Patents

Literature

98results about How to "No flash point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

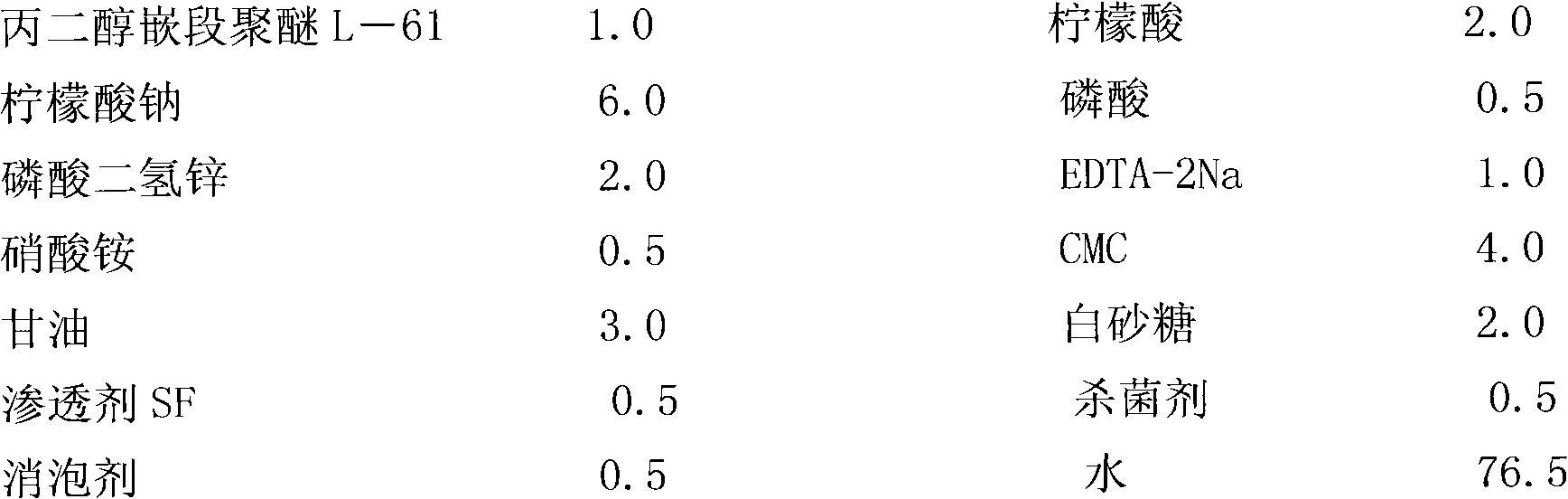

Alcohol-free concentrated fountain solution and preparation method thereof

InactiveCN102303465AStable concentrationPrint color difference is smallPrinting pre-treatmentAlcohol freePhysical well being

The invention provides an alcohol-free concentrated fountain solution and a preparation method thereof. The alcohol-free concentrated fountain solution is prepared from the following components based on 100 parts by weight: 0.5-5 parts of low-foam wetting agent, 8-20 parts of pH value regulator, 3-20 parts of printing plate protective agent, 5-10 parts of a water film regulator, 0.2-1.0 part of decontamination intensifier, 0.1-1.0 part of bactericide, 0.1-1.2 parts of defoamer and the balance of water. The concentrated fountain solution provided by the invention is environmentally-friendly, provides guarantee for the health of workers, and can improve the quality of the printing products.

Owner:冯星枢 +1

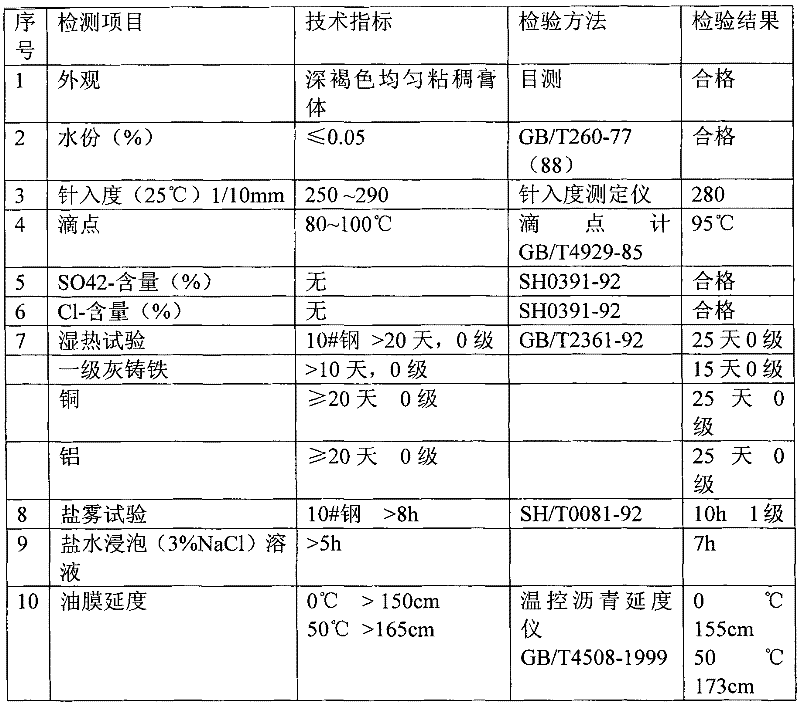

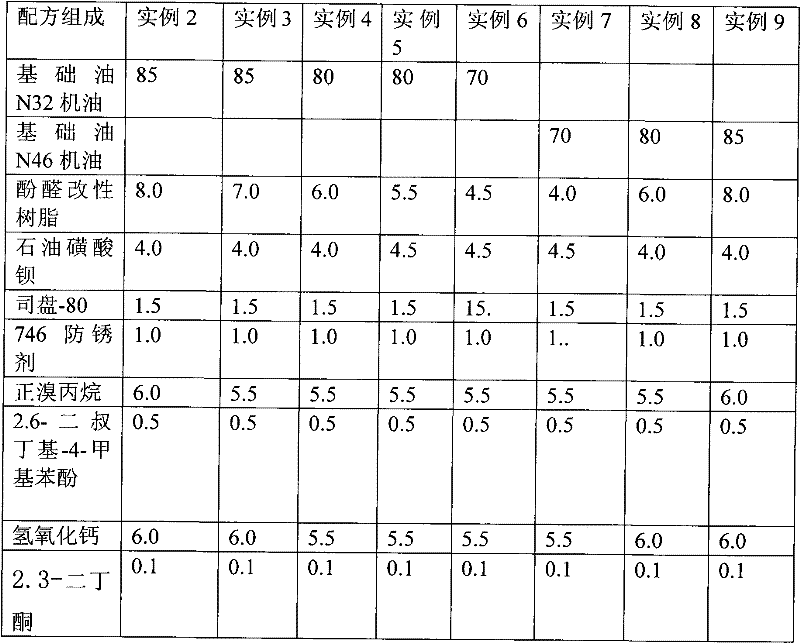

Long-acting antirust grease and preparation method thereof

ActiveCN102229845AImprove physical stabilityGood chemical stabilityLubricant compositionEngineeringFilm-forming agent

The invention belongs to the field of chemistry and relates to long-acting antirust grease and a preparation method thereof. The long-acting antirust grease mainly comprises the following components ( by weight): 70 to 90 parts of base oil, 3 to 6 parts of thickening agent, 4.5 to 8 parts of antirust additive, 4 to 8 parts of film-forming agent, 0.5 to 1 part of antioxidant, and 3 to 6 parts of assistant. The antirust grease has the characteristics that: the application of the grease is easy; the durability is high; the detachment of fasteners at next time is easy; the application range is wide; and the like. The long-acting antirust grease is suitable for outdoor steel fasteners which require anti-corrosion treatment and cannot be coated with paint.

Owner:麻城天安化工股份有限公司

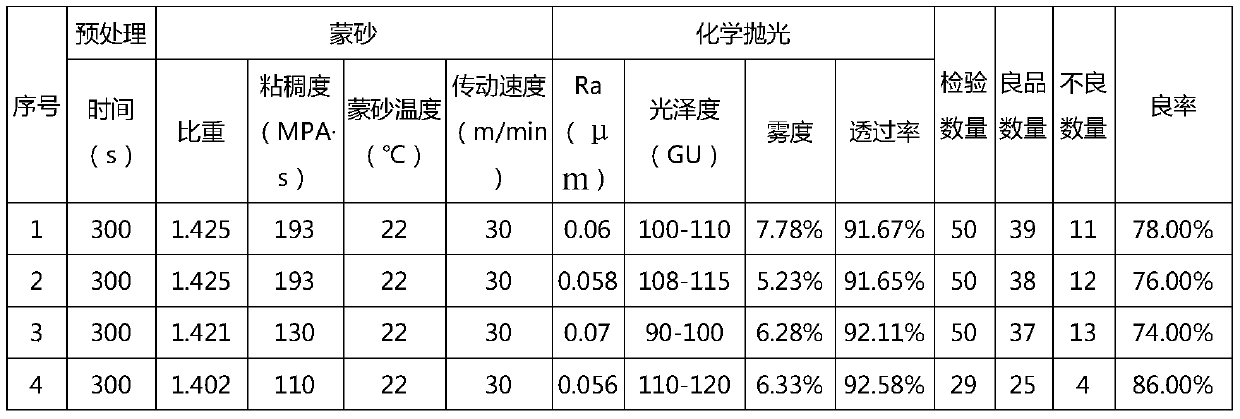

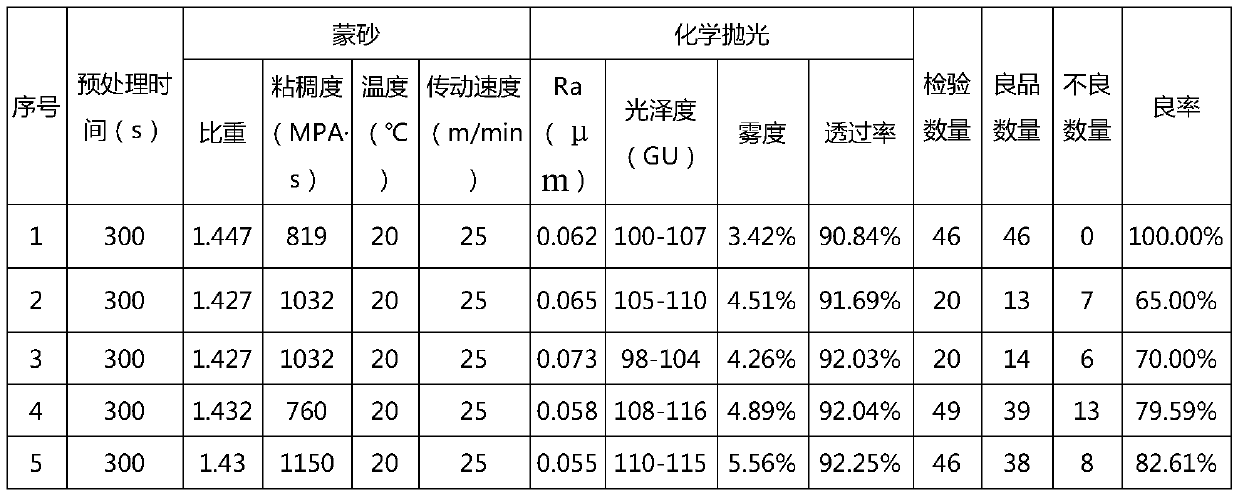

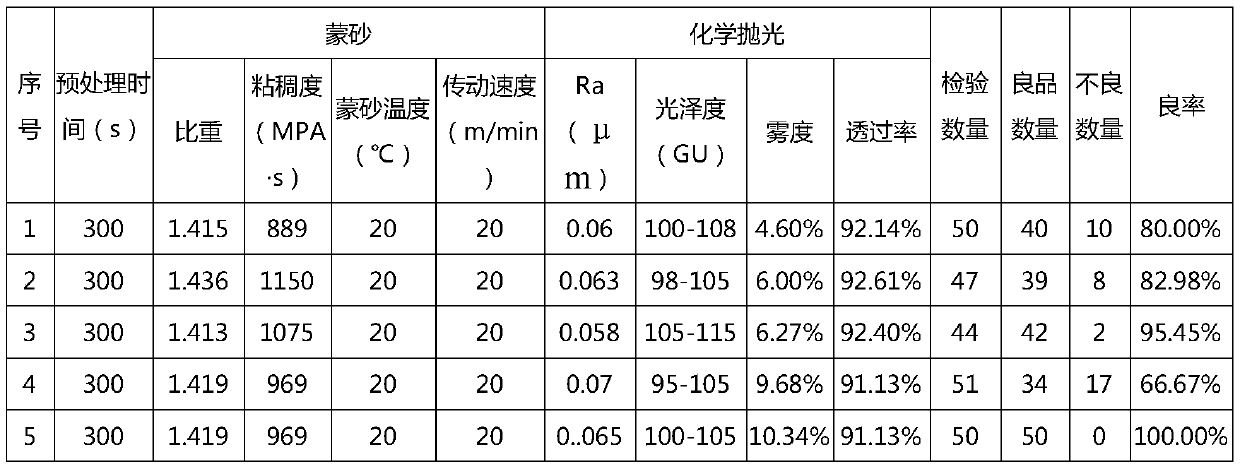

High-alumina glass frosting liquid and preparation method thereof

The invention discloses a high-alumina glass frosting liquid and a preparation method thereof. The high-alumina glass frosting liquid comprises the following components in parts by weight: 30-45 partsof ammonium bifluoride, 5-15 parts of citric acid, 2-5 parts of barium sulfate, 4-10 parts of starch, 2-6 parts of bentonite, 10-20 parts of ferric trichloride, 5-15 parts of potassium fluoride, 6-13parts of potassium nitrate, 2-6 parts of hydrofluoric acid and 10-30 parts of water. The frosting liquid is low in manufacturing cost and high in production yield; and anti-dazzle glass prepared fromthe frosting liquid has the characteristics of high glossiness, low flash point, low roughness and good anti-dazzle effect.

Owner:YICHANG NANBO DISPLAY +1

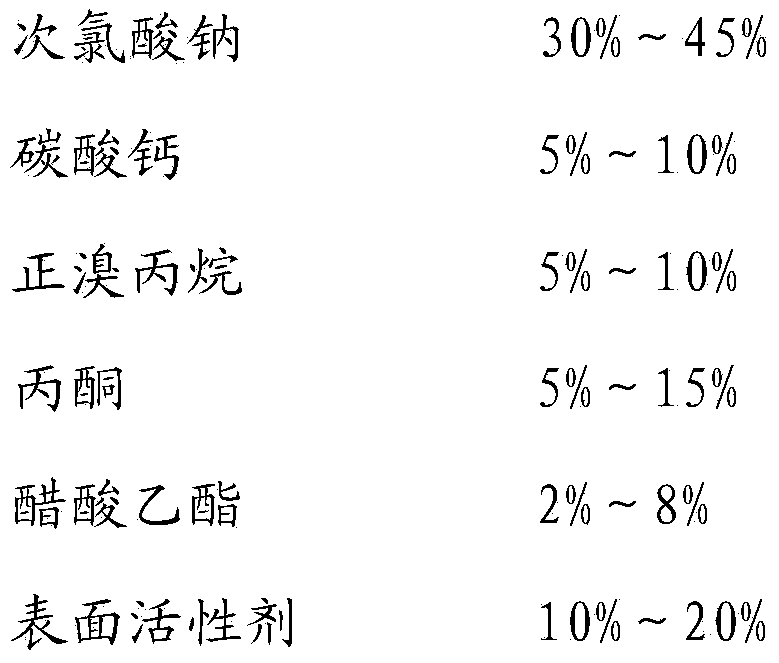

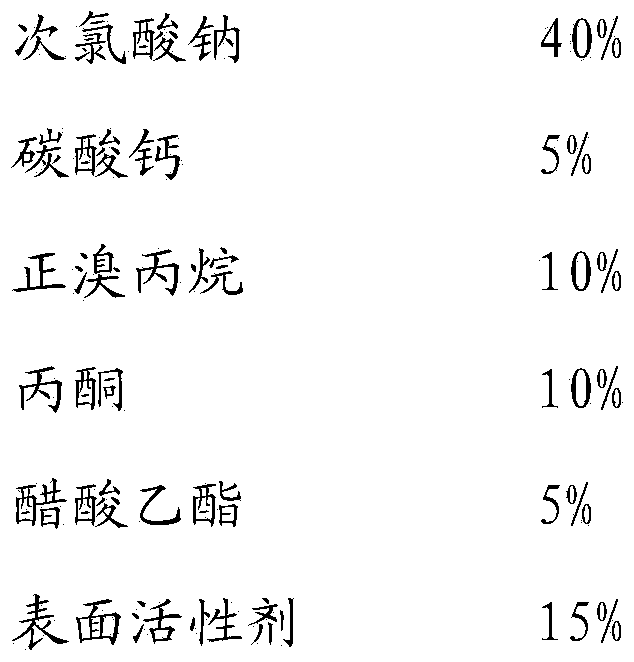

Oil stain cleaning agent

InactiveCN103525583AEasy to cleanGood storage stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsStain

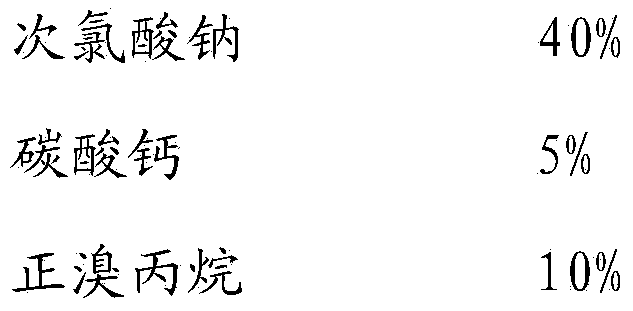

The invention relates to a cleaning agent for silicate products, and in particular relates to an oil stain cleaning agent. The oil stain cleaning agent consists of the following components in percentage by weight: 30-45% of sodium hypochlorite, 5-10% of calcium carbonate, 5-10% of propyl bromide, 5-15% of acetone, 2-8% of acetic ether, 10-20% of surfactant and the balance of de-ionized water. The cleaning agent, added with the sodium hypochlorite with cleaning and blanching functions as well as the propyl bromide, the calcium carbonate, the acetone, the acetic ether, the surfactant and the like with functions of removing stain, removing oil, penetrating and lubricating, can be used for enhancing bonding between the stain and chlorine atoms; the cleaning agent can be used for effectively cleaning water stain and oil stain of the silicate products, and is quite excellent in washing effect; meanwhile, the cleaning agent is strong in cleansing power and low in construction cost, and the cleaning agent, as a liquid preparation, is simple and convenient to use, thereby being a special oil stain cleaning agent for stones.

