Patents

Literature

783 results about "Polydimethyl siloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

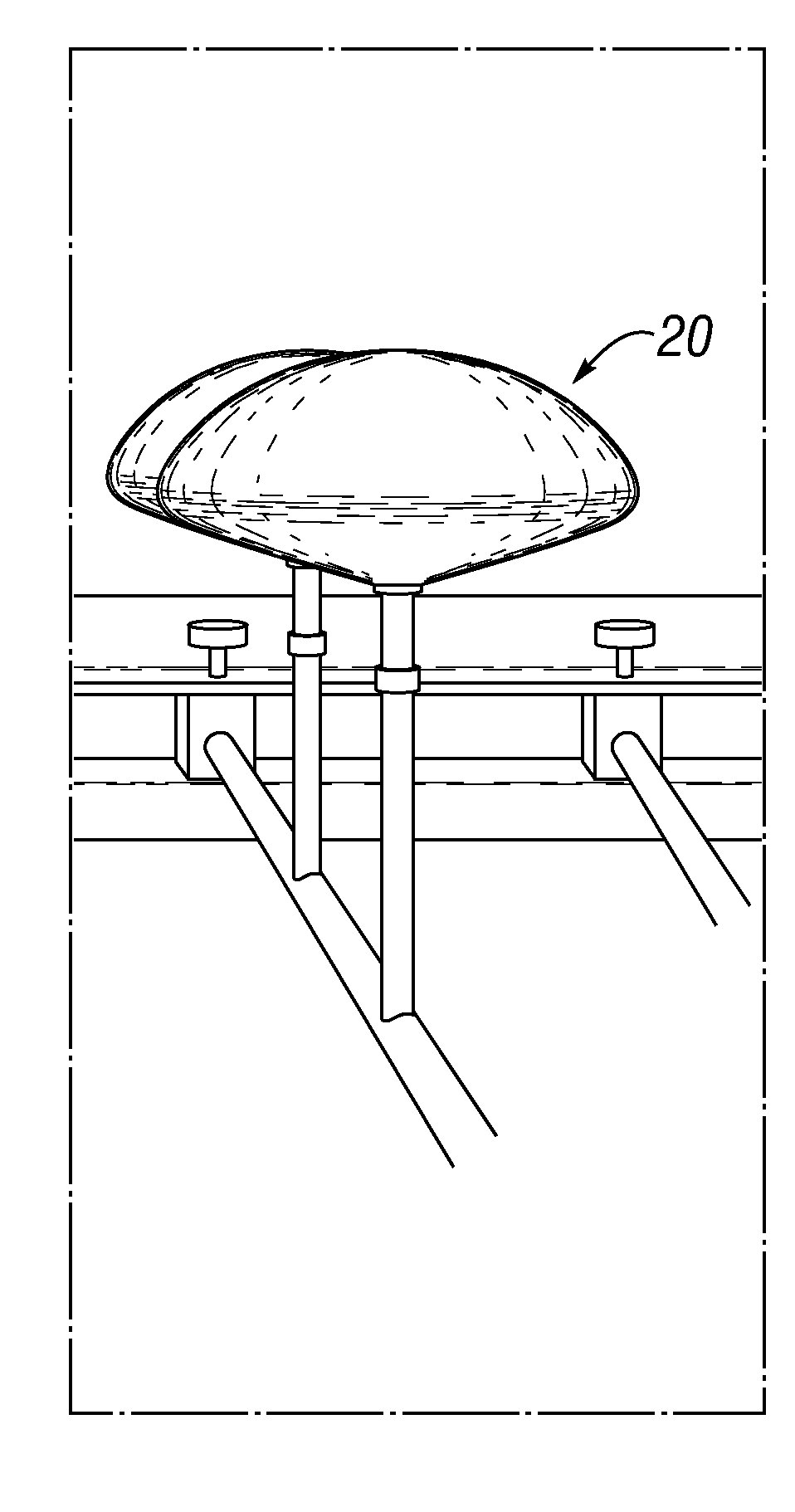

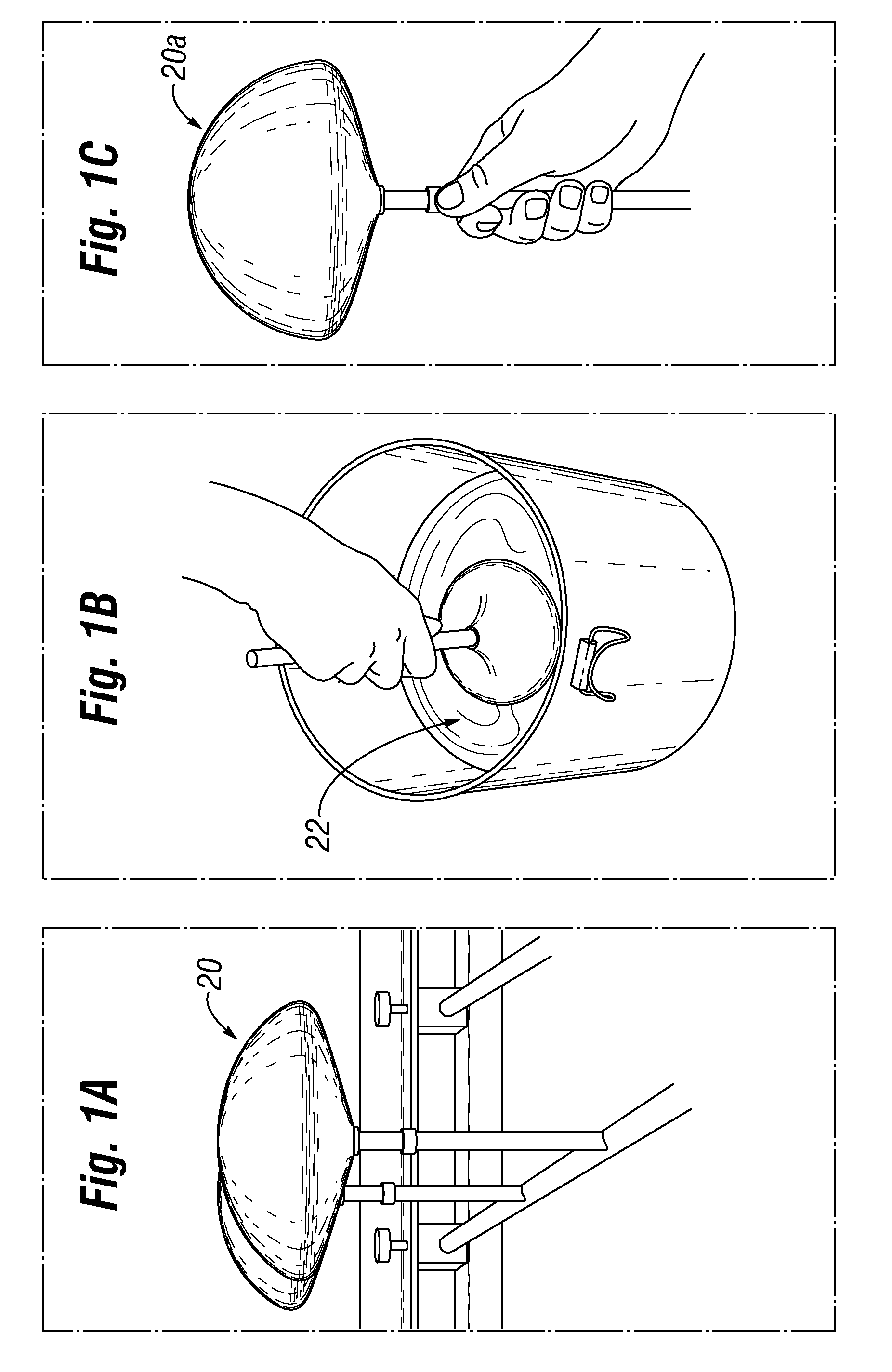

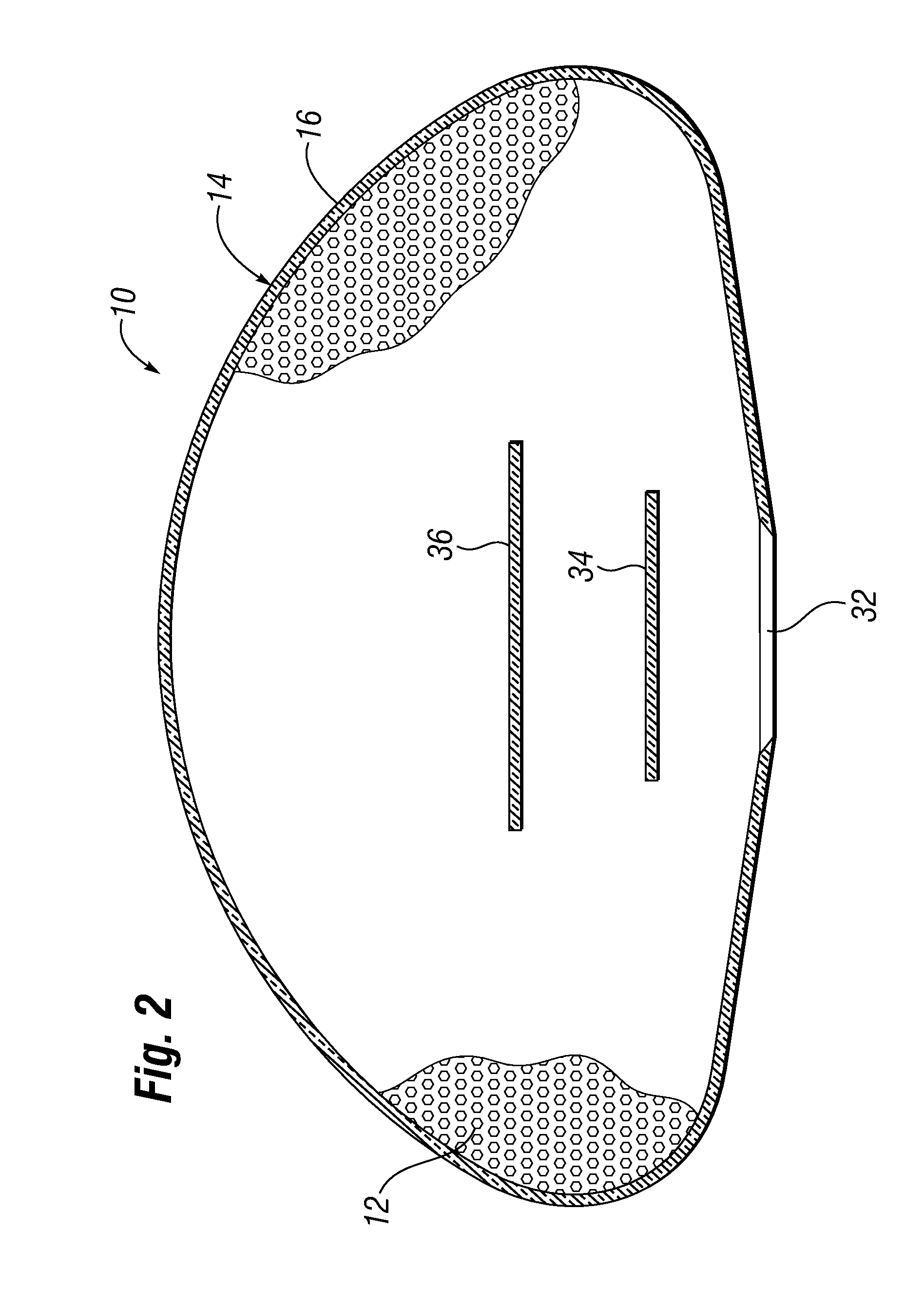

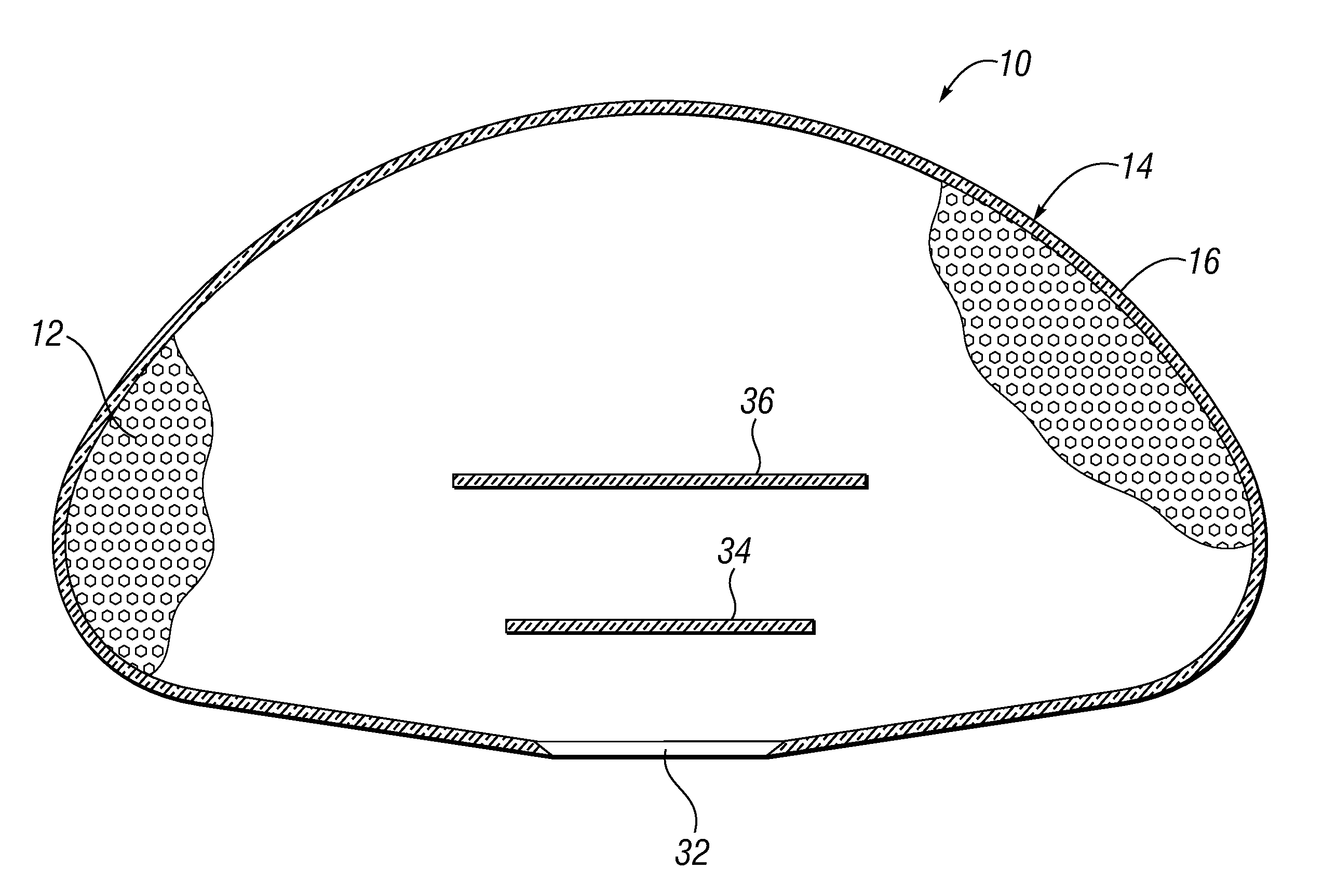

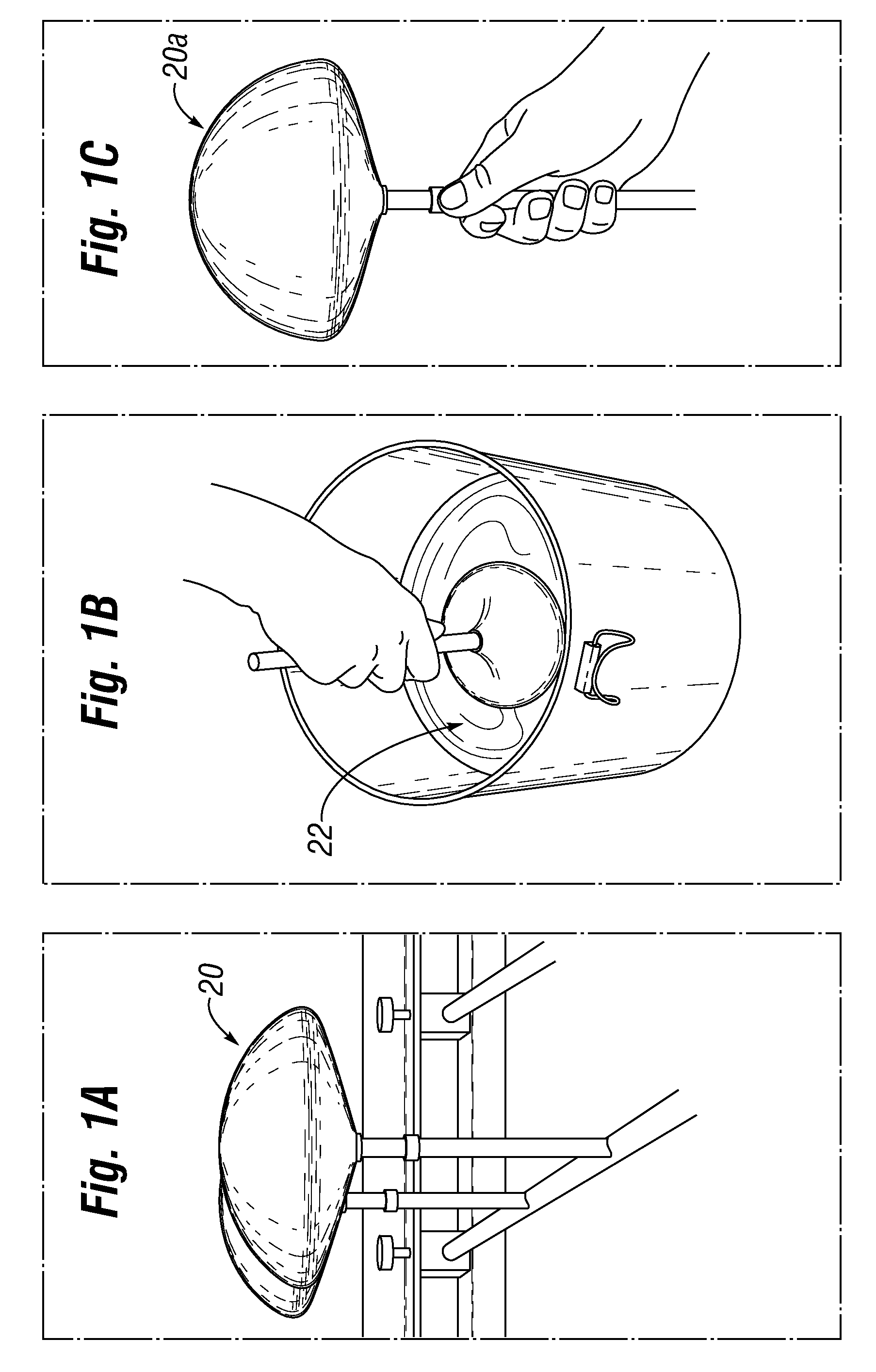

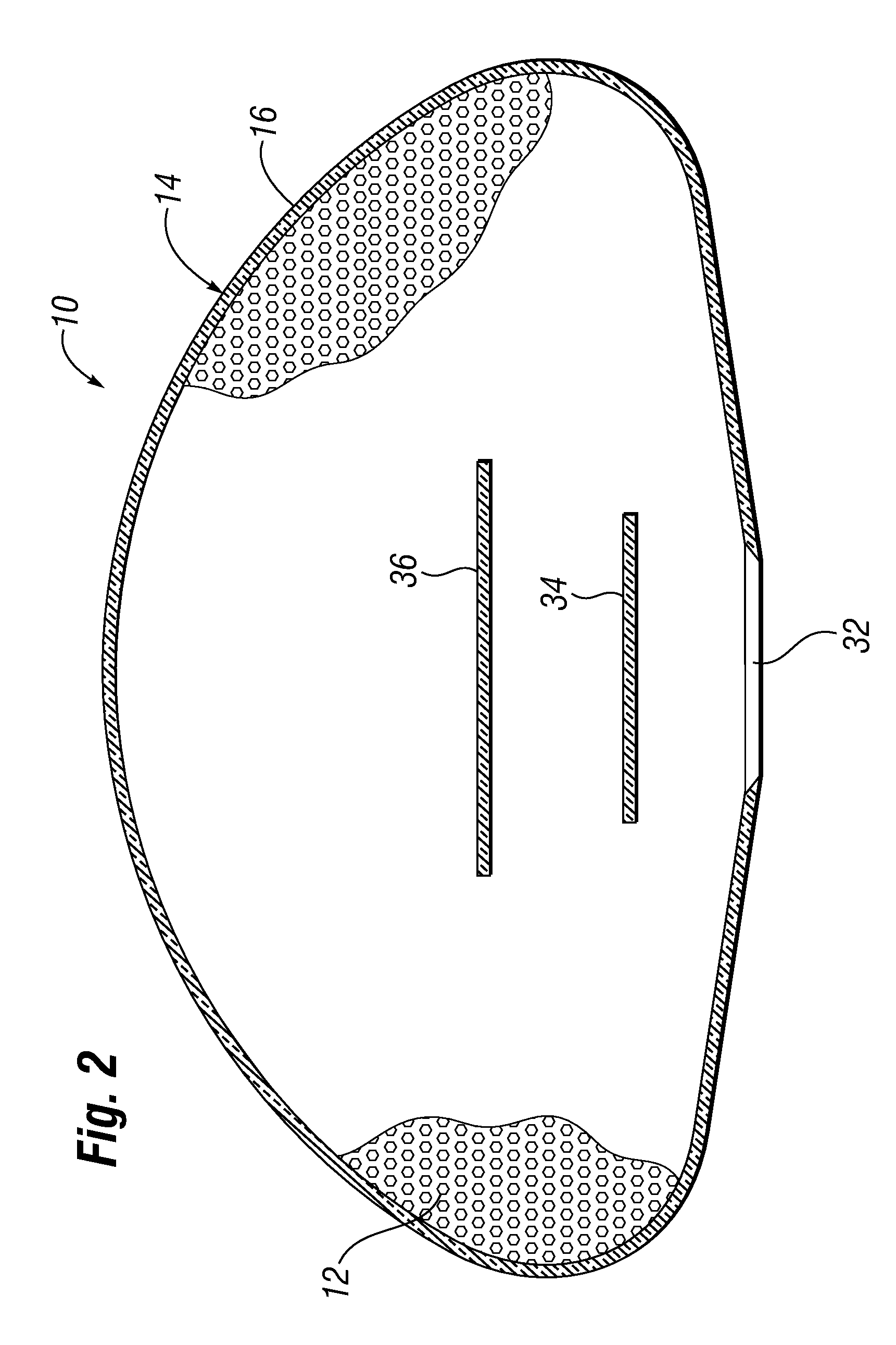

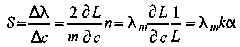

All-barrier elastomeric gel-filled breast prosthesis

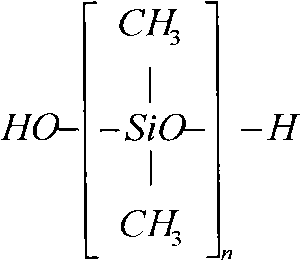

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

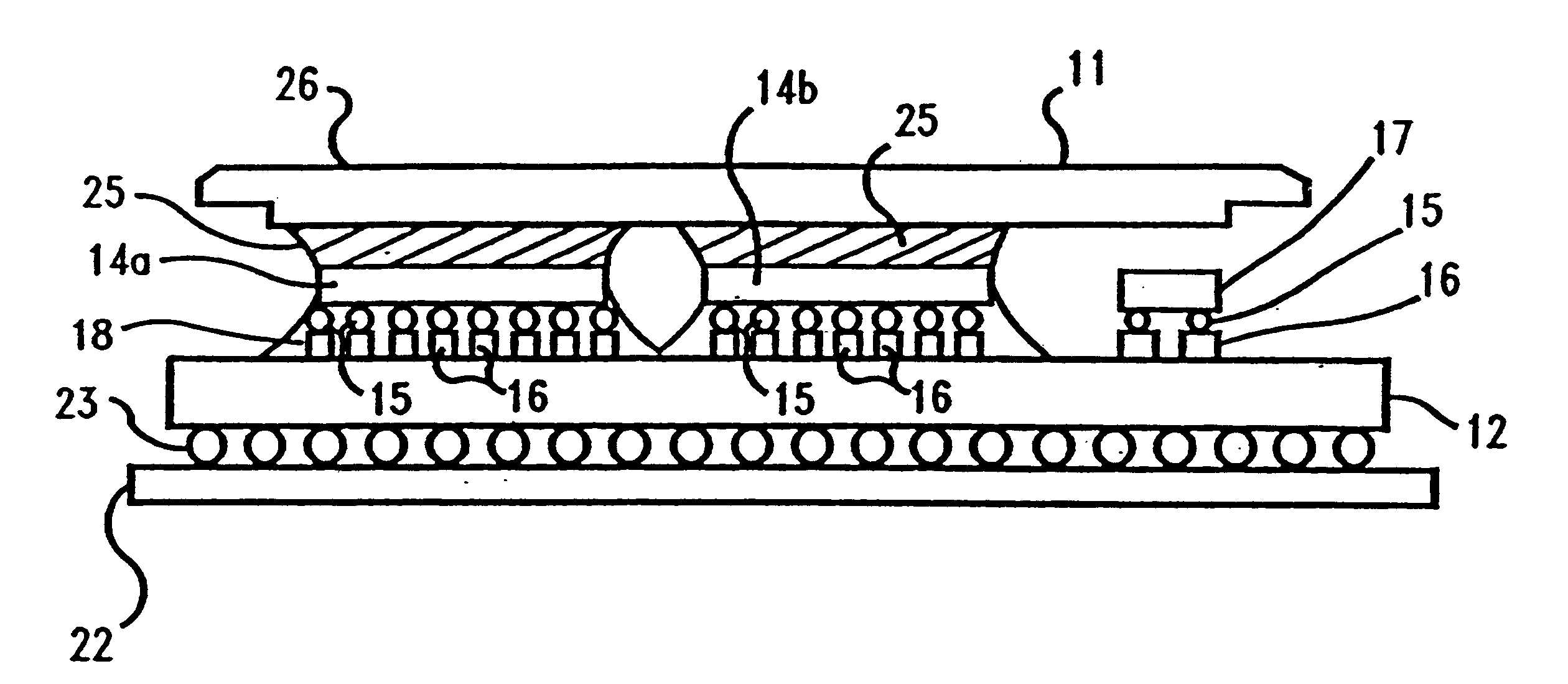

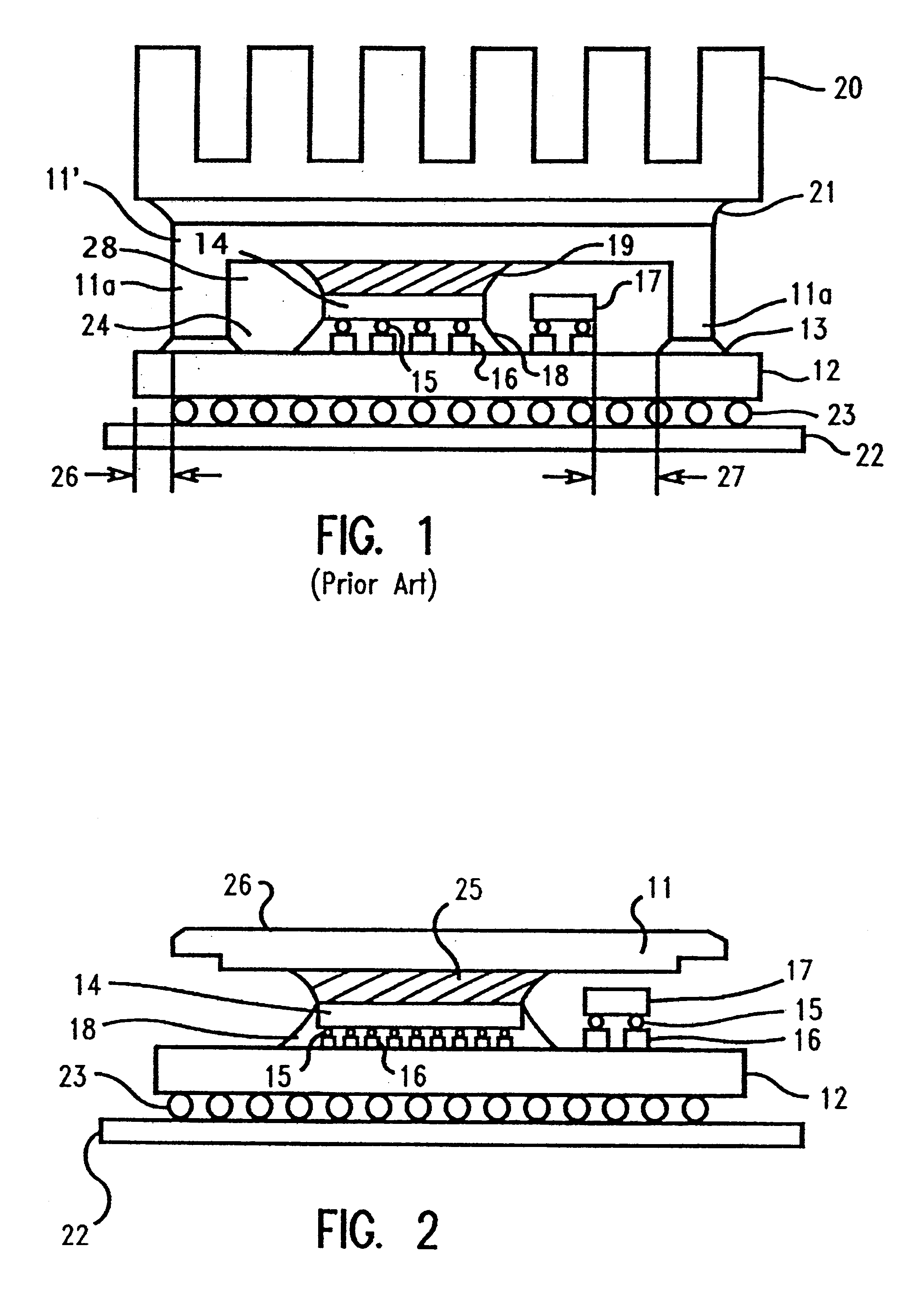

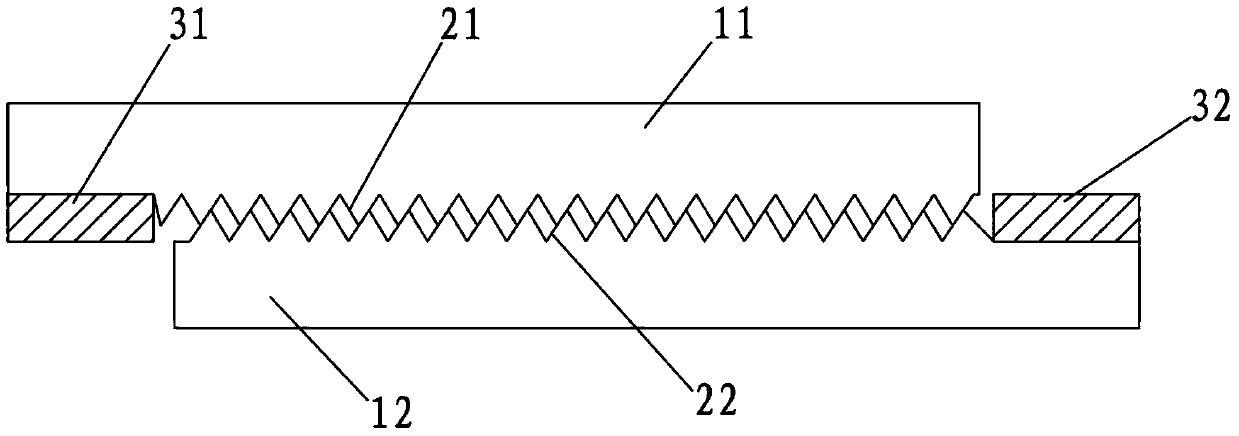

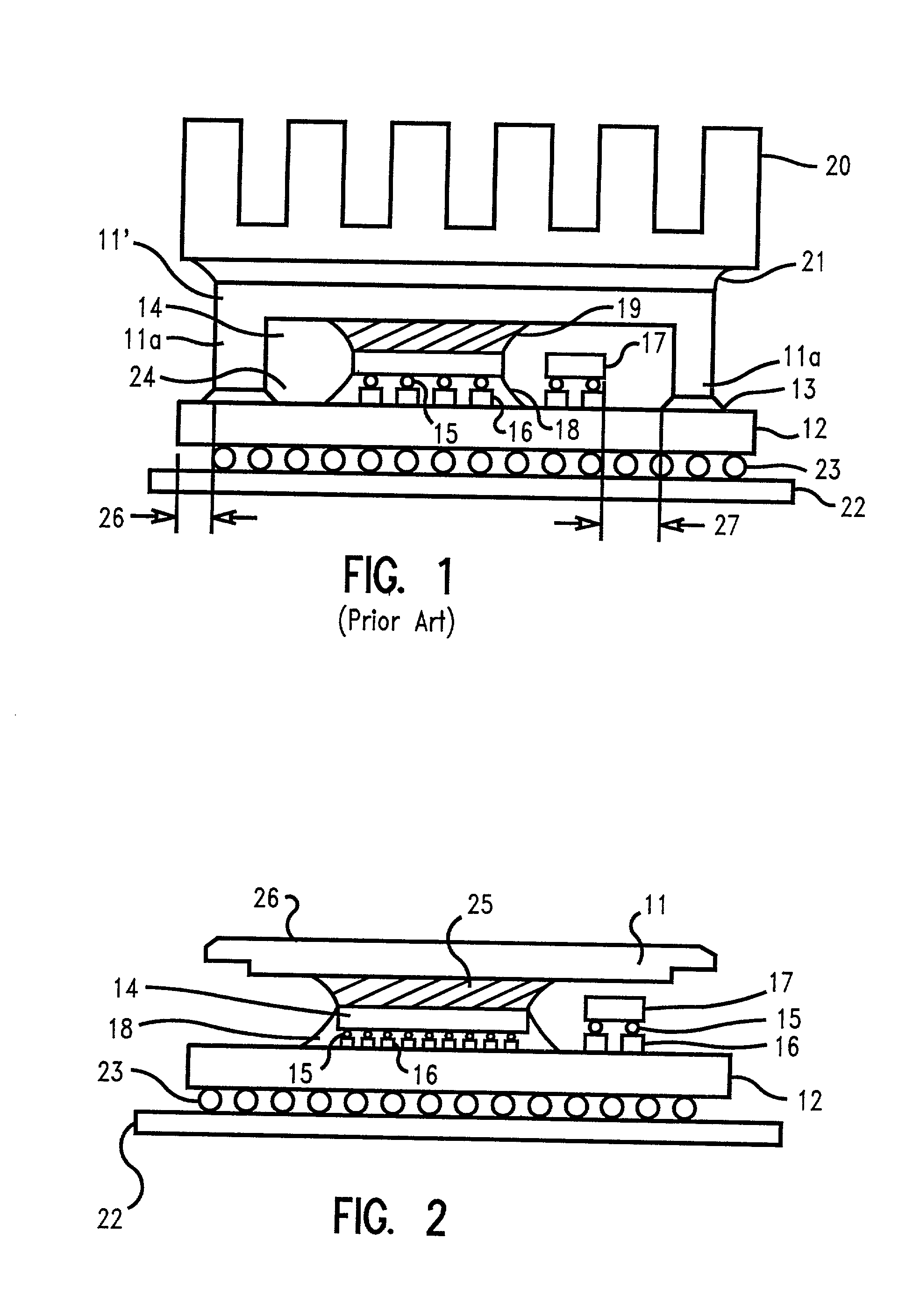

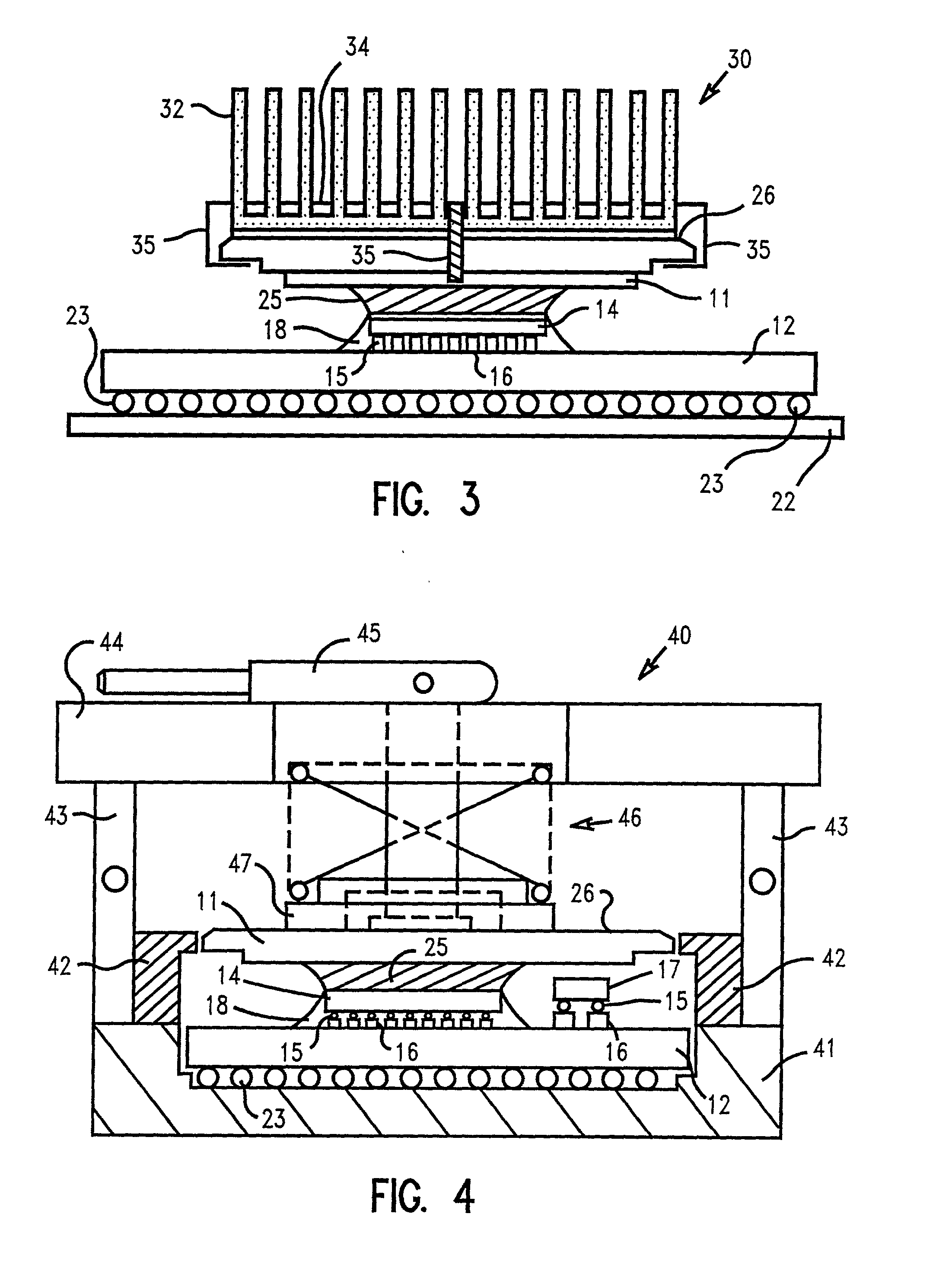

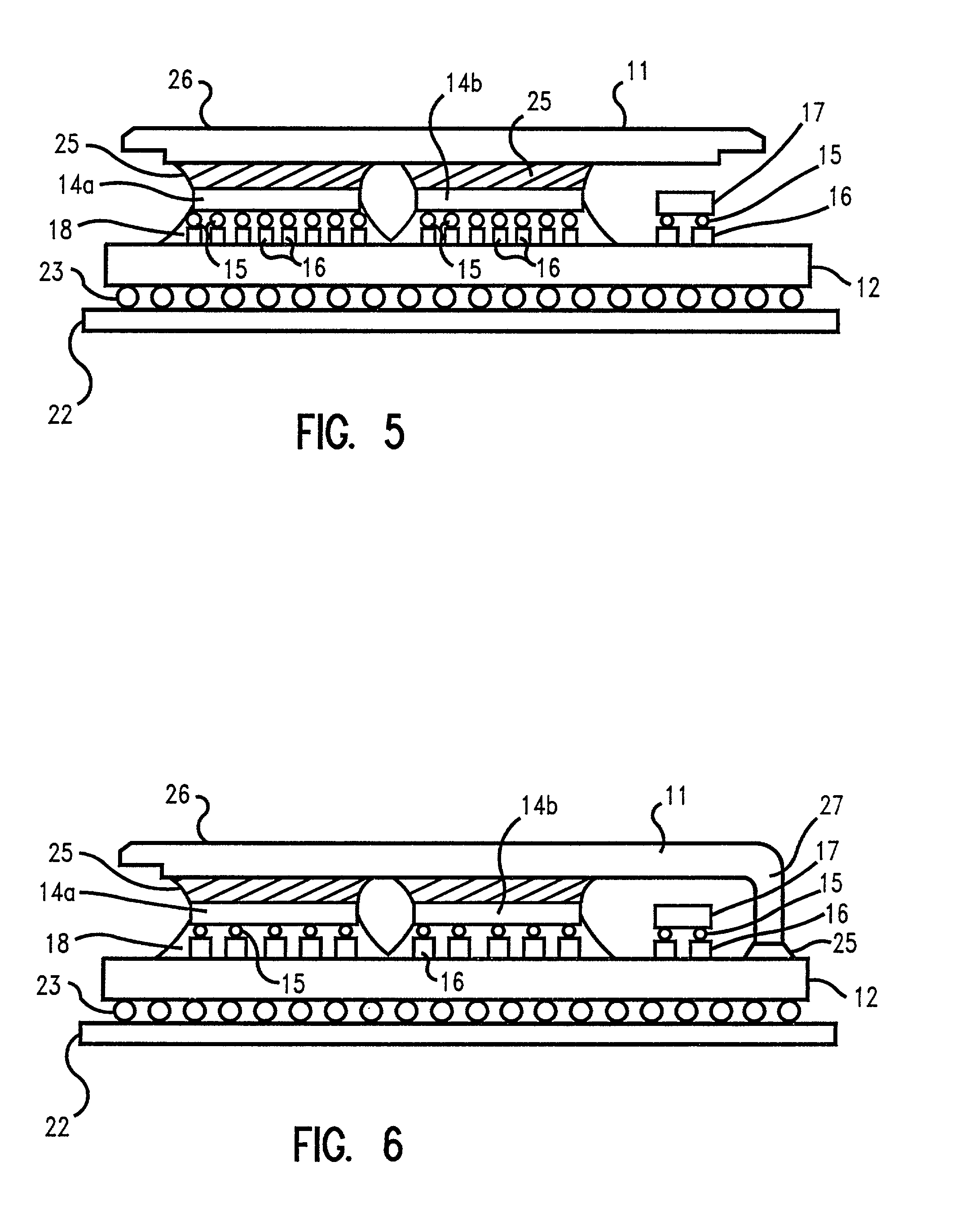

Method for direct attachment of a chip to a cooling member

