Patents

Literature

7164results about How to "Improve antistatic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

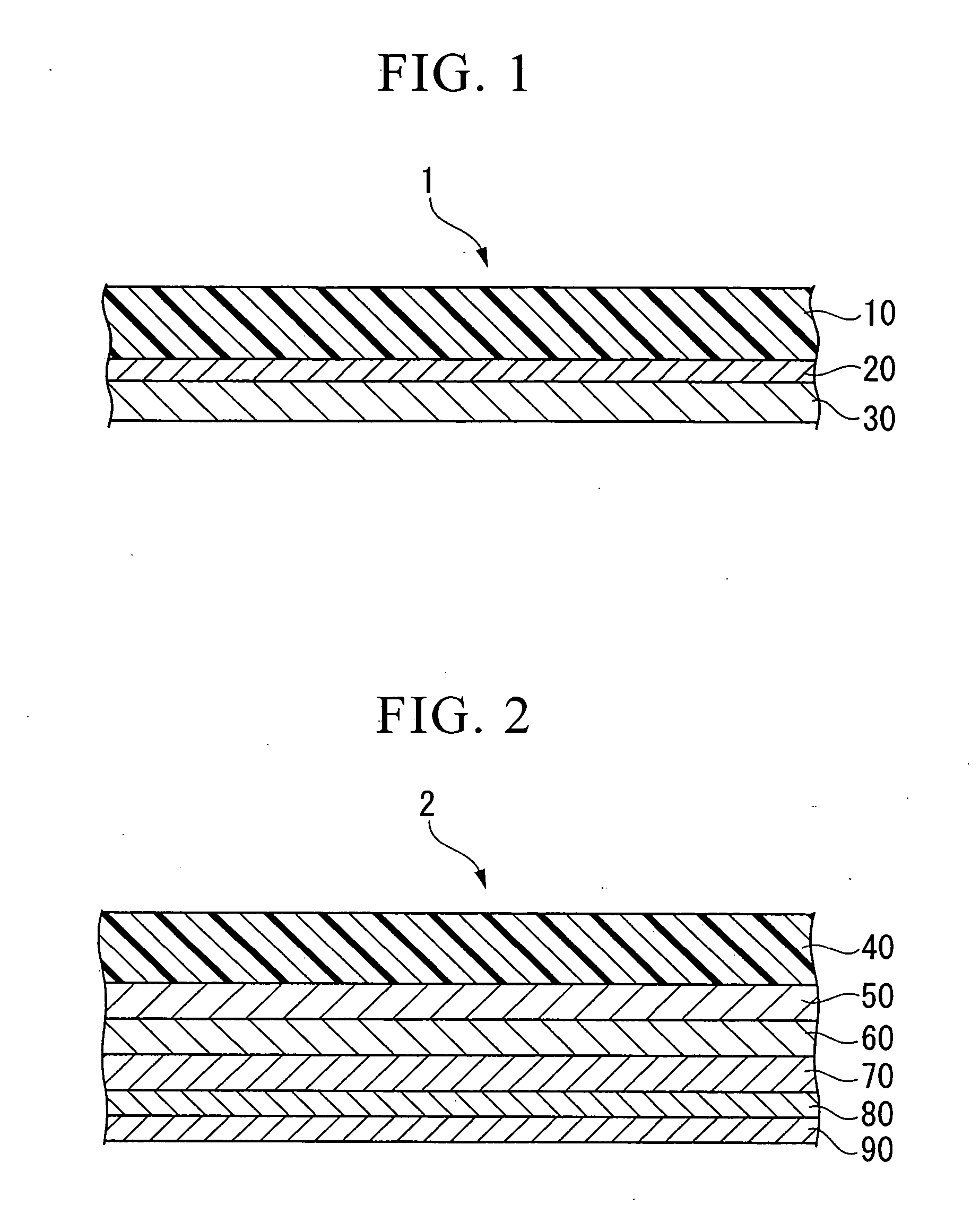

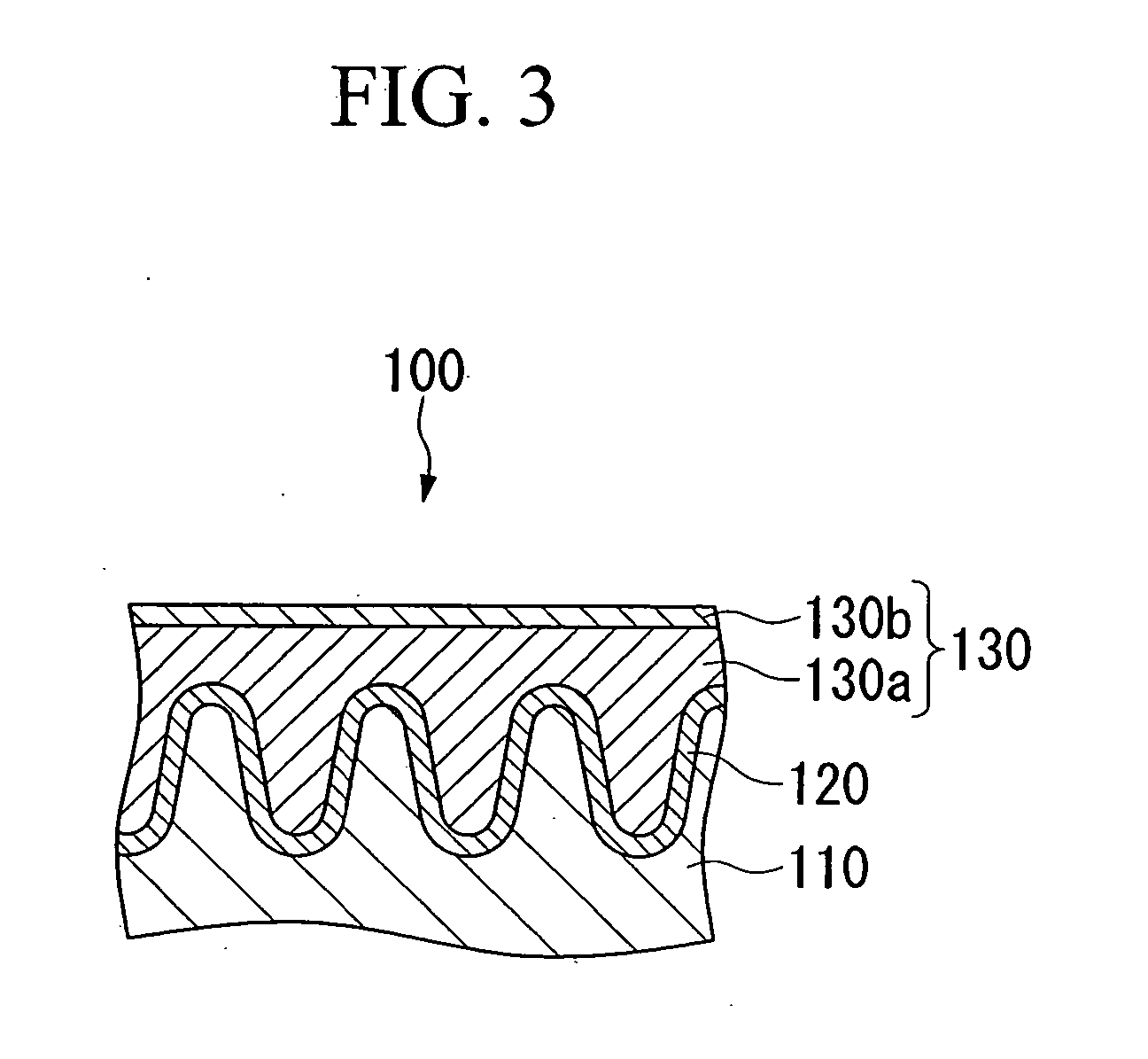

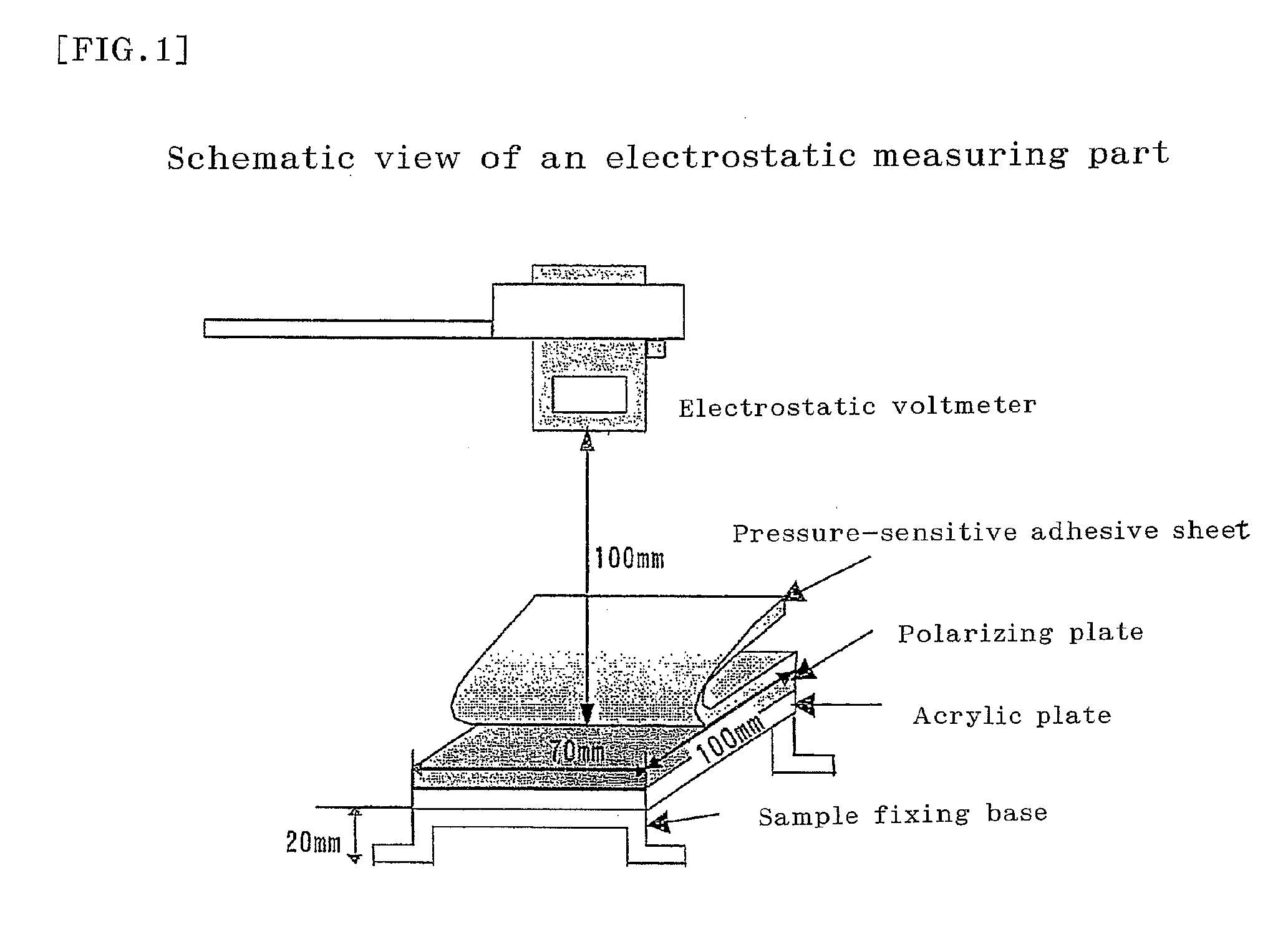

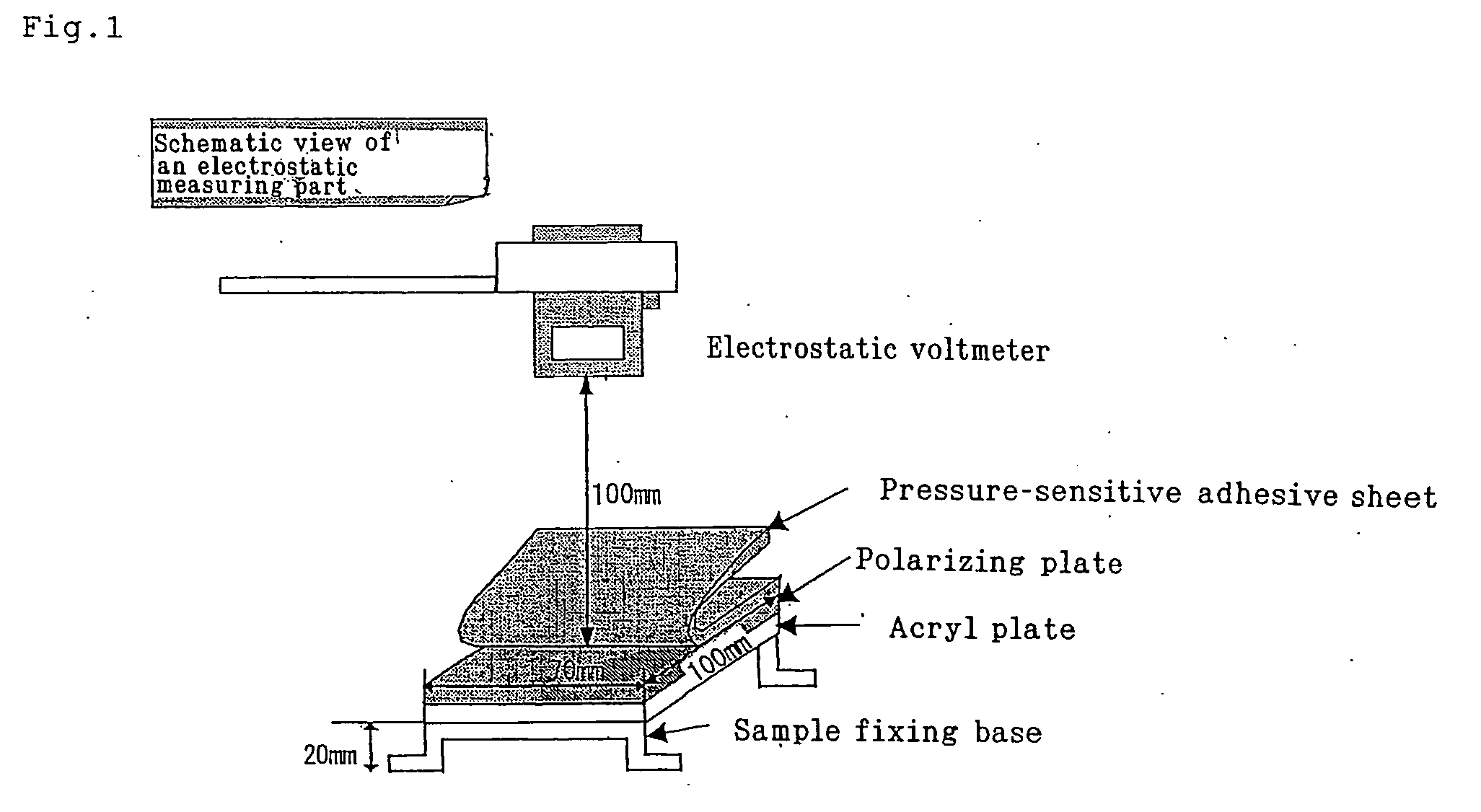

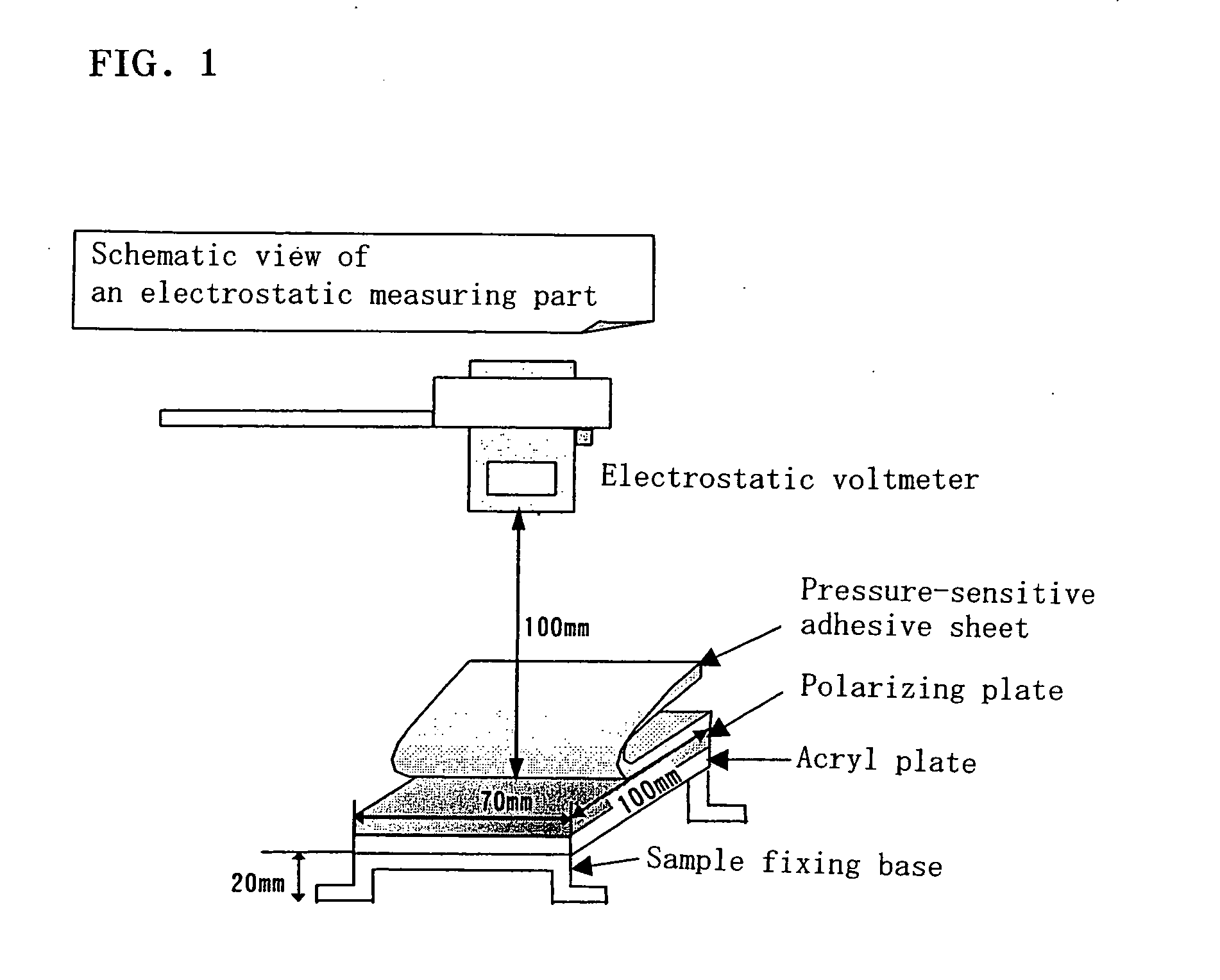

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets and surface protecting films

InactiveUS20060207722A1Optimize timingLow dyeabilityOrganic chemistryNon-macromolecular adhesive additivesCarbon numberHydrogen

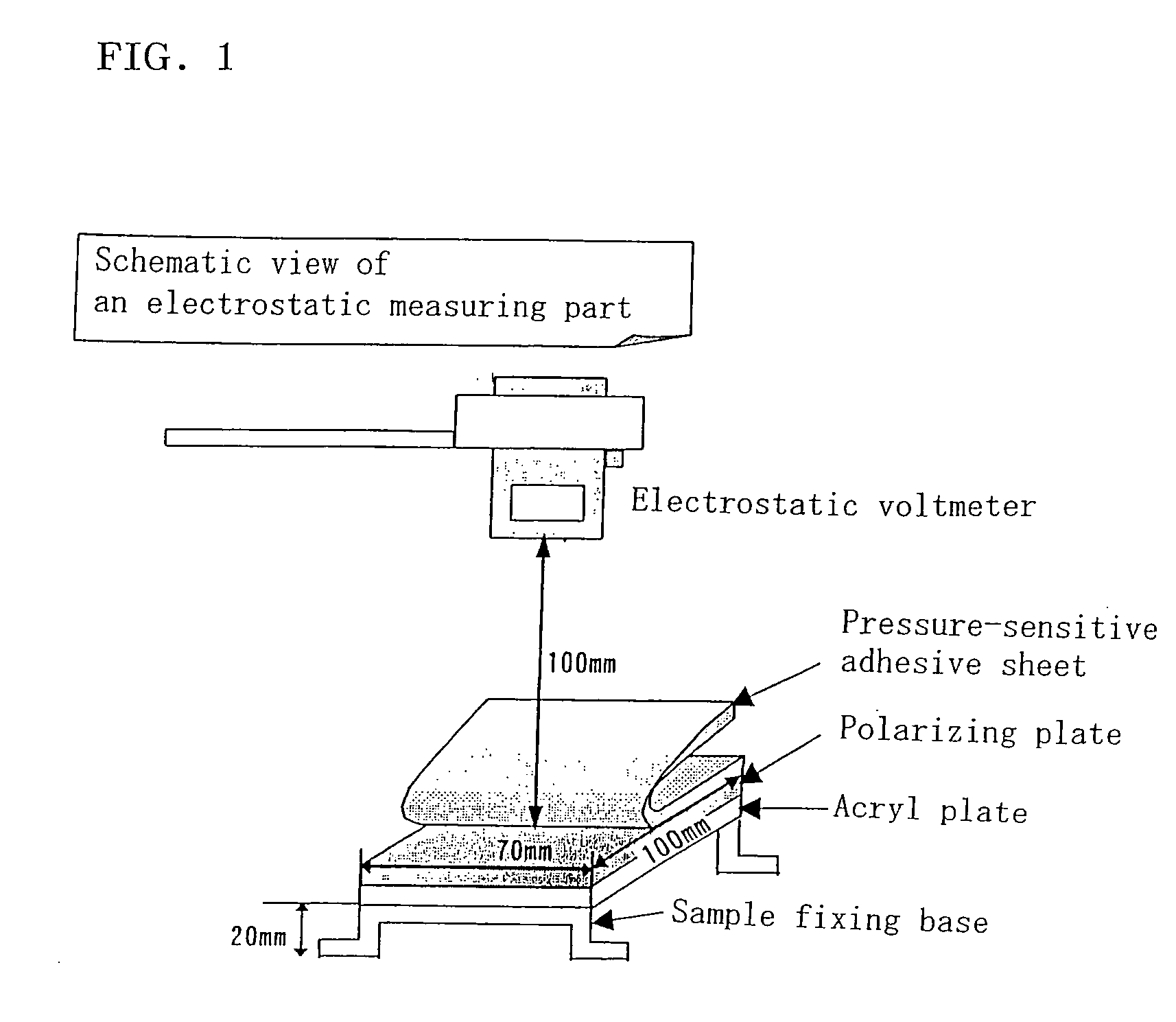

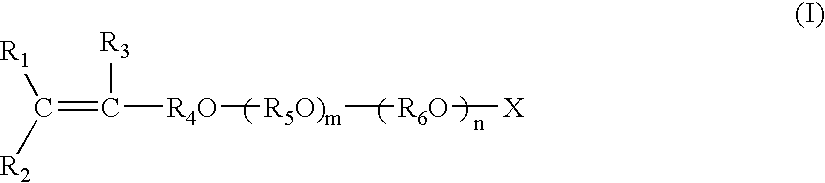

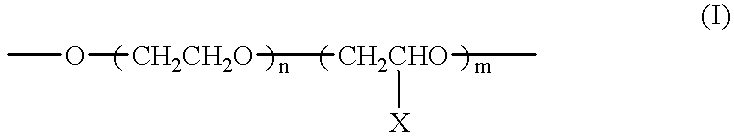

An object of the present invention is to provide an antistatic pressure-sensitive adhesive composition which is excellent in antistatic property and antistatic property with time of a non-electrification-prevented adherend (subject to be protected) upon peeling, and has reduced stainability in an adherend and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets using the same. There is provided a pressure-sensitive adhesive composition comprising an ionic liquid, and a (meth)acryl-based polymer containing, as a monomer component, 0.01 to 20% by weight of a reactive surfactant shown by the following general formula (I) as a monomer unit. [in the formula (I), R1, R2, and R3 indicate likewise or differently hydrogen or the methyl group, R4 indicates an alkylene group of 0 to 30 in carbon number (further, 0 in carbon number means that there is no R4), R5 and R6 indicate likewise or differently alkylene groups of 1 to 30 in carbon number, m indicates the number of 0 to 50 (may not be an integer), n indicates the number of 0 to 100 (may not be an integer), m+n indicates the number of 1 to 150 (may not be an integer), and X indicates hydrogen or an anionic hydrophilic group]

Owner:NITTO DENKO CORP

Explosion prevention PVC sheath material for mine cable and preparation method thereof

InactiveCN101159174AImprove antistatic performanceImprove flame retardant performancePlastic/resin/waxes insulatorsOther chemical processesPlasticizerPolyvinyl chloride

