Patents

Literature

166results about How to "Reduce production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

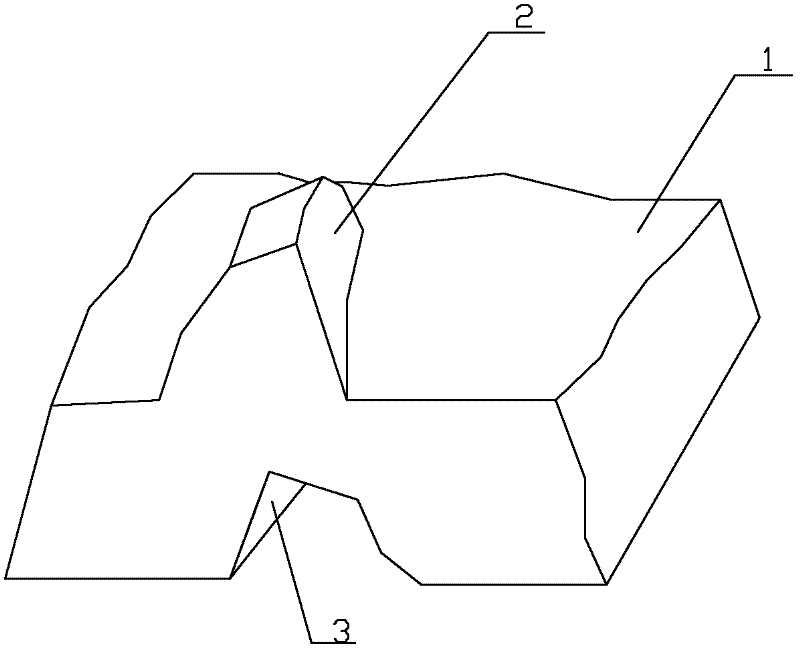

Mining method employing solid filling and fully-mechanized coal mining hybrid working face

ActiveCN104405437AAvoid pollutionSolve the tunnelingUnderground miningSurface miningSolid massFilling materials

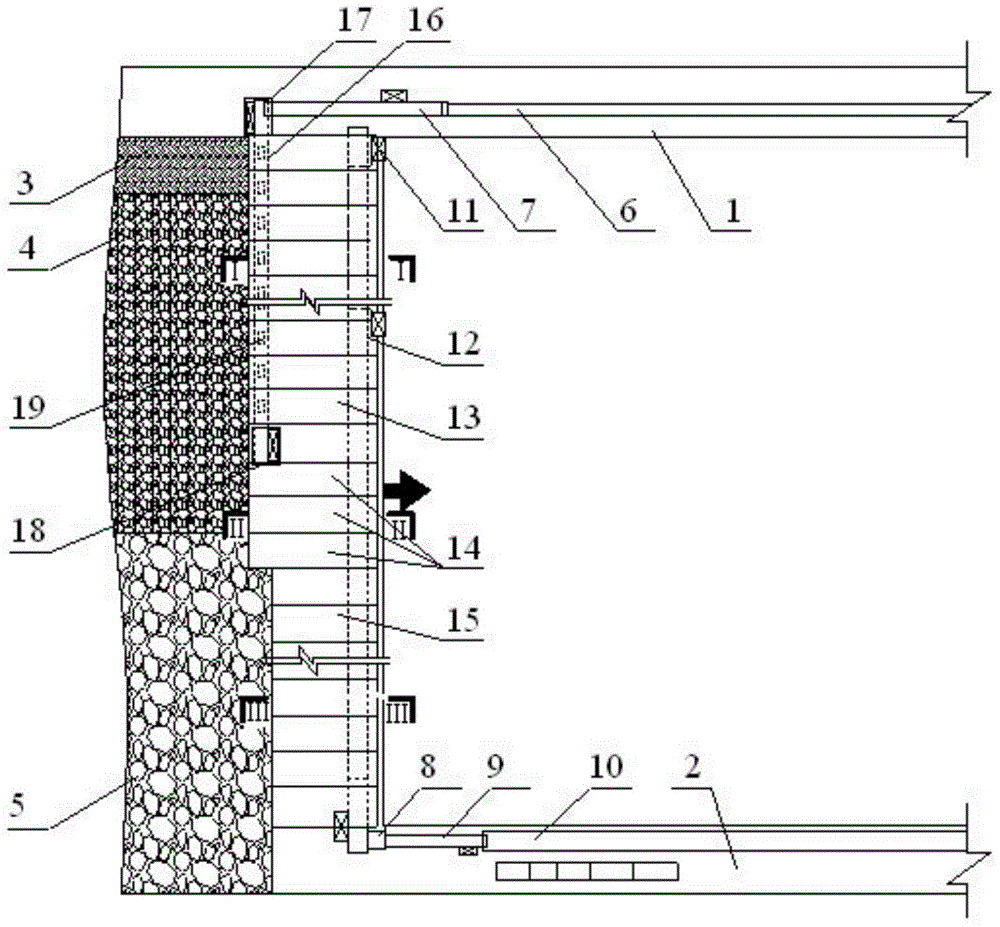

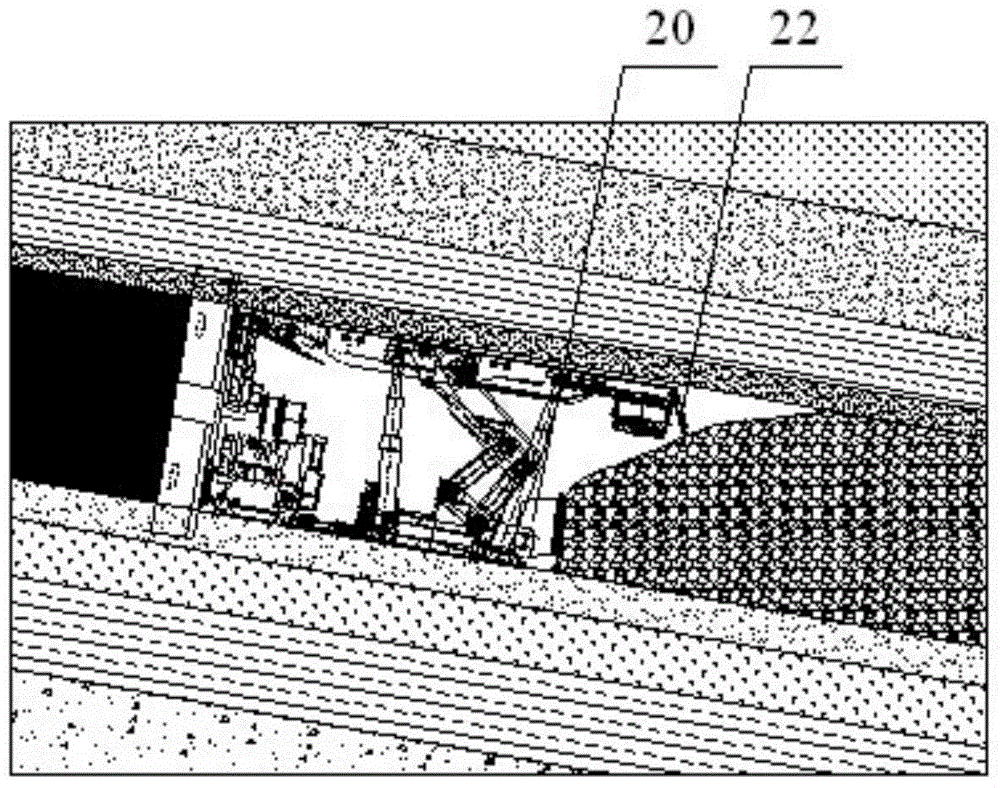

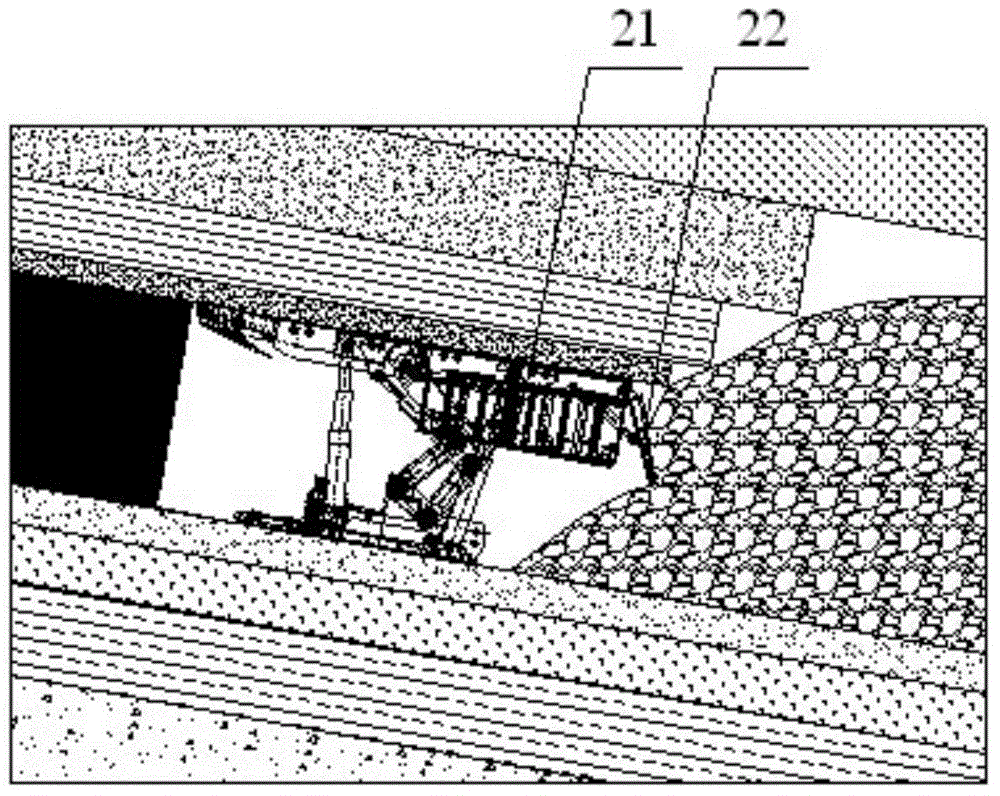

The invention discloses a mining method employing a solid filling and fully-mechanized coal mining hybrid working face, namely a method for carrying out coordinated and combined mining by combining solid filling with fully-mechanized coal mining on the same coal face. Coal mining is carried out by adopting a strike retreating-longwall mode; coal cutting, coal charging and coal handling procedures are the same as those of a fully-mechanized coal mining process; a solid filling section of the hybrid working face is used for supporting a roof by virtue of a filling and mining hydraulic support; solid filling materials are backfilled to a goaf management roof by virtue of a porous hopper conveyor which is suspended behind and below of the filling and mining hydraulic support; a fully-mechanized coal mining section is used for supporting the roof by virtue of a fully-mechanized coal mining hydraulic support; the goaf is managed by adopting a caving method. The mining method is beneficial for giving play to dual advantages of solid filling and fully-mechanized coal mining; the problem of environmental pollution caused by accumulation of solid wastes such as gangue, coal ashes and construction wastes on the ground is reduced by solid filling; the working face is lengthened by combining with fully-mechanized coal mining; tunneling of a mining roadway is reduced; the single yield and single effect of the working face are improved; the requirements of a modern mine on production capacity are met.

Owner:CHINA UNIV OF MINING & TECH +1

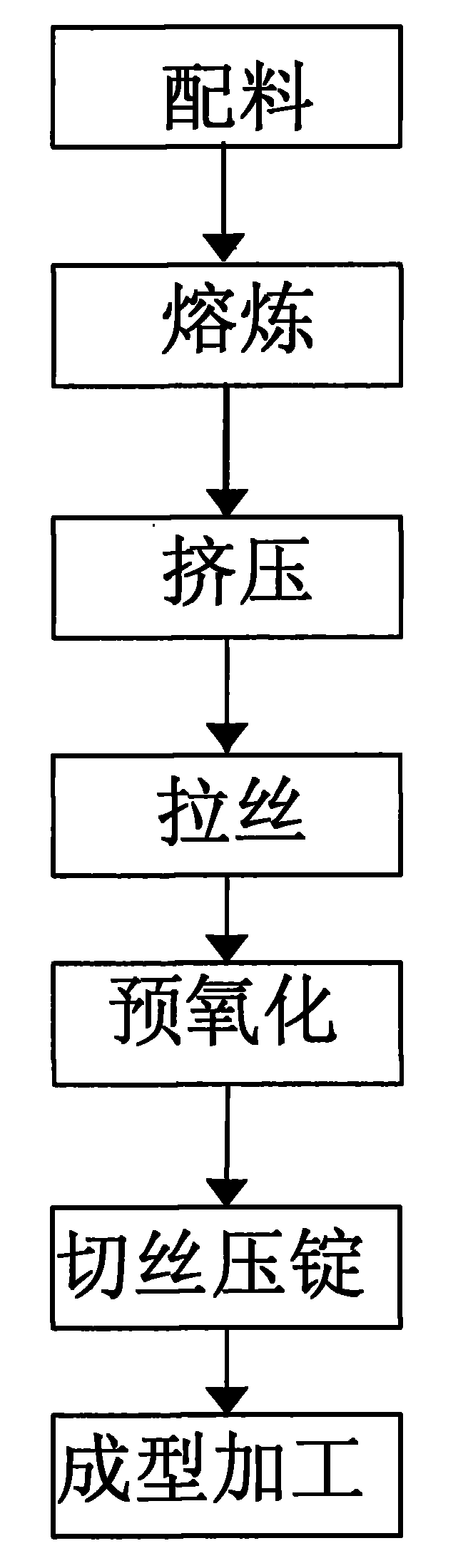

High-performance silver cadmium oxide material and manufacturing method thereof

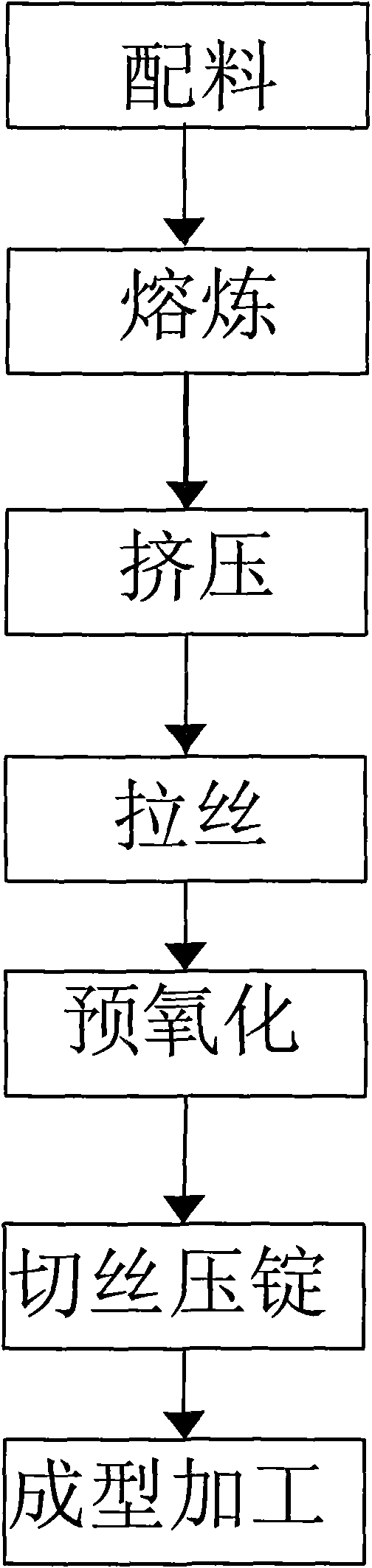

The invention relates to a high-performance silver cadmium oxide material and a manufacturing method thereof, which are characterized in that the silver cadmium oxide material comprises the following components: 85 to 97 percent of silver, 2 to 15 percent of cadmium, 0.01 to 0.5 percent of nickel, 0.01 to 1 percent of tin and 0.01 to 0.5 percent of rear earth mixture. The manufacturing method of the high-performance silver cadmium oxide material is characterized in that: a given quantity of silver, cadmium, nickel, tin and rare earth mixture are measured to be arranged inside a middle-frequency induction furnace to be smelted and cast, the cast ingot is extruded by an extruding machine to be thick wires, the thick wires are stretched by a wire-drawing die to be thin wires, the thin wires are pre-oxidized by an internal oxidization furnace, then the thin wires are cut and preformed and finally is processed and formed. The anti-oxidization performance, electric-arc burning loss resistance and the abrasion resistance of the silver cadmium oxide material are improved, and the service life is prolonged, so the high-performance silver cadmium oxide material can be applied to different working environments, has low production cost, simple manufacturing method and low requirements on the device and the production.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

