Patents

Literature

2053results about How to "Improve the operating environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

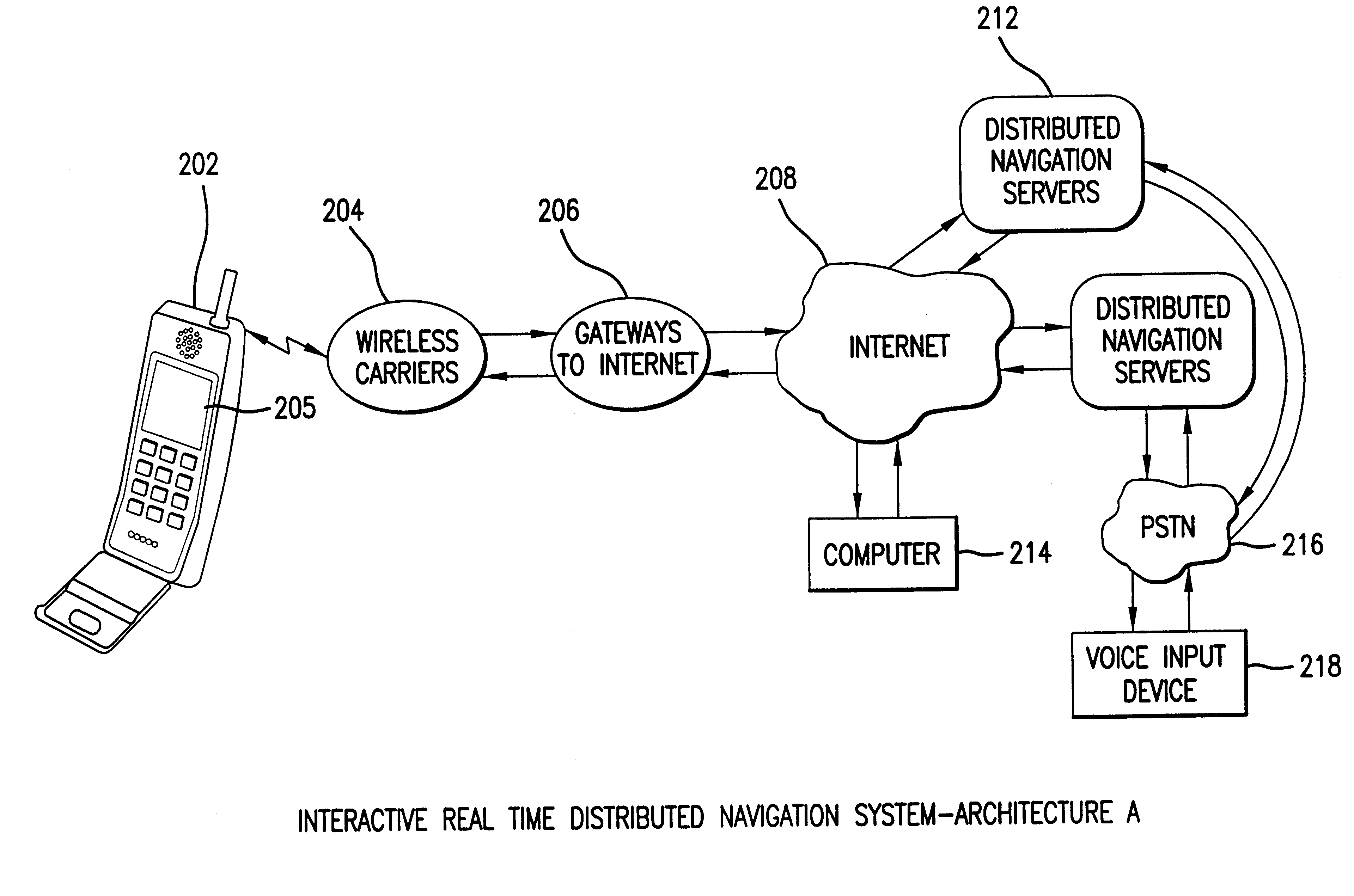

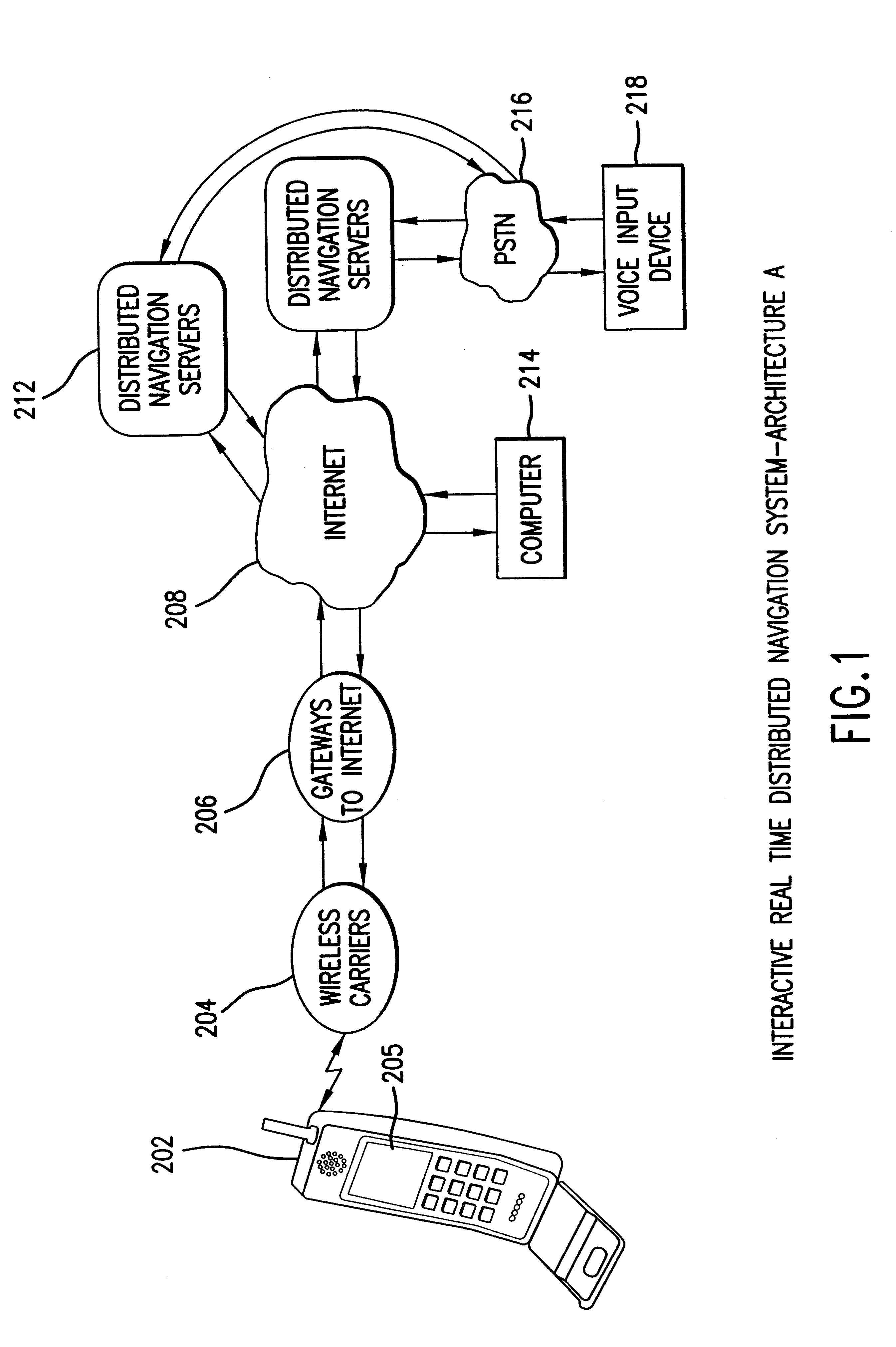

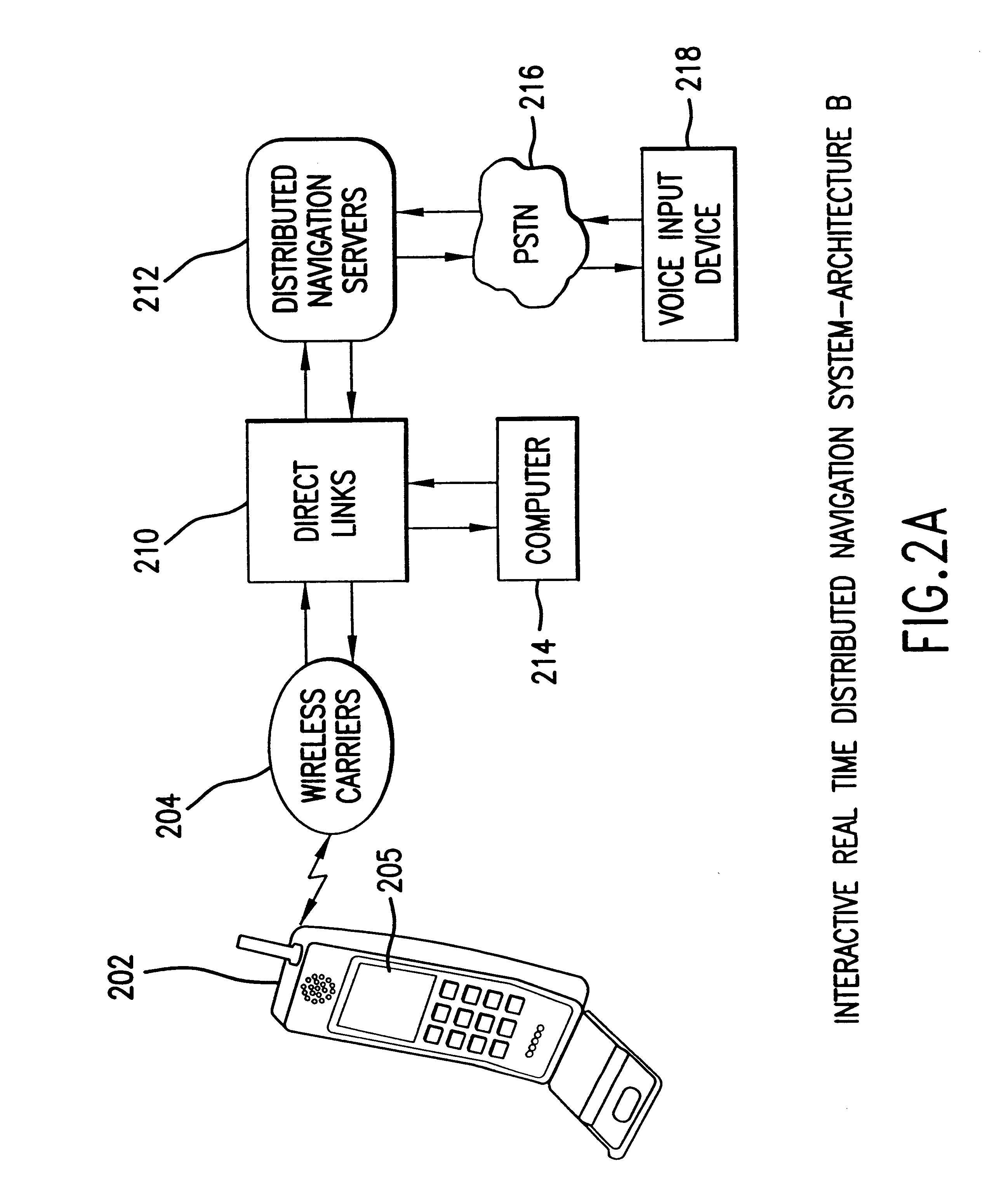

Method and system for an efficient operating environment in a real-time navigation system

InactiveUS6405123B1Enhance operating environmentImprove performanceInstruments for road network navigationControl with pedestrian guidance indicatorOperating environmentMulti method

A method and system for interactive real-time distributed navigation employs improved techniques for input and output. The method and system may receive inputs through a wireless device. The operating environment simplifies and reduces these inputs. In some embodiments, the system receives non-deterministic input to generate deterministic information using a number of methods. The system may also employ improved output techniques including methods for pacing navigational prompts provided by a navigation system, and methods of providing navigational information to a number of users. The method and system are applicable to text, graphics or audible navigation systems.

