Patents

Literature

293results about How to "Strong emulsifying ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano material-based water-based oil field injection agent and preparation method thereof

InactiveCN101735787AReduce water injection pressureIncrease water injectionDrilling compositionOil productionMagnesium

The invention relates to a nano material-based water-based oil field injection agent and a preparation method thereof. The injection agent consists of 20 to 60 weight percent of diesel oil, 30 to 70 weight percent of surfactant, 1 to 10 weight percent of nano material and 1 to 20 weight percent of auxiliary agent, wherein the nano material is one or more of nano silicon dioxide, nano titanium oxide, nano magnesium oxide and nano aluminum oxide after surface modification. The preparation method thereof comprises the following steps that: firstly, weighing the diesel oil in proportion; secondly, adding the nano material in the diesel oil; thirdly, emulsifying and dispersing the mixture in an emulsifying machine; fourthly, adding the surfactant and the auxiliary agent into the emulsified and dispersed mixture; and finally, mechanically stirring to disperse the mixture at room temperature or in a water bath to obtain stock solution of the nano water-based injection agent. The injection agent can be mixed with water at any proportion to obtain homogeneous emulsified dispersion. After the emulsified dispersion is injected in the oil field through a specific process, the water injection pressure can be obviously reduced, the amount of water injection can be increased and the oil production efficiency can be improved so as to achieve the purpose of energy conservation and injection increase.

Owner:SHANGHAI UNIV

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

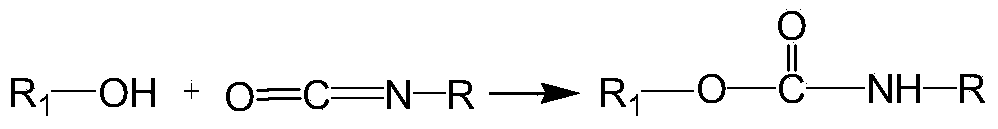

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

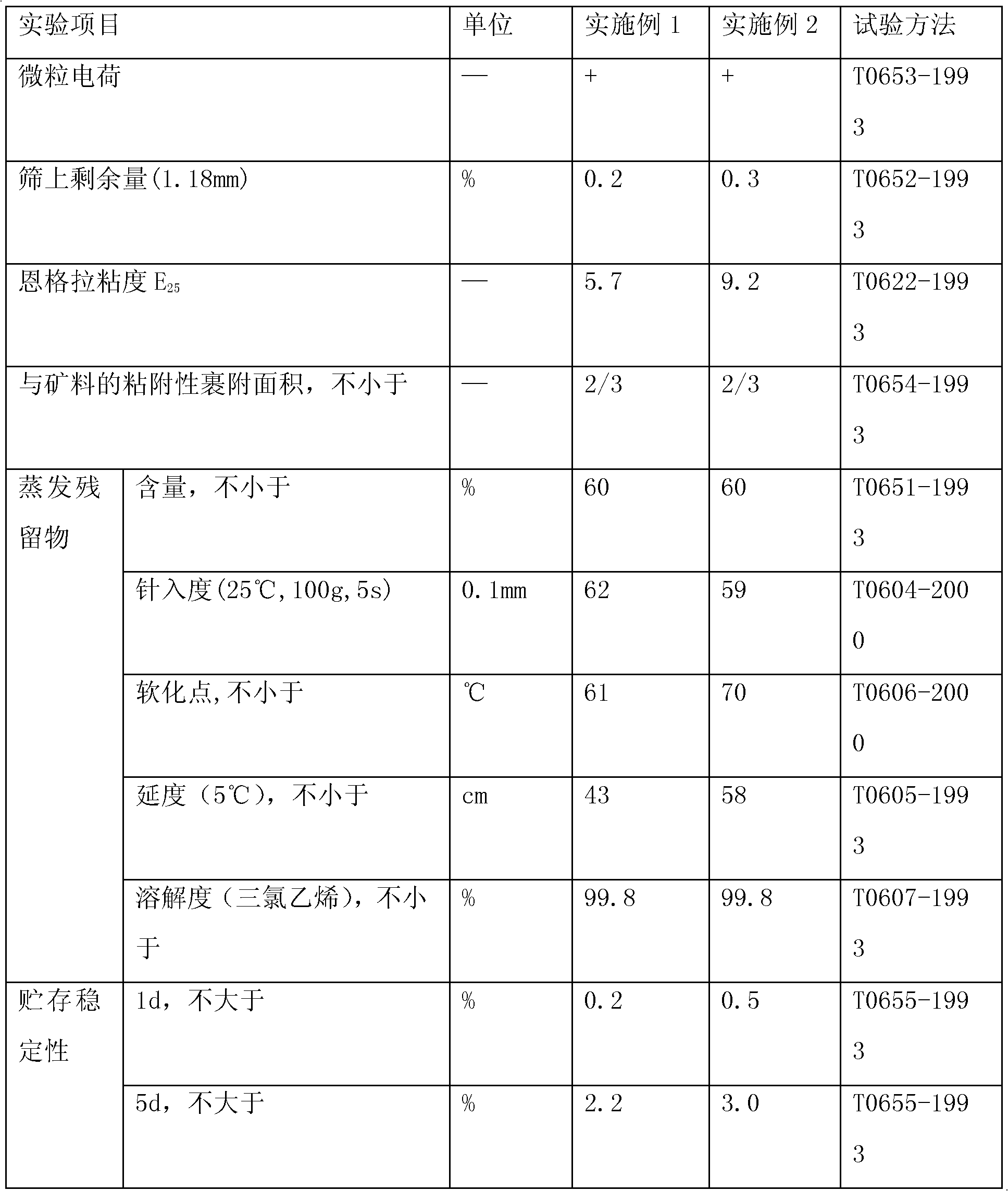

SBS polymer modified emulsified asphalt and preparation method

The invention belongs to the modified emulsified asphalt field, and more specifically relates to a SBS polymer modified emulsified asphalt and a preparation method, the SBS polymer modified emulsified asphalt is prepared by the following raw materials by mass percentages: 40-65% of SBS polymer modified emulsified asphalt, 25-50% of water, 2-10% of cation asphalt emulsifier, 0.1-2.0% of composite emulsified stabilizing agent and 0.2-2.0% of acid, wherein SBS polymer modified asphalt is prepared by mixing and reacting a SBS polymer modifier and matrix asphalt, and the mass of the SBS polymer modifier accounts for 3.5%-5.5% of that of the SBS polymer modified asphalt. The prepared SBS polymer modified emulsified asphalt has stable property, and can be used as a cement asphalt mortar layer and the like for a road tack coat, a seal layer, surface treatment, a slurry seal layer and a high speed railway plate-type ballastless track.

Owner:CHINA PETROLEUM & CHEM CORP

Bicontinuous-phase thorough cleansing oil and preparation method thereof

PendingCN112057406AImprove securityImprove high temperature resistanceCosmetic preparationsMake-upAlkanePolymer science

The invention discloses bicontinuous-phase thorough cleansing oil and a preparation method thereof, and belongs to the technical field of cosmetics. The cleansing oil is prepared from, by mass, 75-95%of a cosmetic matrix and 5-25% of a surfactant, wherein the cosmetic matrix is prepared from a component A, a component B and a component C, the component A is prepared from 1-10% of alkane (alkene)hydrocarbon grease and 30-80% of ester grease, the component B is prepared from 1-10% of ether grease and 3-15% of vegetable fat, and the component C is prepared from 0.01-1% of an antioxidant, 0-10%of active ingredients and 0.01-0.5% of essence. The prepared bicontinuous-phase thorough cleansing oil can be used even if the hand is wet, a bicontinuous phase is formed after the amount of solubilizing water in the oil is increased, water-phase ingredients and oil-phase ingredients can be uniformly fused, thick makeup does not need to be kneaded, the color makeup fusing speed is high, the cleansing oil can be removed after being smeared slightly, the self-emulsifying capacity is high, the nanoscale emulsification particle size washing performance is good, the pure natural vegetable oil in the formula is moist and moist in skin feeling and not sticky, and therefore the effect of combining makeup removal and skin nourishing is achieved.

Owner:上海典雅生物科技有限公司

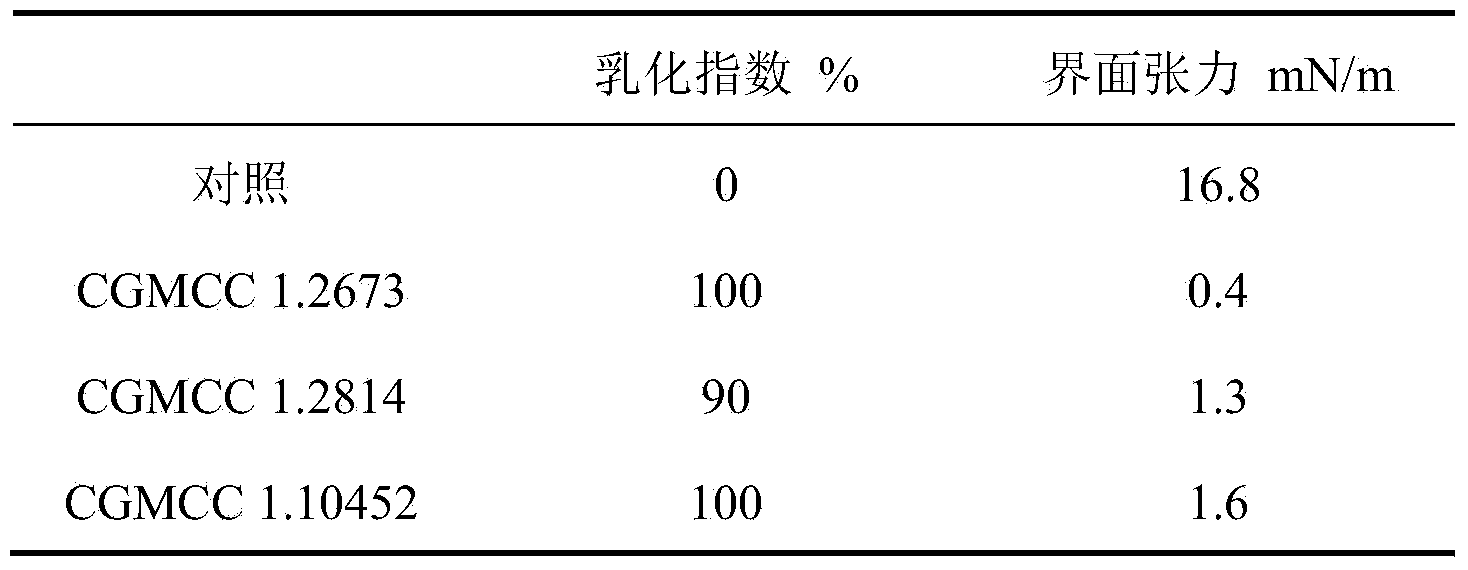

Strong emulsibility microbe wax cleaning and preventing bacterial agent and application thereof

ActiveCN104109516AStrong emulsifying abilityReduce interfacial tensionCleaning apparatusFluid removalInhibition zoneOil production

The invention discloses a strong emulsibility microbe wax cleaning and preventing bacterial agent and an application, which belongs to the oil field chemical technology field. The wax cleaning and preventing bacterial agent mainly comprises pseudomonas aeruginosa and geobacillus sp, has strong emulsification capability, and is capable of dispersing crude oil, promoting crude oil to flow, changing adherence force of borehole wall, preventing the accumulation of wax crystal on the borehole wall, and playing the paraffin inhibition and wax cleaning effects. By increasing the initial application amount of the bacteria liquid and prolong the well closing time, a stable paraffin inhibition zone can be formed due to adhesion of bacteria on borehole wall, near wellbore formation can be cleaned, and the paraffin inhibition and oil increase effects can be increased. After on-site enforcement, the well cleaning and chemical paraffin inhibition works can not be carried out in recent half year in the test wells, so that the wax cleaning and preventing bacterial agent has good paraffin inhibition effect in the well. The oil production is increased by about 30% daily, pump efficiency is increased about 10%, the surface tension of the output liquid is decreased to 20-25%, and the crude oil condensation point is decreased by 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

