Patents

Literature

447results about How to "High haze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

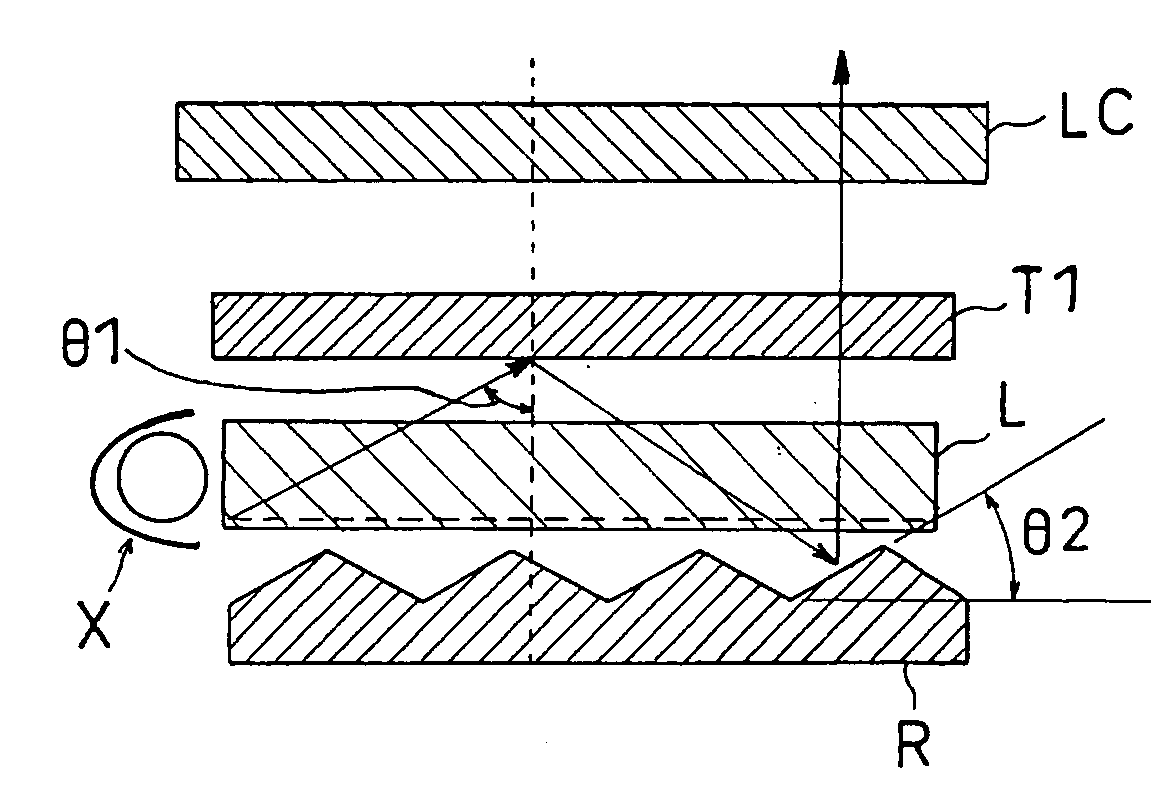

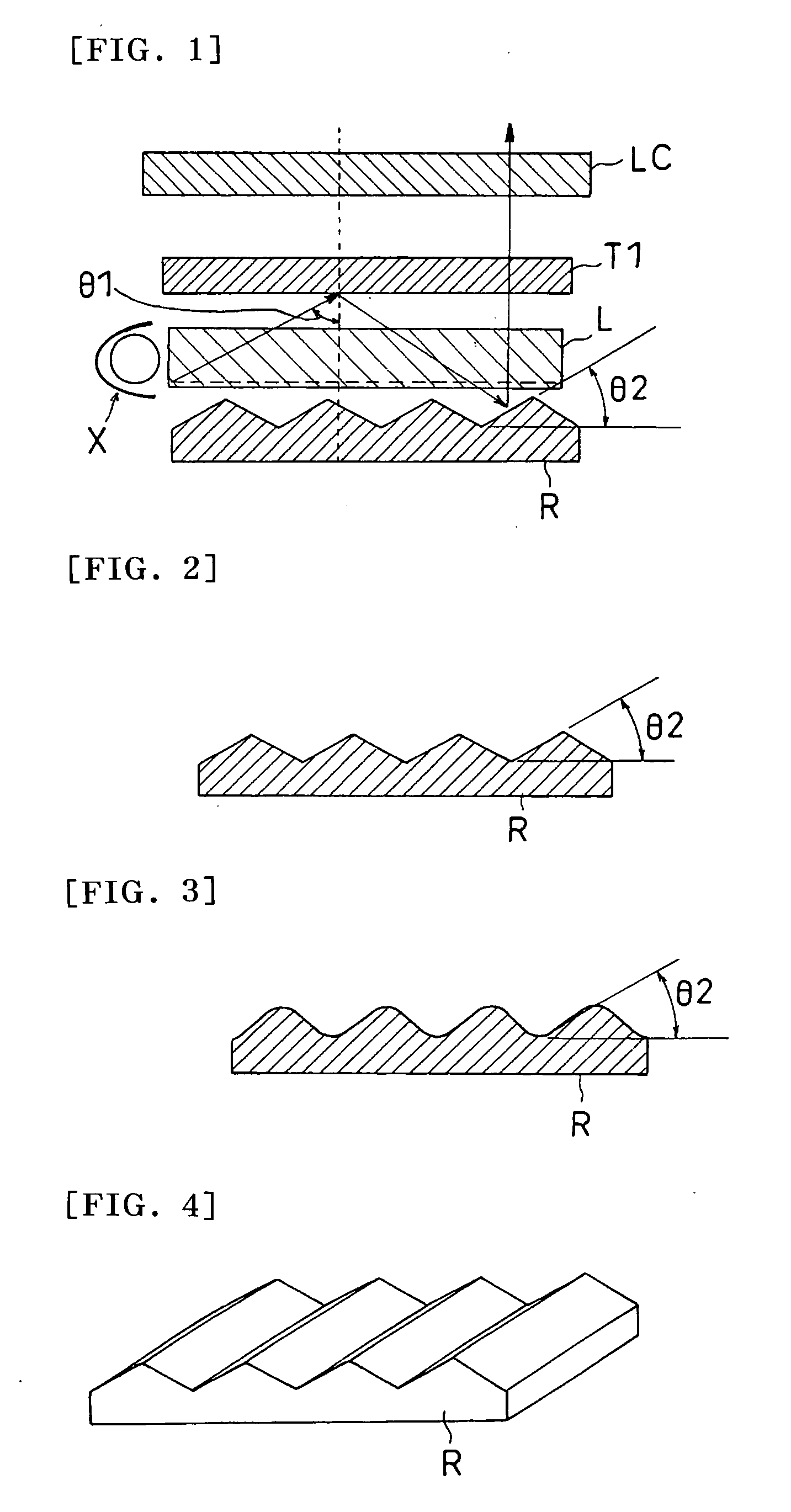

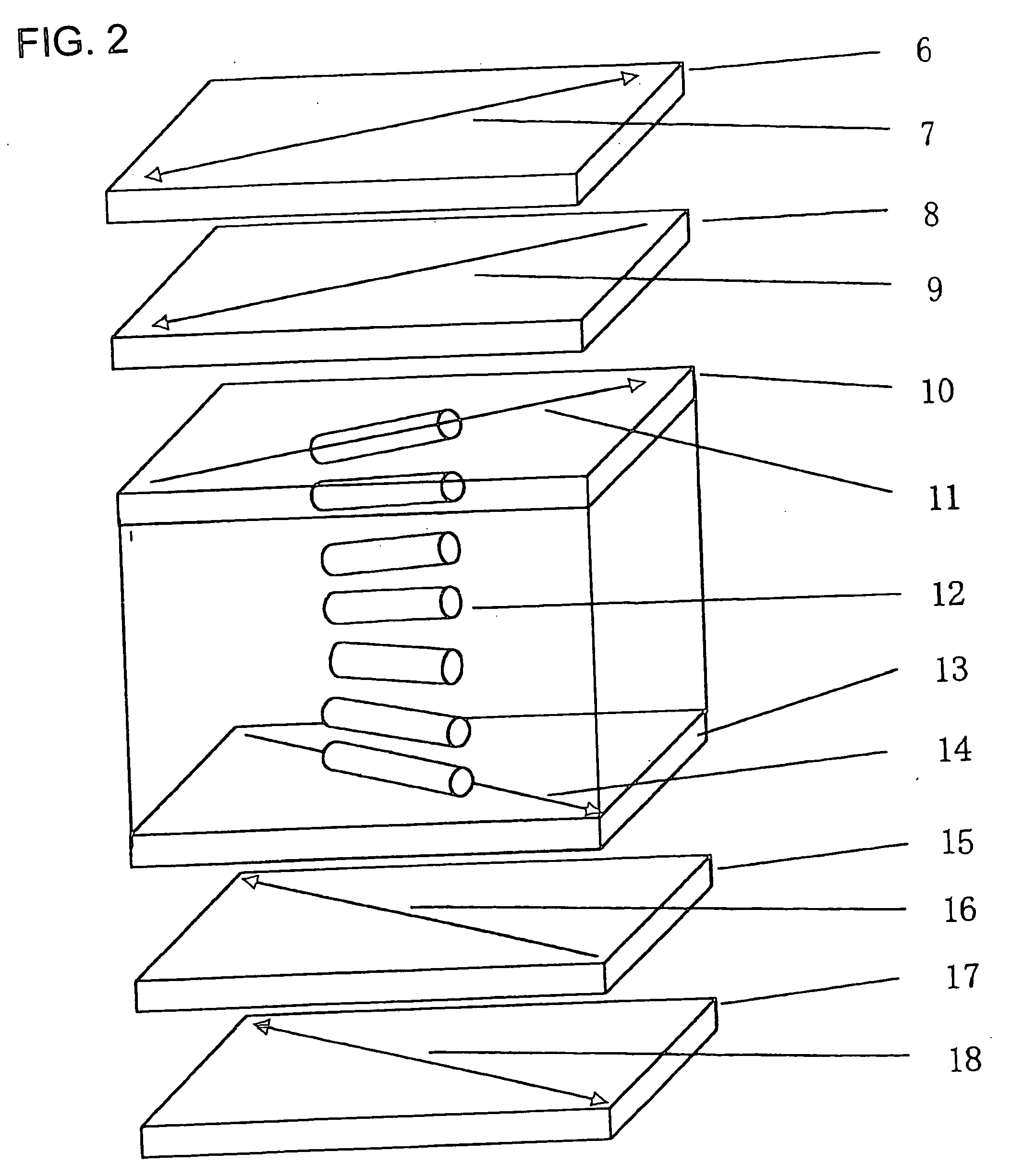

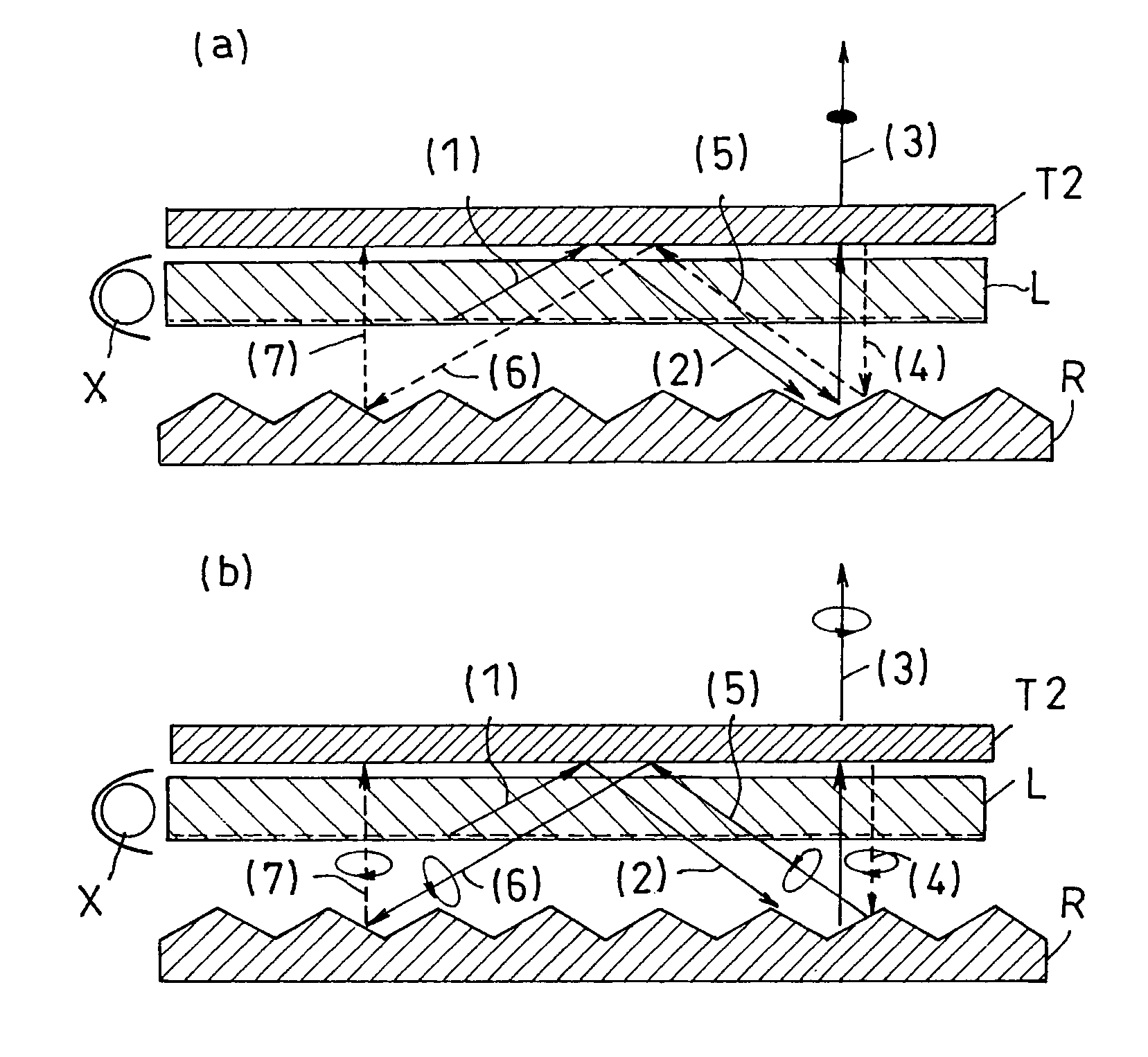

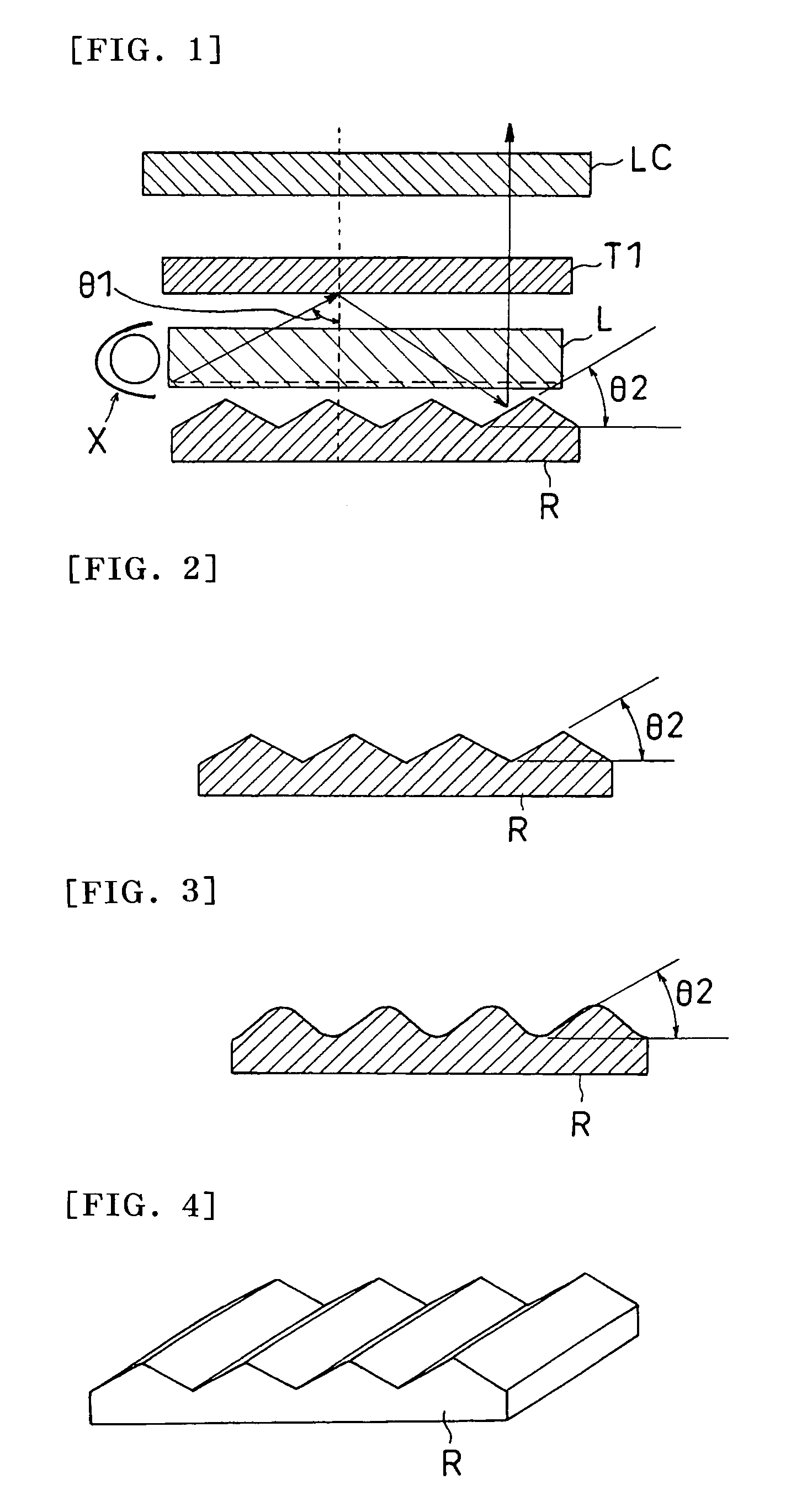

Light source device and crystal display device

InactiveUS20070014127A1Improve efficiencyLow costMechanical apparatusElongate light sourcesTransmittanceLight reflection

A light source comprising sidelight type backlight light guide plate (L), wherein a transmittance angle dependent layer (T1) which transmits normally incident light and reflects obliquely incident light is disposed on one surface of the sidelight type backlight light guide plate (L), and a reflection plate (R) having a repetitive slope structure is disposed on the other surface of the sidelight type backlight light guide plate (L). The invention light source is less in absorption loss due to repetition of light reflection and the like.

