Patents

Literature

355 results about "Hydrogenated vegetable oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

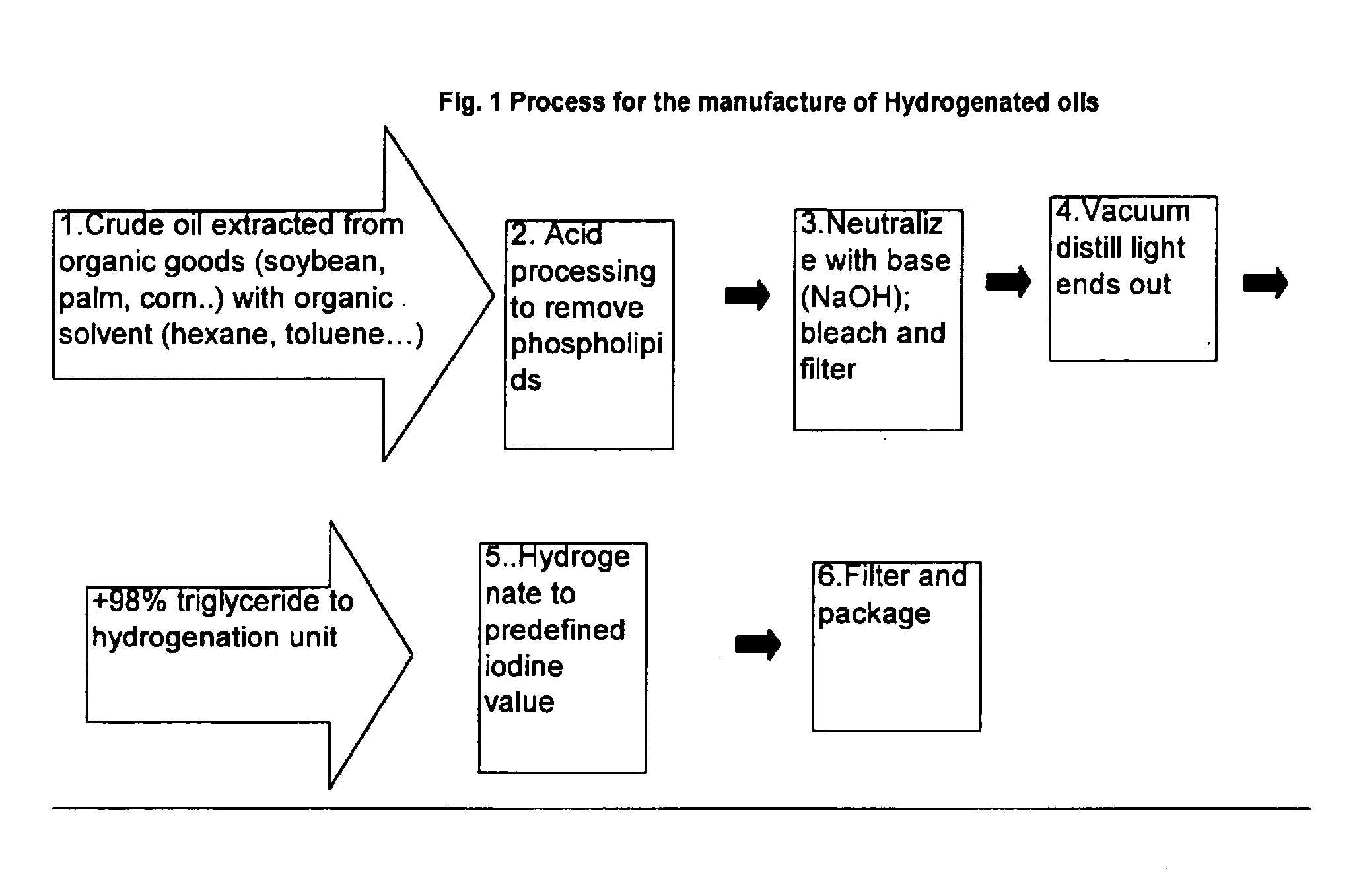

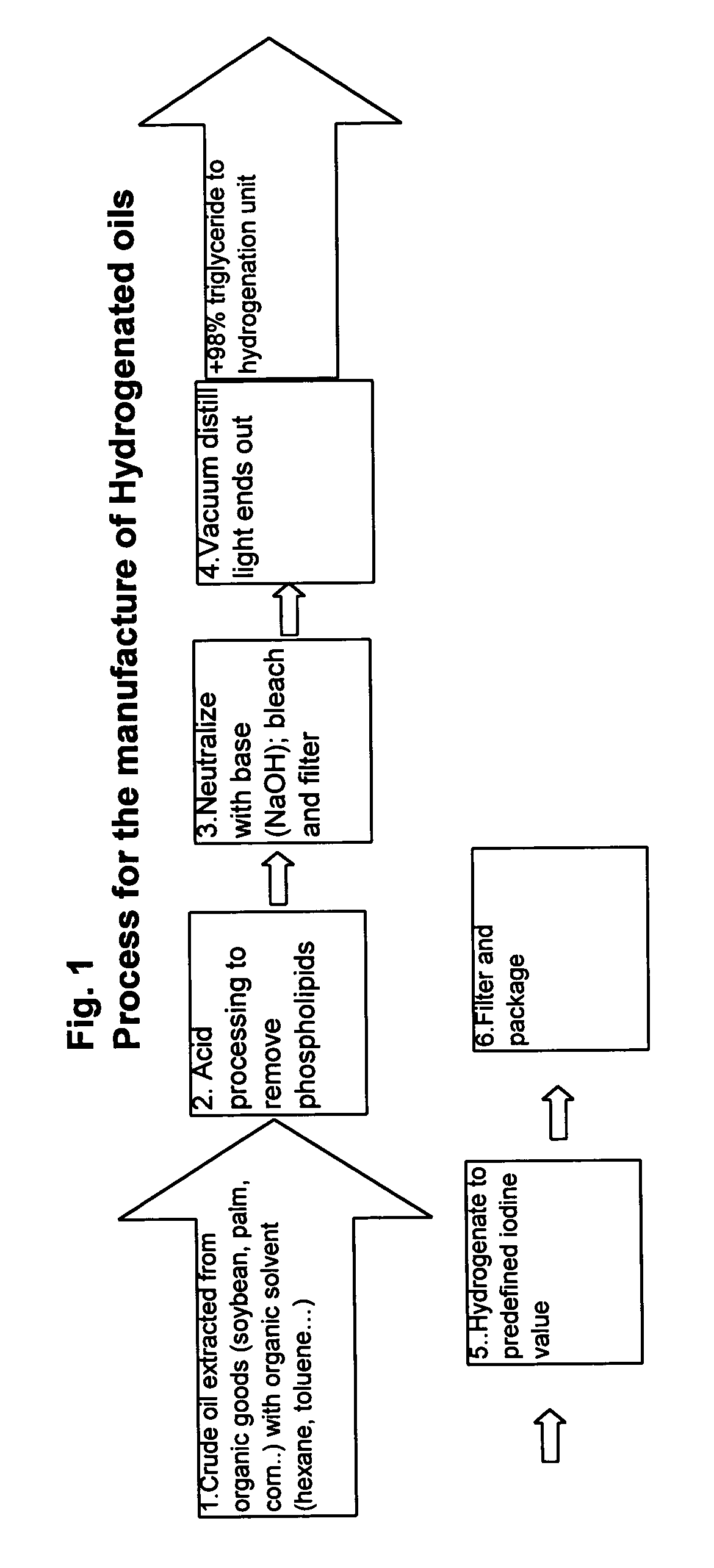

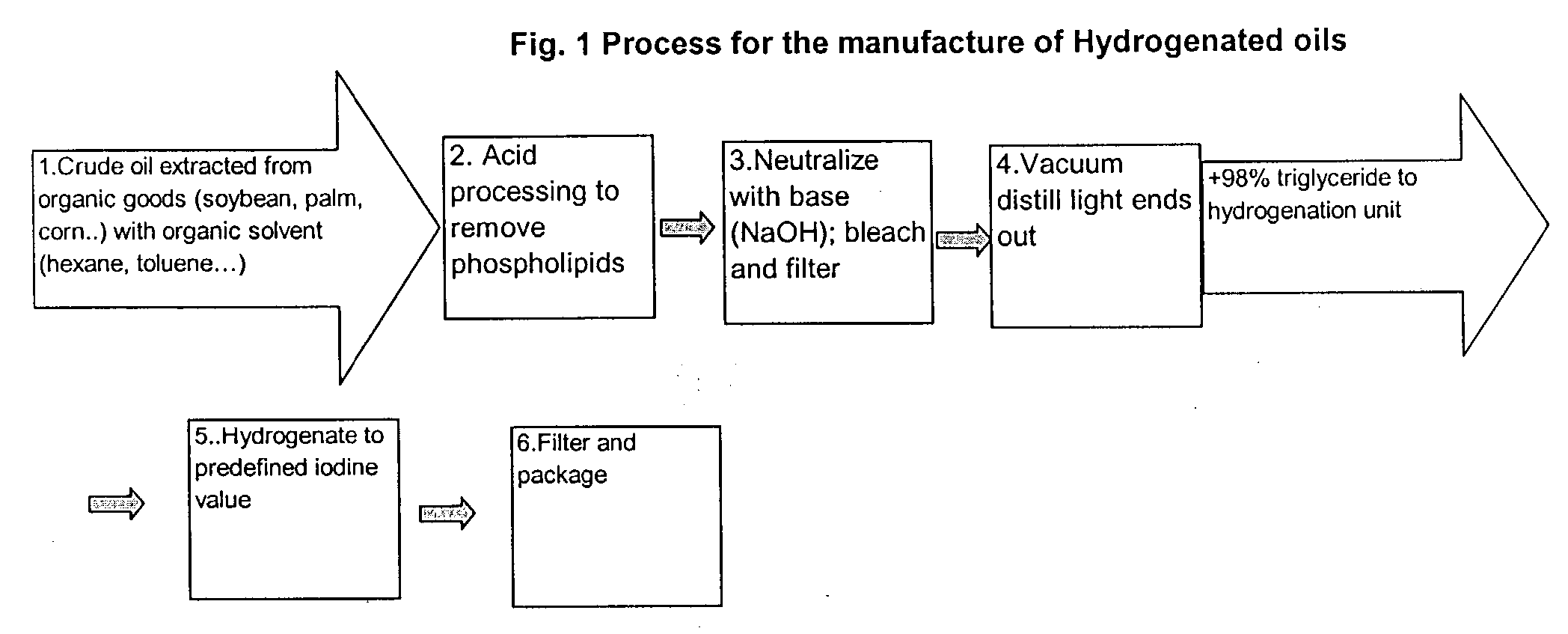

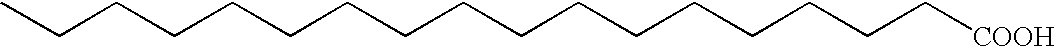

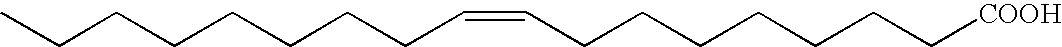

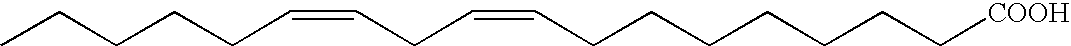

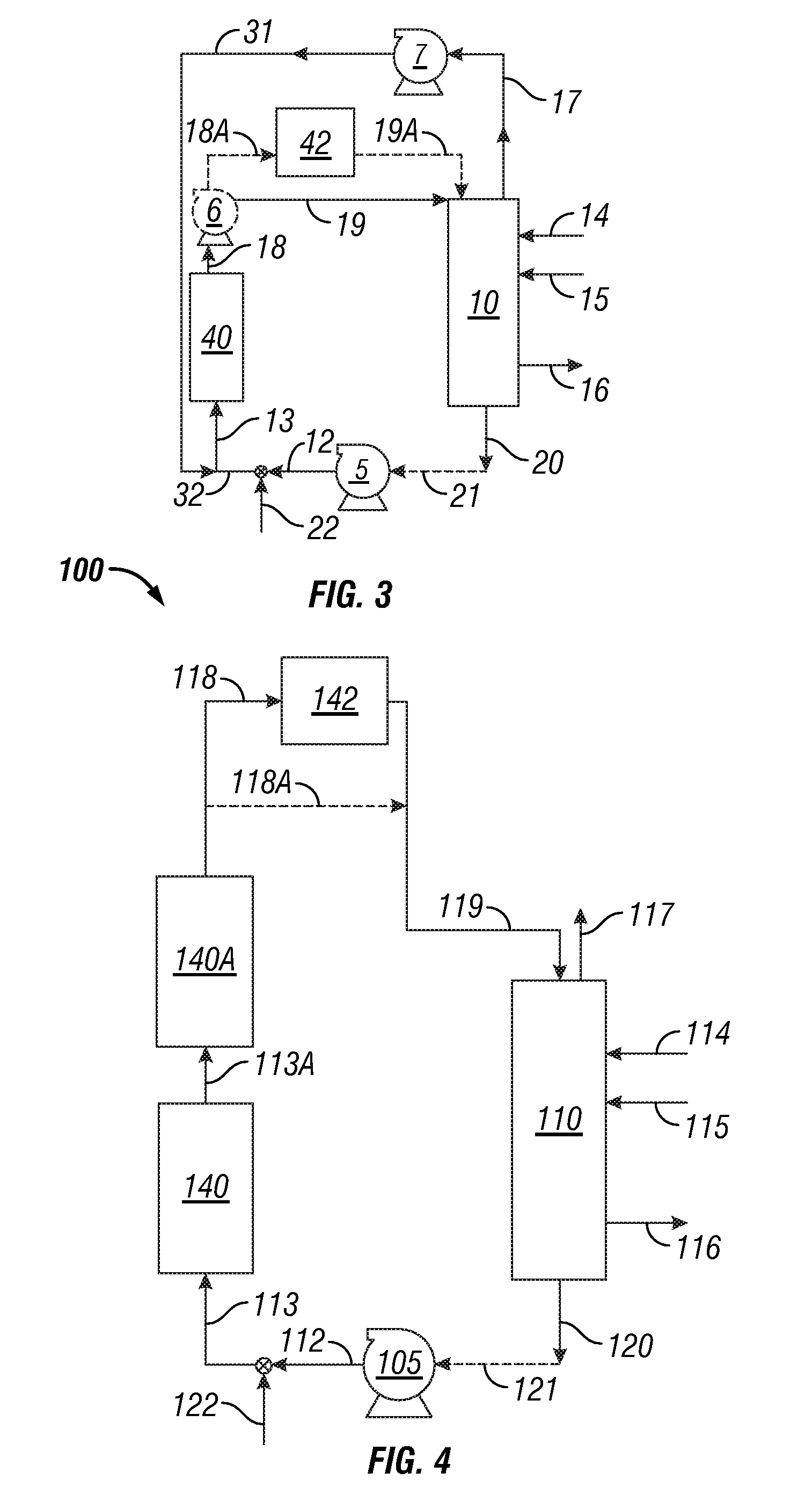

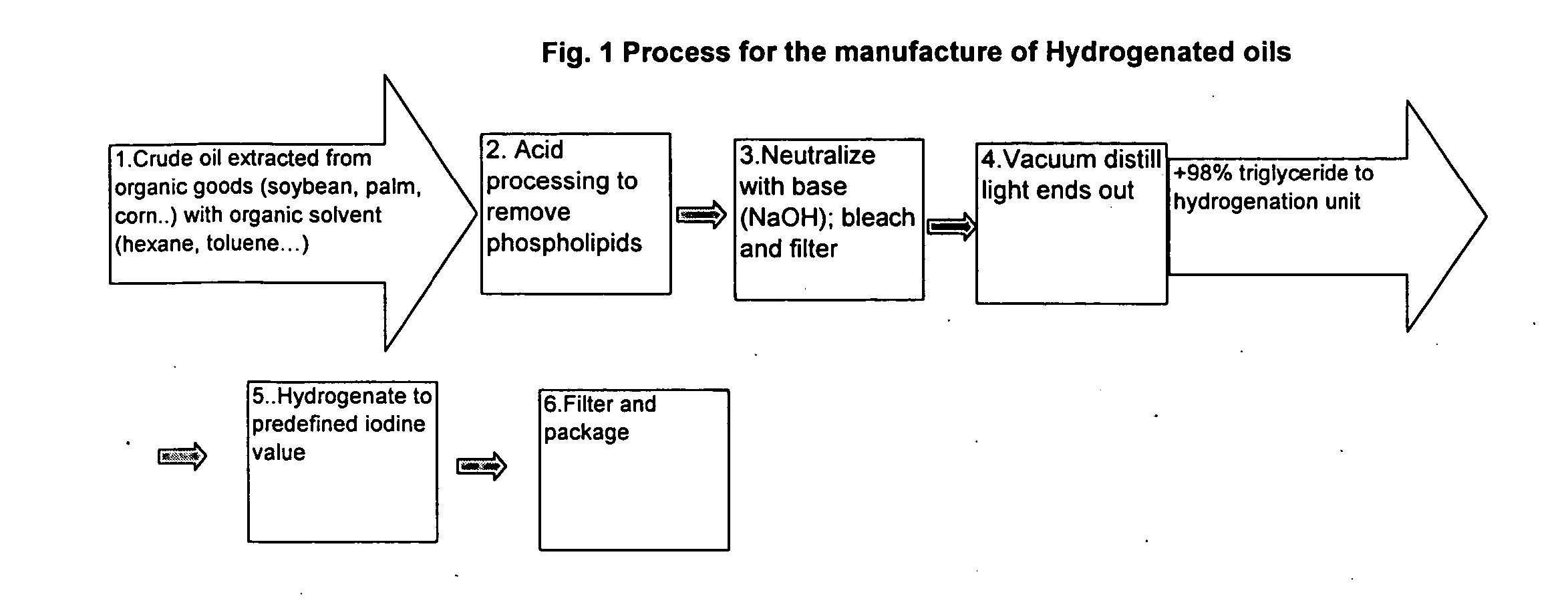

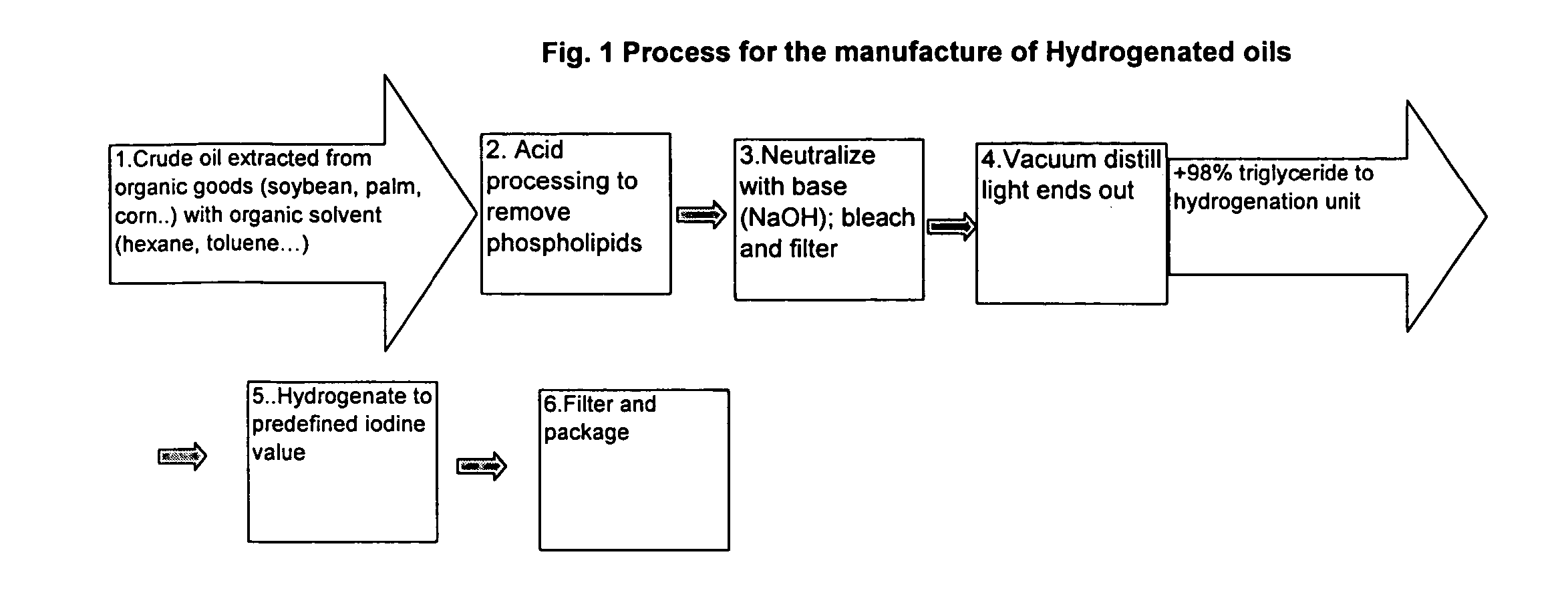

Hydrogenated oils are vegetable oils whose chemical structure has been altered to prevent rancidity in foods, which increases shelf life and saves money for food manufacturers. The process of hydrogenation involves the addition of hydrogen atoms to the oil's available double bonds.

