Multicomponent white conductive fiber and preparation method thereof

A technology of conductive fiber and production method, applied in fiber treatment, conductive/antistatic filament manufacturing, conjugated synthetic polymer artificial filament, etc., can solve the problems of poor discharge effect, low whiteness, high whiteness, etc. Achieve the effects of post-processing, high whiteness, and whiteness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

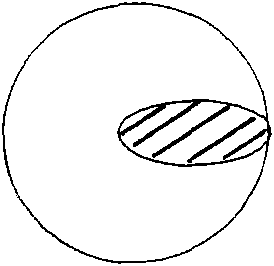

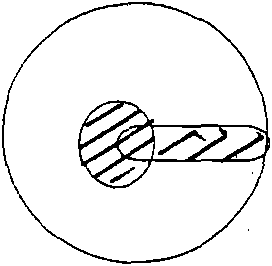

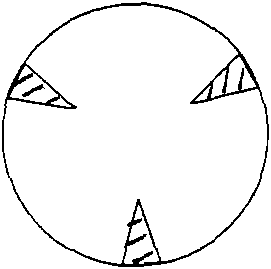

Image

Examples

Embodiment 1

[0028] 65 parts of nano-conductive powder (tin oxide coated on the surface of titanium dioxide or antimony oxide coated on the surface of titanium dioxide) with moisture less than 100 ppm after vacuum drying, 35 parts of polytrimethylene terephthalate with moisture less than 100 ppm after drying and calcium stearate Or magnesium stearate is mixed and then fed into the screw extruder. The set temperature of the screw is 250°C. After blending and extruding, it is pelletized and dried, and the moisture content is controlled below 100ppm. The dried conductive masterbatch is put into No. 1 spinning box, set the screw temperature at 265°C, and the melt density of the masterbatch after extrusion is 2.8g / m 3 ;Dried good antistatic agent (1%wt relative to fiber-forming polymer), low powder content conductive masterbatch (1%wt relative to fiber-forming polymer, conductive powder is titanium dioxide surface coating tin oxide or titanium dioxide The surface is coated with antimony oxide) ...

Embodiment 2

[0031] Using the same conductive masterbatch as in Example 1, common full-dull polyethylene terephthalate, antistatic masterbatch varieties and additions, spinning temperature and winding conditions, change the conductive masterbatch and common full-dull polyethylene terephthalate. The mass ratio of ethylene terephthalate is 50:50. It is spun with an open eccentric spinneret, the winding speed is set at 2500m / min, the fineness is controlled at about 140dtex / 8F, and the volume resistivity of the obtained pre-oriented yarn is 10 3~4 The Ω·cm tone L value is 54, and the length of the exposed portion of the conductive component in the circumferential direction accounts for 6.3% of the circumference of the single fiber section.

[0032] The wound pre-oriented yarn is stretched. The temperature of the first hot roller of the stretching machine is set to 90°C, the temperature of the second hot roller is 130°C, the stretching ratio is 1.9, and the stretching speed is 500m / min. The vol...

Embodiment 3

[0034] Adopt the same conductive masterbatch manufacturing process as in Example 1 (nano conductive powder is zinc oxide), conductive powder content, fiber-forming polymer, antistatic masterbatch kind and addition, spinning temperature, composite ratio and winding Conditions, use the open eccentric spinneret to spin, set the winding speed to 2500m / min, control the fineness to about 140dtex / 8F, and the volume resistivity of the obtained pre-oriented yarn is 10 5 Ω·cm, the color tone L value is 64, and the length of the exposed part of the conductive component in the circumferential direction accounts for 2.8% of the circumference of the single fiber section.

[0035]To stretch the wound pre-oriented yarn, the temperature of the first hot roller of the stretching machine is set to 90°C, the temperature of the second hot roller is 130°C, the stretching ratio is 1.7, and the stretching speed is 500m / min. The volume resistivity of the fully oriented silk after stretching is 10 5 Ω...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com