Owner:NITTO DENKO CORP

Cellulose acylate film, process for producing cellulose acylate film, polarizing plate and liquid crystal display device

ActiveUS20060093759A1Improve image qualityViewing angle is smallLiquid crystal compositionsFlat articlesCrystallographyIn plane

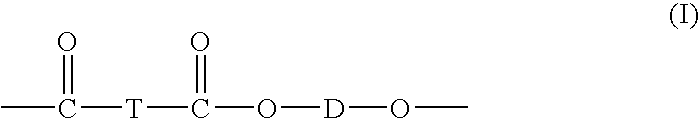

A cellulose acylate film that has: an in-plane retardation Re and a retardation Rth in a thickness direction at a wavelength of 590 nm, which are satisfied with ranges of expressions (I) to (III); a coefficient of a thermal expansion of from 20 ppm / ° C. to 100 ppm / ° C.; and a haze of from 0.01 to 0.8, and a polarizing plate and a display device using the same. 20≦Re≦50 Expression (I) 70≦Rth≦200 Expression (II) 1.0≦Rth / Re≦3.0 Expression (III) In the foregoing expressions, each of Re and Rth is a value at 25° C. and 60% RH, and has a unit of nm.

Owner:FUJIFILM CORP

Optical element containing nanocomposite materials

InactiveUS6844047B2High hazeHigh light transmittanceDiffusing elementsRecord information storageParticulatesMicrometer

Disclosed is an optical element comprising substrate with a surface feature having a roughness average (Ra) of from 1 to 200 micrometers containing a dispersion of minute layered particulates in a polymer binder.

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

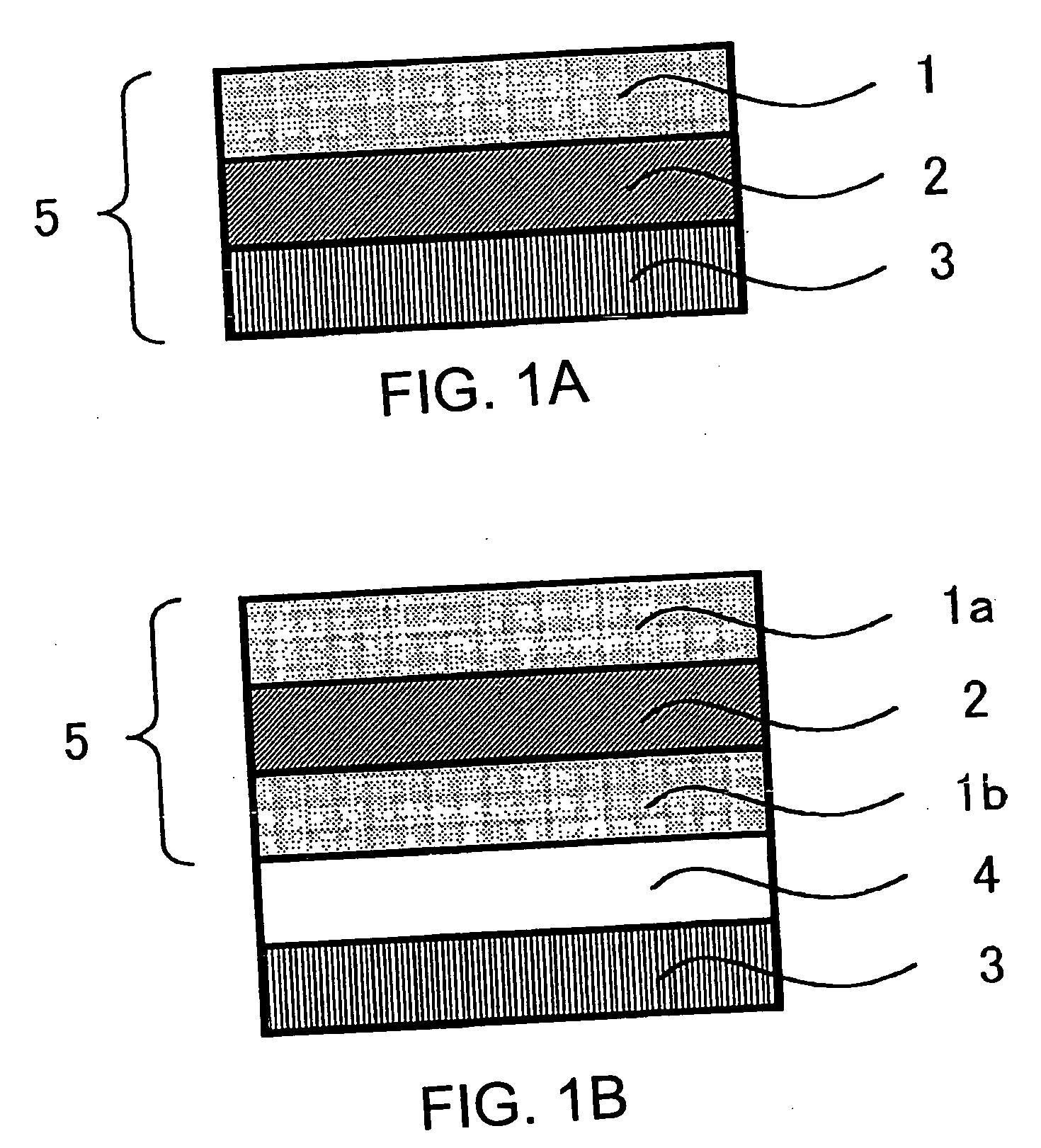

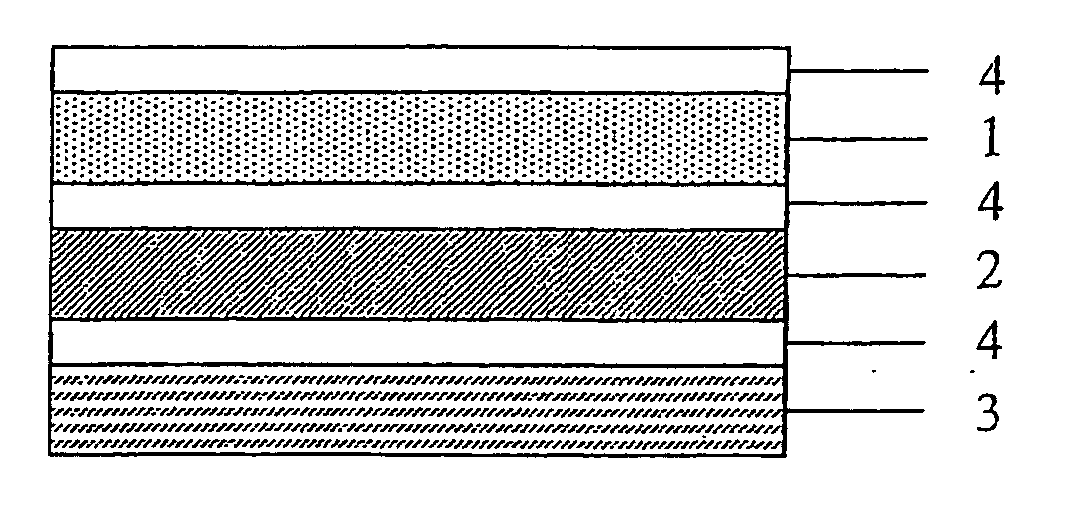

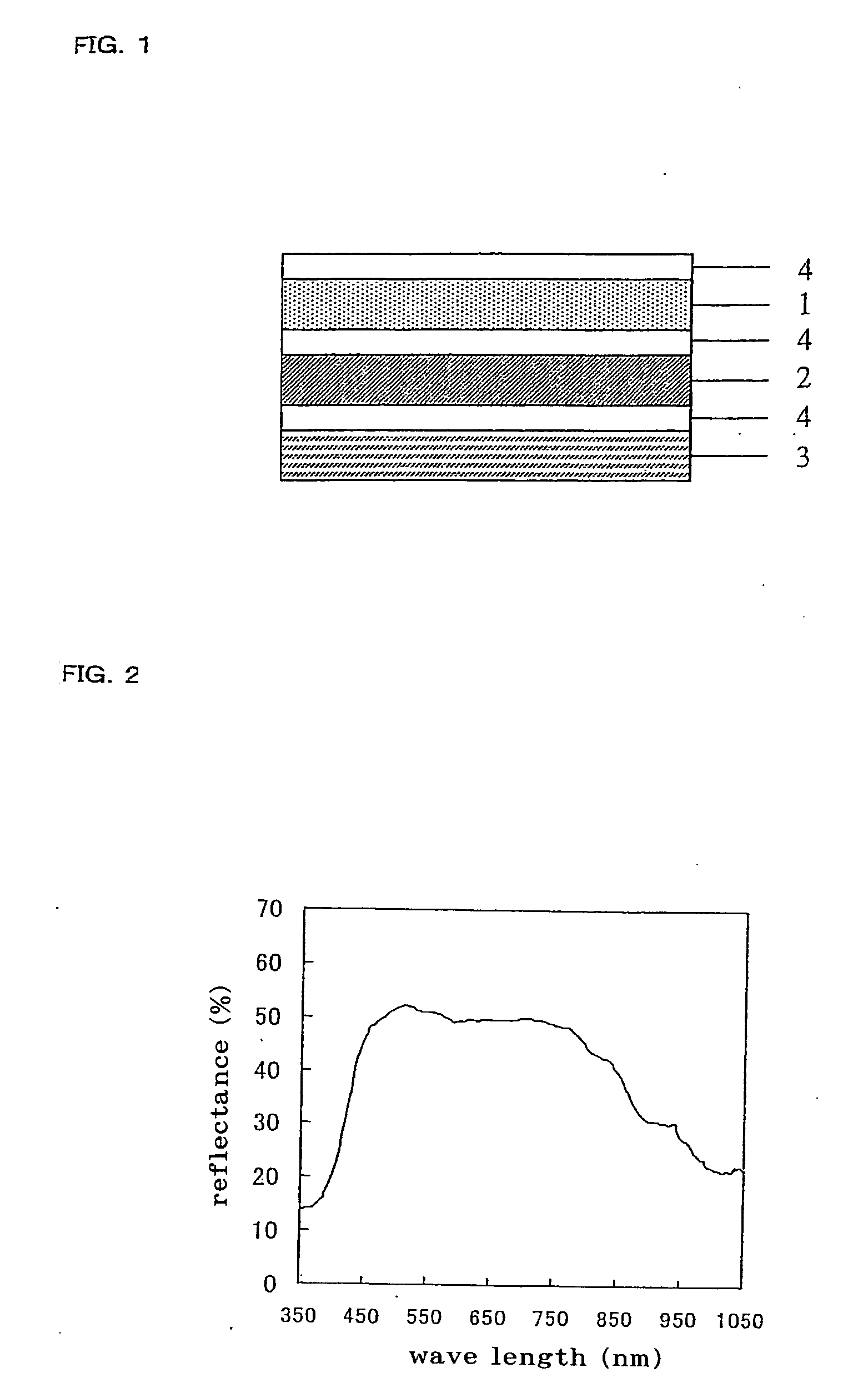

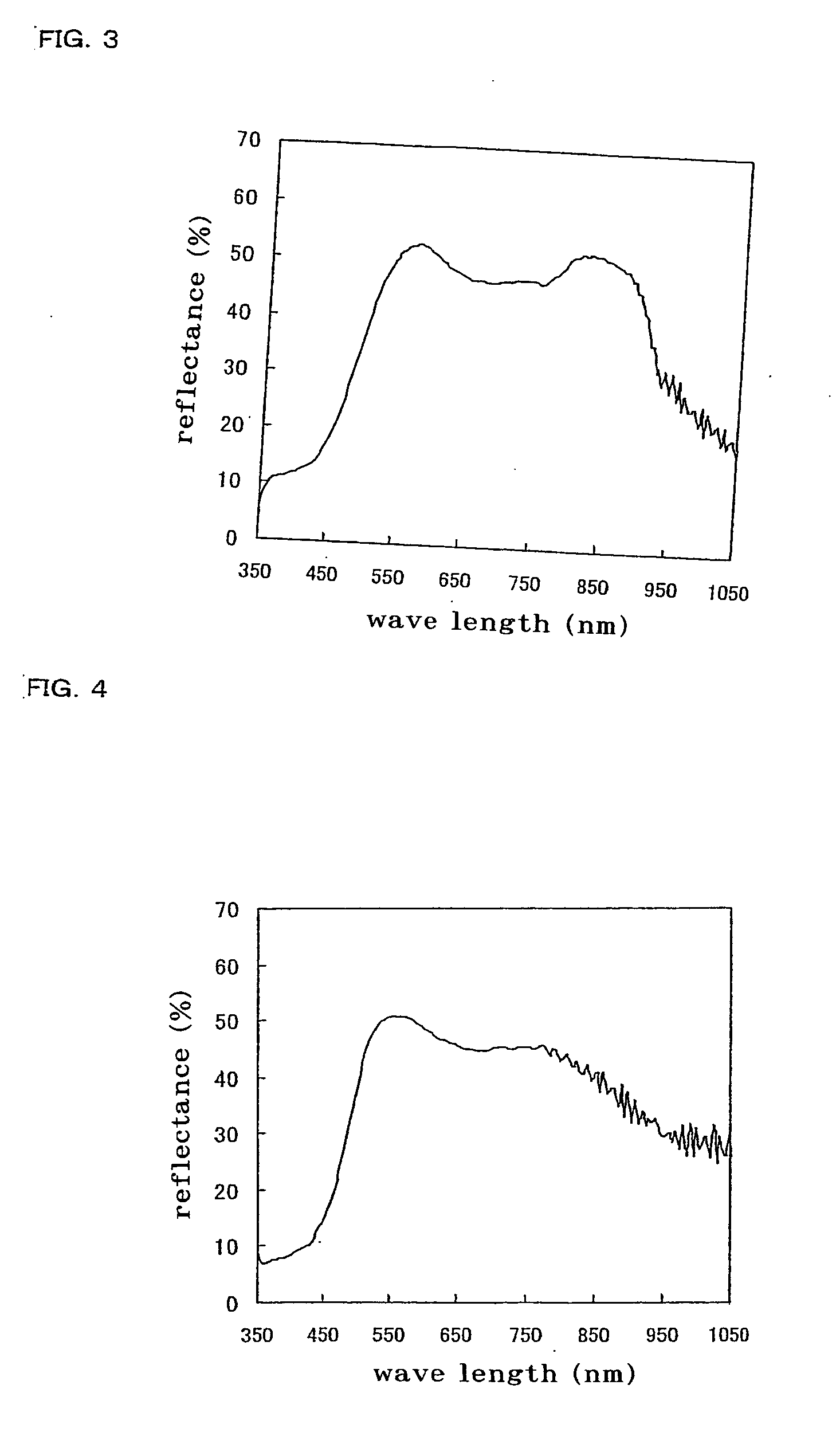

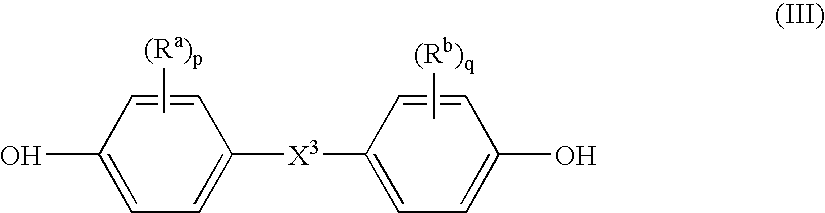

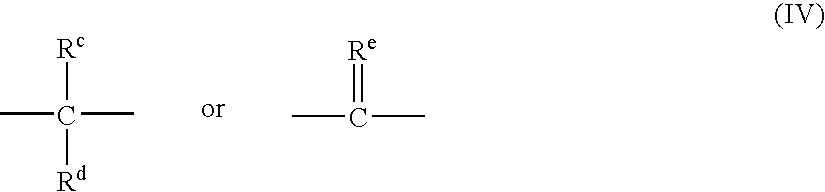

Broad band-cholesteric liquid crystal film and process for producing the same, circularly polarizing plate, linearly polarizing element, illuminator, and liquid-crystal display

InactiveUS20060119783A1Wide reflection bandIncreased durabilityLiquid crystal compositionsPolarising elementsLiquid-crystal displayUltraviolet lights

A broad band cholesteric liquid crystal film of the present invention comprises a cholesteric liquid crystal film obtained by polymerizing a liquid crystal mixture containing a polymerizable mesogen compound (a), a polymerizable chiral agent (b) and a photopolymerization initiator (c) between two substrates with ultraviolet light, and has a reflection bandwidth of 200 nm or more. The broad band cholesteric liquid crystal film of the present invention has a broad reflection band and is excellent in durability.

Owner:NITTO DENKO CORP

Anti-glare flame-retardant polycarbonate material, and preparation method and application thereof

The invention discloses an anti-glare flame-retardant polycarbonate material which comprises the following components by weight percent: 85-95 percent of polycarbonate, 2-12 percent of flame retardant, 0.1-1 percent of flame-retardant synergist, 0.1-5 percent of anti-glare agent, 0.3-2 percent of anti-ultraviolet agent, 0.05-3 percent of blue light absorbent, 0.2-3 percent of antioxidant and 0.2-2 percent of lubricating agent. The anti-glare flame-retardant polycarbonate material not only has an excellent anti-glare function, but also has higher light transmittance, and is capable of absorbing the blue wave band of the LED lighting spectrum at the same time. The invention further discloses a preparation method of the anti-glare flame-retardant polycarbonate material, which comprises the following steps: firstly preparing flame-retardant masterbatches, organic silicon microbead anti-glare masterbatches and blue light absorption masterbatches, and then preparing the anti-glare flame-retardant polycarbonate material, so that the performance anti-glare flame-retardant polycarbonate material is improved. The anti-glare flame-retardant polycarbonate material is particularly suitable for preparing an optical housing for LED lighting.

Owner:CGN JUNER NEW MATERIALS +1

Lamp lens or bezel with visual effect

InactiveUS20030189838A1Broad paletteImprove lighting qualityPoint-like light sourceMeasurement apparatus componentsCamera lensVisibility

Lenses and bezels for lamps provide an appealing aesthetic look in the form of a colored glow at the edges of the lens or bezel by incorportation of an photoluminescent material in a molded polycarbonate body. The lenses are particularly suitable for use as an automotive outer lens, and can also improve the quality of the light emitted through this outer lens by interacting with the light bulb. The emitted beam is of a legal color and intensity as defined per the SAE J578 standard. The lighting performance may also be improved in such manner as reducing glare, increasing brightness or producing a beam that enhances road visibility at night to the human eye.

