Patents

Literature

3403 results about "Urethane acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

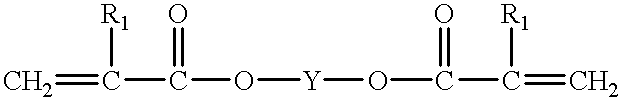

In the present paper we discuss UV-curable urethane acrylate coatings. The urethane acrylate oligomer is the main part of the coatings composition, which determines the properties of both the liquid and the cured coating.

Abrasion resistant urethane coatings

InactiveUS6228433B1Improve wear resistanceResistant to stainsPolyurea/polyurethane coatingsThin material handlingOligomerReactive diluent

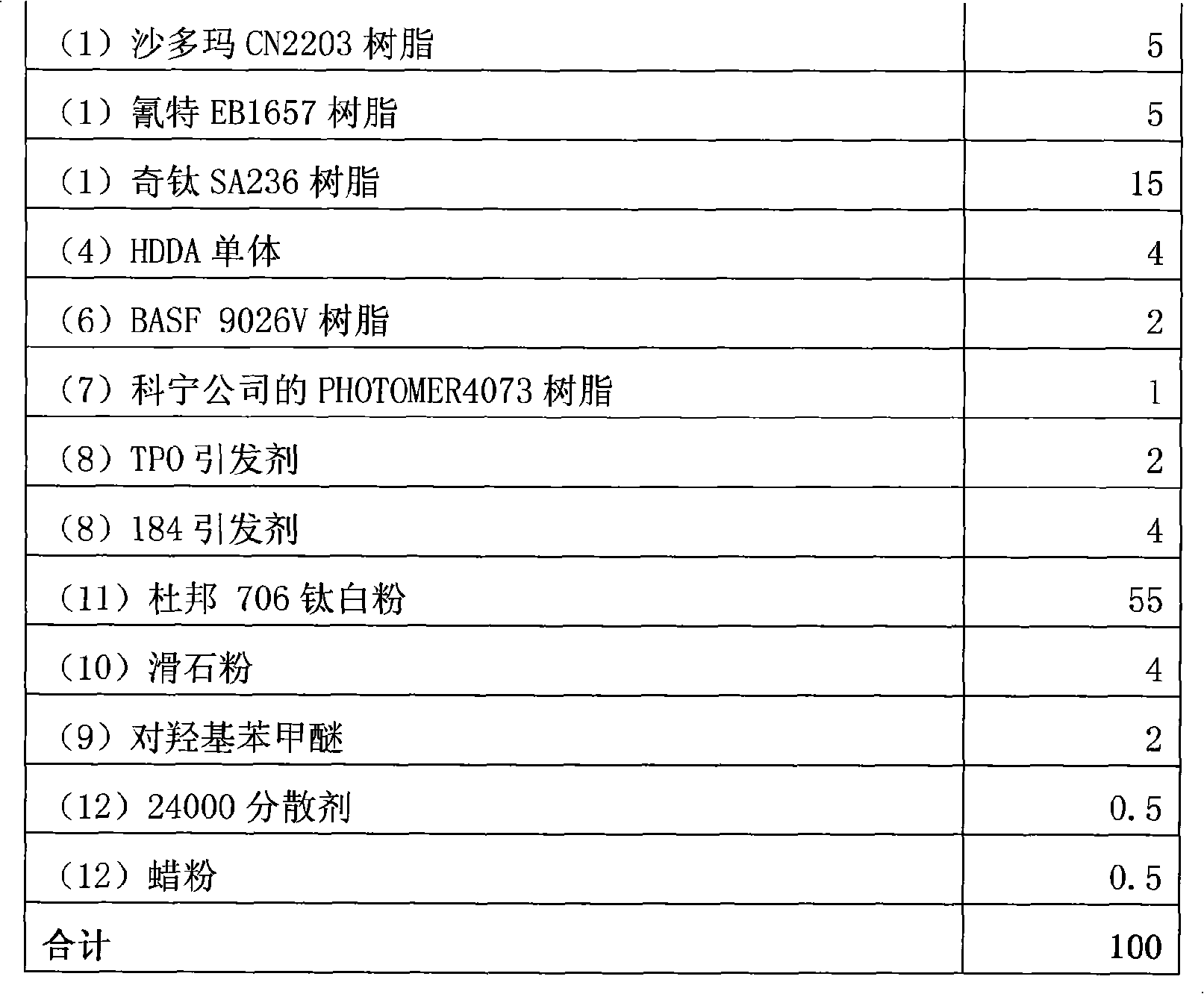

A radiation curable and abrasion resistant coating composition is provided comprising: (a) 70% to 98% by weight of an urethane-acrylate oligomer; (b) 2% to 30% of fine particles of a filler capable of imparting abrasion resistance having an average particle size in the range of 1-20 microns; (c) optionally a reactive diluent; and (d) optionally an synthetic resin. The coatings when applied to wood floorings impart superior abrasion resistance.