Owner:LIUZHOU XINLEI TECH

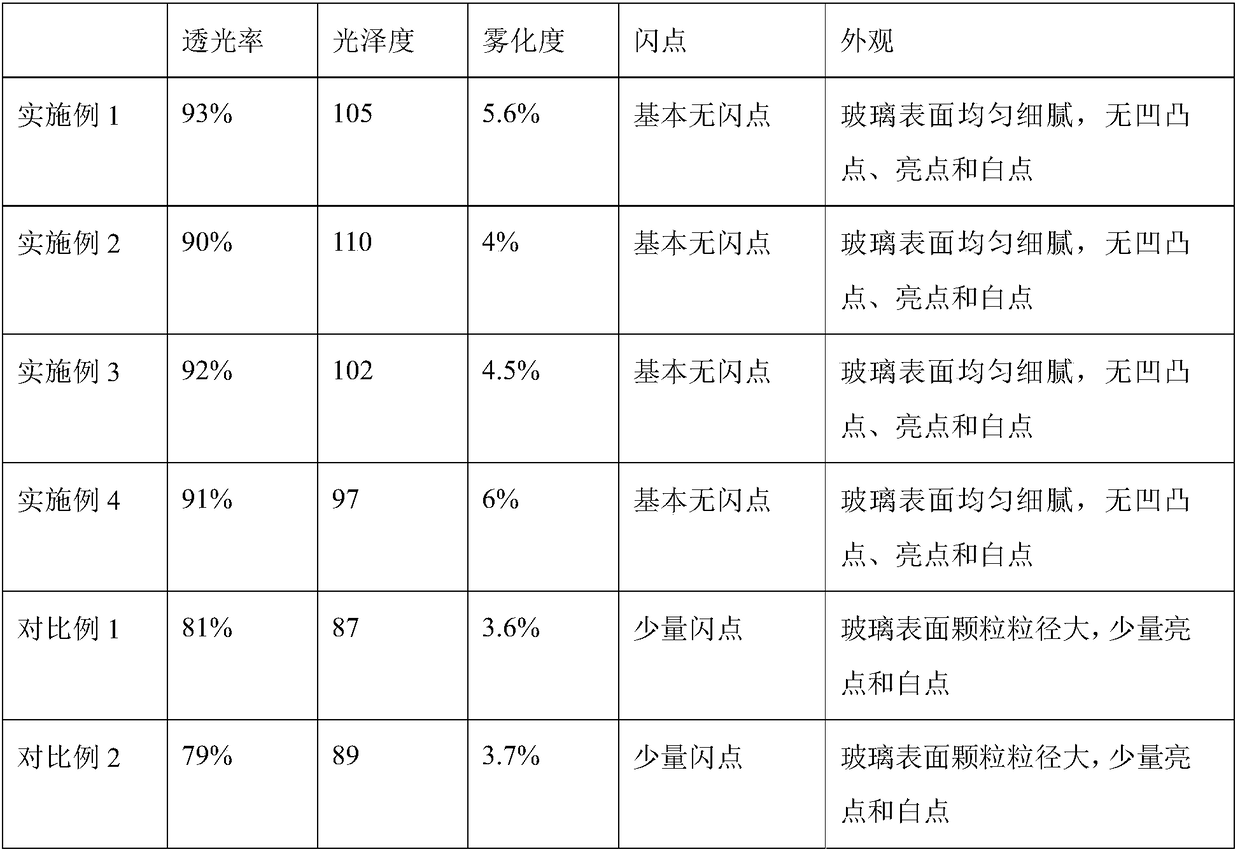

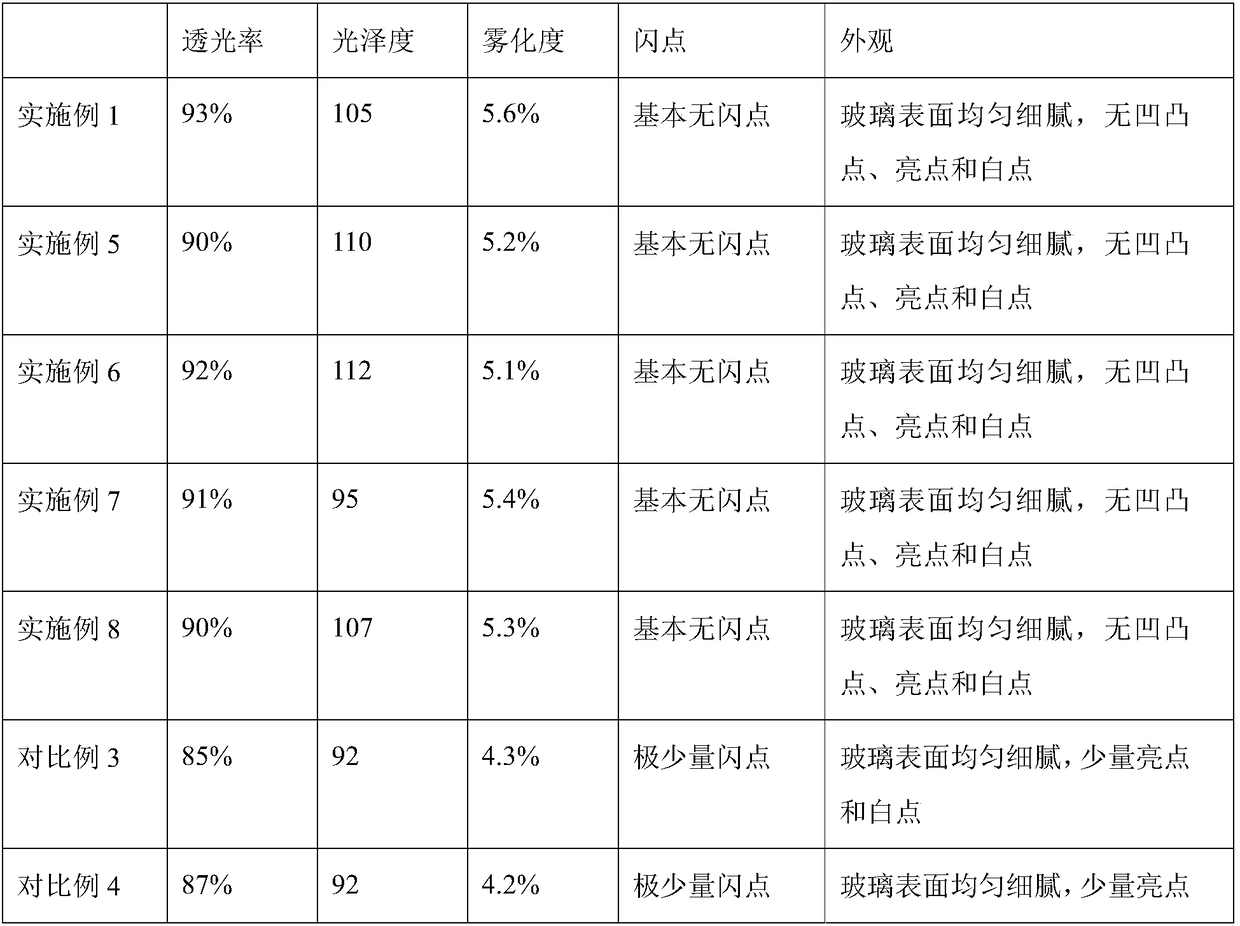

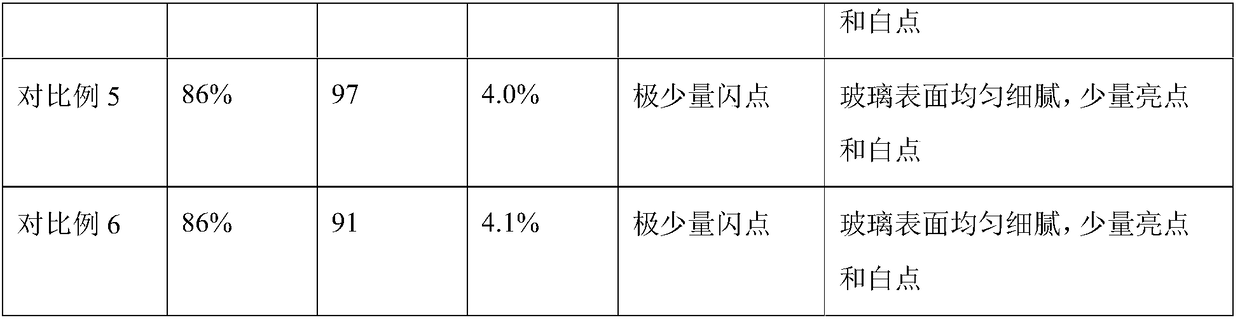

Frosting liquid, preparation method and uses thereof, and anti-glare glass preparation method

The invention relates to a frosting liquid, a preparation method and uses thereof, and an anti-glare glass preparation method, and provides a frosting liquid, which is prepared by mixing the followingraw materials by weight: 10-17 parts of ammonium fluoride, 7-12 parts of sulfuric acid, 3-5 parts of calcium fluoride, 3-5 parts of ammonium sulfate, 15-20 parts of potassium sulfate, and 130-140 parts of water. The invention further provides the an anti-glare glass preparation method, which comprises: (1) placing a glass in a frosting liquid; and (2) introducing a gas into the frosting liquid, and carry out a reaction. According to the present invention, the anti-glare glass prepared by using the frosting liquid through the preparation method has advantages of high light transmittance, highgloss, fine surface particles, uniform particle distribution and the like.

Owner:LENS TECH CHANGSHA

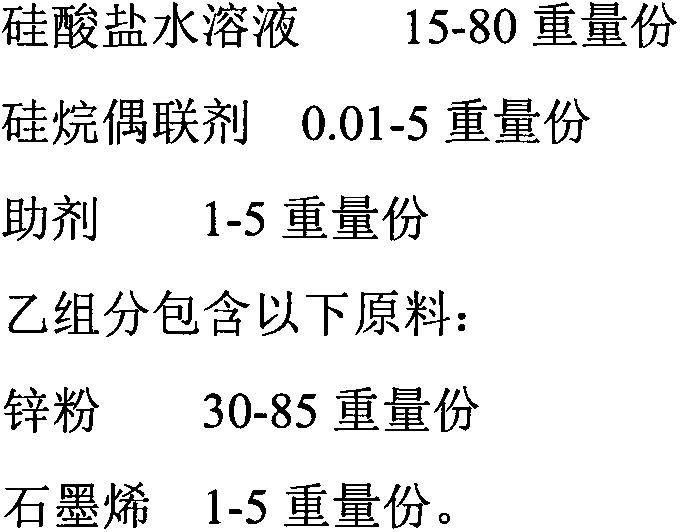

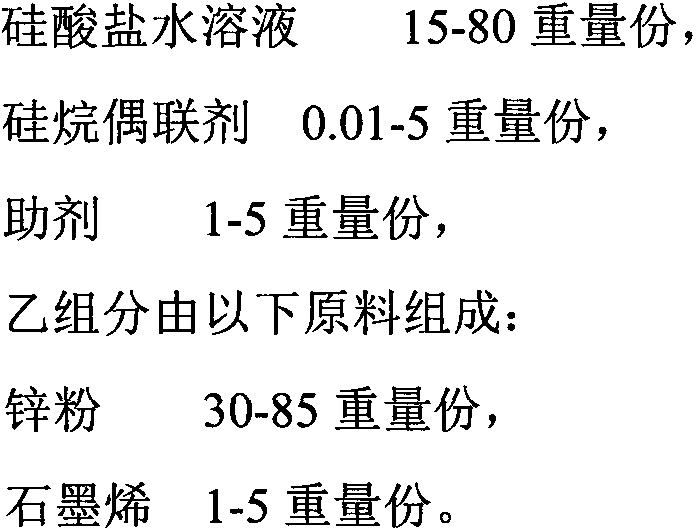

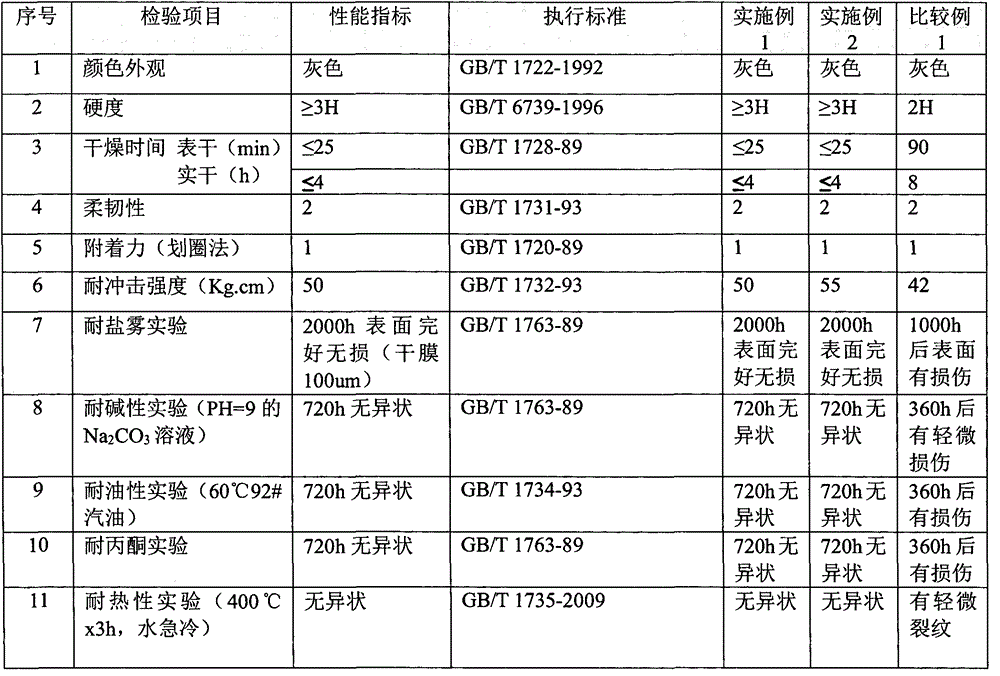

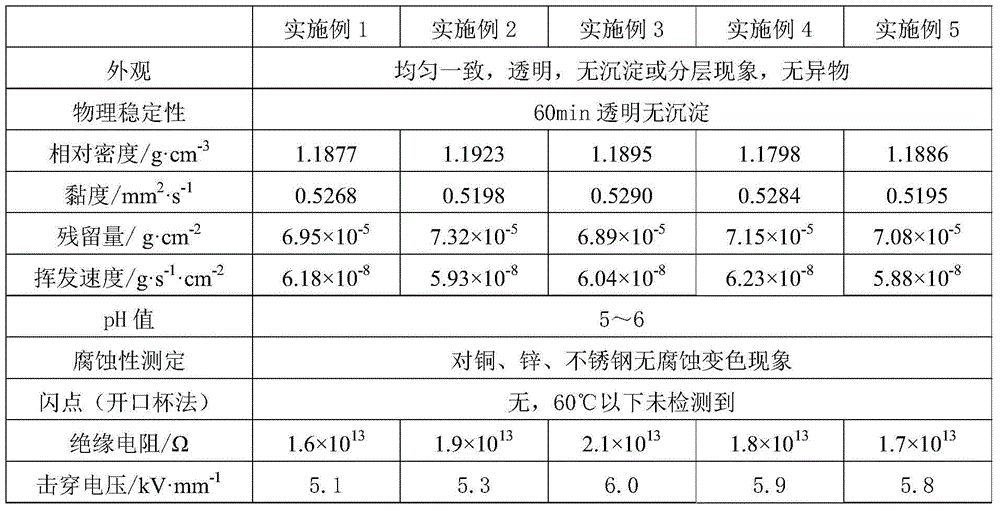

Environment-friendly water-based ceramic base anticorrosion material

ActiveCN105086529ASimple processShort construction periodAnti-corrosive paintsWater basedUltraviolet

The invention relates to an environment-friendly water-based ceramic base anticorrosion material. The environment-friendly water-based ceramic base anticorrosion material comprises first components and second components, wherein the first components comprise the following raw materials of a silicate aqueous solution, silane coupling agents and additives. The second components comprise the following materials of zinc powder and grapheme. The environment-friendly water-based ceramic base anticorrosion material has the advantages that water serves as a solvent, the material is free of poison and pollution, and VOC emission is zero; the environment-friendly water-based ceramic base anticorrosion material is resistant to high temperature and high in self-repairing capacity, a coating can be dried fast, the corrosion resistance is high, and the weather resistance is excellent; except oil paint and alkyd paint, the environment-friendly water-based ceramic base anticorrosion material can be matched with other anticorrosion finishing paint for use; the environment-friendly water-based ceramic base anticorrosion material is preventive to ultraviolet erosion, resistant to salt mist and various organic strong solvents and capable of being welded and cut with paint; the environment-friendly water-based ceramic base anticorrosion material can meet the requirement of long-acting inside and outside corrosion preventing engineering with the PH value being 5.5-8 under a medium environment in ship engineering, container engineering and other ocean engineering.

