Patents

Literature

1294 results about "Single filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

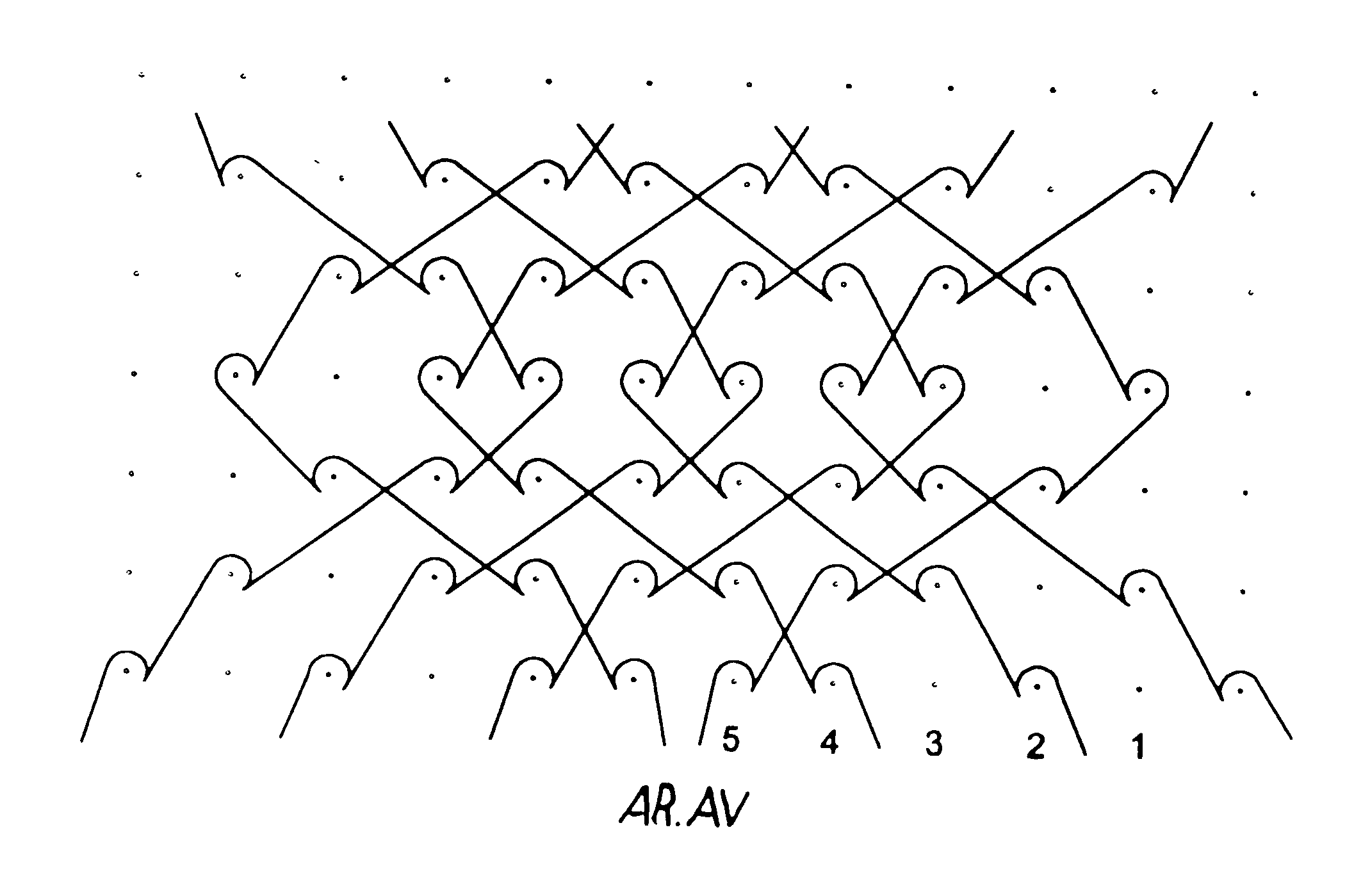

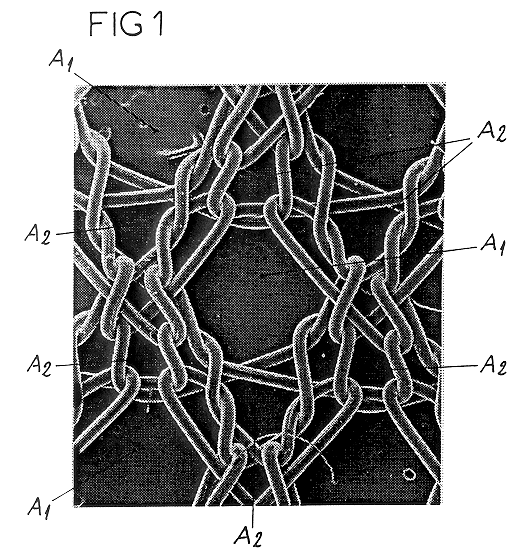

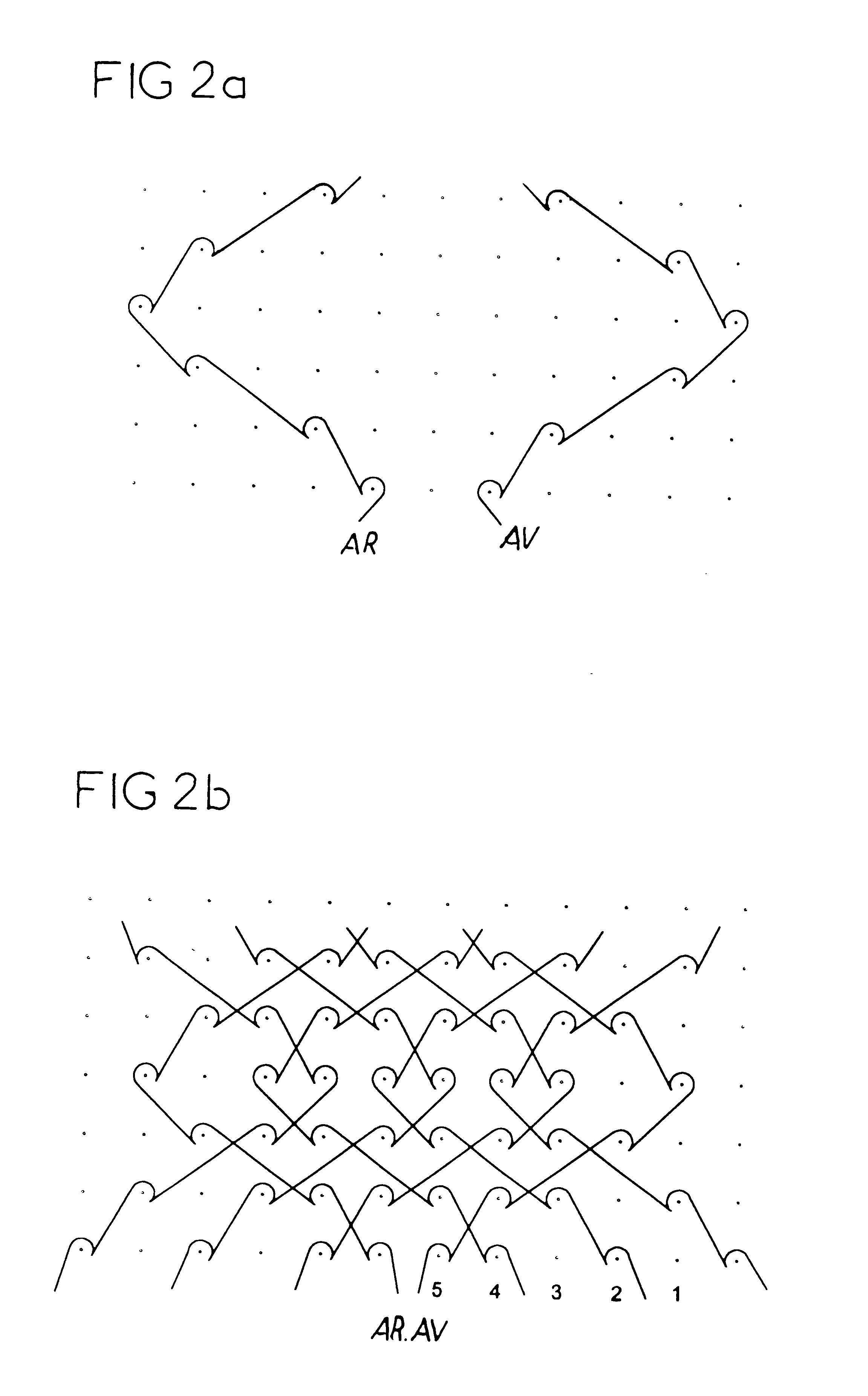

Isoelastic prosthetic filet stitch fabric

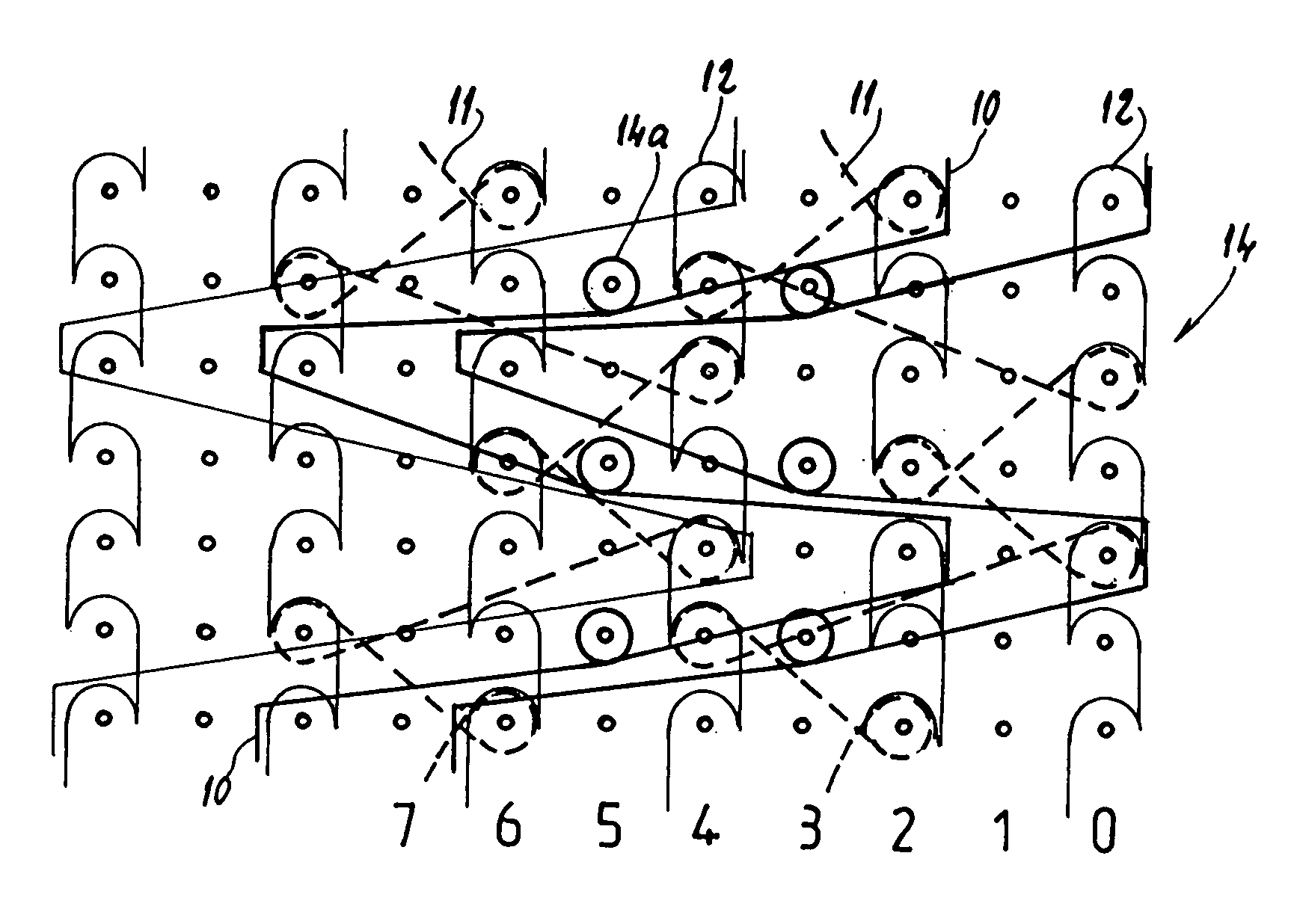

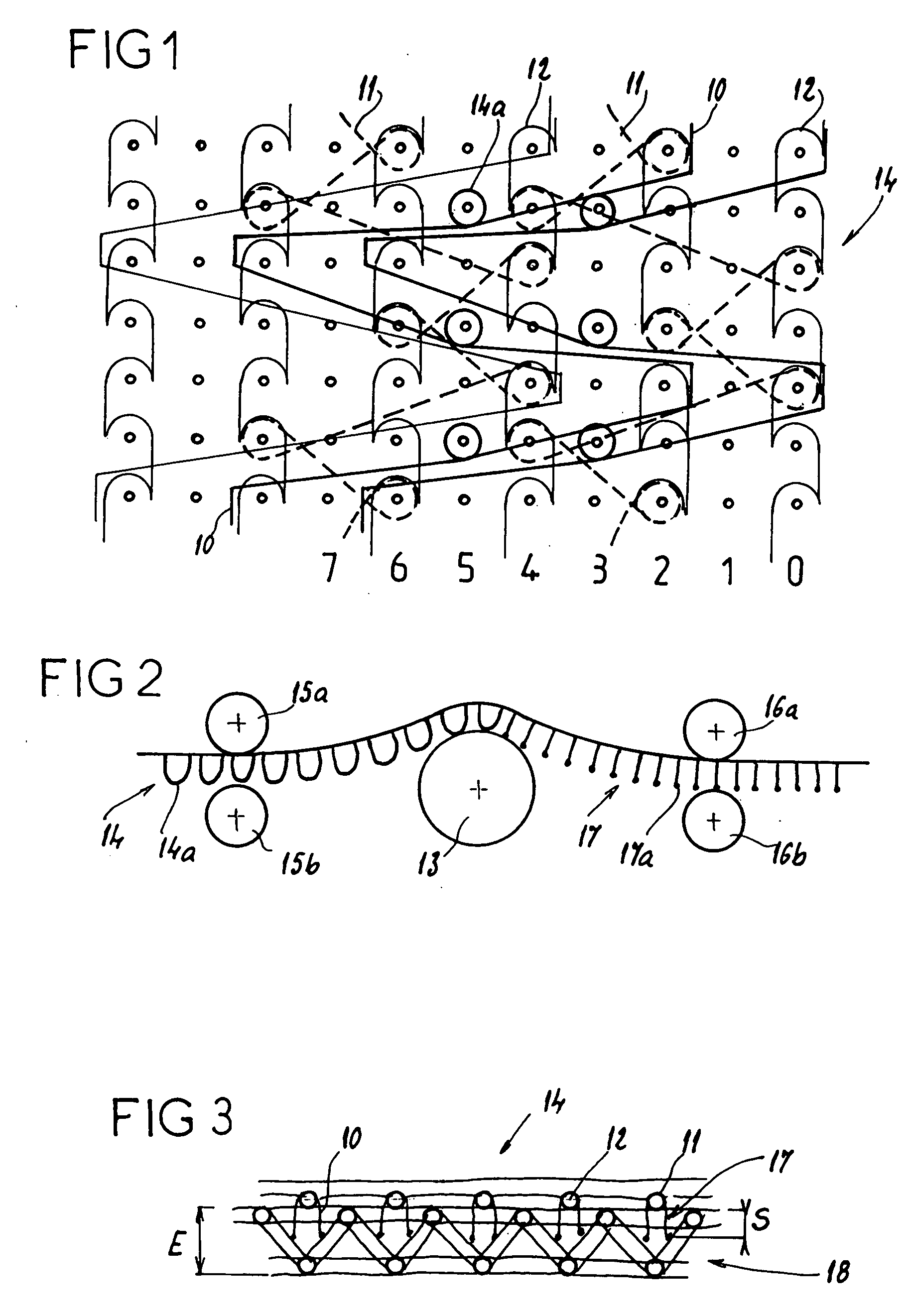

This knit is produced on the basis of a biocompatible polymer material monofilament, whose pattern is defined by a front lap and a rear lap of yarns knitted together and determines a plurality of cells each having a substantially polygonal shape. The pattern gives the knit a multidirectional tensile behavior such as obtained by a front lap capable of being obtained by knitting according to a scheme 5-4 / 4-3 / 2-1 / 0-1 / 1-2 / 3-4 and by a rear lap capable of being obtained by knitting according to a scheme 0-1 / 1-2 / 3-4 / 5-4 / 4-3 / 2-1.

Owner:SOFRADIM PROD SAS

Enhanced ballistic performance of polymer fibers

ActiveUS7964518B1Synthetic resin layered productsPersonal protection gearFiber ChemistryPhysical strength

Ballistic resistant materials having improved strength and lighter weights. More particularly, improved ballistic resistant fabrics produced from drawn, high modulus fibers having a reduced fiber diameter and improved physical strength properties, without changing other properties such as fiber chemistry, binder resin type and binder resin content. The fabrics incorporate low denier per filament monofilament fibers, low denier per filament multifilament fibers, or a combination of low denier per filament monofilament fibers and low denier per filament multifilament fibers in a specialized fabric construction to form fine fiber layers and fabrics having enhanced strength and fiber areal density without altering the fabric weight, or having reduced fabric weight without a corresponding reduction in ballistic performance.

Owner:HONEYWELL INT INC

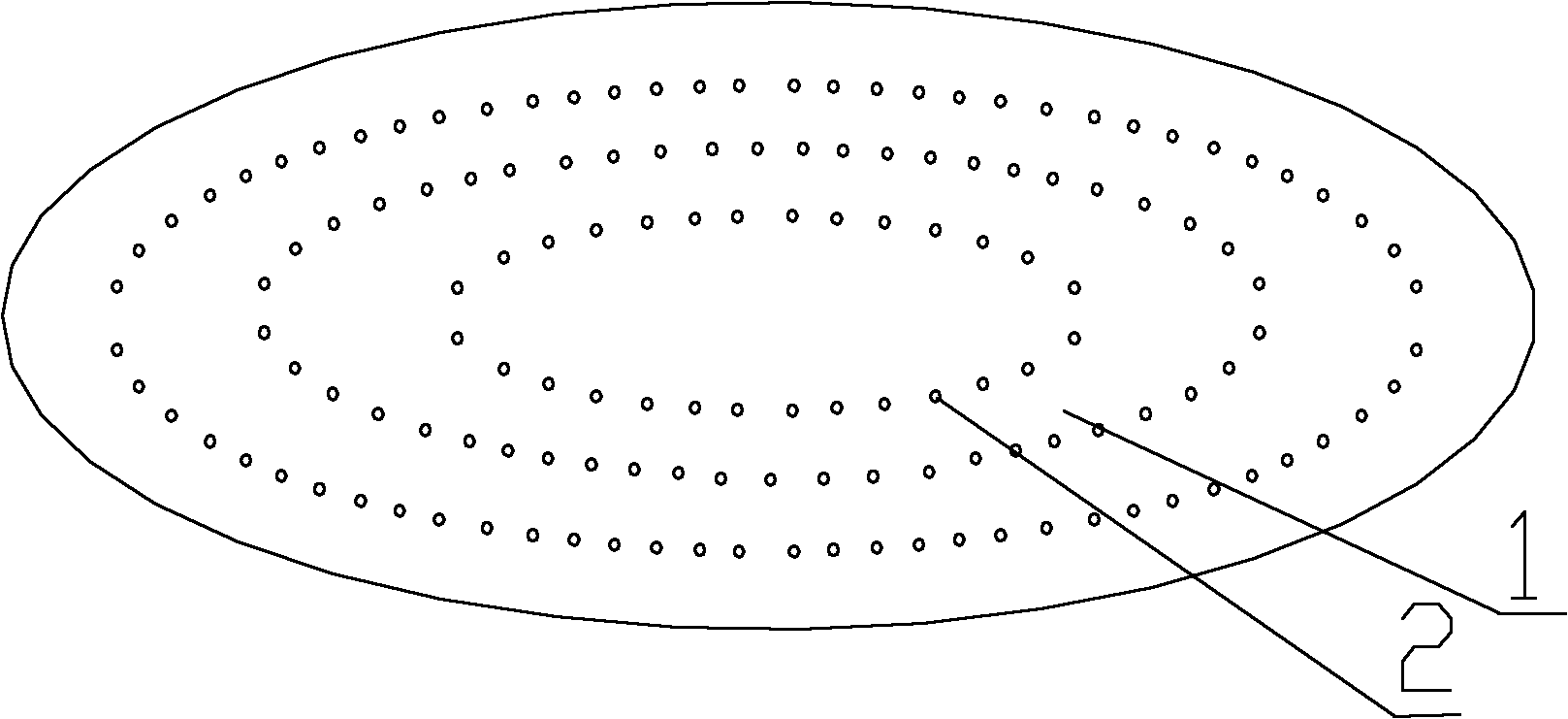

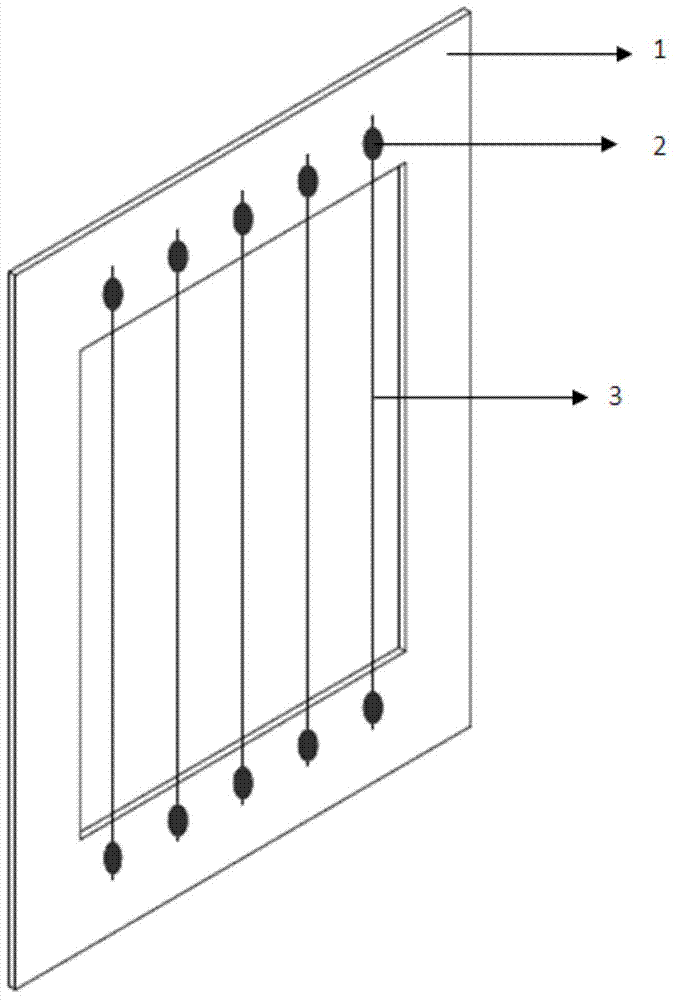

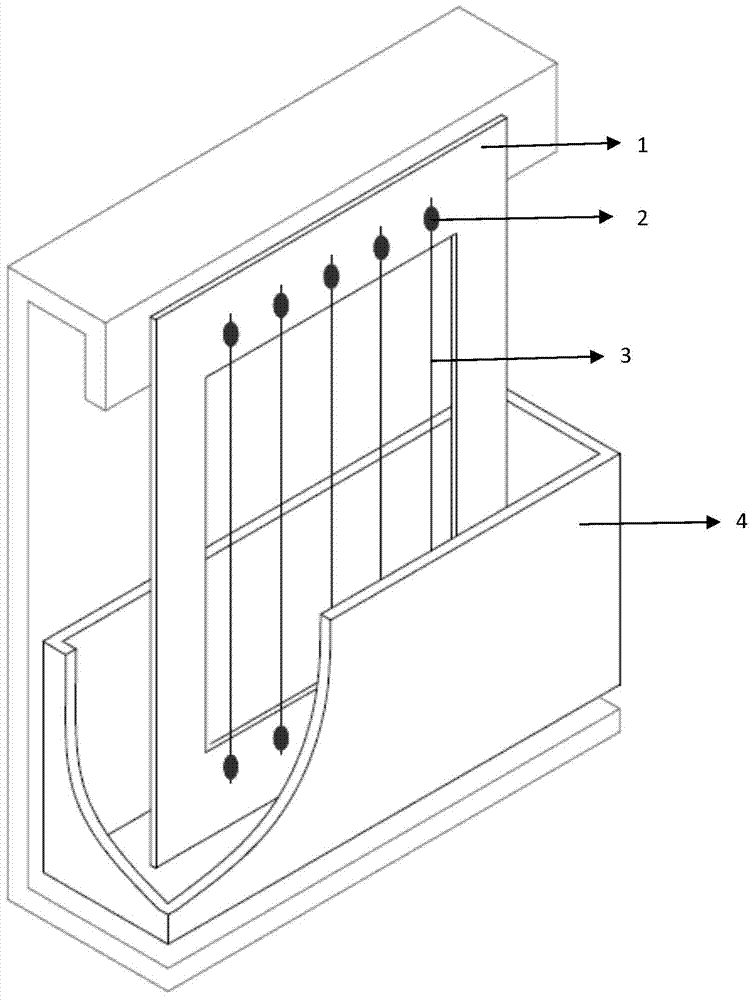

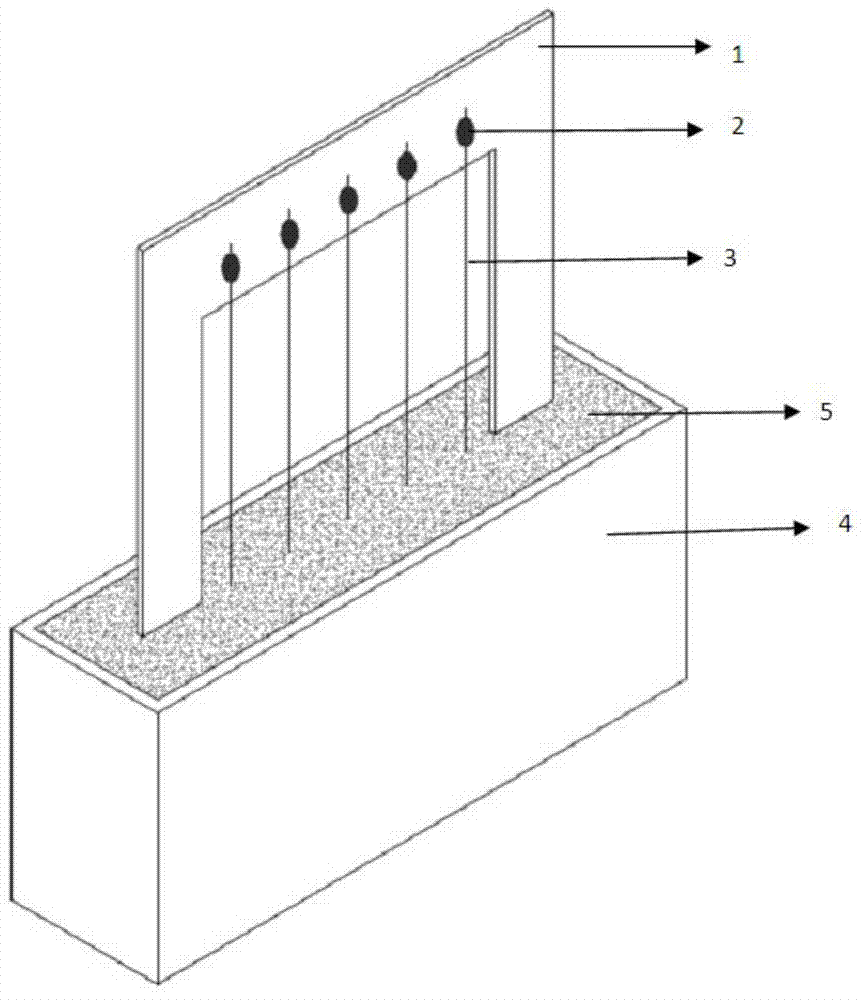

Special-shaped spinneret plate for spinning heavy denier yarns

InactiveCN102851757AImprove cooling uniformityImprove dyeing effectFilament/thread formingPolymer scienceSpinning

A special-shaped spinneret plate for spinning heavy denier yarns comprises an elliptic body (1). 90-192 spinning holes (2) are arranged on the body (1). One side of each spinning hole (2) is a feed inlet. The other side of each spinning hole (2) is a discharge outlet. The plurality of spinning holes (2) are arranged in a three-layered concentric ellipse structure from inside to outside. The spinneret plate is capable of producing glazed heavy denier yarns of 300-500D. Due to heavier filament number, diameters of micropores are slightly larger than those of round holes of products of conventional specification, and flow speed of melts in the micropores can be lowered effectively. In addition, the ellipse spinneret plate is different from conventional round spinneret plates, distribution of the micropores is facilitated, enhancement of cooling effect of spun fibers is facilitated, cooling uniformity of the heavy denier yarn is improved, and dyeing effect of the heavy denier yarn is also improved.

