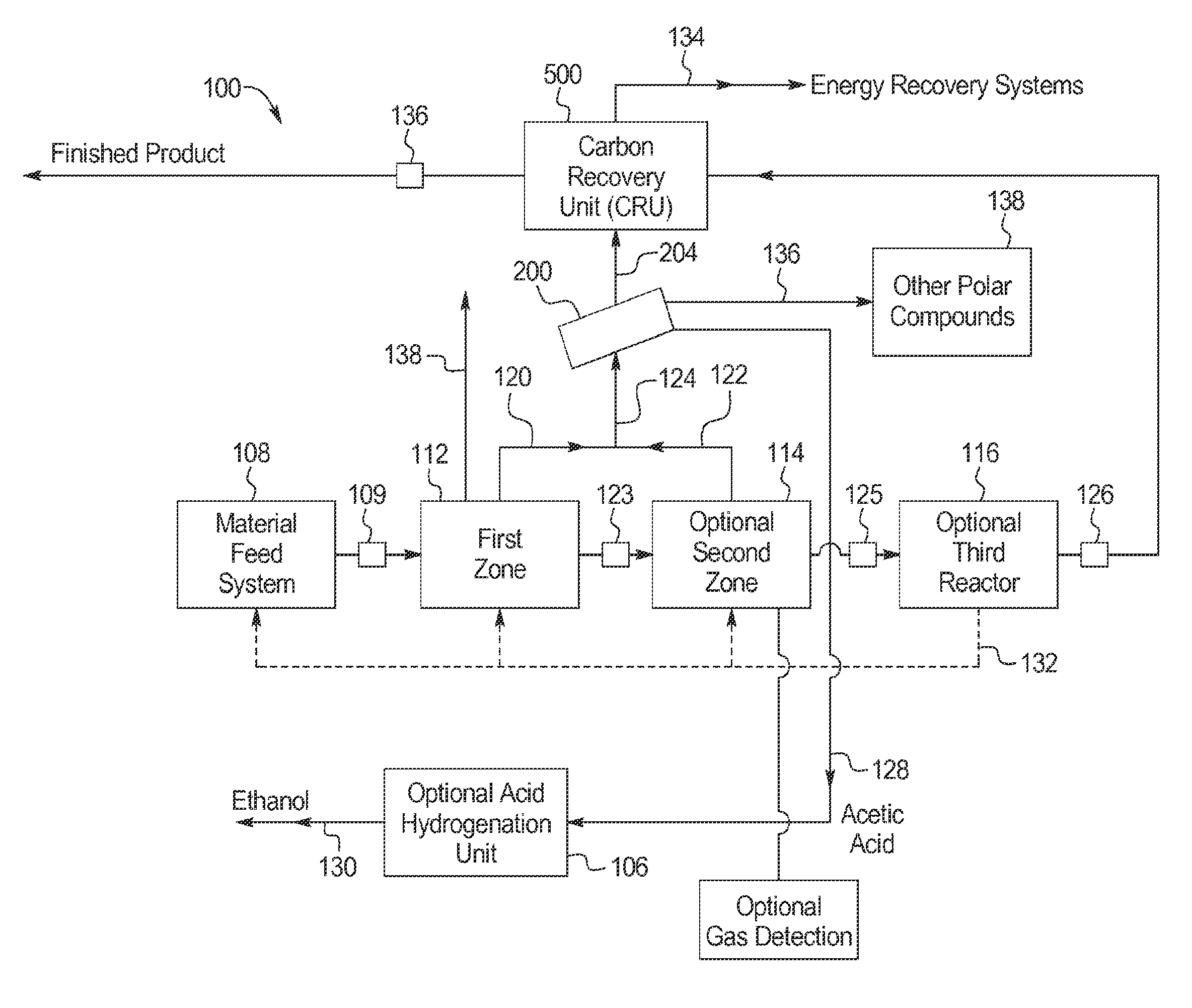

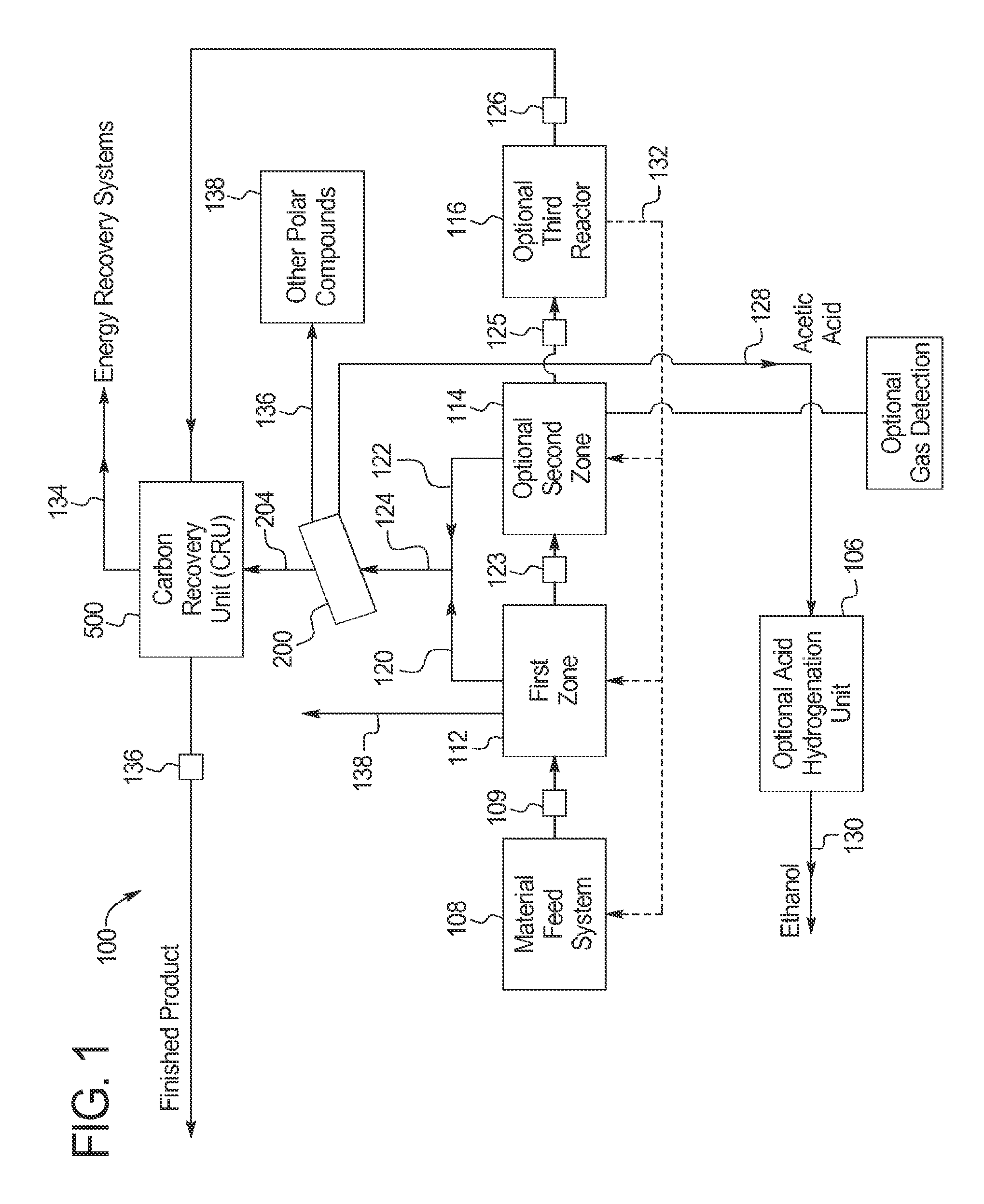

High-carbon biogenic reagents and uses thereof

ActiveUS20120285080A1High carbon contentImprove energy efficiencyCoke quenchingCoke oven safety devicesHigh carbonReagent

This invention provides processes and systems for converting biomass into high-carbon biogenic reagents that are suitable for a variety of commercial applications. High carbon biogenic reagents are also provided.

Owner:CARBON TECH HLDG LLC

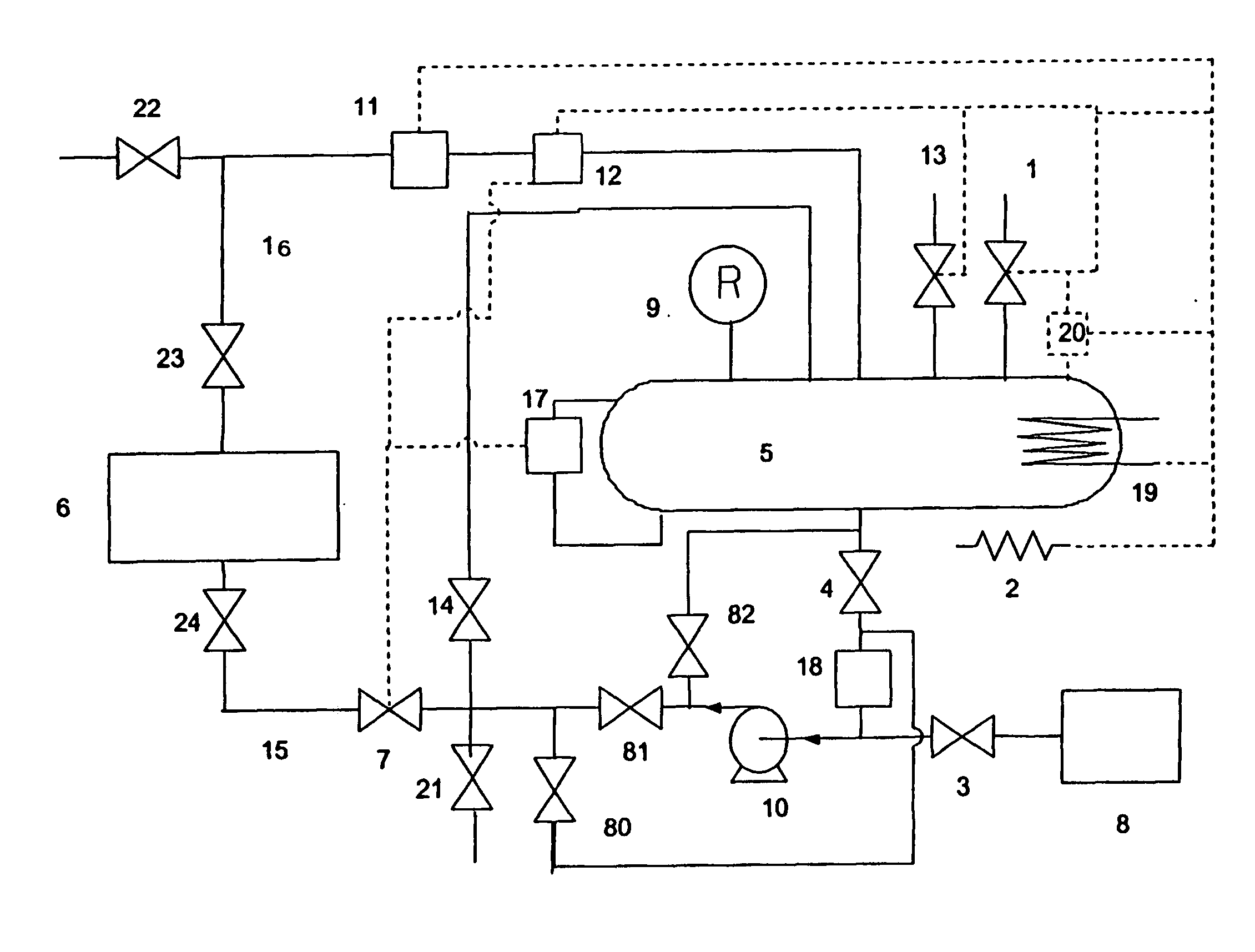

Safe and automatic method for preparation of coke for removal from a coke vessel

InactiveUS7037408B2Prevent leakageReduces and eliminates dangerousThermal non-catalytic crackingDirect heating destructive distillationSteam pressureDrill

A safe, efficient and repetitively operable coke vessel decoking system is disclosed. In a preferred embodiment the closed system comprises a coker vessel pressure-tightly sealed to a top head system, which includes a closure housing with a laterally moveable horizontal closure member therein and a cutting head enclosure, which further comprises a drill stem guide, an access door, and a cutting assembly mounted therein. A novel feature of the invention is a steam purge / blocking system whereby steam pressure is maintained in the closure housing during the coking cycle to maintain seal integrity. Personnel safety during decoking operations is greatly enhanced by eliminating dangerous manual tasks associated with the prior art such as unbolting and removing top head devices. The system can be remotely and repetitively operated through numerous coking / decoking cycles without removal of any system element.

Owner:CHEVROU USA INC

Unmanned vehicle comprising a protection device

ActiveUS20110185975A1Save energyImprove securityElectric devicesPedestrian/occupant safety arrangementElectrical conductorEngineering

Unmanned vehicle to carry out an animal-related action, provided with a frame and a control device to control the vehicle and a locomotion device to move the unmanned vehicle, and with a protective device to protect the vehicle against obstacles, wherein the protective device includes a touchable electrical conductor which extends on the outside of, advantageously around, the vehicle, and a voltage source to supply voltage to the conductor under the control of the control device.