The invention relates to an anti-explosion polyvinyl chloride sheath material for mining cables and a preparation method thereof. The preparation method comprises mixing evenly polyvinyl chloride resin 100 parts by weight, plasticizer 30-80 parts by weight, stuffing 0-60 parts by weight, high-conductivity carbon black 10-40 parts by weight, anti-static agent 0-10 parts by weight, and other auxiliary agent 3-20 parts by weight by a high-speed mixer, extruding at 130-170 DEG C by a single- or double-screw extruder after being melted, water-cooling drawing bar or wind-cooling die-surface hot cutting and granulating, oven-drying, and packaging to obtain the finished product. Compared with the prior art, the invention has the advantages of excellent durable anti-static property and flame retardant property.

Owner:SURREY HI TECH INC

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS20060076541A1Improve conductivityImprove heat stabilityHybrid capacitor separatorsHybrid capacitor electrolytesConductive polymerSolvent

A conductive composition comprises a π conjugated conductive polymer, a polyanion, and a hydroxy group-containing aromatic compound containing two or more hydroxy groups. An antistatic coating material comprises the conductive composition and a solvent. An antistatic coating is produced by applying the antistatic coating material. A capacitor comprises an anode composed of a porous valve metal body; a dielectric layer formed by oxidizing a surface of the anode; and a cathode formed on the dielectric layer, wherein the cathode has a solid electrolyte layer comprising the conductive composition.

Owner:SHIN-ETSU POLYMER CO LTD

Method for fabricating multifunctional protective face fabric

InactiveCN101092776AImprove antistatic performanceSolve the existing illsSingeingHeating/cooling textile fabricsYarnEngineering

This invention discloses a processing method for multifunction safety fabrics including: 1, process of anti-static fabrics: a, spinning, b, merging to anti-static yarn, c, weaving them to anti-static fabrics, 2, dying and arrangement of the fabrics: a, pretreatment of the fabrics, b, dying, 3, functional arrangement to the fabrics: a, preparing flammable inhibitor, b, flammable arrangement, c, waterproof, oil-proof and dust proof.

