Patents

Literature

101 results about "CAPRYLHYDROXAMIC ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

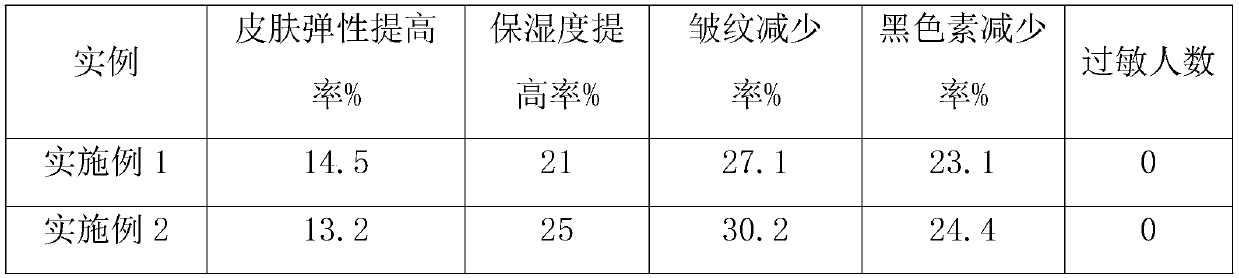

Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

InactiveCN105726456AGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedVegetable oil

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

Broad-spectrum antibacterial cosmetic antiseptic and application thereof

InactiveCN102920612AImprove compatibilityLess irritatingCosmetic preparationsHair cosmeticsIrritationPhenethyl alcohol

The invention discloses a broad-spectrum antibacterial cosmetic antiseptic comprising the components of, by mass: 8-12% of caprylhydroxamic acid, 38-45% of phenethyl alcohol, and 46-54% of methylpropanediol. The antiseptic provided by the invention has the advantages that: (1) the antiseptic has broad-spectrum antibacterial activity, and can effectively inhibit Gram-negative and positive bacteria, yeasts and molds; (2) the antiseptic does not contain traditional antiseptic and bactericide, and is a cosmetic-use complex system completely satisfying a concept of no antiseptic addition; and the antiseptic has low irritation and high safety; and (3) the antiseptic has good compatibility with most of cosmetic raw materials; and the antibacterial capability of the antiseptic is not affected by surfactant, proteins and Chinese herbal medicine additives in cosmetics.

