Solar condensing mirror with adjustable focus and application thereof

A technology of solar energy and concentrating mirrors, which is applied in the field of solar adjustable focus dish concentrating mirrors, which can solve the problems of poor quality, easy breakage, and increased product costs, and achieve the effects of simple installation methods, improved concentrating effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

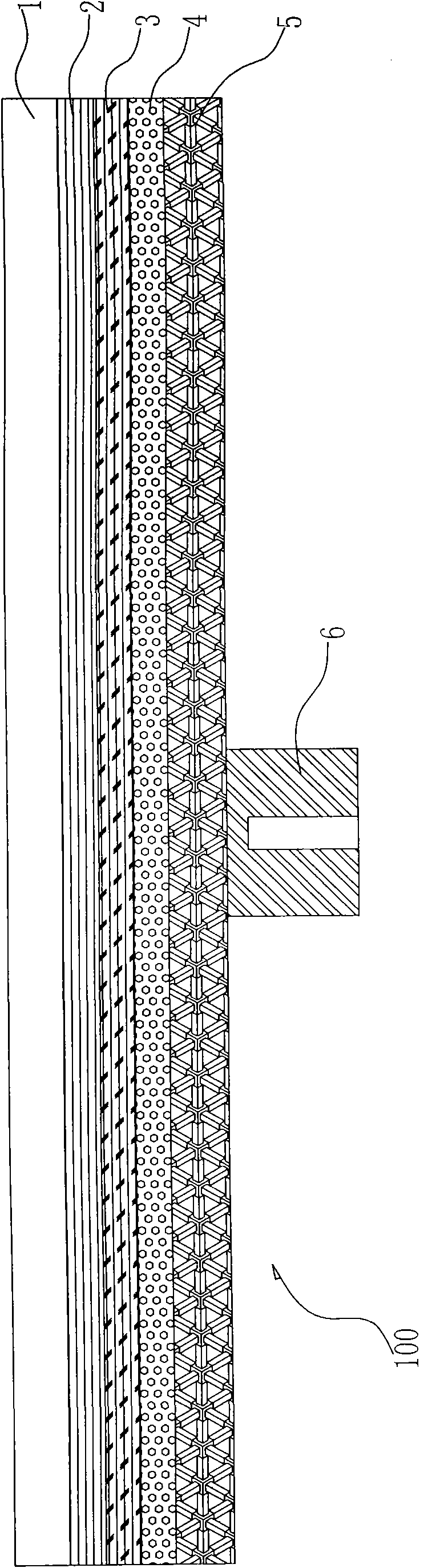

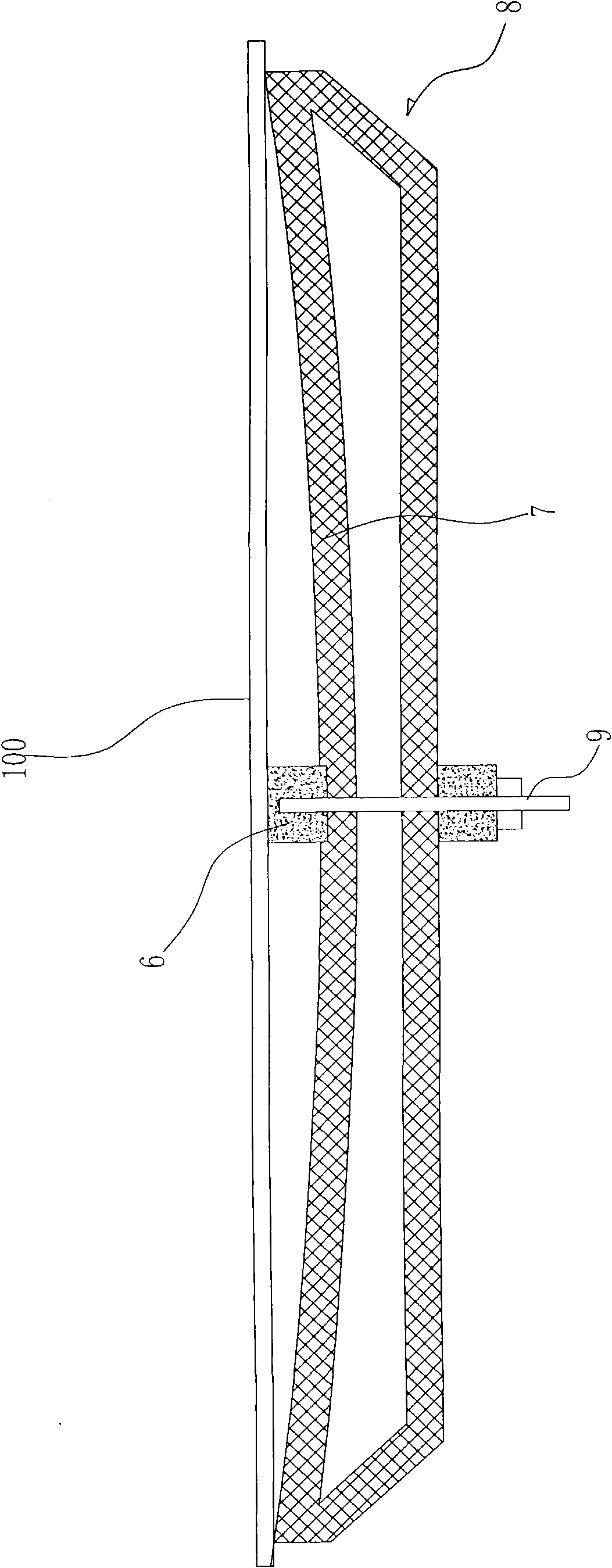

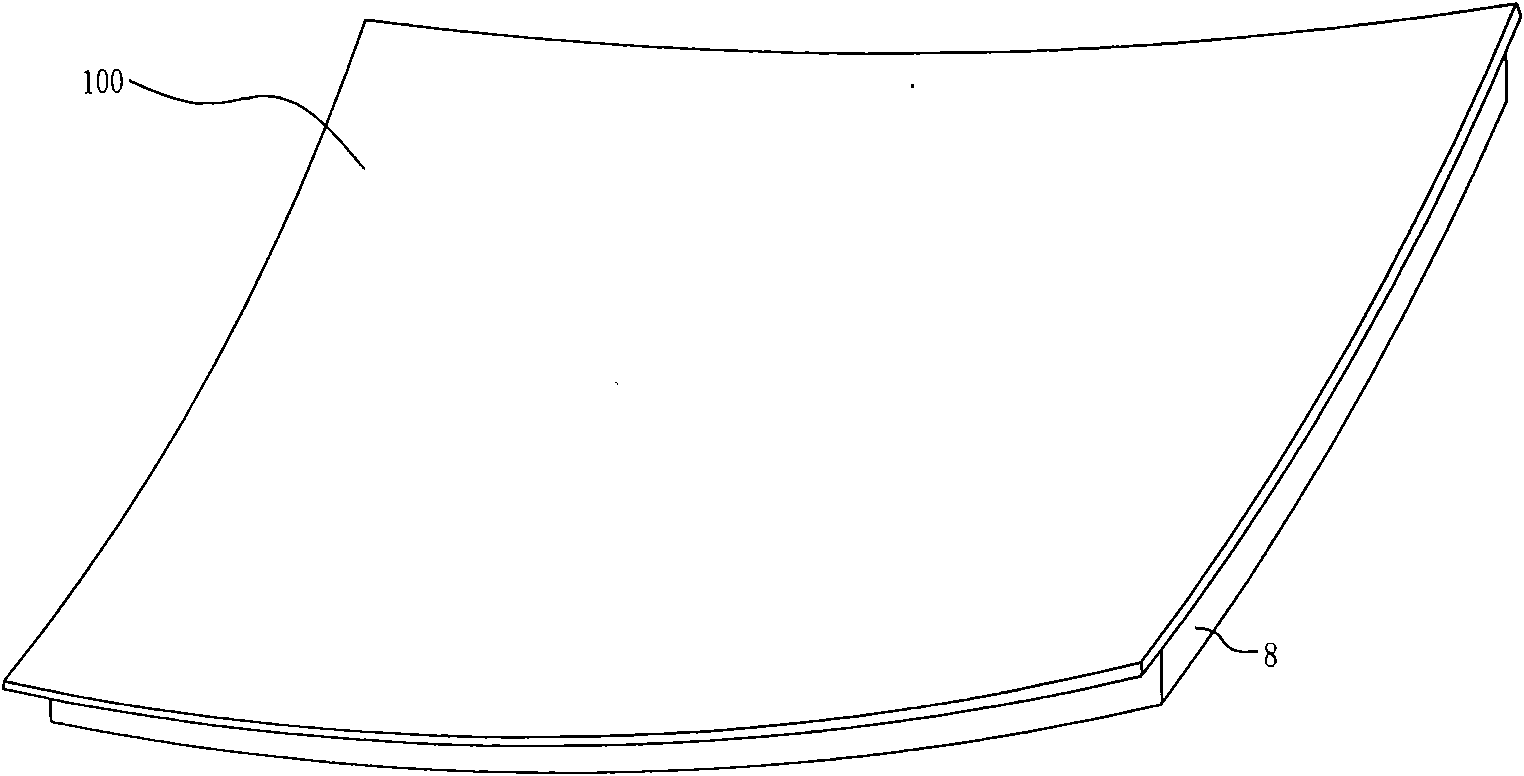

[0026] Such as figure 1 As shown, the high-reflection reinforced composite silver-coated glass mirror 100 is a composite structure, and its composite layer structure is as follows: it is successively composed of ultra-white high-transmittance flat tempered glass 1 (generally, thinner and large-area glass is selected), silver-coated Reflective layer 2, silver-plated protective layer 3 (which can be metal plating such as copper and nickel, or resin and fluorocarbon paint), laminated layer 4 (EAV laminated protective layer), and backplane layer 5. The backplane layer 5. It can be glass steel FRP; it can also be PET, TPE, TPT and other back films; tempered glass, etc.

[0027] In addition, there is a radian adjusting screw interface 6 fixed on the back plate layer 5 (usually by bonding) for connecting with the adjusting mechanism.

[0028] Specifically, the ultra-clear flat tempered glass 1 is made of float glass after cutting and grinding, and then physically air-cooled tempered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com