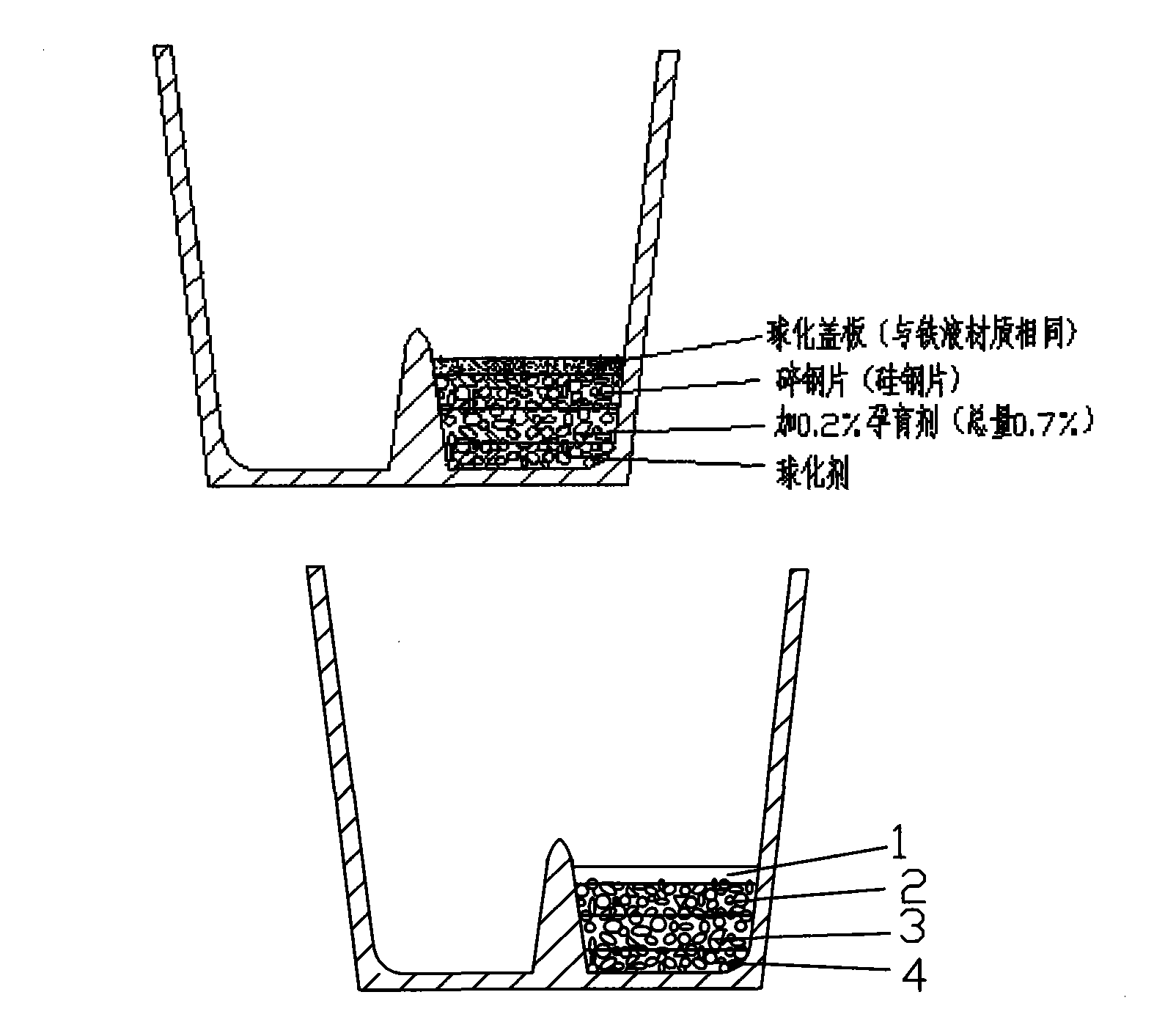

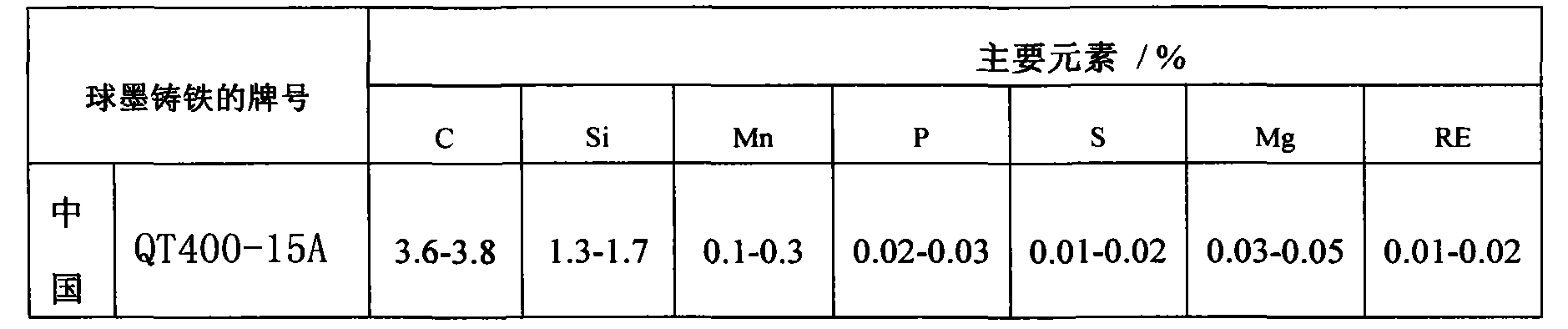

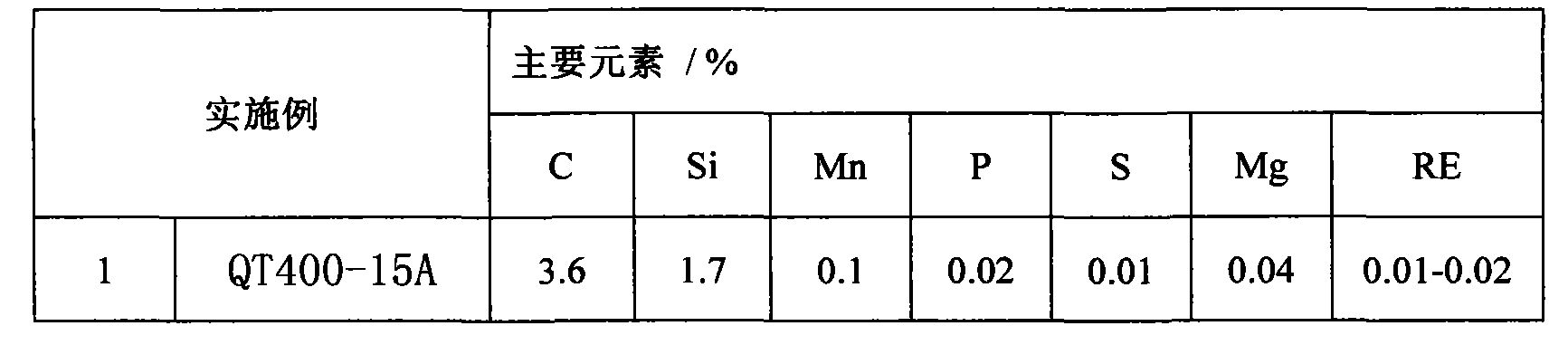

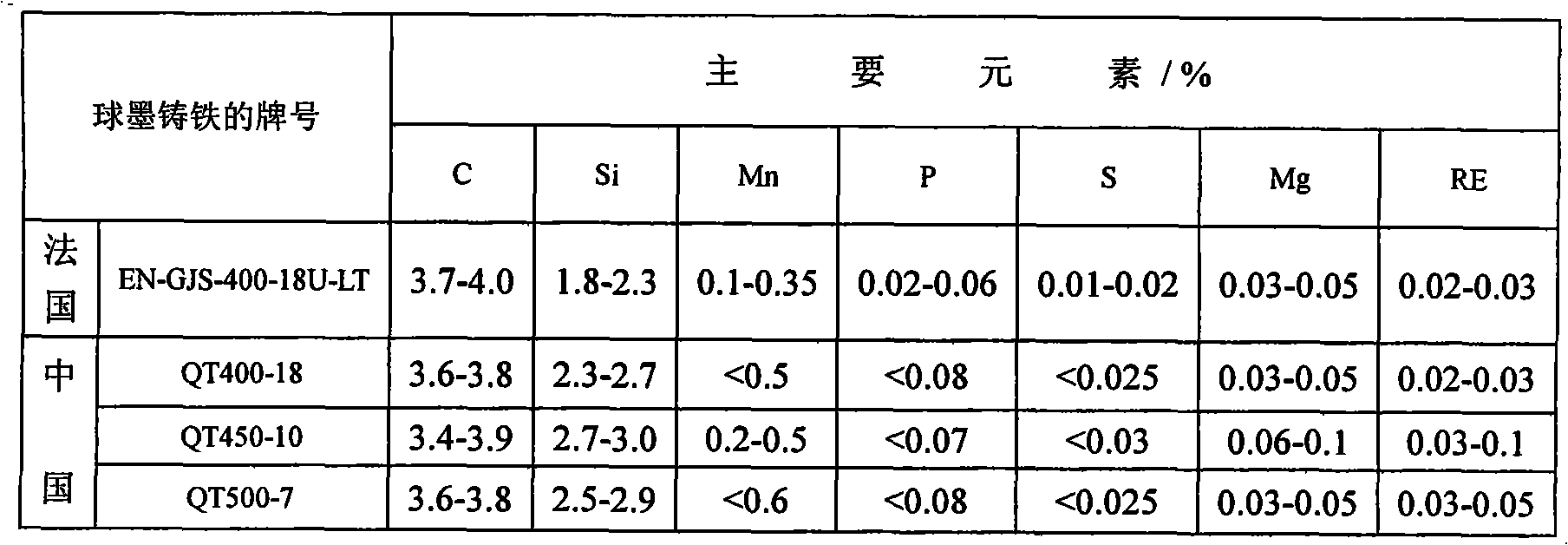

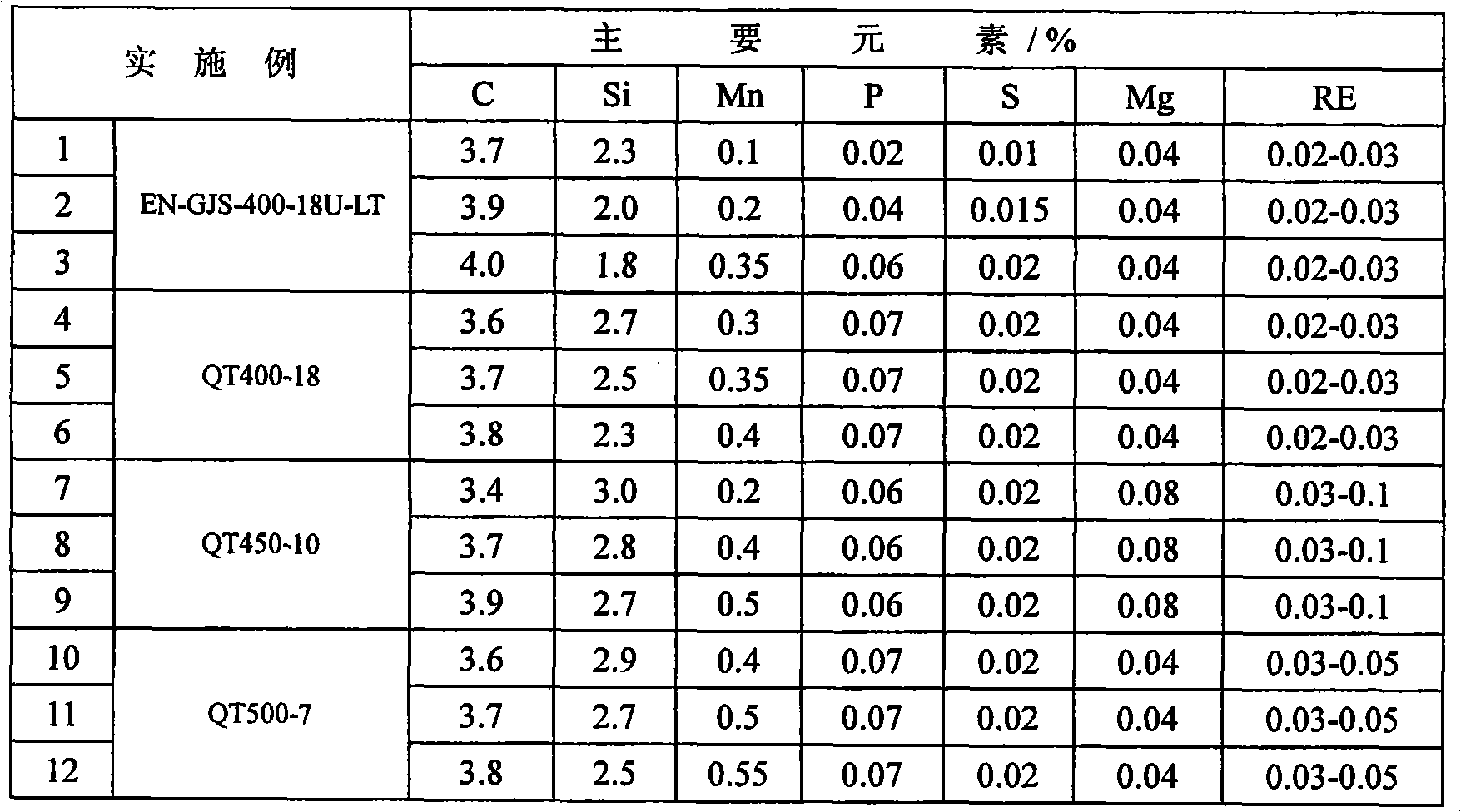

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

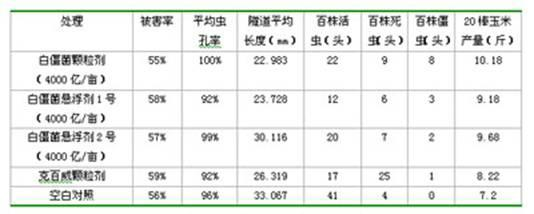

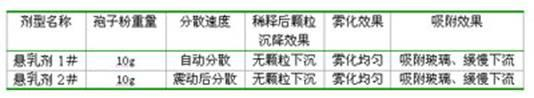

Beauveryia bassiana pesticide suspoemulsion and preparation method thereof

InactiveCN102067886APromote commercializationFast production process requirementsBiocideAnimal repellantsSporeEcological farming

The invention relates to a beauveryia bassiana pesticide suspoemulsion and a preparation method thereof. The invention is characterized in that the beauveryia bassiana pesticide suspoemulsion includes the following materials in part by weight: 20 to 80 parts of beauveryia bassiana spore powder; 10 to 60 parts of emulsified dispersant; 10 to 30 parts of thickening agent; 10 to 30 parts of suspension stabilizer; 10 to 30 parts of spreader; 10 to 60 parts of sugar; and 1 to 10 parts of peptone. The activity of spores is increased, the variety of chemical aids in use is small, moreover, the suspoemulsion can be easily dissolved in water and degraded so that the environmental pollution can be reduced, the adhesion rate of the spores on the body surfaces of inserts is increased, the infection process of the suspoemulsion is quicker than the infection process of raw powder, the requirement of the formulation production process is low, the method is quite simple, and the application in fields is simple. After being diluted by water, the suspoemulsion is in the form of milky, translucent liquid, emulsification is complete, no sediments exist, the stability is high, and the suspoemulsion does not have foreign odor. The dilution factor is high, the packaging and transportation cost is saved, and the transportation of the pesticide is safe. The invention promotes the popularization and commercialization of bassiana and the development of the rural ecological agriculture in China.

Owner:JILIN ACAD OF AGRI SCI

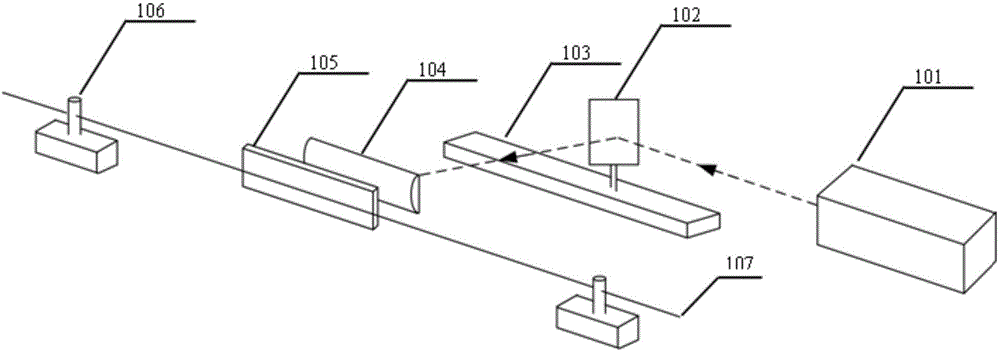

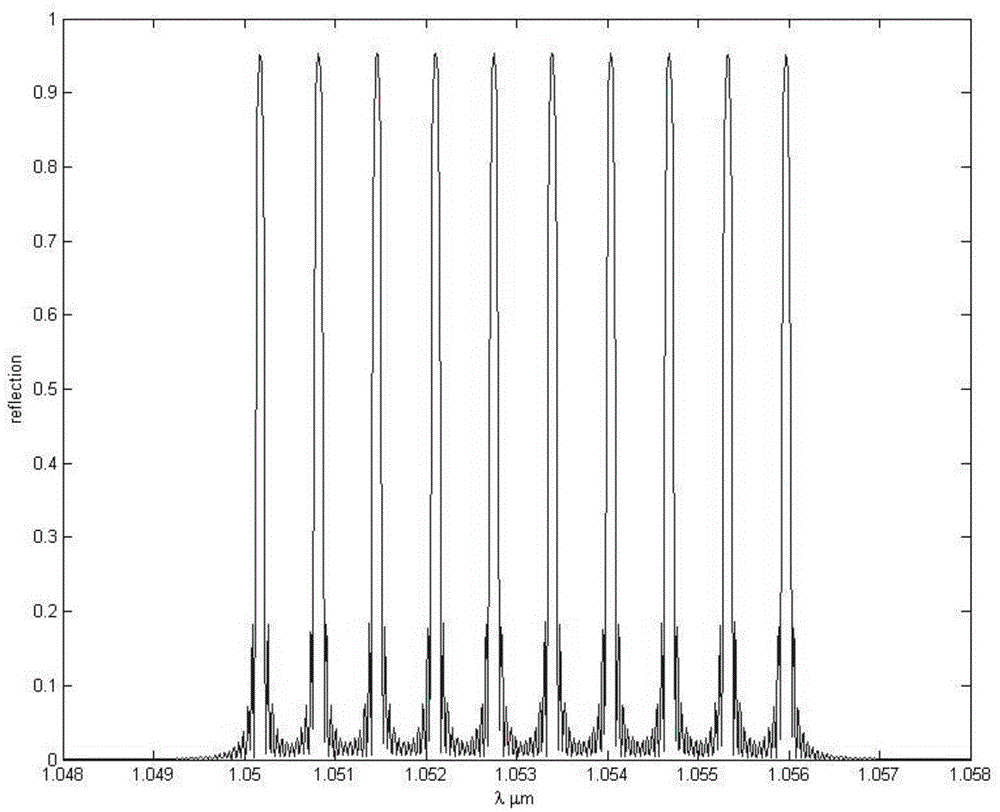

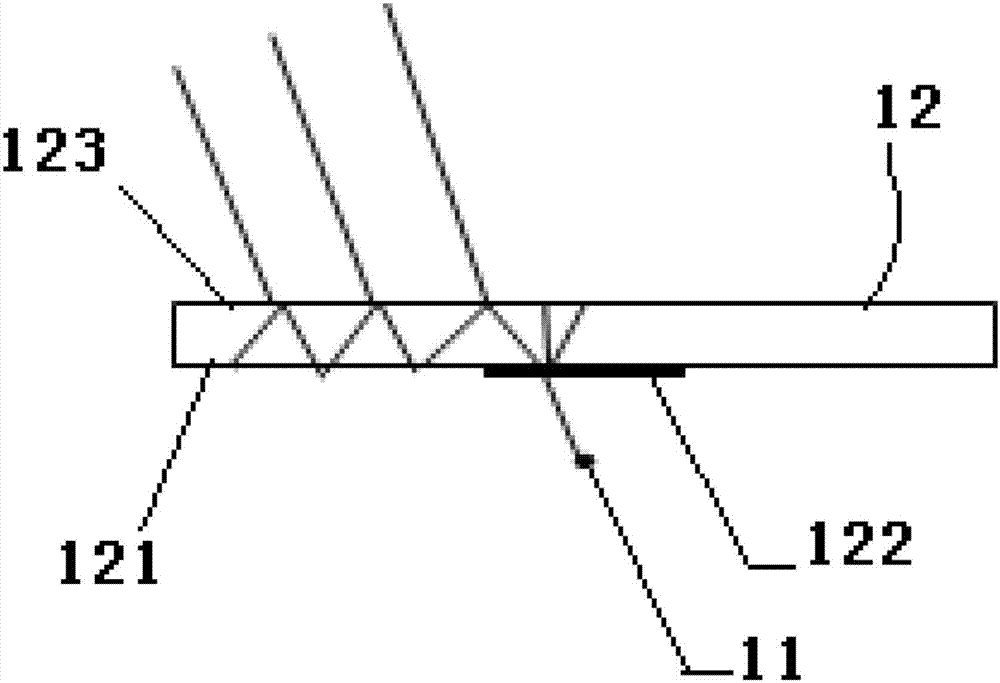

Inscribing method for sampling fiber bragg grating

InactiveCN103984056AReduce production requirementsWide range of applicationsCladded optical fibrePhotomechanical exposure apparatusLight sourceFiber Bragg grating

The invention discloses an inscribing method for a sampling fiber bragg grating. A specific device adopted in the method structurally comprises an ultraviolet source (101), a holophote (102), a controllable electric horizontal-moving platform (103), a cylindrical lens (104), a grating phase mask plate (105) and an optical fiber clamping and stretching system (106). According to the inscribing method for the sampling fiber bragg grating, the Prague type sampling fiber bragg grating can be inscribed, and the inscribed sampling fiber bragg grating has high practicability in the aspects of multi-channel filtering and dispersion compensation. According to the inscribing method for the sampling fiber bragg grating, the structure is simple, stability is high, and adjustability is strong.

Owner:UNIV OF SCI & TECH OF CHINA

Visible light curing glue and preparation method thereof

InactiveCN106118579AFast curingAvoid dangerAdditive manufacturing apparatusNon-macromolecular adhesive additivesLight energyOperability

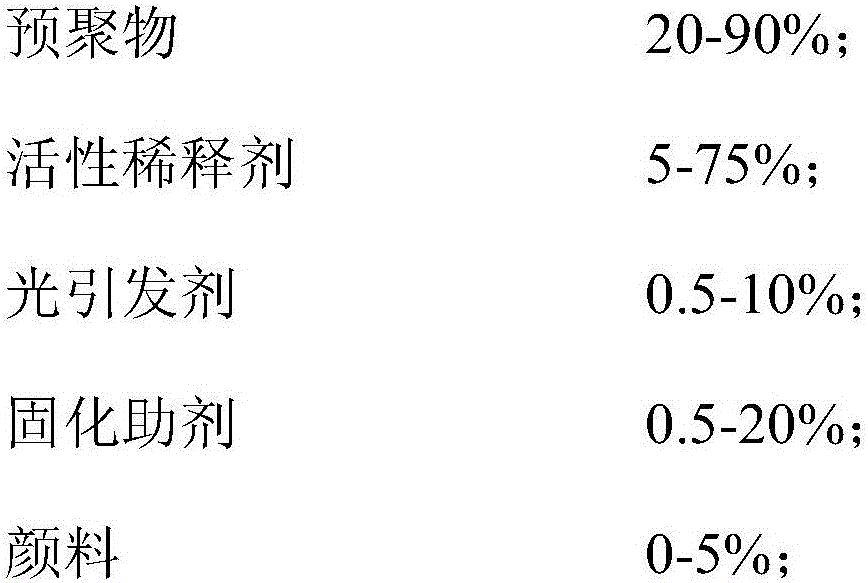

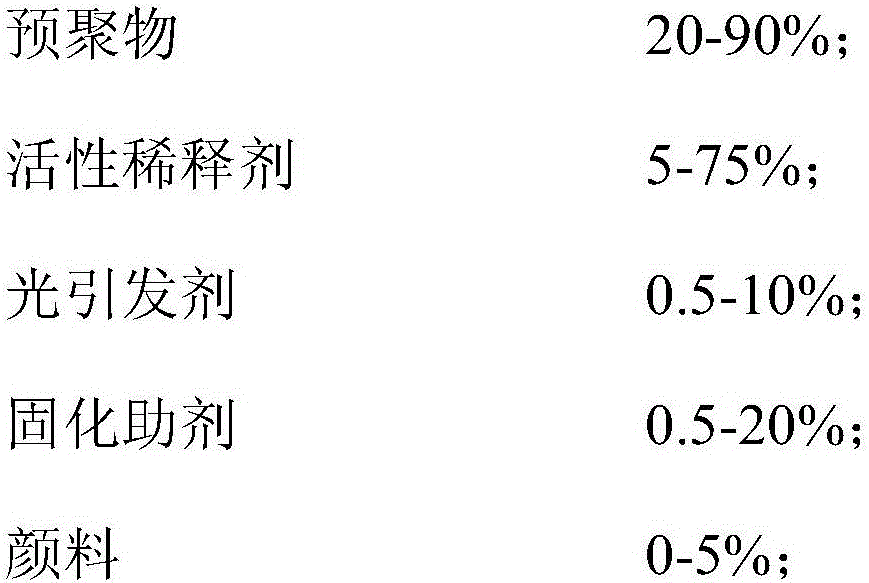

The invention discloses a visible light curing glue, including the following components by weight: 20-90% of a prepolymer, 5-75% of a reactive diluent, 0.5-10% of a photoinitiator, 0.5-20% of a curing agent, and 0-5% of a pigment, wherein the total weight of the above components is 100%. The visible light curing glue can be rapidly cure under visible light irradiation, and the curing needs little light energy and short curing time. The invention also provides a preparation method of the visible light curing glue. The preparation method has the advantages of simpleness, convenience, high safety and strong operability.

