Patents

Literature

46results about How to "Reduce interference fringes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

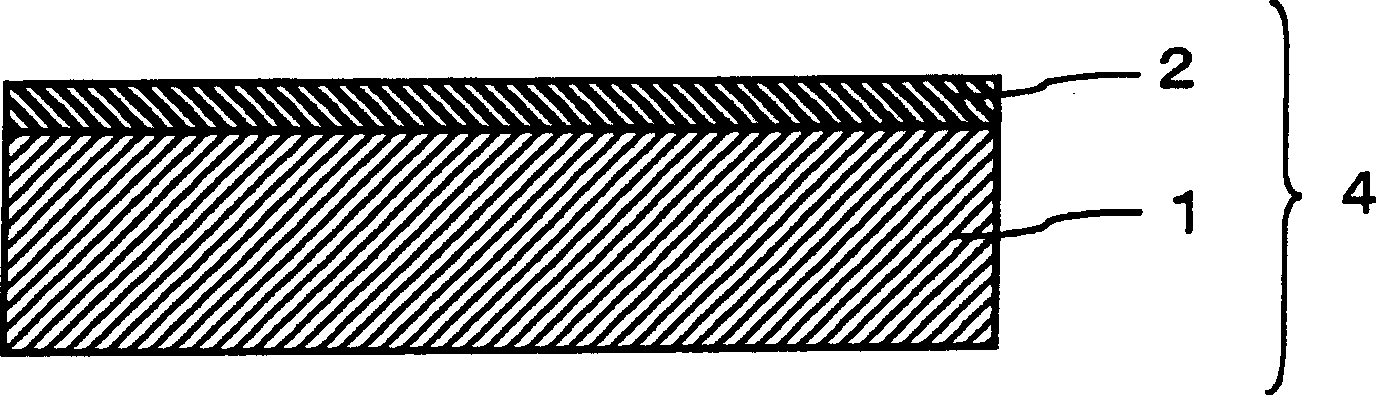

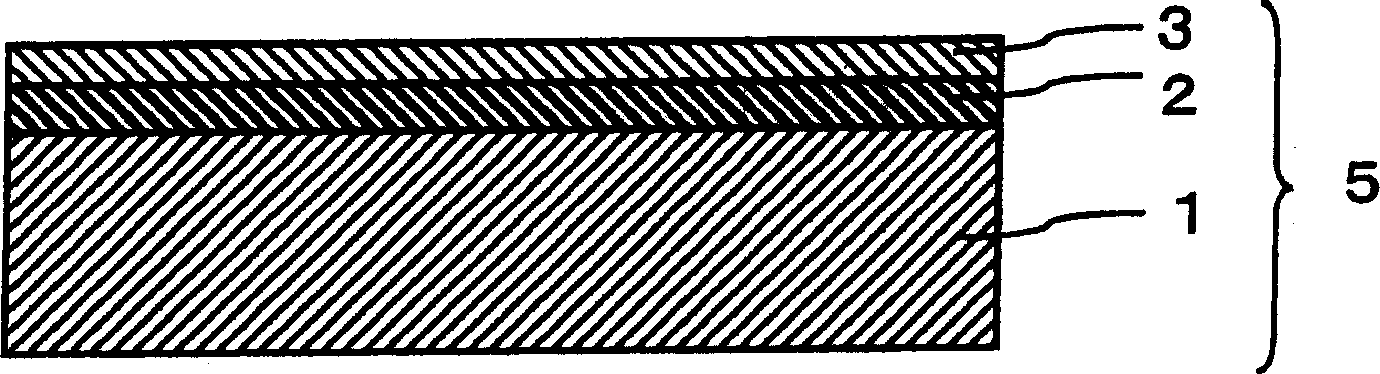

Hard coating film, antireflective hard coating film, optical element and image display device

InactiveCN1906235AHigh hardnessReduce interference fringesSynthetic resin layered productsCellulosic plastic layered productsHardnessUrethane acrylate

Owner:NITTO DENKO CORP

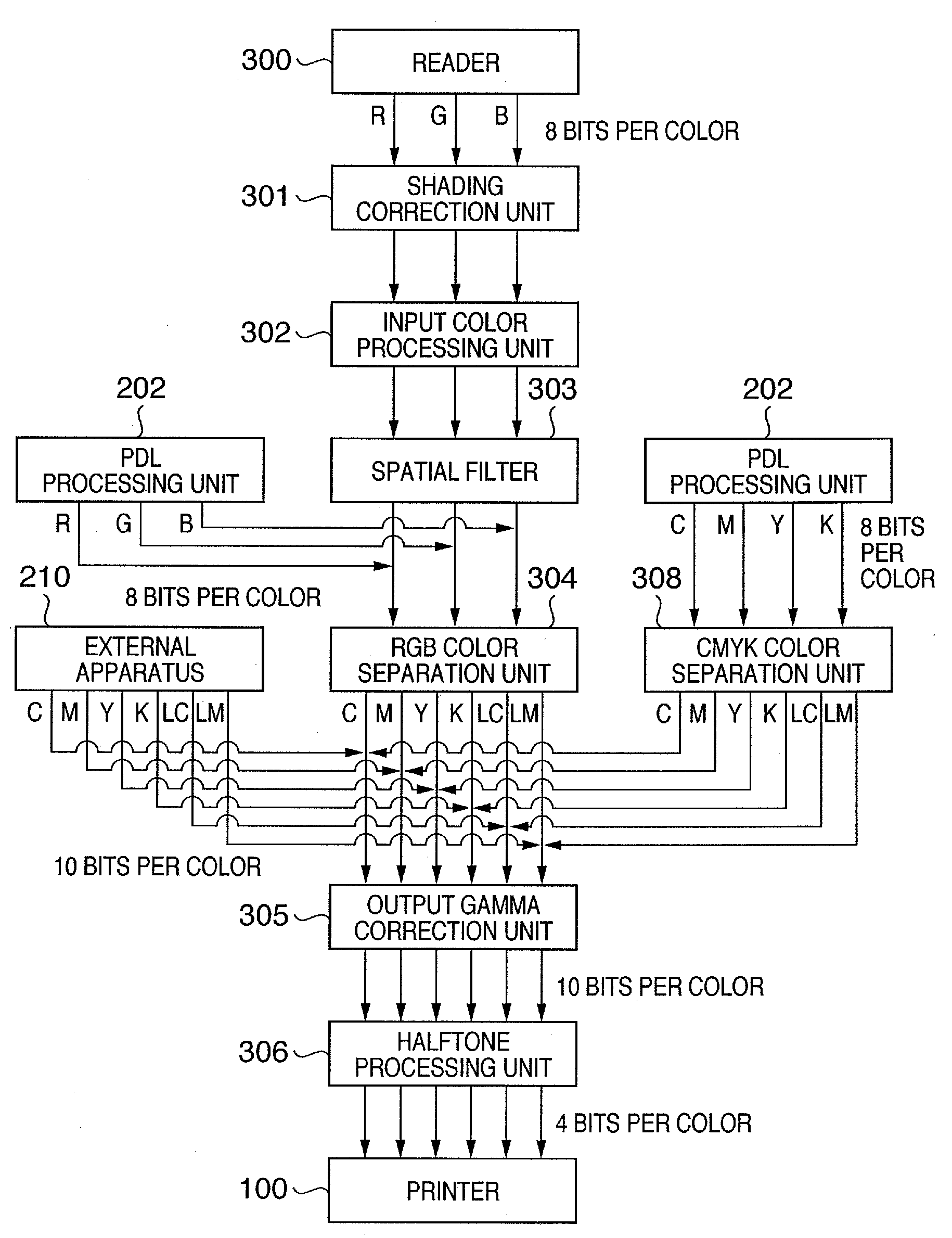

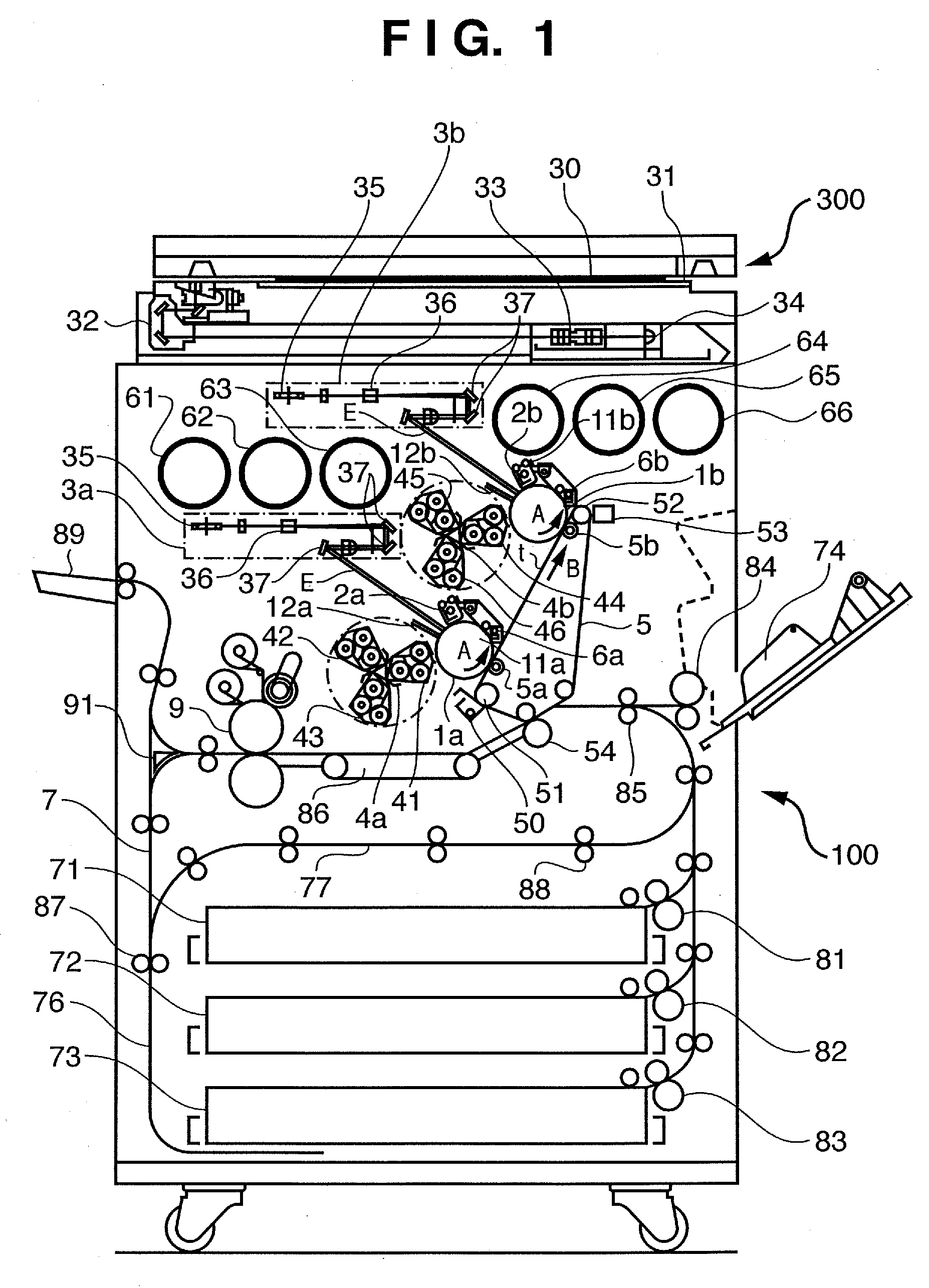

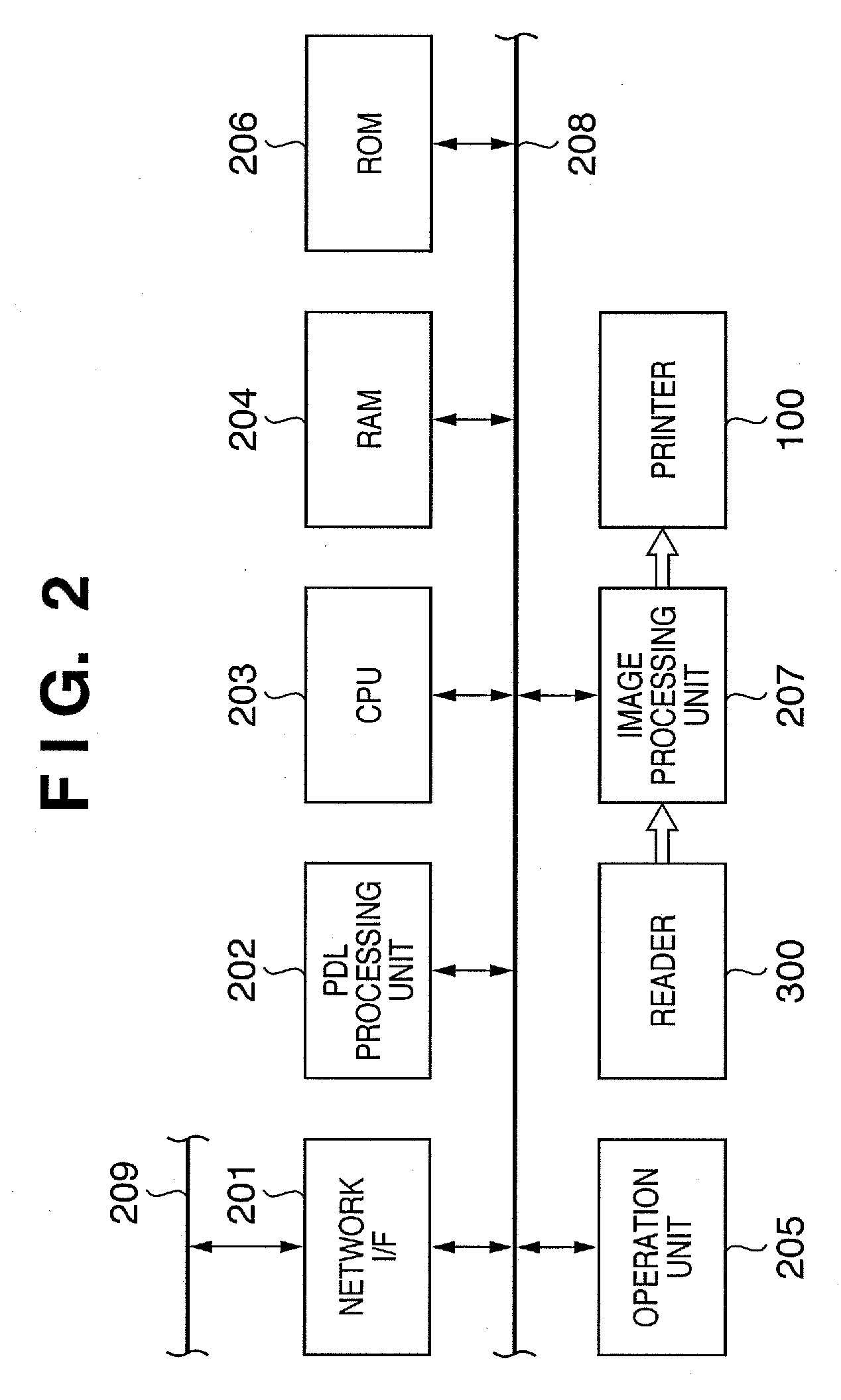

Image processing apparatus and method therefor

InactiveUS20070046961A1Reduce generationReduce interference fringesDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

A combination to minimize moiré can be determined theoretically or empirically in four-color printing, but it is very difficult to find a combination to minimize moiré in printing using five or more colors. To solve this problem, image data is color-separated into image data corresponding to plural colorant. Multilevel dither processing is performed to the image data corresponding to the plural colorant. At this time, dither matrices having the same screen angle, the same screen ruling, and different threshold setting methods are applied to the respective image data corresponding to dark colorant and light colorant having the same hue and different lightness values.