Owner:SPEC CHEM IND INC

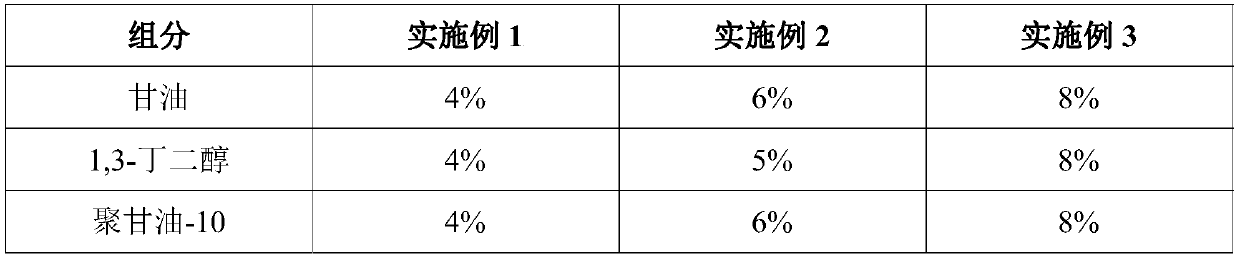

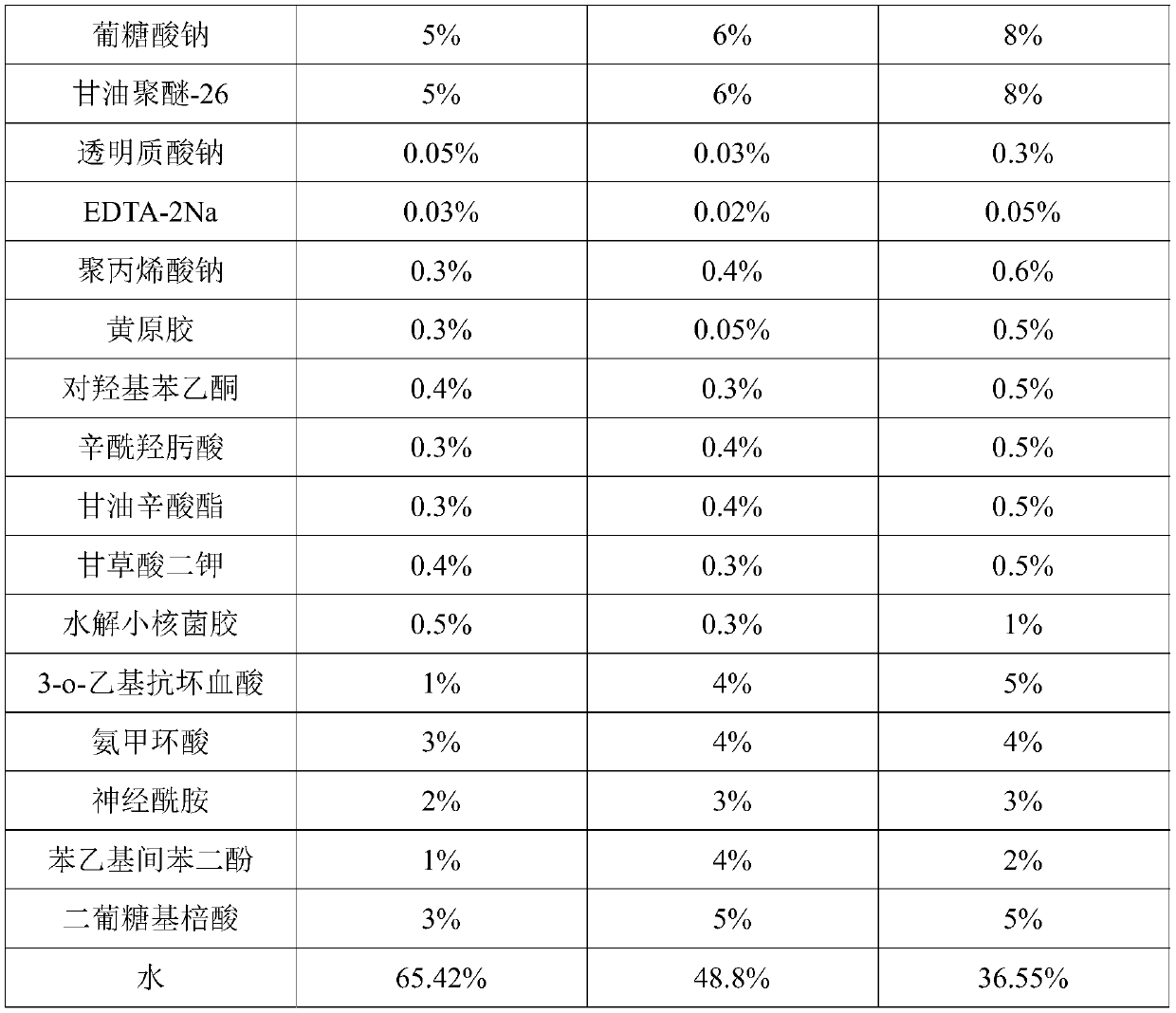

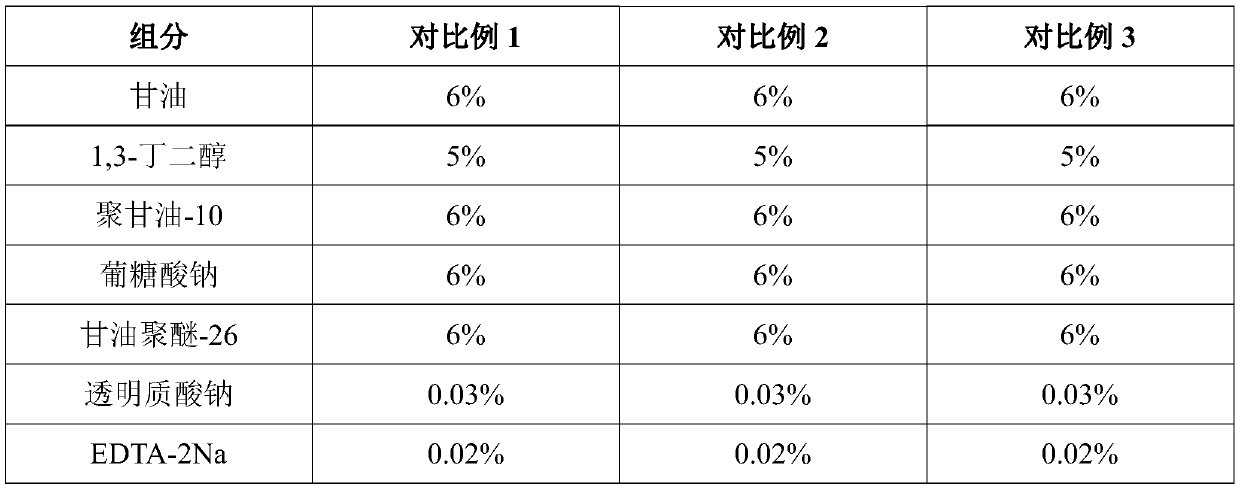

Whitening essence and preparation method thereof

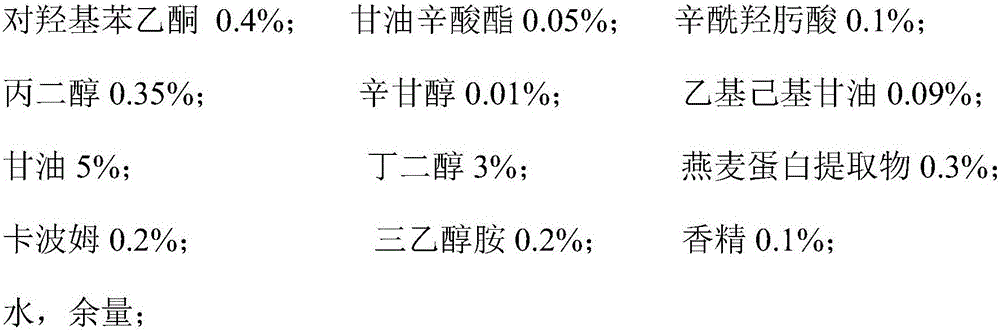

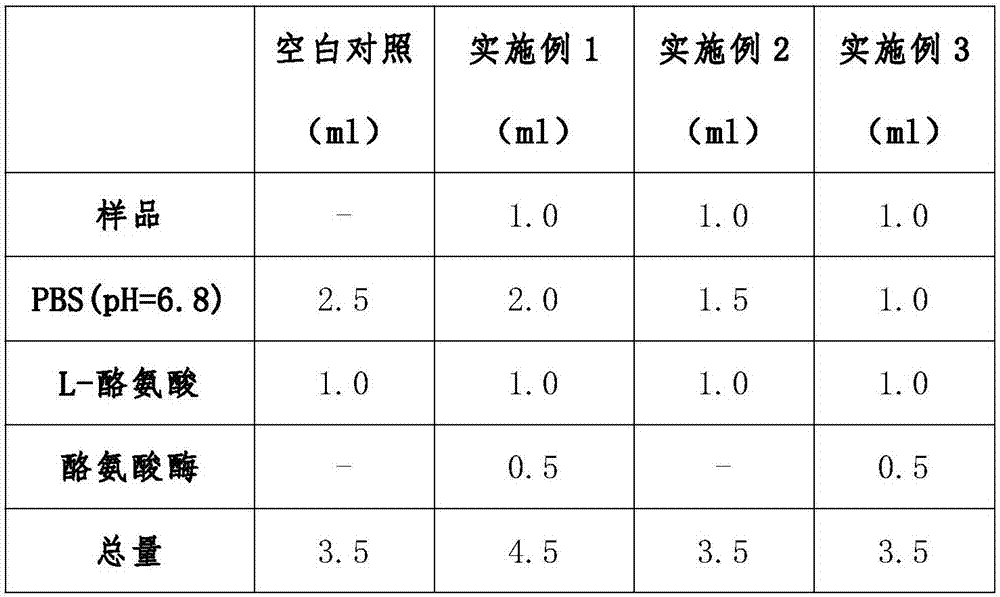

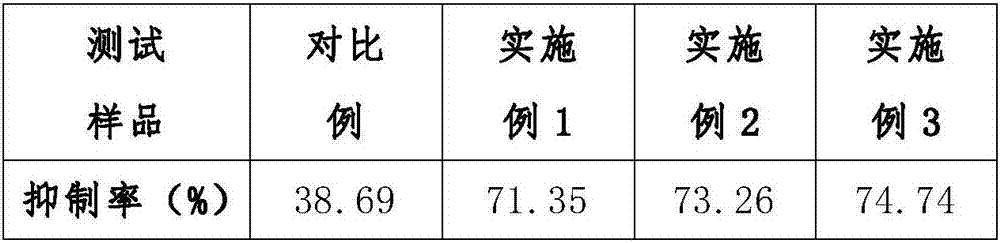

PendingCN111067818AInhibit transferPhotoprotectiveCosmetic preparationsToilet preparationsAcropustulosisButanediol

The invention provides whitening essence and a preparation method thereof. The whitening essence consists of the following components of glycerine, 1,3-butanediol, sodium hyaluronate, EDTA-2Na, polyglycerol-10, sodium polyacrylate, xanthan gum, hydroxyacetophenone, dipotassium glycyrrhizinate, hydrolyzed sclerotium gum, gluconic acid sodium salt, glycereth-26, caprylhydroxamic acid, glycerol caprylate, 3-o-ethyl ascorbic acid, tranexamic acid, ceramide, phenethyl resorcinol, diglucosyl gallic acid and water. The whitening essence disclosed by the invention can refrain conversion of tyrosine tomelanin before the tyrosine is in preparation of conversion to the melanin, so that the activity of the tyrosinase is also high, generation of more melanin cannot be caused, and transfer of skin melanin can also be restrained. Besides, the whitening essence has powerful antioxidant ability, has light protection effects on skin, can control dermatitis, and is a whitening product most comprehensivein action mechanism at present, so that whitening effects can be achieved.

Owner:广州市柏姿生物科技有限公司

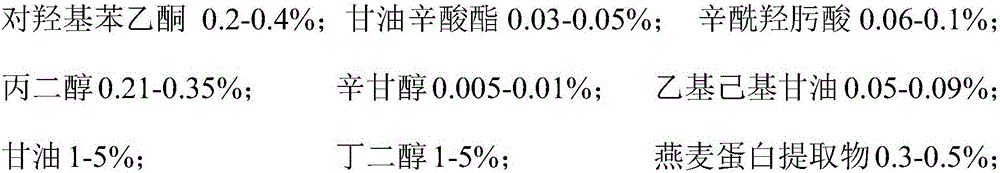

Anticorrosive component-free composition having antibiosis effect, and preparation method and application thereof

ActiveCN107432834AHas activity against Gram bacteriaSynergistic sterilizationAntibacterial agentsCosmetic preparationsCaprylyl GlycolCAPRYLHYDROXAMIC ACID

The invention discloses an anticorrosive component-free composition having an antibiosis effect. The composition comprises, by weight, 20-45% of p-hydroxyacetophenone, 3-10% of glycerol caprylate, 6-15% of caprylhydroxamic acid, 21-40% of propylene glycol, 0.5-1.5% of caprylyl glycol and 5-15% of ethylhexylglycerin, and the sum of the weight percentages of all above components is 100%. The anticorrosive component-free composition having the antibiosis effect has the advantages of no irritation, non-allergy, protruding antibiosis effect, harmlessness to human bodies, and no toxic or side effects, and can be safely applied to cosmetics. The invention also discloses a preparation method of the anticorrosive component-free composition having the antibiosis effect. The preparation method of the composition has the advantages of few steps, simple flow, and safety in operation. The invention further discloses an essence and a preparation method thereof. The essence has the advantages of good antibiosis effect, wide antibiosis range, no toxicity, harm or irritation, and high use safety, and the preparation method of the essence has the advantages of few steps, simple flow, and safety in operation.

Owner:广州市皓雨化妆品有限公司

Skin barrier repairing essence containing oligopeptide, ceramide, and glyceryl glucoside

InactiveCN108514541ARepair skin barrier function problemsGood treatment effectCosmetic preparationsToilet preparationsBetaineKetone

The invention discloses a skin barrier repairing essence containing oligopeptide, ceramide, and glyceryl glucoside. The essence comprises following components: water, glycerin, 1,3-propylene glycol, betaine, xylitol, anhydroxylitol, xylityl glucoside, oligopeptide-1, butylene glycol, honey extract, urea, panthenol, propylene glycol, caprylhydroxamic acid, glycerol caprylate, p-hydroxyl phenyl ethyl ketone, 1,2-hexanediol, glyceryl glucoside, ceramide 3, hydrogenated lecithin, sucrose stearate, and polyglycerol-10 stearate. The essence comprises multiple natural plant extracts and can prevent the aging of skin, repair the skin barrier, and treat various skin inflammations caused by hormones. Moreover, multiple natural plant extracts can nourish the skin and repair the skin barrier.

Owner:广州珈源日化用品有限公司

Multi-effect skin-tendering mask

InactiveCN107669593AGood skin rejuvenation effectGood moisturizing effectCosmetic preparationsToilet preparationsBetaineHamamelis virginiana

The invention discloses a multi-effect skin-tendering mask which comprises the following components by weight: 67.55 parts of water, 4 parts of butanediol, 0.2 part of allantoin, 0.4 part of hydrolytic Sclerotium Gum, 0.1 part of disodium, 0.1 part of sodium hyaluronate, 0.15 part of poly(sodium L-glutamate), 3 parts of betaine, 5 parts of licorice extract, 8 parts of cherry blossom extract, 5 parts of North American witch hazel water, 0.5 part of oat seed extract, 2 parts of nicotinamide, 0.5 part of Aloe barbadensis Mill gel, 2.2 parts of beta-glucan, 0.5 part of isoascorbic acid, 2 parts ofglycerol caprylate, 4.5 parts of propylene glycol and 0.4 part of caprylhydroxamic acid. The multi-effect skin-tendering mask has the advantages of non-preservative formula and good skin-tendering effect, and is capable of effectively increasing skin moisturizing ability, promoting skin health, increasing skin transparency, enhancing skin immunity, making skin full and elastic, and making skin smooth and smooth.