Owner:JIANGSU HUAYA FIBER

Method for producing an electrically conductive yarn, the electrically conductive yarn and use of the electrically conductive yarn

InactiveUS6032450ACounteracts brittlenessImprove adhesionInorganic material artificial filamentsContinuous wound-up machinesTextile fiberYarn

A method for producing an electrically conductive compound yarn. An electrically conductive monofilament metal thread is spun into a compound yarn together with textile fibers. A compound yarn of this type is particularly suitable for producing woven and knit materials.

Owner:SPOERRY 1866 AG

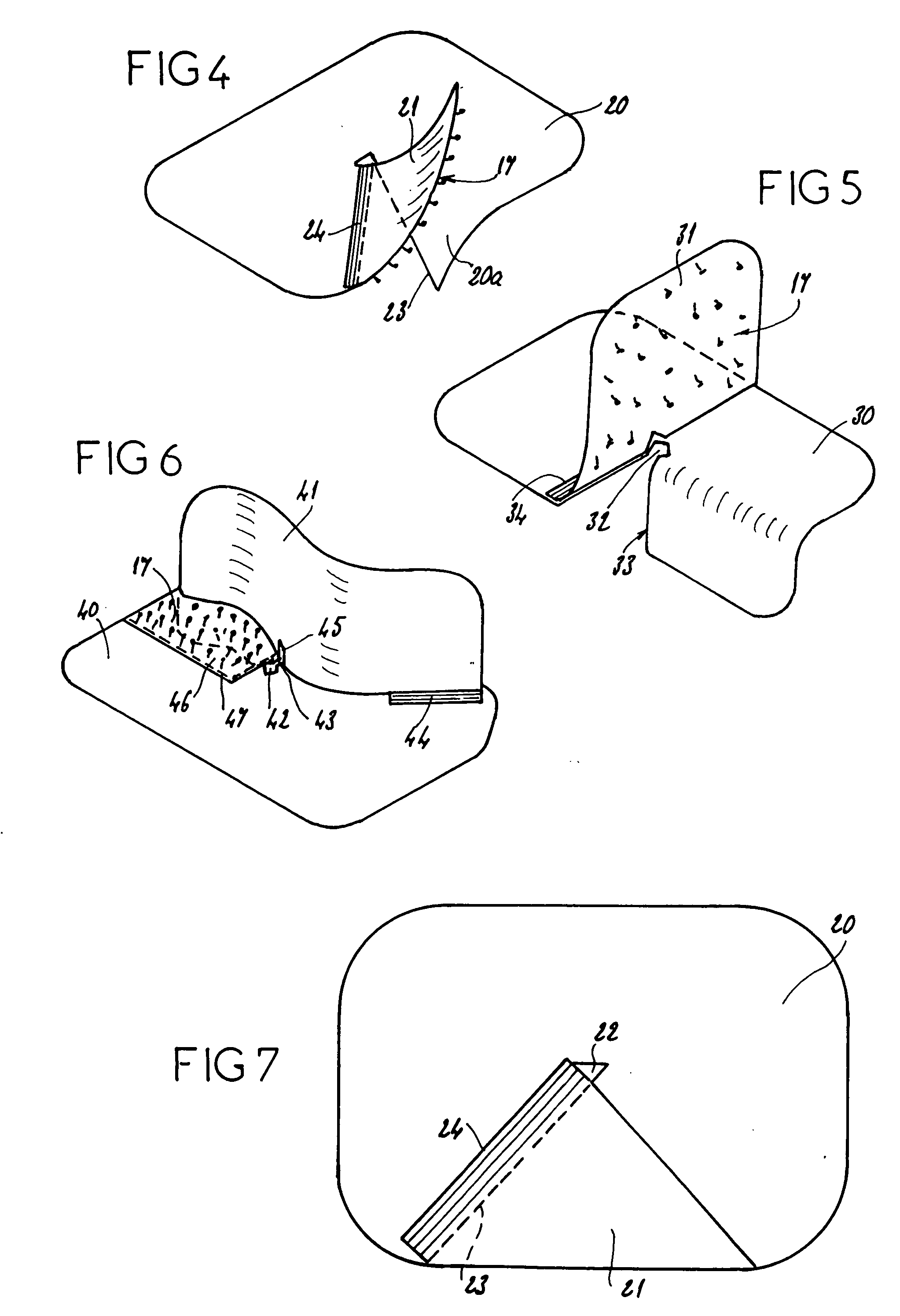

Adhering prosthetic knitting fabric, method for making same and reinforcement implant for treating parietal deficiencies

ActiveUS20040054376A1Sufficiently secureIncrease widthMedical devicesCircular knitting machinesEnthesisProsthesis

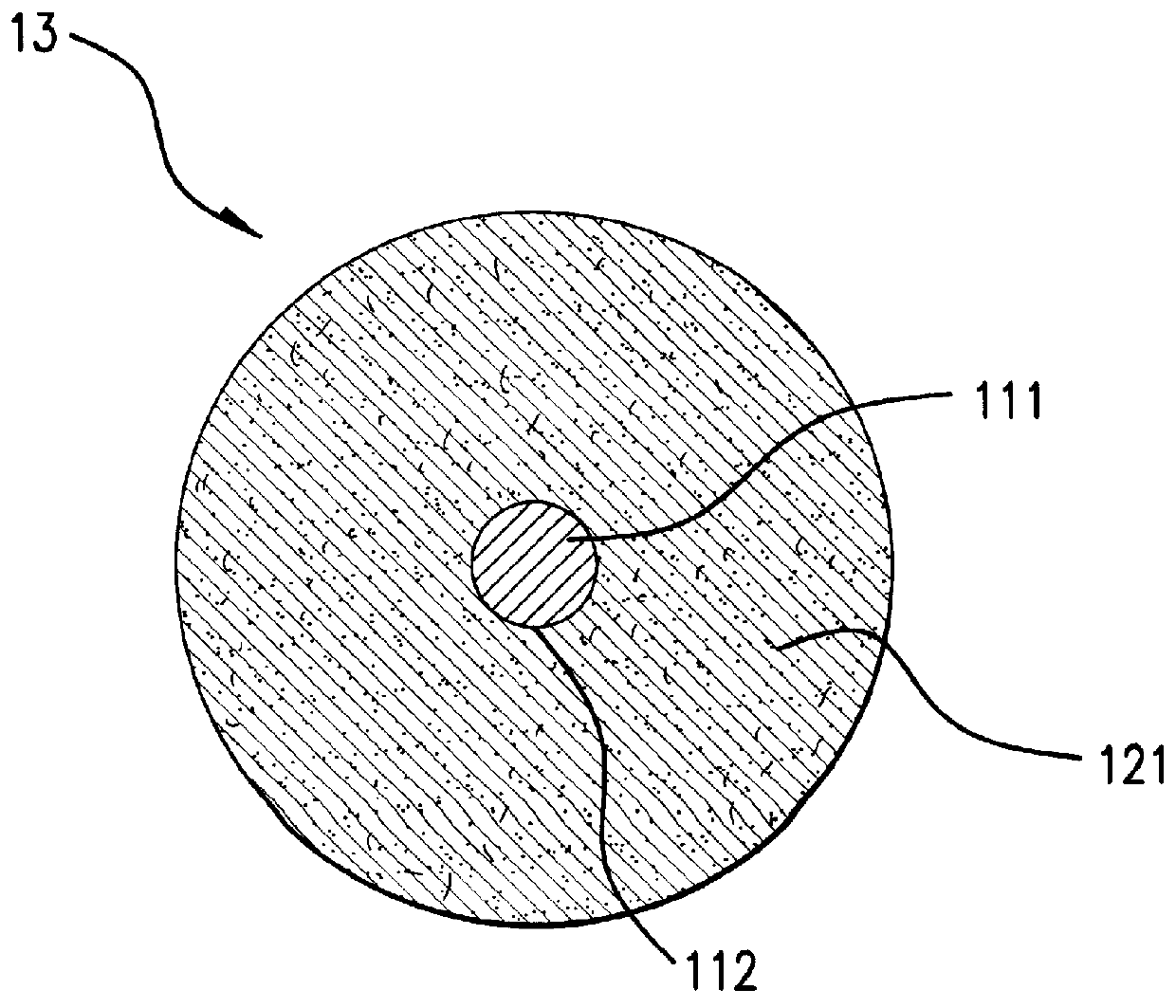

A prosthetic knit for medical or surgical use which has a structure made of monofilament and / or multifilament yarn which is biocompatible and optionally partially bioabsorbable. According to the invention, this knit comprises a monofilament sheet forming, on one face of the knit, spiked naps which protrude perpendicularly with respect to said sheet, that is to say naps each having a substantially rectlinear body and, at the free end of this body, a head of greater width than that of this body.

Owner:SOFRADIM PROD SAS

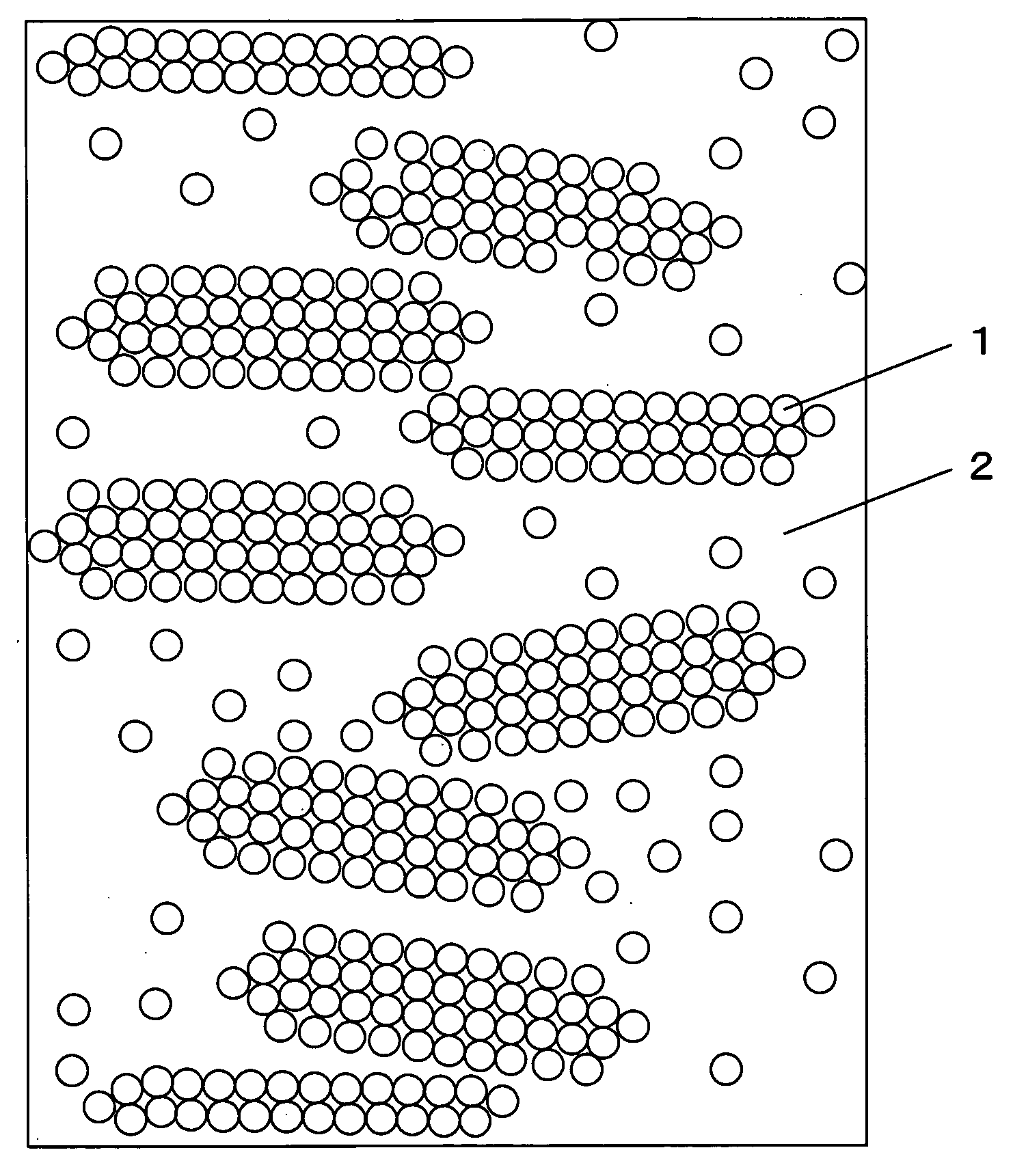

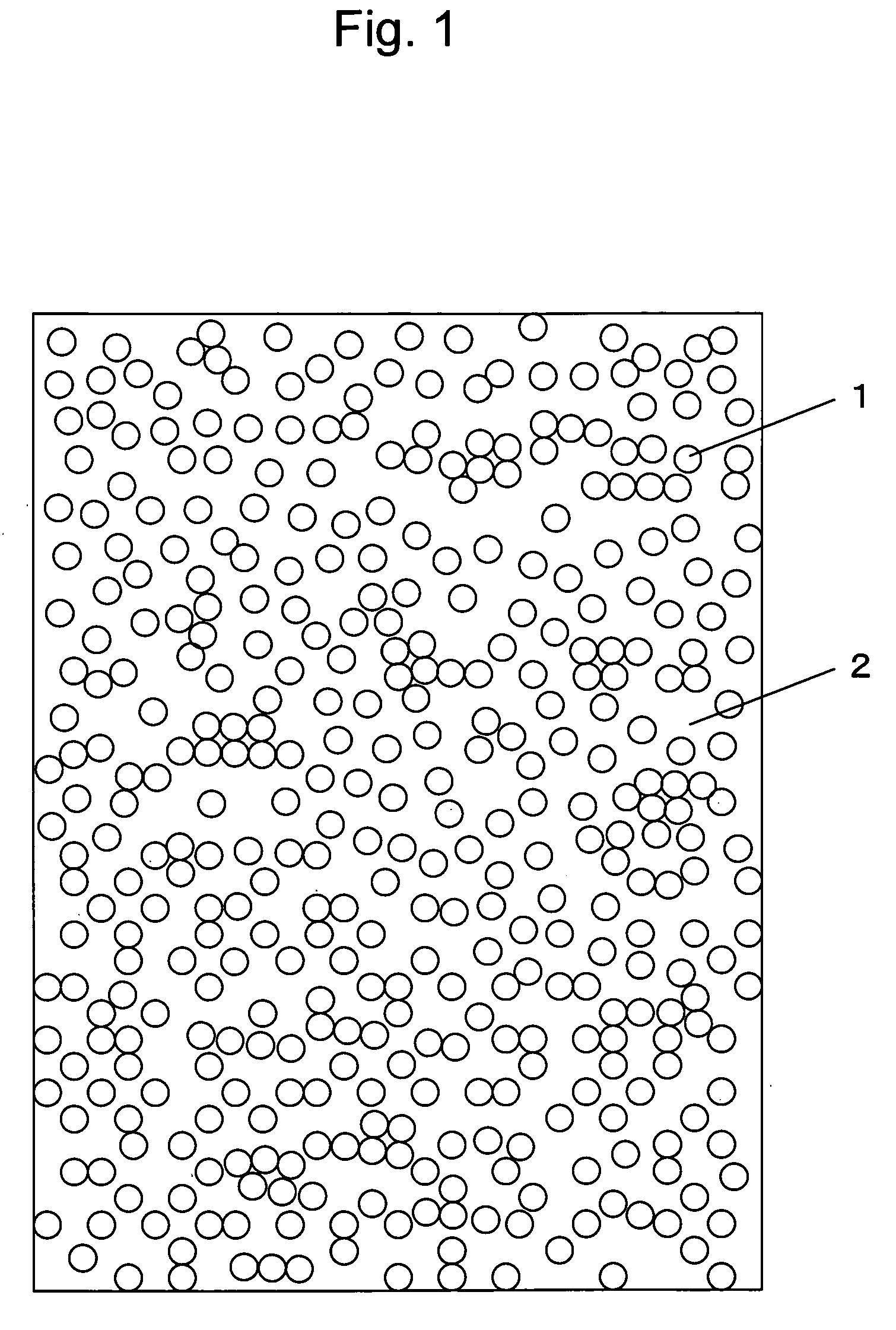

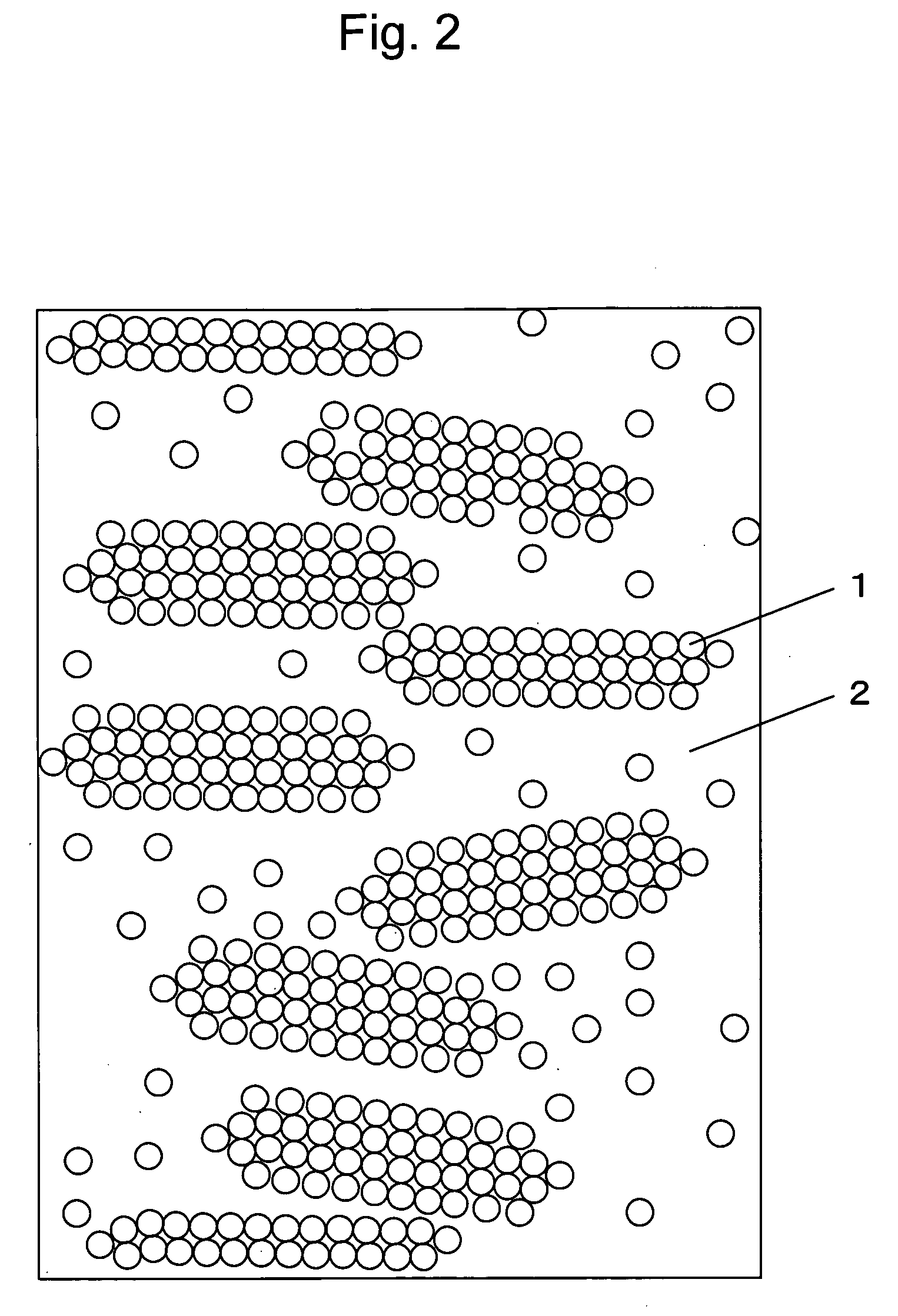

Fiber-Reinforced Thermoplastic Resin Molded Article, Molding Material, and Method for Production of the Molded Article

ActiveUS20090004453A1Improve mechanical propertiesEasy to operateSynthetic resin layered productsSpecial tyresCompression moldingCarbon fibers

According to the present invention, a fiber-reinforced thermoplastic resin molded article in which monofilamentous carbon fibers are contained in a thermoplastic resin in a high content, such fibers having long fiber lengths and being randomly arranged, is provided. Also, a molding material comprising monofilamentous carbon fibers and monofilamentous thermoplastic resin fibers, in which the carbon fibers are contained in a high content, such fibers having long fiber lengths and being randomly arranged, is provided. In addition, a method for producing a fiber-reinforced thermoplastic resin molded article, comprising molding the molding material by compression molding, is provided.

Owner:TORAY IND INC

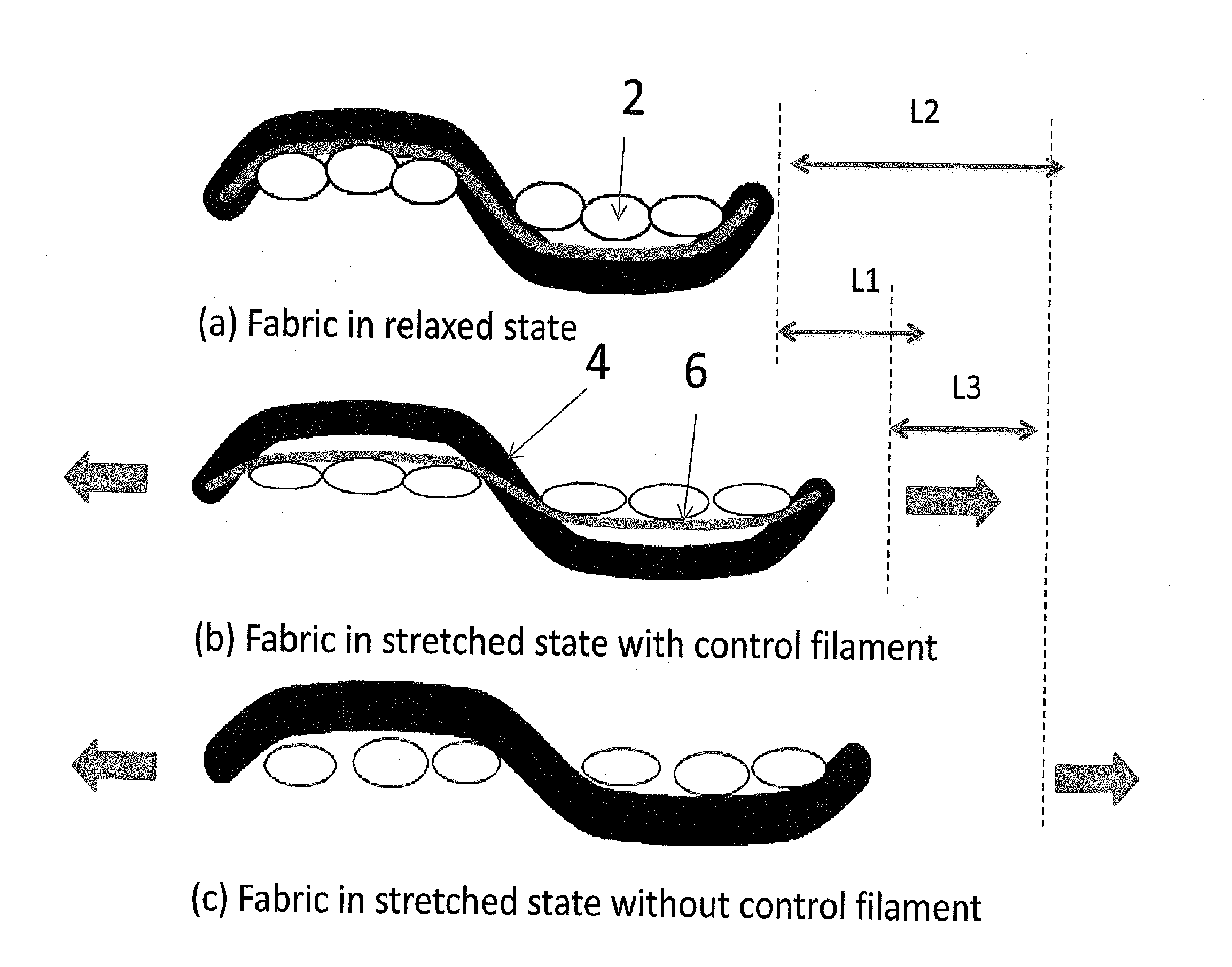

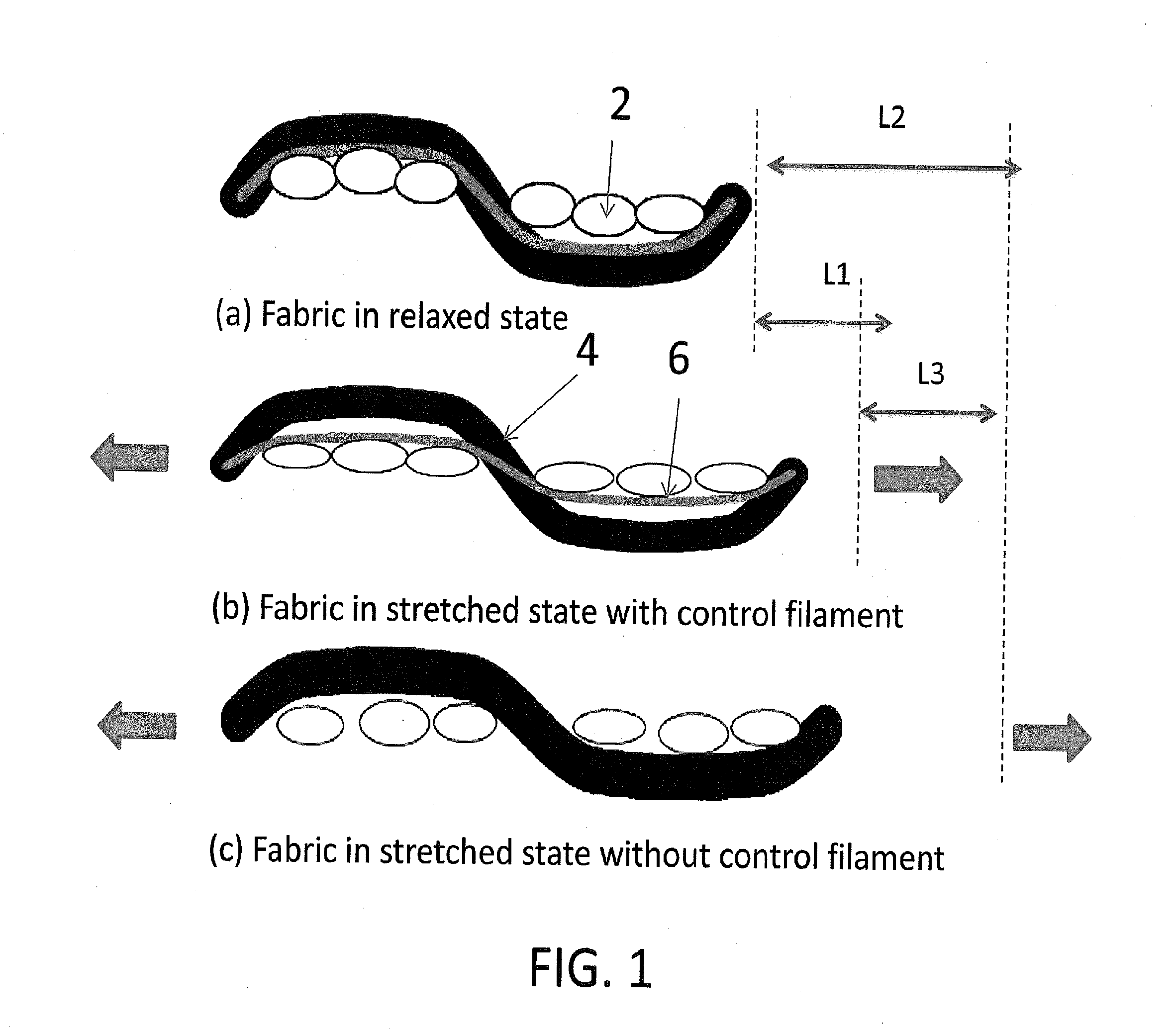

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

Processing method for mercerized knitted bedding fabric

InactiveCN102433678AMoisturize evenlySoft touchMercerising of indefinite length fabricsSingeingTextile printerPolymer science

The invention discloses a processing method for a mercerized knitted bedding fabric. The processing method mainly adopts a production technology of double-calcination single yarn, first refining and then mercerizing, and grey yarn is sequentially subjected to yarn singeing, yarn steaming, knitting, grey cloth singeing, refining, dewatering, cylinder drying, mercerizing, dyeing, dewatering, scutching, drying, printing, forming and pre-shrinking and finally is checked and stored in a cabin. The mercerized knitted bedding fabric has the advantages of high conformality, low shrinkage, wide width and the like, and can meet the requirement on the knitted bedding fabric; compared with a woven fabric, the mercerized knitted bedding fabric has higher elasticity, water absorption and air permeability, is more smooth and fine in handfeel, and has better comfortableness.

