Patents

Literature

102results about How to "Reduce production intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

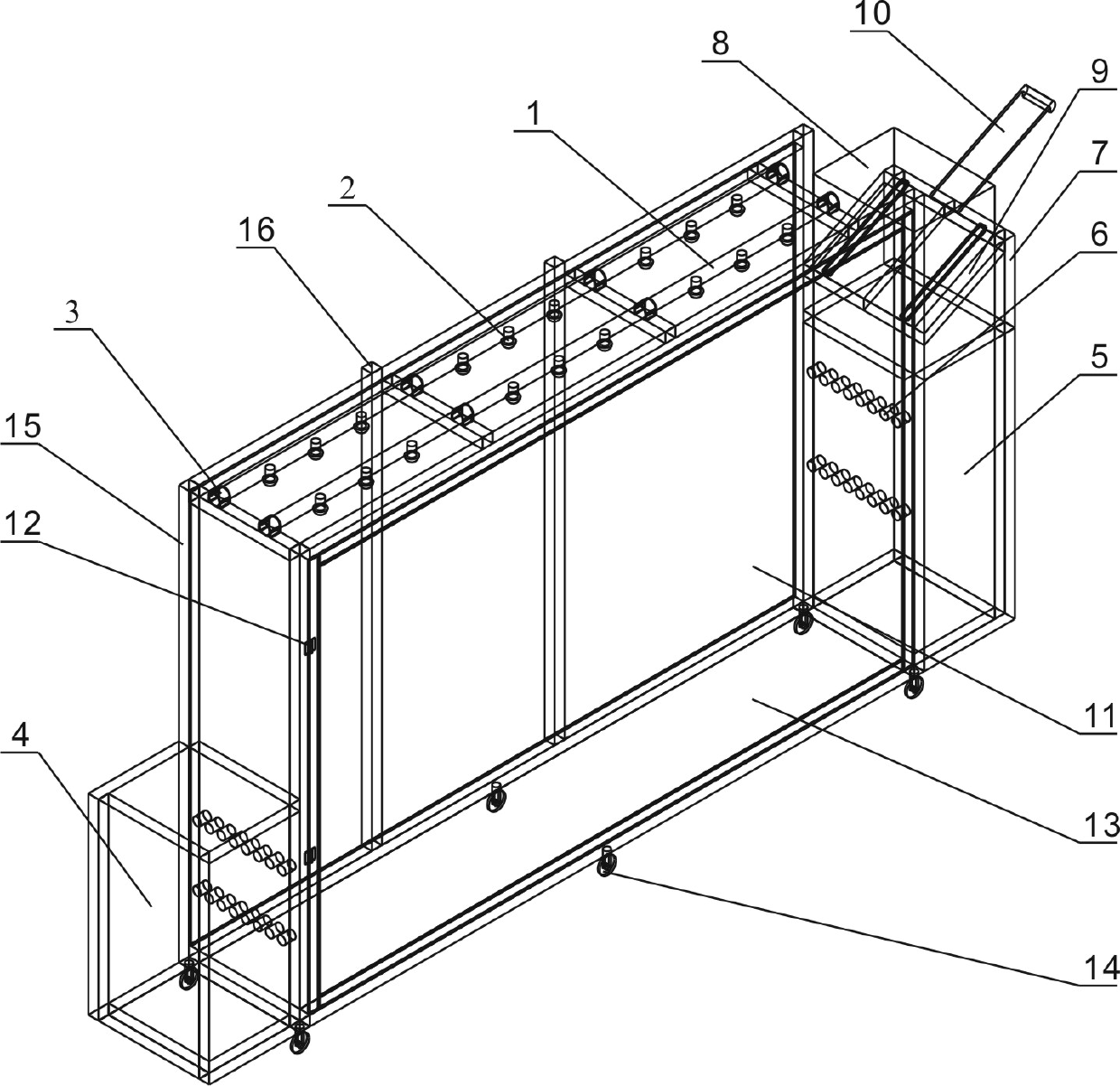

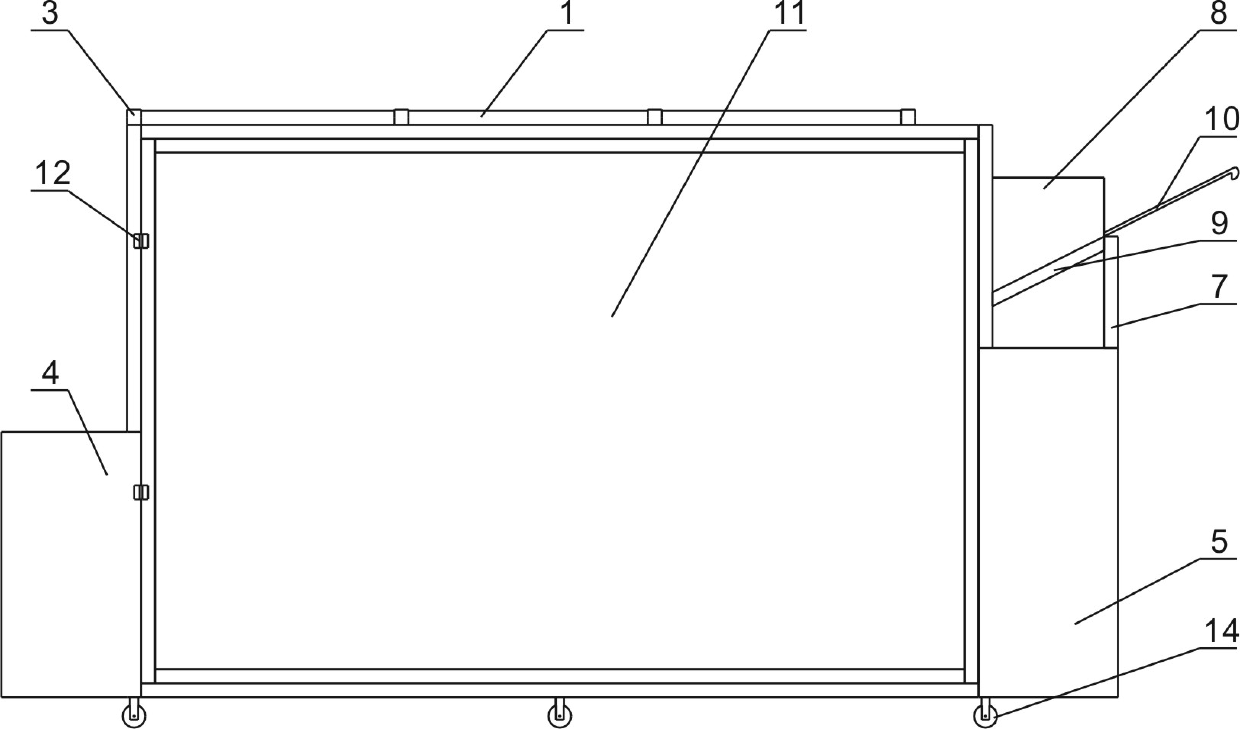

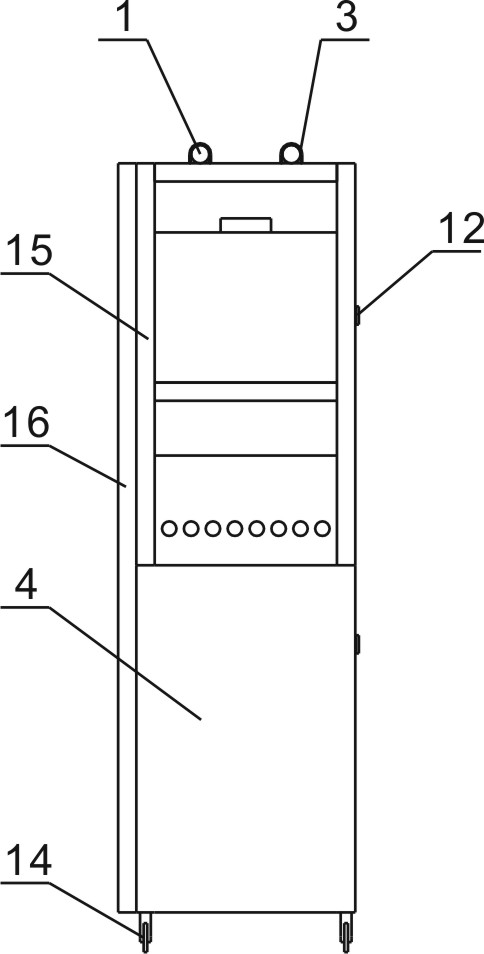

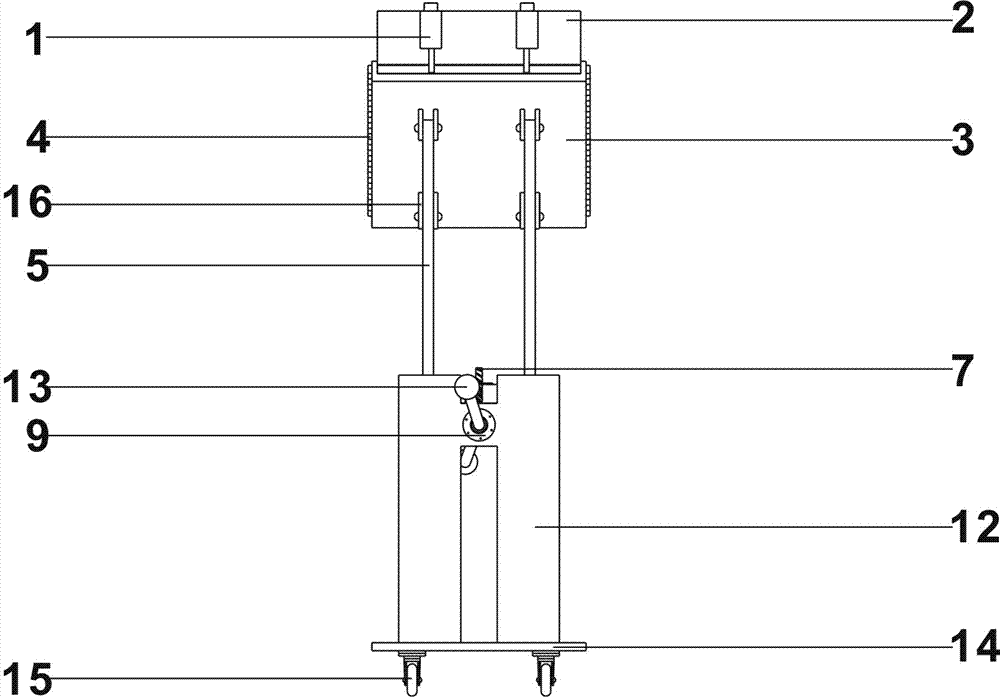

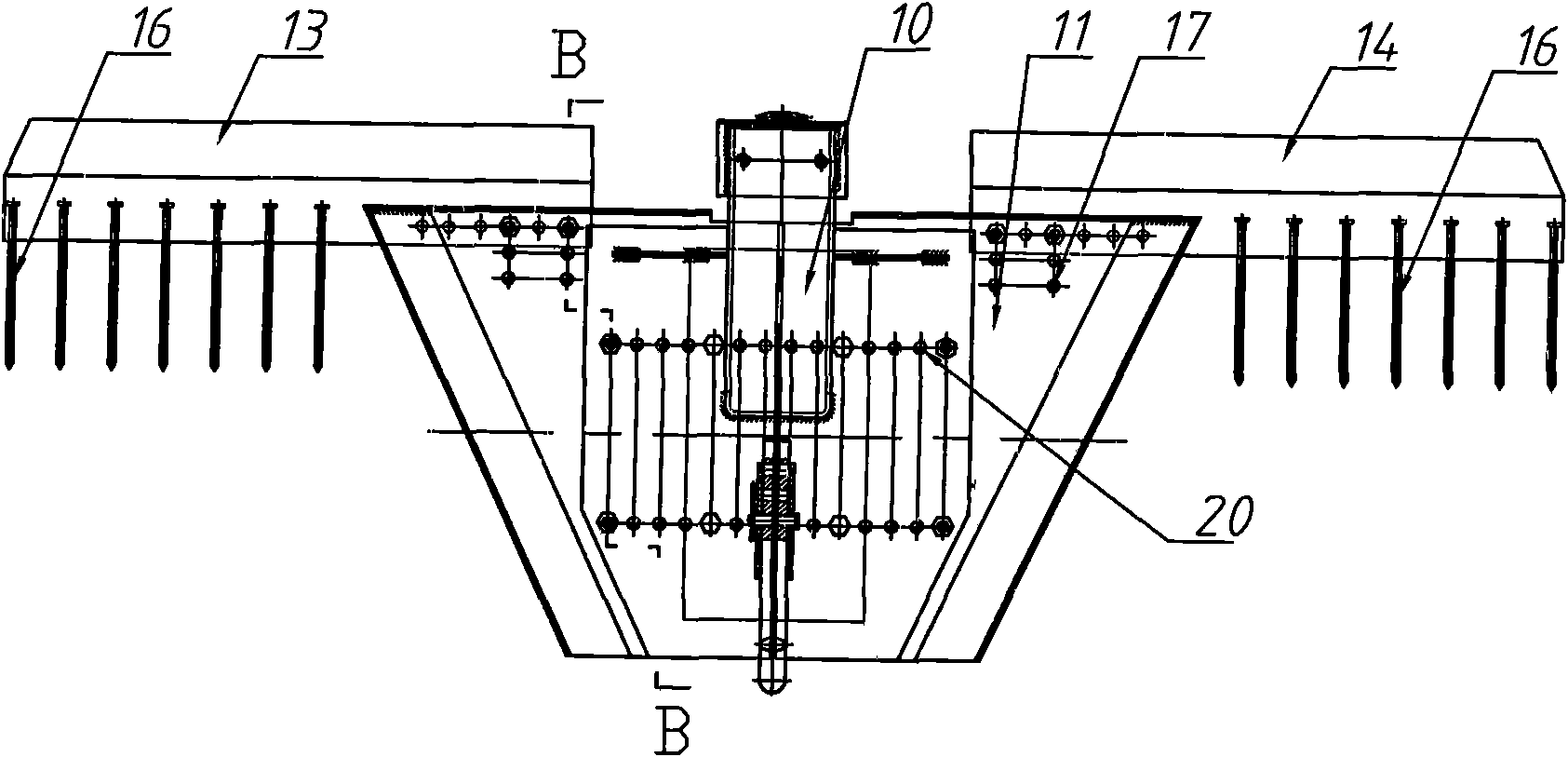

Multi-operating mode frame type portable landslide testing device for geomechanical model

ActiveCN102681028AReduce sizeOvercome the cycleEarth material testingGeological measurementsLandslideEngineering

A multi-operating mode frame type portable landslide testing device for a geomechanical model belongs to the field of geological hazard model test. The testing device comprises a frame-beam-type testing bed, a rainfall simulator, a water level regulator and a self-weight horizontal loading mechanism, wherein the frame-beam-type testing bed mainly comprises a cuboid framework, a front panel, a rear panel and a base plate; the rainfall simulator is arranged at the top of the frame-beam-type testing bed and comprises a plurality of spraying pipes and nozzles on the spraying pipes and is used for simulating rainfall in the frame-beam-type testing bed; the water level regulator comprises a left-side trough and a right-side trough respectively formed on the left and the right sides of the frame-beam-type testing bed, and a plurality of drainage holes are respectively formed on the right panel of the left-side trough and the left panel of the right-side trough and used for changing the water levels of water level simulation libraries in the left-side trough and the right-side trough; and the self-weight horizontal loading mechanism is arranged above the right-side trough and used for bearing weights, so as to exert horizontal load to the landslide model in the frame-beam-type testing bed.

Owner:中部知光技术转移有限公司

Method for treating glyphosate mother liquid

InactiveCN101190926AReduce heat transfer efficiencyReduce production intensityOrganic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsChemistryGlyphosate toxicity

The invention provides a treatment method of mother liquor of glyphosate, which is applicable in large-scale production and has low cost and can improve the recovery rate of triethylamine that is an activator and is used in the synthesis of glyphosate, wherein, in the technical process that the glyphosate mother liquor adopts a glycin method to prepare the glyphosate, the acidic hydrolysis of glyphosate is finished and the pure crystalloid of the glyphosate precipitates in the system, then the residual of the mother liquor is the mother liquor of the glyphosate. By controlling the charge-in mixture ratio and system temperature and adjusting the pH to a certain range, the method of the invention can obtain the triethylamine simply in a high recovery ratio which normally can reach over 90 percent.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