Owner:LELY PATENT

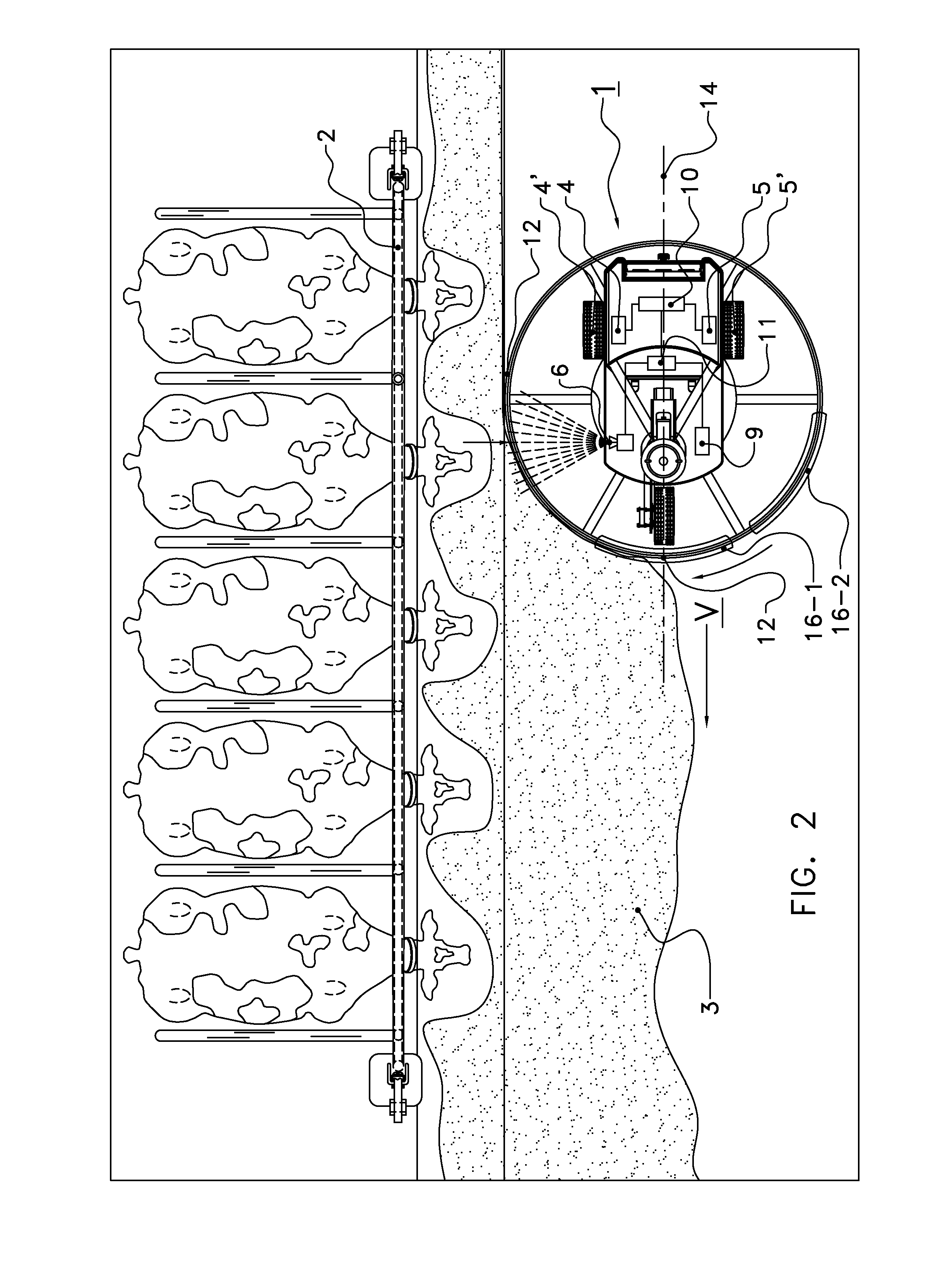

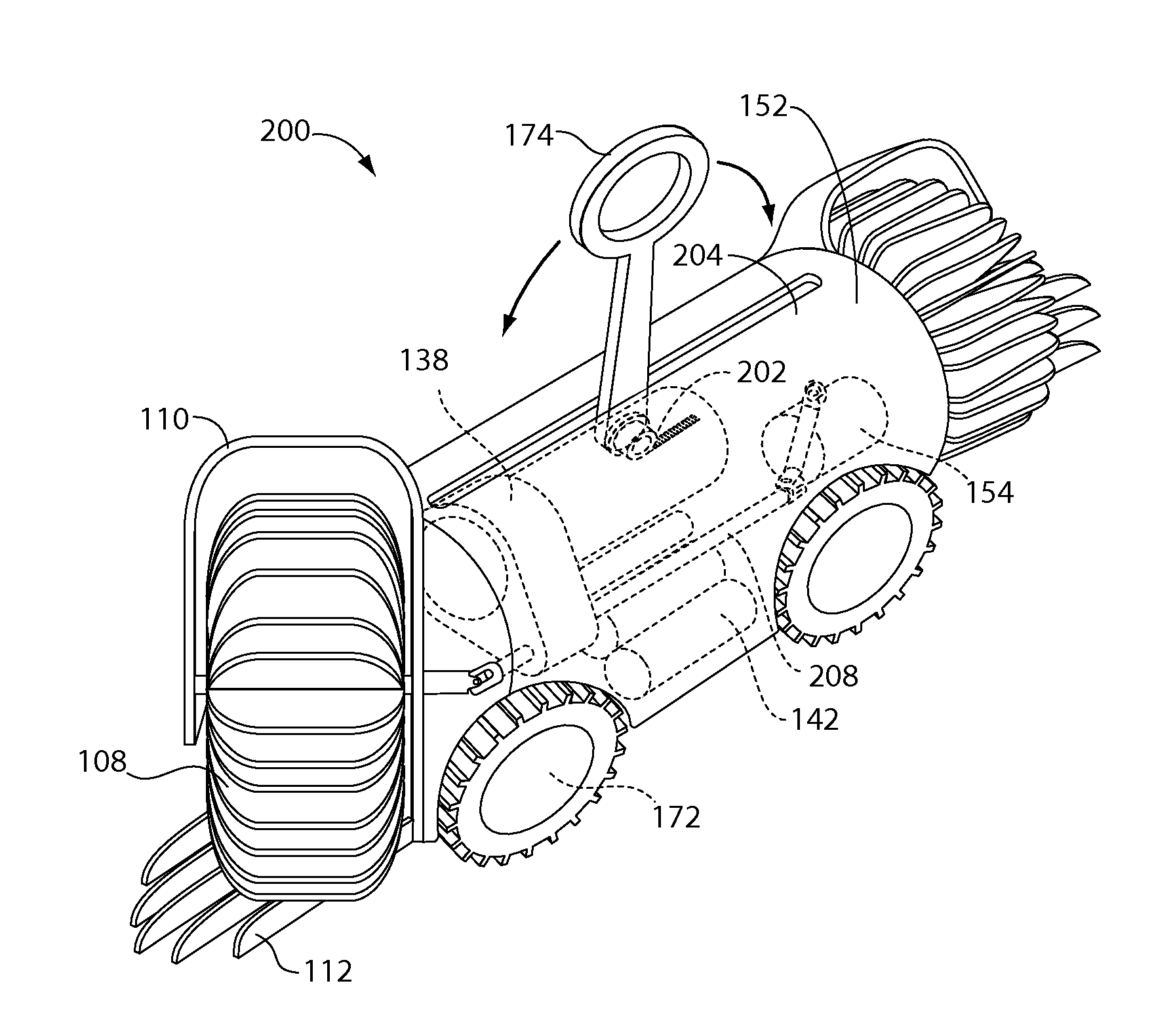

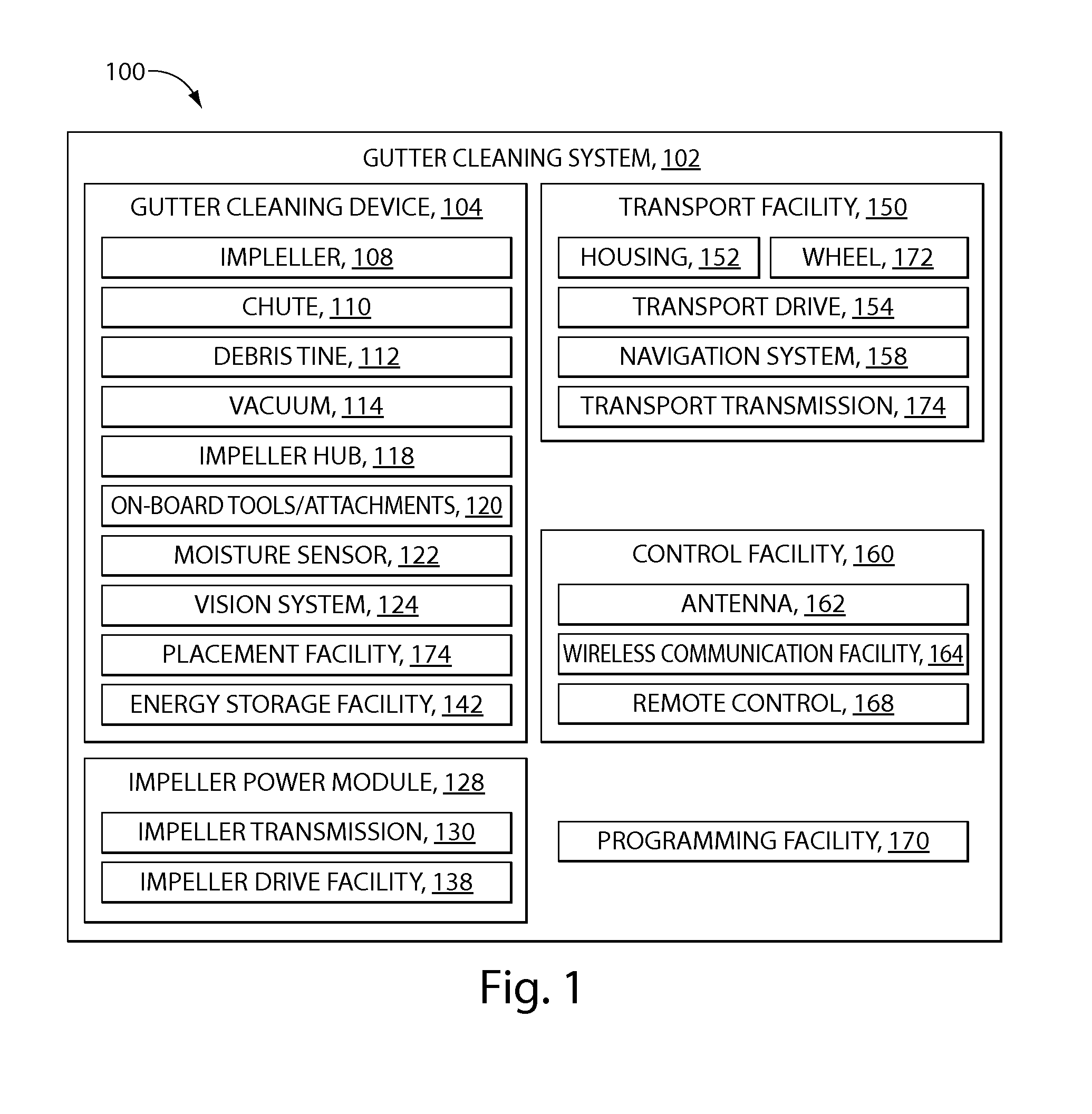

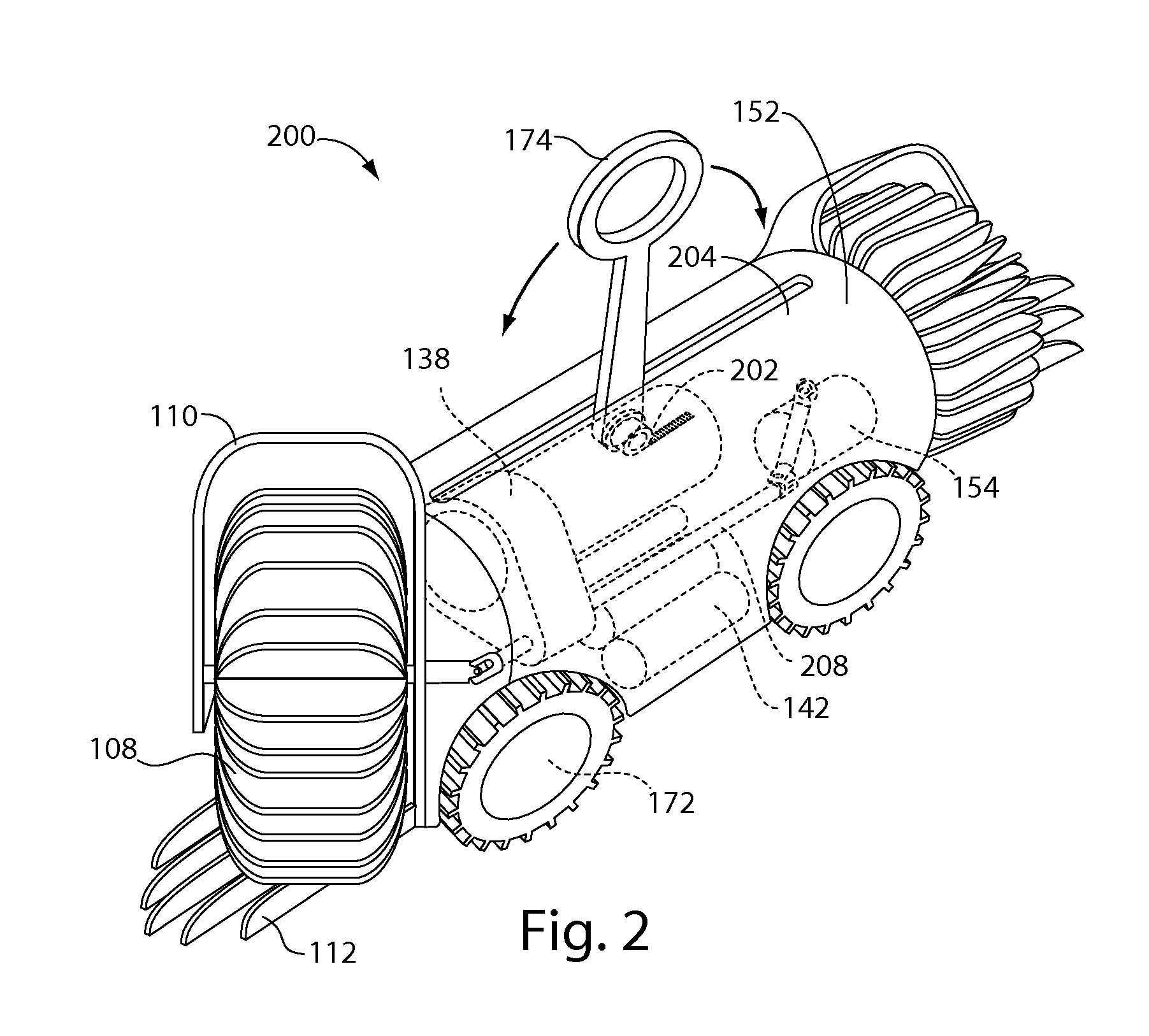

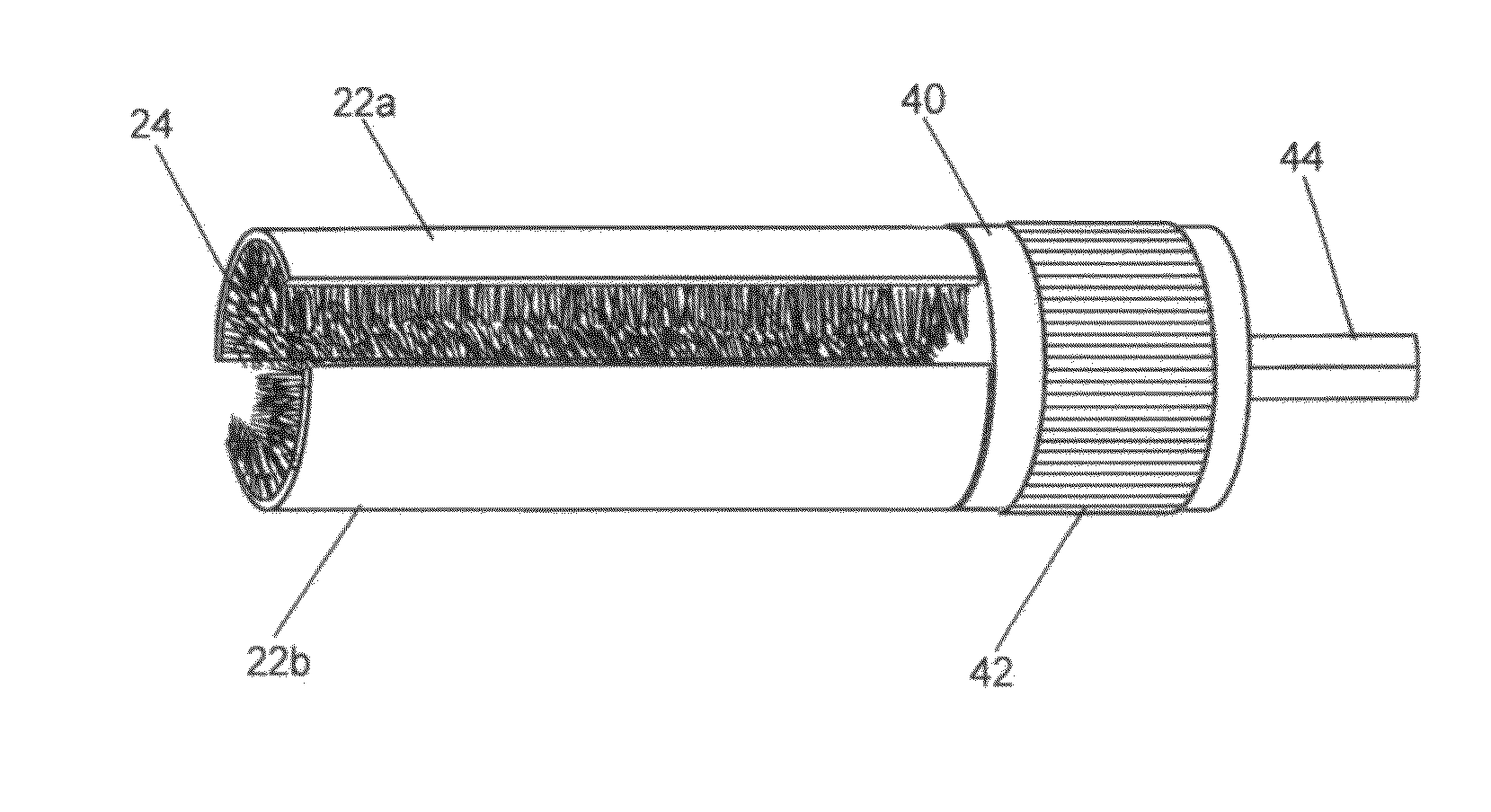

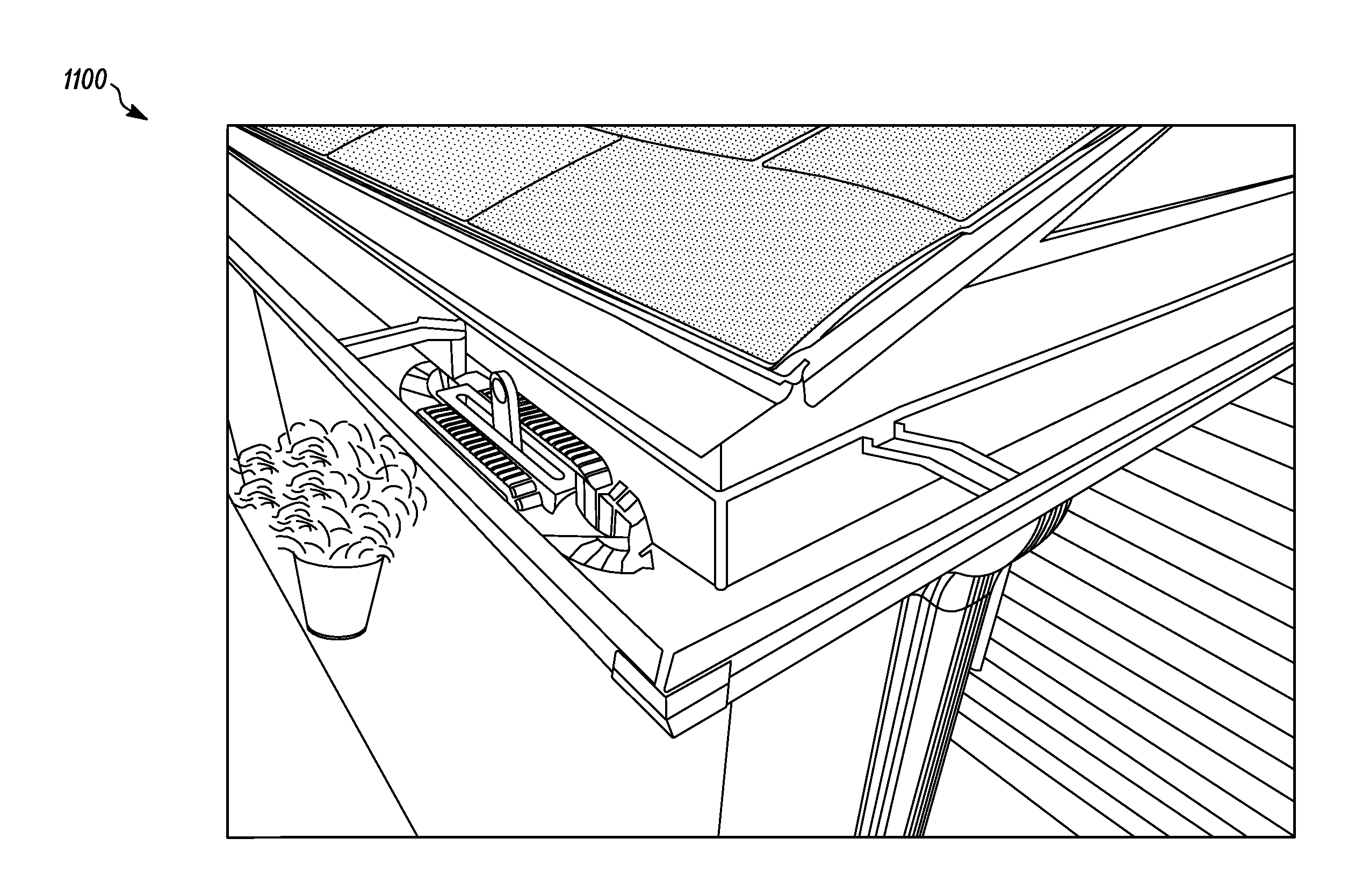

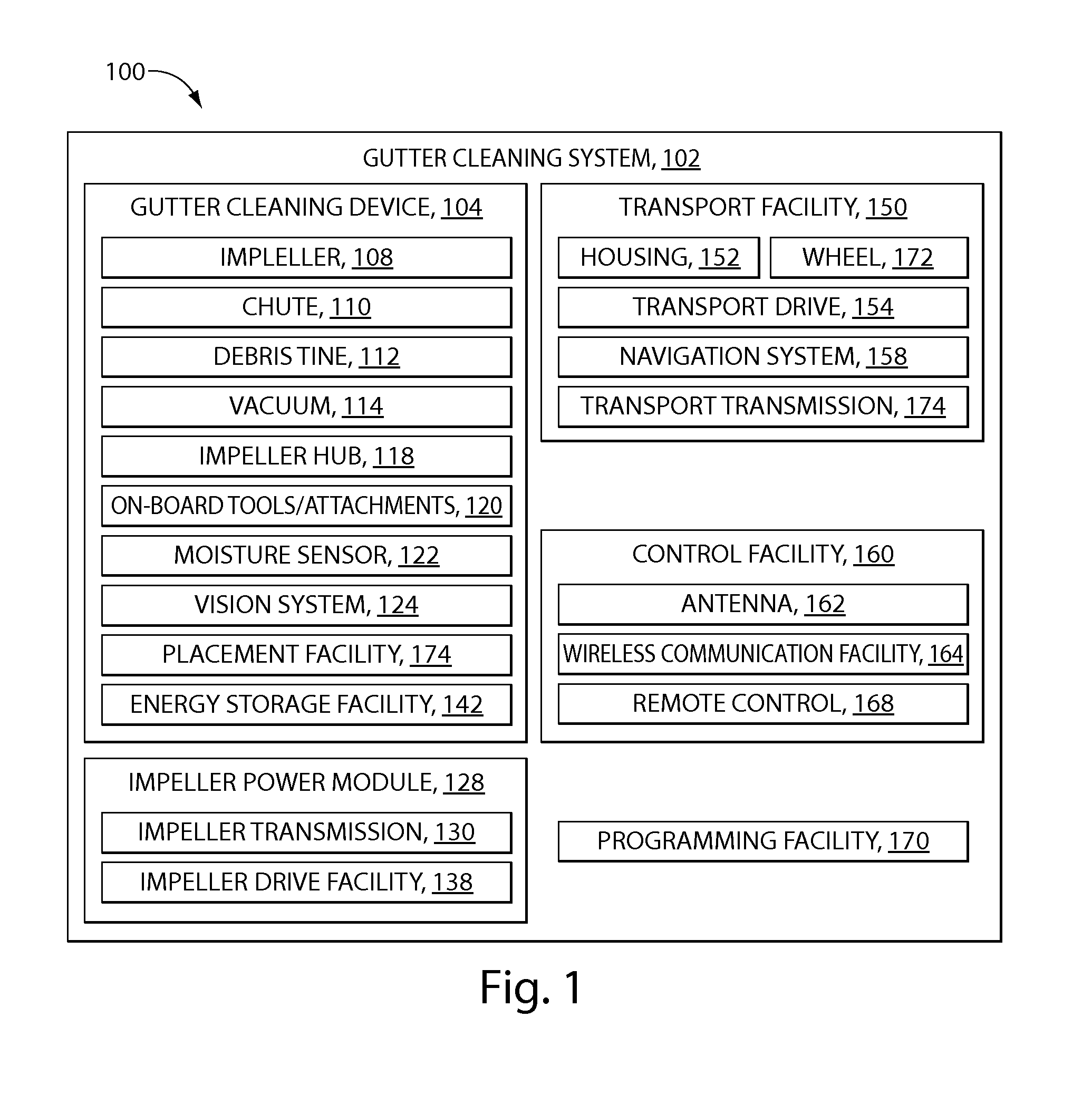

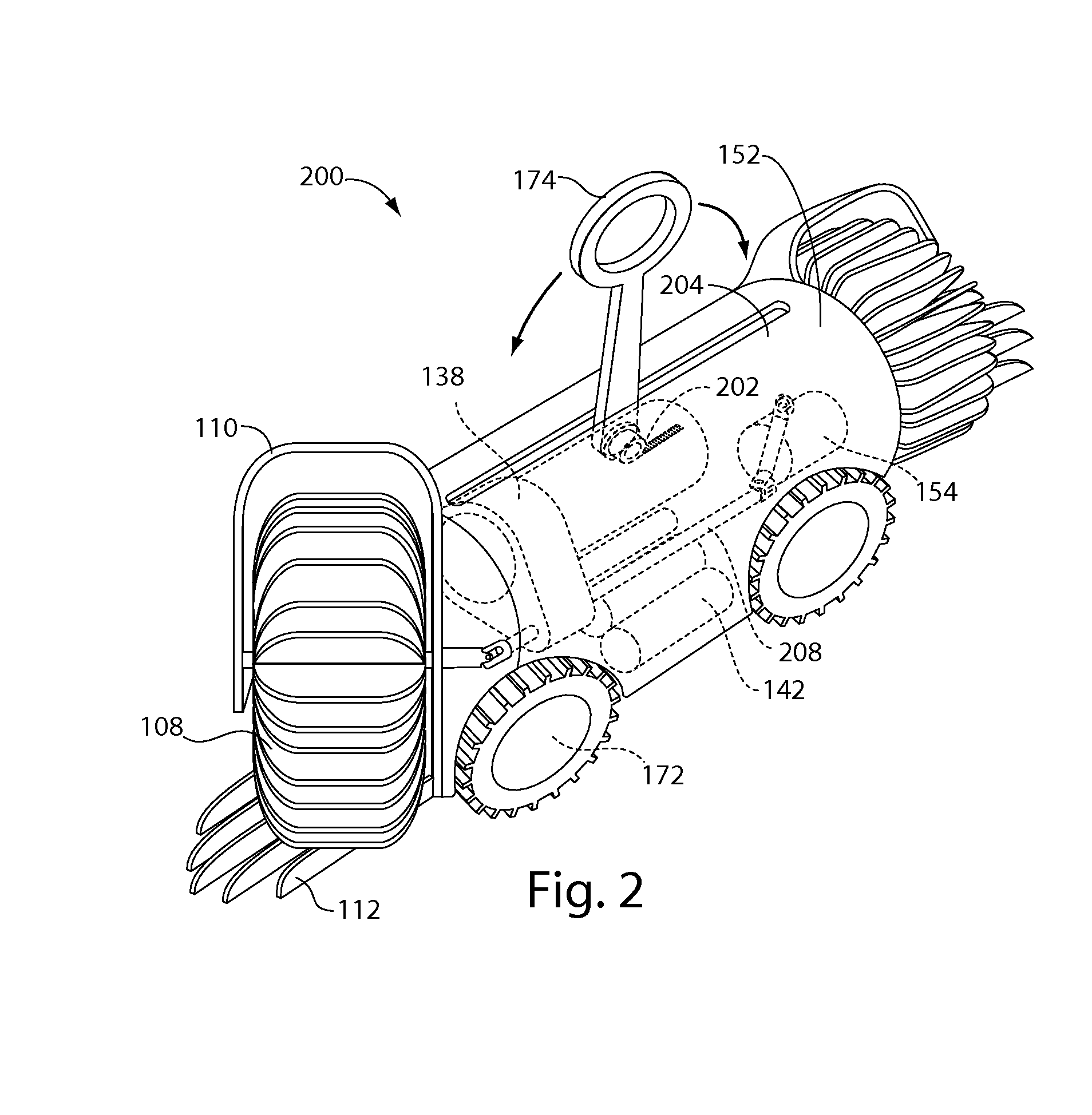

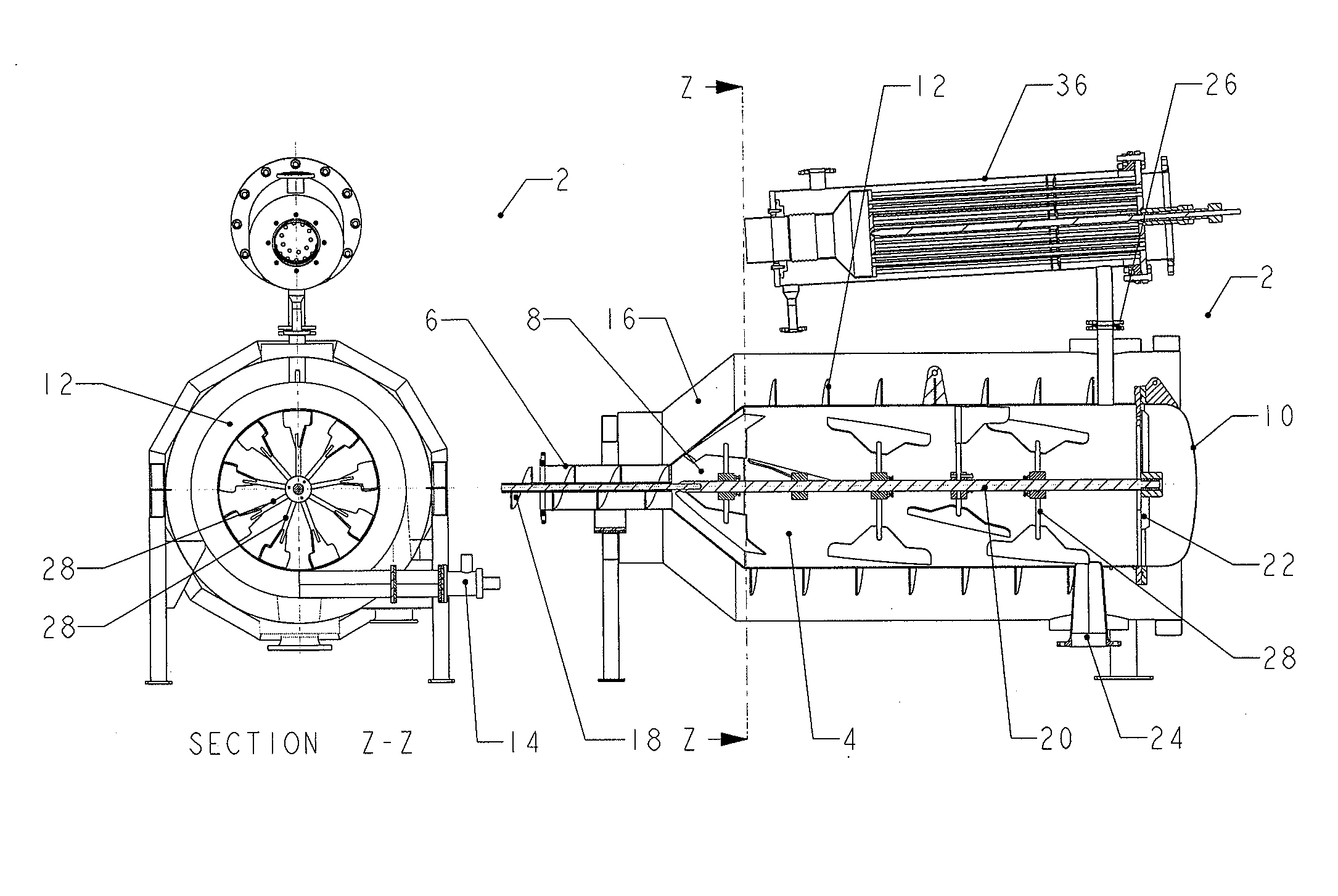

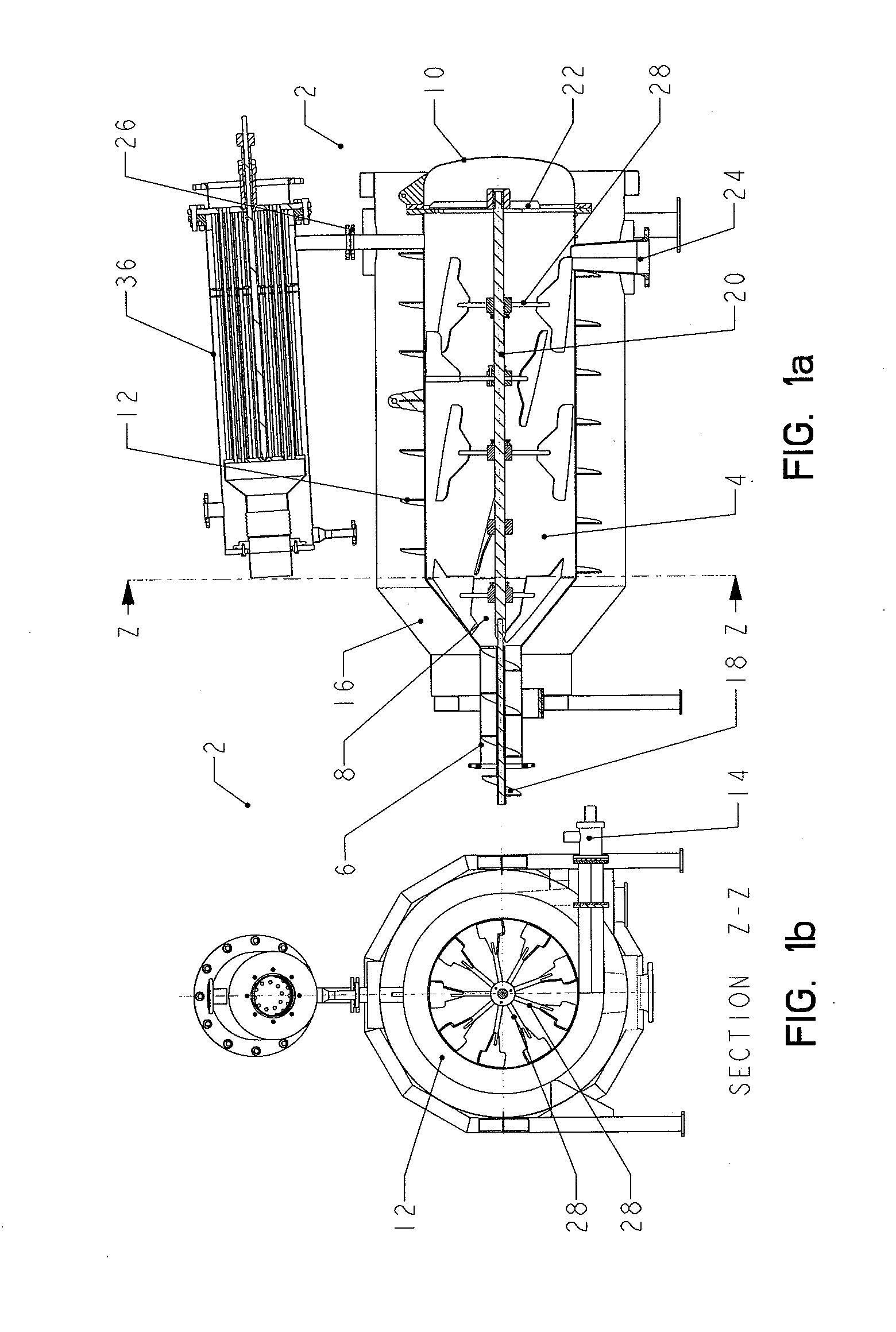

Systems and methods for robotic gutter cleaning along an axis of rotation

In embodiments of the present invention, a gutter-cleaning device comprises a housing containing an impeller drive facility, the housing configured to fit into a gutter, an impeller, disposed at an end of the housing and driven by the impeller drive facility, and a transport facility for transporting the housing along the gutter. The impeller may have an axis of rotation, the axis of rotation oriented toward an inside corner of the gutter and the impeller drive facility may be adapted to rotate the impeller on the axis of rotation. Transport of the housing through the gutter may cause the impeller to travel along an axis of motion, the axis of motion differing from the axis of rotation.