Owner:WUHU SHENGLUO TEXTILE INDAL

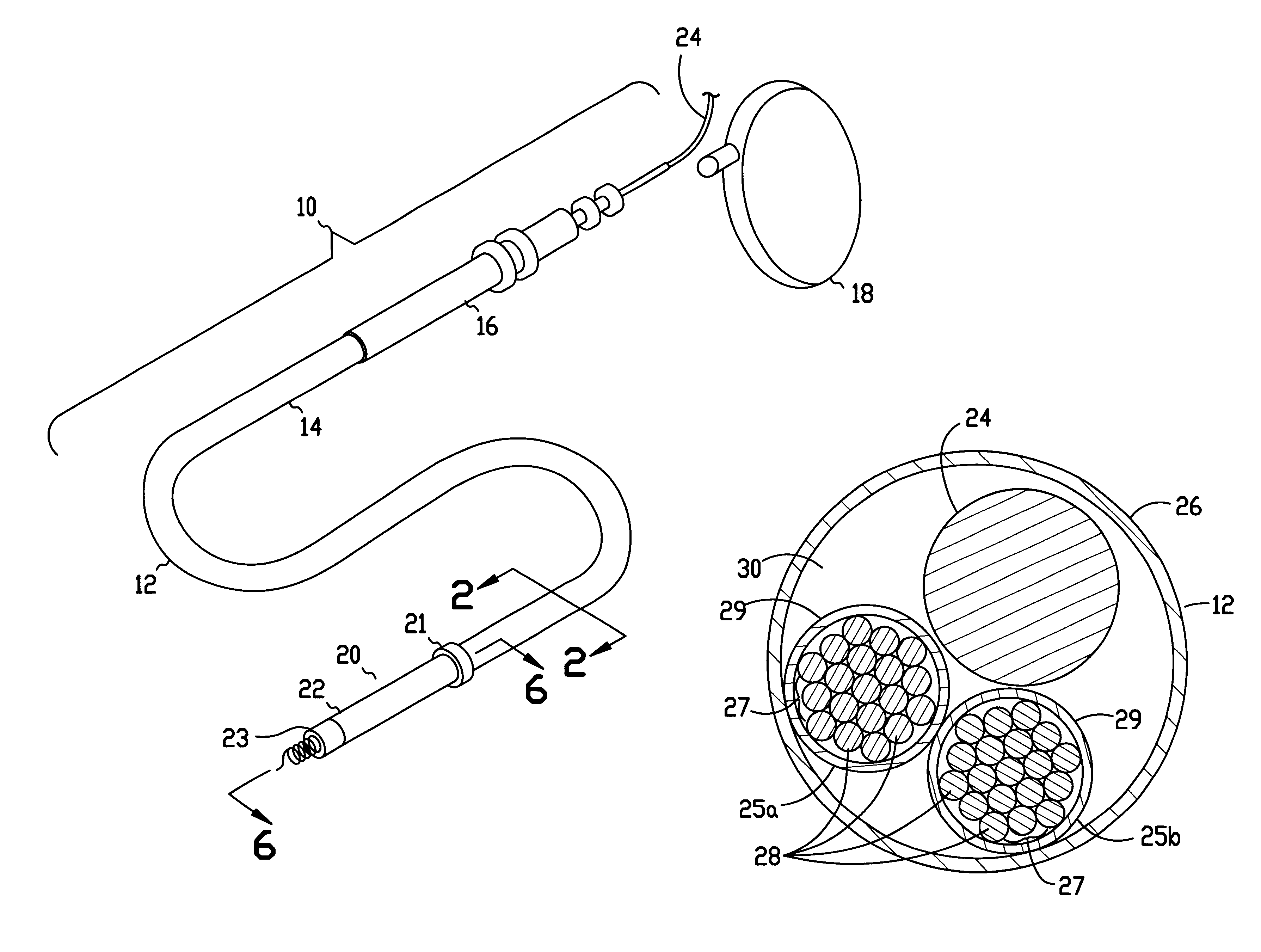

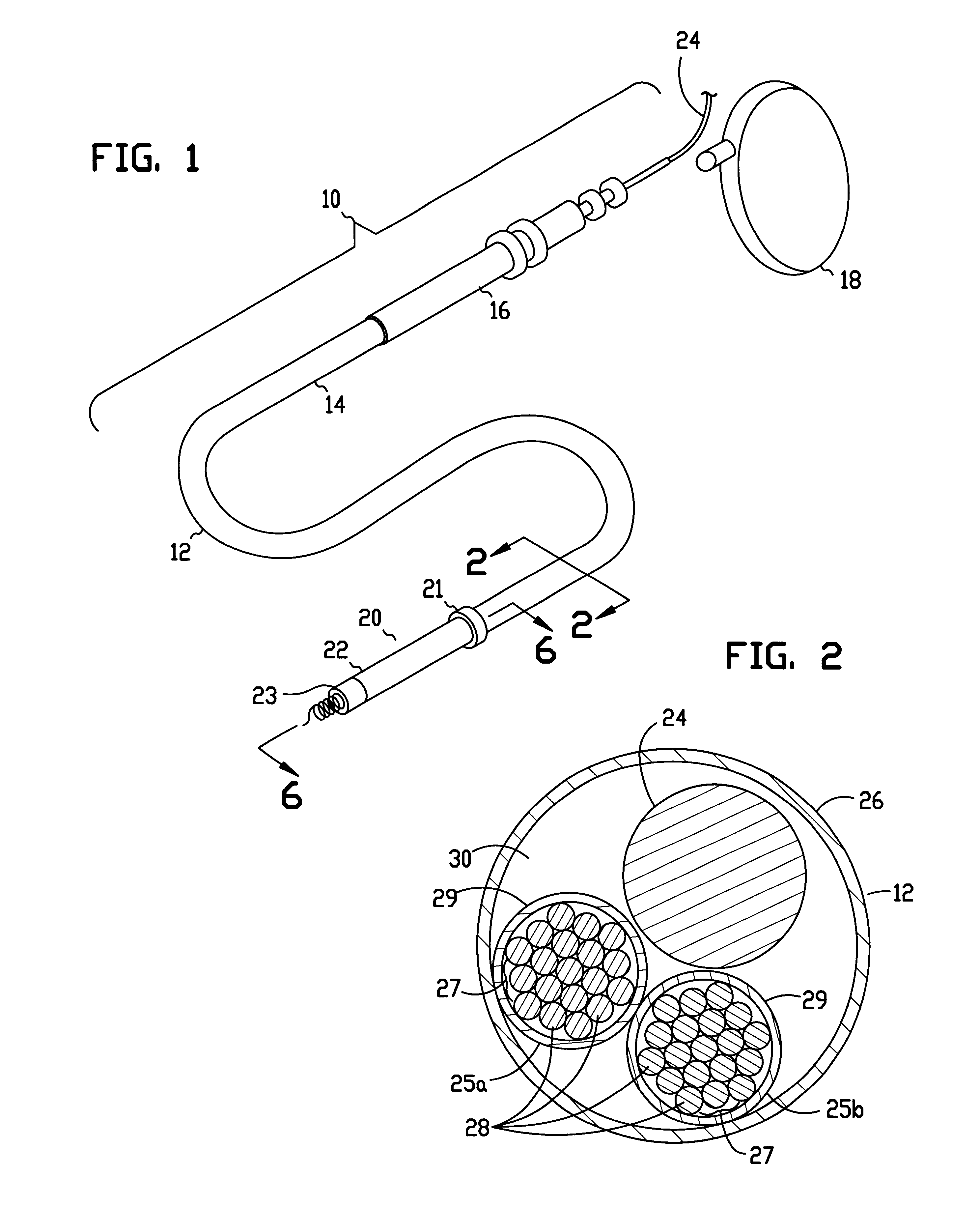

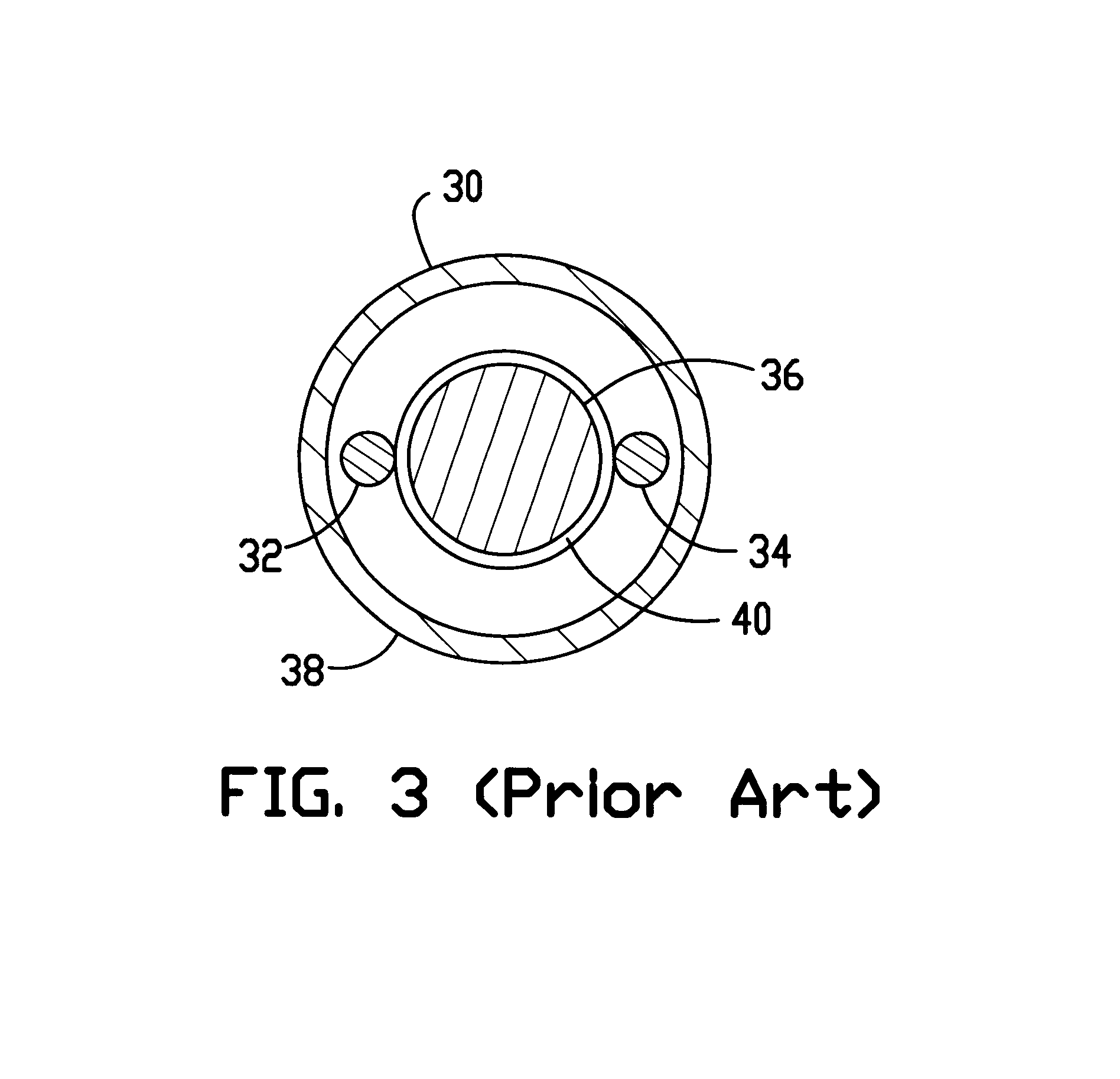

Cardiac lead with minimized inside diameter of sleeve

InactiveUS6324415B1Transvascular endocardial electrodesDiagnostic recording/measuringElectrical conductorCardiac pacemaker electrode

A lead assembly adapted for endocardial fixation to a human heart is provided. The lead assembly includes a lead body that has a proximal end provided with a connector for electrical connection to a cardiac stimulator. The cardiac stimulator may be a pacemaker, a cardioverter / defibrillator, or a sensing instrument. The distal end of the lead body is connected to a tubular electrode housing. The lead body consists of one or more noncoiled conductor cables surrounded by a coextensive insulating sleeve. Each conductor cable consists of a conducting element covered by a coextensive insulating sleeve. The conducting element may be a single filament wire or a plurality of individual conductor wires. In contrast to conventional leads, the lead body of the present invention does not require coiled conductor wires. Lead body diameters of 1.04 mm or smaller are possible.

Owner:INTERMEDICS

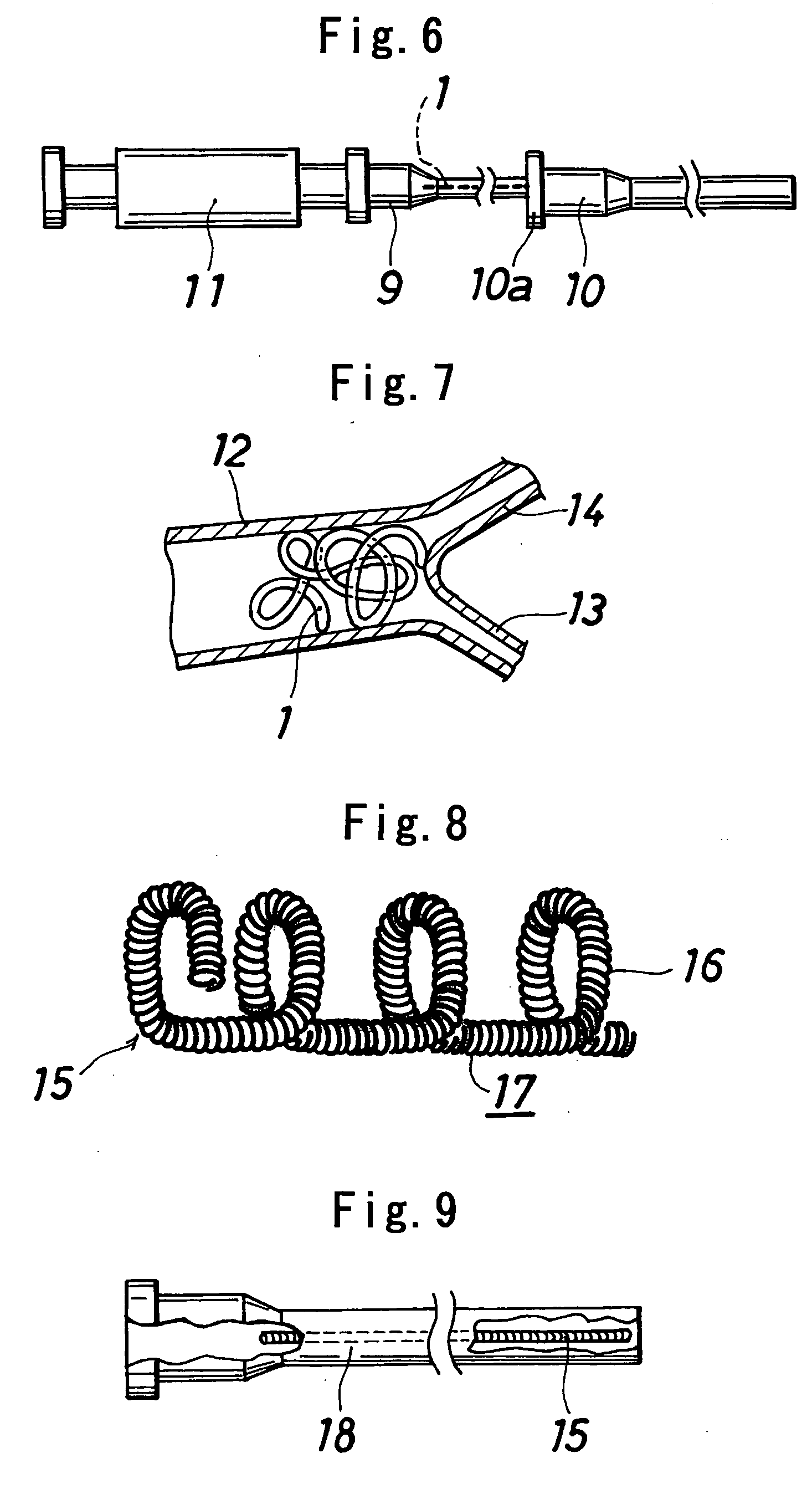

Carbon fibers, acrylic fibers, and production processes thereof

InactiveUS6103211AMonocomponent synthetic polymer artificial filamentThin material handlingCarbon fibersTurbine

PCT No. PCT / JP97 / 01716 Sec. 371 Date Jan. 20, 1998 Sec. 102(e) Date Jan. 20, 1998 PCT Filed May 22, 1997 PCT Pub. No. WO97 / 45576 PCT Pub. Date Dec. 4, 1997The object of the present invention is to provide carbon fibers with high tensile strength as a resin impregnated strand even if the single filaments constituting the carbon fibers are thick. The carbon fibers of the present invention consisting of a plurality of single filaments are characterized by satisfying the following relation: sigma > / =11.1-0.75dwhere sigma is the tensile strength of the carbon fibers as a resin impregnated strand (in GPa) and d is the average diameter of the single filaments (in mu m). The carbon fibers can be preferably used as a material for forming energy-related apparatuses such as CNG tanks, fly wheels, wind mills and turbine blades, a material for reinforcing structural members of roads, bridge piers, etc., and also a material for forming or reinforcing architectural members such as timber and curtain walls.

Owner:TORAY IND INC

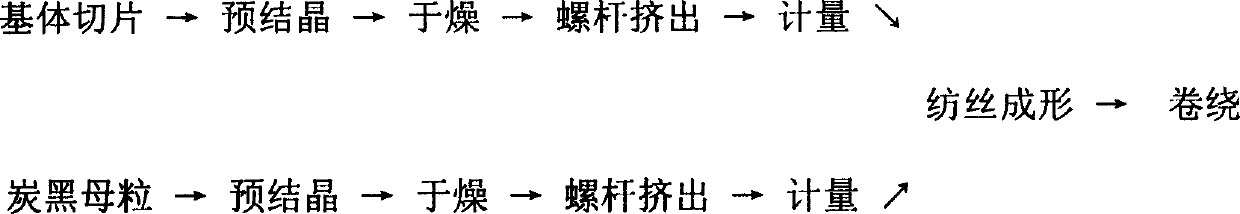

High-efficient conductive fibre and preparing method thereof

InactiveCN1584140AWith special effectsImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a kind of effective electric fibre. It contains: 5-9 %(w) electric charcoal parent-particle, 92-95%(w) PET polyester powder, and the electric parent-particle terylene, nitrile, or cotton fiber contains: 1-6%(w) selection-CT-928, 0 / 5-2%(w) 1010 and 0.5-2%(w) PLTP (antioxidant), 5-20%(w) dispersant-polyethene cere 2000 1-5%(w) magnesium stearic acid. The preparation method is: first, use electric charcoal as the electric component, and separate it evenly is polyester carrier by enwrap and disperse. Secondly produce the parent-particle by high-speed whisking, mix and extrude. Finally, use twin-screw to the filature and then obtain the electric fibre which has good peparative in ployester carrier. And the quality of spin is good. The invention has a low cost, high filature speed and good electric; the conductivity of one thread is 10000-1000000 ohm / cm.

Owner:浙江工程学院

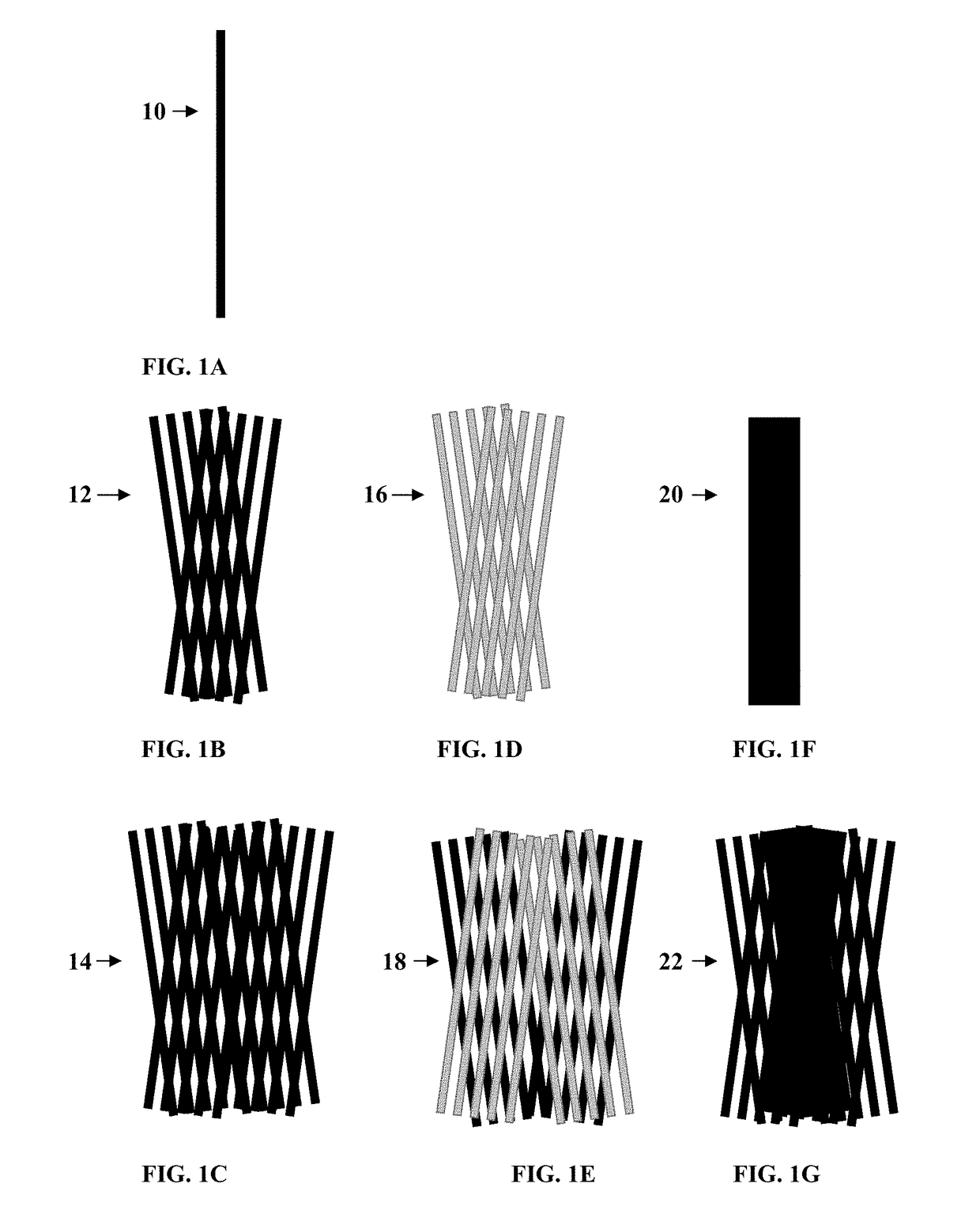

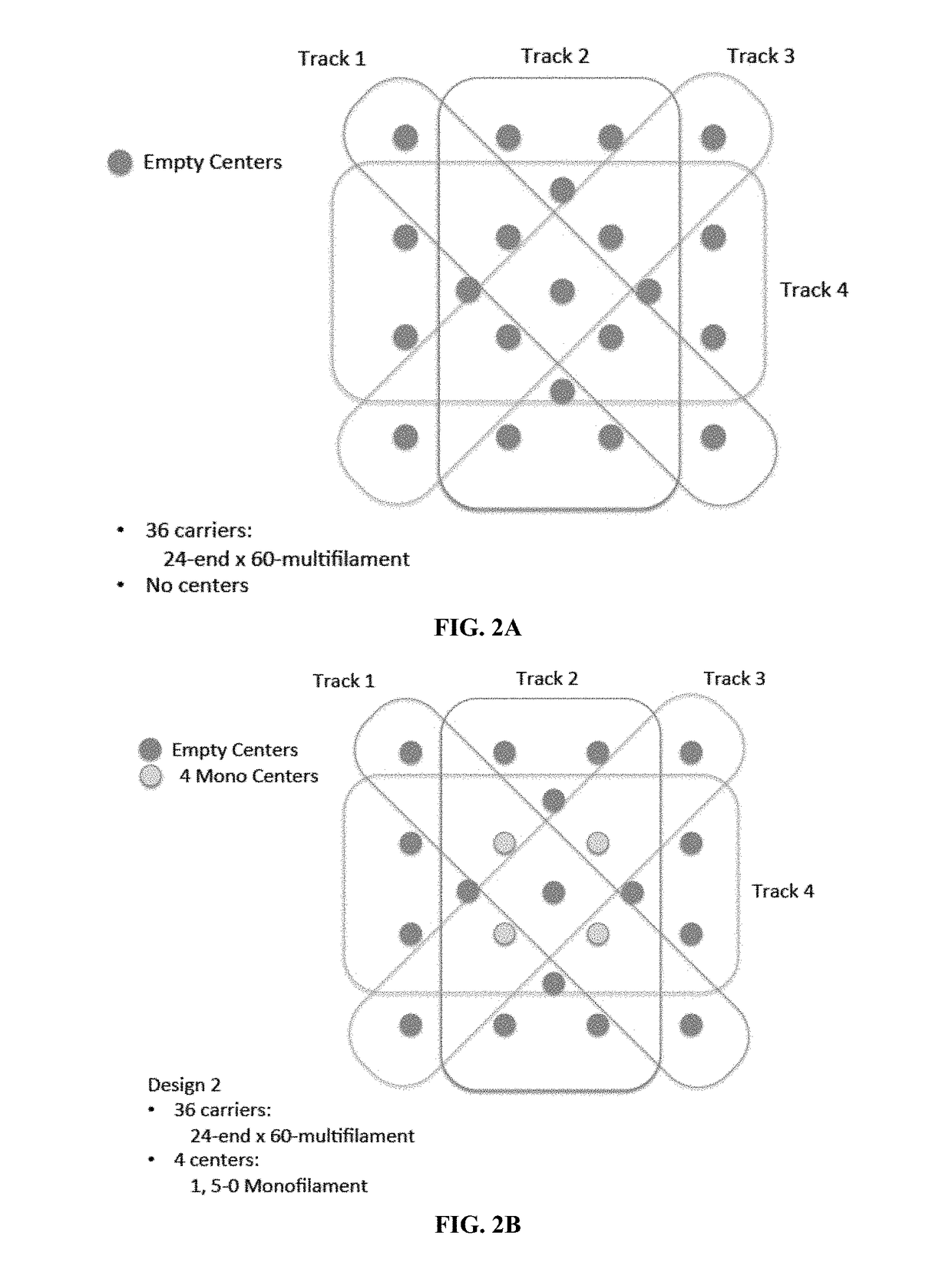

Complex braided scaffolds for improved tissue regeneration

Implantable medical devices and prosthesis for rapid regeneration and replacement of tissues, and methods of making and using the devices, are described. The medical devices include a complex three-dimensional braided scaffold with a polymer composition and structure tailored to desired degradation profiles and mechanical properties. The composite three-dimensional braided scaffolds are braided from yarn bundles of biodegradable and bioresorbable polymeric fibers and / or filaments. Monofilament fibers and / or multifilament fibers can be twisted / plied in different combinations to form multifilament yarns, composite multifilament yarns, or composite yarns. The medical devices are useful as both structural prosthetics taking on the function of the tissue as it regenerates and as in vivo scaffolds for cell attachment and ingrowth.