Owner:CANON KK

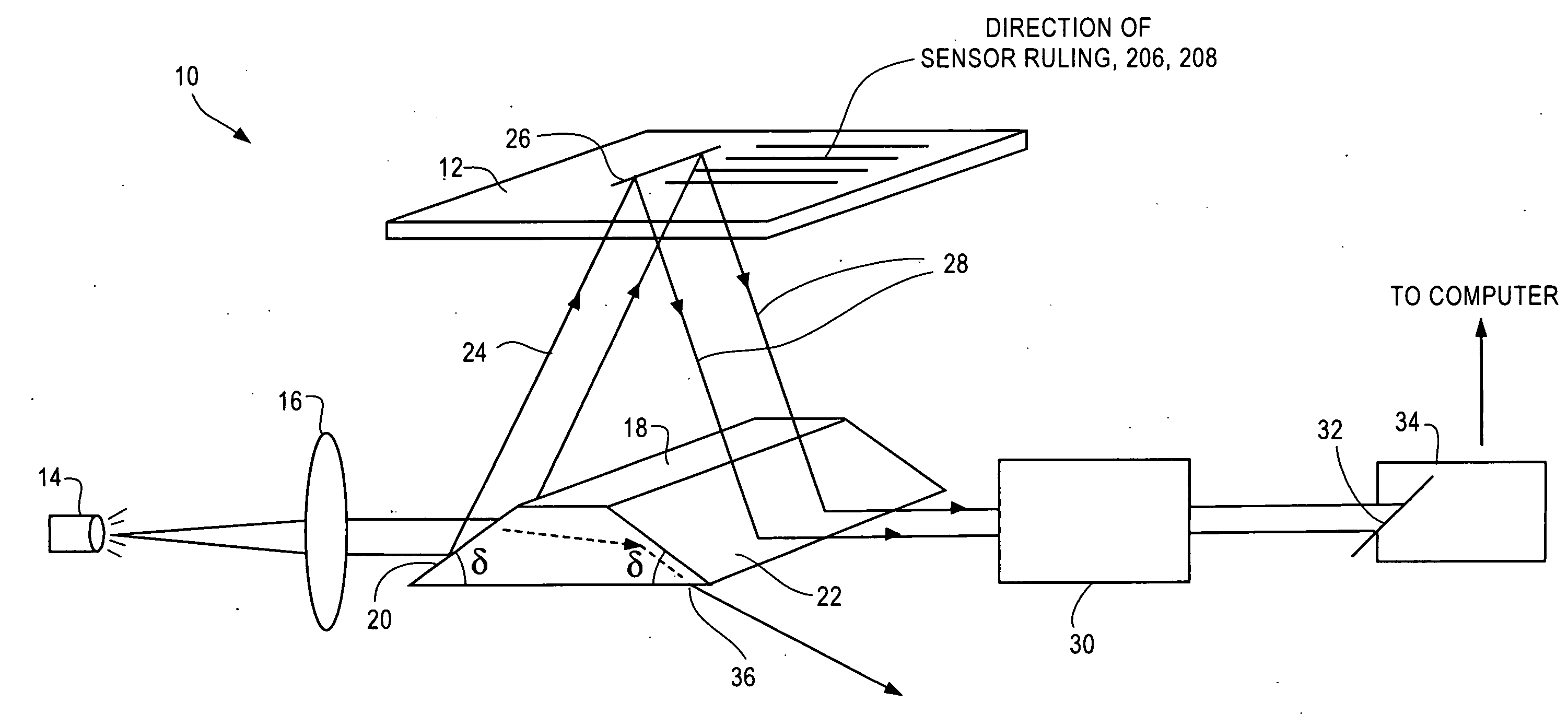

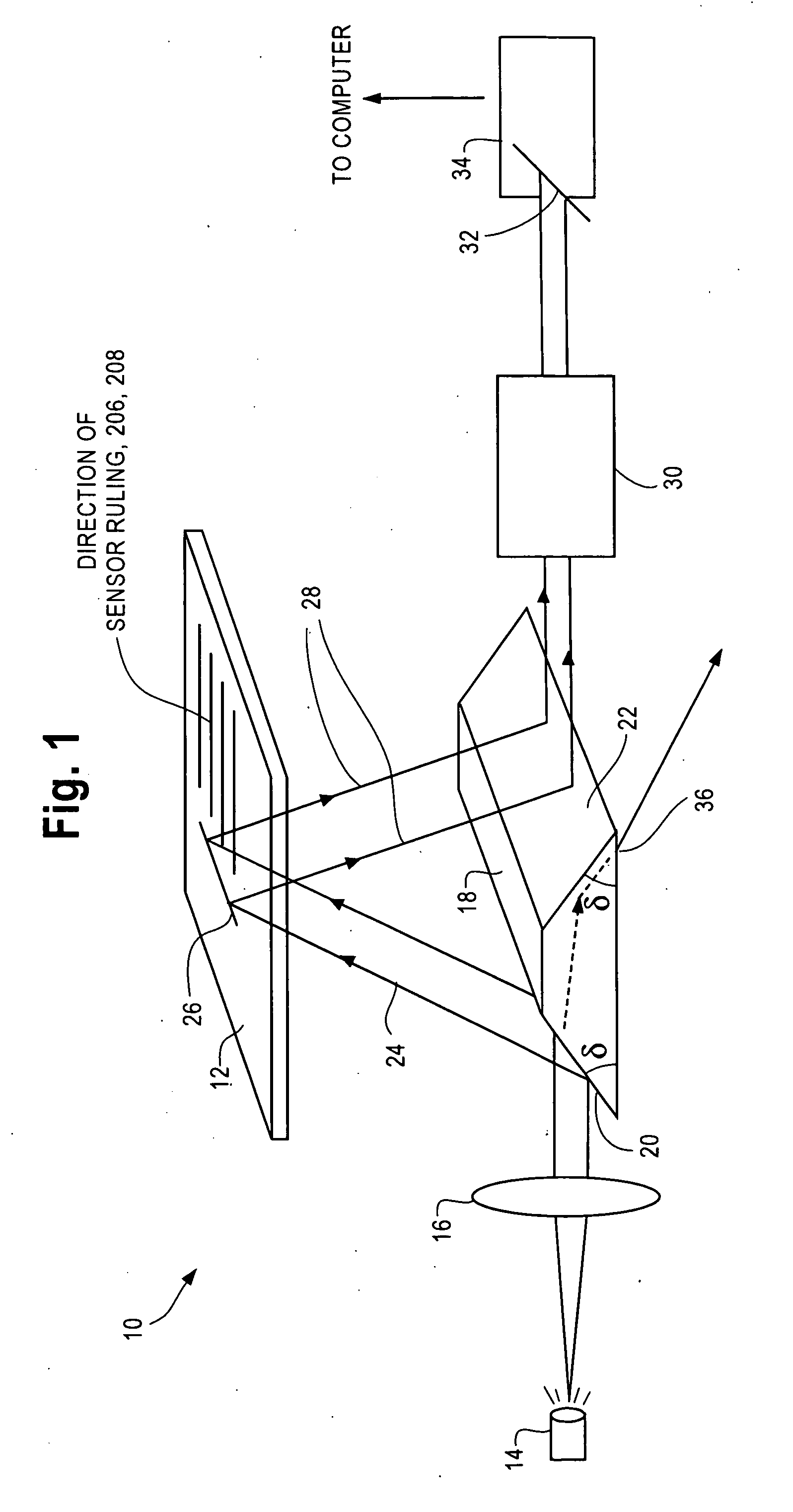

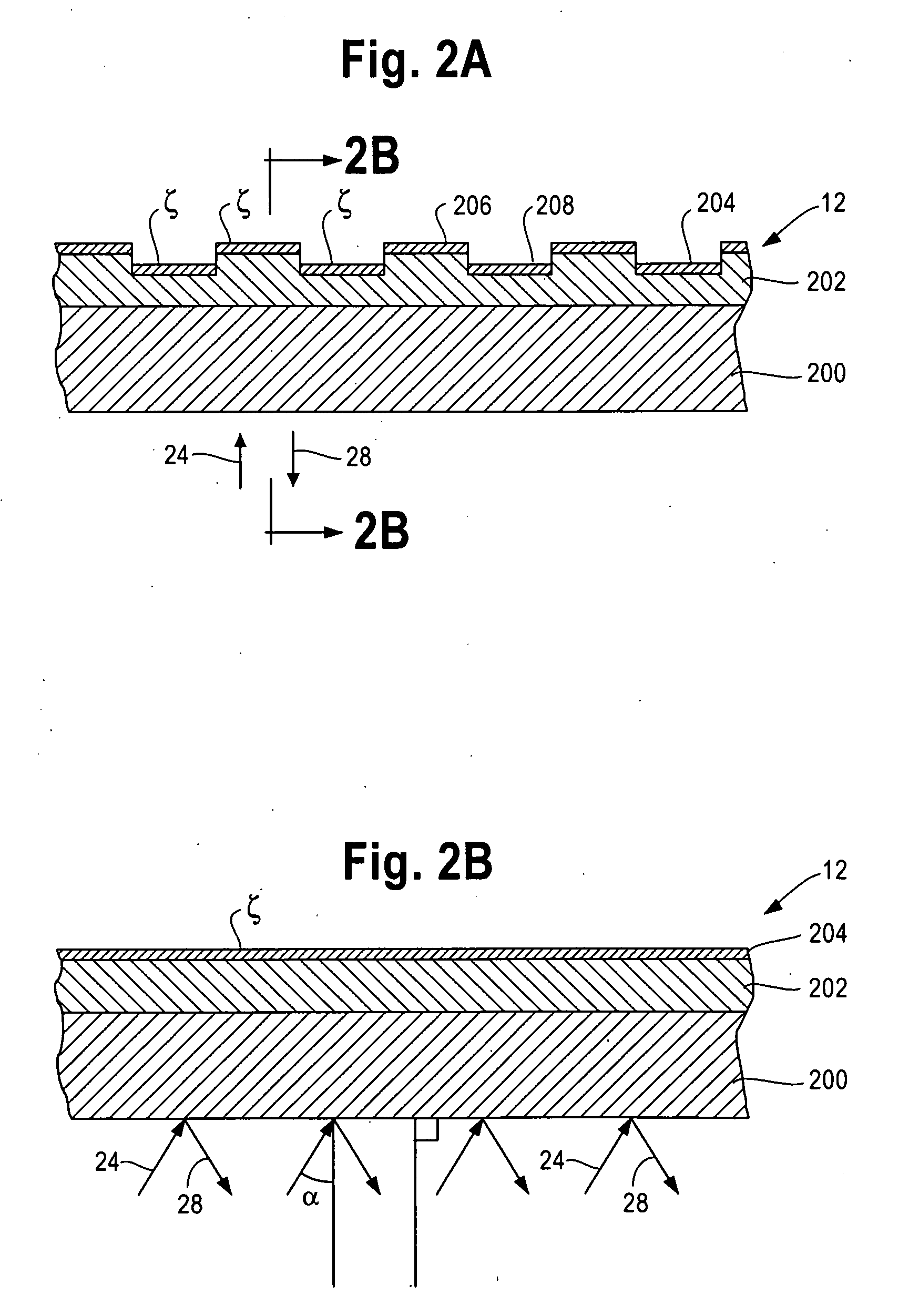

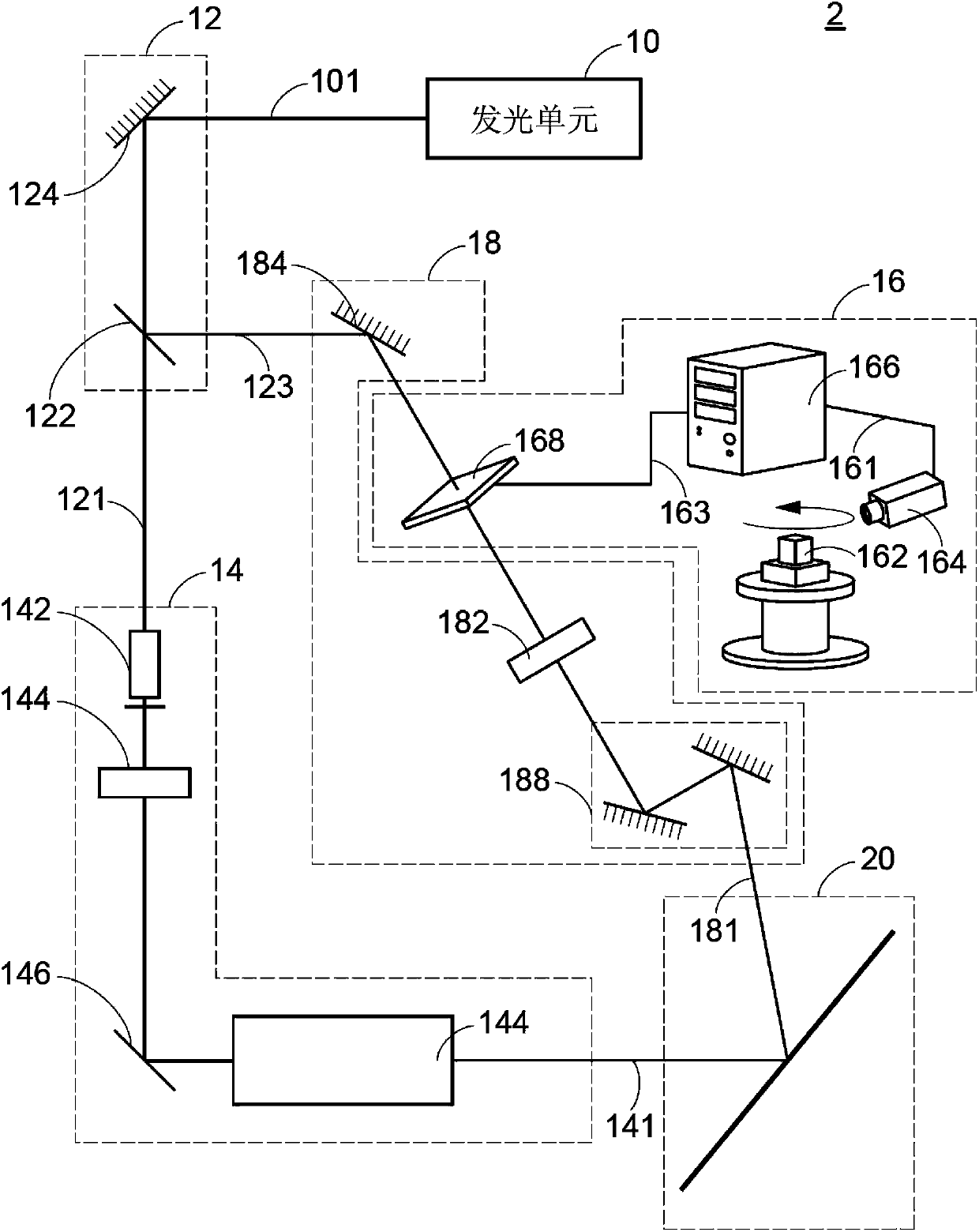

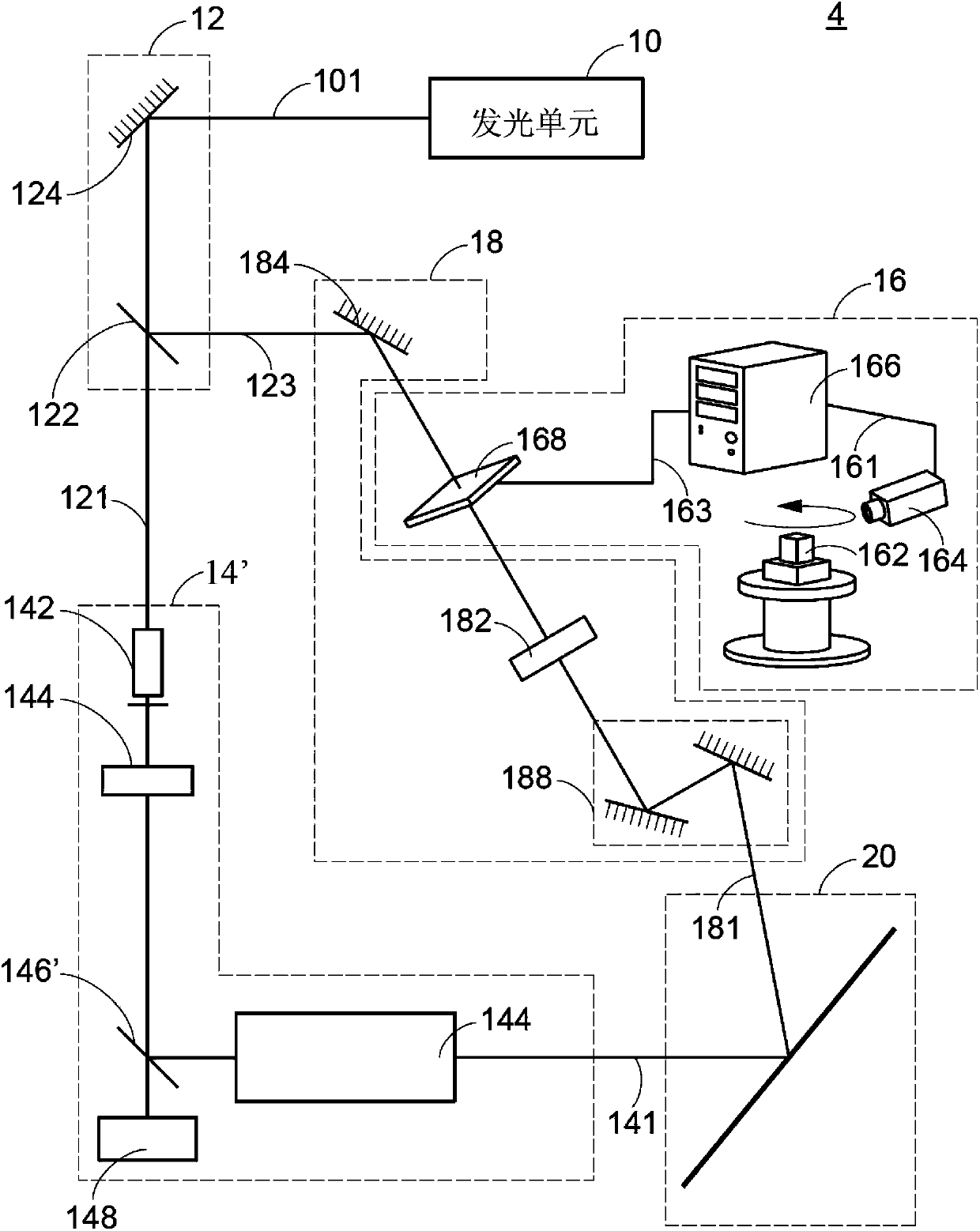

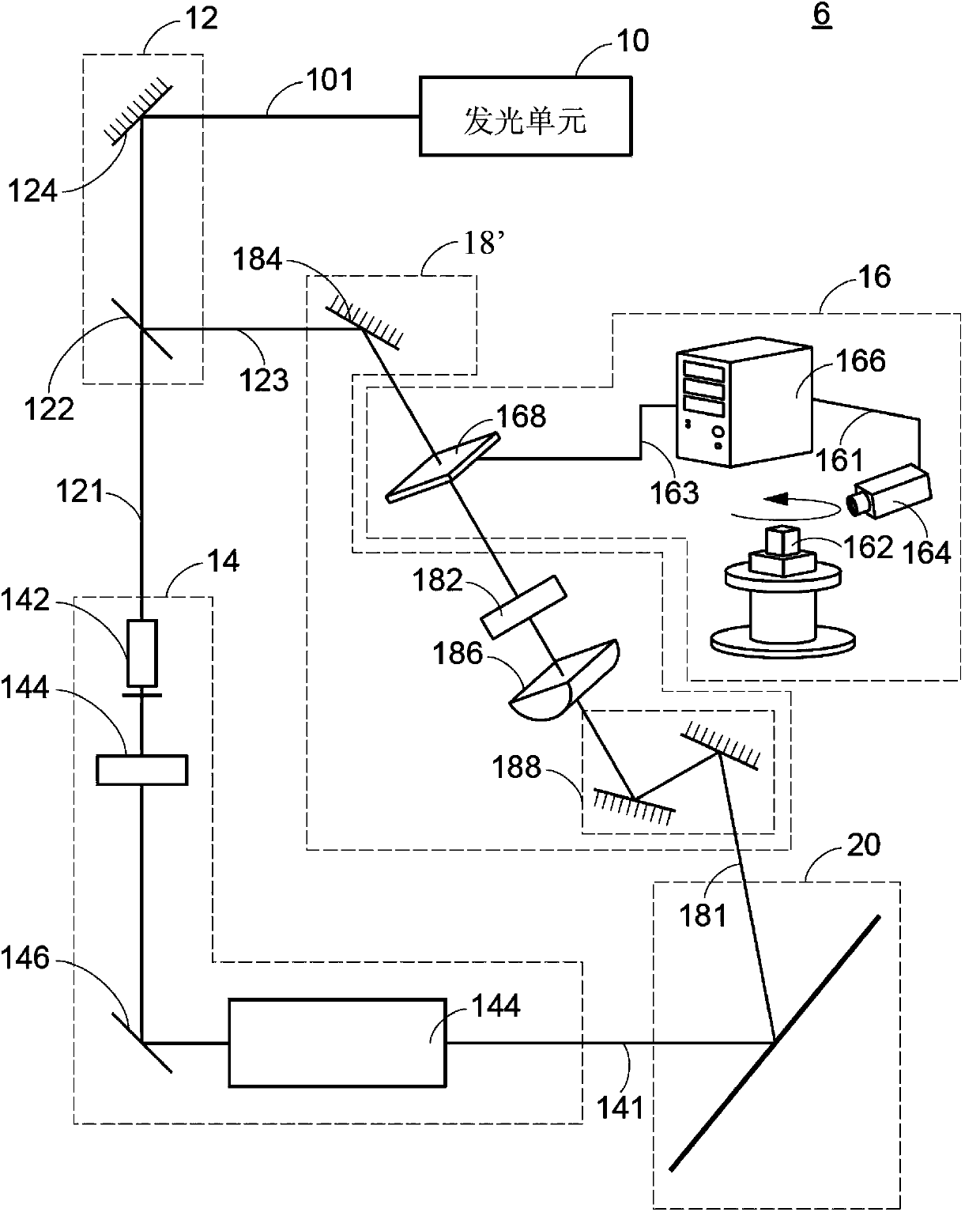

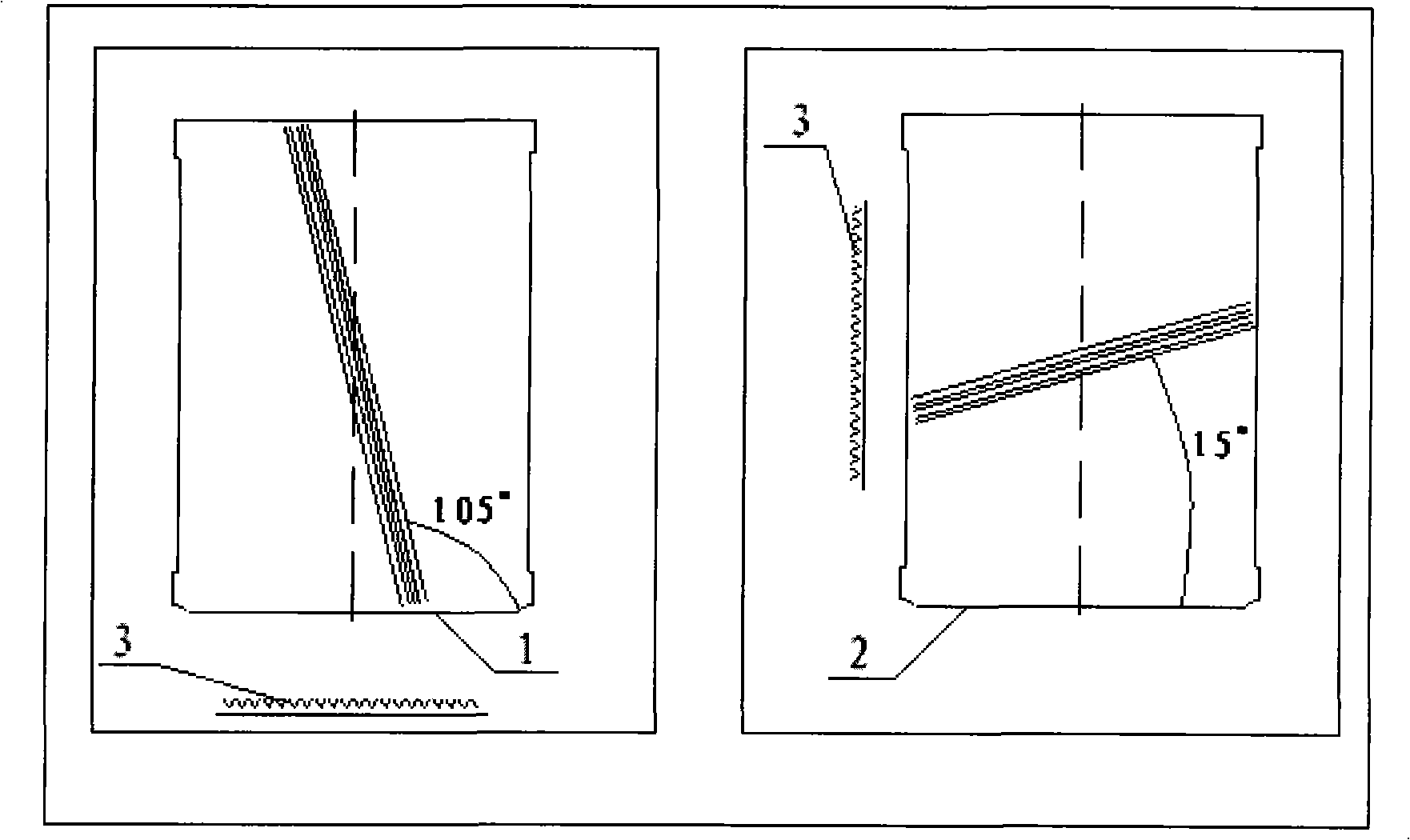

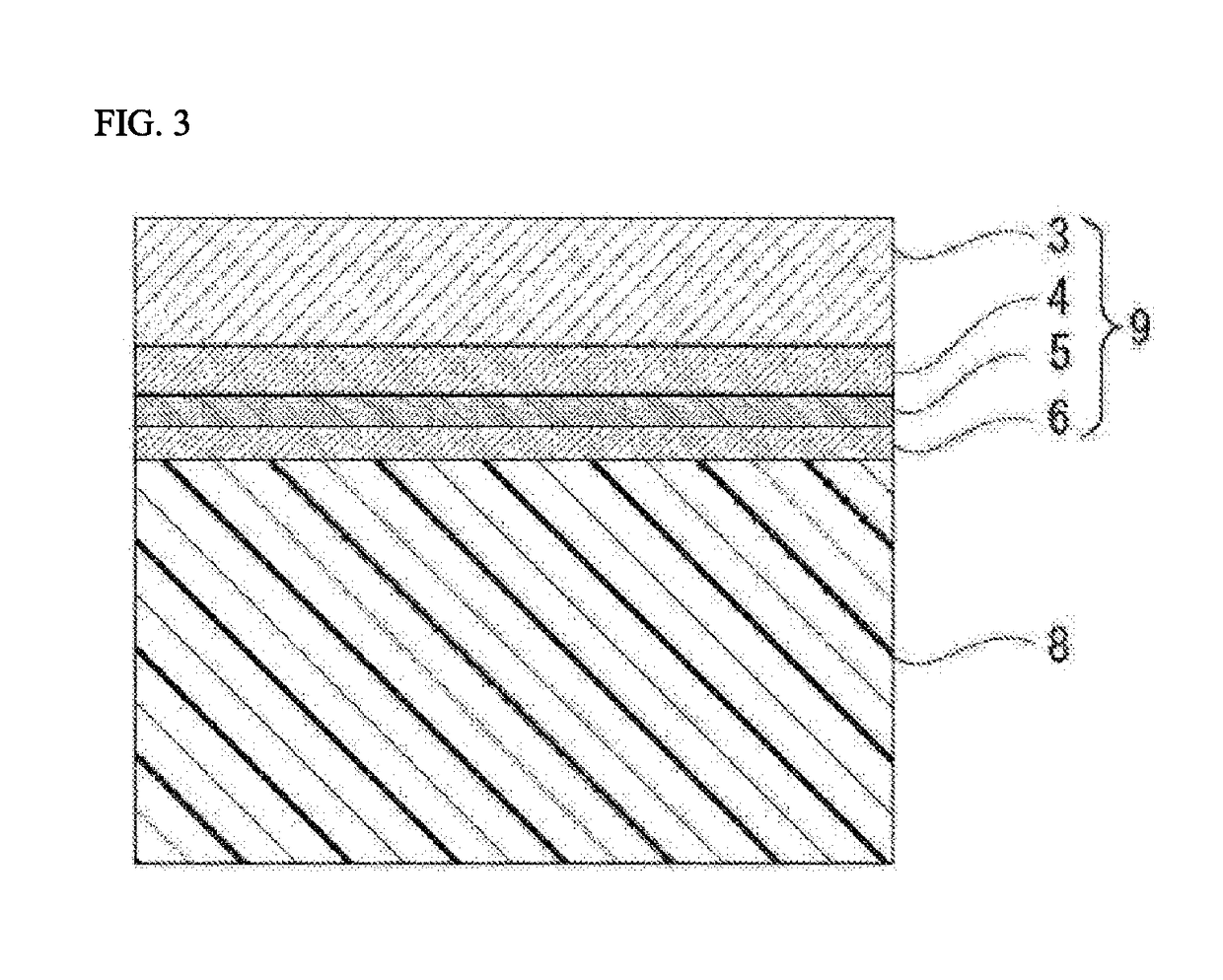

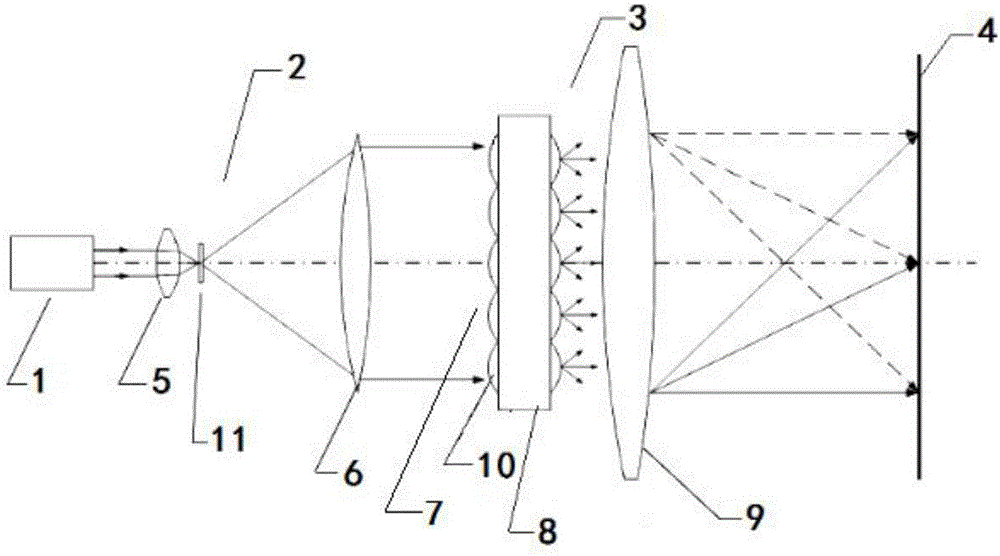

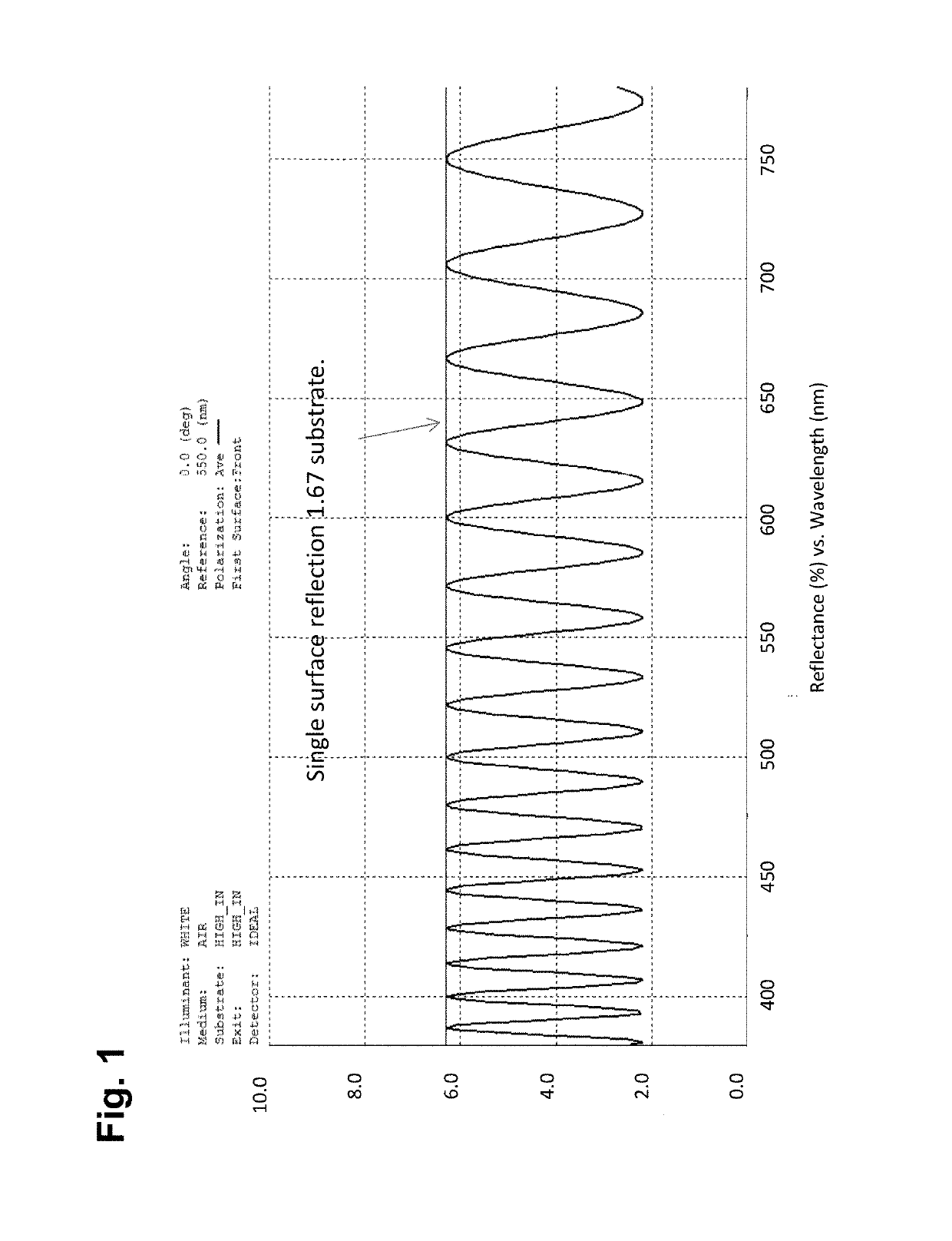

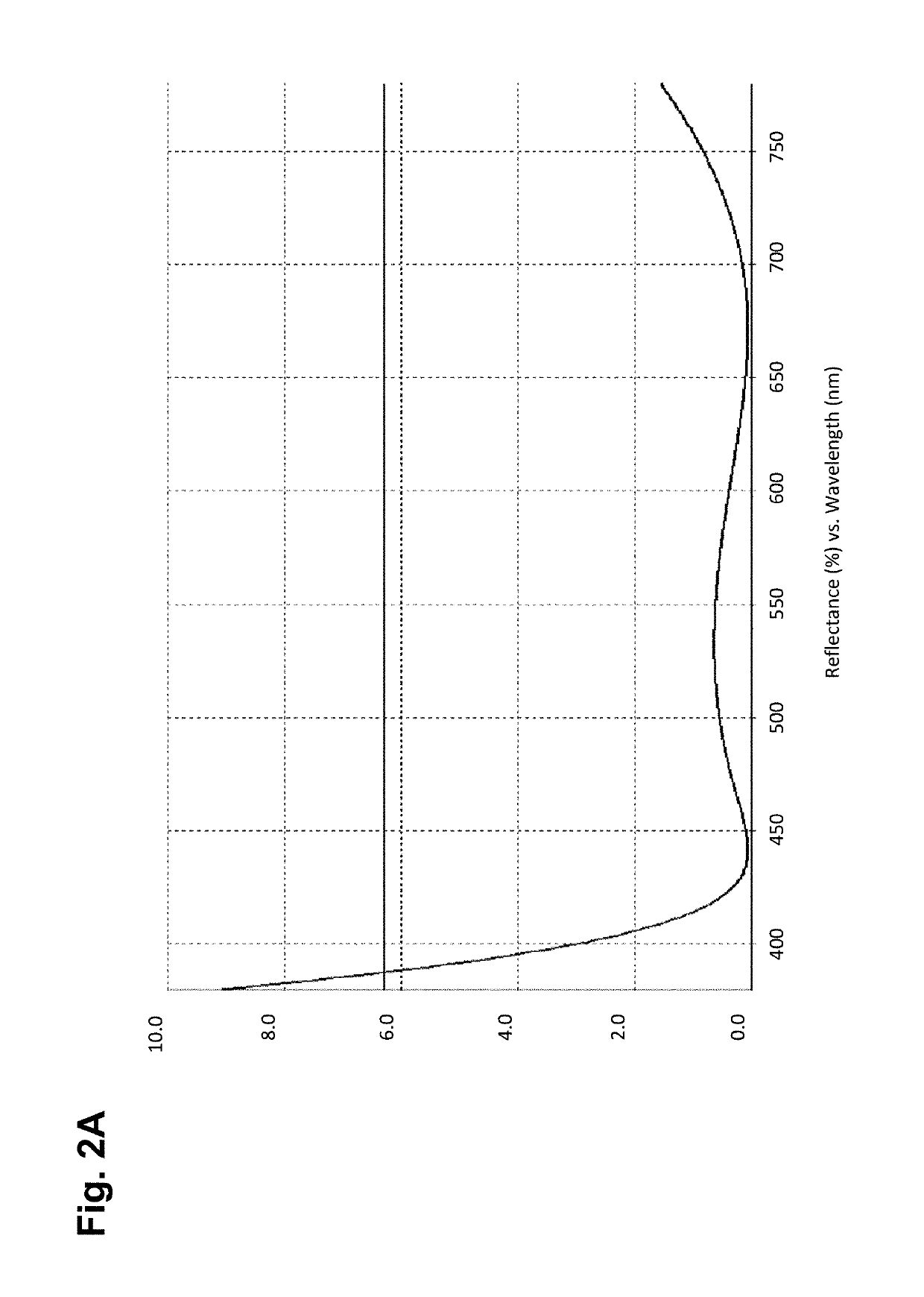

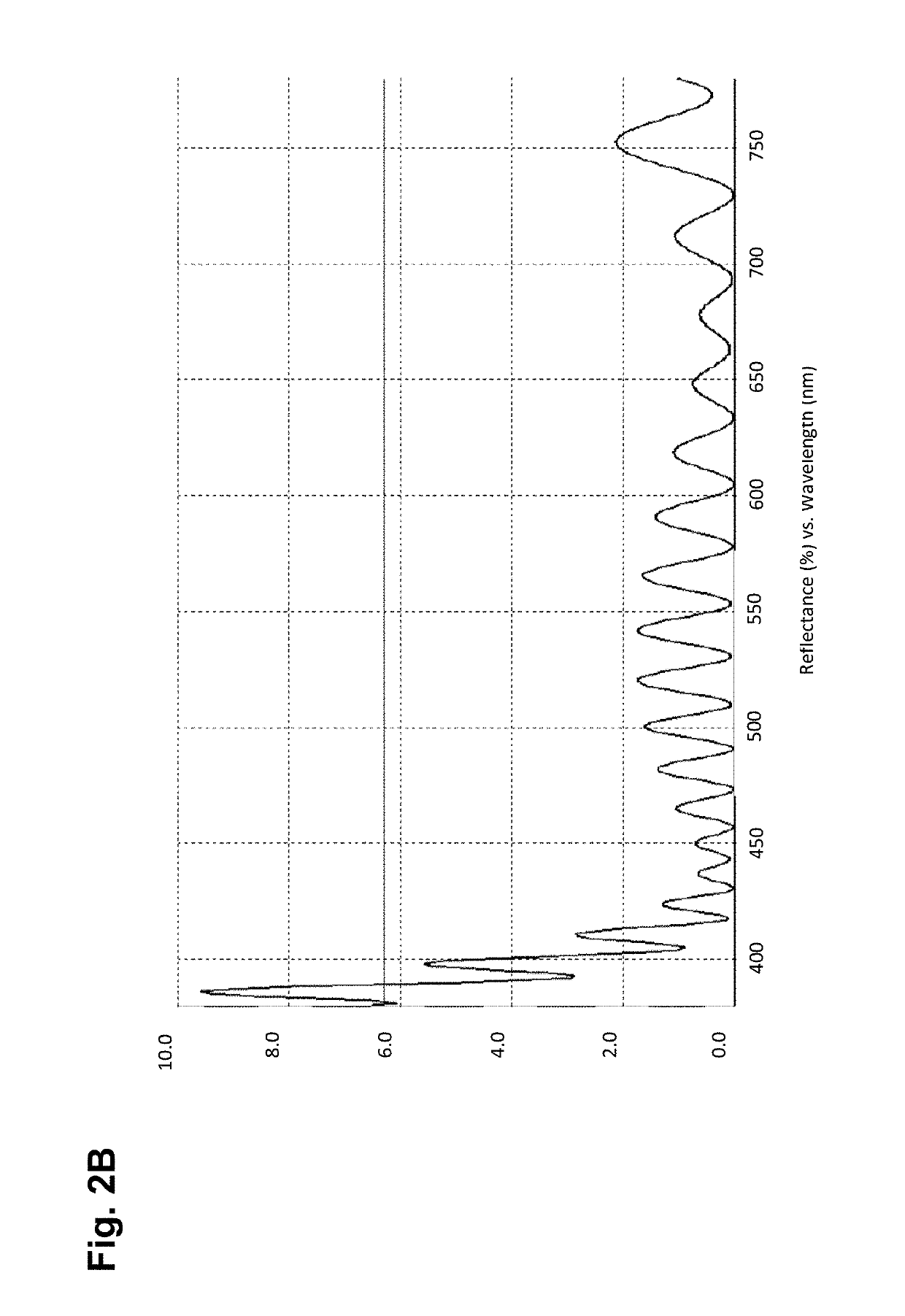

Efficient optical arrangement for illumination and detection of Label-Free biosensors and method to reduce interference fringes in label-free imaging

InactiveUS20100195099A1Accurate measurementReduce interference fringesRadiation pyrometrySpectrum investigationPrismAngle of incidence

An optical arrangement for illuminating a surface of a biosensor is described. The biosensor is preferably a sensor having periodic surface grating structure. The arrangement includes a light source generating light, collimating optics for collimating the light from the light source, and first reflecting surface receiving light from the collimating optics and directing incident light onto a surface of the biosensor and a second spatially separated reflecting surface receiving light reflected from the surface of the biosensor. The arrangement further includes telecentric optics (e.g., telecentric lens) receiving light from the second surface of the prism. The telecentric lens directs light onto an entrance slit of a spectrometer. The arrangement increases the light collection efficiency at the spectrometer as compared to prior art to prior art arrangements. The use of an incoherent light source and an arrangement in which incident light impinges upon the biosensor surface at a non-normal angle of incidence parallel to the direction of the grating lines on the sensor eliminates undesirable interference fringes in peak wavelength value measurements of the sensor.

