Brightness enhancement film manufacturing method, backlight module, flat panel display and electronic device

A manufacturing method and technology of a brightness enhancement film, which are applied in the field of flat panel displays and electronic devices, and the field of brightness enhancement film manufacturing, can solve problems such as water ripples of the brightness enhancement film and affect the yield of backlight assembly, and achieve enhanced haze, reduction of water ripples and Interference fringe phenomenon, enhanced diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

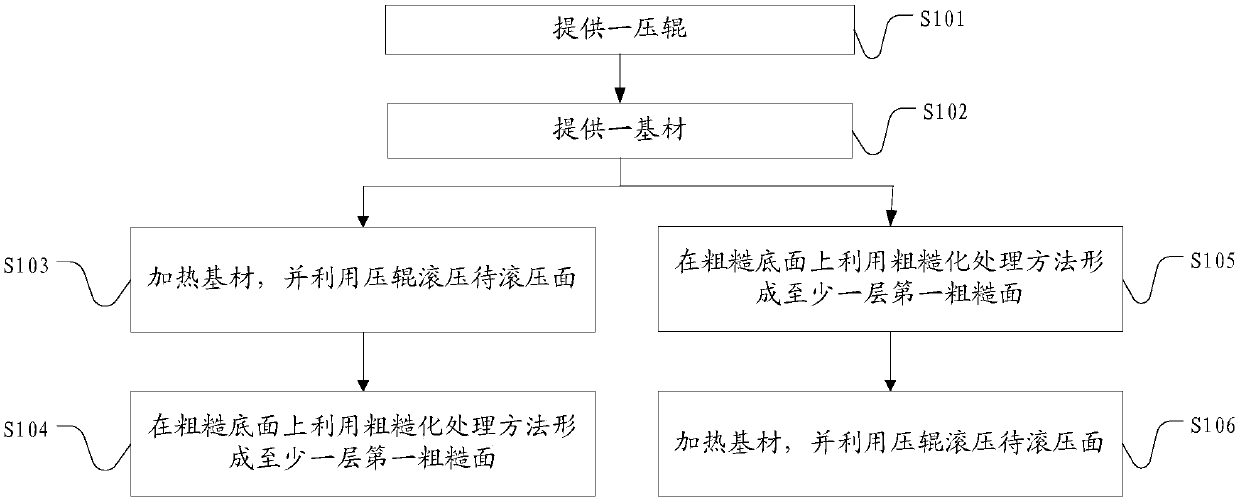

[0028] In order to solve the problem that in the prior art, the structure of the rough surface on the light-incoming side of the brightness enhancement film is relatively smooth, which cannot effectively increase the haze value, resulting in insufficient concealment, easy to produce water ripples, and the structure of the rough surface has certain rules. It is easy to produce problems such as interference fringes. This embodiment proposes a method for manufacturing a brightness enhancement film that can increase the haze value of the brightness enhancement film, enhance its concealing power, and reduce water ripples and interference fringes. figure 1 As shown, the brightness enhancing film manufacturing method includes:

[0029] S101, providing a pressing roller;

[0030] S102. Provide a substrate, the substrate incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com