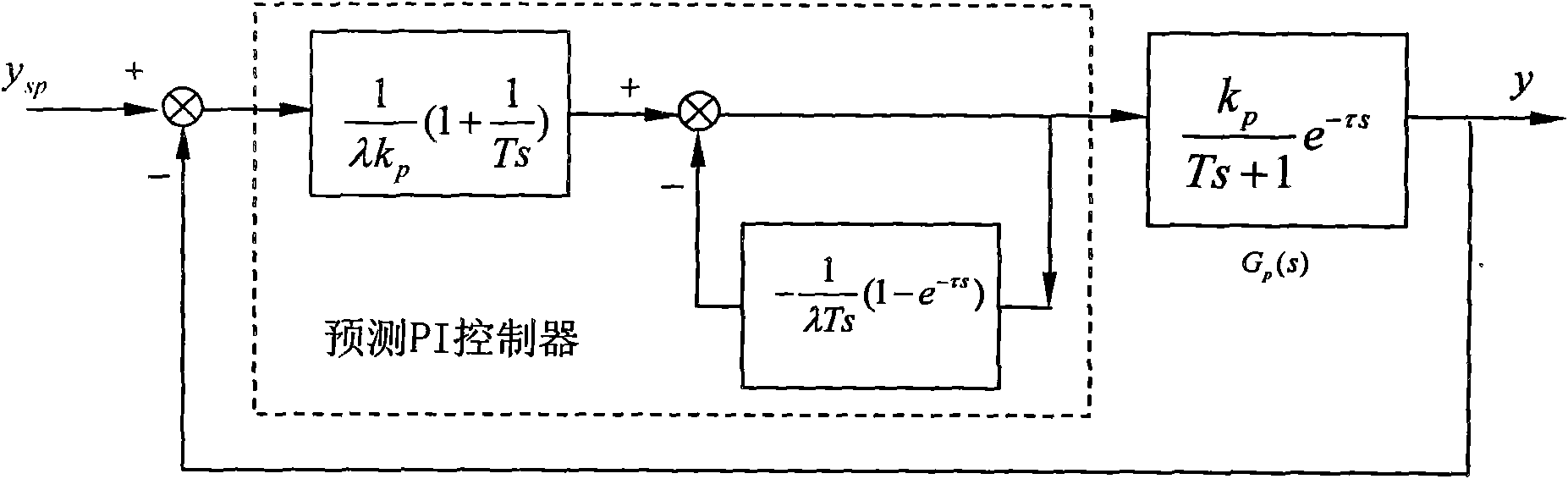

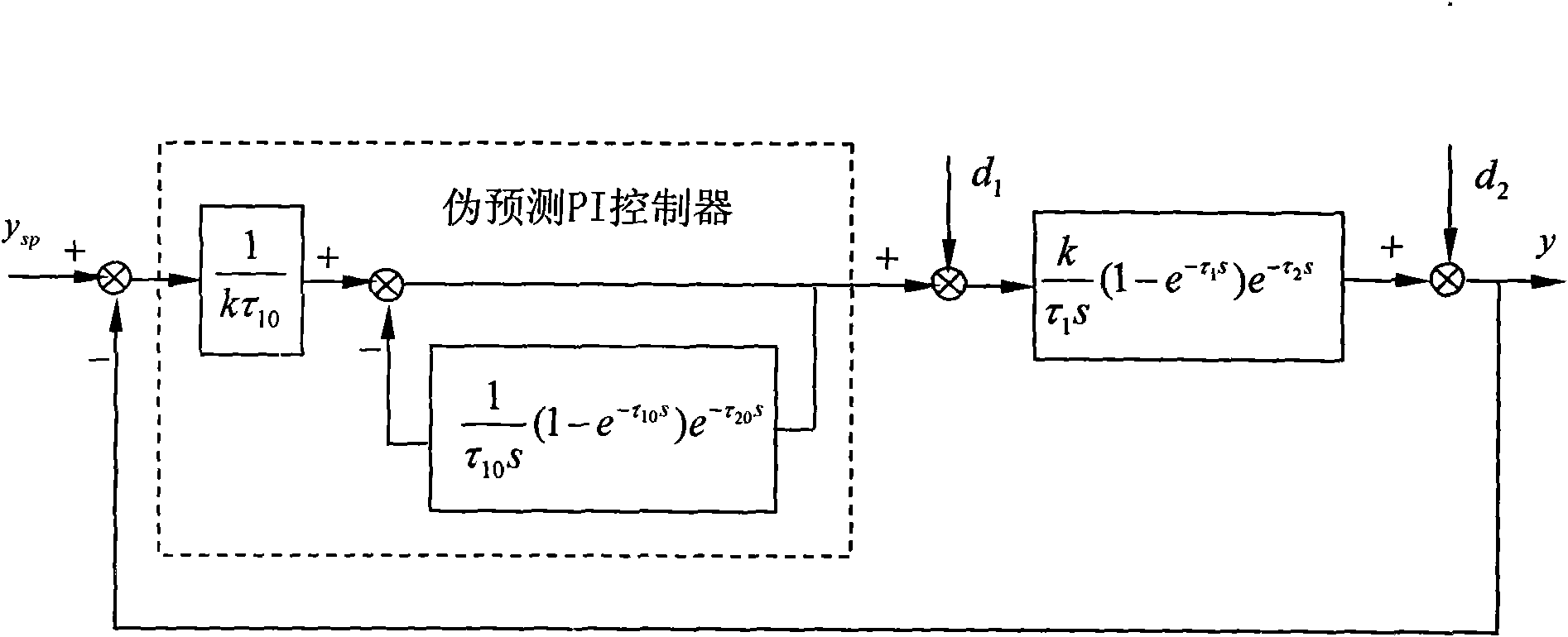

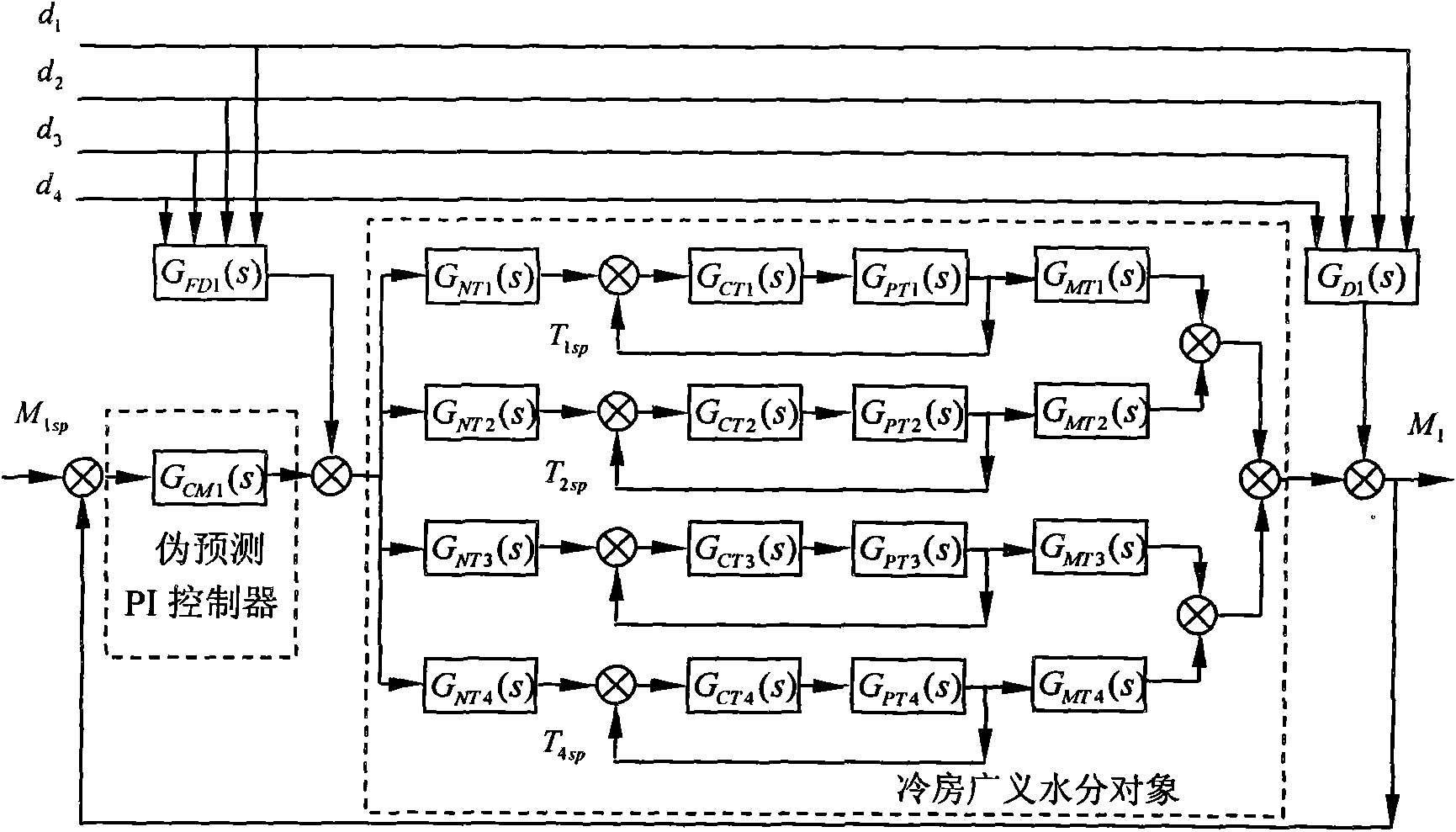

Control method applied to threshing and redrying production line

InactiveCN101673087AReduce production intensityQuality improvementControllers with particular characteristicsAdaptive controlProduction lineTemperature control

The invention relates to a control method applied to a threshing and redrying production line, providing a predictive PI controller based on a model. The control method is composed of a PI control item and a predictive control item. Based on a flue-curing barn temperature object, four flue-curing barn temperature controllers are designed by an advanced predictive PI control algorithm, thus avoiding the problems of low regulation speed and big fluctuation of the traditional PID control algorithm; based on a cooling room generalized moisture object and an outlet generalized moisture object, thecooling room moisture control scheme and the outlet moisture control scheme are respectively designed by adopting self-adaption anti-interference pseudo prediction PI control algorithm, thereby greatly improving control precision and enterprise economic benefit. The invention has the advantages that the control method is a control algorithm based on the model, and the PI control item can improve controller robustness; the predictive control item can predict future control function according to the control function in a certain past period, eliminating control blindness, and ensuring that the production is totally in autocontrol in the closed loop mode.

Owner:DONGHUA UNIV

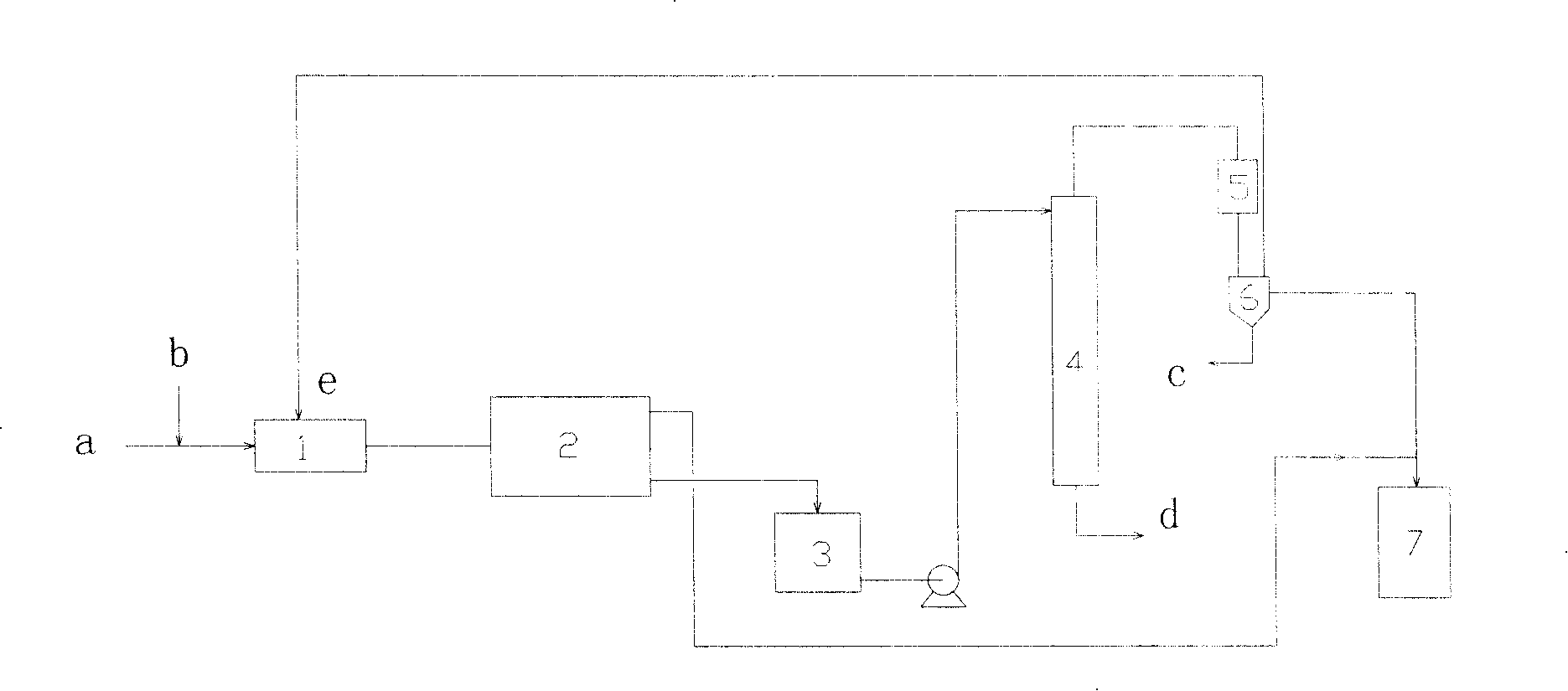

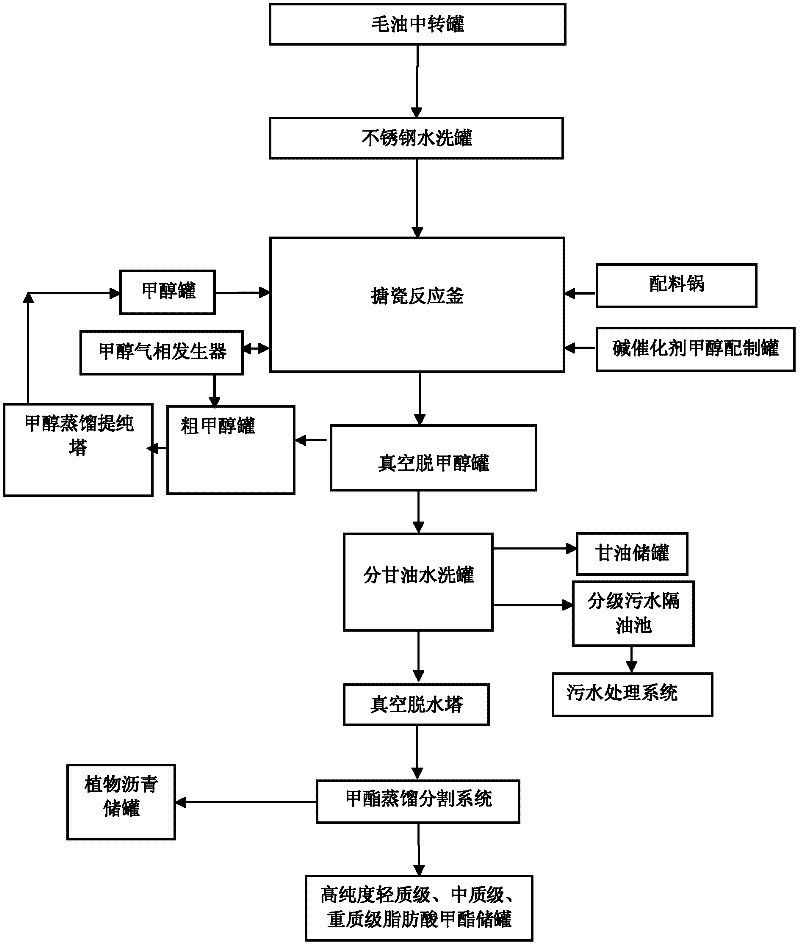

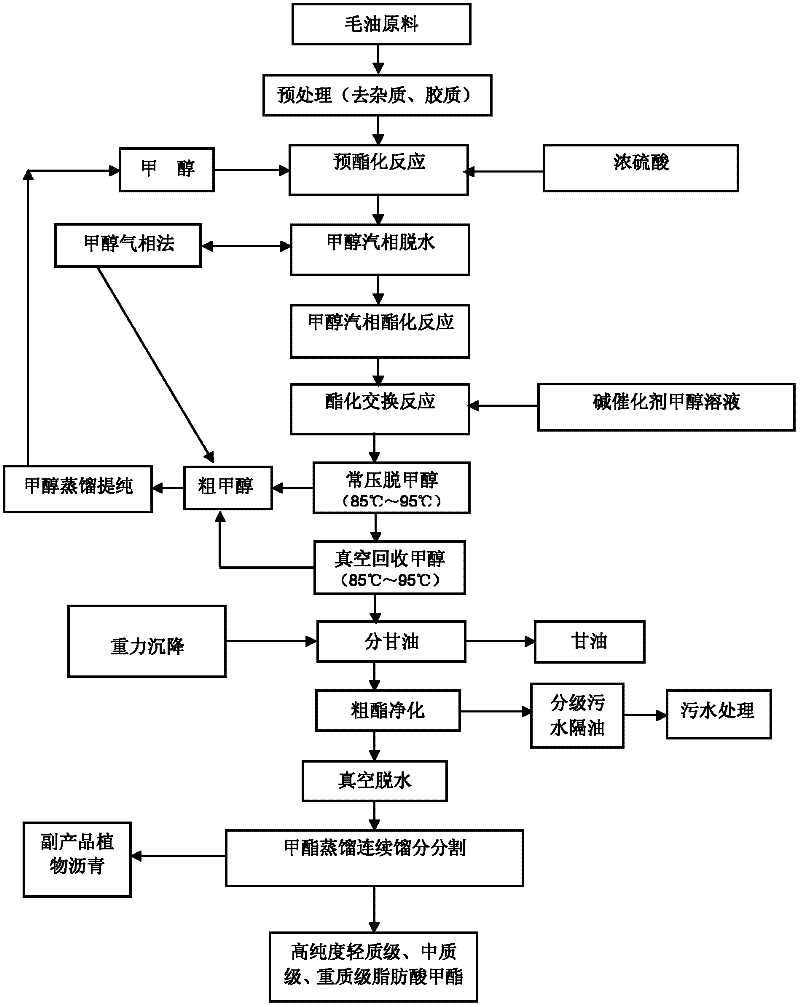

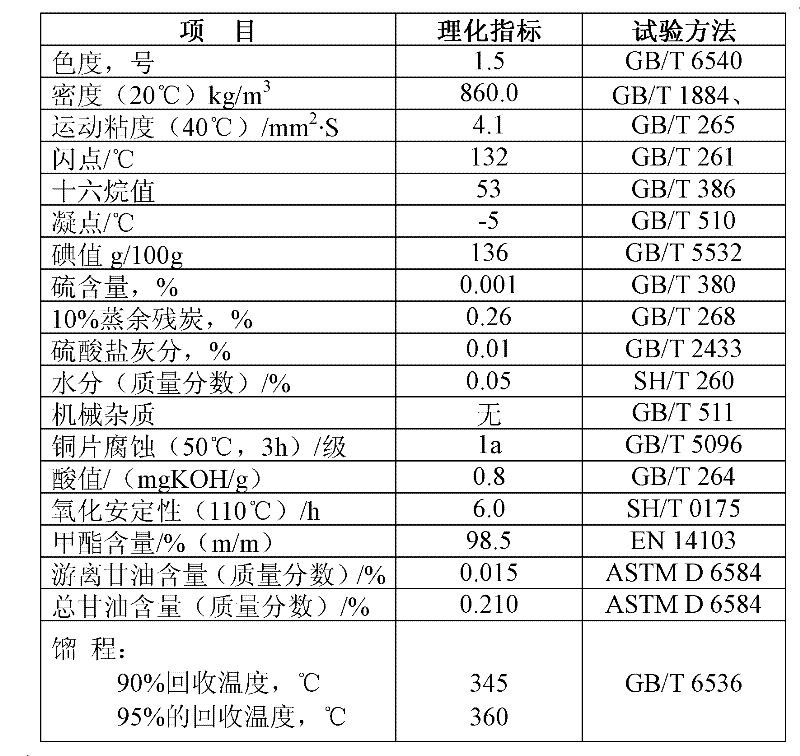

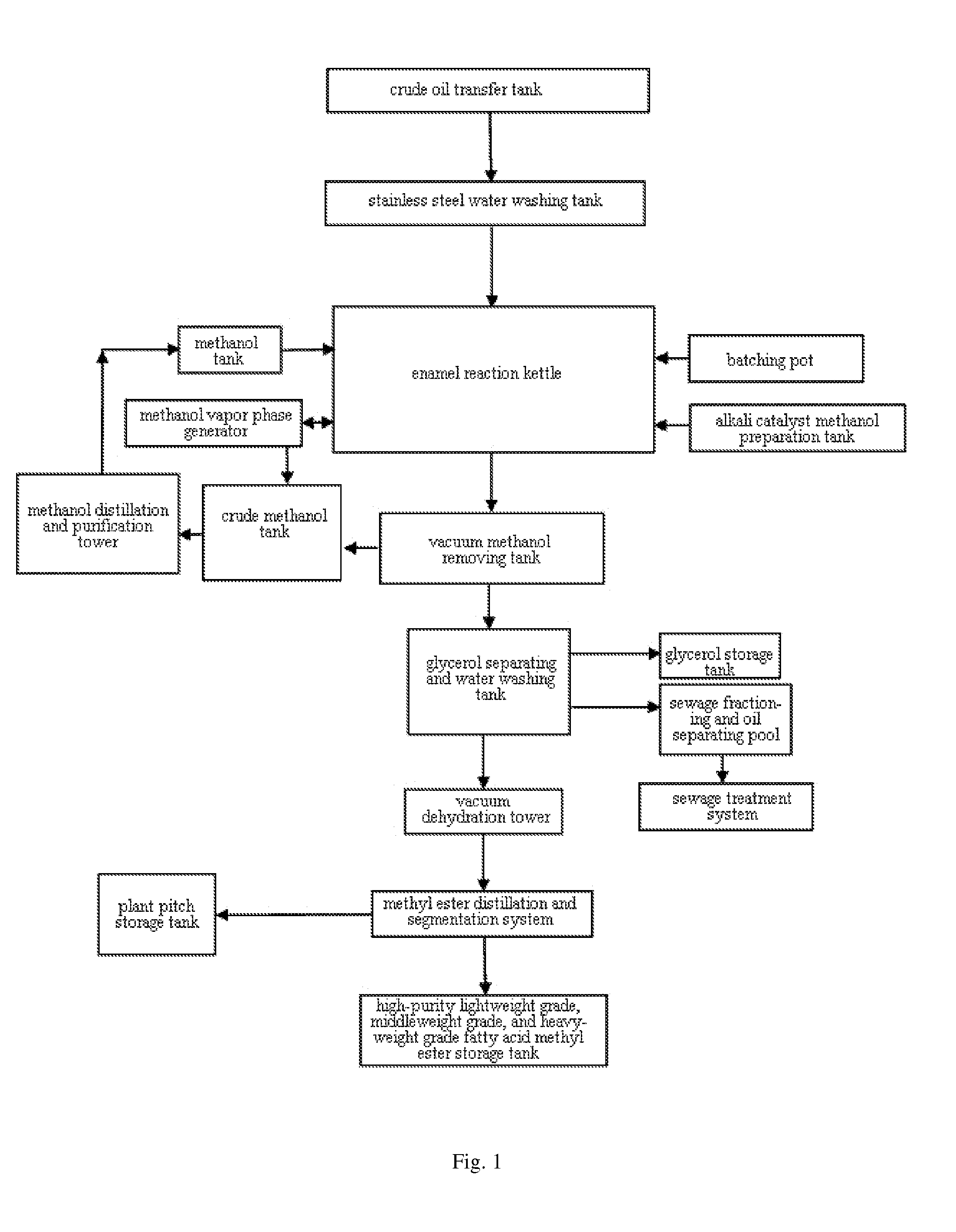

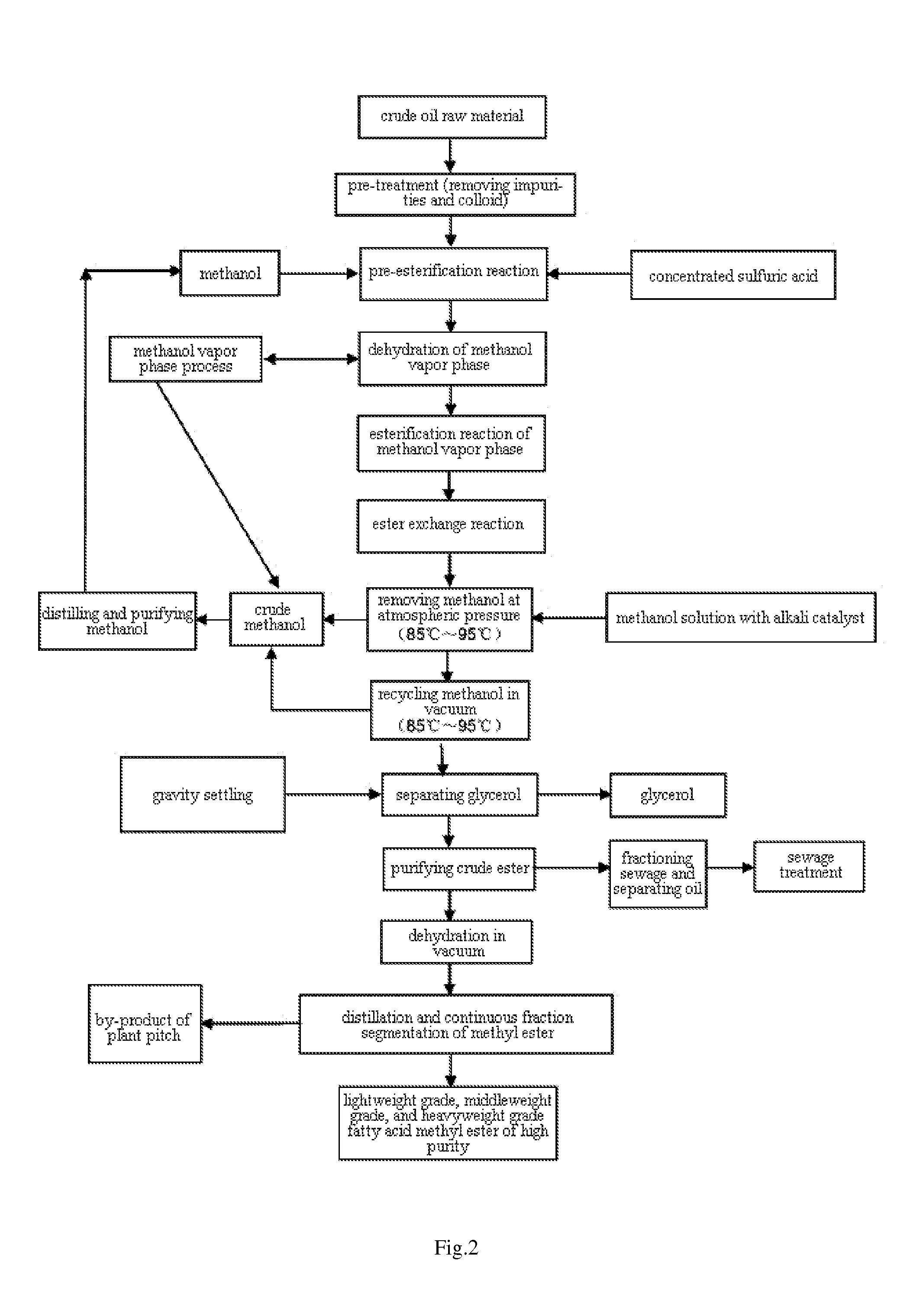

Method for preparing high-purity biodiesel

InactiveCN102311883AWide variety of sourcesBroad quality requirementsFatty oils/acids recovery from wasteFatty acid esterificationDistillationTransesterification

