Electrified cleaning agent for precise instruments and preparation method of electrified cleaning agent

A technology of precision instruments and cleaning agents, applied in the field of cleaning agents, can solve problems such as inability to perform deep cleaning, and achieve the effects of enhancing dissolving ability, effectively removing dirt, and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

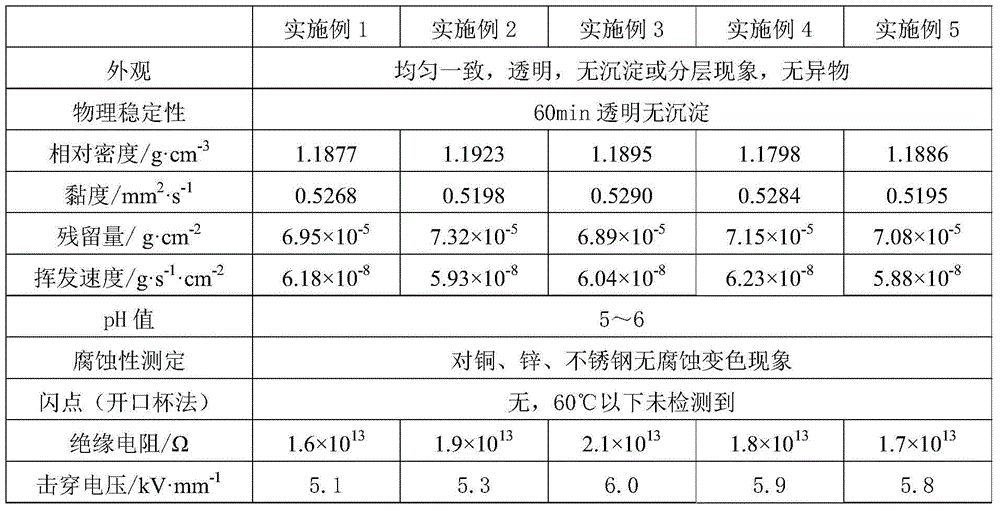

Examples

Embodiment 1

[0019] A charged cleaning agent for precision instruments, comprising in parts by weight: 3 parts of cocamidopropyl betaine, 2 parts of nonylphenol polyoxyethylene ether, 1 part of tetradecyl dimethyl benzyl ammonium chloride, 2 parts of sodium tripolyphosphate, 3 parts of trisodium phosphate, 4 parts of sodium bicarbonate, 1 part of sodium nitrite, 2 parts of 2-phenoxyethanol, 3 parts of pine oil, 1 part of antistatic agent, 2 parts of polyhydroxypolyamine Parts, 3 parts of ethyl acetate, 4 parts of ethanol.

[0020] The antistatic agent is dodecyl benzyl dimethyl ammonium chloride; the polyhydroxypolyamine is tetrahydroxyethylenediamine.

[0021] The preparation method of the above-mentioned charged cleaning agent for precision instruments comprises the following steps:

[0022] Step 1: Add cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyldimethylbenzyl ammonium chloride and sodium tripolyphosphate to ethanol, heat and stir at 30°C for 30min, and cool to...

Embodiment 2

[0026] A charged cleaning agent for precision instruments, comprising in parts by weight: 5 parts of cocamidopropyl betaine, 4 parts of nonylphenol polyoxyethylene ether, 2 parts of tetradecyl dimethyl benzyl ammonium chloride, 3 parts of sodium tripolyphosphate, 4 parts of trisodium phosphate, 6 parts of sodium bicarbonate, 3 parts of sodium nitrite, 4 parts of 2-phenoxyethanol, 5 parts of pine oil, 2 parts of antistatic agent, 4 parts of polyhydroxypolyamine Parts, 5 parts of ethyl acetate, 6 parts of ethanol.

[0027] The antistatic agent is tetradecyl benzyl dimethyl ammonium chloride; the polyhydroxy polyamine is hexahydroxypropyl propylene diamine.

[0028] The preparation method of the above-mentioned charged cleaning agent for precision instruments comprises the following steps:

[0029] Step 1, add cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyldimethylbenzyl ammonium chloride and sodium tripolyphosphate to ethanol, heat and stir at 40°C for 10m...

Embodiment 3

[0033] A charged cleaning agent for precision instruments, comprising in parts by weight: 6 parts of cocamidopropyl betaine, 5 parts of nonylphenol polyoxyethylene ether, 3 parts of tetradecyl dimethyl benzyl ammonium chloride, 4 parts of sodium tripolyphosphate, 7 parts of trisodium phosphate, 8 parts of sodium bicarbonate, 6 parts of sodium nitrite, 5 parts of 2-phenoxyethanol, 6 parts of pine oil, 3 parts of antistatic agent, 7 parts of polyhydroxypolyamine Parts, 8 parts of ethyl acetate, 7 parts of ethanol.

[0034] The antistatic agent is cetyl benzyl dimethyl ammonium chloride; the polyhydroxypolyamine is dialkylhydroxyethylenediamine.

[0035] The preparation method of the above-mentioned charged cleaning agent for precision instruments comprises the following steps:

[0036] Step 1: Add cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyldimethylbenzyl ammonium chloride and sodium tripolyphosphate to ethanol, heat and stir at 30°C for 30min, and cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com