Owner:X BODY

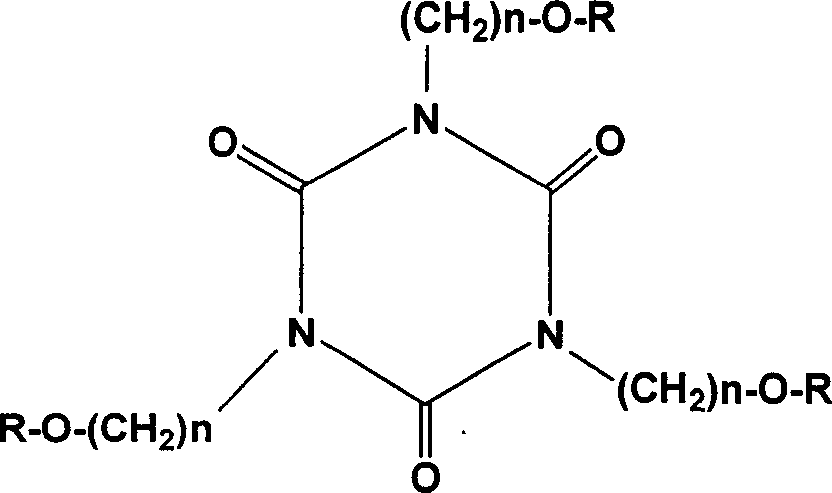

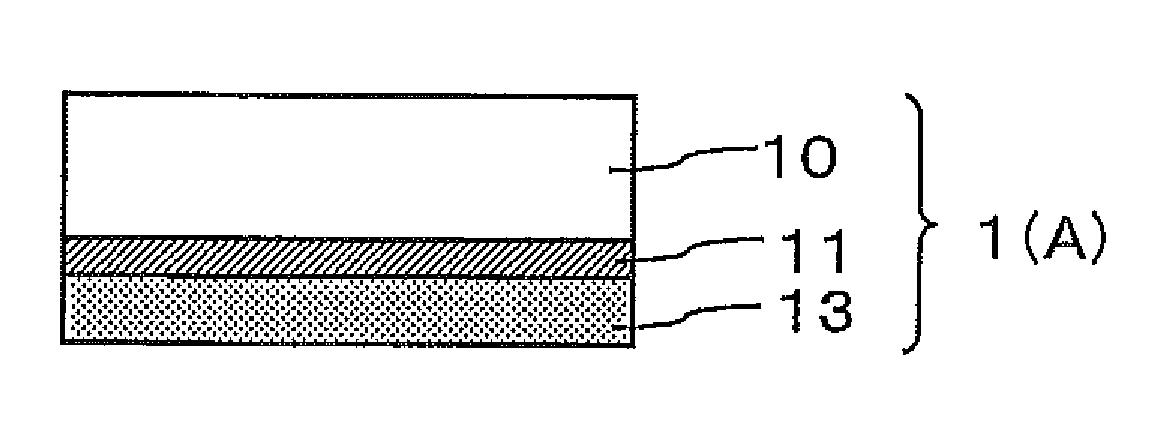

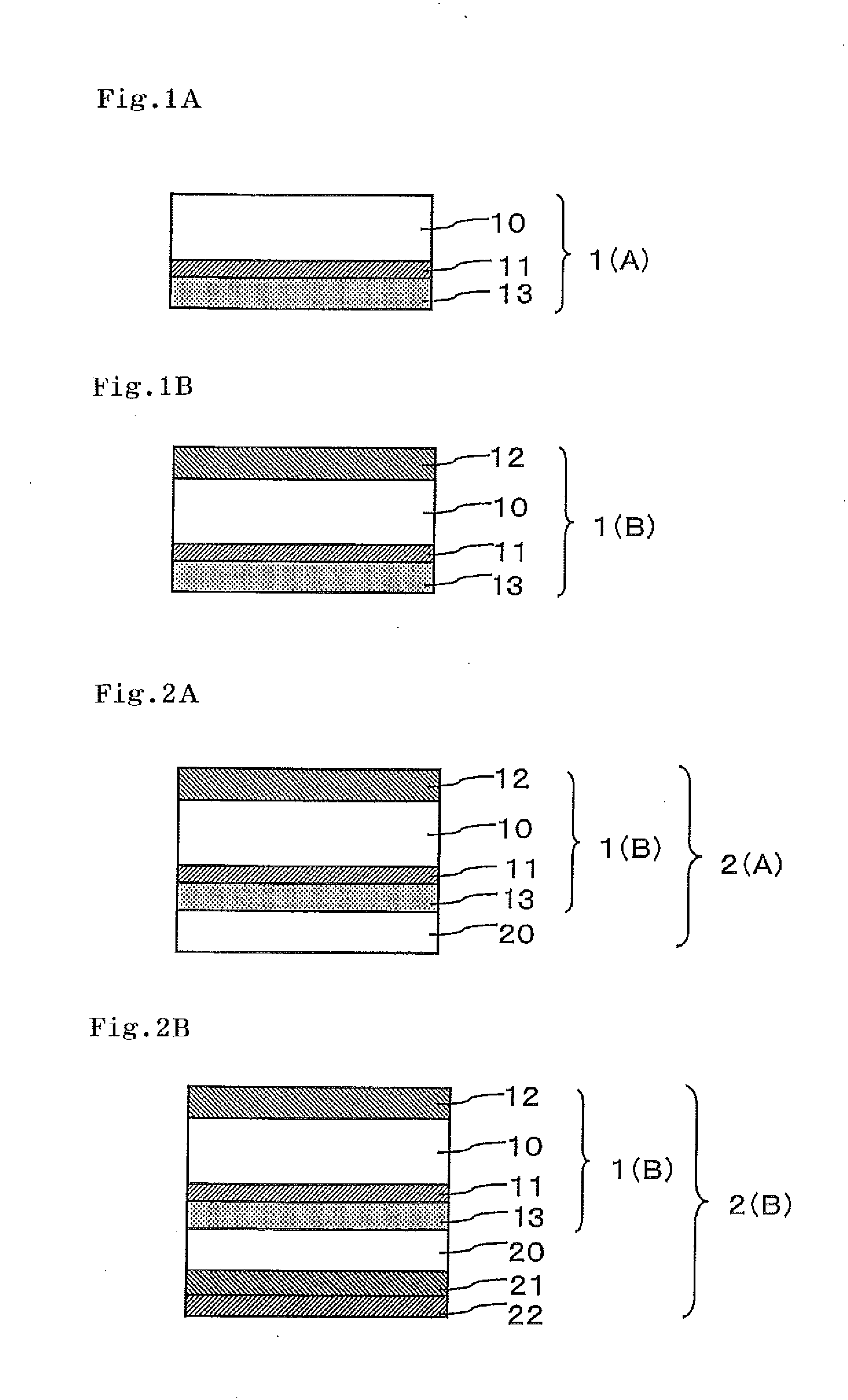

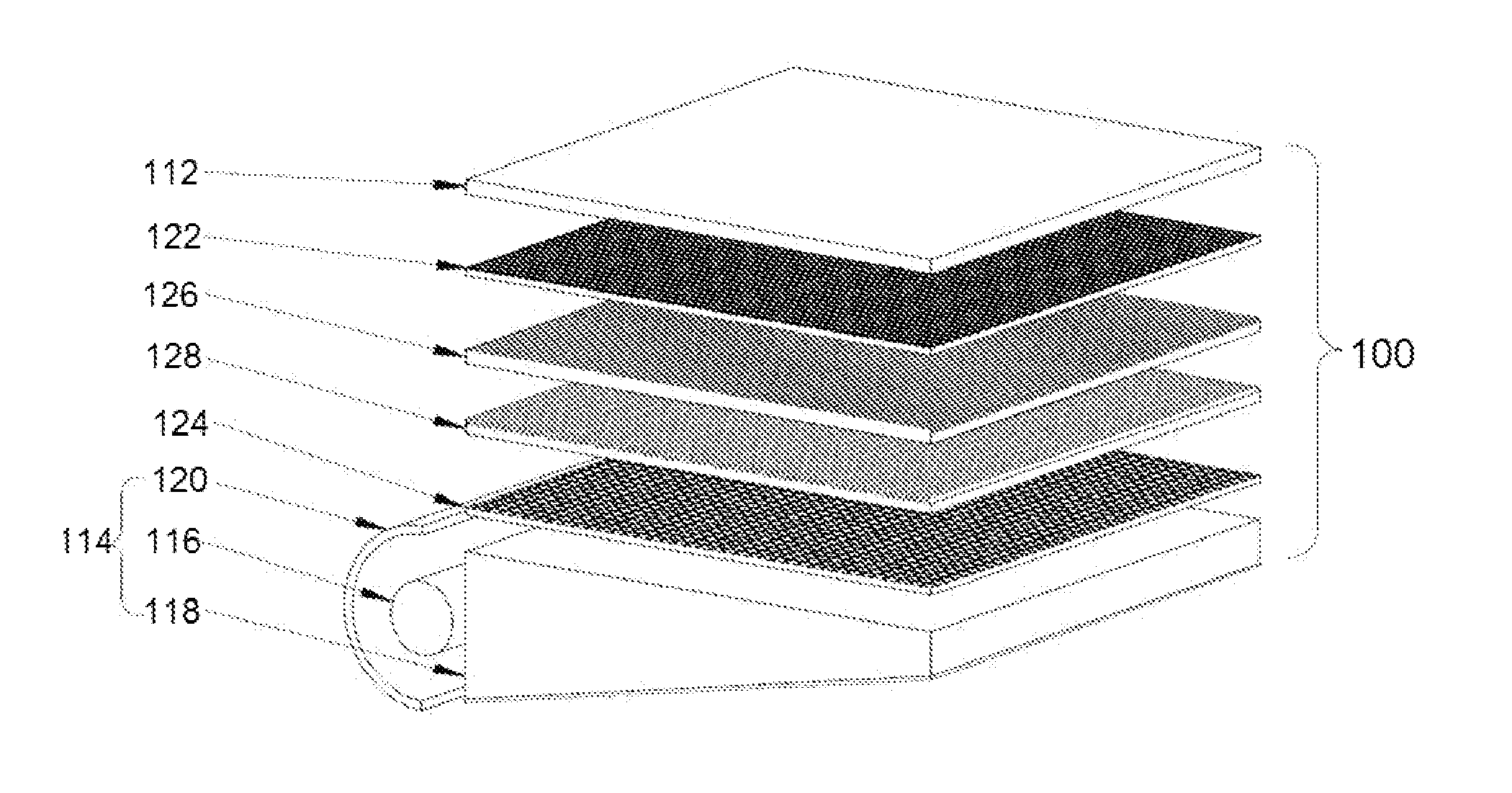

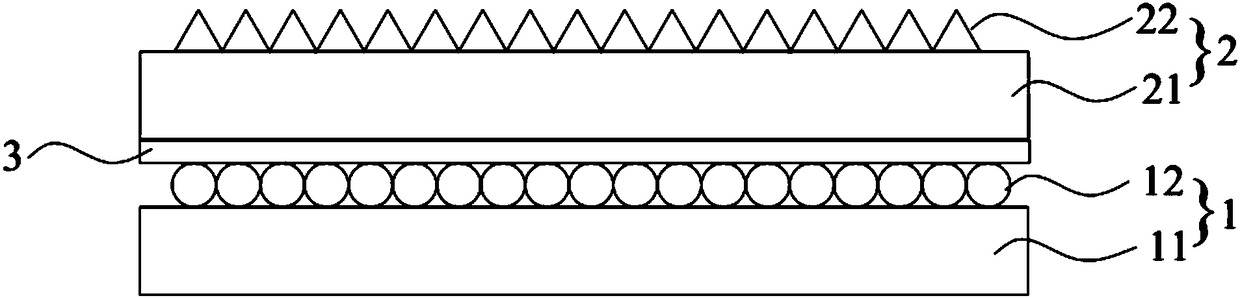

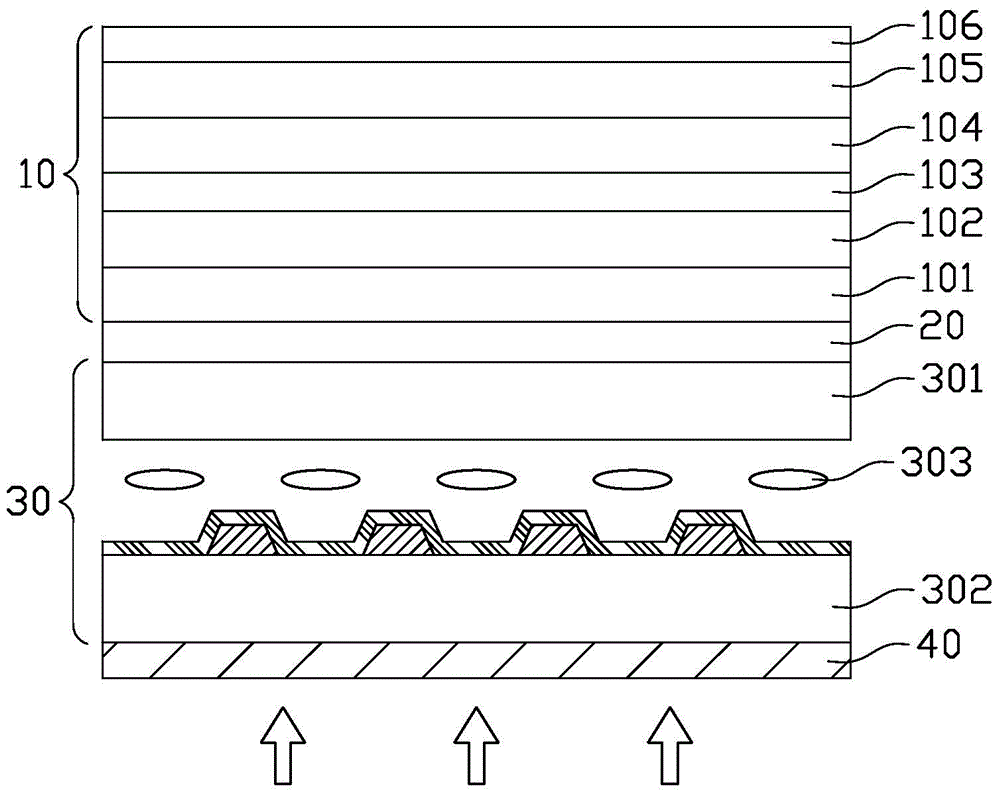

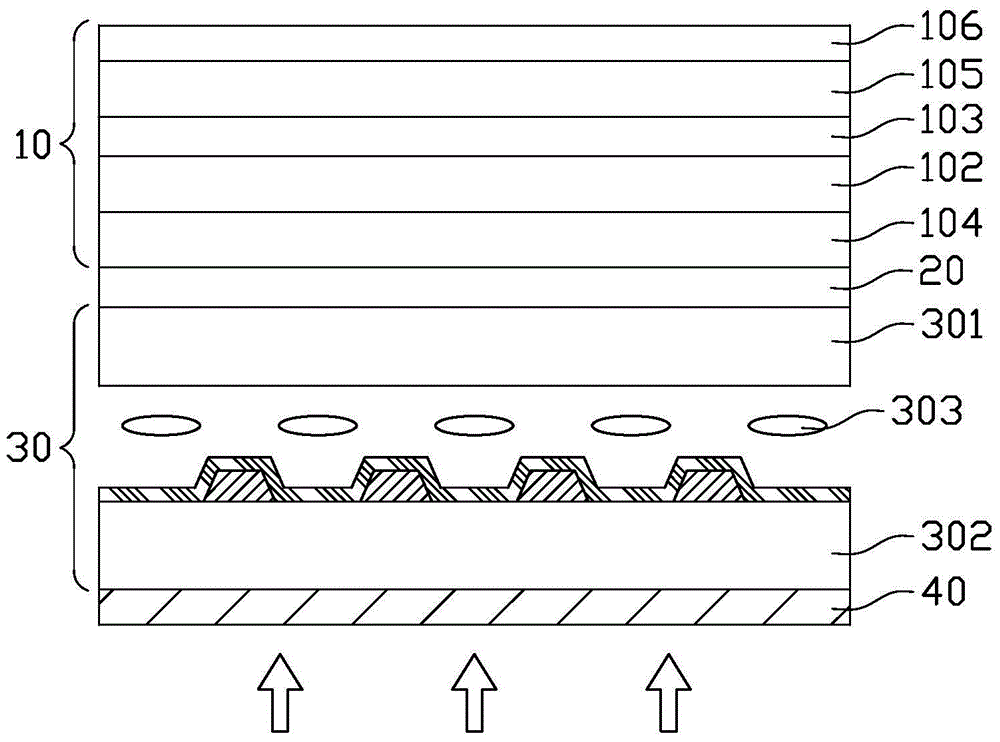

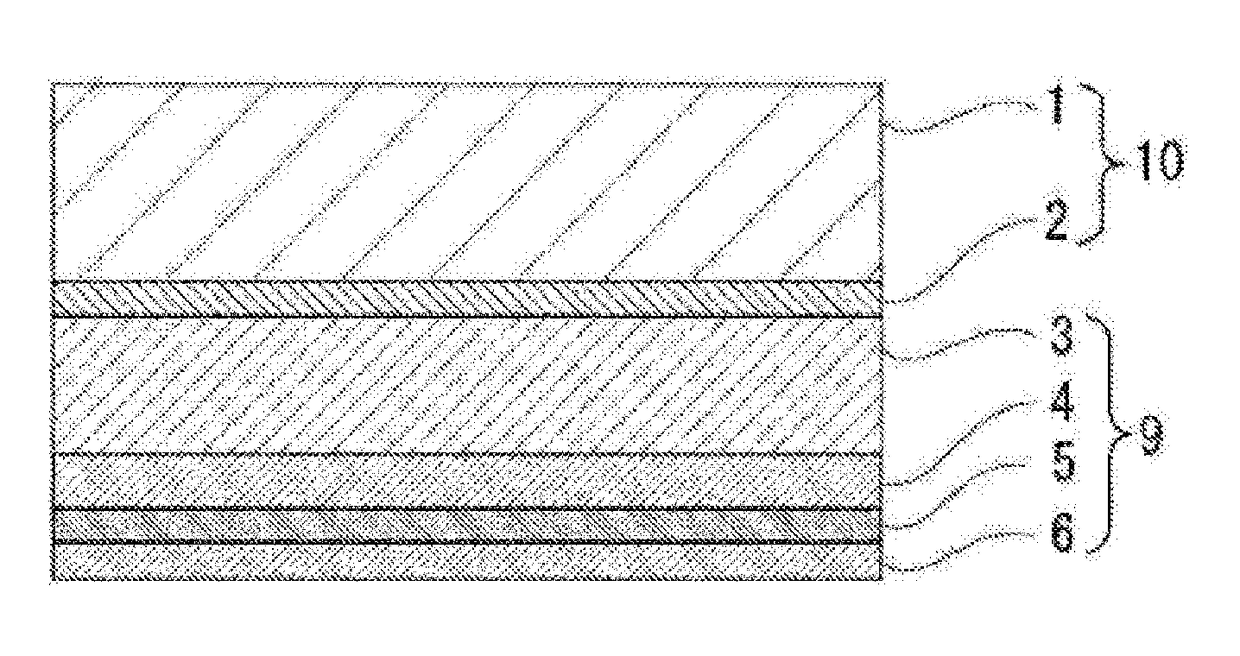

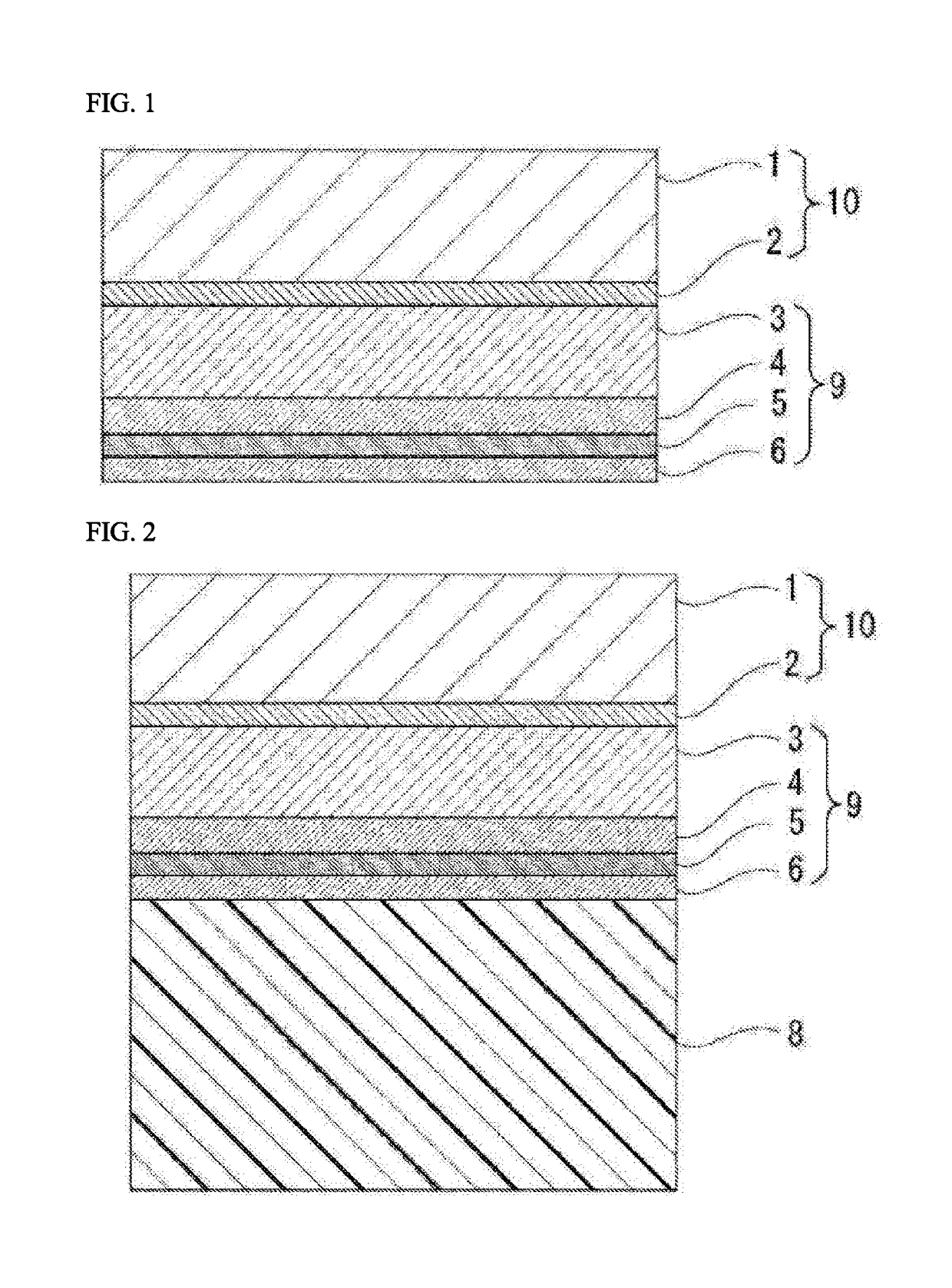

Resin film with pressure-sensitive adhesive layer, laminated film, and touch panel

InactiveUS20130194221A1Satisfied levelGood lookingFilm/foil adhesivesSynthetic resin layered productsOligomerRefractive index

A resin film with pressure-sensitive adhesive layer of the invention includes a first transparent resin film, an oligomer blocking layer, and a pressure-sensitive adhesive layer laminated in this order, wherein the oligomer blocking layer is a cured layer formed by curing a composition containing a curable compound and inorganic oxide particles, the oligomer blocking layer has a thickness of 120 nm or more, the oligomer blocking layer has a refractive index difference of 0.04 or less from the pressure-sensitive adhesive layer, and an anchoring strength between the oligomer blocking layer and the pressure-sensitive adhesive layer is 1 N / 25 mm or more.The resin film with pressure-sensitive adhesive layer can prevents the oligomer blocking layer from causing interference fringes, in which even when made thin, the oligomer blocking layer satisfies the requirements including oligomer blocking properties and scratch resistance, and also has good adhesion to the pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