The invention relates to a method for preparing high-purity biodiesel with crude oil. The method comprises: pretreating the raw material of crude oil to remove impurities; subjecting the pretreated crude oil raw material to pre-esterification with concentrated sulfuric acid as a catalyst; then conducting transesterification with the presence of a base catalyst; recovering methanol and separating glycerin, thus obtaining coarse fatty acid methyl ester; subjecting the obtained coarse fatty acid methyl ester to purification, distillation, and segmentation so as to obtain high-purity fatty acid methyl ester.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

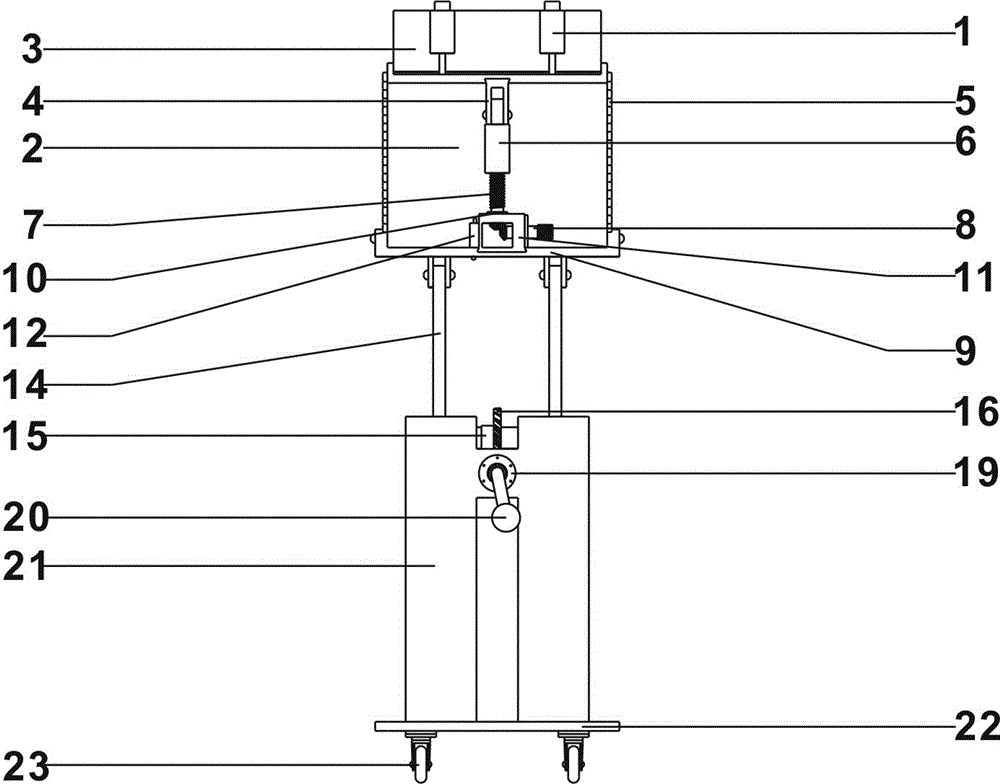

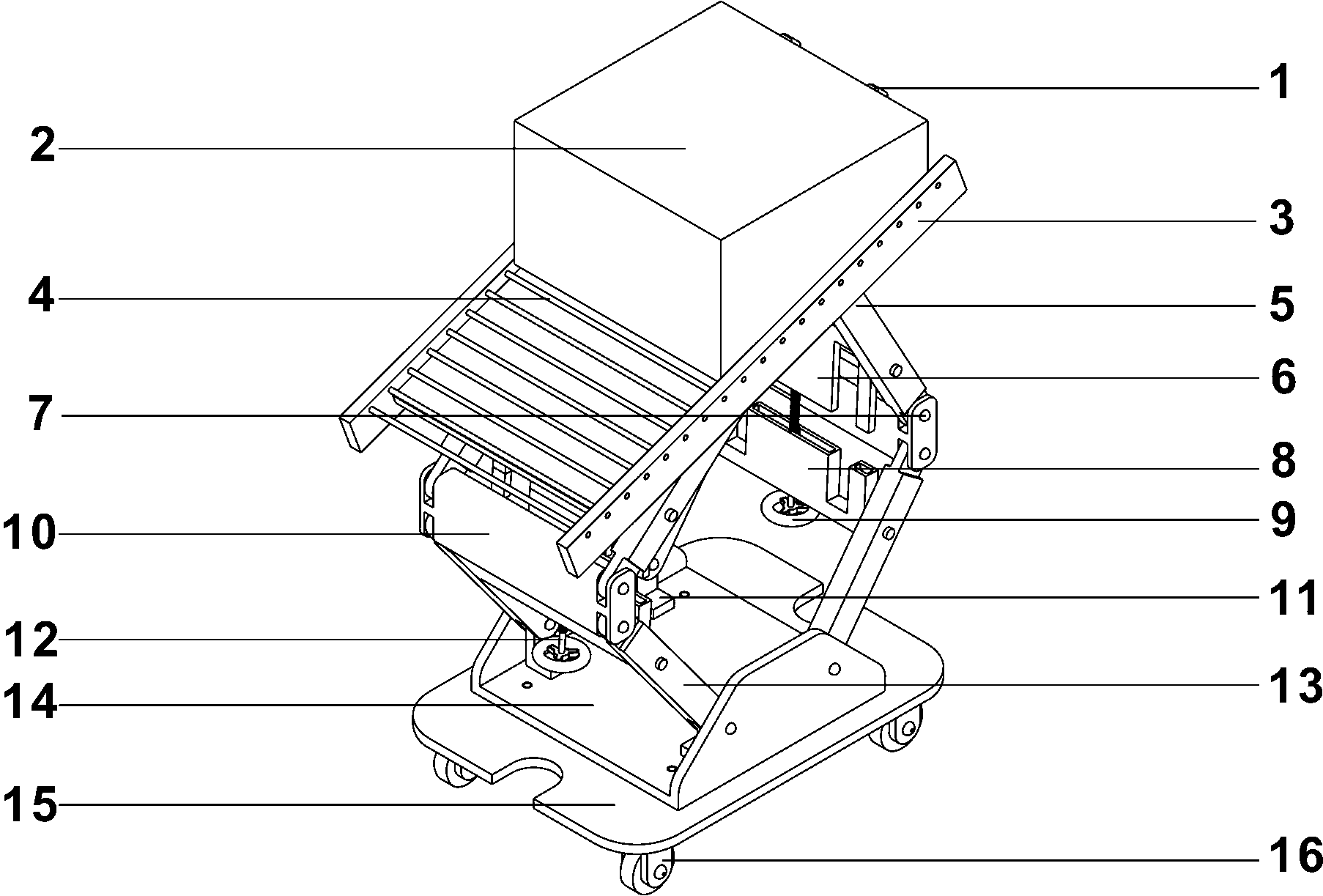

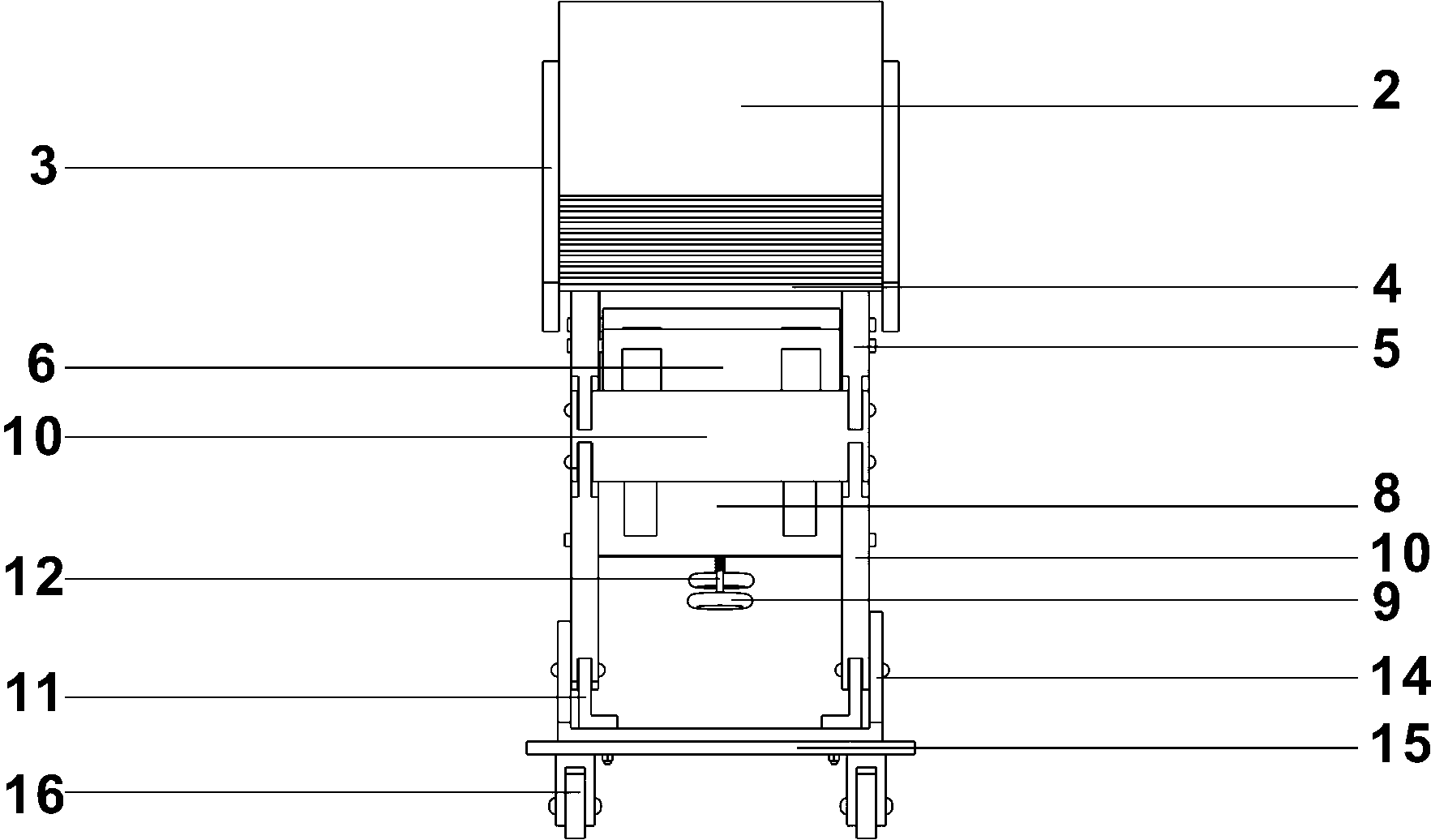

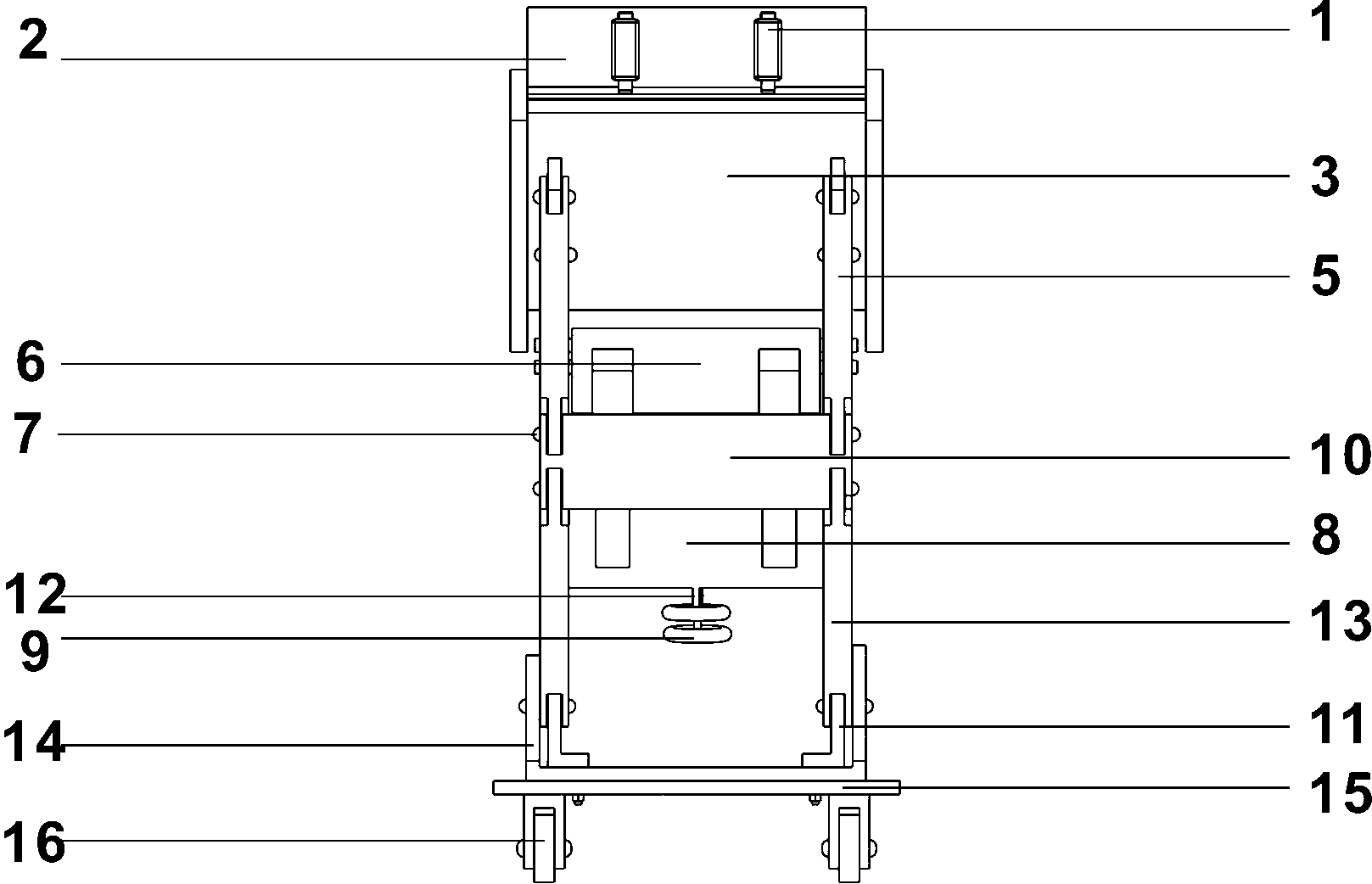

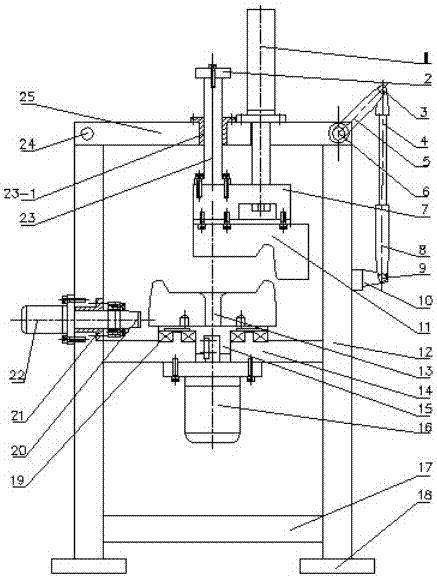

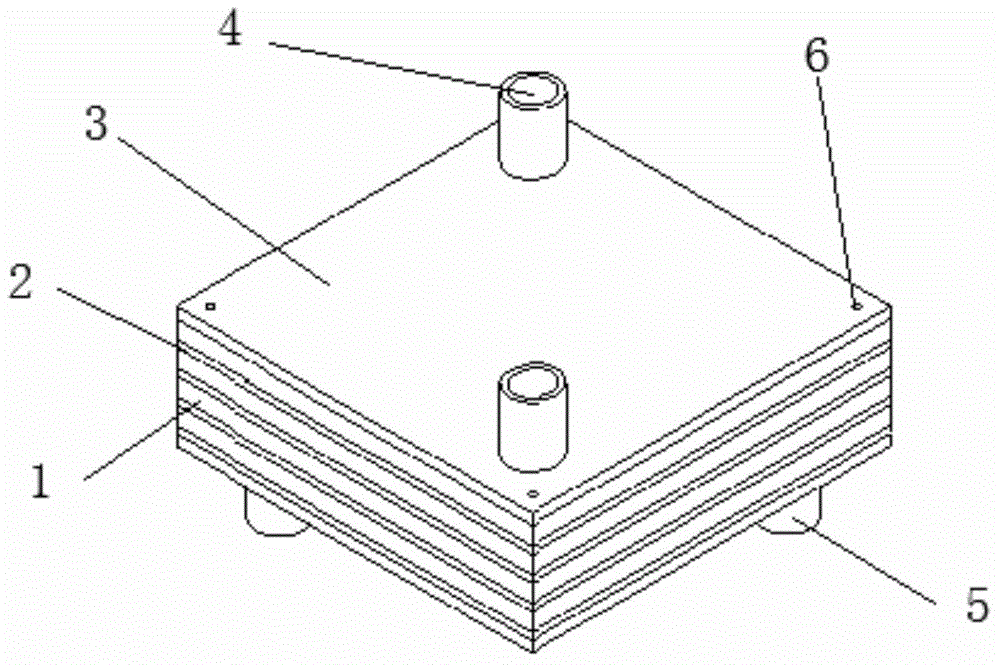

Manual lifting deadweight loading device for landslide physical model test

ActiveCN102980785AReduce production intensitySimple structureStructural/machines measurementLandslidePhysical model

The invention discloses a manual lifting deadweight loading device for a landslide physical model test, which comprises a bottom plate, a lifting mechanism, an angle adjustment mechanism and a thrust loading mechanism, wherein the lifting mechanism is positioned on the bottom plate; the upper end of the lifting mechanism is connected with the angle adjustment mechanism; the lifting mechanism is used for driving the lifting of the angle adjustment mechanism; the angle adjustment mechanism comprises a support plate, a slide panel, a screw rod, a sleeve and a horizontal knob; the support plate is connected with the upper end of the lifting mechanism; the front end of the support plate is articulated with the front end of the slide panel; the screw rod is arranged at the rear end of the support plate in a supporting manner; the sleeve is sleeved at the upper part of the screw rod; the screw rod is connected with the sleeve by screw threads; the lower end of the screw rod is engaged with the end part of the horizontal knob by a bevel gear; the rotation of the horizontal knob can drive the screw rod to rotate; the top end of the sleeve is articulated with a slide connecting block; the slide connecting block is contacted with the rear part of the bottom surface of the slide panel; the thrust loading mechanism comprises a loading platform used for bearing weight; the bottom surface of the loading platform is slidingly matched with the top surface of the slide panel; and the loading platform can slide back and forth along the slide panel.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing light porous particle controlled release fertilizer

ActiveCN104262005AImprove water absorptionGood fertilizer effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDipotassium phosphate

The invention discloses a method for preparing a light porous particle controlled release fertilizer. The method comprises the following steps: uniformly mixing CRT screen glass powder, 5-20 percent of monopotassium phosphate, dipotassium phosphate, potassium sulfate, tripotassium phosphate, potassium chloride, zinc dihydrogen phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, cobalt oxide and manganese oxide, pressing, molding, feeding the mixture into a roller kiln at the temperature of 650-660 DEG C, and preserving the temperature to be 780-790 DEG C for 15-30 minutes; and reducing the temperature to be 50-80 DEG C or below at a rate of 100-200 DEG C per minute, thereby obtaining the light porous particle controlled release fertilizer. The light porous particle controlled release fertilizer prepared by the invention can be widely applied to the fields of indoor horticulture, urban gardening, street planting and farmlands. The preparation process is simple in operating process and low in cost, the production cost of the controlled release fertilizer can be effectively reduced, the environment is protected, wastes are changed into valuable materials, and the light porous particle controlled release fertilizer is suitable for large-scale industrial production and has obvious economic benefits and environmental protection benefits.

