Method and device for reducing temperature of thin-strip continuous casting lower closed chamber

A closed chamber and thin strip technology, which is applied in the field of reducing the temperature of the closed chamber under continuous casting of thin strips, can solve the problems of reducing the rolling temperature of the steel strip, reducing the drop of the closed room temperature, difficult to effectively roll, etc. The effect of rolling temperature, preventing high temperature deformation, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

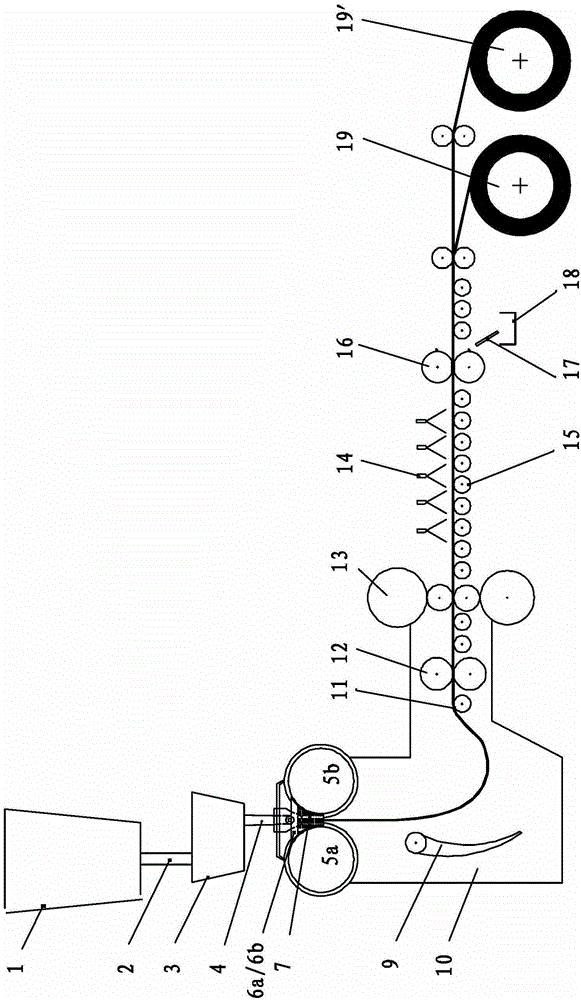

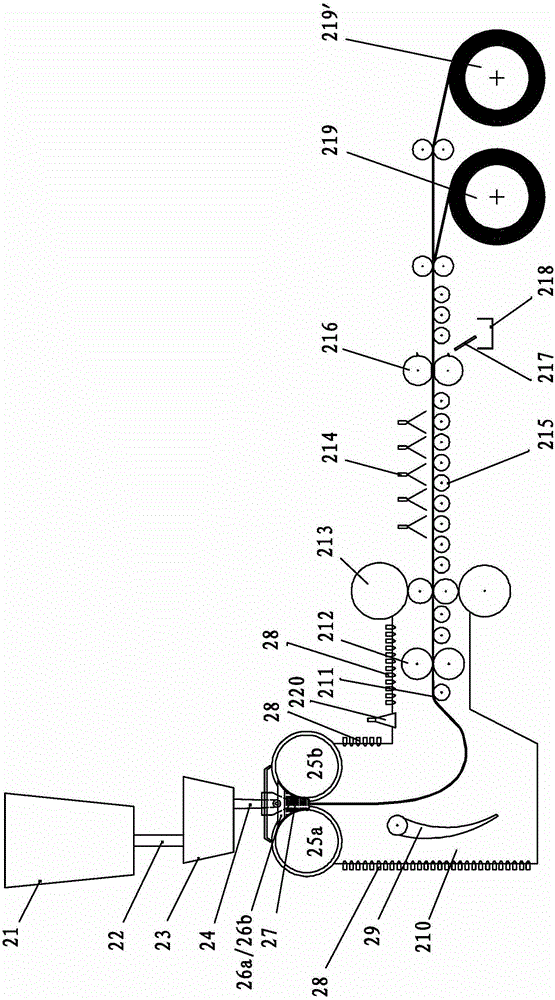

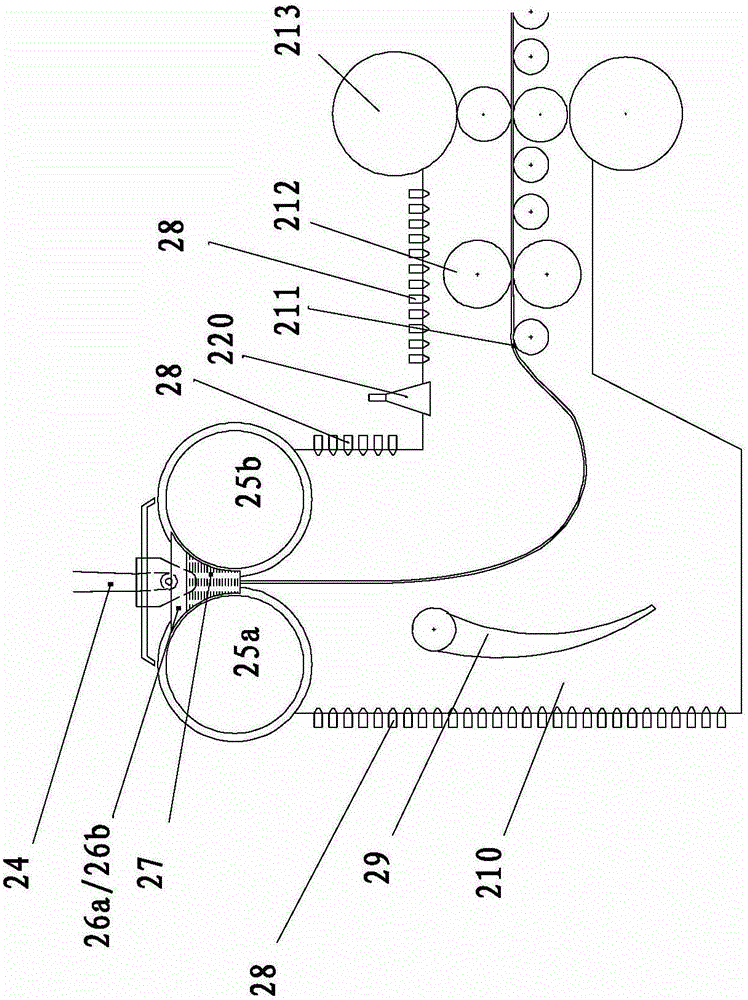

[0065] Such as image 3 As shown, 80 passages 28 are evenly arranged per square meter on the surrounding walls of the airtight chamber 210 under thin strip continuous casting, and liquid nitrogen with a pressure of 0.1 MPa is injected into the passages 28. Start to work, inject liquid nitrogen in the airtight chamber 10 downwards. The pressure in the channels injected with liquid nitrogen is 0.1MPa, and the flow rate of liquid nitrogen in each channel is 1m 3 / h, the diameter of the channel pipeline is 15mm, so that the lower airtight chamber 210 can quickly cool down, and the ambient temperature of the lower airtight chamber can reach 380°C during long-term production, which can effectively prevent the high-temperature deformation of the steel structure frame of the lower airtight chamber, and avoid the welding interface of the lower frame. risk of cracking.

[0066] Liquid nitrogen gasifies quickly after entering the lower airtight chamber 210. Gasification is a typical he...

Embodiment 2

[0071] Such as image 3 As shown, 65 passages 28 are evenly arranged per square meter on the surrounding walls of the airtight chamber 210 under thin strip continuous casting, and liquid nitrogen with a certain pressure and a certain flow rate is passed in the passages 28. These passages 28 are in the process of shrinking before casting. Just start working, inject liquid nitrogen into the airtight chamber 210 downwards. The pressure in the channels injected with liquid nitrogen is 0.3MPa, and the flow rate of liquid nitrogen in each channel is 5m 3 / h, the diameter of the channel pipe is 20mm, so that the lower airtight chamber 210 can quickly cool down, and the ambient temperature of the lower airtight chamber can reach 390°C during long-term production, which can effectively prevent the high-temperature deformation of the steel structure frame of the lower airtight chamber, and avoid the welding interface of the lower frame. risk of cracking.

[0072] Liquid nitrogen gasif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com