Owner:唐天

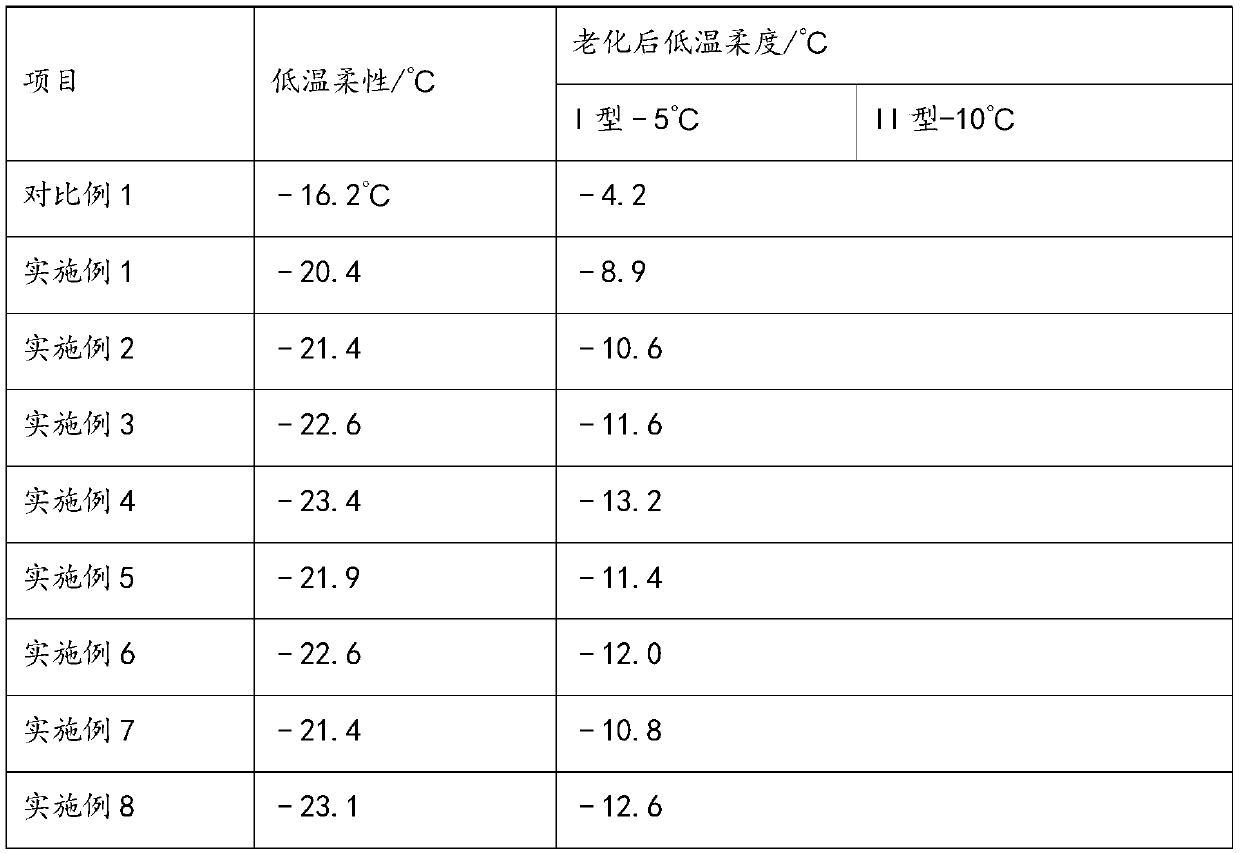

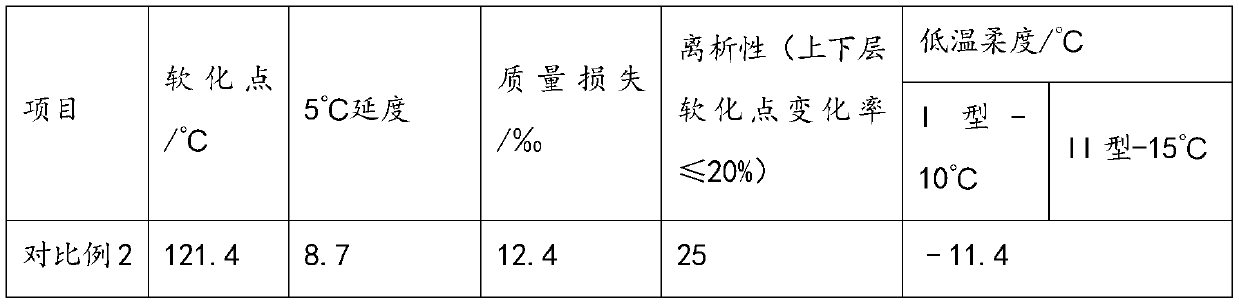

Efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and preparing method

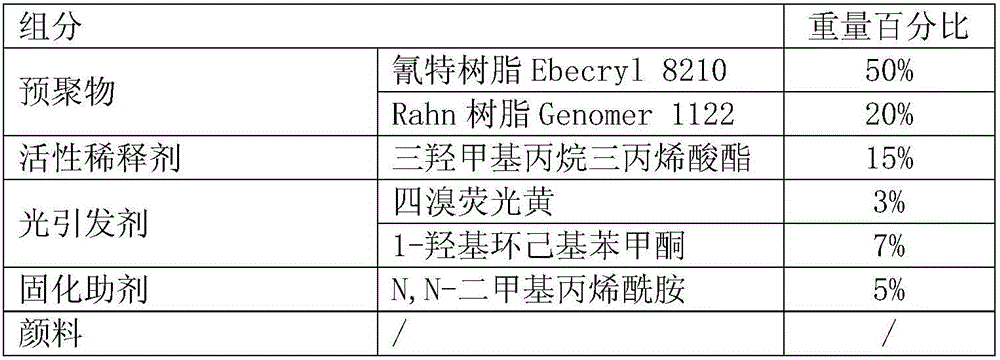

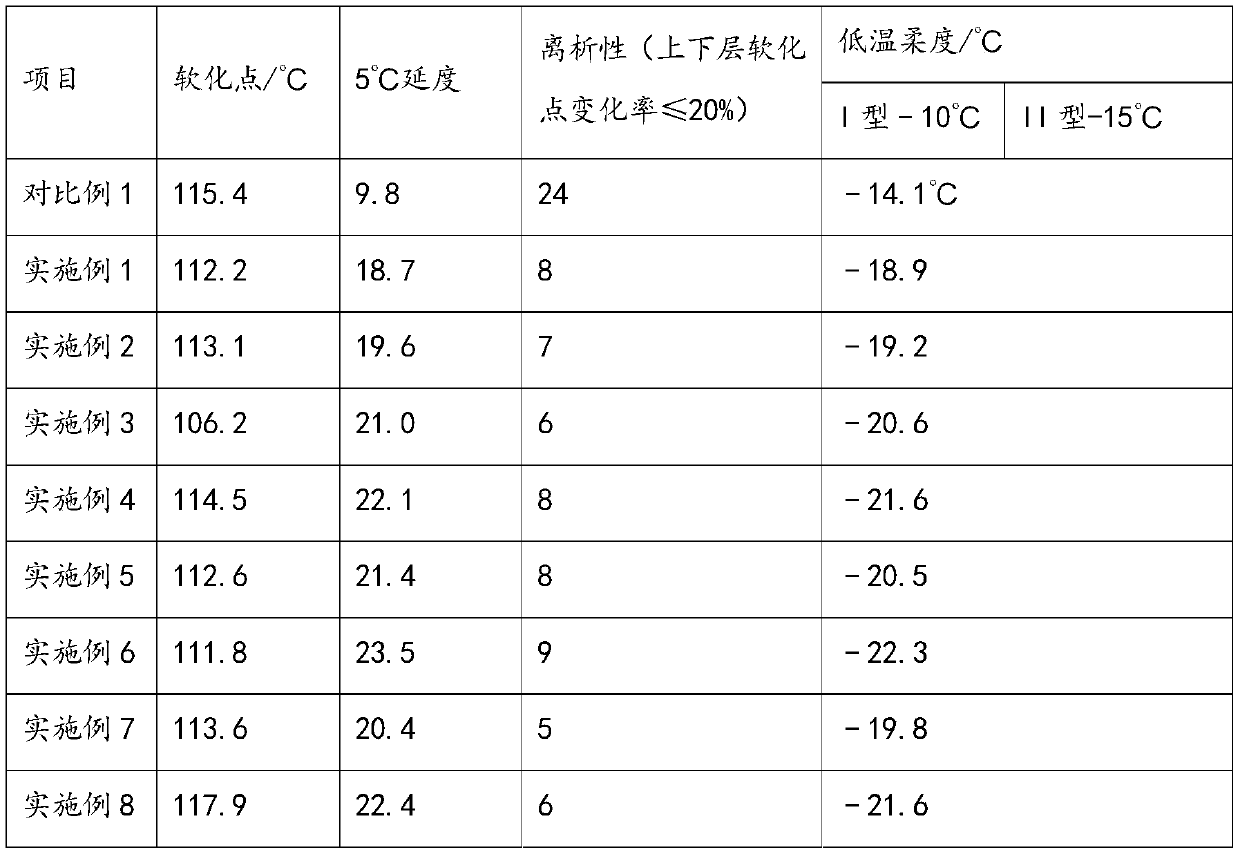

InactiveCN110042670AFast swelling rateGood compatibilitySynthetic resin layered productsConstructions elementsEnvironmental resistanceBituminous waterproofing

The invention relates to an efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and a preparing method. The preparing method comprises the steps of mixing anduniformly stirring 34-54 parts of matrix asphalt and 1.5-15 parts of softening oil, increasing the temperature to 150-170 DEG C, starting to add 10-15 parts of waste rubber powder and 0.01-0.03 part of an activating agent, increasing the temperature, maintaining the temperature at 170-180 DEG C, conducting development for 60-80 minutes at the rotation speed of 20-200 r / min, afterwards, adding 4-15parts of waste rubber powder, conducting stirring development for 10-20 minutes, conducting cutting and grinding once through a colloid mill, adding 15-30 parts of a filler, and then conducting stirring development for 30-60 minutes to obtain a modified asphalt coating material; conducting coating and cladding technologies on the prepared modified asphalt coating material, and then conducting cooling rolling to prepare the rubber-powder-modified asphalt waterproof coiled material. According to the efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material andthe preparing method, by adding the activating agent, all technology parameters of the batching period are greatly adjusted, the technology time can be shortened, the technology temperature and stirring speed can be lowered, and the prepared product also has better performance indexes, has excellent storage stability and application performance, and is an efficient, energy-saving and environment-friendly product.

Owner:YUZHONGQING WATERPROOF MATERIALS CO LTD

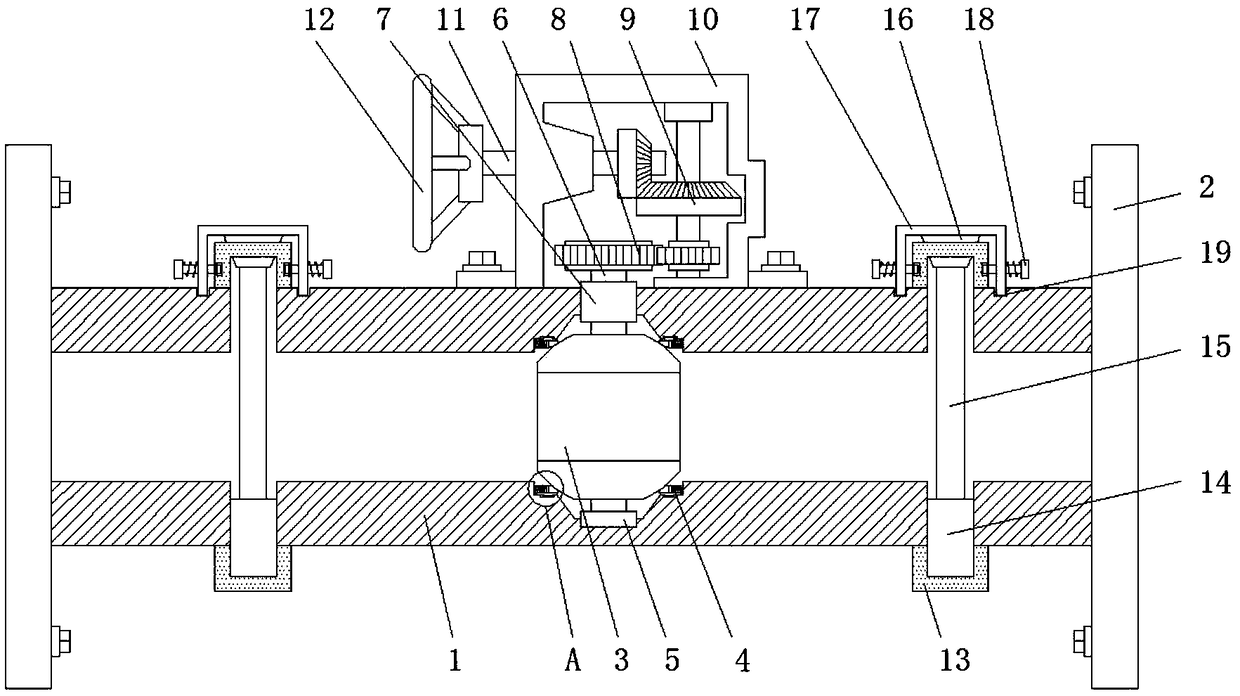

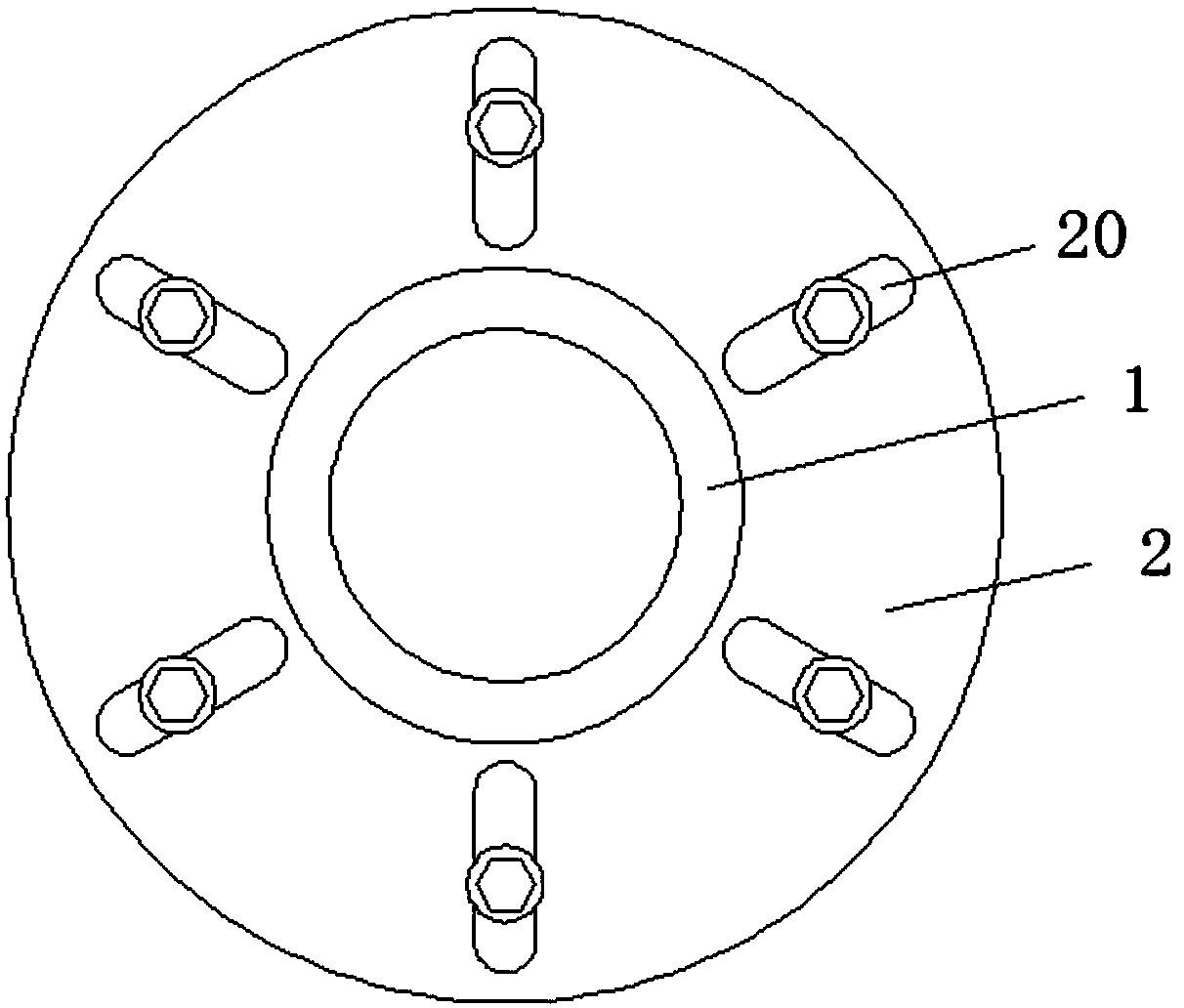

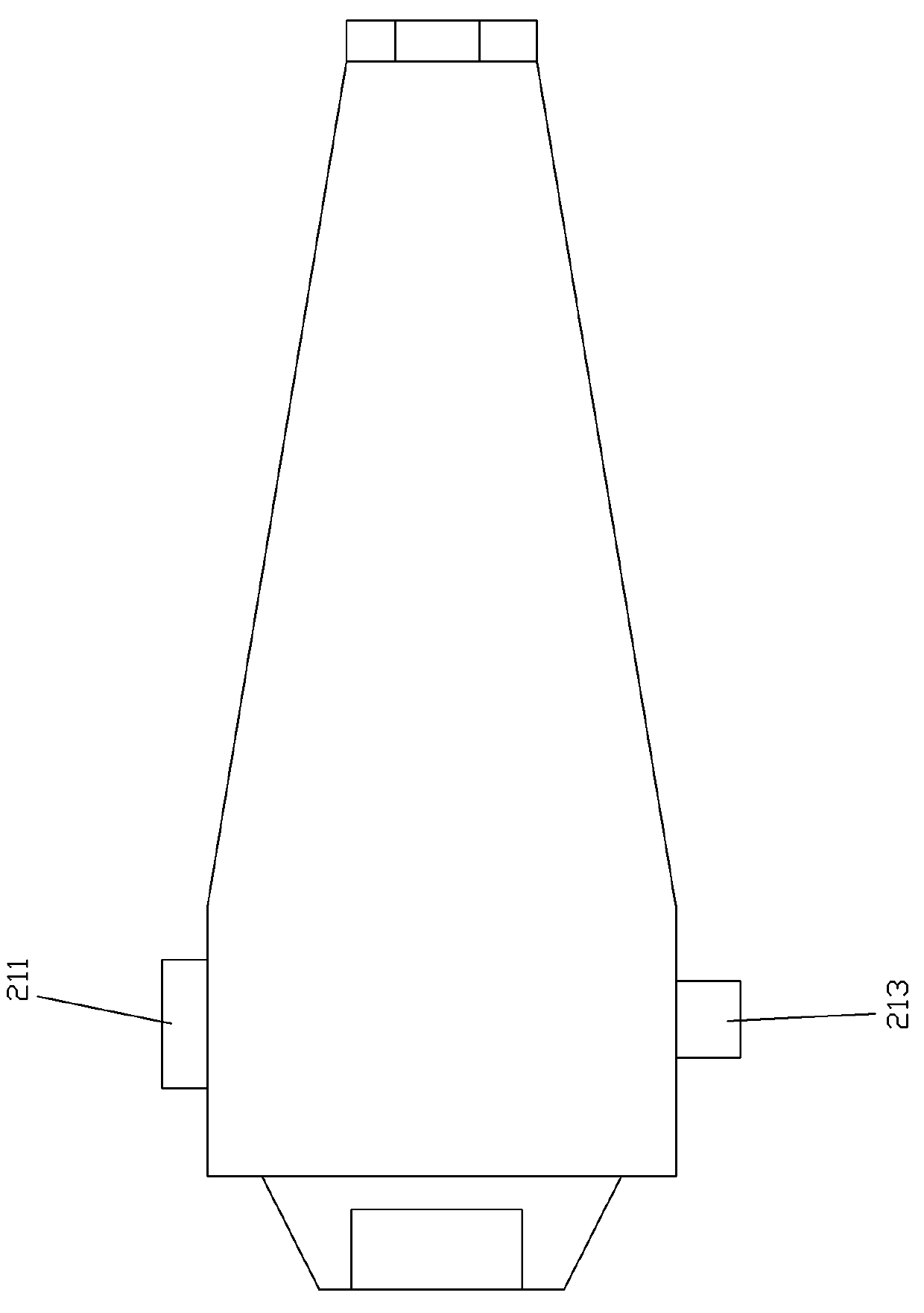

Volume control type sewage pipe connecting valve

InactiveCN108775417AAccurate volume controlHigh rotation accuracyPlug valvesOperating means/releasing devices for valvesGear driveWater flow

The invention relates to the technical field of drainage valves, and discloses a volume control type sewage pipe connecting valve. The volume control type sewage pipe connecting valve comprises a pipebody. Flange plates are fixedly connected to the left and right ends of the pipe body, a ball valve body is fixedly installed on the middle portion of an inner cavity of the pipe body, sealing fasteners are fixedly installed at the junction between the upper and lower outer walls of the ball valve body and the inner wall of the pipe body, the bottom end of the ball valve body is fixedly connectedwith the inner wall of a valve seat bearing in a sleeving mode, the bottom end of the valve seat bearing is fixedly connected with the inner bottom of the pipe body, the top end of the ball valve body is fixedly connected with an upper valve stem, and a valve top bearing is fixedly connected to the outer wall of the upper valve stem in a sleeving mode. According to the volume control type sewagepipe connecting valve, by arranging a gear set, a handle rotates two circles to drive a first bevel gear to rotate one circle, so that a driven gear drives a driving gear to rotate by ninety degrees,that is, the handle rotates two circles to drive the ball valve body to rotate an opening and closing period, so that higher rotation precision is conveniently obtained under the condition of manual rotation, and the control amount of the equipment to the pipeline water flow is more accurately controlled.

