Patents

Literature

140results about How to "Good antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terylene FDY oil and preparation method thereof

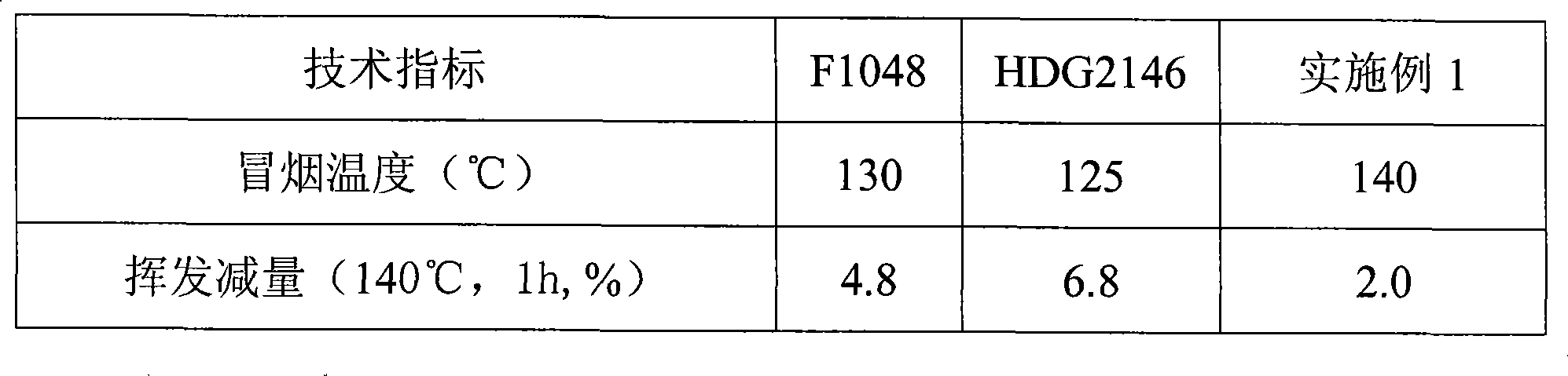

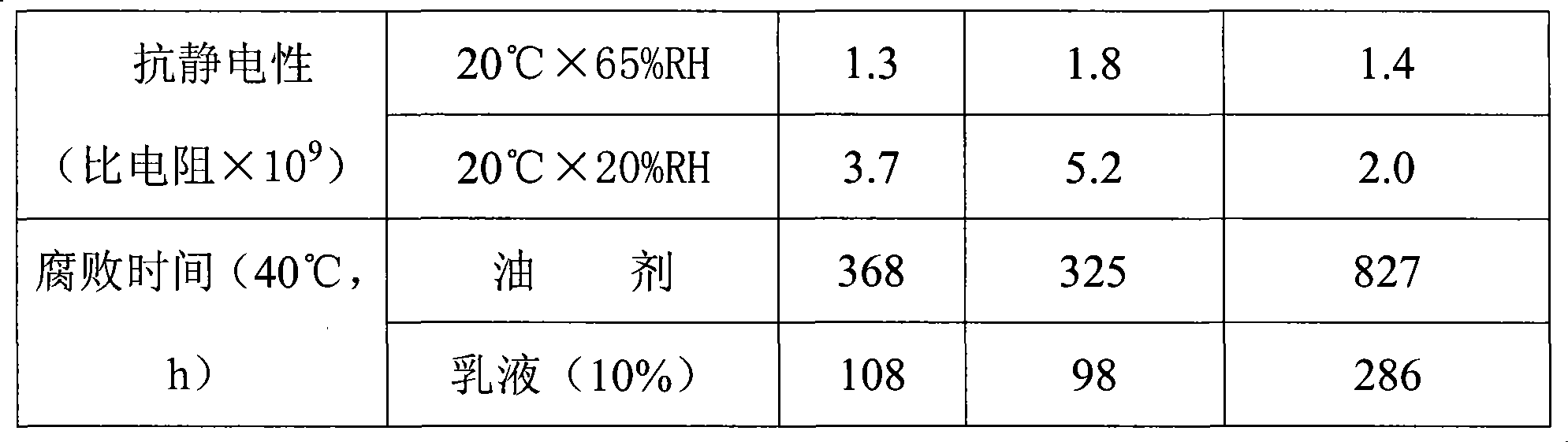

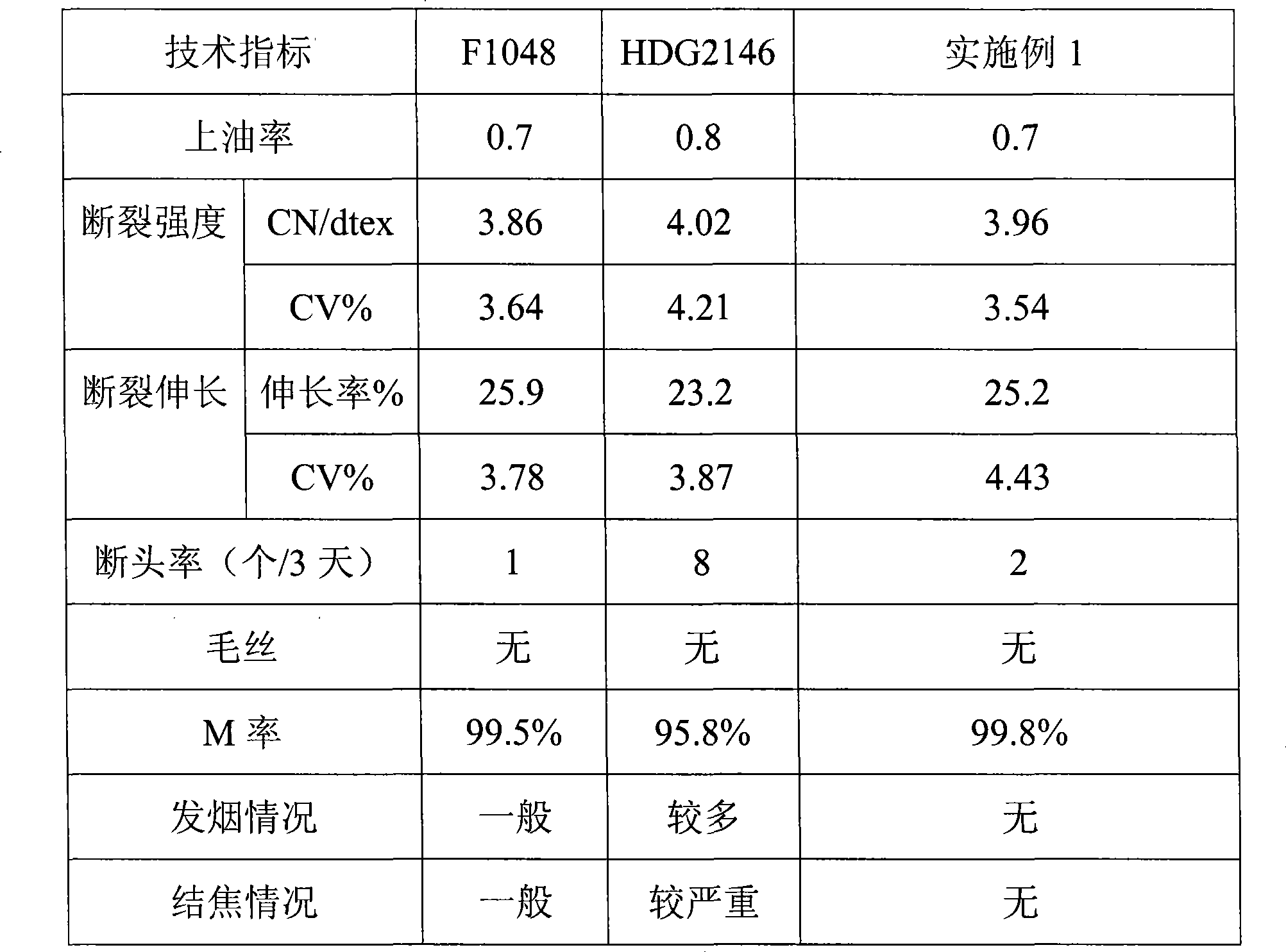

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

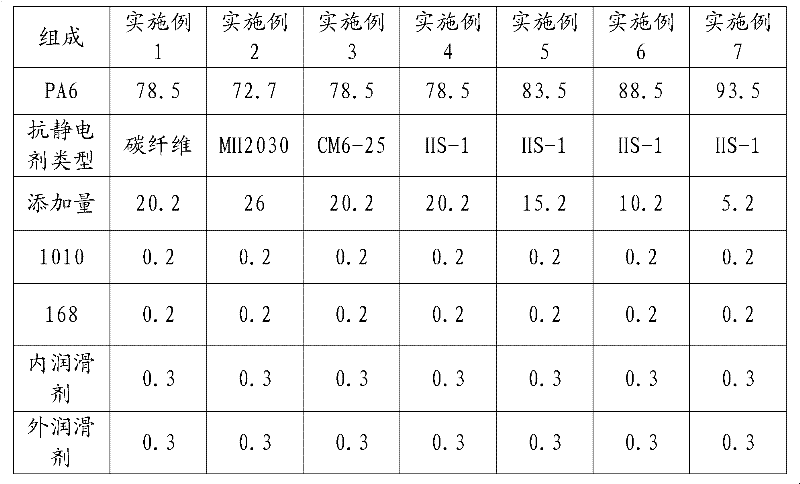

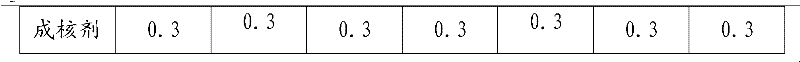

Antistatic nylon material and preparation method thereof

The invention discloses an antistatic nylon material and a preparation method thereof. The antistatic nylon material comprises the following components in percentage by weight: 72-94 percent of polyamide, 5-26 percent of antistatic agent, 0.2-0.6 percent of antioxidant, 0.2-0.8 percent of lubricant and 0.3-0.6 percent of nucleating agent. The surface resistivity of a polyamide material is greatly reduced, and the volume resistivity of the antistatic nylon material is controlled to be 107-1010ohm and maintains in the stable state for a long time. The invention provides an economic, applicable and permanent antistatic nylon material with obvious and stable antistatic effect.