Owner:SHENZHEN BRILLIANT NEW MATEIRALS CO LTD

High-strength and high-tenacity low-alloy wear-resistant steel and preparing method thereof

ActiveCN105568165AAchieve isothermal transitionNo changeProcess efficiency improvementQuenchingWear resistant

The invention discloses high-strength and high-tenacity low-alloy wear-resistant steel and a preparing method thereof. The high-strength and high-tenacity low-alloy wear-resistant steel comprises the following components in a percent by mass: 0.40-0.60 of C, 0.60-1.2 of Si, 0.30-1.0 of Mn, 0.25-0.35 of Cr, 0.15-0.25 of Mo, 0.40-0.60 of Cu, 0.10-0.15 of Re, 0-0.025 of P, 0-0.025 of S and the balance of Fe and unavoidable impurities. A liquid quenching hot isothermal quenching heating processing technology used as a heating processing technology in the preparing method comprises the following steps: 1), heating a casting obtained through casting to 820-860DEG C and carrying out austenization; 2), placing the casting in a quenching medium and carrying out quenching; 3), taking out the casting after the surface temperature of the casting is cooled to 200-320DEG C; and 4), immediately transferring the hot casting into a 260-330DEG C heat holding furnace, carrying out bainite isothermal transformation for 1-2h, and then taking out and air-cooling the casting. The bainite structure of the obtained workpiece is fine, the inner structure is lower bainite, and the central structure is upper bainite plus lower bainite. The structure distribution surface is high in strength, great in hardness, resistant to wear and great in central structure tenacity. The high-strength and high-tenacity low-alloy wear-resistant steel is particularly suitable for bucket teeth, crankshafts and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Electrified cleaning agent for precise instruments and preparation method of electrified cleaning agent

InactiveCN104479905AImprove surface activityStrong emulsifying abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium bicarbonateAlcohol

The invention provides an electrified cleaning agent for precise instruments and a preparation method of the electrified cleaning agent. The cleaning agent comprises cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyl dimethyl benzyl ammonium, sodium tripolyphosphate, trisodium phosphate, sodium bicarbonate, sodium nitrite, 2-phenoxyethyl alcohol, pine oil, an antistatic agent, polyhydroxy polyamine, ethyl acetate and ethyl alcohol. The preparation method comprises the following steps: firstly adding cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyl dimethyl benzyl ammonium and sodium tripolyphosphate to ethyl alcohol, so as to obtain a mixture I; adding trisodium phosphate, sodium bicarbonate, the sodium nitrite and 2-phenoxyethyl alcohol to ethyl acetate, so as to obtain a mixture II; and finally mixing the mixture I with the mixture II, and then adding the residual components, so as to obtain the cleaning agent. The cleaning agent is excellent in performance, and can be used as the electrified cleaning agent for the precise instruments.

Owner:DONGCHEN LEADER TESTING

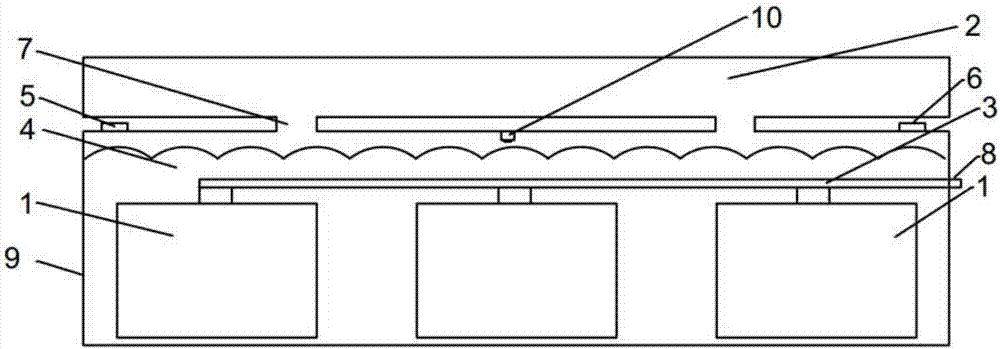

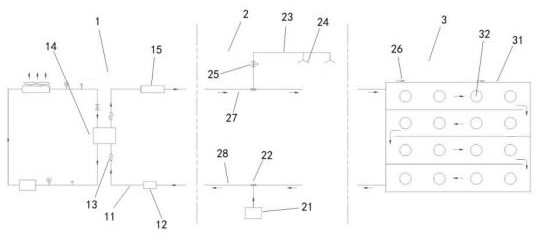

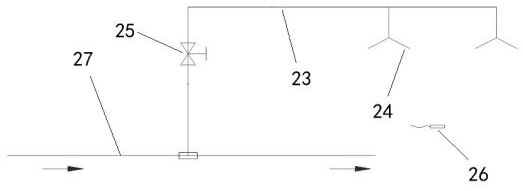

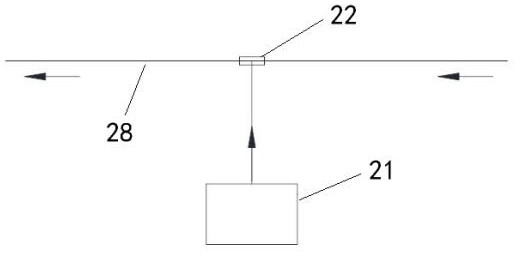

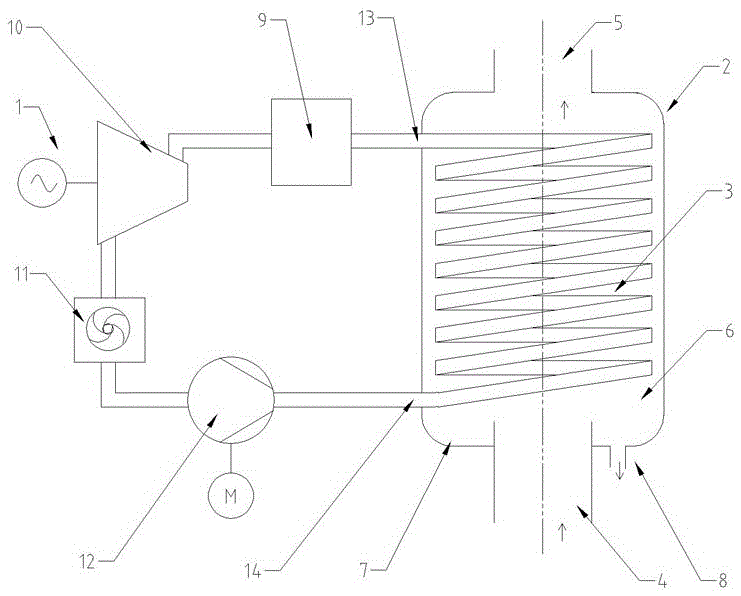

Evaporative cooling flame retardant battery system

PendingCN107134605AHigh dielectric strengthReduce viscositySecondary cellsFluorocarbonHigh power density

The invention provides an evaporative cooling flame retardant battery system which is simple in structure, economical and durable, has a good heat dissipation function and has a flame retardant function. The evaporative cooling flame retardant battery system comprises a battery, a tank body, cooling liquid, a connector, a pressure relief valve, an electromagnetic valve, a cooler, a pipeline and total positive / negative connector and a pressure sensor; the battery is connected with the connector, and is immersed in the cooling liquid; the cooling liquid is fluorocarbon. The evaporative cooling flame retardant battery system has heat dissipation and flame retardant functions at the same time; the evaporative cooling flame retardant battery system has a simple structure and does not need special maintenance; the internal temperature balance and heat dissipation of the system are operated spontaneously, fans, pumps and other equipment are not needed in the internal of the system; compared with the traditional air cooling and liquid cooling, the heat dissipation effect of the system is better, the structure is simpler, the safety is higher, and the system is especially suitable for a high-power-density battery system.