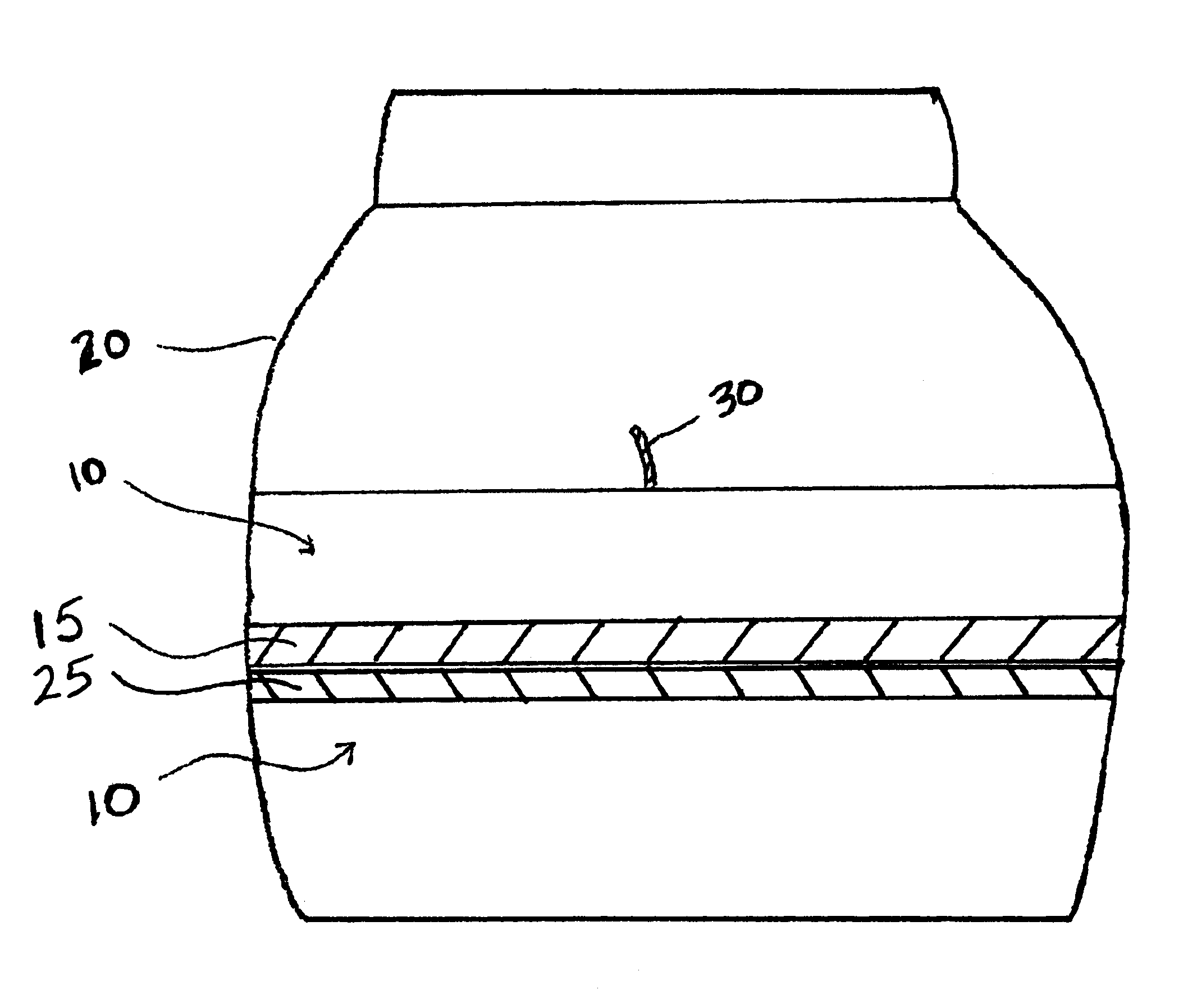

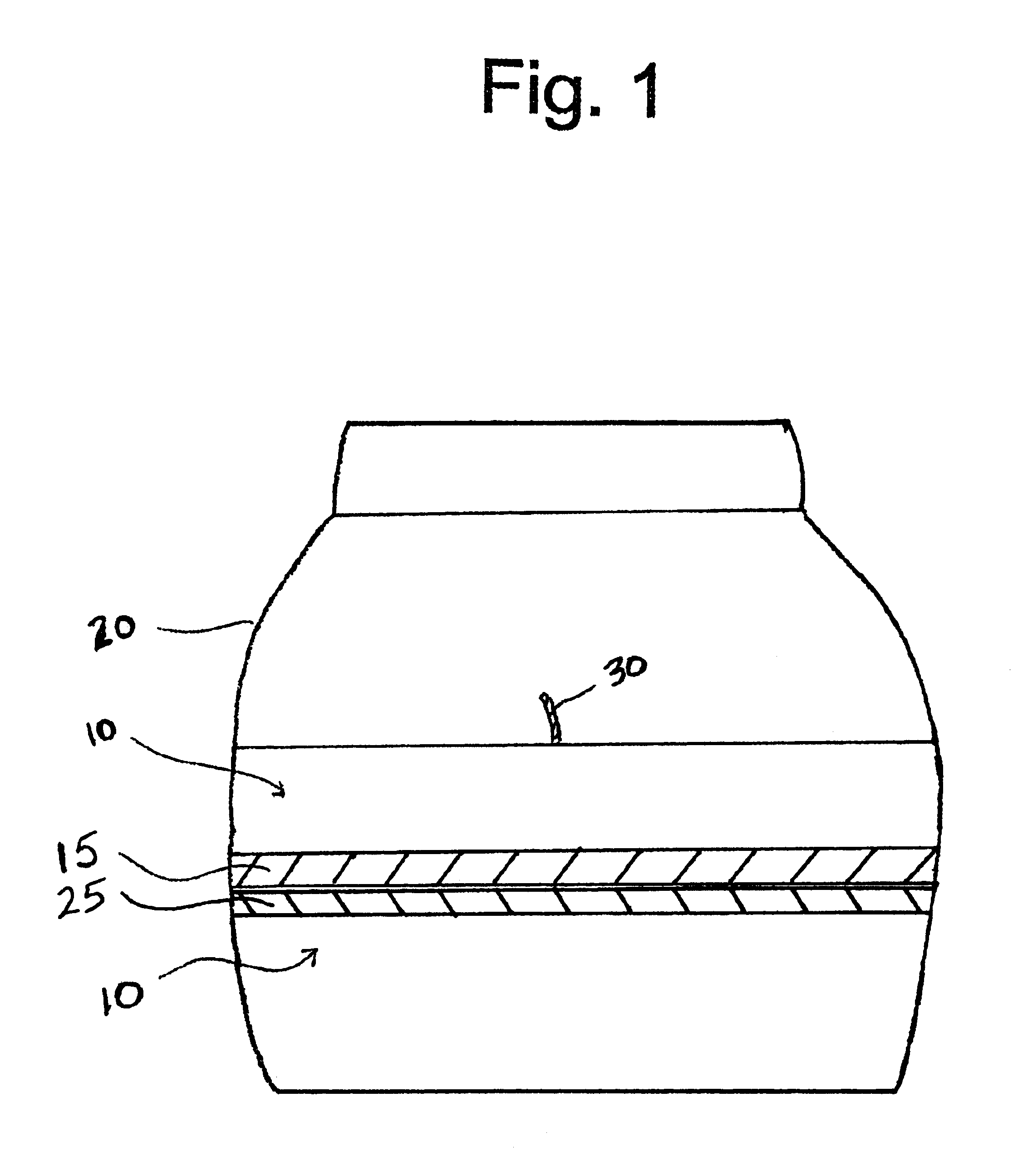

Vegetable oil candle

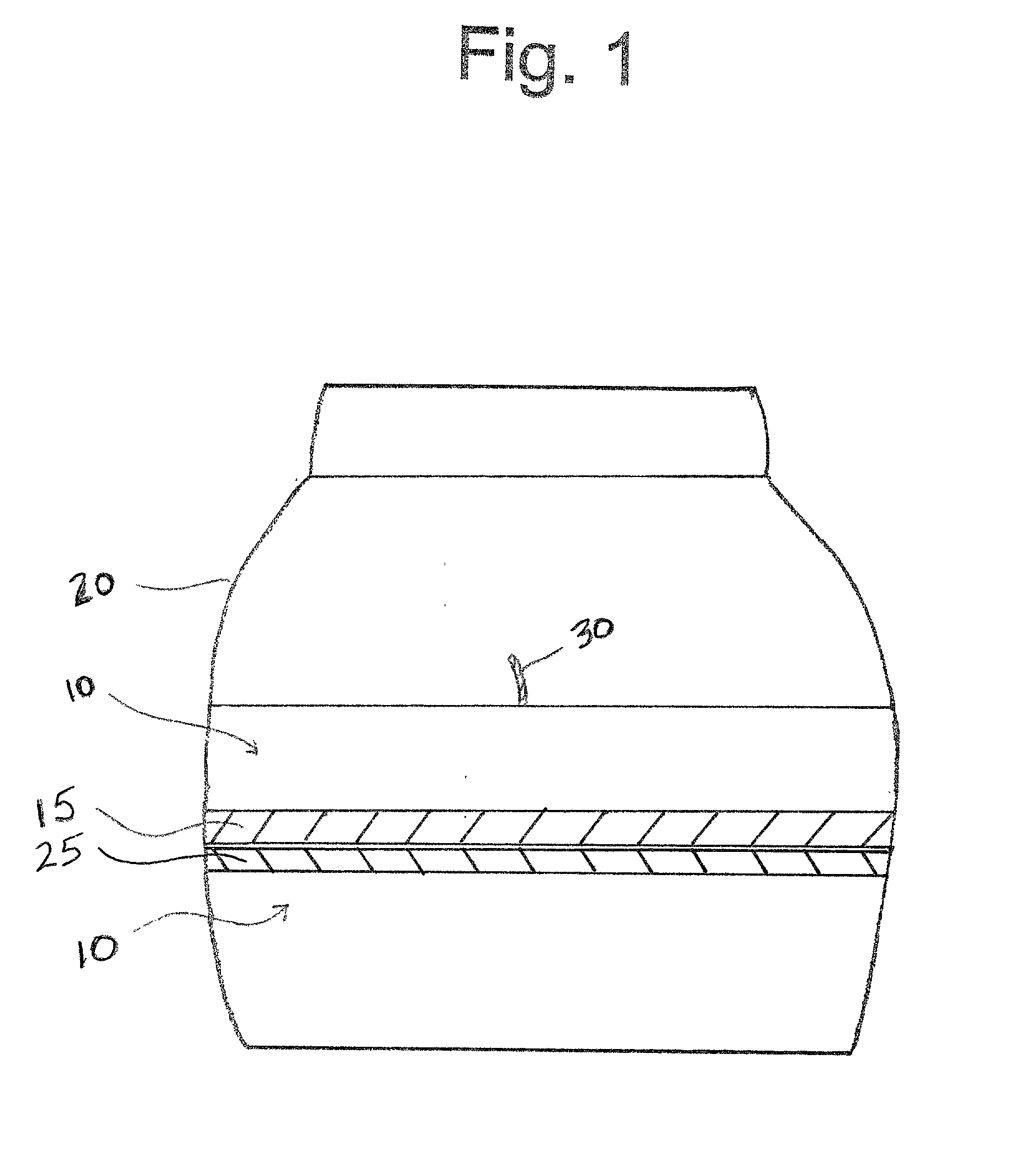

InactiveUS6730137B2Novel burning and fragrance characteristicBiofuelsSolid fuelsParaffin waxVegetable oil

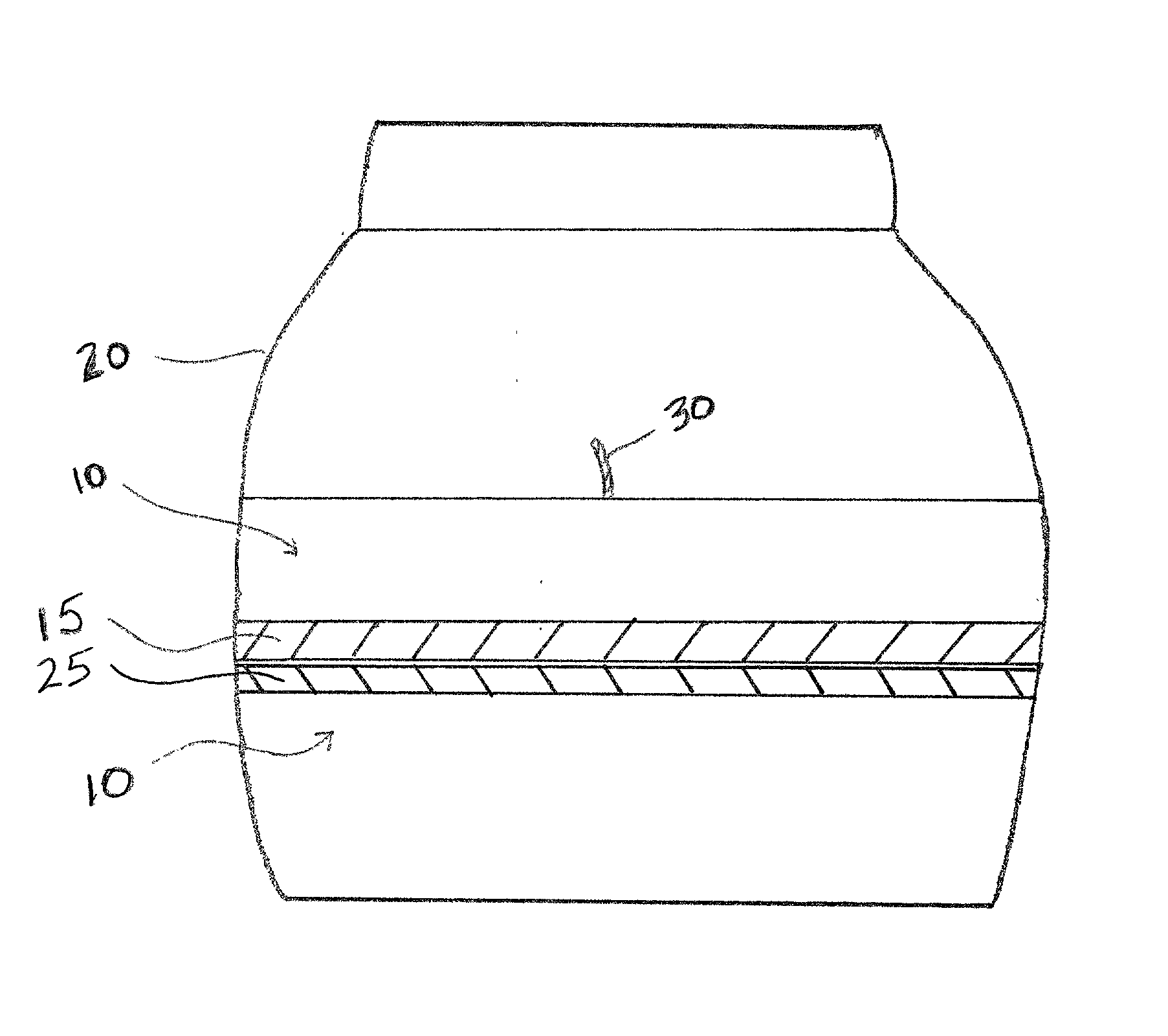

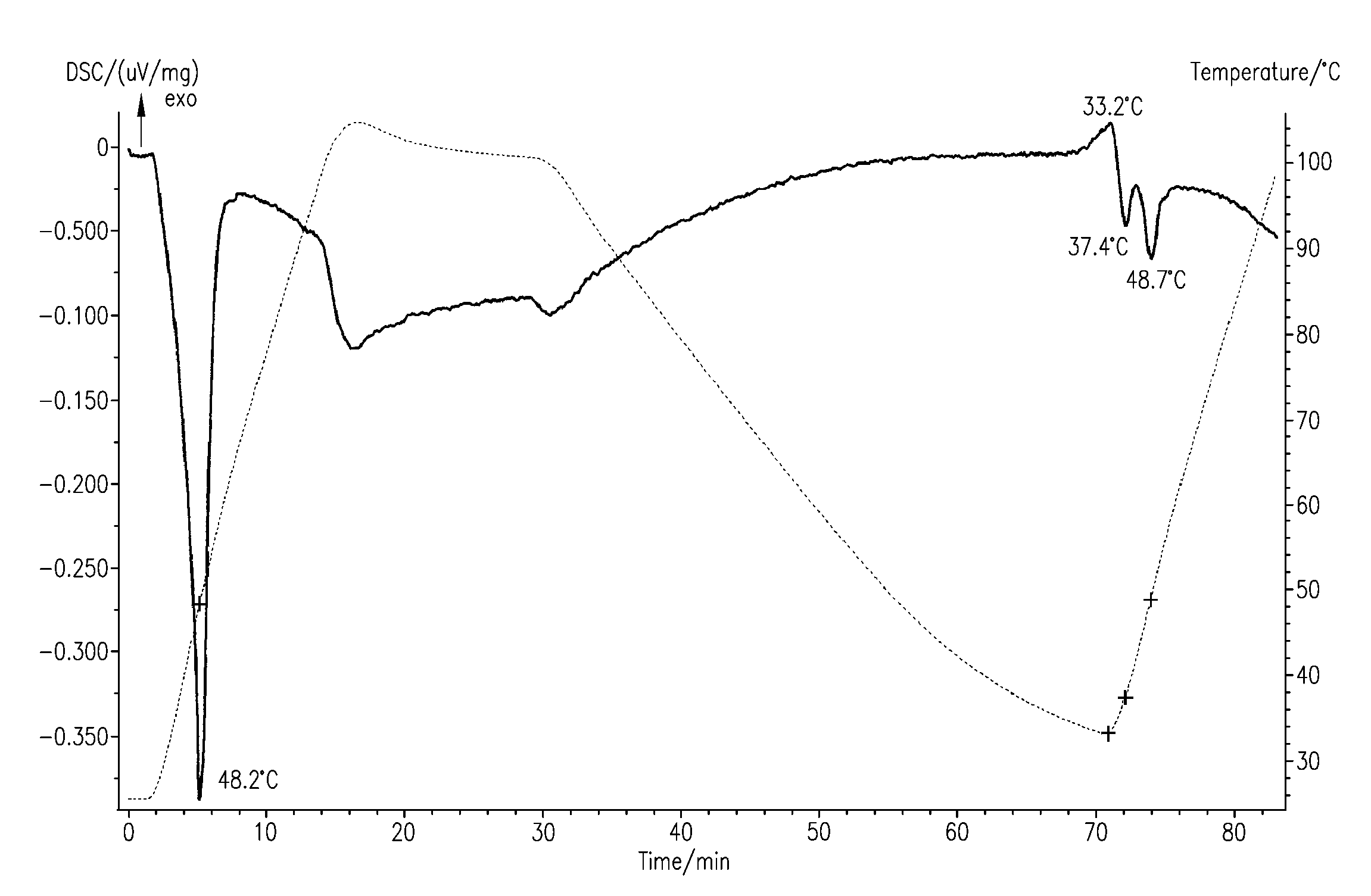

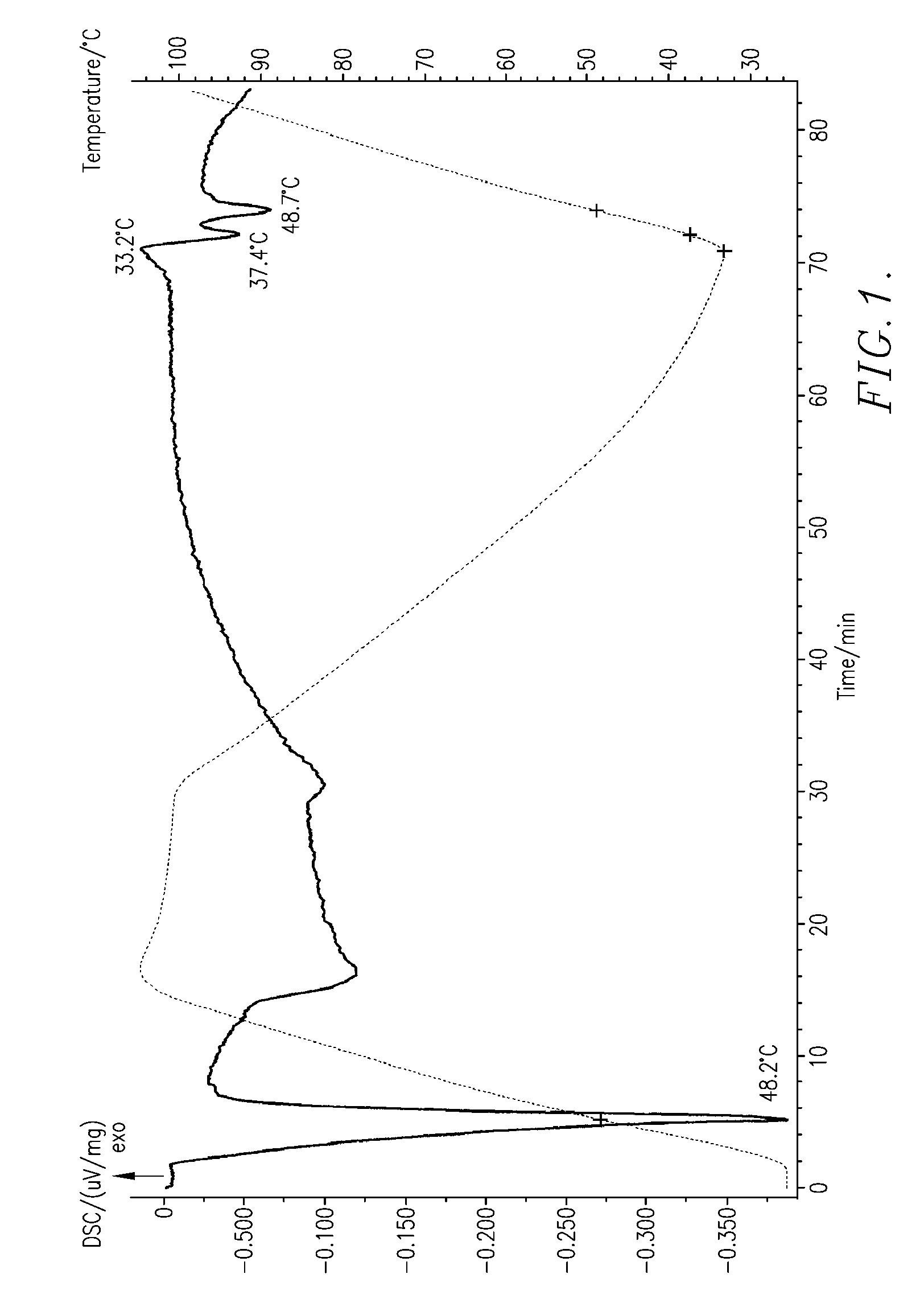

A candle composition has a paraffin wax mixture of a high melting point paraffin wax and a low melting point paraffin wax, and a hydrogenated vegetable oil that is present in a greater amount than the mixture of the varying grades of paraffin wax, and the vegetable oil contains no more than 0.15% free fatty acid, with the remainder being triglycerides. Candles of the composition have good burn characteristics, particularly good fragrance intensity and produce a unique crystallization effect after the first burn.