Owner:JINQIU TEXTILE ARRANGEMENT

Polymer/graphene anti-static coating, preparation method and application thereof

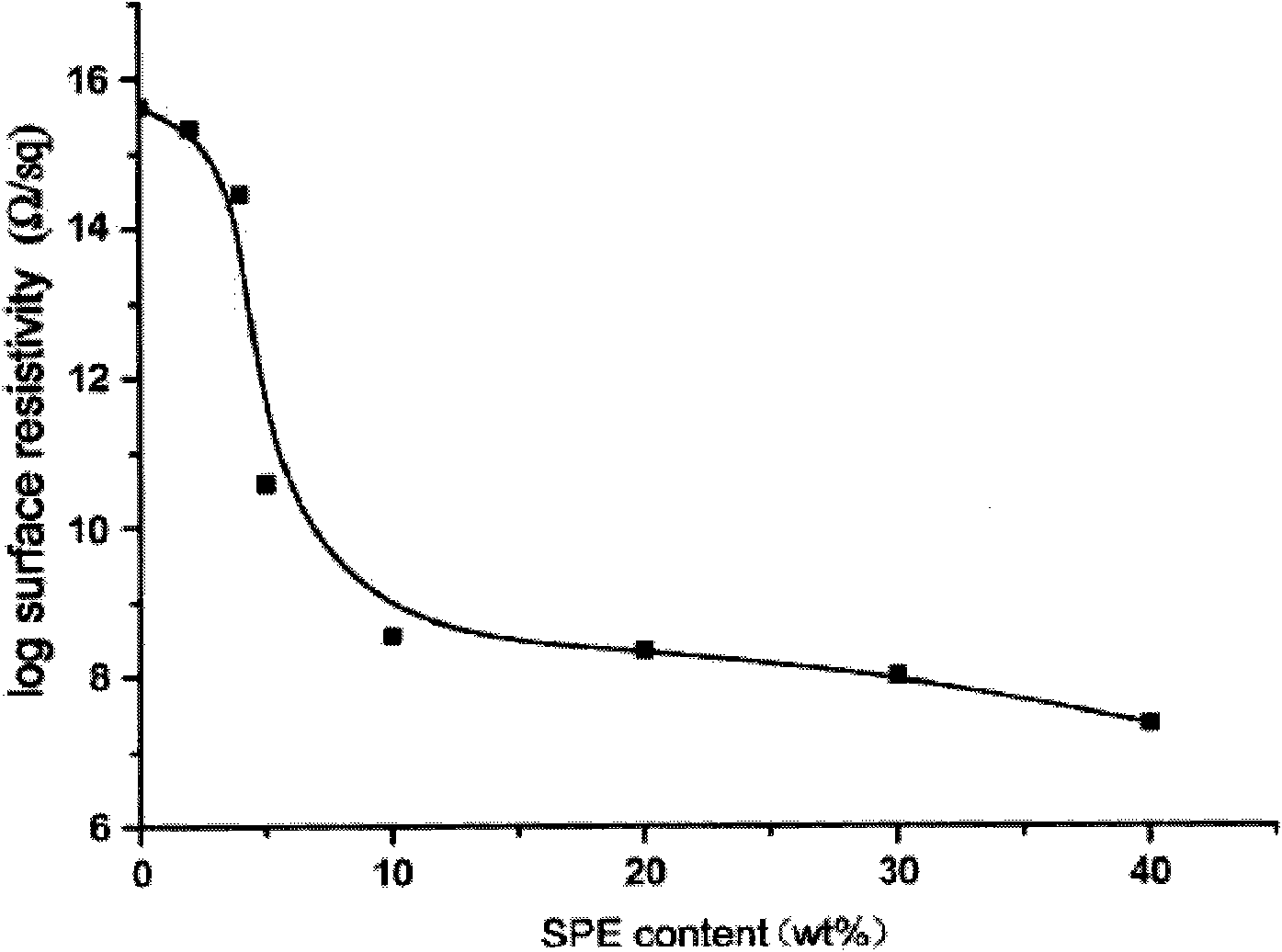

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

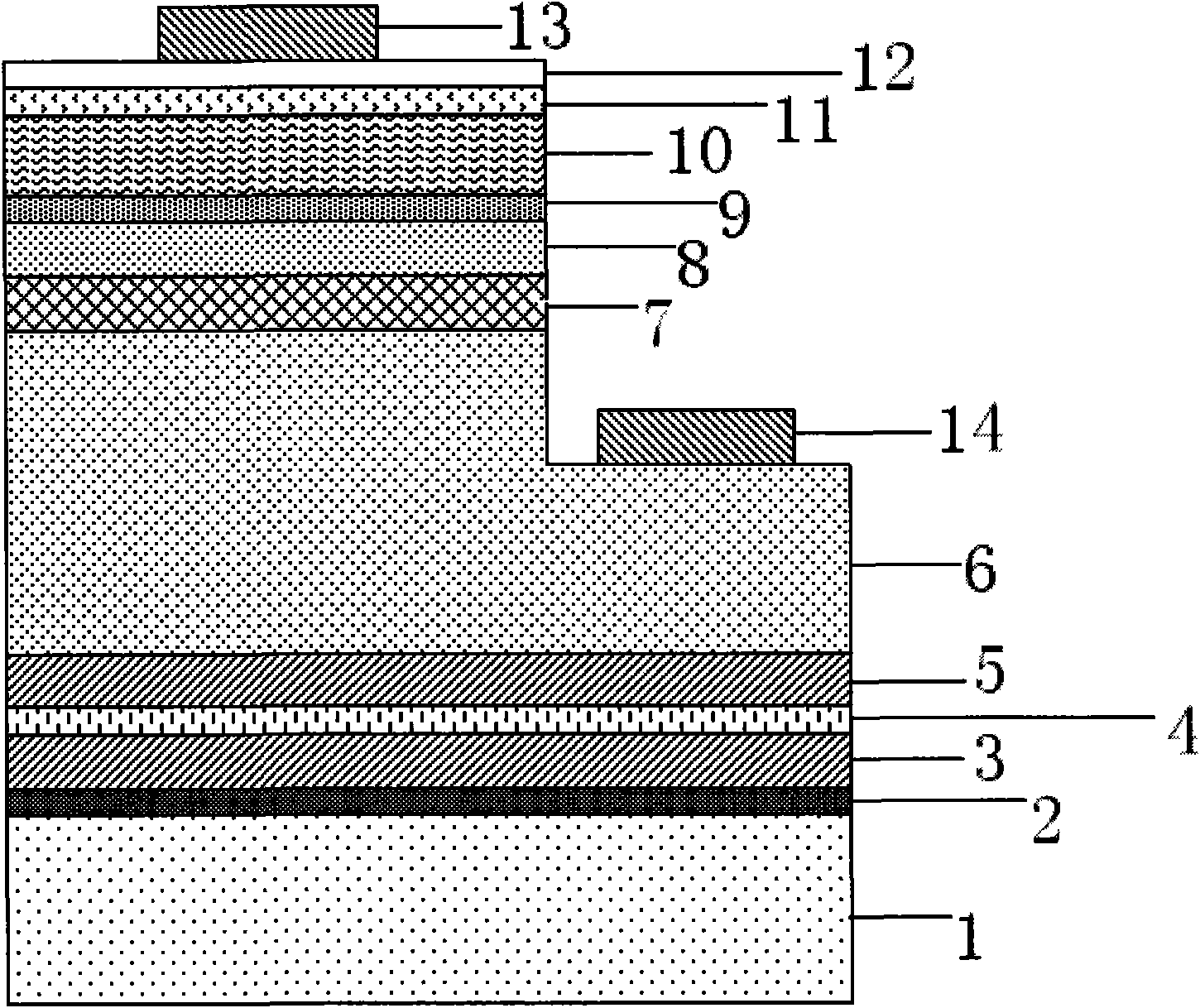

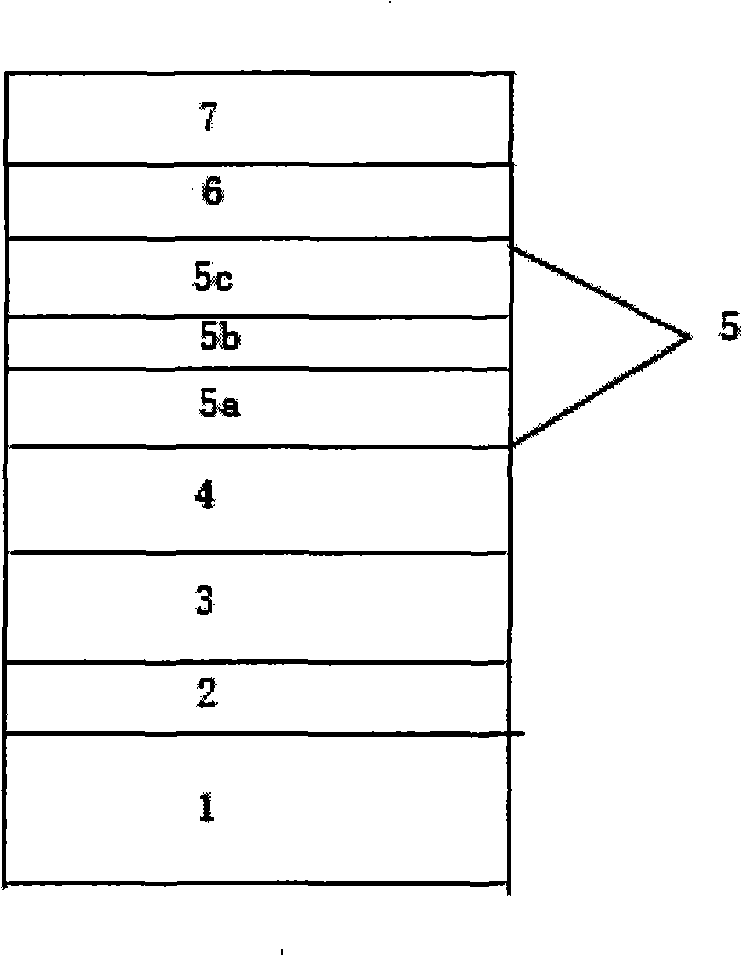

Method for enhancing antistatic ability of GaN-based light-emitting diode

ActiveCN101645480AImprove crystal qualityImprove antistatic performanceSemiconductor devicesGalliumContact layer

The invention discloses a method for enhancing the antistatic ability of GaN-based light-emitting diode. The epitaxial wafer structure of the light-emitting diode sequentially comprises an underlay, alow-temperature buffer layer, an unadulterated GaN high-temperature buffer layer, an aluminum gallium nitride / GaN superlattice structure, the unadulterated GaN high-temperature buffer layer, an N type contact layer, an N type GaN conductive layer, a light-emitting layer multiple quantum well structure MQW, a P type aluminum gallium nitride electric barrier layer, a P type GaN conductive layer and a P type contact layer in a sequence from down to up. In the invention, the aluminum gallium nitride / GaN superlattice periodic structure is inserted in the unalloyed GaN high temperature buffer layer. The insertion of the aluminum gallium nitride / GaN superlattice periodic structure can effectively improve crystal quality of materials, thereby enhancing the antistatic ability of the GaN-based light-emitting diode and improving the reliability and the stability of devices.

Owner:HC SEMITEK CORP

Resin composition and jig for use in transportation

InactiveUS6344513B1Excellent static charge dissipating performanceLittle changeSemiconductor/solid-state device manufacturingSpecial tyresFiberCarbon fibers

Owner:TEIJIN LTD

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Preparation method of functional master batch of polyolefin and its application

ActiveUS7282538B2Maintain good propertiesReducing flowability and spinnabilityThin material handlingGraft polymer adhesivesFiberPolymer science

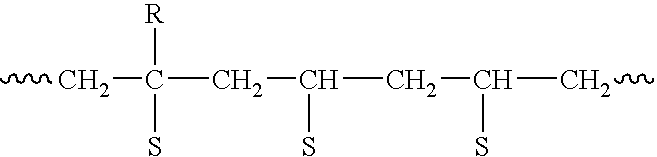

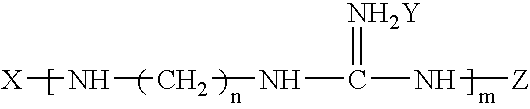

The present invention belongs to the field of polymerization and processing of polymer and relates to the preparation of a kind of functional polyolefin master batch. The functional master batch is produced by liquid phase, melt phase, or solid phase reaction after mixing the polyolefin resin, polyamine and guanidine salt oligomer, olefin monomer and initiator. The molecular structure of functional polyolefin master batch is shown below:wherein R is a polyamine and guanidine salt oligomer bonded onto polyolefin molecular chain by covalence bond, while S is one selected from hydrogen, chlorine, methyl, or phenyl group.Blending mentioned functional master batch with the corresponding polyolefin, the various antimicrobe products, such as fibers, film, pipe and other plastic articles can be obtained. Besides endowing products with excellent permanent antimicrobe property, it also provides fibers with good-dyeable and antistatic ability and bumpers with easy-paintable ability.

Owner:SHANGHAI SUJIE SCI TECH

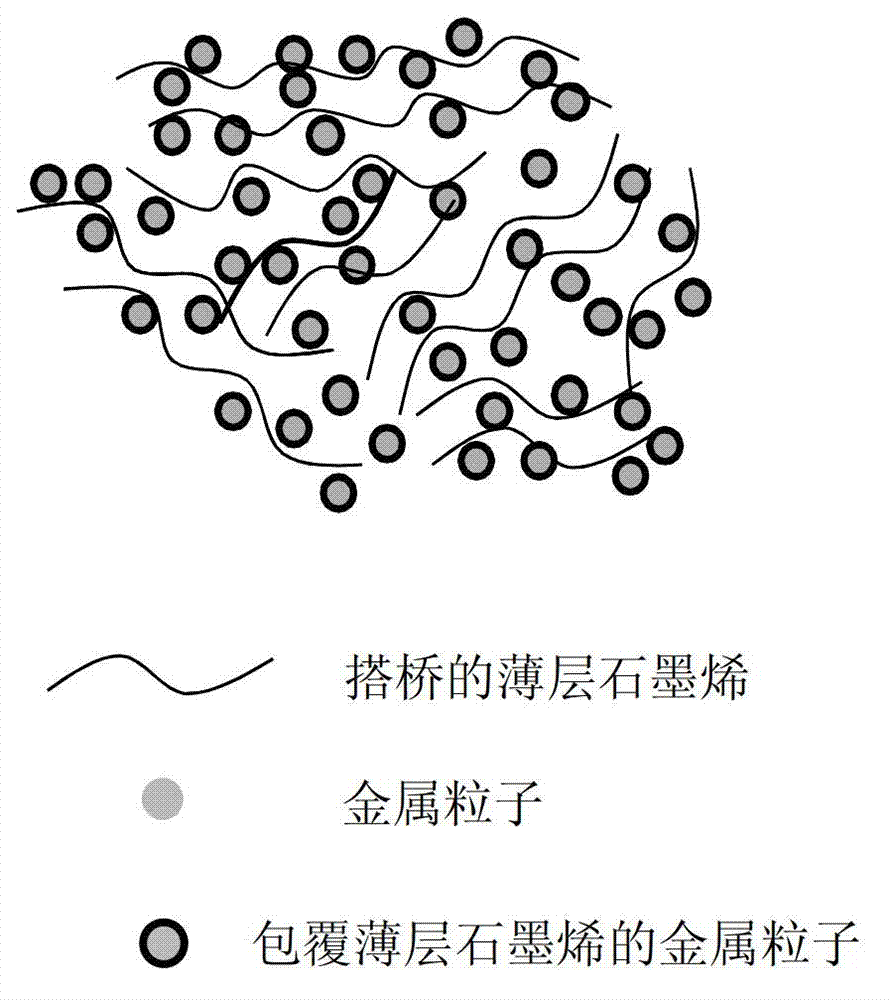

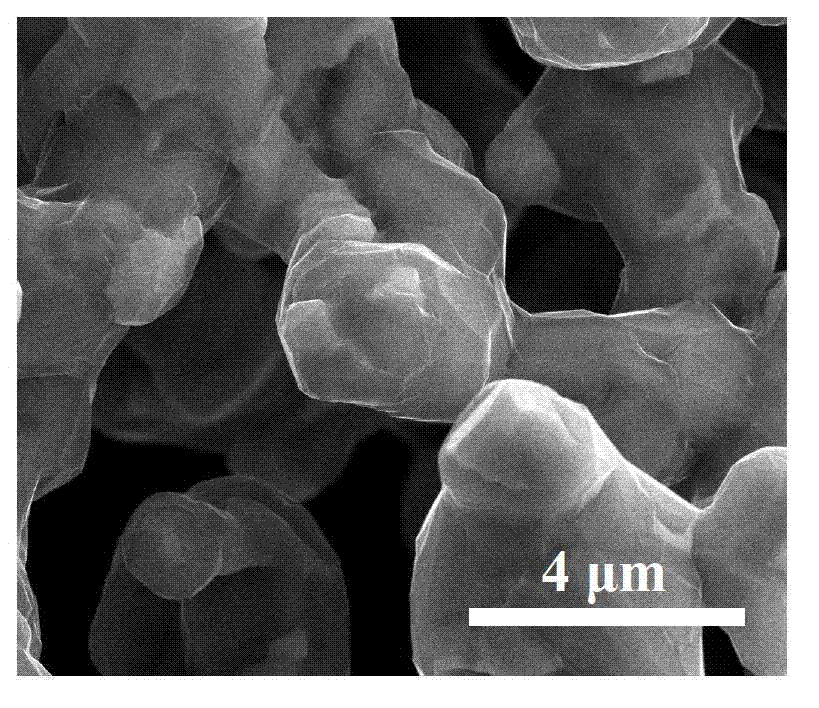

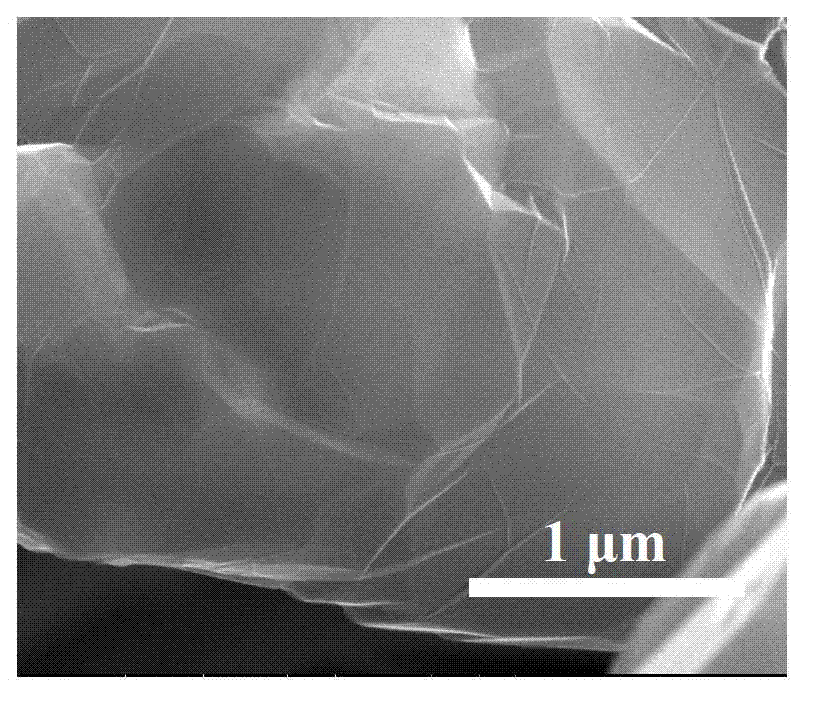

Material adopting thin graphene and metal powder composite structure, preparation method and application thereof

