Furrowing type ridger

A ridging machine and ditch-type technology, which is applied in the direction of tillage machines, agricultural machinery and implements, wheels with shovel grips, etc., can solve problems such as single ridging mode, unfavorable planting, and large ridging resistance , to achieve the effect of flexible use, rich ridging modes, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the drawings.

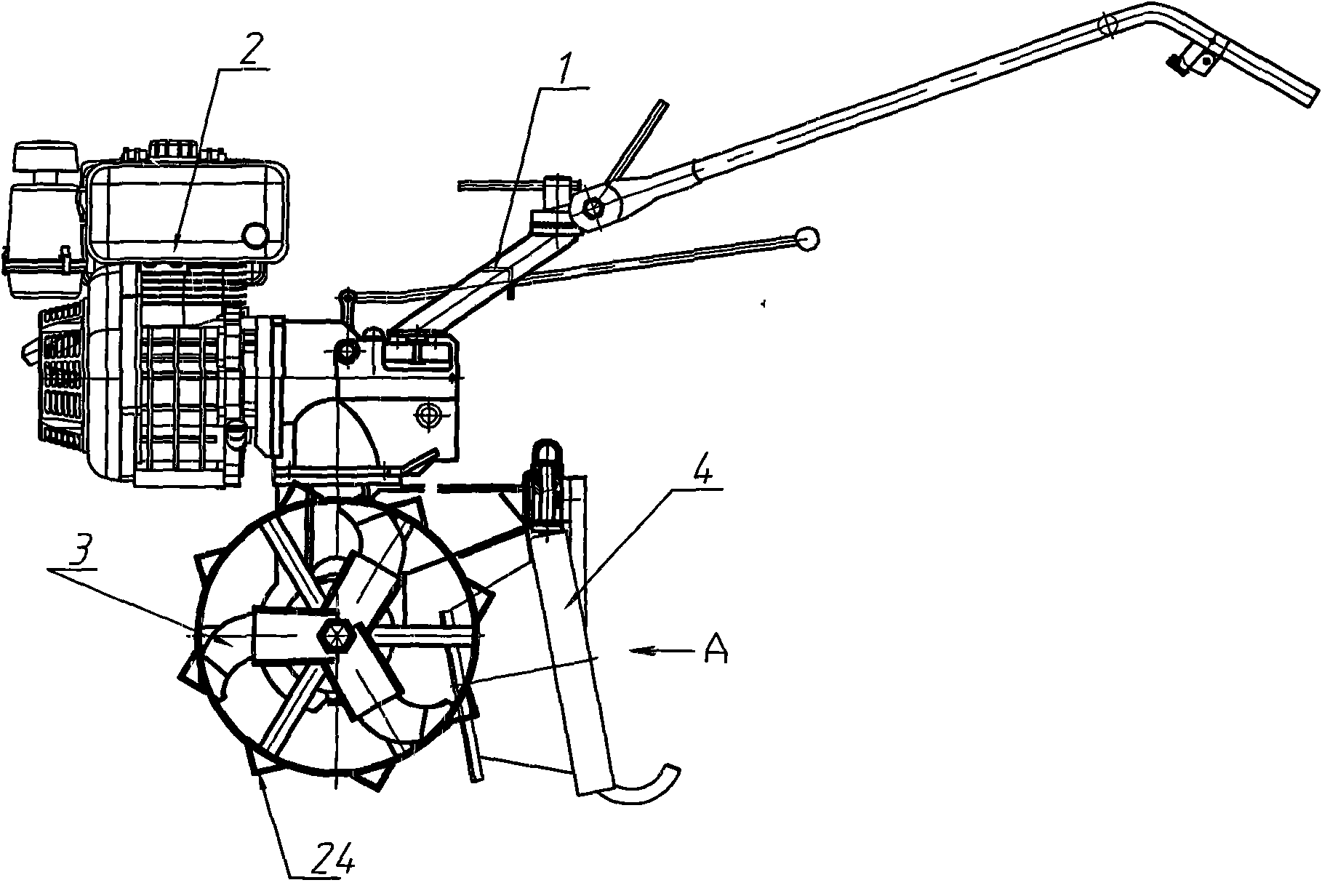

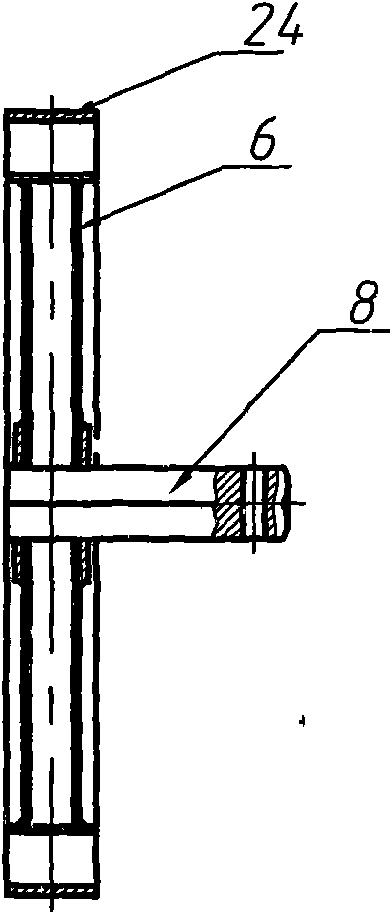

[0025] See figure 1 As can be seen from the figure, the ditch ridger of the present invention is mainly composed of frame 1, power part 2, cutter 3, shaper 4 and operating part. The frame is the installation foundation of the entire ridger. The power part (engine), shaper and operation part are all installed on the basis of the frame.