Owner:FABLED ENVIRONMENTAL PROTECTION TECH SUZHOU CO LTD

Skin care cream with eczema repair function

InactiveCN107115213AImprove permeabilityImprove shielding effectCosmetic preparationsToilet preparationsCentella asiatica extractGlycyrrhiza glabra Root

The invention discloses a skin care cream with an eczema repair function. The skin care cream is prepared from the following materials: hydrogenated lecithin, potassium lauryl phosphate, camellia-seed oil, evening primrose oil, cetostearyl alcohol, olive fruit oil, vitamin E, phytosterol oleate, polydimethylsiloxane, ethylenediamine tetraacetic acid disodium, polyglycerol-10, Carbomer, arginine, sodium hyaluronate, a creased mulan bark extract, a Japanese thuja branch extract, a shaddock peel extract, a glycyrrhiza glabra root extract, a purslane extract, a centella extract, a pomegranate extract, saccharide isomerate, glycerol caprylate, caprylhydroxamic acid and water. The skin care cream with the eczema repair function has a mild nature, is low in irritation and is high in acid and alkali stability and cold and heat resistance.

Owner:广州瑞誉化工科技有限公司

Skin base liquid having micro-ecological balance self-repairing function and preparation method thereof

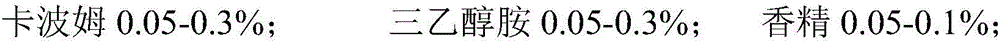

InactiveCN107137343AIncrease finesseImprove completenessCosmetic preparationsToilet preparationsALPHA-ARBUTINGlucoside

The invention discloses a skin base liquid having a micro-ecological balance self-repairing function. The skin base liquid comprises, by weight, 0.05-0.1% of sodium hyaluronate, 0.05-0.2% of carbomer, 0.05-0.2% of triethanolamine, 0.05-0.1% of disodium ethylenediaminetetraacetate, 1.5-2.5% of lubrajel oil, 0.05-0.1% of methyl p-hydroxybenzoate, 2-3% of apple fruit cell culture extract, 0.5-1% of glycerol glucoside, 2-3% of ganoderma lucidum extract, 2-5% of palmitoyl tripeptide-5, 2-5% of alpha-arbutin, 0.5-1% of dendrobium officinale extract, 0.5-1% of caprylhydroxamic acid and 0.5-2% of azone. The skin base liquid can effectively repair cell damage, promote cell metabolism, make dark and uneven color skin bright and moist and make skin fine, soft and youthful.

Owner:北京鑫宝洪泽化妆品有限公司 +1

Composition capable of lowering sensitivity and hormone dependency in skin care and preparation method of composition

InactiveCN110384652AImprove and protect barrier functionHormone freeCosmetic preparationsToilet preparationsCentella asiatica extractOpuntia dillenii

The invention discloses a composition capable of lowering sensitivity and hormone dependency in skin care and a preparation method of the composition, and belongs to the technical field of skin care treatment. According to the implementation mode, the composition capable of lowering the sensitivity and the hormone dependency in skin care is characterized by being prepared from the following content of a centella asiatica extract, a calendula extract, a chamomile extract, a radix glycyrrhizae / radix scutellariae / opuntia dillenii haw extract, a bacillus / soybean fermentation product extract, human-like collagen, a bisabolol / ginger root extract, tocopheryl acetate, allantoin, ceramide, caprylhydroxamic acid, tocopherol, folic acid, panthenol, an emollient, a humectant, a bacteriostat and water.All the components of the composition influence each other and act synergistically, the skin is nourished, moisturized, improved and protected, and the skin problems such as skin allergy, eczematousdermatitis and hormone dependent dermatitis caused by multiple reasons can be solved; and the composition is free of toxicity and hormones and suitable for being used for a long term or a short term,and has large market application demands.

Owner:杨智浩

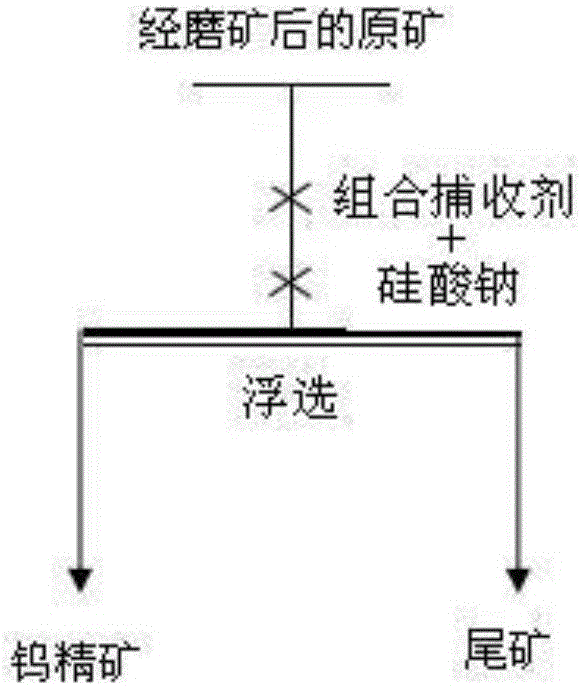

Combined collecting agent for flotation of scheelite and gangue minerals and flotation method thereof

The invention provides a combined collecting agent for flotation of scheelite and gangue minerals and a flotation method thereof. The combined collecting agent for flotation of the scheelite and the gangue minerals is a mixture formed by combining caprylhydroxamic acid and sodium oleate with the mass ratio of 1:1-1:6. The flotation method comprises the steps that S1, the scheelite is ground until the 0.074 mm fineness accounts for 90% of the total; S2, sodium silicate is added into the ground scheelite, and size mixing is conducted for about 25-30 minutes; and S3, the caprylhydroxamic acid and the sodium oleate with the mass ratio of 1:1-1:6 are added for flotation collecting, and flotation is conducted for 6-8 minutes. The combined collecting agent for flotation of the scheelite and the gangue minerals is simple in ingredient, high in selectivity and good in flotation separating effect.

Owner:CENT SOUTH UNIV

Small molecule hyaluronic acid skin pre-essence and preparation method thereof

InactiveCN107432849APromote new lifePrevent agingCosmetic preparationsToilet preparationsHigh concentrationVitamin C

The invention provides small molecule hyaluronic acid skin pre-essence and a preparation method thereof and belongs to the technical field of skin care products. The skin pre-essence comprises, by weight, 10 to 15 parts of deionized water, 25 to 35 parts of small molecule hyaluronic acid, 0.8 to 1.2 parts of sodium hyaluronate, 3 to 5 parts of yeast extract, 10 to 15 parts of oligopeptide-1, 1 to 3 parts of betaine, 1.5 to 2.5 parts of trehalose, 1 to 2 parts of fructosan, 1.8 to 2.2 parts of beta-glucan, 0.5 to 2.5 parts of sodium polyacrylate, 8 to 12 parts of Anthemis nobilis extract, 1 to 3 parts of p-hydroxy phenyl ethyl ketone, 1 to 2 parts of caprylhydroxamic acid, 10 to 15 parts of an alcoholic composition, 6 to 10 parts of vitamin C and 8 to 15 parts of squalene. The small molecule hyaluronic acid skin pre-essence has small molecular weight, easily penetrates into the skin, significantly improves water content of the skin base, inhibits the production of melanin, fades the spots, fast fills damaged cells, well improves acnes, is prepared from pure natural raw materials and has a high concentration, strong practicability and high safety.

Owner:北京汲度美容科技有限公司

Skin nourishing and moisturizing restoration essence cream containing soluble beewax and preparation method thereof

ActiveCN109568215AProtective structureCondition the skinCosmetic preparationsToilet preparationsSolubilityCentella asiatica extract

The invention discloses skin nourishing and moisturizing restoration essence cream containing soluble beewax. The skin nourishing and moisturizing restoration essence cream comprises an ingredient A,an ingredient B, an ingredient C and an ingredient D, wherein the ingredient A is prepared from deionized water, polyglutamic acid, glycerol, mycose, witchhazel extracts, chrysanthellum indicum extracts, propanediol and allantoin; the ingredient B is prepared from soluble beewax, hydrogenated vegetable oil and low erucic acid rapeseed oil; the ingredient C is prepared from oligopeptides-1, tripeptide-3, arginine / lysine polypeptide and glycyrrhiza glabra extracts; and the ingredient D is prepared from centella extracts, radix scutellariae extracts, tea extracts, german chamomile extracts, rosemary extracts, rhizoma polygoni cuspidate extracts and 1-3propanediol-caprylhydroxamic acid. The essence cream disclosed by the invention can form a layer of special protection film on the surface layer of cells; the essence separated out from the film can nourish, moisturize and restore skin; the effect of effectively resisting ultraviolet ray radiation can also be achieved, so that the skin is protected from being injured; and the skin oxidization can be delayed after use of the essence cream every day.