Owner:BEAUTYAVENUES

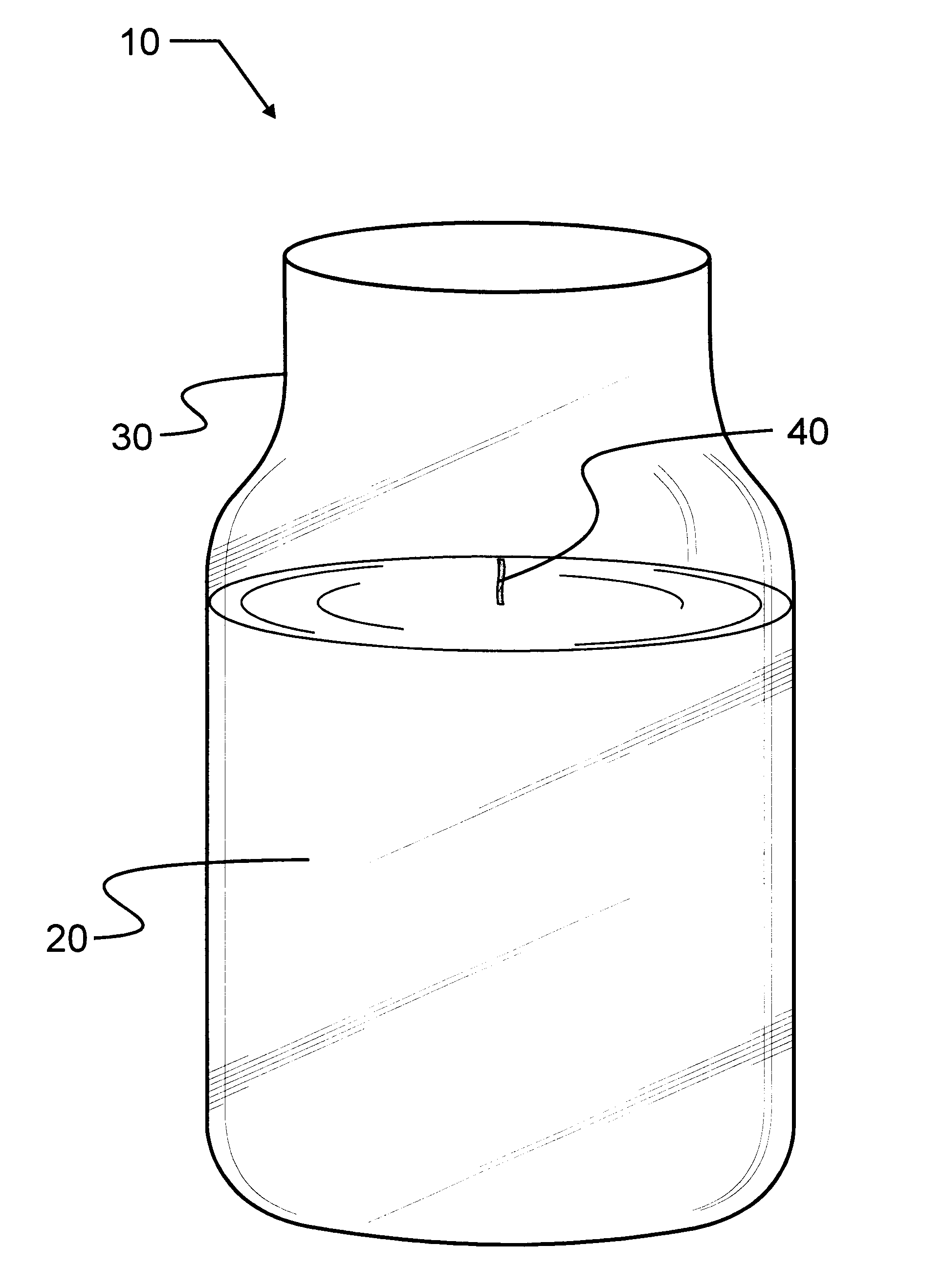

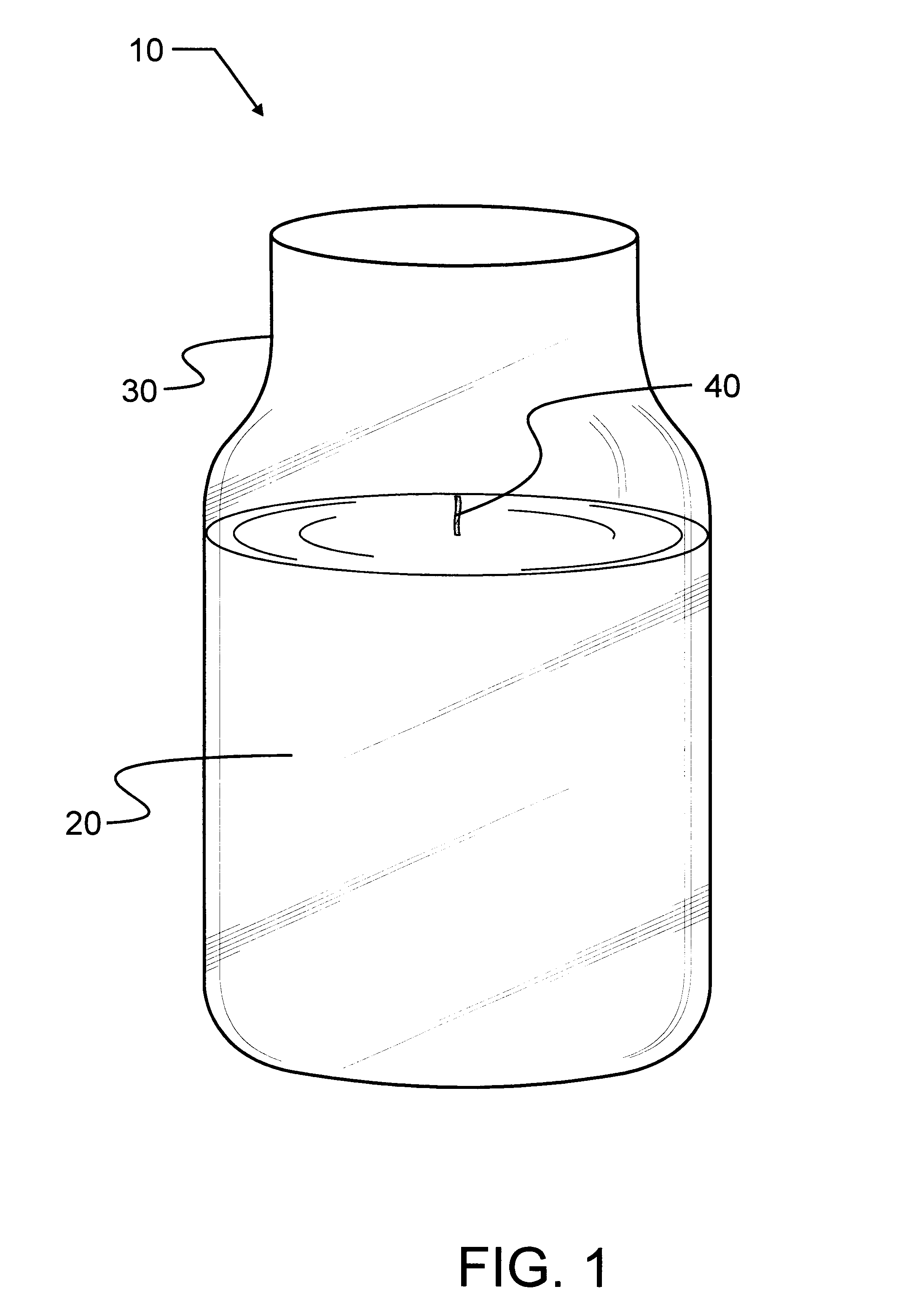

Soybean wax candles

InactiveUS6599334B1Increase profitWithout and crackingSolid fuelsCapillary burnersVegetable oilAlpha-olefin

A solid fuel candle which is highly adapted for use both in a container and also as a free-standing candle includes at least 85 percent hydrogenated soybean oil, approximately 0 to 4 percent synthetic wax composition, approximately 0 to 4 percent of a second hydrogenated vegetable or petroleum oil, approximately 0 to 10 percent fragrance or scent, and approximately 0 to 3 percent dye. The hydrogenated vegetable oil most preferably has an iodine value of approximately 50 and a melting point of approximately 125 degrees Fahrenheit, with a free fatty acid content of less than one-tenth of one percent. The synthetic wax composition is most preferably formed from alpha olefin monomers and oligomers under free radical conditions at relatively low pressures to yield a highly branched polymer wax having congealing and melting points lower than the starting alpha olefin material and a higher molecular weight.

Owner:ANDERSON JILL M

Wax for hot melt adhesive applications

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

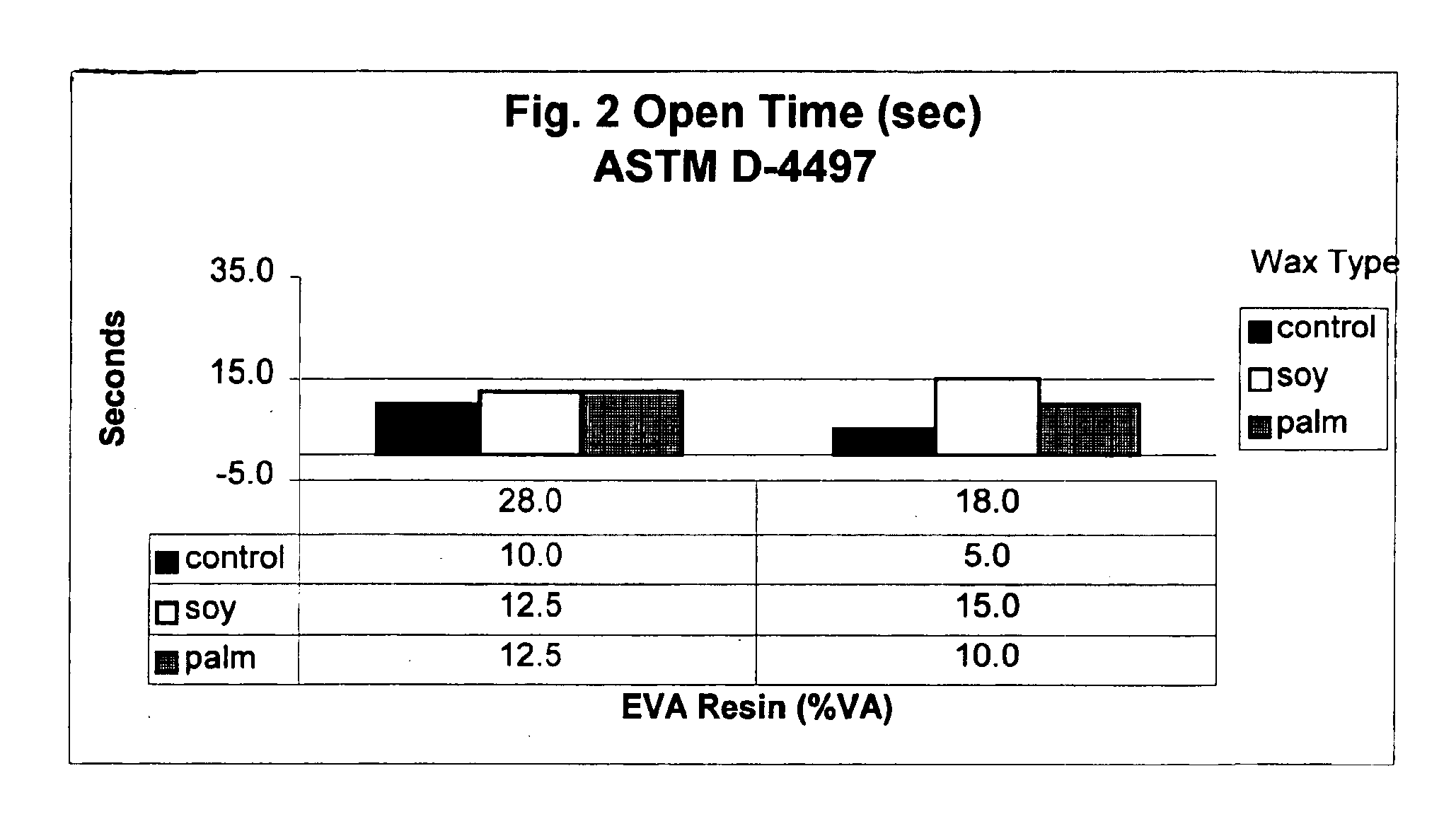

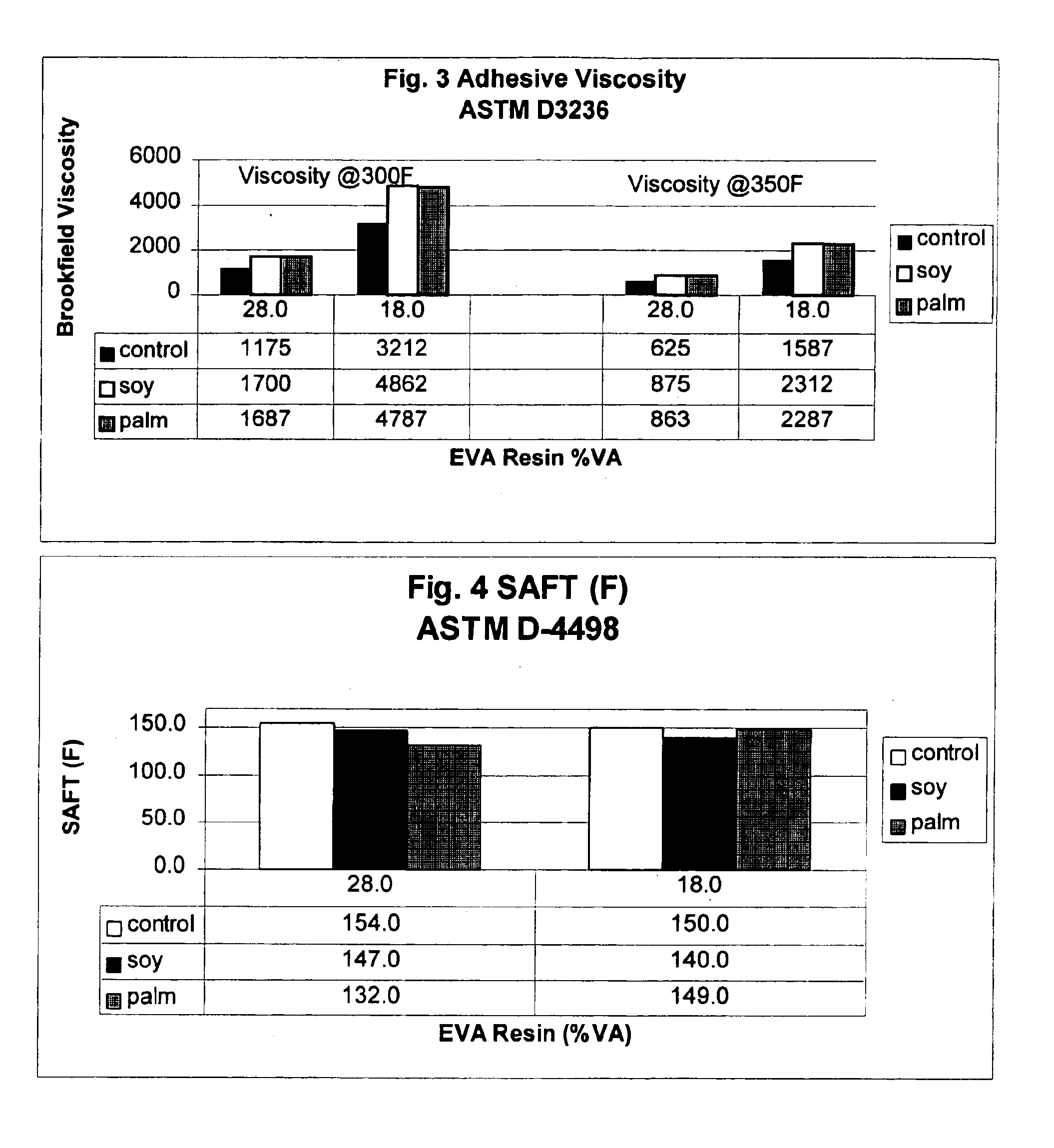

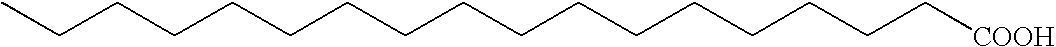

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

Vegetable oil candle

InactiveUS20030091949A1Novel burning and fragrance characteristicBiofuelsSolid fuelsParaffin waxVegetable oil

A candle composition has a paraffin wax mixture of a high melting point paraffin wax and a low melting point paraffin wax, and a hydrogenated vegetable oil that is present in a greater amount than the mixture of the varying grades of paraffin wax, and the vegetable oil contains no more than 0.15% free fatty acid, with the remainder being triglycerides. Candles of the composition have good burn characteristics, particularly good fragrance intensity and produce a unique crystallization effect after the first burn.