ActiveCN103192072AImprove antioxidant capacityImprove corrosion resistanceCarbon compoundsGas phaseSlurry

The invention discloses a material adopting a thin graphene and metal powder composite structure, a preparation method and an application thereof. The material adopting the composite structure comprises metal powder bridged by and coated with thin graphene. The preparation technology of the material comprises the steps as follows: mixing transition metal powder or reduced transition metal powder with the thin graphene, and growing the thin graphene on the surface of the transition metal powder through CVD (chemical vapor deposition) and coating the surface of the transition metal powder with the thin graphene, so as to obtain the metal powder bridged by and coated with the thin graphene; or growing the thin graphene on the surface of the transition metal powder through the CVD, and then compositing the metal powder with the thin graphene to obtain a target product. The invention has the advantages that the technology is simple; the oxidation resistance and the corrosion prevention of the metal powder can be enhanced, meanwhile, the metal powder has good heat conduction, antistatic and electromagnetic shielding properties, the service life of the metal powder can be prolonged, and the cost can be reduced; and besides, the material has a wide application prospect in antistatic performance, thermal management, heat conduction and radiation, electromagnetic shielding, catalysts, sintering activators, electro-conduction slurry, batteries, cemented carbide and the like.

Owner:苏州格瑞丰纳米科技有限公司

Resin material, preparation method and applications of resin material

The invention belongs to the technical field of high-polymer materials and discloses a resin material, a preparation method and applications of the resin material. The resin material disclosed by the invention comprises the following components in parts by weight: 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid. The preparation method for the resin material disclosed by the invention comprises the following steps of: weighing 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid; putting in a high-speed mixing machine and fully mixing; delivering a mixed material into a twin-screw extruder by using a metering material conveying device; fully mixing the material under the shearing actions of screws; performing extrusion, bracing, cooling and grain cutting on a molten blend; and packaging into a finished product. The resin material disclosed by the invention has an anti-static dustproof effect, is excellent in surface effect and can be used for manufacturing card readers or electrical equipment enclosures and the like.

Owner:HEFEI GENIUS NEW MATERIALS

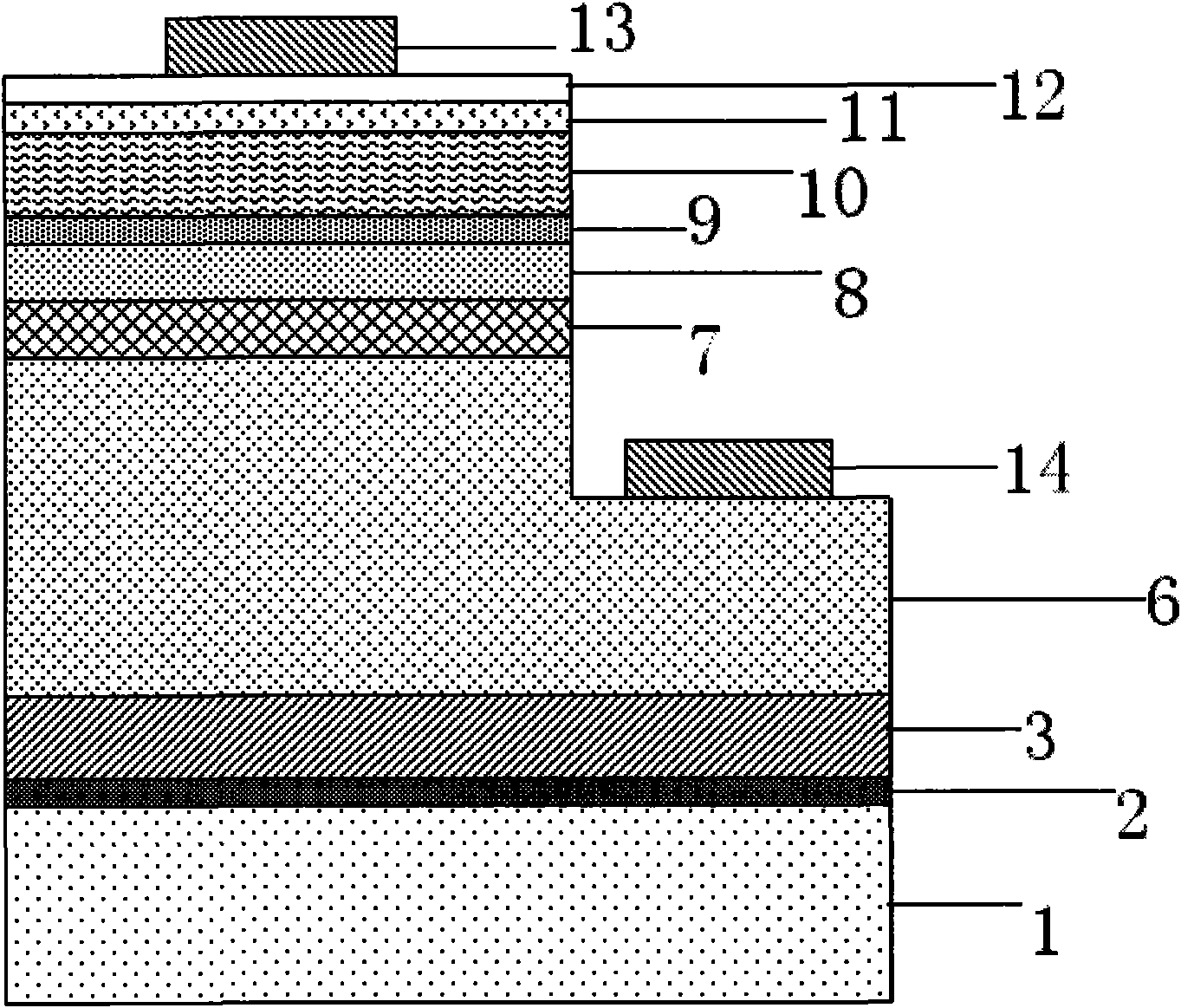

Coating liquid for forming transparent conductive film, substrate with transparent conductive film, and display device

InactiveUS20040016914A1Decreased electrical conductionReduce surface resistanceConductive layers on insulating-supportsCathode-ray/electron-beam tube vessels/containersSilica particleDisplay device

Disclosed is a coating liquid for forming a transparent conductive film, comprising conductive fine particles having an average particle diameter of 1 to 200 nm, silica particles having an average particle diameter of 4 to 200 nm and a polar solvent. The silica particles are in the form of chain silica particles having 2 to 10 silica particles on an average being connected. The content of an alkali in the silica particles is not more than 1000 ppm in terms of an alkali metal M. Also disclosed is a substrate with a transparent conductive film, comprising a substrate, a transparent conductive fine particle layer formed on the substrate and containing conductive fine particles having an average particle diameter of 1 to 200 nm and silica particles having an average particle diameter of 4 to 200 nm and / or chain silica particles having 2 to 10 silica particles on an average being connected, and a transparent film provided on the transparent conductive fine particle layer and having a refractive index lower than that of the transparent conductive fine particle layer. A display device using the substrate with a transparent conductive film is further disclosed. The coating liquid for forming a transparent conductive film is capable of forming a transparent conductive film having low surface resistance, excellent antistatic properties, excellent electromagnetic blocking properties, high film strength and excellent adhesion to a substrate.

Owner:CATALYSTS & CHEM

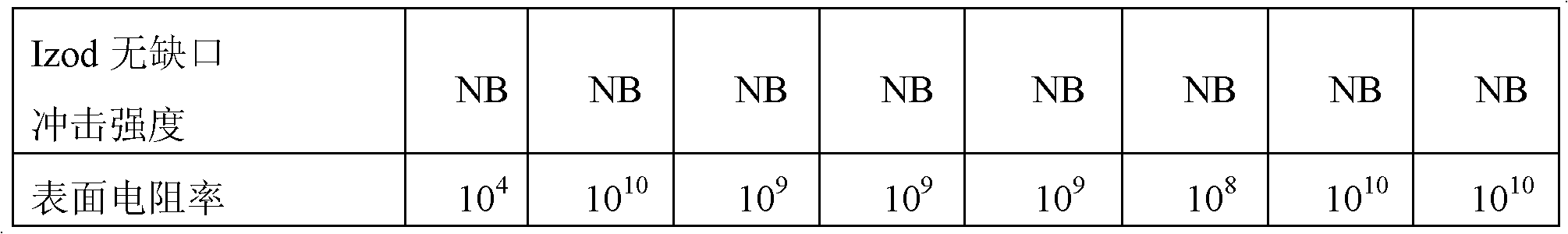

Adhesive film and image display device

InactiveUS20070031660A1Improve bindingImprove adhesionSynthetic resin layered productsLaminationAntistatic agentWater dispersible

An adhesive film prevents static charge on peeling generated when removed from an adherend and also improves adhesion between a base material and an adhesive layer, where an under coat layer containing an organometallic is formed on the base material and then an adhesive layer is formed on the base material. Alternatively, an adhesive film showing high adhesion with a glass substrate, and including an antistatic layer, which prevents static charge on peeling generated when the surface protective film is removed, and improves adhesion between a base material and an adhesive layer, where the adhesive film includes a base material, an adhesive layer made of a water dispersible adhesive including, and an antistatic layer, containing a water soluble or water dispersible conductive material, interposed between them, and the adhesive film is stuck onto an image display device.