Owner:浙江维珍生物科技有限公司

Lycopene anti-wrinkle, compacting and repairing mask

InactiveCN107374992AAntioxidantAnti-agingCosmetic preparationsToilet preparationsPolyethylene glycolOxidation resistant

The invention discloses a lycopene anti-wrinkle, compacting and repairing mask, which is prepared from glyceryl polymethacrylate, 1,3-propanediol, xanthan gum, phytosphingosine, pectin, a beet root extract, a cladosiphon okamuranus extract, propylene glycol, serine, an opuntia streptacantha stem extract, sodium alginate, acacia senegal gum, cetyl phosphate, carbomer, sodium hyaluronate, a lactobacillus / eriodictyon californicum fermentation product extract, allantoin, a Chinese ganoderma extract, butylene glycol, ectoin, methylserine, triethanolamine, hydrolyzed vegetable protein, glycereth-26, potassium cetyl phosphate, caprylhydroxamic acid, disodium EDTA (Ethylene Diamine Tetraacetic Acid), sodium lauroyl lactylate, PEG (Polyethylene Glycol)-40 hydrogenated castor oil and the like. The lycopene anti-wrinkle, compacting and repairing mask has the advantages of being safe, free from toxic and side effects, oxidation-resistant and anti-aging, whitening, being capable of quite well nourishing skin, and having quite good functions of resisting a wrinkle, compacting the skin, repairing the skin, moisturizing and nourishing.

Owner:吕玲

Soothing anti-allergy facial mask and preparation method

InactiveCN107929190AGood moisturizing effectEffective protectionCosmetic preparationsToilet preparationsCAPRYLHYDROXAMIC ACIDMedicine

The invention discloses a facial mask with a soothing anti-allergy efficacy, and aims at providing a soothing anti-allergy facial mask which not only can effectively protect cells and provide water tothe cells for a long time, but also can improve the activity of the cells and strengthen the expression of growth factors so as to repair the injured cells, and not only can achieve a soothing anti-allergy repairing effect, but also can reduce the cost price of the formula. According to the technical scheme, the soothing anti-allergy facial mask is prepared from the following components by mass percent: 0.1 to 0.6 percent of hydrophilic thickening agent, 2 to 4 percent of glycerinum, 4 to 7 percent of 1,3-butanediol, 0.1 to 10 percent of fucogel-1, 2 to 8 percent of soothing composition, 0.5to 3 percent of moisturizing composition, 0.1 to 0.5 percent of symsavetm, 0.1 to 0.9 percent of caprylhydroxamic acid, 0.1 to 0.6 percent of triethanolamine, 0.01 to 0.05 percent of EDTA-2Na, and thebalance of deionized water. The invention belongs to the technical field of cosmetics.

Owner:广州市中通生化制品有限公司

Skincare product with ceramide composition and preparation method of skincare product

PendingCN111329782APromote repairImprove the bactericidal effectCosmetic preparationsToilet preparationsAlkaneWhite petrolatum

The invention discloses a skincare product with a ceramide composition. The skincare product comprises the following components: caprylic / capric triglyceride, white oil, glycerinum, stearic acid, cetostearyl alcohol, polydimethyl siloxane, petroleum jelly, camellia-seed oil, cetearyl glucoside, glyceryl stearate, PEG-100 glyceryl stearate, an essence, EDTA (ethylene diamine tetraacetic acid) disodium, caprylhydroxamic acid, p-hydroxyacetophenone, polyacrylamide, C13-14 isoparaffin, polyoxyethylene 7 lauryl ether, ceramide compositions, carbopol, sodium hydroxide, allantoin, butanediol, plant extracts and the balance of purified water. The skincare product is applicable to various types of skin, activity of skin can be recovered, and metabolism can be promoted. By adjusting the ratio of ceramide, the balance of moisture of stratum corneum can be maintained, and skin barrier functions lost because of use of organic solvents or surfactants can be recovered.

Owner:福建百想生物科技有限公司

Formula of anti-wrinkle product

InactiveCN108904408ABalance secretionTo promote metabolismCosmetic preparationsToilet preparationsFine lineAnthemis

The invention discloses a formula of an anti-wrinkle product. The formula comprises the following components of, by weight, 61.25% of water, 9% of butanediol, 1% of carnosine, 3% of tremella fuciformis extracts, 1% of hydrolyzed collagen, 3% of erythritol, 3% of glycereth-26, 1% of saccharide isomerate, 1% of aloe barbadensis leaf extracts, 3% of anthemis nobilis flower extracts, 3% of portulaca oleracea extracts, 3% of pelargonium graveolens extracts, 1% of tripeptide-1, 5% of 1,2-hexanediol, 0.05% of ethylhexylglycerin, 0.1% of caprylhydroxamic acid, 1% of fullerene, 0.5% of hydrolyzed hyaluronic acid, and 0.1% of disodium EDTA. According to the formula of the anti-wrinkle product, the skin can be moisturized, microcirculation is improved, skin cells are activated, secretion of the skinis balanced, skin metabolism is promoted, the skin is tightened, fine lines are repaired, the anti-wrinkle and anti-aging effects are achieved, inflammation eliminating and swelling diminishing can beachieved, epidermal cells are repaired, and the certain curative effects on skin symptoms such as acnes and comedo are achieved.

Owner:余荣华

Anti-aging weight-losing and skin-tightening essence

InactiveCN111297753ASolve saggingImprove firmnessCosmetic preparationsToilet preparationsArginineButanediol

The invention provides an anti-aging weight-losing and skin-tightening essence which comprises the following ingredients in percentage by mass: 3 to 5 percent of butanediol, 1 to 3 percent of glycerin, 0.05 to 0.2 percent of hyaluronic acid, 0.5 to 2 percent of betaine, 0.5 to 1.5 percent of biosaccharide gum-1 solution, 0.5 to 1.5 percent of a mixture of hydrolyzed collagen and euglena gracilis polysaccharide, 0.1 to 0.5 percent of arginine, 0.1 to 0.5 percent of p-hydroxyacetophenone, 0.02 to 0.1 percent of caprylhydroxamic acid solution, 1.75 percent of a skin conditioner, 0.35 percent of athickening agent and 0.05 percent of a chelating agent. The mixture of hydrolyzed collagen and euglena gracilis polysaccharide is used, and enters the epidermal layer through the skin to realize targeted reticular energy release; elastic fiber cells, glial cells and epithelial cells are fast and continuously activated; the metabolic growth regeneration is accelerated; the elasticity is enhanced;the problem of skin looseness and sagging is solved; and the effect of improving the skin tightness is achieved. The anti-aging weight-losing and skin-tightening essence also uses the hydroxyacetophenone, and has anti-oxidization capability on the skin; the activity of COX-2 can be inhibited; the skin oxidization is delayed; and the luster is maintained.

