Patents

Literature

280results about How to "Improve cooling uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

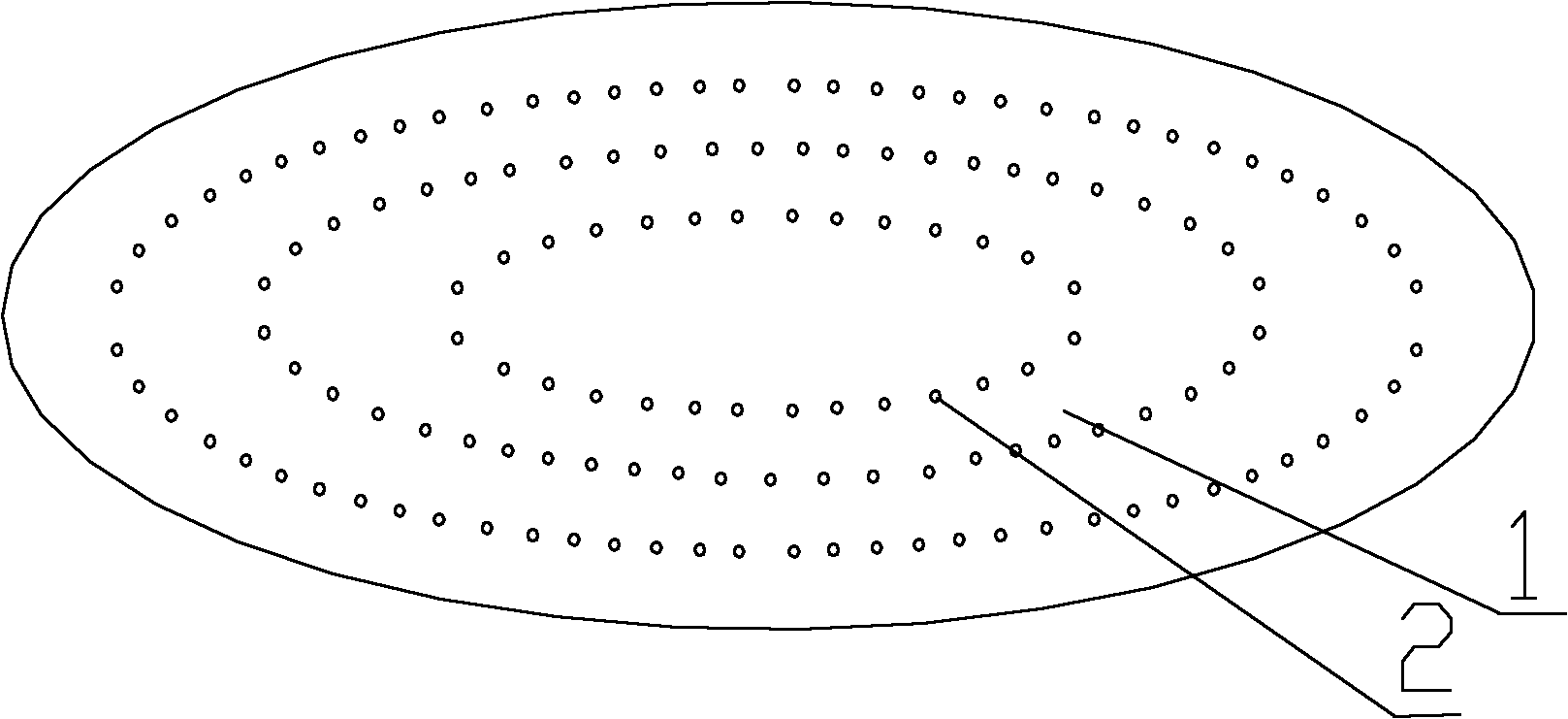

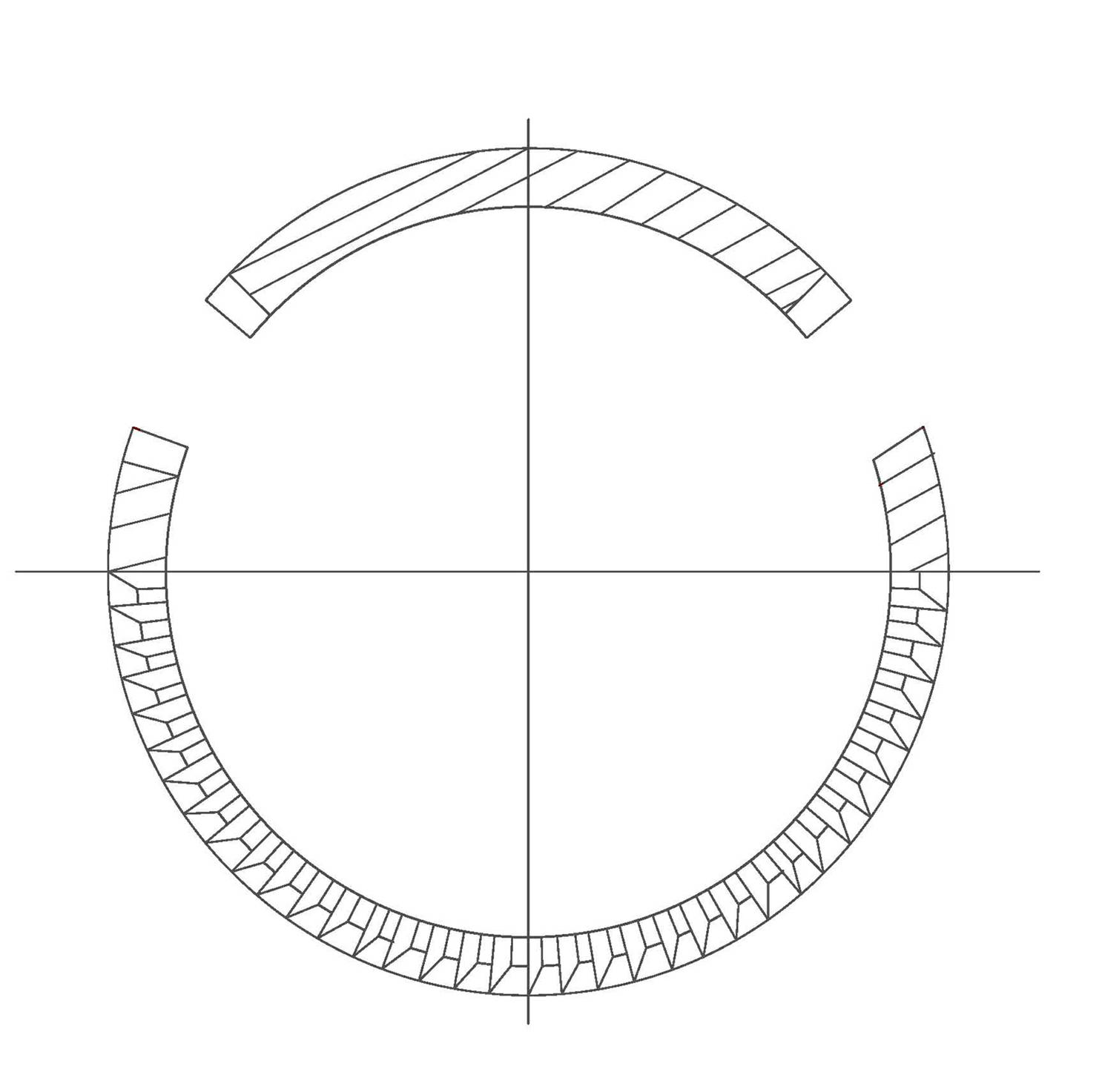

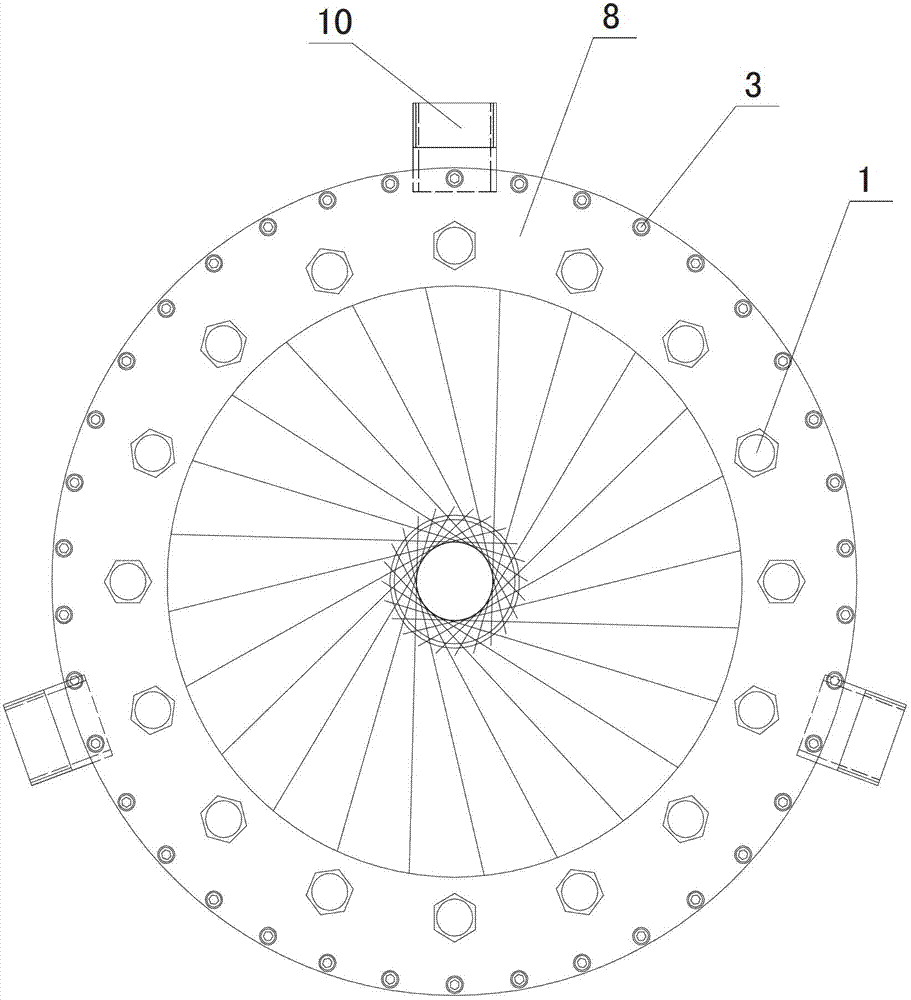

Special-shaped spinneret plate for spinning heavy denier yarns

InactiveCN102851757AImprove cooling uniformityImprove dyeing effectFilament/thread formingPolymer scienceSpinning

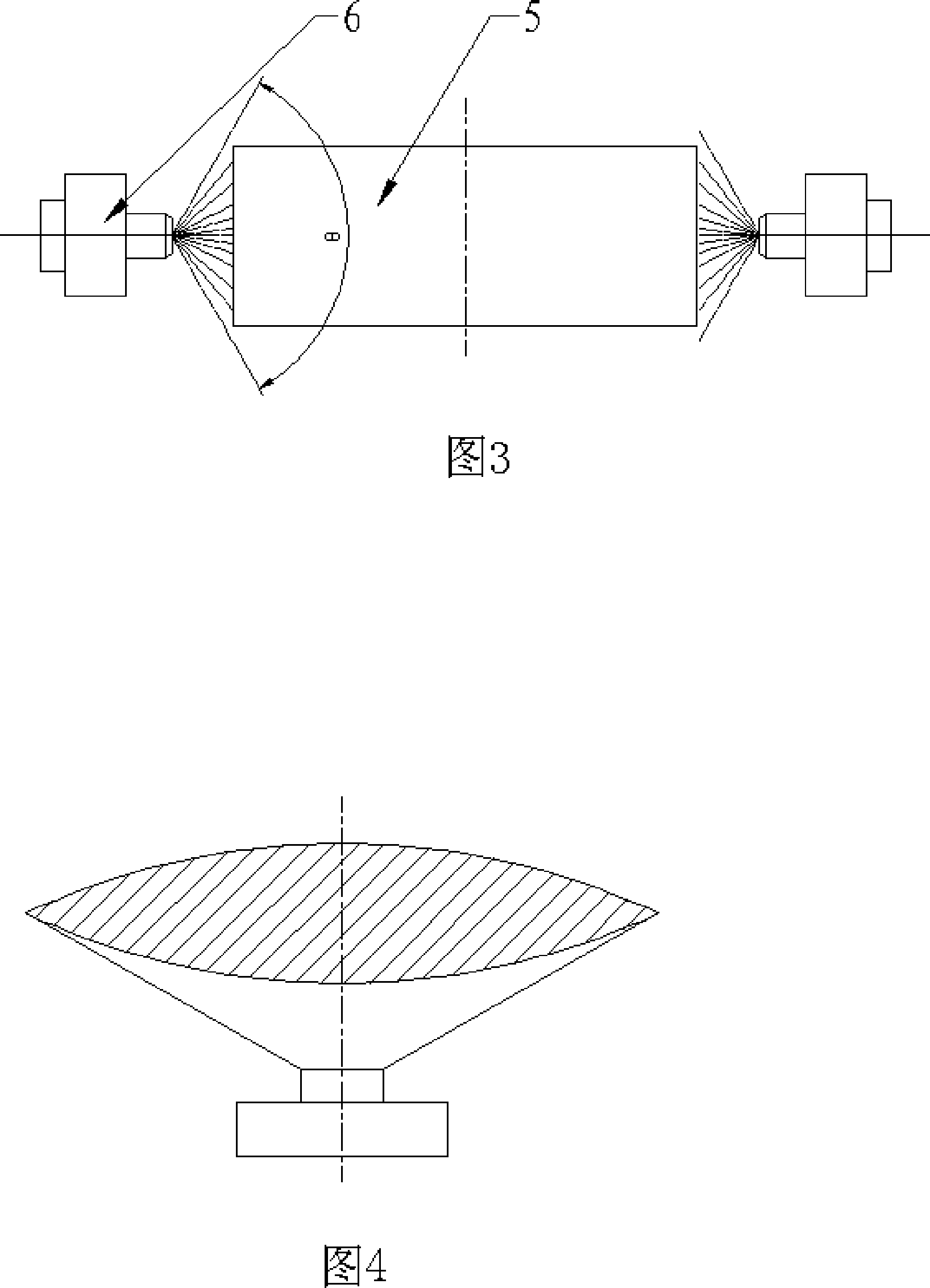

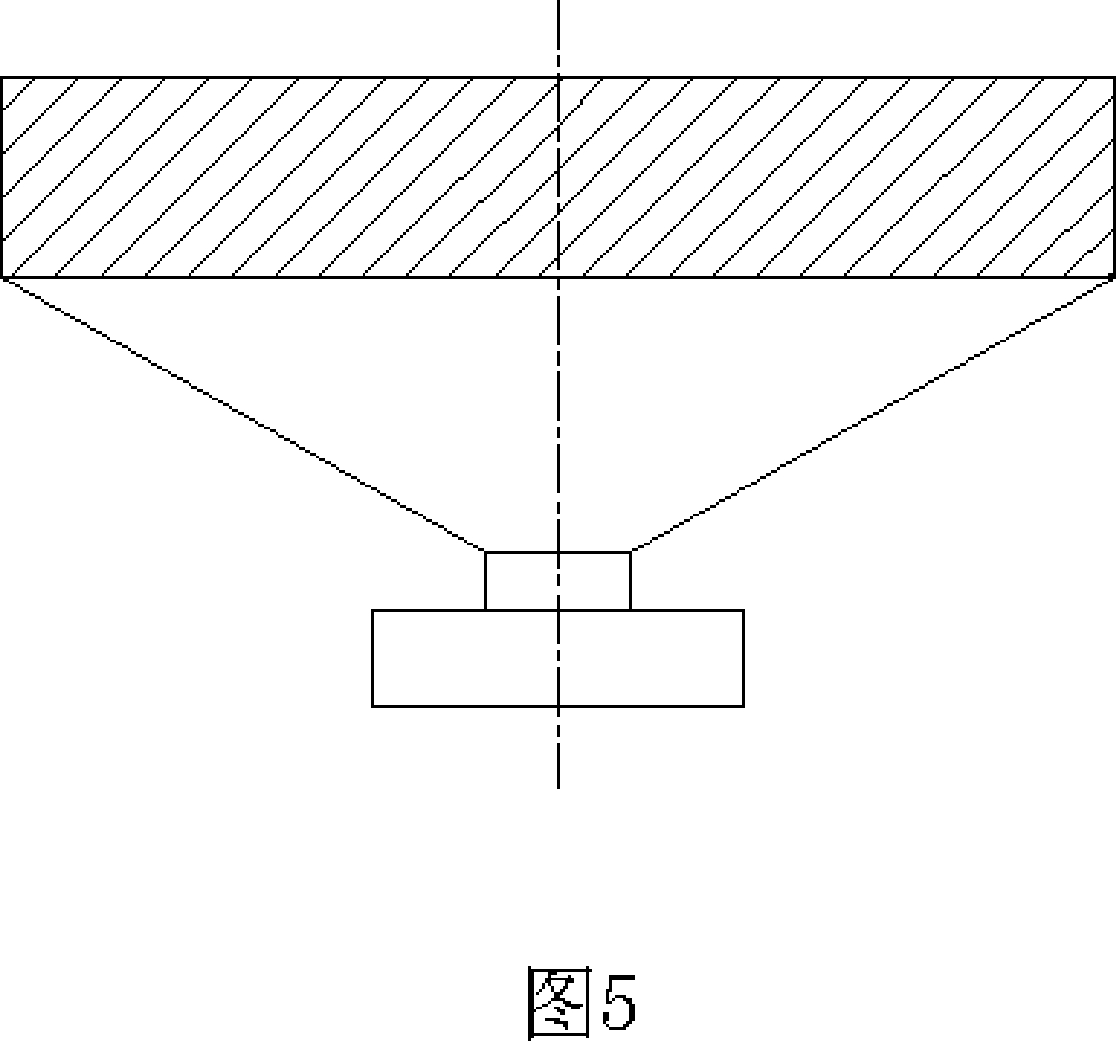

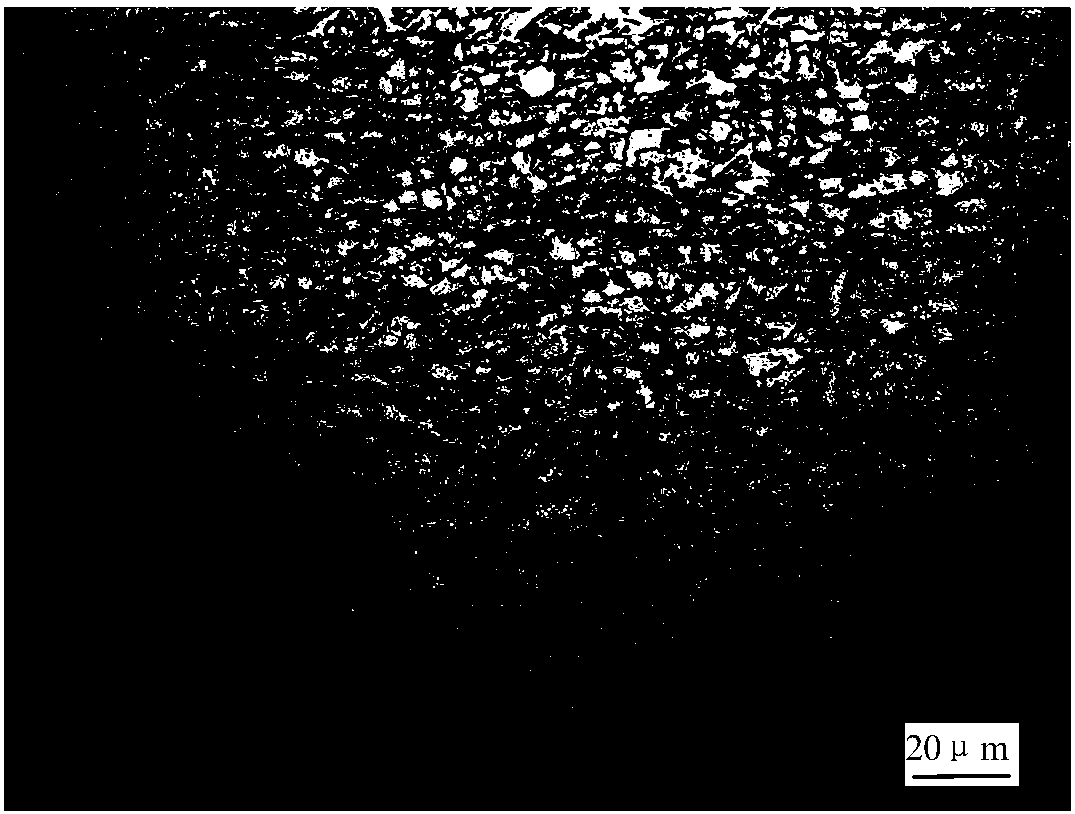

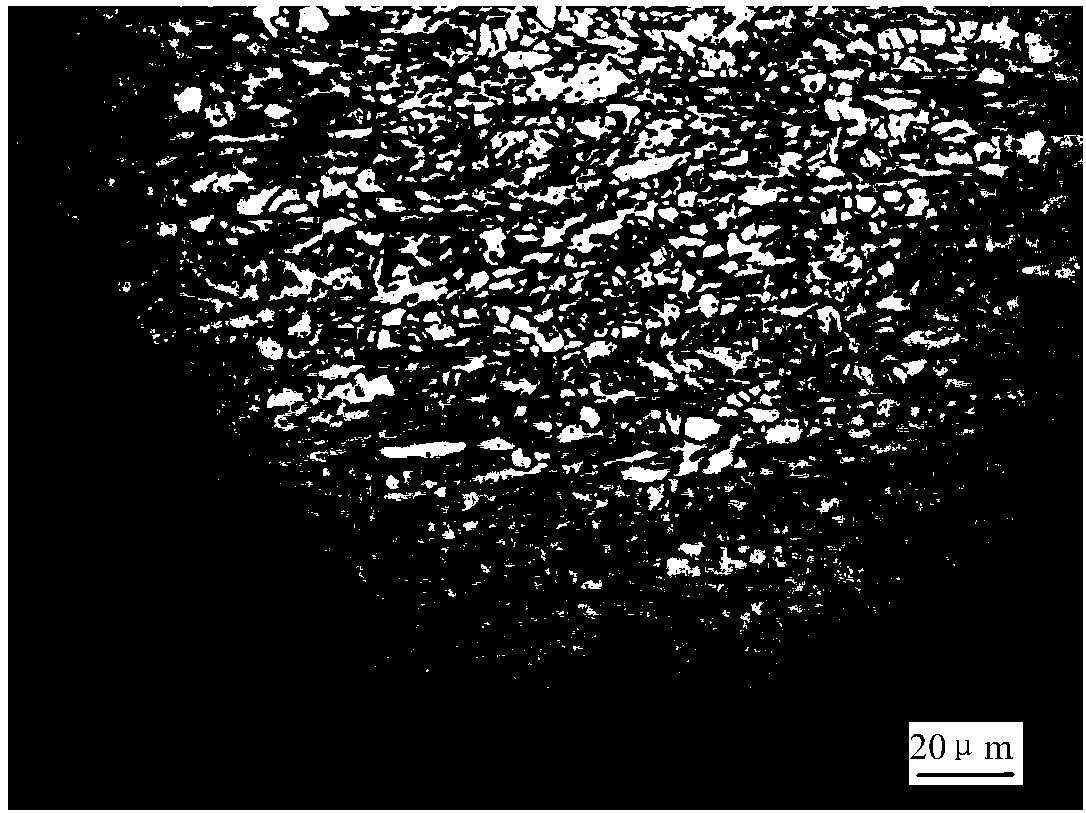

A special-shaped spinneret plate for spinning heavy denier yarns comprises an elliptic body (1). 90-192 spinning holes (2) are arranged on the body (1). One side of each spinning hole (2) is a feed inlet. The other side of each spinning hole (2) is a discharge outlet. The plurality of spinning holes (2) are arranged in a three-layered concentric ellipse structure from inside to outside. The spinneret plate is capable of producing glazed heavy denier yarns of 300-500D. Due to heavier filament number, diameters of micropores are slightly larger than those of round holes of products of conventional specification, and flow speed of melts in the micropores can be lowered effectively. In addition, the ellipse spinneret plate is different from conventional round spinneret plates, distribution of the micropores is facilitated, enhancement of cooling effect of spun fibers is facilitated, cooling uniformity of the heavy denier yarn is improved, and dyeing effect of the heavy denier yarn is also improved.