Owner:IROBOT CORP

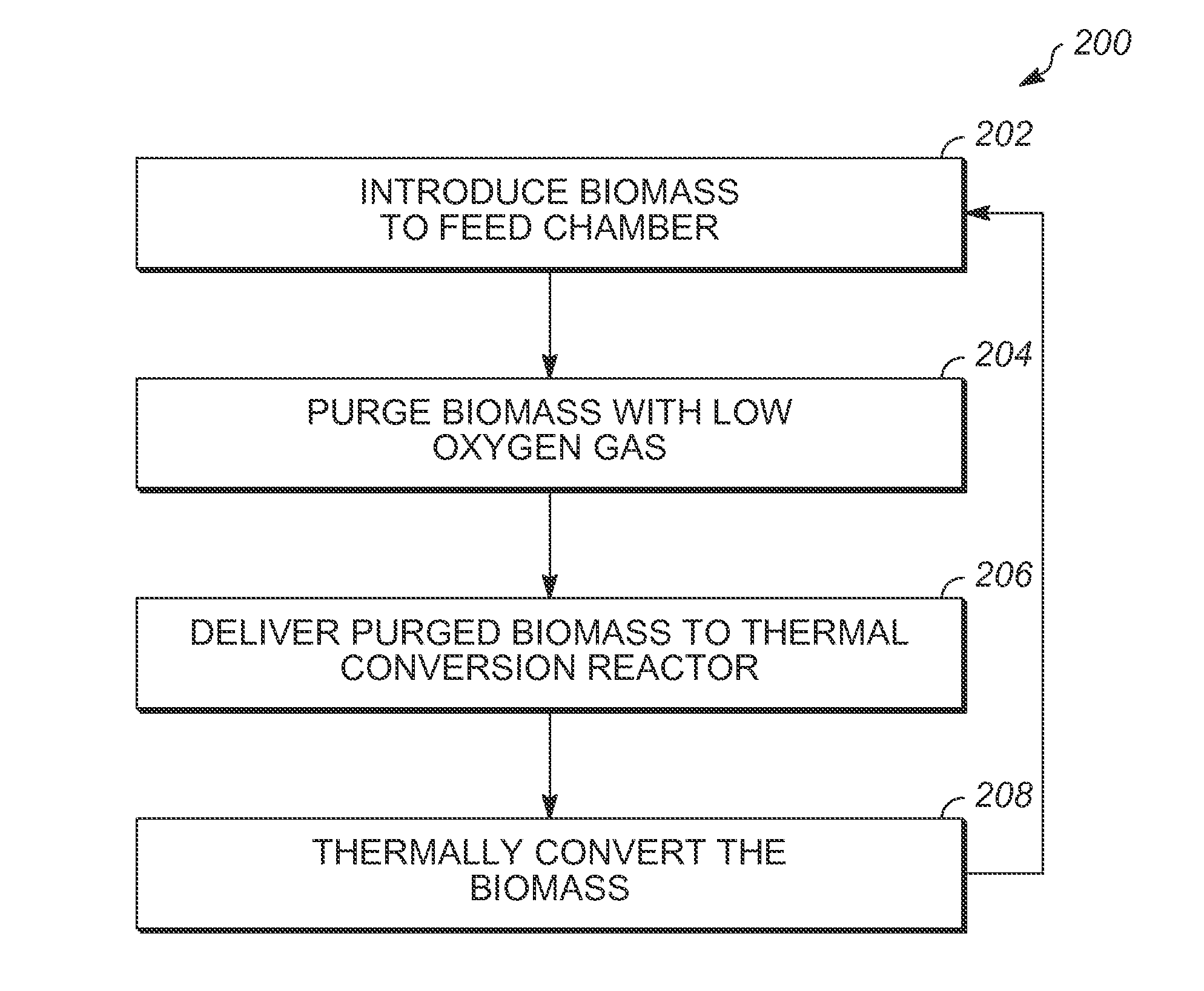

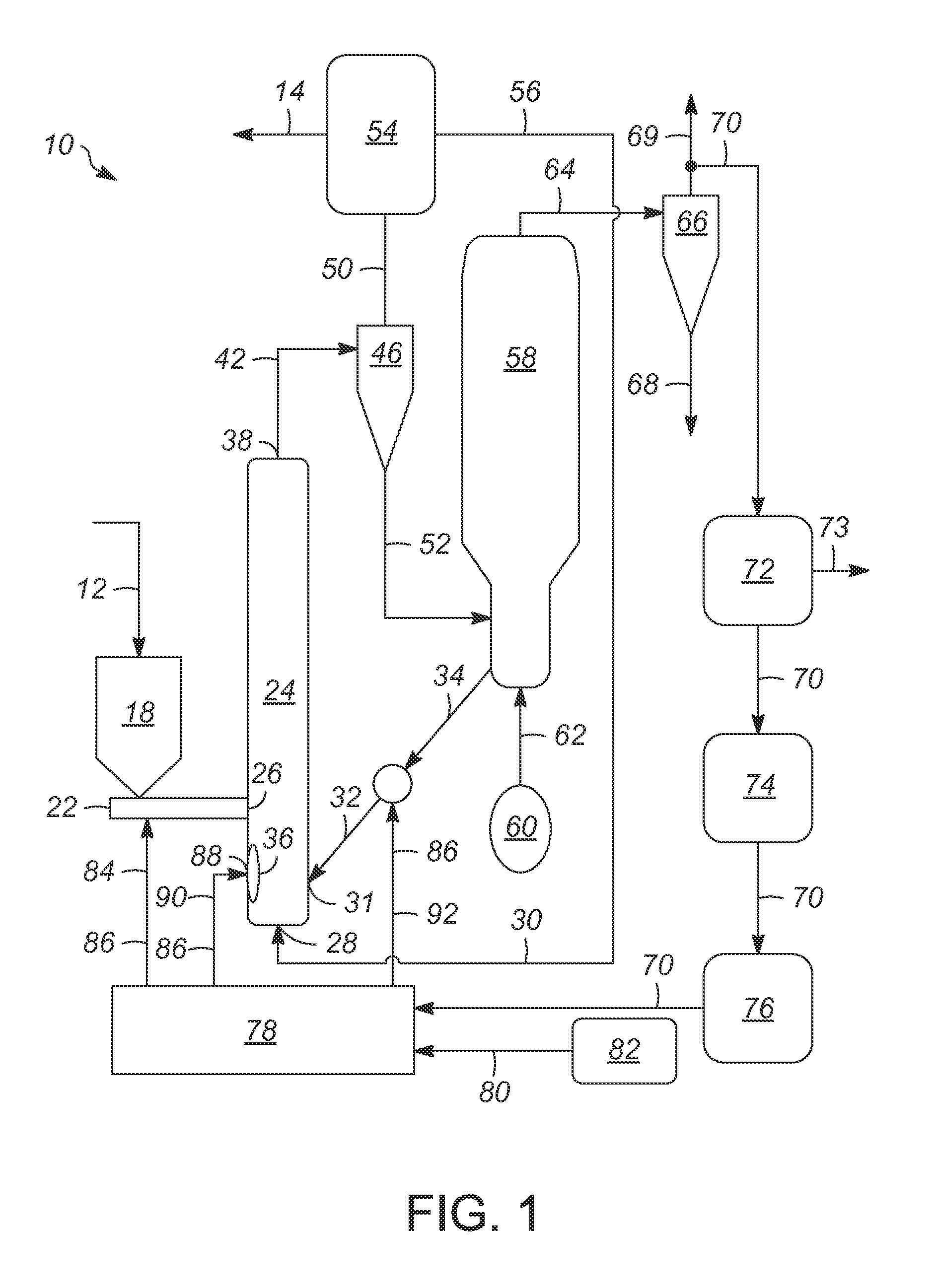

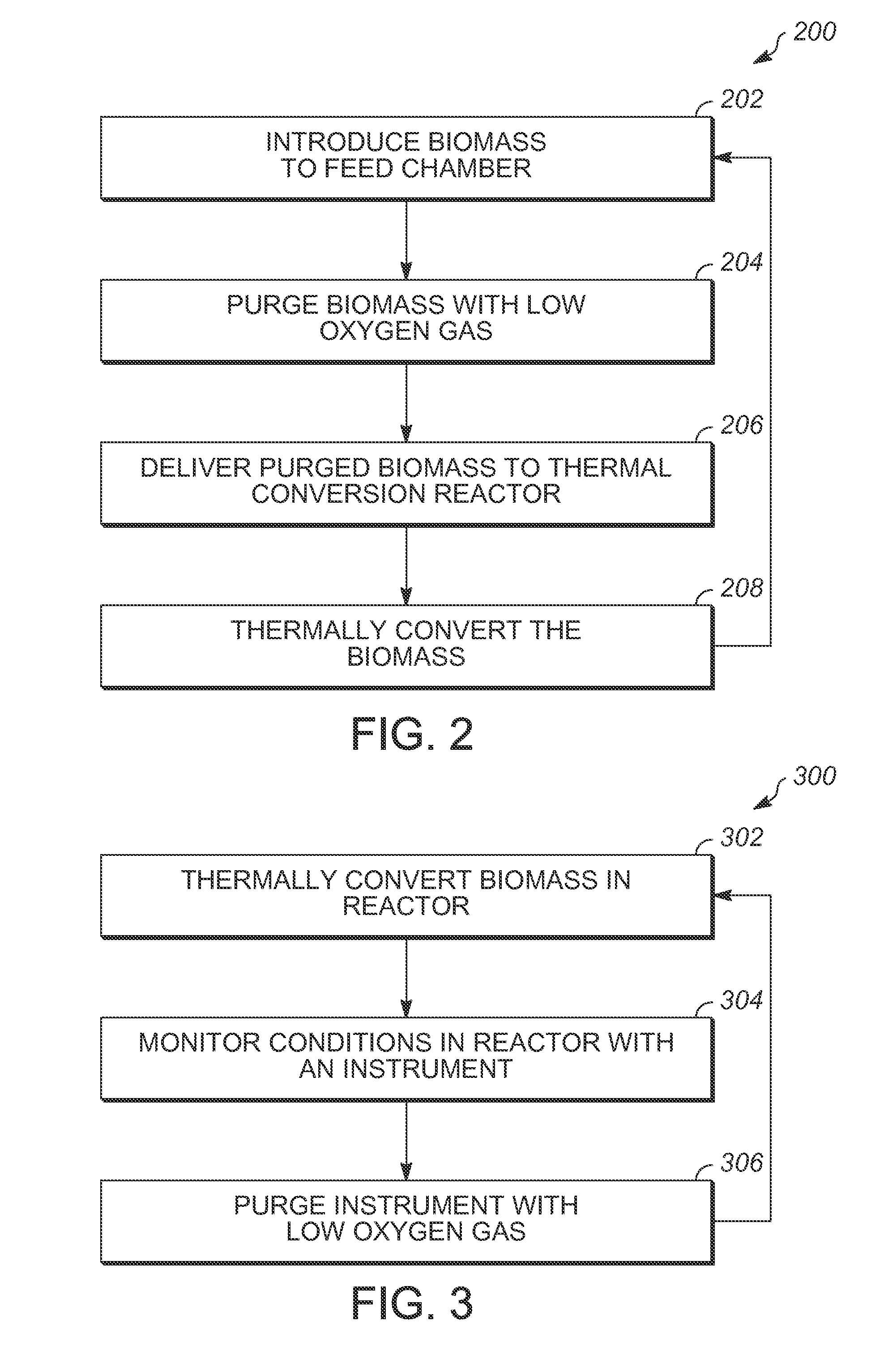

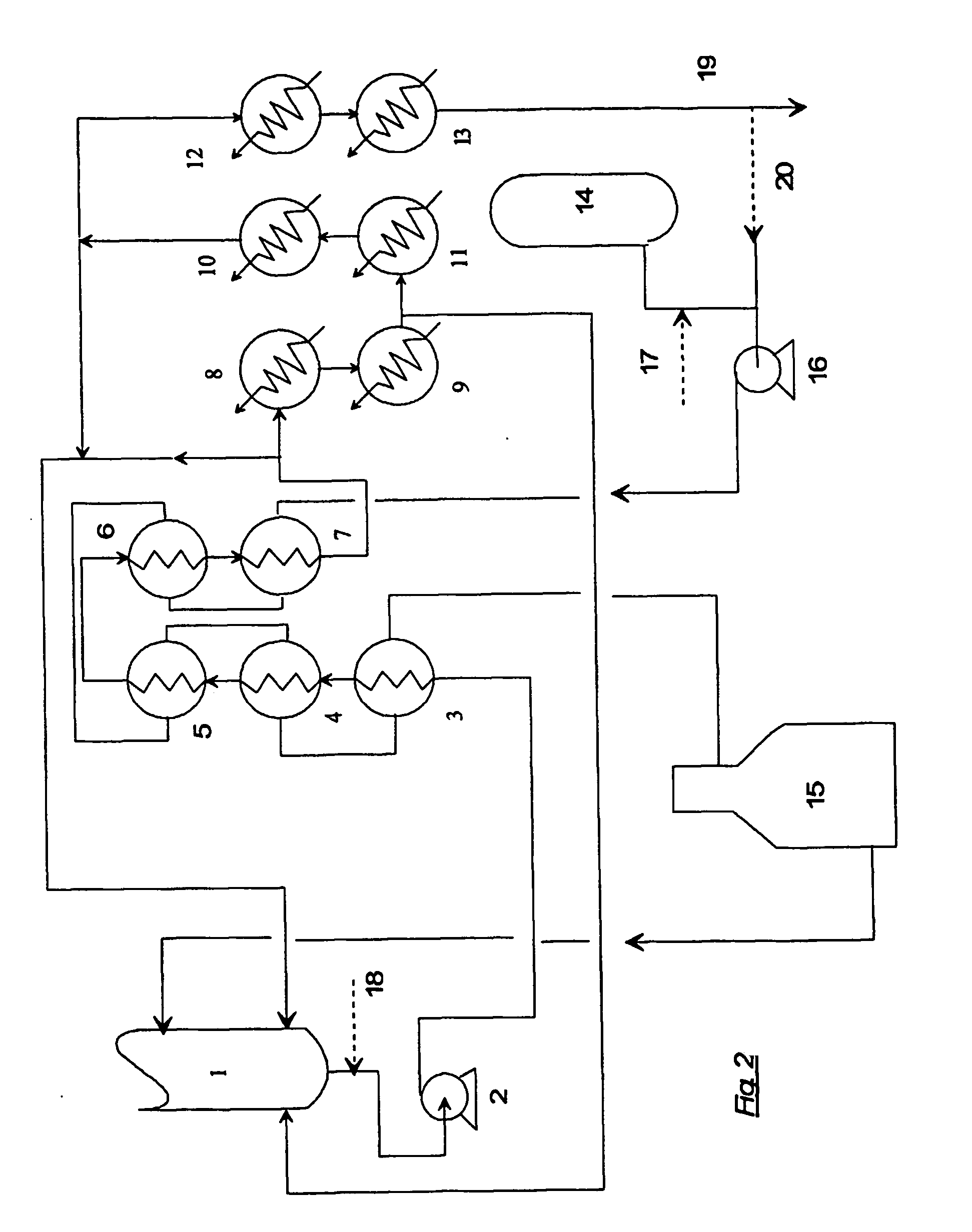

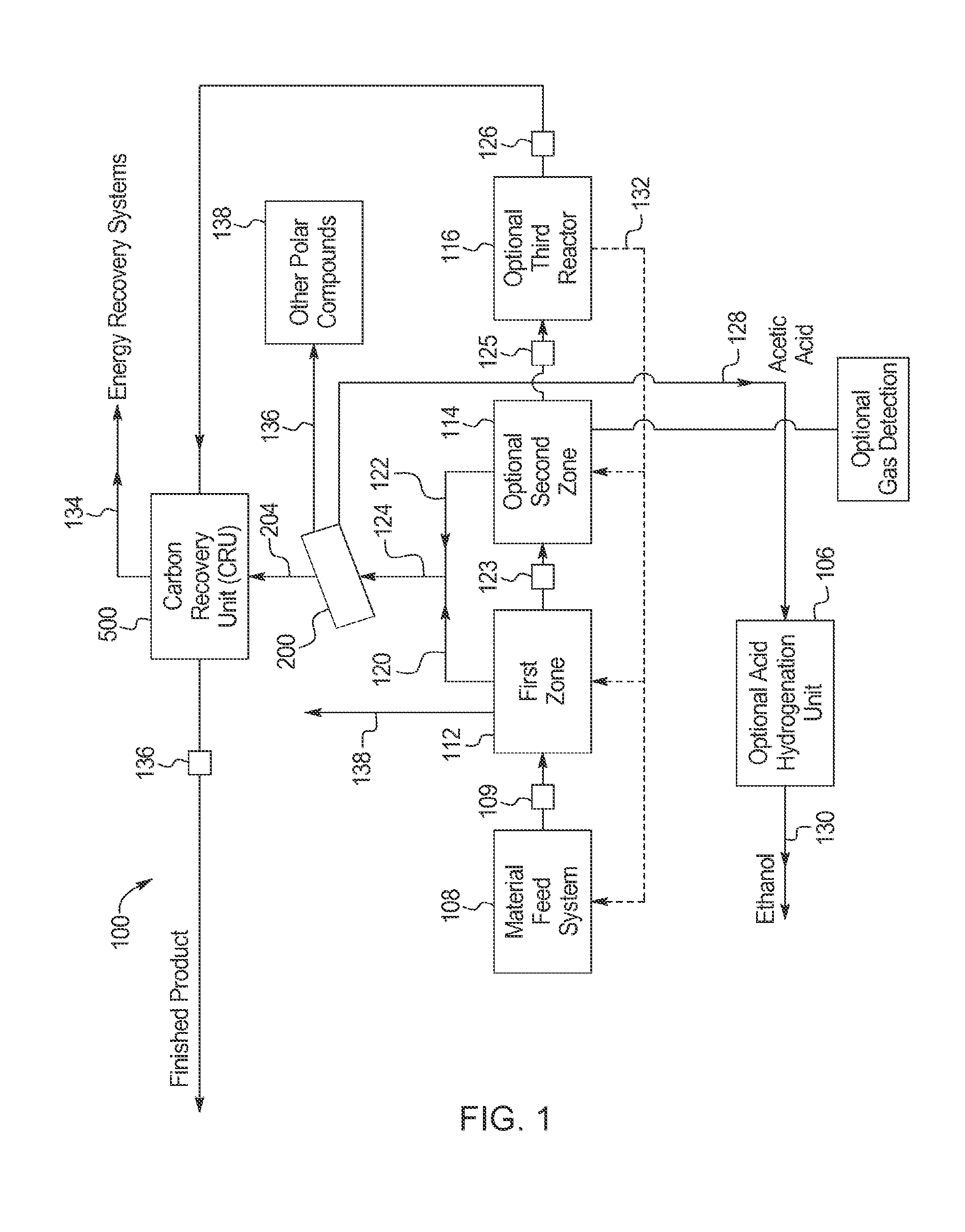

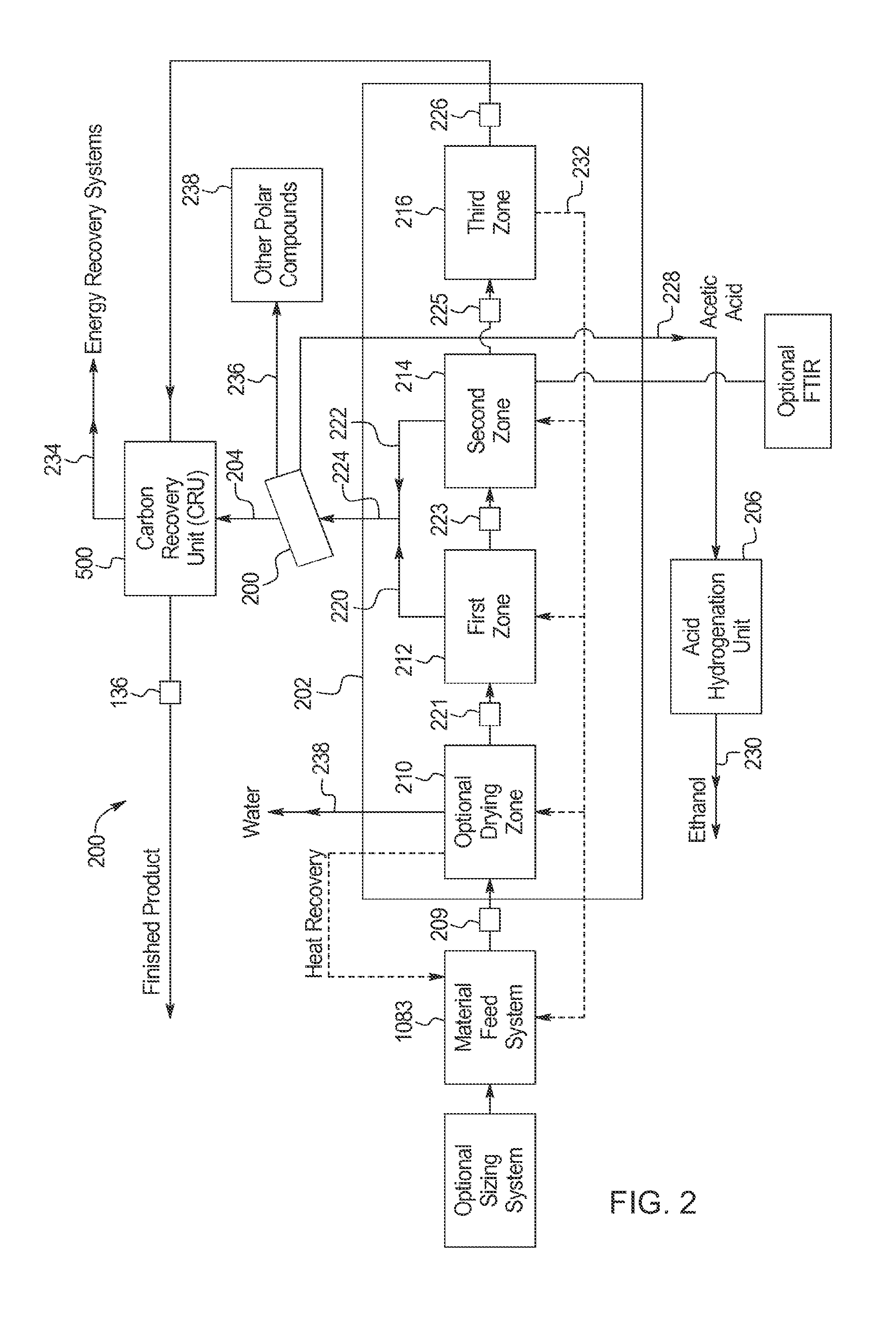

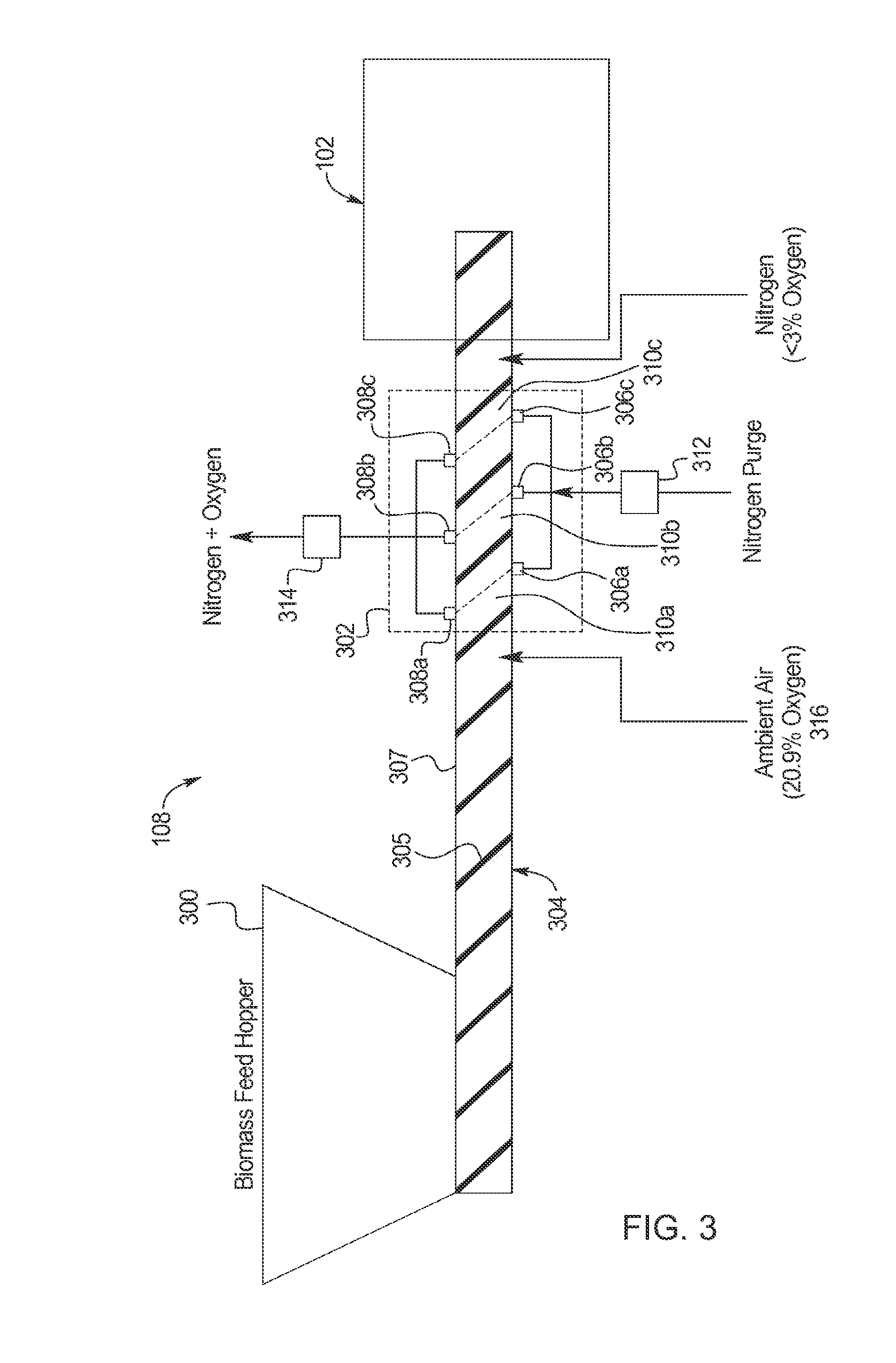

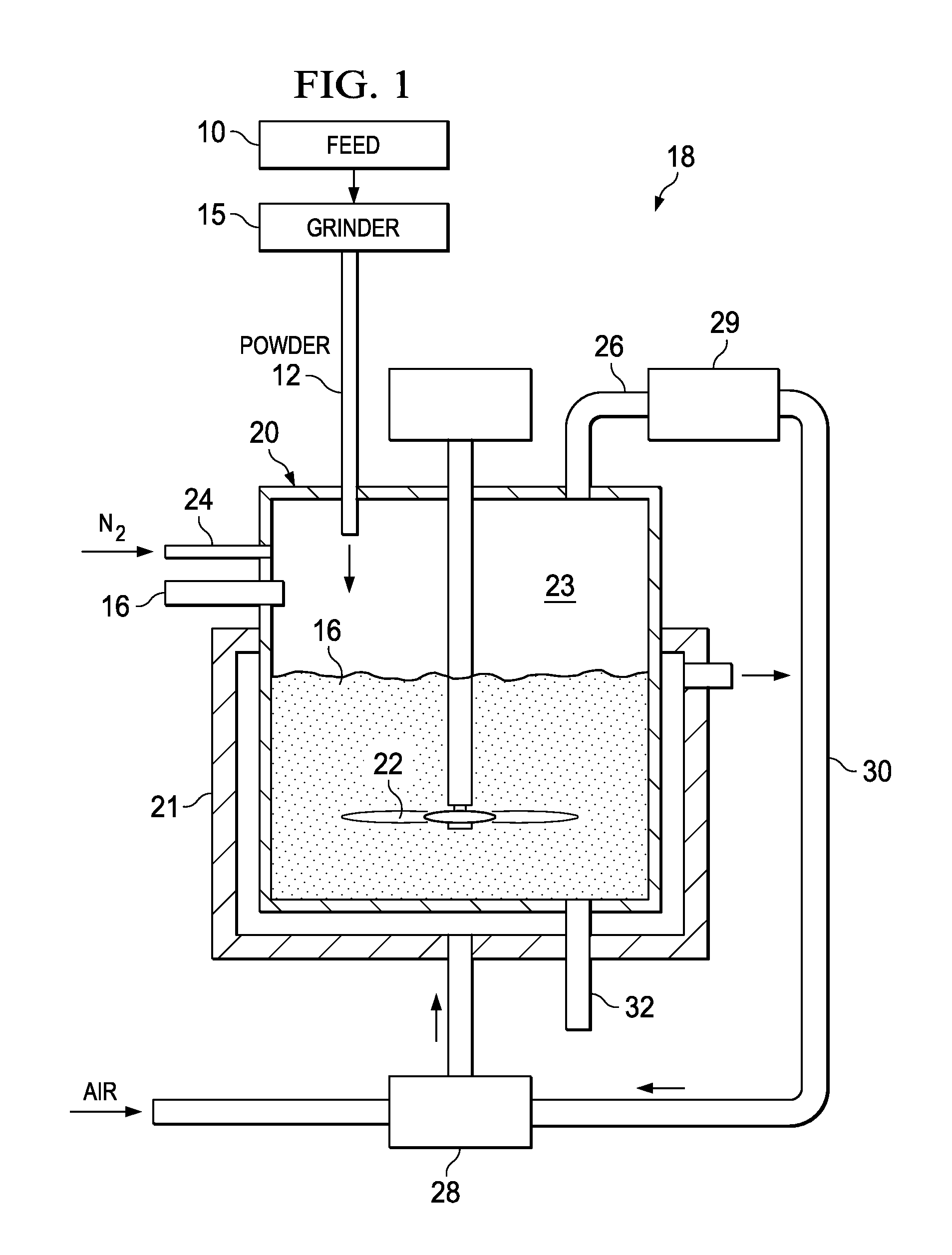

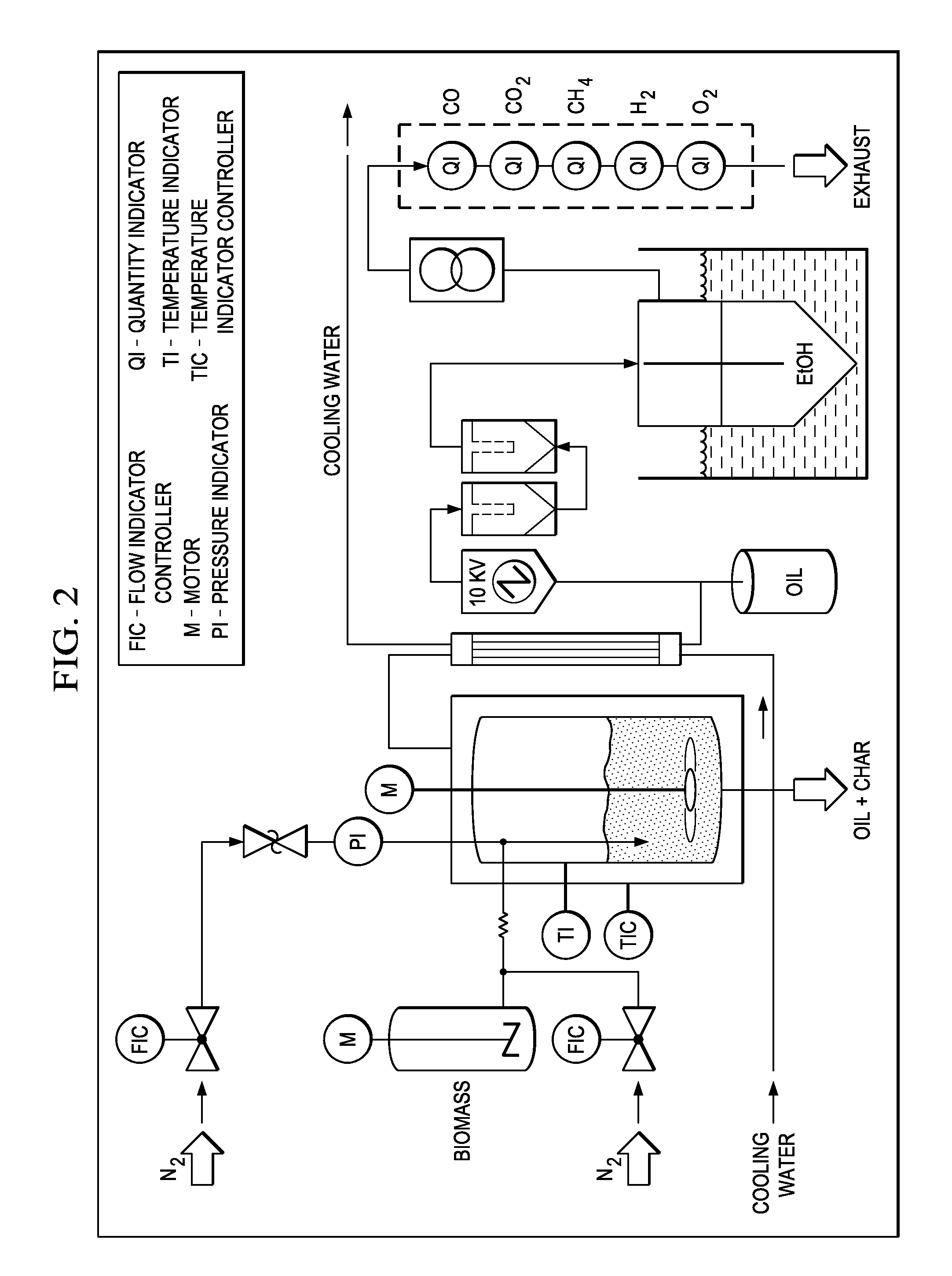

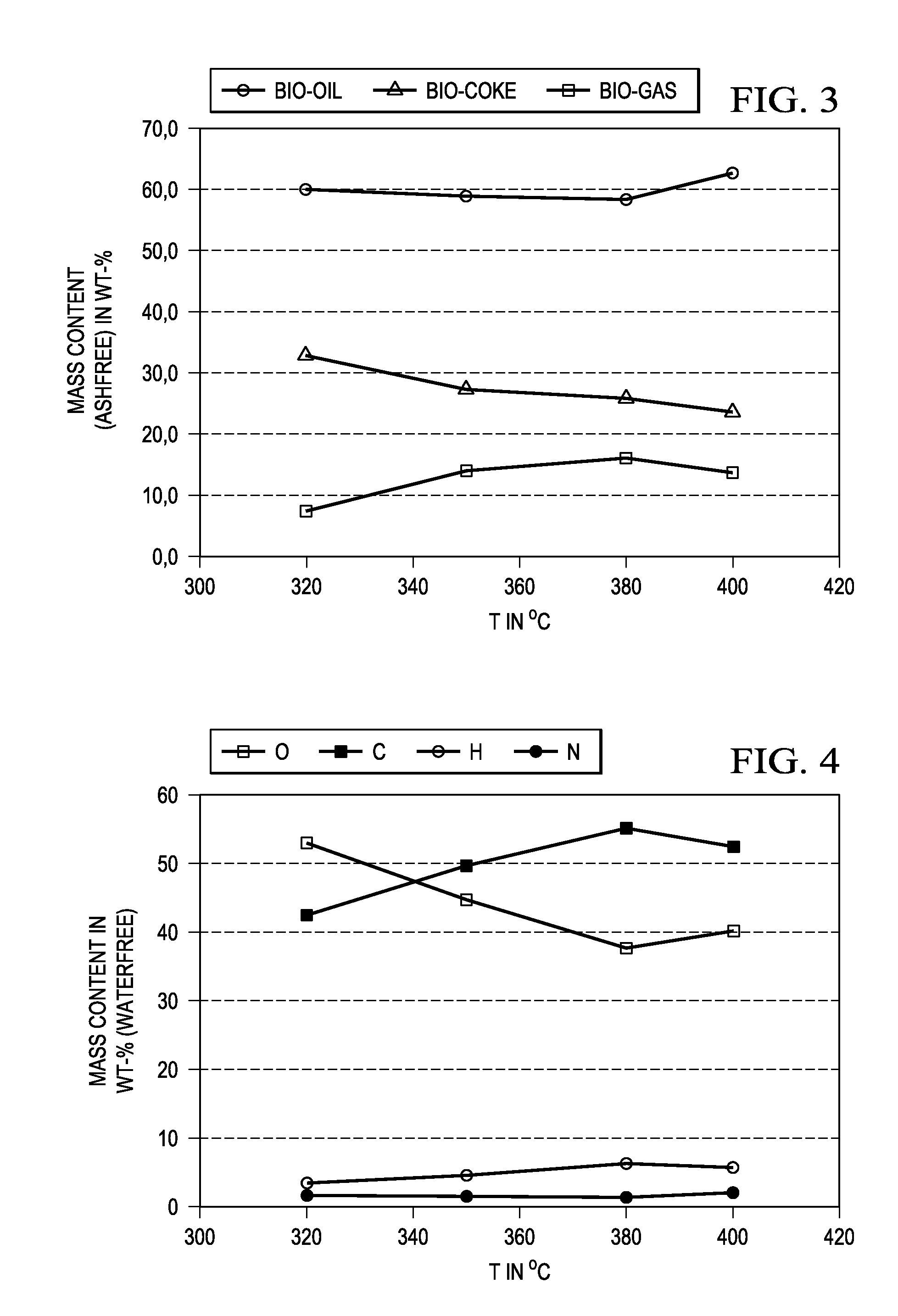

Methods and apparatuses for thermally converting biomass

Methods and apparatuses for thermally converting or pyrolyzing biomass are provided. In one embodiment, a method of thermally converting biomass includes introducing the biomass to a reactor feed chamber. The method provides for flowing a low oxygen gas into the reactor feed chamber to purge the reactor feed chamber and biomass of oxygen. The method also includes delivering the purged biomass to a thermal conversion reactor and thermally converting the biomass in the thermal conversion reactor.

Owner:ENSYN RENEWABLES

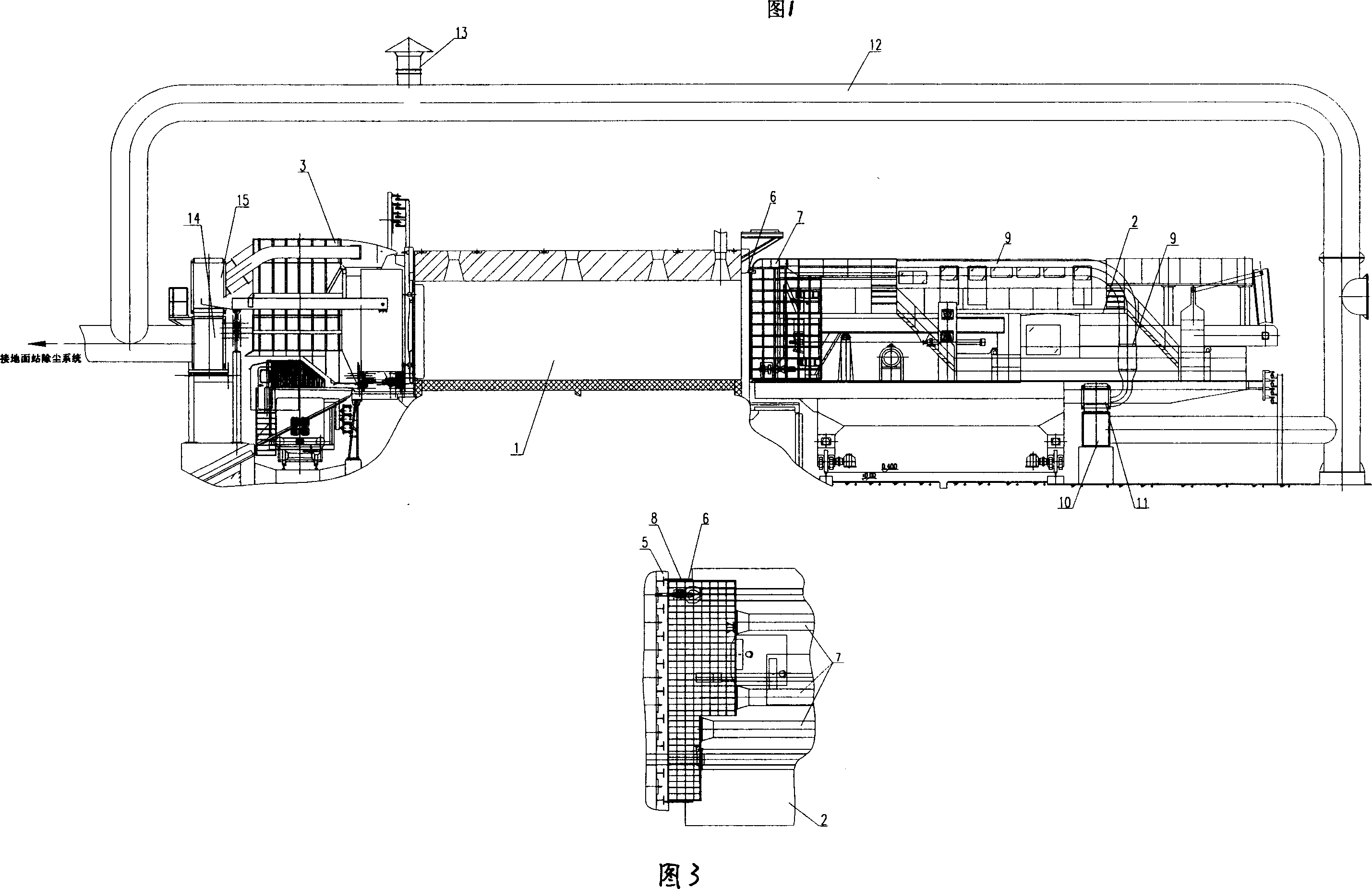

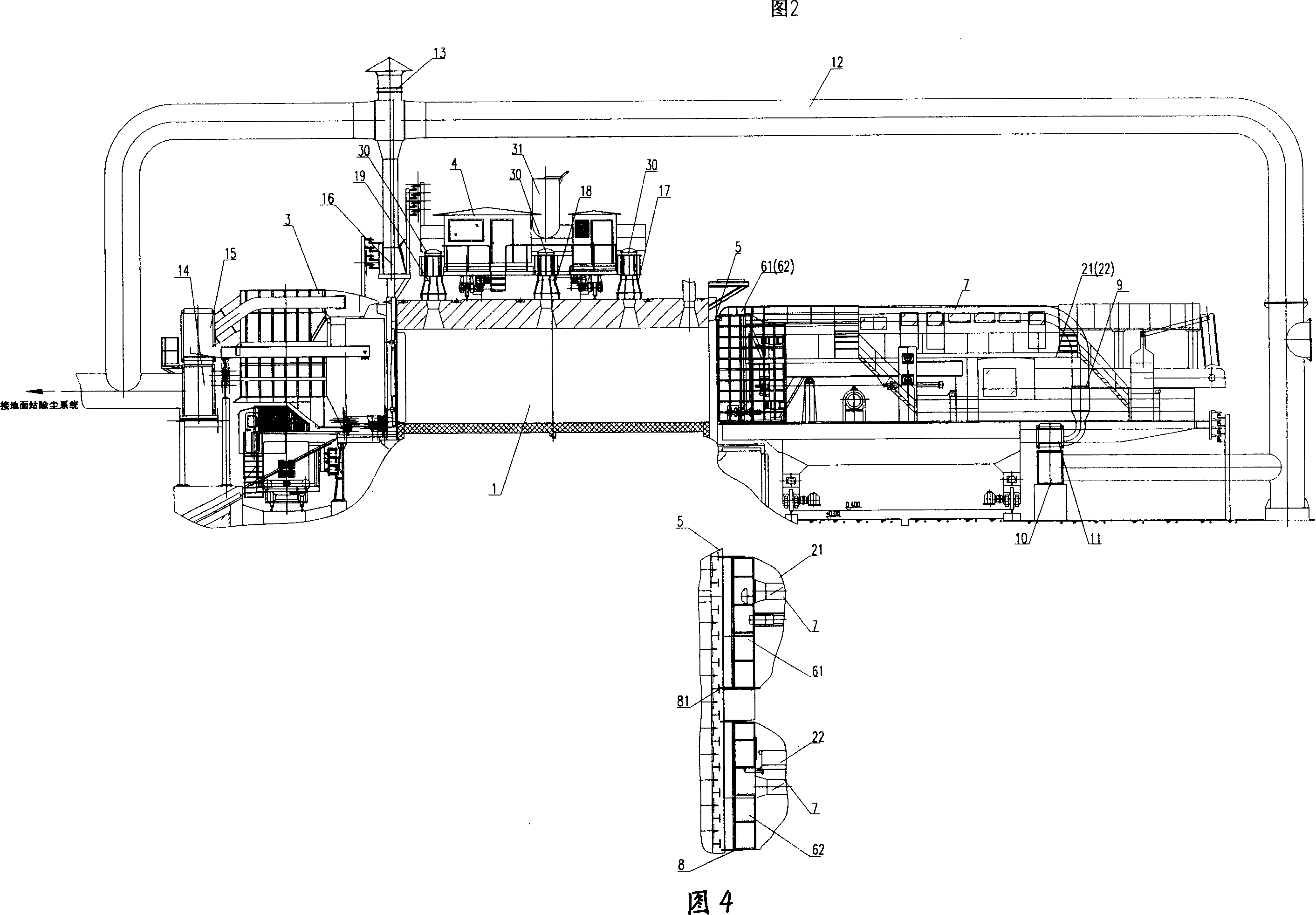

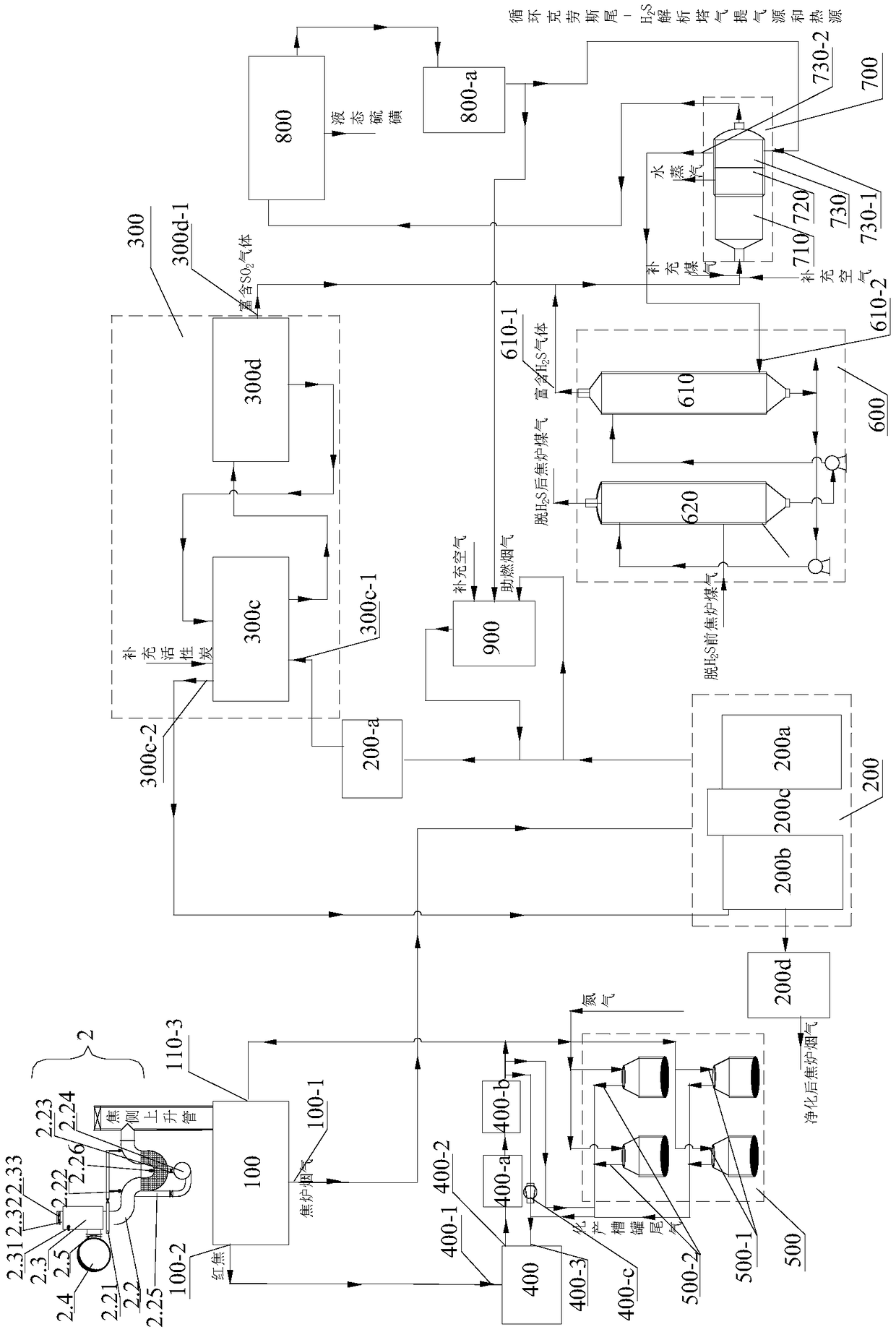

Tamping coke oven smoke treatment system and smoke treatment method thereof

InactiveCN101085922ALow investment costLow running costOven incrustations prevention/removalCarbonizationProduct gas

The invention provides a tamping coke oven smoke treating system. The side of tamping coke oven is equipped with smoke collection device, the gas gathering pipe of said smoke collection device is combined and connnected with smoke conveying pipe through pipe stepless connection uint; the railway on top of coke oven is equipped with closed depressurized diversion special purpose locomotive, said closed special locomotive is connected with smoke collection convey pipe; one side of coke oven is provided with smoke removal coke guide. The invention aslo provides a method for treating smoke in tamping coke oven, which comprises following steps: said smoke collection device collecting smoke caused by coal loading with large air quantity; DAS special purpose locomotive entering into carbonization room with coal cake and turning on qir quantitty adjustment valve, determining valve open degree according to parabola air discharge quantity, top of coke oven sucks air for depression. The invention can treat the smoke from coke oven and oven top, and the discharge meets one- grade standard in china for coking industry.