Owner:BIOREZ INC

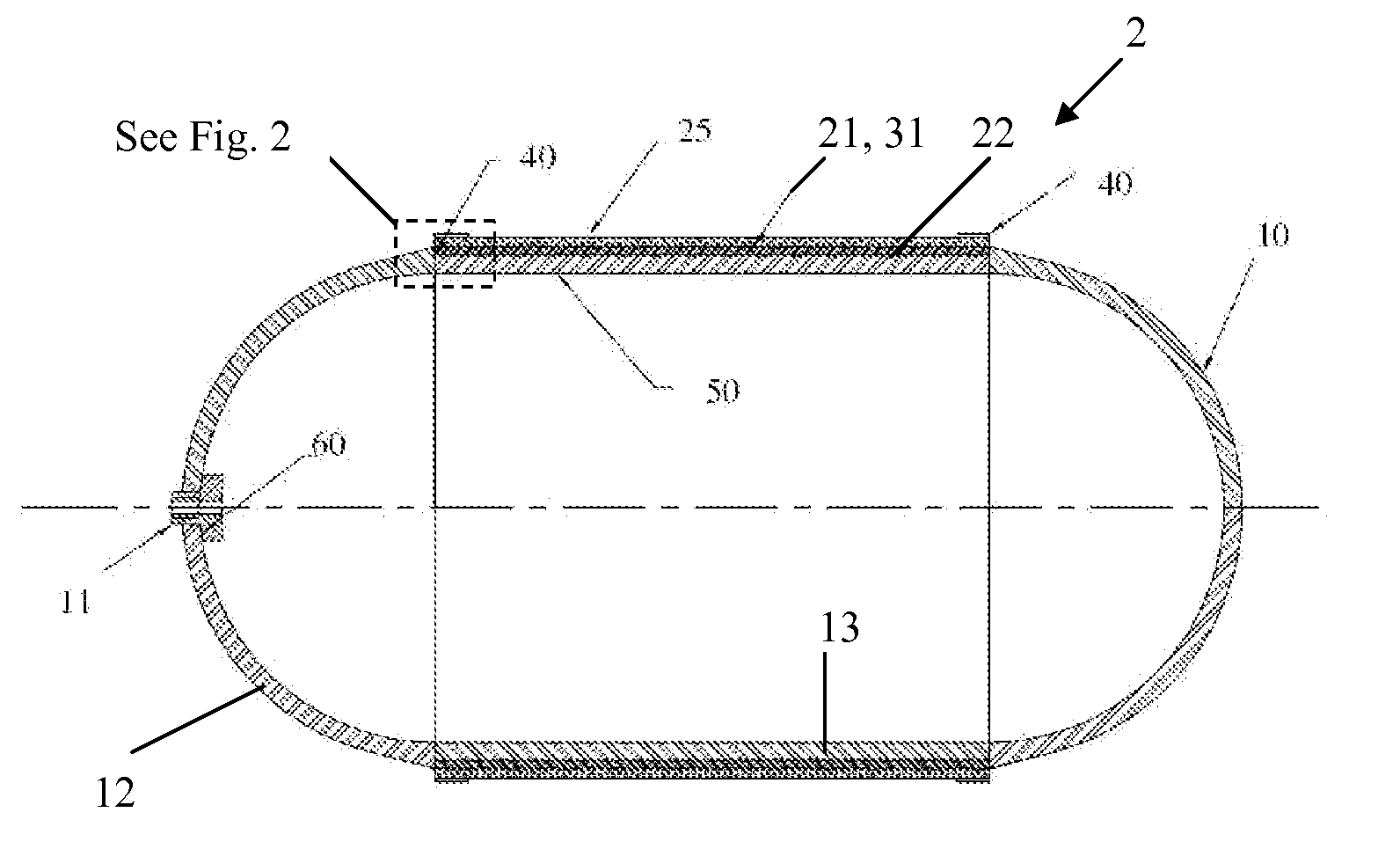

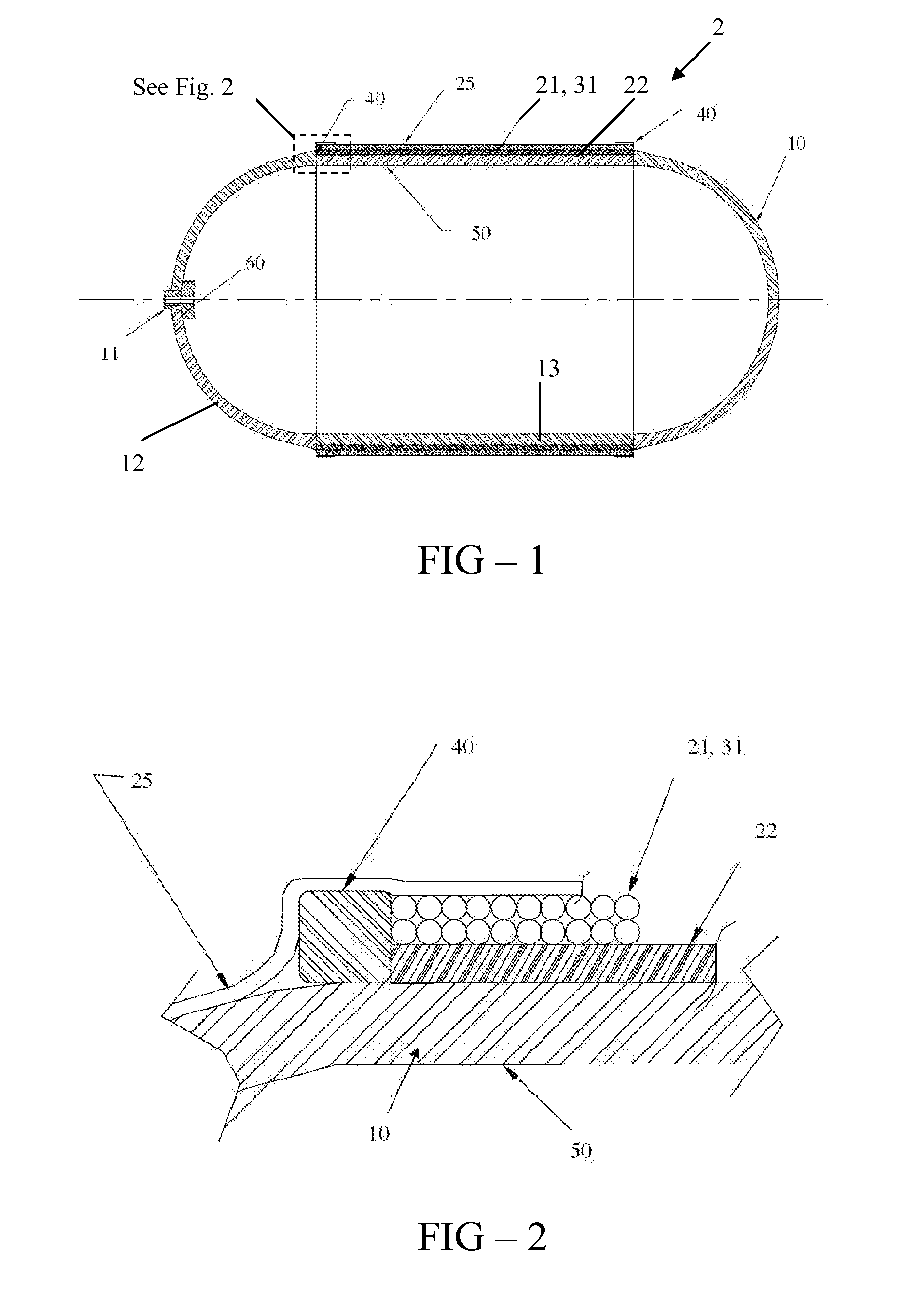

Wire wrapped pressure vessels

ActiveUS20090095796A1High strengthIncrease winding densityVessel manufacturingVessel geometry/arrangement/sizeGlass fiberWire rod

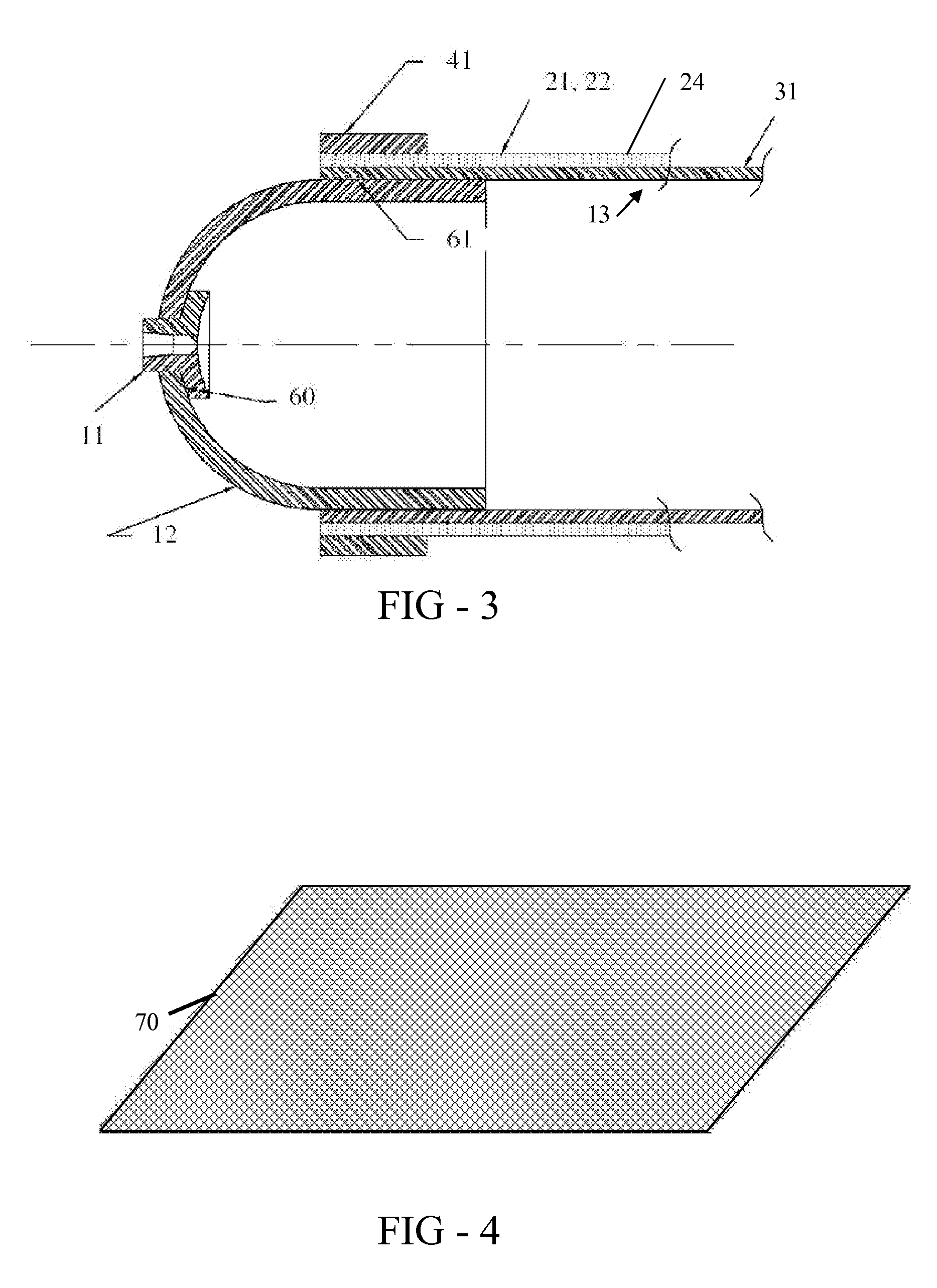

A pressure vessel (2) for the storage of fluid has a core (10) made of metal or polymer and is wrapped either completely or partially from outside with a high strength fibers (21, 22) for reinforcement wherein one of the reinforcing fibers is a metal wire (21) of a single filament or cables of multi filaments having strength from 2000 MPa to 6000 MPa. The wire has a plastic ductility of over 20% in reduction in area (RA) at tensile fracture. The metal wire (21) is made of steel or nickel or titanium or their respective alloys. The core (10) of the vessel (2) is first wrapped with a resin covered ceramic fibers such as carbon, fiberglass and subsequently wrapped with the metal wire (21) with or without other fibers (22). The metal wires (21) can be of different diameters in parallel or cabled forms.

Owner:WIRETOUGH CYLINDERS

Lyocell multifilament

ActiveUS20050019564A1Low modulusLow tenacity lowMonocomponent cellulose artificial filamentCellulosic plastic layered productsYarnEngineering

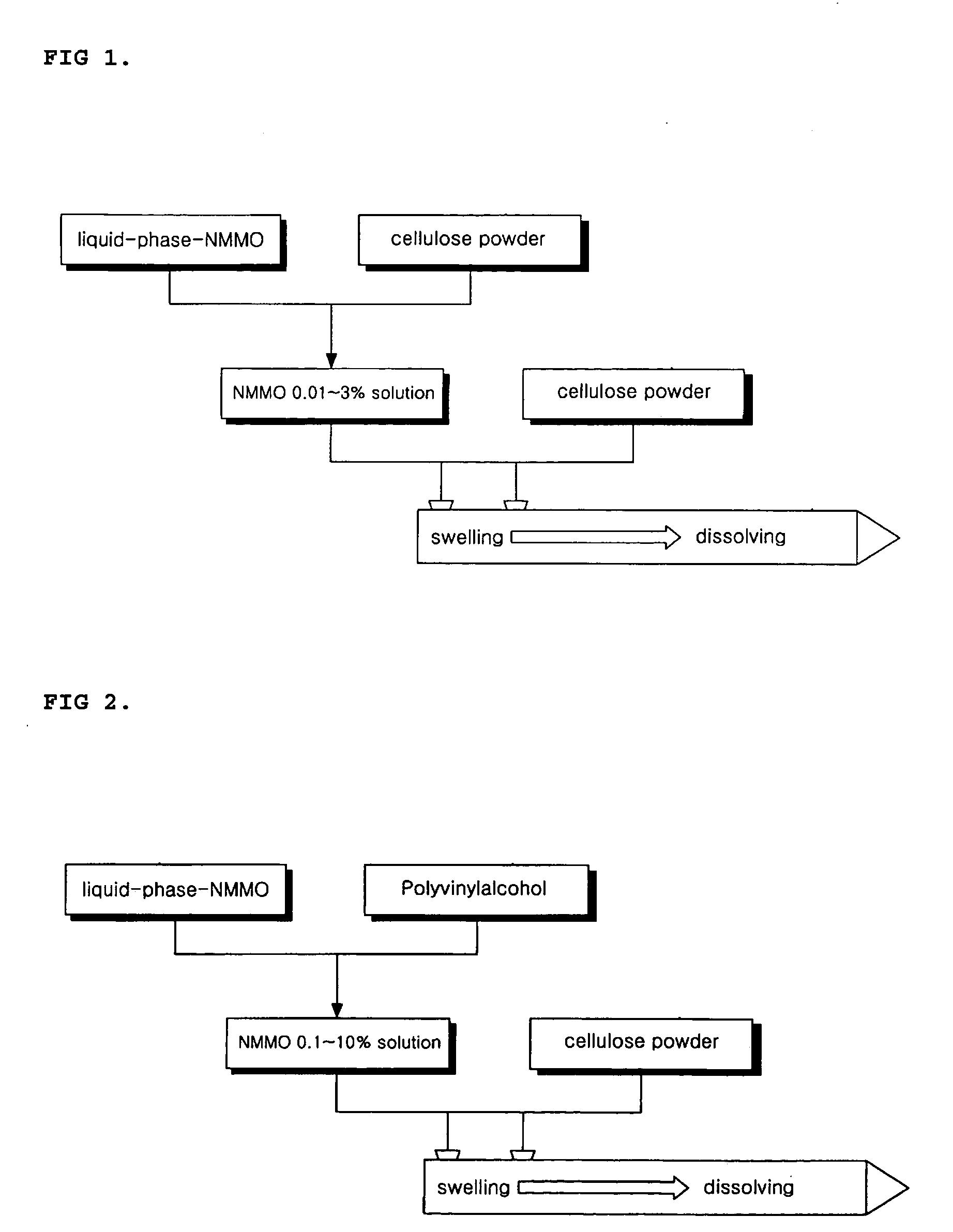

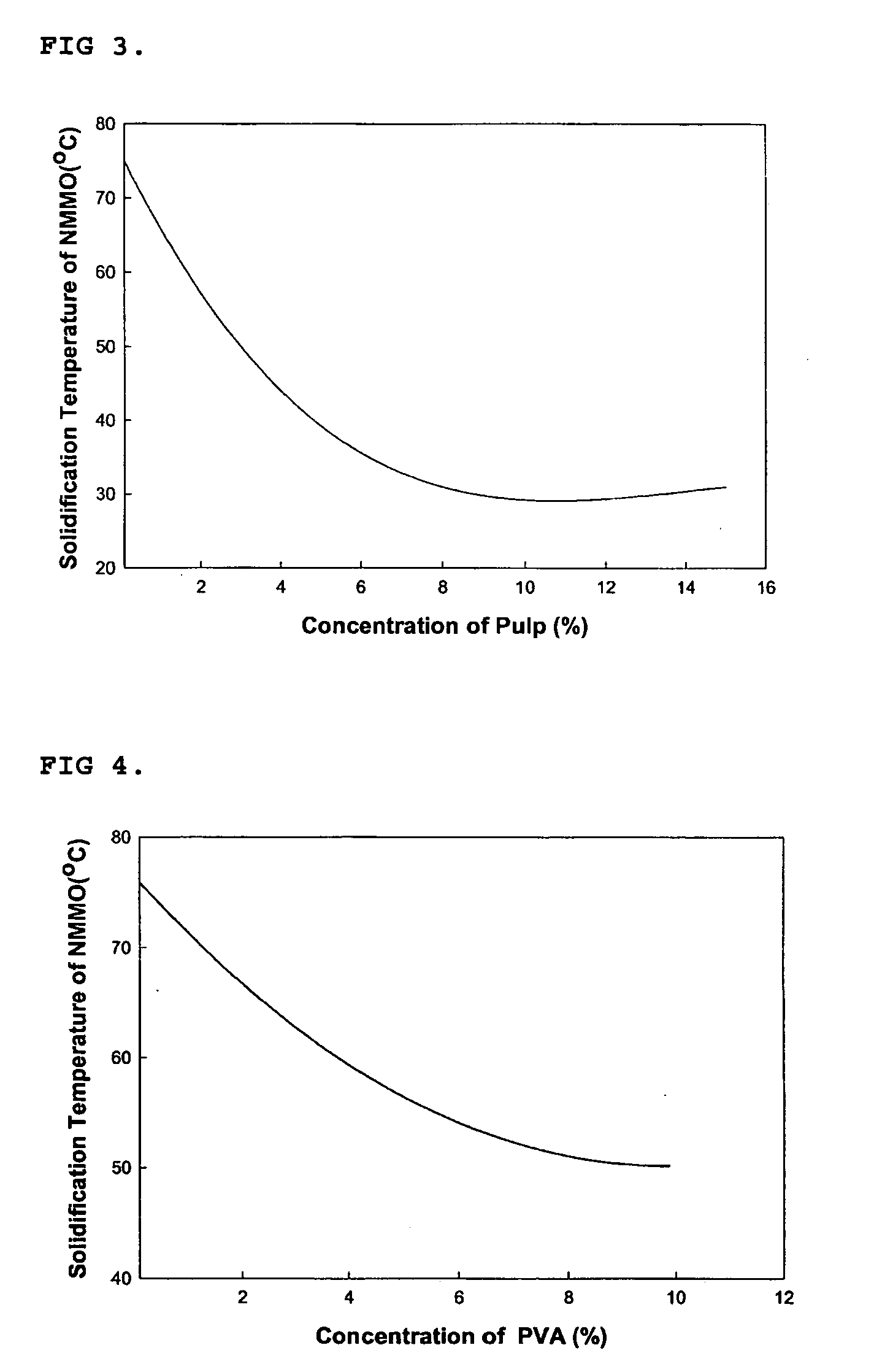

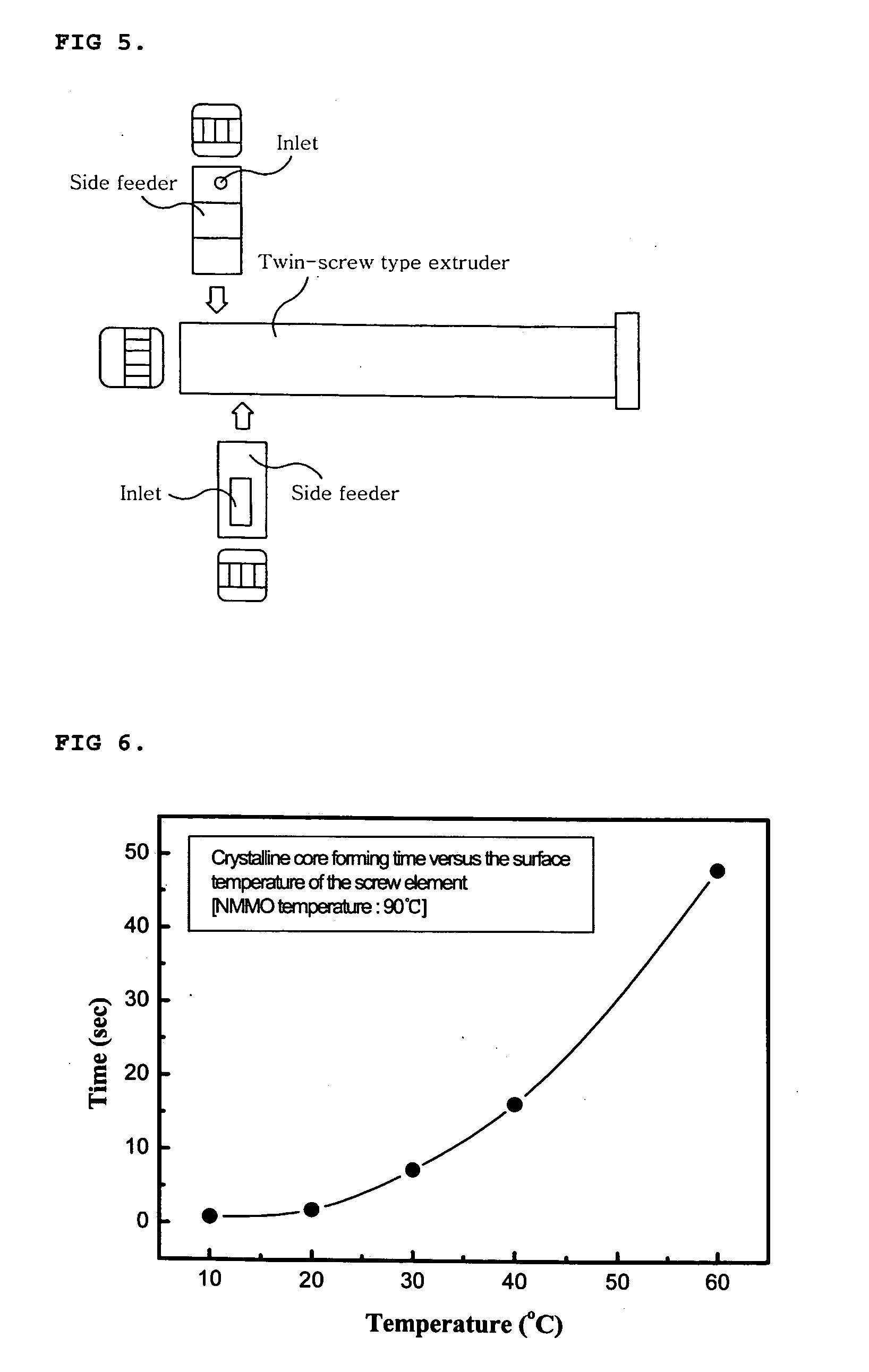

The present invention relates to a high tenacity, high modulus and low shrinkage lyocell multifilament yarn suitable for use in tire cords and MRG (mechanical rubber goods). The lyocell multifilament yarn is a cellulose-based fiber for industrial applications, which is produced by dissolving pulp having a degree of polymerization (DPW) of 700-2,000 and preferably 800-1,400, and a α-cellulose content of more than 90% and preferably more than 92%, in N-methylmorpholine N-oxide (NMMO) hydrate, at a pulp concentration of 5-15% by weight and preferably 8-13% by weight. The lyocell monofilament according to the present invention is characterized by the following stress-strain profile: (1) the lyocell monofilament analyzed after drying is elongated by less than 3.0% and has an initial modulus of 150-400 g / d, when it was subjected to an initial stress of 3.0 g / d; (2) it is elongated by 3.0-7.0% when it was subjected to a stress greater than the initial stress but smaller than 6.0 g / d; and (3) it is elongated from a tensile tenacity of at least 6.0 g / d until the yarn is broken.