Owner:SHENZHEN KEJU NEW MATERIAL

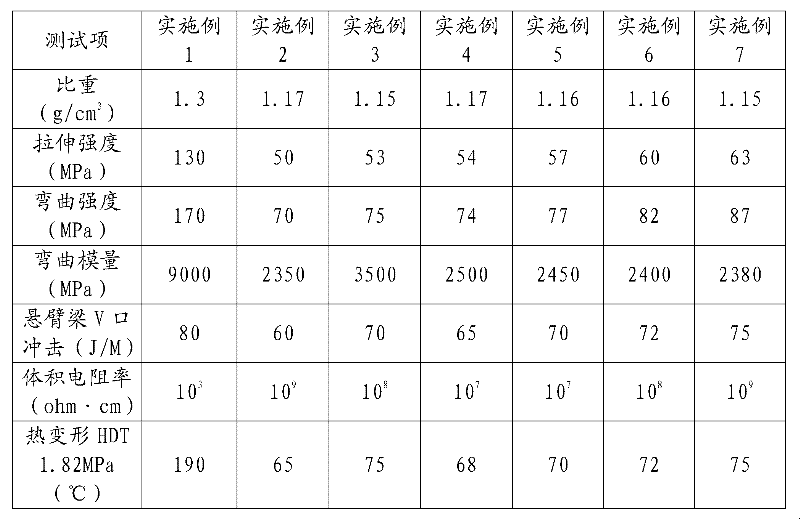

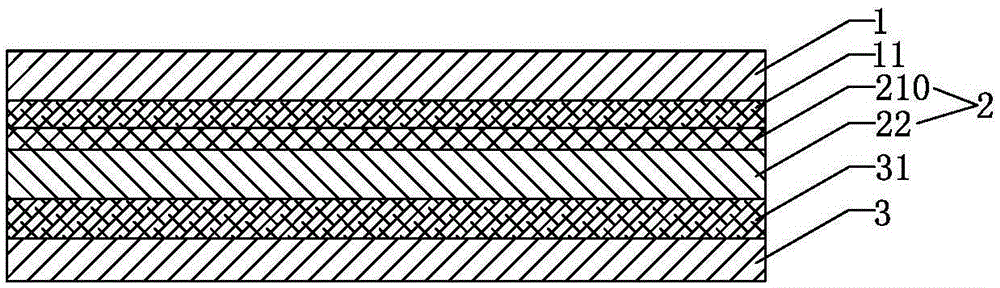

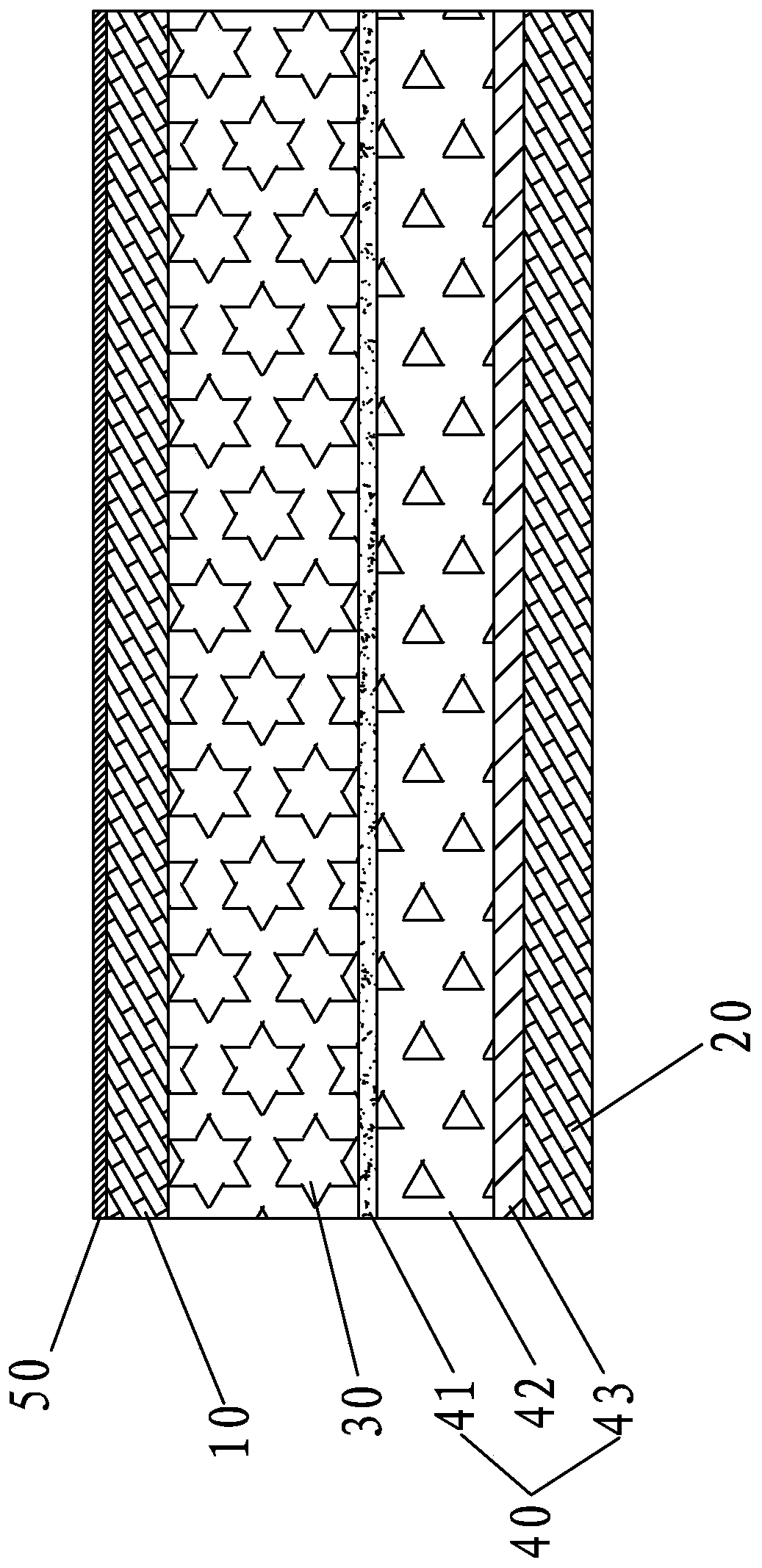

Anti-microbial and anti-static complex film and preparation method thereof

InactiveCN105315912AGood antibacterial effectGood antistatic effectAntifouling/underwater paintsFilm/foil adhesivesTectorial membraneAdhesive

The invention relates to the technical field of protective films, in particular to an anti-microbial and anti-static complex film. The anti-microbial and anti-static complex film comprises a protective film, a protective adhesive layer, a use film layer, a stripping adhesive layer and a stripping film, wherein the protective film, the protective adhesive layer, the use film layer, the stripping adhesive layer and the stripping film are arranged in sequence from top to bottom; the upper surface of the protective adhesive layer is attached to the protective film, and the lower surface of the protective adhesive layer is attached to the use film layer; the upper surface of the stripping adhesive layer is attached to the use film layer, and the lower surface of the stripping adhesive layer is attached to the stripping film; the use film layer comprises an anti-microbial and anti-static functional layer and a base film, and the anti-static functional layer and the base film are arranged in sequence from top to bottom; the upper surface of the anti-microbial and anti-static functional layer is attached to the lower surface of the protective adhesive layer, and the lower surface of the anti-microbial and anti-static functional layer is attached to the upper surface of the base film; the lower surface of the base film is attached to the upper surface of the stripping adhesive layer. The complex film has both a good anti-microbial effect and a good anti-static effect, and is diversified in function, simple in structure, low in production cost and high in practicability.

Owner:NALI OPTICAL MATERIAL DONGGUAN

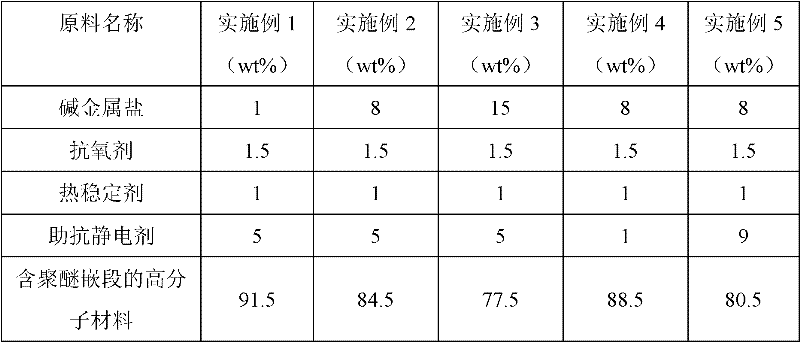

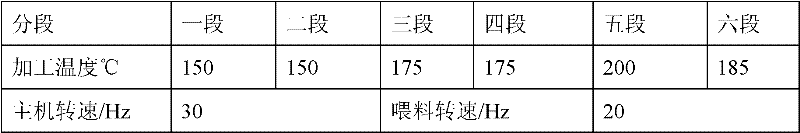

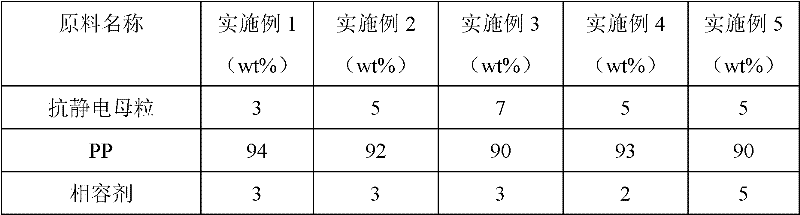

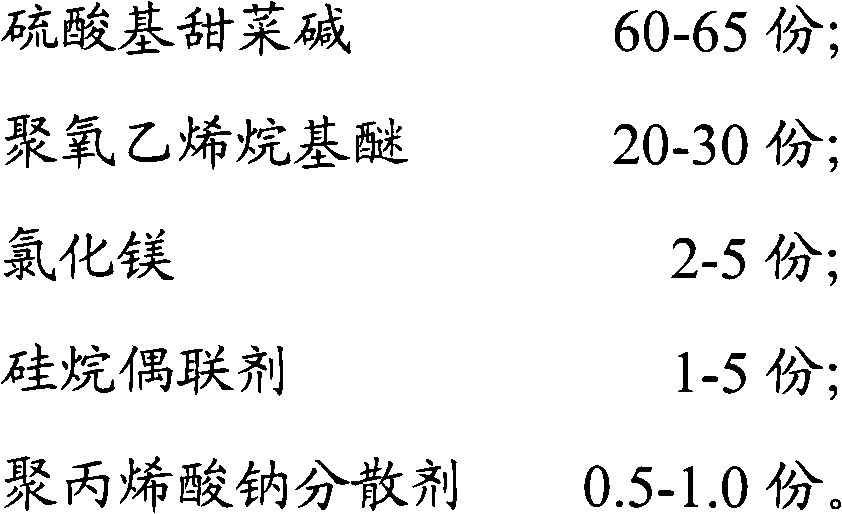

Permanent anti-static PP (polypropylene) composite material and preparation method thereof

ActiveCN102399393ALong-lasting antistatic effectGood antistatic effectOther chemical processesSurface resistivityPolypropylene

The invention relates to a permanent anti-static PP (polypropylene) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of anti-static master batch, 80 to 95 percent of PP and 1 to 5 percent of compatilizer. The preparation method comprises the following steps of: weighing the raw materials according to weight proportion; placing the raw materials into a high mixing machine to mix the raw materials for 2 to 5 minutes; discharging; and then carrying out extrusion pelletizing by a double-screw extruder, wherein a processing temperature is in the range of 190 to 220 DEG C and screws have revolution of 35 to 40Hz. Compared with the prior art, the permanent anti-static PP composite material has the advantages of sustained anti-static effect, permanent anti-static effect, good anti-static effect, high comprehensive mechanical property, performance close to pure PP, light color, capability of being prepared into various colors, low cost, good heat resistance and the like. The surface resistivity of the permanent anti-static PP composite material can reach 106 to 108 ohm.m.

Owner:上海日之升科技有限公司

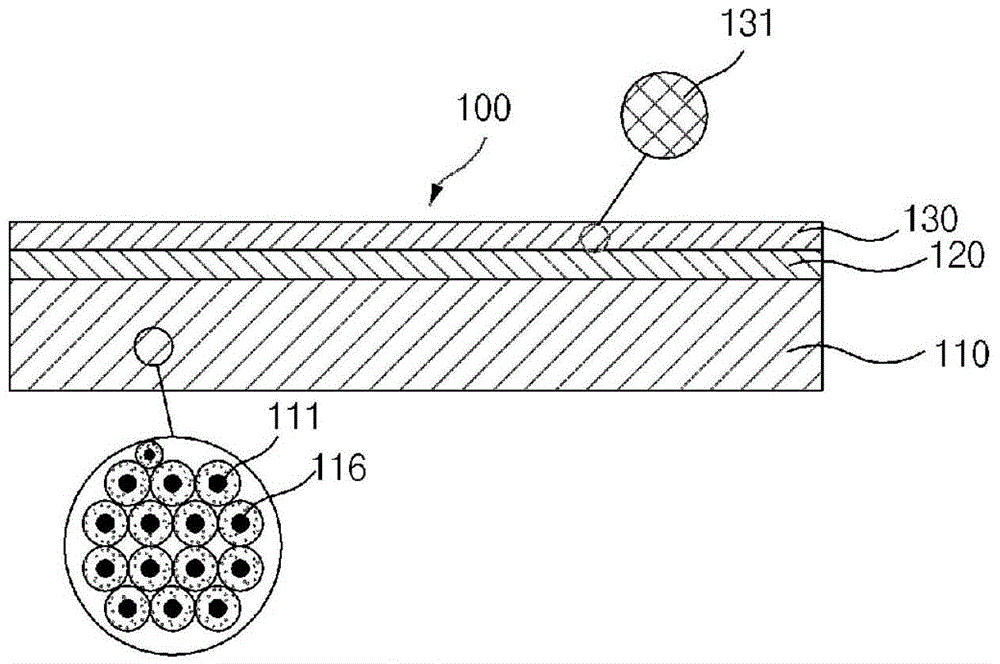

Biodegradable polyester/recycled polyester sheath-core fiber and preparation method thereof

InactiveCN104762695ABiodegradableLow costElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesPolymer scienceAdipic acid

The invention relates to a biodegradable polyester / recycled polyester sheath-core fiber and a preparation method thereof. The biodegradable polyester / recycled polyester sheath-core fiber is composed of a sheath layer and a core layer, wherein the sheath layer consists of biodegradable polyester, poly adipic acid / butylene-terephthalate and an antistatic functional material, and the core layer is recycled polyester. The preparation method comprises the following steps: compounding the PBAT with the antistatic functional material subjected to surface modification, respectively performing vacuum tumbler drying and screw melt extrusion with the recycled polyester, and performing composite spinning to prepare the biodegradable polyester / recycled polyester sheath-core fiber. According to the prepared biodegradable polyester / recycled polyester sheath-core fiber, the PBAT fiber as the sheath layer has a biodegradability performance, and the core layer adopts the recycled polyester which can be recycled, so that the product cost is greatly lowered. The biodegradable polyester / recycled polyester sheath-core fiber has a good antistatic function and is light in color, also has good mechanical property and rebound resilience, is soft in handfeel, and can be blended with cotton, wool and other synthetic fibers, is an economic and environmental-friendly fiber, and can be widely applied to fields of products of home textiles and blankets.