Owner:TELENAV

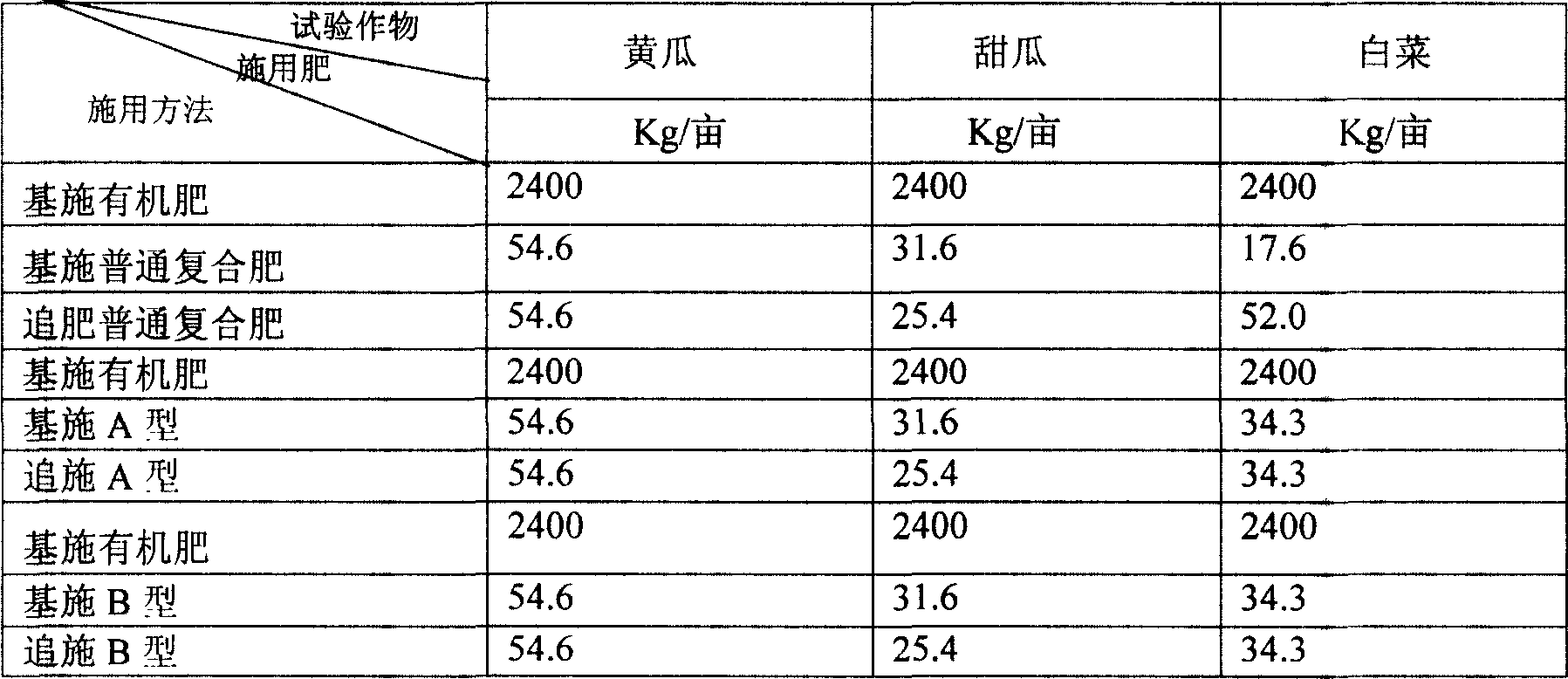

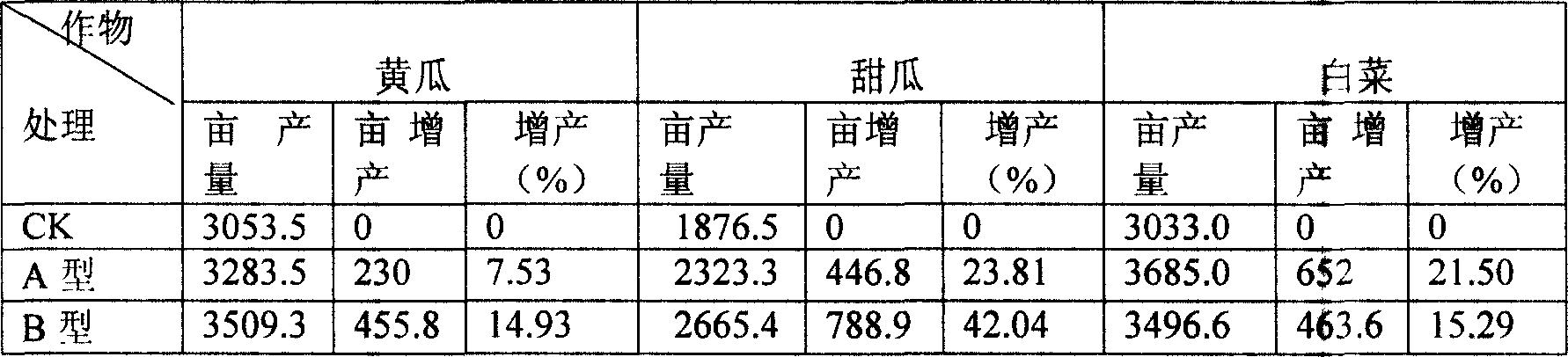

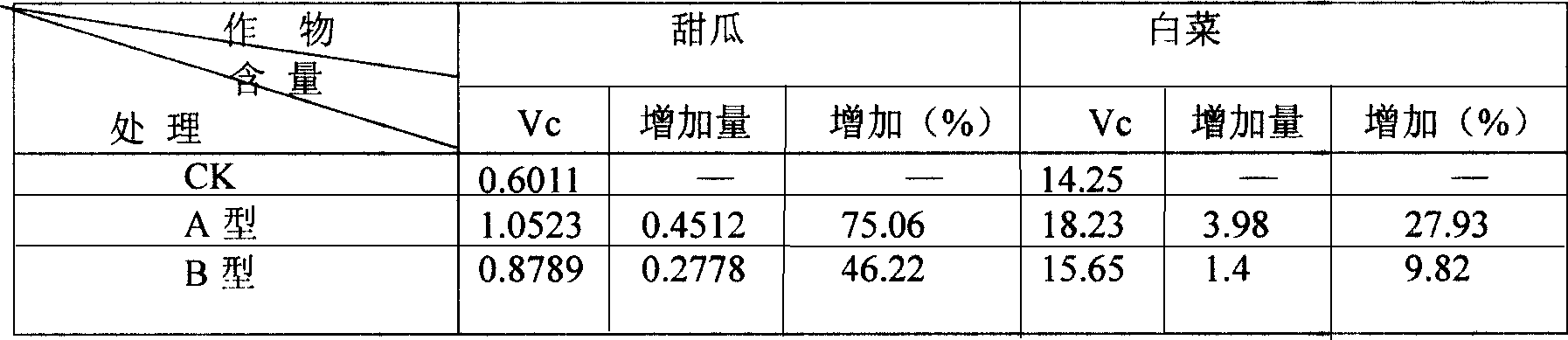

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

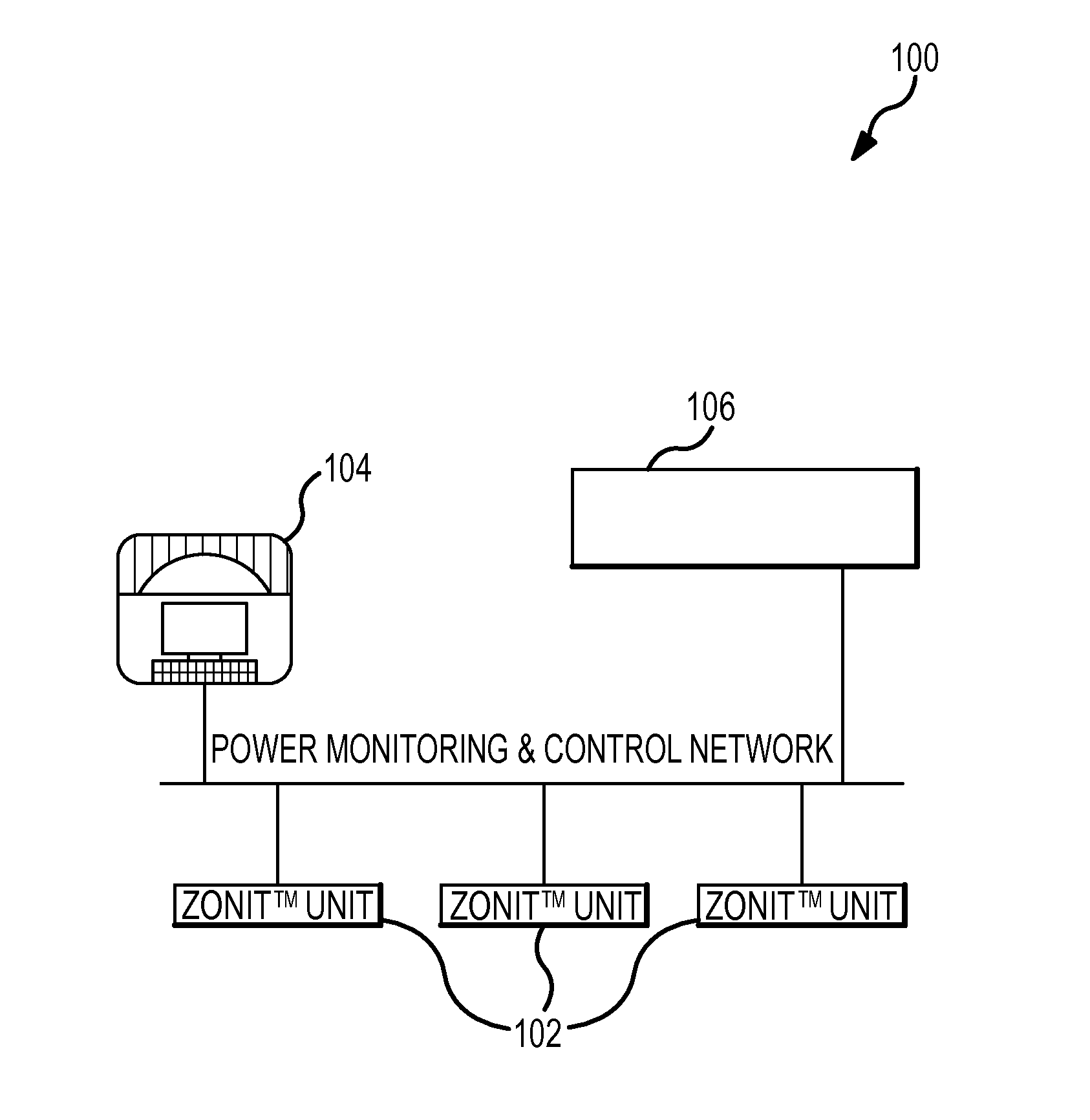

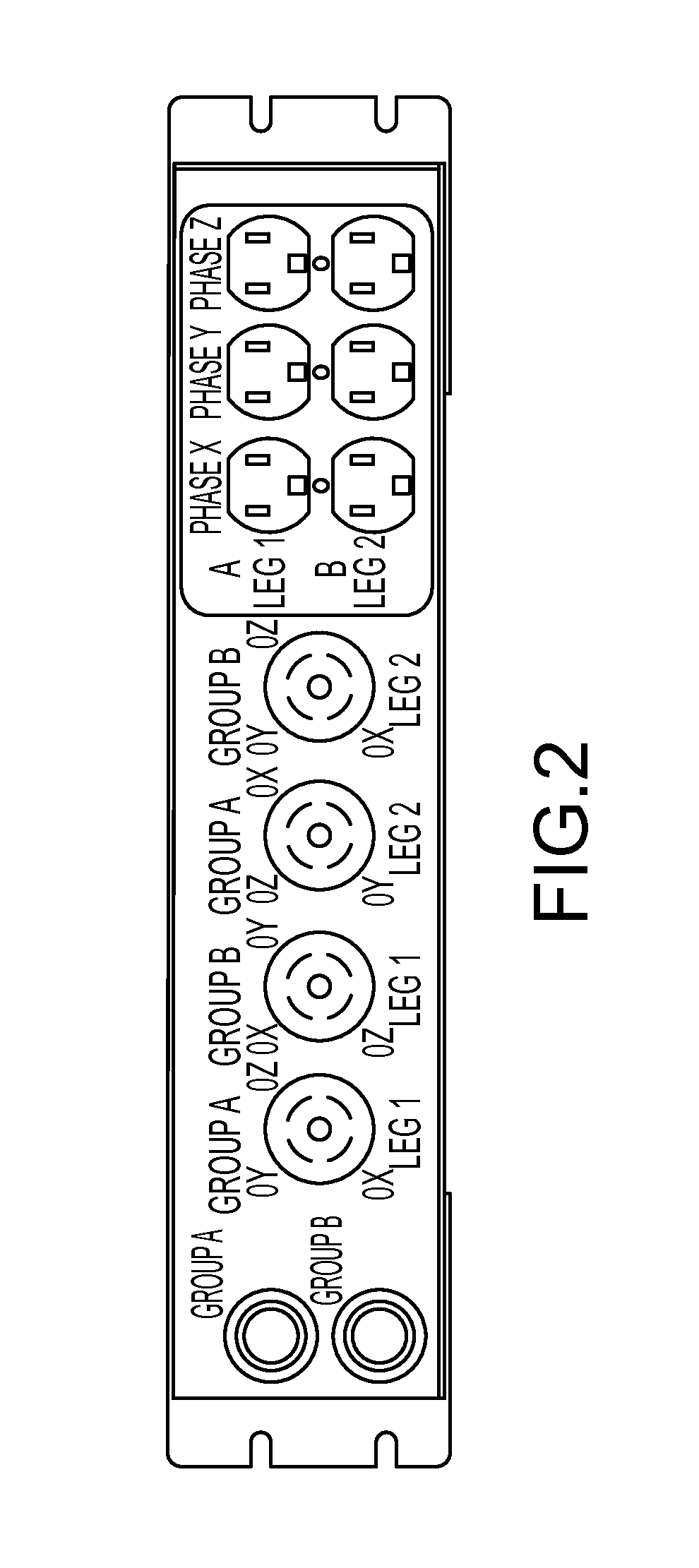

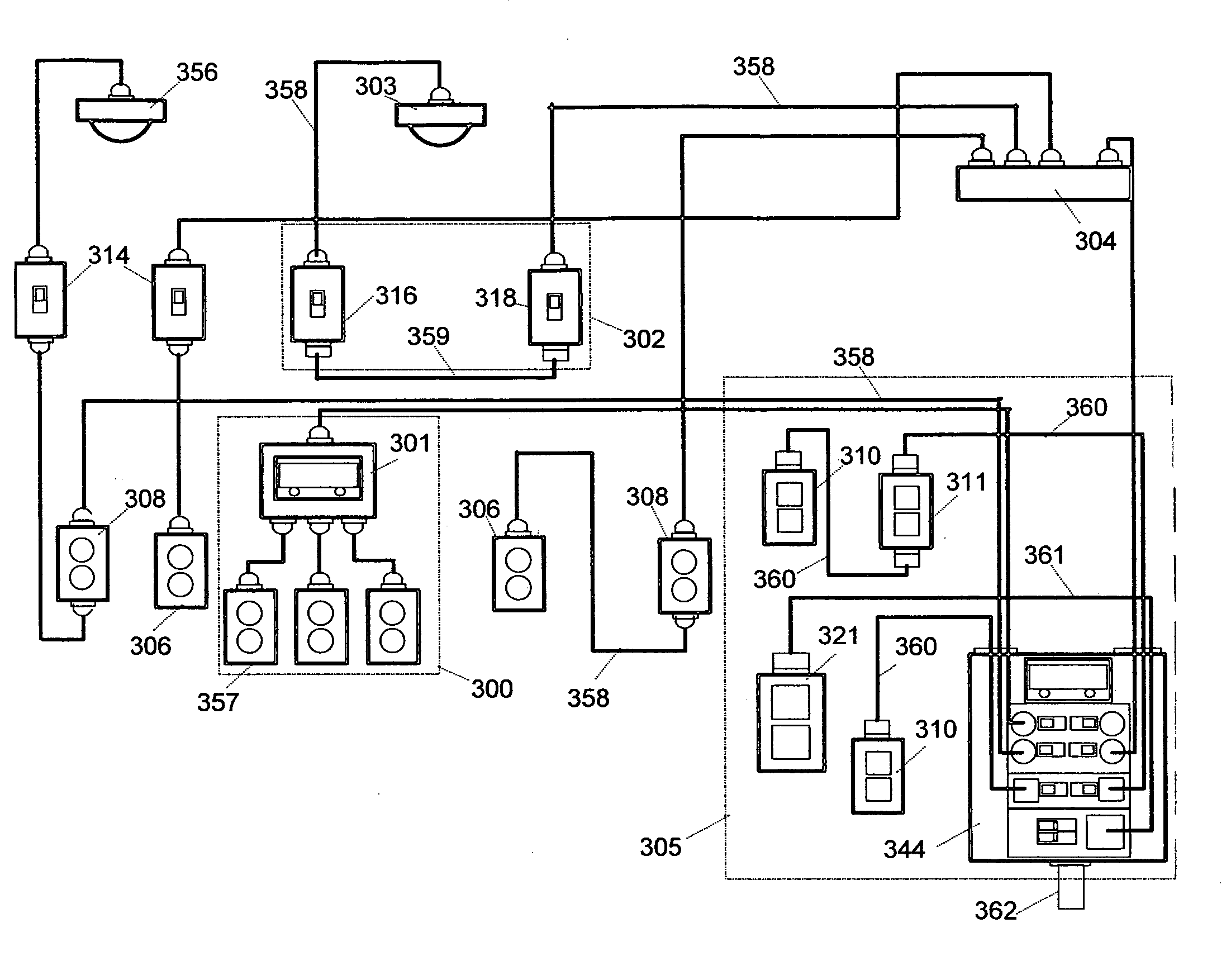

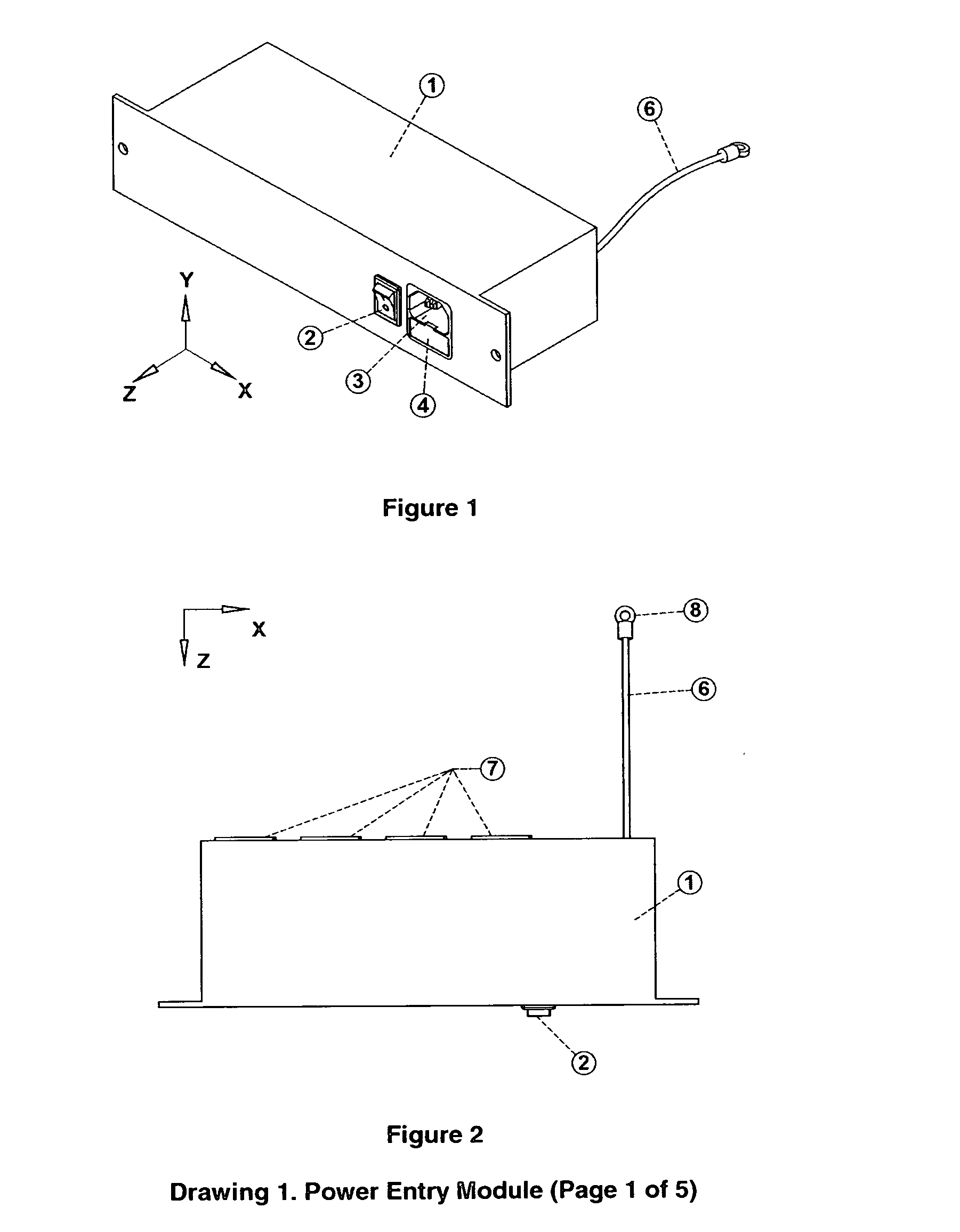

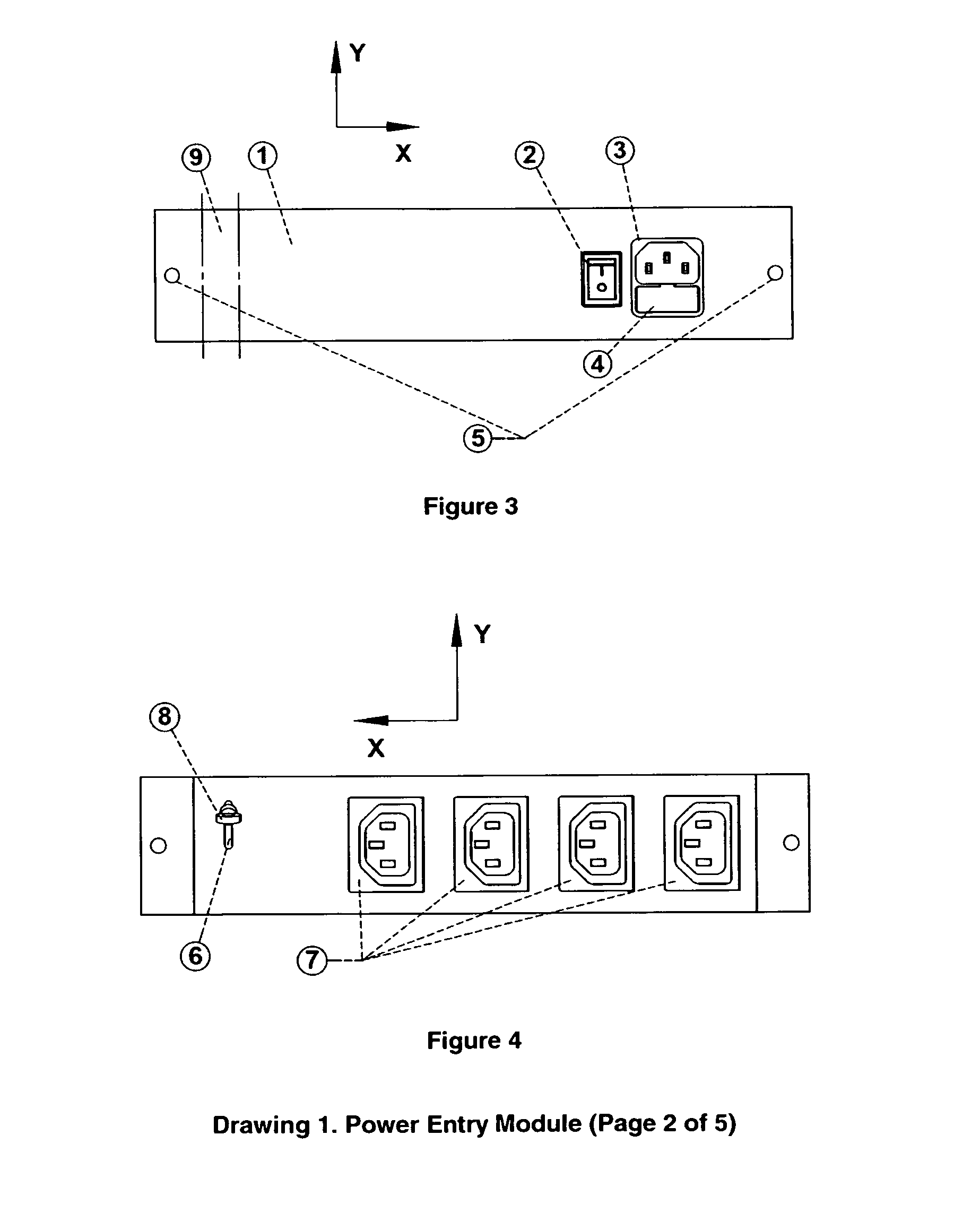

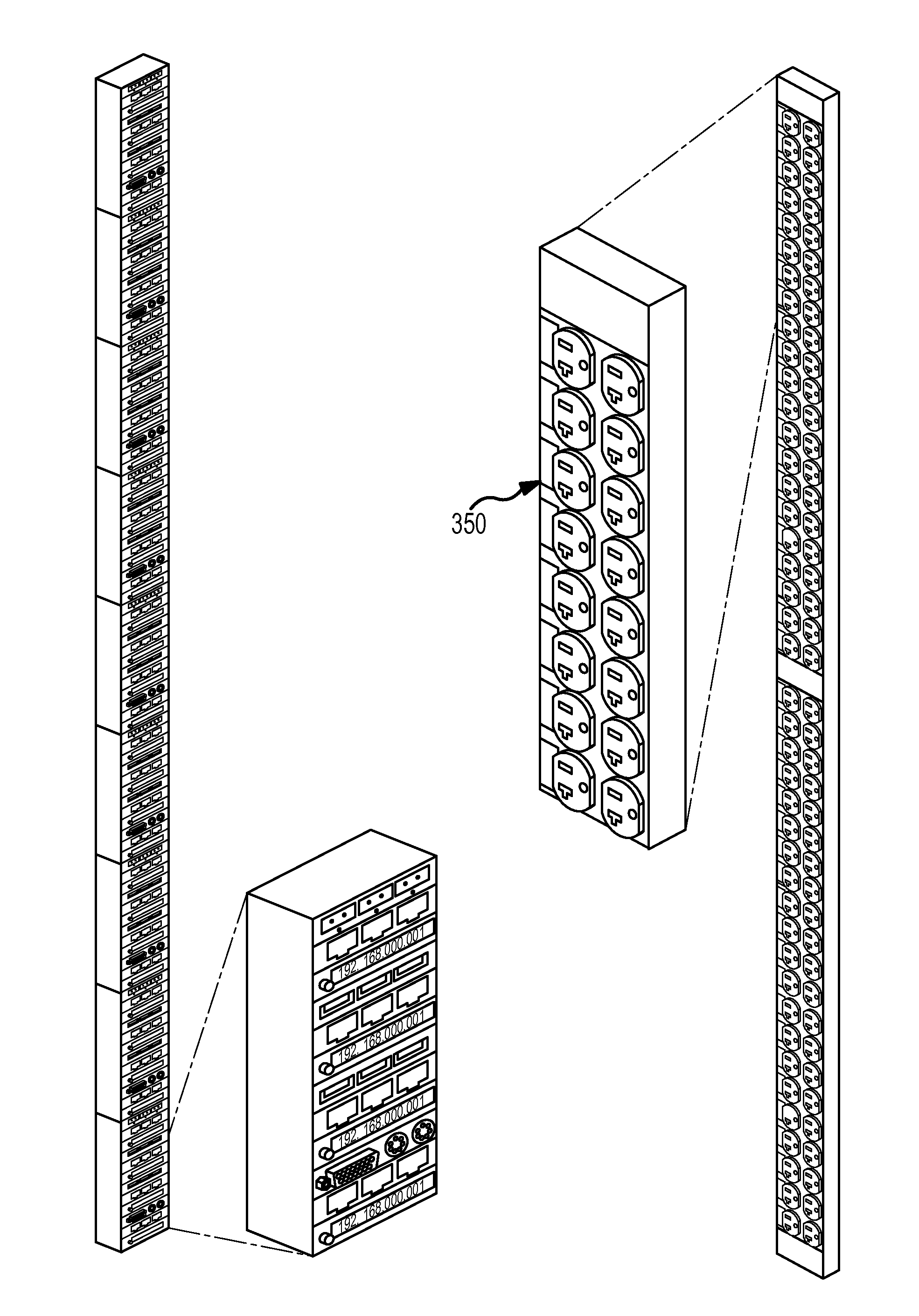

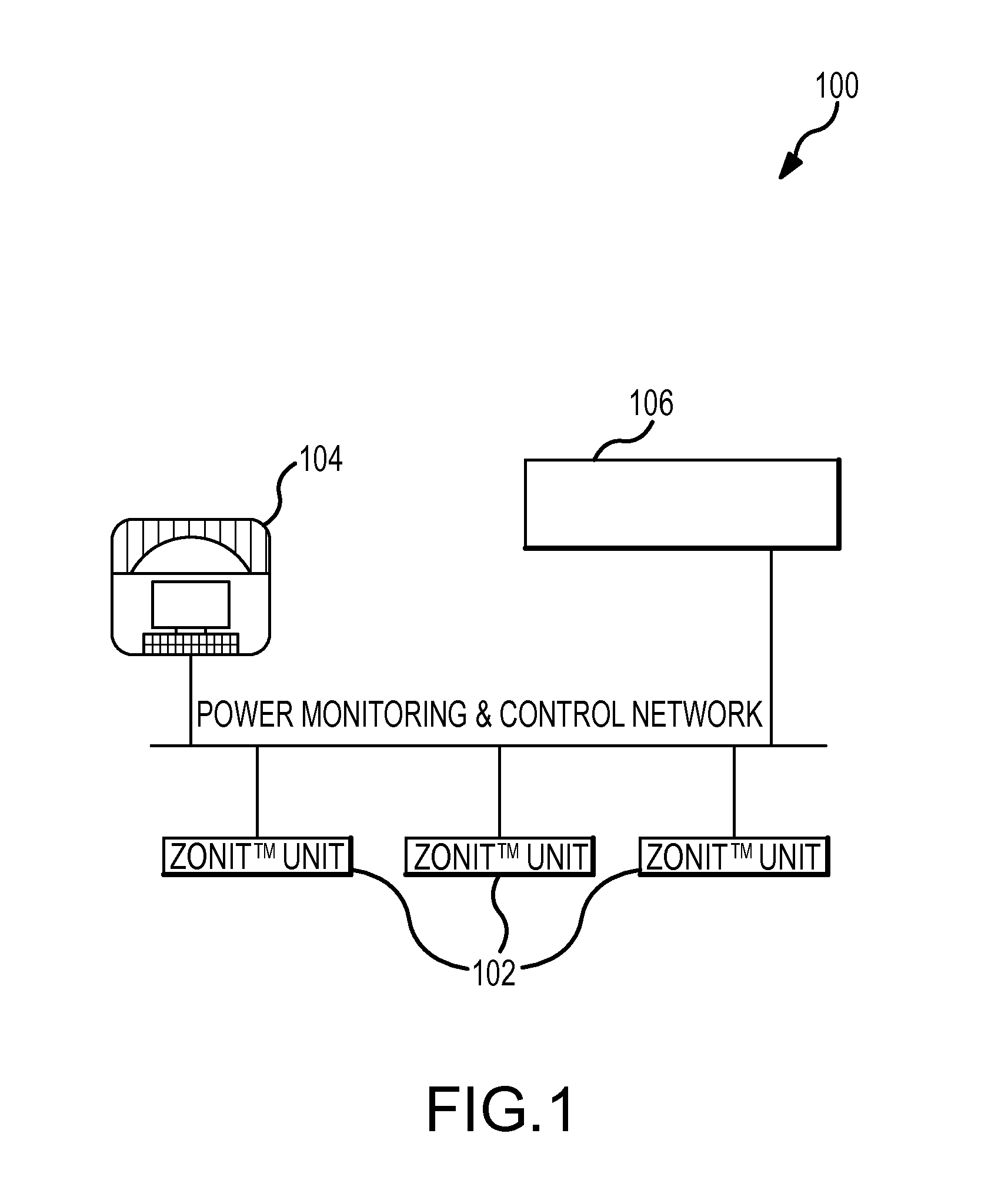

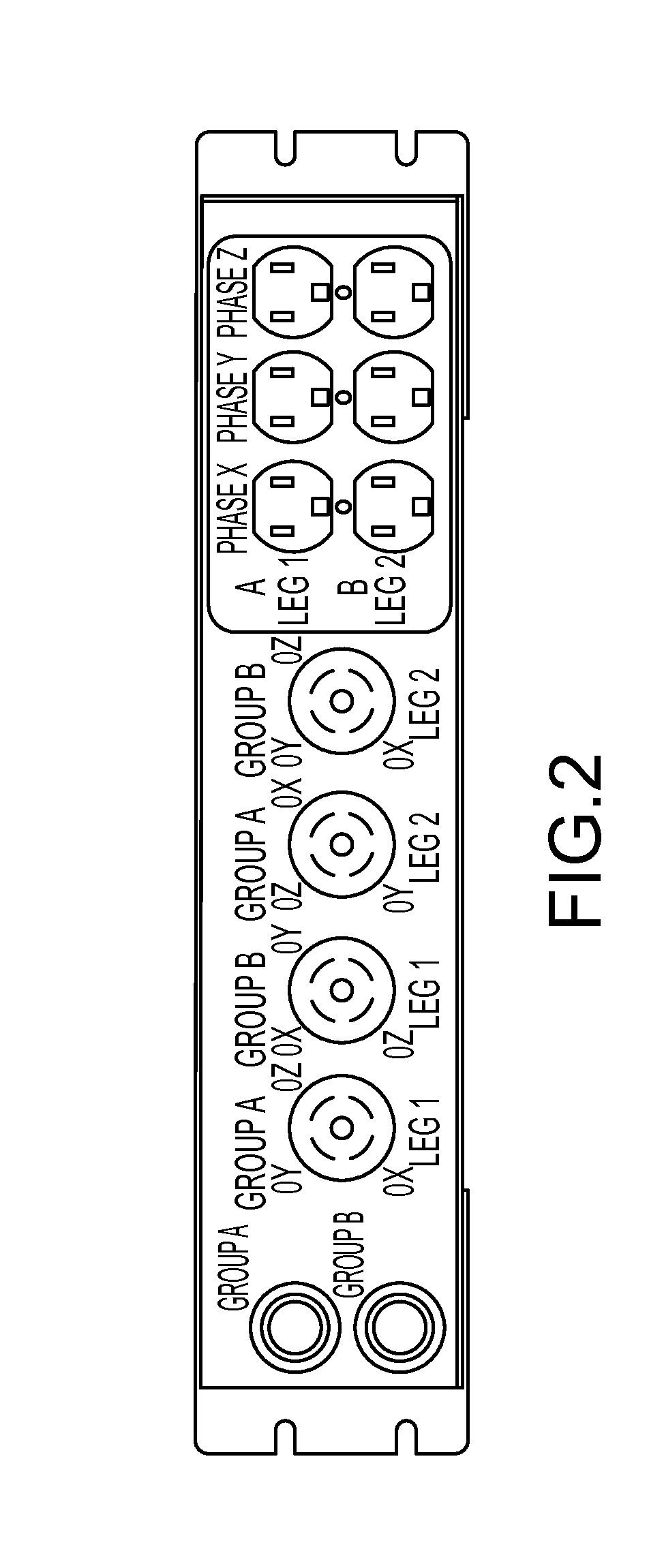

Power distribution systems and methodology

InactiveUS20120092811A1Little and no down timeEffectively and accurately executedCoupling device connectionsBoards/switchyards circuit arrangementsData centerDistribution power system

The invention addresses the needs associated with the entire data center power distribution lifecycle—design, build, operation and upgrades. The design and construction is facilitated by a system for prefabricating power whips that accommodate changing data center needs. The invention also allows for upgrading power supply components without powering down critical equipment. Improved power and network strips and associated logic further facilitate data center operation.

Owner:ZONIT STRUCTURED SOLUTIONS LLC

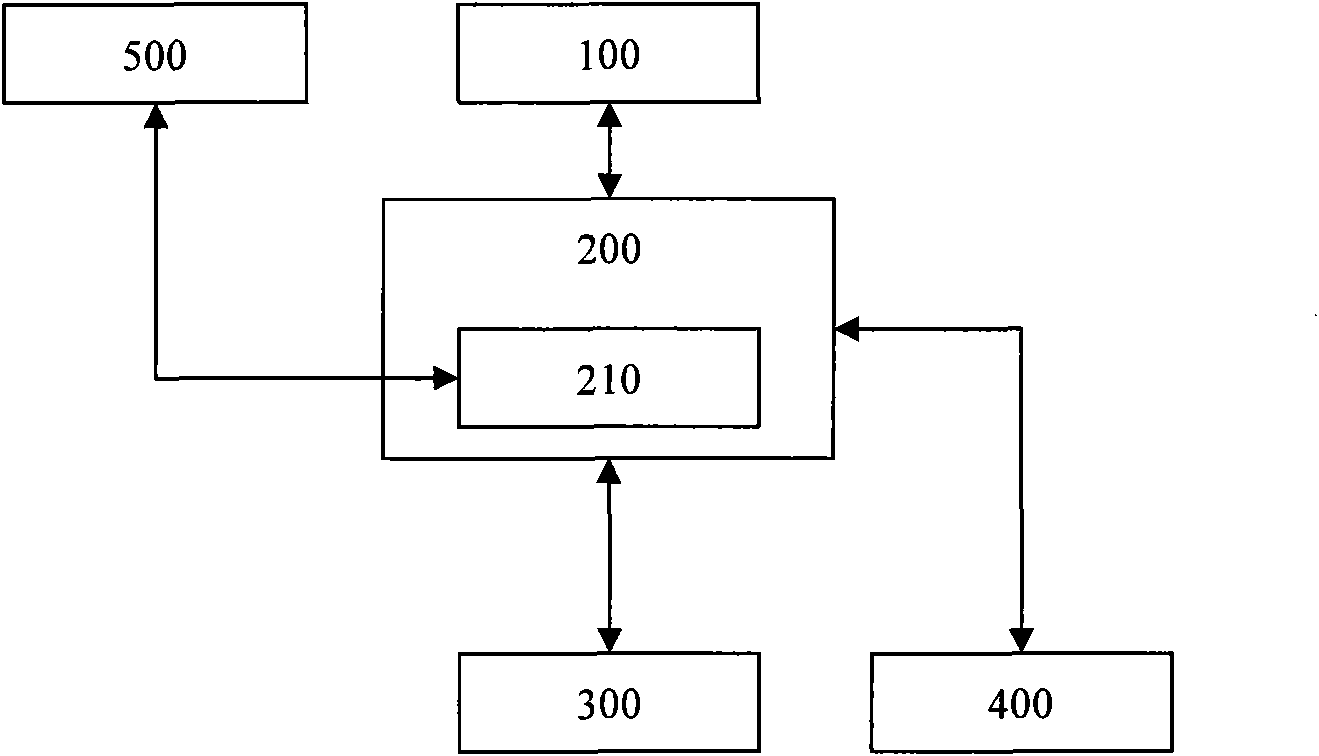

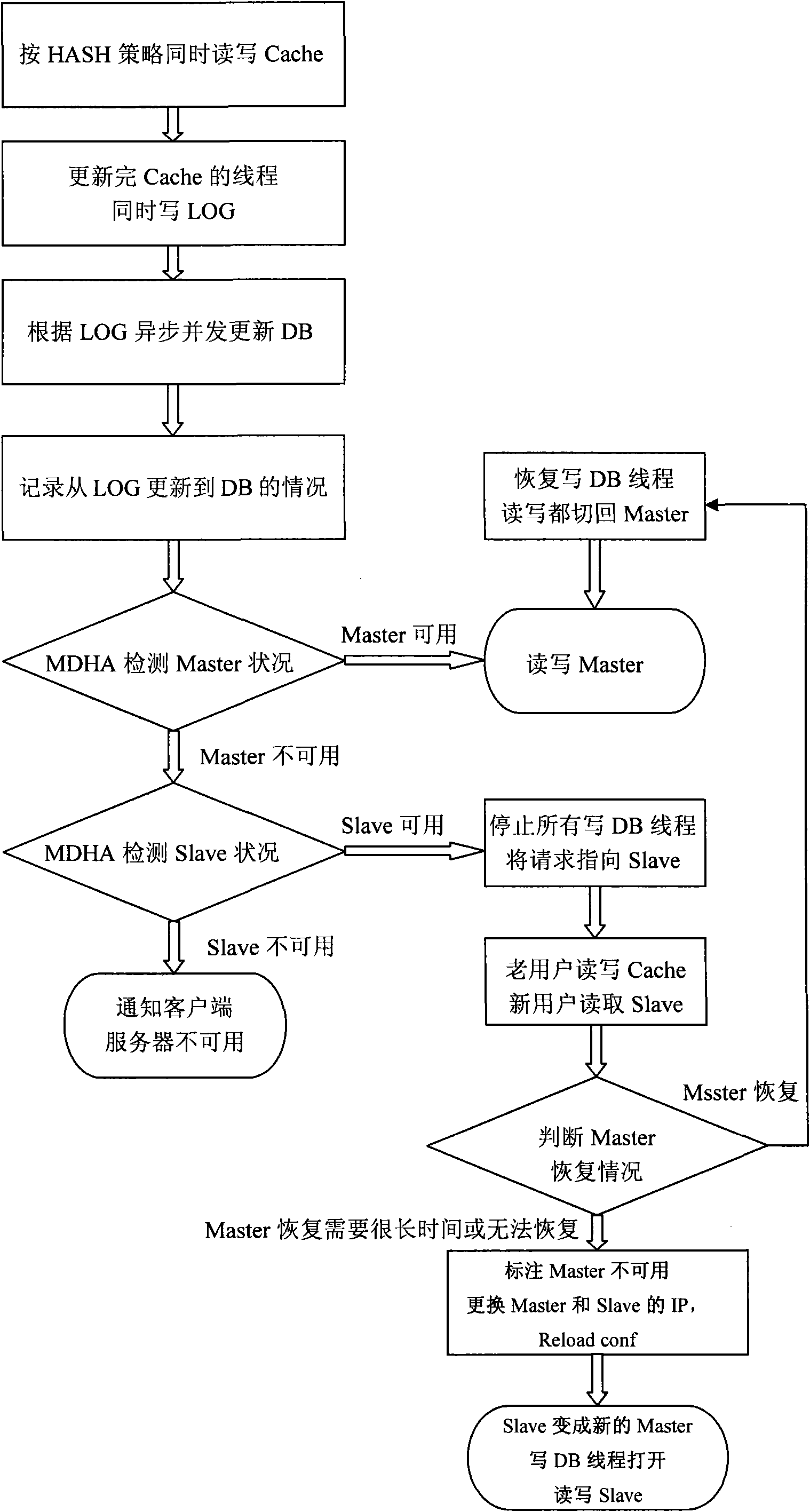

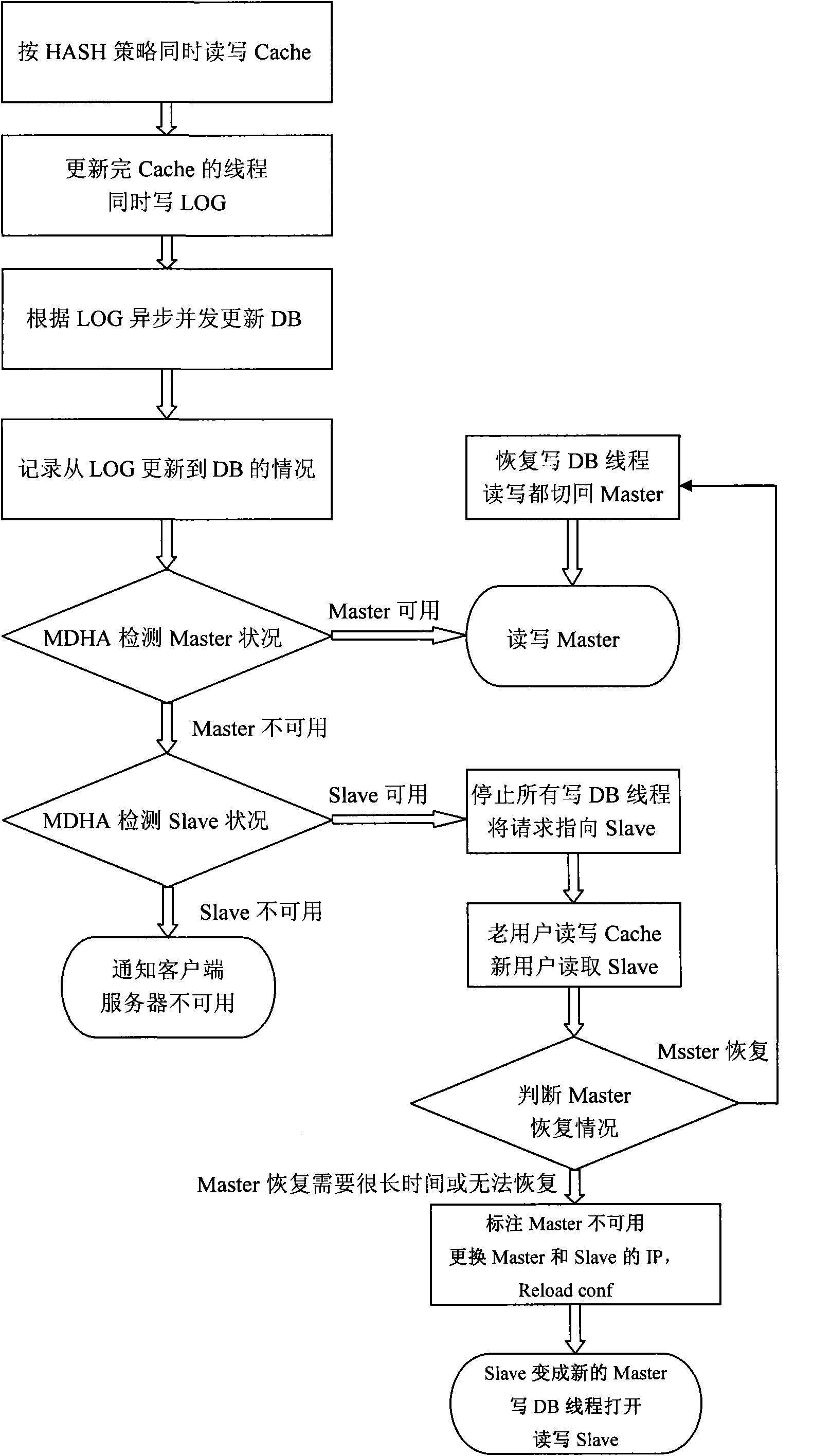

Database fault automatic detection and transfer method

ActiveCN101876924AGuarantee continuityImprove reliabilityRedundant operation error correctionSpecial data processing applicationsSQLDatabase server

The invention discloses a database fault automatic detection and transfer method which is configured with a client (100), a cache memorizer (200), an MDHA module (210), a management terminal (500) and a plurality of database server groups (300 and 400), and comprises the main steps that each database server group is divided into a master server (300) and a slave server (400); the MDHA module (210) is arranged between the client (100) and a database and is used for detecting the database; when the client connection is started, a detection thread is set up; when in running, the client (100) can be used for detecting the master server (300) through the MDHA module (210); when the master server (300) is detected to be abnormal, the MDHA module (210) leads the access of the client to be automatically switched into the slave server; and when the master server is recovered, intermediate leads the access of the client to be switched into the master server. The method can be applied into a small and medium size data base management systems adopting a My SQL system, can guarantee the continuity of the service operation of a network server, and improves the reliability.