Owner:JIANGSU HUAYA FIBER

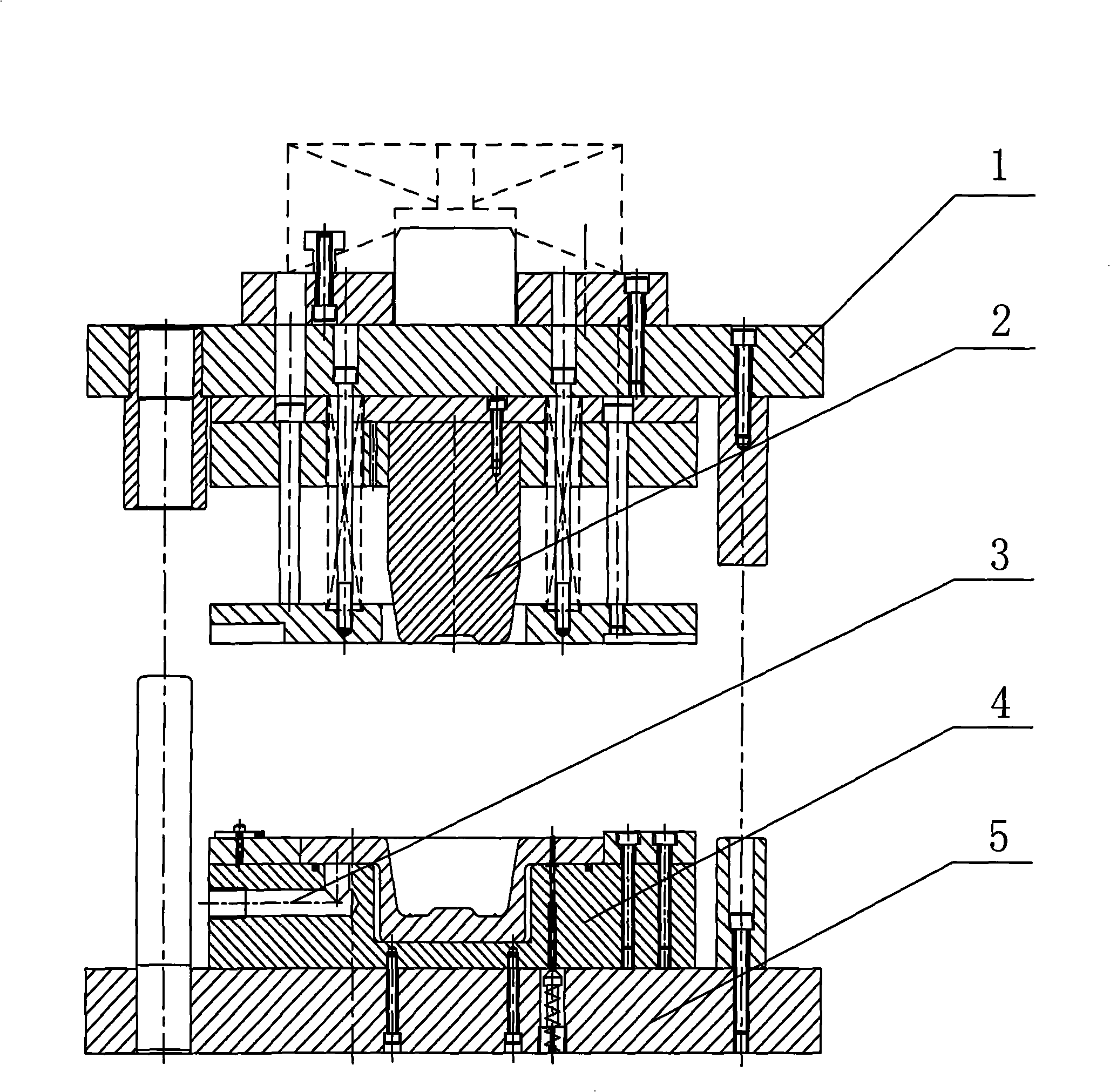

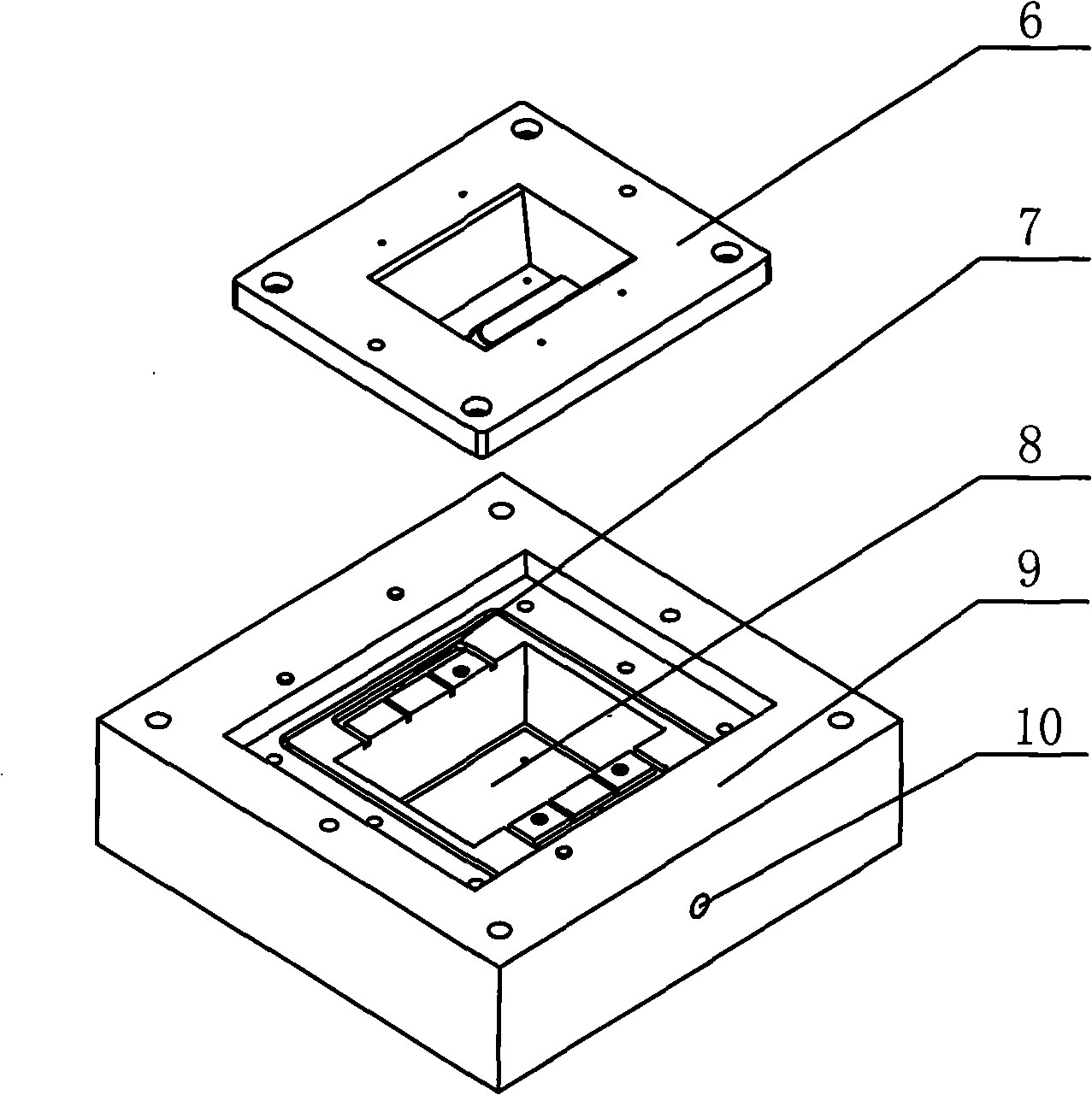

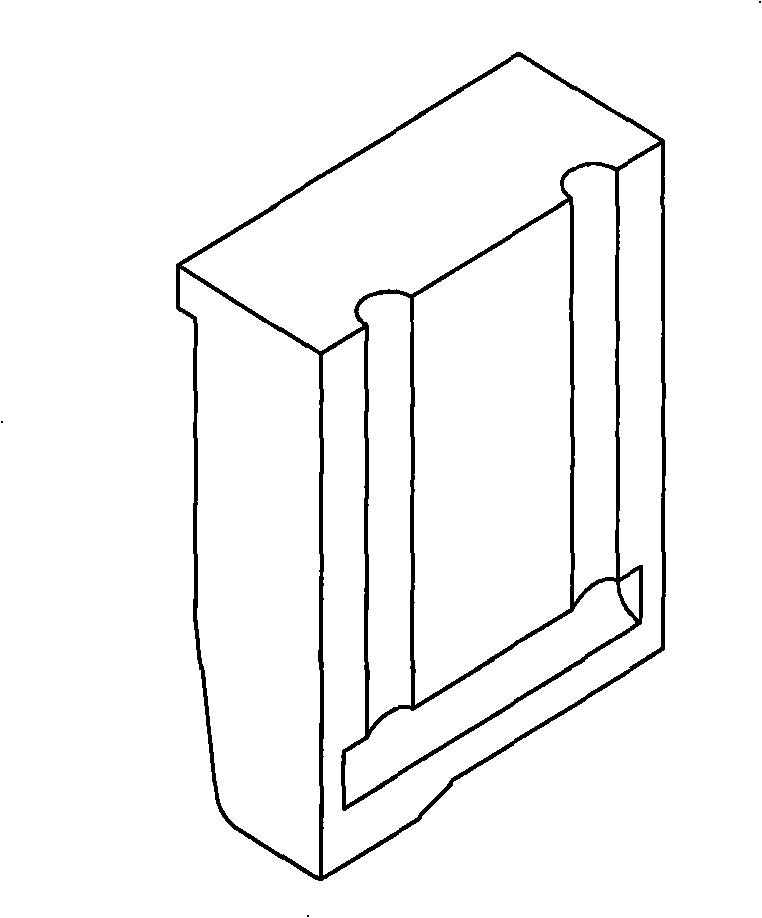

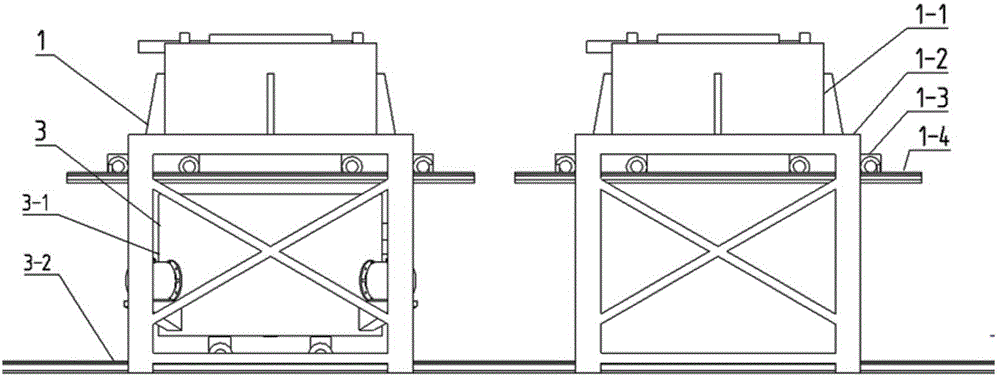

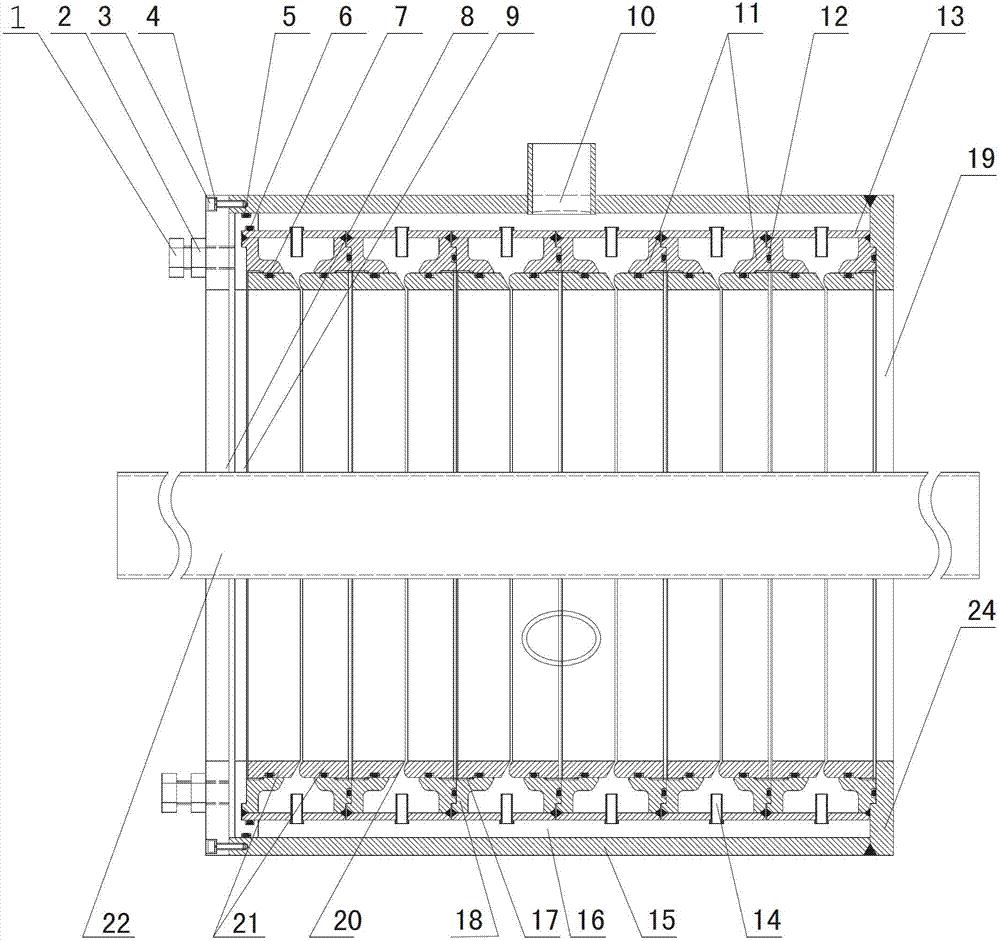

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

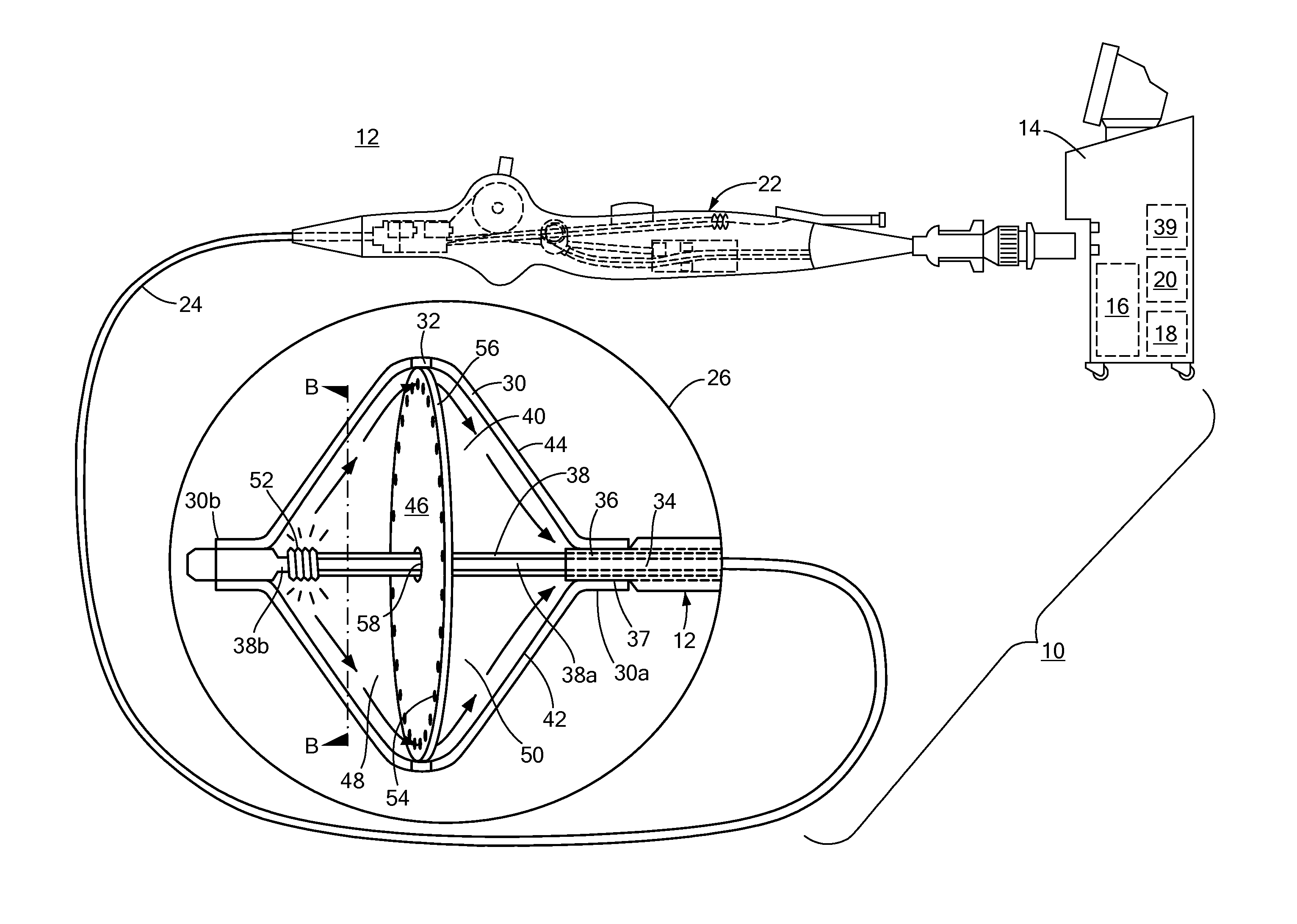

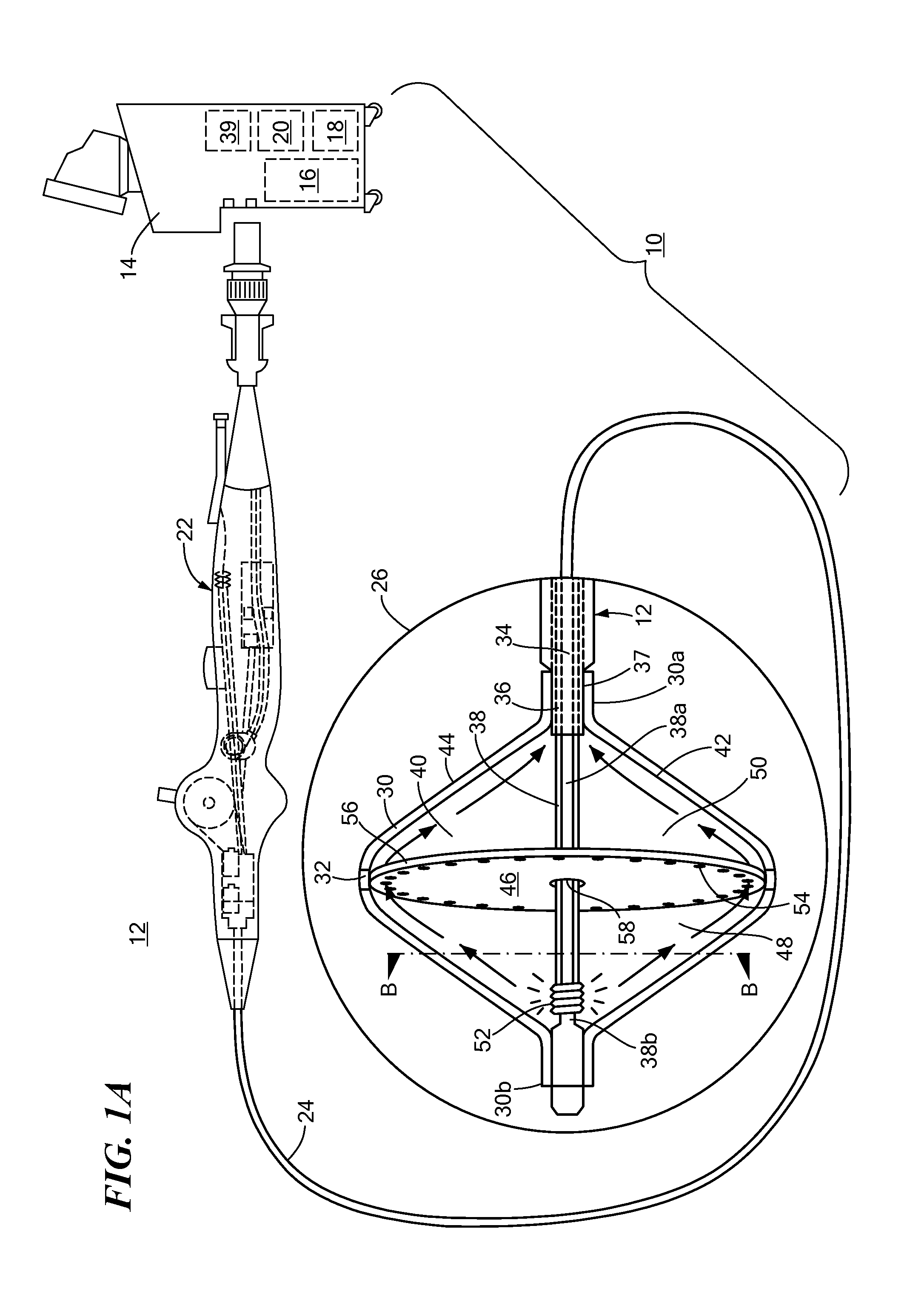

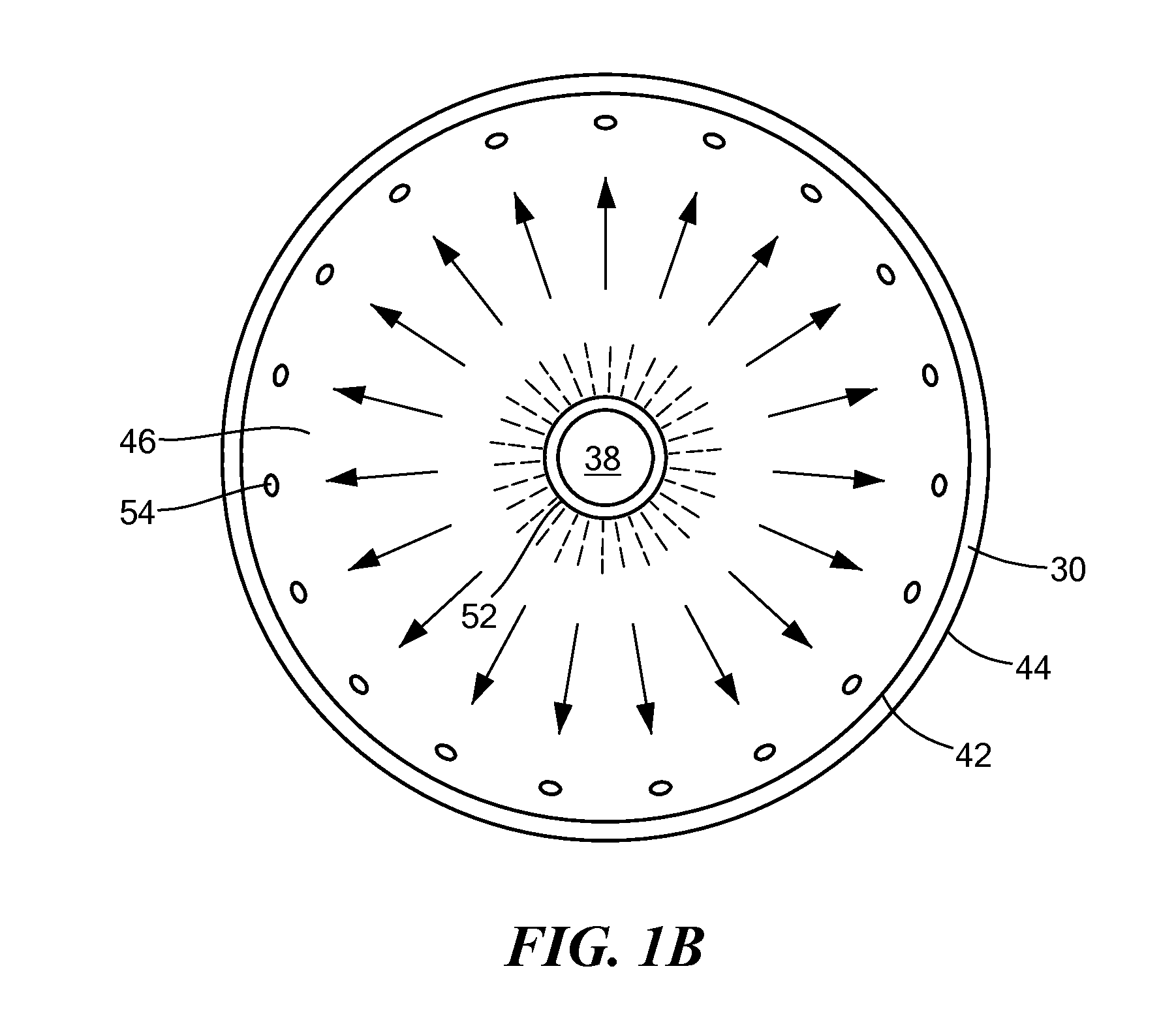

Balloon design to enhance cooling uniformity

ActiveUS20130197499A1Improve cooling uniformityImprove efficiencyDiagnosticsCatheterBalloon catheterFluid injection

A device, system, and method for enhancing cooling uniformity and efficiency of cryogenic fluids and providing a treatment element the shape of which can be adjusted for multiple purposes. The device may include a balloon catheter and fluid dispersion element, the fluid dispersion element directing the flow of coolant from a fluid injection element the interior wall of the balloon. The method of changing the shape of the treatment element may include retracting and extending a shaft to which the distal neck of a balloon is coupled, so that the balloon goes from a first shape to a second shape.