Owner:SHANGHAI SHEEP IND +1

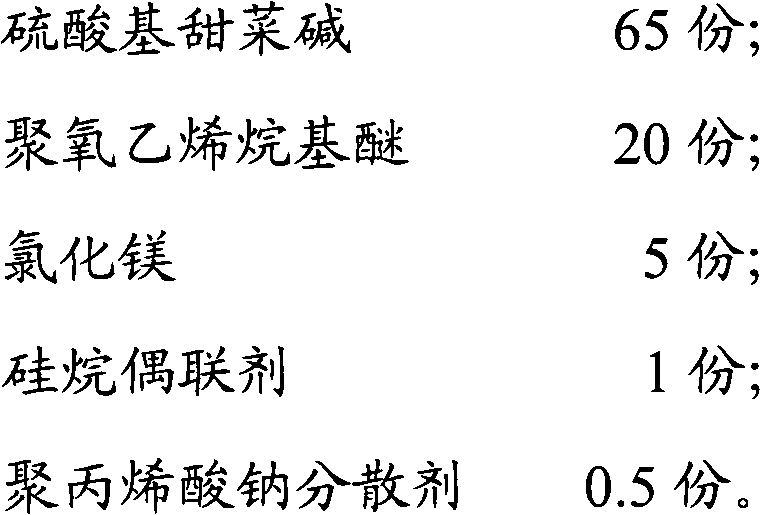

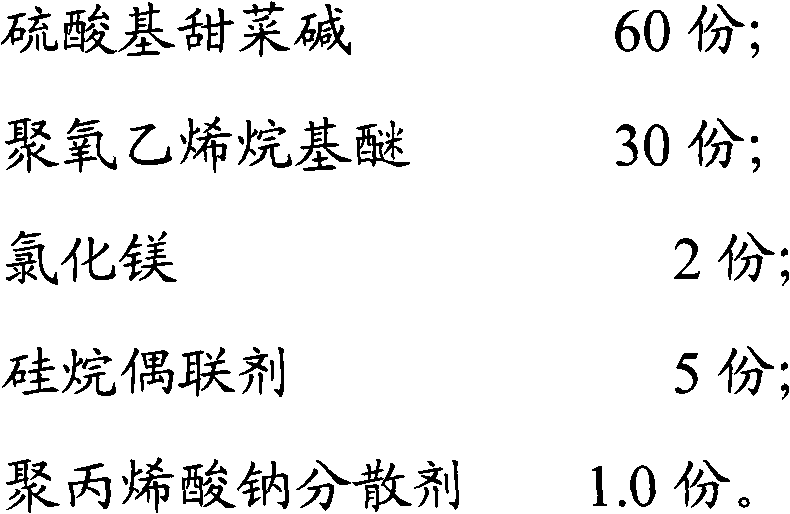

Antistatic agent for silk fabrics

The invention discloses an antistatic agent for silk fabrics. The antistatic agent comprises, by weight, 56 parts of dimetyl terephthalate, 18 parts of phenol, 50 parts of maleic anhydride, 16 parts of tetrabutyl titanate, 22 parts of glycol, 18 parts of tetrabutyl titanate, 18 parts of cyclohexanone, 10 parts of powdered steatile and 12 parts of zinc acetate. The product prepared by the invention has a simple production technology and low production cost; silk fabrics treated by the antistatic agent can keep original flexibility and handle, has good antistatic effect and is water washing resistant, safe and harmless.

Owner:SUZHOU KAQITE TEXTILE

Antistatic silica gel composition and preparation method thereof

The invention relates to an antistatic silica gel composition which comprises the following components in percentage by weight: 45-80 percent of methyl vinyl gum, 15-50 percent of white carbon black, 1-4 percent of hydroxy silicone oil, 0.2-1.6 percent of hydrogen-contained silicone oil, 0.1-0.5 percent of demolding agent and 0.1-4 percent of antistatic agent, wherein the antistatic silica gel composition is prepared through the following steps of: proportionally adding the methyl vinyl gum, the hydroxy silicone oil, the hydrogen-contained silicone oil and the demolding agent into a vacuum kneader for kneading; then adding the white carbon black in batches and then adding the next batch of white carbon black after the last batch of white carbon black is fully agglomerated; after all the raw materials are agglomerated, opening nitrogen, introducing steam, heating and keeping the constant temperature for 1-2 hours at the high temperature of 160-170 DEG C; and then reducing the temperature, proportionally adding the antistatic agent in the temperature reducing process, stirring for 30 minutes to 1 hours, discharging after the temperature is reduced to 60-80 DEG C and then filtering through a rubber filter press to obtain the antistatic silica gel composition after a sizing is cooled. Thereby, the invention has good antistatic effect and can be widely used for working occasions with higher static requirements.

Owner:DONGGUAN HONGDA NEW MATERIAL

Method for producing anti-pilling and antistatic cashmere sweaters

InactiveCN102860593AIncrease binding forceGood antistatic effectWeft knittingFibre treatmentYarnEngineering

The invention discloses a method for producing anti-pilling and antistatic cashmere sweaters, which comprises the following steps of: blending cashmeres with milk protein fibers according to a mass ratio of (5:1)-(5:2), wherein in the step of twisting, the single twist of a cashmere blended yarn is 520-550 twists / m, and the direction of twist faces a Z twist; in the step of two-for-one twisting, the ply twist of the cashmere blended yarn is 360-380 twists / m, and the direction of twist faces a S twist; and the ratio of the single twist to the ply twist is 0.32-0.47; and then, carrying out weaving, sweater forming, antistatic finishing steps so as to obtain an anti-pilling cashmere sweater. The cashmere sweater prepared by using the method disclosed by the invention is not pilled after being used for a long time, and has an excellent antistatic function, therefore, the service life of the cashmere sweater is long.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

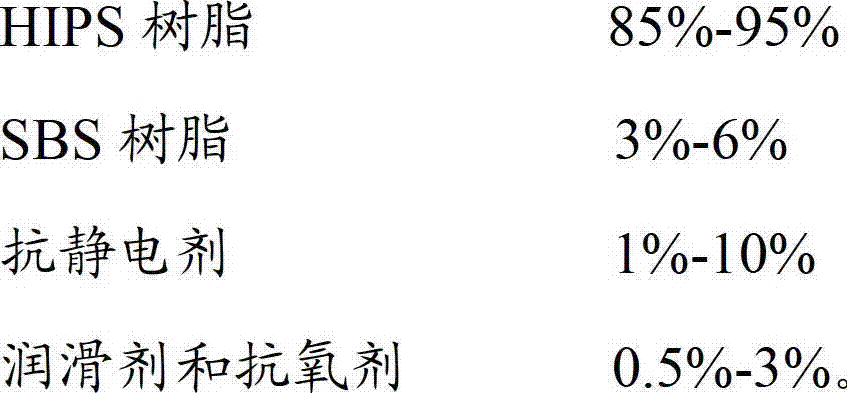

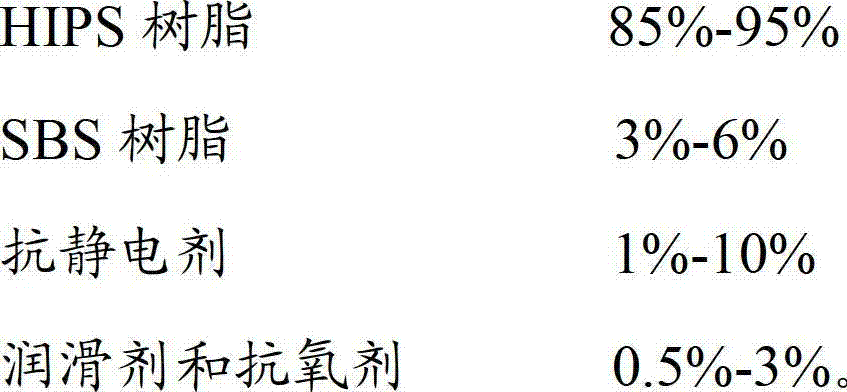

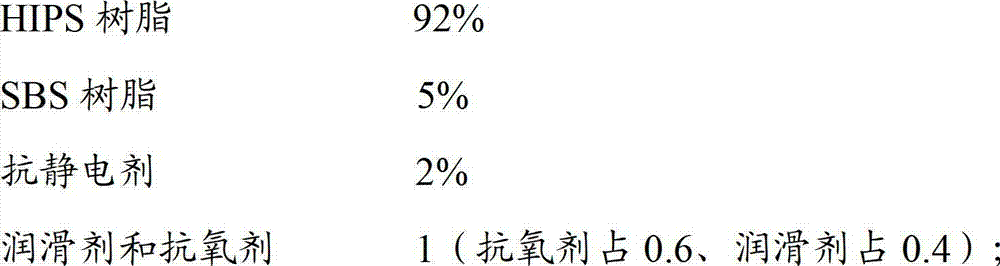

HIPS composite, and preparation method and application thereof

InactiveCN103044837AGood antistatic effectImprove mechanical propertiesChemistryButadiene-styrene rubber

The invention is suitable for the field of engineering plastics, and provides an HIPS (High Impact Polystyrene) composite, and a preparation method and an application thereof. The HIPS composite comprises HIPS resin, SBS (Styrene Butadiene Styrene) resin, an antistatic agent, a lubricant and an antioxidant. The HIPS composite has a favorable mechanical property such as shock resistance while having an excellent antistatic effect through using the special antistatic agent and being used in coordination with HIPS and SBS. According to the preparation method of the HIPS composite, the HIPS composite has a favorable mechanical property such as shock resistance while having an excellent antistatic effect through using the special antistatic agent and being used in coordination with HIPS and SBS.

Owner:ANHUI KEJU NEW MATERIALS

Flame-retardant and antistatic EVA (ethyl vinyl acetate) foam composite material and preparation method thereof

The invention discloses a flame-retardant and antistatic EVA (ethyl vinyl acetate) foam composite material and a preparation method thereof, and belongs to the field of macromolecular composite foam materials. The flame-retardant and antistatic EVA foam composite material comprises the following components of vinyl-vinyl acetate copolymer, a composite flame retardant agent, an antistatic agent, afoaming agent AC, stearic acid, zinc stearate, zinc oxide, and dicumyl peroxide, wherein the composite flame retardant agent is graphene-coated zinc hexahydroxystannate; the antistatic agent is a nitrogen-doped graphene nanometer hollow spehre. The flame-retardant and antistatic EVA foam composite material has the advantages that by adopting the novel composite flame retardant agent and the novelantistatic agent, the excellent flame-retardant property and antistatic property are simultaneously realized; the formula is scientific and reasonable, the certain innovativeness is realized, and thetechnology process is simple and practical.

Owner:FUZHOU UNIV

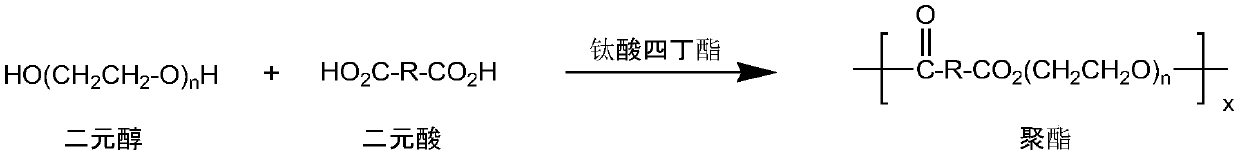

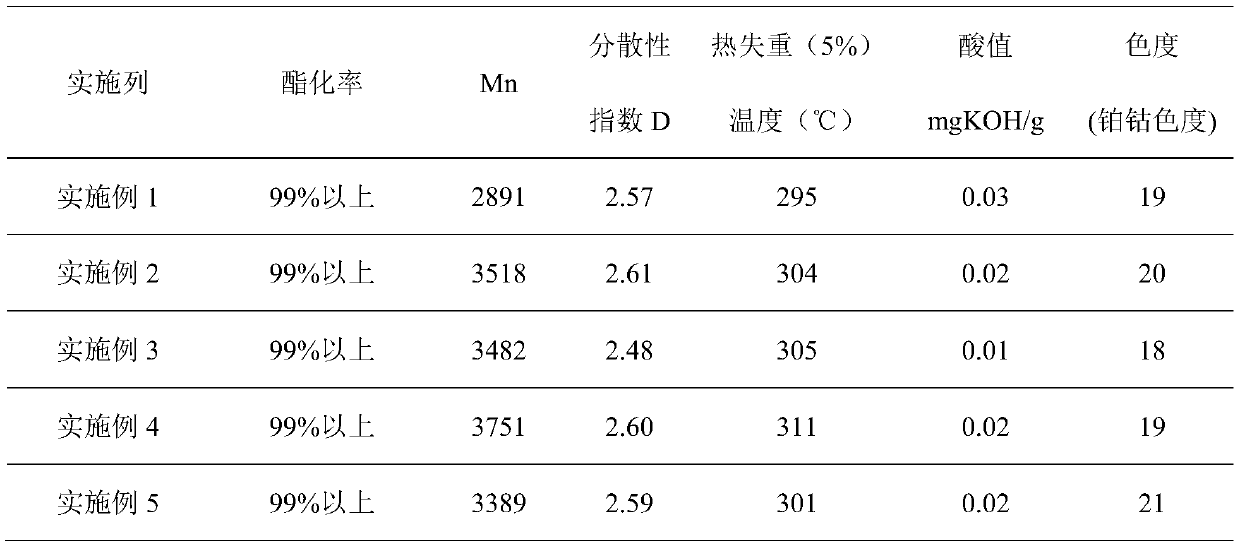

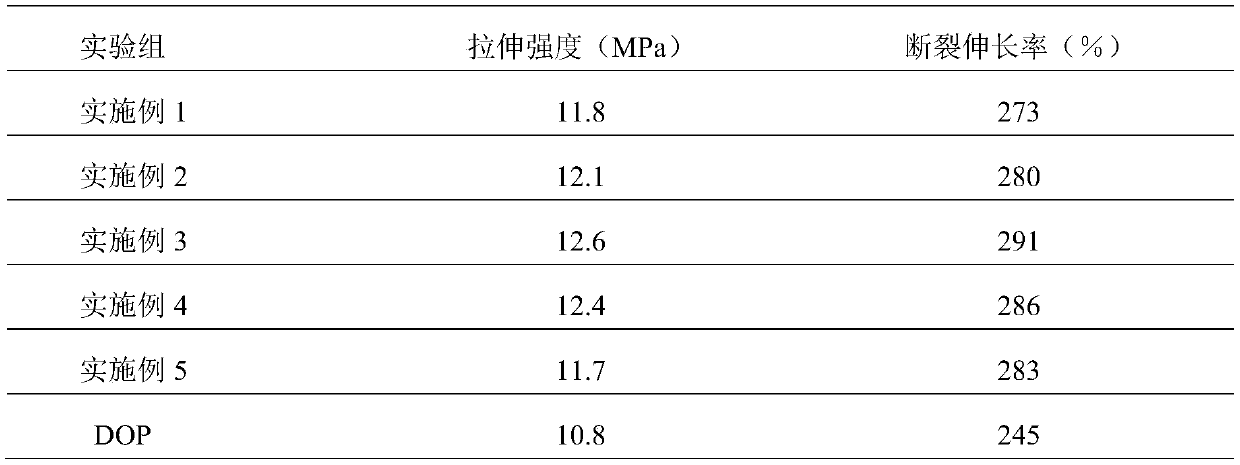

Synthetic method of ethanediol polyester plasticizer

ActiveCN110078902ASimple preparation processThe results of the polycondensation reaction are remarkablePlasticizerDiol

The invention discloses a synthetic method of an ethanediol polyester plasticizer. The ethanediol polyester plasticizer is synthesized from diol and binary acid by polycondensation under the action ofa catalyst by controlling parameters such as temperature, pressure, time and the like of a reaction process. The molecular weight range Mn of the polyester plasticizer is 2,800-3,800, the polymerization degree n is 15-20, when serving as a low-temperature plasticizer to be applied to a soft PVC sheet, the polyester plasticizer has better compatibility and excellent heat stability and meets the basic requirement of the plasticizer, tensile strength, breaking elongation and low temperature flexibility of the polyester plasticizer are excellent, and besides, an obtained PVC product has a betteranti-static effect.