Owner:四川国创成电池材料有限公司

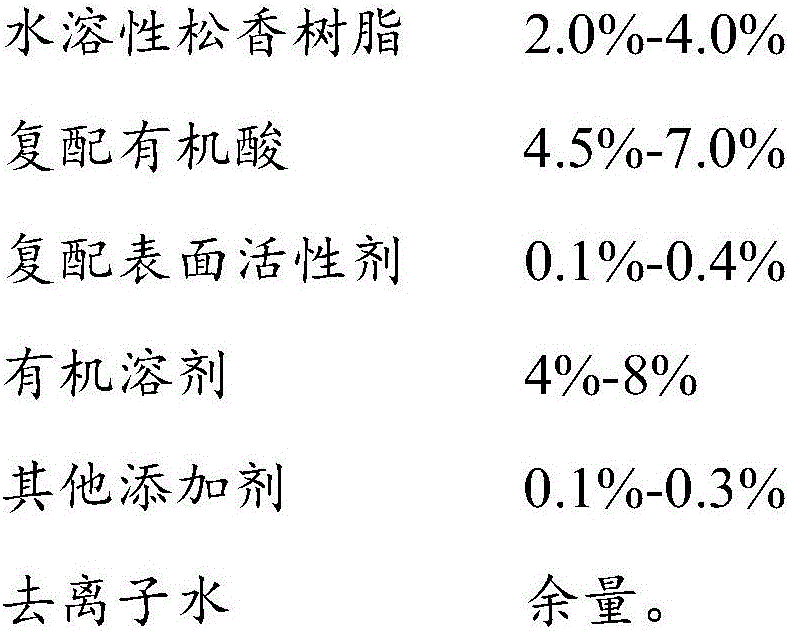

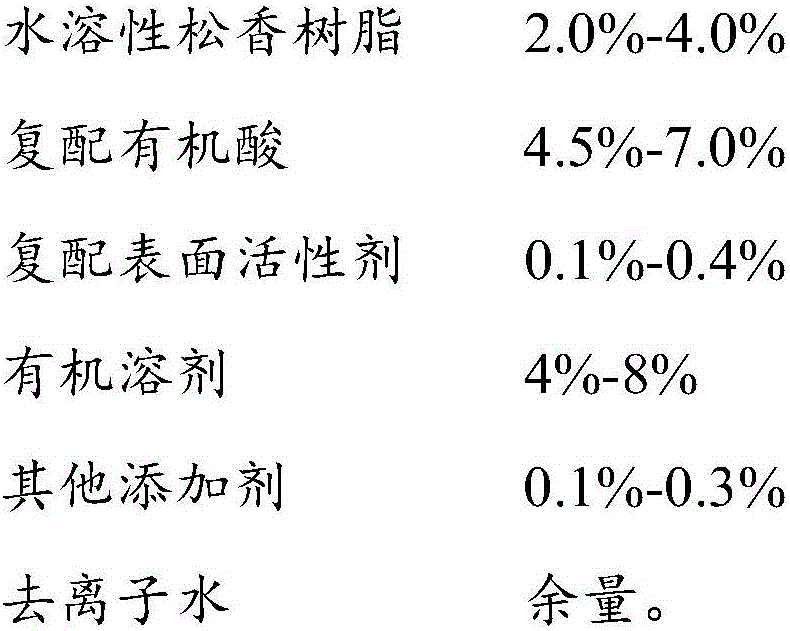

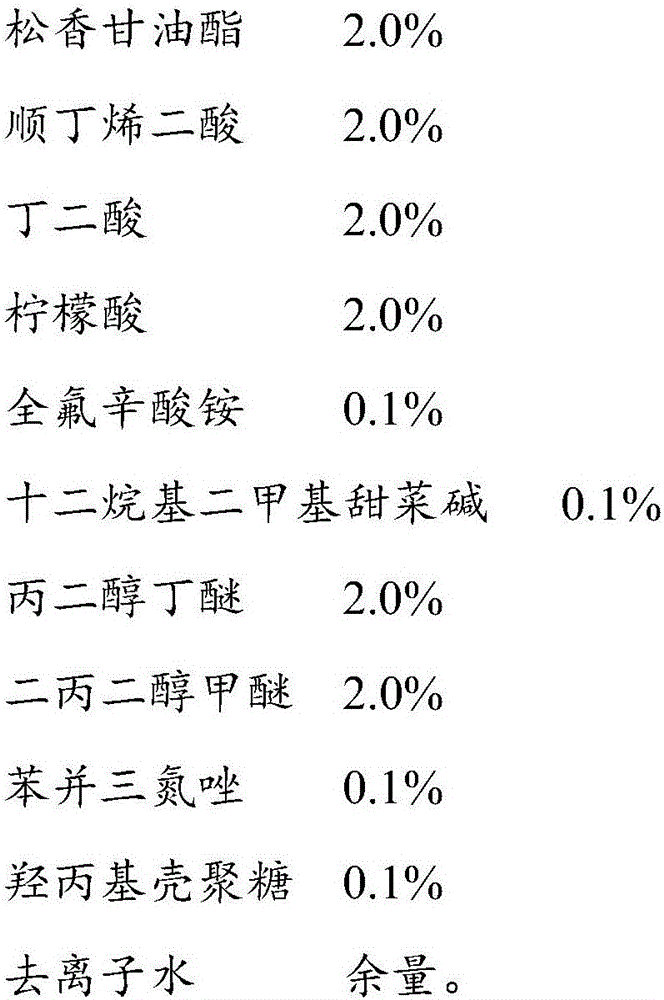

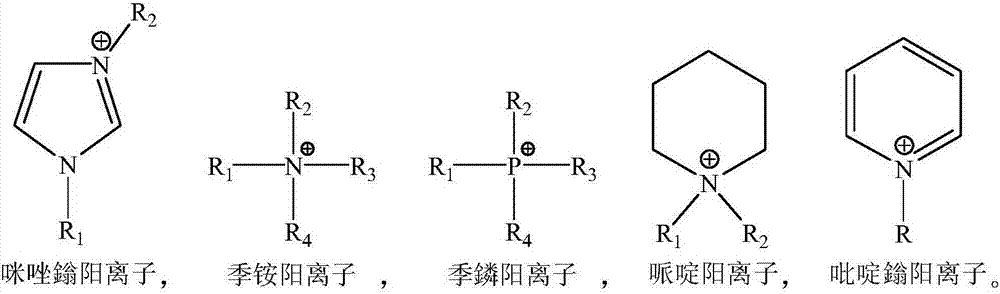

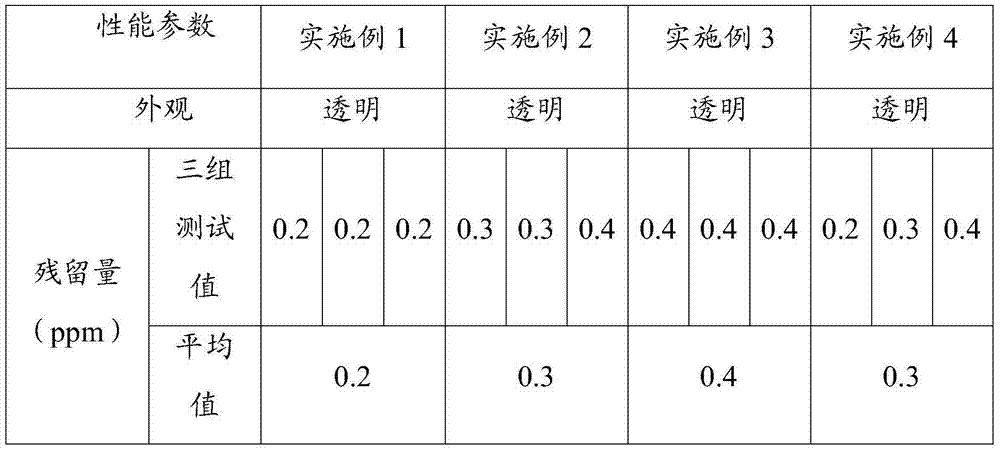

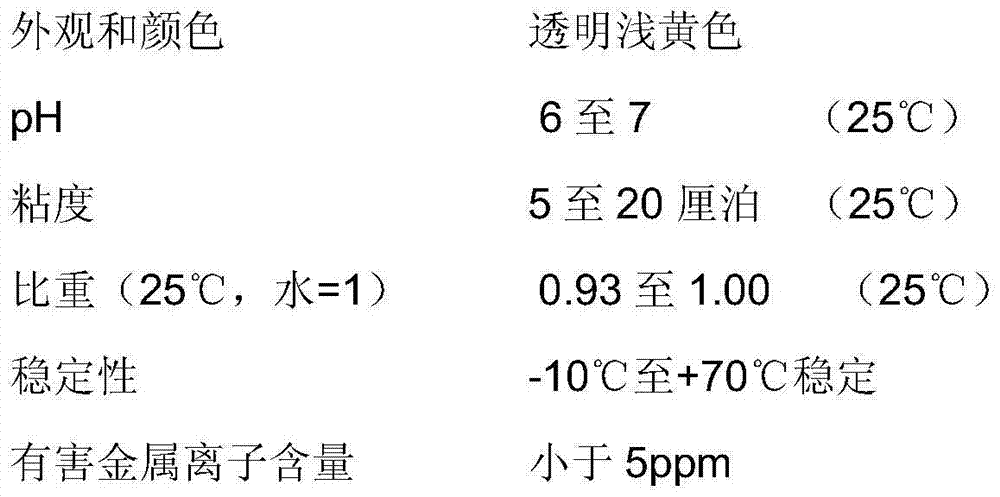

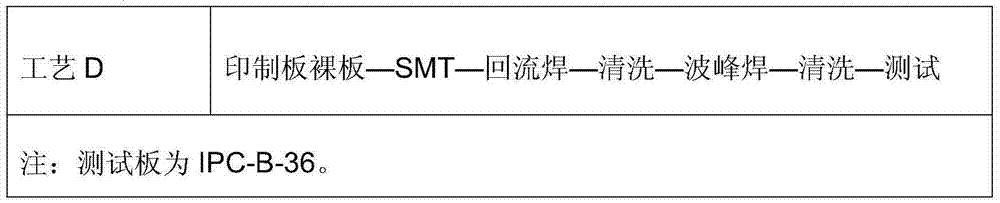

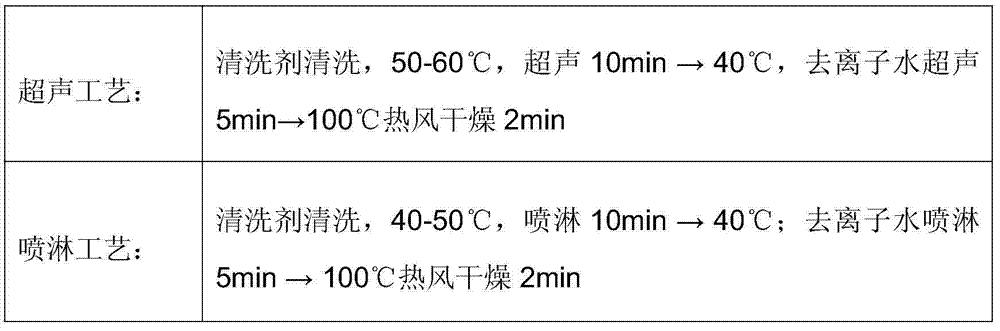

Water-base scaling powder and preparation method and application thereof

ActiveCN106493487AGood weldabilityExcellent tin penetration performanceWelding/cutting media/materialsSoldering mediaWater basedTin

The invention discloses water-base scaling powder and a preparation method and application thereof. The water-base scaling powder is prepared from, by mass, 2.0-4.% of water-soluble rosin resin, 4.5-7.0% of formulated organic acid, 0.1-0.4% of formulated surfactant, 4-8% of organic solvent, 0.1-0.3% of other additives and the balance deionized water. On one hand, the water-base scaling powder is completely suitable for a wave-soldering welding technology, and has the advantages that the weldability is high, the tin penetration property is excellent, postwelding residues are few on the plate surface, the surface insulation resistance is extremely high and the water-base scaling powder is easy to clean; on the other hand, the water-base scaling powder is mild in smell, and in the welding process, the scaling powder is low in smog, high in wettability, free of flashing point and safe to use, and the affinity of the scaling powder is good for water. The preparation method is environmentally friendly and safe, harmless to human body and free of flashing point, the technological conditions are easy to control, and the properties of the prepared water-base scaling powder are stable.

Owner:SHENZHEN UNIBRIGHT TECH

Low-toxicity screening washing water for screen printing

InactiveCN103232906AGood cleaning effectReduce pollutionNon-ionic surface-active compoundsDetergent solventsActive agentEnvironmental chemistry

The invention relates to a low-toxicity screening washing water for screen printing, belonging to the technical field of screen printing. The low-toxicity screening washing water is prepared from the following raw materials in parts by weight: 20-40 parts of ethylene glycol monobutyl ether, 5-10 parts of ethanol, 1-8 parts of isopropanol, 3-10 parts of sodium hydroxide, 3-9 parts of polyether L61, 4-12 parts of alkylphenol polyoxyethylene, 5-15 parts of dimethyl siloxane, 5-10 parts of emulsifier, 2-9 parts of dispersing agent, 2-5 parts of surfactant and 50-75 parts of deionized water. The low-toxicity screening washing water for screen printing solves the problem of high toxicity in the screening washing water in the prior art, and thus, has better cleaning effect and lower pollution; and the screening washing water is water-based without flash point, and thus, has the advantages of high storage and use safety, low organic volatile content, high cleaning speed, no corrosivity for equipment, and no strong pungent odor.

Owner:李莉

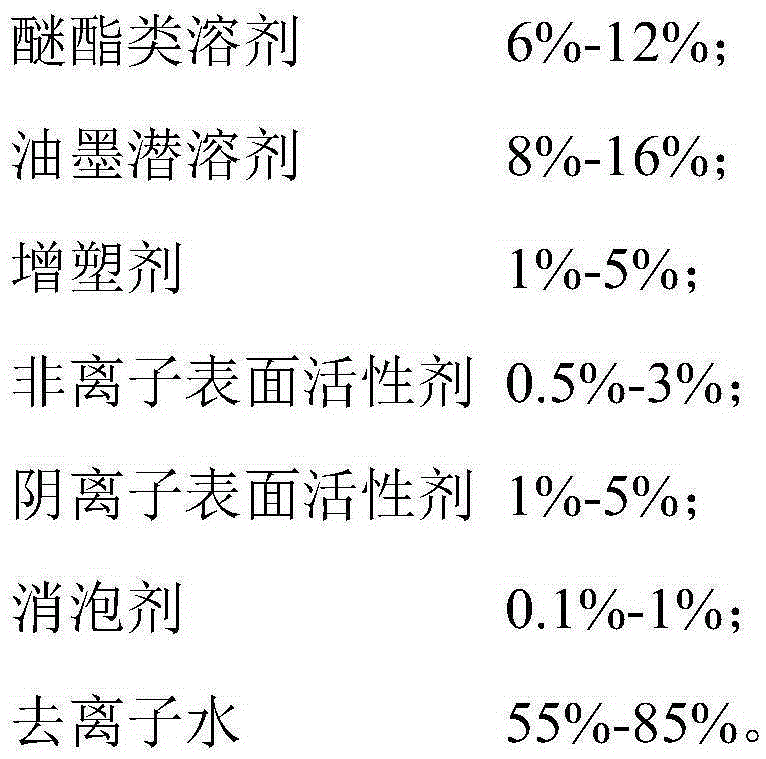

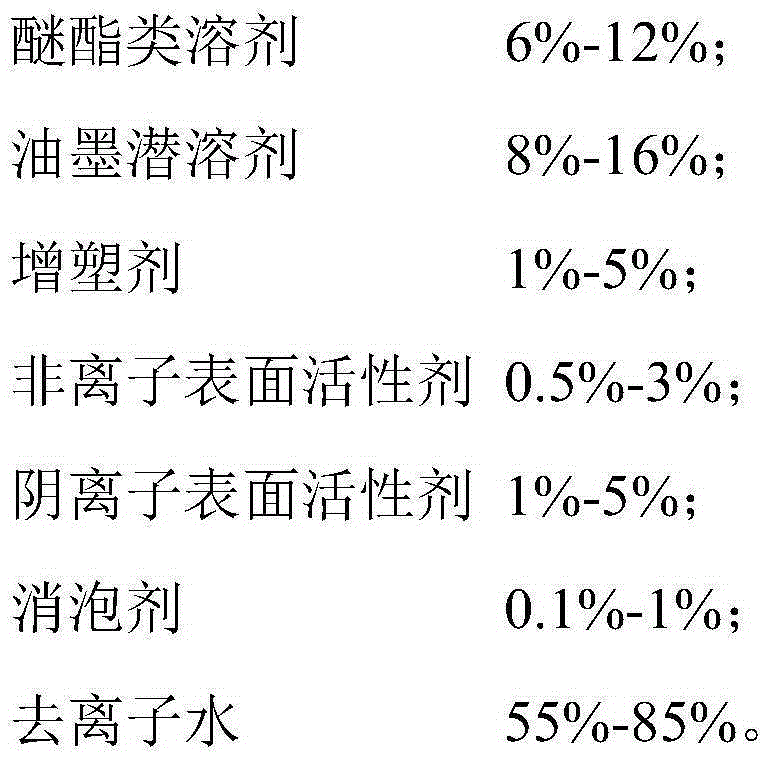

Environment-friendly type water-based cleaning agent and application

The invention relates to the technical field of cleaning agents, in particular to an environment-friendly type water-based cleaning agent and an application. The cleaning agent comprises components in percentage by mass as follows: 6%-12% of an ether ester type main solvent, 8%-16% of a printing ink latent solvent, 1%-5% of a plasticizer, 0.5%-3% of a non-ionic surfactant, 1%-5% of an anionic surfactant and 55%-85% of deionized water. The raw materials of the cleaning agent adopt components such as the organic solvents, the latent solvent, the surfactants and the like, the prepared environment-friendly type water-based cleaning agent does not contain halogens and acidic and alkaline substances and has the characteristics of good cleaning capacity, neutral and environment-friendly performance, safety in use, avoidance of flash points and the like, and moreover, the environment-friendly type water-based cleaning agent is non-corrosive to metals such as an aluminum alloy of a screen frame and the like and is suitable for cleaning non-cured printing ink.

Owner:SHENZHEN UNIBRIGHT TECH

Organic deoxidant for boiler feed water

ActiveCN102092864AFast deoxygenationAvoid corrosionScale removal and water softeningTriethanolamineWater supply

The invention relates to an organic deoxidant for boiler feed water. The deoxidant is prepared from the following raw materials in percentage by weight: 5 to 30 percent of hydrazide derivative, 2 to 25 percent of organic amine and the balance of water. The molecular formula of the hydrazide derivative is R<1>-CO-NH-R<2>, wherein R<1> and R<2> refer to substituent groups; the R<1> is CH3, CH3(CH2), NH2, NH2-NH, C6H5-NH, COOH, alkyl, naphthenic base, halogeno-group or heteroaryl; and the R<2> is CH3, CH2(CH3), NH2, NH2-NH, C6H5, COOH, alkyl, naphthenic base, halogeno-group or heteroaryl. The organic amine is cyclohexanamine, morpholine, triethanolamine, diethanolamine, monoethanolamine or amine shown as the molecular formula of R<3>-NH2, wherein R<3> is direct chain alkyl with 1 to 20 carbon atoms, branched chain alkyl, naphthenic base or aryl. The invention has the advantages that: the deoxidant is suitable for water supply systems of medium and high-pressure boilers in which primary or secondary demineralized water is taken as feed water; oxygen removing speed is high; and pH regulating agents such as ammonia water and the like are not required to be added additionally.

Owner:北京莱柯倍耳技术有限公司

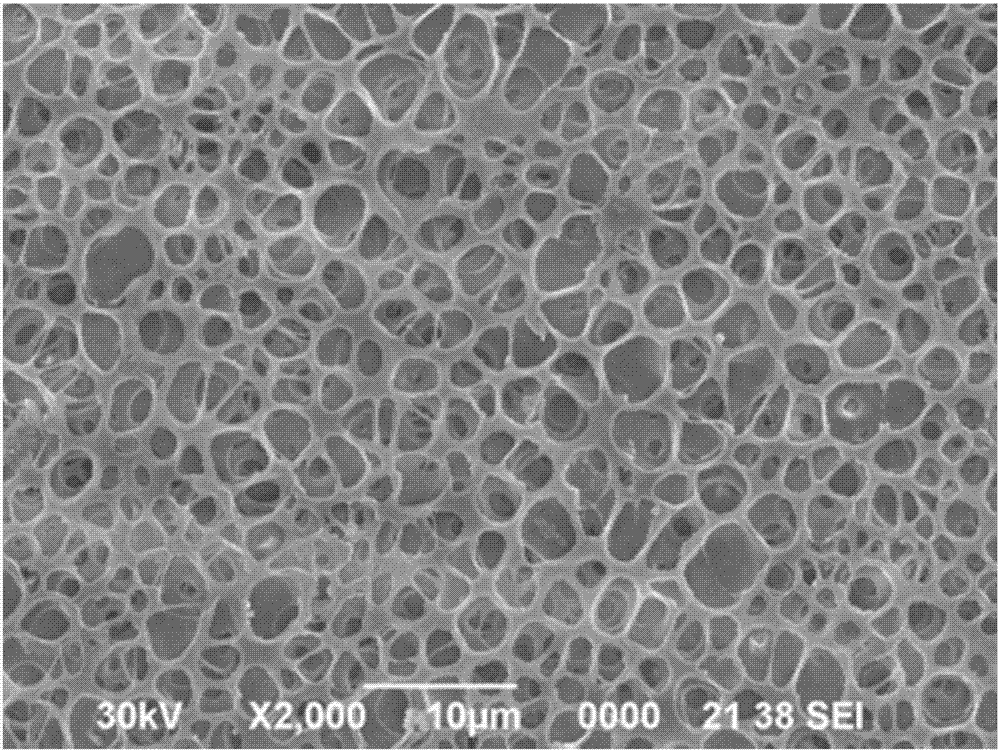

Aromatic polyamide compound diaphragm, preparation method thereof and secondary battery

ActiveCN107305937AImprove thermal stabilityGood chemical stabilityLi-accumulatorsCell component detailsGlass fiberShrinkage rate

The invention relates to an aromatic polyamide compound diaphragm, a preparation method thereof and a secondary battery. The aromatic polyamide compound diaphragm provided by the invention comprises a glass fiber and aromatic polyamide. The hot-shrinkage rate of the compound diaphragm at 300 DEG C is below 30%. The invention also provides the preparation method for the aromatic polyamide compound diaphragm. The compound diaphragm provided by the invention has excellent mechanical property and heat resistance and is especially suitable for the secondary battery.

