Visible light curing glue and preparation method thereof

A technology for curing glue and visible light, applied in the field of material chemistry, can solve the problems of complex post-processing procedures, high technical requirements, expensive equipment, etc., and achieves low production cost and R&D technical requirements, low digital light source system requirements, and good surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing visible light curing glue includes the following steps:

[0038] 1) Divide the active diluent of the formula into two parts, which are respectively recorded as the first active diluent and the second active diluent;

[0039] 2) Take the first reactive diluent, the formula amount of the prepolymer and the formula amount of the pigment respectively, and sequentially add them into the first reactor, stir until fully dissolved, and mix evenly to obtain the first mixture;

[0040] 3) Move the first mixture into a light-shielded and closed second reaction kettle, and add the curing aid of the formula to obtain the second mixture;

[0041] 4) Dissolve the formulated amount of photoinitiator in the second reactive diluent in a dark environment, and then put it into the second reactor, then stir under vacuum until it is fully dissolved and mix well to obtain the third mixture ;

[0042] 5) Filter the third mixture under a light-proof environment to remove insoluble...

Embodiment 1

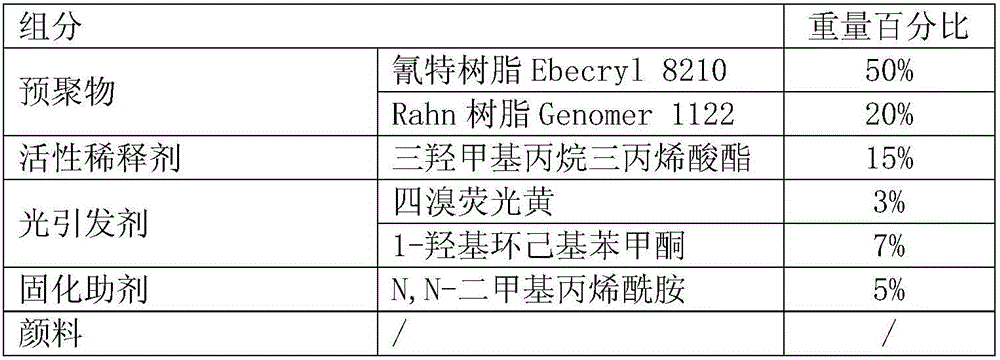

[0044] A visible light curing glue, including the following components in terms of weight percentage:

[0045]

[0046] According to the above components, follow the steps below to obtain visible light curing glue:

[0047] 1) Divide the formula amount of active diluent into two parts, denoted as the first active diluent and the second active diluent respectively, which account for 80% and 20% of the formula amount of active diluent respectively;

[0048] 2) Take the first reactive diluent and the prepolymer of the formula amount respectively, add them to the first reactor in turn, stir for 1 hour under the condition of 500r / min, and mix evenly to obtain the first mixture;

[0049] 3) Move the first mixture into a light-shielded and closed second reaction kettle, and add the curing aid of the formula to obtain the second mixture;

[0050] 4) Dissolve the formulated amount of photoinitiator in the second reactive diluent in a dark environment, and then put it into the second reactor, con...

Embodiment 2

[0054] A visible light curing glue, including the following components in terms of weight percentage:

[0055]

[0056] According to the above components, follow the steps below to obtain visible light curing glue:

[0057] 1) Take the two active diluents of the formula, mix them evenly, and divide them into two parts, which are respectively recorded as the first active diluent and the second active diluent, which respectively account for 70% and 30% of the total active diluent ;

[0058] 2) Take the first reactive diluent, the formulated amount of prepolymer and the formulated amount of pigment respectively, and sequentially add them into the first reactor, stir for 1.5h under the condition of 300r / min, and obtain the first mixture after uniform mixing;

[0059] 3) Move the first mixture into a light-shielded and closed second reaction kettle, and add the curing aid of the formula to obtain the second mixture;

[0060] 4) Dissolve the formulated amount of photoinitiator in the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com