Owner:永椿化工新材料有限公司

Antistatic resin sand and preparation method thereof

The invention provides antistatic resin sand which is characterized in that the raw materials comprise the following components in part by weight: 200 to 270 parts of urea, 370 to 530 parts of formaldehyde, 15 to 25 parts of urotropine, 110 to 150 parts of filler and 18 to 25 parts of other auxiliary materials; and the antistatic resin sand also comprises an antistatic agent of which the weight is 0.2 to 0.6 percent of the total weight of the components. The invention also provides a production method of the antistatic resin sand, which comprises the following steps of synthesizing urea resin, carrying out kneading process, carrying out drying process, carrying out grinding process, carrying out ball milling and sieving, carrying out pelletizing process, carrying out size stabilization process, mixing, packaging and the like. According to the antistatic resin sand and the preparation method thereof, which are provided by the invention, the antistatic resin sand has antistatic capacity; various requirements on the surface treatment on an airframe are met; and particularly, in the using process of the antistatic resin sand, antistatic liquid does not need to be sprayed to the resin sand.

Owner:溧阳市乔森塑料有限公司

Novel antistatic finishing agent composition for polyester fabric

The invention discloses a novel antistatic finishing agent composition for a polyester fabric. The novel antistatic finishing agent composition is prepared from the following components in parts by weight: 18 to 25 parts of ethyl acrylate, 1 to 5 parts of sodium oleate, 5 to 8 parts of magnesium stearate, 15 to 20 parts of polyethylene glycol diamine, 15 to 20 parts of coconut oil acid monoethanolamine, 16 to 19 parts of dimethyl terephthalate, 11 to 15 parts of sodium diethylhexyl sulfosuccinate, 4 to 8 parts of sodium pyrophosphate, 2 to 4 parts of potassium tartrate, 50 to 60 parts of ethyl alcohol and 70 to 90 parts of deionized water. The antistatic finishing agent has softening and smoothening effects, and friction force between polyester fabrics can be reduced, so that the antistatic finishing agent has good antistatic effect; the prepared antistatic finishing agent is biologically degraded easily, and environment pollution is not caused.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

Atnistatic neylon fiber and preparation method

InactiveCN1958891AGood antistatic effectGood mechanical propertiesElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentChemistryMelt spinning

The present invention discloses an antistatic nylon fibre and its preparation method. Said antistatic nylon fibre is made up by using (by weight portion) 89-96 portions of nylon 6 chip, 3-10 portions of polymer type antistatic agent and 1 portion of adjuvant. Its preparation method includes the following steps: uniformly mixing and stirring the above-mentioned materials for 30 min, then under the condition of nitrogen gas protection placing the obtained mixture into a melt spinning machine to make melt spinning at 265 deg.C-275 deg.C.

Owner:GUANGDONG XINHUI MEIDA NYLON

Fabrication method of antistatic dedusting filter cloth

The invention relates to a fabrication method of antistatic dedusting filter cloth. The fabrication method comprises the following steps: 1. treating acrylic fiber with a copper salt to form modified acrylic fiber treated by the copper salt; 2. mixing the modified acrylic fiber with polyester staple fiber to form mixed fiber; 3. making a textile assistant; 4. spraying the textile assistant into the mixed fiber before the mixed fiber is opened and enters a hopper; and 5. transferring the mixed fiber with the textile assistant into the hopper to be made into the dedusting filter cloth according to basic production procedures of non-woven fabric. In the fabrication method, firstly the modified acrylic fiber treated by the copper salt is mixed with the polyester staple fiber, then the textile assistant composed of an antioxidant and a stabilizer is sprayed, and finally the dedusting filter cloth is made. The fabrication method has the advantages that the modified acrylic fiber is integrally mixed with the polyester staple fiber, and the textile assistant is sprayed into the mixed fiber, thus avoiding volatilization of the copper salt in the dedusting filter cloth, reaching good antistatic effect of the dedusting filter cloth and ensuring safety production.

Owner:JIANGSU FILTERTEX FILTER MATERIAL

Antistatic sheet and preparation method thereof

InactiveCN106146871ALow priceLong-lasting and effective antistatic effectElectrically-conductive paintsHeat deflection temperatureAntistatic agent

The invention discloses an antistatic sheet and preparation method thereof. The antistatic sheet comprises a polyolefin sheet and permanent macromolecule antistatic layers coated on one surface or two surfaces of the polyolefin sheet, and antistatic liquid containing the permanent macromolecule antistatic agents is coated on the surface of the polyolefin sheet and then dried and solidified to form the permanent macromolecule antistatic layers. The antistatic sheet is suitable for mass industrial production, low in cost, durable, effective and good in antistatic effect, low in environment temperature-humidity influence, high in heat-resisting deformation temperature, good in mechanical property and wide in application, and surface electrical resistivity is 105-1010ohm / o.

Owner:GUANGDONG ZHENGYE TECH

Anti-static agent for cloth

The invention relates to an anti-static agent for cloth. The anti-static agent is prepared from the following raw materials including ethoxy alkylamine, polyethylene glycol diglycidyl ether, tetrabutyl titanate, surfactants, zinc acetate, glycol, glycerin, lauryl ether, octadecyl imidazoline, alkyl quaternary ammonium salts, isopropanol, linear alkylbenzene sulfonate, fatty alcohol-polyoxyethyleneether, sodium stearate, alkenyl sulphonate, white soap powder, phenol salicylate, epoxy resin, phenol, cyclohexanone, xylene and dibutyltin oxide. The anti-static agent has the beneficial effects that (1) the cost is low; a textile product can maintain the original flexibility and hand feeling after being treated by the anti-static agent; the anti-static effect is good; water washing resistance and heat resistance are good; meanwhile, meanwhile, the influence on the hand feel of the textile is small; no injury is caused on the skin; (2) the long-effect maintenance can be realized; the anti-static agent can be used for cloth and can also be widely applicable to various rubber and plastic products.

Owner:ANHUI HONGYUAN NONWOVEN FABRIC

Antistatic plastic-wood composite board and preparation method thereof

The invention relates to an antistatic plastic-wood composite board and a preparation method of the antistatic plastic-wood composite board. The preparation method comprises the steps of mixing wood flour, plastic particles, maleic anhydride grafted plastic particles, glyceryl monocaprate, dodecyl diethanolamine and industrial white oil at high speed, cooling and crushing to obtain plastic-wood composite grains; and then mixing the plastic-wood composite grains, copper powder, stearic amide, talcum and zinc stearate at high speed, and carrying out fusion blending and extrusion forming by adopting an extruder. The antistatic plastic-wood composite board is convenient to produce and manufacture, low in cost, low in consumption of plastic and wood, environment-friendly, high in modulus and rigidity, creep-resistant, and excellent in antistatic effect, can be repeatedly regenerated and does not generate warping deformation. The plastic-wood composite board can be used as outdoor desks and chairs, wooden stools, picnic tables, flower tanks, guardrails, indicators and other products to be widely applied parks, courts, municipal administration and other occasions like the traditional plastic-wood boards, and can also be used in chemical industry, petroleum and other special environments.

Owner:江苏森诺塑胶科技有限公司

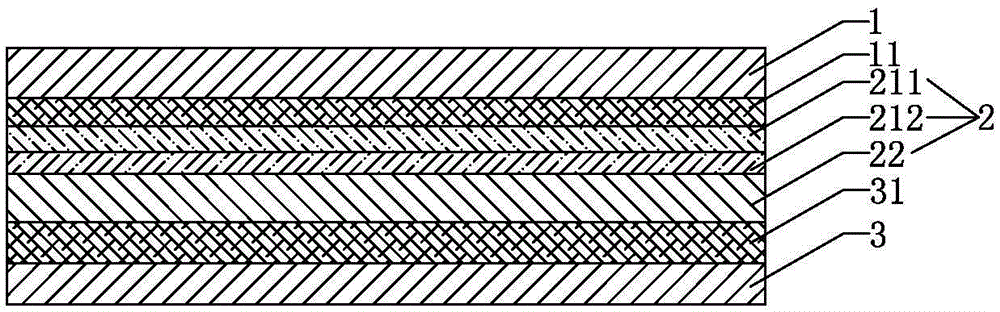

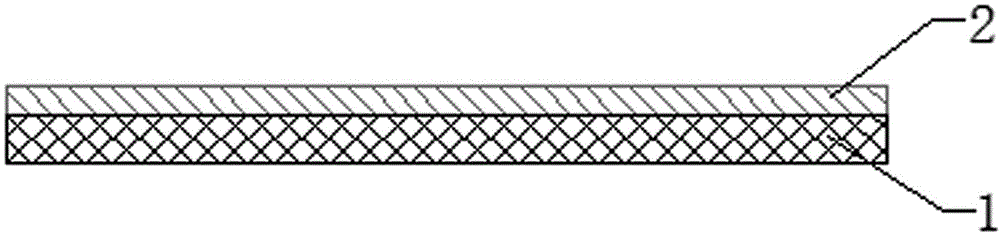

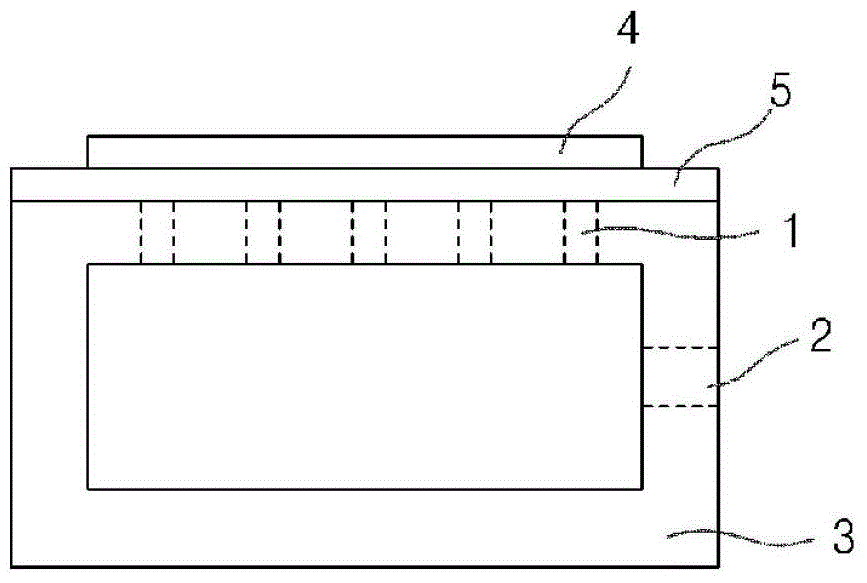

Composite film for flour packaging and manufacturing method thereof

ActiveCN103770411AThe production process is simple and easy to controlReduce the adsorption rateFlexible coversWrappersFunctional monomerPolyurethane adhesive