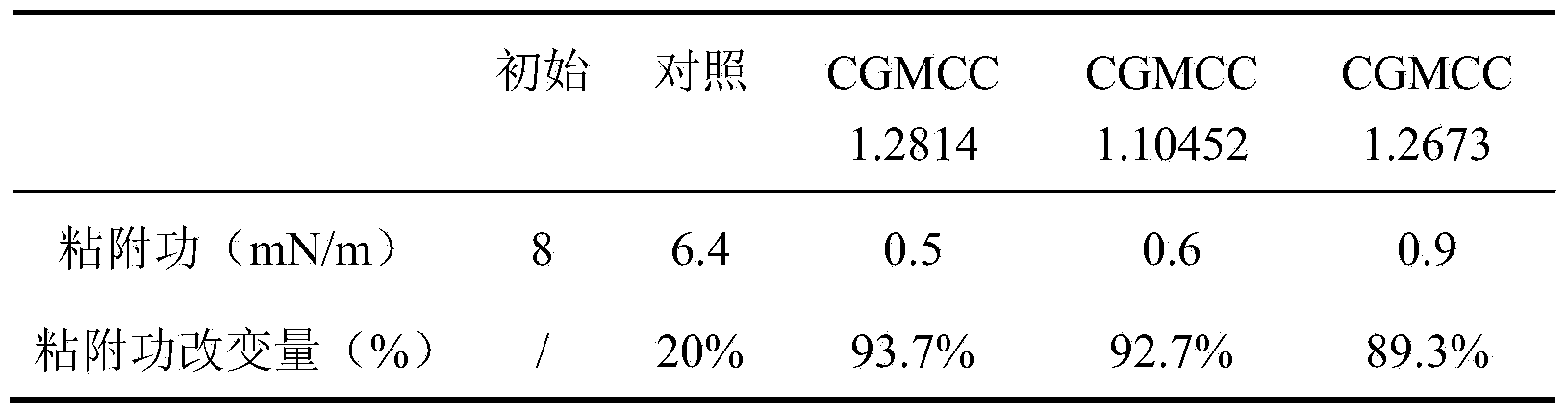

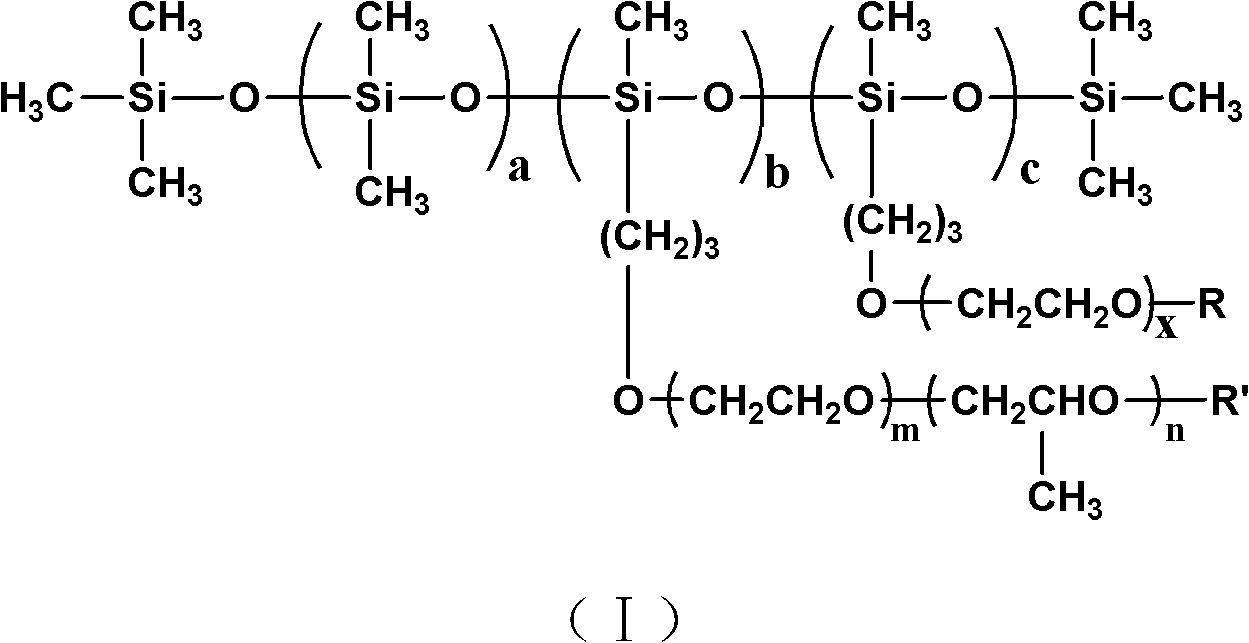

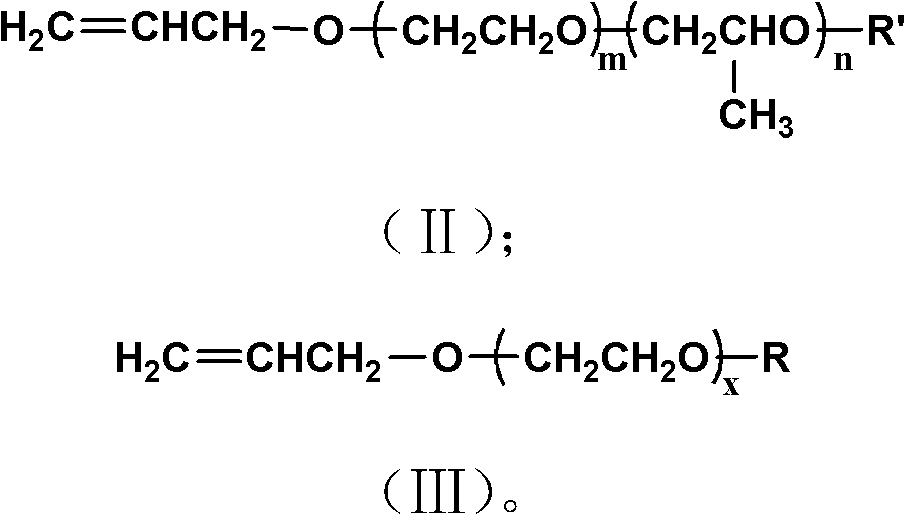

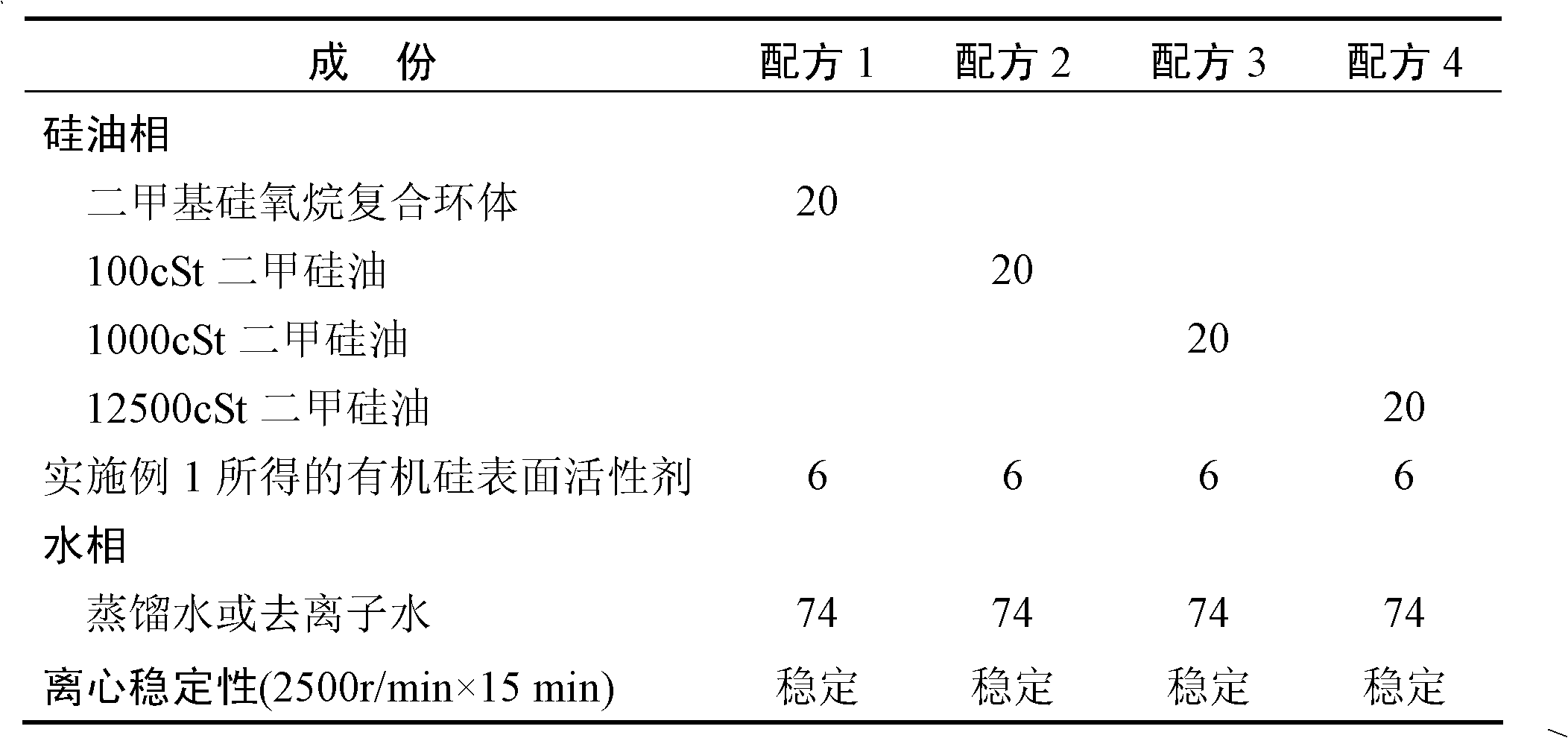

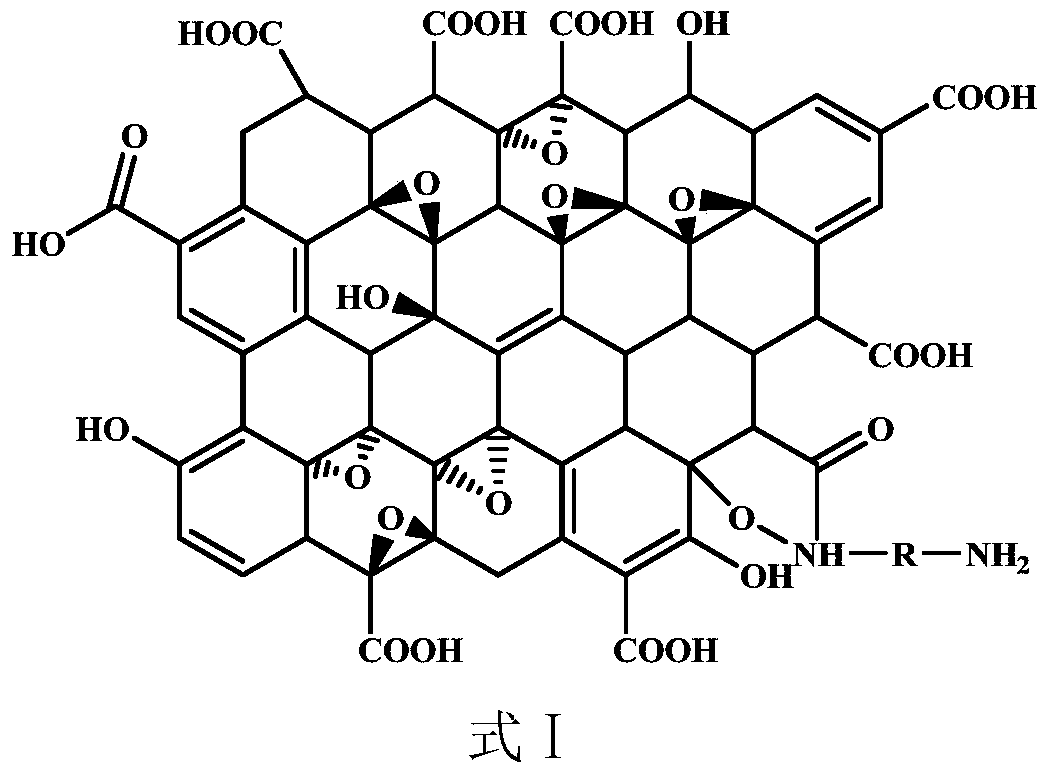

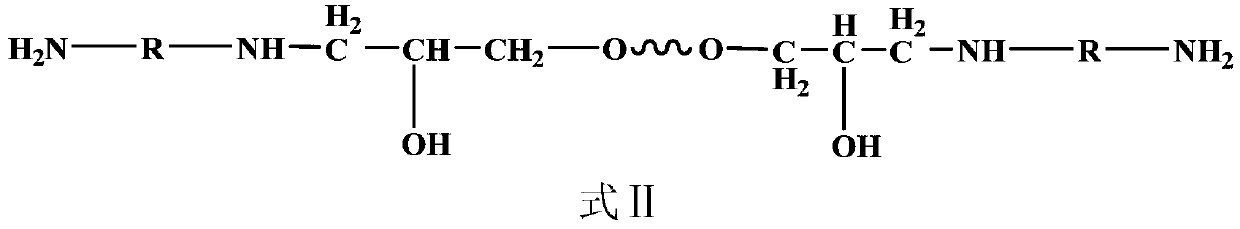

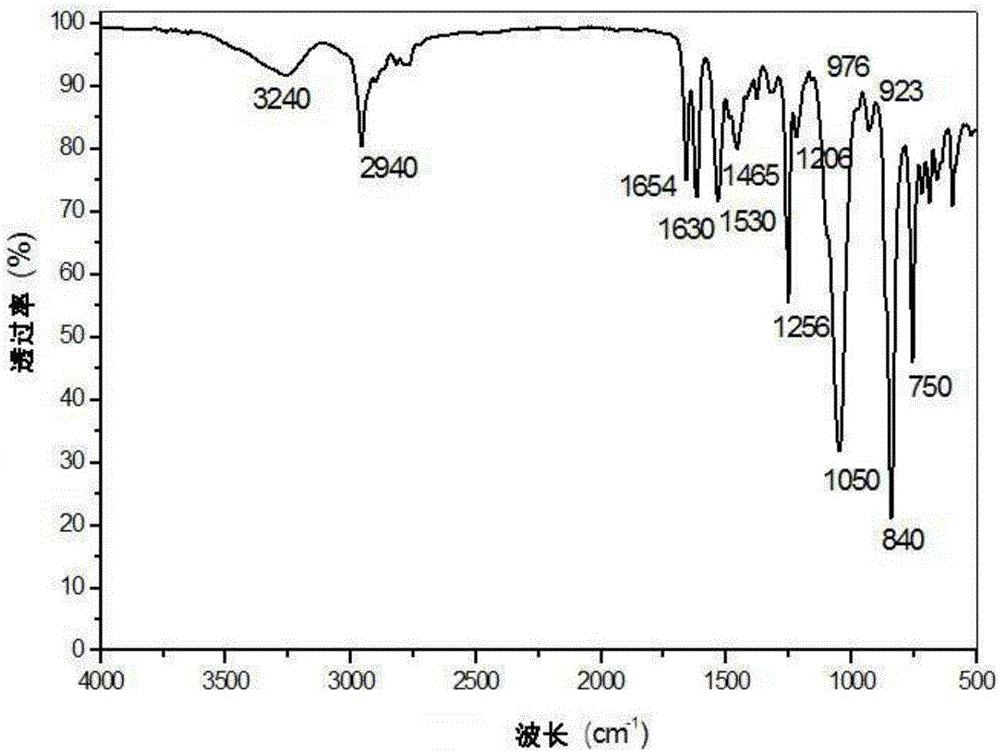

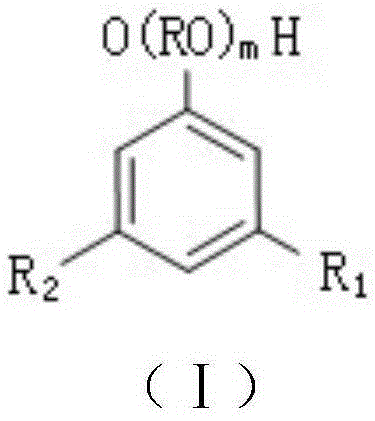

Organosilicon surfactant and preparation method and application thereof

ActiveCN103182271AStrong emulsifying abilityGood emulsifying effectSilicon organic compoundsTransportation and packagingSingle useEmulsion

The present invention discloses an organosilicon surfactant and a preparation method and application thereof. The organosilicon surfactant has a structure shown as a formula (I), wherein c is not 0; a, b and c are all integers and 10<a+b+c<200; m=0-40; n=0-30; x=3-30; x, m and n are integers, and m and n are not 0 simultaneously; R is a C6-C20 straight-chain alkyl or a isomer long-chain alkyl, or alkylphenyl group; and R' is H, CH3, C2H5, C3H7 or C4H9. The organosilicon surfactant has a novel structure, and excellent emulsifying ability. The organosilicon surfactant has excellent emulsifying ability for polydimethylsiloxane in a large viscosity range and various modified polydimethylsiloxane, can achieve good emulsion effects by single-use, and does not need to be compounded with other emulsifiers. The emulsification process is simple, a homogenizer or other special emulsification processes can be canceled, a stable O / W type silicone oil emulsion is prepared and the use is easy.