Owner:BEIJING SHOUGANG ZHONGYE ELECTROMECHANICAL EQUIP

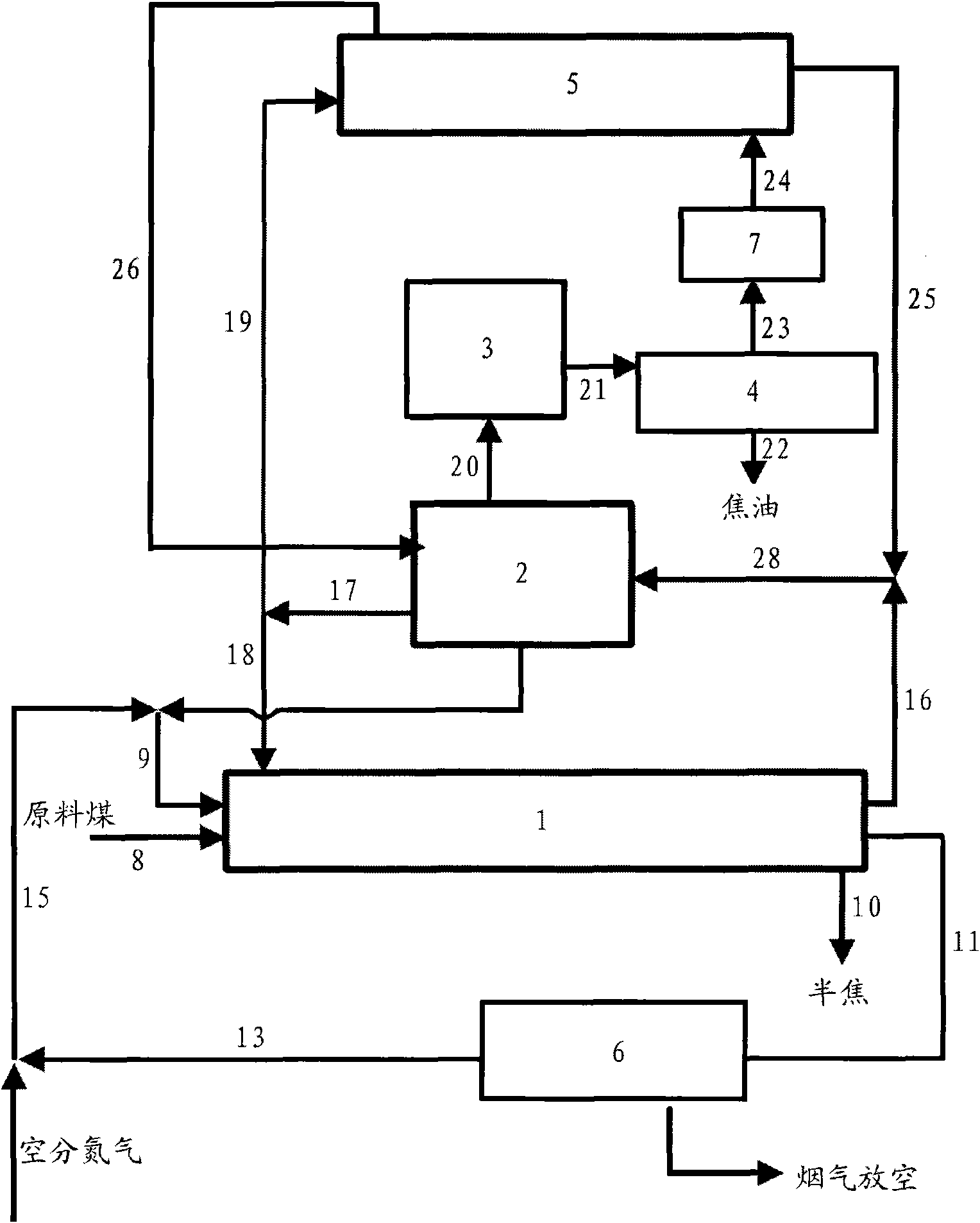

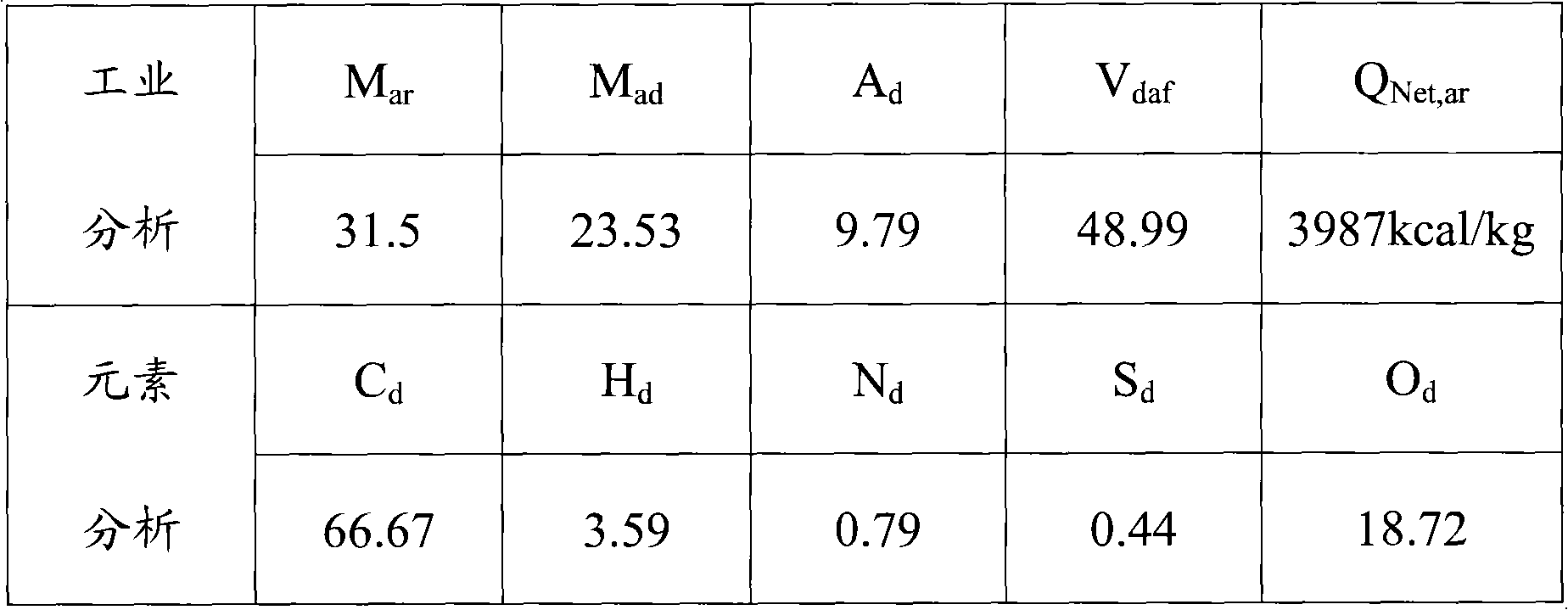

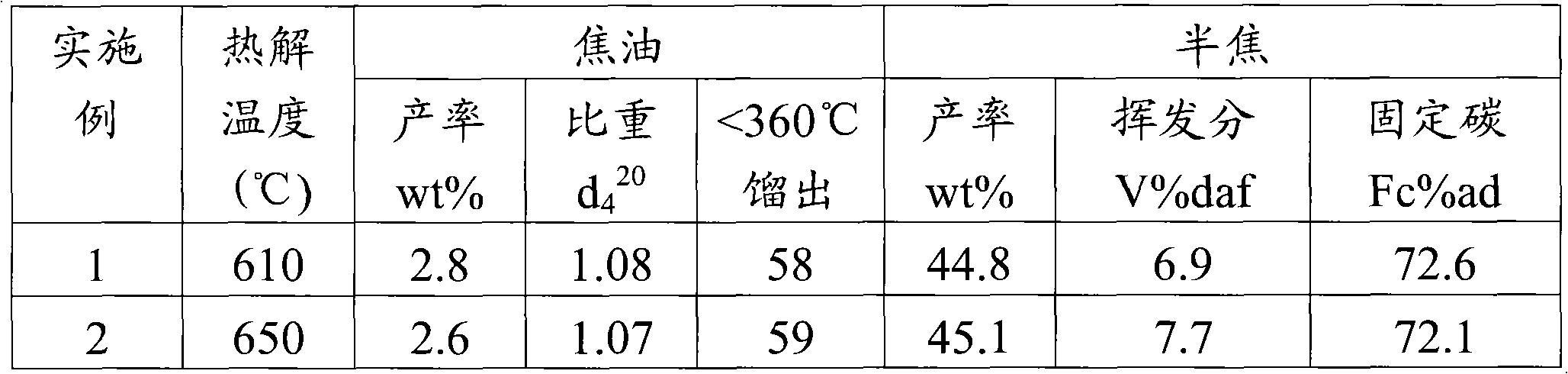

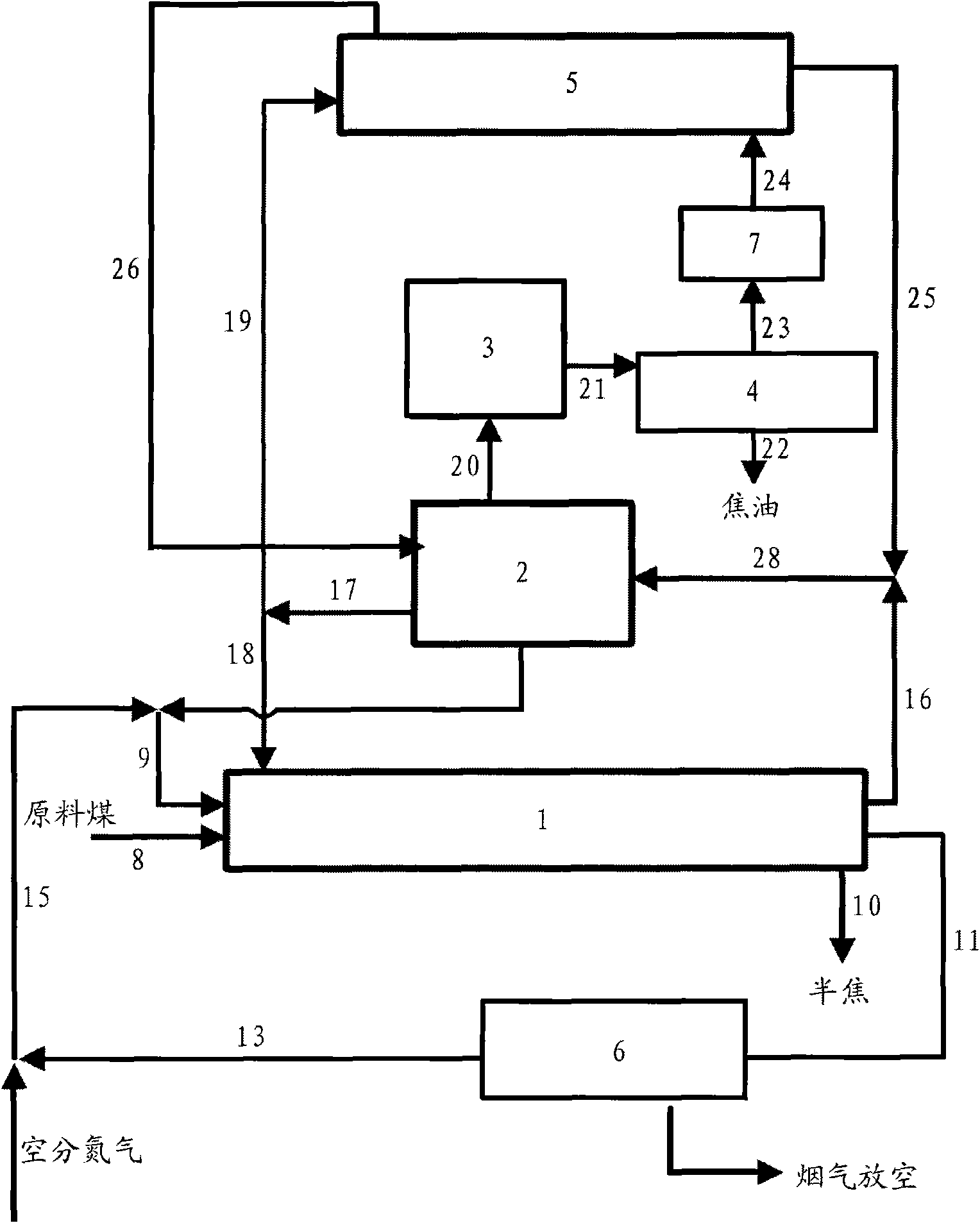

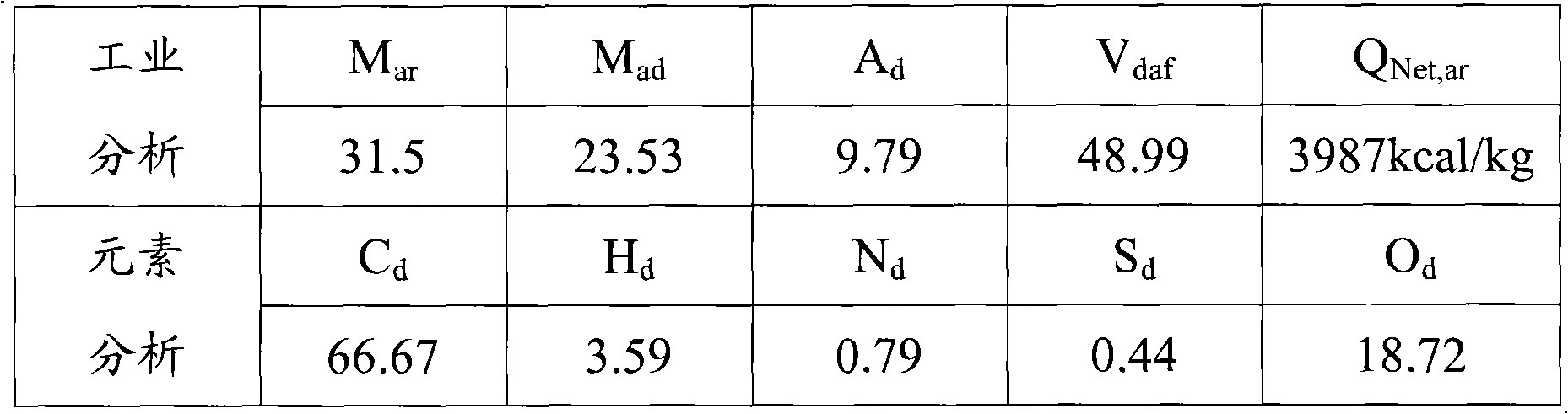

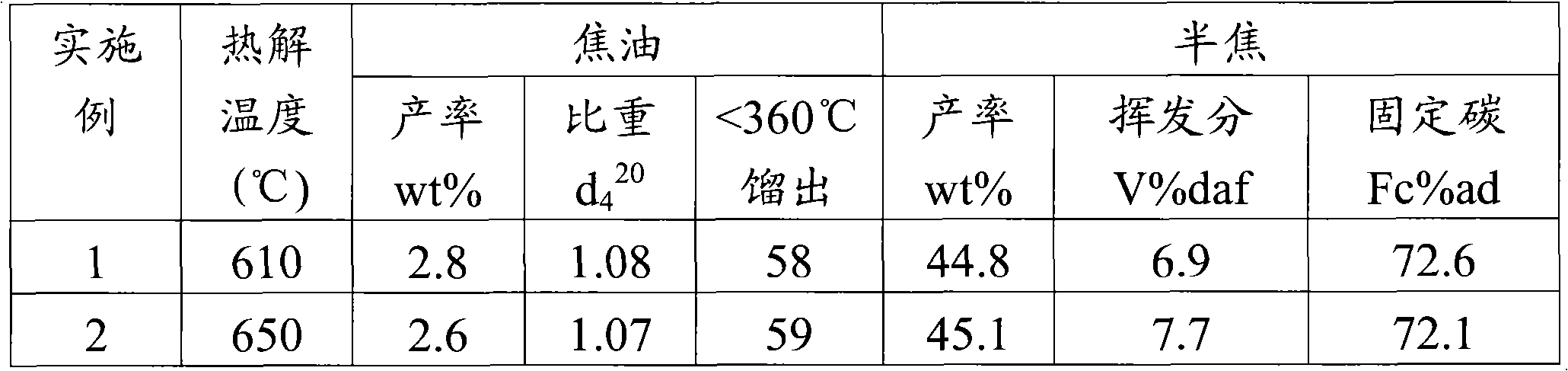

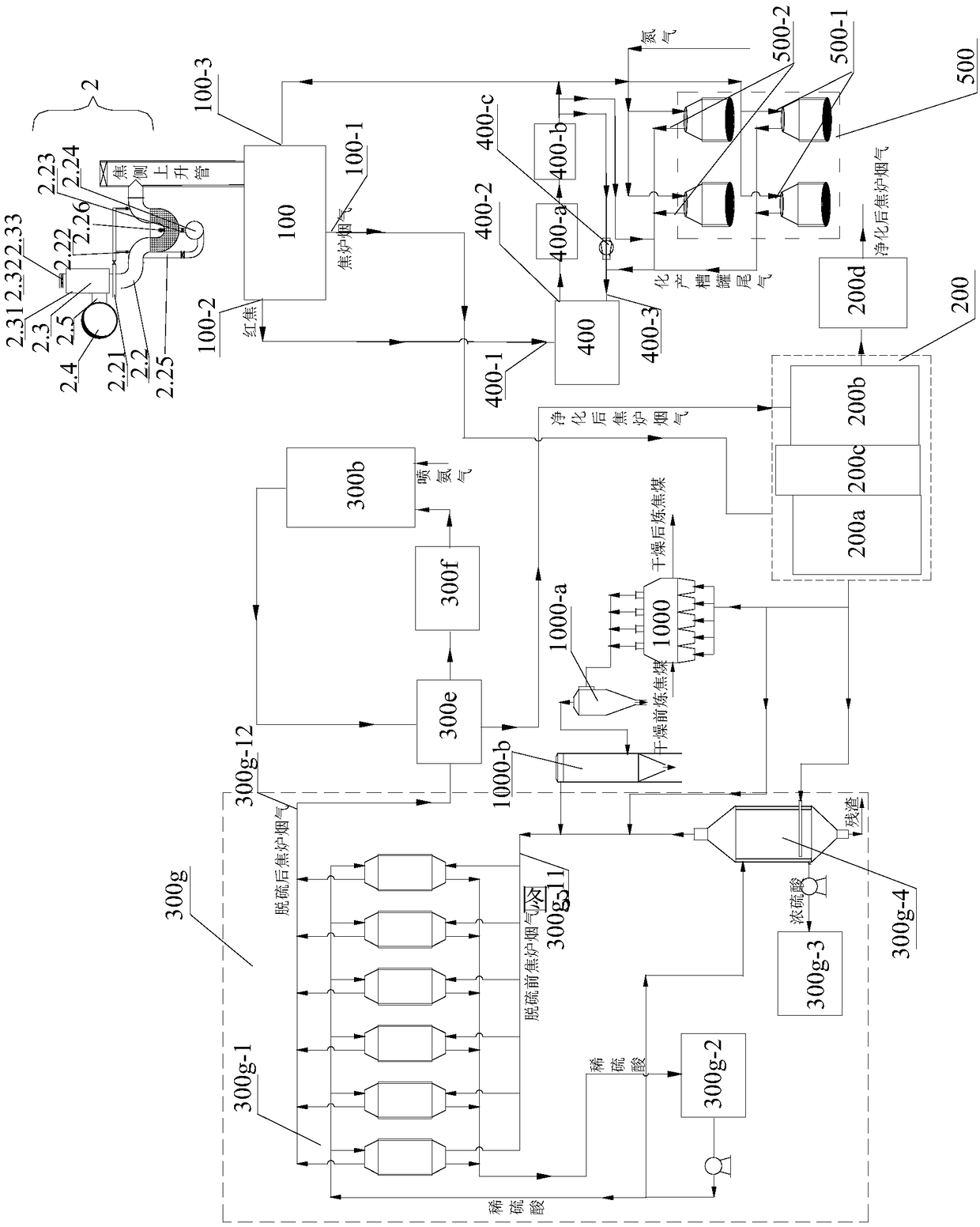

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Cleaning method

ActiveUS20050139238A1Detergent mixture composition preparationHollow article cleaningHydrocotyle bowlesioidesProcess engineering

The method for cleaning chemical process and hydrocarbon processing apparatuses is performed by establishing a closed flow circulation loop, under specific operating conditions and in the presence of hydrocarbon-based fluids. The cleaning method is monitored by performing chemical / physical analysis. After cleaning the apparatus(es) can be immediately inserted back into the process. An optional degassing step can also be performed, in case the apparatus(es) has to be disassembled for inspection of maintenance.

Owner:FERRARA

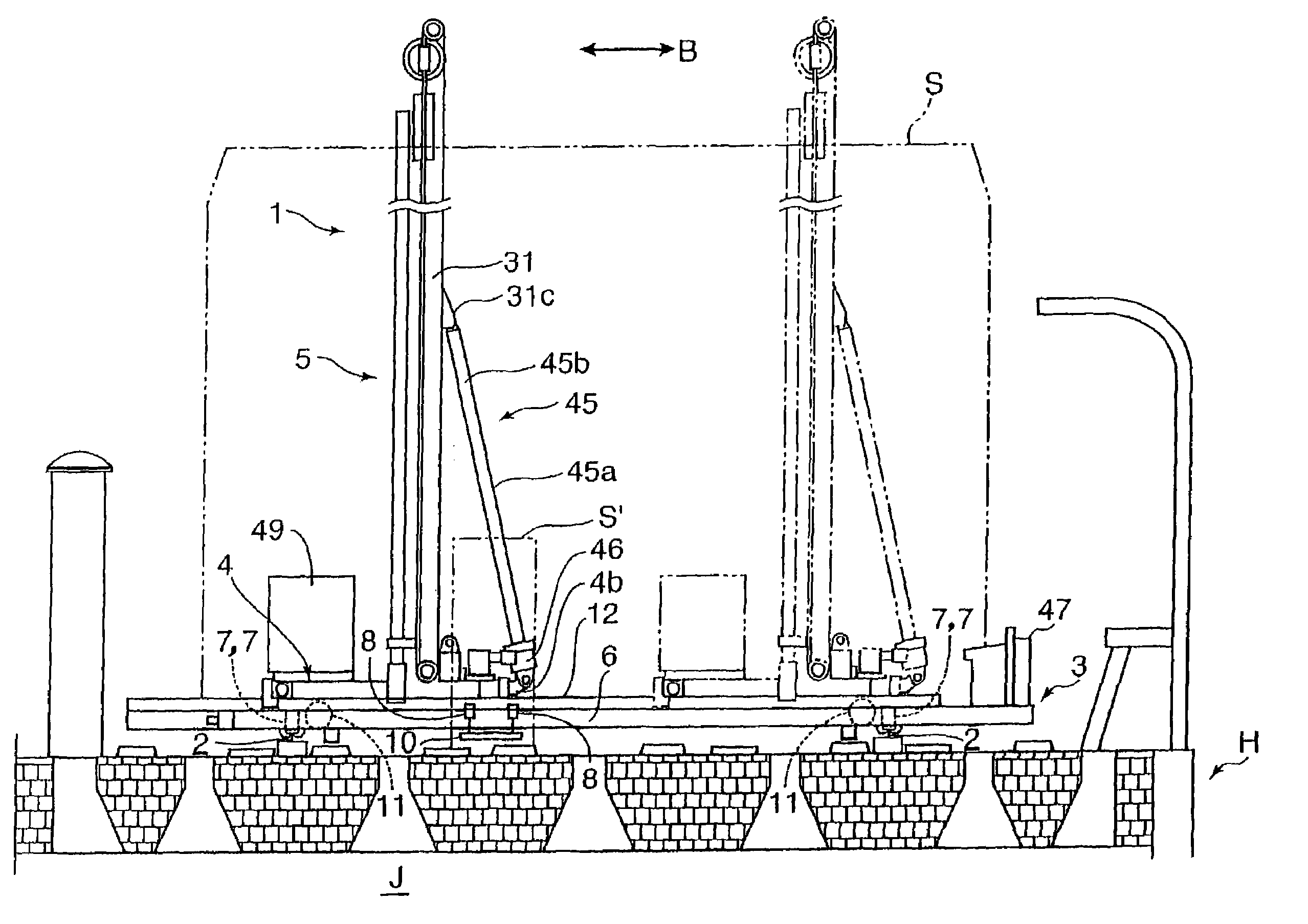

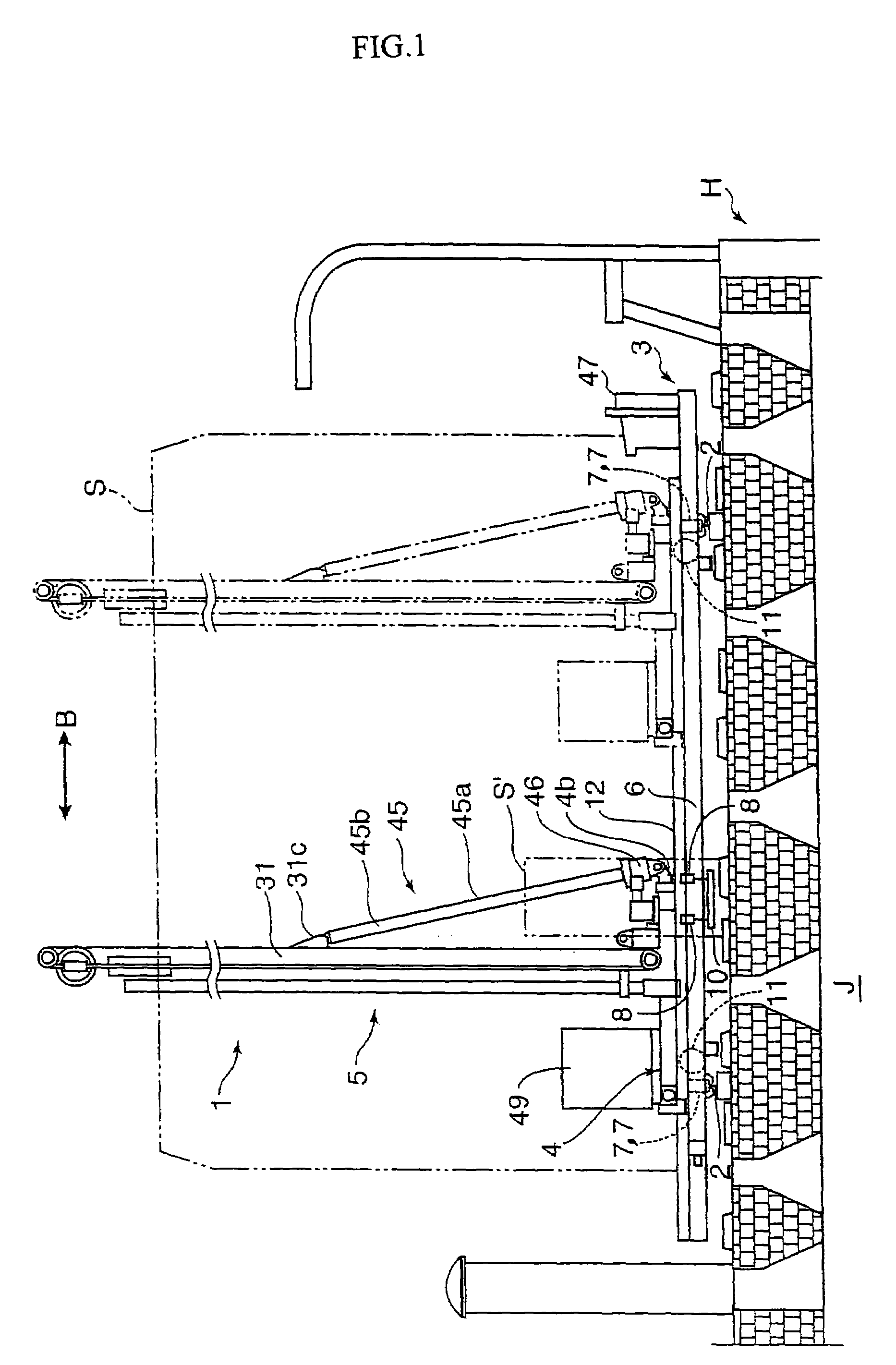

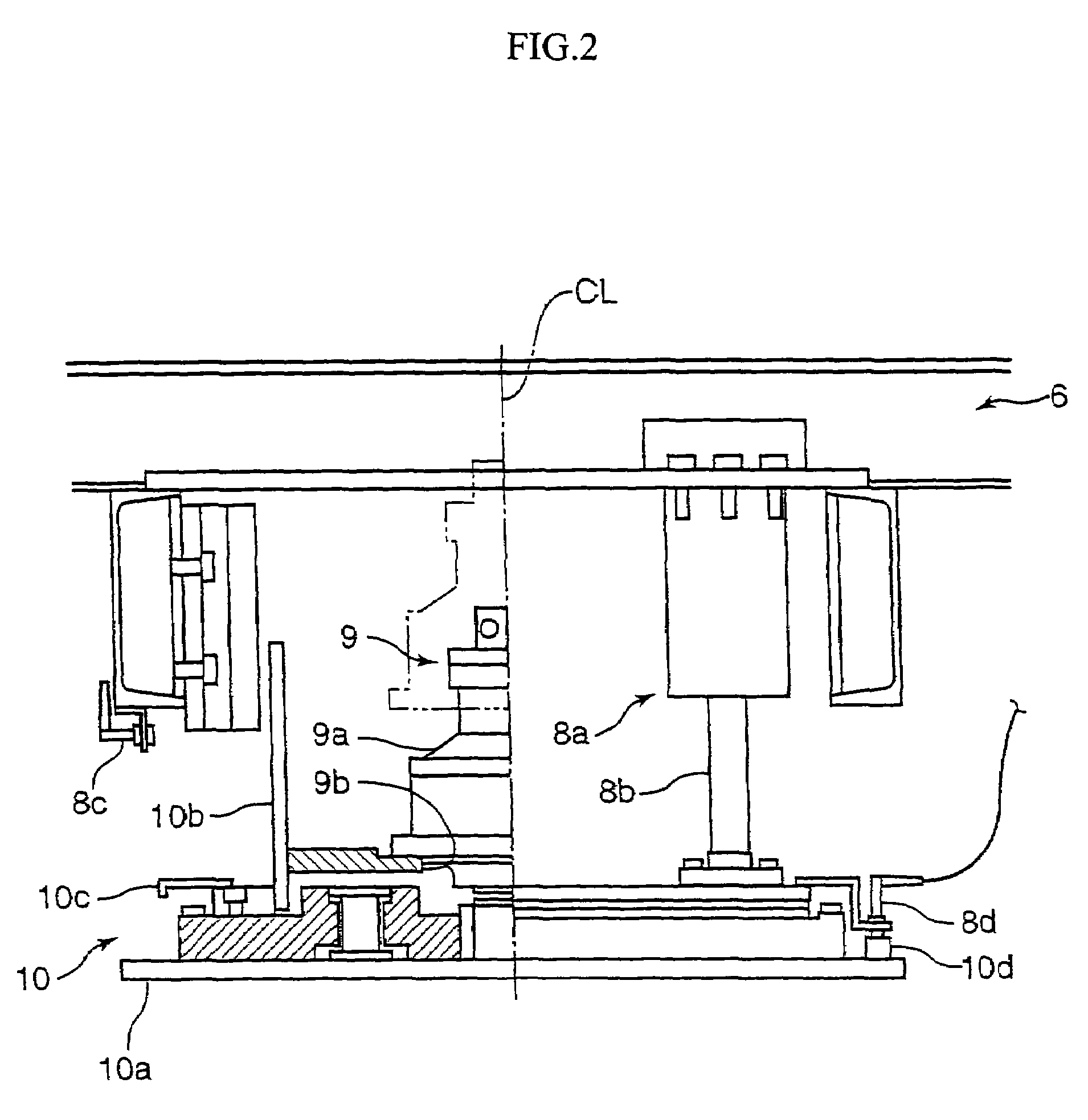

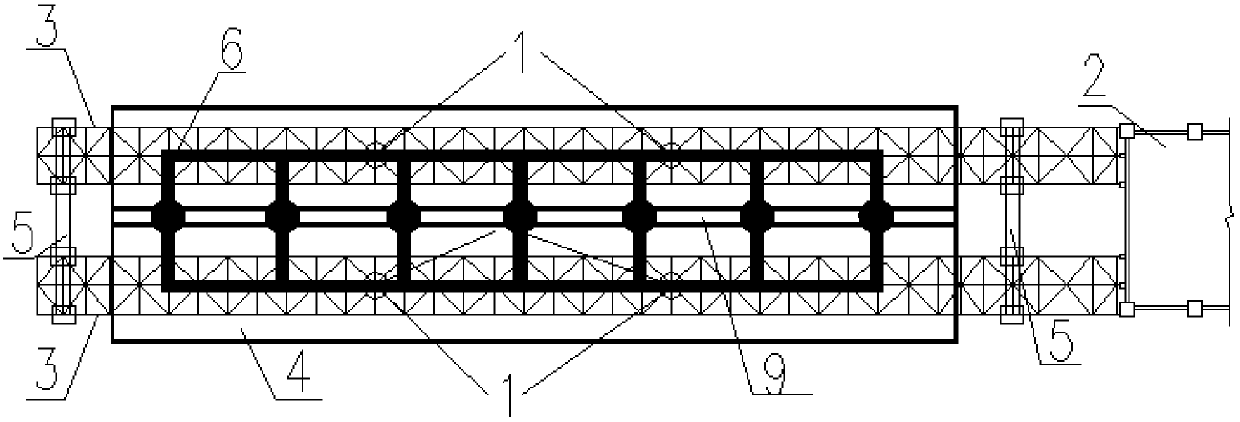

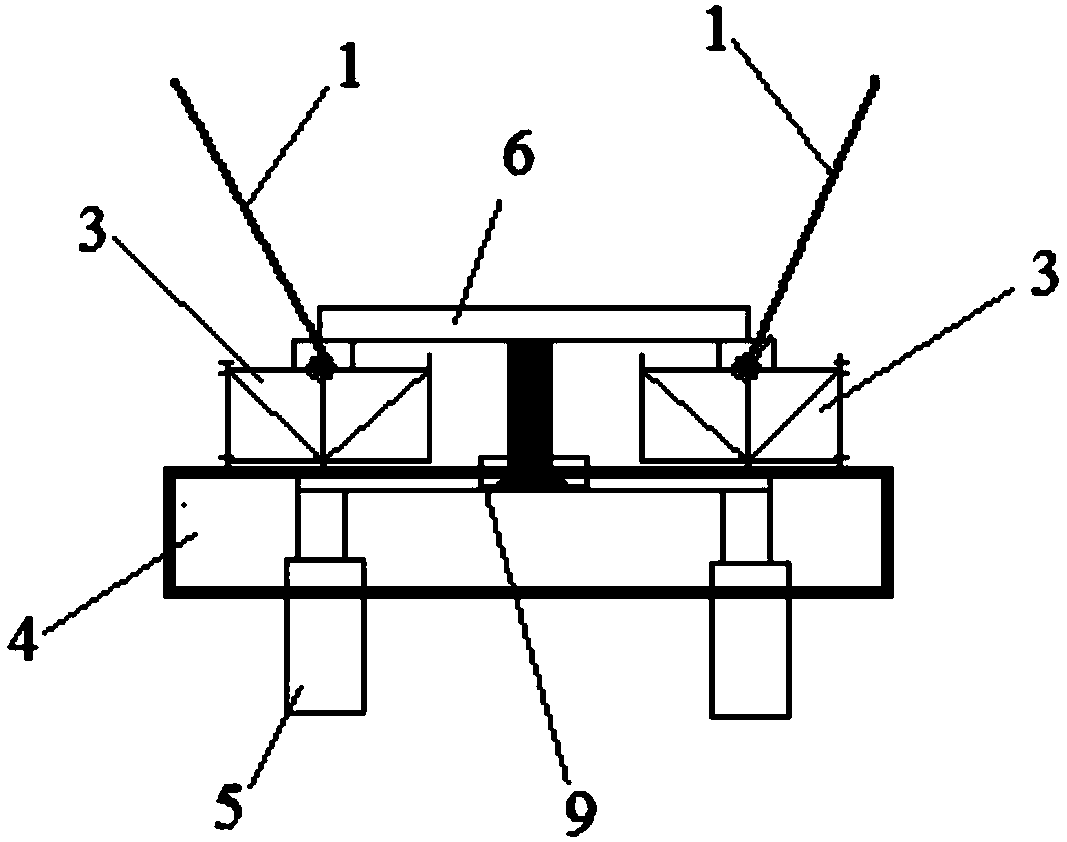

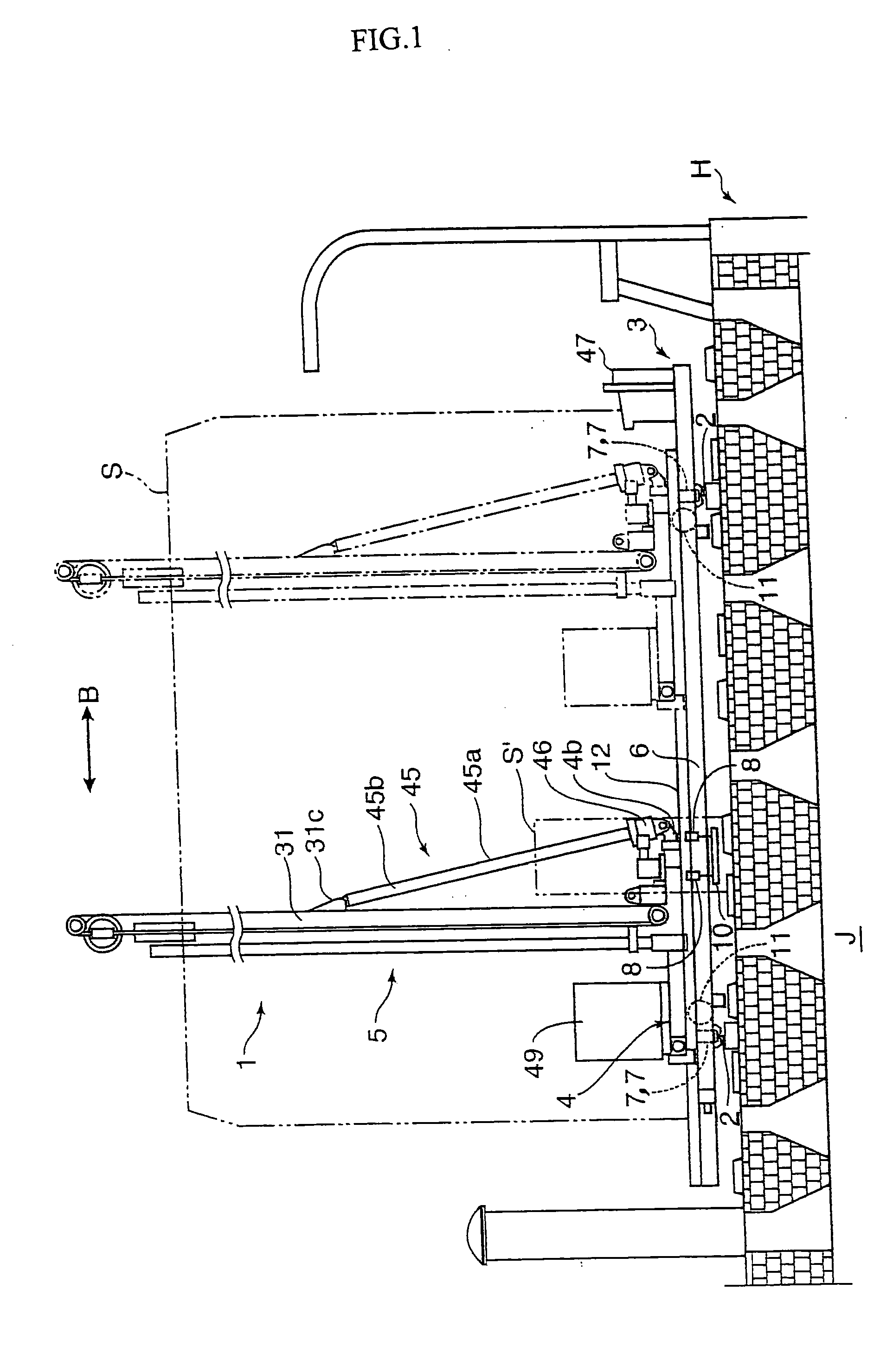

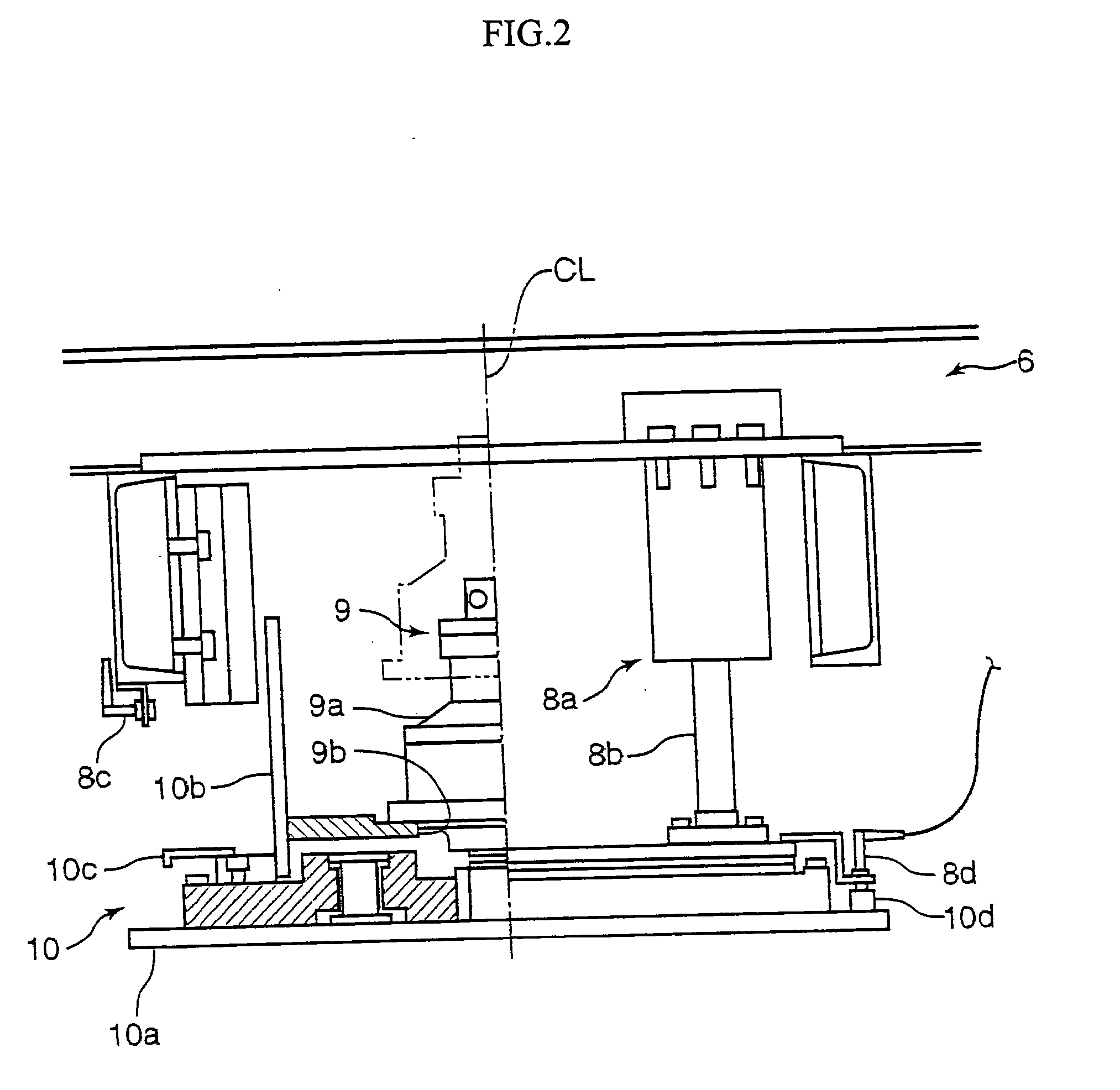

Coke oven repairing apparatus

ActiveUS7547377B2Repairable rangeLinings repairBrickwork leakage repair/preventionCoke ovenEngineering

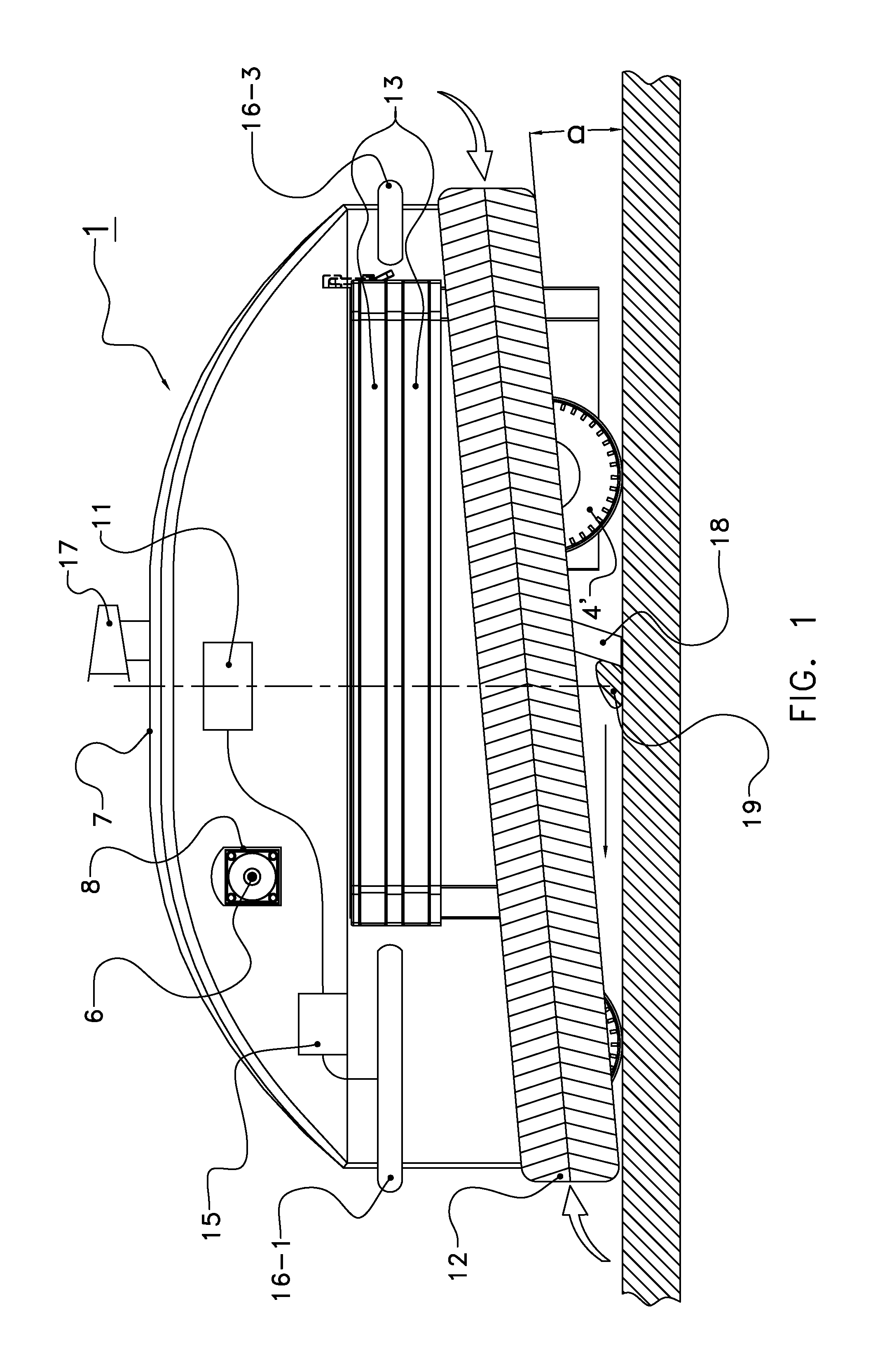

A coke-oven repairing apparatus comprising: a traveling carriage 3 which travels in the direction of coke oven battery with the carriage straddled on the rails placed on the top of a coke oven; a traversing carriage 4 provided on said traveling carriage 3, which moves in the direction orthogonal to the direction of coke oven battery; and a working device 5 for making repairs on the oven walls within the coke oven which is mounted on said traversing carriage 4, wherein the working device 5 includes: a guide post 31 which stands on the traversing carriage 4, and is also coupled, at its lower end portion, to a supporting portion provided on the traversing carriage through a pivot shaft 42; a lance 32 which ascends or descends along the guide post 31; and a derricking device 45 which tilts the guide post 31 between a forward-tilted posture and a backward-tilted posture using the pivot shaft 42 as the fulcrum to oscillate the lance 32 inserted in a coke-oven carbonizing chamber through a charging-hole, within the carbonizing chamber.