Owner:济南霜叶红生物科技有限公司

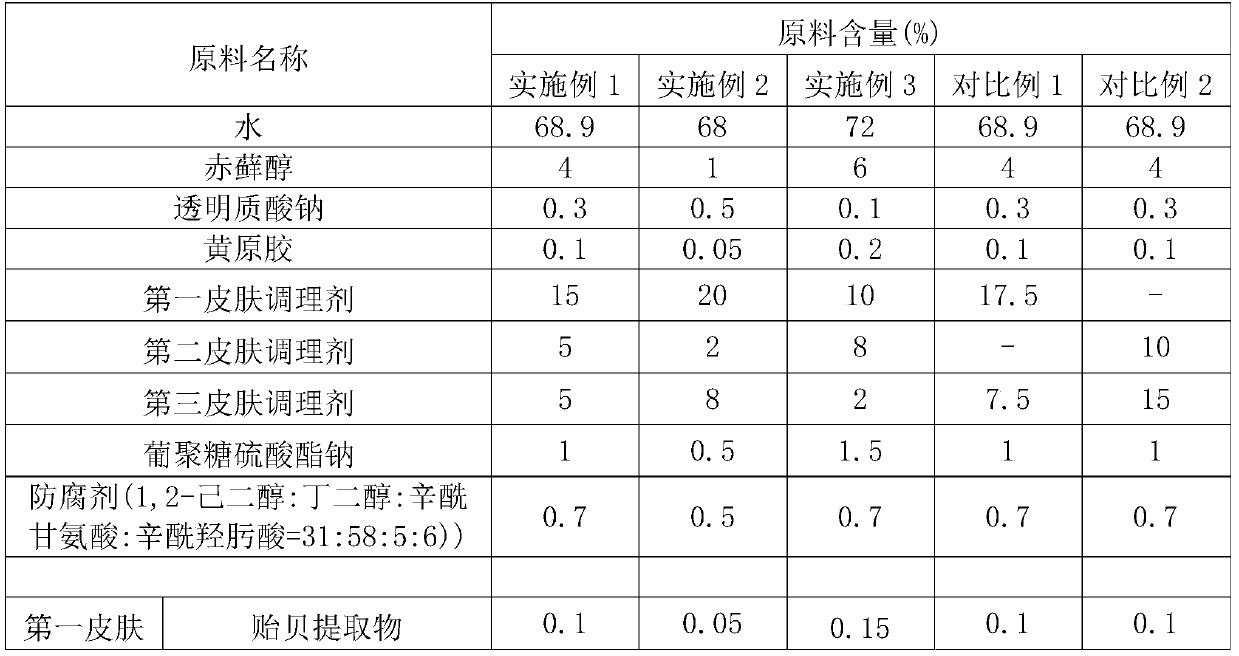

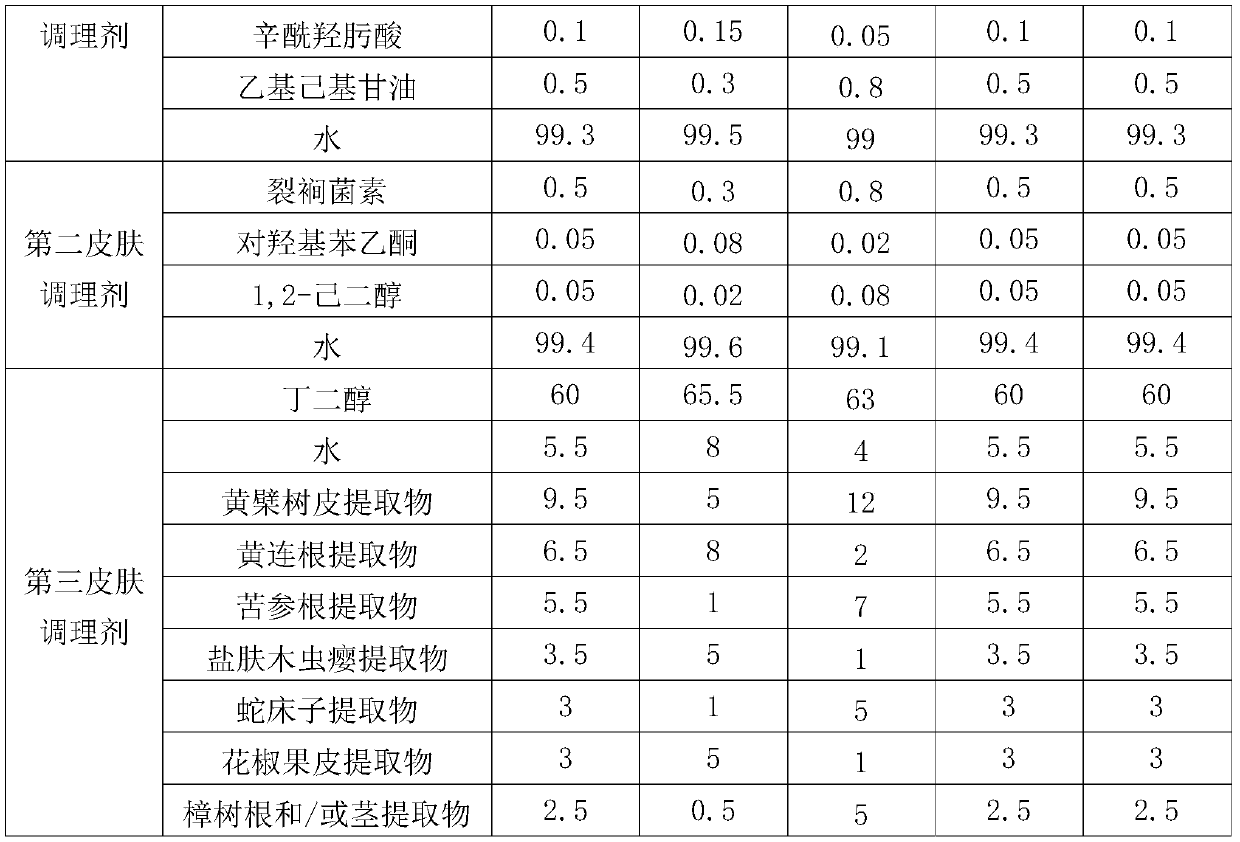

Composition with effects of nourishing and repairing skin and application thereof

The invention relates to the field of preparation of cosmetics, and provides a composition with the effects of nourishing and repairing skin. The composition is at least prepared from, by weight, 1-5parts of glycerin, 5-10 parts of propylene glycol, 1-5 parts of beta-glycan, 1-5 parts of betaine, 0.5-2 parts of oligopeptide-1, 1-5 parts of niacinamide, 0.5-2 parts of glycosylglycerol, 0.5-2 partsof ceramide 1, 0.5-2 parts of trehalose, 0.1-1 part of Arabic gum, 0.1-1.5 parts of polydimethylsiloxane, 0.1-1.5 parts of phospholipid, 0.1-1.5 parts of cetearyl alcohol, 0.05-0.5 part of polysorbate-20, 0.05-0.5 part of EDTA disodium, 0.1-1.5 parts of 1,2-hexanediol and 0.1-1.5 parts of caprylhydroxamic acid. The invention further provides a daily necessity. The daily chemical product is selected from one of a nourishing lotion, repair water, an essence, masking liquid, a liquid spray and a face cream; the component of the daily chemical product comprises the composition.

Owner:宁德市萨度生物科技有限公司

Anti-atopic cream

InactiveCN104736141AHas a therapeutic effectInhibition amountAerosol deliveryOintment deliveryAllergic dermatitisTherapeutic effect

The present invention relates to an anti-atopic cream comprising: a first component comprising Houttuynia cordata, Acori gramineri Rhizoma, Saposhnikoviae Radix, Astragalus membranaceus Radix, Eriobotryae Folium, Sophorae flavescentis Radix, Saururus chinensis, Phellodendron bark, Centella asiatica, Arisaematis Rhizoma and Aster yomena; and a second component comprising glycerol, a caprylic or capric triglyceride, sunflower seed oil, butylene glycol, butylene glycol dicaprylate or dicaprate, macadamia seed oil, polyglyceryl-3 methylglucose distearate, PEG-4 olivate, meadowfoam seed oil, dimethicone, cetyl ethylhexanoate, oxidized corn oil, cetearyl alcohol, tocopheryl acetate, glyceryl acrylate or acrylic acid copolymer, stearyl glycyrrhetinate, sodium chloride, sodium acrylate or sodium acryloyl dimethyl taurate copolymer, algin, isohexadecane, caprylyl glycol, polysorbate 80, allantoin, caprylhydroxamic acid, propylene glycol, disodium EDTA and ceramide 3 and, in the anti-atopic cream, the first component and the second component are mixed in a weight ratio of between 5:5 and 7:3. According to the present invention, when the anti-atopic cream is applied to a DNCB induced atopic dermatitis mouse, the blood IgE is reduced and at the same time the amount of discharged histamine produced from the mast cells is suppressed, thereby making it possible to provide an anti-atopic cream having a therapeutic effect in atopic dermatitis.

Owner:NJY LIFE ENG

General moisturizing mask liquid

InactiveCN111419761AAbundant sources of raw materialsRich sourcesCosmetic preparationsToilet preparationsBiotechnologyCentella asiatica extract

The embodiment of the invention discloses a general moisturizing mask liquid. The mask liquid comprises water, propylene glycol, caprylhydroxamic acid, glycerol caprylate, a glycyrrhiza glabra root extract, a chamomilla recurutita leaf extract, a polygonum cuspidatum extract, a centella asiatica extract, a camellia sinnensis leaf extract, a scutellaria baicalensis root extract, a rosmarinus officinalis leaf extract, phenoxyethanol, caprylyl glycol, carbomer, sodium hyaluronate, methylparaben and hydroxyethyl cellulose. The mask liquid contains various plant extraction essences, is moist but not greasy, instantaneously permeates into and is adsorbed on the lipid part of the skin, and can better moisturize cuticle, and permeate and nourish the delicate skin. The skin sensitivity problem is relieved, and the skin roughness and dryness problem is finely repaired. Skin sagging is reduced and prevented, skin compactness loss and skin elasticity loss are avoided, and skin oxidation resistanceis achieved for a long time.

Owner:广州怡嘉生物科技有限公司

Spot removing and skin whitening skin nursing dressing and preparation method thereof

InactiveCN108543106ATo promote metabolismMetabolic desalinationAbsorbent padsBandagesVitamin C ethylInflammation

The invention discloses a spot removing and skin whitening skin nursing dressing and a preparation method thereof. The spot removing and skin whitening skin nursing dressing is prepared from the following components in parts by weight: 0.02-3 parts of hyaluronic acid, 0.2-8 parts of styrene-acrylic acid ester copolymer, 0.02-3 parts of carbomer, 0.3-15 parts of glycerin, 0.04-2 parts of allantoin,0.05-10 parts of arbutin, 0.05-8 parts of vitamin C ethyl ether, 0.05-10 parts of safflower extract, 0.01-1 part of caprylhydroxamic acid, 0.4-6 parts of hexandiol, 0.01-1 part of pH regulator and 33-99 parts of water. The spot removing and skin whitening skin nursing dressing provided by the invention has the efficacy of physical occlusion for protection, acceleration in skin metabolism, inhibition of melanin generation, antisepsis, inflammation resistance, elimination of scytitis, prevention of hyperpigmentation, elimination of freckle in multiple directions and skin whitening, is simple inpreparation process, does not contain some chemical stimulating substances and is particularly suitable for people with skin sensitivity.

Owner:珠海市雅莎医疗器械有限公司

Hydrating mask containing fullerene, hyaluronic acid and polypeptides

InactiveCN109589297APowerful antioxidantScavenging active oxygenCosmetic preparationsToilet preparationsWater basedBetaine

The invention provides a hydrating mask containing fullerene, hyaluronic acid and polypeptides and relates to the technical field of cosmetics. The hydrating mask contains fullerene, a moisturizer, betaine, trehalose, plant extract, caprylhydroxamic acid, glyceryl caprylate, sodium hyaluronate, polypeptides, a preservative, hydroxyethyl cellulose, ascorbic acid, ethylhexylglycerin, xanthan gum, PEG-40 hydrogenated castor oil and essence. The hydrating mask contains rich fullerene, the plant extract and polypeptides, can resist oxidation forcefully and scavenge free radicals, fullerene binds with vitamins and polypeptides after being added to composition, active oxygen produced under various conditions can be eliminated, the oxidation resistance lasts for a long time, aging and wrinkles canbe resisted effectively, and a water base is kept.