Owner:PRISM ENTERPRISES

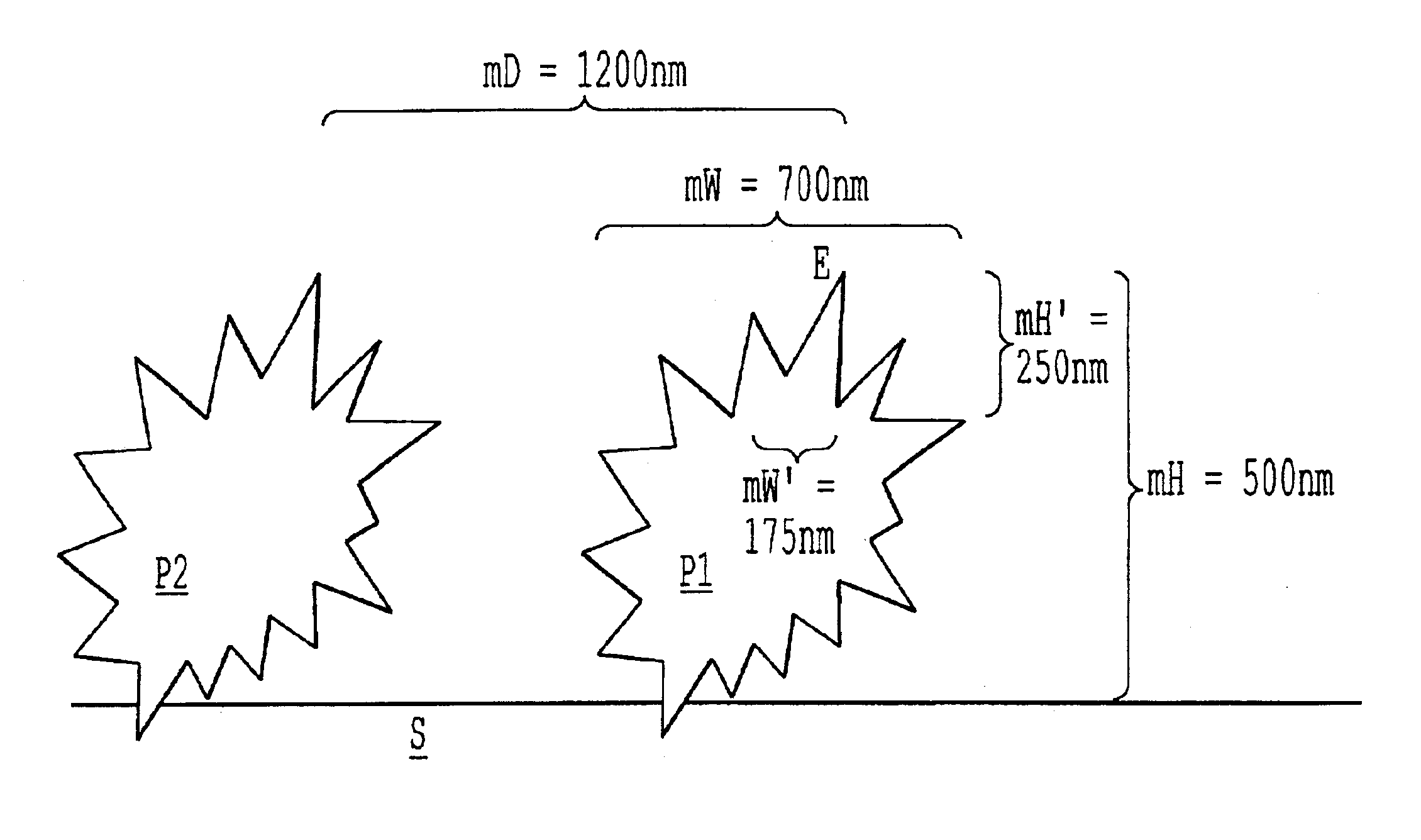

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

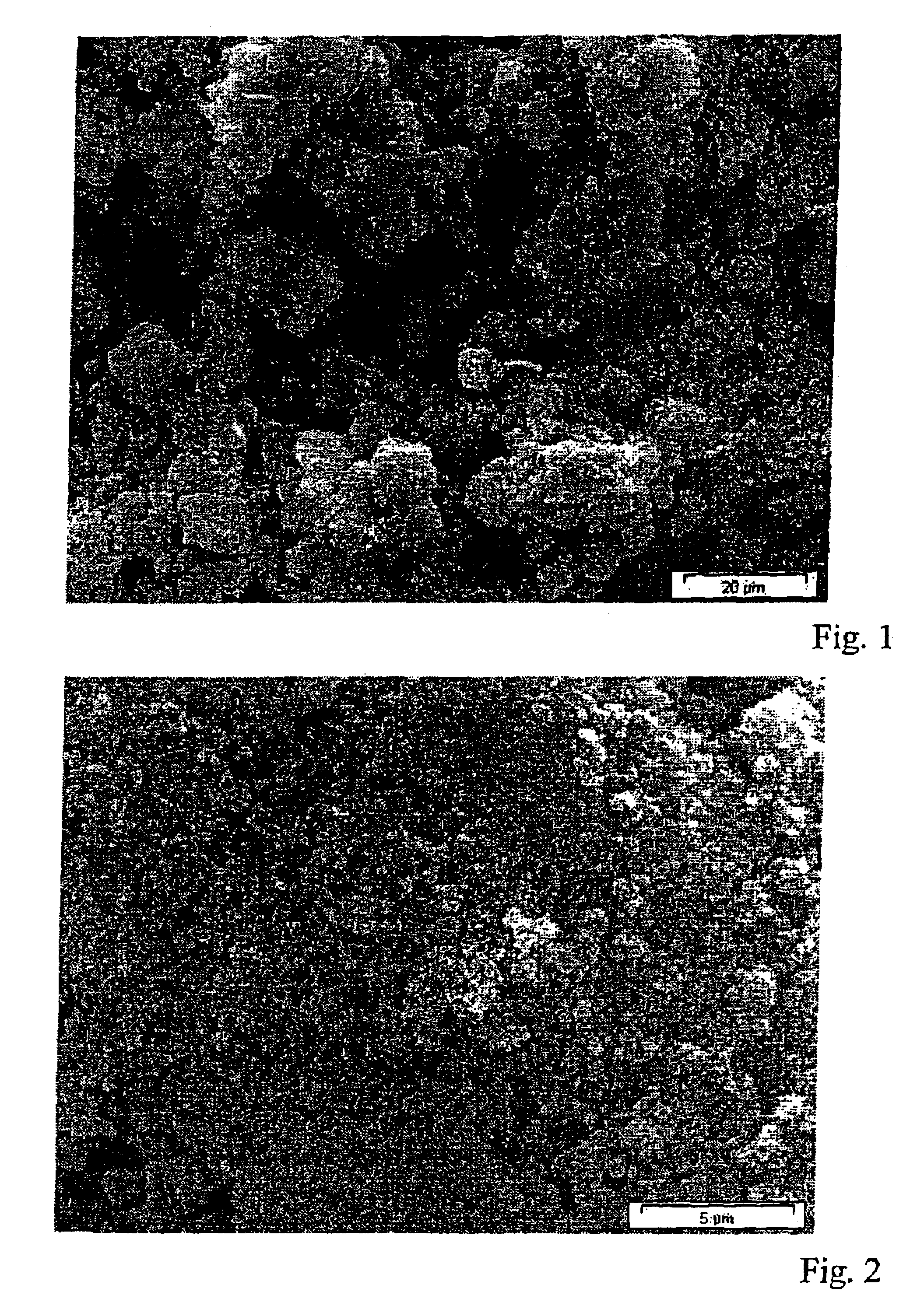

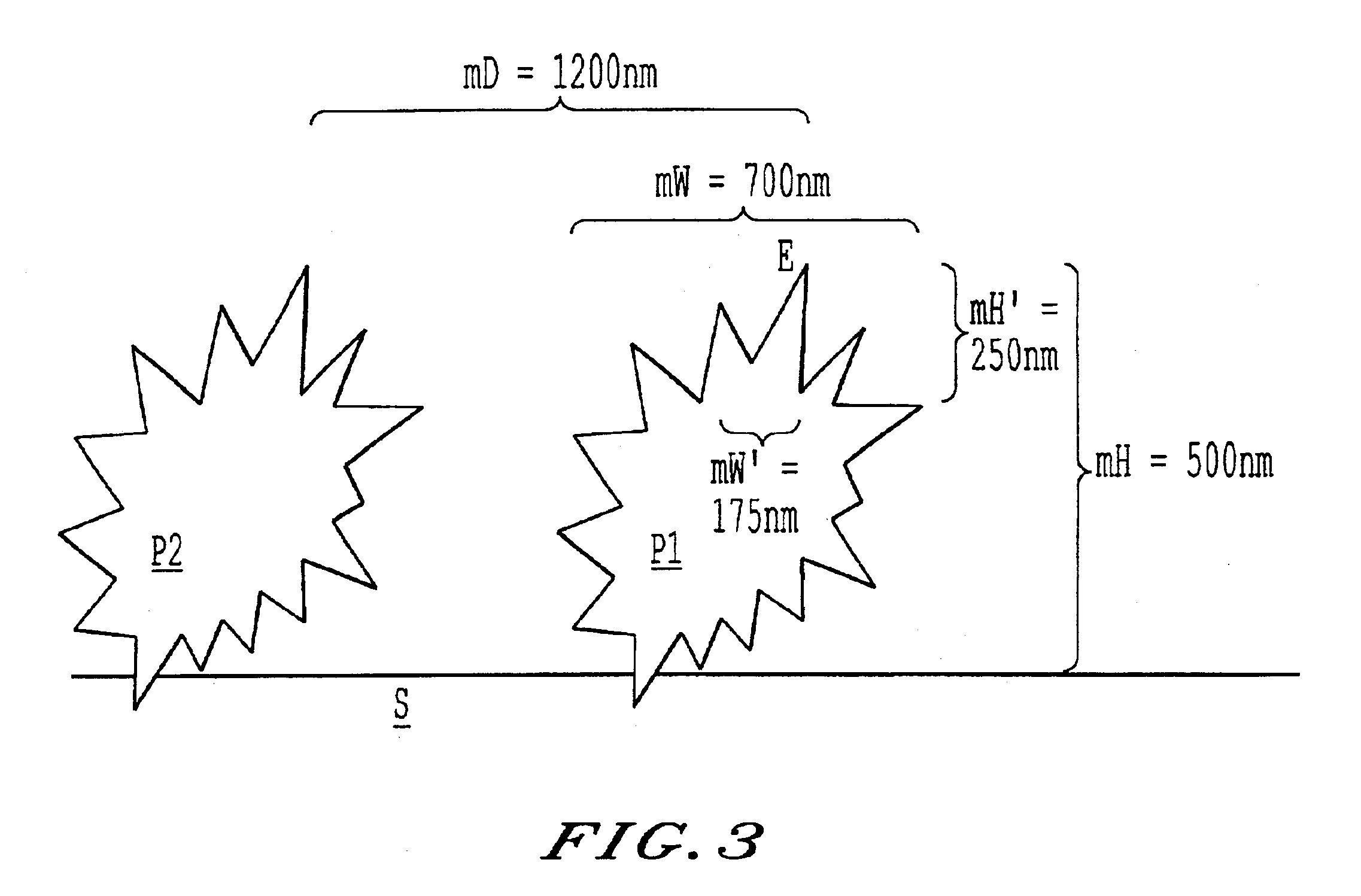

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Ultraviolet light curing offset printing ink and preparation method thereof