Owner:广州标美药用辅料有限公司

Oil-based polyamide assistant emulsifier for drilling fluids, and preparation method thereof

InactiveCN105907381AStrong emulsifying abilityHigh temperature resistanceDrilling compositionPolymer sciencePolyamide

The invention discloses an oil-based polyamide assistant emulsifier for drilling fluids, and a preparation method thereof. The oil-based polyamide assistant emulsifier is prepared through a dehydration polycondensation reaction of diacid anhydrides, polyalkenepolyamine and aliphatic acid, wherein a molar ratio of the diacid anhydrides to polyalkenepolyamine to aliphatic acid is 1:1:1.4-4. The emulsifier is a macromolecular polymer surfactant, per unit mass of the emulsifier contains more lipophilic and hydrophilic groups, and the emulsifying efficiency is high; hydrophilic groups in the molecular structure is an amido structure, so the emulsifier has good high-temperature resistance; and the emulsifier and a wetting agent have synergism, so the wetting reversal of solid phase surface is facilitated.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

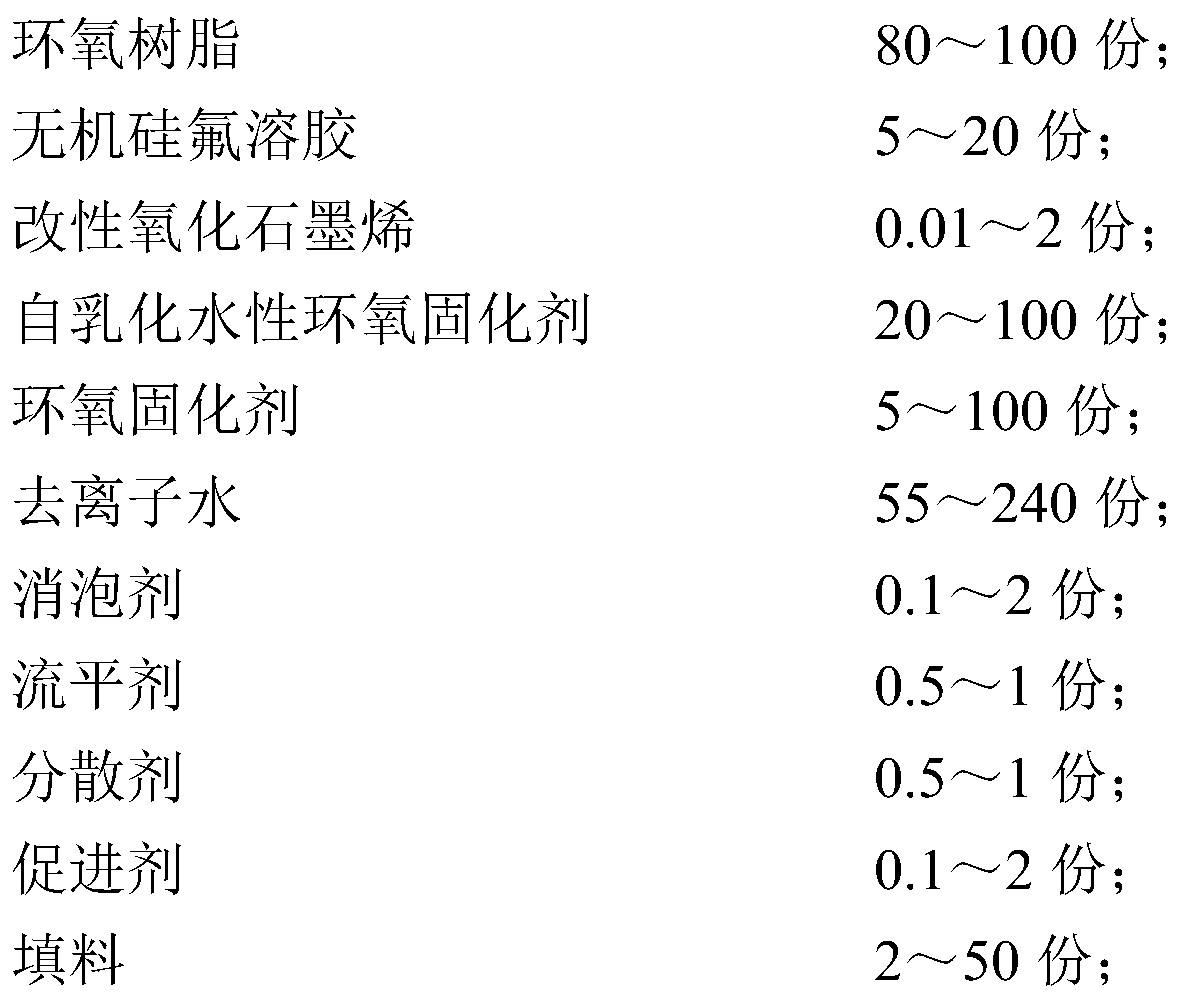

Low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof

ActiveCN110330862AWear-resistantLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceFluorographene

The invention discloses a low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof. The molecular structure of the coating contains structures such as epoxy groups, polyether, silicon fluoride and graphene; in the stage of emulsifying epoxy resin of the coating, the coating has excellent aqueous property and high emulsifying capability owing to a self-emulsifying aqueous epoxy curing agent, the coating has good compatibility with the epoxy resin, and the stability of emulsion is improved. In a curing stage of modification of a graphene oxide modified coating, it is ensured that the self-emulsifying water-based epoxy curing agent does not separate out from a coating layer to form a stable coating layer; a flexible micro-region is formed by flexiblelong-chain polyether in the coating layer, so that the mechanical property of a coating film is improved; by silicon-fluorine sol, the surface energy of the coating film is reduced; graphene is grafted into the molecular structure through chemical bonds, after the dispersion performance is improved, the graphene can cover a metal surface efficiently, and the corrosion resistance of the coating layer is improved. Therefore, the coating provided by the invention has excellent properties of adhesion, hardness, acid and alkali resistance, water resistance and the like after film formation, variouscomponents are compatible well, and the coating can be used for metal parts and the like.

Owner:中科广化(重庆)新材料研究院有限公司 +2

Well cementation oil-based slurry flushing liquid and preparation method thereof

ActiveCN105315978AStrong emulsifying abilityPlay a drag roleDrilling compositionChemistryNonionic surfactant

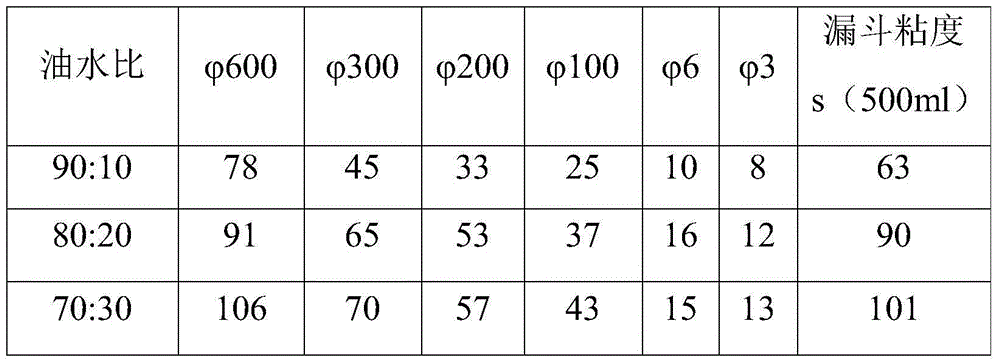

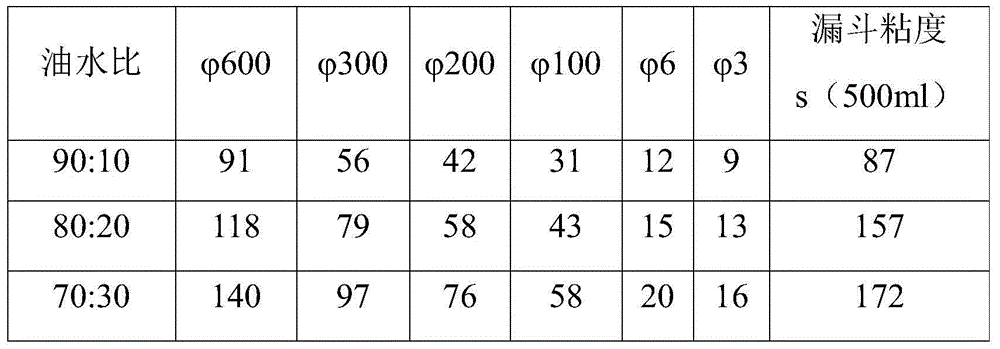

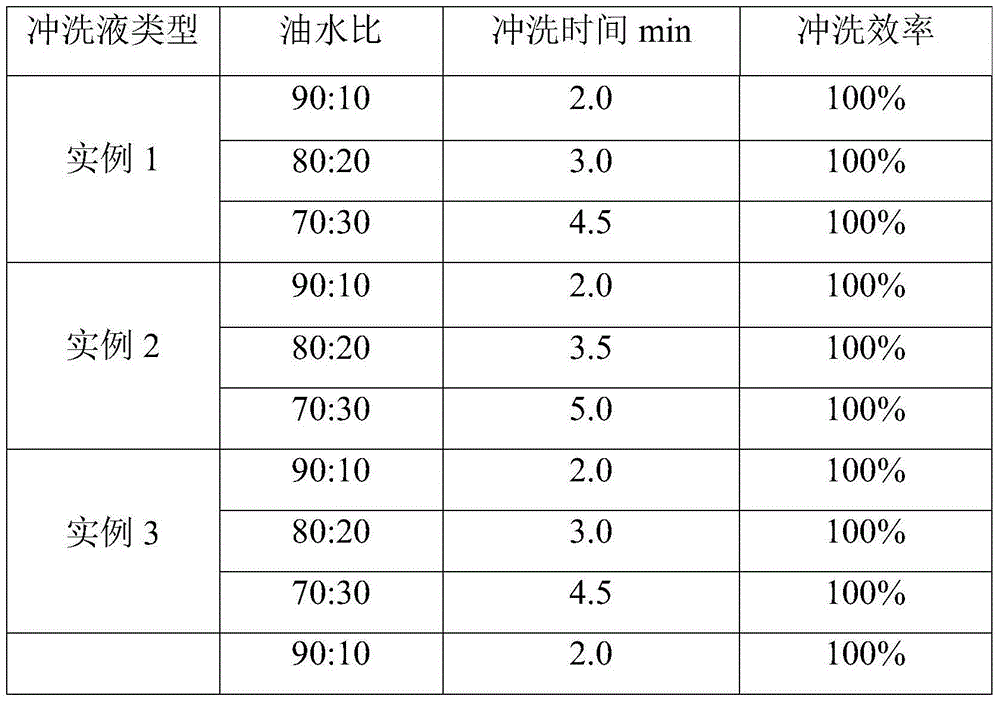

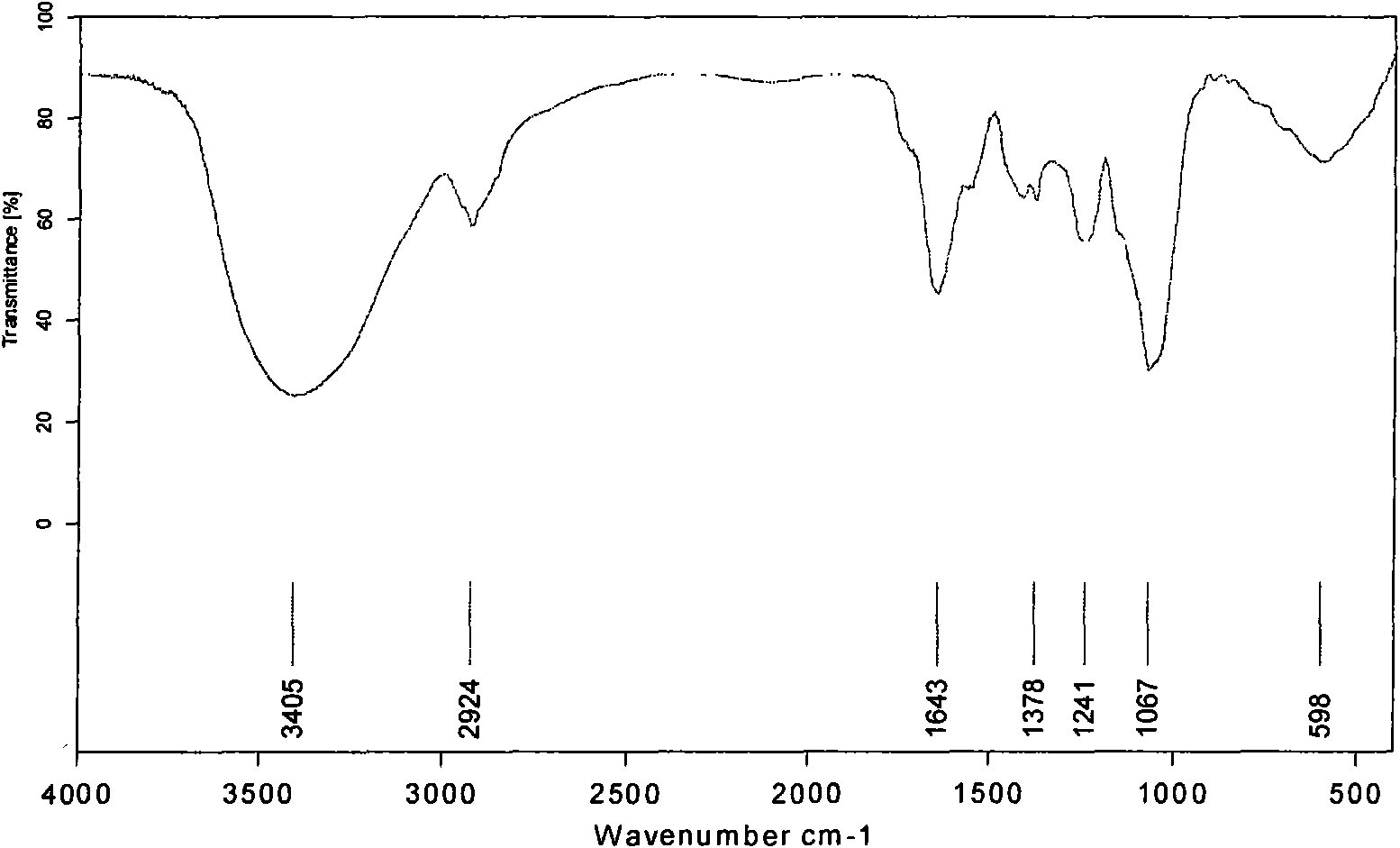

The invention discloses a well cementation oil-based slurry flushing liquid and a preparation method thereof. The flushing liquid comprises the components of, by weight, 100 parts of water, 4-8 parts of a nonionic surfactant, 5-8 parts of an anionic surfactant, 4-5 parts of an amphoteric surfactant, 1-2 parts of Span 80, 1-2 parts of Tween 80, and 0.2-3.5 parts of a tackifying and shear-strength-improving agent. The method comprises the following steps: according to the formula, the tackifying and shear-strength-improving agent is added, and the material is well mixed by stirring; the other components are added, and the mixture is well mixed by stirring, such that the well cementation oil-based mud flushing liquid is obtained. The flushing liquid provided by the invention has certain shearing strength and viscosity. Under the effect of hydraulic machinery, a dragging effect can be performed on oil slurry and oil films. Also, the flushing liquid has high emulsifying effects, and can be used for emulsifying the oil films and residual oil, such that viscose oil-based drilling fluid can be effectively cleaned. The flushing fluid is suitable to be used for flushing oil-based drilling fluid with high plastic viscosity and shearing force.