Owner:HYOSUNG ADVANCED MATERIALS CORP

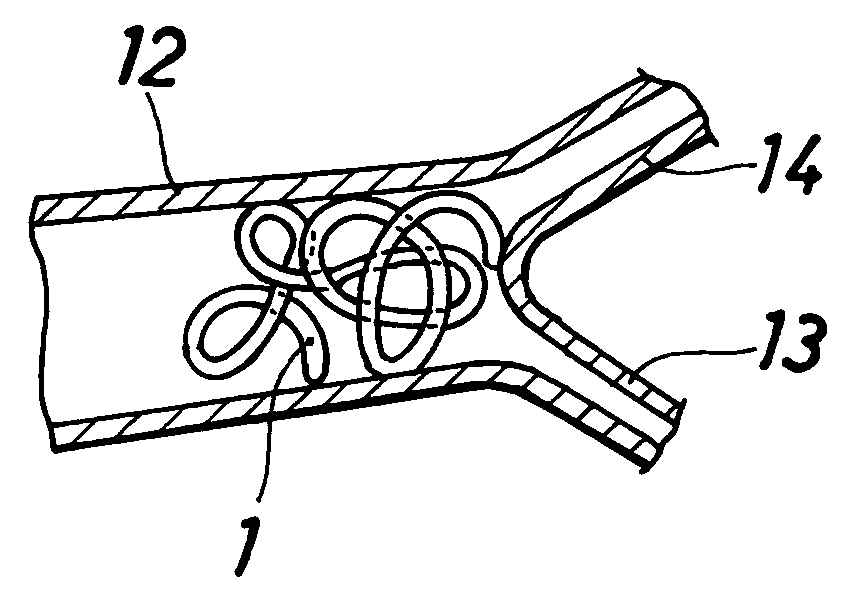

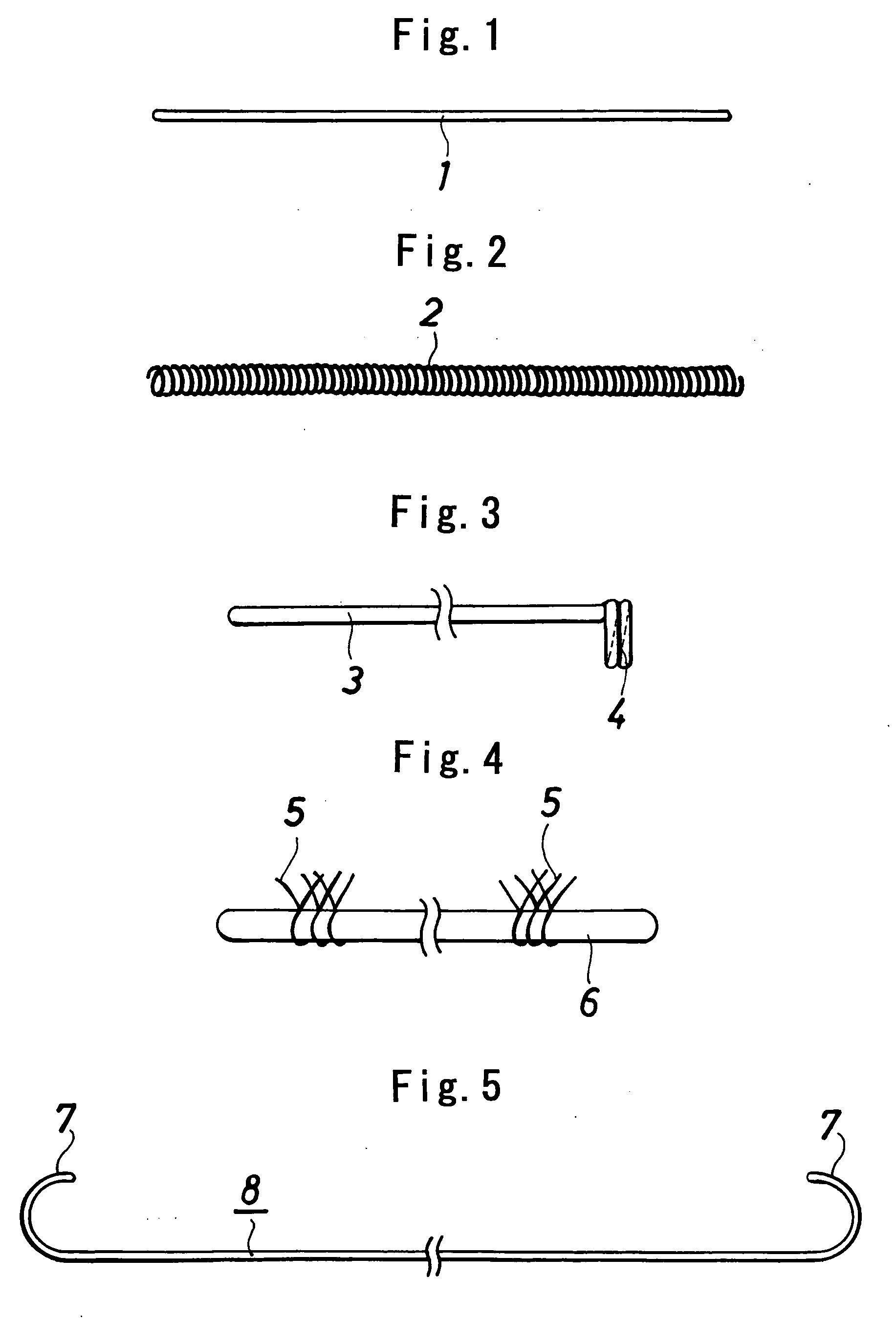

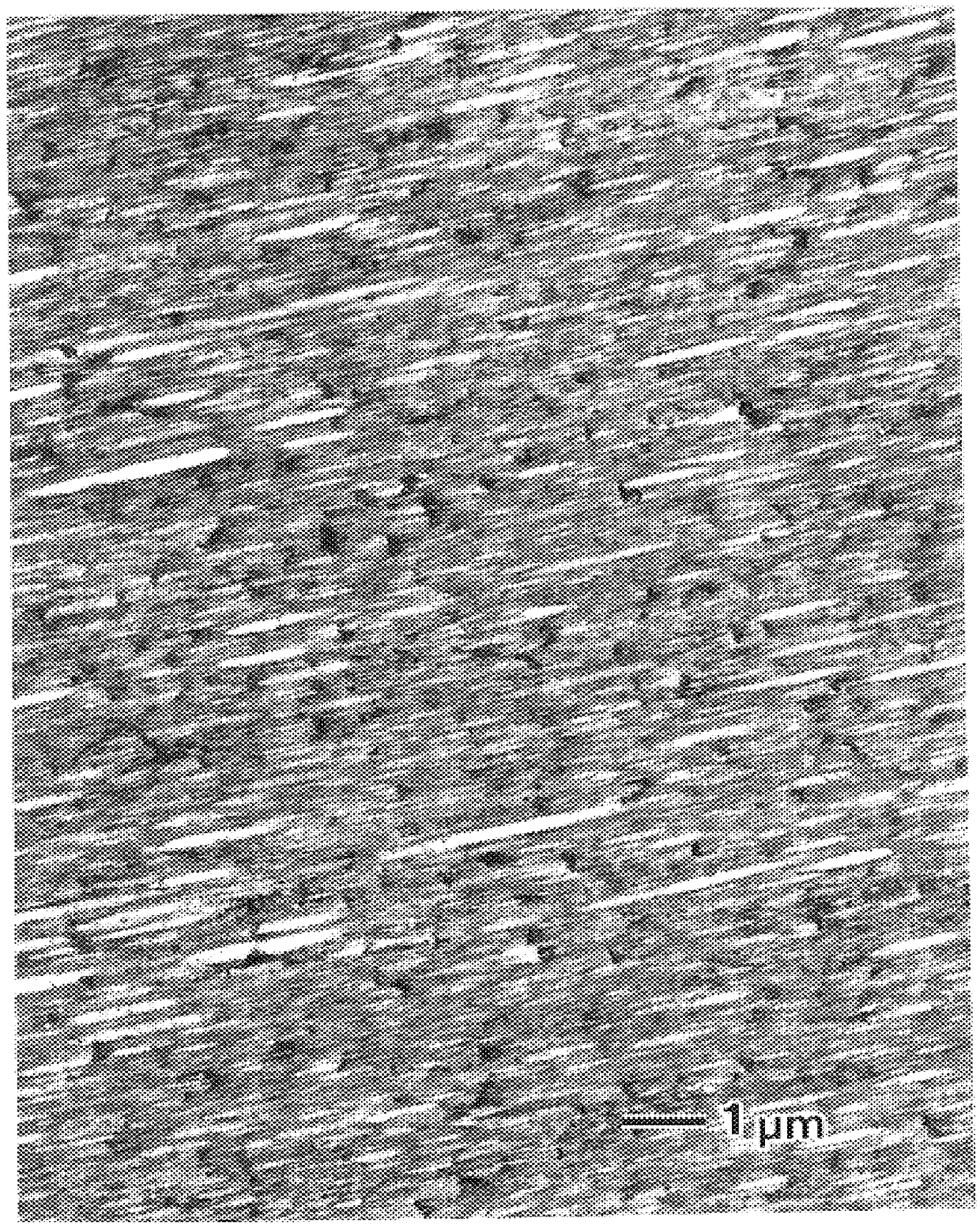

Vasoocclusive article

Poly(L-lactic acid) (200,000 in weight average molecular weight and 175° C. in melting point) is melt-spun at 200° C. and drawn to obtain a single filament having a diameter of 0.05 mm. Two lengths of the filament are twisted to prepare a filamentous substance, which is cut to a length of 7 cm to obtain a vasoocclusive article 1 in the form of a single line. The occlusive article is free of the problems conventionally experienced.

Owner:MEDICOS HIRATA

Degradable monofilament and preparation process thereof

InactiveUS6090910AHigh strengthSlow hydrolysis velocitySuture equipmentsCosmetic preparationsAbsorbable sutureYoung's modulus

A degradable copolymer filament comprising an internal structure having the following separate phases: (a) a matrix phase comprised as a primary component of a polymer segment which exhibits a tensile Young's modulus of 2 GPa or less and a strength retention of 50% or more after two weeks in water at 37 DEG C., pH 7.3, and (b) a micro-dispersed phase comprised as a primary component of a polymer segment which exhibits a tensile strength of 200 MPa or more and a strength reduction greater than the matrix phase in water at 37 DEG C., pH 7.3. The weight ratio of each component in the matrix phase and dispersed phase is 50:50 to 95:5, respectively, and the dispersed phase a needle structure oriented by stretching in the fiber direction. A degradable monofilament having an excellent mechanical strength and flexibility, moderate hydrolyzability, high ligature stability and being suitable as a material of surgical absorbable suture can be obtained. A preparation process is also provided.

Owner:MITSUI CHEM INC

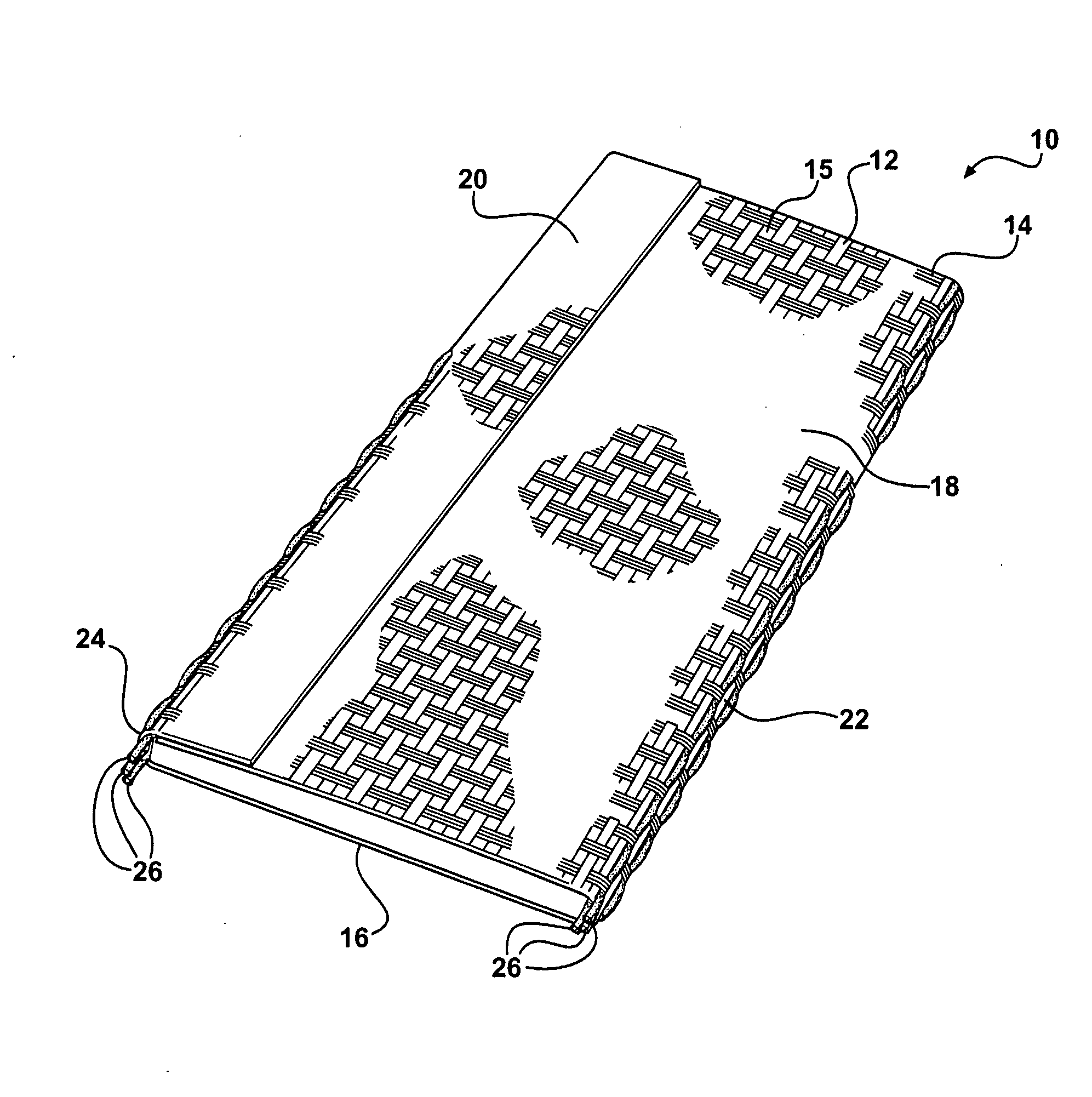

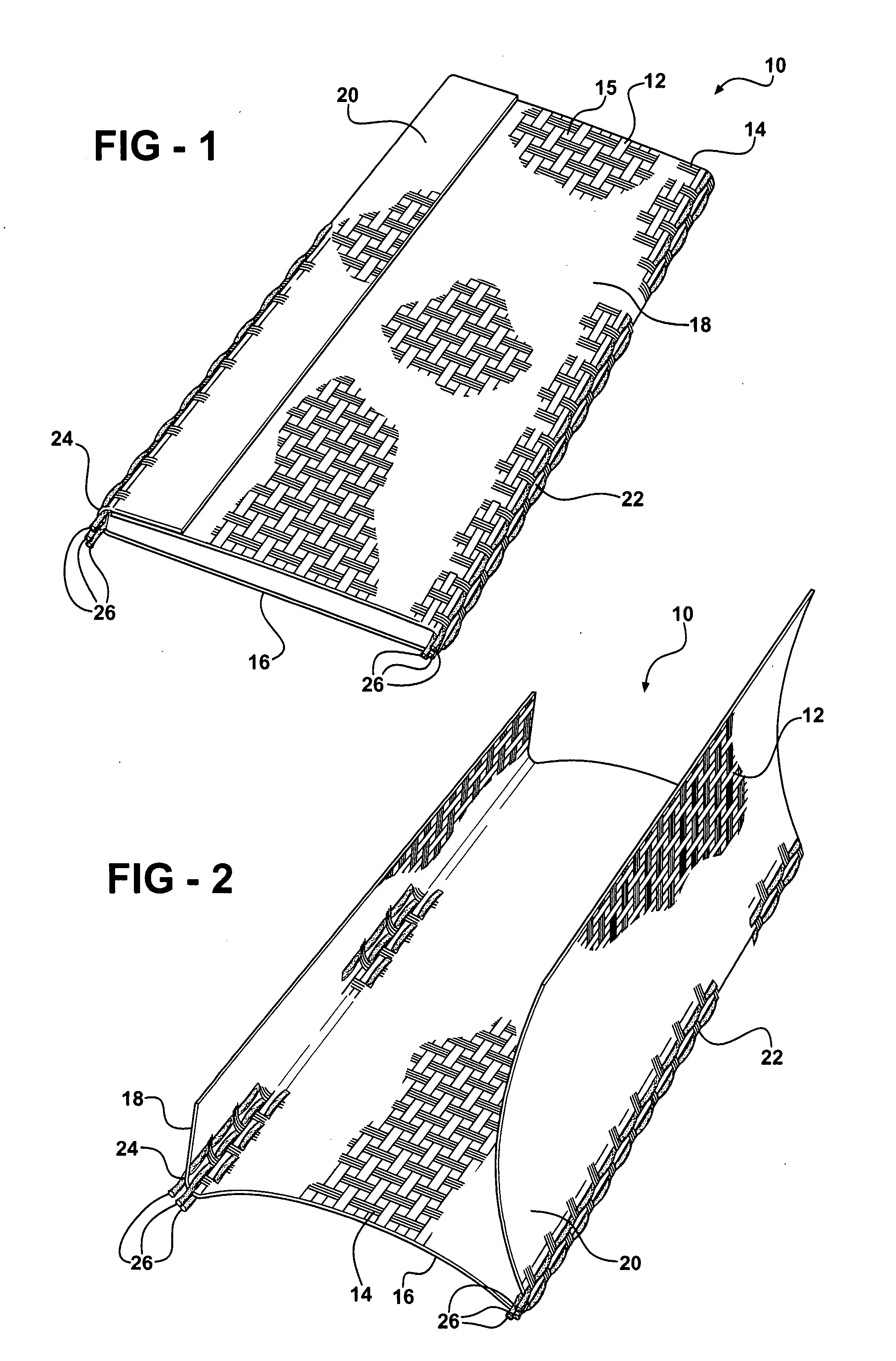

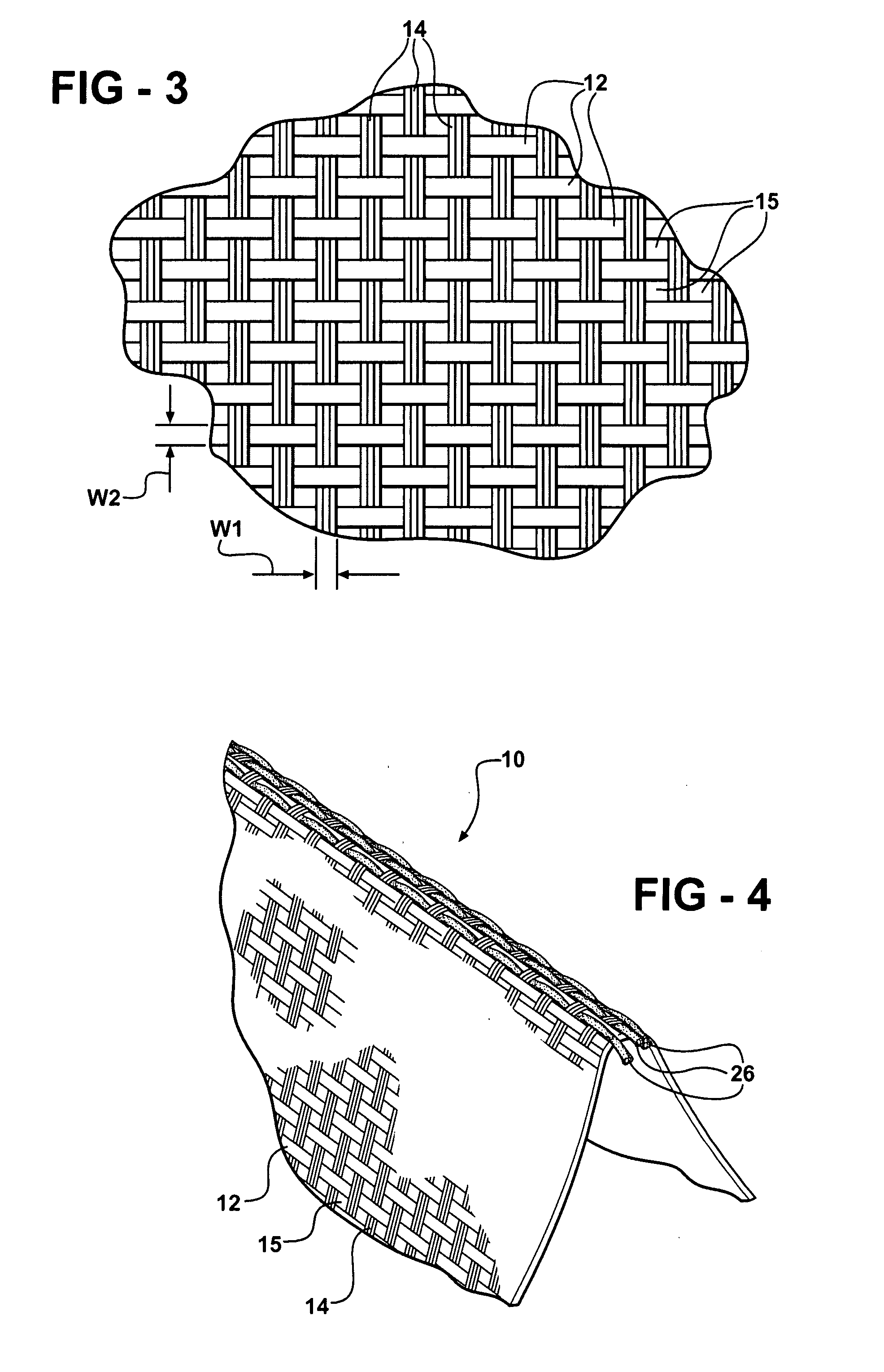

Low profile textile wire bundler sleeve

A low profile fold protective textile sleeve for bundling elongate members has longitudinally and laterally interlaced monofilament warp and fill yarns. Flat profile monofilaments are employed in the warp direction and round monofilaments in the fill direction. The flat monofilaments are considerably wider than they are thick, and provide the sleeve with flexibility and bending out of the plane of the sleeve. The round monofilaments may be sized so that their diameter is about the same as the thickness of the flat monofilaments, and they can be bundled together so that the effective width of each bundle approximates the width of the flat monofilament yarns with which they are intertwined. The round monofilaments are heat-set along at least a portion of their length to provide biased living hinge regions of the sleeve, while also lending strength and stiffness to the sleeve along the fill direction.