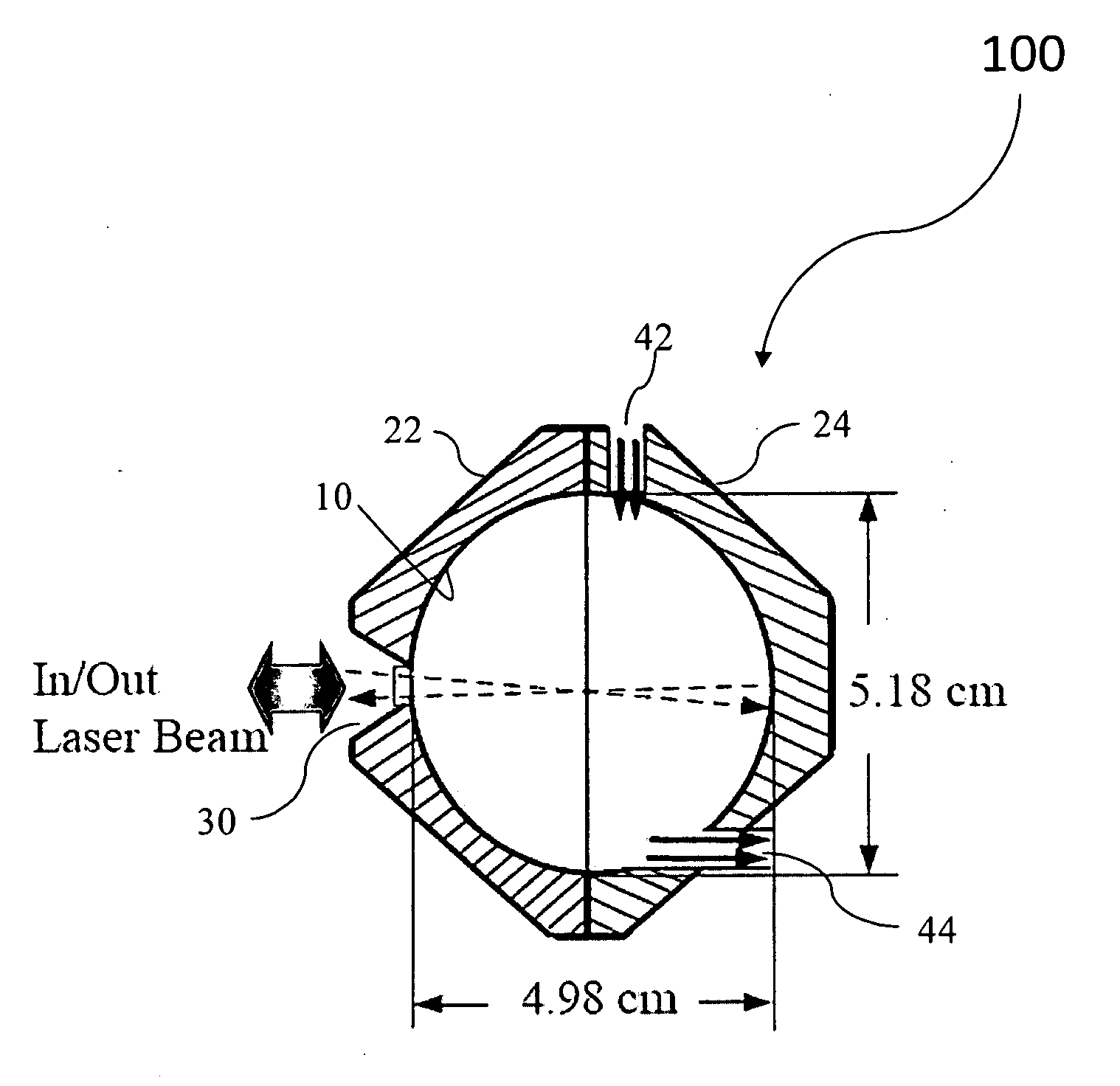

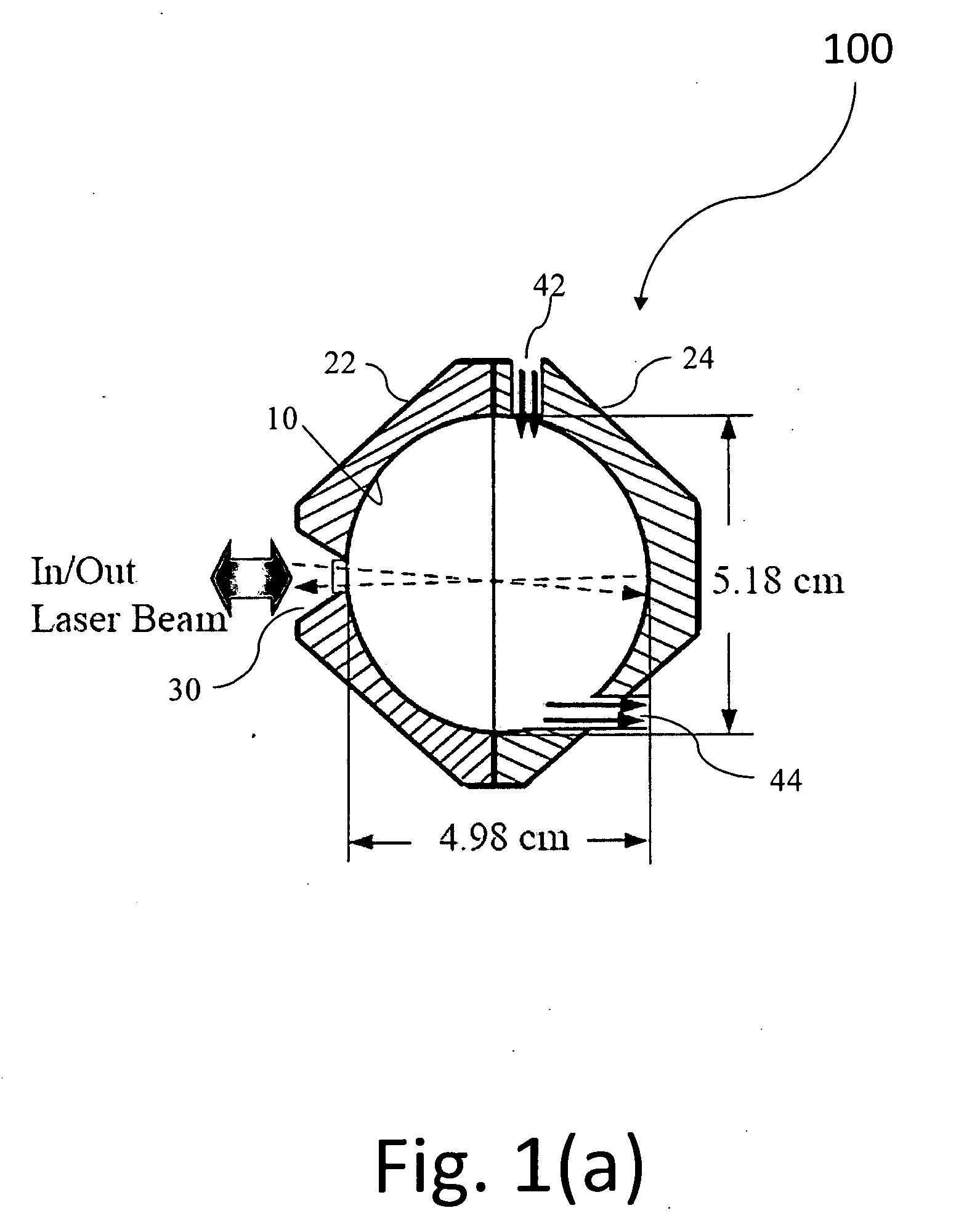

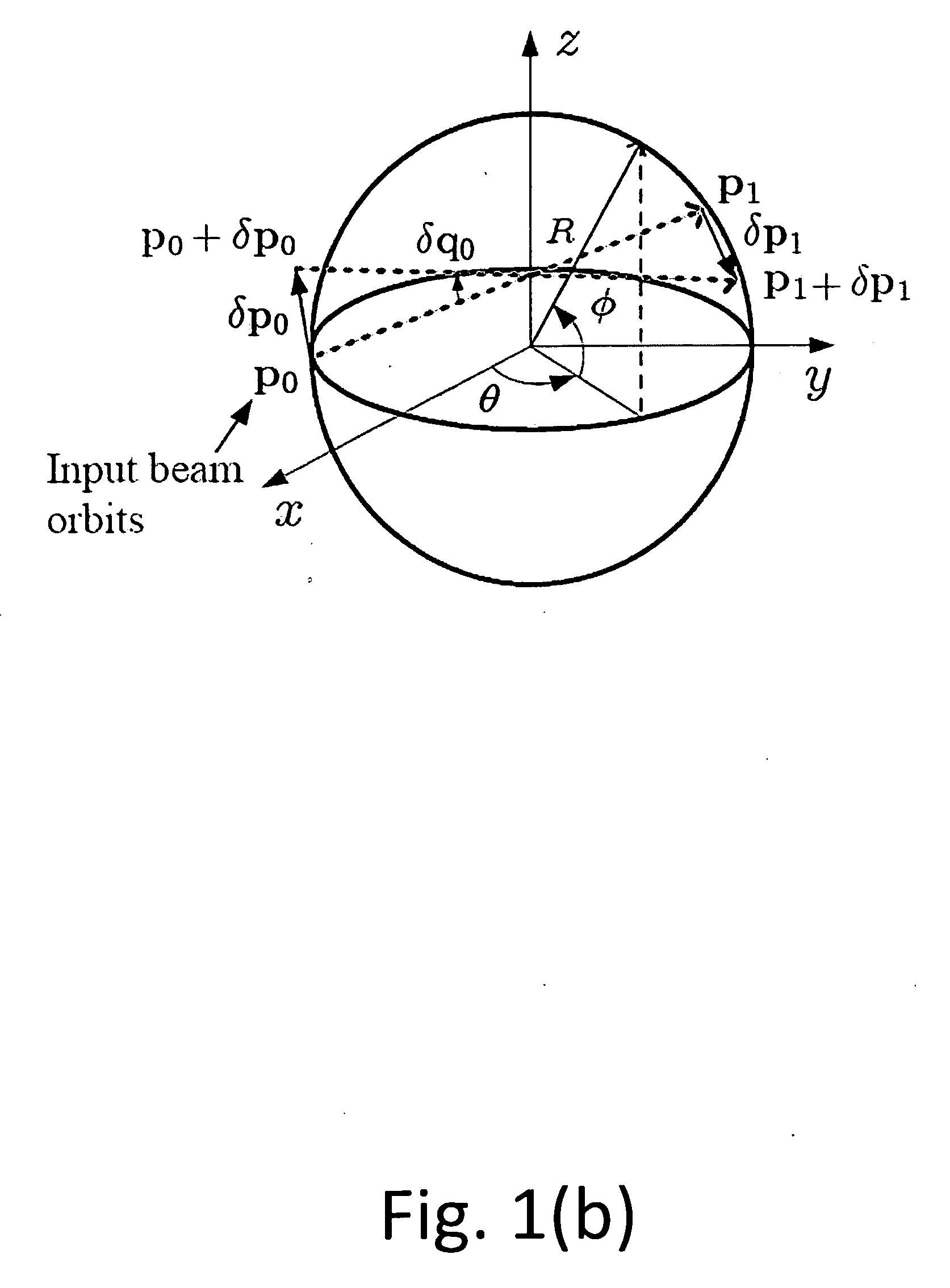

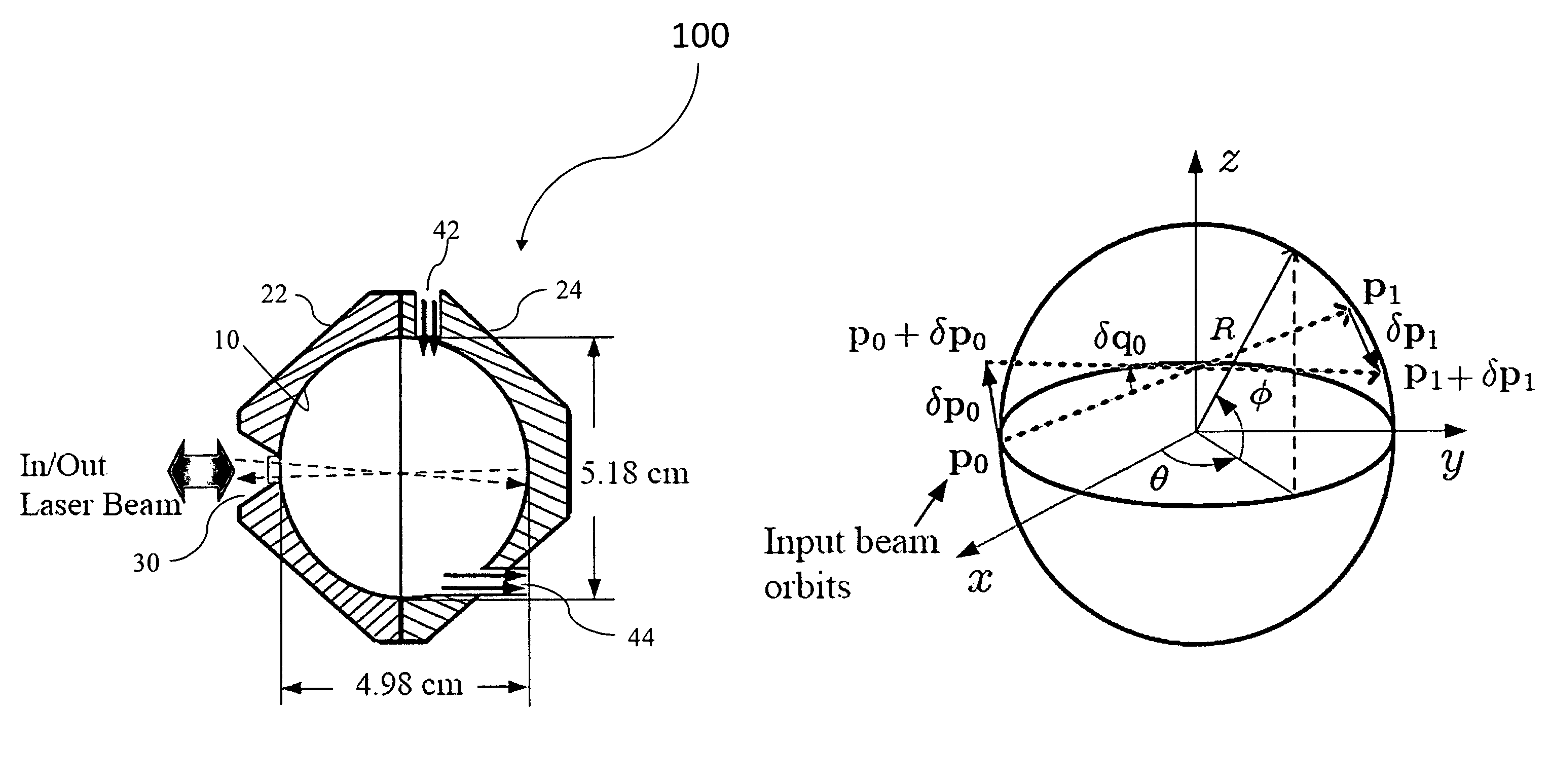

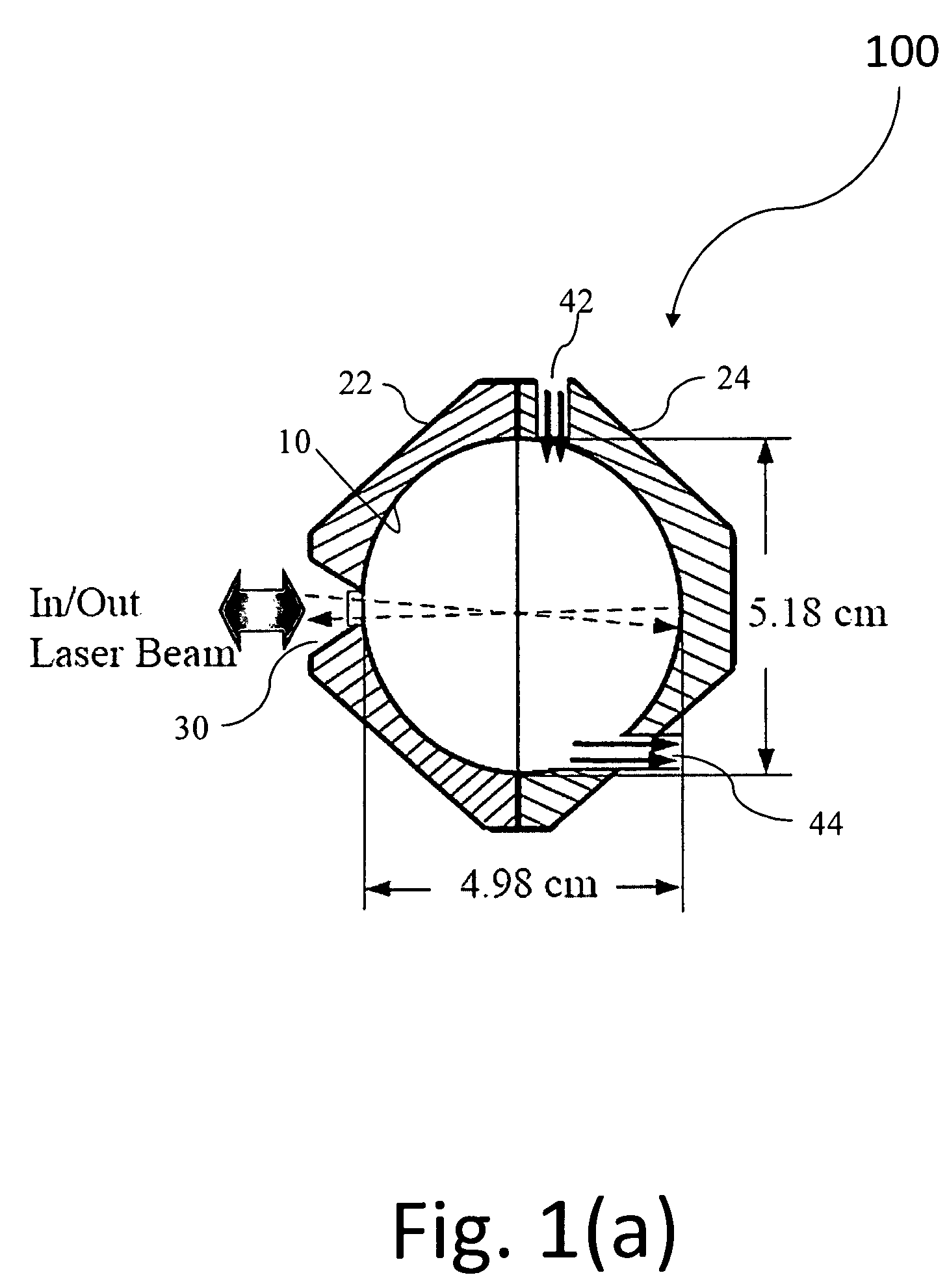

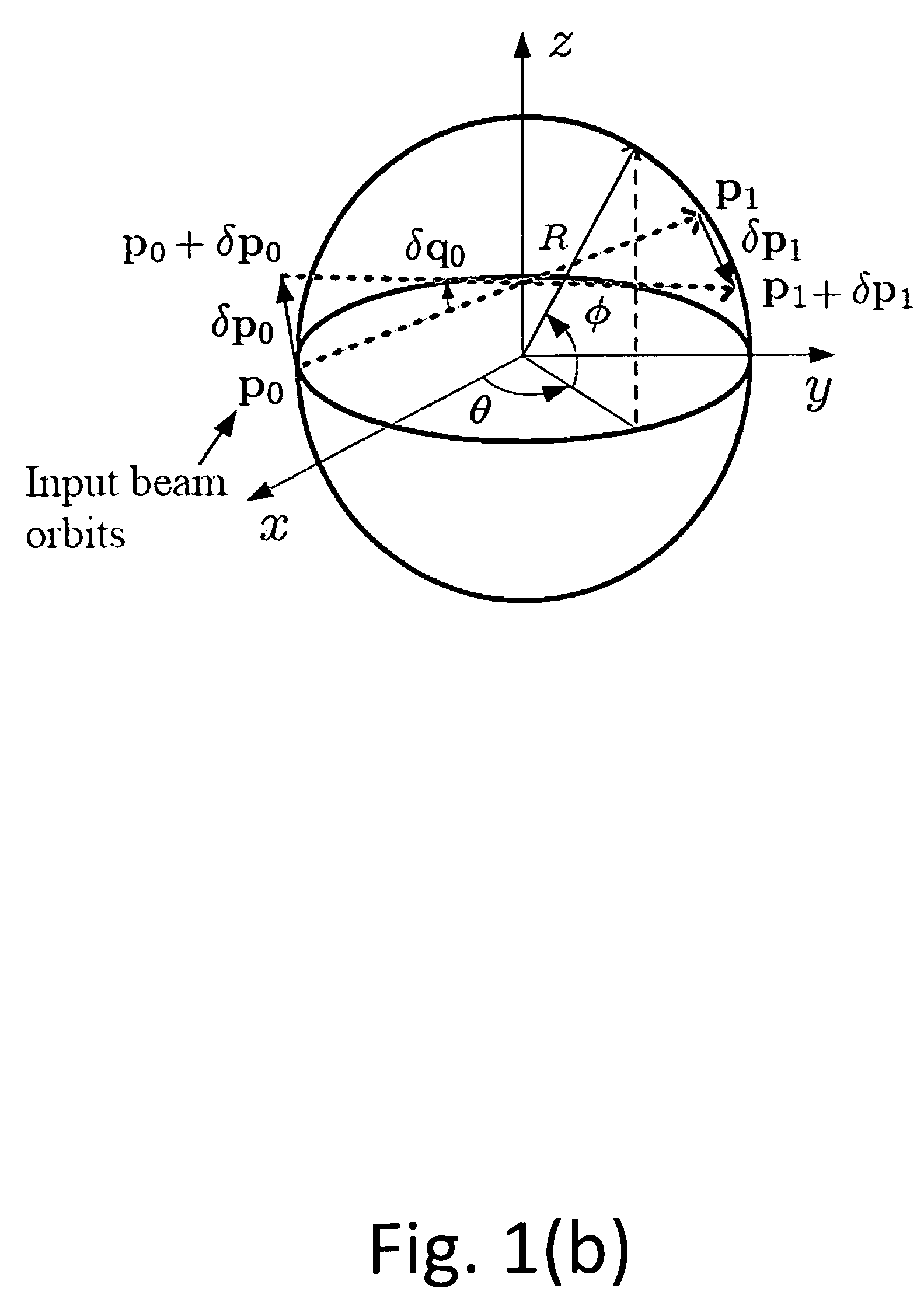

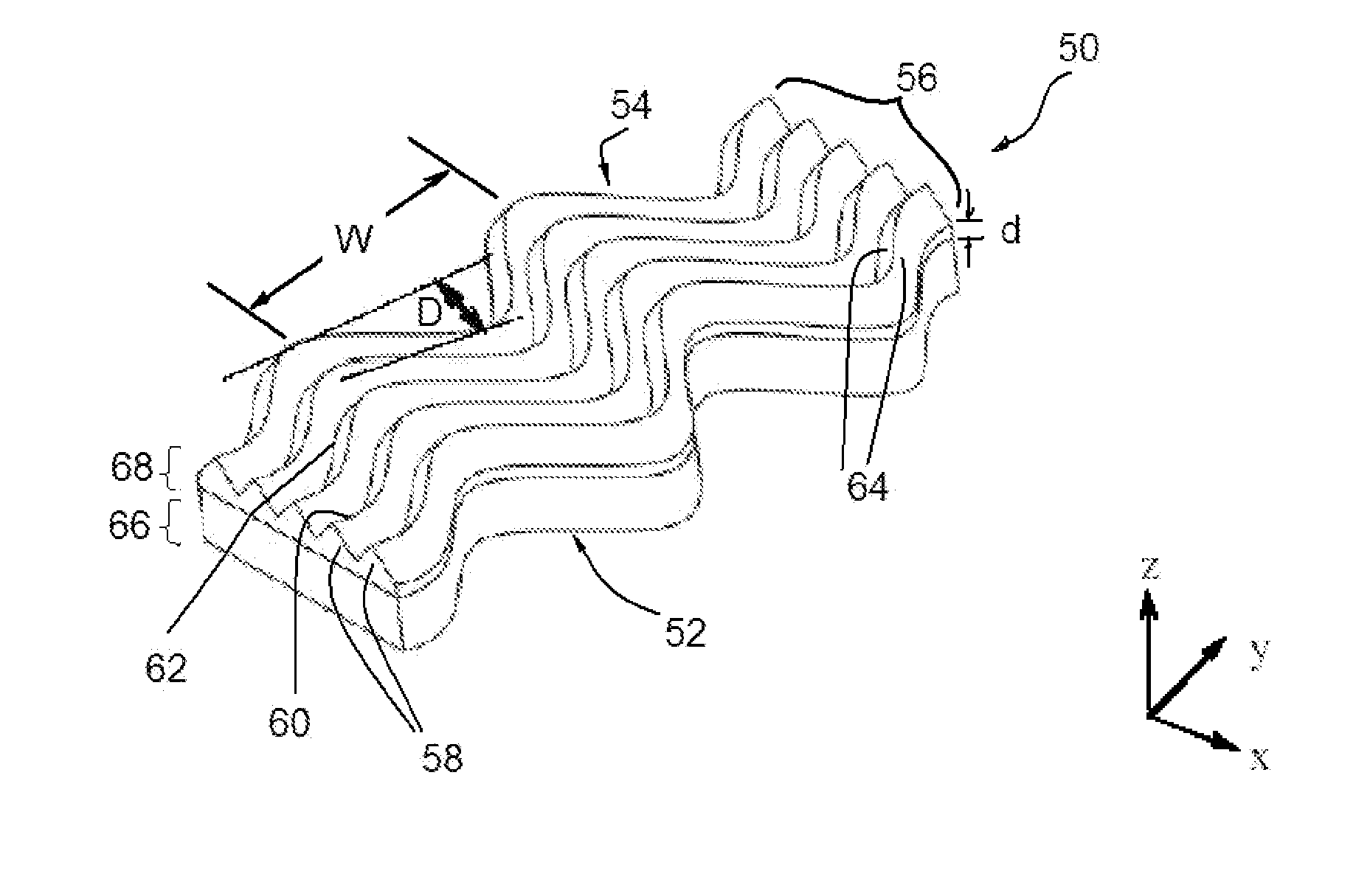

Rotationally Asymmetric Chaotic Optical Multi-Pass Cavity

ActiveUS20090059235A1Simple structureHigh mechanical/temperature stabilityAdditive manufacturing apparatusPhotometrySpectroscopyBeam direction

The present invention relates to a rotationally asymmetric chaotic optical multi-pass cavity useful in optical gas sensing spectroscopy, optical delay lines, and laser amplification systems, for example. The cavity may include a single closed mirror having a light reflective surface that is deformed in two orthogonal directions and more particularly, but not exclusively, in the shape of a quadrupole in both horizontal and vertical planes. The cavity includes a light entry port and a light exit port which may be the same or separate ports, as well as a gas inlet and a gas outlet. The optical path length, the beam divergence rate, and the spot pattern are controlled by selecting the cavity deformation coefficients and the input beam direction to achieve the desired beam path and beam quality.

Owner:THE TRUSTEES FOR PRINCETON UNIV

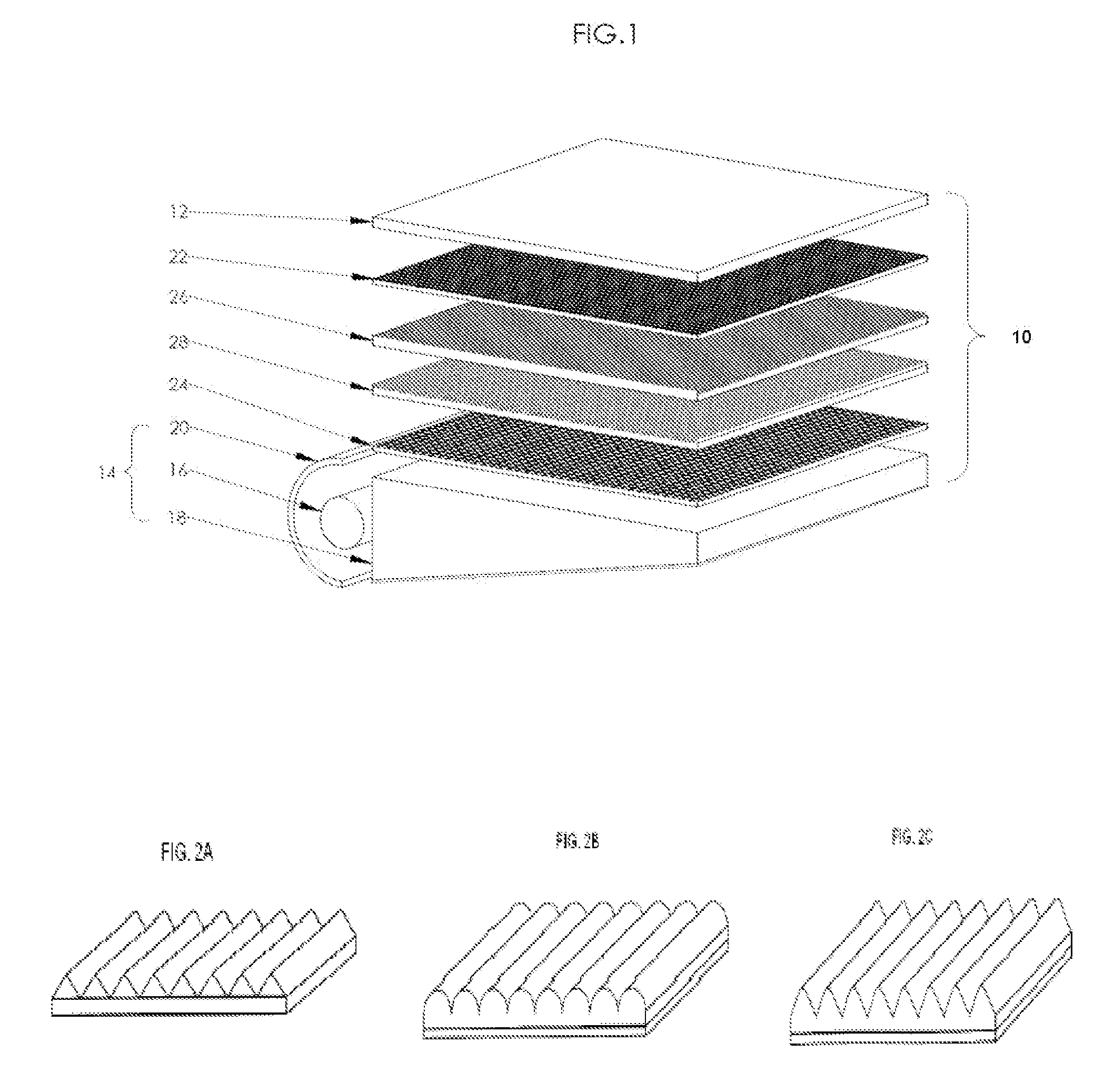

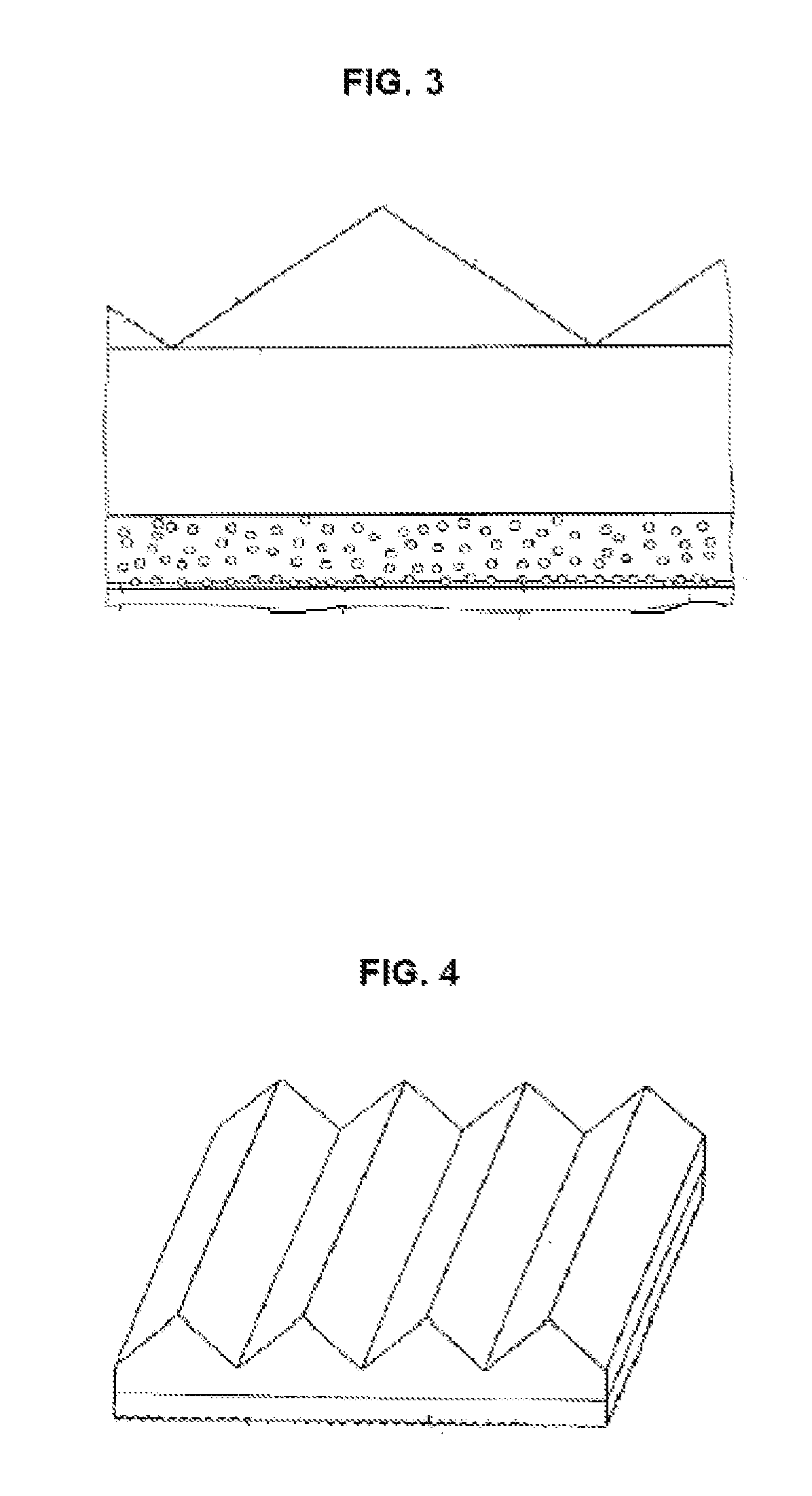

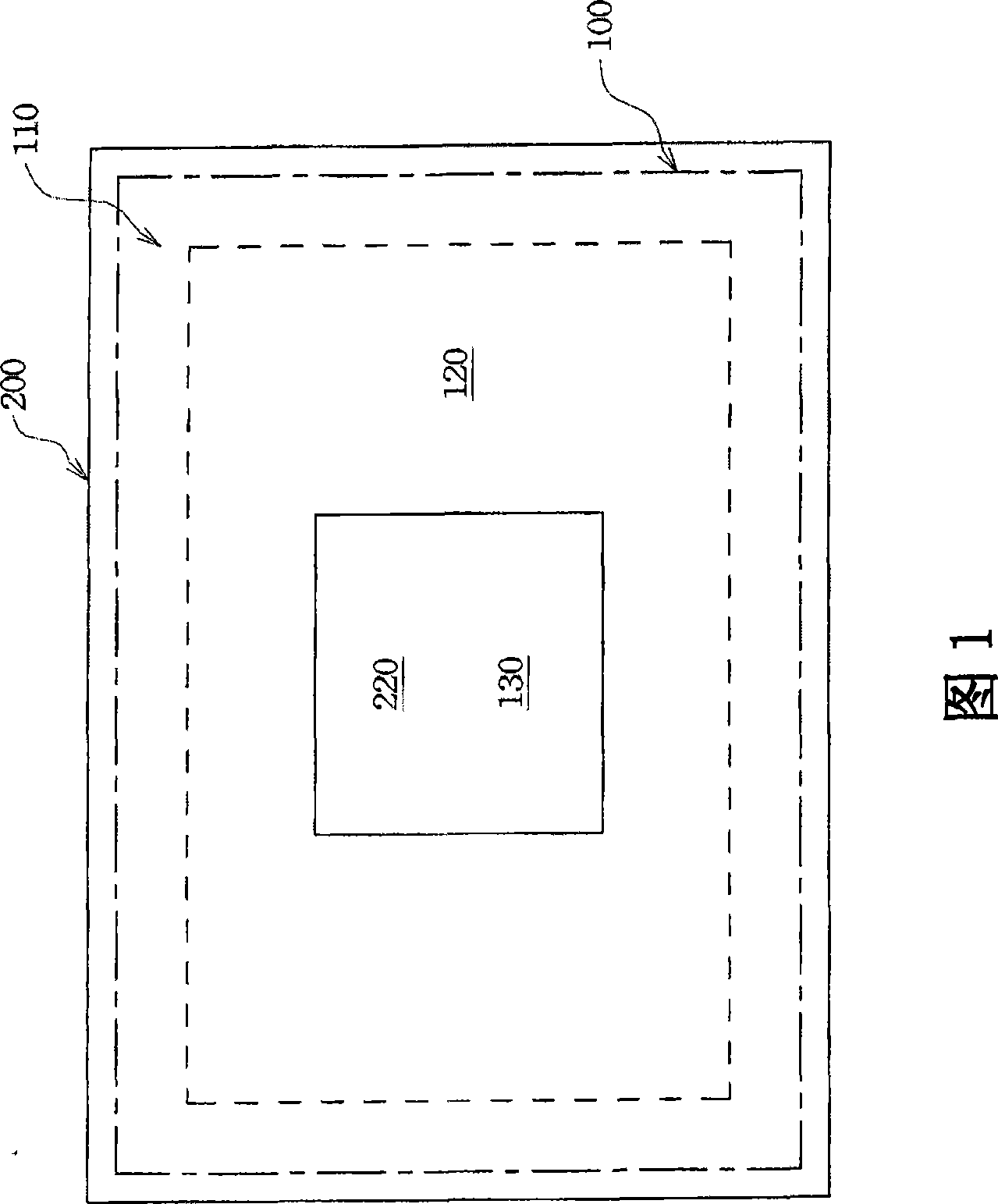

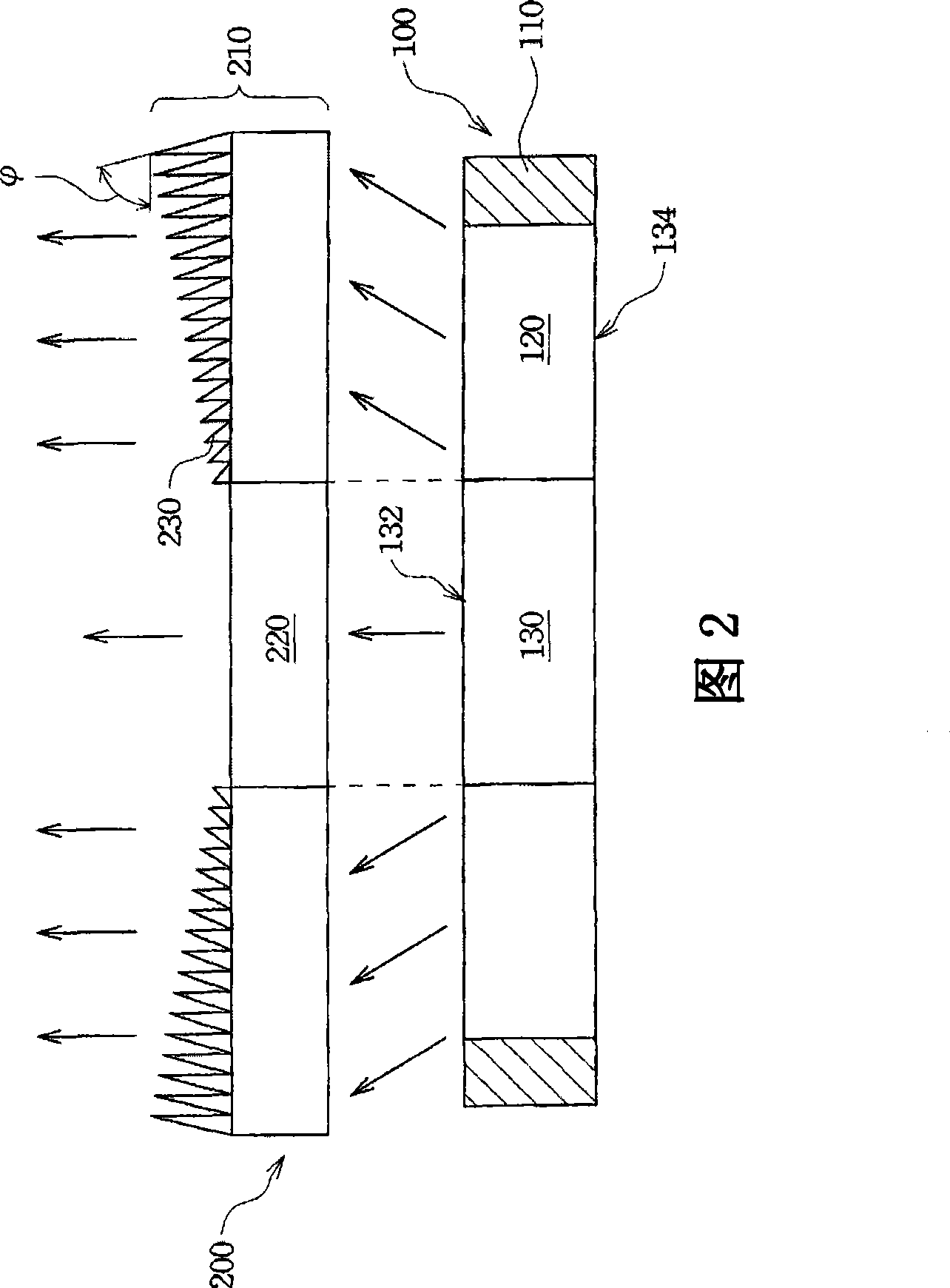

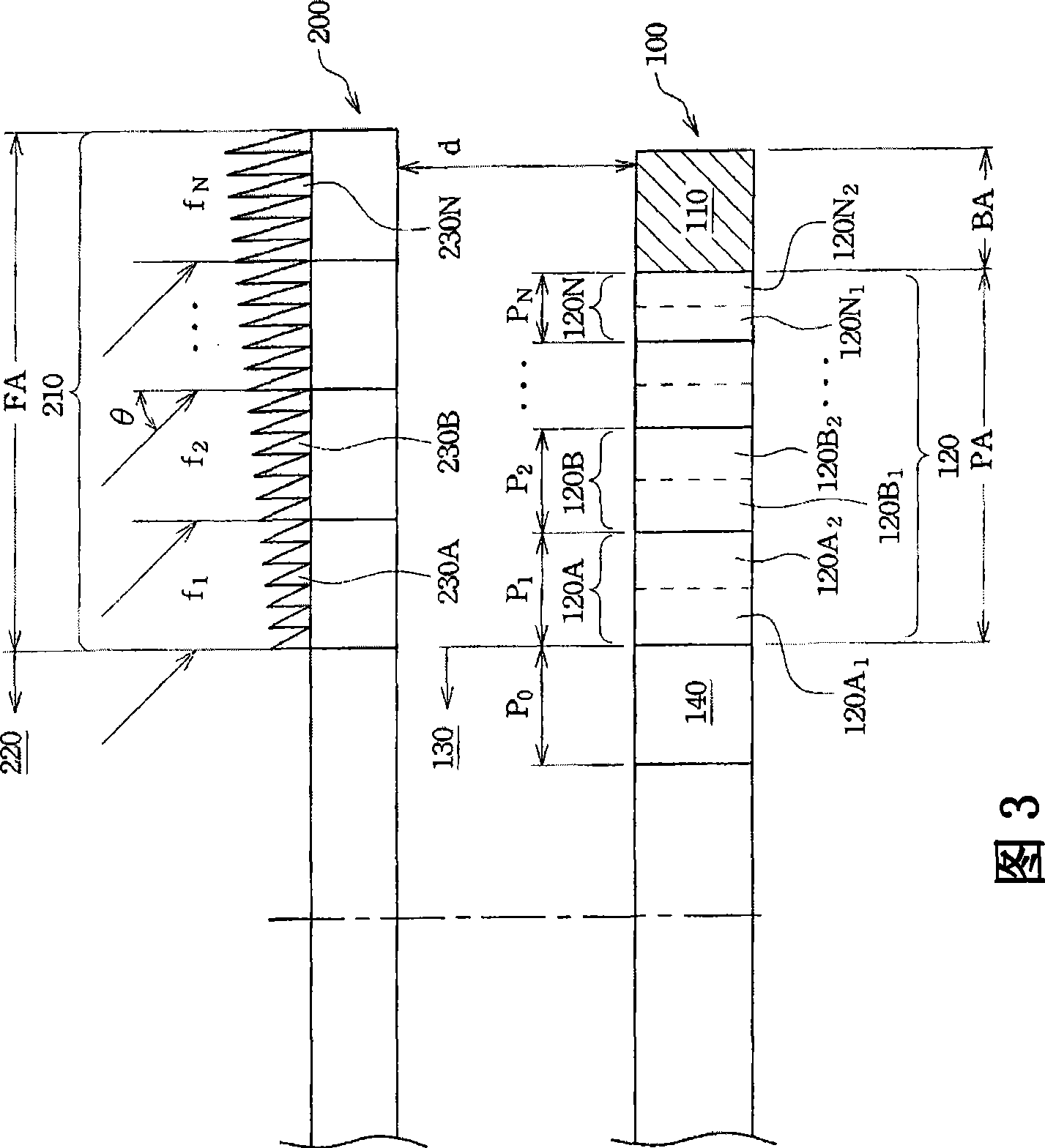

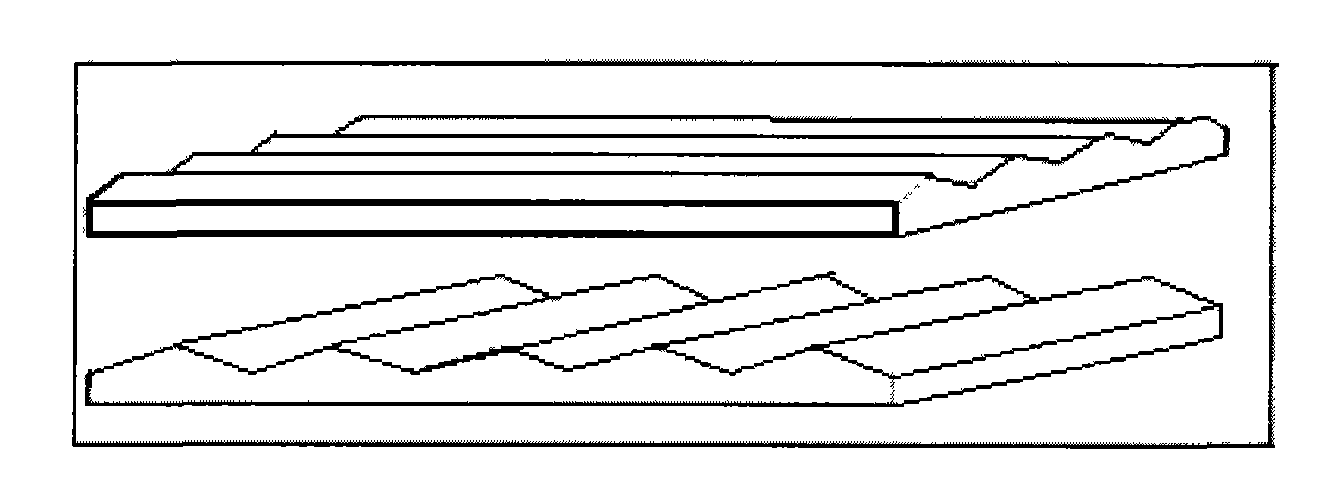

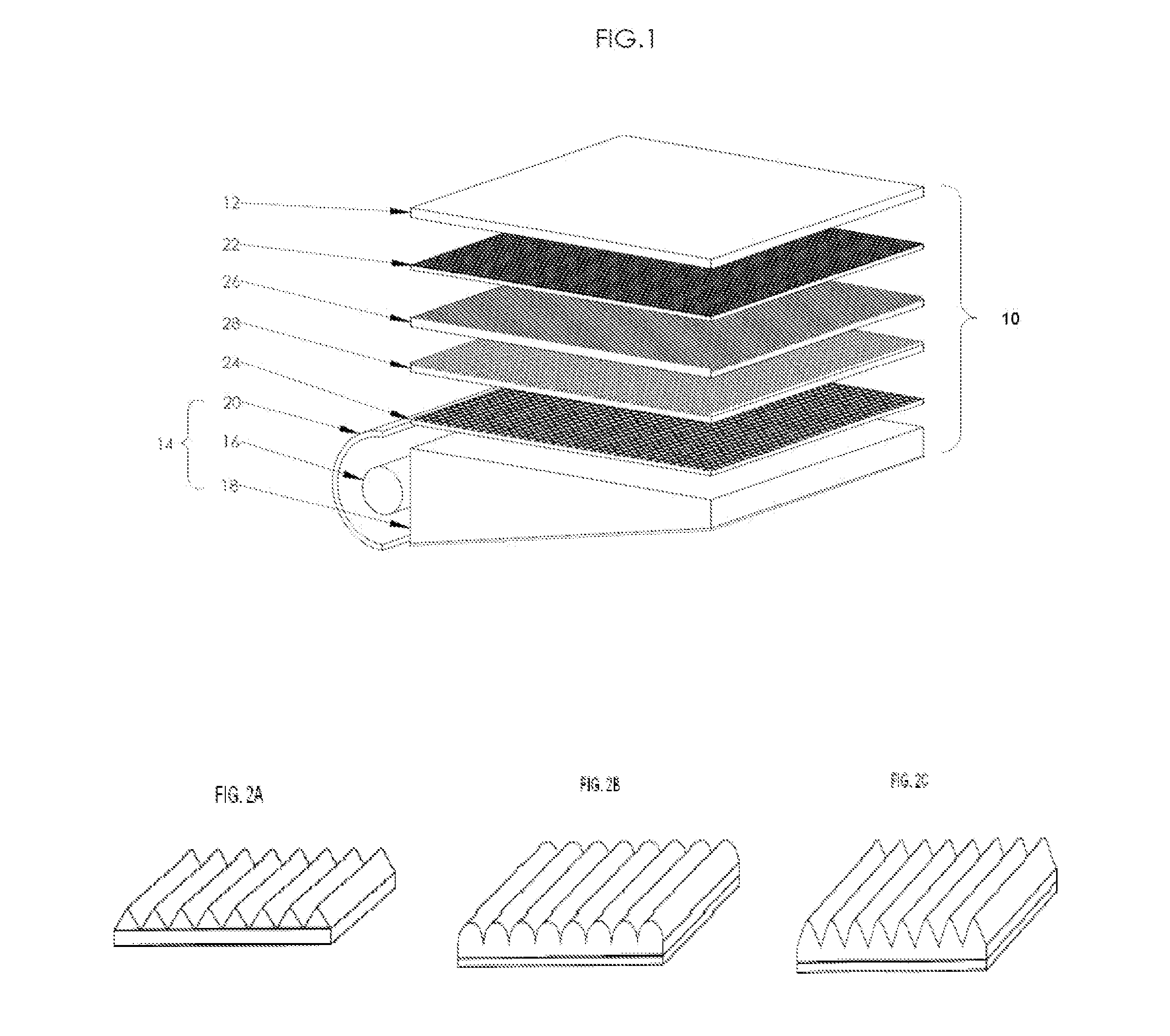

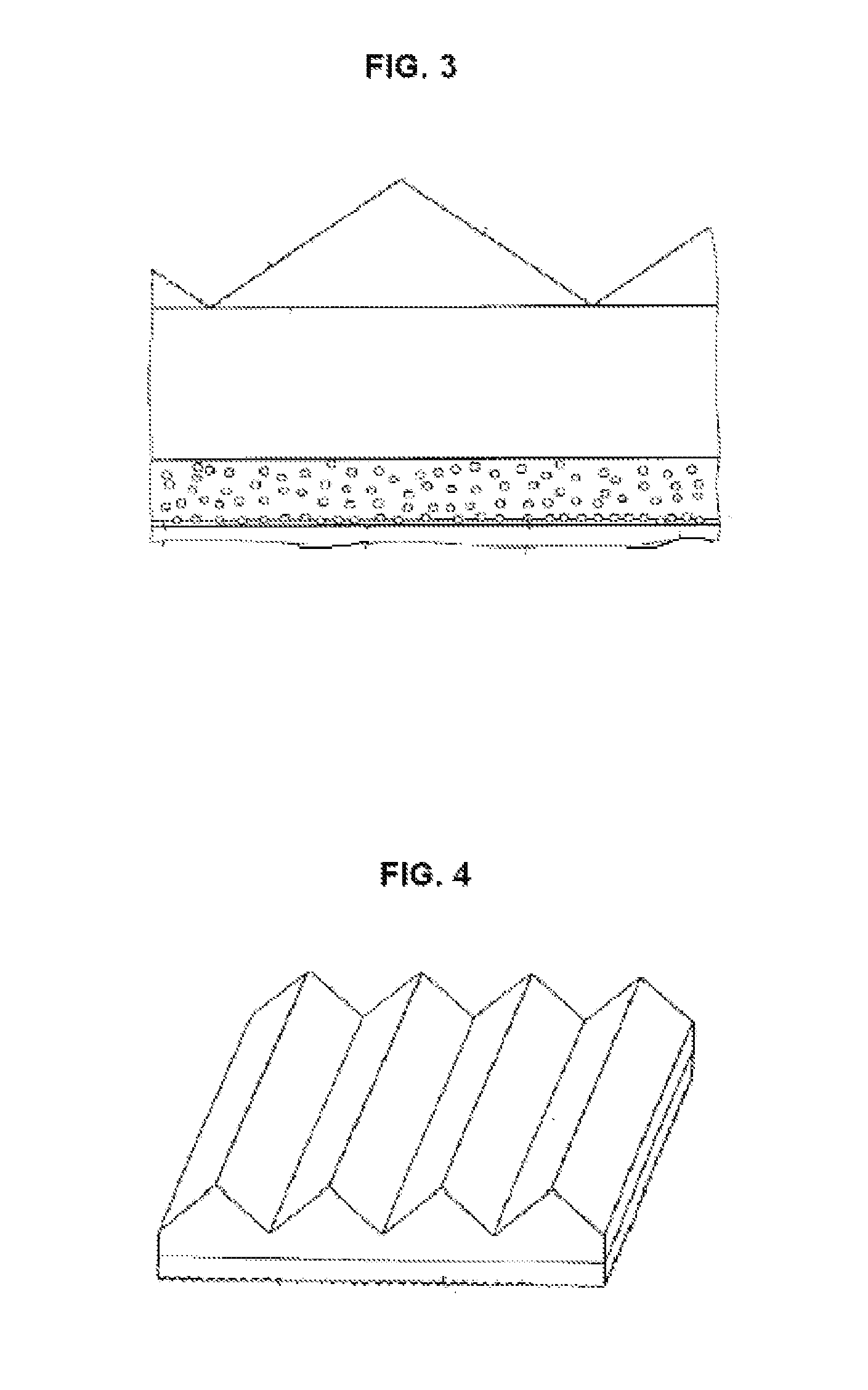

Luminance enhancement optical substrates with Anti-interference-fringe structures

ActiveUS20110025946A1Improve luminanceIncrease brightnessIlluminated signsOptical light guidesPrismEngineering

An optical substrate having a structured light output surface that comprises rows of laterally arranged snaking, wavy or meandering longitudinal prism structures. The prism structures at the light output surface may be viewed as comprising rows of laterally meandering longitudinal prisms and / or sections of curved segments coupled end-to-end to form the overall meandering longitudinal prism structures. The laterally meandering rows of longitudinal prism structures are arranged in parallel laterally (side-by-side), defining parallel peaks and valleys (a facet is defined between each adjacent peak and valley). In one embodiment, the lateral waviness is regular with a constant or variable wavelength and / or wave amplitude (or extent of lateral deformation). The lateral waviness may generally follow a sinusoidal profile, or other curved profile. The structured light output surface may further include varying peak heights along each wavy prism structure and / or pre-defined structural irregularities such as non-facet flat section distributed in the structure surface.