Owner:上海黑桃互动网络科技股份有限公司

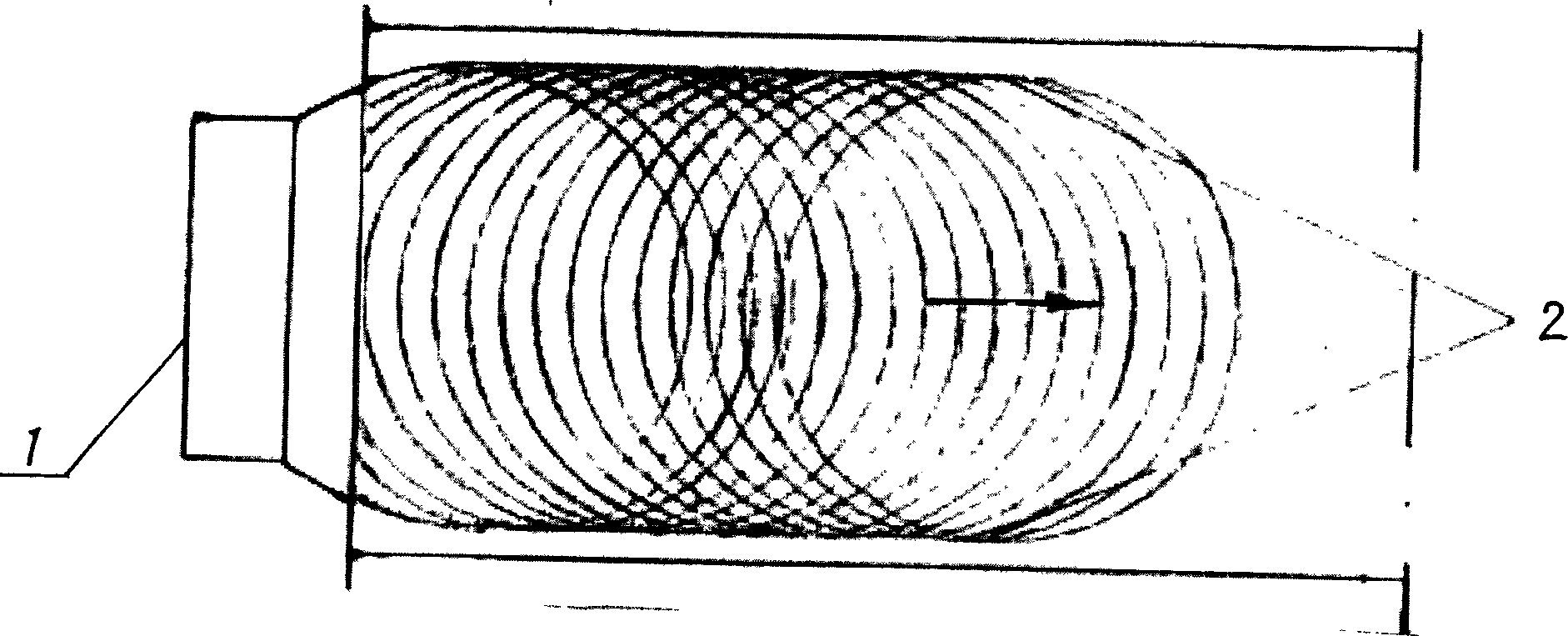

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1603021AControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsForced-airEngineering

The invention simultaneously solves building the contact organization, the performance is uneven question. The invention has provides a kind of gas spray cooling system and the method, namely after the spinning machine, style touches in front of the air blower a section of air cooled table place above, two sides symmetrical establishes the gas spray chiller, first builds above the contact from the coil, key to builds the contact to leave the atomization to cool, then style touches the forced-air cooling line again from the underneath forced-air cooling, and uses the' good spirit installment concentratly blowing the contact place. The intensity difference between the line material build contact through the gas spray cooling system and the no build contact is fall to 5~7MPa; The overall intensity of the line material may enhance 20~25MPa; Improves the surface quality; Simultaneously decreases the ambient temperature, improves the operating environment.

Owner:UNIV OF SCI & TECH LIAONING

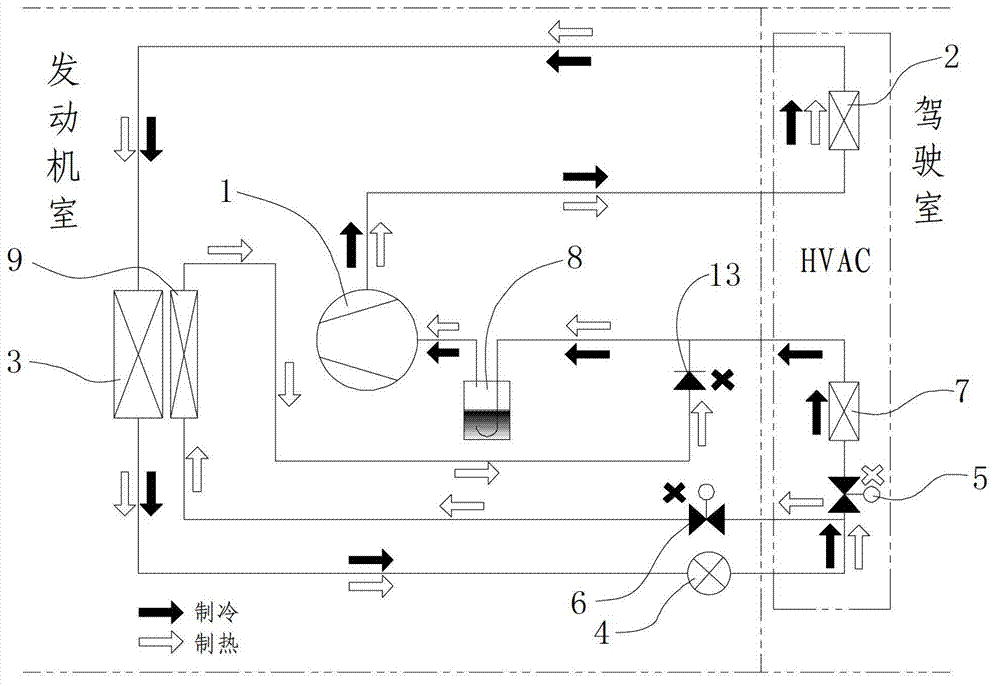

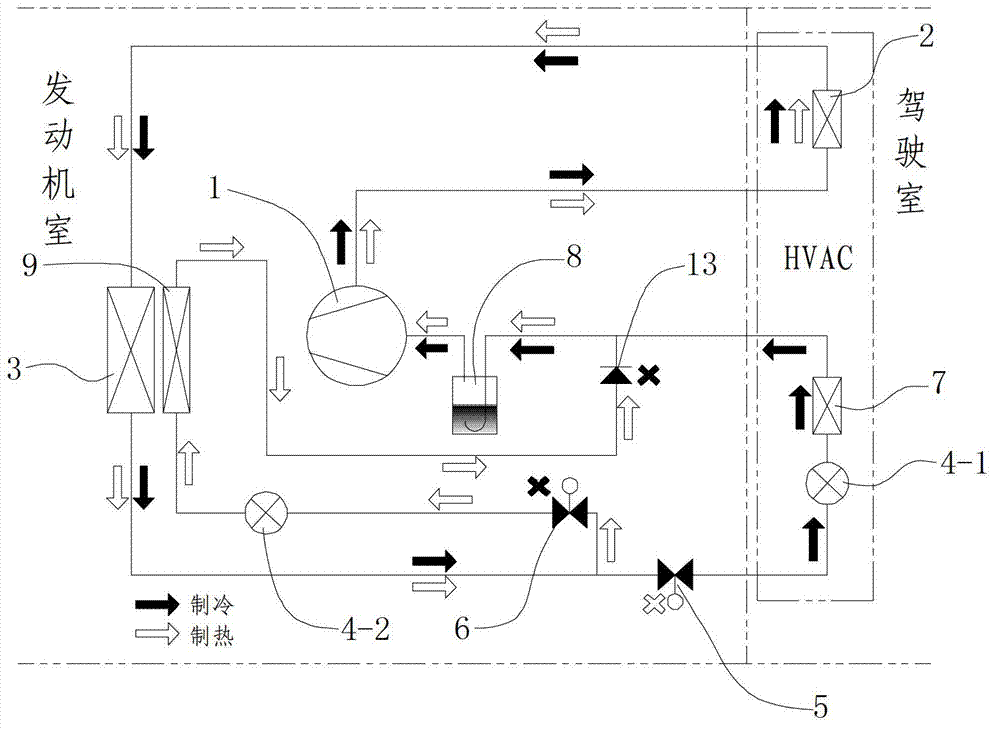

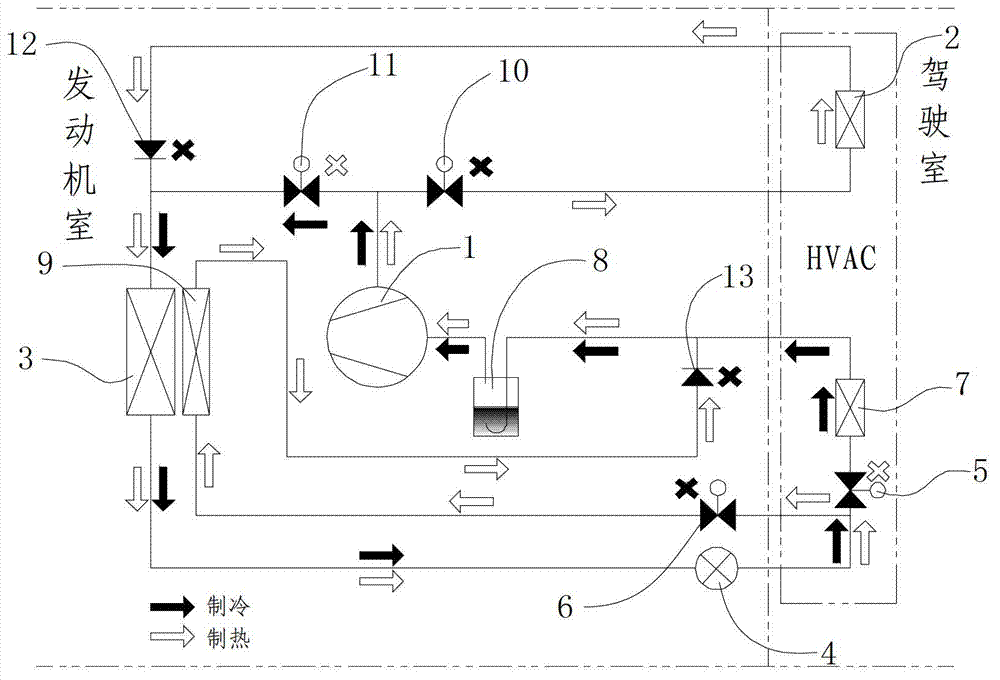

Heat pump air-conditioning system of electric vehicle

InactiveCN102788397AImprove the operating environmentIncrease temperatureEfficient regulation technologiesSpace heating and ventilation detailsElectric vehicleEvaporator

The invention relates to a heat pump air-conditioning system of an electric vehicle. The heat pump air-conditioning system comprises a compressor, a condenser inside the vehicle, a condenser outside the vehicle, expansion valves, a first stop valve, a second stop valve, an evaporator inside the vehicle and a liquid and gas separator. The heat pump air-conditioning system is characterized by further comprising an evaporator outside the vehicle. A first stroke section is formed between an outlet of the compressor and an inlet of the condenser outside the vehicle, and the condenser inside the vehicle is serially connected onto the stroke section; a second stroke section is formed between an inlet and an outlet of the condenser outside the vehicle; a third stroke section is formed between an outlet of the condenser outside the vehicle and an inlet of the liquid and gas separator and comprises a first branch and a second branch, the first stop valve and the evaporator inside the vehicle are serially connected to form the first branch, the second stop valve and the evaporator outside the vehicle are serially connected to form the second branch, and the expansion valves are arranged at front ends of the two evaporators; and a fourth stroke section is formed between the inlet and an outlet of the liquid and gas separator. The evaporator outside the vehicle is arranged behind the condenser outside the vehicle, heat discharged from the condenser outside the vehicle is transferred to the evaporator outside the vehicle, so that the temperature of the periphery of the evaporator outside the vehicle is increased, and working conditions at the temperature below minus 5 DEG C are met.

Owner:TIANJIN SANDEN AUTO AIR CONDITIONING

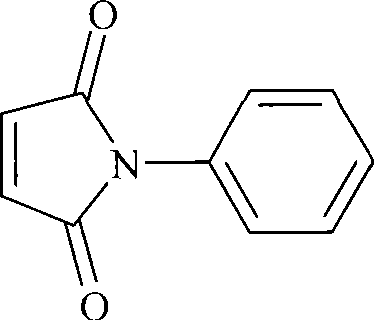

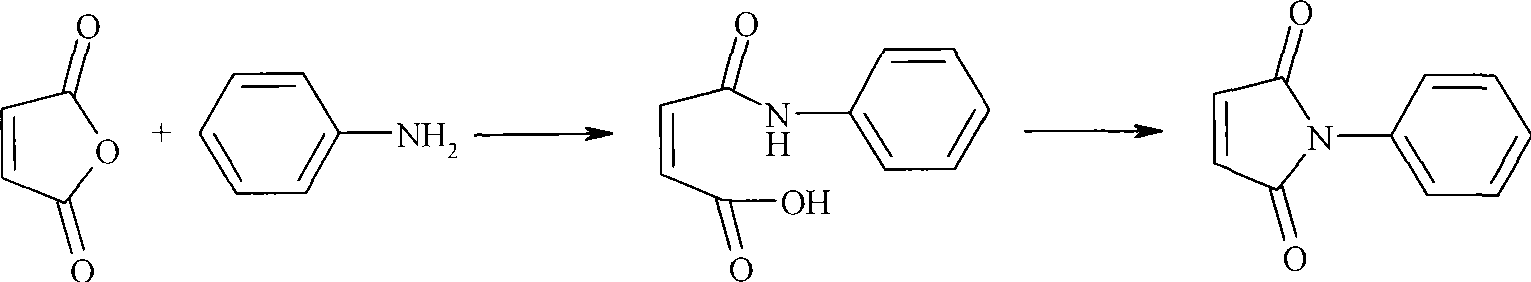

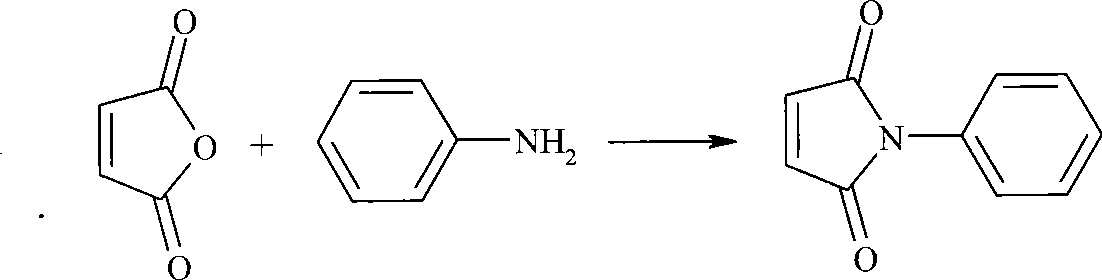

Preparation of N-phenyl maleimide

The invention discloses a method for preparing N-benzyl maleimide which adopts maleic anhydride and aniline as raw materials to take imidation reaction in benzene reaction solvent in the presence of an inhibitor and a mixed dehydration catalyst to obtain the target product of the invention. The purity of the N-benzyl maleimide prepared by the one-step method of the invention reaches more than 98.5 percent, and the yield is 90-92 percent. Compared with the prior art, the method has the advantages of less reaction time, short period and safe and convenient operation. A post-processing method of directly drying out the solvent and recycling the solvent is adopted, so that the yield is improved, three wastes are reduced, the operational environment is improved and the quality of products is stable. The method is applied to the large-scale industrial production.

Owner:SHANGHAI HUAYI GRP CO

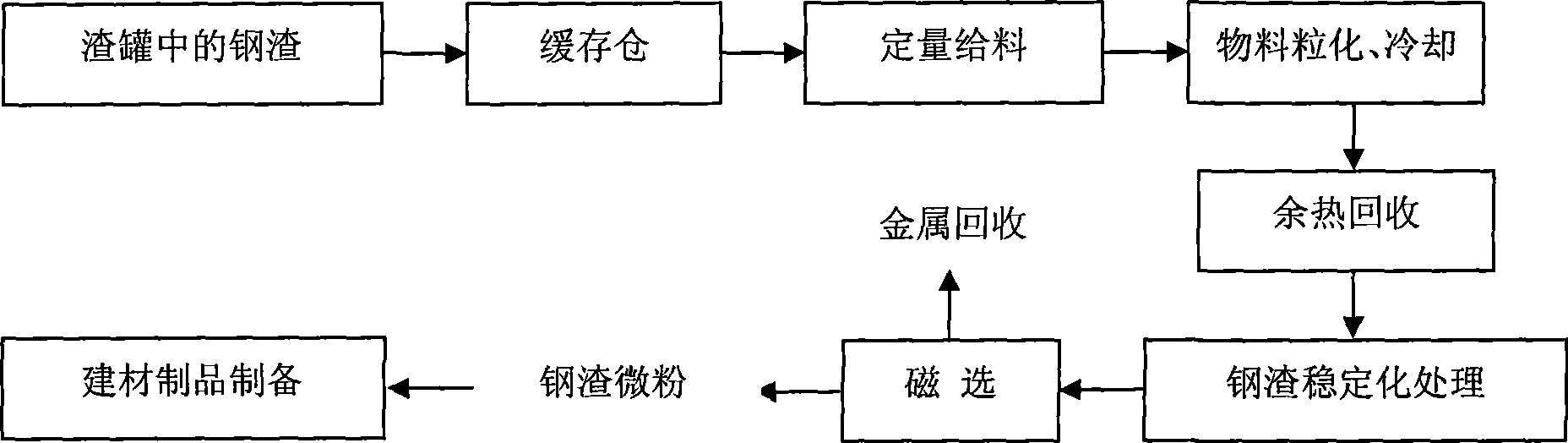

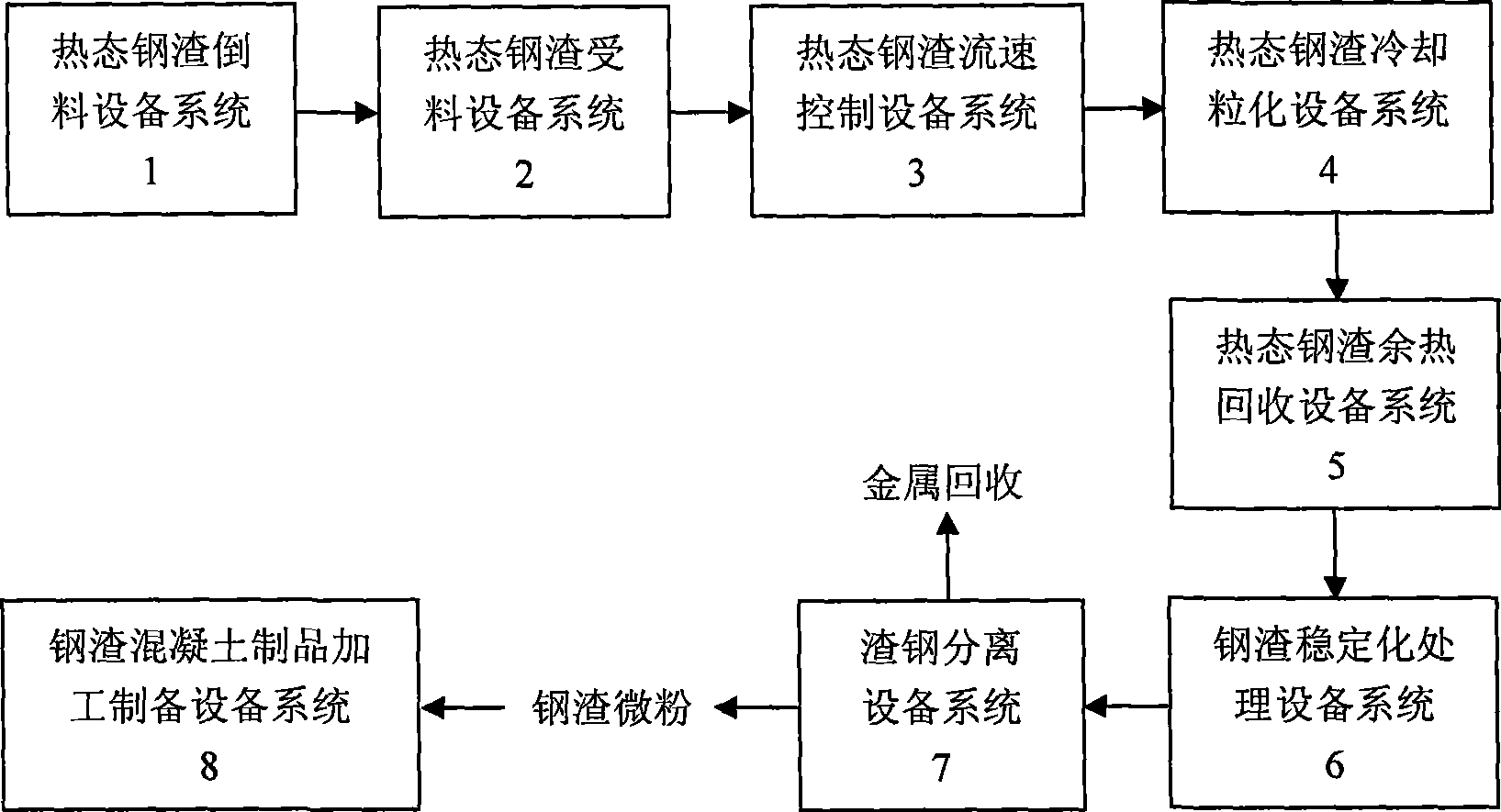

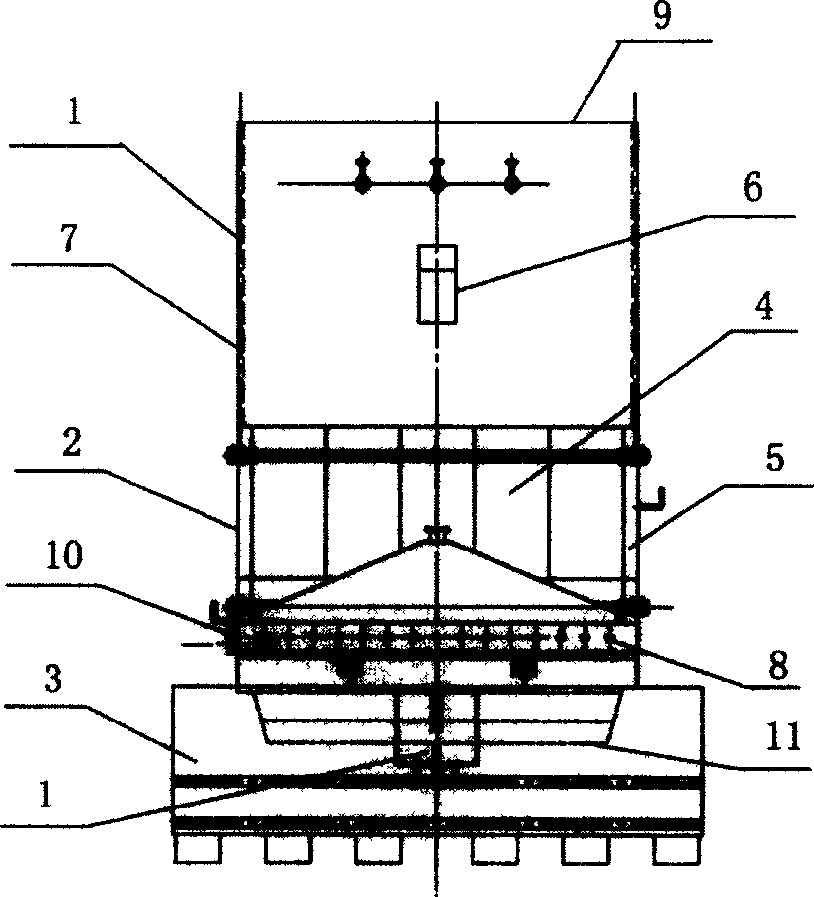

Method for recovery of waste heat of steel slag and comprehensively processing and utilizing steel slag

InactiveCN101413037AAvoid water explosionImprove energy efficiencyIncreasing energy efficiencyRecycling and recovery technologiesThermal stateSlag

The invention provides a mehtod for recovering waste heat of steel slag and comprehensively processing and using the steel slag, and belongs to the technical field of steel slag treatment. The method comprises the following steps: a thermal state steel slag material discharging system discharges steel slag into a thermal state steel slag material receiving system for primary crushing; the crushed steel slag is subjected to secondary crushing by a thermal state steel slag velocity control system and quantificationally fed into a thermal state steel slag cooling granulating system for re-crushing and cooling, high-temperaure hot air generatd in the cooling process is collected by a thermal state steel slag waste heat recovery system and enters a heat exchange system to form vapor for power generation or heat supply; the cooled steel slag enters a steel slag stabilizing treatment system, and the steel slag after the stabilizing treatment is treated by a steel slag separation system to obtain steel slag tailing micropowder and metal slag steel respectively; and, the steel slag micropowder is mixed with other materials and used to prepare concrete products by a steel slag concrete product processing preparation system. The method has the advantages of adaptability to various types of steel slag to be processed, good operational environment and no secondary pollution.

Owner:SHOUGANG CORPORATION

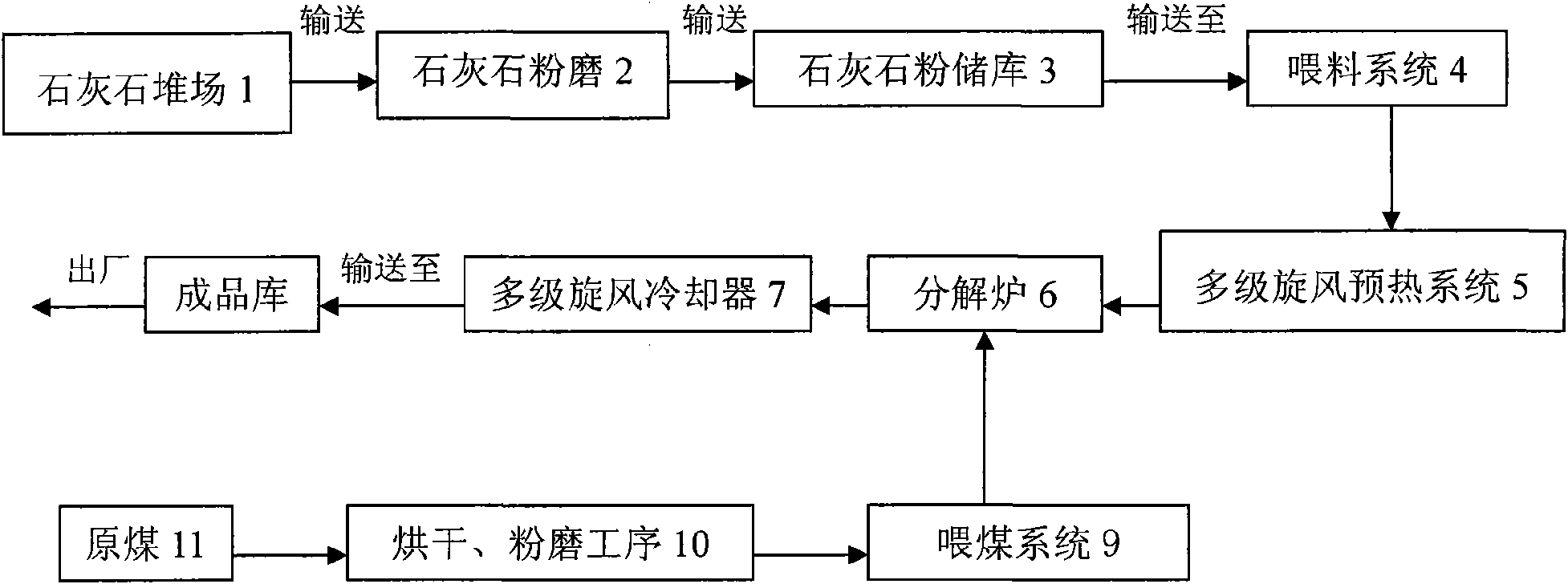

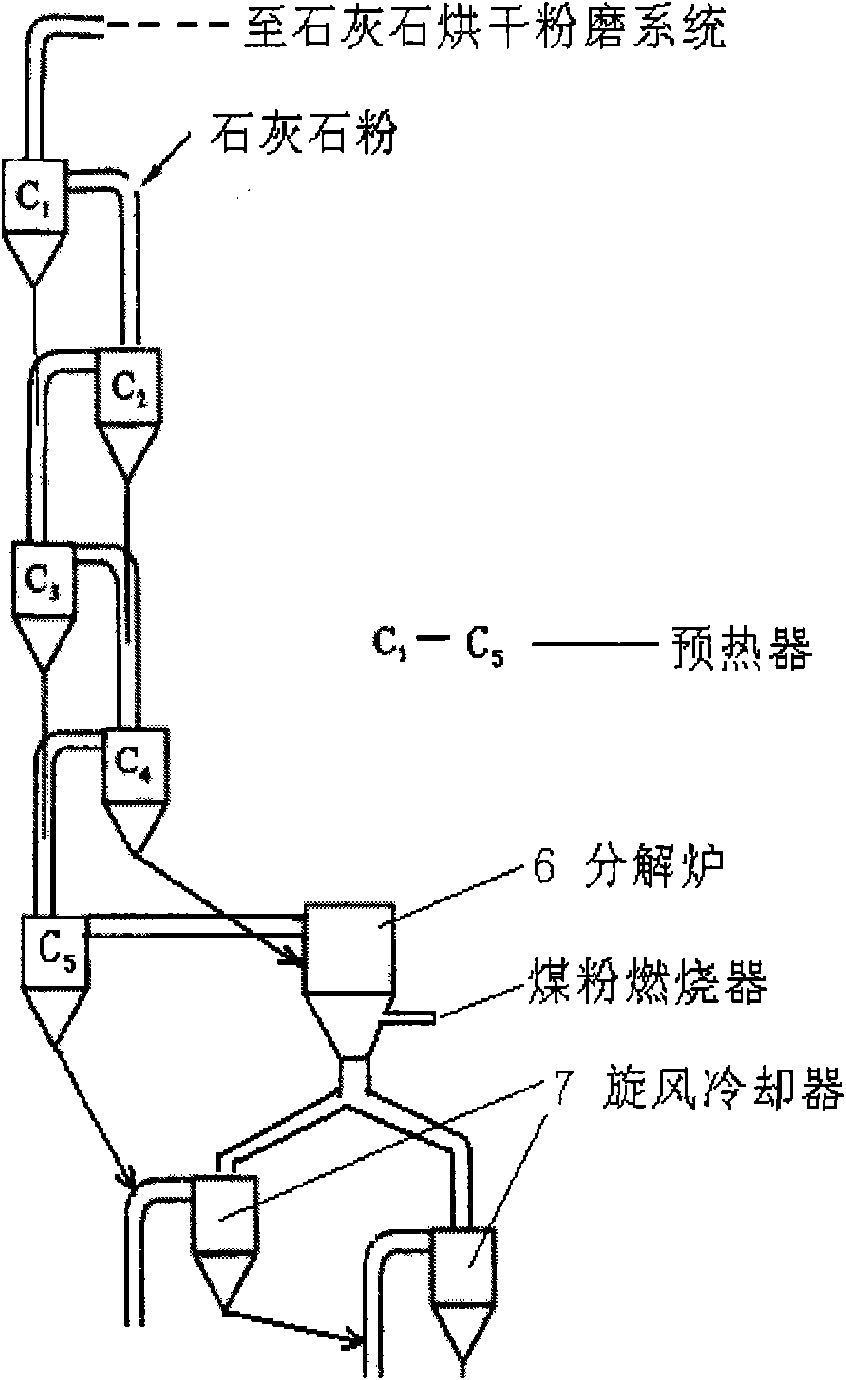

Calcination process of active lime

The invention discloses a calcination process of active lime. The calcination process adopts a preheating-suspension calcination device comprising a multi-stage cyclone preheating system, a decomposing furnace and a multi-stage cyclone cooler. The calcination process is characterized in that limestone powder which is broken and homogenized into blocks is ground into fine powder, the fine powder is placed in a storage tank for homogenization, then preheated by the multi-stage cyclone preheating system and sent to the decomposing furnace for calcination, thereby preparing the active lime, and the active lime is further cooled by the multi-stage cyclone cooler for obtaining the active lime; wherein the main control temperature of the decomposing furnace is 850-950 DEG C; and the calcination time is 3-5 seconds. The calcination process utilizes the preheating-suspension calcination reaction method for calcining the active lime, and fuel can use low-grade fuel-biluminous coal. Compared with the traditional process, the calcination time is short, the effective utilization rate of the lime product is high, the product quality is stable, the energy consumption is low, and a production region has no environmental pollution; meanwhile, the calcined active lime is the fine powder, the use is very convenient, and the range of applications is broader in comparison with the active lime calcined by the traditional process, thereby being conductive to promotion and implementation.