Owner:张健

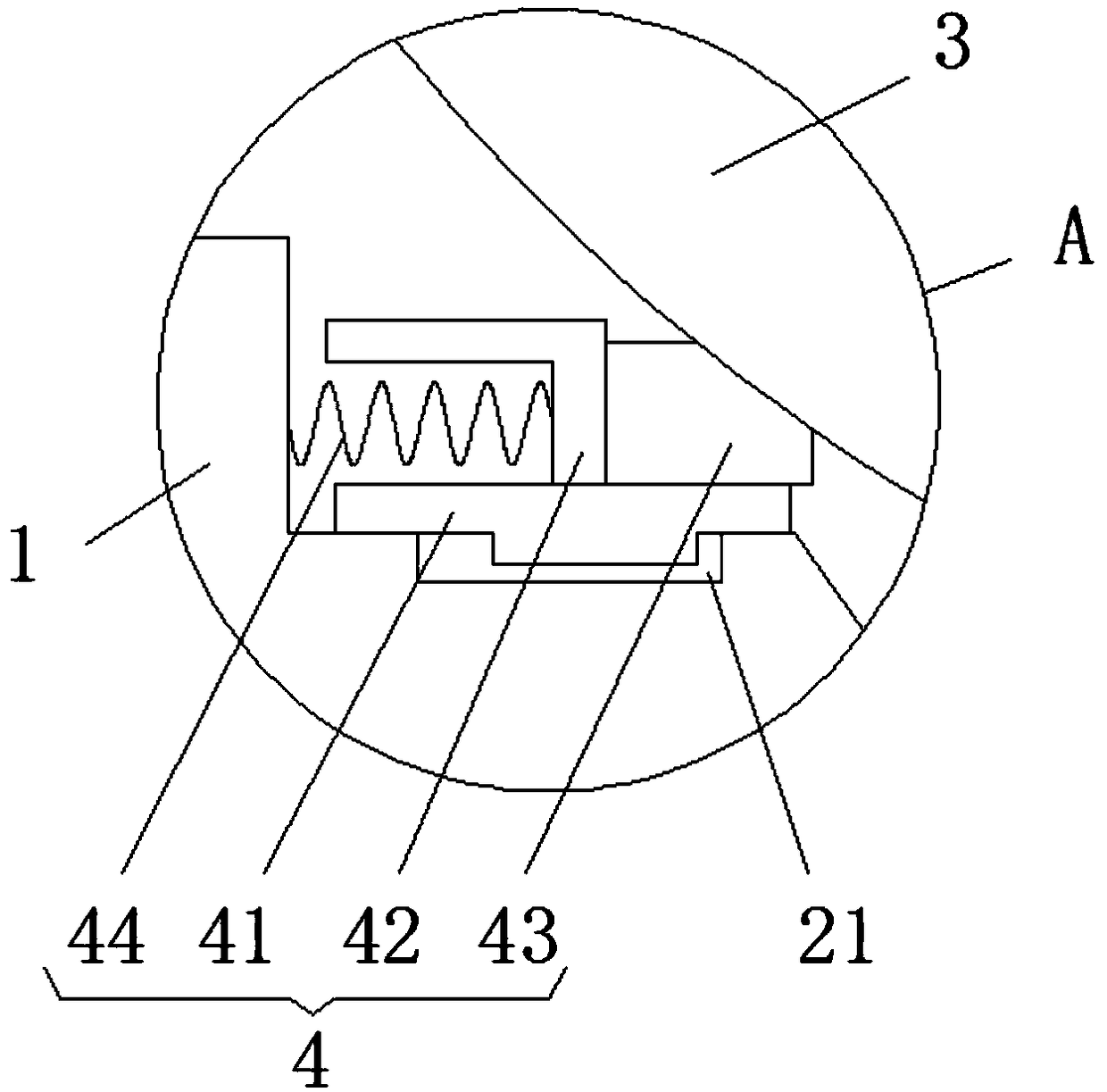

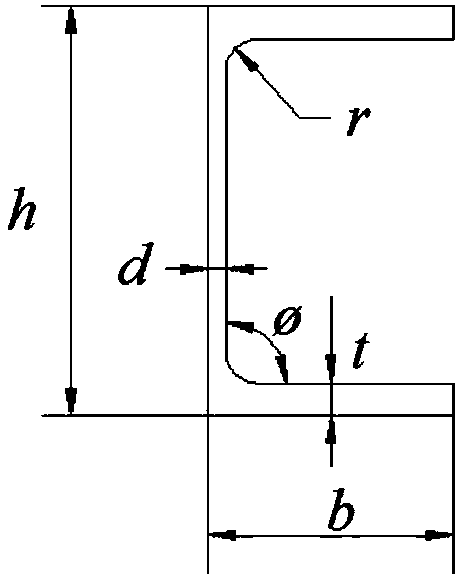

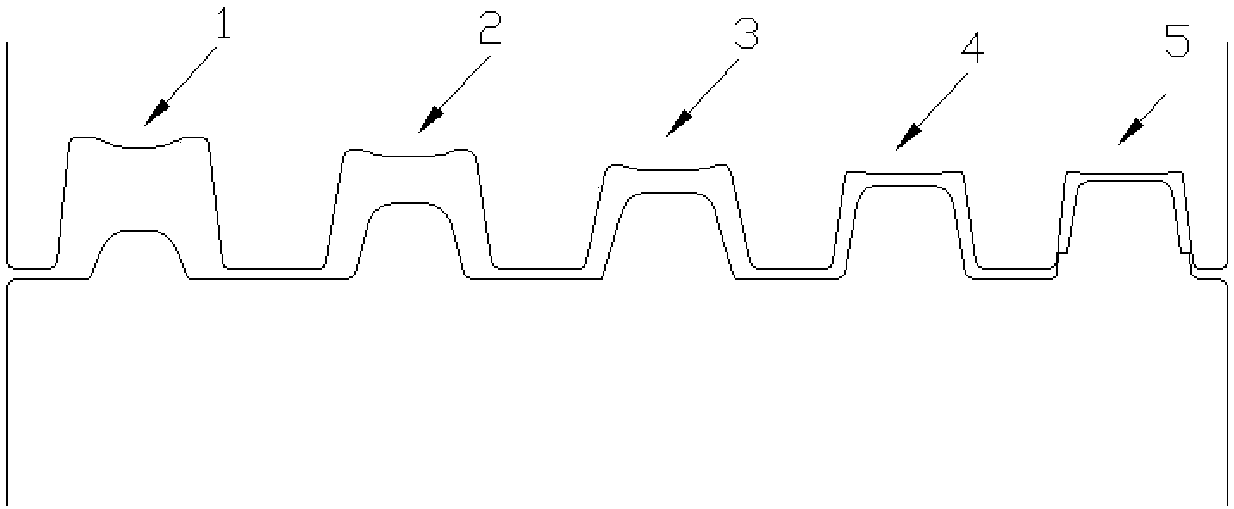

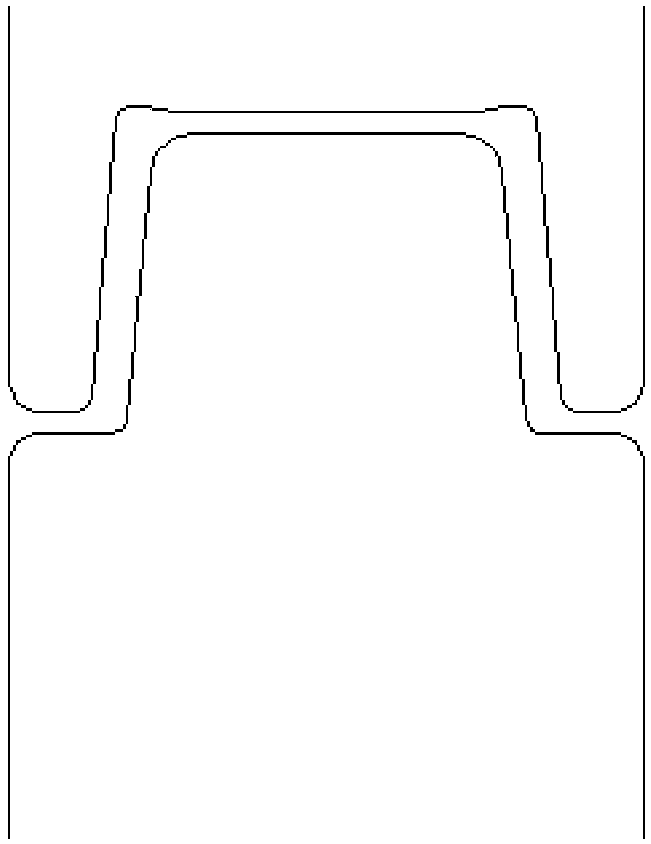

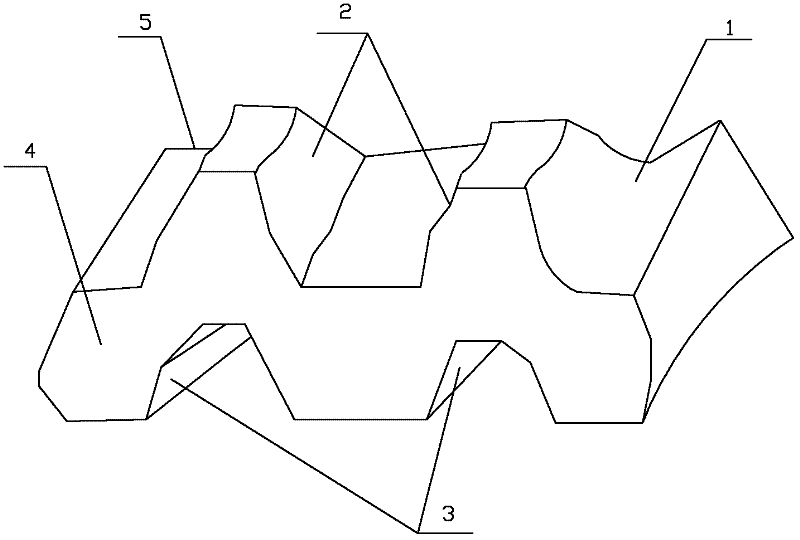

Parallel wide-flange-edge channel steel and production method thereof

ActiveCN108160705AIncrease the bearing rangeImprove the efficiency of steel structure manufacturingElongated constructional elementsMetal rolling arrangementsManufacturing efficiencyEngineering

The invention provides parallel wide-flange-edge channel steel and a production method thereof. According to the channel steel, the specific value of the web height and the flange edge width is smaller than or equal to 1.7. The related channel steel is characterized in that the flange edge is wide, and the inner face and the outer face of the flange edge are parallel, the bearing range of the flange edge can be widened effectively, the difficulty of follow-up machining of flange edge perforating, bolt connecting, welding and the like can be reduced, and the manufacturing efficiency of the later-stage steel structure is improved. According to the production method, hole type design with side pressure is adopted in a reversible roughing mill, the wide-flange-edge channel steel can be produced with short-end-face steel blanks, casting blank applicability is widened, rolling stability of casting blanks in the reversible rough mill initial gate is improved, the production difficulty of thechannel steel is lowered, the requirement for the equipment is lowered, the production efficiency is improved, and the product pass percent is increased. Compared with a traditional channel steel production method, the production method can produce the channel steel with wider flange edge.

Owner:SHANDONG IRON & STEEL CO LTD

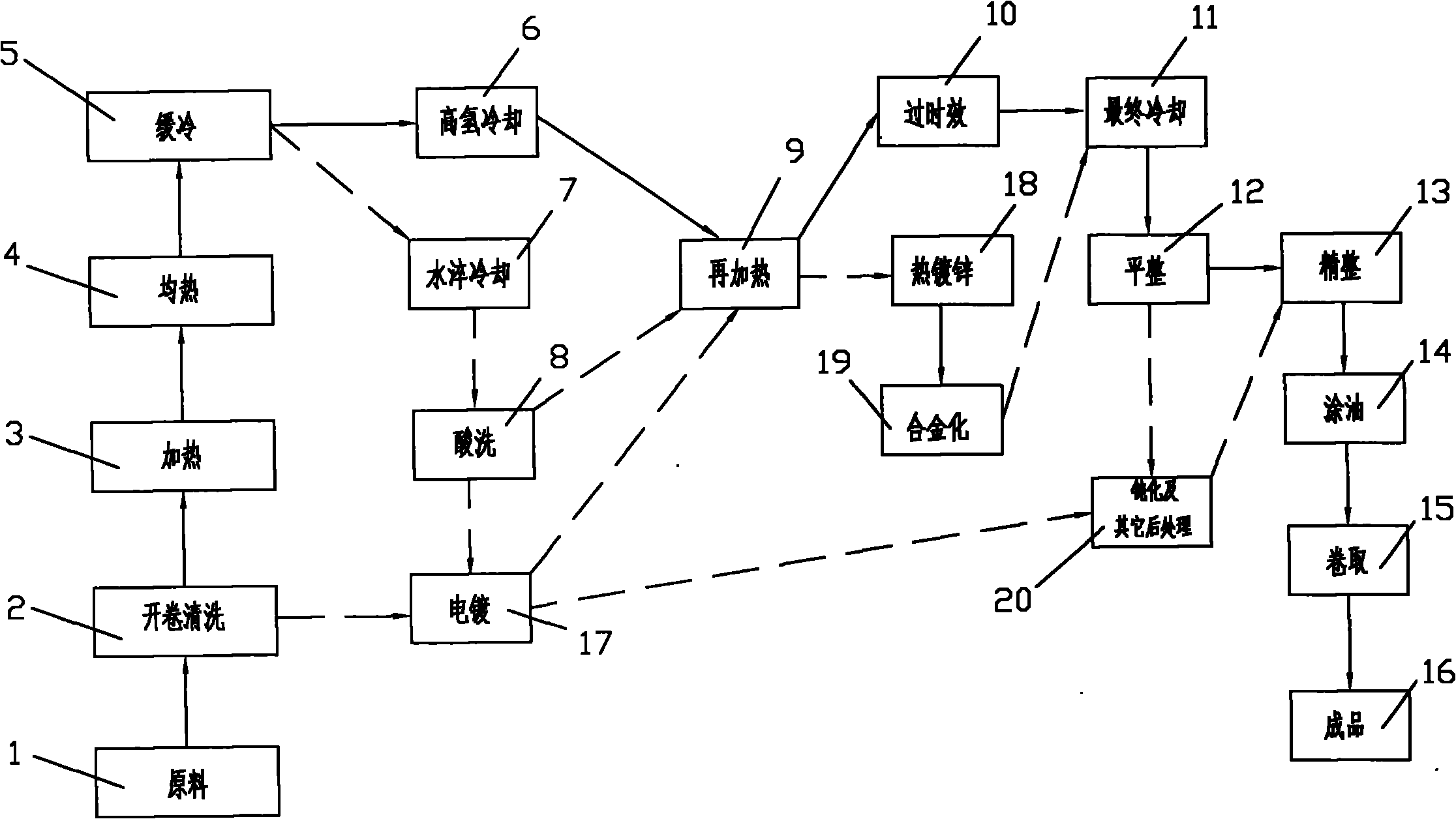

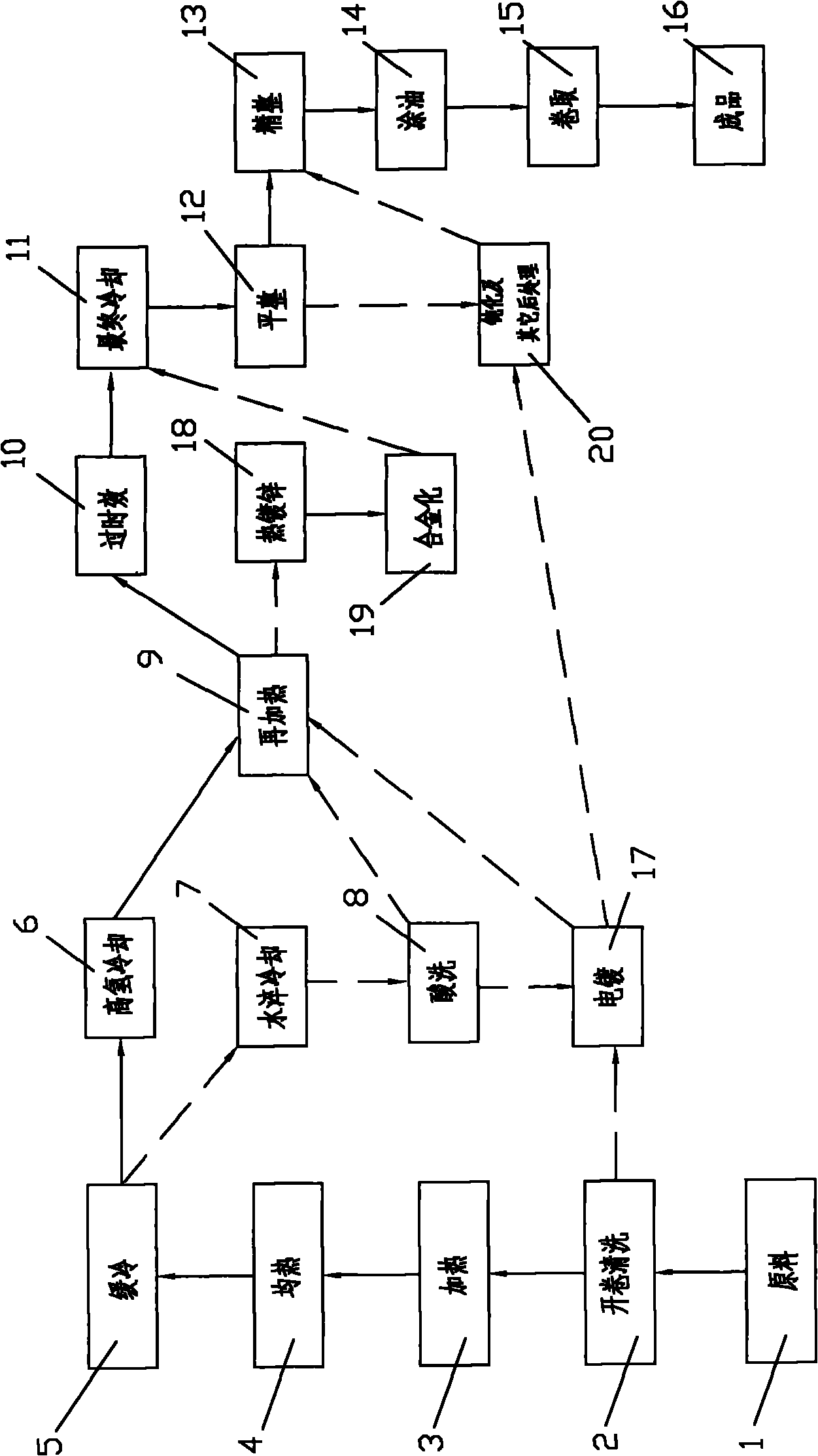

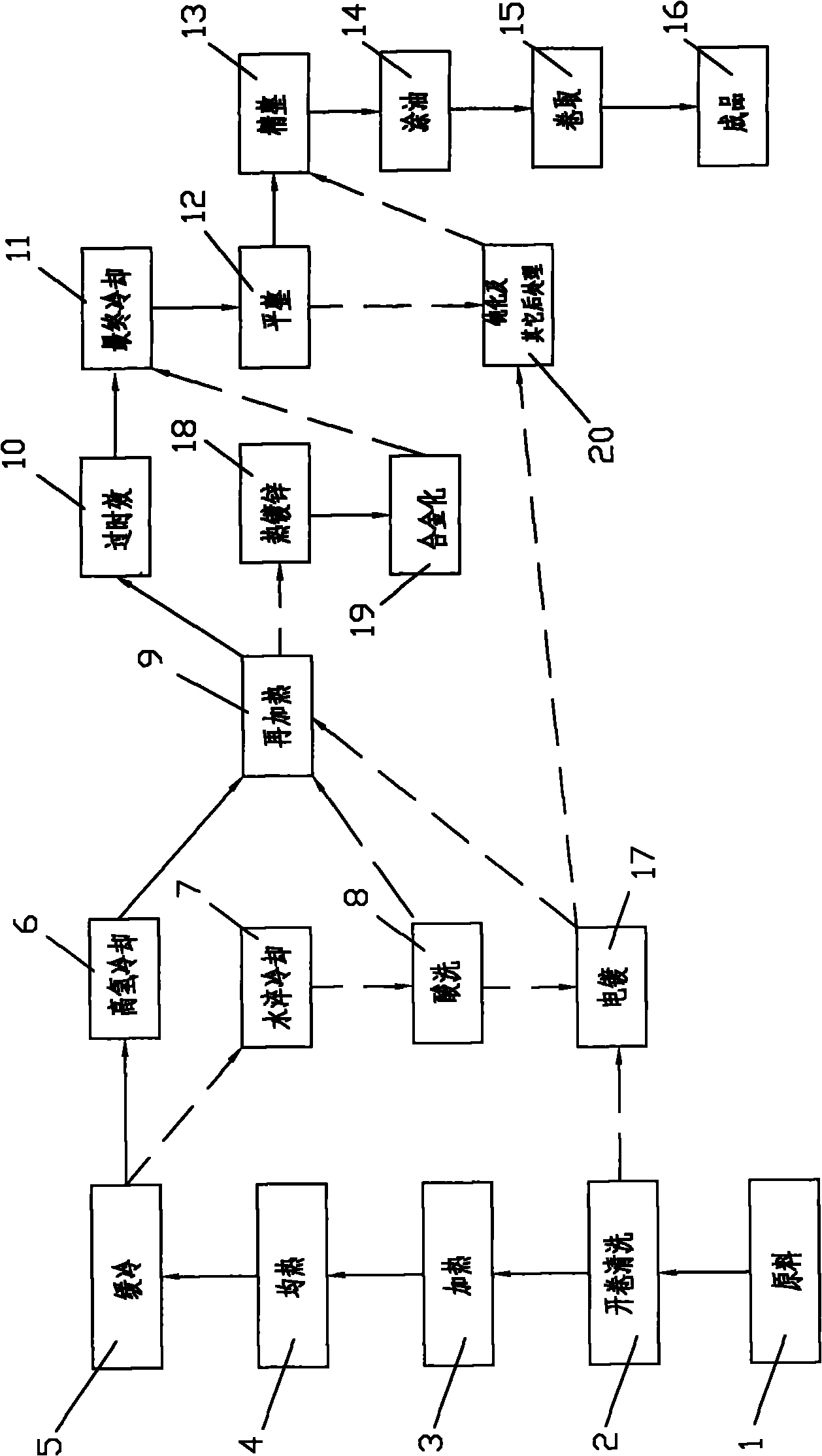

Flexible strip steel treating line suitable for producing various high-strength steel

ActiveCN101812579ARich varietyMeet actual needsHot-dipping/immersion processesElectrolysis componentsStrip steelSlow cooling

The invention discloses a flexible strip steel treating line suitable for producing various high-strength steel. The flexible strip steel treating line comprises an uncoiling working position, a washing working position, a heating working position, a soaking working position and a slow cooling working position, a jet cooling working position or a water quenching cooling working position in turn, wherein a reheating working position and then an overaging working position or a hot galvanizing working position and a cladding alloying and annealing working position are arranged after the jet cooling working position; a moveable bypass channel is arranged to connect the reheating working position and the overaging working position respectively; a final cooling working position and a flatting working position are connected after the overaging working position and the hot galvanizing working position; then, a finishing working position and an oil coating working position, or a passivating working position and other post-treatment working positions are connected; the finishing working position and the oil coating working position are connected to a coiling working position to finish a finished product; an acid cleaning working position and an electroplating working position are arranged corresponding to the water quenching and cooling working position; the reheating working position can be connected after the acid cleaning working position directly; an uncoiling and washing working position can be directly connected before the electroplating working position; and the bypass channel or a switching device is arranged after the electroplating working position to respectively and correspondingly connect the reheating working position or directly connect the passivating working position and the other post-treatment working positions.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat insulation dry-mixing composition, plastering method thereof and board prepared by the composition

InactiveCN101549988AReduce manufacturing costSave oil resourcesCovering/liningsSolid waste managementGypsumEmulsion

The present invention relates to a heat insulation dry-mixing composition, a plastering method thereof and a board prepared by the composition. The heat insulation dry-mixing composition comprises the following components mixed according to a weight ratio: 15-2000 parts of hollow glass ball, 0.3-15 parts of short silk fiber, 5-200 parts of gypsum powder, 1-150 parts of emulsion powder, 0.3-150 parts of cellulose and 15-2000 parts of cement. The heat insulation dry-mixing composition of the invention has the advantages of low cost, excellent heat insulation effect, no aging, no cracking, no breaking-off and fire resistance. At the state of same thickness, the board prepared by the heat insulation dry-mixing composition according to the invention has better heat insulation effect compared with the heat insulation plate prepared by polystyrene material and perlite material. Furthermore the heat insulation dry-mixing composition and the board prepared by the composition can be directly adhibited and installed on the outer wall of building and have same lifetime with the building. The heat insulation dry-mixing composition is a novel product which gives attention to the convenient operation, low producing cost and environment-protecting energy-saving requirements.