Owner:广州灵润生物科技有限公司

Skin-caring and itching-relieving lotion for middle-aged and aged people and preparation method of skin-caring and itching-relieving lotion

InactiveCN107569417ARegulate immune functionImprove disease resistanceCosmetic preparationsToilet preparationsCAPRYLHYDROXAMIC ACIDOlder people

The invention relates to the field of articles for daily life, and provides a skin-caring and itching-relieving lotion for middle-aged and aged people. The skin-caring and itching-relieving lotion isprepared from the following raw materials in parts by weight: 0.5-2.5 parts of an emulsifier S21, 0.5-1.5 parts of an emulsifier S2, 13-25 parts of glycerol, 1-5 parts of licorice root, 50-72 parts ofdeionized water, 1-5 parts of allantoin, 0.08-0.4 part of Carbomer 940, 0.07-0.3 part of EDTA-2Na, 0.5-2.5 parts of radix scutellariae, 0.01-0.2 part of hyaluronic acid, 0.05-0.6 part of essence, 0.1-1 part of honey, 3-10 parts of succus aloes folii siccatus, 0.3-2 parts of caprylhydroxamic acid, 0.2-1.2 parts of chamomile essential oil, and 0.2-1.2 parts of hamamelis virginiana essential oil. The skin-caring and itching-relieving lotion for middle-aged and aged people provided by the invention has the advantage that the skin dryness and pruritus of old people can be effectively alleviated.

Owner:HANGZHOU COCO HEALTHCARE PRODS

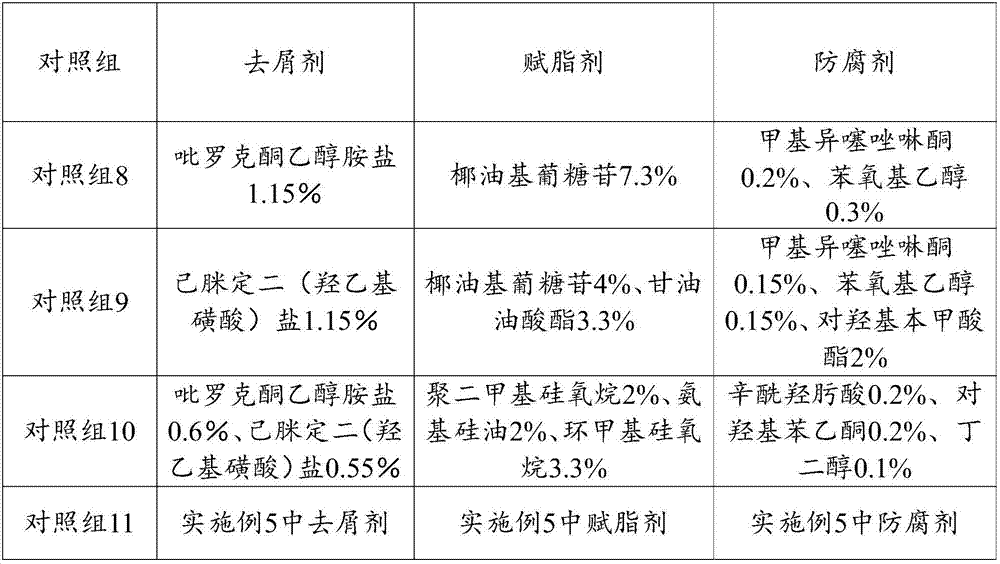

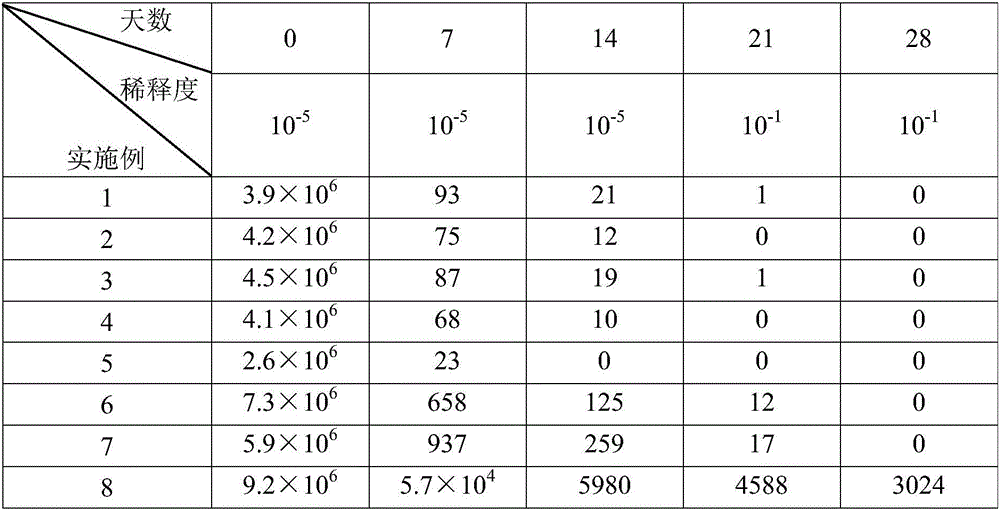

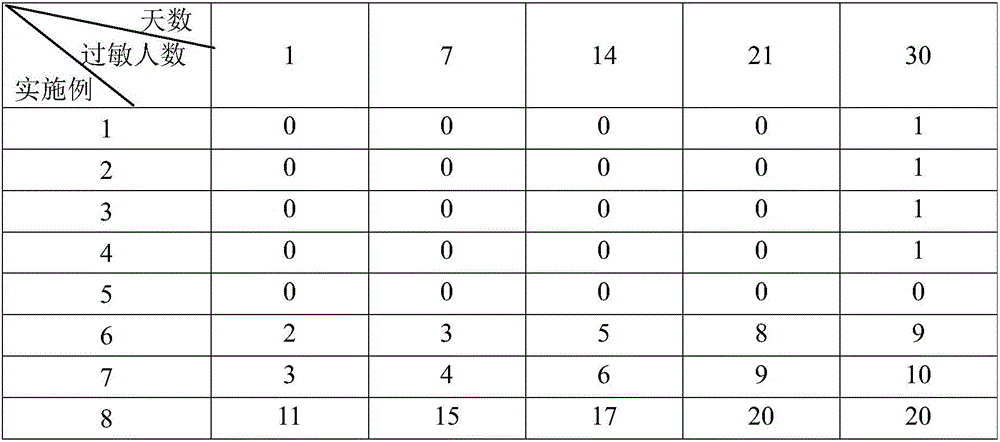

Ginseng oil-control anti-dandruff and silicone oil-free shampoo and preparation method thereof

InactiveCN107375066APromote circulationMeet the needs of cleaningCosmetic preparationsHair cosmeticsPiroctone olaminePhytosterol

The invention discloses a ginseng oil-control anti-dandruff and silicone oil-free shampoo, which comprises at least one of an anti-dandruff agent, a fatting agent and a preservative. The anti-dandruff agent consists of piroctone olamine, hexamidine diisethionate and a plant anti-dandruff agent; the fatting agent comprises phytosterol macadamiate, C12-13 alcohol lactate, coco-glucoside, olive oil PEG-6 polyglycerol-6 ester, dipentaerythityl tetraisostearate, glyceryl oleate and tri-C12-13 alkyl citrate; the preservative includes caprylhydroxamic acid, p-hydroxy acetophenone, glycerol octanoate and butylene glycol. At the same time, the invention discloses a preparation method of the ginseng oil-control anti-dandruff and silicone oil-free shampoo. The shampoo provided by the invention can reach the effects of deep oil control dandruff removal, meet the cleaning needs of people, effectively promote blood circulation and provide scalp nutrients, also can repair broken hair, split hair and improve hair quality, makes hair black, shiny and smooth, and also is mild and non-irritating, safe and healthy.

Owner:曾万祥

Foamed mask

InactiveCN106691891AGuaranteed anti-corrosion performanceSuitable for useCosmetic preparationsToilet preparationsCAPRYLHYDROXAMIC ACIDFoaming agent

The invention discloses a foamed mask comprising the following components in percentage by weight: 0.03-0.5% of a first skin conditioner, 0.6-1.5% of a second skin conditioner, 1-7% of glycerol, 0.3-2% of a humectant, 0.5-3% of cocamide MEA (monoethanolamine), 3-15% of potassium cocoyl glycinate, 3-15% of a first surfactant, 3-15% of a second surfactant, 2-8% of a first thickener, 0.2-1.5% of a second thickener, 0.1-1.5% of polyvinylpyrrolidone, 2-15% of a foaming agent, 0.05-0.5% of an essence, 0.02-0.3% of EDTA (ethylenediamine tetraacetic acid) disodium, and the balance of water, wherein the first skin conditioner comprises 100% of dipotassium glycyrrhizinate, and the second skin conditioner comprises 63-67% of 1,2-hexanediol, 4-6% of caprylhydroxamic acid, and 28-32% of 1,3-propanediol. The mask is prepared by adding a naturally-extracted essence, is not added with a preservative, is natural and nonirritant, has an antiallergic property at the same time, and is particularly suitable for people with sensitive skins to use.