Owner:CHINA PETROLEUM & CHEM CORP +1

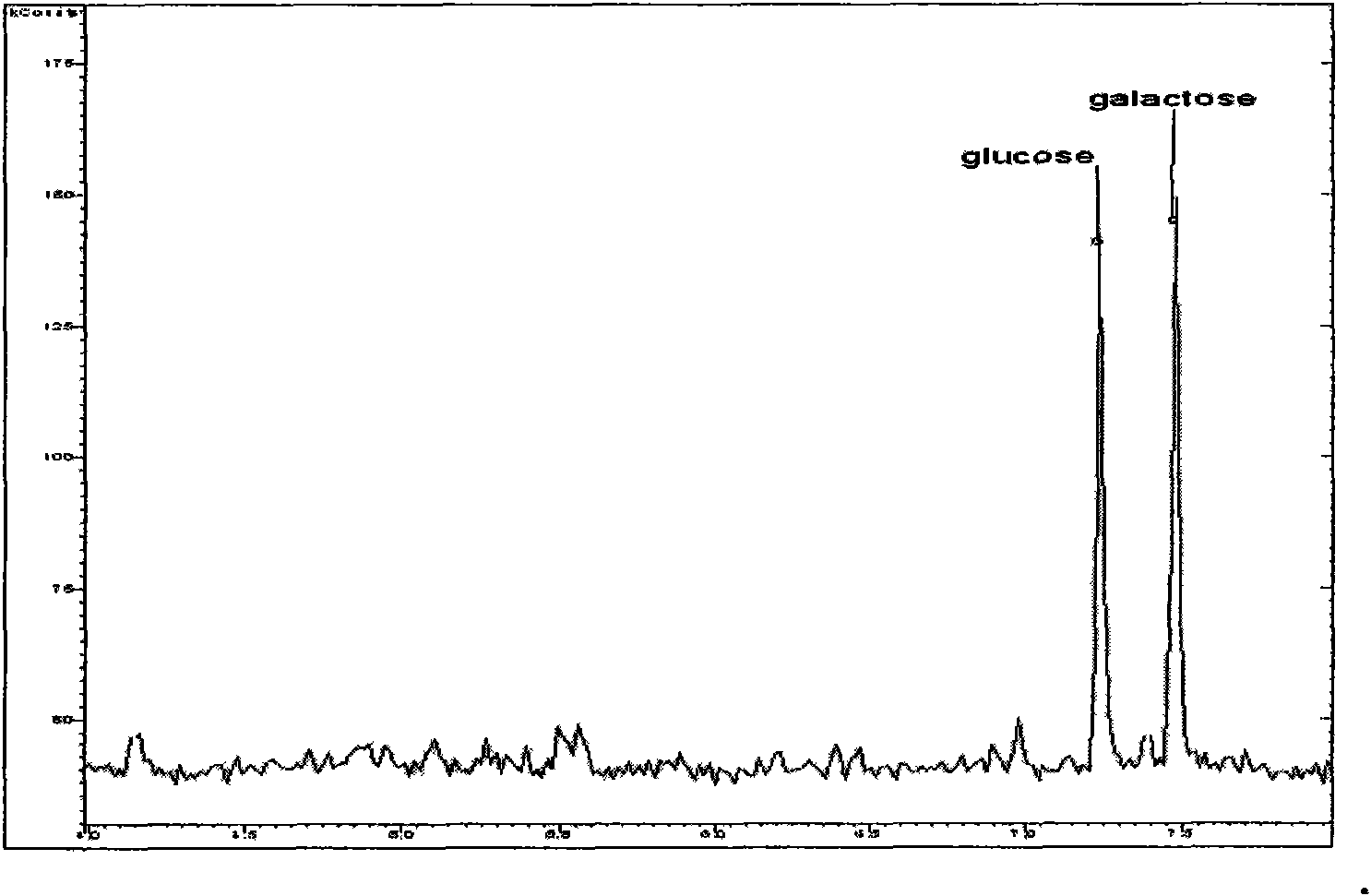

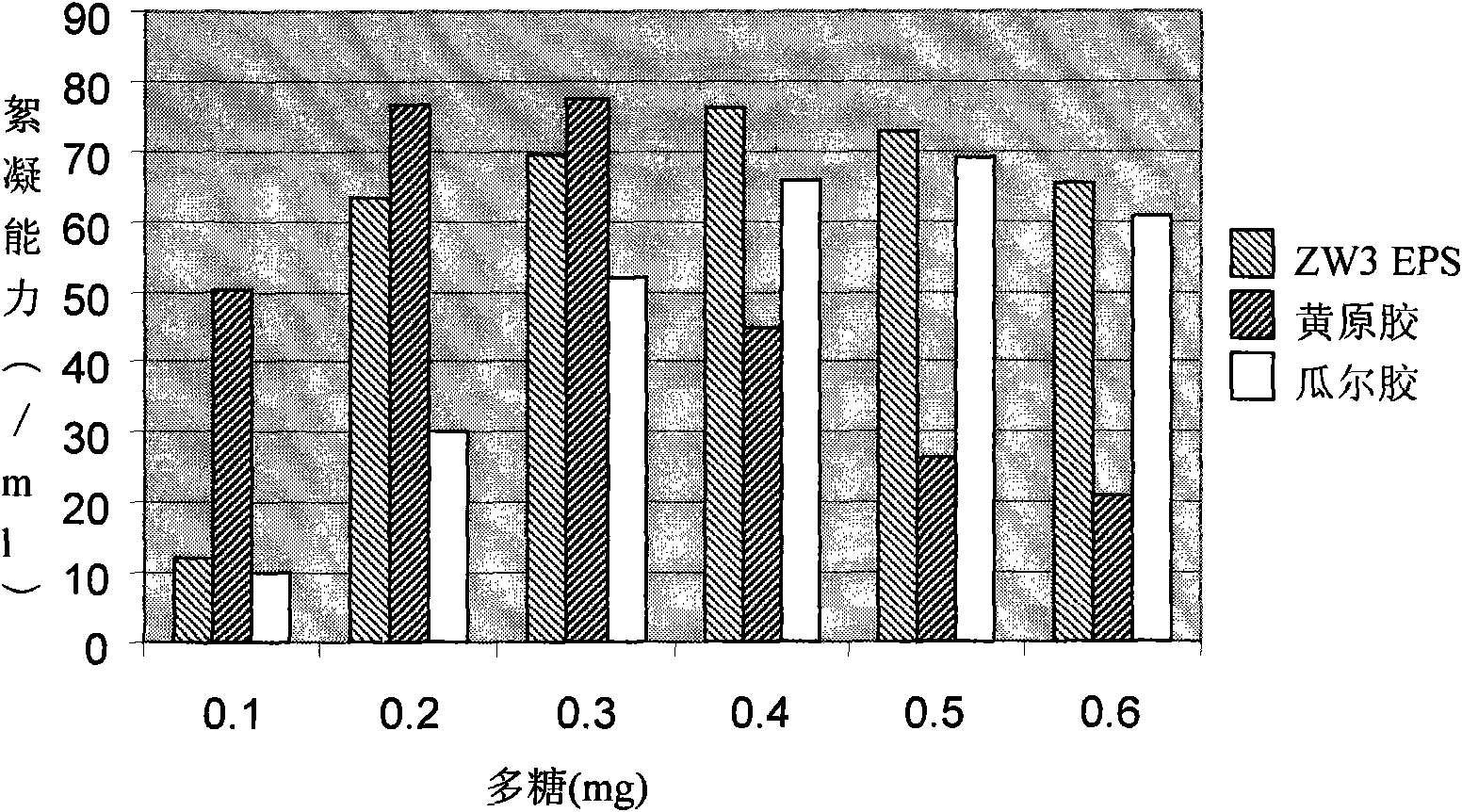

Kefiranofaciens subsp.kefiranofaciens ZW3 strain

InactiveCN101586090ABiodegradablePromote growthBacteriaMicroorganism based processesDownstream processingKefir Grain

The present invention relates to a Kefiranofaciens subsp.kefiranofaciens ZW3 strain which is obtained from the Kefir grains through filtering separation and is preserved in Laboratory of culture collection of the Microbiology, Chinese Academy of Science. The preservation data is December 18, 2008, and the preserving number is CGMCC2809. The ZW3 strain of the invention has the advantages of excellent thermal stability, strong emulsifying capacity and high yield of exopolysaccharide. The exopolysaccharide which is obtained by separating and purifying the fermentation broth of the ZW3 strain is the macromolecule biological polysaccharides. The exopolysaccharide not only can be used as the thickening agent and the emulsifier in the food industry, but also can be used as the probiotics for promoting the growth of other probiotics in the intestional canal. The exopolysaccharide is also related with the functions of anti-tumor, anti-fistula, immunoregulation, cholesterol lowering or blood pressure regulating of the probiotics. Furthermore the exopolysaccharide has biodegradability and has no harm to the human body and the environment. The exopolysaccharide can be used as an effective flocculant in the food fields of wastewater treatment, drinking water product, downstream processing, etc.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method for peanut bioactive peptide

ActiveCN102250998AHas antibacterial activityHas good antibacterial activityFermentationSolubilityHydrolysate

The invention discloses a preparation method for peanut bioactive peptide. The method comprises the following steps: adding peanut protein powder to distilled water, carrying out stirring, followed by standing and microwave treatment to obtain peanut protein powder suspension liquid; adjusting a pH value of the peanut protein powder suspension liquid through a hydrochloric acid solution, then adding compound plant hydrolase Viscozyme L, followed by carrying out the microwave treatment to secondarily carry out enzymolysis to obtain a enzymatic hydrolysate, then killing the enzymes and carryingout cooling to a room temperature; adjusting a pH value of the enzymatic hydrolysate through a sodium hydroxide solution or the hydrochloric acid solution, then adding protease and carrying out the microwave treatment to secondarily carry out the enzymolysis, then killing the protease and carrying out cooling to the room temperature, followed by carrying out centrifugating and freeze drying to obtain the peanut bioactive peptide. The prepared peanut bioactive peptide product provided by the present invention has functional properties of high dissolubility, high emulsibility, strong foamability, good emulsion stability, good foam stability and the like. In addition, the method provided by the present invention is applicable for the industrial production.

Owner:SHANDONG PEANUT RES INST

Cleaning agent for stainless steel-aluminum alloy plate combined electric kettle and preparation method

The invention discloses a bright cleaning agent for a stainless steel-aluminum alloy plate combined electric kettle, which is generally used for spraying and ultrasonic washing, and can simultaneously remove oil, wax and other pollutants on the surface of stainless steel and aluminum alloy of the electric kettle to achieve strong polishing and oxidation resistance and other effects, and a preparation method. The bright cleaning agent is prepared from the following raw materials in percentage by weight: 0.1-0.5% of sodium hydroxide, 1-5% of sodium carbonate, 1-4% of potassium metasilicate pentahydrate, 1-3% of potassium pyrophosphate, 1-3% of borax decahydrate, 1-4% of sodium tripolyphosphate, 0.1-1.8% of penetrant, 0.5-2% of special low-foaming surfactant for spray degreasing, 0.5-3% of special surfactant for removing molten wax, 0.5-2% of Y-73 low-foaming surfactant for ultrasonic washing, 0.5-3% of Y-75 low-foaming surfactant for ultrasonic washing, 1-3% of defoaming agent and the balance of water.

Owner:DALIAN SANDAAOKE CHEM

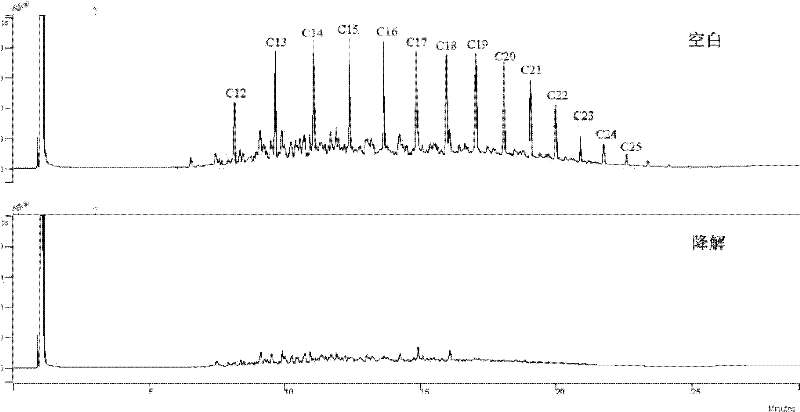

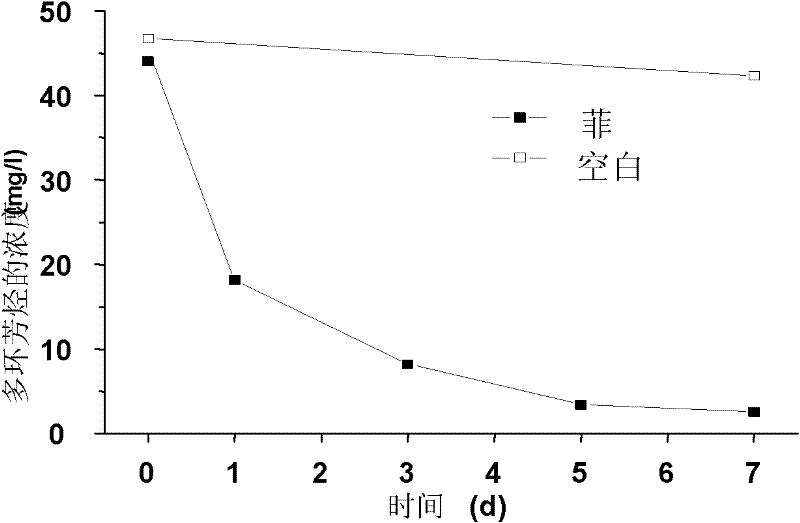

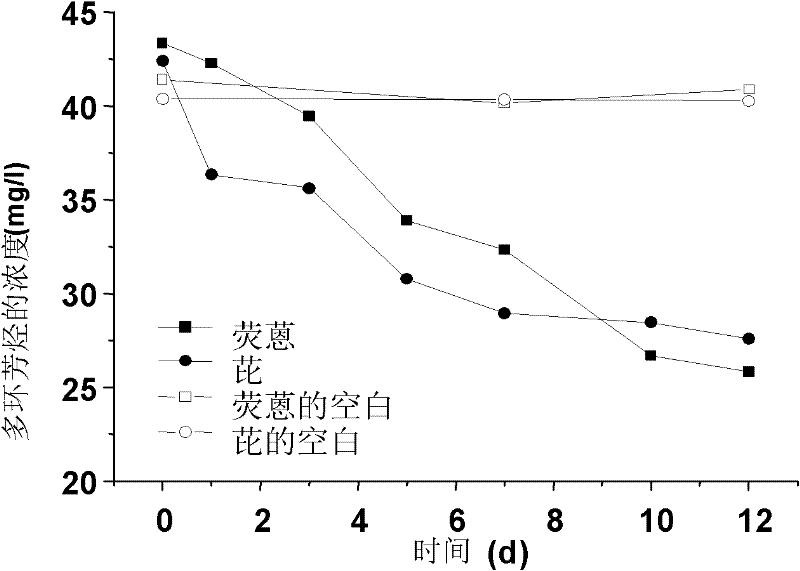

Pseudomonas aeruginosa and application thereof

InactiveCN102533589AStrong emulsifying abilityGood ability to degrade polycyclic aromatic hydrocarbonsBacteriaTransportation and packagingCarbon sourceResting Cell

The invention discloses a pseudomonas aeruginosa CCTCCM208114 and application of the pseudomonas aeruginosa in petroleum pollutant degradation. The pseudomonas aeruginosa provided by the invention has the following characteristics that: 1) the pseudomonas aeruginosa has high-efficient petroleum hydrocarbon degradation capability; 2) the pseudomonas aeruginosa is capable of co-metabolizing fluorene in an inorganic salt culture medium in the presence of n-tetradecane; 3) a resting cell system of the pseudomonas aeruginosa has good polycyclic aromatic hydrocarbon degradation capability and can tolerate high polycyclic aromatic hydrocarbon concentration; 4) the pseudomonas aeruginosa has a wide substrate spectrum; and 5) the pseudomonas aeruginosa grows in an LB (Luria Bertani) culture medium or an inorganic salt culture medium (straight-chain paraffin or polycyclic aromatic hydrocarbon serves as the unique carbon source and energy source) and can generate biological surfactant. The pseudomonas aeruginosa can be widely applied to the field of bioremediation of petroleum compound pollution and is suitable for large-area popularization and application.