InactiveUS6413353B2High bonding strengthAdequate flowSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentHeat flowSilanes

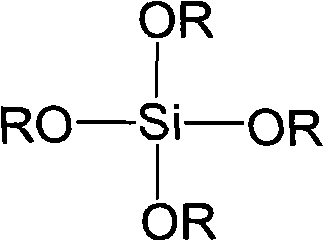

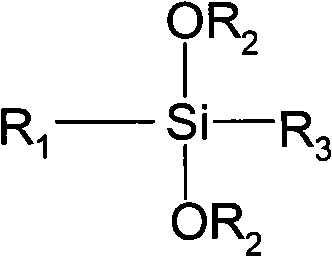

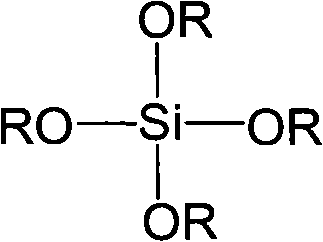

A semiconductor chip module uses a silicone adhesive between the semiconductor chip and a cap, said adhesive having sufficient bond strength to secure said cap to said chip without additional mechanical constraint while providing a direct thermally conductive path and permitting sufficient heat flow from said chip to said cap to maintain steady state operation of said semiconductor chip. The preferred silicone adhesive comprises a primerless, two-part polysiloxane-based adhesive made by reacting polydimethyl siloxane, an organosilicon compound, a polysiloxane, and a silane, in the presence of a catalyst.

Owner:IBM CORP

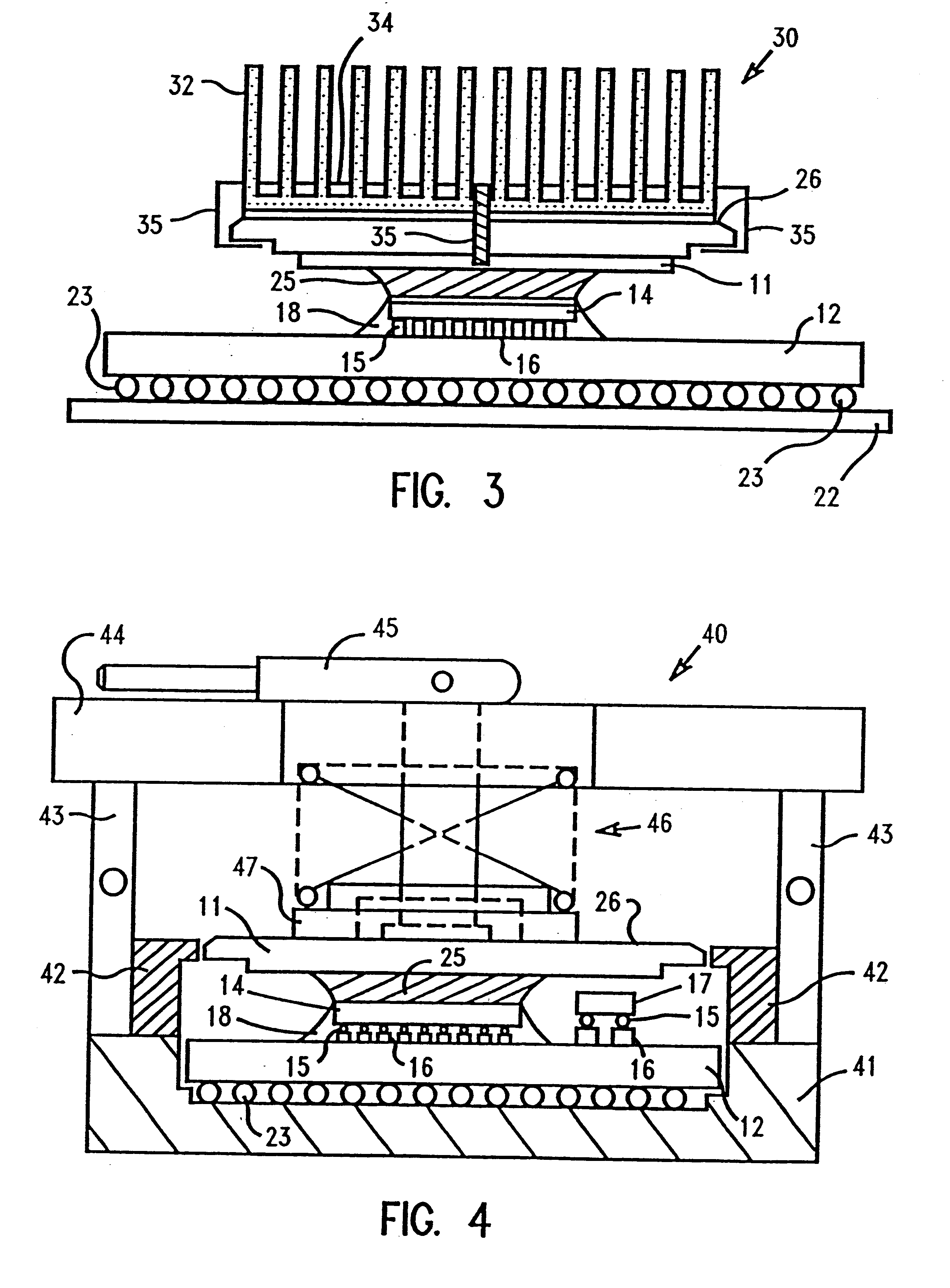