Owner:BEIJING LIULIHE CEMENT

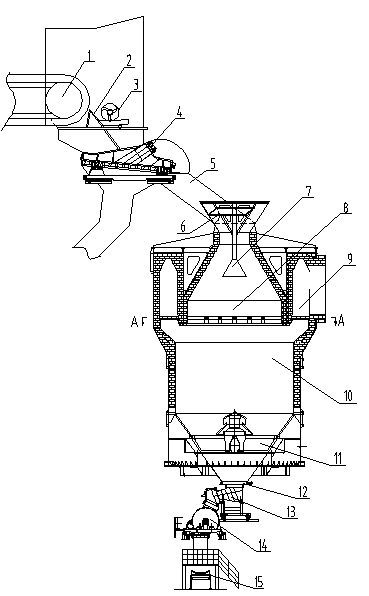

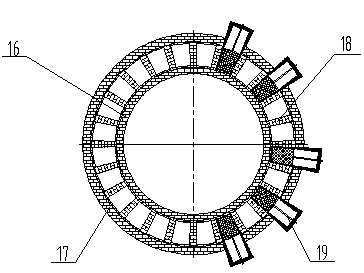

Sintering furnace type cooling device

ActiveCN103234359AReduce height differenceImprove qualityHandling discharged materialThermal energyFlue gas

A sintering furnace type cooling device relates to the technology field of sintering cooling devices. An outlet of a sintering machine is provided with a single roll crusher; an outlet of the single roll crusher is provided with a hot sinter screen; the hot sinter screen is connected with an inlet of a chute; an outlet of the chute is connected with a furnace opening of a cooling furnace; a distributing device is arranged inside the furnace opening of the cooling furnace; a ventilation device is arranged at the bottom of the cooling furnace; a discharging device is connected under the ventilation device; a belt conveyer is arranged under the discharging device; the cooling furnace comprises a pre-store area which is arranged on the upper portion, a cooling area which is arranged on the lower portion and an annular flue area which is arranged on the periphery of the pre-store area; radial supporting columns which are integrally and radially distributed are arranged at the bottom of the annular flue area; a high-temperature flue gas adjustment plate is coated on two adjacent radial supporting columns; and the high-temperature flue gas adjustment plate is capable of sliding along a diametrical direction of the annular flue. The sintering furnace type cooling device has the advantages of effectively overcoming the defects that an existing sintering cooling system is serious in air infiltration and low in waste heat utilization rate, achieving efficient heat replacement, improving the temperature of the flue gas and reducing energy consumption in cooling.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

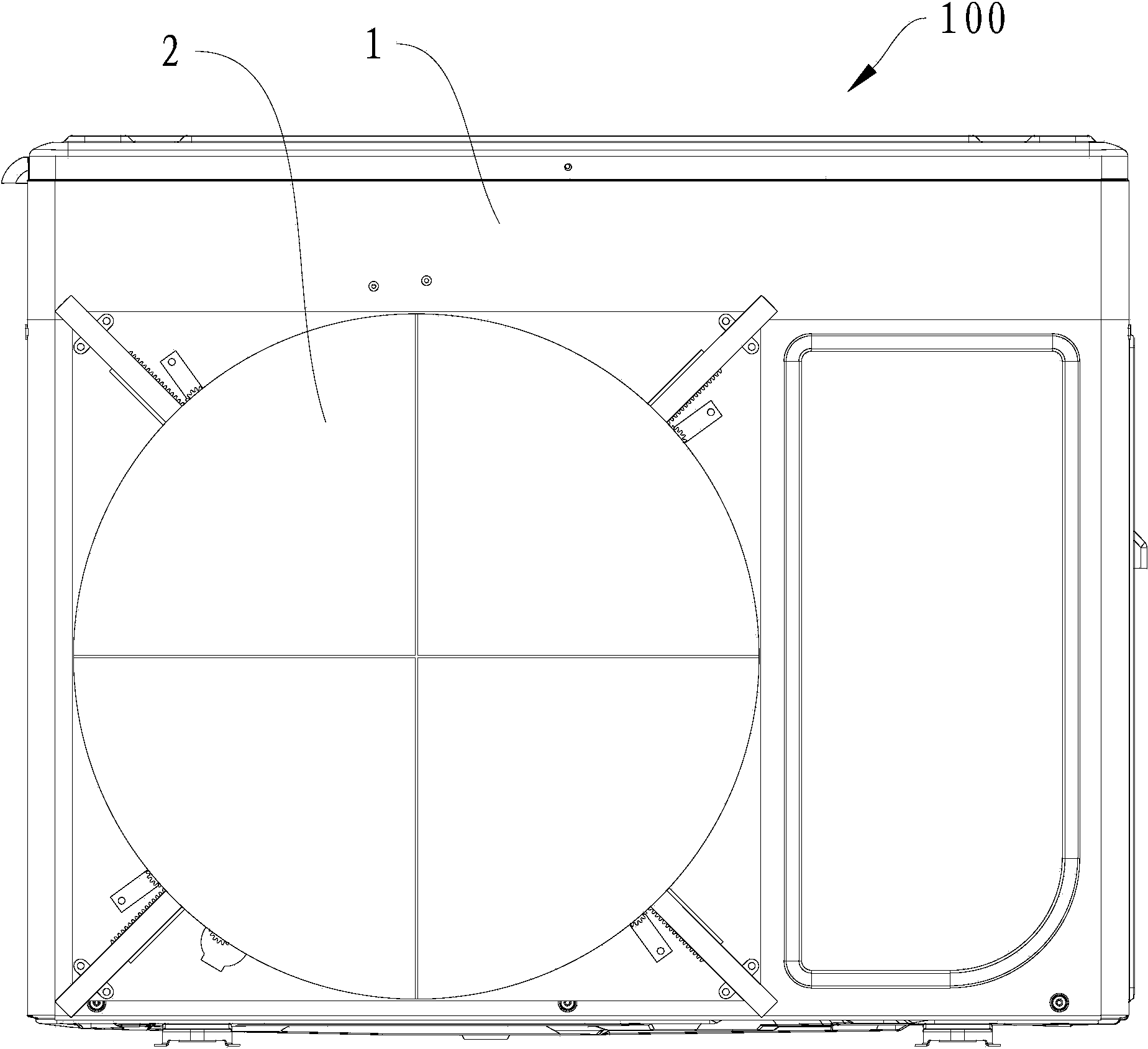

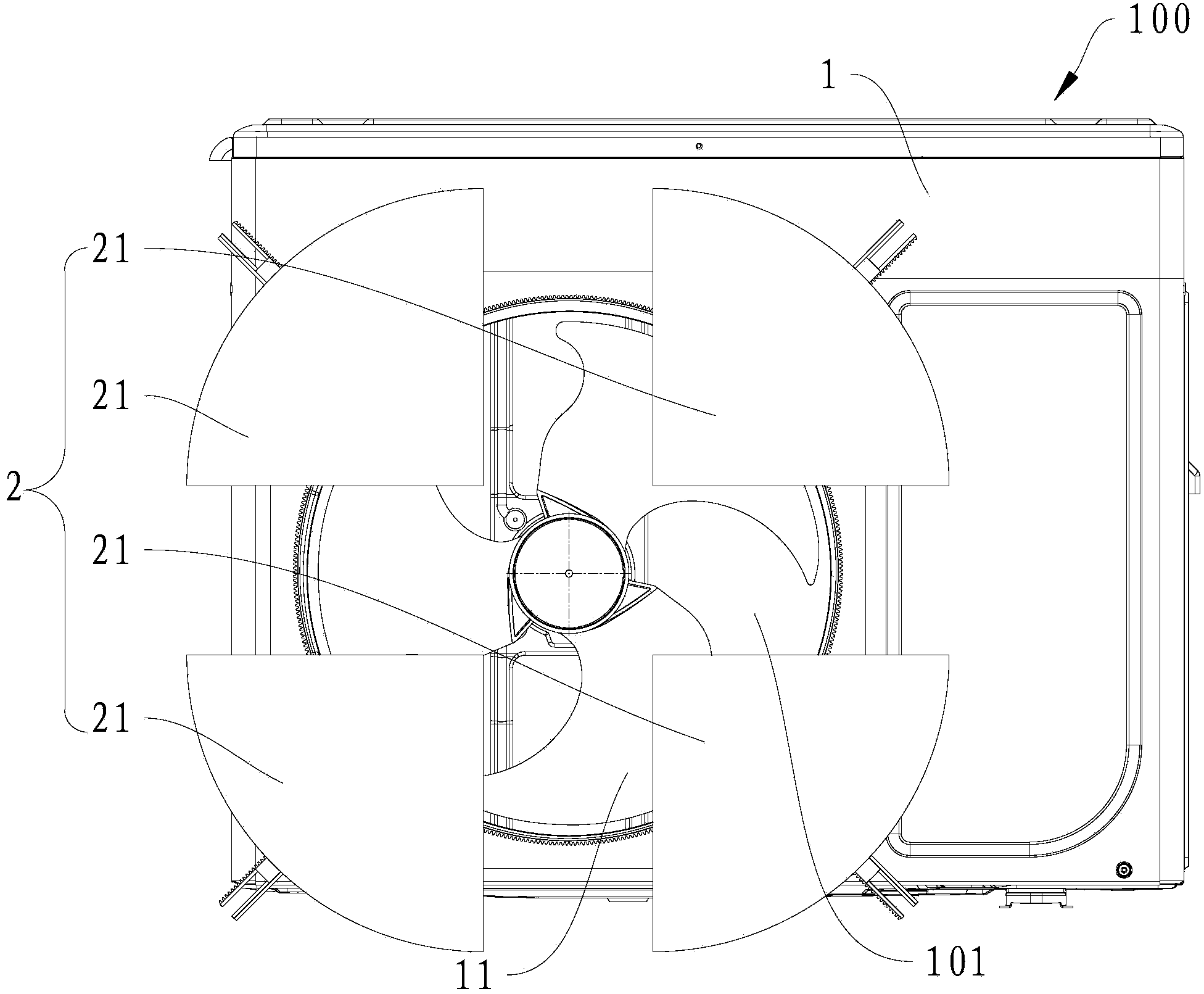

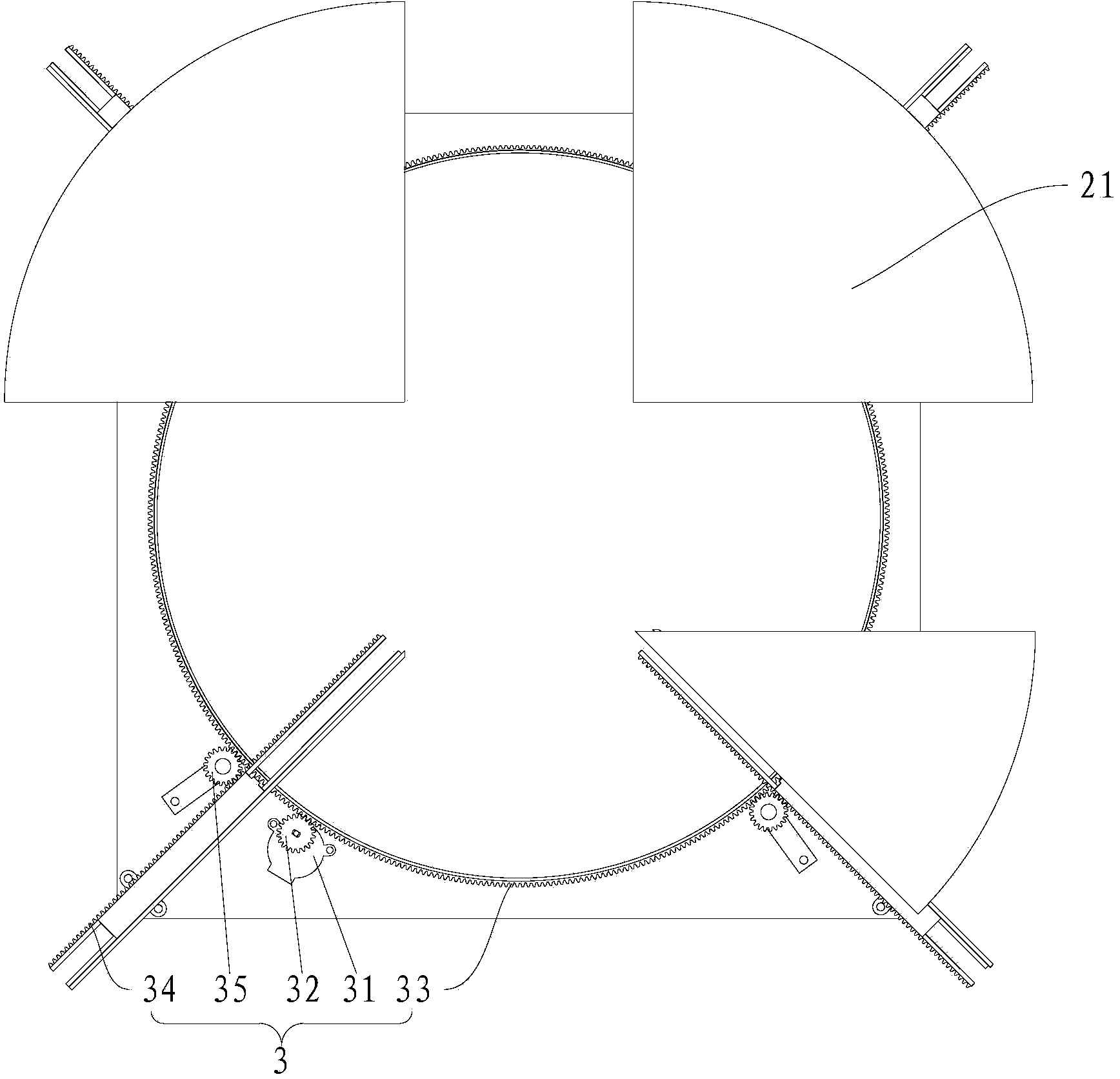

Outdoor unit of air conditioner and control method of same

ActiveCN104359164AExtended service lifeImprove securityMechanical apparatusSpace heating and ventilation safety systemsWaste management

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Automatic accurate weighing device for powdery material

InactiveCN101105409ANo leakageNo pollution in the processWeighing apparatus with automatic feed/dischargeMotor speedGrating

The invention discloses a powdery material accurate weighing device, which comprises a raw material tank and a weighing cup. The invention is characterized in that the feeding process is operated under vacuum, a high-level switch and a low-level switch are disposed above a vacuum intake tank, an auger conveying mechanism is disposed below the vacuum intake tank, the spiral pitch has two classes, the motor speed has two classes, a optical fiber grating pressure sensor is disposed below a weighing bunker, an automatic reverse turning bed is disposed in the weighing bunker, the signal from a material level switch and the optical fiber grating pressure sensor is transmitted to PLC, and the PLC outputs control signal to a motor of a vacuum pump, vacuum air passages and material control valves. The invention remarkably improves the weighing accuracy from above plus or minus 10 g error of the existing automatic weighing to within plus or minus 1 g error, even lower. It has the advantages of whole sealing operation under vacuum condition, no dust pollution, improved operating environment, accurate weighing, and good consistency. The invention is helpful for further improving the production quality of friction wafer product; and has high spreading and application values, and good market prospect.