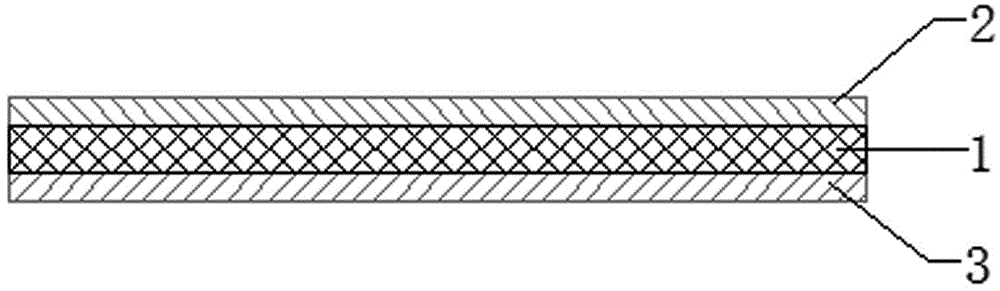

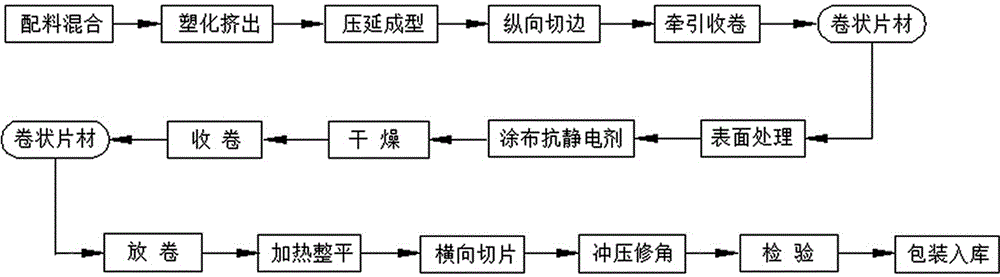

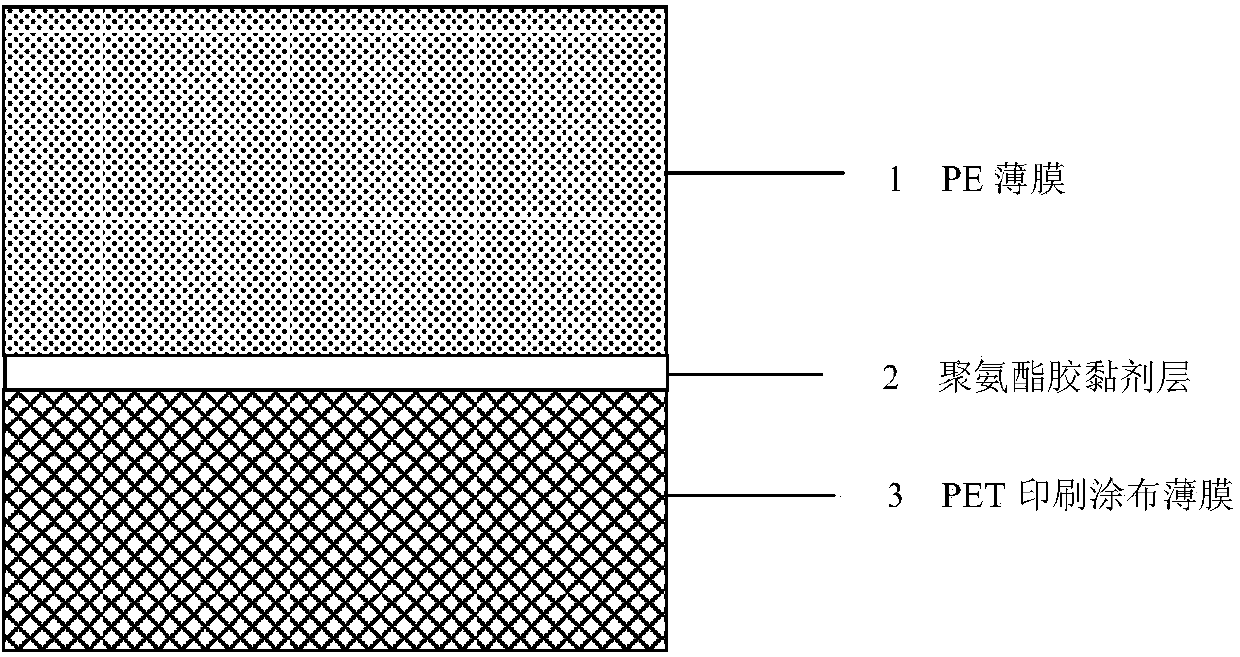

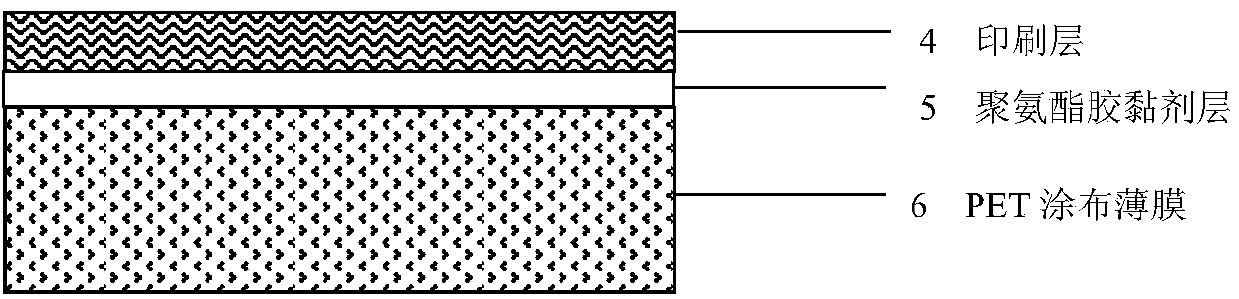

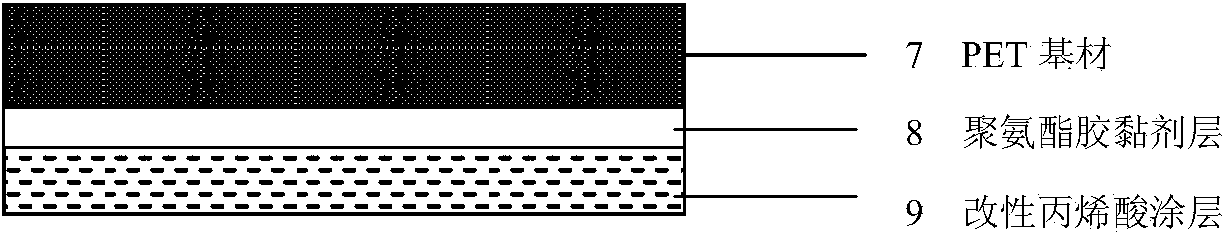

The invention relates to a composite film for flour packaging and a manufacturing method thereof. The composite film comprises three layers (figure. I), namely a PET (polythylene terephthalate) litho-coated thin film, a PE (polyethylene) thin film and a polyurethane adhesive layer arranged between the PET litho-coated thin film and the PET thin film, wherein the PET litho-coated thin film comprises three layers (figure. II), namely a PET coated thin film, a printed layer on the coated thin film and a polyurethane adhesive layer arranged between the PET coated thin film and the printed layer; the PET coated thin film comprises three layers (figure. III), namely a PET base material, a modified crylic acid coating layer on the surface of the base material and a polyurethane adhesive layer arranged between the PET base material and the modified crylic acid coating layer; the modified crylic acid coating layer is obtained by coating the surface of the PET base material with crylic acid emulsion through a coating technology; the modified crylic acid emulsion is prepared from the following raw materials in percentage by weight: 5-10 percent of a functional monomer, 8-12 percent of an adhesive monomer, 6-8 percent of a cohesion monomer, 0.02-0.08 percent of chondroitin sulfate, 0.2-0.5 percent of an emulsifier, 0.05-0.2 percent of a defoaming agent, 0.05-0.1 percent of an initiator, 0.02-0.1 percent of electrolyte, 1-3 percent of ammonia water and 67-75 percent of deionized water. The composite film disclosed by the invention can well achieve the effect of electrostatic dust (powder) absorption during flour packaging and is high in thermal sealing performance.