Owner:广西丰岭肥业有限公司

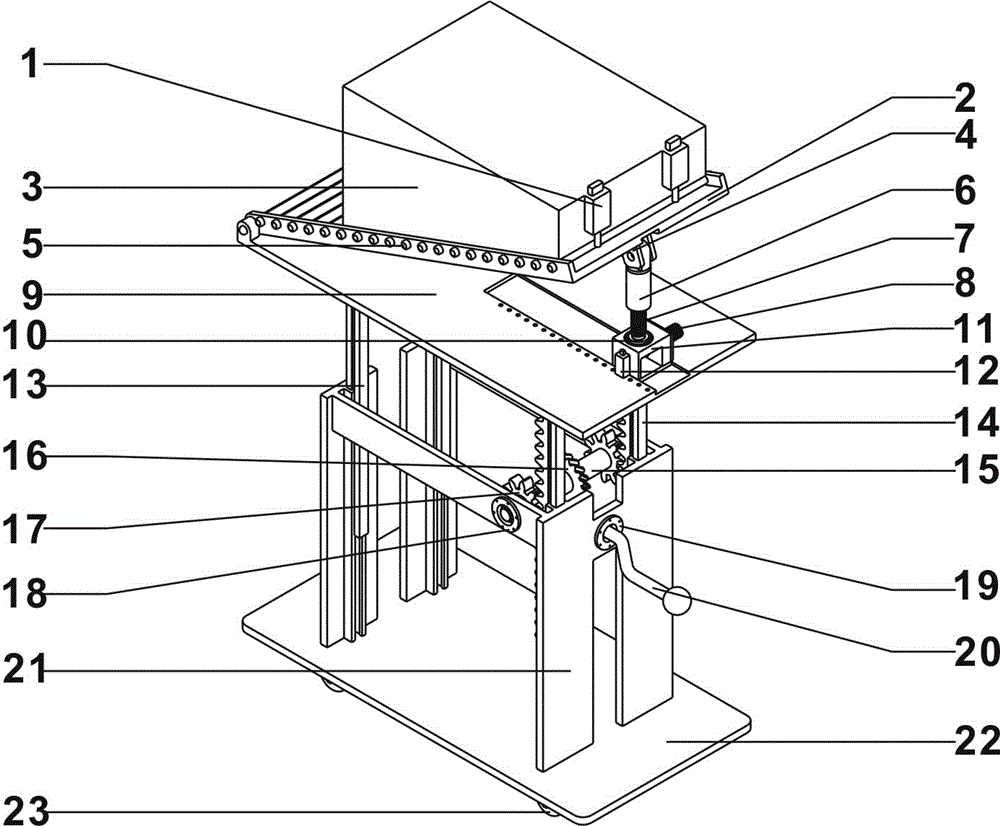

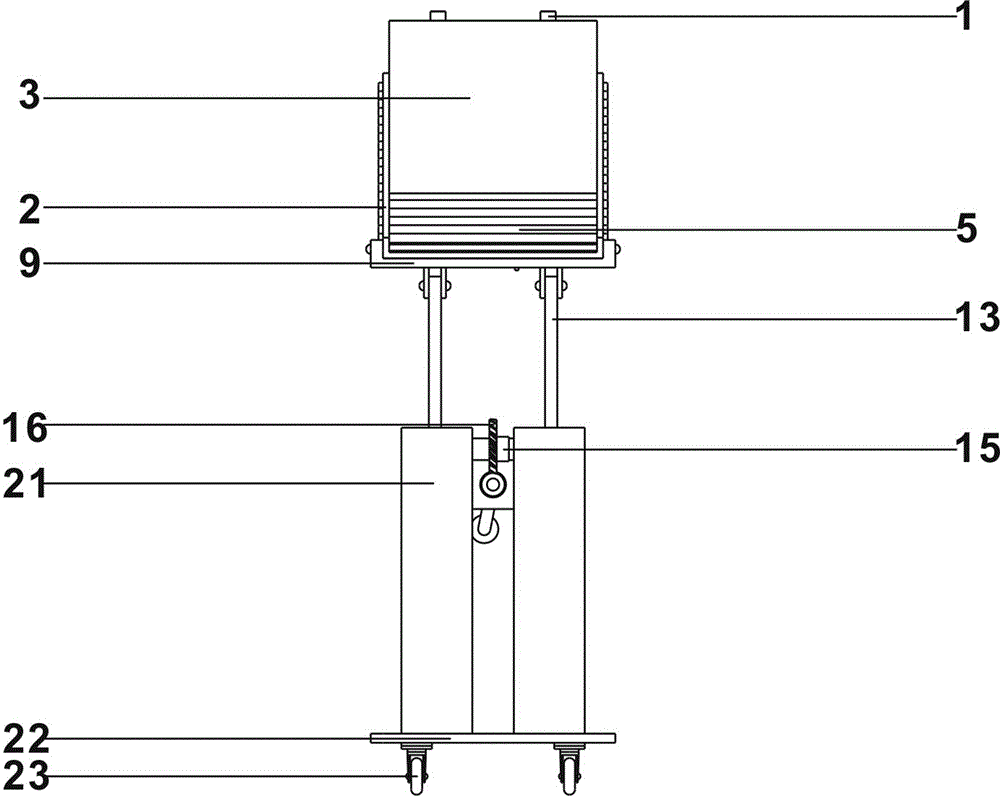

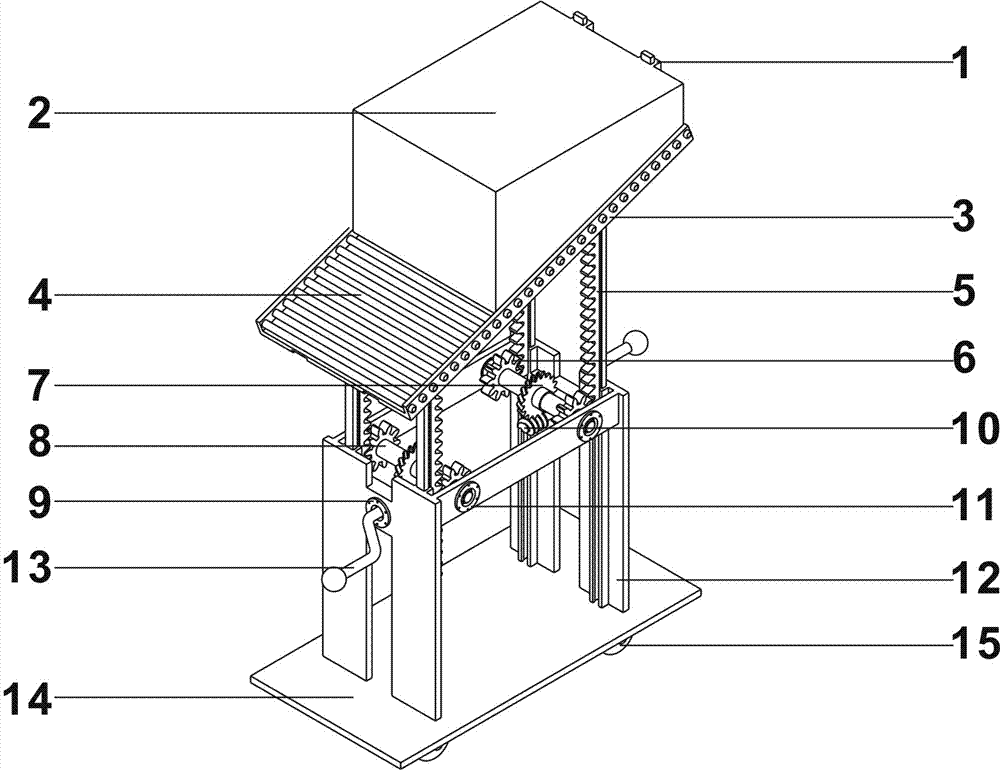

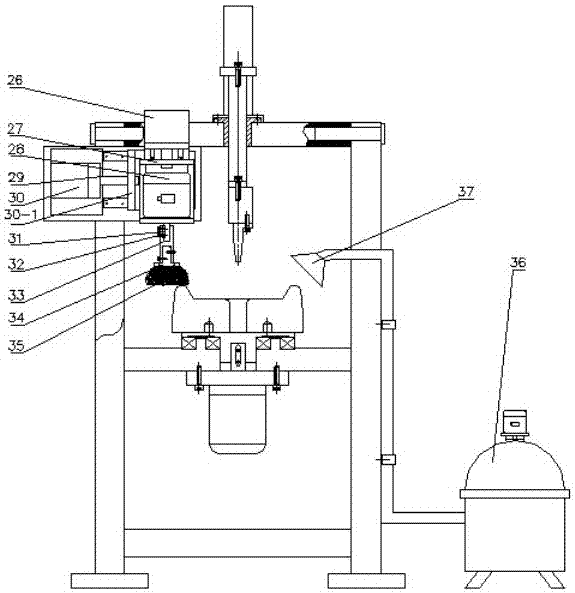

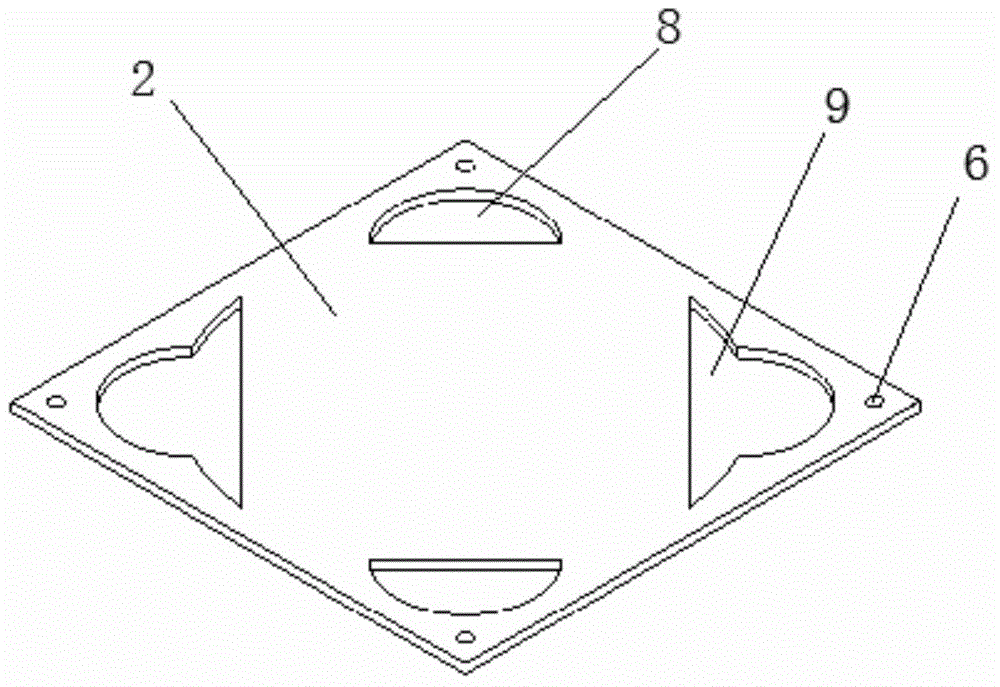

Manual rack type dead-weight loading device for landslide physical model test

ActiveCN103033607AReduce production intensitySimple structureEarth material testingDrive shaftLandslide

The invention discloses a manual rack type dead-weight loading device for a landslide physical model test. The device comprises a bottom plate, a sliding surface adjusting mechanism and a thrust loading mechanism, wherein the sliding surface adjusting mechanism is located on the bottom plate and comprises a sliding panel, two groups of racks and gears which are mutually meshed, two transmission shafts, two groups of worm wheels and worms which are mutually meshed, two rocking handles and a guide holder; the guide holder is fixed on the bottom plate; vertical guide grooves are formed at the front part and the rear part of the guide holder respectively; one group of racks are located in the guide groove at the front part of the guide holder, while the other group of racks are located in the guide groove at the rear part of the guide holder; each group of racks and one of worm wheels are arranged on the guide holder through the transmission shafts; each worm is connected with one of the rocking handles; the front end of the sliding panel is hinged with the tops of the group of racks which are located at the front part of the guide holder, while the rear end of the sliding panel is arranged on the group of racks which are located at the rear part of the guide holder; the thrust loading mechanism comprises a loading platform; the bottom of the loading platform is in sliding fit with the top surface of the sliding panel; and the loading platform can slide along the sliding panel forth and back.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

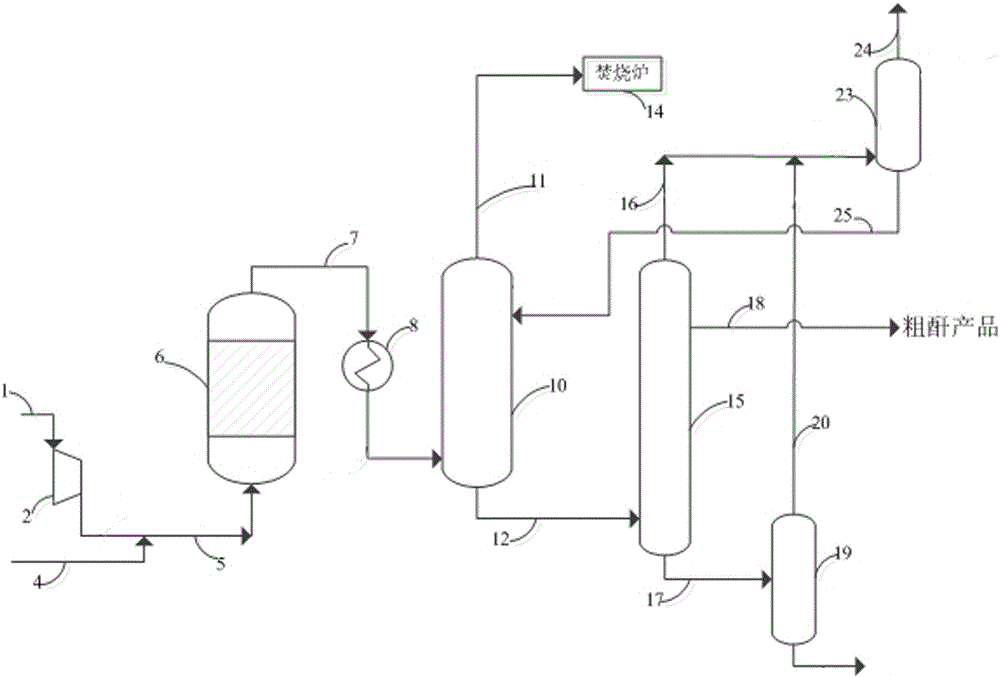

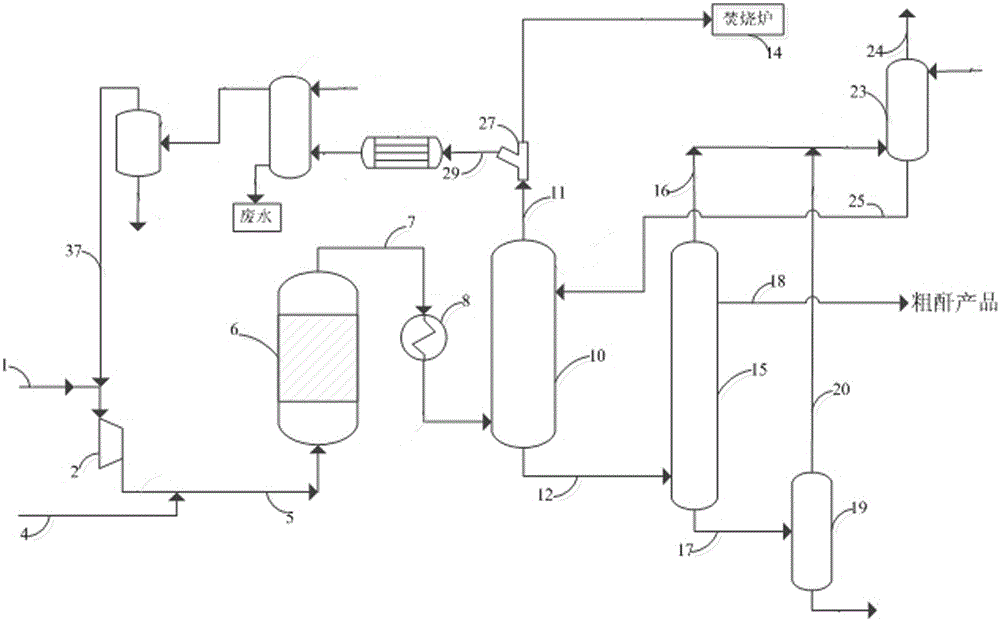

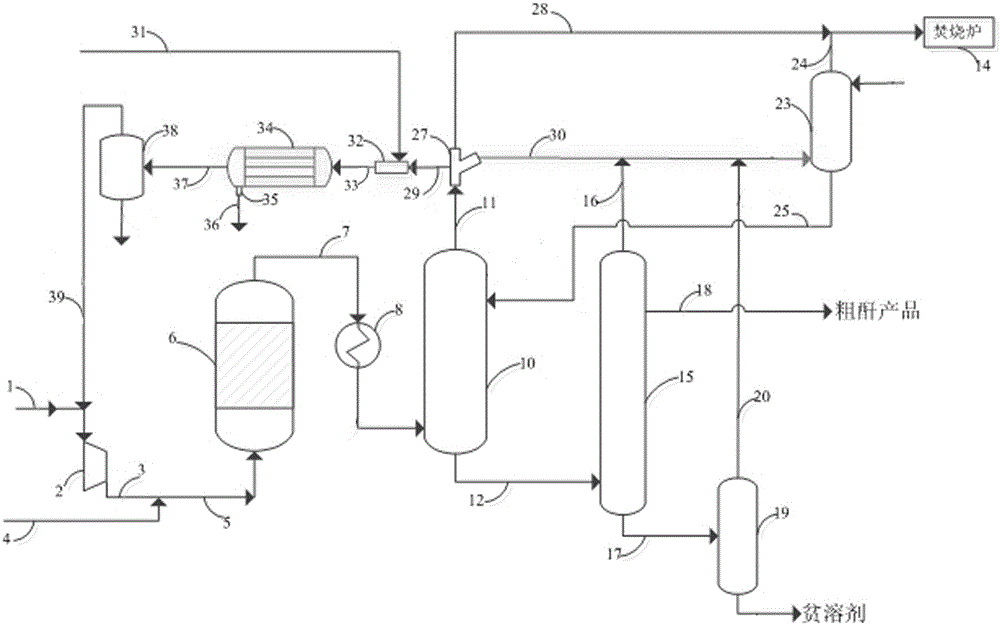

Maleic anhydride tail gas treatment equipment and maleic anhydride tail gas treatment process

InactiveCN105001185ALower conversion rateHigh selectivityOrganic chemistryDispersed particle separationVapor–liquid separatorGas cooler

The invention relates to maleic anhydride tail gas treatment equipment, which comprises an air compressor, a maleic anhydride reactor, a gas cooler, a maleic anhydride absorption tower, a burning furnace, a maleic anhydride desorption tower, a lean oil flash evaporation tower, a tail gas washing tower, a gas flow distributor, a moisturizing device, a tail gas deacidification device and a gas-liquid separator, wherein the devices are connected through pipelines, the gas flow distributor comprises an inlet and at least three outlets, the inlet is connected with the tail gas outlet of the maleic anhydride absorption tower, the first outlet is connected with the moisturizing device, the second outlet is connected with the burning furnace, and the third outlet is connected with the tail gas washing tower. The present invention further provides a tail gas treatment process using the treating equipment. Compared with the equipment and the process in the prior art, the equipment and the process of the present invention have the following characteristics that n-butane, maleic anhydride and the maleic anhydride absorption solvent in the tail gas are reused at a maximum. In addition, the condenser with a condensate discharge port is used and the acid organic compounds in the tail gas are eluted by a lot of water vapor carried by the tail gas so as to reduce the equipment investment cost and the produced waste acid water.