Owner:李红

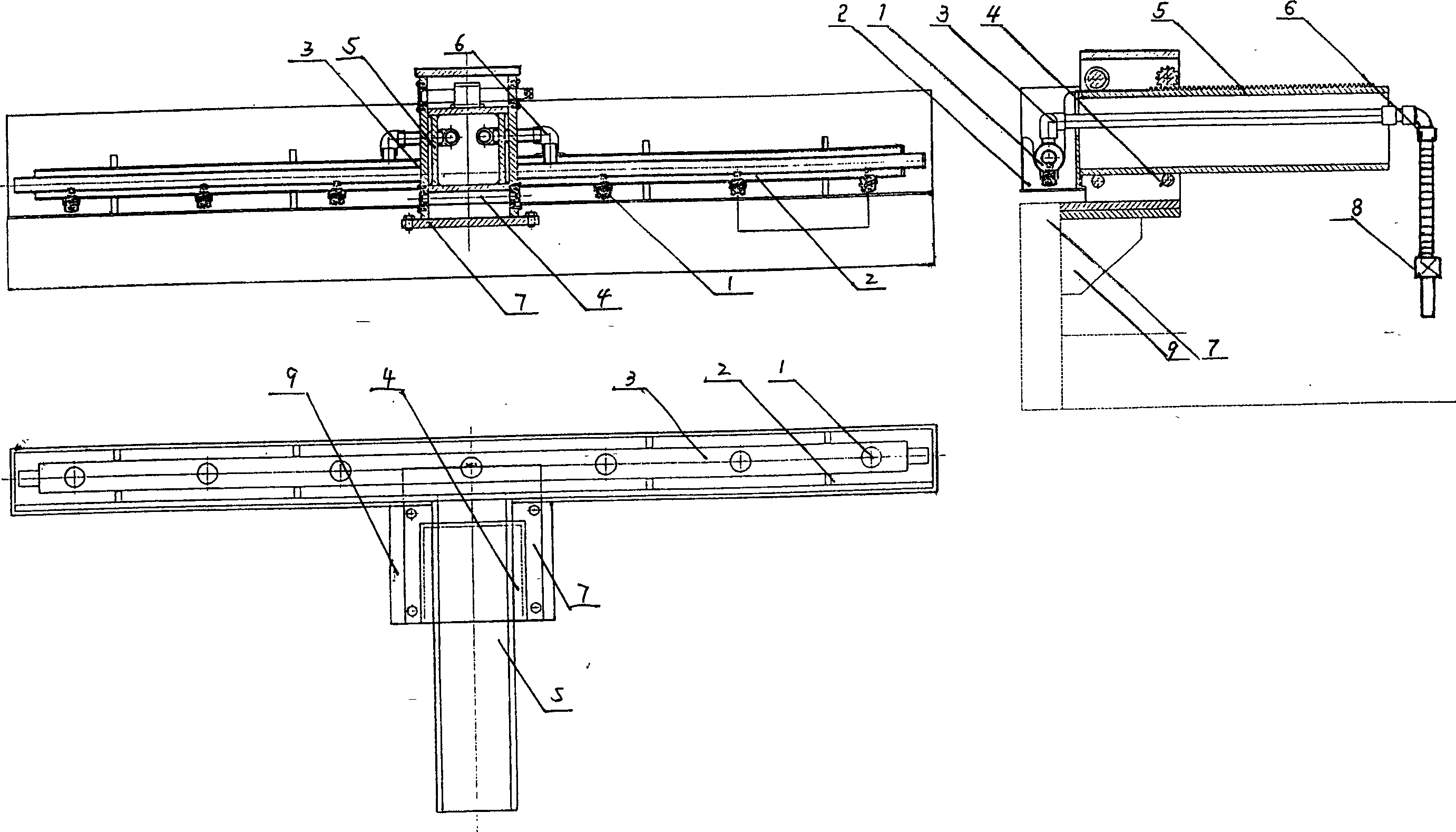

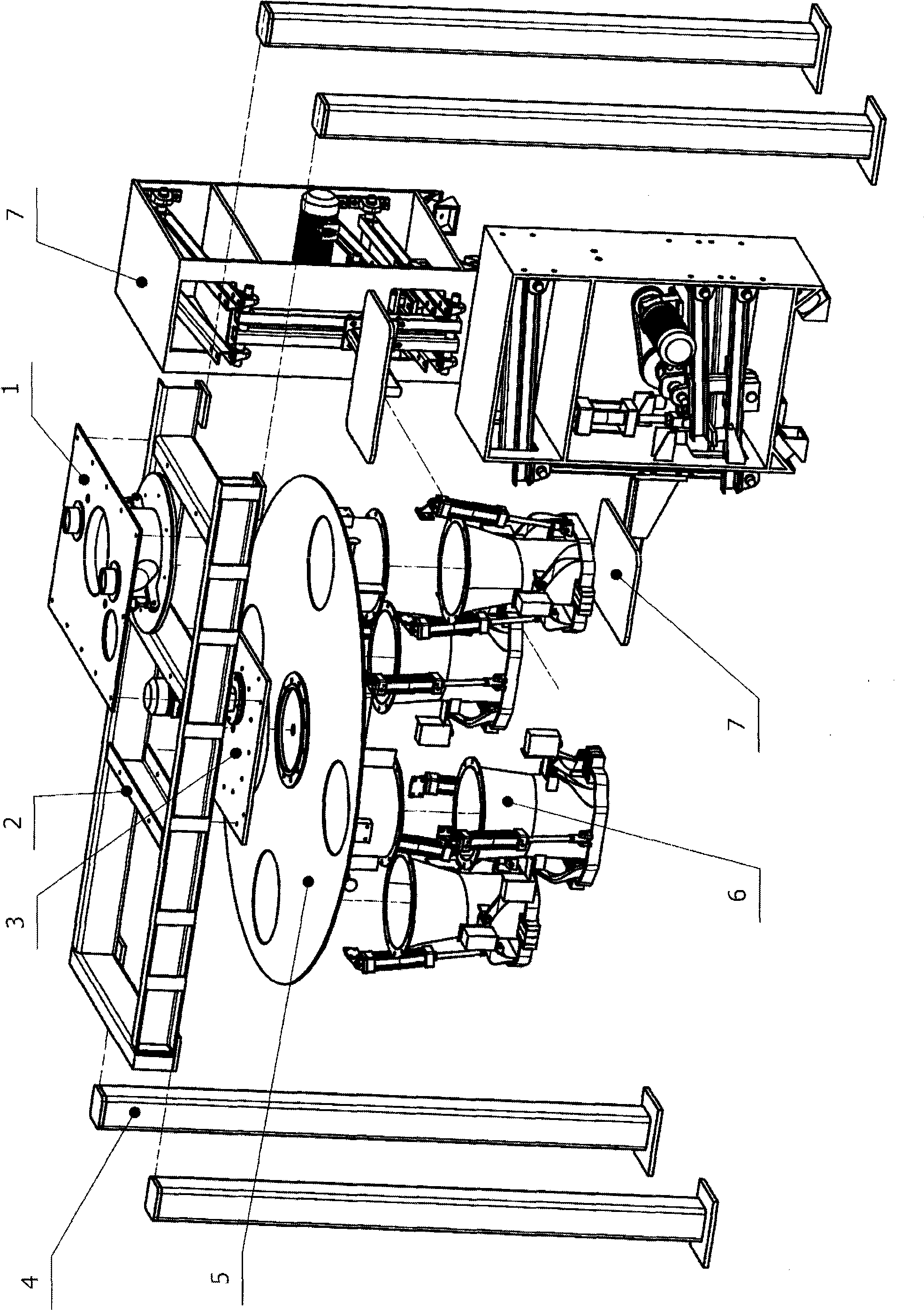

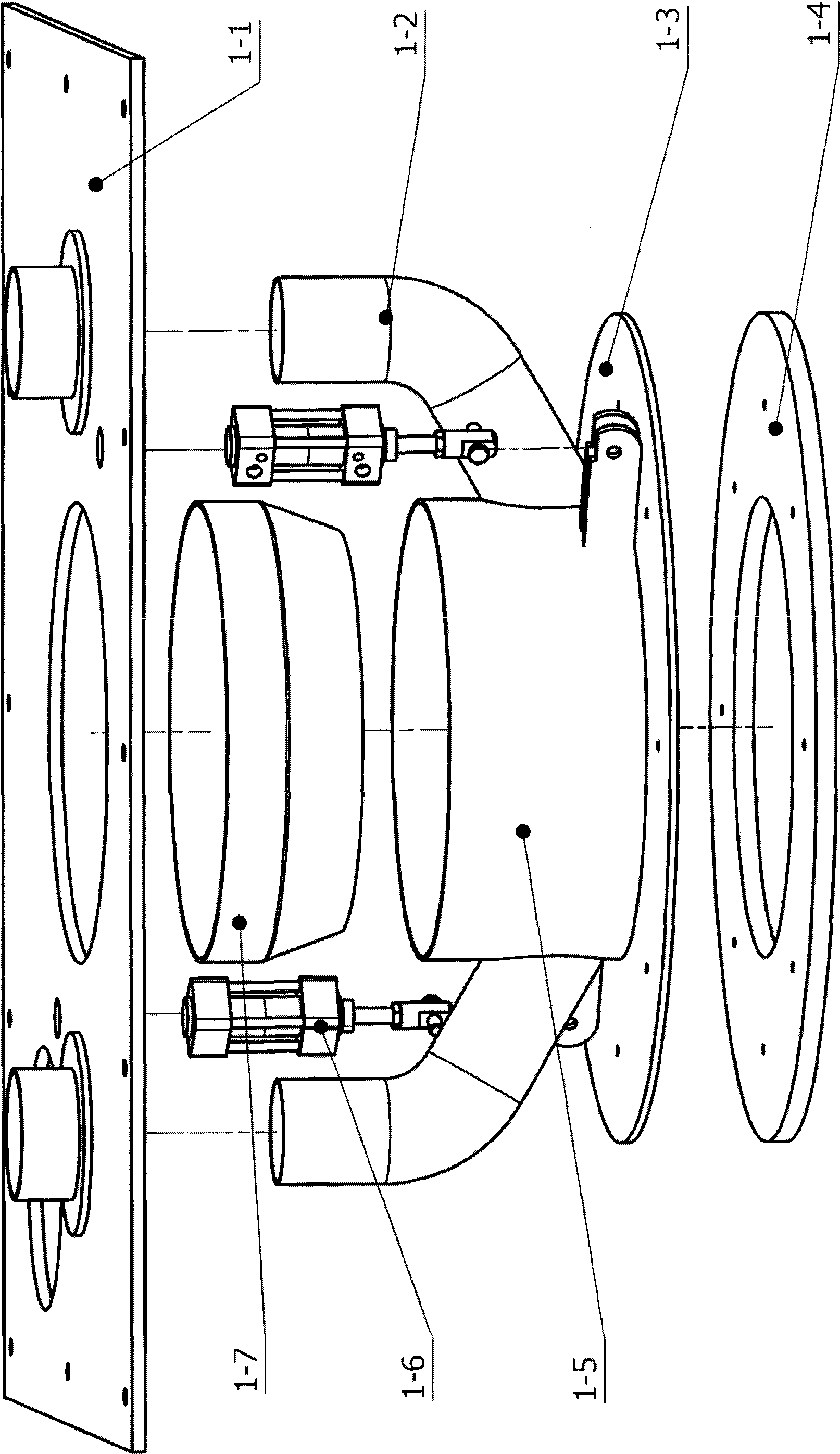

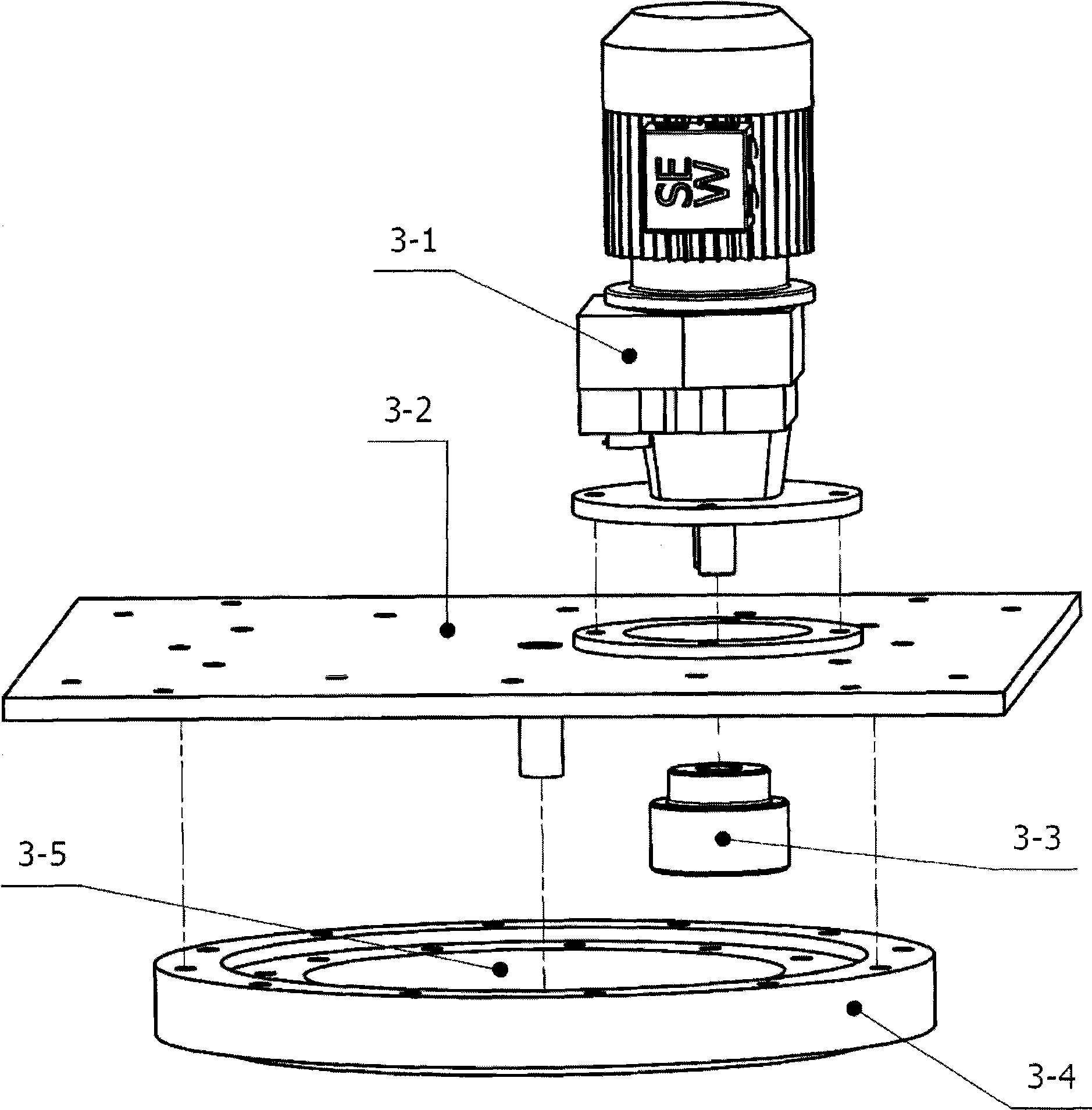

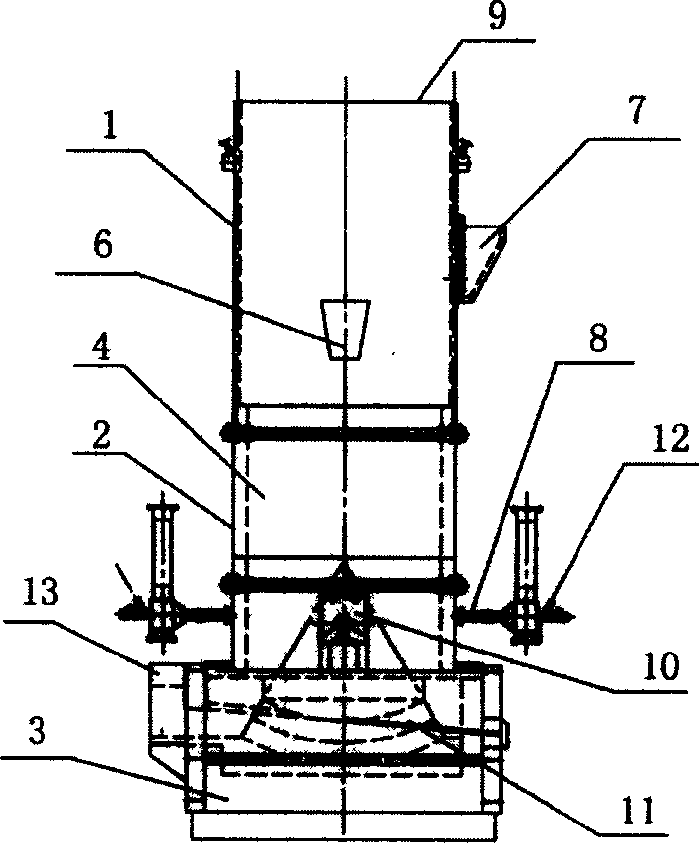

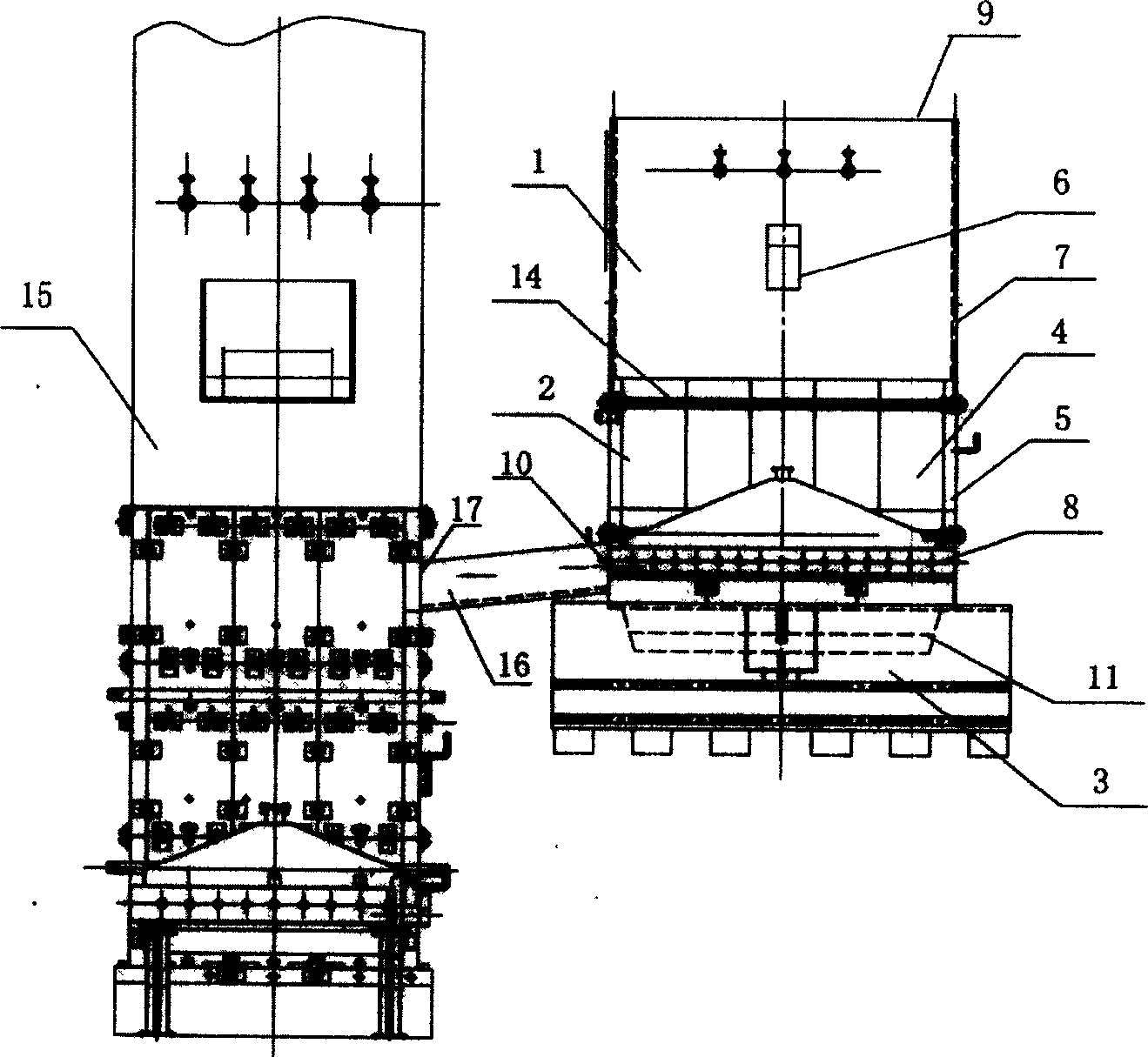

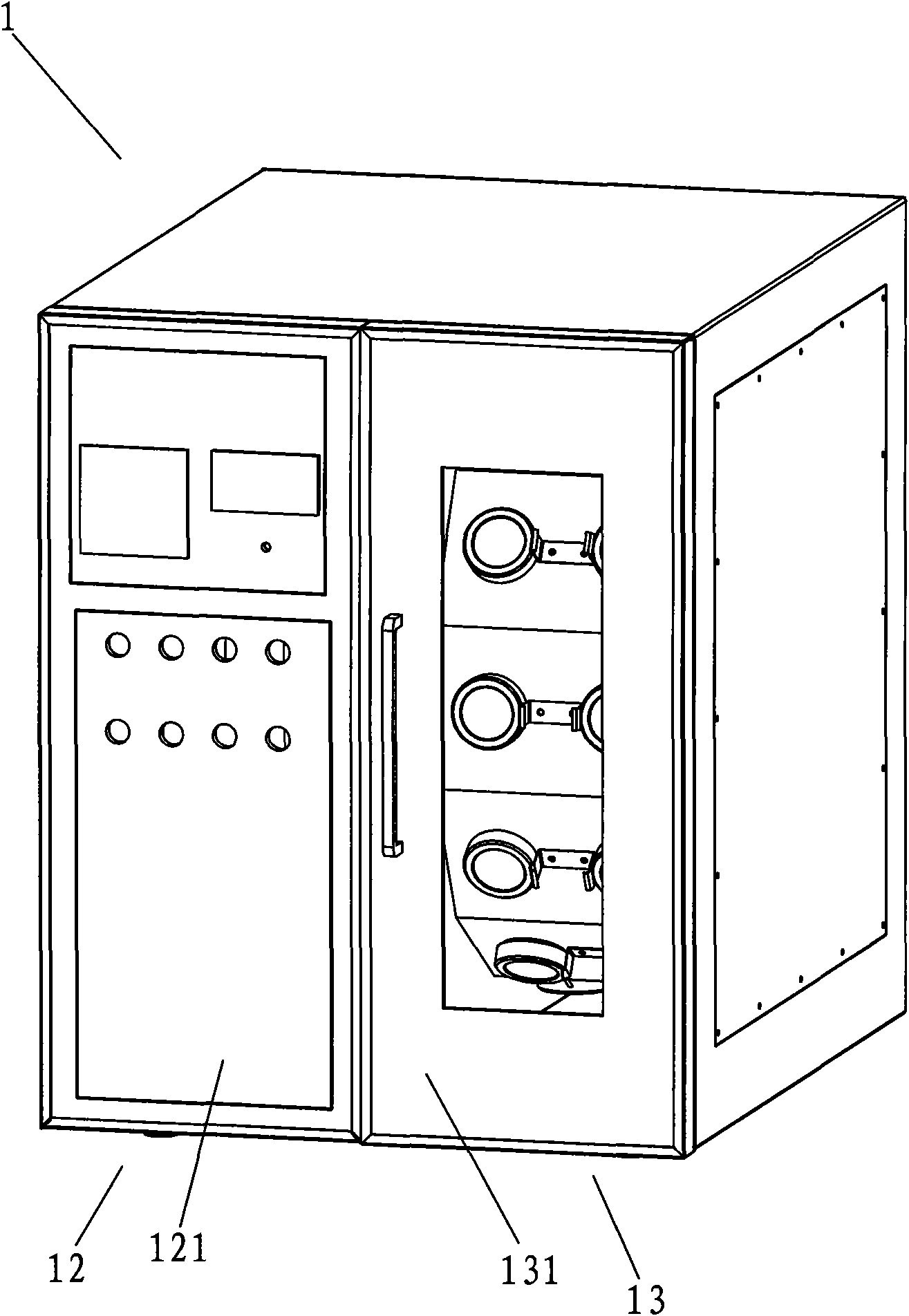

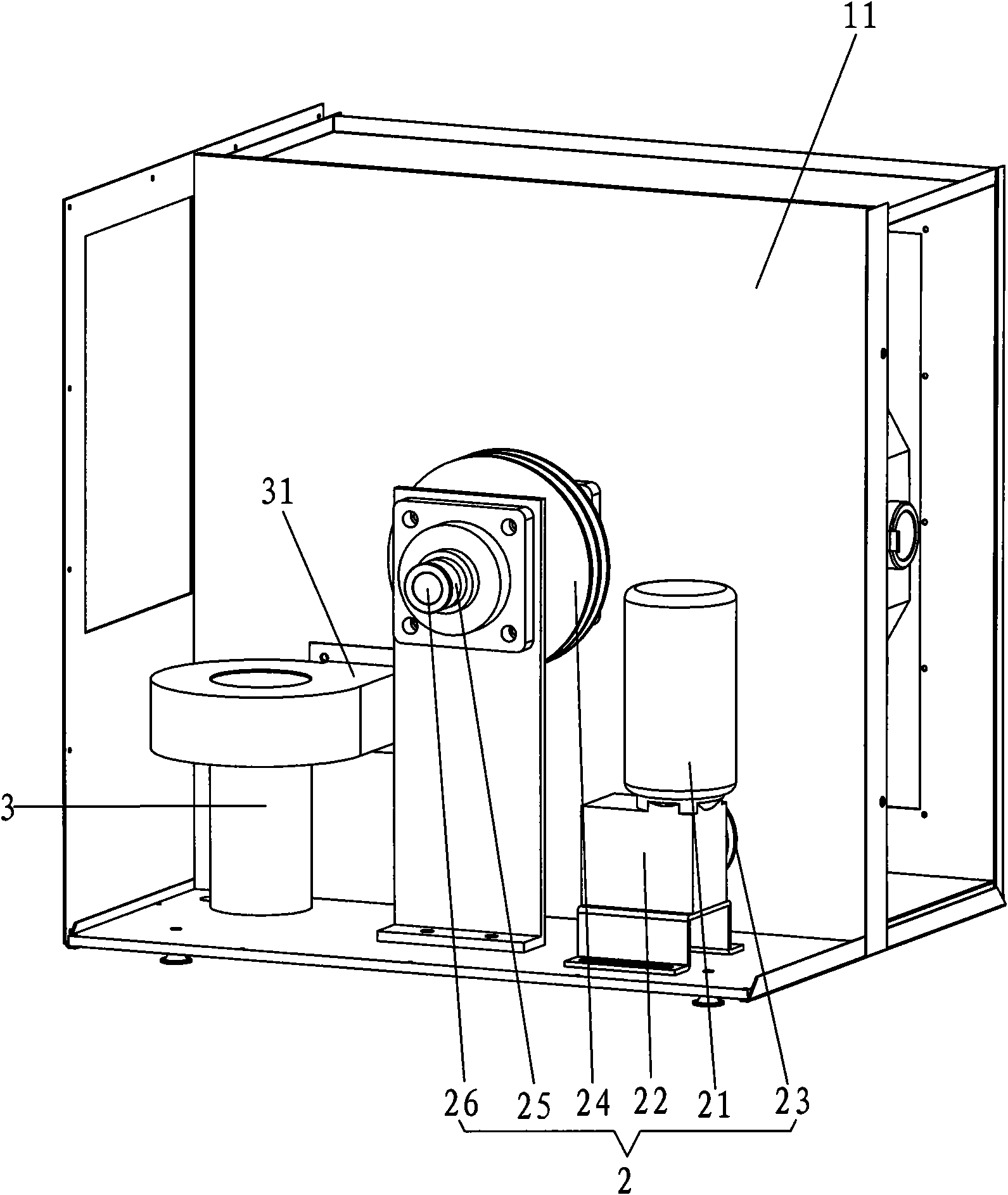

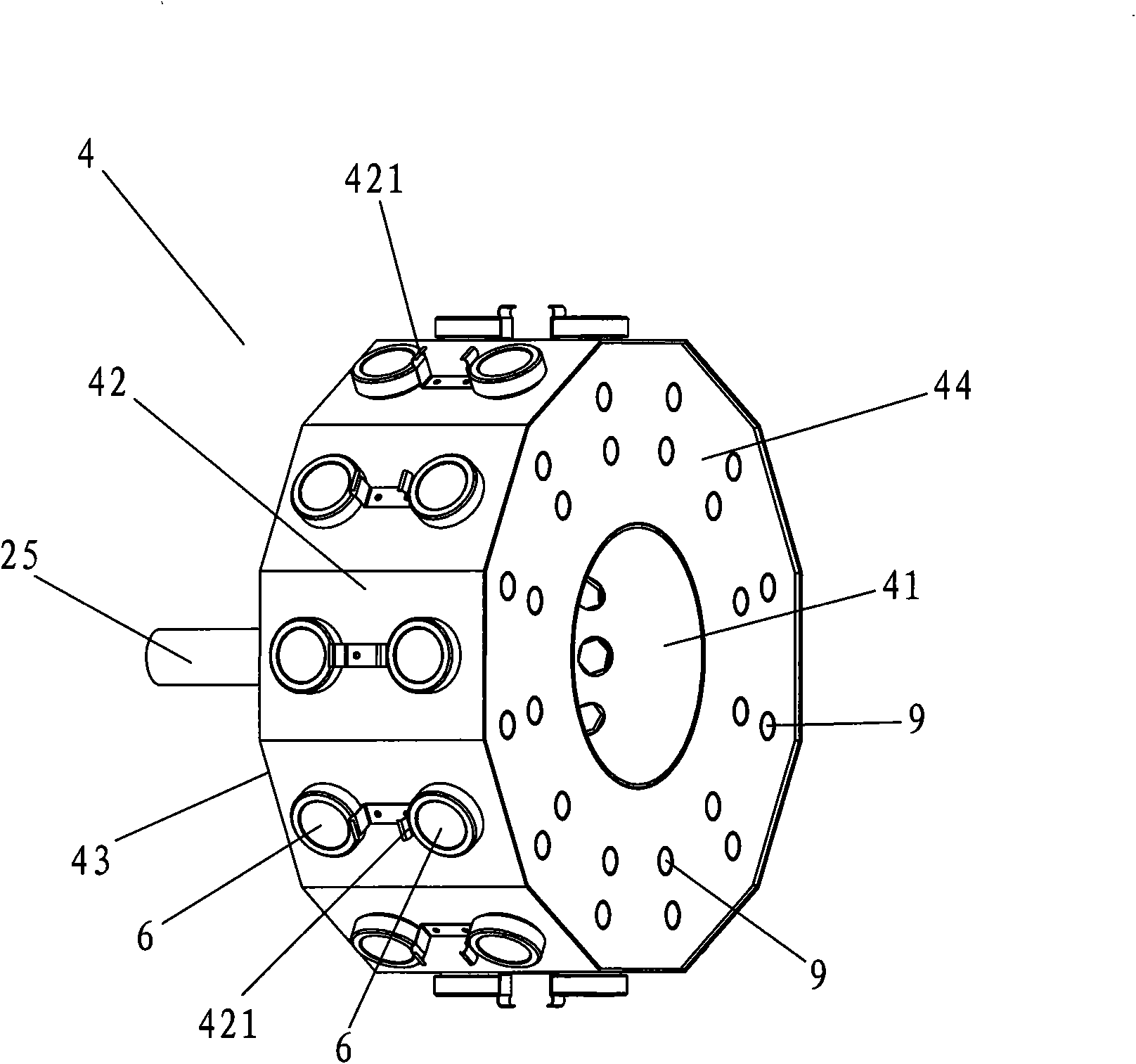

Rotary type semi-automatic packer

InactiveCN101475060AIncrease production capacityReduce labor intensitySolid materialPackaging automatic controlSemi automaticCompound (substance)

The invention relates to a rotary semiautomatic packing machine for packing fine powder materials, which is suitable to be used for semiautomatic packing of power materials in petrochemical, chemical, food, medicine or the like fields. The invention aims to solve the problems that the prior fine powder material packing machine is low in production capacity and has a severe operational environment. The packing machine comprises a charging barrel 1, a frame 2, a rotation driving mechanism 3, a supporting upright post 4, a rotary disc 5, bag holders 6, vibration compactors 7, and the like. The frame 2 is connected with the supporting upright post. The rotation driving mechanism 3 is fixed in the middle of the frame 2. The charging barrel is fixed on the frame 2 and is positioned at the outer side of the rotation driving mechanism 3. The rotary disc 5 is fixed at the lower end of the rotation driving mechanism 3 and is provided with a plurality of blanking barrels. The lower end of each blanking barrel is fixed with one bag holder 6. The vibration compactors 7 are positioned at the outer side of the bag holders 6 and are distributed in a circle having a center which is the rotation center of the rotary disc 5. With a rotary structure, the packing machine automatically separates the actions in a process of filling the powder materials into bags and all actions can be carried out at the same time, thereby eliminating time for waiting for the air exhaust of the materials. Therefore, the rotary semiautomatic packing machine can improve product efficiency greatly and improves operational environment.

Owner:HARBIN BOSHI AUTOMATION

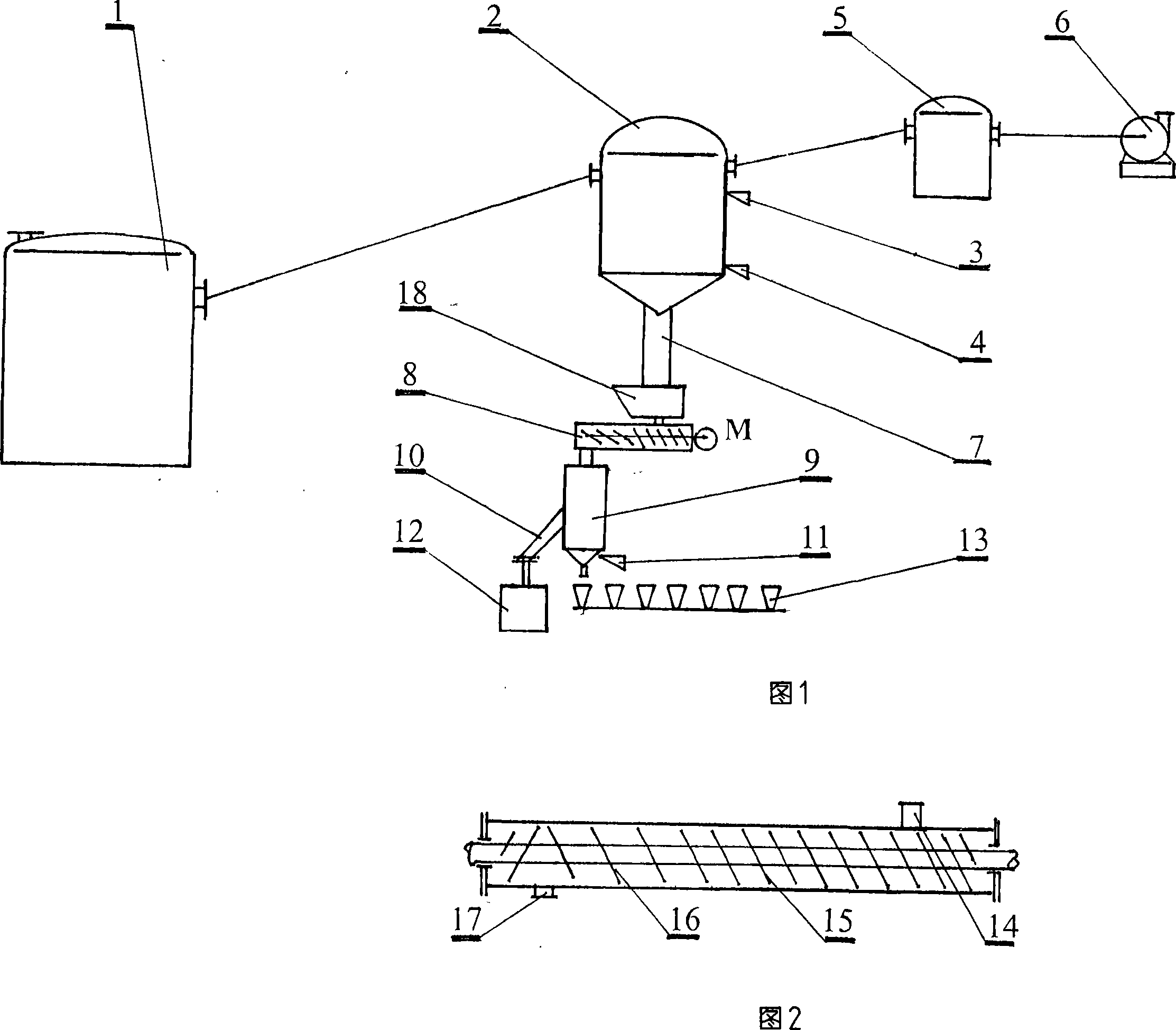

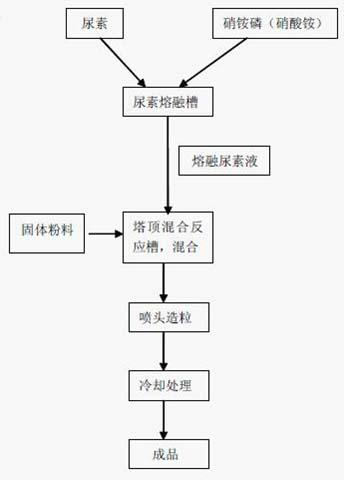

Method for producing urea-based compound fertilizer by high tower granulation

ActiveCN102584395AImprove liquidityReduce the presence of air bubblesFertiliser formsFertilizer mixturesFertilizerChemistry

The invention discloses a method for producing a urea-based compound fertilizer by high tower granulation. The method comprises the following steps of: (1) adding a fluxing agent and urea into a melting tank, melting the urea at low temperature, and adding into a mixing reaction tank on the top of a tower; (2) adding other raw materials into the melted urea solution in the mixing reaction tank on the top of the tower, and mixing and stirring to obtain mixed and melted slurry; and (3) spraying the mixed and melted slurry by using a granulation nozzle in the high tower, and granulating in the tower. The method has the advantages that operating temperature and energy consumption are low, the liquidity of the slurry is high, a few bubbles exist in the mixed slurry, a small amount of biuret is generated, the operating environment is good, and the like; and high tower granulation production can be stably, normally and continuously performed.

Owner:WENGFU (GRP) CO LTD

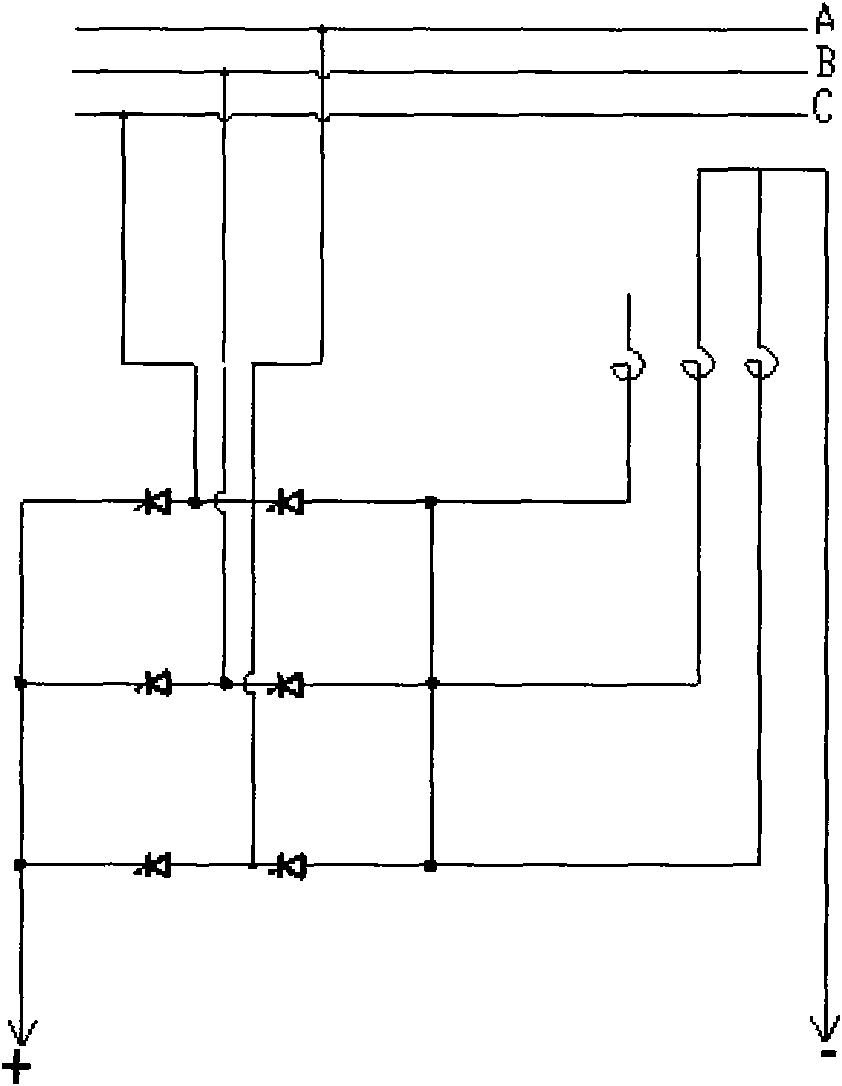

Modular power distribution and control system

InactiveUS20080291607A1Improve the operating environmentSignificantly reliablePrinted circuit assemblingLine/current collector detailsElectric powerSystems engineering

The principals and methods described in our application—provide essential tools for designing a convenient, safe, cost efficient power distribution and control system, which could become industry-standard method, benefiting: providers, users and service personnel of the system.The outlined principals, methods could effectively and efficiently support development and installation of power distribution systems for variety of projects, including: residential, commercial and industrial. In addition, the proposed methods could be used in the designs of power distribution to and within variety of electro-mechanical devices or machines.Designs based on proposed technology will outperform the existing methods in terms of its: superior reliability, safety, quality and costs.Proposed technology will help to transform the existing labor-intense installations into practically plug-n-play type of installations. For any given project, a pre-designed fabrication kit, containing newly developed, agency approved sub-assemblies and support components, as specified in our application, could be made available and delivered directly to the installation site. Kit containing a section of or an entire system could be pre-tested at the factory.The proposed technology could significantly lower the labor costs, while improving labor safety, quality and repeatability. Labor intense operations: wire crimping, outlet / switch hook-ups, etc.—could be practically eliminated during installation.Power distribution systems designed by proposed methods will offer better quality, installation and utilization safety, and lower costs. In addition, utilization of shielded cables and shielding of other components within a system, could significantly lower electrical power emissions, which could benefit the environment, and ease requirements on other technologies.

Owner:BRAUNSTEIN ZACHARY L

Smelting method and device of molten lead oxidation slag

An apparatus for smelting the oxide slags of molten lead is composed of the upper furnace body with water jacket-type or membrane-type side wall, smoke outlet, flux inlet and oxide slag inlet, the lower furnace body with water jacket-type wall, nozzle inlet and slag discharging outlet, and the furnace bottom with refractory liner and lead outlet. Its method includes reducing step and smoking step.