Owner:NITTO DENKO CORP

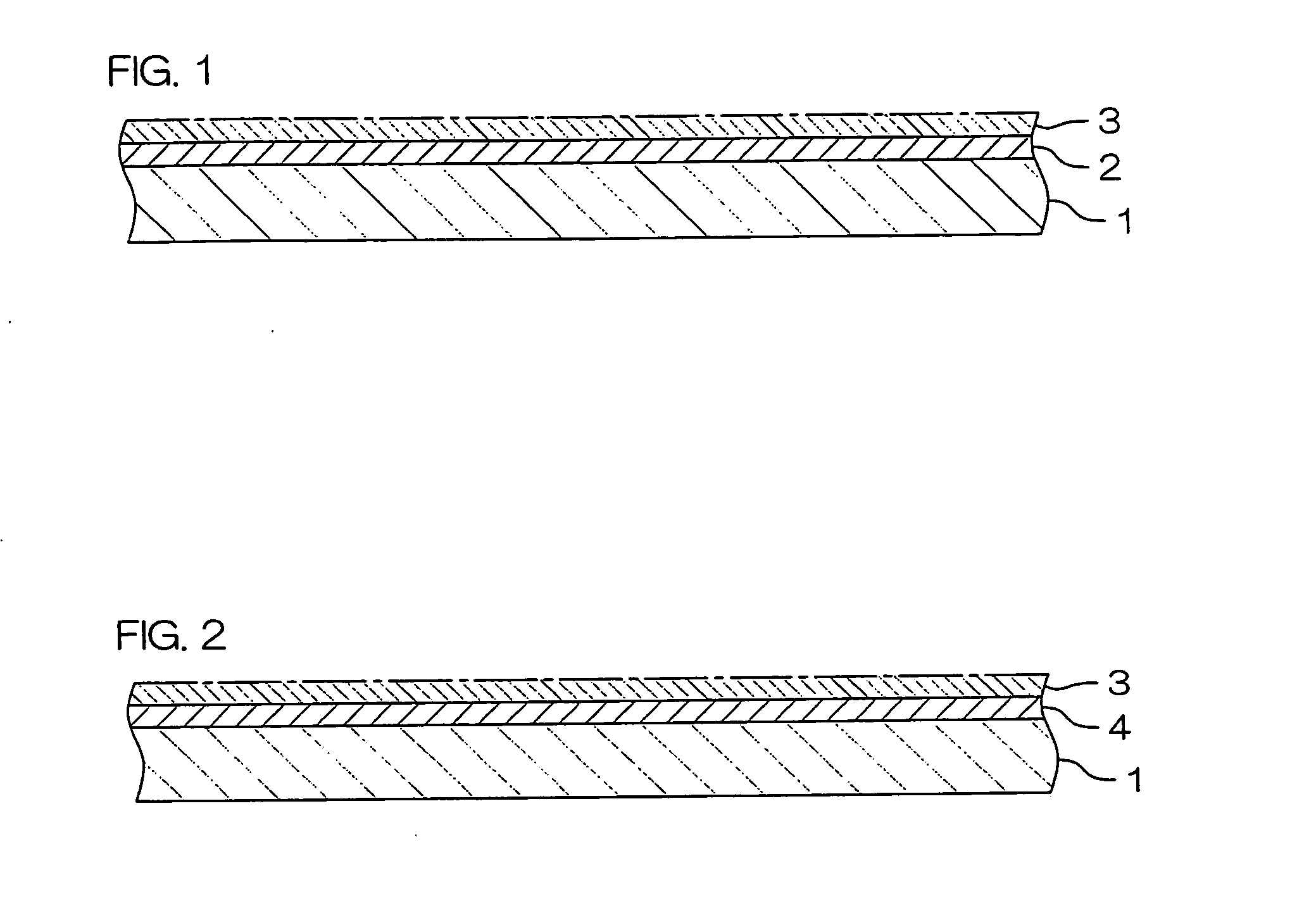

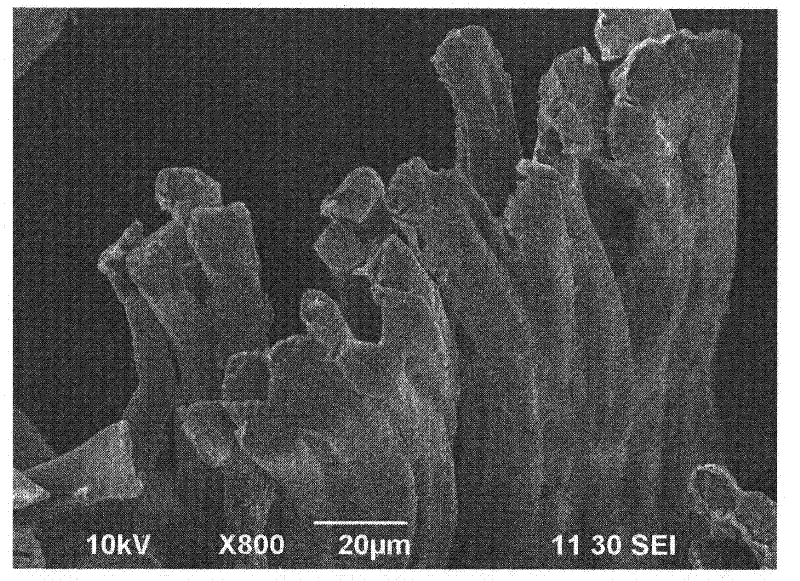

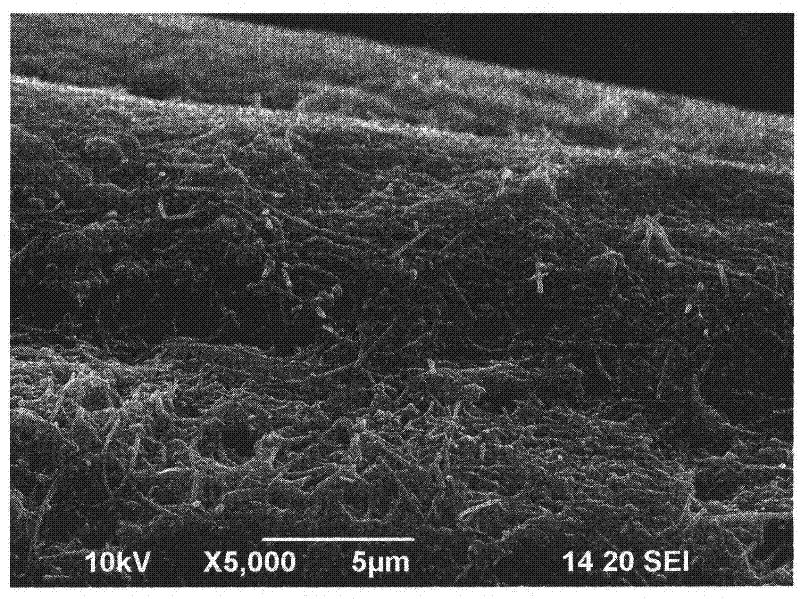

Electroconductive fibers with carbon nanotubes deposited thereon, electroconductive threads, fiber structure, and process for producing same

ActiveCN102131980AImprove conductivityGood flexibilityFibre typesUltrasonic/sonic fibre treatmentPolymer scienceMicrometer

Owner:HOKKAIDO UNIVERSITY +1

Conductive polymer solution, antistatic coating material, antistatic hard coat layer, optical filter, conductive coating film, antistatic tacky adhesive, antistatic tacky adhesive layer, protective material, and method for producing the same

ActiveUS20060202171A1Enhance thermostabilityImprove conductivityConductive materialOrganic conductorsConductive coatingPolymer dissolution

The conductive polymer solution of the present invention contains a π-conjugated conductive polymer, a solubilizable polymer, a phase transfer catalyst, and an organic solvent. The method for preparing a conductive polymer solution of the present invention comprises adding a phase transfer catalyst adding an organic solvent to an aqueous polymer solution prepared by dissolving the π-conjugated conductive polymer and a solubilizable polymer in water.

Owner:SHIN-ETSU POLYMER CO LTD

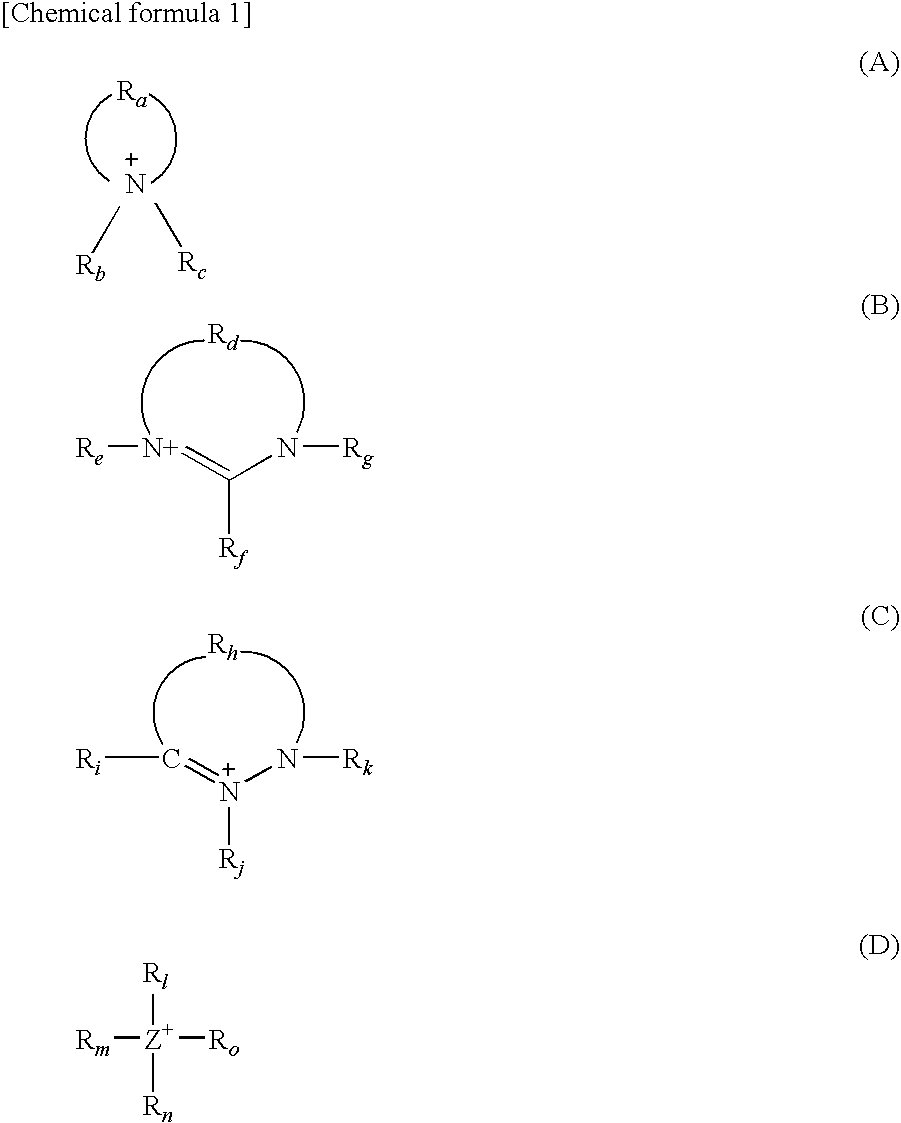

Adhesive composition, adhesive sheet, and surface protective film

ActiveUS20090163626A1Improve heat resistanceGood weather resistanceFilm/foil adhesivesSynthetic resin layered productsMeth-Ionic liquid

Disclosed is a pressure sensitive adhesive composition characterized by containing an ionic liquid and a polymer which contains, as a monomer unit, 0.1-10% by weight of a (meth)acrylate with a hydroxyalkyl group having 3-12 carbon atoms. The present invention provides a pressure sensitive adhesive composition which is excellent in antistatic property of a no-electrification-prevented adherend upon peeling, and has reduced staining of an adherend and is excellent in adhesion reliance. Also disclosed is an antistatic pressure sensitive adhesive sheet or surface-protecting film prepared using the composition. Also disclosed is an antistatic pressure sensitive adhesive sheet or surface-protecting film prepared using the composition.

Owner:NITTO DENKO CORP

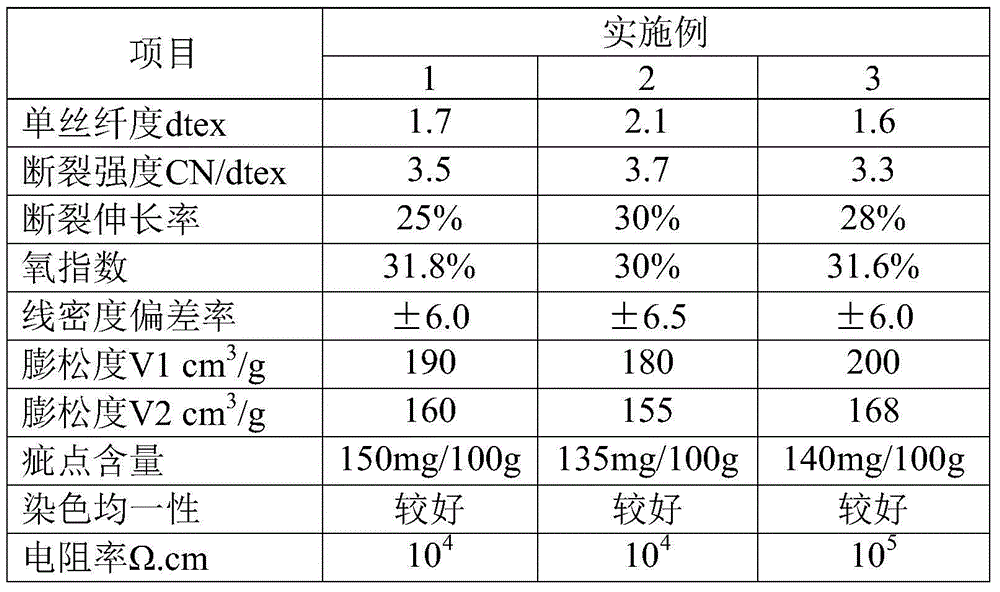

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Special material for antistatic impact fire resistant polyethylene pipe

InactiveCN1657561AImprove antistatic performanceMeet the use requirementsTubular articlesPolymer scienceAntistatic agent

An antistatic, anti-impact and flame-retarded polyethene used for pipeline is proportionally prepared from high-density polyethene, antistatic agent, flame retarder, flame-retarded synergist, toughening agent, optical stabilizer and antioxidizing agent through mixing part of polyethene with others, extruding out to become particles, mixing with rest of polyethene, dual-screw extruding out, cooling, drying and cutting to become particles.