Owner:KANSAI COKE & CHEM

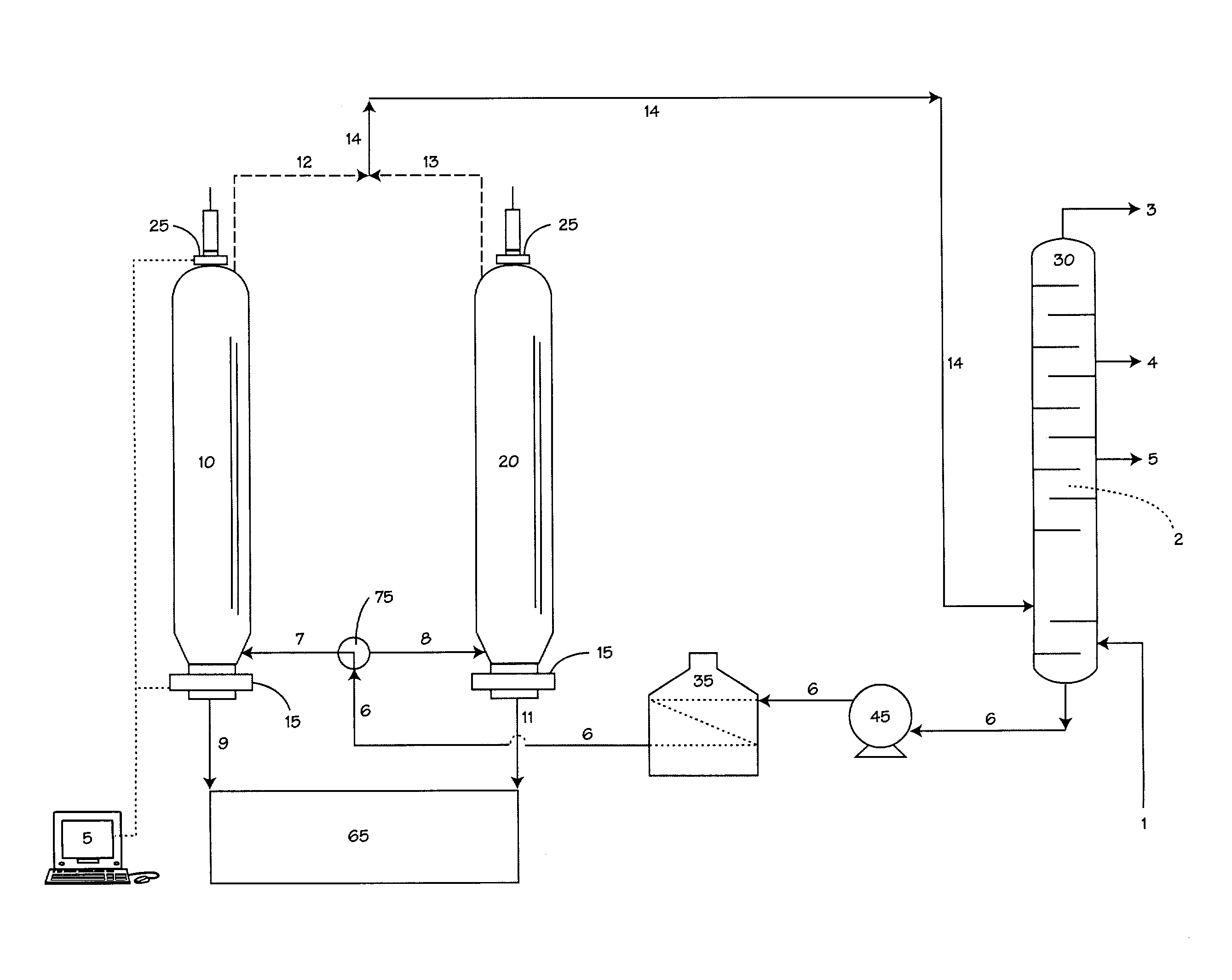

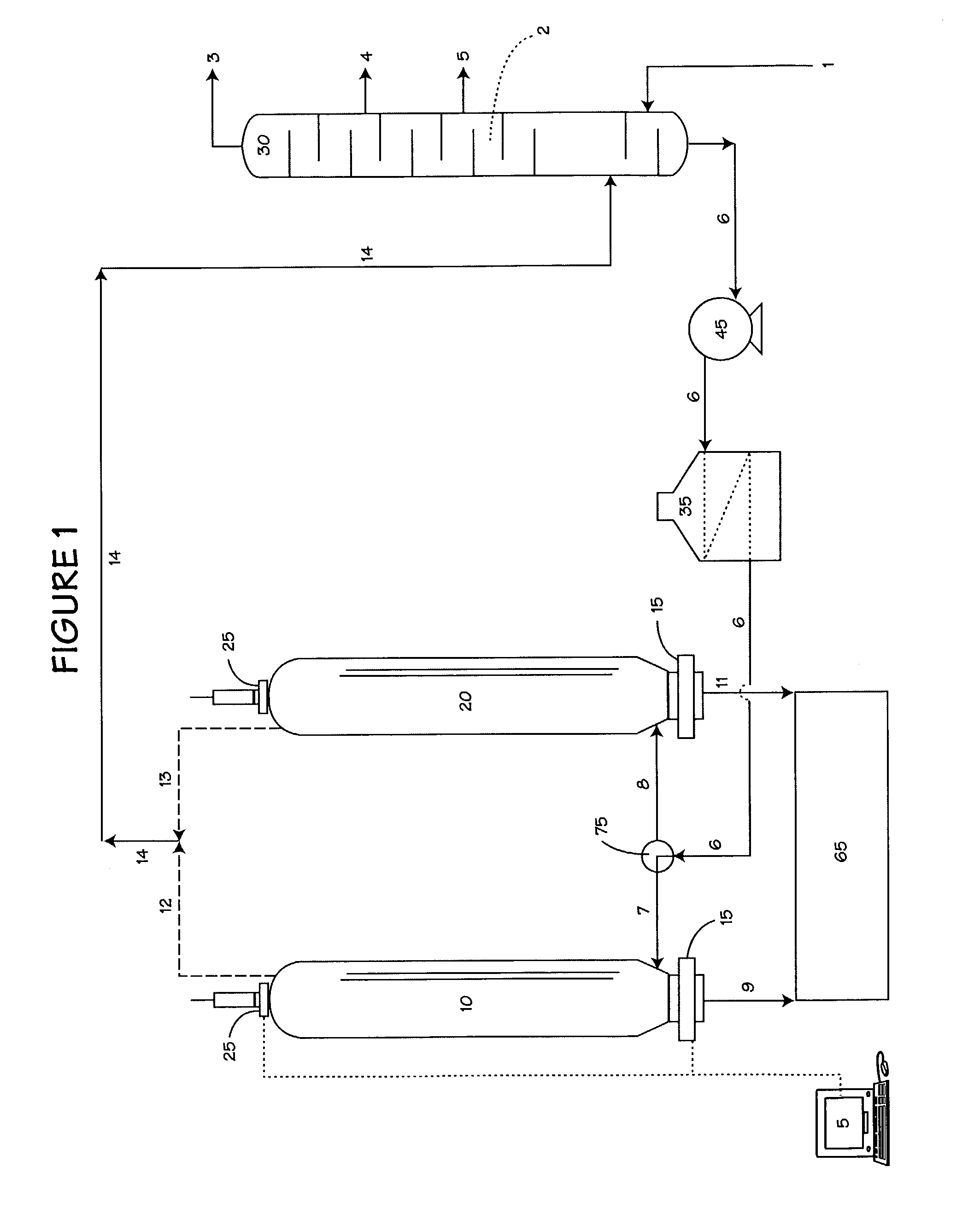

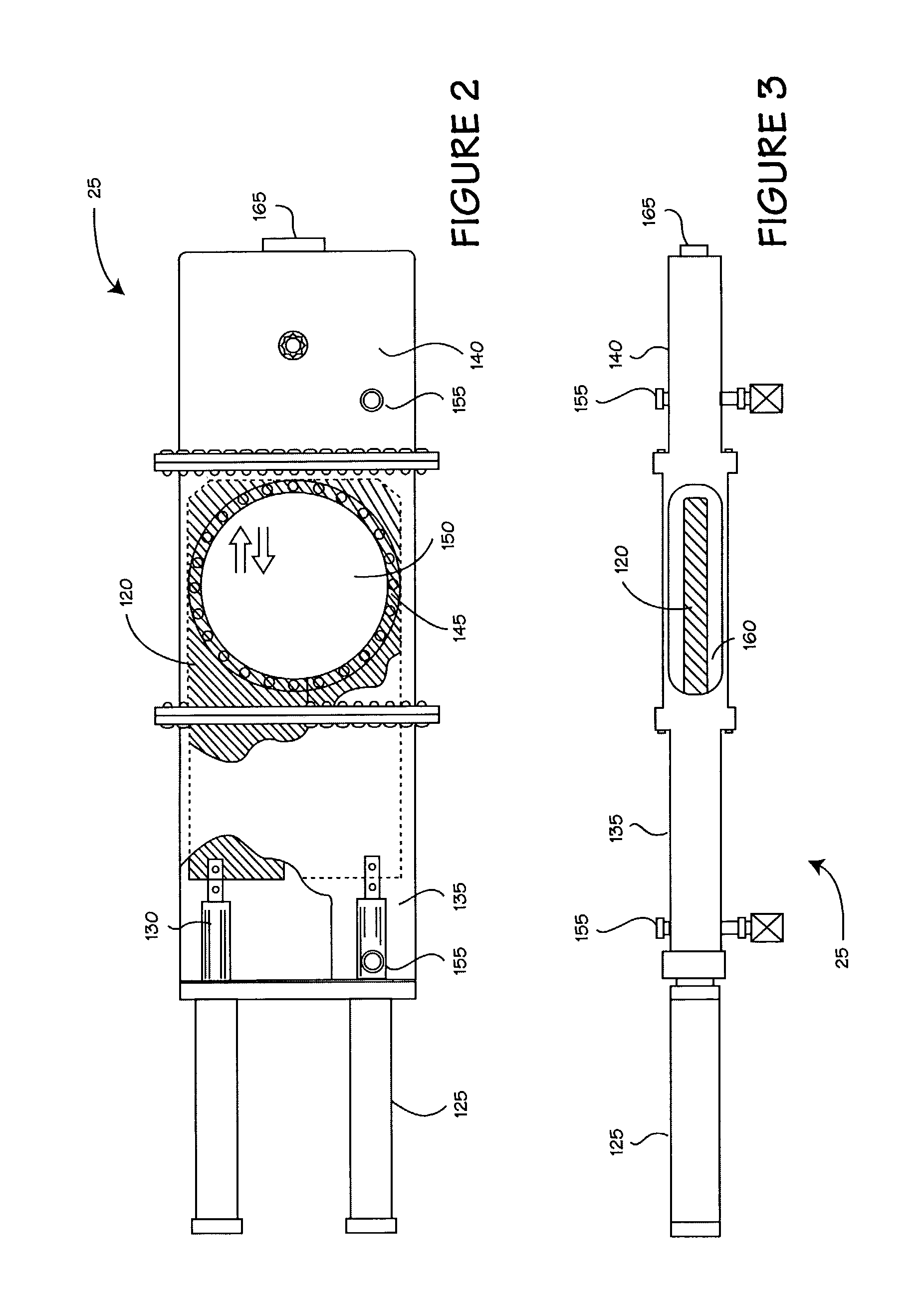

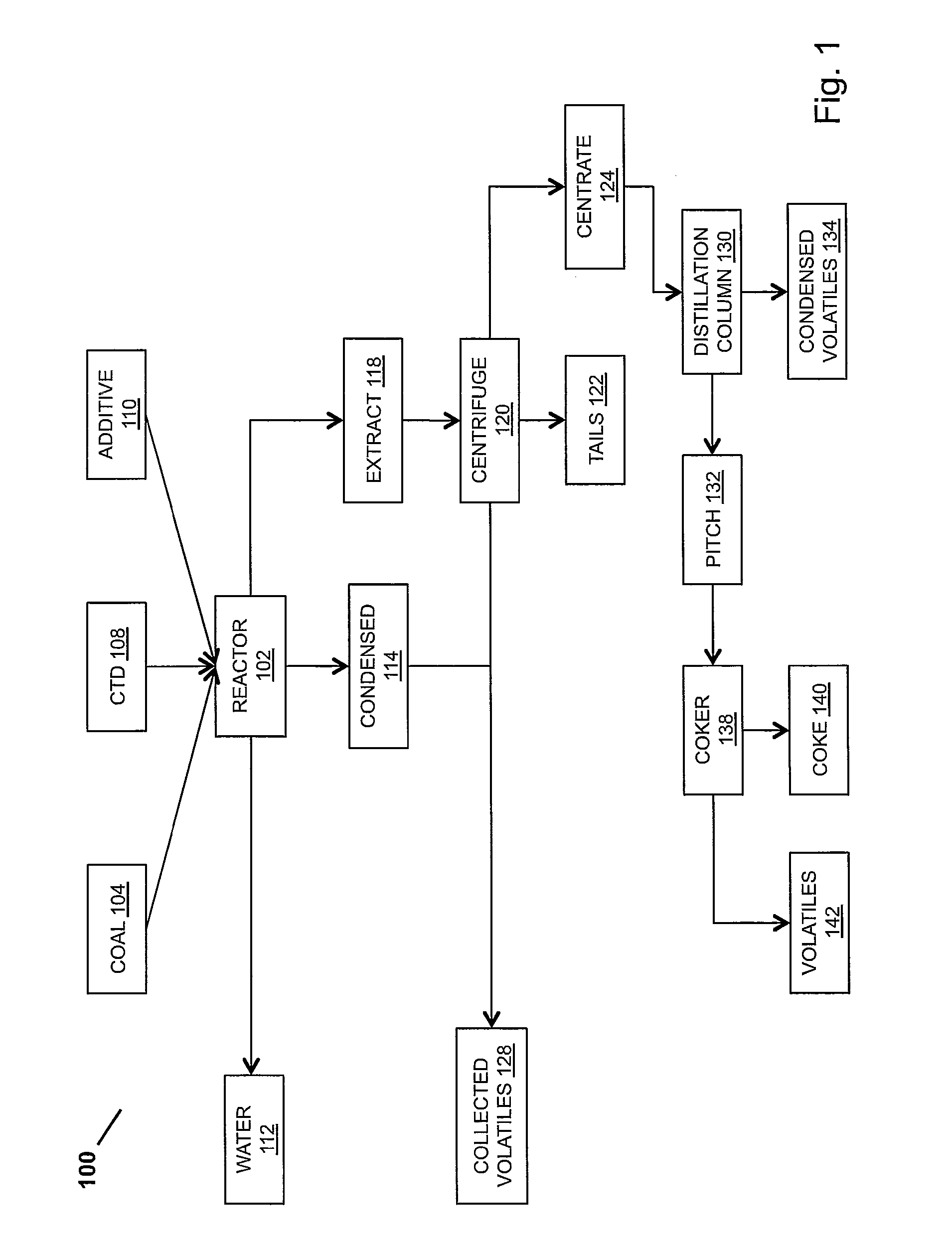

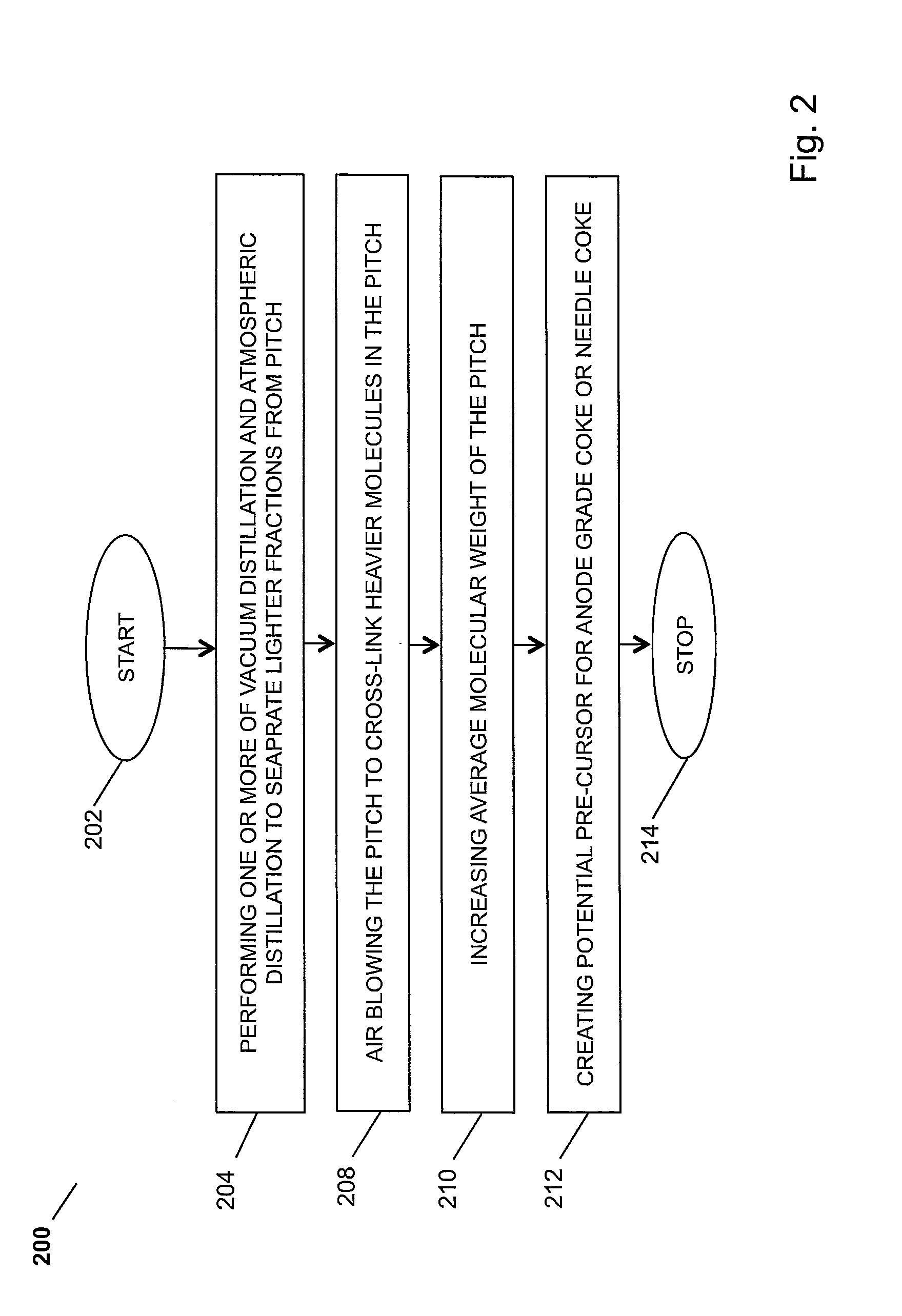

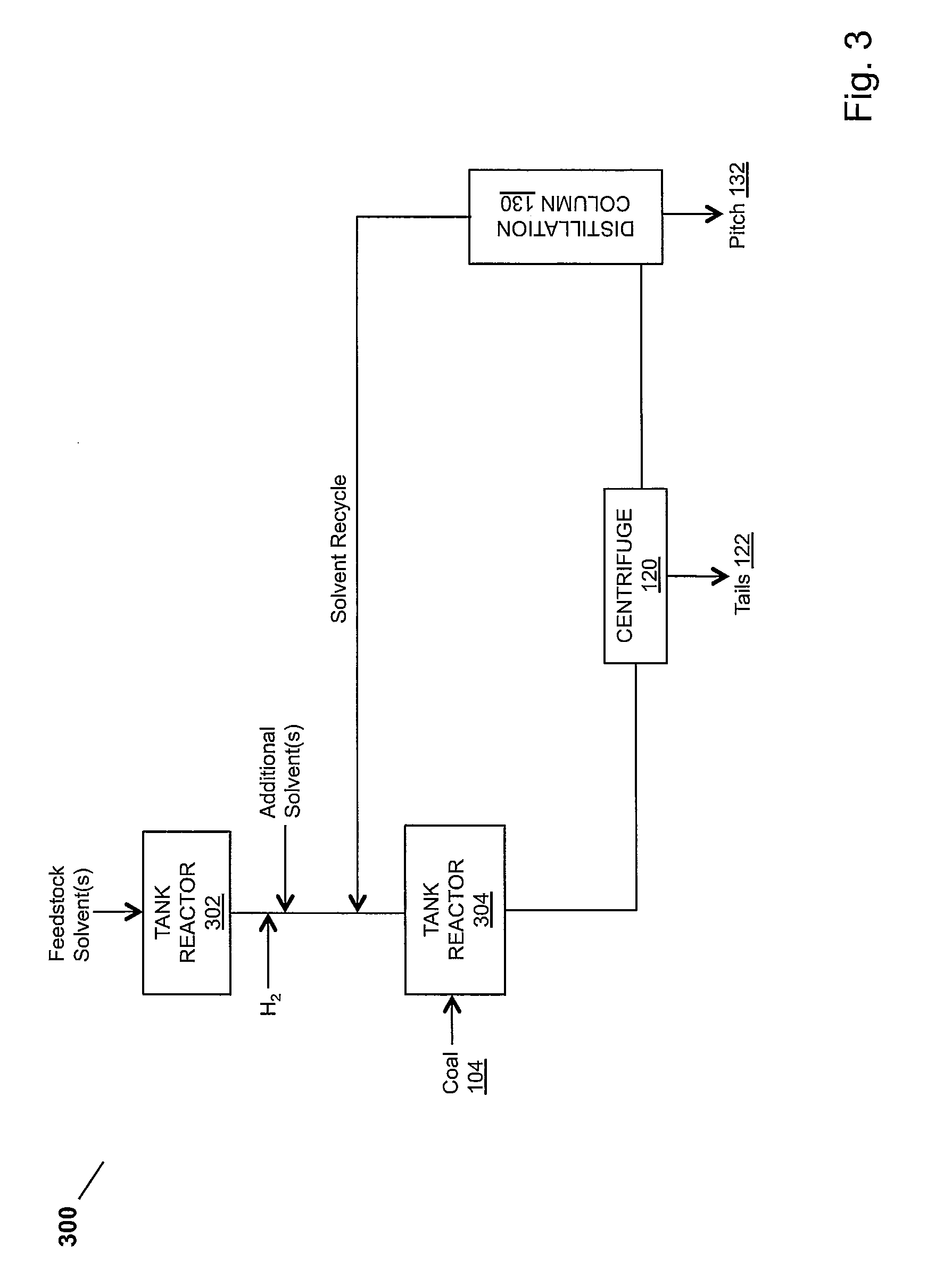

Modular Coal Liquefaction System

InactiveUS20120076703A1Low production costImprove solubilityOven incrustations prevention/removalLiquid hydrocarbon mixture productionTruck-trailerDownstream processing

The present disclosure provides methods and systems of a modular coal liquefaction system. A modular coal liquefaction system may include a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing, wherein the reactor, heater, and centrifuge are adapted to be modular. The system may further include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may further include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke. The system may be adapted to be modularly disposed on a rail car. The system may be adapted to be modularly disposed on a semi-truck trailer.

Owner:WEST VIRGINIA UNIVERSITY

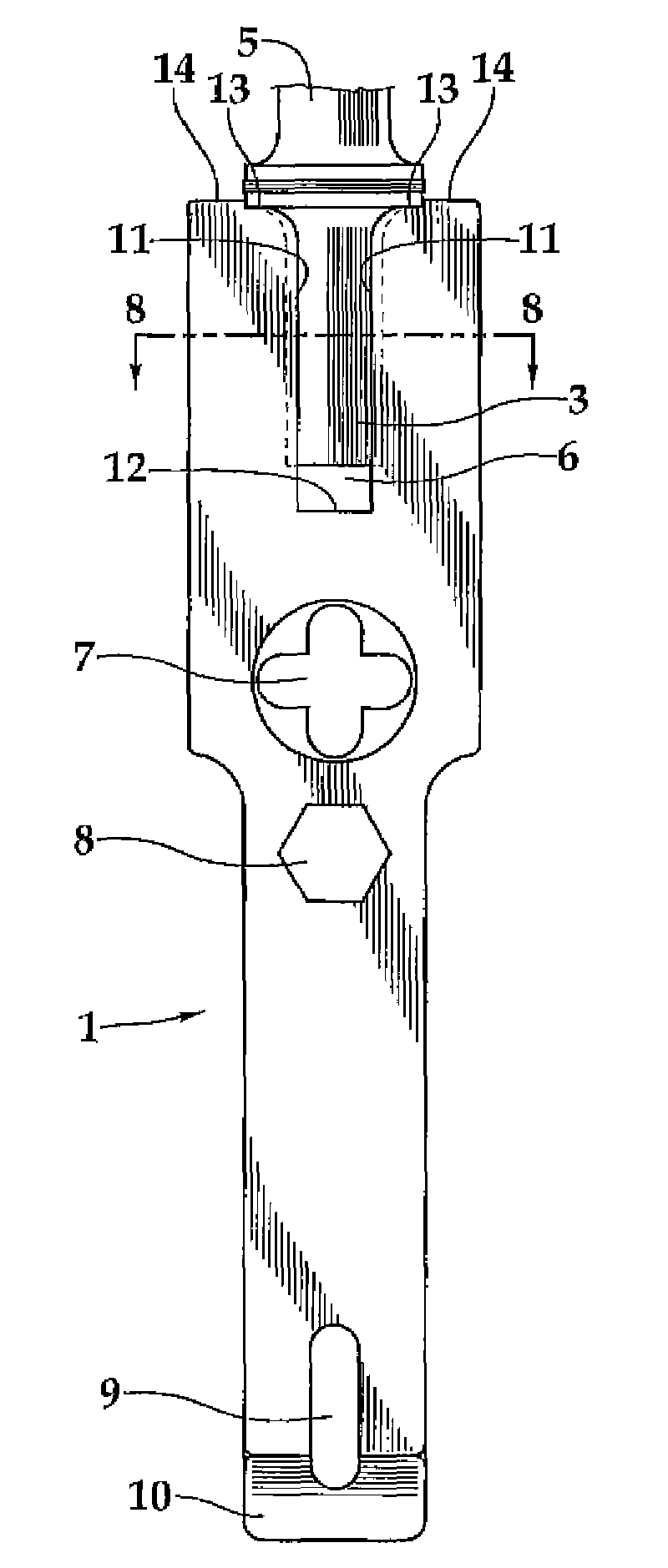

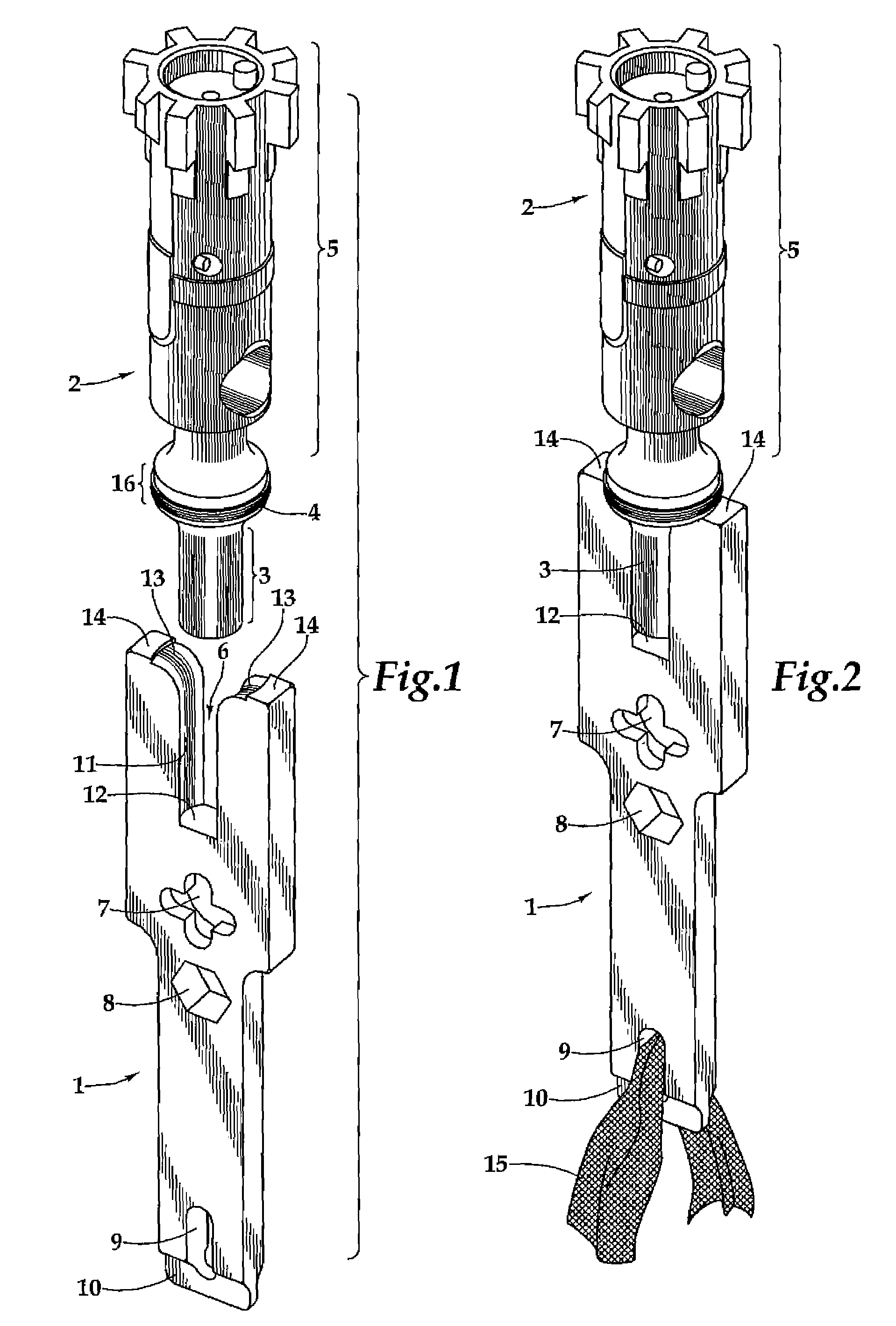

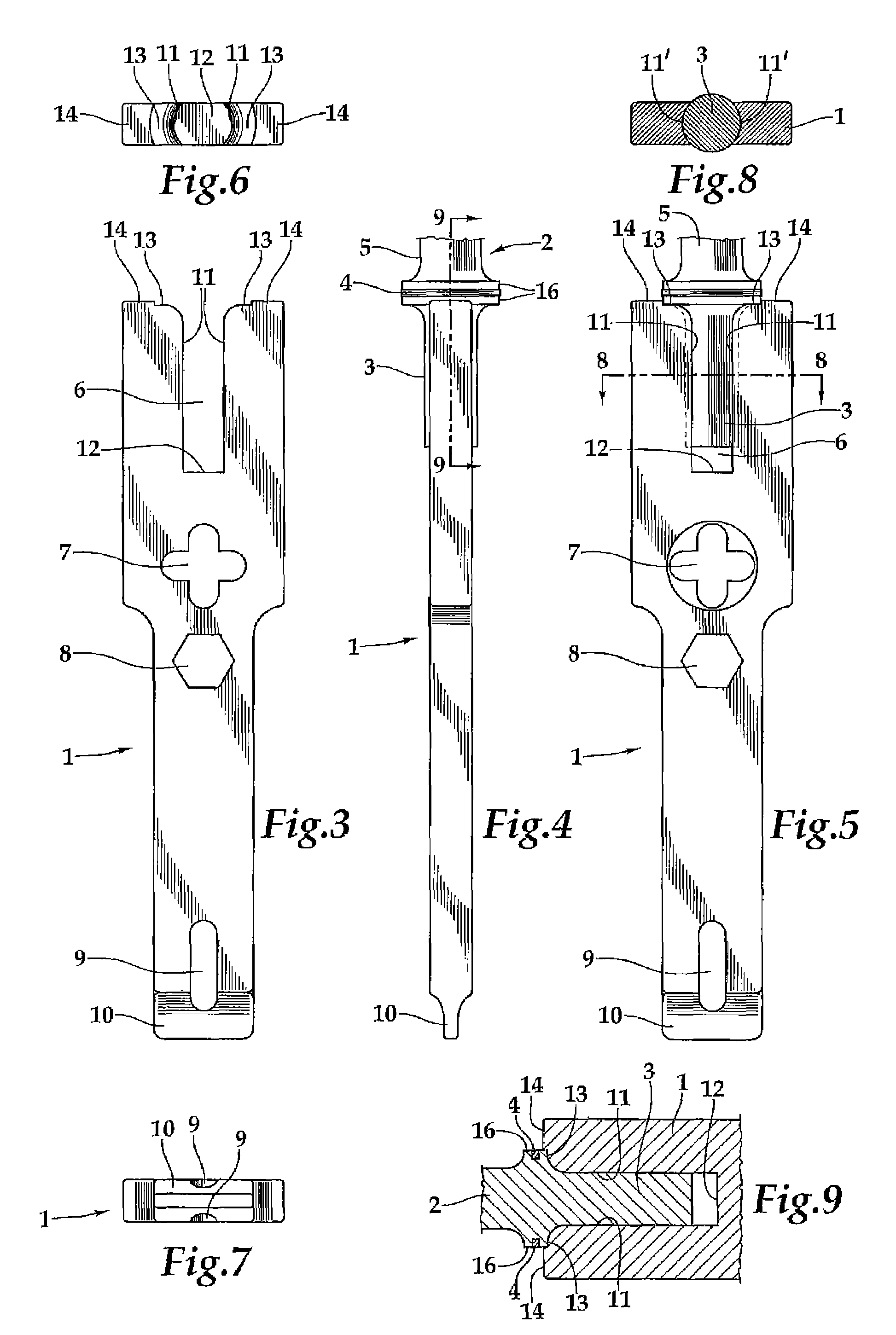

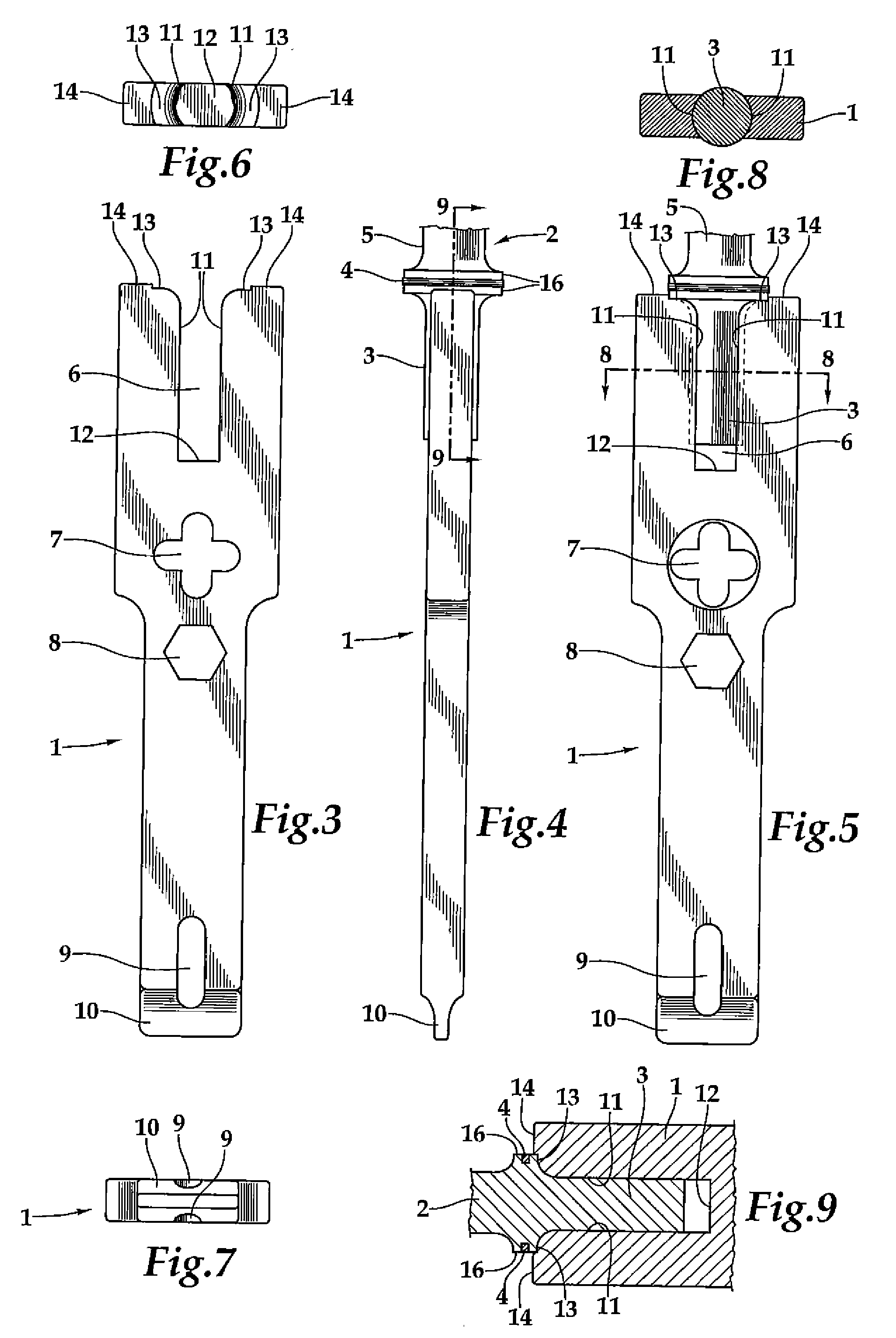

Rifle bolt cleaning tool

A rifle bolt cleaning tool comprising a single piece of material with an annular bolt scraping chamber comprising a bottom and two inner walls that extend from the bottom of the scraping chamber upward and spread outward to form two top surfaces of the scraping chamber. The inner walls of the scraping chamber are concave in shape so as to fit snugly around a tail end of a rifle bolt. The distance between the two inner walls of the scraping chamber is roughly equivalent to the outside diameter of a rifle bolt. The inner walls of the scraping chamber extend upward from the bottom of the scraping chamber by a distance that is slightly greater than the length of the tail end of the bolt.