Owner:HAINAN SHINER IND

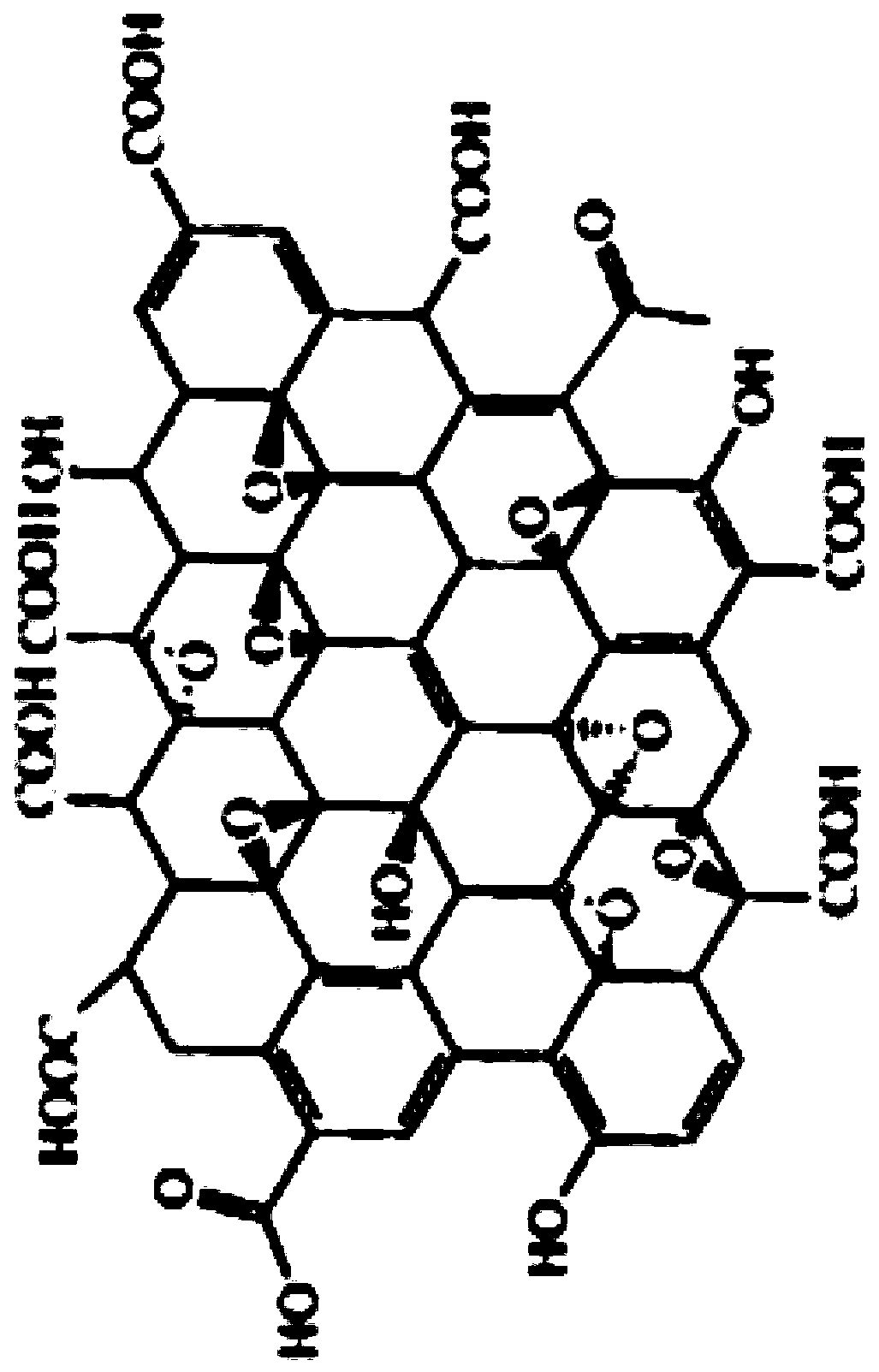

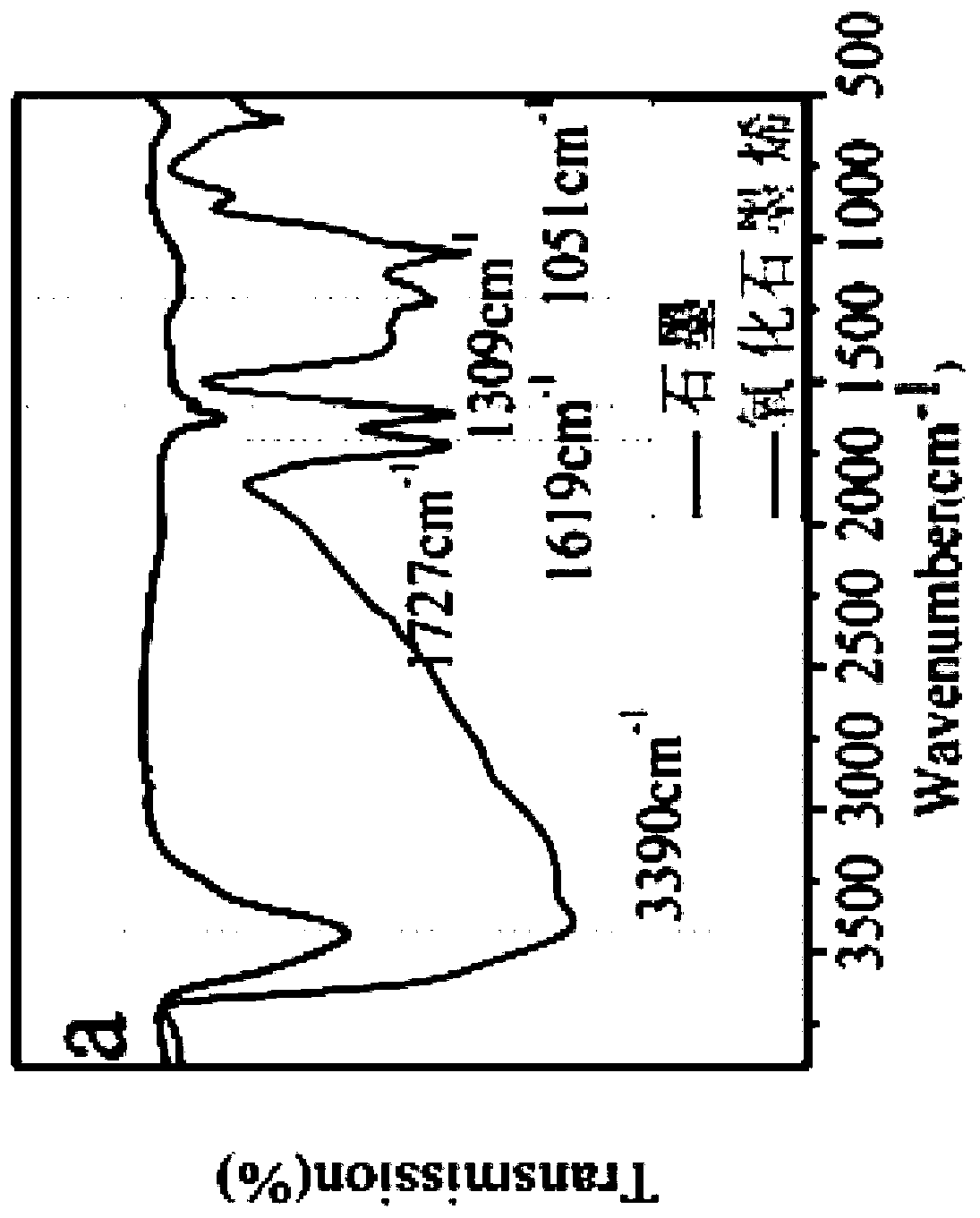

Modified graphene composite polyethylene material and preparation method thereof

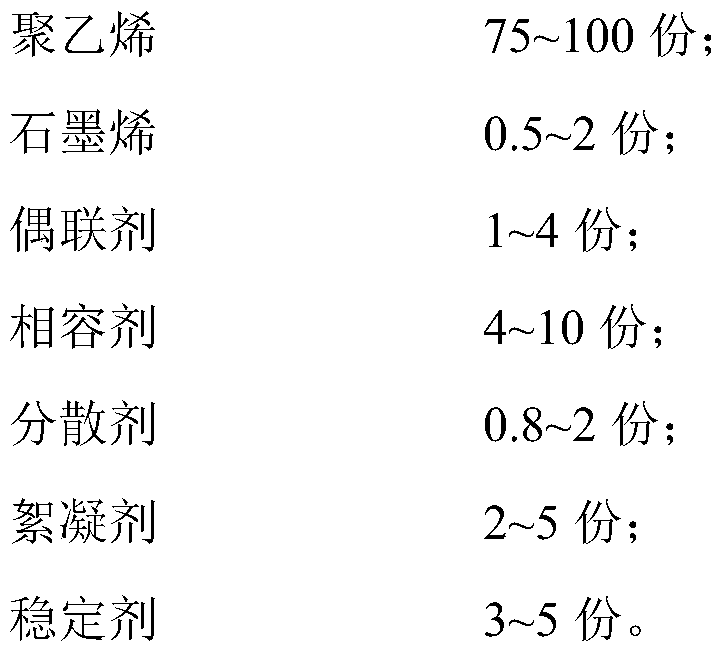

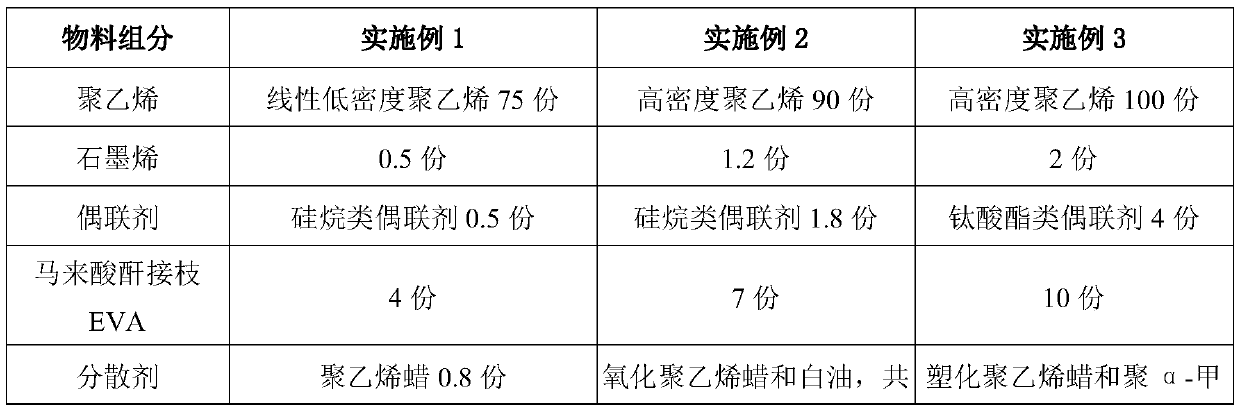

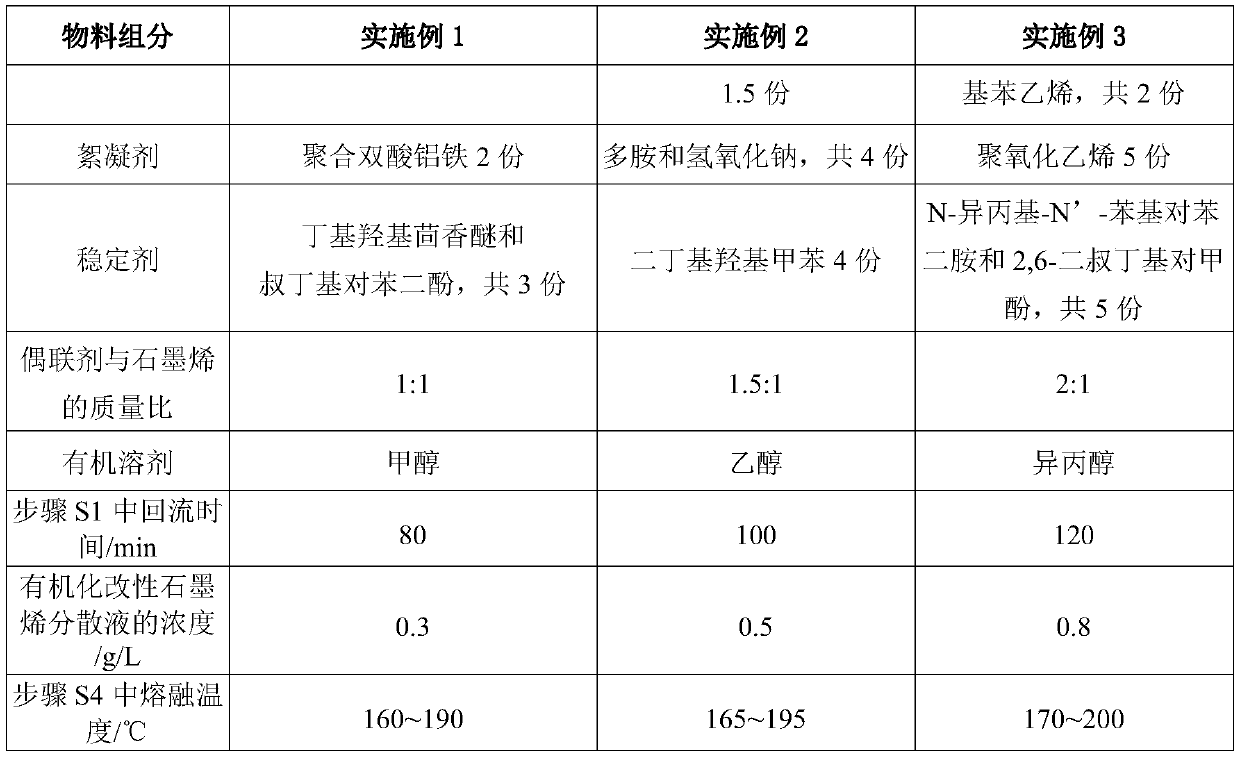

The invention provides a modified graphene composite polyethylene material, which comprises, by weight, 75-100 parts of polyethylene, 0.5-2 parts of graphene, 1-4 parts of a coupling agent, 4-10 partsof a compatilizer, 0.8-2 parts of a dispersing agent, 2-5 parts of a flocculating agent and 3-5 parts of a stabilizer. Compared with the method in the prior art, the method of the invention has the following characteristics that graphene is used as the antistatic agent and the reinforcing agent, and is organically modified with the coupling agent, the maleic anhydride grafted EVA is used as the toughening compatilizer to form the antistatic toughening and reinforcing system of the polyethylene material, and finally the polyethylene material obtains the stable physical and chemical propertiesthrough the flocculating agent and the stabilizer, so that the composite polyethylene material with good mechanical properties and good antistatic properties is prepared in the case of the feeding ofa small amount of the modifier.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

G75 electronic yarn impregnating compound and preparation method thereof

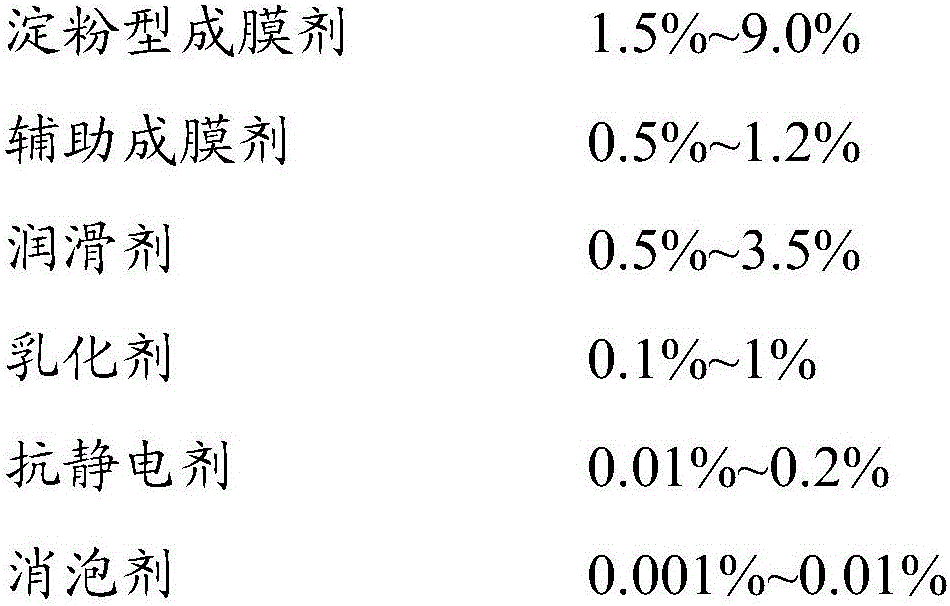

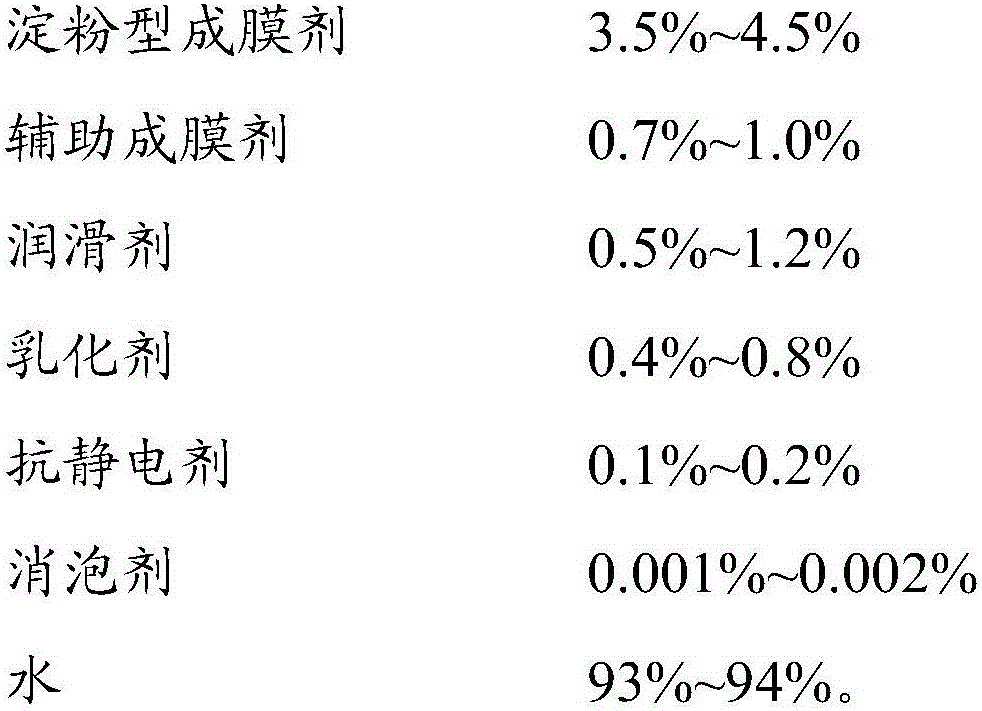

The invention relates to a G75 electronic yarn impregnating compound and a preparation method thereof. The G75 electronic yarn impregnating compound is prepared from, by weight, 1.5-9.0% of a starch type film forming agent, 0.5-1.2% of an auxiliary film forming agent, 0.5-3.5% of a lubricant, 0.1-1% of an emulsifier, 0.01-0.2% of an antistatic agent, 0.001-0.01% of a foaming agent and 86-95% of water. The starch type film forming agent is etherification high straight chain starch and etherification crosslinking starch. The auxiliary film forming agent is water-based epoxy resin. The G75 electronic yarn impregnating compound has the excellent film forming performance, the starch film formed by coating glass fiber with the G75 electronic yarn impregnating compound can effectively reduce hair of glass fiber, the good antistatic effect is achieved, meanwhile, the strength of the glass fiber can be enhanced, and the glass fiber has the good tensile property.