Owner:HANGZHOU FACECARE COSMETICS

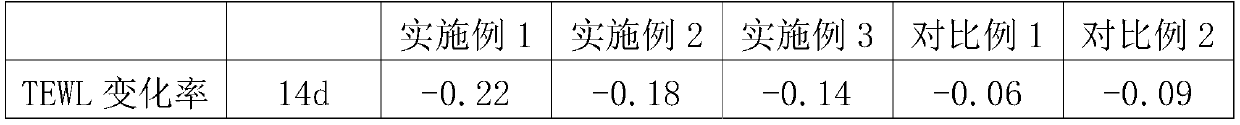

Repair essence and preparation method thereof

ActiveCN111214429AImproves moisture retentionReduce inflammationCosmetic preparationsToilet preparationsBiotechnologyRhus chinensis

The invention relates to repair essence and a preparation method thereof. The repair essence comprises the raw material components of water, a hydrating agent, a thickening agent, a mussel extract, caprylhydroxamic acid, ethylhexylglycerin, schizophyllan, hydroxyacetophenone, 1, 2-hexanediol, a cork tree bark extract, a rhizoma coptidis extract, a radix sophorae yellowish sophora extract, an acardiaceae rhus chinensis insect gall extract, a common cnidium fruit extract, a Chinese prickly ash peel extract and a redleaf litse root and / or stem extract. The repair essence contains various naturalcomponents, when the repair essence is used for a long term, the water holding capacity of skin and muscle can be improved, the drying and sensitive symptoms can be effectively relieved, the inflammation can be alleviated, and the couperose skin can be improved. The repair essence is good to absorb, the components are safe and non-irritating, and the preparation method is simple, and is suitable for promotion and application.

Owner:广州市逸轩精细化工有限公司

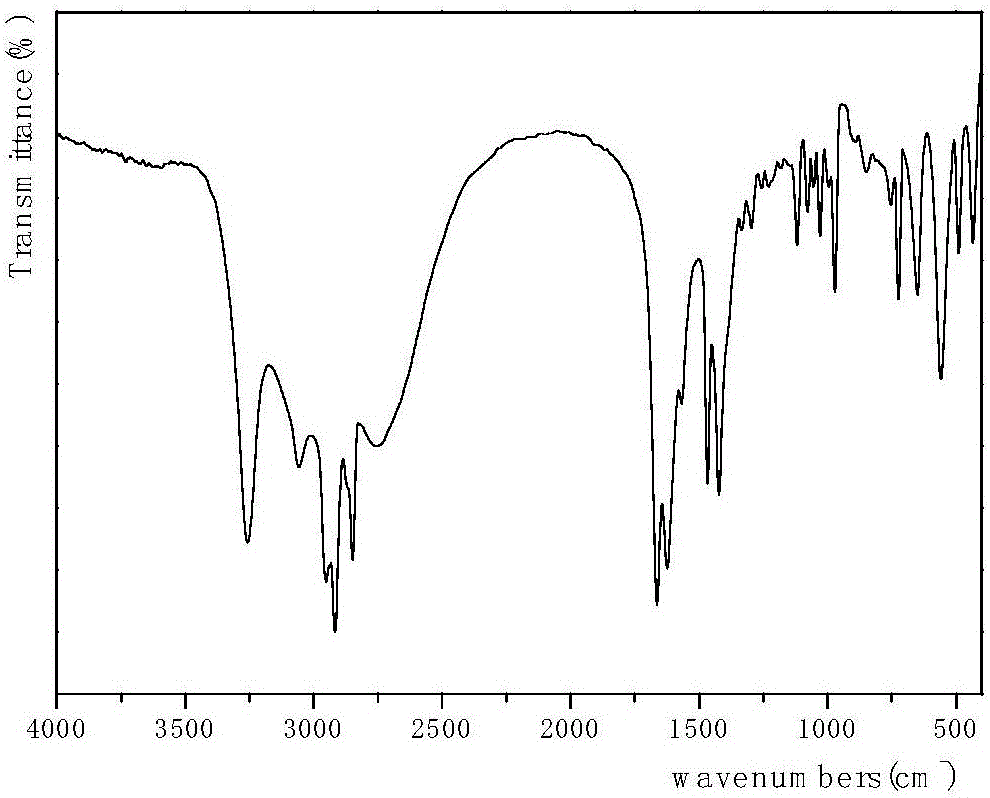

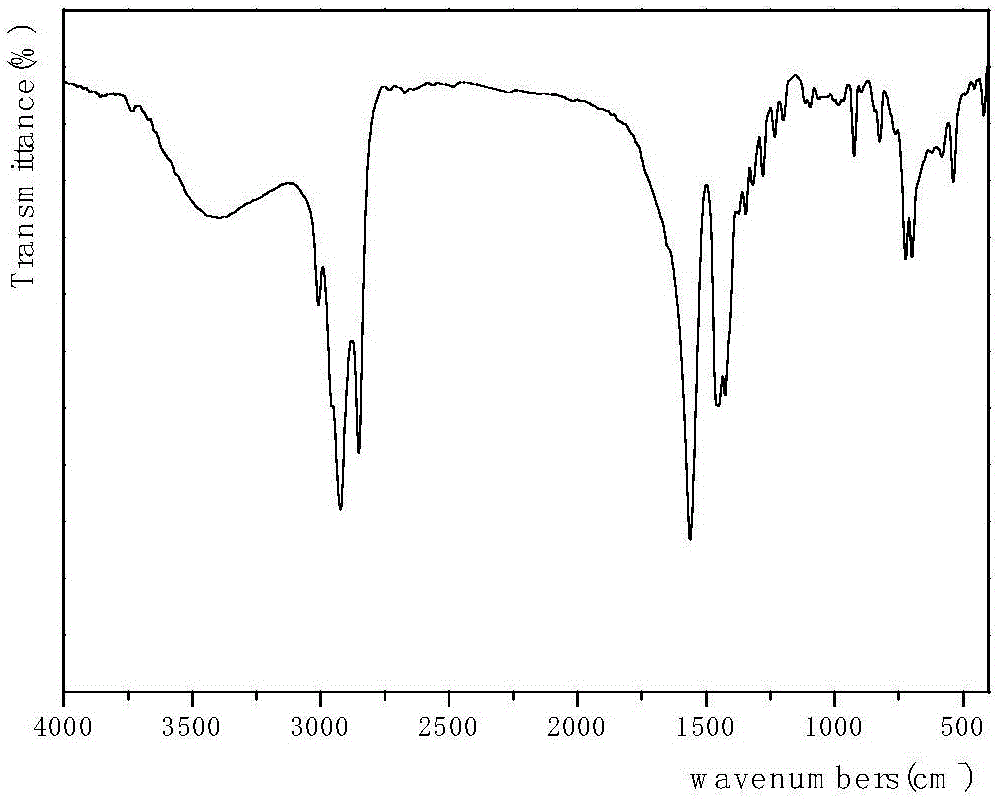

Process for preparing caprylhydroxamic acid

ActiveCN104592056ASolve the explosion hazard of decompositionRaw materials are easy to getOrganic chemistryCAPRYLHYDROXAMIC ACIDHydroxylamine

The invention belongs to the field of chemical engineering and relates to a process for preparing caprylhydroxamic acid. The process comprises the steps sequentially: adding hydroxylamine hydrochloride into a reactor, adding an alcoholic solution, and stirring to dissolve; adding n-octoate into the reactor, and stirring and mixing uniformly; then, adding 4-dimethyl aminopyridine, adding a solid base, controlling the temperature to be 5-15 DEG C, and adjusting the pH value of the solution in the reactor to be 5.0-6.5; controlling the temperature of the solution to be 20-40 DEG C at normal pressure, reacting for 1-3 hours, cooling to the temperature of -10 DEG C to 0 DEG C after reacting ends, filtrating sodium chloride or potassium chloride, and carrying out vacuum concentration, cooling crystallization and centrifugal separation, so as to obtain a crude product; and recrystallizing the crude product in a solvent, and drying, thereby obtaining caprylhydroxamic acid, of which the content is over 99%. According to the process, the used raw materials are easily obtained; the reaction conditions are mild, so that the danger of decomposed explosion of hydroxylamine resulting from too-high temperature is excellently avoided; the reaction medium is an alcohol-water system, is safe and cheap and can be repeatedly applied mechanically, so that the production cost is reduced greatly, and industrial production and market promotion are facilitated.