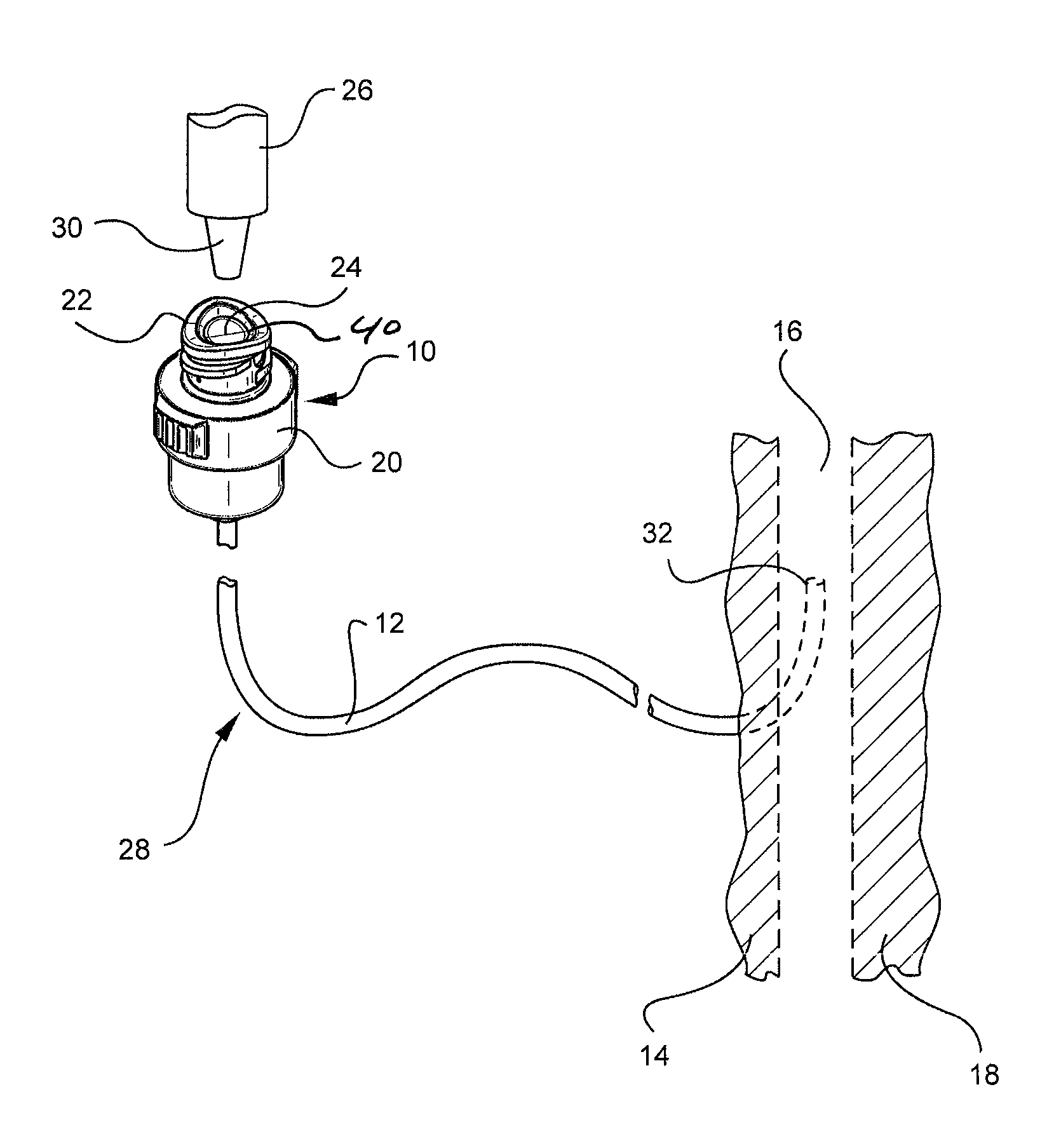

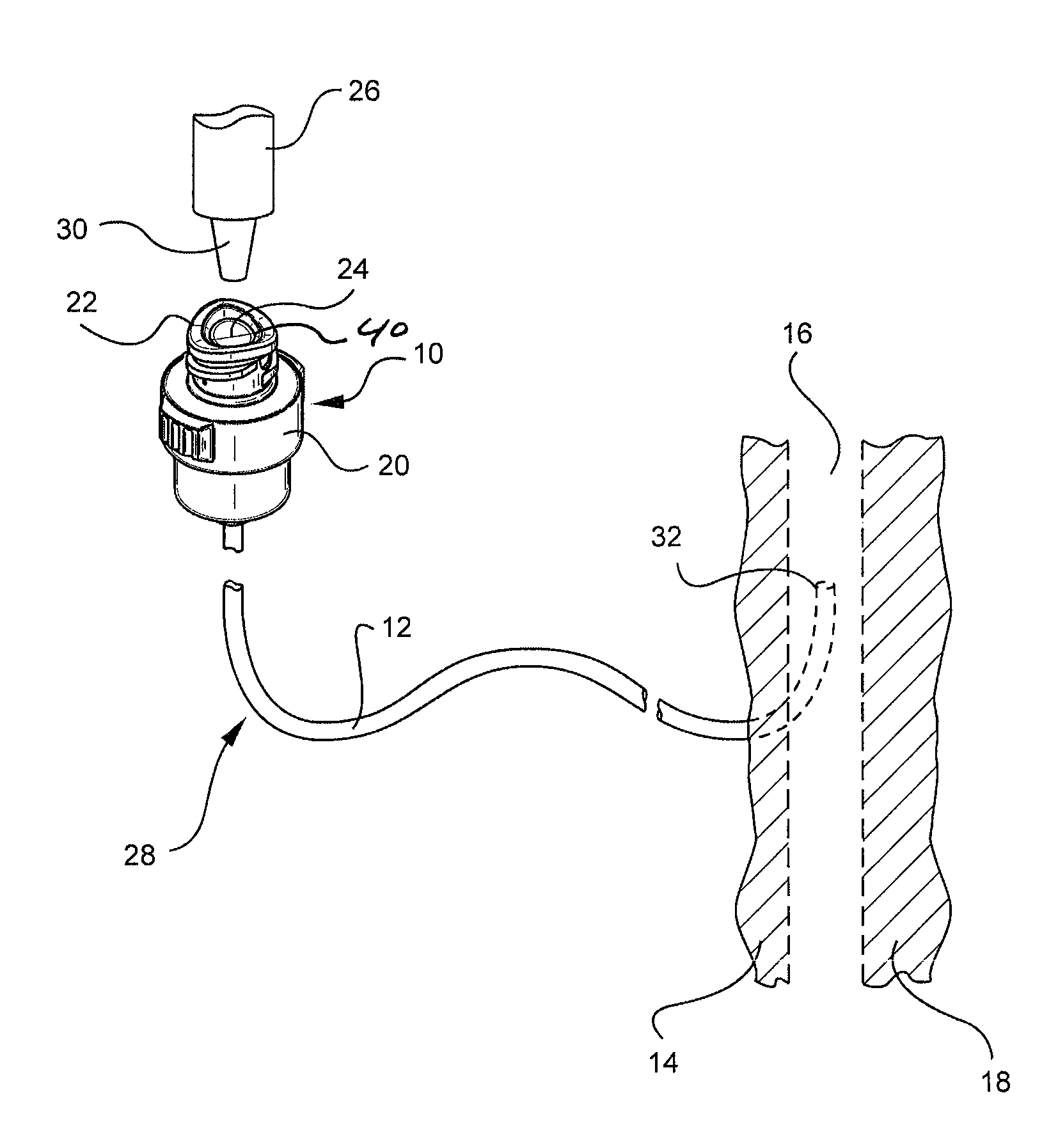

Antimicrobial lubricant compositions

ActiveUS20100137379A1Reduce complicationsFacilitate smooth and reliable actuationBiocidePretreated surfacesAmmonium compoundsChlorhexidine Acetate

Antimicrobial lubricant compositions are disclosed. The antimicrobial lubricant compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. The compositions include an oil lubricant. Representative lubricants may include polydimethyl siloxane, trifluoropropyl copolymer polysiloxane, and a copolymer of dimethylsiloxane and trifluoropropylmethylsiloxane. The compositions include rheology modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include of aldehydes, anilides, biguanides, bis-phenols, quaternary ammonium compounds, cetyl pyridium chloride, cetrimide, alexidine, chlorhexidine diacetate, benzalkonium chloride, and o-phthalaldehyde.