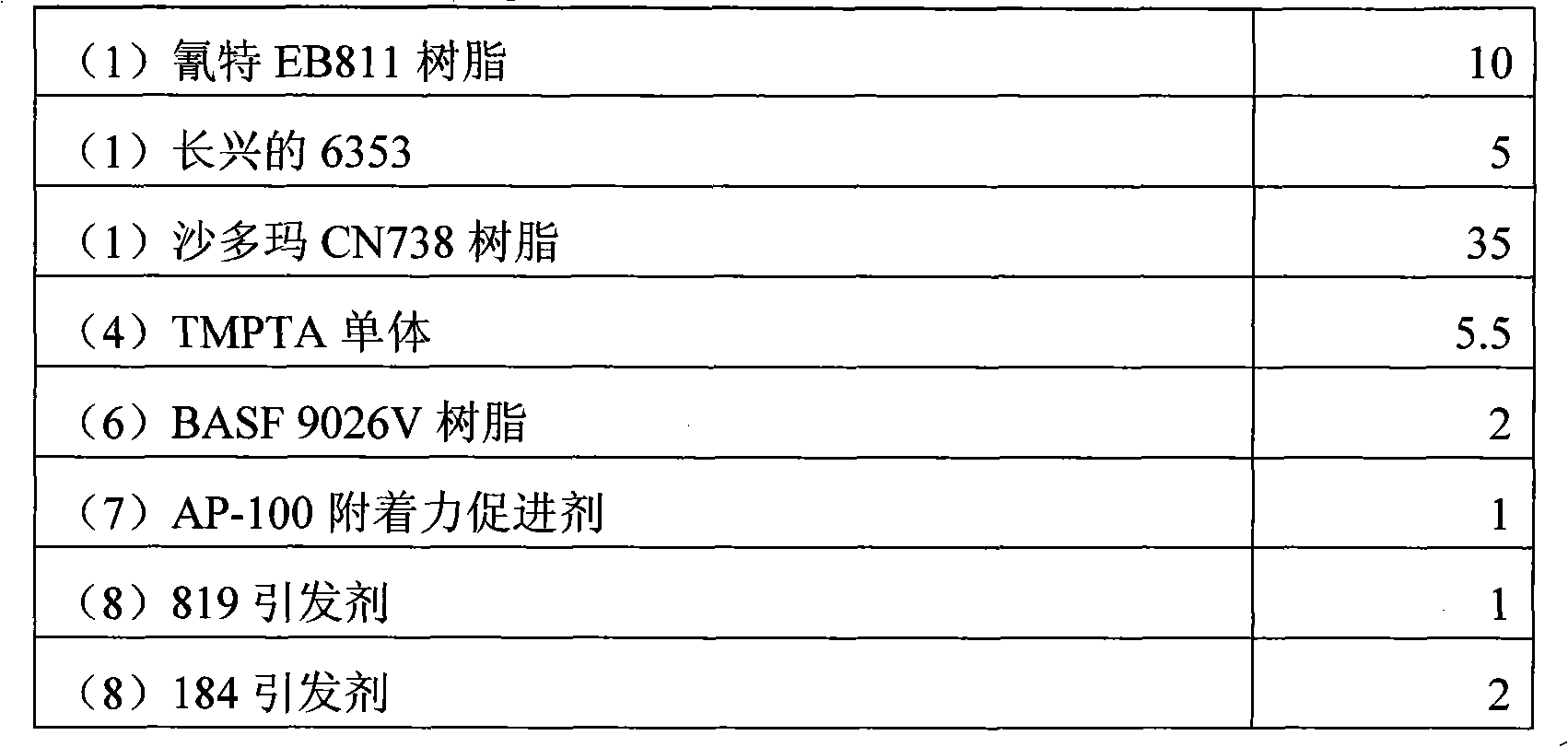

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

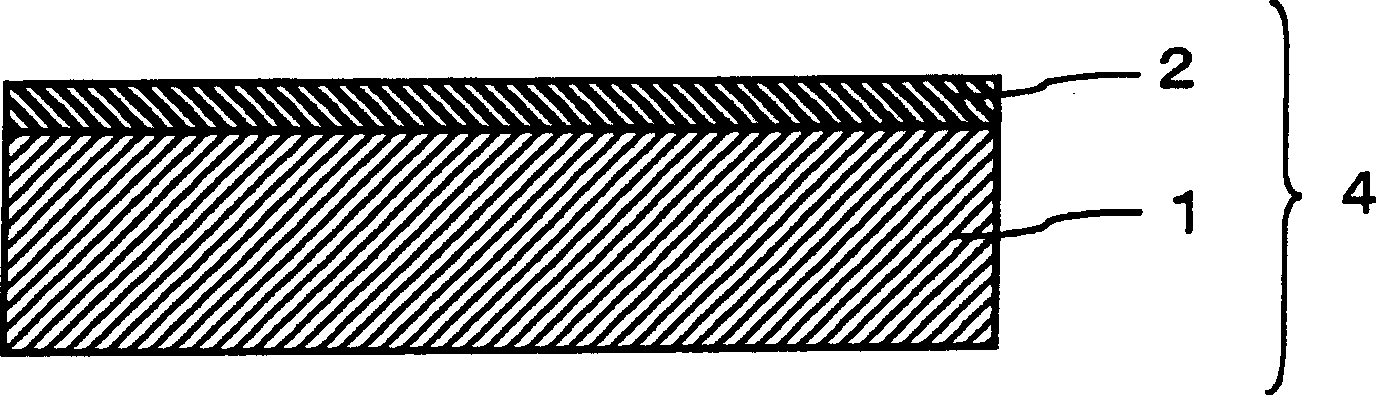

Hard-coated film and method of manufacturing the same

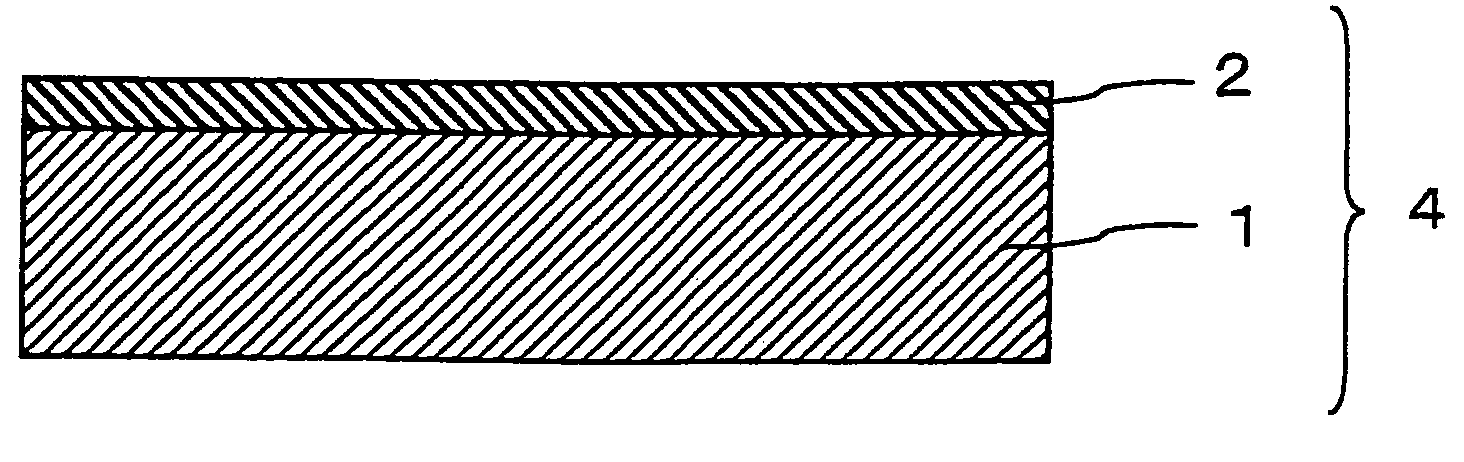

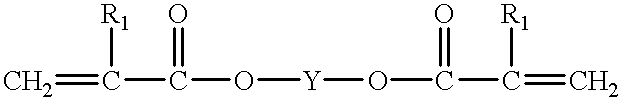

InactiveUS20060134400A1Increase elasticityIncrease flexibilitySynthetic resin layered productsPretreated surfacesMeth-Polyol

The invention is directed to a hard-coated film, comprising: a transparent film substrate; and a hard-coating layer formed on at least one side of the transparent film substrate, wherein the hard-coating layer is made from a material containing a urethane acrylate, a polyol (meth)acrylate and a (meth)acrylic polymer having an alkyl group containing at least two hydroxyl groups. There can be provided a hard-coated film that has high hardness and good flexibility and is resistant to curling due to hardening and shrinking and a method of manufacturing a hard-coated film in which a reduction in production efficiency associated with an increase in the number of manufacturing steps is prevented.

Owner:NITTO DENKO CORP

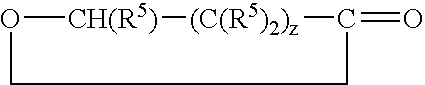

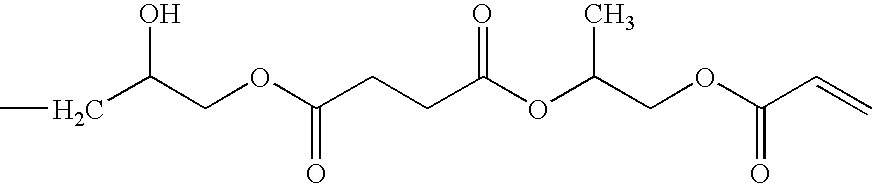

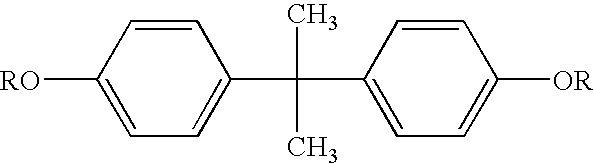

UV curable coating composition

The present invention is directed to a non-aqueous composition curable by UV radiation broadly comprising a mixture of two UV curable urethane acrylates. The invention is also directed to a coating process using such composition. One of the urethane acrylates is the reaction product of an isocyanate and a specific OH functional lactone ester (meth)acrylate. The other urethane acrylate is the reaction product of an isocyanate and a specific hydroxy functional (meth)acrylate.

Owner:ALLNEX NETHERLANDS BV

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition for medical adhesive tape

InactiveUS20060216523A1Good moisture permeabilityLess generationSurgical adhesivesPolyureas/polyurethane adhesivesVitrificationOligomer

An adhesive composition for medical adhesive tapes, comprising a base polymer containing a pressure-sensitive adhesive polymer obtained by crosslinking or curing a precursor containing a urethane acrylate oligomer and an ultraviolet (UV) initiator, the base polymer having a glass transition temperature (Tg) of 0° C. or less.