Owner:SABIC GLOBAL TECH BV

Light diffusion agent mother material used for light diffusion film, preparation method and application thereof

ActiveCN101812220AHigh light transmittanceHigh hazeFlat articlesNon-linear opticsLiquid-crystal displayMicrosphere

The invention provides a light diffusion agent mother material used for a light diffusion film, a preparation method and application thereof. A light diffusion agent is compounded from organic polymer cross linking microspheres with different refractive indexes and grain diameters, the light diffusion agent mother material is prepared from 100 weight parts of polyester resin, 60 to 100 weight parts of compounded light diffusion agents and 1 to 7 weight parts of diffusion resin through high-speed diffusion and fused extrusion grain cutting by a double-screw extruding machine. The invention also provides a high-transparency heat-resistance light diffusion film prepared by using the light diffusion agent mother materials as additives. The light diffusion layer of the light diffusion film is formed by mixing the light diffusion agent mother materials and polyester slices according to the mixture ratio of 40 to 60 weight percent of polyester slices and 40 to 60 weight percent of the light diffusion agent mother materials. The light diffusion film prepared by the invention has high light transmission rate, high mist degree, excellent heat resistance performance and excellent dimension stability, and is particularly suitable for being used as the light diffusion film in a back light module of a large-dimension liquid crystal display.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

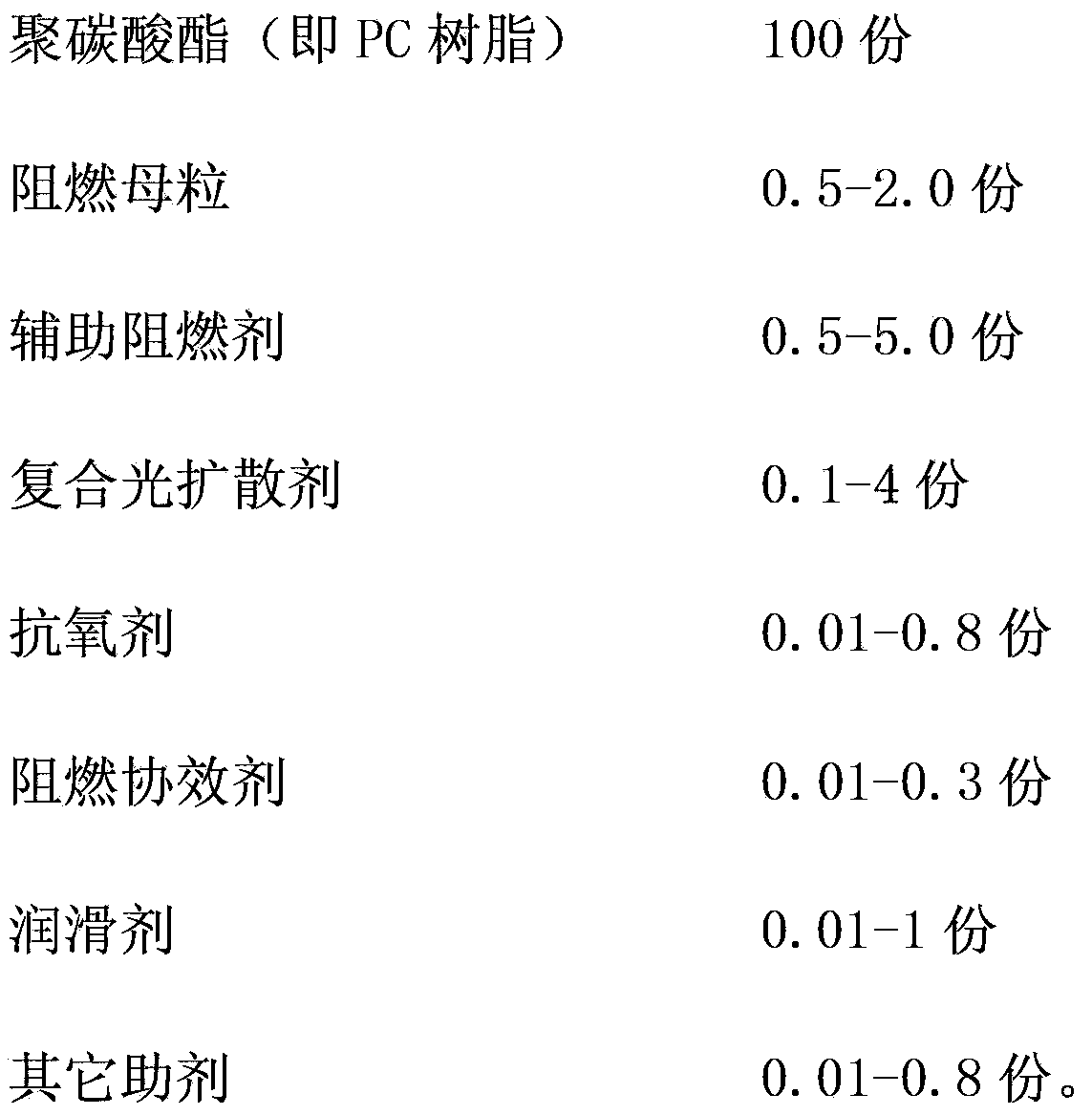

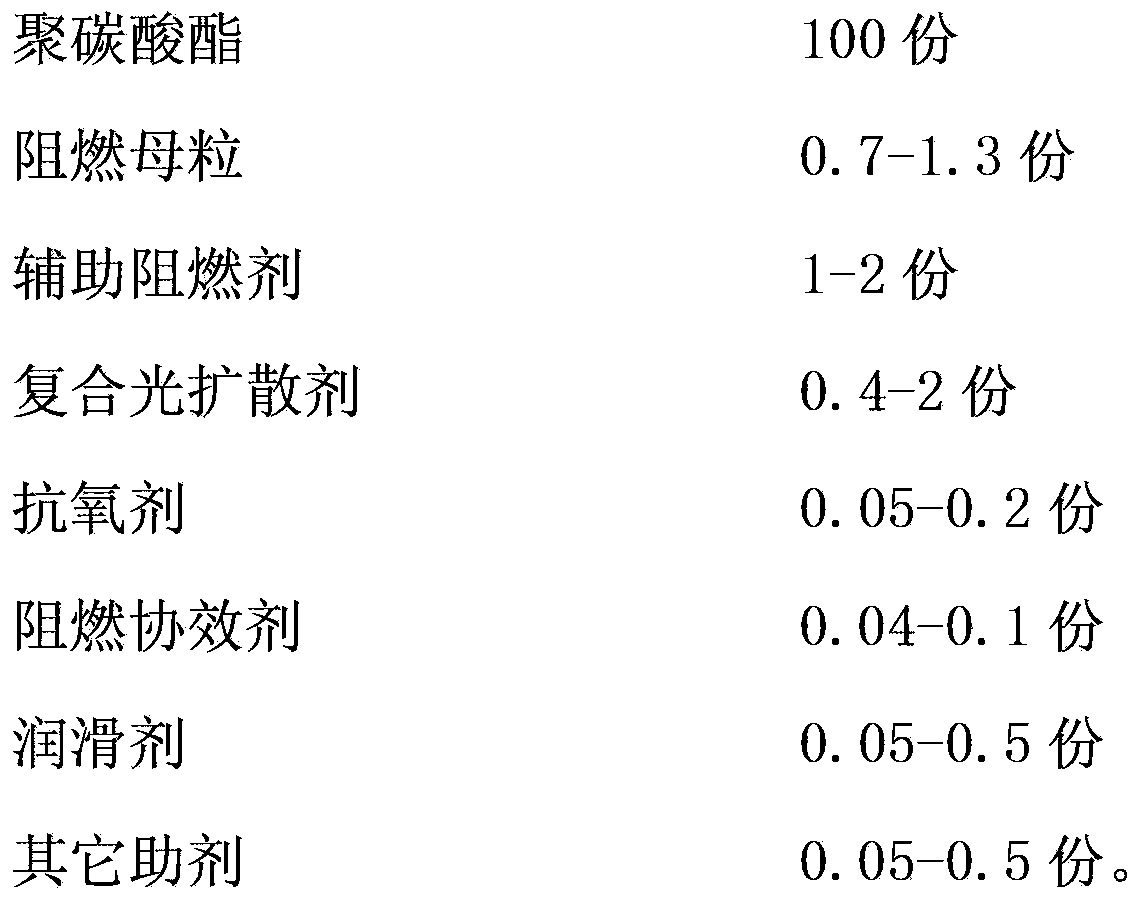

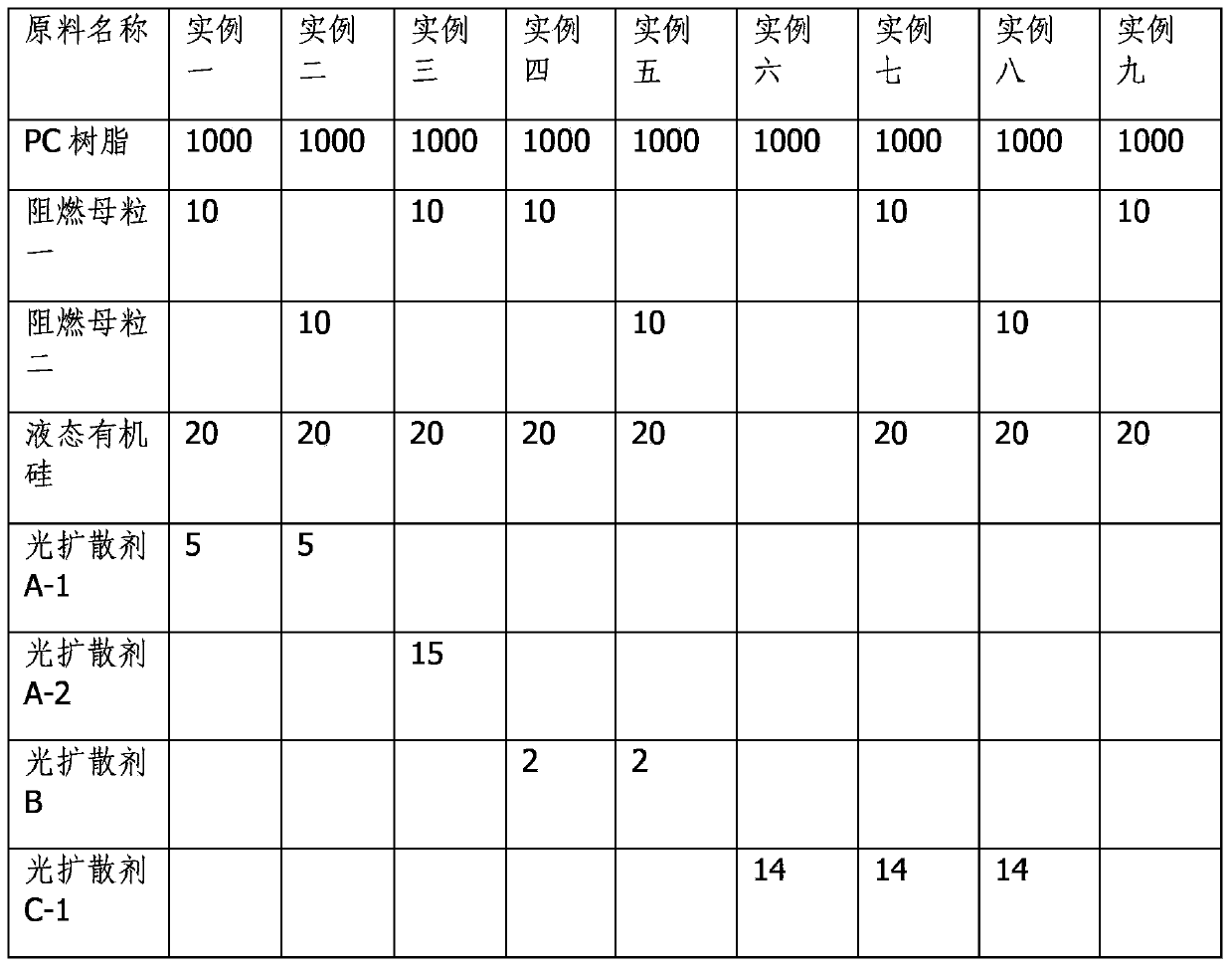

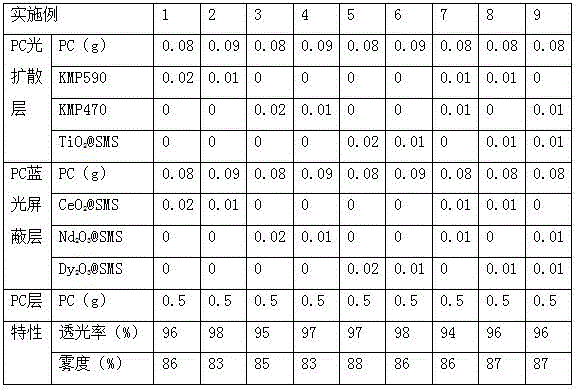

Polycarbonate material with excellent transparent light diffusion function and preparation method thereof

The invention discloses a PC (Polycarbonate) material with an excellent transparent light diffusion function and a preparation method thereof. The PC material is composed of polycarbonate, flame retardant masterbatch, an auxiliary flame retardant, a compound light diffuser, an antioxidant, a flame retardant synergist, a lubricant and other auxiliaries. The principle ingredient of the PC material is PC resin; the PC material is extruded by two steps, wherein the first step is to blend a sulfonate type major flame retardant and an organic silicon flame retardant with the PC resin by melting and granulate the mixture through extrusion by virtue of a twin-screw extruder so as to obtain the light diffusible flame retardant masterbatch, and the second step is to add the compound light diffuser, the flame retardant masterbatch, the antioxidant, the flame retardant synergist, the lubricant and other auxiliaries for further melting blending by taking PC as the major ingredient, and then extrude and granulate the mixture. The flame-retardant light diffusible PC material provided by the invention can be widely applied to an LED (Light-Emitting Diode) lamp, the backlight of a liquid crystal display, a transmission type screen, a decorative lighting billboard, an advertisement lamp box and the like in the lighting field.

Owner:NANTONG DONGFANG PLASTIC CO LTD

Transparent polypropylene formulations that become opaque upon exposure to sufficient heat

InactiveUS6561122B1Improve clarityEase of productionThermometer detailsDiffusing elementsRefractive indexEthylene Homopolymers

Unique transparent polypropylene articles that can be tailored to become opaque when exposed to a sufficiently high temperature and which returns to substantially the same transparency level upon cooling. Such formulations include non-polypropylene polymeric constituents that exhibit refractive index measurements similar to the base clarified polypropylene at lower temperatures, as well as melting temperatures well below that for the base clarified polypropylene. Upon exposure to temperatures in close proximity to the melting temperature of the non-polypropylene polymeric constituents, the refractive index for such constituents will then become modified to the extent that the overall article appears at least partially opaque. In particular, the non-polypropylene polymeric constituents should exhibit melting temperatures well below that for the base clarified polypropylene, from about 60 to about 100° C. (well below the typical polypropylene melting temperatures of roughly about 160-190° C. for homopolymer and about 140-170° C. for typical random copolymer, both nucleated or non-nucleated). In this manner, a temperature sensitivity measuring thermoplastic article may be provided, and may be tailored to specific temperature ranges dependent on the melting temperatures exhibited by the non-polypropylene polymeric constituents. Methods of measuring temperature levels via the transformation of transparent polypropylene formulations to at least partially opaque versions thereof are also encompassed within this invention.

Owner:MILLIKEN & CO

Light diffusing sheet and backlight unit using the light diffusing sheet

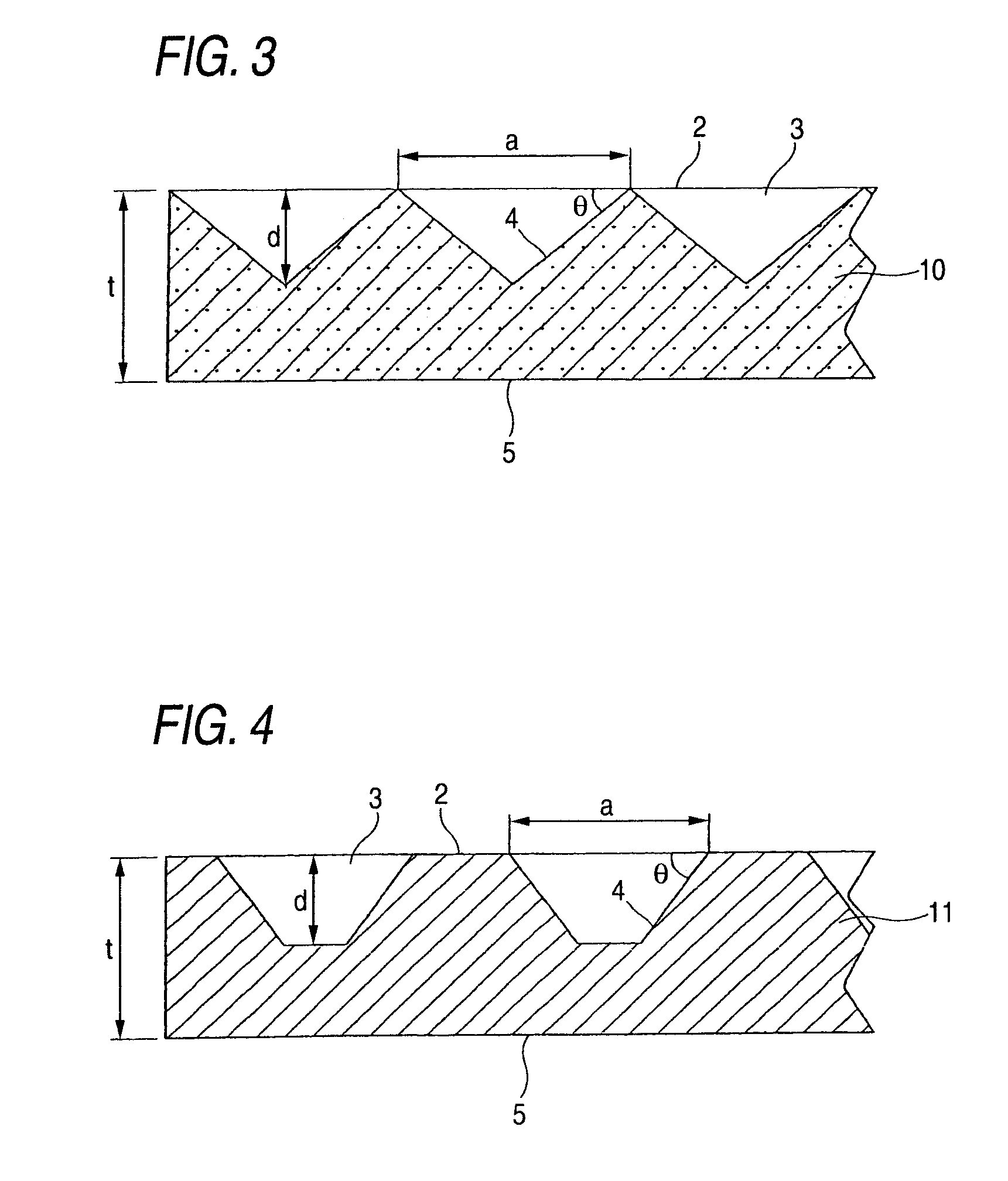

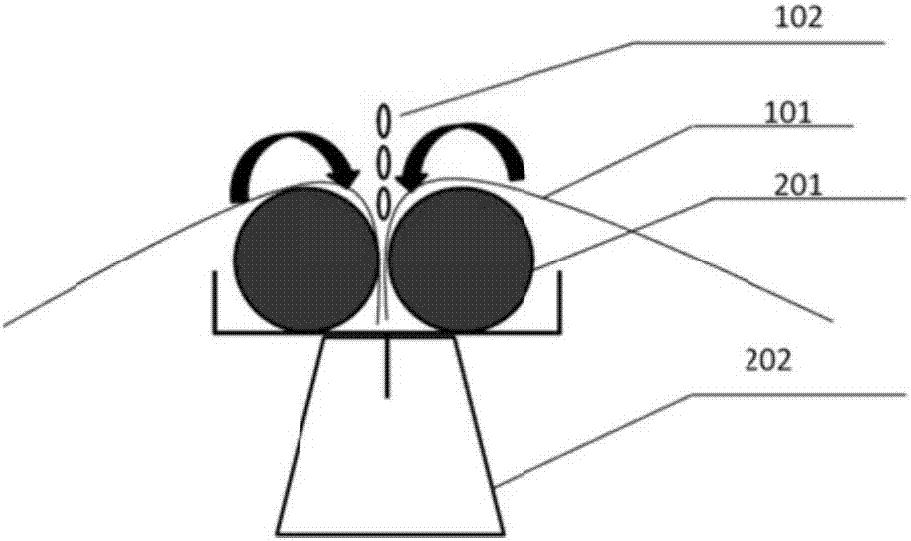

InactiveUS7645058B2Well formedContinuous and efficient productionMechanical apparatusDiffusing elementsProduction rateLight emission

To provide a light diffusing sheet which enables the light from a lightguide plate or light source of a backlight unit to be conducted to lens film after having been converted to diffused light having a small brightness peak angle, and which generates neither a moiré or interference fringe nor luminance unevenness, and is advantageous also in terms of productivity and cost, and to provide a backlight unit having this light diffusing sheet incorporated therein, and the surface of the sheet with fine recesses formed therein serves as a light emission side. The light diffusing sheet comprises a light-transmitting resin, characterized by having fine recesses formed in at least one of the surfaces thereof, the fine recesses having a shape which is any of the shapes of an inverted polyangular pyramid, an inverted truncated polyangular pyramid, an inverted cone, and an inverted truncated cone.