Owner:BECTON DICKINSON & CO

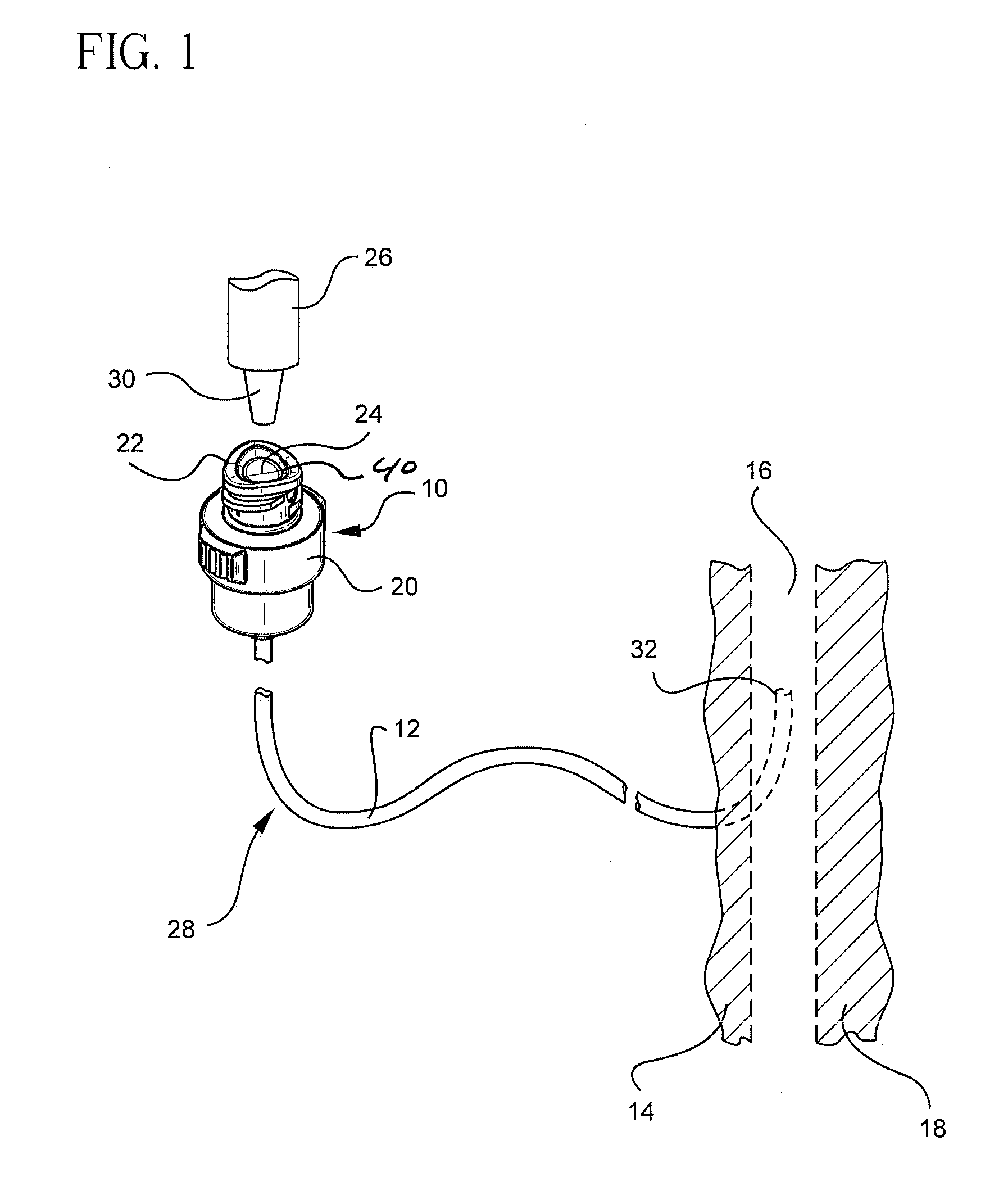

Fluorin-silicon modified core-shell structure polyurethane-acrylate emulsion preparation method

InactiveCN1951968AImprove water resistanceGood oil resistancePolyurea/polyurethane coatingsPropanoic acidPolydimethyl siloxane

The invention discloses a preparing method of fluorosilicate-composite emulsion with polyurethane-acrylate as nuclear shell structure, which is characterized by the following: dehydrating the composite liquid of macromolecular diatomic alcohol and dihydroxy-terminated polydimethyl siloxane; adding diisocyanate; adding dimethylol propionic acid, diatomic alcohol chain-extending agent and catalyst (disilicon acid dibutyl tin); cooling; emulsifying; extending chain in the water through polyamine chain-extending agent; obtaining the aqueous polyurethane dispersion modified by organic silicon as seed; dripping the fluorine acrylate monomer to do emulsion polymerization.

Owner:UNIV OF SCI & TECH OF CHINA +1

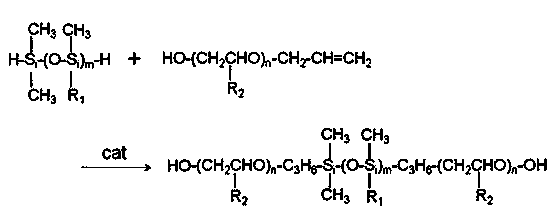

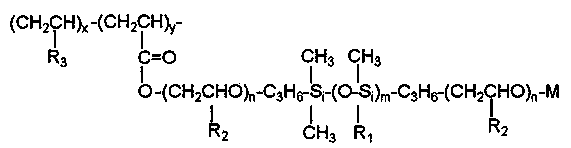

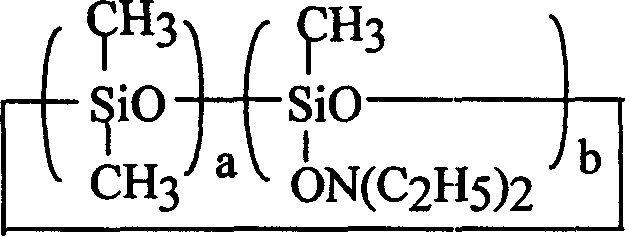

Polyether modified organic silicon defoamer, and preparation method and application thereof

ActiveCN103819630AImprove surface activityGood defoaming activityFoam dispersion/preventionAlkanePolymer science

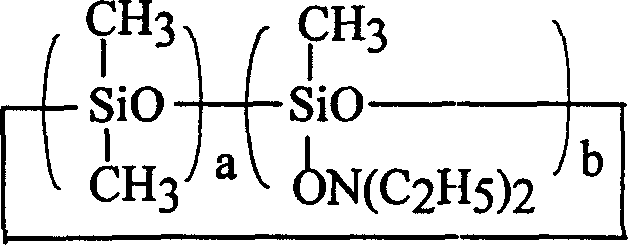

The invention belongs to the technical field of chemical engineering, and discloses polyether modified organic silicone oil that adopts a comb structure shown in formula (1) and a preparation method and application as a defoamer, and overcomes the service restrictions of conventional organic silicone defoamers. The preparation method comprises the following steps: compounds such as short polyols polydimethyl siloxane or polymethyl phenyl siloxane in which end groups are hydrogen, allyl alcohol polyether, aliphatic esters or alkanes amides that contain end alkenyl are selected as raw materials to synthesize the polyether modified organic silicone oil. According to the invention, as a defoamer, the polyether modified organic silicone oil has good characteristics of self-emulsifying property, self-dispersing property, steady emulsifying property, good defoaming and foam inhibiting performance, high temperature resistance, and acid and alkali resistance.

Owner:威尔(福建)生物有限公司

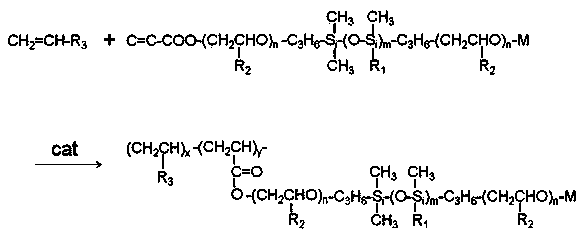

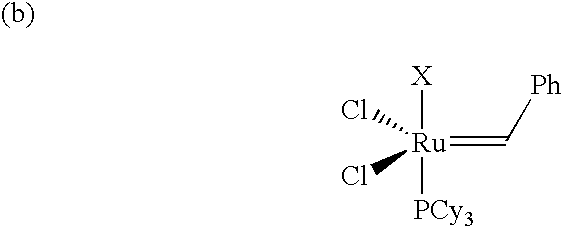

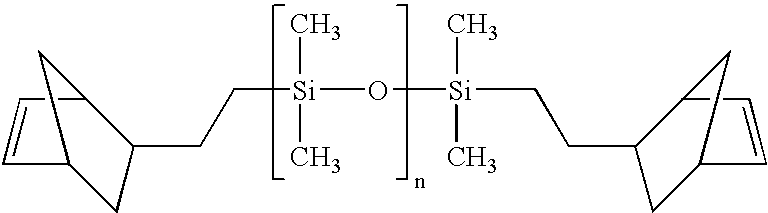

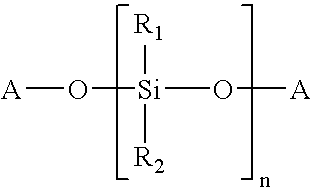

Composition curable by metathesis reaction

InactiveUS6844409B2Increase alkalinityImpression capsGroup 8/9/10/18 element organic compoundsEndcappingOligomer

A composition curable by a metathesis reaction and comprising an olefin-containing resin system and metathesis catalyst. The resin system comprises siloxane-based oligomers or polymers end-capped and / or tethered with olefin functional groups that are capable of undergoing a metathesis reaction. The composition also includes a ruthenium carbene complex catalyst, whereby the catalyst initiates the metathesis reaction of the composition. The oligomer or polymer may be, for example, one or a combination of a telechelic polydimethylsiloxane end-capped with norbornenylethyl groups, a polydimethylsiloxane tethered and end-capped with norbornenylethyl groups, a tri-functional polydimethylsiloxane end-capped with norbornenylethyl groups, or a quadri-functional polydimethylsiloxane end-capped with norbornenylethyl groups. The catalyst may be, for example, a ruthenium carbene complex, such as 1,3-bis-(2,4,6-trimethylphenyl)-2-(imidazolidinylidene) dichloro(o-isopropoxyphenylmethylene) ruthenium.

Owner:THE KERR

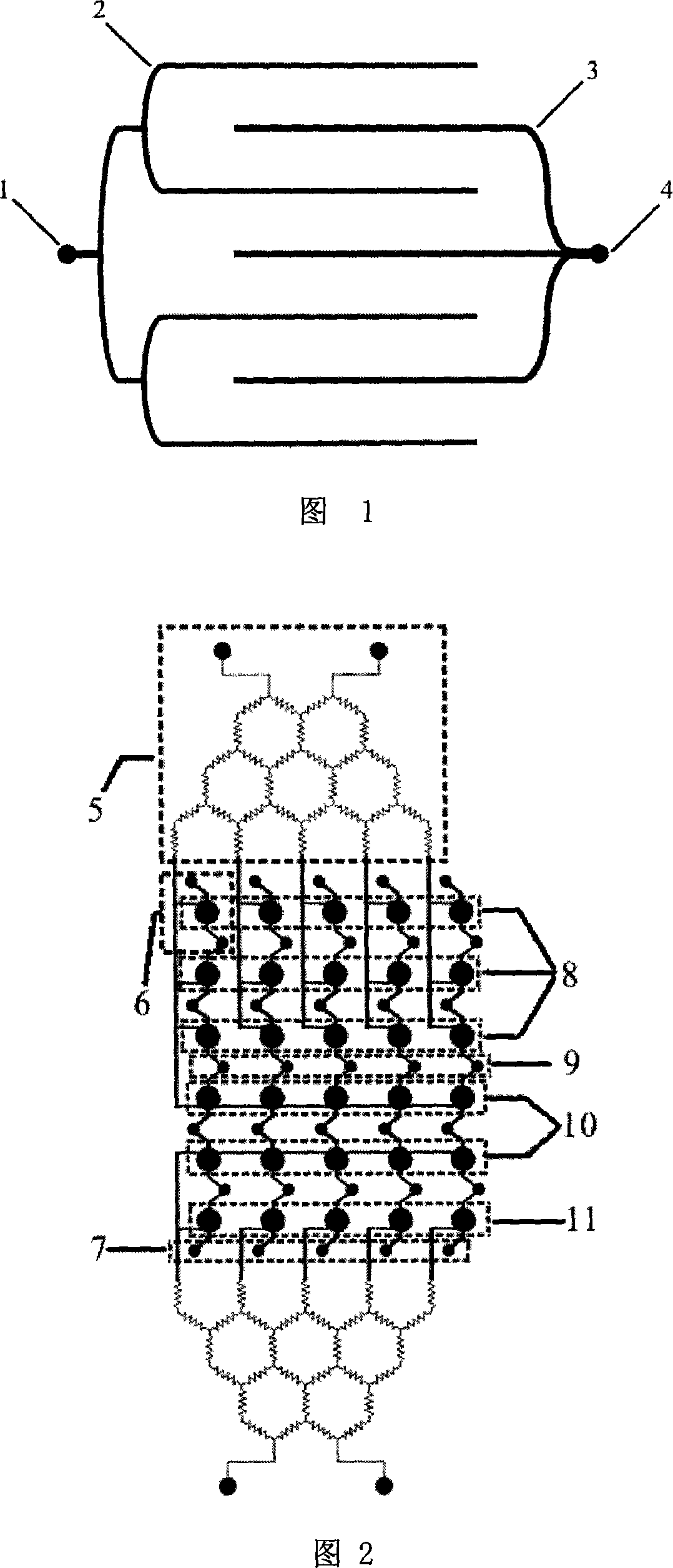

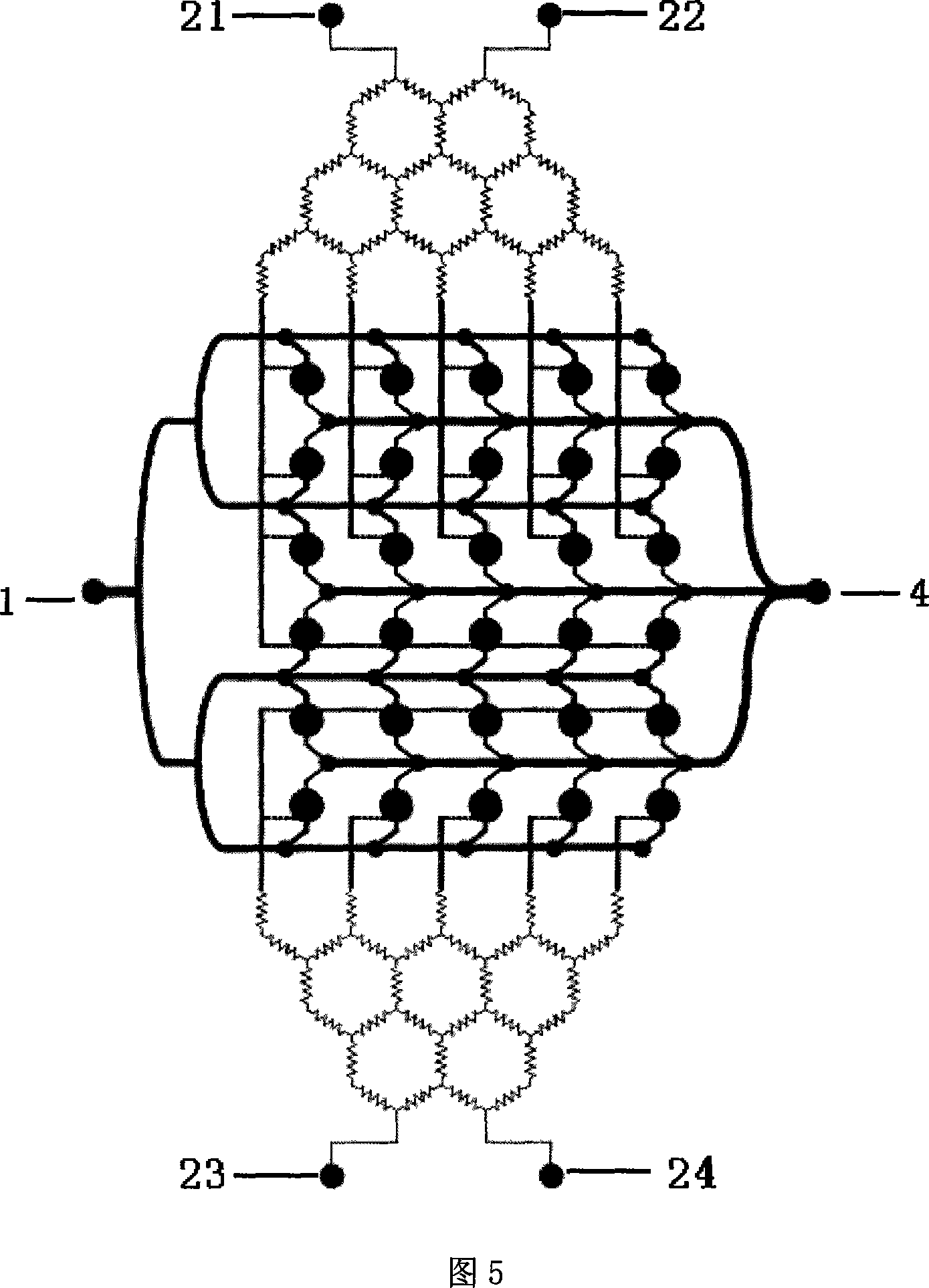

Three-dimensional high-flux medicaments sifting chip and manufacture method thereof

InactiveCN101245311ALow costShort cycleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringPolydimethyl siloxane

The invention discloses a three-dimensional high-flux drug screening PDMS-glass chip and the preparation method thereof, which makes uses of micro-electro processing and micro-plastic film technologies to produce the three-dimensional PDMS-glass chip with a two-layer micro-channel structure. A cell injection and waste liquid output channel of a first layer of PDMS chip is bonded with another layer of polydimethyl siloxane chip together, a drug concentration gradient channel and a quantitative cell culture chamber are arranged on the other layer of PDMS chip, the quantitative cell culture chamber is connected with an outlet channel of the drug concentration gradient channel, the quantitative cell culture chamber is respectively connected with a cell sample injection hole drilling position and a waste liquid outlet hole drilling position by the channel; the three-dimensional high-throughput drug screening PDMS-glass chip can overcome the shortcomings of heavy workload, great reagent and drug consumption, long screening period and high development cost of the traditional drug screening technology. The three-dimensional high-flux drug screening PDMS-glass chip can realize miniaturization of the chip, high flux, low cost, small reagent consumption, accurate and reliable test data and the simple design requirements of the operational process in the drug screening application on cell level.