Owner:3M INNOVATIVE PROPERTIES CO

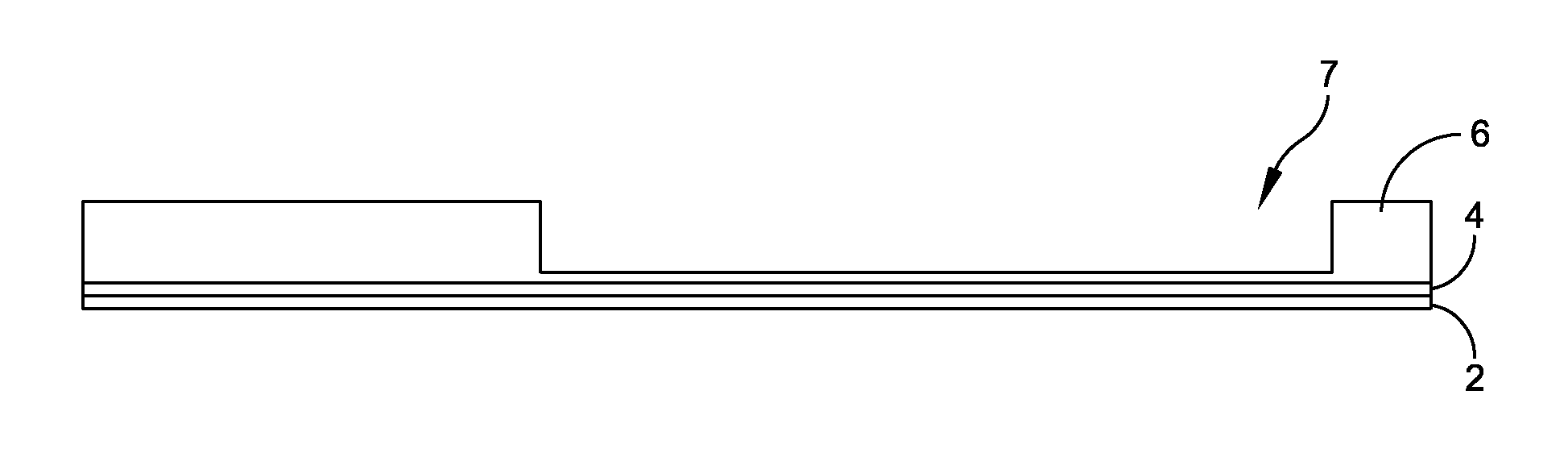

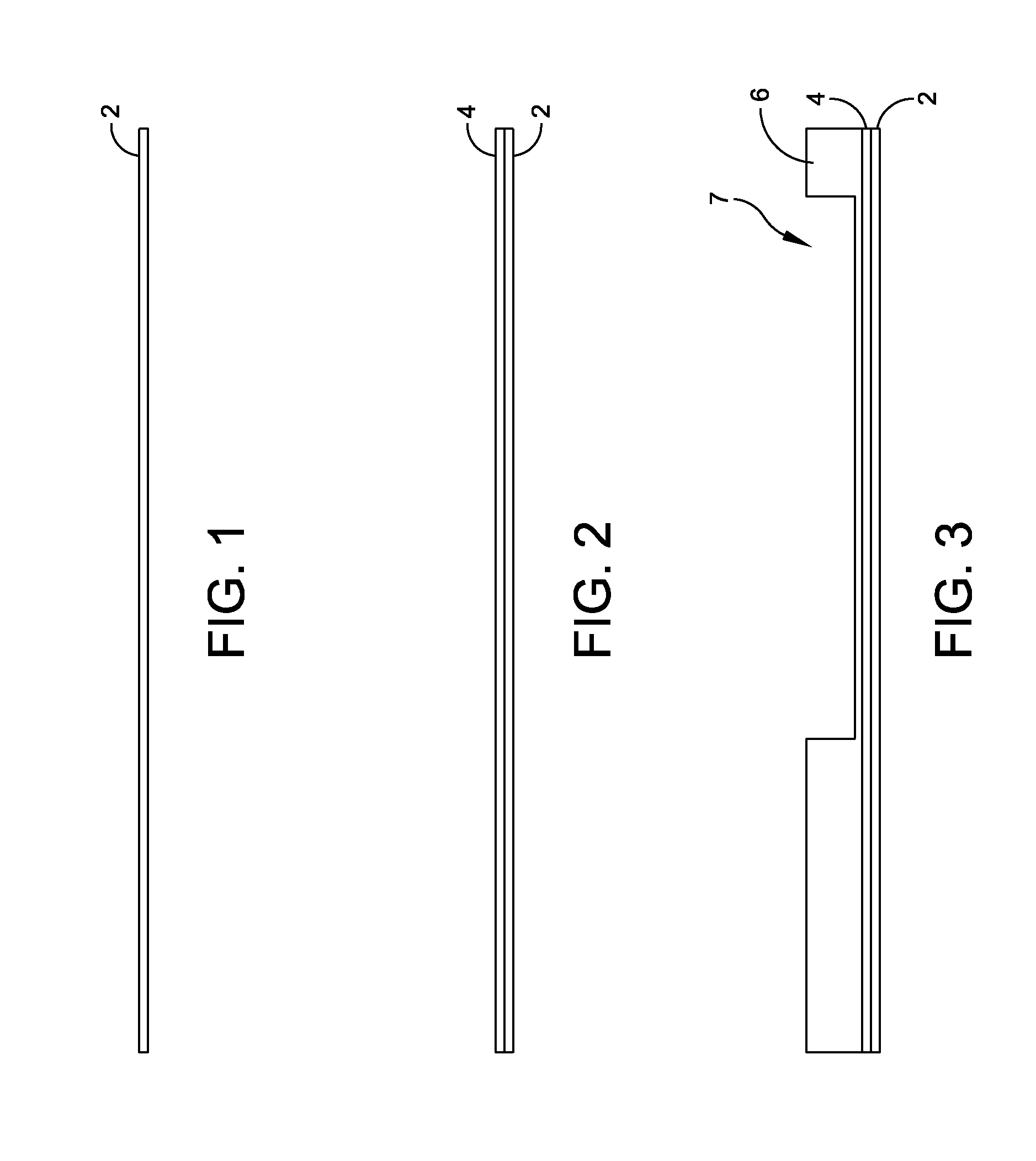

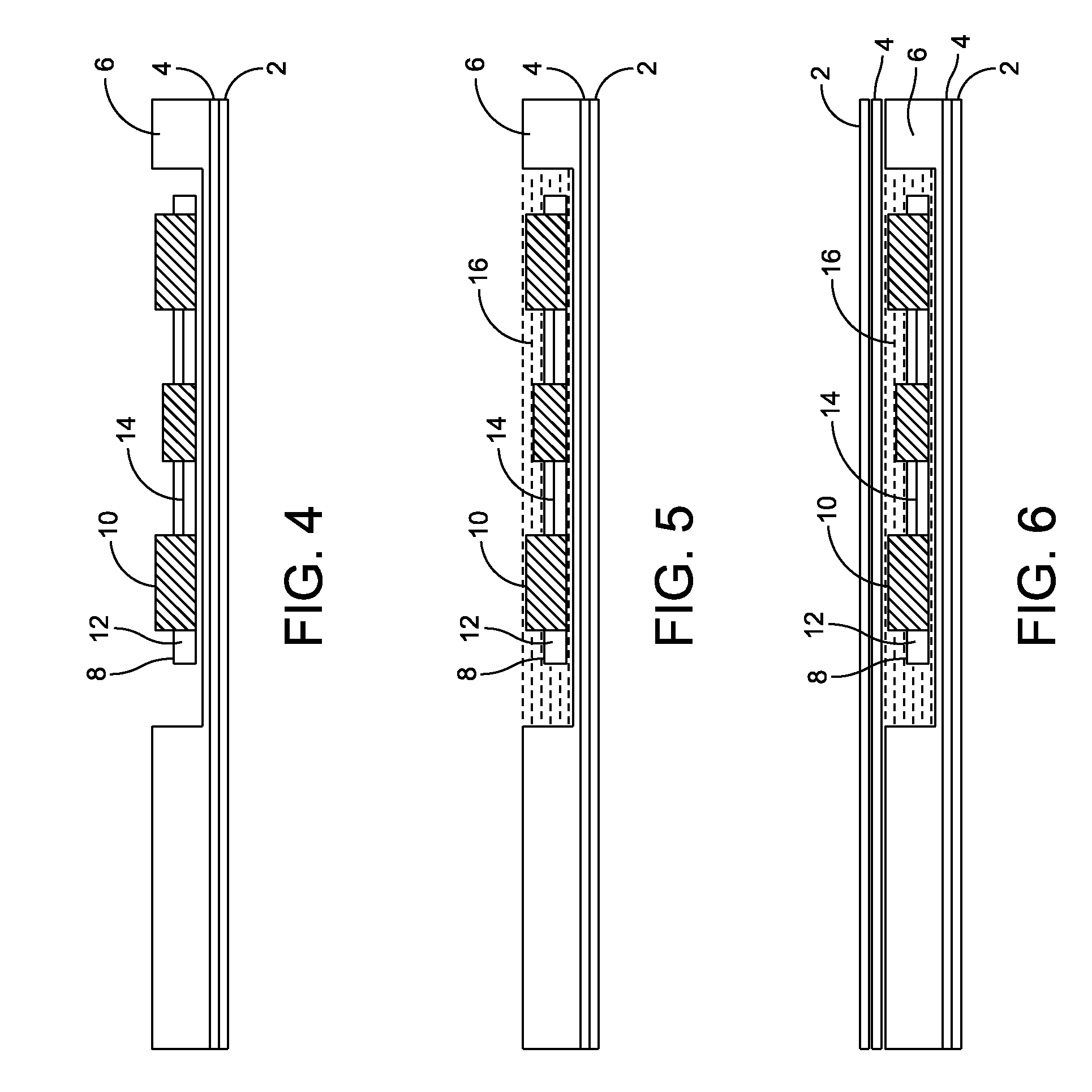

Information carrying card comprising a cross-linked polymer composition, and method of making the same

The disclosure provides a cross-linkable polymer composition, a core layer for an information carrying card comprising such cross-linked composition, resulting information carrying card, and methods of making the same. A crosslinkable polymer composition comprises a curable base polymer resin in a liquid or paste form, and a particulate thermoplastic filler. The base polymer resin is selected from the group consisting of urethane acrylate, silicone acrylate, epoxy acrylate, urethane, acrylate, silicone and epoxy. The particulate thermoplastic filler may be polyolefin, polyvinyl chloride (PVC), a copolymer of vinyl chloride and at least another monomer, or a polyester such as polyethylene terephthalate (PET), a compound or blend thereof.

Owner:X CARD HLDG

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Abrasion resistant coatings

InactiveUS7375144B2Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsDiacrylate esterUrethane acrylate