Owner:DAQING OILFIELD CO LTD

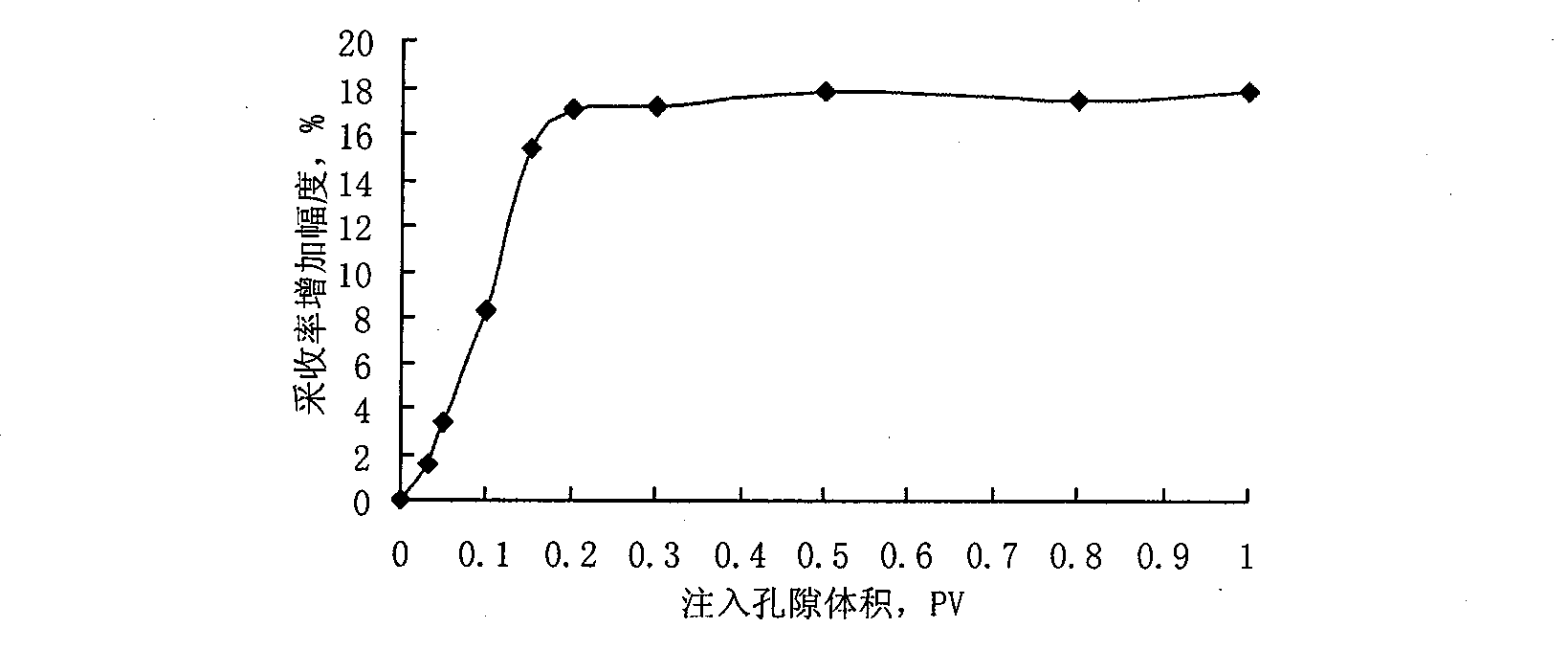

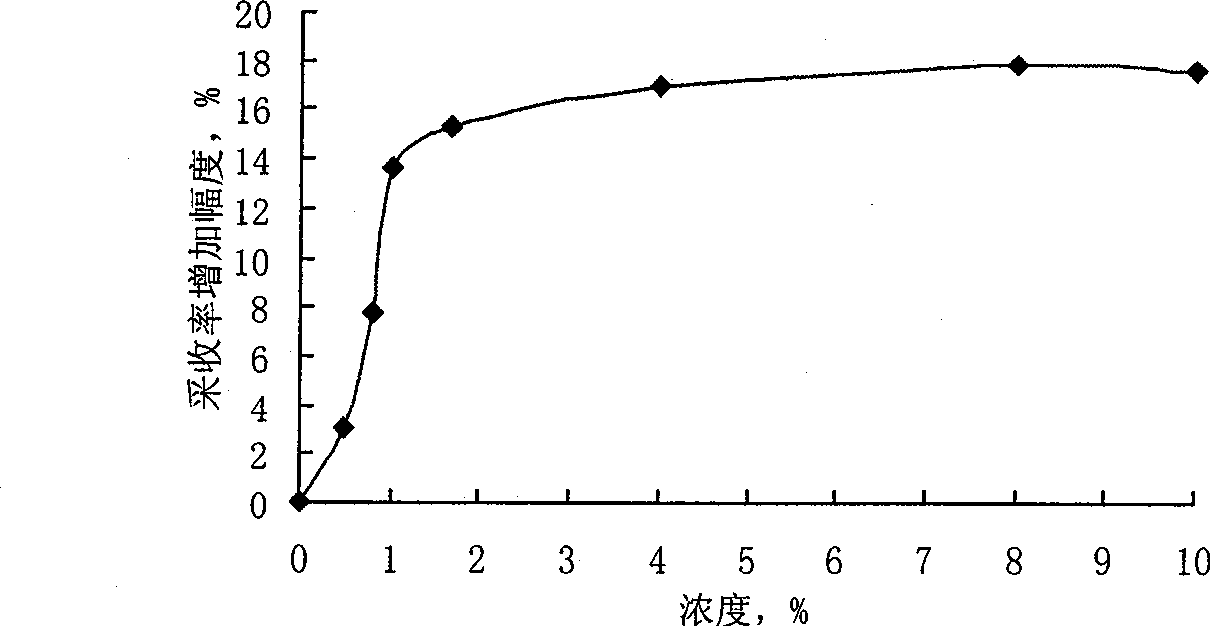

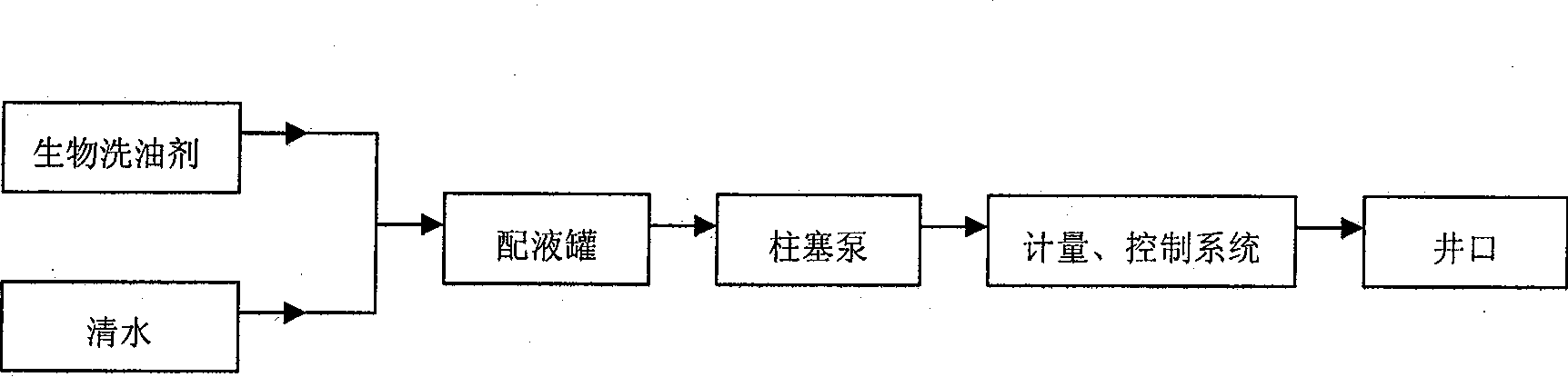

Biological oil displacement agent and production method and use thereof

InactiveCN101451062AObvious effect of "increasing oil and reducing water"Significant oil increase and precipitation" effectBacteriaCleaning apparatusWater contentEnzyme

The invention relates to a biological oil cleaning agent, a method for producing the same and application thereof. The biological oil cleaning agent contains 1.85 to 2.75g / L of coarse biological enzyme extract and 9.75 to 13.45g / L of coarse biosurfactant product. The biological oil cleaning agent has good effect of deplugging and oil displacement; a core displacement test shows the permeability restoration ratio of rock core deplugged by the biological oil cleaning agent averagely exceeds 95 percent and can further improve the extraction yield by over 17 percent on the basis of driving water to ultimate water content.

Owner:BEIJING FLTY GASOLINEEUM SCI& TECH

Emulsion explosive used in deep water blasting and preparation method thereof

InactiveCN102675005AStrong emulsifying abilityImprove stabilityNon-explosive/non-thermic compositionsMicrocrystalline waxMass ratio

The invention provides an emulsion explosive, which is prepared by forming a latex matrix through an emulsion effect on a water phase and an oil phase and then sensitizing the latex matrix, wherein the mass ratio of the oil phase to the water phase is 89-94:6-11; the water phase is prepared from ammonium nitrate, sodium nitrate, a crystal form improver and water in the weight ratio of 65-74:8-13:0.1-0.3:8-11; and the oil phase is prepared from emulsion explosive special composite grease, wax, microcrystalline wax, vaseline and a composite emulsifier according to the weight ratio of 2.0-4.7:1-2.5:0.4-1.2:0.5-2:2-3. According to the emulsion explosive, the particle diameter of the emulsified latex matrix is less than 3 mum by using an emulsifier with superior performance; and after physical sensitization of pearl sand, the emulsion explosive with water resistance which is suitable for deep water blasting is prepared. The invention also provides a preparation method of the emulsion explosive.

Owner:GUANGDONG HONGDA BLASTING

Method for preparing monolaurin

The invention discloses a method for preparing monolaurin, which comprises the following steps: taking camphor tree seed oil as a raw material; adding degumed and dehydrated camphor tree seed oil into an esterification and alcoholysis reactor, and adding acidic ionic liquid 1-methyl-3-(3-sulfopropyl) imidazole catalyst to reacting at the temperature of between 135 and 145 DEG C until the acid value is reduced to below 0.5, wherein the temperature the dosage of the catalyst is 3 to 4 percent of the weight of the oil and the molar ratio of the alcohol to the oil is 1.5-2.5:1; performing centrifugal separation, adding the esterified and alcoholized amphor tree seed oil into a catalysis and alcoholysis reactor, and adding the alkaline ionic liquid of 1-butyl-3-methyl imidazole salt to react at the temperature of between 165 and 175 DEG C until the total content of the monofatty glyceride is over 90.0 percent, wherein the dosage of the catalyst is 0.4 to 0.6 percent of the weight of the oil and the molar ratio of the alcohol to the oil is 6-7:1; performing centrifugal separation, washing with the water at the temperature of between 15 and 35 DEG C; and performing vacuum dehydration and decoloration. The monofatty glyceride content in the product is over 90.0 percent; the monolaurin content is over 85.0 percent; and the process of molecular distillation can be saved. The technology is reasonable, energy-saving and environment-friendly; and most of the glycerol can be recycled, and the discharge of acid, alkali and salt is greatly reduced.

Owner:南昌香樟林高科技有限公司

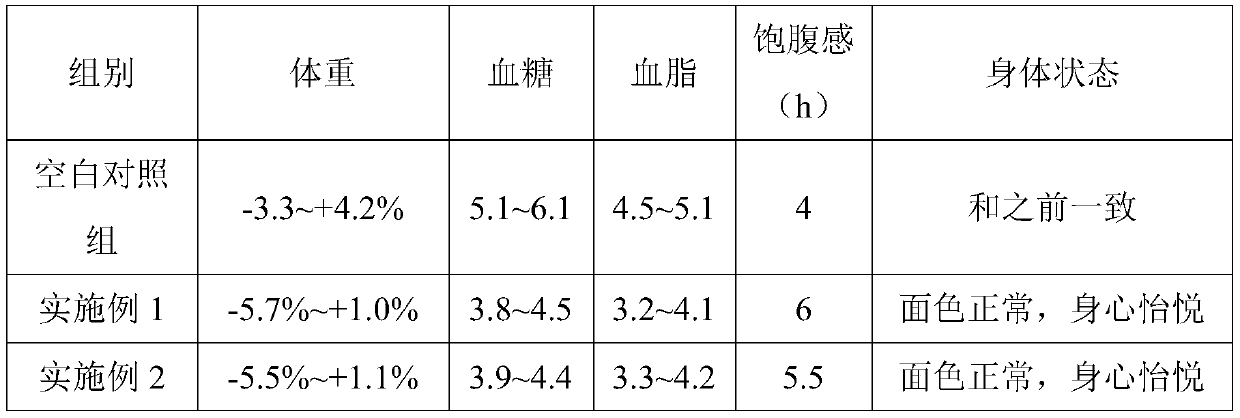

Functional meal replacement powder for balancing nutrients and preparation method of functional meal replacement powder

InactiveCN111528483ARich in nutrientsMeet daily needsVitamin food ingredientsNatural extract food ingredientsBiotechnologyFiber

The invention provides functional meal replacement powder for balancing nutrients. The functional meal replacement powder comprises the following raw materials in parts by weight of 36-50 parts of protein substances, 14-24 parts of dried milk, 7-13 parts of puffed cereal powder, 10-20 parts of dietary fibers, 1-3 parts of a sweetening agent,1-2 parts of a stabilizing agent, 2-6 parts of microcapsule powder, 1-3 parts of complex vitamins, 1-3 parts of composite mineral substances, and 0.035-0.07 part of a conditioning agent. Large granule materials are crushed, and the products are screened with a 100-mesh sieve, placing all substances in a three-dimensional blender mixer, uniform mixing is performed, and subpacking is performed. The prepared meal replacement powder can meet requirements ofvarious types of human bodies, particularly obesity crowds.