Owner:CHINA ENFI ENG CO LTD +1

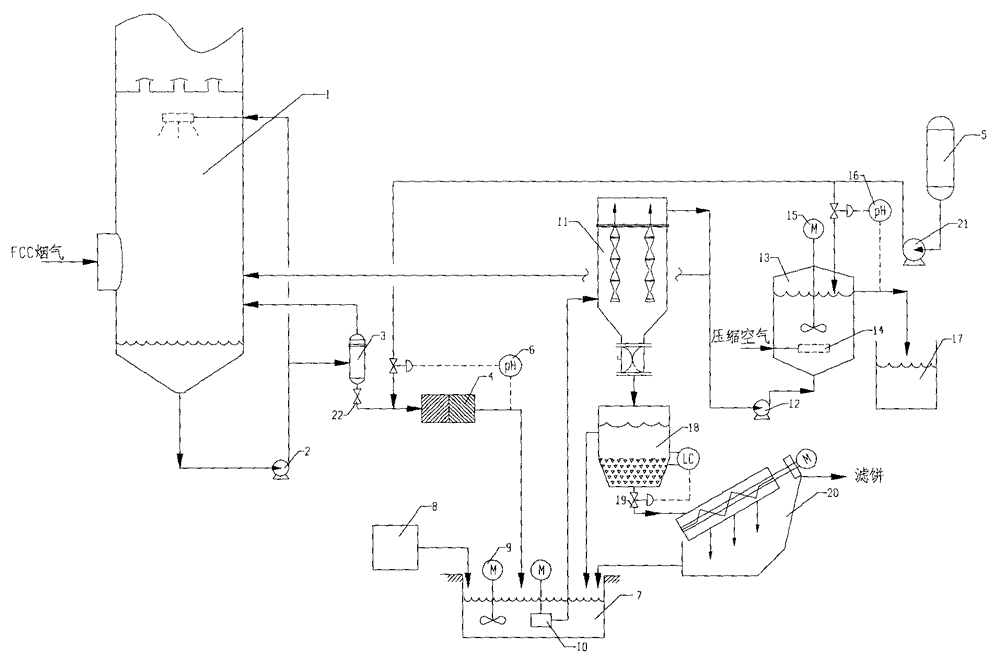

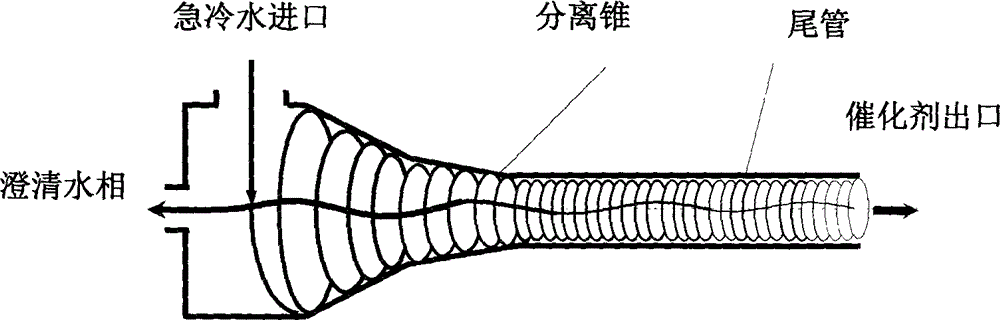

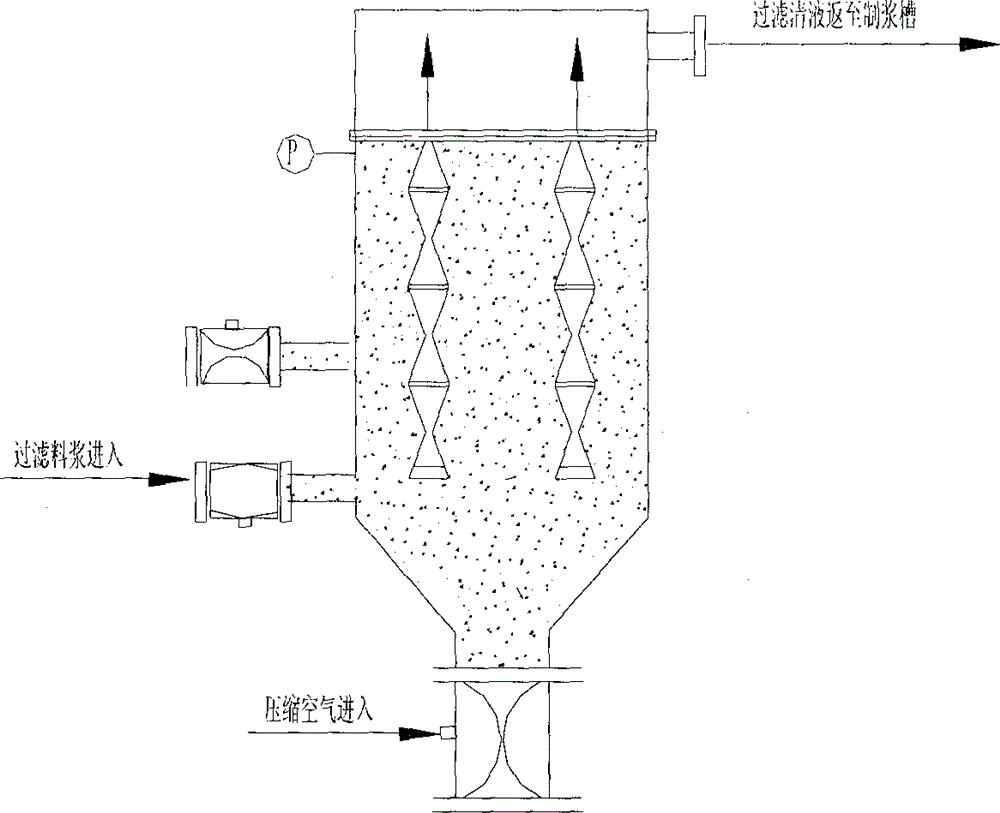

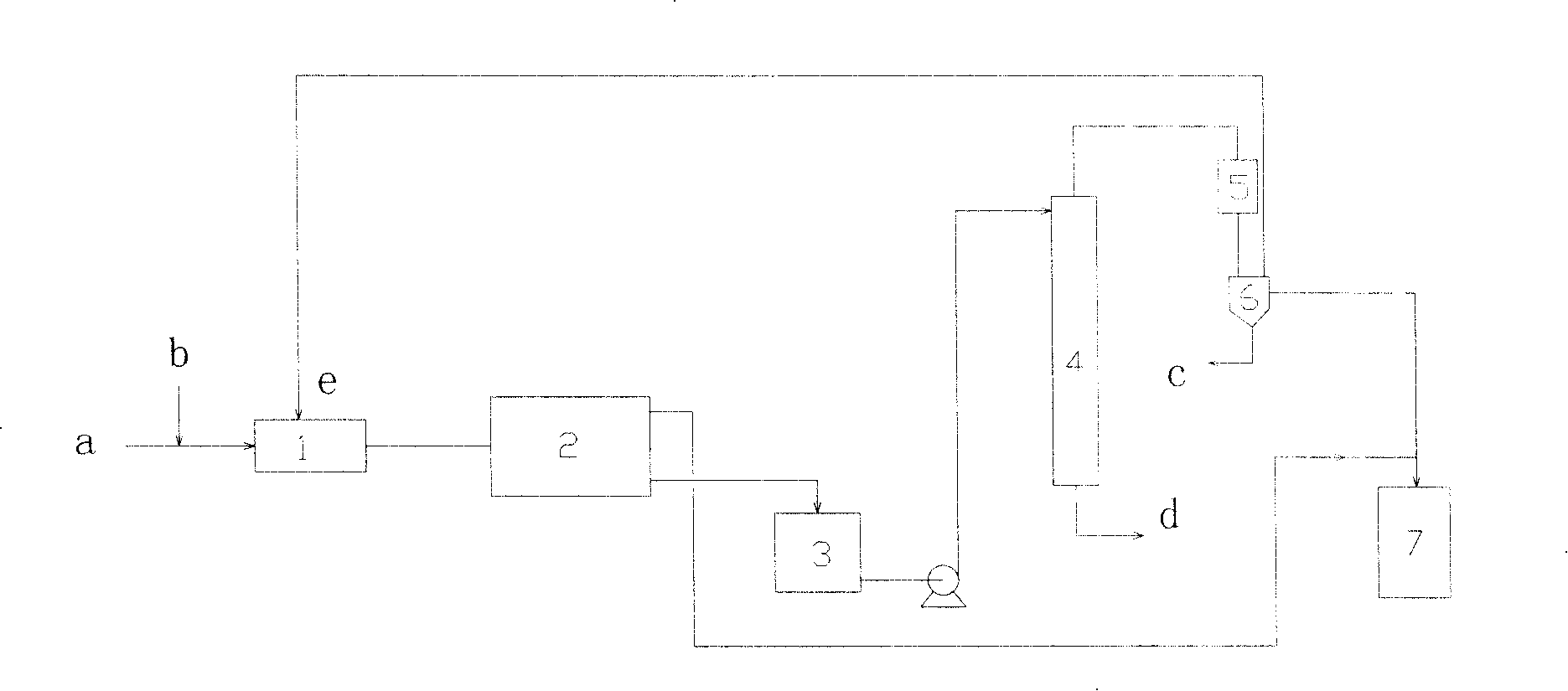

Process for treating waste liquid from catalytic cracking flue gas desulfurization

InactiveCN104418447AReduce dust concentrationReduce wearWater/sewage treatment by centrifugal separationSludge treatmentLiquid wasteSlurry

The invention provides a process for treating waste liquids from catalytic cracking flue gas desulfurization. The process comprises the following steps: enabling a part of waste liquids from a quenching washing tower to enter a hydraulic cyclone separator so as to be subjected to solid-liquid separation, returning the thin liquids to the quenching washing tower so as to be recycled, enabling the thick liquids to enter a neutralization reactor so as to be subjected to neutralization reaction, enabling the neutralized waste liquids to enter a slurry pond so as to be mixed with a flocculating agent uniformly, and enabling the mixture to enter an expansion-drum type filter so as to be subjected to solid-liquid separation with a thick slurry and a supernatant being obtained; returning part of the supernatant to the quenching washing tower so as to be recycled, discharging the remaining supernatant into an oxidation tank, removing the pseudo-COD containing sulfite roots and bisulfite roots by oxidizing, and directly discharging the qualified sewage; enabling the thick slurry to enter a settling pond from the bottom of the expansion-drum type filter so as to be further settled, feeding the thick slurry subjected to settlement into a dewatering machine so as to be concentrated and dewatered, directly transporting the filter cakes obtained by dewatering the thick slurry, returning the filtrate from the dewatering of the thick slurry to the slurry pond, and mixing the filtrate with the waste liquids so as to be retreated. The process provided by the invention has the advantages of a stable and efficient treatment effect, strong shock resistance, low investment and small floor area occupation and convenience of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

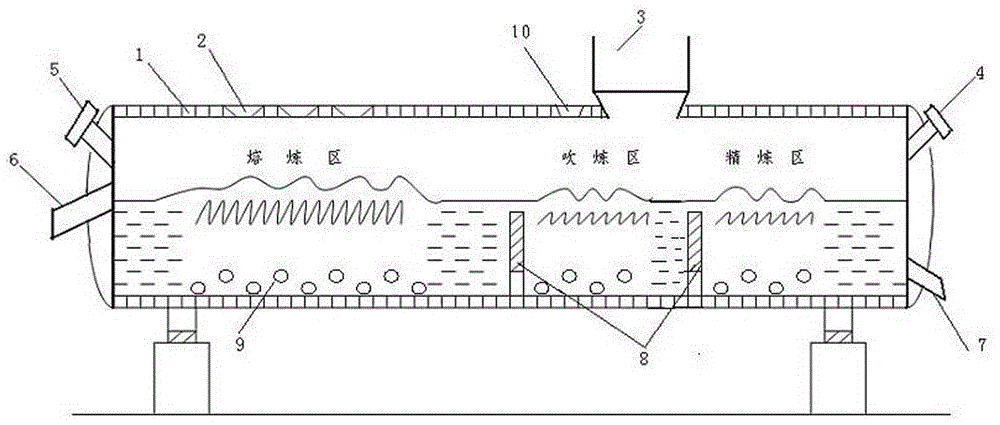

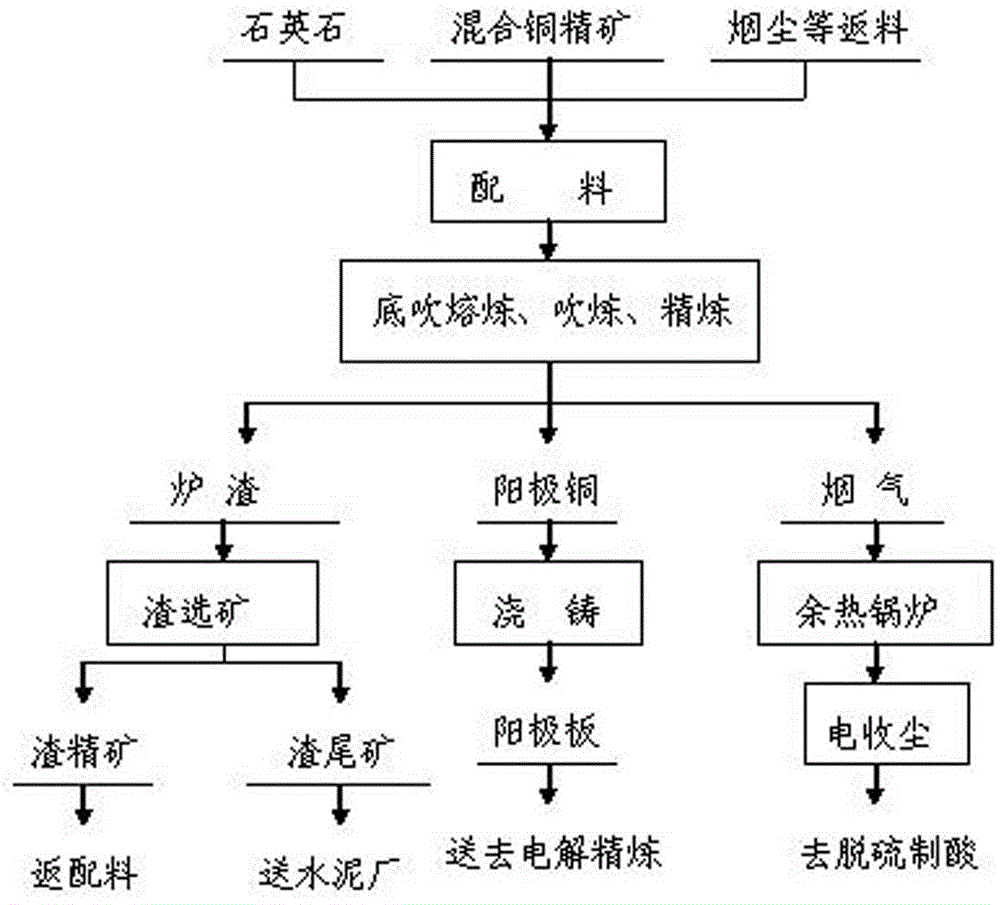

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

Power distribution systems and methodology

ActiveUS20160070282A1Increase rate of changeMinimal costCoupling device connectionsLevel controlData centerDistribution power system

The invention addresses the needs associated with the entire data center power distribution lifecycle—design, build, operation and upgrades. The design and construction is facilitated by a system for prefabricating power whips that accommodate changing data center needs. The invention also allows for upgrading power supply components without powering down critical equipment. Improved power and network strips and associated logic further facilitate data center operation.

Owner:ZONIT STRUCTURED SOLUTIONS LLC

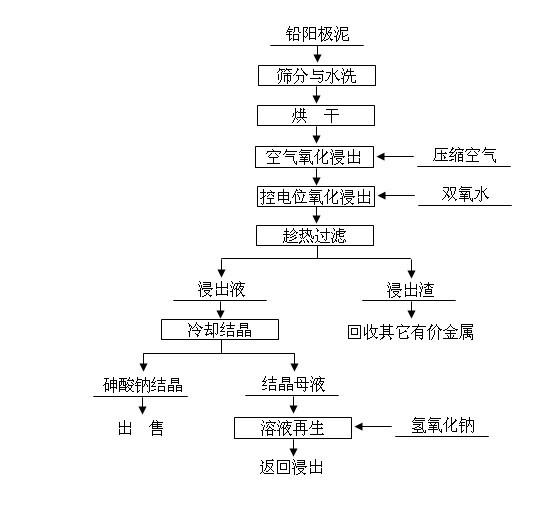

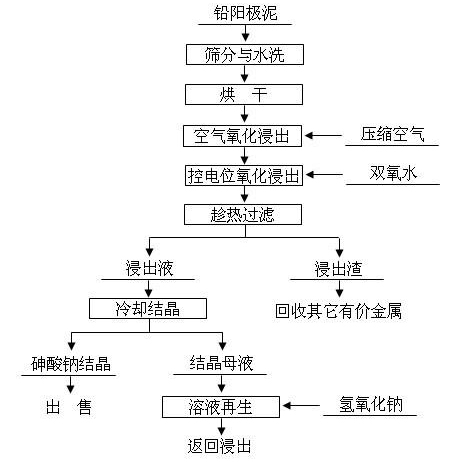

Method for removing and recovering arsenic from lead anode slime

ActiveCN101928838AHigh removal rateAvoid secondary pollutionProcess efficiency improvementArsenic pollutionSodium hydroxide

The invention discloses a method for removing and recovering arsenic from lead anode slime, which comprises the following steps of: performing screening, hot water washing and baking on the lead anode slime, performing oxidation leaching by controlling potential in sodium hydroxide solution, oxidizing the arsenic by using compressed air and hydrogen peroxide as oxidants respectively, adding the oxidized arsenic into alkaline leachate, and ensuring metals such as bismuth, lead, stibium and copper are oxidized and then enter alkaline leaching residue together with noble metals; and after alkaline oxidization leaching process is finished, filtering while hot, performing cooling crystallization on the leachate to generate sodium arsenate crystals, supplementing certain sodium hydroxide to crystallization mother liquor, returning the crystallization mother liquor to the leaching process, and separating and recovering the arsenic and other valuable metals from the lead anode slime. The arsenic leaching rate is over 98.0 percent and the secondary arsenic pollution is free; and the method has the advantages of low requirement on equipment materials, safe operation, low labor intensity, short treatment time and good operating environment.

Owner:YONGZHOU FUJIA NON FERROUS METALS

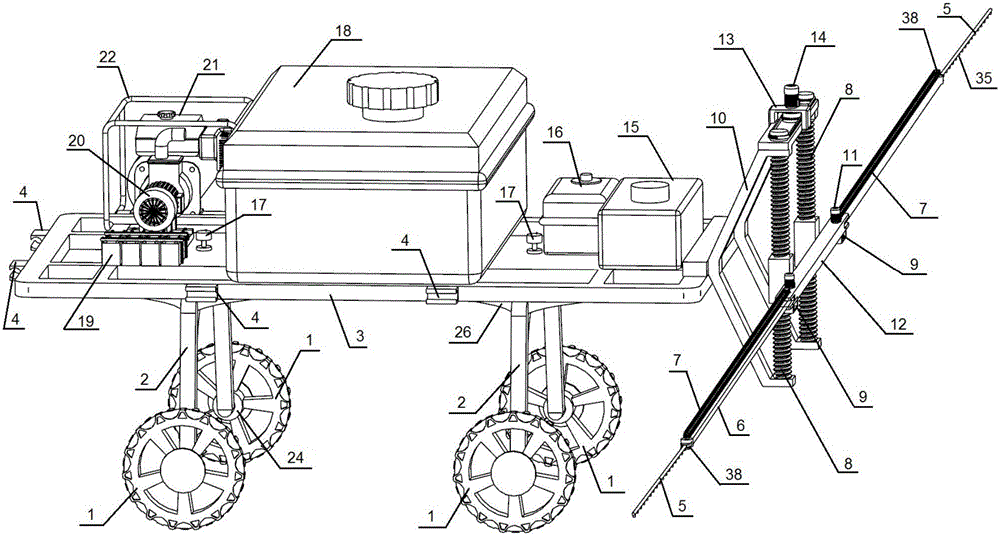

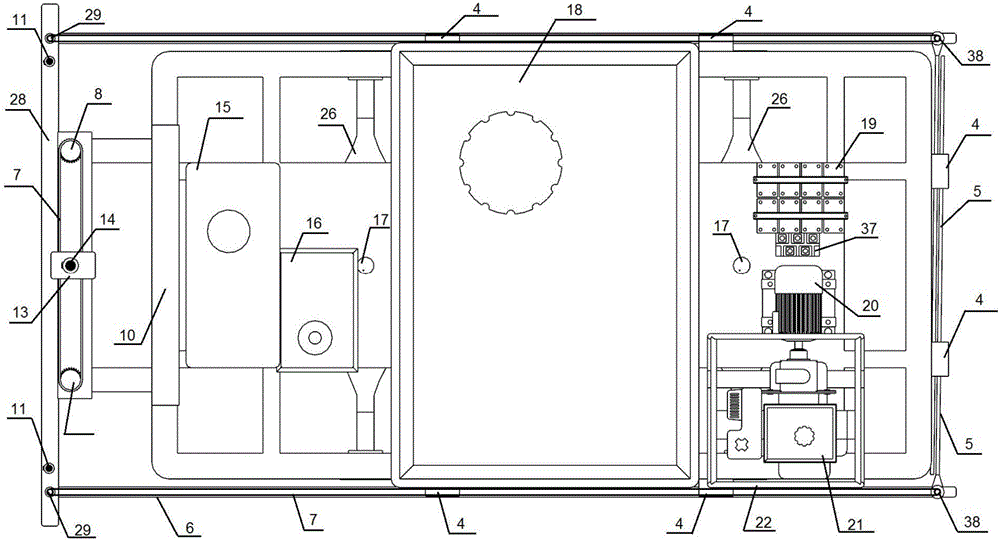

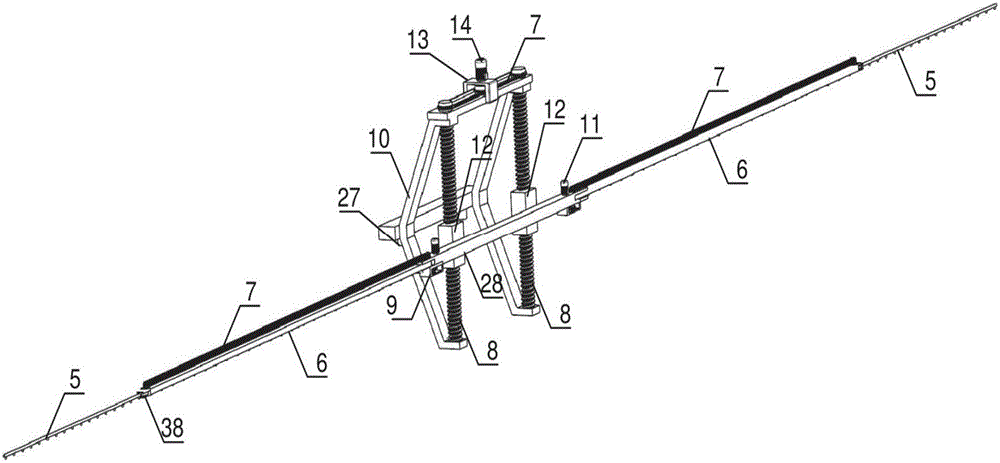

Multi-ground-clearance self-steering intelligent sprayer and control method

ActiveCN106719539AReduce weightImprove space utilizationInsect catchers and killersElectric machineryTurning frames

The invention discloses a multi-ground-clearance self-steering intelligent sprayer and a control method. The sprayer comprises a vehicle platform, two self-steering traveling mechanisms, a controllable lifting spraying device, a gasoline power generation and supply device and a control device, and each self-steering traveling mechanism is connected with the vehicle platform by adopting a rotation structure; the controllable lifting spraying device is fixed at the tail of the vehicle platform and comprises a sprayer lifting mechanism, a spraying rod device and a drug mixing device, the spraying rod device is arranged on the sprayer lifting mechanism and connected with the drug mixing device, and a spraying rod can move up and down along with traction of the sprayer lifting mechanism; the drug mixing device is fixed in the middle of the vehicle platform and provides drug to spraying equipment for spraying, the gasoline power generation and supply device is fixed on the front portion of the vehicle platform and serves as a stable voltage power source of the equipment, and the control device is connected with driving equipment, a control motor and multiple sensors. Four hub motors are controlled by the control device to realize self-steering of wheels at differential speeds, and the sprayer is high in control accuracy and small in turning radius.

Owner:JIANGSU UNIV

Method for treating glyphosate mother liquid

InactiveCN101190926AReduce heat transfer efficiencyReduce production intensityOrganic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsChemistryGlyphosate toxicity

The invention provides a treatment method of mother liquor of glyphosate, which is applicable in large-scale production and has low cost and can improve the recovery rate of triethylamine that is an activator and is used in the synthesis of glyphosate, wherein, in the technical process that the glyphosate mother liquor adopts a glycin method to prepare the glyphosate, the acidic hydrolysis of glyphosate is finished and the pure crystalloid of the glyphosate precipitates in the system, then the residual of the mother liquor is the mother liquor of the glyphosate. By controlling the charge-in mixture ratio and system temperature and adjusting the pH to a certain range, the method of the invention can obtain the triethylamine simply in a high recovery ratio which normally can reach over 90 percent.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

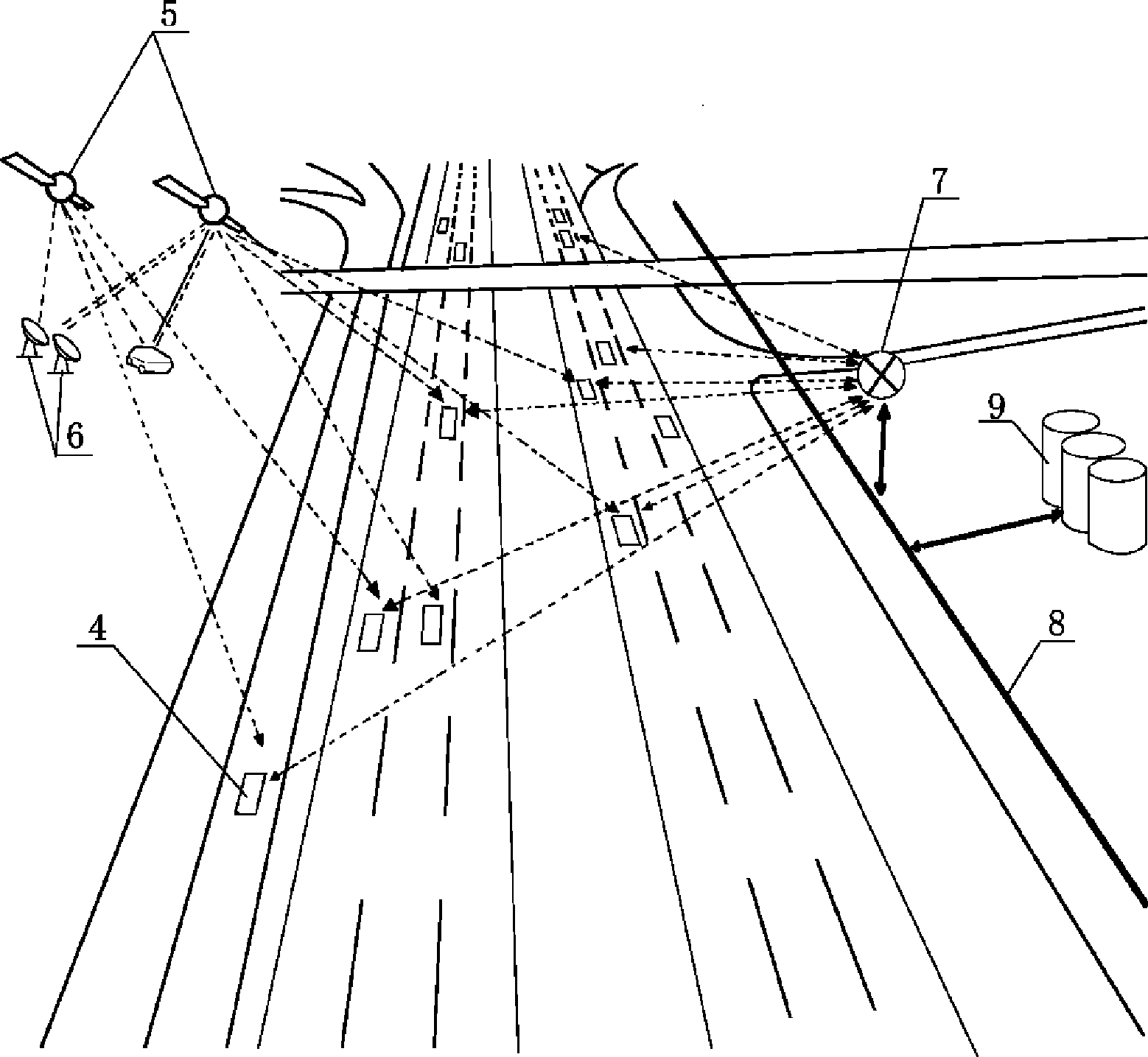

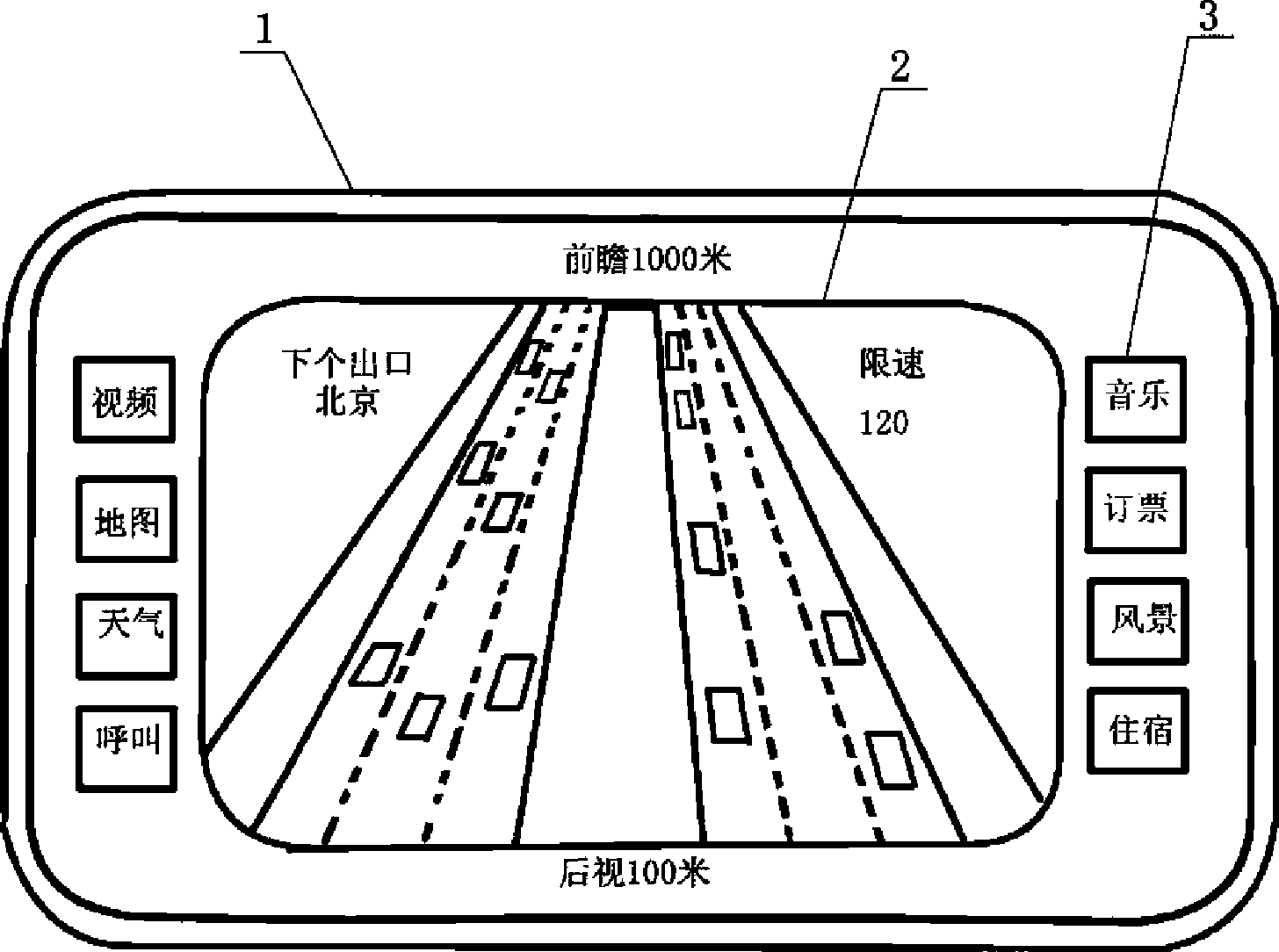

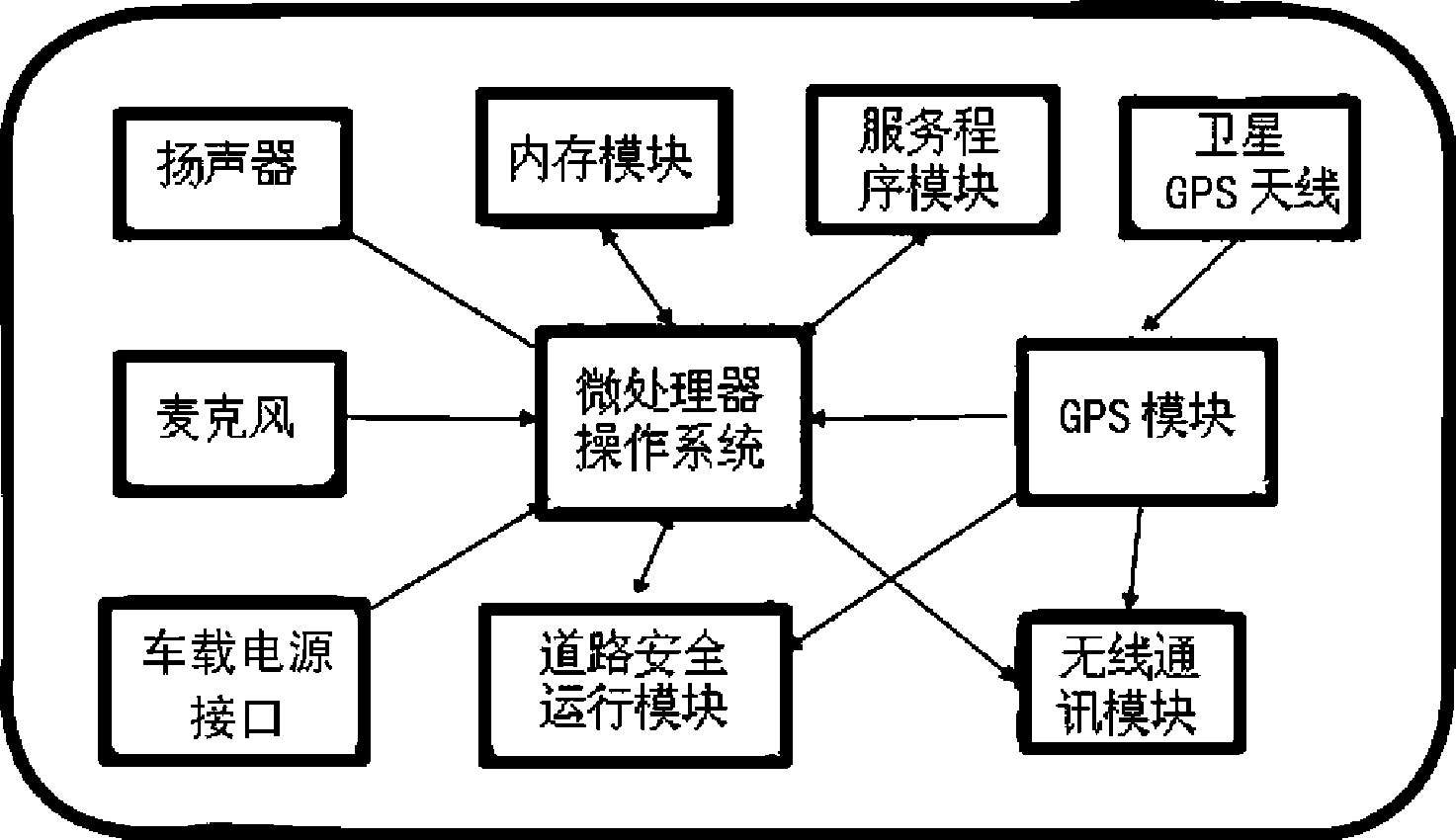

Vehicle mounted electronic alarm system for road safety

InactiveCN101488287AAvoid tailgatingReduce property damageBeacon systems using radio wavesRoad vehicles traffic controlDriver/operatorPrivate network