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

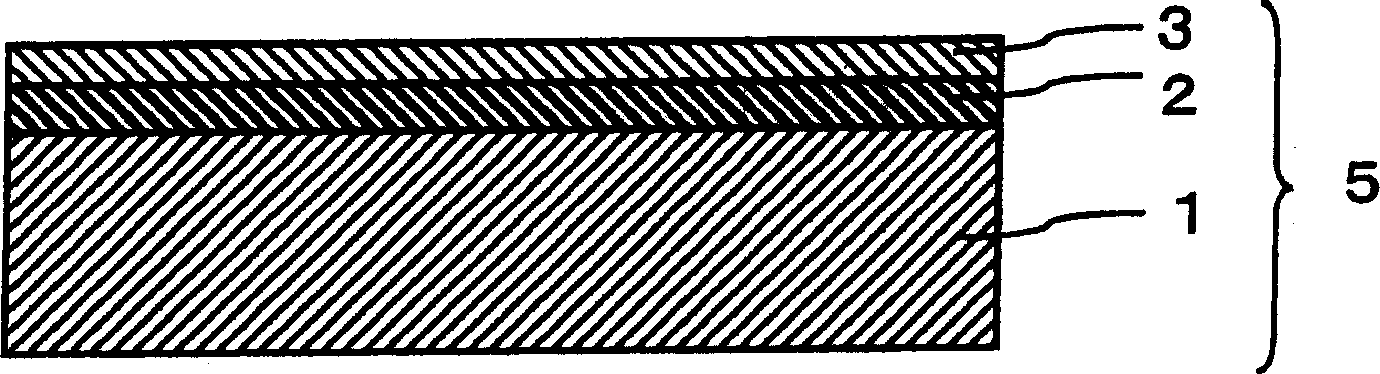

Hard coat film, antireflection hard coat film, optical element and image display

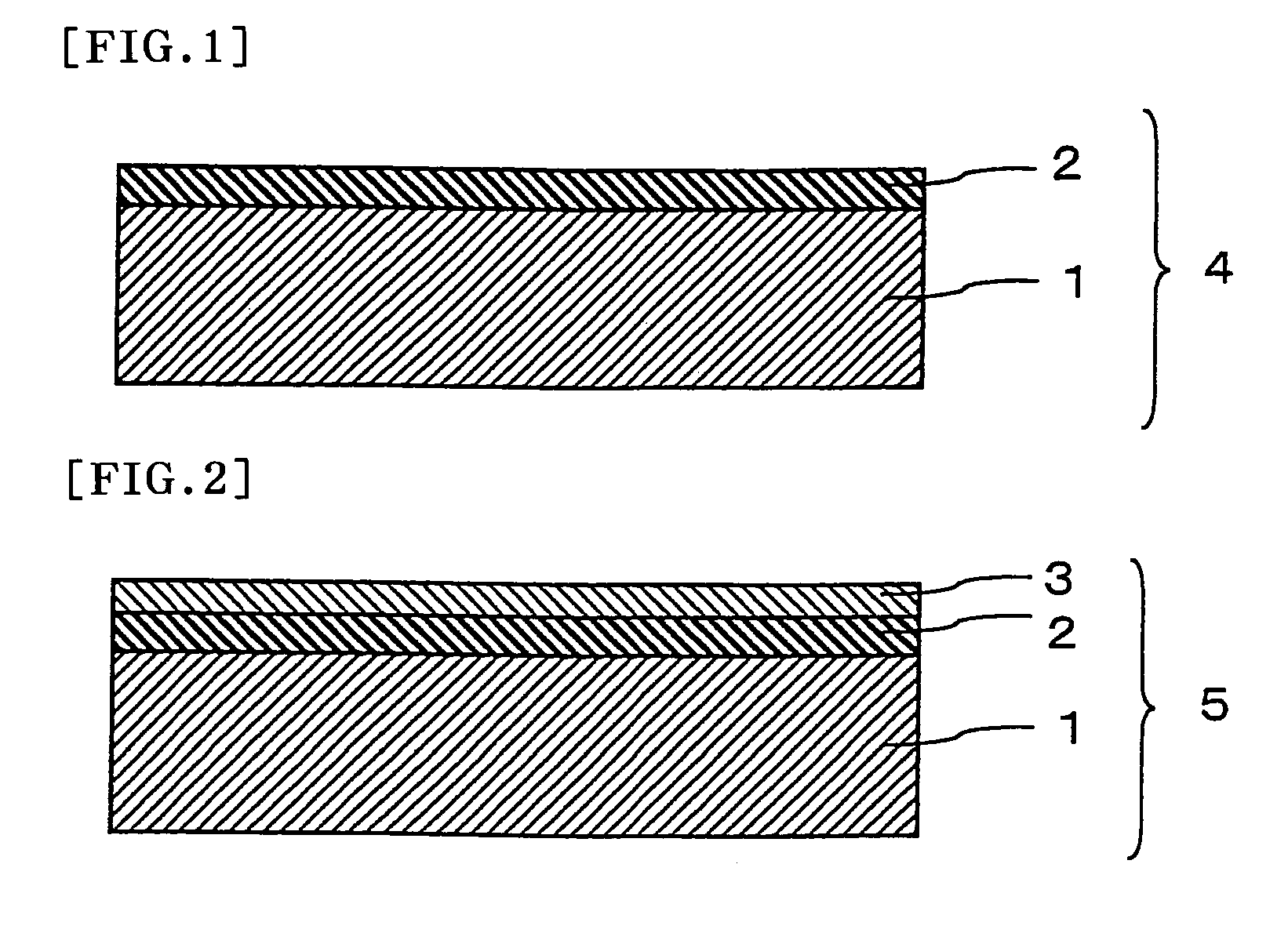

InactiveUS20070178297A1Suppress cracksCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsOptoelectronicsHardness

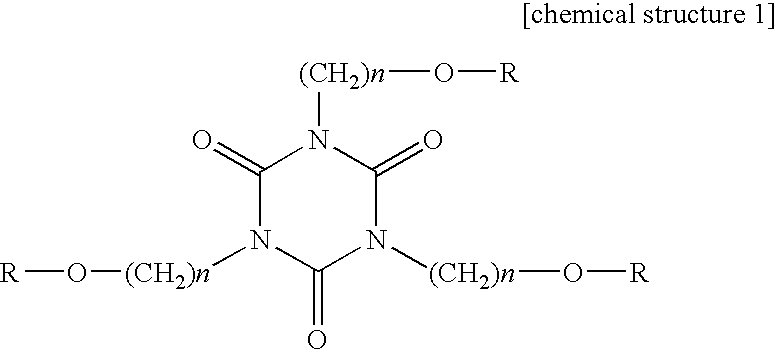

A hard coat film of the present invention comprises a hard coat layer, which is a cured coat layer, provided on at least one side of a transparent plastic film substrate, wherein a hard coat layer forming material comprises urethane acrylate (A); isocyanuric acid acrylate (B) and inorganic ultrafine particles (C), and has a high hardness and suppresses curling due to cracking and cure shrinkage.

Owner:NITTO DENKO CORP

Abrasion resistant urethane coatings

InactiveUS20010051229A1Reduce contentRapidly cured and polymerizedSynthetic resin layered productsSpecial tyresOligomerReactive diluent

Owner:PERMAGRAIN PROD

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Abrasion resistant coatings

InactiveUS20060286383A1Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsPolymer scienceDiacrylate ester

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

Golden blue ray-resistant protection film and preparation method thereof

InactiveCN103614089ASimple preparation processReduce manufacturing costFilm/foil adhesivesPolyurea/polyurethane coatingsPolyesterTectorial membrane

The invention relates to the technical field of protection films, and particularly relates to a golden blue ray-resistant protection film and a preparation method thereof. The golden blue ray-resistant protection film comprises a main film layer, a protection film layer and a release layer, wherein a blue ray-resistant layer is arranged on the upper surface of the main film layer; a first adhesive layer is arranged between the blue ray-resistant layer and the protection film layer; a second adhesive layer is arranged between the lower surface of the main film layer and the release layer; the blue ray-resistant layer is prepared from 2-10 parts by weight of nano CeO2:Er fluorescent powder and 100 parts by weight of acrylic ester; the acrylic ester is one or a mixture of more of urethane acrylate, epoxy acrylate, methacrylate and polyester acrylate. The preparation method is simple in preparation technology, and low in production cost; large-scale popularization and application are facilitated; the prepared protection film has an effect of resisting the blue ray, and has absorption and conversion functions on bluish violet high-energy short waves; the filtration rate at the blue ray wave band of 360-500nm can be up to over 90%. Therefore, the eye health is well protected.

Owner:NALI OPTICAL MATERIAL DONGGUAN +1

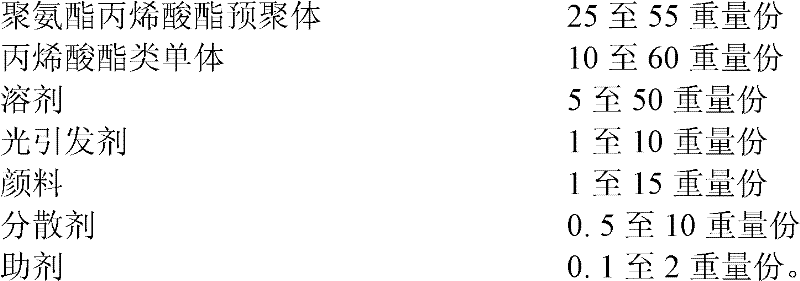

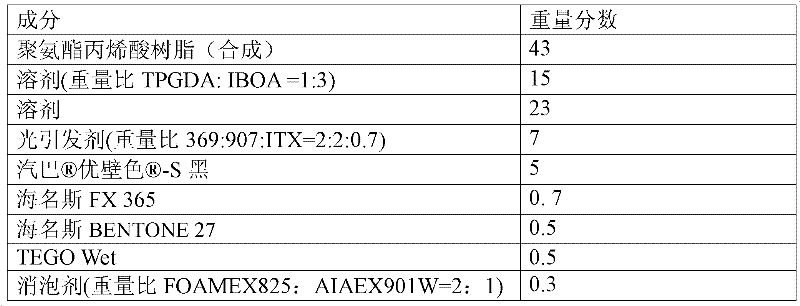

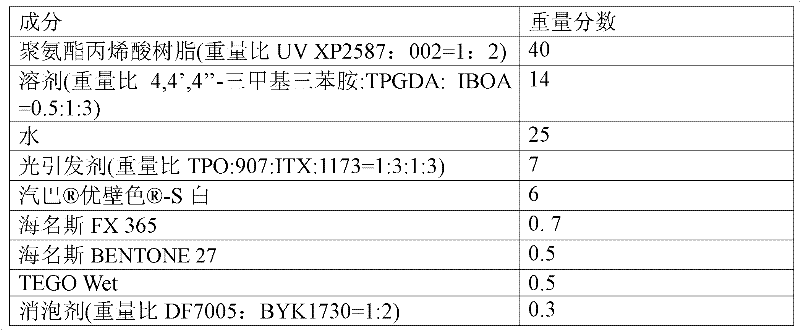

Colorful ultraviolet (UV) light solidifying paint

InactiveCN102212311AEasy constructionFast constructionPolyurea/polyurethane coatingsUltravioletUrethane acrylate

The invention provides a colorful ultraviolet (UV) light solidifying paint. The paint comprises the following components in parts by weight: 25-55 parts of polyurethane acrylate prepolymer, 10-60 parts of acrylate monomer, 5-50 parts of solvent, 1-10 parts of photoinitiator, 1-15 parts of pigment, 0.5-10 parts of dispersing agent and 0.1-2 parts of auxiliary, wherein the acrylate monomer is a mixture of a single-functionality monomer, a double-functionality monomer and a high-functionality monomer. According to the invention, the paint is used so as to overcome the problems such as large volatility, difficult construction and the like in the existing colorful UV light solidifying paint, has the characteristics of low volatile organic compound (VOC), good decorative effect, rapid curing speed and the like, is easy to construct, is suitable for flow line production, and can be used for decoration of base materials such as plastic, wood, metal and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

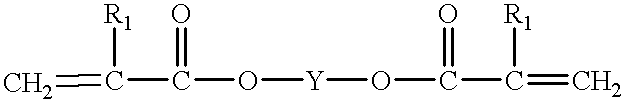

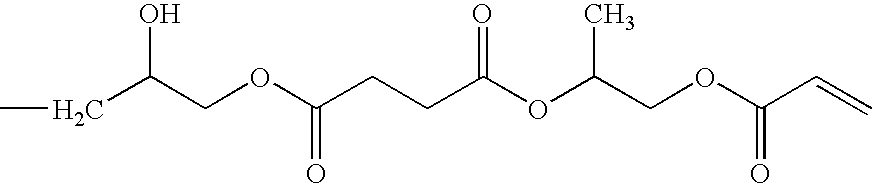

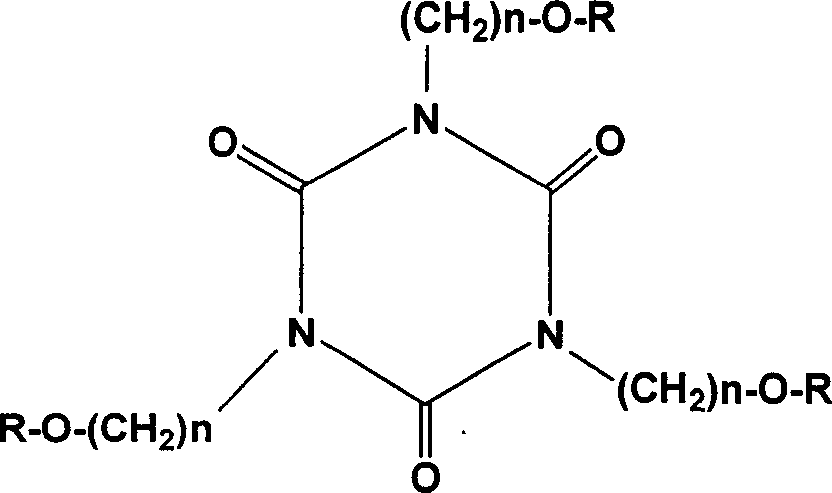

Preparation method and application of resin having double curing groups

InactiveCN101824152AHigh viscosityTo achieve the effect of initial bondingPolyureas/polyurethane adhesivesInksEpoxyUV curing