Owner:TAKIRON CO LTD

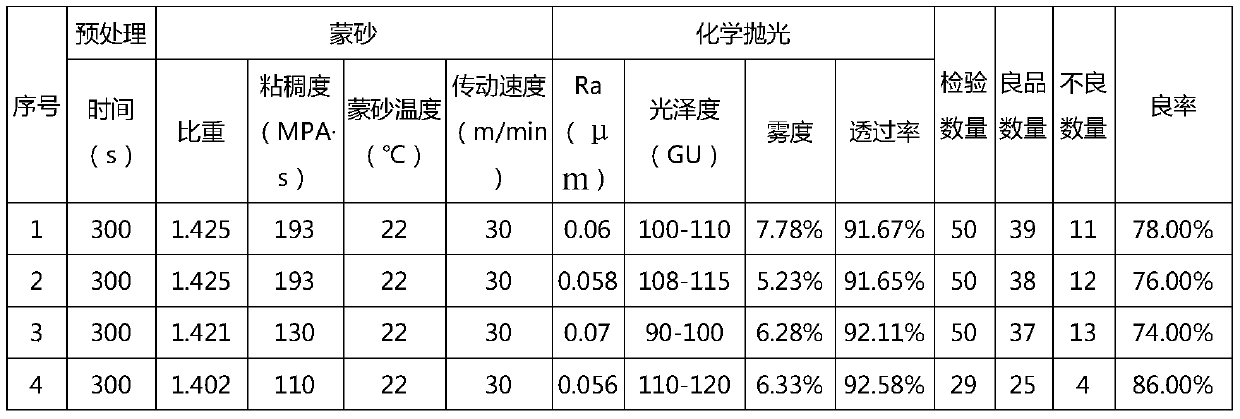

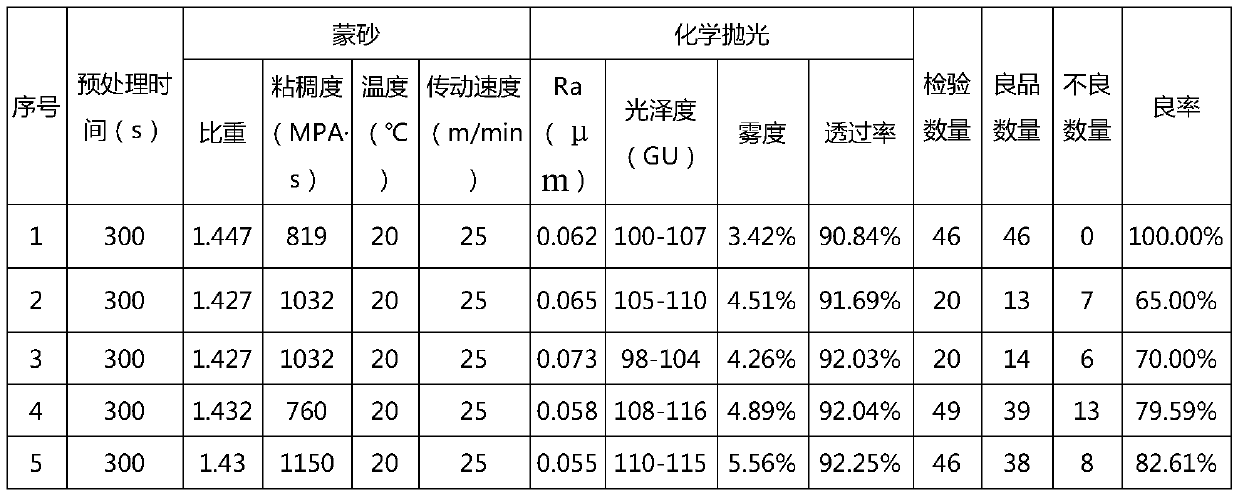

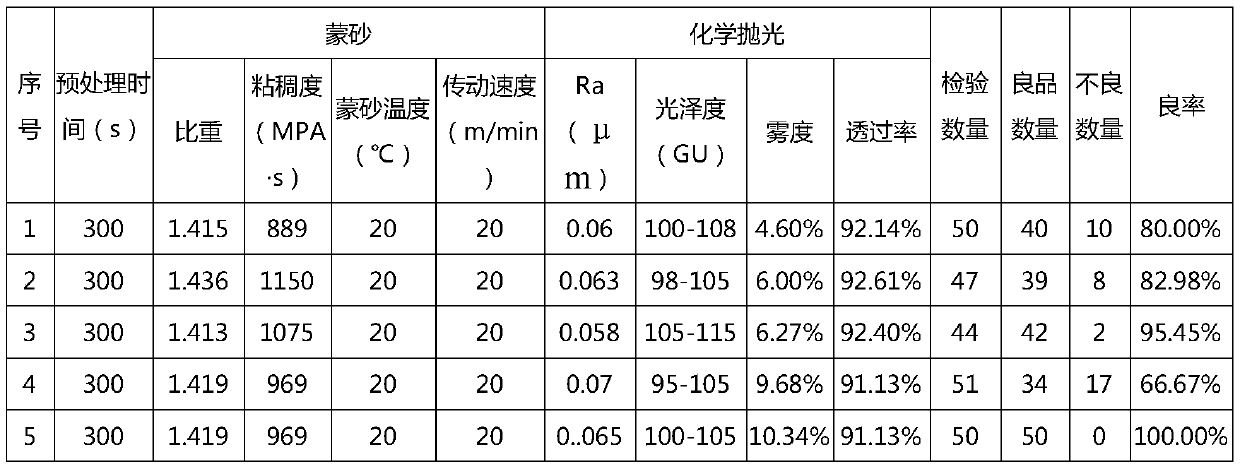

High-alumina glass frosting liquid and preparation method thereof

The invention discloses a high-alumina glass frosting liquid and a preparation method thereof. The high-alumina glass frosting liquid comprises the following components in parts by weight: 30-45 partsof ammonium bifluoride, 5-15 parts of citric acid, 2-5 parts of barium sulfate, 4-10 parts of starch, 2-6 parts of bentonite, 10-20 parts of ferric trichloride, 5-15 parts of potassium fluoride, 6-13parts of potassium nitrate, 2-6 parts of hydrofluoric acid and 10-30 parts of water. The frosting liquid is low in manufacturing cost and high in production yield; and anti-dazzle glass prepared fromthe frosting liquid has the characteristics of high glossiness, low flash point, low roughness and good anti-dazzle effect.

Owner:YICHANG NANBO DISPLAY +1

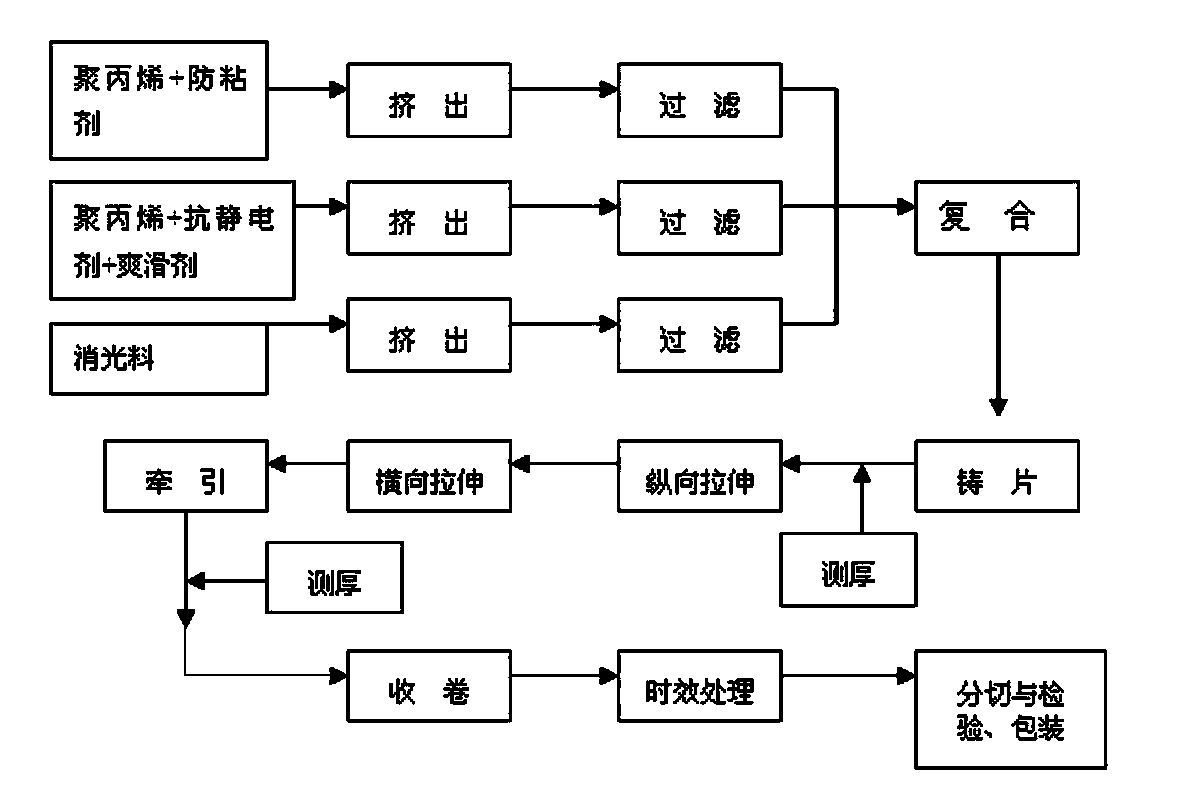

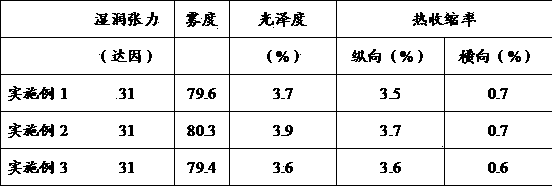

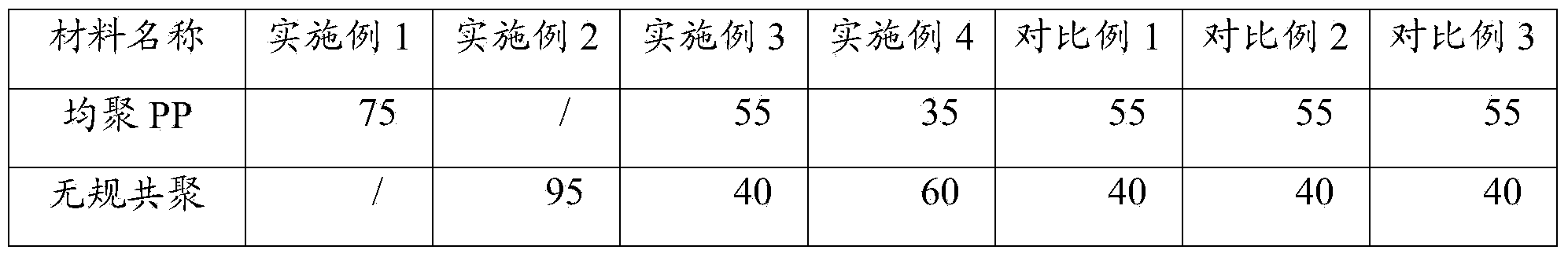

Matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and preparation method thereof

ActiveCN103709517AImprove rigidityIncrease the stretch ratioSynthetic resin layered productsCoatingsAnti adhesivePolypropylene

The invention relates to a matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and a preparation method thereof. The matte BOPP film consists of an inner surface layer, a core layer and an outer surface layer, and is prepared by coextrusion and two-way stretching of the inner surface layer, the core layer and the outer surface, wherein the inner surface layer comprises the following components in percentage by weight: 97.5-98.5% of polypropylene and 1.5-2.5% of adhesive; the core layer comprises the following components in percentage by weight: 98.0-98.4% of polypropylene, 1.0-1.2% of antistatic agent and 0.4-1.0% of slipping agent; the outer surface layer adopts a delustering material which comprises the following components in percentage by weight: 54-56% of polyethylene, 43.7-45.7% of high-density polyethylene and 0.3% of antioxidant. The matte BOPP film and the preparation method have the advantages that the selection and matching of the materials are reasonable, the selected polypropylene material is good in processing performance and high in mechanical strength; the prepared BOPP film is large in elastic modulus and low in heat shrinkage rate; the performance indexes such as haze and glossiness of the outer surface layer are excellent.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

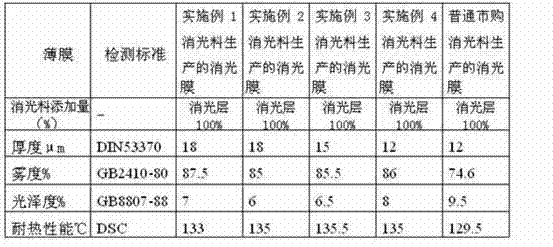

Extinction material for biaxially oriented polypropylene (BOPP) film and preparation method for extinction material

The invention relates to an extinction material for a biaxially oriented polypropylene (BOPP) film and a preparation method for the extinction material. The extinction material is characterized by comprising the following raw materials in part by weight: 30 to 60 parts of polypropylene (PP) resin, 30 to 60 parts of high density polyethylene, 2 to 15 parts of inorganic extinction powder, 2 to 10 parts of polybutylene terephathalate (PBT), 1 to 3 parts of dispersing agent and 0.1 to 1.0 part of antioxidant, wherein the total parts of the components are 100. By the extinction material for the BOPP film, a uniform extinction layer can be provided, high haze and high-temperature resistance are achieved, an extinction layer can be thinned for a BOPP film manufacturer, and the production speed and production efficiency of the extinction film are improved.