The invention discloses an on-vehicle electronic warning system for road safety, comprising a wireless broadband special network established at the side of the road. The wireless broadband is composed of a road-side wireless signal transmitting tower, road-side optical cables and a database computing center and is used for receiving operational data of each vehicle on the road while uninterruptedly sending road feature data to each vehicle. An on-vehicle road safety electronic shield terminal arranged in the vehicle uninterruptedly transmits vehicle locations, time and speed data computed by a satellite and land station signals to the database computing center of the road-side wireless special network subsequent to the reception of a positioning signal from a global positioning system so that all the vehicles share the positioning data, meanwhile, the terminal uninterruptedly receives and reads the road feature data sent by the wireless broadband special network during the traveling, and sends, in case that the distance between vehicles are too close or the vehicle is about to deviate from own traffic lane, warning information to related drives in order to avoid traffic accidents such as vehicle rear-end collision, deviation from the roads, side collision, etc.

Owner:曲涛

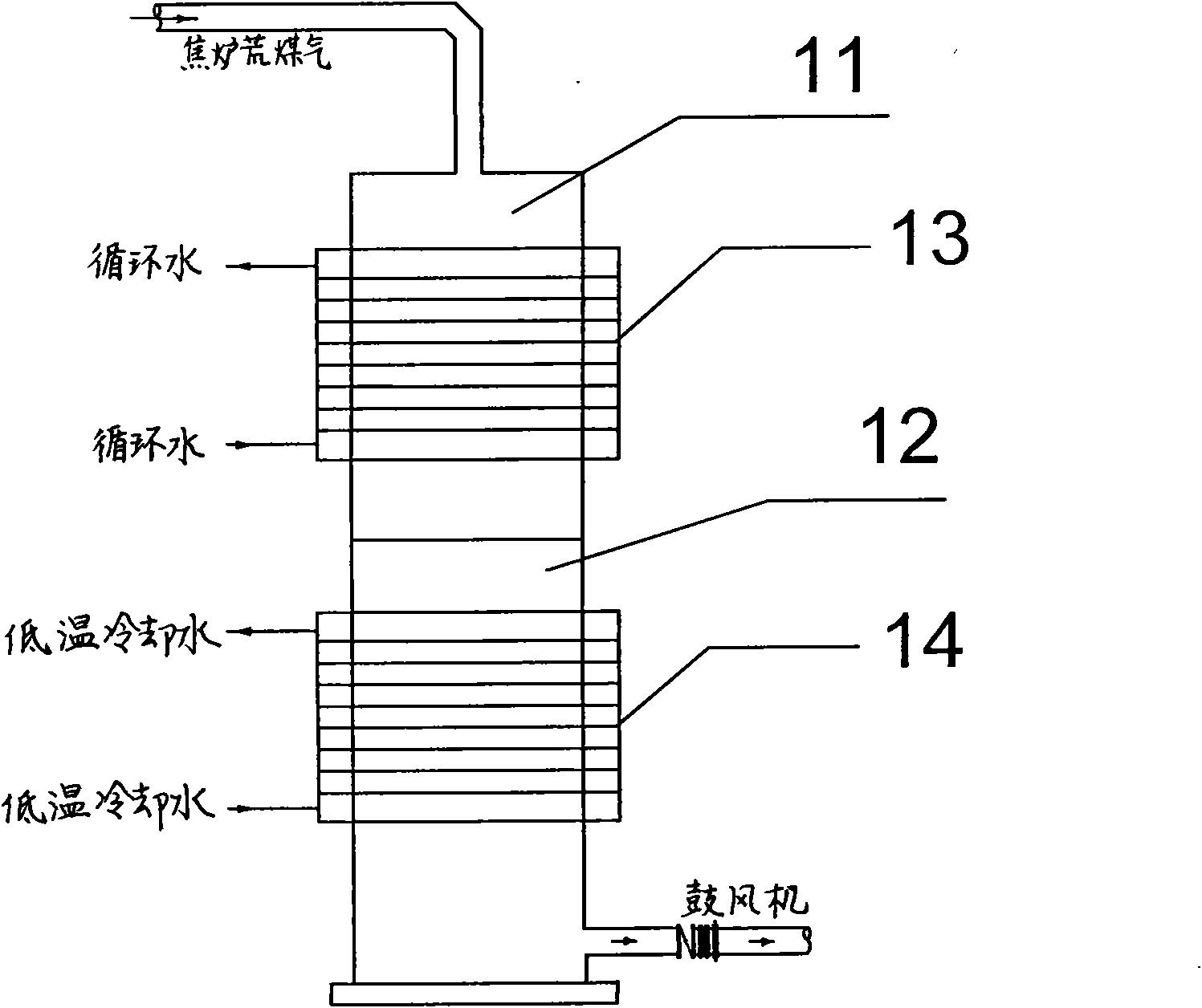

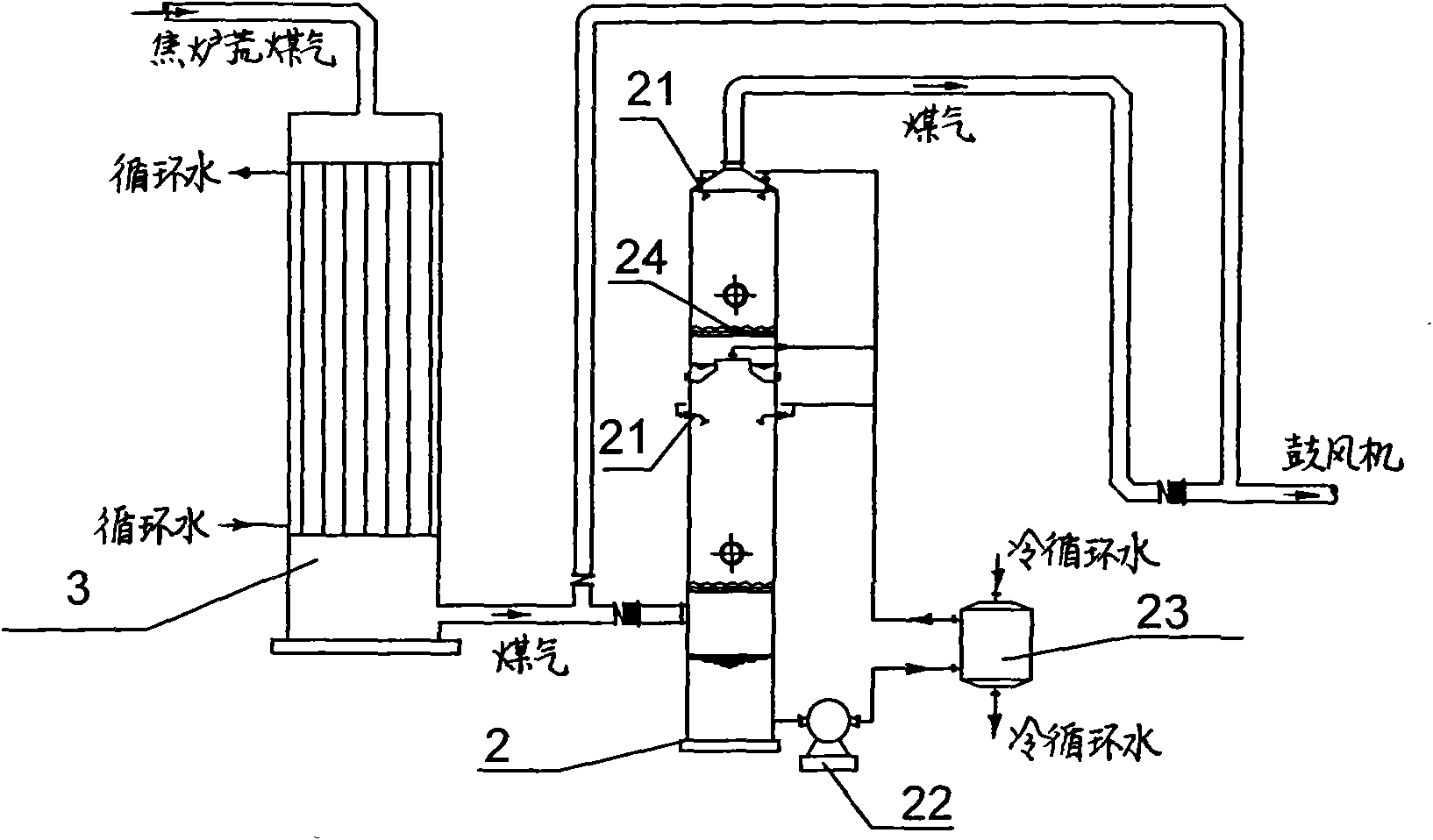

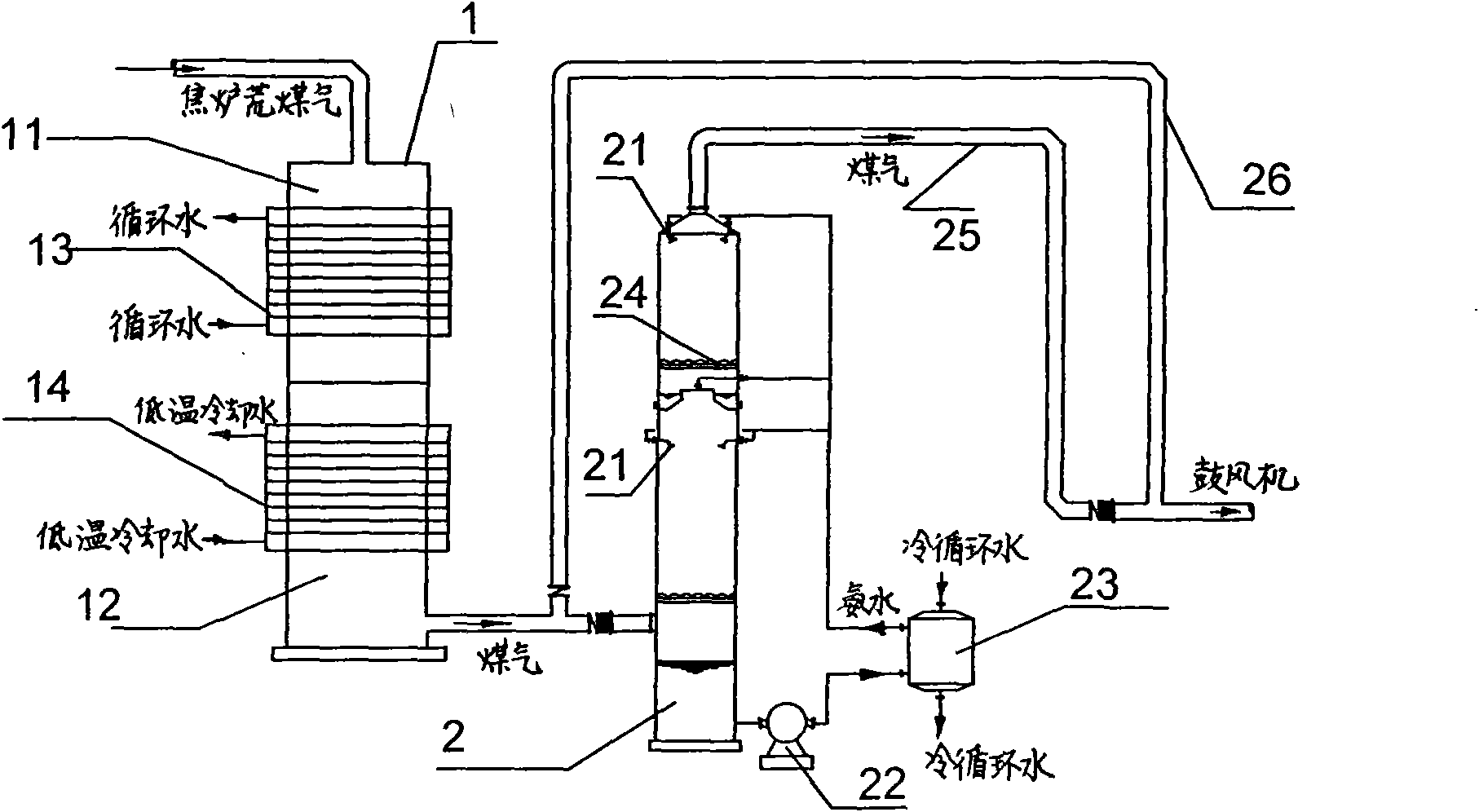

Primary cooling process for coal gas

InactiveCN101608137AImprove cooling efficiencyImprove washing effectGas purification by liquid washingGas dust removalCooling towerTar

The invention discloses a primary cooling process for coal gas. The process comprises the steps of cooling raw gas to between 20 and 30 DEG C through a horizontal-pipe primary cooler provided with a water- circulating section and a low-temperature water-cooling section, spraying the low-temperature water-cooling section of the horizontal-pipe primary cooler with coal-gas condensate of which the tar proportion is between 2 to 10 percent to remove naphthalene separated out from coal gas, and then spraying the inside of a direct-cooling tower with direct-cooling circulating fluid to wash the coal gas and remove suspended tar and dust carried by the coal gas. The process has the advantages of fully utilizing the characteristics of the high cooling efficiency and good naphthalene removal effect of the horizontal-pipe primary cooler and the good washing effect of the direct-cooling tower to perform effective process combination, performing the cooling, naphthalene removal and dust removal of the coal gas more effectively, reducing the blockage of coal-gas after-purification devices, improving equipment operating environment, saving energy and reducing consumption.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Short flow path manufacturing method of heavy rail

InactiveCN1589983AImprove pure qualityEliminate white spot defectsMetal rolling arrangementsEngineeringMolten steel

A short-flow technology for manufacturing the heavy rails with 50 m in length includes such steps as refining molten steel, conticasting, step heating, shaping rolling, fine rolling, sawing by needed size, prebending-cooling, straightening, and inspection. Its advantages are short technological flow, high quality of product and low cost.

Owner:ANGANG STEEL CO LTD

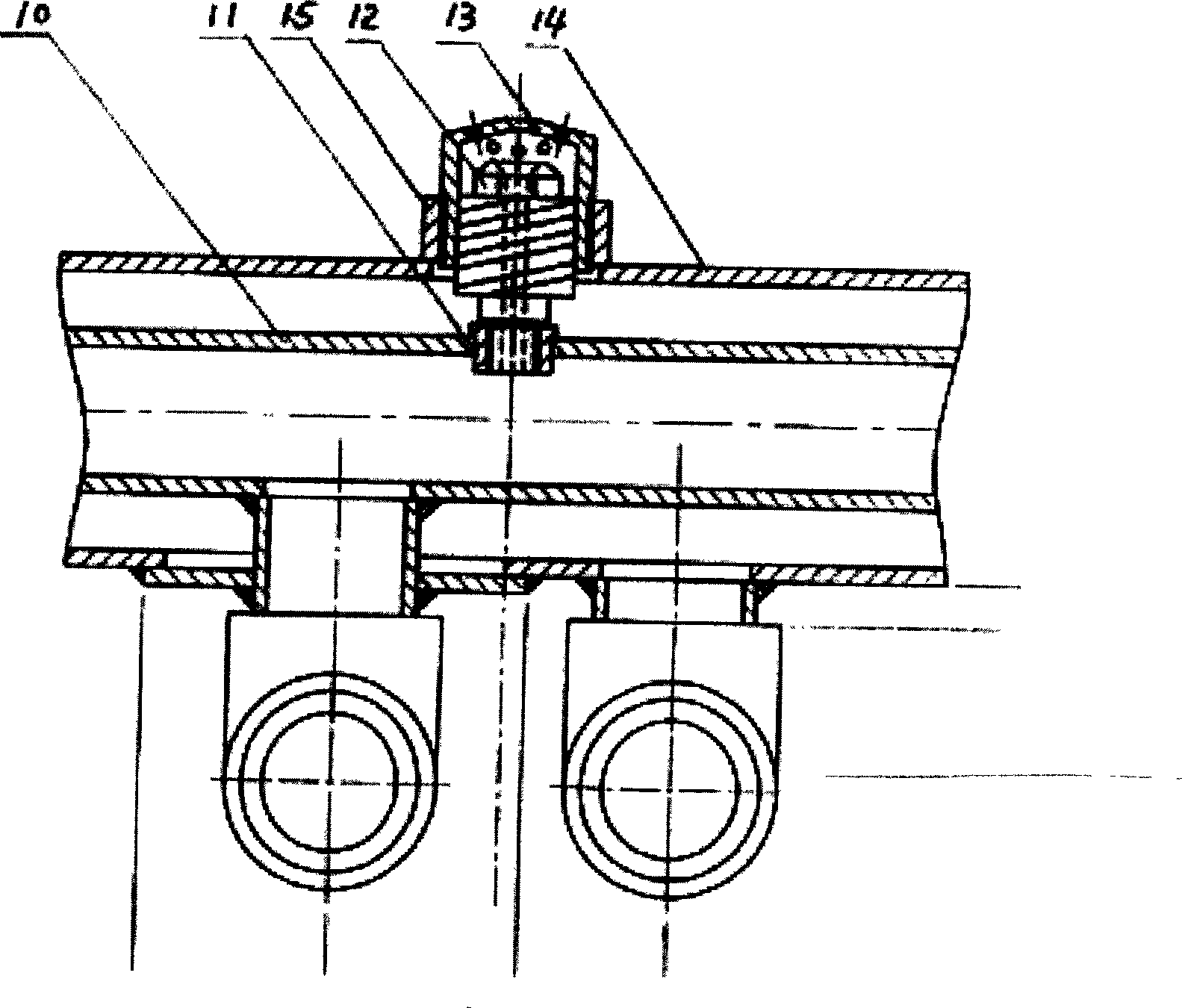

Novel sample dyeing machine

InactiveCN101603260AReduce installationImprove the operating environmentTextile treatment dyeing devicesTextile treatment machine arrangementsState of artThermal energy

The invention discloses a novel sample dyeing machine. The machine comprises a rotary frame arranged in a cylinder, a plurality of sample cups and a plurality of sample cup sleeves, wherein the rotary frame is closed and filled with a solid heat-conducting medium in which a heating device is arranged; the sample cup sleeves are fixed on the rotary frame and buried in the solid heat-conducting medium, and openings of the sample cup sleeves are exposed out of the rotary frame; and the sample cups are fixed in the sample cup sleeves respectively in a mode of being movably taken out. In the machine, the solid heat-conducting medium is used for heat conduction, and the sample cups are not contacted with a heat carrier directly, so that the pollution caused by taking glycerin as the heat carrier does not occur, and the glycerin is not consumed; compared with the prior art, the machine has the advantages of keeping the original operating habits, improving the proofing operation environment, and saving energy, along with environmental protection; the machine adopts the solid heat-conducting medium for heat conduction, and no pressure is generated in the rotary frame; moreover, the wind cooling way is adopted for cooling, so that the assembly of pipes is saved, and the machine can be used after connecting to a power supply.

Owner:SHISHI TAIRUI PRECISION MACHINERY

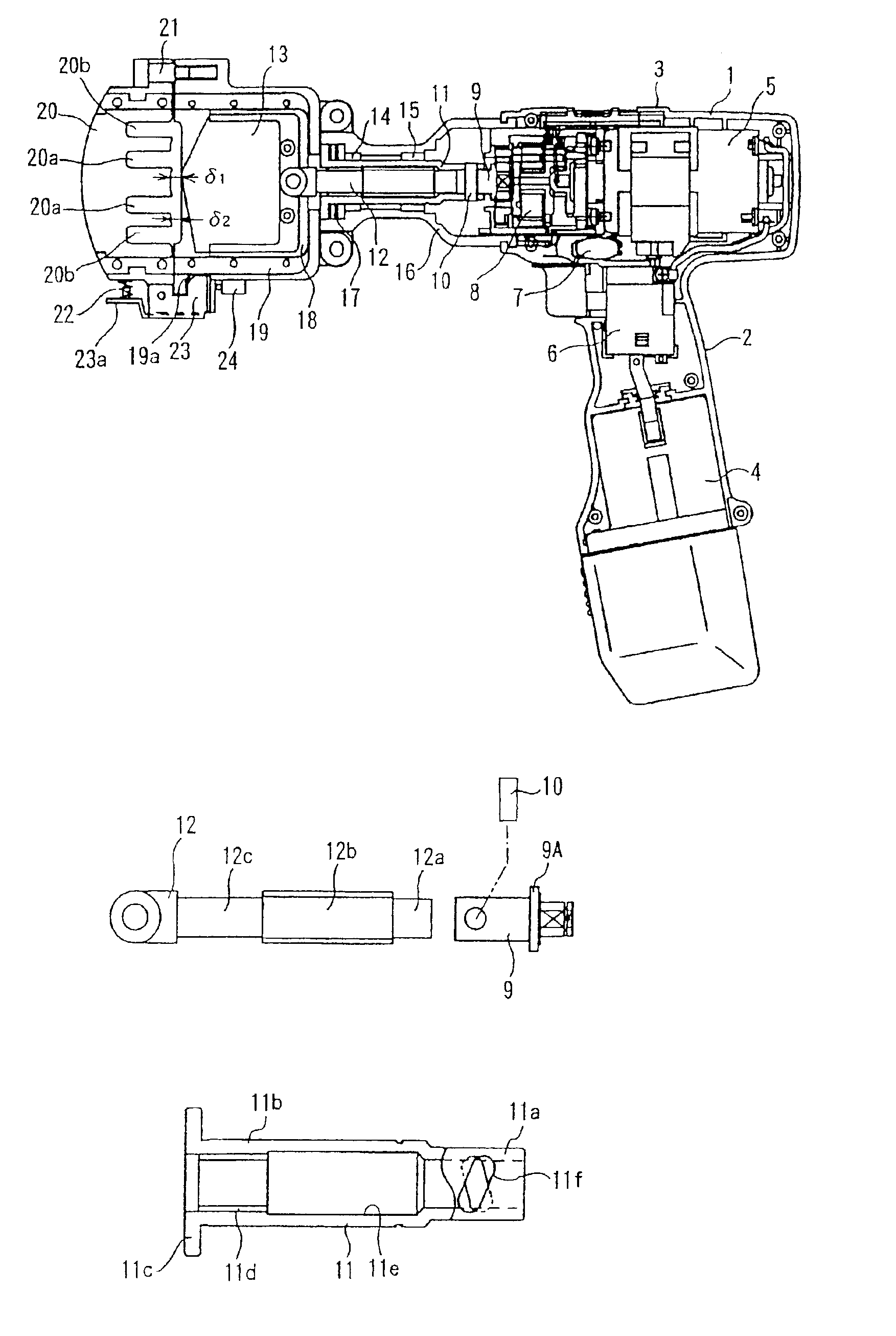

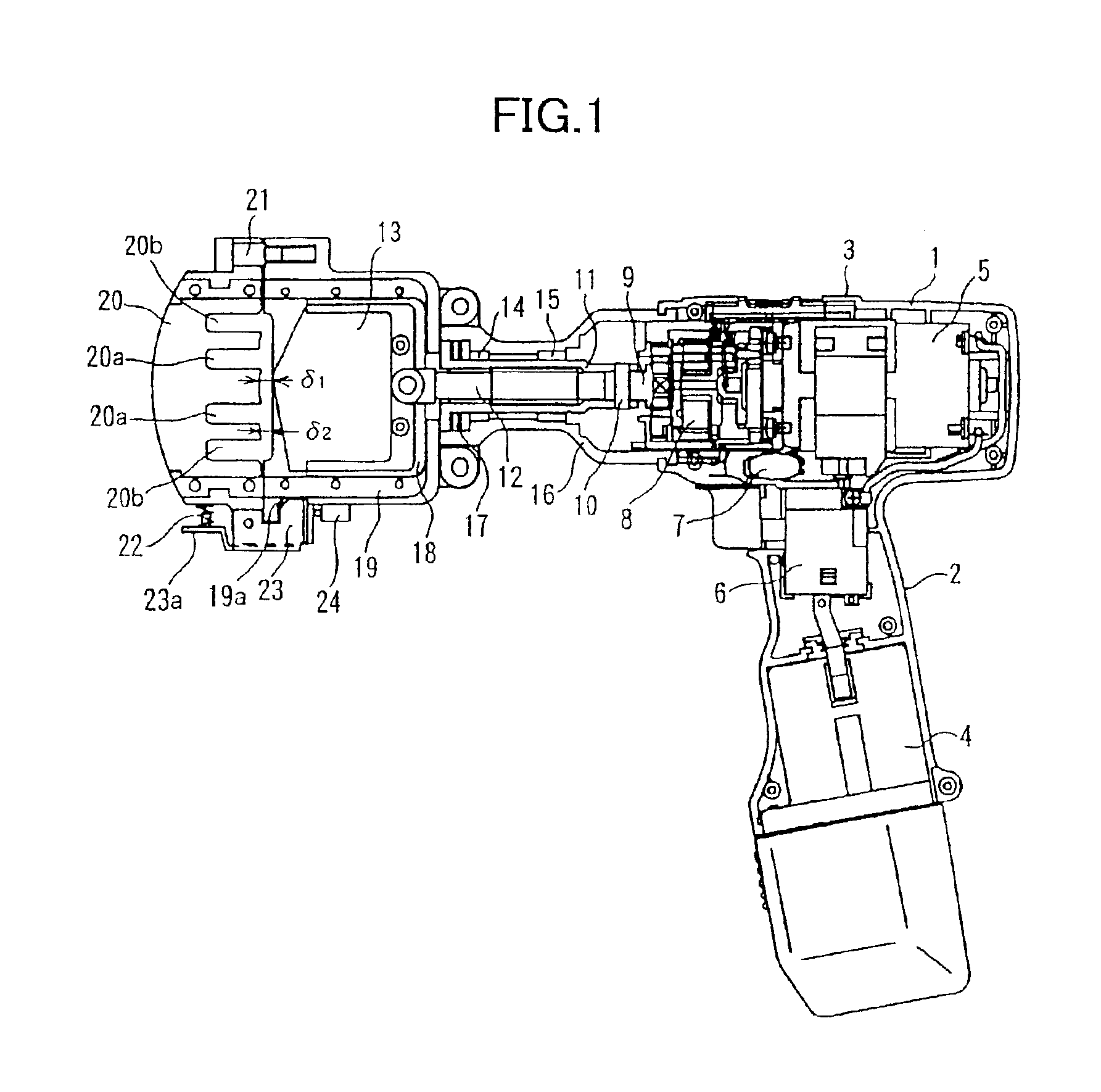

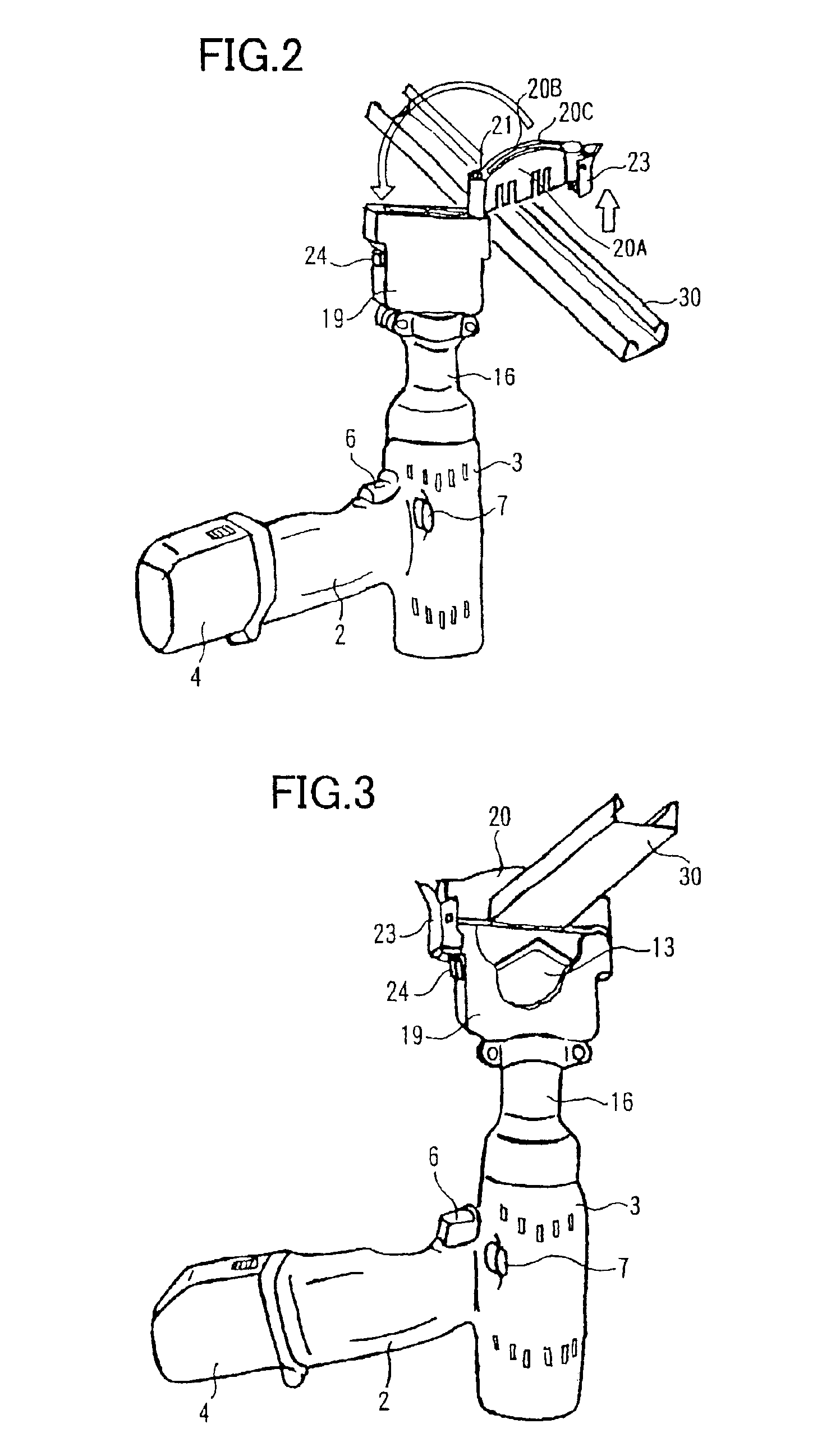

Reciprocal-movement power tool

InactiveUS6938531B2Simple configurationCheap offerCross-cut reciprocating sawsEngineering safety devicesReciprocating motionEngineering

A reciprocal-movement power tool includes a movable blade reciprocally movably provided on a main body. A receiving plate that supports an angle iron to be cut is supported on the main body at a position in front of the movable blade. The movable blade is fixed on a front tip of a rod-shaped shuttle screw. The shuttle screw moves back and forth in the axial direction within a tubular screw shaft. The screw shaft is carved with a female screw portion and is rotated through a joint spindle that is deceleratingly rotated upon rotation of the motor through a deceleration means. The shuttle screw has a male screw portion that is threadingly engageable with the female screw portion.

