Special-shaped spinneret plate for spinning heavy denier yarns

A spinneret, special-shaped technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of poor fiber dyeing effect, high melt flow speed, low production efficiency of coarse denier yarn, etc. Enhanced cooling effect, improved cooling uniformity, improved dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

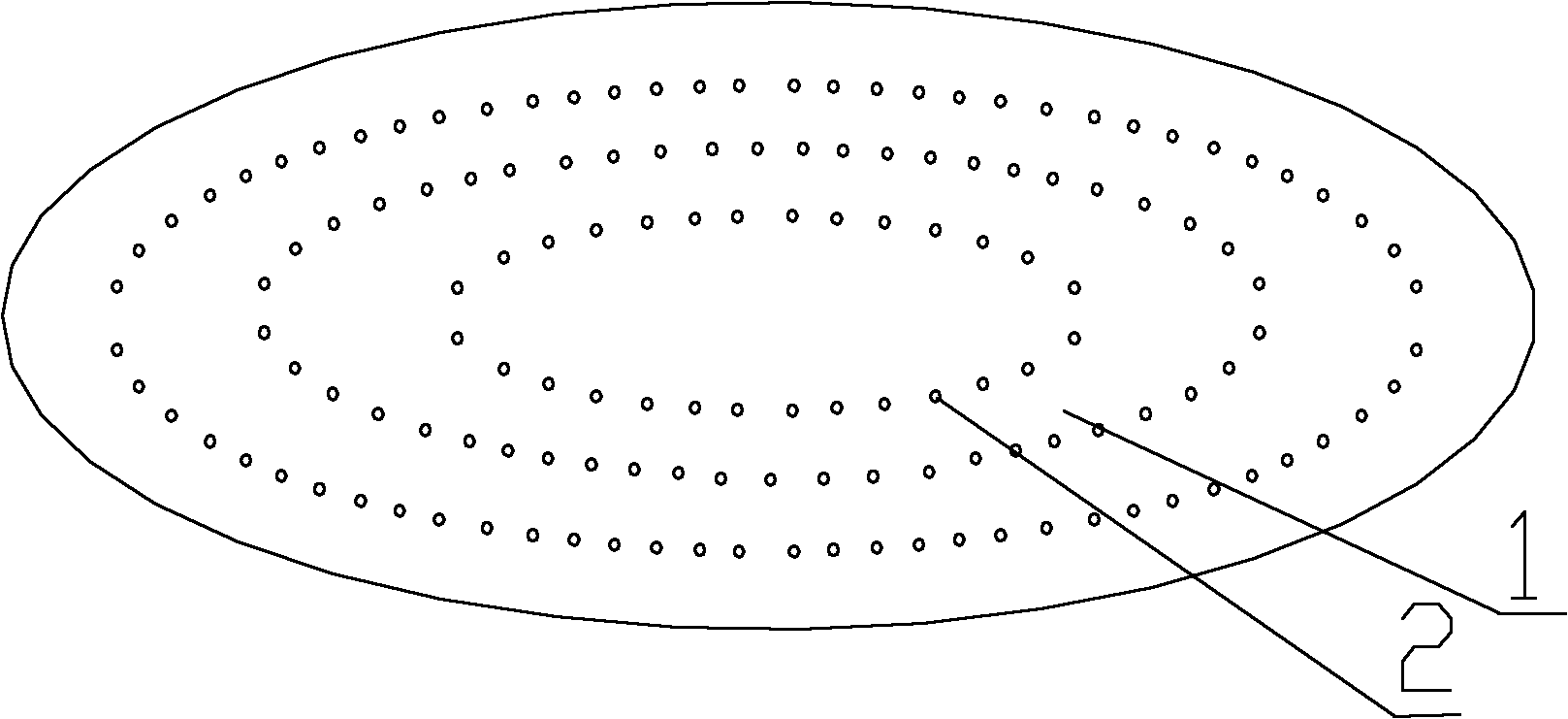

[0021] Such as figure 1 As shown, a special-shaped spinneret for spinning coarse denier yarns includes a spinneret body 1, and a spinneret hole 2 is arranged on the spinneret body 1. One side of the spinneret hole 2 is a feed inlet, and the other side is an outlet. The feed opening, the spinneret body 1 is oval.

[0022] There are 90-192 spinneret holes 2 of the present invention, and a plurality of spinneret holes 2 are arranged in a three-layer concentric elliptical structure from the inside to the outside; the micropores are arranged in three circles, but the micropores in each circle will be arranged in a random order, so that , The cooling effect of the primary fiber is good. Such as figure 1 As shown, there are 28 spinneret holes 2 in the first circle from the innermost layer, 48 in the second circle, and 68 in the third circle.

[0023] The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com