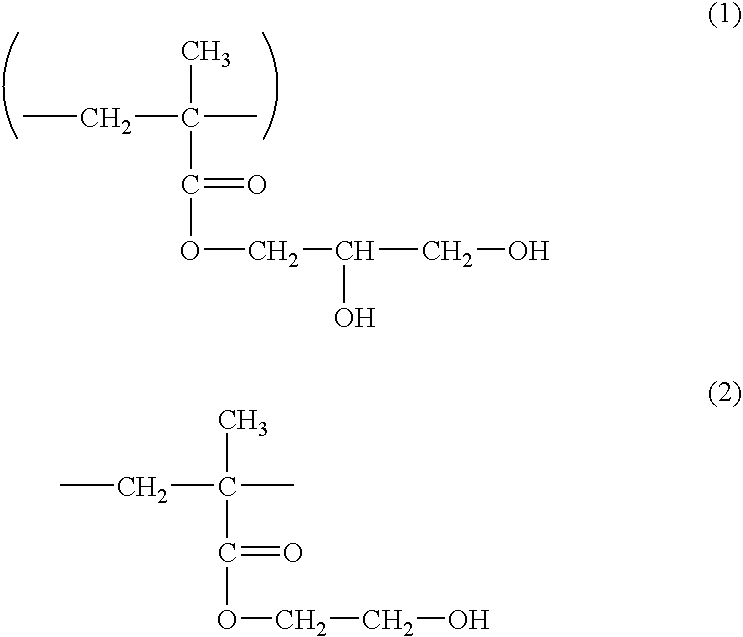

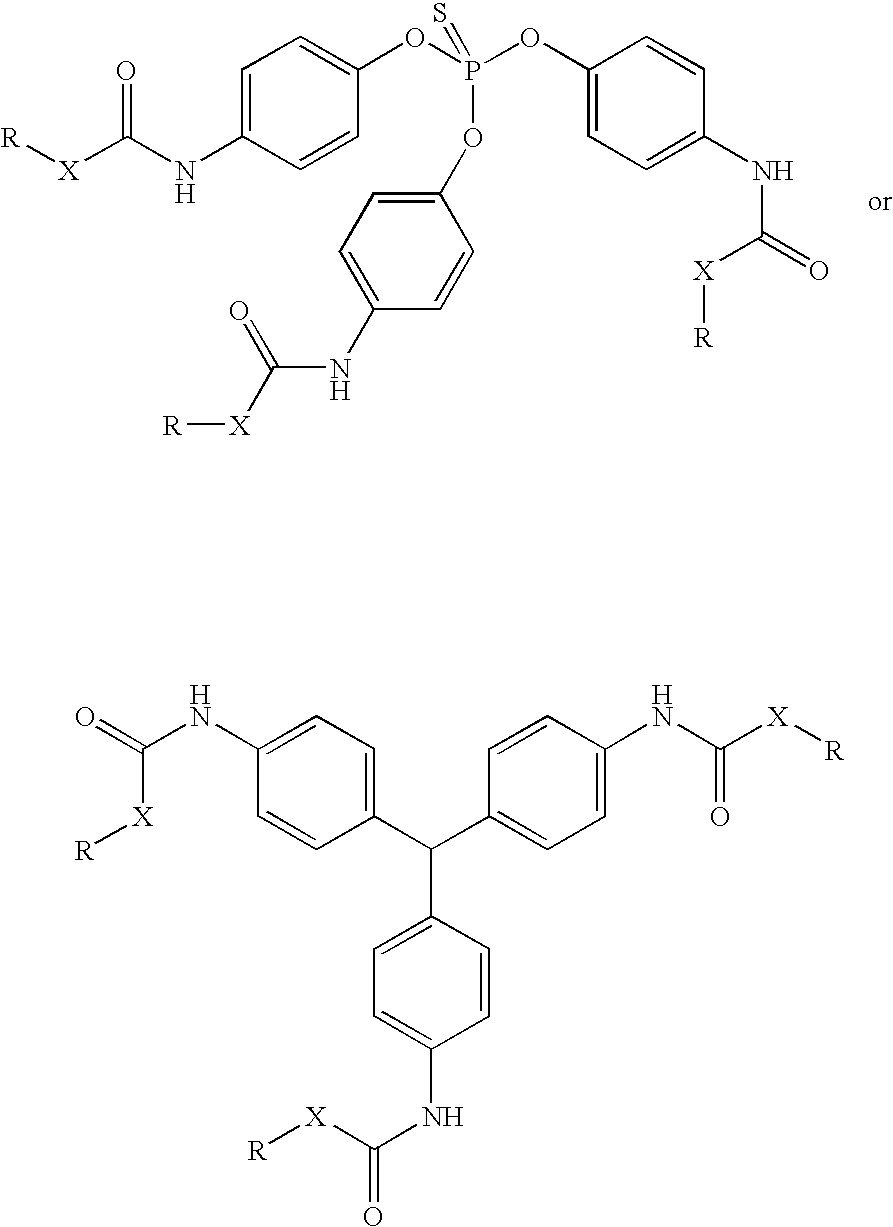

The invention discloses a preparation method and application of resin having double curing groups. The resin having double curing groups comprises epoxy monoacrylate and polyurethane acrylate chain segments and has the following structure. The molecule of the resin having double curing groups has an acrylate double bond (a curing free radical) and an epoxy group (a curing or thermally curing anion), so the brittleness of a cured film is reduced and the flexibility of the cured film is improved and the resin can be used in ultraviolet curing paint, adhesive and ink. The resin can improve large shrinkage factor of a single acrylate free radical curing system and large brittleness and poor flexibility of the UV curing film and the like and can also solve the problem that a several-resin mixed compounding system has unstable performance, uneven local curing, poor compatibility among resin and the like.

Owner:SHENZHEN POLYTECHNIC

Ultraviolet curing transfer adhesive

InactiveCN101942277AReduce consumptionImprove yieldOrganic non-macromolecular adhesivePolyesterOligomer

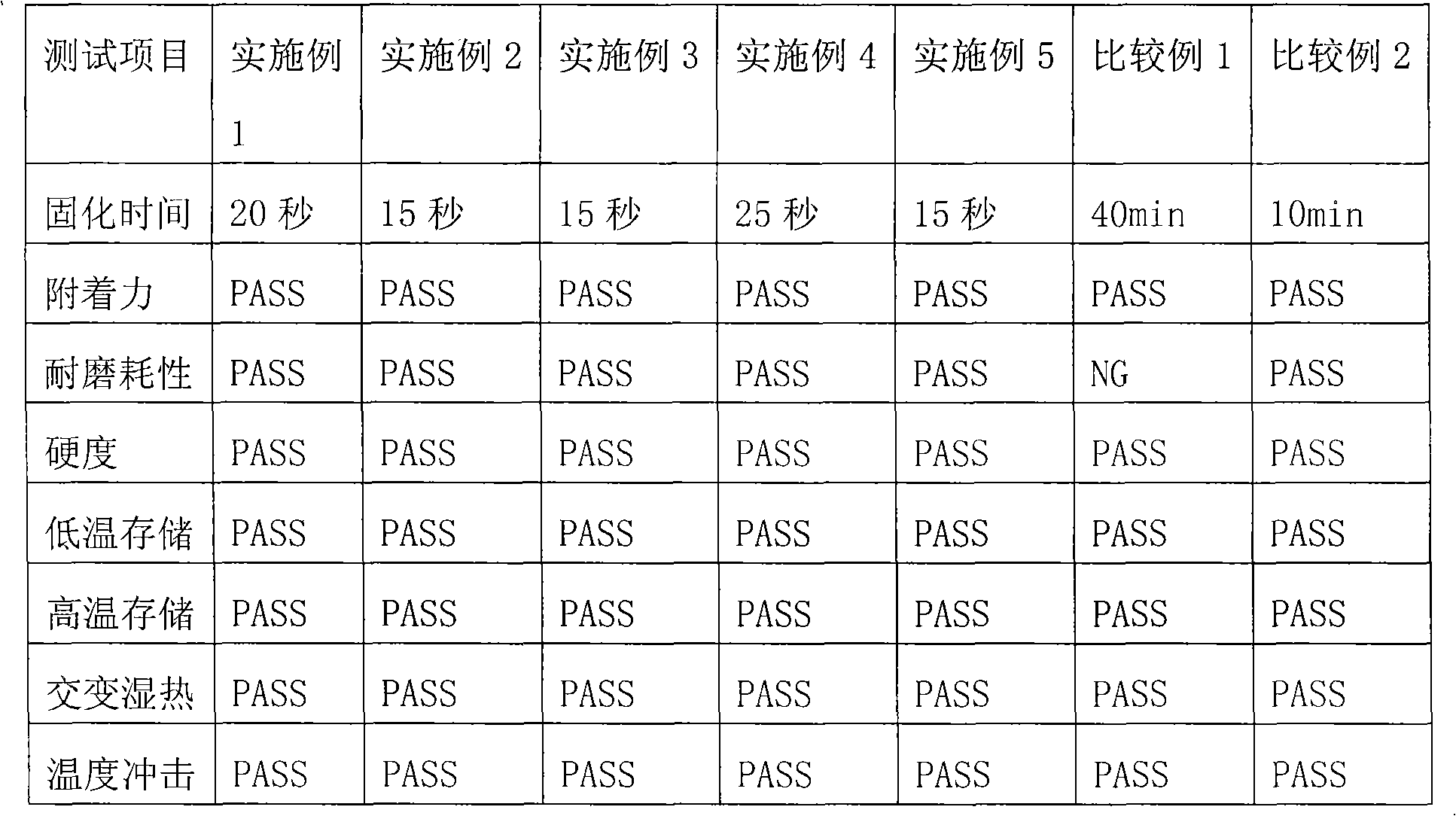

The invention discloses an ultraviolet curing transfer adhesive. The adhesive comprises the following components in percentage by weight: 45 to 67 percent of oligomer, 30 to 52 percent of activated monomer, 2 to 4 percent of free radical photoinitiator, and 1 to 3 percent of auxiliary, wherein the oligomer is one or more of epoxy acrylic ester, urethane acrylate and polyester acrylate; and the activated monomer is one of acrylic ester of a mono-functional group, a bifunctional group or a polyfunctional group. The ultraviolet curing transfer adhesive can form patterns with various shapes, can be cured at the room temperature in 20 seconds, can greatly reduce energy consumption, improve yield, is more suitable for continuous production, can improve the production efficiency, and has stable and reliable performance and high environmental protection property in the high-temperature high-dampness environment.