Owner:JIANGYIN FINE PLASTICS

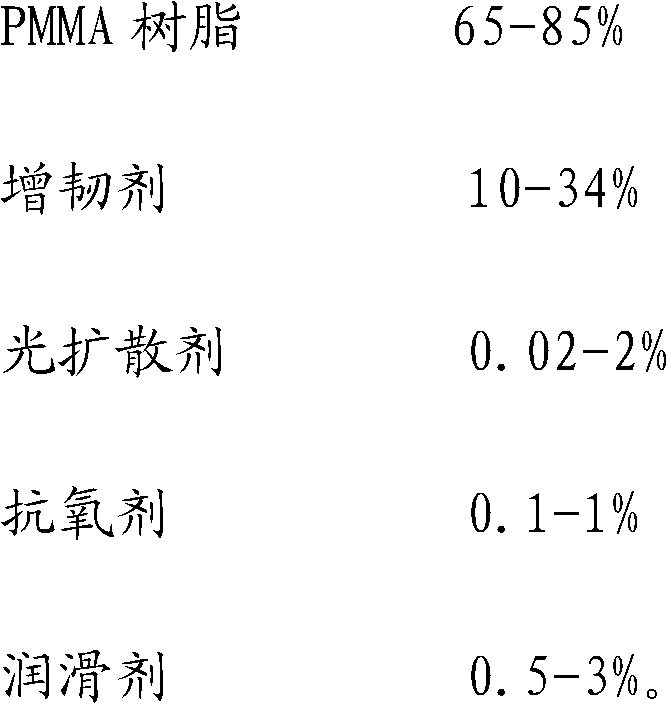

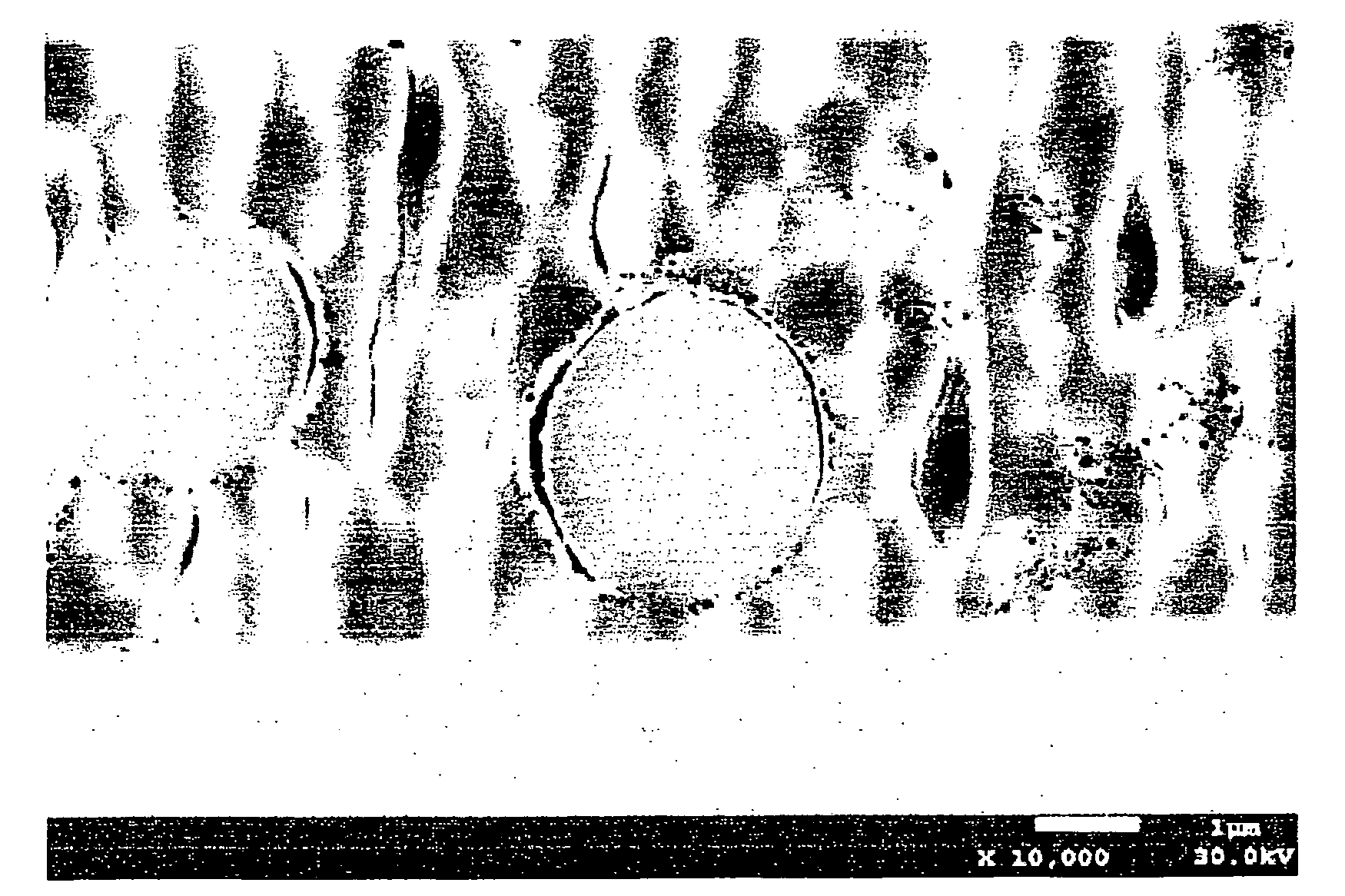

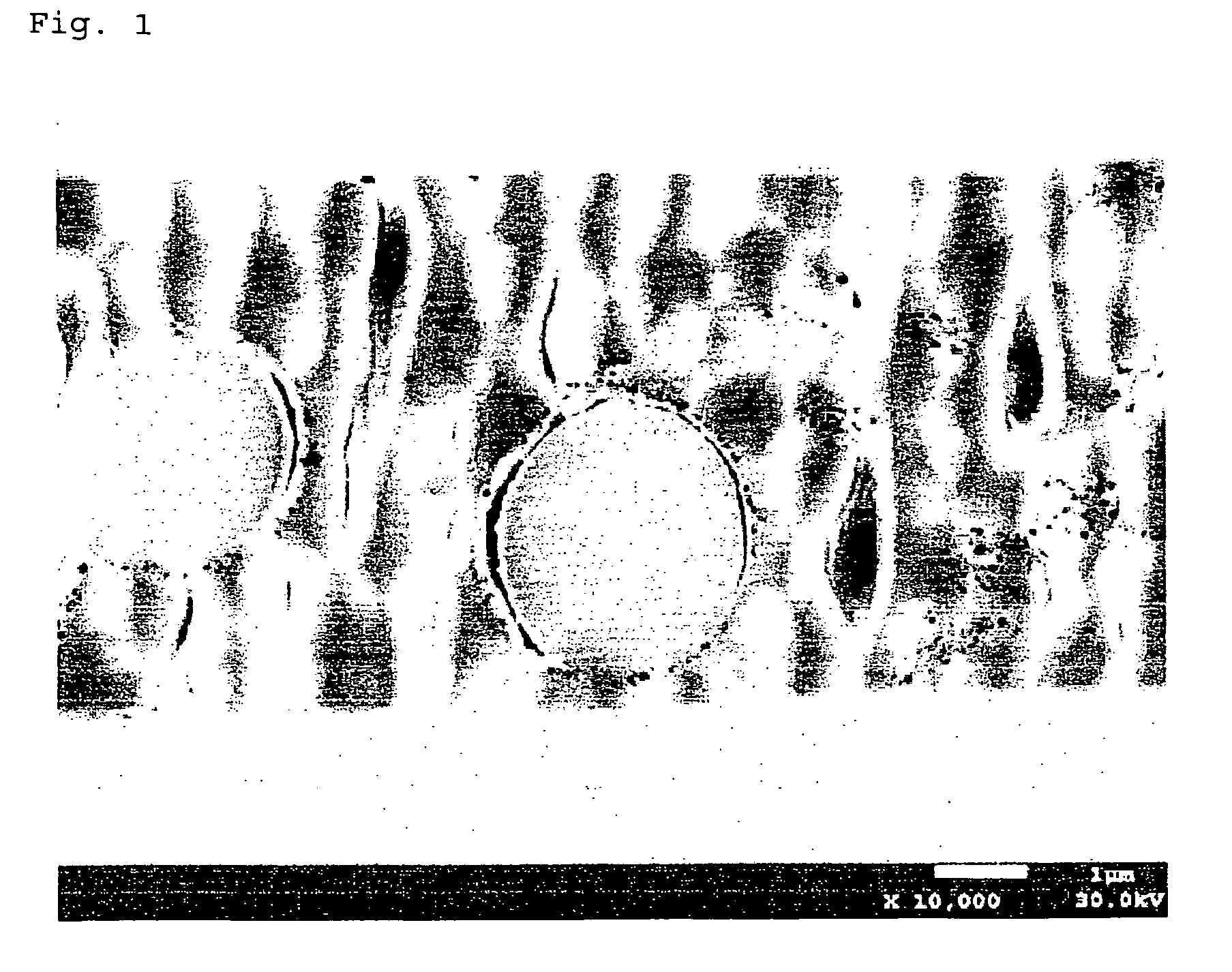

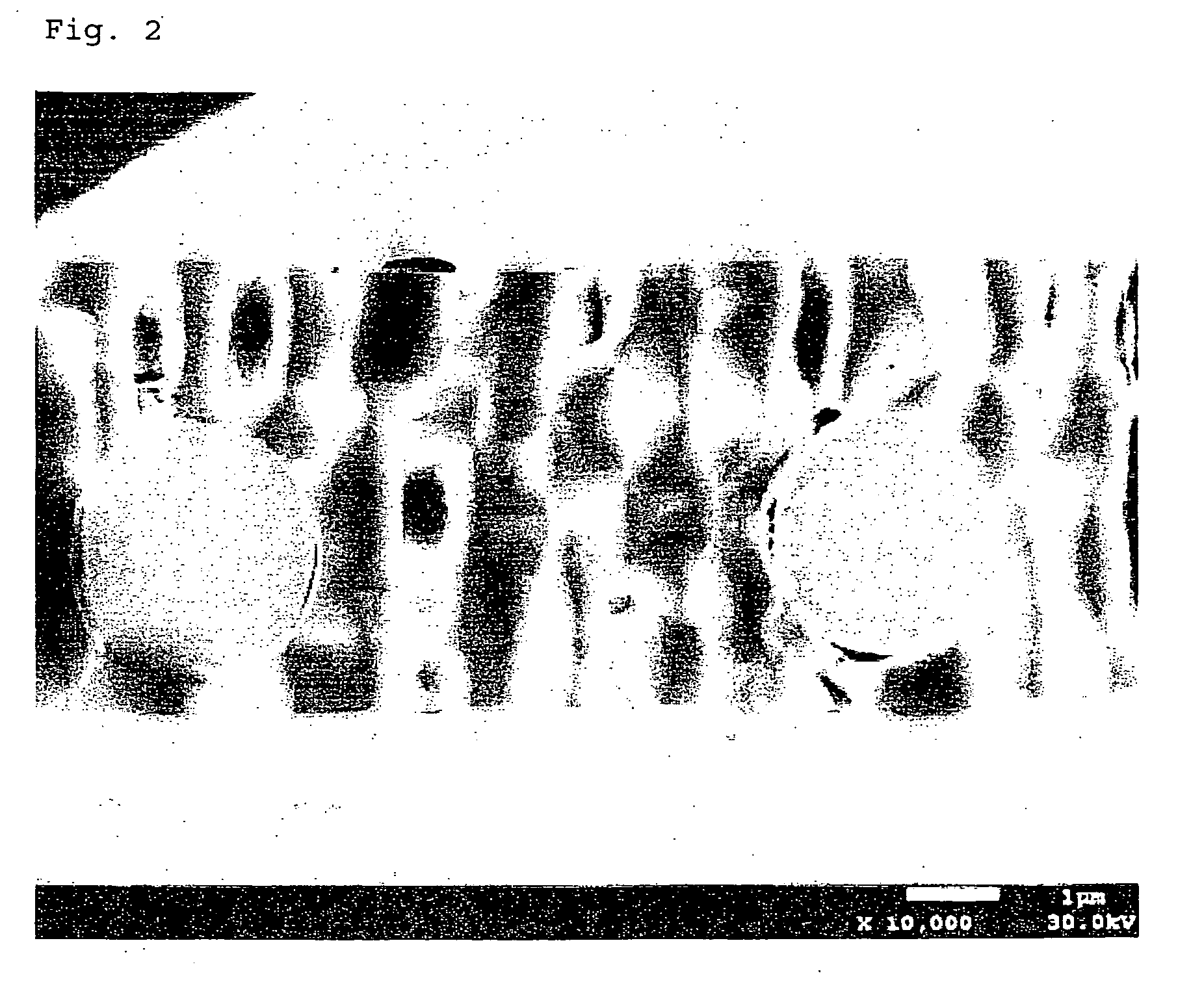

Transparent toughened light-diffusion polymethylmethacrylate material and preparation method for same

The invention discloses a transparent toughened light-diffusion polymethylmethacrylate material and a preparation method for the same. Components of the transparent toughened light-diffusion polymethylmethacrylate material comprise, in weight percentage, 65-85% of PMMA (polymethylmethacrylate) resin, 10-34% of toughening agent, 0.02-2% of light diffusing agent, 0.1-1% of antioxidant and 0.5-3% of lubricant. The transparent toughened light-diffusion polymethylmethacrylate material is high in toughness, transparency and haze, and is capable of meeting comprehensive requirements of optical parts on toughness, transparency and haze, and application range of PMMA is widened.

Owner:SHENZHEN KEJU NEW MATERIAL

Anti-glare material and optical layered product

InactiveUS20090233048A1Highly visible and quality displayReduce in quantityLayered productsRecord information storageSlope angleComposite material

Owner:TOMOEGAWA CO LTD

Crosslinked polyester compositions, method of manufacture, and uses thereof

ActiveUS20080185558A1Effectively crosslinkedImprove scalabilityFibre treatmentSynthetic resin layered productsPolyesterReactive material

A Composition comprises a thermally crosslinked reaction product of a polyester and a carboxy-reactive material. Methods for the manufacture of the composition and articles derived from the composition are also disclosed.

Owner:SABIC GLOBAL TECH BV

Composition applied to atomization film, atomization film and LED lighting equipment

InactiveCN101955723AHigh light transmittanceHigh hazePoint-like light sourceElectric lightingSolventPoint light source

Owner:NINGBO EXCITON TECH

Low temperature resistant halogen-free flame-retardant light scattering polypropylene composition and preparation method thereof

The invention provides a low temperature resistant halogen-free flame-retardant light scattering polypropylene composition and a preparation method thereof. The composition comprises the following components: 72-92.7% of PP resin, 2-5% of flexibilizer, 3-5% of biphasic solvent, 1-10% of halogen-free fire retardant, 1-5% of fireproof liquid oil, 0.1-2% of light scattering agent, 0.1-0.5% of light stabilizing agent, and 0.1-0.5% of anti-oxidant. The composition is prepared by the following steps: baking the PP resin at 70-90 DEG C with an air blast baking oven for 10-14 hours, and controlling the water content below 0.02%; stirring the baked PP resin, the flexibilizer and the biphasic solvent and the liquid fireproof oil according to a proportion in a feed mixer for 3-5 minutes; adding the light scattering agent, the light stabilizing agent and the anti-oxidant, and stirring for 2-4 minutes; adding the halogen-free fire retardant, stirring for 2-4 minutes, and for uniformly mixing the components together; adding the fully mixed materials into a double screw extruder for carrying out extrusion granulation. The low temperature resistant halogen-free flame-retardant light scattering polypropylene material provided by the invention has the advantages of high light transmittance, high haze, good flame retardation performance and impact resistance.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

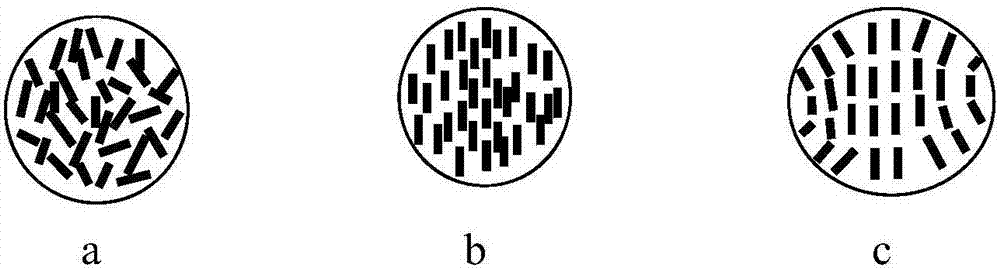

Wide view angle type polymer-dispersed liquid crystal composition, display device and manufacturing method

InactiveCN107286958AHigh voltageVoltage levelLiquid crystal compositionsNon-linear opticsOligomerLiquid-crystal display

The invention relates to a polymer-dispersed liquid crystal composition and a polymer-dispersed liquid crystal display device manufactured by using the polymer-dispersed liquid crystal composition. The polymer-dispersed liquid crystal composition comprises a nematic phase liquid crystal material, an acrylic acid oligomer, a diluting monomer, an initiator, a spacer and the like. The invention provides a highly-crosslinked oligomer which solves the problem of a narrow view angle of an existing dimming membrane and is high in polymer selection curing speed and high in crosslinking density; the highly-crosslinked oligomer is prepared from a diluting monomer which is high in hardness, high in diluting capacity and not liable to yellow; and furthermore, selected liquid crystals no and an oligomer and diluting monomer mixture np meet a condition that np is greater than no. By optimization of selection of the liquid crystal material and the acrylic acid oligomer and optimization of a preparation method, the display device has the characteristics and properties of ultra-wide view angle, driving voltage lower than safety voltage, low haze, high transmittance and the like; and due to the properties, the application range and the application place of the display device are greatly expanded.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

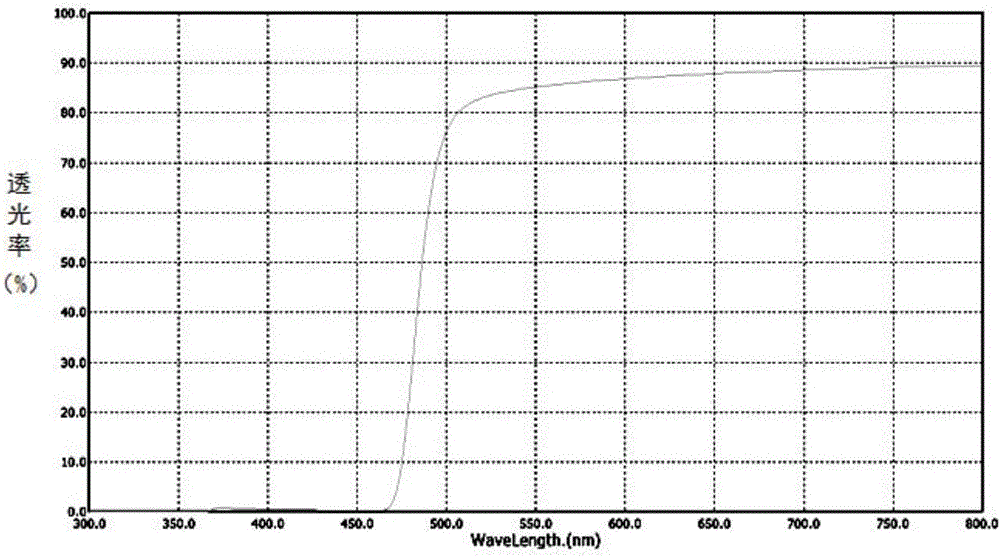

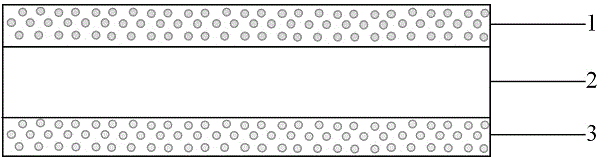

Blue-ray-proof lens and resin raw material thereof

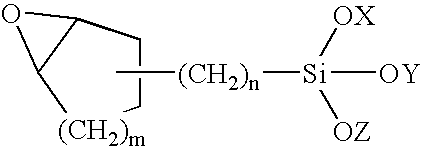

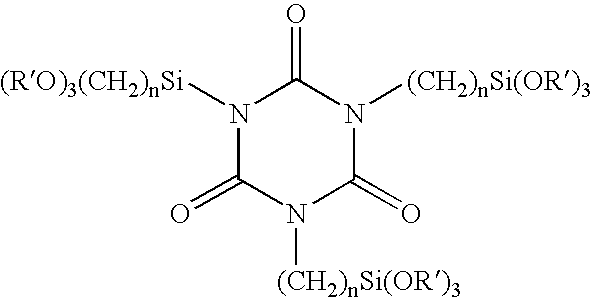

InactiveCN106674852ARealize coating modificationGood dispersionOptical filtersOptical partsHigh energySilanes

The invention relates to the field of a lens and specifically relates to a blue-ray-proof lens and a resin raw material thereof. A substrate polymer and a blue-ray-proof additive are contained in the lens; a nanometer rare earth oxide subjected to surface modification treatment is served as the blue-ray-proof additive; 3-methacryloxy trimethoxy silane and polymethyl methacrylate are contained in a modifying material used for the surface modification treatment. According to the invention, the nanometer rare earth oxide subjected to surface-cladding treatment is added into the substrate polymer, so that the lens has a better converting absorbing function for the 400-470nm high-energy blue ray; the high transparency and low haze of the lens can be guaranteed; the lens can meet the manufacturing requirements of the myopic lens, presbyopic glasses and sun glasses; the lens has wide adaptability.

Owner:HEFEI WIYE OPTICAL TECH CO LTD

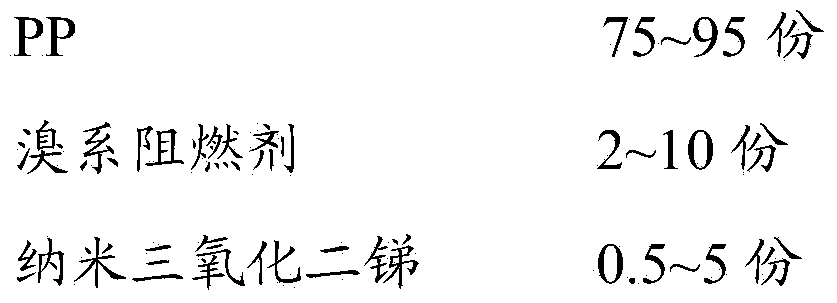

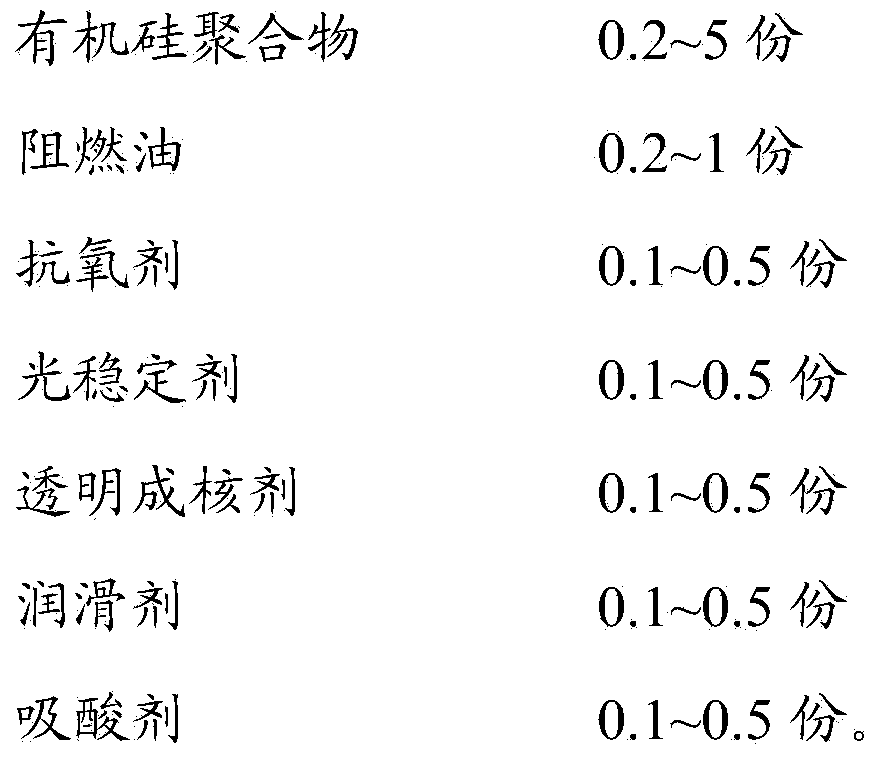

Flame-retardant scraping-resistant photodiffusion PP material and preparation method thereof

The invention provides a flame-retardant scraping-resistant photodiffusion PP material and a preparation method thereof. The flame-retardant scraping-resistant photodiffusion PP material comprises the following components in parts by weight: 75-95 parts of PP, 2-10 parts of a brominated flame retardant, 0.5-5 parts of nano antimonous oxide, 0.2-5 parts of an organosilicon polymer, 0.2-1 part of flame-retardant oil, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of a photostabilizer, 0.1-0.5 part of a transparent nucleating agent, 0.1-0.5 part of a lubricant, and 0.1-0.5 part of an acid absorbent. By selecting specific type of functional additives and under synergistic mechanism of all raw materials, the PP material finally has the advantages of high transparency and haze, flame retardance, scraping resistance, low cost, excellent toughness, light density, excellent yellowing resistance, high thermal deformation temperature, no toxicity and the like and is recyclable, and the usage performance of the PP material can be greatly promoted.

