Dust hood for coke oven

A coke oven dust removal and dust storage technology, which is applied in coke ovens, furnaces to prevent/remove fouling, and the petroleum industry, can solve the problems of the main structure, such as heavy weight, economic losses, and intermittent coke output of coke ovens, and reduce construction costs. Effects of cost and construction difficulty, optimization of air duct system layout, and reduction of safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

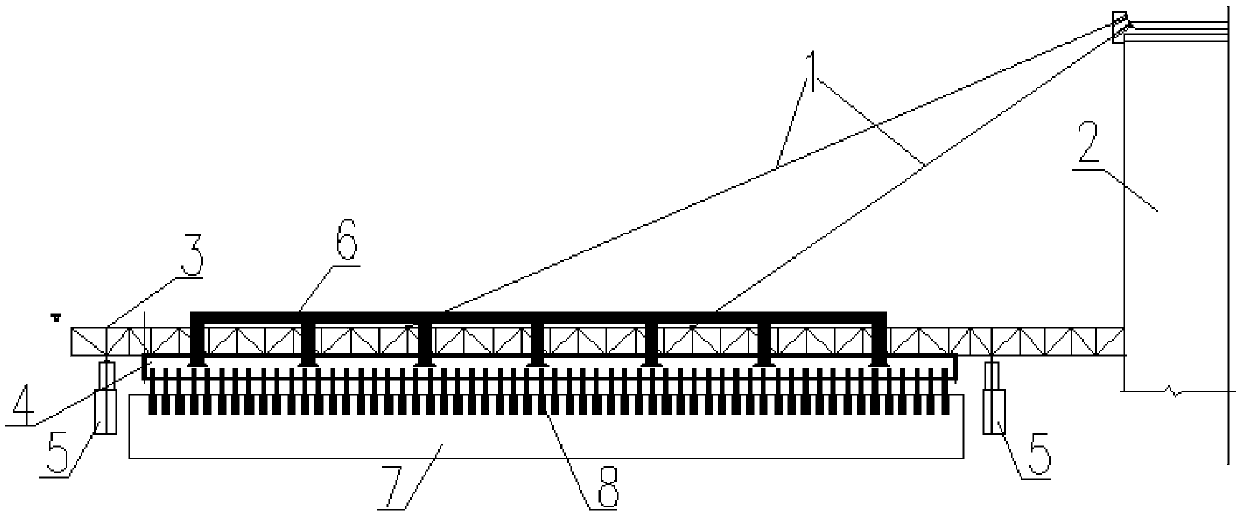

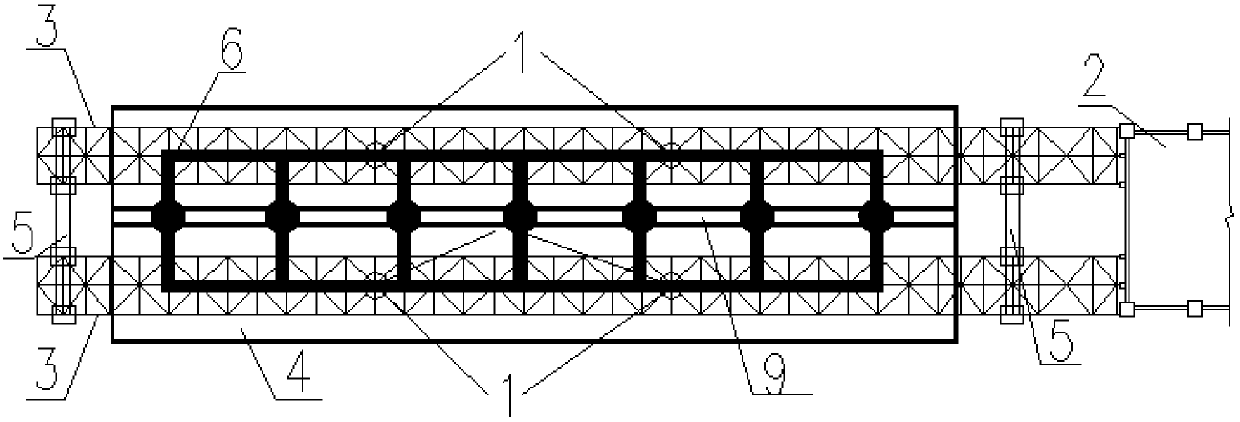

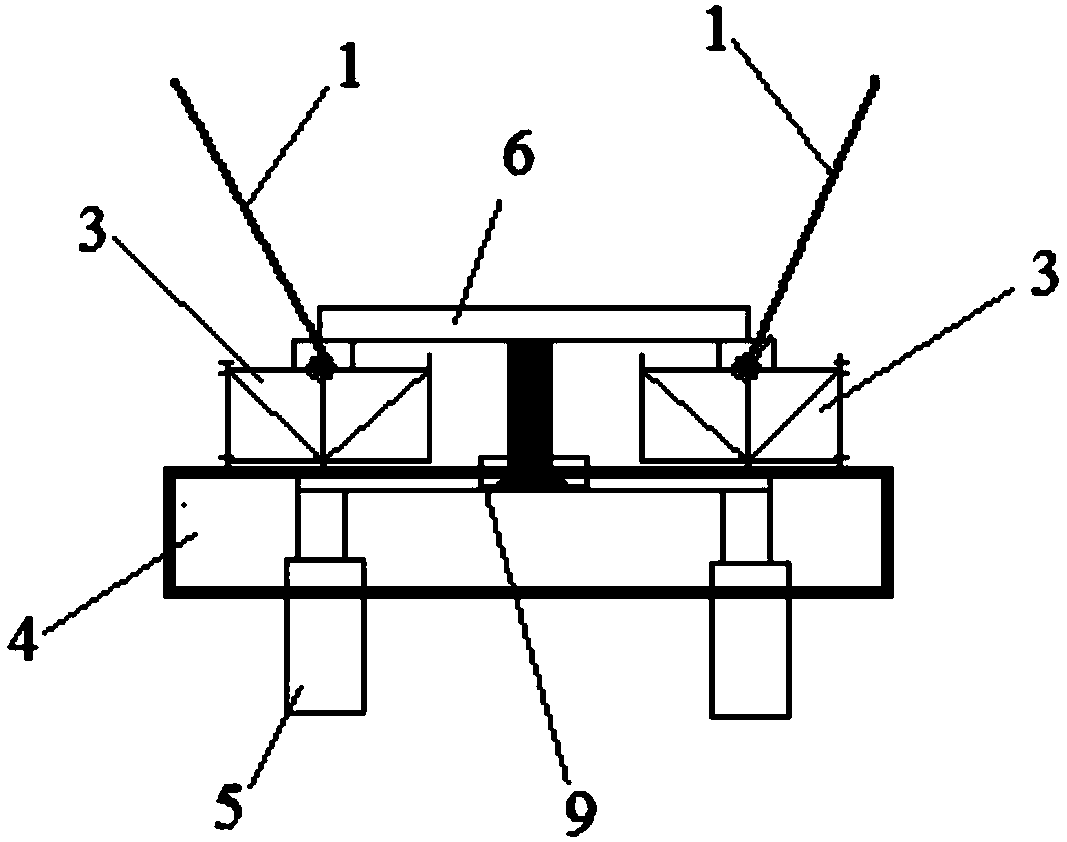

[0024] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0025] In view of the problems of the existing technology, it is necessary to design a light-weight dust removal hood facility, which is constructed in the form of hoisting and partial assembly to improve construction efficiency and safety; affected by the coke oven, the steel truss dust removal hood has been in a high-temperature environment for a long time. Its covering effect also makes the temperature of the coke oven position continue to rise, so it is necessary to perform partial opening and closing when the temperature is too high during use, so that the temperature at the position of the dust removal cover can quickly escape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com