Owner:UBRIGHT OPTRONICS CORP

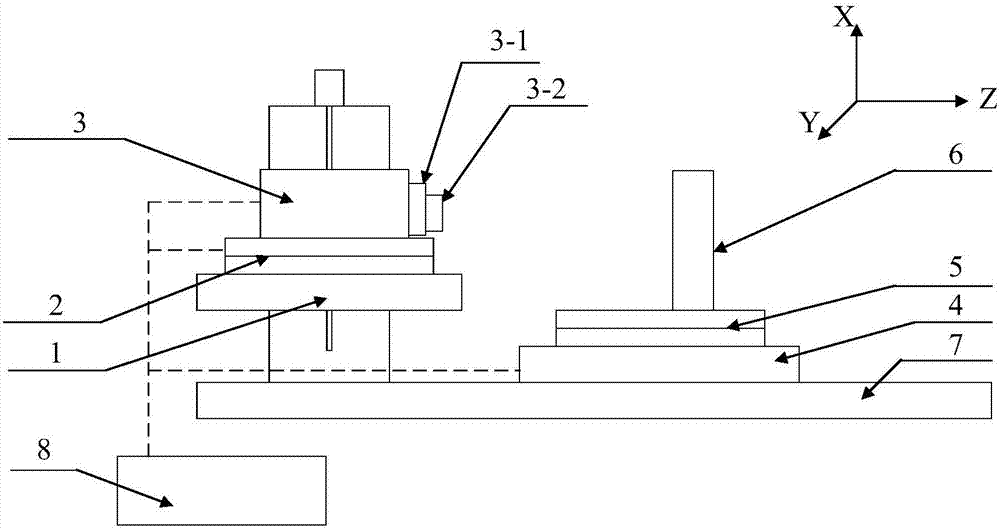

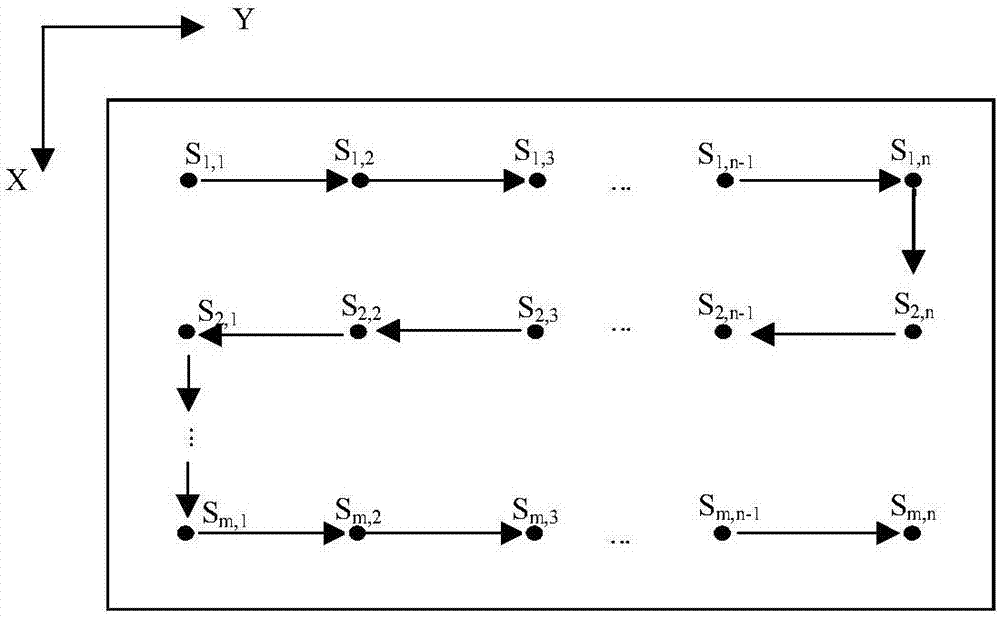

Measuring device and measuring method for stitching interference of planar sub-aperture

ActiveCN106918301AHigh measurement accuracySmall return errorUsing optical meansMeasurement deviceControl system

The invention provides a measuring device and a measuring method for stitching interference of a planar sub-aperture. The measuring device comprises an interferometer, an interferometer splicing displacement table, an interferometer inclination adjusting platform, a measured member splicing displacement platform, a measured member inclination adjusting platform, a measured member, a supporting platform and a control system. The measuring device and the measuring method have advantages of high sub-aperture positioning precision, high measurement precision and full automatic measurement.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

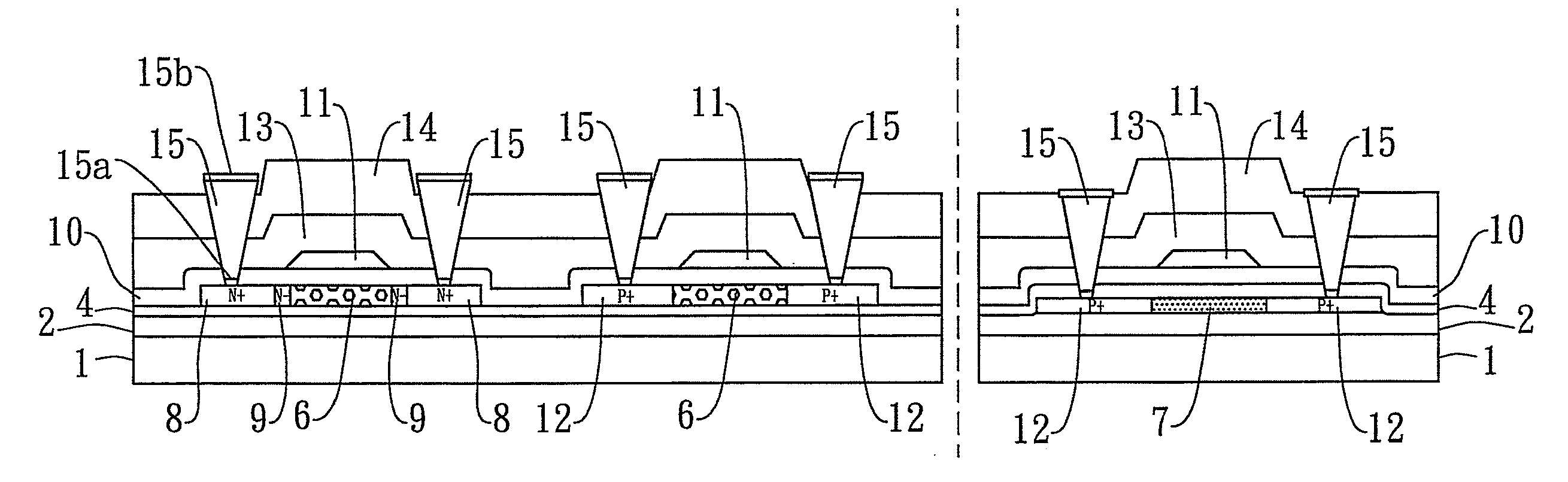

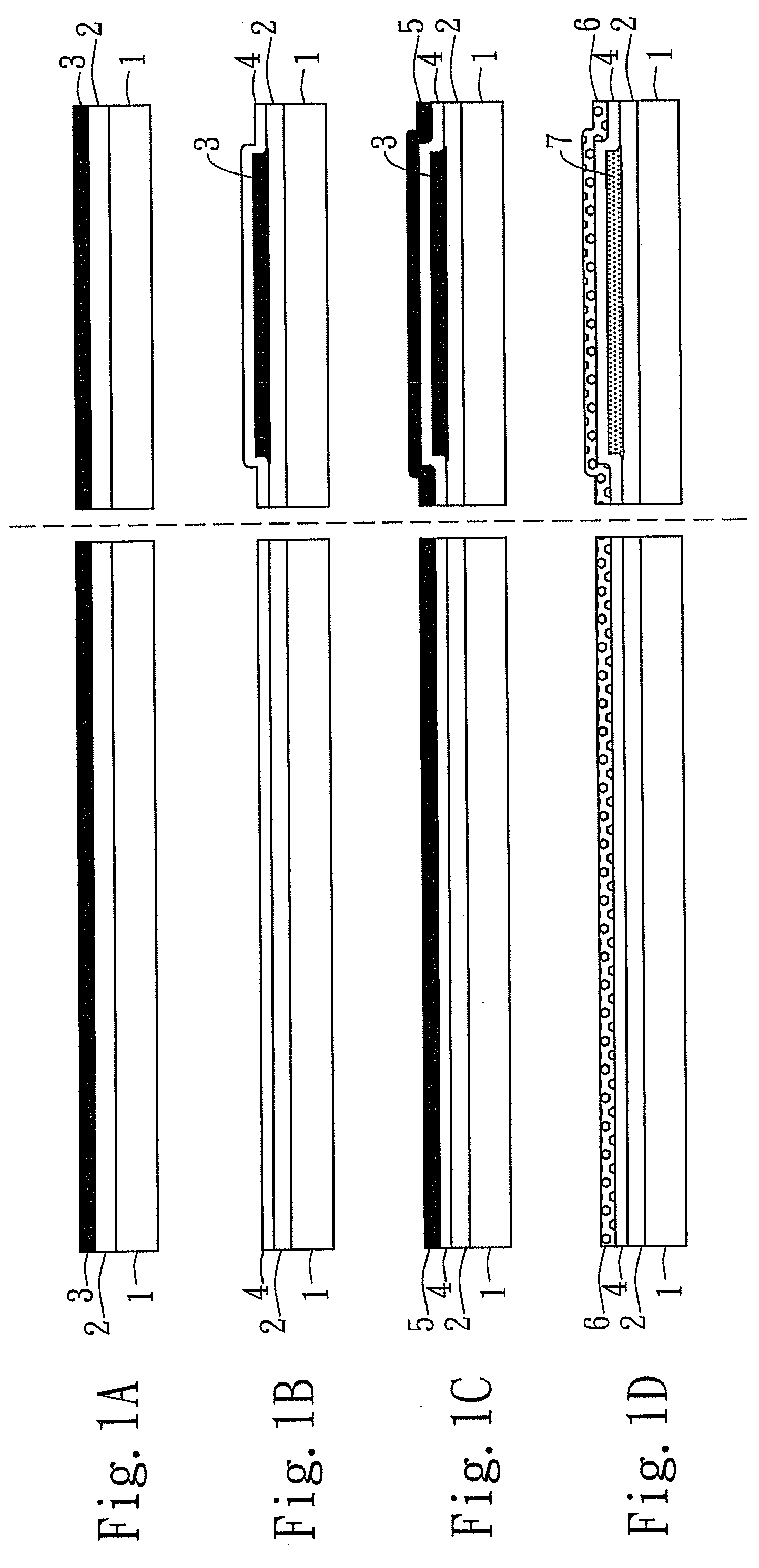

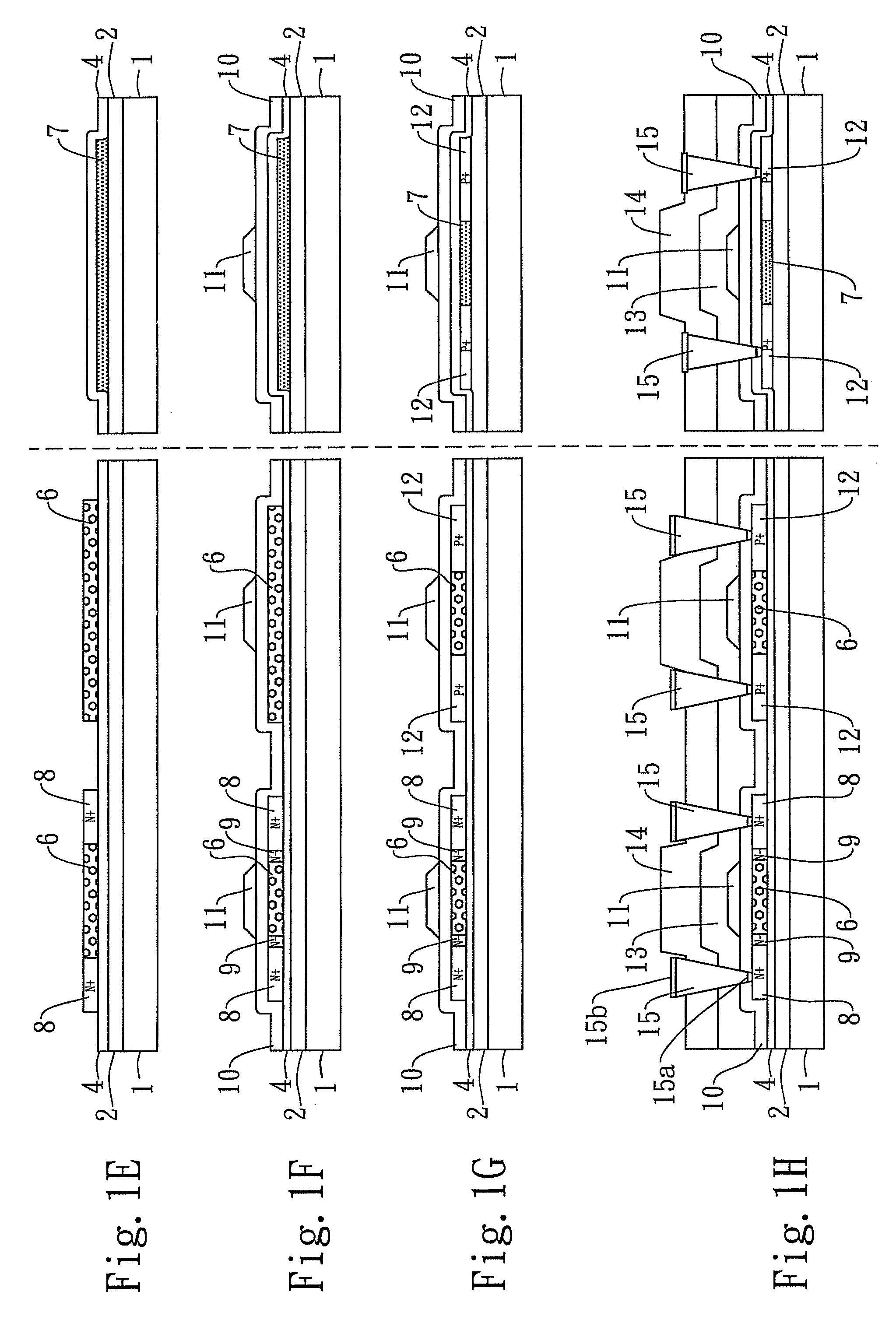

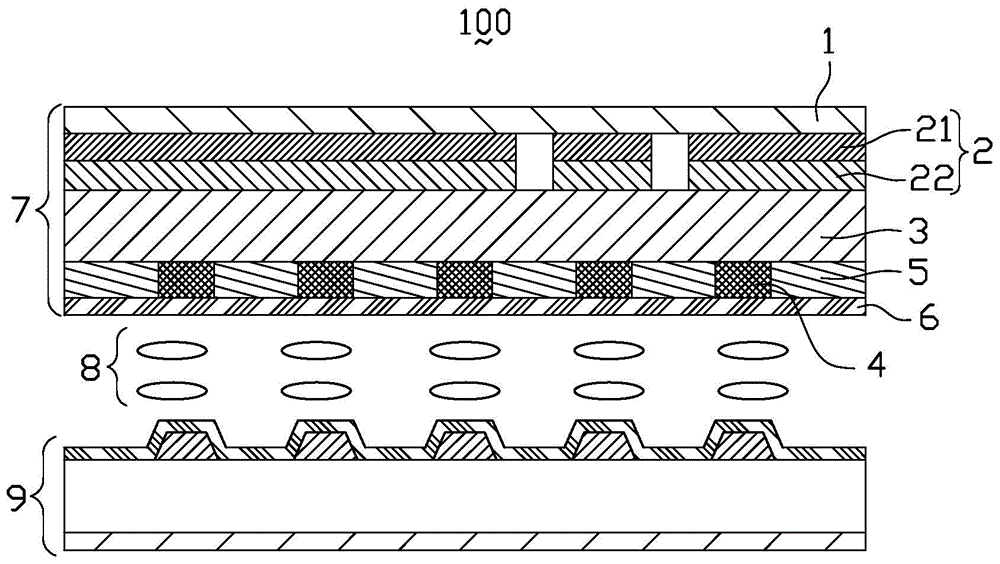

Double-active-layer structure with a polysilicon layer and a microcrystalline silicon layer, method for manufacturing the same and its application

InactiveUS20090194770A1Laser light interferingInterference fringes of laser light can be reducedTransistorSolid-state devicesLaser lightOptoelectronics

A first amorphous silicon layer is formed over a substrate and a second amorphous silicon layer is formed over the first amorphous silicon layer. When a laser annealing process is performed, the second amorphous silicon layer absorbs more laser light than the first amorphous silicon layer does. The first amorphous silicon layer crystallizes into a microcrystalline silicon layer and the second amorphous silicon layer crystallizes into a polysilicon layer. During the laser annealing process, light interference between the first amorphous silicon layer and an underlying buffer layer is eliminated owing to that the second amorphous silicon layer absorbs more laser light. The laser fringe is eliminated. The microcrystalline silicon layer with better crystalline uniformity can serve as an active layer for TFTs in the display area of an OLED display to improve its illumination uniformity.

Owner:INNOLUX CORP

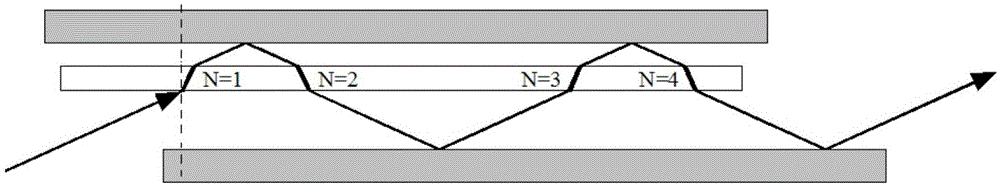

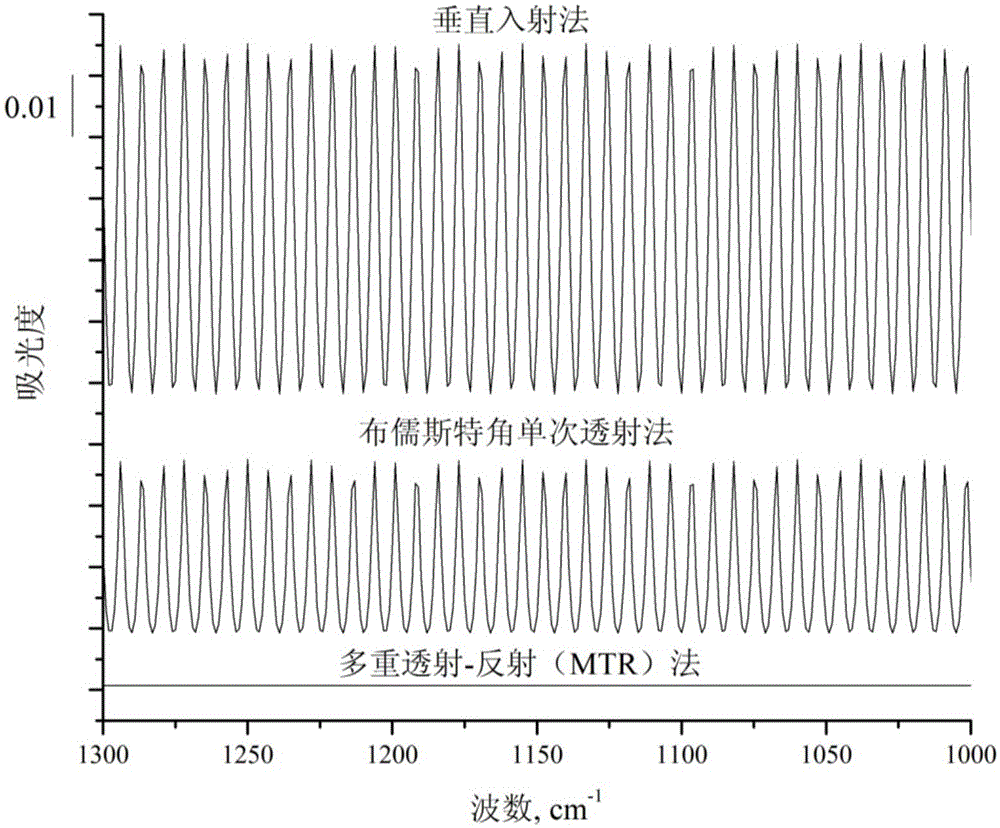

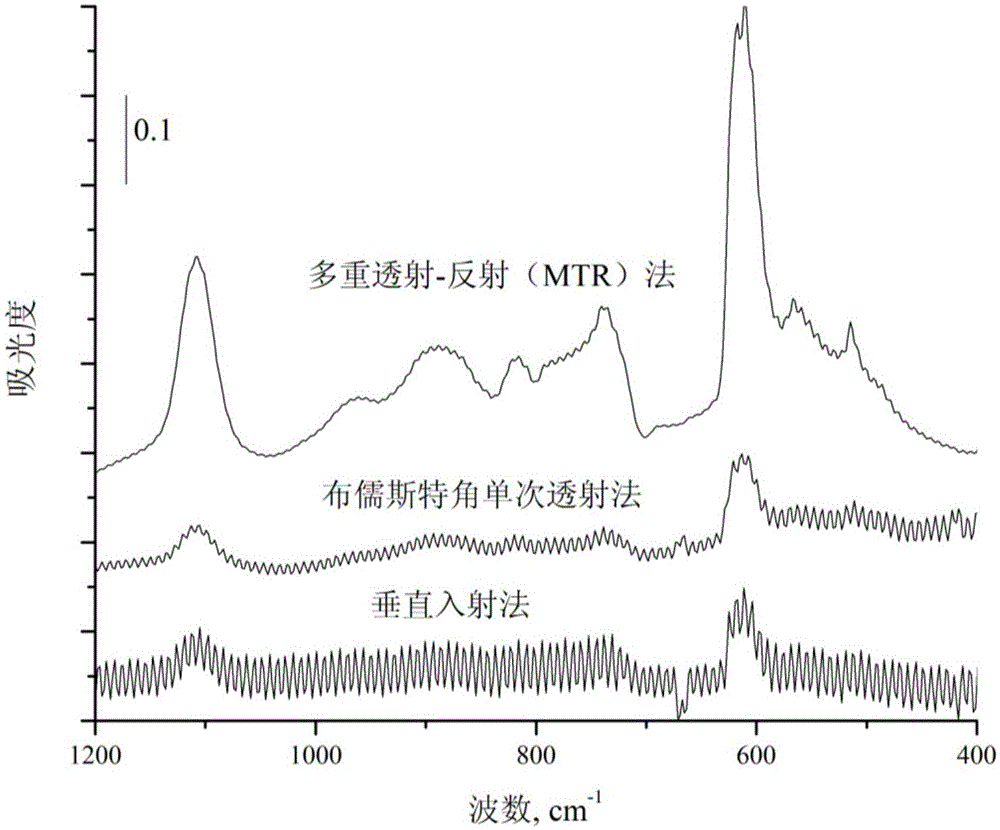

Method for detecting content of substitutional carbon and interstitial oxygen in monocrystalline silicon

InactiveCN105092511AReduce scatterAbsorption peak amplificationMaterial analysis by optical meansSemiconductor materialsOxygen

The invention discloses a method for detecting the content of substitutional carbon and interstitial oxygen in monocrystalline silicon, and belongs to the field of semiconductor material examination and analysis. The method includes the steps that a reference silicon wafer and a sample silicon wafer are placed on a sample fixing rack for repeated transmission-reflection measuring accessories, and p-linear polarization infrared beams are used for executing N times of the transmission-reflection process; the p-linear polarization infrared beams arrive at an infrared detector, infrared absorption spectrograms are obtained, the difference value of the absorbance of the position where the absorption peak of the substitutional carbon and the interstitial oxygen on the infrared spectrogram of the sample silicon wafer is located and the absorbance of the position where the absorption peak of the substitutional carbon and the interstitial oxygen on the infrared spectrogram of the reference silicon wafer is located is calculated, namely the absorbance of the substitutional carbon and the interstitial oxygen in the sample silicon wafer is obtained; the concentration of the substitutional carbon and the interstitial oxygen can be obtained according to the one-time Brewster infrared transmission equation and the Lambert-Beer law. By the adoption of the method, the monocrystalline silicon with the thickness being 0.1-2.0 mm can be measured, and the measuring accuracy is high.