Owner:陈友增

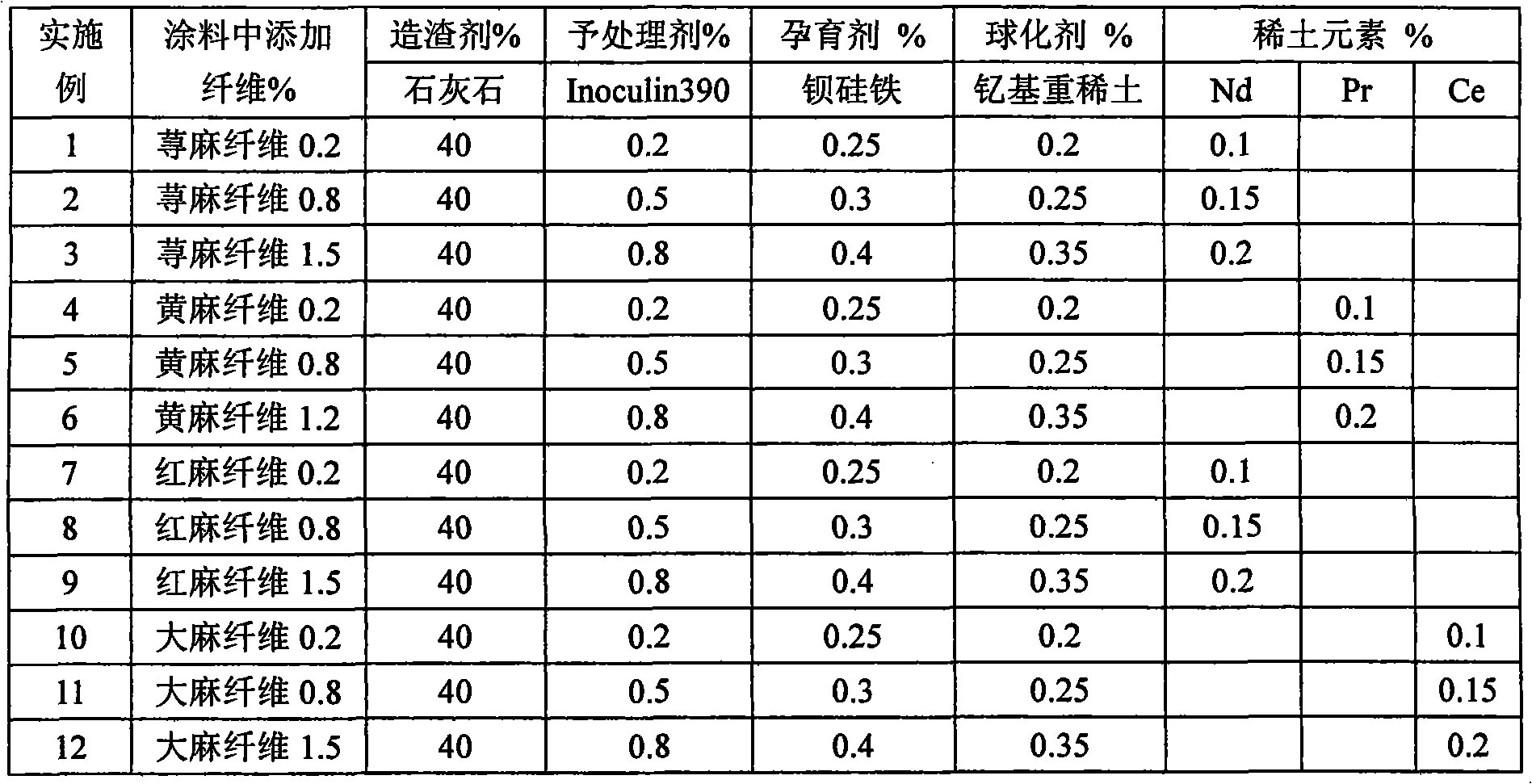

Expendable pattern casting method for manufacturing aerogenerator mainshaft by ductile cast iron

InactiveCN101585071ALower threshold requirementsSimple production processFoundry mouldsFoundry coresLiquid metalDuctile iron

The present invention discloses an expendable pattern casting method for manufacturing an aerogenerator mainshaft by ductile cast iron. The method includes the steps as follows: smelting the ductile cast iron with 3.4-4.0% carbon content in a smelting furnace; after the smelting step, firstly adding 0.2-0.8% by weight of an Inoculin390 pretreating agent according to the weight of the iron liquor in the iron liquid with the temperature 1460+ / -10 DEG C to treat, and then adding 0.25-0.4% by weight of a nucleating agent according to the weight of the ductile cast iron in the iron liquid and stirring it completely before the casting step; and then adding 0.2-0.35% by weight of a nodulizing agent according to the weight of the ductile cast iron; at last, casting the iron liquid with the temperature not less than 1400 DEG C into a moulding box with module; forming and solidifying the iron liquid into cast feeding by the liquid metal in the riser head, and using the residual heat of the cast to perform a heat treatment. The expendable pattern casting method provided by the invention not only can displace the traditional forging technology, but also can mould productions easily, wherein the cast has the advantages of compact structure, good mechanical property and high production efficiency, and the method of the invention can reduce the production cost by more than 40%.

Owner:江苏国冶控股有限公司 +1

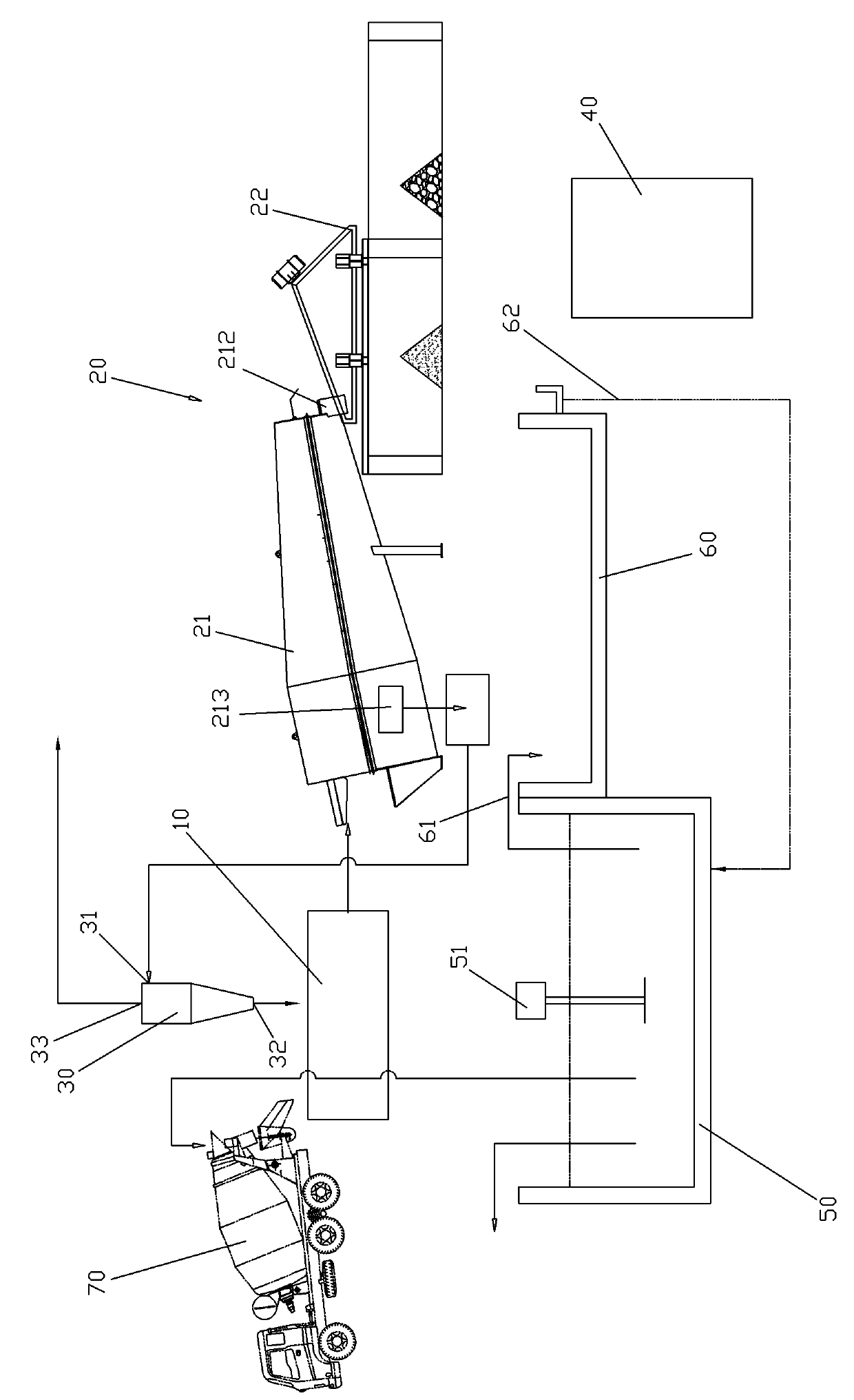

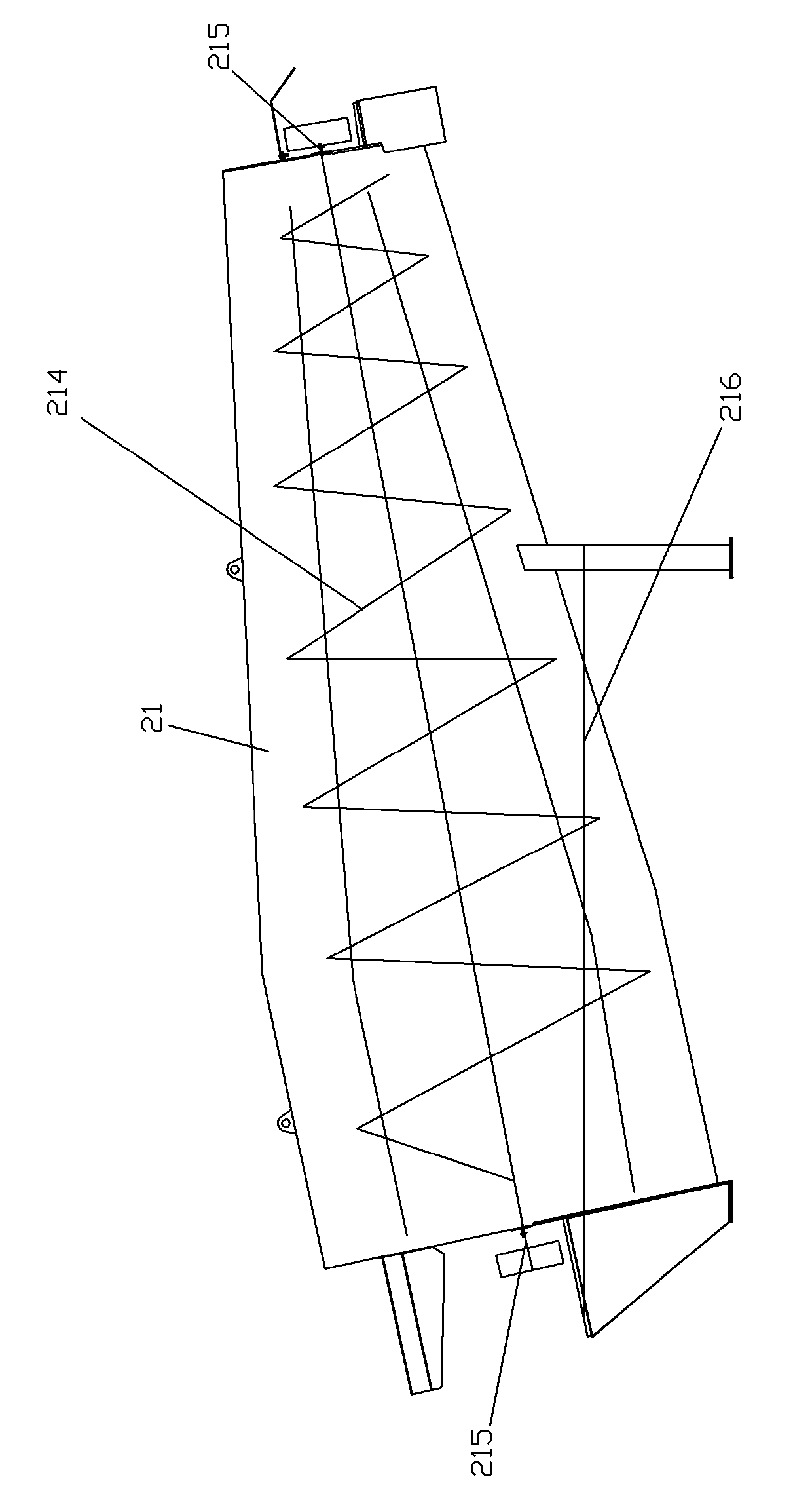

Residual wet concrete recovering system

InactiveCN102555066ASolve the sealing problemAvoid enteringMixing operation plantSolid particlePre treatment

A residual wet concrete recovering system comprises a car washing tank, a sand and rock separating unit and a stirring pool; the sand and rock separating unit comprises a wet concrete recovering machine; the feed opening of the wet concrete recovering machine is connected with the car washing tank; an overflow port is formed on the wet concrete recovering machine; and the recovering system further comprises a pretreatment device used for pretreating muddy water separated by the sand and rock separating unit. Compared with the prior art, the residual wet concrete recovering system has the advantage that after muddy water overflowing from the wet concrete recovering machine is further separated by the pretreatment device, low-concentration muddy water conforming to concrete production requirements is discharged into the stirring pool, the muddy water entering the stirring pool does not contain solid particles any longer, and the concentration of the muddy water is reduced greatly, so that the production quality of concrete is ensured.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Spatial structured light transmitting device

ActiveCN107490869AStructural parameter optimizationMeet the needs of the effectProjectorsOptical elementsIncreased toleranceSpatial structure

The invention discloses a spatial structured light transmission device, wherein an extended light source is combined with a diffraction optical element. Optimized designing is performed on the structure parameter of the diffraction optical element, thereby forming the spatial structured light transmission device based on large-angle incident light, wherein the extended light source transmits large-angle incident light. The diffraction optical element is based on the design of a traditional diffraction element, and a designing restraint for aiming at an incident angle change is added so that the diffraction optical element is suitable for the large-angle incident light and a requirement for the effect of the required structured light can be satisfied. Compared with a traditional single-point light source, the extended light source has advantages of realizing larger light emitting area and more compact structure than that of the single-point light source, and greatly reducing device size. Compared with an array light source, the extended light source has advantages of realizing no directionality in a plane which is parallel with the diffraction optical element, reducing a production requirement, increasing tolerance and realizing lower cost.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

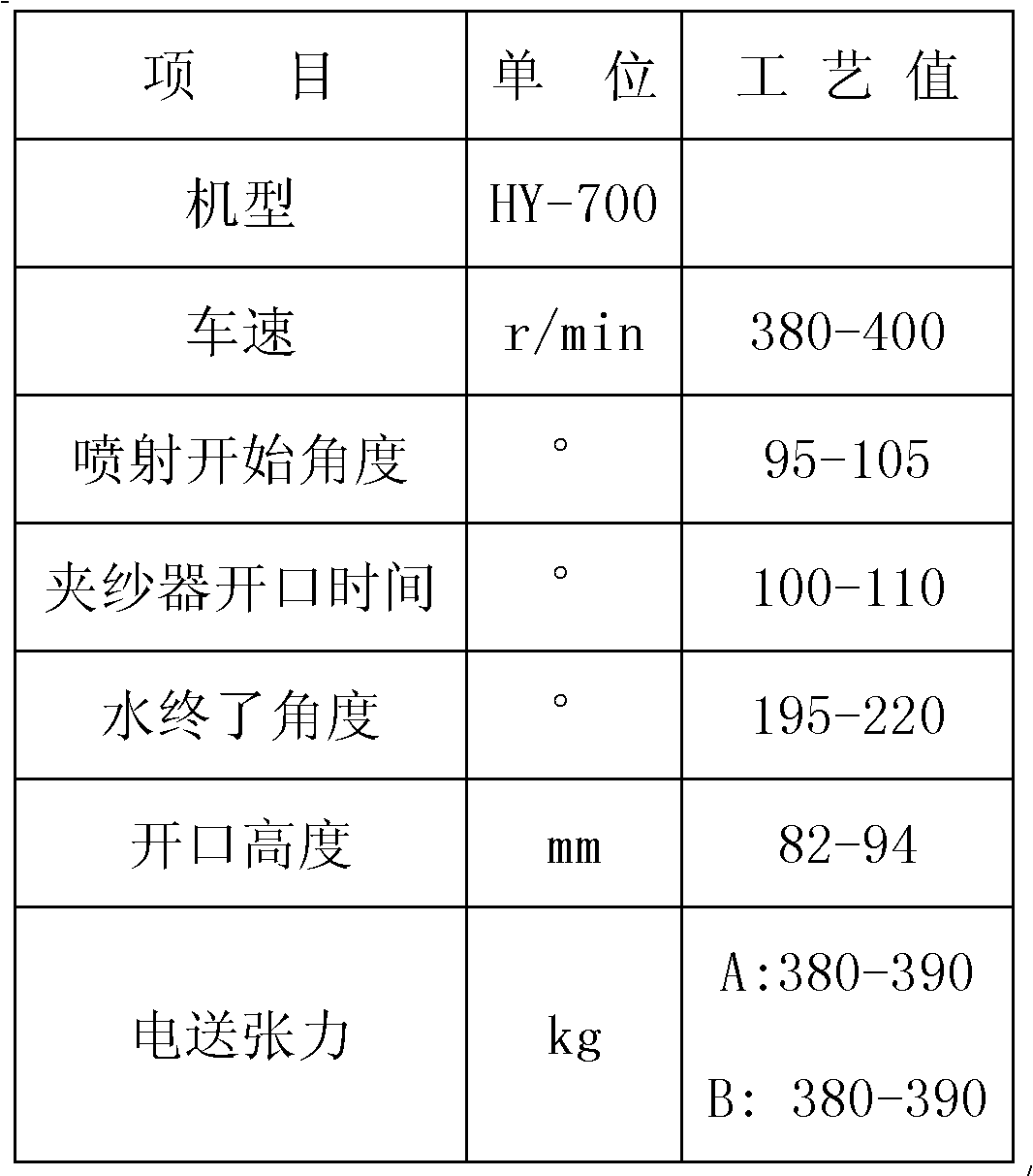

Process for producing multi-weft-direction yarn dye shading fabric

The invention discloses a process for producing a multi-weft-direction yarn dye shading fabric. The method sequentially comprises the following steps of: A) selecting raw materials; B) preparing before weaving; C) weaving on a machine; D) performing full-width refining to size; and E) inspecting and packaging and the like. The produced fabric has various functions, such as a super light resistingfunction, a light adjusting function, a privacy protection function, a decoration function, a heat insulation function, a sound insulation function, a dust filtration function and the like, producing, using and wasting processes do not have toxicity or harm to environment, the shading fabric is a real environment-friendly and healthy product; meanwhile, production requirements and difficulty are reduced, production cost is greatly reduced and the process can be popularized and applied conveniently.

Owner:浙江兴澳科技有限公司

Preparation method of thick film solar cell

InactiveCN102255006AImprove photoelectric conversion efficiencyImprove performanceFinal product manufactureSemiconductor devicesHeterojunctionAmorphous silicon

The invention discloses a preparation method of a thick film solar cell. The thick film solar cell is a flexible substrate amorphous silicon / polycrystalline silicon laminated heterojunction cell, wherein a polycrystalline silicon layer is obtained by crystallizing a small-particle polycrystalline silicon layer at low temperature, and has a small thickness, so that waste of a silicon material is reduced greatly, and the cost is lowered remarkably. The thick film solar cell prepared with the method has the characteristics of low cost, high yield, easiness for production and high photoelectric conversion efficiency of the obtained product.