Owner:FEDERAL MOGUL WORLD WIDE LLC

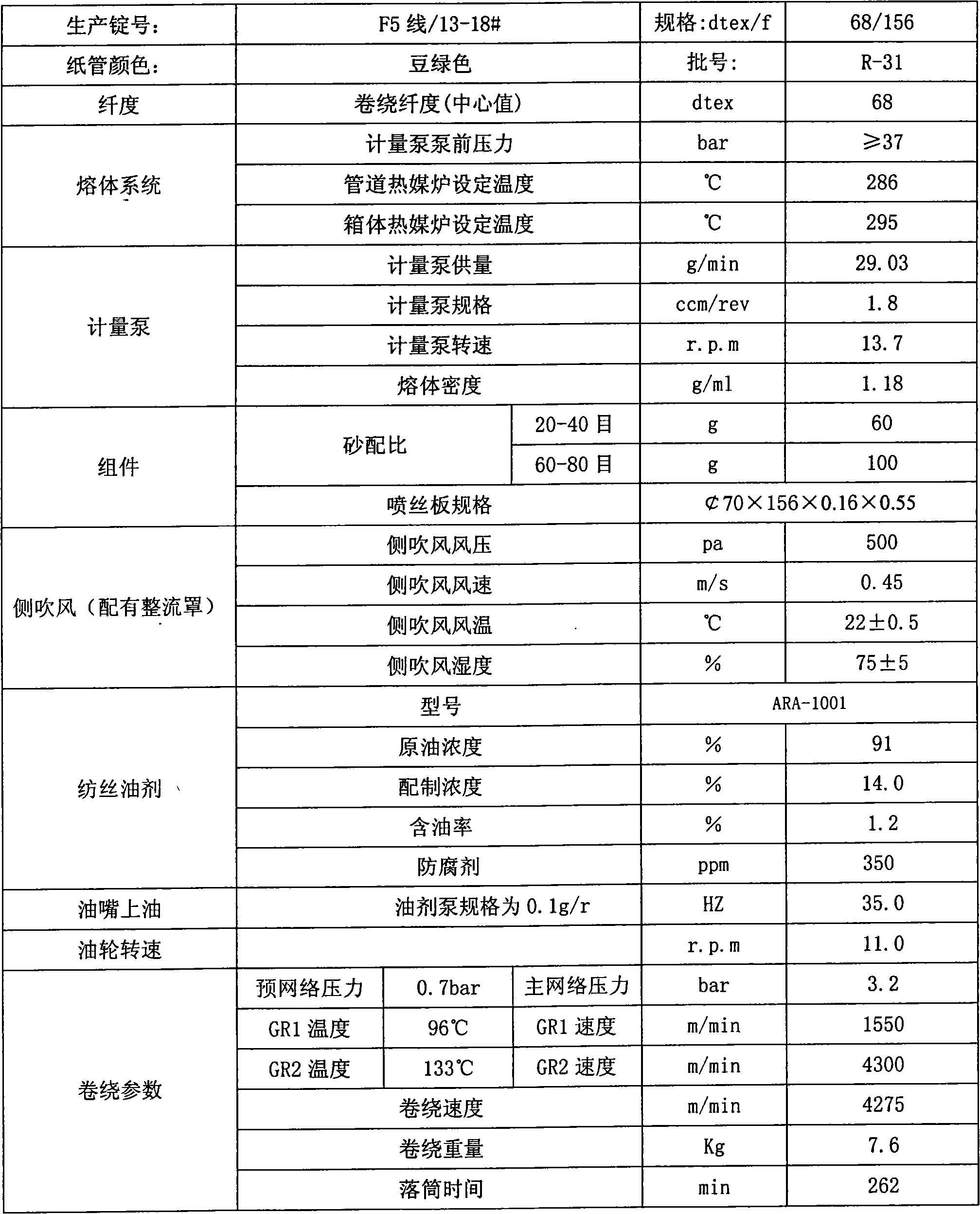

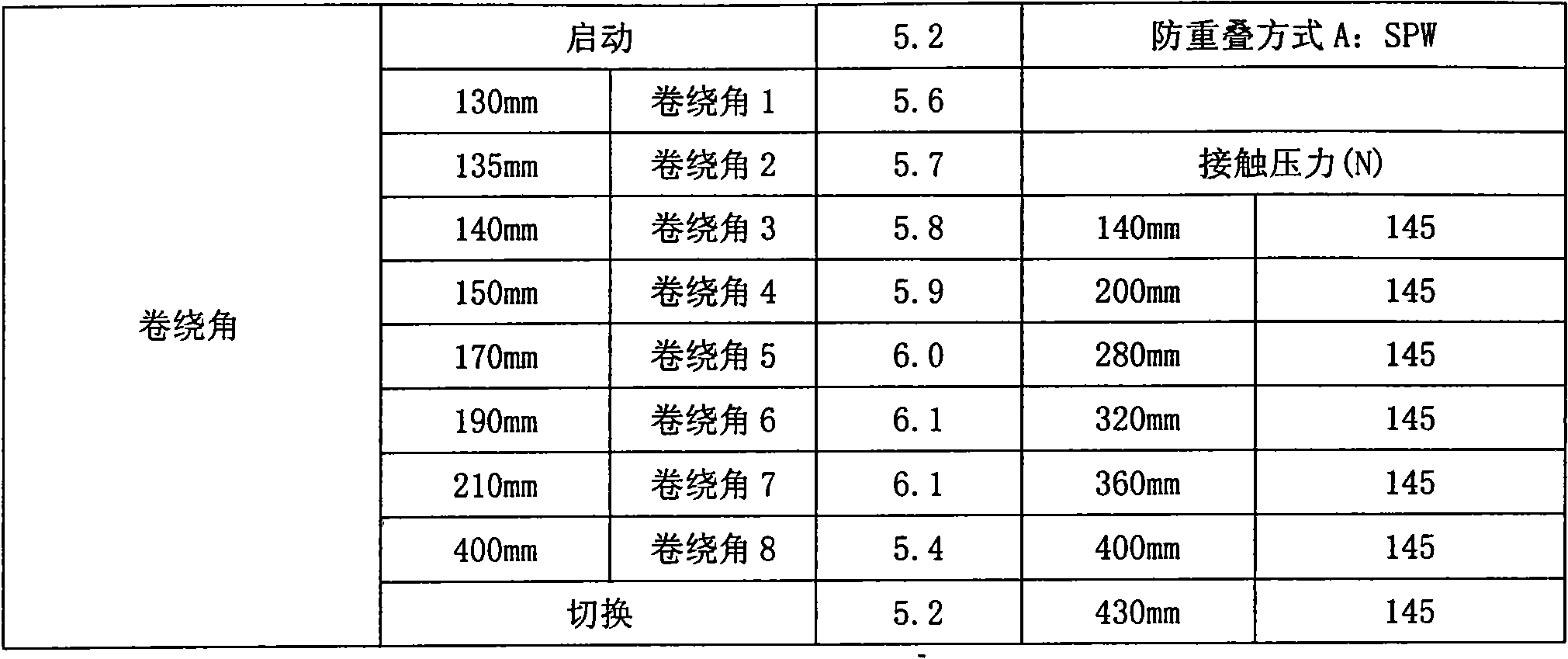

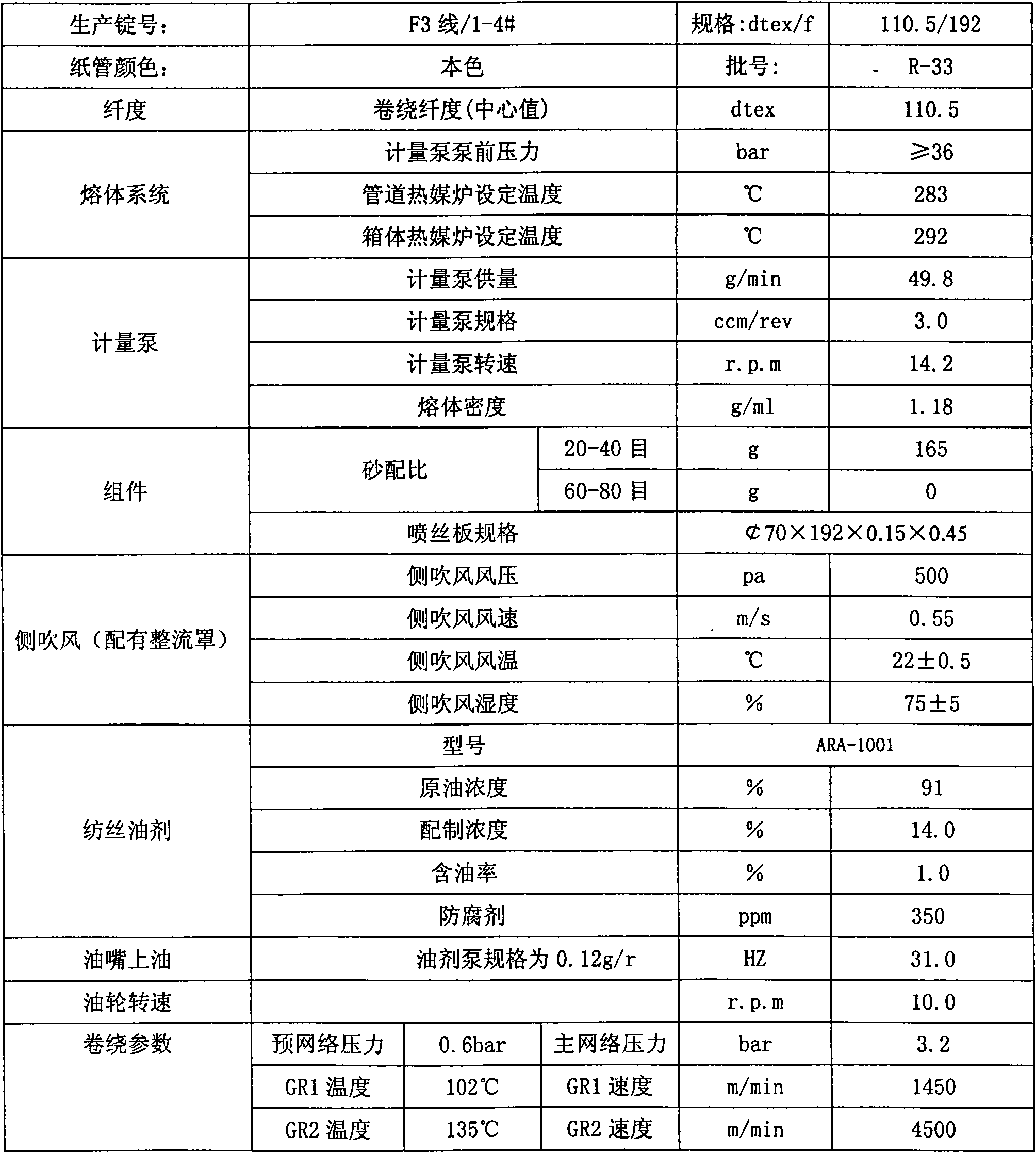

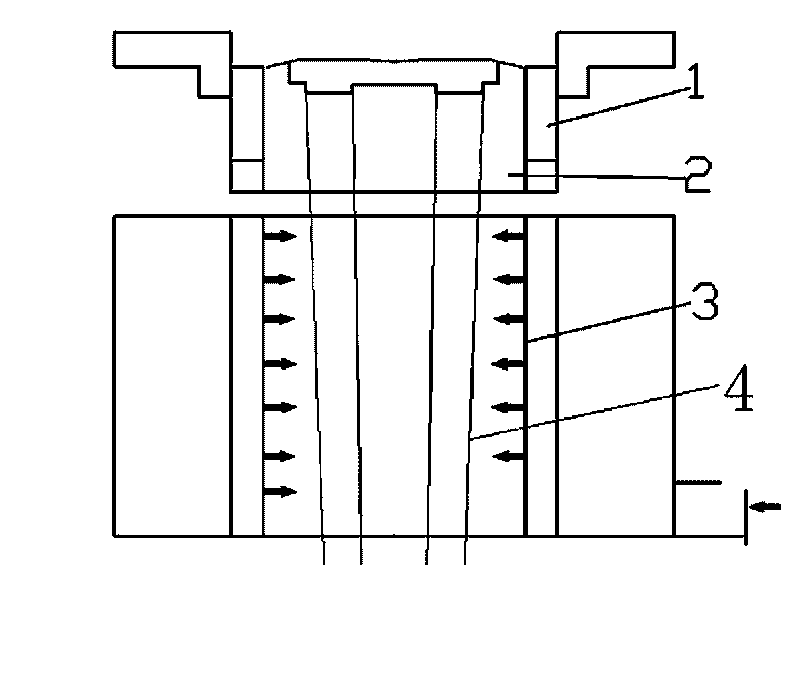

Melt direct spinning superfine denier terylene FDY filament and preparation process thereof

ActiveCN101634051ALow costIncrease productivitySpinning head liquid feederMelt spinning methodsFiberPolymer science

The invention discloses a melt direct spinning superfine denier terylene FDY filament and a preparation process thereof. The superfine denier terylene FDY filament is prepared by the following steps: adopting a production line of a melt direct spinning one-step method, using a spinning plate with the diameter of capillary of 0.15 to 0.2mm, L / D of 2.6 to 3.6 and diameter of plate surface of 70 to 90mm, installing fairing in a fiber cooling area and adopting a two-way oil feeding system to directly produce the superfine denier terylene FDY filament; and the obtained dpf (denier per filament) is 0.3 to 0.6, the number of orifices of one strand of filameter is 144F to 192F. The process routine can improve internal quality, simultaneously greatly reduces the processing cost, and has the capability of replacing imported similar products.

Owner:JIANGSU HUAYA FIBER

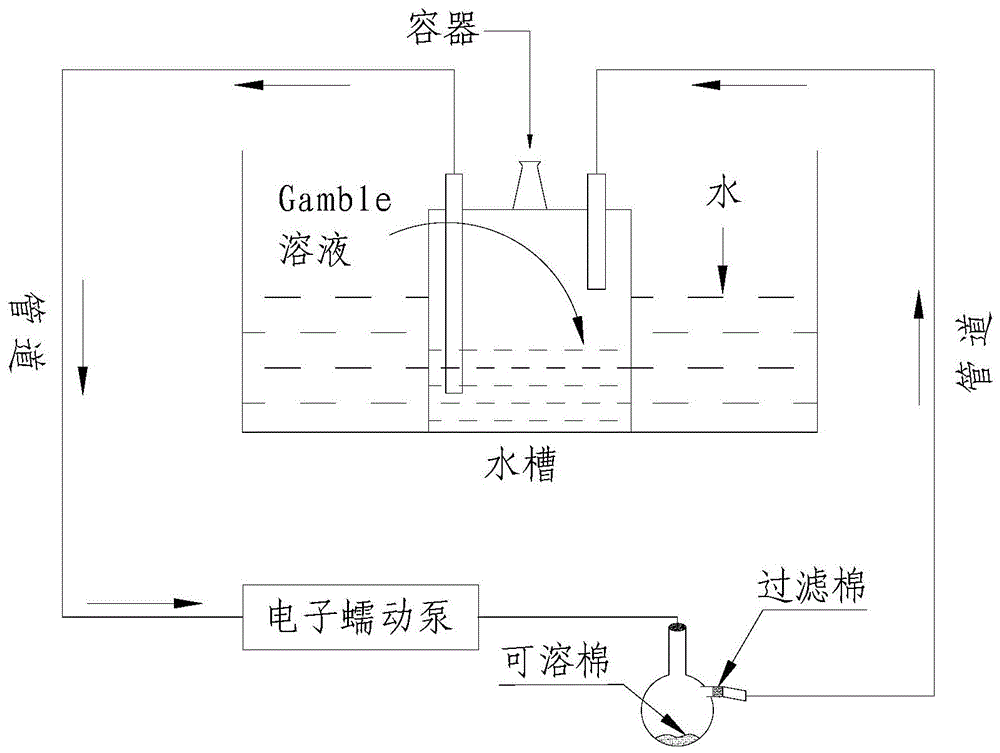

Method for testing interfacial bonding strength of ceramic fiber-reinforced resin matrix composite material

ActiveCN104122202AImplement statistical measurementsSolve the fragileUsing mechanical meansMaterial analysisAdhesivePaperboard

The invention discloses a method for testing the interfacial bonding strength of a ceramic fiber-reinforced resin matrix composite material and relates to ceramic fibers. The method comprises the following steps: bonding the ceramic fibers to a hard paper frame by virtue of an instant adhesive, for straightening and solidifying the ceramic fibers; preparing an embedding mold, putting the ceramic fibers and the hard paper frame into the embedding mold, and introducing resin into the embedding mold; after the resin is solidified, cutting an embedded end together with the embedding mold so as to obtain a sample, and polishing; when the embedding depth of the sample is lower than 1mm, bonding the embedded end with a primary cut part by virtue of quick-dry resin after the polishing process; burning out two sides of the paper frame at an un-embedded end by virtue of naked flame, averagely cutting the upper end of the paper frame according to the quantity of the ceramic fibers, and bonding and reinforcing the paper frame by virtue of a hard paperboard with area equal to that of the cut paper frame; firstly fixing the embedded end at a lower clamp of a testing machine, and then fixing a reinforcing section to an upper clamp of the testing machine; carrying out a single-filament draw-out experiment; recording each withdrawal force value given by a testing machine; observing the shape of an withdrawn end, and measuring the maximal withdrawing length of the single fiber; and calculating the interfacial bonding strength between the fiber and the resin.

Owner:XIAMEN UNIV

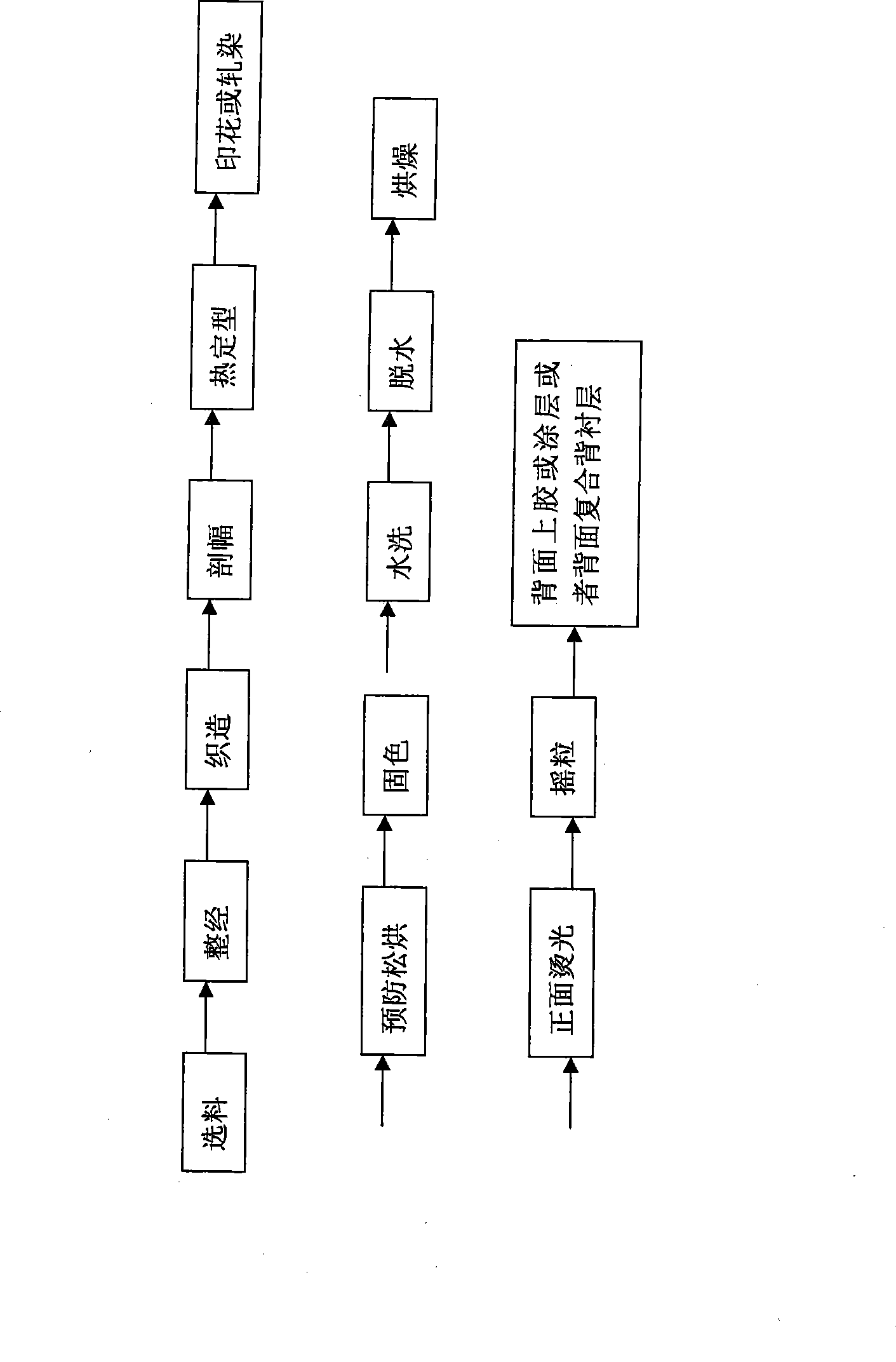

Warp knitting terylene ginning velvet carpet and method of processing the same

InactiveCN101476207AIncrease elasticityGood hygroscopicityWarp knittingHeating/cooling textile fabricsEngineeringMildew

The invention provides a warp knitting terylene polar fleece carpet which belongs to the terylene fibre product technique field. The carpet includes a flocked yarn and a bottom yarn, the flocked yarn is made of 500-780dtex DTY terylene continuous yarn with 80-100 pieces per meter network, the bottom yarn is made of 167-333dtex FDY terylene yarn, a flocked surface height of the flocked yarn is 5-12mm, wherein, single yarn denier of the DTY terylene continuous yarn is more than or equal to 3.5dtex. The carpet has advantages that processing technique is shortened, production process is more environmentally friendly and cleaning, and cost is lower; the carpet has high impact resistance, better elasticity and hygroscopic property, abrasive resistance is second only to chinlon, high heat and solarization resisting property, no-mildew, no-moth-eaten, easy to dye or print, portable and easy to clean; the carpet is rich in polar sphere sense, has strong third dimension and flexible pattern, the carpet color is novel and shibui, has better visual effect that is suitable to be placed in high class hotel guest room, white-collar apartment, high class chamber, hotel aisle and household bathroom.

Owner:常熟市锦绣经纬编有限公司

Process of making poly (trimethylene dicarboxylate) fibers

InactiveUS6923925B2Raise the draw ratioGood orientationLayered productsDrafting machinesPolymer scienceSpinning

A process for preparing poly(trimethylene dicarboxylate) multifilament yarns and monofilaments. One process for preparing poly(trimethylene dicarboxylate) multifilament yarns includes (a) providing a polymer blend including poly(trimethylene dicarboxylate) and about 0.1 to about 10 weight % styrene polymer, by weight of the polymer in the polymer blend, (b) spinning the polymer blend to form poly(trimethylene dicarboxylate) multiconstituent filaments containing dispersed styrene polymer, and (c) processing the multiconstituent filaments into poly(trimethylene dicarboxylate) multifilament yarn including poly(trimethylene dicarboxylate) multiconstituent filaments containing styrene polymer dispersed throughout the filaments. Another process includes spinning at a speed of at least 3,000 m / m and processing a blend including poly(trimethylene dicarboxylate) to form partially oriented poly(trimethylene dicarboxylate) multifilament yarn. A poly(trimethylene terephthalate) yarn including poly(trimethylene terephthalate) multiconstituent filament containing styrene polymer dispersed throughout the multiconstituent filament. The invention is also directed to uses of the filament yarns and monofilament.

Owner:DUPONT IND BIOSCIENCES USA LLC

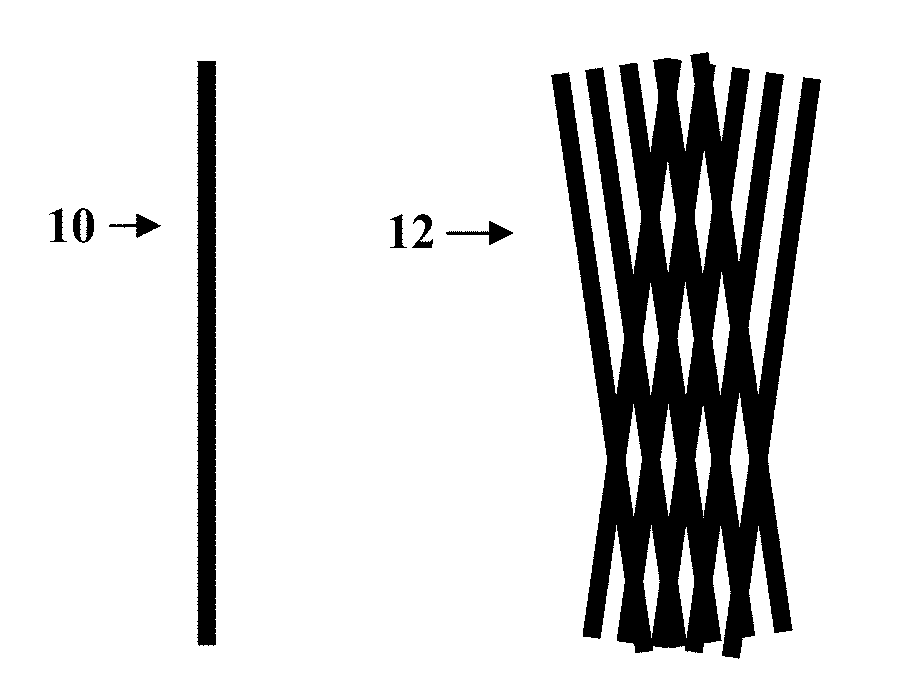

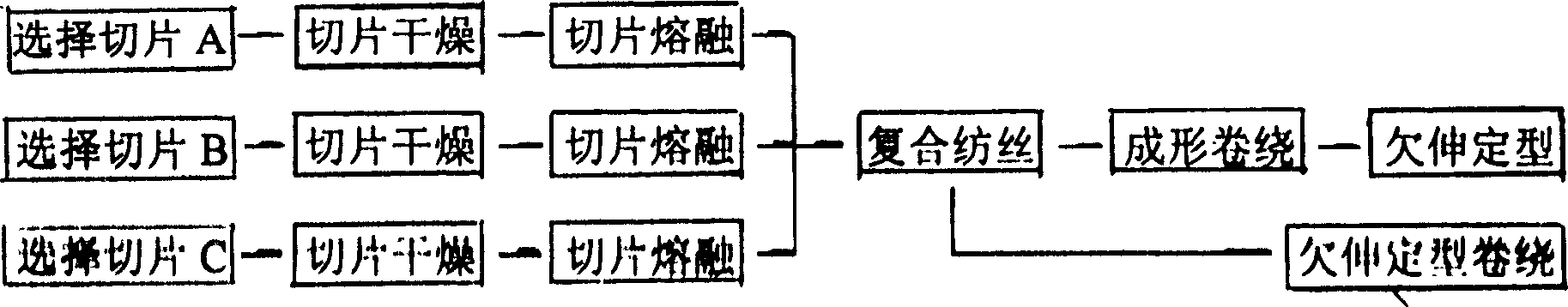

Method for producing three-component self-crimped filament yarn

InactiveCN1676685AFine fiberLow modulusFilament/thread formingConjugated synthetic polymer artificial filamentsEllipseSkin core

This invention is about a kind of producing method of self-curling long filament with superthin structure, with the method of three groups fusing composite spinning. The fibers of the 3 groups are the long fibers with the titer of single fiber 1-6 dtex and the number of pores (12-72)*2. The fibers have at least 7% curling and shrinking percentage after hotly forming and at least 20% curling and shrinking percentage after alkali process. The cross-section of one single fiber is paralleling or eccentric skin-core structural circle, ellipse or snowman. One side of the cross section has fortuitous laminated structure, and the outside fiber ratio is 0.3-0.8 dtex. The producing steps of the self curling long fibers are slice choosing - slice drying - slice fusing - combined spinning - forming curling - drafting to form the shape. By mixing the spinning units and combining the units of big heat shrinking percentage in the paralleling or eccentric skin-core structural way, we can solute the soluble units during the after operation, and separate the outboard fibers of the self curling filaments, making the fibers more slender and modulus smaller. In a word, the curling and shrinking ratio, feeling and amenity have been largely improved.

Owner:SHAOXING GLOBAL CHEM FIBER

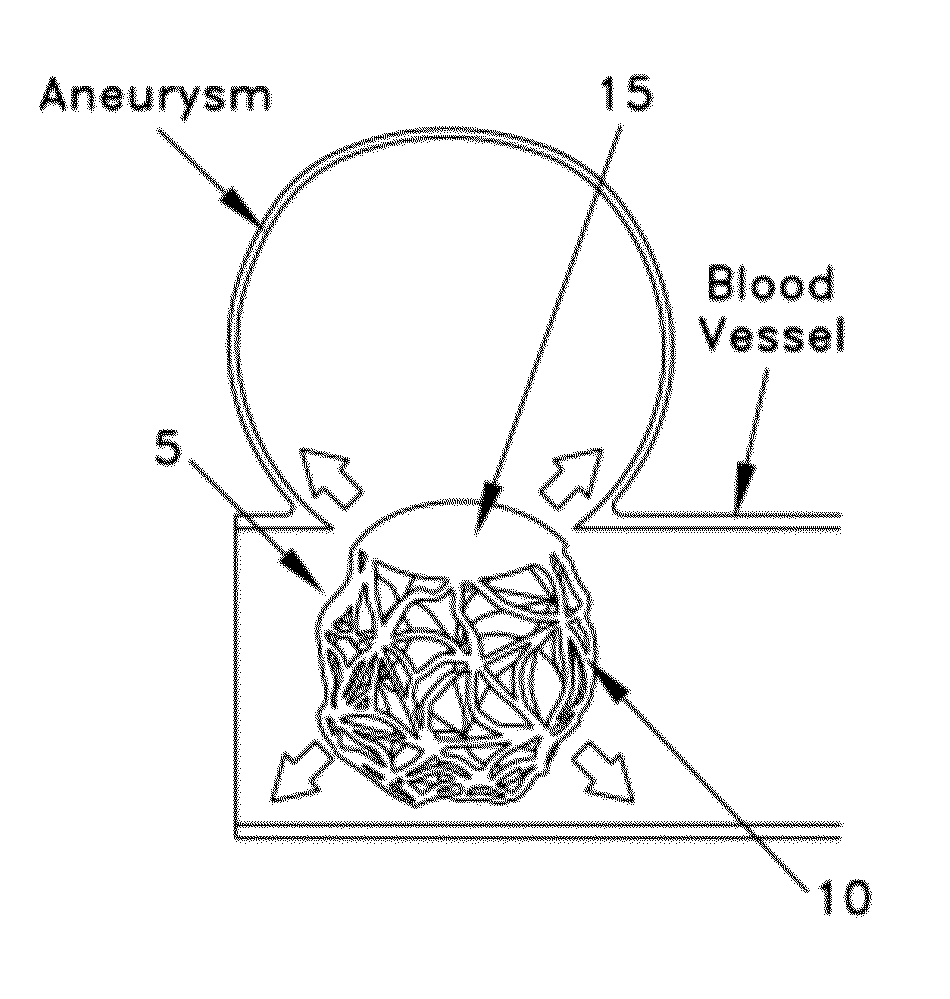

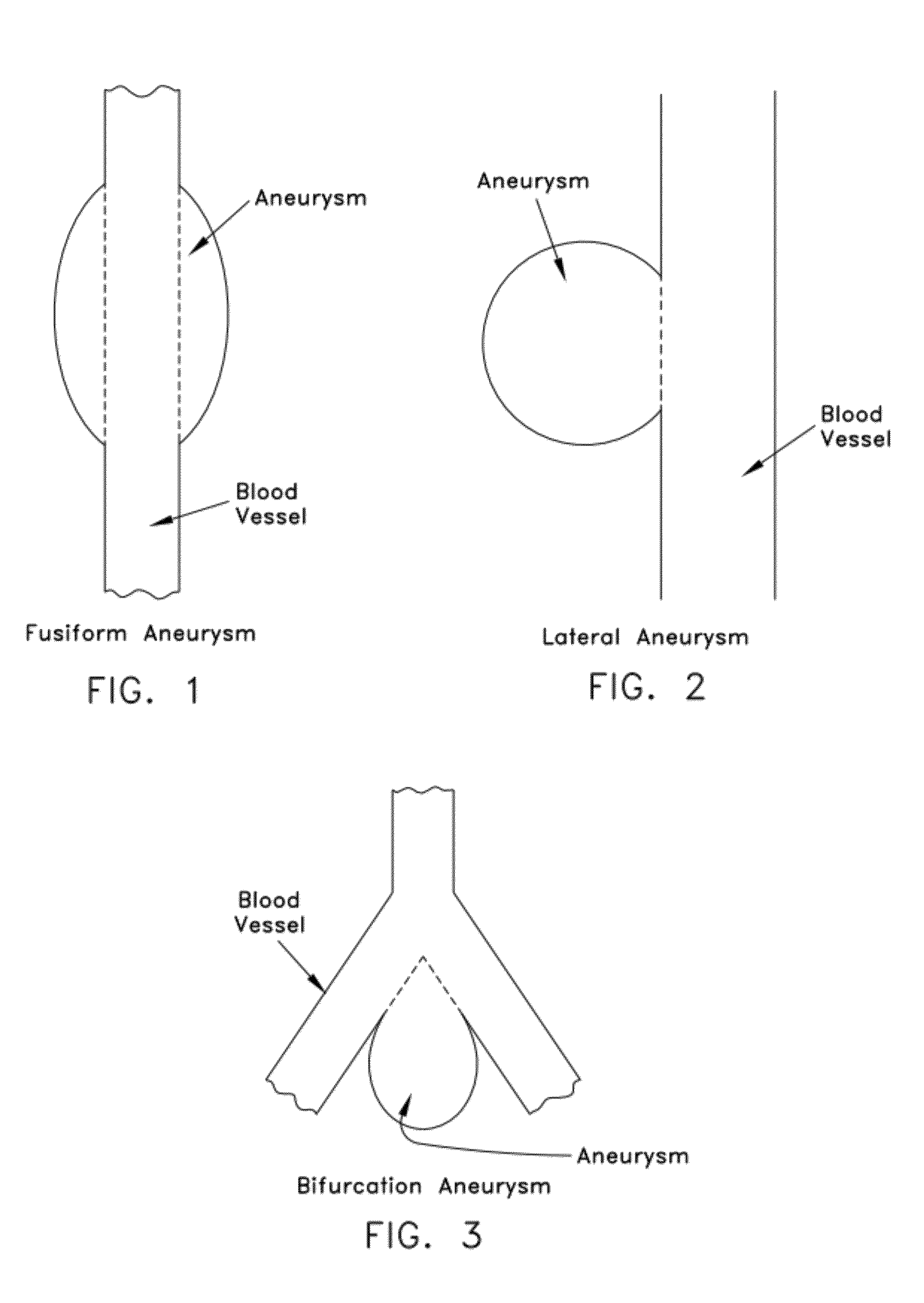

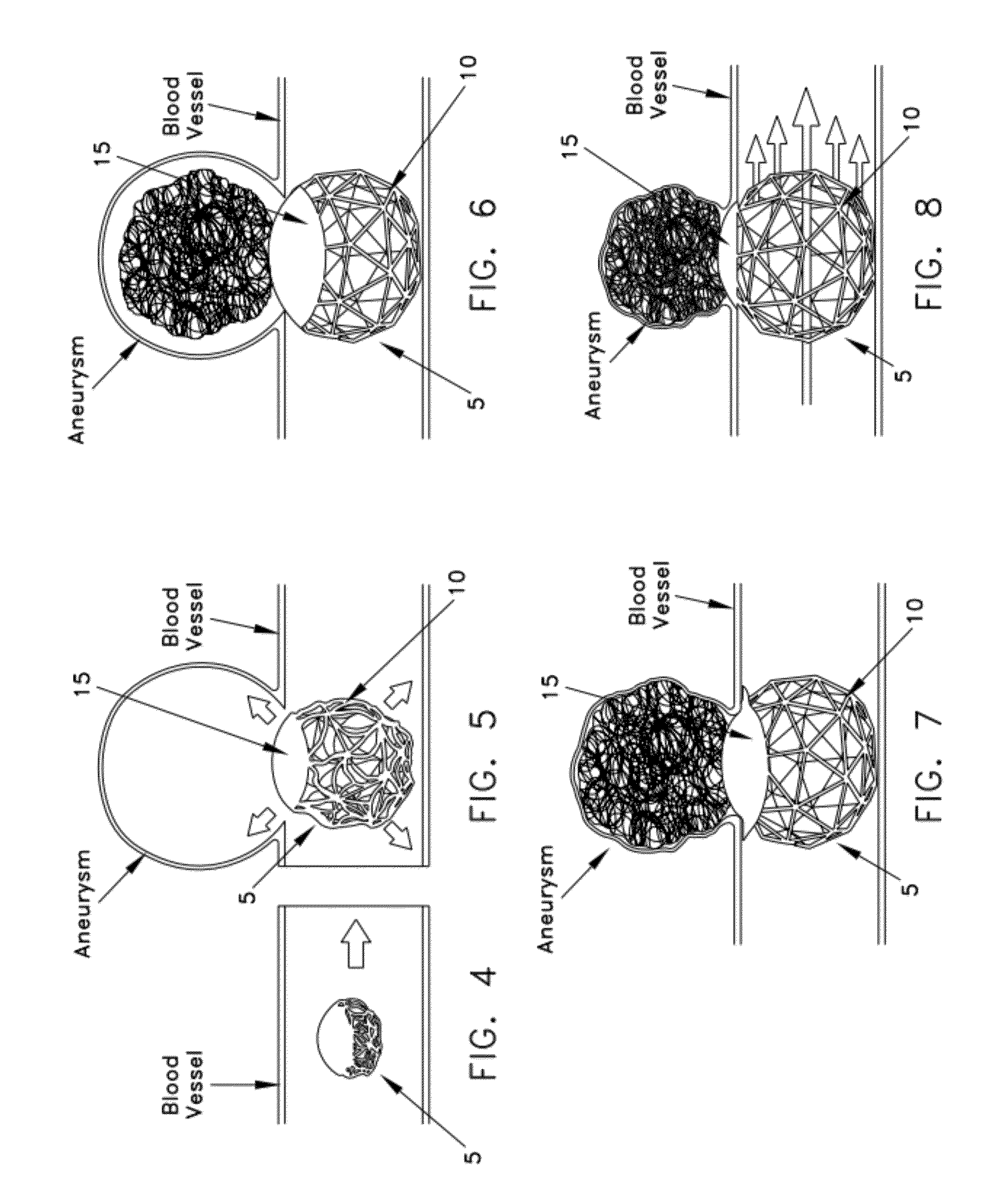

Method and apparatus for restricting flow through an opening in the side wall of a body lumen, and/or for reinforcing a weakness in the side wall of a body lumen, while still maintaining substantially normal flow through the body lumen