Owner:NANJING XIUKE INSTR CO LTD

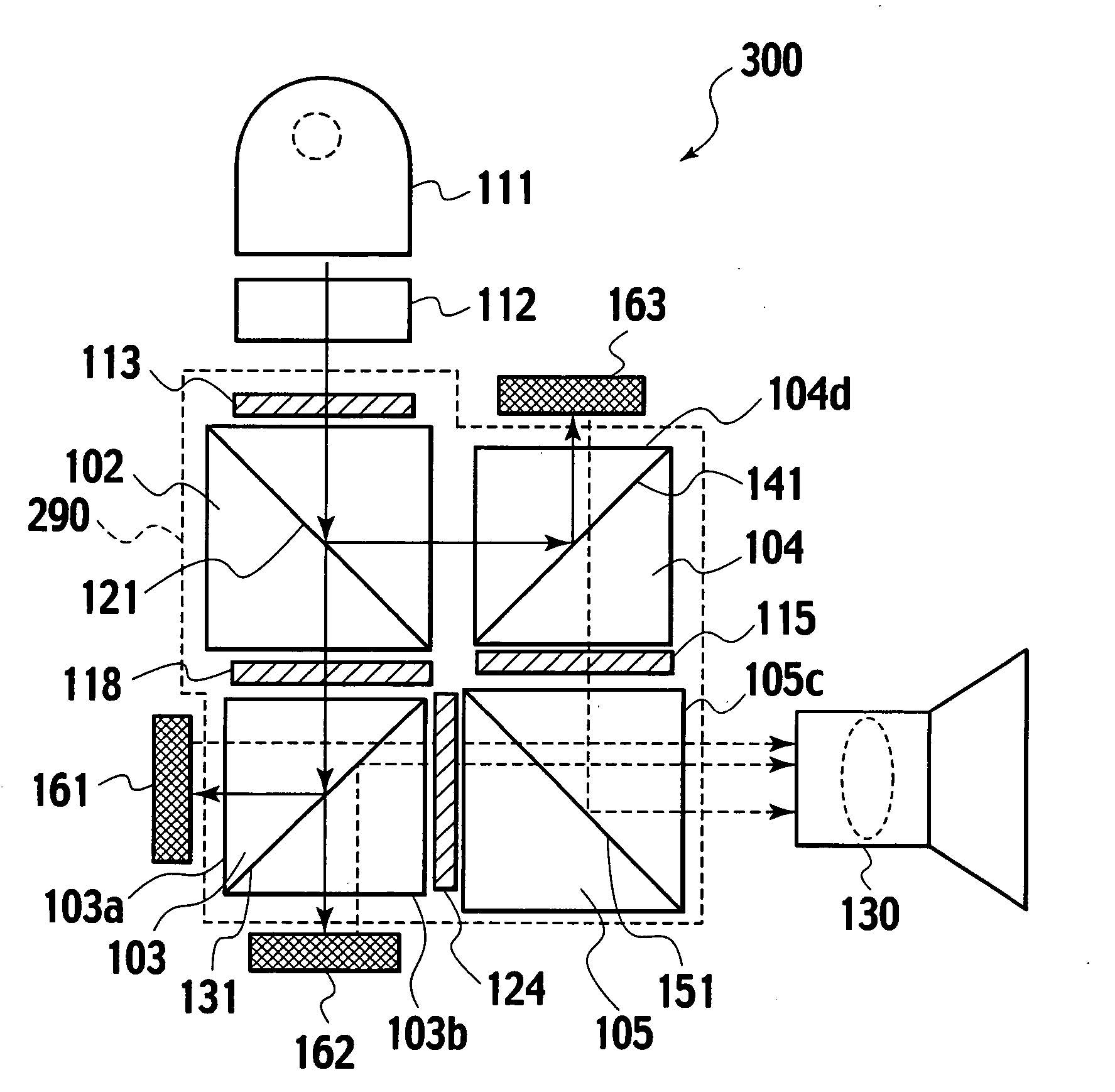

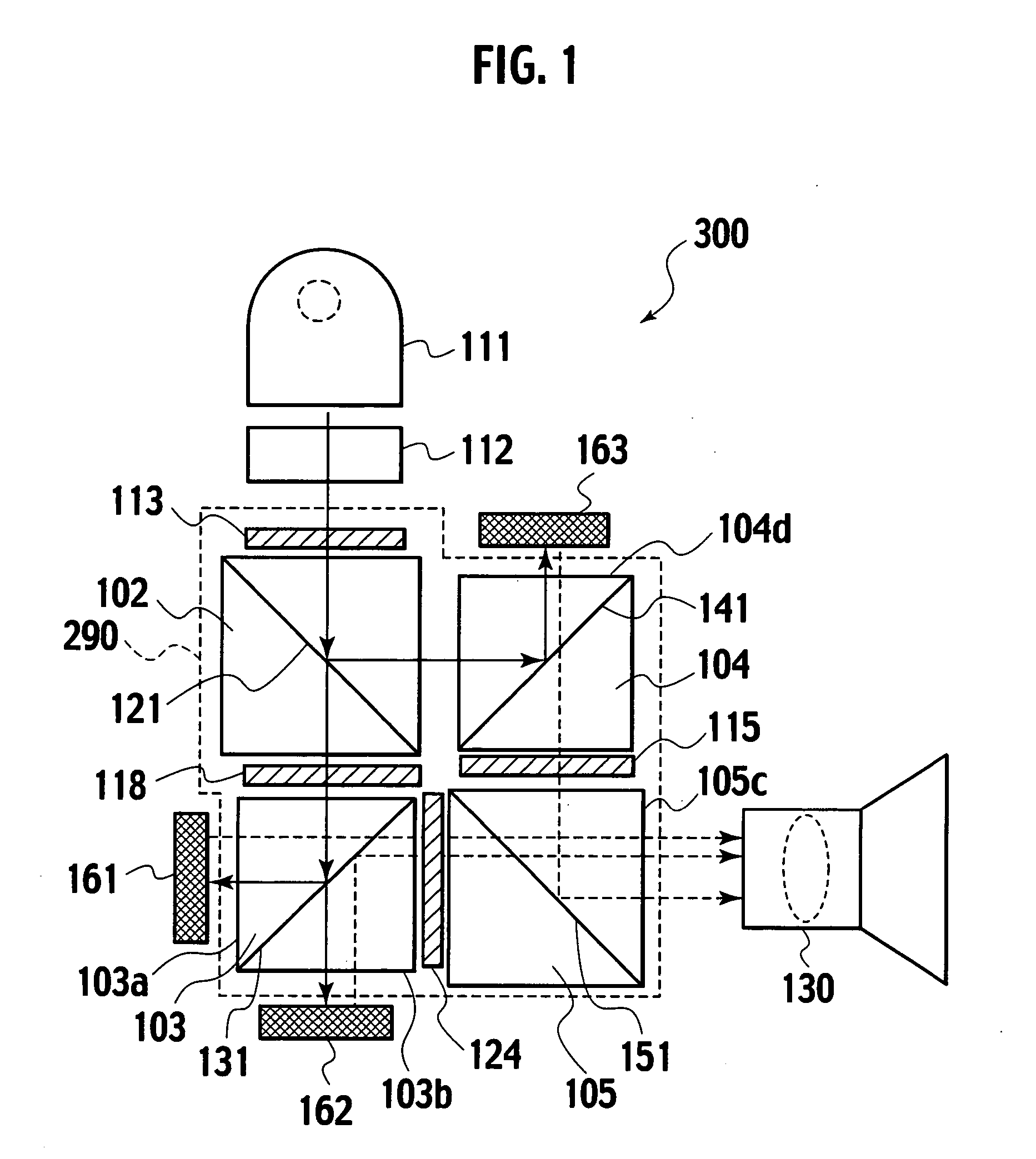

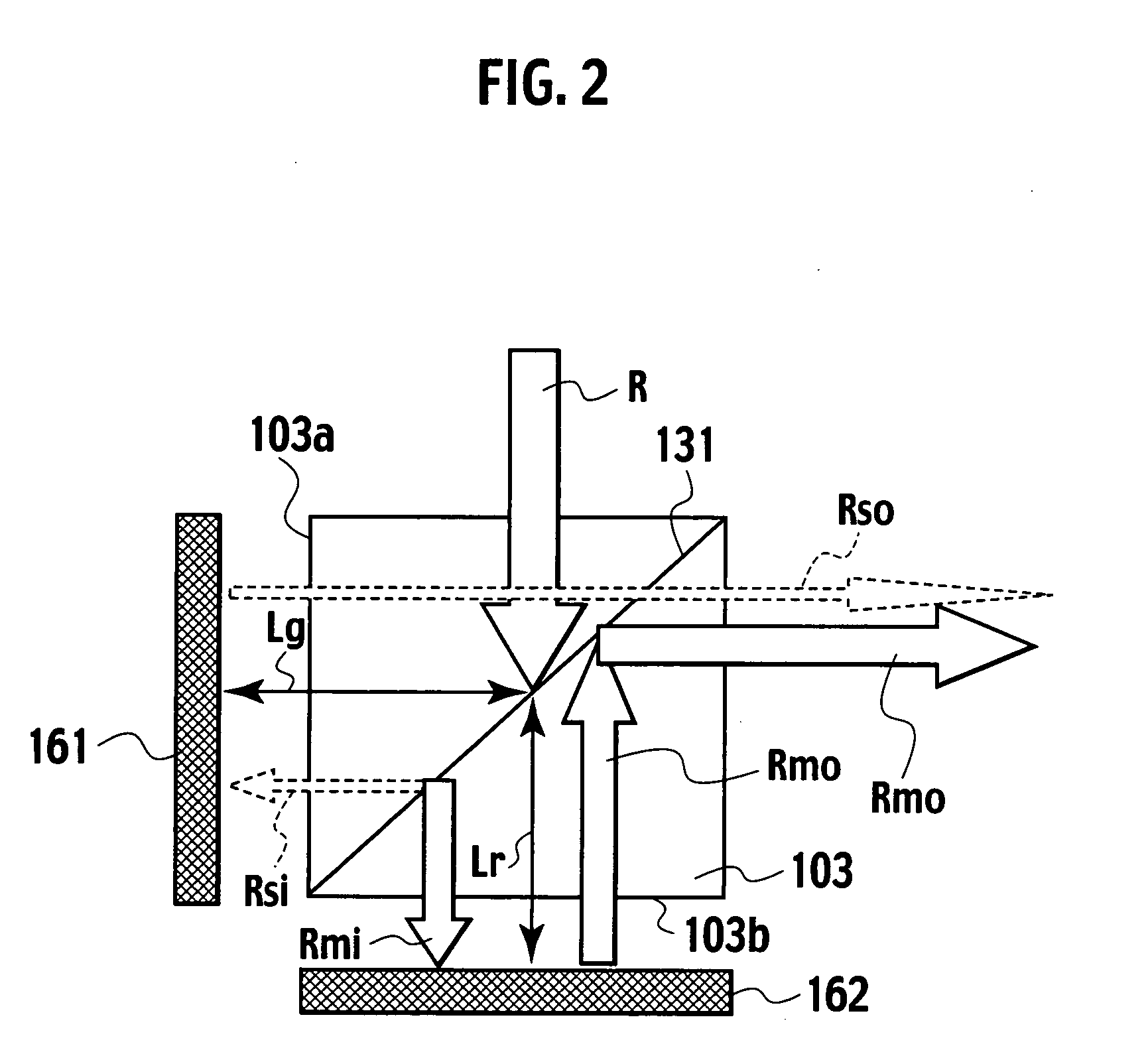

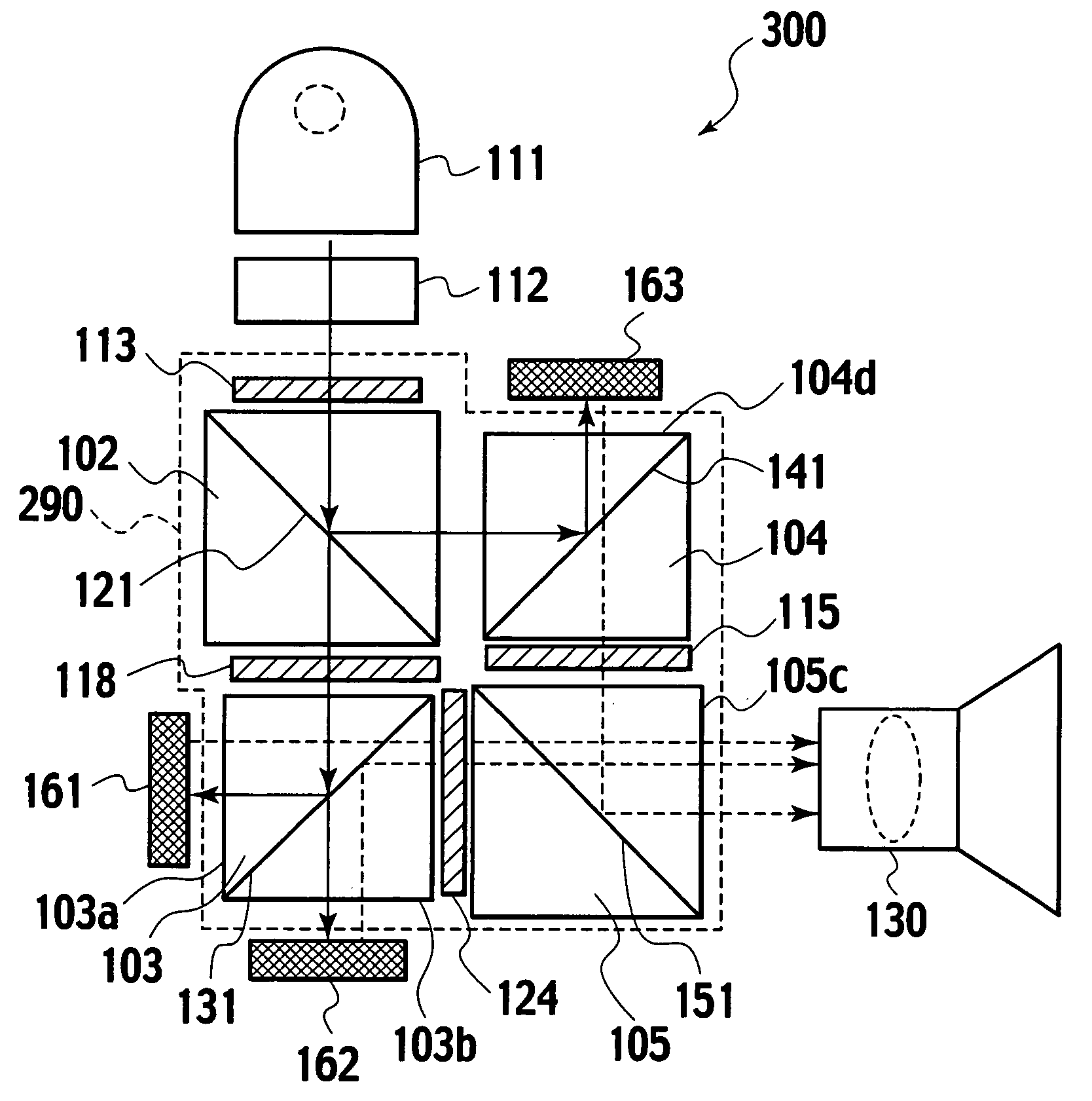

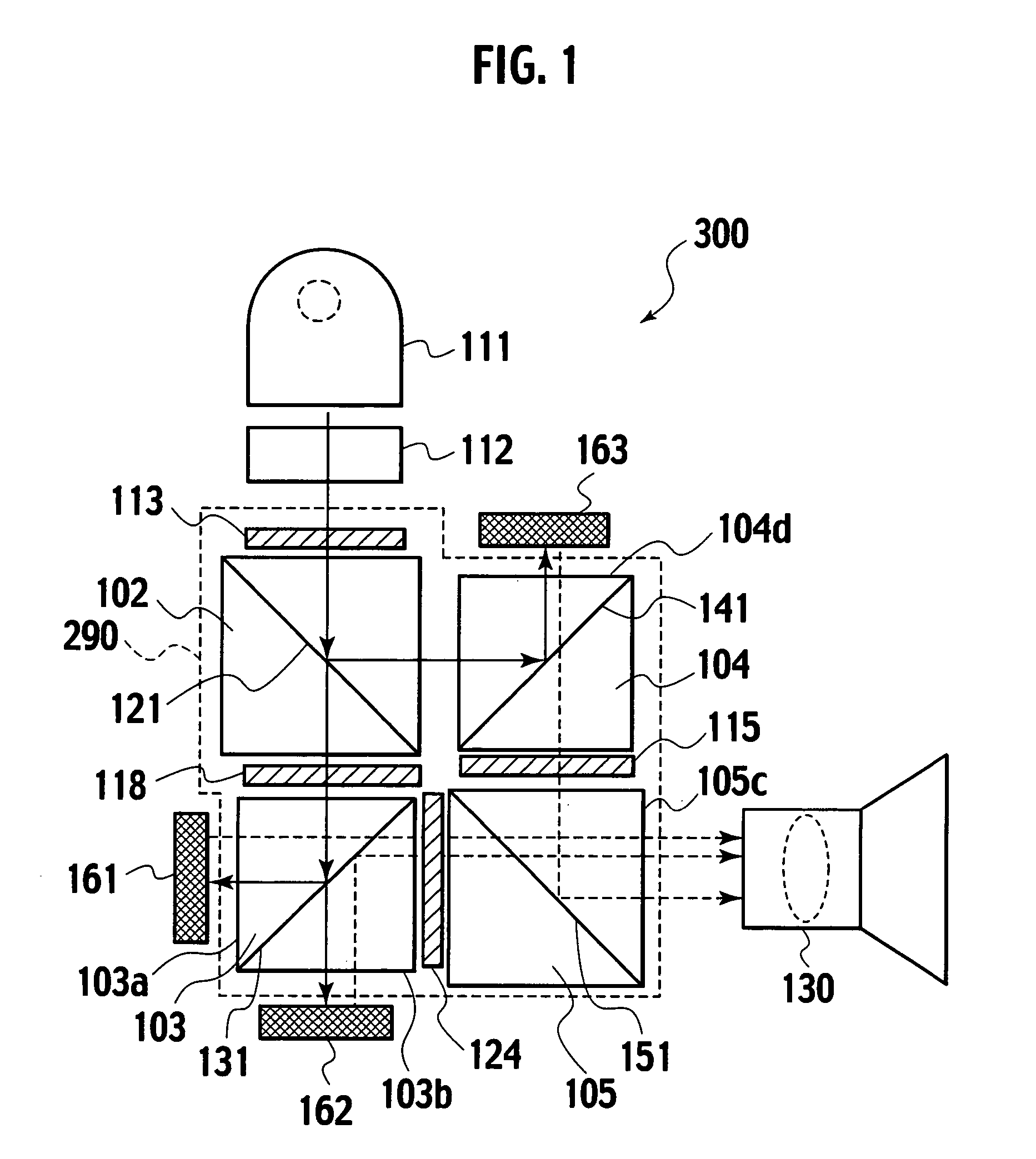

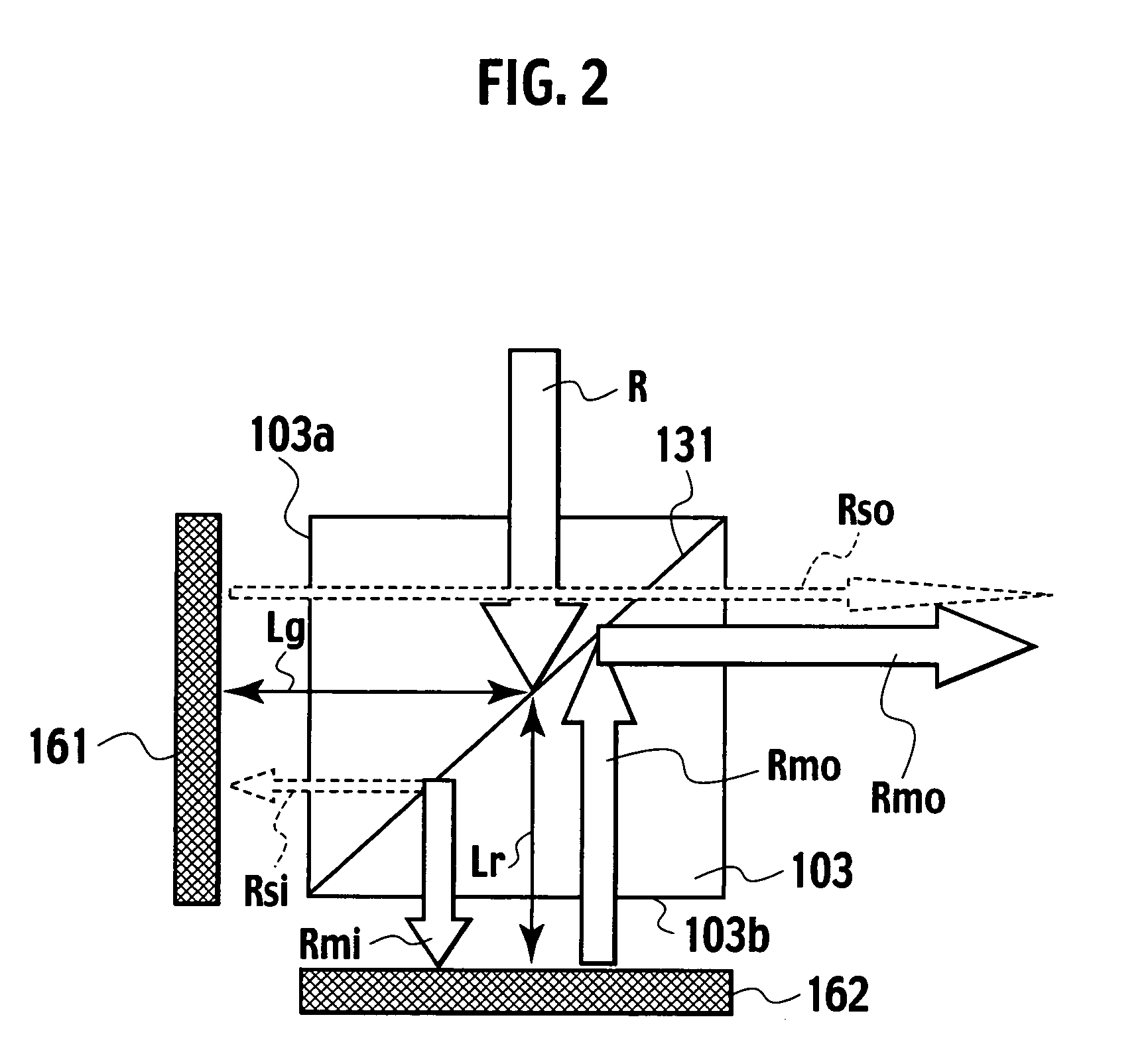

Projection display apparatus

ActiveUS20050243279A1Reduce interference fringesRaise the gradeTelevision system scanning detailsPulse generatorBeam splitterIntegrator

A white light emitted from a light source is homogenized by an integrator optical system, transmitted through a color polarizer (113) to be turned into an R light and a G light of a P polarized light, and transmitted through a color polarizer (118) to be turned into a G light of an S polarized light and an R light of a P polarized light. These R light and G light are subjected to light modulation in a reflection type spatial light modulation element for G and a reflection type spatial light modulation element for R arranged at unequal distances from a polarization split surface of a polarizing beam splitter (103), and emitted from a projection lens having an axial chromatic aberration corresponding to the unequal distances.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Display device

ActiveCN101435944AIncrease squint angleReduce thicknessStatic indicating devicesNon-linear opticsBoundary regionDisplay device

Owner:AU OPTRONICS CORP

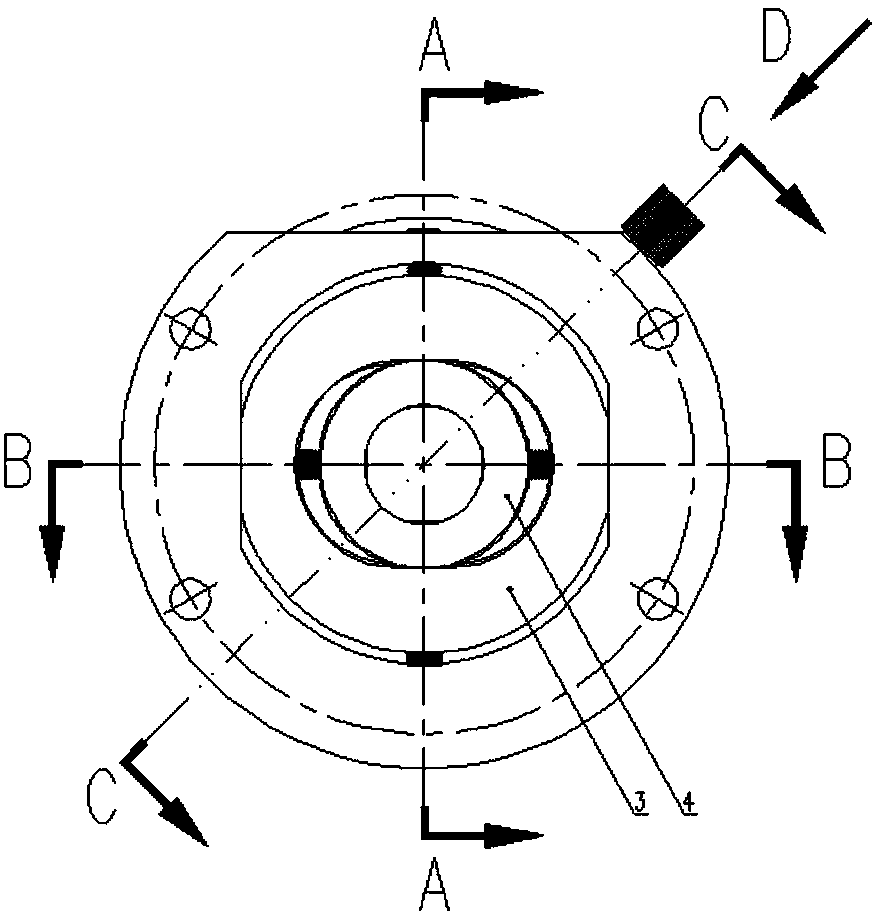

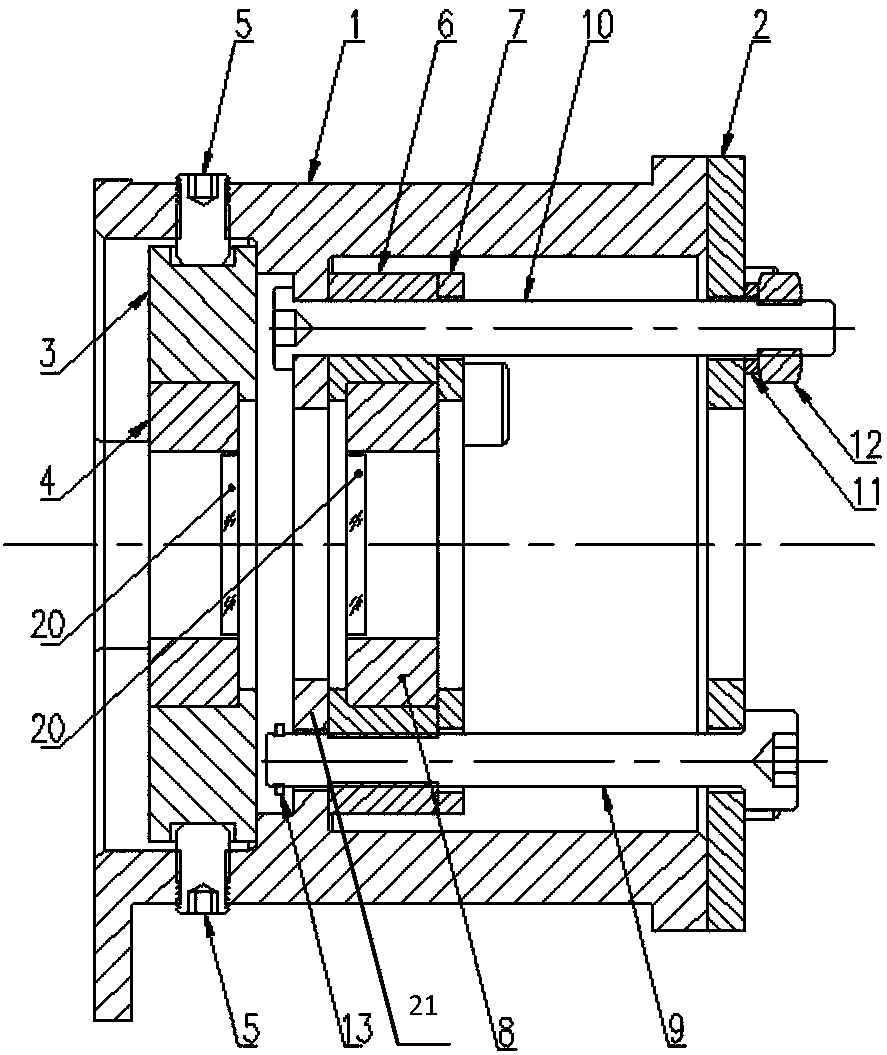

Underwater imaging laser lighting light spot homogenization adjusting device

ActiveCN108169918AHigh adjustment accuracyNo incidental rotation effectWater resource assessmentOptical elementsLight spotOptical axis

The invention belongs to the technical field of optical lighting and imaging, and particularly relates to an underwater imaging laser lighting light spot homogenization adjusting device comprising a lens cone, and a first fixing block, a second fixing block, a first ring and a second ring which are arranged in the lens cone and coaxial with the lens cone. The first fixing block and the second fixing block are used for fixing the first ring and the second ring. The first ring and the second ring are used for fixing two micro-lenses. With application of mechanical structure design, micro-adjustment of relative axial distance error, relative rotating error and relative translation error (plane movement of X and Y directions) between two groups of micro-lenses can be effectively realized by using the mode of four-degree-of-freedom independent adjustment so that the optical axes of the two groups micro-lens arrays are ensured to be strictly aligned, the adjustment accuracy is high, the adjustment method is simple and the light spot quality is great.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Color holographic image forming system

InactiveCN103376725AReduce the number of repeated exposuresIncrease brightnessHolographic object characteristicsColor effectWhite light

A color holographic image forming system is provided. The reference light wave is incident to the film at a fixed reference beam angle. By adjusting an included angle between the object light wave corresponding to respective monochromatic component images and the reference light wave, the reference light wave and the object light wave are interfered with each other to result in a plurality of interference fringes on the film. When a white light is projected on the film, the reconstructed image shows the color effect.

Owner:E LON OPTRONICS

Optical article and process for producing optical article

ActiveCN101498794AEasy to manufactureReduce interference fringesMaterial nanotechnologySynthetic resin layered productsMicroparticleTitanium oxide

The invention provides an optical article which includes a plastic substrate, a primer layer, a hard coat layer and an antireflecting layer, causes almost no interference fringe, and is excellent in light resistance and marresistance, and a process for producing an optical article. According to the invention, an optical article includes a plastic substrate and, formed on a surface thereof, a primer layer and a hard coat layer. The primer layer is formed from a coating composition containing the following components (A) to (C): (A) a polyurethane resin; (B) metal oxide fine particles; and (C) an organosilicon compound, and the hard coat layer is formed from a coating composition containing the following component (D): (D) metal oxide fine particles which do not contain titanium oxide.

Owner:HOYA LENS MFG PHILIPPINES INC

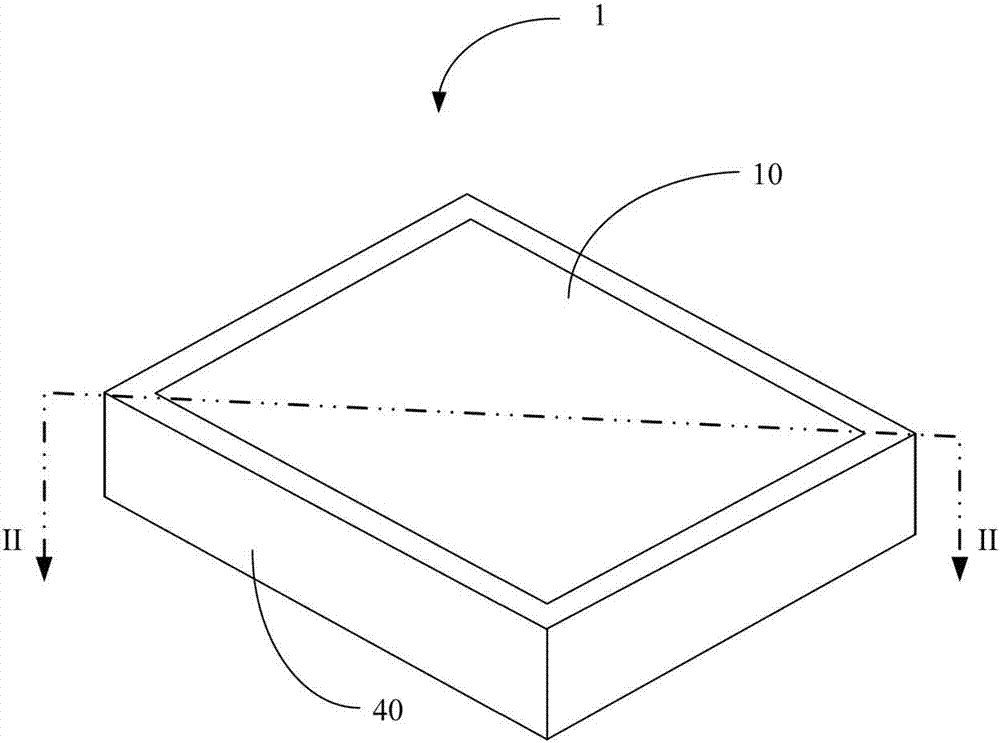

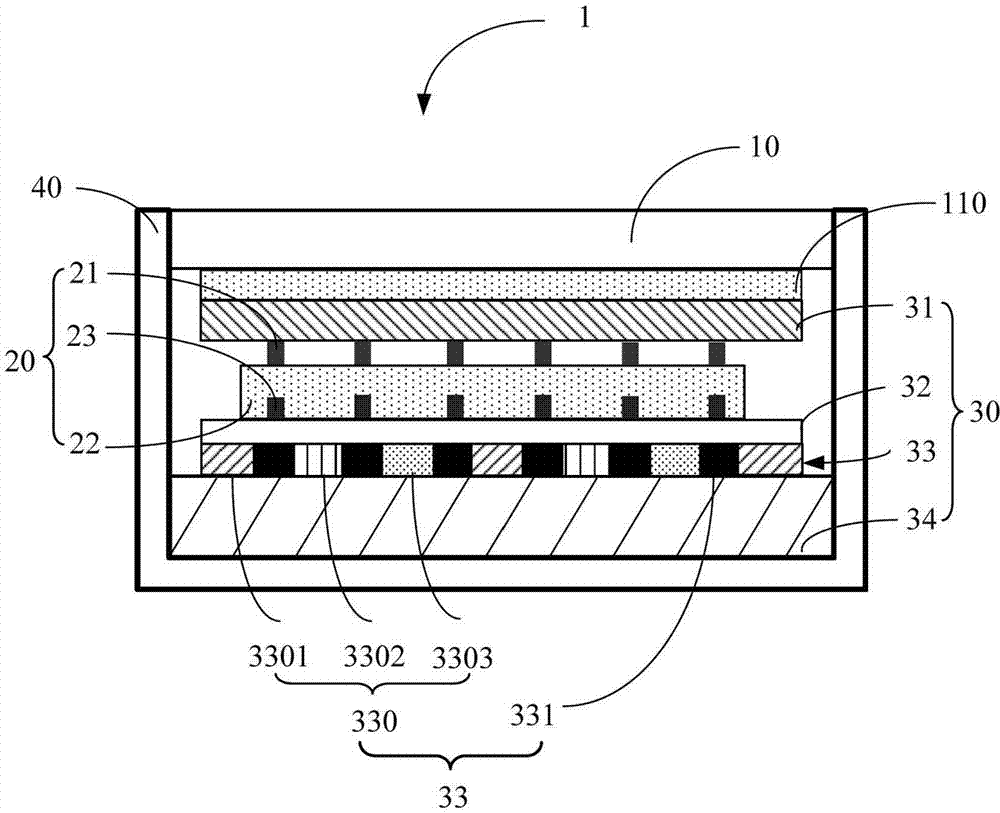

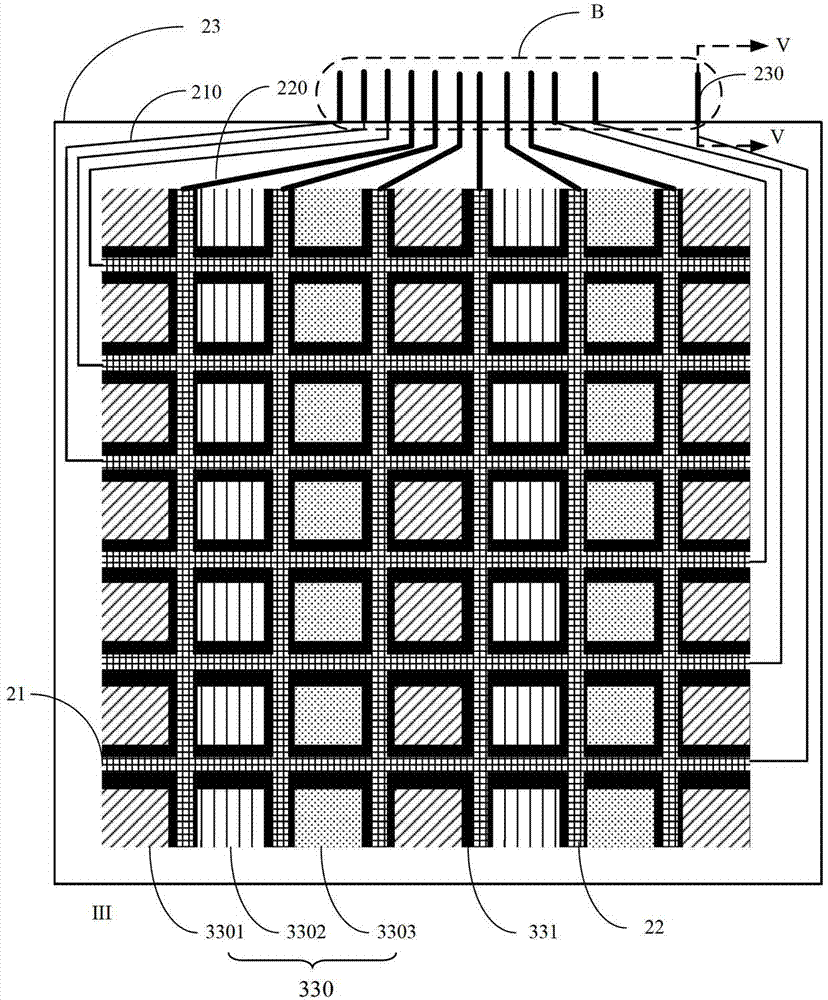

Touch control display device and color filter substrate

ActiveCN104850295AReduce thicknessReduce interference fringesNon-linear opticsInput/output processes for data processingColor gelDisplay device

The invention discloses a touch control display device. The touch control display device comprises a touch control electrode structure and a display module. The display module comprises an upper substrate, a lower substrate and a color filter. The color filter is arranged on one side, which is close to the lower substrate, of the upper substrate, wherein the touch control electrode structure comprises a first sensing electrode made of a metal grid line; and the first sensing electrode is arranged on the surface, which is located on one side opposite to the color filter, of the upper substrate, and is in direct contact with the same. The invention further provides a color filter substrate with the touch control electrode structure on the surface.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