Owner:MEDTRONIC CRYOCATH LP

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624AShort production cycleLow costFurnace typesHeat treatment furnacesSteel platesQuenching

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperature reduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

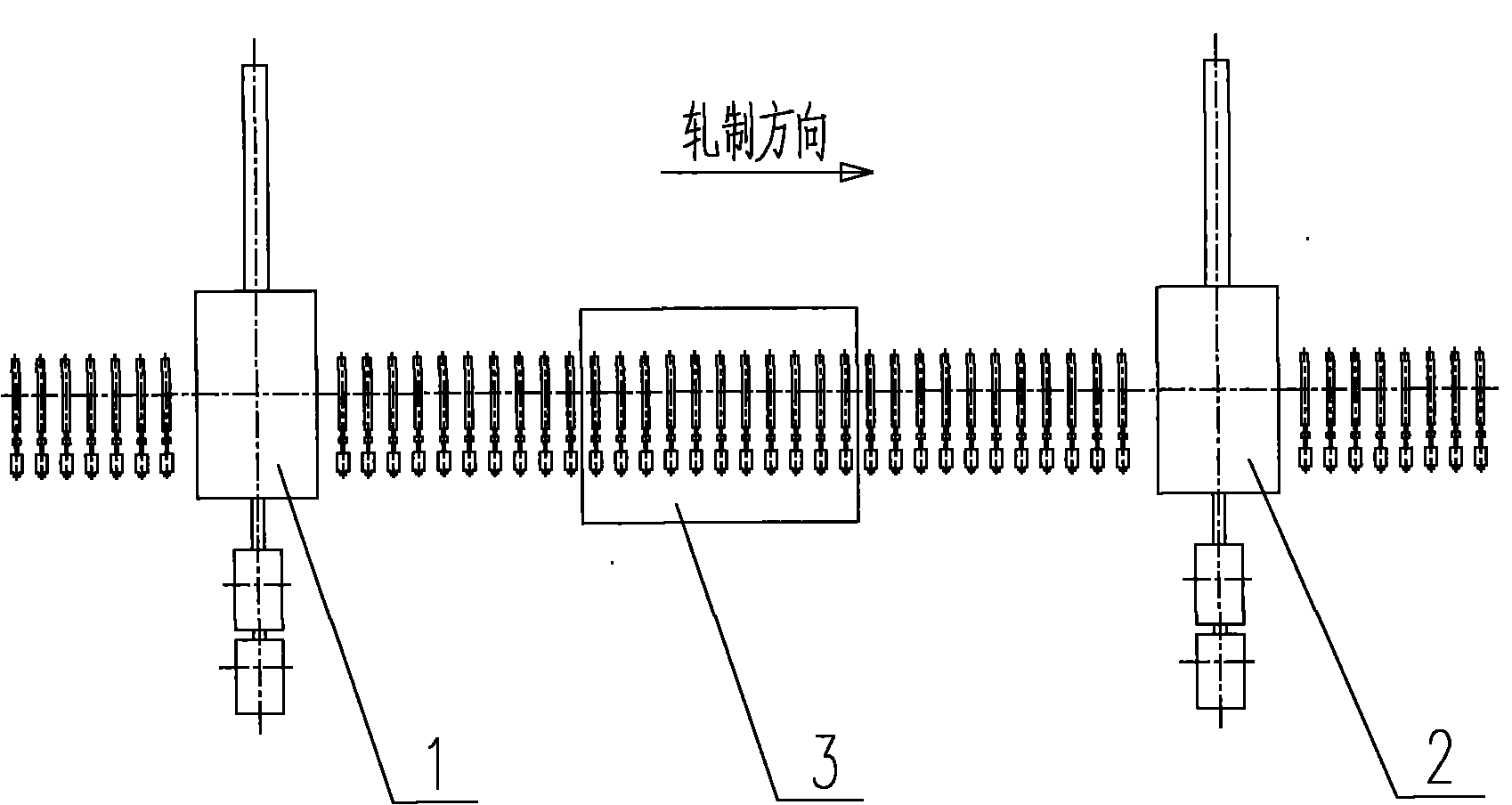

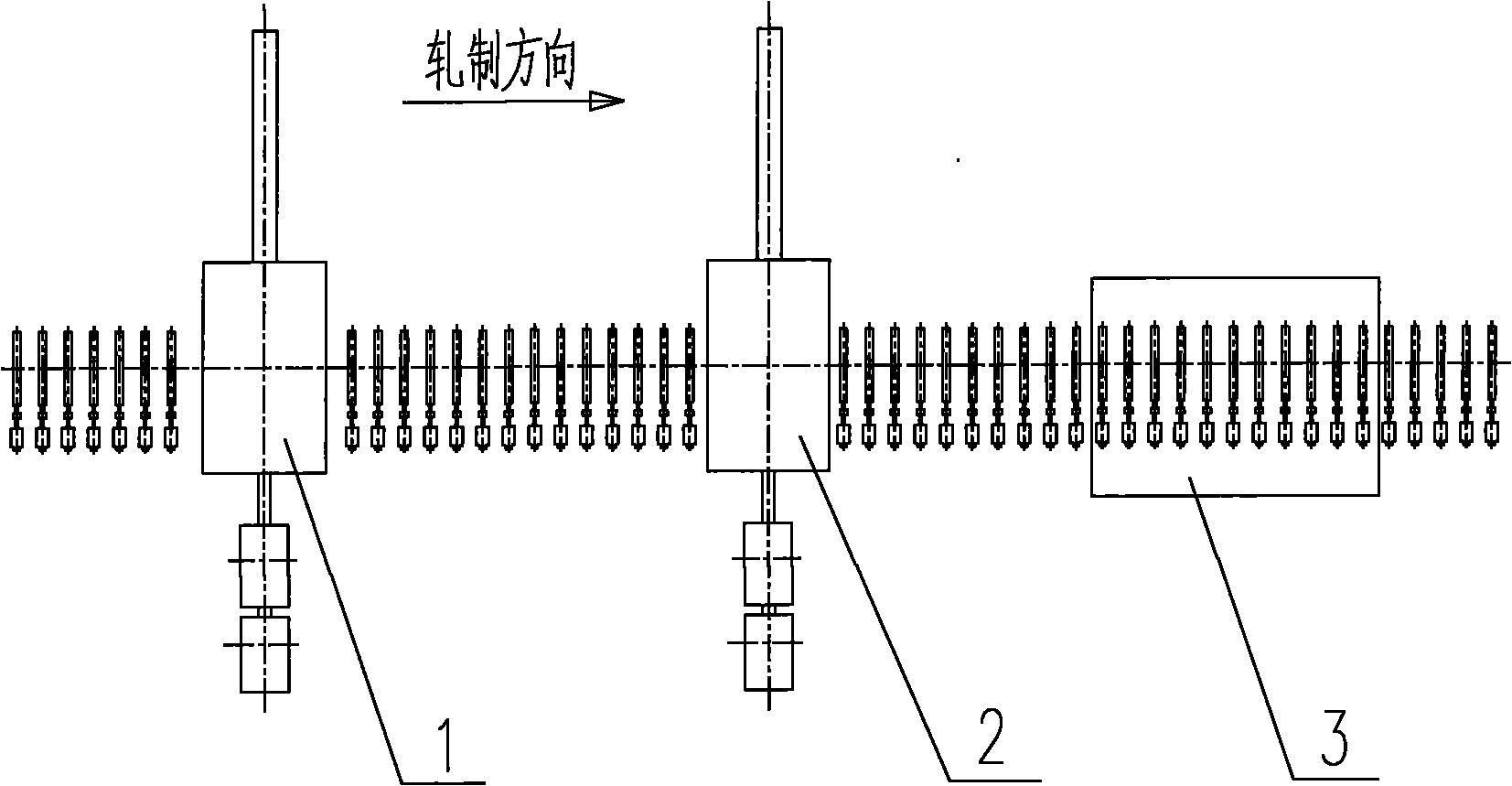

Cooling method of heavy and medium plate controlled rolling intermediate blank

InactiveCN101829688ALess investmentImprove applicabilityTemperature control deviceWater qualityWater cycling

The invention belongs to a producing and cooling technique of rolled steel, relating to a cooling method of a heavy and medium plate controlled rolling intermediate blank, which can be realized by both a single-stand heavy and medium plate roll and a double-stand heavy and medium plate roll. The cooling method comprises the following steps of: transmitting a roughly rolled intermediate blank with the thickness range of 30-110 mm in an austenite recrystallization zone into an intermediate controlled cooling zone from a transmission roller way for rapidly cooling to 800-950 DEG C, and then transmitting the intermediate blank into the roll for rolling in a non- recrystallization zone after short-time air cooling and temperature evening. In the intermediate cooling process, an upper collecting pipe and a lower collecting pipe with high density or ultra-high density are adopted to impact, jet and cool the intermediate blank, and specific technological parameters are accurately controlled by a computer. Water is cooling water for the roll with the pressure of 0.3-1.0 MPa in a common water circulating system for workshops. The intermediate cooling holding time is 30-70% shorter than that of the conventional process so that the production efficiency is improved, and due to austenite grain refinement after intermediate controlled cooling, the mechanical properties of a steel plate can be improved.

Owner:UNIV OF SCI & TECH BEIJING

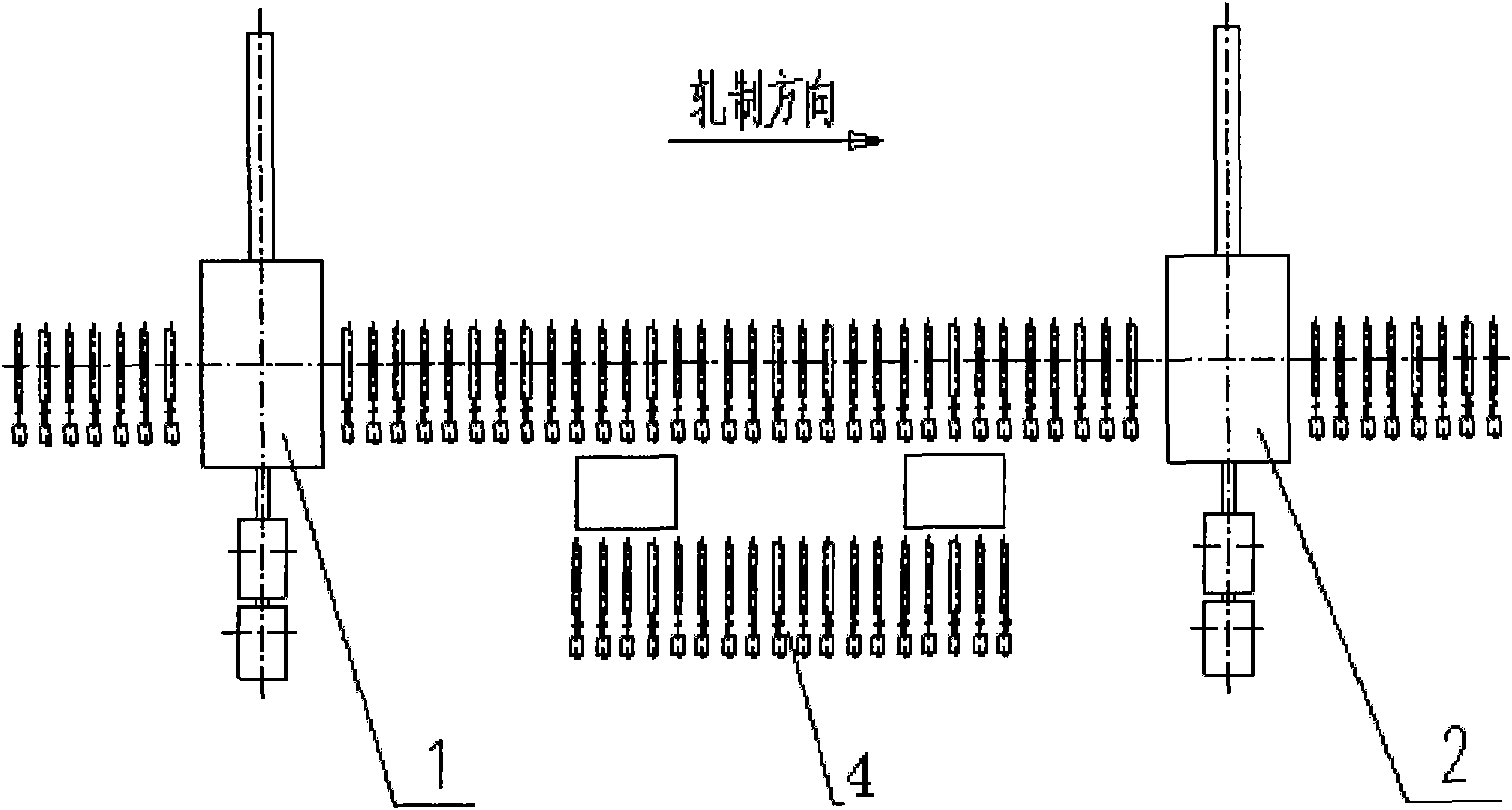

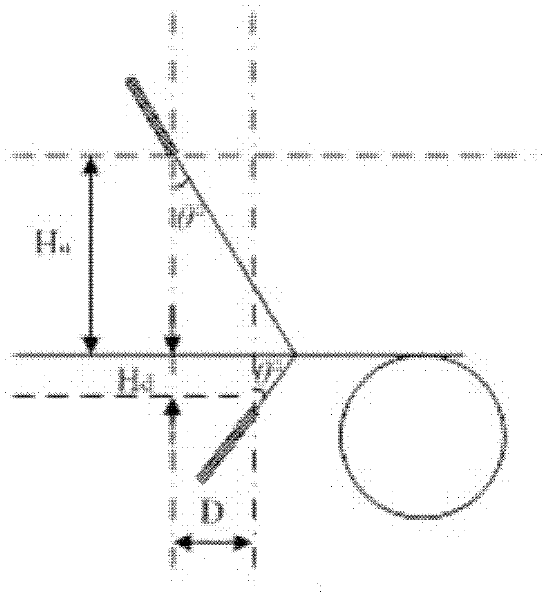

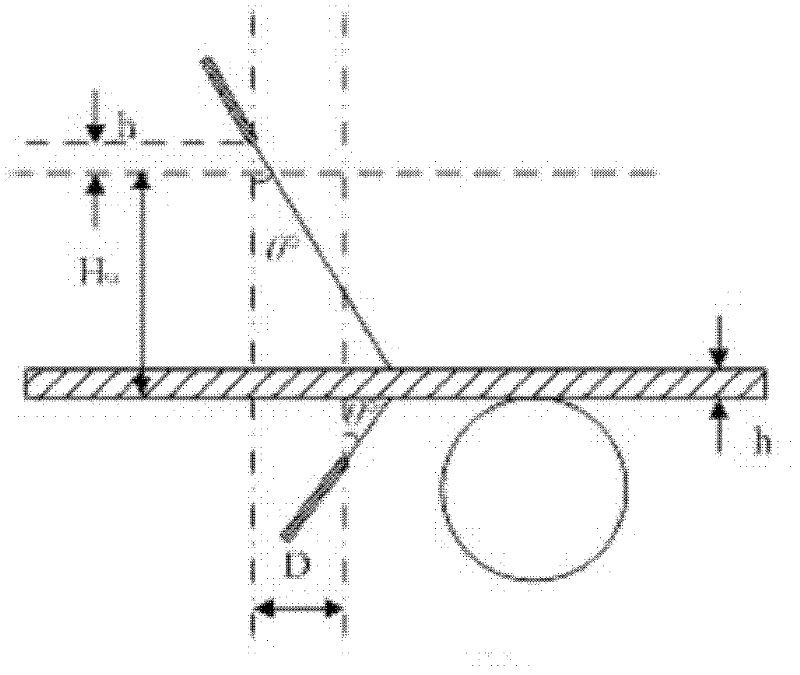

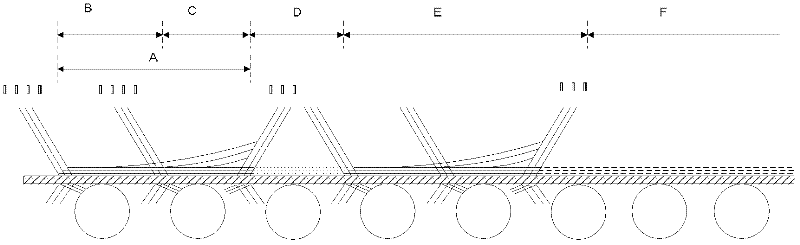

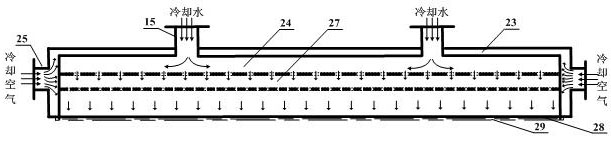

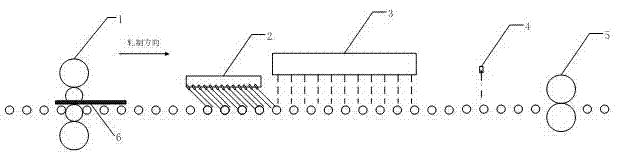

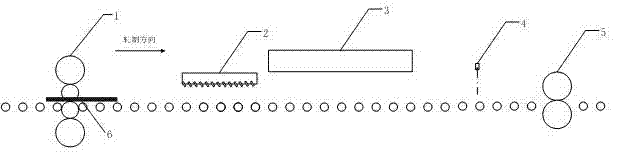

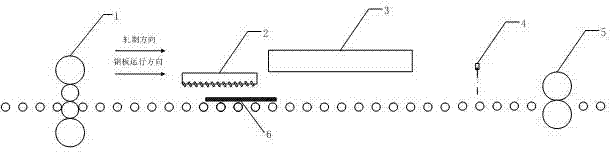

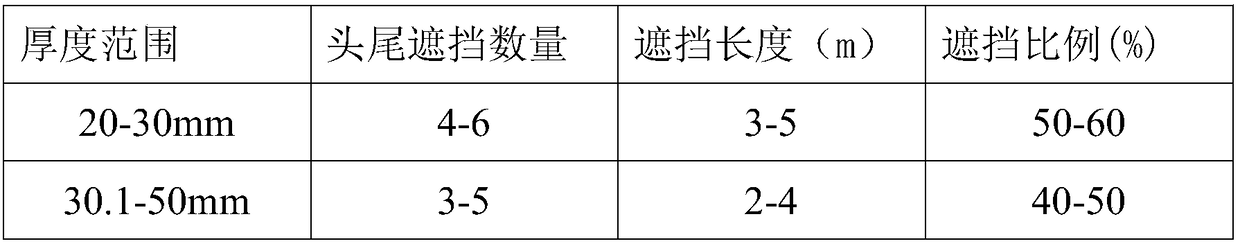

Method for improving ultra-fast cooling uniformity of medium and heavy plate after rolling

ActiveCN102371283AIncrease cooling intensityImprove cooling uniformityTemperature control deviceWork treatment devicesJet flowWater discharge

The invention relates to a method for improving the ultra-fast cooling uniformity of a medium and heavy plate after rolling, the position of a jet flow header can be reasonably adjusted, and the method is characterized in that, 1) the position of an upper header is set as follows: an ultra-fast cooling upper header framework is adjusted up and down in the vertical direction, and the conditions ofthe formula: Hu*tg(theta)=Hd*tg(theta)+D are met; 2) the setting of a soft water seal of a washing water region on the upper surface of a steel plate meets the conditions of the formula: 1 / 2*the sum of flow rates of all forward headers in the region<water amount of the soft water seal<2*the sum of the flow rates of all the forward headers in the region; 3) the flow rate of a lower header is increased to compensate the heat exchange capacity of the lower surface, and the optimal ratio of water supply to water discharge is set to be between 1: 1.1 and 1: 2.5; 4) the measure of clearing residualcooling water on the upper surface is taken, side spraying devices are arranged on the two sides of an ultra-fast cooling roller table, a middle spraying device is arranged on the upper header framework and strong blowing devices are arranged at the two ends of the ultra-fast cooling device; and 5) the head and tail shading control of the speed of the roller table is performed as follows: an ultra-fast cooling control system is used for transformation control of the speed of the roller table of a steel plate head and a tail part low-temperature region according to a speed curve. By adopting the method, the cooling uniformity of a steel plate of the medium and heavy plate after rolling under ultra-fast cooling condition can be realized.