Owner:WUHAN UNIV +1

Organopolysiloxane/polyurea/polyurethane block copolymers

Organopolysiloxane / polyurea / polyurethane block copolymers of general formula (1) B—{[NR4—CR2—SiR2—(O—SiR2)n—CR22—NR4—CO—NH—Y—NH—CO]a-[Z-D-Z-CO—NH—Y—NH—CO]b—[NR4—CR22—SiR2—(O—SiR2)n—CR22—NR4—CO—NH—Y—NH—CO—NH—Y—NH—CO]e}d—B, are obtained by reacting aminomethyl terminal polydimethyl siloxanes with diisocyanates and optional chain extenders, have low softening temperatures and reduced color.

Owner:CONSORTIUM FUR ELEKTROCHEM

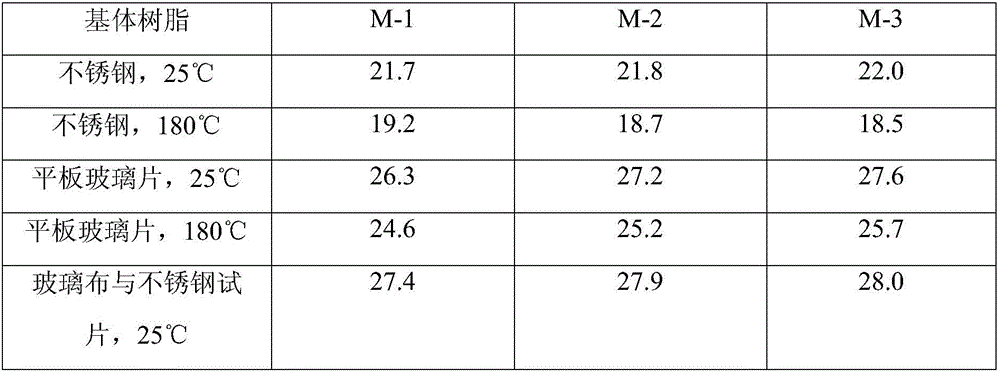

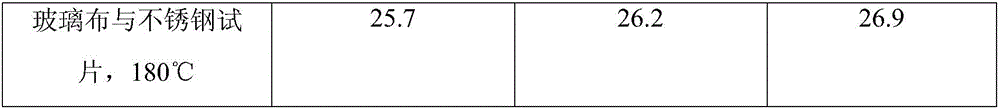

YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and preparation method thereof

The invention relates to a YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and a preparation method thereof. The matrix resin is composed of YASI, an epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; and (2) adding the YASI and epoxy resin into a reaction kettle, stirring and mixing to react, adding the imide oligomer, continuing stirring to react, adding the 3-aminopropyl trialkoxysilane, stirring to react, adding the curing agent, and uniformly stirring and mixing. The resin can be widely used for bonding metals (such as steel, copper, aluminum and the like) and substrates (ceramic, glass, resin-base composite materials and the like), and preparing glass fibers, aramid fibers and carbon-fiber-reinforced polymer composite materials, and thus, has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

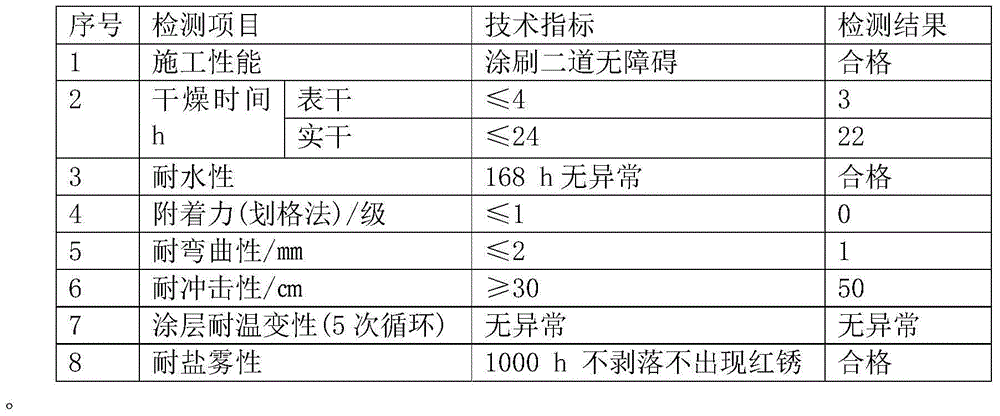

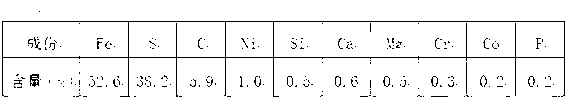

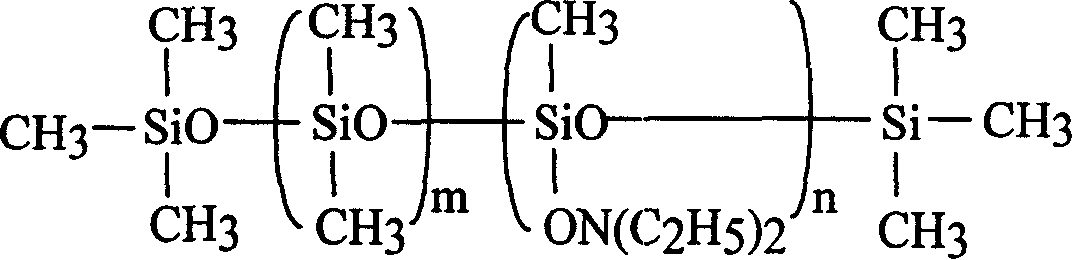

Organosilicone room-temperature-cured anticorrosive coating material

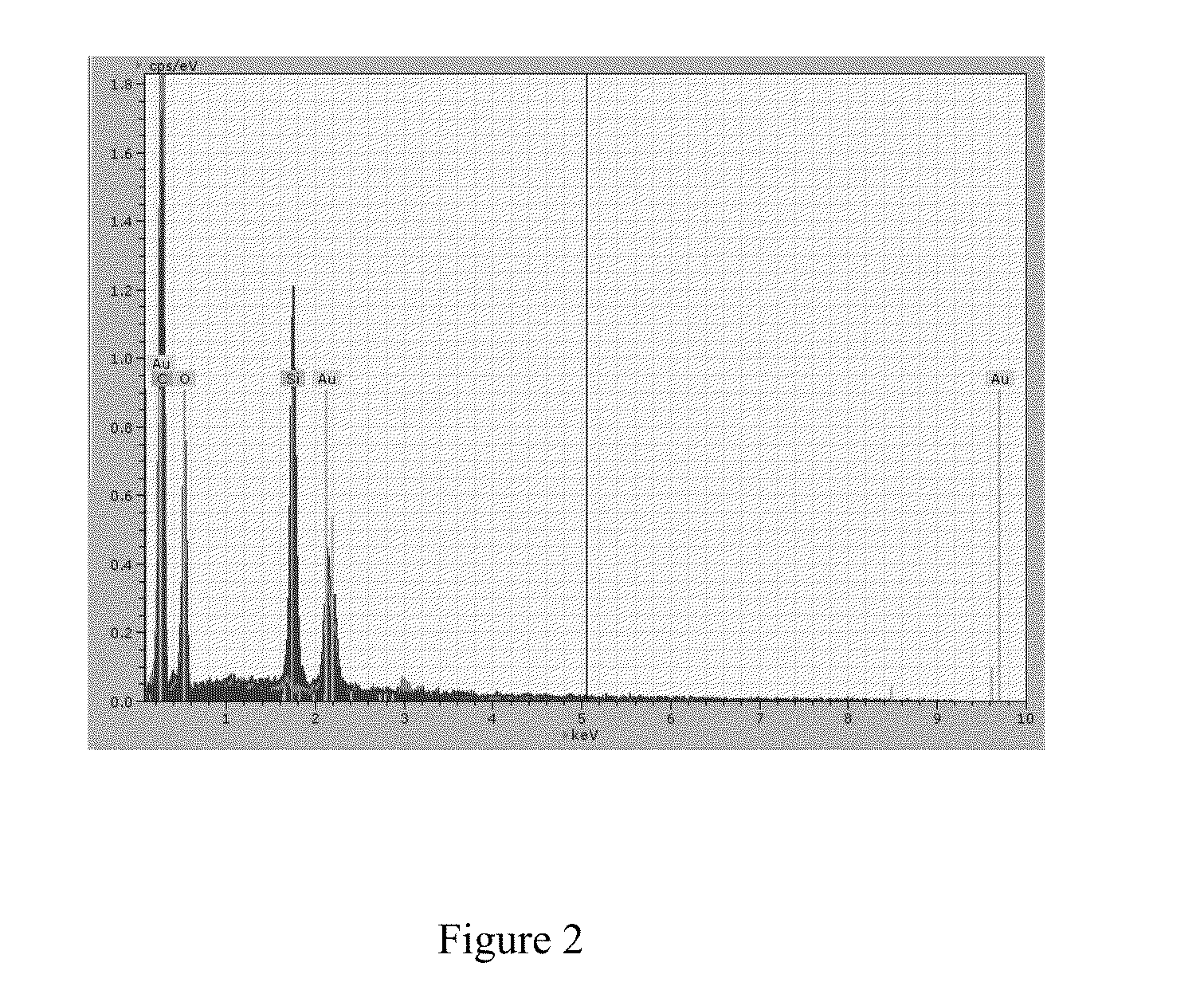

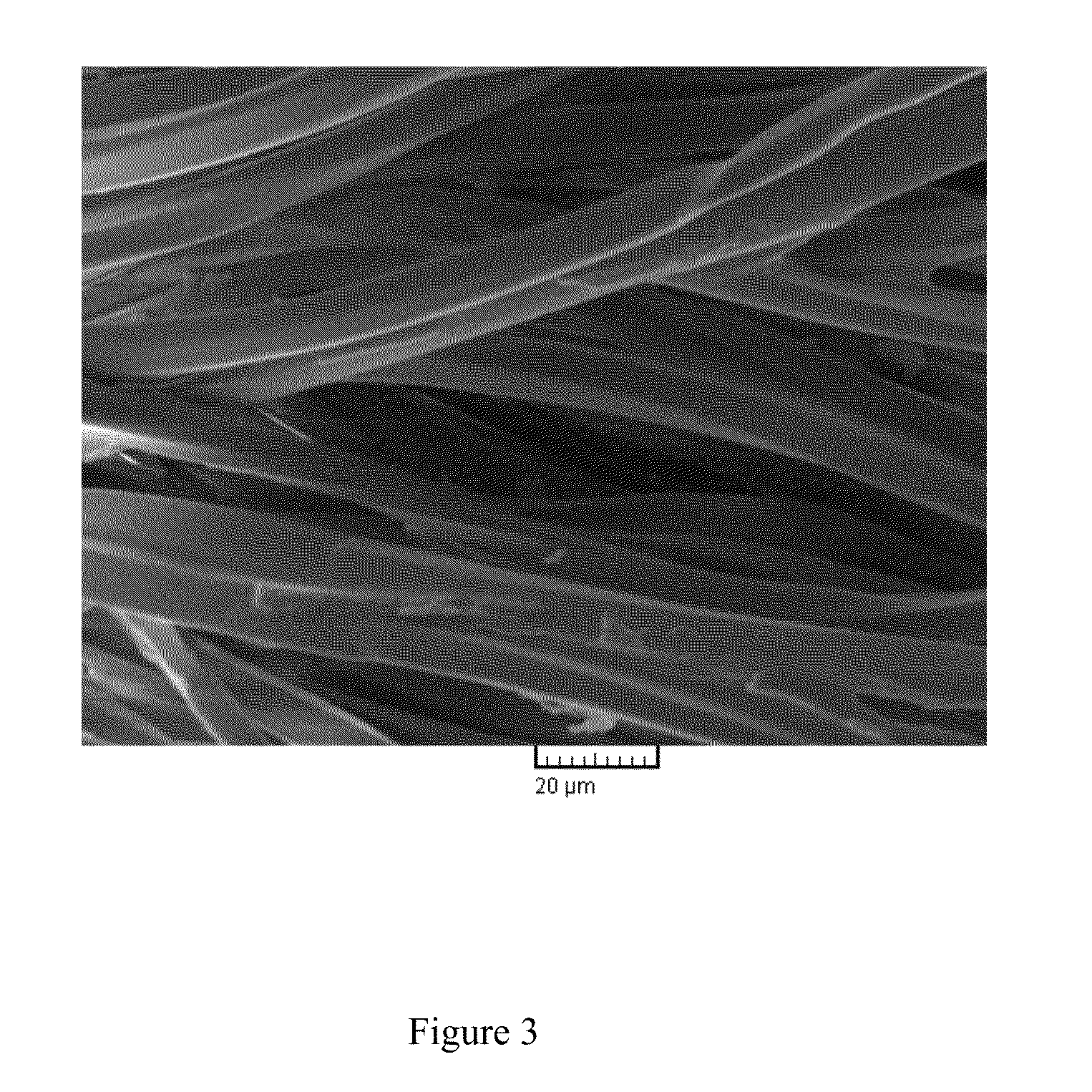

ActiveCN105086823AOvercome the shortcomings of strong static electricityGood dust-proof and hydrophobic functionFireproof paintsAnti-corrosive paintsPliabilitySpray coating

The invention discloses an organosilicone room-temperature-cured anticorrosive coating material. The organosilicone room-temperature-cured anticorrosive coating material is prepared through mixing the following raw material ingredients in parts by weight: 24-40 parts of alpha,omega-dihydroxyl polydimethyl siloxane, 6-10 parts of hydroxy-terminated polyphenylmethyl siloxane, 0.5-5 parts of aerosil, 10-30 parts of aluminum hydroxide powder, 0.5-5 parts of nano calcium carbonate, 5-15 parts of pigment slurry, 5-9 parts of cross-linking agent, 1-2 parts of coupling agent, 0.1-1 part of catalyst, 1-2 parts of modified polytetrafluoroethylene powder and 5-10 parts of thinning agent. According to the coating material disclosed by the invention, coating layers can form uniform and fine paint films, are very good in flexibility and are free of erosion resulting from harsh climate environments and corrosive medium environments; the coating material disclosed by the invention is cured at room temperature, is simple in construction, is directly coated, can be subjected to brush coating and roller coating and can also be subjected to spray coating; the adhesion of the paint films reaches the level 1; the paint films are waterproof and dustproof; the impact resistance is excellent; and the heat and weather resistance and flame retardance are also very excellent.

Owner:浙江香林新材料有限公司

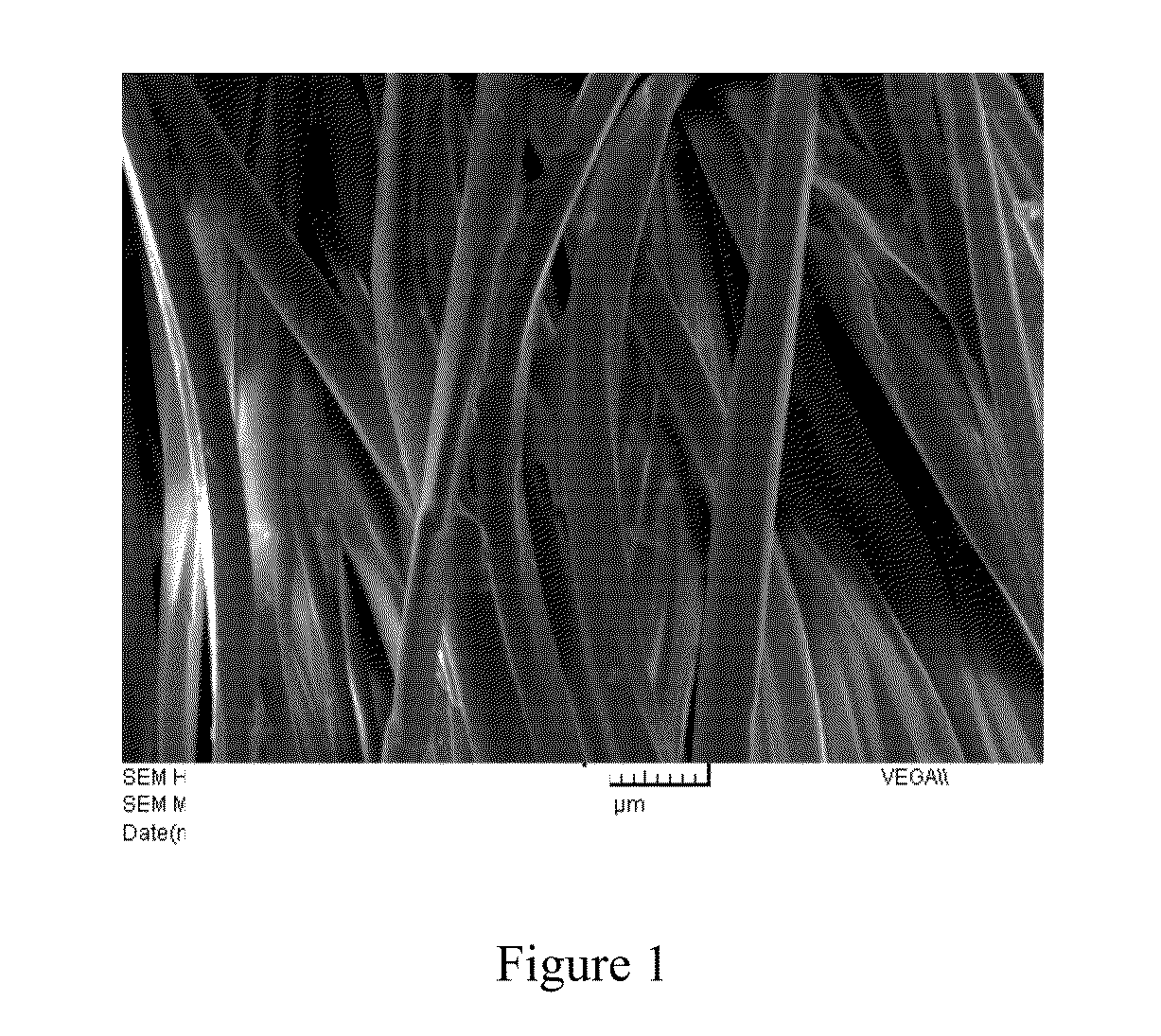

Piezoresistive electronic skin and preparation method thereof

ActiveCN103961073AHigh sensitivityEasy to bendDiagnostic recording/measuringSensorsMicro nanoPolyvinyl alcohol

The invention provides piezoresistive electronic skin and a preparation method thereof. A carbon nano tube thin film is adopted as an electroconductive layer, and a substrate is made by materials, with micro-nano patterns, like polydimethyl siloxane, polyphenyl dioctyl phthalate ethyl diester, polyvinyl alcohol, polyvinyl formal and polyethylene, so that the substrate is enabled to have the advantages of high flexibility, easiness in bending and the like, and the piezoresistive electronic skin is low in working voltage, small in power consumption, high in flexibility and short in response time. More importantly, the patterned flexible substrate is adopted as a base body, so that sensitivity, of the electronic skin, on outside small acting force is improved greatly.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for direct attachment of a chip to a cooling member

InactiveUS20010040006A1High bonding strengthSufficient heat flowSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentHeat flowSilanes

A semiconductor chip module uses a silicone adhesive between the semiconductor chip and a cap, said adhesive having sufficient bond strength to secure said cap to said chip without additional mechanical constraint while providing a direct thermally conductive path and permitting sufficient heat flow from said chip to said cap to maintain steady state operation of said semiconductor chip. The preferred silicone adhesive comprises a primerless, two-part polysiloxane-based adhesive made by reacting polydimethyl siloxane, an organosilicon compound, a polysiloxane, and a silane, in the presence of a catalyst.

