Organosilicone room-temperature-cured anticorrosive coating material

A room temperature curing, anti-corrosion coating technology, applied in anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of poor mechanical strength of the paint film, poor resistance to organic solvents, poor adhesion to substrates, etc., to achieve good dust-proof and hydrophobic Excellent function, heat and weather resistance and flame retardancy, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

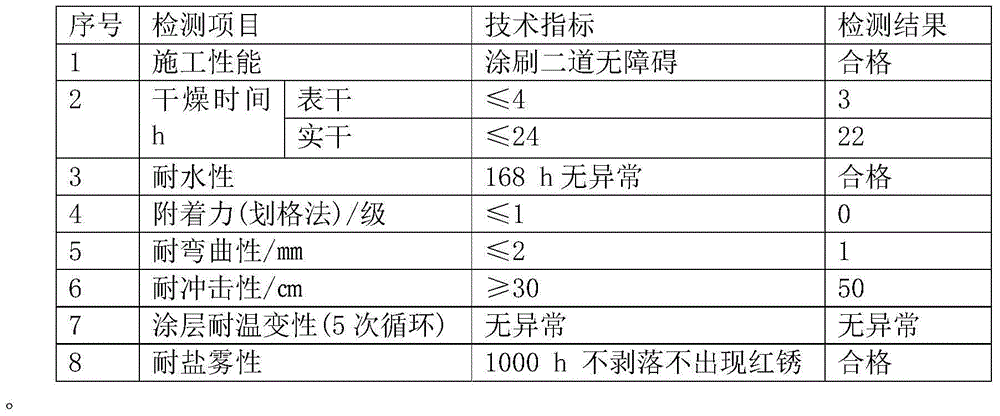

Examples

Embodiment 1

[0030] Silicone room temperature curing anti-corrosion coating formulation:

[0031] α,ω-Dihydroxypolydimethylsiloxane (from low viscosity α,ω-dihydroxypolydimethylsiloxane with viscosity 500mPa.s~2000mPa.s to high viscosity 10000mPa.s~20000mPa.s Viscosity α, ω-dihydroxy polydimethylsiloxane mixed according to the volume ratio of 2:1) 24 parts,

[0032] 6 parts of hydroxyl-terminated polyphenylmethylsiloxane,

[0033] 0.5 parts of fumed silica,

[0034] 10 parts of aluminum hydroxide powder,

[0035] 5 parts of nano calcium carbonate,

[0036] Pigment paste (iron oxide red paste, mixed from α, ω-dihydroxypolydimethylsiloxane and iron oxide red, by weight percentage, α, ω-dihydroxypolydimethylsiloxane ( The viscosity is 15,000-20,000 cs) 70%, iron oxide red 30%) 5 parts,

[0037] 5 parts of crosslinking agent (methyl tributylketoxime base silane),

[0038] 1 part of coupling agent (silane coupling agent KH171),

[0039] Catalyst (dibutyltin dilaurate) 0.1 part,

[0040]...

Embodiment 2

[0048] Silicone room temperature curing anti-corrosion coating formulation:

[0049] α,ω-Dihydroxypolydimethylsiloxane (from low viscosity α,ω-dihydroxypolydimethylsiloxane with viscosity 500mPa.s~2000mPa.s to high viscosity 10000mPa.s~20000mPa.s Viscosity α, ω-dihydroxy polydimethylsiloxane mixed according to the volume ratio of 1:1) 40 parts,

[0050] 10 parts of hydroxyl-terminated polyphenylmethylsiloxane,

[0051] 5 parts of fumed silica,

[0052] 30 parts of aluminum hydroxide powder,

[0053] 0.5 parts of nanometer calcium carbonate,

[0054] Pigment paste (titanium dioxide pigment paste, made by mixing α, ω-dihydroxy polydimethylsiloxane and titanium dioxide, by weight percentage, α, ω-dihydroxy polydimethylsiloxane (viscosity 15,000-20,000 cs) 50%, titanium dioxide 50%) 15 parts,

[0055] 9 parts of crosslinking agent (3 parts of methyltrimethoxysilane + 3 parts of methyltriethoxysilane + 3 parts of vinyltriethoxysilane),

[0056] Coupling agent (1 part of silan...

Embodiment 3

[0066] Silicone room temperature curing anti-corrosion coating formulation:

[0067] α,ω-Dihydroxypolydimethylsiloxane (from low viscosity α,ω-dihydroxypolydimethylsiloxane with viscosity 500mPa.s~2000mPa.s to high viscosity 10000mPa.s~20000mPa.s Viscosity α, ω-dihydroxy polydimethylsiloxane mixed according to the volume ratio of 1:2) 30 parts,

[0068] 8 parts of hydroxyl-terminated polyphenylmethylsiloxane,

[0069] 3 parts of fumed silica,

[0070] 20 parts of aluminum hydroxide powder,

[0071] 2 parts of nanometer calcium carbonate,

[0072] Pigment paste (pigment paste is carbon black paste, which is made by mixing α, ω-dihydroxypolydimethylsiloxane and carbon black, by weight percentage, α, ω-dihydroxypolydimethylsiloxane (viscosity of 15,000 to 20,000 cs) 60%, carbon black 40%) 10 parts,

[0073] 6 parts of crosslinking agent (vinyl tributylketoxime base silane),

[0074] 1.5 parts of coupling agent (diethylaminomethyltriethoxysilane (ND-22)),

[0075] Catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com