Owner:LIKEMIND BRANDS INC

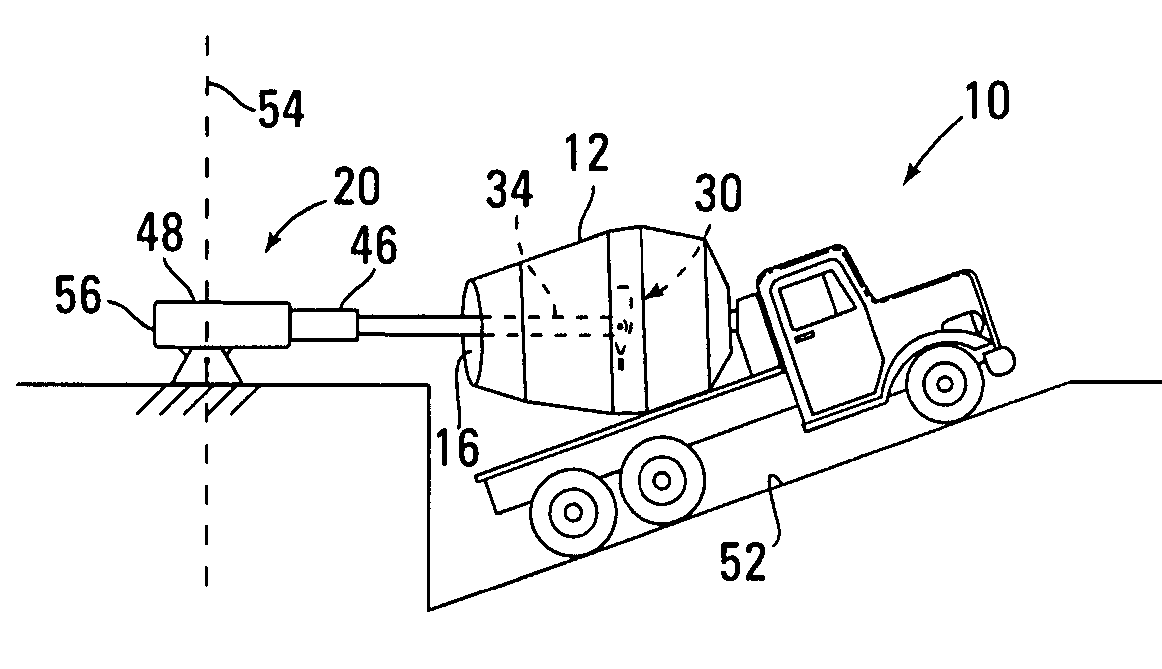

Mechanism for removing concrete accretions from mixing drum

A device for removing accretions of cured concrete from within a mixing drum is herein disclosed. The device includes an impact tool mounted upon a boom that may be inserted into the interior of the mixing drum. The impact tool is mounted upon the boom such that it may be rotated about an axis that is substantially perpendicular to that of the boom. The boom itself may be rotated about an axis substantially aligned with its own the length. In addition, the boom may be rotated laterally and up and down by positioning mechanism. The device may be mounted in a fixed location or it may be mounted upon a mobile platform.

Owner:HAMMERROCK

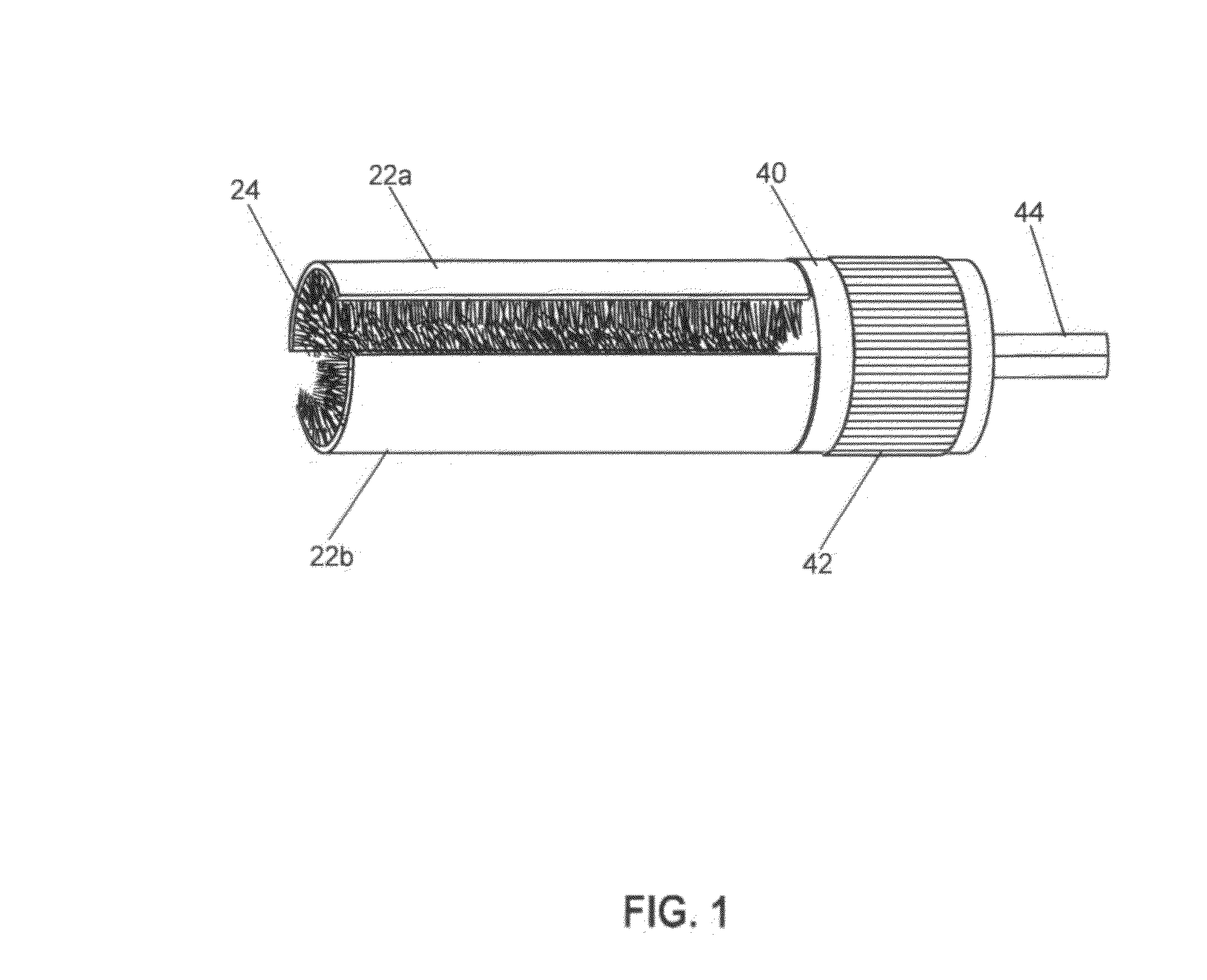

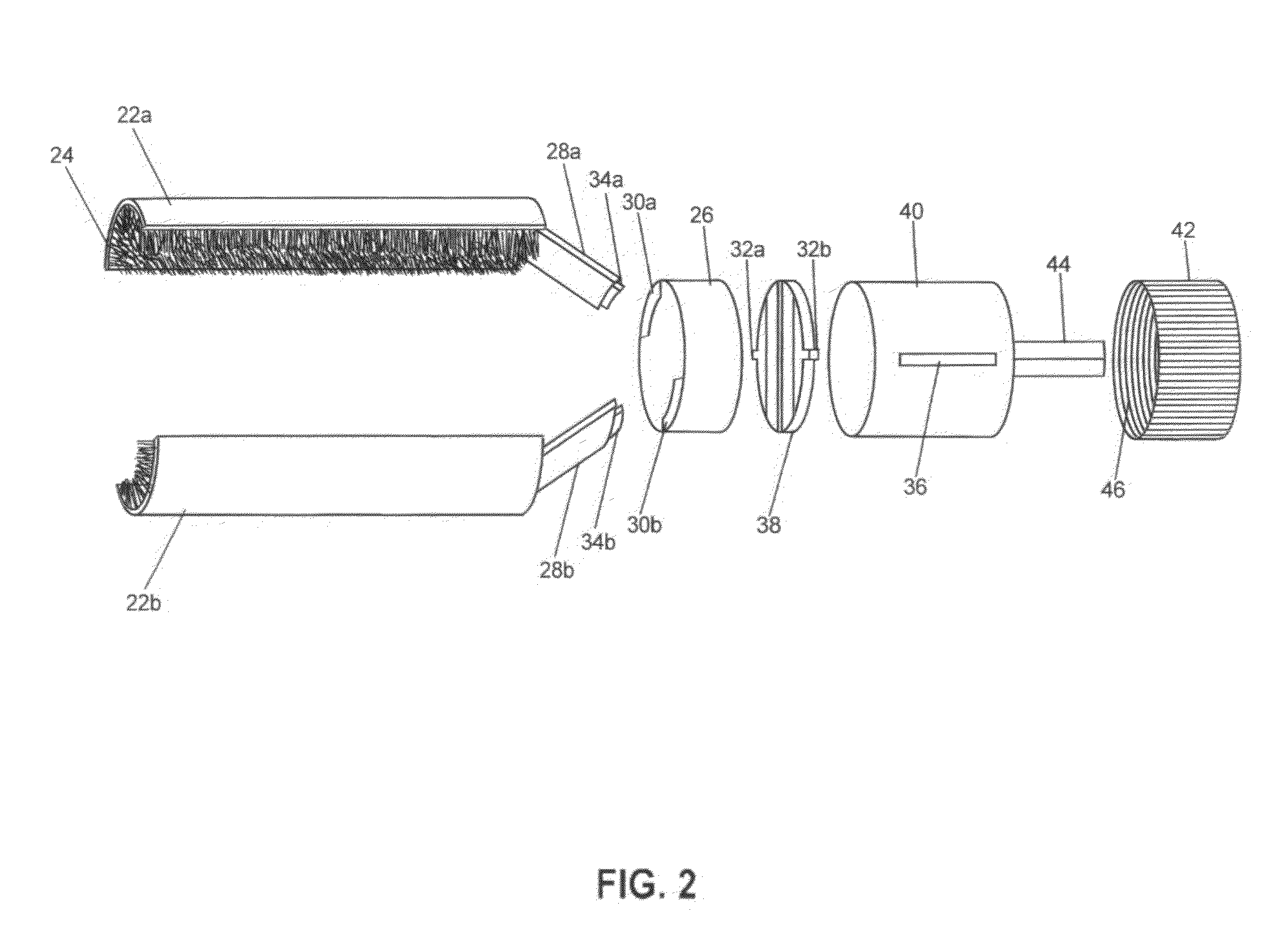

Adjustable bolt cleaner

InactiveUS20120186032A1Hollow article cleaningOven incrustations prevention/removalScrew threadHigh velocity

A adjustable fitting thread cleaning apparatus. The apparatus is specifically used for cleaning the threads of bolts. Bolts of any type namely ones used in the field of autos, machinery and equipment. The apparatus consists of 2 parallel elements that form an inner adjustable diameter. Parallel elements adjust from 7.5 mm to 30 mm in diameter for cleaning bolts in this size range. The apparatus consists of a shaft member with the purpose of connecting to a power drill to be rotated at high velocity speed. This creates an expeditiously quick and thorough clean of the bolt threads when the bolt is inserted in between the parallel elements.

Owner:DONOHUE WILLIAM J +1

Systems and methods for robotic gutter cleaning along an axis of rotation

In embodiments of the present invention, a gutter-cleaning device comprises a housing containing an impeller drive facility, the housing configured to fit into a gutter, an impeller, disposed at an end of the housing and driven by the impeller drive facility, and a transport facility for transporting the housing along the gutter

Owner:IROBOT CORP

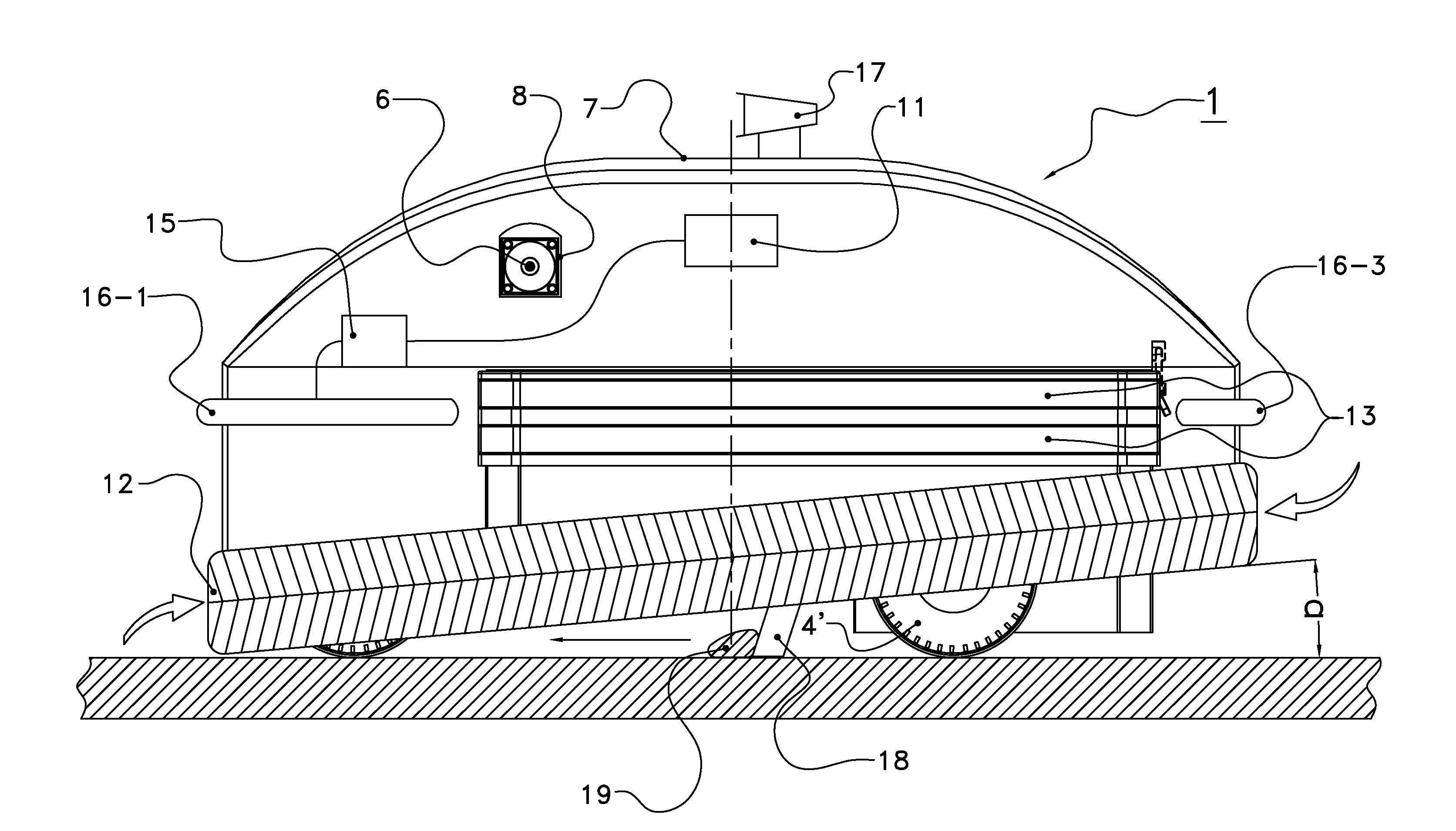

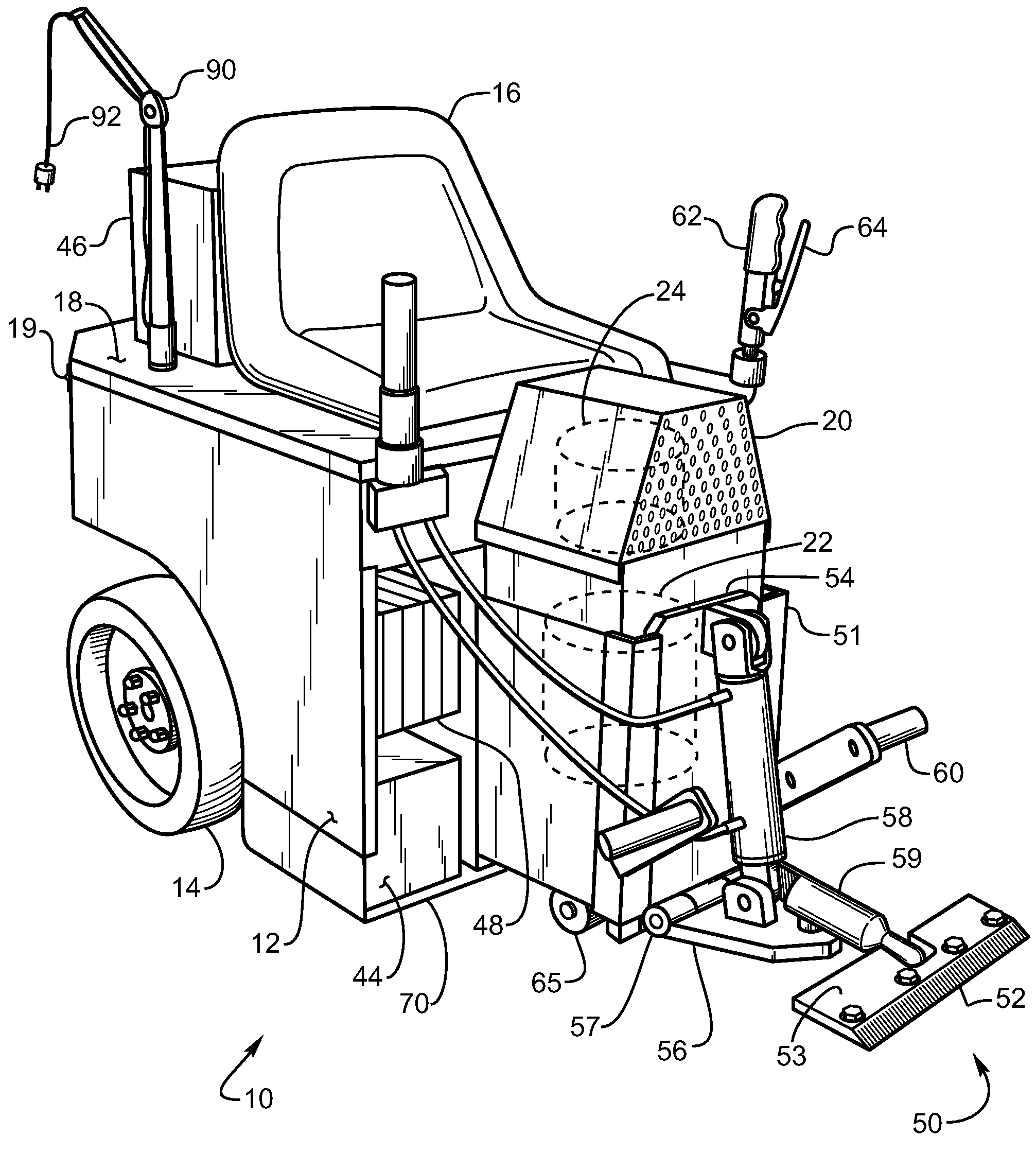

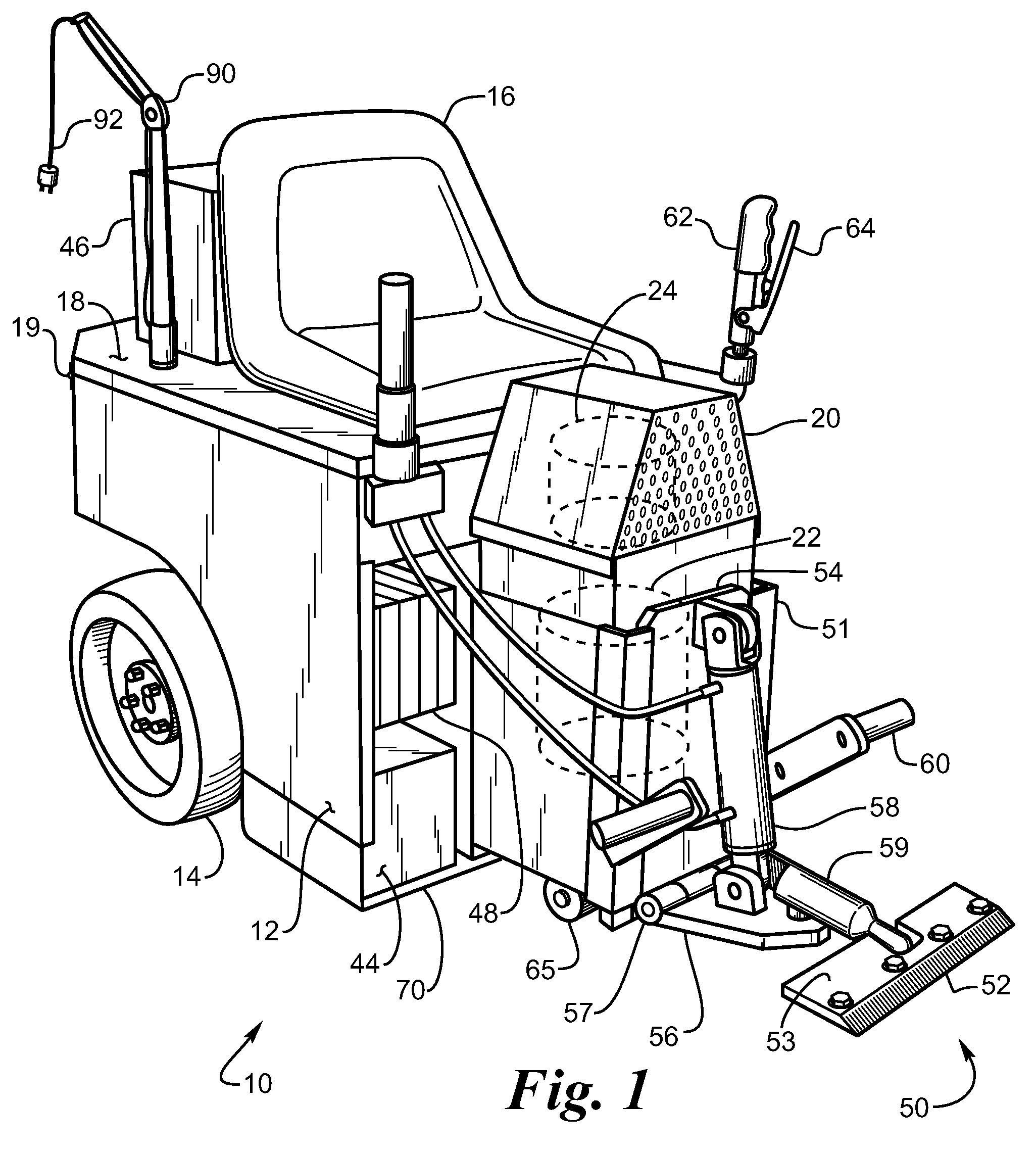

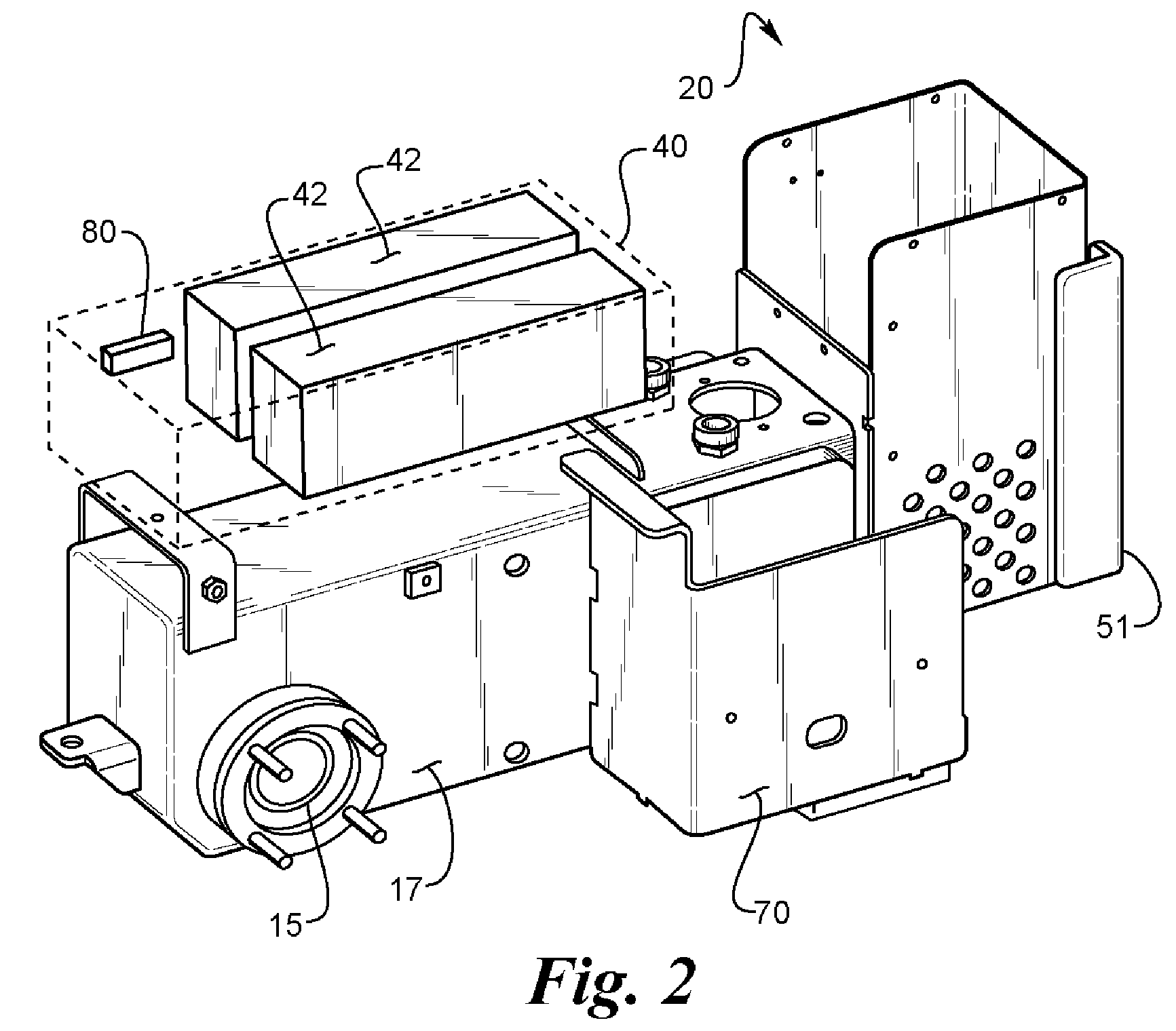

Battery powered riding floor stripping machine

ActiveUS7562412B1Quick and easy changeEasy to addCarpet cleanersFloor cleanersRemote controlHydraulic pump

A floor stripping machine having the electric motor and hydraulic pump placed just aft of the blade engages adds weight to the blade and provides for a narrower more compact design with a lower center of gravity for better maneuverability and ease of access to narrow halls, doorways and rooms. A battery powered floor stripping machine may have batteries stored in the housing under the seat and have auxiliary batteries behind the seat on top of the housing for easy of removing the batteries for recharging. Additional batteries and or weights can be used on either side of the housing. In alternative embodiments the floor stripping machine can be remote controlled. Battery management with the auxiliary batteries being recharged during the day allows for eight hours of use. A trunk may store batteries, which can be slid onto a trailing cart to change batteries.

Owner:NAT FLOORING EQUIP INC

Process for producing high-carbon biogenic reagents

ActiveUS20140075834A1Improve energy efficiencyImprove a product attributeCoke quenchingCoke oven safety devicesHigh carbonCombined use

Owner:CARBON TECH HLDG LLC

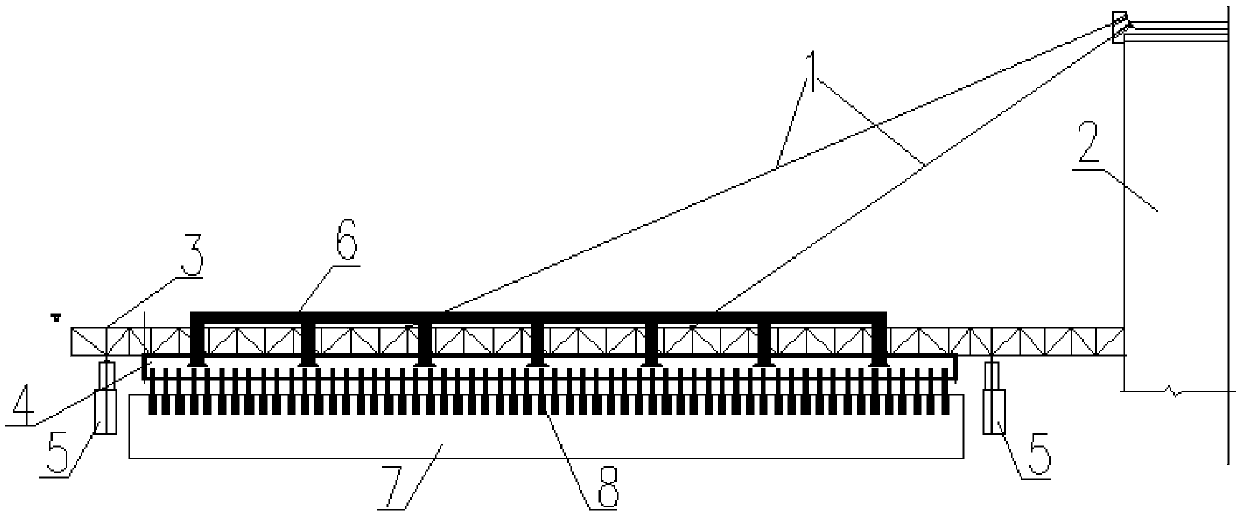

Dust hood for coke oven

ActiveCN107828430AOptimize layoutReduce security risksOven incrustations prevention/removalFire protectionDust control

The invention discloses a dust hood for a coke oven. The dust hood comprises horizontally distributed steel trusses (3), which are fixed on a coal tower (2) through stay cables (1). Two ends of the steel trusses are supported through columns (5). A fire insulation and dust storage layer (4) is arranged below the steel trusses (3). By the above technical scheme, the main-body structure of the steeltrusses will not be exposed to a fire scene caused by coke discharging, safety risk during the application period is reduced, and service life is prolonged. The original full-coverage roof truss is changed into the two-row steel trusses, and the refuge floor material is lightweight fire insulation boards fitted with lightweight keel. Thus, deadweight is greatly reduced. Construction can be completed through prefabricated assembly and hoisting. Thus, building cost and construction difficulty are greatly reduced. With the arrangement of local folding boards and by optimization of an air-duct system, functions of heat dissipation, dedusting, fire protection and the like are integrated into the dust hood. The dust hood has good environmental-protection value.

Owner:WUHU XINXING DUCTILE IRON PIPES

Rifle bolt cleaning tool

A rifle bolt cleaning tool comprising a single piece of material with an annular bolt scraping chamber comprising a bottom and two inner walls that extend from the bottom of the scraping chamber upward and spread outward to form two top surfaces of the scraping chamber. The inner walls of the scraping chamber are concave in shape so as to fit snugly around a tail end of a rifle bolt. The distance between the two inner walls of the scraping chamber is roughly equivalent to the outside diameter of a rifle bolt. The inner walls of the scraping chamber extend upward from the bottom of the scraping chamber by a distance that is slightly greater than the length of the tail end of the bolt.

Owner:LIKEMIND BRANDS INC

Biomass pyrolysis in refinery feedstock

ActiveUS20110184215A1Accelerated pyrolysisIncrease costPreheating coke ovensDirect heating destructive distillationHot liquidsBiomass

This invention relates to biomass pyrolysis through the use of a hot liquid refinery feedstock as a heat transfer medium, preferably a vacuum gas oil feedstock.