Owner:IBM CORP

Low-superficial area ratio marine antifouling coating of silicofluoride block polymer and its production

InactiveCN101029207ALower surface energyLow costAntifouling/underwater paintsPaints with biocidesMethacrylatePolydimethyl siloxane

A fluosilicate block polymer low-surface energy marine anti-fouling coating and its production are disclosed. The coating consists of base material polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer, accessory methyl silicone oil and di-n-octyl ester phthalate and coating solvent butyrin acetate. The process is carried out by mixing methyl silicone oil with di-n-octyl ester phthalate to obtain coating accessory, mixing polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer with pigment to obtain coating base material and pigment mixture, adding coating accessory into mixture of coating base material and pigment, mixing, dissolving it into butyrin acetate and laying aside. It has excellent anti-fouling effect and no environmental pollution.

Owner:XIAMEN UNIV

All-barrier elastomeric gel-filled breast prosthesis

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

Method for superhydrophobic finishing of textile

The invention provides a method for superhydrophobic finishing of textile, comprising the following steps of: (1) padding the textile in silicon dioxide hydrosol, and drying; and (2) padding the textile treated in the step (1) in water emulsion of siloxane, polysiloxane and hydroxyl polydimethyl siloxane or the water emulsion of a mixture of the siloxane, the polysiloxane and hydroxyl polydimethyl siloxane in the presence of a catalytic synergistic agent, preliminarily drying and baking. The contact angle between the fabric treated with the method and water is greater than 150 degrees; the textile has the superhydrophobic performance; in the processing flow of the method disclosed by the invention, an organic solvent is prevented from being used from beginning to end; the fabric is completely treated in a waterborne system; the processing method is environment-friendly and is easy for industrialization; and the used raw materials have wide sources and low cost.

Owner:TAICANG BAONI IND CO LTD

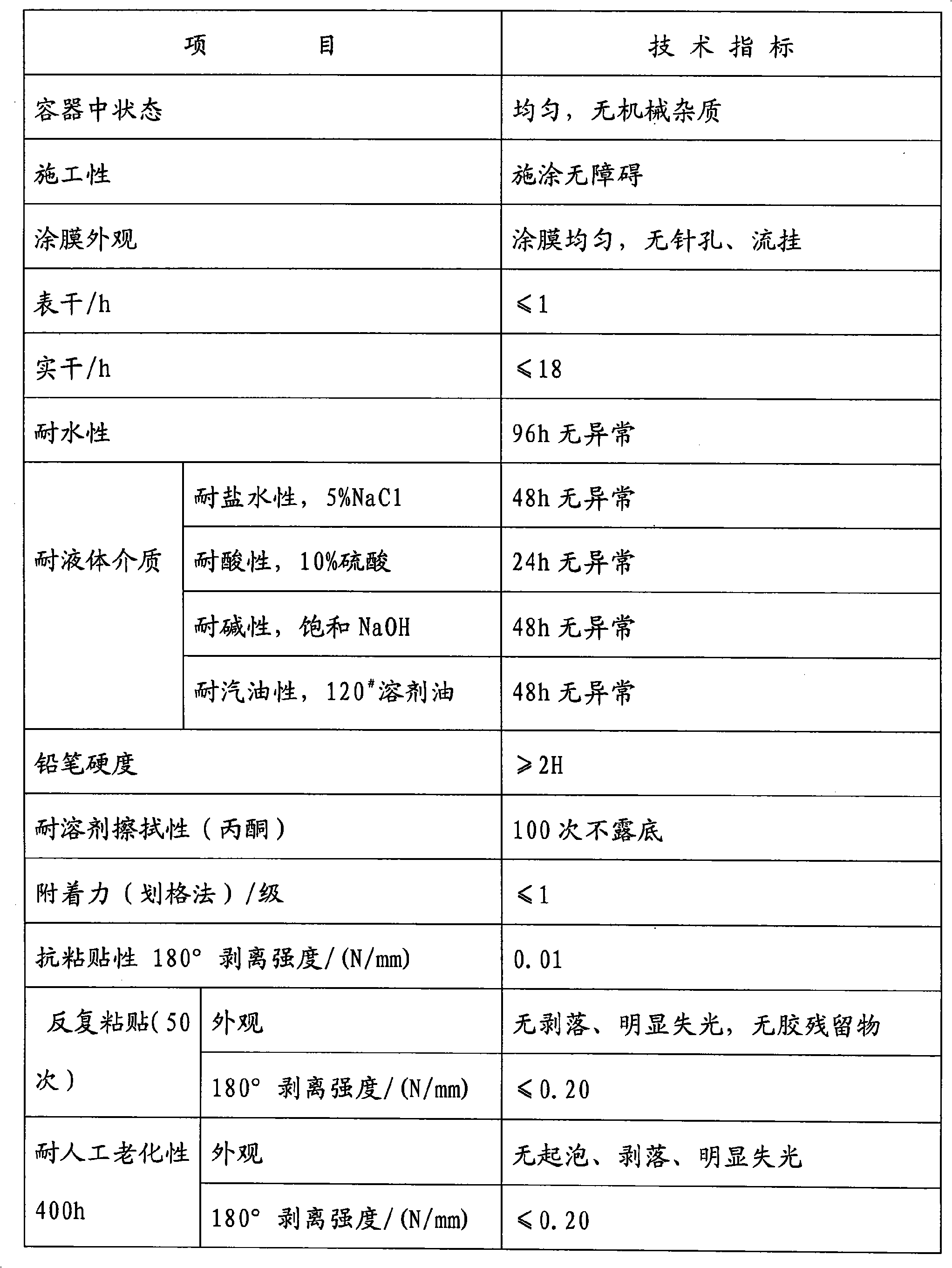

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

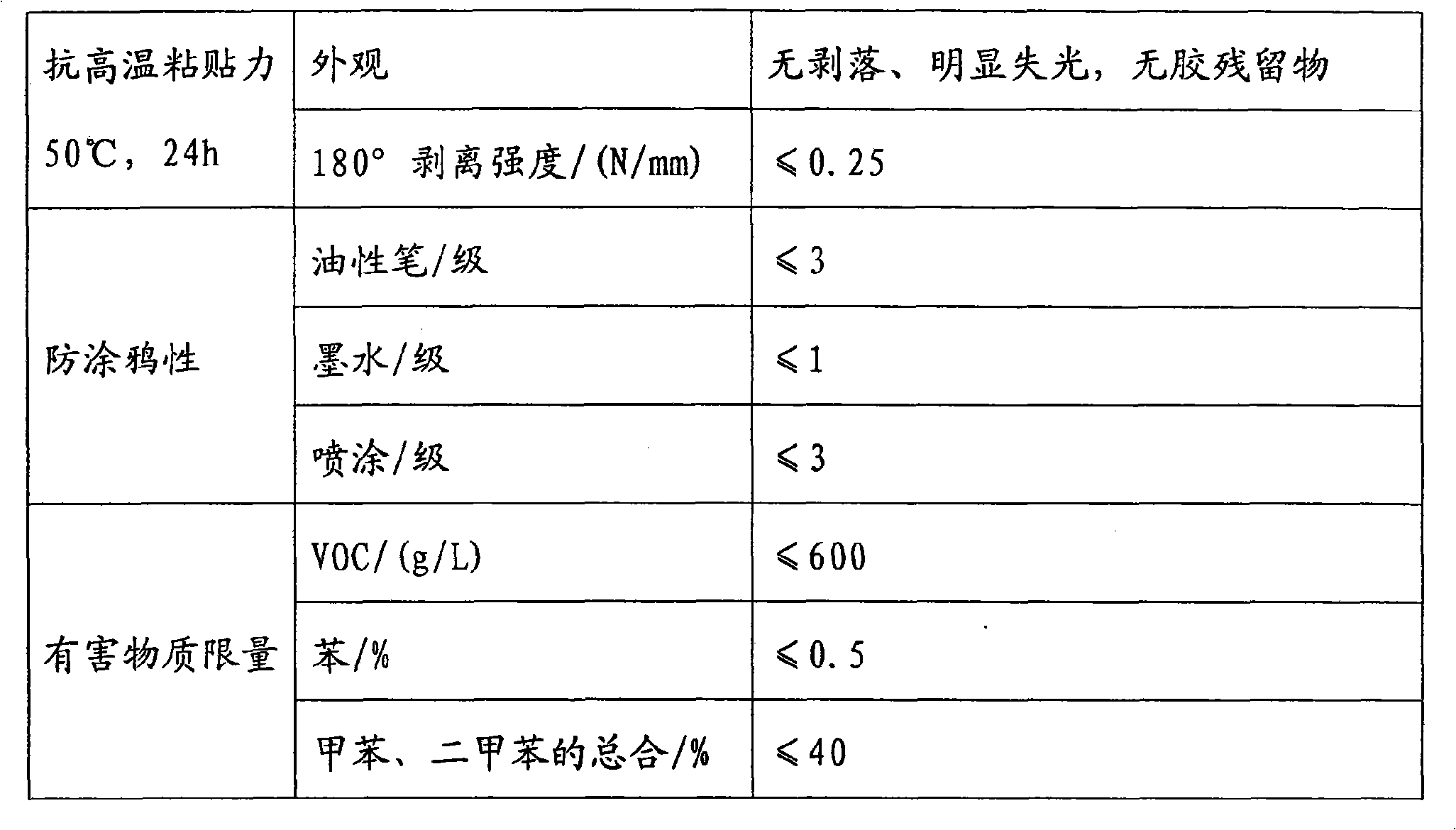

Ferrous sulfide dirt neutral complexing cleaning agent and preparation method thereof

ActiveCN103194325ATo achieve the purpose of safe productionImprove anti-corrosion performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical industrySodium acetate

The invention relates to an equipment cleaning agent which is used in the field of petroleum and chemical industry, in particular to a ferrous sulfide dirt neutral complexing cleaning agent which is used for washing a synthesized ammonia low-temperature methanol washing unit system in the petroleum chemical industry and the coal chemical industry. The ferrous sulfide dirt neutral complexing cleaning agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of sodium gluconate, 7 to 11 parts of sodium salicylate, 20 to 26 parts of gadoliniam diethylene triamine pentaacetic acid, 20 to 26 parts of sodium ethylene diamine tetracetate, 40 to 46 parts of propenoic acid-itaconic acid copolymer, 25 to 32 parts of disodium polyepoxysuccinicate, 12 to 15 parts of sodium hydroxyphenylace, 3 to 7 parts of triethanolamine, 3 to 7 parts of hydrogen peroxide, 0.1 to 0.3 part of lauryl sodium sulfate, 0.1 to 0.3 part of polydimethyl siloxane fluid and 40 to 45 parts of water. The ferrous sulfide dirt neutral complexing cleaning agent is free from generating hydrogen sulfide when cleaning the ferrous sulfide dirt and corroding the equipment and has strong capacity for complexing the iron ions, the removal speed is fast, the decontamination rate is more than 98 percent, the neutralization and passivation are unnecessary to carry out after the chemical washing, and the equipment can be put into operation immediately.

Owner:GANSU HEIMA PETROCHEM ENG

Organosilicon sealant for LED (light-emitting diode) packaging

The invention relates to an organosilicon sealant for LED (light-emitting diode) packaging, belonging to the technical field of organosilicon sealants. The organosilicon sealant comprises a component A and a component B. The component A comprises 15-25 parts of divinyl polydimethylsiloxane silicon resin and 2-6 parts of platinum catalyst. The component B comprises 50-58 parts of divinyl polydimethylsiloxane silicon resin, 50-88 parts of methylhydropolysiloxane, 2-8 parts of reaction inhibitor, 30-40 parts of fumed silica, 2-10 parts of additive KH-560 and 20-25 parts of TiO2. The vinyl silicon resin, hydrogen-containing silicon oil and tetramethyltetravinylcyclosiloxane are subjected to addition reaction under the condition of the platinum catalyst to prepare the organosilicon electronic packaging adhesive with favorable comprehensive properties. The sealant is very suitable for LED packaging.

Owner:BLUESTAR CHENGDU NEW MATERIALS

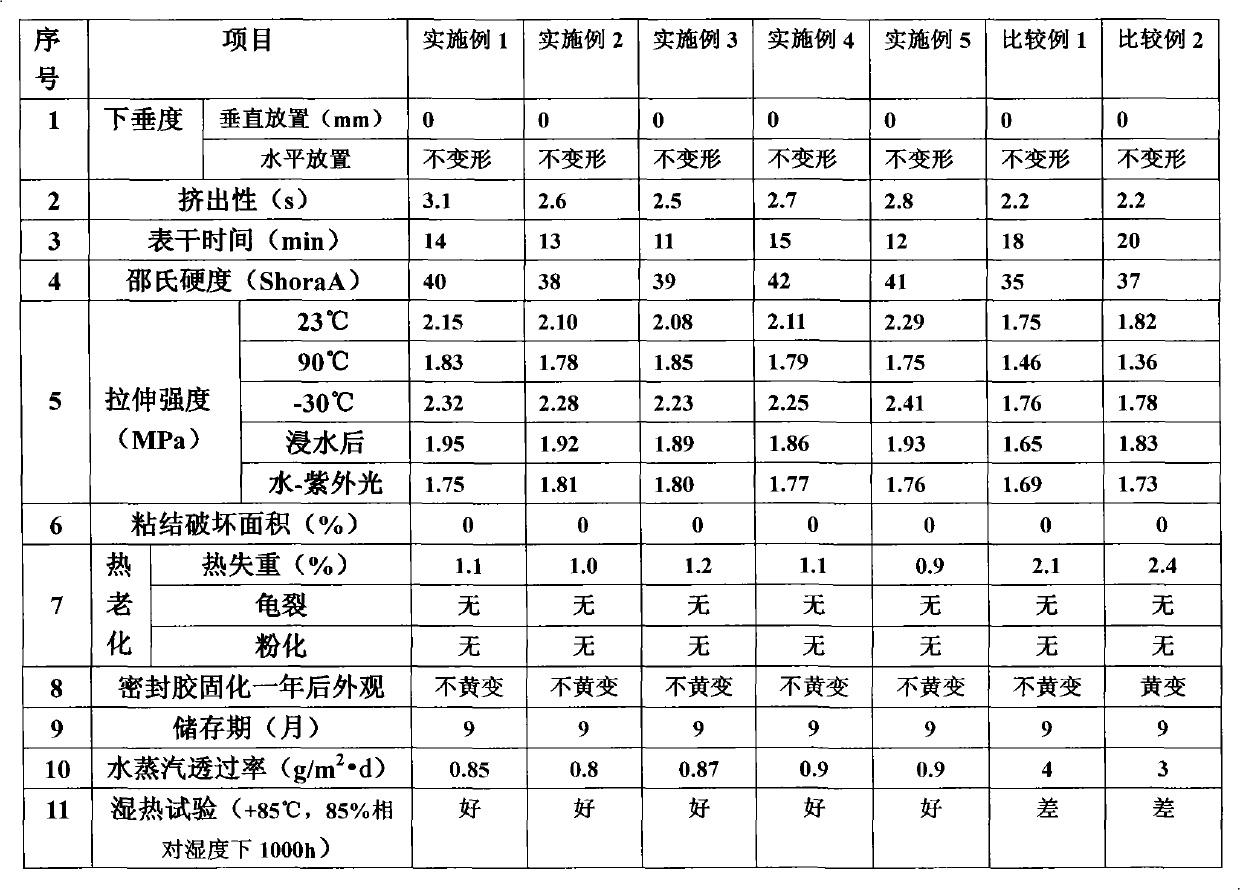

Sealant for acrylic ester modified solar photovoltaic module and preparation method thereof

ActiveCN101792653APrevent penetrationNo precipitationOther chemical processesOrganic non-macromolecular adhesiveWater vaporPolydimethyl siloxane

The invention relates to a sealant for acrylic ester modified solar photovoltaic module and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 90 parts of alpha, omega-dihydroxy polydimethyl siloxane, 10-15 parts of acrylic ester, 0.5-0.8 part of catalyzer A, 0.8-1.2 parts of catalyzer B, 20-30 parts of activated calcium carbonate, 25-60 parts of silicon powder, 4-6 parts of fumed silica, 11-15 parts of crosslinking agents, 2-3 parts of silane coupling agents and 5-8 parts of plasticizer. The invention has the advantages that the permeation of water vapor can be inhibited effectively, and the permeation rate of the water vapor is less than 1; due to the adoption of ester modification by acrylic ester, no monomer is separated in the process of solidification and after solidification; the resistance to weather and corrosion is ideal; and the process of the recommended preparation method is simple, which is not strict on process requirements and equipment.

Owner:江苏明昊新材料科技股份有限公司

Composite type flexible pressure and displacement sensitive element and preparation method thereof

InactiveCN103743438AIncreasing the thicknessImprove flexibilityMeasurement devicesConductive polymer compositeCopper foil

The invention relates to a composite type flexible pressure and displacement sensitive element and a preparation method thereof, and belongs to the technical field of measurement. The composite type flexible pressure and displacement sensitive element comprises a displacement sensitive layer, a pressure sensitive layer and an insulated encapsulation layer, wherein the displacement sensitive layer is formed by a copper foil coil covering a polyimide film; the pressure sensitive layer is formed by a conductive polymer composite material which is embedded in Polydimethyl Siloxane; the insulated encapsulation layer is formed by a flexible polymer material which is vulcanized at the outer parts of the displacement sensitive layer and the pressure sensitive layer; information of pressure and displacement can be obtained through detecting the impedance change of the copper foil coil. The composite type flexible pressure and displacement sensitive element prepared by the invention has dual functions of pressure measurement and non-contact displacement measurement and can be applied to the fields of multi-sensitive electronic skin preparation or pressure measurement and non-contact displacement measurement between small narrow curved layers of a whole machine and complete equipment in an intelligent manufacturing complete process.