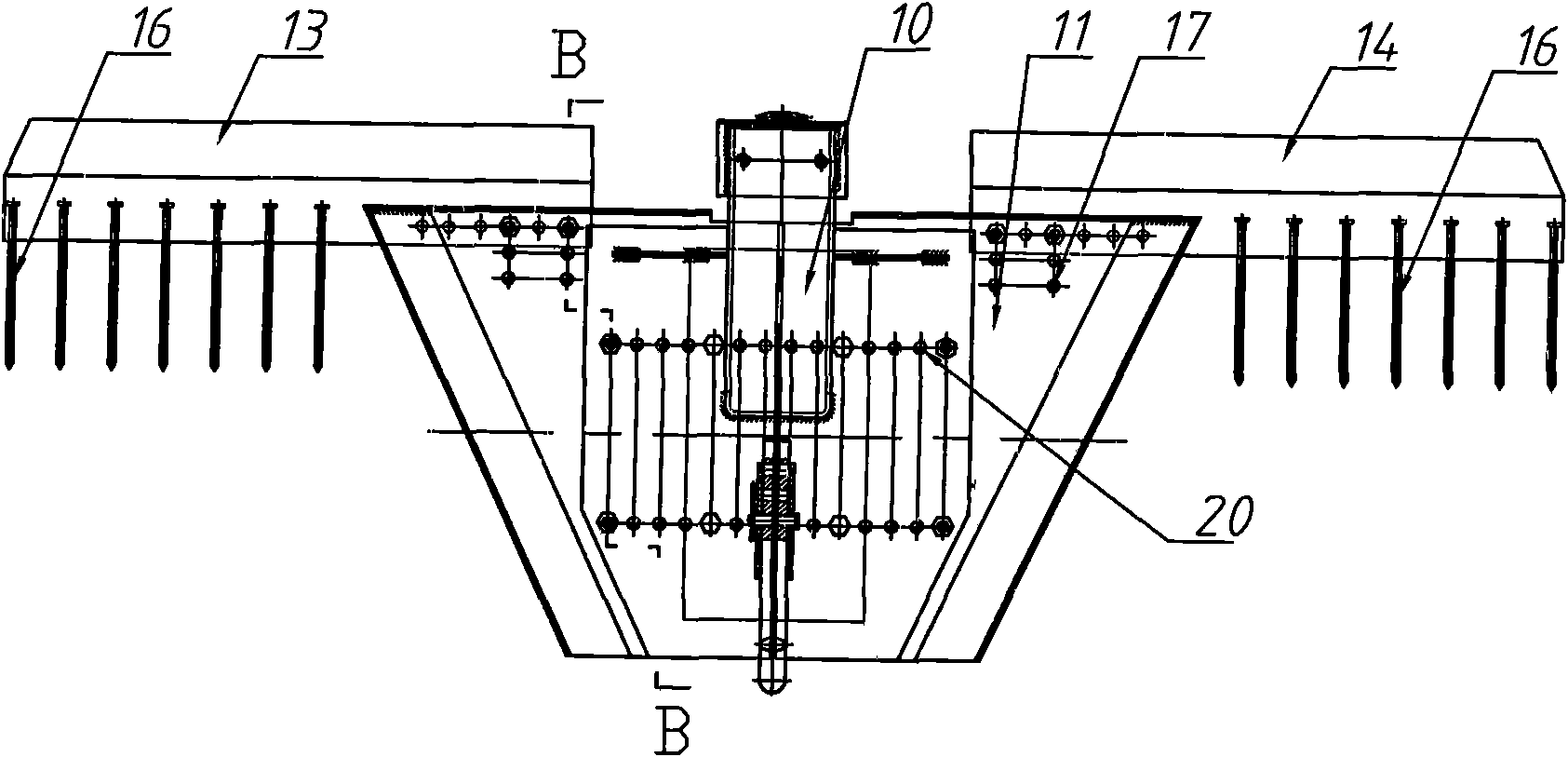

[0026] The cutter 3 is installed symmetrically on the two ends of the power output shaft 7 for cutting large pieces of soil. The blade 5 on the cutter has a spiral structure. The different spiral directions determine the accumulation of fine soil. see Figure 5 , The blade 5 of the present invention spirals outwards, so the shredded soil is separated and piled up on both sides, forming a ditch in the middle, and naturally forming a ridge between the two ditches. The traditional blade spirals inward, and the soil piles up in the middle to form a ridge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com