Owner:NINGBO ZHETIE JIANGNING CHEM

Process for refining crude glycerin and recovering byproducts

InactiveCN102229521AHigh purityAchieve purificationOrganic compound preparationHydroxy compound separation/purificationGlycerolFatty acid

The invention discloses a process for refining crude glycerin and recovering byproducts. The process for refining the crude glycerin and recovering the byproducts comprises the following steps of: diluting the crude glycerin with water; preheating the crude glycerin to 30 to 60 DEG C; introducing the crude glycerin into an ion exchange column with cation exchange resin; allowing the crude glycerin to enter a storage tank A, preserving the heat to be between 30 and 60 DEG C and standing to layer; after layering, introducing the bottom layer of liquid into an ultrafiltration membrane component and allowing the upper layer of liquid to enter a storage tank B; introducing the permeating liquid of the ultrafiltration membrane into an anion exchange column and then introducing the permeating liquid into a cation exchange column; evaporating, concentrating or distilling effluent to obtain high-purity glycerin; returning the non-permeating liquid to the storage tank A; standing liquid in the storage tank B to layer; separating out the upper layer of oil layer; washing the oil layer with hot water; standing and separating; and taking the upper layer of oil layer to obtain fatty acid. The process is high in processing efficiency, simple in process and low in cost. By the process, the high-purity glycerin can be produced efficiently; the fatty acid can be recovered from the crude glycerin; and production cost is reduced.

Owner:江门市鸿捷精细化工有限公司

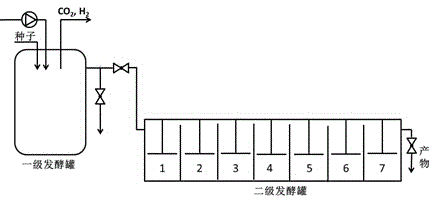

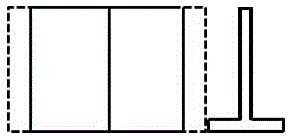

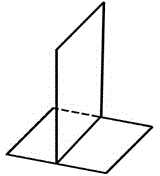

Device and method for producing butyl alcohol through continuous fermentation of lignocellulose

ActiveCN104946516AReduce consumptionReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateCellulose

The invention discloses a device for producing butyl alcohol through continuous fermentation of lignocellulose. A primary fermentation tank is a stirring kettle type fermentation tank, and a secondary fermentation tank is a cuboid tubular fermentation tank; vertical partition plates are arranged in the tubular fermentation tank to divide the tubular fermentation tank into multiple same reaction units; the lower end of the partition plate is fixedly connected with the bottom of the fermentation tank, and a water channel is reserved at the upper end of the partition plate; each reaction unit is equipped with an inverted T-shaped barrier plate; the T-shaped barrier plate is fixedly connected with the front and back ends of the reaction unit; and the top end of the reaction unit is fixedly connected with the top of the fermentation tank. According to a method for producing butyl alcohol through continuous fermentation using the device, the secondary fermentation tank is an empty tank before fermentation; and the fermentation liquid flows from the primary fermentation tank and through the top of the first reaction unit of the secondary fermentation tank by use of liquid level difference, overflows to each reaction unit step by step and finally flows out of the last reaction unit. By adopting the device and method disclosed by the invention, continuous production of butyl alcohol can be realized, the operation process is simple, the equipment utilization rate is high, and relatively high total solvent yield and solvent productivity can be obtained at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

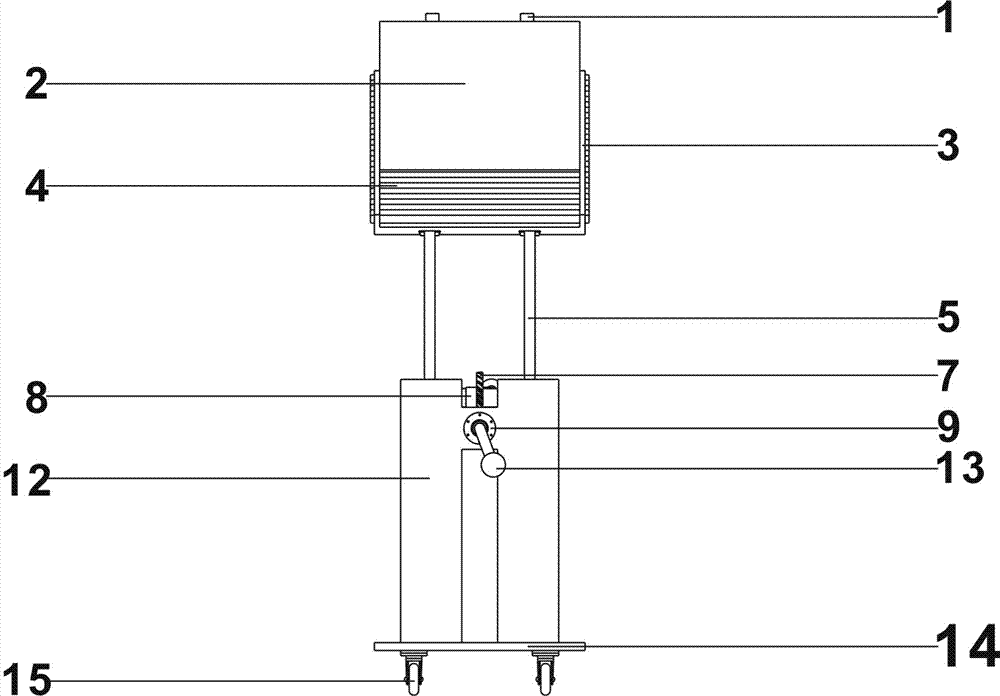

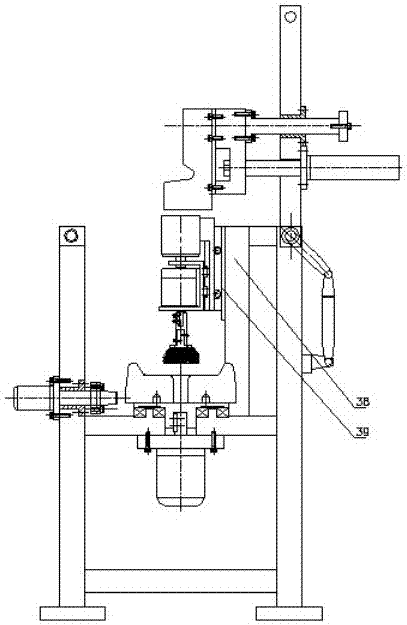

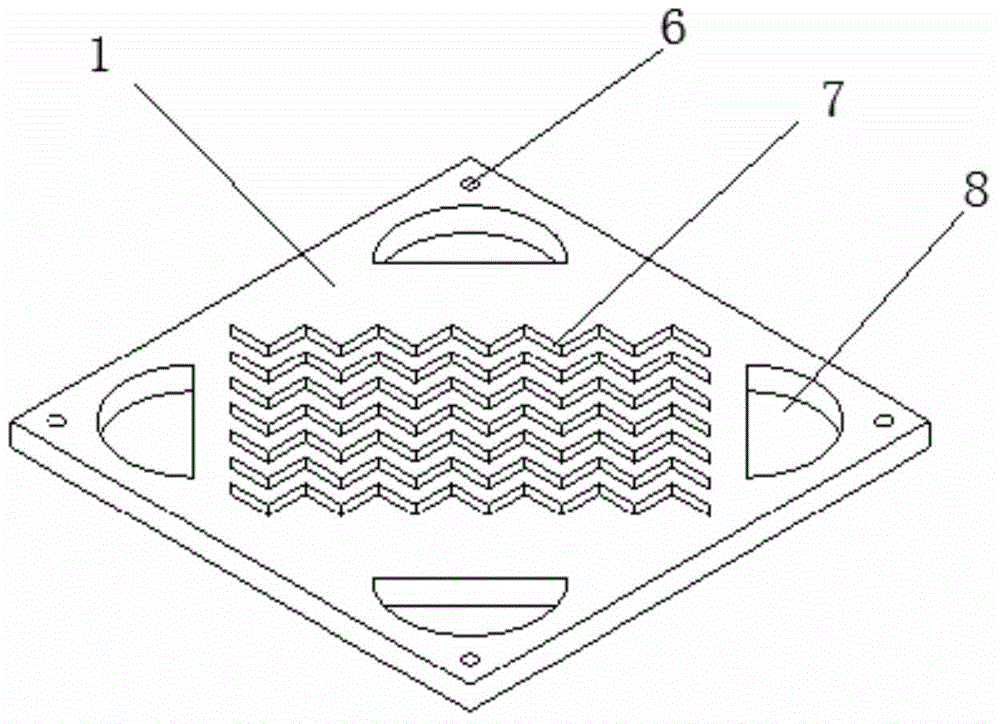

Manual screw type self weight loading device for physical landslide model test

ActiveCN103018425AReduce production intensitySimple structureEarth material testingPhysical modelEngineering

The invention discloses a manual screw type self weight loading device for a physical landslide model test. The self weight loading device comprises a bottom plate, a sliding surface adjustment mechanism and a thrust loading mechanism, wherein the sliding surface adjustment mechanism is positioned on the bottom plate and comprises a sliding panel, upper connecting rods, lower connecting rods, a supporting plate, inserting blocks, inserting grooves, screw rods and hand wheels; the supporting plate is fixed to the bottom plate; the front part and the rear part of the supporting plate are hinged with the lower ends of a pair of the lower connecting rods respectively; the upper ends of the lower connecting rods are hinged with the upper connecting rods to form connecting rods; each pair of the upper connecting rods is hinged with one inserting block; each pair of the lower connecting rods is hinged with one inserting groove; the screw rods penetrate through the inserting grooves and are in threaded connection with the corresponding inserting blocks; the bottom ends of the screw rods are fixed with the hand wheels; the front end of the sliding panel is hinged with the tops of a pair of the upper connecting rods at the front part of the supporting plate; the rear end of the sliding panel is hinged with the tops of a pair of the upper connecting rods at the rear part of the supporting plate; the thrust loading mechanism comprises a loading platform; and the loading platform can slide frontwards and backwards along the sliding panel as the bottom surface of the loading platform is in sliding fit with the top surface of the sliding panel.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