Owner:QINGDAO UNIV OF SCI & TECH

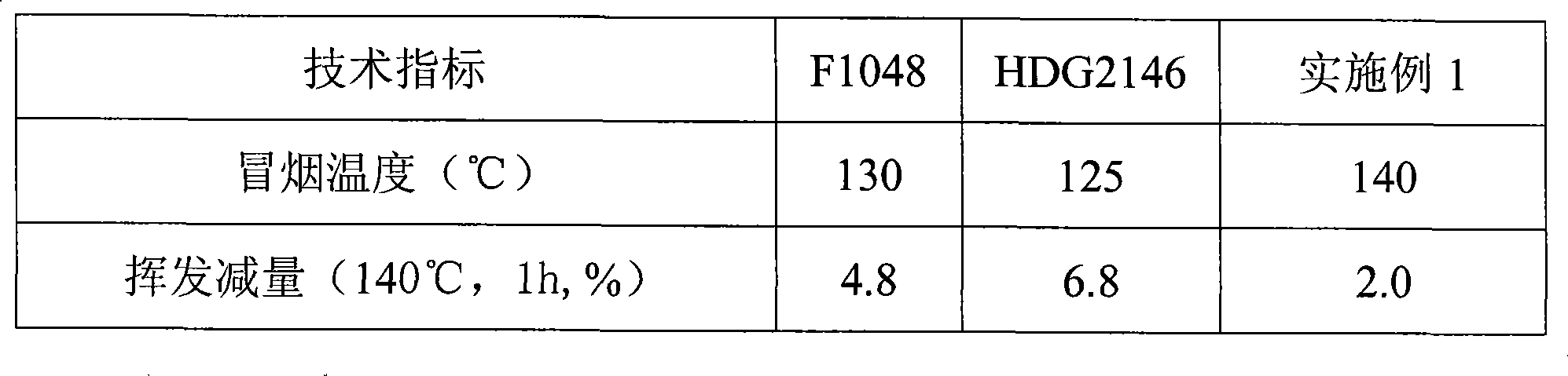

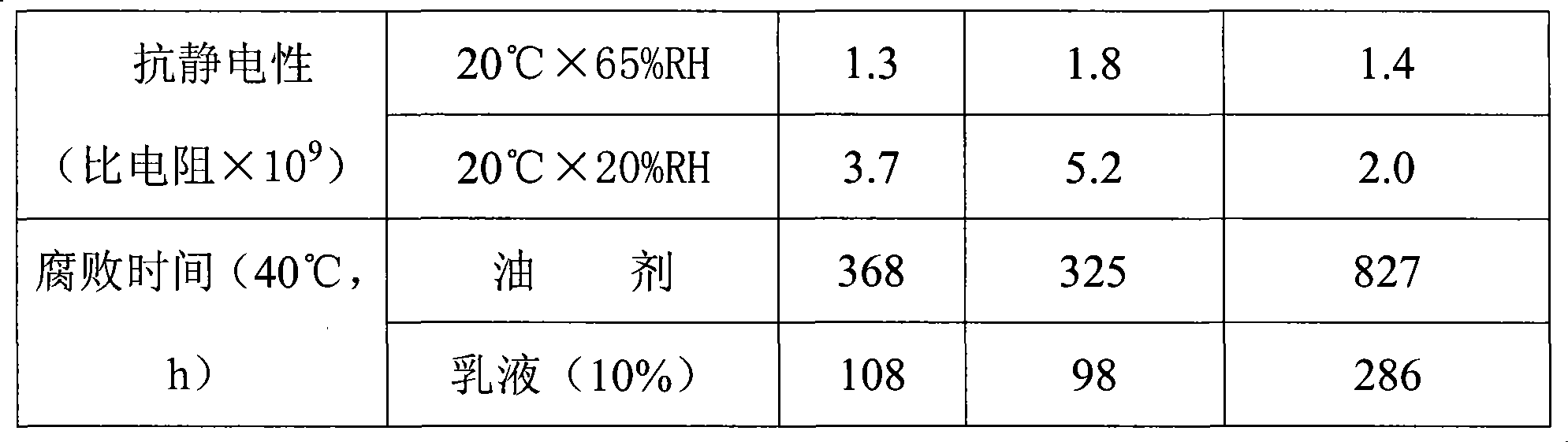

Terylene FDY oil and preparation method thereof

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

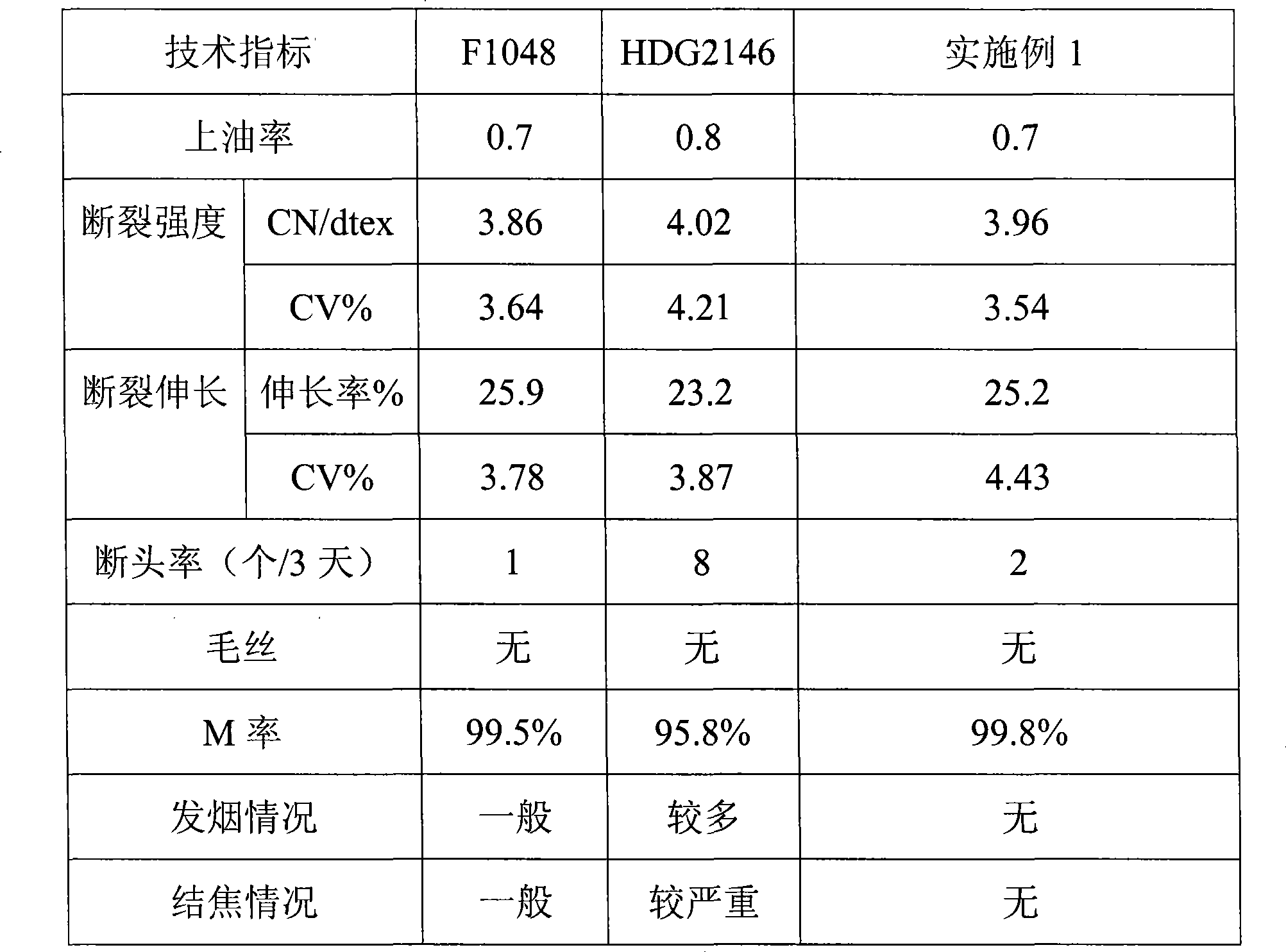

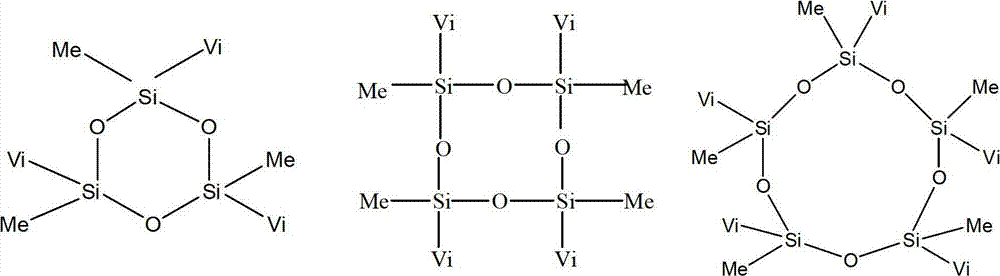

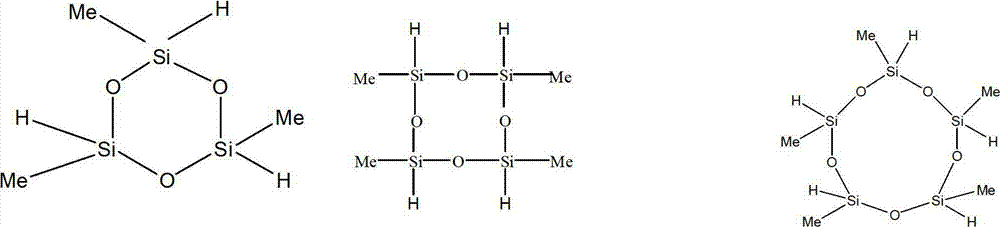

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

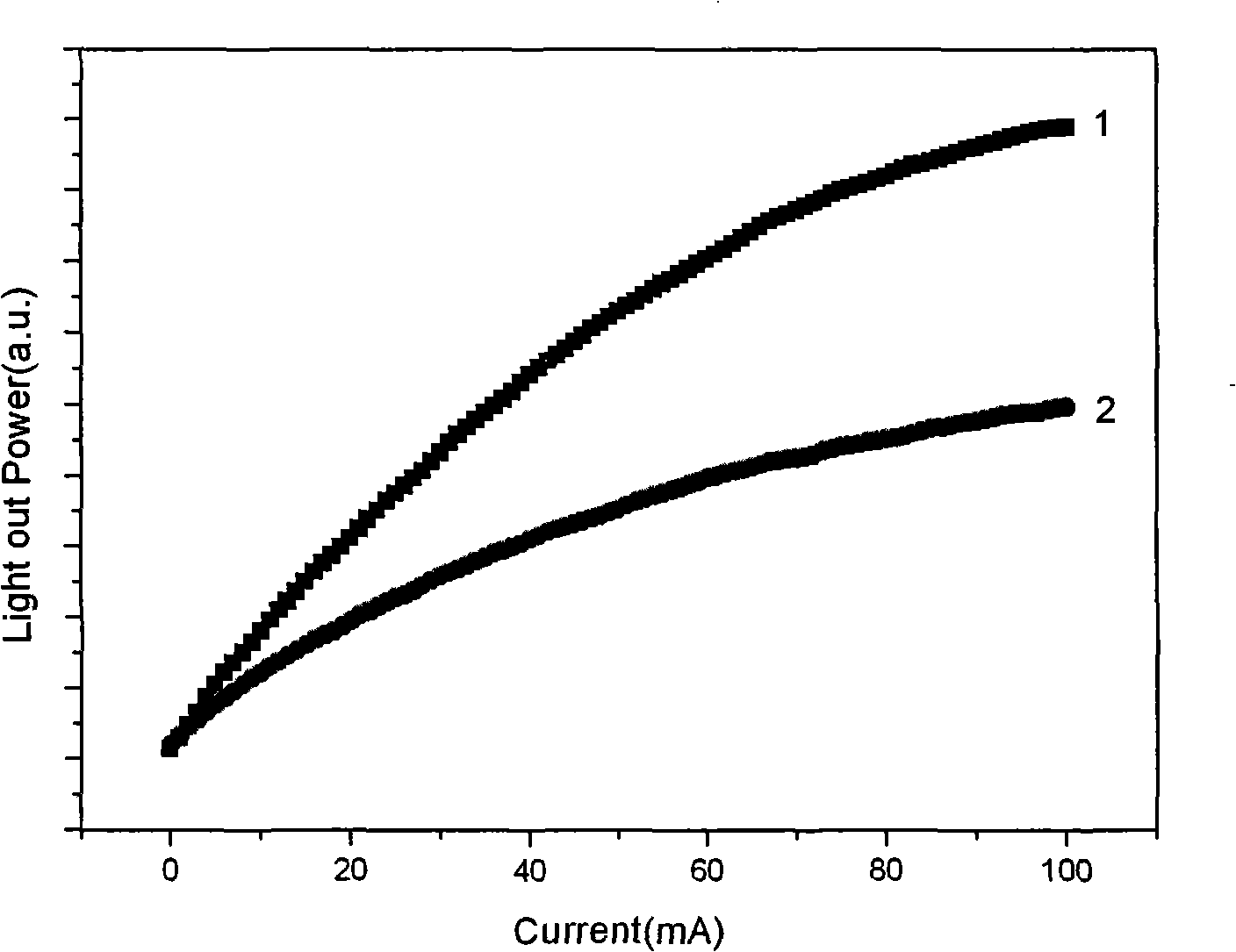

Manufacturing method of green light LED

ActiveCN101359710AReduce V-shaped defectsReduce precipitationSemiconductor devicesGreen-lightGreen led

The invention relates to a method for fabricating a green LED, which is mainly characterized in that through the introduction of an insert layer into an epitaxial growth InGaN / GaN quanta well, V type defects between the InGaN and the GaN is reduced and In precipitation is reduced; thus, the green LED with high brightness and strong antistatic ability can be obtained. With the introduction of the insert layer, the brightness of a 300micronx300micron green LED chip at 520nm under 20mA is improved from 100mcd to 250mcd and the antistatic ability of the chip is increased from HBM 500V (human-body model) to HBM 4000V.

Owner:EPILIGHT TECH +2

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

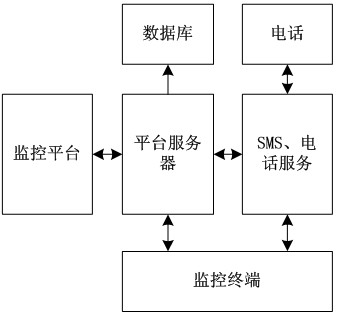

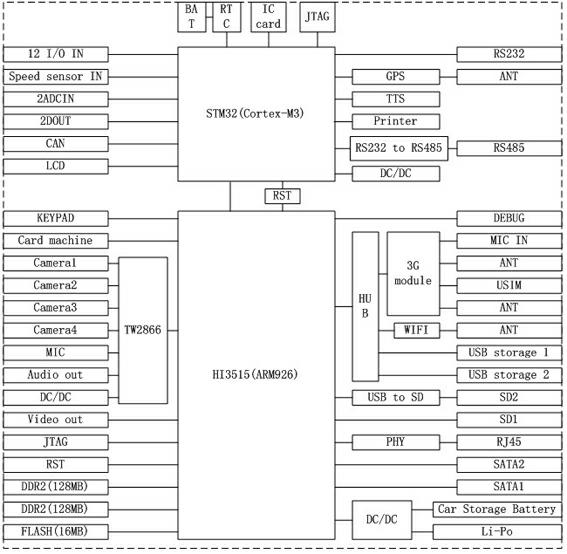

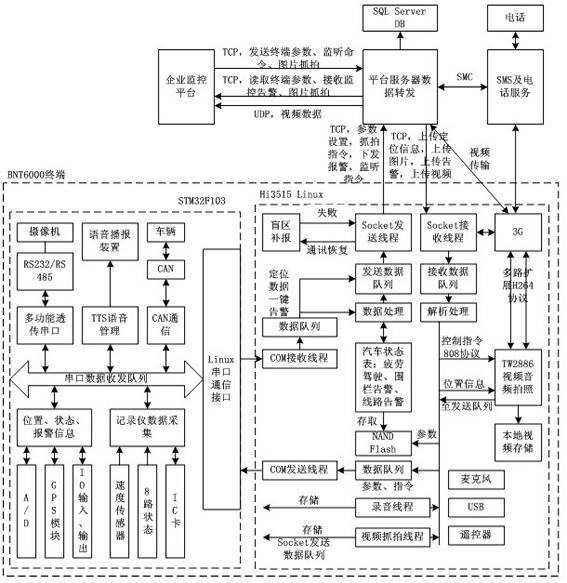

Beidou satellite monitoring safe driving system based on 3G network

InactiveCN102651173AImprove securitySubstantial market returnsRoad vehicles traffic controlVideo monitoringThird generation

The invention discloses a Beidou satellite monitoring safe driving system based on a 3G (third generation) network. The Beidou satellite monitoring safe driving system comprises a platform server positioned in a monitoring center and a monitoring terminal at a vehicle end, wherein the monitoring terminal is connected with the platform server through a network communication system; a monitoring platform, a database, SMS (short message service) and telephone service are operated on the platform server; and the monitoring terminal comprises a housing and a mechanism circuit arranged in the housing. According to the Beidou satellite monitoring safe driving system disclosed by the invention, under the concept of an inter-vehicle network, three major functions, namely positioning by a Beidou vehicle-mounted satellite, 3G wireless video monitoring and vehicle driving recording are firstly integrated, double-CPU (central processing unit) real-time processing, a DSP (digital signal processing) algorithm, an optimization transceiving queue scheduling algorithm, a double-code stream, a special file system, identity comparison identification and other technologies are integrated, video signals collected by a video camera are compressed, encoded and then converted to a compressed code stream, and real-time transmission is realized through the 3G network.