Owner:BEAUTYAVENUES

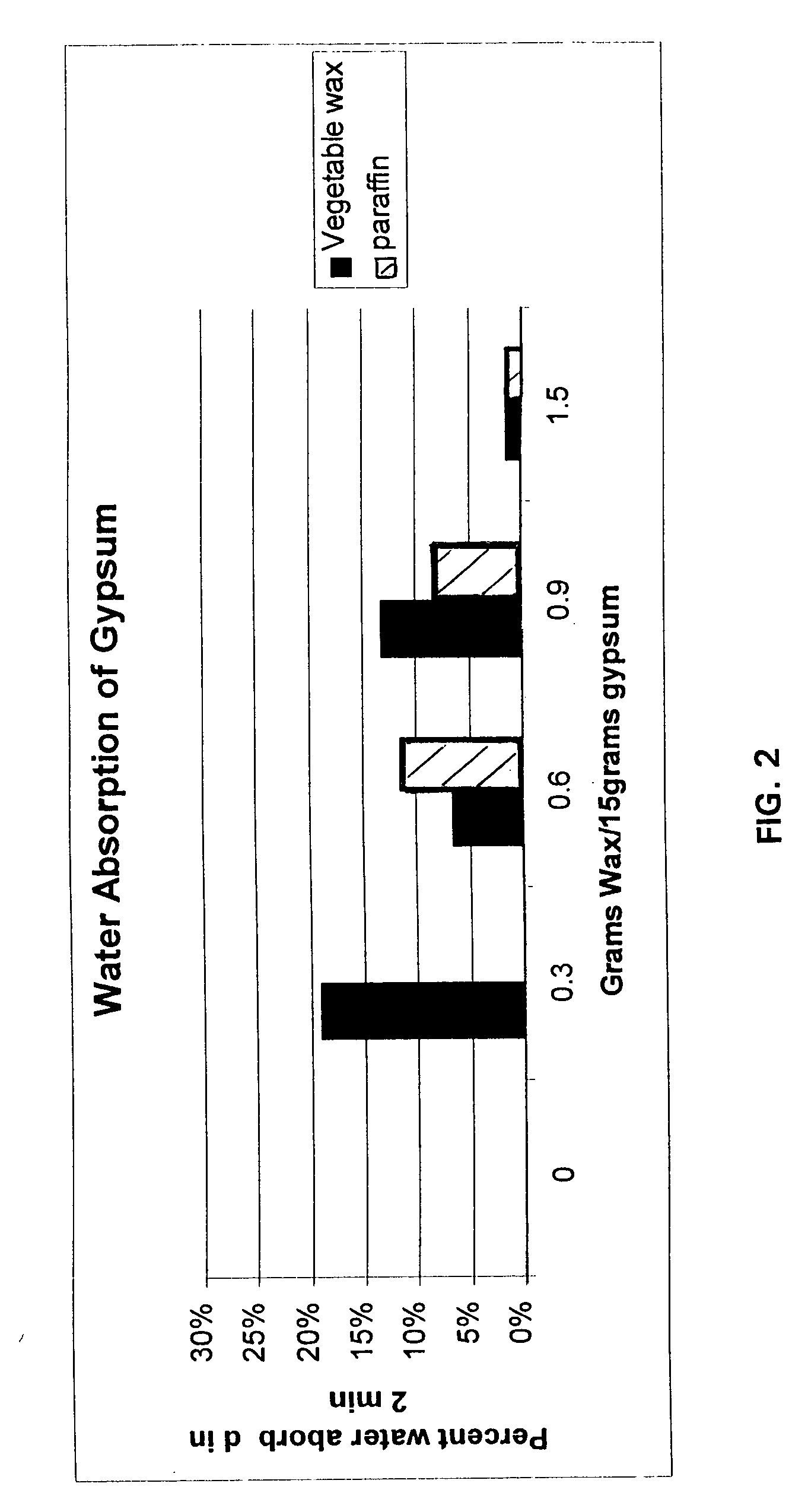

Additive to render gypsum board moisture resistant

InactiveUS20060196391A1Improve waterproof and moisture-proof performanceMore water resistantBuilding componentsCoatingsStearic acidMoisture barrier

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used to render gypsum board resistant to water. Unlike petroleum-derived waxes used for the same purpose, vegetable derived waxes are renewable and readily converted into forms such as emulsions or powder that facilitate incorporation into gypsum board manufacturing. Such water resistant materials are characterized by enhanced moisture barrier properties. The compositions have a low iodine value (between 2-5), and melting points between approximately 120-185 degrees F. (Mettler Drop Point). The wax comprises a triglyceride whose fatty acids are predominantly stearic acid (C18). The composition is used as an additive in the manufacture of water resistant gypsum board.

Owner:HRD CORP

Tea jelly sweet

The invention discloses a tea jelly sweet which is prepared from raw material in the formula in parts by weight: 4-10 parts of functional composition, 30-60 parts of maltitol, 30-40 parts of starch syrup, 3.5-7 parts of plural gel, 0.1-10 parts of lecithin, 0.1-3 parts of hydrogenated vegetable oil, 1-3 parts of peppermint oil and 20-40 parts of water, wherein the functional composition comprises one or several of ultra-micropowder or extractions or original materials of pu-erh tea, black tea, green tea, Oolong tea, white tea, yellow tea and dark tea and other functional factors; and the plural gel comprises modified starch, gelatine, agar and carrageenan. The invention has the characteristics of defined functions, attractive appearance, natural aroma, good taste and the like, has no artificially-synthesized pigment and essence and sweetner causing decayed tooth and is suitable for groups to eat for a long term so as to improve the sub-health state.

Owner:云南龙润茶业集团有限公司

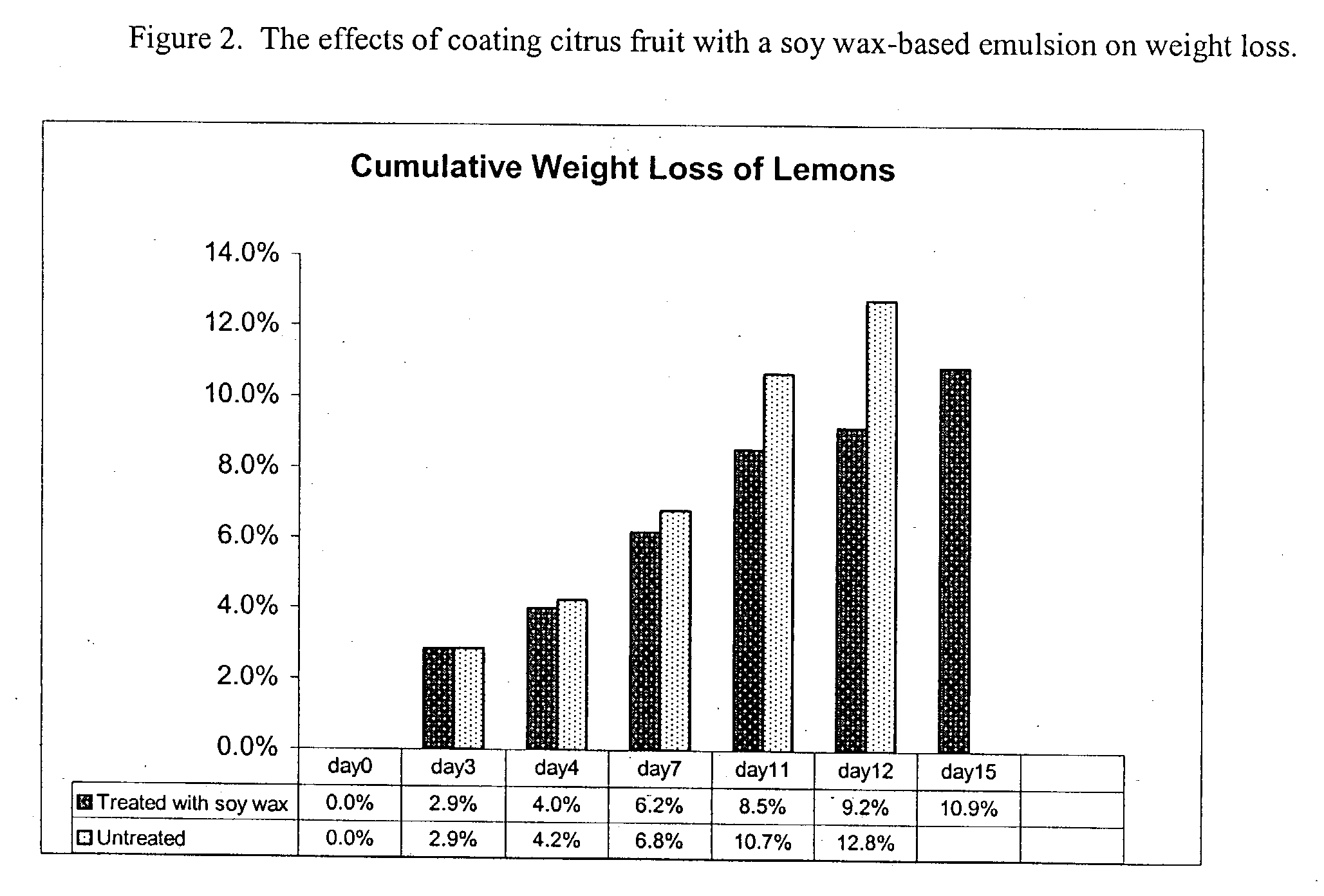

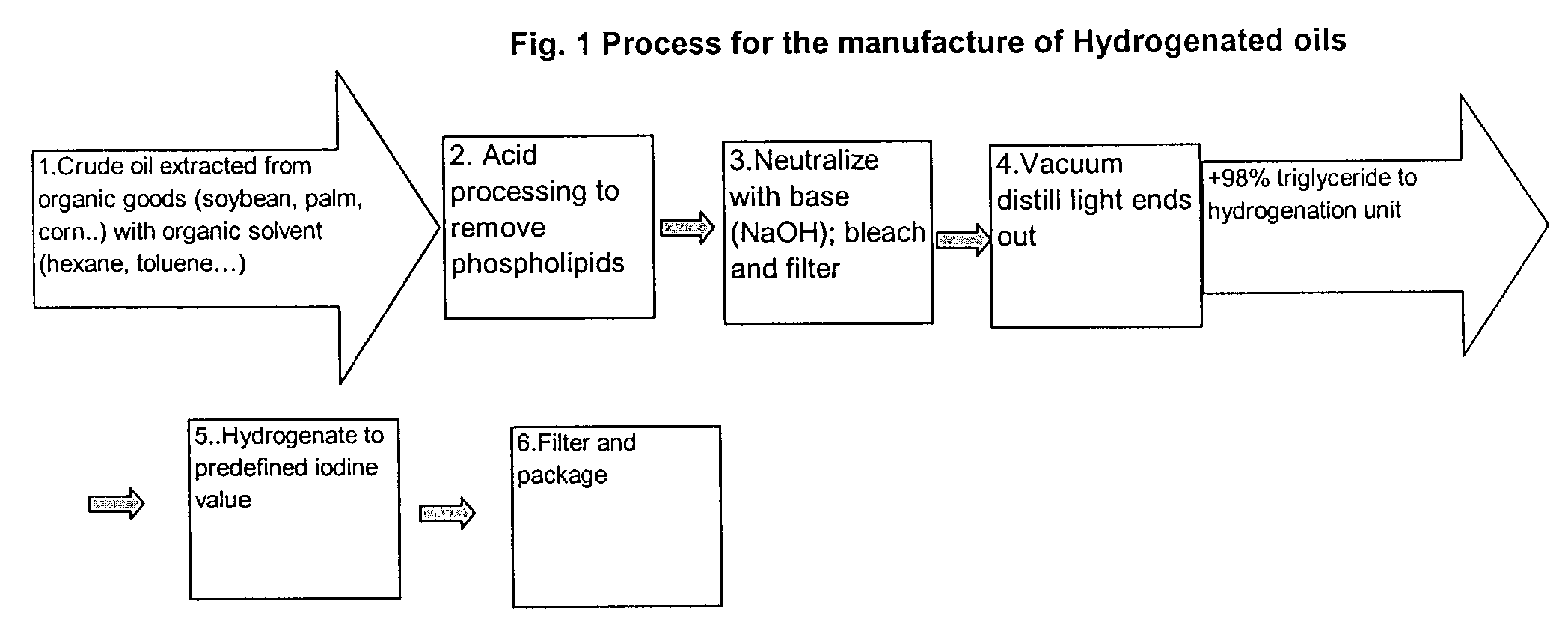

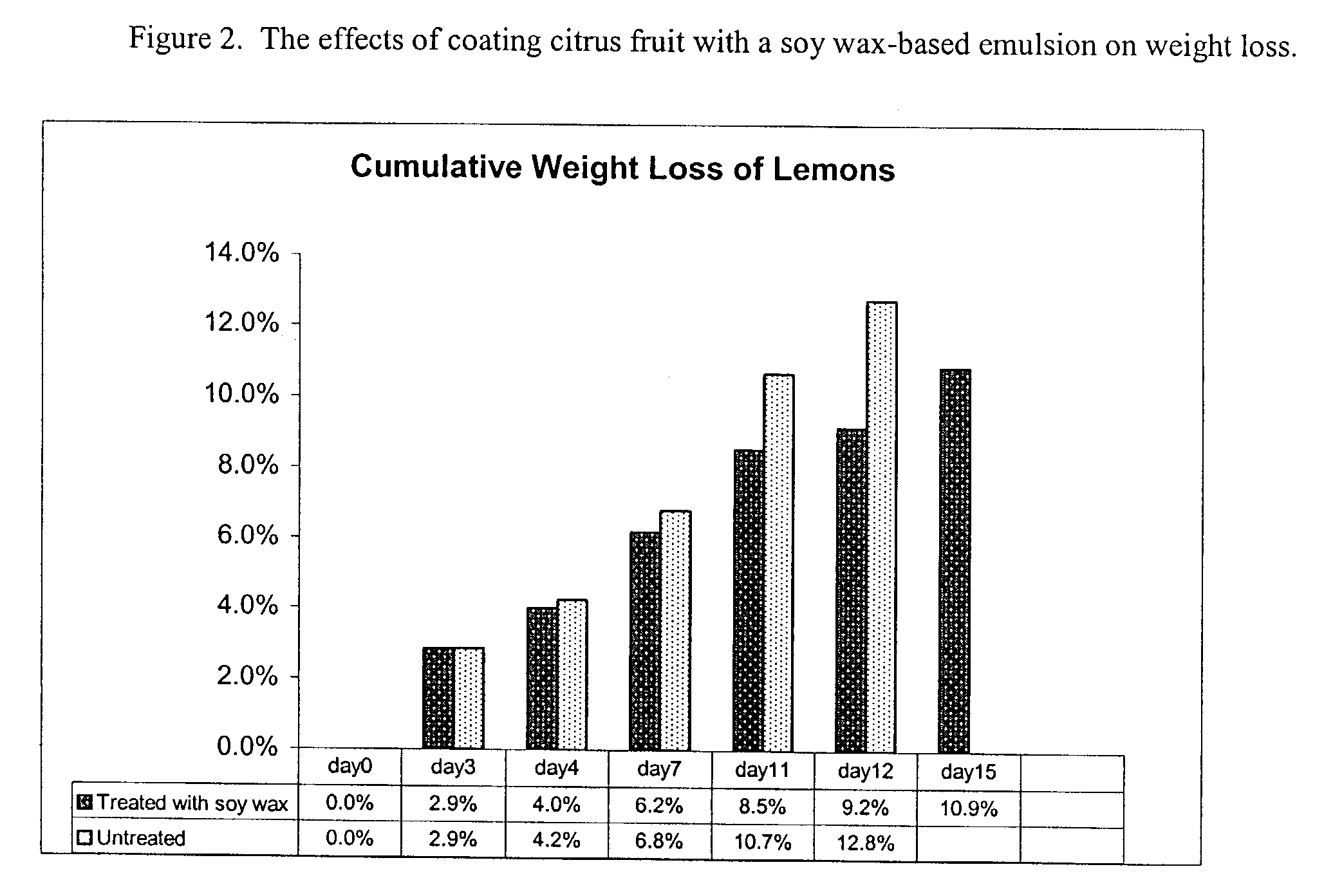

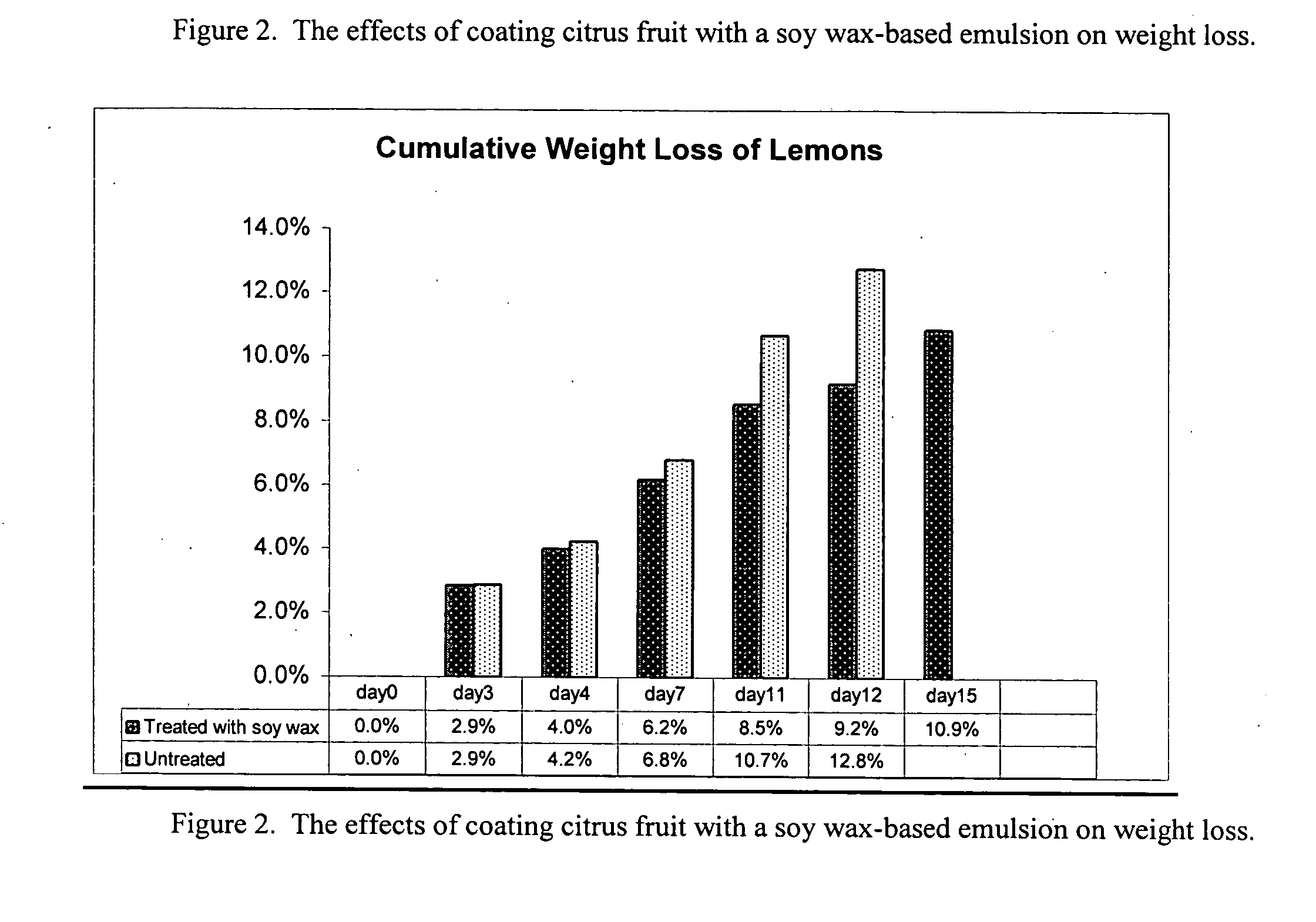

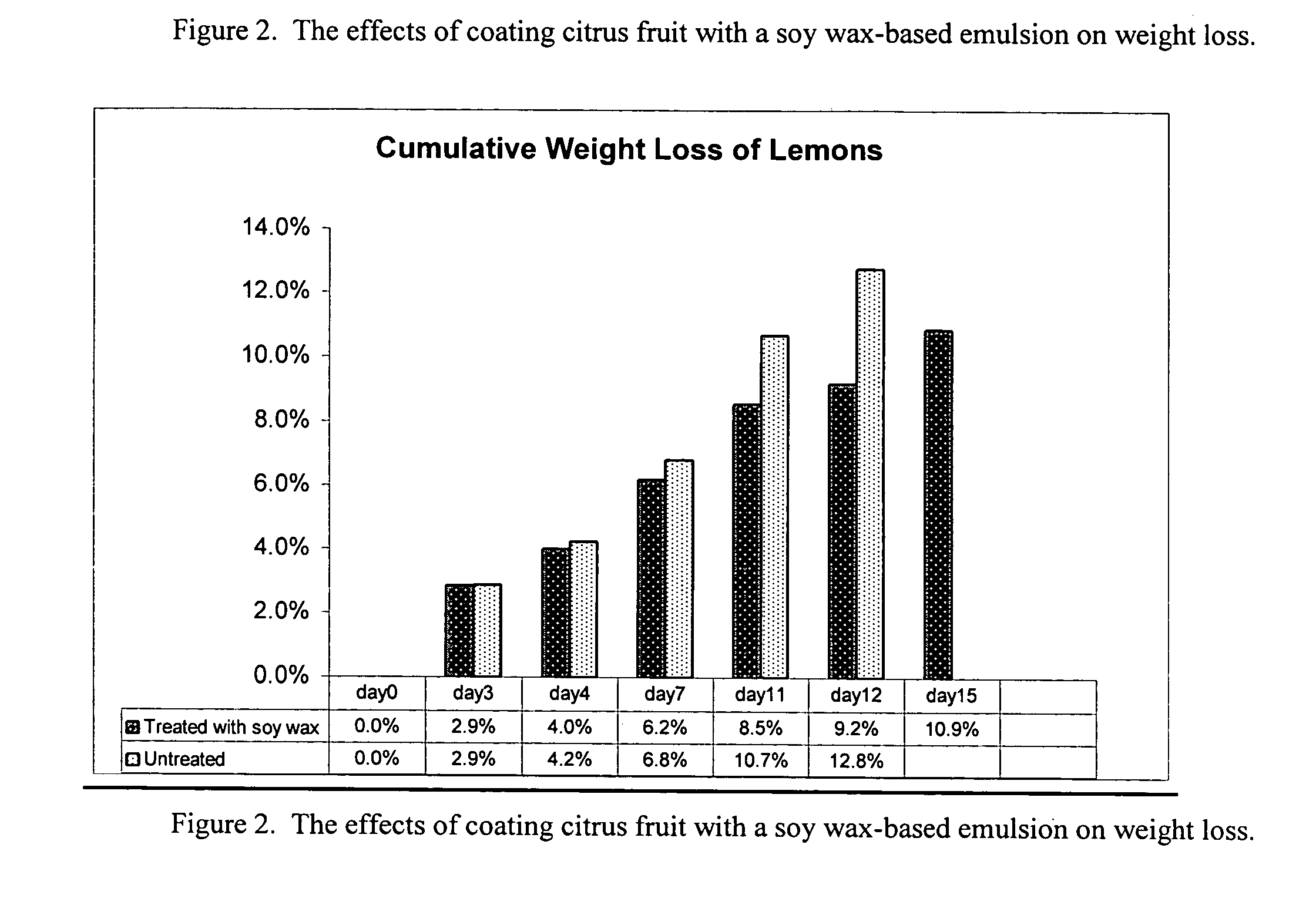

Novel wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid or ricinoleic acid. The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:MARCUS OIL & CHEM