Owner:青岛自然珍萃健康科技有限公司

Meat product phosphate-free water-retaining agent and use method thereof

ActiveCN104814113AIncrease concentrationImprove water holding capacityMeat/fish preservation using chemicalsDicarbonatePhosphate

The present invention relates to a meat product phosphorus-free water-retaining agent and a use method thereof. The phosphate-free water-retaining agent comprises 3-5 parts of dicarbonate, 20-30 parts of glycerin, 10-20 parts of monosaccharide and / or sugar alcohol thereof, 5-10 parts of edible gums, 5-10 parts of soybean phospholipids and water as the rest. The use method of the phosphate-free water-retaining agent is as follows: firstly conducting forward direction salt penetration to pickle the meat into dried meat and then soaking the dried meat in the phosphate-free water-retaining agent to conduct reverse direction penetration. The use method of the phosphate-free water-retaining agent enables the enhanced penetration capacity of the water locking substances in the phosphate-free water-retaining agent, and improves the water locking effects of the phosphate-free water-retaining agent within the meat cells.

Owner:山东紫燕食品有限公司

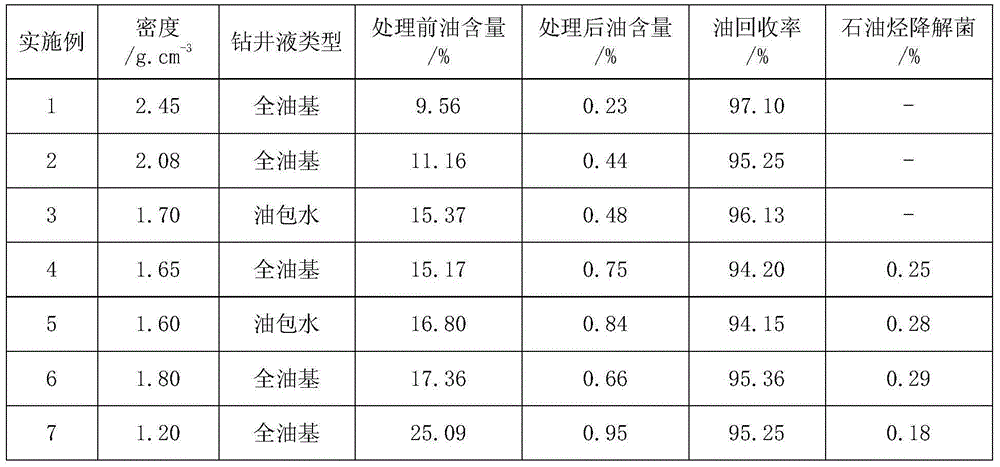

Oil base drill chip processing method

InactiveCN104373065AHigh recovery rateImprove wetting abilityFlushingDrilling compositionEnvironmental resistancePetroleum

The invention relates to an oil base drill chip processing method, belongs to the field of environment protection, and particularly belongs to the technical field of drilling waste processing in oil and natural gas industry. The method comprises the following steps of: (1) demulsification: adding demulsifying agents accounting for 0.4 percent to 1.0 percent of the mass of oil base drill chips into the oil base drill chips in a stirring state; (2) cleaning: adding a non-ionic surfactant solution accounting for 10 percent to 30 percent of the mass of the oil base drill chips and an anionic surfactant solution accounting for 20 percent to 30 percent of the mass of the oil base drill chips into the demulsified oil base drill chips in the first step in the stirring state to obtain an oil-water-solid mixture; (3) separation: carrying out centrifugal separation on the mixture in the step (2); and (4) processing by hydrocarbon degradation bacteria: regulating the pH of the separated oil base drill chips and then adding nutrients, nutrient providers, bulking agents and the hydrocarbon degradation bacteria. The method has the advantages that the oil recovery rate is higher than 94 percent; the oil content of the drill chips is less than 0.3 percent; the operation is simple; the equipment investment is low; and reclamation and harmlessness are realized.

Owner:CHINA PETROCHEMICAL CORP +1

Electrified cleaning agent for precise instruments and preparation method of electrified cleaning agent

InactiveCN104479905AImprove surface activityStrong emulsifying abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium bicarbonateAlcohol

The invention provides an electrified cleaning agent for precise instruments and a preparation method of the electrified cleaning agent. The cleaning agent comprises cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyl dimethyl benzyl ammonium, sodium tripolyphosphate, trisodium phosphate, sodium bicarbonate, sodium nitrite, 2-phenoxyethyl alcohol, pine oil, an antistatic agent, polyhydroxy polyamine, ethyl acetate and ethyl alcohol. The preparation method comprises the following steps: firstly adding cocamidopropyl betaine, nonylphenol polyoxyethylene ether, tetradecyl dimethyl benzyl ammonium and sodium tripolyphosphate to ethyl alcohol, so as to obtain a mixture I; adding trisodium phosphate, sodium bicarbonate, the sodium nitrite and 2-phenoxyethyl alcohol to ethyl acetate, so as to obtain a mixture II; and finally mixing the mixture I with the mixture II, and then adding the residual components, so as to obtain the cleaning agent. The cleaning agent is excellent in performance, and can be used as the electrified cleaning agent for the precise instruments.

Owner:DONGCHEN LEADER TESTING

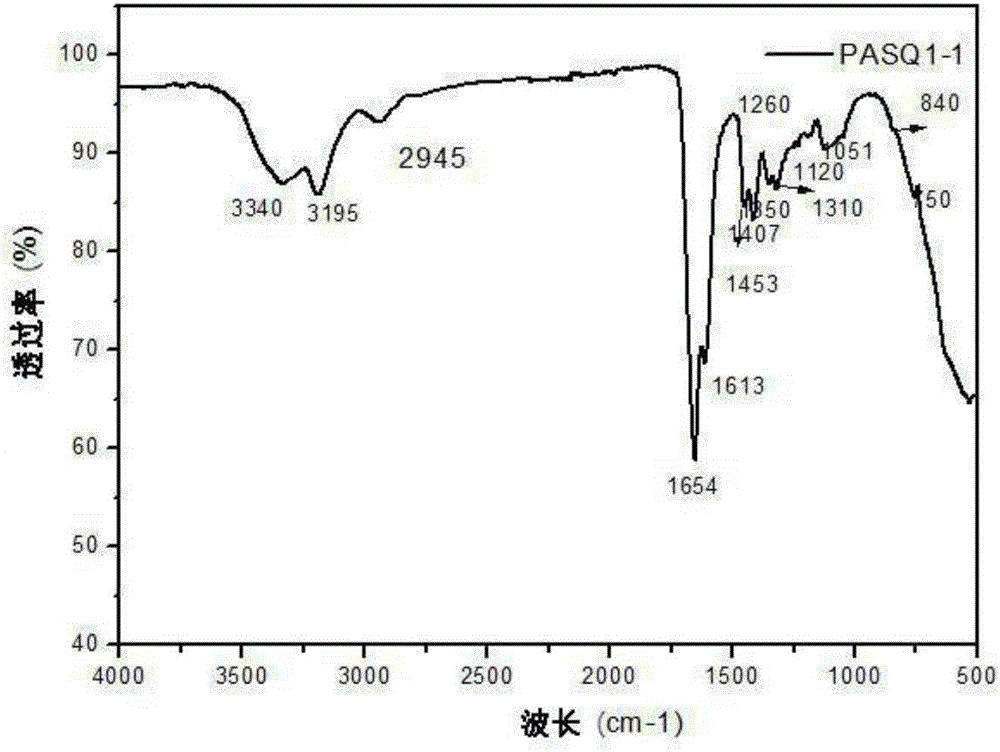

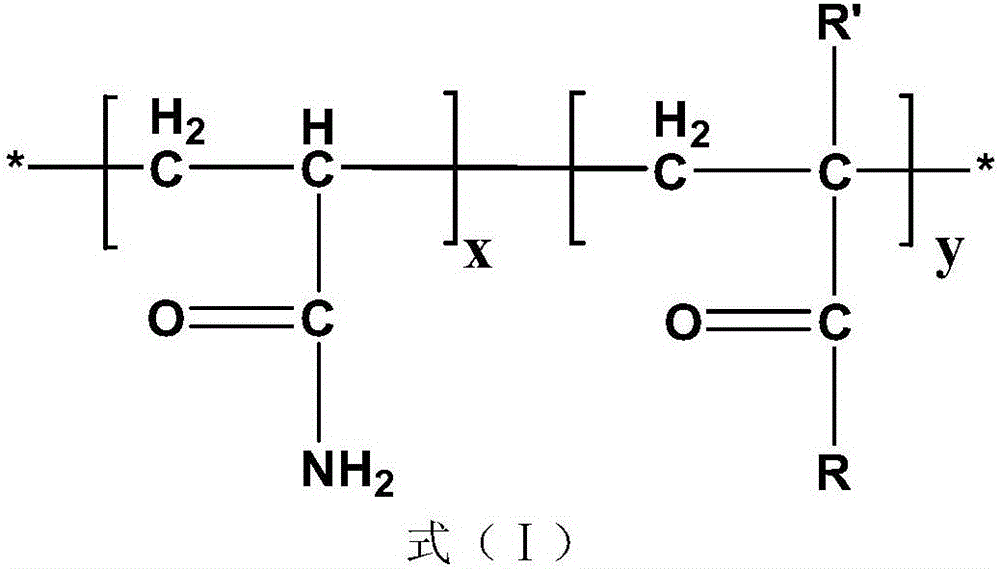

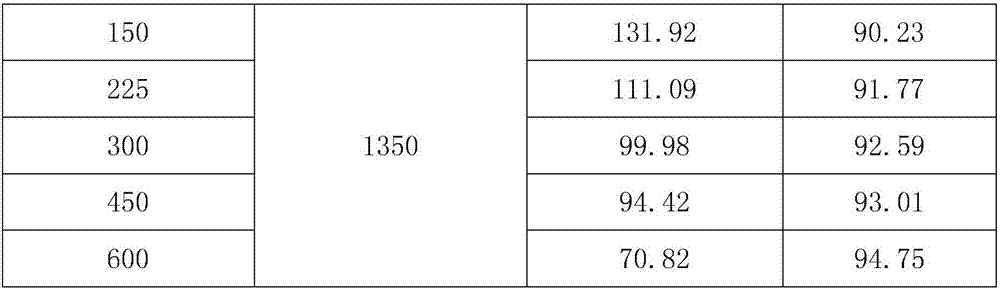

Polymer viscosity reducer for thickened oil and preparation method thereof

ActiveCN110627930AStrong emulsifying abilityEnhance amphipathicDrilling compositionPolymer scienceReducer

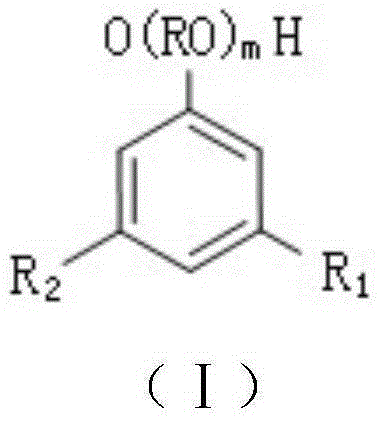

The invention relates to a polymer viscosity reducer for thickened oil. The polymer viscosity reducer is a hydrophobically modified polyacrylamide and has a structural formula shown as formula (I), wherein n represents the total number of polyacrylamide monomers, ranges from 60,000 to 100,000, preferably from 7,000 to 85,000; x represents the number of acrylic monomers, ranges from 10,000 to 40,000, preferably 20,000 to 350,000; m represents the number of hydrophobic monomers, and ranges from 4000 to 10000, preferably from 6000 to 8000. The invention also relates to a preparation method and application of the polymer viscosity reducer for thickened oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

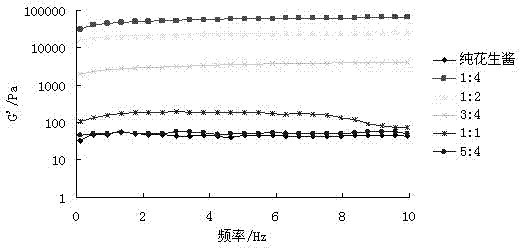

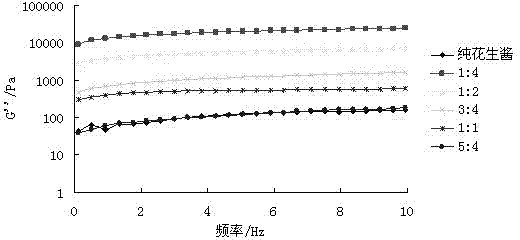

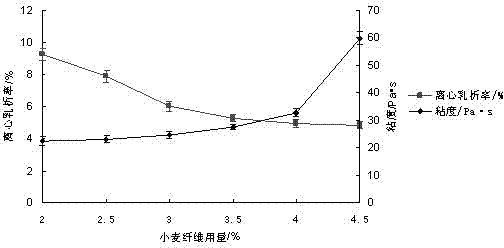

Method for improving peanut butter rheological characteristics by wheat fibers and composite emulsifier

InactiveCN103829292AEvenly distributedOptimize the best parametersFood ingredient as clouding agentFood preparationDeep processingOrganoleptic

The invention discloses a method for improving peanut butter rheological characteristics by wheat fibers and a composite emulsifier and belongs to the technical field of peanut product deep-processing. Water is added into raw peanut pulp as a raw materials so that the peanut butter is transformed into a stable oil-in-water structure and has rheological characteristic similar to that of pure peanut butter; and through combination of adsorption of free grease in the raw peanut pulp by wheat fibers and emulsification effects produced by the composite emulsifier, a peanut butter product which has long-term stability, is uniform, is not layered and has good rheological characteristics is produced. The peanut butter product has a centrifuged milk precipitation rate of 4.23% reduced by 57.5% than the centrifuged milk precipitation rate of the pure peanut butter and has good rheological characteristics, smearing characteristics and sensory quality. The peanut butter product satisfies current requirements on peanut butter stability and smearing characteristics and reduces damage caused by trans-fatty acids in the peanut butter on the health.

Owner:JIANGNAN UNIV

Organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and preparation method thereof

ActiveCN106632839AReduce surface tensionHigh temperature resistantDrilling compositionPolymer scienceFiltration

The invention relates to an organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and a preparation method thereof. The preparation method for the viscosity reducer comprises the following steps: uniformly mixing and stirring acrylamide, organic silicone quaternary ammonium salt containing double bond and solvent, thereby acquiring a mixed solution; introducing nitrogen, heating to 60-80 DEG C, adding an initiator while stirring, and then reacting for 5-12 hours at 60-80 DEG C, thereby acquiring a reaction solution; cooling the reaction solution and then putting into acetone or ethyl alcohol, performing suction filtration, soaking, washing and drying, thereby acquiring the heavy oil viscosity reducer. The preparation method provided by the invention is simple in operation and low in cost; the prepared viscosity reducer has better heat resistance, salt tolerance and viscosity reducing effects in lower concentration and is easy to demulsify and dewater; the later water treatment difficulty can be reduced; the viscosity reducer need not be compounded with the other auxiliaries, has excellent overall performance and is green and environment-friendly.