Owner:广东志广生物科技有限公司

Environment-friendly nano modified halogen-free flame retardant polypropylene and preparation method thereof

The invention discloses environment-friendly nano modified halogen-free flame retardant polypropylene and a preparation method thereof. The environment-friendly nano modified halogen-free flame retardant polypropylene comprises the following raw materials in parts by weight: 66 parts of polypropylene matrix, 20 parts of halogen-free expanded flame retardant, 2 parts of conductive packing, 1-3 parts of nano modified particles, 1-3 parts of additive, 5 parts of compatilizer, 1 part of an antioxidant and 2 parts of a lubricating agent. The preparation method comprises the following steps: evenly mixing the polypropylene matrix, the compatilizer, the antioxidant and the lubricating agent by virtue of a high-speed mixer, and then putting the mixed material into a precision open mill; after the mixed material is melted, adding the halogen-free expanded flame retardant and the conductive packing, melting and mixing; and then adding the nano modified particles and the additive; and mixing in the precision open mill, thus obtaining polypropylene. According to the environment-friendly nano modified halogen-free flame retardant polypropylene, the nano modified particles and hollow glass beads are adopted as flame retardant synergists, so that the flame retardant property of the polypropylene can be improved, the viscosity of polypropylene polymer melt can also be significantly reduced, the processability is improved, the heat stability is improved, and the environment-friendly nano modified halogen-free flame retardant polypropylene is excellent in yellowing resistance, good in impact resistance and good in bending strength.

Owner:HENAN UNIV OF SCI & TECH

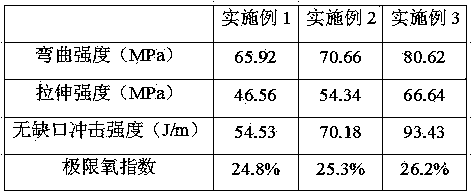

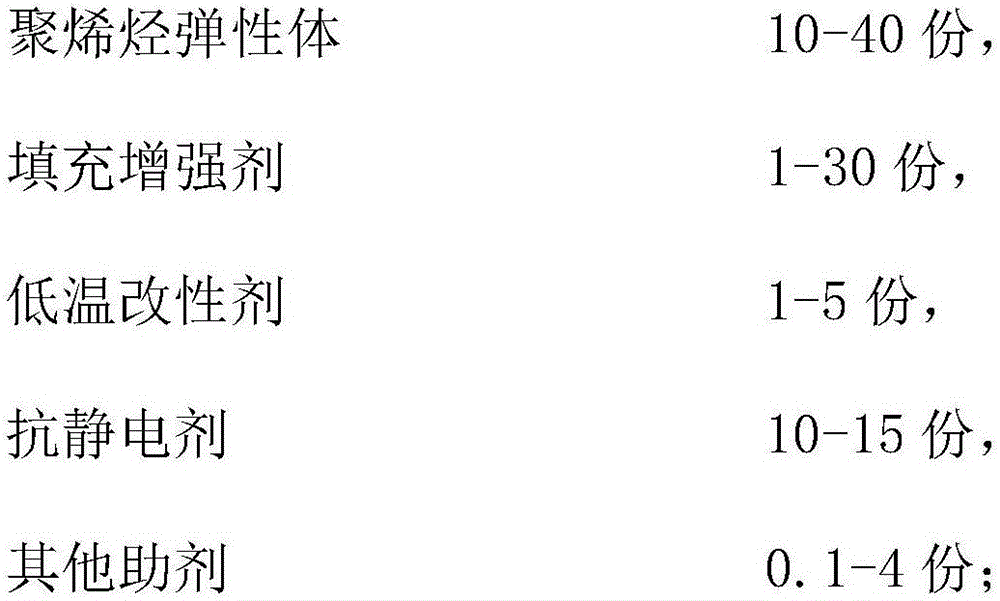

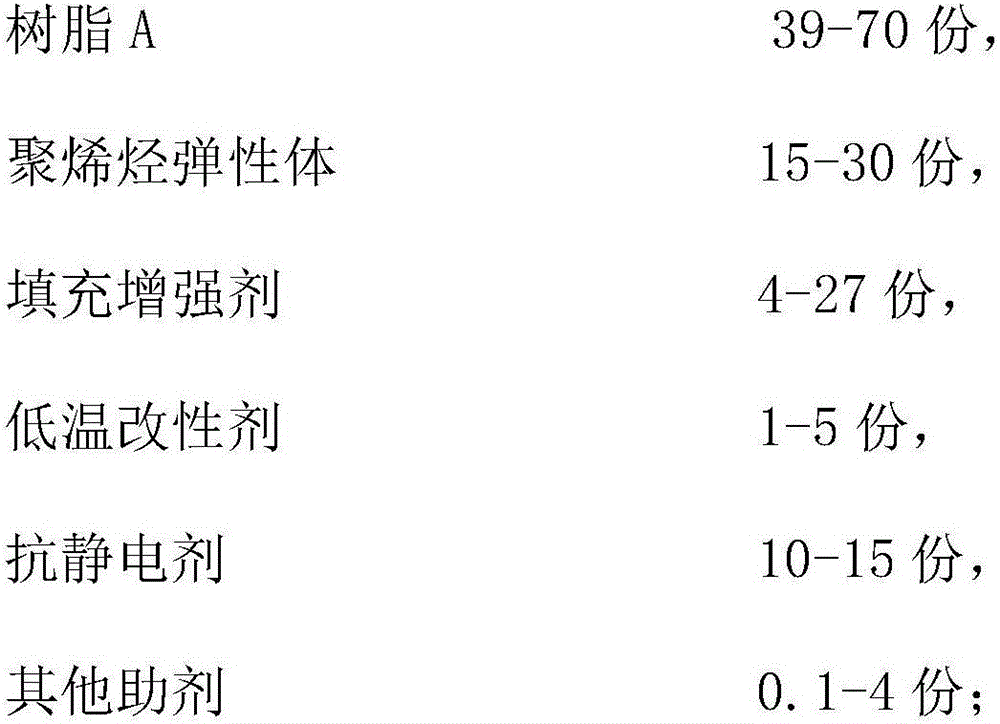

Ultra-low-temperature-resistant antistatic polypropylene composition and preparation method thereof

InactiveCN106589612AImprove low temperature impact toughnessImprove rigidityElastomerAntistatic agent

The invention provides an ultra-low-temperature-resistant antistatic polypropylene composition and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight: 39-90 parts of resin A, 10-40 parts of polyolefin elastomer, 1-30 parts of a filling enhancer, 1-5 parts of a low-temperature modifier, 10-15 parts of an antistatic agent and 0.1-4 parts of other auxiliary agents. The ultra-low-temperature-resistant antistatic polypropylene composition provided by the invention has good low-temperature impact toughness (particularly multi-shaft low-temperature impact strength) and good rigidity, and maintains good dimensional stability.

Owner:TIANJIN KINGFA NEW MATERIAL

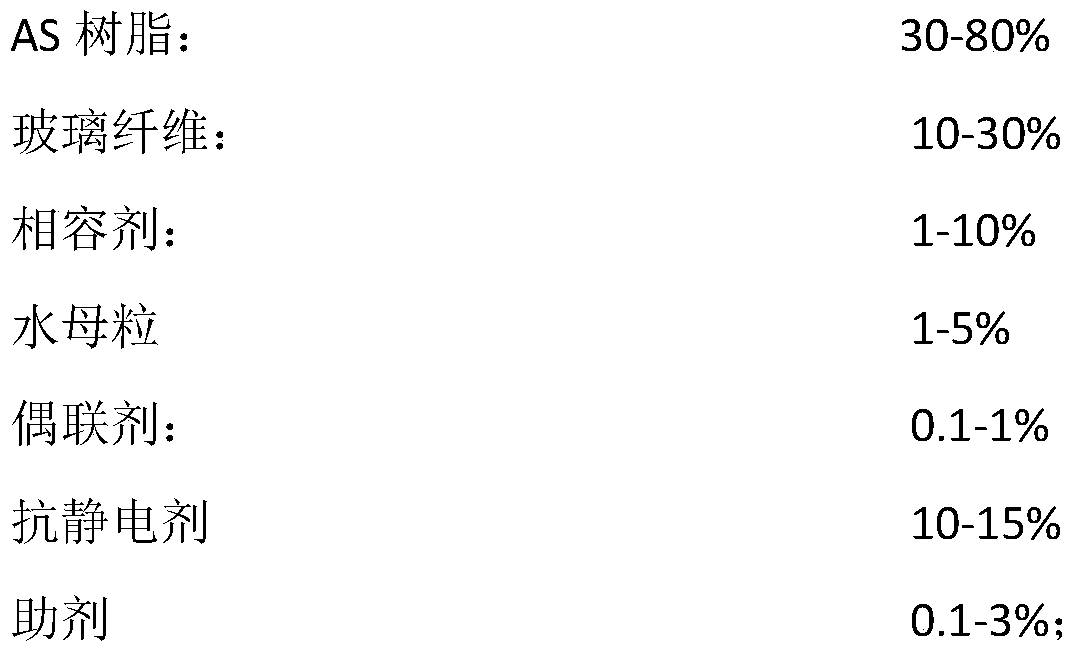

Low-odor antistatic high-performance glass fiber reinforced AS composition and preparation method thereof

InactiveCN105524367AEfficient removalDoes not affect mechanical propertiesGlass fiberAntistatic agent

The invention relates to a low-odor antistatic high-performance glass fiber reinforced AS composition, which contains, by weight, 30-80% of AS resin, 10-30% of glass fiber, 1-10% of a compatilizer, 1-5% of jellyfish granules, 0.1-1% of a coupling agent, 10-15% of an antistatic agent and 0.1-3% of an auxiliary agent. The total percentage of the above components is 100%. The antistatic agent is a permanent antistatic agent and contains molecular distilled glycerin monostearate component, which is specifically hardened palm glyceride. The jellyfish granules used in the invention are easily available, has advantages of simple preparation technology and low cost, can effectively remove odor and will not influence mechanical property of the composition. By adding the antistatic agent, surface resistivity of the AS composition can be reduced from 1016 Omega to 109 Omega, and the antistatic effect is good.

Owner:TIANJIN KINGFA NEW MATERIAL

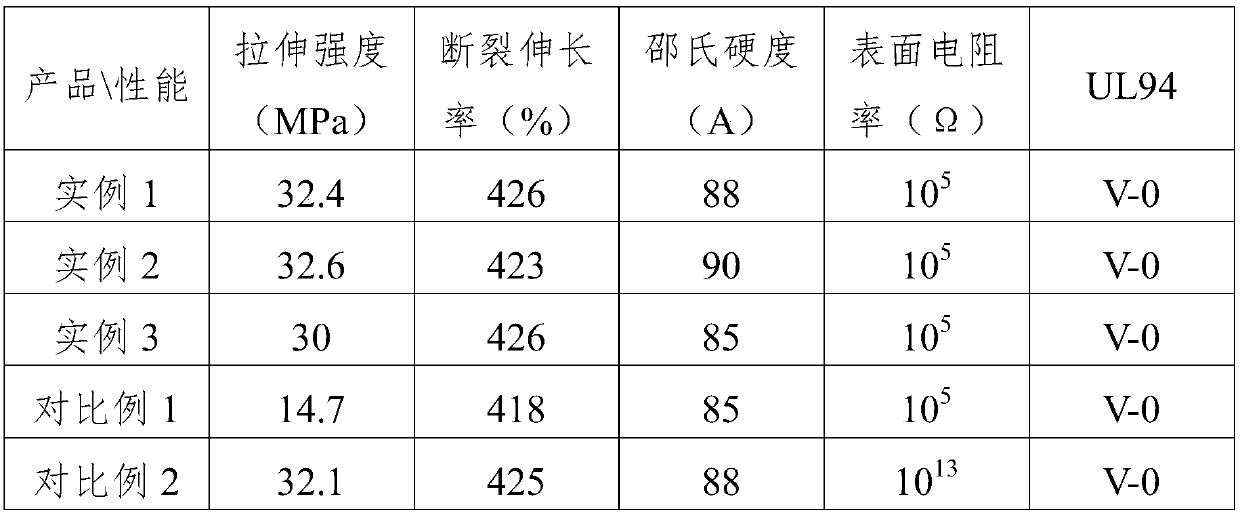

Antistatic flame-retardant thermoplastic polyurethane elastomer

The invention discloses an antistatic flame-retardant thermoplastic polyurethane elastomer which is prepared from the following components in parts by weight: 80 parts of TPU, 20 parts of LLDPE, 8 parts of C nano material, 12 parts of composite flame retardant, 4 parts of antimonous oxide, 5 parts of compatilizer, 0.3-0.4 part of lubricant, 0.5-0.7 part of dispersant, 0.2-0.4 part of flow prompting agent and 0.2 part of antioxidant. A preparation method of the antistatic flame-retardant thermoplastic polyurethane elastomer comprises the following steps: preparing the materials according to theformula; stirring in a stirrer, and mixing uniformly; finally, adding a parallel twin-screw extrusions pelletizer, and performing melt blending and extrusion to obtain a material strip; performing water cooling, blow drying in air and dicing to obtain a product. Through test, the flame retardance of the material can reach the current globally universal highest level UL94V-0 of flame retardance, the surface resistivity is 105Ohm / cm<2>, the tensile strength reaches 32.4MPa, the elongation reaches 426%, the hardness (Shore A) is 90A, all properties of the product meeting the customer needs.