Preparation method of insulating oil taking vegetable oil as raw material

InactiveCN101538500ACause some damagesRapid and complete biodegradationFatty-oils/fats refiningFatty-oils/fats productionVegetable oilSodium Bentonite

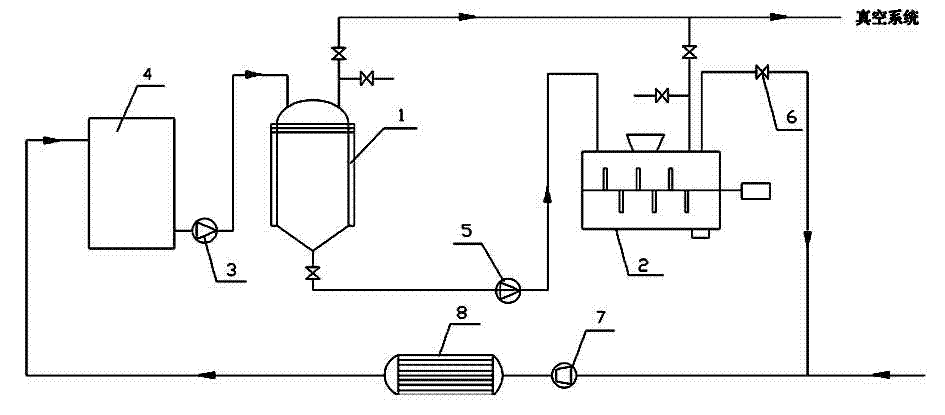

The invention provides a preparation method of insulating oil taking vegetable oil as raw material, which comprises the following steps of: 1) neutralizing the vegetable oil with alkali; 2) conducting reduced pressure distillation on the vegetable oil after being neutralized with alkali; 3) hydrogenating the vegetable oil after the reduced pressure distillation; 4) conducting deep refinement to the hydrogenated vegetable oil: adding citric acid which accounts for 0.3 to 1.0 percent of the weight of the vegetable oil to the hydrogenated vegetable oil, conducting reduced pressure distillation for 1 to 2 hours at the pressure of 20 to 50 mmHg and the temperature of 80 to 90 DEG C; and then adding bentonite which accounts for 0.1 to 0.3 percent of the weight of the vegetable oil, conducting reduced pressure distillation for 1 to 2 hours at the pressure of 20 to 50 mmHg and the temperature of 80 to 90 DEG C; 5) conducting reduced pressure distillation again to the vegetable oil after the deep refinement; and 6) adding an additive to the vegetable oil being treated with the reduced pressure distillation again.

Owner:CHONGQING UNIV +1

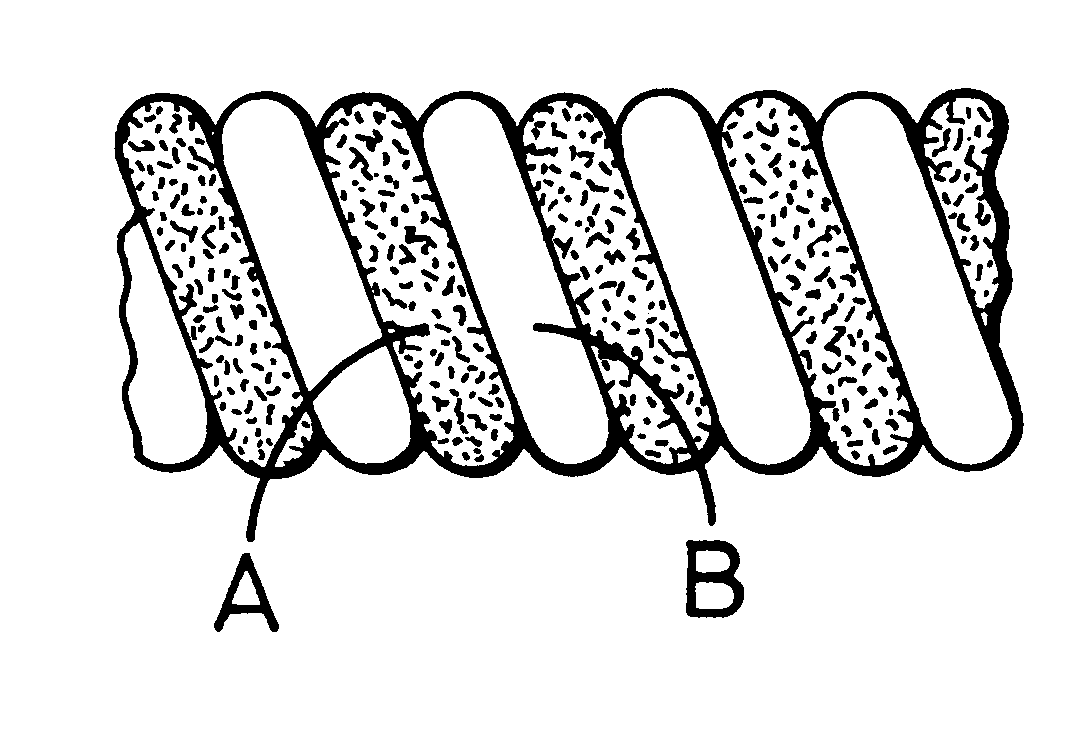

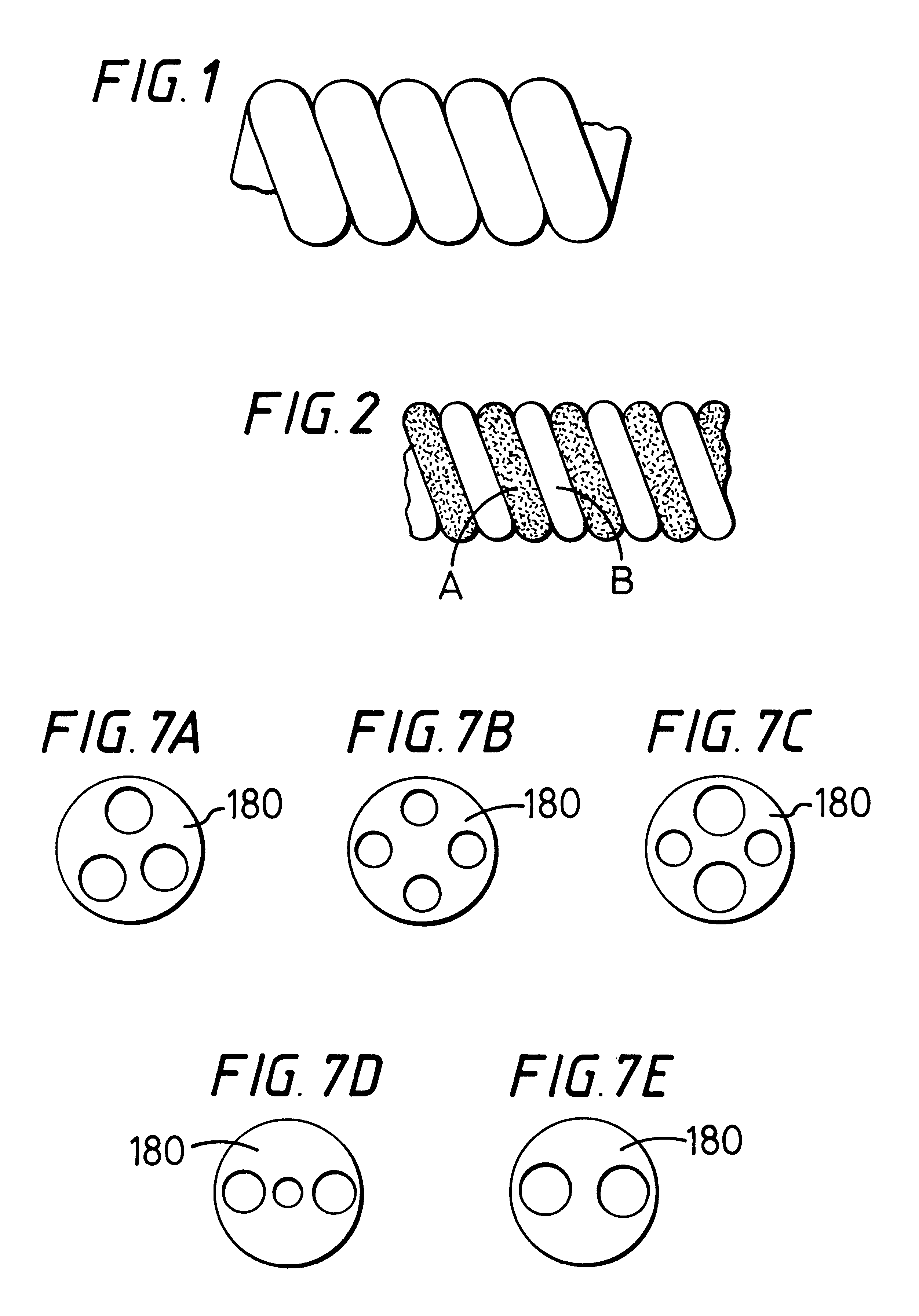

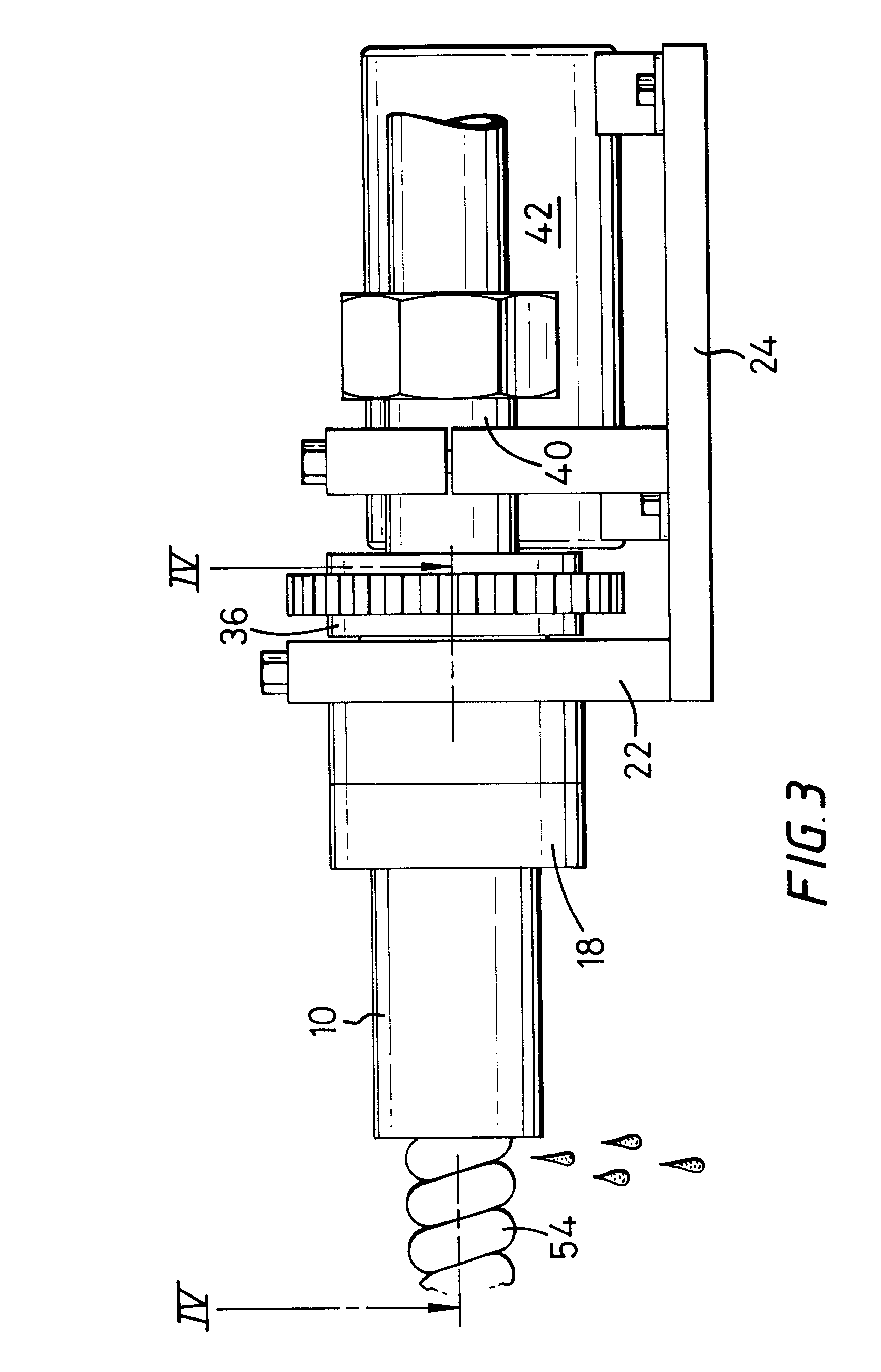

Helical food product

A food product comprising one or more plastic food substrates is formed into a helical configuration and coated with a fluid barrier agent to prevent reannealing of adjacent turns of the product. The fluid barrier agent may be an edible vegetable oil such, for example, as hydrogenated vegetable oil, Soya oil, rape oil, sunflower oil, safflower oil, peanut oil or a mixture of such oils. The product may define a single helix or a multiple helix, e.g. a double or triple helix.

Owner:BERNARD MATTHEWS FARMS

Shortening composition

ActiveUS20050214436A1Improve stabilityImprove the organoleptic and physical propertiesDough treatmentBakery productsBiotechnologyVegetable oil

The present invention relates to a shortening system, for use as dough fat or filling fat; for instance, a shortening system containing, consisting essentially of, or consisting of, unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil, sunflower oil, corn oil, ricebran oil, or cottonseed oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of an emulsifier composition comprising a monoglyceride and / or diglyceride, an alpha tending emulsifier and an ionic emulsifier as well as to methods for making and using such a shortening system and products from the use of such a shortening system.

Owner:DUPONT NUTRITION BIOSCIENCES APS

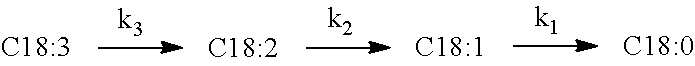

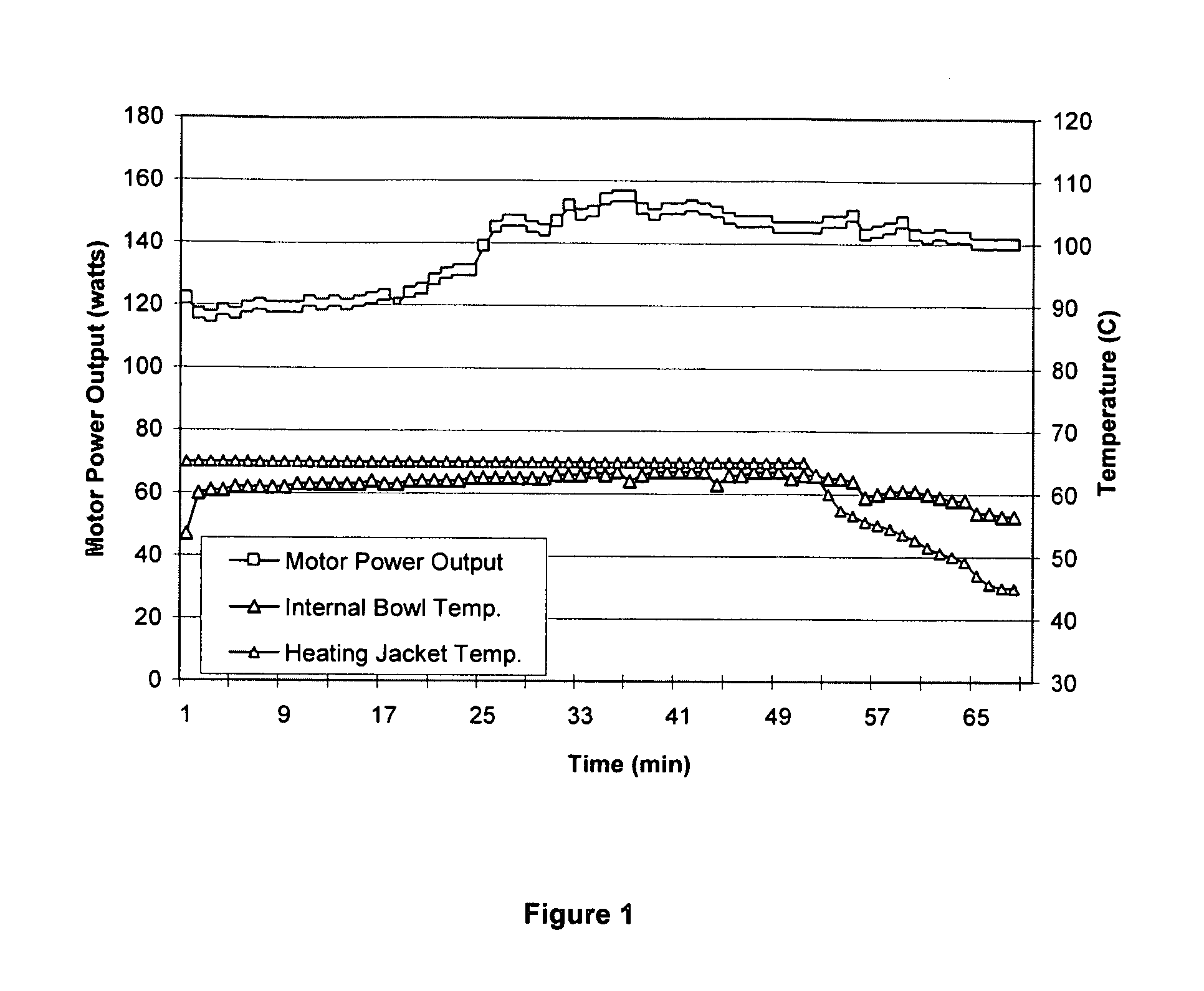

Process and catalyst for production of low trans fat-containing triglycerides

InactiveUS20080161588A1Improve product appearanceImprove textureFatty acid hydrogenationFatty acids production/refiningVegetable oilHydrogenation process

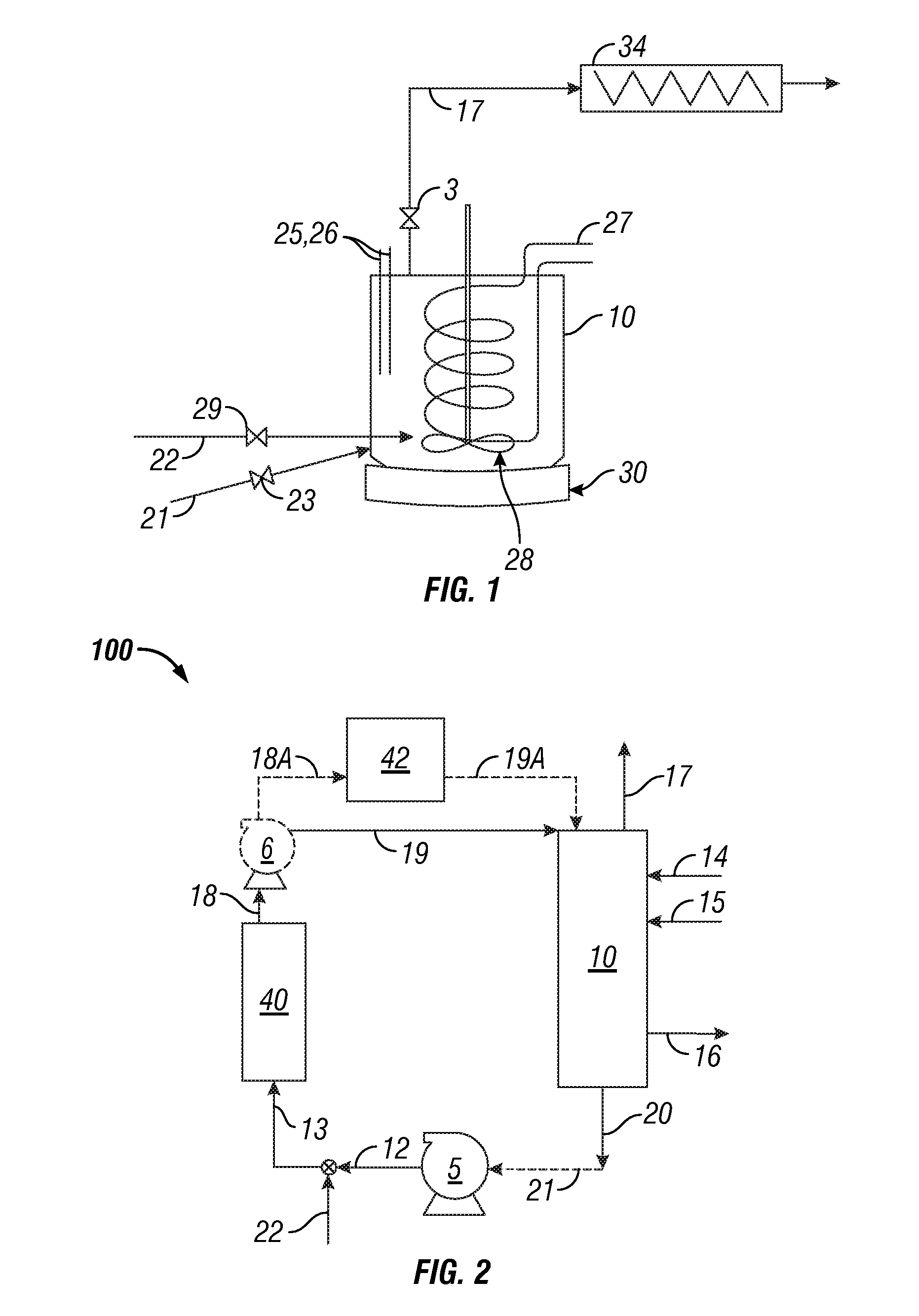

Hydrogenated vegetable oil exhibiting superior thermal stability and containing reduced levels of saturates and trans fatty acids are produced using an activated hydrogenation catalyst and / or an improved hydrogenation process incorporating high shear. The use of a high shear mechanical device incorporated into the hydrogenation process as a reactor device is shown to be capable of enabling reactions that would normally not be feasible under a given set of reaction pressure and temperature conditions. For example, the hydrogenation process described herein enables a reduction of hydrogenation time, and operation at lower temperatures than current processes. The resulting hydrogenated vegetable oil is particularly useful in frying, confectionery baking, and other applications where a product with a low trans fat content or higher thermal stability is desirable. The hydrogenated oil produced may comprise less than 10 weight % of trans fatty acids with less than 5 weight % of linolenic acid (C18:3).