Owner:江苏沃特新材料科技有限公司

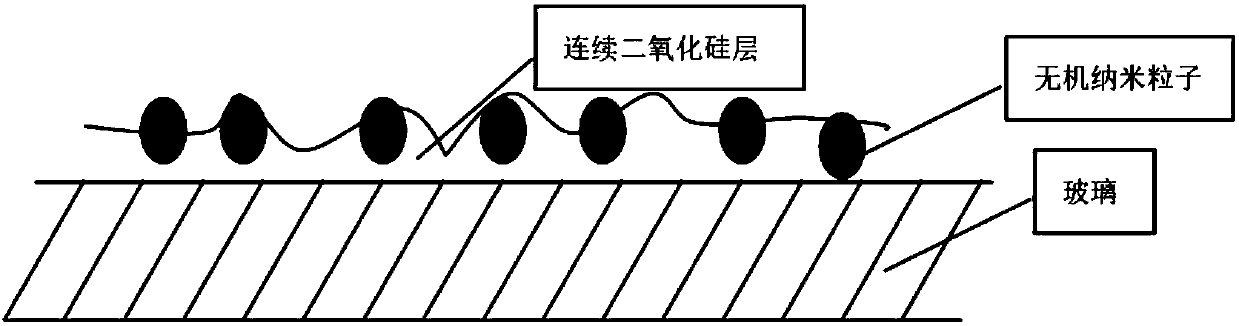

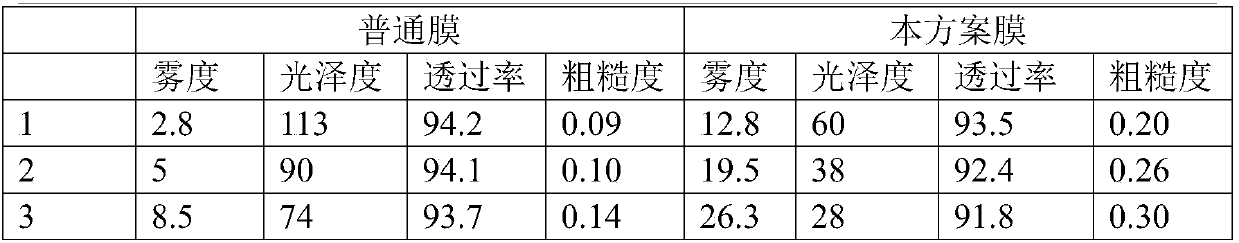

High-haze low-gloss anti-glare film and preparation method thereof

The invention relates to a high-haze low-gloss anti-glare film and a preparation method thereof, in particular to specific anti-dazzle liquid for constructing the high-haze low-gloss anti-glare film and a wet spraying film forming mode thereof. According to the high-haze low-gloss anti-glare film and the preparation method thereof provided by the scheme, first, the specific anti-dazzle liquid which is added with high-refraction index inorganic nano-particles is prepared; then, the anti-dazzle liquid is sprayed on the surface of glass by a wet method; next, the glass is baked for a certain timeat a certain temperature; finally, a layer of the anti-glare film is constructed on the surface of the glass. The anti-glare film is a nano-particle-doped rough surface with an uneven surface; the anti-glare film is endowed with the performance of high haze and low gloss through the structure and morphology.

Owner:SHENZHEN ACAD OF AEROSPACE TECH +1

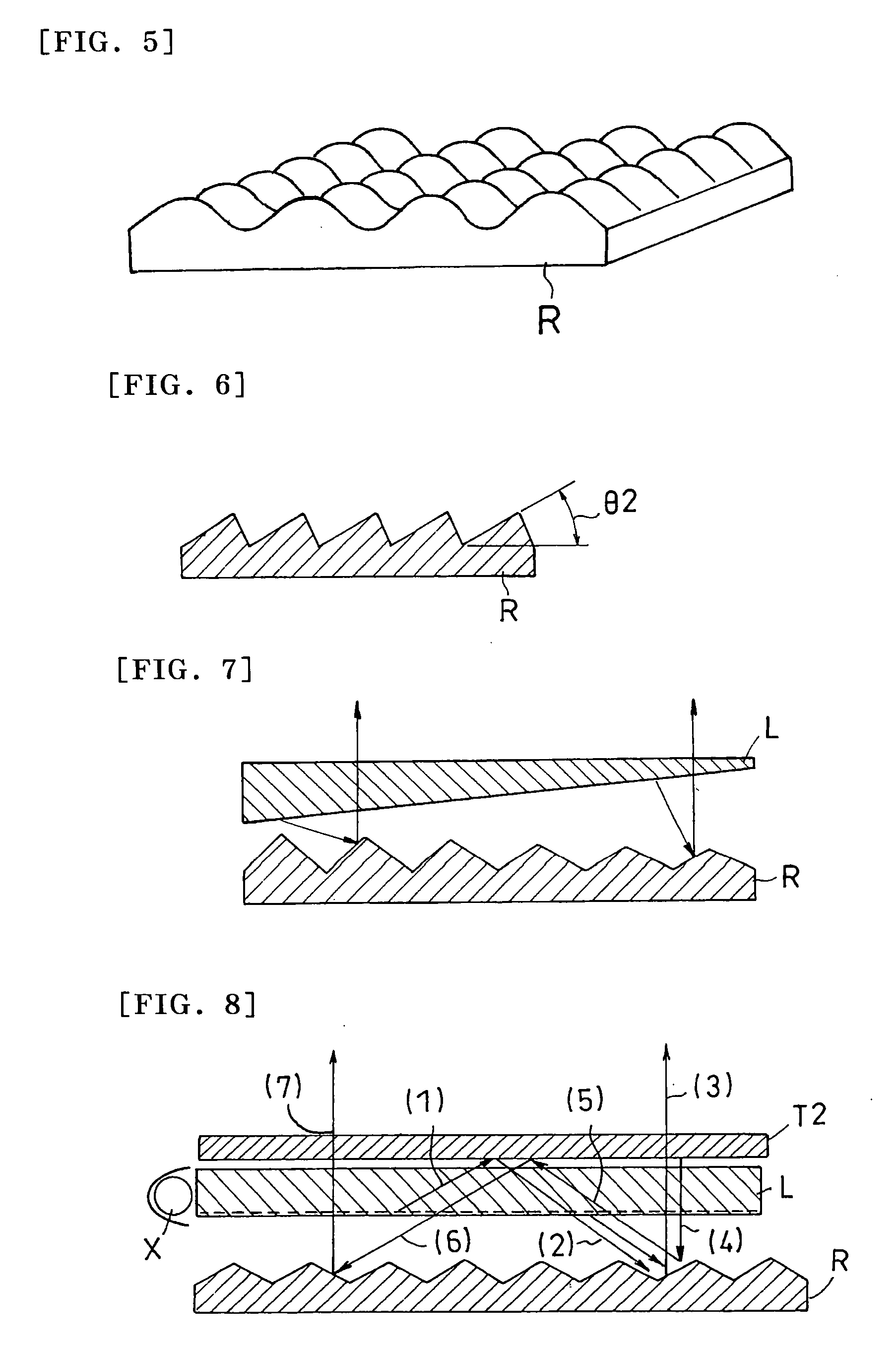

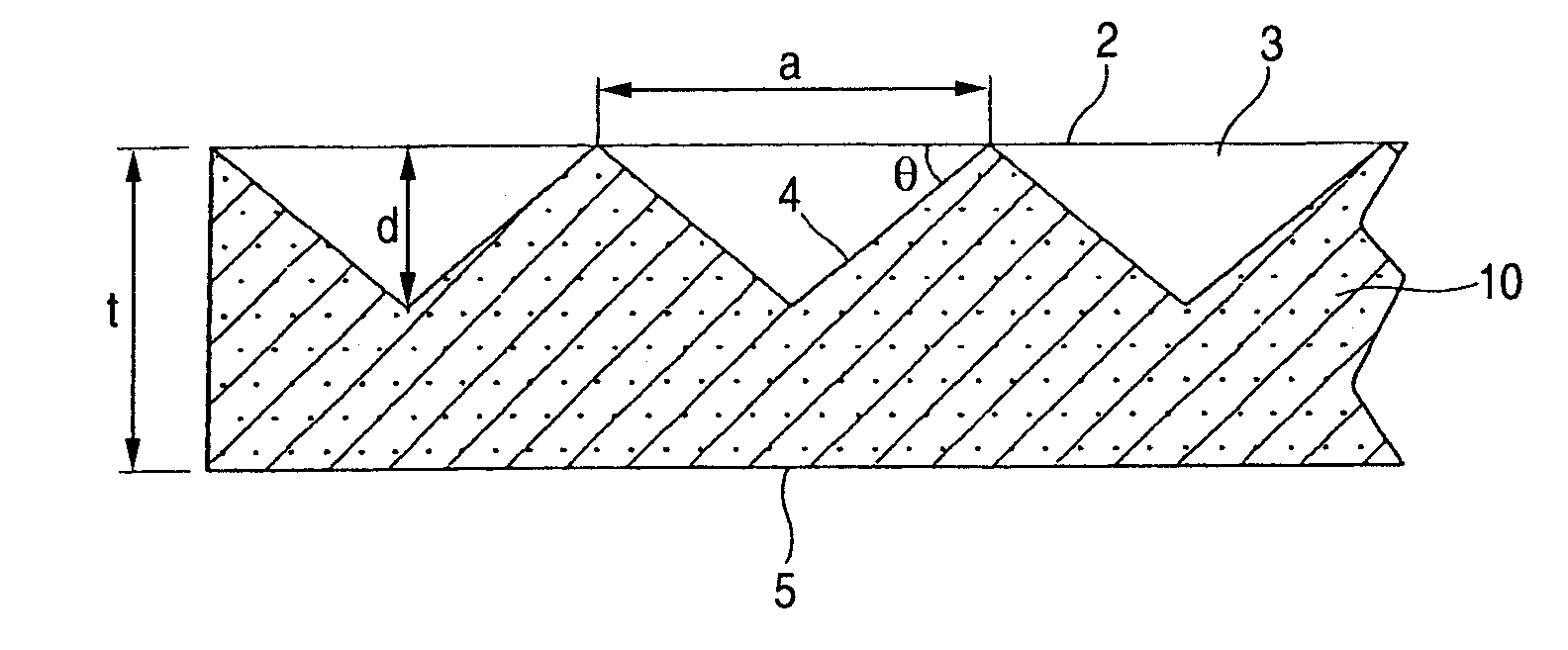

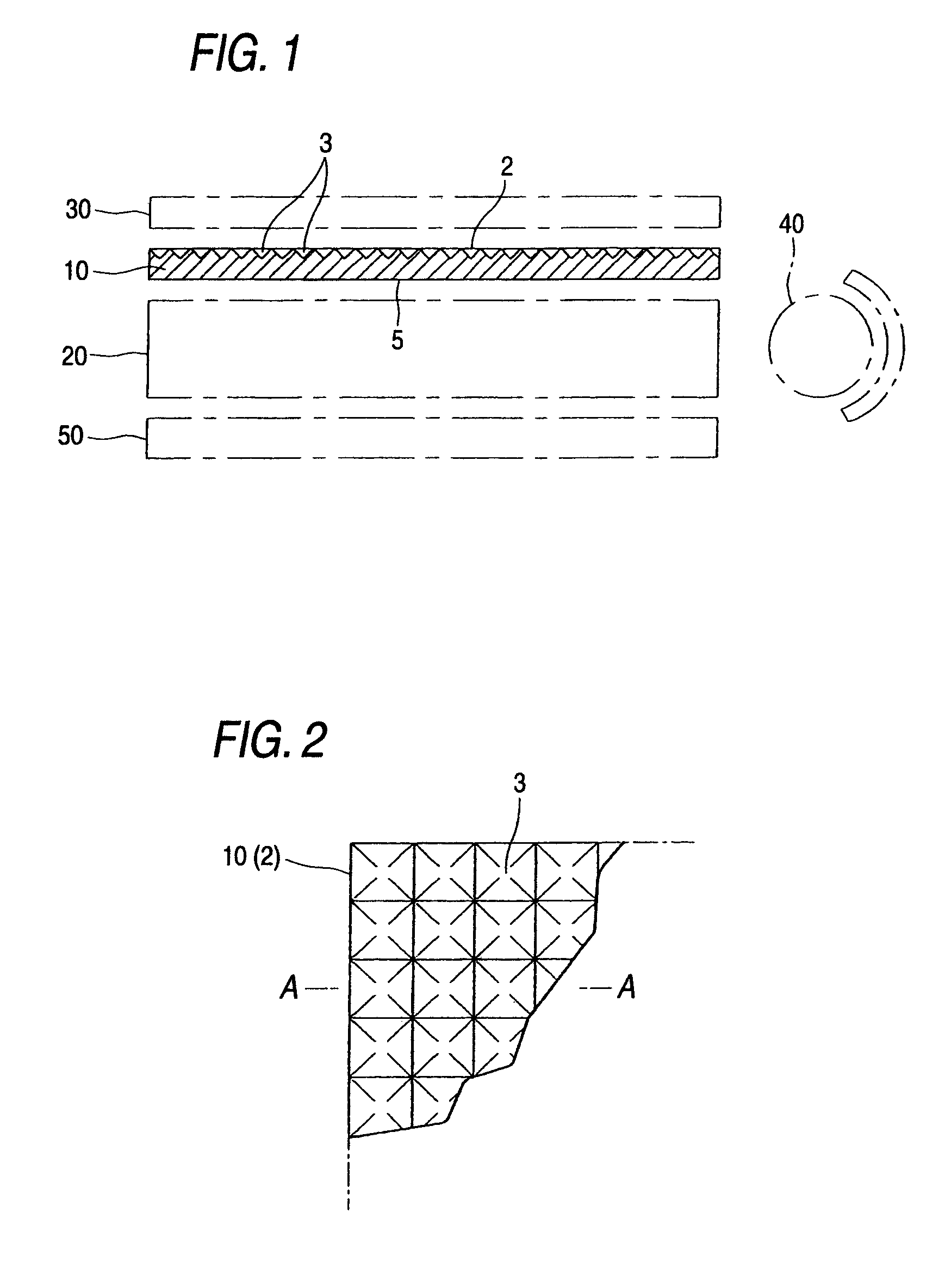

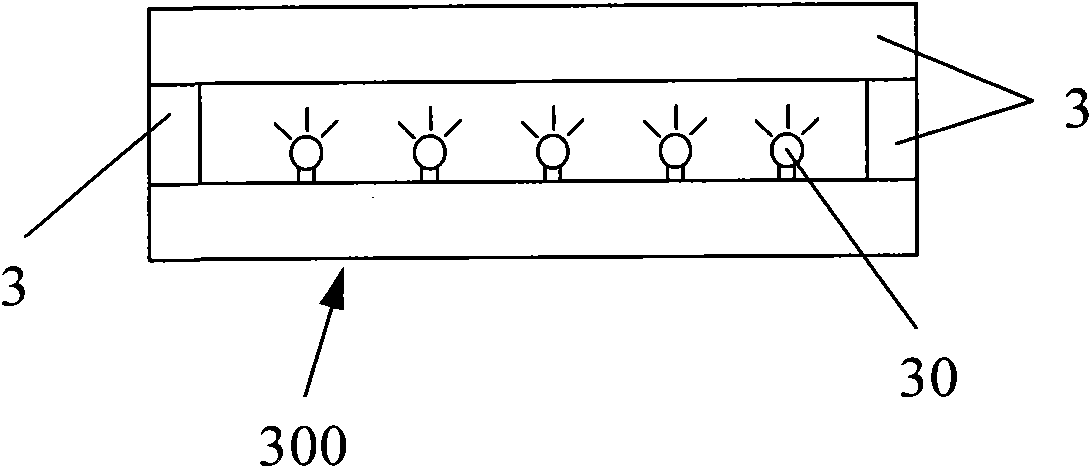

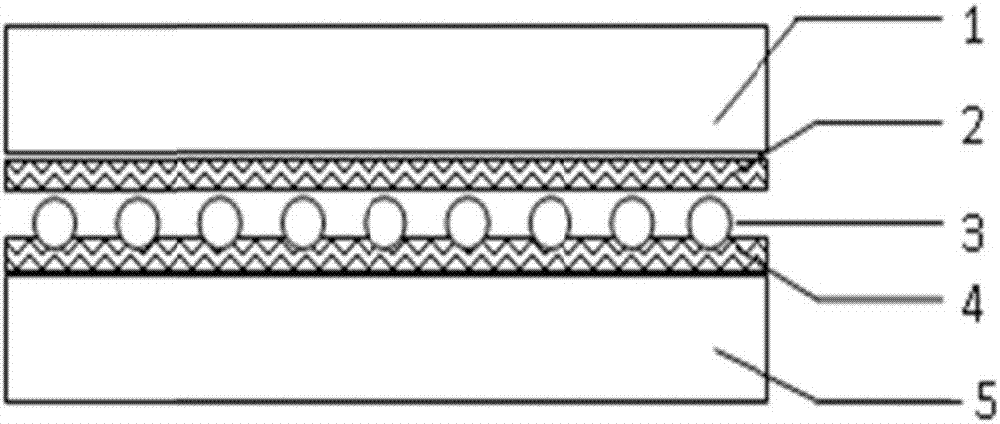

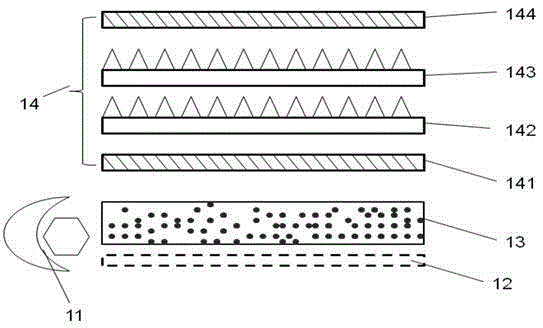

Light source device and crystal display device

InactiveUS7841730B2Less in absorption lossLow costMechanical apparatusElongate light sourcesTransmittanceLight reflection

A light source comprising sidelight type backlight light guide plate (L), wherein a transmittance angle dependent layer (T1) which transmits normally incident light and reflects obliquely incident light is disposed on one surface of the sidelight type backlight light guide plate (L), and a reflection plate (R) having a repetitive slope structure is disposed on the other surface of the sidelight type backlight light guide plate (L). The invention light source is less in absorption loss due to repetition of light reflection and the like.

