Production technology of composite lithium base lubricating grease

A technology of base grease and production process, applied in the field of production process of complex lithium base grease, can solve problems such as the danger of energy consumption and operation, and achieve the effects of avoiding potential danger, reducing energy consumption and soap content, and reducing production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] At 1.6m 3 Into the pressure saponification kettle, add 400 kg of 100℃ kinematic viscosity 10mm 2 / s Mineral base oil, 75 kg of 12-hydroxystearic acid, 25 kg of sebacic acid, 23 kg of lithium hydroxide monohydrate, 70 kg of water, cover, then stir and raise, when the temperature reaches 150℃, the pressure is 0.5MPa , Constant temperature and pressure reaction for 90 minutes. Relieve the pressure to normal pressure, then stir and heat up to 150℃, add 100℃, the kinematic viscosity is 10mm 2 / s 550 kg of mineral base oil, continue to stir and heat to 215 ℃, constant temperature for 10 minutes. Transfer the composite soap liquid to the blending kettle, wash the kettle with 50 kg of base oil and transfer it to the blending kettle together, turn on the cooling water, under the pressure of 0.8~0.9MPa, stir and circulate shear for 90 minutes, and wait until the temperature drops to At 105°C, add 40 kg of the additives used in extreme pressure lithium complex grease, and continue ...

Embodiment 2-4

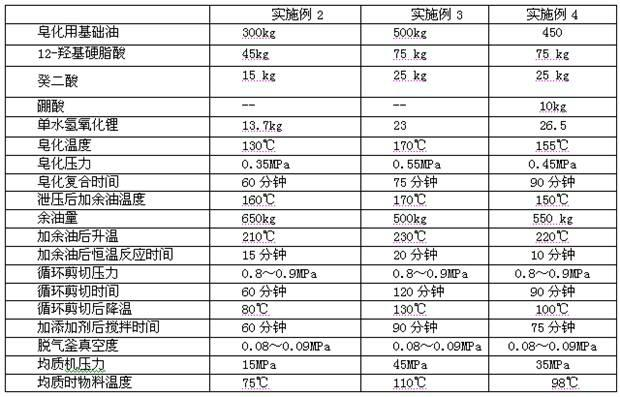

[0021] The process methods of Examples 2-4 are as in Example 1, and the specific material ratio and reaction parameters are shown in Table 2.

[0022] Table 2 Material ratio and reaction parameters of Examples 2-4

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com