Polyester spinning oil and preparation method thereof

A spinning oil and polyester technology, which is applied in the field of polyester spinning oil and its preparation, can solve the problems of inability to adhere quickly and evenly, poor fiber cohesion, insufficient oil wettability, etc., and achieve good antistatic effect. , High adhesion and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of polyester spinning oil, comprising higher fatty acid triethanolamine salt, lauroyl diethanolamine, pentaerythritol oleate, smoothing agent, antistatic agent, preservative, emulsifier, anti-splash agent and penetrating agent, The composition of the spinning oil by weight is as follows: 8-12 parts of higher fatty acid triethanolamine salt, 10-20 parts of lauroyl diethanolamine, 13-24 parts of pentaerythritol oleate, 67-76 parts of smoothing agent, antistatic 5-10 parts of preservative, 5-10 parts of preservative, 10-13 parts of emulsifier, 1-2 parts of anti-splashing agent, 0.1-0.4 parts of penetrant;

[0028] Higher fatty acid triethanolamine salt as a sizing agent can improve the sizing performance of the oil;

[0029] Both pentaerythritol oleate and lauroyl diethanolamine have good heat resistance and viscosity properties, which can improve the wettability and temperature resistance of oils;

[0030] In this embodiment, the smoothing...

Embodiment 2

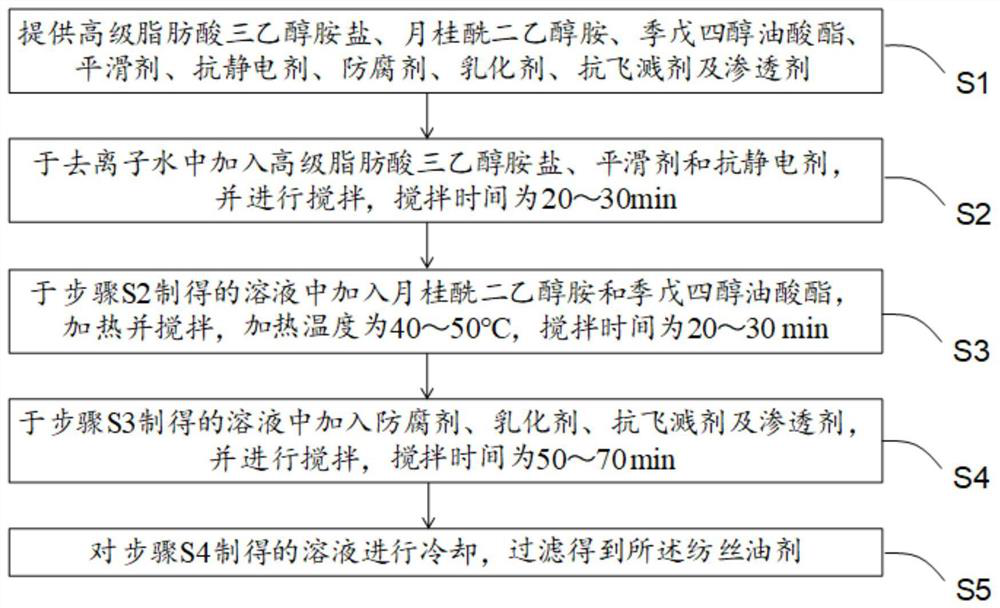

[0038] see figure 1 As shown, based on the same inventive concept, this embodiment provides a preparation method of polyester spinning oil, comprising the following steps:

[0039] S1: Provide higher fatty acid triethanolamine salt, lauroyl diethanolamine, pentaerythritol oleate, smoothing agent, antistatic agent, preservative, emulsifier, anti-splashing agent and penetrating agent, and the proportion of spinning oil by weight The composition is as follows: 8-12 parts of higher fatty acid triethanolamine salt, 10-20 parts of lauroyl diethanolamine, 13-24 parts of pentaerythritol oleate, 67-76 parts of smoothing agent, 5-10 parts of antistatic agent, 5-20 parts of preservative 10 parts, emulsifier 10-13 parts, anti-splash agent 1-2 parts, penetrant 0.1-0.4 parts;

[0040] In this embodiment, the smoothing agent is any one of fatty acid ester, polyol ester, monoalkyl polyether, dialkyl polyether, polyalkyl polyether, end-capped polyether and ethylhexyl palmitate One or a combi...

Embodiment 3

[0047] The present embodiment provides a kind of preparation method of antistatic type spinning finish, comprises the following steps:

[0048] S1: Provide higher fatty acid triethanolamine salt, lauroyl diethanolamine, pentaerythritol oleate, smoothing agent, antistatic agent, preservative, emulsifier, anti-splashing agent and penetrating agent, and the proportion of spinning oil by weight The composition is as follows: 8 parts of higher fatty acid triethanolamine salt, 10 parts of lauroyl diethanolamine, 24 parts of pentaerythritol oleate, 10 parts of sodium lauryl sulfate, 72 parts of smoothing agent, 5 parts of preservative, castor oil polyoxyethylene ( 20-40) 13 parts of ether, 1.5 parts of anti-splash agent, 0.3 parts of penetrant;

[0049] Among them, ethylhexyl palmitate is selected as the smoothing agent, imidazole compounds are selected as the preservative, and the components and contents of the anti-splash agent are: 12.5% polymer polyisobutylene, 12.5% ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com