Owner:NORTHEASTERN UNIV

Acne removing and antiallergic cream and preparation method thereof

InactiveCN103565714ANo drug resistanceAnti-acidificationCosmetic preparationsToilet preparationsPolyethylene glycolGlycerol

The invention discloses an acne removing and antiallergic cream which is prepared by mixing stearyl alcohol polyether-2, stearyl alcohol polyether-20, glycerin stearate, PEG (Polyethylene Glycol)-100 stearate, stearic acid, cetearyl alcohol, aloe oil, polydimethyl siloxane, isopropyl myristate, propyl p-hydroxybenzoate, methyl p-hydroxybenzene, tocopherol, azone, bisabolol, glycerol, xanthan gum, EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, propylene glycol, ethanol, menthol, salicylic acid, a golden cypress extractive, a scutellaria baicalensis extractive, an India chinaberry leaf extractive, a spiraea ulmaria extractive, a bee milk extractive, an aloe leaf extractive, tea tree oil and sodium hydroxide. The acne removing and antiallergic cream disclosed by the invention can be used for removing acnes, promoting the facial blood circulation and skin cell regeneration, improving the skin tolerance and reducing or eliminating the allergic reaction of the skin; the allergic tolerance of the skin is improved, so that the cream is safe and effective; no any spices are added, so that allergens are greatly reduced.

Owner:SHENZHEN GUAFEN BIOTECH

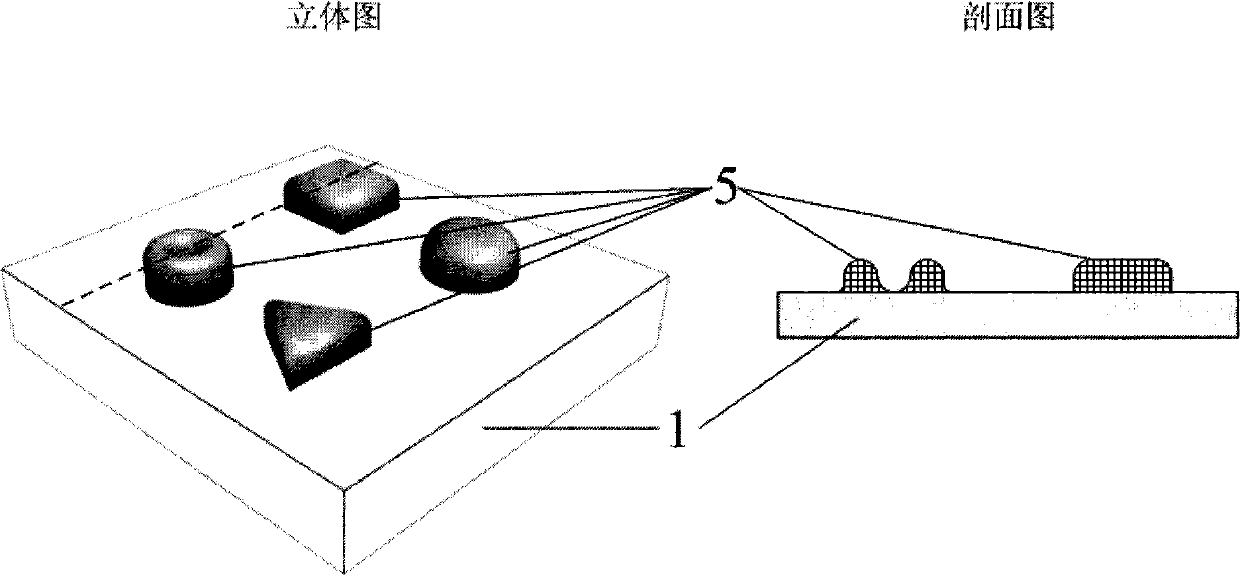

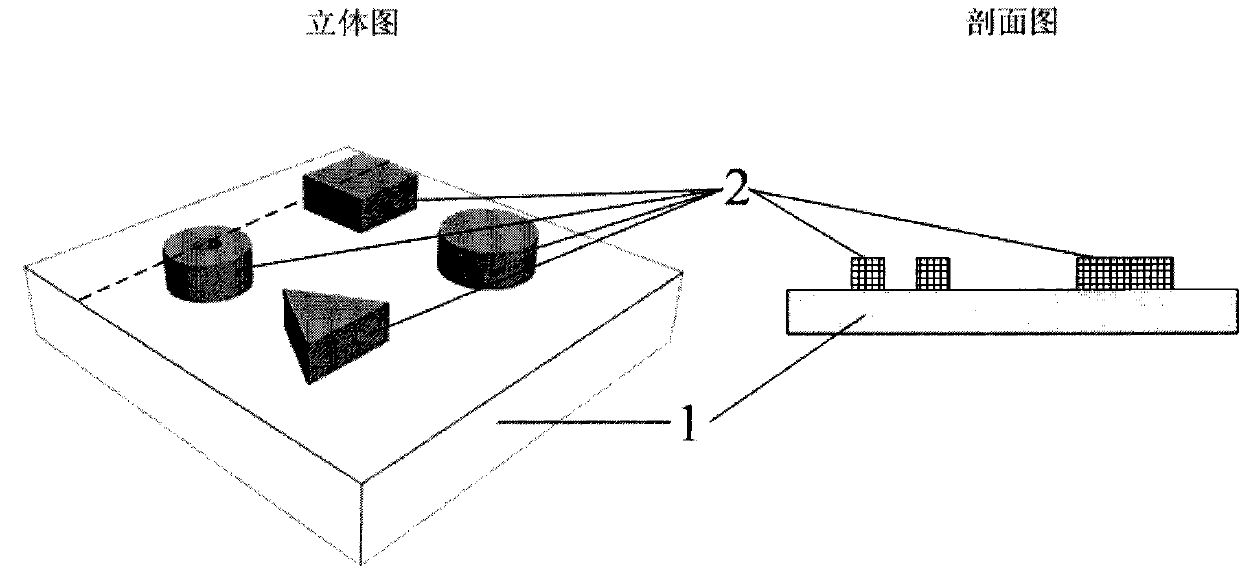

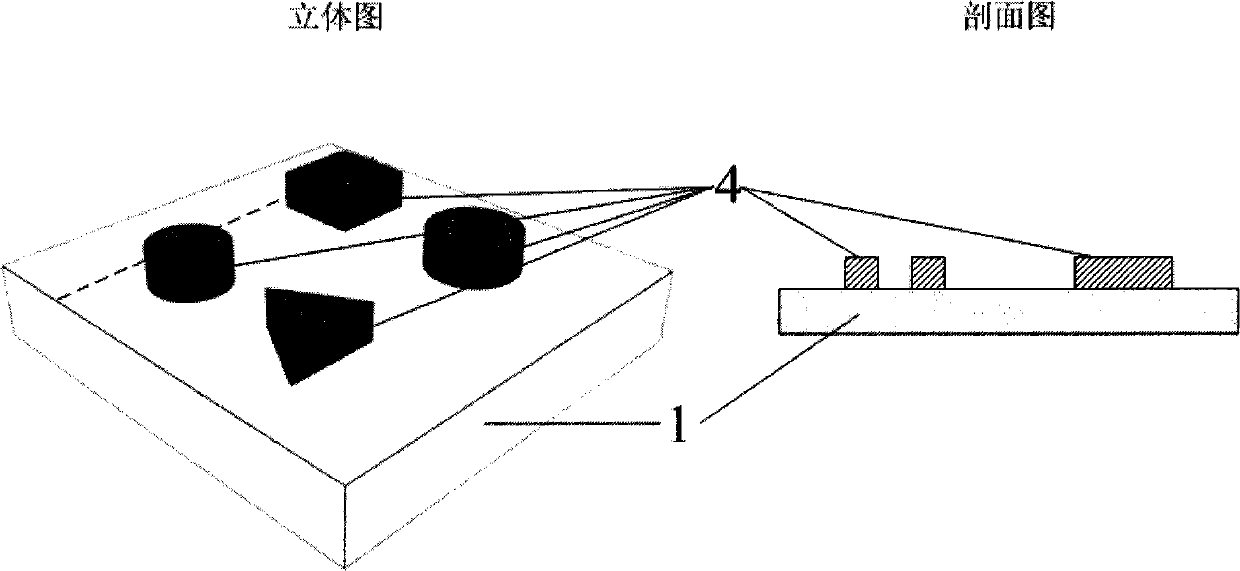

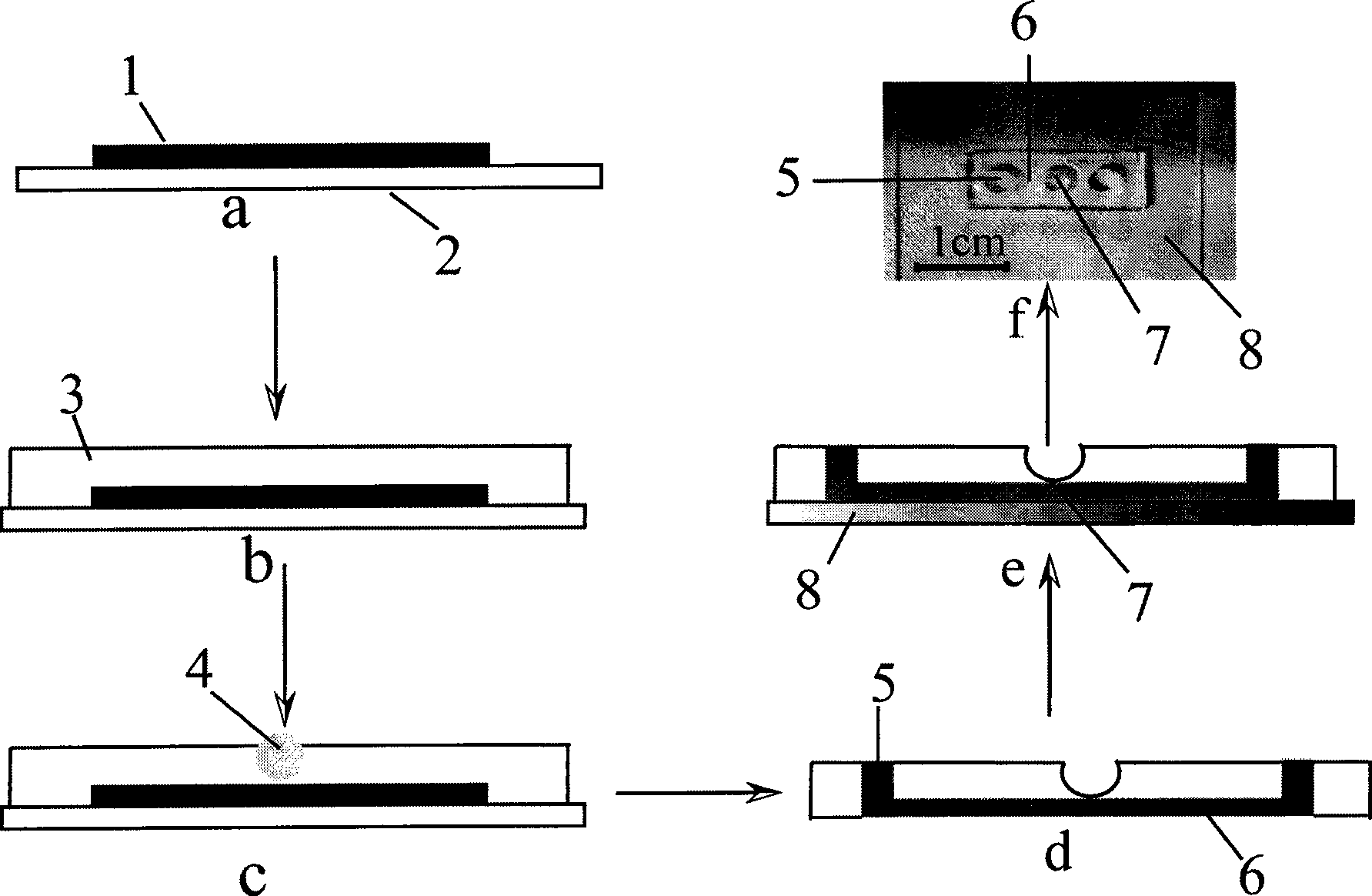

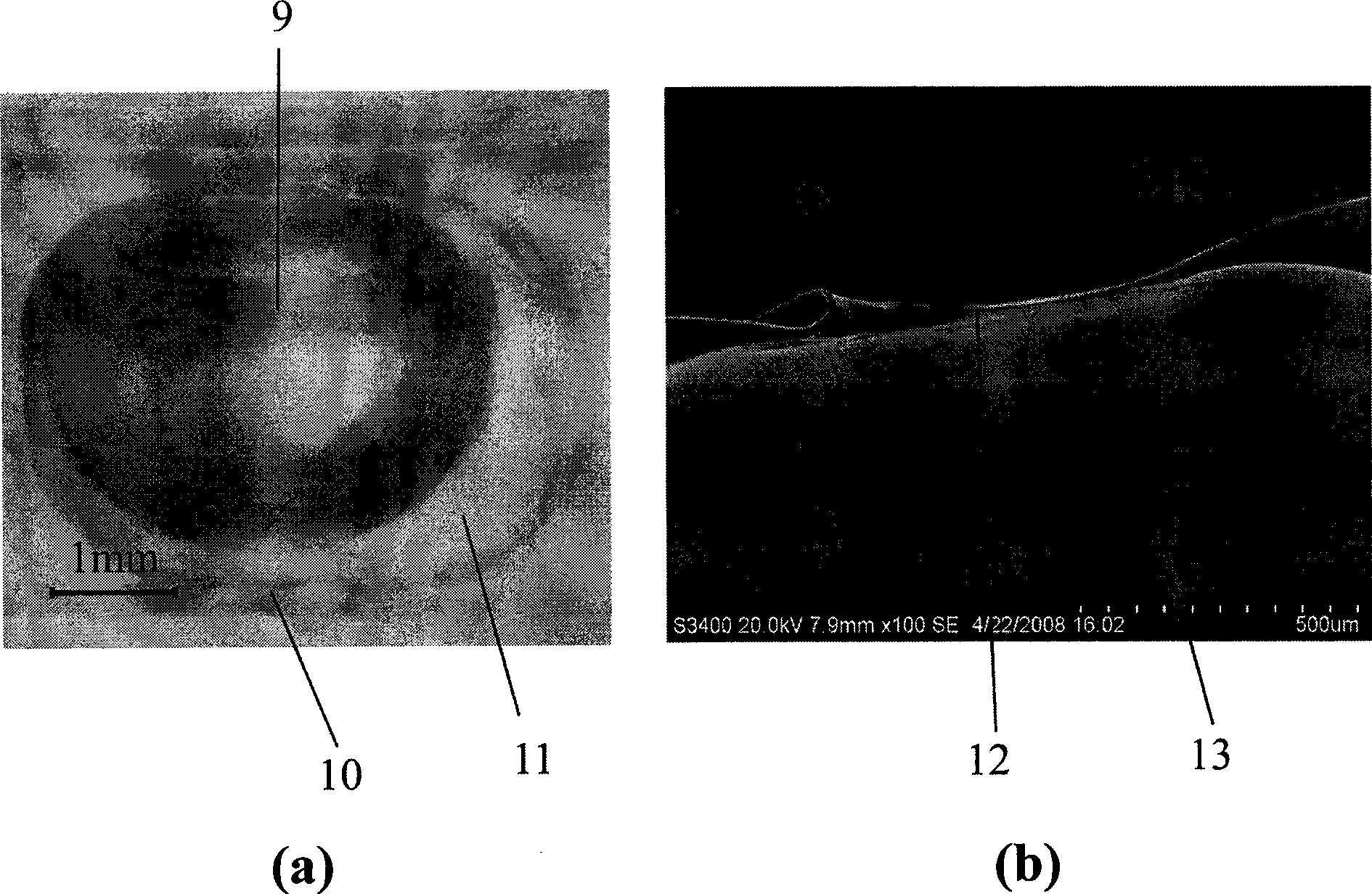

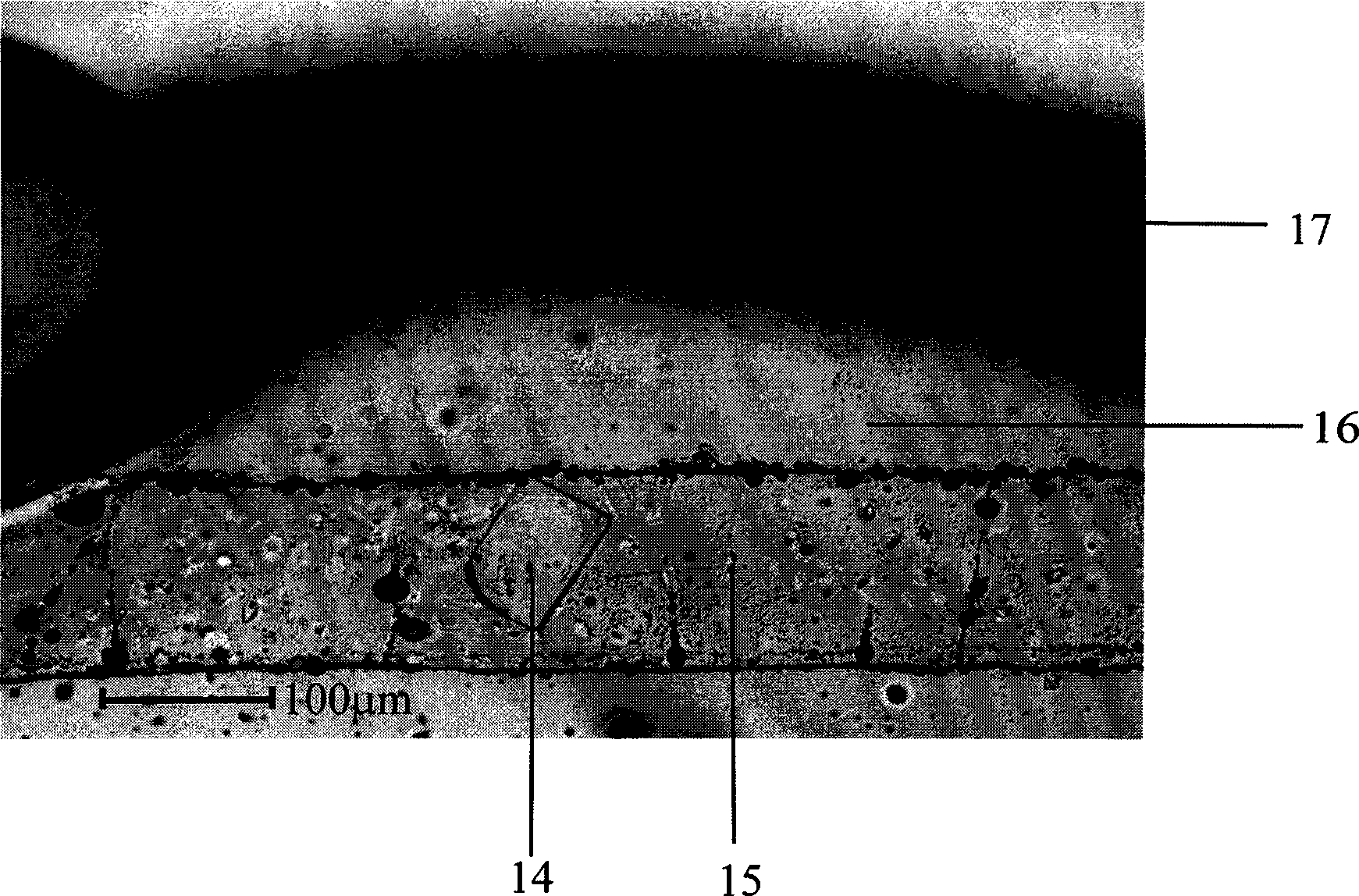

Method for manufacturing three-dimensional smooth curved surface microstructure based on SU-8 thick photo-resist