Owner:PHILLIPS 66 CO

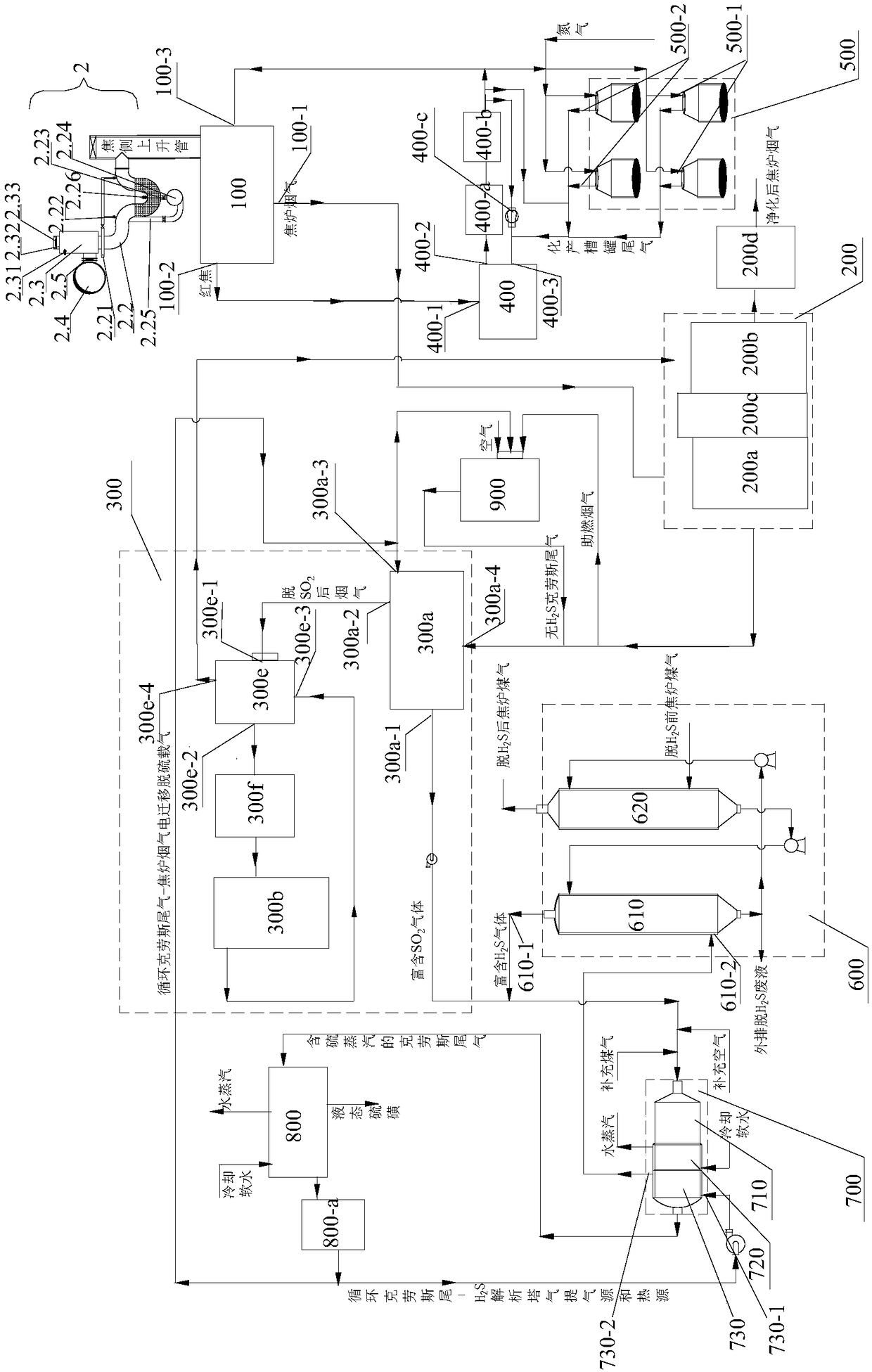

Coking waste gas purification system

ActiveCN108654362AEfficient recyclingReduce pollutionCombination devicesCoke quenchingCombustion chamberChemical products

The invention discloses a coking waste gas purification system, which belongs to the field of energy saving and environment protection of the coking industry. The coking waste gas purification systemcomprises a coking smoke generating and processing system, a dry quenching system and a tank nitrogen sealing system, wherein the coking smoke generating and processing system comprises a coke oven, acoke oven horizontal flue and a coke oven smoke desulfurization and denitrification device; the dry quenching system comprises a dry quenching furnace; the tank nitrogen sealing system comprises a chemical product storage device; the dry quenching furnace is provided with a circulating inert gas outlet and a circulating inert gas inlet; each tank of the tank nitrogen sealing system is respectively provided with a chemical product tank gas inlet used for introducing nitrogen, and a chemical product tank gas outlet used for emitting chemical product tail gas; the circulating inert gas outlet ofthe dry quenching furnace is connected with three gas pipelines, wherein one gas pipeline is connected with the circulating inert gas inlet of the dry quenching furnace for importing circulating inert gas to cool cokes in the dry quenching furnace, another gas pipeline is connected with the chemical product tank gas outlet of the chemical product storage device for importing into spreading tail gas blow gas pipeline of the circulating inert gas, and the final gas pipeline is connected with an in-furnace gas inlet arranged on the coke oven for importing the spreading tail gas dilution coke oven combustion chamber gas of the circulating inert gas. According to the coking waste gas purification system, coking chemical product tail gas can be fully recovered and utilized, and tail gas waste heat can be effectively recovered.

Owner:武汉钢铁有限公司

Apparatus and method for pyrolysis of organic waste

ActiveUS20100282587A1Photosensitive materialsCoal charges mechanical treatmentProcess engineeringPyrolysis

A gasification reactor includes a wiper system including at least one wiper blade operable to wipe an interior surface of the reactor. A condenser unit of the gasification reactor includes a scraper system including at least one scraper segment operable to scrape an interior surface of the condenser unit.

Owner:ITERO DEV LTD

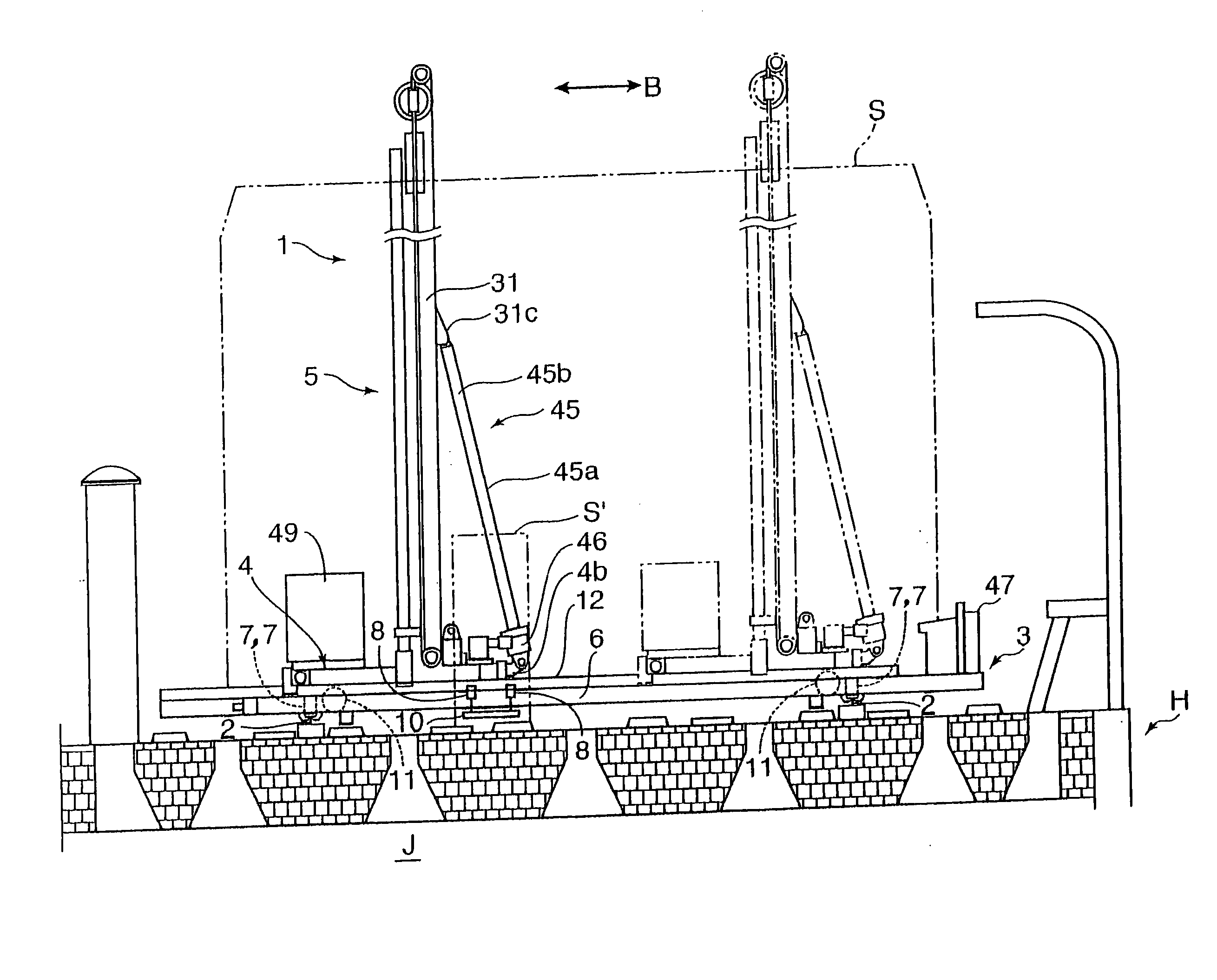

Cook oven repairing apparatus

ActiveUS20070102278A1Continuous operationWide rangeLinings repairBrickwork leakage repair/preventionCoke ovenEngineering

A coke-oven repairing apparatus comprising: a traveling carriage 3 which travels in the direction of coke oven battery with the carriage straddled on the rails placed on the top of a coke oven; a traversing carriage4 provided on said traveling carriage 3, which moves in the direction orthogonal to the direction of coke oven battery; and a working device 5 for making repairs on the oven walls within the coke oven which is mounted on said traversing carriage 4, wherein the working device 5 includes: a guide post 31 which stands on the traversing carriage 4, and is also coupled, at its lower end portion, to a supporting portion provided on the traversing carriage through a pivot shaft 42; a lance 32 which ascends or descends along the guide post 31; and a derricking device 45 which tilts the guide post 31 between a forward-tilted posture and a backward-tilted posture using the pivot shaft 42 as the fulcrum to oscillate the lance 32 inserted in a coke-oven carbonizing chamber through a charging-hole, within the carbonizing chamber.

Owner:KANSAI COKE & CHEM

Center Feed System

ActiveUS20100252409A1Facilitate controlled dispensingGood dispersionThermal non-catalytic crackingCharging-discharging device combinationsProcess engineeringHeat distribution

The present invention features a center feed system for use within a delayed coking system, or any other similar system. The center feed system features an inlet sleeve which slidably engages a retractable nozzle, with inlet and outlet, in fluid connection with a feed source of residual byproduct, allowing residual byproduct to flow from the feed source into the interior of a vessel, thus effectuating or inducing even thermal distribution throughout the vessel.