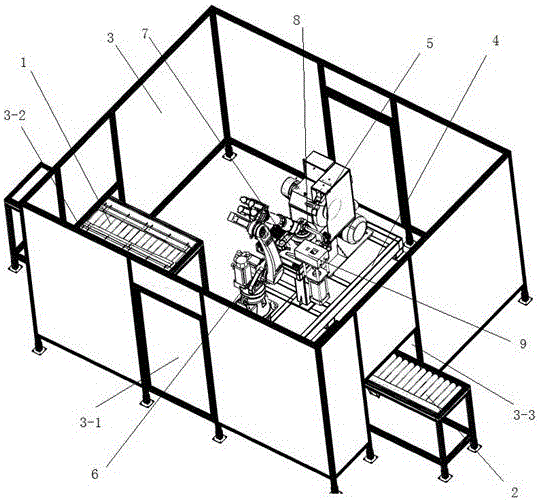

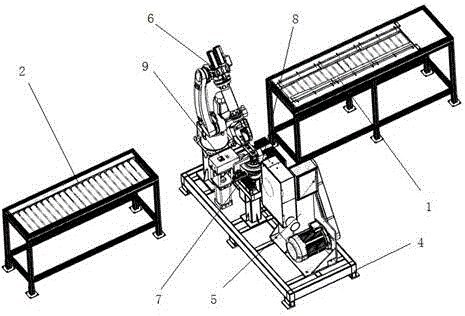

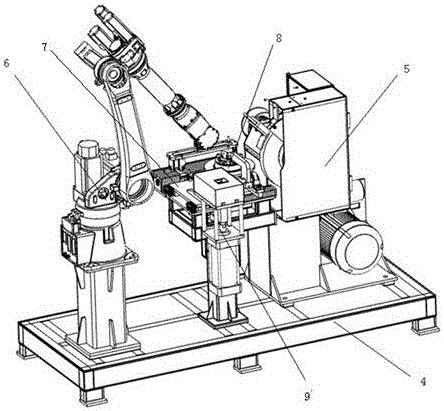

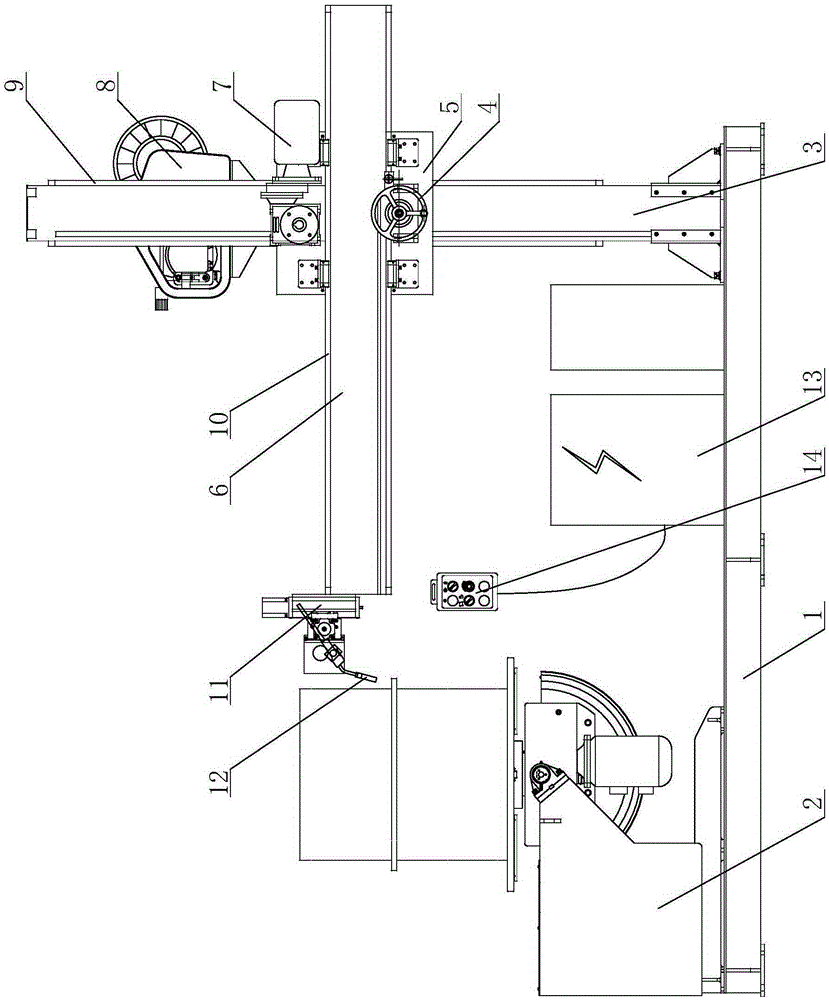

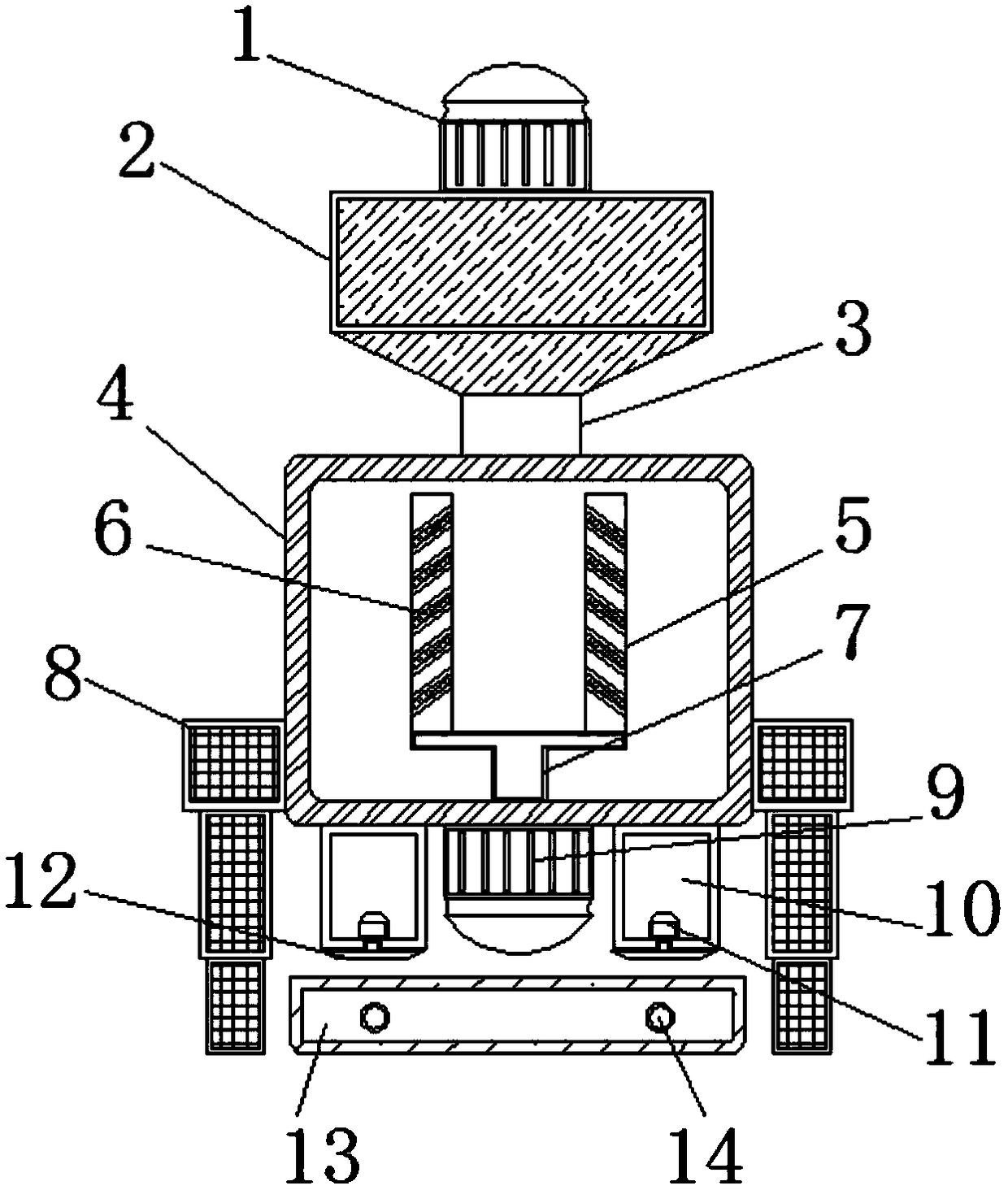

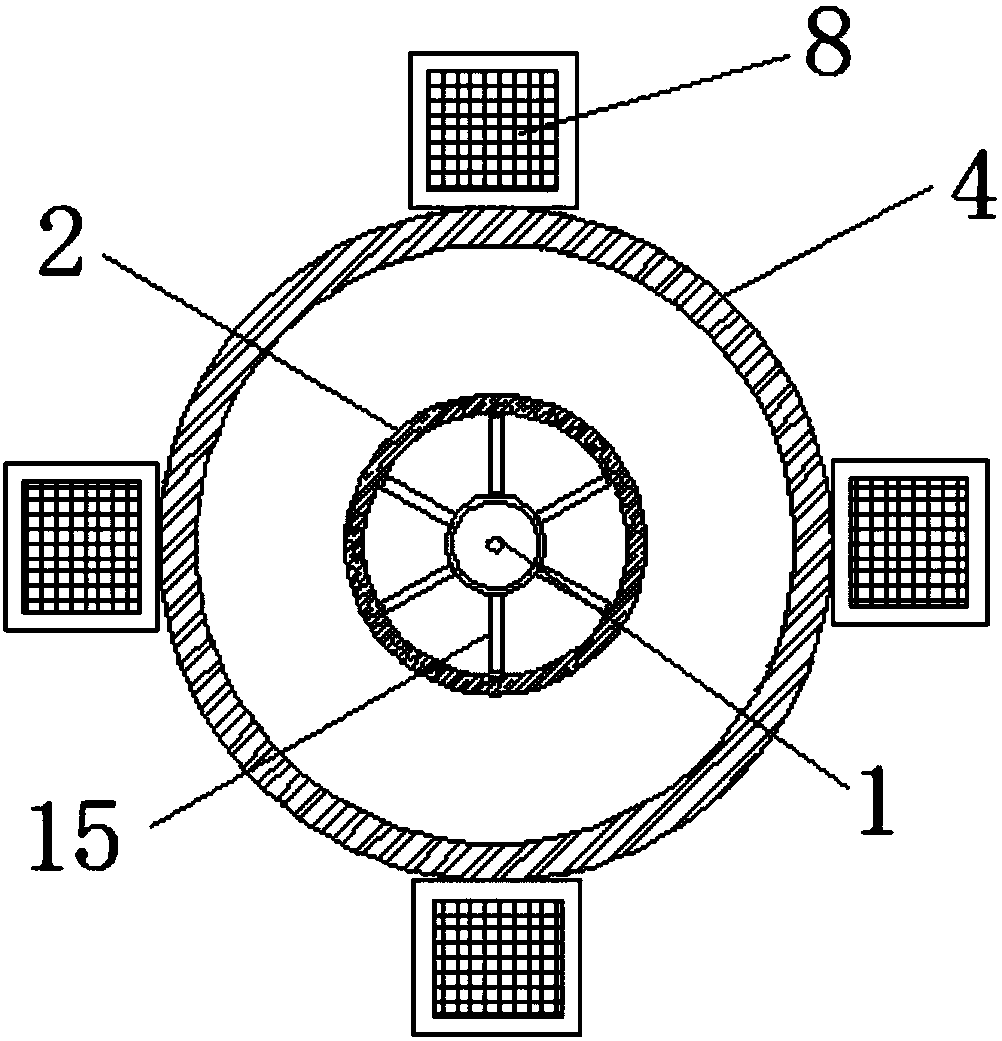

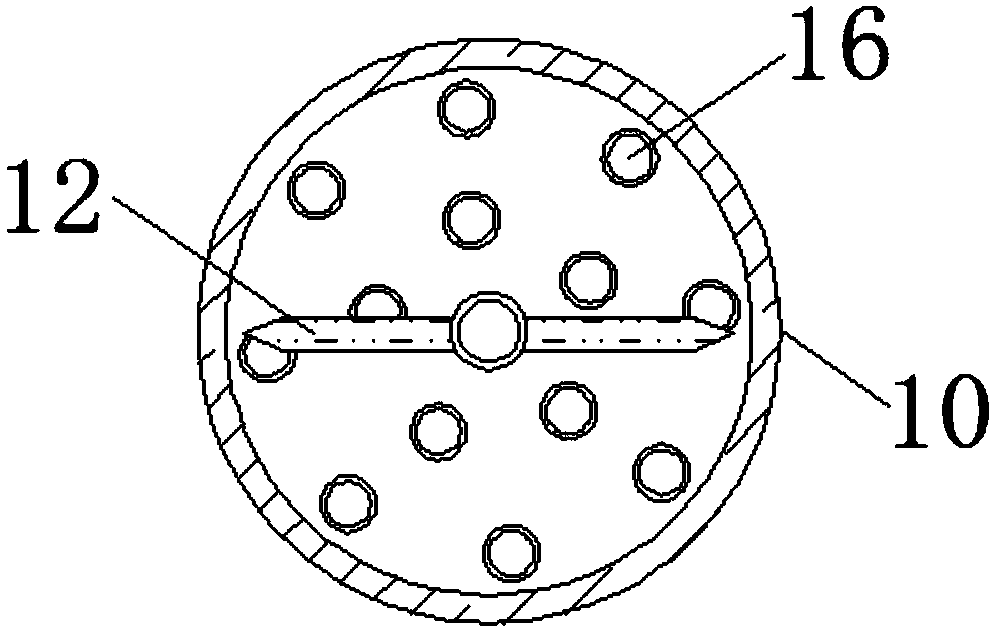

Full-automatic production line for disc-shaped workpiece polishing

ActiveCN106514458ASimple working processReduce production intensityGrinding machinesGrinding feedersProduction lineGrinding wheel

The invention discloses a full-automatic production line for disc-shaped workpiece polishing. The full-automatic production line comprises a feed frame, a discharge frame, a middle base, a grinding wheel machine, a mechanical arm, an automatic feeding worktable and a workpiece pressing device; the grinding wheel machine, the mechanical arm and the automatic feeding worktable are arranged on the middle base; the feed frame and the discharge frame are arranged on two sides of the mechanical arm of the middle base; the automatic feeding worktable is between the grinding wheel machine and the mechanical arm; a mechanical arm base of the mechanical arm is mounted on a bracket of the middle base; transposition clamping mechanisms are respectively below two ends of a working bracket of the mechanical arm; and the workpiece pressing device is mounted on one side of a main body of the automatic feeding worktable. The full-automatic production line for disc-shaped workpiece polishing realizes full automation of polishing of disc-shaped workpieces through corresponding matched machining equipment, can largely reduce the working intensity of workers after use, and greatly improves the production efficiency.

Owner:江苏三叶智能装备股份有限公司

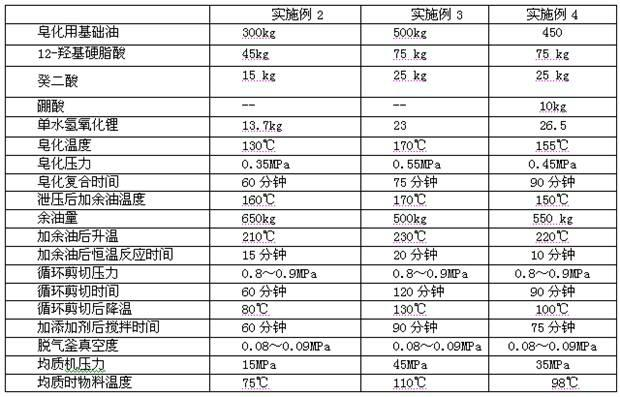

Production technology of composite lithium base lubricating grease

InactiveCN102358863AReduce production intensityAvoid potential hazards arising from safetyLubricant compositionThermodynamicsPhysical chemistry

The invention relates to production technology of composite lithium base lubricating grease, in particular includes following steps: (1) adding base oil, acid, alkali and water for saponification into a pressure saponification kettle, closing the kettle to be airtight, stirring and heating the base oil, acid, alkali and water to raise temperature, and conducting a saponification reaction under certain pressure and temperature; (2) after a constant temperature constant pressure reaction finishes, decompressing to normal pressure, adding part of remaining oil, continuing to raise the temperature to obtain composite soap oil, and transferring the soap oil to a mixing kettle; (3) cutting and cooling liquid materials in the mixing kettle in cycling mode, adding required additive agents, and continuing to cut, stir and mix the liquid materials in cycling mode; and (4) after cutting and mixing the liquid materials evenly, pumping an air releasing kettle to corresponding vacuum degree, homogenizing the materials through a homogenizer to release air to obtain products. The production technology shortens saponification composite time, improves production efficiency, reduces energy loss and soap content, is simple in operation, and avoids potential danger on operational workers caused by overflowing in normal pressure saponification.

Owner:无锡惠源高级润滑油有限公司

Improved automatic lubricant cleaning device for hub forging die

PendingCN107350188AImprove labor efficiencyReduce production intensitySpraying apparatusHollow article cleaningHydraulic cylinderEngineering

The invention discloses an improved automatic lubricant cleaning device for a hub forging die. The improved automatic lubricant cleaning device is composed of a hydraulic lifting cylinder, a limit block, a hinge A, a hydraulic piston rod, a fixed connection rod, a hinge shaft, a connection plate, a hydraulic cylinder, a hinge B and the like. The improved automatic lubricant cleaning device disclosed by the invention is capable of increasing labor efficiency and lowering production intensity, and high in universality; and corresponding cleaning scraping plates can be arranged according to surface shapes of different hub dies, and changed through a universal bolt connector, so that an equipment cost is saved.

Owner:CITIC DICASTAL

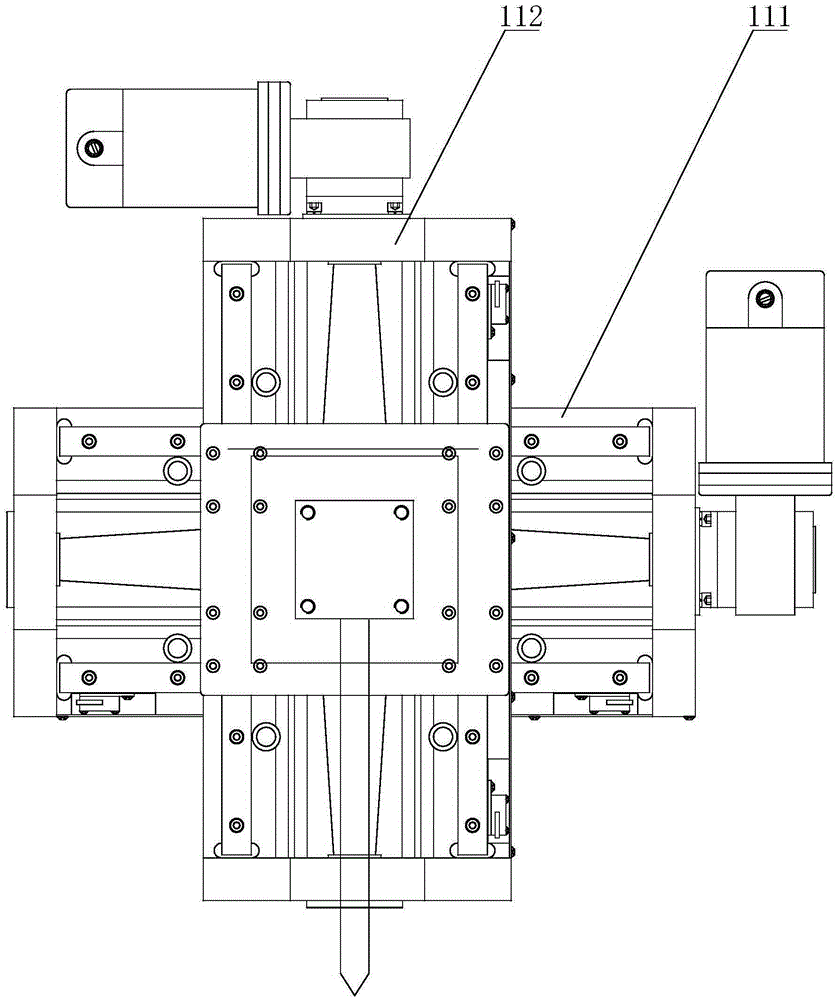

Pipe flange welding workstation

InactiveCN105382452ASimple structureCompact structureWelding/cutting auxillary devicesAuxillary welding devicesWorkstationUltimate tensile strength

The invention discloses a pipe flange welding workstation. The pipe flange welding workstation comprises a base, wherein a positioner is arranged on one end of the base; the positioner is electrically connected with a controller; a workbench which can drive a workpiece to rotate or turnover is arranged on the positioner; a stand column which is perpendicularly arranged is arranged at the other end of the base; a wire feeder is mounted on the stand column; the wire feeder is electrically connected with the controller; a lifting base is mounted on the stand column in an up-and-down moving manner; a cross arm is mounted on the lifting base in a horizontal moving manner; a precise micro manipulator is mounted on the end head of one end, which is close to the positioner, of the cross arm; the precise micro manipulator is controlled by the controller; a welding gun is mounted on the precise micro manipulator; the welding gun is electrically connected with the controller. The pipe flange welding workstation disclosed by the invention is simple and compact in structure, flexible and convenient to operate, durable, and convenient and swift to mount and dismantle. According to the pipe flange welding workstation, the production intensity is effectively reduced, the production cost is reduced, and the welding efficiency and the welding quality are improved.

Owner:WUXI SANHONG MACHINERY EQUIP

Preparing method for high abrasion resistance and high heat resistance automobile clutch surface patch

ActiveCN107035800AEliminate internal stressImprove mechanical propertiesFriction liningFiberConductor Coil

The invention discloses a preparing method for a high abrasion resistance and high heat resistance automobile clutch surface patch. The method comprises the following steps that oxidized graphene and nano-diamond modified composite fiber cloth is immersed in nano aluminum titanate / phosphorus boron molybdenum silicon composite modified water soluble phenol-formaldehyde resin to be dipped, and after dipping is finished, the composite fiber cloth is dried in a drying tower; then, the dried composite fiber cloth is subjected to strip tearing, and winding and forming are conducted on a winding machine; a mold blank obtained after winding is arranged in a die to be subjected to hot press forming, the mold blank obtained after hot press is placed in an oven to be subjected to heat treatment, and after heat treatment is finished, a product is cut, the surface is ground, and the automobile clutch surface patch with the needed specification is manufactured. According to the preparing method, filling particles and other components are not needed, in other words, the pulp dipping step is removed in the technology, the modified composite fiber cloth is directly immersed in the modified water soluble phenol-formaldehyde resin, and then the high abrasion resistance and high heat resistance automobile clutch surface patch can be prepared. Heat treatment is adopted in the method, the method is scientific and reasonable, inner stress of products can be completely eliminated, and the mechanical performance of the products is improved.

Owner:来安县隆华摩擦材料有限公司

Method for preparing high purity biodiesel

ActiveUS20140194634A1Wide raw material sourceReduce energy consumptionFatty oils/acids recovery from wasteFatty acid esterificationTrans esterificationPtru catalyst

Disclosed is a method for preparing high purity biodiesel from crude oils. The method comprises the steps of: pre-treating the crude oil raw material to remove impurities; pre-esterifying the pre-treated crude oil raw material under the effect of a catalyst of concentrated sulfuric acid; and then carrying out an ester exchange reaction in the presence of an alkali catalyst; recycling methanol, and separating glycerol, so as to obtain a crude fatty acid methyl ester; and subjecting the obtained fatty acid methyl ester to purification, distillation and segmentation to obtain a high-purity fatty acid methyl ester.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Preparation method of environment-friendly porous rock granular material

ActiveCN104261688ALower the foaming temperatureImprove water absorptionGlass shaping apparatusGlass productionPorosityManganese

The invention relates to a preparation method of an environment-friendly porous rock granular material, which comprises the following steps: carrying out crushing and ball milling on screen glass to obtain CRT (cathode ray tube) screen glass powder; putting the CRT screen glass powder, manganese peroxide, sodium nitrate, lithium nitrate and antimony trisulfide in a ball mill, and carrying out ball milling to form a mixture; adding the mixture into a mold, sending into a roller hearth kiln, keeping the temperature for 5-10 minutes, and heating to 770-780 DEG C at the rate of 4-8 DEG C / minute; heating to 780-790 DEG C at the rate of 0.2-1 DEG C / minute; and cooling to 50-80 DEG C below at the rate of 80-200 DEG C / minute, crushing and screening to obtain the environment-friendly porous rock granular material. The environment-friendly porous rock granular material has the advantages of high strength, high water absorptivity, high aeration porosity, low foaming temperature and low use cost, and can not generate environment pollution in the production and use process. The environment-friendly porous rock granular material can be stored underground as excellent rain water, is a water purification material of rivers, lakes, reservoirs, fish ponds and the like, and can also be used as a heat-insulation fireproof construction material and other novel materials.

Owner:天津仁新玻璃材料有限公司

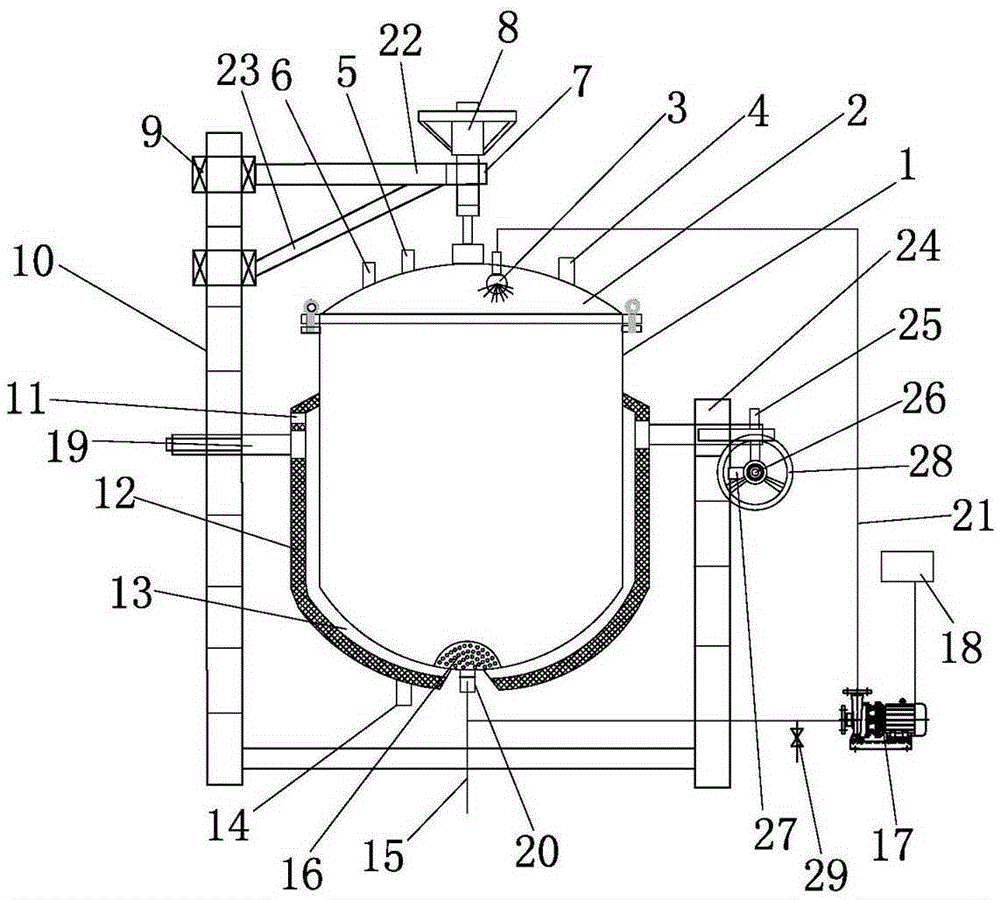

Multifunctional digester

ActiveCN105193239AQuality assuranceSimple structureSteam cooking vesselsMicrocomputerAdditive ingredient

The invention relates to a multifunctional digester, effectively solving the problems that statically soaked toxic ingredients are slow in dissolution speed, manual stirring is not uniform, the labor intensity is great and the production efficiency is low. The multifunctional digester is characterized in that a pot body is mounted on a support, the upper end of an extension rod on one side of the support is provided with a support cantilever, a pot cover is hung on the support cantilever and is connected with an upper opening of the pot body, the bottom of the pot body is provided with a water outlet, the outer part of the pot body is provided with a thermal insulation layer, an interlayer is formed between the pot body and the thermal insulation layer, the bottom of the thermal insulation layer on one side of the water outlet is provided with a condensate water outlet, a side wall of the thermal insulation layer is provided with a steam inlet, a filter net covered on the water outlet is arranged in the pot body, the lower end of the water outlet is connected with a steam pipeline and a centrifugal pump, an outlet of the centrifugal pump and a spray ball in the top of the pot cover are communicated, the centrifugal pump and a microcomputer time switch are connected, and the pot cover is provided with a safety valve, a pressure gauge and a vent valve. The multifunctional digester is simple in structure, convenient to use and good in effect, and the production intensity is lowered, and the quality of a finished decoction piece product is ensured.

Owner:HENAN AOLITE PHARMA

Continuous casting process for producing high-titanium wear-resisting steel on straight arc slab continuous casting machine

The invention relates to a continuous casting process for producing high-titanium wear-resisting steel on a straight arc slab continuous casting machine. The continuous casting process comprises the following steps of: adopting full-protection casting for continuous casting, adopting long nozzle shielding argon gas casting from a steel ladle to a tundish and adopting immersion type water gap protection casting from the tundish to a crystallizer, wherein molten steel in the tundish adopts an alkaline covering agent and a tundish slag double-layer covering agent; adopting an eddy current probe to detect the liquid surface of the crystallizer in a fully-automatic manner in a casting process, and automatically controlling continuous-casting speed according to degree of superheat of the tundish; enabling protective slag on the surface of the crystallizer to be adaptive to high-titanium molten steel; and adopting a mode of quickly cooling the front part and slowly cooling the middle part and the rear part for a secondary cooling region of the crystallizer. According to the continuous casting process, secondary oxidization of molten steel in the casting process can be effectively prevented, stability of titanium in the molten steel is guaranteed, and the protective slag is prevented from being denatured; and meanwhile, separation of large-particle titanium compounds in steel can be restrained by optimizing and cooling, so that the problems that titanium compound particles in die casting are relatively great and are not even in distribution are solved, and the titanium compounds in the steel are guaranteed to be fine and uniformly distributed.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Micro-channel plate heat exchanger with triangular corrugated flowing channel

InactiveCN104864751AImprove heat transfer efficiencyReduce processing costsLaminated elementsStationary plate conduit assembliesPlate heat exchangerHeat resistance

The invention discloses a micro-channel plate heat exchanger with a triangular corrugated flowing channel. The micro-channel plate heat exchanger comprises a channel plate, partition layer plates, clamping plates, hot fluid inlet-outlets, cold fluid inlet-outlets and liquid collecting hole channels. The partition layer plates are arranged on two sides of the channel plate, the channel plate and the partition layer plates are alternatively stacked and pressed to form a cold and hot fluid heat exchange channel, fluid distribution channels are formed in the partition layer plates, the cold and hot fluid heat exchange channel is communicated with the fluid distribution channels, and the liquid collecting hole channels are formed in four corners of the channel plate. The clamping plates are arranged on the outer sides of the channel plate and the partition layer plates, and the hot fluid inlet-outlets and the cold fluid inlet-outlets are formed in the clamping plates and are respectively connected with the liquid collecting hole channels. The micro-channel plate heat exchanger is small in size, compact in structure, large in heat transfer area per unit size, high in heat exchange efficiency, low in heat loss, convenient to install and clean, long in service life and free of welding heat resistance and is suitable for high-precision electronic devices, cooling heat-dispassion parts of precise instruments and micro-electronic mechanical systems.

