Optical diffusion barrier with high haze and high brightness and liquid crystal display backlight source using optical diffusion barrier

A technology of optical diffusion and high brightness, applied in the field of optical diffuser film and liquid crystal display backlight, it can solve the problems of limited light-gathering ability and covering ability of thin film, and achieve high haze and brightness, high light-gathering ability and haze, and less combination. The effect of the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

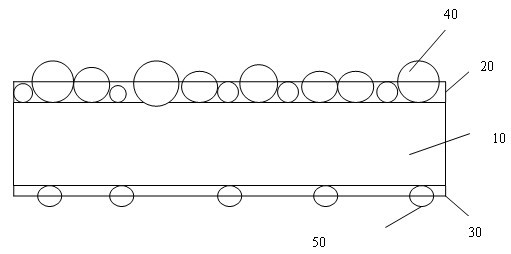

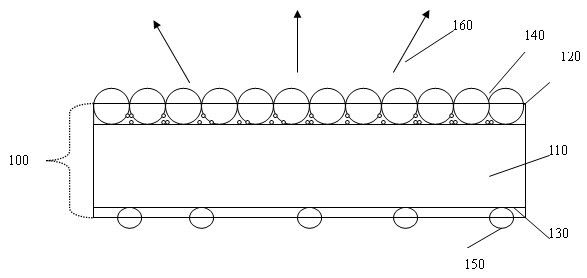

[0019] Example 1: as figure 2 As shown, the optical diffusion film 100 mainly includes a transparent PET substrate 110 , a diffusion coating 120 including round PMMA diffusion particles 140 and an anti-adhesion coating 130 including round PMMA anti-adhesion particles 150 . In a specific embodiment, the diffusion particles in the diffusion layer 120 are combined according to the proportions in Table 1, the large-particle diffusion film particles are closely arranged together, and the small-particle diffusion particles are dispersed and filled in the diffusion coating 120. The difference in refractive index between the diffusing particles and the substrate and resin coating scatters light. The thickness of the diffusion layer 120 is strictly controlled to be 1 / 2 of the particle size of the large-particle diffusion particles 140 inside, and half of the large-particle diffusion particles 140 are buried in the diffusion coating 120 , and the other half is exposed on the diffusion ...

Embodiment 2

[0022] Example 2: as figure 2 As shown, the optical diffusion film 100 mainly includes a transparent PET substrate 110 , a diffusion coating 120 including round PMMA diffusion particles 140 and an anti-adhesion coating 130 including round PMMA anti-adhesion particles 150 . In a specific embodiment, the diffusion particles in the diffusion layer 120 are combined according to the proportions in Table 2, the large-particle diffusion film particles are closely arranged together, the small-particle diffusion particles are dispersed and filled in the diffusion coating 120, and the small particles are used The difference in refractive index between the diffusing particles and the substrate and resin coating scatters light. The thickness of the diffusion layer 120 is strictly controlled to be 1 / 2 of the particle size of the large-particle diffusion particles 140 inside, and half of the large-particle diffusion particles 140 are buried in the diffusion coating 120 , and the other half...

Embodiment 3

[0025] Example 3: as figure 2As shown, the optical diffusion film 100 mainly includes a transparent PET substrate 110 , a diffusion coating 120 including round PMMA diffusion particles 140 and an anti-adhesion coating 130 including round PMMA anti-adhesion particles 150 . In a specific embodiment, the diffusion particles in the diffusion layer 120 are combined according to the proportions in Table 3, the large particles of the diffusion film are closely arranged and arranged together, the small particles of the diffusion particles are dispersed and filled in the diffusion coating 120, and the small particles are used The difference in refractive index between the diffusing particles and the substrate and resin coating scatters light. The thickness of the diffusion layer 120 is strictly controlled to be 1 / 2 of the particle size of the large-particle diffusion particles 140 inside, and half of the large-particle diffusion particles 140 are buried in the diffusion coating 120 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com