Owner:微宏先进膜公司

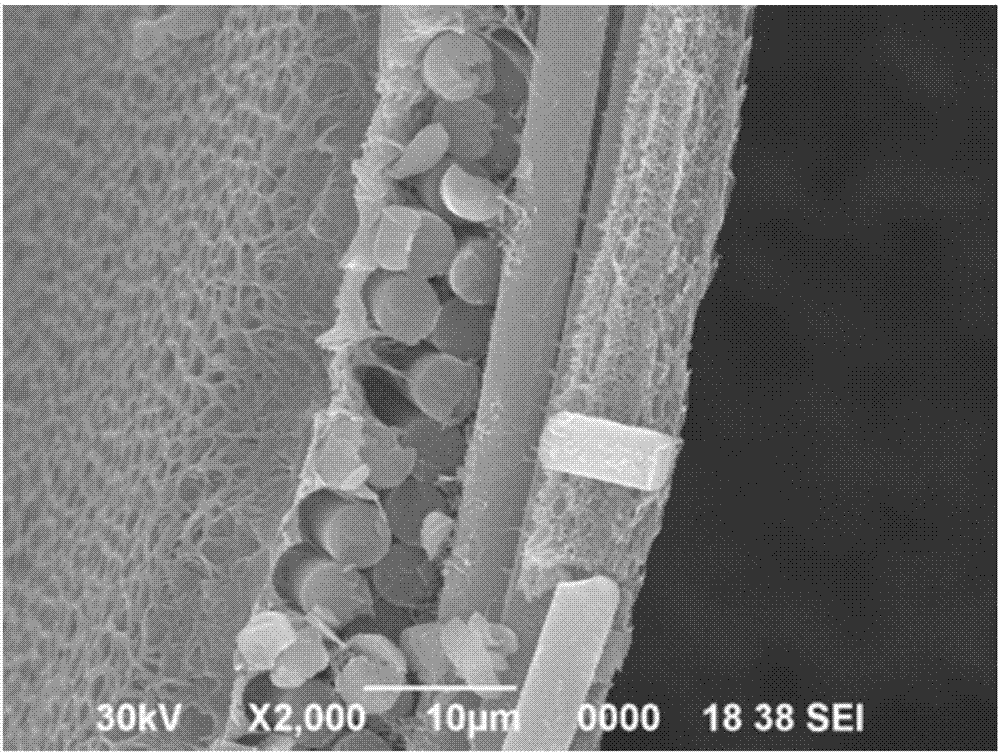

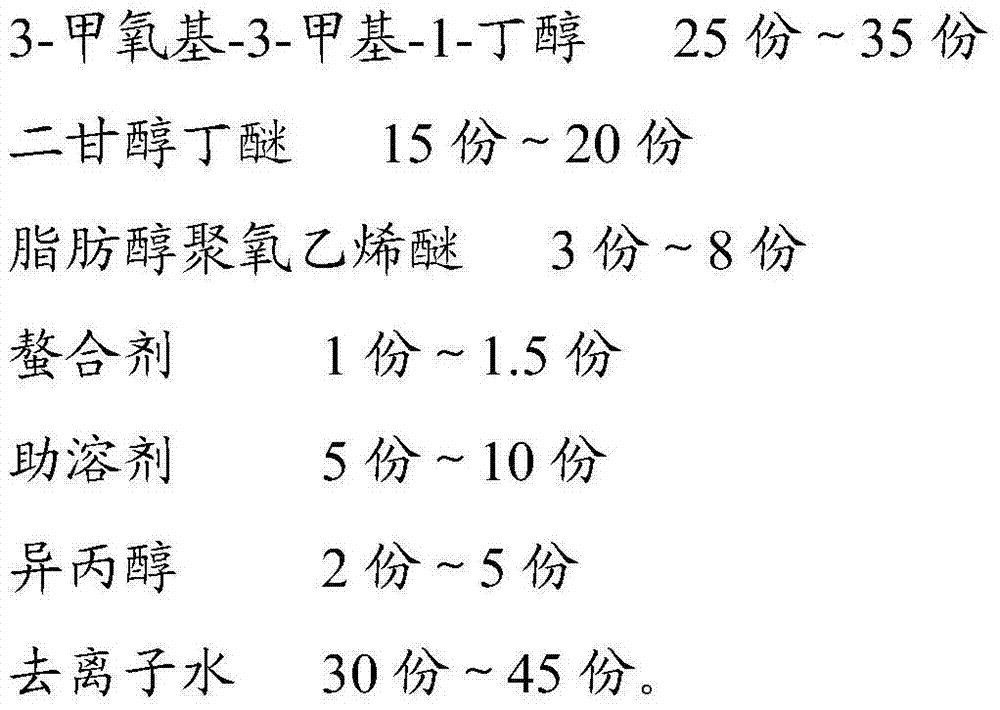

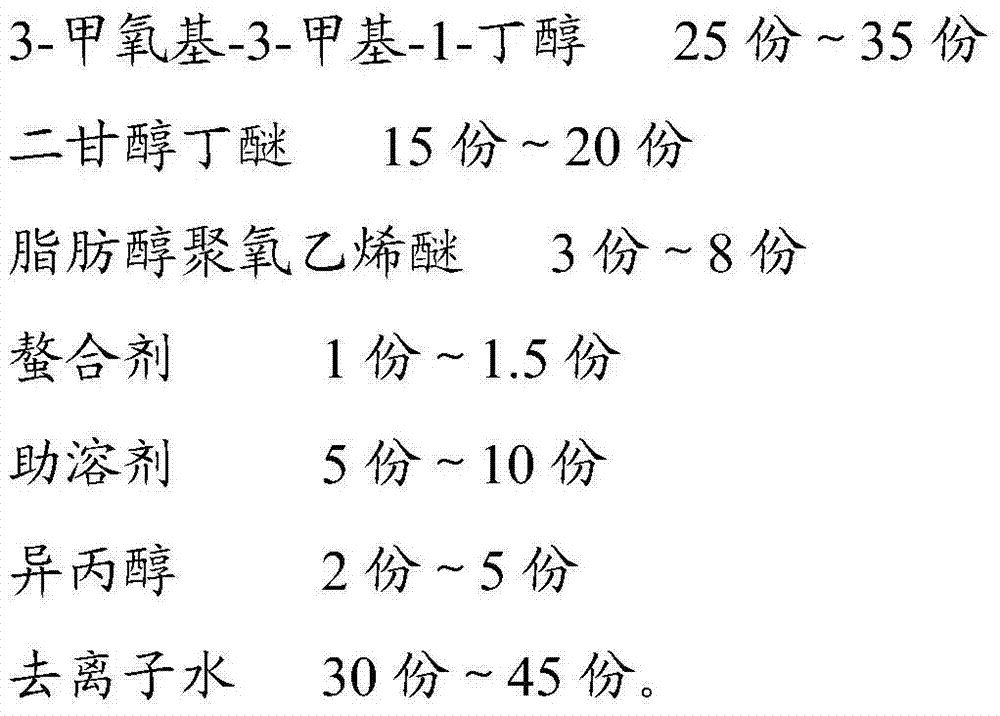

Water-based circuit board cleaning agent and preparation method thereof

InactiveCN103497851AImprove chelation abilityGood water solubilityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsWater basedN-Butanol

The invention discloses a water-based circuit board cleaning agent and a preparation method thereof. The water-based circuit board cleaning agent comprises the following components in parts by weight: 25-35 parts of 3-methoxy-3-methyl-1-butanol, 15-20 parts of butyl carbitol, 3-8 parts of fatty alcohol-polyoxyethylene ether, 1-1.5 parts of chelating agent, 5-10 parts of cosolvent, 2-5 parts of isopropanol and 30-45 parts of deionized water. The preparation method of the water-based circuit board cleaning agent comprises the following steps: firstly, mixing the chelating agent with the deionized water, heating to 40-45 DEG C and stirring for 6-12 minutes; secondly, controlling the temperature within the range from 28 DEG C to 31 DEG C, adding the fatty alcohol-polyoxyethylene ether, the cosolvent, the 3-methoxy-3-methyl-1-butanol, the butyl carbitol and the isopropanol, continuously stirring for 1 hour and then standing for 10-15 minutes to obtain the water-based circuit board cleaning agent. The preparation method of the water-based circuit board cleaning agent disclosed by the invention has the beneficial effects of simple steps and stable process, and prepared product is environment-friendly and harmless, high in cost performance and high in cleaning ability.

Owner:SHANGHAI LIMEI CHEM CO LTD

Neutral water base cleaning agent combination for circuit board

InactiveCN104845768AEasy to cleanEffective protectionSurface-active non-soap compounds and soap mixture detergentsWater basedMoisture absorption

The invention provides a neutral water base cleaning agent combination for a circuit board. The neutral water base cleaning agent combination comprises the following components in percentage by weight: 0.02 to 2% of C8-18 linear chain alkyl sulfhydryl, 0.02 to 2% of a specific sulfhydryl compound, 1 to 15% of an alcohol ether solvent, 0.02 to 5% of a nonionic surface active agent, water-soluble organic amine pH regulator and the balance of deionized water, wherein the specific sulfhydryl compound is a thiol-connected, benzene ring-free and nitrogenous five-membered heterocycle compound, and the adding amount of the water-soluble organic amine pH regulator is according to the ratio of 1:1 of an amine value to a thiol value in components. The neutral water base cleaning agent combination has a good capacity of removing flux residues after the circuit board is welded, can form composite hydrophobic organic membranes on most metal surfaces, and metals at PCB weld points and in electronic components are effectively protected and are prevented from being subjected to moisture absorption, corrosion and color change.

Owner:SHENZHEN MAKER TECH CO LTD

Vehicle-mounted battery fireproof heat source management synchronization device and use method

PendingCN111725582AFast heat conductionHigher than heatSecondary cellsFire rescueHeat managementIn vehicle

The invention relates to a vehicle-mounted battery fireproof heat source management synchronization device and a use method. The device comprises a liquid storage device, a liquid storage device control valve, a fire extinguishing pipeline, a spray head or a spray hole, a fire extinguishing pipeline control valve, an inductive probe, a water inlet connecting pipe and a water outlet connecting pipe, a sealed circulating flow channel is formed among the heat exchange pipeline, the water inlet connecting pipe, a vehicle-mounted battery pack module and the water outlet connecting pipe, fire extinguishing heat exchange liquid is stored in the liquid storage device, and the liquid storage device control valve, the fire extinguishing pipeline control valve and the inductive probe are all connected with a vehicle-mounted computer controlling the heat source management system and the vehicle-mounted battery pack module and are synchronously controlled by the vehicle-mounted computer. The vehicle-mounted battery fireproof heat source management synchronization device is ingeniously combined with an existing vehicle-mounted battery heat management system; under the condition that normal operation of an existing vehicle-mounted battery thermal management system is kept, professional fire extinguishing equipment of a battery module is omitted, the integration degree of resources is improved, the structural layout of the whole vehicle is simplified, the requirement for light weight of the whole vehicle is met, cost is saved, and the working mileage of the whole vehicle is increased.

Owner:ZEPHYR INTELLIGENT SYST SHANGHAI CO LTD

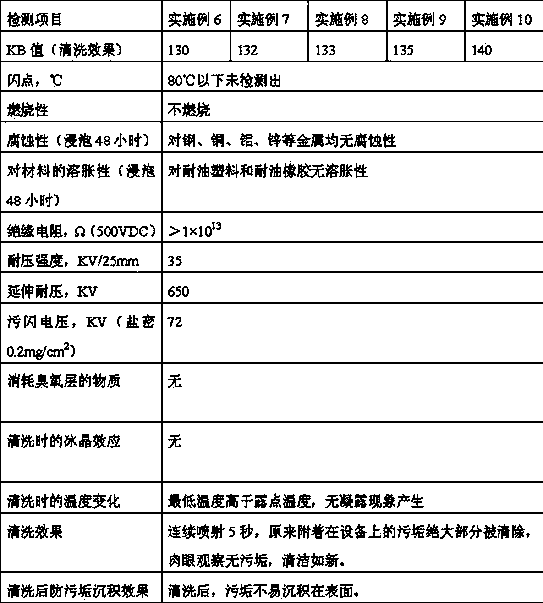

Electrified cleaner for electric appliances and preparation method of electrified cleaner

ActiveCN104212658AReduce cleaning timesExtended service lifeOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsEthyleneglycol monobutyl etherTriethanolamine

The invention discloses an electrified cleaner for electric appliances. The electrified cleaner is prepared from the following components, namely 20-30 parts of trichloro ethylene, 15-25 parts of carbon tetrachloride, 15-25 parts of propylene glycol butyl ether, 10-20 parts of triethanolamine, 5-10 parts of N-fatty acyl ethanol glutamate, 1-2 parts of polyvinylpyrrolidone, 1-3 parts of pentaerythritol, 4-6 parts of N-methyl-2-pyrrolidone, 3-5 parts of ethylene glycol monobutyl ether and 1-3 parts of dodecyl dimethyl quaternary ammonium caprolactone. The electrified cleaner is capable of cleaning the electric appliances during normal working and effectively removing oil stains and dust on the surfaces of the electric appliances; oil stains are not easy to deposit again on the cleaned electric appliances so that the cleaning times of the electric appliances are reduced, and therefore, the service lives of the electric appliances can be prolonged; the ice-crystal effect and the condensation phenomena are prevented in the cleaning process, and as a result, the surface insulation values of the appliances do not drop obviously and no corrosion damage is caused to the appliances; the electrified cleaner for electric appliances is safe to use, free of flashing point and does not burn; besides, the electrified cleaner is an environment-friendly material, contains no substance that may deplete the ozone sphere and thus causes no pollution to the environment.

Owner:博仕能源江苏有限公司

Environment-friendly efficient water-based dry cleaning agent for airplane maintenance and preparation method thereof

ActiveCN109234052AGood removal effectRemove completelyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedHazardous substance

The invention relates to an environment-friendly efficient water-based dry cleaning agent for airplane maintenance. The environment-friendly efficient water-based dry cleaning agent is composed of thefollowing components in parts by weight: 5-20 parts of compound surfactant, 0.1-3 parts of complexing agent, 2-12 parts of composite metal corrosion inhibitor, 0.05-0.6 part of film-forming agent, 0.5-12 parts of cosolvent and the balance of deionized water (complementing to 100 parts). The dry cleaning agent contains no hazardous substances, such as heavy metal, strong base, nitrite, phosphorus,amine and amide, contains no high-toxicity and high-volatility organic solvents, such as hydrochloric ether, phenol and ketone, is physiologically harmless, is easy to biodegrade and is mild, free from flashing point, multifunctional, high-efficient, safe, environment-friendly and energy-saving; the dry cleaning agent has excellent effects of cleaning and protecting paint, is capable of quickly and thoroughly cleaning various light and heavy oil stains and complex dirt on airplane surface, has an excellent dry cleaning effect, can keep clean for a long time and is capable of effectively reducing frictional resistance in flight; after dry cleaning, a protective layer is formed, so that the generation rate of dirt on the airplane surface is reduced.