Owner:NORTHEASTERN UNIV

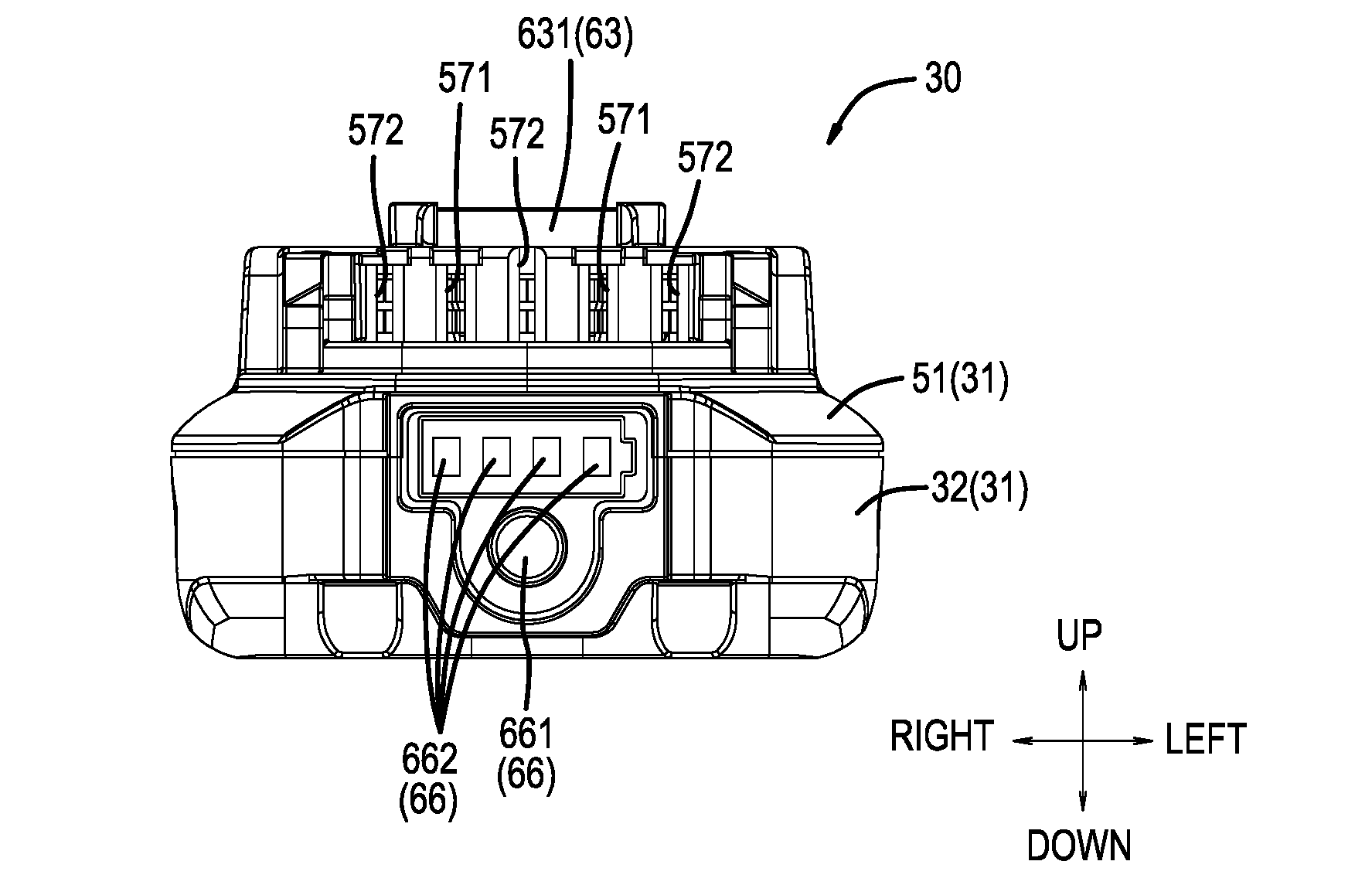

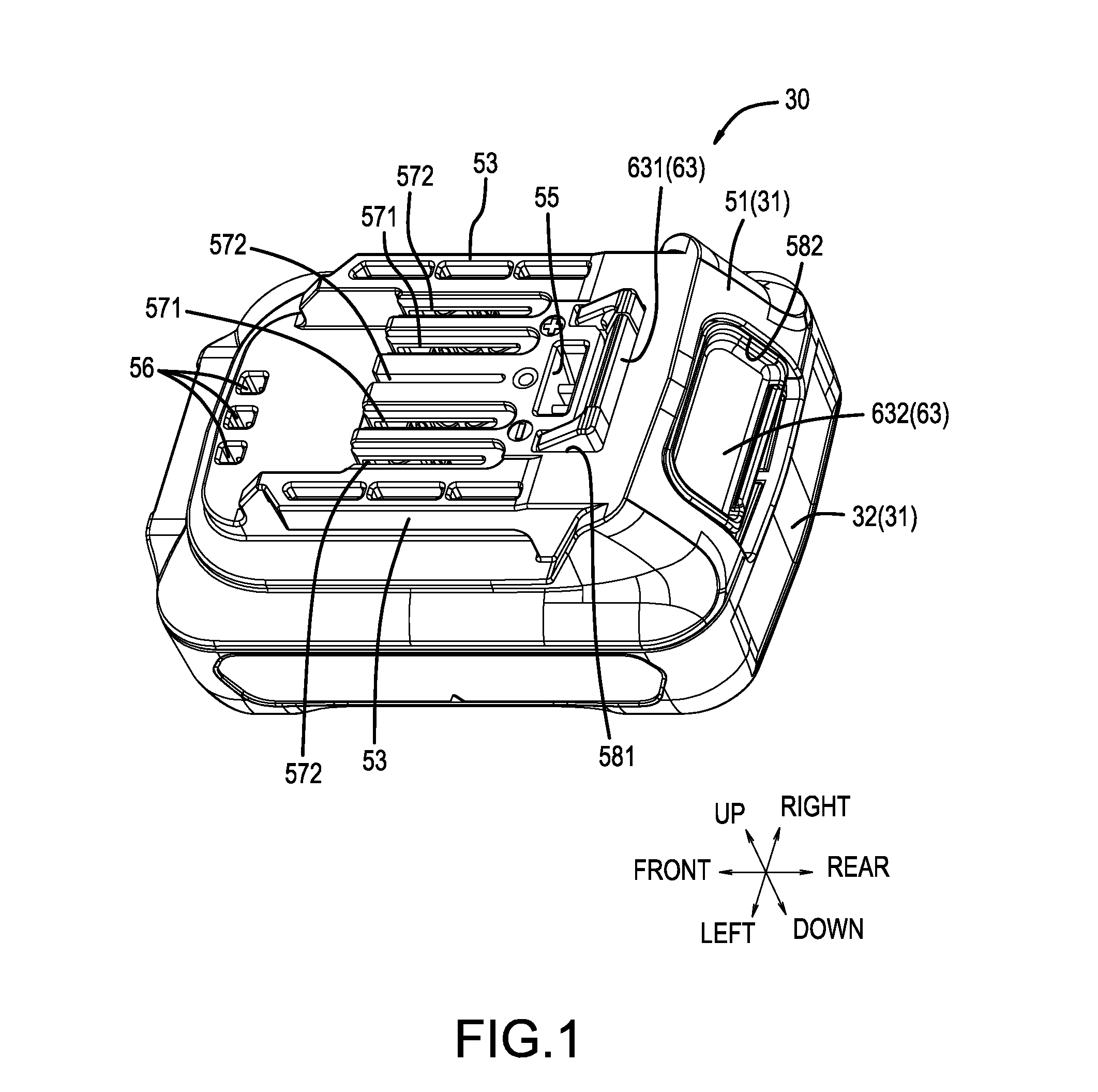

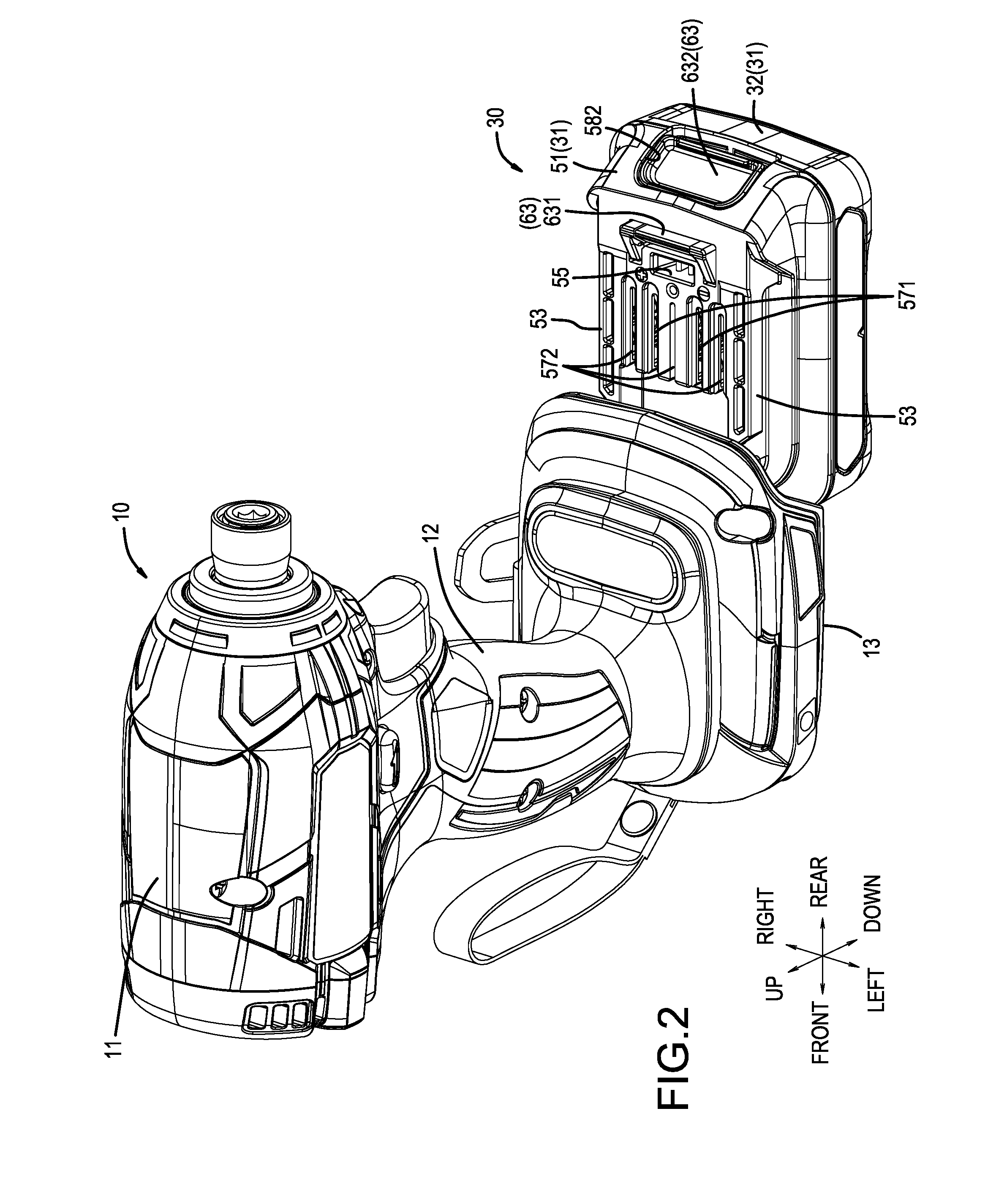

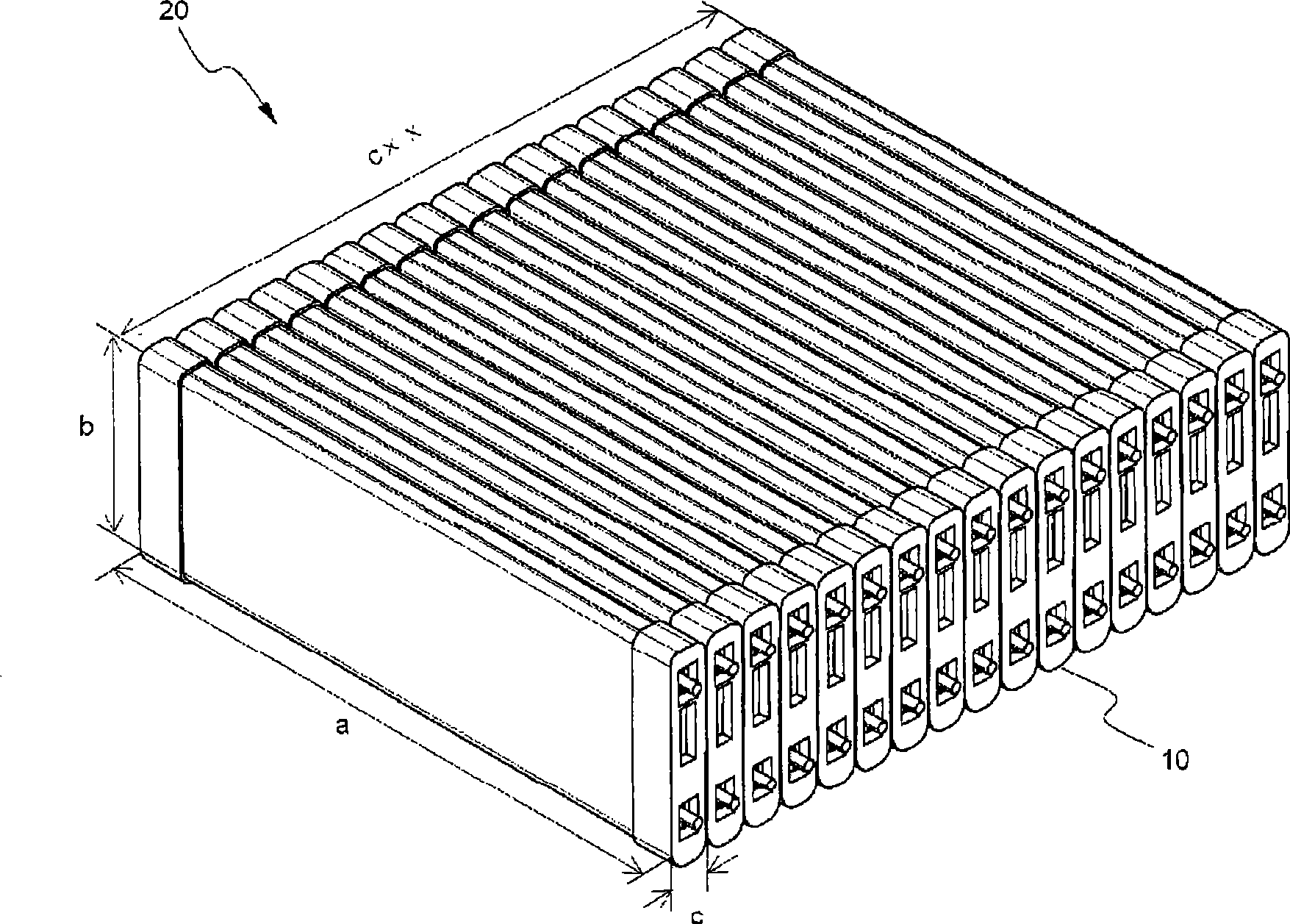

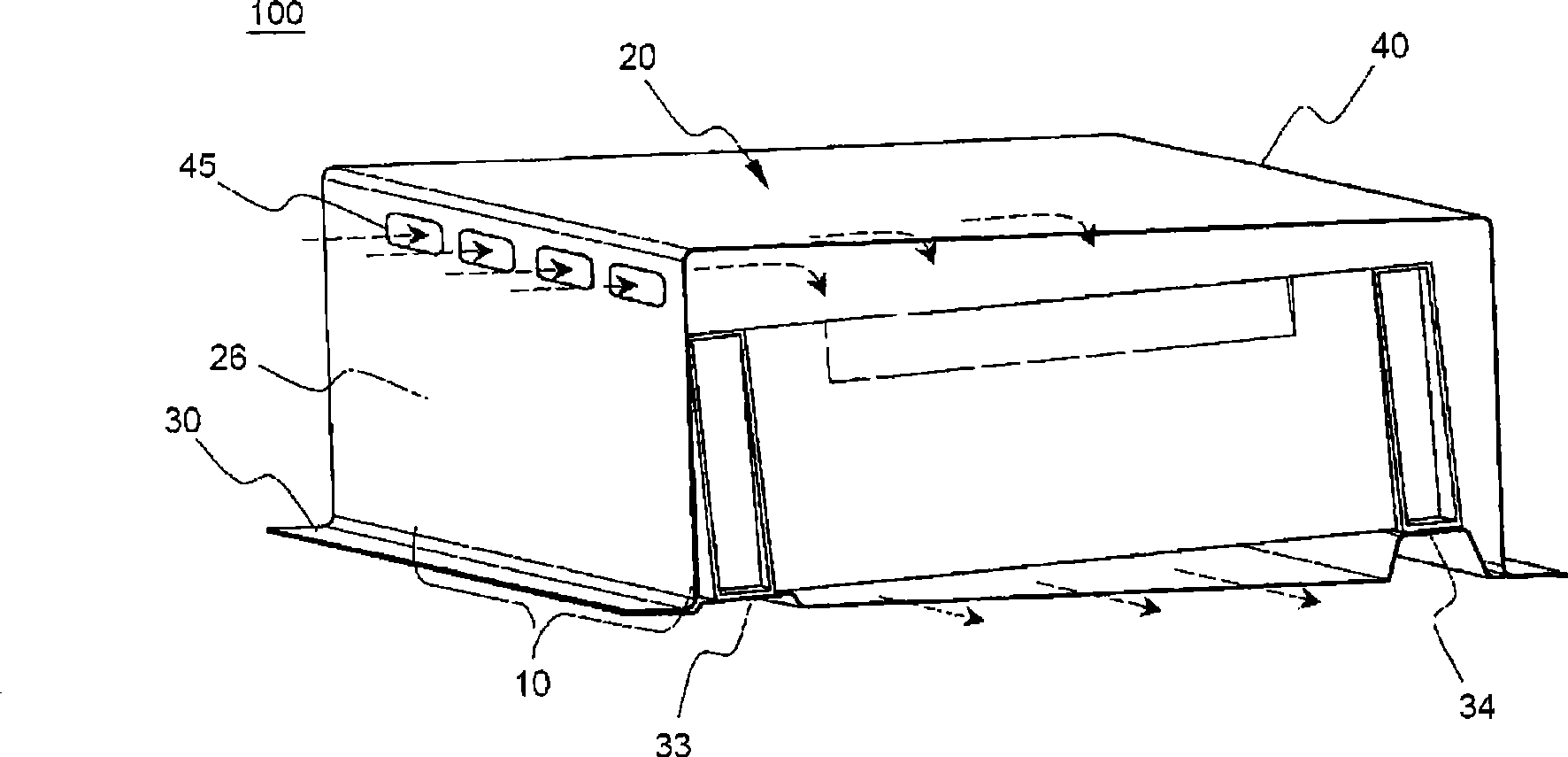

Battery pack

ActiveUS20160240901A1Improve cooling uniformityReducing cooling unevennessSecondary cellsCell component detailsEngineeringBattery cell

As a cooling draft flows from a rear side to a front side of battery cells (72) inside a battery pack (30), it is divided into two cooling drafts (F1, F2) in a left-right direction, which is the direction that the battery cells (72) are disposed in parallel, and those two cooling drafts respectively flow through a plurality of passageways that longitudinally extend along the battery cells (72). More particularly, a second battery cell (722) is cooled by the cooling draft flowing in a second ventilation-path volume (Q2) before a first battery cell (721) and a third battery cell (723) are cooled by cooling drafts respectively flowing in a first ventilation-path volume (Q1) and a third ventilation-path volume (Q3), which are longer than the second ventilation-path volume (Q2).

Owner:MAKITA CORP

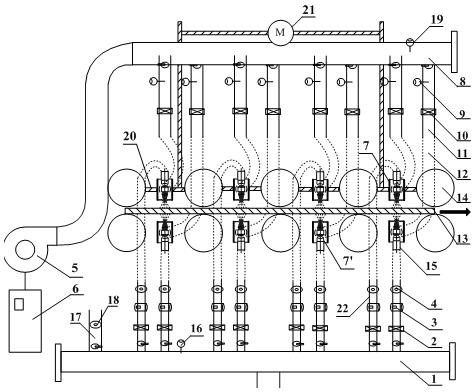

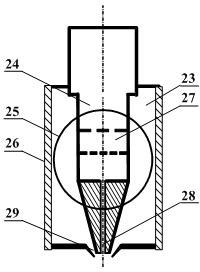

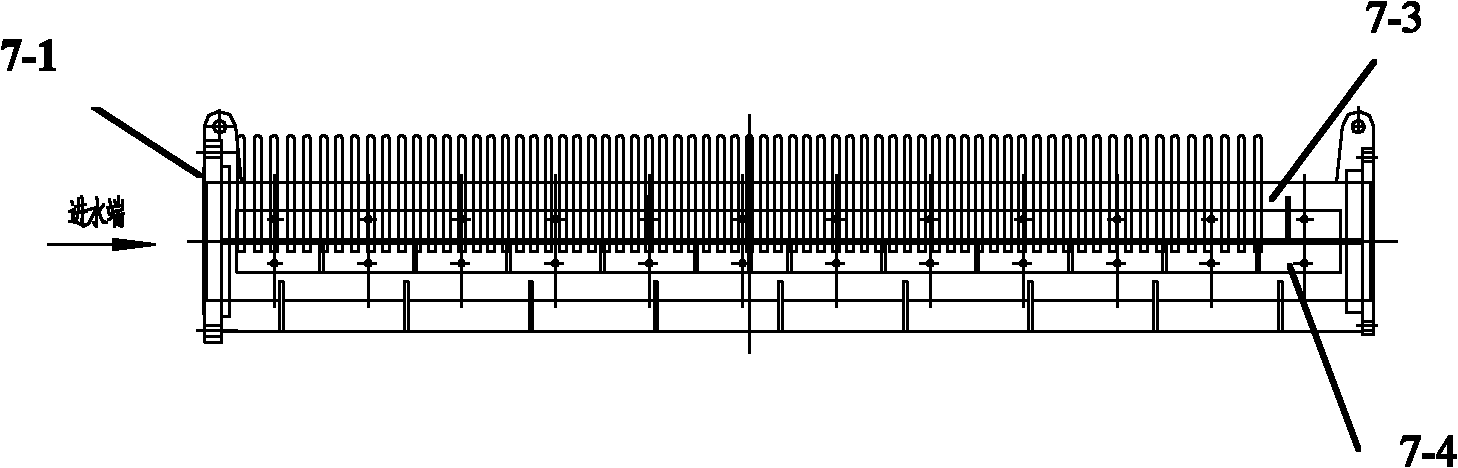

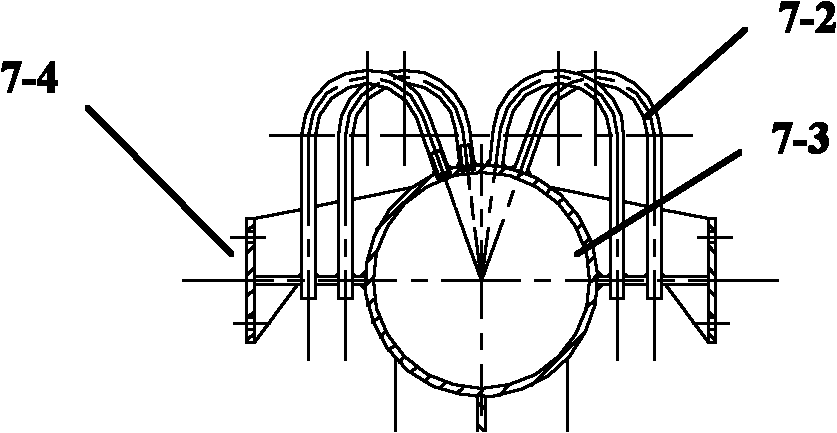

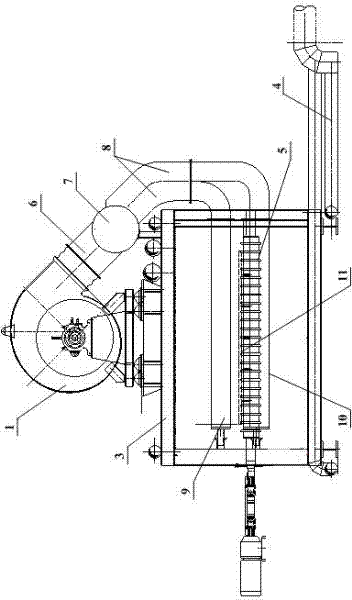

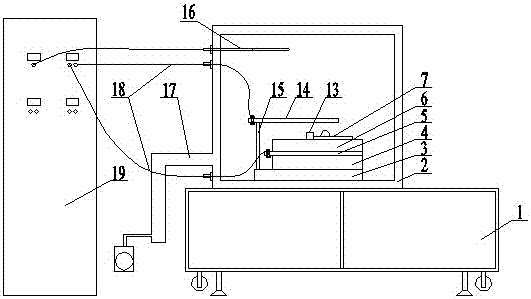

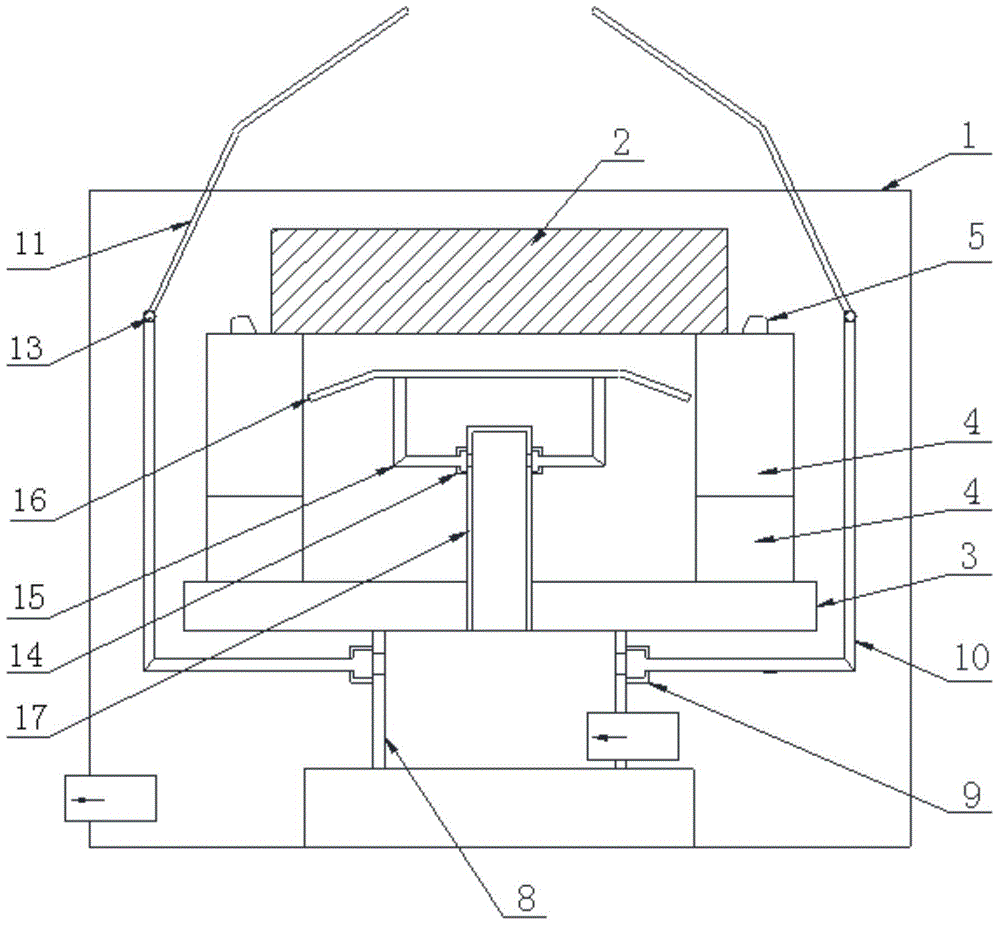

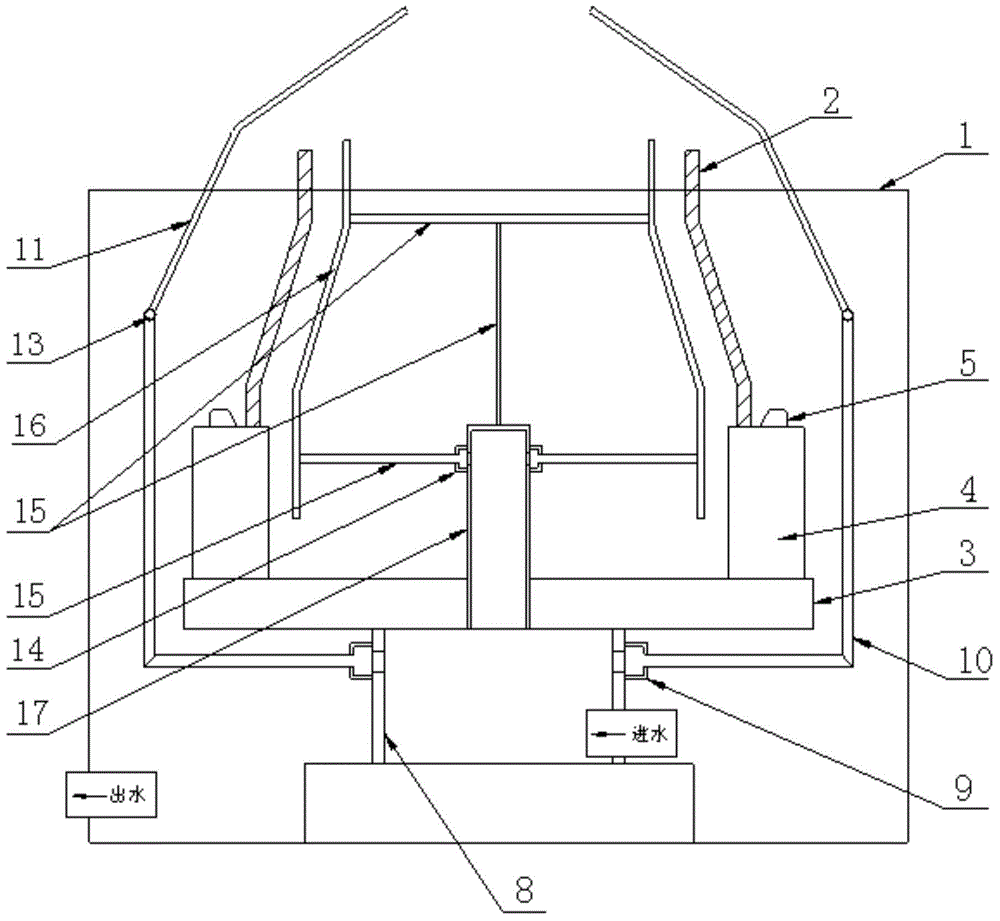

Vapor cooling system for use in offline heat treatment of thin medium and thick plates

ActiveCN102424902AGood atomization effectGood cooling uniformityQuenching devicesWater jetExperience management

The invention discloses a vapor cooling system for use in offline heat treatment of thin medium and thick plates, which comprises a water supply system, an air supply system, vapor spray nozzles and a control system, and is characterized in that: the vapor spray nozzles are symmetrically arranged above and below a rollway gap along the conveying rollway, the upper spray nozzle and an upper rollway are fixed on a movable upper frame, and the lower spray nozzle is fixed on a fixed frame; the water and air supply systems are led into the vapor spray nozzles by a shunt water collecting header anda shunt air collecting header respectively; a water supply pipe is provided with a valve, a flow meter and a regulating valve and is used for providing stable and reliable cooling water into an innerwater storage cavity in the spray nozzle from the side of the spray nozzle; and the control system consists of an experience management system and a PLC system, the experience management system makesa vapor cooling policy and cooling procedure and sends the cooling procedure to the PLC system to execute the cooling procedure, and the PLC system realizes the regulation of the intensity of coolingof the spray nozzle and the regulation of the state of water spraying. The vapor cooling system can solve the nonuniform cooling problem aroused by the high-pressure water jet cooling in the conventional thin medium and thick plate offline quenching.