Owner:ZHEJIANG UNIV

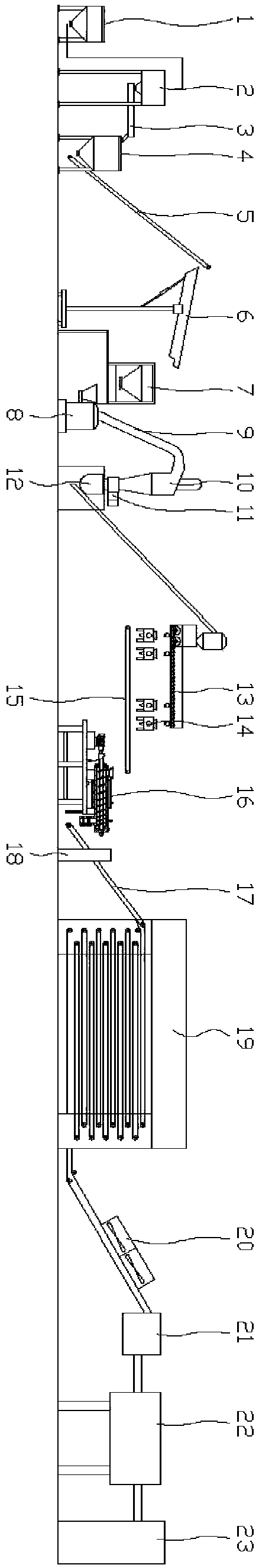

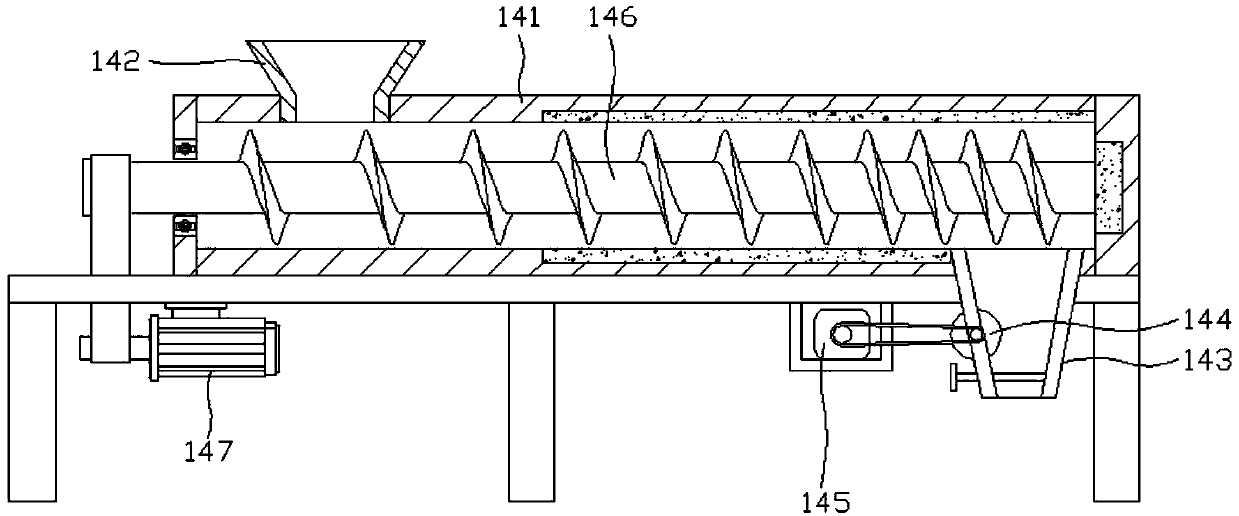

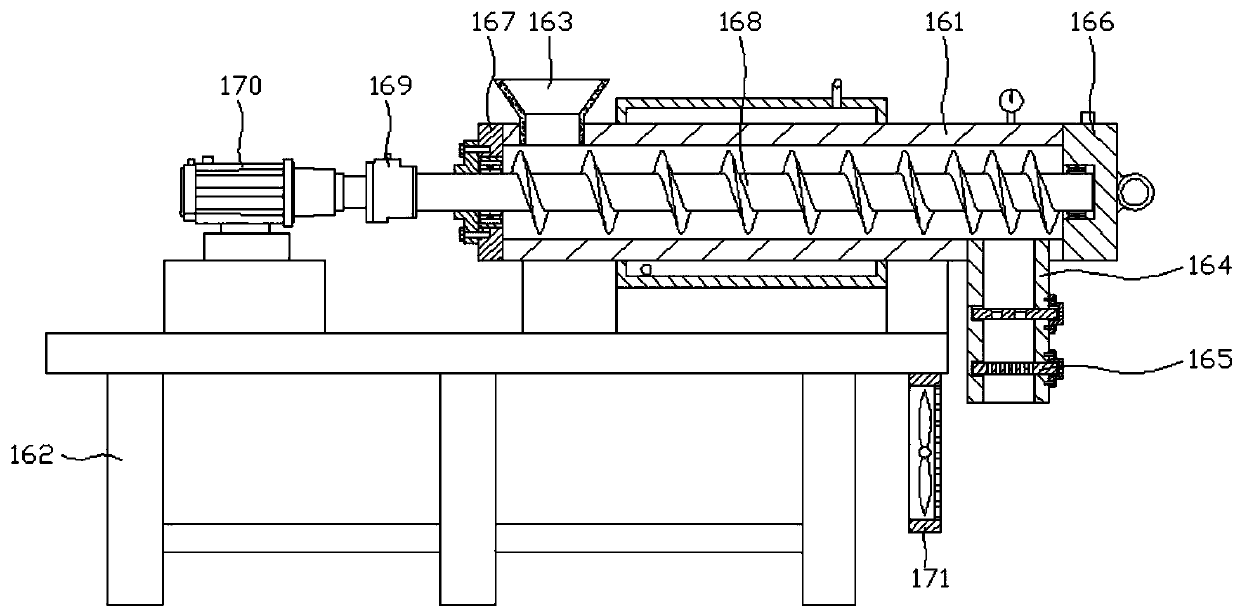

Extrusion rice noodle production method and production line

PendingCN108669436AReduce manual involvementReduce manual interventionFood shapingCleaning using liquidsProduction lineDistributor

The invention discloses an extrusion rice noodle production method and a production line. The extrusion rice noodle production line comprises a first elevator, a sand removing equipment, a rice distributor, a rice immersion tank, a jet rice washing machine, a water draining square bucket, a crushing machine, a material storing and feeding machine, a stirring machine, an aging machine, a rice doughconveyer, a rice noodle extrusion machine, an aging conveyer, a refrigeration aging machine, an unfreezing device, a noodle loosing machine, a cutting machine, and a stacking machine. The extrusion rice noodle production method and the production line are capable of reducing artificial intervention, reducing production intensity, and improving production quality.

Owner:湖南元喜福食品有限公司

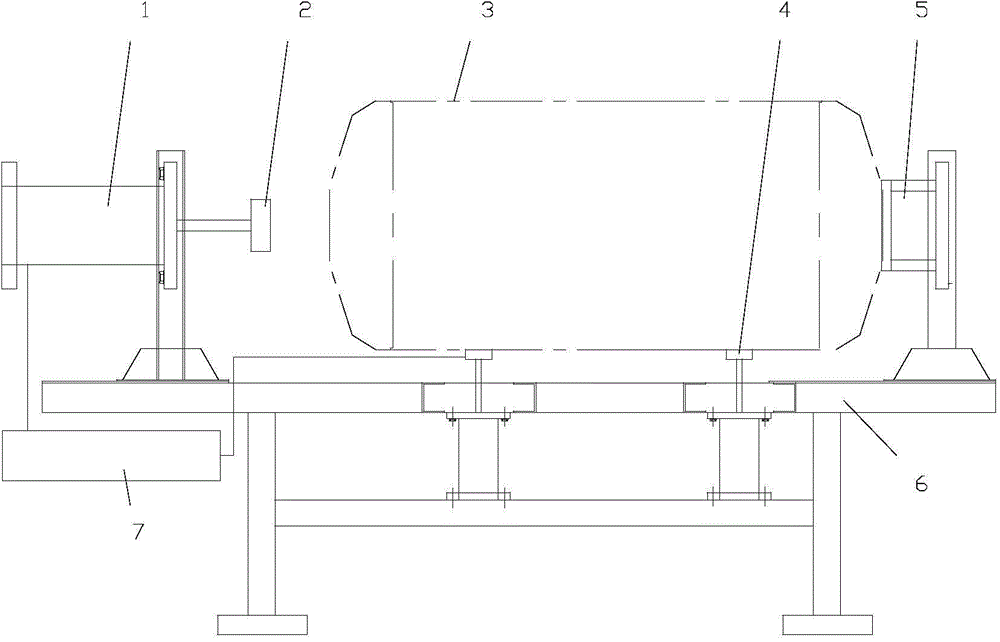

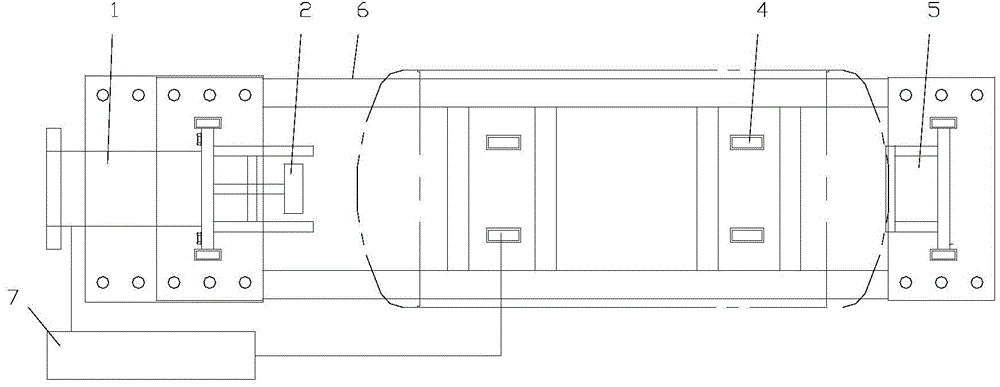

Low-temperature heat insulation gas cylinder horizontal seal head assembly device

InactiveCN104384810AEasy to operateEasy to produceWelding/cutting auxillary devicesAuxillary welding devicesGas cylinderGas supply

The invention relates to a low-temperature heat insulation gas cylinder horizontal seal head assembly device. A propulsion cylinder is fixed at the left end of a frame, a front end seal head clamping device is fixed on a piston of the propulsion cylinder, a rear end seal head clamping device is fixed at the rear end of the frame, a gas cylinder rotating and jacking device is fixed in the middle of the frame, and a gas supply device is fixed onto the frame and hermetically communicated with the propulsion cylinder and the gas cylinder rotating and jacking device. The low-temperature heat insulation gas cylinder horizontal seal head assembly device is safe, reliable and high in efficiency.

Owner:XINXING ENERGY EQUIP

Device for modified plastic production

The invention discloses a device for modified plastic production. The device comprises a stirring motor, stirring blades, a material guiding opening and a filter screen, a material stirring box is installed under the stirring motor, and a feeding pipeline is installed at and connected with the portion under the material stirring box; a double-screw extruder is connected to the portion below the feed pipeline, an extruding screw rod is arranged inside the double-screw extruder, and a plastic heating piece is fixedly arranged inside the extruding screw rod; a supporting frame is arranged at theouter side of the plastic heating piece, a drive motor is arranged on the inner side of the supporting frame, and discharging molds are arranged on left and right sides of the drive motor; cutting motors are fixedly arranged below the discharging molds, and cutting blades are arranged at and connected with the portions under the cutting motors. The device for the modified plastic production adoptsthe material stirring box and the stirring blades, can conveniently stir plastic particles with different types, and improves the stirring uniformity of different plastic particles.

Owner:杨传平

Preparation of 5'-deoxynucleoside monophosphate

ActiveCN101503432AAdaptableReaction is easy to controlSugar derivativesSugar derivatives preparationOrganic solventPhosphoric acid

The invention discloses a preparing method of 5'-deoxyribonucleoside monophosphate, which comprises the following steps: (1) mixing 2'-deoxyribonucleoside, phosphorus oxychloride and trialkyphosphate to obtain a crude solution containing 5'-deoxynucleotide; (2) hydrolyzing the 5'-deoxynucleotide crude solution obtained from the step (1) in a solution with pH higher than or equal to 8.0 so as to an obtain hydrolysis liquid; (3) mixing an organic solvent, i.e. halogenated hydrocarbon, with the hydrolysis liquid obtained from the step (2), and extracting the mixture to obtain an organic phase and an aqueous phase; (4) condensing the aqueous phase to obtain a condensed liquid; and (5) placing the condensed liquid obtained from the step(4) at a temperature of 10-15 DEG C to obtain the solid 5'-deoxyribonucleoside monophosphate.