Owner:CHENGDU YIMENG HENGXIN TECH

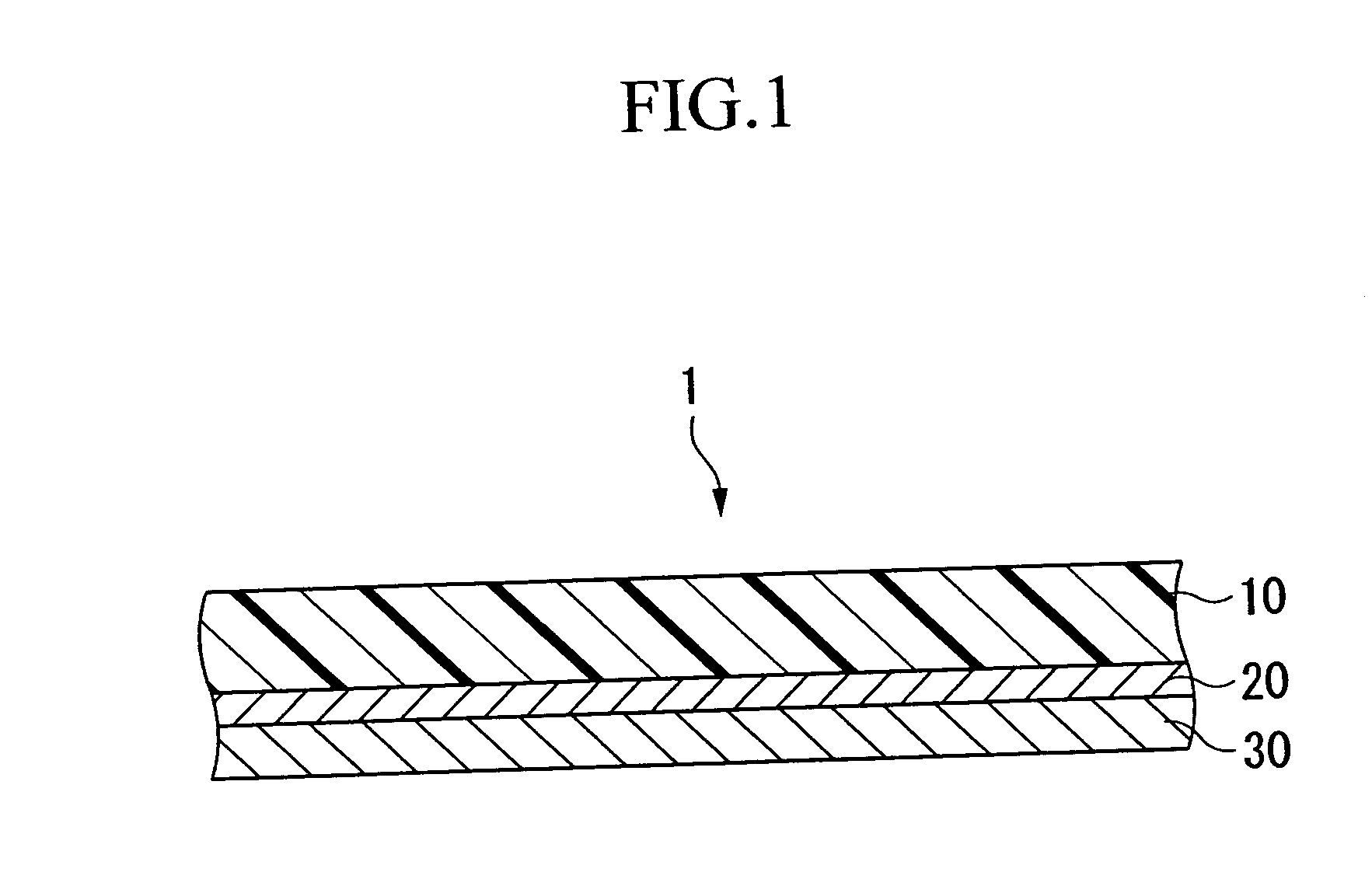

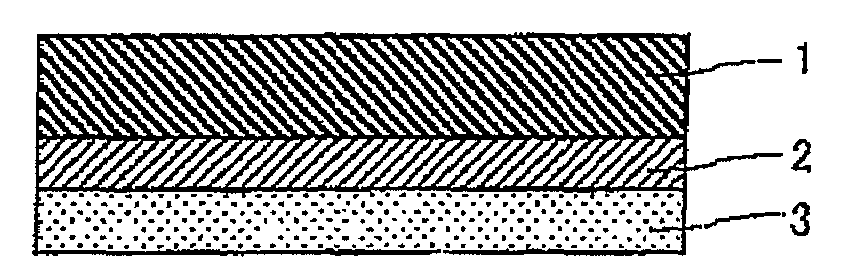

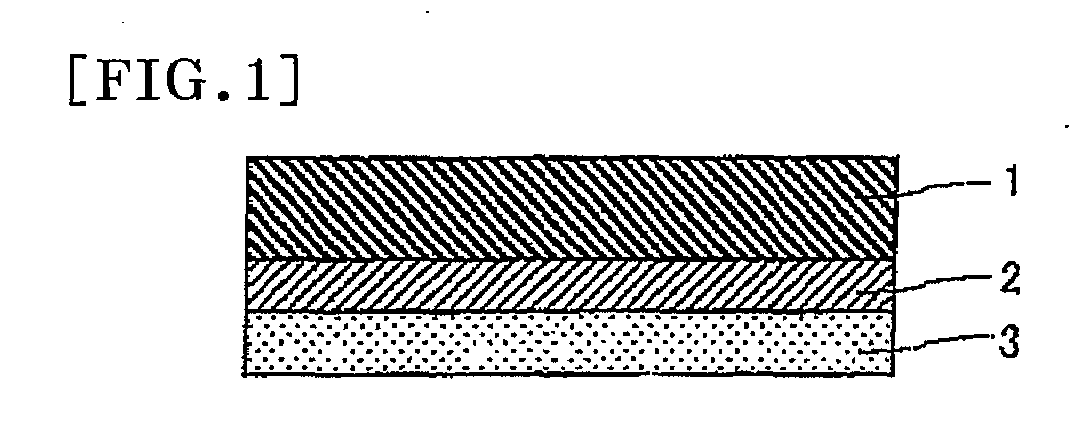

Antistatic Adhesive Optical Film and Image Display

ActiveUS20080118752A1Good effectMaintain good propertiesThin material handlingMetal layered productsOptical propertyAntistatic agent

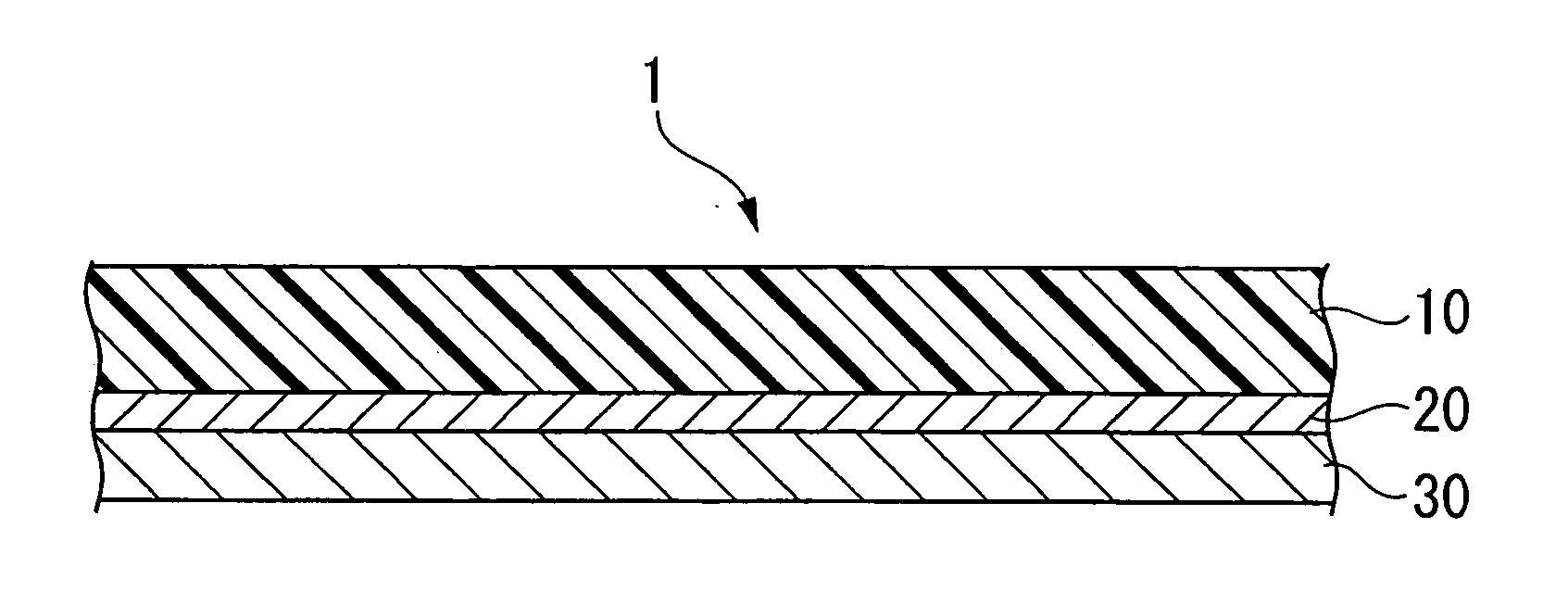

The present invention aims at providing an antistatic pressure-sensitive adhesive optical film exhibiting excellent antistatic effect, optical properties, and water resistance and having excellent adhesion between the antistatic layer and the pressure-sensitive adhesive layer. An antistatic pressure-sensitive adhesive optical film, the optical film having an antistatic layer laminated on at least one side of the optical film, and a pressure-sensitive adhesive layer further laminated on the antistatic layer, wherein the antistatic layer comprises a conductive polymer and a sulfonic acid compound as raw material components, and the pressure-sensitive adhesive layer is formed of an acryl-based pressure-sensitive adhesive containing nitrogen.

Owner:NITTO DENKO CORP

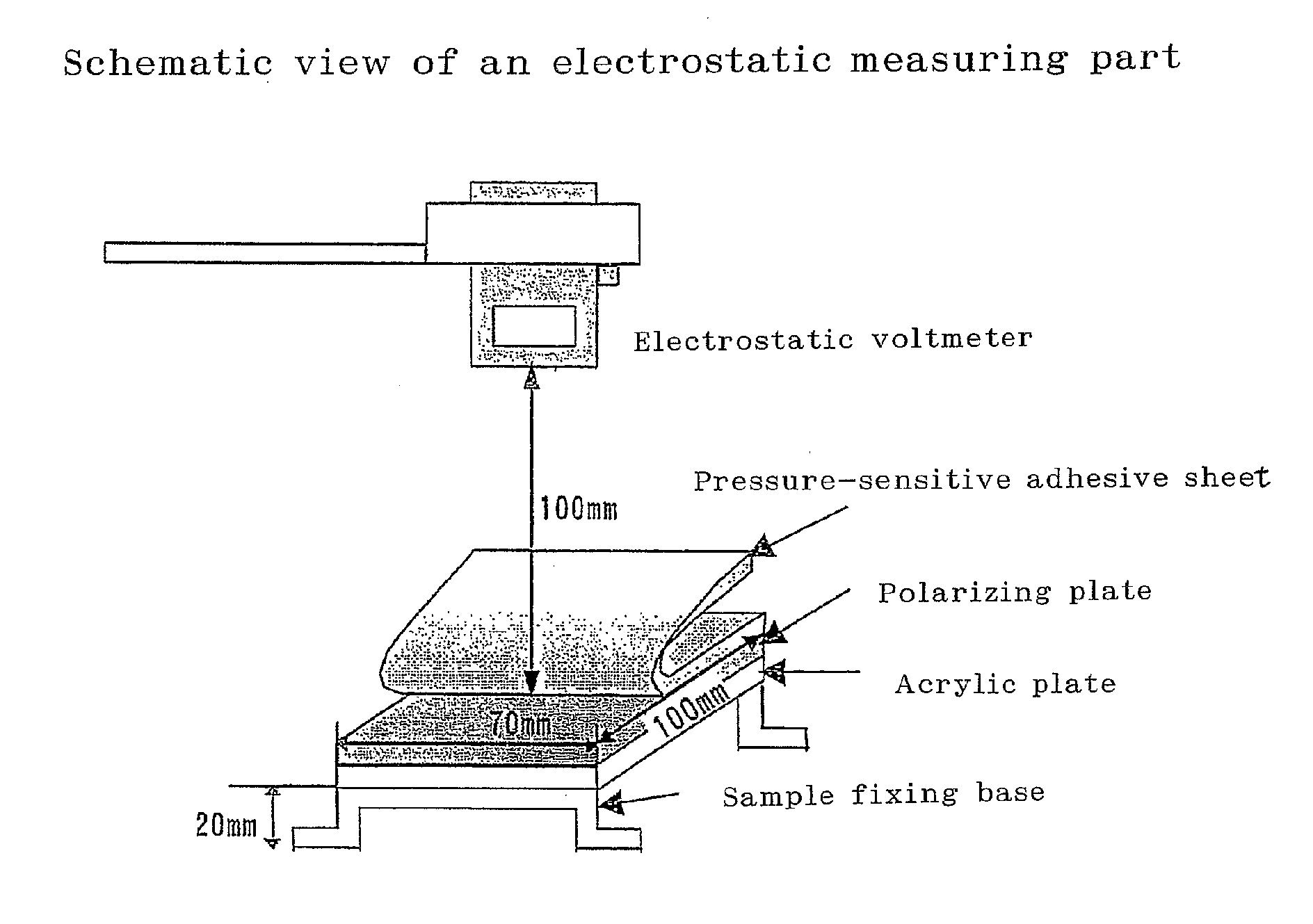

Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheets

ActiveUS20050244633A1Excellent pressure-sensitive adhesive propertyStaining propertyNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberMeth-

An object of the present invention is to provide an electrostatic pressure-sensitive adhesive composition which is excellent in antistatic property of pressure-sensitive adhesive sheets upon peeling, and has reduced stainability in an adherend (subject to be protected) and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets and a surface protecting film using the same. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a monomer component, 15 to 100% by weight of a (meth)acrylic acid alkylene oxide adduct, 0 to 85% by weight of a (meth)acryl-based monomer having an alkyl group of a carbon number of 1 to 14 other than the adduct, and 0 to 85% by weight of other polymerizable monomer, and an alkali metal salt.