Owner:华阳新兴科技(天津)集团有限公司 +2

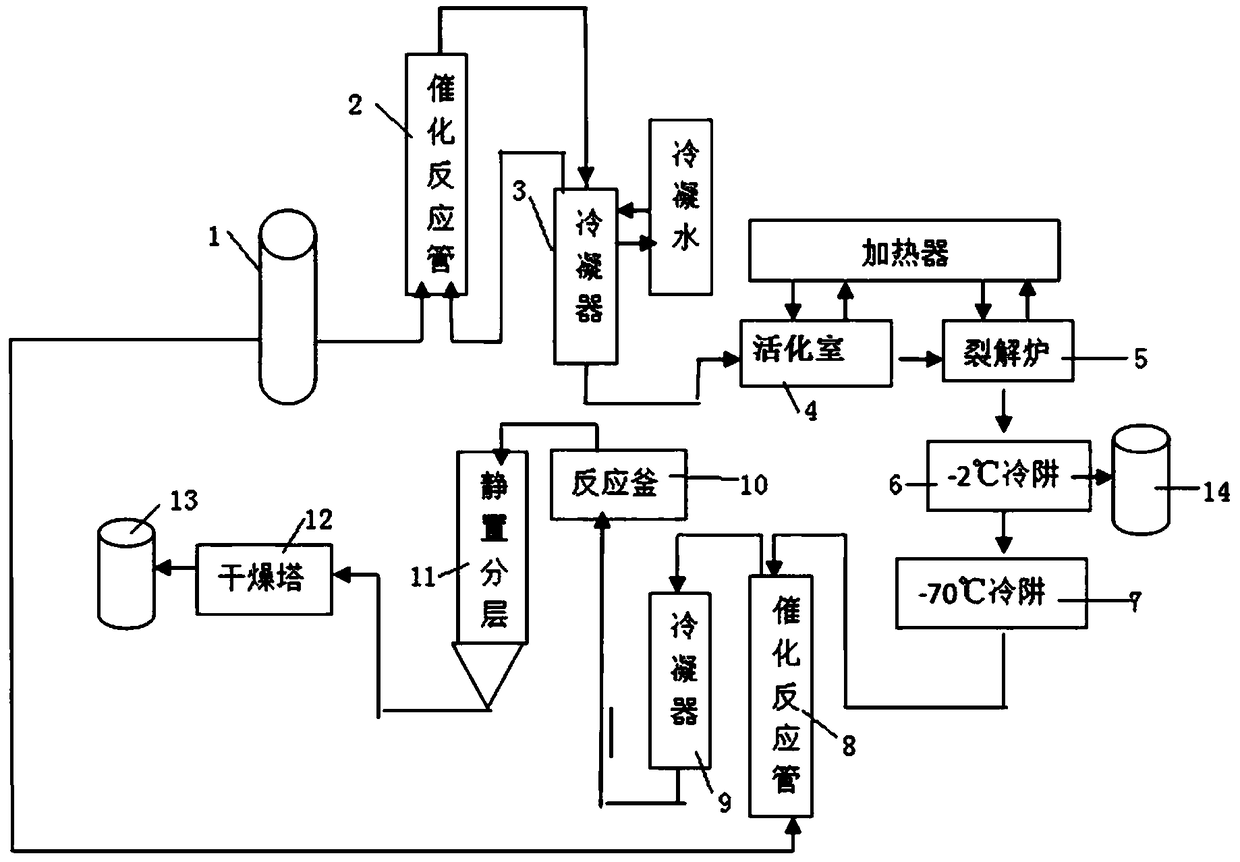

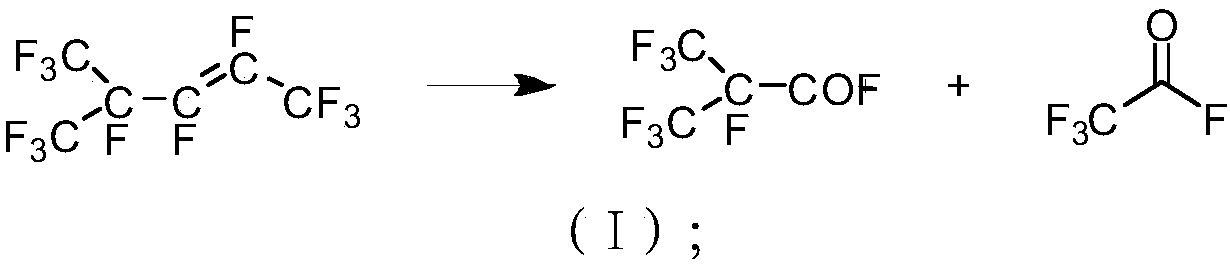

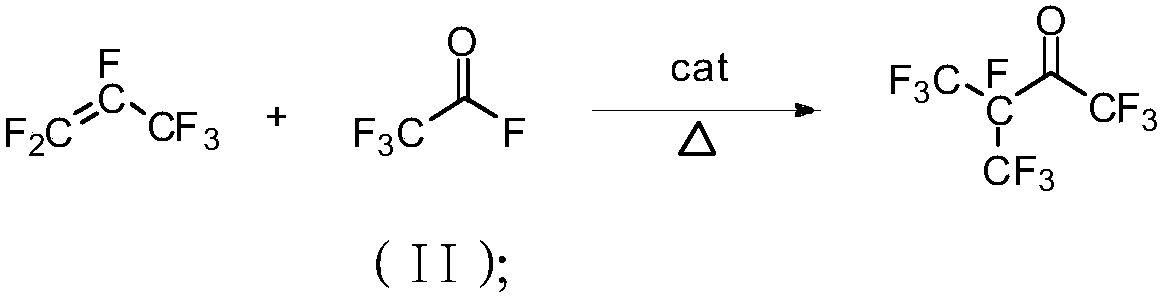

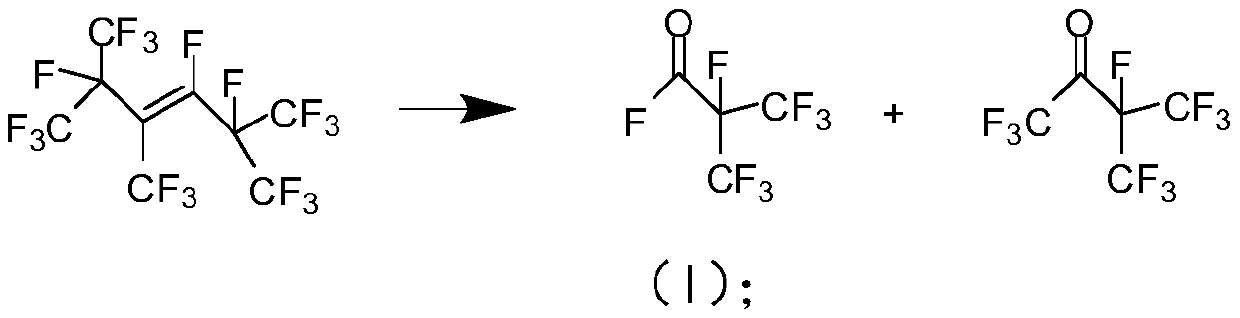

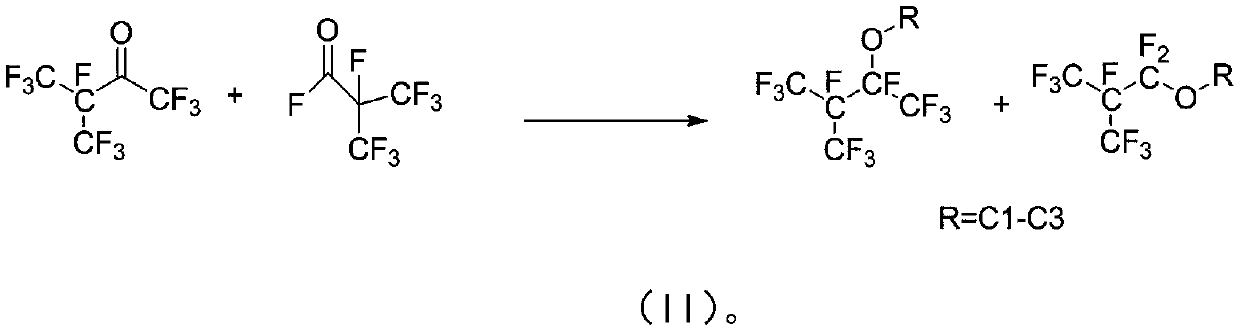

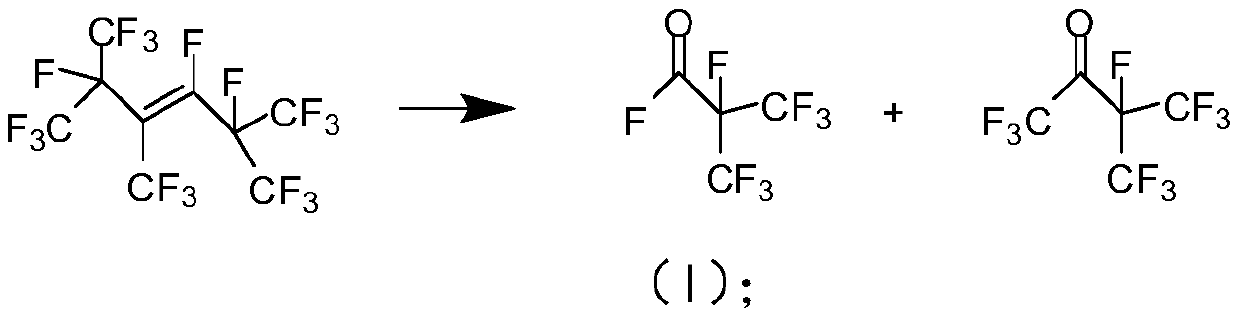

Method for cracking hexafluoropropylene dipolymer to prepare perfluoro amyl ether and perfluoro amyl ether

InactiveCN109503364AProduct highThe product perfluoroacetyl fluoride is highOrganic compound preparationCarbonyl compound preparation by condensationChemical industryHexafluoropropylene

The invention belongs to the field of fluorine chemical industry and specifically relates to a method for cracking hexafluoropropylene dipolymer to prepare perfluoro amyl ether and perfluoro amyl ether. The preparation method comprises the steps: 1) perfluoro pentacarbonyl ketone preparation: 1.1) sending the hexafluoropropylene dipolymer into an oxidizing furnace to perform cracking reaction withoxygen under the first catalyst condition; separating a cracked product to obtain perfluoro acetylfluoride; 1.2) preparing the perfluoro pentacarbonyl ketone under the second catalyst action with hexafluoropropylene and the perfluoro acetylfluoride prepared in the step 1.1) as raw materials; 2) selectively adding tertiary amine or a phase transfer catalyst into an inert dipole non-proton organiccompound solution to react under the alkali metal fluoride action with the pentacarbonyl ketone obtained in the step 1) and an alkylation reagent as the raw materials, so as to prepare the perfluoro amyl ether. According to the method disclosed by the invention, hexafluoropropylene tripolymer is utilized as a raw material to generate the perfluoro pentacarbonyl ketone, and then the perfluoro pentacarbonyl ketone reacts with the alkylation reagent to generate the perfluoro amyl ether; thus, the conversion efficiency is high, conditions are moderate, and the whole technological process is simpleto operate.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

Practical multifunctional high-efficiency environment-friendly water-based paint remover, as well as preparation method and application thereof

ActiveCN109370297ANo pollution in the processGood corrosion inhibitionChemical paints/ink removersActive agentHazardous substance

The invention relates to practical multifunctional high-efficiency environment-friendly water-based paint remover. The water-based paint remover is prepared from the following components in parts by weight: 35-45 parts of a main solvent, 2-8 parts of cosolvent, 2-11 parts of accelerant, 0.5-5 parts of a complexing agent, 2-12 parts of compound metal corrosion inhibitor, 0.5-6 parts of compound surfactant, 0-3 parts of solubilizer, 1-6 parts of a thickening agent and deionized water which is filled until the total amount is 100 parts. The water-based paint remover does not contain harmful substances including heavy metal, strong base, nitrite, chromate, phosphorus, amine, amide, does not contain organic solvents such as hydrochloric ether, phenol, acetone and the like with high toxicity andstrong volatility, has no flash point, low VOC, low odor, bio-degradability, no environmental pollution, mild property, safety for human body, high paint removing speed and complete removal, has excellent rust inhibition for various base materials, and does not damage coating surfaces.

Owner:华阳新兴科技(天津)集团有限公司 +2

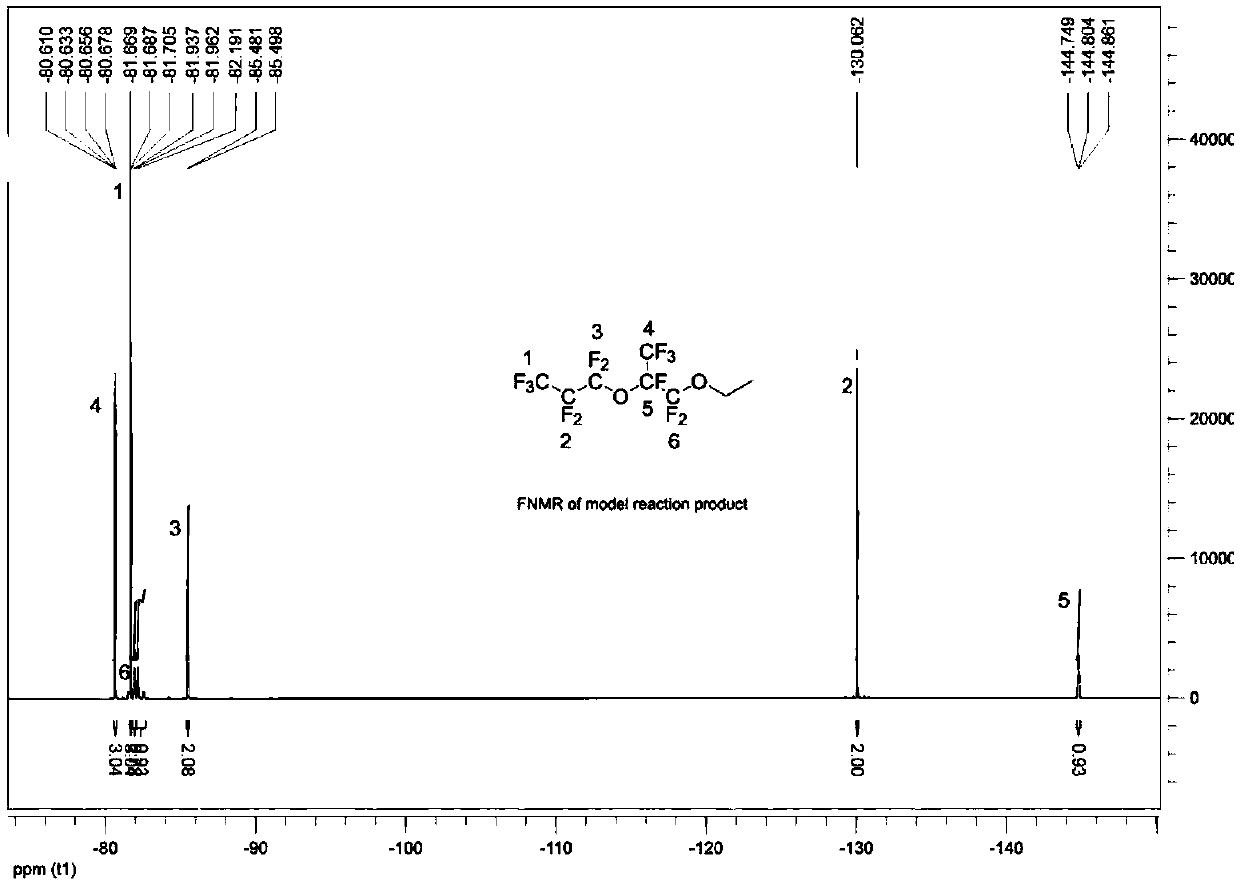

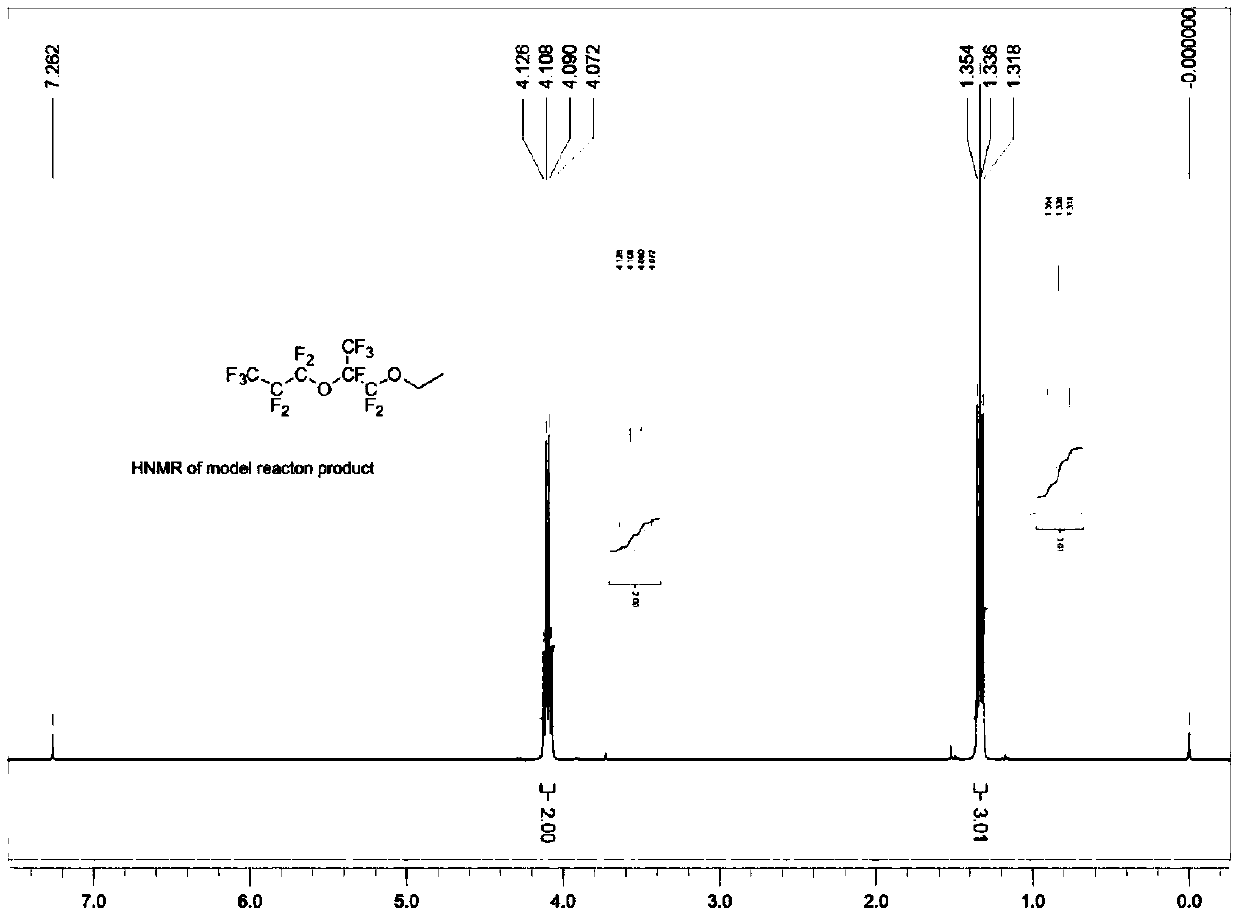

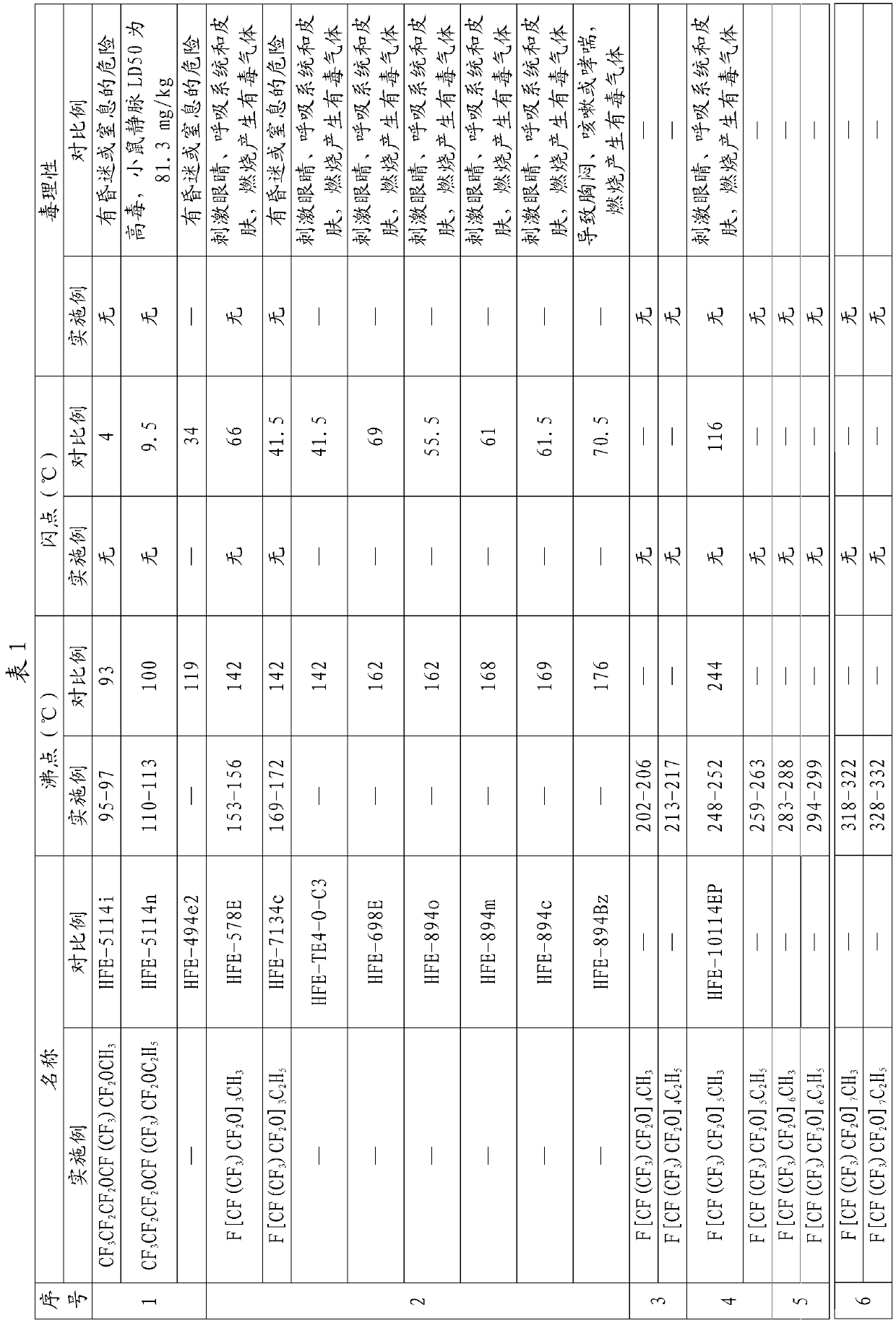

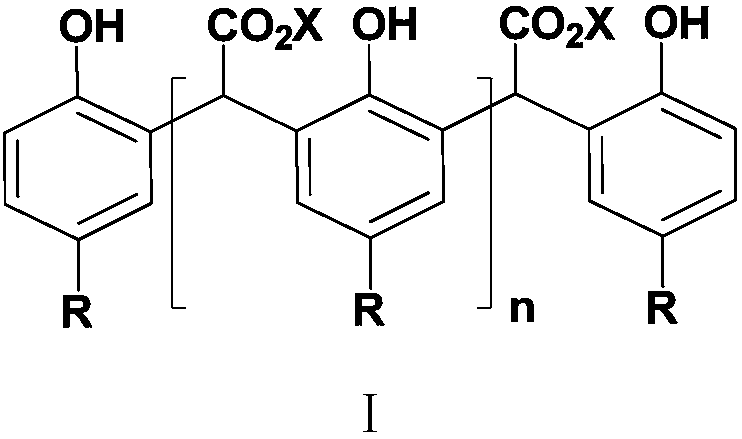

Hydrofluoroether compound and preparation method and application thereof

ActiveCN109608312AHydrophobicChemically inertHeat-exchange elementsNon-surface-active detergent solventsHalogenHydrofluoroether