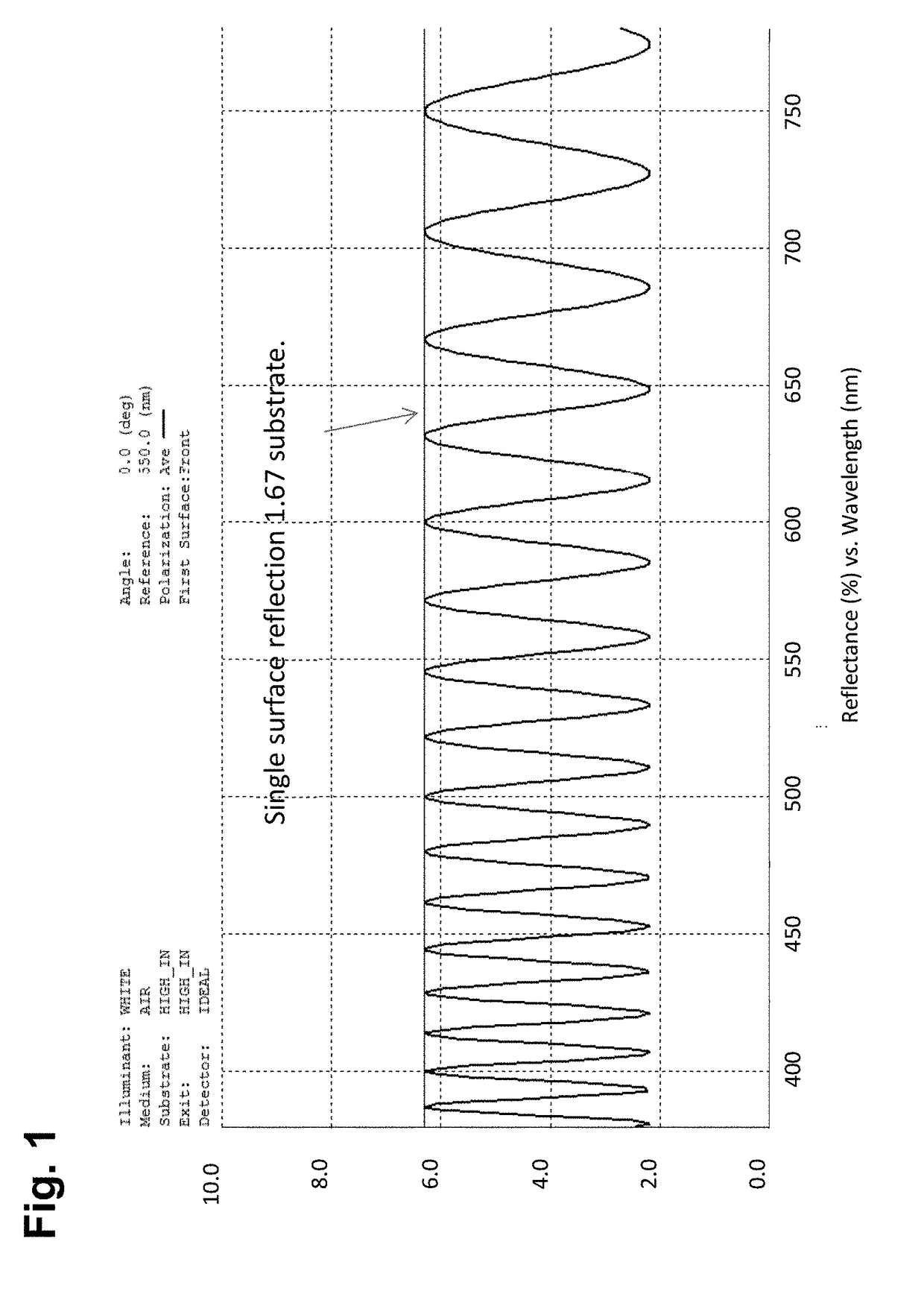

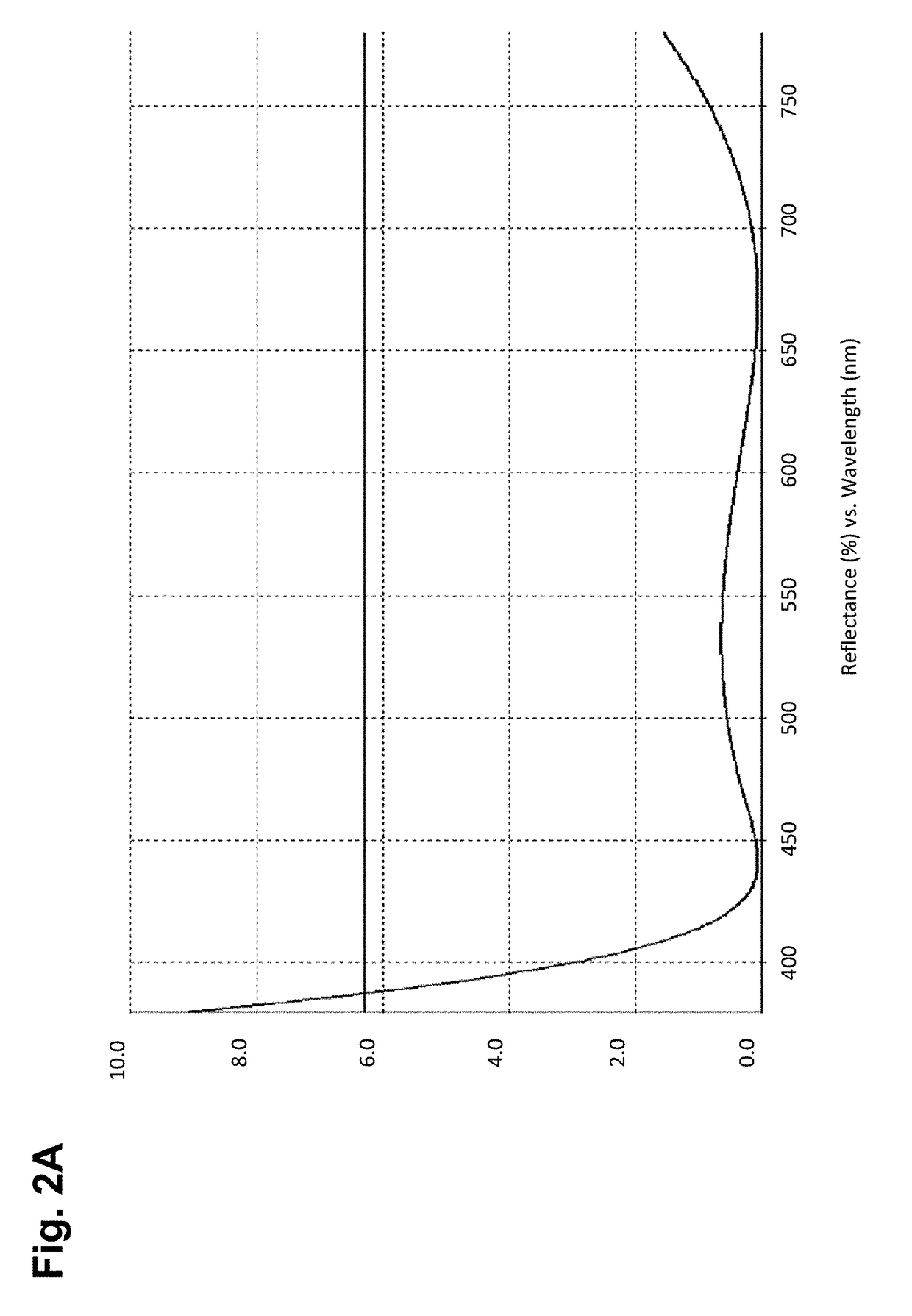

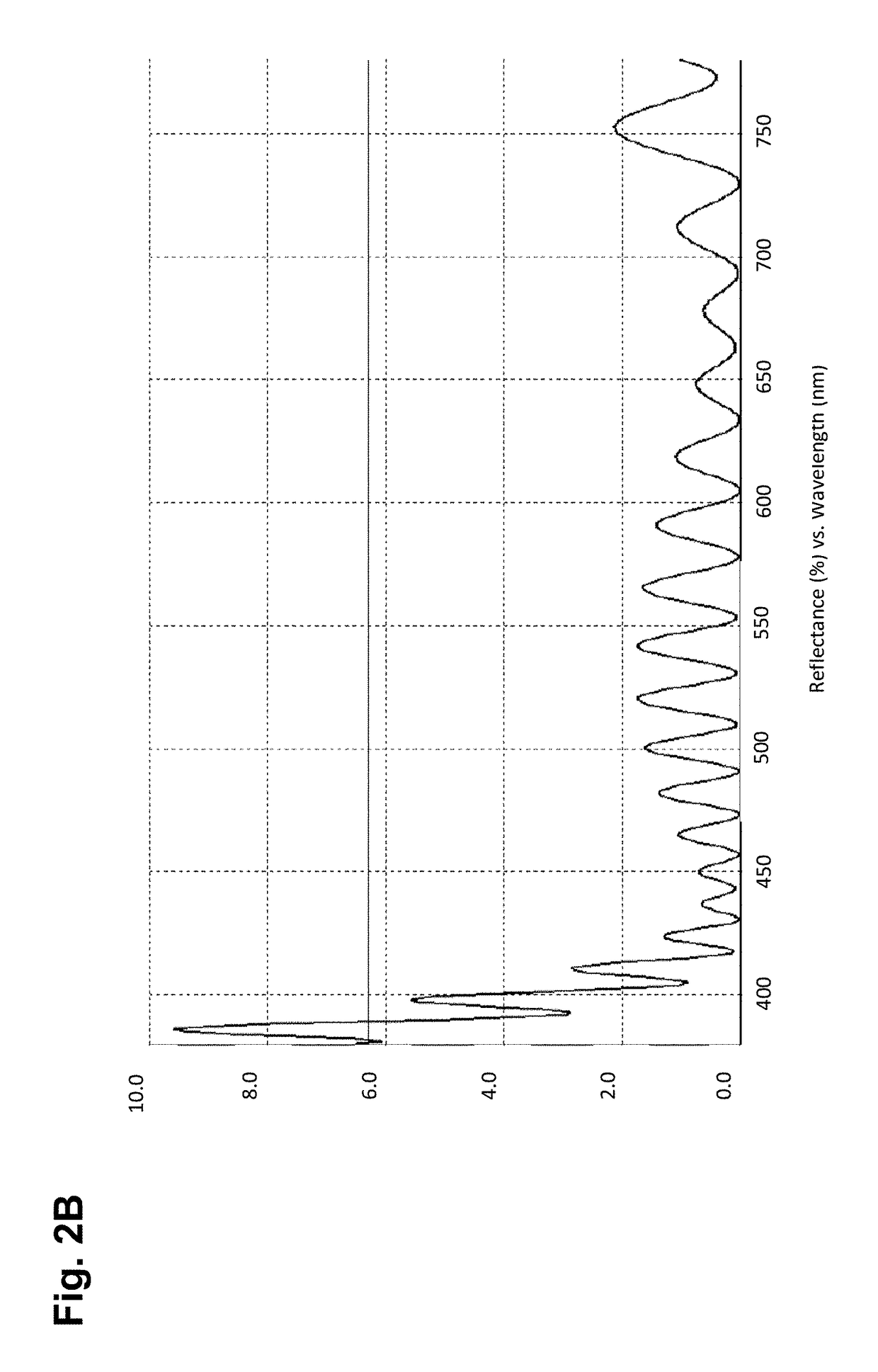

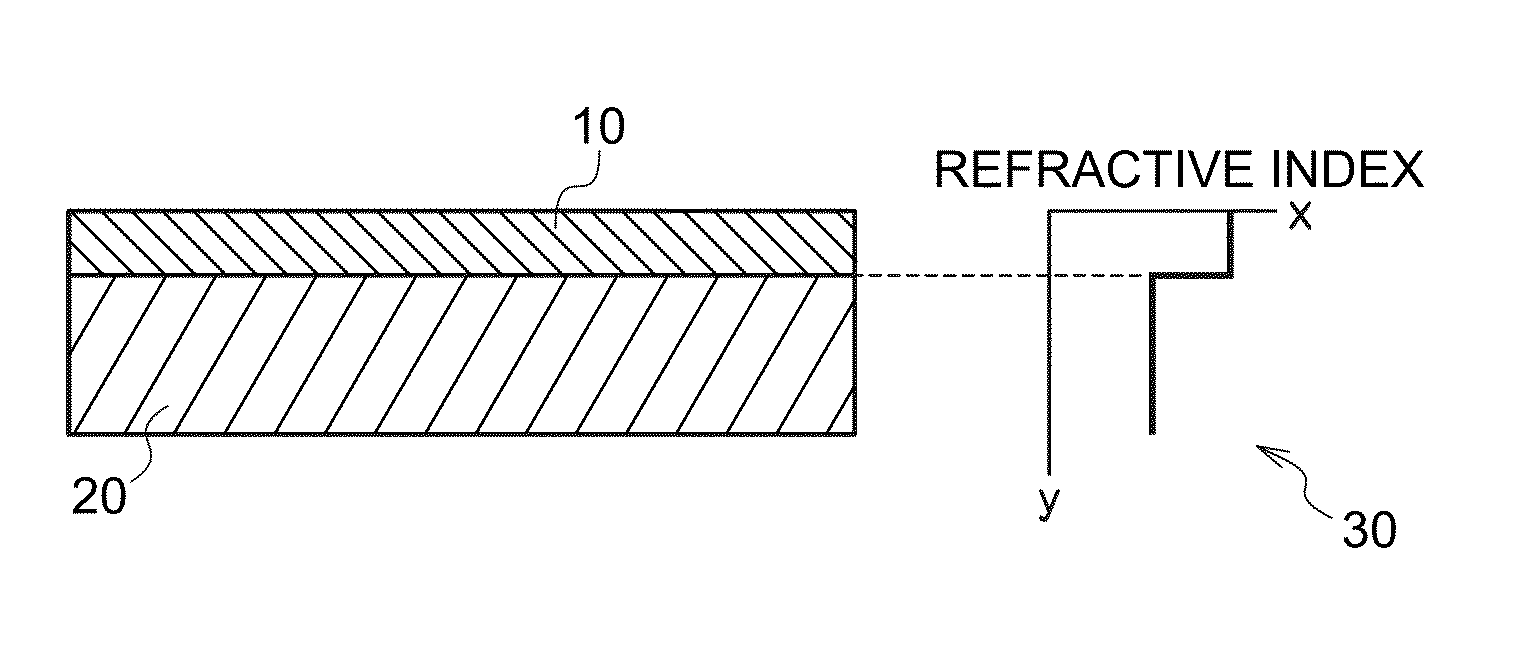

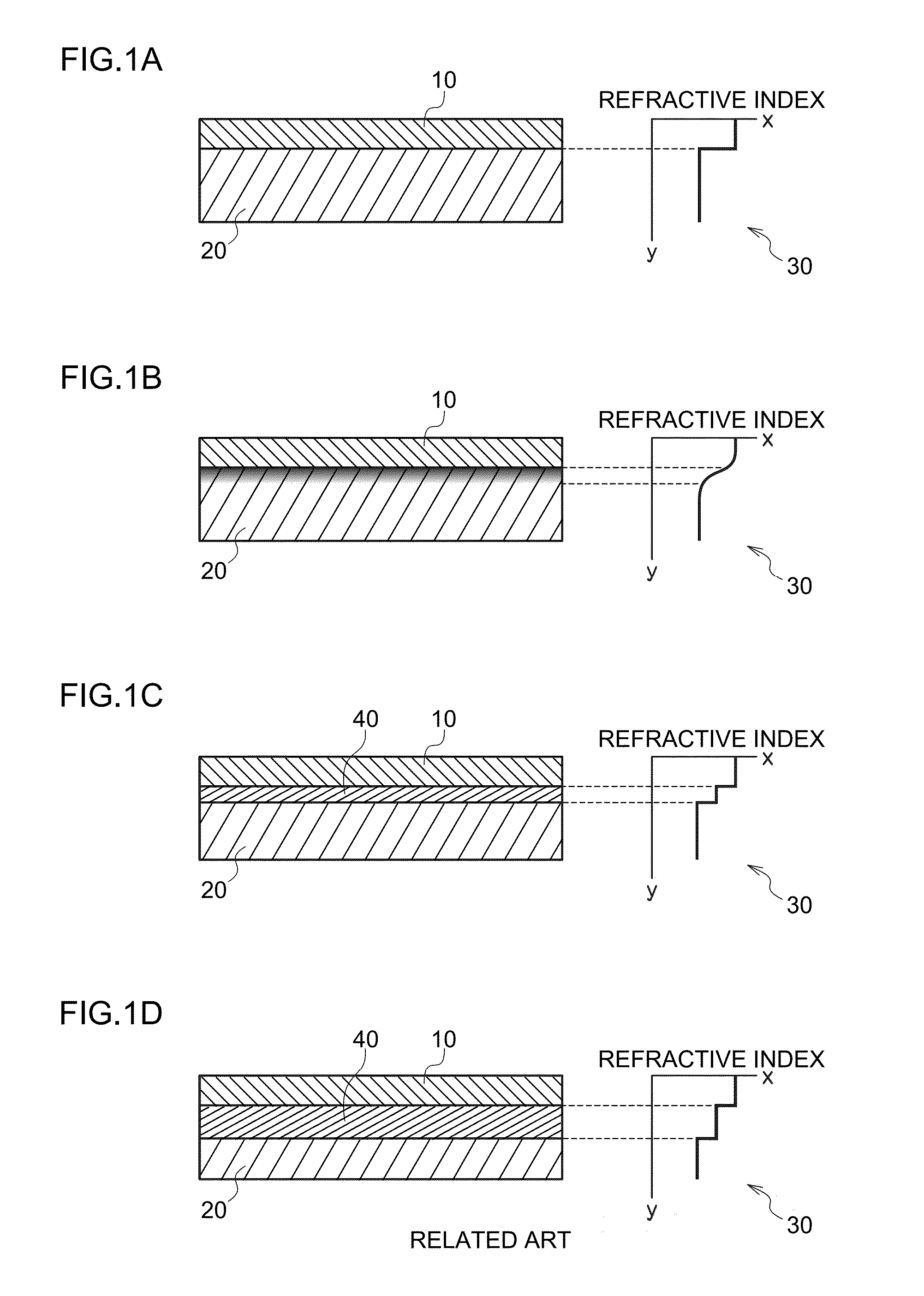

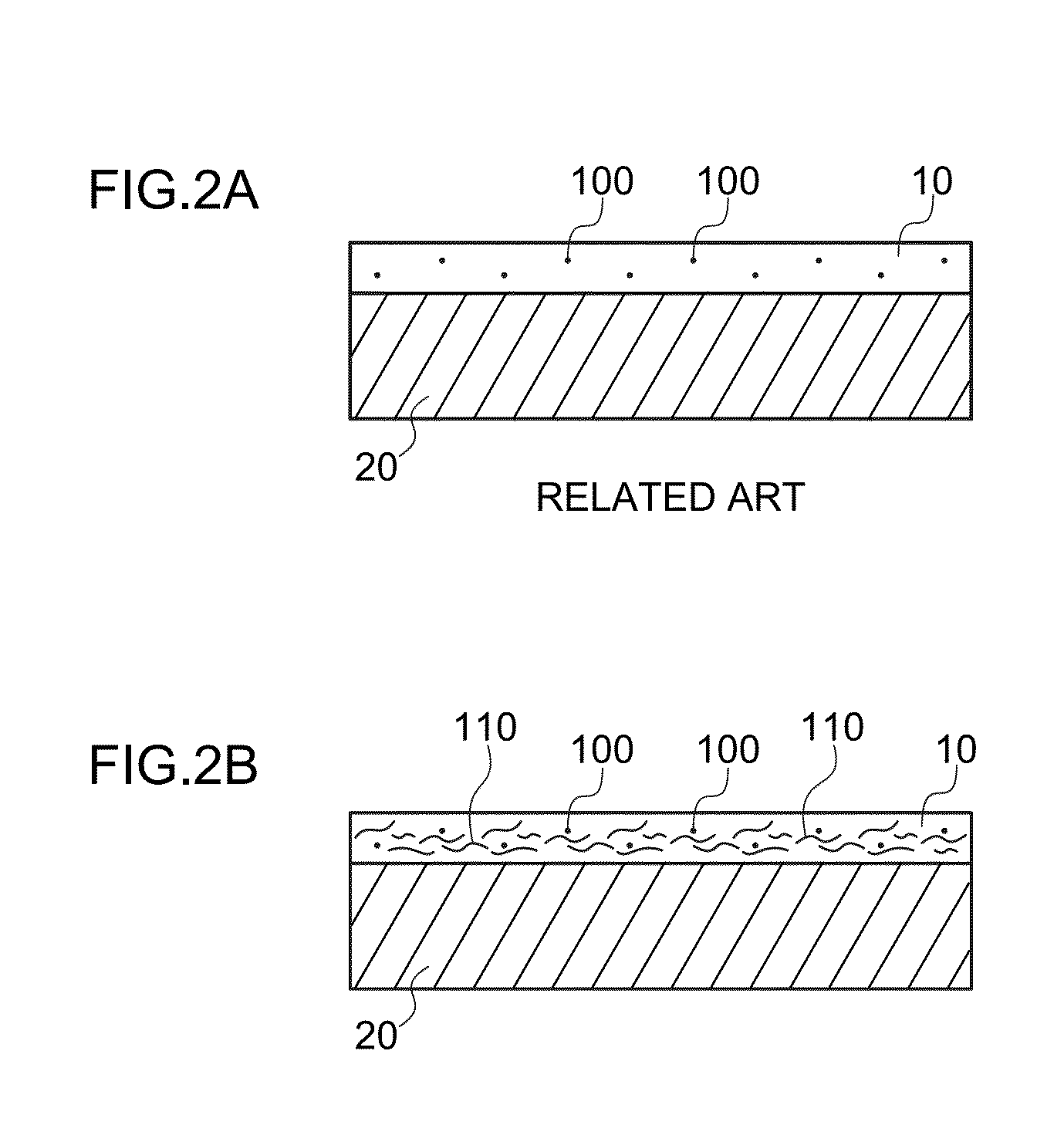

Index matching layers

ActiveUS20180067337A1Reduces interference fringeReduce interference fringesOptical partsOptical elementsRefractive index matchingEngineering

Optical devices such as eyeglass lenses and digital displays having improved optical characteristics achieved, in part, through incorporation of an index matching system between material layers having different refractive indices.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Optical composite film, backlight and liquid crystal display module

InactiveCN108549177AReduce micro-aggregationReduce interference fringesDiffusing elementsNon-linear opticsDiffusionComposite film

The invention provides an optical composite film, a backlight and a liquid crystal display module. The optical composite film comprises a microprism diffusion film and a brightness enhancement prism film which are bonded together, and the microprism diffusion film and the brightness enhancement prism film are respectively arranged on the light incident surface and the light exiting surface; the microprism diffusion film comprises a first light transmissive substrate and a microprism diffusion structure, the microprism diffusion structure comprises light transmissive spherical particles on thefirst light transmissive substrate facing away from the light incident surface, and the light transmissive spherical particles are regularly and orderly arranged on the first light transmissive substrate. According to the optical composite film, the microprism diffusion film is close to the light exiting surface of a light guide plate, the light from the light guide plate is firstly atomized by the microprism diffusion film, the microscopic convergence of the light guide plate or dots on the light is reduced, the shielding property is improved, and interference fringes between the light guideplate and an LCD panel can be reduced.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Rotationally asymmetric chaotic optical multi-pass cavity

ActiveUS8294898B2Simple structureImprove stabilityAdditive manufacturing apparatusPhotometryNon symmetricSpectroscopy

Owner:THE TRUSTEES FOR PRINCETON UNIV

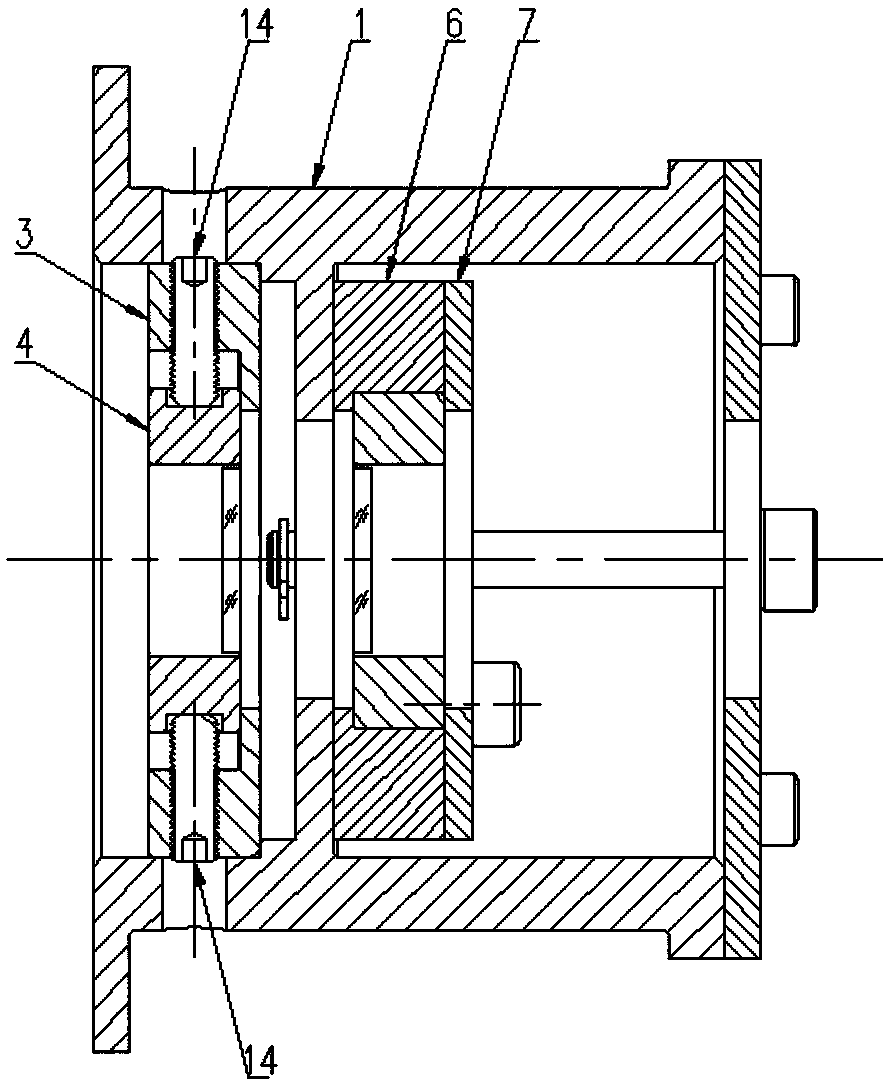

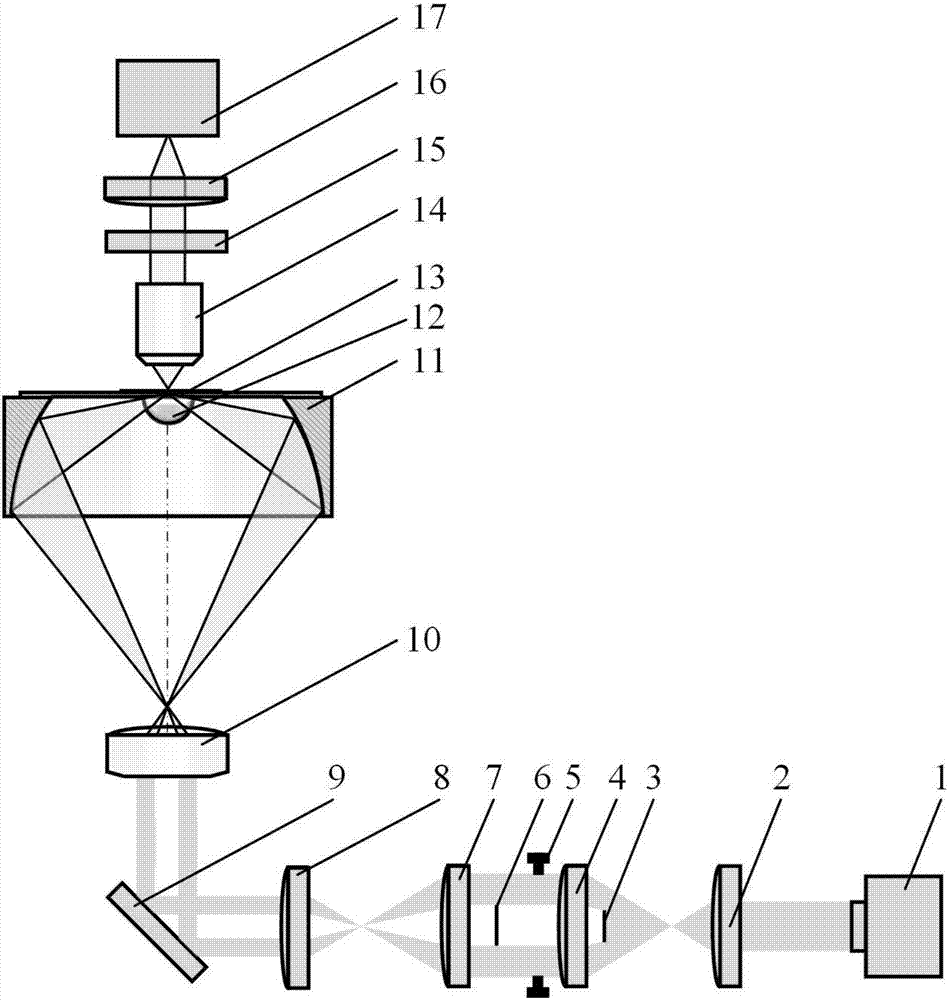

Total internal reflection fluorescence microscopic imaging device of dual variable-diameter ellipsoidal reflector

ActiveCN106980176AChange sizeExtended axial informationMicroscopesTotal internal reflectionImaging quality

The invention relates to a total internal reflection fluorescence microscopic imaging device of a dual variable-diameter ellipsoidal reflector and belongs to the field of optical microscopic illumination. The device uses annular light modulated by a diaphragm and a shading film, generates a large-vertex-angle hollow-cone light beam focused at the first focal point of the ellipsoidal reflector after the annular light is reflected by the ellipsoidal reflector, thereby achieving a total internal reflection fluorescence imaging phenomenon. The device can change the vertex angle of the hollow cone by moving the shading film and adjusting the diaphragm so as to finally change the excitation depth of an evanescent field and to expand the axial image of a fluorescence image. The shading film and the diaphragm can be adjusted in parallel so as to enhance the applicability of the instrument. The annular illumination light from 0 to 360 degrees provided by the device can achieve shadowless illumination, thereby reducing the interference fringes in the image, increasing the contrast of the image, and improving image quality.

Owner:HARBIN INST OF TECH

Projection display apparatus

ActiveUS7273279B2Reduce interference fringesRaise the gradeTelevision system scanning detailsPulse generatorIntegratorBeam splitter

A white light emitted from a light source is homogenized by an integrator optical system, transmitted through a color polarizer (113) to be turned into an R light and a G light of a P polarized light, and transmitted through a color polarizer (118) to be turned into a G light of an S polarized light and an R light of a P polarized light. These R light and G light are subjected to light modulation in a reflection type spatial light modulation element for G and a reflection type spatial light modulation element for R arranged at unequal distances from a polarization split surface of a polarizing beam splitter (103), and emitted from a projection lens having an axial chromatic aberration corresponding to the unequal distances.