Owner:NORTHEASTERN UNIV

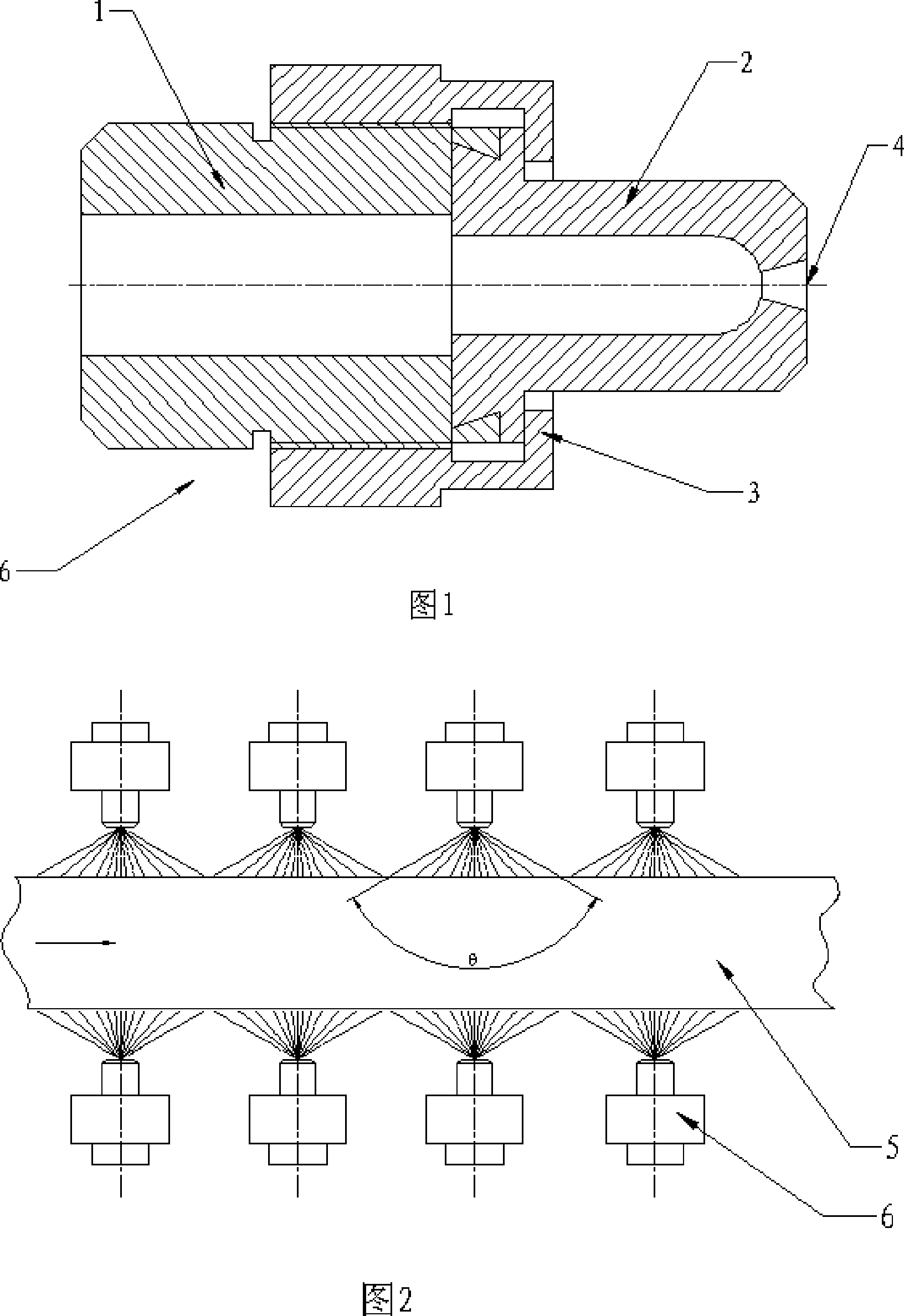

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

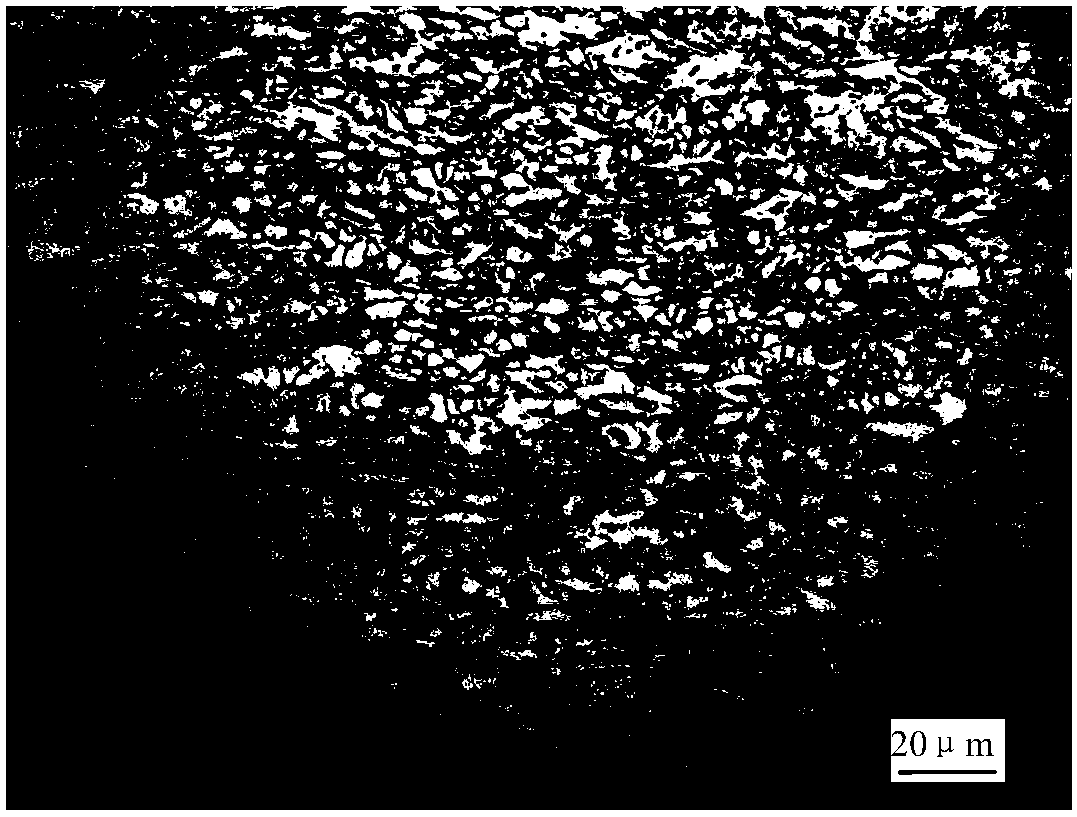

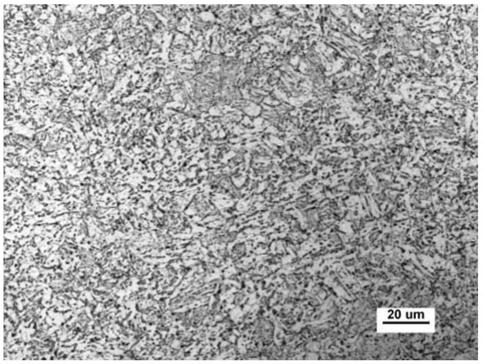

Ultra-wide high-toughness hot-rolled thick plate for low-temperature pipeline, and production method thereof

The invention discloses an ultra-wide high-toughness hot-rolled thick plate for a low-temperature pipeline, and a production method thereof. The steel is prepared from 0.030 percent to 0.055 percent of C, 0.16 percent to 0.30 percent of Si, 1.45 percent to 1.70 percent of Mn, 0.04 percent to 0.07 percent of Nb, 0.012 percent to 0.025 percent of Ti, 0.20 percent to 0.40 percent of Cr, less than orequal to 0.14 percent of Mo, less than or equal to 0.20 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.030 percent of Al, less than or equal to 0.010 percent of P, less than or equal to 0.0015 percent of S, 0.0005 percent to 0.0020 percent of O, 0.001 percent to 0.004 percent of N, 0.0010 percent to 0.0045 percent of Ca, larger than or equal to 1.8 percent of Ca / S, 0.30 percent to 0.60 percent of (Mo+Ni+Cr+Cu), and the balance Fe and inevitable impurities. The rough rolling starting temperature is 1080 to 1130 DEG C, the finish rolling temperature is 980 to 1030 DEG C, the precision rolling starting temperature is 820 to 860 DEG C, the precision rolling finish rolling temperature is 740 to 760 DEG C, the cooling speed is 8 to 15 DEG C / s, and the hot straightening speed is 0.7 to 1.2m / s. The finished product steel plate has the thickness being larger than or equal to 21mm and the width being larger than 4300mm, and has excellent low-temperature toughness.

Owner:ANGANG STEEL CO LTD

Wide and heavy steel plate for high-strength high-toughness and low-yield-ratio hot-bending bend and production method of wide and heavy steel plate

The invention provides a wide and heavy steel plate for a high-strength high-toughness and low-yield-ratio hot-bending bend and a production method of the wide and heavy steel plate. The steel plate comprises, by weight percentage, 0.055%-0.080% of C, 0.16%-0.30% of Si, 1.76%-1.95% of Mn, 0.051%-0.080% of Nb, 0.010%-0.025% of Ti, 0.09%-0.13% of V, 0.25%-0.45% of Cr, 0.20%-0.35% of Mo, less than 0.25% of Ni, less than 0.25% of Cu, 0.010%-0.035% of Al, not larger than 0.010% of P, not larger than 0.002% of S, 0.001%-0.004% of N and the balance iron and inevitable impurities, wherein (Mo+Ni+Cr+Cu) is controlled within the range of 0.6%-1.0%, CEIIW is controlled within the range of 0.50%-0.55%, and CEPcm is controlled within the range of 0.19%-0.23%. The production method includes the steps ofmolten iron pretreatment, converter smelting, external refining, continuous casting, heating, rolling, cooling and heat treatment. The microstructure of the wide and heavy steel plate is a compositestructure of bainite and ferrite, and the performance meets the requirement of manufacturing X90-grade hot-bending bends with ultra-wide and thick walls in a low-temperature environment.

Owner:ANGANG STEEL CO LTD

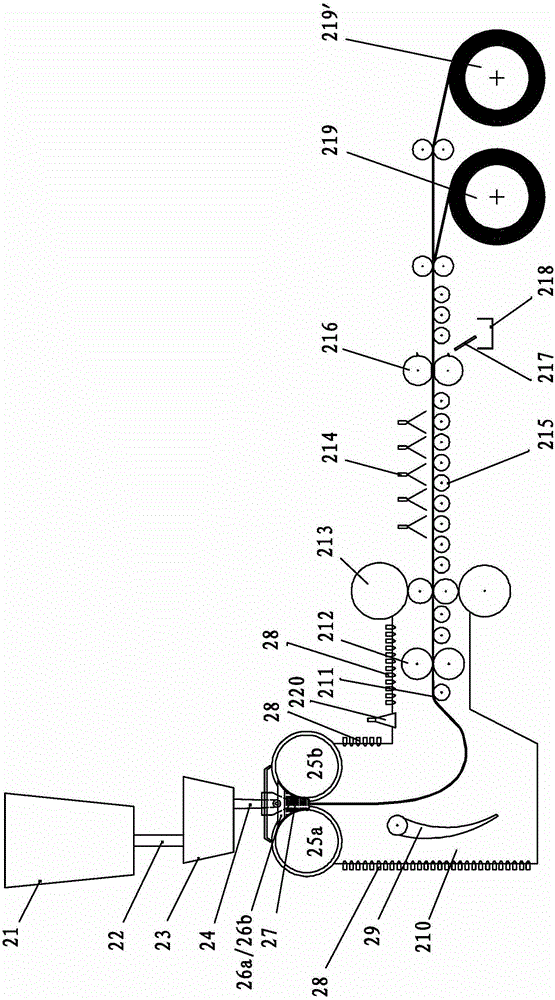

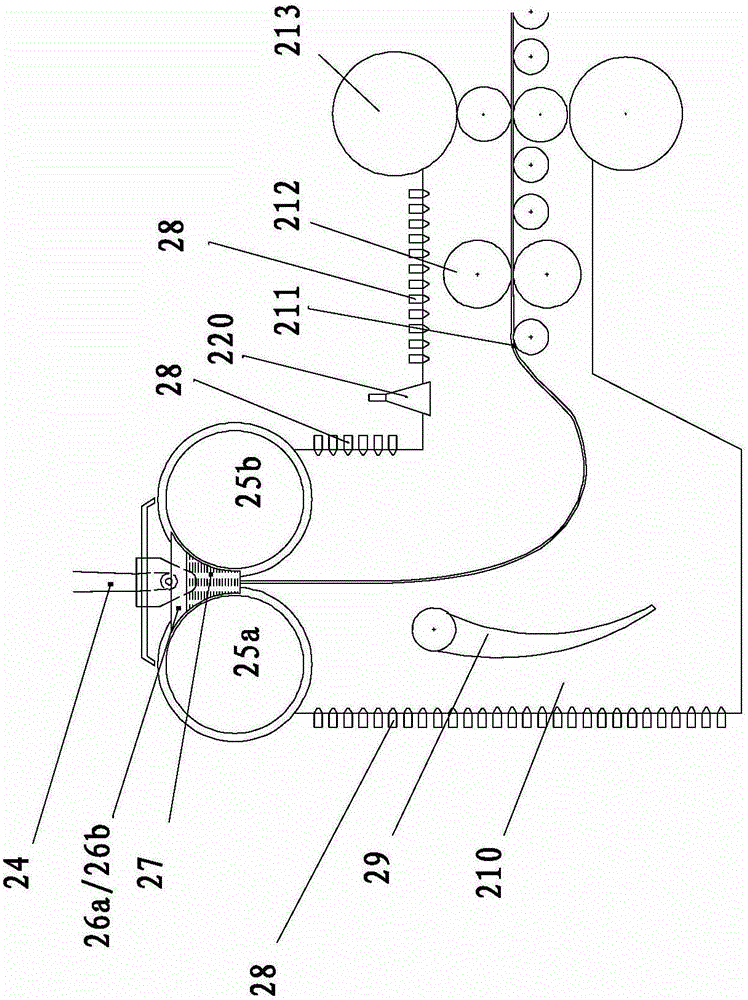

Method and device for reducing temperature of thin-strip continuous casting lower closed chamber

The invention discloses a method and device for reducing the temperature of a thin-strip continuous casting lower closed chamber, and relates to the field of thin-strip continuous casting. The problem that an existing process cannot give consideration to strip steel anti-oxidation and rolling temperature reduction of the thin-strip continuous casting lower closed chamber at the same time is solved; the following improvements are performed on the basis of an existing dual-roller thin-strip continuous process, wherein the improvements include that liquid nitrogen is injected into the closed chamber, a plurality of channels leading to the lower closed chamber are evenly distributed on the surrounding wall of the thin-strip continuous casting lower closed chamber, and the liquid nitrogen is injected into the channels; the flow and the pressure of the liquid nitrogen in each channel are adjusted; and closed-loop control over the oxygen concentration of the lower closed chamber is carried out; and closed-loop control over the online rolling temperature is carried out, and the inlet temperature is controlled to range from 900 DEG C to 1150 DEG C. By means of the method and device, the aim of rapid cooling of the thin-strip continuous casting lower closed chamber can be achieved, steel strip oxidation is effectively prevented, the lower steel strip rolling temperature is achieved, the steel strip cooling homogeneity is improved, and the plate shape and the surface quality of strip steel are better improved.

Owner:BAOSHAN IRON & STEEL CO LTD

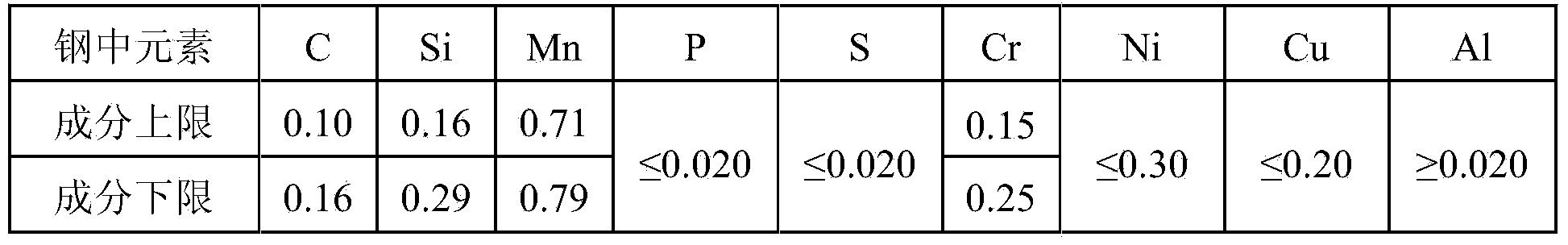

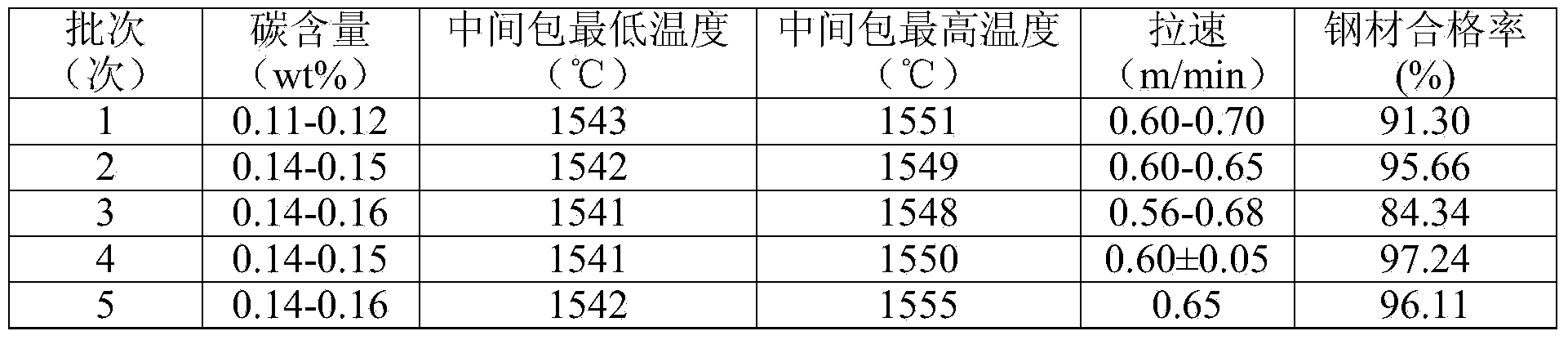

Method for controlling quality of bloom hypo-peritectic steel continuous casting billet

InactiveCN103433438AReduce the degree of solidification phase transition shrinkageImprove cooling uniformityCooling methodsMelting point