Owner:NITTO DENKO CORP

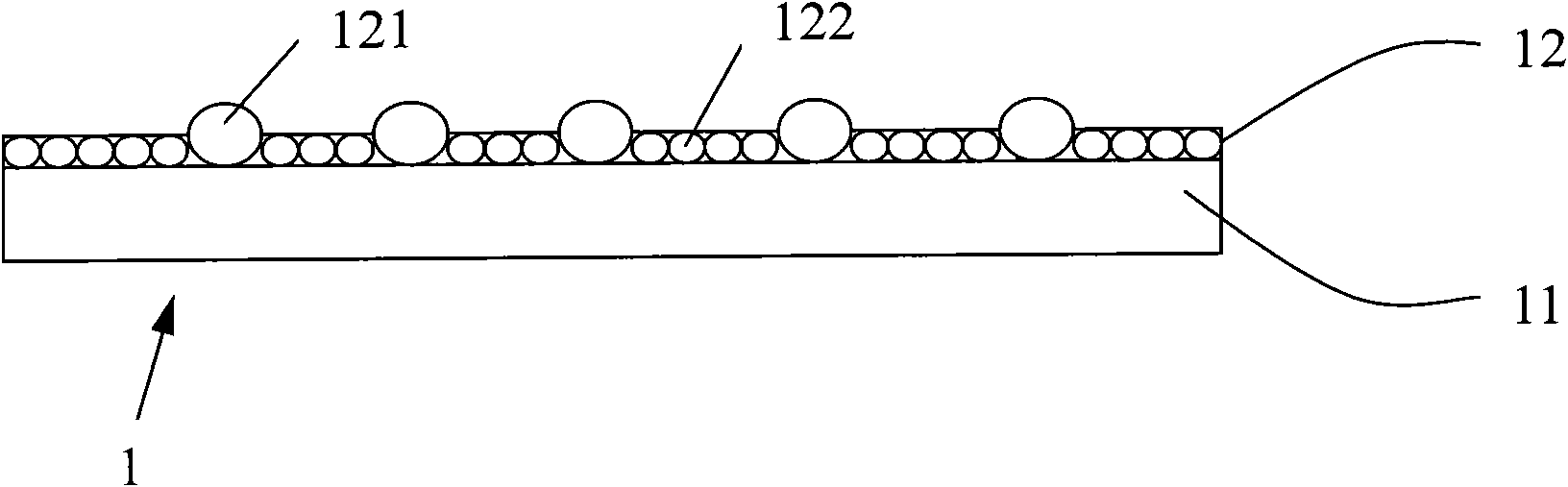

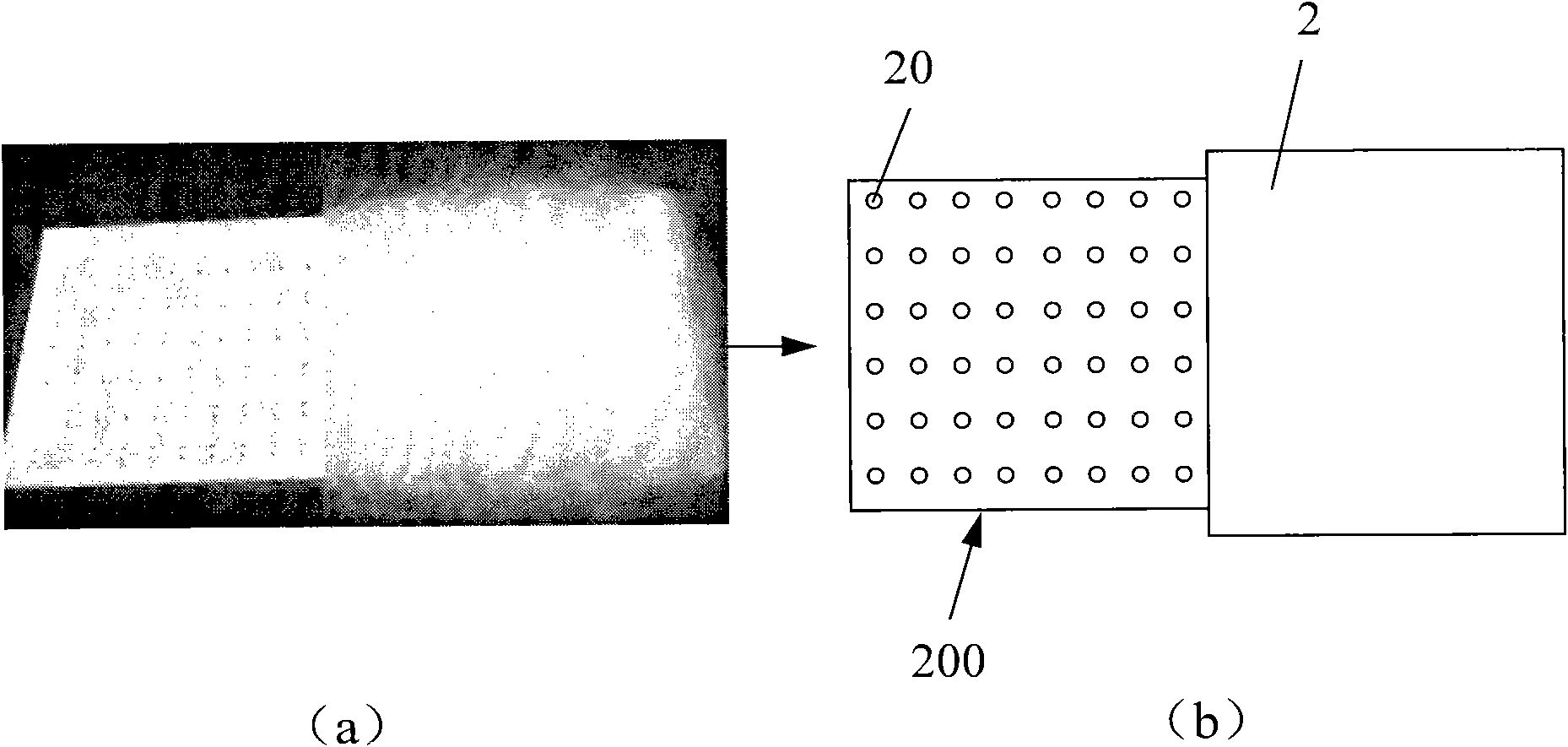

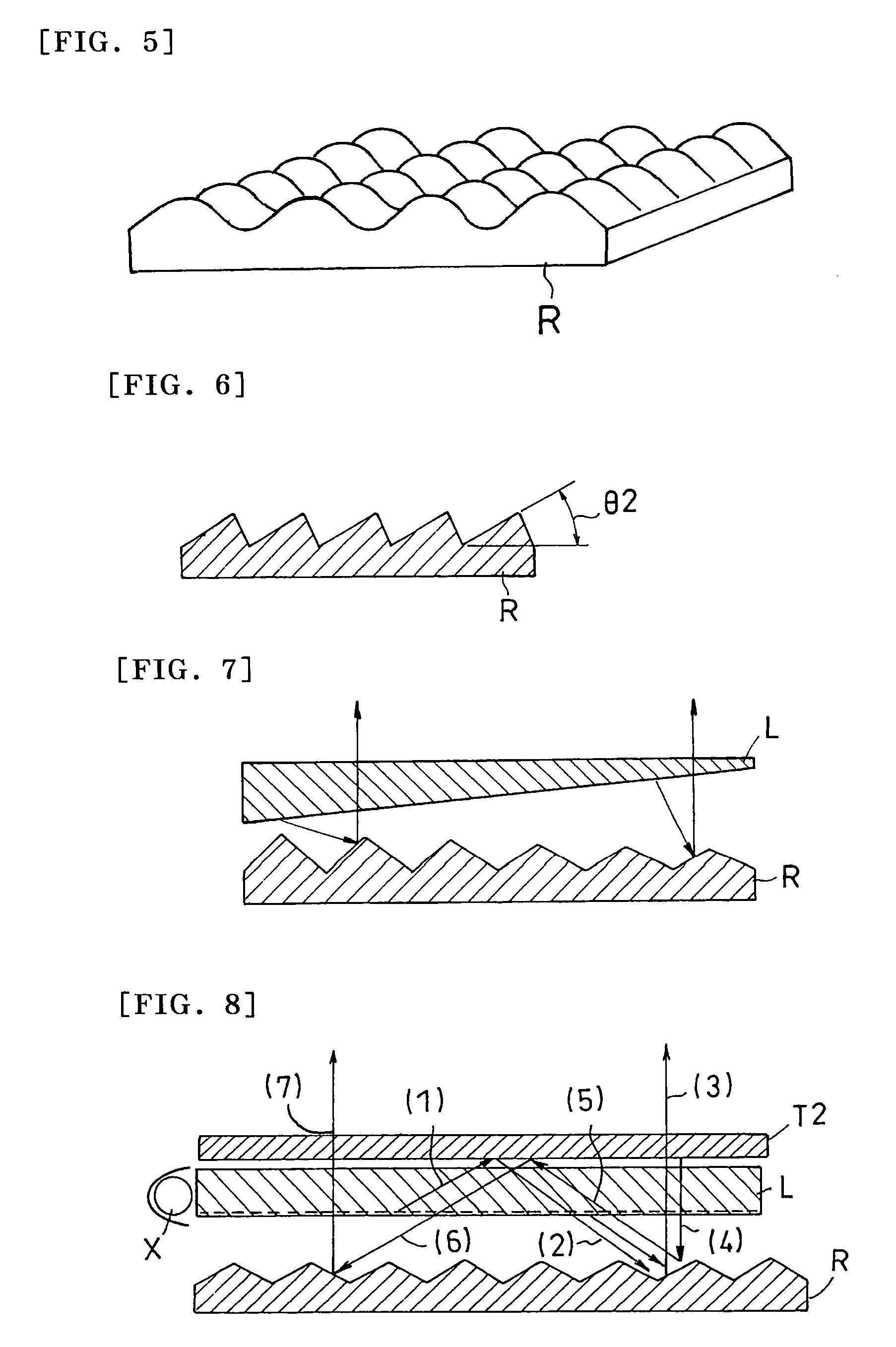

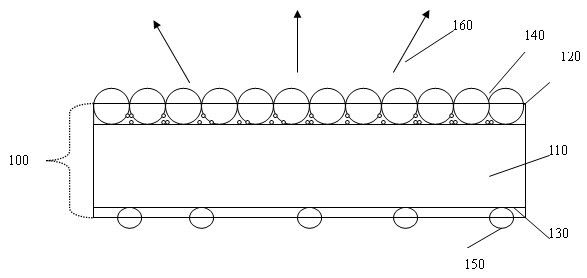

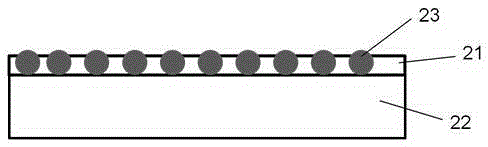

Optical diffusion barrier with high haze and high brightness and liquid crystal display backlight source using optical diffusion barrier

ActiveCN102508326AImprove spotlight effectHigh hazeDiffusing elementsNon-linear opticsLiquid-crystal displayMaximum diameter

The invention relates to an optical diffusion barrier with high haze and brightness and a liquid crystal display backlight source using the optical diffusion barrier. A diffusion particle consists of particles with two particle diameters, the large-diameter particles are mutually and tightly in contact and distributed on the surface of a base material, the small-diameter particles are filled in gaps among the large-diameter particles, and the diffusion particles comprise spherical particles with the following particle diameters in percentage by weight: 82-92% of spherical particles with the particle diameter of 15-30 microns, and 8-18% of spherical particles with the particle diameter of 0.5-6 microns; and the geometric diameter proportion of the large-diameter particles to the small-diameter particles is within 5 / 1-30 / 1, and the thickness of a diffusion coating is 5 / 10-6 / 10 of the maximum diameter of the diffusion particles. The optical diffusion barrier disclosed by the invention has higher haze and light condensation capability by controlling the particle diameters and the proportion of the two kinds of diffusion particles and controlling the thickness of the diffusion coating; in addition, the liquid crystal display backlight source manufactured by the optical diffusion barrier, disclosed by the invention, has very higher haze and brightness.

Owner:HEFEI LUCKY SCI & TECH IND

Liquid Composition Containing Hollow Particle, Process For Producing The Same, And Optical Article

InactiveUS20080227893A1High hazeLarge particle sizeDiffusing elementsCoatingsForeign matterOrganic solvent

A hollow particles-containing liquid composition which comprises:(A) crosslinked hollow particles having particle diameters of 0.4 μm or more and containing 40 mass % or more of a toluene insoluble, in an amount of 5 to 70 mass %,(B) a reactive diluent (B1) and / or an organic solvent (B2) in an amount of 95 to 30 mass % [the total mass of the crosslinked hollow particles (A) and the reactive diluent (B1) and / or the organic solvent (B2) is 100 mass %], and(C) a dispersing agent in an amount of 0 to 30 parts by mass relative to 100 parts by mass of the total of the crosslinked hollow particles (A) and the reactive diluent (B1) and / or the organic solvent (B2). There are provided a hollow particles-containing liquid composition which is low in foreign matter content and can give a high haze, a process for production thereof, and an optical article.

Owner:JSR CORPORATIOON

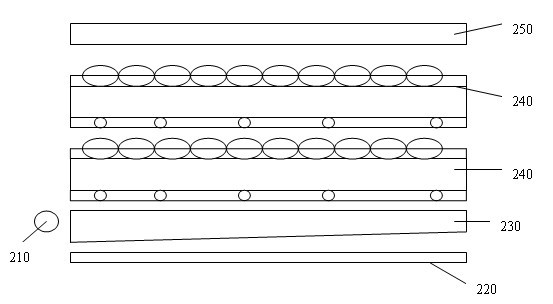

Photodiffusion film with blue light shielding function

InactiveCN103955016AHigh hazeModerate light transmittanceDiffusing elementsOptical filtersManufacturing technologyTransmittance

The invention relates to a photodiffusion film with a blue light shielding function. The photodiffusion film is composed of a base material layer, a photodiffusion layer and a blue light shielding layer, wherein the two surfaces of the base material layer are provided with the photodiffusion layer and the blue light shielding layer respectively. According to the photodiffusion layer, organic silicon resin spherical micro-powder is evenly dispersed in base materials, the thickness of the organic silicon resin spherical micro-powder is 5% - 20% of the thickness of the whole film, and the weight of the organic silicon resin spherical micro-powder is 0.5% - 2% of the total weight of the photodiffusion layer. According to the blue light shielding layer, blue light shielding particles are evenly dispersed in the base materials, the thickness of the blue light shielding particles is 5% - 20% of the thickness of the whole film, and the weight of the blue light shielding particles is 0.5% - 2% of the total weight of the blue light shielding layer. The photodiffusion film has the advantages of being high in haze, moderate in light transmittance, and good in stability of haze and light transmittance and has a blue light shielding function. Solutions are not used during photodiffusion film manufacturing, and therefore environmental friendliness is realized. Meanwhile, manufacturing technology is simple, price is low, application prospects are good, and market value is high.

Owner:SHANGHAI UNIV

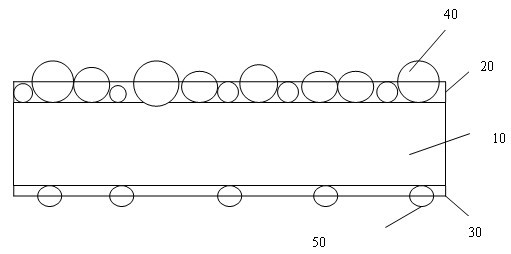

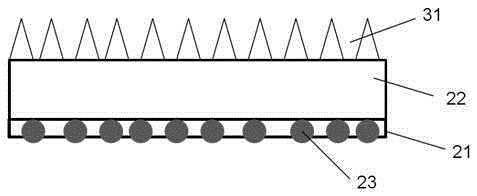

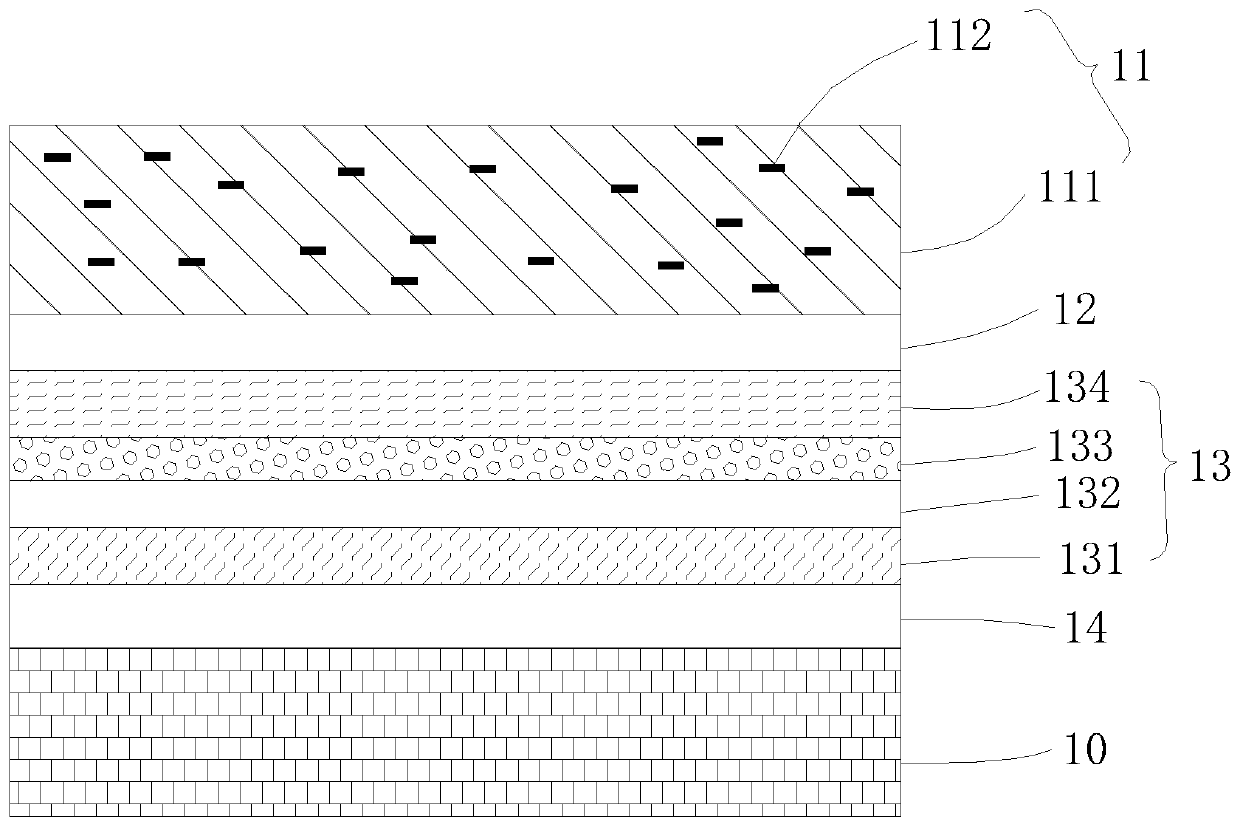

Basal membrane of composite brightness enhancement film

ActiveCN105353431AHigh hardnessIncrease surface tensionNon-linear opticsOptical elementsTectorial membraneUltraviolet lights

The invention discloses a basal membrane of a composite brightness enhancement film. The basal membrane comprises a support body and an antistick protection layer coating the surface of the support body, wherein the antistick protection layer is formed by solidifying a coating liquid composed of an ultraviolet light solidification resin and diffusion particles under the condition of ultraviolet light, and the haze scope ranges from 40% to 90%. The coating liquid of the antistick protection layer is prepared by the following components in parts by weight: 5 to 40 parts of a high-functionality polyurethaneacrylate prepolymer, 10 to 40 parts of an activated monomer, 1 to 5 parts of a photoinitiator, 0.5 to 3 parts of a levelling agent, 0.5 to 3 parts of a dispersing auxiliary and 20 to 60 parts of an organic solvent. According to the composite brightness enhancement film provided by the invention, when a protective membrane is laid for the brightness enhancement film, the protective membrane can be smoothly attached, and the problem of leftovers of residual gum is eliminated; and besides, the antistick protection layer has an atomization diffusion effect and can be applied to the basal membrane of the composite brightness enhancement film.