Owner:HITACHI KOKI CO LTD

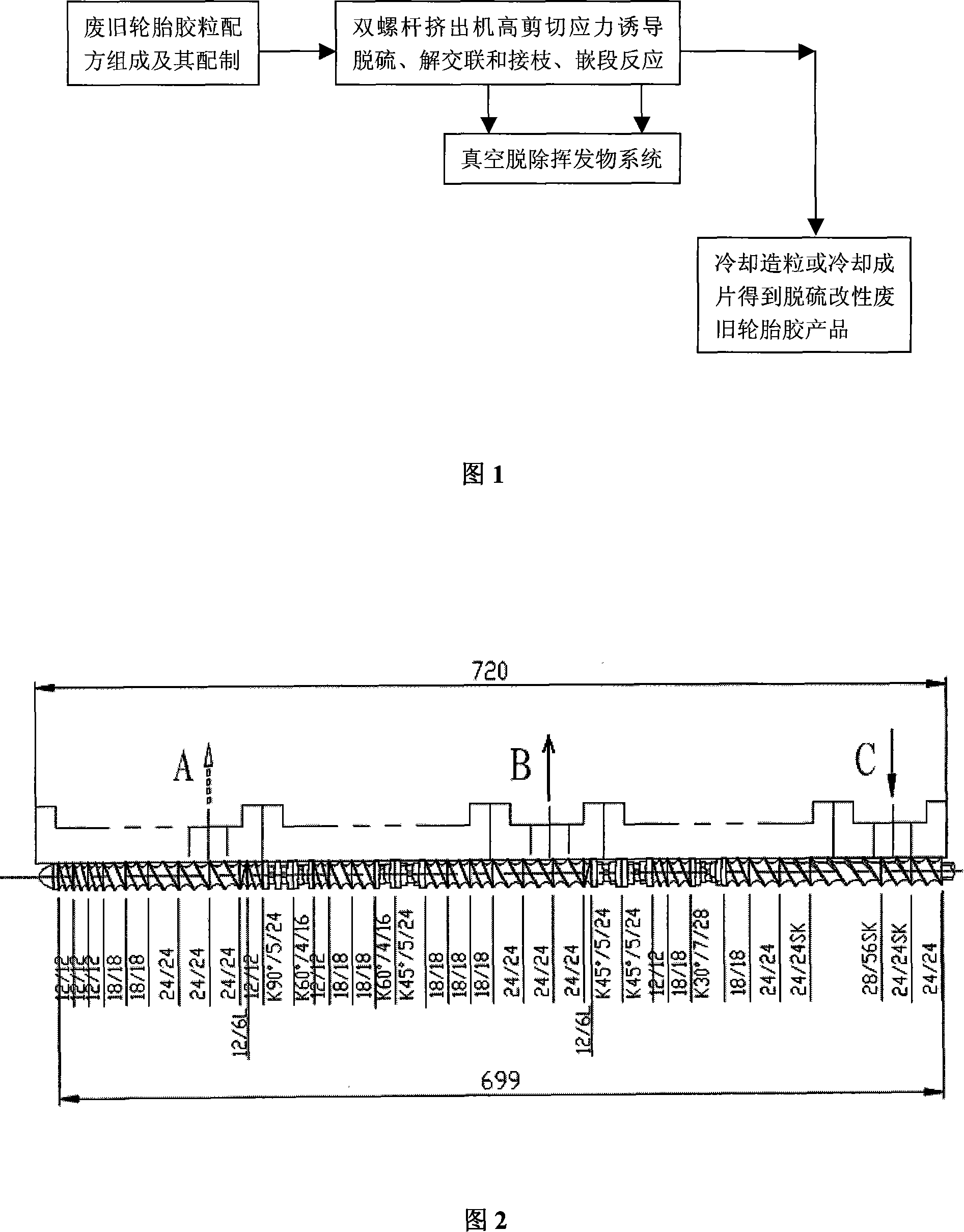

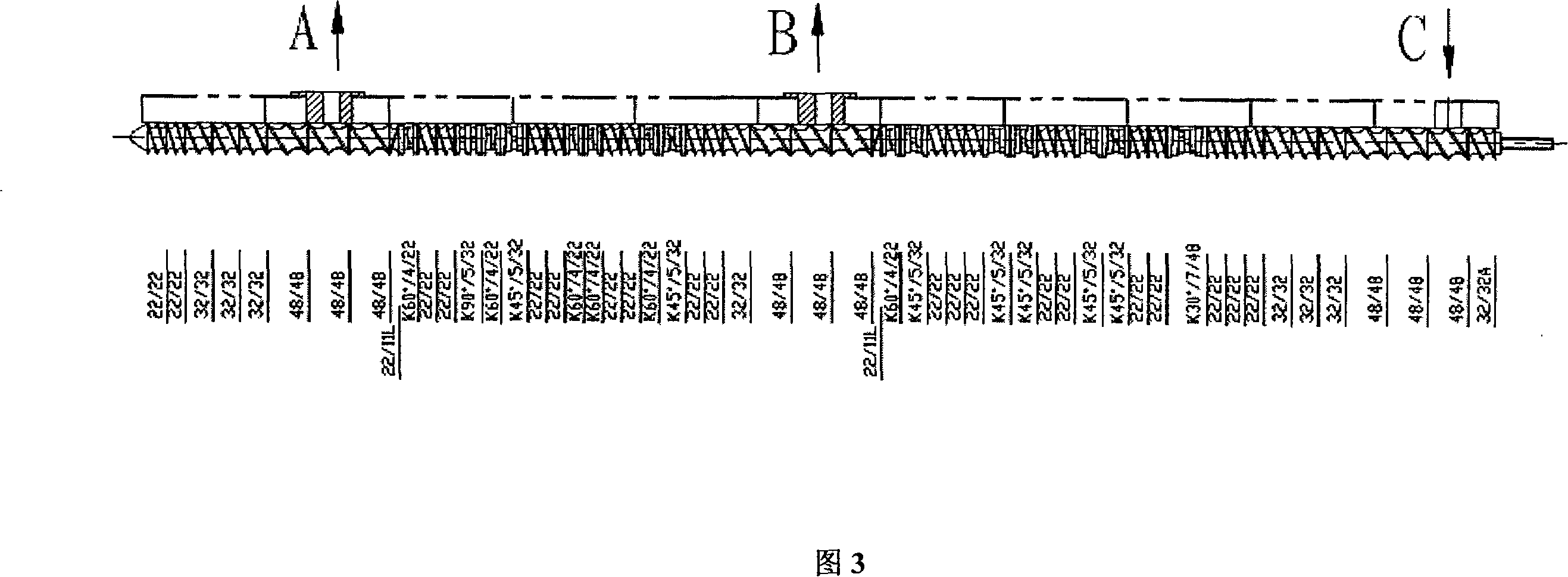

High shear stress induced desulfurization and modification method for waste and old tyre rubber

InactiveCN101168600AReduce pollutionImprove mechanical propertiesPlastic recyclingStress inducedEnergy expenditure

The invention relates to high shearing stress induced desulfurization of recycled tyre rubber, and a modified method. Linear high-molecular substances accounting for 5 to 50 percent of the percentage content of the reagent total weight, recycled tyre rubber powder accounting for 49 to 94 percent of the percentage content of the reagent total weight, and stabilization accessory ingredient accounting for 0.01 to 1.8 percent of the percentage content of the reagent total weight are mixed; the mixture is added into a high rotation speed and high shearing type co-rotating twin-screw extruder all together to be molten and extruded to operate the desulfurization reaction; through water cooling, pelleting, and drying or through roll calendering cooling and sheeting out, desulfurization modified regenerated rubber resultant is obtained. The invention integrates the desulfurization reaction, as well as the smelting process, the refining process, and the rubber filtering process into a whole, the efficiency of the desulfurization process is high, the production rate is high, the energy consumption is low, and the macro scale and the large scale are easy; the desulfurization reaction is easy to be controlled; the pollution of the reaction process to environment is small, and the mechanical property of the resulfurized material of the desulfurization resultant is good.

Owner:NANJING TECH UNIV +1

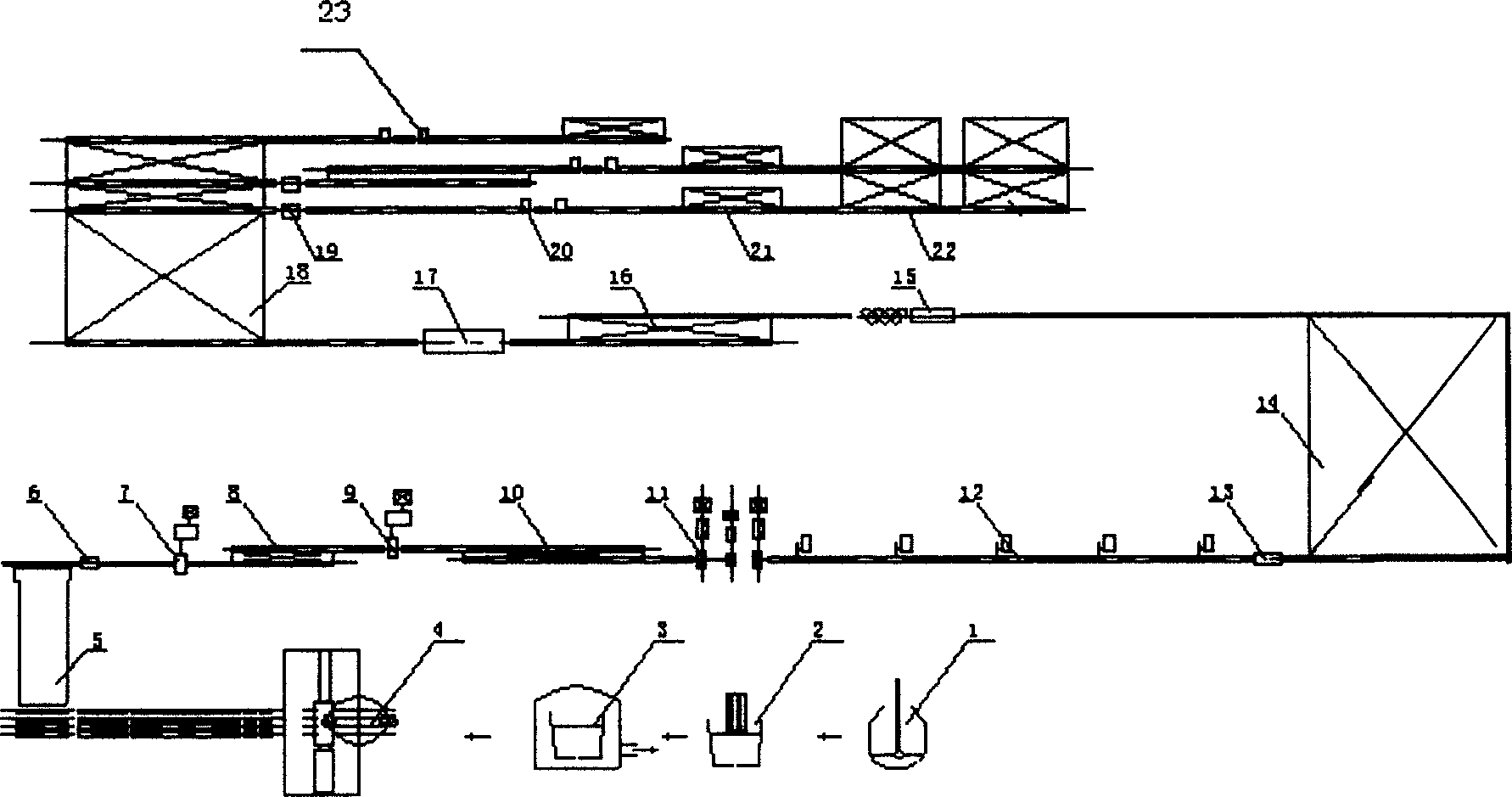

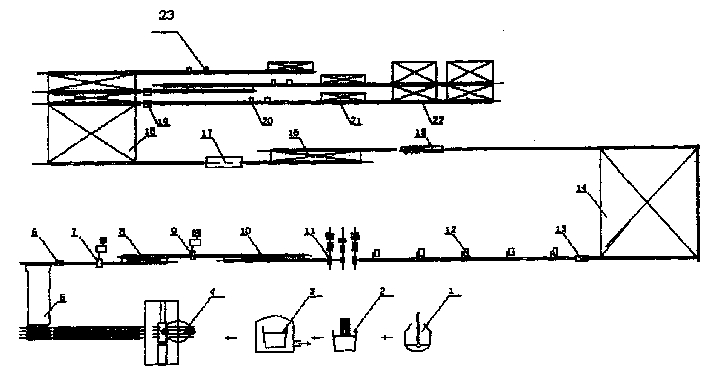

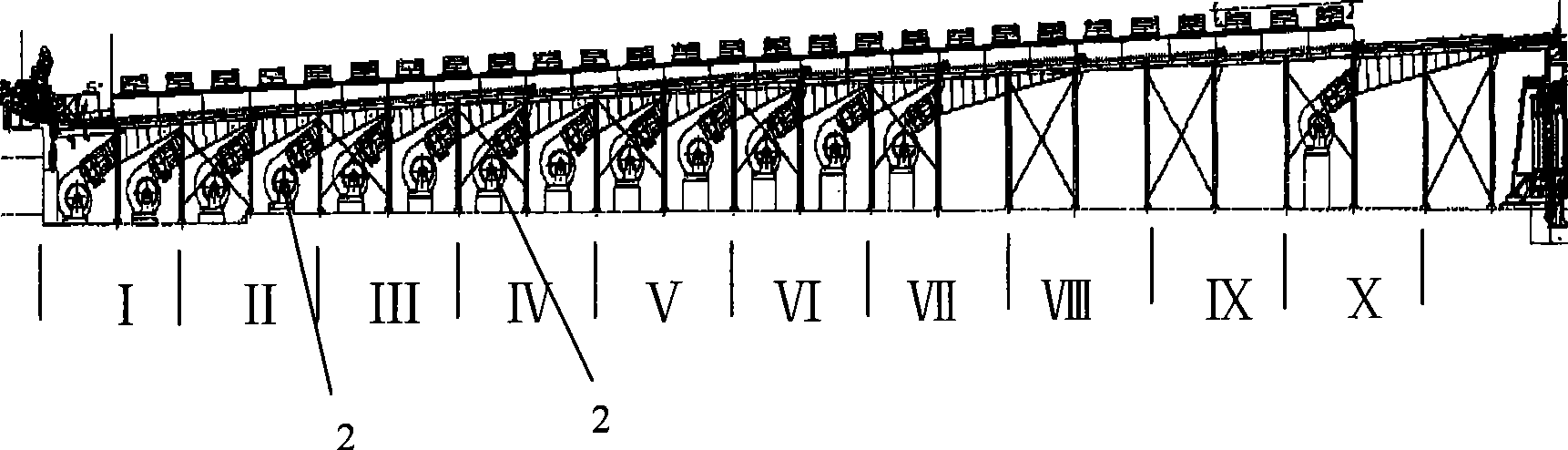

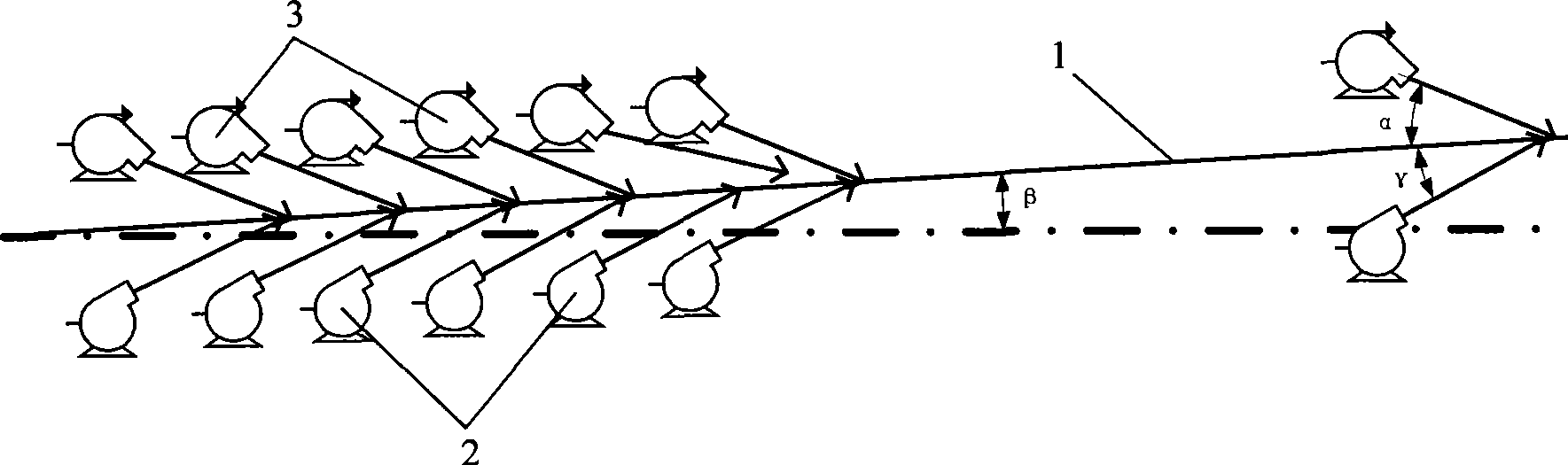

Stelmor line cooling method and cooling apparatus of high-speed rod-rolling mill

ActiveCN101480669ACool evenlyRealize top and bottom air coolingWork treatment devicesMetal rolling arrangementsWire rodEngineering

The invention relates to a cooling method and a cooling device for a stelmor wire of a high-speed wire mill. The cooling device for a stelmor wire of a high-speed wire mill adopts the structure that the lower side of a transport roller way of a stelmor wire is sequentially provided with a plurality of upper draught fans along the direction of the transport roller way, the upper side of the transport roller way of the stelmor wire is also sequentially provided with a plurality of lower draught fans along the direction of the transport roller way, the upper draught fans are arranged on a steel structural frame which can be conveyed in a hanging way, an air outlet of each upper draught fan is symmetrical to an air outlet of each lower draught fan relative to the transport roller way, and an included angle between the air direction of each upper draught fan and the transport roller way is equal to an included angle between the air direction of each lower draught fan and the transport roller way. The cooling method is applicable to the cooling device. Furthermore, additionally provided with the the draught fans on the transport roller way, the cooling device realizes the upper air cooling and the lower air cooling of the wires, increases the cooling speed, and causes the wires to be cooled more evenly, thereby the invention solves the problems of nonuniform wire contact-point structure and nonuniform mechanical property.

Owner:BAOSHAN IRON & STEEL CO LTD

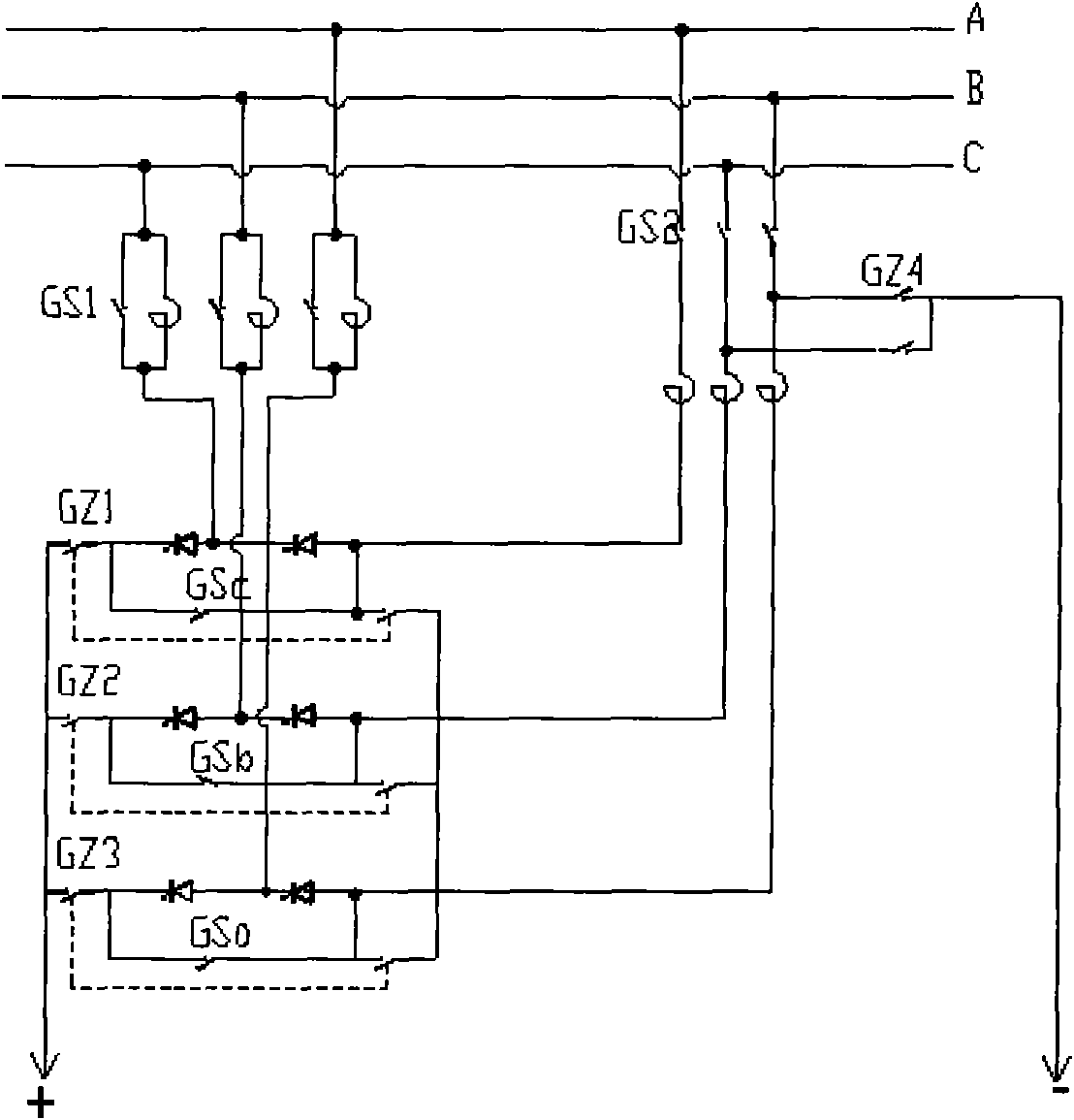

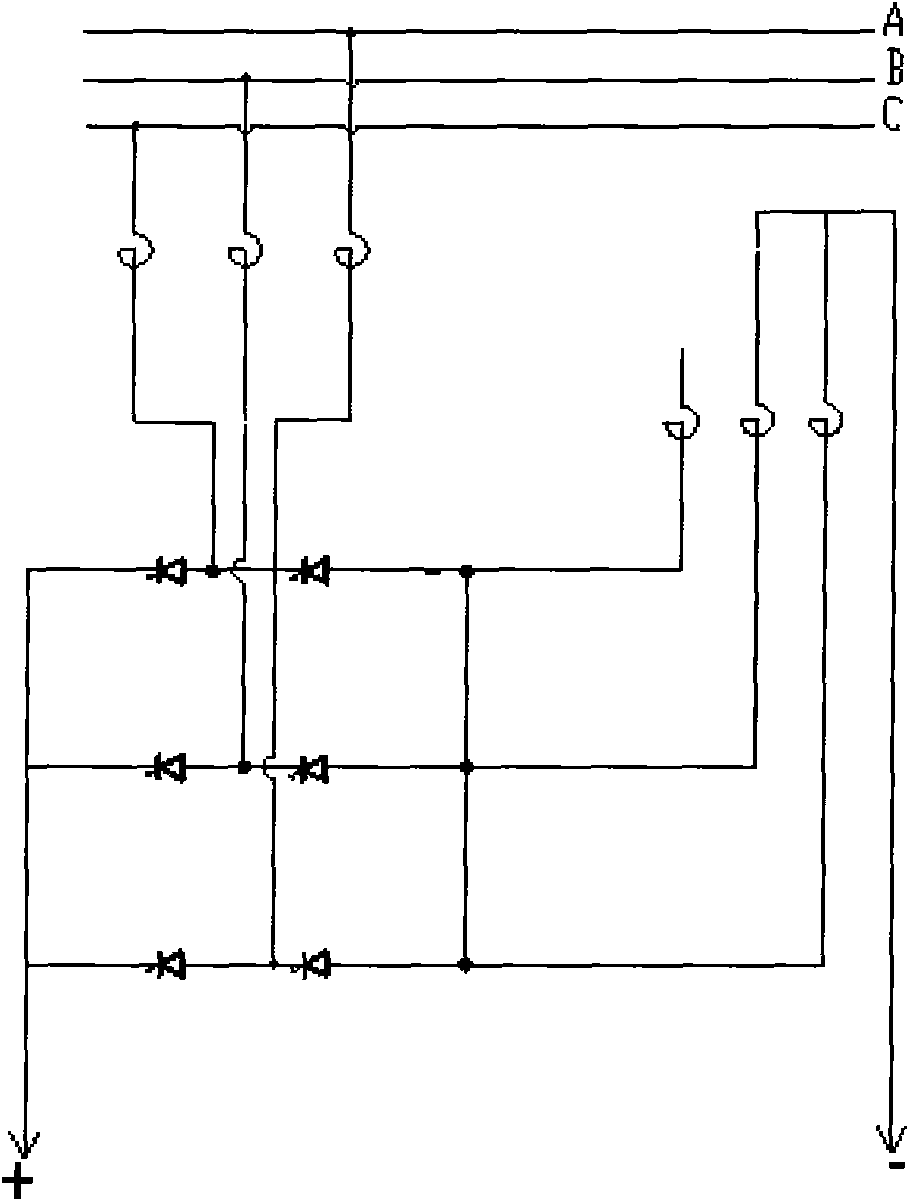

Static var compensator (SVC) and DC ice melting device and realization method thereof

InactiveCN101673950AImprove overall economyImprove the operating environmentOverhead installationReactive power adjustment/elimination/compensationOxideEngineering

The invention proposes a static var compensator (SVC) and DC ice-melting device and a realization method thereof. Primary equipment comprises a thyristor rectifier, a reactor, an AC / DC filter, a disconnecting switch, a zinc oxide arrester and the like, wherein the thyristor rectifier is also taken as the thyristor controlled reactor (TCR) valve bank; the reactor is the phase-change smoothing TCR;the thyristor rectifier and the reactor are designed into the detachable structures, therefore, the thyristor rectifier and the reactor are detached and reassembled to form different topological structures by arranging the disconnecting switch between the detachable structures and operating the line disconnecting switch, so as to realize the switchover between the DC ice-melting function and the SVC function and solve the problem of the heavy-current high-voltage and high-capacity DC ice-melting device and the problem of system reactive power compensation.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com