Owner:HRD CORP

Wax emulsion coating applications

Owner:MARCUS OIL & CHEM

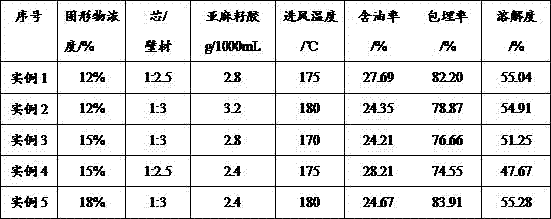

Acid-resistant non-dairy creamer and preparation method thereof

ActiveCN101919454ARaw materials are simpleSolve the problem of acid intoleranceEdible oils/fatsMonoglycerideVegetable oil

The invention discloses acid-resistant non-dairy creamer and a preparation method thereof, and the acid-resistant non-dairy creamer comprises the following components by weight percent: 20-35% of partially hydrogenated vegetable oil, 5-15% of starch sodium octenylsuccinate, 0.3-0.7% of monoglyceride, 0.3-0.7% of sodium stearoyl lactylate, 0.2-0.4% of silicon dioxide and the balance of glucose syrup. A product can solve the difficult problem that the non-dairy creamer in the prior art has no acid resistance, simplify the application method of the non-dairy creamer in the prior art, reduce the uncertainty of the process, reduce auxiliary supplementary materials required during applications and expand the range of the applications.

Owner:JIAHE FOODS IND CO LTD

Plant lipid cream and production method thereof

InactiveCN101647496AFine foamImprove the decorative effectEdible oils/fats production/working-upDispersitySucrose

The invention discloses a plant lipid cream and production method thereof. The plant lipid cream is prepared by the steps that proteolytic enzyme is utilized to restrict hydrolyzed soy separation, soas to obtain soy proteolysis solution; the soy proteolysis solution is mixed with partially hydrogenated plant oil, sucrose, starch syrup, sodium alginate tech grade, carrageenan, microcrystalline cellulose, phosphate, edible emulsifier; and then filtering, aqueous phase material preparation, oil phase material preparation, mixing, blending, secondary homogeneity, aging, filling and packing are carried out sequentially. The invention modifies enzymolysis of isolated soy protein, dissolubility, dispersity and emulsibility are obviously improved, and the functional characteristic is close to casein, thus substituting application of nutrose in plant lipid cream; plant raw materials are adopted, raw material cost is reduced, thus having positive significance on nutrition and health care function; the product has favourable mouthfeel and flavour; and the production method of the invention is based on plant lipid cream similarity processing technology, utilizes biological enzyme technology and has wide applicability.

Owner:GUANGDONG IND TECHN COLLEGE

Polyol made from partialy hydrogenated, fully epoxidized natural oils

InactiveUS20110065821A1Low densityResistant to yellowingFatty acid hydrogenationFatty acid oxidationVegetable oilGram

A method is disclosed for making a polyol comprising: fully-epoxidizing a partially hydrogenated vegetable oil to obtain a fully-epoxidized vegetable oil derivative having an iodine value less than 4 g I2 / 100 gram, an EOC of from 4.0 to 5.7% and a Gardner color value of 2 or less; and then reacting the fully-epoxidized vegetable oil derivative with a ring opener to form a polyol having a hydroxyl number from 40 to 80 mg KOH / gram, a number average molecular weight of at least 1500 Daltons, a dynamic viscosity less than 10 pascal-seconds, and an EOC below 3.0 wt %.

Owner:CARGILL INC

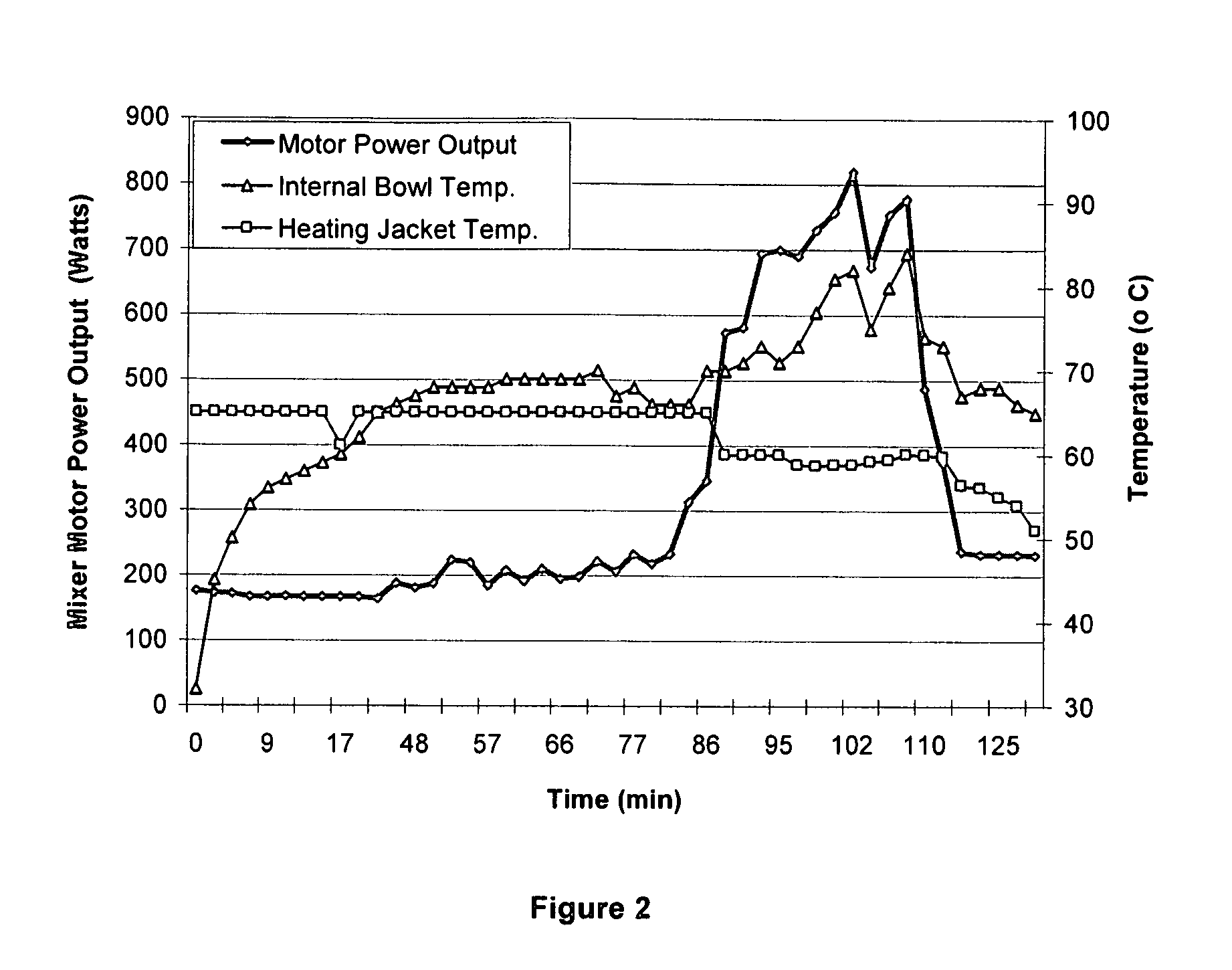

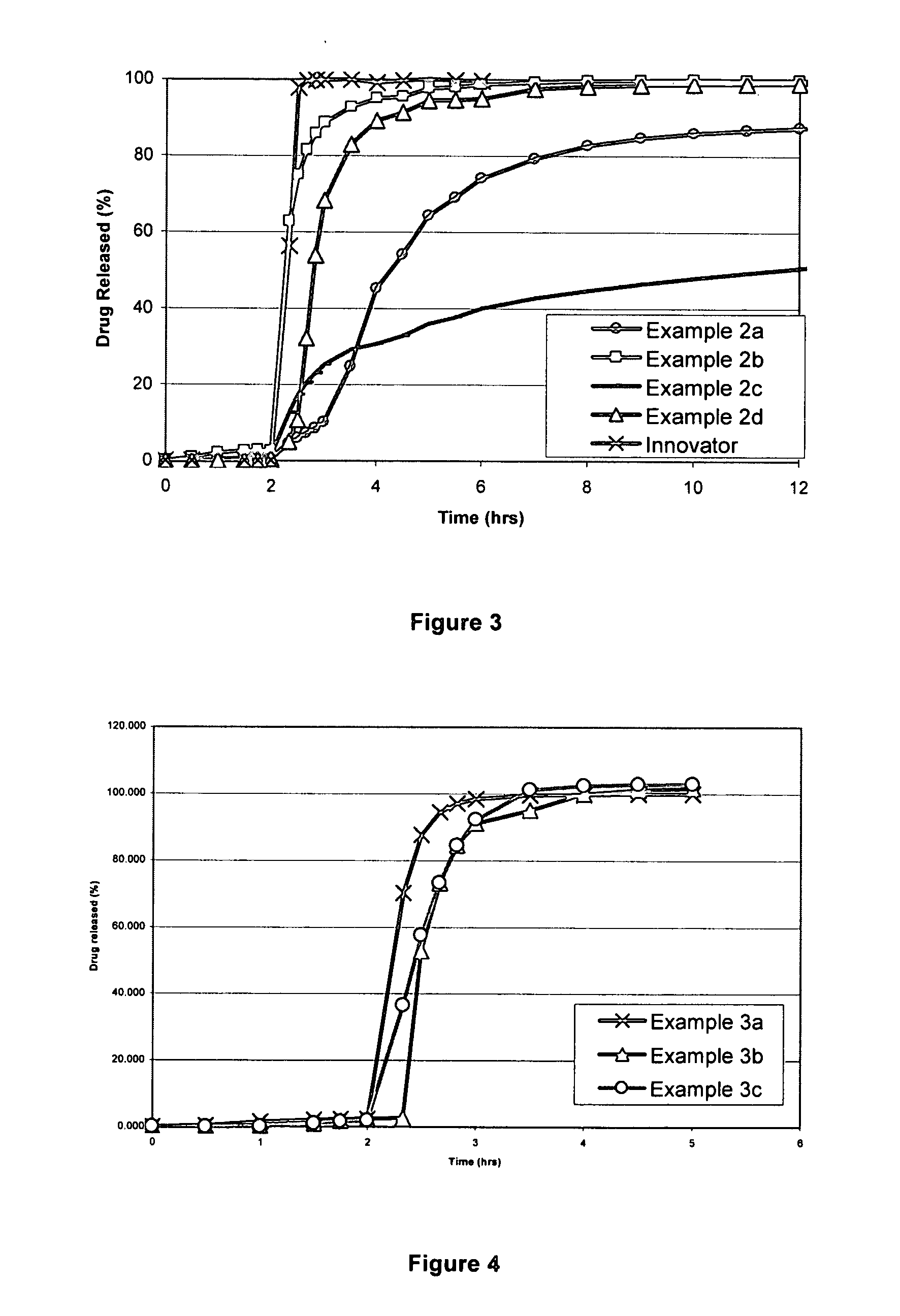

Delayed release pharmaceutical oral dosage form and method of making same

InactiveUS20070190139A1Inhibition of agglomerationBiocideElcosanoid active ingredientsVegetable oilImmediate release

The present invention relates to a multi layer pharmaceutical oral dosage form having delayed release and immediate release properties and method of making same. The delayed release formulation substantially behaves as an enterically coated dosage form but without the formulation and the application of an enteric coating. The delayed release formulation is characterized by a mixture of one or more active ingredients and one or more excipients selected from the group of solid aliphatic alcohols, mixtures of esters of saturated fatty alcohols and saturated fatty acids, natural or synthetic waxes, hydrogenated castor oil, hydrogenated vegetable oil, gums, and mixtures thereof; pH dependent soluble polymers; and optionally an opacifying agent.