Owner:东莞市贝特利新材料有限公司

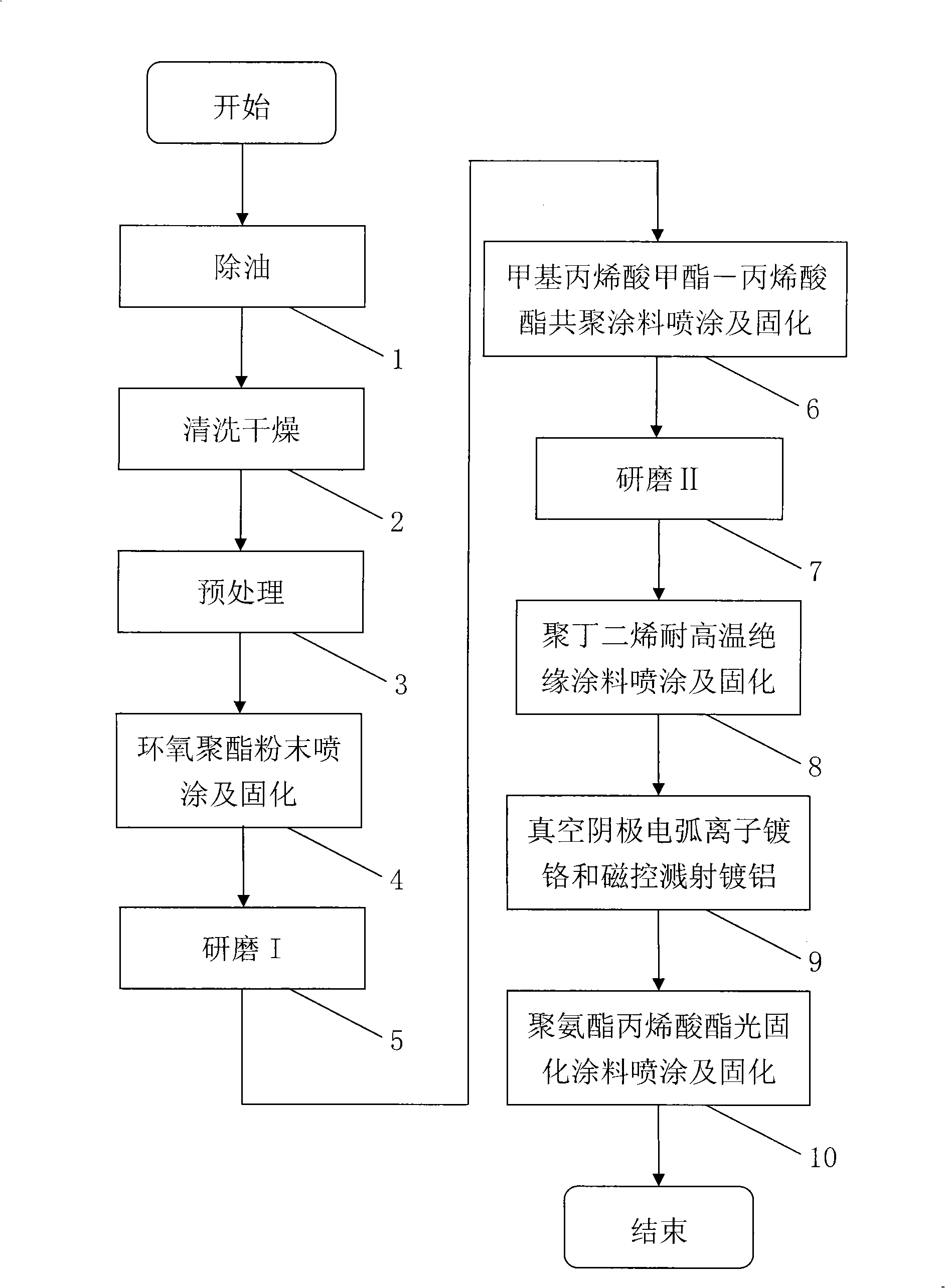

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

Ultraviolet light curing nano antibacterial woodenware paint and preparation method thereof

InactiveCN1927971AEase of industrial productionNo harmAntifouling/underwater paintsPaints with biocidesLacquerUltraviolet lights

The present invention discloses one kind of ultraviolet ray cured nanometer antibiotic woodenware lacquer and its preparation process. The ultraviolet ray cured nanometer antibiotic woodenware lacquer includes epoxy acrylate, polyurethane acrylate, diluent, nanometer inorganic antiseptic, nanometer inorganic stuffing and photoinitiator. The preparation process includes adding nanometer inorganic antiseptic and nanometer inorganic stuffing into the diluent, stirring to disperse homogeneously, adding epoxy acrylate, polyurethane acrylate and photoinitiator and mixing homogeneously. The woodenware lacquer with nanometer inorganic antiseptic can inhibit the growth and propagation of bacteria and microbes to produce long term antibiotic effect.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