Owner:SHANDONG UNIV

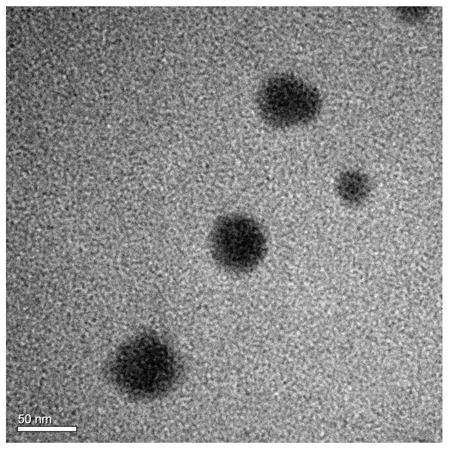

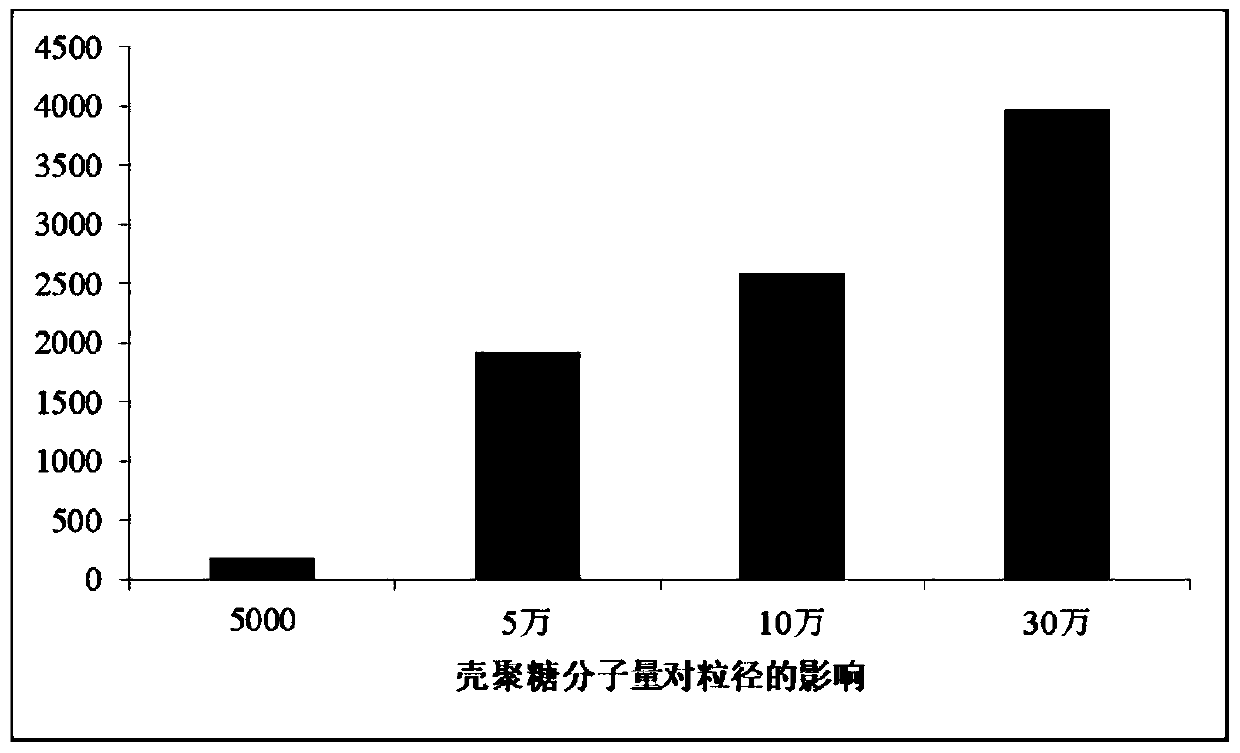

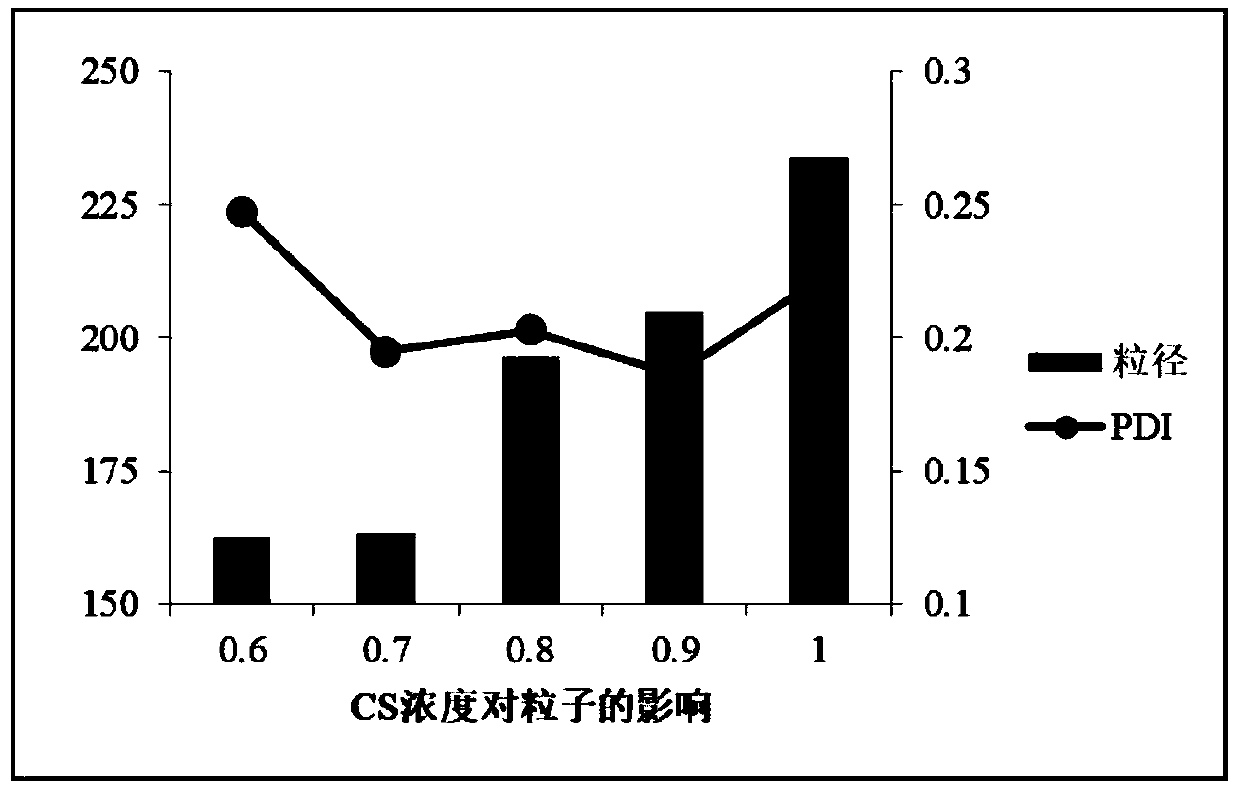

Isolated soybean protein chitosan nano gel and preparation method and application thereof

ActiveCN110432377ASolve solubilityFix stability issuesPeptide preparation methodsLipidic food ingredientsSolubilityIrritation

The invention relates to the technical field of Pickering emulsions, and particularly relates to an isolated soybean protein chitosan nano gel and a preparation method thereof and an application of the isolated soybean protein chitosan nano gel in preparation of Pickering emulsions. The preparation method comprises the following steps: using isolated soybean protein and chitosan as raw materials,and performing complex coacervation with protein polysaccharide to obtain SPI / CS suspension liquid; lyophilizing the suspension liquid to obtain generated SPI / CS powder; dispersing the SPI / CS powder in ultrapure water to form SPI / CS suspension liquid, afterwards adding corn oil to the above suspension liquid, and conducting high-speed dispersion to obtain the stable Pickering emulsion. The preparation method for Pickering emulsions has characteristics of simple preparation process, high stability of the emulsion, less emulsifier dosage, low irritation and low toxicity, environmental friendliness and insusceptibility to various factors of system environment, and can effectively solve the problems that plant essential oils and DHA / EPA have low solubility in water and limited stability and bioavailability, facilitates to reasonably design a delivery system based on food-grade emulsion and has good application prospects.

Owner:OCEAN UNIV OF CHINA

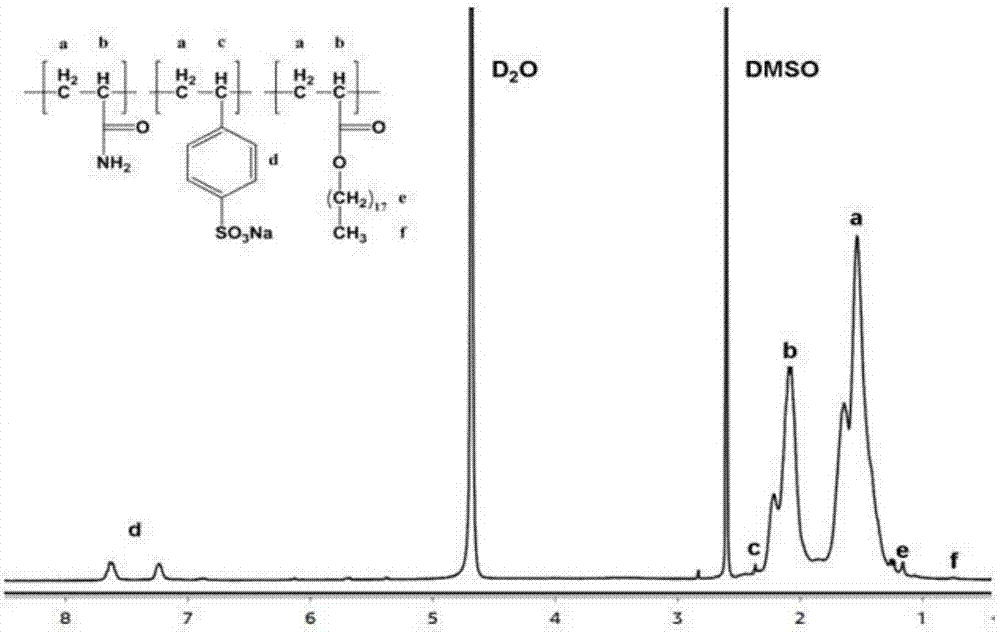

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Preparation method of modified starch nanocrystal

The invention provides a preparation method of modified starch nanocrystal, belonging to the technical field of the development of modified starch. The principle of the preparation method provided by the inversion is based on the situation that the difference of the acid tolerance is caused by the hemi-crystal capability of a starch structure, an amorphous region of starch particles is restrictively hydrolyzed by dilute acid, and the acid-resistant starch microcrystal particles can be formed, wherein the sizes of the acid-resistant starch microcrystal particles are 10-100nm. The particles are ultramicro, so that the particles are easily absorbed onto an oil-water interface, and have a certain surface activity, and the surface activity of the particles can be greatly improved after the particles are modified on surfaces in an esterification way by the DDSA (dodecenly succinic anhydride) through an enzymic method. 0.5% of the modified nanocrystal is added, so that a water and weak-polarity methylbenzene (1:1) oil-water system can form stable O / W type emulsion, the emulsifying capacity reaches 76%, and the median diameter of the emulsion D50=55 microns; after the emulsion is placed for four months under room temperature (0.2% of sodium azide bacteriostat is added), the particle size distribution of the emulsion can not be obviously changed. The modified starch nanocrystal prepared by the preparation method provided by the invention is high in emulsifying capacity, and high in emulsifying stability, thereby being wide in industrial application prospect.