Owner:DELTAVALVE

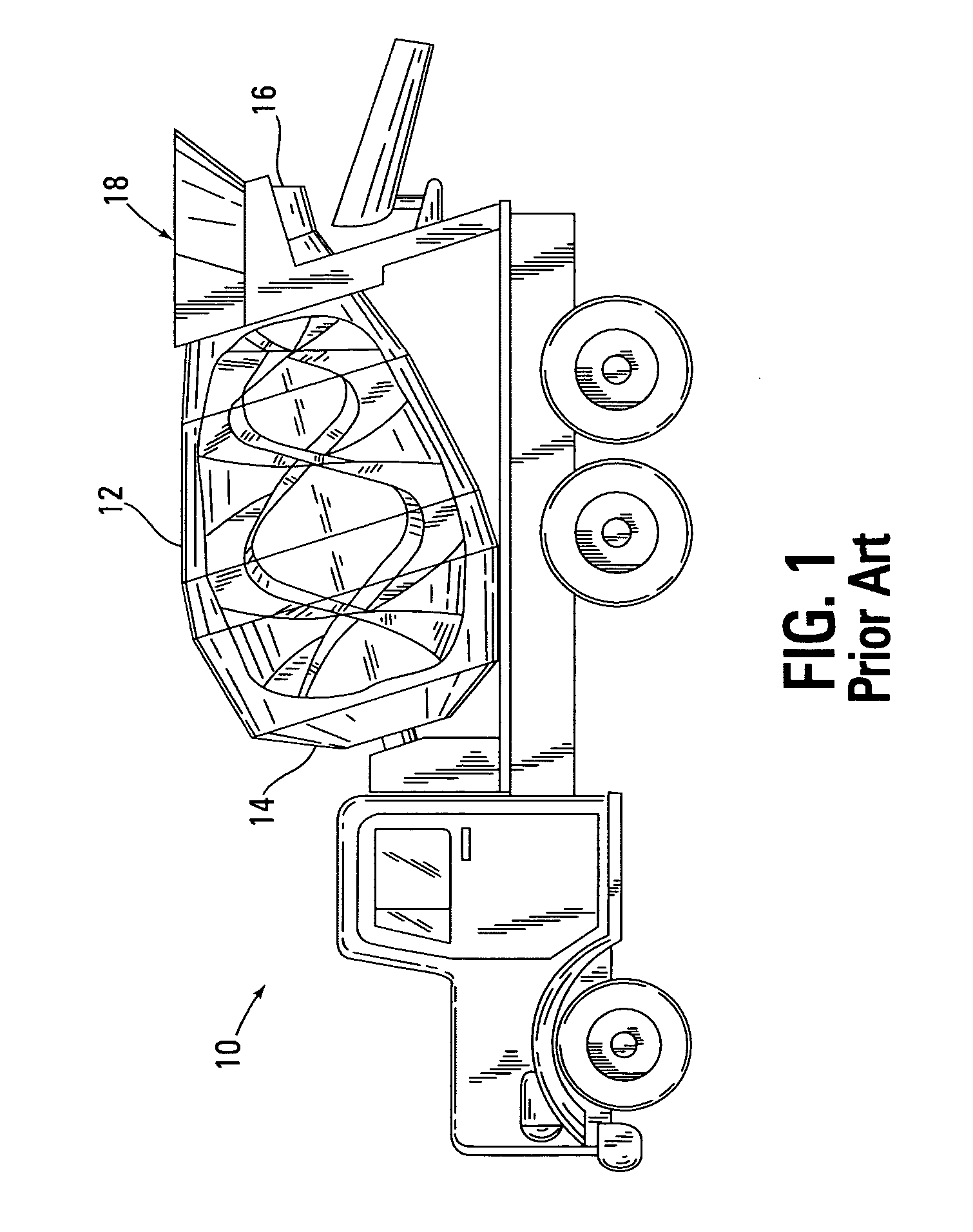

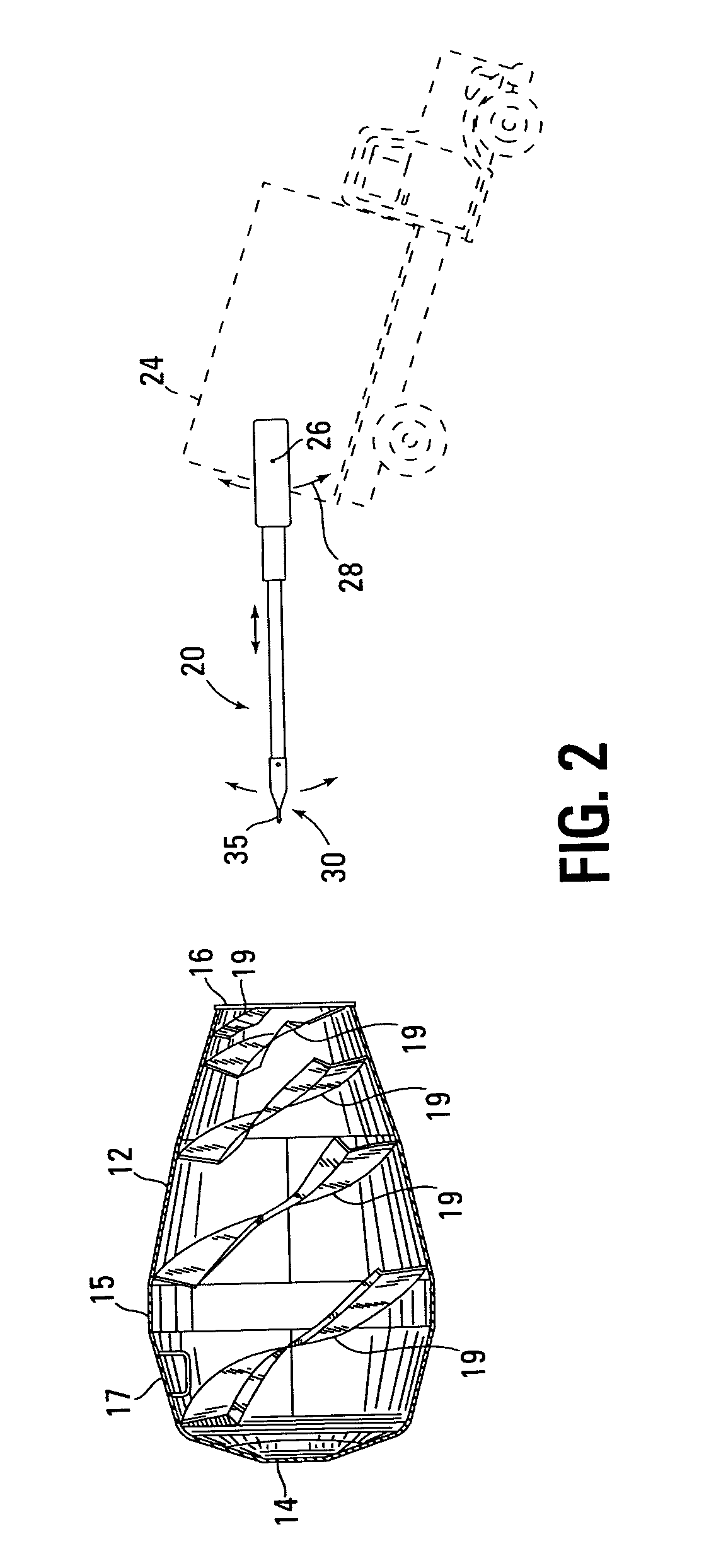

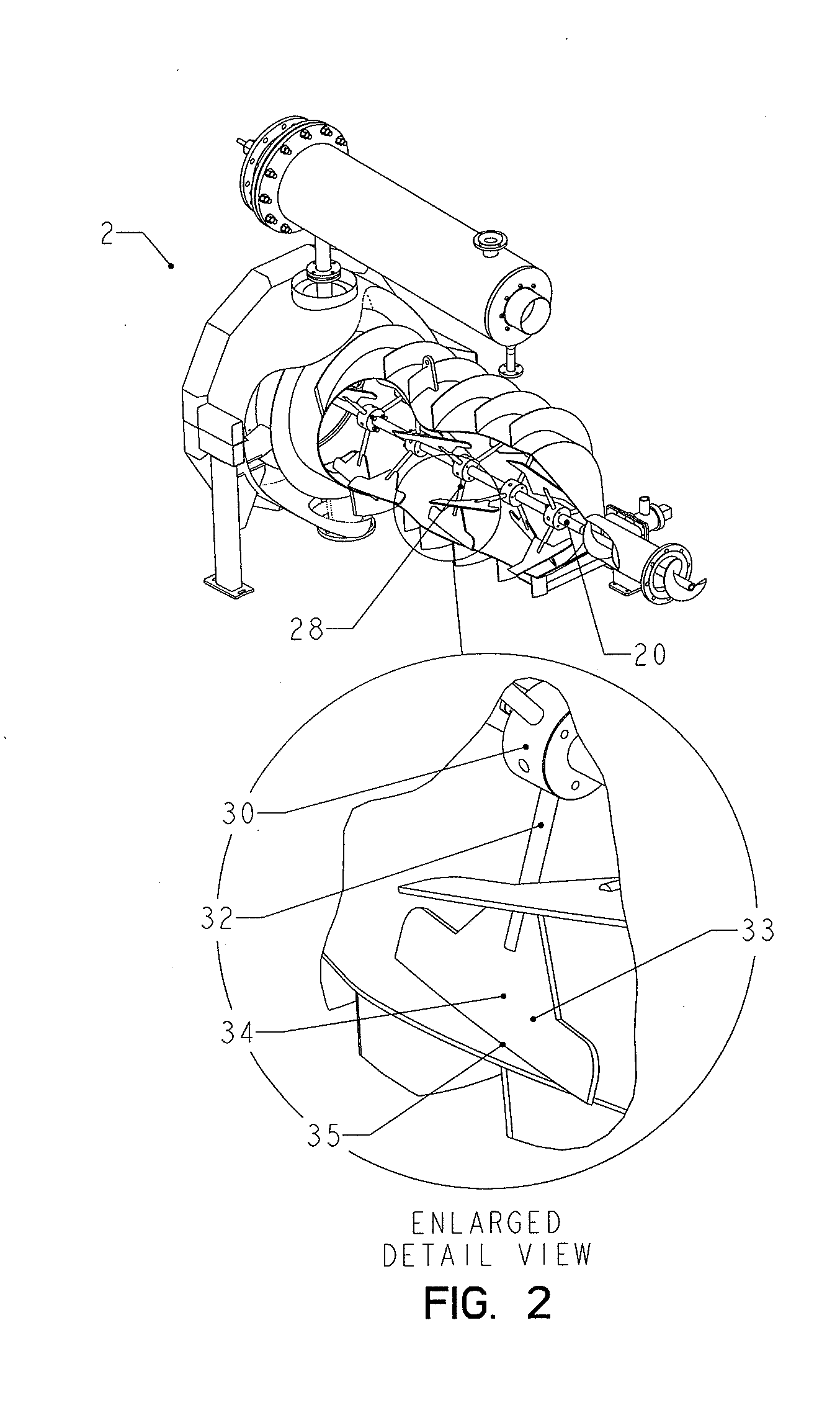

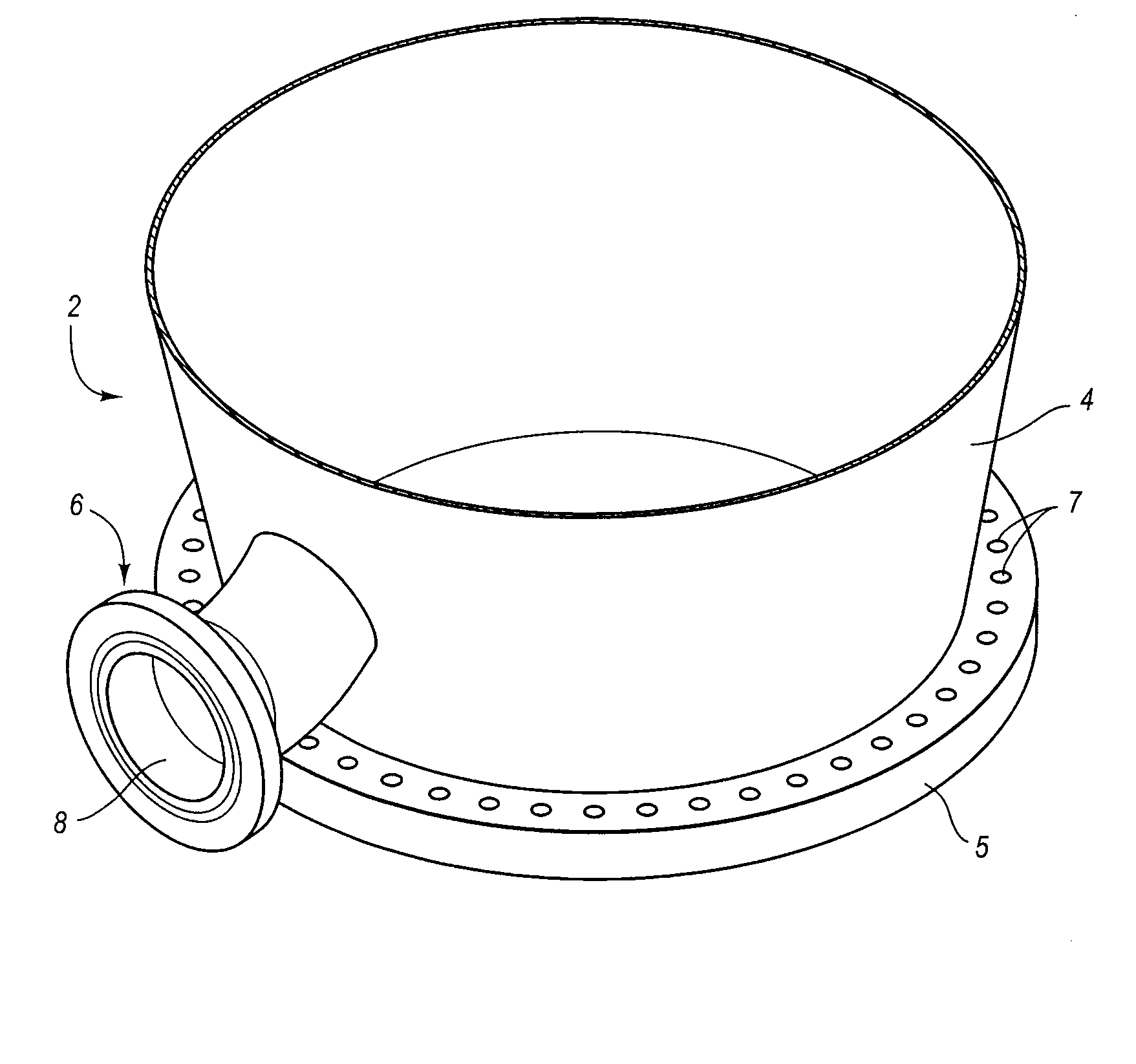

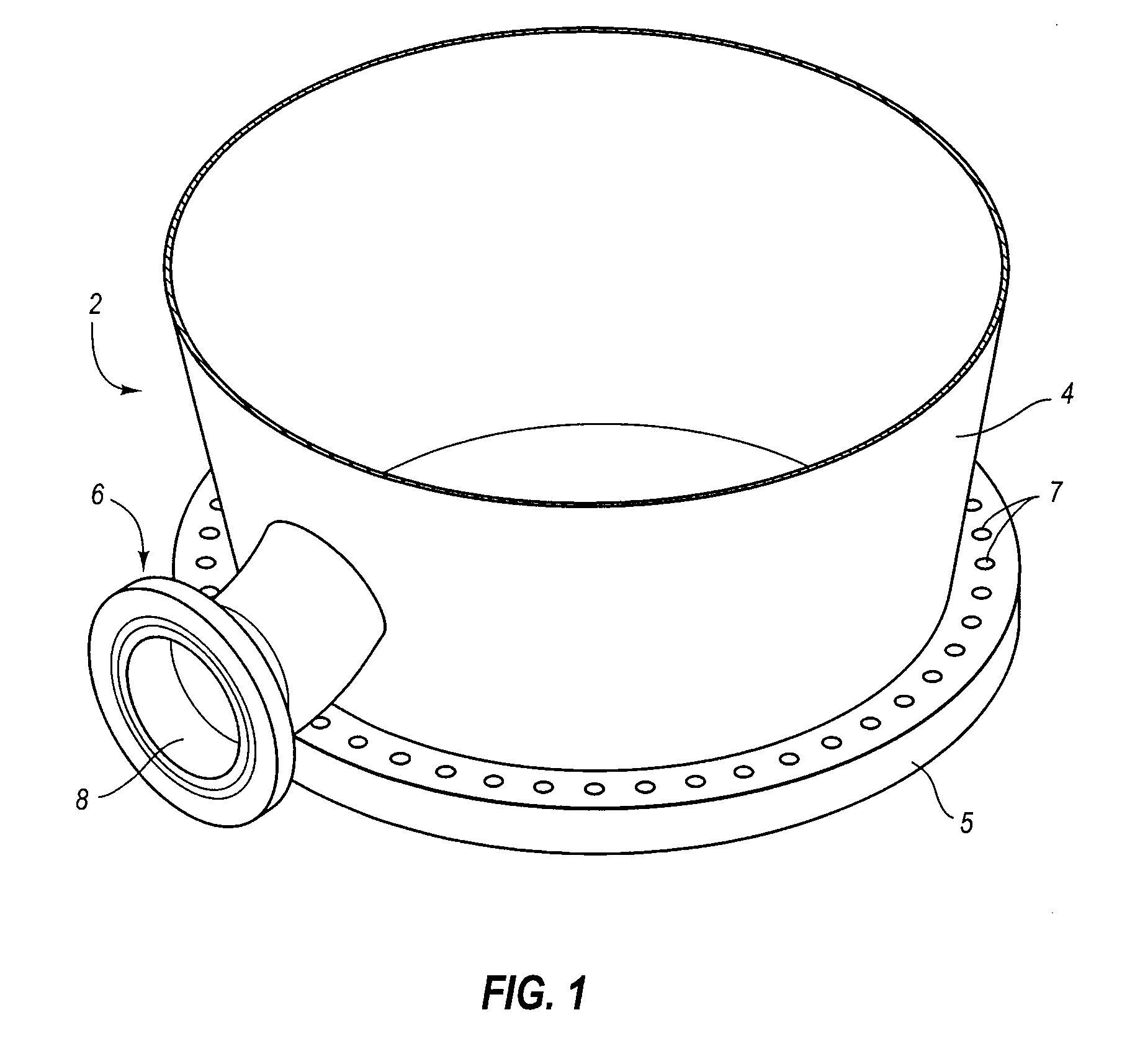

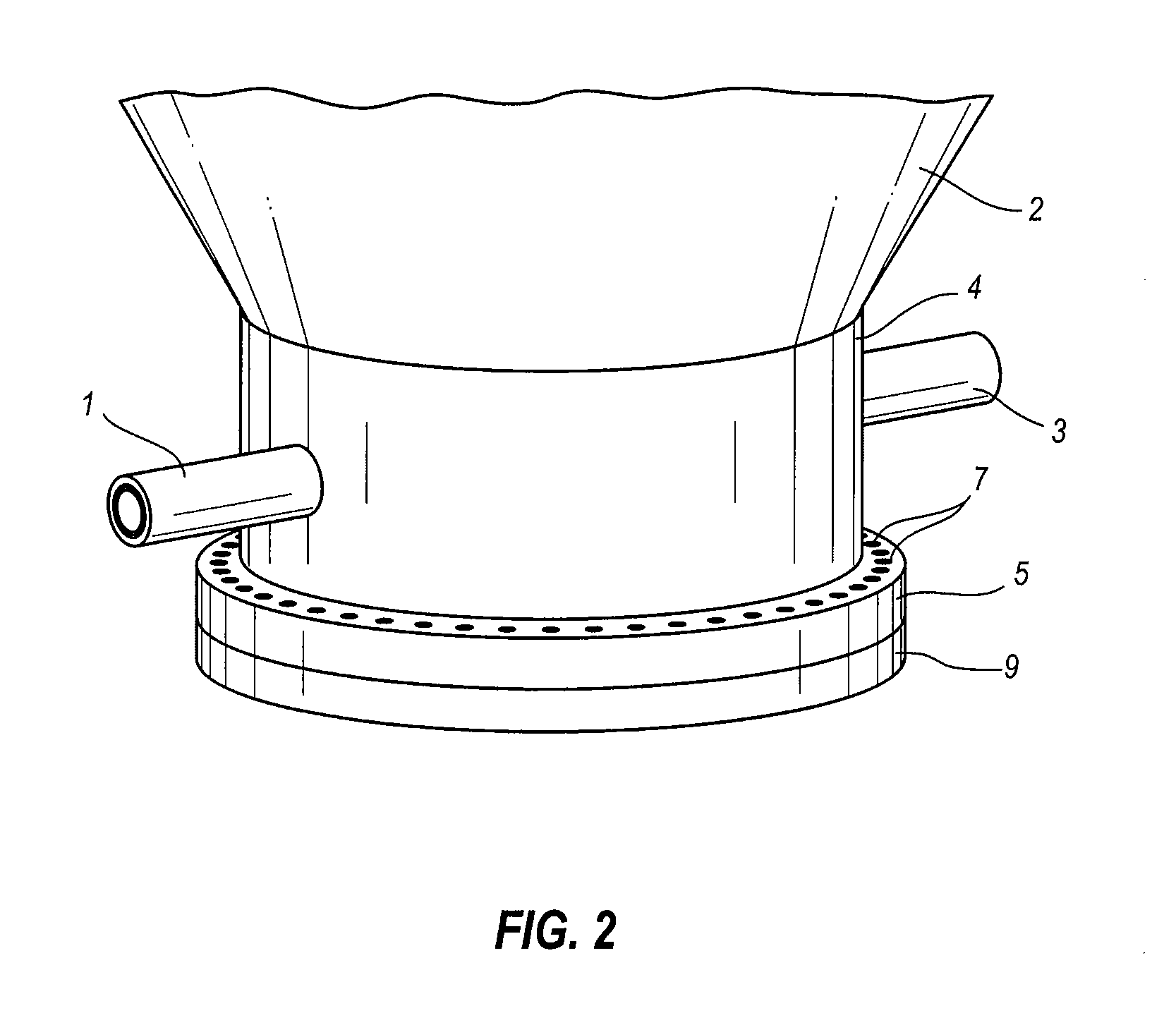

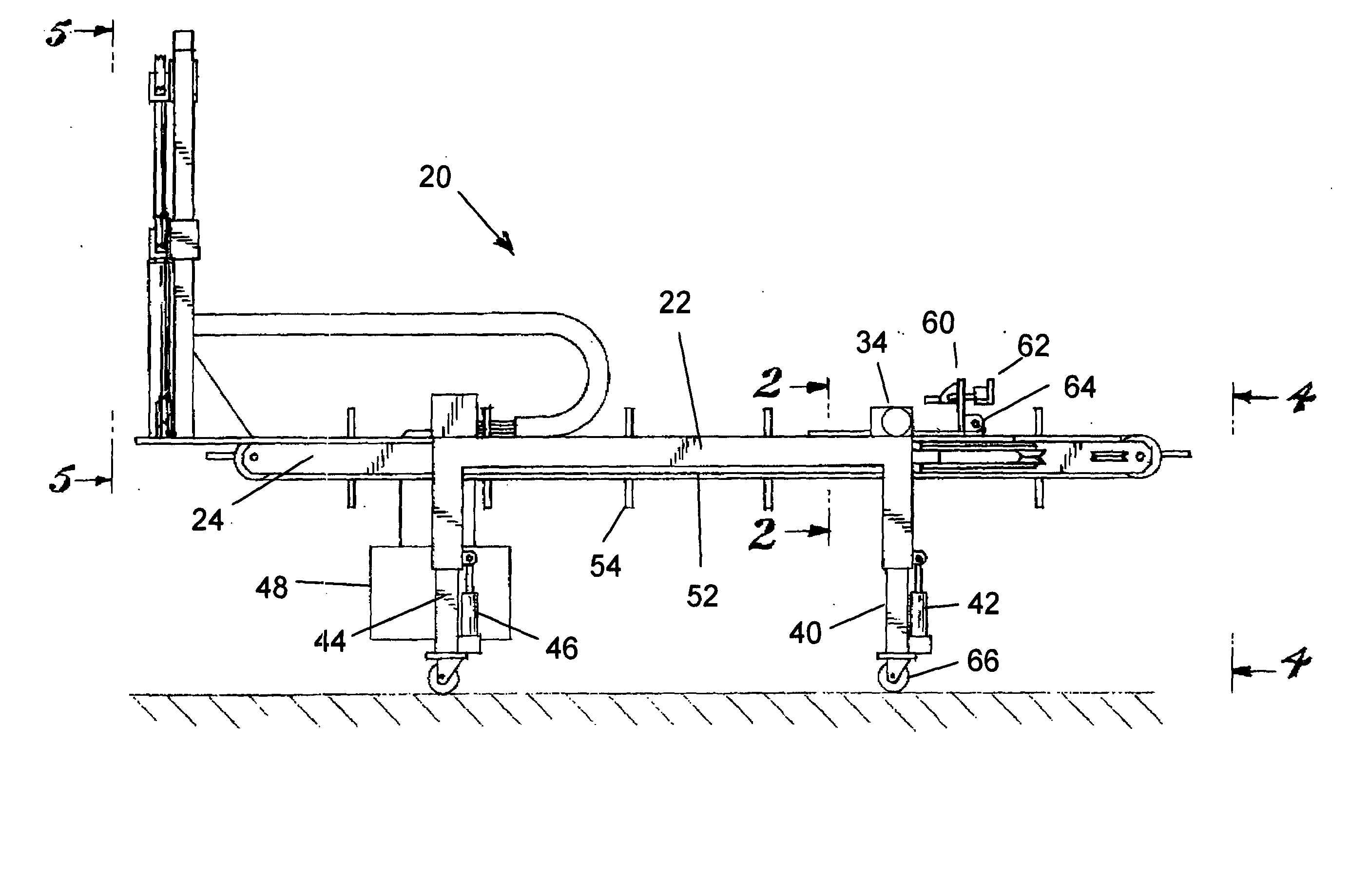

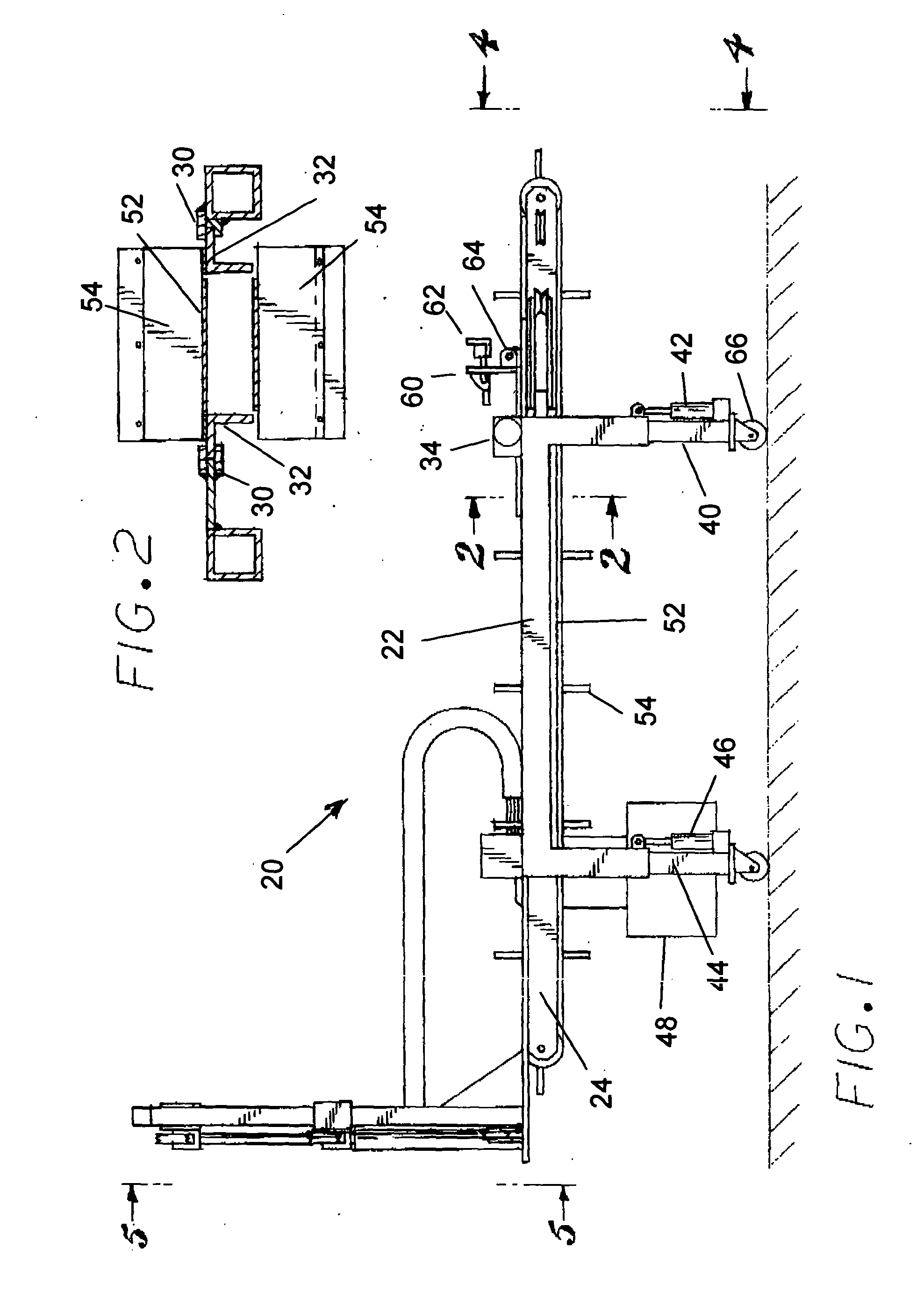

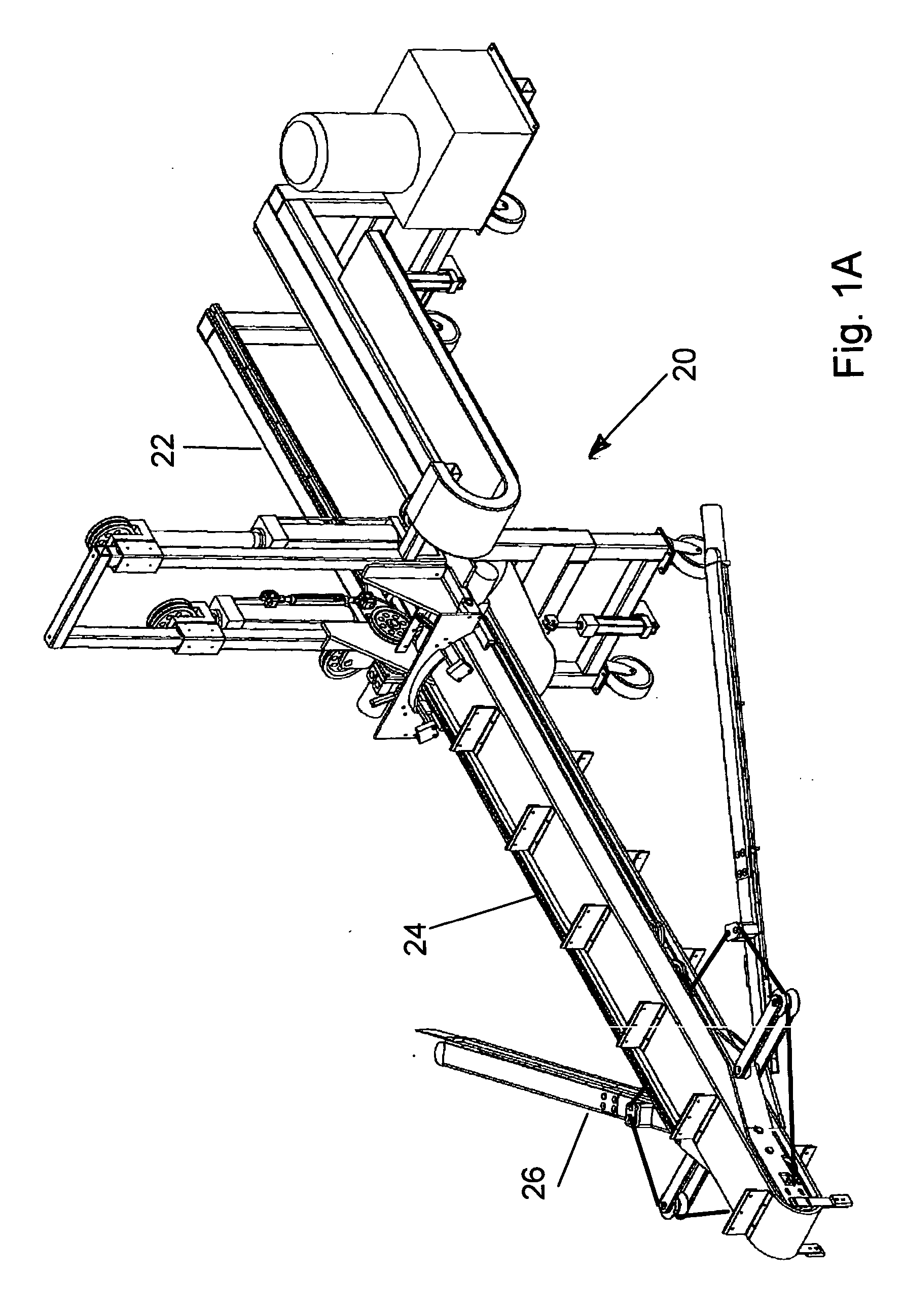

Wine pomace extraction apparatus and method

InactiveUS20050016393A1Minimize macerationMinimize releaseBy-product recoveryBeer fermentationEngineeringPomace

The present invention relates to an apparatus and method for wine pomace extraction from wine processing tanks in a manner so as to minimize maceration of the wine pomace so as not to taint wine entrained within the pomace. In the present invention, wine pomace is mechanically transported out the processing tank by a conveyor means. Wine pomace is guided into the collecting path of the conveyor means by a mechanical sweeper attached to the conveyor means. In a preferred embodiment, a conveyor with sweeper wing attachments is mounted on a portable cart. The invention is positioned into the processing tank through an entry portal and secured to a tank containing pomace. The conveyor transports pomace to a receiver bin until the majority of pomace is extracted. Sweeper wings are deployed to guide remaining pomace into the collecting path of the conveyor.

Owner:SOBERANIS DAVID L

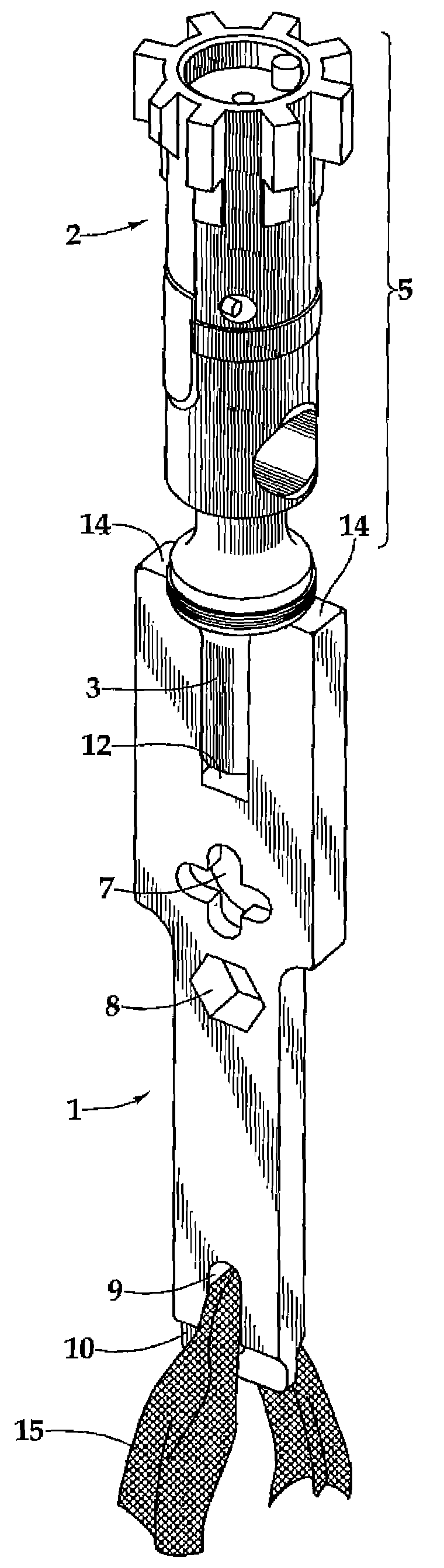

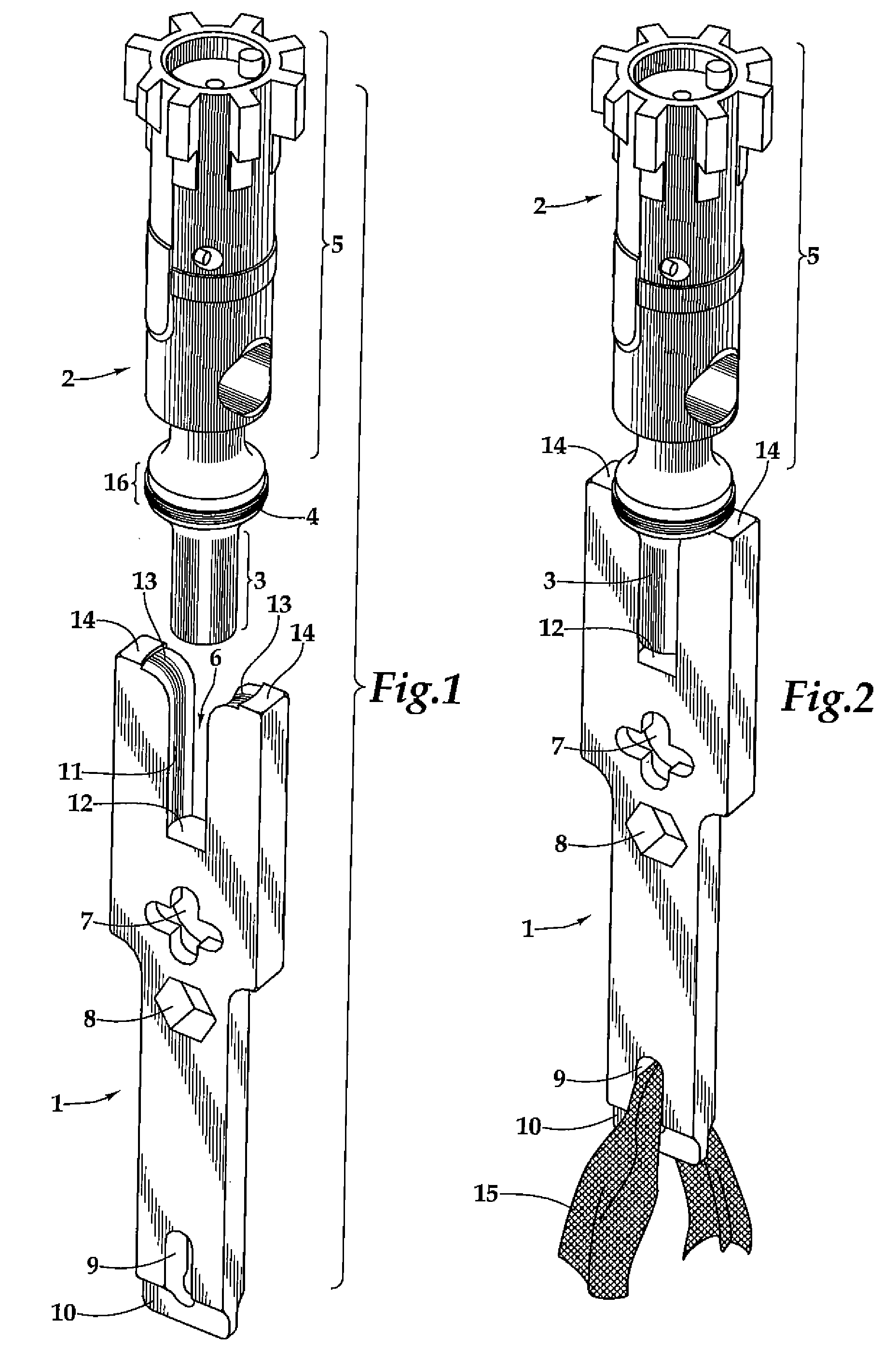

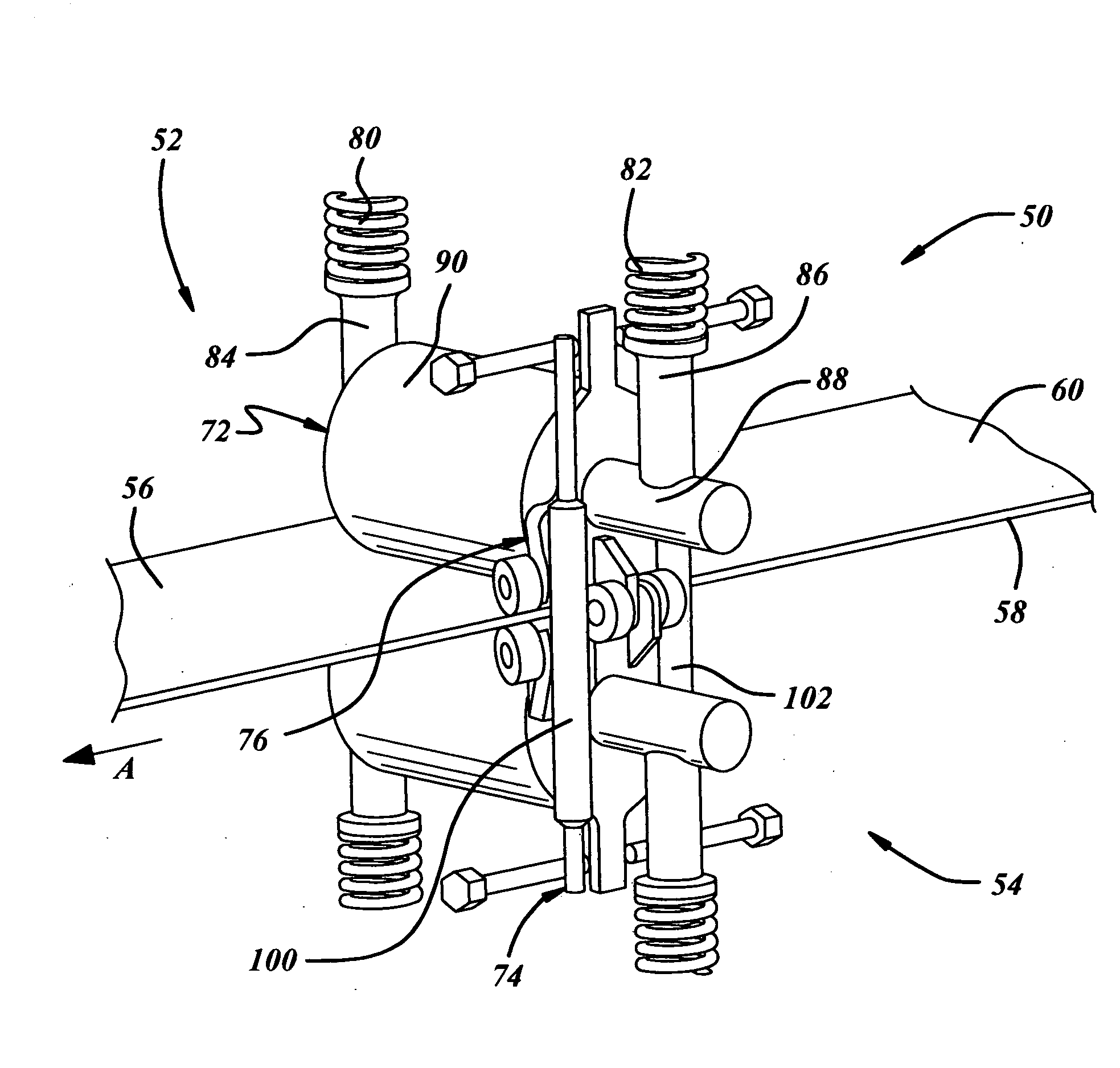

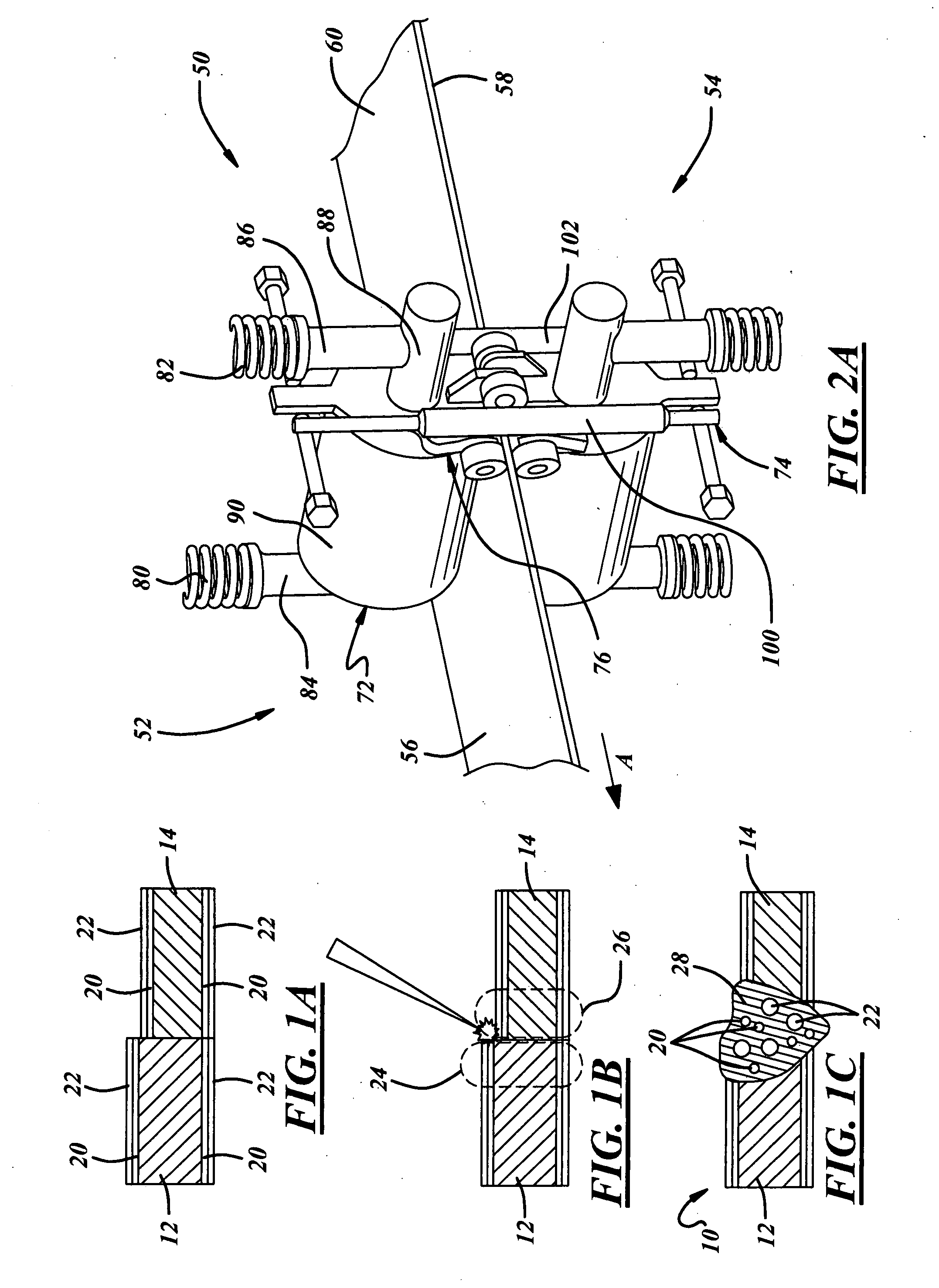

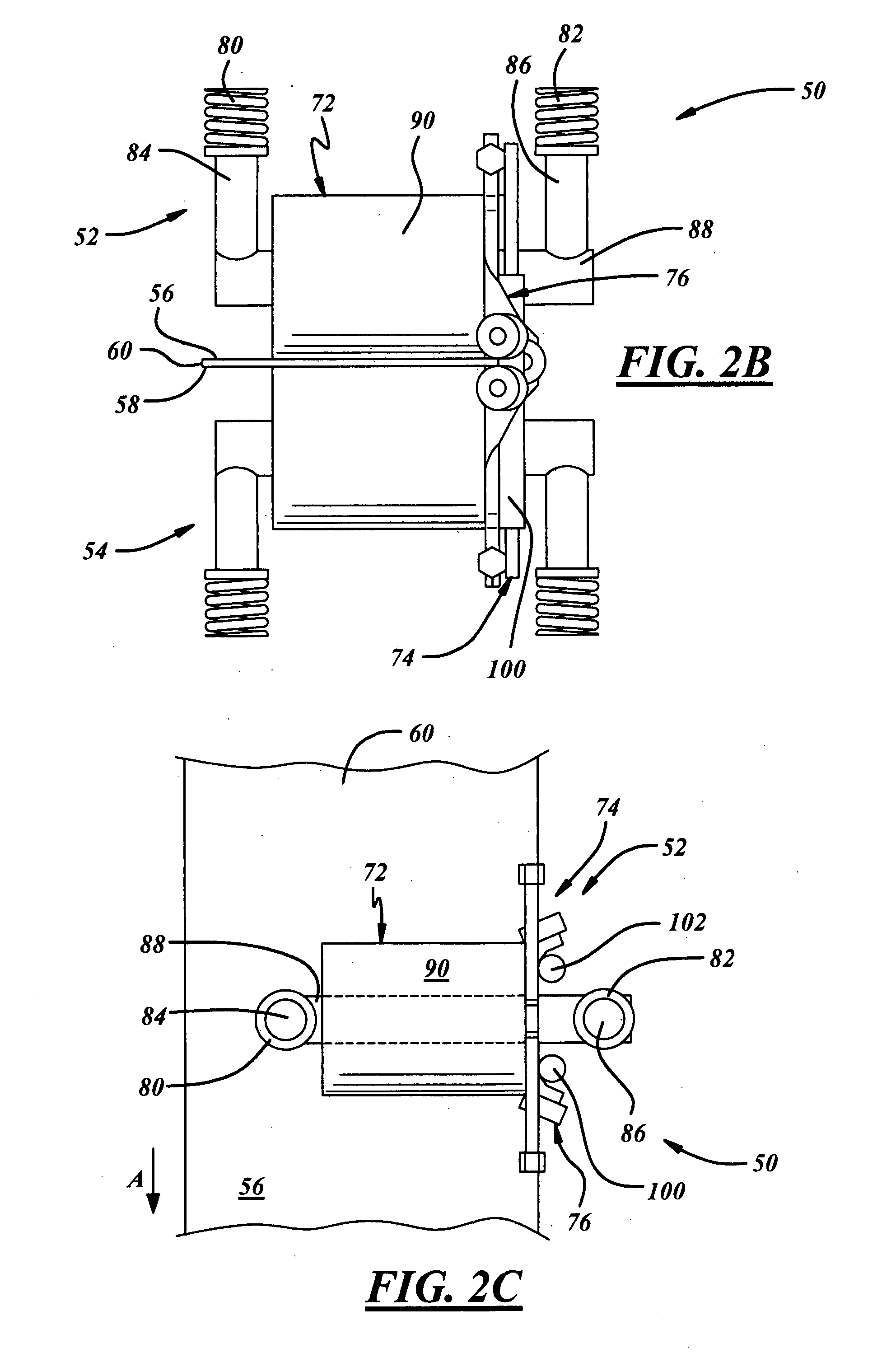

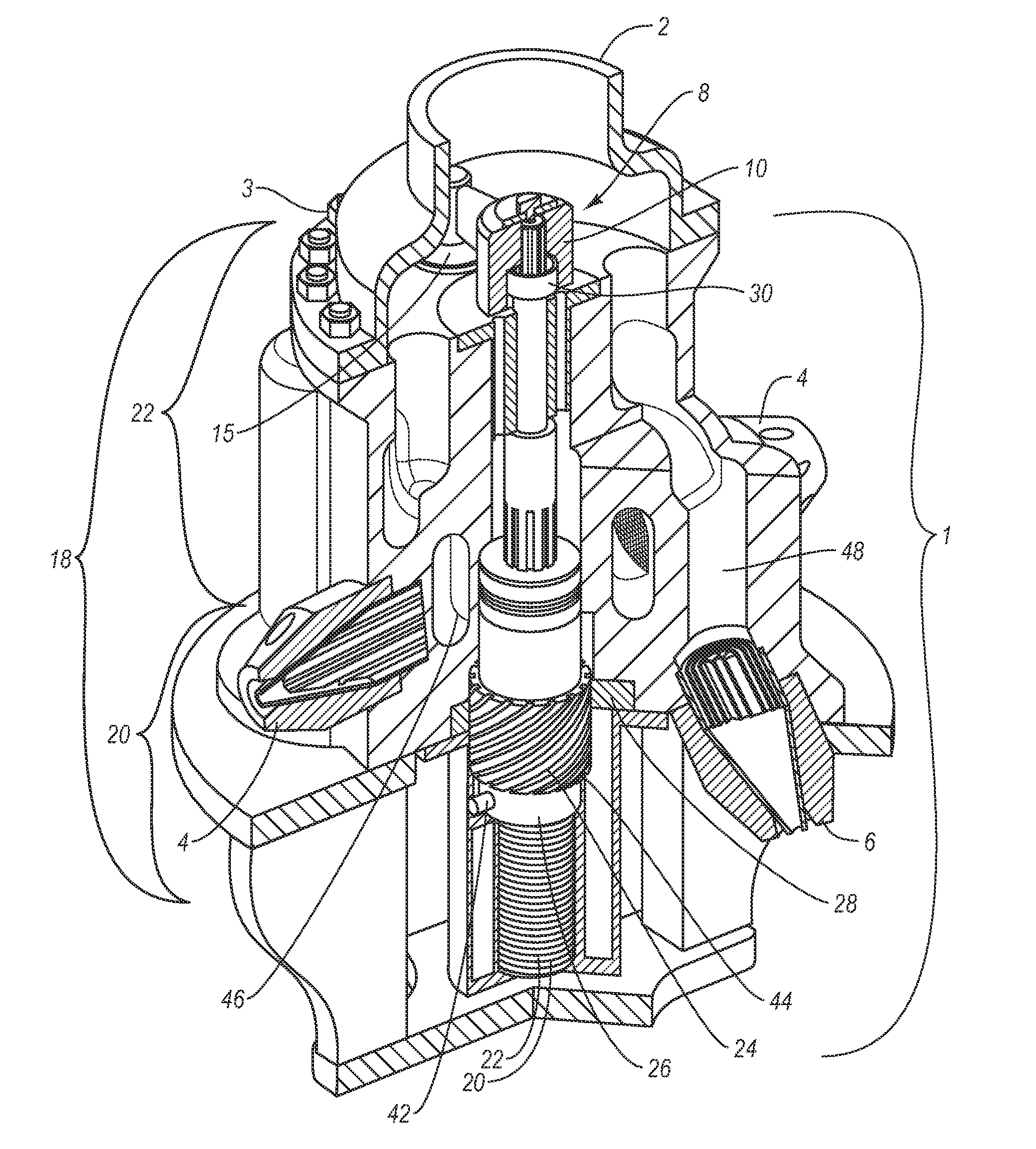

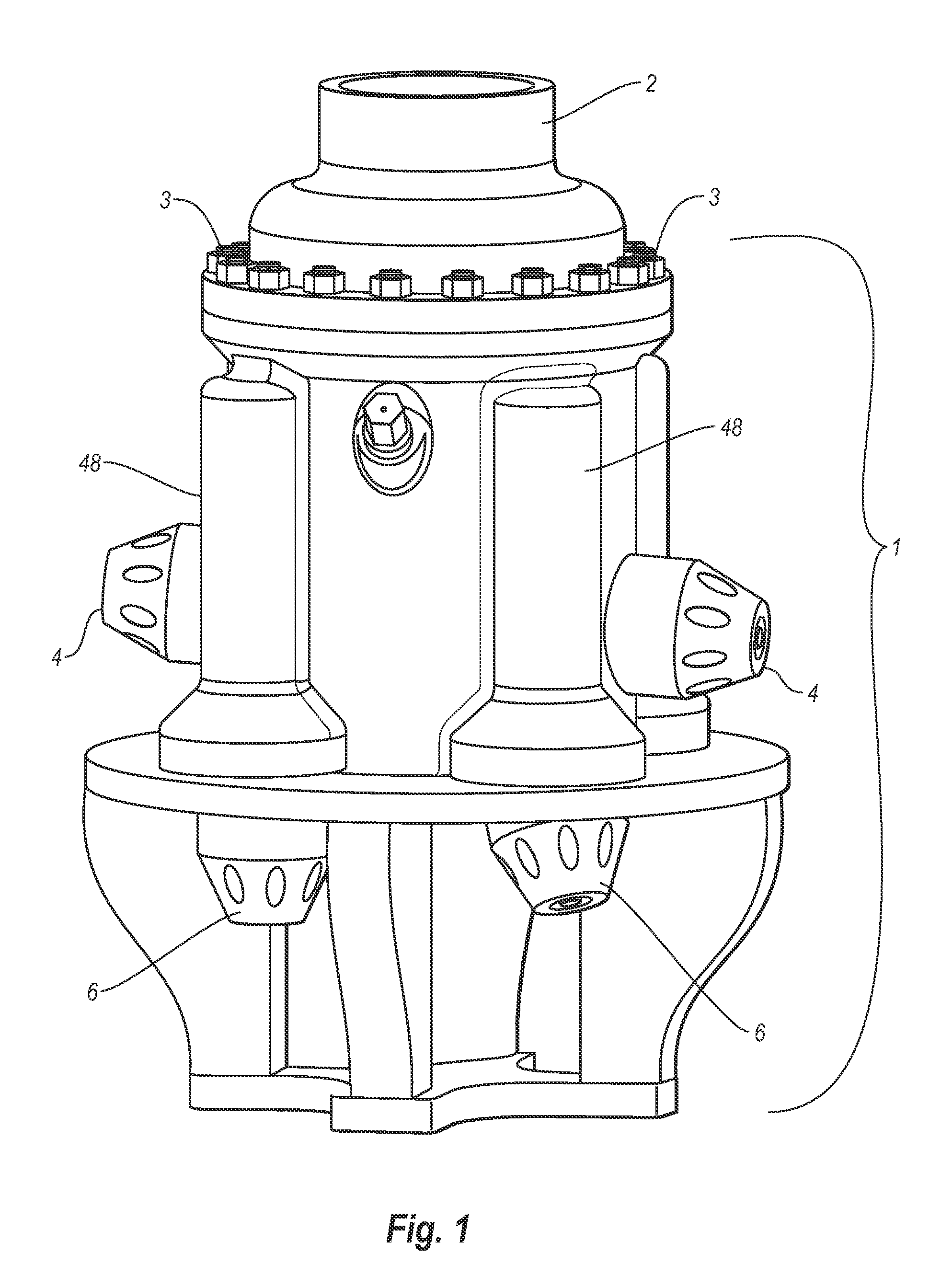

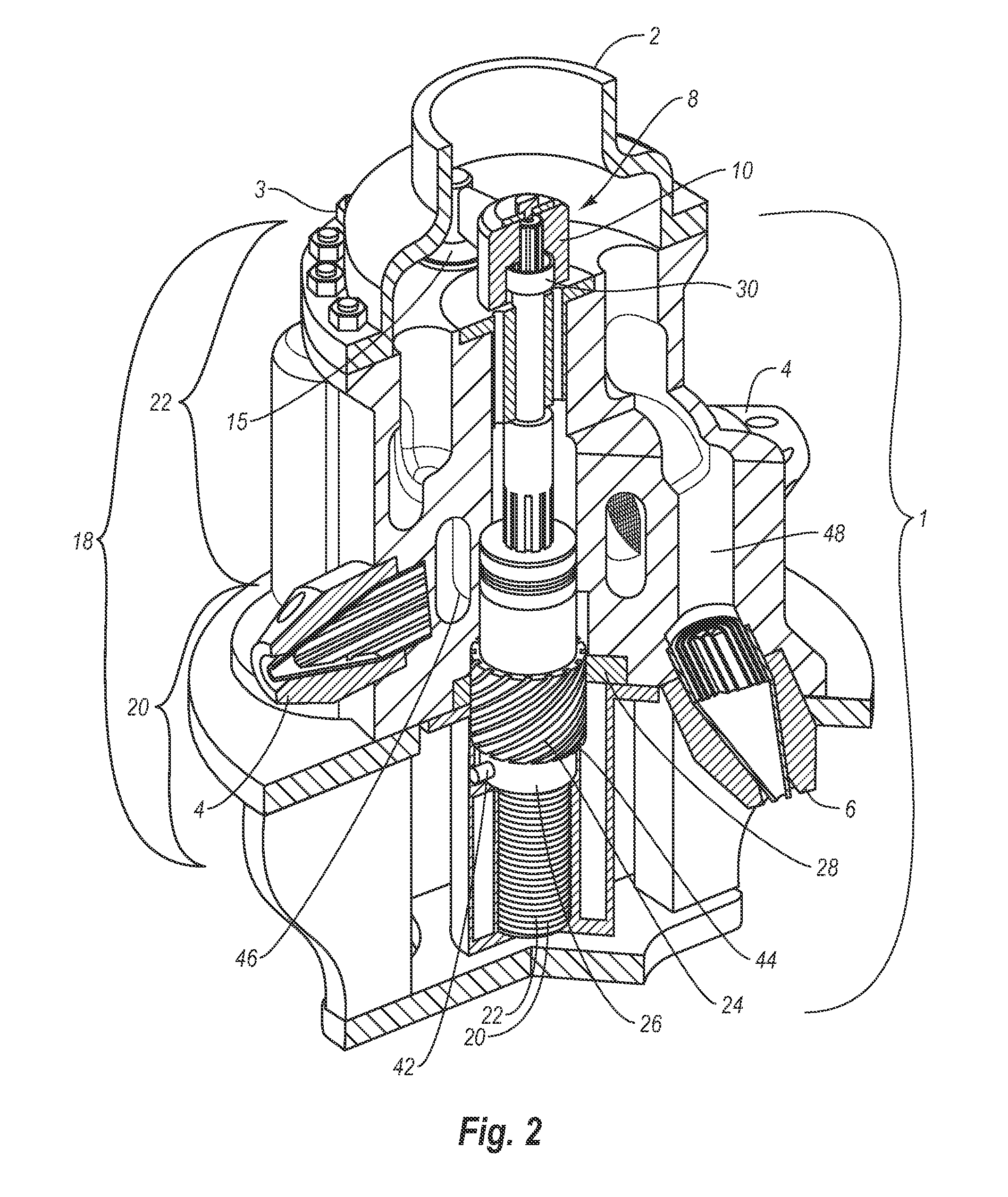

Remotely controlled decoking tool used in coke cutting operations

ActiveUS7473337B2Promote sportsImprove convenienceCoke oven safety devicesCharging-discharging device combinationsEngineeringHigh pressure

The present invention relates to a system that allows an operator to remotely switch between cutting and boring while removing solid carbonaceous residue from large cylindrical vessels called coke drums comprising a cutting head for ejecting high pressure fluids into the coke bed; a flow diversion apparatus; and a shifting apparatus.

Owner:ETHICON ENDO SURGERY INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com