Owner:孙昌红

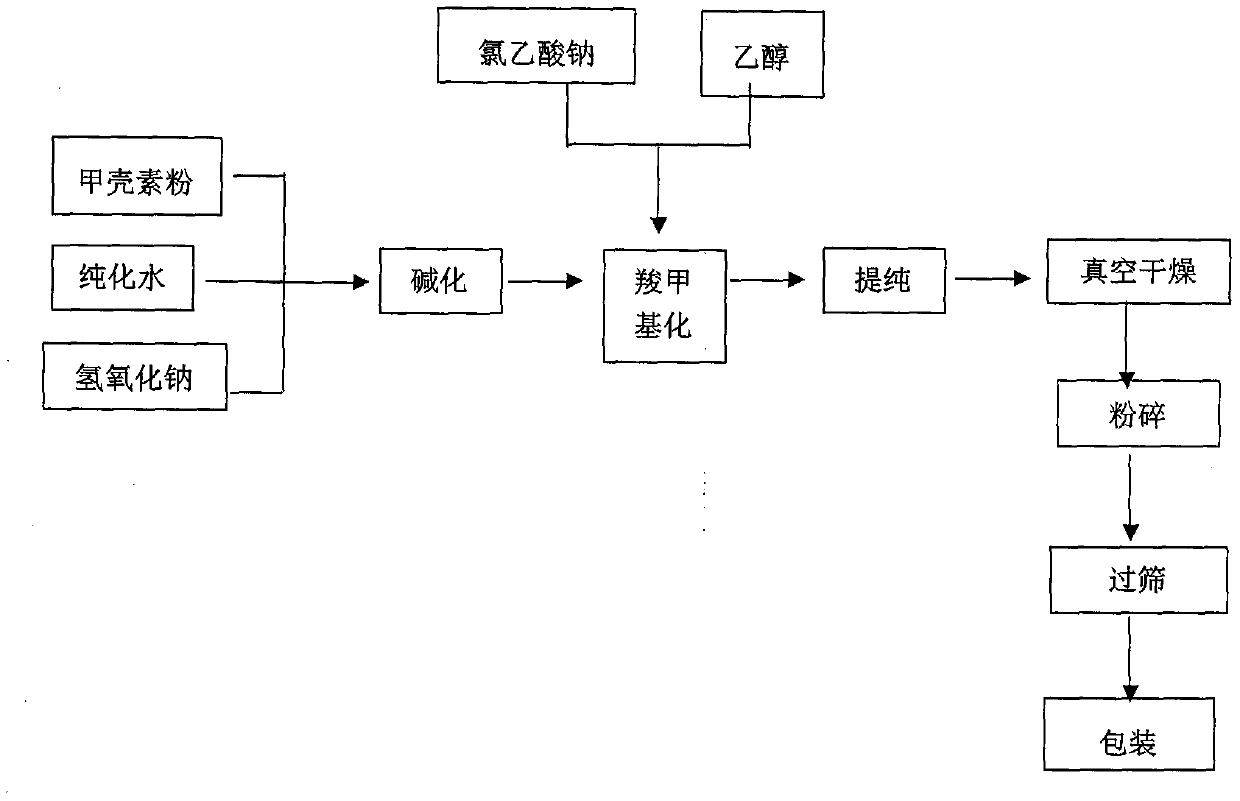

New method for preparing water-soluble carboxymethyl chitosan from chitin

The invention relates to a new method for improving a production process of water-soluble carboxymethyl chitosan by taking chitin as a raw material and sodium chloroacetate as a reactant. The method is characterized by taking chitin powder instead of chitosan powder as the raw material and adopting sodium chloroacetate for replacing high-irritation and corrosion chloroacetic acid used in conventional production for reaction, wherein the ethanol solution in certain concentration is used as the reaction solvent. The prepared carboxymethyl chitosan is capable of dissolving within the pH scope from 6.0 to 8.0, the degree of substitution is more than 80%, the degree of deacetylation is more than 70% and the purity is more than or equal to 85%. The chitosan derivative has excellent bacteria resistance, bacteriostasis, and moisture absorption and moisture retention performance and can be further purified for wide application to the fields of medicines, food or cosmetics. See abstract figuresfor the details of a schematic diagram for the process of preparing water-soluble carboxymethyl chitosan from chitin.

Owner:青岛童医生海洋生物科技股份有限公司

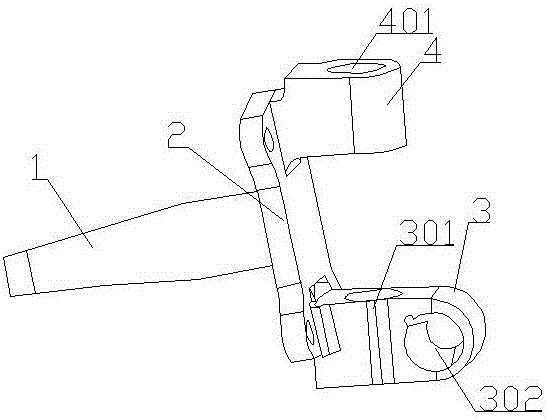

Automobile steering knuckle and manufacturing method thereof

The invention discloses an automobile steering knuckle and a manufacturing method thereof. The automobile steering knuckle comprises a fixing plate with one side connected with a rotating shaft, a first shaft sleeve and a second shaft sleeve, wherein the first sleeve and the second sleeve are arranged on the other side of the fixing plate; a main pin hole and a rotating-arm supporting hole perpendicular to the main pin hole are formed in the first shaft sleeve, and a fixing hole used in cooperation with the main pin hole in the first shaft sleeve is formed in the second shaft sleeve. The fixing plate comprises a base plate and two inserting plates symmetrically arranged on the two sides of the base plate, and the first shaft sleeve and the second shaft sleeve are arranged on the two inserting plates on the two sides of the base plate respectively. In addition, the invention also provides a forging method of the automobile steering knuckle, and the method includes the steps of material putting, preheating, blank preparing, heating again and side cutting. The automobile steering knuckle has the advantages of being high in strength, light in weight, easy to use, convenient to install and stable in firm, and using of people is greatly convenient.

Owner:WUHU HEXU MACHINERY

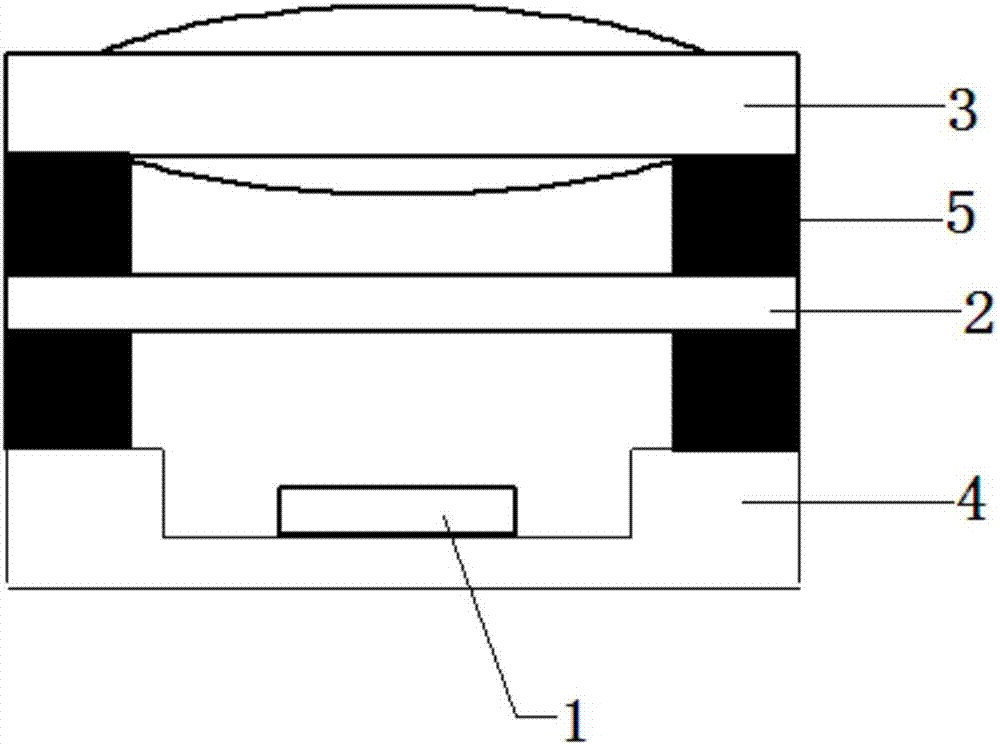

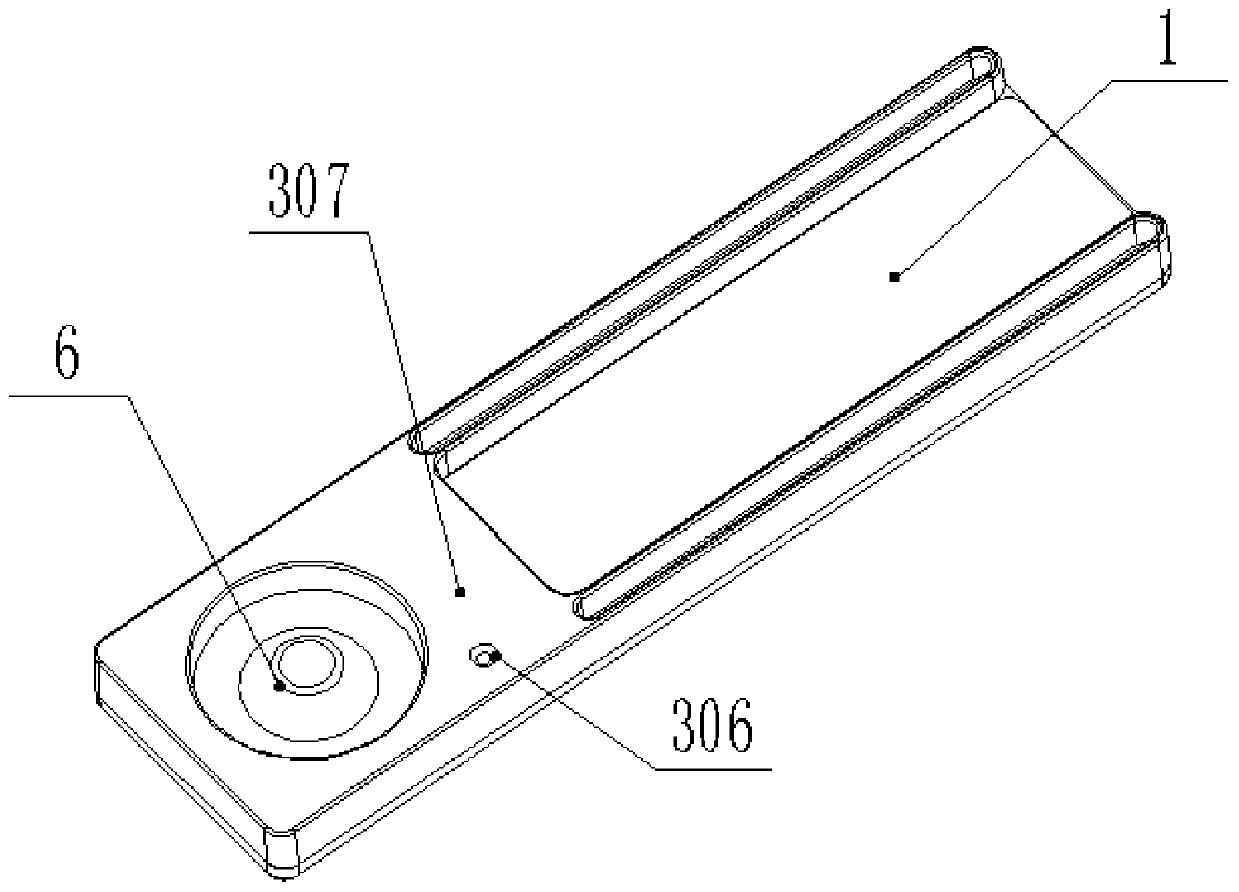

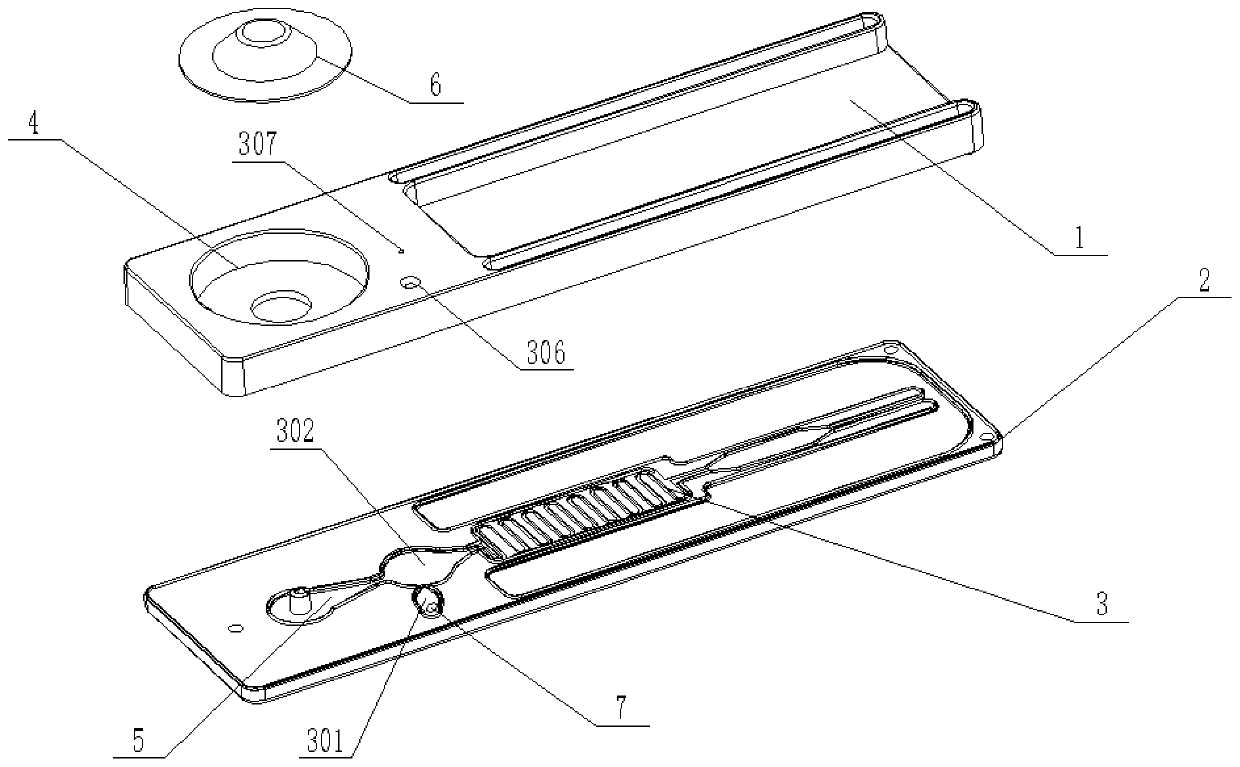

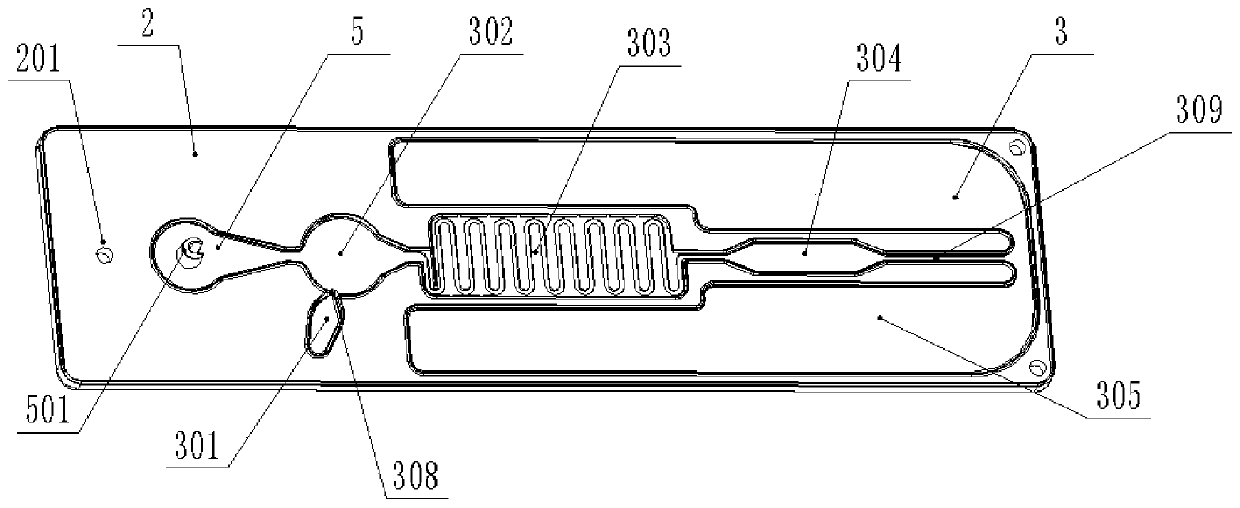

Single-channel fluorescence immunoassay micro-fluidic chip

PendingCN110470604AGuaranteed correctnessSimple structureFluorescence/phosphorescenceMicro fluidicFluorescence

The invention discloses a single-channel fluorescence immunoassay micro-fluidic chip, and relates to the technical field of biological detection. The chip comprises a chip body which is provided witha closed micro-channel for a sample to flow. The micro-channel comprises a mixing bin, a reaction bin, a capture bin and a waste liquid bin which are sequentially communicated, and further comprises afirst vent hole communicated with the outside atmosphere and a sample adding port communicated with the mixing bin. A delay channel for communicating the reaction bin with the capture bin is arrangedbetween the reaction bin and the capture bin, and the delay channel is used for allowing the sample to flow in a zigzag manner. A solid reagent ball used for carrying out an immune reaction with thesample is arranged in the mixing bin, and the reagent ball contains an antibody / antigen coated with a fluorescent marker and a magnetic bead. A magnet used for adsorbing a conjugate generated by the immune reaction of the antibody and the antigen is arranged on the bottom wall of the capture bin. Thus, the immune reaction is fully carried out, the conjugate is captured and gathered in a flowing manner, and the correctness of the detection result is ensured. Moreover, the micro-channel is easy to produce, and the production cost is reduced.

Owner:四川微康朴澜医疗科技有限责任公司

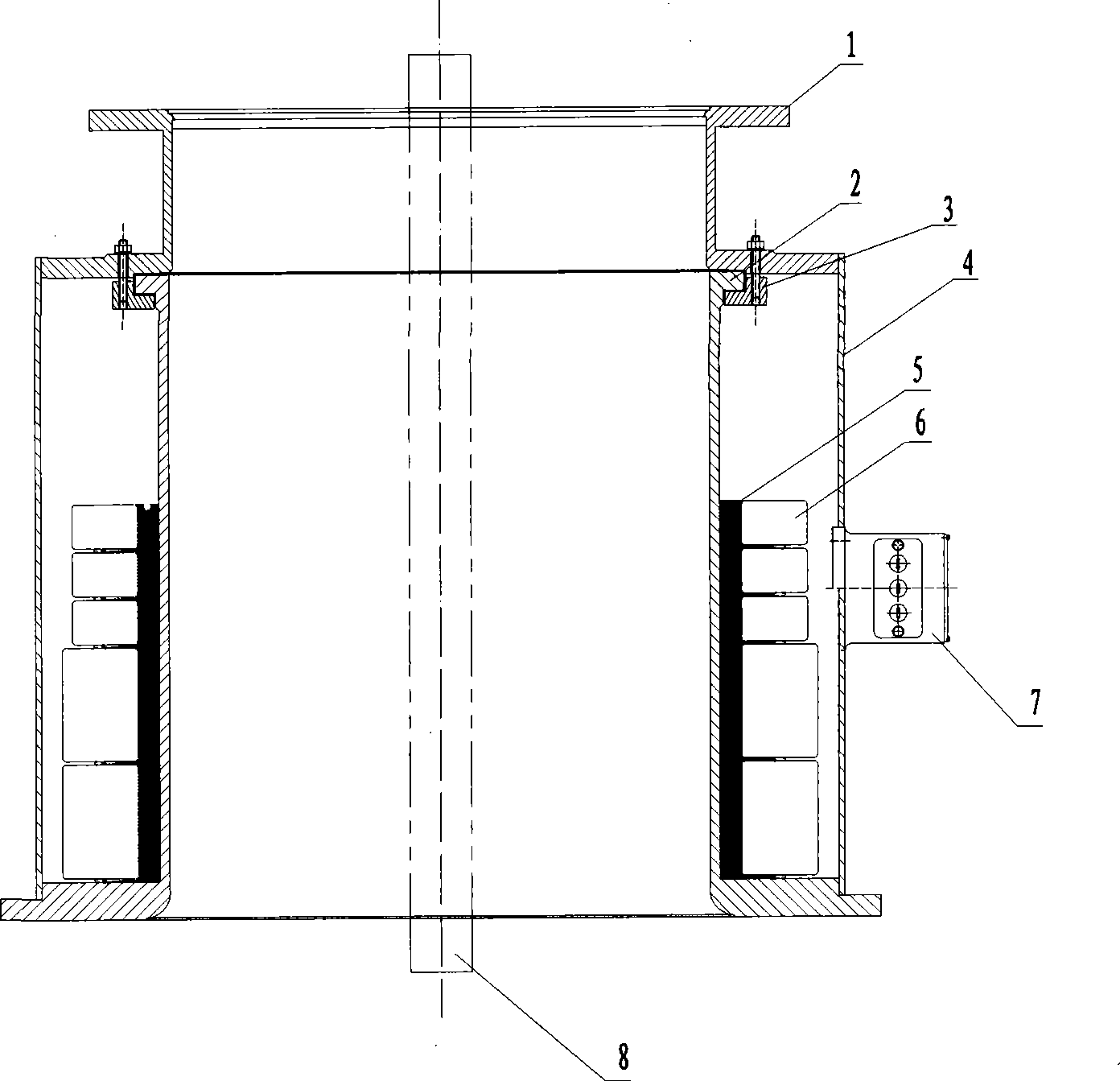

Current mutual inductor for GIS

InactiveCN101388284AImprove operational safetyReduced effects of gas insulation propertiesTransformersInductancesInductorHigh pressure

The invention discloses a current transformer for a GIS, belonging to the field of high voltage apparatuses, which comprises an internal shield cylinder and a coil which is sleeved on the internal shield cylinder, and is characterized by further comprising an upper flange, wherein the upper flange is hermetically connected with the upper end of the shield cylinder, and the upper end of the shield cylinder is provided with ring-shaped convex edges, a semi-circular fastening element in an L-shape cross section is arranged on the lower portion of the convex edges, and the semi-circular fastening element is connected with the upper flange, a ring-shape tray is arranged on the lower end of the internal shield cylinder, and is used to bear the coil, and insulating resin is poured between the coil and the outer walls of the internal shield cylinder.