Owner:HEFEI LUCKY SCI & TECH IND

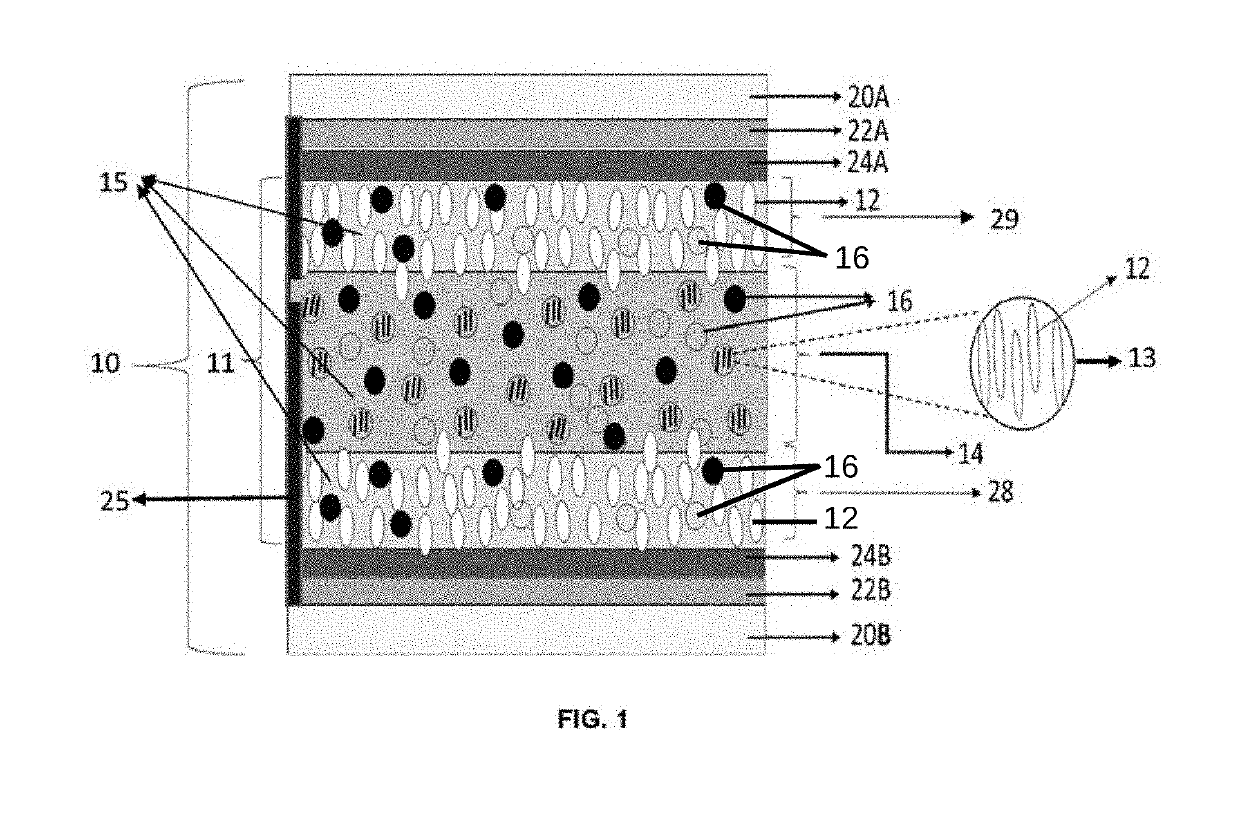

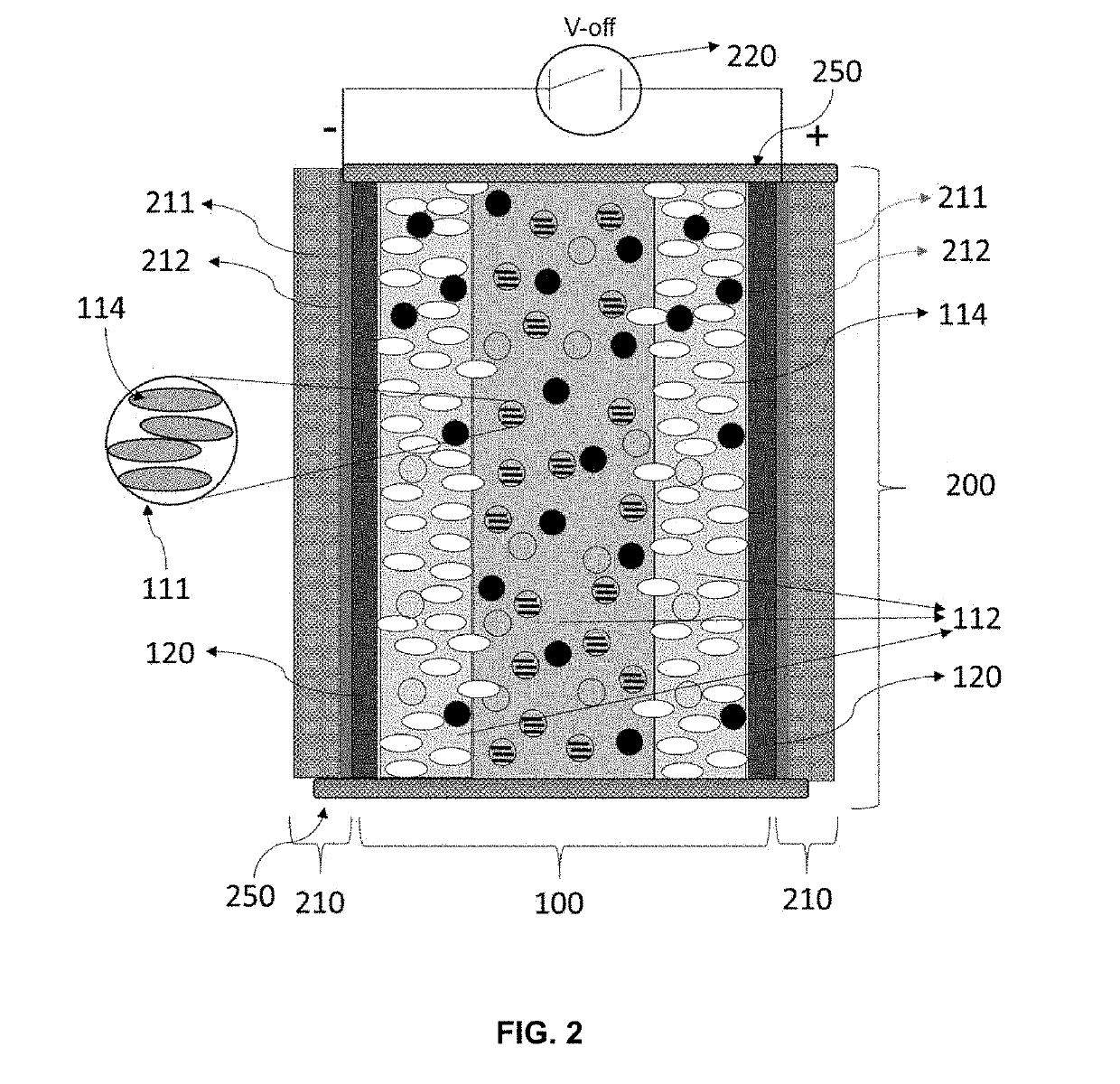

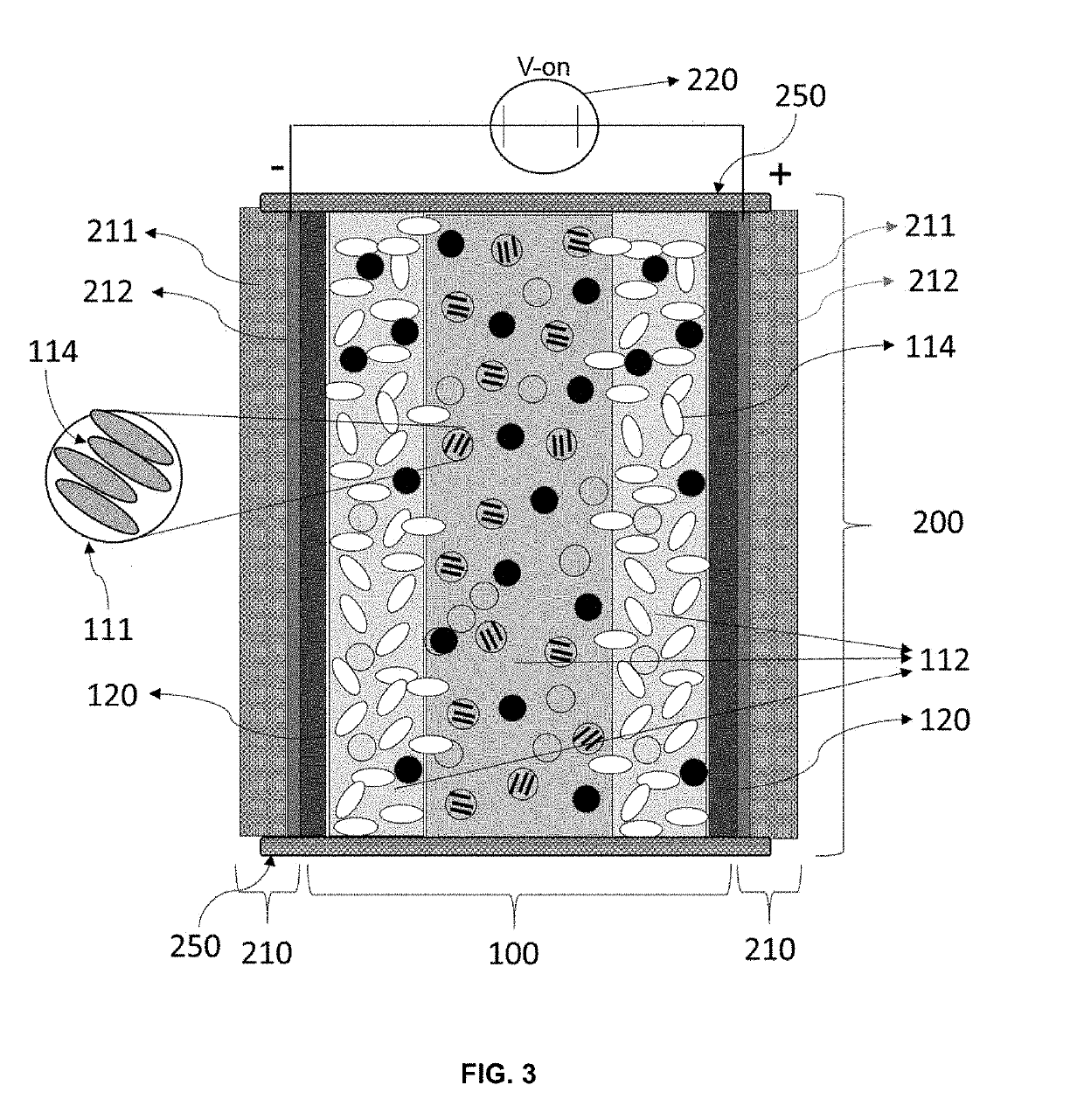

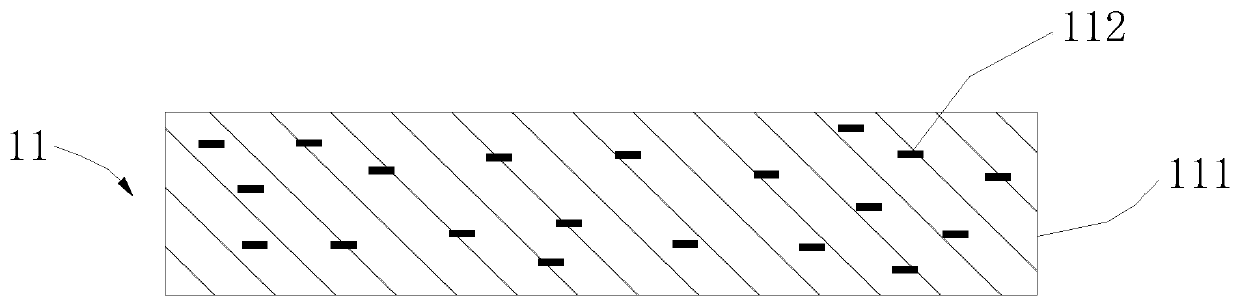

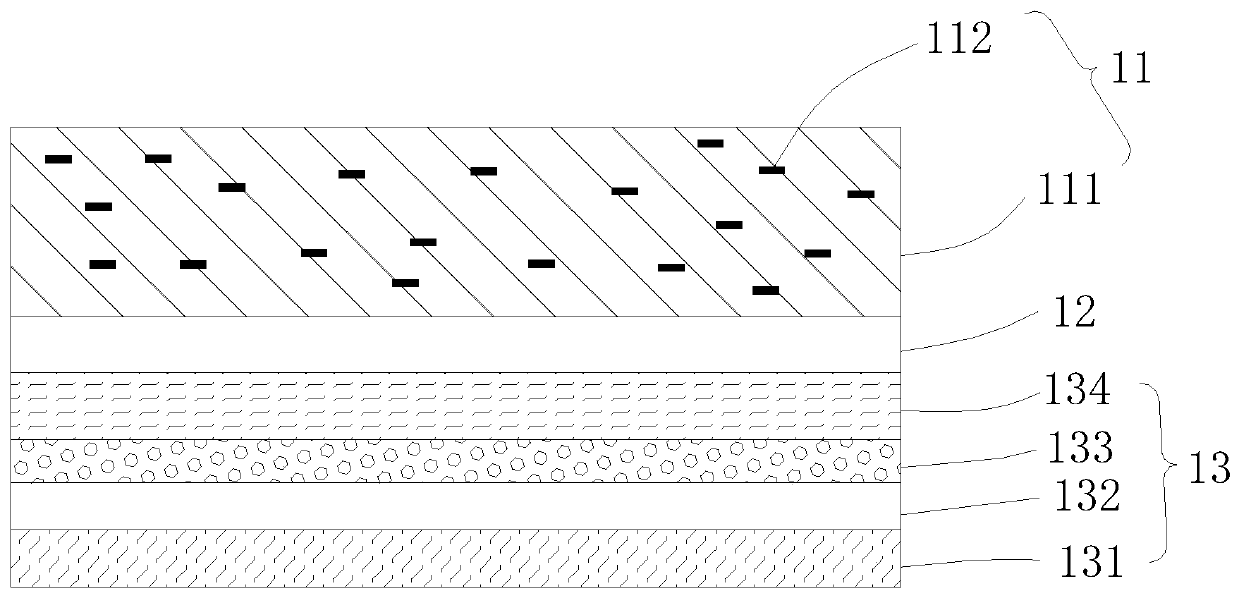

Liquid Crystal Composite, Liquid Crystal Element, and Associated Selectively Dimmable Device

InactiveUS20190278115A1Low hazeHigh voltage requirementsLiquid crystal compositionsNon-linear opticsLiquid crystalPolymer

Described herein are reverse-mode polymer dispersed liquid crystal (PDLC) compositions with a plurality of domains. In addition, selectively dimmable reverse-mode PDLC elements and devices using the aforementioned compositions are also described, which are transparent when no voltage is applied and opaque when a voltage is applied.

Owner:NITTO DENKO CORP

Transparent plastic articles comprising certain polymeric components to provide temporary and reversible opacity characteristics

InactiveUS6727317B2High hazeReduce sharpnessThermometer detailsOrganic chemistryLow-density polyethyleneEthylene Homopolymers

Unique transparent plastic (preferably though not necessarily polypropylene) articles that can be tailored to become opaque when exposed to a sufficiently high temperature and which returns to substantially the same transparency level upon cooling are provided. Such formulations include polymeric constituents that exhibit melting temperatures well below that for the majority clarified polypropylene, and thus which appear to become amorphous upon exposure to temperatures above such a lower melting temperature, thereby affecting the crystalline formation of the clarified polypropylene to the extent that opacity dominates the appearance thereof. Such lower melting temperature polymeric constituents include species such as low melt flow (up to 10) metallocene polyethylene and / or low density polyethylene, both of which exhibit melting temperatures of from about 60 to about 100° C., well below the typical polypropylene melting temperatures of roughly about 150° C. for homopolymer and about 165° for typical random copolymer. Preferably, as well, the melt flow for the polypropylene may be anywhere from about 1 to about 20, with the most preferable formulation comprising polyethylene and polypropylene components exhibiting similar melt flow properties (e.g., with a difference of at most 5 units) for better mixing results. Methods of producing such temperature sensitive transparent polypropylene formulations and articles are also encompassed within this invention.

Owner:MILLIKEN & CO

Radiation refrigeration film, radiation refrigeration composite film and radiation refrigeration product

ActiveCN111114031AExcellent radiation cooling effectHigh hazeRoof coveringWallsThin membraneComposite material

The invention relates to a radiation refrigeration film. The radiation refrigeration film comprises a matrix layer and a filler distributed in the matrix layer, the refractive index of the material ofthe matrix layer is n, n is 1.3 to 1.7, the refractive index of the filler is m, the difference between n and m is x, an absolute value of x is greater than or equal to 0.05%, the emissivity of the radiation refrigeration film in an atmospheric window of 7-14 microns is greater than or equal to 80%, the heat reflectivity of the radiation refrigeration film in a wave band of 300-2500nm is greaterthan or equal to 10%, and the glossiness of the radiation refrigeration film is less than or equal to 20GU. Through selection of the material and the filler of the matrix layer and adjustment of the relationship of the refractive index, the radiation refrigeration effect of the radiation refrigeration film is excellent, and the glossiness is low. The invention further provides a radiation refrigeration composite film and a radiation refrigeration product, light pollution in the using process can be effectively reduced, and the excellent radiation refrigeration effect is guaranteed.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com