Owner:JVC KENWOOD CORP

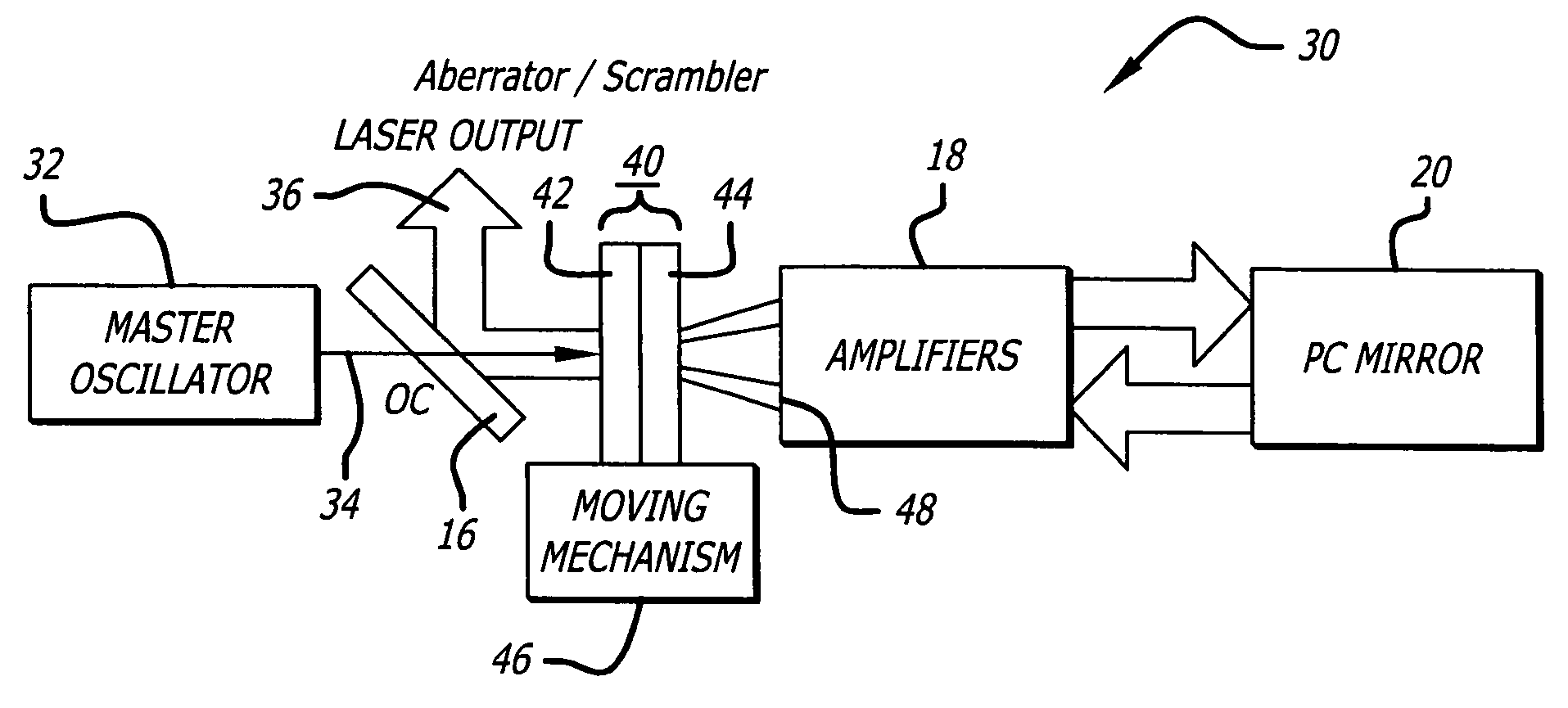

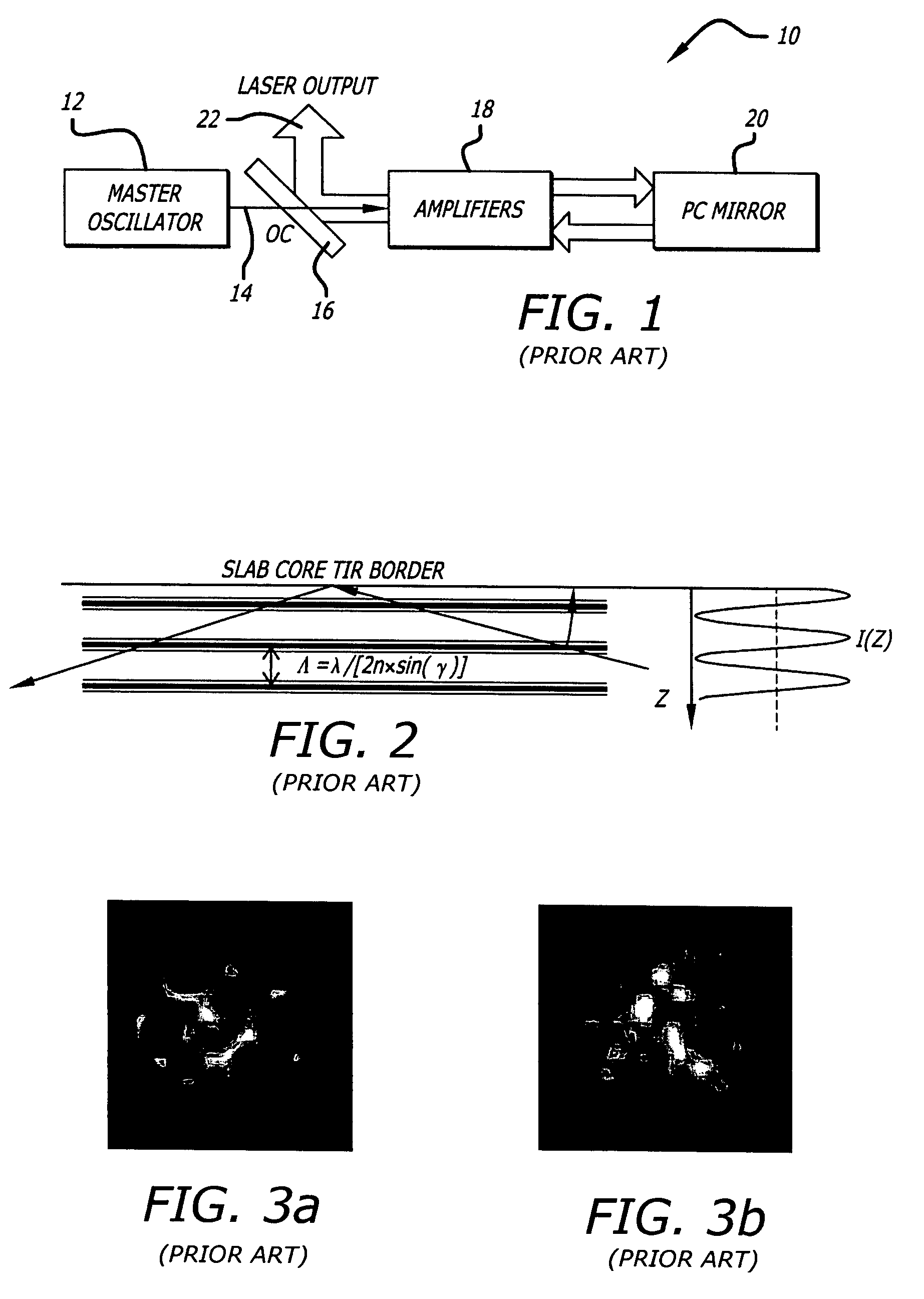

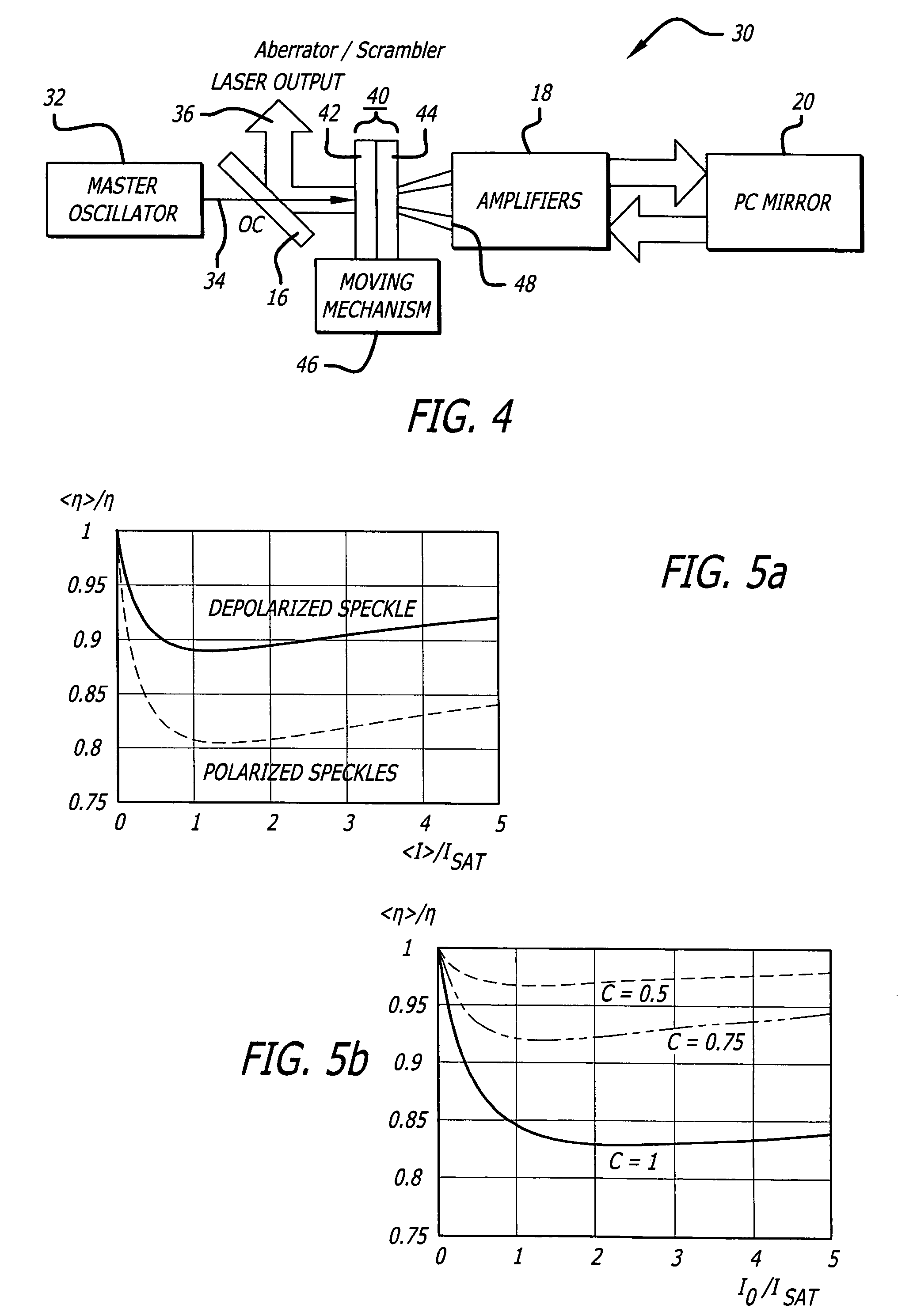

Laser amplifier power extraction enhancement system and method

ActiveUS7391558B2Reduce contrastIncrease spatial homogenizationOptical devices for laserNon-linear opticsAudio power amplifierTime changes

Owner:RAYTHEON CO

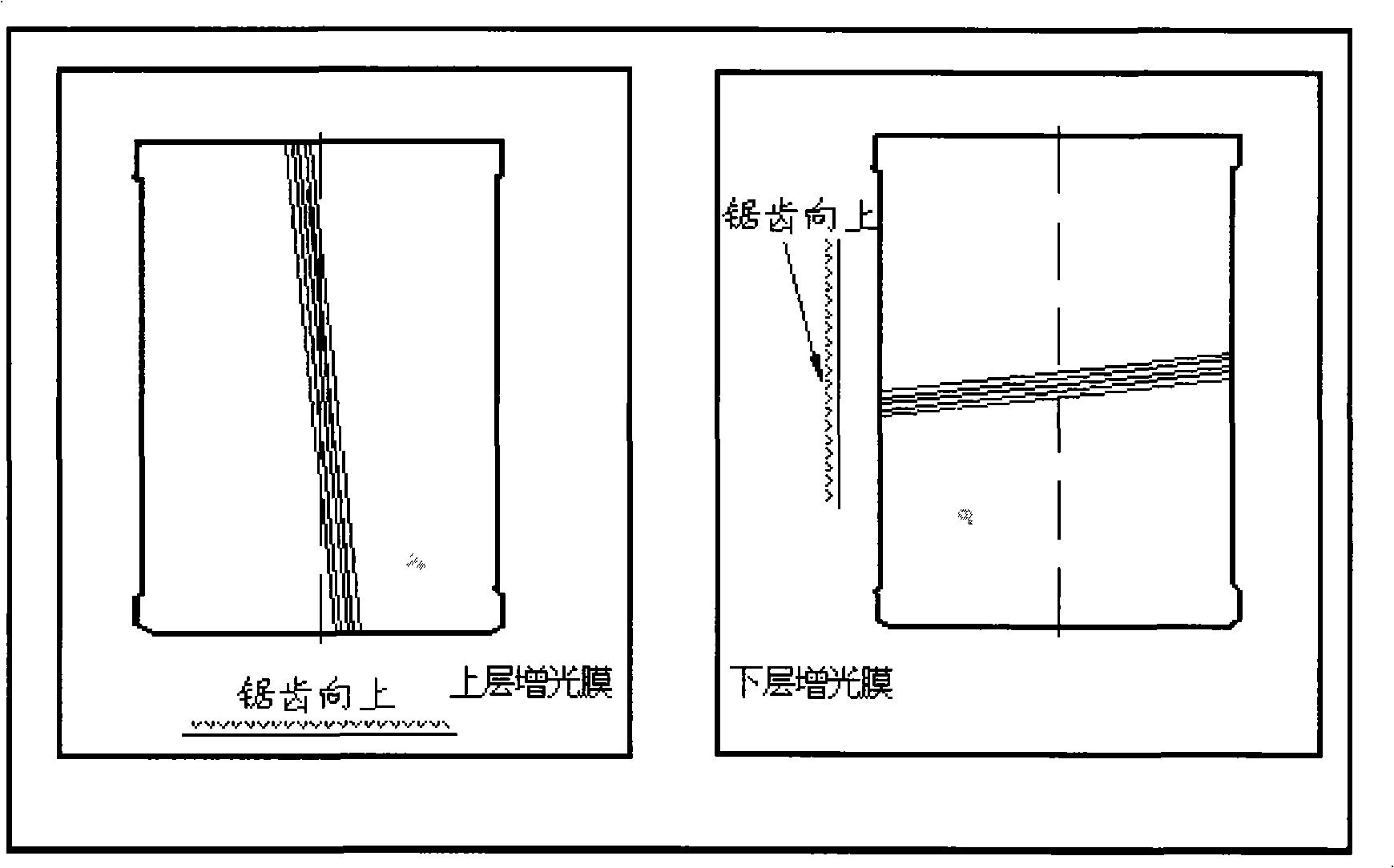

Backlight product interference grain processing process

InactiveCN101311790ASave thickness spaceGood product uniformityDiffusing elementsNon-linear opticsPhysicsBrightness perception

The invention provides an interference line treatment technology of a backlight product used for smoothing out the interference line after the backlight product passes through an LCD to improve the display effect of an LCD panel. The invention comprises an intensifying film. The angle of the intensifying film is adjusted to 15 degrees, 30 degrees or 45 degrees from the conventional angle of 6 degrees or 94 degrees according to the angel of LCD combined with backlight, or the intensifying film selects the sawing distance of 90 / 20 or 90 / 50, so the angle of the intensifying film is matched with the angle of an LCD polaroid, thus achieving the aim of smoothing out the interference line. In addition, by adopting the interference line treatment technology, the brightness of the product can be increased; cost can be saved and the market competitive strength of the product is improved.

Owner:星磊电子(深圳)有限公司

Touch control display panel and touch control display device using touch control display panel

ActiveCN104635368AReduce interference fringesImprove display qualityNon-linear opticsInput/output processes for data processingTouch SensesDisplay device

The invention provides a touch control display panel. The touch control display panel comprises a display substrate, a touch control sensing layer and an upper polarizer. The touch control sensing layer is located at the upper part of the display substrate, and the touch control sensing layer is used for sensing the touch control position. The upper polarizer is located at the surface of a back display substrate of the touch sensing level, and comprises a haze pressure-sensitive adhesive layer. The invention further provides a touch control display device using the touch control display panel. The touch control display panel and the upper polarizer of the touch control display device comprise the haze pressure sensitive adhesive layer, so that the interference stripe between the touch control sensing layer and the display substrate is reduced, the display quality is improved; moreover, it is beneficial for light and thin design of a product.

Owner:KUSN INFOVISION OPTOELECTRONICS

Light directing film

ActiveUS20150268389A1Improve luminanceIncrease brightnessMechanical apparatusDiffusing elementsPrismOptoelectronics

The present invention discloses a light directing film comprising a first structured major surface, a second major surface opposite to the first structured major surface, wherein the first structured major surface comprises a first prism element and a second prism element meandering in a wary manner.

Owner:UBRIGHT OPTRONICS CORP

Sheet for three-dimensional molding

InactiveUS20170100920A1Good moldabilityImprove scratch resistanceSynthetic resin layered productsConstructions elementsInorganic particleShell molding

The present invention provides a sheet for three-dimensional molding, said sheet having excellent scratch resistance and moldability and effectively suppressing interference fringes. Provided is a sheet for three-dimensional molding, said sheet having at least a surface protection layer laminated upon a substrate, wherein the surface protection layer is formed from a cured product of a resin composition that includes an ionizing radiation-curable resin and inorganic particles having an average particle size of 100 nm or more, and the content of the inorganic particles in the surface protection layer is 40 mass % or more.

Owner:DAI NIPPON PRINTING CO LTD

Terahertz light beam expansion uniformizing device

InactiveCN105911702AReduce interference fringesEasy to divergeOptical elementsBeam expanderIntegrator

The invention relates to a terahertz light beam expansion uniformizing device. The front end of the uniformizing device is provided with a terahertz light source, and the uniformizing device further comprises a light expander, an integrator and an imaging focal plane, the beam expander is arranged between the terahertz light source and the integrator, the focal plane is arranged behind the integrator, the light expander comprises a second convex lens and a first convex lens between the second convex lens and the terahertz light source, the integrator comprises two lens arrays, a lens and a condensing lens, the two lens arrays are fixedly arranged in the front and back sides of the lens respectively, the lens is arranged in front of the condensing lens, the imaging focal plane is arranged at the real focal point of the condensing lens, and the photocenters of the first and second convex lenses and the condensing lens and the center of the terahertz light source are in the same straight line. The terahertz light beam expansion uniformizing device is simple in structure, and can be used to obtain large-area flat terahertz light spots with uniform energy distribution.

Owner:YANTAI RAYTRON TECH

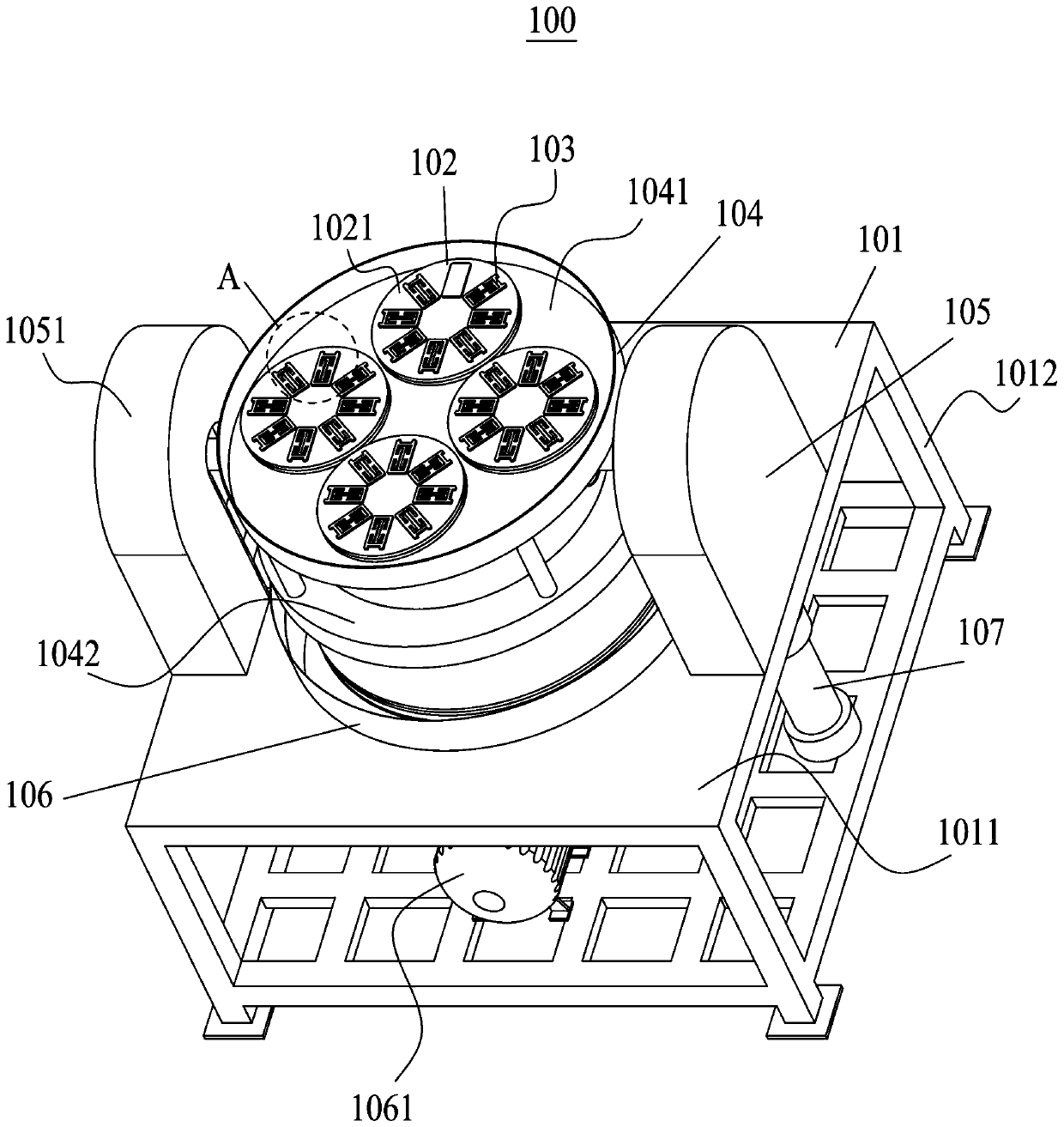

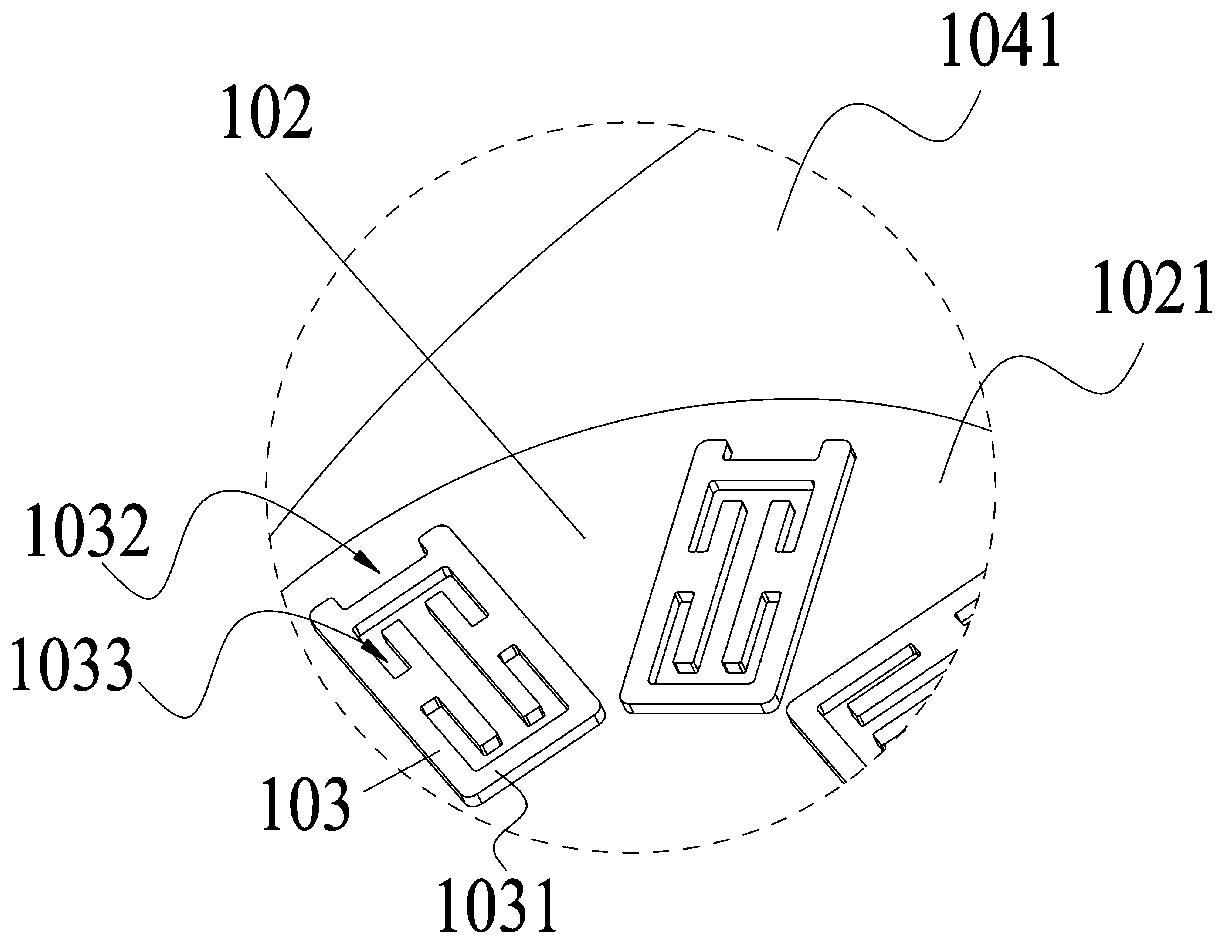

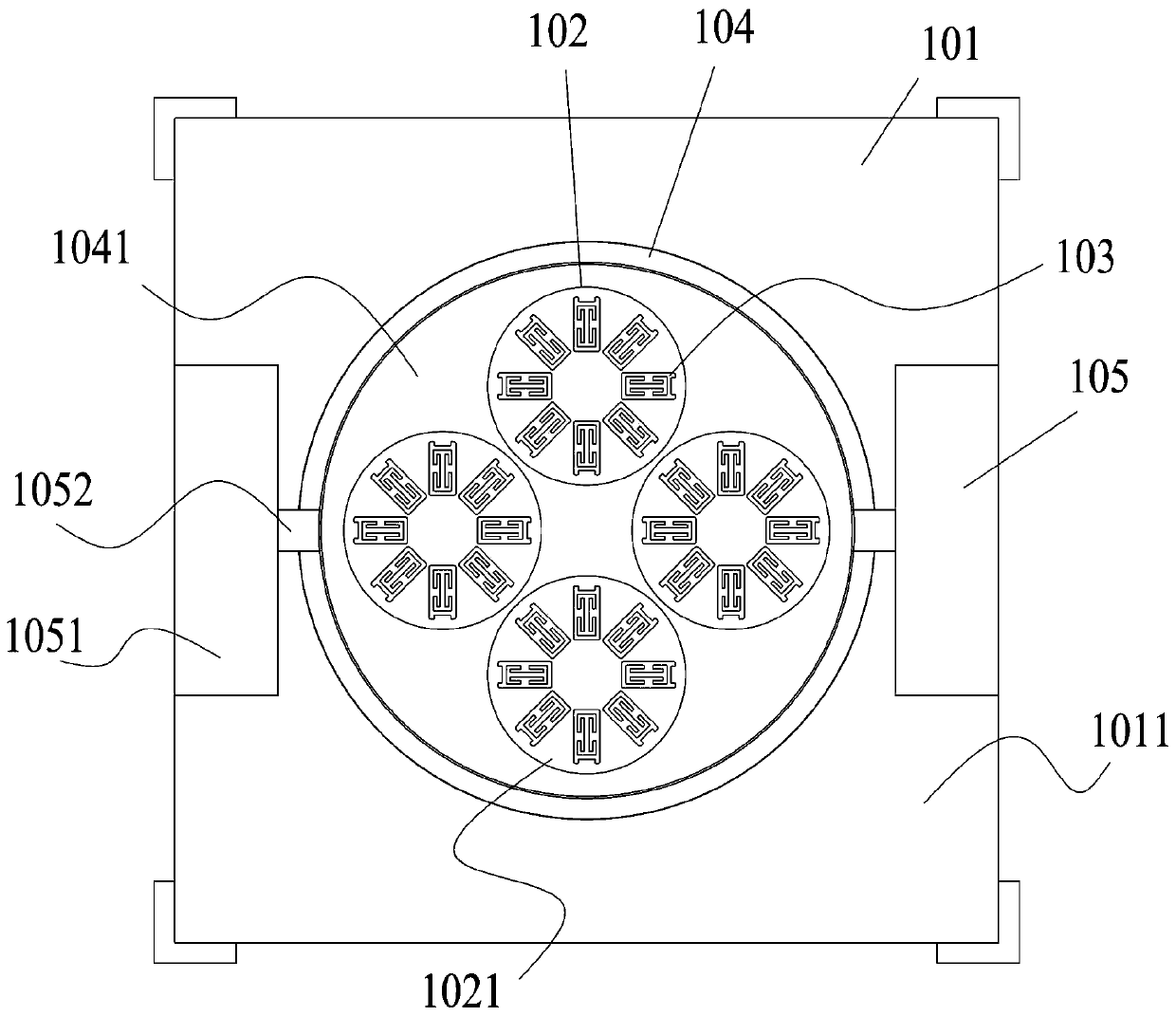

Glass cover plate machining method and polishing machine related to glass cover plate machining

PendingCN110170918AReduce knife marksReduce interference fringesPolishing machinesGrinding machinesGlass coverMachining

The invention discloses a glass cover plate machining method and a polishing machine related to glass cover plate machining, and relates to the glass machining technology. The polishing machine comprises at least two jig discs a fixing disc device, a turnover mechanism, a polishing device and a lifting device, wherein each jig disc is provided with at least two jigs for fixing a glass cover plate;the fixing disc device is fixed to a turnover shaft rod of the turnover mechanism; the turnover mechanism comprises a power device for driving the turnover shaft rod, and the turnover shaft rod is used for driving a first fixing disc and a second fixing disc to turn at the same time; the polishing device is used for polishing the glass cover plates; and the lifting device is used for driving a polishing carpet layer and the glass cover plates arranged on the fixing disc device to contact during polishing treatment or go away from each other during non-polishing treatment. Through the polishing machine provided by the invention, interference fringes in the camera shooting hole forming zones of the glass cover plates can be decreased, and the optical requirements for the camera shooting hole forming zones of the glass cover plates are met.

Owner:深圳市信濠光电科技股份有限公司

Index matching layers

ActiveUS10444538B2Reduce interference fringesOptical partsOptical elementsEyeglass lensesOptical property

Optical devices such as eyeglass lenses and digital displays having improved optical characteristics achieved, in part, through incorporation of an index matching system between material layers having different refractive indices.

Owner:HOYA OPTICAL LABS OF AMERICA INC

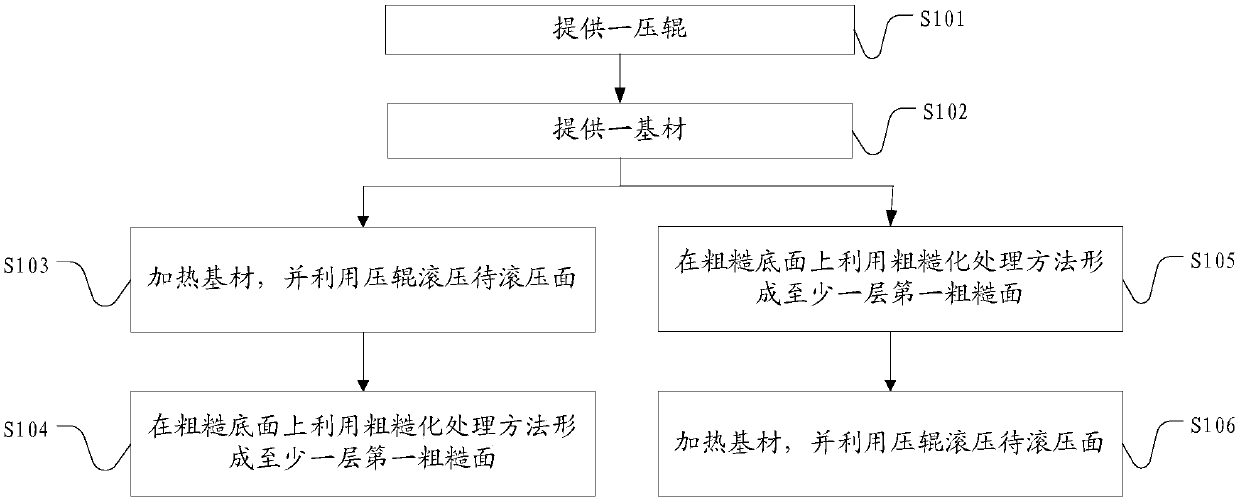

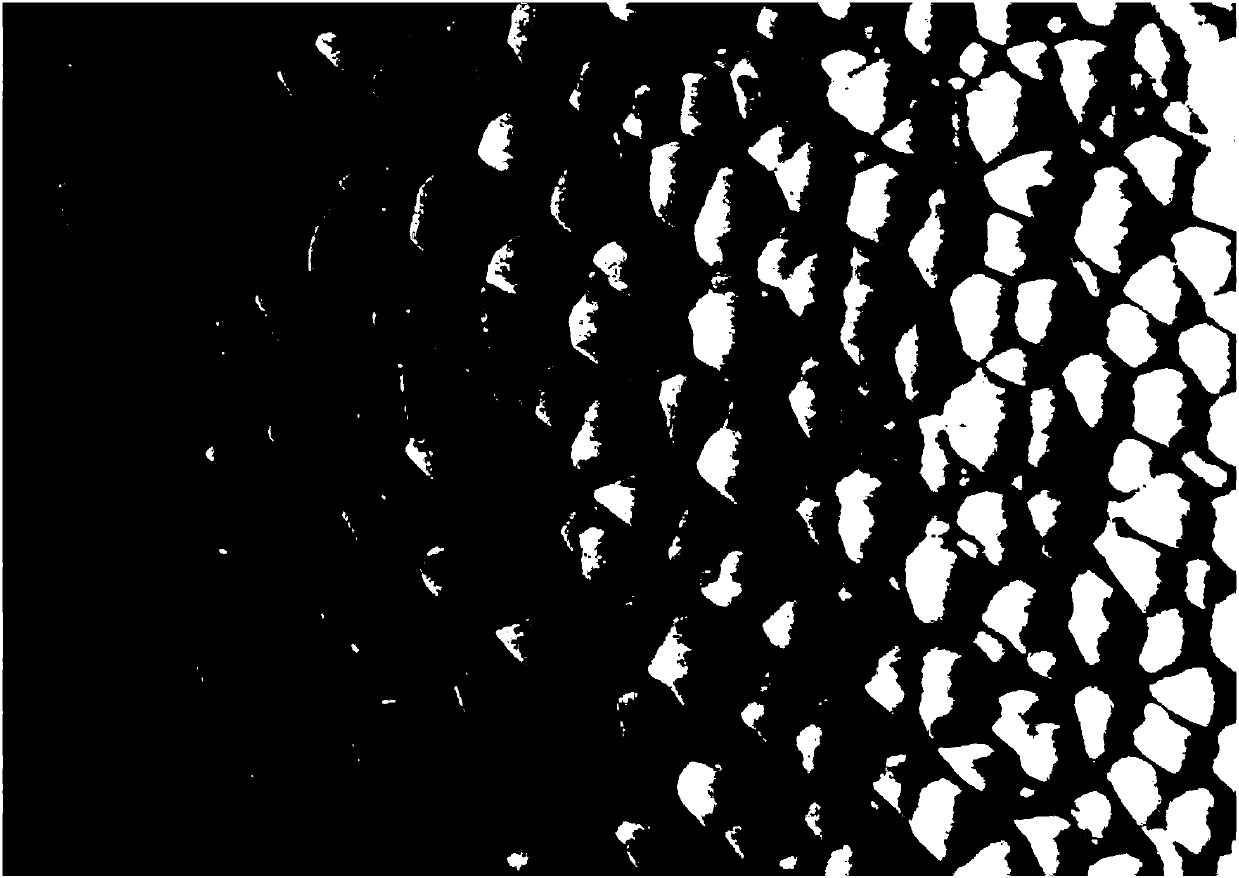

Brightness enhancement film manufacturing method, backlight module, flat panel display and electronic device

InactiveCN109991693AFacilitated DiffusionHigh hazePrismsDiffusing elementsRough surfaceDisplay device

The invention discloses a brightness enhancement film manufacturing method, a backlight module, a flat panel display and an electronic device. With a method of, after a press roller and a substrate are provided, heating the substrate, using the press roller to roll the surface to be rolled and forming at least one first rough surface on the rough bottom by using a roughening treatment method, or amethod of, before the press roller rolls the surface to be rolled, forming at least one first rough surface on the rough bottom by using a roughening treatment method, the light-incident surface of the brightness enhancement film has a multi-layered rough surface structure, and the light emitted from the light source is necessary to pass through the multi-layered rough surface when passing through the brightness enhancement film manufactured by the brightness enhancement film manufacturing method provided by the invention, thereby enhancing the diffusion of the light incident. The brightnessenhancement film manufacturing method provided by the invention greatly enhances the haze of the light-incident surface of the brightness enhancement film and is beneficial to reduce the occurrence ofwater ripples and interference fringes. Moreover, since the substrate in the embodiment does not need to be doped with particles, the adverse effect on assembly yield is reduced.

Owner:惠州市聚飞光学材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com