Owner:CHINA XD ELECTRIC CO LTD

Low water-reducing and high slump loss resistant type polycarboxylate superplasticizer master batch

The invention discloses a low water-reducing and high slump loss resistant type polycarboxylate superplasticizer master batch which is applicable to the condition that the quality of materials such as cement, mineral admixtures, flooring and the like is low and has the characteristic that the slump loss resistance is high in the middle and later periods of initial high water reduction. According to the limit of mass percent of 40% of mother solution, the total mass of the raw synthesis materials is 1000, and the dosage ratio is as follows: the dosage of a polyether macromonomer is 360-375; the dosage of acrylic acid is 22.0-35.0; if mercaptoacetic acid MSDS is selected as a chain transfer agent, the dosage is 1.25-1.65%; if mercaptopropionic acid MPA is selected as the chain transfer agent, the dosage is 1.37-1.80; if hydrogen peroxide serves as an oxidant, the dosage is 2.0-3.5; if vitamin C is selected as a reducing agent, the dosage is 0.55-0.75; the dosage of liquid caustic soda is 10-15; and the balance of water. The synthesized polycarboxylate superplasticizer has a moderate molecular weight of about 57000-62000; and the polycarboxylate superplasticizer master batch is moderate in main chain length, high in side chain density, low in water-reducing rate and high in slump loss resistance and has outstanding effects aiming at poor materials.

Owner:HUBEI UNIV OF TECH

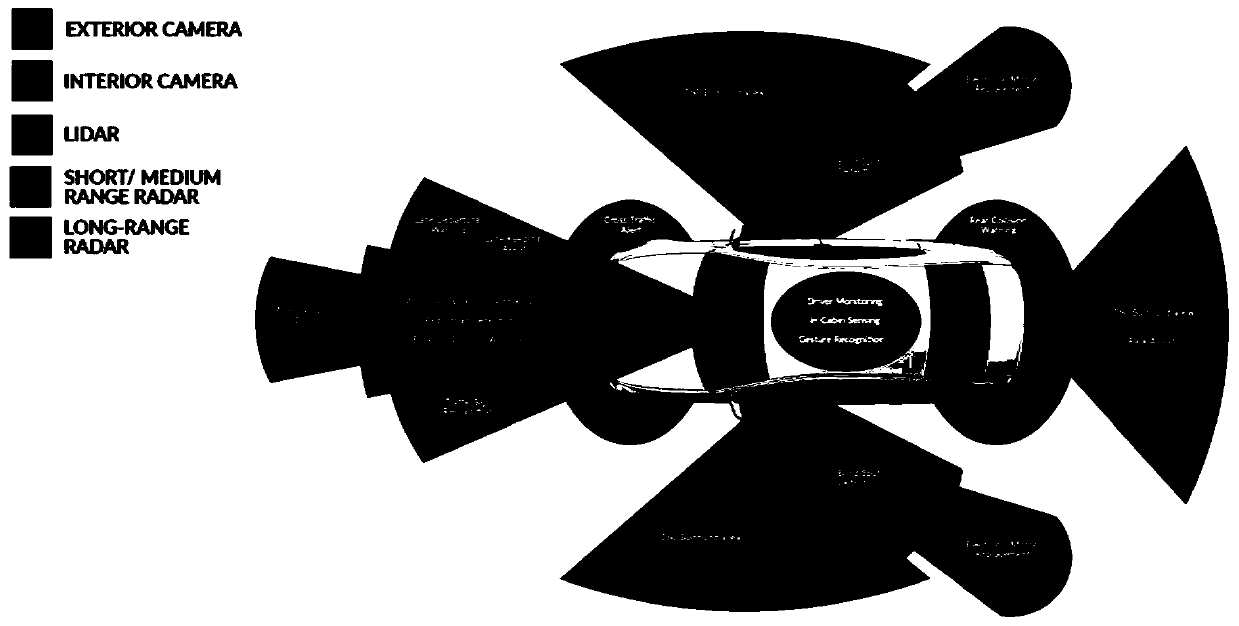

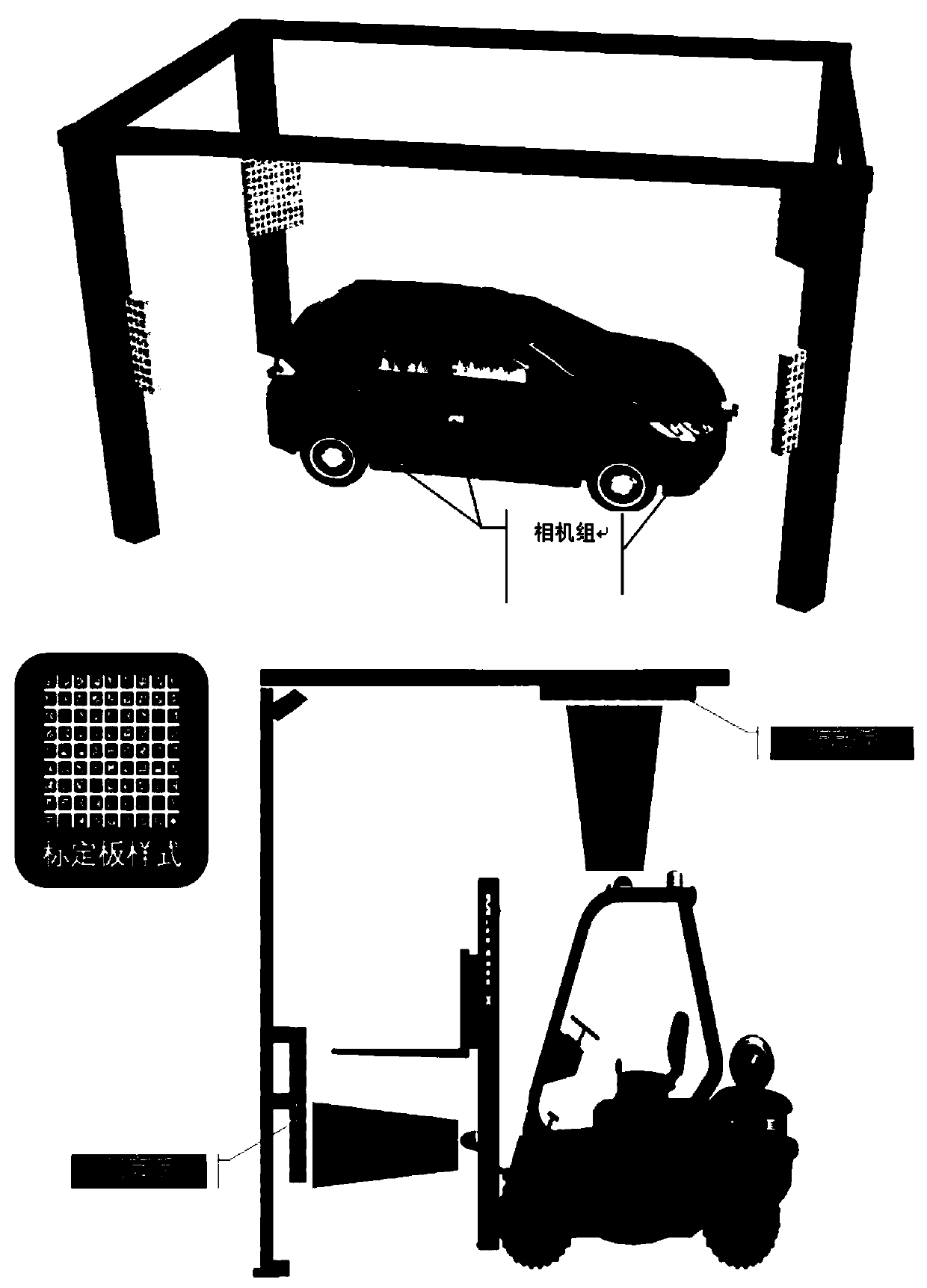

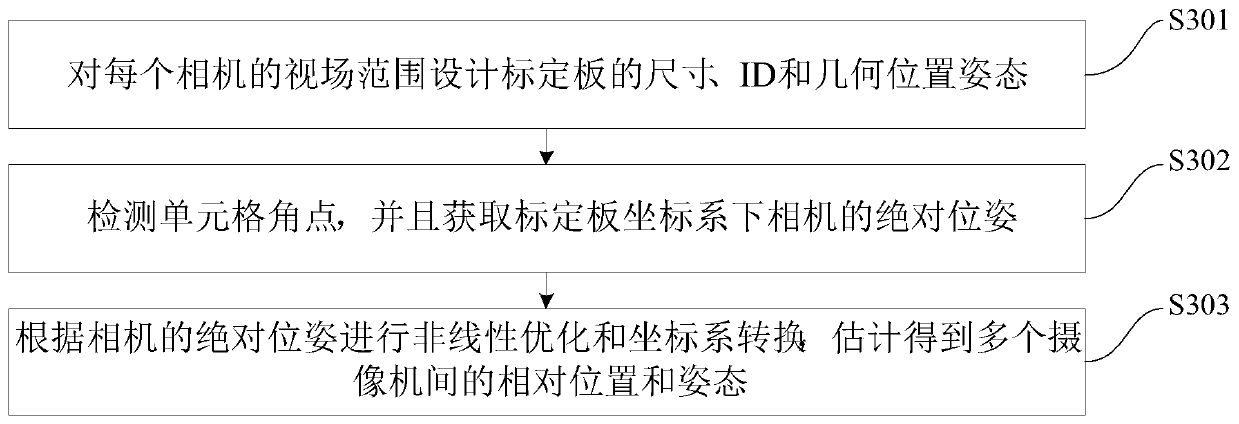

Camera group calibration method and device based on global calibration frame

ActiveCN110827361AReduce production requirementsLow installation process requirementsImage analysisInternal combustion piston enginesMedicineComputer graphics (images)

The invention discloses a camera group calibration method and device based on a global calibration frame, and the method comprises the following steps: designing the size, ID and geometric position posture of a calibration plate for the view field range of each camera; detecting cell corner points, and obtaining an absolute pose of the camera under a calibration plate coordinate system; carrying out nonlinear optimization and coordinate system conversion according to the absolute poses of the cameras, and estimating and obtaining the relative positions and poses of the multiple cameras. According to the method, by constructing a global calibration frame, the relative positions and attitudes of a plurality of cameras are estimated, and the method has important theoretical and practical values.

Owner:TSINGHUA UNIV

Preparation method of water-soluble chitosan-oligosaccharide

InactiveCN102786607AControl weight average molecular weightControl the degree of degradation reactionHydrolysateWater soluble

A preparation method of water-soluble chitosan-oligosaccharide comprises the following steps: (1) dissolving chitosan in an acetic acid solution to prepare a chitosan acetic acid solution with a concentration of 2.0-4.0 g / ml; (2) heating to 55-65 DEG C, adding a 1-5% H2O2 solution according to a molar ratio of the chitosan to hydrogen peroxide of 1:1.5-1:2.5, adjusting the pH to be 5.5-6.5, continuously stirring for hydrolyzation to obtain a hydrolysate; (3) sampling, adding strong alkali liquor till no flocculent precipitate is generated so as to determine the hydrolysate; (4) continuously performing hydrolyzation for not more than 2 hours; (5) adding a degradation reaction terminator to obtain a preliminary product; (6) processing the preliminary product by a spray-drying process to obtain the water-soluble chitosan-oligosaccharide. Compared with the prior art, the invention has the advantages that: the degradation reaction terminator is used for controlling the degree of the degradation reaction so as to control the weight average molecular weight of the obtained chitosan-oligosaccharide; real production requirements are met; and large scale production requirements are met.

Owner:ZHEJIANG OCEAN UNIV

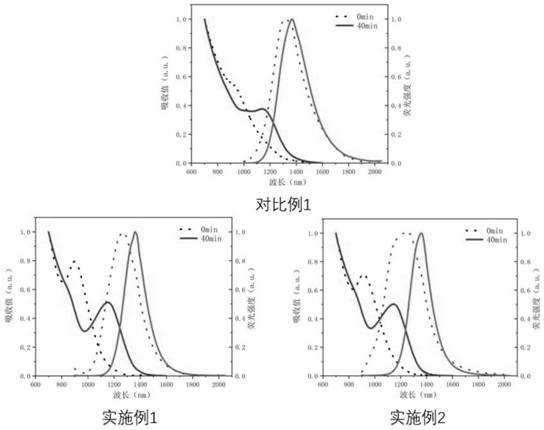

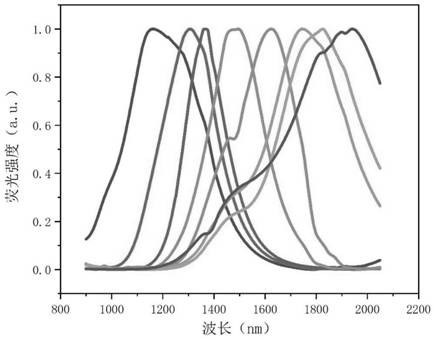

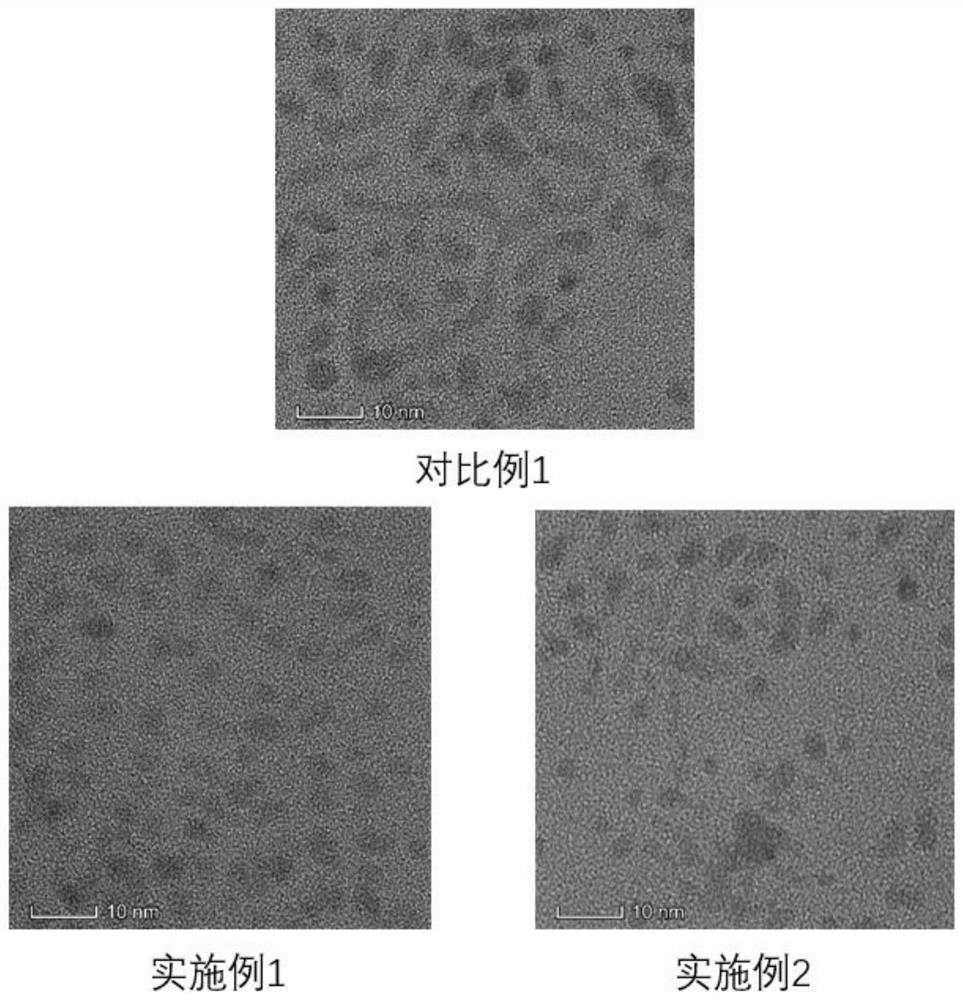

Method for controllably synthesizing near-infrared silver telluride quantum dots

ActiveCN112960655AReduce usageHigh preparation temperatureLuminescent compositionsMetal selenides/telluridesQuantum yieldQuantum dot

The invention discloses a silver precursor, a tellurium precursor and a preparation method for controllably synthesizing silver telluride quantum dots. The method comprises the following steps: mixing one or more silver mercaptide with organic phosphine to prepare an activity-adjustable silver precursor, and thermally injecting the tellurium precursor synthesized in air, thereby obtaining the silver telluride quantum dot. The method is easy to operate, good in repeatability and low in cost. The emission wavelength of the silver telluride quantum dot is adjustable in a range of 1150nm-2000nm by regulating and controlling the types and the proportion of thiol and phosphine, the proportion of a silver source to a tellurium precursor and the reaction time, the half-peak width of the emission wavelength is narrow, and the fluorescence quantum yield can reach more than 10%. The method can be used in the field of biomedical imaging, can also be used for preparing other nano materials containing silver or chalcogenide elements, and is suitable for large-scale industrial production.

Owner:NANKAI UNIV

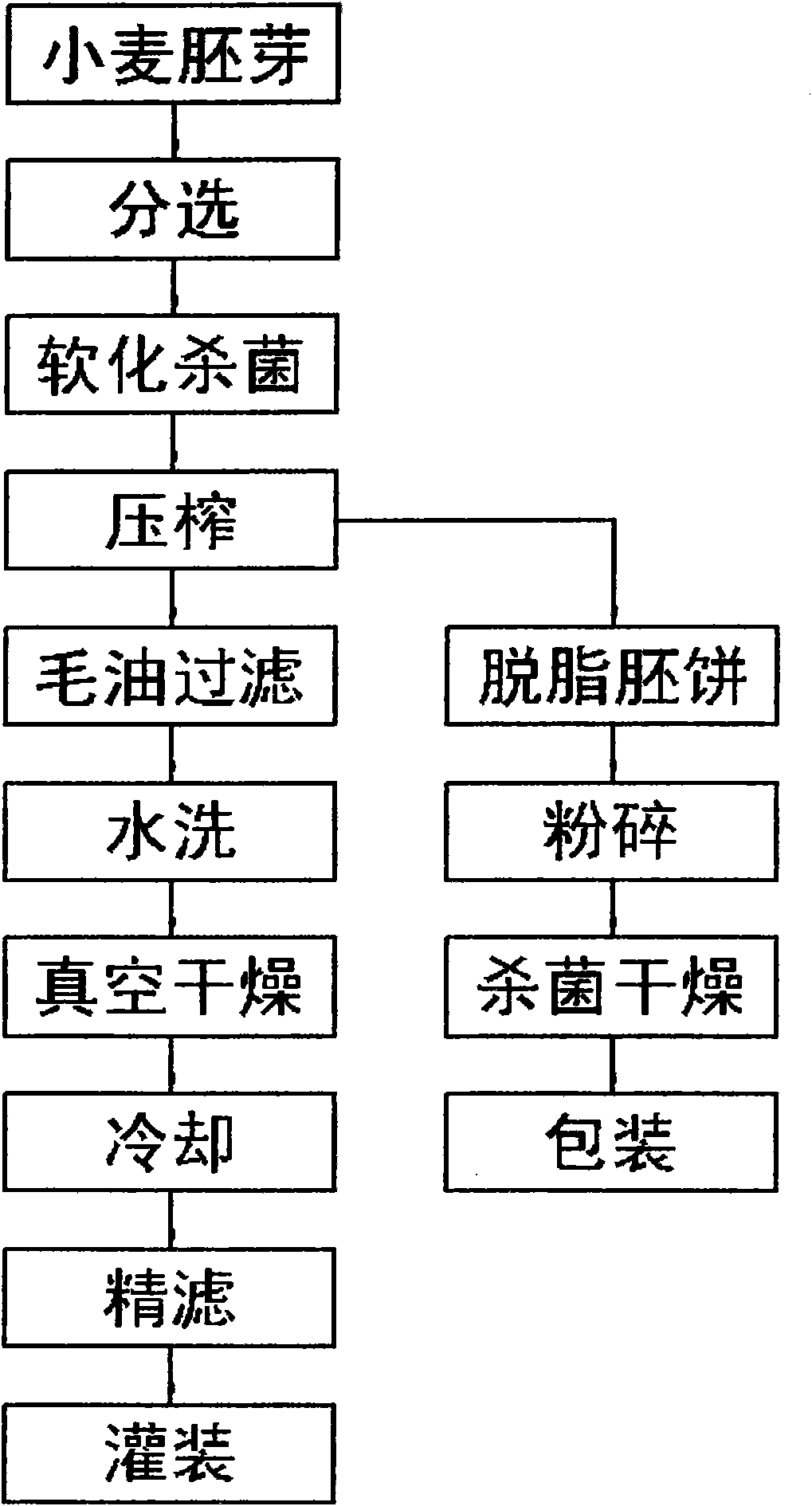

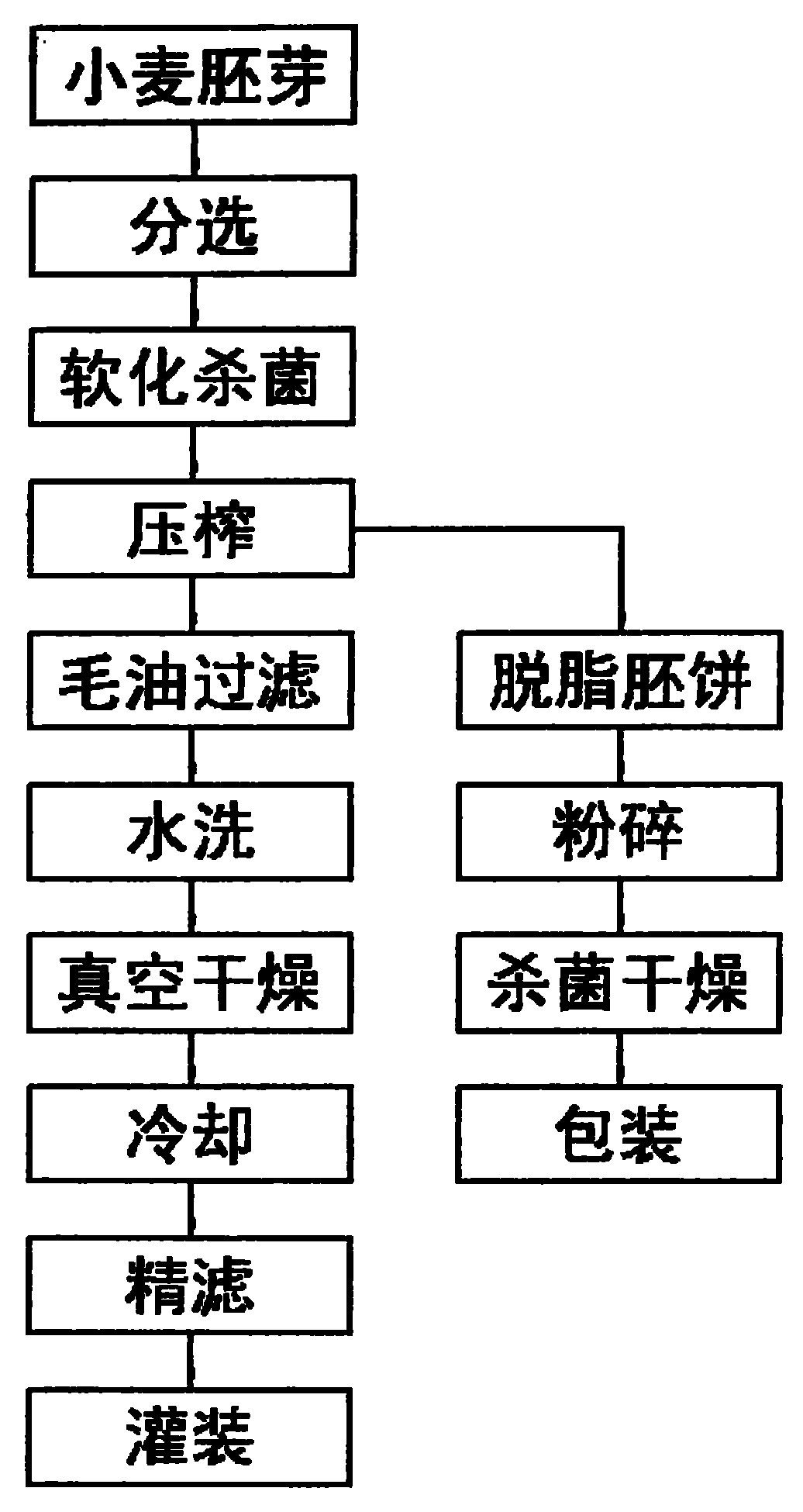

Method for squeezing and extracting wheat-germ oil at low temperature

The invention discloses a method for squeezing and extracting wheat-germ oil at a low temperature, which comprises the following steps of: removing flour and bran from fresh wheat germs with a sorting machine until the purity of the wheat germs reaches 99 percent; softening and sterilizing the wheat germs; adding the wheat germs into an oil press to automatically squeeze oil; washing with water, namely adding the crude oil after being filtered into an oil refining kettle, indirectly heating the oil to 75 DEG C, starting to stir at a rotation speed of 20 to 40rpm, adding 5 percent hot water of which the temperature is 85 DEG C through a sprayer, stopping stirring 5 minutes later, and after standing the oil for 2 hours, discharging water and the precipitate; drying under vacuum, namely drying under vacuum when the temperature of the oil reaches 75 DEG C so as to reduce the water content to 0.05 percent; and performing refining filtration, namely, performing cold water circulation on the germ oil to reduce the temperature to 30 DEG C, and filtering the germ oil with a 400-mesh sieve to remove suspended matters and impurities. The method has the advantages of obtaining natural full-cream wheat-germ oil, along with low cost, low requirements on production, simple process, massive popularization, low nutrition ingredient loss and no chemical solvent residue.