Owner:INTELGENX CORP

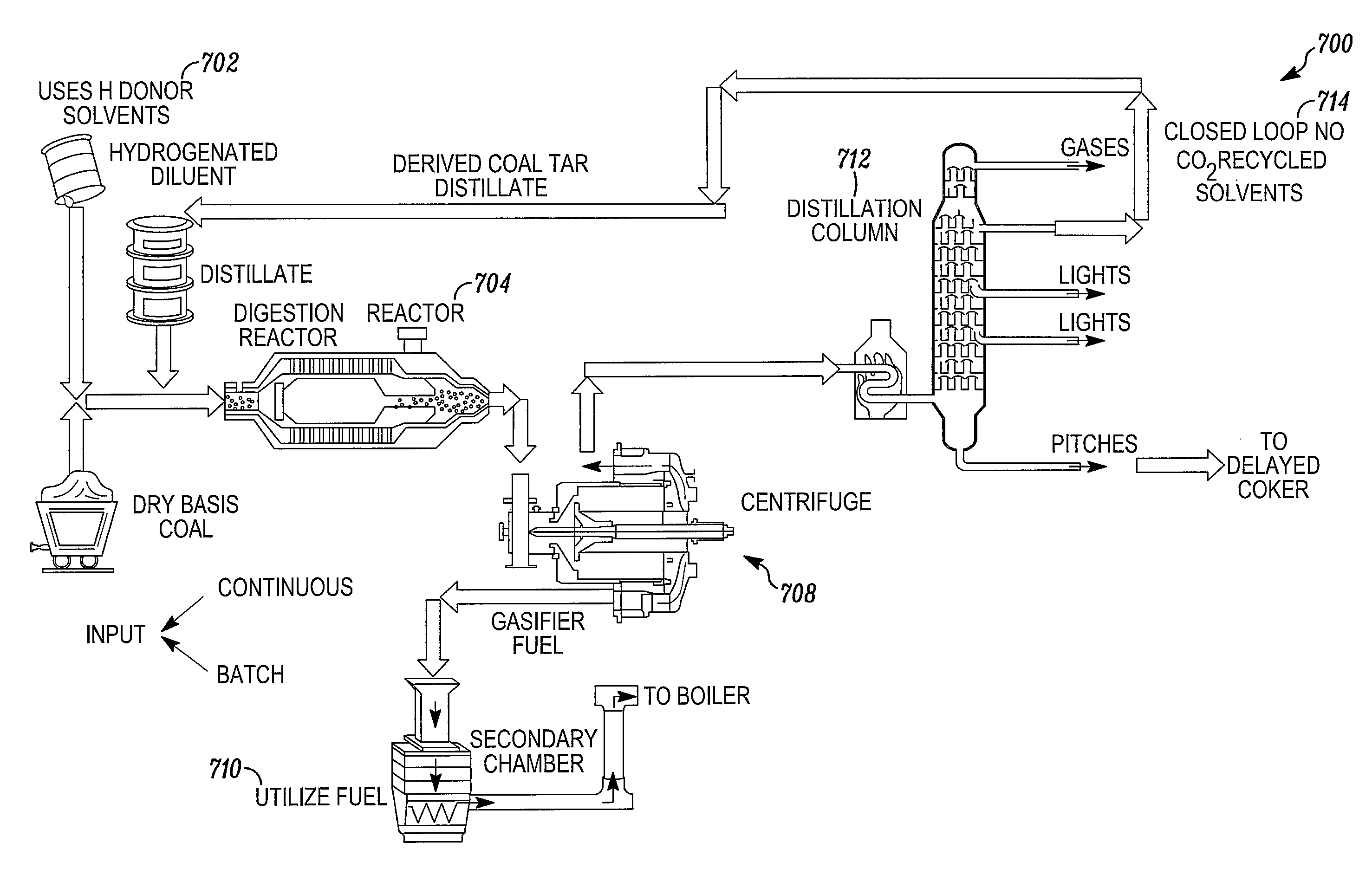

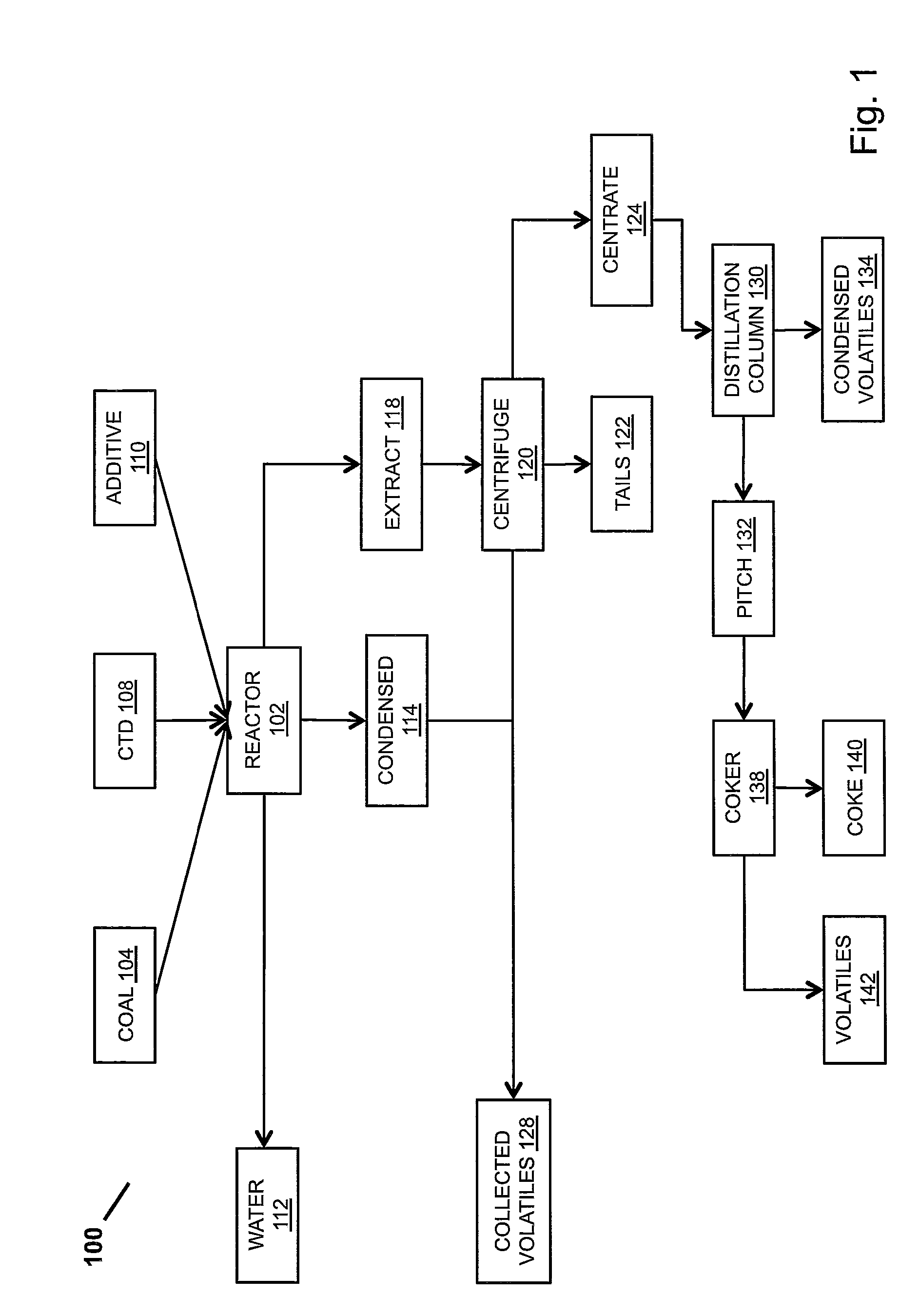

Modular Coal Liquefaction System

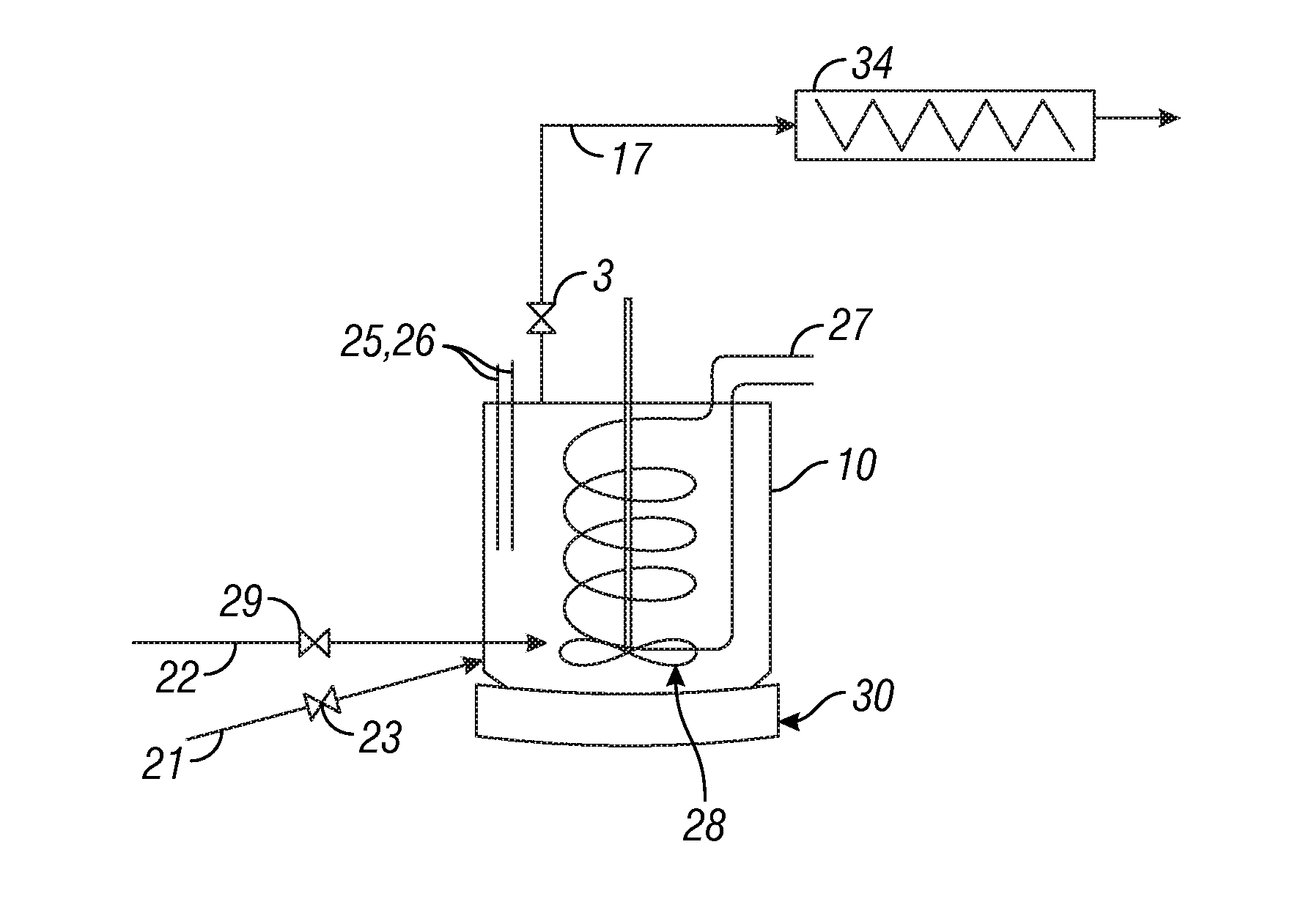

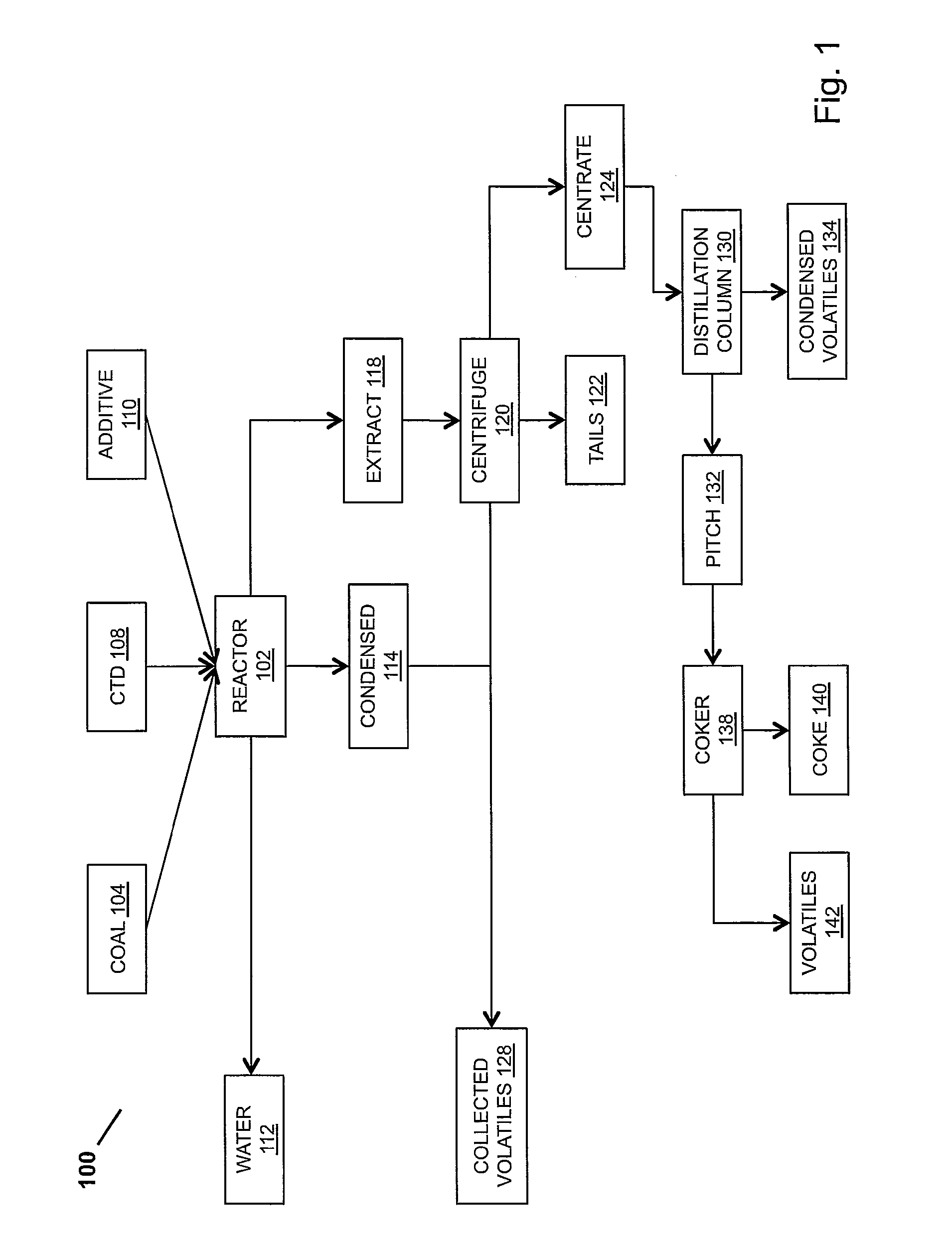

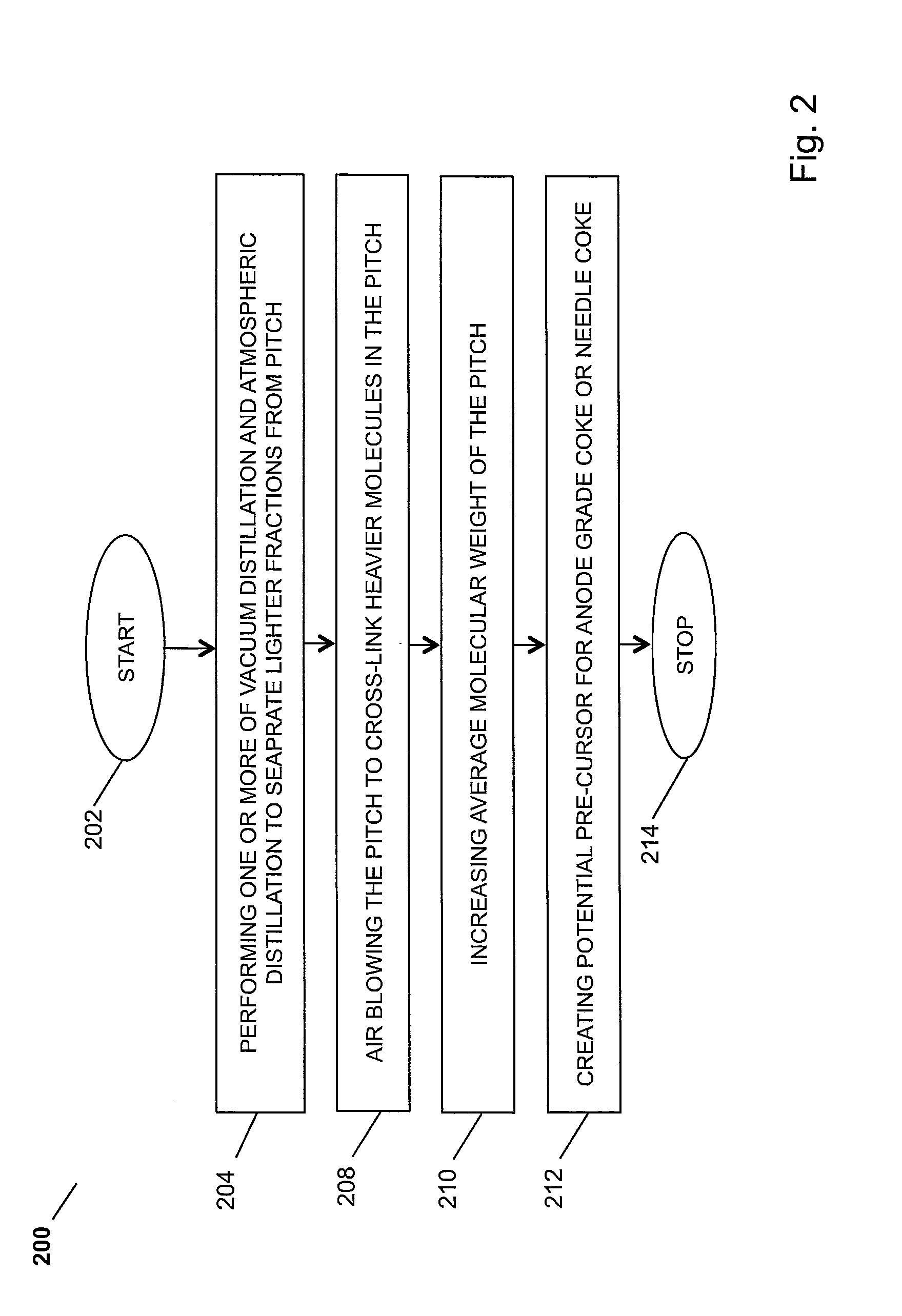

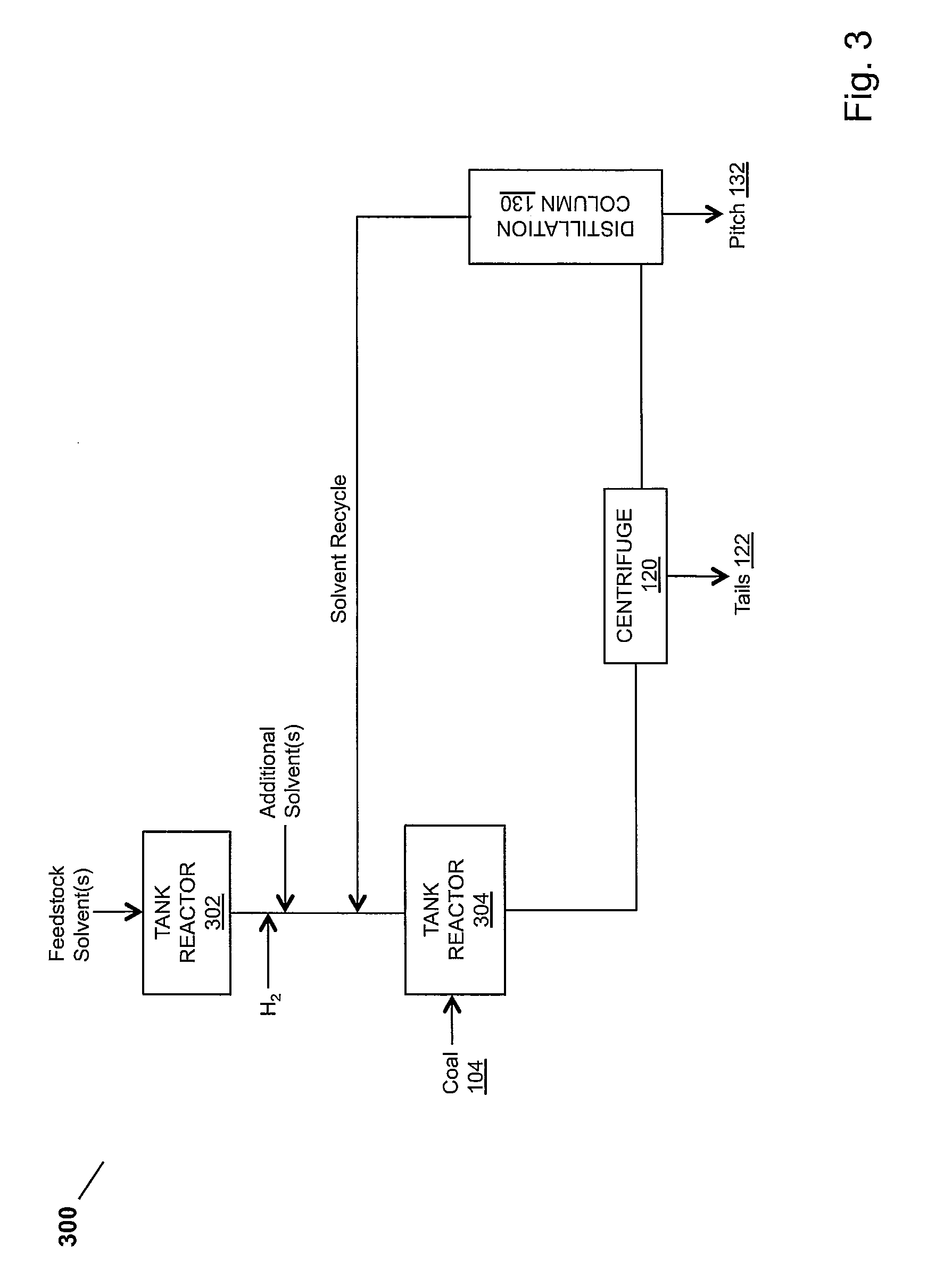

InactiveUS20120076703A1Low production costImprove solubilityOven incrustations prevention/removalLiquid hydrocarbon mixture productionTruck-trailerDownstream processing

The present disclosure provides methods and systems of a modular coal liquefaction system. A modular coal liquefaction system may include a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing, wherein the reactor, heater, and centrifuge are adapted to be modular. The system may further include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may further include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke. The system may be adapted to be modularly disposed on a rail car. The system may be adapted to be modularly disposed on a semi-truck trailer.

Owner:WEST VIRGINIA UNIVERSITY

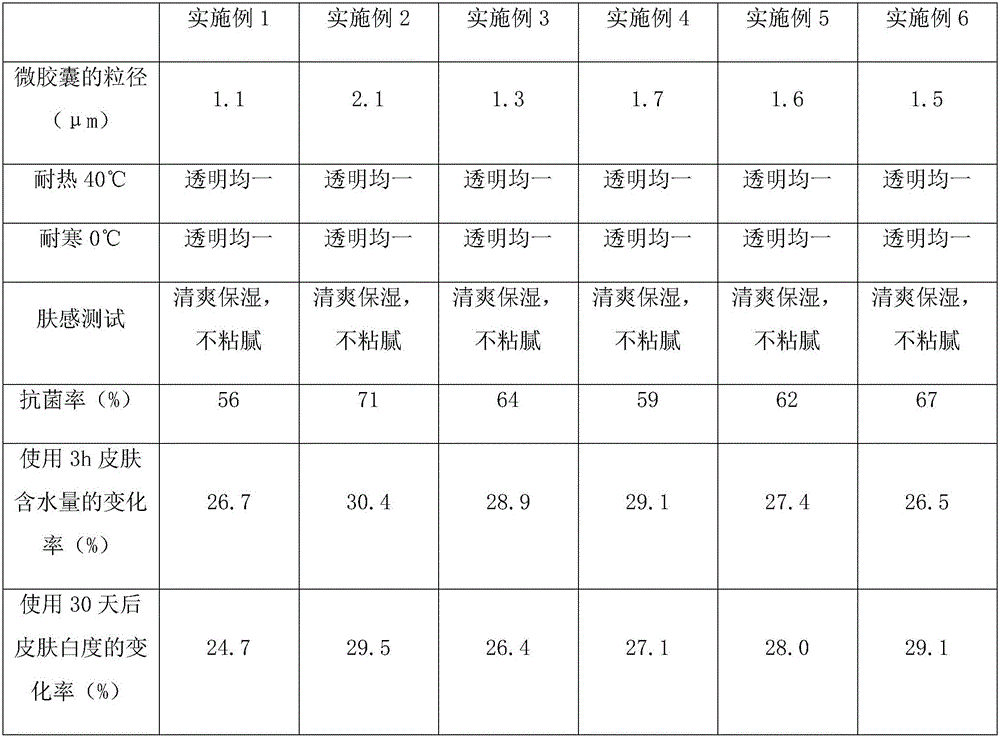

Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

InactiveCN105726456AGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedVegetable oil

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

Novel wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. The emulsions are stable, and are characterized by having an average particle size less than 1000 nanometers. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F (49-94 degrees C) (Mettler Drop Point). The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:HRD CORP

Cocoa butter substitute chocolate for 3D (three-dimensional printing) printing and preparation method thereof

InactiveCN104938738ASimple processNo temperature adjustmentAdditive manufacturing apparatusCocoaButter cocoaCocoa Powders

The invention discloses cocoa butter substitute chocolate for 3D (three-dimensional printing) printing. The cocoa butter substitute chocolate is prepared from the following raw materials in percentage by weight: 35-40% of hydrogenated vegetable oil, 10-25% of cocoa powder, 25-40% of white granulated sugar, 5-15% of skimmed milk powder, 0.5-1.0% of an emulsifying agent and 0.05-0.2% of essence. The cocoa butter substitute chocolate is prepared by the steps of pretreating raw materials, mixing, finely grinding, refining, filling, melting and the like. The cocoa butter substitute chocolate has stable mobility, temperature regulation is not required, the production process is simplified, the heat resistance is good, the cocoa butter substitute chocolate can be prepared into chocolate products having original chocolate characteristics and flavor and of novel and artistic models through the digital 3D printing technology.

Owner:天舜(杭州)食品股份有限公司

Non-hydrogenated vegetable oil based margarine for puff pastry containing an elevated diglyceride emulsifier

ActiveUS20070148313A1Sufficient structureHigh than usual level of diglycerides functionDough treatmentFatty acid esterificationGreek letter betaGlycerol

A mono-, di-, and triglyceride emulsifier is provided that is obtained by the interesterification or glycerolysis of triglycerides with glycerol. The diglyceride portion w / w is at least about 65% to about 80%, and most preferably from about 70% to about 80%. The high diglyceride emulsifier is useful in preparing a margarine from a selected quantity a non-hydrogenated vegetable oil and from an amount of saturated fat for use in puff pastry products. The puff pastry is trans fat free and a less than usual percentage of saturated fats. A preferred structured puffpastry margarine is prepared by mixing on a weight to weight basis about 14 parts of the high diglyceride emulsifier that is in predominantly stable beta crystal form, from about 14 to 27 parts of a non-hydrogenated vegetable oil, and from about 40 to about 52 parts of a saturated fat.

