Circulating water cooling structure and method for coke discharging device of dry distillation furnace

A circulating water cooling and carbonization furnace technology, applied in the field of mechanical equipment cooling, can solve problems such as jamming, large deflection, and affecting the uniformity of discharge, and achieve the effects of reducing working temperature, avoiding high temperature deformation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing: 4

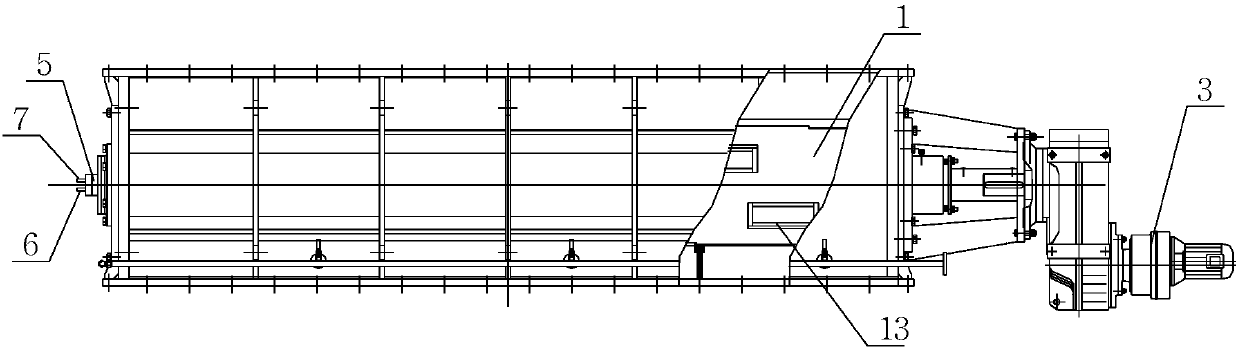

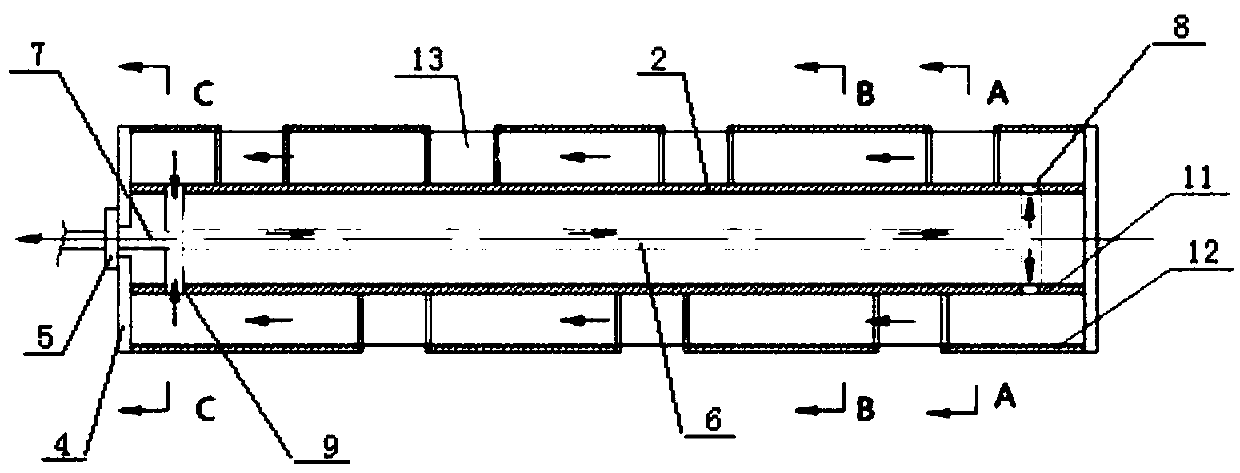

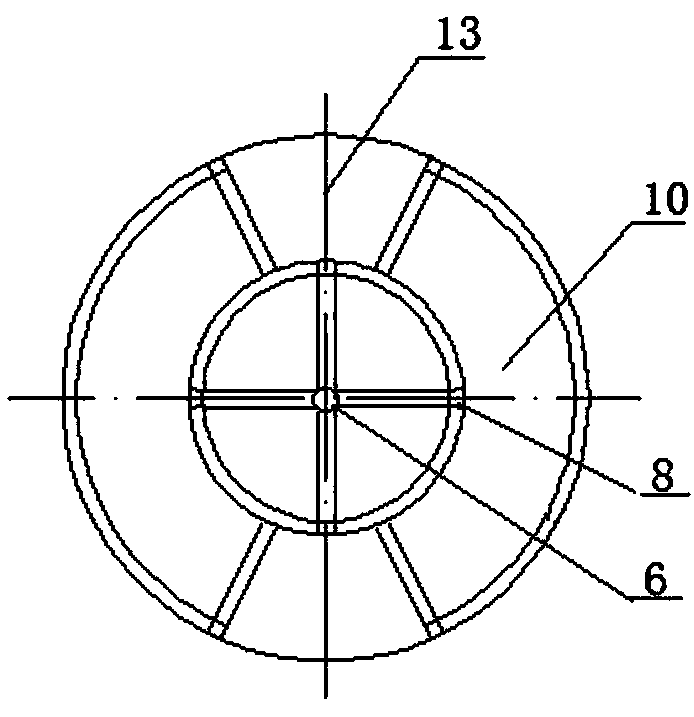

[0027] The present invention relates to a circulating water cooling structure of a dry distillation furnace coke discharge device, such as figure 1 As shown, the defocusing device includes a housing, a defocusing drum 1, a rotor shaft and a driving device 3, the driving device 3 drives the defocusing drum 1 to rotate through the rotor shaft, and the defocusing drum 1 is provided with a plurality of Hopper 13; as Figure 2-Figure 5 As shown, the rotor shaft is the rotor hollow shaft 2; the cylinder body of the coke discharge drum 1 except the hopper 13 is composed of an inner cylinder body 11 and an outer layer cylinder body 12 to form a water-cooled jacket 10, and the inner layer cylinder body 11 is set The water inlet 8 is connected to the water inlet pipe 6, and the water outlet 9 is connected to the water outlet pipe 7. The water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com