Owner:LAIWU IRON & STEEL GRP

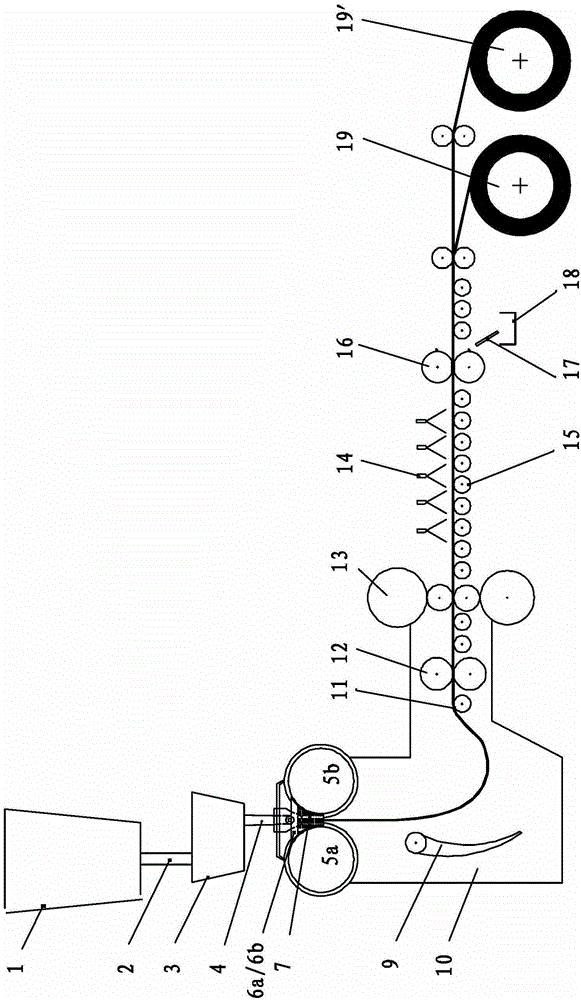

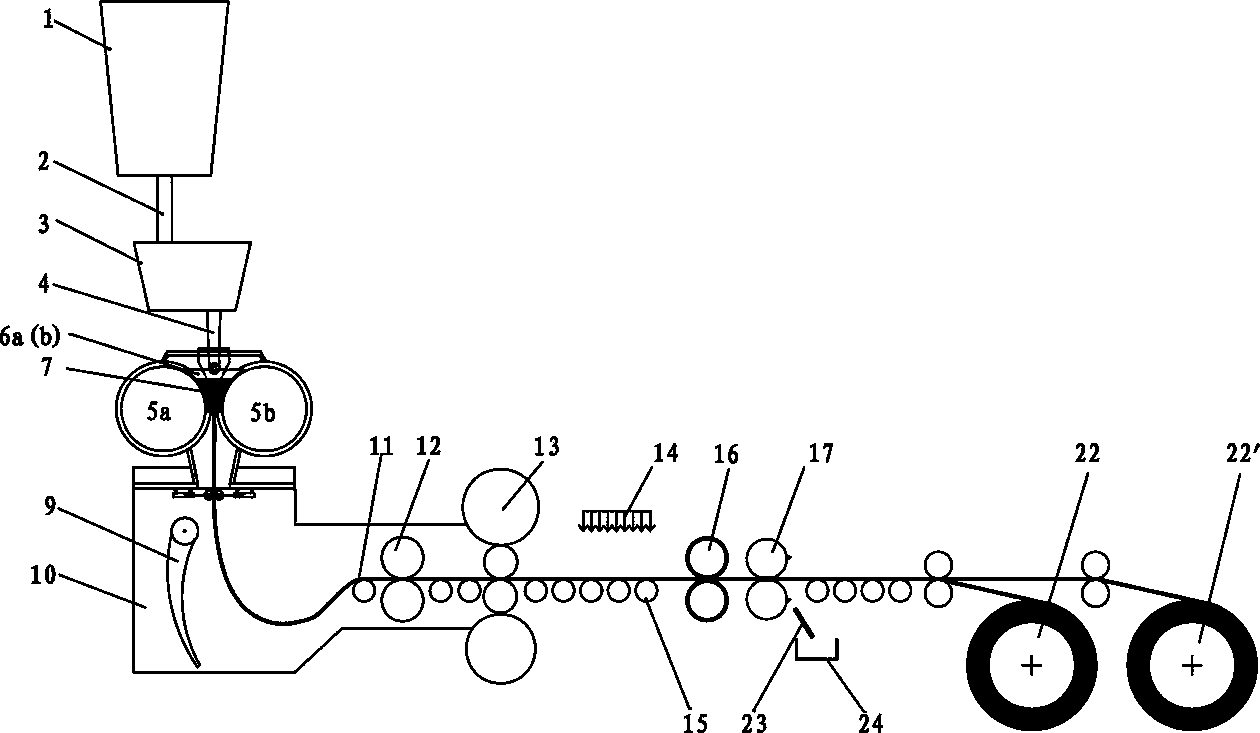

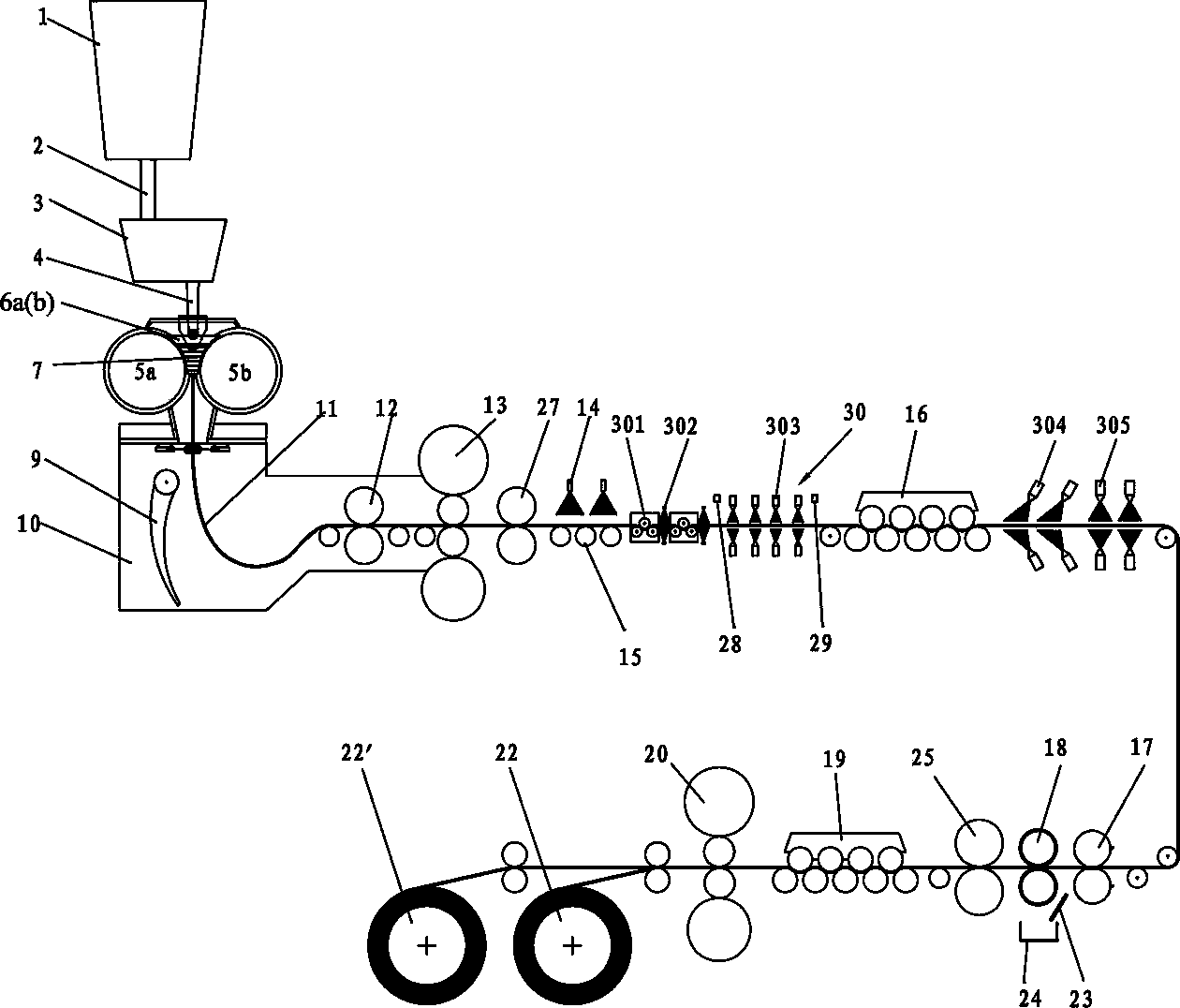

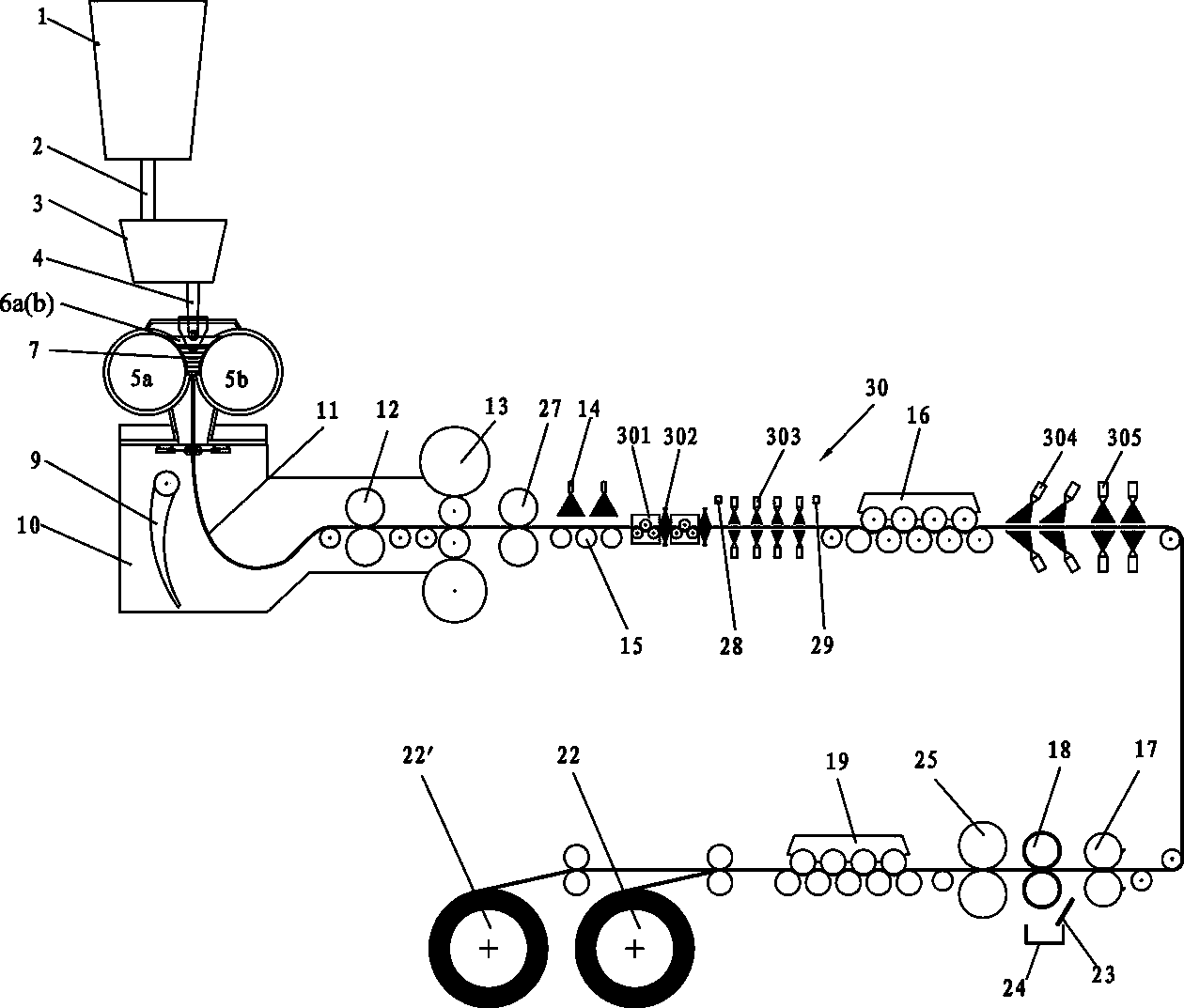

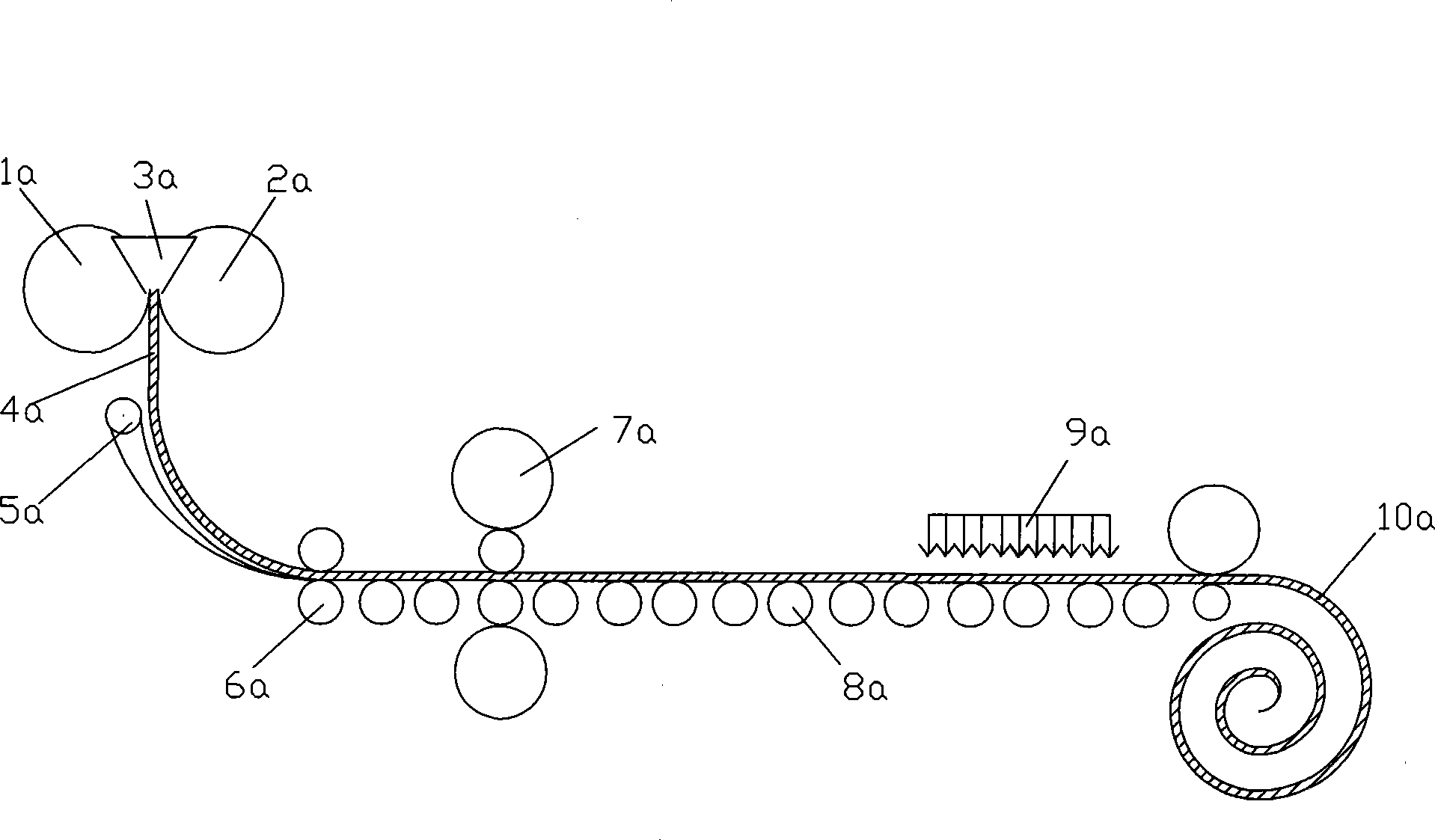

Method for producing high-strength thin strip steel in short process

ActiveCN103658177AFast jetImprove cooling uniformityWork treatment devicesMetal rolling arrangementsProduction rateProduction line

A method for producing high-strength thin strip steel in a short process comprises the first step of carrying out smelting and casting, wherein a twin roll strip casting technology is adopted, the second step of carrying out online hot rolling, the third step of carrying out cooling, wherein atomization cooling is adopted, the atomized cooled water mist is directly sprayed on the surface of the strip steel, the fourth step of carrying out scale breaking and blowing for sweeping, the fifth step of carrying out anti-oxidation intensive cooling and scale removing, wherein gas along with dry ice is directly sprayed on the surface of the strip steel for scale removing and intensive cooling, the sixth step of carrying out jet flow for scale removing, wherein solid-liquid mixed media are sprayed to the surface of the strip steel at a high speed, and the seventh step of carrying out straightening and reeling up. According to the method, the twin roll strip casting technology is utilized for producing the thin high-strength strip steel containing copper, hot rolling is performed on the casting belt, and then staged intensive cooling, oxide skin controlling and acid-free scale removing are combined and performed on the casting belt, so that the length of a production line is further shortened, and productivity is enhanced; meanwhile, the strength of the strip steel is increased through intensive cooling, the malleability of the strip steel is improved through grain refinement, and pollution to the environment is reduced by the adoption of the acid-free scale removing method.

Owner:BAOSHAN IRON & STEEL CO LTD

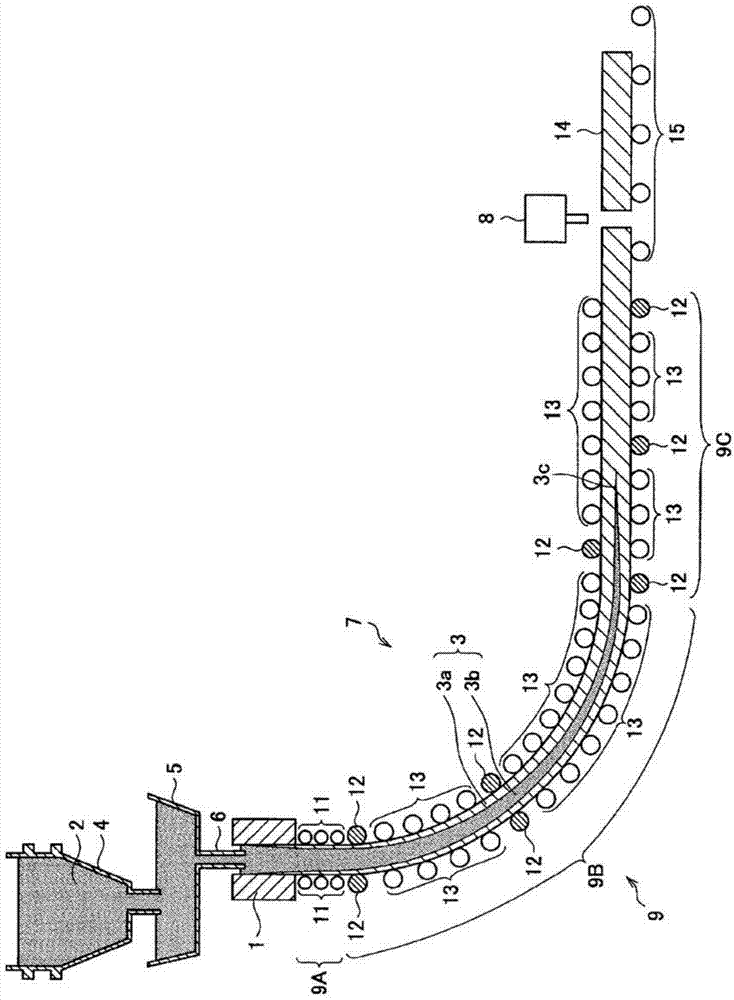

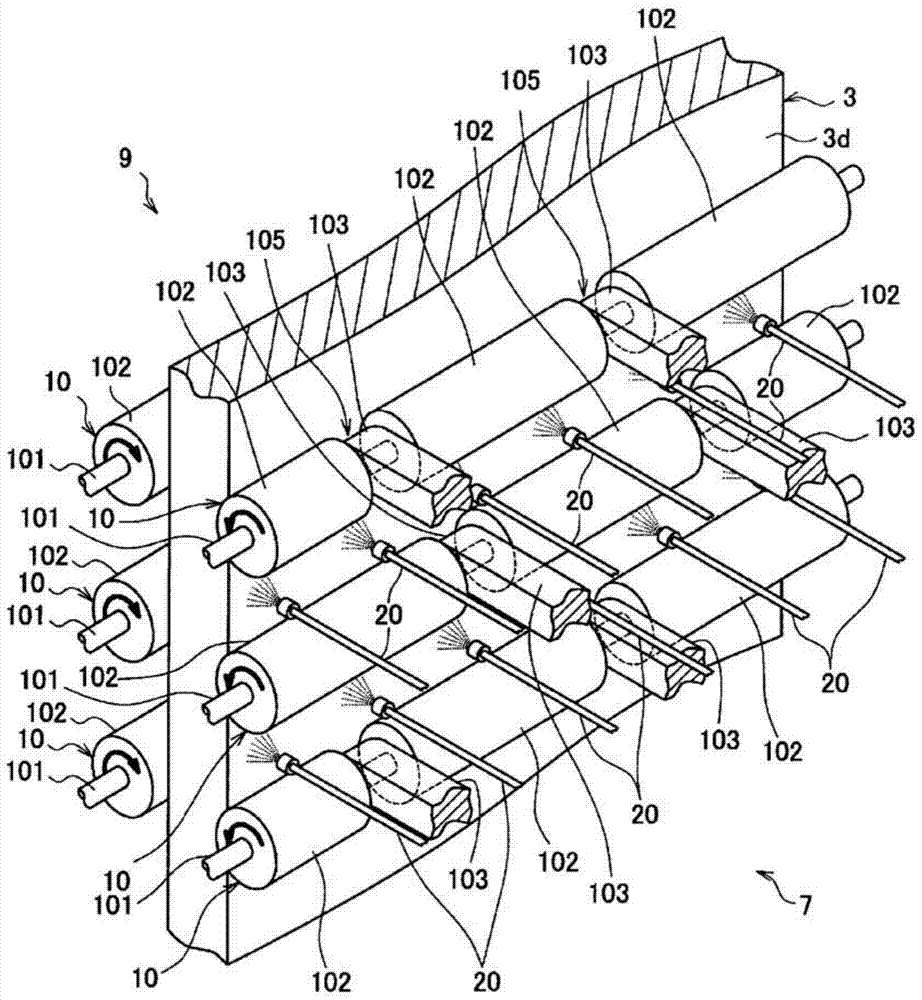

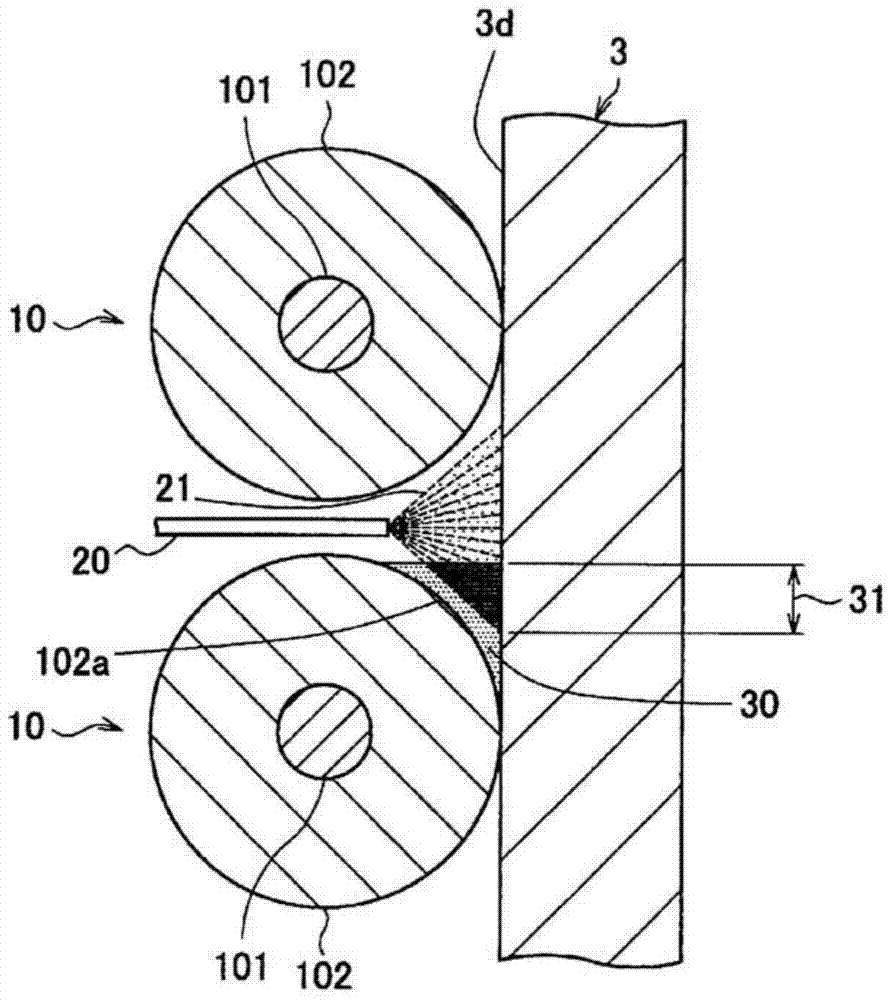

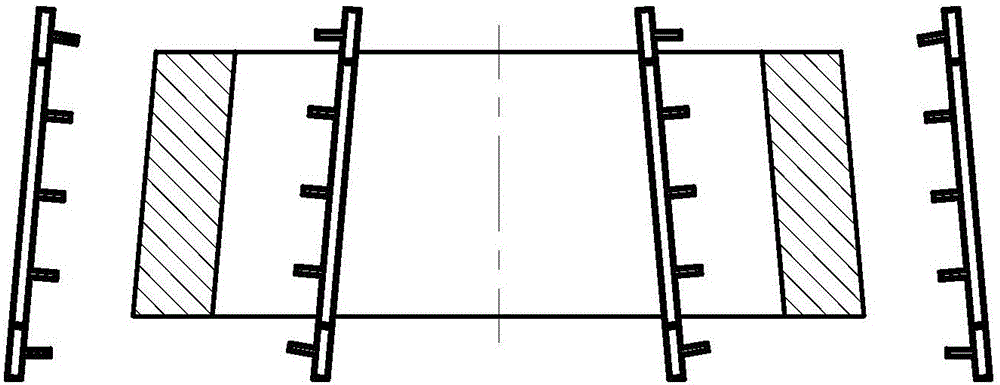

Secondary cooling method and secondary cooling device for continuous casting machine

ActiveCN103842113AImprove cooling uniformityThe heat transfer coefficient does not increaseEngineeringContinuous casting

This secondary cooling device for a continuous casting machine is provided with a plurality of pairs of support roller and a plurality of nozzles, and each support roller has: a plurality of roller sections split in the widthwise direction of a cast strand; and grooves provided between the roller sections. The grooves provided to each upstream-side support roller and downstream-side support roller adjacent in the direction of conveyance are disposed offset from each other in the widthwise direction. A first nozzle among the plurality of nozzles is disposed at a first nozzle position set between a roller section provided to an upstream-side support roller and a groove provided to a downstream-side support roller.

Owner:NIPPON STEEL CORP

Alternative cooling control method of hot rolling H-section steel flange

ActiveCN103056175AUniform temperatureImprove cooling uniformityWork treatment devicesMetal rolling arrangementsStrip millWater flow

The invention belongs to the metal pressure machining technical field and particularly relates to an alternative cooling control method of a hot rolling H-section steel flange. The alternative cooling control method of the hot rolling H-section steel flange mainly solves the problems that H-section steel is different in metallographic organizational structure, easy to bend and not uniform in mechanical performance. The technical scheme of the alternative cooling control method of the hot rolling H-section steel flange comprises installing a cooling device on a centring device of an H-section steel rolling mill; adjusting distance between the cooling device and H-section steel billets; detecting a distance signal at the head or tail of the H-section steel billets and transmitting the distance signal to a remote computer through a thermal detector before the H-section steel billets are bit by the rolling mill; controlling an electronic control valve which is arranged on the cooling device through the remote computer to control the opening of a water cooling nozzle of the cooling device and water flow and water pressure of cooling water injected from the water cooling nozzle; and then performing alternative injection water cooling on the H-section steel flange. The alternative cooling control method of the hot rolling H-section steel flange has the advantages of improving the cooling uniformity, reducing the internal stress and improving the comprehensive mechanical performance of rolled pieces.

Owner:SHANXI ANTAI STEEL CO LTD

X80 wide and heavy steel plate with good low-temperature toughness and for hot bends and production method thereof

The invention provides an X80 wide and heavy steel plate with good low-temperature toughness and for hot bends and a production method thereof. The steel plate is prepared from 0.055%-0.080% of C, 0.16%-0.35% of Si, 1.55%-1.75% of Mn, 0.025%-0.050% of Nb, 0.011%-0.025% of Ti, 0.05%-0.09% of V, 0.21%-0.45% of Cr, less than 0.20% of Mo, less than 0.25% of Ni, less than 0.20% of Cu, 0.010%-0.035% ofAl, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.001%-0.004% of N, and the balance of Fe and inevitable impurities. The production method comprises the steps of hot metal pretreatment, converter smelting, external refining, continuous casting, heating, rolling, cooling and heat treatment. A microstructure is a combination of bainite and ferrite.

Owner:ANGANG STEEL CO LTD

Ultra fast cooling and conventional laminar flow cooling method for medium plate

ActiveCN102513383AVarious control modesAchieve high cooling rate processWork treatment devicesMetal rolling arrangementsSheet steelUltra fast

The invention discloses an ultra fast cooling and conventional laminar flow cooling method for a medium plate, comprising the steps of rolling to obtain a medium plate of 40-100mm; positively and quickly air cooling the medium plate by delivering through a post-rolling cooling device to a straightening machine, inversing a transmission roller motor after the medium plate is straightened, so that the plate is subjected to quick air cooling by the post-rolling cooling device and returned to a post-rolling roller before an ultra fast cooling device by the post-rolling cooling device; controlling a program which calculates the water cooling procedure according to the cooling starting step, ultra fast cooling stopping step, laminar flow cooling stopping step and self-tempering temperature of the rolling process of the medium plate; controlling the ultra fast cooling device or / and a conventional laminar flow cooling device by a process instruction to carry out the cooling program corresponding to the steel plate; allowing the steel plate to pass through the cooling device and the straightening machine and sending to a cooling bed. Great cooling speed, sectional cooling and cooling speed big range adjustable process is realized by using the method provided in the invention, by use of the ultra fast cooling device alone or in combination with the laminar flow cooling.

Owner:NORTHEASTERN UNIV

Direct quenching device for medium plate and quenching process thereof

InactiveCN102061363AReduce processShorten the production cycleQuenching devicesTemperature controlDistributor

The invention provides a direct quenching device for a medium plate and a quenching process thereof. The device comprises a high-level water tank, a water quantity distributor, upper quenching coolers, upper accelerating coolers, upper fine-tuning coolers, lower quenching coolers, lower accelerating coolers, lower fine-tuning coolers, edge shielding devices, side spraying devices and a purging device. The quenching method comprises the following steps: carrying out controlled rolling, and controlling the finished rolling temperature at 780-850 DEG C; calculating the speed of a roller way, the group number of the coolers to be started, the water quantity of the coolers and the edge shielding quantity according to the plate thickness and the steel grade by utilizing a computer, and then transferring the plate to a controlled cooling area according to a predetermined speed; and starting the coolers and the corresponding side spraying devices according to the position sequence of the plate, wherein, the finished cooling temperature range is 150-450 DEG C. The direct quenching device has the characteristics of low fabrication cost, and fast and uniform cooling speed, and can stably produce the flat quenching plate with the quenching thickness of 9-60mm, and is simple and convenient in maintenance; and compared with the traditional out-line quenching method, the quenching process provided by the invention has the characteristics of short process flow and less energy consumption.