The invention belongs to the field of hydrofluoroethers, in particular to a hydrofluoroether compound and a preparation method and an application thereof. The hydrofluoroether compound is representedby that follow formula: F [CF(CF3)CF2O]<x>-R<H>; where x = 2-7; RH=CH3, C2H5, n-C3H7 or i-C3H7. The hydrofluoroether compound provided by the invention only contains fluorine, the only halogen element, does not contain ozone-destructive substances, and is an environmentally friendly non-flammable heat transfer agent, a solvent and a cleaning agent.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

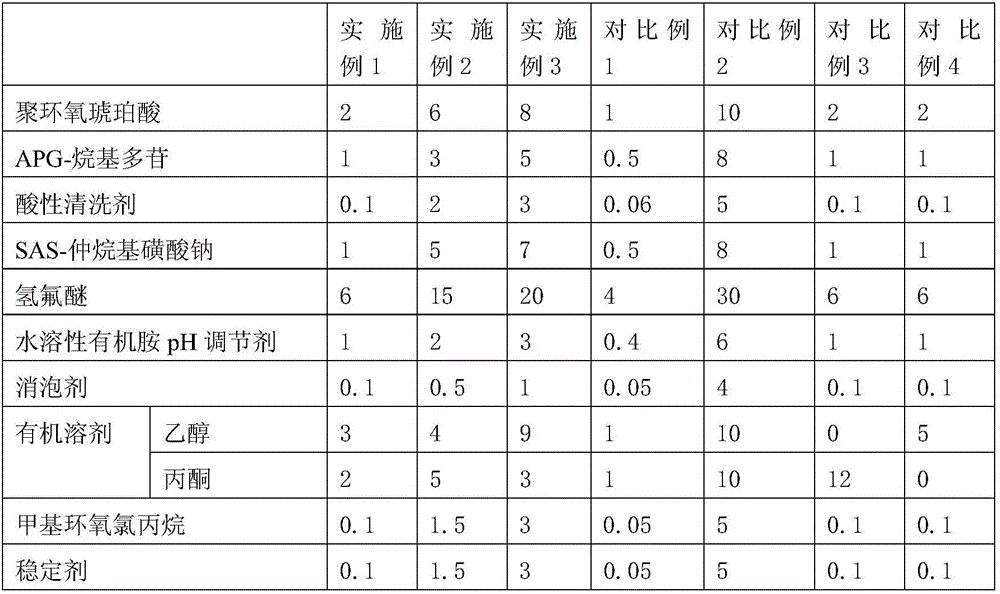

Electronic component cleaning agent

ActiveCN105754765AFast volatilization rateGood storage stabilitySurface-active non-soap compounds and soap mixture detergentsChemistryWater soluble

The invention discloses an electronic component cleaning agent. The electronic component cleaning agent comprises the following components: polyepoxysuccinic acid, alkyl polyglycoside (APG), an acid cleaning agent, secondary alkyl sodium sulfonate (SAS), hydrofluoroether, a water soluble organic amine pH value regulator, a defoaming agent, methyl epichlorohydrin, a stabilizer and an organic solvent. The invention provides a cleaning agent used for an electronic component. The cleaning agent takes hydrofluoroether with ODP of 0 as a main solvent to be matched with other components, environmental protection, low toxicity and low greenhouse effect requirements are met, the cleaning agent has good cleaning property, produces fewer foams, is non-corrosive, low in volatility, less in residue and low in viscosity and can well clean the electronic component without producing harmful effect to the electronic element.

Owner:WUJIANG ZHENYU SEWING EQUIP

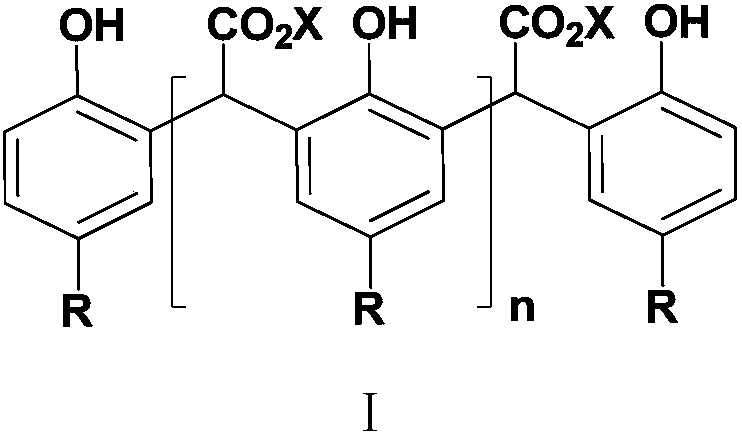

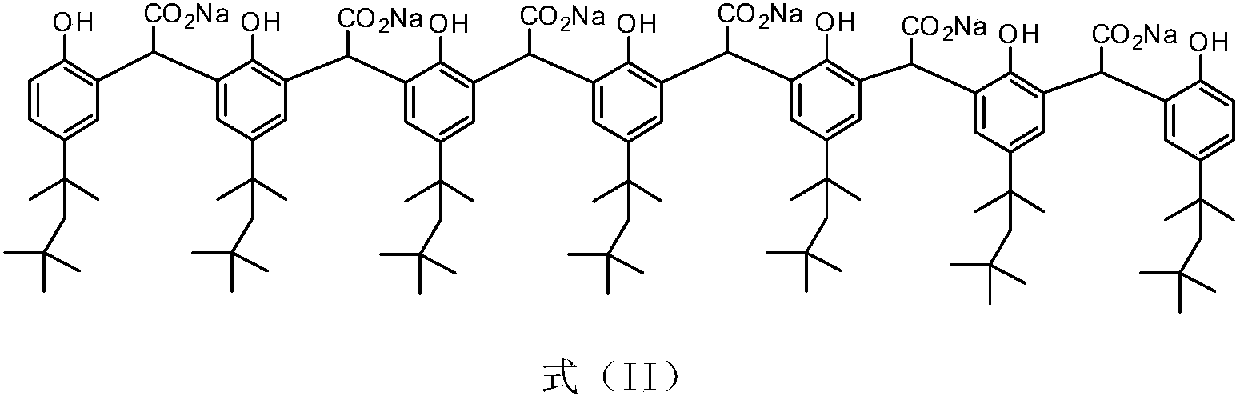

Mini-emulsion used for thickened oil recovery and preparation method thereof

The invention belongs to the technical field of petrochemical engineering, and specifically relates to mini-emulsion used for thickened oil recovery and a preparation method thereof. The mini-emulsioncomprises the following ingredients in parts by weight: 40-60 parts of an organic solvent, 0-8 parts of a nonionic surfactant, 4-20 parts of an anion oligomeric surfactant and 120-150 parts of deionized water, wherein the anion oligomeric surfactant is an oligomer of a paralkyl phenol derivative. The mini-emulsion is prepared by the following steps: dispersing the nonionic surfactant and the anion oligomeric surfactant into the organic solvent and slowly dropping the deionized water into the mixed solution, so as to form the mini-emulsion. The obtained mini-emulsion does not have flash pointsand is good in viscosity reduction capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

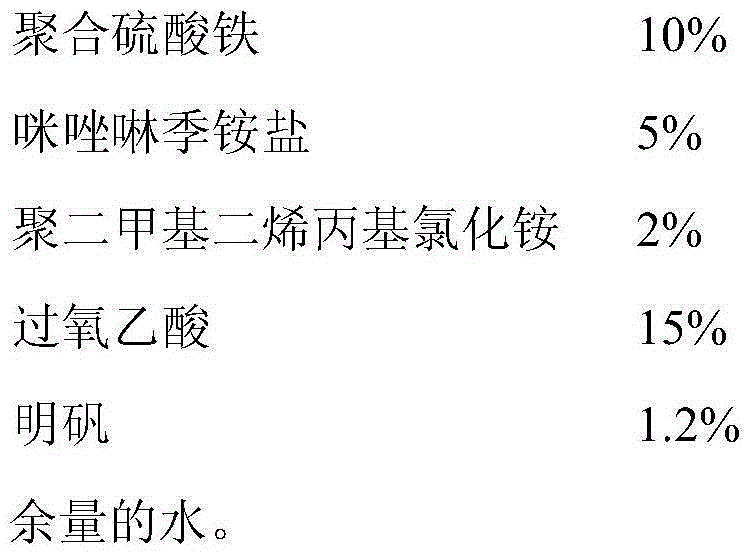

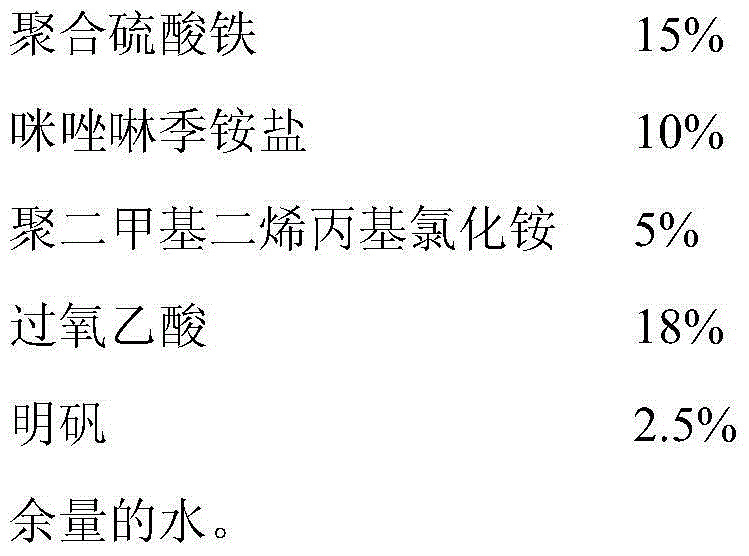

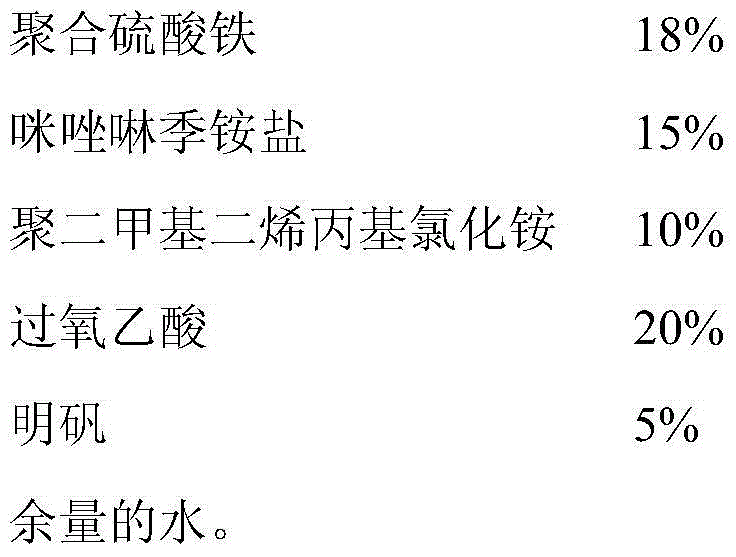

Novel water-supply composite water treatment agent

InactiveCN104628103AWill not corrodeFast flocculationFatty/oily/floating substances removal devicesWater contaminantsBenzoic acidOxygen

The invention provides a novel water-supply composite water treatment agent which is composed of imidazoline quaternary ammonium salt, polyferric sulfate, polydimethyl diallyl ammonium chloride, peroxyacetic acid, alum and water. The imidazoline quaternary ammonium salt is prepared by the following steps: adding benzoic acid and triethylenetetramine into a 250ml three-neck flask in a mole ratio of 1:1, and meanwhile, adding xylene as a water carrying agent; and heating by an electric jacket, starting stirring, carrying out acylation reaction for 2 hours after the temperature rises to 150 DEG C, slowly heating to 220 DEG C, carrying out cyclization reaction for 2 hours to obtain an imidazoline intermediate, cooling the system to 90 DEG C, adding isopropanol and water as solvents, and carrying out quaterization reaction for 4 hours. The production technique comprises the following steps: (1) sequentially adding the polyferric sulfate, imidazoline quaternary ammonium salt, polydimethyl diallyl ammonium chloride, peroxyacetic acid and alum into a reaction kettle, charging nitrogen into the reaction kettle, and starting stirring; and (2) heating to 80-120 DEG C, and stirring uniformly until all the raw materials are completely dissolved, thereby obtaining the novel water-supply composite water treatment agent.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

