Nano material-based water-based oil field injection agent and preparation method thereof

A technology of nanomaterials and injection enhancers, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of high cost, and achieve significant effects of increasing production capacity, reducing water injection pressure, and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of nanometer water-based injection booster stock solution: Weigh 40wt% of the total amount of diesel oil, add 2wt% of γ-(methacryloyloxy)propyl trimethoxysilane modified nano-silica, the average particle size About 20nm, activation degree ≥ 99%, emulsification machine 7000rpm emulsification dispersion 2min, then add other surfactants and additives, OP-10 accounted for 15wt%, Span80 accounted for 25wt%, sodium dodecylsulfonate accounted for 10wt%, Ethanol accounted for 8wt%, water bath at 40°C, and mechanically stirred for 10 minutes to obtain the original solution of nanometer water-based injection enhancer.

[0021] Preparation of nanometer water-based dispersion: measure 1L of tap water, add 10wt%, 15wt%, 20wt% of the above-mentioned injection booster stock solution, stir and mix evenly, and obtain nanometer water-based dispersion.

[0022] The TEM photomicrograph of nano-silica modified by γ-(methacryloyloxy)propyltrimethoxysilane is as follows: figure 1...

Embodiment 2

[0024] Preparation of nano-water-based injection booster stock solution: Weigh 40wt% of the total amount of diesel oil, add 2wt% oleic acid-modified nano-silica, the average particle size is about 30nm, the activation degree is ≥99.5%, and the emulsifier is 7000rpm Emulsify and disperse for 2 minutes, then add other surfactants and additives, sodium petroleum sulfonate accounted for 15wt%, oleic acid accounted for 20wt%, cetyltrimethylammonium chloride accounted for 10wt%, ethanol accounted for 13wt%, water bath 60 ℃ , and mechanically stirred for 10 minutes to obtain the original solution of nanometer water-based injection enhancer.

[0025] The preparation of the nano water-based dispersion is the same as in Example 1.

[0026] TEM photomicrograph of oleic acid modified nano-silica as figure 2 shown.

Embodiment 3

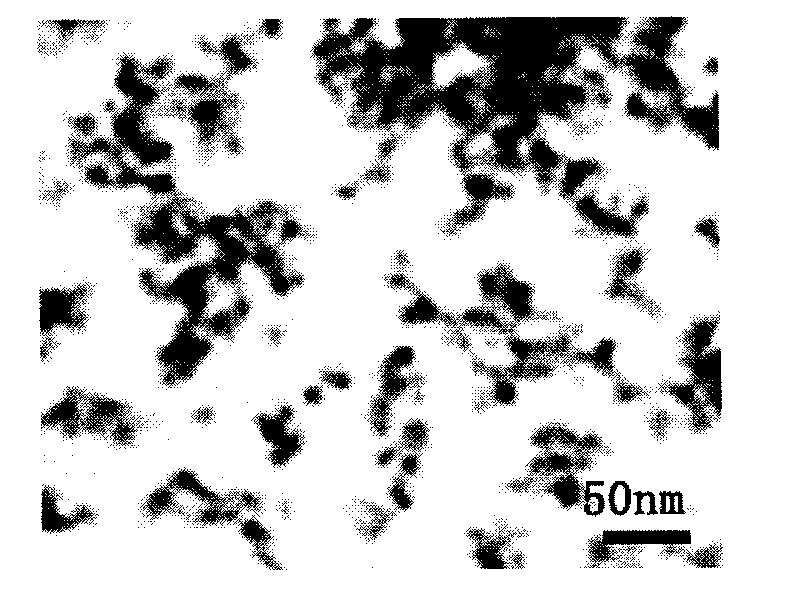

[0028] Preparation of nano-water-based injection booster stock solution: Weigh 35wt% of the total diesel oil, add 2wt% simethicone modified nano-silica, the average particle size is about 50nm, the activation degree is ≥ 98%, emulsified Machine 4000rpm emulsification dispersion 5min, then add other surfactants and additives, sodium dodecylbenzenesulfonate accounted for 15wt%, oleic acid accounted for 15wt%, NP-10 accounted for 13wt%, ethylene glycol accounted for 20wt%, at room temperature Stir mechanically for 20 minutes to obtain the original solution of nanometer water-based injection enhancer.

[0029] The preparation of the nano water-based dispersion is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com