Owner:UNIV OF SCI & TECH BEIJING +1

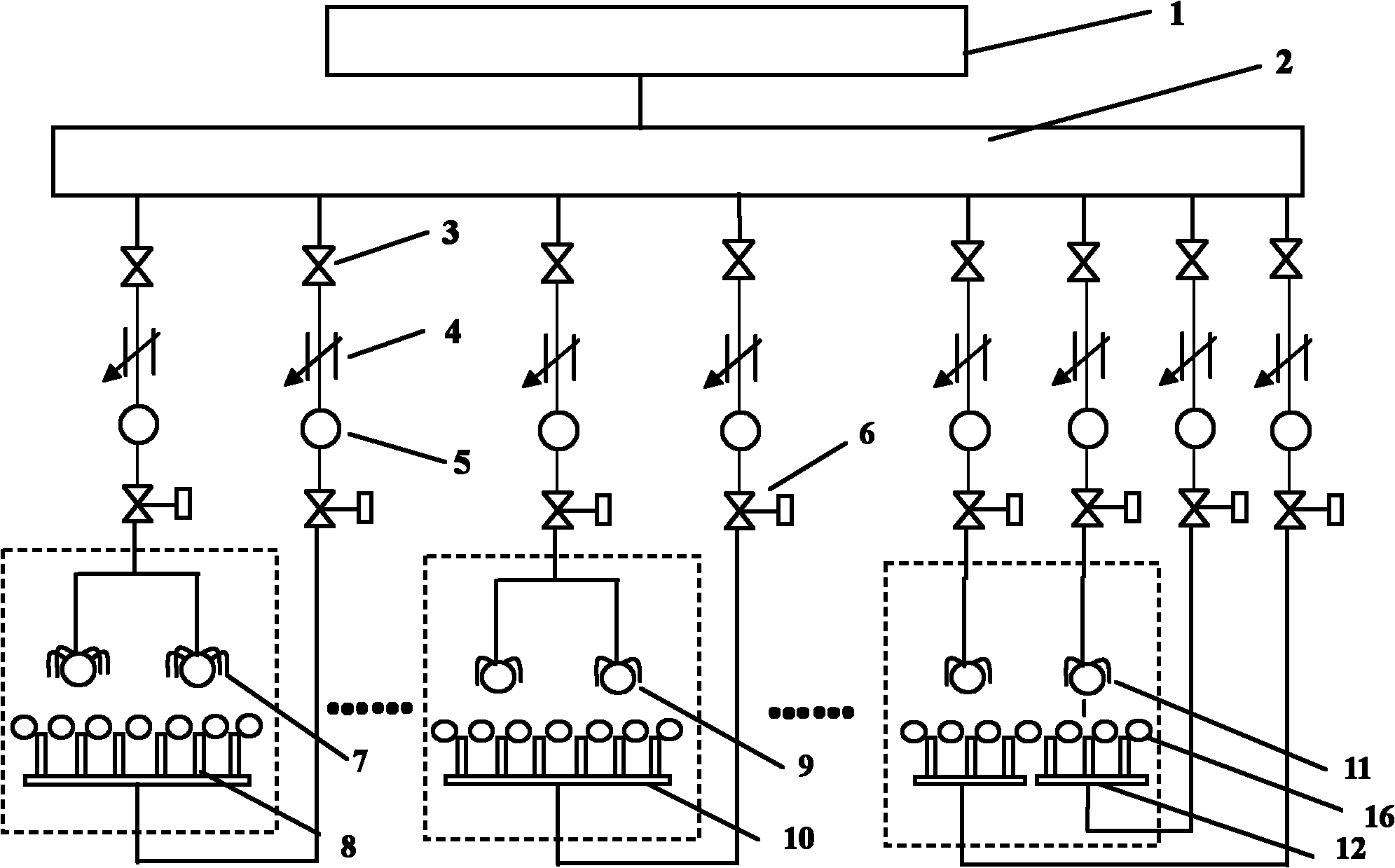

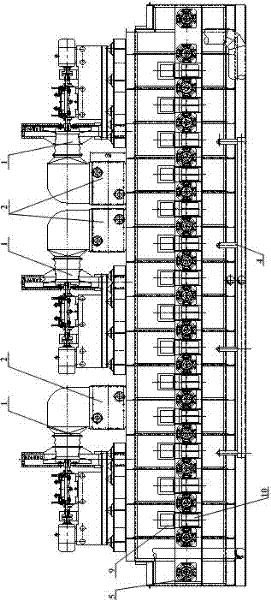

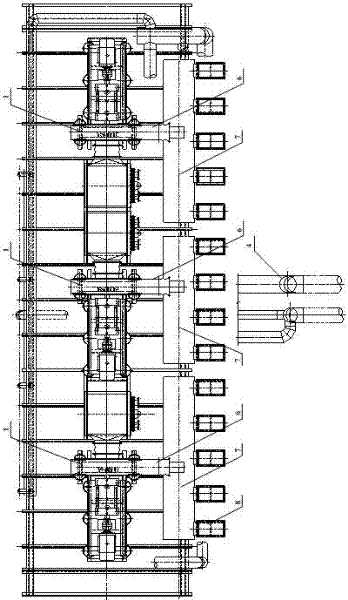

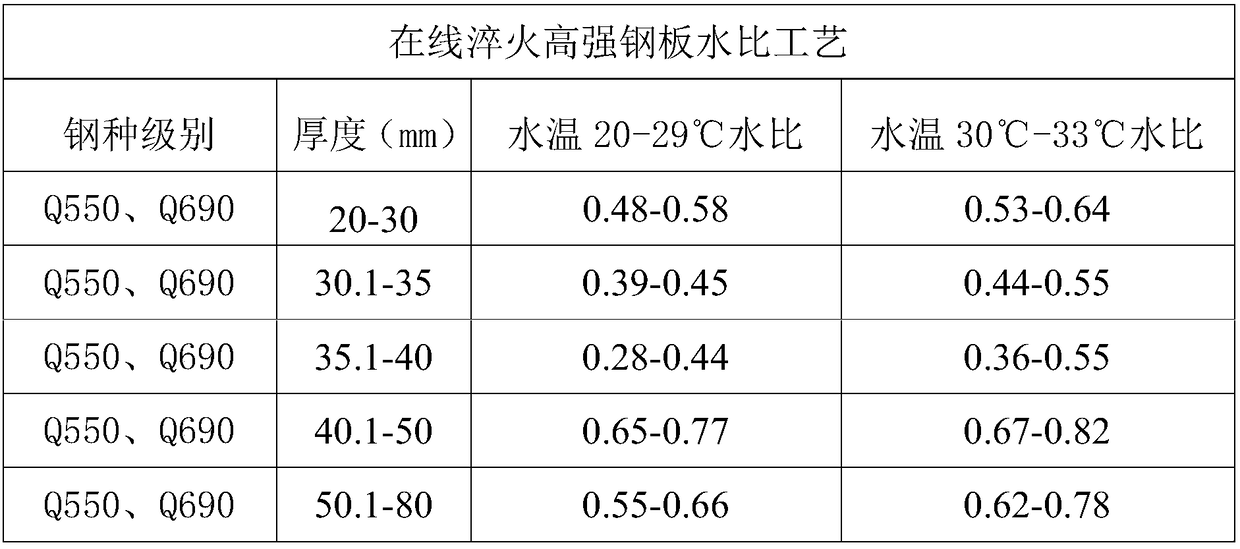

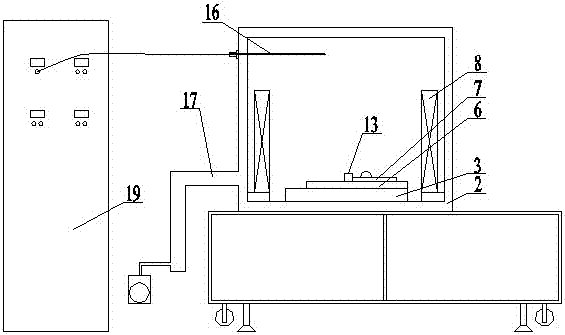

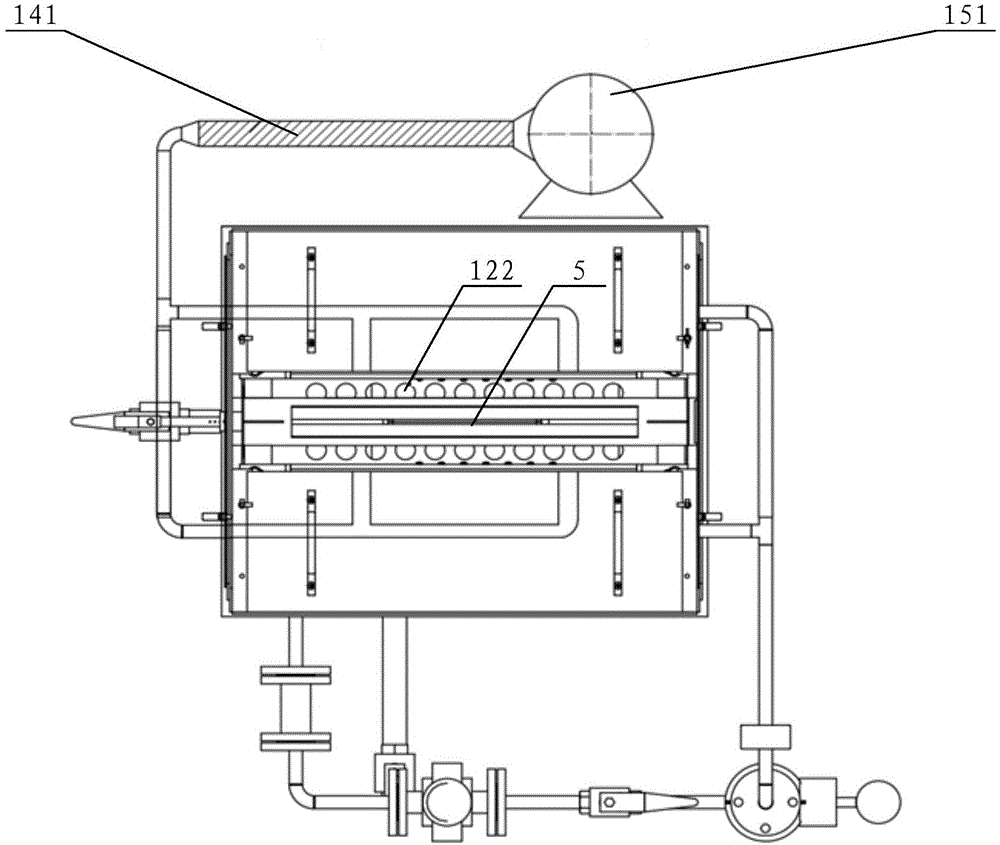

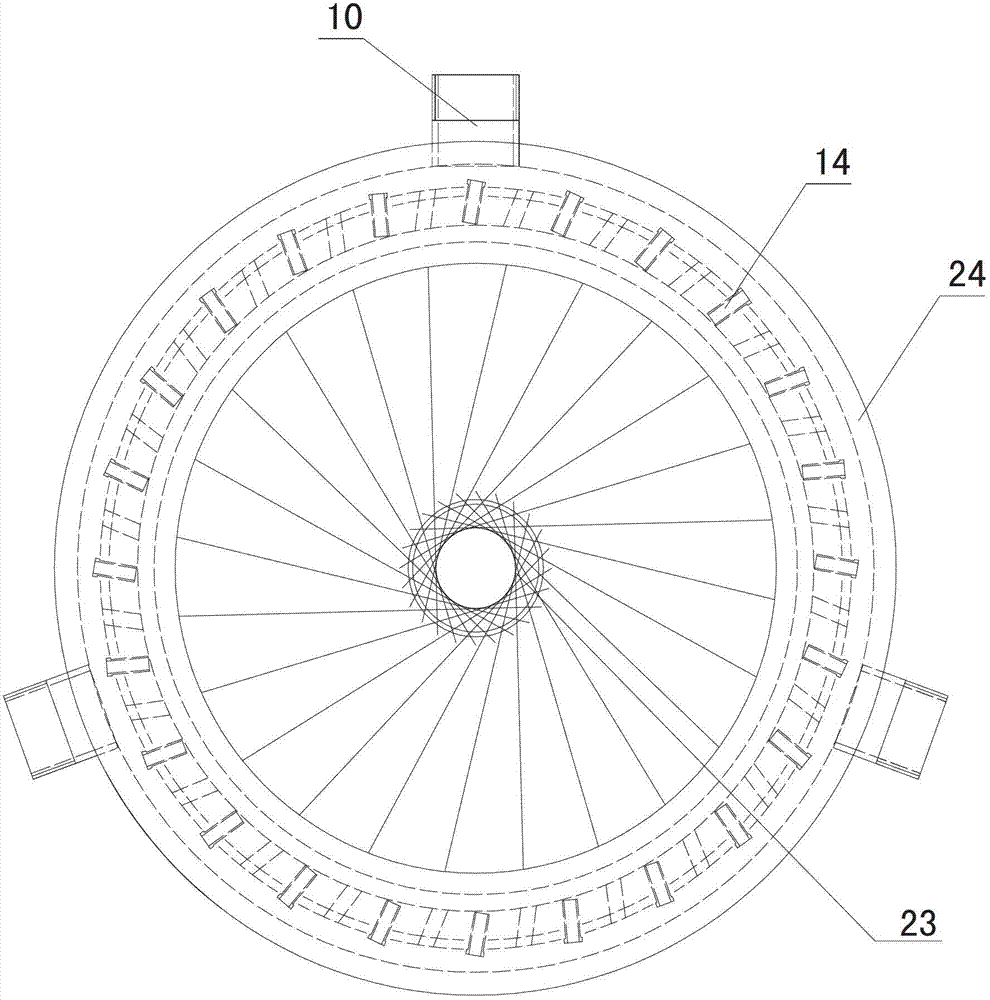

Strong wind cooling system for medium plate heat treatment

ActiveCN102517430AReduce supply wind fluctuationsImprove cooling uniformityFurnace typesQuenching agentsControl mannerMathematical model

The invention discloses a strong wind cooling system for medium plate heat treatment, which comprises a cooling air supply system and a control system; a steel plate is performed with strong wind cooling in a cooling chamber arranged along a conveying roller way, a plurality of cooling segments are held in the cooling chamber, each cooling segment is provided with an air supply system and a heat exchanger, and the cooling and cooling air circulation of the steel plate at the cooling segment are controlled by a process control system; the control mode of the conveying roller way comprises single transmission and group frequency conversion; the control system is composed of a transmission instrument system, a PLC system and a process control system; the process control system is used for dispatching a model parameter database according to a production plan, regulating a strong wind cooling strategy by a created strong wind cooling mathematical model, calculating a strong wind cooling procedure, and sending the cooling procedure to the PLC system to be executed and displayed on an interface; the process control system triggers the PLC to work by an inlet metal detector signal, and the PLC system is used for respectively executing the working procedures of the air supply system and the roller way system. The system disclosed by the invention has the advantages of improving the production efficiency and simplifies the operation steps.

Owner:NORTHEASTERN UNIV

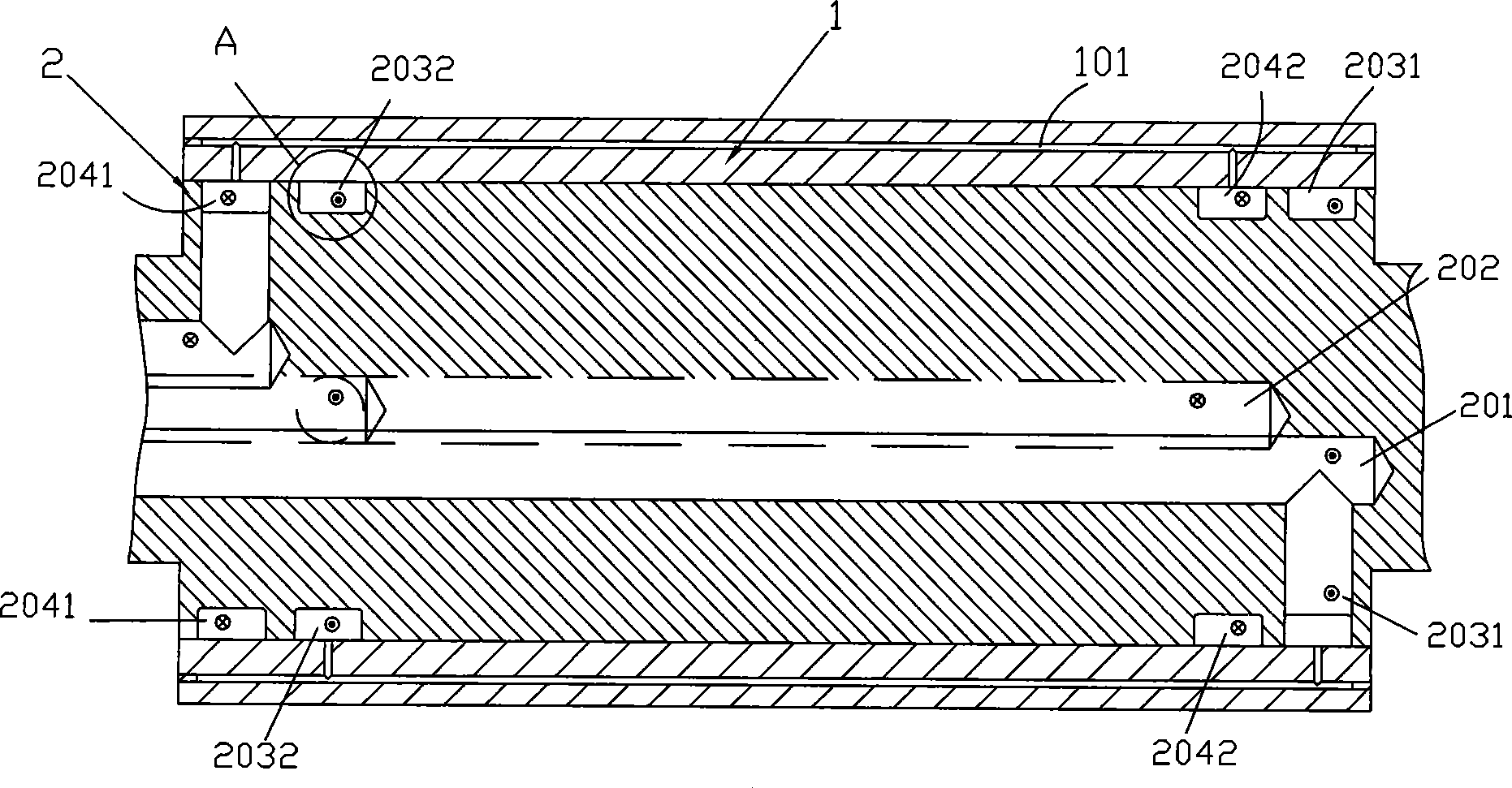

Control method of roll forming of twin-roll thin strip continuous casting cooling roll

The invention discloses a method for controlling a roll shape of a double-roll thin-strip continuous-casting and cooling roll. The double-roll thin-strip continuous-casting adopts a cooling roll connected with cooling water; the cooling roll comprises a roll sleeve and a roll shaft; a cooling water channel is formed in the roll sleeve and used for water flowing; a water input and output channel is axially formed in the roll shaft, and at least two water collecting ring grooves which are connected with the water input and output channel and the cooling water channel in the roll sleeve are formed on two sides of the outer circumference thereof; the inner wall of the inner circumference of the roll sleeve corresponding to the water collecting ring groove of the roll shaft is coated with a layer of heat resistance material; and the thermal conductivity of the heat resistance material is smaller than that of the roll sleeve material. The method can facilitate the cooling uniformity of the inside of the cooling roll sleeve and the roll surface by adding the coating for the water collecting ring grooves inside the cooling roll sleeve, thereby avoiding the partial thermal expansion inconformity resulted from the uneven heat transmission, and avoiding the damage to the surface coatings of the cooling roll sleeve and the cooling roll resulted from the partial thermal stress generated by the partial thermal expansion inconformity. The device can improve the service life of the cooling roll and acquire casting strips with good quality and strip shape.

Owner:BAOSHAN IRON & STEEL CO LTD

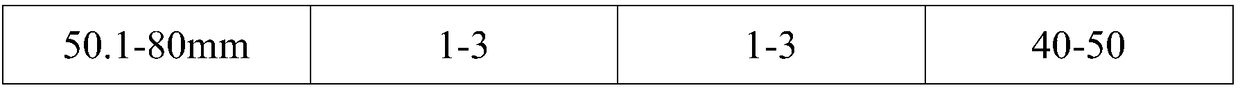

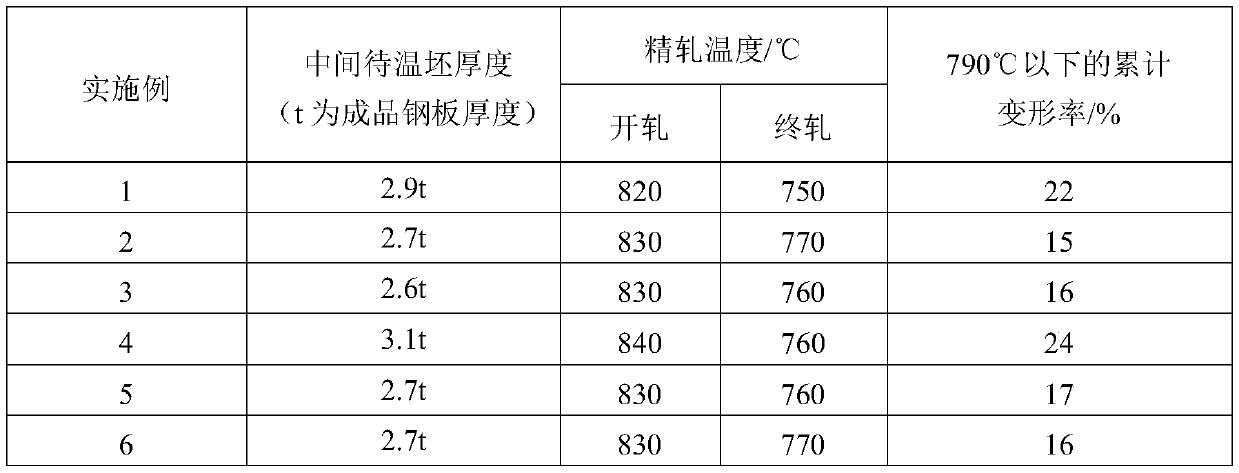

Plate shape control method of online-quenched high-strength steel plate

ActiveCN109266815AUniform deformationImprove cooling uniformityTemperature control deviceFurnace typesProduction lineSheet steel

The invention provides a plate shape control method of an online-quenched high-strength steel plate. The high-strength steel plate is formed by continuously casting blanks through the plate shape control method. The plate shape control method comprises the following steps of 1, heating, 2, descaling, 3, rolling, 4, online quenching, 5, retarded cooling and 6, tempering. The plate shape control method is applicable to a medium-thickness plate production line without arrangement of a pre-straightening machine, through a plate shape control technology, the plate shape quality of the online-quenched high-strength steel plate is improved, after tempering, the plate shape unevenness is controlled to be 7mm / 2m or below, hardening and tempering for remedy and size changing are avoided, the production cost is reduced, and the yield is increased.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Middle and large-sized battery pack of excellent cooling efficiency

ActiveCN101401228AAchieve flowImprove cooling efficiencySecondary cellsCell component detailsBattery packCooling efficiency

Disclosed herein is a middle- or large-sized battery pack comprising a battery module including a plurality of unit modules horizontally stacked while each unit module is vertically erected on one side, the battery module being mounted in a sealed space of a housing member, wherein the housing member is provided at the upper or lower end of one side thereof with a coolant inlet port and at the lower or upper end of the opposite side thereof with a coolant outlet port, the battery module is mounted in the housing member such that the upper or lower end surface of the battery module is tilted toward the coolant inlet port by a predetermined angle, whereby a coolant introduced through the coolant inlet port in parallel with the battery module passes perpendicularly through the unit modules and is then discharged to the opposite side, and gaps (vertical flow channels) defined between the unit modules at the tilted upper or lower end surface of the battery module are arranged in parallel with the direction in which the coolant is introduced, whereby the cooling efficiency and the cooling uniformity of the battery pack are improved while the battery pack has a compact structure.

Owner:LG ENERGY SOLUTION LTD

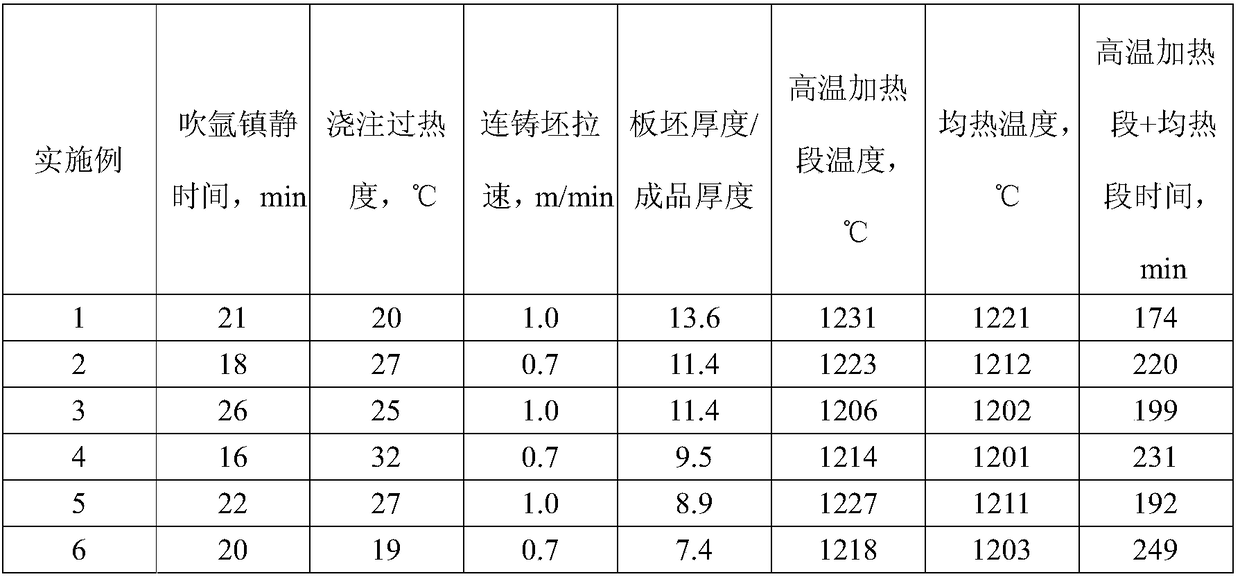

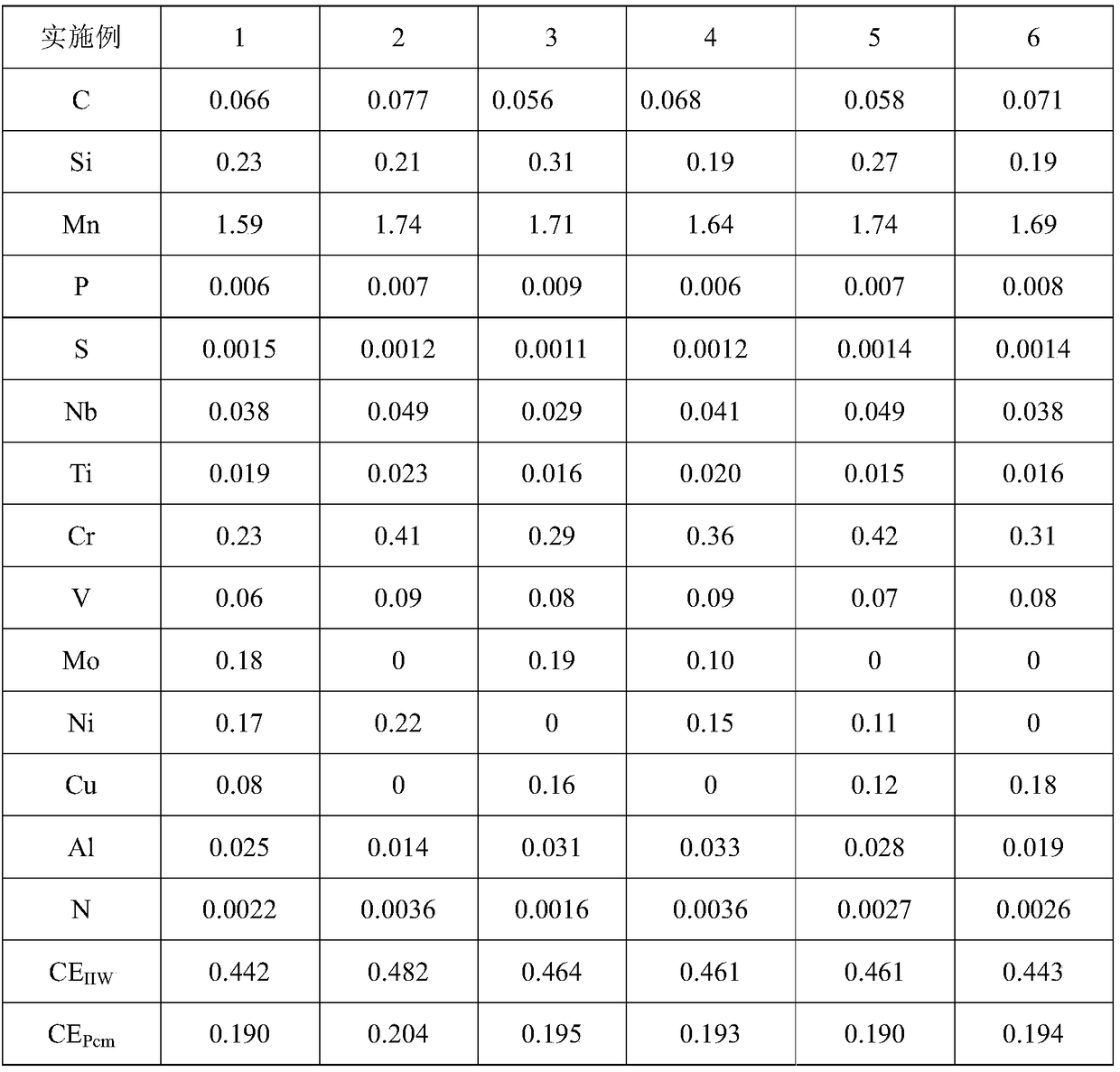

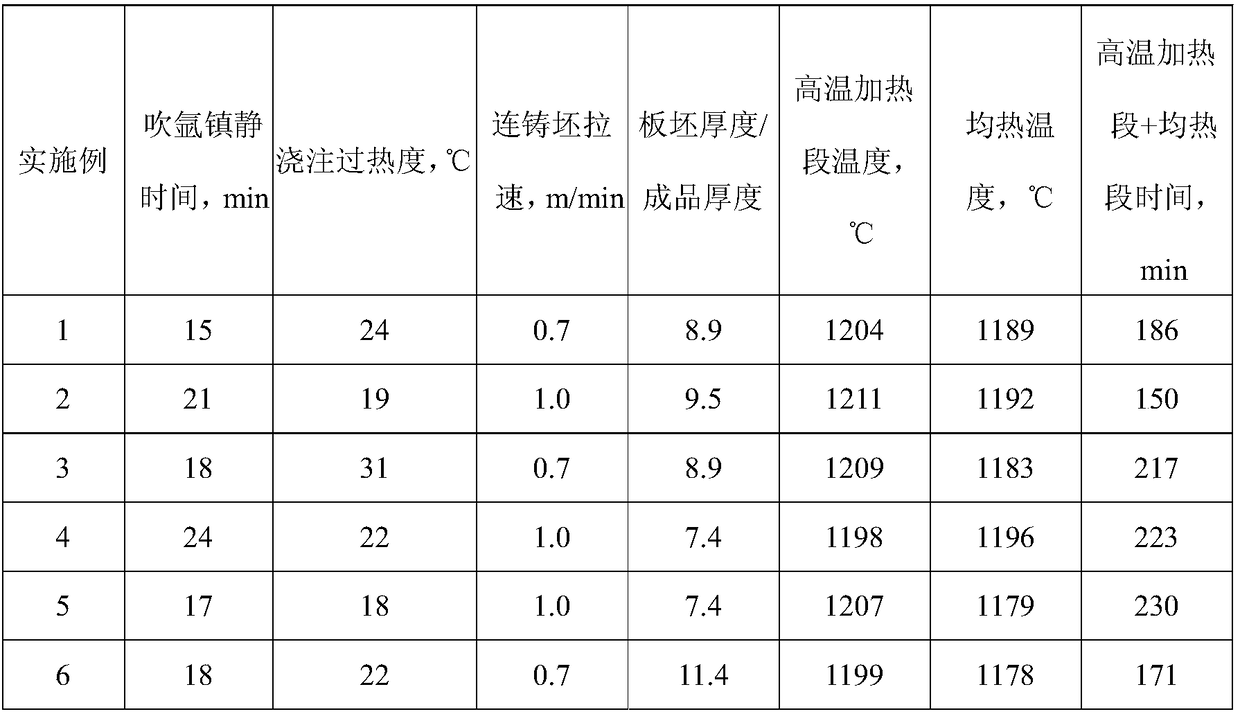

Ultrawide thick-wall and low-yield-ratio steel for X80 straight welding pipes and production method thereof

The invention discloses ultrawide thick-wall and low-yield-ratio steel for X80 straight welding pipes and a production method thereof. The steel contains 0.045-0.065% of C, 0.26-0.40% of Si, 1.60-1.80% of Mn, P not more than 0.010%, S not more than 0.0015%, 0.04-0.06% of Nb, 0.008-0.020% of Ti, 0.10-0.24% of Ni, 0.16-0.25% of Cu, Mo not more than 0.12%, Cr not more than 0.30%, 0.45-0.75% of Ni+Cu+Mo+Cr, 0.010-0.030% of Al, 0.0010-0.0040% of N, and the balance of Fe and inevitable impurities. The heating temperature of casting blanks is 1190-1220 DEG C; the uniform heating temperature is 1170-1200 DEG C; the rough rolling temperature is 1100-1140 DEG C; the finish rolling temperature is 810-840 DEG C; and the cooling temperature is 710-750 DEG C. The thickness of finished steel plates is not lower than 30 mm; the width is not lower than 4320 mm; and the low-temperature toughness and the strain resistance are excellent.