Owner:高翔

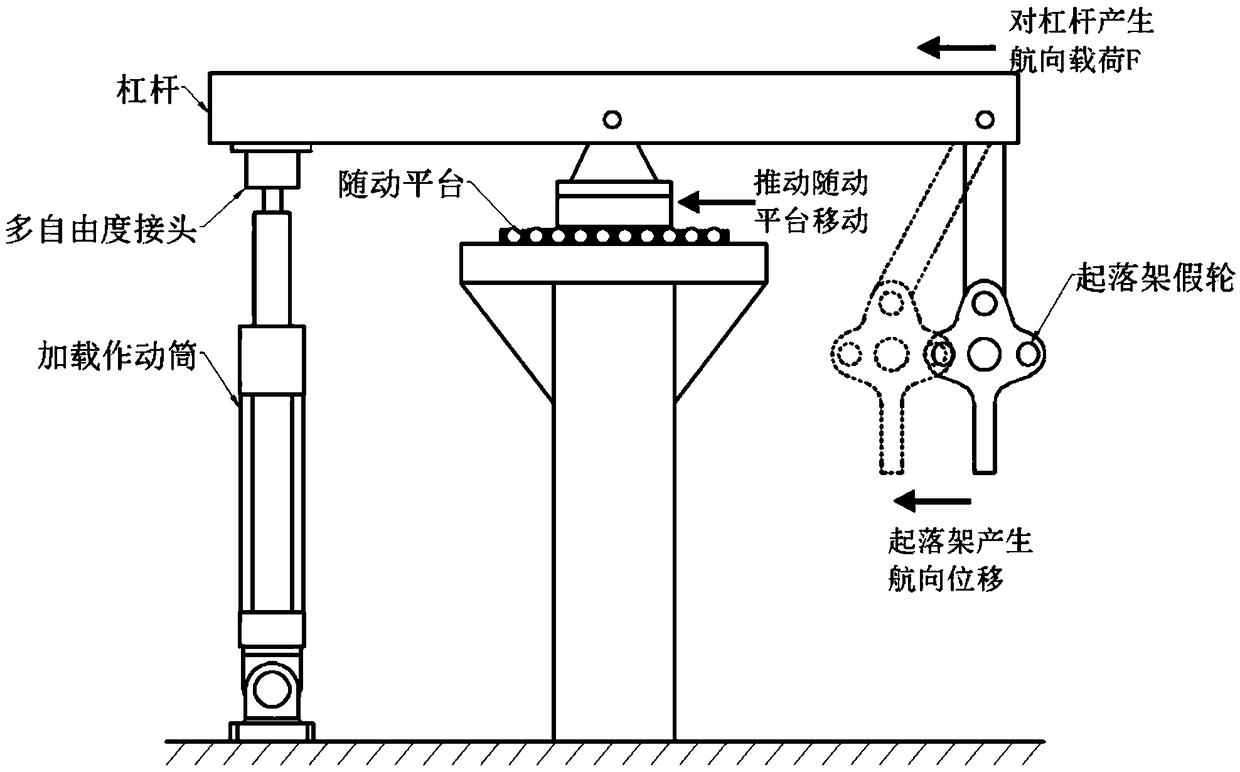

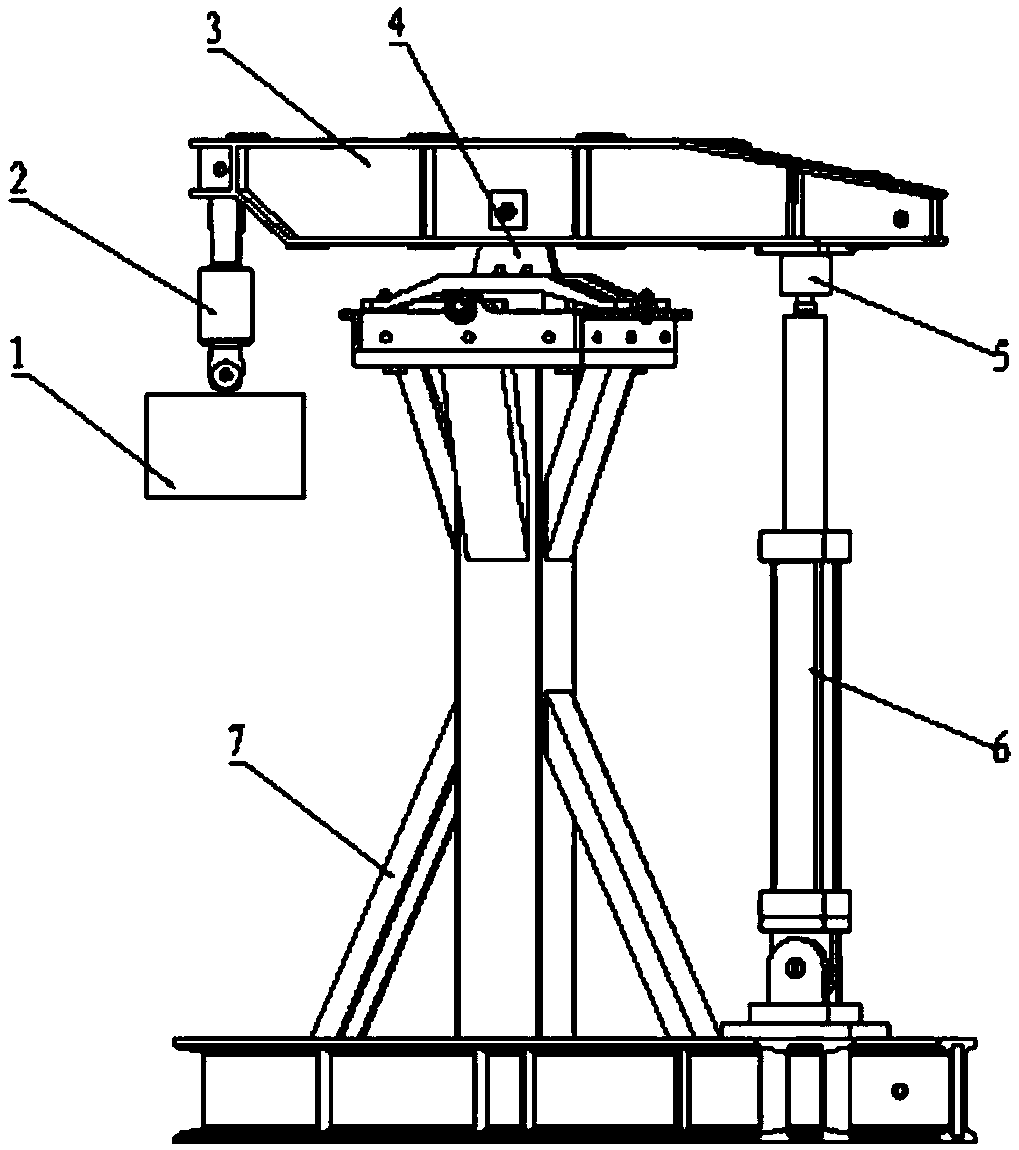

Airplane landing gear loading device and method

InactiveCN109506919AEliminate lossGuaranteed stabilityMachine part testingJet aeroplaneControl system

The invention discloses an airplane landing gear loading device. The device comprises a horizontally arranged loading crowbar, wherein one end of the loading crowbar is vertically connected with a landing gear dummy wheel, a force measuring sensor is connected between the loading crowbar and the landing gear dummy wheel, and the other end of the loading crowbar is connected with a hydraulic actuating cylinder through a multi-degree-of-freedom joint; the lower part of the middle of the loading crowbar is hinged to a movable bearing base, and the movable bearing base is placed on a bearing column; the force measuring sensor and the hydraulic actuating cylinder are both electrically connected to a control system. According to a loading process, when a landing gear is loaded in a test, the control system controls load application of the landing gear through the force measuring sensor, the landing gear is deformed in a loading process, the loading crowbar is inclined, the hydraulic actuating cylinder is retracted, the movable bearing base horizontally moves along with the deformation of the landing gear to compensate for a loading end of the landing gear, and the force measuring sensoris inclined because of the loading deformation of the landing gear, so that loading of the landing gear approaches to a loading direction at the examination standard to the maximum degree.

Owner:CHINA AIRPLANT STRENGTH RES INST

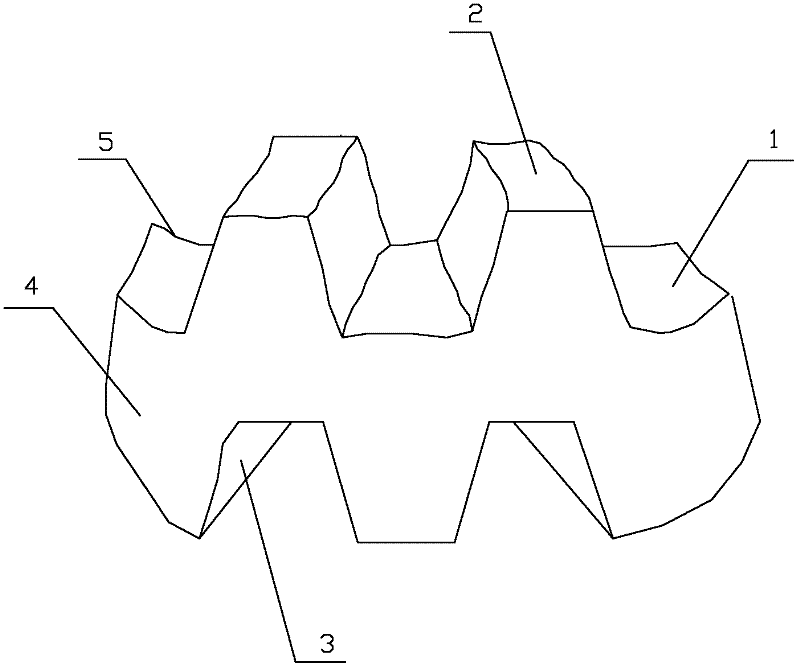

Irregular micro electrolysis iron carbon filling material

ActiveCN102336456AEasy to handleIncrease contact reaction areaWater/sewage treatmentElectrolysisFilling materials

The invention relates to an irregular micro electrolysis iron carbon filling material, which is in a blocky shape. At least one irregular bulge and at least one irregular groove are respectively distributed and arranged on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are correspondingly distributed and arranged at top and bottom on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are approximately in a gear shape, and the whole of the filling material is inclined and / or has the radian. The technology solves the technical problems of the traditional filling material that the production cost is high, the contact reaction area is small, the reverse flushing is not easy, in addition, the effect is poor, the service life is short, and the like. The irregular micro electrolysis iron carbon filling material has the advantages that the large contact reaction area is realized, the sewage treatment effect is good, the reverse flushing is easy, in addition, the effect is good, the labor operation quantity is reduced, and the production cost and the use cost are reduced.

Owner:常州海龙环保设备厂

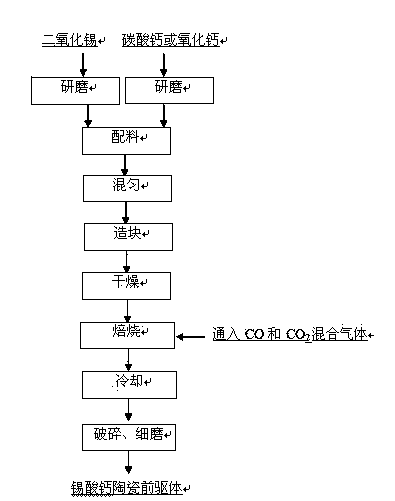

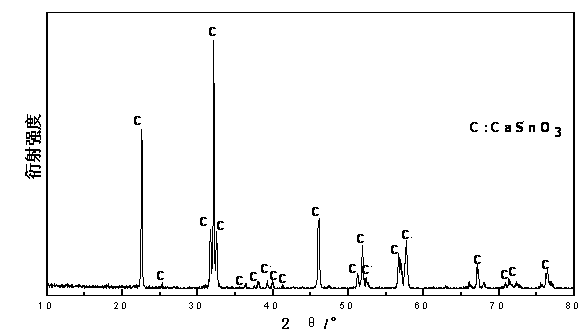

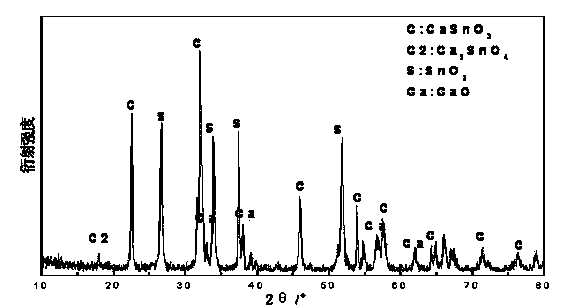

Preparation process of calcium stannate ceramic material precursor

ActiveCN103466562ANo emissionsLow firing temperatureSelenium/tellurium compundsTin dioxideMixed materials

The invention provides a preparation process of a calcium stannate ceramic material precursor. The preparation process comprises the following steps: respectively grinding stannic oxide and calcium carbonate (or calcium oxide) into powder with certain granularity; mixing the stannic oxide and the calcium carbonate (or calcium oxide) at the Sn:Ca molar ratio of 1:(1-1.1) to obtain a mixed material; agglomerating and drying the mixed material; placing the mixed material into CO / CO2 atmosphere, heating and roasting, wherein the roasting temperature is 800 to 1,000 DEG C, the roasting time is 15 min to 60 min, and the CO volume concentration [CO / (CO+CO2)] of the roasting atmosphere is 10% to 25%; and cooling, crushing and levigating the roasted product to obtain the calcium stannate ceramic material precursor. The process has the characteristics of low sintering temperature, short roasting time, high stannum conversion rate, short process flow, simplicity and convenience in operation and the like. The whole roasting process is performed under a solid condition, without a special requirement on roasting equipment, so that the industrialized production is easy to realize.

Owner:CENT SOUTH UNIV

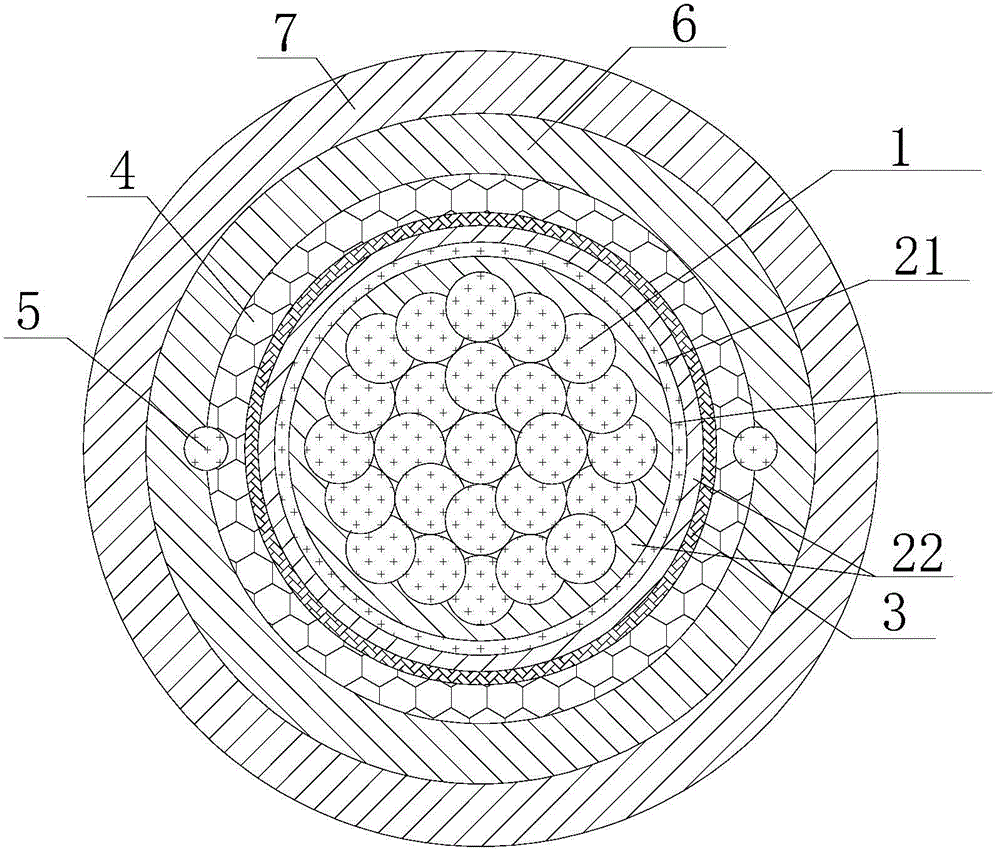

Production process of cable for high-speed train

ActiveCN104700960AThe production process is simpleThe production process is easy to masterCable/conductor manufactureTemperature resistanceCorrosion

The invention discloses a production process of a cable for a high-speed train. The process comprises the steps of preparing a cable core; wrapping the cable core; wrapping an isolation layer; arranging a tensile rope; wrapping an insulating layer; modifying the insulating layer. According to the cable produced by the production process for the high-speed train, the production process is simple and easily controlled, the requirements on the production is obviously less than those of the requirements on traditional production of the cable for the high-speed train, production-related parameters can be accurately and easily mastered, and therefore, the production automation and the product quality inspection accuracy can be improved; meanwhile, the conductive cable core is of a tight structure, and the structure strength and toughness are obviously superior to those of the traditional cable for the highs-speed train, so that the tension resistance, impact resistance and vibration resistance of the cable can be greatly improved; in addition, the external isolating performance, high temperature resistance, corrosion resistance and flame retardant performance are improved; the external complex electromagnetic interference resistance of the cable is effectively improved, thus the protection capacity of the cable can be improved, and as a result, the safety and stability of the cable in operation can be improved.

Owner:HEBEI RUIGUANG CABLE

Process for extracting salicin from populus euphratica fallen leaves

ActiveCN104262421AReduce pollutionReduce manufacturing costSugar derivativesSugar derivatives preparationSolventChemistry

The invention discloses a process for extracting salicin from populus euphratica fallen leaves. The process is characterized by comprising the following steps: adding calcium oxide into populus euphratica fallen leaf shreds, and adding water for decomposing; extracting the solution twice at the temperature of 30 DEG C, collecting filtrate, and combining the filtrate; adjusting the pH value to 10.0-12.5, allowing the solution to stand, and collecting the filtrate; concentrating the filtrate, adding a clarifying agent or an adsorbent for decolorizing while stirring at the temperature of 70 DEG C, and colleting the filtrate; adjusting the pH value to 3.0-5.0 at a normal temperature, allowing the solution to stand, and collecting the filtrate; adding ammonium water or ammonia gas into the filtrate for adjusting the pH value to 7.0-9.0, concentrating the filtrate till the specific weight is 1.2, and crystalizing the filtrate at the normal temperature in a static manner for 72 hours; and separating a crystal, drying the separated crystal at 80 DEG C, and smashing the dried crystal. The process has the beneficial effects that water with low environmental pollution is taken as an extraction solvent, so that the production cost and the workshop requirement are lowered; ash is removed by adopting sulfuric acid or sulfate, and the crystal is obtained through the crystallizing step, so that the purity of a final product is increased, and can be over 65 percent in general; and natural fallen leaves of populus euphratica in autumn are taken as raw materials, so that damage to vegetation is prevented.

Owner:TUMU SHUKER KUNSHEN PLANT EXTRACTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com