Owner:JIANGNAN UNIV

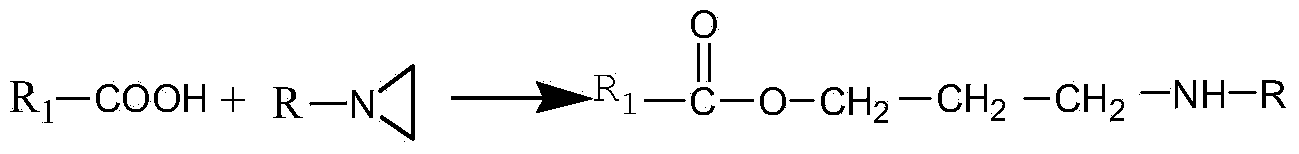

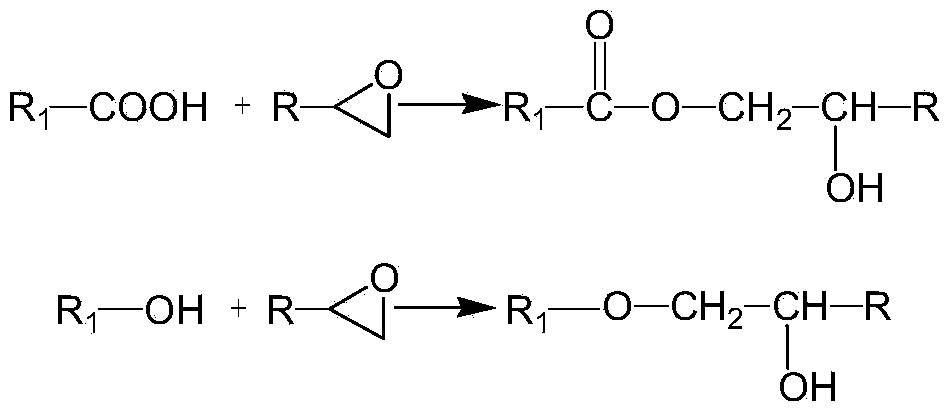

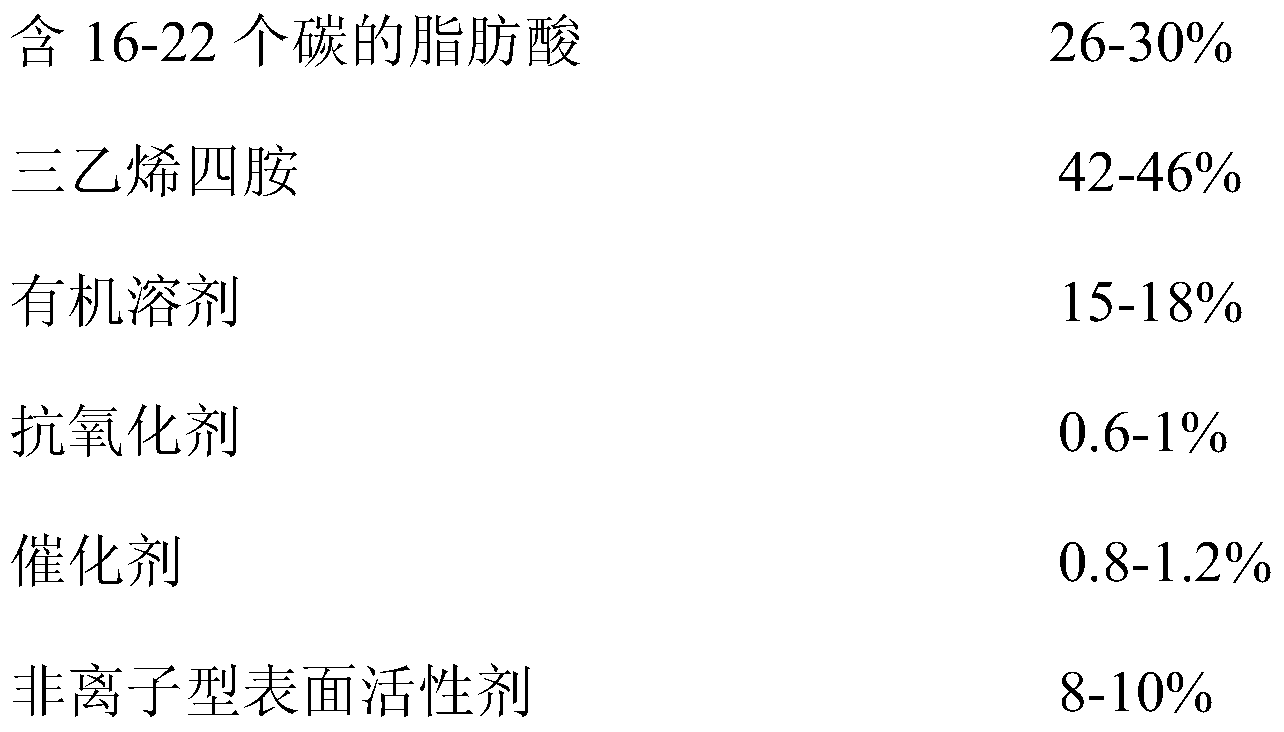

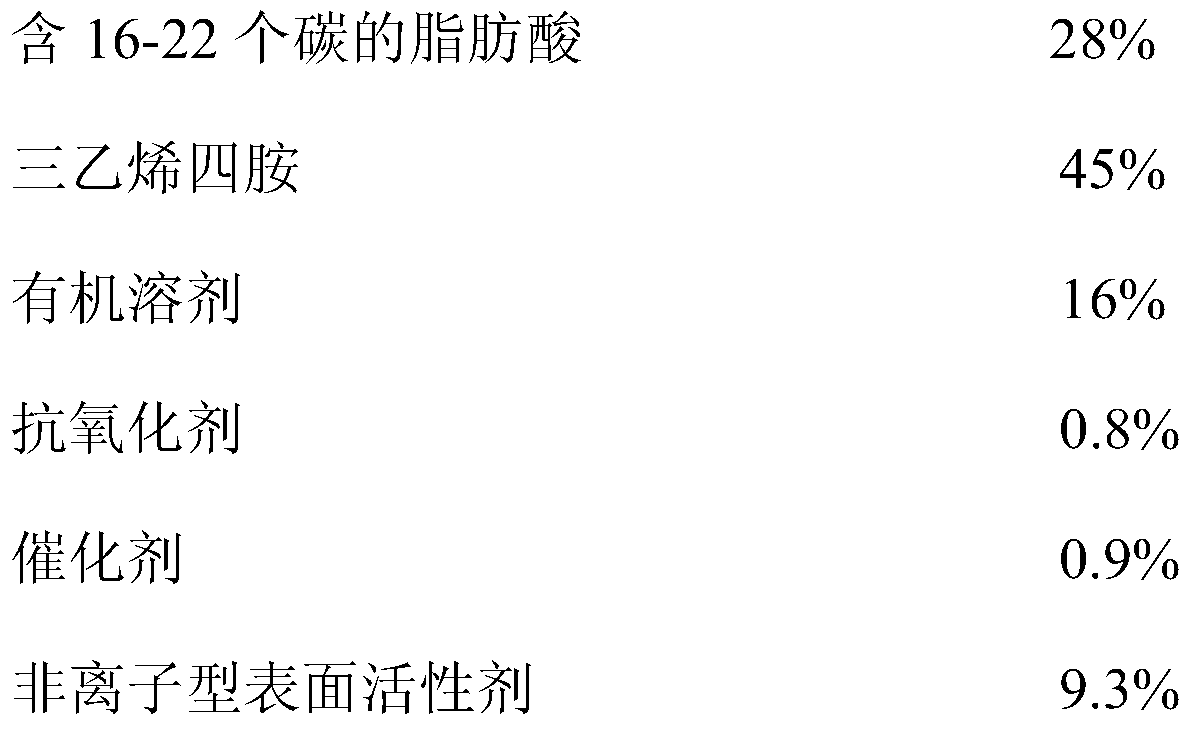

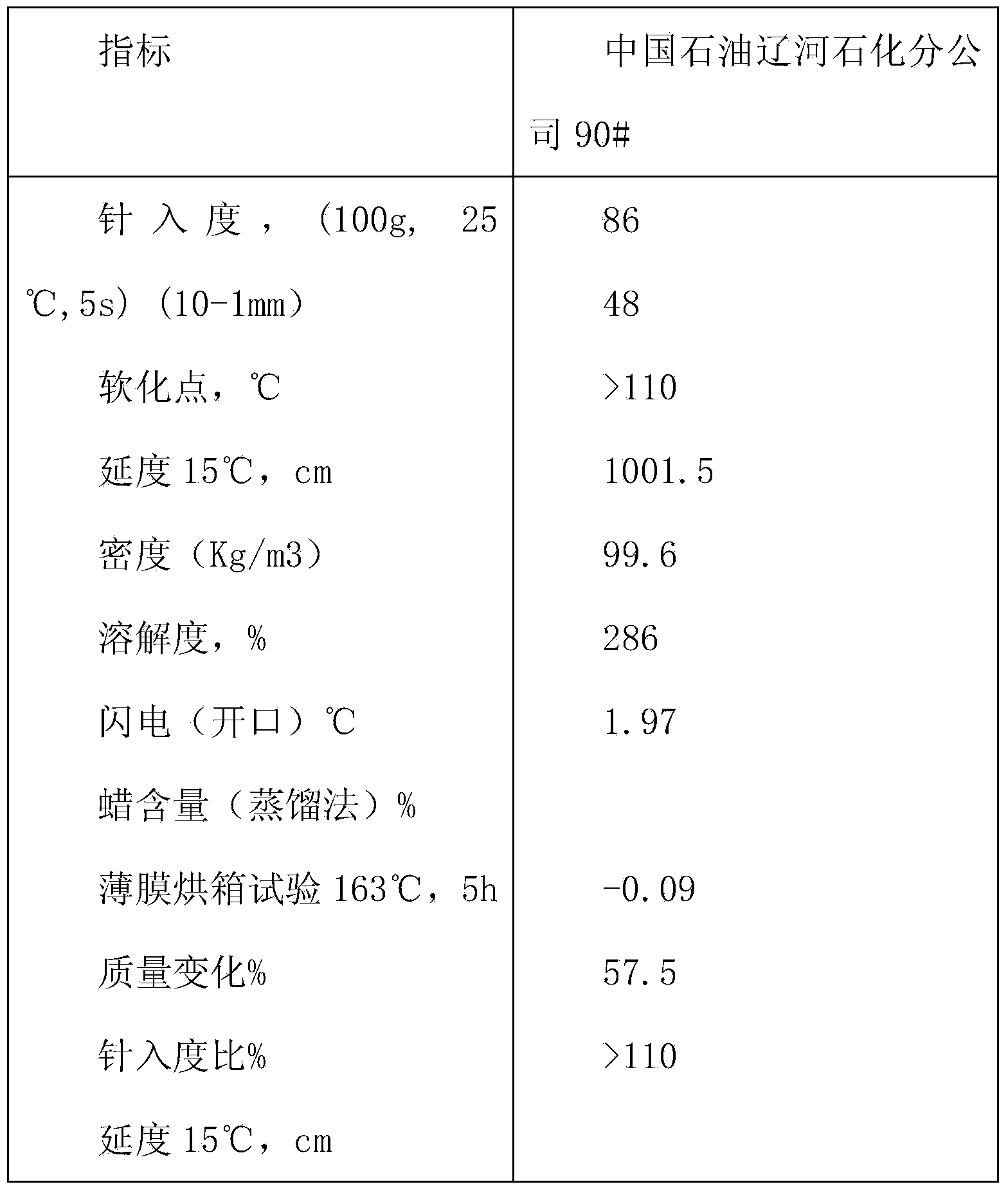

Slow breaking and quick setting cationic asphalt emulsifier and preparation method thereof

InactiveCN103923325AImprove work efficiencyStrong emulsifying abilityBuilding insulationsChemistryTetramine

The invention discloses a slow breaking and quick setting cationic asphalt emulsifier, consisting of the following components: fatty acid containing 16-22 carbons, triethylene tetramine, organic solvent, antioxidant, catalyst and nonionic surfactant. In the preparation process of the slow breaking and quick setting cationic asphalt emulsifier, the asphalt emulsifier is prepared by adopting a microwave heating technology, so that the synthesis time is 2.5-3h shorter than the traditional time. When the emulsified asphalt prepared from the slow breaking and quick setting cationic asphalt emulsifier is used for a thin slurry sealing layer, the consumption is 0.8-1.2%; moreover, a pavement can be quickly set, the open traffic time can be shortened to 30-40min, and quick traffic can be realized. The asphalt content of the emulsified asphalt prepared from the slow breaking and quick setting cationic asphalt emulsifier can reach 70%. The whole synthesis process does not pollute the ambient environment.

Owner:抚顺职业技术学院

Compound nonionic surfactant

ActiveCN105396503AImprove performanceImprove permeabilityTransportation and packagingMixingFatty alcoholSURFACTANT BLEND

The invention belongs to the technical field of surfactants and particularly relates to a compound nonionic surfactant which is prepared by compounding the following components in parts by weight: 20-80% of a component A and 20-80% of a component B, wherein the component A is formed by the combination of one or more of cardanol polyoxy alkyl ether, and the component B is formed by the combination of one or more of fatty alcohol polyoxy alkyl ether. The compound nonionic surfactant gives full play to the advantages of good low-temperature fluidity, strong emulsifying capacity and good decontamination and oil removing effects of the cardanol polyoxy alkyl ether, so that the compound nonionic surfactant can be applied to multiple fields including spinning, daily chemical, pesticides, metal processing and the like to replace conventional APEO.

Owner:联泓(江苏)新材料研究院有限公司

Spent meal for treating surface of copper and copper alloy and method for preparing same

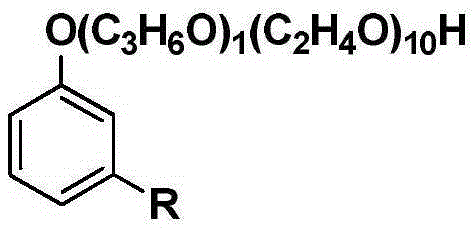

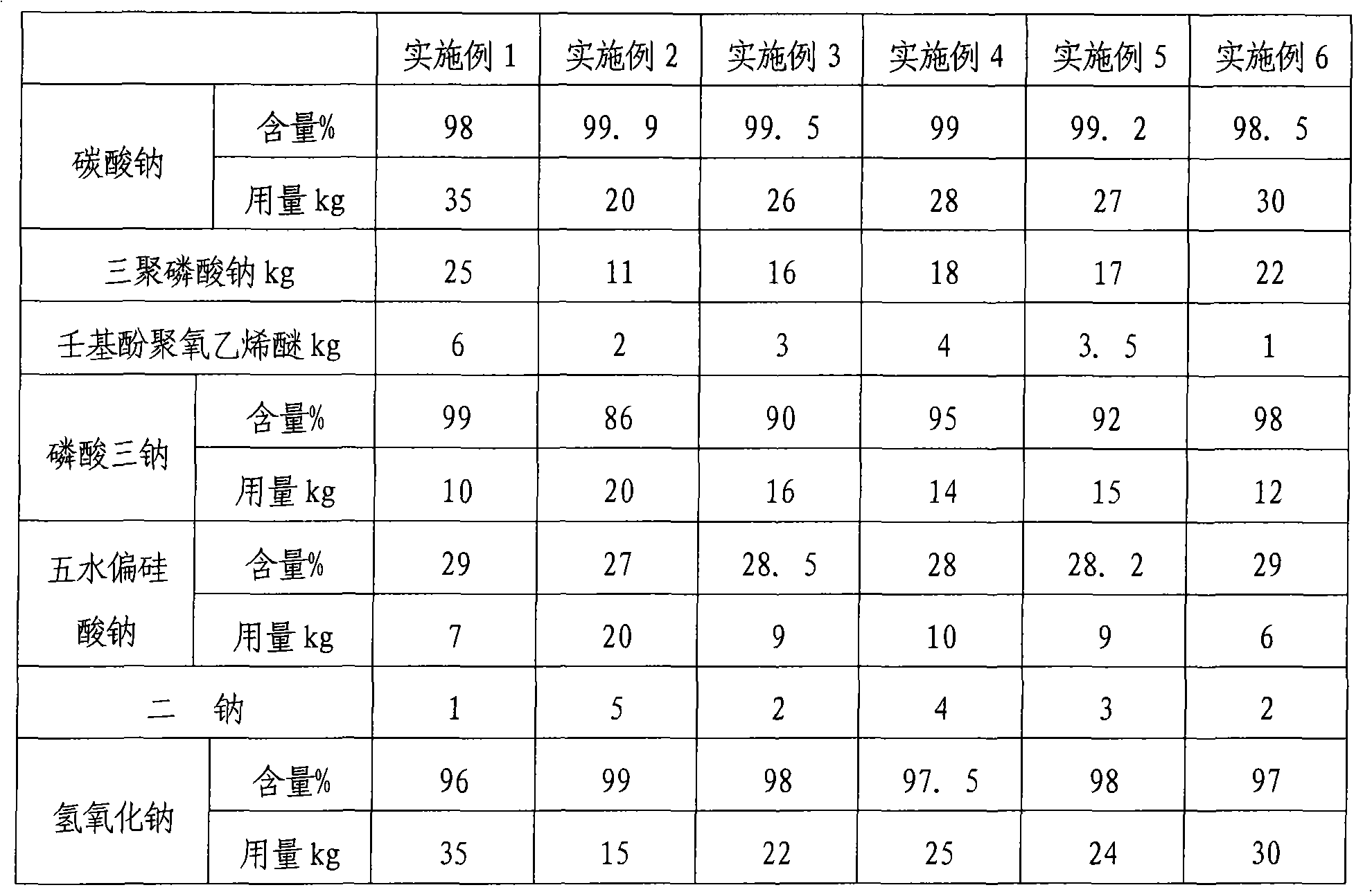

InactiveCN101285204AStrong emulsifying abilityImprove permeabilitySodium metasilicateSodium phosphates

The invention discloses spent meal used for processing the surface of copper and copper alloy and a method for preparing the same. The compositions and the proportions of the spent meal are: 20 to 35 portions of sodium carbonate, 10 to 25 portions of trimeric sodium phosphate, 1 to 6 portions of nonylphenol polyoxyethylene ether, 10 to 20 portions of trisodium phosphate, 6 to 20 portions of sodium metasilicate pentahydrate, 1 to 5 portions of disodium, 15 to 35 portions of sodium hydroxide, and all the proportions being weight portions. The method for preparing the spent meal comprises the following steps of: evenly mixing and stirring the sodium carbonate and the trimeric sodium phosphate; adding the nonylphenol polyoxyethylene ether and evenly stirring; adding the trisodium phosphate and the sodium metasilicate pentahydrate and evenly stirring; and adding the disodium and the sodium hydroxide and evenly stirring to receive a finished product. The spent meal has strong emulsifying capacity and permeability, has the dirt dissolving capacity increased by 2 to 3 times and the cleaning period shortened by 1 to 3 times, does not discolor degreasing fluid during using, does not have corrodibility, does not destroy workpieces, is easily biodegraded and is advantageous to environmental protection.

Owner:JIANGSU DEMEI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com