Owner:ANGANG STEEL CO LTD

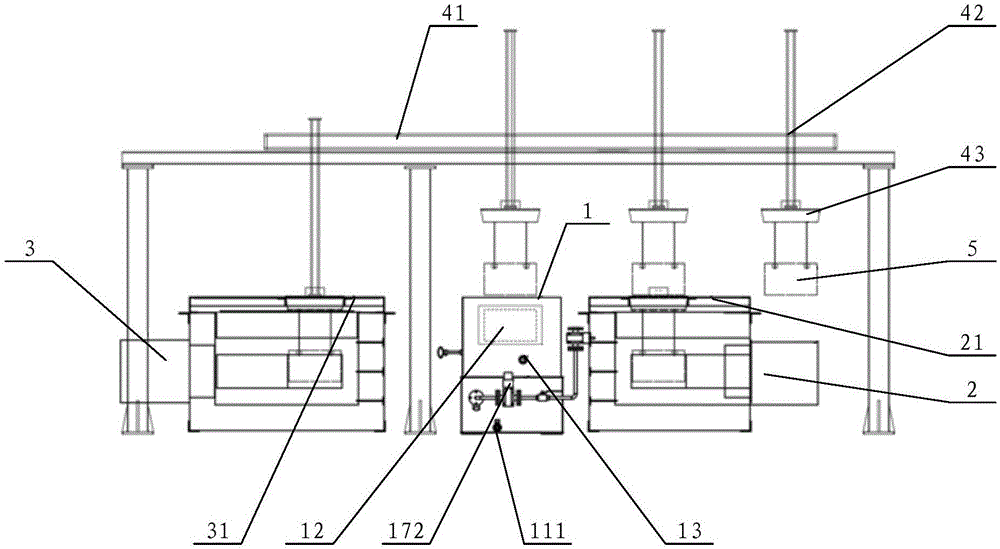

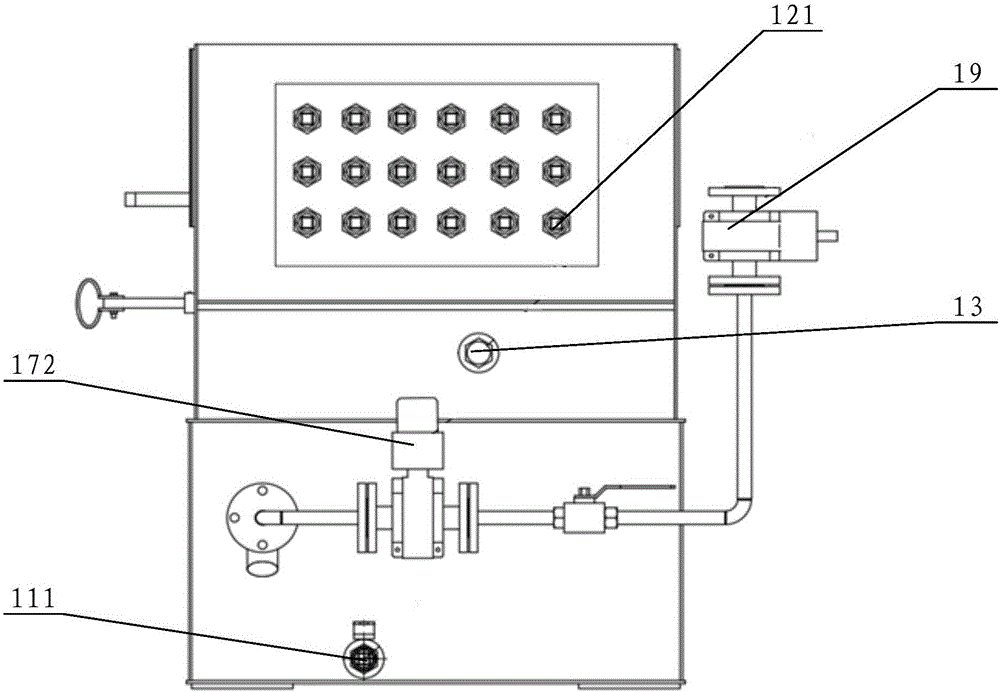

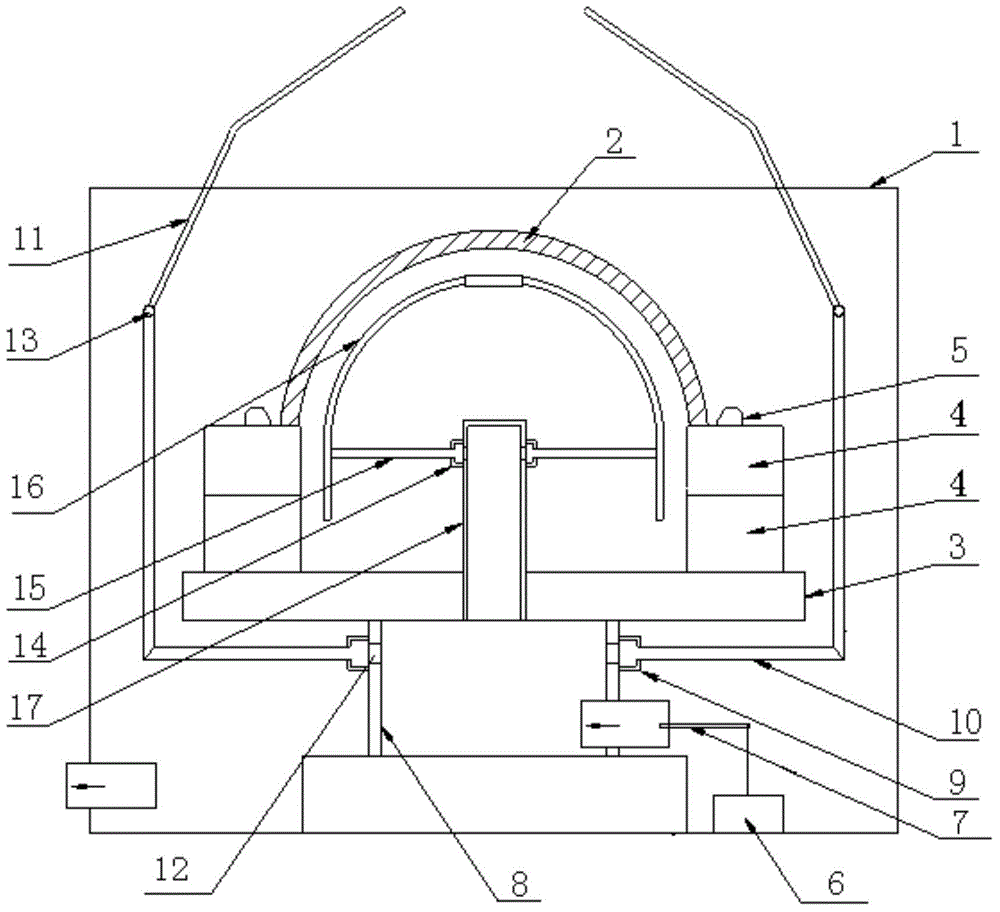

Spraying and quenching device for aluminum alloy tubular workpiece and application method of spraying and quenching device

ActiveCN105803170AStrong cooling capacityImprove controllabilityFurnace typesHeat treatment furnacesQuenchingAutomatic control

The invention discloses a spraying and quenching device for an aluminum alloy tubular workpiece and an application method of the spraying and quenching device. The spraying and quenching device comprises heating furnaces, a supporting and transferring system, a water tank, spraying systems, a rotating system, a guiding and limiting system and an automatic control system. Furnace mouths of the heating furnaces face downwards. The supporting and transferring system is used for supporting a workpiece during the heating process, transferring the workpiece to a quenching section during the quenching process and preventing water entering the heating furnaces. The water tank is used for water collecting and water proofing during the quenching process and is arranged under the heating furnaces. The spraying system is used for cooling and quenching and is composed of a plurality of rod-shaped spraying units. The rotating system mainly comprises carrier rollers and the corresponding motor devices, wherein the carrier rollers are distributed evenly along the tubular workpiece in the circumferential direction. The rotating system is matched with the guiding and limiting system which is arranged in the same way, and accordingly the tubular workpiece is made to make steady rotary movements during the spraying and quenching process. The automatic control system is used for controlling the operation of various systems. The multiple heating furnaces share a quenching and cooling device and a control device, the quenching and cooling device can move between different heating furnaces, the manufacturing cost is lowered, the working efficiency is high, and industrial production requirements can be met.

Owner:CENT SOUTH UNIV

Material wettability improvement device and method based on multi-field coupling

ActiveCN107052494AImprove wettabilityWay to overcomeMuffle furnacesPreparing sample for investigationEngineeringMechanical engineering

The invention provides a material wettability improvement device and method based on multi-field coupling. The material wettability improvement device comprises an operation platform, a vacuum furnace stored on the operation platform, a high-voltage power supply control box, an ultrasonic auxiliary device, an electric field auxiliary device and a magnetic field auxiliary device. A rack on one side of the vacuum furnace is provided with a guide rail stand column. The upper end of the guide rail stand column is provided with a movable cross beam. An ultrasonic transducer is fixed to the cross beam. An ultrasonic variable-pressure rod stretches into the vacuum furnace through a corrugated pipe. The electric field auxiliary device is arranged below the ultrasonic variable-pressure rod. A sample is stored on an insulating ceramic plate and positioned through a stop block. The inner side of the vacuum furnace is further provided with a magnetic field power coil which generates a variable magnetic field after being applied with current. By adoption of the material wettability improvement device and method, the sample can be wetted under mutual assistance of an ultrasonic vibration load, an electric field and the magnetic field, and the problems that existing additionally arranged auxiliary equipment is simplex in applying mode, the ultrasonic applying mode is large in power loss, and simplex assistance is unobvious in sample wettability improvement effect are solved.

Owner:HENAN UNIV OF SCI & TECH

Cylinder type specific cutter grinder

The invention relates to a cylinder type specific cutter grinder, which is fence cylinder type. The cylinder type specific cutter is a grinding cutter having fixation crossing combination with an internal tooth and an outer tooth. The cylinder type specific cutter includes movable and stationary specific cutter rings (5, 2) of prepared material initial grinding, movable and stationary specific cutter rings (19, 14) of coarse grinding, movable and stationary specific cutter rings (20, 15) of micro refining, and movable and stationary specific cutter rings (21, 16) of ultramicro refining. The movable and stationary specific cutter rings in the cylinder type specific cutter grinder fully employ independent inventive fence cylinder type combination cutter. The invention provides a reasonable grinder for the exploitation and application of the grinder, especially for ultramicro refining flexible, soft, hard and plastic or the like specific material taking fiber as representative.

Owner:钟元龙 +1

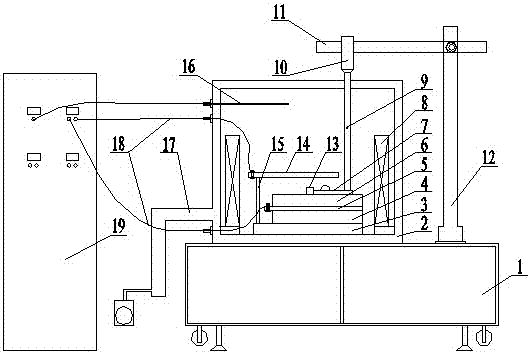

Quenching experimental device and quenching experimental method

InactiveCN106834634AReduce stressEasy to shapeFurnace typesHeat treatment process controlAlloyHigh pressure

The invention discloses a quenching experimental device and a quenching experimental method, relates to the technical fields of aluminum alloy heat treatment equipment and technology simulation machines, and aims at solving the technical problems that a conventional quenching experimental device easily leads to reduction of plate shape quality and comprehensive mechanical properties of aluminum alloy plate strips. The quenching experimental device comprises a cooling mechanism; the cooling mechanism comprises a water tank; an upper region of the water tank is provided with a cooling nozzle assembly, the cooling nozzle assembly is provided with at least two rows of nozzles, the nozzles comprise water nozzles for spraying water and gas nozzles for injecting gas, and the nozzles adopt a cooling way of high-pressure inclined injection; a lower region of the water tank is provided with a heater for heating cooling water in the water tank; the air inlets of the gas nozzles communicate with a frequency conversion fan through an air supply pipeline, and an interface of the air supply pipeline is provided with a first pressure sensor, a first flowmeter and a first valve.

Owner:NORTHEASTERN UNIV

Super high-speed quenching device for steel tube

ActiveCN102876874ASuppresses bending deformationSpeed up heat exchangeFurnace typesHeat treatment furnacesSpray nozzleWater spray

The invention discloses a super high-speed quenching device for a steel tube and relates to a cooling device. The quenching device comprises a shell with water inlets; a plurality of inclined seam nozzle units are arranged in the shell and are pressed against each other in parallel; gaps are reserved between the shell and the inclined seam nozzle units and are cooling water layers; each inclined seam nozzle unit has an annular structure, and sequentially consists of a water guide plate, a flow stabilization layer wall plate and a nozzle adjustment sleeve plate from exterior to interior; a plurality of water guide columns are uniformly distributed on the circumference of each water guide plate; the extension lines of the water spraying directions of all the water guide columns are intersected to form an inscribed circle, and the diameter of the inscribed circle is less than or equal to that of the steel tube to be cooled; the water guide columns of the adjacent inclined seam nozzle units are staggered; an inner cavity which is formed by the flow stabilization layer wall plates has a shape of a funnel with a wide exterior and a narrow interior; each nozzle adjustment sleeve plate is annular; gaps between the nozzle adjustment sleeves plates are inclined seam nozzles; the inclined seam nozzles are inclined seams of which the width is gradually reduced from exterior to interior.

Owner:沈阳科安捷材料技术有限公司

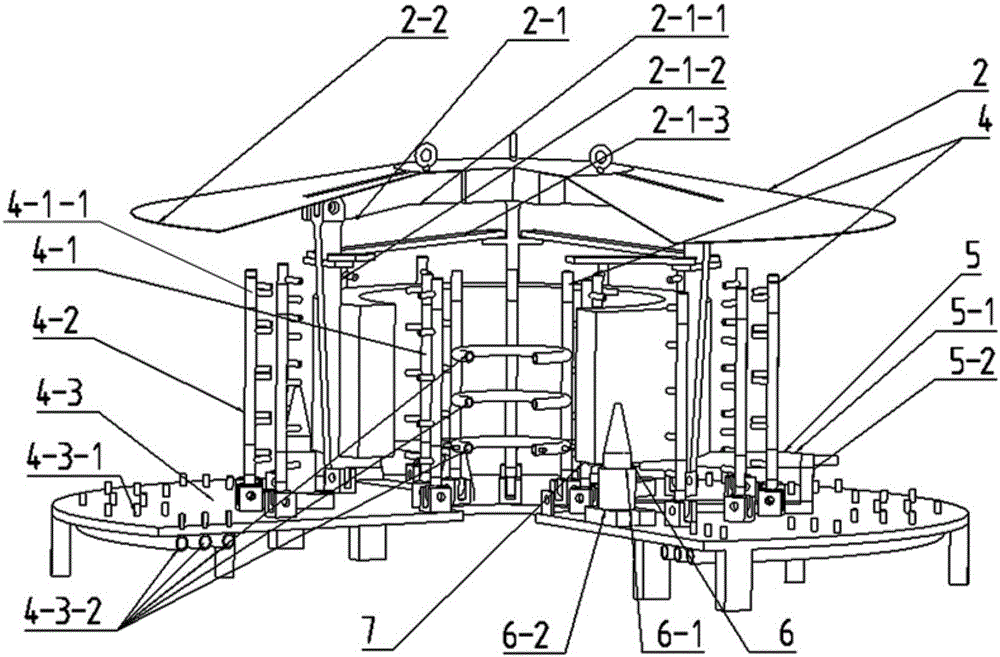

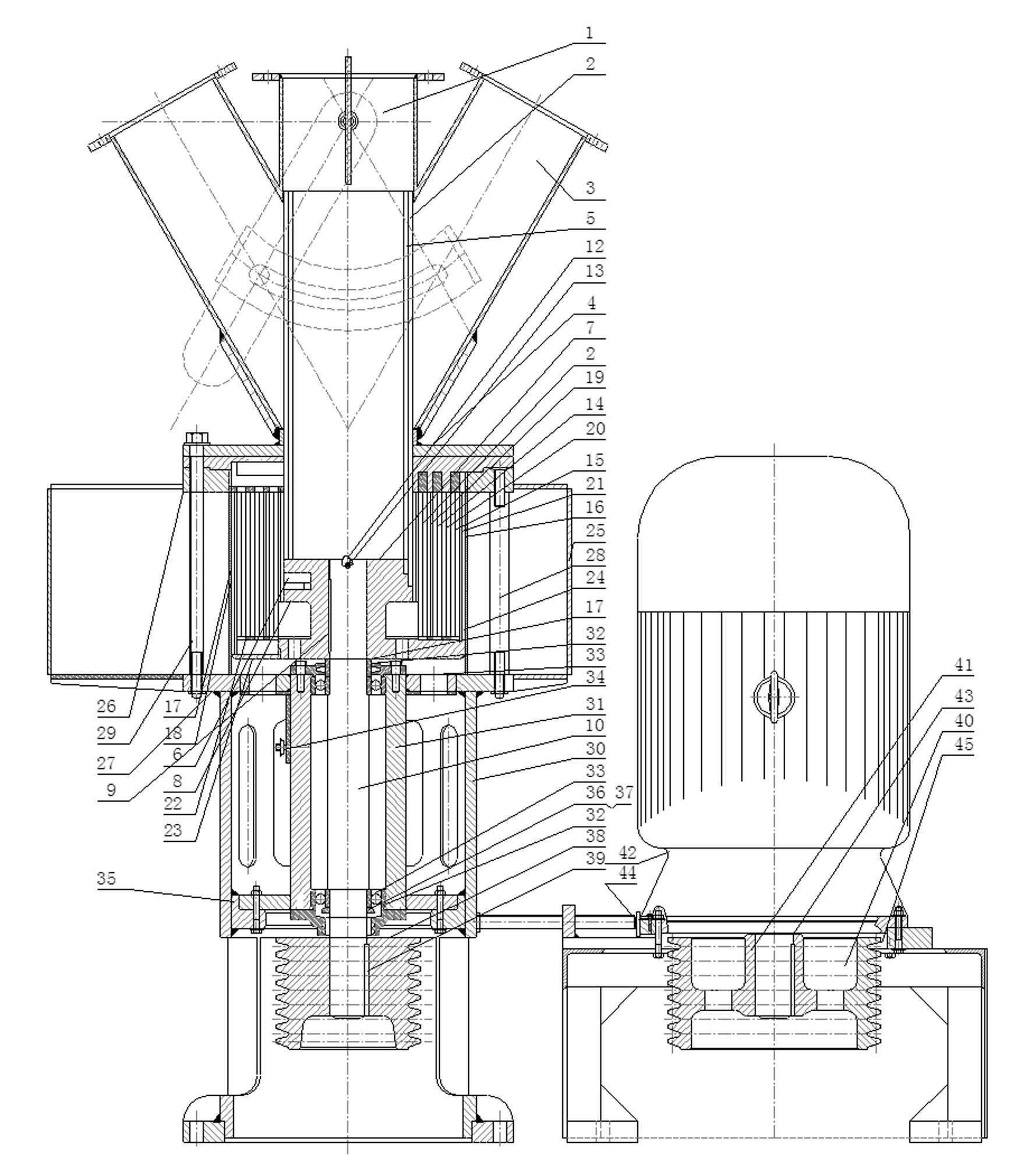

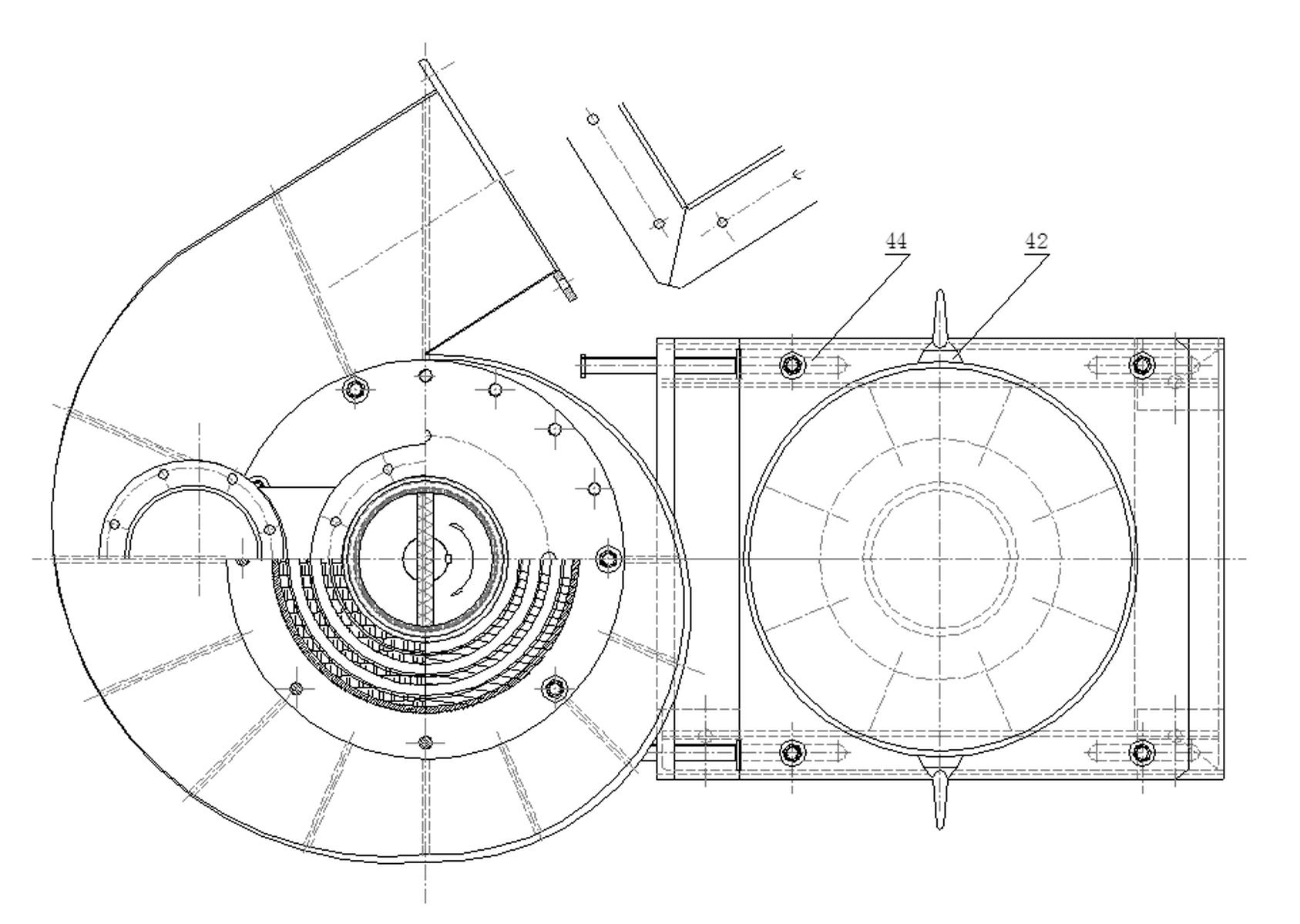

Rotating vertical water spray quenching equipment for quenching large complicated forged components

The invention discloses rotating vertical water spray quenching equipment for quenching large complicated forged components. The rotating vertical water spray quenching equipment is suitable for quenching large end socket class, cake class and tapered cylinder class forged components and is characterized by designing a series of copying and exchangeable inner water spray systems and iron support pads. The equipment is provided with a universal platform, and different inner water spray systems and iron support pads can be changed in consideration of different types of forged components, so that the equipment is highly targeted. The equipment is simple to operate and stable in running and is energy-conservative and efficient.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com