Owner:XIAMEN HAIENDE PHOTOELECTRIC NEW MATERIAL

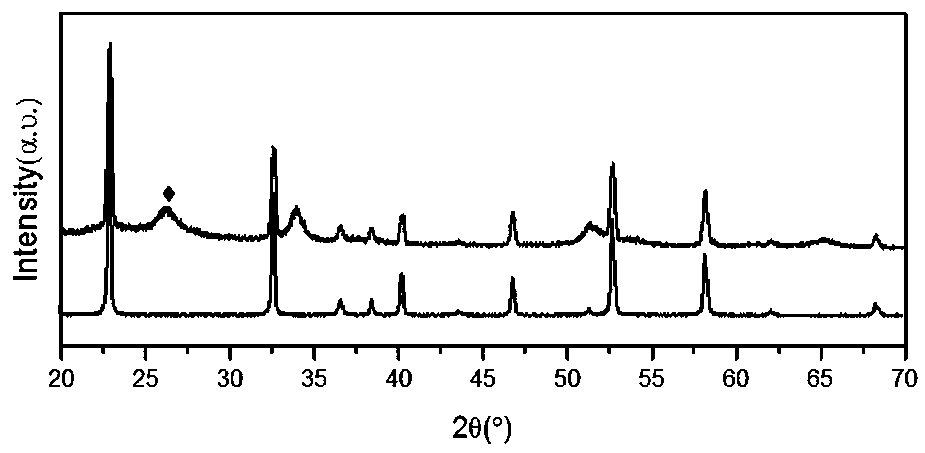

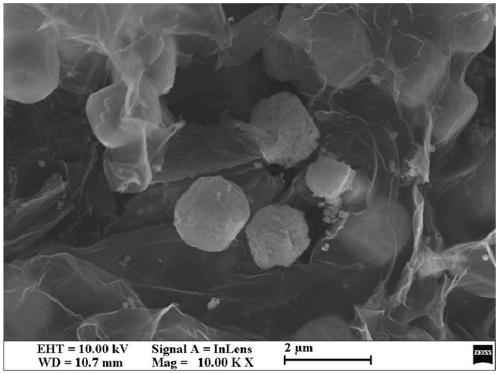

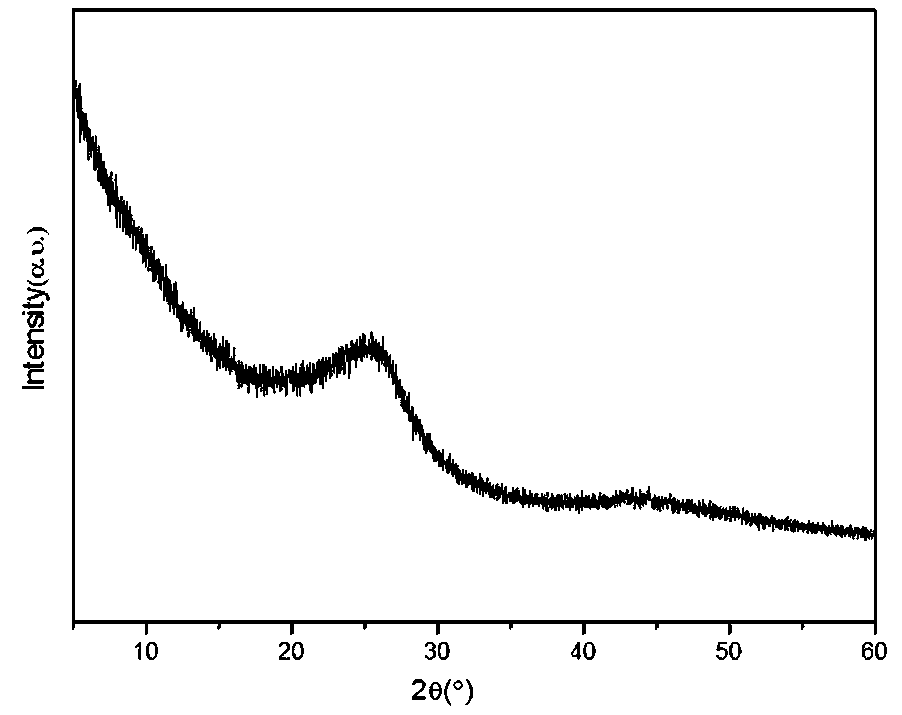

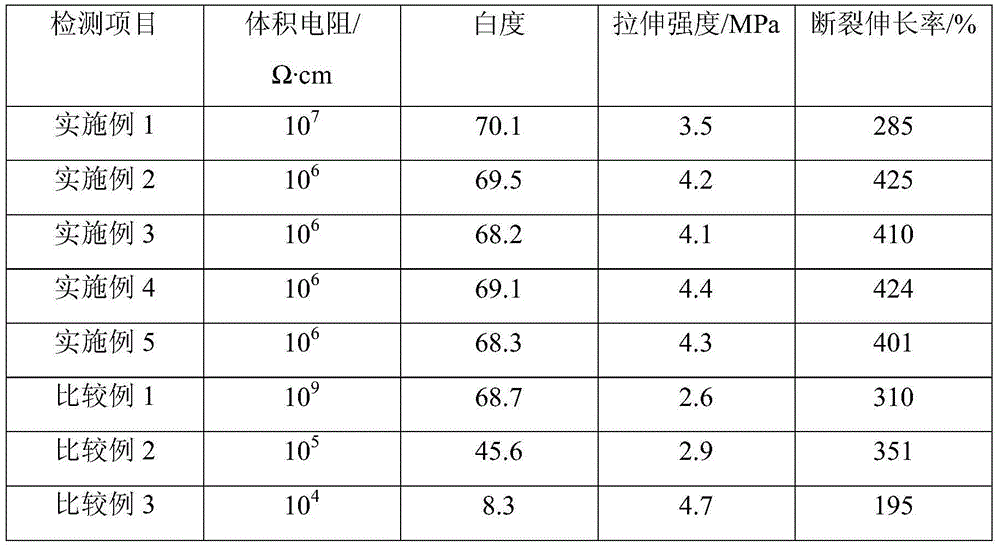

Light-colored anti-static silicone rubber and preparation method thereof

The invention belongs to the field of modification of rubber products and particularly relates to anti-static silicone rubber which takes conductive flaky silica powder as packing and a preparation method thereof. The preparation method comprises the steps as follows: firstly, enabling an Sn-Sb precursor to form a film on the surface of the silica powder slowly and evenly, and then evenly covering the surface of the silica powder with an Sn-Sb composite material through calcination; performing a series of operations such as closed mixing, open mixing and plate vulcanization on the silica powder with an Sn-Sb composite material coating layer, raw rubber and related packing to prepare the anti-static silicone rubber product. The anti-static silicone rubber prepared with the method is lighter in color and excellent in mechanical property and anti-static property.

Owner:CHANGZHOU UNIV

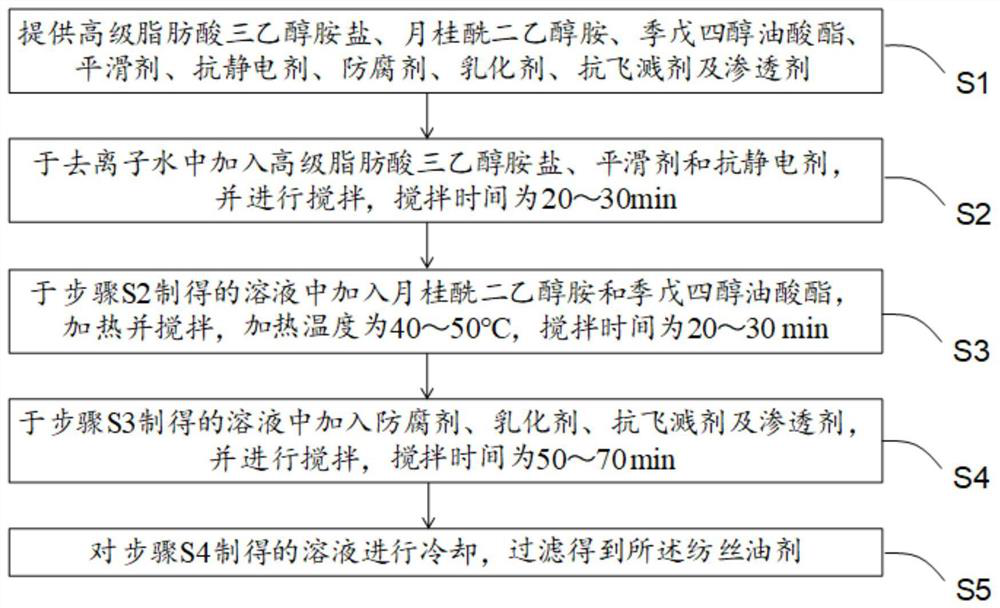

Polyester spinning oil and preparation method thereof

InactiveCN111691013AImprove clusteringImprove wettabilitySynthetic polymer filament chemical after-treatmentPolyesterYarn

The invention discloses polyester spinning oil. The polyester spinning oil is prepared from higher fatty acid triethanolamine salt, lauroyl diethanolamine, pentaerythritol oleate, a smoothing agent, an antistatic agent, a preservative, an emulsifying agent, an anti-splashing agent, and a permeating agent. According to the polyester spinning oil and the preparation method thereof, the bundling performance of the oil can be improved very well by taking the higher fatty acid triethanolamine salt as a bundling agent; the pentaerythritol oleate and the lauroyl diethanolamine have good heat resistance and viscosity properties, and can improve the wettability and temperature resistance of the oil very well; the anti-splashing agent is added, so that the viscosity of the oil is improved, and meanwhile, the tension surface of the oil is greatly increased; therefore, the attachment degree of the oil is high; the permeating effect of the oil is good through the permeating agent; and more oil permeates into yarns.

Owner:科凯精细化工(上海)有限公司

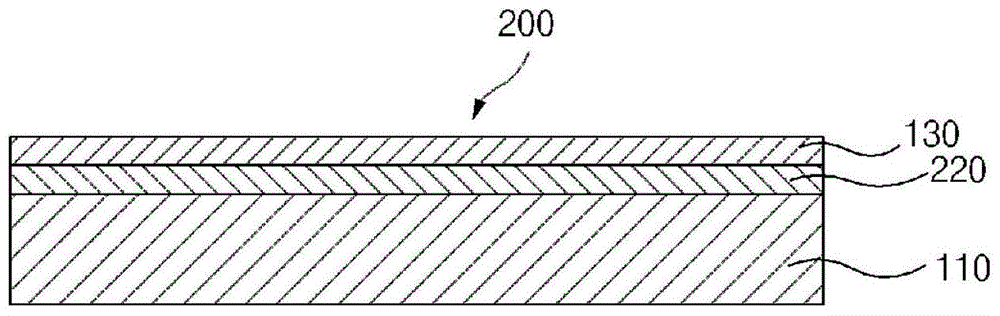

Buffer sheet used in vacuum chuck that adsorbs object to be processed

ActiveCN103608912AGood antistatic effectLow costSemiconductor/solid-state device manufacturingPositioning apparatusCarbon nanotubeMaterials science

Disclosed is a buffer sheet used in a vacuum chuck that adsorbs an object to be processed. The buffer sheet of the present invention is coupled to the upper side of the vacuum chuck which adsorbs and fixes the object to be processed, and includes a non-woven sheet and an ESD coating layer comprising carbon nanotube on the non-woven sheet so that the object to be processed is mounted. According to the present invention, an antistatic effect is excellent since the ESD coating layer comprising the carbon nanotube with electrical conductivity is applied.

Owner:TOP NANOSYS

Antistatic antibacterial far-infrared moisture-absorbing and quick-drying down fabric manufacturing method

ActiveCN110406213AGood touchSoft touchGarment special featuresElectroconductive/antistatic filament manufacturePolyesterYarn

The invention relates to an antistatic antibacterial far-infrared moisture-absorbing and quick-drying down fabric manufacturing method, wherein the down fabric comprises a fabric body, the fabric bodycomprises a surface layer, an inner layer and a down layer, and further comprises a windproof heat locking layer, the surface layer and the windproof heat locking layer are integrally sewn by suturesto form an accommodating channel for filling down, down is filled into the accommodating channel to form the down layer, the windproof heat locking layer comprises a separation cotton lining layer, asilk-like cotton layer and a lining cloth layer, the separation cotton lining layer, the silk-like cotton layer and the lining cloth layer are integrally compounded, the silk-like cotton layer is sandwiched between the separation cotton lining layer and the lining cloth layer, the lining cloth layer is attached to the inner layer, the weight of the silk-like cotton is 40-80 g, the surface layer and / or the inner layer are formed by interweaving with yarns, the yarns are graphene oxide polyester yarns, and the graphene oxide polyester yarn comprises 1-5% by mass of graphene oxide and 90-95% bymass of polyester. According to the present invention, the product has advantages of antistatic property, antibacterial property, far infrared property, moisture absorption, quick drying, low cost andgood warm keeping effect.

Owner:柯林(福建)服饰有限公司

Fireproof mud used for power cable and preparation method thereof

The invention discloses fireproof mud used for installation of a power cable, and belongs to the technical field of fireproof mud. The fireproof mud is composed of, by weight, the raw materials of 25-28 parts of condensed polycyclic aromatic hydrocarbon resin, 15-20 parts of epoxy resin, 8-10 parts of chlorinated paraffin, 14-18 parts of clay, 11-13 parts of porcelain clay powder, 7-9 parts of perlite, 6-9 parts of quartz sand, 5-7 parts of bauxite chamotte, 2-4 parts of magnesium hydroxide, 6-8 parts of tributyl citrate, 4-6 parts of ethylene glycol, 7-9 parts of ammonium phosphate, 2-4 parts of antioxidant, 1-2 parts of anti-corrosion agent and 1-3 parts of antistatic agent. The invention further discloses a preparation method of the fireproof mud used for installation of the power cable. The fireproof mud is easy to prepare, environmentally friendly, low in pollution and good in durability, and has the effects of good fire resistance, corrosion resistance, water resistance and static resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com