A method for making a device for causing thrombosis of an aneurysm, wherein said device comprises a single elastic filament configurable between (i) an elongated, substantially linear configuration, and (ii) a longitudinally-contracted, substantially three-dimensional configuration, said method comprising:providing a sheet of shape memory material;producing a single filament, two-dimensional interim structure from said sheet of shape memory material;mounting said single filament, two-dimensional interim structure to a fixture so that said single filament, two-dimensional interim structure is transformed into said longitudinally-contracted, substantially three-dimensional configuration; andheat treating said single filament, two-dimensional interim structure while it is mounted to said fixture so as to produce said device in its longitudinally-contracted, substantially three-dimensional configuration.

Owner:CORNELL UNIVERSITY

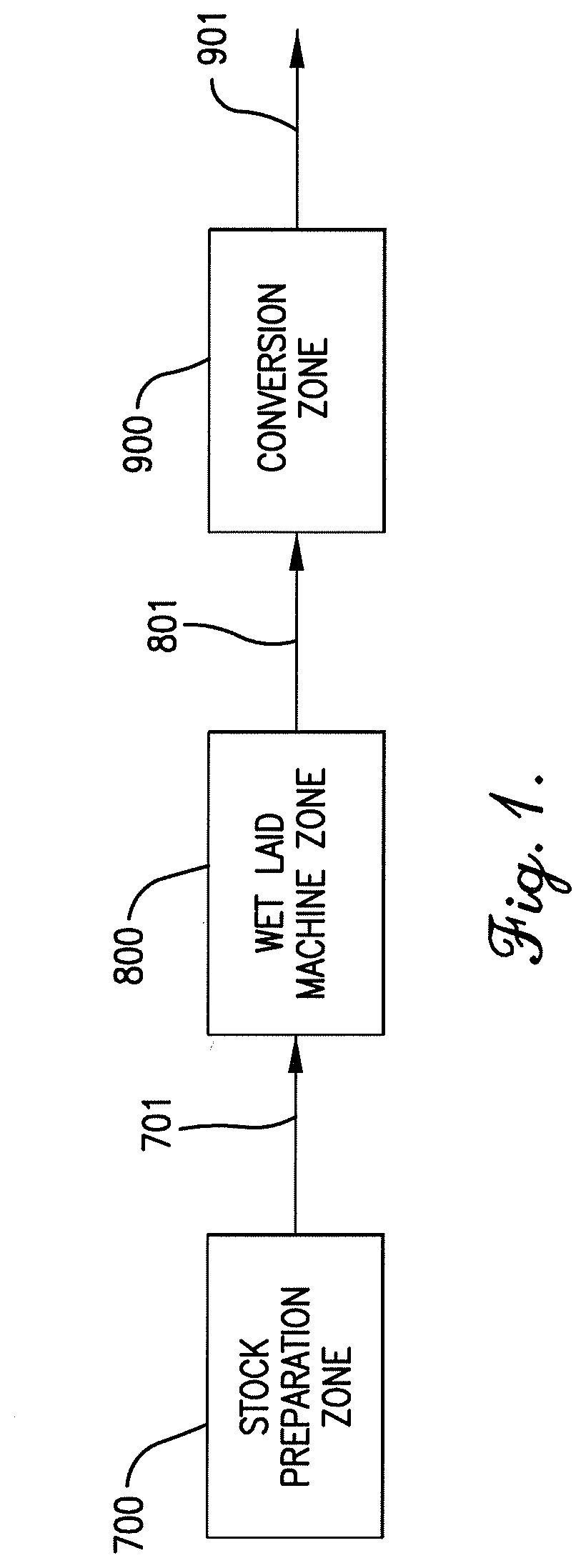

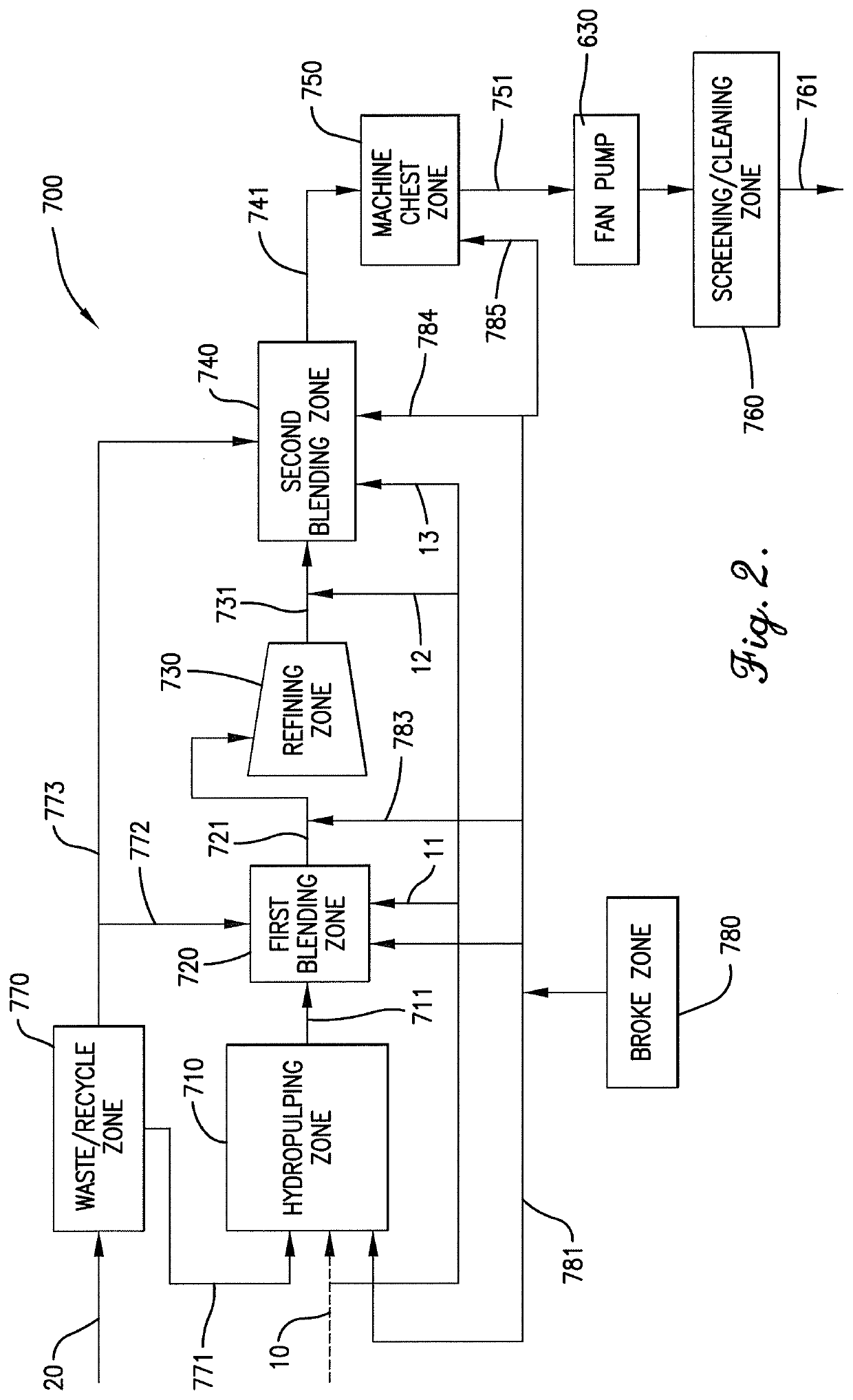

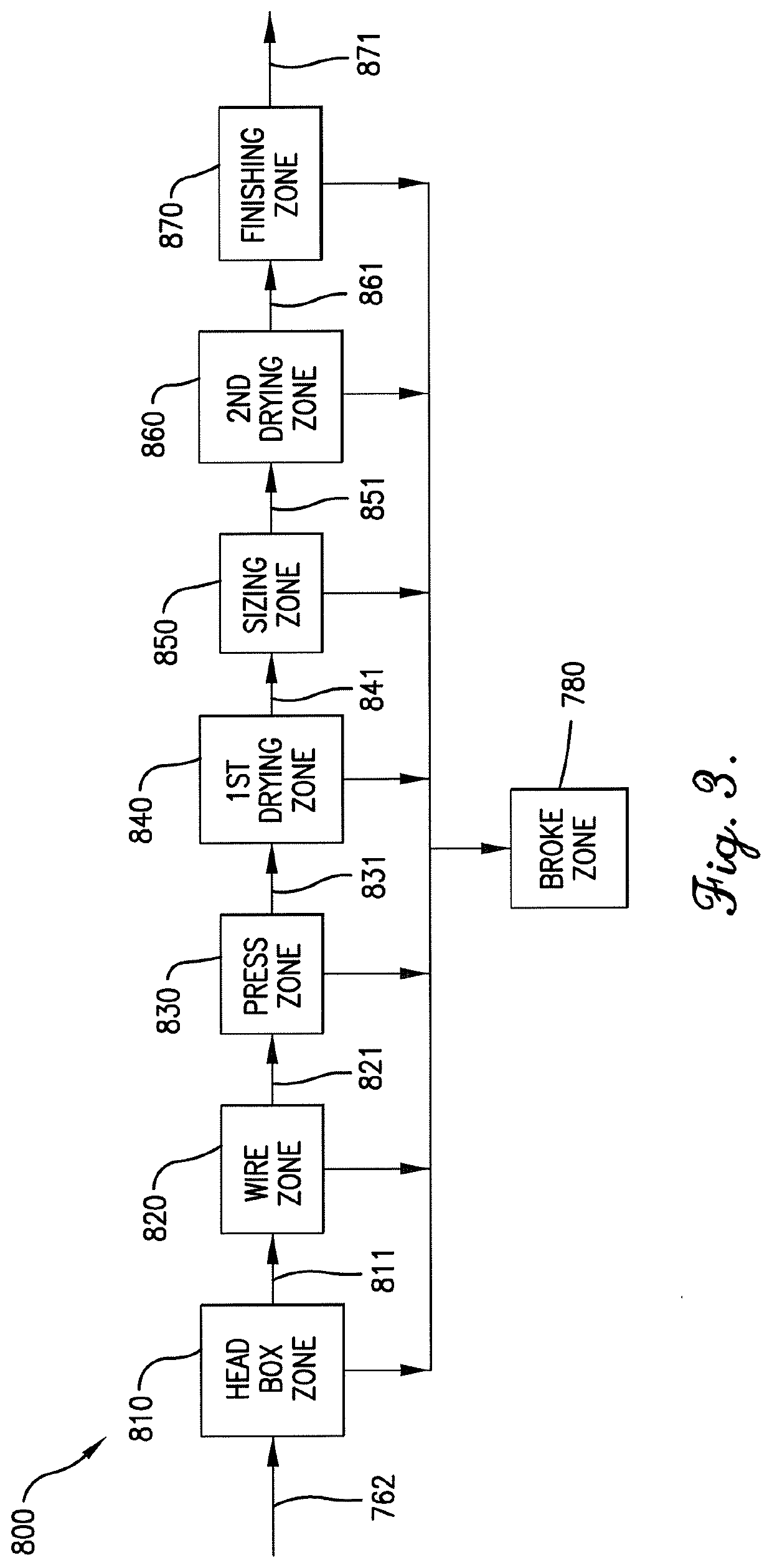

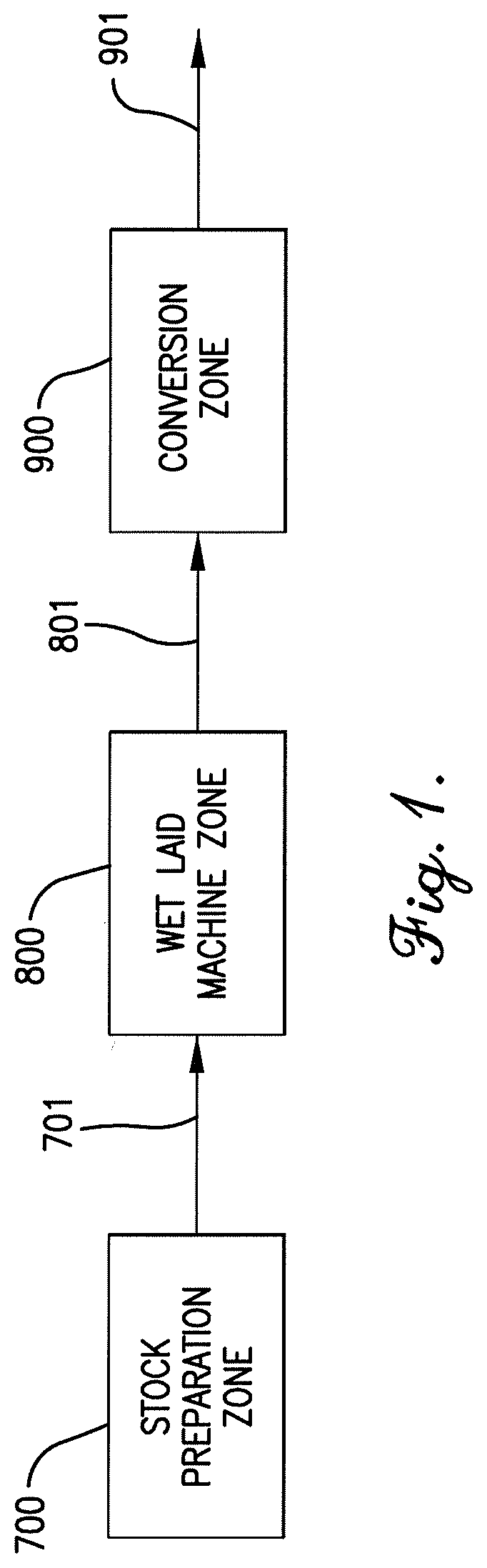

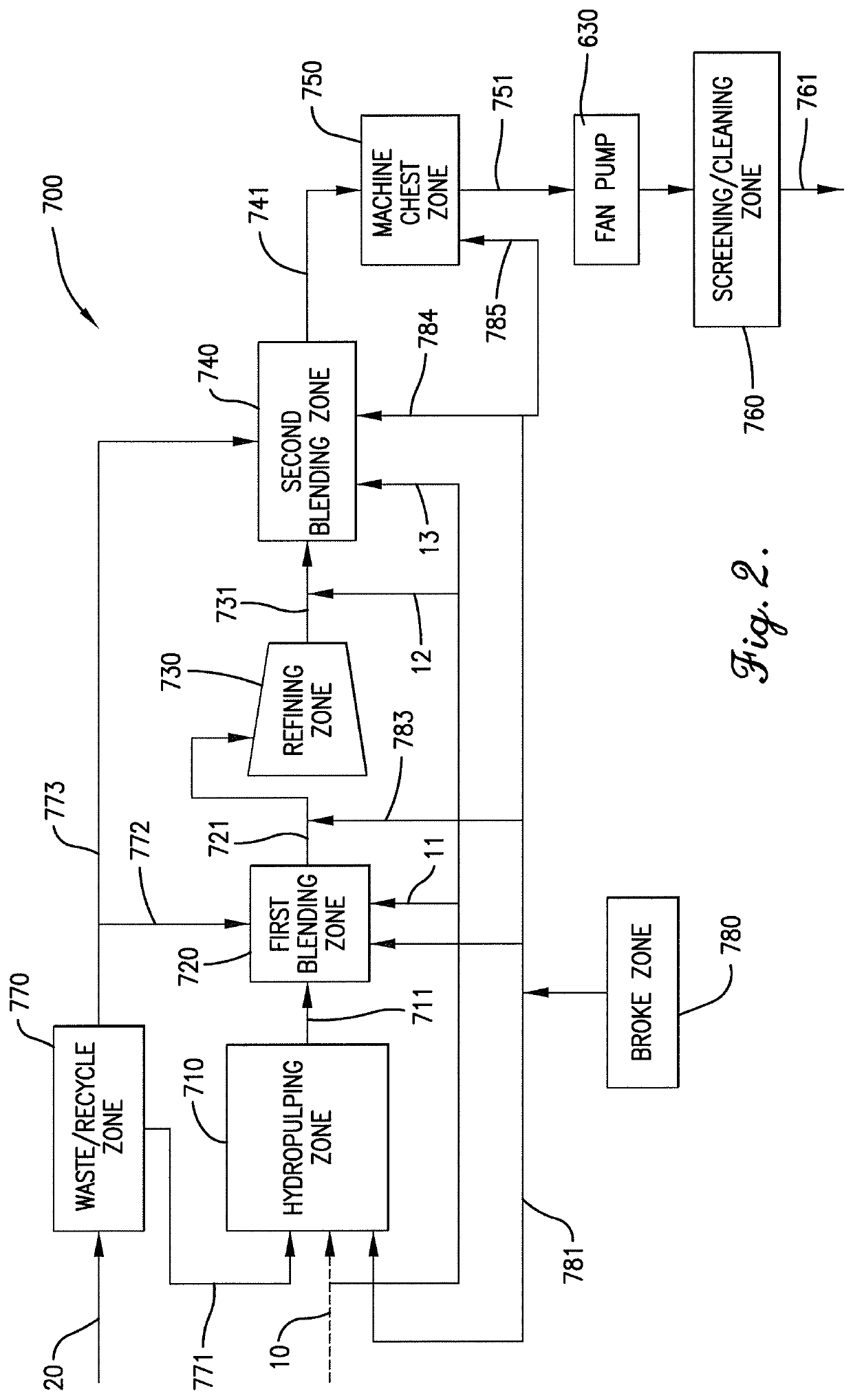

Compostable wet-laid articles comprising cellulose and cellulose esters

InactiveUS20200063365A1Reduce consistencyLow variabilityFlexible coversWrappersPolymer scienceCellulose fiber

Wet laid products including packaging is obtained from co-refined cellulose fibers and synthetic fibers are made biodegradable, and can also be compostable and soil biodegradable. The synthetic fibers include staple cellulose ester fibers. Desirably, such staple cellulose ester fibers have a denier per filament of 3 or less, a cut length of 6 mm or less, are crimped, or are non-round and crimped, and have a degree of substitution of 2.5 or less.

Owner:EASTMAN CHEM CO

Biological soluble fiber mat, preparation method thereof and vacuum insulated panel using mat

ActiveCN105274728AEffective insulationWith green characteristicsFibreboardThermal insulationAdhesiveSoluble fiber

The invention relates to a biological soluble fiber mat, a preparation method thereof and a vacuum insulated panel using the mat. The mat is a fiber mat containing biological soluble fibers including 85-100wt% of biological soluble fibers and 0-15wt% of cured adhesives. The biological soluble fibers penetrate through one another and intertwine or are in overlapping joint in the form of single filaments or distributed in an interwoven mode. Few biological soluble fibers extend close to the thickness direction of the mat. The adhesives are dispersed among signal filaments, closely adhered to one another and do not independently exist. The average fiber diameter of a biological soluble fibers is less than or equal to 30 [mu]m and the average fiber length is less than or equal to 250 mm. Harm of fiber dust generated during manufacture and usage of the fiber mat to human bodies can be effectively avoided.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

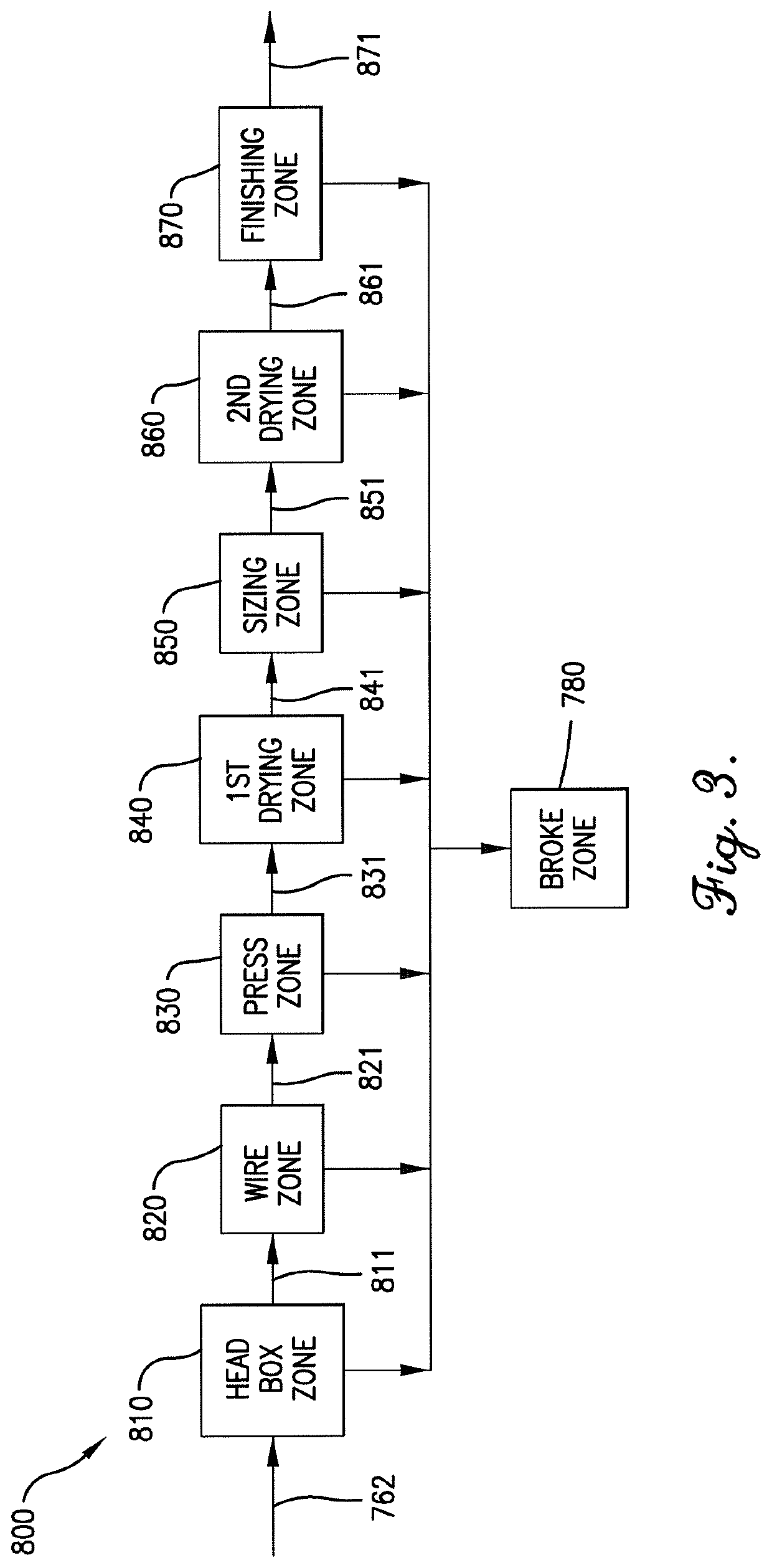

Composition of matter in a post-refiner blend zone

ActiveUS20200063358A1Reduce consistencyLow variabilityWater-repelling agents additionReinforcing agents additionPolymer scienceCellulose fiber

After cellulose fibers and cellulose ester fibers are co-refined, they are fed to a blend tank continuously feeds a wet laid process. The composition in the blend tank includes co-refined cellulose fibers and cellulose ester fibers and one or more additives, and the cellulose ester fibers have a denier per filament (DPF) of less than 3, a cut length of less than 6 mm, crimped, or non-round with a DPF of less than 3.