Owner:CARAVAN INGREDIENTS

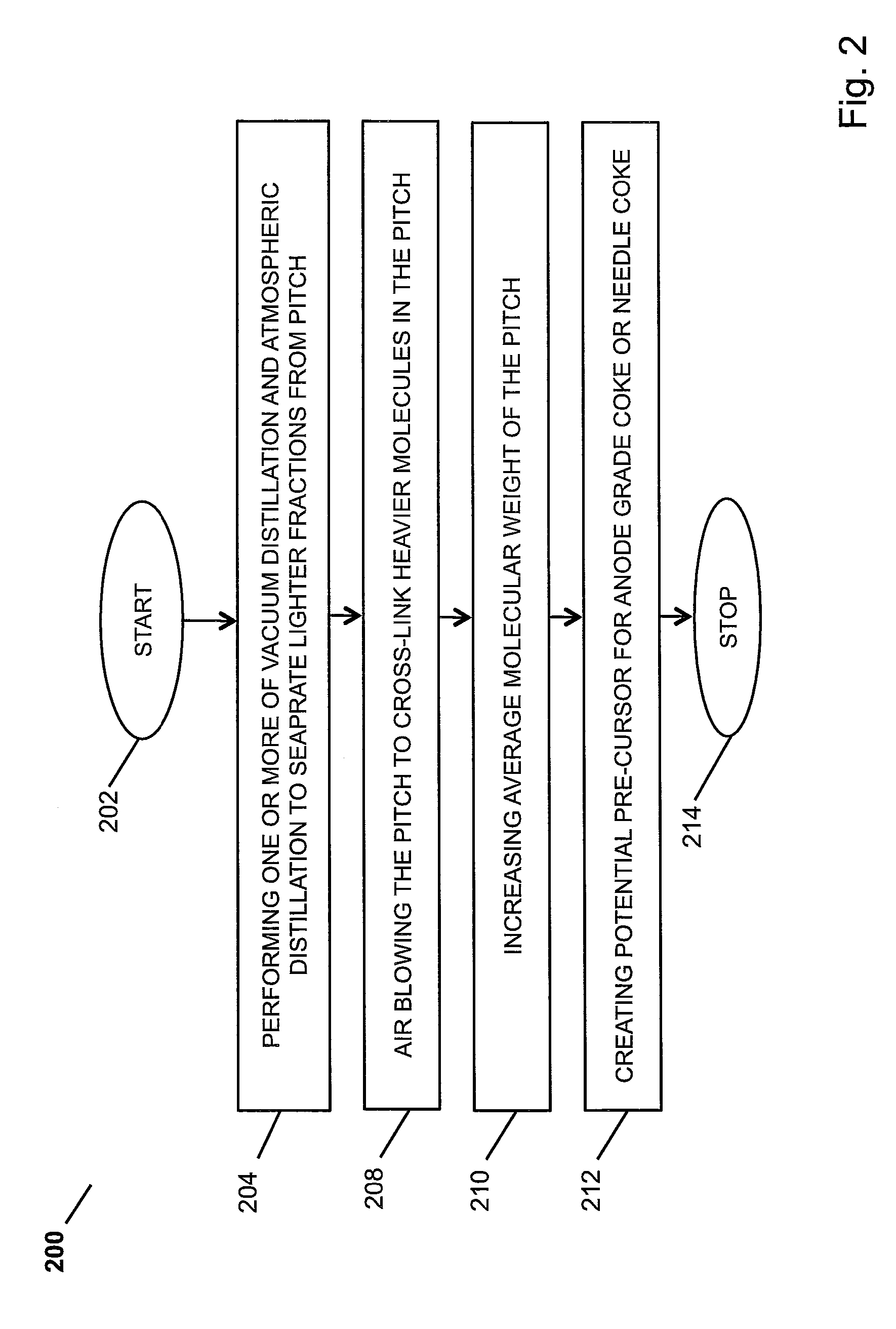

Hydrogenated Vegetable Oil in Coal Liquefaction

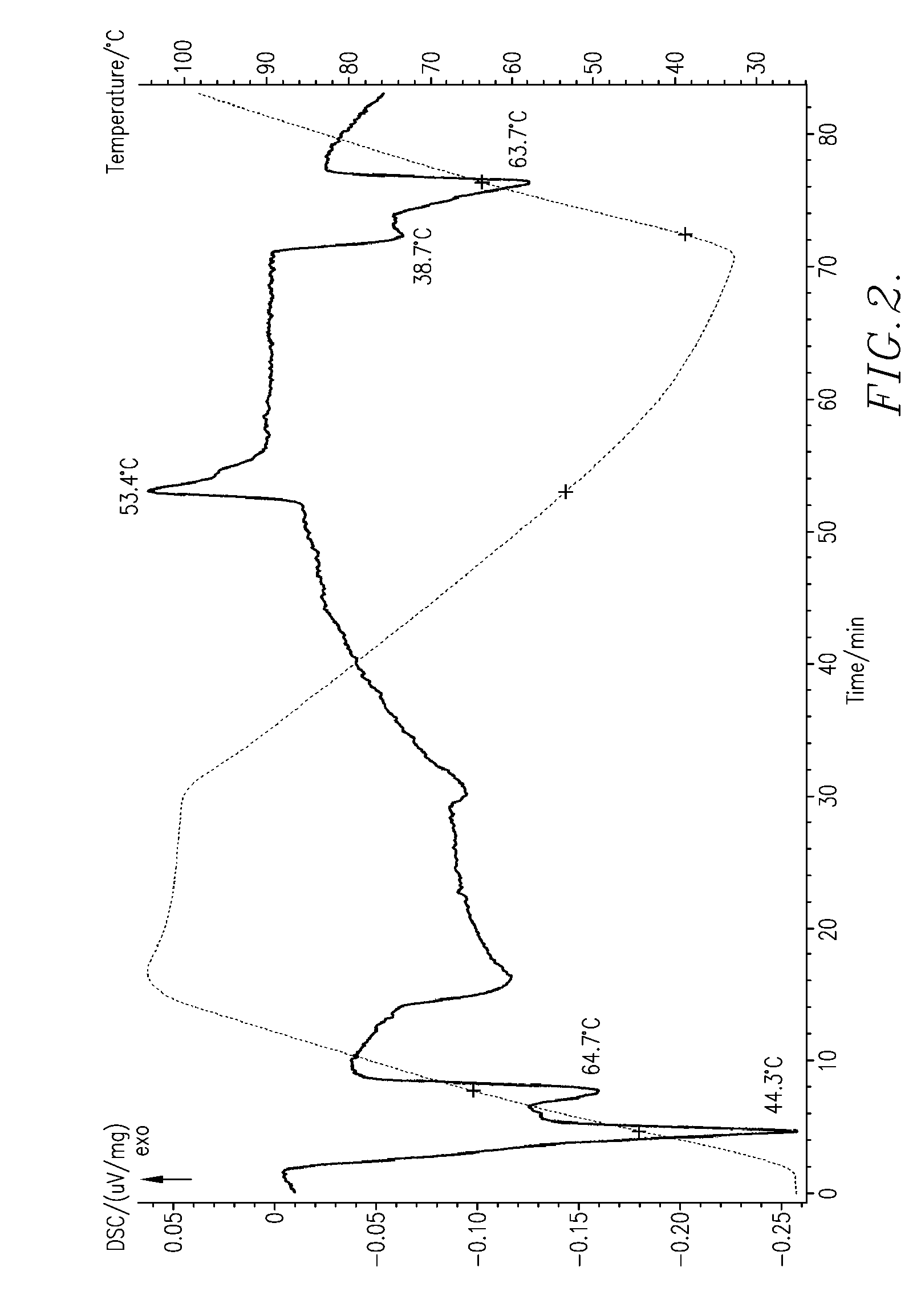

InactiveUS20120091042A1Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

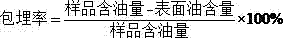

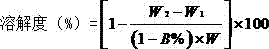

Linseed oil and linseed gum vegetable fat powder and preparation method thereof

The invention discloses linseed oil and linseed gum vegetable fat powder and a preparation method thereof. According to the vegetable fat powder, soy protein isolate (SPI) and maltodextrin (MD) are used as wall materials, linseed oil is used as a core material, linseed gum is used as an emulsifying agent, and a spray drying technology and a microcapsule technique are adopted, so that the vegetable fat powder is prepared. Compared with traditional vegetable fat powder using hydrogenated vegetable oil as a raw material, the vegetable fat powder prepared by the preparation method disclosed by the invention does not contain trans-fatty acid, so that the danger of the trans-fatty acid is greatly reduced; besides, the vegetable fat powder disclosed by the invention also has various health-care functions of preventing thrombosis, reducing blood lipid, regulating immunity, restraining cancer and the like; in addition, the microcapsule preparation technique is adopted, and liquid fat is converted into powdery solid, so that the fat oxidation risk is greatly reduced, the fat stability is strengthened, the storage period of the product is prolonged, and the special smell of the linseed oil is also concealed; and the vegetable fat powder has multiple advantages of being simple in technology, low in cost, easy to control and store, high in stability, high in water solubility and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Micro capsule for choline chloride for ruminant stomach and its preparing method

InactiveCN1561979AAvoid damageReduce deliquescenceMetabolism disorderAnimal feeding stuffBiotechnologySilicon dioxide

A through-rumen microsoftgel choleaevin as feed additive is prepared from the SiO2 carried choleaevin as core and the hydrogenated plant oil as shell through proportionally mixing, and granulating.

Owner:ZHEJIANG UNIV

Shortening system

InactiveUS20090220653A1Improve sensory propertiesGreat tasteFatty acid hydrogenationEdible oils/fats ingredientsGeometric isomerVegetable oil

A shortening system, such as a spray shortening system; for instance, a shortening system containing unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil or canola oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of conserved trans monoglyceride and / or diglyceride, advantageously a monoglyceride or a mono- and diglyceride that is mostly monoglyceride, based on a highly unsaturated ‘oil, such as a highly unsaturated vegetable oil, e.g., canola or soybean oil,’ which has been selectively and partially hydrogenated so as to result in conservation of the geometric isomer of the C18:1 ester, namely the C18:1t or elaidic ester, as well as to methods for making and using such a shortening system, products from the use of such a shortening system, and the monoglyceride and / or diglyceride constituent of the shortening system, and methods for making and uses thereof.

Owner:AS DE DANSKE SUKKERFABRIKKER

Soft chewable anesthetic lozenges

A soft, chewable lozenge for relief of mouth pain contains, by weight, 10-60% hydrogentated starch hydrolysate, 3-60% hydrogenated mono- and di-saccharides, 1-20% hydrogenated vegetable oil, 0.5-27% gelatin, 0.25-7.5% anesthetic and 1-25% water. A method for treating mouth and throat pain by administering to a patient in need a soft, chewable, non-sticky anesthetic lozenge is disclosed.

Owner:SINGH MOHINDER

Feed additive composition for ruminants and method of producing the same

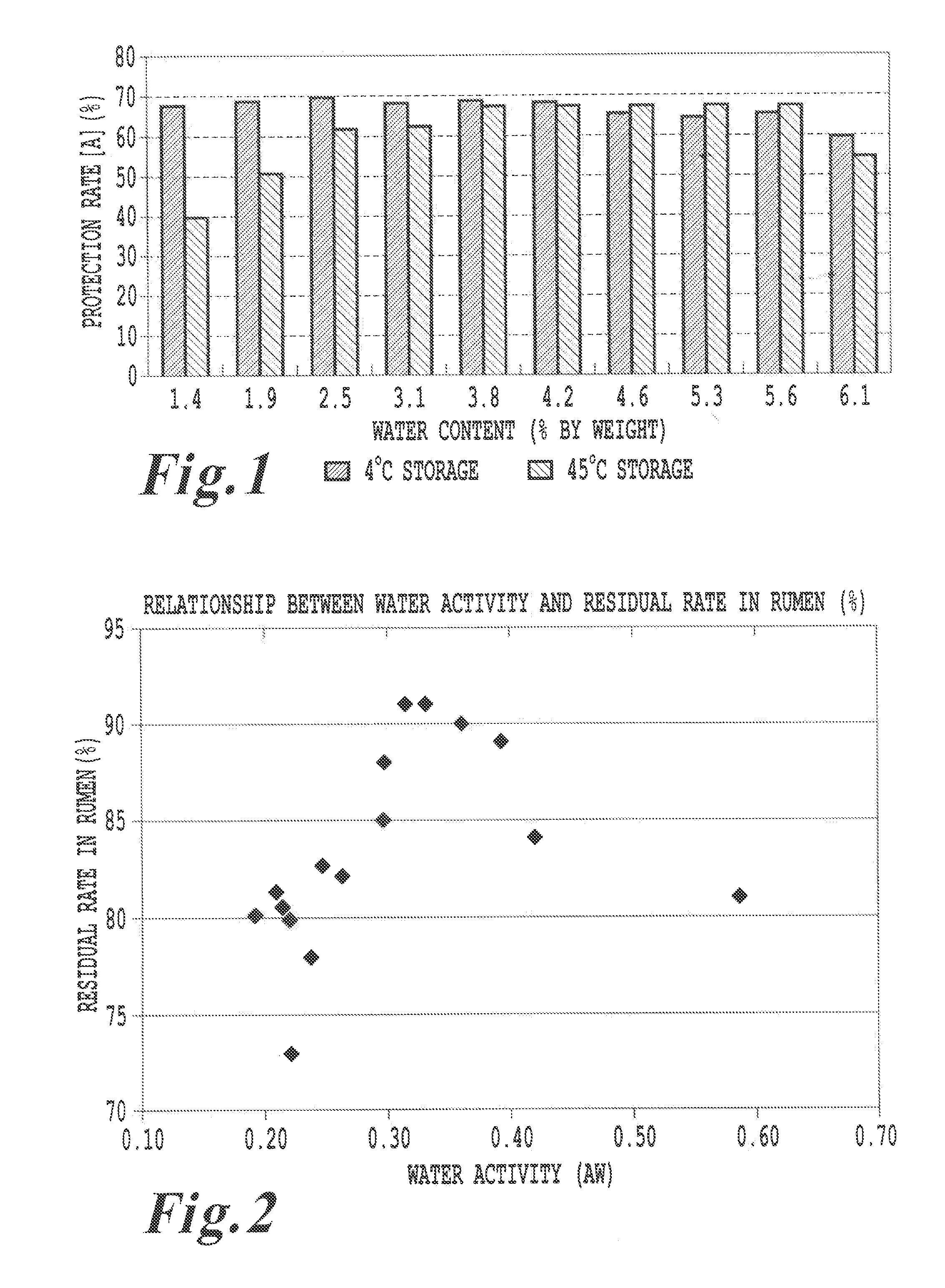

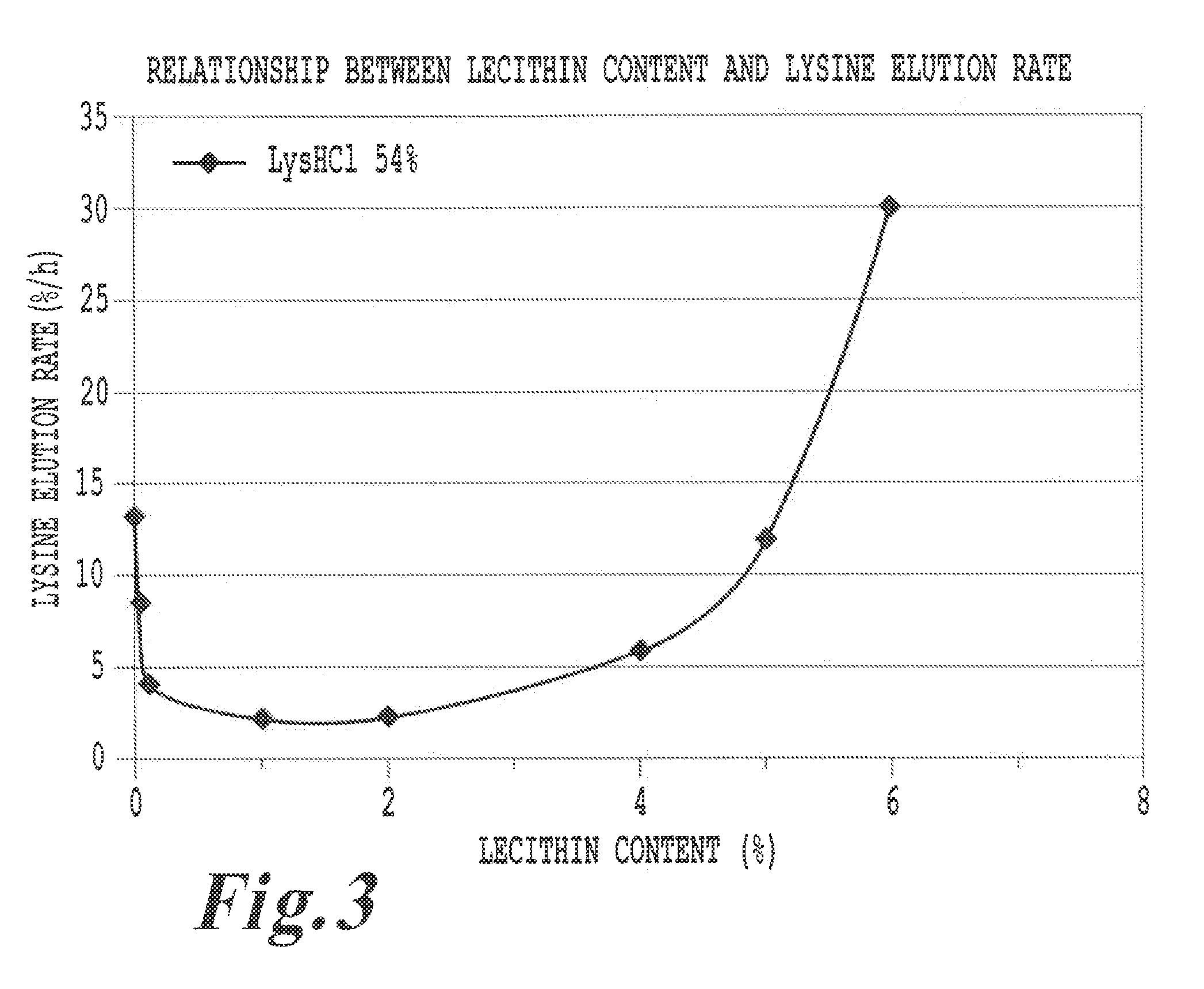

ActiveUS20110081444A1Promote milk productionImprove efficiencyAnimal feeding stuffAccessory food factorsFeed additiveProtective Agents

A feed additive composition includes a protective agent, lecithin in an amount of 0.05 to 6% by weight relative to a total weight of the composition, a basic amino acid in an amount of at least 40% by weight and less than 65% by weight relative to the total weight of the composition, and water. A method of producing a feed additive composition includes preparing a molten mixture of at least one protective agent, lecithin and at least one basic amino acid, and solidifying the molten mixture by immersing the molten mixture in water or an aqueous liquid. The protective agent includes hydrogenated vegetable oils and / or hydrogenated animal oils having melting points of greater than 50° C. and less than 90° C.

Owner:AJINOMOTO CO INC

Glass fiber soaking agent and preparation method thereof

The invention discloses a glass fiber soaking agent, which is mainly prepared from the following ingredients in percentage by weight: 2 to 6 percent of modified straight chain starch, 1 to 5 percent of modified amylopectin, 0.5 to 5 percent of microcrystalline wax, 0.5 to 5 percent of hydrogenated vegetable oil, 0.1 to 1 percent of quaternary ammonium salt cation lubricating agents, 0.1 to 1 percent of span 80, 0.01 to 0.5 percent of alkane sulfonate surfactants, 0 to 2.0 percent of modified epoxy resin bonding agents, 0 to 0.05 percent of defoaming agents and the balance water. The glass fiber soaking agent has the advantages that the physical and chemical properties of the glass fiber electronic weaving yarn can be fully improved, the stiffness is between 50 and 80, the tensile intensity is higher than 52 CN / TEX, and the yarn fracture and fuzzing problems in the weaving process are effectively solved.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

Fat-coated fodder acidifying agent

ActiveCN103931898ASave materialHigh weightAnimal feeding stuffAccessory food factorsVegetable oilSolvent

The invention discloses a fodder acidifying agent coated with fat. The fodder acidifying agent is prepared according to the following steps: firstly compressing such a solvent at gaseous state at normal temperature and under normal pressure as liquefied oil gas into liquid and storing in a storage tank; dissolving a coating material such as hydrogenated vegetable oil into the liquid solvent; uniformly mixing a solution containing the coating material with an acidifying agent particle material in a pressure container so that the surfaces of acidifying agent particles are uniformly coated with the coating material; stirring and decompressing to release the solvent, and finally collecting a coated acidifying agent. The fodder acidifying agent disclosed by the invention has the advantages that a fat-soluble coating of the fodder acidifying agent is prepared by use of a subcritical fluid coating technique and the process is simple; the weight percentage of the acidifying agent in the coated acidifying agent is as high as 80%, so the coating materials are greatly saved and the production cost is lowered.

Owner:河南启明饲料有限公司

Wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. The emulsions are stable, and are characterized by having an average particle size less than 1000 nanometers. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (49-94 degrees C.) (Mettler Drop Point). The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:HRD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com