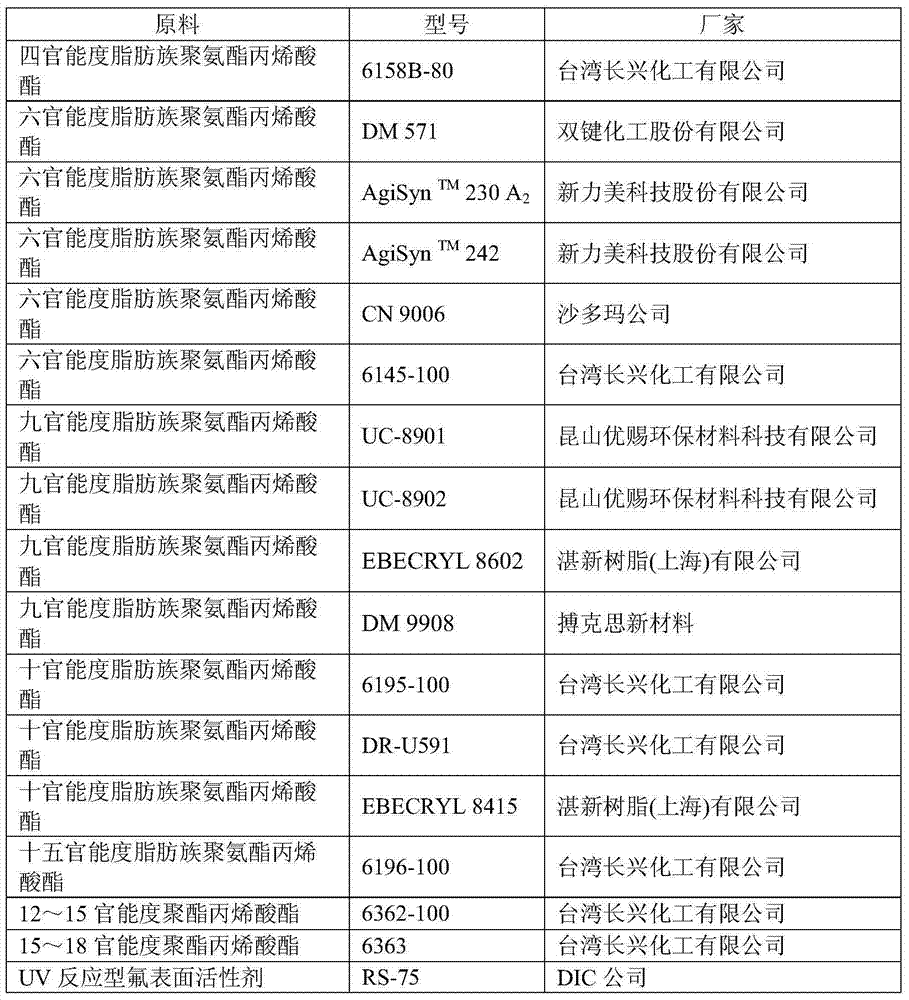

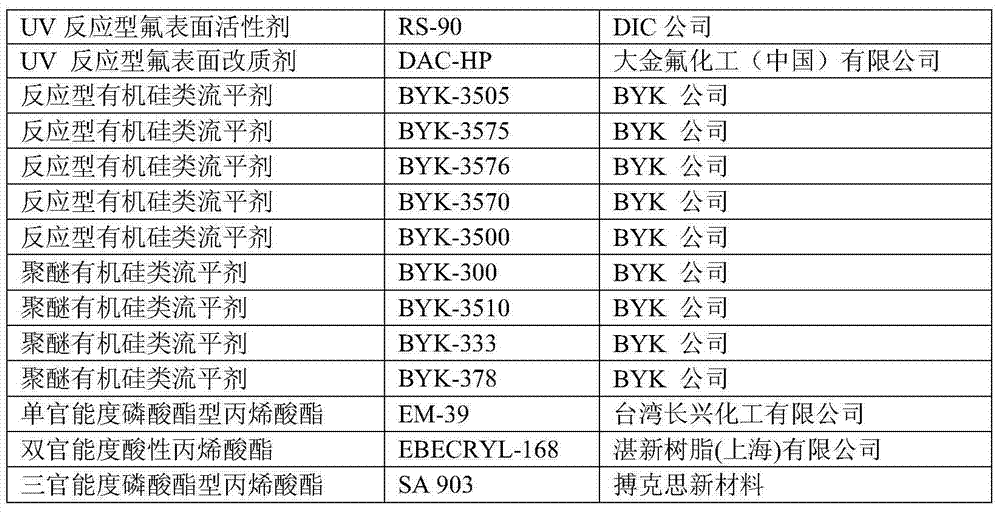

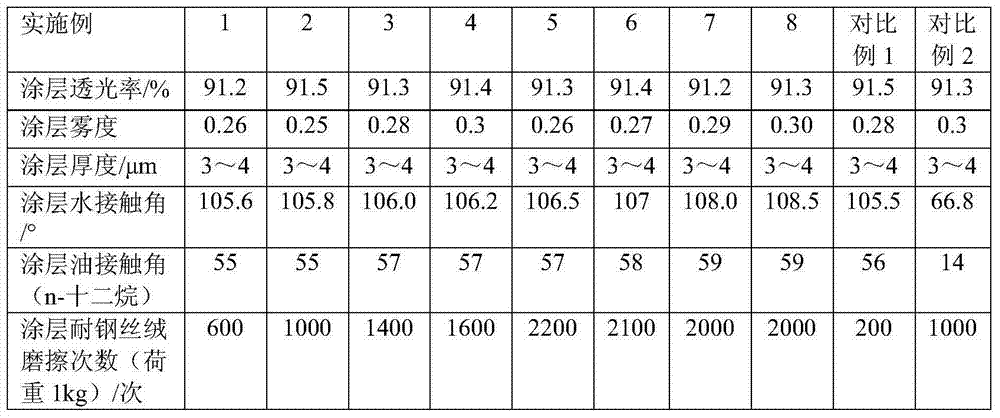

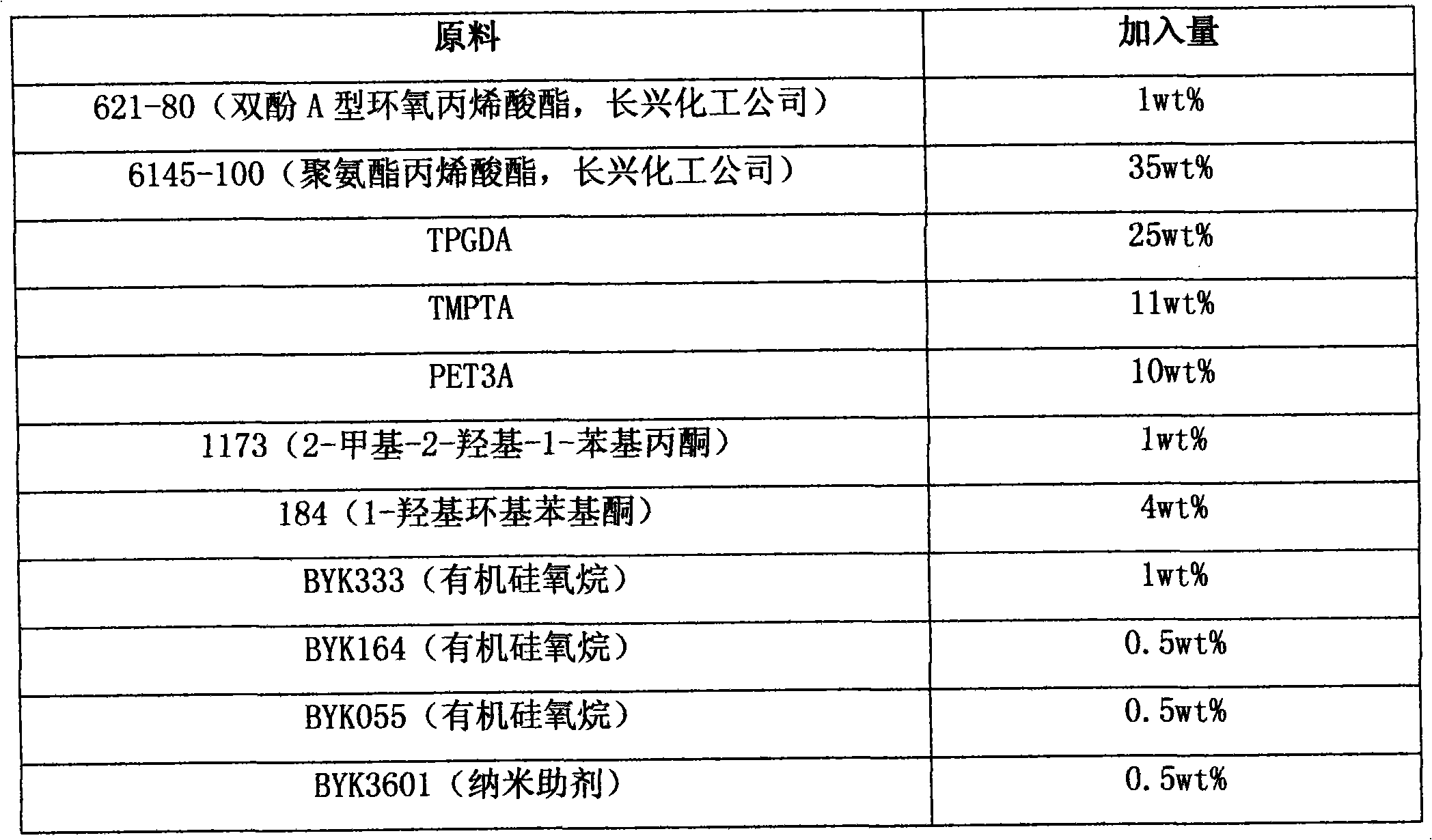

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

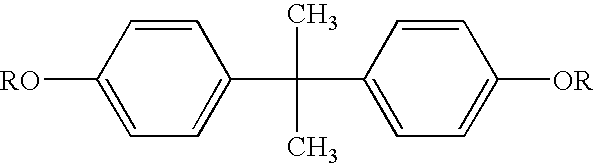

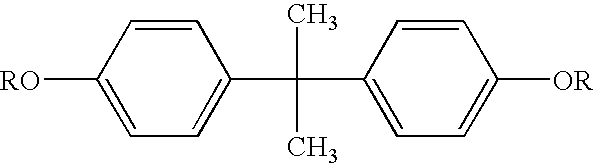

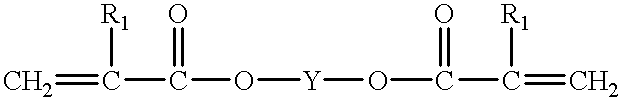

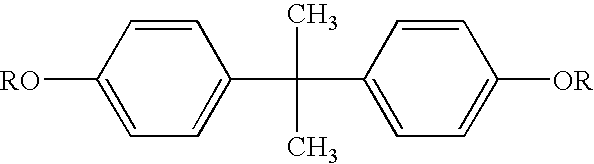

Aromatic urethane acrylates having a high refractive index

ActiveUS20080312403A1Simple as possible to prepareSuitable for productionMaterial nanotechnologyCarbamic acid derivatives preparationRefractive indexUrethane acrylate

The invention relates to novel aromatic urethane (meth)acrylates having a high refractive index, a process for the preparation thereof and a process for the production of holographic media.

Owner:COVESTRO DEUTSCHLAND AG

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

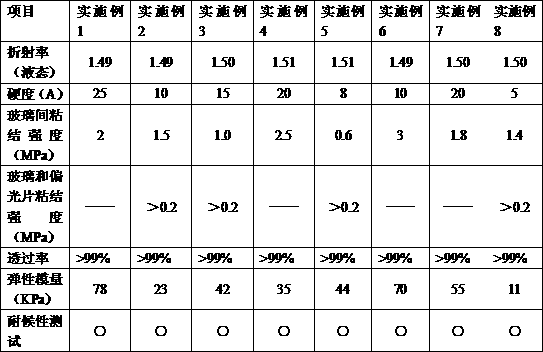

Ultraviolet curing liquid state optical cement and preparation method thereof

ActiveCN103242796ATransparent appearanceHigh viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUltravioletRefractive index

The invention relates to ultraviolet curing liquid state optical cement which is prepared from the components in parts by mass as follows: 40-70 parts of polyurethane acrylate oligomer, 20-40 parts of (methyl) acrylic ester, 0.1-5 parts of photoinitiator, 1-10 parts of silane coupling agent and 0-10 parts of assistant. The invention further provides a preparation method of the ultraviolet curing liquid state optical cement. Besides the characteristics of transparent appearance, stable viscosity, low energy required for curing, quick curing speed, high refractive index and the like, the ultraviolet curing liquid state optical cement provided by the invention further has the excellent characteristics of great bonding strength, low hardness after curing, good flexibility and excellent weather ability.

Owner:NICHE TECH KAISER SHANTOU

Hard coating film, antireflective hard coating film, optical element and image display device

InactiveCN1906235AHigh hardnessReduce interference fringesSynthetic resin layered productsCellulosic plastic layered productsHardnessUrethane acrylate

Owner:NITTO DENKO CORP

Ultraviolet curing coating

InactiveCN101638554AImprove anti-pollution performanceEasy to cleanPolyurea/polyurethane coatingsEpoxy resin coatingsUrethane acrylatePhotoinitiator

The invention relates to an ultraviolet curing coating which is characterized in that the ultraviolet curing coating comprises 1-35 wt% of epoxy acrylate, 1-35wt% of urethane acrylate, 20-50wt% of polyfunctional acrylate monomer, 1-15wt% of additive and 1-10wt% of photoinitiator. The coating formed by ultraviolet curing coating obtained by adopting the technical scheme has the advantages of good pollution resistibility, easy cleaning, high strength, strong adherence, high toughness and difficult stripping.

Owner:FOSHAN SHUNDE HEYGEY LIGHT CURING MATERIALS

High-solid-content UV (Ultraviolet)-curing aqueous urethane acrylate dispersion liquid and preparation method thereof

InactiveCN102030884AImprove curing efficiencyReduce consumptionPolyurea/polyurethane coatingsDistillationAdhesive

The invention discloses a high-solid-content UV-curing aqueous urethane acrylate dispersion liquid and a preparation method thereof, wherein the method comprises the following steps of: firstly carrying out the monoesterfication reaction on the partial hydroxide group at the tail end of hyperbranched polyester and the anhydride group of dicarboxylic anhydride to obtain an intermediate I; carrying out the end capping reaction on an isocyanate group in diisocyanate and the hydroxide group in a hydroxyalkyl methacrylate monomer to obtain a reaction intermediate II; carrying out the reaction on the residual hydroxide group of the intermediate I and the residual isocyanate group of the reaction intermediate II to obtain a reaction intermediate III; and carrying out alkali neutralization, aqueous dispersion and reduced-pressure distillation on the reaction intermediate III to remove an organic solvent to obtain the UV-curing urethane acrylate aqueous dispersion liquid. The dispersion liquid has the characteristics of high solid content, relatively low viscosity, UV curability, good mechanical performance of a paint film and the like, conforms to the concept of environmental protection, can be applied to the fields of environment-friendly coatings, aqueous ink, aqueous adhesives, fabric coating agents and the like and has broad prospect.

Owner:SOUTH CHINA UNIV OF TECH

Transfer printing type ultraviolet light curing ink composition, preparation method thereof and mobile phone casing using ink composition

InactiveCN101993629AImprove adhesionClear patternInksTelephone set constructionsPolyesterAcrylic resin

The invention provides a transfer printing type ultraviolet light curing ink composition and a preparation method thereof. The ink composition comprises main body resin, a thinner, pigment and photoinitiators, and addition agents are included or not included, wherein the main body resin is polyester acrylate resin, modified acrylic resin, high-functionality-degree aliphatic urethane acrylate and hydroxy acrylic resin, the hydroxy acrylic resin is thermoplastic hydroxy acrylic resin, and the hydroxyl value content is between 45 and 70 mg KOH / g. The invention also provides a mobile phone casing using the ink composition, wherein the mobile phone casing sequentially comprises a substrate, a primer layer, a gloss oil layer and an ink pattern layer from bottom to top, and the ink pattern layer is obtained from the ink composition through transfer printing. When the transfer printing type ultraviolet light curing ink composition is adopted, the adhesive force between the ink layer and a contact layer can be enhanced, and in addition, when the surface of the contact layer is lower, the cured ink layer can effectively avoid the phenomenon of edge contraction.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com