ActiveCN101950126AGood chemistryExcellent thermalDecorative surface effectsPhotomechanical apparatusResistCross-link

The invention discloses a method for manufacturing a three-dimensional smooth curved surface microstructure based on SU-8 thick photo-resist. The method is characterized in that the microstructure with smooth curved surface characteristic is manufactured by combining stamping technology of polydimethyl siloxane (PDMS) and the refluxing characteristic of non-crosslinked SU-8 photo-resist. The method comprises the following steps of: manufacturing an SU-8 master die by photo-etching technology; pouring PDMS to form a female die by using the master die; converting the PDMS female die into an SU-8 male die by using the stamping technology; stripping the PDMS die; and refluxing the SU-8 male die which is not subjected to exposure and cross-linking reaction under the environment of high temperature of between 55 and 120 DEG C to form the three-dimensional microstructure with smooth curved surface characteristic. Compared with the conventional gray scale mask technology, diverging light exposure technology and positive photo-resist refluxing method, the smooth curved surface microstructure provided by the invention has the characteristics of simple and convenient machining, low cost, stable structure, large structure curvature range and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Non-fluoro hydrophobic aqueous-based polyurethane resin dispersion, and production method and use thereof

ActiveUS20150086713A1Increase crosslink densityImprove washing resistanceFibre treatmentPolyurea/polyurethane coatingsPolymer scienceCarboxylic acid

The present invention provides a cross-linking non-fluoro hydrophobic aqueous polyurethane dispersion, which is produced by selecting a compound comprising alcohols, amines, acids, saturated or unsaturated (double-bonded or epoxidized) aliphatic long chain carbon-carbon groups or polydimethylsiloxane comprising alcohol groups, amines, oxosilane to be reacted with IPDI to obtain a PU prepolymer; adding a compound having tertiary amines to neutralize the carboxylic acid of PU prepolymer and adding water to disperse the PU prepolymer; and adding a ambient temperature cross-linking agent to obtain a cross-linking hydrophobic aqueous PU dispersion of the present invention. The hydrophobic aqueous-based PU resin has no fluorine which is friendly to the environment, and may further self cross-links on its applications on fabric, paper, wood, glass and metal surfaces, respectively on drying at ambient temperature which is energy saving process. Its cross-linking reaction of this hydrophobic PU system that will achieve a long-lasting water repellent surface treatment.

Owner:TAMKANG UNIVERSITY

Low modulus silicone sealing gum and its manufacturing method

ActiveCN1618915ALow modulusExcellent displacement abilityOther chemical processesCross-linkChemical reaction

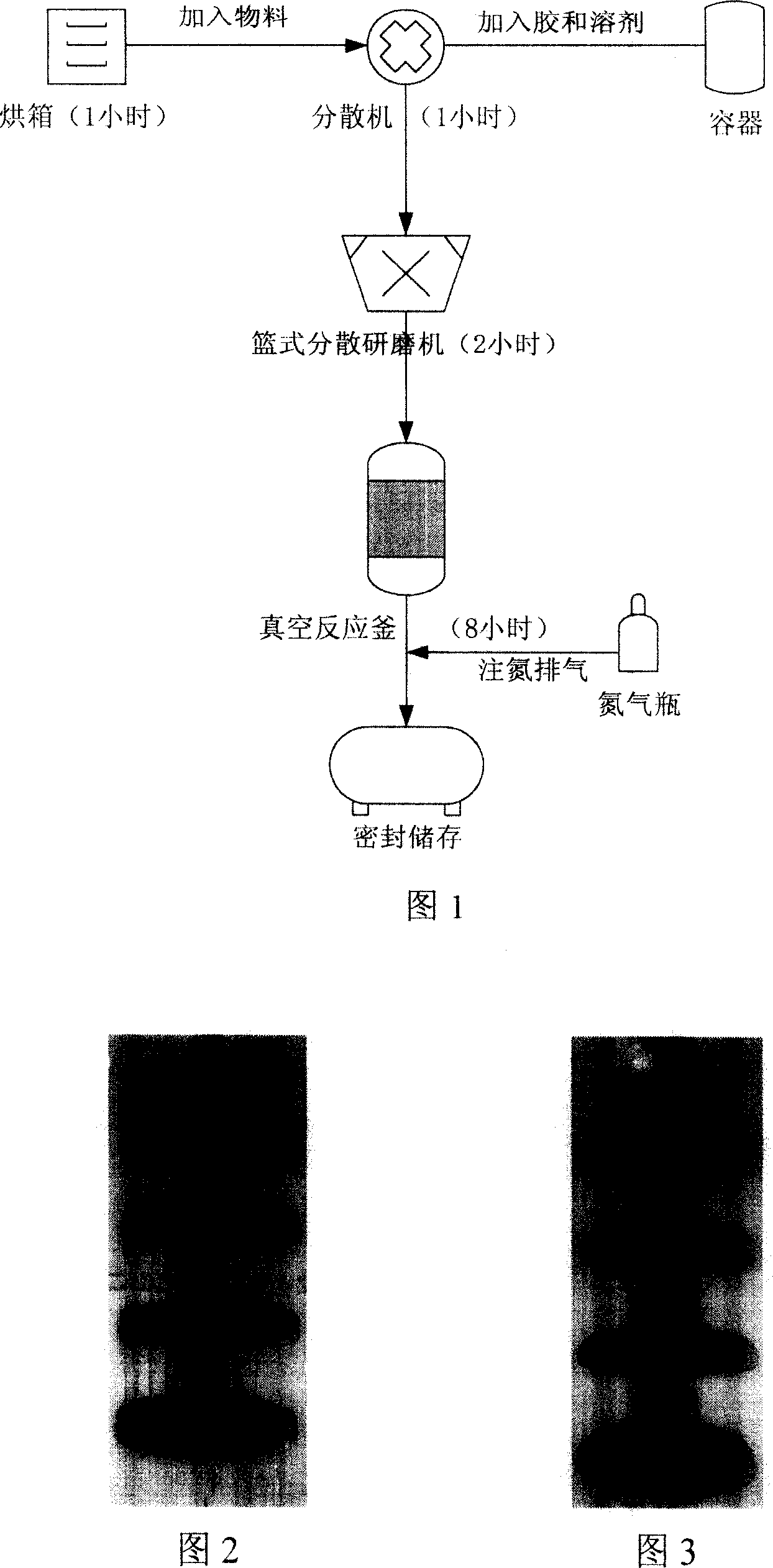

A low-modulus silicone sealant for the expansion joint of express way, airport runway, tunnel, bridge, etc is prepared from alpha, omega-dihydroxy polydimethyl siloxane and filler through proportionally vacuum kneading at 80-150 deg.C while dewatering for 30-300 min, high-speed stirring while cooling to obtain basic material, proportionally mixing chain enlarging agent, cross-linking agent, thixotropic agent, polydimethyl siloxane and toluent diisocyanate, stirring, and vacuum reaction at 20-600 rpm for 30-90 min.

Owner:CHENGDU GUIBAO SCI & TECH

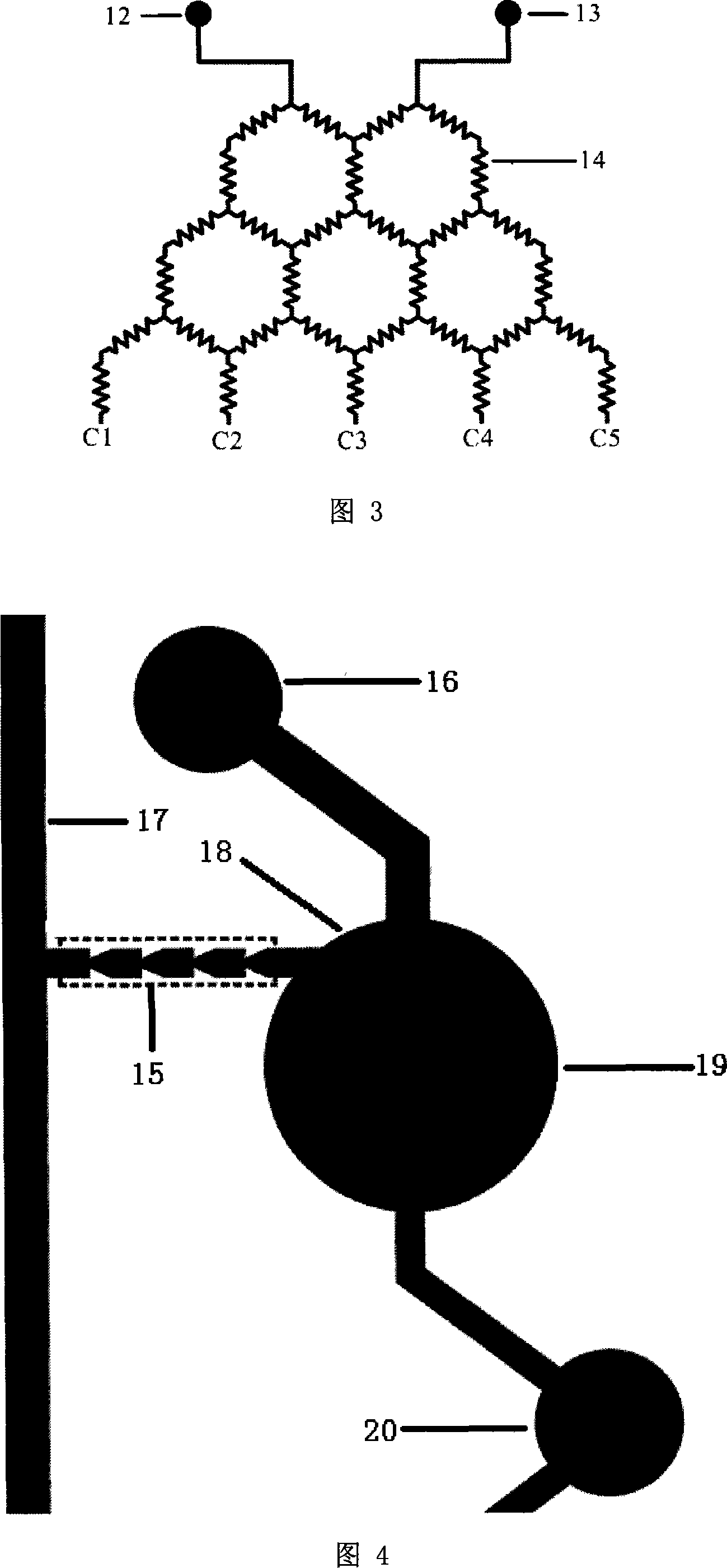

Micro-fluidic apparatus integrated with PDMS film, manufacturing method and application thereof

InactiveCN101530775AImprove breathabilitySimple preparation stepsVolume/mass flow by thermal effectsFixed microstructural devicesFlat glassGlass chip

The invention relates to a micro-fluidic apparatus integrated with a polydimethyl siloxane (PDMS) film, which is structurally characterized in that a flat glass sheet is pasted with a PDMS sheet, the pasting face of the PDMS sheet and the glass is provided with a groove to form a micro-fluidic pipeline, the surface of the PDMS sheet on the upper part of the central position of the micro-fluidic pipeline is a concave spherical surface, the thickness of the PDMS sheet between the lowest point of the concave spherical surface and the micro-fluidic pipeline is less than or equal to 10 microns, the PDMS sheet at two ends of the micro-fluidic pipeline is respectively provided with pores, and the pores are communicated with the micro-fluidic pipeline so as to form a fluid storage tank. The micro-fluidic apparatus can be applied to experiments such as film evaporation and crystallization or biological molecule concentration and the like in a micro-fluidic system. Special equipment is not needed to manufacture the micro-fluidic apparatus, the manufacturing step is simple, the cost is low, and the micro-fluidic apparatus is easily popularized and used in common laboratories. The invention also discloses a method for manufacturing the micro-fluidic apparatus.

Owner:NANJING UNIV

Paint for preventing covering ice for insulator and its preparation method

InactiveCN1995251AGood water repellencyStrong hydrophobic migration propertiesCoatingsChemistryOxide

The invention discloses an anti-insulator ice-coating paint and making method, which comprises the following parts: 100g polydimethyl siloxane, 100-150g organic solvent, 12-15g conductive fill, 10g carbon fiber powder, 15-30g aluminium hydroxide, 3g silica, 3g zinc oxide and 7g silane coupler, wherein the paint is coated on the insulator surface to prevent ice from covering, which improves stability of electric system operation.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Antistatic garment softener and preparation method thereof

InactiveCN103669000AImprove antistatic performanceComfortable to wearFibre treatmentCellulosePolymer science

The invention discloses an antistatic garment softener and a preparation method thereof. The antistatic garment softener comprises the following raw materials in parts by mass: 10-15 parts of poly-dimethyl siloxane bi-quaternary ammonium salt, 0.1-0.3 part of simethicone, 5-8 parts of a thickening agent, 0.15-0.2 part of glycerinum, 0.1-0.5 part of esterquats, 1-2 parts of essence and 36-42 parts of water, wherein the thickening agent is carboxymethylcellulose sodium. With adoption of the antistatic garment softener, a garment is softer and more comfortable, the antistatic property of the garment is greatly improved, the high convenience is brought for a user, and the washed garment is more comfortable to wear. The raw materials of the antistatic garment softener are easy to get, and the preparation technology is simple and practical and can be widely popularized and applied.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

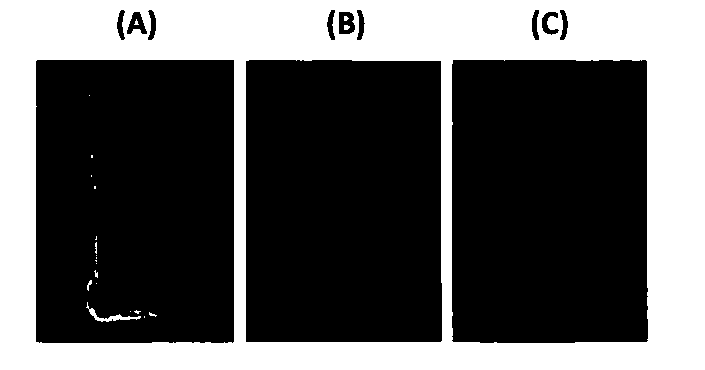

Double-C-type cavity-based sensitive membrane embedded optical fiber hydrogen sensor

PendingCN108152220ASimple structureFlexible operationColor/spectral properties measurementsPhysicsHollow core

The invention relates to a double-C-type cavity-based sensitive membrane embedded optical fiber hydrogen sensor. The double-C-type cavity-based sensitive membrane embedded optical fiber hydrogen sensor is characterized by comprising a broadband light source, a spectrum analyzer, a single-mode fiber, a circulator and a double-C-type hydrogen sending head; PDMS (polydimethysiloxane) separates a hollow-core fiber into two C-type cavities, one of the C-type cavity forms an interference structure, and the other C-type cavity is embedded with hydrogen sensitive materials to serve as a sensing area.When the concentration of hydrogen rises, Pt / WO3 power reacts with the hydrogen to produce heat, the volume of a PDMS membrane can be increased to lead to movement of an interference spectrum, so thatby detecting the change in interference wavelength, the concentration of the hydrogen can be detected. The double-C-type cavity-based sensitive membrane embedded optical fiber hydrogen sensor solvesthe shortcomings that existing optical fiber hydrogen sensors are large in sensing area, inappropriate to remove control, prone to leading to falling-off of hydrogen sensing materials and complex to manufacture, and meanwhile, is simple in structure and manufacturing, flexible in operation, compact in sensing structure, small in size and applicable to long-term utilization.

Owner:CHINA JILIANG UNIV

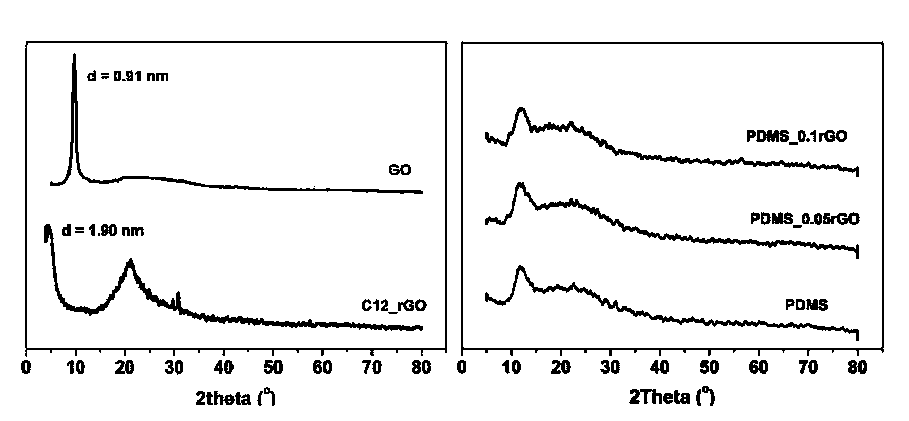

Graphene-polysiloxane composite material and preparation method thereof as well as micro-fluidic chip and application thereof

ActiveCN103436017AImprove mechanical propertiesUniform and stable performanceFluid heatersLaboratory glasswaresCross linkerPolydimethyl siloxane

The invention discloses a graphene-polysiloxane composite material. The graphene-polysiloxane composite material mainly comprises a polysiloxane matrix and graphene, wherein the graphene is uniformly dispersed in the polysiloxane matrix; the graphene is modified by a hydrophilic group; the polysiloxane matrix is polydimethylsiloxane or derivatives thereof. A preparation method of the graphene-polysiloxane composite material comprises the following steps: firstly, placing a graphene oxide solid in N,N-dimethylformamide and placing aliphatic amine in a uniform dispersion liquid; secondly, reacting at a certain temperature to obtain graphene modified by the hydrophilic group; thirdly, adding the graphene in a precursor of organic siloxane, adding a cross-linking agent, standing a mixed system and heating and curing the mixed system to obtain the graphene-polysiloxane composite material. The composite material disclosed by the invention can be prepared and formed to obtain a micro-fluidic chip which can be used as a light heating platform for application. The graphene-polysiloxane composite material has the advantages of favorable mechanical property, strong heat-conducting property, excellent conducting performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

Antimicrobial lubricant compositions

ActiveUS8426348B2Reduce complicationsFacilitate smooth and reliable actuationBiocidePretreated surfacesChlorhexidine AcetateAmmonium compounds

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com