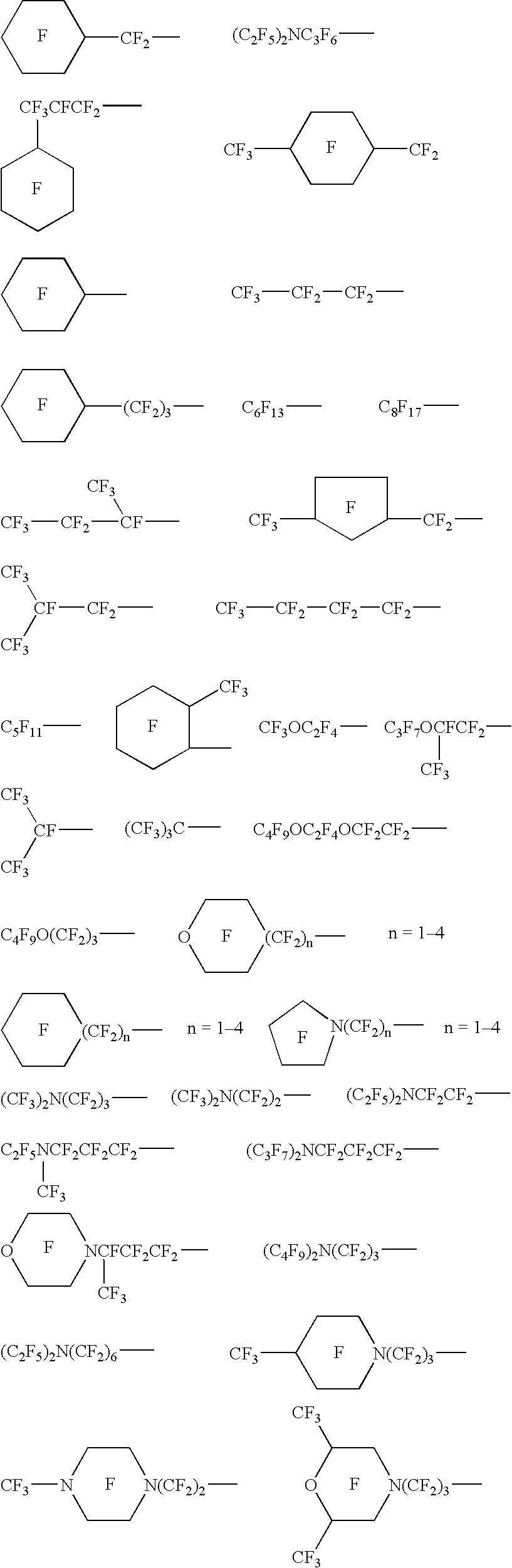

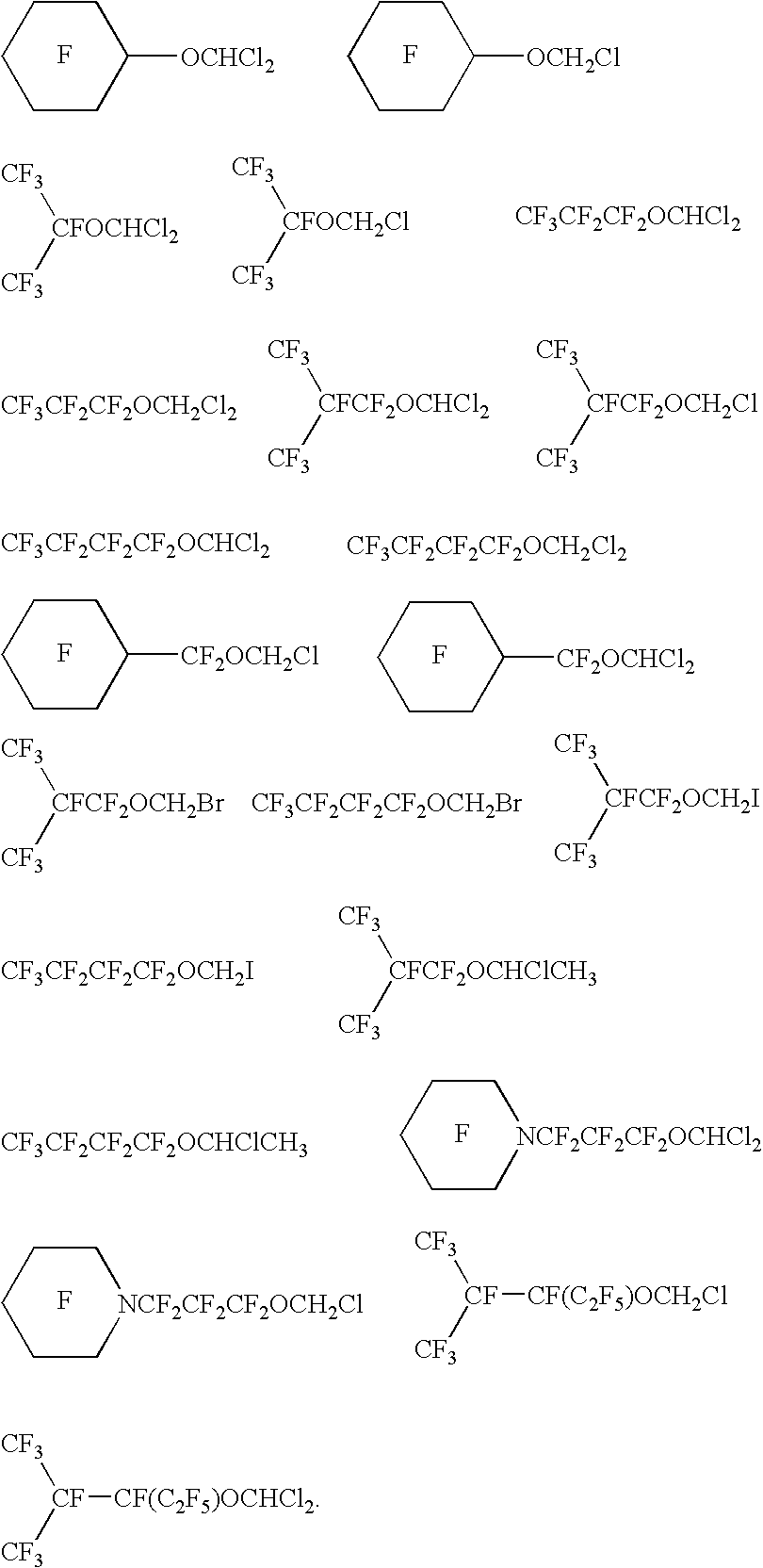

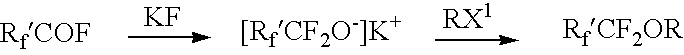

Perfluoroalkyl haloalkyl ethers and compositions and applications thereof

InactiveUS6953606B2Useful and advantageous propertyUseful pointOrganic detergent compounding agentsOrganic chemistryEtherSurface-active agents

Described are compositions comprising perfluoroalkyl haloalkyl ethers and, optionally, surfactant; uses for perfluoroalkyl haloalkyl ether compounds and compositions thereof, optionally comprising surfactant; and perfluoroalkyl haloalkyl ethers.

Owner:3M INNOVATIVE PROPERTIES CO

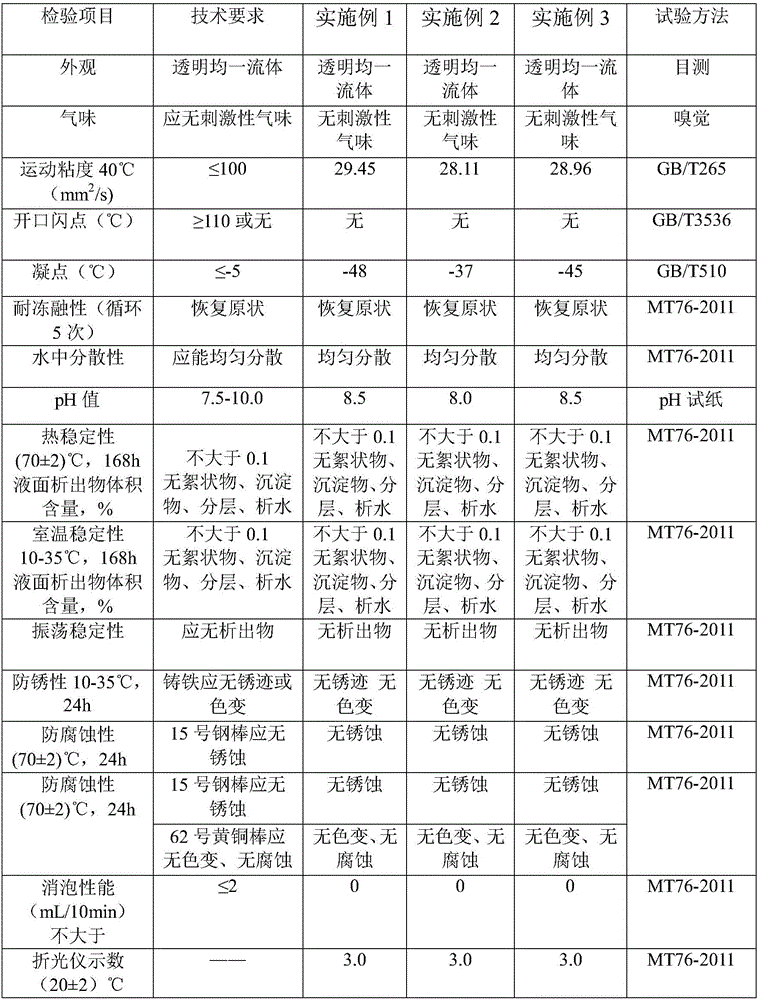

Novel environment-friendly fire-retardant concentrated solution for hydraulic supports

InactiveCN106190510AGood chemical stabilityImprove the lubrication effectLubricant compositionMonoisopropanolamineFire retardant

The invention discloses a novel environment-friendly fire-retardant concentrated solution for hydraulic supports. The concentrated solution is prepared from the following raw materials in percentage by weight: 10-20% of alizarin oil, 8-15% of acetal monoisopropanolamine, 5-10% of zinc dichromate, 4-10% of sodium ethylenediaminetetramethylene phosphonate, 3-7% of organosilicon quaternary ammonium salt, 2-5% of acetal monoisopropanolamine maleate compound, 2-4% of sodium hydroxide, 0.3-0.5% of polyisobutylene succimide, 0.2-0.4% of titanate coupling agent, 0.1-0.5% of barium naphthanate and the balance of water. The novel environment-friendly fire-retardant concentrated solution for hydraulic supports can satisfy the antirust and anticorrosion requirement of tiny gaps, has the advantages of wide applicability, favorable chemical stability, favorable lubricating property, easy cleaning, no flash point and high safety factor, is degradable, can not influence the environment, obviously enhances the production efficiency, and saves the production cost.

Owner:山东星邦高分子材料有限公司

Method of simultaneously preparing perfluoroamyl ether and perfluoroisobutyl ether

InactiveCN109734562AImprove conversion efficiencyMild conditionsEther preparation by compound additionHexafluoropropyleneKetone

The invention belongs to the field of fluorine chemical engineering and particularly relates to a method of simultaneously preparing perfluoroamyl ether and perfluoroisobutyl ether. The method includes: 1) subjecting hexafluoropropene trimer to cracking reaction with oxygen in an oxidation furnace under catalyst condition so as to prepare perfluoro five-carbon ketone and perfluoro isobutyryl fluoride; 2) adding an alkylation reagent to the perfluoro five-carbon ketone and perfluoro isobutyryl fluoride, and selectively adding tertiary amine or a phase transfer catalyst into an inert dipolar aprotic organic compound solvent under the action of an alkaline metal fluoride, and allowing to react to prepare perfluoroamyl ether and perfluoroisobutyl ether. The hexafluoropropene trimer is used asa raw material herein to generate perfluoro five-carbon ketone and perfluoro isobutyryl fluoride under the action of a catalyst; no separation is required then; a mixture is directly subjected to reaction with the alkylation reagent to generate perfluoroamyl ether and perfluoroisobutyl ether; the conversion efficiency is high; the conditions are mild; the whole process is simple to perform.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

Environment-friendly wetting type dust suppressant, preparation method, use method and application thereof

PendingCN112111247AReduce surface tensionImprove wettabilityOther chemical processesActive agentEnvironmental chemistry

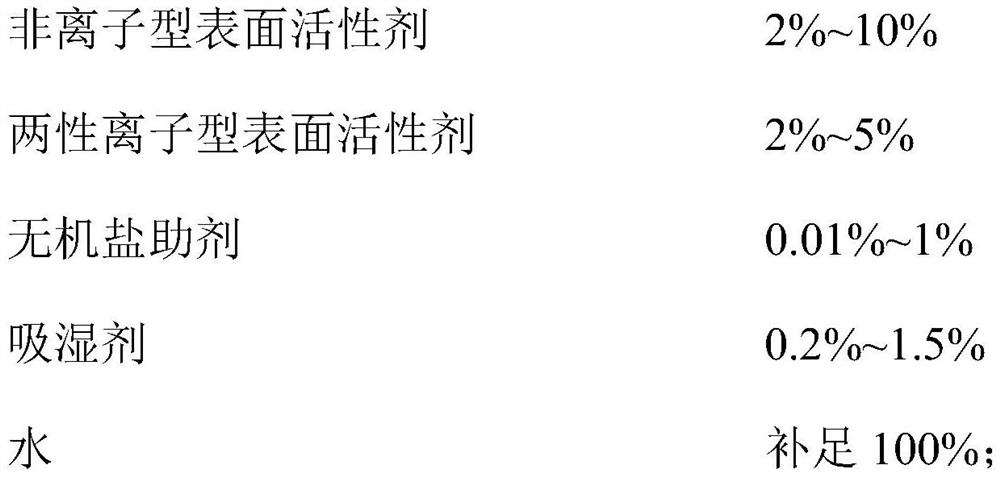

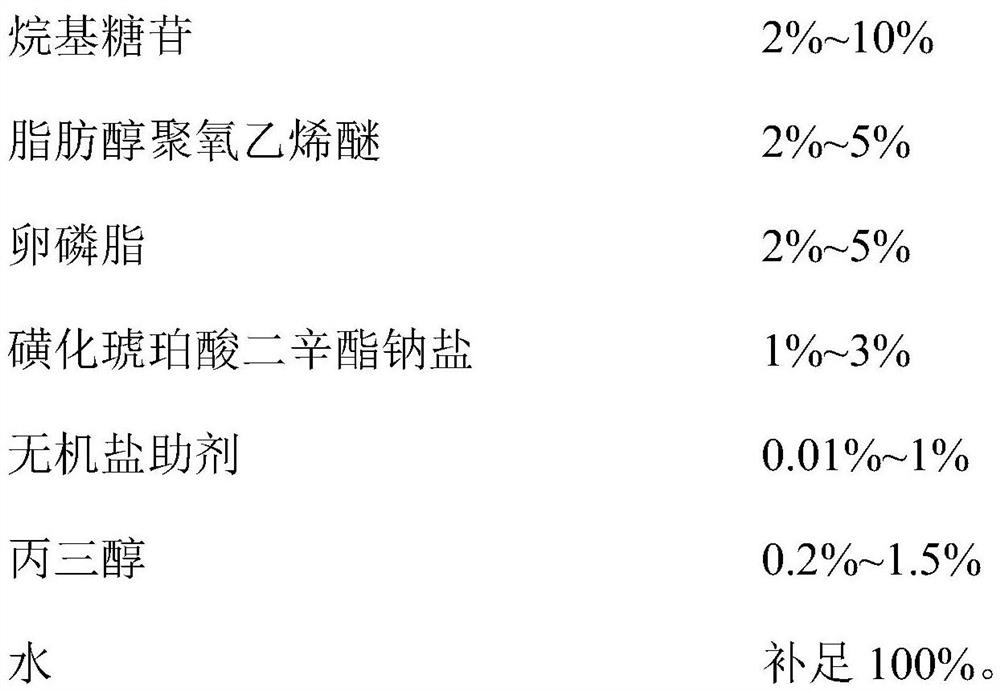

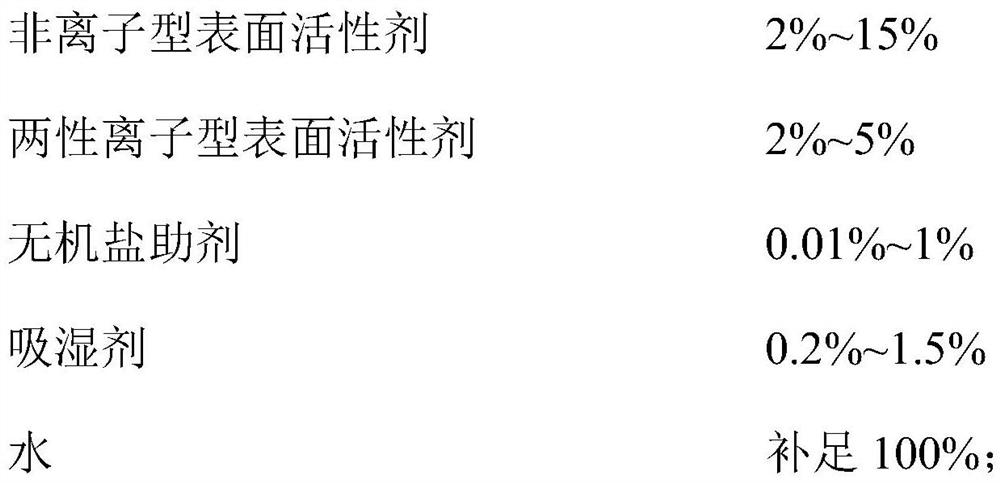

The invention provides an environment-friendly wetting type dust suppressant, a preparation method, a use method and application thereof. The environment-friendly wetting type dust suppressant is prepared from the following components in percentage by mass: 2-10% of a non-ionic surfactant, 2-5% of a zwitterionic surfactant, 0.01-1% of an inorganic salt additive, 0.2-1.5% of a moisture absorbent and the balance of water, wherein the non-ionic surfactant comprises alkyl glycoside and fatty alcohol-polyoxyethylene ether, and the zwitterionic surfactant is prepared from lecithin. According to theenvironment-friendly wetting type dust suppressant provided by the invention, the surface tension of water is reduced by adding the wetting agent, so that dust particles, especially hydrophobic dust particles, can be wetted more easily, the dust starting wind speed is increased, and dust raising is relatively not likely to happen; and the environment-friendly wetting type dust suppressant can be used in places such as storage yards, roads, belt transportation and the like, and achieves the purpose of effectively treating dust pollution in open environments.

Owner:上海仙缘环境技术有限公司

Device for achieving flue gas power generation and removing harmful substance in flue gas simultaneously

InactiveCN105457440ASpread evenlyAchieve the effect of gravity retention of smoke and dustCombination devicesGas treatmentHazardous substanceFlue gas

The invention relates to device for achieving flue gas power generation and removing harmful substance in flue gas simultaneously. The device comprises a flue gas treatment system, a transduction system and an electric generator; the flue gas treatment system is composed of a shell, an evaporative condenser, a flue gas inlet and a flue gas outlet; the transduction system comprises a working medium evaporator, a working medium turbine, a condenser and a working medium compressor which are sequentially connected; the output end of the working medium compressor and the input end of the working medium evaporator are connected with a working medium outlet and a working medium inlet of a heat exchanger respectively; the working medium turbine drives the electric generator. According to the device for achieving flue gas power generation and removing harmful substance in the flue gas simultaneously, heat in flue gas is utilized to conduct heating, so that an organic working medium is evaporated, the working medium turbine is pushed to generate power, the heat utilization rate is high, and meanwhile harmful substances in the flue gas can be removed.

Owner:XIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com