Owner:烟台东方化学有限公司

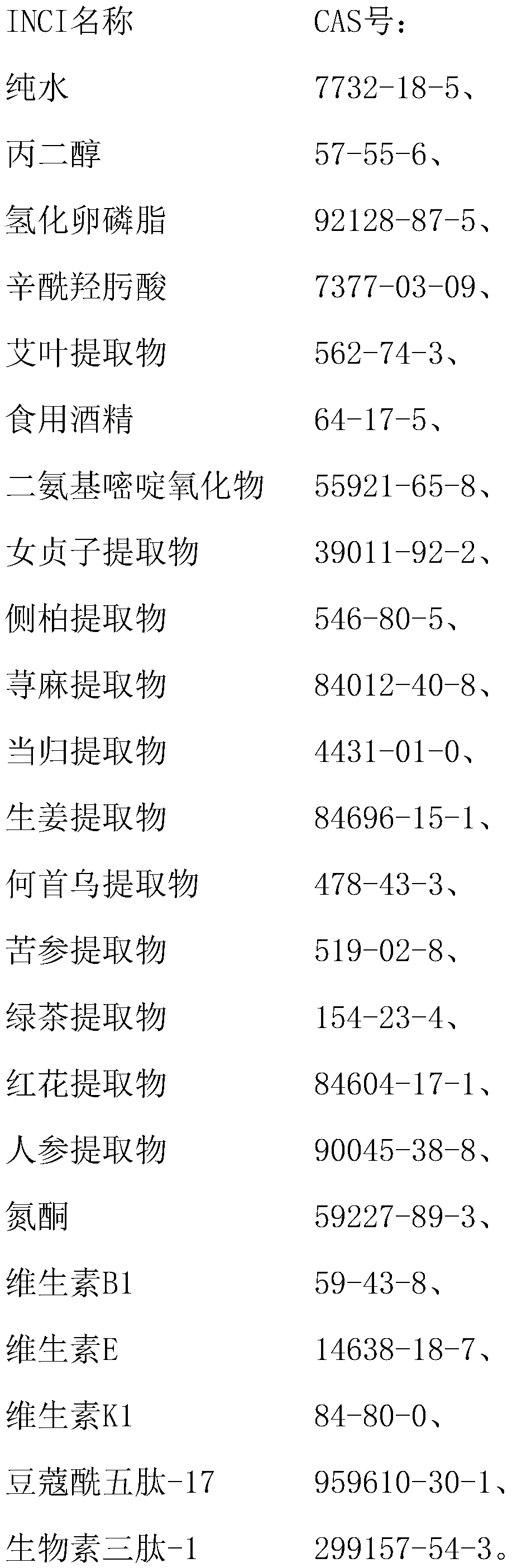

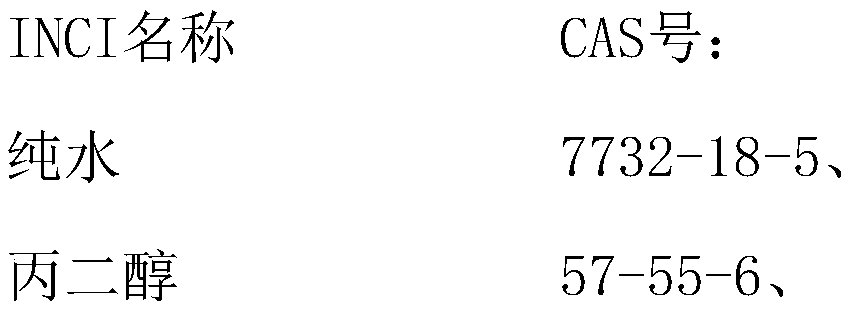

Hair nourishing and growing composition and preparation method thereof

PendingCN111544360AIncrease elasticityHigh glossCosmetic preparationsHair cosmeticsBiotechnologyHydroxamic acid

The invention discloses a hair nourishing and growing composition and a preparation method thereof. The hair nourishing and growing composition is composed of the following raw materials: pure water,propylene glycol, hydrogenated lecithin, caprylhydroxamic acid, a folium artemisiae argyi extract, edible alcohol, diaminopyrimidine oxide, a glossy privet fruit extract, a platycladus orientalis extract, a nettle extract, an angelica sinensis extract, a ginger extract, a polygonum multiflorum extract, a radix sophorae flavescentis extract, a green tea extract, a safflower extract, a ginseng extract, azone, vitamin B1, vitamin E, vitamin K1, myristoyl pentapeptide-17 and biotin tripeptide-1. The traditional Chinese medicine composition is prepared by taking traditional Chinese medicine extracts as main materials and cooperating with propylene glycol, hydrogenated lecithin, capryloyl hydroxamic acid and other components, and low-temperature physical wall breaking is adopted in the preparation process, so that effective components are fully released; constant-low-temperature extraction is carried out to completely retain the characteristics of raw materials; multi-stage membrane separation and purification are achieved, safety and purity are achieved, and pesticide residues and heavy metal are avoided; any chemical component is not added, and the pure original fragrance is enjoyed.

Owner:广东悦生生物科技有限公司

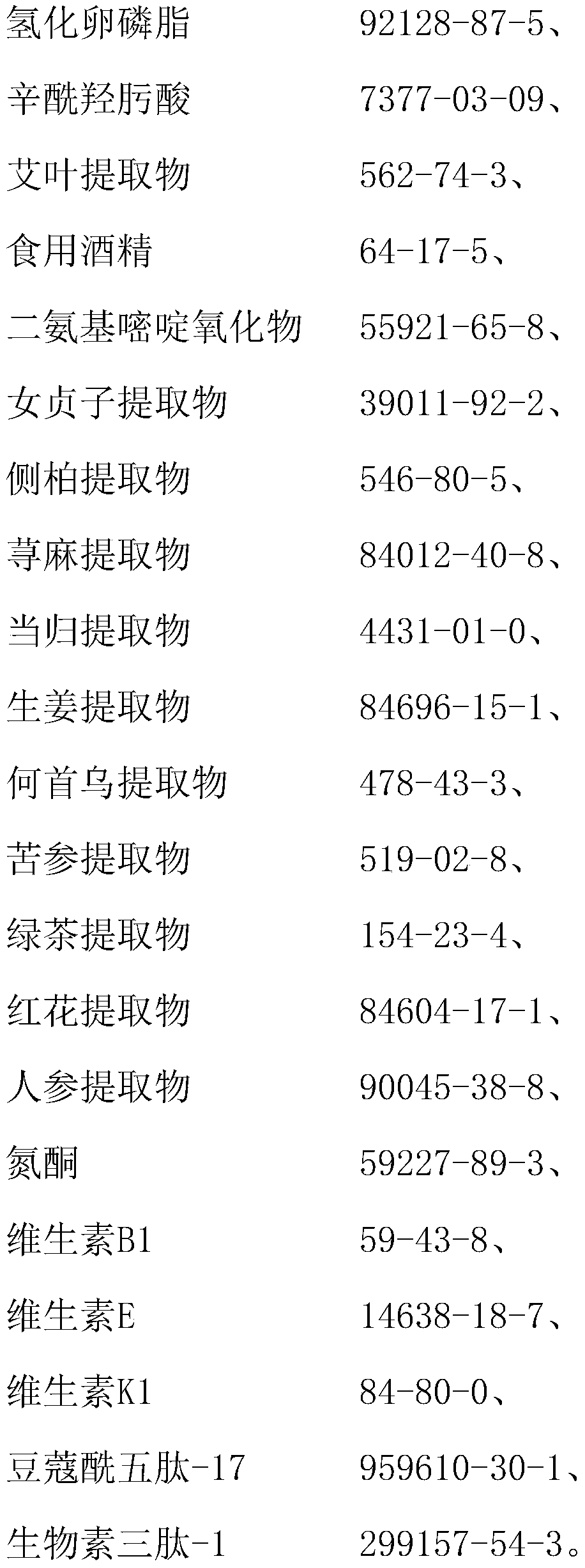

Moisturizing stock solution and preparation method thereof

InactiveCN106924139AGood moisturizing effectEliminate worriesCosmetic preparationsToilet preparationsMethacrylateAdditive ingredient

The invention discloses moisturizing stock solution. The moisturizing stock solution comprises a component A, a component B, a component C and deionized water, wherein the component A contains propylene glycol, glycerol, xylitol, hydroxyethyl cellulose, Carbomer and hyaluronic acid; the component B contains triethanolamine; and the component C contains panthenol, polyglutamic acid, glyceryl polymethacrylate, aloe extract, hamamelis virginiana extract, purslane extract, hydrolysis pome cactus flower extract, glycine, caprylhydroxamic acid, hydrogenated castor oil and pelargonium graveolens leaf oil. The moisturizing stock solution disclosed by the invention is added with plant moisturizing and hydrating ingredients, and achieves good face skin moisturizing and hydrating effects, so that skin is fine, smooth, transparent and like new; meanwhile, an additive-free preservative is used, so that face skin is not stimulated, and worries of a customer are eliminated. The invention also discloses a preparation method of the moisturizing stock solution with simple technology, high production efficiency and no environmental pollution.

Owner:广州帝臣生物科技股份有限公司

Water-holding and moisturizing essence and preparation method thereof

InactiveCN109662926APromotes division growthEnhance anti-inflammatoryCosmetic preparationsToilet preparationsFlavoring essencesCetearyl glucoside

The invention relates to water-holding and moisturizing essence and a preparation method thereof. The water-holding and moisturizing essence is prepared from, by weight, a component A, a component B and a component C, wherein the component A comprises deionized water, dipropylene glycol, sodium hyaluronate (HA), NANO sodium hyaluronate, a PEG / PPG-17 / 6 copolymer, an amino acid moisturizing agent (trimethylglycine trimethylglycocoll), cetearyl glucoside, an acrylates / vinyl isodecanoate crosspolymer, an ammonium acryloyldimethyltaurate / VP copolymer and ethylene diamine tetraacetic acid; the component B comprises triethanolamine (TEA); the component C comprises panthenol, a CH collagen crosslinked polymer, beta-glucan, Xinlishi, SUCUS, Tridermol Hydrant, Waterin, phellinus linteus extracts, CalmYang, caprylhydroxamic acid and flavor essence. All the components in the formula have synergetic effects so that the product can achieve the effects of penetrating into pores and intensively moisturizing the skin; water is supplemented, the skin is moisturized, and the skin dryness phenomena caused by season, age, skin type and the like are effectively improved.

Owner:广州锦同生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com