Owner:SHANGHAI ZHAOWEI TECH DEV

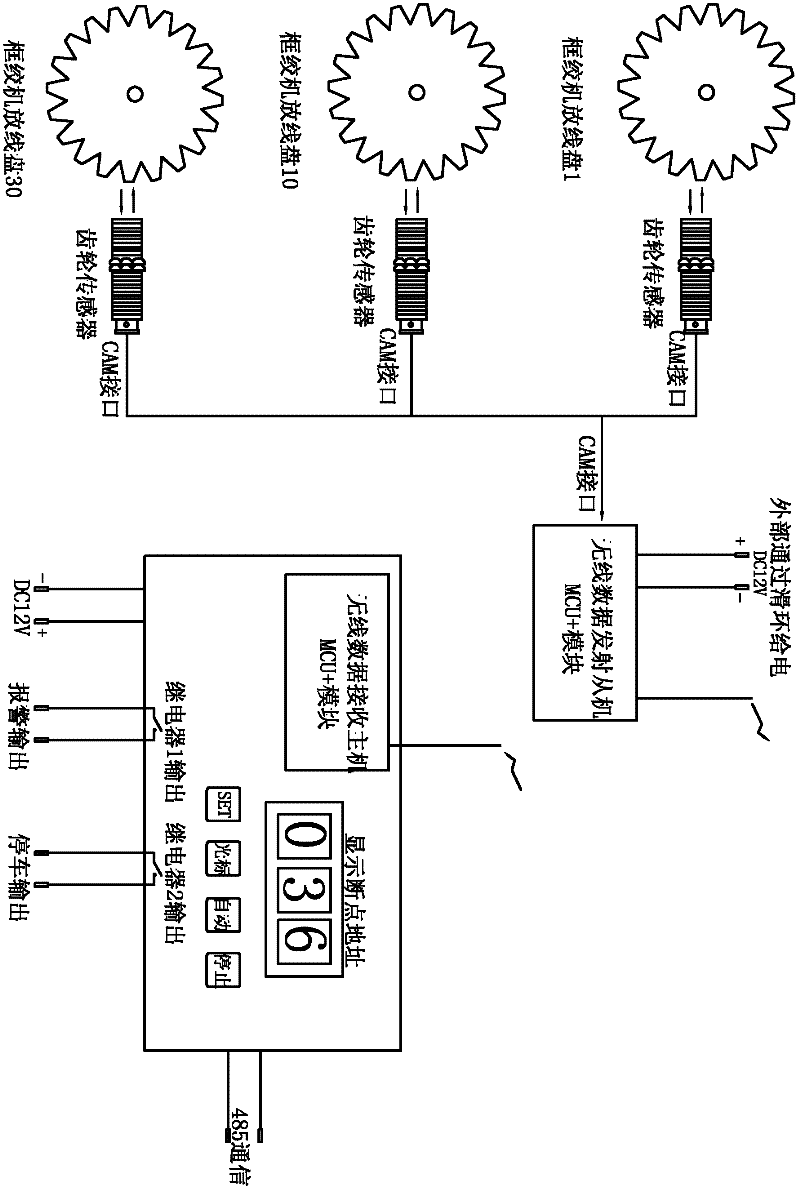

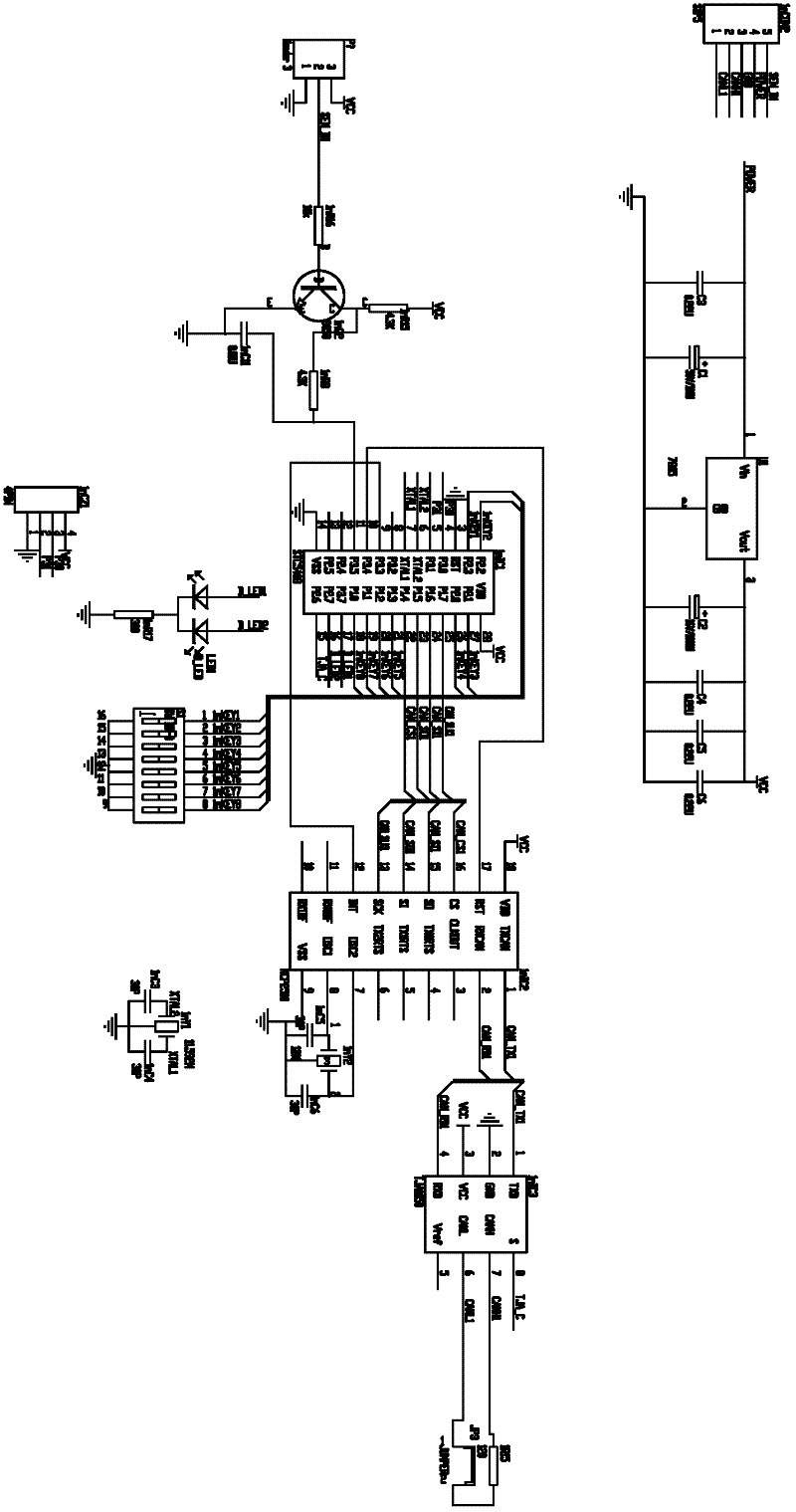

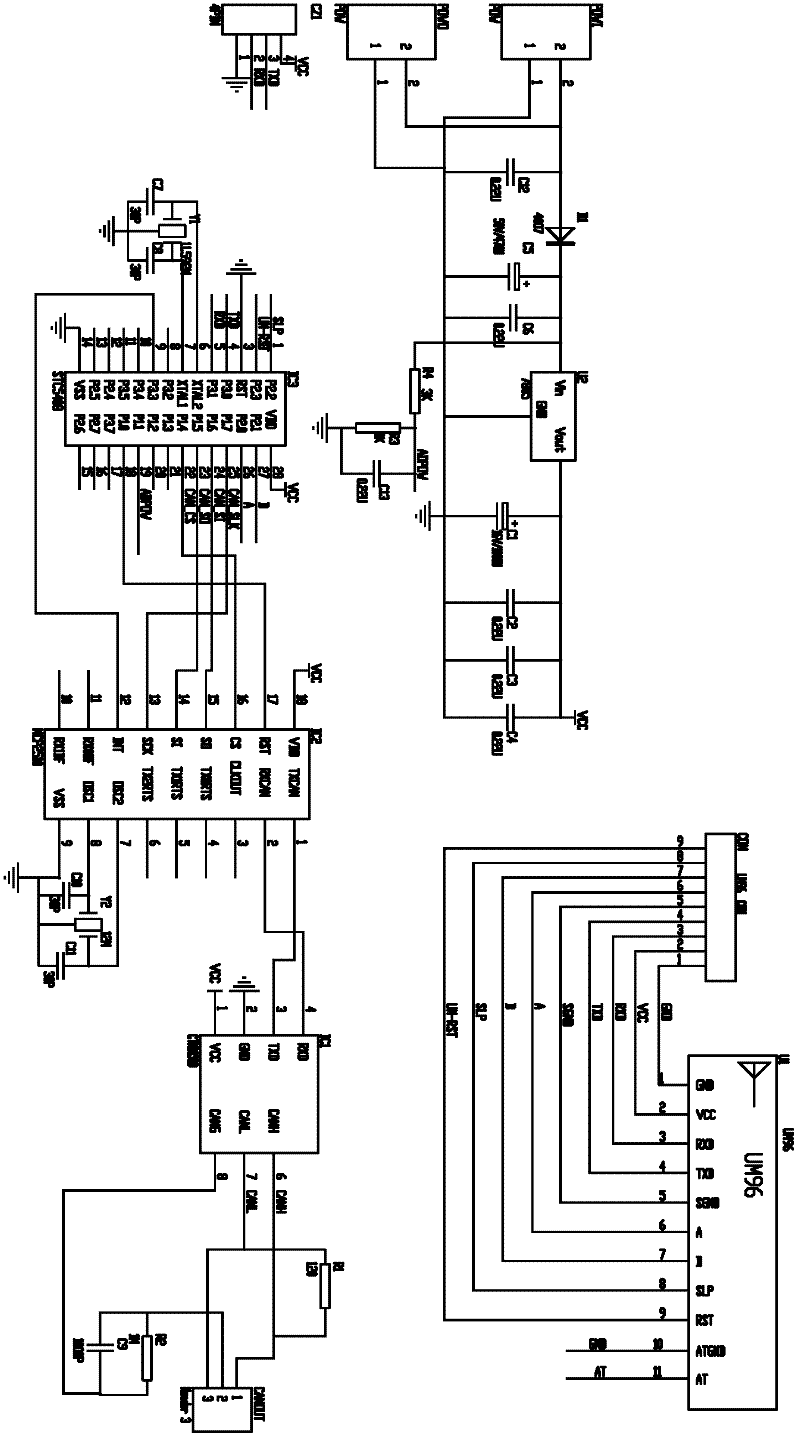

Intelligent frame-type strander break line stop apparatus

InactiveCN102231307AImprove anti-jamming performanceReduce the amount of wiringCable/conductor manufactureCamEngineering

The invention discloses an intelligent frame-type strander break line stop apparatus. The apparatus comprises: a plurality of sensors, MCUs, a wireless sub-transmitter, a wireless receiving host. Quantities of the sensors are corresponding to the quantities of payoff reels of the frame-type strander. The sensors are used for detecting whether each payoff reel rotates or not and outputting pulse signals according to rotation states of each payoff reel. The quantities of the MCUs are corresponding to the quantities of the sensors. MCUs are used for postponing outputting the output pulse signals of the sensors. The wireless sub-transmitter comprises a wireless transmitting module, wherein signal output terminals of the MCUs are connected with the wireless transmitting module through a CAM bus. The wireless receiving host comprises a wireless receiving module. And the wireless receiving host is used to receive wireless sub-transmitter signals and output alarm and stop control signals. By using the invention, intelligent monitoring of working states of the frame-type strander can be achieved, and instant alarm and stop can be performed.

Owner:温州市洞头友邦电子电器厂

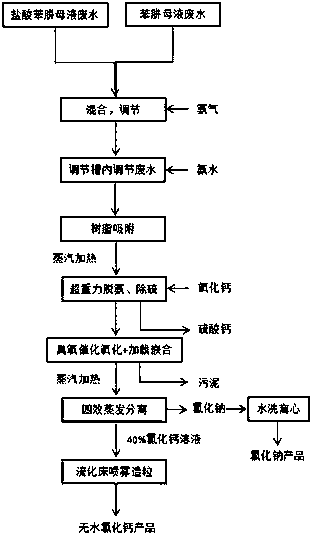

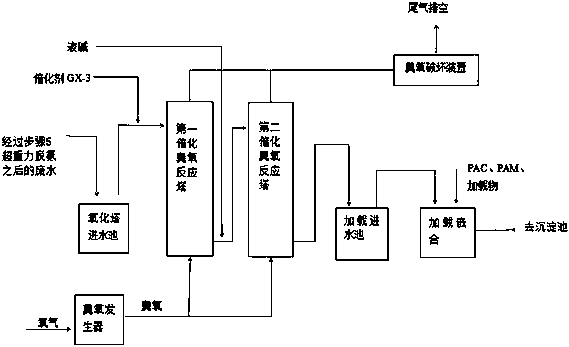

Treatment technology for high-concentration production wastewater

ActiveCN109534570ARealize comprehensive utilizationImprove ammonia removal efficiencyCalcium/strontium/barium chloridesSpecific water treatment objectivesHigh concentrationPhenylhydrazine hydrochloride

The invention relates to a treatment technology for high-concentration production wastewater. The high-concentration production wastewater comprises phenylhydrazine hydrochloride mother liquor wastewater and phenylhydrazine mother liquor wastewater, and the phenylhydrazine hydrochloride mother liquor wastewater and the phenylhydrazine mother liquor wastewater are treated by adopting the process flow comprising macro-porous resin adsorption, super-gravity stripping deamination, sulfur removal, ozone catalytic oxidation, loading chimerism, four-effect downstream evaporation concentrating separation and fluidized bed spray granulation. The treatment technology can reduce the treatment cost, and can recycle effective ingredients in the production wastewater.

Owner:QIDONG A&P CHEM FACTORY

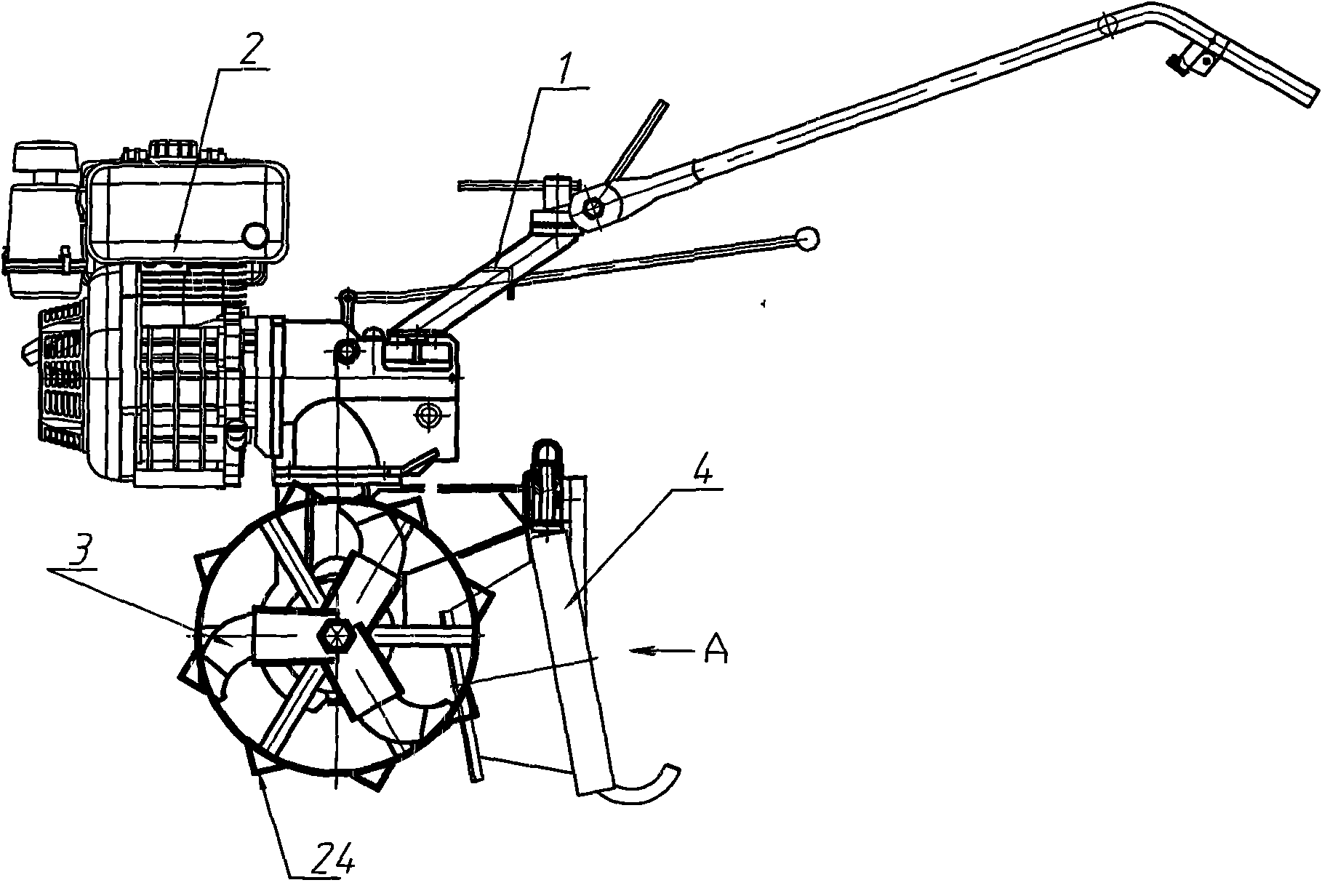

Furrowing type ridger

InactiveCN101617576ANovel ridging modeRich ridging modesTilling equipmentsWheels with spade lugsEngineeringRidge

The invention relates to a furrowing type ridger which comprises a frame, a cutting tool and a shaper. A blade on the cutting tool is of an outward helical structure; the shaper is mounted behind the cutting tool on the frame and comprises a furrowing type plate base, a furrowing type plate, a soil breaker, a left clean-up scraper and a right clean-up scraper, wherein the furrowing type plate base is mounted on the central line of the frame; the furrowing type plate is of an inverted trapezoid and is mounted on the furrowing type plate base; the soil breaker is vertically mounted at the front end of the furrowing type plate base; and the left clean-up scraper and the right clean-up scraper are symmetrically mounted at two sides of the furrowing type plate. Road wheels are arranged at two ends of a power output shaft and positioned at the outer side of the cutting tool. The invention has novel ridging mode and stronger adaptability and can carry out ridging and furrowing simultaneously. The road wheels are hard to slide due to being mounted at two ends of the power output shaft and are easier to move. The furrowing type ridger has the advantages that the ridging effect is good, the ridge height is proper, and the cross-section shape and the dimension of the ridge can be designed according to the requirements of users, therefore, the use is flexible.

Owner:陈恳

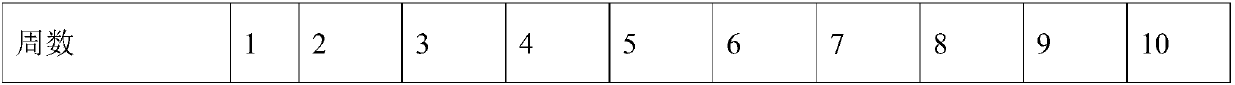

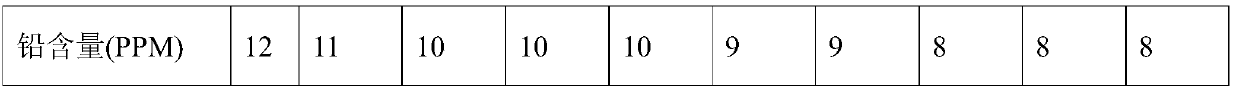

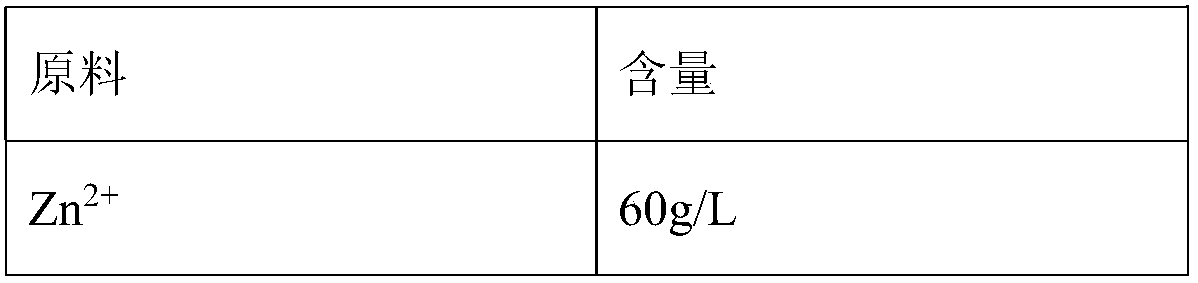

Zinc electrolysis anode plate and preparing method thereof

ActiveCN109680301AAvoid corrosionReduce Pb contentAnodisationPhotography auxillary processesElectrolysisAlloy

The invention discloses a preparing method of a zinc electrolysis anode plate. The preparing method comprises the following steps that firstly, under low current density, anode oxidization is conducted, and a dense PbO2 protection layer anode plate is obtained; secondly, electroplating of an MnO2 protection layer is conducted on the anode plate; thirdly, by mass percent, 20-30% of an Mn(NO3)2 solution is prepared; and fourthly, a chemical MnO2 deposition layer is generated on the anode plate, the fourth step is repeatedly conducted 2-5 times, and the zinc electrolysis anode plate is obtained.The invention further provides the zinc electrolysis anode plate. The preparing method of the zinc electrolysis anode plate and the zinc electrolysis anode plate have the following beneficial effectsthat an electrolytic zinc product with the extremely low Pb content can be obtained at the beginning of production; the current efficiency is improved, the production intensity is lowered, and the production efficiency is improved; and dissolving of Pb alloy materials is effectively prevented, the service life is longer, and the lead content in product zinc is lower.

Owner:湘西土家族苗族自治州质量检验及计量检定中心

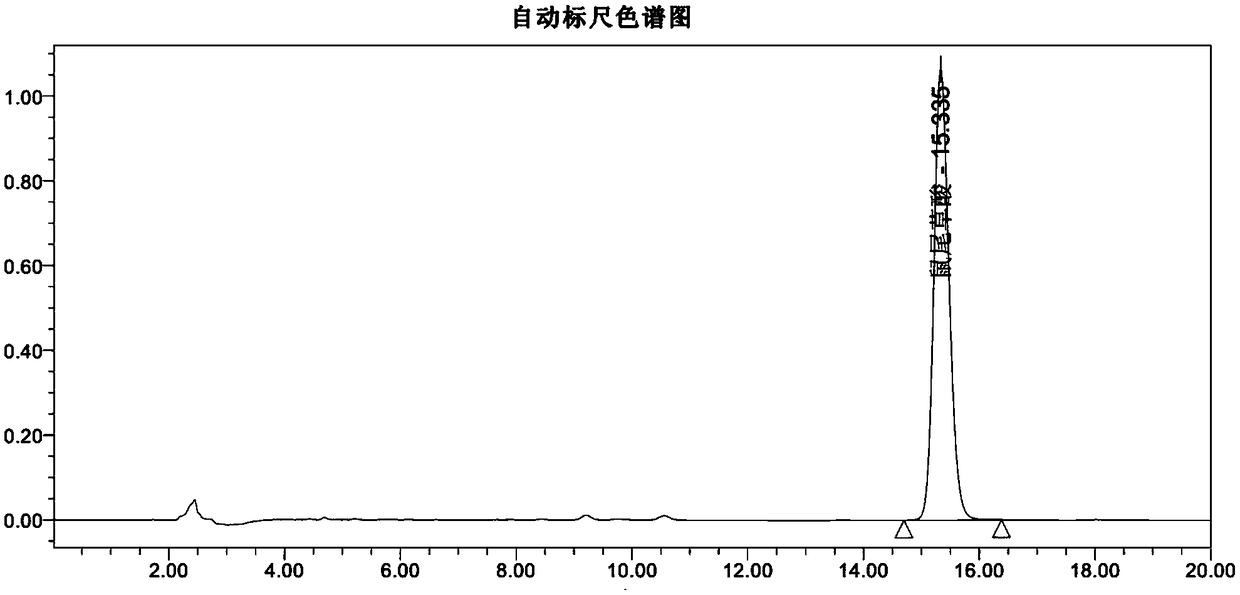

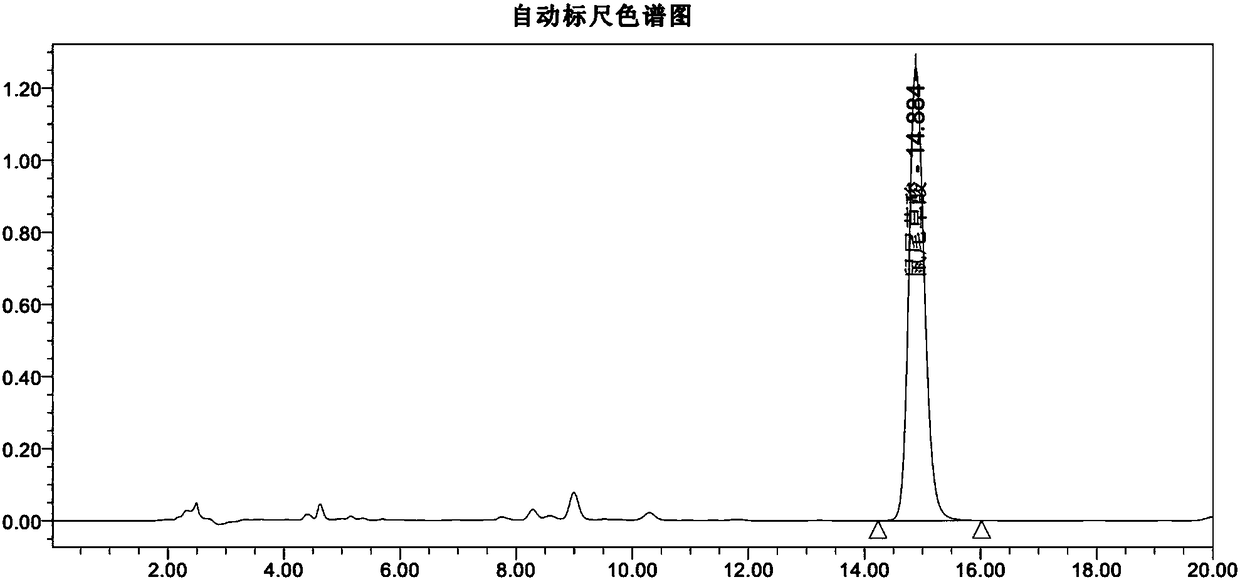

Method for refining carnosic acid through molecule distillation

InactiveCN109160878AShort stayAvoid damageMolecular distillationCarboxylic compound separation/purificationOxalateCacodylic acid

The invention discloses a method for refining carnosic acid through molecule distillation. The method comprises the following steps: (1) carrying out carnosic acid dissolution promotion, namely dissolving a carnosic acid product of a low content with a cosolvent; (2) carrying out primary film distillation dehydration and degassing, namely putting the carnosic acid with the cosolvent into a primaryfilm distillation column to carry out primary film distillation dehydration and degassing; (3) carrying out secondary molecule distillation separation, namely pumping a dehydration degassing liquid into a secondary molecule distillation to carry out secondary molecule distillation separation so as to obtain light and weight components, wherein the light component is a part with a part of the carnosic acid; (4) carrying out third molecule distillation separation, namely pumping the heavy component of secondary molecule distillation into a third molecule distiller to carry out third molecule distillation separation so as to obtain light and heavy components, wherein the light component is the carnosic acid. The method has the characteristics of being short in operation time, low in production intensity, low in energy consumption, low in production cost, and the like, and meanwhile is high in product purity and easy in continuous industrial production.

Owner:HUNAN NUOZ BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com