Owner:NITTO DENKO CORP

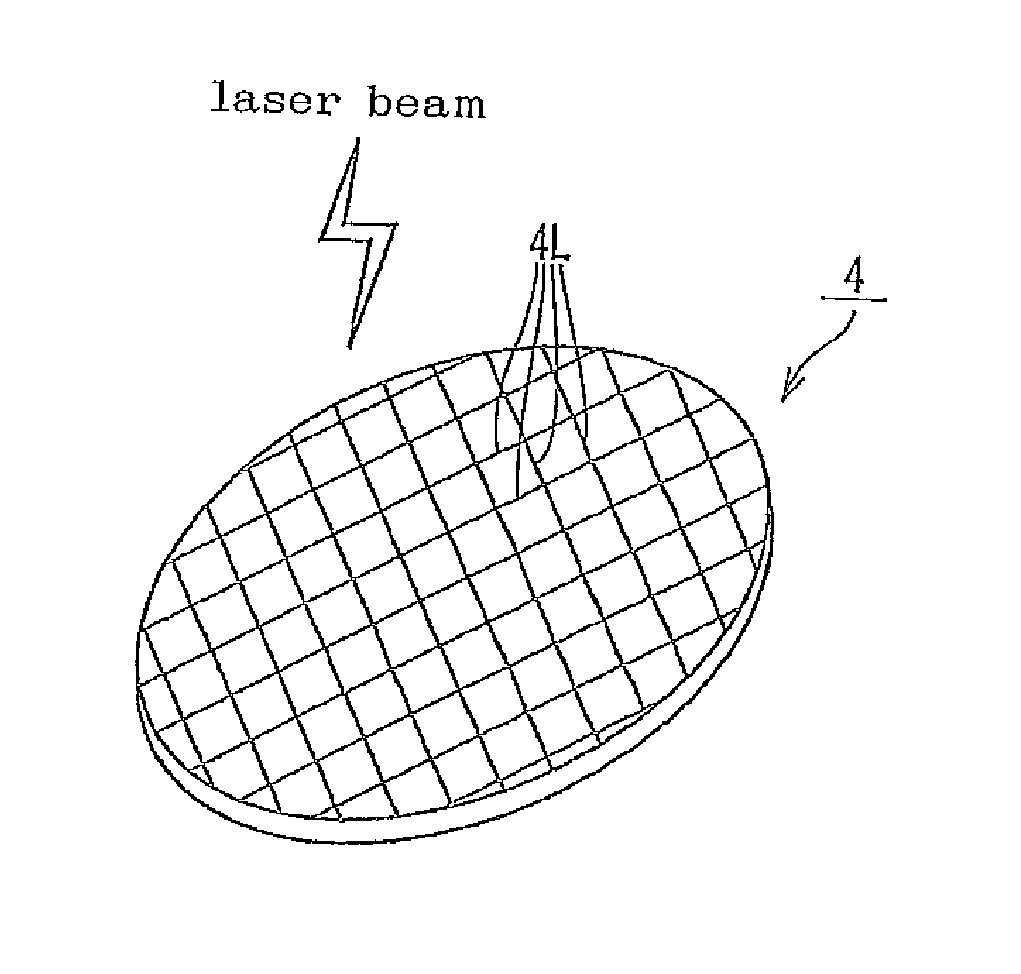

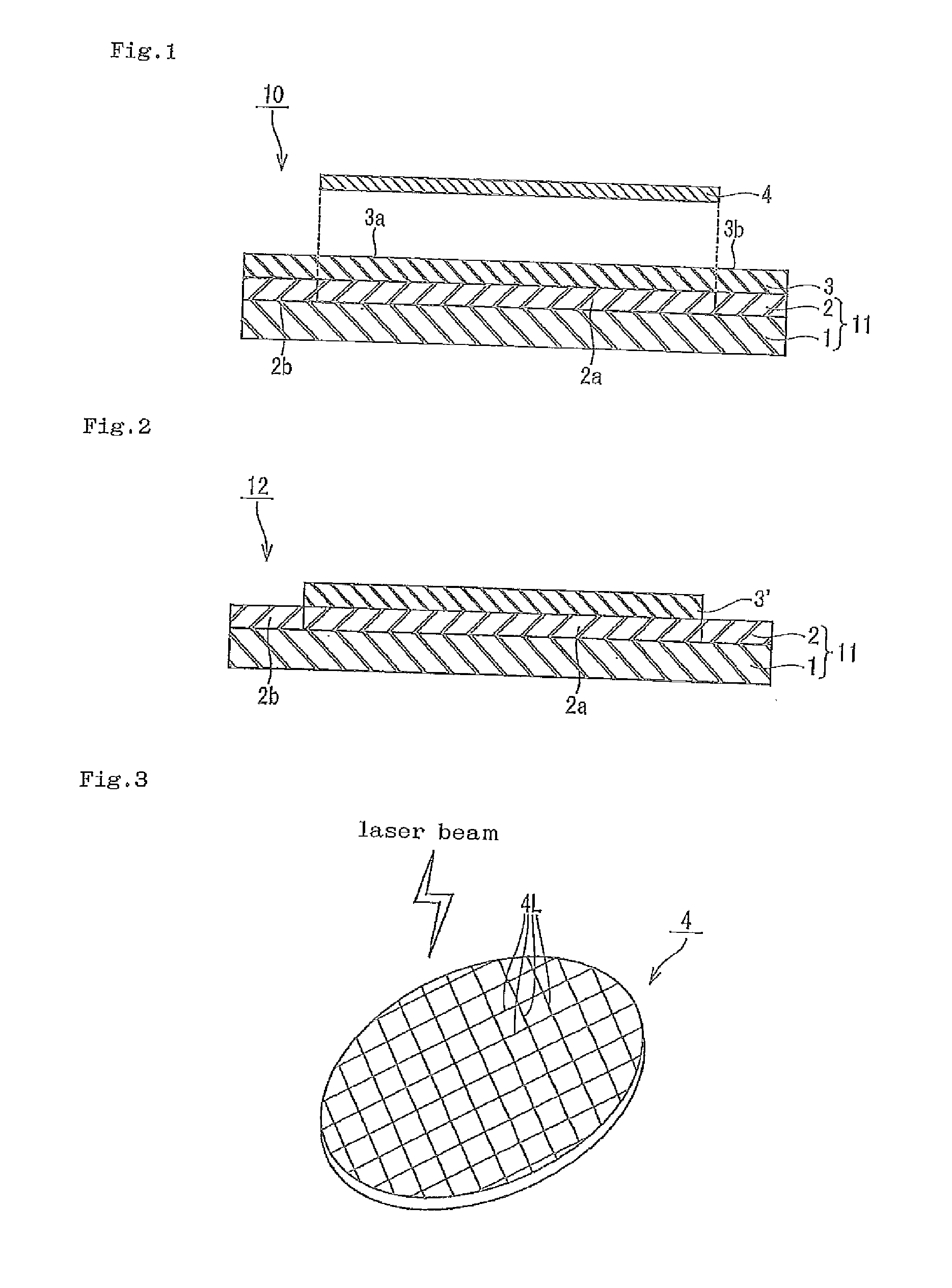

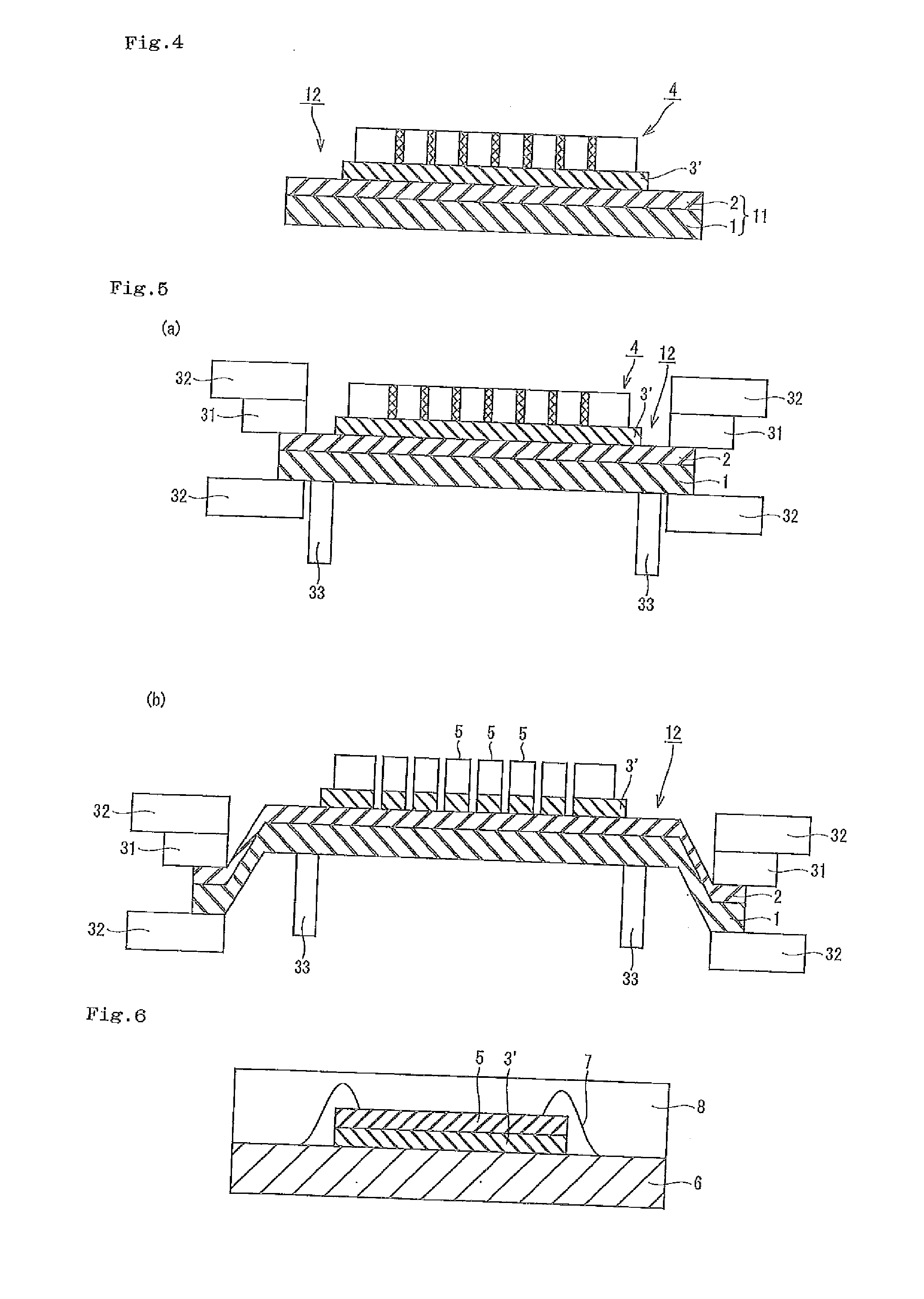

Dicing die bond film

InactiveUS20120061805A1Good tackinessImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDie bondingPolymer chemistry

The present invention provides a dicing die bond film in which peeling electrification hardly occurs and which has good tackiness and workability. The dicing die bond film of the present invention is a dicing die bond film including a dicing film and a thermosetting type die bond film provided thereon, wherein the thermosetting type die bond film contains conductive particles, the volume resistivity of the thermosetting type die bond film is 1×10−6 Ω·cm or more and 1×10−3 Ω·cm or less, and the tensile storage modulus of the thermosetting type die bond film at −20° C. before thermal curing is 0.1 to 10 GPa.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets and surface protecting films

ActiveUS20060057371A1Reduce stain propertyPrevent electrificationNon-macromolecular adhesive additivesEster polymer adhesivesPressure sensitiveChemistry

An object of the present invention is to provide a pressure-sensitive adhesive composition which is excellent in antistatic property of a non-electrification-prevented adherend (a subject to be protected) upon peeling, and has reduced stainability in an adherend and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets and surface protecting films using the same. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a main component, a (meth)acryl-based monomer having an alkyl group of a carbon number of 6 to 14, wherein the pressure-sensitive adhesive composition contains an ethylene oxide group-containing compound and an alkali metal salt, and the alkali metal salt is contained at an amount of less than 1 part by weight relative to 100 parts by weight of the (meth)acryl-based polymer.

Owner:NITTO DENKO CORP

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

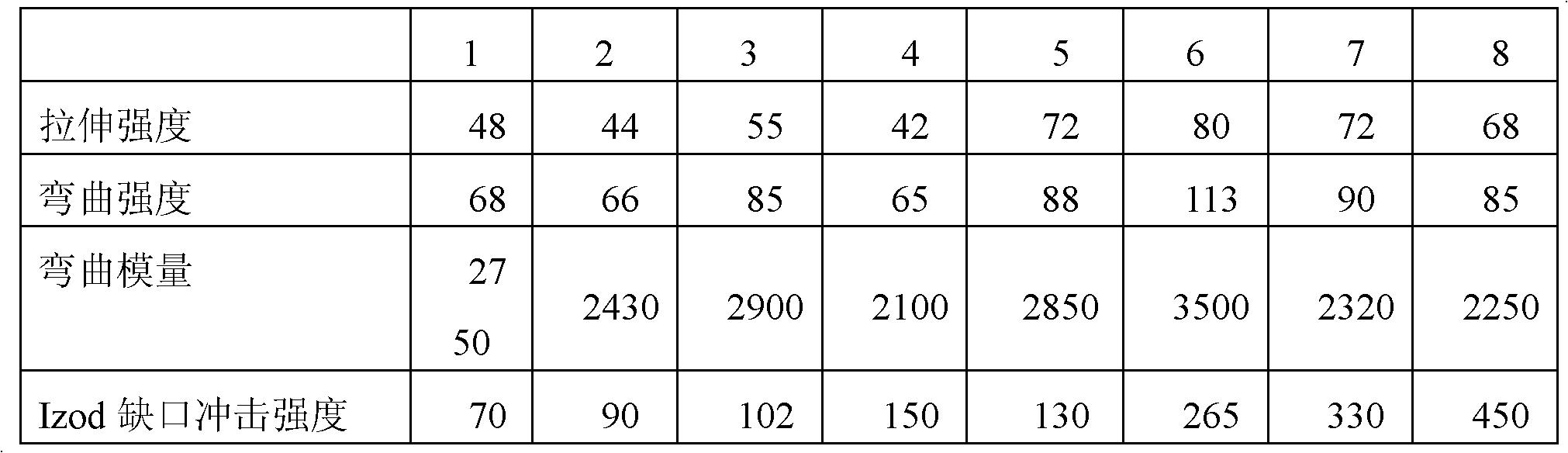

Flame-retardant polycarbonate resin composition and its injection moldings

InactiveUS6150443AImprove antistatic performanceImprove stabilityPlastic/resin/waxes insulatorsDomestic articlesElastomerAntistatic agent

Provided are a flame-retardant polycarbonate resin composition capable of being formed into moldings having good impact resistance, high strength and good thermal stability that are intrinsic to polycarbonate resins and having good antistatic properties and good flame retardancy, and also injection moldings of the composition. The composition comprises 100 parts by weight of a resin or resin mixture of (A) from 50 to 100% by weight of a polycarbonate resin and (B) from 0 to 50% by weight of a styrenic resin, from 1 to 50 parts by weight of (C) a flame retardant, and from 0.1 to 5 parts by weight of (D) an anionic antistatic agent, and has a sodium sulfate content of at most 0.05% by weight. Optionally, the composition may contain (F) a fluoro-olefinic resin, (G) a rubber-like elastomer, and (H) an inorganic filler.

Owner:IDEMITSU KOSAN CO LTD

Antistatic adhesion-resistant slippery linear low density polyethylene composition and method of making the same

ActiveCN101012322AGuaranteed performanceMeet production requirementsLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antistatic blocking resistant smooth linear low-density polyethylene composition based on LLDPE as base, which comprises the following parts: 0.05-0.2% opening agent, 0.05-0.3% smooth agent, 0.05-0.3% antistatic agent, 0.05-0.2% anti-oxidant and 0.05-0.2% manufacturing and heat stabilizer, wherein the opening agent contains inorganic blocking resistant agent or organic opening agent; the smooth agent is amide, soap or organic silicane; the main auxiliary anti-oxidant is hindered phenol and phosphorus anti-oxidant; the antistatic agent adopts composite pattern of non-ionic typed antistatic agent and ion-typed antistatic agent. The making method compress the following steps: adopting LLDPE as base; adding blended auxiliary material into graining stage; or graining auxiliary agent into mother grain; adding mother grain; manufacturing specific material.

Owner:SINOPEC YANGZI PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com