Owner:EASTMAN CHEM CO

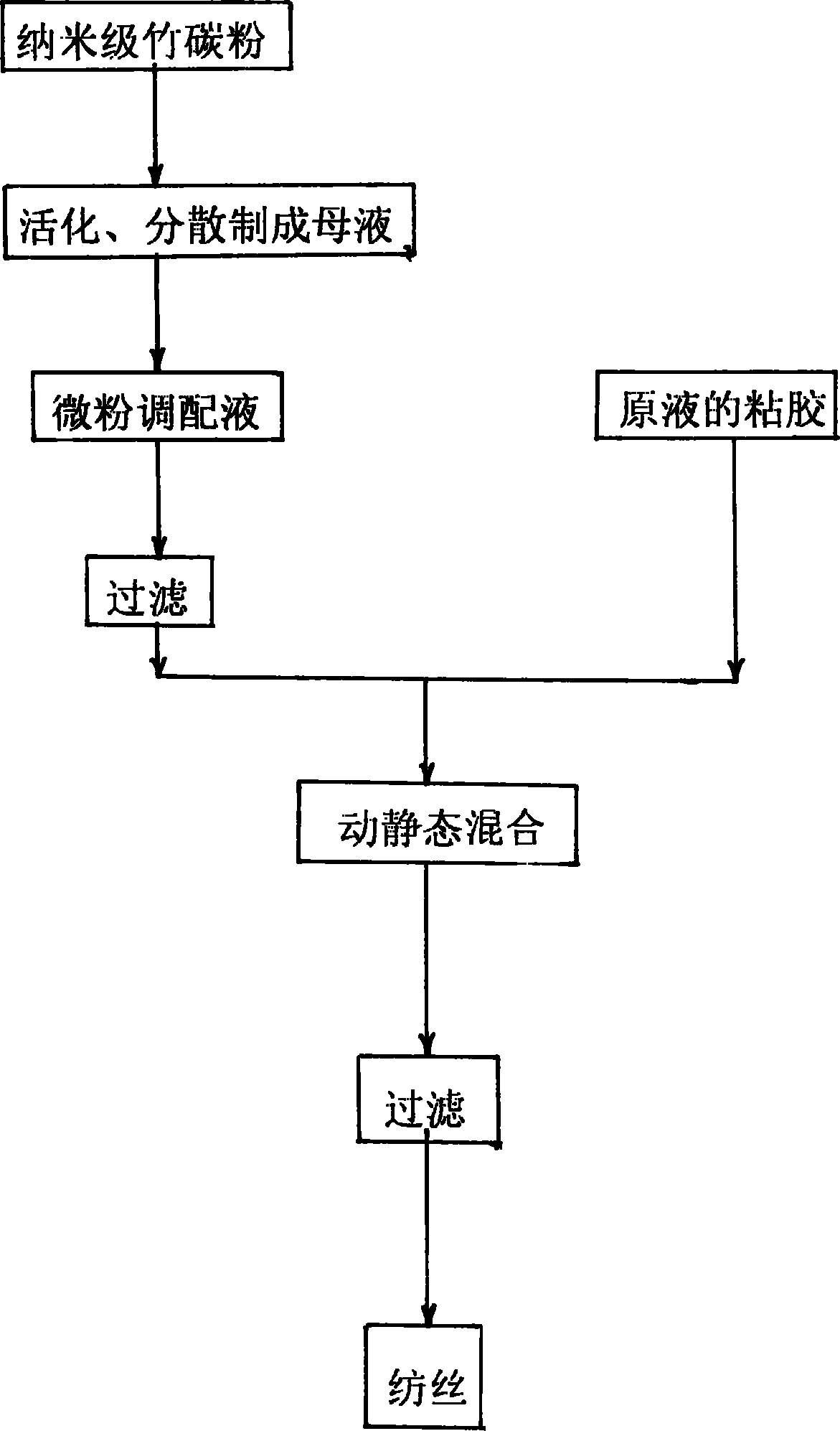

Bamboo charcoal viscose filament and its making method

ActiveCN1995499AIncrease functional valueChange a single functionMonocomponent cellulose artificial filamentFilament/thread formingHuman healthMother liquor

The invention discloses a bamboo carbon viscose filament and the manufacturing method. The fiber is characterized in that after bamboo carbon powder solution is mixed with the viscose solution with the proportion of 0.1-2%, the spinning is run; and bamboo viscose filament product with 30 of the number of monofilament, 0% of the deviation of the number of monofilament, 4. 8mg / 100g of residue, 0.35% of oil percentage, 3. 5 grade of dyeing evenness, and 99. 8% of anti escherichia coli and gold aureus is obtained. The manufacturing method comprises preparing the bamboo carbon powder mother solution, preparing the bamboo carbon powder matching solution, rubbing and filtering of the bamboo carbon powder solution, mixing with the viscose solution, and filtering. The invention is benefit for human health and can improve the performance and added value of viscose fiber product. It is favor of environmental protection.

Owner:YIBIN GRACE

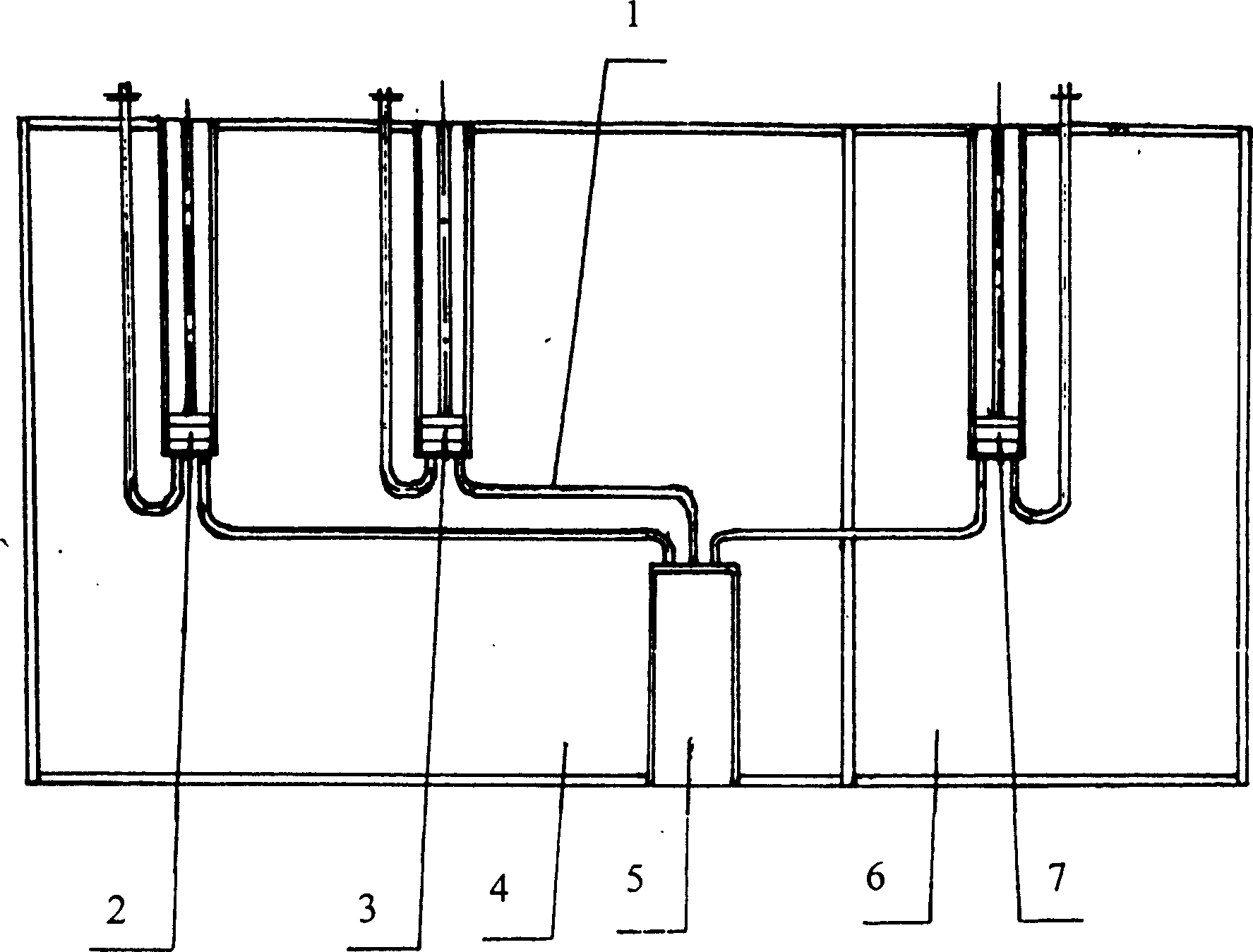

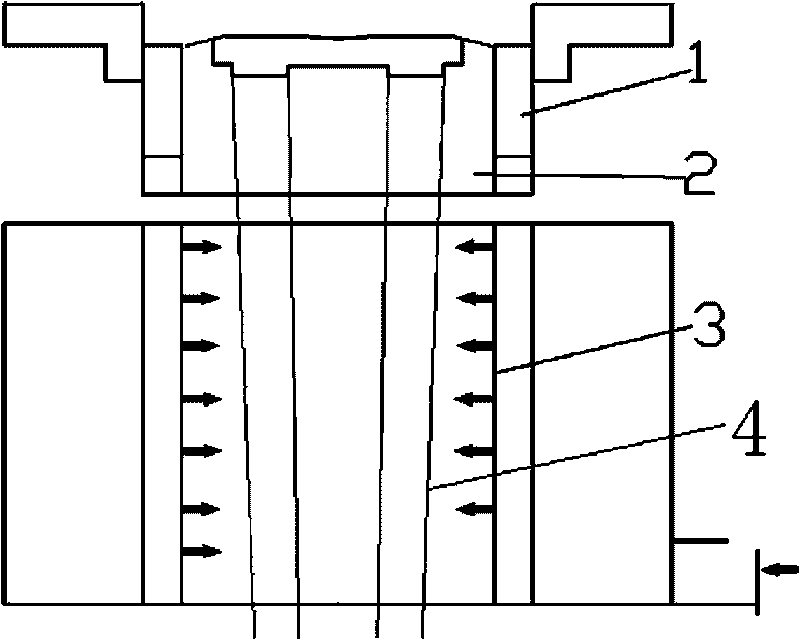

Method for producing fine denier nylon FDY filament with aromatic function

InactiveCN101736433AHas aroma functionSimple production processFilament/thread formingFilament-forming treatmentMasterbatchFiber

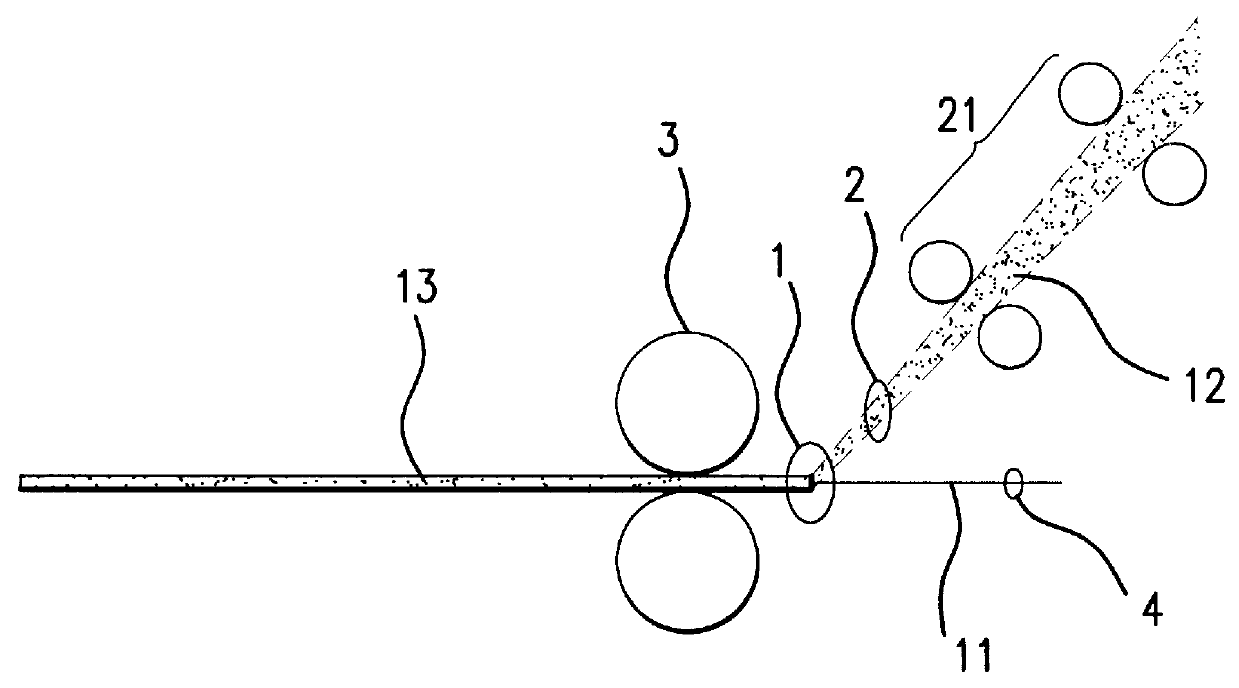

The invention relates to a method for producing a fine denier nylon FDY filament with aromatic function. The technical problem to be solved is to produce a filament that the filament number is between 0.5 and 1.0dtex, and the aroma retention time is long. In the production method, the weight ratio of three raw materials, namely nylon chips to fine denier nylon masterbatch to aromatic microcapsules is 1:5-20 percent: 0.5-10 percent. The process comprises the following steps of: 1) keeping steady pressure in a spinning component; 2) adopting 40-100-mesh metal sand for filtration; 3) adopting a spinneret plate, wherein the aperture of the spinneret plate is between 0.1 and 0.3mm, and the slenderness ratio is 2-4; 4) arranging an annealing device (1) behind the spinning component, and forming a windless region (2) with the height of between 20 and 40cm between the annealing device (1) and cross air blow (3); 5) ensuring that the position of a beam concentration point is 600 to 1,000mm away from the spinneret plate; and 6) ensuring that the spinning winding speed is between 3,000 and 5,000m / min.

Owner:HANGZHOU NORMAL UNIVERSITY

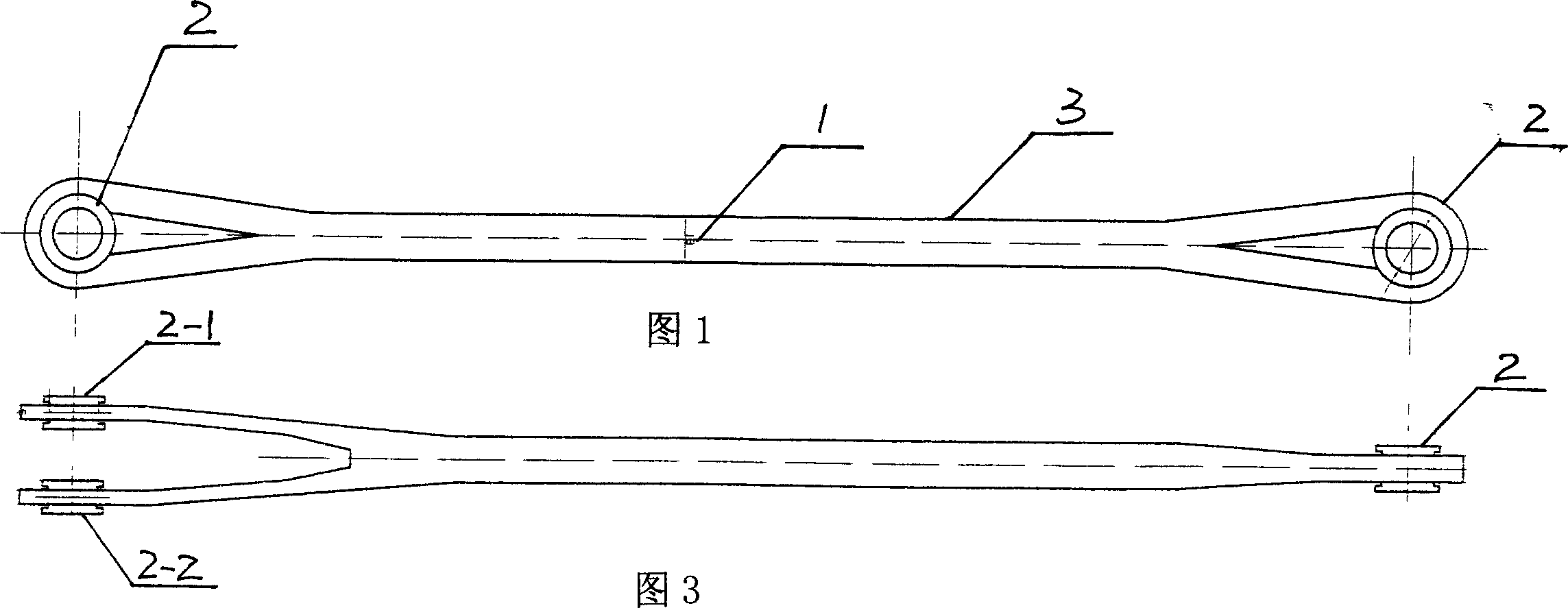

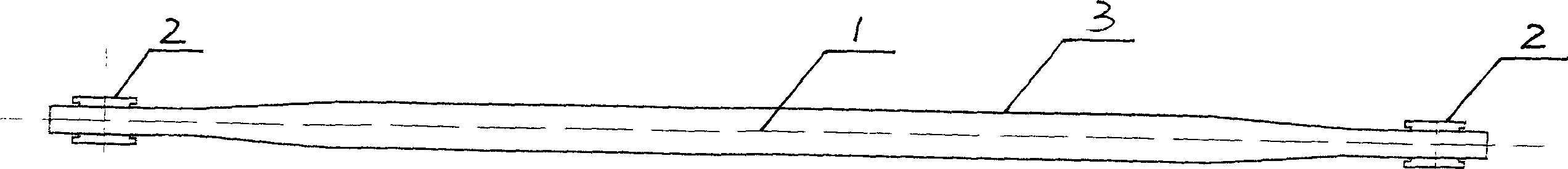

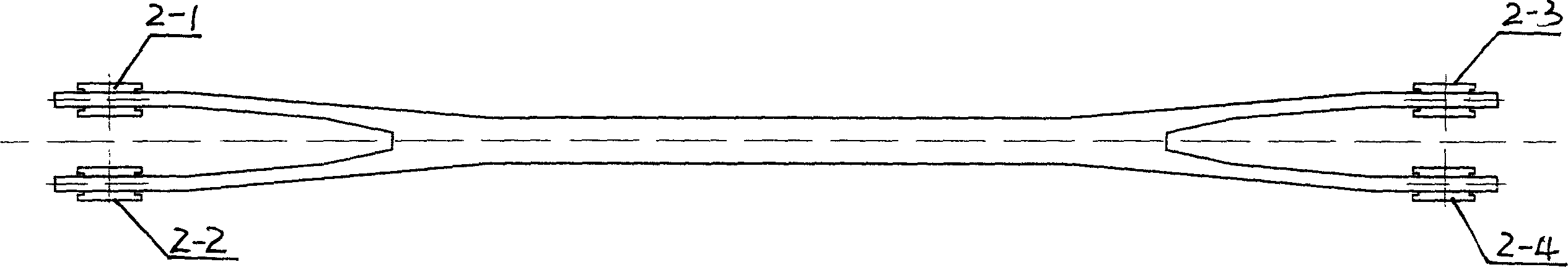

Glass fiber impregnating resin wound-type composite insulator core and preparing method

ActiveCN1731539AReduce loadReduce the effective distance to the groundSuspension/strain insulatorsEpoxyGlass fiber

The invention relates to a spiral-wound composite insulator bar for high-voltage transmission line in electric network and method for making same. The spiral-wound composite insulator bar has metal rings inlayed in its two ends. On the external diameter of metal rings wounded filaments, which are bound with, resinate glass fiber. The method comprises the steps of: getting some compound; melting resin; mixing melted glass fiber with resin solution and stirring with 150 turns per minute; enwinding continuously and modeling the glass fiber and epoxy resin radical solution in high temperature. The invention has the advantage of simple structure and low cost, of reducing tower's load and the effective distance from current transmission line to the earth. The spiral-wound composite insulator bar with cross wrap can meet the requirement of tensile strength, increasing bending strength.

Owner:吴亚民

Non-woven fabric, and sheet and artificial leather produced from the same

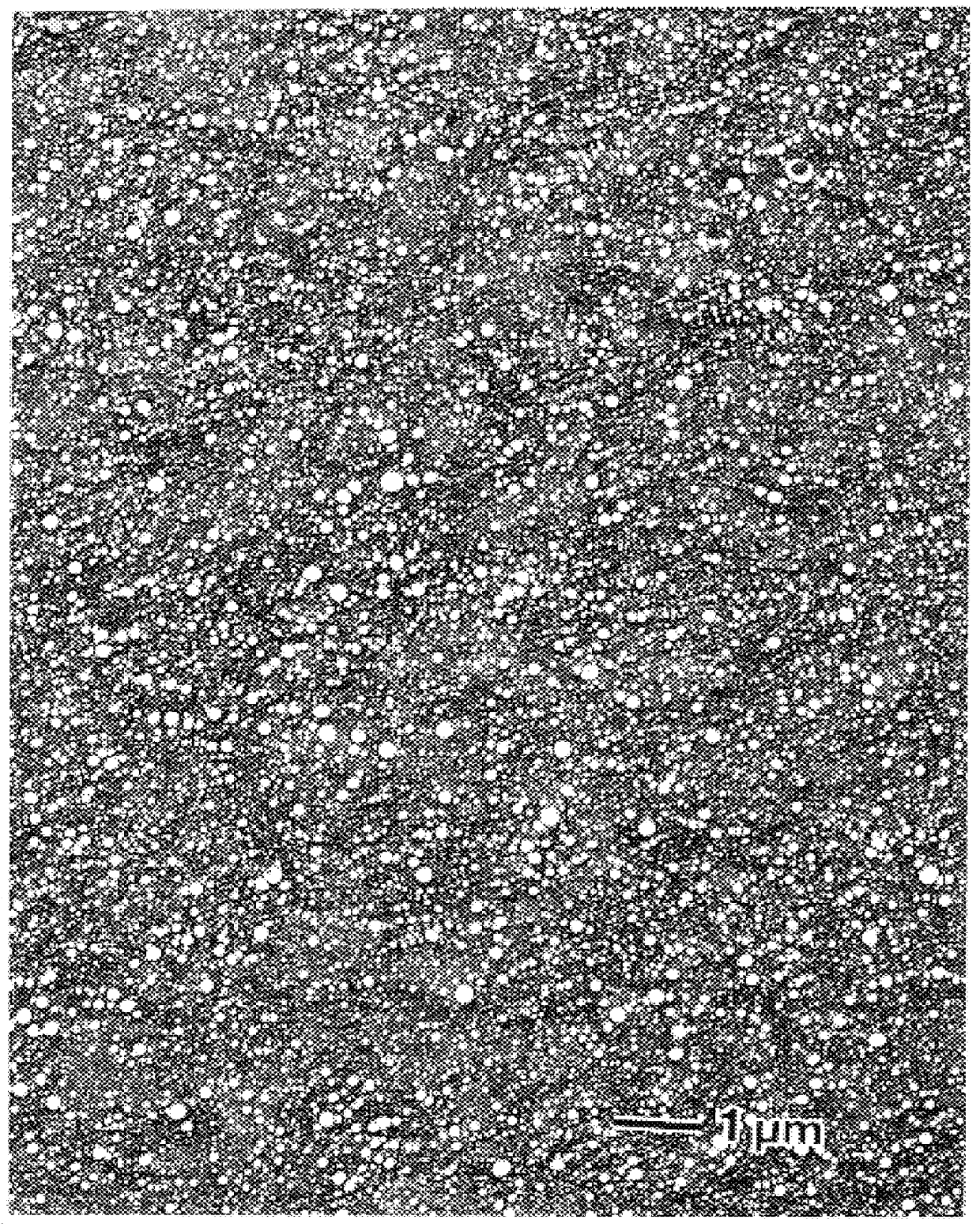

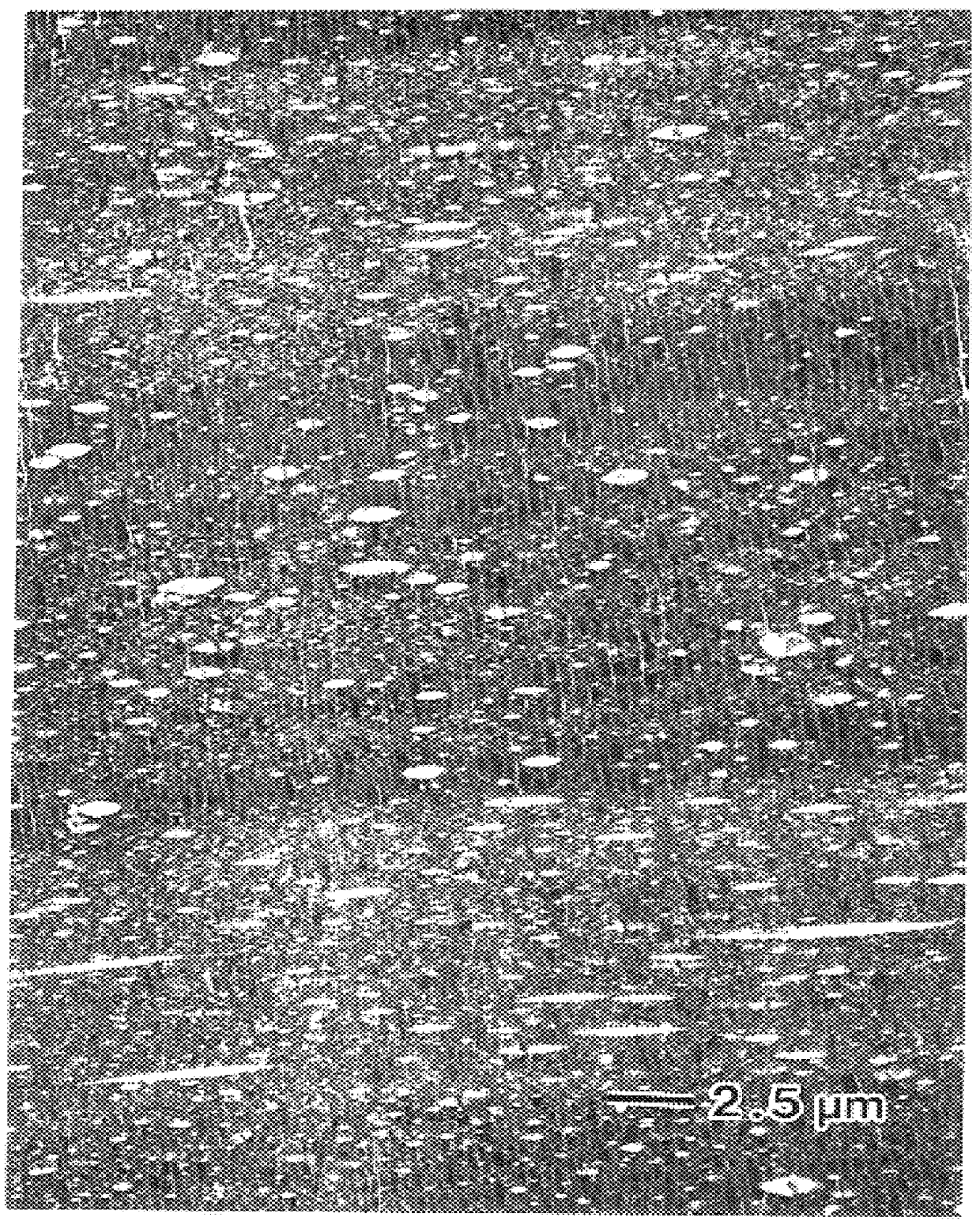

InactiveUS6566287B1Satisfies requirementFine and uniform and fiber space structureSynthetic resin layered productsWoven fabricsNonwoven fabricElectron scanning microscopy

A non-woven fabric having such a structure that fine fibers having a small fineness are entangled with one another and a sheet obtained by impregnating the non-woven fabric with an elastic polymer satisfy the following requirements:the fine fibers should be obtained by splitting a strippable and splittable composite short fiber comprising at least two components; the fine fibers should have a monofilament size of 0.01 to 0.5 denier; the fine fibers should form a fine non-woven fabric structure that they are entangled with one another at random; the apparent density should be 0.18 to 0.45 g / cm3; the average area of spaces between fibers in the cross section of the non-woven fabric measured by the image analysis of an electron scanning microscope should be 70 to 250 mum2; and the non-woven fabric should have such a uniform structure that the standard deviation of the area of a space between fibers in the cross section of the non-woven fabric measured by the image analysis of the electron scanning microscope is 200 to 600 mum2.The non-woven fabric and sheet are advantageously used as a substrate for artificial leather.

Owner:TEIJIN LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com